Page 1

Operator’s Manual

42" FRONT BLADE

ATTACHMENT

For Cub Cadet Series 2000 Tractors

(Requires 190-307 Weight Bracket Kit)

INSTALLATION

AND

MAINTENANCE INSTRUCTIONS

Model Number

302

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 772-9048B

(12/01)ECO 07686

Page 2

CONTENTS

Section Page

Safe Operation ....................................................................................................... 2

To The Owner ........................................................................................................ 4

I Introduction ............................................................................................................ 5

II Assembly ................................................................................................................ 6

III Installation .............................................................................................................. 9

IV Removal and Attachment ........................................................................................ 10

V Adjustments and Operation .................................................................................... 12

VI Additional Accessory Requirements ...................................................................... 14

Warranty ................................................................................................................. 16

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

SAFE OPERATION PRACTICES

WARNING

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply with

the instructions may result in personal injury.

I. GENERAL OPERATION

1. Read, understand and follow all instructions in this

manual and on the machine before starting. Keep

this manual in a safe place for future reference and

for ordering replacement parts.

2. Only allow responsible adults familiar with the

instructions to operate the machine. Know controls

and how to stop the machine quickly.

3. Do not put hands or feet near moving parts.

4. Clear the area of objects such as rocks, toys and/

or wire. A small object may have been overlooked

and could be accidentally thrown in any direction

and cause injury to you or a bystander. Always

wear safety glasses or eye shields during

operation or while performing and adjustment or

repair, to protect eyes from foreign objects.

5. Never carry passengers.

6. To ensure the area is clear, always look down and

behind before and while backing up.

7. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

8. Never leave a running machine unattended.

Always disengage attachment, place transmission

in neutral, set park brake, stop engine and remove

key before dismounting.

9. Raise the blade when not in use.

10. Do not operate the machine while under the

influence of alcohol or drugs.

11. Watch for traffic when operating near or crossing

roadways.

12. Use extra care when loading or unloading the

machine onto or off of a trailer or truck. The unit

should not be driven under power up or down a

ramp because the unit could tip over, causing

serious personal injury. The unit must be pushed

manually to load or unload properly.

13. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals, or

sneakers.

14. Check overhead clearance carefully before driving

under power lines, wires, bridges or low hanging

tree branches, before entering or leaving

2

Page 3

buildings, or in any other situation where the

operator may be struck or pulled from the unit,

which could result in serious injury.

15. Disengage power take-off, thoroughly depress the

brake pedal, and shift into neutral before

attempting to start engine.

16. Operate blade only in daylight or in good artificial

light.

17. Make adjustments only when the blade is attached

to the tractor.

18. Keep the blade in the lowest possible position

when changing the angle, reversing or removing

the blade. Be sure that your feet are not under the

blade when the adjustments are made.

19. No person should be allowed near the working

area when the blade is being operated.

20. Never operate the tractor at high speeds. A

collision with a hidden obstacle may damage the

blade cutting edge and unseat the driver.

21. Do not overload the machine capacity by

attempting to clear show at too fast a rate. Take

the time to do the job in a safe manner.

22. Be careful to avoid catching the blade on stumps

or other immovable objects.

23. Never tow another object with the blade or use the

blade as a battering ram.

24. To ensure maximum side and ground clearance,

do not transport the blade in the angled or tilted

position.

25. Use extreme care when operating close to ditches,

fences or on hillsides.

TRANSPORTING

26. Be sure that the blade in fully raised and is in the

straight forward position when in transport.

27. When turning close to buildings or passing through

narrow areas, be sure to allow sufficient clearance

for the blade.

28. Avoid heavily-traveled roads when moving

equipment, if at all possible.

AFTER OPERATING

29. Always wait for the tractor to come to a complete

stop, lower blade to the ground, shut off the engine

and set the parking brake before leaving tractor.

II. SLOPE OPERATION

Slopes are a major factor related to loss of control and

tip-over accidents which can result in severe injury or

death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not

work on it.

DO:

1. Operate up and down slopes, not across.

2. Remove obstacles such as rocks, limbs, etc.

3. Watch for holes, ruts, bumps, and objects hidden

under the soil (e.g. rocks). Uneven terrain could

overturn the machine or cause it to slide.

4. Use slow speed. Choose a low enough gear so

that you will not have to stop or shift while on the

slope. Always keep tractor in gear when going

down slopes to take advantage of engine braking

action.

5. Use extra care with attachments. These can

change the stability of the machine.

6. Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed

or direction. Rapid acceleration or braking could

cause the front of the machine to lift, tip sideways

or slide which could cause serious injury.

7. Avoid starting or stopping on a slope. If tires loose

traction, raise the blade and proceed slowly

straight down the slope.

8. For your safety, use the slope gauge included as

part of the tractor manual to measure slopes

before operating this unit on a sloped or hilly area.

