Page 1

Operator’s Manual

60" MOWER DECK

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

Model Number

291

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 770-0841F

ECO 07819

(12/01)

Page 2

CONTENTS

Section Page

Safe Operation Practices ..................................... ....... ...... ...... ....... ....................................... .. 2

To The Owner ......................................................................................................................... 5

I Tractor and Deck Preparation ................................................................................................ 6

II Installation and Removal of Deck Assembly ........................................................................... 8

III Adjustments ................... ....... ...... ....... ...... ....... ...... ....... ...... ....................................... ............... 12

IV Maintenance .................. .......................... ................................ ................................. ............... 15

Lubrication Guide ....................... ....... ...... ....... ...................................... ....... ...... ....... ...... .. ....... 18

Product Graphics ..................................................................................................................... 19

Warranty ........................ ................................. ................................ ......................................... 20

WARNING

The engine exhaust, s ome of its constituents, and certain veh icle components of the tractor, to which this

mower deck is at tached, contain or emit chemic als known to the State of Cali fornia to cause cancer, birth

defects or other reproductive harm.

WARNING

The units which use this mower deck attachment are equipped with an internal combustion engine and should

not be used on or near any unimproved forest-covered, brush-covered, or grass-covered land unless the

engine’s exhaust s ystem is e quipped with a spark arreste r meeting ap plicabl e local o r state la ws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California, the above is required by law (Section 4442 of the California Public Resources Code).

Other States may have similar laws. Fe deral laws app ly to federal l ands. A spa rk arrest er muffler is available

at your nearest engine authorized service center.

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY W ITH THESE INSTRUCTIONS MAY RE SULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

Your lawn mower was built to be operated according to the rules for safe operation

in this manual. As with any type of power equipment, carelessness or error on the

DANGER

I. GENERAL OPERATION

1. Read, understand and follow al l instructions in the

manual and on th e machine before st arting. Keep

this manual in a sa fe place for future and regular

reference and for ordering replacement parts

2. Only allow responsible individuals familiar with the

instructions to operate the machine. Know the

controls and how to stop the machine quic kly.

part of the operator can result in injury. This lawn mower is capable of amputating

hands and feet or throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

SAFE OPERATION PRACTICES

3. Do not put hands or feet under the cutting deck or

near rotating parts.

4. Clear the area of objects such as rocks, toys, wire,

etc. which could be picked up and thrown by the

blades. A small object may have been overlooked

and could be accidentally thrown by the mower in

any direction and cause injury to you or a

bystander. To help avoid a thrown objects injury,

keep children, animals, bys tander s a nd hel pers at

2

Page 3

least 75 feet from the mower while it is in

operation. Always wear safe ty glasses with side

shields or safety goggles during operation or

while performing an adjustment or repair, to

protect eyes from foreign objects. Stop the blades

when crossing gravel drives, walks or ro ads.

5. Be sure the area is clear of other people be fore

mowing. Stop machine if anyone enters the area.

6. Never carry passengers.

7. Disengage the blades before shifting into reverse

and backing up. Always look down and behind

before and while backing.

8. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without either the entire grass

catcher or the chute guard in place.

9. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and ex cessive

speed.

19. Check overhead clearance carefully before

driving under power lines, wires, bridges or low

hanging tree branches, before entering or leaving

buildings, or in any other situation where the

operator may be struck or pulled from the unit,

which could result in serious inj ury.

20. Disengage the power take-off, set the parking

brake and shift into neutral before attempting to

start the engine.

21. Your mower is designed to cut normal residential

grass. Do not attempt to mow through unusually

tall, dry grass (e.g. pasture) or piles of dry leaves.

Debris may build up on the mower deck or

contact the engine exhaust presenting a potential

fire hazard.

22. Use only accessorie s approved for the machine

by Cub Cadet. Read, understand and follow all

instructions provided with approved accessories.

II. SLOPE OPERATION

10. Never leave a running machine unattended.

Always turn off the blades, place the transmission

in neutral, set the parking brake, stop the engine

and remove key before leaving the area.

11. Turn off blades when not mowing.

12. Stop the e ngine a nd wait until the bla des come to

a complete stop before (a) removing the grass

catcher or unclogging chute, or (b) making any

repairs, adjusting or removing any grass or debris.

13. Mow only in daylight or good artificial li ght.

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or cr oss ing

roadways.

16. Use extra care when loading or unloading the

machine onto a trailer or truck. Thi s unit should

not be driven under power up or down a ramp

onto a trailer or truck, becaus e the unit could tip

over causing serious personal injury. The unit

must be manually pushed on a r amp to load or

unload properly.

17. Never make a cutting height adjustment while the

engine is running if the operator must dismount to

do so.

Slopes are a major factor related to loss of control and

tip-over accidents, whic h can resul t in seve re inj ury or

death. All slopes r equire extra caution. If y ou cannot

back up the slope or i f you feel uneasy on it, do not

mow it.

For your safety, use the slope gauge (provided in

tractor Operator’s Manual) to measure slopes before

operating the unit on a sloped or hilly area. If the slope

is greater than 15 degrees, as shown by the slope

gauge, do not operate the unit on that area or serious

injury could result.

DO:

Mow up and down slopes, not across.

Remove obstacle s su ch as ro cks , limb s, etc.

Watch for holes, ruts or bumps. Uneven terrain c ould

overturn t he mach ine. Tall grass can hide obstacles.

Use slow speeds. Choo se a low enough gear s o that

you will not have to stop or shift while on the slope.

Always keep the machine in gear when goin g down

slopes to take advantage of engine braking action.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other

attachments. These can change the stability of the

machine.

18. Wear sturdy, rough-soled work shoes and clos efitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals

or sneakers.

Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid engagement or braking could cause the front of

the machine to lift and rapidly flip over backwards

which could cause serious injur y.

3

Page 4

Avoid starting or stopping o n a s lope. If the ti res l ose

traction, disengage the blades and proceed slowly

straight down the slope.

