Application Note

Ctek Automation Control Application

APN007

Release 4.02.02

Ctek – Things That Move Data

.

25 July 2014

i

Contents

TABLE OF FIGURES.........................................................................................................................................................IV

INTRODUCTION: .............................................................................................................................................................. 1

THEORY OF OPERATION ............................................................................................................................................... 1

NAVIGATION AND TOP LEVEL FUNCTIONS: ........................................................................................................... 2

Automation Control Panel.................................................................................................................................................................2

Automation Control Configuration ....................................................................................................................................................2

USER INTERFACE AND CONFIGURATION SPECIFICS ........................................................................................... 4

Execute New Configuration ...............................................................................................................................................................4

Unit Configuration .............................................................................................................................................................................4

Location Name: ...................................................................................................................................................................................... 5

SMS Remote Control: ............................................................................................................................................................................. 6

Logging On/Off:...................................................................................................................................................................................... 6

Log Rate: ................................................................................................................................................. Error! Bookmark not defined.

Alarms On/Off: ....................................................................................................................................................................................... 6

Alarm Delivery Method: ......................................................................................................................................................................... 6

Destination Phone Number for Alarms:................................................................................................................................................. 6

Destination email address for Alarms: ................................................................................................................................................... 6

Log Delivery Parameters: ...................................................................................................................................................................... 6

Email address for this device: ................................................................................................................................................................ 6

Email User Name and Password ............................................................................................................................................................ 6

SMTP Server Address and Port: ............................................................................................................................................................. 6

Authentication and SSL Encryption:....................................................................................................................................................... 7

Display Group Names:............................................................................................................................................................................7

I/O Modules ......................................................................................................................................................................................7

Add:........................................................................................................................................................................................................ 8

