Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

InstallatIon InstructIons

RZT & Z-Force Light Kit — Model 19B70032100

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-09717

(March 5, 2014)

Page 2

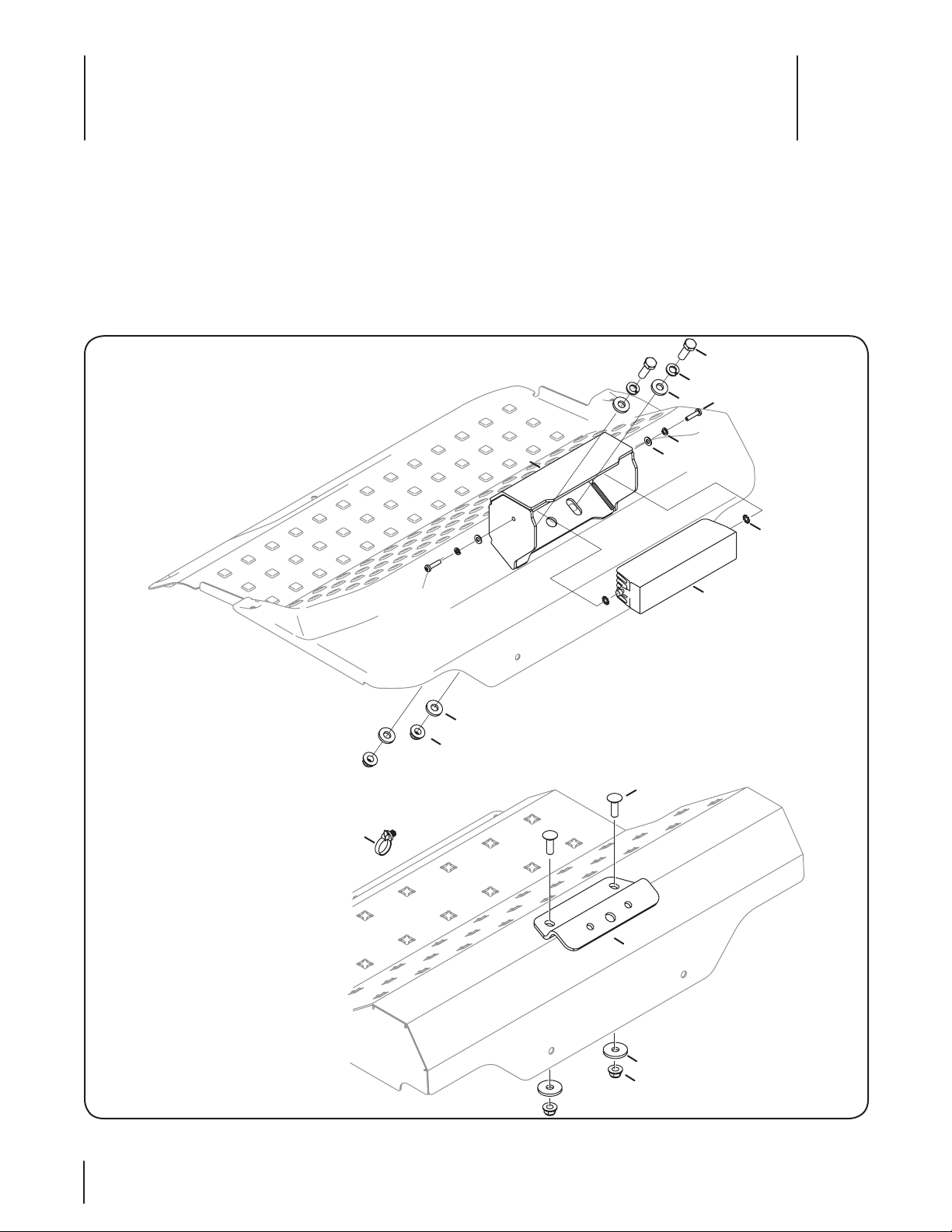

Installation

14

4

13

8

1

5

3

11

9

7

6

6

10

2

13

12

1

To the Owner

Thank you for purchasing a Cub Cadet Light Kit. Please be aware

that this Light Kit was designed for use with 2014 and newer Cub

Cadet RZT and Z-Force models equipped with either lap bars or

a steering wheel . This covers a range of product specifications

for various models. Characteristics and features discussed and/or

illustrated in this manual may not be applicable to all models.

Contents of Carton

We reserve the right to change product specifications, designs

and equipment without notice and without incurring obligation.