DO NOT:

Do not turn on slopes unless abso lutely nec essary. If

necessary, turn slowly and gradually across and down

slope, if possible.

Do not mow near drop-offs, di tc hes or em ban km ents.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could

cause sliding.

Do not try to stabilize the machine by putting your foot

on the ground.

Do not use the optional grass catcher on steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not al ert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and in

watchful care of an adult other than the operator.

2. Be alert and turn the machine off if children enter

the area.

3. Before and when backing up, look behind and

down for small children.

4. Never carry children, even with the blades off.

They may fall off and be seri ously inj ured or may

interfere with safe machine operation.

5. Never allow children under 14 years old to

operate the machine. Children 14 years and older

should only operate the machine under close

parental supervision and proper ins truction .

6. Use extra care when approaching blind corner s,

shrubs, trees or other objects that may obscure

your vision of a child or other hazar d.

7. Remove the key when the machine is left

unattended to prevent unauthorized operation.

IV. SERVICE

1. Use extreme care in handli ng gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the en-

gine hot or running. Allow the engine to cool at

least two minutes before refueling.

c. Replace the fuel cap securely and wipe off any

spilled fuel before starting the engine as it may

cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and oth-

er sources of ignition.

e. Never refuel the machine indoors because fuel

vapors will accumulate in the area.

f. Never store the fuel container or machine

inside where there is an op en flame or spark ,

such as a gas hot water hea ter, space hea ter

or furnace.

2. Never run a machine inside a closed area. Engine

exhaust fumes can be lethal.

3. To reduce fire hazard, keep the machine free of

grass, leaves or other debris build-up. Cle an up

oil or fuel spillage. Allow the machine to cool at

least 5 minutes before storing.

4. Before cleaning, repairing or ins pecting, stop the

engine and remove key. Make certain the blades

and all moving parts have stopped. Disconnect

the spark plug wires and move them away from

the spark plugs to prevent accidental starting.

5. Frequently check all nuts, bolts and screws for

proper tightness to ensure the equipment is in

safe working condition, especially the blade nuts.

Also visually inspect blades for damage (e.g.,

excessive wear, bent, cracked). Replace only

with blades that meet original equipment

specifications.

6. Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

7. After striking a foreign object, stop the engine,

remove the wires from the spark plugs and

thoroughly inspect the mower for any damage.

Repair the damage before restarting and

operating the mower.

8. Grass catcher components are subject to wear ,

damage and deterioration, which could expose

moving parts or allow objects to be thrown . For

your safety, frequently check the components

and replace with manufacturer’s recommended

parts when necessary.

9. Mower blades are sharp and can cut. Wrap the

blades or wear gloves, and use extra caution

when servicing blades.

4

Page 5

10. Check brake operation frequently. Adjust and

service as required.

11. Muffler, engine and belt guards become hot

during operation and can cause a burn. Allow to

cool down before touching.

12. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are extremely dangerous.

13. If the machine should begin to vibrate abnormally,

stop the engine and check immediately for the

cause. Abnormal vibration is a warning of trouble.

14. Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

a. Prior to disposal, contact your local Environ-

mental Protection Agency to determine the

proper method for disposing of the waste. Re-

WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

cycling centers are established to properly dispose of materials in an environmentally safe

fashion.

b. Use proper containers when draining fluids.

Do not use food or beverage containers that

may mislead someone into drinking from

them. Properly dispose of the containers immediately following the draining of fluids.

c. DO NOT pour oil or other fluids into the

ground, down a drain or into a stream, pond,

lake, or other body of water. Observe Environmental Protection Agency regulations when

disposing of oil, fuel, coolant, brake fluid, filters, batteries, tires and other harmful waste.

15. We do not recommend the use of a pressure

washer or garden hose to clean your unit. They

may cause damage to electrical components;

spindles; pulleys; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceability.

TO THE OWNER

Contained in this manual are instructions covering

installation and maintenance of the 60 inch Model 190291 mower deck.

Information provided will guide you through the

preparation, installation and removal processes.

Proper completion of the adjustment procedures will

help to ensure optimal performance from the mower

deck.

Maintenance procedures outlined in this manual, if

performed as instructed, will provide for a continued

high level of performance and prolonged service life

from the mower deck.

Throughout this manual, the reader will be directed to

refer to various figures. These figures depict and

indentify parts which are relevant to the associated

text. Careful attention to these figures will greatly assist

the reader during both installation and maintenance

processes.

If you have difficulties with the attachment, have

questions regarding the operation or maintenance of

this equipment, or desire additional information not

found in the manual, contact your dealer. If you need

help locating a dealer in your area, contact the

Customer Dealer Referral Line by calling:

1-877-282-8684

NOTE

References to LEFT and RIGHT indicate that

side of the tractor when facing forward while

seated in the drivers seat. Reference to FRONT

indicates the grille end of the tractor; to REAR,

the drawbar end.

5

Page 6

SECTION I. TRACTOR AND DECK PREPARATION

WARNING

When handling the mower deck, b e car eful not

to cut yourself on the sharp blades.

