Page 1

Hydrostatic Zero-Turn

0

Commercial Riding Mower

Professional Turf Equipment

MODEL

19HP Tank, 53BB5DAV150

20HP Tank, 53AB5E6V150

23HP Tank, 53BB5DBW15

24HP Tank, 53AB5ETW150

25HP Tank, 53AB5D8X150

27HP Tank, 53AB5BDX150

28HP Tank, 53AB5FEZ150

OPERATOR’S AND SERVICE MANUAL

Page 2

TABLE OF CONTENTS

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A.Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B.Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C.Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A.General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B.Related to Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C.When Mowing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

A.General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B.Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C.Initial Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

D.Zero Turn Break-In and Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance and Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 4

A.Mower Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

B.Hydraulic Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

C.Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D.Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

E.Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

F.

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

G.Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

A.High Speed Tracking Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

B.Engine RPM Check and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C.Deck Corner Ball Wheel Roller Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D.Deck Center Anti-Scalp Roller Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

E Lap Bar Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

F Deck Leveling Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warranty

This product may be covered by one or more of the following patents:

D409,208; 5,946,894; 6,070,690; Pending

2

Page 3

FORWARD

The Tank Hyd rostatic Zero-Tur n Commer cial Ridi ng Mower provides super b maneuverability,

mid-mount cutt ing capability for professional landscapers, commercial lawn ser vice companies, professio nal t urf man agers a nd gol f cour se su perin tendent s. The mac hine in cor po rates

many safety features that should be studied by all operators and maintenance personnel

before use. The list of safety precautions should receive particular attention.

This manual presents all of the operating and mai ntenance instruc tions necessar y to keep

your mower at peak efficiency. If operated and maintained properly, your mower will give

dependable service.

CAUTION:

Only thoroughly trai ned persons should operate and maintain this

mower. This machine can cause serious injur y to anyone who misuses it and does not understand its operation. For their personal

safety, all operators and maintenance personnel are required to

read this entire manual before operating the mower.

Hazard control and accident prevention are partially dependent

upon the design and configuration of the equipment. Not withstanding, these factors are also dependent upon the awareness, concern,

prudence and proper training of the personnel involved in the operation, transport, maintenance and storage of the equipment.

3

Page 4

GENERAL SAFETY

OPERATIONS

A. DANGER

1. Do not operate machine in con fined areas

where exhaust gases can acc umulate.

2. Do not operate machine without mower c hut e

deflector in place and operational.

3. Do not carry pas se ngers.

B. WARNING

1. Do not operate machines under the influence

of alcoh ol or drugs.

2. Do not operate machines wi th out all guards

and safety devices in place and functional.

3. Do not start machines if there are fuel or oil

leaks or spillage — clean it up.

4. Do not operate machines near spilled or leaking fuels .

5. Do not stop or park machine ov er dry leaves,

grass, debris, etc. that could be comb ust i ble.

6. Use extreme care wh en backing up.

7. Do not operate machine on slo pes greater

than 15 de grees (27%).

8. Do not operate machines on slopes when

tractio n i s reduced (wet gr ass, ice, sof t

ground , l o ose grou nd , l eaves , pi n e needle s ,

debris, etc.).

9. Avoid turning dow nhill if possible, go slowly

and use extra care when turning downhill.

10. Do not operate machines durin g reduce visibility (low light, fog, rain, etc.).

11. Do not operate machines wi th non-approv ed

attachments.

12. Do not operate machines that are dam-

aged... .. have mach i ne repaired.

13. Do not operate machines that have not been

properly maintained.

14. Use onl y repla cem ent p arts that a re th e sam e

or equiv alent to the original eq ui pment.

15. Do not mod ify m ach i nes or any of their c omponents, especially the engine gov ernor!

16. Do not oper ate ma chine f or mor e than 2 hours

without hearing protection.

C. CA UTION

1. Use proper protective equip m ent when operating machine (gloves, boots, and hearing

protect ion are recommended).

2. Read entire machine Operator’s Manual.

3. Make sur e operators are full y trained in the

safe use of the machine.

4. Follow all safety instructions when using the

machine.

5. Keep al l safety signs legible and pr operly

installed.

6. Do not check for hydraulic l eak s with any pa rt

of the body.

7. Do not add f uel to a mac hine when the en gine

is running and/ or t he exhaust sy st em i s hot.

8. Keep m achine c lean and f ree o f de bris , g r ass ,

leaves, oil, grease, etc.

9. Place lap bars in neutral/start position, set

park brake, disengage P.T.O., turn engine off,

and remove ignition k ey before you dismount

from machine.

10. Use machines laterally or diagonally across

slopes, avoid going downhill when possible.

11. Go slowly and use extra care when descending slopes .

12. Disengage P.T.O. when crossing surfaces

such as asphal t, co ncrete, loose ground,

sand, gravel, etc .

13. Use extra care when loading and unloading

machines from trucks or trailers.

SAFETY PRECAUTIONS

A. General

1. Read this Operator’ s Manual before starting

the mower. Study the controls and learn the

proper sequence of operation.

2. Do not allow anyone to op erate or maintai n

this ma c h ine who has not re ad this ma nu al .

Never pe rmit children to operate this machine.

3. Never carry passengers.

4. Do not remo ve any shields, guard s or safety

devices. If a shield, guard or safety device is

damaged or doe s not function, repai r or

replace it be fore opera ting the mower.

5. Always wear saf ety glasses and safety shoes

when oper atin g or ma intai ning this mo wer. Do

not wear loose-fitting cloth i ng.

6. Disconnect the spark plug wi res and remove

the key from th e igniti on to prevent th e engi ne

from accident al l y st arting before perf orming

any maint enance on this mower.

7. Never run the engine indoors without adequat e ve ntilation. E xhaus t f um es are de a dl y.

8. To avoid serious burns, do not touch the

engine, exhaust pipe or muffler while the

engine is running or until it has cooled after it

has been shut off.

9. The liquid in the battery is dilute sulfuric acid.

Alway s wear saf ety glas ses and rub ber glo ves

when working on the battery. Do not overfill

the battery.

10. Lead-acid batteries generate hydrogen and

oxygen gases which form an explosive mixture. Keep sparks and flam es awa y at all

times.

4

Page 5

11. When looking for oil leaks, never run your

hand over hydraulic hoses, lines or fittings.

Ne v er tighten or adju st hydraulic hoses, lines

or fittings while the system is under pressu re.

If high-pre ss ure oil penet rate s the s kin , the oil

must be rem oved withi n a few hours by a doctor familiar with this form of injury or serious

complications may result.

B. Related to Fuel

1. Fuel is hig hly f l am m able and its vapors can

expl ode if ignited. Plea se respect it.

2. Do not smoke or permit others to sm ok e

while handli ng fuel.

3. Always use appro ved contai ners for fuel and

fill slowly to decrease the chance of static

electricity buildup and spillage.

4. Store fuel in well ventilated and unoccupied

buildi ngs away from sparks and flames.

5. Wh e n di spen si ng gaso l i ne into approved containers, place the contai ner on the ground

when refueling to av oi d a possible static el ec tricity ignition of fuel vapors.

6. Do not fill c ontainers whil e it i s inside a vehicle, trunk, the bed of a pickup or f l oor of a

trailer .

7. Always shut off the en gi ne and permit it to

cool before removing the fuel tank cap.

8. Always fill the fuel tank outdoors.

9. If the fuel container spout w ill n ot fit inside the

fuel tank op eni ng, use a funnel.

10. When filling the fuel t ank, s t op when the fuel

reaches on e inc h from t he top. This space i s

necessary for tank expansion.

11. Wipe up any spilled fuel.

Do not overfill

C. When Mowing

1. Keep adults, chil dren and pets aw ay from the

area to be mowed.

2. When oper ating this mower in the fo rward

direct ion, DO NOT allo w t he st eerin g levers to

return to the neut ral position on their own.

Always maintai n a firm gri p on t he l evers,

opera te them smooth l y and avoid any sudden

movements of the levers when starting or

stopping.

3. If the mower is equipped for side discharge,

nev er us e the m ow e r with out the di scha rge

chute insta lled and plac ed in the do w n posit ion .

4. Always rem ove debris an d ot her objects from

the area to be mo we d.(

grass will reduce traction.)

5. Mow only in daylight.

6. Watch for holes, sprinkler heads and ot her

hidden haza rds.

7. Avoid driving too close to trees, creeks,

ditches, sand traps and other obstacles.

8. Before backing up, check behind you and

watch where you’re going.

9. Always reduce speed when making a turn,

and when grass is wet.

10. Always mo w across slopes , never up and

down the slope. Do not oper ate on steep

slopes and slow down before turning.

