Page 1

310-3000

Integrated Hydrostatic Transaxle

Service and Repair Manual

BLN-51259

Revision Dec. 2008

Page 2

Table of Contents

Section

Page

Foreword........................................................................................................................ i

Description and Operation........................................................................................... ii

Introduction.................................................................................................................. 1

General Description.................................................................................................................... 1

Introduction................................................................................................................................. 1

Hydraulic Schematic.................................................................................................................... 2

Technical Specifi cations............................................................................................................ 3

Product Identifi cation.................................................................................................................. 3

Safety............................................................................................................................. 4

Personal Safety........................................................................................................................... 4

Tool Safety................................................................................................................................... 4

Work Area Safety......................................................................................................................... 4

Servicing Safety........................................................................................................................... 4

Troubleshooting............................................................................................................ 5

Service and Maintenance............................................................................................. 6

External Maintenance..................................................................................................... 6

Service and Maintenance Procedures............................................................................ 6

Fluids.............................................................................................................................. 7

Brake Maintenance......................................................................................................... 8

Return to Neutral Setting Hand Control.......................................................................... 9

Return to Neutral Setting Foot Control........................................................................... 10

Purging Procedures....................................................................................................... 11

Repair........................................................................................................................... 12

General Instructions...................................................................................................... 12

Required Tools.............................................................................................................. 12

Torque Specifi cations.................................................................................................... 12

Transaxle Removal....................................................................................................... 12

Limited Disassembly..................................................................................................... 12

How to Use This Manual............................................................................................... 13

Brake Assembly..........................................................................................................14,15

Bypass Assembly........................................................................................................... 16

Control Arm Assembly............................................................................................... 17,18

Torque Bracket Assembly.............................................................................................. 19

Fan and Pulley Assembly.............................................................................................. 20

Input Shaft Assembly.................................................................................................... 21

Charge Pump Assembly............................................................................................... 22

Lower Housing/Filter/Manifold Assembly...................................................................... 23

Planetary Differential Assembly............................................................................... 24,25

Motor/Center Section/Pump Assembly............................................................... 26,27,28

Directional Control Assembly........................................................................................ 29

Transaxle Installation.................................................................................................... 30

Assembly After a Complete Tear-down......................................................................... 30

Parts List................................................................................................................. 31,32

Glossary of Terms.................................................................................................. 33,34

310-3000 IHT

Page 3

FOREWORD

Headquartered in Sullivan, Illinois, Hydro-Gear® is

a world leader in the design, manufacture, and service of quality hydrostatic transaxles for the lawn

and garden industry. The mission of our company

is to be recognized by our customers and the industry as a world-class supplier and the quality

leader in everything we do.

This Service and Repair Manual is designed to

provide information useful in servicing the 3103000 Hydro-Gear Integrated Hydrostatic Transaxle

(IHT).

Also included is a glossary of terms that are

frequently used throughout the industry and in

Hydro-Gear service publications. Understanding

terminology is very important!!

It is necessary, and good shop practice, that your

service area be equipped with proper tools and the

mechanics to be supplied with the latest information available. All repair procedures

illustrated in this guide are suggested, but preferred methods of repair.

Repair procedures require that the transaxle unit

be removed from the vehicle.

Some cleaning solvents are fl ammable. To avoid

possible fi re, do not use cleaning solvents in an

area where a source of ignition may be present.

This is not a certifi cation, test or study guide for

a certifi cation test. If a technician is interested in

certifi cation they should contact an agent rep-

resenting the ESA (Engine Service Association)

(610) 363-3844 or their Hydro-Gear Distributor.

Many distributors will be hosting certifi cation test-

ing. These study guides will cover most of the

products and manufacturers in our industry.

For more information about Hydro-Gear or our

products, please contact your Central Service

Distributor, visit www.hydro-gear.com or call our

Technical Service Department at (217) 728-2581.

310-3000 IHT i

Page 4

SECTION 1. DESCRIPTION AND OPERATION

INTRODUCTION

The purpose of this manual is to provide useful information for servicing the Hydro-Gear

310-3000 Integrated Hy dro stat ic Transaxles

(IHT). This man u al includes transaxle general de scrip tion, hy drau lic sche mat ic, tech ni cal

spec i fi ca tions, product iden ti fi ca tion, safe ty,

trou ble shoot ing, main te nance, and re pair pro ce dures.

The transaxle normally will not require servicing during the life of the vehicle in which it is

in stalled. Should other ser vic ing be required,

the transaxle will need to be thoroughly cleaned

be fore be gin ning most procedures.

Please refer to the instructions titled “How to

Use This Man u al” in the Repair Section for an

ex pla na tion of the lay out of the disassembly,

in spec tion, and re as sem bly portions of this

manual.

®

GENERAL DESCRIPTION

The 310-3000 is a self con tained unit de signed

for the transfer and con trol of pow er. It provides

an in fi nite ly vari able speed range be tween zero

and maximum in both forward and re verse

modes of operation.

The transaxle uses a variable displacement

pump with a max i mum displacement of 10

cc per rev o lu tion, and motor with a fi xed dis-

place ment of 21cc per rev o lu tion. The vari able

dis place ment pump fea tures a cradle swashplate with a di rect-pro por tion al displacement

con trol. Re vers ing the di rec tion of the swash-

plate re vers es the fl ow of oil from the pump

and thus re vers es the di rec tion of the motor

output ro ta tion. The pump and motor are of the

axial piston de sign and utilize spherical nosed

pistons which are held against a thrust race by

internal com pres sion springs.

The 310-3000 has a self con tained fl u id sup ply

and an in ter nal fi l ter. The fl uid is drawn through

the in ter nal res er voir and feeds the fi xed dis-

place ment gerotor charge pump. Ex cess fl u id in

the charge circuit is dis charged over the charge

re lief valve and dumps back to case. Charge

check valves in the center section are used to

control the make up fl

pres sure side of the loop.

The transaxle is fi lled and tested at the factory

and should not re quire fl uid or fi lter changes

un less the fl uid be comes con tam i nat ed.

A cam style, block lifting bypass is utilized in

the 310-3000 to permit moving the vehicle for a

short dis tance at a maximum speed of 2 m.p.h.

(3.2 km/hr) with out start ing the engine.

ow of the fl uid to the low

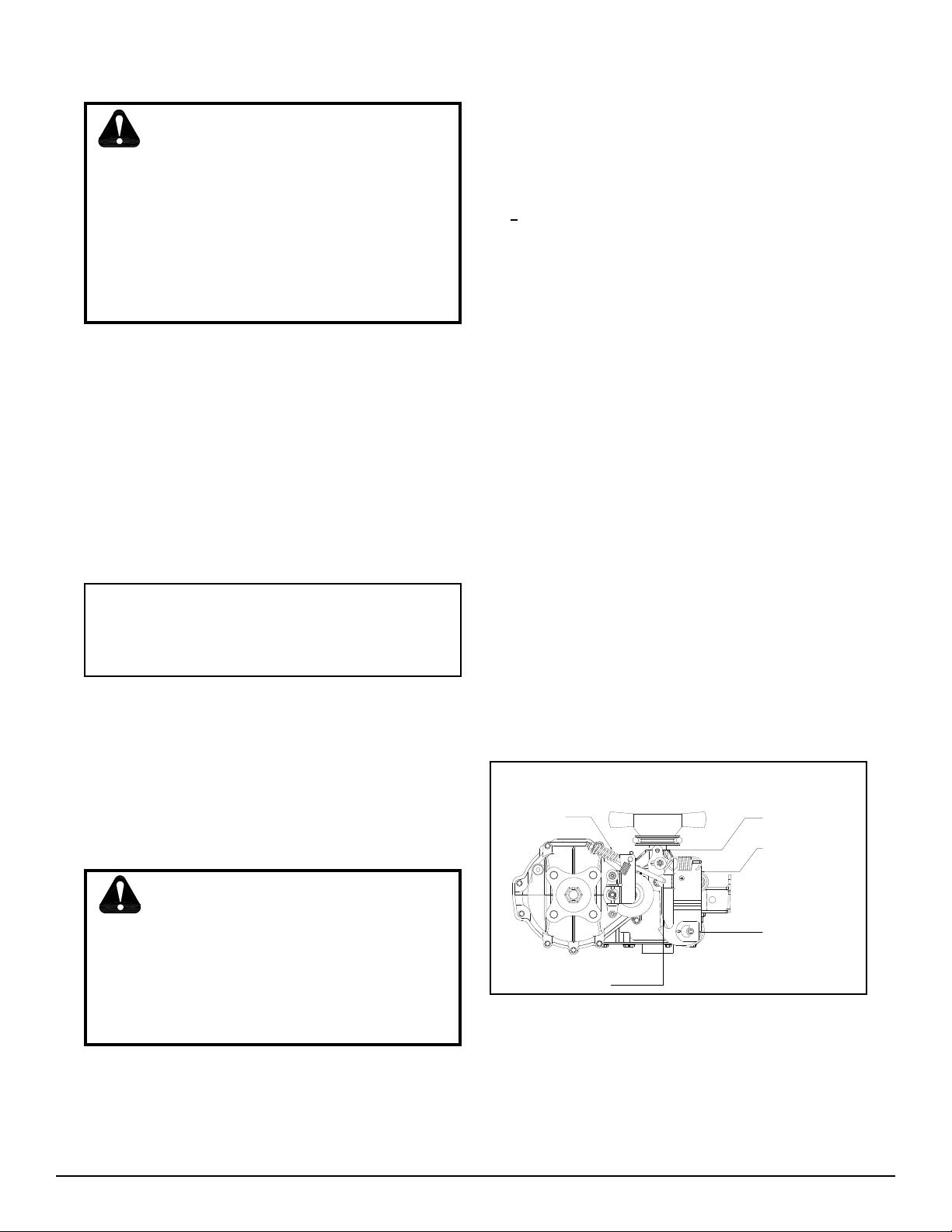

WARNING

Actuating the bypass will result in the

loss of hy dro stat ic braking capacity. The

machine must be sta tion ary on a level

surface and in neutral when actuating

the bypass.