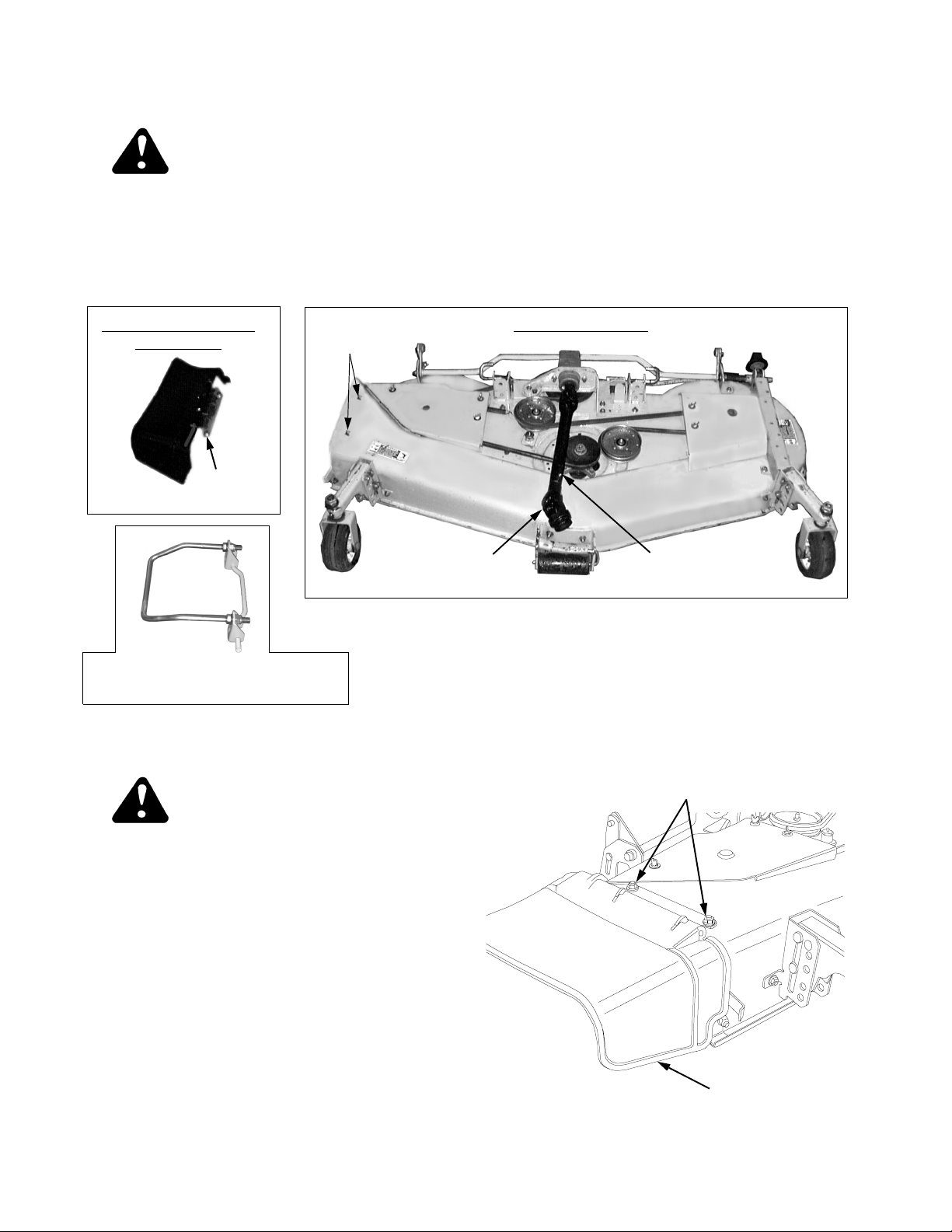

Remove the top and break down the sides of the crate

to remove the deck components from the shipping

container. Cut the tie straps securing the chute

deflector assembly and front drive shaft to the deck

assembly. Remove all padding material from the drive

shafts. Refer to Figure 1.

NOTE: The mower deck front lift bracket/rod assembly

is shipped on the tractor. If not already done, cut the tie

strap securing the front lift bracket/rod assembly to the

front of the tractor frame. Pull the center of the tractor’s

quick latch rod downward to remove the lift bracket assembly from the tractor.

CHUTE DEFLECTOR

ASSEMBLY

HINGE

BRACKET

FRONT LIFT BRKT /ROD ASS’Y.

—SHIPPED ON TRACTOR

A. DECK PREPARATION

WARNING

FASTENERS

FRONT DRIVE

SHAFT

Figure 1

DECK ASSEMBLY

REAR DRIVE

SHAFT

Hex Flange Lock Nuts

& Carriage Bolts

Do not operate the mower deck without the

chute deflector installed and in the down

position.

Install the chute deflector onto the right side of the deck

over the discharge chute opening as follows:

1. Remove the two carriage bolts and hex flange lock

nuts from the deck housing at the discharge chute

opening.

2. Position the chute def lec to r as sembly on the deck

above the discharge opening, aligning the two

holes in the hinge bracket with the holes in the

deck housing.

3. Insert the carriage bolts from the unde rside of the

deck and through the holes in the hinge bracket.

Secure with the two hex flange lock nuts (See Figure 2).

CHUTE

DEFLECTOR

Figure 2

6

Page 7

B. TRACTOR PREPARATION

NOTE

Tractors built Mfg. Cod e 1K060G and a fter are

equipped with a deck downst op feature. In the

raised position, the downstop will prevent the lift

links from being adequately lowered to allow installation of the deck. If the deck is being installed on a tractor which does not have the

downstop feature, skip the following step 1 and

go to step 2.

1. If installing the deck on a tractor with the deck

downstop feature, make certain the downstop is in

the lowered position as follows (See Figure 3):

a. If necessary, use the tractor’s lift handle to

raise the center lift and relieve any p ressure

from the downstop arm.

b. Lower the deck downstop by continuously

turning the height adjustment knob counterclockwise.

LEFT

LIFT

ROD

NOTCH

HOLD

DOWN

LIFT STOP BRACKET

RELEASE TAB

Figure 4A

LEFT

LIFT

LINK

SLOT

VIEWED FROM

RIGHT SIDE

LIFT

UPWARD

LOWER

RAISE

HEIGHT

ADJUSTMENT

KNOB

Figure 3

2. The left lift link of the tractor must be raised to pro-

vide clearance f or sliding the mower deck under,

or out from under, the tractor. Referring to Figures

4A through 4D, lock the left lift link in its deck in-

stallation position as follows:

a. Use the tractor lift system lever to lower the lift

links.

b. Holding the left lift rod downwar d, lift upward

on the release tab of the lift stop bracket while

raising the rearwar d end o f th e l if t l ink to align

the notch of the rod with the slot of the link

(See Figures 4A and 4B).

c. Swing the lift rod forward until fully to the front

of the lift link slot (See Figures 4C and 4D).