11. Be careful when c rossing gra vel paths or

roadways. Always turn off the blade clutch

switch and wait until the b lades stop rotati ng

and raise the c utting deck to the transport

position. Always allo w other vehic l es t o have

the right-of-way.

12. If you hit a solid object while mo wi ng, turn off

the bl ade c lutc h s witc h, pla ce the le ft and ri ght

steering levers in the neutral, opened-out

position, move the throttle to slow, set the

parking bra k e, shut off the engine and take

the key fr om t he i gnition swit ch. Inspect fo r

damage. Repair any damage. Make sure the

.

blades ar e in good condition and t hat the

blade bolt s are tight before restarting the

engine.

13. Never leave the mower unat tended without :

turning off th e blade clutch switch; placing the

left and right st eeri ng levers in the neutral

opened-ou t po sition; moving t he t hrottle to

slow; setting the parking brake; shutting off

the engi ne an d tak ing the k e y f rom th e ig niti on

switch.

14. Never walk or st and on the dis charge s ide of a

mower with the engine running. Turn off the

blade clut c h switch if anot her person

approaches while you are op erating the

mower .

15. Never attempt to operate the traction un it

without the mowing deck attached.

16. Keep the mower and especially the engine

and hydraulic components clean and free of

grease, grass and lea ves to reduce the

chance of fire and to permit proper cooling.

Note

: debris and l oose

5

Page 6

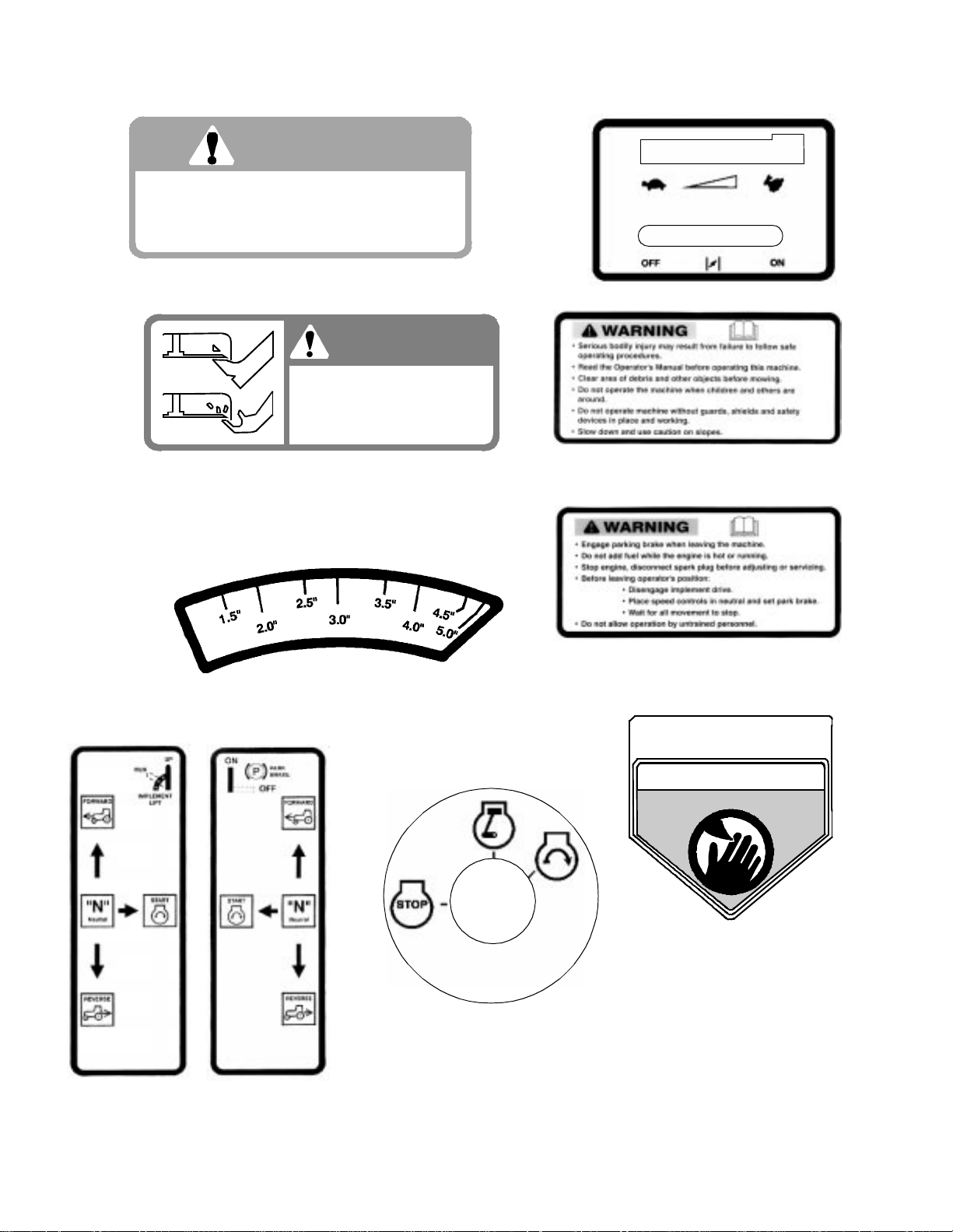

SAFETY DECALS AND LABELS

WARNING

SHIELD MISSING

DO NOT OPERATE

Part Number: 00030635

Part Number: 00030633

Part Number: 01003859

DANGER

ROTATING BLADE

Do not put hands or feet

under or into mower when

engine is running.

Part Number: 01003858

Part Number: 01003449

Part Number: 01003450

TO REDUCE THE RISK OF INJURY,

DO NOT OPERATE MOWER UNLESS

DISCHARGE C HU T E COVER OR G R AS S

CATCHER IS IN ITS PROPER PLACE.

