Page 1

Professional Shop Manual

2000 Series Tractors

(2011 Model year and Newer)

NOTE: These materials are for use by trained technicians who are experi enced in the service and repair of outdo or power

equipment of the kind described in this publication, and are not intende d for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experie nced and trained professio nal. Read, understand, and follow all

instructions and use common sense when working on powe r e quip ment. T his includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2011 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

Professional shop manual intent ........................................................................1

Fasteners ...........................................................................................................1

Assembly ...........................................................................................................3

Description of the 2000 series tractor ................................................................3

Model and Serial Numbers ................................................................................ 4

Chapter 2: Engine Related Parts

Muffler ................................................................................................................5

Fuel tank removal/replacement ..........................................................................6

Throttle cable adjustment .................................................................................10

Choke cable adjustment ..................................................................................10

Choke and Throttle levers and cables .............................................................11

Engine removal/installation ..............................................................................13

Chapter 3: Brakes

Brake adjustment .............................................................................................17

Brake puck/rotor replacement ..........................................................................19

Brake shaft assembly .......................................................................................21

Brake rod adjustment 2.......................................................................................3

Chapter 4: Body

What is covered by this chapter .......................................................................25

Hood ................................................................................................................25

Hood components: side vent removal ..............................................................26

Hood components: Headlight removal .............................................................27

Hood components: grille removal ....................................................................28

Hood components: pivot bracket removal ........................................................30

Fender and running board ...............................................................................31

Dash Panel ......................................................................................................35

Chapter 5: Drive system

Transmission fluid filter ....................................................................................39

Transmission fluid change ............................................................................... 40

Drive shaft ........................................................................................................41

Hydro neutral control adjustment..................................................................... 42

Transmission removal/replacement .................................................................44

Forward drive pedal shaft ................................................................................48

Reverse drive pedal shaft ................................................................................ 50

Transmission Disassembly.............................................................................. 52

Transmission Assembly ...................................................................................61

I

Page 4

Chapter 6A: Manual Steering

Steering alignment ...........................................................................................67

Front wheels ....................................................................................................69

Front wheel bearings .......................................................................................70

Axles ................................................................................................................71

Steering sector gear and steering pinion gear .................................................72

Steering shaft ...................................................................................................74

Pivot bar ...........................................................................................................78

Steering housing ..............................................................................................79

Greasing the steering housing .........................................................................80

Chapter 6B: Electronic Power Steering

Rubber Torsion Coupling................................................................................. 81

EPS Module .....................................................................................................81

EPS motor & gearbox ......................................................................................82

Troubleshooting the EPS................................................................................. 83

EPS removal/replacement ...............................................................................88

Chapter 7: electrical system

Introduction ......................................................................................................93

RMC Module ....................................................................................................93

Key switch ........................................................................................................94

RMC Module ....................................................................................................96

To identify a faulty RMC module: .....................................................................97

PTO Switch ......................................................................................................99

Brake Switch ....................................................................................................99

Reverse Safety Switch ...................................................................................100

Seat Safety Switch .........................................................................................100

Seat circuit (GTX2154LE) ..............................................................................101

Starter solenoid ..............................................................................................102

PTO Relay ..................................................................................................... 102

Start Circuit ....................................................................................................103

Run Circuit .....................................................................................................106

Run Circuit / Reverse Caution mode .............................................................107

Engine shut-down circuits ..............................................................................108

Charging circuit ..............................................................................................109

PTO Circuit ....................................................................................................114

Reverse Mower Control (RMC) circuit operation ........................................... 116

Deck lift circuit ................................................................................................118

Electrical diagnosis ........................................................................................119

Electronics .....................................................................................................119

Electrical environment: AC Vs. DC ................................................................ 120

Ohm’s Law .....................................................................................................121

Kirchhoff’s current law ....................................................................................121

Kirchhoff’s voltage law . .................................................................................. 122

How the system is wired together ..................................................................122

Types of circuits .............................................................................................123

Series .............................................................................................................123

II

Page 5

Parallel ...........................................................................................................123

Series/parallel ................................................................................................124

Shorts .............................................................................................................124

Opens ............................................................................................................124

Increased resistance ......................................................................................124

The Tools .......................................................................................................125

Digital Multi-meter ..........................................................................................126

Wiring diagram or schematic .........................................................................127

Fused jumper wires ........................................................................................127

Test lights .......................................................................................................127

Self-powered continuity lights ........................................................................127

Ammeters and specialized charging system testers ......................................128

Batteries .........................................................................................................129

Charging the battery ......................................................................................129

Checking battery condition .............................................................................130

Battery Testers ...............................................................................................131

Adjustable load testers ...................................................................................131

Fixed load testers ...........................................................................................132

Conductance testers ......................................................................................132

Battery discharge test ....................................................................................133

Storage of batteries ........................................................................................133

Electrical Troubleshooting ..............................................................................134

Voltage Drop Test ..........................................................................................136

Testing switches ............................................................................................139

Diodes ............................................................................................................140

Relay.............................................................................................................. 142

Schematics ....................................................................................................143

Chapter 8: Decks and lift systems

Cutting decks .................................................................................................147

Deck removal/installation ...............................................................................147

Cleaning the deck ..........................................................................................149

Blades ............................................................................................................150

PTO belt .........................................................................................................152

Deck Belt ........................................................................................................154

Deck Belt Routings ........................................................................................155

Spindle pulleys and spindle shafts .................................................................158

Spindle removal/installation ...........................................................................159

Spindle overhaul ............................................................................................160

Leveling the deck ...........................................................................................162

Deck Gauge Wheel Adjustment .....................................................................164

Deck lift shaft bushings ..................................................................................165

Deck lift shaft assembly (manual) ..................................................................166

Deck lift shaft assembly (electric) ..................................................................169

Deck lift actuator (electric lift)......................................................................... 172

Electric PTO clutch ........................................................................................174

Evaluating the PTO clutch .............................................................................176

III

Page 6

Chapter 9: Maintenance intervals

Lubrication .....................................................................................................179

Engine maintenance .......................................................................................179

The spark plugs .............................................................................................180

Air filter and pre-cleaner................................................................................. 181

Oil change ......................................................................................................183

Oil filter........................................................................................................... 184

Fuel system.................................................................................................... 184

Servicing the fuel system ...............................................................................185

Fuel filter ........................................................................................................185

Clean the engine............................................................................................ 186

IV

Page 7

Introduction

CHAPTER 1: INTRODUCTION

Professional Shop Manual intent

This Manual is intended to provide service dealers with an introduction to the electrical and mechanical aspects

of the 2000 series tractor.

• Detailed service information about the engine will be provided by the engine manufacturer.

Disclaimer: The information contained in this manual is correct at the time of writing. Both the product and the information about the product are subject to change without notice.

About the text format:

NOTE: is used to point out information that is relevant to the pro cedure, bu t doe s not fit as a step in the pr ocedure.

• Bullet points: indicate sub-steps or points.

! CA UTION! CA UTION

! WA RNIN G! WA RNIN G

! DANGER! DANGER

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD or Cub Cadet be liable for poor text interpretation or poor execution of the procedures described in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or Cub Cadet Technical Support.

Fasteners

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

Warning indicates a potentially hazardous situation that, if not avoi ded, could result in death of

serious injury.

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

• Most of the fasteners used on these mowers are sized in fractional in ches. The eng ine and tran smissions

are metric. For this reason, wrench sizes are frequently identified in the text, and measur ements are given

in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

1

Page 8

2000 Series Tractors

! CAUTION! CAUTION

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Grooming and attire:

! WARNING! WARNING

! CAUTION! CAUTION

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

! DANGER! DANGER

2

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all power

equipment. All the labels in the world cannot protect a technician from an instant of

carelessness.

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

Page 9

Introduction

Assembly

Torque specifications may be noted in the part of the text that covers assembly, they may also be summarized in

tables along with special instructions regarding thread locking or lubrication. Whichever method is more appr o pr i at e

will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a

step-by-step procedure guide that does not require the user to hunt for information.

The level of assembly instructions provided will be determined by the complexity and of reassembly, and by the

potential for unsafe conditions to arise from mistakes made in assembly.

Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating the same

procedure two or three times in the manual.

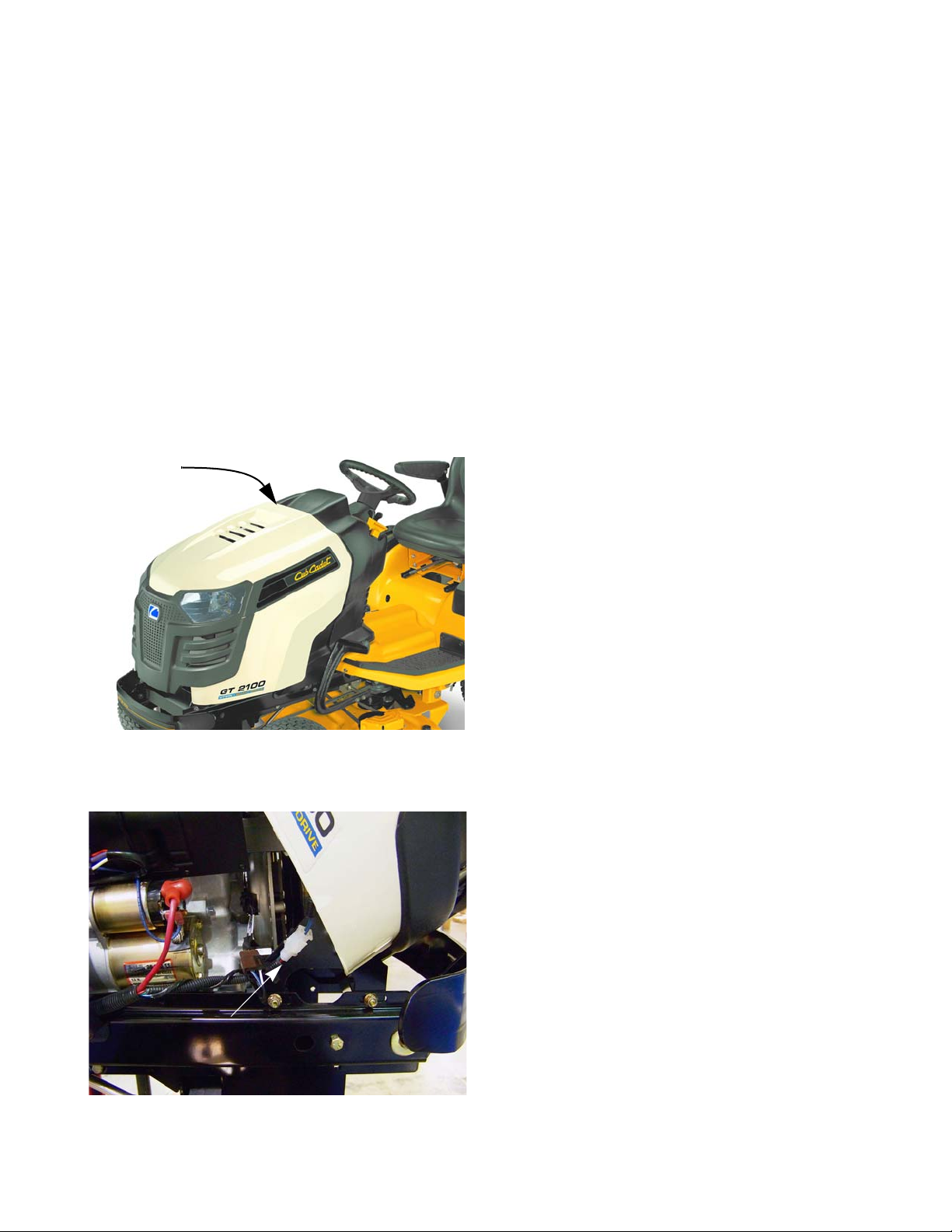

Description of the 2000 series tractor

The Cub Cadet 2000 series tractor has been substantially up-dated for the 201 1 season. These tractors feature:

• Kohler Command horizontal shaft engines.

Figure 1.1

• A drive shaft that transfers power efficiently to the

transmission without the need for belts.

• Cast-iron transmission and front axle.

• 12 gauge steel ladder frame.

• Electric PTO Clutch.

• Manual and electric deck lift systems are available.

• Adjustable tilt steering column (available on most

models.

The 50

th

Anniversary model also features:

• Electronic Power Steering.

• Electric deck lift is standard.

• 54” fabricated deck.

• A special 2-tone painted hood.

Figure 1.2

• A custom front bumper.

3

Page 10

2000 Series Tractors

Model and Serial Numbers

The model and serial number tag can be found

under the seat. See Figure 1.3.

The serial number is located to the right of the model

number as shown above. See Figure 1.3.

The model number is 14W-3AE-010. The break down of what the number mean is as follows:

Model number

Figure 1.3

Serial number

14 ........................................Garden tractor

.......W..................................Sales revision

...........-................................Marketing revision

.............3. ............................Frame

.................A.........................Engine (A = Kohler twin 23 hp)

....................E......................Deck lift (E = electric)

.........................- ..................Deck (The 50

.............................010 .........Customer number

The serial number is 1C281B20053. The serial number reads as follows:

1 ..............................................................................................Engineering level

..C............................................................................................ Month of production (C=March)

.....28 .......................................................................................Day of the month

.........1 .....................................................................................Last digit of the year

...........B................................................................................... Plant it was built in (Willard, OH)

..............2 ................................................................................Assembly line number

th

anniversary model is the only version that comes equipped with a deck)

.................0053 ....................................................................... Number of unit built

4

Page 11

Engine Related Parts

CHAPTER 2: ENGINE RELATED PARTS

This chapter covers the engine accessories th at ar e m anuf ac tu re d by Cu b Ca de t.

IMPORTANT: The engine is manufactured by Kohler. Refer to the Kohler manual for engine specific service

information.

Muffler

To Remove/replace the muffler:

1. Remove the hood by following the procedures

described in Chapter 4: Body.

