Page 1

Operator’s Manual

Model 190-002

30” Hydraulic

Tiller Attachment

REQUIRED FOR USE:

Weight Kit Bracket

(190-307-100)

Suitcase Weights (3 Req’d)

(190-390-100)

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

CUB CADET CORP. P.O. BOX 368023 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices................................................................... 3

Slope Gauge ..................................................................................................... 6

To the Owner .................................................................................................... 7

Loose Parts........................................................................................................ 7

Assembling the Tiller.......................................................................................... 7

Preparing the Tractor ........................................................................................ 9

Mounting the Tiller ............................................................................................ 12

Know the Tiller ................................................................................................... 14

Operating the Tiller ............................................................................................ 15

Maintenance ...................................................................................................... 18

Storage .............................................................................................................. 21

Troubleshooting ................................................................................................. 22

Templates .......................................................................................................... 23

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new tiller attachment. It will help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from your local authorized Cub Cadet

dealer.

You can locate the model number by looking at the left side of the tiller frame near the top. A sample model

plate is explained below.

(Model Number) (Serial Number)

Copy the model number here:

Copy the serial number here:

CUB CADET CORP.

P.O. BOX 368023

CLEVELAND, OHIO 44136

CALLING WARRANTY SERVICE

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1-(800)-528-1009 to locate your nearest Cub Cadet dealer. Before contacting your local

dealer, be sure to have your unit’s model number and serial number ready. See previous

section to locate this information.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this

manual before attempting to operate this machine. Failure to comply with these instructions may result

in personal injury. When you see this symbol—heed its warning.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet, and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

General Operation

• Read this operator’s manual carefully in its entirety

before attempting to assemble this machine. Read,

understand, and follow all instructions on the

machine and in the manual(s) before operation. Be

completely familiar with the controls and the proper

use of this machine before operating it. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

• This machine is a precision piece of power

equipment, not a plaything. Therefore, exercise

extreme caution at all times. Your unit has been

designed to perform one job: to till soil. Do not use it

for any other purpose.

• Never allow children under 14 years old to operate

this machine. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent. Only responsible

individuals who are familiar with these rules of safe

operation should be allowed to use your machine.

• Thoroughly inspect the area where the equipment is

to be used. Remove all stones, sticks, wire, bones,

toys and other foreign objects which could be

picked up and thrown by the tiller tines in any

direction which could cause serious personal injury

to the operator or any others allowed in the area.

Plan your tilling pattern to avoid discharge of

material toward roads, sidewalks, bystanders and

the like. To help avoid tine contact or a thrown

object injury, keep children, bystanders and helpers

at least 75 feet from the tiller attachment while it is in

operation. Stop tiller if anyone enters the area.

• Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair to protect eyes from foreign objects that

may be thrown from the machine in any direction.

• Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Shirts and pants that cover

the arms and legs and steel-toed shoes are

recommended. Loose fitting clothes and jewelry

can be caught in movable parts. Never operate a

unit in bare feet, sandals, slippery or light weight

(e.g. canvas) shoes.

• Do not put hands or feet near or under rotating

parts. Keep clear of the tiller tines at all times as the

rotating tines can cause injury.

• Never operate the tiller without the rear deflector in

its proper place.

• Disengage the PTO and raise the tiller attachment

when crossing gravel drives, walks, or roads.

• Watch for traffic when operating near or crossing

roadways. This machine is not intended for use on

any public roadway.

• Do not operate while under the influence of alcohol

or drugs.

• Use tiller attachment in daylight or in good artificial

light only.

• Never carry passengers.

• Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

• Use a slow ground speed when tilling soil for the

first time. Fast speeds may cause you to lose

control and may also damage the machine.

• Disengage the PTO and raise the tiller attachment

before shifting into reverse and backing up. Always

look down and behind before and while backing up

to avoid a back-over accident.

• Disengage the PTO and raise the tiller attachment

before making sharp turns. Leaving the tiller

lowered and engaged may adversely affect the

steering and control of the tractor.

• Use extra caution when making turns, especially in

tight areas or around obstacles. The tiller

attachment extends beyond the back of the tractor

and could strike an adjacent object (e.g. tree, fence,

bystander etc.) which could damage the machine or

cause personal injury.

• Check overhead clearances carefully before driving

under power lines, wires, bridges, low hanging tree

branches, before entering or exiting buildings, or

any other situation where the operator may be

struck or pulled from the unit, which could result in

serious personal injury.

• Disengage the PTO and raise the tiller attachment

when not in use.

• Never leave a running machine unattended. Always

disengage PTO, place transmission in neutral, set

3

Page 4

parking brake, turn engine off and remove key

before dismounting.

• Disengage the PTO, stop the engine and wait until

the tiller comes to a complete stop before making

any repairs, adjustments, or removing any rocks or

debris.

• Use extra caution when loading or unloading the

machine into a trailer or truck. A tractor with a tiller

attachment should not be driven up or down a ramp

onto a trailer or truck under power, the unit could tip

over causing serious personal injury. The unit must

be pushed manually to load or unload properly.

• Follow all manufacturer’s recommendations for use

of counterweights to improve machine stability.

• If situations occur which are not covered in this

manual, use care and good judgment. Contact your

dealer for assistance. Telephone 1-800-528-1009

for the name of your nearest dealer.