The 310-3000 utilizes an in-line fl oat ing disc

brake con trolled by a "cam" style ac tu at ing

arm.

ii

310-3000 IHT

Page 5

310-3000 IHT

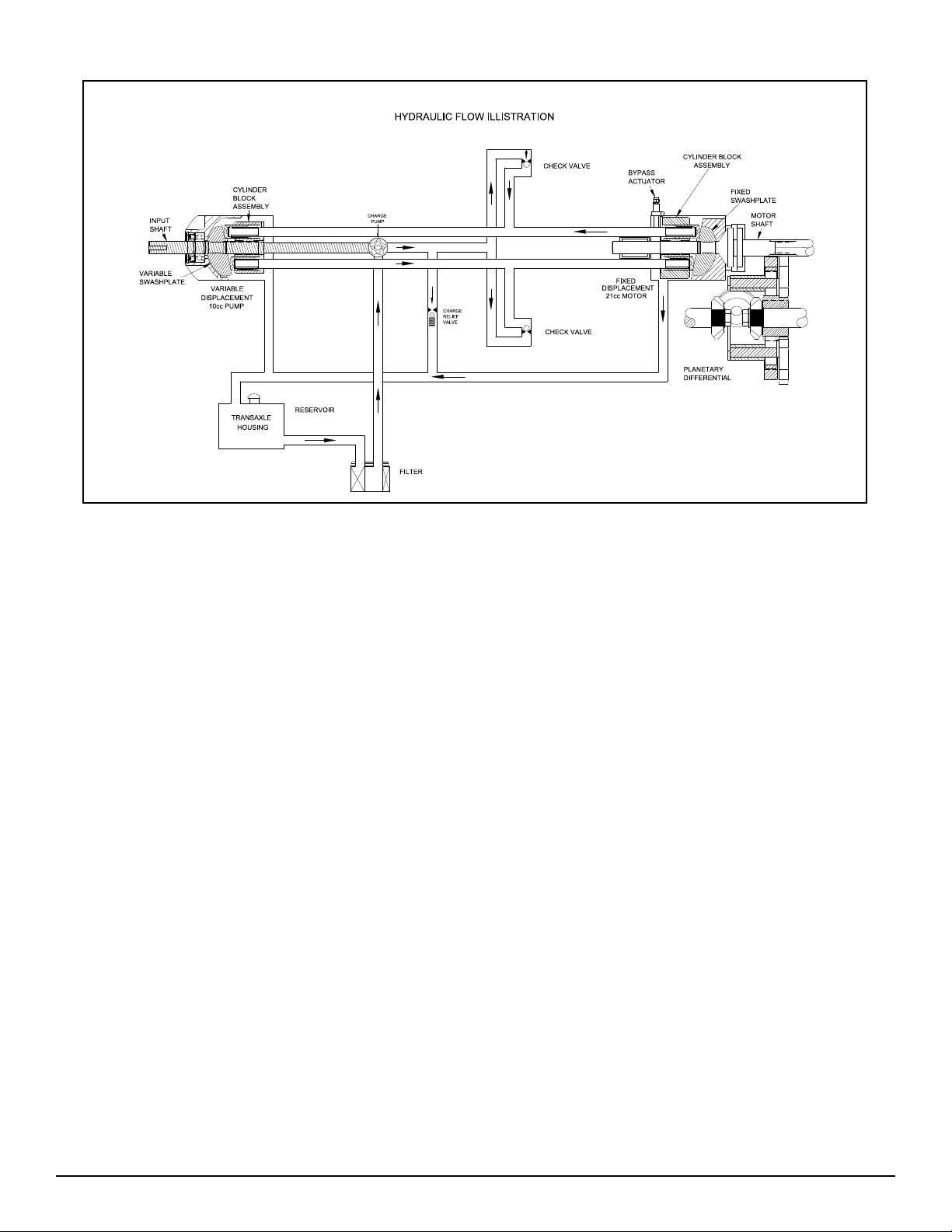

Figure 1. 310-3000 Hydraulic Flow Illustration

HYDRAULIC SCHEMATIC

Figure 1 provides an illustration of the hydraulic oil circuit. The oil supply for the hydraulic

system of the 310-3000 IHT is also utilized for

the lu bri ca tion of the planetary differential drive

gears.

The input shaft and pump cylinder block are

turned in one direction only by the engine/drive

belt/pul ley com bi na tion. Output of the oil fl ow

is con trolled by the direction and amount that

the swashplate is angled. As the pump pistons

com press they force the oil to fl ow through one

of two pas sage ways (forward or reverse) in

the center section (or valve body) to the motor

cylinder block and motor shaft. Since the motor has a fi xed dis place ment angle it is forced

to turn with the fl ow of oil. As the angle of the

swashplate is in creased the amount of oil being

pumped will increase and cause a higher RPM

output of the motor. Re vers ing the angle of the

pump swashplate will re verse the direction of

oil fl ow.

During the operation of the transaxle, fl uid

is “lost” from the hydraulic loop through leak

paths de signed into the product for lubrication

pur pos es (around pistons, under the rotating

cylinder blocks, etc.). This “lost” fl uid returns

to the trans mis sion housing and must be made

up in the loop. A charge pump is included on

the 310-3000 IHT to supply this makeup fl ow.

The make up fl ow is controlled (or directed) by

the check valves. Each check valve will either

be held opened or closed (depending upon the

direction of vehicle op er a tion) by the system

operating pressure (closed) or by charge pressure (open) from the charge pump.

The charge pump maintains a continuous fl ow

of oil as long as the input shaft is turning. All

of the oil being pulled into the charge pump

fi rst must pass through an internal fi lter. Any

oil not needed by the transmission for make

up fl ow is

310-3000 IHT 1

Page 6

dis charged through the charge relief valve. The

charge relief valve maintains the charge pres sure at no more than 40 PSI.

The motor cylinder block mounts onto the

splined motor shaft which drives the planetary

dif fer en tial gear/dif fer en tial as sem bly.

The bypass feature in the 310-3000 IHT has

a me chan i cal le ver which lifts the motor block

off of the center section running surface, allowing any oil fl owing from the pump block to

be dis charged into the housing without turning

the mo tor.

TECHNICAL

SPECIFICATIONS

Table 1. Technical Specifi cations

Overall Transaxle Reduction

30.15:1

Input Speeds

Maximum: 3600 RPM

Minimum: 1800 RPM

Maximum Tire Diameter

23 inch; 584 mm

Axle Shaft Options

Type: Keyed

Diameter: 1 inch; 25.4 mm

Type: Flanged

Diameter: Hub

Technical specifi cations for the 310-3000 IHT

are given in Table 1.

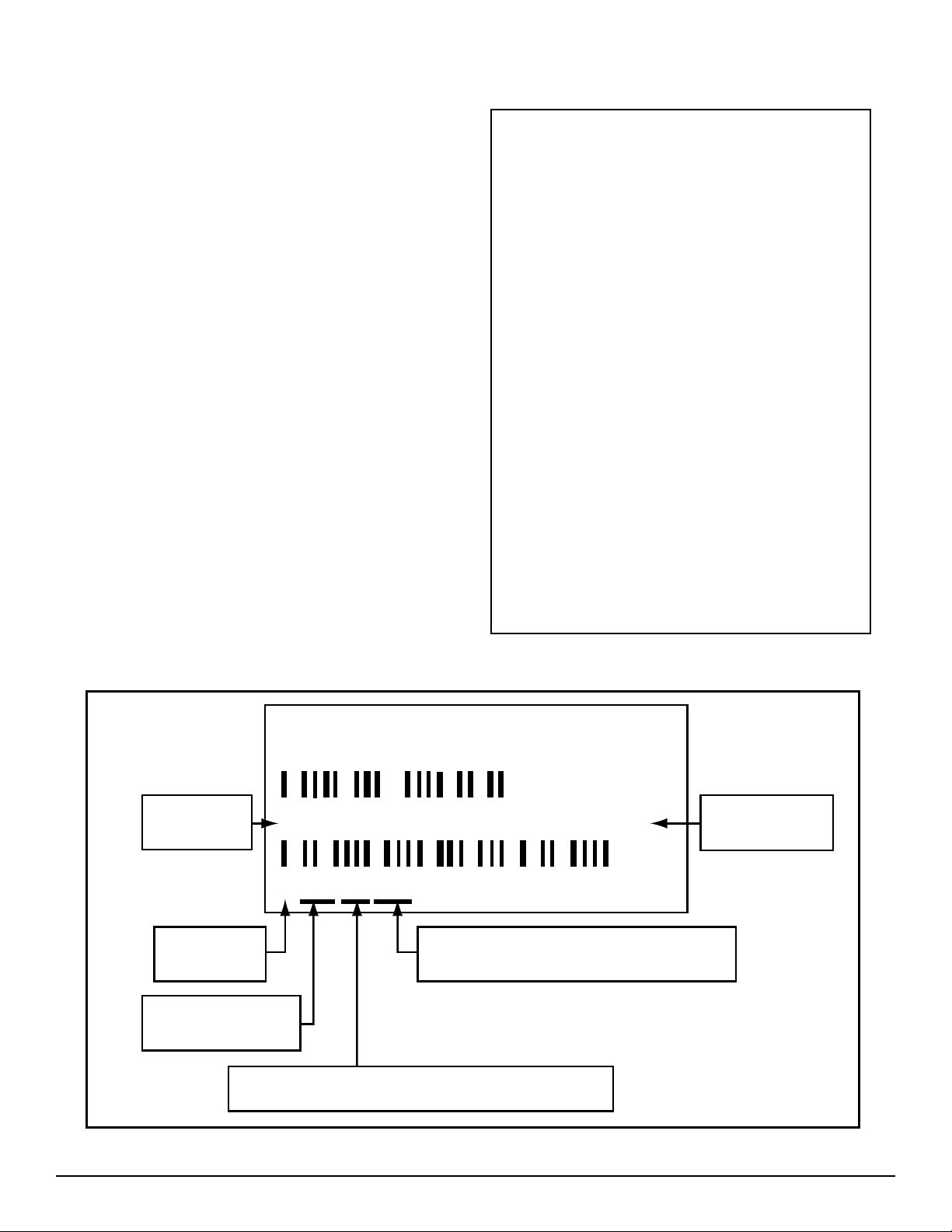

PRODUCT IDENTIFICATION

The model and confi guration of the 310-3000

IHT can be determined from the la bel shown

in Fig ure 2.

HYDRO - GEAR

SULLIVAN, IL. U.S.A.

OEM Model

Number

Year Built

165758

8 328 T1 476

(unique for that model - for that day)

Brake Type

Disc

Weight of Unit

58 lb; 26 kg

310-3000

Made in U.S.A.

Serial Number

Hydro-Gear

Number

2

Date

(Julian - day of year)

Type of Product and Build Information

Figure 2. 310-3000 Confi guration Label

310-3000 IHT

Page 7

SECTION 2. SAFETY

This symbol points out important

safe ty instructions which, if not followed, could

en dan ger the personal safety and/or property

of your self and others. Read and follow all

in struc tions in this manual before attempting

main te nance on your transaxle. When you see

this symbol - HEED ITS WARN ING.

WARNING

POTENTIAL FOR SERIOUS INJURY

Inattention to prop er safety, operation, or

maintenance pro ce dures could result in

per son al injury, or dam age to the equip ment. Before servicing or re pair ing the

310-3000 IHT, ful ly read and un der stand

the safe ty pre cau tions de scribed in this

sec tion.

PERSONAL SAFETY

Certain safety precautions must be observed

while servicing or repairing the 310-3000 IHT.

This sec tion addresses some of these pre cau tions but must not be considered an all-inclusive

source on safe ty in for ma tion. This section is

to be used in conjunction with all other safety

ma te ri al which may apply, such as:

Other manuals pertaining to this ma chine

Local and shop safety rules and codes

Governmental safety laws and reg u la tions

Be sure that you know and understand the

equip ment and the hazards associated with it.

Do not place speed above safety.

Notify your supervisor whenever you feel there

is any hazard involving the equipment or the

per for mance of your job.

Never allow untrained or unauthorized per son nel to service or repair the equipment.

Wear appropriate clothing. Loose or hanging

clothing or jewelry can be hazardous. Use the

ap pro pri ate safety equipment, such as eye

and hear ing protection, and safety-toe and

slip-proof shoes.

Never use compressed air to clean debris from

yourself or your clothing.

TOOL SAFETY

Use the proper tools and equipment for the

task.

Inspect each tool before use and replace any

tool that may be dam aged or defective.

WORK AREA SAFETY

Keep the work area neat and orderly. Be sure

it is well lit, that extra tools are put away, trash

and refuse are in the proper containers, and dirt

or debris have been removed from the working

ar eas of the ma chine.

The fl oor should be clean and dry, and all ex-

ten sion cords or similar trip hazards should be

re moved.

