Page 1

Owner’s Manual

♦SET-UP ♦OPERATION ♦MAINTENANCE

IMPORTANT: Read Safety Rules and Instructions Carefully

PRINTED IN CANADA OGRM-7004

Page 2

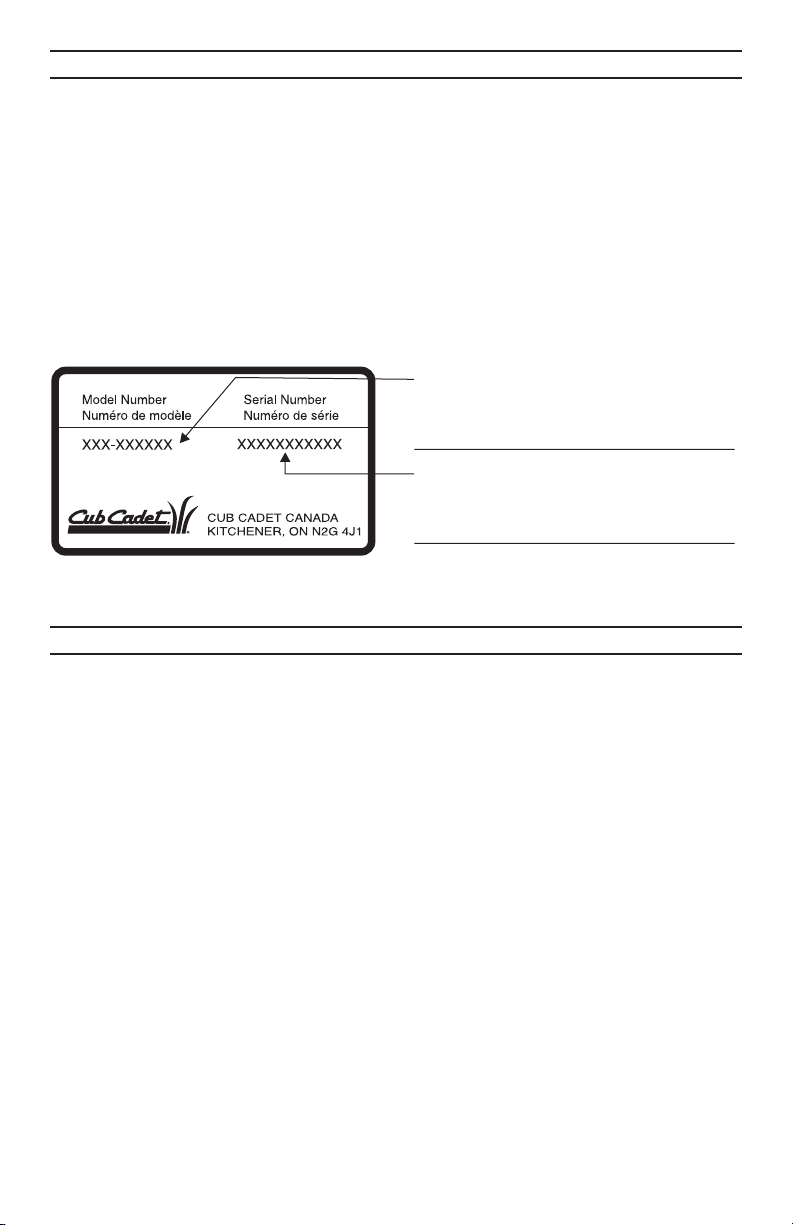

CALLING CUSTOMER SUPPORT

LOCATE YOUR MODEL NUMBER AND SERIAL NUMBER which appears on your unit

•

and record the information in the space provided below.

IMPORTANT: You must have these numbers, along with the date and proof of

purchase to receive warranty or service.

If you are having difficulty assembling this product or if you have any questions regard

•

ing the controls, operation or maintenance of this unit, please call an authorized dealer.

Please have your model number and serial number ready when you call.

•

NOTE: Although both numbers are important, you will be asked to enter only your serial

•

number before your call can be processed.

This is where your model number will be,

record model number here:

This is where your serial number will be,

record serial number here:

TABLE OF CONTENTS

-

CALLING CUSTOMER SUPPORT .......................................2

TABLE OF CONTENTS ..............................................2

IMPORTANT SAFE OPÉRATION PRACTICES ..............................3

SLOPE GAUGE ....................................................7

TRACTOR SET-UP..................................................8

CONTROLS .....................................................10

OPERATION .....................................................12

OPERATING THE LAWN TRACTOR ....................................13

ADJUSTMENT ...................................................14

LUBRICATION ...................................................18

MAINTENANCE ...................................................18

OFF-SEASON STORAGE ...........................................24

ATTACHMENTS & ACCESSORIES .....................................25

TROUBLE SHOOTING GUIDE ........................................26

WARRANTY......................................................27

REPLACEMENT PARTS .............................................28

2

Page 3

This unit has been inspected against the manufacturers quality check list. In case of a discrep

ancy, please call us. We will make every effort to ship the part(s) by courier within one working

day of your call.

IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not

followed, could endanger the personal safety and/or property of yourself and

others. Read and follow all instructions in this manual before attempting to operate

this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol— heed its warning.

DANGER: This machine was built to be operated according to the rules for safe

operation in this manual. As with any type of power equipment, carelessness or

error on the part of the operator can result in serious injury. This machine is

capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

-

GENERAL OPERATION

Read, understand, and follow all instruc

•

tions on the machine and in the manual(s)

before attempting to assemble and oper

ate. Keep this manual in a safe place for

future and regular reference and for order

ing replacement parts.

Be familiar with all controls and their

•

proper operation. Know how to stop the

machine and disengage them quickly.

Never allow children under 14 years old to

•

operate this machine. Children 14 years

old and over should read and understand

the operation instructions and safety rules

in this manual and should be trained and

supervised by a parent.

•

Never allow adults to operate this machine

without proper instruction.

•

To help avoid blade contact or a thrown

object injury, keep bystanders, helpers,

children and pets at least 75 feet from the

machine while it is in operation. Stop ma

chine if anyone enters the area.

•

Thoroughly inspect the area where the

equipment is to be used. Remove all

stones, sticks, wire, bones, toys, and other

foreign objects which could be picked up

and thrown by the blade(s). Thrown ob

jects can cause serious personal injury.

•

Plan your mowing pattern to avoid dis

charge of material toward roads,

sidewalks, bystanders and the like. Also,

avoid discharging material against a wall

or obstruction which may cause dis

charged material to ricochet back toward

the operator.

•

Always wear safety glasses or safety gog

gles during operation and while performing

an adjustment or repair to protect your

eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

Wear sturdy, rough-soled work shoes and

•

-

close-fitting slacks and shirts. Loose fitting

clothes and jewelry can be caught in mov

-

able parts. Never operate this machine in

bare feet or sandals.

Be aware of the mower and attachment

•

discharge direction and do not point it at

anyone. Do not operate the mower without

the discharge cover or entire grass catcher

in its proper place.

•

Do not put hands or feet near rotating

parts or under the cutting deck. Contact

with the blade(s) can amputate hands and

feet.

•

A missing or damaged discharge cover

can cause blade contact or thrown object

injuries.

•

Stop the blade(s) when crossing gravel

drives, walks, or roads and while not cut

-

ting grass.

•

Watch for traffic when operating near or

crossing roadways. This machine is not in

tended for use on any public roadway.

•

Do not operate the machine while under

the influence of alcohol or drugs.

-

•

Mow only in daylight or good artificial light.

•

Never carry passengers.

-

•

Disengage blade(s) before shifting into re

verse. Back up slowly. Always look down

and behind before and while backing to

avoid a back-over accident.

-

•

Slow down before turning. Operate the

machine smoothly. Avoid erratic operation

and excessive speed.

-

3

-

-

-

-

Page 4

Disengage blade(s), set parking brake,

•

stop engine and wait until the blade(s)

come to a complete stop before removing

grass catcher, emptying grass, unclogging

chute, removing any grass or debris, or

making any adjustments.

Never leave a running machine unat

•

tended. Always turn off blade(s), place

transmission in neutral, set parking brake,

stop engine and remove key before dis

mounting.

Use extra care when loading or unloading

•

the machine into a trailer or truck. This unit

should not be driven up or down ramp(s),

because the unit could tip over, causing

serious personal injury. The unit must be

pushed manually on ramp(s) to load or un

load properly.

Muffler and engine become hot and can

•

cause a burn. Do not touch.

Check overhead clearances carefully be

•

fore driving under low hanging tree

branches, wires, door openings etc.,

where the operator may be struck or

pulled from the unit, which could result in

serious injury.

Disengage all attachment clutches, de-

•

press the brake pedal completely and shift

into neutral before attempting to start engine.

•

Your machine is designed to cut normal

residential grass of a height no more than

10”. Do not attempt to mow through unusually tall, dry grass (e.g., pasture) or

piles of dry leaves. Dry grass or leaves

may contact the engine exhaust and/or

build up on the mower deck presenting a

potential fire hazard.

•

Use only accessories and attachments ap

proved for this machine by the machine

manufacturer. Read, understand and follow

all instructions provided with the approved

accessory or attachment.