If the slope is greater than 15 degrees as shown on

the slope gauge, do not operate this unit on that

area or serious injury could result.

DO NOT:

1. Do not turn on slopes unless absolutely

necessary. If necessary, turn slowly and gradually

across and down slope, if possible.

2. Do not operate on excessively steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted

to the machine. Never assume that children will remain

where you last saw them.

1. Keep children out of the operating area and in

watchful care of an adult other than the operator.

2. Be alert and turn off the machine if children enter

the area.

3. Before and while backing up, look behind and

down for small children.

4. Never carry children. They may fall off and be

seriously injured or interfere with safe machine

operation.

3

Page 4

5. Never allow children to operate the machine.

6. Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

vision.

IV. SERVICE

1. Use extra care in handling gasoline and other

fuels. They are flammable and vapors are

explosive.

a. Use only an approved container.

b. Never remove gas cap or add fuel with the

engine hot or running. Allow engine to cool at

least two minutes before refueling. Wipe dry

any spilled fuel. Do not Smoke.

c. Never refuel the machines indoors.

d. Never store the machine or fuel container

inside where there is an open flame or spark,

such as a water heater, space heater or similar

appliance.

2. Never run a machine inside an enclosed area.

3. Check frequently and keep nuts and bolts tight and

equipment in safe working condition.

4. Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed.

5. To reduce fire hazard, keep machine free of grass,

leaves or other debris build-up. Clean up oil or fuel

spillage. Allow machine to cool before storing.

6. Stop and inspect the equipment for damage if you

strike an object. Repair, if necessary, before restarting and operating the machine.

7. Never make adjustments or repairs with the

engine running.

8. Check brake operation frequently. Adjust and

service as required.

9. Muffler, engine, and belt guards become hot

during operation and can cause a burn. Allow to

cool down before touching.

10. Do not change the engine governor settings or

overspeed the engine.

11. If the machine should begin to vibrate abnormally,

stop engine and check immediately for the cause.

Abnormal vibration is a warning of trouble.

Danger: This equipment was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any of these rules, you may cause serious injury to yourself or others.

TO THE OWNER

The 42-inch Front Blade Attachment, Model Number 302, is designed for use on Cub Cadet Series 2000 Tractors.

The blade may be used for moving snow, terracing or grading operations.

Please keep this manual. The instructions in this manual explain the minor assembly required; installation and seasonal removal; and the adjustment and operating procedures for the blade. Read this manual carefully to familiarize

yourself with the equipment before you install and utilize the front blade.

Read and observe all WARNING and CAUTION statements. They are included to provide for the protection of the

equipment installer and user, and to ensure prolonged service life of the equipment.

WARNING: To increase traction and stability of the tractor when using the front blade attachment, the

rear weight bracket with a minimum of two suitcase weights should be installed on the tractor. The Rear

Weight Bracket Kit is available as kit number 190-307-100, which includes only the bracket and mounting hardware. The individual 42 pound suitcase weights can be ordered under part number 759-3389.

NOTE: References to LEFT and RIGHT indicate the left and right sides of the tractor when facing forward in the

driver’s seat, unless specifically instructed to reference from a different position on the tractor. Reference to

the FRONT indicates the grille end of the tractor; to the REAR indicates the draw bar end.

If you have difficulties with the attachment, have questions regarding the operation or maintenance

of your equipment, or desire additional information not found in the manual, contact your dealer. If you

need help locating a dealer in your area, contact the Customer Dealer Referral Line by calling:

1-877-282-8684

4

Page 5

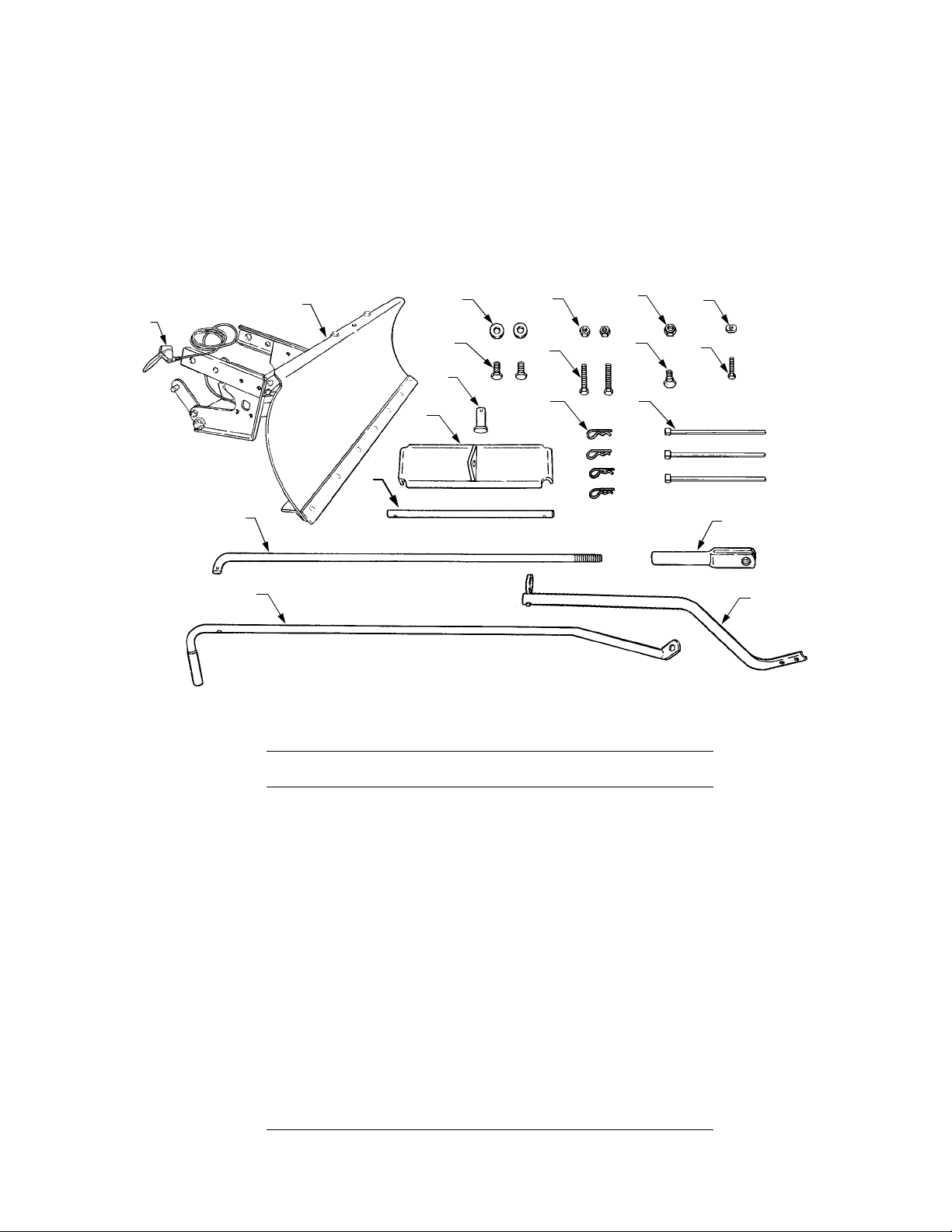

SECTION I. INTRODUCTION

This section will familiarize you with the components of the Model 190-302 — 42” Blade Attachment.

Select a firm and level surface that is large enough to accommodate both the Front Blade assembly and the tractor

when installing the blade. Carefully remove the front blade assembly, sub components, and hardware pack from the

shipping container. Refer to Figure 1 to confirm that all parts are present and to acquaint yourself with the part

descriptions. Throughout the manual the parts shown in Figures 1 will be identified by name, followed by their callout

number in parenthesis, to aid in assembly and installation.

NOTE: Some components may have been further pre-assembled at the factory

1

2

7

3

6

11

10

9

8

12

13

14

15

16

19

17

18

4

5

Figure 1

REF.

NO.

1 N/A Blade Assembly, w/Pivot Cable attached 1

2 746-3059A Pivot Cable Assembly 1

3 747-3240 Blade Lift Rod 1

4 10991 Adjustment Clevis 1

5 N/A Handle Support Tube Assembly 1

6 N/A Blade Pivot Handle Assembly 1

7 711-3401 Rod, .5 x 12.5 Lg. 1

8 603-0271 Lift Bracket 1

9 711-0654 Clevis Pin 1

10 710-0505 Hex Cap Screw, 7/16-14 x 1.0 GR5 2

11 736-0407 Belleville Washer, .45 x 1.0 x .062 2

12 712-3004A Hex Flange Locknut, 5/16-18 2

13 710-3180 Hex Cap Screw, 5/16-18 x 1.75 GR5 2

14 714-0147 Internal Cotter Pin 4

15 712-0431 Hex Flange Locknut, 3/8-16 1

16 738-0234 Shoulder Screw, 1/2 x .29; 3/8-16 1

17 712-0127 Flat Nut, 10-24 1

18 710-1233 Oval Hd. Cntsk. Screw, 10-24 x 1.375 1

19 725-0157 Cable Tie 3

PART

NO. DESCRIPTION QTY.

5

Page 6

SECTION II. ASSEMBLY

A. TRACTOR PREPARATION.

WARNING

Disengage the PTO, engage the brake lock,

and stop the tractor engine before performing

any preparation procedures. Place the tractor

on a firm and level surface before beginning

installation procedures.