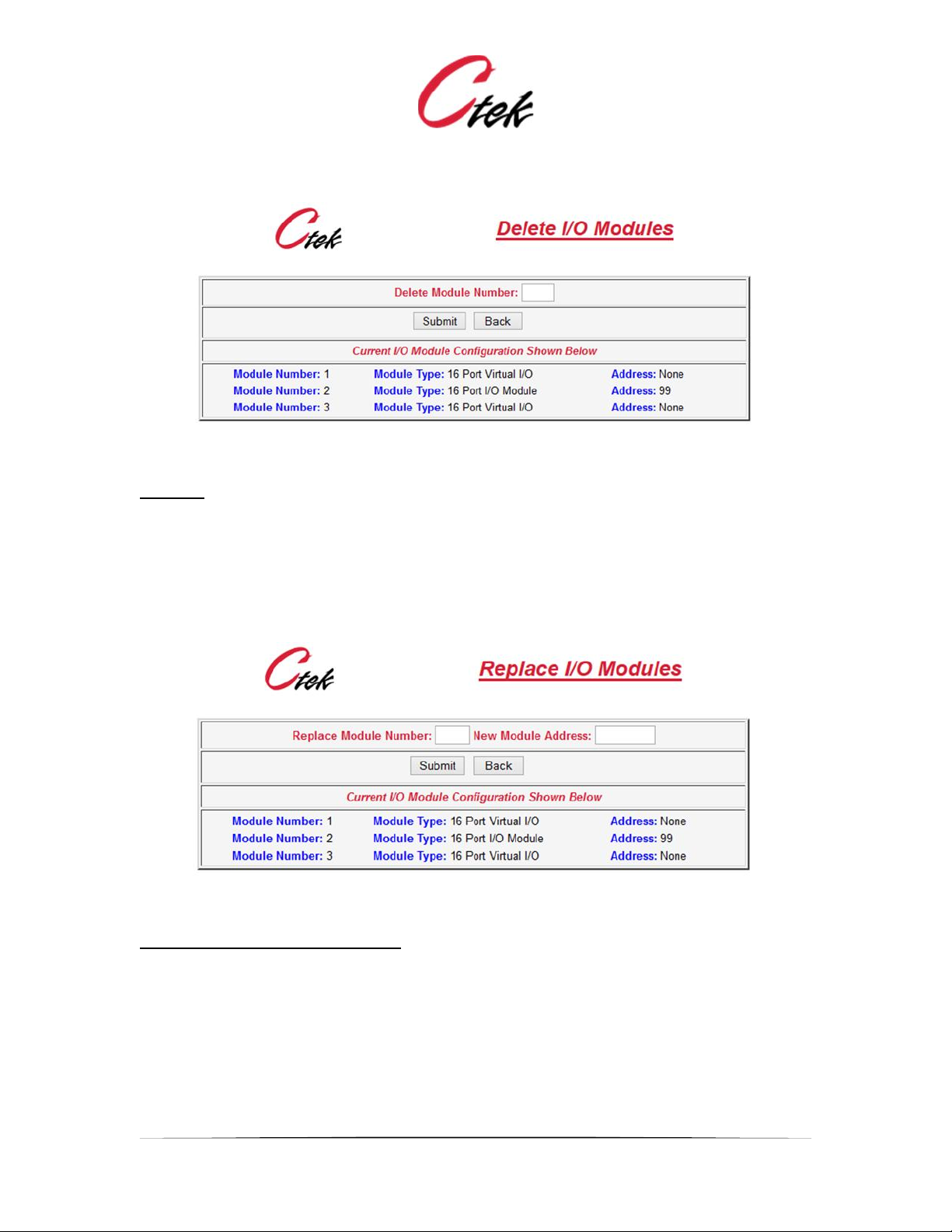

Delete:.................................................................................................................................................................................................... 8

Replace:.................................................................................................................................................................................................. 9