Part Number: 01002166

Part Number: 01003451

DANGER

KEEP HANDS and FEET AWAY

Part Number: 01003857

Part Number: 01003452

6

Page 7

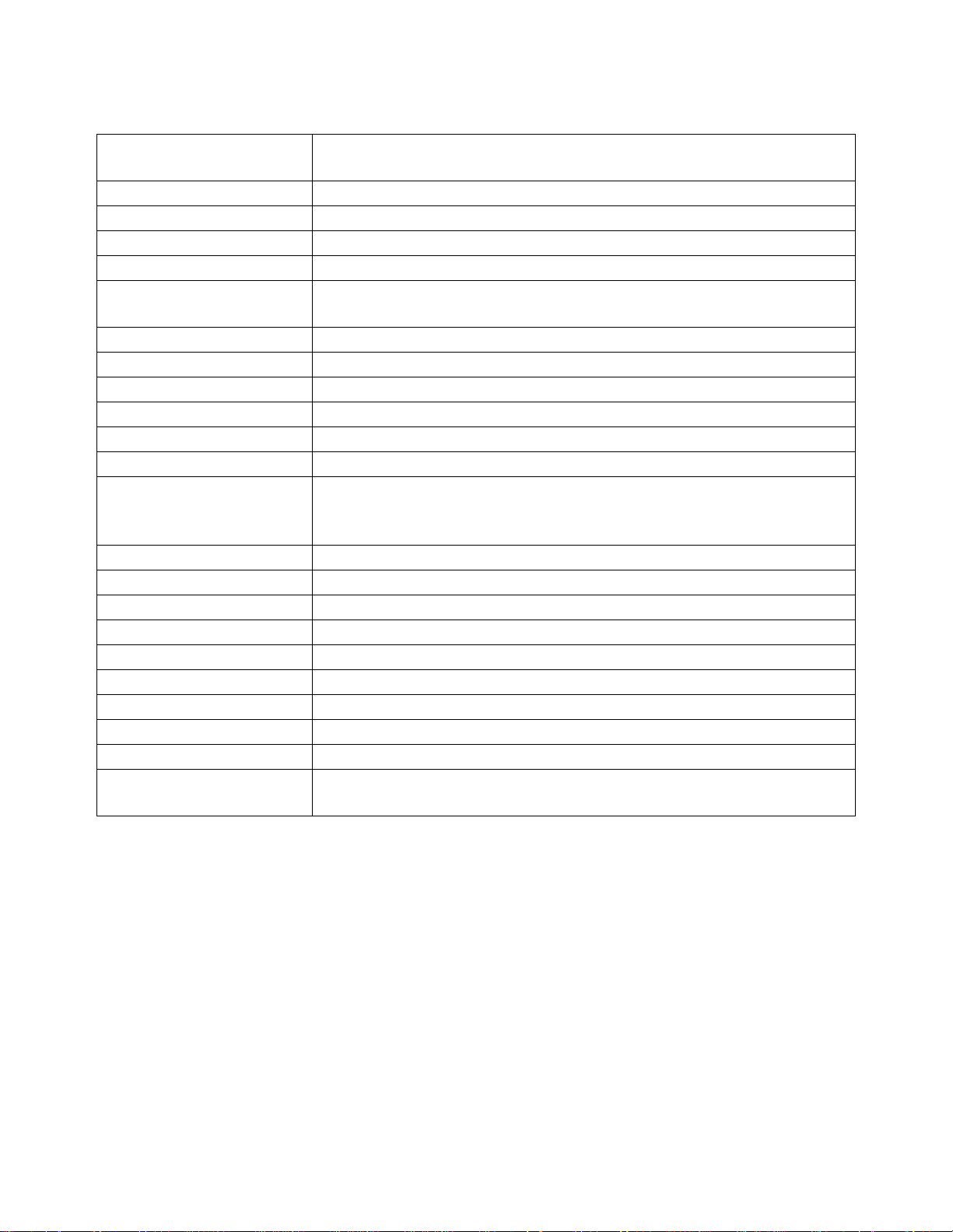

SPECIFICATIONS

Engine: 19HP Kawasaki, 20HP Honda, 24HP Honda, 23HP Kawasaki,

25HP Kawasaki, 27HP Kohler, 28HP Generac

Type: Vertical air cooled V-Twin

Air Cleaner: Paper Element

Lube System: Pressurized with oil filter

Starter: 12-volt electric

Traction Drive: Engine to two variable-speed hydraulic wheel motors on each

drive wheel

Hydraulic Tank: 10 quart capacity, One quart filter

Cutter Deck;Drive: 48", 54", 60", & 72” Belt Driven

Clutch: Electric

Deck Lift: Hand lever w/pin lock for height adjustment

Cutting Height: 1-1/2" to 5"

No. of Blades 3, belt-driven, power take-off from engine

Controls: Engine ignition and start switch; throttle; choke; left and right

steering le ver s; ele ctric blade clutch s witch; parki ng br ake; mo wer

deck lift

Parking Brake: Mechanical linkage attached to the brake handle

Front Caster Wheels: 13 x 6.50 x 6

Tire Pressure: 8-10 psi Rear, 20-25 psi front caster

Drive Wheels: 60" deck & 72” deck, 24x12 - 12

Frame: 2" Steel square tube and plate, all welded construction

Seat: Adjustable seat with armrests. 5" Adjustment

Fuel Tank: Two 6.5 gallon w/individual shutoff valves

Ground Speed: 0-10 + MPH forward. 0-4 MPH reverse

Instrumentation Hour meter, Tachometer, Maintenance-minder

Net Weight: 950 lbs w/48" deck, 980 lbs. w/54" deck, 1070 lbs. w/60" deck,

1330 lbs w/72” deck

7

Page 8

OPE RATIN G IN ST R U CT ION S

Figure. 1 Figure. 2

Electric Blade

Clutch Switch

Ignition Switch

Tach and

Hour Meter

A.General

1. When Mo wi n g:

a. Keep adults, children, and pets away from

the area to be mowed.

b. When operating this mower, in the forward

direction, do not allow the steering levers

to return to Neutral on their own. Always

maintain a firm grip on the levers , operate

them smoothly and avoid any sudden

movements of the lev ers when s tarting and

stopping.

c. If the mower is equipped for side dis-

charge, never use the mower without the

discharge chute installed and placed in the

down position.

d. Always remove debris and other objects

from the area to be mowed (Note: debris

and loose grass will reduce traction).

e. Mow only in daylight.

f. Wat ch f or holes, sprinkler heads, and other

hidden hazards.

g. Avoid driving too close to trees, creeks,

ditches, sand traps, and other obstacles.

h. Before backing up, check behind and

watch where you are going.

i. Always reduce speed when making a turn,

and when grass is wet.

j. Always mow across slopes, never up and

down the slope. Do not operate on steep

slopes and slow down before turning.

Avoid tur ning downhill if possible, start at

the bottom and work up to the top. Use

extra care and go slowly when turning

downhill.

k. Be careful when crossing gravel paths or

roadways. Always turn off the blade clutch

switch and wait until the blades stop rotat-

Engine throttle

Choke Lever

ing and raise the cutting deck to the transport position. Always allow other vehicles

to have the right of way.

l. If you hit a solid object while mowing, turn

off the blade clutch switch, place the steering levers in the neutral, opened-out position, move the throttle to slow, set the

parking brake, shut off the engine, and

take the key from the ignition switch.

Inspect for damage. Repair the damage.

Make sure the blades are in good condition

and that the blade bolts are tight before

restarting the engine.

m. Nev er leave t he mower unattended without

observing the following: turn off the blade

clutch switch, placing the steering levers i n

the neutral open-out position, moving the

throttle to slow, setting the parking brake,

shutting off the engine and taking the key

from the ignition switch.

n. Never walk or stand on the discharge side

of the mower when the engine is running.

Turn off the blade clutch switch if another

person approaches while you are operating the mower.

o. Never attempt to operate the traction unit

without having the mowing deck attached.

p. Keep the mower and especially the engine

and hydraulic components clean and free

of grease, grass, and leaves to reduce the

chance of fire and permit proper cooling.

2. Safety Awareness when Mowing

a. Do not operate on steep slopes, those

above 15 degrees (27% slope).

b. Avoid turning downhill if possible, if not use

extra care and go slowly.

8

Page 9

c. Avoid turning when going downhill, traction

is at a minimum going downhill.

d. Do not operate with discharge side of the

mowe r toward st reets, buildings, p l ay-

grounds, parking lots, other machines, ani-

mals, and other people.

e. Avoid operation or use extreme care if the

traction surface is wet, unstable, or slip-

pery.

f. Use extra care when grass clippings,

leaves, pine needles, or debris are present

as traction can be reduced.

g. Slow-down before turn ing and come to a

complete stop before any zero t urn maneu-

ver.

h. Do not stop machine or park machine over

combustible materials such as dry grass,

leaves, debris, etc.

3. To Mow Grass and Produce a Striped P attern

a. Pick a point on the opposite side of the

area to be mowed (post, tree, shrub, etc.).

b. If on an hillside, star t at the bottom so that

the turns are uphill rather than downhill.

c. Align the mower so as to head directly

toward the object on the far side.

d. Slowly increase the speed of the machine

to match cutting conditions, terrain, and

operator familiarity with the controls and

keep the machine headed directly toward

the alignment object. Do not go fast as to

reduce cut quality or to be uncomfortable

in controlling the speed and direction of the

machine.

e. When approaching the other end of a strip,

slow down or stop before turning. A U-turn

is recommended unless a zero turn is

required. The speed of a U-turn that will

allow for machine controllability and minimal turf defacement will be dependent on

several factors including: the speed of the

turn, the radius of the turn, the tire tread

pattern, the traction coefficient of the tire to

the traction surface, the slope of the traction surface.

f. Remem ber, a zero turn requires that the

forward or reverse travel of the machine be

stopped prior to the initiation of the turn or

severe turf defacement can occur.

g. To prevent rutting or grooving of the turf,

change the direction that the strips are

mowed by approximately 45 degrees the

next and each subsequent time that the

area is mowed.

B.Controls

Engine Ignition and Start Switch:

1.

ure 1.) Located on the instrument housing

below the rig ht side of the operator’s seat.

When the key is inserted and turned clockwise, 45 deg ree s, the ign itio n ci rcuit is cl osed.

Turning the switch fu rther aga in st spring pressure starts the engine. The engine will only

start if the blade clut ch switch is in th e “off”

position, the parking brake is engaged and

the left and right steeri ng lever s are in the

neutral, opened-out position. The ke y sh ould

always be re m oved from the swit ch if the

operator l eaves the m ower’s seat.

Engine Throttle Control:

2.

Located on th e left side of the mow er next to

the operat or’s seat. Mo ving th e thr ottle cont rol

from the rear to the front will increase the

engine spee d fr om slow to fast.

Left and Right Steering Levers:

3.

3.) These hinged le ve rs ope n out to the sid e in

the neutral position to permit the operator to

be seated or to leave the mower’s seat. The

operator, when seated, can pull the levers up

to the operating position, a comfortable forearm’s length away. These levers control all of

the movements of the mower. Pushing both

lev ers forward causes the mower to move forward. Pulling both lev ers bac k causes the

mower to move bac k ward. Pushing one lever

ahead of the ot her lever cau ses the traction

wheel on the side where the lever is ahe ad t o

rotate f aster than the other traction wheel,

making the mo we r tu rn tow ard t he side w here

the le ver is behind. When on e l ever is pushed

forward and the other l ever pulled back the

same amount, one traction wheel will turn in

reverse a nd the mower will turn within its own

length.