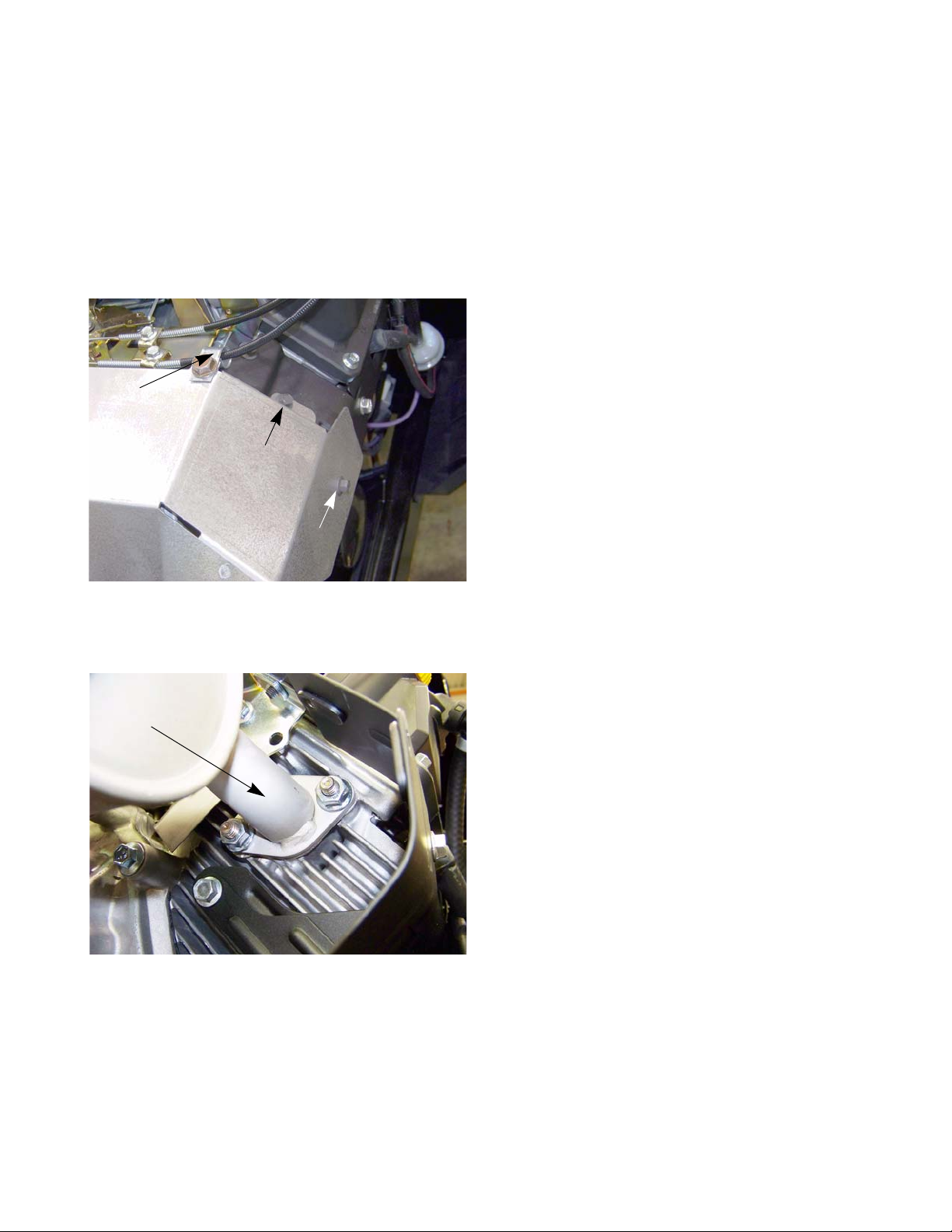

2. Remove the screw that holds the conduit clamp to

Conduit clamp

the heat shield using a 1/2” wrench. See Figure 2.1.

3. Remove the four screws (two on each side) that hold

the heat shield to the engine using a 5/16” wrench.

Exhaust pipe

Heat shield screws

4. Slide the heat shield off of the engine.

Figure 2.1

5. Remove the two nuts that hold each exhaust pipe to

the cylinder head using a 1/2” wrench.

See Figure 2.2.

6. Remove the muffler and exhaust pipes.

NOTE: The exhaust pipes are welded to the muffler. The

pipes and the muffler are serviced as one assembly.

7. Clean and remove all gasket material from the cylinder head (and the exhaust pipes if they are being

reused).

8. Using new gaskets, install the muffler by following the

previous steps in reverse order.

Figure 2.2

NOTE: Tighten the exhaust nuts to a torque of 246 in lbs

(27.8 Nm).

9. Test drive the mower in a safe area before returning

it to service.

5

Page 12

2000 Series Tractors

Fuel tank removal/replacement

Remove/replace the fuel tank by following these steps:

Gasoline and its vapors are extremely flammable. Use common sens e when working aroun d

! CAUTION! CAUTION

1. Safely drain the gasoline from the fuel tank.

2. Disconnect the seat switch. See Figure 2.3.

NOTE: On the GTX2154LE, it will be necessary to

cut the wire tie that holds the seat switch

connector to the seat frame.

NOTE: When reconnecting the seat switch plug on

the GTX2154LE, it must be wire tied back

together and attached to the seat frame.

Failure to do this can cause the connector to

get caught in the seat bracket and rip the

wires out of the seat. If this happens, the

tractor will shut down when the brake is

released and the whole seat must be

replaced.

3. Push the barbed fastener on the seat switch harness out of the hole in the fender.

the fuel system

Figure 2.3

4. Remove the four socket headed cap screws that

hold the seat tracks to the fender using a T-40 torx

driver. See Figure 2.4.

Figure 2.4

6

Page 13

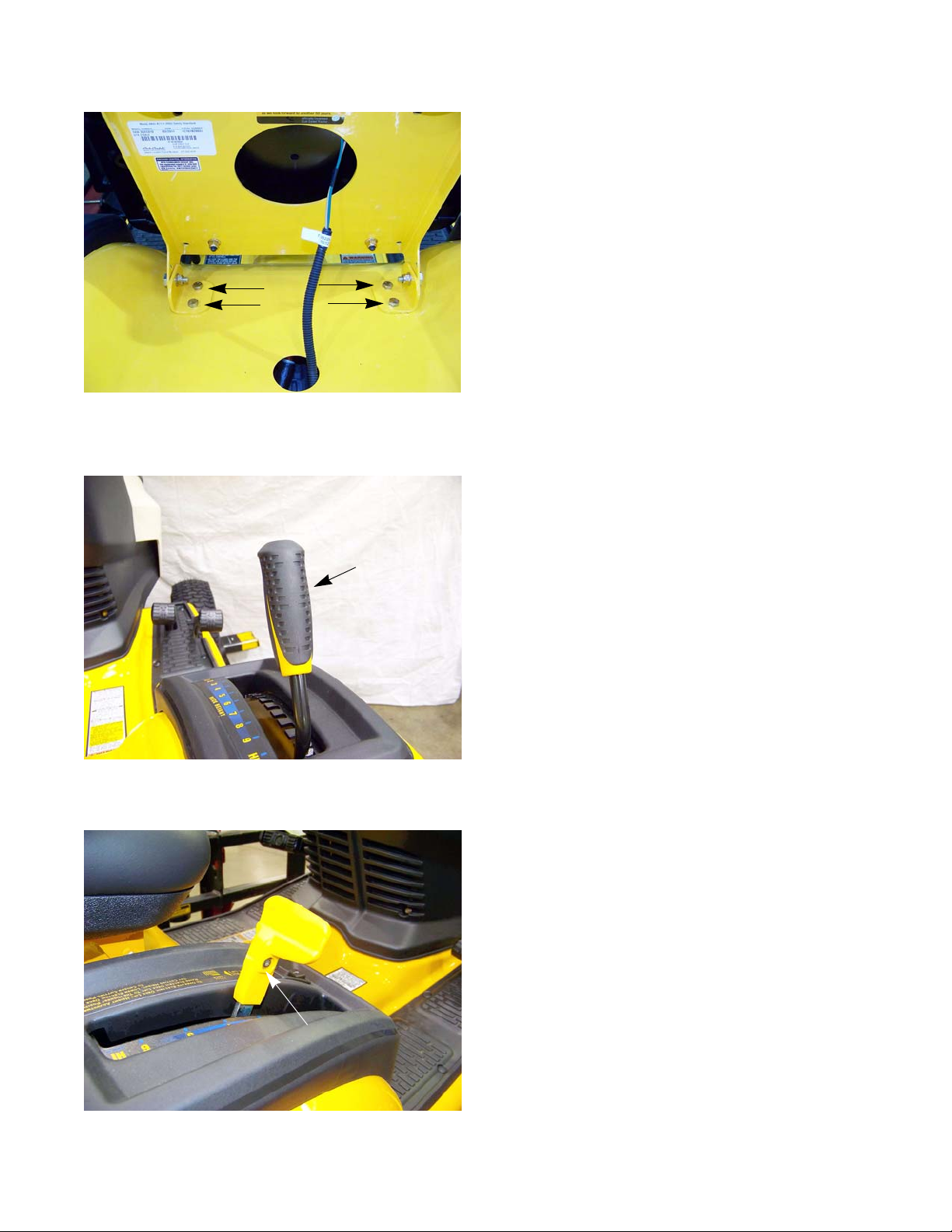

Figure 2.5

Engine Related Parts

NOTE: On the GTX2154LE:

• Remove the four screws, indicated by the arrows

in Figure 2.5, that hold the seat frame to the fender

using a 7/16” wrench.

• Remove the two screws that hold the rear of the

fender to the frame using a 7/16” wrench.

On manual deck lift models:

5. Remove the deck lift lever grip. See Figure 2.6.

NOTE: A blow-gun with air pressure regulate d to less than

Grip

Figure 2.6

On electric deck lift models:

6. Remove the screw that holds the deck cutting height

7. Pull the cutting height lever off of the shaft.

8. Disconnect the deck lift switch.

25 PSI (1.72 Bars), may be inserted into the small

hole at the end of a rubber grip to inflate it slightly,

easing removal.

lever to the shaft using a T40 torx driver.

Screw

Figure 2.7

7

Page 14

2000 Series Tractors

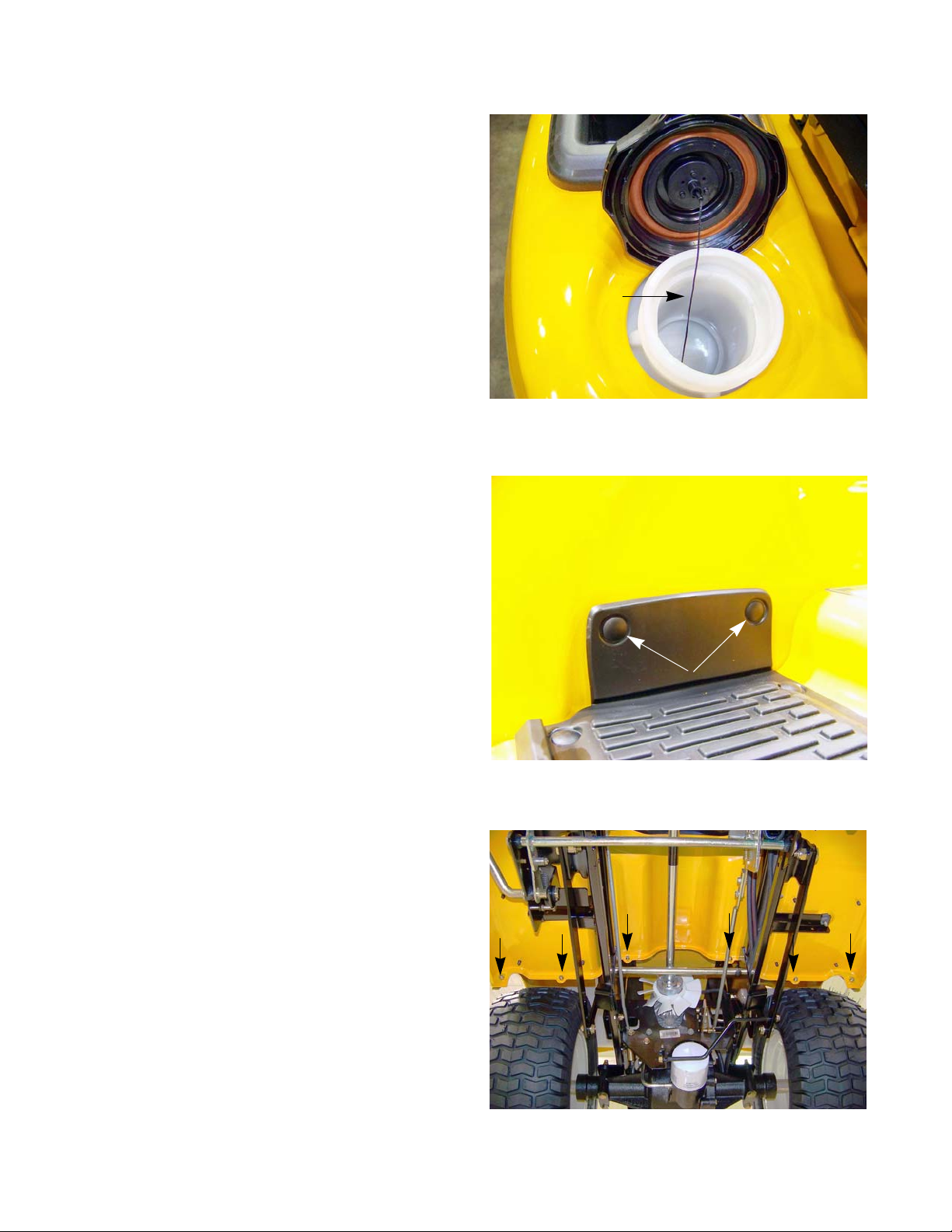

9. Unthread the fuel cap.

10. Pull the fuel cap tether retainer out of the fuel tank

using a long pair of pliers. See Figure 2.8.

NOTE: The fuel cap tether is manda ted by the EPA.

If it is broken, the fuel cap must be replaced.

Tether

Figure 2.8

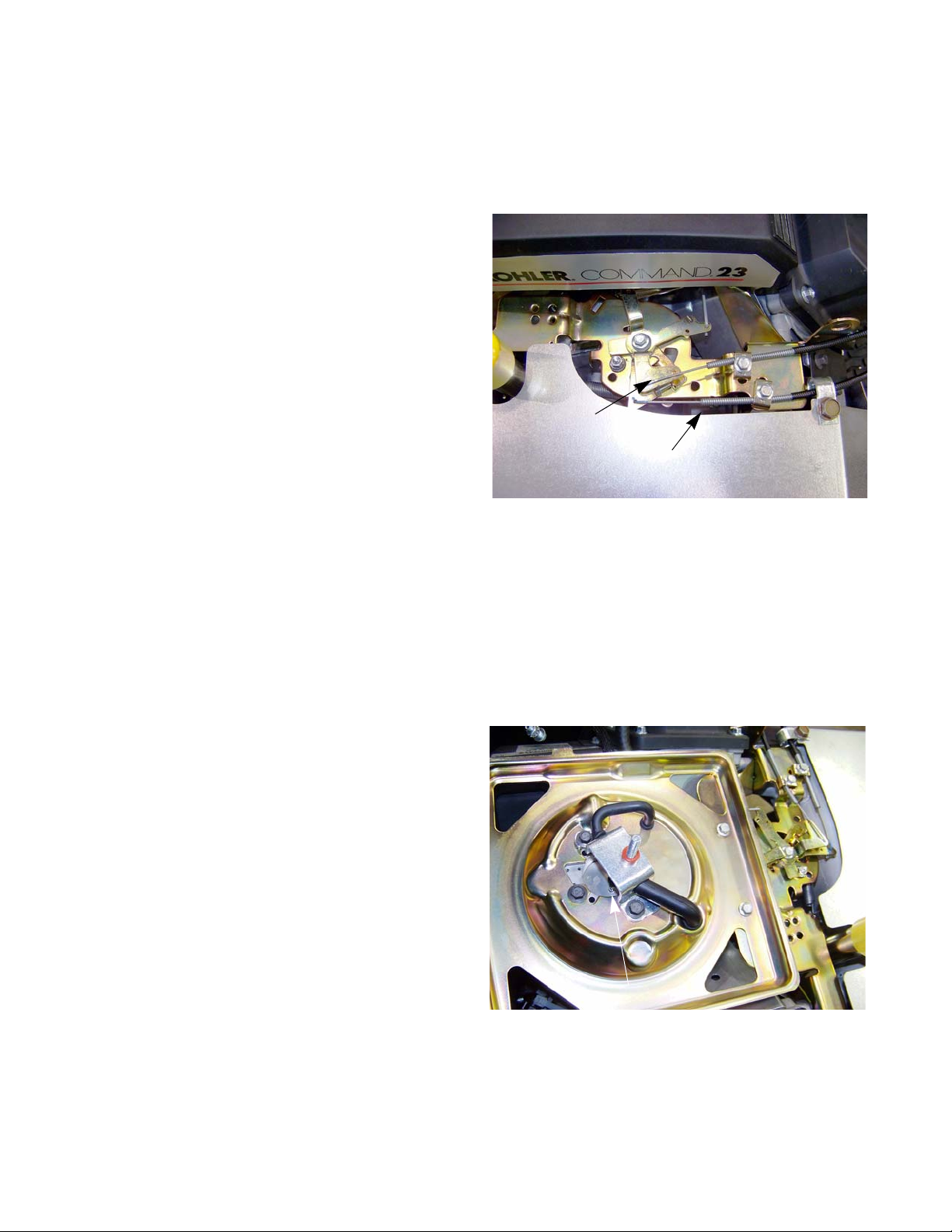

11. Gently pry out the barbed fasteners that hold the

end of the running board mats to the fender.