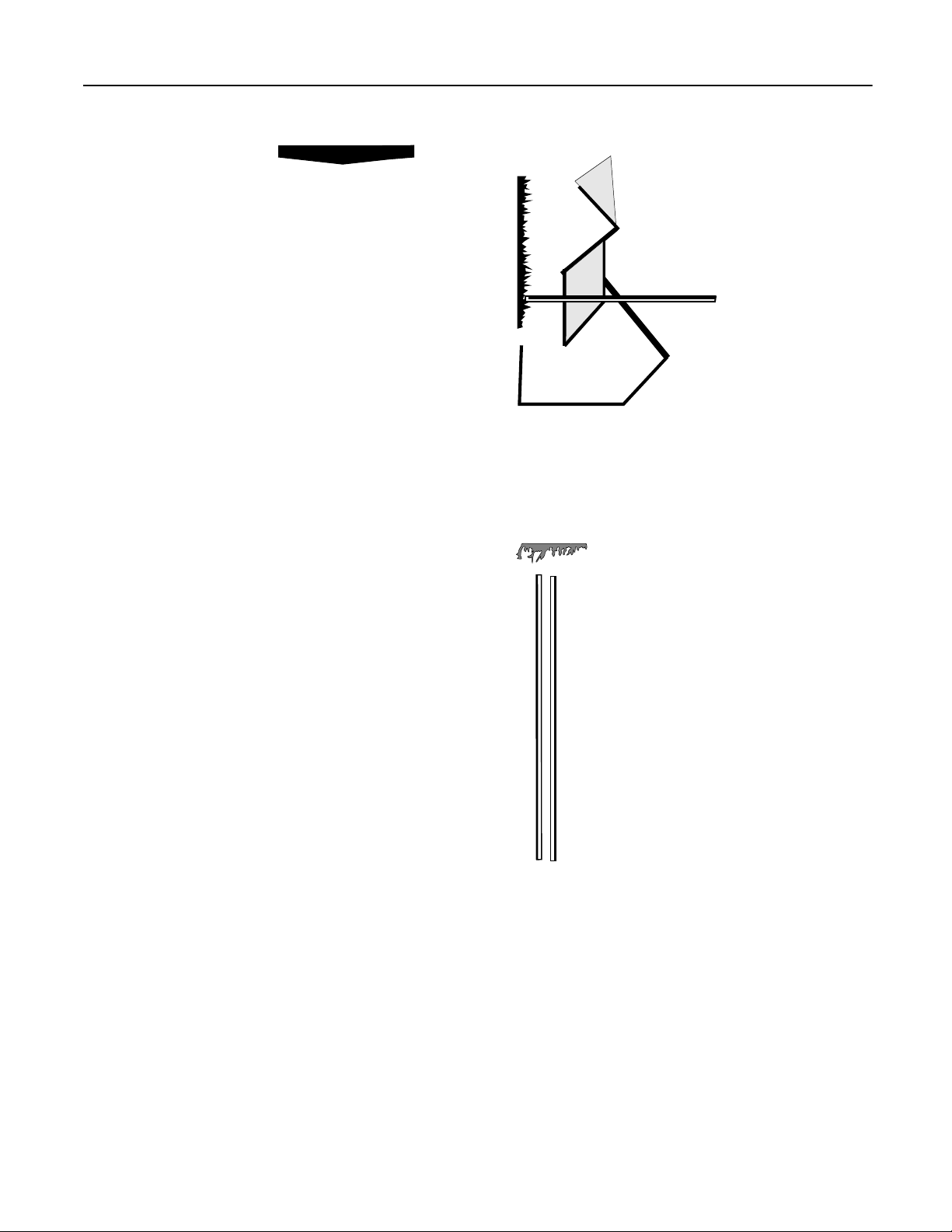

Slope Operation

Slopes are a major factor related to loss of control and

tip-over accidents which can result in severe injury or

death. Operation on slopes requires extra caution. If

you cannot back up the slope or if you feel uneasy on it,

do not till it. For your safety, use the slope gauge

included as part of this manual to measure slopes

before operating this unit on a sloped or hilly area. If the

slope is greater than 10 degrees as shown on the slope

gauge, do not operate this unit on that area or serious

injury could result.

Do:

• Till up and down slopes, not across. Exercise

extreme caution when changing direction on slopes.

• Watch for holes, ruts, bumps, and hidden objects

(e.g. rocks etc.) which can be under the soil.

Uneven terrain could overturn the machine which

may cause personal injury.

• Use slow speed. Choose a low enough speed

setting so that you will not have to stop or shift while

on the slope. Always keep the machine in gear

when going down slopes to take advantage of the

engine braking action.

• Keep all movements on slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid engagement or braking could cause the front

of the machine to lift and rapidly flip over backwards

which could cause serious personal injury.

• Avoid starting and stopping on a slope. If tires lose

traction, Disengage the PTO and proceed slowly

straight down the slope.

• Use extra care with the tiller attachment as it can

change the stability of the machine.

• Follow all manufacturer’s recommendations for

wheel weights or counterweights to improve the

stability of the machine.

Do Not:

• Do not turn on slopes unless necessary; then, turn

slowly and gradually downhill, if possible.

• Do not till near drop-offs, ditches or embankments.

The machine could suddenly overturn if a wheel or

the attachment is over the edge, or if the edge

caves in.

• Do not operate machine on wet grass. Reduced

traction could cause sliding and loss of control of the

machine.

• Do not try to stabilize the machine by putting your

foot on the ground.

• Do not till slopes greater than 10 degrees as shown

on the slope gauge.

Children

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the machine and the tilling activity. They do not

understand the dangers. Never assume that children

will remain where you last saw them.

• Keep children out of the tilling area and under the

watchful care of a responsible adult other than the

operator.

• Be alert and turn the machine off if a child enters the

area.

• Before and while moving backwards, look behind

and down for small children.

• Use extreme care when approaching blind corners,

doorways, shrubs, trees, or other objects that may

obscure your vision of a child who may run into the

machine.

• Never carry children, even with the attachment

disengaged. They may fall off and be seriously

injured or interfere with safe machine operation.

• Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

• Remove key when machine is unattended to

prevent unauthorized operation.

Never allow children under 14 years old to operate a

power mower. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained and

supervised by a parent.

Service

Safe Handling of Gasoline:

To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

• Use only an approved gasoline container.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Never fuel machine indoors because flammable

vapors will accumulate in the area.

4

Page 5

• Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

• Never over fill fuel tank. Fill tank to no more than ½

inch below bottom of filler neck to provide space for

fuel expansion.

• Replace gasoline cap and tighten securely.

• If gasoline is spilled, wipe it off the tractor’s fender.

Move unit to another area. Wait 5 minutes before

starting the engine.

• Never store the machine or fuel container inside

where there is an open flame, spark, or pilot light as

on a water heater, space heater, furnace, clothes

dryer, or other gas appliances.

• To reduce fire hazard, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

• Allow machine to cool at least 5 minutes before

storing.

General Service:

• Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

• Before cleaning, repairing, or inspecting, make

certain the tines and all moving parts have stopped.

Disconnect the spark plug wire and ground against

the engine to prevent unintended starting.

• Never attempt to make adjustments or repairs to the

machine while the engine is running.

• Never check for leaks in the hydraulic lines with

your hands. Hot, high pressure fluid can escape

through a pin hole leak and cause serious injury by

puncturing the skin and causing blood poisoning.

• Muffler, engine and belt guards become hot during

normal operation and can cause a burn. Hydraulic

hoses, fittings and fluid also become hot during

normal operation. Allow the machine, tiller

attachment, and its related hardware time to cool

before cleaning, repairing, or inspecting.

• Check the tine mounting bolts at frequent intervals

for proper tightness. Also, visually inspect tines for

damage (e.g., bent, cracked, worn etc.) Replace

tines with the original equipment manufacture’s

(O.E.M.) tines only, listed in this manual. “Use of

parts which do not meet the original equipment

specifications may lead to improper performance

and compromise safety!”

• Tiller tines are sharp and can cause serious injury.

Wrap the tines or wear gloves, and use extra

caution when servicing them.

• Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

• After striking a foreign object, stop the engine,

disconnect the spark plug wire and ground against

the engine. Thoroughly inspect the machine for any

damage. Repair the damage before starting and

operating.

• Check brake operation frequently as it is subjected

to wear during normal operation. Adjust and service

as required.

• If the tractor or tiller attachment should begin to

vibrate abnormally, stop the engine and check over

the equipment immediately for the cause. Abnormal

vibration is a warning of a problem.

• Do not change the engine governor setting or

overspeed the engine.

• Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can harm

the environment.

• Maintain or replace safety and instruction labels, as

necessary.

Your Responsibility

Restrict the use of this power machine to persons who read, understand and follow the warnings and

instructions in this manual and on the machine. The safety label on the equipment is reproduced

below. Take a moment to study the label before operating the unit. Always maintain safety while

operating or servicing the equipment.

5

Page 6

SECTION 2: SLOPE GAUGE

6

Page 7

SECTION 3: TO THE OWNER

Model 190-002-100, 30-inch hydraulic tiller attachment is designed for use on Series 2000 Lawn Tractors with 23”

rear tires only. It will NOT fit nor operate properly or safely on ANY other tractor. Using this tiller attachment requires

the use of weight kit bracket 190-307-100 and suitcase weights part number 190-390-100 (three weights required).

The instructions in this manual are divided into sections. Carefully read all sections and study the illustrations to

ensure proper installation and usage of this attachment. Read and observe all WARNING and CAUTION

statements. They are included to provide for the protection of the equipment installer and user, and to ensure the

prolonged service life of the equipment.