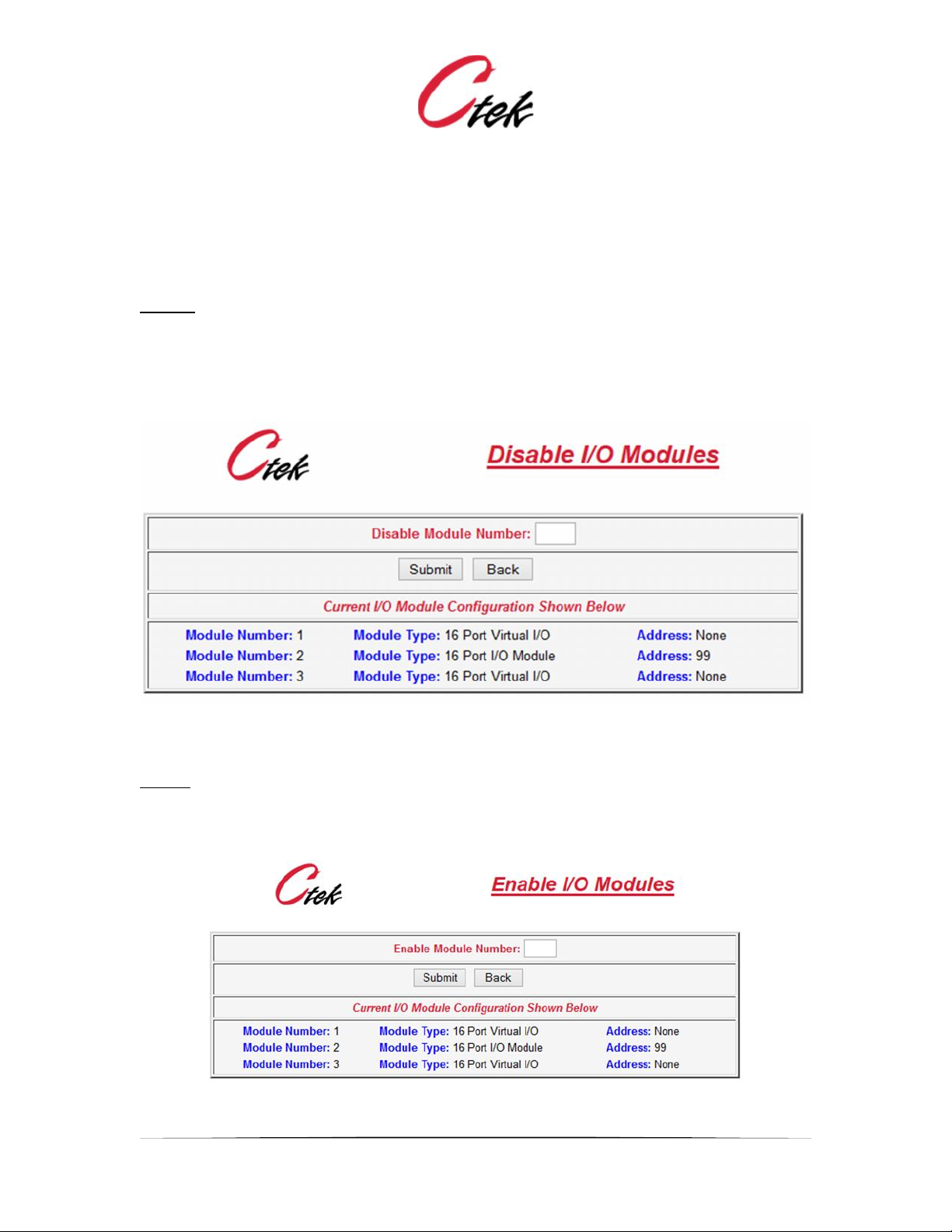

Disable.................................................................................................................................................................................................. 10

Enable .................................................................................................................................................................................................. 10

Configure Outputs ...........................................................................................................................................................................11

Output Configuration Screens ............................................................................................................................................................. 12