See Figure 2.9.

12. Remove the six nuts and bolts, indicated by the

arrows in Figure 2.10, that hold the fender to the

running board using a pair of 7/16” wrenches.

13. Lift the fender off of the tractor.

Barbed fasteners

Figure 2.9

Figure 2.10

8

Page 15

Vent hose

Engine Related Parts

14. Re-install the fuel cap.

15. Disconnect the vent hose from the roll over valve.

See Figure 2.11.

Roll over valve

Figure 2.11

Roll out

16. Roll the fuel tank towards the rear of the tractor until it

is free from the tractor. See Figure 2.12.

17. Disconnect the fuel line from the fuel tank.

18. Install the fuel tank by following the previous steps in

reverse order.

19. Test run the tractor in a safe area before returning it

to service.

Figure 2.12

9

Page 16

2000 Series Tractors

Throttle cable adjustment

If the engine does not achieve its high (no load) speed when the throttle is moved to the full throttle position,

check the cable adjustment before performing any other engine or carburetor inspections.

To adjust the throttle cable:

1. Raise the hood and locate the engine contro l panel.

2. Operate the throttle lever while observing its direction of movement. See Figure 2.13.

3. Loosen the screw that secures the throttle cable

clamp.

4. Push and hold the throttle arm at the full throttle

position.

5. While holding the throttle arm, remove the slack in

the cable by pulling the cable jacket back through

the clamp.

Choke cable

6. Tighten the screw in the clamp to secure the cable.

7. Start the engine.

8. Check the engine RPMs using a tachometer.

NOTE: Refer to the service manual provided by the

engine manufacturer for any further engine

speed adjustments needed.

Choke cable adjustment

If the engine is difficult to start or runs roughly after it warm s up, ch eck the choke c able setting befor e performing

any other engine or carburetor inspections.

To adjust the choke cable:

1. Remove the air filter.

2. Locate the engine control panel.

3. Loosen the screw that secures the choke cable

clamp.

4. Move the choke arm until the choke plate is fully

closed.

NOTE: Look down the carburetor throat to confirm

that the choke plate is fully closed.

See Figure 2.14.

Throttle cable

Figure 2.13

5. While holding the choke arm, remove the slac k in

the cable by pulling the cable jacket back through

the clamp.

6. Tighten the screw in the clamp to secure the cable.

7. Check the operation of the cable and choke plate.

8. Re-install the air filter.

9. Test run the tractor in a safe area before returnin g it to ser vic e.

10

Choke plate closed

Figure 2.14

Page 17

Choke and Throttle levers and cables

Control lever assemblies

Figure 2.15

Engine Related Parts

To remove/replace levers and cables:

NOTE: The choke and throttle cables must be removed

with the lever assemblies before they can be separated and replaced.

1. Remove the dash by following the procedures

described in Chapter 4: Body.

2. Remove the three screws that secure the control

lever assemblies in place using a 3/8” wrench.

See Figure 2.15.

3. Rotate the levers while pulling the assemblies out of

the dash.

4. Remove the cables:

Figure 2.16

Screw

4a. Squeeze in the ears on the cable jacket fittings.

See Figure 2.16.

4b. Slide the cable jackets out of the bracket.

4c. Un-hook the cables from the levers.

NOTE: If just replacing the cables, install the cables by fol-

low steps 1 - 4 in reverse order.

5. Remove the screw that holds the lever ret ainer to the

bracket using a 5/16” wrench. See Figure 2.17.

Figure 2.17

11

Page 18

2000 Series Tractors

6. On the side of the lever assembly that has the slot,

lift the shaft that the levers pivot on enough to slide

the spring off. See Figure 2.18.

7. Slide the lever assembly toward the side with the

slot until the assembly clears the other side.

8. Slide the levers off of the indexing plate.

See Figure 2.19.

9. Install the levers and cables by following the previous steps in reverse order.

Spring

Slot

Figure 2.18

12

Indexing plate

Figure 2.19

Page 19

Engine removal/installation

Figure 2.20

Fuel pump

Engine Related Parts

It may be necessary to remove the engine to perform

engine repairs such as replacing the ignition coil, flywheel,

alternator or to work on the cylinder heads.

To remove the engine:

1. Remove the hood by following the procedures

described in Chapter 4: Body.

2. Disconnect the negative battery cable from the battery.

3. Remove the muffler by following the proced ures

described in the muffler section of this chapter.

4. Clamp off the fuel line just below the fuel pump.

See Figure 2.20.

Oil drain hose

Ground cable

Figure 2.21

Engine harness

Starter trigger wire

Starter cable

5. Disconnect the ground cable from the left side of the

engine using a 1/2” wrench. See Figure 2.21 .

6. Disconnect the PTO clutch harness.

7. Disconnect the engine harness.

8. Disconnect the starter wires. See Figure 2.22.

9. Remove the starter.

Figure 2.22

13

Page 20

2000 Series Tractors

10. Remove the dash by following the procedures

described in Chapter 4: Body.

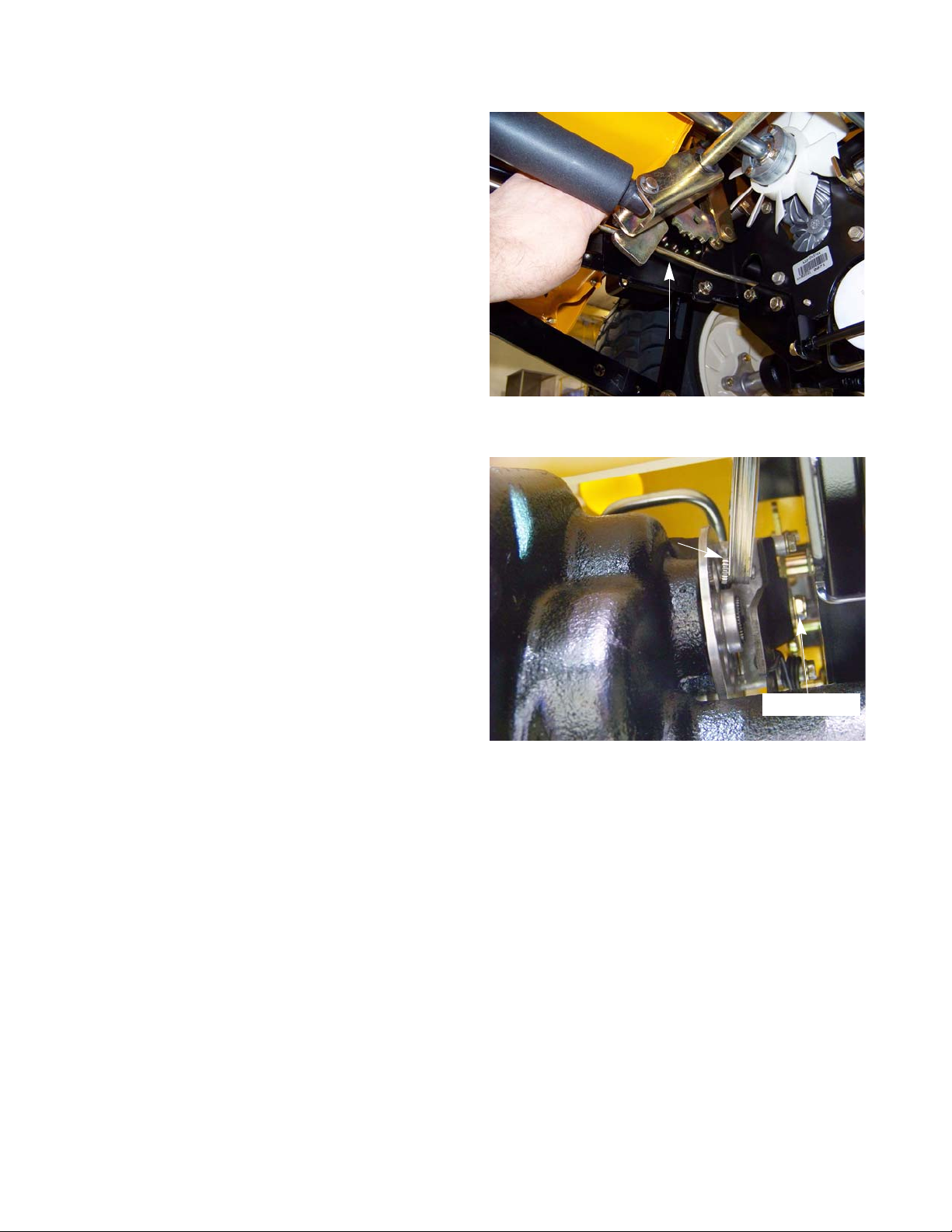

11. Disconnect the drive shaft from the engine by

removing the four patch bolts using a 7/16” wr en ch .

See Figure 2.23.

12. Remove the four nuts and bolts, indicated by the

arrows in Figure 2.24, that hold the engine to the

sub frame using a pair of 9/16” wrenches.

Drive shaft

Figure 2.23

13. Attach a lift chain to the engine’s lifting points.

See Figure 2.25.

NOTE: The lift chain should be approximately 2’ -

2.5’ (61 - 76 cm) long and is of sufficient

strength to safely support weight of the

engine.

14. Using an engine hoist, gently lift the engine while

sliding it off of the drive shaft and out the front of the

tractor.

NOTE: Be careful sliding the engine off of the drive

shaft. If the drive shaft coupling gets caugh t,

it will come apart, spilling the blue rollers on

the ground.

14

Figure 2.24

Lift points

Figure 2.25

Page 21

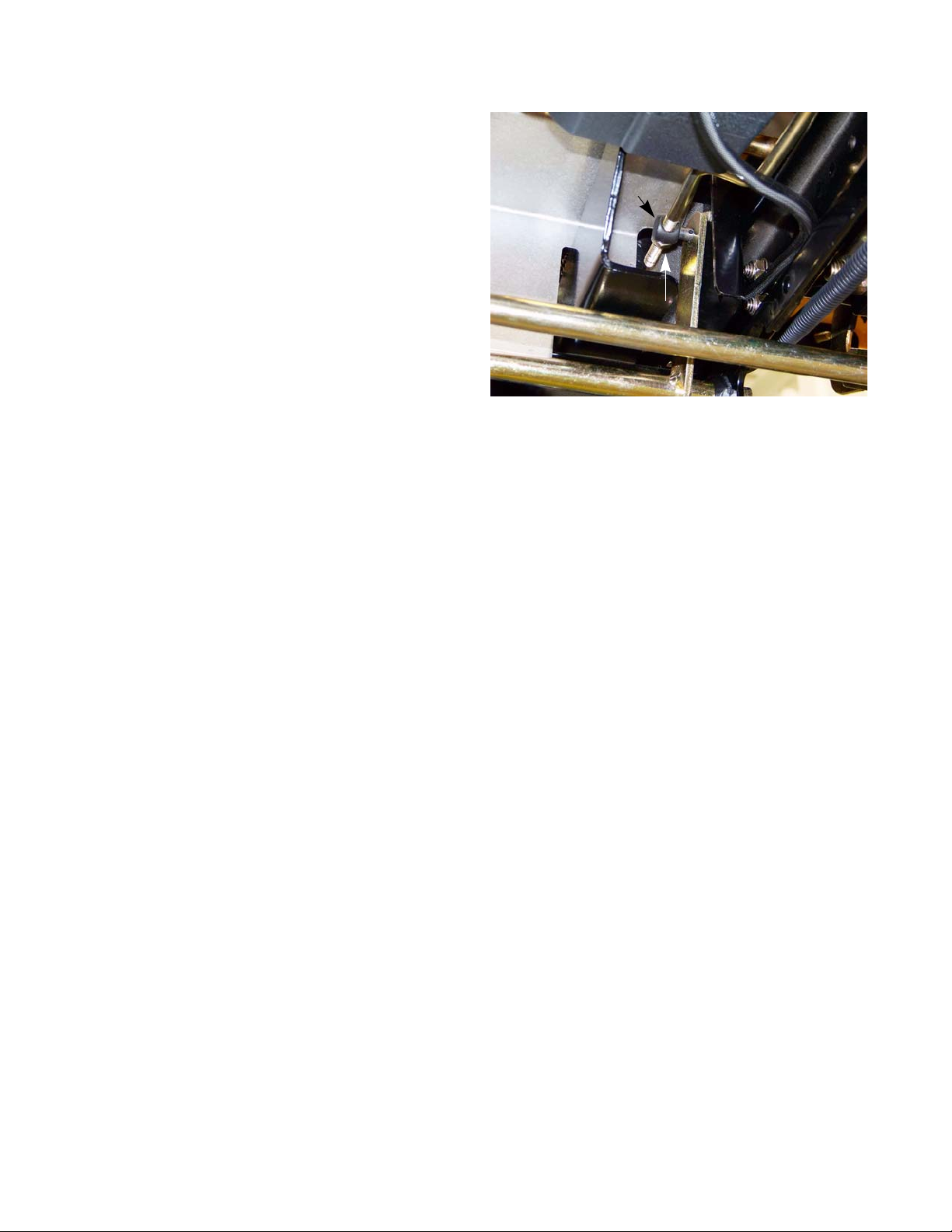

Blue rollers

Engine Related Parts

NOTE: If the front drive shaft coupling comes apart:

• Remove the engine.

• Insert the rollers in between the drive shaft end

and the coupler housing one at a time, until all

eight are in place. See Figure 2.26.