SERVICING SAFETY

Certain procedures may require the vehicle to

be dis abled in order to prevent possible injury

to the servicing tech ni cian and/or by stand ers.

The loss of hydrostatic drive line power may

re sult in the loss of hydrostatic braking capability. Proper brake maintenance is very important

should this condition develop.

Some cleaning solvents are fl ammable. Use

only approved cleaning materials: do not use

ex plo sive or fl am ma ble liquids to clean the

equip ment.

To avoid pos si ble fi re do not use cleaning sol-

vents in an area where a source of ignition may

be present.

Discard used cleaning material in the ap pro pri ate containers.

310-3000 IHT 3

Page 8

SECTION 3. TROU BLE SHOOT ING

WARNING

Do not attempt any ser vic ing or ad just ments with the engine run ning.

Use extreme caution while inspecting

the drive belt assembly, and all vehicle

link age!

Follow all safety pro ce dures out lined in

the ve hi cle owner’s manual!

Table 2. Troubleshooting Checklist

Possible Cause

UNIT OPERATES IN ONE DI REC TION ONLY

Control linkage bent or out of ad just ment

Drive belt slipping or pulley damaged

Oil level low or contaminated oil

Excessive loading

Brake setting incorrect

Loose parts

Bypass assembly sticking

Air trapped in hydraulic system

Repair or replace linkage

Repair or replace drive belt or pulley

UNIT IS NOISY

Fill to proper level or change oil

Reduce vehicle loading

Adjust brake to proper setting

Repair or replace loose parts

Repair or replace valve or linkage

Purge hydraulic system

In many cases problems with the 310-3000IHT

are not re lat ed to a de fec tive trans mis sion or

axle, but are caused by slip ping drive belts,

par tial ly en gaged bypass valves, and loose

or dam aged control linkages. Be sure to perform all op er a tion al checks and adjustments

outlined in Sec tion 4 be fore as sum ing the unit

is mal func tion ing. Table 2 below provides a

troubleshooting check list to help determine

the cause of op er a tion al prob lems.

Corrective Action Refer To:

Control Linkage Repair, Page 17

Pulley Repair, Page 20

Fluid Maintenance, Page 7

Vehicle Specifi cations

Brake Adjustment, Page 8

Appropriate Repair Pro ce dure

Bypass Repair, Page 16

Purging Procedure, Page 11

UNIT HAS NO/ LOW POWER

Engine RPM low

Control linkage bent or out of ad just ment

Brake setting incorrect

Drive belt slipping or pulley damaged

Oil level low or contaminated oil

Excessive loading

Bypass assembly sticking

Air trapped in hydraulic system

Debris buildup around transaxle

Brake setting incorrect

Cooling fan damaged

Oil level low or contaminated oil

Excessive loading

Air trapped in hydraulic system

Damaged seals, housing, or gaskets

Air trapped in hydraulic system

Adjust to correct setting

Repair or replace linkage

Adjust brake to proper setting

Repair or replace drive belt or pulley

Fill to proper level or change oil

Reduce vehicle loading

Repair or replace valve or linkage

Purge hydraulic system

UNIT OPERATING HOT

Clean off debris

Adjust brake to proper setting

Repair or replace cooling fan

Fill to proper level or change oil

Reduce vehicle loading

Purge hydraulic system

TRANSAXLE LEAKS OIL

Replace damaged com po nent

Purge hydraulic system

Vehicle Specifi cations

Control Linkage Repair, Page 17

Brake Adjustment, Page 8

Pulley Repair, Page 20

Fluid Maintenance, Page 7

Vehicle Specifi cations

Bypass Repair, Page 16

Purging Procedure, Page 11

Brake Adjustment, Page 8

Cooling Fan Repair, Page 20

Fluid Maintenance, Page 7

Vehicle Specifi cations Purging

Procedure, Page 11

Appropriate Repair Procedure

Purging Procedure, Page 11

4

310-3000 IHT

Page 9

SECTION 4. SERVICE AND MAINTENANCE

NOTE: Any servicing dealer attempting a war ran ty re pair must have prior

approval be fore con duct ing main te-

®

nance of a Hydro-Gear

less the ser vic ing deal er is a cur rent

Authorized Hy dro-Gear Ser vice Center.

product un-

EXTERNAL MAINTENANCE

Reference Table 4., Page 13 for tools required

in the maintenance of the 310-3000 IHT.

Regular external maintenance of the 310-3000

IHT should include the following:

1. Check the vehicle operator’s manual for

the rec om mend ed load ratings. In sure the

cur rent ap pli ca tion does not ex ceed load

rat ing.

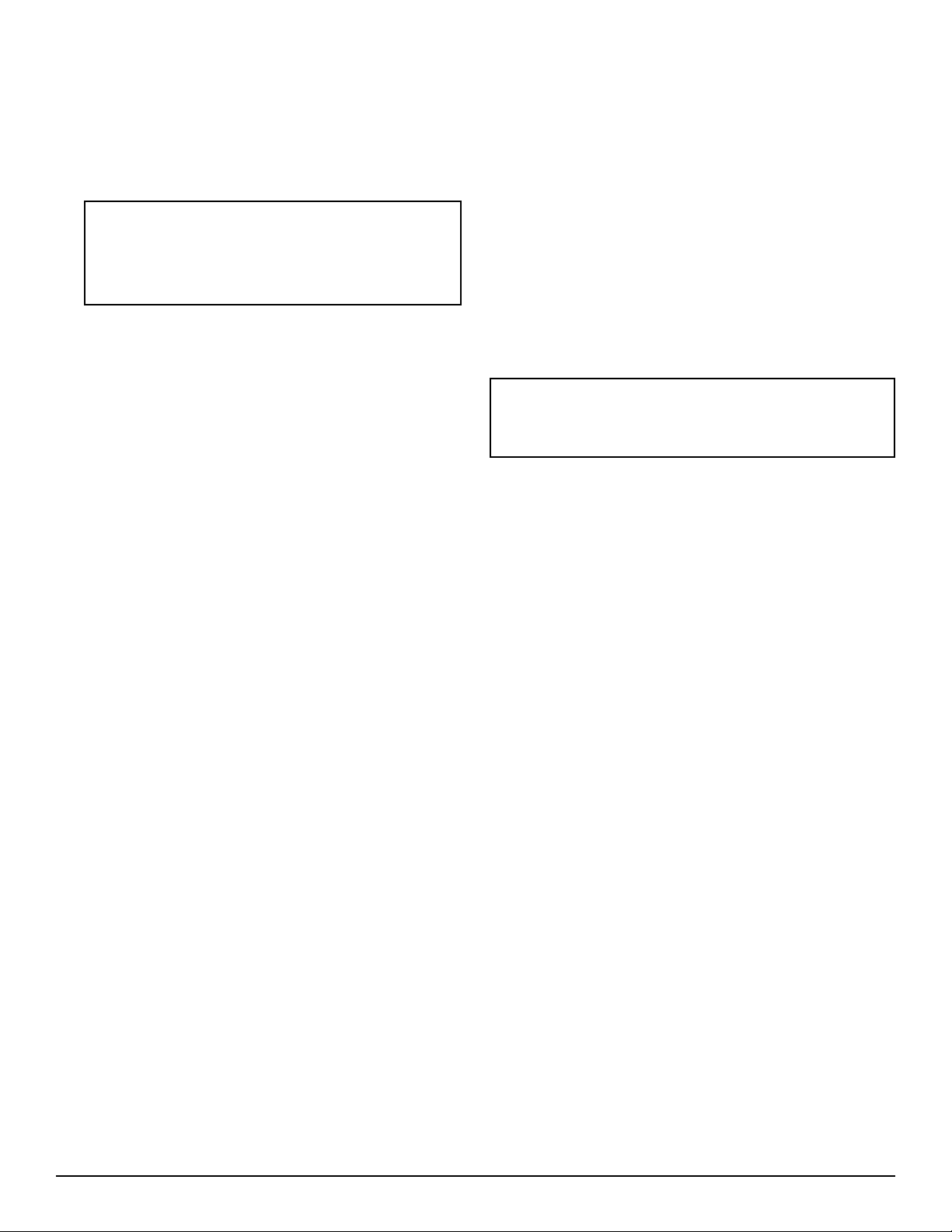

2. Check oil level See Figure 3, Page 7.

3. Inspect the vehicle drive belt, idler pulley(s),

and idler spring(s). Insure that no belt slip page can occur. Slippage can cause low

in put RPM to the transaxle

5. Inspect the axle parking brake and ve hi cle

link age to insure proper actuation of the

park ing brake.

6. Inspect the vehicle control linkage to the

di rec tion al control arm on transaxle. Also,

in sure the con trol arm is se cure ly fastened

to the trun nion arm of the transaxle.

7. Inspect the bypass mechanism on the transaxle and ve hi cle linkage to insure it ac tu ates

and re leas es fully.

SERVICE AND

MAINTENANCE

PROCEDURES

All the service and maintenance procedures

pre sent ed on the following pages can be per formed while the 310-3000 is mounted on the

ve hi cle. Any servicing beyond those giv en must

be per formed after the unit has been removed

from the ve hi cle. Additional pro ce dures are

pro vid ed in Section 5. Repair Procedures.

4. Inspect the transaxle cooling fan for broken

or dis tort ed blades and remove any ob structions (grass clip pings, leaves dirt, etc.).

310-3000 IHT 5

Page 10

FLUIDS

FLUID CHANGE

The fl uids used in Hydro-Gear® products have

been carefully selected, and only equivalent, or

better prod ucts should be sub sti tut ed.

Typically, an engine oil with a minimum rating of

9 cSt (55 SUS) at 230° F (110° C) and an API clas si fi ca tion of SJ/CD is rec om mend ed. A 20W-50

engine oil has been se lect ed for use by the

factory and is rec om mend ed for normal op er at ing tem per a tures.

FLUID VOLUME

Fluid volume information is provided in Table

3.

