Page 1

SERIES 3000

SERVICE MANUAL

770-10227

Page 2

Series 3000 Technical Handbook

Table of Contents

Section

Pre-Delivery Check List and Service Specifications 1999 ................................................................................1

Engineering Updates 1999................................................................................................................................2

Fender Removal and Reinstallation ..................................................................................................................3

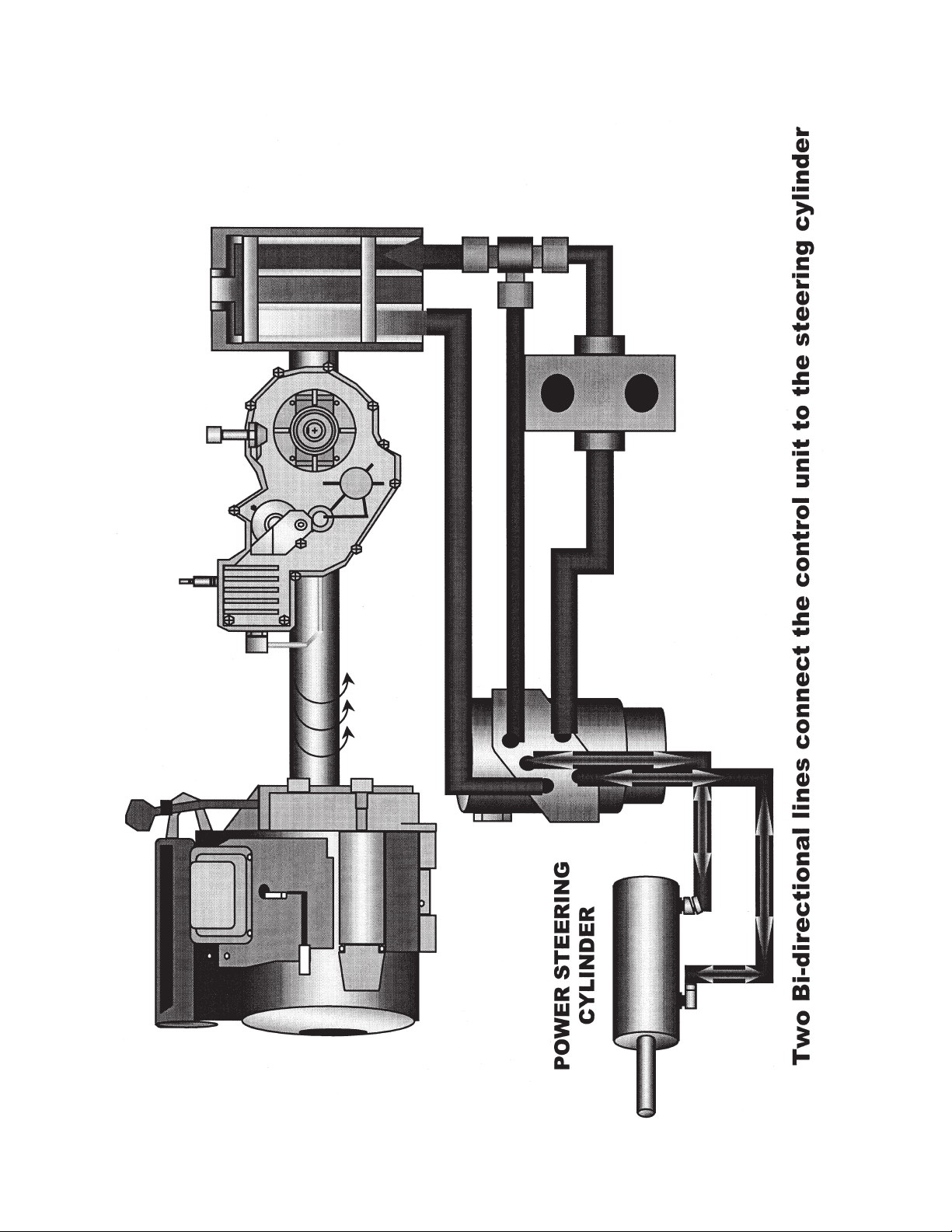

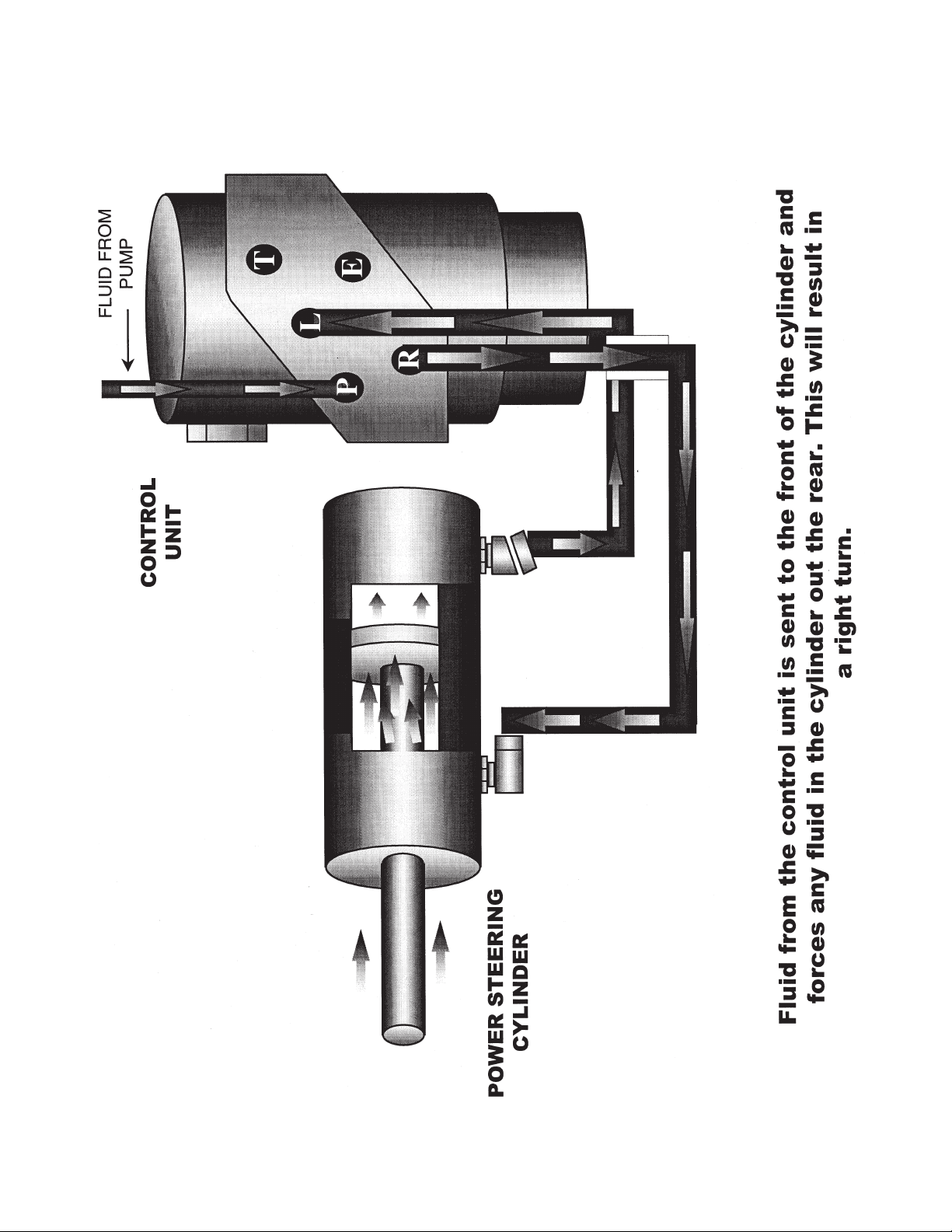

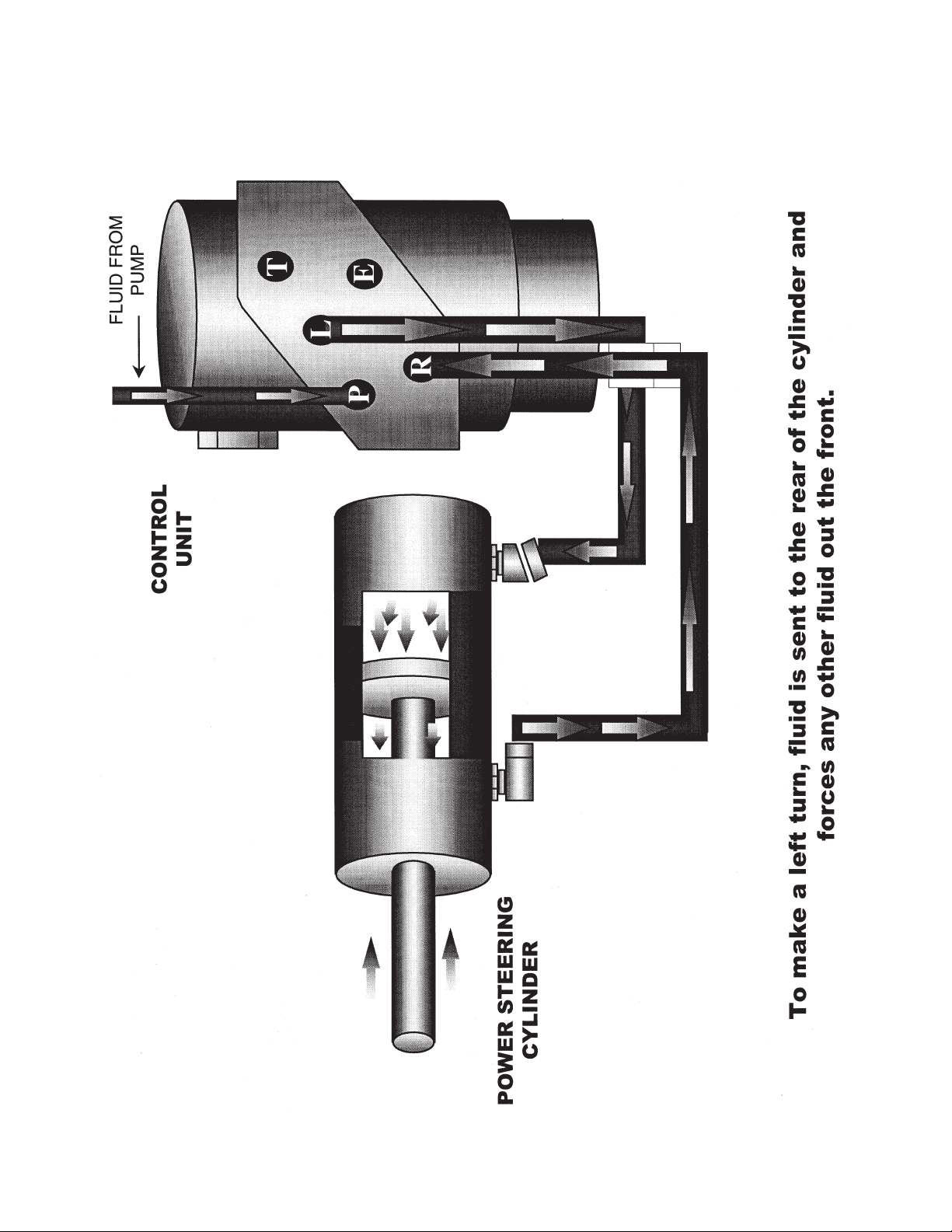

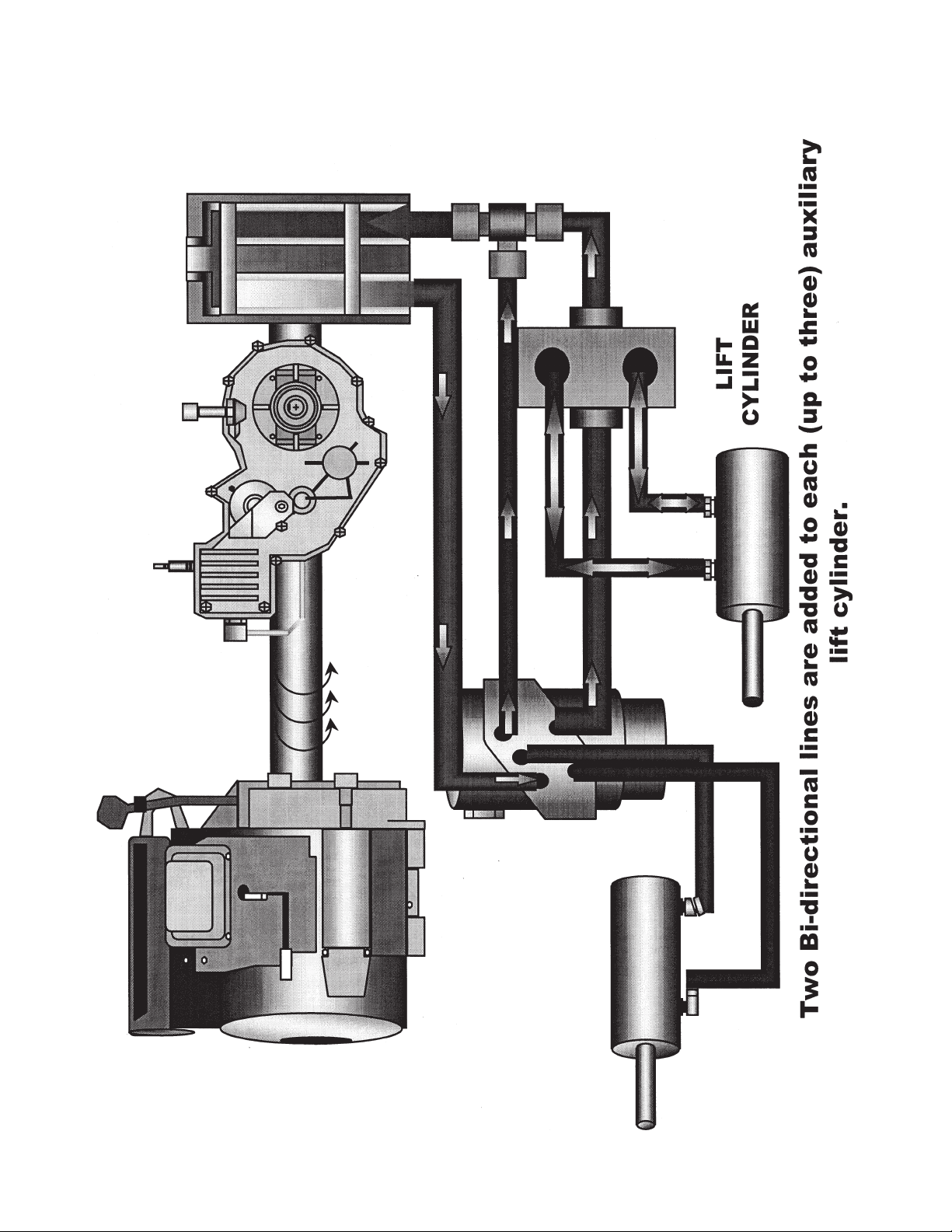

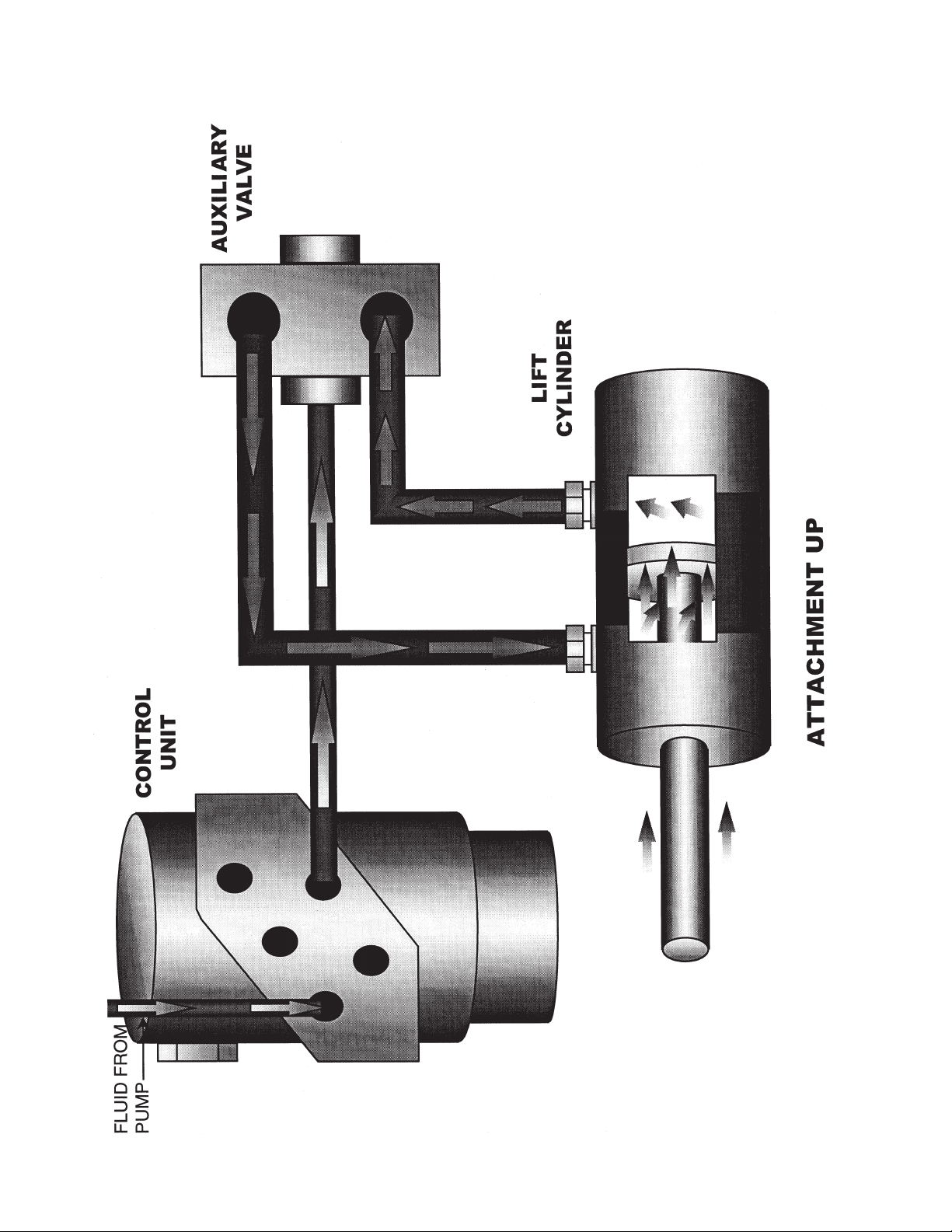

Hydraulic Step by Step Flow Charts .................................................................................................................4

Power Steering Cylinder Removal and Replacement .......................................................................................5

Power Steering Pump Disassemble, Inspect and Reassemble ........................................................................6

Center Lift Cylinder Removal and Replacement ...............................................................................................7

Pump Adapter Removal and Replacement.......................................................................................................8

BDU-21L-500 Pressure Test Procedure ...........................................................................................................9

Hydraulic Steering Pump Removal and Replacement ....................................................................................10

Hydraulic Valve Removal and Replacement...................................................................................................11

Engine Removal and Replacement.................................................................................................................12

Transmission Removal and Installation ..........................................................................................................13

Transmission Inspection and Disassembly .....................................................................................................14

Transmission Reassembly ..............................................................................................................................15

Neutral Control Adjustment .............................................................................................................................16

3000 Series Electrical .....................................................................................................................................17

BDU-21L Transmission ...................................................................................................................................18

Page 3

Pre- Delivery Check List

1000, 1500, 2000, 2500, 3000 Series

CUSTOMER NAME_____________________________

ADDRESS____________________________________

CITY_________________________________________

STATE________________________ZIP____________

HOME PHONE NUMBER________________________

ENGINE INFORMATION:

ENGINE MAKE__________________________________

ENGINE MODEL NUMBER_________________________

ENGINE SPEC. NUMBER__________________________

ENGINE SERIAL NUMBER_________________________

CHECK-ADJUST AS REQUIRED. Inspection time for these checks are not reimbursable as warranty. Repairs that are determined

to be necessary due to defects in material or workmanship are reimbursable under warranty.

Manuals Complete: (Use Operator Manual and related

manuals during checks).

Owners Manual.

Engine Manual (If Applicable).

Attachment Manual (If Applicable).

Battery & Connections:

Check battery for specific gravity (1.265).

Charge battery at 4 amps max. to 1.265 specific

gravity if needed.

Tires & Wheels:

Check & adjust pressure in tires as specified in

Operator’s Manual.

Tighten lug nuts / bolts as specified in Operator’s

Manual.

Check Lights & Indicators:

Check headlights / taillights (If Applicable).

Check all dash lights (If Applicable).

Check hour meter / service minder (If Applicable).

Lubrication:

Check engine oil level.

Check transmission oil level.

Air Cleaner & Connections:

Remove air cleaner cover to verify air filter & pre

cleaner is installed.

Insure retaining bolt seal is installed.

Insure proper installation of breather hose.

Check operation of throttle & choke cables.

Steering:

Check for 1/16 to 5/16 inch toe in. (Refer to

Operator’s Manual).

Insure equal travel right & left.

MODEL NUMBER______________________________

SERIAL NUMBER______________________________

ATTACHMENT MODEL NUMBER_________________

ATTACHMENT SERIAL NUMBER_________________

TRANSMISSION INFORMATION:

TRANSMISSION MAKE______________________________

TRANSMISSION MODEL NUMBER_____________________

TRANSMISSION SERIAL NUMBER_____________________

Hydrostatic / Gear Drive:

Check brakes.

Check for neutral when brake pedal is depressed.

Check for neutral when forward & reverse pedal is