In order to start the engine, both steering

lev ers must be opened out to the side in the

neutral position; the parking brake must be

engaged; and the blad e clu tch s w itch m us t be

“off”. However, once the engine starts, the

parking bra k e must be release d before the

operator pl aces the steering levers in to the

operating position or the engine will

automatically shut off.

Note:

neutral when released, but they should be

placed in neutral b y the driver. If the Drive

Handles are not placed in neutral, the tractor

may creep.

(See Fig-

(See Figure 2.)

(See Fi gure

The Steering Le ver will return tow ard

9

Page 10

Steering Levers

Deck Lift Handle

Brake

Note: The 19hp

and 23hp use the 5

gallon fuel tank.

Figure. 3

Electric Blade Clutch Switch:

4.

(See Figur e

1.) Located on the right side of the mower

beside the i gnition swit ch . Thi s i s an “on/off”

push pull switch that controls the electric

blade c l ut ch which supplies po wer to the cutting b lades through the PT O. The switch must

be turned off to start the engi ne and should

be turned off for safety any time another person approaches the mower or the mowing

deck is raised to the tr ansport position. Power

to the electric clutch will also be cut off if the

opera to r leaves the operator’s seat.

Parking Br ake :

5.

(See Figure 3.) Located on

the left side of t he traction unit. Th e handle is

an ov ercenter le ver which ap pl i es the drumtype brake on each drive w heel when the handle is pulle d to the rear. The brake mus t be

engaged in order to start the engine.

Deck Lift Handle and Foot Pedal Lift

6.

Assist:

(See Figur e 3.) Located on the right

front corner of t he mowing deck . Raise the

mowing deck to the transport position, by pulling the lever to the rear and moving it inward

into the stop for transport. To lower the mowing dec k, pul l the deck lift handle and move it

outward. This lower’s the deck to the cutting

position .The foot pedal lift assist (n ot pictured

above) can provi de “li ft assist” to the ha nd

lever or with “foot effort only”. To provide

assistan ce to the lift handle: re m ove the

detent pin f rom t he pedal assembl y. Fold the

pedal down to the horizontal position so the

hole in the pe dal al i gns with the hole in the

lever. Re-install the det ent pin. Pull on the Li ft

handle an d de pres s the f oot p eda l to r ais e the

deck. Lifting with “foot effort only” depress the

foot pedal (the hand lev er will lock into transport position if f ully depres sed). To relea se the

lift mechanism depress the foot pedal, move

the hand l e v er out wa rd a nd slo w ly red uc e f oo t

pedal effort to lower the m echanism. To service the unit: Remove the detent pin from the

Figure. 4

Fuel Shutoff Valve

pedal assembly. Fold the pedal up to vertical

position so the hol e i n t he pedal aligns with

the hole in the lever. Reinstall the detent pin.

This is the requi red position for the foot pedal

for the foot platform to tilt forward and to

access some of the machines components.

Fuel Shutoff Valve:

7.

(See Figur e 4.) Located

on top of the fuel tank(s). When tu rned in a

clockwise direction until it stops, it will shut off

the flow of fue l to t he engine. When tu rned in

a counterclockwise direction it will open and

allow fuel to flow to the engine. Close thi s

valve if you are not going to run the mower for

a period of 30 minutes or more to pre vent

flooding the engine.

Seat Adjustment Lever:

8.

The Seat Adjustment Le ver is located beneath the seat. The

Seat Adjustment Lever is used to move the

seat fo rward and backward. To place the seat

in the desired position pull the seat adjustment lever to the left then push the seat forward or back to the desired position. Release

the lever so the seat will lock in place.

Digital Tachometer and Hour Meter:

9.

Figure 1) Located on the right side of the

mower in front of the igni tion s witch. When the

machine is running the tachometer displays

engine rpm. When the m achine is off the

tachometer displays running time.

Choke Lever:

10.

(See Figure 2) The Choke

Lever is located on the left instrumen t pa nel

next to the se at. The Chok e Lever is oper at ed

manually. Having t he Choke Lever in the ON

position h el ps the engine to start during initial

start-up. During normal operation the Choke

Lever should be in the OFF position.

Note:

each recommended lubrication int erval. There

is a flashing “OIL” at each recom m ended

engine oil and filter change.

There will be a flashing “LUBE” for

(See

10

Page 11

C.Initial Adjustments

1. Chec k th e fluid levels and ti res:

Note:

before starting the engine.

a.

b.

Note:

SAE 10W40 engine oil, rated for service SJ.

c.

d.

These checks should be made daily,

Fuel:

Using a good grade of unleaded,

regular gasoline (for a gasoline engine), fill

the fuel tank (beside the engine on the left

or right side of the mower). When the fuel

reaches one inch from the top of the tank,

stop. DO NOT OVERFILL. Space must be

left for expansion.

Engine Oil:

(Filled at the factory before

shipment.) Pull out the oil dipstick, wipe it

off and reinsert it. Pull it out again and read

the oil level. If it is below the operating

range, add oil through the fill tube using a

funnel to bring it up to the top of the operating range.

Gasoline Engine: Use SAE 10W30 or

Hydraulic Oil:

(Filled at the factor y before

shipment.) The hydraulic oil tank is located

beneath the operator’s seat. Always wipe

off the area around the oil tank fill neck

before checking the oil level to prevent dirt

from contaminating the oil. Remove the

cap and make sure the oil level is up to the

lowest hole on the oil tank fill neck. The top

hole is for venting. If the oil level is low, fill

with a good grade of SAE20W-50 oil.

Tires:

8-10 psi Rear, 20-25 psi Front

Caster Tires

the procedur es below to set the appropriate

angle to the mowing deck.

a. Park the mower on a flat paved surface,

engage the parking brake, shut off the

engine, remove the key from the ignition

switch, remove connection of the spark

plugs and using the transport lever, lower

the mowing deck into the cutting position.

b. Using a ruler, pencil and paper, measure

and note the distance from the paved surface to the bottom edge of the mowing

blade at the front and the back of the deck

on each side of the mower. (Four dimensions.)

Note:

should be 1/8"-1/4" below the rear edge of the

deck so that the blades are cutting grass in

only the front half of their circular path. This

decreases fricti on and reduces the drive

power required.

The front edge of the mowing deck

c. If the dimension at the front of the mowing

deck is 1/8"-1/4" lower than the dimension

at the rear of the deck on each side of the

mower, do not adjust. If not, you will need

to adjust the Deck Lift Spring Assist (See

Figure 5). You may also need to adjust the

Deck Links (See Figure 5).

Deck Lift Spring inner nut

Note:

properly seat the bead to the rim. The normal

working pressure for the traction tires is 8-10

psi. The front caster wheels should be i nflated

to 20-25 psi.

New tires are overinflated in order to

2. Check that all Nuts, Bo l ts and Screws ar e

Tight.

3. Check the tension of the deck drive b elts.

a. Remove the deck cover

b. The tension of the deck drive belts are

maintained by a spring mechanism that

adjusts for wear and stretch.

c. Examine the belts for cuts, fraying, and

excessive wear. Replace if any of these

are detected.

d. Replace the deck cover.

Adjust the Mowing Deck:

4.

The cutting height

is set any where in the range of 1- 1/2" to 5".

You may need to adjust the mowing deck to

achie ve the prop er angle for mowing. Fol l ow

11

Figure. 5

Deck Li nks

d. Lower the mower deck to the cutting posi-

tion. With a wrench loosen the inner rear

nut on the Deck Lift Spring Assist. To

adjust the deck up or down, use a wrench

and with a few turns, adjust clockwise or

counter clockwise the outer rear nut of the

Deck Lift Spring Assist. Repeat this procedure on the opposite side of the Mower.

Once the deck is adjusted, retighten bolts.

e. With the deck still in the cutting position,

adjust the Deck Links. With a wrench

loosen the top inner bolt of the Deck Link.

To adjust the side of the deck up or down

turn the top bolt clockwise or counter

Page 12

clockwise a few turns. Adjust both front

and rear Deck links as necessary.

Retighten nuts.

f. Raise the mowing deck to the transport

position using the transport lever.

g. Use the transport lever to lower the mow-

ing deck to the cutting position and repeat

step “b.” above to make sure that the

desired cutting height has been attained. If

the dimensions are not correct, repeat

steps “c.” through “f.” abov e.

5. Lubricate all fittings li sted in the maintenance section.

D. Zero Turn Break-In And Operating

Procedures

DANGER:

Reread the “When Mowing” Safety Precautions.

The following procedures are suggested for operators of ride-on machines which have zero turn

capabilities.