References to LEFT and RIGHT indicate the left and right sides of the tractor and tiller attachment when facing

forward in the operator’s position. Reference to the FRONT indicates the grille end of the tractor and reference to

the REAR dictates the drawbar end where the tiller attaches.

SECTION 4: LOOSE PARTS

The tiller attachment is shipped with the following loose parts in the crate. Please remove all loose parts from the

crate before discarding it. Refer to Figure 1 to identify the parts, noting that these parts may be referred to again in

the following sections of the manual.

Attachment

Hardware Kit

w/ Elect Lift

Tiller Frame w/Roller

Hydraulic Pump Assembly

Rear Tine Shield

(for use w/out roller)

Figure 1

SECTION 5: ASSEMBLING THE TILLER

Attachment Hitch Assembly

The attachment hitch assembly is shipped with a

separate hardware kit that is needed to mount the

assembly to the tractor. See Figure 1.There is also an

electric wiring harness necessary for the lift operation of

the attachment hitch.

The attachment hitch assembly is shipped complete.

This assembly includes the electric lift cylinder, a wiring

harness, and an electric switch that will control the lift

cylinder.

Hydraulic Pump Assembly

The hydraulic pump assembly is shipped together with

a V-belt and a bracket with mounting hardware

attached to it.

The two hydraulic hoses, which are enclosed in a

protective sleeve, are packaged separately from the

hydraulic pump assembly and need to be attached to it.

Both hoses have female connectors on either end and

will attach to male connectors on both the hydraulic

pump assembly and the tiller assembly itself.

7

Page 8

To connect the hydraulic hoses to the hydraulic pump

assembly:

• Locate both male hydraulic fittings on the hydraulic

pump. Notice that the fittings are not the same

diameter.

Figure 2

• Thread the end of the small diameter hose onto the

male end of the hydraulic pump by hand, making

sure to not cross thread the connectors.

• Once the fittings are hand tight, use two wrenches

to tighten the connection. One wrench will prevent

the hose from spinning while tightening, and the

other will be used to tighten the connectors

together. Tighten firmly.

• Repeat this step for the large diameter hydraulic

hose.

Tiller Frame and Roller Assembly

The tiller frame and the roller come shipped as an

assembly. The tiller does not get shipped with the

hydraulic fluid that is required to drive the tiller. Before

adding fluid, the two hydraulic hoses that are attached

to the hydraulic pump assembly need to be installed on

the tiller.

The large diameter hydraulic hose needs to be

attached to the tiller frame. There is a male fitting on the

front, right side of the tiller frame. Attach the large

hydraulic hose to the tiller frame using the same

method that was used when attaching to the hydraulic

pump. Refer to Figure 3.

The small diameter hydraulic hose has to be attached

to the hydraulic control valve. Refer to Figure 3. Attach

the hydraulic hose using the same procedure that was

used to attach this hose to the hydraulic pump.

Figure 3

There is a short hydraulic hose that is connected to the

hydraulic motor on one end that was removed from the

hydraulic control valve for shipping (refer to Figure 3).

After installing the small diameter hydraulic hose to the

control valve, attach the short hose to the male fitting on

top of the control valve.

Hydraulic Fluid

The tiller attachment operates using hydraulic fluid. The

fluid should be added to the tiller once the hydraulic

hoses are connected. The following list includes fluids

which are approved for use in this tiller:

• Mobile 424

• Texaco TDH

• Shell Donax

• Farmland TF

• Citgo TF

• Sun Tractor Fluid

• Amoco 1000

• Shell TTF

Remove the dipstick/reservoir cap and add 4.5 gallons

of hydraulic fluid as noted above. Replace the dipstick.

Recheck the hydraulic fluid after the tiller has been

mounted on the tractor and the hydraulic pump has

been engaged. The hydraulic hoses, hydraulic pump,

motor, and valve, and the hydraulic filter will fill up once

the hydraulic pump has been engaged. Hence, the fluid

level will then need to be rechecked and more fluid will

need to be added to maintain the proper fluid level of

the reservoir.

NOTE: Refer to the maintenance section for

information pertaining to changing the hydraulic fluid

and filter after use.

8

Page 9

SECTION 6: PREPARING THE TRACTOR

NOTE: References to LEFT and RIGHT indicate the left

and right sides of the tractor and tiller attachment when

facing forward in the operator’s position.

NOTE: If the tractor is equipped with a mower deck,

remove it now. Refer to the tractor’s operator’s manual

for instruction on removing the mower deck and

hardware.

IMPORTANT: The use of this tiller attachment requires

the use of the weight bracket 190-307-100, and the

weight kit part number 190-390-100 on the front of the

machine. It is recommended that three weights be used

(three 42lb. suitcase weights). Without front weights,

steering will be extremely difficult and there is potential

for backwards tip over on uneven surfaces. Install these

pieces while preparing the tractor for tilling.

Installing the Lift Switch

The lift switch for the tiller attachment requires

permanent mounting to the tractor’s dash. Remove the

wiring harness from the electric lift cylinder, a part of the

attachment hitch assembly, by unplugging the

connector located near the electric lift cylinder. Refer to

Figure 1.

The lift switch is shipped in a separate bag that can be

found in the box with the electric lift cylinder.

Figure 4

• Secure the lift switch by threading on the nut

removed in the last step, now.

• Working under the dash, connect the five slot

connector in the lift switch wiring harness to the lift

switch.

• Feed the opposite end of the wiring harness, the

end with the two slot connector on it, down toward

the right side of the frame. Continue routing the

harness toward the rear of the tractor between the

running board and the right frame, being certain to

attach it where it will not get pinched by moving

parts.

Drilling a hole in the dash is required to mount the lift

switch and a template is provided on page 23 for

correct placement of the hole. Retrieve the template

from the rear of the book following the instructions from

that page, and secure it to the dash panel with tape.

Refer to Figure 4. Complete the following steps to

properly install the lift switch and electric harness:

• Open the hood of the tractor and carefully inspect

the area below the marked hole location as seen in

Figure 4. Check the area for wires and secure them

as necessary to prevent damage.

• Using a 1/2” drill bit, drill a hole through the plastic

dash panel being certain to center on the drill bit on

the marked location.

• The hex nut is installed on the lift switch prior to

shipping, remove the nut now. Working from

underneath the dash, push the switch through the

newly drilled hole in the dash panel with the threads

showing on the outside and the flat edge of the

threads facing right. Refer to Figure 5.

Figure 5

• Route the wire harness at the back of the tractor

over the hitch plate. Then route it toward the left

side of the tractor where the connector for the

electric lift cylinder will be after the attachment hitch

is mounted.

9

Page 10

IMPORTANT: If working on or with the battery for any

reason, disconnect the NEGATIVE (Black) wire from it’s

terminal first, followed by the POSITIVE (Red) wire.

When reattaching the battery cables, always connect

the POSITIVE (Red) wire to the positive (+) battery

terminal first, followed by the NEGATIVE (Black) wire to

the negative (-) battery terminal. Be certain that the

wires are connected to the correct terminals, reversing

them could change the polarity of the battery and cause

damage to your engine’s alternating system.

WARNING: Batteries contain an explosive

gas. Work on the battery in a well ventilated

area and do not allow a spark or an open

flame near the battery.

Working under the hood again, there are two wires that

need to be connected. These wires provide power to

the wiring harness for the electric lift cylinder.

• The terminal connector attached to the short blue

wire needs to be connected to the positive side of

the battery. This is the wire with the fuse holder

attached. Connect this wire along with the red

(positive) battery cable to the positive side of the

battery.