•

Data indicates that operators, age 60 years

and above, are involved in a large percent

age of riding mower-related injuries. These

operators should evaluate their ability to

operate the riding mower safely enough to

protect themselves and others from seri

ous injury.

•

If situations occur which are not covered in

this manual, use care and good judgment.

Contact customer assistance.

SLOPE OPERATION

Slopes are a major factor related to loss of

•

control and tip-over accidents which can

result in severe injury or death. All slopes

require extra caution. If you cannot back

up the slope or if you feel uneasy on it, do

not mow it.

For your safety, use the slope gauge in

•

cluded as part of this manual to measure

-

slopes before operating this unit on a

sloped or hilly area. If the slope is greater

than 15 degrees as shown on the slope

gauge, do not operate this unit on that

area or serious injury could result.

DO:

Mow up and down slopes, not across. Ex

•

ercise extreme caution when changing

direction on slopes.

Watch for holes, ruts, bumps, rocks, or

•

other hidden objects. Uneven terrain could

overturn the machine. Tall grass can hide

obstacles.

Use slow speed. Choose a low enough

•

speed setting so that you will not have to

stop or shift while on the slope. Tires may

lose traction on slopes even though the

brakes are functioning properly. Always

keep machine in gear when going down

slopes to take advantage of engine braking action.

•

Follow the manufacturer’s recommendations for wheel weights or counterweights

to improve stability.

•

Use extra care with grass catchers or other

attachments. These can change the stabil

ity of the machine.

•

Keep all movement on the slopes slow and

gradual. Do not make sudden changes in

speed or direction. Rapid engagement or

braking could cause the front of the ma

chine to lift and rapidly flip over backwards

which could cause serious injury.

•

Avoid starting or stopping on a slope. If

tires lose traction, disengage the blade(s)

and proceed slowly straight down the

slope.

DO NOT:

-

•

Do not turn on slopes unless necessary;

then, turn slowly and gradually downhill, if

possible.

•

Do not mow near drop-offs, ditches or em

bankments. The mower could suddenly

turn over if a wheel is over the edge of a

cliff, ditch, or if an edge caves in.

-

-

-

-

-

4

Page 5

Do not try to stabilize the machine by putt

•

ing your foot on the ground.

Do not use a grass catcher on steep

•

slopes.

Do not mow on wet grass. Reduced trac

•

tion could cause sliding.

Do not shift to neutral and coast downhill.

•

Over-speeding may cause the operator to

lose control of the machine resulting in se

rious injury or death.

Do not tow heavy pull behind attachments

•

(e.g. loaded dump cart, lawn roller, etc.)

on slopes greater than 5 degrees. When

going down hill, the extra weight tends to

push the tractor and may cause you to

loose control. (e.g. tractor may speed up,

braking and steering ability are reduced,

attachment may jack-knife and cause trac

tor to overturn).

CHILDREN

Tragic accidents can occur if the operator

•

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. They do not understand the dangers. Never assume that

children will remain where you last saw

them.

a. Keep children out of the mowing area

and in watchful care of a responsible

adult other than the operator.

b. Be alert and turn machine off if a child

enters the area.

c. Before and while backing, look behind

and down for small children.

d. Never carry children, even with the

blade(s) shut off. They may fall off and

be seriously injured or interfere with

safe machine operation.

e. Use extreme care when approaching

blind corners, doorways, shrubs, trees

or other objects that may block your vi

sion of a child who may run into the

machine.

f. Disengage the cutting blade(s) before

shifting in reverse. The “No-Cut-In Re

verse” feature is a reminder not to cut

in reverse and to help avoid back over

accidents. Do not defeat it.

g. Keep children away from hot or run

ning engines. They can suffer burns

from a hot muffler.

h. Remove key when machine is unat

tended to prevent unauthorized

operation.

Never allow children under 14 years old to

-

•

operate the machine. Children 14 years

old and over should read and understand

the operation instructions and safety rules

in this manual and should be trained and

-

supervised by a parent.

TOWING

Tow only with a machine that has a hitch

•

designed for towing. Do not attach towed

equipment except at the hitch point.

Follow the manufacturers recommendation

•

for weight limits for towed equipment and

towing on slopes.

Never allow children or others in or on

•

towed equipment.

On slopes, the weight of the towed equip

•

ment may cause loss of traction and loss

of control.

Travel slowly and allow extra distance to

•

stop.

Do not shift to neutral and coast downhill.

•

SERVICE

SAFE HANDLING OF GASOLINE:

To avoid personal injury or property

•

damage use extreme care in handling gasoline. Gasoline is extremely flammable

and the vapors are explosive. Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which

can ignite. Wash your skin and change

clothes immediately.

a. Use only an approved gasoline con

tainer.

b. Never fill containers inside a vehicle or

on a truck or trailer bed with a plastic

liner. Always place containers on the

ground away from your vehicle before

filling.

c. When practical, remove gas-powered

-

equipment from the truck or trailer and

refuel it on the ground. If this is not

possible, then refuel such equipment

on a trailer with a portable container,

-

rather than from a gasoline dispenser

nozzle.

d. Keep the nozzle in contact with the rim

of the fuel tank or container opening at

-

all times until fueling is complete. Do

not use a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes

-

and other sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel

while the engine is hot or running. Al

5

-

-

-

Page 6

low engine to cool at least two minutes

before refueling.

h. Never over fill fuel tank. Fill tank to no

more than ½ inch below bottom of filler

neck to allow space for fuel expansion.

i. Replace gasoline cap and tighten se

curely.

j. If gasoline is spilled, wipe it off the en

gine and equipment. Move unit to

another area. Wait 5 minutes before

starting the engine.

k. To reduce fire hazards, keep machine

free of grass, leaves, or other debris

build-up. Clean up oil or fuel spillage

and remove any fuel soaked debris.

l. Never store the machine or fuel con

tainer inside where there is an open

flame, spark or pilot light as on a water

heater, space heater, furnace, clothes

dryer or other gas appliances.

m. Allow a machine to cool at least 5

minutes before storing.

GENERAL SERVICE:

Never run an engine indoors or in a poorly

•

ventilated area. Engine exhaust contains

carbon monoxide, an odorless, and deadly

gas.

• Before cleaning, repairing, or inspecting,

make certain the blade(s) and all moving

parts have stopped. Disconnect the spark

plug wire and ground against the engine

to prevent unintended starting.

•

Periodically check to make sure the blades

come to complete stop within approxi

mately (5) five seconds after operating the

blade disengagement control. If the blades

do not stop within the this time frame, your

unit should be serviced professionally by

an authorized Service Dealer.

•

Check brake operation frequently as it is

subjected to wear during normal operation.

Adjust and service as required.

•

Check the blade(s) and engine mounting

bolts at frequent intervals for proper tight

ness. Also, visually inspect blade(s) for

damage (e.g., excessive wear, bent,

cracked).

Replace the blade(s) with the original

•

equipment manufacturer’s (O.E.M.)

blade(s) only, listed in this manual. “Use of

parts which do not meet the original equip

ment specifications may lead to improper

performance and compromise safety!”

Mower blades are sharp. Wrap the blade

•

or wear gloves, and use extra caution

when servicing them.

Keep all nuts, bolts, and screws tight to be

•

sure the equipment is in safe working con

dition.

Never tamper with the safety interlock sys

•

tem or other safety devices. Check their

proper operation regularly.

-

After striking a foreign object, stop the en

•

gine, disconnect the spark plug wire(s)

and ground against the engine. Thor

oughly inspect the machine for any

damage. Repair the damage before start

ing and operating.

Never attempt to make adjustments or re

•

pairs to the machine while the engine is

running.

Grass catcher components and the dis-

•

charge cover are subject to wear and

damage which could expose moving parts

or allow objects to be thrown. For safety

protection, frequently check components

and replace immediately with original

equipment manufacturer’s (O.E.M.) parts

only, listed in this manual. “Use of parts

which do not meet the original equipment

specifications may lead to improper perfor

-

mance and compromise safety!”

•

Do not change the engine governor set

tings or over-speed the engine. The

governor controls the maximum safe oper

ating speed of the engine.

•

Maintain or replace safety and instruction

labels, as necessary.

•

Observe proper disposal laws and regula

tions for gas, oil, etc. to protect the

environment.

-

-

-

-

-

-

-

-

-

-

-

-

6

Page 7

OWNER'S

MANUAL

SAFETY LABEL

WARNING - Your Responsibility:

Restrict the use of this power machine to persons who

read, understand and follow the warnings and instruc

tions in this manual and on the machine.