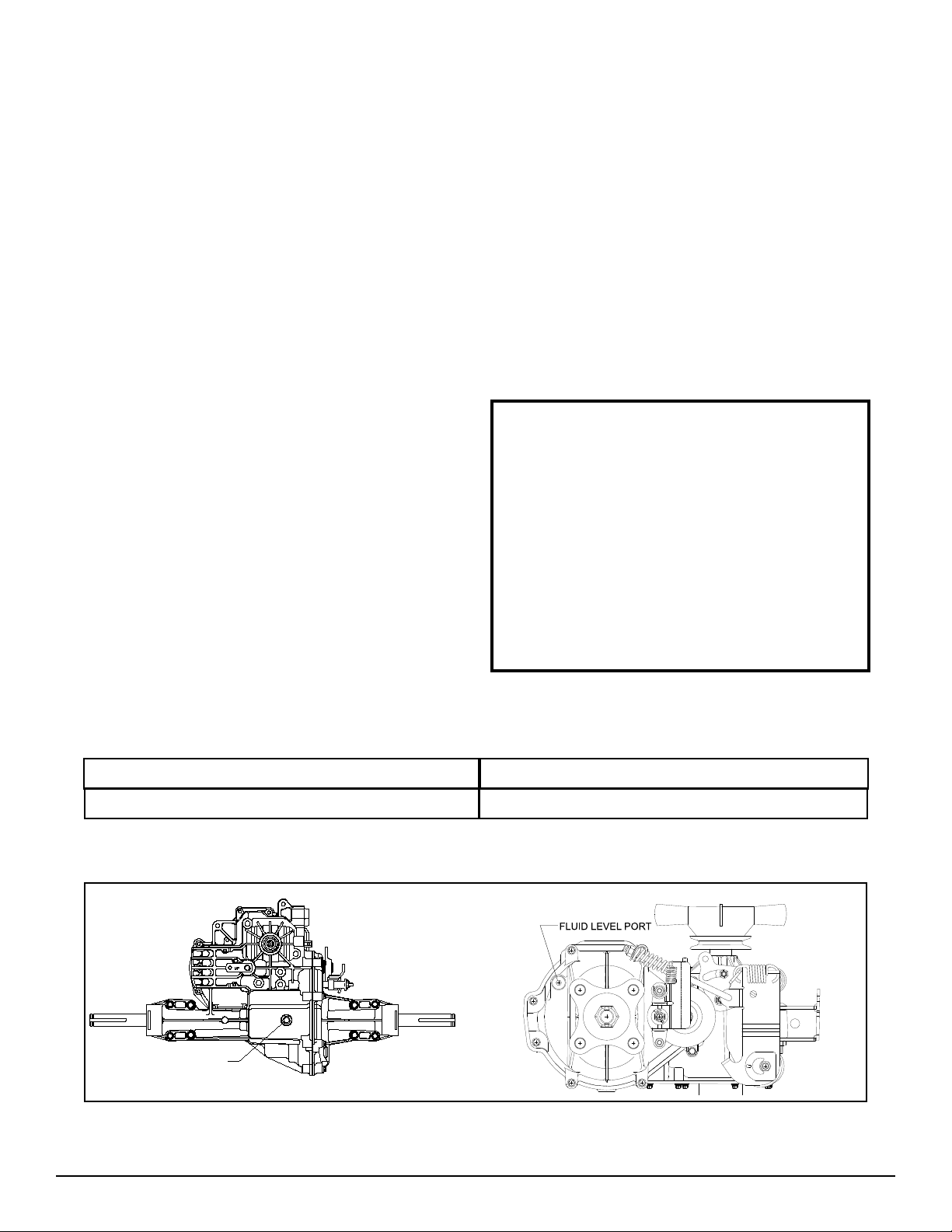

FLUID LEVEL

Certain situations may require additional fl uid to

be added or even replaced. Refer to Figure 3

for the prop er fi ll port and fl uid level port lo ca -

tions. Fill the unit until fl uid fl ows out of the fl uid

level port. Recheck the fl uid level once the unit

has been operated for approximately 1 minute.

Purging may be required. Refer to the purging

procedures, Page 11.

This transaxle is factory fi lled and does not

re quire a regular oil change. In the event of

oil con tam i na tion or degradation an oil change

may improve performance.

Using the transaxle removal procedure from

Sec tion 5, Page 12, remove the transaxle and

drain the oil from the top fl uid fi ll port. Fill unit

per Table 3, re in stall the transaxle and perform

the purging pro ce dures, Page 11.

In the event a fl uid change and fi lter inspection

is required, refer to Page 23, Disassembly/As sem bly instructions.

Caution

Do not overfi ll.

If you overfi ll the transaxle while the unit

is "cold", it may overfl ow as it reaches

normal op er at ing tem per a tures. The oil

level should not be above the man u fac tur er’s suggestions out lined in this

manual. This will al low the space need ed

for the oil to ex pand as it warms up.

Fluid Description

20W-50 engine oil

FLUID FILL PORT

Table 3. Fluid Volumes for the 310-3000 IHT

Volume

0.95 gal. (121.6 oz) (3.59 liters)

Figure 3. 310-3000 Fluid Fill and Level Ports

6

310-3000 IHT

Page 11

BRAKE MAINTENANCE

BRAKE SETTING

1. Remove the brake arm bias spring, and

then the cotter pin securing the brake castle

nut.

2. Insert a 0.015" (.381 mm) feeler gage be tween the brake disc and top brake puck,

and then set the brake by tightening or

loos en ing the cas tle nut.

3. Adjust brake gap to 0.015" (.381 mm) clear ance.

4. Install the cotter pin to secure the castle nut,

and then install the brake arm bias spring.

RETURN TO NEUTRAL SETTING

(OPTIONAL FEA TURE)

The return to neutral mechanism on the trans mis sion is designed to set the di rec tion al control

into a neutral position. An optional feature, it is

available in two versions. One version provides

hand con trol, and the other, foot control. Setting

pro ce dures are provided on pages 9 and 10.

WARNING

POTENTIAL FOR SERIOUS IN JU RY

Certain procedures require the vehicle

engine to be operated and the vehicle to

be raised off of the ground. To prevent

pos si ble injury to the servicing tech ni cian and/or by stand ers, insure the

ve hi cle is properly secured.

310-3000 IHT 7

Page 12

RETURN TO NEUTRAL SETTING

HAND CONTROL

4. Apply the vehicle brake, start the engine and

increase the throttle to full engine rpm.

WARNING

POTENTIAL FOR SERIOUS INJURY

Certain procedures re quire the vehicle

en gine to be operated and the vehicle

to be raised off of the ground. To pre vent pos si ble injury to the ser vic ing

tech ni cian and/or by stand ers, in sure

the ve hi cle is prop er ly se cured.

The return to neutral mechanism on the

trans mis sion is designed to set the di rec tion al con trol into a neutral position when the

vehicle park ing brake is en gaged. Fol low the

procedures below to properly adjust the return

to neutral mechanism on the transaxle:

1. Confi rm the transaxle is in the operating

mode (bypass disengaged). Raise the

ve hi cle’s drive tires off the ground to allow

free ro ta tion.

NOTE: It may be necessary to remove

the drive tire from the axle hub to ac cess the linkage control and the transaxle control arm.

2. Remove the Original Equipment Man u fac tur er’s (OEM’s) control linkage at the

control arm. Refer to Figure 4.

5. Check for axle rotation. If the axles do not

ro tate, go to Step 6. If the axles rotate, go

to Step 7.

6. Stop the vehicle engine. Adjust the OEM

link age according to the OEM manual. Re check ac cord ing to step 4 and 5. Stop the

vehicle en gine. Re place the brake pull rod

onto the re turn ac tu at ing arm. Install the

washer and a new cot ter pin securing the

brake pull rod to the ac tu at ing arm. Refer

to Figure 4.

7. Note the axle directional movement . Stop

the vehicle’s engine. Loosen the adjusting

puck screw until the puck can be rotated.

Rotate the adjusting puck the opposite di rec tion of the wheel rotation on the control

link age side in 5 degree increments. Tighten

the adjusting puck screw. Refer to Table 5.

Required Torque Values, Page 13. Re check

ac cord ing to step 4 and 5. Stop the vehicle

en gine. Ad just the OEM linkage according

to the OEM man u al. Recheck according

to Step 4 and 5. Stop the vehicle engine.

Re place the brake pull rod onto the return

ac tu at ing arm. Install the washer and a new

cot ter pin se cur ing the brake pull rod to the

ac tu at ing arm. Refer to Figure 4.

3. Remove the cotter pin and washer se cur ing

8

the brake pull rod to the return actuating

arm. Remove the brake pull rod from the

return actuating arm. Re fer to Figure 4.

WARNING

Do not attempt any adjustments with the

engine running. Use extreme caution

while inspecting all vehicle linkage!

Follow all safety procedures outlined in

the vehicle owner’s manual!

BRAKE PULL ROD

COTTER PIN AND WASHER

(HIDDEN)

Figure 4. Return to Neutral, Hand Control

CONTROL ARM

RETURN ACTUATING ARM

ADJUSTING PUCK

310-3000 IHT

Page 13

RETURN TO NEUTRAL SETTING

FOOT CONTROL

WARNING

POTENTIAL FOR SERIOUS IN JU RY

Certain procedures re quire the vehicle

en gine to be operated and the vehicle to

be raised off of the ground. To pre vent

pos si ble injury to the ser vic ing tech ni cian and/or by stand ers, in sure the

ve hi cle is prop er ly se cured.

The return to neutral mechanism on the trans mis sion is designed to set the di rec tion al control into a neutral po si tion when the operator

re moves their foot from the foot control. Fol low

the pro ce dures below to prop er ly adjust the return to neu tral mech a nism on the transaxle:

1. Confi rm the transaxle is in the operating

mode (bypass disengaged). Raise the

ve hi cle’s drive tires off the ground to allow

free ro ta tion.

3. Start the engine and increase the throttle to

full engine rpm.

4. Check for axle rotation. If the axles do not

ro tate, go to Step 5. If the axles rotate, go

to Step 6.

5. Stop the vehicle’s engine. Adjust the OEM

linkage according to the OEM manual. Re check according to Step 3 and 4. Stop the

ve hi cle engine. Refer to Figure 5.

6. Note the axle directional movement . Stop

the vehicle engine. Loosen the adjusting

puck screw until the puck can be rotated.

Rotate the adjusting puck the opposite direction of the wheel rotation on the control

linkage side in 5 degree increments. Tighten

the ad just ing puck screw. Refer to Table 5.

Required Torque Values, Page 13. Recheck

ac cord ing to Step 3 and 4. Stop the vehicle

engine. Ad just the OEM linkage according

to the OEM man u al. Re check according to

Step 3 and 4. Re fer to Fig ure 5.

NOTE: It may be necessary to remove

the drive tire from the axle hub to ac cess

the linkage control and the transaxle

con trol arm.

2. Remove the Original Equipment Man u fac tur er’s (OEM’s) control linkage at the control

arm. Refer to Figure 5.

WARNING

Do not attempt any adjustments with the

engine running. Use extreme caution

while inspecting all vehicle linkage!

Follow all safety procedures outlined in

the vehicle owner’s manual!

CONTROL ARM

RETURN

ACTUATING

ARM

ADJUSTING

PUCK

Figure 5. Return to Neutral, Foot Control

310-3000 IHT 9

Page 14

PURGING PROCEDURES

Due to the effects air has on effi ciency in hy-

dro stat ic drive applications, it is critical that it

be purged from the system.

These purge procedures should be im ple ment ed any time a hydrostatic system has

been opened to facilitate maintenance or any

additional oil has been added to the system.

Air creates ineffi ciency because its com pres -

sion and ex pan sion rate is higher than that of

the oil normally approved for use in hydrostatic

drive systems.

The resulting symptoms in hydrostatic systems

may be:

1. Noisy operation

2. Lack of power or drive after short term op er a tion

3. High operation temperature and ex ces sive

ex pan sion of "oil", in the latter case, oil may

over fl ow.

Before starting, make sure the transaxle/ trans mis sion is at the proper oil level. If it is not, fi ll

to the manufacturers sug ges tions outlined in

the vehicle owners manual.

The following procedures should be performed

with the ve hi cle drive wheels off the ground,

then repeated under normal op er at ing conditions.

1. With the bypass valve open and the engine

run ning, slowly move the directional control

in both forward and reverse directions 5 to 6

times, as air is purged from the unit, the oil

level will drop and bubbles may ap pear in

the oil. After stopping the engine, add oil, as

nec es sary. Fill to the level out lined in Figure

3, Page 7.

2. With the bypass valve closed and the engine

run ning, slow ly move the directional control

in both forward and reverse directions (5 to

6 times). Check the oil level, and add oil as

re quired after stopping engine.

3. It may be necessary to repeat Steps 1 and 2

until all the air is completely purged from the

system. When the transaxle moves forward

and reverse, purging is complete.

CAUTION

DO NOT OVERFILL.

