Page 1

Ownerts

Manual

5

H.P.

20"

Auger

Propelled

SnowThrower

Model

Number

317-262-1

00

Read Safety

Thank

you

lmportant:

Rules

and

Instructions

CarefullY

for

purchasing

an

American-built

product.

WARNING:

This unit

is equipped

with an

iRTeTnsl

cambustion

engine

and

should

not be used

on or

near any unlrDproved

forest-covered,

brush-covered

or

grass-covered

land unlessthe€DOnes

exhhuSlsystem

is equipped

with a_.spark

arrester

meeting applicable

local or state

laws

(if

any).

lf a spark

arrester

[s

gcort

iT\trould

be

maintained

in

effective

working order

by the

operator.

nanrrr

ln the

-State

of bahfornia

the

above

is required by

law

(Secti

on

4442 of

the Cai'i'*

;blic

Resources

Codet

Other

states

may

have

similar

laws.

Federal

laws apply on

federal

lands.

A spark arrestirE

..1'

muffler is

ava

lable

through

your

nearest authorized

service dealer.

CUB

CADET

CORPORATTON

.

P.O.

BOX 368023

.

CLEVELAND,

OHIO

44136-9723

Page 2

BLE OF

CONTEN

CONTENT

Chokc

Control

PAGE

Page 3

-r

1[

wanrurr.rc

Your

snow

thrower was

built to be operated according

to

the

rules for

safe

operation in this manual.

As with any

type

of

TRAINING

MAINTAINING

SAFETY

This

symbol

points

out

important

safety instructions

which, if not followed,

could

endanger

the

personal

safety and/or

property

of

yourself

and others. Read

and

follow

all

instructions

in

this manual

before attempting

to operate

your

snow thrower. failure to

comply

with

these

instructions may result

in

personal

injury.

When

you

see

this

symbol.

heed

rts

warning.

power

equipment,

carelessness or error

on the

part

of

the

oper-

ator can result

in serious injury. lf

you

violate

any of

these

rules,

you

may

cause serious injury to

yourself

or

others.

Read

this owner's

guide

carefully

in its entirety before

attempting to

assen'3€

c. operate

this

machine.

Be completely

familiar with

the controls and the

proper

use of th

s

-a:.

ne

before

operating

it. Keep

this manual

in a safe

place

for

f

uture and regular reference

a^ a

'c,

ordering

replacement

parts.

Never

allow children

under 14

years

old to operate a

snow thrower.

Children

.

.1

,.ea-s

oid and

over should

only

operate snow thrower

under close

parental

supervision.

Onri

9s-9s.s

*"11

acquainted

with

these rules

of safe operation

should be allowed to

use

your

snon :hrower.

No

one

should operate

this

unit

while

intoxrcated or while taking

medication

tbat

rrnpdrrS

the

senses

or

reactions.

Keep

the

area of operation

clear of

all

persons,

especially

small children

and

pets.

Exercise

caution

to avoid

slipping

or

falling, especially

when

operating in reverse

PREPARA.

TION

@2

3.

4.

5.

6.

reparr.

to

protect

eyes from foreign

objects that may

be

thrown from the

machine

in

any

drrec:bon.

OPERATION

15.

Do nol

put

hands

or

te€t near

or under

rotatrng

parts.

Keep

ctear ol discharge

Thoroughly

inspect

the area where

the equipment

is

to

be used

and remove

ar ooor mals

sleds,

boards, wires

and other foreiqn

obtects

7.

Disengage

all

clutches and shift into

neutral

before

slarting

engine.

B Do not

operate equipment wrthout weanng

adequate

wrnler

outer

garments.

Do not

wear

lew-

elry,

long

scarfs or

other

loose

clothing which

could

become entangled

in moving

parts.

Wear

footwear

which will

rmprove looting

on slippery

surfaces

9. Before

working with

gasoline,

extinguish all cigarettes

and

other sources

of

ignition.

Check the

fuel

before starting

the engine.

Gasoline is

an extremely flammable

fuel. Do not

fill the

gaso-

line tank

indoors, while

the engine

is running,

or until engine has

been allowed to

cool at least

two

minutes. Replace

gasoline

cap

securely and wipe

off any spilled

gasoline

before

starting

the engine

as it may

cause a fire

or explosion.

10.

Use a

grounded

three

wire

plug-in

for all

units

with

electric drive motors

or electrrc starting motors

1 1.

Adjust

collector housing

height

to clear

gravel

or crushed

rock

surface.

12. Never

attempt

to make

any adjustments

while engine is running

(except

where

specif ically

recommended

by manufacturer).

'1

3. Let

engine

and machine

adjust to

outdoor temperature before starting to clear snow.

14. Always

wear

safety

glasses

or

eye shields during operation or while

performing

an adlustment

or

opening

and auger

at all times.

Exercise

extreme caution when

operating

on or crossing

gravel

drives, walks,

or

roads.

Stay

alert for hidden

hazards

or

traffic.

Do not

carry

passengers.

After

striking a foreign

object,

stop the

engine,

remove

wire from

spark

plug.

and thoroughly

inspect

the

snow thrower for

any damage. Repair

the damage

before

restarlrng

and operating

the snow thrower.

lf the

snow thrower should

start to vibrate

abnormally,

stop

the

engrne and check immedrately

for

the cause. Vibration is

generally

a

warning

of

trouble

Stop engine whenever

you

leave

the operating

position.

belore unclogging the collector, impel-

ler housing

or discharge

guide,

and making any

repairs,

adjustments, or inspections. Never

place

your

hand in the

discharge

or

collector openrngs.

Use

a stick or wooden

broom

handle

to

unclog the discharge

opening.

Take

all

possible precautions

when leaving the

unit unattended.

Disengage the

collector

impeller,

shift into neutral,

stop the engine,

and

remove the key.

16

tt.

18.

19

20.

Page 4

161

22

I

sroP

I

23.

24.

25.

zo.

27.

MAINTE.

NANCE

&

STORAGE

SAFETY

DECALS

D0

]l0T

USE

HAi{DS

T0

uilcLoc

DISCHARGE

CHUTE.

This safety decal

is located on

the auger housing.

lt is very im-

portant

that

you

follow its

in-

structions.

Also replace it, if

damaged.

21.

When cleaning,

repairing,

or

inspecting,

make certain

collector/impeller

and all

moving

parts

have

stopped.

Disconnect

spark

plug

wire and

keep

away

from

plug

to

prevent

accidental

starting.

Do

not run

engine

indoors,

except

when starting

engine

and transporting

snow thrower in or

out

of building.

Open

doors.

Exhaust

fumes are dangerous.

Do not clear

snow

across

the face

of slopes.