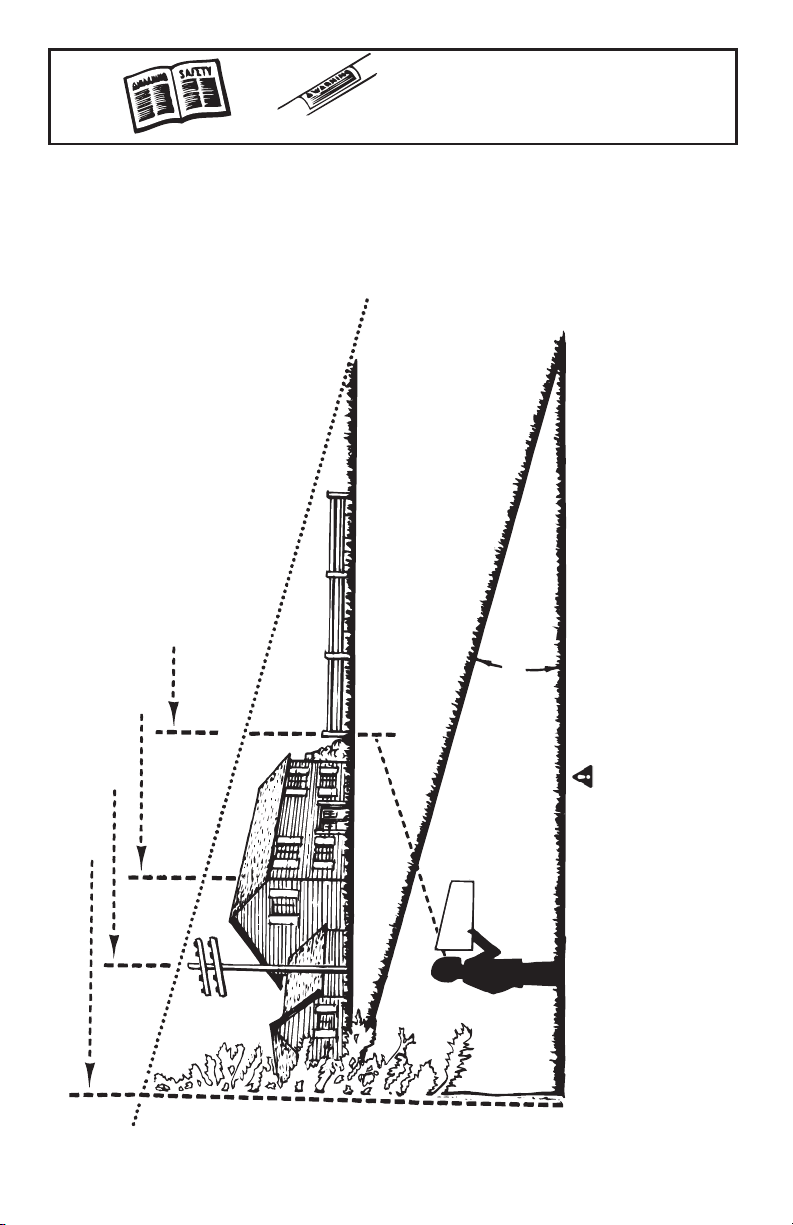

SLOPE GAUGE

SLOPE

o

OR A FENCE POST

-

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

A CORNER OF A BUILDING

A POWER POLE

FOLD ON DOTTED LINE, REPRESENTING A 15

15º

DANGER

Do not mow on inclines with a slope in excess excess of 15 degrees ( a rise of approximately 2½ feet every

10 feet). A riding mower could overturn and cause serious injury. If operating a walk-behind mower on such a

slope, it is extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

7

Page 8

This owner’s manual covers various models of

lawn tractors. The units illustrated may vary

slightly from your unit. Follow only those in

structions which pertain to your model lawn

tractor.

IMPORTANT: This unit is shipped WITHOUT

GASOLINE. Check oil before starting en

gine. Do not overfill. After assembly, service

engine with gasoline and oil as instructed

in the separate engine manual packed with

your unit.

NOTE: Reference to right or left hand

side of the unit is observed from the

driver’s seat, facing forward.

Tools Required For Assembly

(1) ½" socket wrench (for steering wheel)

(1) 9/16" wrench or socket wrench (for seat)

(2) 7/16 wrenches or socket wrenches

(for battery)

TRACTOR SET-UP

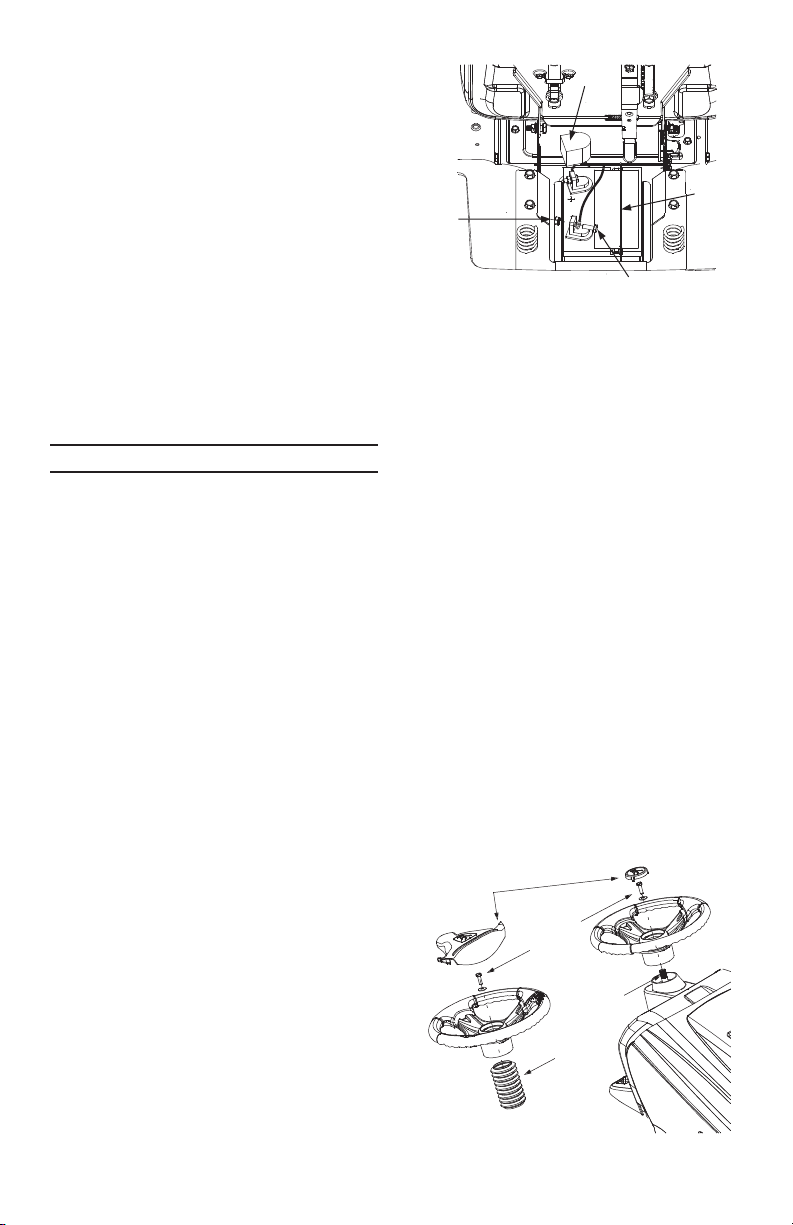

ATTACHING THE BATTERY CABLES

NOTE: The positive battery terminal is

marked Pos. (+). The negative battery

terminal is marked Neg. (–).

The positive cable (heavy red wire) is se-

•

cured to the positive battery terminal (+)

with a hex bolt and hex nut at the factory.

Make certain that the rubber boot covers the

terminal to help protect it from corrosion.

•

Remove the hex bolt and hex nut from the

negative cable.

•

Remove the black plastic cover, if present,

from the negative battery terminal and attach

the negative cable (heavy black wire) to the

negative battery terminal (–) with the bolt

and hex nut.

•

Make certain the hold-down rod is in posi

tion over the battery, securing it in place.

See Figure 1.

CHARGING THE BATTERY

If battery is put into service after date shown

on top of battery, charge the battery with a

battery charger before using your unit. A

charger with an output of six amps should

be used and the battery should be charged

for one hour. This charging will help extend

the life of the battery.

If a charger with a six amp output is not

available, a lower output charger may be

used for a longer period of time. Do not

charge the battery at a rate higher than six

amps as it can damage the battery and re

duce its useful life.

Rubber

-

Boot

-

Hex

Nut

FIGURE 1

Hex Bolt

If a charger is not available but the battery

will start the lawn tractor, the battery can be

charged by mowing for a minimum of one

hour using the engine’s charging system.

The lawn tractor should be ran at full throttle

during this process.

NOTE: More than one hour of mowing

may be needed to fully charge the bat

tery since the output of the engine’s

charging system is typically less than

six amps.

ATTACHING THE STEERING WHEEL

The hardware for attaching the steering

•

wheel is located under the steering wheel

cap. Carefully pry off the steering wheel cap

and remove the hardware.

NOTE: There are two different styles of

steering wheel caps. See Figure 2.

Styles vary by model.

•

Remove the steering bellow (not required

on all models) from the lift lever on the

right hand side of lawn tractor. Place steer

ing bellow over the steering shaft

extending through the dash.

-

Steering Wheel

Cap/Insert

Hex Bolt

and

Washer

Steering

Shaft

Steering

Bellow

-

FIGURE 2

8

HoldDown

Rod

-

-

Page 9

NOTE: If the openings on each end of

the steering bellow are two different

sizes, the smaller end goes down

against the dash of the lawn tractor.

Position the front wheels of the tractor so

•

they are pointing straight forward.