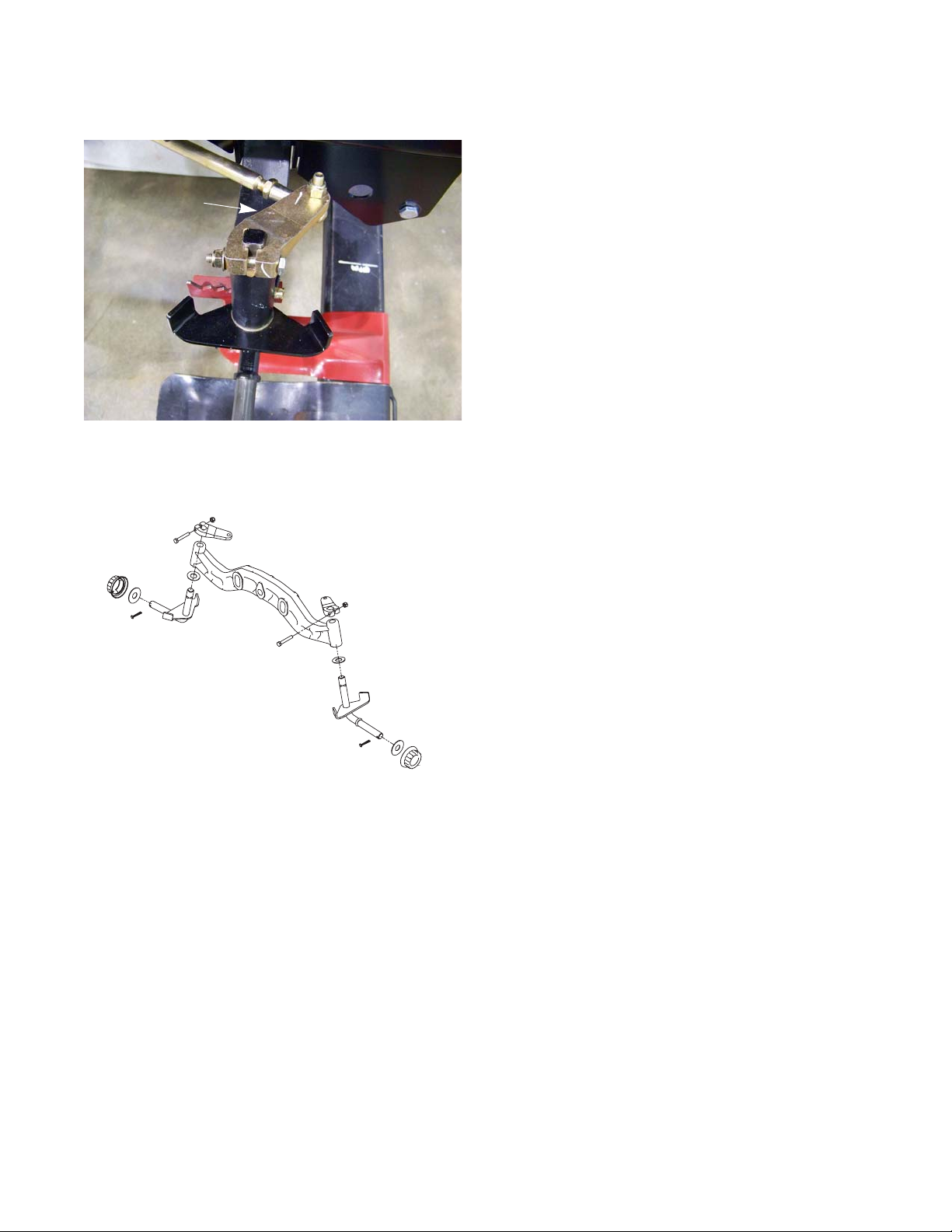

Figure 2.26

To install the engine:

1. Install an alignment stud into one of the drive shaft

coupler holes on the engine. See Figure 2.27.

Alignment stud

Coupling spacer

Coupling

Figure 2.27

Alignment stud

NOTE: To make an alignment stud: See Figure 2.27.

• Obtain a 1/4” x 20 bolt that is a minimum of 4” long.

• Cut the head off of the bolt.

• Grind a tapper onto the side of the bolt the head

was on.

2. Insert three of the bolts into the coupling and the

spacer.

3. Slide the engine into place, using the alignment stud

to guide the drive shaft coupler into place.

See Figure 2.28.

4. Start the three coupling bolts.

5. Remove the alignment stud.

Figure 2.28

Coupling bolts

6. Install the fourth coupling bolt.

7. Tighten all of the coupling bolts to a torque of 10 - 12

ft lbs (14 - 16 Nm).

15

Page 22

2000 Series Tractors

8. Install the engine mounting nuts and bolts.

9. Remove the engine lift chain.

10. Install the dash by following the steps described in Chapter 4: Body.

11. Install the starter.

12. Reconnect the starter wires.

13. Reconnect the engine harness.

14. Reconnect the ground cable to the base of the engine.

15. Reconnect the fuel line to the fuel pump.

16. Install the muffler by following the procedures described in the muffler section of this chapter.

17. Install the hood.

18. Check the oil and fuel levels, top off as needed.

19. Test drive the tractor in a safe area before returning it to service.

16

Page 23

Brakes

CHAPTER 3: BRAKES

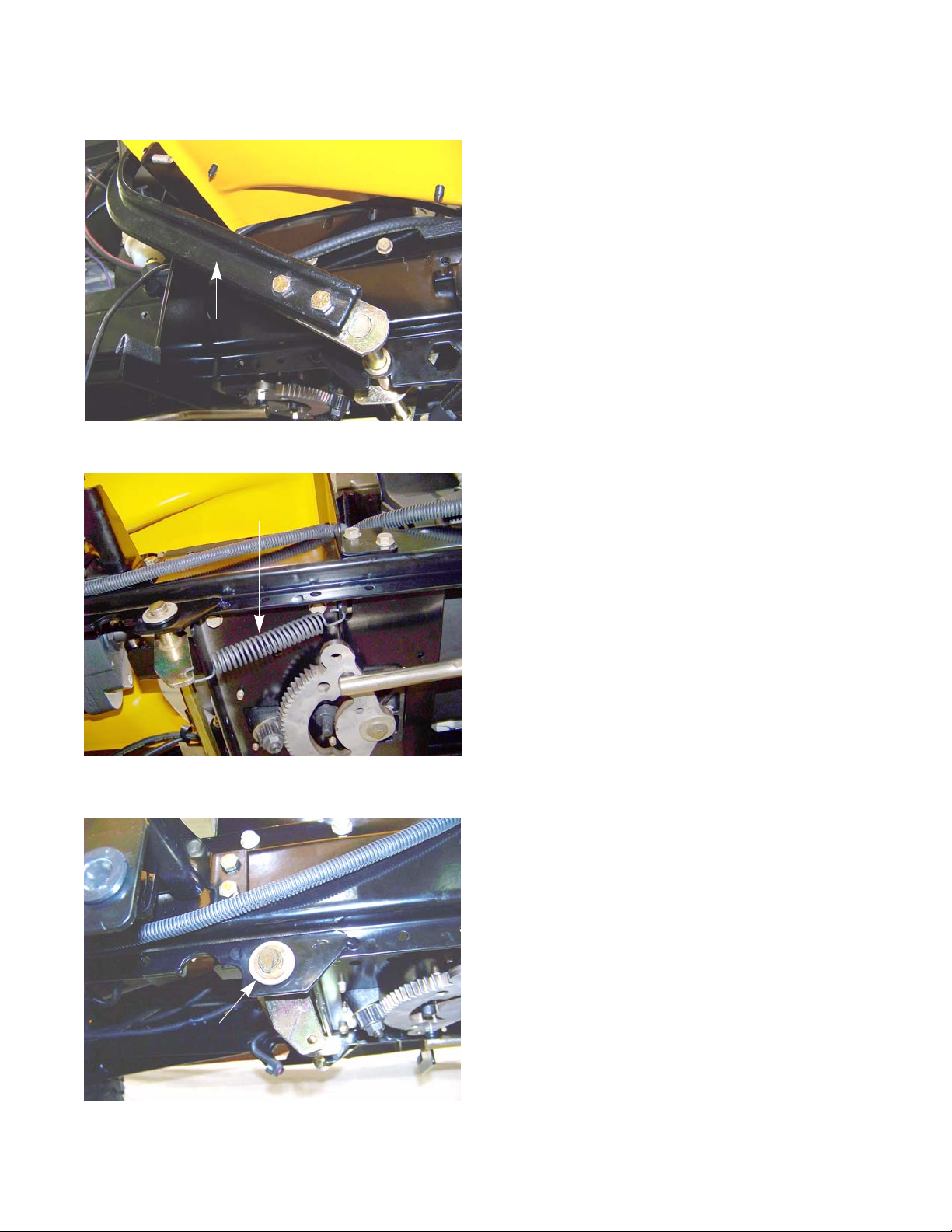

Brake adjustment

The transmission on the 2000 series tractor is driven by a Hydro-Gear BDU-10L pump. The pump will provide the

braking action when it is in operation. There is a mechani cal brake on the side of the tran smission. This brake is used

primarily as a parking brake. It is also used as a back up brake in cas e of a failure of the hydro pump.

The operation of the brakes should be tested before performing any adjustments.

To test the operation of the brakes:

1. Disengage the hydro pump by-pass rod by pulling it

out and hooking it. See Figure 3.1.

2. Set the parking brake by depressing the brake pe da l

and lifting-up on the parking brake lever.

3. Attempt to push the tractor. If it can be pushed by

hand without skidding a rear wheel, check and adjust

the brakes.

4. Release the parking brake.

By-pass rod

Outer latch plate

travel limit pin

5. Attempt to push the tractor again. If it cannot be

pushed with reasonable effort, check the hydro pump

by-pass and adjust the brakes.

Figure 3.1

Inner latch plate

6. Visually inspect the linkage to confirm that it functions

properly.

• Beneath the floor panel, on the left side of the trac-

tor there are two semi-circular latch plates (bell

cranks).

• The outer latch plate rotates with the drive control

pedals. The inner latch plate rotates with the

clutch/brake pedal.

6a. With the clutch/brake pedal fully released:

• The travel limit pin should be resting against the

front of the curved slot. See Figure 3.2.

Figure 3.2

17

Page 24

2000 Series Tractors

• The rod that connects the clutch/brake latch

plate to the heavy brake actuator spring should

not droop. See Figure 3.3.

• Check the brake pedal shaft bushings for wear.

Adjust the brakes by:

NOTE: The brake is located between the frame and

the transmission on the right side of the tractor. It is a tight fit, but it can be reached from

the under side of the tractor aft, of the rear

axle.

No droop

Figure 3.3

0.010” feeler gauge

NOTE: In Figure 3.4, the by-pass rod was removed

for a clearer view of the caliper.

1. Wiggle the brake rotor slightly, and attempt to insert

a 0.010” (0.38mm) feeler gauge between the rotor

and either pad.

NOTE: There is a fixed pad in the transaxle hous-

ing.

NOTE: There is a moving pad in the brake caliper.

2. Adjust the gap, if necessary, so that the feeler

gauge slips between the pad and the rotor with light pressure. See Figure 3.4.

2a. Turn the nut to adjust the gap.

NOTE: The gap should be in the range of 0.010” - 0.015” (0.25mm - 0.38mm)

2b. Apply and release the brake pedal, then re-check the gap.

NOTE: If the brake seems to be sticking, or the rotor is discolored from dragging, fix the cause of the sticking

and replace the rotor.

3. Re-test the operation of the brakes before returning the tractor to service.

Figure 3.4

Adjuster nut

18

Page 25

Brakes

Brake puck/rotor replacement

On transmission used on the 2000 series tractor , the brake pucks are wearing p a rts that will need to be serviced

from time to time. If the tractor is operated with the parking brake dragging, the pucks will wear out rapidly and the

brake rotor will develop hot spots. If the tractor is operated long enough, the rotor may have grinding marks on it with

excessively worn pucks.

! CA UTION! CA UTION

NOTE: The brake pucks and the rotors are serviced at the same time.

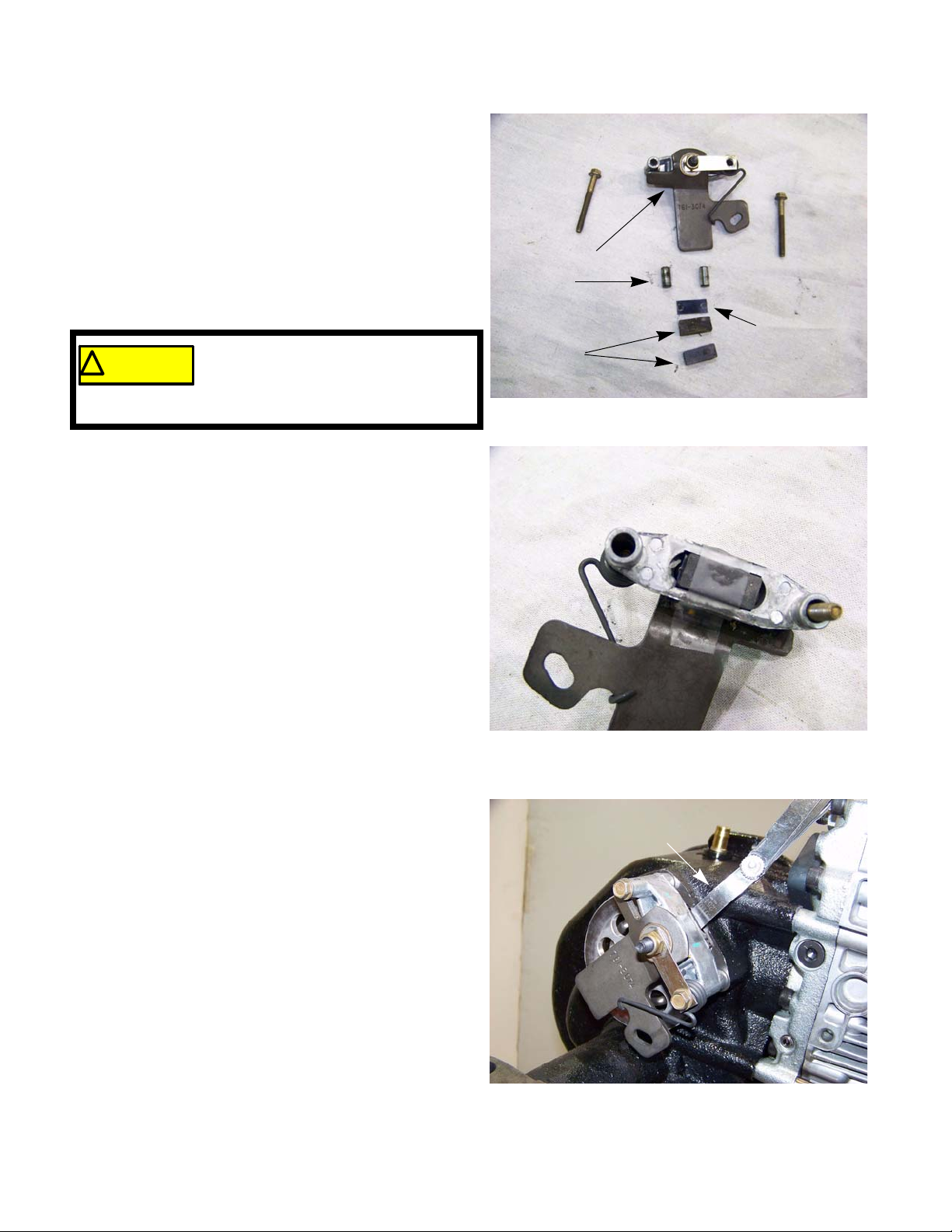

Screws

If the rotor shows hot spots or any other signs of damage, including warpage, it must be

replaced. Failure to do so can result in the failure of the brakes

To remove/replace the brake pucks and rotor:

1. Lift and safely support the rear of the tractor.

2. Remove the transmission by following the procedures describe in Chapter 5: Drive.

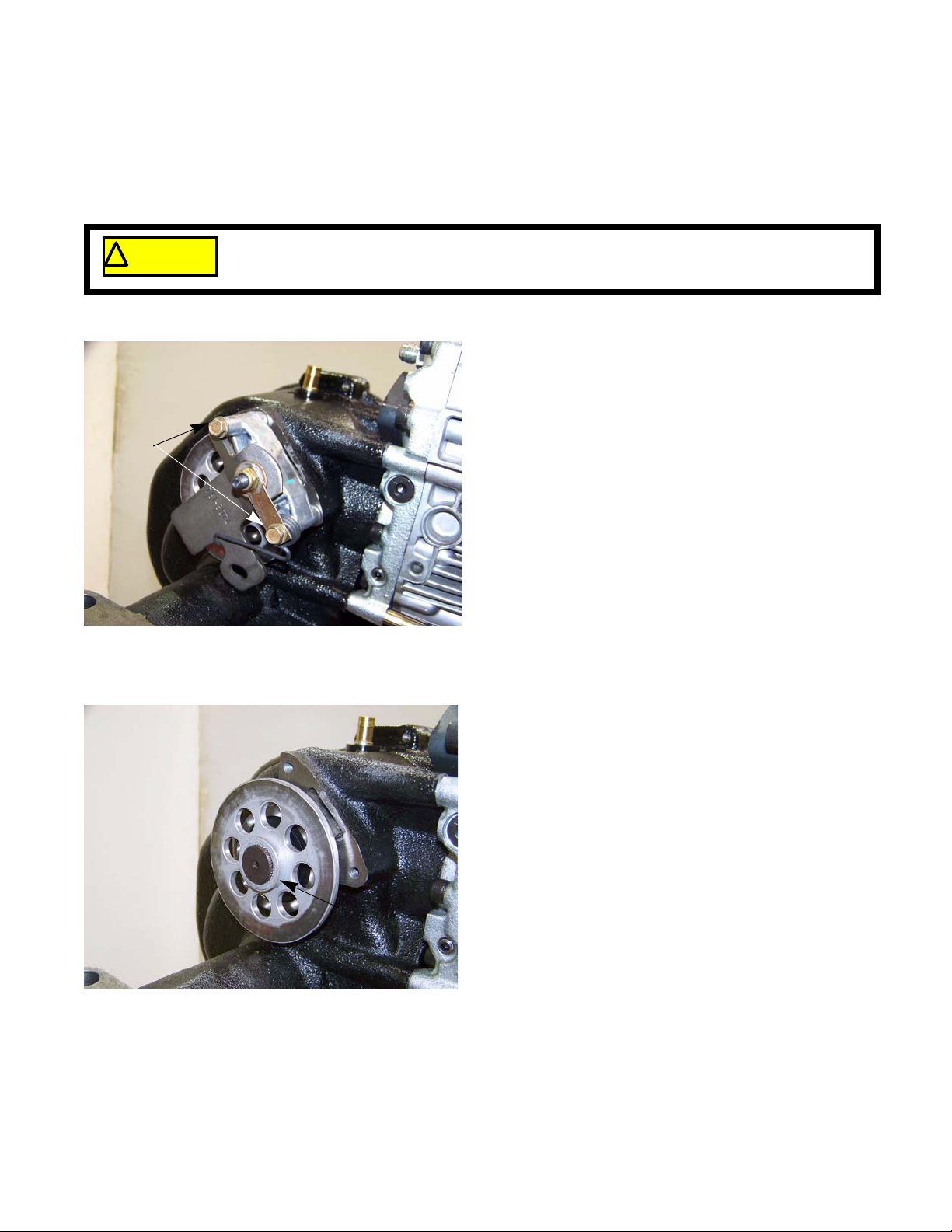

3. Remove the two screws that secure the brake caliper

to the right transmission housing using a 3/8” wrench.

See Figure 3.5.

4. Lift the caliper off of the transmission.

Figure 3.5

Figure 3.6

5. Remove the brake disk from the output shaft.

See Figure 3.6.

NOTE: The center flange of the brake disk faces outward.

Flange

19

Page 26

2000 Series Tractors

6. With the caliper on a work bench, remove the brake

puck, backing plate and the two brake pins.

See Figure 3.7.

7. Inspect all the components of the brake assembly

for damage or wear: brake pads, puck plate, actu ator pins, actuator arm, anti-rotation bracket, yoke,

torsion spring, flat washer and locking hex nut.

8. Check for free movement of the brake pins. A dry

lubricant can be used on the brake pins sparingly.

Never put grease or anti-seize on

! CA UTION! CA UTION

of the pucks.

9. Slide the brake pins into the caliper.

10. Place the backing plate in the caliper.

11. Place a new puck into the caliper. See Figure 3.8.

NOTE: A piece of scotch tape may be used to hold

brake pins. It can migrate to the brake

pucks, preventing the braking action

the new brake pucks in place for assembly.

The tape will grind away when the brakes

are applied.

Caliper

Pins

Backing plate

Pucks

Figure 3.7

12. Place a new brake puck into the recess in the transmission. Use a piece of scotch tape to hold it in

place.

13. Slide the brake rotor in place, shoulder out.

14. Mount the brake caliper to the transmission. Apply a

small amount of releasable thread locking compound such as Loctite® 242 (blue) to the mounting

bolts and tighten to a torque of 80 - 120 in-lbs (9 -

13.5 Nm).

15. Wiggle the brake rotor slightly and insert a 0.010”

(0.38mm) feeler gauge between the rotor and either

pad.

16. Adjust the gap, if necessary, so that the feeler

gauge slips between the pa d and the rotor with light

pressure. See Figure 3.9.

16a. Turn the nut to adjust the gap.

NOTE: The gap should be in the range of 0.010” -

0.015” (0.25mm - 0.38mm)

16b. Operate the brake cam arm a few times, then

re-check the gap.

17. Install the transmission by following the procedures

described in Chapter 5: Drive System.

Figure 3.8

0.010” feeler gauge

18. Test drive the tractor in a safe area before returning

it to service.

20

Figure 3.9

Page 27

Brake shaft assembly

Brake pedal

Brakes

To remove/replace the brake shaft:

1. Remove the cutting deck by following the procedures

described in Chapter 8: Cutting Decks and Lift shaft.

2. Lift and safely support the tractor.

3. Remove the forward drive pedal shaft by following

the procedures described in Chapter 5: Drive System.

4. Disconnect the brake pedal by removing the two nuts

and bolts that attach it to the brake pedal shaft using

a pair of 1/2” wrenches. See Figure 3.10.

Figure 3.10

Brake shaft return spring

Figure 3.11

5. Disconnect the brake shaft return spring.

See Figure 3.11.

6. Remove the E-ring and washer(s) fr om the right side

of the brake shaft. See Figure 3.12.

7. Remove the hex bushings from both ends of the

brake pedal shaft.

E-ring

Figure 3.12

21

Page 28

2000 Series Tractors

8. Slide the brake pedal shaft to the left enough for it to

clear the frame on the right side.

9. Lower the shaft enough to gain access to the cotter

pin that secures the brake rod to the pedal shaft.

10. Remove and discard the cotter pin.

See Figure 3.13.

11. Remove the pedal shaft from the tractor.

12. Install the brake pedal shaft by following the previous steps in reverse order.

NOTE: The cotter pin that secures the br ak e ro d to

the pedal shaft can be replaced with a bow

tie clip (714-04040). This will make it easier

to perform the brake rod adjustment.

13. Perform a brake rod adjustment by following the

procedures described in the brake rod ad jus tm en t section of this chapter.

14. Test drive the tractor in a safe area before returning it to service.

Cotter pin

Figure 3.13

22

Page 29

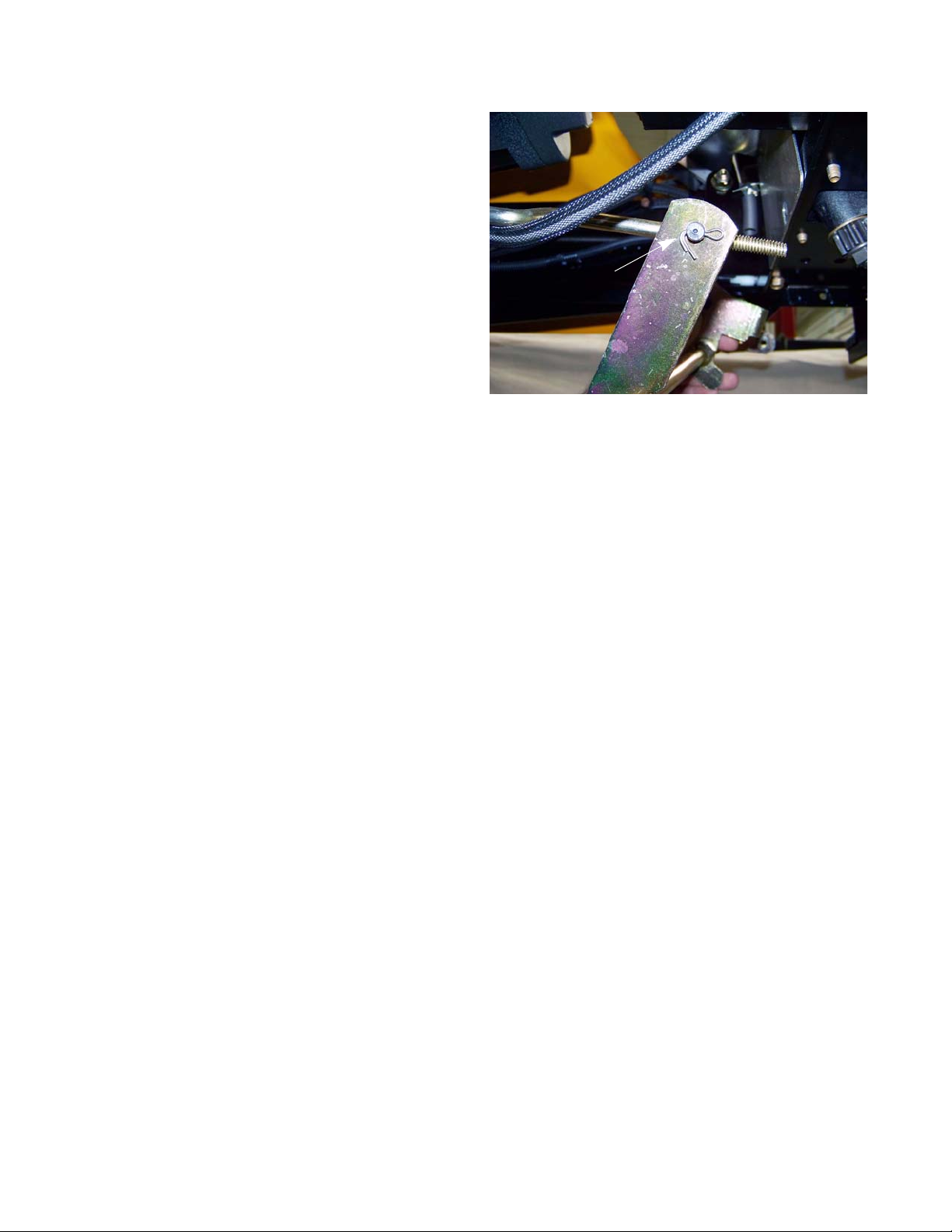

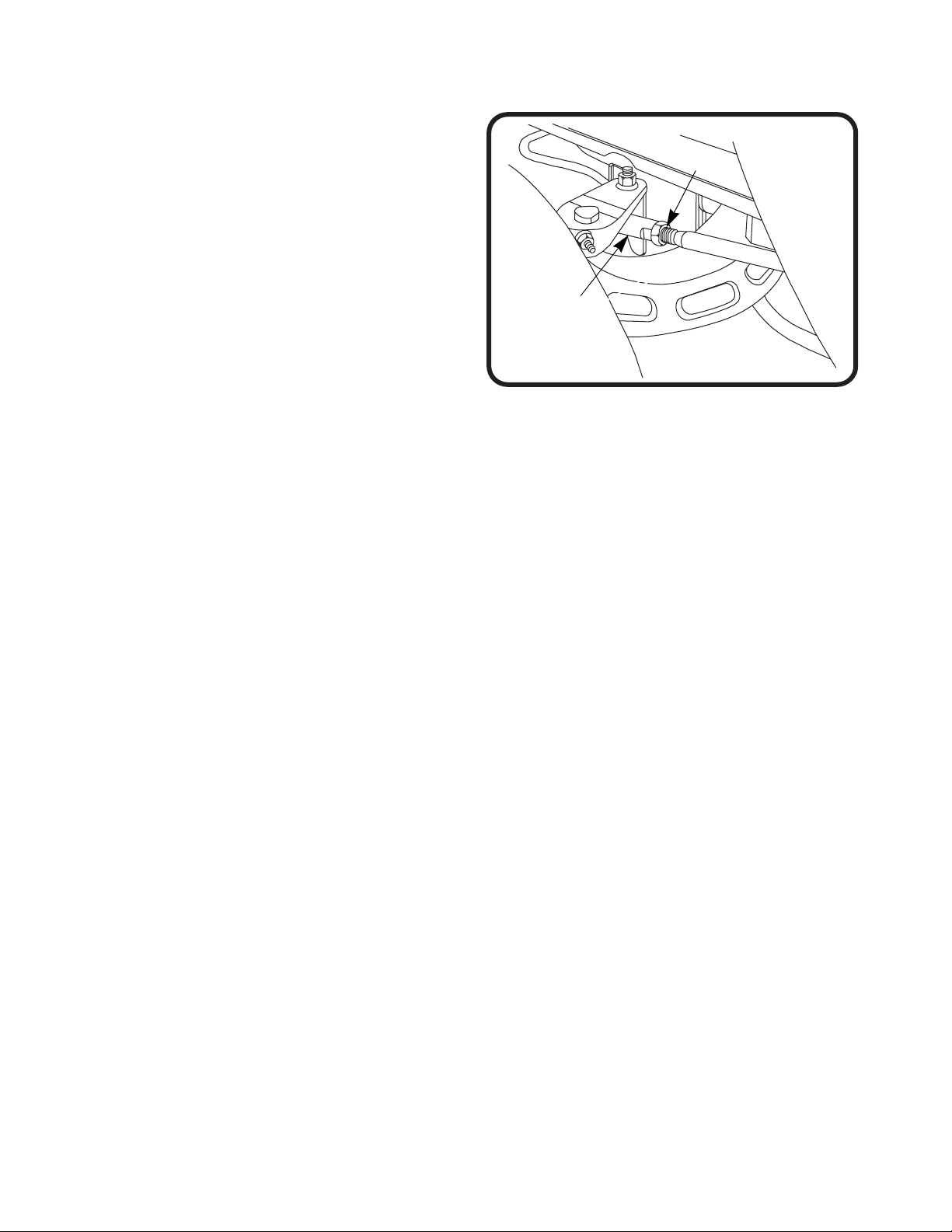

Brake rod adjustment

E-ring

Brakes

NOTE: The brake rod should not come out of adjustment

on its own. If the brake rod does need to be

adjusted, check for a bent rod, worn bushing and

worn brake pucks.