Figure 4B

SWING

LIFT ROD

FORWARD

Figure 4C

LIFT LINK

LOCKED

VIEWED FROM

RIGHT SIDE

Figure 4D

7

Page 8

SECTION II. INSTALLATION AND REMOV AL OF M O WE R DECK

A. INSTALLATION OF DECK

After locking the left lift link as desc ribed in Section I

(step B-2), start the tractor and use the hydraulic lift to

fully raise the left lift link (See Figure 5). Stop engine.

LEFT LIFT LINK

FULLY RAISED

Figure 5

Remove the internal cotter pins, flat washers, and

adjustment clevis pin s to ad just the fr ont c aster whe el

arms to their highest setting (lowest deck setting) in the

height adjustment brackets of the deck (See Figure 6).

PIVOT LINK

SHOULDER BOLT

ROTATE

ADJUSTMENT

KNOB

DETENT

HUB

DETENT PIN

GUIDE

BRACKET

SLOT

Figure 7

Install the mower deck on the tractor as follows:

1. Place the tractor and mo wer deck on a firm and

level surface. Position the mower deck on the left

side of the tractor with the front of the deck toward

the front of the tractor (See Figure 8)

CASTER

WHEEL

ARM

FLAT

WASHER

TOP

HOLE

ADJUSTMENT

CLEVIS PIN

HGT. ADJ.

BRACKET

INTERNAL

COTTER PIN

Figure 6

Adjust the rear deck rollers to their highest setting

(lowest deck setting) as follows:

1. From the left/rear of the dec k, pull th e adjustment

knob rearward to disenga ge the detent pin of the

knob from the hole i n the detent hub ( See Figure

7). Hold the knob rearward.

2. Turn the knob clockwise until the shoulder bolt

fastened to the roller pivot link is at the top of the

slot in the roller guide bracket (See Figure 7).

3. Release the knob and turn a s necessary to align

the detent pin with the nearest hole in the hub.

SLIDE

UNDER

Figure 8

8

Page 9

WARNING

NOTE

Before installing the mower deck, place the

PTO switch in the “OFF ” position, engage the

parking brake lever, and turn ignition key to the

“OFF” position. ALW AYS stop t he engine afte r

utilizing the tractor h ydraulic lift system. When

handling the mower deck, be careful not to c ut

yourself on the sharp blades.

2. Slide the deck under the tractor until the slots of

the LH and RH rear deck br ackets align approximately with the tractor lift links (See Figure 9).

3. Pull outward and cock the deck support pins in the

rear dec k brac kets so that both spring-loaded pins

are held in the disengaged position against the

inner surface of the deck brackets (See Figure 9).

REAR DECK

BRACKET

SLOT

PIN LOCKED IN

DISENGAGED

POSITION

DECK

SUPPORT

PIN

Figure 9

4. Use the tractor lift system to lower the lift links.

NOTE: If installing the deck on a tractor with the

deck downstop feature, make certain the

downstop is in the lowered position (Refer to

Section 1 step B-1).

The following step 6 appl ies only to the initial

installation of the mower deck on the tracto r.

6. Loosen the hex jam nuts on the front lift br acket /

rod assembly and back off (unscrew) the hex lock

nuts until approxi mately 1/2 inch fro m the ends o f

the threads (See Figure 11).

FRONT

LIFT

ROD

LOCK WASHER

FRONT LIFT

BRACKET

HEX

JAM

NUT

HEX

LOCK

NUTS

Figure 11

7. From the front of the tractor, slide the outer pins of

the front lift brac ket into the latch receiver slots of

the tractor. Press the lift bracket rearward until

both sides are firmly captured in the latch receivers

by the quick latch rod (See Figure 12).

QUICK LATCH ROD

LATCH RECEIVER SLOTS

5. Unlock the left lift link by sliding the left lift rod fully

rearward in the slot of the lift link (See Figure 10).

LEFT

LIFT

ROD

LH LIFT

LINK

Figure 10

FRONT

LIFT

BRACKET

CAPTURE IN

RECEIVER SLOTS

Figure 12

9

Page 10

8. From the side of the tractor, r aise the fr ont lift r od

and roll the deck forward until the lift rod aligns with

slots of the deck front roller bracket. Lower the lift

rod into the front roller bracket slots and slide the

deck rearward to engage the lift rod fully forward

in the slots of the roller bracket (See Figure 13).

FRONT ROLLER

BRACKET SLOTS

FRONT

LIFT ROD

Figure 13

NOTE

If unable to align th e support pins with the lift

link holes, loosen the two h ex lock n uts on the

front lift rod to allow the deck to be moved

farther rearward.

SUPPORT PIN

FULLY EXTENDED

THROUGH LIFT LINK

(BOTH SIDES)

9. Guide the LH and RH lift link s into t he sl ots of the

rear deck brackets and release the deck support

pins by aligning with the inner holes of the deck

brackets (See Figure 14).

NOTE: The handle of the support pins s hould be

positioned to the rear of the deck brackets as

shown in Figure 15.

LIFT LINK

SLOT

REAR

DECK

BRACKET

DECK

SUPPORT

PIN

INNER HOLE

Figure 14

Figure 15

NOTE

The following st ep 11 applies onl y to the initial

installation of the mower deck on the tracto r.

11. Tight en the hex l ock nuts on the front lift rod until

the rod just contacts the fr ont of both slots in the

deck front roller bracket. F or now, tighten the hex

jam nuts and lock washers until just snug a gainst

the front lift bracket. Refer to Adjustments—

Section 3 for final adjustment of front lift rod.

12. Compress the auto-lok collar of the deck drive

shaft rearward, then cock to lock the collar in the

released position (See Figure 16).

COMPRESS

AUTO-LOK

COLLAR

THEN COCK

TO LOCK

10. Maneuver each side of the deck slightly to align the

support pins with the holes of the lift links. The

spring tension will push the pins inward and, if

aligned, through the hole in each implement lift

link (See Figure 15).