Place the steering wheel over the steering

•

shaft, positioning steering wheel as de

sired.

Place the washer

•

with the cupped

side down over

the steering shaft.

Crowned

Side

Cupped

Side

Secure with hex

bolt. See Figure 2.

Place the steering wheel cap over the

•

center of the steering wheel and seat it

with your hand. See Figure 2.

If your unit is equipped with a steering in

•

sert packed in a plastic bag with the

literature, snap it over the round steering

wheel cap. See Figure 2.

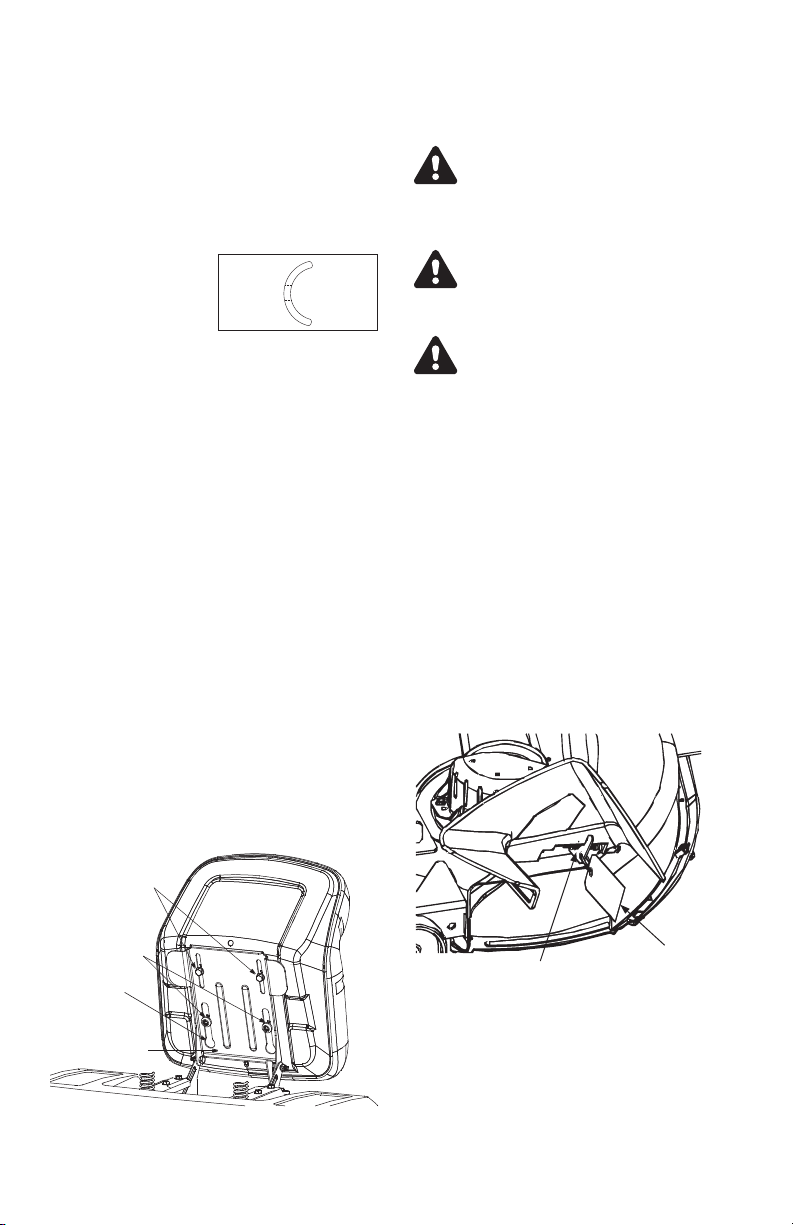

ATTACHING THE SEAT

For shipping reasons, seats are either fastened to the tractor seat’s pivot bracket with

a plastic tie, or mounted backward to the

pivot bracket. In either case, free the seat

form its shipping position and remove the

two hex screws (or knobs, on models so

equipped) from the bottom of seat before

proceeding with instructions below.

•

Position the shoulder screws (found on the

base of the seat) inside the slot openings

in the seat pivot bracket.

•

Slide the seat slightly rearward in the seat

pivot bracket, lining up the rear slots in the

pivot bracket with the remaining two holes

in the seat’s base.

Select desired position for the seat, and

•

secure with the two hex screws/knobs re

moved. Do not overtighten. See Figure 3.

Shipping Brace Removal

WARNING: Make sure the tractor’s

engine is off, remove the key from

the ignition switch and apply the

-

tractor’s parking brake before

removing the shipping brace.

WARNING: The shipping brace,

used for packaging purposes only,

must be removed and discarded

before operating your riding mower.

WARNING: The mowing deck is

capable of throwing objects. Failure

to operate the tractor without the

discharge chute properly in place

could result in serious personal

-

injury and/or property damage.

Locate the shipping brace and accompa

•

nying warning tag on the right side of the

mower, between the discharge chute and

the cutting deck. See Figure 4.

While holding the discharge chute with

•

your left hand, remove the shipping brace

with your right hand by grasping it between your thumb and index finger and

rotating it clockwise.

•

Carefully allow the discharge chute to pivot

downward. See Figure 4.

•

Discard the shipping brace and accompanying warning tag.

-

-

Hex Screws

(optional knobs)

Shoulder

Opening in

Slot

Pivot

Bracket

FIGURE 3

Shipping Brace

Warning Tag

FIGURE 4

INSTALLING THE MULCHING PLUG

(optional)

•

Locate the square hole found in the cutting

deck surface by pivoting the discharge

chute upward.

9

Page 10

Carriage Bolt

Cupped

Washer

Discharge Chute in

Proper Operating Position

FIGURE 5

Install the mulch plug and secure it in

•

place with the carriage bolt, cupped

washer and plastic wing nut as illustrated

in Figure 6.

Remove the mulching plug for standard

•

side discharge mowing. See Figure 5.

TIRE PRESSURE

For shipping purposes, the tires on your unit

may be over inflated. Tire pressure should

be reduced before unit is put into operation.

Recommended operating tire pressure

should be 12 p.s.i.

Check sidewall of tire for manufacturer’s

maximum tire pressure. If this information

does not appear on your tire, maximum tire

pressure under any circumstances is 30

p.s.i. Equal tire pressure should be maintained on all tires.

FINAL ASSEMBLY

Make certain all nuts and bolts are tightened

securely.

CONTROLS

IGNITION SWITCH

The ignition switch is located on the right

side of the tractor’s dash. To start the en

gine, insert the key into the ignition switch

and turn clockwise to the START position.

Release the key into the ON position once

engine has fired. See Figure 7 .

Refer to Starting The Engine in the Operation

section of this manual for detailed starting in

structions.

Never leave a running machine

unattended. Always disengaged

PTO, shift into neutral, set parking

brake, stop engine and remove key

to prevent unintended starting.

Wing

nut

FIGURE 6

CHOKE CONTROL

On some models, moving the

throttle lever all the way forward

activates the engine’s choke

control. On all other models the

choke control can be found on

the left side of the dash panel and is acti

vated by pulling the knob outward.

Activating the choke control closes the

choke plate on the carburetor and aids in

starting the engine. Refer to “Starting the Engine”.

THROTTLE CONTROL

LEVER

The throttle lever is located on the left side of

the dash panel. This lever controls the speed of

the engine, and on some

models, when pushed all

the way forward, the

choke control also.

When set in a given po

sition, the throttle will

maintain a uniform en

gine speed.

IMPORTANT: When op

erating the tractor with the cutting deck

-

engaged, be certain that the throttle lever is

always in the FAST (rabbit) position.

DECK ENGAGEMENT / LIFT LEVER

Found on the right side of the tractor, the

deck engagement/lift lever is used to set the

-

mowing deck’s cutting height and engage

the power to the cutting deck or other (sepa

rately available) attachments. To operate,

move the lever to the right and forward, be

fore placing it a notch for your desired

cutting height. Moving the lever to the right

and all the way rearward placing it into the

BLADES STOP position disengages power

to the cutting deck/ attachment.

10

Mulching Plug

Choke

Position

Fast

Position

-

Slow

Position

-

-

-

-

-

Page 11

H

A

B

C

FIGURE 7

A - Clutch-brake Pedal

B - Choke Control

C - Throttle Control Lever

D - Deck engagement/

D

E

F

Lift Lever (PTO)

E - Ignition Switch

F - Shift Lever

G - Speed Control

Lever/Parking Brake

H - Seat Adjustment Lever

G

(optional)

NOTE: The deck engagement/lift le

ver must be in the disengaged

(BLADES STOP) position when starting the engine, when traveling in

reverse and if the operator leaves the

seat.

PARKING BRAKE

To set the parking brake,

fully depress the

clutch-brake pedal. Move

the speed control lever

all the way to the rear

and release it into the

parking brake position.

Release the clutch-brake

pedal to allow the park

-

6

5

4

3

2

1

ing brake to engage.

To release the parking

brake, depress the

P

clutch-brake pedal and

move the speed control

lever out of the notches

to the desired position. Release the speed

control lever and the clutch-brake pedal.