If you overfi ll the transaxle while the unit

is "cold", it may overfl ow as it reaches

normal op er at ing tem per a tures. The

oil level should not be above the level

shown in fi gure 3, Page 7. This will al low

the space need ed for the oil to ex pand

as it warms up.

10

310-3000 IHT

Page 15

SECTION 5. REPAIR

NOTE: Any servicing dealer attempting

a war ran ty re pair must have prior ap prov al be fore con duct ing main te nance

®

of a Hydro-Gear

ser vic ing deal er is a cur rent Authorized

Hy dro-Gear Ser vice Center.

product un less the

GENERAL INSTRUCTIONS

Cleanliness is a primary means of assuring

sat is fac to ry life on repaired units. Thoroughly

clean all exposed surfaces pri or to any type

of main te nance. Cleaning of all parts by using a sol vent wash and air drying is usually

adequate. As with any precision equipment, all

parts must be kept free of foreign ma te ri al and

chemicals.

Protect all exposed sealing surfaces and open

cav i ties from damage and foreign material. The

external surfaces should be cleaned before be gin ning any repairs.

TRANSAXLE REMOVAL

It is necessary to remove the 310-3000 from

the ve hi cle before performing the repair procedures pre sent ed in this section. Use the following pro ce dure to prepare the unit for removal

from the ve hi cle.

1. With the vehicle wheels on the ground,

loos en the nut (119, Figure 19) Page 31,

retaining the hub (118, Fig ure 19) on the

control side of the transaxle only. Use an

air im pact wrench and a 1-1/8” socket to

loos en the hub.

2. Lift the vehicle wheels from the ground and

remove the nut completely.

3. Remove the wheel from the hub.

4. Using a wheel or gear puller, remove the

hub from the shaft.

CAUTION

Upon removal, it is recommended that all seals,

O-rings, and gaskets be re placed. During in stal la tion light ly lu bri cate all seals, O-rings, gaskets

with a clean pe tro leum jelly prior to as sem bly.

Also pro tect the inner diameter of seals by

cov er ing the shaft with a cellophane (plastic

wrap, etc.).

Parts requiring re place ment must be re placed

from the ap pro pri ate kits identifi ed in the Items

Listing, found at the end of this man u al.

REQUIRED TOOLS

A list of tools required for the repair of the 3103000 IHT is provided in Table 4, Page 13.

TORQUE SPECIFICATIONS

Torque specifi cations for fasteners used on the

310-3000 IHT are provided in Table 5.

USE CARE IN REMOVING THE HUB TO

PRE VENT CRACKING.

LIMITED DISASSEMBLY

The following procedures are presented in

the or der in which they must be performed

to com plete ly disassemble the unit. Do not

dis as sem ble the unit any farther than is necessary to ac com plish the required repairs.

Each disassembly procedure is followed by a

corresponding as sem bly procedure, and the

disassembly pro cess can be halted after any

given pro ce dure.

Assembly is accomplished by performing the

assembly por tions of the procedures. If the

unit has been completely dis as sem bled, a

summary of the assembly procedures, in the

order in which they should occur, is giv en on

Page 30.

310-3000 IHT 11

Page 16

HOW TO USE THIS

MANUAL

Many of the parts and subassemblies of this

transaxle can be removed and serviced in de pen dent ly of other components. The dis as sem bly, inspection, and as sem bly por tions of

this man u al are therefore laid out in subsections. Each as sem bly is treated as a unit, and

the dis as sem bly, inspection, and assembly

pro ce dures follow one an oth er.

Where some components and assemblies must

be removed before a given assembly can be

serviced, that information is given at the be gin ning of the disassembly instructions.

Table 4. Required Tools

Subassemblies removed to reach another

com po nent or feature need not be fully dis as sem bled. They may be reassembled intact

following the necessary repairs.

Each assembly is provided with an exploded

view showing the parts involved. At the end of

the manual, after the reassembly summary, a

com plete exploded views and items lists are

pro vid ed.

Miscellaneous

310-3000 Service & Repair Manual

Loctite

Flat Blade Screw Driver

Torque Wrench

Air Impact Wrench

Pliers

Needle Nose

External Snap Ring

Internal Snap Ring

Allen Wrenches

5 mm, 6 mm, 1/4 inch

Sockets

3/8" Drive: 7/16", 1/2", 13/16"

1/2” Drive: 9/16", 15/16", 1-1/8"

#8 Internal Torx Drive

#10 Internal Torx Drive

Socket Drivers

3/8", 1/2"

Combination Wrenches

7/16", 1/2", 9/16", 13/16", 15/16", 1-1/8"

Table 5. Required Torque Values

Operation Torque Item De scrip tion

Center Section Screws (Item #4) 525-700 lb-in (59-79 Nm) 44 Screw

Lower Housing Screws (Item # 50) 135-185 lb-in (15-21 Nm) 50 Screw

Charge Pump Cover Screws (Item # 29) 87-108 lb-in (9-12 Nm) 29 M6 x 1-22

Axle Shaft Jam Nut (Item # 73) 660-800 lb-in (75-90 Nm) 73 5/16-18

Right Hand Housing Screws (Item # 80) 230-290 lb-in (26-33 Nm) 80 5/16-18

Axle Hub Nut (Item # 119) 200-295 lb-ft (271-400 Nm) 119 3/4-16

Pulley Nut (Item # 115) 360-520 lb-in (41-59 Nm) 115 Jam Nut

Fan Screws (Item # 107) 35-50 lb-in (4-6 Nm) 107 Screw

Bypass Screw (Item # 138) 42-62 lb-in (5-7 Nm) 138 10-32 x 1/2

Torque Bracket Nut (Item # 142) 160-210 lb-in (18-24 Nm) 142 5/16-18

Control Arm Stud (Item # 36) 50-120 lb-in (6-14 Nm) 36 5/16-24

Trunnion Shaft Nut (Item # 95) 180-240 lb-in (20-27 Nm) 95 5/16-24

Control Bearing Screw(Item # 92) 190-240 lb-in (22-27 Nm) 92 Screw

Control Arm Nut (Item # 95) 85-120 lb-in (10-14 Nm) 95 5/16-24

Adjusting Puck Screw (Item # 88) 250-320 lb-in (28-36 Nm) 88 5/16-24 x 1-3/4

Brake Nuts (Item # 127) 80-120 lb-in (9-14 Nm) 127 1/4-20

12

310-3000 IHT

Page 17

BRAKE ASSEMBLY

(128), and wash er (77).

Refer to Figures 6 and 7.

DISASSEMBLY

The following procedure is for model 324-3000.

Reference microfi che for other models.

1. Remove lock nut (95), washer (77), brake

spring (134), and washer (77) from brake

pull rod (152).

2. Remove cotter pin (129), and washer (77)

from brake pull rod (152).

3. Remove brake pull rod (152) and set

aside.

4. Remove the cotter pin (129), castle nut

5. Remove brake arm (124), and brake arm

bias spring (141).

6. Remove brake anti-drag compression spring

(151), and two brake pins (125).

7. Remove upper nut (127), lock washer (126),

wash er (139), and spacer (130) which se cure brake yoke as sem bly (122).

8. Remove lower nut (127), and lock washer

(126) se cur ing brake yoke assembly

(122).

9. Remove brake yoke assembly (122), puck

plate (131), and outer brake puck (120).

10. Remove brake disc (85), and inner brake

puck (120).

REF. Part Name

2 Right Hand Housing As sem bly

77 Washer

85 Brake Disk

95 Lock Nut

120 Brake Puck

122 Brake Yoke Assembly

123 Square Head Bolt

124 Brake Arm

125 Brake Pin

126 Lock Washer

Figure 6. Brake Assembly

310-3000 IHT 13

REF. Part Name

127 Nut

128 Castle Nut

129 Cotter Pin

130 Spacer

131 Puck Plate

134 Brake Spring

139 Washer

141 Brake Arm Bias Spring

151 Anti-Drag Compression Spring

152 Brake Pull Rod

Page 18

INSPECTION

1. Inspect the brake pucks (120) for excessive

wear.

7. Install brake arm (124) onto brake yoke as sem bly.

8. Install washer (77), and castle nut (128).

2. Replace with new if necessary.

ASSEMBLY

1. Install inner brake puck (120), and brake

disc (85).

2. Assemble the brake yoke assembly, by in stall ing puck plate (131), outer brake puck

(120) into brake yoke (122).

3. Install the brake yoke assembly onto two

mounting studs on housing assembly (2).

Use of a feeler gage (0.015”) (.381 mm)

may be help ful in re tain ing the brake yoke

assembly at this step.

4. Install at upper bolt spacer (130), washer

(139), lock wash er (126), and nut (127).

5. Install at lower bolt lock washer (126), and

nut (127) to secure the brake yoke as sem bly.

6. Install brake anti-drag compression spring

(151), and two brake pins (125).

9. Insert a (0.015”) (.381 mm) feeler gage be tween brake disc (85) and top brake puck

(120). Adjust the brake by turning castle nut

(128) until it is snug but not tight against the

feeler gage. (The brake gap must be ad just ed to a (0.015”) (.381 mm) clearance.

10. Install cotter pin (129) to secure castle nut

(128).

11. Install brake arm bias spring (141) to brake

arm (124) and top brake arm bolt.

12. Install brake pull rod (152) into brake arm

(124) and ac tu at ing arm (35).

13. Secure brake rod (152) to actuating arm

(35) by in stall ing washer (77) and cotter

pin (129).

14. Secure brake pull rod (152) to brake arm by

in stall ing wash er (77), brake spring (134),

wash er (77), and lock nut (95). Set to the

di men sion shown in Figure 7.