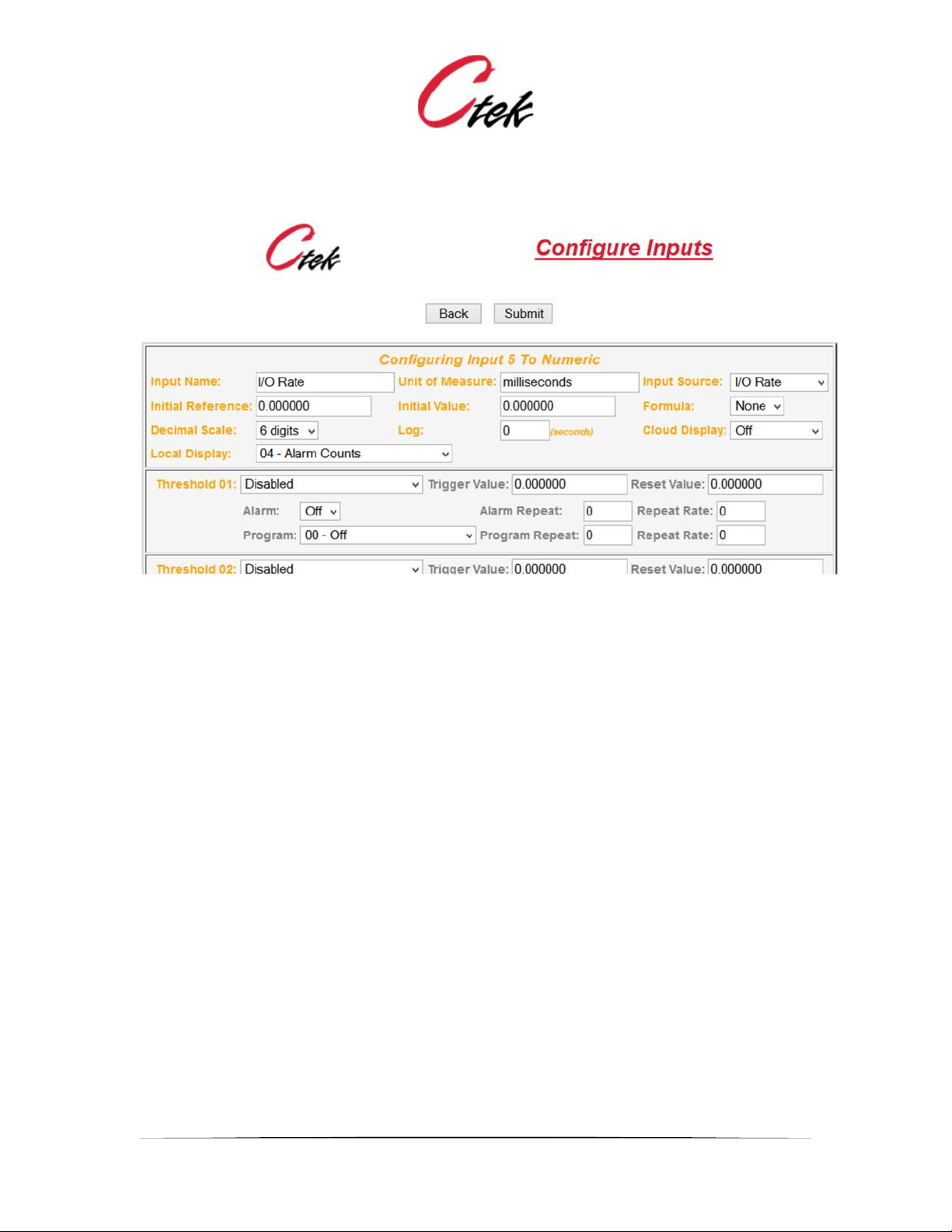

Configure Inputs ..............................................................................................................................................................................15

Input Configuration Screens ................................................................................................................................................................ 15

25 July 2014

ii

More About Digital Inputs and Outputs ..........................................................................................................................................24

Understanding The Input and Output Polarity Setting ........................................................................................................................ 24

Min/Max Range and Sensor Calibration: ............................................................................................................................................ 25

Analog Input Processing....................................................................................................................................................................... 26

Thresholds............................................................................................................................................................................................ 26

Thresholds – An Example .....................................................................................................................................................................27

Pulse Input - Latching ........................................................................................................................................................................... 28

Configure Formulas .........................................................................................................................................................................29

Current Input Pin: ................................................................................................................................................................................ 30

Other Input Pin: ................................................................................................................................................................................... 30

Output Pin = ......................................................................................................................................................................................... 30

Constant Value = .................................................................................................................................................................................. 30

Correction: ........................................................................................................................................................................................... 30

Min Range: ........................................................................................................................................................................................... 30

Max Range: .......................................................................................................................................................................................... 30

Max – Min Range ................................................................................................................................................................................. 30

Min Units:............................................................................................................................................................................................. 30

Max Units: ............................................................................................................................................................................................ 30

Max – Min Units: .................................................................................................................................................................................. 31

Ent ........................................................................................................................................................................................................ 31

Sub ....................................................................................................................................................................................................... 31

Add.......................................................................................................................................................................................................31

Mul....................................................................................................................................................................................................... 31

Div ........................................................................................................................................................................................................ 31

Xch .......................................................................................................................................................................................................31

An explanation of the standard conversion formula ........................................................................................................................... 31

Programs .........................................................................................................................................................................................33

Program Edit Fields .............................................................................................................................................................................. 34

Function Library ................................................................................................................................................................................... 34

LOG AND LOGGING ........................................................................................................................................................ 35

Set Up and Management .................................................................................................................................................................35

Logging Rules...................................................................................................................................................................................35

Digital Inputs ........................................................................................................................................................................................ 35

Analog, Pulse, and Numeric In puts ...................................................................................................................................................... 35

Digital Outputs ..................................................................................................................................................................................... 35

Numeric Outputs.................................................................................................................................................................................. 35

THE CONTROL PANEL ..................................................................................................................................................36

Provisioning the Control Panel ........................................................................................................................................................36

APPENDIX A – FUNCTION LIBRARY .........................................................................................................................38

Function List ....................................................................................................................................................................................38