Figure 16

10

Page 11

NOTE

If you do not lock the drive s haft auto- lok col lar

in the released position (step 12), it will be

necessary to compress and hold the collar

rearward when connecting the shaft (step 13).

13. Slide the de ck driv e shaft ful ly onto the PTO sh aft

of the tractor (See Figure 17). The auto-lok collar

of the drive shaft should snap into the locked

position when the shaft i s properly positioned on

the PTO shaft.

PTO SHAFT

DECK DRIVE

SHAFT

Figure 17

14. Refer to Adjustments—Section 3 for mower

deck leveling adjustment procedures.

B. REMOVAL OF DECK

Place the tractor and mower deck on a firm and level

surface with enough room to sl ide the deck out from

the left side of the tractor.

WARNING

Before removing the mower deck, place the

PTO switch in the “OFF ” position, engage the

parking brake lever, and turn ignition key to the

“OFF” position. Always stop the engine after

utilizing the tractor h ydraulic lift system. When

handling the deck, be careful not to cut yourself

on the sharp blades.

1. Support the deck drive shaft to prevent it from

dropping; then pull the auto-lok collar rearward

and slide the drive s haf t o ff o f t he PT O s ha ft ( See

Figures 16 and 17).

2. Using the tractor hydraulic lift system, lift the

mower deck so that the caster wheels are off the

ground. Stop the engine.

3. Remove the internal cotter pins, flat washers, and

adjustment clevis pins to adjust the front caster

wheel arms to their highest setting (lowest deck

setting) in the height adjustment brackets of the

deck (See Figure 6).

4. Adjust the rear deck roller s to their highes t settin g

(lowest deck setting) as follows:

a. From the left/rear of the deck, pull the ad just-

ment knob rearward to disengage the detent

pin of the knob from the hole in the detent hub

(See Figure 7). Hold the knob rearward.

b. Turn the knob clockwise until the shoulder bolt

in the roller pivot link is at the top of the slot in

the roller guide bracket (See Figure 7).

c. Release the knob an d turn as necessary to align

the detent pin with the nea rest hole in th e hub.

5. Use the tractor lift system to lower the deck to the

ground. NOTE: If removing the deck from a tractor

with the deck downsto p feature, make cer tain the

downstop is in the lowered position (Refer to

Section 1 step B-1).

6. Pull outward and cock the deck support pins in the

deck hanger brackets so that both sprin g-loa ded

pins are held in the di sengaged position against

the inner surface of the deck brackets (See

Figure 9).

7. Lock the left lift link in its deck installation/removal

position as follows:

a. Holding the left lift rod d ownward, lift upward

on the release tab of the lift stop bracket while

raising the rea rw ard e nd of the lift link to al ig n

the notch of the rod with the slot of the link

(See Figures 4A and 4B).

b. Swing the lift rod forward until fully to the front

of the lift link slot (See Figures 4C and 4D).

8. Use the hydraulic lift to fu lly raise the LH an d RH

lift links (See Figure 5). Stop the engine.

9. Roll the deck forward to disengage the front lift rod

from the slots of the front roller bracket (See Figure

13). Hold the front lift rod upward and slide the

deck rearward until the lift rod r ests on top of the

roller bracket.

10. From th e front o f the tract or, pull the c enter o f the

quick latch rod do wnward to release the front lift

bracket/rod assembly. Slide the front lift bracket

assembly from the latch receiver slots of the

tractor (See Figure 12).

11. From th e left side of the tractor, s lide the mower

deck out from under the tractor.

11

Page 12

SECTION III. ADJUSTMENTS

DECK LEVELING ADJUSTMENTS

NOTE

Tractors built Mfg. Cod e 1K060G and a fter are

equipped with a deck downs top feature which

can be used to set the downstop position of the

mower deck, regardless of whether the deck

caster wheels contact the ground.

The 60" mower deck is equipped with ground following

front caster wheels and is designed to be operated with

the caster wheels and rear rollers on the ground.

However, if the deck is being installed on a tractor

equipped with the downs top feature, the deck can be

suspended off the ground by utilizing the deck height

adjustment knob to set the downstop position. In either

case, to ensure an even cu t on all ty pes of ter rain , the

mower deck should be pr operly leveled. The side to

side leveling proced ure will result in the left and right

blades having corresponding cutting-edge-to ground

measurements within 1/16 inch of eac h other. Also,

the cutting blades will have a downward tilt toward the

front of the tractor of appr oximately 1/8 inc h. To level

the mower deck, proceed as follows:

WARNING

Before making any a djustme nts, pl ace th e PTO

switch in the “OFF” po siti on, en ga ge th e pa rking

brake lever, and turn the ignition key to the “OFF”

position. When adjusting the mower deck, be

careful not to cut yo urself on the sharp blades.

A. SIDE TO SIDE LEVELING ADJUSTMENT

NOTE: Check for proper tire infla tion before checking

and/or making a leveling adjustment.

1. Position the tractor on a hard, level surface, and

use the tractor hydraulic lift system to raise the

deck to its highest position. Stop engine.

2. To prevent contact with the surface below, adjust

the front caster wheel arms and rear rollers to their

highest setting (lowest deck setting). If necessary,

refer to C. SETTING THE CUTTING HEIGHT.

3. Carefully rotate the outer cutting blades so that

they are positioned perpendicular to the tractor

frame (See Figure 18).

4. Referring to Figure 19, measure and record the

distance from the l evel surface to the outer-mos t

cutting edge of the right blade. Repeat this step for

the left blade. If the two blade heights are not within 1/16 inch, the deck must be leveled. Note whether the left blade had the larger or sm al ler di sta nc e

between the cutting edge and level su rface. If th e

two blade heights are within 1/16 inch, p ro ce ed t o

step B. FRONT LIFT ROD ADJUSTMENT.

1

Finger guard

1.

2. Blade

3. Hard Level Surface

4. Measure This Distance

2

4

3

Figure 19

5. Side to side lev eling is attained by adjusting the

hex lock nut on the bottom of the LH lift rod,

located below the LH lift link (See Figure 20).