NOTE: The parking brake must be set if the

operator leaves the seat with the engine

running or the engine will automatically

shut off.

IMPORTANT: Always set the parking

brake when leaving the tractor unattended.

SHIFT LEVER

The shift lever is located in the center of

the console and has

F

N

R

three positions, F

(Forward), N (Neutral) and R (Reverse).

The clutch-brake

pedal must be fully

Shift

Knob

depressed and the

tractor must not be in

motion when the moving shift lever.

IMPORTANT: Never force the shift lever.

Doing so may result in serious damage to

the tractor’s transmission.

NOTE: If difficulty is encountered while at

tempting to shift, release the clutch-brake

pedal slightly before fully depressing the

pedal again.

SPEED CONTROL LEVER

The speed control lever, located on the

right side of the center console, allows you

to regulate the ground speed of the lawn

tractor. To use, depress the clutch-brake

pedal and move the lever out of the parking

brake notch and forward to increase the

tractor’s ground speed. When a desired

speed has been reached, release the lever

into an appropriate notch to maintain that

speed.

To slow the tractor’s ground speed, de

press the clutch-brake pedal and move the

speed control lever rearward and release it

into a notch.

-

-

11

Page 12

SAFETY INTERLOCK SYSTEM

WARNING: Read, understand, and

follow all instructions and warnings

on the machine and in this manual

before operating.

This tractor is equipped with a safety inter

lock system for the protection of the

operator. If the interlock system should ever

malfunction, do not operate the tractor. Con

tact an authorized service dealer. The safety

interlock system prevents the engine from

cranking or starting unless the parking brake

is engaged, and the deck engagement/lift le

ver is in the disengaged (BLADES STOP)

position.

The engine will automatically shut off if the

•

operator leaves the seat before engaging

the parking brake.

The engine will automatically shut off if the

•

operator leaves the tractor’s seat with the

deck engagement/ lift lever in ANY position

other than BLADES STOP.

The engine will automatically shut off if the

•

deck engagement/lift lever is moved out of

the BLADES STOP position with the speed

control lever in position for reverse travel.

OPERATION

BEFORE STARTING ENGINE

WARNING: Read, understand, and

follow all instructions and warnings

on the machine and in this manual

before operating.

•

Service the engine with oil and gasoline as

described in the engine manual.

•

Depress the clutch-brake pedal and set the

parking brake.

•

Place the deck engagement/lift lever in the

DISENGAGED (BLADES STOP) position.

STARTING THE ENGINE

WARNING: Do not operate the lawn

tractor if the interlock system is

malfunctioning because it is a

safety device, designed for

protection.

NOTE: To open the hood simply lift up

on both sides of the hood.

•

Insert the tractor key into the ignition

switch.

•

Activate the choke control (a warm engine

may not require choking).

WARNING

GO UP AND DOWN SLOPES NOT ACROSS -

•

AVOID SUDDEN TURNS.

-

-

-

AVOID SERIOUS INJURY OR DEATH.

•

DO NOT OPERATE THE UNIT WHERE IT

•

COULD SLIP OR TIP

IF MACHINE STOPS GOING UPHILL, STOP

•

.

BLADE(S) AND BACK DOWNHILL SLOWLY.

DO NOT MOW WHEN CHILDREN OR OTHERS

•

ARE AROUND

NEVER CARRY CHILDREN.

•

LOOK DOWN AND BEHIND BEFORE AND

•

.

WHILE BACKING.

KEEP SAFETY DEVICES (GUARDS, SHIELDS,

•

AND SWITCHES) IN PLACE AND WORKING.

REMOVE OBJECTS THAT COULD BE THROWN

•

BY THE BLADE(S).

KNOW LOCATION AND FUNCTION OF ALL

•

CONTROLS

BE SURE BLADE(S) AND ENGINE ARE

•

.

STOPPED BEFORE PLACING HANDS OR FEET

NEAR BLADE(S)

BEFORE LEAVING OPERATOR’S POSITION,

•

.

DISENGAGE BLADE(S), PLACE THE SHIFT

LEVER IN NEUTRAL, ENGAGE BRAKE LOCK,

SHUT ENGINE OFF AND REMOVE KEY.

READ OPERATOR’S MANUALS.

•

Turn the ignition key clockwise to the

START position. After the engine starts, re

lease the key. It will return to the ON

position.

IMPORTANT: Do NOT hold the key in the

START position for longer than ten seconds

at a time. Doing so may cause damage to

your engine’s electric starter.

•

After the engine starts, deactivate the

choke control and place the throttle control

in the FAST position.

IMPORTANT: Do NOT leave the choke con

trol on while operating the tractor. Doing so

will result in a “rich” fuel mixture and cause

the engine to run poorly.

STOPPING THE ENGINE

WARNING: If you strike a foreign

object, stop the engine. Remove

wire from spark plug, thoroughly

inspect the unit for any damage,

and repair the damage before

restarting and operating the mower.

-

-

12

Page 13

NOTE: If any problems are encoun

tered, refer to the Trouble Shooting

Chart.

If the blades are engaged, place the deck

•

engagement/lift lever in the BLADES STOP

position.

Depress the clutch-brake pedal to bring the

•

tractor to a complete stop.

Turn the ignition key counterclockwise to the

•

OFF position.

Engage the tractor’s parking brake.

•

Remove the key from the ignition switch to

•

prevent unintended starting.

OPERATING THE LAWN TRACTOR

WARNING: Always look down and

behind before and while backing up

to avoid a back-over accident.

WARNING: Before leaving the

operator’s position. Always place the

deck engagement/ lift lever in the

BLADES STOP position, shift into

neutral, set parking brake, stop

engine and remove key to prevent

unintended starting.

• Move throttle control lever to full throttle.

NOTE: Always operate the tractor with the

throttle control lever in the FAST (rabbit) position for the most efficient use of the cutting

deck or other (separately available) attachments.

•

Place the shift lever in either the FORWARD

or REVERSE position.

•

Release the parking brake by depressing

the clutch-brake pedal and positioning the

speed control lever in desired position.

IMPORTANT: First-time operators should use

slower speeds. Become completely familiar

with the tractor’s operation and controls be

fore operating the tractor in at higher speed

positions.

•

Release clutch-brake pedal slowly to put

unit into motion.

•

The lawn tractor is brought to a stop by de

pressing the clutch-brake pedal.

NOTE: When operating the unit initially,

there will be little difference between

the highest two speeds until after the

belts have seated themselves into the

pulleys during the break-in period.

WARNING: Before leaving the

operator’s position for any reason,

disengage the blades, place the

speed control lever in neutral,

engage the parking brake, shut

engine off and remove the key.

IMPORTANT: When stopping the tractor for

any reason while on a grass surface, always:

Place the shift lever in neutral.

•

Engage the parking brake,

•

Shut engine off and remove the key.

•

Doing so will minimize the possibility of having

your lawn ‘‘browned’’ by hot exhaust from

your tractor’s running engine.

If unit stalls with speed control in high speed,

or if unit will not operate with speed control le

ver in a low speed position, proceed as

follows.

Place shift lever in NEUTRAL.

•

Restart engine.

•

Place speed control lever in high speed po

•

sition.

Release clutch-brake pedal fully.

•

Depress clutch-brake pedal.

•

Place speed control lever in desired posi-

•

tion.

•

Place shift lever in either FORWARD or REVERSE, and follow normal operating

procedures.

ENGAGING THE CUTTING BLADES

WARNING: Keep feet and hands

away from the discharge opening, the

blades or any part of the deck. When

the unit is used for anything other

than mowing operations, the blade

drive should be disengaged.

To engage power to the cutting deck or other

(separately available) attachment, proceed as

follows:

•

Move the deck engagement/lift lever to the

right and forward.

•

Place the lever a notch for your desired cut

ting height.

-

•

Moving the lever to the right and all the way

rearward placing it into the BLADES STOP

position raises and disengages power to the

cutting deck.

NOTE: The deck engagement/lift lever

must be in the disengaged (BLADES

STOP) position when starting the en

gine, when traveling in reverse and if

the operator leaves the seat.

13

-

-

-

-

Page 14

MOWING

WARNING: To help avoid blade

contact or a thrown object injury,

keep bystanders, helpers, children

and pets at least 75 feet from the

machine while it is in operation.

Stop machine if anyone enters the

area.

The following information will be helpful

when using the cutting deck with your trac

tor.

WARNING: Plan your mowing

pattern to avoid discharge of

materials toward roads, sidewalks,

bystanders and the like. Also, avoid

discharging material against a wall

or obstruction which may cause

discharged material to ricochet

back toward the operator.

Be sure that the lawn is clear of stones,

•

sticks, wire, or other objects which could

damage lawn mower or engine.

For best results and to insure more even

•

grass distribution, do not mow when lawn

is excessively wet.

Do not mow at high ground speed, espe-

•

cially if a mulch kit or grass collector is

installed.

•

For best results it is recommended that the

first two laps be cut with the discharge

thrown towards the center. After the first

two laps, reverse the direction to throw the

discharge to the outside for the balance of

cutting. This will give a better appearance

to the lawn.

•

Do not cut the grass too short. Short grass

invites weed growth and yellows quickly in

dry weather.