Exercise

extreme

caution

when changing

direc-

tion on

slopes.

Do not attempt

to clear

steep

slopes

Never operate

snow

thrower

without

guards,

plates,

or other

safety

protectton

devices

in

place

Never operate

snow

thrower

near

glass

enclosure,

automobiles,

window

wells, drop

off, etc .

without

proper

ad.justments

of

snow

thrower

discharge

angle.

Keep

children and

pets

away

Do

not overload

machine capacity

by attempting

to clear

snow

at

too

fast a rate.

Never operate

the machine

at

high

transport

speeds

on slippery

surfaces.

Look behind and

use care

when backing.

28.

Never

direct

discharge

at

bystanders

or

allow

anyone

in front of unit.

29.

Disengage

power

to collector/impeller

when

transporting

or

not

in

use'

30. Use

only

attachments

and accessories

approved

by

the

manufacturer

of snow

thrower

(such

as

wheel

weights, counter

weights, cabs,

etc.).

31.

Never operate

the snow

thrower

without

good

visibility

or

light.

Always be

sure of

your

footing

and

keeo a

firm

hold on the

handles.

walk,

never

run

with the snow

thrower.

32.

Muffler and

engine

become

hot and

can

cause

a burn.

Do

not touch'

33.

Check

shear

bolts,

engine

mounting

bolts,

etc.,

at frequent

intervals

for

proper

tightness

to be

sure

equipment

is in safe

working condition.

34.

Never store

the

machine

with fuel

in the

luel

tank

inside a building

where

ignition

sources

are

present,

such

as

hot water

and

space

heaters,

clothes

dryers,

and

the

like. Allow

engine

to cool

before

storing

in any

enclosure.

35.

Always

refer to owner's

guide

instructions

for

important

details

if

snow

thrower is

to be stored

for an extended

period.

36.

Run machine

a

few

minutes after

throwing

snow

to

prevent

freeze up

of collector/impeller.

37. Check

clutch

controls

periodically

to

verify

they engage

and

disengage

properly

and

readjust

if necessary.

Refer

to owner's

guide for adjustment

instructions.

The safety

decals

are

located near any

area

of

potential

danger

and are

easily

visible

to the opera-

tor. These

are

meant to

warn the operator

of

the danger.

lt is

very important

to

follow the

instruction

on

these decals

to

maintain safety.

This

safety

decal

is

located

on

the discharge

chute.lt

is

very

imponant

that

you

follow

its

instructions.

Also

replace

it.

if

damaqed.

AI|()ID IIIJURY

FR(IM

ROTATIIIG

AUGER.

I(EEP HAI{I)S,

TEET,

AI{O CLOTHI]IG

ATYAY!

Page 5

ASSEMBLING

YOUB

UN|T

TOOLS

REQUIRED

CHUTE

ASSEMBLY

FUEL

&

OIL

MIXTURE

.

Socket wrench

set

.

A

pair

of

pliers

.

Screwdrivers

(Phillips

head)

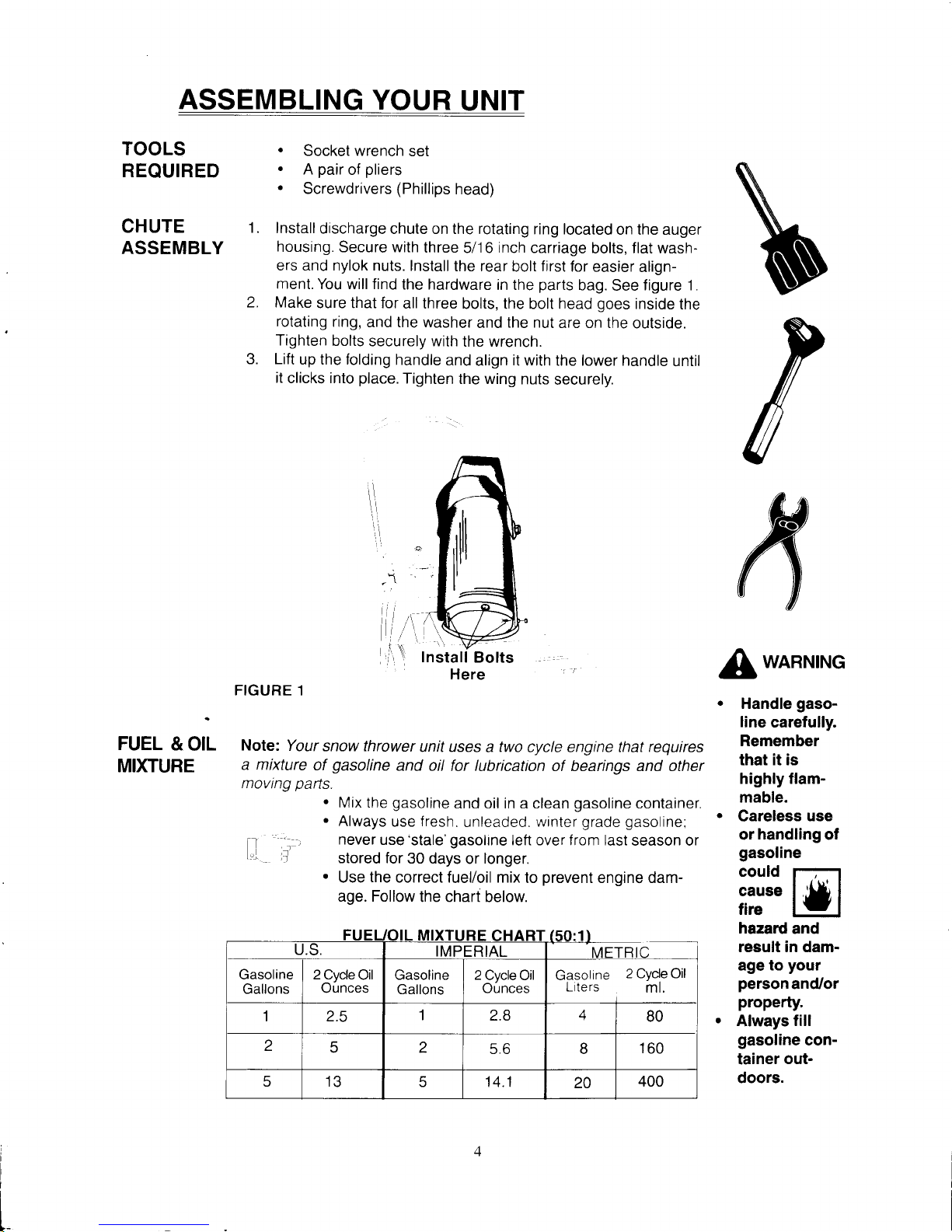

Install

discharge

chute on the rotating

ring located

on the auger

housing.