If you have any problems or questions concerning the Light Kit,

phone your local Cub Cadet dealer or contact us directly. Cub

Cadet’s Customer Support telephone numbers, website address

and mailing address can be found on the back cover of this

manual. We want to ensure your complete satisfaction at all times.

2

Page 3

Ref. Part Number Description Qty.

1 603-05077 Headlight Bracket 1

2 703-09867 Headlight Mounting Bracket 1

3 710- 0276 Carriage Screw, ⁄-18 x 1.00 2

4 710- 0376 Hex Screw, ⁄-18 x 1.00 2

5 710- 04879 Machine Screw, #8-32 x .750 2

6 712- 04 06 3 Flange Lock Nut, ⁄-18 4

7 725-06054 Headlight Assembly 1

8 73 6- 0119 Lock Washer, ⁄ 2

9 736 -0147 External Tooth Lock Washer, #10 2

10 736- 0231 Flat Washer, .344 x 1.125 x .120 2

11 736-0722 Lock Washer, #10 2

12 736-0931 Flat Washer, .203 x .403 x .040 2

13 736-3008 Flat Washer, .344 x .750 x .120 4

14 726-0470 Cable Tie, 19 x 8.39 1

NS 725-06069A Headlight Harness 1

NS 725-06070A Headlight Adapter Harness 1

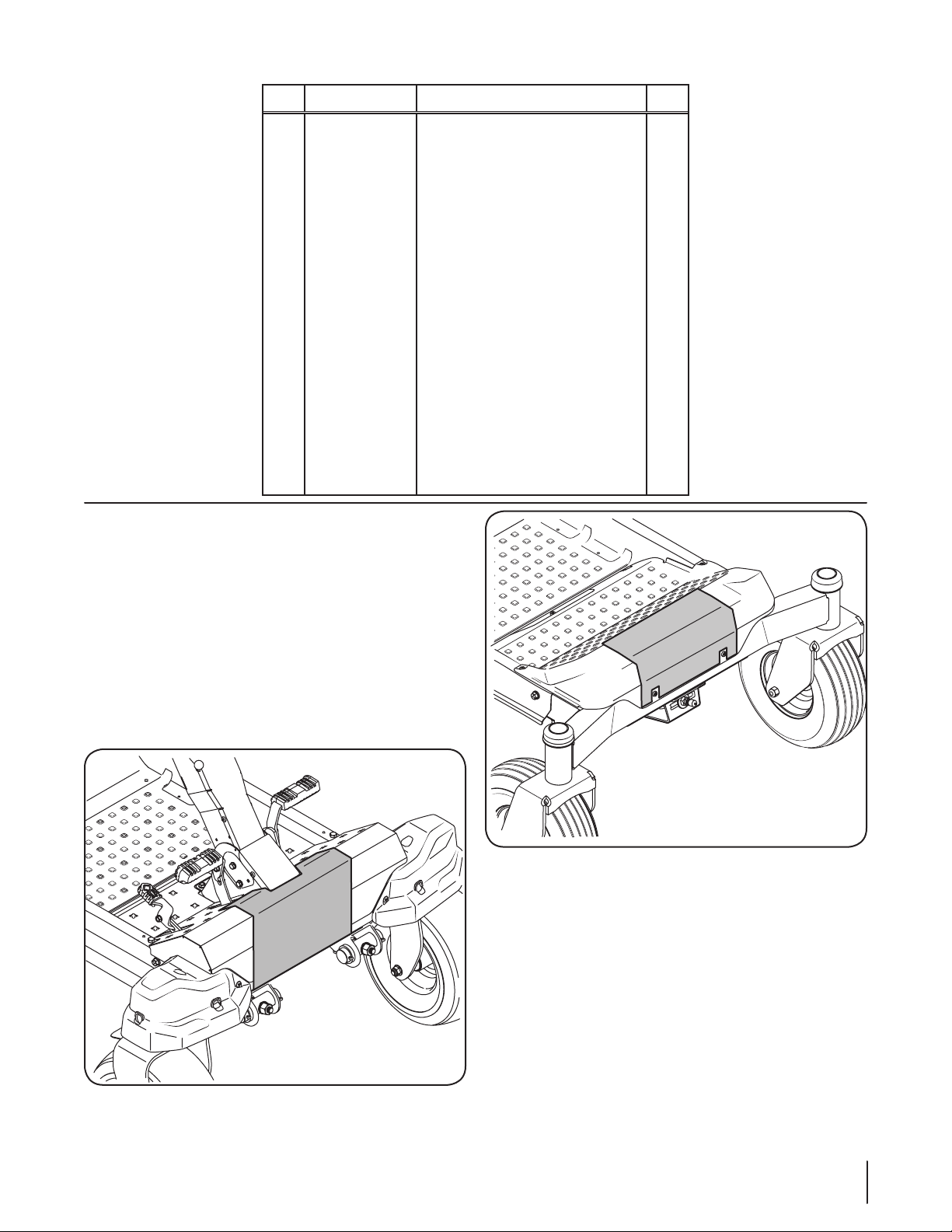

Installation

1. Using the appropriate stencil from pages 6-7 of the

manual, mark the location of the holes to be drilled in the

floorboard. There is a separate template for fabricated and

stamped floorboards.

NOTE: There are two edges for the templates, one edge is

used for steering wheel models and one edge is for lapbar

models.

2. Align the template according to the instructions and tape

in place. See Figure 1-1 for the RZT-S and Z-Force SZ and see

Figure 1-2 for RZT-L and Z-Force L/LZ models. Center-punch

the holes to mark the location of the holes to be drilled.