Function Descriptions ......................................................................................................................................................................38

25 July 2014

iii

Digital I/O – Set .................................................................................................................................................................................... 38

Numeric I/O – Set................................................................................................................................................................................. 39

Math functions..................................................................................................................................................................................... 39

Note on Remote Commands ................................................................................................................................................................ 40

Remote I/O - Set................................................................................................................................................................................. 40

Note On Timer/Counter ....................................................................................................................................................................... 40

Timer/Counter/Ext/Clk – Start [Note – Changed In Release 4.02.02]................................................................................................. 42

Timer/Any – Stop ................................................................................................................................................................................. 43

Important Notes on Motor Group Control .......................................................................................................................................... 43

Motor Group Control ........................................................................................................................................................................... 44

Application Status - Set ........................................................................................................................................................................ 45

25 July 2014

iv

Table of Figures

FIGURE 1 – THEORY OF OPERATION ................................................................................................................................................1

FIGURE 2 - TOP LEVEL NAVIGATION ...............................................................................................................................................2

FIGURE 3 - AUTOMATION CONTROL CONFIGURATION MENU..................................................................................................4

FIGURE 4 - UNIT CONFIGURATION....................................................................................................................................................5

FIGURE 5 - MANAGE I/O MODULES...................................................................................................................................................7

FIGURE 6 - MODULE ADD SCREEN....................................................................................................................................................8

FIGURE 7 - MODULE DELETE SCREEN .............................................................................................................................................9

FIGURE 8 – I/O MODULE REPLACEMENT.........................................................................................................................................9

FIGURE 9 - DISABLE I/O MODULE....................................................................................................................................................10

FIGURE 10 - ENABLE MODULE.........................................................................................................................................................10

FIGURE 11 - OUTPUT CONFIGURATION SCREEN .........................................................................................................................11

FIGURE 12 OUTPUT - PHYSICAL/DIGITAL .....................................................................................................................................12

FIGURE 13 - OUTPUT VIRTUAL/DIGITAL .......................................................................................................................................12

FIGURE 14 - OUTPUT VIRTUAL/NUMERIC .....................................................................................................................................13

FIGURE 15 - OUTPUT PIN DEFINITIONS..........................................................................................................................................14

FIGURE 16 - INPUT CONFIGURATION SCREEN .............................................................................................................................15

FIGURE 17- INPUT PHYSICAL/DIGITAL ..........................................................................................................................................16

FIGURE 18 - INPUT PHYSICAL/ANALOG.........................................................................................................................................16

FIGURE 19 - INPUT PHYSICAL/PULSE .............................................................................................................................................17

FIGURE 20 - INPUT VIRTUAL/DIGITAL ...........................................................................................................................................17

FIGURE 21 - INPUT VIRTUAL/NUMERIC.........................................................................................................................................18

FIGURE 22 - INPUT PIN DEFINITIONS..............................................................................................................................................21

FIGURE 23 - INPUT SOURCES (DIGITAL) ........................................................................................................................................22

FIGURE 24 - INPUT SOURCES (DIGITAL VIRTUAL)......................................................................................................................22

FIGURE 25 - INPUT SOURCES NUMERIC.........................................................................................................................................23

FIGURE 26 - INPUT DEFINITIONS (NUMERIC) ............................................................................................................................... 24

FIGURE 27 - ANALOG INPUT PROCESSING....................................................................................................................................26

FIGURE 28 - THRESHOLD AND DIRECTION...................................................................................................................................27

FIGURE 29 - INPUT FORMULA SELECTION SCREEN....................................................................................................................29

FIGURE 30 - EDIT INPUT FORMULA.................................................................................................................................................30

FIGURE 31 - STANDARD CONVERSION FORMULA ...................................................................................................................... 32

FIGURE 32 – PROGRAM SELECT.......................................................................................................................................................33

FIGURE 33 – PROGRAM EDIT SCREEN ............................................................................................................................................34

FIGURE 34 - CONTROL PANEL SELECTION AT LOGIN................................................................................................................ 36

FIGURE 35 - SAMPLE CONTROL PANEL DISPLAY........................................................................................................................37

Application Note – Automation Control Application

APN007 25 July, 2014

1

Introduction:

Ctek's Automation Manager is an optional firmware application available for the Ctek

Z4200/Z4400 series SkyRouter. It provides the logic and control necessary to create

sophisticated automation applications that evaluate analog, digital, and pulse sensor inputs, and,

based on sensor inputs, and programming logic, control output devices.