Secure with

three

5/16

inch

carriage

bolts, flat wash-

ers and nylok

nuts. Install

the rear

bolt

first

for

easier align-

ment.

You will find

the hardware

in the

parts

bag.

See

figure 1.

Make

sure that for

all three

bolts, the bolt head

goes

inside

the

rotating

ring,

and the washer

and

the nut

are on the

outside.

Tighten

bolts

securely with

the wrench.

Lift

up the folding

handle

and

align

it

with the lower handle

until

it

clicks into

place.

Tighten

the wing

nuts

securely.

Install

Bolts

Here

:

'

FIGURE 1

Note:

Your

snow thrower

unit uses a two

cycle engine that

requires

a mixture

of

gasoline

and oil for lubrication

of bearings and other

moving

parls.

.

Mix the

gasoline

and oil in a clean

gasoline

container.

.

Always

use

fresh.

unleaded.

winter

grade gasoline

I

a.,

never

use'stale'gasolne

lett over f rom last

season or

teL

tr

stored for

30 days

or

longer.

.

Use

the

correct fuel/oil mix

to

prevent

engine dam-

age. Follow

the chart

below.

2.

J.

\

r

I

't.

I

wnnNtNG

Handle

gaso-

line

carefully.

Remember

that it is

highly flam-

mable.

Careless

use

or

handling

of

gasoline

could

r--t

ff:*u

hazard

and

result in damage

to

your

person

and/or

property.

Always

fill

gasoline

con-

tainer

out-

doors.

i

I

L

S.

IMPERIAL

ME

Gasoline

Gallons

2 Cvcle

Oil

Ounces

Gasoline

Gallons

2

Cvcle Oil

Ounces

Gasoline

2 Cyde Oil

Liters

ml.

'l

2.5

1

2.8

A

BO

z

z

5.6 B

160

6

1?

5 14.1

20

400

Page 6

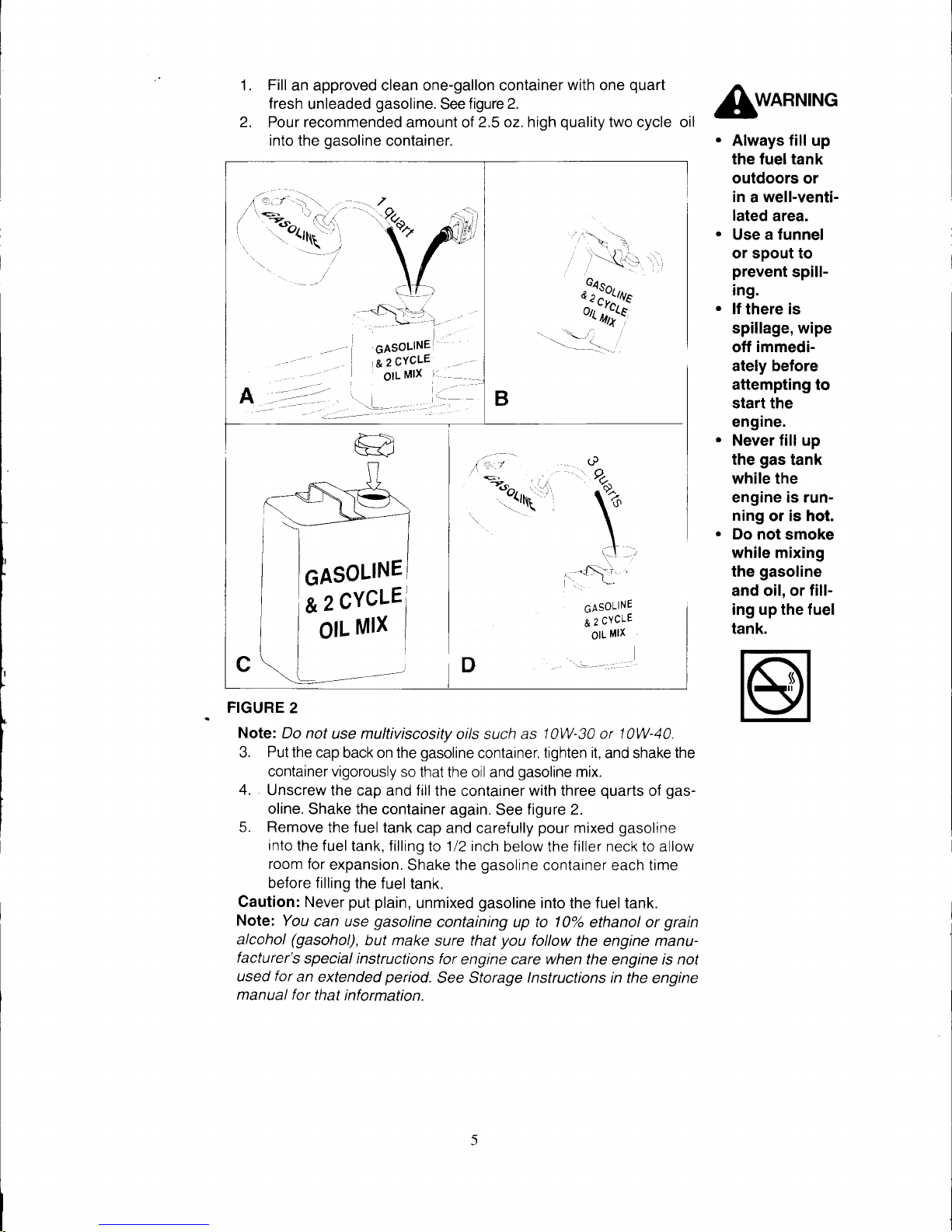

1.

Fill

an approved clean one-gallon container

with one

quart

fresh

unleaded

gasoline.

See

figure 2.

2. Pour recommended

amount ol

2.5

oz.

high

quality

two cycle

into the

gasoline

container.

oil

WARNING

Always fill

up

the fueltank

outdoors

or

in

a well-venti-

lated

area.

Use a funnel

or spout to

prevent

spilling.

lf there is

spillage, wipe

off

immediately before

attempting

to

start the

engine.

Never fill up

the

gas

tank

while the

engine is running

or is hot.

Do not

smoke

while mixing

the

gasoline

and oil,

or filling up the fuel

tank.

\,

o?fgj'u

ou

iif,

-Y--i..,

1

d

Yz

t

-\:i

GAsoLINE

I

&2

cYcLE',)

2\tt

vl--,

olL

Mlx

I

GASOLINE

&

2

CYCLE

olL

Mlx

FIGURE

2

Note:

Do not

use multiviscosity

oils such as

10W-30 or 10W-40.