Figure 1-1

Figure 1-2

3Section 1 — inStallation

Page 4

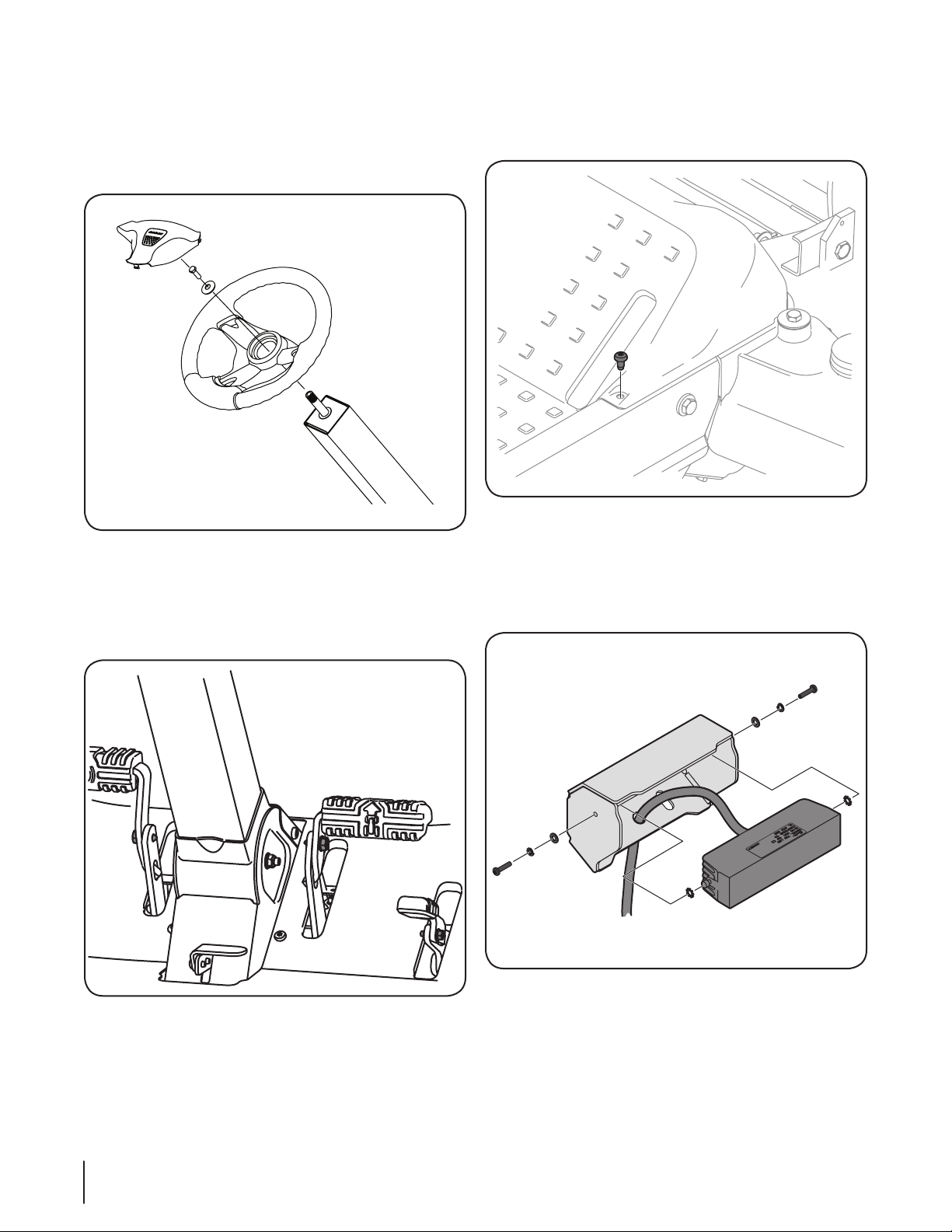

3. Before beginning installation, remove the steering wheel

from the steering wheel column on the RZT-S/Z-Force SZ

models. Remove the steering wheel by carefully removing

the steering wheel cover, then remove the hex screw

and belleville washer securing the steering wheel to the

steering wheel column. See Figure 1-3.

Figure 1-3

4. The three pedals on the RZT-S/Z-Force SZ will also have

to be removed to get the floor board off the tractor. The

drive/reverse pedals are secured with a hex screw and the

brake pedal is secured by a hex screw and flange lock nut.

See Figure 1-4. Remove the screws and the pedals.

5. On all models the floor board needs to be removed to

properly drill the mounting holes and route the wiring. To

remove the floor board, remove the screws securing it to

the frame. See Figure 1-5.

Figure 1-5

6. Drill the holes using the center-punched locations marked

in step 2 and remove burrs.

7. Feed the headlight harness adapter on the headlight

assembly (#7) through the middle hole in the welded

headlight bracket (#1). See Figure 1-6.

Figure 1-4

4 Section 1 — inStallation

Figure 1-6

NOTE: If the headlight assembly is shipped with a headlight

harness installed, it needs to be removed and then replaced

with the harness shipped with the kit.

8. Install the headlight assembly (#7) onto the headlight

bracket (#1) using two external tooth lock washers (#9), two

lock washers (#11), two flat washers (#12) and two machine

screws (#5) as shown in Figure 1-6.

Page 5

This page was intentionally left blank.

5Section 1 — inStallation

Page 6

Center and align on

steering column

5/16” Drill

Lapbar

Models

Cut-out for

1/2” Drill

5/16” Drill

Floorboard Models

Template for Stamped

Center and align on

mounting hardware

6 Section 1 — inStallation

Lapbar

Models

Cut-out for

Page 7

Template for Fabricated

Fold Fold

5/16” Drill

Floorboard Models

Center and align on steering column

1/2” Drill

5/16” Drill

FoldFold

7Section 1 — inStallation

Page 8

This page was intentionally left blank.