OUTER BLADES

PERPENDICULAR TO FRAME

Figure 18

HEX LOCK NUT

LH LIFT LINK

LH LIFT ROD

Figure 20

6. Turn the hex lock nut upward (tighten) on the

threads of the lif t rod to raise the left side o f the

mower deck. Turn the lo ck nut down (loosen) on

12

Page 13

the lift rod threads to lower the left side of the

mower deck.

7. Recheck the measurements described in step 4. If

the blade measurements are not within 1/16 inch,

repeat steps 4 and 6 until the correct measur ement is obtained.

B. FRONT TO BACK LEVELING

The front lift rod must be correctly adjusted to maintain

the proper pitch of the deck when mowing uneven terrain.

1. Adjust the front caster wh eel arms and rear deck

rollers to their highest setting (lowest deck setting).

2. Position the mower blades so the ends of each

blade point to the front and the r ear of the tractor

(See Figure 21).

CHUTE

DEFLECTOR

RIGHT HAND BLADE POINTING

TO FRONT AND REAR

Figure 21

3. Refer to Figure 22. Measu re and record the distance from the front cutting edge to the ground

(measure A), and from the rear cutting edge to the

ground (measure B) , for both outer blades. The

front edge of each blade (measure A) should be

lower than its back edge (m easure B) by approxi mately 1/8 inch.

the rod does not contact the front of the slot, tighten the

corresponding lock nut as needed.

FRONT

LIFT

ROD

HEX JAM NUT

LOCK WASHER

FRONT LIFT

BRACKET

HEX

LOCK

NUTS

Figure 23

5. Tighten the rear jam nuts and lock washers

against the backs ide of the front lift bracket after

adjustment of the rod has been completed.

C. SETTING THE CUTTING HEIGHT

NOTE

Cutting height adjustment should be performed only

AFTER the mower deck has been properly leveled.

If the mower deck is inst alled o n a tract or without the

deck downstop feature, the cutting height is set by

positioning the front caste r wheel arms in one of five

settings in the height adjustment bracket of the deck.

If the deck is instal led on a tractor with the downstop

feature,

deck height adjustment knob to set the deck downstop

position or by positioning the caster wheels in one of

five settings.

the cutting height is set by using either the

REAR

CUTTING

EDGE

B

FRONT

CUTTING

EDGE

A

Figure 22

4. Adjust the front lift rod as follows to attain the

proper pitch of the mower deck (See Figure 23).

• Loosen the hex jam nut s a nd l oc k was her s on the

front lift rod.

• From the front of the tractor, turn the front hex lock

nuts clockwise to raise the front of the deck, or

counterclockwise to lower the front of the deck.

• Recheck the measurements described in step 3

and readjust the hex lock nuts until the proper

measurements are obtained.

NOTE: The front lift rod should be fully to the front of

both slots in the deck front roller bracket. If one side of

USING THE CASTER WHEELS AND ROLLERS TO

SET CUTTING HEIGHT

WARNING

Before adjusting the caster wheel/roller positions, place the PTO switch in the “OFF” position, engage the parking brake lever, and t urn

the ignition key to the “OFF” position.

NOTE

Note the index holes of th e height adjustment

bracket are not sequential (top to bottom) in

relation to their corresponding height setting,

and the lower hole in the caster arm is used for

settings 2 and 4 (See Figure 24).

1. Use the tractor lift system to raise the mower deck

off the ground.

13

Page 14

2. Remove the internal cotter pin, flat washer, and adjustment clevis pin from the height adjustment

bracket. Position the caster wheel arm in the desired

height setting and insert the adjustment clevis pin

(See Figure 24). Secure with the flat washer and internal cotter pin. Repeat for other side.

CASTER WHEEL ARM

1

ADJUSTMENT

CLEVIS PIN

3

5

NOTE

Because the weight of the mower deck may

cause some settling of the roller linkage, the

cutting blades should be measured to ensure

they are level or up to 1/8" lower i n the front. If

the mower deck has been pr operly levele d per

the previous instructions, measuring just the

right hand cutting blade is sufficient.

5. Carefully rotate the outer cutting blades so that the

ends of the right blade point to the front and rear of

the tractor (Refer to Figure 21).

2

4

HGT. ADJ.

BRACKET

INDEX HOLE POSITION 1 = LOWEST DECK SETTING

INDEX HOLE POSITION 5 = HIGHEST DECK SETTING

Figure 24

3. From the left/rear of the dec k, pull th e adjustment

knob rearward to disenga ge the detent pin of the

knob from the hole in the detent hub. While holding

the knob rearward turn the roll er adjustme nt knob

as necessary to align the shoulder bolt in the roller

pivot link with the corresponding height index

setting on the roller guide bracket (See Figure 25).

ROLLER

ADJ. KNOB

SET IN

POSITION 3

1

3

5

2

4

SHOULDER BOLT

1

2

3

4

5

6. Lower the deck to level surface below.

7. Holding the ch ute deflector upward, measur e the

distance between the front most cutting edge of

the blade and the surface. Repeat for the rear most

cutting edge and compare the two measurements.

a. If the front measurement is the same as, or up

to 1/8" less than the rear measurement, no adjustment is required.

b. If the rear measurement i s greater than 1/8"

higher than the front measurement, turn the

roller adjustment knob clockwise as needed to

raise the roller and achieve the specified pitch

of the deck .

c. If the front measurement is greater than the

rear measurement, turn the roller adjustmen t

knob counterclockwise as needed to lower the

roller and achieve the specified pitch of the

deck. Remember the detent pin of th e adjustment knob should engage the nearest hole in

the detent hub.

USING HEIGHT ADJUSTMENT KNOB — TRACTORS WITH DECK DOWNSTOP ONLY

Each full rotation of the height adjustment knob equals

approximately a 1/4 inch adjustment in the deck height

setting, and there are four detent positions per rotation.