3.

Put

the

cap back on the

gasoline

container,

tighten it,

and shake

the

container vigorously

so that

the oil and

gasoline

mix.

4.

Unscrew

the cap

and

fill

the container with three

quarts

of

gas-

oline.

Shake the container

again. See

figure 2.

5. Remove

the fuel tank

cap

and carefully

pour

mixed

gasoline

into

the fuel

tank, filling to 112 inch

below the filler neck to allow

room for

expansion.

Shake the

gasoline

container each time

before filling

the

fuel tank.

Caution: Never

put plain,

unmixed

gasoline

into the fuel tank.

Note: You

can use

gasoline

containing up to

10%

ethanol or

grain

alcohol

(gasohol),

but make

sure

that

you

follow the engine manu-

facturer's

special instructions

for

engine

care

when

the engine is not

used

for

an

extended

period.

See Storage lnstructions in the

engine

manual

for that

information.

Page 7

N

CONTROLS

Note:

/t is

very important

to know

and understand the

controls

and

.A,

safety

devices

of

your

snow thrower

before

you

attempt

to operate

AWARNING

THROTTLE

IGNITION

SWITCH

CHOKE

CONTROL

PRIMER

BUTTON

ELECTRIC

STARTER

AUGER

CLUTCH

CONTROL

DISCHARGE

CHUTE

CONTROL

SNOW

DISCHARGE

DEFLECTOR

This

deflector is

used to

control the

distance that

the

snow

will

be thrown.

t--l

it.

Make

sure that

the operator

of the

snow thrower has

read

:

lts |

this manual

and understood

the

Safety Operation Rutes

on

'

The

operation

pages

2

& 3 before running

the unit for

the first time.

Refer

of

any

snow

to the

manual

again for

ctarification whenever

any

question

arises.

thrower

can

result

in for-

The

snow thrower

does not have

a

remote throttte

for

controlling the

:'-T-obi"g-

:

3:

::l I I

3

:

3

::: :::T;ff

i:i ll:."*',:".'"W

l"mml;i

"'"'l

n

"-

llijfu

tr

This

switch

is

used to start

and

stop the engine. Insert

key in the

eyes

resulting

switch

and turn

switch to

ON

position

to start the

engine;turn

switch

in

severe

eye

to

OFF

position

to

stop the

engine.

damage.

Pro-

tect

your

eyes

This

control

is

used to

enrich the fuel

mixture

to start a cold

engine. with

safety

A warm

engine will

normally

not require

choking to

start.

You

can

glasces

or eye

locate

the

operating

position

for

the choke control on the

decal.You shie|ds

when-

may

have

to

partially

close

the

choke to allow the cold

engine to run ever

you

oper-

smoothly

until it warms

up.

ate

this

unit.

.

This

machine

This

button helps

in

starting

a cold engine

Depress

the

primer

but-

can

be danger-

ton to

supply

extra

fuel

mixture

to

start

the

cold engrne. Do

not

ous if used

prime

a warm

engine

since it will flood

the

engine.

carelessly.

So

On electric

start models,

plug

the

cord for the

electric

starter swrtch

be ca.reful

in

into

the receptacle

on

the unit. Next,

plug

the

other end into

a t20V

handling

it'

AC household

receptacle.

Next

depress the

starter

button to start

'

Never ignore

the motor

and

crank the

engrne.

safety

devices

Note: You

can start these

electric

start engines manuatty with

the

ortYTass

starter rope.

See

instructions

on how

to use electric

starter.

.

Never

operate

This

control

starts and

stops the

auger. Pull the

control back against

ll"

the handle

to

start the

auger; release

the

control to stop the auger.

thrower

with-

When the

auger

touches

the

ground

the

snow thrower moves for-

out

all

guards,

ward. Do not

manually

turn

the

auger

in

a clockwise

direction

covers,

and

because that

will loosen

the

belt

and unthread the

pulley

shields in

place.

This

control is

used to rotate

the

discharge

chute to the desired

direction. Turn

crank

clock-

wise

to rotate

the chute to

\ \ \N- -.1/ l.r Snn*

\l \r -/t/\

Snow

-r=i4

-_/.

_'-.-

Dischar.

!ru /

**

*Derrectr

rl

\\\\

|

\\

t =

Spark

rition

--

,6i

Plug

the right, turn

it counter-

.

,1q

-.<.

r--ts

Discharge

clockwise to rotate

the

Ayg"! 7b

,

vYw

*

Derlector

chute to the left.

""#f:i

\\

|

,

=)

lgnition

\,

\

Switch -',

Move deftector

up to throw

e'i;1;"tffi.Discharge

.

^h^,^, +, ,r+hav. ma,,a ^^{r^^

'

'

t

/'-

I

-{

\l

Chute Control

snow

further;

move

flgflon-

Choke

tor down to

throw snow

c'J},i',Jr E\11

--f_l!!r$

tFql'l:

FIGURE

3

6

ctoser.

Starter

Page 8

opennnruc rne

urur

Note:

The

snow

thrower

engine is

designed to operate

at cold tempera-

tures and will

be difficult

to

start in warm weather.

Avoid

operating

your

snow thrower in warmer

conditions

since

engine

may

vapor lock

and stop

running

after a short time.

Never

run the

engine

indoors

or in enclosed,

poorly

ventilated

areas.

Engine

exhaust

contains

CARBON

MONOXIDE,

an

ODORLESS,

DEADLY

gas.

Pull

Start Models:

See figure

4.

1. Insert

key

in ignition

switch and

turn key to

ON

position.

2. Move

choke control lever

to the

ON

position

on cold engines. lf the

engine

is warm

from

operation,

this

step

may

not

be

necessary.

3.

Push

the

primer

button two

or three times holding

finger

over

vent

hole. Allow

a

few

seconds between

each

push

for

air

to

enter bulb

through

vent hole.

You may have

to

prime

more for

the

initial

start at

temperature

below 150F/-1OoC.

4.

Grasp the starter rope

handle

and

slowly

pull

out the rope

until

you

feel a resistance.

Allow

the

rope to rewind

slowly,

then

pul

it

out rapidly

to start

the

engine.

Let the rope return

slowly to

the

starter. lf the

engine

does not

start after three

pulls, push

primer

button one

more

time

and

pull

the

starter rope.

FIGURE

4

----'

5.

Once

the

engine

starts

and

gradually

warms

up, move the

choke

lever

to the

OFF

position.

Be

prepared

to

move the

choke

lever

to

the

ON

position

if

the

engine

sputters

during

warm

up.

6. Allow

the

engine

to

warm

up before

snow throwing.