14

5.64 + 0.06

BRAKE ROD ASSEMBLY

Figure 7. Brake Pull Rod Assembly Ad just ment

310-3000 IHT

Page 19

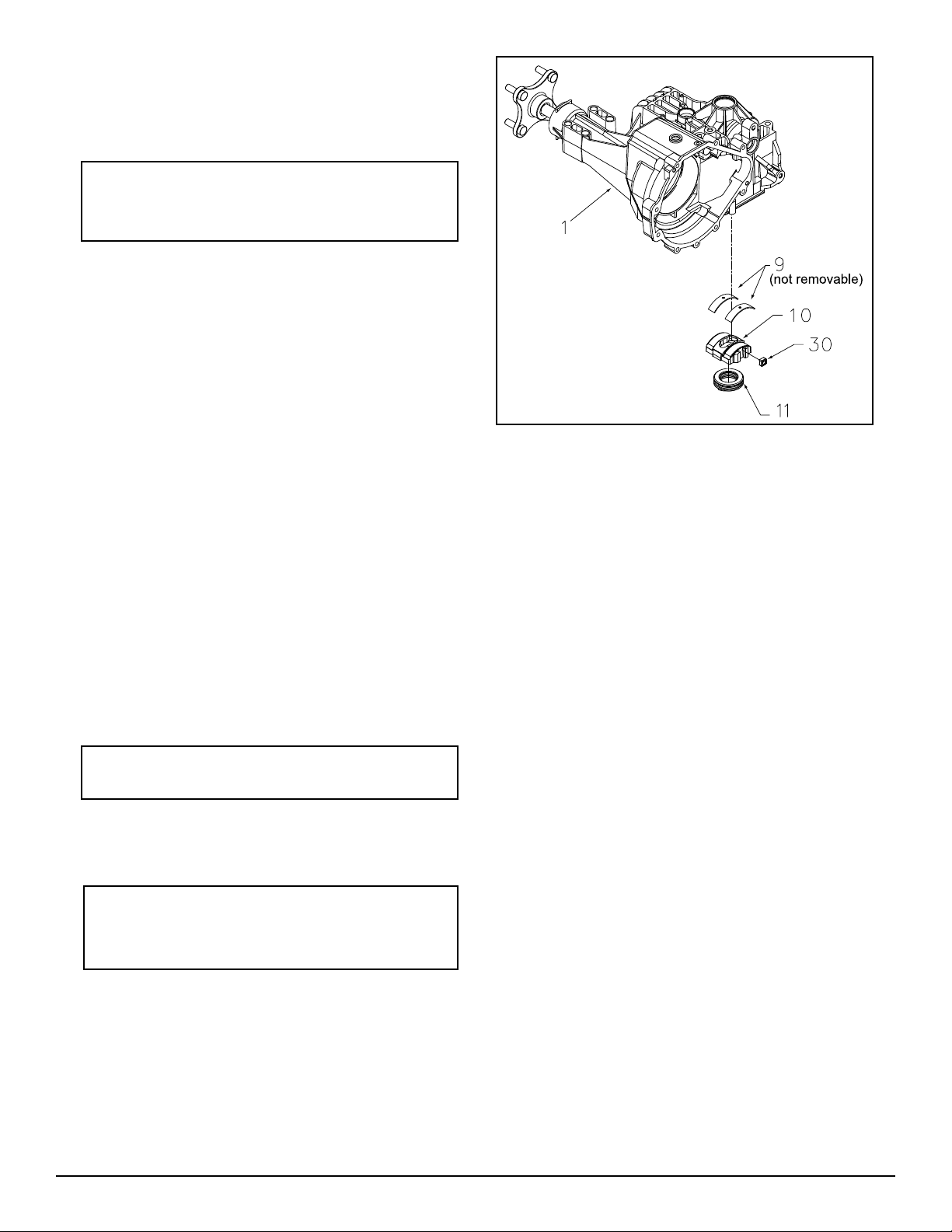

BYPASS ASSEMBLY

Refer to Figure 8.

DISASSEMBLY

1. Remove self tapping screw (138), and ex ten sion spring (136).

2. Remove snap ring (42), and bypass arm

(41).

3. Remove bypass lip seal (40).

INSPECTION

1. Inspect spring pin (137) for damage.

ASSEMBLY

1. If necessary, install new spring pin (137).

2. Install bypass lip seal (40).

3. Install bypass arm (41), and snap ring

(42).

4. Install self tapping screw (138), and ex ten sion spring (136).

REF. Part Name

1 Main Housing

40 Lip Seal

41 Bypass Arm

42 Retaining Ring

136 Spring

137 Spring Pin

138 Screw

Figure 8. Bypass Assembly

310-3000 IHT 15

Page 20

CONTROL ARM ASSEMBLY

Refer to Figure 9, Page 18

DISASSEMBLY

NEUTRAL ASSEMBLY

NOTE: The brake pull rod (152), washer

(77), and cotter pin (129) must be re moved before disassembling the Neu tral

Assembly (refer to Brake Assembly).

2. Inspect trunnion arm lip seal (33), and re place if nec es sary.

ASSEMBLY

CONTROL ARM ASSEMBLY

1. Install trunnion arm lip seal (33), into main

housing (1).

2. Install stud (36), per Table 5, Page 16 and

fric tion puck (37).

1. Remove bolt (88) and adjusting puck (48).

2. Remove neutral spring (46), actuating arm

(35), return arm (34), and washer (87).

CONTROL ARM ASSEMBLY

1. Remove upper lock nut (95), washer (77),

spring (93), spacer (94), washer (77), and

fric tion puck (37).

2. Remove lower lock nut (95), and trunnion

spac er (106), from the trunnion arm (31).

3. Remove control arm (26).

4. Remove friction puck (37), and stud (36), if

necessary.

INSPECTION

1. Inspect bearing (89), and replace if nec es sary. Remove bear ing by removing

coun ter sink screw (92), and washer (90).

3. Install control arm (26), onto trunnion arm

(31), and stud (36), with washer (77) and

nut (95) per Table 5, Page 13.

NOTE: If bearing (89) must be replaced,

install bear ing (89), washer (90), and

coun ter sink screw (92).

4. Install friction puck (37), washer (77), spring

(93), spac er (94), washer (77), and lock nut

(95). Tighten locknut to 120 in. lbs. (14 Nm),

then back off (1) full turn.

NEUTRAL ASSEMBLY

1. Install washer (87), return arm (34), actuating arm (35), and neutral spring (46).

2. Install adjusting puck (48), and bolt (88).

3. Reference Pages 9, 10 for proper neutral

adjustment procedures.

16

310-3000 IHT

Page 21

REF. Part Name

26 Control Arm

31 Trunnion Arm

32 Trunnion Bushing

33 Trunnion Arm Lip Seal

34 Return Arm

35 Actuating Arm

36 Stud

37 Friction Puck

46 Spring

48 Adjusting Puck

Figure 9 Control Arm Assembly

REF. Part Name

77 Washer

87 Washer

88 Screw

89 Bearing

90 Locating Spacer

92 Countersink Screw

93 Spring

94 Spacer

95 Locknut

106 Trunnion Spacer

310-3000 IHT 17

Page 22

TORQUE BRACKET

ASSEMBLY

Refer to Figure 10.

DISASSEMBLY

1. Remove lock nut (142), and bolt (143), from

torque brack et (102).

2. Remove torque bracket (102), from main

hous ing (1).

ASSEMBLY

1. Install torque bracket (102), onto main hous ing (1).

2. Install lock nut (142), and bolt (143), to se cure torque brack et (102) to main housing

(1). Reference Table 5, Page 13 for torque

values.

REF. Part Name

1 Main Housing

102 Torque Bracket

142 Lock Nut

143 Bolt

Figure 10. Torque Bracket Assembly

18

310-3000 IHT

Page 23

FAN AND PULLEY

ASSEMBLY

Refer to Figure 11.

DISASSEMBLY

1. Remove jam nut (115) from input shaft

(12).

2. Remove fan/pulley assembly (104), (103),

(107).

INSPECTION

1. Inspect fan (104) for broken and/or dam aged blades. If necessary to replace fan

(104), re move screws (107), and fan (104),

from pul ley (103).

ASSEMBLY

1. Install fan/pulley assembly (104), (103),

(107) onto in put shaft (12).

2. Secure fan/pulley assembly (104), (103),

(107) onto shaft (12) by installing jam nut

(115), per table 5, Page 13.

REF. Part Name

1 Main Housing

12 Input Shaft

103 Pulley

104 Fan

107 Screw

115 Jam Nut

Figure 11. Fan and Pulley Assembly

310-3000 IHT 19

Page 24

INPUT SHAFT ASSEMBLY

Refer to Figure 12.

DISASSEMBLY

1. Drain the oil from the transaxle.

2. Remove snap ring (7), input shaft lip seal

(5), and spacer (4).

3. Remove input shaft assembly (12), (8),

(6).

4. Remove washer (13) from cavity.

INSPECTION

1. Inspect bearing (8) for damage and, if

nec es sary replace bearing, remove wire

re tain ing ring (6) and bear ing (8) from in put

shaft (12).

ASSEMBLY

1. Carefully install washer (13) onto top of

spring in cav i ty.

REF. Part Name

1 Main Housing

4 Spacer

5 Lip Seal

6 Wire Retaining Ring

7 Snap Ring

8 Ball Bearing

12 Input Shaft

13 Block Thrust Washer

Figure 12. Input Shaft Assembly

2. Press bear ing (8) onto in put shaft (12) and

secure by in stall ing wire retaining ring (6).

3. Install input shaft assembly (12), spacer (4),

and lip seal (5) into input bearing bore of

main housing (1).

4. Secure input shaft assembly (12) by in stall ing retaining ring (7).

20

310-3000 IHT

Page 25

CHARGE PUMP ASSEMBLY

Refer to Figure 13.

DISASSEMBLY

Note: Before disassembling, note the

ori en ta tion of the charge pump cover

(54). Scribe or mark the charge pump

cover (54) for correct orientation during

as sem bly.

1. Remove two screws (29) from the charge

pump cover (54), and remove charge pump

cover (54).

2. Remove o-ring (53) and gerotor assembly

(52).

INSPECTION

1. Inspect gerotor assembly (52), cavity of

charge pump cov er (54), plate on which

cov er is mounted for damage or ex ces sive

wear.

REF. Part Name

1 Main Housing

29 Screw

52 Gerotor Assembly

53 O-ring

54 Gerotor Cover

Figure 13. Charge Pump Assembly

ASSEMBLY

1. Install gerotor assembly (52) onto input shaft

(12) (not shown).

2. Install new O-ring (53) into charge pump

cov er (54).

3. Install charge pump cover (54), making sure

it is prop er ly oriented.

4. Secure charge pump cover (54) by installing

two screws (29), per Table 5, Page 13.

310-3000 IHT 21

Page 26

LOWER HOUSING/FILTER/

MANIFOLD ASSEMBLY

Refer to Figure 14.

NOTE: Charge Pump assembly must be

removed before the following steps can

be performed.

DISASSEMBLY

1. Remove the eleven housing screws (50) and

low er cover (51), and remove sealant.

2. Remove screw O-rings (157).

3. Remove spring (145) and ball (146).

4. Remove fi lter (55) and charge manifold

(56).

5. Remove O-ring (144).

INSPECTION

1. Inspect fi lter (55) and manifold (56), replace

if necessary.

2. Inspect O-ring (144) and screw O-rings

(157).

ASSEMBLY

1. Install O-ring (144) onto center section as sem bly (3), re fer to Figure 134

2. Install fi lter (55) and charge manifold (56).

3. Install spring (145) and ball (146).

4. Install screw O-rings (157).

5. Dry fi t lower cover (51) on housing, using

screws (29) to align cover and manifold

(56).

6. Remove screws (29) and cover (51). Apply

sealant (79) to lip of main hous ing (1).

REF. Part Name

1 Main Housing

29 Capscrew

49 Not Used

50 Screws

51 Lower Cover

52 Gerotor Assembly

53 O-Ring

54 Gerotor Cover

Fig ure 14. Lower Housing/Filter/Man i fold Assembly

REF. Part Name

55 Filter

56 Charge Manifold

144 O-Ring

145 Spring

146 Ball

156 Manifold O-Ring

157 Screw O-Ring

7. Reinstall cover (51) and screws (29), ref-

8. Secure lower cover (51) to main housing

22

er ence Table 5, Page 13.

(1) by in stall ing the eleven housing screws

(50), reference Table 5, Page 13.

310-3000 IHT

Page 27

PLANETARY DIFFERENTIAL

ASSEMBLY

2. Remove all sealant from both hous ings and

in spect seal lands for damage when clean ing.

Refer to Figure 15, next page.

NOTE: Brake Assembly, and optional Return to Neutral have to be re moved be fore

the fol low ing steps can be per formed.

DISASSEMBLY

1. Remove the axle hub assembly (118) on con trol

side by re mov ing nuts (119), and hub as sem blies (118).

2. Remove the eight torx head screws (80) that

secure the R.H. hous ing assembly (2).

3. Remove R.H. housing assembly (2), while

holding axle shaft (76) in place.

4. Remove the two housing pins (117).

5. Remove washer (71) from axle shaft (76).

6. Re move spur gear (60), and thrust plate

(62).

3. If miter gear (65) needs re placed, remove jam

nut (73) from axle shaft (76).