Initially set the deck downstop as follows (Refer to

Figure 26):

1. To remove the weight of the deck from the downstop

arm, use the tracto r lif t sy stem to r aise th e d eck. Adjust the caster whe els a nd r oller s to th eir h ighe s t position.

Figure 25

4. Release the knob and turn a s necessary to align

the detent pin with the nearest hole in the hub.

Make certain the pin is ful ly engaged in the hole

(See Figure 7 on Pg. 8).

2. Fully lower the de ckstop by continuously turning

the height adjustment knob counterclockwise.

3. Use the tractor lift system to lower the deck to the desired height setting, then turn the adjustment knob

clockwise until it stops t urning freely. Turn t he knob to

nearest detent po siti on.

14

Page 15

4. Reposition the caster wheels and roller so that

they are appoximately 1/2 inch above the ground.

5. For subsequent minor adjustments from this

position, use the tractor lift system to raise the deck,

then turn the adjustment knob as necessary to

attain the desired height setting (one full turn

equals approximate ly 1/4"). Reposi tion the caste r

wheels and rollers if necessary.

NOTE: To use the caster wheels/rollers for setting the

cutting height on tractors equipped with the deck

downstop, make certa in to lower the downstop using

the height adjustment kn ob. Then follow the previous

instructions for setting the cutting height using the

caster wheels and rollers.

SECTION IV. MAINTENANCE

A. CLEANING AND BLADE CARE

WARNING

Before performing any maintenance, place the

PTO switch in the “OFF” position, engage the

parking brake lever, turn the ignition key to the

“OFF” position and remove the key from the

switch. When servicing the mower d eck, be care ful not to cut yourself on the sharpe ned blades.

Clean the underside of the mower deck at the end of

the mowing season or when buildup of cut material on

the underside is noticed.

Once a month remove the thumb screws, bell washers,

and belt covers (Refer to Figure 29) to remo ve any accumulated grass clippings from around the spindle pulleys

and V-belt. More of ten whe n m owi ng tall, d ry gr a ss.

The cutting blades must be kept sharp at all times. Sharpen the cutting edges of the blades evenly so that the

blades remain balanced and the same angle of sharpness is maintained. If the cutting edge of a blade has

been sharpened to within 5/8 inch of th e wind wing radius

(See Figure 27), it is recommended that new blades be

installed. New blades are available at your authorized

dealer.

WIND

WING

Figure 27

When removing the blades, use a 1-1/8 inch wrench to

hold the head of the spindle bolt whil e loosening the

hex nut securing the bl ade. A block of wood may be

placed between the deck housing and the cutting edge

5/8" FROM

RADIUS

LOWER

RAISE

HEIGHT

ADJUSTMENT

KNOB

Figure 26

of the blade to as sist in remova l of the hex nut (Refer

to Figure 28).

HEX NUT

WOOD BLOCK

1-1/8" WRENCH

IN POSITION

Figure 28

When reinstalling the blades, be sure they are installed

so that the wind wings are pointing upward toward the

top of the deck. Tighte n the nuts to 90 to 110 ft-lbs.

(122 to 149 N·m).

After replacing the blades, apply grease to the

exposed threads at th e bottom of the spindle bolts to

prevent rust buildup.

B. LUBRICATION

After every 10 hours of operation and/or before putting

the deck into winter storage, lubricate the spindle

assemblies and the spindle belt idler arm with 251H EP

grease or an equivalent No. 2 multipurpose lithium

grease. The lube fitting for the outer spindles can be

accessed by removing the button plugs in the belt

covers. Use grease liberally. Excess grease will be

expelled from the inverted upper se als of the spindle

assemblies. Listen for the muffled crackling noise of

grease being ex pelle d through the seal to ind icate th e

spindle assembly is fully greased (Refer to Figure 29).

Apply grease to all other lube fittings after every 50

hours of operation. Refer to

LUBRICATION GUIDE.

15

Page 16

3 & 4

2

1

2

2

3 & 4

1

5

1. Spindle Belt Cover

2. Thumb Screws and Bell Washers

3. Button Plugs - Access to Spindle

Lube Fitting

C. SPINDLE BELT REPLACEMENT

A worn spindle belt will affect the quality of cut from the

mower deck and should be replaced. Referring to

Figures 29 and 30, replace the spindle belt as follows:

NOTE

The two hex flange lock nuts and carriage bolts

securing the lef t side of the g ear box mounting

bracket (See Figure 30) are re moved from the

deck when replacing the belt. Clean any

accumulated grass clippings from the

underside of the mower deck to ensure prope r

reassembly of these fasteners.

REMOVE SPINDLE BELT

1. Remove the thumb s crews and bell washers securing the RH and LH belt covers (See Figure 29).

Slide the tabs of the LH belt cover from the channel

bracket to remove the cover.

NOTE

Note the routing of the spindle belt to help

ensure proper installation of the new belt.

4

4. Spindle Assembly Lube Fittings

5. Idler Arm Lube Fitting

6. Channel Bracket

6

Figure 29

WARNING

The idler bracke t and movable flat idler pulley

are under spring tension. To prevent possible

injury, use caution when handling the idler

pulley.

2. Push the movable fla t idler pulley (2, Figure 30)

toward the left side of the deck to relieve belt

tension; then roll the spin dle belt off the movable

flat idler pulley.

3. Slide the belt off and over the LH spin dle pulley.

Then pull the belt under the LH belt cover

mounting strap; off the fixed flat idler pulley and

center spindle pulley.

4. Remove the two hex flange lock nuts and carriage

bolts (10, Figur e 30) securing the le ft side of the

gear box mounting bracket to the deck.

5. Remove the two hex flange lock nuts and carriage

bolts (11, Figure 30 ) securing the r ight side of th e

gear box mounting bracket to the deck plate.

6. Lift the gear box/mounting bracket assembly an d

slide the belt off and underneath the drive pulley.

7. Remove the belt from the deck.

16

Page 17

2

1

9

11

3

8

10

1

7

Spindle Pulleys

1.

Movable Flat Idler Pulley

2.