The

engine

will

operate

at full

throttle when

it warms

uo.

Electric

Start

Model:

See figure

5.

Note:

Ihe

electric

starter is

designed

to

operate on 120

votts AC

household

power

supply

using

the

power

cord supptied with

your

snow thrower.

When

using the

power

cord, match

the wide

btade

of

the

plug

to the

wide

slot of

the receptacle.

7. Follow

steps 1-3

from

"pull

start model"

section.

B.

Plug

power

cord into

receptacle

on the starter

switch first,

then

plug

the

other

end

of the

cord into

a

standardl20 volts

AC

household

outlet.

Do

not

use

any extension

cord to lengthen

the

power

cord

supplied

with the

unit.

WARNING

STARTING

ENGINE

.

Wear

safety

glasses

while

operating

the

unit.

.

Never

direct

discharge

at

bystanders

or

allow anyone

in

front

of the

unit.

.

Never

direct

discharge

towards

win-

dows.

.

Neveroperate

the

unit

without allguards,

clvens, and

shields

in

place.

.

Stop the

engine

whenever leaving

the operating

position.

.

Stop the

engine,

remove the

key, and

dis-

connect

the

spark

plug

before unclogging

auger

housing

or

discharge

chute and/or

before

mak-

ing

repairs

or

adjustments.

.

To

reduce

the

risk

of fire,

keep

the unit

clean

and

free

from

spilled

gas,

oil;

and

other

I

debris.

Page 9

a Make sure

that there

is no moisture

on the cord

ends

or

.r.

A

receptacles

when

plugging

in the

cord.

AWARNING

9.

Push the starter

button

to

crank

the engine.

Do

not crank

the

engine

for more

than 15 seconds

without allowing

the

electric

'

Do not use

starter

to cool

for around

10 minutes.

Attempt

further cranking

snow tltrower

only atter

the starter

has

cooled

down.

on surfaces

4\

Do not

push

the

primer

button

while

the engine

is

above

ground

A

o"i"g

"I""k"d.

level'

such

as

Electric start engines

can be

severely

damaged

if

you

the roof of a

do not follow

proper

starting

instructions.

building'

Release

starter

button

once

the engine starts

and

gradually

move the choke

lever to the

OFF

position.

Disconnect

the

power

cord

from

(i)

household

receptacle

and

then from

(ii)

starter

switch

on the snow

thrower.

Store

the

cord

in

a dry

place.

10

rnE-

--

S[ey

away

frorn the

front

of

your

snow

t|trcrer

unit

whcn the

augGf

is turnIng.

Avoid

plcking

up

gravel

wfth the

augor

since

this could

damage

the

unit and/or

cause

serious

injury

to the

operator.

Always

be

alert to

the

hidden

hazardsthatmight

be struck

by

the

auger.

Should

you

hit a

foreign

object

with

the

auger

stop

the

engine

imme-

dlately,

remove

key,

dlsconnect

sparkplugand

inspect

the

machlne

for

any

damage.

Repair

dam-

age

before

operating

the

unit

again,

11.

.--,/Y

;'-

Starter---=--.

itrS.Button\g

-,

!v/

(9

STOPPING

ENGINE

THROWING

SNOW

.1.

2.

.A.

Always disconnect

power

r Ievn

A

cord

from the

household receptacle

first, then

unplug

t.1

';i

r-=\

\.{ir

\

\./

\

/,/

{==/'

from

starter

switch.

Turn

ignition key to the OFF

position.

Remove the

key from the switch

if

you

are

leaving the

operating

position

and/or

before

making repairs

or adjustments.

Allow the

unit

to

run for a few

minutes before

storing.

Note:

Ihe snow

thrower will be

pulled

forward by

the auger as

the

handle

is raised.

The

unit

will also

move

forward

when the auger

comes

in contact

with the accumulated

snow.

1. Before entering

the area

where snow

needs

to be cleared,

,adjust

the

position

of the discharge

chute

so

that snow

will be

thrown

in

the

desired direction.

Note: Snovv should

not

be

thrown towards

buildings,

automobiles,

or

people.

Always try to throw

snow down

wind.

2. Adjust the deflector

on

top

of

the discharge

chute

up or

down

to

control

the distance

that the snow

will

be

thrown. See

figure

6.

n

Disengage

auger drive before

A

adiusting

discharge

deflector.

3.

Review the area

to be cleared

of

snow

and establish

a

pattern

for

the

most efficient

snow

removal.

4.

Inspect the area

for

possible

obstructions

like

gravel

and

rocks.

Remove,

if

any.

5.

Begin snow

removal

by clearing

a

path

down

the center

of a

walk or

driveway along

your

pattern

for snow

removal. Gradually

widen

the

path

throwing

snow

to both sides.

Allow

the

snow

thrower

to

move

the snow at

its own

pace.

6.

When clearing

wet and

heavy snow,

you

may

have

to

push

down

the

handle and dow

down.

But allow

engine

to work

at

f ull

throttle'

Lower

The

Chute

For

Shorter

Distance

FIGURE

6

FIGURE 5

Page 10

ADJUSTMENTS

To avoid serious

bodily injury on

the

job

when

performing

adiustments,

maintenance or

lubrication,

stop

the engine,

remove

key from the switch

and disconnect the spark

plug.

Follow safety

instructions

mentioned

here

and safety

labels on the unit.

REMOVING

ENGINE

COVER /COWLING:

ln many of the adjustment and

service tasks,

you

will

have to

first remove the en-

gine

cover/cowling,

perlorm

the task, and

reinstallthe cover.

A. Remove key from the ignition switch.

B. Remove the three screws

holding the discharge

chute

to the rotating

ring.

Remove the chute.

See

figure 7.

C.

Remove the two hex bolts

from

the

top of the engine

cover.

D. Remove two screws

and

flat washers

each

from

inside the auger

housing,

rear of the cover, and both sides of

the cover.

E. Remove the

fuel

tank cao and

lift the

cover and

cowling carefuily up and

away

from the engine exhaust

pipes.

Reinstall

the

cap on

the fuel tank. Do

not lose

the hardware.

During

reassembly of cover and cowl-

ing, remove

fuel tank

cap

first. Next,

make sure

that the metal

grommet

for

engine starter

rope is in

position

between cowlings.

The

tabs at

lower

front

of cover must be

positioned

to

the inside

of belt cover on

the left and

inside

the lower

cowling on

the right.

Leave retaining

screws loose until all

are

in

place,

then tighten them

securely. Reinstall fuel tank

cap.

La.

FIGURE

7

AUGER

Note:

Ihe length

of the auger ctutch cable

is adjustable,

However,

you

wilt not have to do

CLUTCH

this frequently

since the operating tension

on the drive belt

is maintained by the clutch

CABLE

engaging

spring on

the

end of

the

cable.