• The short black wire in the lift switch wiring harness

needs to be connected along with the black

(negative) battery cable to the negative side of the

battery.

Attachment Hitch Mounting Bolts

The attachment hitch, which will mount over the

hitchplate on the rear of the tractor, requires the

permanent installation of mounting bolts that the

attachment plate will hang on once installed.

Locate the shoulder bolts, washers, and locking nuts

that are packed separately in the box with the

attachment hitch.

To mount the shoulder bolts, a drill with a 7/16” drill bit

will be used. Drilling the holes in the frame will require

the rear tires of the tractor to be removed. Be certain to

stabilize the tractor with blocks or jack stands to prevent

it from tipping while the rear wheels are off.

IMPORTANT: Some newer units may already have the

necessary mounting holes drilled to the correct size.

Read the following instructions up to the bulleted

paragraph on page 11 above Figure 9 to verify if the

tractor’s frame needs to be drilled.

Figure 6

Removing the Rear Wheels

To remove the rear wheels, a 3/4” socket with an

extension, or a star (lug nut) wrench with a 3/4”

opening, is necessary. Loosen the four lug nuts slightly

that hold each wheel on before jacking the rearend of

the tractor up. Raise the rearend of the tractor up, block

the frame of the tractor for support, and remove the

lugnuts and wheels on both sides of the machine.

Installing the Shoulder Bolts

There is a template located on page 25 that will be used

to locate the exact position for drilling the hole. Follow

the instructions given on that page for cutting the

template correctly. Figure 6 shows the basic location

where the following work will be performed with the

tractor’s body parts eliminated for clarity.

• Working on the left side of the frame in the rear of

the tractor as shown in Figure 7, attach, with tape,

the template which was cut out from the back of this

manual. Make certain that the lower edge of the

template piece is lined up along the top edge of the

frame rail. Also, align the right side of the template

piece along the left edge of the hitch plate, and be

certain the left half of the existing hole on the tractor

frame is exposed and lined up with the half of the

marked existing hole on the template. It is critical

that the template is set correctly for proper drilling.

Refer to Figure 7.

10

Figure 7

Page 11

• To mark the hole to ensure proper centering of the

new hole to be drilled, place the pointed end of a

center punch on the cross hairs of new hole

position. Using a hammer, strike the end of the

center punch to create a permanent mark in the

metal frame and carefully remove the template.

• Using a 7/16” drill bit, set it on the mark just made

by the center punch and drill completely through

the frame. Carefully remove any sharp edges

around the hole with a file.

Enlarged Hole

(Drill Here)

Hitch Plate

Frame Rail

Hydraulic Pump Assembly Hanging Brackets

The hydraulic pump assembly attaches to the tractor

using hangers that are permanently affixed to the

tractor’s frame. These brackets are shipped with the

hydraulic pump assembly. The hardware to mount the

brackets to the tractor is shipped attached to the

brackets and will need to be removed before installing.

The side frame brackets will require two 9/16”

wrenches to install on the tractor.

• Install the bolts from the outside of the frame with

the threads on the inside of the frame. Use Figure

10 to determine the position of the hole in the

frame.

• Holding the bolt through the hole with one hand,

slide the small hole of the side frame bracket over

the bolt threads making certain that the curved

portion of the bracket is facing outward. Refer to

Figure 10.

Figure 8

Move to the right side of the tractor and locate the

existing hole to be enlarged. Refer to Figure 8.

• Again using the 7/16” drill bit, carefully drill

completely through the hole marked “Enlarged

Hole” as shown in Figure 8. The original hole in the

tractor’s frame is not large enough to accommodate

the correct mounting hardware.

• With both holes drilled to the correct dimension, the

shoulder bolts and related hardware need to be

installed. Both shoulder bolts are identical but the

one that will be mounted on the left side receives

the extra washer which is thinner than the other

two. Refer to Figure 9 for the correct mounting of

the hardware. Reinstall the rear wheels and remove

the frame blocks.

Figure 9

Figure 10

• Thread the locking nut onto the bolt threads and

tighten. Repeat this step on the other side. These

brackets will not need to be removed when using a

mower deck.

The rear mounting bracket for the hydraulic pump

assembly has two bolts and lock nuts that hold it to the

tractor’s frame. This bracket will be mounted toward the

rear of the tractor directly in between the left and right

frame rails. Refer to Figure 10 for the correct location of

the mounting holes.

Installing the rear mounting bracket will require two 3/4”

wrenches.

• First position the rear mounting bracket against the

cross bar on the rear of the frame with the long

slotted lower portion toward the rear of the tractor.

• The cross bar has holes drilled to match those on

the rear mounting bracket. Align the holes and

install the bolts with the threaded part of the bolt

toward the back of the tractor.

• Thread on the locking nuts and tighten firmly.

The rear mounting bracket will not need to be removed

when a mowing deck is installed.

11

Page 12

SECTION 7: MOUNTING THE TILLER

Installing the Attachment Hitch

The attachment hitch, which has the electric lift cylinder

attached to it, attaches to the rear of the tractor’s frame

over the hitch plate. There is a short clevis pin and

cotter pin mounted to the lower portion of the

attachment hitch during shipping, remove them now

and set them aside.

Holding the attachment hitch with the hitch hooks facing

the tractor, place the hitch hooks over the mounting

bolts and allow the attachment hitch to rest on the hitch

plate of the tractor. Install the clevis pin removed

earlier, into the holes that line up between the

attachment hitch and the hitch plate, and secure with

the cotter pin. This clevis pin holds the attachment hitch

in place during use.

NOTE: Be careful to insure that the hydraulic pump

assembly clears the tractor’s transmission as the

tractor is moving toward the tiller attachment.

• Release the left and right hitch latches by removing

the clevis pin and cotter pin that secure them in a

locked position.

Figure 12

Figure 11

The electric lift wiring harness is mounted near the rear

frame of the tractor on the right side. Plug the connector

from the electric lift wiring harness into the mated plug

on the electric lift cylinder. This will supply electric

power to the lift cylinder.

Attaching the Tiller Assembly

Before continuing, be certain that the hydraulic hoses

are connected to both the tiller assembly and the

hydraulic pump assembly. Set the hydraulic pump

assembly directly in front of the tiller on the ground as

far as the hoses will allow. Align the tractor so it can be

pushed straight back to the tiller attachment.

To attach the tractor and the tiller assembly together,

proceed as follows:

• With the tractor not running, push it backwards

toward the tiller attachment over the hydraulic

pump assembly.

• The attachment hitch, which is mounted to the

tractor, has a cross bar running through it that the

sleeve hitch attaches to. Push the tractor

backwards to the point where the crossbar ends

slide into the channels below the hitch latches.

Doing this will require some aligning of the tiller with

the attachment hitch. Once the two are attached,

lock the parking brake on the tractor and reinstall

the clevis pins that lock the hitch latches into place.

• Remove the clevis pin and spacers from the end of

the electric lift cylinder by removing the cotter pin.

Slide the clevis pin out and set aside the hardware.

• Maneuver the unattached portion of the electric lift

cylinder in between the slotted channels of the

sleeve hitch. Raise or lower the cylinder using the

lift switch on the tractor’s dash if necessary.

• Connect the electric lift cylinder to the sleeve hitch

using the clevis pin and spacers removed earlier.