WARNING

The exhaust system and surrounding areas are

HOT. To avoid personal injury, allow the tractor

to cool before beginning any blade installation

procedures.

NOTE

WARNING

When installing the lift bracket (8), the tractor lift

links must be positioned within the slots at

each side of the lift bracket, with the center lift

rod tab of the bracket positioned as shown in

Figure 3.

4. Install the lift bracket (8) onto the tractor lift links,

align the holes, and insert the rod (7) through the

lift bracket and lift links. Install an internal cotter pin

(14) in the other end of the rod (See Figure 3).

TRACTOR

LIFT LINK

LIFT BRACKET

SLOTS

Remove the mower deck and front lift rod

assembly, or any other attachment from the

tractor.

1. Remove the front bumper from the frame by

removing the hex wash. tapp screw from each side

(See Figure 2). Store the screws and bumper for

later reassembly.

FRONT

HEX WASH. HD.

TAPP SCREW

(BOTH SIDES)

BUMPER

Figure 2

2. Place the tractor lift handle in the No. 2 height

position

3. Install an internal cotter pin (14) in the hole at one

end of the rod (7).

INTERNAL

COTTER PIN

CENTER

LIFT ROD

TAB

ROD

LIFT

BRACKET

Figure 3

B. BLADE ASSEMBLY PREPARATION. Some front

blade components may have been further preassembled at the factory. If so, skip those steps

which have already been completed.

WARNING

Although the blade assembly has been partially

assembled at the factory, the pivot latch

components and the contact surfaces between

the pivot plate and A-frame should be checked

for proper lubrication. If necessary, apply a

liberal amount of a good grade grease to the

contact surfaces and apply spray lube to the

latch components.