ASSEMBLY

1. If necessary, install L.H. Axle shaft assembly

(76) into main hous ing (1). If necessary, re as sem ble axle shaft assembly (76) by in stall ing

wash er (70), miter gear (65), and jam nut (73)

onto axle shaft (76).

2. Install differential thrust plate (68) into main

housing (1).

3. Install planetary carrier (64) into main hous ing

(1).

4. Reassemble the two miter gears (66) onto differential shaft (67), and install assembly into

planetary carrier (64).

5. Install 51T ring gear (63) into main housing

(1).

7. Remove 21T sun gear (61), and sleeve bear ing

(96).

8. Remove the planetary gears (59).

9. Remove washer (70), and axle shaft (76).

10. Remove the four carrier pins (58) from plan e tary car ri er (64).

11. Remove 51T ring gear (63) from main hous ing

(1).

12. Remove the two miter gears (66), and dif fer en tial shaft (67).

13. Remove planetary carrier (64) and dif fer en tial

thrust plate (68).

14. If necessary, remove the second axle shaft

assembly (76) from main hous ing (1).

15. Remove the seal from the shaft, if necessary.

INSPECTION

1. Inspect all gears for excessive wear or dam age

and re place if necessary.

6. Install the four carrier pins (58) into planetary

carrier (64).

7. If necessary, re as sem ble axle shaft as sem bly

(76) by in stall ing washer (70), miter gear (65),

and jam nut (73) onto axle shaft (76).

8. Install R.H. Axle shaft assembly (76) partway

into as sem bled differential components.

NOTE: It will be necessary to support the RH

axle shaft in the partially installed position

while steps 9 through 16 are completed.

9. Assemble sleeve bearing (96) and sun gear

(61), slid ing them onto R.H. axle shaft. The

smaller diameter on the sun gear OD should

be “IN”.

10. Install the four 15T planetary gears (59) on

pins (80) . Make sure the planetary gears are

properly aligned with the sun gear. Mate the

bevel gear on the end of the R.H. axle shaft

with the bevel gears in the differential assembly. Continue to support the R.H. axle shaft.

310-3000 IHT 23

Page 28

REF. Part Name

1 Main Housing

2 R.H. Housing Assembly

58 Carrier Pin

59 Planetary Gears

60 67t Spur Gear

61 21t Sun Gear

62 Planetary Thrust Plate

63 51t Ring Gear

64 Planetary Carrier

65 Differential Miter Gear

66 Differential Miter Gear

67 Differential Shaft

68 Differential Thrust Plate

D

C

B

A

REF. Part Name

70 Washer

71 Washer

63 51t Ring Gear

64 Planetary Carrier

65 Differential Miter Gear

66 Differential Miter Gear

73 Hex Jam Nut

76 Axle Shaft

80 Torx Head Screws

96 Bearing Sleeve

REF. Part Name

117 Housing Pin

118 Axle Hub Assembly

119 Hex Nut

D

B

C

A

Figure 15. Planetary Differential Assembly

11. Install the planetary thrust plate (62).

12. Install the 67T spur gear (60) onto the

21T sun gear (61).

13. Slide washer (71) onto axle shaft (76).

14. Install the two housing pins (117) into the

main housing.

15. Apply a bead of sealant to the R.H. hous-

ing (2).

24

16. Install R.H. housing (2) by sliding it down

the axle shaft (76), over motor shaft as-

sembly (24, Figure 15) and onto main

housing (1).

17. Secure housings by installing the eight

housing screws (80), per Table 5, Page 13.

18. After the transaxle has been installed in

the vehicle, install the axle hub assem-

blies (118), according to the instructions

in "Transaxle installation," Page 30.

310-3000 IHT

Page 29

MOTOR/CENTER SECTION/

PUMP ASSEMBLY

Refer to Figures 16 and 17, (next pages).

NOTE: Brake Assembly, Input As sem bly,

Charge Pump Assembly, and Low er

Hous ing/Filter/Manifold As sem bly have

to be removed before the fol low ing steps

can be per formed.

DISASSEMBLY

1. Remove washer (82), snap ring (83), washer

(82), 16T pin ion gear (28), spacer (27), and

shaft (28).

(25) for ex ces sive wear (grooving or smearing).

2. Inspect each piston (23), spring (18), and

pis ton seat (22) in the mo tor cylinder block

as sem bly.

3. Inspect seal lands of the 21cc motor cylinder block as sem bly (21) for excessive wear

(groov ing or smearing).

4. Inspect the two running surfaces of center

section as sem bly (3) for excessive wear

(groov ing or smearing). Abnormal wear

pat terns will usually be visible. Any wear

de tect able when a fi ngernail is dragged

across the surface is cause for rejection.

2. Remove motor thrust bearing re tain er

(57).

3. Remove motor thrust bearing (25), and 21cc

motor cyl in der block assembly (21).

4. Remove each piston (23), spring (18), and

piston seat (22) from the 21cc motor cylinder

block assembly.

5. Remove bypass plate (38) from center sec tion assembly (3).

6. Remove the three screws (44) from center

section as sem bly (3).

7. Lift center section assembly (3) out of main

housing (1).

8. Remove the two center section assembly

pins (43).

9. Remove bypass actuator (39) from the cen ter section (3).

10. Remove 10cc pump cylinder block as sem bly

(15).

5. Inspect each piston (17), spring (18), piston

seat (16).

6. Inspect seal lands of 10cc pump cylinder

block assembly (15) for excessive wear

(groov ing or smearing).

ASSEMBLY

1. Install pump cylinder block thrust washer

(13) and spring (14) onto input shaft assembly (12).

2. Install piston washers (18), springs (17), and

pistons (18) in cylinder block (15).

3. Install pump cylinder block assembly (15).

Be sure spring tension is even around the

entire block.

4. Install the two center section assembly pins

(43).

5. Install center section assembly (3) into main

housing (1). Make sure center section seats

fully on its mating surface.

11. Remove each piston (17), spring (18), pis ton

seat (16) from the 10cc pump cylinder block

as sem bly (21).

12. Remove block spring (14), and block thrust

washer (13) from shaft (12, Figure 10)

6. Secure center assembly section (3) by in stall ing three screws (44) reference Table

5, Page 13. Ap ply a few drops of loctite on

screws when in stall ing.

7. Install bypass plate (38) into center section

assembly (3).

INSPECTION

1. Inspect running surface of thrust bearing

310-3000 IHT 25

Page 30

NOTE: To hold bypass plate (38) in po si tion, apply a small drop of grease to its

slot before installing.

8. Install spacer (27), 16T pinion gear (28),

wash er (82), snap ring (83), and washer

(82) onto motor shaft (24).

13. Again using the assembly tool to compress

pistons (22), slide thrust bearing (25), be hind

the tool, into its cavity in front of the cyl in der

block (21) and as sem bled pistons.

NOTE: The thick race of thrust bearing

(25) must face the pis tons.

9. Insert the motor shaft assembly far enough

to seat the motor cylinder block (21).

10. Install piston washers (18), springs (17), and

pistons (16) in cylinder block (21).

11. If not already available, make an assembly

tool from 28 ga. sheet metal as shown in

Fig ure 16. The assembly tool must be free

of burrs and rough edges.

12. Using the assembly tool to compress pis tons

(22), install cylinder block assembly (21).

Be careful not to dislodge bypass plate

(38) when installing the cylinder block as sem bly.

Break sharp edges, both sides

14. While holding the cylinder block assembly

(21) and the thrust bearing (25) in place,

with draw the assembly tool from between

the thrust bearing and the pistons.

15. Install motor thrust bearing retainer (57)

16. Reassemble the planetary differential as sem bly and in stall removed components

as di rect ed in their respective assembly

pro ce dures.

Use 28 gauge

sheet metal

2.250 inch

1.125 Radius

6.000 inch

Figure 16. Motor Cylinder Block Assembly Tool

26

310-3000 IHT

Page 31

REF. Part Name

1 Main Housing

3 Center Section Assembly

13 Block Insert Washer

14 Block Spring

15 10cc Cylinder Block

16 Pistons

17 Springs

18 Piston Washers

19 Block Spring

Figure 17. Motor/Center Section/Pump Assembly

REF. Part Name

20 Bushing

21 21cc Cylinder Block

22 Pistons

23 Springs

24 Motor Shaft

25 Thrust Bearing

27 Spacer

28 16t Pinnion Gear

REF. Part Name

38 Bypass Plate

43 Pin

44 Screws

53 O-Ring

57 Bearing Retainer

82 Washer

83 Retaining Ring

144 O-ring

310-3000 IHT 27

Page 32

DIRECTIONAL CONTROL

ASSEMBLY

Refer to Figure 18.

NOTE: The Motor/Center Section/Pump

Assembly must be disassembled before

this procedure can be completed.

DISASSEMBLY

1. Remove swashplate assembly (10). Dis as sem ble swashplate assembly by removing

thrust bearing (11) from swashplate (10).

The thick race of thrust bearing must face

pis tons.

2. Remove slot guide (30).

INSPECTION

1. Visually inspect (in place) the two cradle

bear ings (9), which are staked in upper

housing. Do not remove the Cradle Bearings (9) from housing (1).

ASSEMBLY

1. Install slot guide (30).

2. As sem ble swashplate as sem bly (10) by in stall ing thrust bearing (11) into swashplate

(10).

REF. Part Name

1 Main Housing

9 Cradle Bearing

10 Variable Swashplate

11 Thrust Bearing

30 Slot Guide

Figure 18. Directional Control Assembly

Note: As sem ble thrust bear ing with thick

race fac ing pistons.

3. Install swashplate assembly (10) into main

NOTE: When in stall ing swashplate as sem bly (10), use fl at head screwdriver

to hold slot guide (30) in place.

28

housing (1). The swashplate (10) will couple

with slot guide (30).

310-3000 IHT

Page 33

TRANSAXLE INSTALLATION

ASSEMBLY AFTER A

Use the following pro ce dure to complete in stal la tion of the transaxle on the ve hi cle.

1. Install and secure the transaxle on the ve hi cle according to instructions in the vehicle

own er’s manual.

2. Install the hub assembly (118, Figure 13) on

the shaft. Install hex nut (119, Figure 13).

3. With the vehicle raised, install the wheel

on the hub, and retain with the wheel lug

nuts.

4. Lower the vehicle wheels to the ground, and

torque the nut re tain ing the hub to 290 to

295 lb.-ft., using an air im pact wrench.

5. Tighten the wheel lug nuts.

COMPLETE TEAR-DOWN

If the unit has been torn down completely, the

fol low ing sum ma ry identifies the assembly

pro ce dures necessary to com plete ly assemble

the unit, in the order they must be completed.

Each as sem bly procedure is located by a page

ref er ence.