To adjust the brake rod:

1. Remove the cutting deck by following the procedures

described in Chapter 8: Cutting Decks and Lift Systems.

2. Lift and safely support the tractor.

3. Remove the E-ring and washers from the right side of

the forward drive pedal shaft. See Figure 3.14.

Figure 3.14

Figure 3.15

4. Slide the drive pedal shaft to the left until it stops.

5. Remove the E-ring and washer(s) fr om the right side

of the brake pedal shaft. See Figure 3.15.

6. Slide the brake pedal shaft to the left until it stops.

E-ring

7. Disconnect the brake rod from the brake pedal shaft

by removing the cotter pin and discarding it.

See Figure 3.16.

Figure 3.16

Cotter pin

23

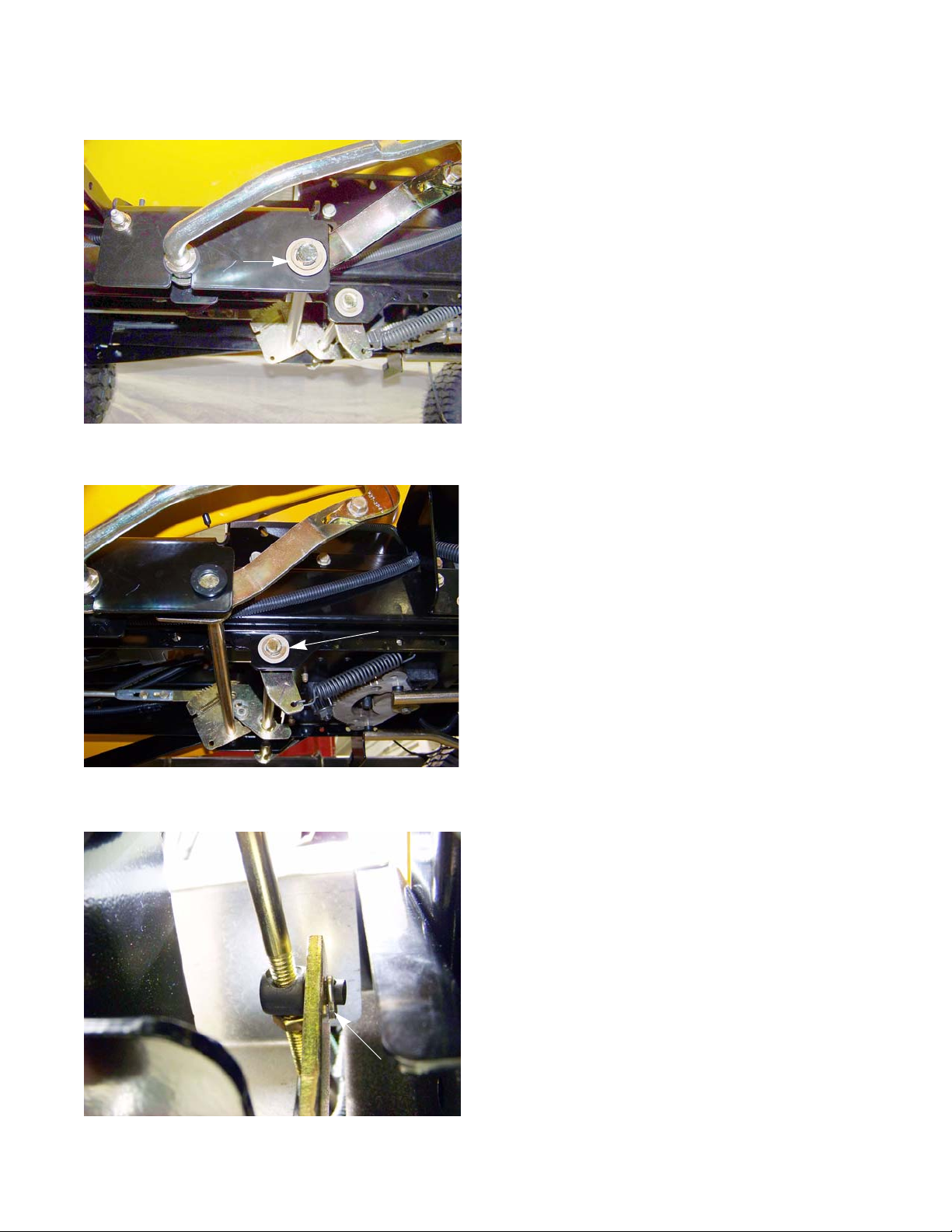

Page 30

2000 Series Tractors

8. Loosen the jam nut. See Figure 3.17.

9. Tighten or loosen the ferrule as needed so that it

aligns with the hole in the bell crank of the brake

pedal shaft with no slack in the brake spring.

10. Tighten the jam nut.

11. Attach the brake rod to the brake pedal shaft.

NOTE: The cotter pin that secures the br ak e ro d to

the pedal shaft can be replaced with a bow

tie clip (714-04040).

12. Slide the brake pedal shaft to the right until it stops.

13. Install the E-ring and washer(s) on to the brake

pedal shaft.

NOTE: If the bushings popped out while shifting the

shafts, re-install them before installing the E-rings.

14. Slide the forward drive pedal shaft to the right until it stops.

15. Install the E-ring and washer(s) on to the drive pedal shaft.

16. Test drive the tractor in a safe area before returning it to service.

Ferrule

Jam nut

Figure 3.17

24

Page 31

Body

CHAPTER 4: BODY

What is covered by this chapter

The intent of this chapter is to describe the removal and disassembly of the major body panels on the tractor.

•Hood

•Seat

• Fenders

• Dash panel

NOTE: It is not absolutely necessary to remove the mowing deck for any procedures covered in this section.

The technician may choose to remove the mowing deck so that it is easier to reach some parts of the

tractor.

Hood

Lift here

Hood removal:

1. The hood is front-hinged. See Figure 4.1.

2. Open the hood by lifting the rear edge to tilt it forward.

Figure 4.1

3. Disconnect the headlight harness. See Figure 4.2.

Headlight harness connector

Figure 4.2

25

Page 32

2000 Series Tractors

4. The hood hinges on a pair of shoulder bolts that fit

into slots in the hood bracket.

5. The hinge travel is limited by a tab that fits into a

channel in the hood bracket.

6. Open the hood far enough to align the tabs with the

slots, then lift the hood off of the tractor.

See Figure 4.3.

Hood components: side vent removal

Slot

Figure 4.3

1. Carefully pry the vent free of the lock tabs.

2. Pull the vent out of the hood assembly.

3. Install the hood side vent by pressing it into the

hood-side opening until the lock tabs click into

place, securing the vent.

2 lock tabs on top

2 lock tabs on bottom

Figure 4.4

26

Page 33

Hood components: Headlight removal

Figure 4.5

Body

1. With the spade terminals disconnected, rotate the

lamp holder (socket) to release it from the grille

assembly. See Figure 4.5.

LED headlight assembly

Figure 4.6

Single-pin 1156-style lamp

Socket

NOTE: The GTX2154LE has a LED headlight assembly. It

is removed the same way as the incandescent

headlight assemblies.

2. Rotate the bulb to release it from the socket.

See Figure 4.7.

NOTE: The LED assembly does not come apart.

3. Install the replacement lamp following the above

steps in reverse order.

Ground terminal

Power terminal

Figure 4.7

27

Page 34

2000 Series Tractors

Hood components: grille removal

1. Remove the hood assembly from the tractor, and

place it on a stable work surface.

2. Disconnect the wires from the headlights.

3. Remove the two screws, one in each head lig h t

housing, that hold the upper corners of the grille to

the hood using a 5/16” wrench. See Figure 4.8.

4. Remove the four screws, indicated by the arrows in

Figure 4.9, using a 3/8” wrench.

Screw +

washer

Figure 4.8

5. Slide the heat shield out of the hood.

Figure 4.9

28

Page 35

Screws

Figure 4.10

Body

6. Remove the two screws that hold the pivot bracket

and grille to the hood assembly using a 3/8” wrench.

See Figure 4.10.

7. Unlatch the tabs, where the screws were in step 3,

while pushing the grille out of the hood.

Locating tab

Figure 4.11

Lock tabs

8. Once removed, the headlight lens may be removed

for cleaning by carefully prying the two lock tabs at

the inner edge. See Figure 4.11.

NOTE: The locating tab at the outer edge of each len s has

no locking feature.

9. Assemble and install the grille by reversing the steps

used to remove it.

• Tighten the small screws to a torque of 15-35 in-

lbs. (1.7-4.0 N-m).

• Tighten the large screws to a torque of 35-50 in-lbs

(4.0-5.7 N-m).

29

Page 36

2000 Series Tractors

Hood components: pivot bracket removal

1. Remove the hood assembly from the tractor, and

place it on a stable work surface.

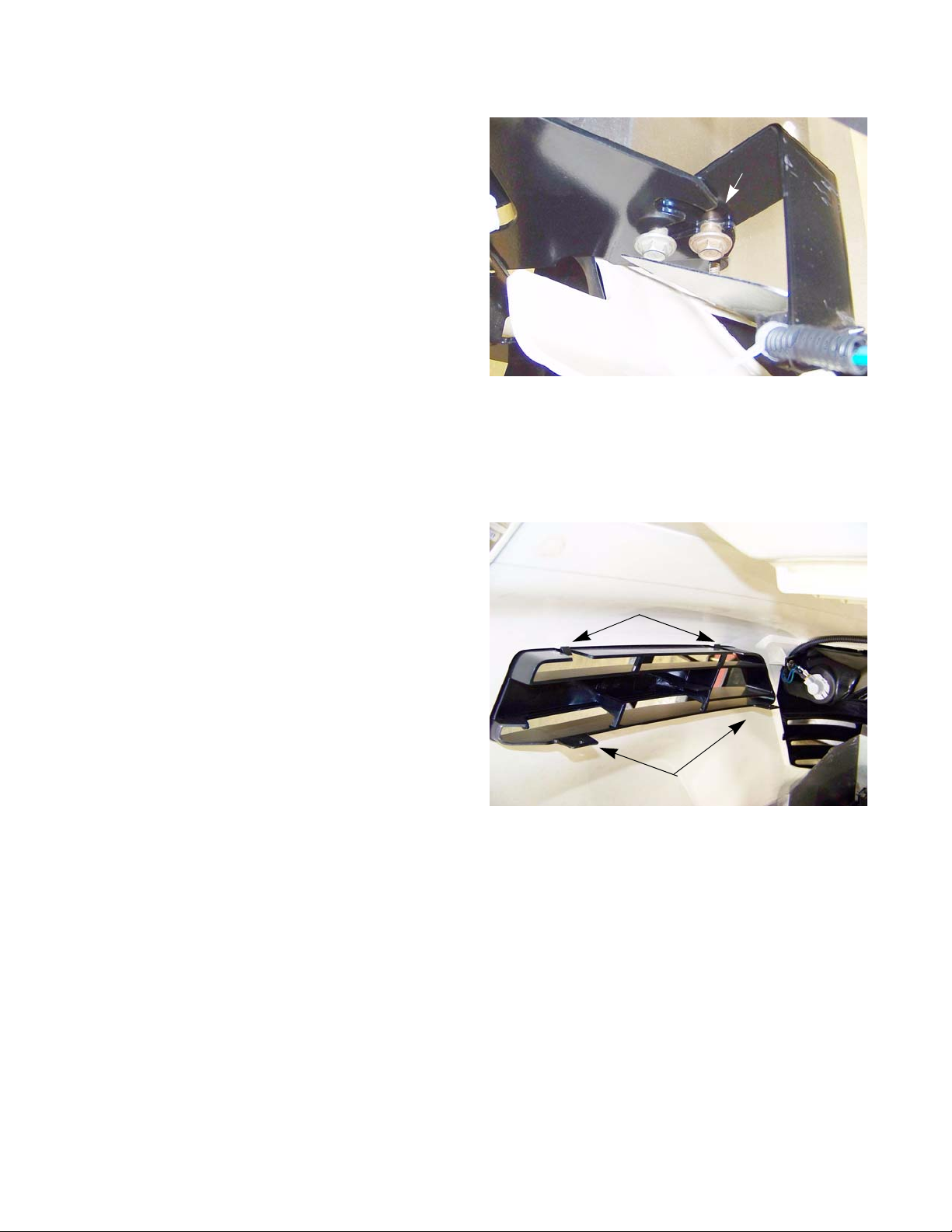

2. Remove the four screws, indicated by the arrows in

Figure 4.12, using a 3/8” wrench.

3. Slide the heat shield out of the hood.

Figure 4.12

4. Remove the two screws that hold the pivot bracket

and grille to the hood assembly using a 1/2” wrench.

See Figure 4.13.

5. Remove the four screws, indicated by the arrows in

Figure 4.14, that hold the outer arms of the pivot

bracket to the hood using a 3/8” wrench.

6. Assemble and install the grille by reversing the

steps used to remove it.

Screws

Figure 4.13

• Tighten the small screws to a torque of 15-35

in-lbs. (1.7-4.0 N-m).

• Tighten the large screws to a torque of 25-45

in-lbs (2.80-5.1 N-m).

30

Figure 4.14

Page 37

Fender and running board

On the Cub Cadet 2000 series tractor, the fender and the running board are two pieces. It may be necessary to

remove the fender and running board to gain access to items such as the deck lift shaft

When removing the fender and running board, it is generally easier to remove both of them as one piece.

NOTE: When working on the fuel tank, only the fender needs to be removed.

To remove/replace the fender:

1. Disconnect the seat switch. See Figure 4.15.

NOTE: On the G TX2154LE, it will be necessary to cut the

wire tie that holds the seat switch connector to the

seat frame.

NOTE: When reconnecting the seat switch plug on the

GTX2154LE, it must be wire tied back together

and attached to the seat frame. Failure to do this

can cause the connector to get caught in the seat

bracket and rip the wires out of the seat. If this

happens, the tractor will shut down when the brake

Barbed fastener

2. Push the barbed fastener on the seat switch harness

Figure 4.15

is released and the whole seat must be replaced.

out of the hole in the fender.

Body

Screws

Figure 4.16

3. Remove the four socket headed cap screws that hold

the seat tracks to the fender using a T-40 torx driver.

See Figure 4.16.

31

Page 38

2000 Series Tractors

NOTE: On the GTX2154LE:

• Remove the four screws, indicated by the

arrows in Figure 4.17, that hold the seat frame

to the fender using a 7/16” wrench.

• Remove the two screws that hold the rea r of the

fender to the frame using a 7/16” wrench.

On manual deck lift models:

4. Remove the deck lift lever grip. See Figure 4.18.

NOTE: A blow-gun with air pressure regulated to

less than 25 PSI (1.72 Bars), may be

inserted into the small hole at the end of a

rubber grip to inflate it slightly, easing

removal.

Figure 4.17

Grip

On electric deck lift models:

4. Remove the screw that holds the deck cutting

height lever to the shaft using a T40 torx driver.