6

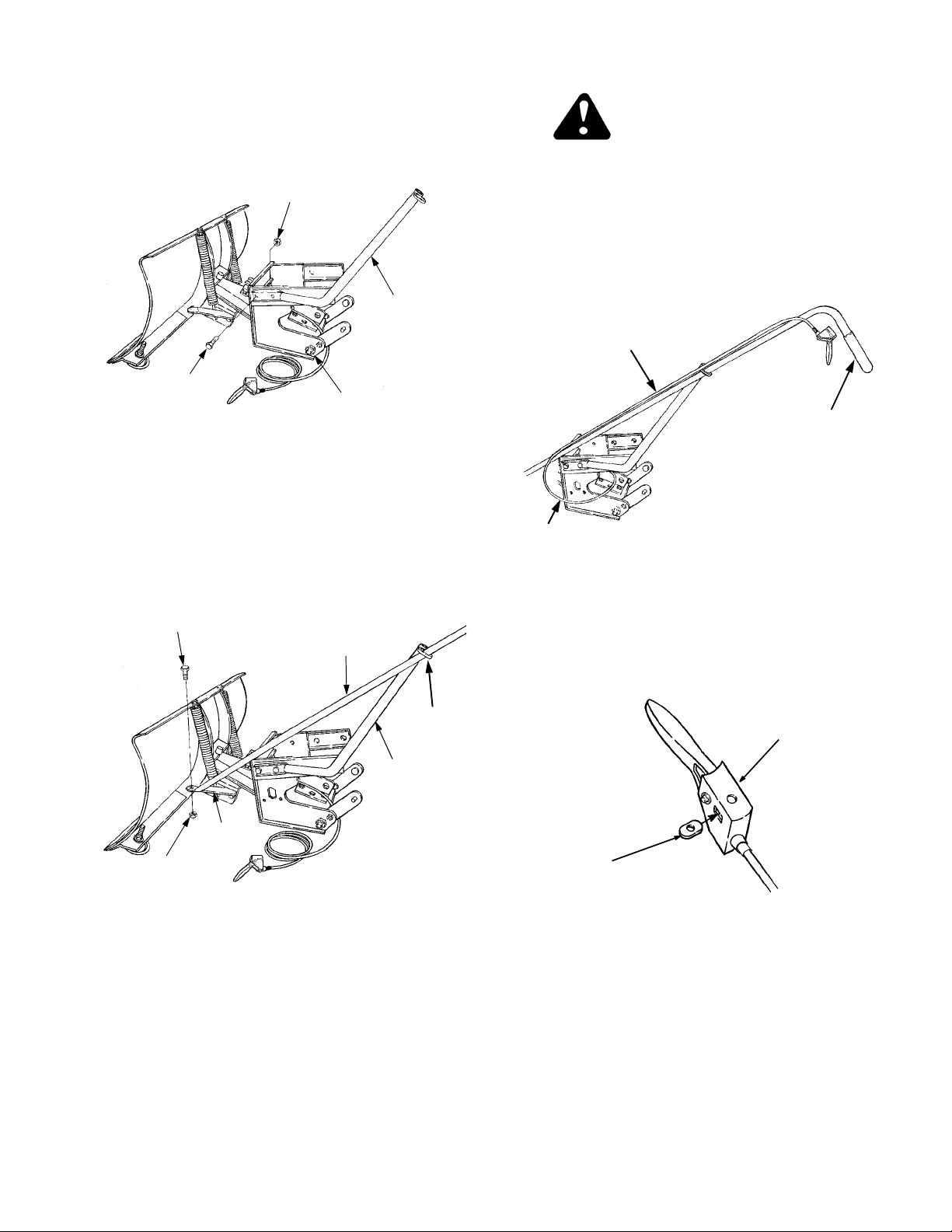

Page 7

1. Assemble the handle support tube (5) to the LH

blade hitch assembly using the hex cap screws

(13) and hex lock nuts (12). See Figure 4.

HEX FLANGE

LOCK NUT

CAUTION

Route the cable as shown in Figure 6. Make

certain the cable has a smooth, even bend and

will not be kinked or pinched.

3. Route the pivot release cable along the upper

surface of the blade pivot handle to the top of the

handle (See Figure 6).

HANDLE

SUPPORT

TUBE

HEX CAP

SCREW

BLADE HITCH

ASSEMBLY

Figure 4

2. Slide the blade pivot handle (6) through the eyelet

of the handle support tube (5). Attach to the blade

angle arm of the pivot plate with the shoulder bolt

(16) and flanged lock nut (15). See Figure 5.

SHOULDER

BOLT

BLADE PIVOT

HANDLE

EYELET

PIVOT

RELEASE

CABLE

BLADE

PIVOT

HANDLE

SMOOTH

BEND

Figure 6

4. Slide the flat weld nut (17) into the release cable

trigger housing. See Figure 7.

TRIGGER

HOUSING

LOCK

NUT

ANGLE

ARM

Figure 5

HANDLE

SUPPORT

TUBE

FLAT

WELD

NUT

Figure 7

7

Page 8

5. While holding the flat weld nut (17) in position,

place the cable trigger housing under the blade

pivot handle (6) and fasten with the oval hd. cntsk.

screw (18). See Figure 8.

OVAL HD.

CNTSK. SCREW

BLADE

PIVOT

HANDLE

7. If not already done, screw the adjustment clevis (4)

onto the threaded end of the lift rod (3).

NOTE

When attaching the lift rod assembly to the

blade’s A-frame assembly, the rod must be

inserted from left to right as shown in Figure 10.

FLAT WELD NUT

IN SLOT

TRIGGER

ASSEMBLY

Figure 8

NOTE

When installing the center cable tie, make

certain it is positioned far enough from the

support tube eyelet to prevent the cable from

binding on the eyelet when the blade pivot

handle is moved to either of the angled

positions.

6. Secure the blade release cable to the pivot handle

with the three tie straps (19) as shown in Figure 9.

Cut excess from tie strap ends.

CABLE

TIE

LIFT ROD

INTERNAL

COTTER PIN

BLADE

A-FRAME

Figure 10

8. Install the lift rod (3) in the front lift bracket of the Aframe assembly and secure with an internal cotter

pin (14). See Figure 10.

9. Loosen, BUT DO NOT REMOVE, the four screws

that fasten the front support plate to the LH and RH

hitch plates. See Figure 11.

RH & LH

PLATESHITCH

FOUR

SCREWS

SUPPORT

TUBE

EYELET

Figure 9

BLADE

PIVOT

HANDLE

BLADE

RELEASE

CABLE

FRONT

SUPPORT

PLATE

Figure 11

8

Page 9

SECTION III. INSTALLATION

A. BLADE INSTALLATION.

WARNING

Place the tractor and front blade on a firm and

level surface. Disengage the PTO, engage the

brake lock, stop the tractor engine and remove

the key from the switch before beginning

installation procedures.

WARNING

The exhaust system and surrounding areas are

HOT. To avoid personal injury, allow the tractor

to cool before beginning any blade installation

procedures.

1. Position the blade assembly directly in front of the

tractor with the LH and RH hitch plate channel

brackets aligned with the channels of the tractor

frame.

QUICK

ATTACH

LATCH

BELLEVILLE

WASHER

(BOTH SIDES)

HEX CAP

SCREW

(BOTH SIDES)

FRONT FRAME

CHANNEL

MOUNTING

ARM & PIN

(BOTH SIDES)

Figure 12

NOTE

PUSH HERE

BLADE HITCH

ASSEMBLY

NOTE

To ease insertion into the tractor frame

channels, apply a light coating of grease to the

channel brackets of the blade hitch assembly.

2. Pushing evenly on both sides as indicated in Figure 12, slide the blade hitch assembly into the tractor frame channels.