1. Orientation:

a. Read the entire Operator’s Manual.

b. Sit on the machine, adjust the seat before-

and-after, then adjust the speed/directional

(lap bar) controls (they can be adjusted

before-and-after , as well as up-and-down

— 9/16" wrench required).

c. Become familiar w it h all o f th e ma ch ine

controls, instrumentation, safety and

instruction signs, and safety devices.

d. Move (or have moved) the machine to a

safe, level area with no obstructions including objects, pedestrians, and animals.

2. Initia l Ope rat ion :

a. Use protective equipment for eyes, hands,

hearing, feet, legs, head and other areas of

the body if needed — safety eye glasses,

gloves, earplugs, boots, hats, etc.

W ARNING:

Hearing Protection is required for all operator

exposure exceeding two (2) hours.

b. Ensure that the area is free of animals and

bystanders, especially children!

c. Survey the area where the equipment is to

be used to make sure it is free of debris,

sticks, stones, wires, bones, and other foreign objects which could cause injury to

bystanders, damage to the machine, or

damage to nearby facilities.

d. Inspect the machine to make sure:

1. All guards, shields (including mower

chute deflector) are in their proper place,

are secure, and are functional.

2. That there are no spilled or leaking fuel

or oil sources, nor loose fuel or hydraul ic

tank caps, hoses or fittings.

3. That there are no loose or missing hardware nor any missing items.

4. That no non-approved devices are

installed.

5. That all safety signs and decals are

properly installed and legible.

e. This is a one person mac hine, operator

only! Riders are not permitted under any

circumstance!

f. To start the engine on the machine:

1. Make sure the park brake is set to the

“ON” position, both lap bars are in the

neutral/start (opened-out) position, and

the Power Take Off (PTO also referred to

as blade control switch) is in the “off”

(down) position.

2. Move the choke control forward and the

engine speed control (throttle) forward

(half way).

3. Inser t the ignition key, turn the switch

toward the spring-loaded “Start” position,

maintain the Start position until the

engine begins to run, then release the

switch (it will return to the “Run” position).

4. Retard the choke slowly by moving it

rearward. If the engine is “cold”, the

choke may need to be partially applied

for a few minutes. Be sure to totally

retard the choke after the engine has

“warmed up”.

g. Check safety devices:

1. With the park brake engaged, move one

of the lap bars (speed/directional control)

from the neutral/start position to the neutral position (out of the slot, toward the

center of the machine) — the engine

should stop running. Move the lap bars

back to the neutral/start position and the

engine should run.

2. Repeat this procedure with the opposite

side lap bars.

3. With the park brake engaged and the lap

bars in the neutral/start position,

advance the engine speed control completely forward (Hi-idle), engage the PTO

control switch (pull upward), then lift off

the seat — the engine should stop running. Sit down and the engine should

12

Page 13

run. Turn off the PTO by pushing the

control switch down.

h. To dri ve in the FORWARD direction:

1. Set the engine speed to 2000 to 2500

rpm (refer to tachometer on right control

panel). This must be increased to full

speed (3525-3675 rpm) after becoming

familiar wit h the machine.

2. Release the park brake.

3. Move both lap bars out of the neutral/

star t position to the neutral position

(toward center of machine). Slowly, move

both lap bars toward the front of the

machine until the machine begins to

move forward — release the lap bars

and the machine should stop. The more

that the lap bars are moved toward the

front of the machine, the faster the

machine will move in the forward direction. Release the lap bars and the

machine should stop traveling f orward.

(This is a safety check, the normal procedure is for the operator to slowly bring

the lap bars to the neutral position).

4. Do not advance the lap bars rapidly as

this could cause turf defacement, loss of

traction, and/or instability.

5. To turn, advance one lap bar ahead of

the other and the machine will turn

toward the opposite from the side that

was advance d — I.E. to turn clockwise

(to the Right), move the LEFT lap bar f orward more than the right side, and to

turn counter-clockwise (to the LEFT),

move the RIGHT lap bar forward more

than the left side. NOTE: If one lap bar is

in the neutral position and the other is

advanced, the turn side tire will not

rotate and a “pivot turn” will be executed

— turf defacement could occur (if on

grass) as well as potential damages to

the traction surface and the tire. If the lap

bar on the turn side is not brought all the

way to neutral, then the turn side tire will

continue to rotate and a “U-turn” will be

executed with a low potential for turf

defacement as well as traction surface

and tire damage.

i. To drive in the REVERSE direction:

1. Make sure no bystanders, animals, or

objects are behind the machine. Look

behind the machine, and use extreme

care.

2. Slowly, move both lap bars toward the

rear of the machine until the machine

begins to move rearward. Release the

lap bars and the machine should stop.

The more the lap bars are moved toward

the rear of the machine, the faster the

machine will move in the reverse direction. Release the lap bars and the

machine should stop traveling in rev e rs e

(this is a safety check, the normal procedure is for the operator to slowly bring

the lap bars to the neutral position).

3. Do not retard the lap bars rapidly as this

could cause turf defacement and/or loss

of traction.

4. To tur n, retard one lap bar ahead of the

other and the machine will turn toward

the same side that was retarded — I.E.,

to turn counter-clockwise (to the LEFT),

move the LEFT lap bar rearward more

than the right side, and to turn clockwise

(to the RIGHT), move the RIGHT lap bar

rearward more than the left side. NOTE:

If one lap bar is in the neutral position

and the other is retarded, the turn side

tire will not rotate and a “pivot turn” will

be executed. Turf defacement could

occur (if on grass) as well as potential

damages to the traction surface and the

tire. If the lap bar on the turn side is not

brought all the way to neutral, then the

turn side tire will continue to rotate and a

“U-turn” will be executed with a low

potential for turf defacement as well as

traction surface and tire damage.

j. T o perform a “zero turn”:

1. Please note, a zero turn maneuver can

not be executed while the machine is

moving in the Forward or, Reverse directions, the machine must come to a stop

first.

2. To turn clockwise, slowly move the LEFT

lap bar forward while simultaneously

moving the RIGHT lap bar rearward.

Release both lap bars and the machine

should stop turning.

3. To turn counter-clockwise, slowly move

the RIGHT lap bar forward while simultaneously moving the LEFT lap bar rearward. Release both lap bars and the

machine should stop turning (this is a

safety check, the normal procedure is for

the operator to slowly bring the lap bars

to the neutral position).

3. Start the Engine:

a. Open the fuel shutoff valve.

b. Sit on the Seat. Set the parking brake

“On”.

c. M ove the left and right steering levers to

the neutral, opened-out position.

d. Turn the electric blade clutch switch “Off”.

13

Page 14

e. Push the throttle control to a position a

third of the way between slow and fast.

f. Insert the key in the ignition and start

switc h and turn the switch to “On”.

g. Gasoline Engine: If the engine is cold,

push the choke to the on position.

h. Turn the ignition key in a clockwise direc-

tion to the “Start” position until the engine

starts.

Note:

position for more than 10 seconds o r you may

damage the starter. If the engine d oes not st art

in this time, wait about 30 seconds and try

again.

i. Gasoline Engine: Once the engine starts,

Operatin g the Mower :

4.

ing-ra di us mower is not like operating a tractor-typ e riding mo wer . The z ero-turning -rad ius

mower is much more maneuverable and

much les s fatiguing to operate. Ho weve r, getting use d to the fingertip control of the zeroturning-radi us mower ta kes some prac t i ce.

We strongly recommend that you locate a

“test area” where you can operate the mower

for about 30 minutes without being disturbed.

a. Get into the operator’s seat.

b. Start the engine.

c. Use the transport lever to r aise the mowing

d. After the engine has warmed, adjust the

e. Release the parking brake.

f. Fold in the steering levers to the operating

Do not hold the key in the “Start”

push the choke on halfway and as the

engine warms, push the choke off all the

way.

Operating a zero-turn-

deck to the transport position. Make sure

the blade clutch switch is off.

throttle to the fast position.

position.

levers backward the faster the mower w ill

go backward.

i. To turn, pull the lever back on the side to

which you want to turn. The farther back

you pull the lever, the faster and more

sharply you will turn. Initially, you will have

to be careful to avoid tur ning to fast and

too far.

j. After you have mastered operating the

mower, use the transport lev er to lower the

mowing deck to the cutting position and

pull on the electric blade clutch switch to

start the blades rotating.

k. Practice mowing in straight passes. When

you feel confident, slowly practice mowing

around obstacles such as trees.

5. Parking the Mower:

a. Push off the electric blade clutch switch.

b. Use the Deck Lift Handle to raise the mow-

ing deck to the transport position.

c. Dr ive the mower to the cleanup or storage

area.

d. Move the throttle to slow.

e. Place the steering levers in the neutral

position.

f. Set the parking brake.

g. Turn off the ignition switch and take the key

from the switch.

h. Close the fuel shutoff valves.