5. Pull the cutting height lever off of the shaft.

6. Disconnect the deck lift switch.

32

Figure 4.18

Screw

Figure 4.19

Page 39

Tether

Body

7. Unthread the fuel cap.

8. Pull the fuel cap tether retainer out of the fuel tank

using a long pair of pliers. See Figure 4.20.

NOTE: The fuel cap tether is mandated by the EPA. If it is

broken, the fuel cap must be replaced.

Figure 4.20

9. Remove the reverse drive pedal using a 9/16”

wrench. See Figure 4.21.

Reverse pedal

Figure 4.21

Screw

10. Remove the forward drive pedal using a 9/16”

wrench.

Forward

pedal

11. Remove the two screws, one on each side, that hold

the front of the running board to the running board

brackets using a 1/2” wrench.

Figure 4.22

33

Page 40

2000 Series Tractors

12. Gently pry up the rubber foot pad on one side of the

tractor enough to gain access to the screw under it.

See Figure 4.23.

13. Remove the screw using a 1/2” wrench.

14. Repeat steps 10 & 11 on the other side of the tractor.

15. Remove running board brackets by removing the

two screws, indicated by the arrows in Figure 4.24,

that hold each of them to the frame using a 1/2”

wrench.

Rubber foot pad

Screw

Figure 4.23

16. Lift the rear of the fender far enough for it to clear

the fuel tank and slide the fender off of the tractor.

NOTE: If the running board and fender need to be

separated:

• Remove the six nuts and bolt s, indicated by the

arrows in Figure 4.25, that hold the fender to

the running board using a pair of 7/16”

wrenches.

17. Install the fender and running board b y following the

previous steps in reverse order.

NOTE: The seat switch connector on the

G TX2154LE must be wire tied back together

and attached to the seat frame. Failure to do

this can cause the connector to get caught in

the seat bracket and rip the wires out of the

seat. If this happens, the tractor will shut

down when the brake is released and the

whole seat must be replaced.

Figure 4.24

Figure 4.25

34

Page 41

Dash Panel

Body

The dash panel may be removed to provide access to the

tilt steering column, power steering, or to replace the da sh

or dash support brackets.

Cover

1. Remove the steering wheel

1a. Remove the cover from the center of the steer-

ing wheel. See Figure 4.26.

1b. Remove the bolt that holds the steering wheel

to the steering shaft using a 1/2” wrench.

1c. Lift the steering wheel off of the shaft.

2. Disconnect the negative battery cable.

Figure 4.26

Figure 4.27

Choke cable

3. Remove the bowtie clip that holds the control rod to

the cruise/parking brake lever. See Figure 4.27.

4. Slide the control rod out of the cruise/parking brake

lever.

.

Bow tie clip

5. Disconnect the throttle cable from the control panel

on the engine. See Figure 4.28.

NOTE: Mark the cable and the hole it goes into to ensure it

goes back into the proper hole on re-assembly.

6. Disconnect the choke cable from the control panel on

the engine.

Throttle cable

Figure 4.28

NOTE: Mark the cable and the hole it goes into to ensure it

goes back into the proper hole on re-assembly.

35

Page 42

2000 Series Tractors

7. Disconnect the PTO switch. See Figure 4.29.

8. Disconnect the hour meter.

9. Remove the two screws, indicated by the ar ro ws in

Figure 4.30, that hold the left side of the dash to the

dash support bracket using a 3/8” wrench.

Hour meter

PTO switch

Figure 4.29

10. Remove the two screws that hold the right side of

the dash to the dash support bracket using a 3/8”

wrench. See Figure 4.31.

36

Figure 4.30

Screws

Figure 4.31

Page 43

Figure 4.32

Body

11. Remove the two screws, indicated by the arrows in

Figure 4.32, from the bottom of the operators side of

the dash using a 3/8” wrench.

12. Remove the two screws, indicated by the arrows in

Figure 4.33, that holds the base of the left side panel

to the frame using a 1/2” wrench

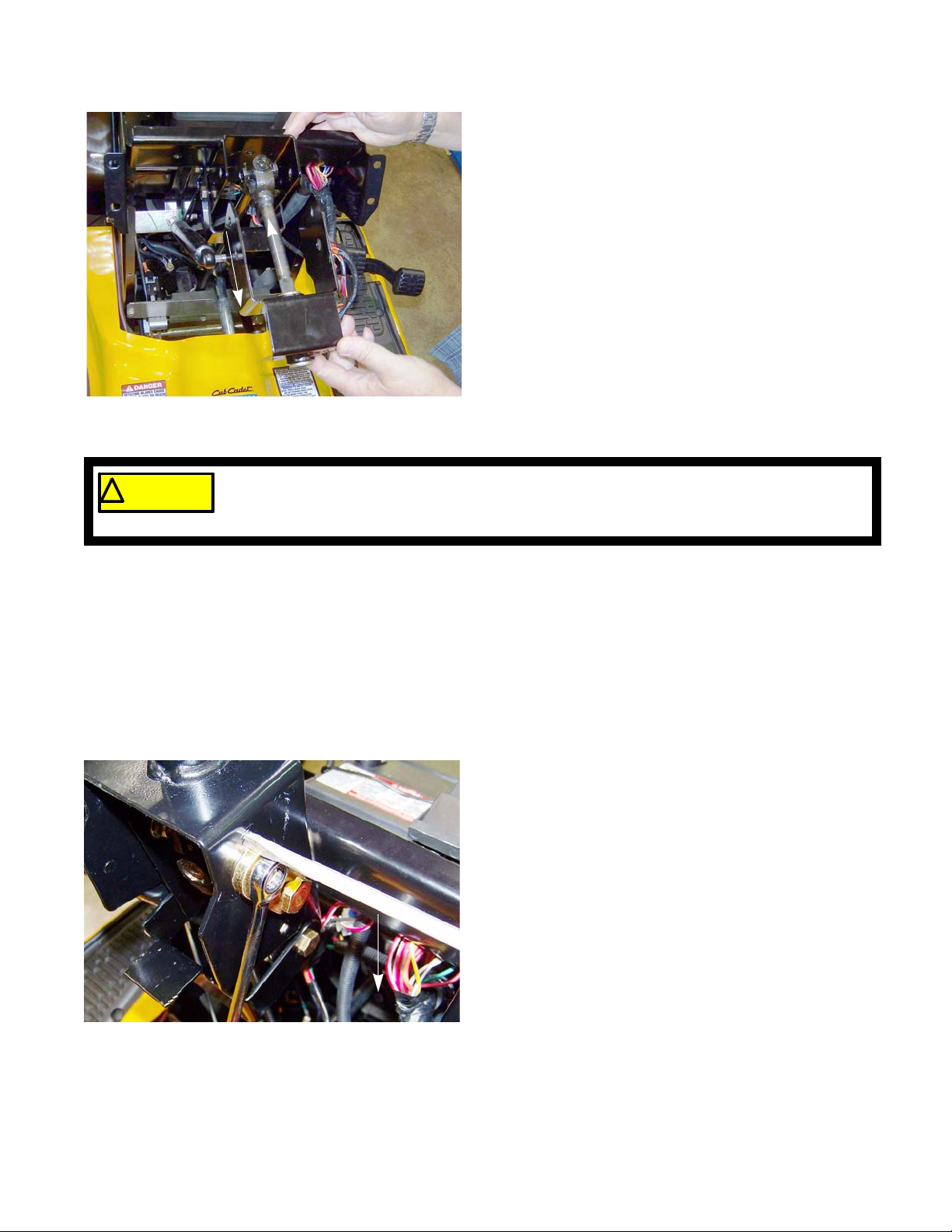

13. Lift up on the dash enough to disconnect the RMC

module and the key switch.

14. Lift the dash panel off of the tractor.

15. Assembly notes:

• Assemble tractor by reversing the disassembly

process.

• Tighten fasteners to a torque of 20-22 in-l bs. (2.25-

2.50 N-m).

Figure 4.33

NOTE: The seat switch connector on the GTX2154LE must be wire tied back together and attached to the

seat frame. Failure to do this can cause the connec to r to ge t cau g ht in th e sea t br acket and rip the

wires out of the seat. If this happens, the tractor will shut down when the brake is released and the

whole seat must be replaced.

• Test all tractor controls and features before return-

ing the tractor to service.

37

Page 44

2000 Series Tractors

38

Page 45

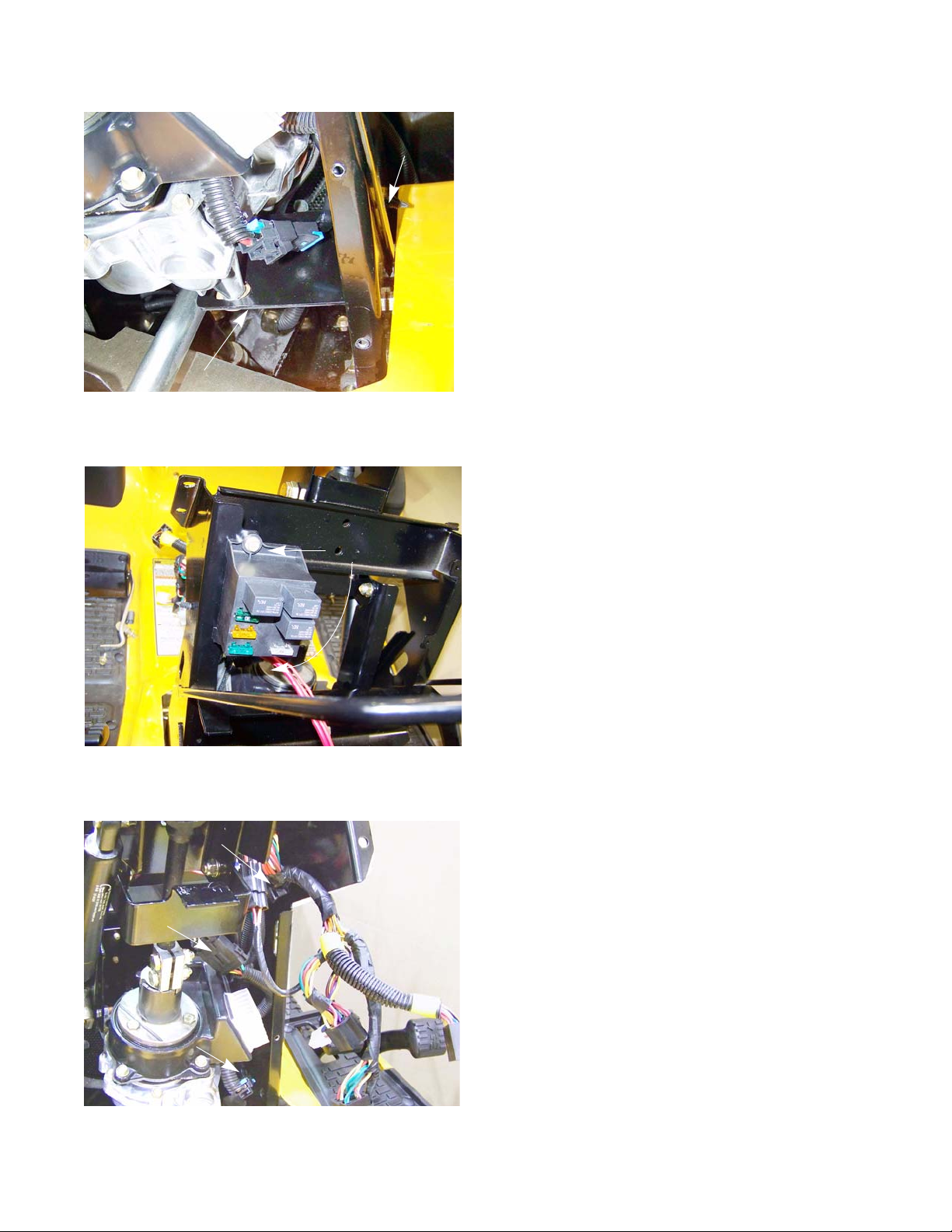

Transmission fluid filter

Anti-sway rod

Drive

CHAPTER 5: DRIVE SYSTEM

The oil filter should be changed every 100 hours.

NOTE: The filter can be changed without draining all of the

transmission fluid.

To change the transmission fluid filter:

1. Remove the deck as described in chapter 8: Cutting

Decks and Lift Systems.

2. Lift and safely support the rear of the tractor.

3. Remove the nut that secures the anti-sway rod to the

transmission torque bracket. See Figure 5.3.

4. Slide the anti-sway rod out of the torque bracket.

Oil filter

Figure 5.1

Figure 5.2

5. Clean around the oil filter to prevent any dirt from getting into the transmission.

6. Place a suitable container under the transmission filter to catch any fluid that may be spilled while changing the filter.

7. Pre-fill a new filter with Cub Cadet Drive System Fluid

Plus oil (#737-3120).

8. Apply a light coating of oil to the O-ring of the new filter.

NOTE: To minimize the amount of oil lost, have the new fil-

ter ready to be installed as the old filter is removed.

9. Remove and discard the oil filter using a suitable

strap wrench. See Figure 5.2.

10. Quickly install the oil filter hand tight.

1 1. Check the transmission oil level by using the dip stick

at the rear of the tractor. Top off as needed.

12. Test drive the tractor in a safe area before returning it

to service.

39

Page 46

2000 Series Tractors

Transmission fluid change

NOTE: The transmission is filled with a high quality,

specially blended oil. It only needs to be

changed if it is contaminated.

To change the transmission fluid:

1. Remove the deck as described in chapter 8: Cutting

Decks and Lift Systems.

2. Lift and safely support the rear of the tractor.

3. Clean the transmission around the drain plug area.

4. Remove the drain plug using a 16 mm wrench.

See Figure 5.1.

5. Remove the dip stick.

6. Remove the oil filter by following the procedures

described in the transmission oil filter section of this

chapter.

7. Install the oil drain plug.

8. Pre-fill a new filter with Cub Cadet Drive System Fluid Plus (#737-3120).

9. Apply a light coating of Cub Cadet Drive System Fluid Plus to the O-ring of the new filter.

10. Install a new oil filter hand tight.

11. Fill the transmission with 182 oz (5.4 L) of Cub Cadet Drive System Fluid Plus (#737-3120)

NOTE: The Cub Cadet Drive System Fluid Plus (#737-312 0) is a synthetic blended oil d esigned specifically for

Cub Cadet transmissions.

12. Purge the transmission while the tractor is still supported off of the ground.:

Drain plug

Figure 5.3

12a. Move the by-pass rod to the by-pass position.

12b. Start the engine.

12c. Cycle the drive pedal from full forward to full reverse six times.

12d. Move the by-pass rod to the drive position.

12e. Cycle the drive pedal from full forward to full reverse six times.

13. Test drive the tractor before returning it to service.

40

Page 47

Drive shaft

Drive

Hydro pump

Figure 5.4

To remove/replace the drive shaft:

1. Remove the deck as described in chapter 8: Cutting

Decks and Lift Systems.

2. Remove the dash by following the procedures

described in Chapter 4: Body.

3. Remove the fender and running board by following

the procedures described in Chapter 4: Body.

4. Remove the four screws that attach the drive shaft to

the hydro pump using a 7/16” wrench.