The Automation Manager also provides a simple, GUI based rapid development environment

used to create and deploy applications using the Automation Manager

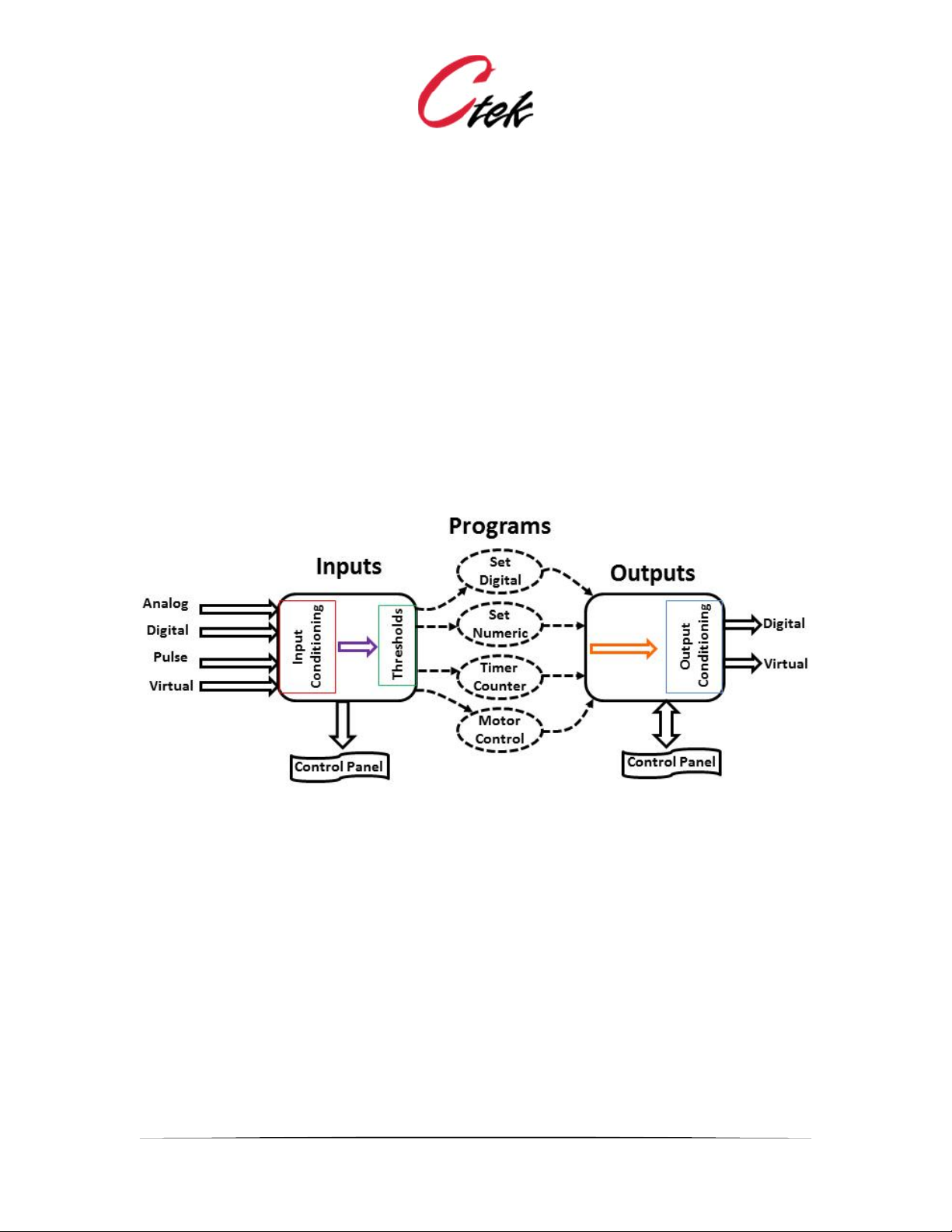

Theory of Operation

Figure 1 depicts the high-level operation of Ctek’s Automation manager. The text below figure 1

explains the flow of information through the Automation Manager.