NOTE

The blade hitch assembly is fully inserted when

the pins of the hitch assembly mounting arms

are locked in the quick attach latch on each side

of the tractor frame. See Figure 12.

3. Using one hex cap screw (10) and belleville washer (11) per side, secure the blade hitch assembly

to the tractor frame channels as shown in Figure

12.

4. Tighten the four screws in the front support plate

which were loosened during the blade preparation

procedures.

Make certain the tractor’s implement lift handle

is in the No. 2 height position.

5. Turn the adjustment clevis on the lift rod to align

with the hole in the lift bracket tab, then insert the

clevis pin (9) and secure with an internal cotter pin

(14). See Figure 13.

CLEVIS

PIN

LIFT

BRACKET

COTTER PIN

ADJUSTMENT

INTERNAL

CLEVIS

LIFT

ROD

Figure 13

9

Page 10

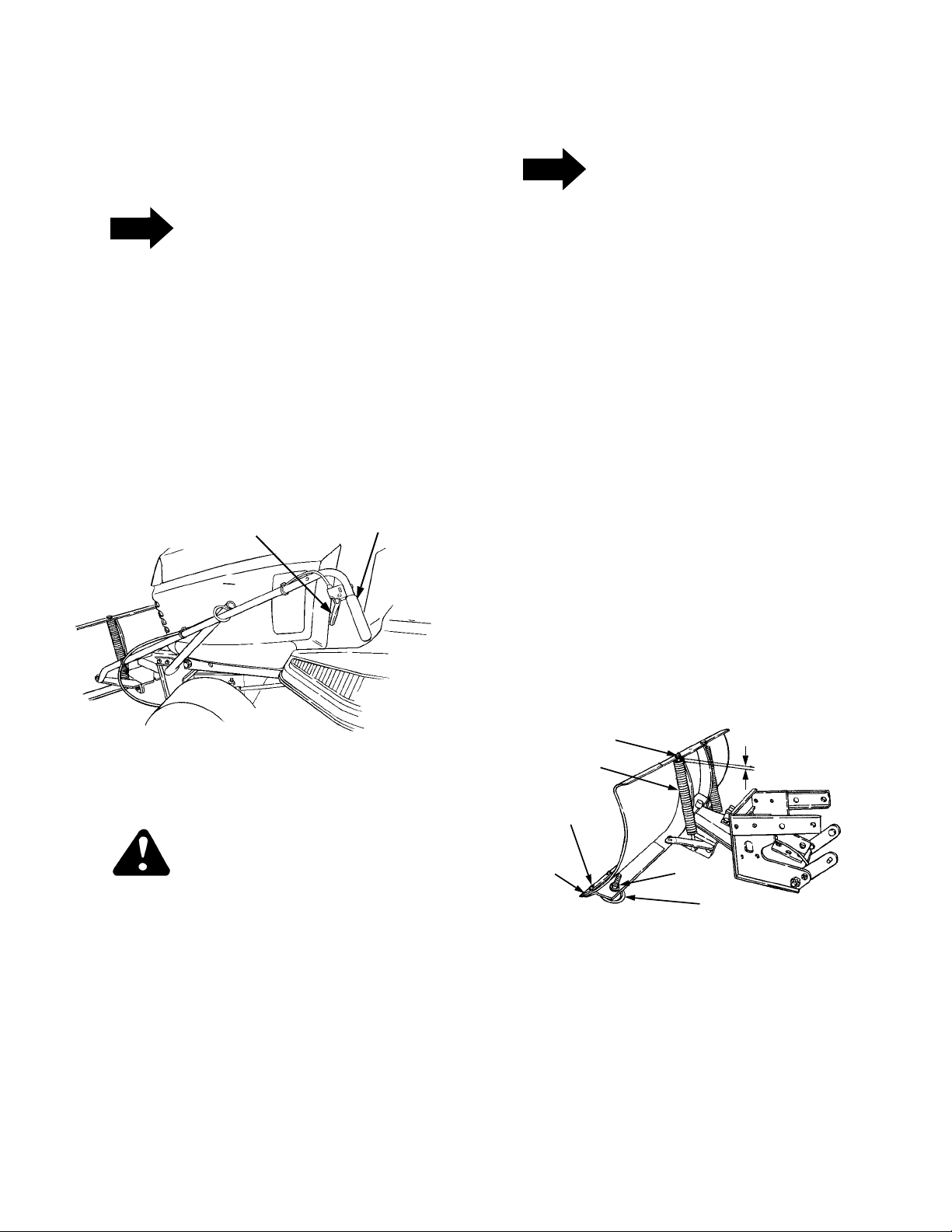

SECTION IV. REMOVAL AND ATTACHMENT

A. BLADE REMOVAL

NOTE

These removal and attachment instructions

apply to a blade assembly which has been

originally assembled and installed according to

Sections II and III of this manual.