Drive Pulley

3.

Fixed Flat Idler Pulley

4.

Spindle Belt

5.

LH Belt Cover Mounting Strap6.

Figure 30

INSTALL NEW SPINDLE BELT

1. Lift the gear box/mounting bracket assembly to

install the belt around the r ear an d left side of the

drive pulley, and through the center opening of the

mounting bracket.

2. Secure the gear box mounting bracket to the deck

with the four carriage bolts and hex flange lock

nuts.

3. Route the backside of the belt around the rear and

right side of the movable flat idler pulley.

5

1

7.

8.

9.

10.

11.

4

Idler Bracket

Gear Box Mounting Bracket

Idler Spring

Carriage Bolts and Flange Lock Nuts

Carriage Bolts and Flange Lock Nuts

6

5. Route the belt as follows:

• around the left spindle pulley

• around the rear of the fixed flat idler pulley

• around the front of the center spindle pulley

• to the right spindle pulley

6. After making certain the belt is properly engaged in

each pulley, pivot the movable flat idler pulley

toward the left side of the deck to loosen belt

tension and allow the spindle belt to be rolled onto

the right hand spindle pulley.

4. Loop the belt and slide it under the LH belt cove r

mounting strap.

7. Install the belt cov ers and secure with the t humb

screws and bell washers.

17

Page 18

LUBRICATION GUIDE

The life of any machine depends upon the care it is given. Proper lubrication is a very important part

of that care.

NOTE: We do not recomme nd the use of a pressure

washer or garden hose to clean your unit. They may

cause damage to electrical components; spindles;

pulleys; bearings; or the engine. T he use of water will

result in shortened life and reduce serviceability.

Be certain that all lub rication fit tings are as semble d in

place, using the lubrication illustration as a guide.

Always lubricate the deck thoroughly before taking it to

the field. Use a pressure lubricating gun.

Be sure all fittings are free from dirt and pa int so the

lubricant is certain to enter the bearing.

Miscellaneous working parts not provided with

lubrication fittings should be oiled daily with a good

grade of lubricating oil.

Lubricant is cheap. Use plenty of it. Worn parts can be

expensive to replace.

Keep your supply of lubricating oil and grease stored in

clean containers, and covered to protect from dust and

dirt.

Keep the lubricating gun nozzle clean and wipe dirt

from the grease fittings before lubricating.

The symbols in the il lus tr ati on s i ndicate the method of

application and the hourly intervals to apply the

lubricant.

Use a pressure lubricating gun

and apply 251H EP grease (or

equivalent No. 2 multi-purpose

lithium grease) sufficient to flush

out the old grease and d irt. Lu bricate at the hourly intervals indicated on the symbols.

1

10

50

50

5

4

Deck Spindles — Every 10 Hours of Operation

1.

Idler Bracket — Every 10 Hours of Operation

2.

Deck Drive Shaft — Every 50 Hours of Operation

3.

Castor Wheels — Ev ery 50 Hours of Operation

4.

Front Castor Spindles — Every 50 Hours of Operation

5.

10

2

50

3

50

3

18

50

4

50

5

Page 19

PRODUCT GRAPHICS

Keep safety product graphi cs (decals) clean. Replac e

any safety graphic that is damaged, destroyed,

KEEP HANDS AND FEET AWAY FROM

ROTATING PARTS.

REMOVE OBJECTS THAT CAN BE

THROWN BY THE BLADE IN ANY

DIRECTION. WEAR SAFETY GLASSES.

DO NOT MOW WHEN CHILDREN OR

OTHERS ARE AOUND. NEVER CARRY

CHILDREN.

USE EXTRA CAUTION ON SLOPES. DO

NOT MOW SLOPES GREATER THAN 15°.

MOW UP AND DOWN, NOT ACROSS.

AVOID SUDDEN TURNS, USE LOW GEAR.

READ OPERATOR'S MANUAL. KEEP SAFETY DEVICES WORKING.

60" DECK SAFETY GRAPHIC – LOCATED

ON LEFT SIDE OF MOWER DECK

missing, painted over or can no longer be read.

Replacement safety graphics are available through

your dealer.

DEFLECTOR and SAFETY GRAPHIC –

LOCATED ON RIGHT SIDE OF DECK

HANDS AND FEET SAFETY GRAPHIC –

LOCATED ON DEFLECTOR CHUTE

19

Page 20

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Cub Cadet

LLC with respect to new merchandise purchased and used in

the United States, its possessions and territories.

Cub Cadet LLC warrants this product against defects for a

period of two (2) years commencing on the date of original

purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or

workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance

with the Operator’s Manual furnished with the product, and

has not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril

or natural disaster. Damage resulting from the installation or

use of any accessory or attachment not approved by Cub

Cadet LLC for use with the product(s) covered by this manual

will void your warranty as to any resulting damage.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear parts or

component failures will be covered on the product for a period

of 90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in materials or workmanship of

OTHER component parts. Normal wear parts and

components include, but are not limited to: batteries, belts,

blades, blade adapters, grass bags, rider deck wheels, seats,

snow thrower skid shoes, shave plates, auger spiral rubber,

and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact Cub Cadet LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-877-282-8684, or log

on to our Web site at www.cubcadet.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to

applicable manufacturer’s warranty for terms and

conditions.

b. Log splitter pumps, valves, and cylinders have a sepa

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal

deterioration of the exterior finish due to use or

exposure.

d. Cub Cadet LLC does not extend any warranty for

products sold or exported outside of the United States,

its possesions and territories, except those sold

through Cub Cadet LLC’s authorized channels of

export distribution.

e. Parts that are not genuine Cub Cadet parts are not

covered by this warranty.

f. Service completed by someone other than an

authorized service dealer is not covered by this

warranty.

g. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind Cub Cadet LLC. During the period of the

warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. Cub

Cadet LLC shall not be liable for incidental or

consequential loss or damage including, without

limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Cub Cadet LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-877-282-8684

Loading...

Loading...