MAINTENANCE AND

SERVICE

WARNING:

Disconnect the spark plug wires or remove the

key from the ignition to prevent the engine

from accidentally starting before performing

any maintenance on this mower.

WARNING:

When operating this mower forward, do not

allow th e steerin g levers to return to the ne utral position on their own. Always maintain a

firm grip on the steering levers, operate them

smoothly and avoid any sudden movements of

the levers when starting or stopping.

g. To go forward, move both steering levers

slightly forward and the mower will slowly

move forward. The farther you move the

levers forward the faster the mower will go

forward.

h. To back up, move both steering levers

slightly backward and the mower will slowly

move backward. The farther you move the

A. Mower Deck

1. Removing th e Mower Deck:

a. Apply the parking brake. Remove ignition

key and both spark plug caps.

b. Lower the cutter deck to the ground. Cap-

ture the lift handle by placing the height of

cut clevis pin above the lift handle.

c. Remove tension of the PTO belt by moving

the belt tensioning rod.

Note:

tension due to the weight of the deck. When

removing t he lift linkage from the deck the tension of the springs will go from the deck to the

lift handle. Not capturing the lift handle while

removing the lif t linkage from the deck will

cause it to snap back.

14

There is a certain amount of spring

Page 15

Figure. 6

Linch Pins

Linch Pins

Height of Cut Clevis Pin

d. Detach the mower drive belt.

e. Remove six linchpins (See Fig. 6) (4) from

the deck and (2) from the front of the

mower. Remove the linchpins on the left

and right rear side of the cutter deck (2);

remove the linchpins on the left and right

front side of the cutter deck (2); and

remove the linchpins on the front of the

mowe r (2).

f. Turn front caster wheels outward.

g. Shift the deck toward the ignition switch

side of the mower and remove.

h. To install reverse the process.

2. Changing a Blade:

a. Remove the Key from the ignition and dis-

connect the spark plug.

b. Jack up the front of the mowing deck about

one foot and block it in that position.

c. W rap a rag around one end of the blade

and grasp it to prevent it from turning, or

secure the blade by placing a block of

wood between the blade and the deck

housing.

d. Use a 1-1/8" socket wrench on the pulley

side of the spindle to secure.

e. Remove the hex nut using a 1-1/8" wrench.

f. Remove the hex nut.

g. To replace the blade reverse the above

process and tighten nut to 100-120 lb ft.

WARNING:

Never mow with dull blades! Blades that are

bent should be replaced! The cutting blades

are sharp and can cause severe injury. Wrap

the cutting surface of the blade with a rag to

avoid injury.

a. Set the parking brake.

b. Clean any debris from the blades. Keep

blades sharp and free of build up at all

times.

c. Sharpen blades evenly at the original 30°

angle to maintain balanced cutting blades.

Do not sharpen the underside of the

blades. Use a electric blade sharpener, a

conventional electric grinder or a hand file

to sharpen the blades.

d. Replace any blade with severe nicks or

dents that cannot be removed by filing.

e. Check the balance of the blade after

sharpening by placing it on a blade balancer. Do not use un-balanced blades.

f. If the blade dips on one end, file stock off

of the cutting surface on that end.

Note:

anced—REPLACE.

Blades that cannot be easily bal-

3. Changing the Blade Drive Bel ts:

a. Set the parking brake. Remove ignition ke y

and both spark plug caps.

b. Unscrew the wing nuts from the deck cov-

ers and remove both covers.

c. Using a 1/2" socket breaker bar or socket

rachet insert the male end into the 1/2"

opening in the lower idler arm assembly

and pull the idler arm clockwise. While

holding the idler arm back, loosen the

blade drive belt from the pulley and slide

the belt away from the pulley.

d. Remove tension of the PTO belt by moving

the belt tensioning rod. Loosen the belt

retaining bolt.

15

Page 16

Cover

Plate

Spindle

Figure. 7

e. Pull the tensioner pulley away from the belt

and remove the PTO belt then remove the

blade drive belt.

f. Reverse the process to install the belt.

Note:

tighten. Adjus t the idler pulley so that a tenpound pull with a spring scale between two

pulleys defl ects the belt about 1/2".

When replacing belts do not over-

4. Changing the Spindle Assembly

a. Jack up the front of the mowing deck about

one foot and block it in that position.

b. Make sure the blade clutch is disengaged.

c. Remove the deck cover.

d. Remove the drive belts. (See 3. Changing

Blade Drive Belts.)

e. Remove the cutter blade. (See 2. Chang-

ing a Blade.)

f. Using a wrench or socket rachet remove

four hex nuts, and the four hex head cap

screws. Remove the spindle assembly.

B.Hydraulic Oil

WARNING:

Never overf ill t he hydr aulic units. Damage c an

occur if the oil level is not within the proper

operating range.

Note:

small quantiti es and recheck the oil level

before ad ding more. It i s im portant th at y ou do

not overfill the reservoir.

hen adding hydraulic oil, do so in

W

Figure. 8

1. Adding Hydraulic Oil

Hydraulic Tank

(use SAE20W 50)

a. Place the Mower on a level surface and

engage the parking brake.

b. Stop the engine and remove the key

from the igniti on sw itch.

c. Clean the area around the Hydraulic Oil fill

neck.

d. Remove the hydraulic fill cap and check

the level. The correct level is up to the lowest hole of the oil tank fill neck.

e. Pour hydraulic oil into the reservoir up to

the lowest hole in t h e o il tank fill neck, if

necessary.

2. Draining Hydraulic Oil

Used hydraulic oil must be disposed of properly. Do not

pour it down a drain or sewer, or du mp it on op en land , th is

creates an environmental hazard . Please be aware o f the

environment when disposing of used oil.

a. Place the Mower on a level surface and

engage the parking brake.

b. Stop the engi ne and remove the key from

the ignition switch.

c. Rem ove the mower deck. See section on

Mower Deck.

d. Raise the seat forward to expose the

hydraulic oil fill point.

e. Clean the area around the hydraulic fill oil

cap.

f. Remove hydraulic fi ll o il c ap.

g. Place a suitable container (at least 2 gal-

lon) under the hydraulic reser voir and filter.

h. Remove the hydraulic filter to allow hydrau-

lic oil to drain. Remove the drain plug from

the bottom of the hydraulic oil tank to drain.

Replace the plug.

i. Place a small pan under the pump motor

frame. Remove fill oil cap from hydraulic

reservoir for faster drainage. Remove nut

16

Page 17

caps and drain oil from both left and right

pumps. Replace and retighten nuts.

Hydraulic pumps

c. Store the battery with a full charge. A dis-

charged battery will freeze (refer to the

table below).

Specific Gravity Freezing Temp (°F)

1.265 -71

1.250 -62

1.200 -16

Figure. 9

Unfasten hos e and dra in from

this side of both pumps.

j. Coat new filter seal with oil before installa-

tion. Install new hydraulic oil filter filled with

new oil.

k. Add proper amount of hydraulic oil to res-

ervoir.

l. Run and purge gearboxes. Check oil level.

m. Add proper amount of hydraulic oil to res-

ervoir and repeat step L.

C.Electrical Circuit

Danger:

Read General Safety Precautions Nos. 9 and 10.

Battery:

1.

operator’s seat. Remove the fillcaps and

check the level of th e l iq uid el ectrolyte in the

battery ev ery 50 oper ating hours. If the le v el in

any of th e six cell s has dropped belo w the

bottom of the split ring inside t he f ill ho le , re fill

the cell with distilled water. To keep the outside of the battery clean, brush on a strong

solution of bica rbona te of soda an d w ater and

rinse with clean water. Keep the contacts and

cable en d s c l ea n with a wir e brus h an d make

sure the c onnections are t i ght . Coat the terminals with petroleum jelly to prevent corrosion.

Battery Stora ge:

2.

long periods of t i m e th e following guidelines

should be taken.

a. Disconnect the battery cables from the ter-

b. Clean the battery before storing. A dirty

The battery is located beneath the

When st oring the Mo w er for

minals and remove the battery. You will

have to remov e the control panel to access

the battery strap. Replace control panel.

battery will lose its charge over time.

1.150 5

1.100 16

d. Re charge batter y when ever the specific

gravity value is less than 1.225

3. B atter y Removal

Warning:

When removing the cables from the battery

follow these steps to avoid a short between

the wrench and the frame.

a. Remove the Negative (black) cable.

b. Remove the Positive (red) cable.

c. Release the hold down straps.

d. Remove the battery without tipping.

4. Installing the Battery

Note:

tory fully charged and filled with electrolyte.

a. Attach the Positive (red) cable.

b. Attach the Negative (black) cable.

c. Attach the rubber battery strap.