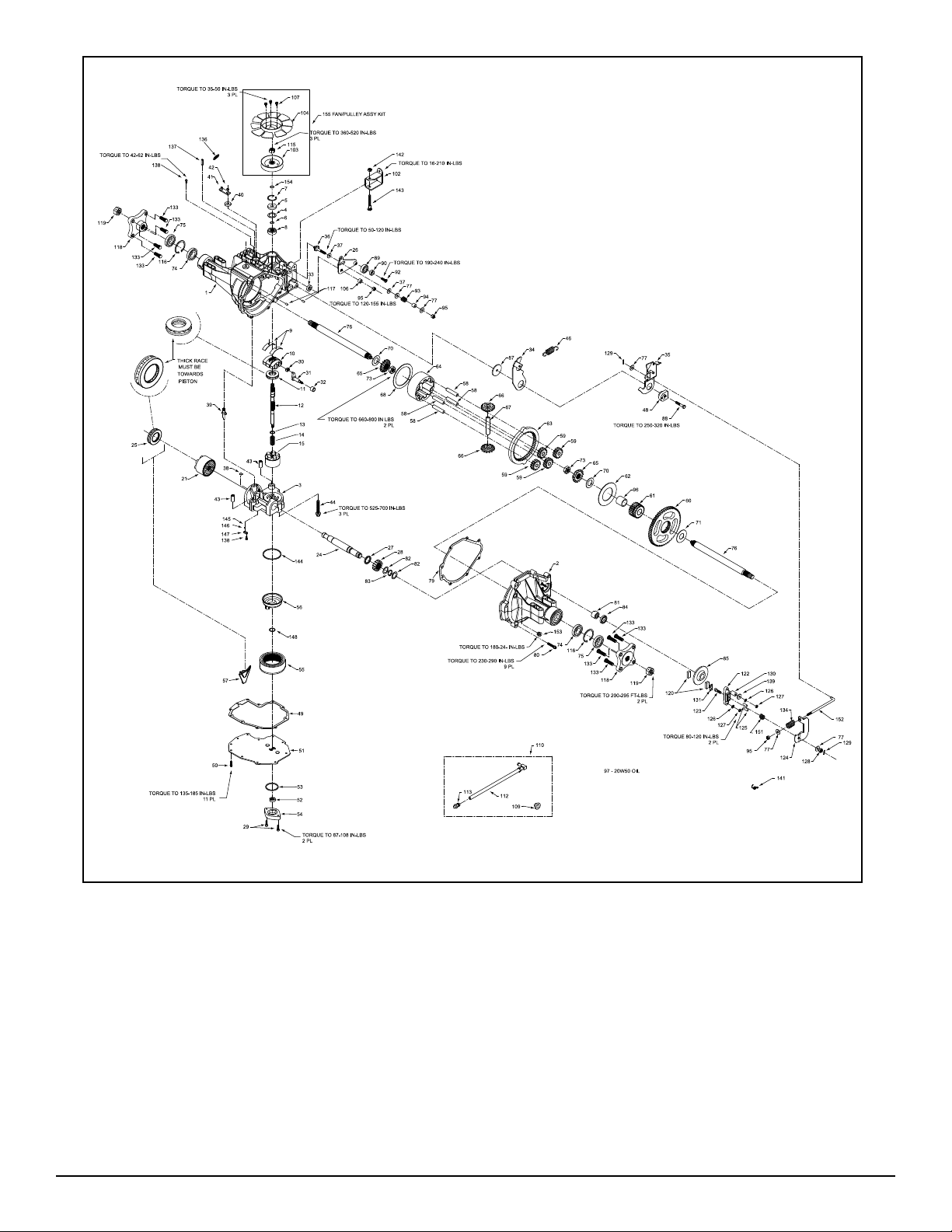

The part reference numbers provided in each

assembly pro ce dure are keyed to the individual

exploded views, and are also keyed to the com plete unit exploded view, Figure 19.

1. Assemble the Directional Control Assembly

(Page 29).

2. Assemble the Motor/Center Section/Pump

Assembly (Page 26,27,28).

3. Assemble the Planetary Differential As sem bly (Page 24,25).

4. Assemble the Lower Housing/Filter/Man i fold

Assembly (Page 23).

5. Assemble the Charge Pump Assembly

(Page 22).

6. Assemble the Input Shaft Assembly (Page

21).

7. Assemble the Fan and Pulley Assembly

(Page 20).

8. Assemble the Torque Bracket Assembly

(Page 19).

9. Assemble the Control Arm Assembly (Page

17,18).

10. Assemble the Bypass Assembly (Page

16).

11. Assemble the Brake Assembly (Page

14,15).

310-3000 IHT 29

Page 34

Figure 19. 310-3000 IHT Exploded View

30

310-3000 IHT

Page 35

ITEMS LIST

Part numbers are not provided in this manual. See Service Schematic or Distributor for part numbers.

NO. DESCRIPTION

1 Main Housing Assembly

2 R.H. Housing Assembly

3 Center Section Assembly

4 Spacer

5 Lip Seal

6 Wire Retaining Ring

7 Retaining Ring

8 Ball Bearing

9 Cradle Bearing

10 Variable Swashplate

11 Thrust Bearing

12 Input Shaft

13 Block Thrust Washer

14 Block Spring

15 10cc Cylinder Block Assembly

21 21cc Cylinder Block Assembly

24 Output (Motor) Shaft

25 Thrust Bearing

26 Control Arm

27 Spacer

28 16T Pinion Gear

29 Cap Screw M6 X 1-22

30 Slot Guide

31 Trunnion Arm

32 Trunnion Bushing

33 Lip Seal

34 Return Arm

35 Actuating Arm

36 Stud 5/16 - 24

37 Friction Puck

38 Bypass Plate

39 Bypass Actuator

40 Lip Seal

41 Bypass Arm

42 Retaining Ring

43 Pin

44 Screw

46 Neutral Spring

48 Adjusting Puck

50 Screw , Self-Tapping

51 Lower Cover

52 Gerotor Assembly

53 O-Ring

54 Gerotor Cover

55 Filter

56 Charge Manifold

57 Retainer, Motor Bearing

58 Pin, Carrier

59 15T Planet Gear

60 67T Spur Gear

61 21T Sun Gear

62 Planet Thrust Plate

63 51T Ring Gear

64 Planetary Carrier

65 Miter Gear, Differential (SPLINED)

66 Miter Gear, Differential

67 Shaft , Differential

68 Differential Thrust Plate

69 Flange Bearing

70 Washer

71 Washer

73 Hex Jam Nut, 5/8 - 18

74 Ball Bearing 6205-1

75 Seal, 1” ID X 2.0472” X 0.375”

76 Shaft, Axle

77 Washer

NO. DESCRIPTION

79 Gasket Material/Sealant

80 Torx Head Screw 5/16 - 18

81 Needle Bearing

82 Washer

83 Retaining Ring

84 Lip Seal

85 Brake Disc

87 Washer

88 Screw 5/16 - 24 X 1-3/4

89 Bearing

90 Spacer, Locating

91 O-Ring

92 Countersunk Screw

93 Spring Spacer

94 Spacer

95 Nut, Hex Lock 5/16 - 24

96 Sleeve Bearing

97 20W50 Oil

102 Torque Bracket

103 Pulley

104 Fan

106 Spacer, Trunnion

107 Screw

109 Vent Bushing

110 Fitting Kit

111 Cap-Vent Assembly

113 Hose/ Fitting Assembly

115 Jam Nut

116 Retaining Ring

117 Std Hlds Pins

118 Hub Assembly 7/16 - 14

119 Nut, Hex 3/4 - 16

120 Puck, Brake

121 Rib Neck Bolt, 2”

122 Brake Yoke

123 Bolt, Square-Head

124 Arm, Brake

125 Pins, Brake

126 Lock Washer, 1/4"

127 Nut, 1/4 - 20

128 Nut, Castle

129 Cotter Pin

130 Spacer

131 Puck Plate

132 Rib Neck Bolt, 3”

133 Wheel Stud 7/16-14

134 Brake Spring

136 Extension Spring

137 Spring Pin

138 Screw , Stap 10-32 X .5

139 Washer

141 Spring, Brake Arm Bias

142 Hex Lock Nut 5/16 - 18

143 Bolt 5/16 -15 X 2.5

144 O-Ring

145 Spring, Relief

146 Ball , 7/16

151 Compression Spring Brake Anti-Drag

152 Brake Pull Rod

153 Plug, Straight Thread

154 Wire Retaining Ring

155 Fan/ Pulley Assembly

157 Screw O-Ring

180 Manifold Kit

202 Manifold O-Ring Kit

203 Seal Kit (310-3000)

310-3000 IHT 31

Page 36

SECTION 6. GLOSSARY OF TERMS

Axial Piston: Type of design for hydraulic motors and pumps in which the pistons are arranged

parallel with the spindle (input or output shaft).

Bantam Duty: A descriptive term relating to the product capacity (meaning: light duty).

Bypass Valve: A valve whose primary function is to open a path for the fl uid to bypass the motor

or pump. Also referred to occasionally as the freewheel valve or dump valve.

Case Drain Line (Return Line): A line returning fl uid from the component housing to the res-

er voir.

Cavitation: A concentrated gaseous condition within the fl uid causing the rapid implosion of a

gas eous bubble.

Center Section: A device which acts as the valve body and manifold of the transmission.

Charge Pump: A device which supplies replenishing fl uid to the fl uid power system (closed

loop).

Charge Pressure: The pressure at which replenishing fl uid is forced into a fl uid power system.

Charge Relief Valve: A pressure control valve whose primary function is to limit pressure in the

charge circuit.

Check Valve: A valve whose primary function is to restrict fl ow in one direction.

Closed Loop: A sealed and uninterrupted circulating path for fl uid fl ow from the pump to the

motor and back.

Decay Rate: The ratio of pressure decay over time.

End Cap: See “Center Section”

Entrained Air: A mechanical mixture of air bubbles having a tendency to separate from the liquid

phase.

Gerotor: A positive displacement pump frequently used as a charge pump.

Hydraulic Motor: A device which converts hydraulic fl uid power into mechanical force and mo-

tion by transfer of fl ow under pressure.

Hydraulic Pump: A device which converts mechanical force and motion into hydraulic fl uid pow er

by producing fl ow.

Hydrostatic Pump: See “Hydraulic Pump”

32

310-3000 IHT

Page 37

Hydrostatic Transaxle: A multicomponent as sem bly including a gear case and a hydrostatic

trans mis sion.

Hydrostatic Transmission: The combination of a hy drau lic pump and motor in one housing to

form a de vice for the control and transference of power.

Inlet Line: A supply line to the pump.

Integrated Hydrostatic Transaxle (IHT): The com bi na tion of a hydrostatic transmission and

gear case in one housing to form a complete transaxle.

Manifold: A conductor which provides multiple con nec tion ports.

Neutral: Typically described as a condition in which fl uid fl ow and system pressure is below that

which is required to turn the output shaft of the motor.

Pressure Decay: A falling pressure.

Priming: The fi lling of the charge circuit and closed loop of the fl uid power system during start

up, fre quent ly achieved by pressurizing the fl uid in the inlet line.

Purging: The act of replacing air with fl uid in a fl uid power system by forcing fl uid into all of the

com po nents and allowing the air a path of es cape.

Rated Flow: The maximum fl ow that the power sup ply system is capable of maintaining at a

spe cifi c op er at ing pressure.

Scoring: Scratches in the direction of motion of me chan i cal parts caused by abrasive con tam i nants.

Swash Plate: A mechanical device used to con trol the displacement of the pump pistons in a

fl uid power sys tem.

System Charge Check Valve: A valve con trol ling the replenishing fl ow of fl uid from a charge

circuit to the closed loop in a fl uid power system.

System Pressure: The pressure which over comes the total resistance in a system, in

clud ing

all losses.

Valve: A device which controls fl uid fl ow di rec tion, pressure, or fl ow rate.

Variable Displacement Pump: A pump in which the displacement per cycle can be varied.

Volumetric Displacement: The volume for one rev o lu tion.

310-3000 IHT 33

Page 38

NOTES

34

310-3000 IHT

Page 39

NOTES

310-3000 IHT 35

Page 40

© 2008 HYDRO-GEAR

Rev. P2

Printed in U.S.A.

Loading...

Loading...