released.

Grease Pivot Points:

Front axle pivot bar & steering housing.

Each steering knuckle.

Each front wheel.

All grease points on mower deck. (Refer to

Operator’s Manual).

PTO / Attachments:

Check PTO air gap (.014-.017) (If Applicable).

Follow burnishing procedures. (listed on back).

Level deck. (Refer to Operator’s Manual).

Adjust lift assist spring (If Applicable). Inspect

linkage.

Brake Function:

Verify proper brake performance & parking brake.

Refer to Operator’s Manual or Service Manual to

adjust brakes.

Operation:

Verify proper operation of diff. lock (If Applicable) &

transmission.

Check operation of no cut in reverse feature.

Check all safety features of shutdown.

Check Engine Speeds:

Low idle - 1700 RPM.

High idle - 3600 RPM.

(Refer to Operator’s Manual or Engine Service

Manual for adjustment procedures).

Continued On Back

Page 4

Final Inspection:

Check fuel system for leaks. Tank, lines, fittings etc.

Check for missing or loose fasteners & decals.

Clean / polish. Check overall appearance.

Place manuals in a appropriate location (Under Seat)

at conclusion.

P.T.O. CLUTCH BURNISHING PROCEDURE:

Start unit.

Place throttle lever in the 1/2 throttle position.

Cycle P.T.O. clutch 10 times. (10 seconds on / 10 seconds off).

Place throttle lever in the full throttle position.

Cycle P.T.O. clutch 10 times. (10 seconds on / 10 seconds off).

ADDITIONAL ATTACHMENTS:

ATTACHMENT MODEL NUMBER_________________

ATTACHMENT SERIAL NUMBER_________________

ATTACHMENT MODEL NUMBER_________________

ATTACHMENT SERIAL NUMBER_________________

ATTACHMENT MODEL NUMBER_________________

ATTACHMENT SERIAL NUMBER_________________

ATTACHMENT MODEL NUMBER_________________

ATTACHMENT SERIAL NUMBER_________________

NOTES:

Customer Signature____________________________________________________________Date______________

Service Technician Signature_____________________________________________________Date_____________

Page 5

Page 6

1999 Specifications

1 - 2

Cub Cadet 1999 Specifications

SERIES 3000 TRACTORS

Features and General Specifications:

• Hydrostatic Drive w/Cruise Control • Cast Iron Front Axle

• Shaft Drive Transmission • 4.5 Gallon Fuel Tank

• Shaft Drive Deck and Front Attachments • E-Vac PTO System

• Power Steering • Tilt Steering Wheel

• Hydraulic Lift • Differential Lock (3205, 3225)

• Welded Full Length Twin Channel, 9 gauge • Speed:

Steel Frame – 0-7 MPH Forward

• Deck Height Indicator – 0-4 MPH Reverse

• Halogen Headlights • Tires:

• Taillights w/Reverse Lights – 16" x 7.5" Front

• 27" Turning Radius – 24" x 10.5" Rear

Model

Factory No. Series 3000

3165 14A-654-100 16.0 HP B&S Twin Vanguard OHV, Hydro, Power Steering, Power Lift

3185* 14A-665-100 18.0 HP B&S Twin Vanguard, Hydro, Power Steering, Power LIft

3186 14A-668-100 18.0 HP Kohler V-Twin OHV, Hydro, Power Steering, Power Lift

3205 14A-685-100 20.0 HP Liquid Cooled V-Twin Kawasaki OHV, Power Steering, Power Lift,

Differential Lock

3225 14A-688-100 22.0 HP V-Twin Kohler OHV, Power Steering, Power Lift, Differential Lock

*Limited Quantities Available

Model

Factory No. Attachments and Accessories

345 190-345-100 Fan Assist Bagger for 48"/54" Deck

289 190-289-100 48" Deck, Shaft Driven

290 190-290-100 54" Deck, Shaft Driven

291 190-291-100 60" Deck, Shaft Driven (3205 & 3225 only)

343 190-343-100 Hydraulic Front Hitch System

352 190-352-100 54" Front Mounted Snow Blade (Requires 343; Optional 288 or 171)

353 190-353-100 45" Snow Thrower, Shaft Driven (Req. 343)

299 190-299-100 Ag Tires/Rims 23" x 8.5"

249 190-249-100 Ag Tires/Rims 23" x 10.5"

366 190-366-100 Rear Turf Tires/Rims 24" x 10.5"

365 190-365-100 Hydraulic 3 Pt. Hitch, Category “O”

924 190-924-100 ‘A’ Frame Hitch Adapter, Converts Sleeve Hitch Attachments To Cat. “O”

3-Pt. Hitch

163 190-163-100 42"' Lawn Sweeper

653 190-653-100 10 Cu. Ft. Cart

368 190-368-100 10 Cu. Ft. Heavy Duty Dump Cart

425 190-425-100 17 Cu. Ft. Heavy Duty Dump Cart

161 190-161-000 48" Poly Bed Liner (Fits All 10’s)

(Tailgate Section Must Be Cut Out By Dealer)

Page 7

1 - 3

1999 Specifications

Model

Factory No. Attachments and Accessories

162 190-162-000 60" Poly Bed Liner (Fits All 17’s)

(Tailgate Section Must Be Cut Out By Dealer

288 190-288-100 Hydraulic Front Angle Kit (Cannot Be Used w/353)

171 190-171-100 Manual Angle Kit (Cannot Be Used w/353)

412 190-412-100 Rear Wheel Weights (2 per Set) @ 75#

413 190-413-100 Front & Rear Wt. Bracket (Supports 390 Wt.)

190390 190-390-100 Suitcase Weights

506 590-605-100 Mulcher, 48" Deck+

507 590-507-100 Mulcher, 54" Deck++

920 190-920-000 12" Mold Board Plow (Requires 365)

921 190-921-000 Tandem Disc (Requires 365)

922 190-922-000 Spring Cultivator (Requires 365)

400 190-400-100 38" Tiller, 8.0 HP B&S Engine (Requires 365)

206 190-206-100 Series 3000 Tractor Display Stand

NOTES:

+ To Mount on Series 3000 Deck You Must Order Qty. 1 - 603-0624 and 1- 603-0625 From Parts

++ To Mount on Series 3000 Deck You Must Order Qty. 1- 603-0626 and 1- 603-0627 From Parts

It is recommended that the 3165 be equipped with a 48" deck for maximum performance.