1. Drive the tractor with blade to the storage location.

INTERNAL

COTTER PIN

WARNING

Disengage the PTO, engage the brake lock,

stop the tractor engine and remove the key from

the switch before beginning removal

procedures.

WARNING

The exhaust system and surrounding areas are

HOT. To avoid personal injury, allow the tractor

to cool before beginning any blade removal

procedures.

2. Place the implement lift handle in No. 2 position.

3. Remove the adjustment clevis (4) from the lift

bracket by removing the internal cotter pin (14)

and clevis pin (9). See Figure 14.

LIFT

BRACKET

ADJUSTMENT

CLEVIS

LIFT

ROD

BRACKET

Figure 15

5. Remove the hex screws (10) and bell washers (11)

fastening the blade hitch assembly to the tractor

frame channels. See Figure 16

FRONT FRAME

CHANNEL

MOUNTING

ARM PIN

(BOTH SIDES)

BELLEVILLE

WASHER

(BOTH SIDES)

HEX CAP

SCREW

(BOTH SIDES)

QUICK

ATTACH

ROD

BLADE HITCH

ASSEMBLY

CLEVIS

PIN

INTERNAL

COTTER PIN

LIFT

ROD

Figure 14

4. Remove the lift bracket (8) by removing one

internal cotter pin (14) and sliding the rod (7) out of

the implement lift links. See Figure 15.

Figure 16

NOTE

Store all components and hardware removed

with the blade assembly for later reattachment.

6. Push downward and hold the quick attach rod to

release the mounting arm pins and slide the blade

hitch assembly from the frame channel. Refer to

Figure 16.

10

Page 11

B. BLADE REATTACHMENT

2. Slide the blade hitch assembly into the tractor

frame channels. Refer to Figure 12.

WARNING

Place the tractor and front blade on a firm and

level surface. Disengage the PTO, engage the

brake lock, stop the tractor engine and remove

the key from the switch before beginning

installation procedures.

WARNING

The exhaust system and surrounding areas are

HOT. To avoid personal injury, allow the tractor

to cool before beginning any blade installation

procedures.

1. Position the blade assembly directly in front of the

tractor with the LH and RH hitch plate channel

brackets aligned with the channels of the tractor

frame.

NOTE

To ease insertion into the tractor frame

channels, apply a light coating of grease to the

channel brackets of the blade hitch assembly.

3. Secure the blade hitch assembly to the tractor

frame channels using the hex cap screws (10) and

belleville washers (11). Refer to Figure 12.

NOTE

The tractor’s implement lift handle must be

placed in the No. 2 height position.

CAUTION

When installing the lift bracket (8), the tractor lift

links must be positioned within the slots at

each side of the lift bracket, with the center lift

rod tab of the bracket positioned as shown in

Figure 3.

4. Fasten the lift bracket (8) onto the implement lift

links by sliding the rod (7) through the bracket and

links, and secure with the internal cotter pin (14).

Refer to Figure 3.

5. Attach the adjustment clevis (4) to the lift bracket

(8) by aligning the holes and inserting the clevis pin

(9). Secure with the internal cotter pin (14). Refer

to Figure 13.

11

Page 12

SECTION V. ADJUSTMENT AND OPERATION

A. ADJUSTMENTS

1. Blade angling. Refer to Figure 17 and proceed as

follows:

NOTE

The blade has 3 operating positions: 30° to the

right, straight, and 30° to the left.

a. Blade angling is achieved by first squeezing

the trigger assembly on the blade pivot handle.

b. While the trigger is being squeezed, push or

pull the blade pivot handle to angle the blade

30° to the right, 30° to the left, or straight

ahead.

TRIGGER

ASSEMBLY

BLADE PIVOT

HANDLE

2. Skid shoe adjustment.

NOTE

Adjust the skid shoes so the blade cutting edge

just clears the pavement when being used for

snow removal.

Adjust the skid shoes (See Figure 18) to the

appropriate position for the job being performed as

follows:

• Loosen the hex nuts on each shoe.

• Turn the skid shoes to the desired position.

• Tighten the hex nuts.

3. If the wear bar (See Figure 18) becomes worn,

reverse or replace the bar as follows:

• Remove the seven carriage bolts, lock wash-

ers, and hex nuts fastening the wear bar to the

blade.

• Reverse or replace the wear bar and attach with

the carriage bolts, lock washers and hex nuts.

Figure 17

CAUTION

It is important that the blade is locked into

position. After releasing the trigger, push or pull

the blade pivot handle to be certain the blade is

locked into one of the three positions.

4. Maintain the proper trip spring tension (See Figure

18) as follows:

• There should be a 1/4 inch gap between the top

of the spring and the upper lip of the blade.

• Tighten or loosen the hex cap screws on top of

the blade to obtain the proper gap.