One spacer will mount on either side of the electric

lift cylinder shaft and the washer will be placed

outside of the channels on the end of the clevis pin

with the hole in it. Secure the clevis pin with the

cotter pin removed earlier.

• Before attaching the hydraulic pump assembly,

make certain that the hydraulic hoses are routed to

the inside of the hose hook and under the tractor’s

transmission. Refer to Figure 12 for the location of

the hose hook.

12

Page 13

Attaching the Hydraulic Pump Assembly

To mount the hydraulic pump assembly to the tractor,

make certain that it is placed under the center of the

tractor’s frame, resting on the ground, with the hydraulic

hoses attached. Connect the hydraulic pump assembly

as follows:

• The rear of the hydraulic pump assembly has a

“tongue” on it. The tongue is the flat portion toward

the rear of the assembly. Raise the rear of the

assembly up and slide the tongue into the slotted

portion of the rear mounting bracket. Refer to

Figure 13.

• Before raising the front of the hydraulic pump

assembly, remove the front hanger rod by removing

one of the hairpin clips and sliding the rod out.

• Lift the front of the hydraulic pump assembly and

align the holes in the assembly with the holes in the

side frame brackets.

• Install the front hanger rod and secure with the

hairpin clip removed earlier.

With the hydraulic pump assembly installed, locate the

sleeve that surrounds the two hydraulic hoses and slide

it toward the hydraulic pump as far as possible. This will

provide more protection to the hydraulic hoses where it

is necessary.

Installing the PTO Drive Belt

The hydraulic pump drive belt needs to be installed.

This belt connects the tractor’s PTO to the hydraulic

pump which provides power to the tiller attachment.

The following describes how the belt is installed:

• Raise the hood of the tractor and locate the PTO

pulley on the front of the engine.

• Working from the engine compartment, feed the

belt around the front of the PTO pulley and place

the last portion of the belt onto the pulley with the Vgroove of the belt facing into the pulley.

Figure 13

• Lying down on the right side of the tractor, take the

loose portion of the belt and pull it toward the back

of the tractor.

• Keeping light tension on the belt, align the V-groove

of the belt into both mule drive pulleys mounted

slightly in front of the front axle of the tractor. There

should be a single 90° twist of the belt between the

PTO pulley and each mule drive pulley.

• Place a 3/8” ratchet head, set to tighten, into the

square hole near the right hand idler pulley and

apply force. Notice how the pulley moves toward

the outside of the tractor. Doing this will make

installing the remainder of the belt easier.

• Making certain that the belt has a single 90° twist

between the mule drive pulleys and the idler

pulleys, and that the flat side of the belt is resting on

the idlers, apply pressure to the ratchet and finish

routing the belt around the hydraulic pump pulley.

Be sure that the V-groove of the belt is set

completely in the pulley before releasing the

ratchet.

• Recheck the routing of the belt to ensure that it is

resting completely in all the grooves of all the

pulleys before engaging the PTO.

13

Page 14

SECTION 8: KNOW THE TILLER

Figure 14

Lift Switch

The lift switch is located on the right side of the steering

wheel on the dash panel and is used to raise and lower

the tiller attachment and also to determine the depth at

which the tines dig into the ground. See Figure 15.

Figure 15

Pushing forward, or up, on the switch will raise the tiller.

Pulling down, or back, on the switch will lower the tiller.

The electric lifting cylinder will produce a clicking noise

when it reaches its maximum lift or lowered height.

When this noise is heard, immediately release the

switch to prevent damage to the electric lift cylinder.

Tine Direction Lever

The tine direction lever is located on the top of the tiller

attachment on the right side of the unit. Refer to Figure

14. This lever is used to control which direction the tines

turn.

Figure 16

The lever has three positions. F is the forward tilling

position. By pulling the tine direction lever toward the

front of the tractor (refer to Figure 16), this will activate

the tines into forward tilling motion. Forward tilling is

used when cultivating or tilling soft soil.

N is the neutral position. When the lever is in this

position, the tiller tines are not in motion. The N position

is located between the forward and reverse positions

on the lever. Neutral is used whenever transporting the

unit.

14

Page 15

R is the reverse tilling position. The tine direction lever

is pushed toward the back of the machine, or away from

the operator to start the tines in the reverse direction.

Tines spinning in a reverse direction are used for

breaking ground or tilling hard soil.

IMPORTANT: Turn the tractor’s PTO into the off position

before changing tine direction. Do not move the tine

direction lever with the PTO engaged. Doing so will

cause damage to the hydraulic motor.

Tiller Tines

The tiller’s tines are located under the frame of the tiller.

The tines cultivate the soil when placed in contact with

the ground while in motion.

The tines are replaceable and wear should be

expected. Rate of wear will depend on the amount of

time used and the condition of the ground which is

being tilled.

WARNING: Tiller tines are sharp and can

cause serious injury. Wear heavy gloves and

use extra caution when servicing the tines.

Roller

The roller is mounted to the tiller attachment directly

behind the tines. It is a heavy duty round screen

designed to level the tilled soil without compacting it.

The dirt surface after being rolled, helps eliminate the

need for raking soil level after tilling. It is spring loaded

and fully adjustable so it can be used on variable terrain

at all tilling depths.

Hydraulic Pump

The hydraulic pump is a belt driven pump which moves

hydraulic fluid to the hydraulic motor on the tiller via

hydraulic hoses. It is mounted under the center of the

tractor and is activated by the tractor’s PTO.

NOTE: The PTO on the tractor will not function while

the tractor is in the Reverse speed. Use the tiller while

driving forward only.

Hydraulic Reservoir

The hydraulic reservoir is a part of the tiller frame and

can be found directly on top of the tiller in the center. It

has a vented tank cap with a dipstick attached. It is

vented to allow for expansion of the hydraulic fluid as it

heats up and expands during normal use. The opening

on the top of the reservoir acts a checking and a filling

point for the hydraulic fluid.

The hydraulic reservoir holds the oil that drives the tiller

tines. It is important to maintain the correct level of fluid

in the reservoir to prolong the life of the hydraulic motor.

WARNING: Hydraulic hoses, fittings, and

fluid become hot during normal usage. Allow

the machine and its related hardware to cool

down before checking the fluid level or

performing maintenance.

Hydraulic Filter

The hydraulic system on the tiller attachment has a filter

that is located directly to the left of the tine direction

lever. The filter keeps the hydraulic fluid free from

impurities and should be changed according to

manufacturer’s data as listed in the maintenance

section of this manual.

Tiller Stand

The tiller attachment is equipped with a stand which

allows the equipment to stand on its own when it is not

attached to the tractor. It is located on the front left

portion of the tiller frame and when set, will also aid in

the reattaching process to the tractor.

Rear Tine Shield

The rear tine shield, as shown in Figure 1, comes

shipped as a separate item. The rear tine shield is to be

used in place of the roller when the roller is removed. It

is a safety device that prevents tilled debris from being

thrown from the tiller during use.

SECTION 9: OPERATING THE TILLER

IMPORTANT: Using this tiller attachment requires the

use of weight kit bracket 190-307-100 and suitcase

weights part number 190-390-100. It is recommended

that three weights be used (three 42lb. suitcase

weights), especially when using the machine on

uneven surfaces. Without front weights, steering will be

extremely difficult and there is potential for backwards

tip over on uneven surfaces.

Fluid Level

IMPORTANT: Check the tiller’s hydraulic fluid level

before using the unit as described in the assembly

section of this manual. Read instructions carefully.

WARNING: Never check the hydraulic oil

level immediately after using the tiller.