See Figure 5.4.

Drive shaft

5. Remove the four screws that attach the drive shaft to

the engine using a 7/16” wrench. See Figure 5.5.

6. Lift the drive shaft out of the tractor.

NOTE: There is a spacer between the drive shaft and the

engine.

Drive shaft

Figure 5.5

7. Install the drive shaft by following the previous steps

in reverse order.

NOTE: Apply a small amount of a releasable thread lock-

ing compound such as Loctite® 242 (blue) to the

drive shaft screws.

NOTE: Tighten the drive shaft screws to a torque of 10 -

12 ft lbs (14 - 16 Nm).

8. Test drive the tractor in a safe area before re turning it

to service.

41

Page 48

2000 Series Tractors

Hydro neutral control adjustment

NOTE: Neutral control rarely goes out of adjustment on its own. If it needs adjustment, check for damaged

linkage or signs of tampering.

The tractor’s engine and drive system must be operated to complete this pr ocedure. Confirm

! CA UTION! CA UTION

To perform the hydro neutral control adjustment:

1. Lift and safely support the rear of the tractor.

2. By-pass the seat safety switch. See Figure 5.6.

2a. Slide the seat to the full forward position.

2b. Flip the seat up.

2c. Press in the seat bottom until the tang on the

seat switch is fully extended.

that no hazards will be incurred by running the engine or operating the drive system.

• Work in a well vented area to prevent carb on monoxide poiso ning or asphyxiation.

• Be careful to avoid contact with hot parts or moving parts.

Seat switch

2d. Place a spring clamp on the tang to hold the

seat switch in this position.

3. Disconnect the drive control rod from the hydro

pump by removing the bow tie clip. See Figure 5.7.

Figure 5.6

Bow tie clip

Figure 5.7

42

Page 49

Figure 5.8

Drive

4. Start the engine and advance throttle to maximum

RPM.

5. Release the parking brake.

6. Watch both rear tires for movement.

See Figure 5.8.

NOTE: If there is no wheel movement, the hydro pump is

in neutral and doesn’t need to be adjusted. Skip to

step 14.

NOTE: If one or both rear wheels move, the hydro pump

needs to be adjusted.

To adjust the hydro pump:

7. Turn off the engine.

Drive control rod

Figure 5.9

8. Loosen the two screws, indicated by the arrows in

Figure 5.9, that hold the return to neutral bracket to

the transmission torque bracket using a 1/2” wrench.

9. Start the engine and advance the throttle to maximum RPMs.

10. Move the return to neutral bracket forward or backwards until the wheel(s) stops moving.

11. Tighten the two screws using a 1/2” wrench.

12. Confirm that the adjustment did not shift when the

screws were tightened.

13. Turn-off the engine.

14. Set the parking brake.

15. Loosen the two screws at the front of the drive control

rods using a 3/8” wrench. See Figure 5.10.

16. Adjust the length of the drive control rod so that it

slides freely onto the pin on the hydro selector plate.

Install the bow tie clip.

Figure 5.10

17. Tighten the two screws at the front of the drive control rod using a 3/8” wrench.

18. Lower the tractor to the ground.

19. Test the drive system and all safety features before

returning the unit to service.

43

Page 50

2000 Series Tractors

Trans mission removal/replacement

To remove/replace the transmission:

1. Remove the deck as described in Chapter 8 Cutting

Decks and Lift Shaft.

NOTE: If the transmission is being removed to o pen

it up, drain the fluid at this point by following

the procedures described in th e tra nsmission fluid change section of this chapter.

2. Lift and safely support the rear of the tractor.

3. Remove the nut that secures the anti-sway rod to

the transmission torque bracket. See Figure 5.11.

4. Slide the anti-sway rod out of the torque bracket.

Anti-sway bar

Figure 5.11

5. Remove the brake rod:

5a. Remove the E-ring, bushing and washers

from the right side of the forward drive pedal

shaft. See Figure 5.12.

5b. Slide the drive pedal shaft to the left until it

clears the frame.

NOTE: Let the drive pedal shaft hang there.

5c. Remove the E-ring and washer(s) from the

right side of the brake pedal shaft.

See Figure 5.13.

5d. Slide the brake pedal shaft to the left until it

stops.

E-ring

Drive pedal shaft

Brake pedal shaft

Figure 5.12

E-ring

44

Figure 5.13

Page 51

Figure 5.14

Drive

5e. Disconnect the brake rod from the brake pedal

shaft by removing and discarding the cotter pin.

See Figure 5.14.

Cotter pin

Bow tie clip

Brake pedal shaft

Drive pedal shaft

Control rod

Figure 5.15

Bow tie clip

Brake rod

5f. Pull back on the brake rod and maneuver it past

the brake shaft and forward drive shafts.

5g. Unhook the brake rod from the brake spring.

6. Remove the drive control rod:

6a. Remove the bow tie clip that holds the drive

control rod and spring to the bell crank on the

pedal shaft. See Figure 5.15.

6b. Remove the bow tie clip that holds the drive

control rod to the hydro pump. See Figure 5.16.

6c. Slide the control rod off of the pin.

Figure 5.16

45

Page 52

2000 Series Tractors

7. Remove the by-pass rod:

7a. Remove the bow tie clip. See Figure 5.17.

7b. Slide the by-pass rod out the rear of the trac-

tor.

8. Remove the rear wheels by removing the four lug

nuts that secure each wheel to the hubs using a 3/4”

wrench.

By-pass rod

Figure 5.17

9. Remove the four bolts that attach the drive shaft to

the hydro pump using a 7/16” wrench.

See Figure 5.18.

10. Remove the four nuts and bolts (two on each side)

that hold the torque bracket to the frame using a

pair of 1/2” wrenches. See Figure 5.19.

Drive shaft

Figure 5.18

46

Torque bracket nuts and bolts

Figure 5.19

Page 53

11. Support the transmission with a transmission jack to

prevent it from falling while the mounting bolts are

removed.

Saddle to hold transmission

The transmission is very front

! CAUTION! CAUTION

torque bracket clears the frame.

Use of a transmission jack or a saddle made to fit

this transmission and mounted onto a floor jack will

help prevent this from happening.

Figure 5.20

12. Remove the four bolts that fasten the transmission to the frame. See Figure 5.20.

13. Slide the transmission far enough to the left for the brake assembly to clear the hole in the frame.

heavy and can not be balanced on

a floor jack. The transmission will

fall off of the jack as soon as the

Drive

14. Gently lower the transmission until it clears the frame.

NOTE: The dipstick and dipstick tube should remain attached to the rear of the frame.

15. Remove the transmission from the tractor.

16. Install the transmission by following the previous steps in reverse order.

NOTE: The cotter pin that secures the brak e ro d to the pe d al shaft can be rep lac ed with a bo w ti e clip (71 4-

04040).

NOTE: The upper torque bracket nuts and bolts must be installed with the nuts on the outside. The lower

torque bracket nuts and bolts must be installed with the nuts on the inside.

NOTE: Before lowering the tractor to the ground purge the transmission by:

• Move the by-pass rod to the by-pass position.

• Start the engine.

• Cycle the drive pedal from full forward to full reverse six times.

• Move the by-pass rod to the drive position.

• Cycle the drive pedal from full forward to full reverse six times.

• Check the fluid level and top off as needed.

17. Perform a hydro neutral control adjustment by following the step s described in the hydro neutral contro l adjustment section of this chapter.

18. Test drive the tractor before returning it to service.

47

Page 54

2000 Series Tractors

Forward drive pedal shaft

To remove/replace the forward drive pedal shaft:

1. Remove the deck as described in Chapter 8: Decks

and Lift Systems.

2. Remove the screw that holds the forward drive

pedal to the pedal shaft using a 9/16” wrench.

See Figure 5.21.

3. Unhook the forward drive pedal and remove it.

4. Remove the E-ring and hex bushing from each end

of the drive pedal shaft. See Figure 5.22.

Forward drive pedal

Figure 5.21

NOTE: The right side of the pedal shaft will have

shim washers between the E-ring and the

bushing.

5. Slide the pedal shaft towards the left enough to gain

access to the bow tie clip on the drive control rod.

See Figure 5.23.

6. Disconnect the drive control rod from the drive

pedal shaft’s bell crank by removing the bow tie clip.

NOTE: There is a spring that is att ached to the drive

control rod that is also held in place by the

bow tie clip. See Figure 5.23.

E-ring

Figure 5.22

Bow tie clip

Spring

48

Figure 5.23

Page 55

Reverse switch

Figure 5.24

Drive

7. While holding the drive control rod up and out of the

way, slide the drive pedal shaft towards the left

enough for the bell crank to clear the pin on the brake

shaft’s bell crank.

8. Rotate the drive pedal shaft towards the rear of the

tractor enough for the bell crank to clear the brake

pedal shaft’s bell crank.

9. Remove the drive pedal shaft by sliding it towards the

right enough for it to clear the hole in the frame.

10. If the reverse switch is mounted on the drive control

rod, disconnect it. See Figure 5.24.

NOTE: The reverse switch was moved to the transmission

for the 2012 model year.

11. Install the drive pedal shaft by following the previous

steps in reverse order.

12. Perform a hydro neutral control adjustment by following the procedures described in that section of this

chapter.

13. Test drive the tractor in a safe area before re turning it

to service.

49

Page 56

2000 Series Tractors

Reverse drive pedal shaft

To remove/replace the reverse pedal shaft:

1. Remove the deck as described in Chapter 8 Cutting

Decks and Lift Shaft.

2. Remove the screw that holds the reverse pedal to

the pedal shaft using a 9/16” wrench.

See Figure 5.25.

3. Unhook the reverse pedal and remove it.

4. Remove the E-ring and washer from the right side of

the forward pedal shaft.

Reverse pedal

Figure 5.25

5. Disconnect the spring from the bolt in the reverse

pedal channel. See Figure 5.27.

E-ring

Figure 5.26

Spring

50

Figure 5.27

Page 57

Figure 5.28

Drive

6. Remove the E-ring and washer from the reverse

pedal shaft. See Figure 5.28.

7. Slide the reverse pedal towards the right while sliding

the forward pedal shaft left far enou gh for the nut and

bolt of the roller to fit between the frame and the forward pedal’s bell crank.

E-ring

Reverse shaft bell crank

Figure 5.29

´

Forward shaft bell crank

´

8. Rotate the reverse shaft until it s bell crank and r ollers

drop below the bell crank on the forward shaft.

See Figure 5.29.

9. Remove the hex bushings.

NOTE: The split hex bushing on the outboard side will be

difficult to pry off.

10. Slide the reverse shaft out of the frame.

11. Install the reverse pedal shaft by following the previous steps in reverse order.

NOTE: The split hex bush can be shorted to make it easier

to install.

´

1(:

12. Test drive the tractor in a safe area before re turning it

to service.

´

02',),('

Figure 5.30

51

Page 58

2000 Series Tractors

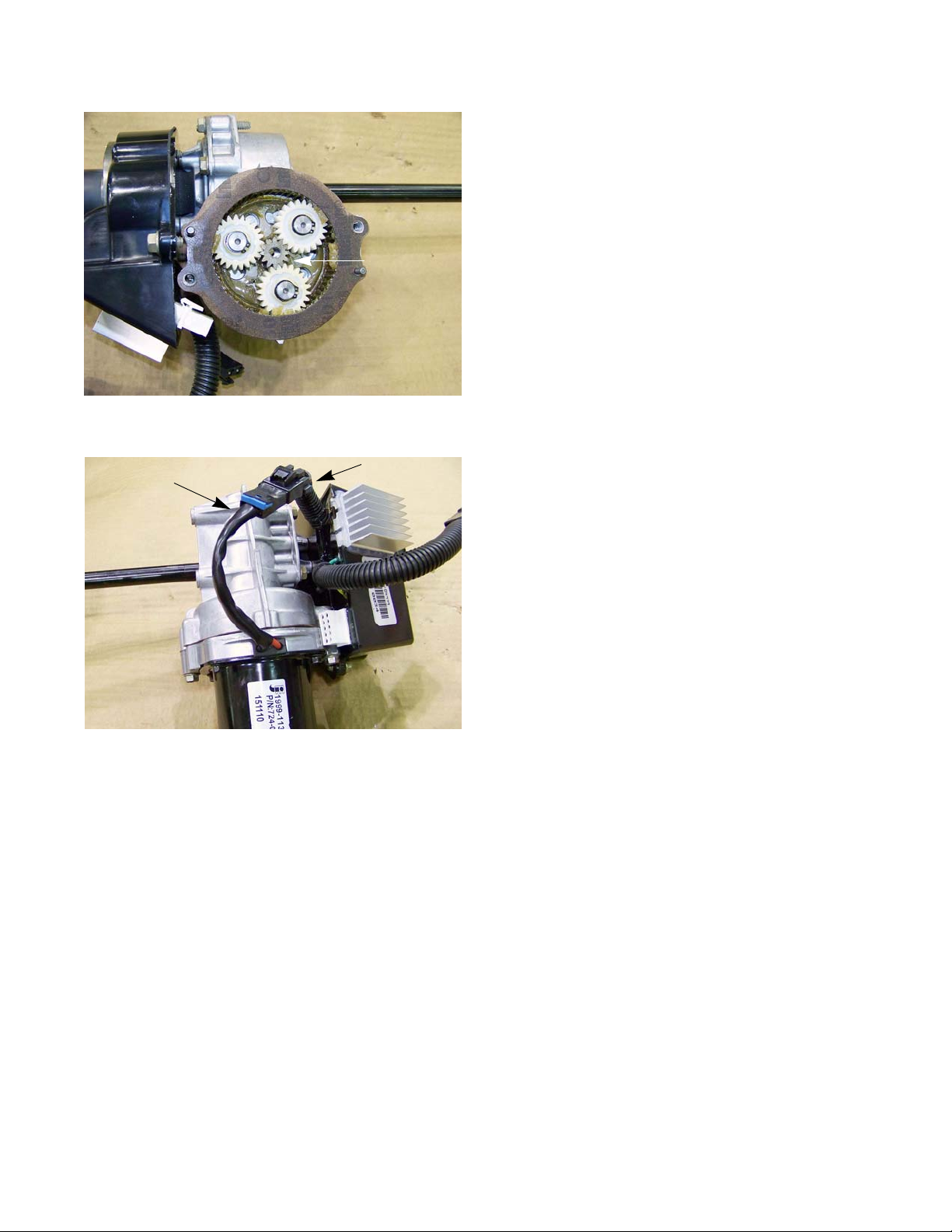

Transmission Disassembly

NOTE: The transmission used on 2000 series trac-

tors is driven by a Hydro-Gear BDU-10L-225

pump. The service procedures for that pump

are available in Hydro-Gear service manual

BLN-50327.

1. Drain the oil from the transmission: See Figure 5.31.

1a. Clean the transmission around the drain plug

area.

1b. Remove the drain plug using a 16 mm

wrench. Leave the drain plug out.

2. Remove the transmission assembly by following the

procedures described in the transmission removal

section of this chapter.

Drain plug

Figure 5.31

3. Disconnect the hydraulic pick up tube to the back of

the BDU-10L using two 11/16 in. wrenches. See

Figure 5.32.

4. Remove the hex cap screw securing the hydraulic