.

lf the auger turns slowly

under

heavy

load

or

you

hear the drive belt

squeal

,

when

entering

heavy

snow, reduce

the length of

the

cable.

This will increase

the

pressure

applied

by the idler

pulley

on the drive

belt.

.

lf

auger

continues

to turn

after

the clutch control

is released, the cable is too

tight. Increase

the

length

of

the cable so that

the

cable

is

slightly slack

when

clutch

control

is released.

1.

Access

the

clutch cable adjusting

nuts

by

removing the engine cover and cowling.

2.

Measure the

spring while the

clutch

control on

the handle is in the disengaged

posi-

tion. Record

this measurement.

3.

Pull

the

clutch control

against the

handle

and

again measure the spring.

Record

this

measurement.

4.

Compare the

two measurements - the figure obtained with the spring extended

should be 7/16th inch

greater

than with

the

spring unextended.

lf it is not,

you

will

need

to

alter

the lenqth

of the

cable.

I

1l

I

I

I

i

I

I

I

I

l'

Page 11

6.

5. To reduce

or extend the lengrth

of the

clutch

cable,

adjust

the

nuts

on the clutch

cable.

See

figure

8. Reducing

the

cable

lengh

will increase

idler

pulley pressure

on

the belt.

Use extreme

caution when

mak-

ing

adjustments

that require

engine to

be running.

i,..:

_.

Keep

hands, feet,

hair

and loose

clothing

away from

any moving

parts.

Start

the

engine

and

pull

back on

clutch

control to

operate the

auger.

Release

the

clutch

control and

check to

be sure that

the auger

stops turning.

FIGURE

Cable must have

some slack when

the

clutch

control is released.

lf the

auger

continues to

turn after the

clutch

control is released,

the

cable is too tight.

Adlust the nuts acccrdrngly.

8.

Reinstall

the

engine

cover/cowling

and

secure

with

the

correct ha.dware.

.

The

carburetor

is

properly

calibrated

and

pre-set

at

the factory

for

eff

icrent

cold

weather

operation. There

are no

adjusting

screws on the

carburetor

.

lf

you

feel,

during operation

of the snow

thrower,

that

the

carburetor

is not

providing

adequate fuel

supply

to

the engrne,

contact

your

nearest

Authorized

Tecumseh

Ser-

vice

Outlet

for

service.

CARBURE.

TOR

I

*l

-,

.

I

\

j'

I

b*"-

Page 12

MAINTENANCE

To

prevent

accidental

starting

of

engine

during

maintenance

or service,

always

remove

ignition

key

from switch.

Apply a few drops

of light

machine oil

to the upper

end

of the

clutch control

cable.

Wipe off any excess

oil.

This

will ensure

free

movement of cable

through

outside casing.

See

figure 9A.

The drive

pulley

end of auger shaft

is supported

by a

sealed

ball

bearing

and

requires no lubrication.

The ball

bearing

on

the other

end of

the

auger

shaft

is also sealed

and

will

not

reouire

lubrication.

At the beginning

of each snow

throwing season,

remove dis-

cl'rarge

chute and

generously

lubricate the steel

flange

at the

back

of

the rotating

ring with light

grease

such

as

Lubriplate.

Rotate the

ring with crank to distribute

the

grease.

See

figure 98.

Remove

the belt cover and

lightly apply

oil to the

pivot point

for the idler

pulley

arm.

MAKE

SURE

THATYOU

DO

NOT

SPILL OIL ON

THE BELT

OR

THE

PULLEYS. See

figure 9C.

The

two-cycle engine used

on this snowthrower

is

lubricated

by

the

gasoline/oil

mixture. Observe

recommended

gasoline

to

oil

mixture

ratio

shown on

pages

4 & 5.

The

drive belt

idler

pulley

has

a sealed

bearing

that

requires

no lubrication.

Remove key from the ignition switch

and disconnect

spark

plug.

Remove the belt cover.

Remove

the engine cover/cowling

following

instructions on

page

9.

Move the

auger control bail

on

the han-

dle and slio the belt out

from

between

the brake lever

and

the

roller

and away

from

the idler

pulley.

See

figure 10.

Remove

the belt from the engine and

1

auger

pulleys.

Install

the new belt

around

the engine

and auger

pulleys

and underneath

idler

pulley.

THE

RIBBED

SIDE OF

THE

PULLEY MUST

BE INSIDE, AGAINST

THE AUGER AND

ENGINE PULLEYS.

Slip belt into

place

between the brake

lever

and the roller.

LUBRICATE

FIGURE 9A

-

\:,

.,,'

n'6t

-

, I

\(-)

FIGURE 98

FIGURE 9C

Removing

Belt Cover

ln

many of

the maintenance

tasks,

you

will

have to

first remove

the

belt cover,

perform

the

task, and

reinstallthe

cover.

A. Remove

key

from the

ignition switch.

B.

Remove

the four screws

from

the side cover.

C.

Remove

the cover.

D. Lubricate

the

pivot point

and

reinstall

the cover

in

reverse order

LUBRICA.

TION

REPLACING

DRIVE

BELT

'1.

2.

4.

5.

6.

1.

2.

?

4.

q

o.

7.

1l

FIGURE

1O

Page 13

8.

q

4.

start

engine; engage

and

disengage auger

clutch control

to be sure that

the

auger

stops turning

when the

clutch control is released.

lf the

auger

does not

stop turning

when control is

released,

adjust the tension

on the

clutch control

cable following

instructions

on

page

6.

Reinstall

the

belt cover

and the

enoine cover/cowlino.

10.

REPLACING

1.

SHAVE

2.

PLATE

SERVICING

1,

SPARK

2.

PLUG

^

Remove

key from

ignition

switch.

Remove

the three

screws and nuts

securing

the

shave

plate

to the

auger housing.

Save the hardware.

See

figure

1 1.

Remove

the worn

blade.

Installthe

new

blade

and

secure

it

with the

three

screws

and nuts

ear-

lier removed.

Remove

key

from the

ignition

switch.

Remove

the

engine

cover following

instructions

on

page

1 1.

Disconnect

wire from

the

spark

plug

and remove

the

plug.

See figure

12A.

Inspect

the

plug

and

clean

carbon

deposit

from the

electrodes

with

a

wire

brush.

lf the

plug

is

burned or

pitted.

replace

it

with a new

plug (part

# 731-0732)

as

recommended

in

the

engine

manual.

Adjust

the

gap

between

electrodes to

.030

inch

using a wire feeler

gauge.

See

figure

128.