Hydraulic oil gets hot during normal usage

and may build pressure in the system.

15

Page 16

Engaging the Tiller

NOTE: Refer to the tractor’s operator’s manual for

information concerning starting and stopping the

tractor, and location and proper usage of its controls.

Before engaging the tiller, complete the following steps:

• Start the tractor’s engine and make certain it is at

operating temperature (the engine is warmed up).

• Verify that the PTO is disengaged.

• Lock the parking brake.

• Raise the tiller to its highest point using the lift

switch.

Select the tine direction by shifting the tine direction

lever into the forward (F) or reverse (R) position

depending on the type of tilling to be performed. Set the

tractor to full throttle and engage the PTO. The tines will

now be turning.

IMPORTANT: Turn the tractor’s PTO into the off position

before changing tine direction. Do not move the tine

direction lever with the PTO engaged. Doing so will

cause damage to the hydraulic motor.

To shift the tine selection lever from one position to

another, first turn off the PTO and wait for the tines to

come to a complete stop. Then shift the lever to any

position as necessary as outlined in Section 8.

Tilling Ground Speed

The tilling ground speed is the speed at which the

tractor travels while the tiller is set in the ground and

working. Correct ground speed is determined by the

soil conditions and the depth of cut.

• Engage the tiller as outlined in the previous section.

• With the tractor, running at full throttle, in position,

use the lift switch to lower the tiller into the ground.

Be aware that as the tiller penetrates the ground, it

will shake and vibrate the tractor initially.

Kit number 190-014-100 is an optional skid shoe kit,

available at your Cub Cadet dealer, that is

recommended for the tiller attachment. The skid shoes

make it simpler to determine tilling depth.

The tines can be lowered from 0” to a maximum 6.5”

tilling depth. It is important to set the tiller depth while

the tractor is NOT in motion. Come to a complete stop

with the tractor before raising or lowering the tiller

attachment, especially when the tines are working in

the ground.

When tilling hard ground or when tilling an area for the

first time, do not till more than 2” at a time. To increase

the tilling depth, lower the tiller on successive passes

over the area.

If tilling softer or previously tilled soil, tilling up to 3” per

pass is acceptable. If vibration or shaking of the tiller

attachment occur, the tiller depth is too deep or the

tractor’s ground speed is excessive.

Using the Roller

When set properly, the roller will help eliminate the

need for after till raking and leveling. The roller has

several height settings that can be used depending on

the depth the tiller is set at.

IMPORTANT: Do not attempt to use the tiller attachment

while backing up. A safety switch on the tractor will

automatically shut off the PTO when the reverse pedal

on the tractor is depressed. Always lift the tiller out of

the ground before backing up.

When tilling hard ground, with the engine running at full

throttle, the ground speed of the tractor should be less

than 30% of the top speed of the tractor. This will vary

based on the soil. If the engine is slowing at all or the

tractor and tiller are vibrating or shaking, the ground

speed should be slowed.

When tilling soft or previously tilled ground, a slightly

higher speed, up to 50% of the total speed of the tractor

is acceptable. Again, if noticeable vibration or shaking

of the tiller attachment occur, reduce ground speed.

A slow ground speed while tilling will produce the finest

tilled soil and a faster ground speed results in soil that is

coarse.

Tilling Depth

The tilling depth is determined using the lift switch. To

set the tilling depth:

Figure 17

To set the height of the roller, first make sure that the

tractor engine is not running and the parking brake is

set. Standing on the right side of roller, facing it, hold

the u-handle located on the back frame of the roller.

While lifting slightly on the u-handle, pull the spring

loaded locking rod clear of the adjustment bar and lift

the roller up or set it down based on the depth of the

tilling to be done. Release the locking rod in one of the

adjustment holes in the adjustment bar to lock the roller

into position.

16

Page 17

For shallow tilling, drop the roller to its lowest position

by putting the locking rod into the highest hole of the

adjustment bar. For deeper tilling, continue to raise the

roller by using lower holes in the adjustment bar. The

lowest hole (highest setting) is used for transporting the

tiller.

Using the Rear Tine Shield

The rear tine shield that was shipped separately with

the tiller assembly must be in place whenever the tiller

is being used without the roller.

To install the rear tine shield:

• Remove the roller assembly completely by

removing the two bolts that attach it to the tiller

frame and disconnecting it from the adjustment bar.

• Remove the long rod that holds the shorter tine

shield that is used with the roller.

• In place of the shorter tine shield just removed,

install the larger tine shield using the existing

hardware.

Figure 18

Figure 18 shows the larger rear tine shield in place with

the adjustment chain holding the tine shield in a

maintenance position. When operating the tiller, adjust

the chain so the rear tine shield touches the ground.

Doing this will help to prevent objects from being thrown

away from the working tines.

Figure 19

Clearance

The left hand side of the tiller attachment lines up

evenly with the left hand tires of the tractor. To get

nearest to an object while tilling, line the object up just

to the left side of the tractor.

The tiller attachment makes the tractor noticeably

longer. Be careful in turns to watch the rear end

clearance of the tiller attachment. In a tight turn, the

tiller sticks out and may strike an object that the tractor

itself normally would not.

Wet Soil

Tilling soil that is wet will result in the formation of large

clumps of soil that will dry solid. The potential to get the

tractor stuck while tilling is increased substantially while

tilling wet soil. If the tractor begins spinning its wheels in

this situation, shut the PTO off on the tractor, raise the

tiller out of the ground, and attempt to drive out of the

area. Resume tilling after the ground has dried.

Cub Cadet offers an optional set of agricultural tires that

would help to increase traction o12.1(os1(o)-12.33(t tr)-6.3( )12.(um)-12.8(o)-0.2(i)-8.4(s.4(t )]TJT[.6(su)-12.3(r)5.fct)-13.5(ac)-8.es(d.)-13.2( )12.S B)-9.7e t5(h)-12.3(lo(ac)-8.a(o)-0.2(l)-8. [(Cu1(C(h)-12.3(e)-0.2 Cade)-12.alffe)-12.3(r)5. abfe)-12.e oukaci

Operating Tips

For best results while tilling, always till the area at least

twice. Always till at right angles as shown in Figure 19.

Turning

The tiller attachment was intended to be used in a

straight line only. Very slight turns while tilling can be

achieved by traveling at a slower ground speed, but

sharp turns during tilling can put excess stress on the

frame of the tiller and tractor and will cause the

equipment to shake and vibrate excessively.

17

Page 18

If the object does not dislodge using this method and

the tines continue to not spin:

• Shut off the PTO immediately, shift the tine

direction lever to neutral (N), raise the tiller to its

highest position, and turn the tractor engine off.

• Lift the roller to its highest position to create easier

access to the tines. Raise the rear deflector, if

necessary, and locate the object that is binding the

tines.

SECTION 10: MAINTENANCE

• Using a broom handle or heavy stick, dislodge the

object from between the tines and the housing. If it

is necessary to reach into the tine area with your

hand to remove an object, use caution around the

tines which may be sharp.

WARNING: Tiller tines are sharp and can

cause serious injury. Wear heavy gloves and

use extra caution when servicing the tines.

WARNING: Before performing any

adjustments, be certain that the tractor’s

engine is not running and the parking brake

is set. If working on the tines, raise the tiller

to its highest point and place blocks under

the edges of the tiller frame to prevent it from

dropping.

Cleaning

It is important after every use to clean the tiller,

especially around the tines. It is much easier to clean

the dirt off of the tiller while it is fresh than if it is left to

dry for a sustained period.