Figure 1 – Theory of Operation

The Automation Manager is an intelligent controller, implemented in software that reacts to inputs

by controlling outputs. In their simplest form inputs are a sensors representation of a real world

value e.g. temperature, pressure, open, closed, etc. And, in their simplest form outputs are

control signals directed back into the real world to start motors, light lights or turn on heaters. The

class of inputs and outputs coming from the real world and directed back into the real world are

called physical inputs and outputs.

Inputs are connected to outputs by programs. A program can only be initiated by an input. On an

input the initiation of a program occurs as a result of the input reaching a defined state or

threshold. For digital inputs the thresholds are true and false while for analog, pulse, and numeric

inputs there can be many threshold values assigned to a single input, each capable of initiating its

own program. In summary physical inputs receive information from sensors and, at predefined

thresholds react to that information by initiating programs that control outputs.

There is another class of inputs and outputs that are known as virtual inputs and outputs or virtual

pins. Virtual pins exist only within the scope of the Automation Control software, they have no

physical connection. Virtual pins can be read and written to, modified by Boolean calculations

Application Note – Automation Control Application

APN007 25 July, 2014

2

(digital), basic math functions (numeric), and can be assigned event thresholds. Virtual pins are

useful to modify processing logic, store intermediate results, and to display values derive from

programs. Just like physical pins virtual inputs are temporary while virtual outputs are persistent.

Note – This document often refers to inputs and outputs as pins or input pins or output pins or

virtual pins depending on their origin.

Navigation and Top Level Functions:

When installed the Automation Control application is found under the applications selection on

the top level SkyRouter administration screen. When selected, the application button presents the

following navigation menu. The last two menu items shown below are related to the Automation

Control option. Other menu choices may also appear depending on the set of features enabled

on the SkyRouter.

Figure 2 - Top Level Navigation

Automation Control Panel

The Automation Control Panel selection provides user access to a dashboard style control and

display of inputs and outputs that have been previously selected. Portions of this functionality are

covered in Unit Configuration, Inputs, and Outputs discussion. A complete description of the

Control Panel is found after the configuration section.

Automation Control Configuration

The Automation Control Configuration selection provides access to the screens used to configure

the application characteristics of the overall application environment, the number and type of I/O

modules installed, specific characteristics for each input and output on each I/O module, and the

formulas and functions that are applied to specific sensors and outputs.

For new installations the recommended sequence is:

1. Configure the unit

2. Configure the modules installed with this unit

3. Configure inputs on each installed module

Application Note – Automation Control Application

APN007 25 July, 2014

3

4. Configure outputs on each installed module

5. Create and assign formulas as required

6. Create and assign programs as required

Once configuration has been completed the selections are deployed using the Execute New

Configuration button. If logging is used the Logs selection can provide useful information about

system operation and can also be used to debug sensor and output installations.