•

Mowing should always be done with the

engine at full throttle.

•

Under heavier conditions it may be neces

sary to go back over the cut area a

second time to get a clean cut.

•

Do NOT attempt to mow heavy brush and

weeds and extremely tall grass. Your trac

tor is designed to mow lawns, NOT clear

brush.

•

Keep the blades sharp and replace the

blades when worn. Refer to Cutting Blades

in the Maintenance section of this manual

for proper blade sharpening instructions.

MULCHING

Some, NOT ALL, models come equipped

with a mulch kit which incorporates special

blades, already standard on your tractor, in a

process of recirculating grass clippings re

peatedly beneath the cutting deck. The

ultra-fine clippings are then forced back into

the lawn where they act as a natural fertilizer.

Observe the following points for the best re

sults when mulching.

Never attempt to mulch if the lawn is

•

damp. Wet grass tends to stick to the un

derside of the cutting deck preventing

proper mulching of the clippings.

Do NOT attempt to mulch more than 1/3

•

the total height of the grass or approxi

mately 1-1/2 inches. Doing so will cause

the clippings to clump up beneath the

deck and not be mulched effectively.

Maintain a slow ground speed to allow the

•

grass clippings more time to effectively be

mulched.

Always position the throttle control lever in

•

the FAST (rabbit) position and allow it to

remain there while mowing. Failing to keep

the engine at full throttle places strain on

the tractor’s engine and does not allow the

blades to properly mulch grass.

NOTE: It is not necessary to remove

the discharge chute to operate the

mower with the mulch kit installed.

38- and 42-inch Decks

To operate the cutting deck without mulch

ing, on models so equipped, simply remove

the mulch plug by unthreading the plastic

wing nut which fastens it to the cutting deck.

This will allow the clippings to discharge out

the side. See Figures 6 and 5.

46-inch Decks

On models so equipped, the mulch kit is

packed separately within the tractor’s crate.

-

Observe the instructions included with the

mulch kit for the best results when mulching.

ADJUSTMENT

-

SEAT ADJUSTMENT

The seat may be adjusted to one of several

positions. Refer to seat installation section of

tractor set-up instructions.

DECK LEVELING ADJUSTMENT

WARNING: Protect your hands by

wearing heavy gloves to grasp the

cutting blade.

-

-

-

-

-

14

Page 15

NOTE: Check the tractor’s tire pres

sure before performing any deck

leveling adjustments. Refer to Tires

later in this section for further informa

tion regarding tire pressure.

The front of the cutting deck is supported by

two lift links that can be adjusted to level the

deck from both front to rear & side to side.

The front of the deck should be between

1/4-inch and 3/8-inch lower than the rear of

the deck. Adjust if necessary as follows:

With the tractor parked on a firm, level sur

•

face, place the deck engagement/lift lever

in the top cutting height notch (not

BLADES STOP) position.

Rotate the blade nearest the discharge

•

chute so that it is parallel with the tractor.

Measure the distance from the front of the

•

blade tip to the ground and the rear of the

blade tip to the ground. The first measure

ment taken should be between 1/4" and

3/8" less than the second measurement.

Determine the approximate distance nec

essary for proper adjustment and proceed,

if necessary, to the next step.

Place the deck engagement/lift lever in the

•

engaged (all the way forward) position.

• Remove the hairpin clip from the ferrule

found at the bottom of the front, left deck

link (hairpin clip is on the inside of the lift

link). See Figure 8 .

•

Pull the ferrule out of the deck hanger and

thread the ferrule up or down, as necessary.

NOTE: Usually only one or two turns are

needed.

•

Insert the ferrule back into the deck hanger

and refasten with the hairpin clip removed

earlier.

•

Repeat the previous steps on the front,

right lift link

•

Check the front-to-rear adjustment by

re-measuring. Check the side-to-side ad

justment by placing a level on the deck

surface.

•

Readjust if necessary.

SETTING THE DECK WHEEL HEIGHT (on

models so equipped)

•

Select the height position of the cutting

deck by placing the Deck Engagement /

Lift Lever in any of the five different cutting

height notches on the right side of the

frame.

FIGURE 8

Adjust the deck wheels so that they are

•

Adjustable Deck Links,

Ferrules & Hairpin Clips

between 1/4-inch and ½-inch above the

ground when the tractor is on a smooth,

flat surface such as a driveway.

-

WARNING: Keep hands and feet

away from the discharge opening of

the cutting deck.

-

NOTE: The deck wheels, on models

so equipped, are an anti-scalp feature

of the deck and are not designed to

support the weight of the cutting deck.

Refer to Deck Leveling Adjustment of this

manual for more detailed instructions regarding deck adjustments.

DECK ENGAGEMENT ADJUSTMENT

WARNING: Never attempt to make

the adjustment while the engine is

running. Always shift to neutral, set

the parking brake, stop engine and

remove key to prevent unintended

starting.

The cutting deck engagement may be ad

justed to make certain the deck is

disengaged when deck engagement/lift lever

is in the BLADES STOP position. Correct ad

justment as follows.

•

With the engine off, place the deck en

-

gagement/lift lever in the BLADES OFF

position.

•

Unthread the shift knob and remove the

two flange screws which secure the shift

cover panel in place. See Figure 11.

•

Remove the cover panel and locate the

deck disengagement rod. See Figure 11.

NOTE: There is a small yellow wire

connected to a spring switch on the

underside of the cover panel. Be care

ful not to damage it when removing

the panel.

15

-

-

-

-

Page 16

Stabilizer Shaft

Assembly

Compression

Spring

Hex

Nut

Disengagement Rod

FIGURE 9

Remove the hairpin clip which secures the

•

disengagement rod to the stabilizer shaft

assembly. See Figure 10.

Pull the rod toward the rear of the tractor

•

(to take up slack), then thread the rod in

ward or outward (usually only one or two

turns) until the rod lines up as precisely as

possible with the hole in the stabilizer

shaft.

NOTE: Threading the disengagement

rod outward (toward the rear of the

tractor) provides for more belt tension.

Threading the disengagement rod inward provides for less belt tension.

•

Reinsert the ferrule and re-secure the rod

with the cotter pin removed earlier.

Check the adjustment by placing the deck

engagement/ lift lever in the BLADES STOP

position. The deck should move up and for

ward, allowing the belt to become loose.

•

Reassemble the cover panel.

•

Start the tractor’s engine and test the deck

engagement/lift lever to be certain the

blades fully disengage when in the

BLADES STOP.

•

Repeat the adjustment procedure if neces

sary.

PARKING BRAKE ADJUSTMENT

WARNING: Never attempt to adjust the

brakes while the engine is running.

Always disengage PTO, move speed

control lever into neutral position, stop

engine and remove key to prevent

unintended starting.

If the tractor does not come to a complete stop

when the brake pedal is completely depressed,

or if the tractor’s rear wheels can roll with the

parking brake applied, the brake is in need of

adjustment. The brake disc can be found on the

Transmission

FIGURE 10

R,

right side of the transmission in the rear of

the tractor. Adjust if necessary as follows:

Looking at the transmission from the right side

of the tractor, locate the compression spring and

brake disc. See Figure 10.

Loosen, but do NOT remove, the hex nut

•

found on the right side of the brake assembly.

See Figure 10.

Using a feeler gauge, set the gap between

•

the brake disc and the brake puck at .011".

Re-tighten the hex nut loosened earlier.

•

SPEED CONTROL ADJUSTMENT

NOTE: When operating the unit initially

or after replacing the belts, there will

be little difference between the highest

two speeds until after the belts have

gone through a break-in period and

-

have seated themselves into the pul

leys.

If the full range of speeds cannot be ob

tained on your unit, adjust the speed control

as follows.

•

Unthread the shift knob and remove the

two flange screws which secure the cover

panel in place. Refer to Figure 11.

-

Knob

Flange Screws

Shift Cover Panel

FIGURE 11

Brake Disc

-

-

16

Page 17

Remove the cover panel and locate the

•

speed control rod. See Figure 14.

NOTE: There is a small yellow wire con

nected to a spring switch on the underside of

the cover panel. Be careful not to damage it

when removing the panel.

Remove the hairpin clip which secures the

•

speed control rod’s ferrule to the speed

bracket. See Figure 14.

At the factory, the speed control rod is ad

justed so that 5/8-in. of the rod is exposed

beyond the ferrule.

Adjust the speed control by threading the

•

ferrule inward so that no more than 3/4-in.

of the rod is exposed beyond the ferrule.

See Figure 12.

Reinsert the ferrule and re-secure the rod

•

with the hairpin clip removed earlier.

Reassemble the cover panel, start the trac

•

tor’s engine and test the full range of

speeds.

IMPORTANT: If the above adjustment did

not result in the tractor obtaining the full

range of speeds, see an authorized service

dealer to have the variable speed drive system inspected and professionally adjusted.

STEERING ADJUSTMENT

(Units With Adjustable Tie Rod)

If the tractor turns tighter in one direction

than the other, or if either the tie rod and ferrule are being replaced due to damage or

wear, the tie rod may need to be adjusted.

To do so, proceed as follows:

NOTE: A replacement cotter pin (part no.

714-0470) is needed to complete this adjust

ment. Have one on hand before proceeding.