The area around the tines is the most important to clean

for this is the area that receives actual contact with the

ground. Using a garden hose in this area as well as on

the top of the tiller is acceptable, but it is important not

to use direct water pressure on the electric lift cylinder.

After washing the underside of the tiller, start the tiller

tines in motion for a couple minutes to help disperse

any water that may lie in the bearings and tine shaft

areas causing excessive corrosion.

Also, avoid direct water contact with the tank cap on top

of the hydraulic reservoir. Wipe this area clean with a

dry rag to avoid possible contamination while checking

the hydraulic fluid.

It is recommended also that the machine be dried off

after washing, if possible. Water that sits on a machine

can cause corrosion over time. An air hose that is

attached to an air compressor is ideal for drying

machinery such as this. If that is not available, a towel

will suffice. Doing this will help prolong the life and

appearance of the tiller.

Lubrication

There are several lubrication points on the tiller

attachment. Using a lithium based lubricant, white

lithium spray lube is recommended, contact all the pivot

points where the tiller pivots when raising and lowering.

These are where the sleeve hitch, the attachment hitch,

and the electric lift cylinder contact the tiller frame.

The attaching clips and the point where they pass

through their pins should also be lubricated. This

should be done every 10 running hours on the tiller to

prevent corrosion and maintain free movement.

The roller needs to be lubricated in several areas. On

each end of the roller shaft that runs through the middle

of the roller is a bearing. Each bearing has a grease

fitting with a removable cap that will require a standard

grease gun to lubricate every 25 running hours. Be

certain to replace the grease fitting cap after lubricating

to prevent contamination.

Also on the roller, use white lithium spray grease on the

spring loaded locking rod where it passes through the

adjustment bar, and where the compression spring is

on the long side of the locking rod. Just above the

locking rod is a clevis pin surrounded by two springs,

lubricate this area also. This spring loaded section

allows the roller to fluctuate and follow uneven ground.

The point where the roller frame attaches to the tiller

frame is a pivot point. The two attaching bolts, where

the roller assembly pivots, need lubrication also.

Changing Hydraulic Filter and Fluid

WARNING: Hydraulic hoses, fittings, and

fluid become hot during normal usage. Allow

the machine and its related hardware to cool

down before checking the fluid level or

performing maintenance.

Hydraulic Filter

The hydraulic filter should be changed every 50 running

hours on the tiller. To change the filter:

• Place a pan (shorter than 1.5”) under the oil filter to

collect the oil that remains in filter when not using.

• Use a filter wrench to loosen the filter. Drain excess

oil into the pan.

• Install a new filter, part #723-0405, by first

moistening the o-ring on the new filter with

hydraulic oil. Tighten the filter until the o-ring makes

contact with the filter base, then tighten 1/4 turn.

18

Page 19

With the new filter in place, remove all tools used to

change the filter from the tiller:

• Start the tiller in motion for about one minute in

order to circulate the oil through the new filter.

• Turn off the tiller and the tractor, lower the tiller until

the top flat portion of the tiller is level with the

ground, and check the hydraulic fluid.

• Remove the dipstick, wipe it clean and tighten it

back down on the hydraulic reservoir. Remove it

again and check the level of the fluid on the

dipstick. Add hydraulic fluid as necessary.

The following list includes fluids which are approved for

use in this tiller:

• Mobile 424

• Texaco TDH

• Shell Donax

• Farmland TF

• Citgo TF

• Sun Tractor Fluid

• Amoco 1000

• Shell TTF

Hydraulic Fluid

The hydraulic fluid in the tiller attachment should be

changed after every 100 hours of operation. To change

the fluid correctly:

Figure 20

• Remove the dipstick from the hydraulic fluid

reservoir and add four gallons of an approved

hydraulic fluid as noted in the previous list.

• Add additional fluid as necessary to reach a full

reading on the dipstick. The hydraulic reservoir will

hold up to 4.5 gallons when empty, but in some

cases it is not possible to remove all of the fluid.

Using this method will help to prevent overfill when

refilling.

• Remove the tiller attachment from the tractor (refer

to the Storage section).

• Carefully pivot the tiller forward so it rests on the

tines (do NOT use the tiller stand for this

procedure), until the front point of the sleeve hitch is

touching the ground.

• Locate the drain plug on the front left side of the

tiller. It is slightly above the front deflector shield.

Refer to Figure 20.

• A drain pan that will hold up to five gallons is

recommended for collecting the used oil. Place the

pan under the drain plug and using a 5/8” wrench,

remove the drain plug and drain the fluid

completely.

• Before reinstalling the drain plug, check the gasket

for cracks or tearing. If necessary, replace the

gasket.

• Reinstall the drain plug and tighten.

• Set tiller back to a level position and set the tiller

stand in place for stability.

Replacing the Tines

The tiller tines will wear out over time based on the

amount of use and type of soil being tilled. There are 20

replaceable tines on the tiller. When the tines are new,

there is 1.5” inches across the cutting end of the tine as

shown in the window of Figure 21. When this distance

measures less than one inch, all the tines need to be

replaced. If the tines get used past this point, they may

become brittle and break off during use causing a

dangerous situation.

WARNING: Tiller tines are sharp and can

cause serious injury. Wear heavy gloves and

use extra caution when servicing the tines.

Removing the tiller tines requires a 9/16” and 3/4”

wrench or socket. The 3/4” wrench fits on the bolt head

and the 9/16” wrench fits on the nut. Remove both inner

and outer shoulder bolts to remove one tine. Take note

of the order of the shoulder bolts and washers as they

hold the tine on. Refer to Figure 21.

19

Page 20

Replace only one tine at a time. This will help to insure

the correct positioning of the tines as they are mounted

on the tine assembly. When installing the new tine, be

certain that the longer shoulder bolt is in the inner hole

toward the center of the tine assembly. Realign the

bolts and washers as shown in Figure 21 and retighten

firmly.

Figure 21

Changing Hydraulic Pump Drive Belt

Allow the machine to cool before performing

maintenance. The muffler and belts will

become hot during normal use.

The hydraulic pump drive belt is located under the

tractor and is driven by the PTO of the tractor. To

remove the belt for inspection or replacement, proceed

as follows:

• Crouch or lie next to the tractor on the right side and

locate the hydraulic pump assembly underneath

the center of the tractor frame. Refer to Figure 22.

• The idler pulley on the right side is attached to the

idler arm and is spring loaded to provide constant

tension to the pulley which keeps the belt tight.

• There is a 3/8” square hole on the outside edge of

the idler arm which is used to relieve belt tension.

Insert the head of a 3/8” ratchet into the square

hole.

• With the ratchet set to tighten, pull on the ratchet

and notice that belt tension is being loosened.

• While holding the ratchet to keep the belt loose,

carefully remove the belt from the large hydraulic

pump pulley and the other stationary idler pulley.

• With the belt removed from the hydraulic pump

assembly, raise the hood of the tractor and locate

the belt where it rests in the pulley of the PTO. The

belt at this point is free of obstruction and can be

removed through the hood opening.

Inspect the belt for any cracks or fraying. Replace if

necessary. Before installing a new belt, check pulley

shafts and bearings for excessive end play and wear.

Make certain that they turn smoothly and freely.

Check pulley grooves for debris build-up or wear. If the

pulleys require cleaning, moisten a cloth with a nonflammable degreasing agent to clean out the grooves.

Refer to the Mounting the Tiller section earlier in this

manual for instructions on installing the hydraulic pump

drive belt.