Cub Cadet 1999 Specifications (continued)

Page 8

NOTES

Page 9

2 - 1

Cub Cadet 3000

1999 3000 Series Engineering Updates

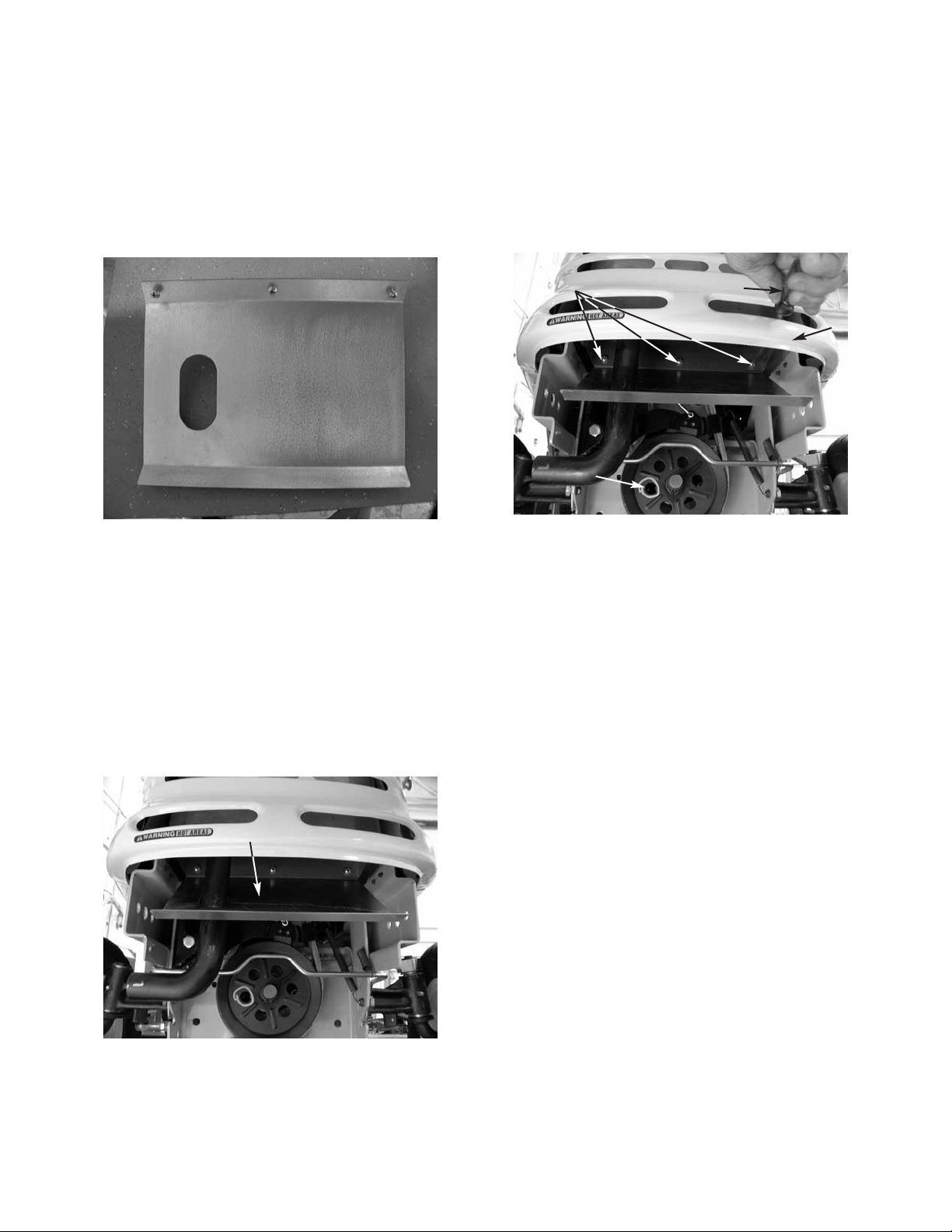

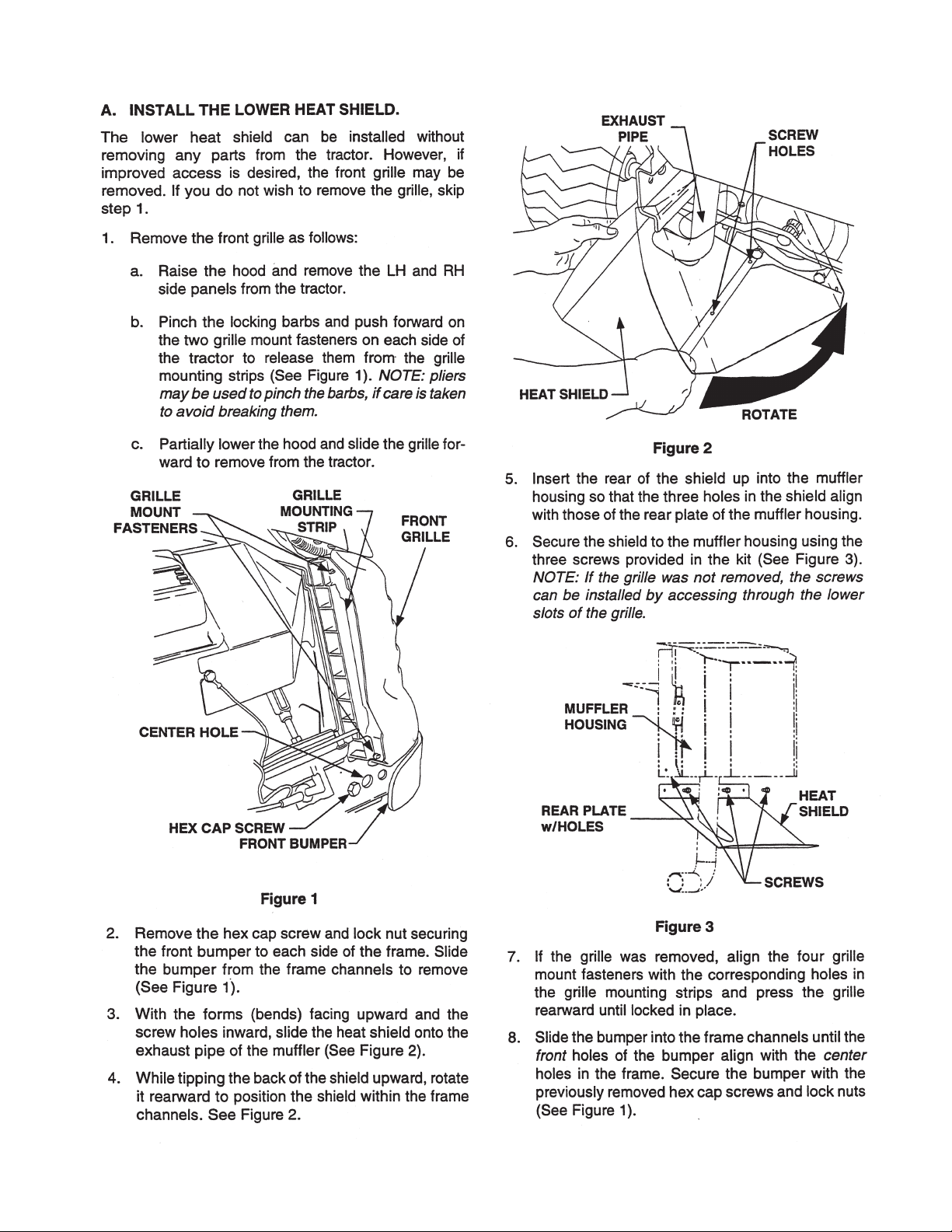

1. Remove both of the hex bolts and lock nuts

securing the front bumper to the frame using a

3/4" socket and a 3/4" wrench.

2. Remove the bumper.

3. Slide the muffler shield over the exhaust pipe and

rotate it into position.

NOTE: Align all three holes in the top of the

muffler shield with the existing shield. Also, the

muffler shield will be slanting towards the bottom

of the front grill assembly.

Heat Shield

Heat Shield

HEAT SHIELD

A heat shield has been installed on all 3000 series

tractors for 1999. The heat shield prevents the

exhaust gases from browning the grass. Use kit #759-

3927. See Service Advisory CC-371.

LIFT LINK

The lift link has been modified by strengthening the

powder metal that connects the lift lever to the

hydraulic valve for 1999.

CHECK VALVE

For 1999, a check valve will be installed to the

hydraulic valve to prevent the decks and other attachments from leaking down during and after usage.

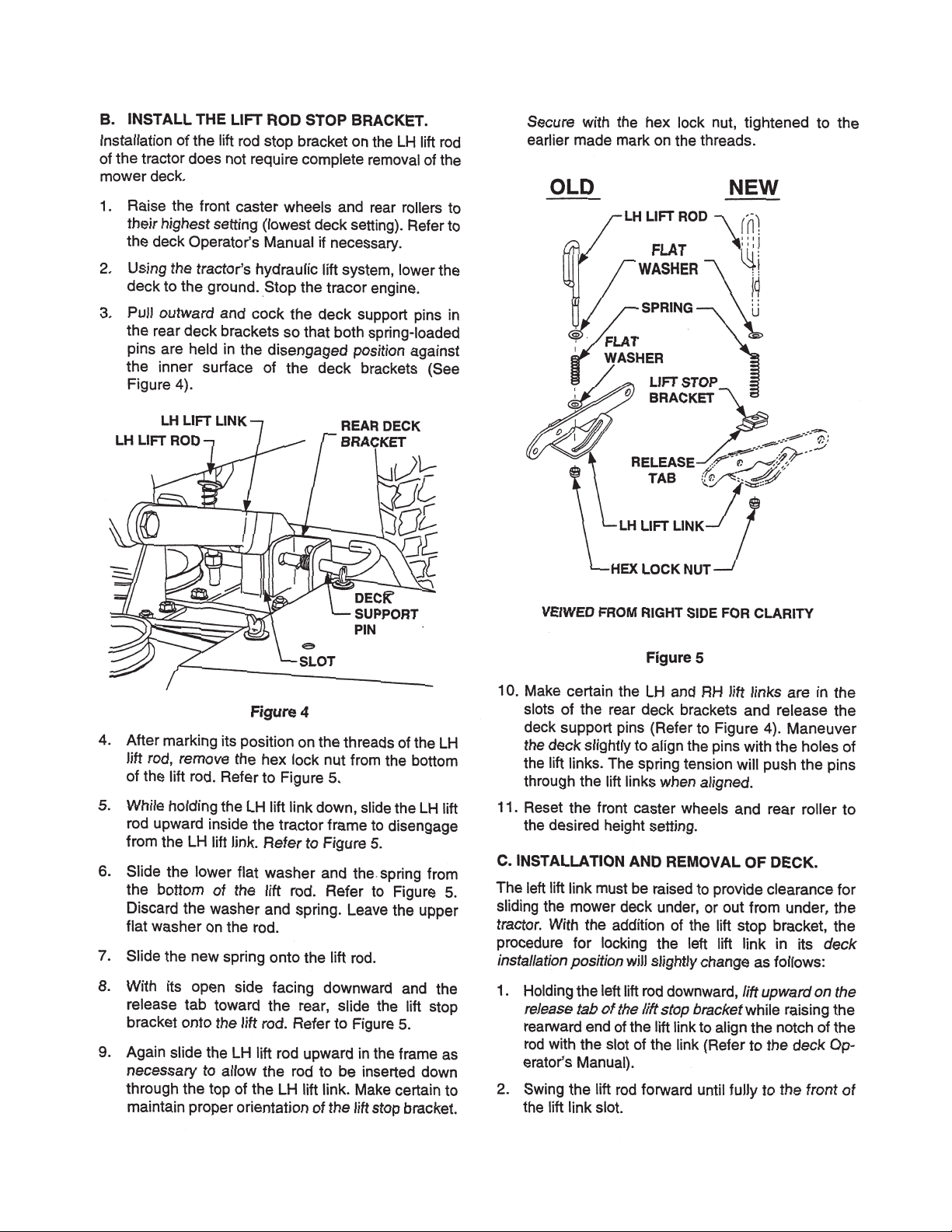

LIFT STOP BRACKET

A lift stop bracket will be installed on the left hand side

of the deck to prevent the deck from hanging up during operations. Use kit #759-3927.