Install

the

plug

and tighten it firmly.

Reconnect

the

plug

wire.

8.

Reinstall

the

engine

cover/cowling.

FIGURE 12A

Electrodes

.030 Gap

FIGURE

128

FIGURE 11

4.

tr

Shave

Plate

Bolts

t2

Page 14

STORAGE

DRAIN CAR.

BURETOR

Carburetor\

'

Never

store

unit

with fuel

in

tank

in

poorly

venti-

lated enclo-

sures,

where

fuelfumes

may reach an

open flame,

spark

or

pilot

light as on

fur-

nace,

water

heater,clothes

dryer,

etc.

.

Gasoline

is

highly

flamma-

ble and cars

F,*f6l

fiun

lEvl

in serious

fire

hazard

result-

ing in damage

to

person

and/

or

property.

.

Drain

fuel into

approved container outdoors andaway

from arry open

flame.

.

Makesurethat

the engine is

cool

to the

touch before

you

start

draining the

fuel.

',:G

\FsTlP--2

/'ffi

DRAIN FUEL

1.

CLEAN U}IIT

1

2.

LUBRICATE

1

Z.

STOP

COR.

ROSION

SERVICE

PARTS

STORE UNIT

3.

Handle

gasoline

carefully.

Drain fuel in approved container

outdoors

and

away

from open

flame.

Do not smoke.

Remove all

fuel from

carburetor

and

fuel tank

to

prevent gum

deoosits.

Drain

fuel into approved container

outdoors

and away

from

any

open

flame. Make sure that the engine

is cool to

the touch.

Do

not

smoke.

Dispose off the

fuel in an

EPA-approved

place.

Run

engine until

the fuel tank

is

empty

and

the engine

stops

due to lack of fuel.

lf

you

had used

gasohol,

follow the

above

steps.

then

put

1/2

ptnt

of fuel-oil mix

(mixed

arcording

to chart on

page

4)

and

run engine

till

fuel tank is dry For

more

details. consult

engine

manual.

Clean

your

snow thrower unit thoroughly.

Wipe

all surfaces

with a rag.

Lubricate wheel hubs.

auger clutch

control bar

with oil.

Lubricate discharge chute

flange. Follow

instructions on

page

8.

Pull

starter handle slowly until

you

feel a resistance

from com-

pression

pressure.

Stop

pulling

the handle. Release

the

starter

tension slowly

to

prevent

engine

from reversing from compression

pressure.

This

position

will

close

the intake and exhaust

ports

and

pre-

vent

corrosion

of

the

piston

and

the cylinder bore.

Inspect

unit

for

damaged or missing

parts

and replace

these as

needed.

Follow

the illustrated

parts

list to order

parts.

Store the

snow

thrower unit indoors,

if

possible,

and cover to

keeo

off dust

and dirt.

1.

3.

1.

Note: /f the unit

is to be

left

unused

for

30

days

or more,

or

if

the unit

a

is to be stored

for the

it atitii,

ir"p,^r"

inl" snow

thrower

fotnwing

A

WARNING

these

instructions

for storaee

1. Locate the bowl

drain below

the

carburetor.

See

f igure 14.

2. Press upward on

bowl drain

and

drain

the carbure-

tor.

(This

is

appli-

cable only

when

your

unit

is

so

equipped.)

Bowl Drain

FIGURE

14

IJ

Page 15

BLESHOOTING

PROBLEM

POSSIBLE

CAUSE REMEDY

Engine

does not

start

1. Key

not in

ON

position

2.

Choke in

OFF

position

3.

Fuel

tank empty

4.

Old

"stale"

fuel

mixture

5. Faulty

spark

plug

6. Engine not

primed

Turn key to

ON

position

Move choke

to ON

position.

Fill fuel tank with

fuel-oil

mix.

Drain the

stale fuel

mixture;

refill

with fresh fuel

mixture.

Replace

spark

plug.

See

page

12.

Push

primer

button two

or three

times following

starting

instructions.

Engine runs

erratic,

sputters

12Incorrect

spark

plug

gap

Choke in

ON

position

after

engine

has

warmed

up

Fuel

contaminated

with

water

and/or

dirt

particles

Gas cap vent hole

plugged

Adjust

gap

to .030".

Move

choke to

OFF

position.

Drain and refillwith fresh

fuel

mixture

Clean

vent

hole

or

replace

cap.

Unit does not

throw snow

'1.

Loose

or broken

drive belt

2. Incorrect

control cable

adjustment

3.

Discharge

chute clogged;

foreign

object lodged in

auger

4.

Carburetor

not supplying

enouoh fuel

Adjust or replace

belt

See

page

1 1.

Adjust

cable length.

See

pages

g

and 10

Stop engine, remove key

and

clean

the

discharge

chute.

Contact

the nearest

Tecumseh

service outlet

Auger

does not stop

turning

when

control is released

1.

lncorrect

adjustment

of

control

cable

Adlust

cable length. See

pages

9

and 10.

Unit vibrates

excessively

1.

Loose

parts

2. Damaged

auger

Stop engine, remove key

and check.

Make necessary repairs;

tighten

bolts.

Take

snow

thrower

to an

authorized

service dealer.

Unit

loses

power

1.

Spark

plug

wire loose

2.

Gas

cap

vent hole

plugged

3. Exhaust

port plugged.

Connect

and tighten spark

plug

wire.

Bemove

ice

and snow from

cap, and

make

sure that the

vent

opening is

clear.

Clean the exhaust

port;

see engine

manual for instructions.

Follow step-by-step

instructions

and observe safety rules to make

adjustments and

repairs

on

your

snow thrower.

For repairs

and adjustments

beyond those

listed above,

please

contact the tactory

or authorized service dealer

near

you.

\

t4

Page 16

HEX CAPSCREW

CARRIAGE

BOLT

PLAIN

WASHER

LOCK WASHER

HEX

CAPSCREW

IDENTIFICATION

Shown

below

are actual

size

hex heads for

standard

screw

sizes.

Example:

a114" screw

has a 7/16 head and thus

requires

a7116 wrench.

To measure

length, use the scale below.

STANDARD

FASTENER

3/4"

Head

screw with

1/2"

S.D.

5/8" Head

screw

with

7/16" S.D.

I

Screw

Shaft

/

Diameler

J

112x2

\crew

Length

SAMPLE:

NUT IDENTIFICATION

lnside

Diameter

l5

IDENTIFICATION

CHART

Hardware

sizes are

given

throughout

this

manual.

lf a

washer or nut

is identified

as

"washer,

112" or

"nul,112",

this

means the

inside

diameter

is 1/2 inch.

lf

a screw

is identified as

"screw.