•

Place the steering wheel in position for

straight ahead travel.

•

In front of the pivot bar, measure the dis

tance horizontally from the inside of the left

rim to the inside of the right rim. Note the

distance.

•

Behind the pivot bar, measure the distance

horizontally from the inside of the left rim

to the inside of the right rim. Note the dis

tance.

•

The measurement taken in front of the

pivot bar should be between 1/16” and

5/16” less than the measurement taken be

hind the pivot bar. If it is not, an

adjustment is necessary. Proceed as fol

lows.

•

Locate the ferrule at the right end of the tie

rod, just to the rear of the right, front tire of

tractor. See Figure 13.

3/4"

Maximum

-

FIGURE 12

-

Tie Rod

Ferrule

Right Axle

Right Front Tire

Right Front Tire

FIGURE 13

Ferrule and

Hairpin Clip

-

Speed Control Rod

FIGURE 14

•

Remove the cotter pin and flat washer

which secures the adjustment ferrule to the

tractors right axle.

•

Two turns at a time, thread the adjustment

-

ferrule toward the right, front tire to

lengthen the tie rod. Or, thread the adjust

ment ferrule away from the right, front tire

to shorten the tie rod.

NOTE: Lengthening the tie rod increases the

tractor’s front tie toe-in. Shortening the tie

rod decreases the tractor’s front tire toe-in.

•

Reinsert the adjustment ferrule and tempo

rarily secure it with the cotter pin removed

earlier.

17

Flat Washer

Cotter Pin

-

-

Page 18

Make certain the steering wheel is in posi

•

tion for straight-ahead travel before again

taking measurements. Continue to repeat

the steps above until a proper adjustment

is achieved.

Secure the tie rod to the right axle with the

•

flat washer removed earlier and a replace

ment cotter pin.

IMPORTANT: Do NOT reuse the original

cotter pin once it has been removed.

LUBRICATION

WARNING: Before lubricating,

repairing, or inspecting, always

disengage PTO, move speed

control lever into neutral position,

set parking brake, stop engine and

remove key to prevent unintended

starting.

Engine

Lubricate the engine with motor oil as in

structed in separate engine manual packed

with your unit.

Rear Wheels

The rear wheels should be removed from the

axles once a season. Lubricate the axles and

the rims well with an all-purpose grease before re-installing them.

Front Axles

Each end of the tractor’s front pivot bar may

be equipped with a grease fitting. If so

equipped, lubricate with a grease gun after

every 25 hours of tractor operation.

Pivot Points & Linkage

Lubricate all the pivot points on the drive

system, brake pedal and lift linkage at least

once a season with light oil.

Steering Shaft and Gear

Lubricate teeth of steering gears with auto

motive multi-purpose grease after every 25

hours of operation or once a season. See

Figure 17.

MAINTENANCE

WARNING: Disconnect the spark

plug wire and ground against the

engine before performing any

repairs or maintenance.

WARNING: Before performing any

maintenance or repairs, place the

deck engagement/lift lever in the

BLADES STOP position, move

-

speed control lever into neutral

position, set parking brake, stop

engine and remove key to prevent

unintended starting.

CLEANING THE ENGINE AND DECK

Any fuel or oil spilled on the machine should

be wiped off promptly. Do NOT allow debris

to accumulate around the cooling fins of the

engine or on any other part of the machine,

especially the belts, pulleys and other mov

ing parts. Clean the underside of the deck

with a wisk broom, scraper or forced air after

each mowing.

IMPORTANT: The use of a pressure washer

or garden hose to clean your tractor is NOT

recommended. It may cause damage to

electrical components, spindles, pulleys,

bearings or the engine. The use of water will

result in a shortened life of the tractor and

reduce its serviceability.

ENGINE

-

Refer to the separate engine manual for en

gine maintenance instructions.

Check engine oil level before each use as instructed in the separate engine manual

packed with your unit. Read and follow instructions carefully.

Changing Engine Oil

(models equipped with an oil drain

sleeve)

For draining oil from the engine’s crankcase

of select model tractors, a plastic oil drain

sleeve is packed with this operator’s manual.

To drain the oil, proceed as follows:

•

Unscrew oil fill cap and remove dipstick

from the oil fill tube. See Figure 15.

•

Snap the small end of oil drain sleeve onto

the oil sump. See Figure 15.

•

Remove drain plug and drain oil into a

suitable container with a capacity of no

-

less than 64 oz.

Oil Sump

Oil Drain Sleeve

FIGURE 15

18

-

-

Page 19

Service the oil filter (if so equipped) as in

•

structed in the separate engine manual

packed with your unit.

Perform the above steps in the opposite or

der after oil has finished draining.

Refill the engine with new motor oil.

•

IMPORTANT: Refer to the separate engine

manual packed with your unit for information

regarding the quantity and proper weight of

motor oil.

Changing Engine Oil

(models equipped with an oil drain valve)

NOTE: Depending on your tractor’s engine

make & model, it may be necessary to re

move the tractor’s side panel in order to

replace the oil filter (if so equipped).

Unscrew the oil fill cap and remove the

•

dipstick from the oil fill tube. See Figure

16.

Pop open the protective cap on the end of

•

the oil drain valve to expose the drain port.

See Figure 16.

Push the oil drain hose (packed with this

•

manual) onto the oil drain port. Route the

opposite end of the hose into an appropriate oil collection container with a capacity

of no less than 64 oz.

• Push the oil drain valve in slightly, then ro-

tate counterclockwise and pull outward to

begin draining oil.

•

Service the oil filter (if so equipped) as instructed in the separate engine manual

packed with your unit.

Perform the above steps in the opposite or

der after oil has finished draining.

•

Refill the engine with new motor oil.

IMPORTANT: Refer to the separate engine

manual packed with your unit for information

regarding the quantity and proper weight of

motor oil.

Air Cleaner

To service the air cleaner, refer to the sepa

rate engine manual packed with your unit.

Fuel Filter

Service the fuel filter, if so equipped, as in

structed in the separate engine manual

packed with your unit.

Spark Plug(s)

The spark plug gap should be cleaned and

the gap reset once a season. Spark plug re

placement is recommended at the start of

each mowing season; check engine manual

for correct plug type and gap specification.

-

Fill Tube

-

FIGURE 16

Drain Port

-

Steering Shaft and Gear

FIGURE 17

NOTE: Your engine is equipped with a

resistor SPARK PLUG, when replacing

plug also use resistor type.

NOTE: This spark ignition system

meets all requirements of the Cana

dian Interference-Causing Equipment

-

Regulations.

CUTTING DECK REMOVAL

WARNING: Shut the engine off,

remove ignition key, set the parking

brake, disconnect the spark plug

wire(s) and ground against the

engine to prevent unintended

starting before removing the cutting

-

deck.

WARNING: Always wear safety

glasses or safety goggles to protect

-

your eyes while removing the

cutting deck.

For performing service on your tractor and in

order to properly mount some (separately

available) attachments, it may be necessary

to remove the tractor’s cutting deck. To due

so, proceed as follows:

-

•

Place the deck engagement/lift lever in the

engaged (all the way forward) position.

19

-

Page 20

Using a spring puller (Part No. 732-0571)or

•

other suitable tool, disconnect the spring

which is attached to a small hook found on

the left, rear portion of the transmission.

See Figure 18.

Place the deck engagement/lift lever in the

•

BLADES STOP position.

Locate the two belt keeper pins, found on

•

either side of the engine pulley, and use a

1/4-inch socket wrench to remove them

from the lower frame. See Figure 19.

NOTE: When reassembling, make cer

tain belt keeper pins are assembled in

the same locations from which they

were removed.

Unpile the deck belt from around the en

•

gine pulley. Return the deck

engagement/lift lever to the engaged (all

the way forward) position.

Locate the deck anti-sway rod and adjust

•

able deck links found near the front of the

cutting deck. See Figures 20 & 21.

First remove the hairpin clip which secures

•

the anti-sway rod to the front portion of the

cutting deck, then remove the hairpin clips

which secure the adjustable deck hangers.

Retain the hairpin clips.

• Carefully lower the front portion of the

deck to the ground.

•

Remove the hairpin clips which secure the

rear deck hangers to the deck stabilizer

bracket. See Figure 21. Retain the hairpin

clips.

•

Carefully lower the rear portion of the deck

to the ground.

NOTE: For normal service and maintenance,

the deck stabilizer bracket doesn’t need to

be removed from the tractor. If removing the

cutting deck in order to mount a

snowthrower attachment, however, the stabi

lizer bracket must be removed. To do so,

simply remove the hairpin clip which secures

the stabilizer rod to the stabilizer bracket. See

Figure 20.

•

Place the deck engagement/lift lever in the

BLADES STOP position to raise the lift

links up, and out of the way.

•

Carefully slide the deck from beneath the

right side of the lawn tractor.