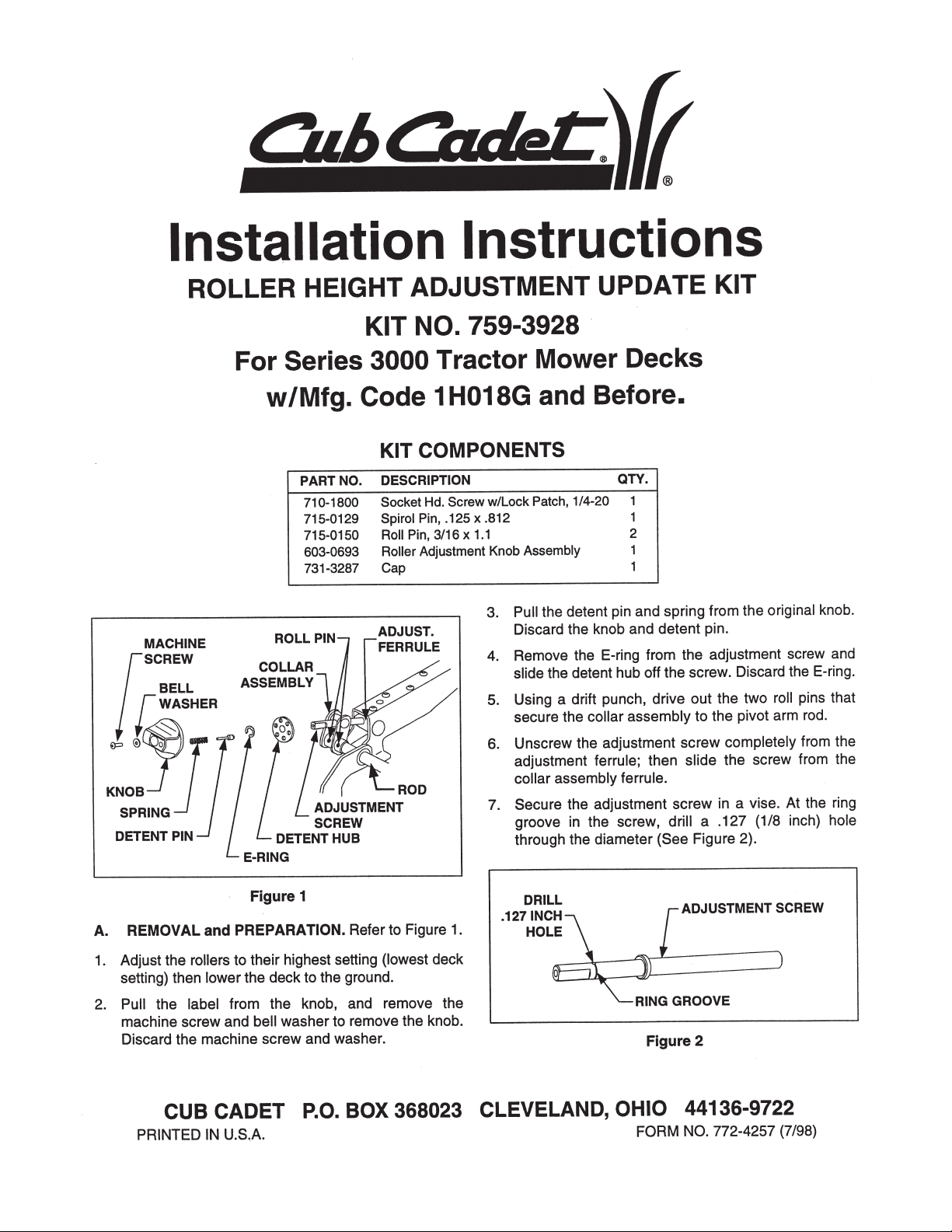

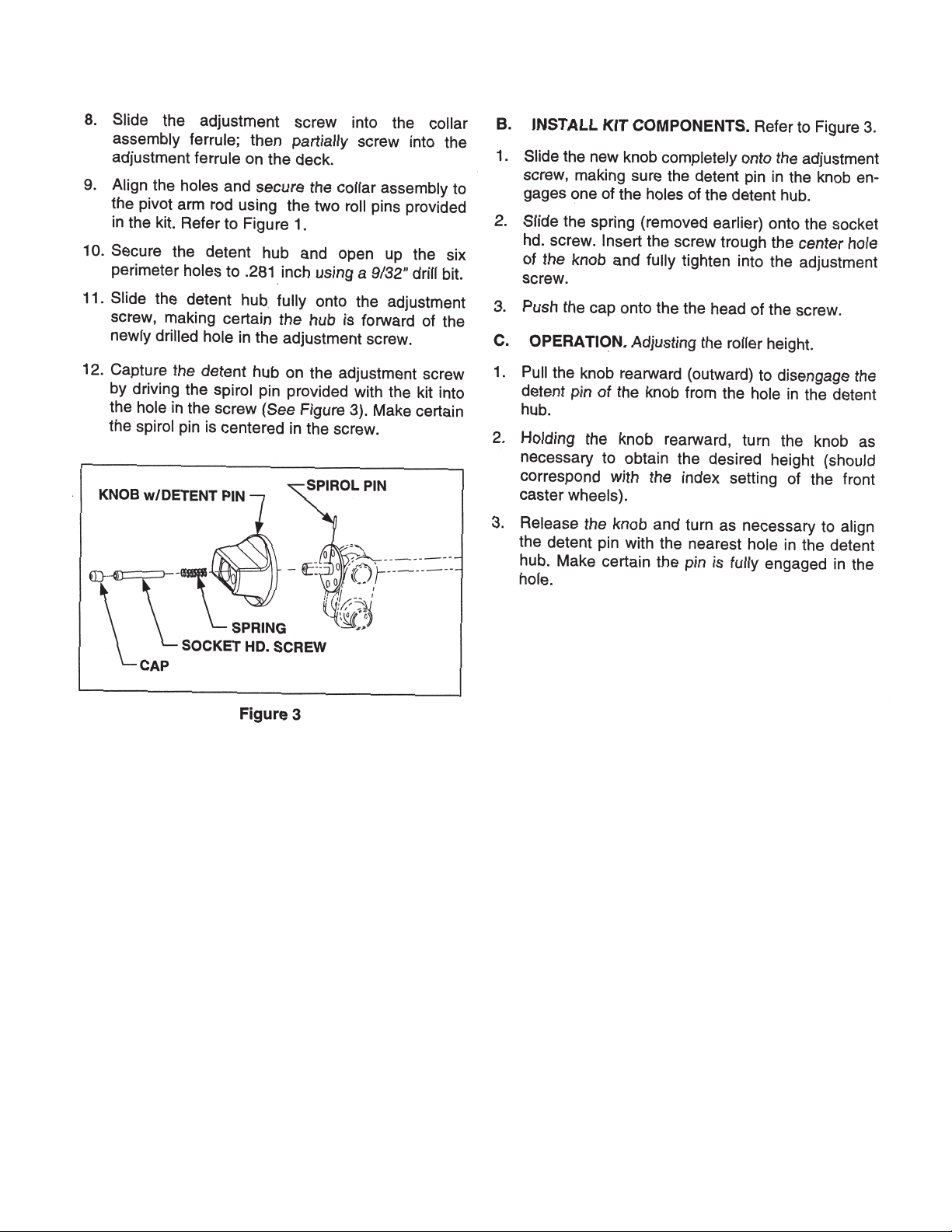

ROLLER HEIGHT ADJUSTER

The rear roller height adjustment mechanism will be

changed for 1999. A newly designed detent pin will

replace the old one, preventing the loss of cutting

height during operations. Use kit #759-3928.

FRONT DECK HANGER ASSEMBLY

The front roller bracket has been redesigned to prevent the front lift rod from detaching during operation.

SEAT IMPROVEMENTS

A safer seat spring, part number 732-0869, can be

installed to level the seat for petite operators. In addition, the seat part number 757-3010A, is now made

out of a softer material for better operator comfort.

See Service Advisory CC-358A Sections 5 and 6.

FRONT MOWER DECK HEIGHT ADJUSTER

The front mower deck height adjuster pins have been

changed from ball detent pins to quick pull pins.

Sheet Metal Screws

Screwdriver

Grill

Mark used in

Production

to Test PTO

Activation

4. Secure the muffler shield with three sheet metal

screws.

NOTE: Use a long flat blade screwdriver through

the air holes in the grill to tighten the sheet metal

screws securely.

5. Install the bumper.

Page 10

2 - 2

Cub Cadet 3000

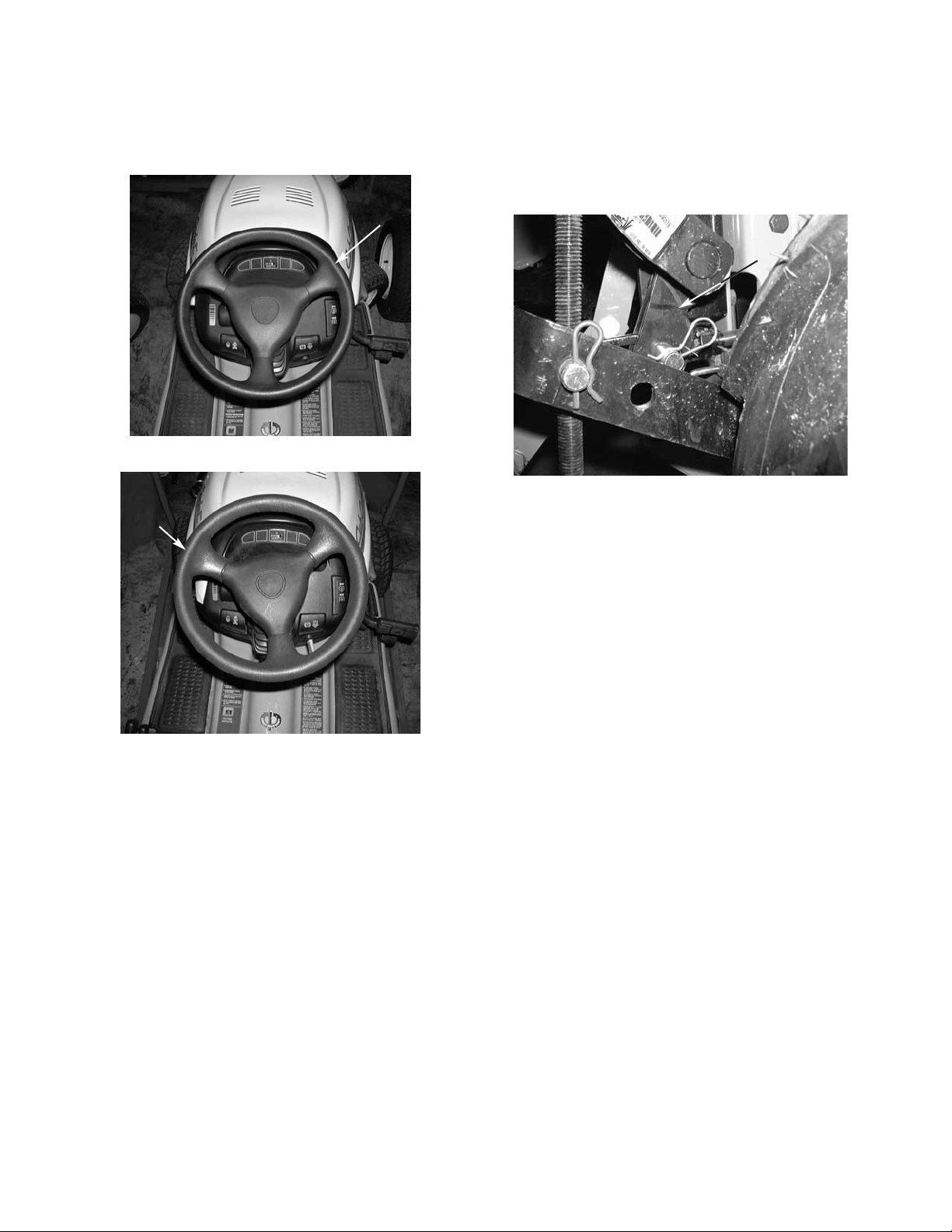

STEERING WHEEL

The thickness of the steering wheel has been

increased for operator comfort.

New Thicker Steering Wheel

Steering

Wheel

Thicker

Old Style Steering Wheel

Steering

Wheel

Thinner

ROCK SHAFT ASSEMBLY FOR 3 POINT HITCH

190-365-100

The cylinder arms have been redesigned with two V

sections cut out to allow for clearance of the clevis nut

on the cylinder shaft. See Service Advisory CC-364.

3000 Series Lift Assembly

Grooved

Out Area

Page 11

2 - 3

Cub Cadet 3000

Page 12

2 - 4

Cub Cadet 3000

Page 13

2 - 5

Cub Cadet 3000

Page 14

2 - 6

Cub Cadet 3000

Page 15

2 - 7

Cub Cadet 3000

Page 16

NOTES

Page 17

3 - 1

Cub Cadet 3000

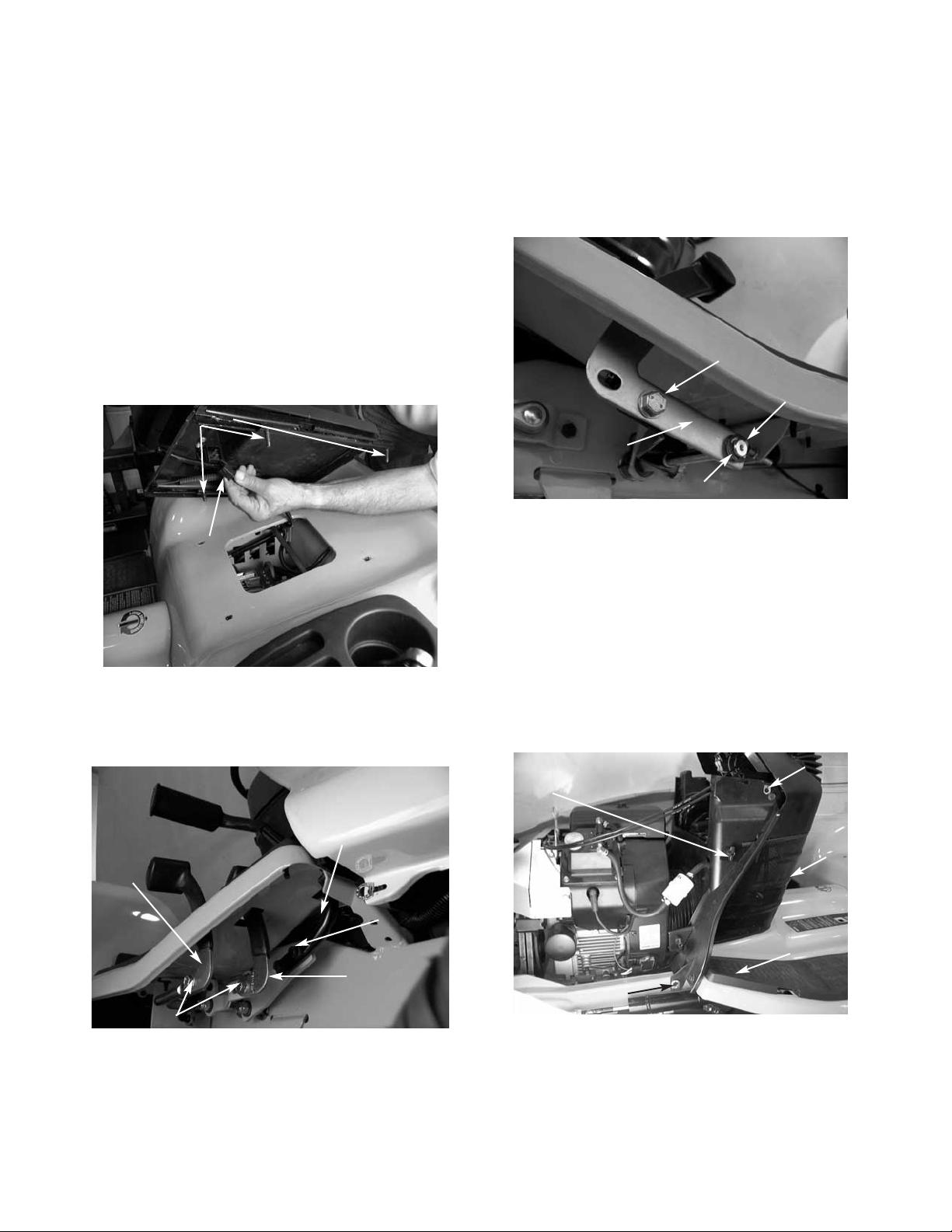

1. Slide the seat back and remove the front two pan

torx head screws using a T30 torx.