8 Section 1 — inStallation

Page 9

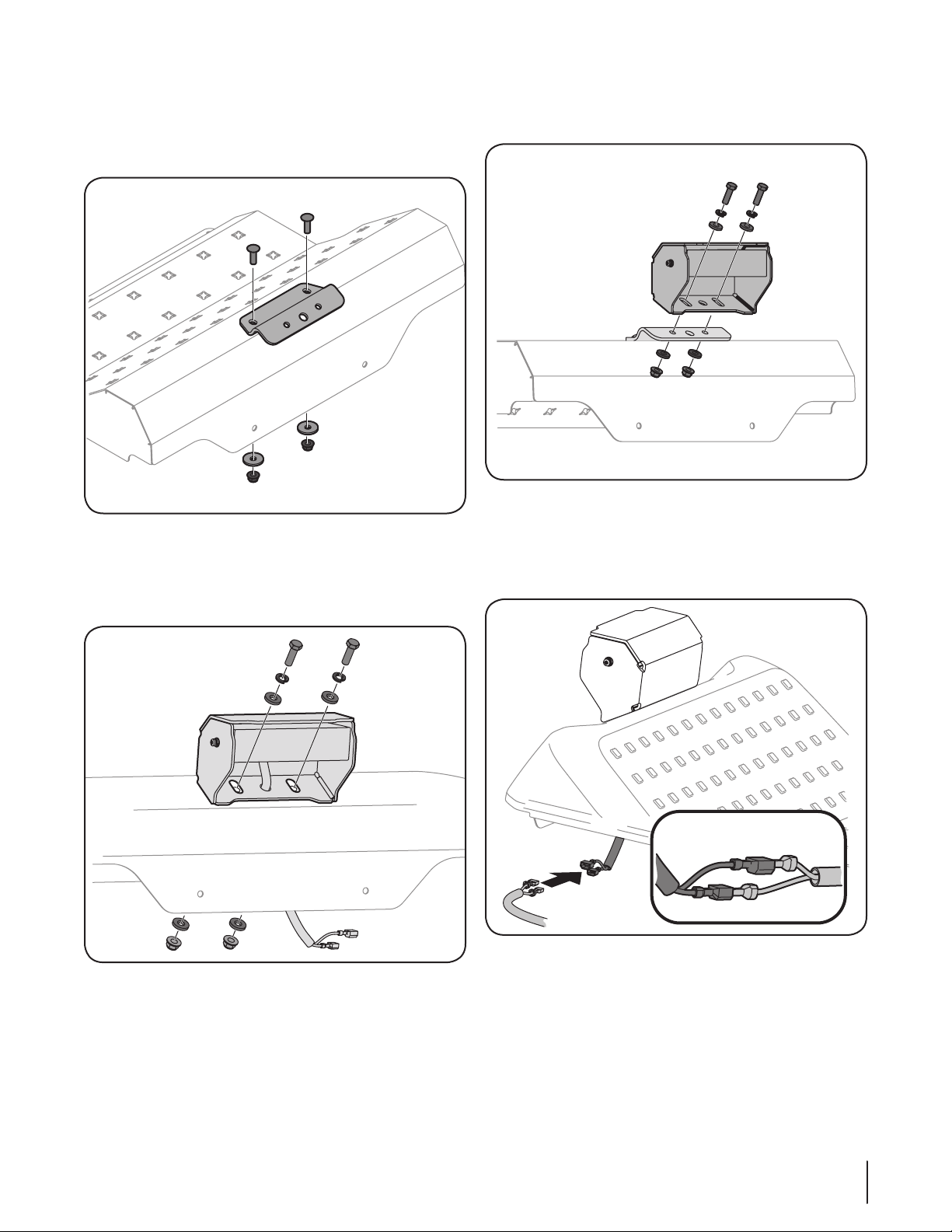

9. On tractors with a fabricated floorboard, the headlight

mounting bracket needs to be installed on the floorboard

before proceeding. Install the headlight mounting bracket

(#2) using two carriage screws (#3), two flat washers (#10)

and two flange lock nuts (#6) as shown in Figure 1-7.

Figure 1-7

10. Install the headlight bracket (#1) to the floor board on

tractors with a stamped floorboard using two hex screws

(#4), two lock washers (#8), four flat washers (#13) and two

flange lock nuts (#6) as shown in Figure 1-8.

11. Install the headlight bracket (#1) onto the headlight

mounting bracket (#2) on fabricated floorboards as shown

in Figure 1-9.

Figure 1-9

NOTE: Be sure not to damage the headlight harness

adapter when installing the headlight bracket (#1).

12. Connect the headlight harness adapter to the headlight

harness as shown in Figure 1-10.

Figure 1-8

NOTE: Be sure not to damage the headlight harness

adapter when installing the headlight bracket (#1).

Figure 1-10

9Section 1 — inStallation

Page 10

13. Place the floorboard with the headlight back onto the tractor,

but do not re-install the screws until instructed to do so.

14. Route the harness as shown in Figure 1-11 on the RZT

models. For Z-Force models skip ahead to step 15.

b. Feed the headlight wire harness along the bottom of

the frame and then up through the hole below the

seat box frame. See Figure 1-13.

Figure 1-11

a. Snap the rosebud clip into the top of the frame. See

Fi gu re 1-12.

Figure 1-12

Figure 1-13

c. Snap the rosebud clip into the frame as shown in

Figure 1-14 and connect the headlight harness to the

main harness.

Figure 1-14

10 Section 1 — inStallation

Page 11

15. Route the harness as shown in Figure 1-15 for the Z-Force

models.

Figure 1-15

a. Snap the rosebud clip into the top of the frame. See

Fi gu re 1-12.

b. Feed the headlight wire harness along the bottom

of the frame and then up through the larger

rectangular frame hole. See Figure 1-15.

c. On Z-Force L models, locate the hole on the inner

LH frame rail. Press the cable tie (#14) into the hole

and secure the wire harness against the frame rail.

On Z-Force S models, use the cable tie (#14) to secure

the headlight harness to the main wire harness.

d. Snap the rosebud clip into the frame as shown in

Figure 1-14 and connect the headlight harness to the

main harness.