5. Jump Starting

The battery is delivered from the fac-

Warning:

Failure to use this starting procedure can

cause sparking, and the gases in the battery

to explode.

a. At tach the end of the red jumper cable to

the Positive terminal (+) of the charged

battery.

b. At tach the other end of the red jumper

cable to the Positiv e terminal (+) of the low

charge bat t ery.

c. Attach the end of the black jumper cable to

the Negative terminal of the charged battery.

d. At tach the other end of the black jumper

cable to the frame of the unit with the low

charge bat t ery.

Fuses:

6.

between th e i gnition and start switch and

There is one f use lo ca ted in t he wi ring

17

Page 18

other elect r i cal co m po nents. This is a standard plug-in type au tomotive f use rated at 7. 5

amp.

Safety Switches:

7.

There are five safety

swi tc hes in the electrica l circuit which control

the engin e. They are (1) th e blade clutch

swi tc h, (2) the parking brake sw itc h, (3) the

left and (4) the right steering lever switches

and (5) the seat switch.They operate so that

in order to start the engine, the blade clutch

swi tch must be off, the parking brake must be

engaged , and both steering levers must be

opened- out to the side in the neut ral position.

Once the engine is started, the seat mu st be

occupied and the parking brake must be

released before either of the steering levers is

folded up to the operating position or the

engine’s electronic ignition will be grounded

out and the engine will stop. Also, the seat

must be occ upied befor e the blade clutch

swi tch can cause the blades to rotate.

Safety Switch Operation Checks:

8.

lowing operational ch ecks should be made

daily.

Blade Clutch Switch:

a.

Sit in the operator’s

seat. With both steering lev ers opened-out

in the neutral position and the parking

brake engaged, turn the blade clutch

switch “on” and try to start the engine. The

engine should not start. If it does, the blade

clutch switch must be replaced. If the

engine does not start, turn the blade clutch

switch “off” and start the engine. Now turn

the blade clutch switch “on” and the blades

should rotate. If the blades do not turn, the

blade clutch switch must be replaced, the

seat switch must be replaced or the electric PTO clutch must be repaired. The airgap should be checked every 300 hrs. (or

less, if severe operating conditions exist

such as when there are many on/off

cycles, mulching operations, material collection systems used, and dusty/dirty conditions), and the air-gap adjusted if more

than 0.035". To inspect, remove the “negative” cable from the batter y and all sparkplug wires. The air-gap should be checked

with feeler gages in the three slots of the

BBC. The air-gap should be adjusted to

0.013" to 0.015". There are three inspection slots i the brake cover. To adjust, successively tighten each of the three gap

adjustment nuts an equal amount. Insert a

feeler gage (0.013" to 0.015") into each

slot as the air gap adjustment nut are tightened. The correct adjustment occurs when

slight contact with the feeler gage occurs.

The fol-

Engage the BBC a couple of times, and recheck the air-gap. If it is not between

0.013" and 0.015", repeat the adjustment

procedure.

Parking Brake Switch:

b.

Sit in the operator’s seat. With both steering levers

opened-out in the neutral position and the

blade clutch switch “off”, release the parking brake and try to start the engine. The

engine should not start. If it does, the parking brake switch must be repositioned or

perhaps replaced. If the engine does not

start, engage the parking brake and start

the engine. Swing one steering lever up to

the operating position and the engine

should stop. If the engine does not stop,

the parking brake switch must be repositioned or replaced.

Left and Right Steering Lever Switches:

c.

Sit in the operator’s seat. With both steering levers opened-out in the neutral position, the parking brake engaged and the

blade clutch switch “off”, swing the left

steering lever up to the operating position

and try to star t the engine. The engine

should not start. If it does, the left steering

lever switch must be repositioned or perhaps replaced. Open the left steering lever

to the neutral position and swing the right

steering lever up to the operating position

and try to star t the engine. The engine

should not start. If it does, the right steering lever switch must be repositioned or

perhaps replaced. If the engine does not

star t, Open the right steer ing lever to the

neutral position and start the engine.

Swing the left steering lev er up to the operating position and the engine should stop.

If the engine does not stop, the left steering

lever switch must be repositioned or

replaced. Open the left steering lever out to

the neutral position and start the engine.

Swing the right steering lev e r up to the

operating position and the engine should

stop. If the engine does not stop, the right

steering lever switch must be repositioned

or replaced.

Seat Switch:

d.

With both steering levers

opened-out to the neutral position, the

parking brake engaged and the blade

clutch switch in the “off” position, start the

engine. Now release the parking brake,

hold down on the back of the operator’s

seat against spring pressure, and swing

one of the steering levers up to the operating position. Release the operator’s seat

and the engine should stop. If the engine

18

Page 19

does not stop, the seat switch must be

replaced. With both steering levers folded

out in the neutral position, the parking

brake engaged and the blade clutch switch

in the “off” position, sit in the operator’s

seat and start the engine. Turn the blade

clutch switch to the “on” position and the

blades should start to rotate. Raise up

slightly off the operator’s seat and the

blades should stop. If the blades do not

stop when you dismount from the operator’s seat, the seat switch must be

replaced.

Electric PTO Clutch:

e.

when the engine is running, the operator is

in the operator’s seat and the blade clutch

switch is turned on.This electric clutch is a

fairly trouble free device. If a problem

develops and the blades do not turn, first

check the 7.5 amp fuse in the yellow, 16gauge wire between terminal “L” (for the

Gasoline Engine) on the ignition switch

and the hour meter and then investigate

the wiring harness and the connections to

the seat switch, the blade clutch switch and

the electric blade clutch. Then check out

the seat switch, the blade clutch switch and

finally the electric blade clutch.

This clutch operates

D.Tires

The two front wheels are caster wheels that are free

to swivel to accommodate the direction of the Mower.

The two rear wheels are used to propel the Mower in

the direction of input from the drive handles. Inflation

pressure of the rear tires is important for stability

while the Mower is in operation. If the tire diameter is

not equal between the two tires, the Mower will pull to

one side .

Inflation Pressure:

1.

a. Traction Tires—20 psi max; 8-10 psi rec-

ommended

b. Front Caster Wheel—28 psi max; 20-25

psi recommended

c. Cutting Deck Ball Wheels—Solid Polyure-

thane.

Use the Following guidelines for maintaining the tires:

a. Balance inflation pressure between the

rear tires to help maintain straight travel

(see tire side wall for proper inflation pressure).

b. Keep the valve caps tightened to prevent

air pressure loss.

Leaking Ti res:

2.

or replace imme diately. The normal procedure

is to remove the wheel and r epl ace it with a

spare. Take the leaking tire to a maint enance

area and repair. If a tire is getting soft, park

the mo wer on the nearest level, paved area. If

the leaking tire is on a traction wheel, put

bloc ks on each side of the oppos ite traction

wheel and jack up the tire that leaks about an

inch off the g round. Loosen and remove the

lug nuts and remove the wheel. Mount a

spare whe el and tire , rep lace the lug nuts , and

using a torque wrench, tighten the m to 60

10 ft-lbs.

If the leaking tire is on a front caster wheel,

block both traction wheels and raise the

caste r whee l s o that t he tir e is a n i nc h of f t he

ground. Loosen and remove the locknut from

the axle assembly and pull the axle assembly

from the caster yoke. The wheel and two

spacer sleeves will drop free. Slip the axle

assembly through one side of the caster

yoke, through a spacer sleev e, a spare wheel,

the other spacer sleeve and finally through

the other side of the caster yoke. Then

tighten the locknut on the end of the axle

assembly.

Lower the mower off the jack and continue

mowing. The wheel with the leaking tire

should be taken to the maintenance area, the

tire inflated to 20 psi and the wheel placed in

a large bucket of water. Carefully inspect the

tire, rim and valve for escaping air bubbles

whic h indicat e a leak. Mar k each leak with a

yellow marking crayon and then deflate the

tire to 8 psi and repeat the inspection. If the

leaks you find are pin hole size to 1/16"

diameter, the tire can be repaired using an

aerosol can of tire inflater and latex sealer

available from any auto supply store. Follow

the directions on the can. If the leaks are

larger than 1/16" diameter, the tire can be

repa ired wit h r ubbe r pl ugs also availabl e in a

kit from any auto supply store. If the tire bead

is damaged, a tube will have to be installed in

the tire or the tire will have to be replaced.

Creeping:

3.

backward movement of the mo wer when the

throttle is on and the lapbars are in the

opened-ou t position. If y our mower cr eeps do

the following.

a. Jack up rear of unit.

b. Place Lapbars in neutral opened-out posi-

tion.

c. Locate jam nuts. (Reference control

assembly in pa rts list ) .