HEX CAP SCREW

SPRING

CARRIAGE

WEAR

BAR

BOLT

HEX

NUT

SHOE

1/4" GAP

Figure 18

12

Page 13

B. OPERATION

open flat areas, the tractor can be operated at

medium speed.

NOTE

The blade is designed for clearing snow,

leveling soft dirt or sand and other light duty

dozer jobs. The spring trip release protects the

blade, tractor and operator from severe shock

loads when the blade comes in contact with

curbs and other obstacles. The blade has a

reversible and replaceable cutting edge.

WARNING

Before operating the tractor, familiarize yourself

with the SAFE OPERATION PRACTICES FOR

RIDING VEHICLES starting on page 2.

WARNING

Operate the tractor at a slow ground speed until

familiar with the operation of the blade.

2. Light grading. For light grading and spreading soil,

sand, gravel, etc., adjust the shoes so they are

even with the cutting edge. Control the blade

position with the tractor implement lift. Operate the

tractor at slow or medium speed.

3. Heavy grading. For heavy grading of soil, sand,

gravel, etc., adjust the shoes so they are slightly

above the cutting edge. Control the blade position

with the tractor implement lift. Operate the tractor

at slow speed.

4. Terracing. For terracing, adjust the shoes so they

are approximately 1/4 inch or more above the

cutting edge, depending on the rate of blade

penetration desired. Angle the blade away from

the trench cut by the blade. Control the blade

depth with the tractor implement lift. Operate the

tractor at slow speed.

Once the desired angle of the terrace is achieved,

level the blade and continue grading until the

desired terrace depth or width is obtained.

CAUTION

Never operate the tractor at high speeds. A

collision with a hidden obstacle may damage

the blade cutting edge and unseat the driver.

1. Pushing snow. Adjust the shoes so the blade

cutting edge just clears the pavement. In large

CAUTION

To avoid an accident or injury, do not allow

adults to operate the blade without proper

instruction. Never allow children to operate.

5. Lubrication. Periodically lubricate the pivot points

between the A-frame and pivot plate with a good

grade of grease. Periodically spray lube the pivot

latch components.

13

Page 14

SECTION VI. ADDITIONAL ACCESSORY REQUIREMENTS

A. WEIGHT KIT

This section describes the proper configuration of the

required weight kit, Model 307.

WARNING

The weight kit, Model 307, must be installed on

the rear of the tractor whenever the blade

assembly is installed on the front of the tractor.

In addition, the weight kit must be used with the

proper weights.

1. At all times that the blade is installed on the front

of the tractor, the weight kit must be installed on

the rear of the tractor. The weight kit

counterbalances the weight of the blade and

provides stability to the tractor.

2. Depending upon the prevailing conditions, a

minimum of two suitcase weights and a maximum

of four weights must be used with the weight kit.

3. Refer to the weight kit Owner’s Manual for detailed

instructions pertaining to the proper installation of

the weight kit onto the rear of the tractor.

B. TIRE CHAINS

Tire chains are recommended when using the 42 inch

Spring Trip Blade. Tire chains are available at your

authorized Cub Cadet Dealer.

14

Page 15

15

Page 16

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Cub Cadet

LLC with respect to new merchandise purchased and used in

the United States, its possessions and territories.

Cub Cadet LLC warrants this product against defects for a

period of two (2) years commencing on the date of original

purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or

workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance

with the Operator’s Manual furnished with the product, and

has not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril

or natural disaster. Damage resulting from the installation or

use of any accessory or attachment not approved by Cub

Cadet LLC for use with the product(s) covered by this manual

will void your warranty as to any resulting damage.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear parts or

component failures will be covered on the product for a period

of 90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in materials or workmanship of

OTHER component parts. Normal wear parts and

components include, but are not limited to: batteries, belts,

blades, blade adapters, grass bags, rider deck wheels, seats,

snow thrower skid shoes, shave plates, auger spiral rubber,

and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact Cub Cadet LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-877-282-8684, or log

on to our Web site at www.cubcadet.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to

applicable manufacturer’s warranty for terms and

conditions.

b. Log splitter pumps, valves, and cylinders have a sepa

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal

deterioration of the exterior finish due to use or

exposure.

d. Cub Cadet LLC does not extend any warranty for

products sold or exported outside of the United States,

its possesions and territories, except those sold

through Cub Cadet LLC’s authorized channels of

export distribution.

e. Parts that are not genuine Cub Cadet parts are not

covered by this warranty.

f. Service completed by someone other than an

authorized service dealer is not covered by this

warranty.

g. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind Cub Cadet LLC. During the period of the

warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. Cub

Cadet LLC shall not be liable for incidental or

consequential loss or damage including, without

limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Cub Cadet LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-877-282-8684

Loading...

Loading...