Figure 22

Hydraulic Hoses

WARNING: Hydraulic hoses, fittings, and

fluid become hot during normal usage. Allow

the machine and its related hardware to cool

down before performing maintenance.

The hydraulic hoses need to be checked regularly for

cracks or leaks. Hydraulic fittings also need to be

checked for leaks or damage. Replace any hose that

shows signs of cracking or leaking to avoid a

dangerous situation.

Hydraulic fittings that are leaking should be checked to

verify that they are tight. If further leaking persists after

tightening, the fitting or the hose may need to be

replaced.

If fluid is lost during repairs, be sure to check the fluid

level and add as necessary.

20

Page 21

SECTION 11: STORAGE

NOTE: Before removing the tiller attachment for

storage, perform all lubrication maintenance as outlined

in the Maintenance section.

Removing the Tiller

NOTE: When removing the tiller attachment, because

the tiller is awkward, it is recommended that the tiller be

removed in a place that will not require it to be moved

regularly. It would also be helpful when removing the

tiller to allow approximately five feet of space in front of

the tractor. This will make the removal process simpler.

Setting the Tiller Stand

Before removing the tiller from the tractor for storage, it

is recommended that the roller be set in the lowest

position and the tiller stand be set.

To set the tiller stand, remove the hairpin clip (refer to

Figure 23) and clevis pin. The tiller stand will be free to

slide in its bracket. Align the tiller stand so the storage

position hole is lined up with the hole in the tiller stand

bracket and reinstall the clevis pin and hairpin clip.

(Sleeve Hitch not Shown for Clarity)

Tiller Stand

Clevis Pin

Hairpin Clip

Tiller Stand

Bracket

• Supporting the weight of the hydraulic pump

assembly with one hand, use the other hand to

slide the front hanger rod out the right side of the

tractor. Set the front of the hydraulic pump

assembly carefully on the ground.

• The rear of the hydraulic pump assembly is

supported by a tongue that is slid inside the rear

mounting bracket mounted to the tractor. Using

both hands, carefully pull the hydraulic pump

assembly towards the front of the tractor and the

assembly will become free of the rear mounting

bracket.

Figure 24

Operating

Position

Hole

Storage

Position

Hole

Figure 23

Removing the Hydraulic Pump Assembly

To remove the hydraulic pump assembly, the hydraulic

pump drive belt must first be removed. See the

Maintenance section for this procedure.

Once the belt is removed, proceed as follows:

• To remove the front hanger rod which suspends the

front of the hydraulic pump assembly, there are two

hairpin clips that hold the front hanger rod in place.

There is one on each side of the tractors frame.

Only one of these pins needs to be removed.

Remove hairpin clip on the left side of the tractor.

At this point, leave the hydraulic pump assembly setting

under the center of the tractor’s frame. With the tiller

unattached, the tractor can be pushed over the

hydraulic pump assembly with hydraulic hoses still

attached.

Releasing the Sleeve Hitch/Removing the Tiller

To release the sleeve hitch from the attachment hitch

on the tractor, locate these items in Figure 25 and

proceed as follows:

• Remove the lower clevis pin on the electric lift

cylinder by first removing the hairpin clip and sliding

out the clevis pin from the right side. Note the order

of the spacers and washer as they rest on the clevis

pin.

• Release the left and right hitch latches. To do this

requires the removal of the clevis pin which locks

the latches in place. Pull the hairpin and slide the

clevis pin out of the sleeve hitch on both sides. At

this point the pivoting hitch latches are free.

• Place the tractor transmission release lever into the

released position and release the parking brake.

21

Page 22

Figure 25

• Holding the hitch latches up will allow the tractor,

with the attachment hitch still mounted, to be

pushed away from the tiller with the sleeve hitch

mounted to it. Only push the tractor away a few

inches.

• The hydraulic pump assembly is still lying on the

ground with the hoses attached. Carefully push the

tractor forward being careful to not damage the

hoses or hydraulic pump assembly.

• There is enough clearance under the left side of the

transmission for the hydraulic pump assembly to

come out without having to raise the tractor.

Removing the Attachment Hitch

The attachment hitch, which has the electric lift cylinder

attached to it, is still attached to the tractor. To remove

the attachment hitch it is necessary to first unplug the

electric lift cylinder from the electric lift harness. This is

located between the rear fender of the tractor and the

electric lift cylinder itself.

It is recommended that the attachment hitch be

removed during non-tilling usage of the tractor. To

remove the attachment hitch, proceed as follows:

• Follow the wires from the electric lift cylinder until

the connector is found. Pull the connectors apart.

• Pull the hairpin clip out of the clevis pin which holds

the attachment hitch to the hitch plate of the tractor

and remove the clevis pin. Refer to Figure 11.

• Using both hands, lift the attachment hitch straight

up approximately one inch in order to get the

hanger slots off of the shoulder bolts they are

resting on. Once this is done, pull the attachment

hitch away from the machine and set it aside.

IMPORTANT: Be certain to store all removed hardware

in a safe place to insure proper reinstallation later.

SECTION 12: TROUBLE SHOOTING

22

Page 23

SECTION 13: TEMPLATES

Dash Panel Template

Instructions:

1. Carefully cut the template along the dotted lines only.

2. Tape the template into position on the dash panel.

3. Continue following instruction given on page 9, Installing the Lift Switch.

23

Page 24

24

Page 25

Rear Frame Template

Existing Hole

Instructions:

1. Carefully cut the template along the dotted lines only.

2. Continue following instruction given on page 10, Attachment Hitch Mounting Bolts.

25

Page 26

Page 27

Page 28

MANUFACTURER’S LIMITED WARRANTY FOR:

TWO-YEAR RESIDENTIAL

ONE-YEAR COMMERCIAL

Proper maintenance of your Cub Cadet equipment is the owner’s responsibility. Follow the instructions in your

operator’s manual for correct lubricants and maintenance schedule. Your Cub Cadet dealer carries a

complete line of quality lubricants and filters for your equipment’s engine, transmission, chassis and

attachments.

Riding mowers, lawn tractors, garden tractors, Cub Cadet

attachments and home maintenance products

This limited warranty for residential users, covers any defect in materials or workmanship in your Cub Cadet

equipment for two years from the date of purchase for the first user purchaser. We will replace or repair any

part or parts without charge through your authorized Cub Cadet dealer.

Batteries have a one-year prorated limited warranty with 100% replacement during the first three months.

V-belts for either the traction drive or any attachments are covered for one year only.

Cub Cadet equipment used commercially is warranted for one year only.

(Commercial use is defined as either having hired operators or used for income producing purposes.)

Items not covered

The warranty does not cover routine maintenance items such as lubricants, filters (oil, fuel, air and hydraulic),

cleaning, tune-ups, brake and/or clutch inspection, adjustments made as part of normal maintenance, blade

sharpening, set-up, abuse, accidents and normal wear. It does not cover incidental costs such as transporting

your equipment to and from the dealer, telephone charges or renting a product temporarily to replace a

warranted product.

There is no other express warranty.

How to obtain service

Contact your authorized Cub Cadet servicing dealer who sold you your Cub Cadet equipment. If this dealer is

not available, see the Consumer Yellow Pages under “lawn mowers” for the name of a dealer near you.

If you need further assistance in finding an authorized Cub Cadet servicing dealer, contact:

Cub Cadet Corporation

Post Office Box 368023

Cleveland, Ohio 44136

How does state law apply?

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

Loading...

Loading...