2. Slide the seat forward and remove the rear two

pan torx head screws using a T30 torx.

3. Pivot the seat assembly to the side and

disconnect the seat safety switch. See figure 1.

NOTE: Be careful not to scratch the fender with

the seat support brackets. It is advisable to use a

towel or cloth under the seat when pivoting the

seat.

4. Remove the seat from the tractor. See figure 1.

5. Remove all the hex bolts securing the three foot

pedals to the right side of the unit using a 9/16

socket. See figure 2.

Fender Assembly Removal and Reinstallation

FIGURE 1.

Torx Screws

Seat Safety

Switch

FIGURE 2.

Hex Bolts

Hex

Bolts

Reverse

Pedal

Forward

Pedal

Brake

Pedal

FIGURE 3.

Hex Bolt

Differential Lock

Out Pedal

Nylon Flange

Bearing

E-Clip

6. Remove the hex bolt securing the differential lock

out pedal on the left side of the unit using a 9/16

socket. Remove the “E” clip and the nylon flange

bearing from the pivot shaft.

FIGURE 4.

Wing

Nut

Side Panel Latch

Dash

Screen

Side Panel Latch

Rubber Foot Pads

7. Remove both rubber floor pads from the running

boards. See figure 4.

8. Lift the hood and remove the battery cover.

9. Remove both side panels from the tractor by

raising the latches horizontally and turning the

latches 1/4 turn. See figure 4.

10. Loosen all four plastic wing nuts holding the dash

panel screen in place. See figure 4.

11. Pull the dash screen towards the rear of the unit

and out of the dash panel. See figure 4.

Page 18

3 - 2

Cub Cadet 3000

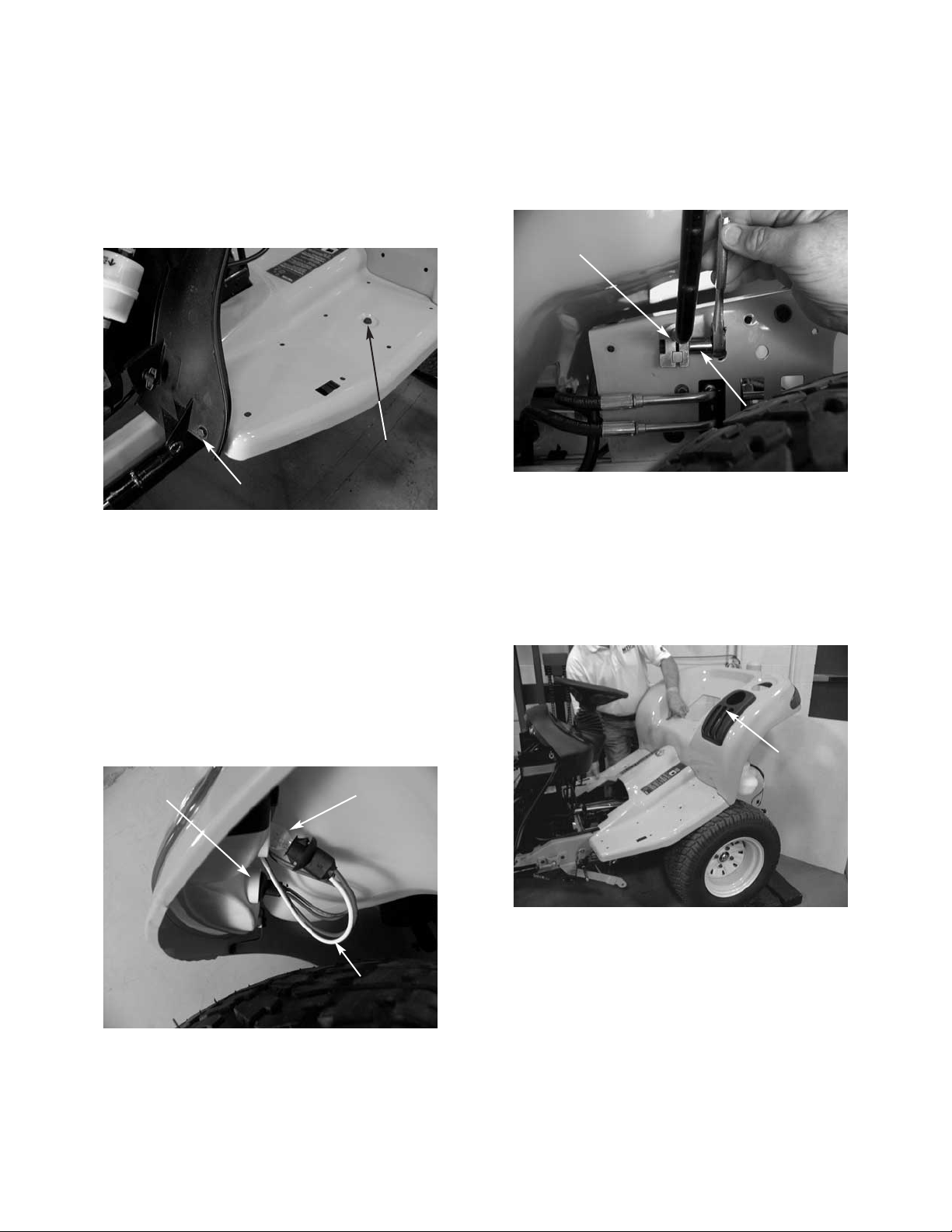

12. Remove all four running board hex bolts from the

tractor using a 1/2” socket. See figure 5.

NOTE: There are two bolts fastening the running

boards to the frame where the foot pads connect

and there are two bolts fastening the running

boards to the dash panel.

FIGURE 5.

Hex Bolt

Hex Bolt

FIGURE 6.

Tail

Light

Reverse

Light

White Wire

for Reverse

13. Remove the fuel cap.

14. Remove the tail light sockets from the tail light

assemblies by pushing in on the sockets gently

and twisting a 1/4 turn. See figure 6.

NOTE: When pulling the sockets out of the tail

light assemblies, it is very important to make sure

the light bulbs come straight out, or the light bulbs

will fall into the tail light assemblies. Also, note

the color of the wires for reinstallation. The white

wires go to the reverse lights. See figure 6.

FIGURE 7.

Hydraulic Lift

Handle Clamp

1/2" Socket

17. Remove the lift handle from the tractor through

the slot in the flap. See figure 8.

NOTE: If the lever is not removed at this time,

damage may occur to the lift knob.

18. Raise and remove the fender assembly.

FIGURE 8.

Slot for

Lift Handle

15. Raise the rear fender high enough to access the

hydraulic lift handle clamp. See figure 7.

16. Loosen the clamp connecting the hydraulic lift

handle to the center lift valve using a 1/2” socket.

19. Reinstall the fuel cap.

Page 19

4 - 1

Cub Cadet 3000

Page 20

4 - 2

Cub Cadet 3000

Page 21

4 - 3

Cub Cadet 3000

Page 22

4 - 4

Cub Cadet 3000

Page 23

4 - 5

Cub Cadet 3000

Page 24

4 - 6

Cub Cadet 3000

Page 25

4 - 7

Cub Cadet 3000

Page 26

4 - 8

Cub Cadet 3000

Page 27

4 - 9

Cub Cadet 3000

Page 28

4 - 10

Cub Cadet 3000

Page 29

4 - 11

Cub Cadet 3000

Page 30

4 - 12

Cub Cadet 3000

Page 31

4 - 13

Cub Cadet 3000

Page 32

4 - 14

Cub Cadet 3000

Page 33

5 - 1

Cub Cadet 3000

CAUTION: Slowly remove the hydraulic lines from the

cylinder. Test for pressure in the lines before removal.

1. Place an oil pan directly under the steering

cylinder. This will catch the hydraulic fluid that will

be drained from the lines and the cylinder.

2. Remove both hydraulic line connectors from the

fittings on the cylinder using an 11/16 and a 5/8

open end wrench. See figure 1.

3. Lower the hydraulic lines down into the oil pan

and allow to drain.

4. Remove the front ball joint NUT

from the steering

arm using a 17mm and 3/4" open end wrench.

See figure 2.

NOTE: Remove the ball joint NUT only

!!!

Removal and Replacement of the Power Steering Cylinder

FIGURE 1.

11/16"

5/8"

FIGURE 2.

17mm

Wrench

3/4

Wrench

5. Remove both of the hex head screws and the hex

flange nuts from the cylinder mounting bracket

using a 9/16 socket and a 9/16 wrench. See

figure 3.

FIGURE 3.

Hex Screws

6. Tilt the cylinder down into a pan and allow the oil

to drain.

7. Remove the front ball joint from the steering arm.

8. Remove the flat washer from the top of the

steering arm.

9. Place the cylinder on a bench and remove the

hex nut securing the cylinder to the mounting

bracket using a 17mm wrench and a 3/4" open

end wrench.

10. Slowly push the cylinder rod into the cylinder until

it is fully closed.

NOTE: At this point, the cylinder and both ball

joints are still in the original positions.

11. Record the exact positions of all the ball joints,

hex nuts and fittings on the cylinder. See figure 4.

12. Measure the distance from the inner edge of the

ball joint hex nut to the cylinder end. Repeat this

step for the opposite end. Write both distances

down. See figure 4.

NOTE: The proper measurements are needed to

keep the steering adjusted properly during

reassembly. These measurements should be

approximately 2.75" on the rod end, and 7/16" on

the mounting bracket end. See figure 4.

13. Remove the ball joints and hex nuts from the

cylinder.

Ball

Joint

Cylinder

Mounting

Bracket

Hex

Nut

Fitting

Page 34

5 - 2

Cub Cadet 3000

FIGURE 4.

Cylinder Rod

Ball

Joint

Ball

Joint

Hex

Jam Nut

Hex

Jam Nut

Hex

Jam

Nut

Elbow

Fitting

Elbow

Fitting

Approx.

2.75"

7/16”

90°

45°

“O” Rings

CAUTION ON THE NEXT STEP: There are “O” rings

between the cylinder block and the fittings. Extreme

care should be used to hold the fittings in place while

loosening the hex jam nuts, or damage will occur to

the “O” rings. Replacement of the “O rings” is

recommended.

14. Hold the hydraulic cylinder elbow fittings in place

with a 5/8 wrench, and loosen the hex jam nuts

with an 11/16 wrench. Slowly back the fittings out

of the cylinder.

15. Replace the “O” rings at this point.

NOTE: The front fitting is a 90 degree and the

rear fitting is a 45 degree.

1. Set the new hydraulic steering cylinder on a

bench.

2. Loosen the hydraulic fitting jam nut until it

bottoms out on the threads.

3. Press the flat washer snug up against the hex

jam nut.

4. Inspect the “O” ring for damage. If damaged,

replace.

5. Press the “O” ring snug up against the flat

washer.

6. Gently screw the fitting into place until the fitting

becomes snug.

NOTE: Do not tighten!!! At this time the “O” ring

will be seated properly in the cylinder port. If it is

over tightened, damage will occur.

Reinstallation of the Hydraulic Fittings to the Cylinder

7. Slowly unscrew the hydraulic fitting to the correct

recorded position.

NOTE: Do not unscrew the fitting more than one

full turn, because the cylinder may leak at the “O”

ring.

8. Hold the fitting in place with a 5/8 wrench, and

tighten the hex nut with an 11/16 wrench.

INSTALL THE SECOND FITTING BY REPEATING

STEPS ONE THROUGH EIGHT IN THIS SECTION.

Page 35

6 - 1

Cub Cadet 3000

Cub Cadet 3000 Series Char-Lynn 2 Series

Steering Control

Figure 1.

The following information may be used in the inspection and repair of Eaton’s Char-Lynn 2 series steering

control units.

Tools required for disassembly and reassembly: 10

mm socket, 7/8 in. socket, ratchet wrench, torque

wrench (160 lb. in. capacity)

Tool List

• 10 mm Socket

• 7/8 in Socket

• Torque Wrench (160 lb-in Capacity)

• Small Blade Screwdriver

The following disassembly procedures may be used

to disassemble the 2 series steering control. The configuration of your steering control may vary from the

pictures shown in this program. The configuration of

each control is determined by model. Different models

may incorporate different component parts and/or

assemblies. These differences may be the width of

the gerotor assembly, spool/sleeve assembly, housing configuration and etc.

When ordering replacement parts, give the product

number and date code. The product and date code is

noted on the serial number tag, which is located on

the side of the valve housing.

It is recommended that the steering control be thoroughly cleaned before any repairs are attempted.

When cleaning, be sure all open ports are sealed.

Figure 2.

To disassemble the steering control, first support the

control in a vertical position with the metering (gerotor) section end up. Using a 10 mm socket wrench,

remove the metering section end cap retaining cap

screws.

NOTE: When using a bench vise to support the control, caution must be used not to use excessive

clamping pressure on the control housing that could

cause housing distortion.

Figure 3.

Page 36

6 - 2

Cub Cadet 3000

Figure 4.

Remove the end cap from the gerotor assembly.

Figure 7.

Figure 6.

Figure 5.

Remove the o-ring seal from the gerotor assemblies

outer ring.

Remove the gerotor assemblies outer ring.

NOTE: The gerotor assembly may/may not remain

intact during removal.

Remove both the seal ring and o-ring seal from the

gerotors inner star.

Page 37

6 - 3

Cub Cadet 3000

Figure 8.

Remove the gerotors inner star from the drive.

Remove the wear plate from the housing assembly.

Remove the o-ring seal from the wear plate.