112 x 2", this

means

the shaft

diameter

is 1/2 inch

and

the shaft of

the

screw

is

2

inches long. lf a screw

is

identified as

"screw,

112-16 x

2", the

number

"16"

means

that

the screw

has 16

threads

per

inch.

SAMPLE:

SCREW

IDENTIFICATION

Shaft

Diameter

Ooooo

9/16"

Head

112"

Head

7/16" Head

screw

with

screw

with

screw

with

3/8" S.D.

5/16' S.D.

1/4"

S.D.

S.D. = Shaft

Diameter

WASHER

AND

NUT IDENTIFICATION

Place

the washer

or nut

on the

above scale to

determine the

in-

side diameter.

The

actual

inside

diameter

can

vary 1116 inch.

Use the scale

for

comparison.

0

3

4

t

i2

1/2

t/2

1/2

3/4

3/4

1.4

1/4

3/4

3/4

1/4

1/4

Nut,

'U2

Page 17

TORQUE

SPECIFICATIONS

FOR

STANDARD

MACHINE

HARDWARE

TOLERANCE!2Oo/"

srzE

SAE

GRADE

#2

.o

SAE

GRADE

#5

a

SAE

GRADE

#8

e9

In./Lbs.

Ft./Lbs.

Nm.

ln./Lbs.

Ft./Lbs.

Nm.

ln./Lbs.

Ft./Lbs.

Nm.

8-32

8-36

10-24

10-32

1t4-20

1t4-28

5/1

6-1

8

5116-24

3/8-16

318-24

7116-14

7/16-20

112-13

1t2-20

9t16-12

9/1

6-1 8

5/8-11

5/8-18

314-10

314-16

718-9

718-14

1-B

1-12

19

2.1

20

2.3

27

3.1

31

3.5

66

7.6

76

8.6

11

15.

12

16.3

20

27.2

23

31.3

30

40.8

35

47.6

50

68.

55

74.8

65

88.4

75

102.

90

122.4

100

136.

160

217.6

180

244.8

140

190.4

155

210.8

220

299.2

240

326.4

30

3.4

31

3.5

43

4.9

49

5.5

--6-

1d3-

10

13.6

17

23.1

19

25.8

30

40.8

35

47.6

s0

68.

55

74.8

75

102.

90

122.4

1 10

149.6

120

163.2

150

204.

180

244.8

260

353.6

300

408.

400

544.

440

598.4

580

788.8

640

870.4

41

4.6

43

4.9

60

6.8

68

7.7

-T

16.3

14

19.

25

34.

25 34.

45 61.2

50

68.

70

95.2

80

108.8

1

10

149.6

120

163.2

150

204.

170

231.2

220

299.2

240

326.4

386

525.

420

571.2

600

816.

660

897.6

900

1,224.

1,000

1,360.

NOTE:

1. These

torque

values

are

to be

used

for all

hardware

ex-

cluding:

lock

nuts, selt-tapping

screws,

thread

forming

screws,

sheet

metal

screws

and

socket

head

setscrews'

2. Recommended

seating

torque

values

for

lock

nuts:

a.

For

prevailing

torque

lock

nuts-use

65%

of

grade

5

torques.

b.

Forflange

whizlock

nuts

(and screws)-use

135"/"

ot

grade 5 torques.

3.

Unless

otherwise

noted

on

assembly

drawings

all

torque

values

must

meet

this specification.

BOLT

HEAD

MARKING

S.A.E.

GRADE:

o

e

€

t6

Page 18

A$Cadet,

LIMITED

WARRANTY

TWO.YEAR

RESIDENTIAL

ONE.YEAR

COMMERCIAL

Proper

maintenance

of

your

Cub

Cadet equipment

is

the owner's

responsibility.

Follow the

instructions

in

your

owner's

manual

for

correct

lubricants and

maintenance

schedule.

Your Cub

Cadet

dealer

carries

a complete

line of

quality

lubricants

and

filters

for

your

equipment's

engine,

transmission,

chassis

and attachments.

RIDING

MOWERS,

LAWN TRACTORS,

GARDEN

TRACTORS,

CUB

CADET

ATTACHMENTS

AND HOME

MAINTENANCE

PRODUCTS

This limited warranty

for

residential users,

covers any

defect

in materials

or

workmanship

in

your

Cub

Cadet

equipment

for two

years

lrom the date

o{

purchase for

the

first user

purchaser.

We will replace or

repa r any

part

or

parts

without

charge

through

your

authorized

Cub

Cadet dealer.

Batteries

have a one-year

prorated

limited warranty

with

100q6 replacement

during the

first three

months.

V-belts

for

either

the traction

drive or

any attachments are covered

for one

year

only.

Cub Cadet

equipment used

commercially

is warranted

for one

year

only.

(Commercial

use

is

defined

as either

having

hired operators or

used

for income

producing

purpose.)

ITEMS NOT COVERED

The warranty

does

not

cover

routine maintenance

items such as

lubricants,

filters

(oil,

fuel,

air

and hydraulic), cleaning, tune-ups, brake

and/or

clutch

inspection,

adiustments

made as

part

of

normal maintenance,

blade sharpening,

set-up,

abuse,

accidents

and

normal

wear. lt does

not

cover

incidental

costs such as transporting

your

equipment

to and

from

the dealer,

telephone

charges

or

renting

a

product

temporarily to

replace a

warranted

product.

There is nb

other express warranty.

HOWTO OBTAIN

SERVICE

Contact

your

authorized

Cub

Cadet servicing dealer

who

sold

you

your

Cub Cadet

equipment.

lf this

dealer

is not

available, see the

Consumer

Yellow Paqes under

"lawn

mowers"

for the

name

of a

dealer

near

you.

lf

you

need further assistance in finding an authorized Cub Cadet

servicing

dealer, contact:

Cub Cadet Corporation

Post

Office Box

368023

Cleveland,

Ohio

441

36-97

23

HOW

DOES STATE

LAW APPLY?

This limited warranty

gives

you

specific

legal rights, and

you

may also have other

rights which

vary

from state to state.

t1

Page 19

Ignition

KeY

Part

No.

125-0201

A

S

S

o

.R

T

E

D

P

A

R

T

S

L

I

Engine

Oil

(2

CYcle)

DENI-731't1227

Luger

Belt

oEM-754'0452

Spark

Plug

Part

No.

RCJ-8Y

Auger

Rubber

RePlacement

Kit

pait

No.753-

0669

Electric

Start

Kit

oEM-390'996-000

Shave

Plate

oEM-731'1728

Page 20

A$edPt

I

t

I

)

FORM

NO.770-0356M

PRINTED IN

U.S.A

Loading...

Loading...