FIGURE 18

-

-

Deck

Anti-sway Rod

FIGURE 19

Adjustable Deck Links

-

FIGURE 20

Rear Deck Hangers

Hook

Spring

Transmission

Belt Keeper Pins

Deck Belt

Deck Anti-sway Rod

and Hairpin Clip

Stabilizer Bracket

FIGURE 21

20

Stabilizer Rod

Page 21

CUTTING BLADES

WARNING: Be sure to shut the

engine off, remove ignition key,

disconnect the spark plug wire(s)

and ground against the engine to

prevent unintended starting before

removing the cutting blade(s) for

sharpening or replacement. Protect

your hands by using heavy gloves

or a rag to grasp the cutting blade.

WARNING: Periodically inspect the

blade adapter and/or spindle for

cracks or damage, especially if you

strike a foreign object. Replace

immediately if damaged.

The blades may be removed as follows.

Remove the deck from beneath the tractor,

•

(refer to Cutting Deck Removal) then

gently flip the deck over to expose its un

derside.

Place a block of wood between the center

•

deck housing baffle and the cutting blade

to act as a stabilizer. See Figure 22.

Use a 15/16" wrench to remove the hex

•

flange nut that secures the blade to the

spindle assembly. See Figure 22.

To properly sharpen the cutting blades, remove equal amounts of metal from both

ends of the blades along the cutting edges,

parallel to the trailing edge, at a 25° to 30°

angle. See Figure 23.

IMPORTANT: If the cutting edge of the

blade has already been sharpened to within

5/8" of the wind wing radius, or if any metal

separation is present, replace the blades

with new ones. See Figure 23.

It is important that each cutting blade edge

be ground equally to maintain proper blade

balance. A poorly balanced blade will cause

excessive vibration and may cause damage

to the tractor and result in personal injury.

The blade can be tested by balancing it on a

round shaft screwdriver. Grind metal from

the heavy side until it balances evenly.

When replacing the blade, be sure to install

the blade with the side of the blade marked

‘‘Bottom’’ (or with a part number stamped in

it) facing the ground when the mower is in

the operating position.

IMPORTANT: Use a torque wrench to

tighten the blade spindle hex flange nut to

between 70 foot-pounds and 90

foot-pounds.

Hex Flange Nut

Wood Block

Spindle Assembly

FIGURE 22

Blade Separation

-

Worn Blade Edge

Wind Wing

Sharpen Edge Evenly

FIGURE 23

BATTERY

The battery is sealed and is maintenance-free. Acid levels cannot be checked.

•

Always keep the battery cables and terminals clean and free of corrosive build-up.

•

After cleaning the battery and terminals,

apply a light coat of petroleum jelly or

grease to both terminals

•

Always keep the rubber boot positioned

over the positive terminal to prevent short

ing.

IMPORTANT: If removing the battery for any

reason, disconnect the NEGATIVE (Black)

wire from it’s terminal first, followed by the

POSITIVE (Red) wire. When re-installing the

battery, always connect the POSITIVE (Red)

wire its terminal first, followed by the NEGA

TIVE (Black) wire. Be certain that the wires

are connected to the correct terminals; re

versing them could change the polarity and

cause damage to your engine’s alternating

system.

Charging the battery:

If the tractor has not been put into use for an

extended period of time, charge the battery

with an automotive-type 12-volt charger for a

minimum of one hour at six amps.

21

5/8"

minimum

-

-

-

Page 22

WARNING: Batteries give off an

explosive gas while charging.

Charge battery in a well ventilated

area and keep away from an open

flame or pilot light as on a water

heater, space heater, furnace,

clothes dryer or other gas

appliances.

Jump Starting

WARNING: When removing or

installing the battery, follow these

instructions to prevent the

screwdriver from shorting against

the frame.

IMPORTANT: Never jump your tractor’s

dead battery with the battery of a running ve

hicle.

Connect end of one jumper cable to the

•

positive terminal of the good battery, then

the other end to the positive terminal of the

dead battery.

Connect the other jumper cable to the

•

negative terminal of the good battery, then

to the frame of the unit with the dead

battery.

WARNING: Failure to use this

procedure could cause sparking,

and the gas in either battery could

explode.

Cleaning the battery:

Keep the terminals and the top of the battery

clean and free from corrosion. Clean the bat

tery with baking soda or a commercial

battery cleaner. If necessary, scrape the bat

tery terminals with a wire brush to remove

deposits. Coat terminals and exposed wiring

with grease or petroleum jelly to prevent cor

rosion.

CAUTION: Do not allow any cleaning solu

tion to get inside the battery.

Battery Failures

Some common causes for battery failure are:

•

incorrect initial activation

•

undercharging

•

overcharging

•

corroded connections

•

freezing

These failures are NOT covered by your

tractor’s warranty.

TIRES

Recommended operating tire pressure is ap

proximately 10 p.s.i. Maximum tire pressure

under any circumstances is 30 p.s.i. Equal

tire pressure should be maintained on all

tires.

When installing a tire to the rim, be certain

rim is clean and free of rust. Lubricate both

the tire and rim generously. Never inflate to

over 30 p.s.i. to seat beads.

WARNING: Excessive pressure

(over 30 p.s.i.) when seating beads

may cause tire/rim assembly to

burst with force sufficient to cause

serious injury.

BELT REPLACEMENT

-

WARNING: Shut the engine off,

remove ignition key, set the parking

brake, disconnect the spark plug

wire(s) and ground against the

engine to prevent unintended

starting before replacing belts.

For performing service on your tractor and in

order to properly mount some (separately

available) attachments, it may be necessary

to remove the tractor’s cutting deck. To due

so, proceed as follows:

Deck Belt (38- and 42-inch Decks)

WARNING: Shut the engine off,

remove ignition key, set the parking

brake, disconnect the spark plug

-

-

-

wire(s) and ground against the

engine to prevent unintended

starting before removing the cutting

deck.

WARNING: Always wear safety

glasses or safety goggles to protect

your eyes while removing the

-

cutting deck.

•

Remove the cutting deck from the tractor

(Refer to Cutting Deck Removal, for de

tailed instructions).

•

Remove the belt guards (located over

each spindle pulley) by removing the

self-tapping screws which secure them in

place. See Figure 24.

•

Remove and replace the belt, reassemble

following the instructions in reverse order.

Deck Belts (46" Deck)

•

Remove the cutting deck from the tractor

(Refer to Cutting Deck Removal) for de

tailed instructions.

-

-

-

22

Page 23

Self-Tapping

Screws

Springs

Belt Guards

FIGURE 24- 42-inch deck shown

Stabilizer Rod

Hairpin Clip

Stabilizer Bracket

FIGURE 25

NOTE: On 46-inch decks, you must also remove both the deck stabilizer bracket and

the stabilizer rod. To do so, remove the hairpin clip which secures the stabilizer rod to

the stabilizer bracket. See Figure 25.

After the deck is removed (and the stabilizer

bracket and rod), the upper deck belt can be

simply lifted off of the double-pulley located

in the rear, center of the cutting deck.

To remove the lower deck belt:

•

Follow all steps above for removing the

upper deck belt.

•

Remove the belt guards (located over

each outer spindle pulley) by removing the

self-tapping screws which secure them in

place. Refer to Figure 24.

•

Using a spring puller (Part No. 732-0571)or

other suitable tool, disconnect the exten

sion spring from the rear of the cutting

deck belt. This will relieve tension on the

lower deck belt.

•

Remove the lower deck belt from around

the idler pulleys, and the three spindle pul

leys.

•

Reassemble new belts, following instruc

tions in reverse order.

FIGURE 26

Drive Belts (Upper and Lower)

NOTE: The engine pulley must be removed

from the engine’s crankshaft in order to

change the tractor’s drive belts. Doing so re

quires an air/impact wrench.

It is recommended that both belts be

changed at the same.

Place the deck engagement/lift lever in the

•

engaged (all the way forward) position.

Unthread the shift knob and remove the

•

two flange screws which secure the cover

panel in place. Refer to Figure 11. Remove

the cover panel.

NOTE: There is a small yellow wire connected to a spring switch on the underside

of the cover panel. Be careful not to damage

it when removing the panel

•

Using a spring puller (Part No. 732-0571)or

other suitable tool, disconnect the spring

which is attached to a small hook found on

the left, rear portion of the transmission.

Refer to Figure 18.

•

Using a spring puller or other suitable tool,

disconnect the two springs which are at

tached to the rear portion of the tractor

frame. See Figure 26.

•

Place the deck engagement/lift lever in the

BLADES STOP position.

•

Locate the two belt keeper pins, found on

either side of the engine pulley, and use a

1/4-inch socket wrench to remove them

-

from the lower frame. Refer to Figure 19.

NOTE: When reassembling, make cer

tain belt keeper pins are assembled in

the same locations from which they

-

-

were removed.

•

Using an impact gun with a 5/8-inch

socket, remove the hex screw with secures

the engine pulley to the engine crankshaft.

23

-

-

-

Page 24

Flange Nut

Transmission Pulley

FIGURE 27

Carefully lower the pulley off of the crank

•

shaft and remove the belt from around it.

Disconnect the battery cables from the ter

•

minals (disconnect the NEGATIVE (Black)

wire from it’s terminal first, followed by the

POSITIVE (Red) wire).

Detach the battery hold-down rod and re

•

move both the battery and battery tray

from the tractor.

Locate the transmission pulley though the

•

battery tray opening. See Figure 27.

Using an impact gun with a 13/16-inch

•