Remove the drive from the spool/sleeve assembly.

Remove the spacer.

Figure 11.

Figure 10.

Figure 9.

Figure 13.

Figure 12.

Remove the o-ring from the control housing.

Page 38

6 - 4

Cub Cadet 3000

The spool/sleeve assembly may be removed from the

control valve housing in either the vertical or horizontal position.

VERTICAL POSITION

Carefully reposition the control valve assembly in the

vertical position with the meter end of the control

valve housing pointing upward. Remove the

spool/sleeve assembly from the control valve housing.

IMPORTANT: Do not bind the spool/sleeve assembly

in the control housing.

Rotate the spool/sleeve assembly slightly and slowly

when removing from the control housing.

HORIZONTAL POSITION

Rotate the spool/sleeve assembly until the cross pin

is horizontal with the porting face flange. Position the

control valve assembly with the porting face on a

clean flat surface.

Remove the spool/sleeve assembly from the metering

section end of the control housing keeping the cross

pin in the horizontal position.

IMPORTANT: Do not bind the spool/sleeve assembly

in the control housing.

Rotate the spool/sleeve assembly slightly back and

forth when removing from the control housing.

Figure 16.

Figure 15.

Figure 14.

Push or pull the spool forward to remove it from the

sleeve.

NOTE: Caution must be used not to dislodge the

spring retaining ring during removal of the spool from

the sleeve.

Using a small screwdriver or similar type tool, remove

the cross pin from the spool/sleeve assembly.

Page 39

6 - 5

Cub Cadet 3000

Figure 20.

Figure 19.

Figure 18.

Figure 17.

Using the small screwdriver or similar tool, remove the

dust seal. Caution must be used not to scratch or

damage the dust seals counter bore when removing

the dust seal.

Turn the valve housing over and remove the two

bearing races and thrust bearing.

Carefully remove the centering springs from the

spool.

NOTE: It is not necessary nor recommended to

remove the external ring from the spool.

Carefully remove the spring retaining ring from the

centering springs.

Page 40

6 - 6

Cub Cadet 3000

Again using a small screwdriver or similar tool,

remove the quad ring seal from the valve housing.

REASSEMBLY

Prior to the reassembly of the steering control,

replace all worn and damaged parts and/or

assemblies along with all seals and sealing rings.

Clean all parts in clean solvent and blow dry with

compressed air.

Lubricate all finished parts surfaces freely with clean

hydraulic fluid during assembly to provide instant

lubrication between rotating surfaces at start-up.

Lubricate all seals and sealing rings with petroleum

jelly to help retain the sealing rings during reassembly

and provide lubrication to the dust and spool seals.

Install the two bearing races and thrust bearing into

the valve housing.

Shown here are both the relief valve check and check

ball assemblies.

The relief valve check assembly is optional.

Using a 7/8 in. socket or end wrench, remove the

relief valve check or check ball plug.

Figure 23.

Figure 22.

Figure 21.

Figure 24.

Page 41

6 - 7

Cub Cadet 3000

After the seal is installed, turn the valve housing over

and remove the sleeve, races and bearing.

Using caution to retain the races, bearing and sleeve

in the valve housing, carefully turn the assembly over

and set it on a clean flat surface. Together, the housing, races, bearing and sleeve create a groove into

which the quad seal can be installed. Lubricate and

install the quad seal in its seat through the input end

of the valve housing.

CAUTION: When installing, be sure the quad seal is

not twisted.

Install the sleeve into the valve housing.

Figure 27.

Figure 26.

Figure 25.

Turn the valve housing over and press the dust seal

into its bore, located in the face of the valve housing.

NOTE: The lip of the dust seal must point away from

the valve housing.

Figure 28.

Page 42

6 - 8

Cub Cadet 3000

Next install one set of the 3 curved centering springs

between the two flat pieces.

To install the centering springs on the spool, first

install the two flat pieces.

Shown here is the correct orientation of the

spool/sleeve centering springs. Two sets of (3) each

curved springs in the center and (1) each flat piece on

the outside.

Figure 31.

Figure 30.

Figure 29.

Figure 32.

Then install the final set of 3 curved centering springs

between the flat piece and the previously installed

curved centering springs.

NOTE: The bowed side of the two sets of 3 centering

springs must point toward each other.

Page 43

6 - 9

Cub Cadet 3000

Push the spool assembly into the sleeve until the centering springs are firmly positioned into the notches

located in the sleeve.

Lubricate the spool assembly and install into the

sleeve, aligning the centering springs with the notches

machined in the sleeve.

Center the centering springs and install the spring

retaining ring over the springs.

Figure 35.

Figure 34.

Figure 33.

Figure 36.

Insert the cross pin into the spool/sleeve assembly.

Page 44

6 - 10

Cub Cadet 3000

Lubricate and install the o-ring seal into the groove

located in the control valve housing.

Lubricate and install the spool/sleeve assembly into

the valve housing.

Supporting the valve housing in the upright position,

lubricate and install the bearing races and thrust bearing.

NOTE: The thrust bearing must be installed between

the two bearing races.

Figure 39.

Figure 38.

Figure 37.

Figure 40

Install the wear plate by aligning the holes in the wear

plate with the cap screw and porting holes in the control housing.

NOTE: The grooved side of the wear plate must point

upward.

Page 45

6 - 11

Cub Cadet 3000

Lubricate and install both the gerotor star and outer

ring. Install by aligning the splines of the star with the

drive. After installation, rotate the gerotors outer ring

to align with the housing cap screw holes.

NOTE: The grooved side of both gerotor star and

outer ring must face upward.

Install the drive, making sure you fully engage the slot

on end of drive with the cross pin in the spool/sleeve

assembly.

Lubricate and install the o-ring seal into the groove

located in the wear plate.

Figure 43.

Figure 42.

Figure 41.

Install drive spacer in gerotor star.

Figure 44.

Page 46

6 - 12

Cub Cadet 3000

Prior to the installation of the end cap, freely lubricate

the gerotor star seal ring.

Lubricate and install the o-ring seal into the groove

located in the gerotors outer ring.

Lubricate and install both the o-ring seal and seal ring

into the gerotor star. Install the o-ring in the groove

located in the star first and then the seal ring.

Figure 47.

Figure 46.

Figure 45.

Figure 48.

Install the end cap onto the gerotor assembly by

aligning the cap screw holes.

Page 47

6 - 13

Cub Cadet 3000

The steering control is now ready for test and installation.

Torque plug to 15 in. lbs.

Install the check ball or optional relief valve check as

shown here.

Install the end cap retaining cap screw and tighten in

a crisscross sequence. Torque to 140-160 in. lbs.

Figure 52.

Figure 51.

Figure 50.

Figure 49.

Page 48

6 - 14

Cub Cadet 3000

Page 49

6 - 15

Cub Cadet 3000

Page 50

6 - 16

Cub Cadet 3000

Page 51

6 - 17

Cub Cadet 3000

Page 52

NOTES

Page 53

7 - 1

Cub Cadet 3000

CAUTION: Slowly remove the hydraulic lines from the

cylinder. Test for pressure in the lines before removal.

1. Place an oil pan directly under the center lift

cylinder. This will catch the hydraulic fluid that will

be drained from the lines and the cylinder.

2. Remove the hairpin from the clevis pin at the rear

of the lift cylinder. See figure 1.

3. Slide the clevis pin all the way to the left rear tire.

4. Pull the cylinder towards the center of the

machine and release the cylinder from the clevis

pin. See figure 2.

5. Pull the cylinder forward applying pressure to the

lift shaft assembly. The lift shaft assembly will

pivot forward with the cylinder, and allow the rear

of the cylinder to pass by the front transmission

support bracket.

Removal and Replacement for the Center Lift Cylinder

FIGURE 1.

Lift

Cylinder

Hairpin

Clevis Pin

FIGURE 2.

Lift Shaft

Assembly

Front Transmission

Support Brkt.

6. Remove both hydraulic connectors from the lift

cylinder using a 7/8” open end wrench.

NOTE: The front connector on the lift cylinder

hydraulic line runs to the top port of the lift valve.

The back connector on the lift cylinder hydraulic

line runs to the bottom port of the lift valve. Be

sure to reinstall the hydraulic lines in the correct

ports during reassembly.

7. Inspect the “O” rings on the connectors for any

damage. If damaged, replace.

8. Pivot the cylinder down 90 degrees and release

the slotted bracket from the lift shaft assembly

cam. See figure 3.

NOTE: Allow the hydraulic fluid to drain

completely from the cylinder into the oil pan.

FIGURE 3.

Hydraulic Connectors

Slotted

Bracket

Clevis Pin

Hole

Lift Shaft

Assembly

Cam

REINSTALL THE CENTER LIFT CYLINDER IN THE

REVERSE ORDER ABOVE.

NOTE: When reinstalling the cylinder to the cam on

the lift shaft assembly, make sure the slotted cylinder

bracket is offset towards the left frame of the tractor.

Clevis

Pin

Page 54

NOTES

Page 55

8 - 1

Cub Cadet 3000

Prior to removing the pump adapter, it is necessary to

remove the fender assembly.

1. Remove the side panels and disconnect the

spark plug wires.

2. Remove all four of the hex head tapp screws that

connect the drive shaft to the pump adapter using

a 3/8 socket. See figure 1.

3. Remove both hex cap screws and lock nuts from

the tilt wheel coupling using a 7/16 wrench and a

7/16 socket. See figure 2.

Removal and Replacement of the Pump Adapter

FIGURE 1.

Pump

Adapter

Tap

Screws

Tap

Screw

Drive

Shaft

FIGURE 2.

Upper

Steering Shaft

Tilt Wheel

Coupling

Hex Cap

Screws

4. Raise the upper steering shaft. See figure 3.

5. Remove the lower steering shaft from the

hydraulic steering pump. See figure 3.

FIGURE 3.

Bottom

Coupling

Half

Drive

Shaft

Sleeve

Bearing

Lower

Steering

Shaft

6. Slide the drive shaft towards the left frame rail.

NOTE: Be careful not to dislodge the blue barrels

on each end of the drive shaft.

7. Remove the fan from the pump adapter and set it

aside.

NOTE: There may be a spacer on the coupler. If

so, set it aside.

8. Loosen the nut securing the pump adapter using

a 9/16 socket. See figure 4.

NOTE: Channel locks may be needed to hold the

pump adapter in place while breaking the pump

adapter nut free.

FIGURE 4.

Page 56

8 - 2

Cub Cadet 3000

9. Finger loosen the pump adapter nut until it is

flush with the end of the hydro input shaft.

10. Place a 13/16 socket against the nut with the

opened end of the socket facing away from the

nut. See figure 6.

11. Place the new pump adapter, cupped side in,

over the opened end of the 13/16 socket. See

figure 5.

12. Finger tighten two of the drive shaft hex screws

across from one another.

13. Using a 3/8 socket, tighten the hex screws

equally a quarter of a turn at a time until the old

hub breaks free. See figure 5.

FIGURE 5.

13/16

Socket

Drive Shaft

Hex Screw

Original Pump

Adapter

New Pump

Adapter

14. Remove the hex screws and new hub. See

figure 5.

15. Remove the hex nut, bell-washer, old pump

adapter, and key from the input shaft.

FIGURE 6.

13/16

Socket

Bell-

Washer

Hex Nut

Drive Shaft

Hex Screws

Original

Pump

Adapter

New Pump

Adapter

INSTALLATION OF THE NEW PUMP ADAPTER

1. Clean the hydrostatic input shaft of any debris.

See figure 7.

2. Apply a light coat of loctite 803 to the taper of the

input shaft. See figure 7.

3. Place the new fan over the cone of the new pump

adapter.

4. Push the new pump adapter and fan onto the

hydro input shaft.

NOTE: The fan will be on the inside of the pump

adapter.

FIGURE 7.

Loctite

Input

Shaft

Fan

5. Install the new bell washer and locknut.

NOTE: Hold the new pump adapter in place with

a drift punch and torque the lock nut to 20 ft. lbs.

See figure 8.

FIGURE 8.

Torque

Wrench

Drift

Punch

Page 57

8 - 3

Cub Cadet 3000

6. Line up the drive shaft with the new pump

adapter.

NOTE: If there is more than an 1/8” gap between

the drive shaft and pump adapter place the

spacer in between the the drive shaft and the

pump adapter. Do not force the spacer in if it

does not fit.

7. Install the new bolts through the drive shaft, pump

adapter, and the fan.

8. Finger tighten the shoulder nuts with the shoulder

facing the fan.

NOTE: The shoulder on the nuts fit into the fan

holes. See figure 9.

FIGURE 9.

Shoulder Nut

Shoulder Nuts

FIGURE 10.

7/16

Bolts

9. Tighten the hex bolts and shoulder nuts securing

the pump adapter assembly, using a 7/16 wrench

and a 7/16 socket. See figure 10.

REINSTALL THE FENDER ASSEMBLY.

Page 58

NOTES

Page 59

9 - 1

Cub Cadet 3000

Prior to performing this test, it is necessary to remove

the deck and fender assemblies.

1. Remove the hex cap screw securing the double

valve clamp to the charge pump using an 11mm

swivel socket. See figure 1.

2. Remove the hydraulic pressure tube end from the

charge pump.

BDU-21L-500 Auxiliary Pressure Test

FIGURE 1.

Hydraulic

Return Tube

Pressure

Tube

Hex

Bolt

Double

Valve

Clamp

6. Install the pressure test kit into the unit with the

pressure gauge standing straight up. See figure 3

and 4.

7. Reinstall the double valve clamp to the charge

pump. See figure 1.

8. Reinstall the power steering pump port plate. See

figure 2.

9. Fasten all hardware securely.

FIGURE 3.

Pressure Gauge

To Steering Pump

To Charge Pump

FIGURE 2.

Pressure Tube

Charge Pump to

Steering Pump

Steering Pump to Rear

of Steering Cylinder

Return

Tube to

Charge

Pump

Port Plate

From Steering

Pump to

Auxiliary

Valve

Steering Pump

to Front of

Steering

Cylinder

Hex Cap

Screw

Hex Cap

Screw

3. Remove both of the hex cap screws from the

power steering pump port plate using a 13mm

wrench. See figure 2.