16. Visually inspect the wire harness routing and confirm

clearance from all moving parts.

17. Re-install the floor board and on RZT-S and Z-Force SZ

models reinstall the steering wheel and pedals.

Operation

Turn the ignition key to the accessory position to turn the light on.

The light will stay on as long as the tractor is running. To turn the

light off, turn the tractor off and remove the key.

11Section 1 — inStallation

Page 12

CUB CADET LLC

MANUFACTURER’S LIMITED WARRANTY

FOR SEPARATELY SOLD ATTACHMENTS AND ACCESSORIES

IMPORTANT: To obtain warranty coverage owner may be required

to present an original proof of purchase and applicable maintenance

records to the servicing dealer. Please see the operator’s manual for

information on required maintenance and service intervals.

The limited warranty set forth below is given by Cub Cadet LLC with

respect to new merchandise purchased or leased and used in the

United States and/or its territories and possessions, and by MTD

Products Limited with respect to new merchandise purchased or

leased and used in Canada and/or its territories and possessions

(either entity respectively, “Cub Cadet”).

Cub Cadet warrants this product (excluding its Normal Wear Parts, as

described below) against defects in material and workmanship for

a period of two (2) years commencing on the date of original retail

purchase or lease and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or workmanship.

Normal Wear Parts are warranted to be free from defects in material

and workmanship for a period of thirty (30) days from the date of

original purchase or lease. Normal wear parts include, but are not

limited to items such as: belts, blades, blade adapters, grass bags,

rider deck wheels, seats, and tires.

This limited warranty shall only apply if this product has been

operated and maintained in accordance with the Operator’s

Manual furnished with the product, and has not been subject to

misuse, abuse, neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril or

natural disaster. Damage resulting from the installation or use of any

part, accessory or attachment not approved by Cub Cadet for use

with the product(s) covered by this manual will void your warranty as

to any resulting damage. In addition, Cub Cadet may deny warranty

coverage if the hour meter, or any part thereof, is altered, modified,

disconnected or otherwise tampered with.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE AND APPLICABLE MAINTENANCE RECORDS,

through your local authorized service dealer. To locate the dealer in

your area:

In the U.S.A.

Check your Yellow Pages, or contact Cub Cadet LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, call 1-877-282- 8684

or log on to our website at www.cubcadet.com.

In Canada

Contact MTD Products Limited, Kitchener, ON N2G 4J1, call 1-800668-1238 or log on to our website at www.mtdcanada.com.

Without limiting the foregoing, this limited warranty does not provide

coverage in the following cases:

a. Routine maintenance items such as lubricants, filters, blade

sharpening, tune-ups, brake adjustments, clutch adjustments,

deck adjustments, and normal deterioration of the exterior

finish due to use or exposure.

b. Service completed by someone other than an authorized

service dealer.

c. Cub Cadet does not extend any warranty for products sold

or exported outside of the United States and/or Canada, and

their respective possessions and territories, except those sold

through Cub Cadet’s authorized channels of export distribution.

d. Replacement parts and\or accessories that are not genuine Cub

Cadet parts.

e. Transportation charges and service calls.

f. Commercial or Institutional Use.

There are no implied warranties, including without limitation

any implied warranty of merchantability or fitness for a

particular purpose. No warranties shall apply after the

applicable period of express written warranty above. No other

express warranties beyond those mentioned above, given by

any person or entity, including a dealer or retailer, with respect

to any product, shall bind Cub Cadet. The exclusive remedy is

repair or replacement of the product as set forth above.

The terms of this warranty provide the sole and exclusive

remedy arising from the sale and/or lease of the products

covered hereby. Cub Cadet shall not be liable for any incidental

or consequential loss or damage including, without limitation,

expenses incurred for substitute or replacement lawn care

services or for rental expenses to temporarily replace a

warranted product.

Some jurisdictions do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions or limitations may not

apply to you.

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of safety features

of the product shall void this warranty. You assume the risk and

liability for loss, damage, or injury to you and your property and/or to

others and their property arising out of the misuse or inability to use

the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased as a

gift.

HOW LOCAL LAWS RELATE TO THIS WARRANTY: This limited

warranty gives you specific legal rights, and you may also have other

rights that vary in different jurisdictions.

GDOC-100177 REV. A

Cub Cadet LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019, Phone: 1-877-282-8684

MTD Products Limited, Kitchener, ON N2G 4J1, Phone: 1-800-668-1238

Loading...

Loading...