When a flat tire occurs, repair

Creeping is the slight forward or

±

19

Page 20

d. Loosen jam nuts on both ends of rod con-

nectors. See Control Assembly in the Illus-

trated Parts Book (ONLY if mower creeps.)

e. Start unit and push throttle all the way on.

f. If unit creeps forward rotate rear rod con-

nectors counter-clockwise. And if unit

creeps in reverse, rotate clockwise.

pin from the clevis pin and pulling the clevis pin from

the brake clevis. Loosen the hex nut and turn the

brake clevis in a clockwise direction one full turn

looking down the brake rod. This will tighten the brake

about .040 inch. Tighten the hex nut and reassemble

the brak e clevis to the brake shaft assembly. Normally,

both brak es should be adjusted and equal amount.

Adjust the appropriate rod connector. The

left rod for the left side of the mower and

the right rod for the right side of mower.

Afterward, retighten jam nuts.

E. Brakes

While the mower is in motion, all braking is performed

dynamically through the hydraulic pumps and traction

motors, controlled by the two steering levers. When the

mower is parked with the engine shut off, the hydraulic

system l oc ks th e trac tion whee ls .

Note:

reverse by pushing, you must release the

dynamic braki ng. Locate the valves on the

pump. Turn valves counter-cl ockwise one

quarter turn to push the unit. After pushing

the mower to t he desired location, retu rn both

valves to the oper ati ng position (See photo

below)

To move the mower forward or in

.

Repair:

2.

The mower is equipped with internal

wet drum brakes a nd will not n ormally require

maintenanc e. If they are not working pr operly,

please contact your service center.

F. Hydraulic System

Hoses:

1.

oil tank to the oil fil t er to the hydr aul ic lines

daily f or l eaks or abrasi on and replace any

damaged hos es. Make certain there are no

kinks or twists in any hose.

Hydraulic Oil Tank and Filter:

2.

Note:

filter after the first 50 hours of operation and

every 500 hours thereafter .

To drain the hydraulic oil tank, place a 2 gallon drain

pan under the drain plug on the bottom of the

hydraulic oil tank. Remove the drain plug, drain the

tank, then replace the plug. Place the drain pan under

the filter and remove the filter by unscrewing in a

counterclockwise direction. The filter will be full of oil,

so empty it into the drain pan. You don’t have to drain

the rest of the hydraulic system. Fill the replacement

filter with a good grade of 20W-50 oil and lubricate the

sealing surface. Screw the filter onto the filter base

until it seats an d then another one-half turn to seal.

Check the hoses from the hy draulic

Change the hydraulic oil and the oi l

Hydro Release Valve

When the mower is parked with the engine running

and the steering levers opened out in the neutral

position, the parking brakes should be applied. The

parking brakes are drum-type brakes mounted on

each traction wheel.They are both engaged by the

same operating lever.

Adjustments:

1.

The parking b rake handle is an

overcenter lever that should engage with

moderate force.

Note:

tighten the brake rods going back to the brake

arms equally. Tighten rods one full turn and

check parking capacity. Repeat Step.

To increase parking brake capacity

To adjust either brake individually, disconnect the

brake rod from the brake arm by removing the cotter

Note:

cap and the area around it before remo ving the

cap to prevent dirt from contaminating the oil.

Always wipe off the hydraulic tank fill

Remove the fill cap and fill the tank with the same

20W-50 oil selected for the filter until the oil level is up

to the level of the second hole in the fill tube. Leave

this air space for expansion. Start the engine and let it

run at idle for about five minutes. Check the filter for

leaks. Idling the engine and the pumps in this way will

purge any air from the system. Shut off the engine

and recheck the oil level in the tank. Top-off if

necessary until the oil level is up to the second hole in

the fill tube.

Note:

ture, turn off engine and re-check hydraulic

oil. If oil appear s foamy or contains excessive

air bubbles, DO NO T OPERATE UNIT. Cont act

service technici an.

After unit is up to operating t empera-

20

Page 21

Hydrostatic Pum ps and Motors:

3.

are the hardest-working co m ponents in the

hydr au lic sy stem. T he y ar e i n oper a tion a ll t he

time the en gine is running. Because of

ex tr em ely close tolera nces, wear i s an important factor in their life.

hydraulic oil an d

harm to the pum ps. Ca vitat ion is a b loc kage in

the supply li nes that produces a partial vacuum causi ng violent bubbling in the hydraulic

oil in the pum p.

Check the two suction hos es (the hoses connected to the filter) daily before starting the

engine. Look for a flatt ened condition or an y

leaks and repair or replace as necessary. A

flattened or leakng suction hose will permit

cavitation t o develop which can de stroy the

pumps in a sh ort time.

Contaminants or foreign matter in the oil will

also damage the pumps . To prevent t hi s, use

a filter that ca ptures particles as small as 30

microns or 30 millionths of a meter in diameter. You can help in the batt l e against dirt by

being very careful when you remove or repair

a component in the hydraulic system. Thoroughly cle an of f any componen t before you

work on it. Plug the ends of any hose or line

you rem ove with a rubber or plastic plug. Use

plastic caps to seal off the ends of hydraulic

fittings . Place an y compon ent you remov e in a

clean plastic bag so it can’t pick up dust or

dirt. Clean your hands frequently when working on the hydraulic components.

Note:

If a pump fails, contact y our Cub Cadet Commercial dealer. Do not disass emb le the pump.

Steering Lever Adjust ments :

4.

mower on level ground with t he engine running, parki ng brake off and s teering levers

opened ou t to the neutral position. If the

Mower begins to creep, adjust the S teering

Levers.

If the mo w er c re eps , firs t de termine wh ether it

creeps to the righ t or left side and which direction the mower moves — to the front or the

rear. To make the adjustment, place th e st eering levers in the opened-out neutral position

and set th e park i ng brake , s hut off the engine,

take t he key from t he ignition switch and pivot

the seat forward. If the mower creeps to the

right, you will adjust the linkage on the left

side of the mower and vice-versa. Remove

the cap screw and lock washer th at secure

the linkage control arm rod end bearing to the

control lever pivot. Loosen the jam nut which

The pumps are not owner-repairable.

Contaminants

cavitation

The pumps

does the greatest

Place the

in the

prevents the rod end bearing from turning . I f

the mower cr eeps f or war d, thre ad the r od en d

bearing one-ha l f t urn clockwise into the l in kage control arm. If th e m ower creeps backward, t hread the ro d e nd be aring one hal f t urn

counterclockwise out of the linkage control

arm. Then tighten th e j am nut and reconnect

the rod end beari ng to the control lever pivot

by replacing the cap screw and lock washer.

After adju st ing the steering l inkage, swing the

seat bac k t o i t s normal position and place the

steering lever on the side you adjusted up to

the operat ing positio n. If y ou f e el a sl ight p ush

forw ard or a sli ght pu ll bac kw a rd fro m the neutral positi on you must ad j us t t he l ever re turn

assembly . To do this, swing the steering lever

back out to the neutral position, pivot the seat

forward and loosen the jam nut on the lever

retu rn rod where it i s threaded into the hexshaped end of the l ever return bolt. If the

steering lever was pushed forward, turn the

hex-shaped lever return bolt clo ckwise onehalf turn off of the lever return rod. If the steering lev er wa s pulled b ac k, turn the he x shape d

lev er return bolt counterclockwise one-half

turn onto the le ver return ro d. Then tigh ten the

jam nut, pivot the se at back into the operating

position and st art the mo wer to check tha t

your adj us tments were made cor rectly.

G. Storage

General:

1.

for a few months, it should be st ored in a dry

location that is not subject to dra st ic c hanges

in temperature. Before storing, the following

maintenanc e procedures should be performed.

a. Clean the mower. The entire tractor and

cutting deck should be washed and

cleaned.

b. Sharpen the blades so that the mower will

be ready to use when needed.

c. Protect the metal surfaces. Repair

scratches with the appropriate touch-up

spray paint. Brush a rust preventive oil on

any unpainted surfaces including the pulleys and blades. (Be careful not to get any

oil on the drive belts.)

d. L ubri cate the mower.

e. Drain the engine oil. The engine should be

warm so that all the oil drains. Replace the

engine oil filter and refill the crankcase with

fresh oil.

f. Gasoline Engine: Drain all the fuel. Close

the fuel tank shutoff valve. Disconnect the

fuel line from the carbuetor and put the end

If your mower will not be in service

21

Page 22

into an approved fuel container . Open the

fuel tank shutoff valve and drain the fuel

tank and line into the approved container.

Replace the fuel line on the carburetor.

Start the engine and allow it to run out of

fuel. This will prevent gum and varnish

deposits from forming. Replace the fuel filter.

g. Gasoline Engine Only: Rem ove the spark

plugs and pour approximately one ounce

of oil into each cylinder. Crank the engine