4. Remove the hydraulic pressure tube end from the

hydraulic steering pump. Charge pump to steering pump. See figure 2.

NOTE: Be careful not to damage the “O” rings. If

damaged, replace.

5. Remove the hydraulic pressure tube from the

unit.

10. Start the unit and allow the hydraulic fluid to

circulate at idle.

11. Slowly increase the throttle to full.

12. Slowly decrease the throttle to idle. Record the

hydro reading at the pressure gauge. See

figure 4.

NOTE: The pressure will be very low if shown at all

on the gauge.

FIGURE 4.

Page 60

9 - 2

Cub Cadet 3000

13. Increase the throttle to full. Record the hydro

reading at the pressure gauge. The reading

should be between 200 PSI and 650 PSI. See

figure 5.

NOTE: This system should not read higher than 650

PSI. The relief valve is set to 650 PSI in the auxiliary

manifold.

FIGURE 5.

FIGURE 6.

14. Remain at full throttle and max out the lift valve.

There should be a PEAK pressure of 1100-1200

PSI. See figure 6.

NOTE: Only hold the lift valve for a short amount

of time. Record the reading and release the lift

valve lever as quick as possible.

IMPORTANT:

System pressure will increase with the

actuation of the power steering and/or deck lift.

If the pressure readings are not

meeting the specifica-

tions, the charge pump is faulty.

If the pressure readings are meeting specifications,

the charge pump is not faulty and the mechanical

system must be checked.

Page 61

9 - 3

Cub Cadet 3000

Bill of Materials

• 2 - 3000 P.S.I. Hydraulic Gauges

• 1 - 200 P.S.I Hydraulic Gauge

• 2 - 9/16-18 Straight Thread O-ring & JIC fitting (JIC

dependent on hose fittings)

• 3 - 3000 P.S.I. hoses of adequate lengths

(Connect as shown in FIG 1)

• 1 - T fitting

• 1 - needle valve

Connection Procedure

1. Remove tractor seat.

2. Remove both check plugs using a 1/4” hex drive.

3. Replace check plugs with the 2 9/16-18 straight

thread O-ring fittings.

4. Connect the T fitting and needle valve to the left

side. (Reverse Hi)

• Connect the 200 P.S.I. gauge to the needle

valve making sure flow can be shut off to this

gauge.

• Connect the 3000 P.S.I. gauge to the T fitting.

5. Connect another 3000 P.S.I. fitting to the right

side. (Forward high pressure port)

Hydrostatic Transmission Pressure Test Setup

FIGURE 1.

Forward ONLY Test Procedure

1. Lift tractor elevating rear tires off the ground.

(Tires will rotate)

2. Remove pin from parking brake. (allowing brake

to be apply while not in neutral)

3. Open needle valve allowing flow to the 200 P.S.I.

gauge (applying reverse can now damage this

gauge).

Charge Pressure Gauge

Forward

High

Pressure

Gauge

Reverse High

Pressure Gauge

4. With tractor running, apply parking brake.

5. Continue holding the brake. depress the forward

foot pedal until max. pressure is seen on right

side gauge.

6. Record pressures from the 200 P.S.I. gauge and

the right side 3000 P.S.I. gauge.

Reverse ONLY Test Procedure

** To test for reverse side high pressure switch the

changes to opposite ports and repeat the similar to

the forward test. **

Conclusion

The 200 P.S.I. gauge sees the charge pressure in the

system, and during this type of the test the pressure

should be 20-40 P.S.I. The right side 3000 P.S.I.

gauge sees the forward high pressure and for this test

should read 1000 to 1400 P.S.I. If the gauges see

values close to this range the hydrostat is functioning

properly.

Page 62

NOTES

Page 63

10 - 1

Cub Cadet 3000

Prior to removing the steering pump, it is necessary to

remove the fender assembly.

CAUTION:

Slowly remove the hydraulic lines from the

hydraulic steering pump. Test for pressure in the lines

before removal.

1. Place an oil pan directly under the hydraulic

steering pump. This will catch the hydraulic fluid

that will be drained from the lines and the pump.

2. Remove all four of the hex head tapp screws from

the drive shaft to the pump adapter using a 3/8

socket.

NOTE: Removal of the drive shaft from the pump

adapter is necessary to allow access to the four

hydraulic steering pump mounting bolts.

Removal and Replacement of the Hydraulic Steering Pump

3. Remove both hex cap screws and lock nuts from

the tilt wheel coupling using a 7/16 wrench and a

7/16 socket. See figure 2.

FIGURE 1.

Pump

Adapter

Tap

Screws

Tap

Screw

Drive

Shaft

FIGURE 2.

Upper

Steering Shaft

Tilt Wheel

Coupling

Hex Cap

Screws

4. Raise the upper steering shaft. See figure 3.

5. Remove the lower steering shaft from the

hydraulic steering pump. See figure 3.

NOTE: The lower steering shaft is splined on

each end and requires lubrication prior to

reassembly.

6. Slide the drive shaft towards the left frame rail.

NOTE: Be careful not to dislodge the blue barrels

on each end of the drive shaft.

FIGURE 3.

Bottom

Coupling

Half

Drive

Shaft

Sleeve

Bearing

Lower

Steering

Shaft

7. Write down the exact locations of all the hydraulic

tubes. See figure 4.

8. Remove both hex cap screws from the steering

pump port plate using a 13mm wrench.

9. Remove the port plate from the hydraulic lines.

NOTE: Pivot the top edge of the port plate

backward (towards the left frame rail), bringing

the plate to horizontal. Push the port plate up and

rotate the port plate counter-clockwise 90

degrees using the main pressure line as the pivot

point. Slide the port plate towards the left frame

rail until the port plate clears the hydraulic lines.

Upper

Steering

Shaft

FIGURE 4.

Charge Pump to

Steering Pump

Steering Pump to Rear

of Steering Cylinder

Steering

Pump to

Charge

Pump

Port Plate

From Steering

Pump to

Auxiliary

Valve

Steering Pump

to Front of

Steering

Cylinder

Page 64

10 - 2

Cub Cadet 3000

10. Remove the hydraulic tubes from the hydraulic

steering pump.

NOTE: If the hydraulic tubes do not want to come

out, use a small mallet and tap them out of the

ports. Be careful not to damage the tubes.

11. Inspect the “O” rings on the connectors for

damage. If damaged, replace.

NOTE: Place a small amount of grease on the

“O” rings and cover the connector surface

completely for reinstallation.

FIGURE 5.

“O” Rings

12. Support the hydraulic steering pump from below.

See figure 6.

13. Remove the four hex cap screws securing the

hydraulic steering pump to the frame using a

10mm wrench. See figure 6.

FIGURE 6.

Hex Cap

Screws

Steering

Pump

FIGURE 7.

Return

Auxiliary

Steering

Steering

Main Pressure

Refer to the 1998 Cub Cadet Technical Update

Seminar manual for inspection and repair of the CharLynn 2 series Steering Control in Section 17.

REASSEMBLE THE HYDRAULIC STEERING PUMP

IN THE REVERSE ORDER.

14. Remove the hydraulic steering pump from the

tractor.

Page 65

11 - 1

Cub Cadet 3000

Prior to removing the hydraulic valve, it is necessary

to remove the fender assembly.

CAUTION: Slowly remove the hydraulic lines from the

hydraulic valve. Test for pressure in the lines before

removal.

1. Place an oil pan directly under the hydraulic

valve. This will catch the hydraulic fluid that

drains from the lines and the valve.

2. Remove the double valve clamp from the valve

body using a 7/16 socket. See figure 1.

3. Remove both hydraulic hose connectors coming

from the hydraulic lift cylinder to the valve body.

See figure 1.

Removal and Replacement of the Hydraulic Valve

FIGURE 1.

Hydraulic Hose

Connectors

Double Valve

Clamp

Squared

Lift Link

Hex Cap Screws

and Lock Nut

Hex Cap

Screws and

Lock Nut

4. Remove the side valve clamp that holds the

return tube to the valve body. See figure 2.

5. Remove the hydraulic return tube from the “T”

fitting with an 18mm wrench. See figure 2.

6. Remove the hydraulic return tube from the

hydraulic valve body. See figure 2.

FIGURE 2.

T Fitting

Side Valve

Clamp

Valve Body

Hydraulic

Return

Tube

7. Remove the side valve clamp that holds the inlet

tube to the valve body using a 7/16 socket. See

figure 3.

NOTE: All the hydraulic lines and tubes going into

the hydraulic valve ports have two “O” rings on

each connector. See figure 4.

FIGURE 3.

Clamp

Hex Cap Screws

and Lock Nuts

Inlet

Tube

8. Remove both hex cap screws and hex flange lock

nuts securing the hydraulic valve to the frame

using a 7/16 socket. See figure 1.

NOTE: The hydraulic valve body must be

secured to the frame with both screws before the

hydraulic tubes can be assembled to the

hydraulic valve during reassembly.

9. Pull the hydraulic valve body away from the

hydraulic inlet tube slowly.

NOTE: If the hydraulic tube does not want to

come out, use a small mallet and tap it out of the

port. Be careful not to damage the valve body or

the hydraulic tube/s.

10. Remove the valve body from the tractor. See

figure 5.

NOTE: Record the correct positions of the nylon

flange bearings on the squared lift link. See

figure 3.

Nylon Flange

Bearing

Page 66

11 - 2

Cub Cadet 3000

FIGURE 4.

“O” Rings

11. Inspect the “O” rings for damage. If damaged,

replace. See figure 4.

12. Remove all the remaining hardware from the

valve body using a 7/16 socket.

FIGURE 5.

Valve Mounting

Bracket

Nylon Flange

Bearing

Squared

Lift Link

Valve

Mounting

Bracket

Hydraulic

Valve

13. Remove the valve mounting brackets. See

figure 5.

NOTE: Write down the correct positions of the

mounting brackets. The brackets can be installed

backwards if not properly marked.

14. Remove the squared lift link.

REASSEMBLE THE HYDRAULIC VALVE IN THE

REVERSE ORDER ABOVE.

Page 67

12 - 1

Cub Cadet 3000

IMPORTANT: Use proper safety procedures when

working on the tractor.

1. Open the hood and remove the battery box cover.

2. Remove the negative and positive battery

terminal connectors from the battery using a 5/16

socket.

3. Remove both of the side panels from the tractor

by raising the latches horizontally and turning the

latches 1/4 turn. See figure 1.

4. Loosen all four plastic wing nuts holding the dash

panel screen in place.

5. Remove the dash panel screen by pulling it

towards the seat.

6. Cut the cable ties securing the headlight wiring

harness to the hood assembly. See figure 2.

7. Remove the headlight bayonet mounts from both

of the headlights by twisting the sockets 1/4 turn

and pulling straight out. See figure 2.

Engine Removal and Replacement

FIGURE 1.

FIGURE 2.

Headlight

Bayonet Mount

Headlight

Bayonet Mount

Hood

Assembly

Headlight

Wiring

Harness

Cable Tie

8. Partially close the hood to allow access to the grill

fasteners. See figure 3.

9. Squeeze all four grill fasteners and release the

grill. See figure 3.

10. Remove the grill and set it aside.

11. Remove all four hood mounting bolts from the

muffler assembly brackets using a 1/2” socket.

See figure 3.

FIGURE 3.

Grill

Hood Mounting

Bolts

12. Remove all four muffler assembly bracket bolts

from the tractor frame using a 1/2” socket. See

figure 4.

13. Remove the muffler assembly from the engine.

NOTE: Move the muffler assembly side to side.

This will allow the muffler to separate from the

exhaust manifolds. See figure 4.

FIGURE 4.

Muffler

Assembly

Bracket

Bolts

Grill

Fastener

Page 68

12 - 2

Cub Cadet 3000

14. Remove both the choke and the throttle cables.

See figure 5.

NOTE: use a marker and mark the holes and

cable alignment before removal.

FIGURE 5.

Throttle

Choke

15. Disconnect the vacuum tube from the E-Vac

check valve. See figure 6.

FIGURE 6.

E-Vac Check

Valve

16. Disconnect the wiring harness, ground cables,

and any sensor connectors from the engine. See

figure 7.

NOTE: Visually inspect the engine from all angles

to make sure all wires and cables are

disconnected from the engine to the frame.

FIGURE 7.

17. Remove the fuel line from the engine.

NOTE: Make sure the fuel line is fully drained and

secured in a safe place during engine removal.

18. Remove both of the hex bolts securing the belt

guard to the engine using a 13mm socket and

extension. See figure 8.

19. Remove the E-vac clip. See figure 8.

NOTE: Push up on the locking clip and slide the

pin away from the engagement arm.

FIGURE 8.

Hex Bolts

Belt

Guard

E-Vac

Clip

20. Remove the battery from the unit.

NOTE: The battery was removed to give direct

access to the drive shaft bolts through the dash

panel area.

Spark Plug

Boot and Wire

Ground to

Heat Shield

Solenoid

Positive

“Hot”

Lead Wire

Starter

E-Vac

Connector

Page 69

12 - 3

Cub Cadet 3000

21. Remove all four of the hex bolts securing the

drive shaft to the engine flywheel using a 7/16

socket and extension. See figure 9.

FIGURE 9.

Hex Bolts

Drive

Shaft

FIGURE 10.

Engine

Pulley

PTO Idler

Arm

Spring

Lock Nuts

and Hex

Bolts

Securing

PTO Idler to

Frame

22. Remove the PTO idler arm extension spring. See

figure 10.

23. Remove both of the hex bolts and flanged lock

nuts securing the PTO idler assembly to the

frame using a 9/16 socket and a 9/16 wrench.

See figure 10.

FIGURE 11.

Hex Bolts

24. Remove the PTO idler assembly from the unit.

25. Remove both of the PTO belts from the engine

pulley.

26. Secure the engine from above using the engine

brackets. See figure 12.

27. Remove all six of the hex bolts and lock nuts from

the engine mounting plate using a 1/2” socket

and a 1/2" wrench. See figure 11.

FIGURE 12.

28. Slowly raise the engine and mounting plate from

the unit while a helper guides the drive shaft out

of the flywheel screen. See figure 12.

FIGURE 13.

NOTE: Use extreme caution while pulling the

drive shaft away from the unit. The drive shaft

couplers will come apart if you are not careful.

Engine

Brackets

Drive

Shaft

Drive Shaft

Couplers

REINSTALL THE ENGINE IN THE REVERSE

ORDER ABOVE.

Page 70

NOTES

Page 71

13 - 1

Cub Cadet 3000

Prior to removing the transmission, it is necessary to

remove the fender assembly.

1. Loosen the fuel line clamp at the gas tank and

slide it down the fuel line.

2. Remove the fuel line from the gas tank.

3. Remove the fuel sensor connector.

4. Remove all four of the hex bolts and lock nuts

from the rear hitch plate panel using a 9/16

socket and a 9/16 wrench. Remove the hitch

plate.

5. Remove the gas tank from the tractor.

6. Remove the oil tube and dipstick from the hitch

plate and slide it back into the transmission.

NOTE: The dipstick and tube will keep debris out

of the transmission.

7. Raise the rear of the unit off the ground.

8. Remove all eight of the rear wheel hub nuts using

a 3/4" socket.

9. Remove the rear wheel assemblies from the unit.

10. Remove the hex bolt securing the double valve

clamp on the charge pump using an 11mm swivel

socket. See figure 1.

11. Remove the hydraulic return tube from the “T”

fitting using an 18mm wrench. See figure 1.

12. Remove the hydraulic steering pressure tube

from the charge pump. See figure 1.

Transmission Removal and Installation

FIGURE 1.

Hydraulic

Return Tube

Pressure

Tube

T Fitting

Hex

Bolt

Double

Valve

Clamp

13. Remove all four of the drive shaft hub screws

from the pump adapter using a 3/8 socket. See

figure 2.

FIGURE 3.

Ferrule

Brake

Lever

Hairpin

14. Remove both hairpins securing the brake rod

ferrules to the brake lever assemblies. See

figure 3.

FIGURE 2.

Pump

Adapter

Tap

Screws

Tap

Screw

Drive

Shaft

Brake

Rod

Compression

Spring

Elastic Lock Nut

15. Remove the shoulder bolt and lock nut securing

the cylinder damper to the frame using a 5/8

wrench and a 7/16 socket. See figure 4.

16. Remove the hairpin from the rear control rod at

the hydro neutral return plate. See figure 4.

FIGURE 4.

Shoulder

Bolt

Damper

Hairpin

Neutral Return Plate

Rear

Control

Rod

Page 72

13 - 2

Cub Cadet 3000

FIGURE 5.

Neutral Return

Spring

Transmission

Support

Bracket

Front

Transmission

Support

Screws

Hex Flange

Lock Nut

17. Brace the transmission.

18. Remove all four of the front transmission support

bracket to frame hex cap screws and hex flange

lock nuts using a 9/16 wrench and a 9/16 socket.

See figure 5.

NOTE: The differential lock cable retainer bracket

is removed along with the transmission support

bracket.

19. Remove the “Z” fitting from the differential lock

actuator arm. See figure 6.

FIGURE 6.

Differential Lock

Actuator Arm

FIGURE 7.

Front of Tractor

Lock Nut

Flat Washer

Elongated

Slot

Lower

Point

20. Remove both transmission to frame “U” bolts

using a 3/4" socket. See figure 7.

NOTE: The “U” bolts have a lower point on one

side. The point goes towards the rear of the unit

during reassembly. See figure 7.

“Z” Fitting

Cable

Retainer

Bracket

21. Lower the transmission from the unit.

NOTE: Be certain that the rear control rod is

removed from the hydro neutral return plate as

the transmission is removed. Also, make certain

the brake levers clear the frame.

FIGURE 8.

Differential

Lock Cable

Fan

Charge

Pump

Brake

Assembly

Brake

Assembly

Oil Fill

Tube

Washers

Washers

Elastic

Lock Nuts

“U”

Bolt

“U”

Bolt

Support Plate Support Plate

REASSEMBLE THE TRANSMISSION TO THE UNIT

IN THE REVERSE ORDER ABOVE.

Page 73

14 - 1

Cub Cadet 3000

1. Inspect the pump adapter to be certain that it is

turning the hydraulic input shaft. See figure 1.

2. Inspect the center hex jam nut and flat washer on

the pump adapter to be certain that it is not loose.

See figure 1.

3. Inspect the connection between the hydro arm

and the trunnion arm behind the neutral return

link. See figure 2.

NOTE: Make sure the flat washer and hex screw

are tight on the hydro arm. Also, check the set

screw on the hydro arm to be certain it is tight.

Transmission Inspection and Disassembly

FIGURE 2.

FIGURE 1.

FIGURE 3.

FIGURE 4.

Hydro

Arm

Hydro Neutral

Return Plate

Set

Screw

Trunnion

Arm

Pump

Adapter

Jam Nut

Flat Washer

Hydro Bypass

Spring Plate

Bypass Valve

(Behind Plate)

Oil Filter

Filter

Nipple

4. Inspect the clearance between the hydro bypass

spring plate and the bypass valve on the hydro

pump. See figure 3.

NOTE: There should be free play in between the

plate and the bypass valve.

5. Remove the hydro oil filter from the transmission

and check for contamination in the filter, filter

nipple, and the inlet cavity. See figure 4.

Input Shaft

Inlet Cavity

Page 74

14 - 2

Cub Cadet 3000

6. Remove both clamps from the hydro pickup tube

using a 7/16 wrench on the upper hex screw and

a 3/8 wrench on the lower hex screw.

7. Remove the hydro pickup tube and inspect the

tube for any contamination that would restrict the

hydro oil flow. See figure 5.

8. Inspect the “O” ring at each end of the hydro pickup tube. If damaged, replace. See figure 5.

9. Inspect the output and input ports where the

hydro pickup tube clamps on. See figure 5.

10. Remove the extension spring from the torque

bracket. See figure 5.

11. Remove all four- 5.5” hex cap screws from the

torque bracket using a 1/2” socket. See figure 6.

12. Remove the torque bracket and all four hex cap

screws from the hydro transmission assembly by

pulling straight up on the torque bracket.

NOTE: The neutral return link comes off with the

torque bracket.

FIGURE 5.

FIGURE 6.

“O”

Ring

Extension

Spring (For

Neutral

Return)

Output

Port

Torque

Bracket

“O”

Ring

Hydro Pickup Tube

Input

Port

Neutral

Return Link

1/2"

Socket

5.5" Hex

Cap Screws

5.5" Hex

Cap Screws

Torque

Bracket

FIGURE 8.

FIGURE 7.

Spring

Washer

“O”

Ring

Differential

Lock

Actuator

Drain

Hole

Hydrostatic

Transmission

Drain Hole

Differential

Transmission

13. Remove the hydrostatic transmission from the

differential transmission and inspect the case

drain holes on the hydro and the differential. See

figure 7.

14. Remove the “O” ring from between the hydro and

differential. See figure 8.

15. Remove the spring washer from between the

hydro and the differential. See figure 8.

16. Pull on the differential lock actuator using a fish

scale and see if it locks in with less than 35

pounds of pull. See figure 8.

17. Grasp both hub assemblies. Rotate the hubs in

opposite directions, in the forward direction

together, and in the reverse direction together,

looking for any binding.

Page 75

14 - 3

Cub Cadet 3000

18. Remove the center hub lock nuts on the hub

assemblies using a 1 and 5/16” socket. See

figure 9.

NOTE: The torque on the center hub nut is 180250 ft-lbs.

19. Remove the brake mounting bracket from the

differential assembly by rotating the brake disk

until the access holes are directly above the hex

washer screws. Using a 1/2” socket and

extension, remove all three hex washer screws

from each side of the differential assembly. See

figure 9.

20. Remove the hex cap screw and belleville washer

from the differential lock actuator arm using a

7/16 socket. See figure 9.

21. Remove the differential actuator arm and all three

flat washers from the differential.

22. Turn the differential over.

23. Remove all the hex washer tapp screws from the

rear cover assembly using a 3/8 socket. See

figure 10.

NOTE: There is a difference in the hardware

lengths. The six bolts that pass through the

transmission cover blocks are 1.25" long. The

remaining hardware is 1” long.

24. Remove and discard the cover assembly gasket.

25. Inspect all the gears in the differential for uneven

wear or damaged teeth. See figure 10.

26. Remove the hex washer tapp screws from the

transmission plate using a 3/8 socket.

FIGURE 9.

7/16” Hex Cap Screw, Belleville Washer

Differential Lock Actuator

Brake Mtg.

Bracket

1-5/16”

Lock Nut

Brake

Disc

Access

Hole

FIGURE 10.

Hex Washer Tap Screw

Transmission

Plate

Gasket

1” Long

Hex

Screws

1-1/4” Long

Hex Screws

Rear Cover

Assembly

Transmission

Cover Blocks

FIGURE 11.

Transmission

Plate Gasket

27. Remove the transmission plate.

28. Remove and discard the second transmission

plate gasket. See figure 11.

29. Remove the complete differential assembly.

NOTE: The differential lock actuator shaft will

come out with the differential assembly.

30. Inspect the outer and inner bearing block assemblies for any damage. See figure 12.

31. Inspect the actuator shaft and make certain it is

not bent.

NOTE: Not all models are equipped with the differential lock out feature. See figure 12.

Page 76

14 - 4

Cub Cadet 3000

FIGURE 14.

FIGURE 15.

FIGURE 13.

FIGURE 16.

Bearing

Block

Bevel

Gear

Needle Thrust

Bearing

Thrust

Washer

Bearing

Block

Flat

Washer

Shims

Output

Shaft

Input Pinon

Gear

Differential

Lock

Housing

Pin Engaged Differential

Lock Collar Ass’y.

Shims

Output

Shaft

Differential

Ass’y.

w/Differential

Lock

Compression

Spring

Axle Spacer

Differential Ass’y.

w/o Differential Lock

9/16 Hex Cap

Screws

Spur Gear 60T

Differential

Lock

Housing

9/16 Hex

Cap Screw

Differential

Gears

Thrust Miter Block

Spur

Gear

14T

32. Write down the shim orientations for both sides of

the output shaft. See figure 13.

33. Remove the output shaft assembly from the case

and inspect for any wear.

34. Remove the input pinion gear assembly from the

case. See figure 15.

35. Remove the four hex cap screws from the

differential housing using a 9/16 socket. See

figure 16.

36. Separate the differential assembly.

37. Remove the large spur gear and the differential

gears together and lay them on the bench.

38. Grasp the large spur gear and pull it away from

the differential gear assembly.

FIGURE 12.

Spur

Gear

Differential Lock

Actuator Shaft

Bevel

Gear

Output Shaft

Inner

Bearing

Block

Outer

Bearing

Block

INSPECT ALL COMPONENTS AND PARTS

BEFORE REASSEMBLY.

Page 77

Page 78

16 - 1

Cub Cadet 3000

FIGURE 1.

FIGURE 2.

FIGURE 3.

The following information will correct forward or rearward movement (creeping).

1. Drive the tractor for a few minutes to warm up the

hydrostatic transmission.

2. Raise the rear of the tractor off the ground.

3. Remove all four of the wheel hub nuts securing

the right rear wheel assembly to the wheel hub,

using a 3/4" socket and extension.

4. Remove the right wheel assembly.

5. Remove the hairpin securing the brake rod ferrule

to the brake lever assembly. See figure 1.

6. Lock the parking brake.

7. Carefully start the tractor and move the throttle

control lever to the full throttle position.

8. Loosen the hex cap screw securing the hydro

neutral return plate to the hydro arm using a 7/16

socket and extension. See figure 2.

NOTE: DO NOT REMOVE THE HEX CAP

SCREW!

NOTE: There is an access hole that will allow the

socket to reach the hex cap screw through the

right rear side frame. See figure 2.

3000 Series Neutral Control Adjustment

9. While observing the axle rotation, slide the hex

cap screw slowly forward or rearward in the neutral return plate until the axle rotation stops.

NOTE: Use the 7/16 socket and extension to

slide the hex cap screw. See figure 3.

10. Tighten the hex cap screw and check to be certain that the axle is not rotating.

REASSEMBLE THE UNIT IN THE REVERSE

ORDER ABOVE.

Brake Rod

Brake Rod

Ferrule

Hairpin

Brake

Lever

Hydrostatic

Transmission

Access

Hole

7/16

Socket

Hex Cap

Screw

Brake

Assembly

Brake

Rod

Extension

Hydrostatic

Transmission

Neutral

Return Plate

Slide

Access

Hole

7/16

Socket

Extension

Page 79

NOTES

Page 80

17 - 1

Electrical

Briggs & Stratton and Kawasaki

Kohler

Page 81

17 - 2

Electrical

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 82

17 - 3

Electrical

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 83

17 - 4

Electrical

629-3056 Wiring Harness 3000 Series — Kohler Engine

Page 84

17 - 5

Electrical

629-3045 Wiring Harness 3000 Series — Kawasaki Engine

Page 85

17 - 6

Electrical

IGNITION OFF

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 86

17 - 7

Electrical

STARTING 1

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 87

17 - 8

Electrical

STARTING 2

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 88

17 - 9

Electrical

RUN / CHARGE

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 89

17 - 10

Electrical

RUN / CHARGE

629-3056 Wiring Harness 3000 Series — Kohler Engine

Page 90

17 - 11

Electrical

LIGHTING

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 91

17 - 12

Electrical

PTO ON 1

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 92

17 - 13

Electrical

PTO ON 2

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 93

17 - 14

Electrical

SAFETY / REVERSE

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 94

17 - 15

Electrical

SAFETY / PTO-SEAT

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 95

17 - 16

Electrical

SAFETY / PTO-BRAKE

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 96

17 - 17

Electrical

SAFETY / OK

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 97

17 - 18

Electrical

SAFETY / OK

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 98

17 - 19

Electrical

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 99

17 - 20

Electrical

629-3057 Wiring Harness 3000 Series — B&S Engine

Page 100

17 - 21

Electrical

629-3057 Wiring Harness 3000 Series — B&S Engine

Loading...

Loading...