Application Note – Automation Control Application

APN007 25 July, 2014

4

User Interface and Configuration Specifics

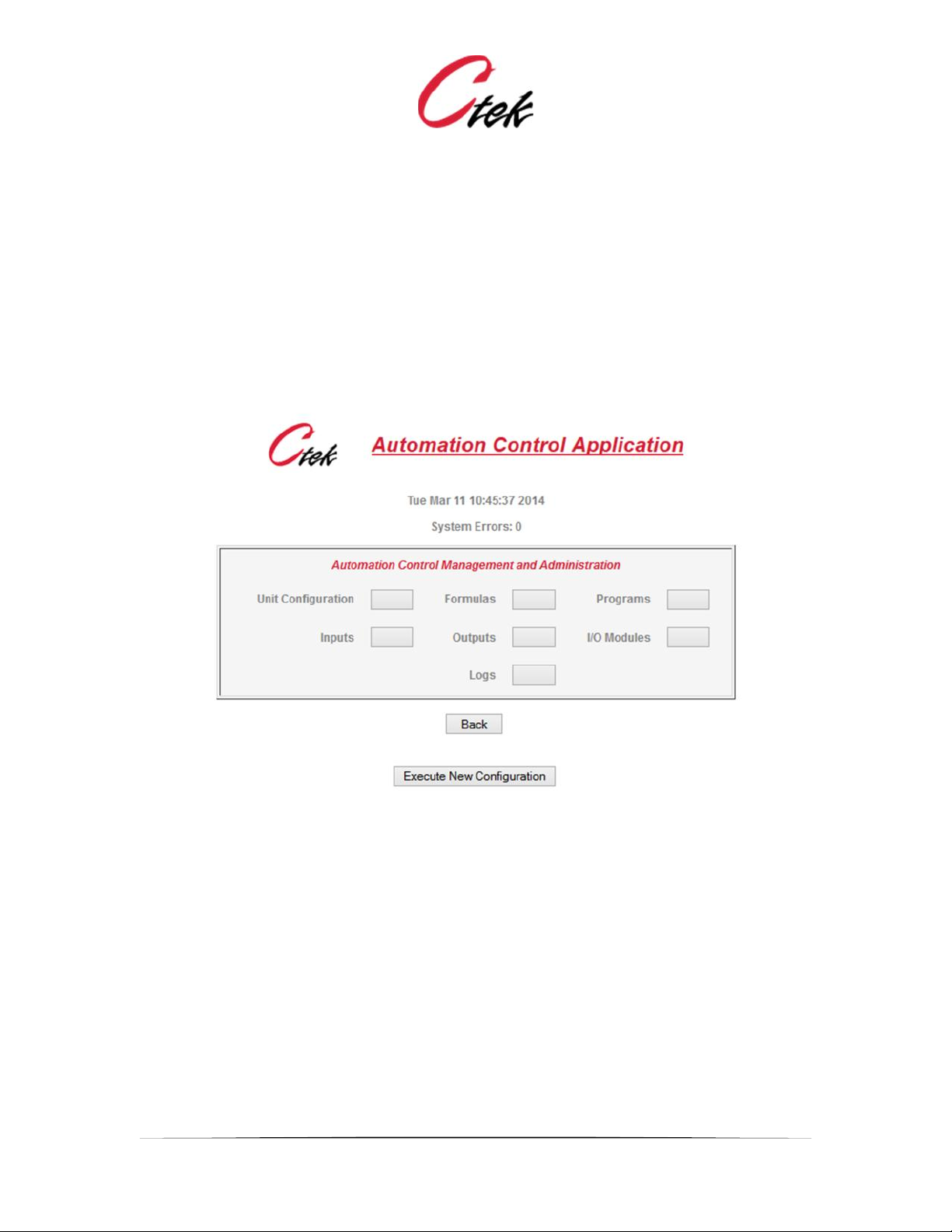

Selecting the Automation Control Configuration item presents the following menu from which the

user can install, configure, and adjust settings on I/O modules and sensors.

Note: System Errors indicates entries made as a result of this application since the last time the

box was restarted. System errors can be caused by a number of events but one common source

is communications problems with I/O modules. Contact Ctek or see TechNotes to recover the

system log contents.

Figure 3 - Automation Control Configuration Menu

Execute New Configuration

The Execute New Configuration button must be pressed before any changes made on any edit

screens will be deployed. The only exception to this rule is that outputs that are changed from

their Output edit screen will take effect immediately and do not require a New Configuration.

A new control panel view is also generated during a new configuration.

Unit Configuration

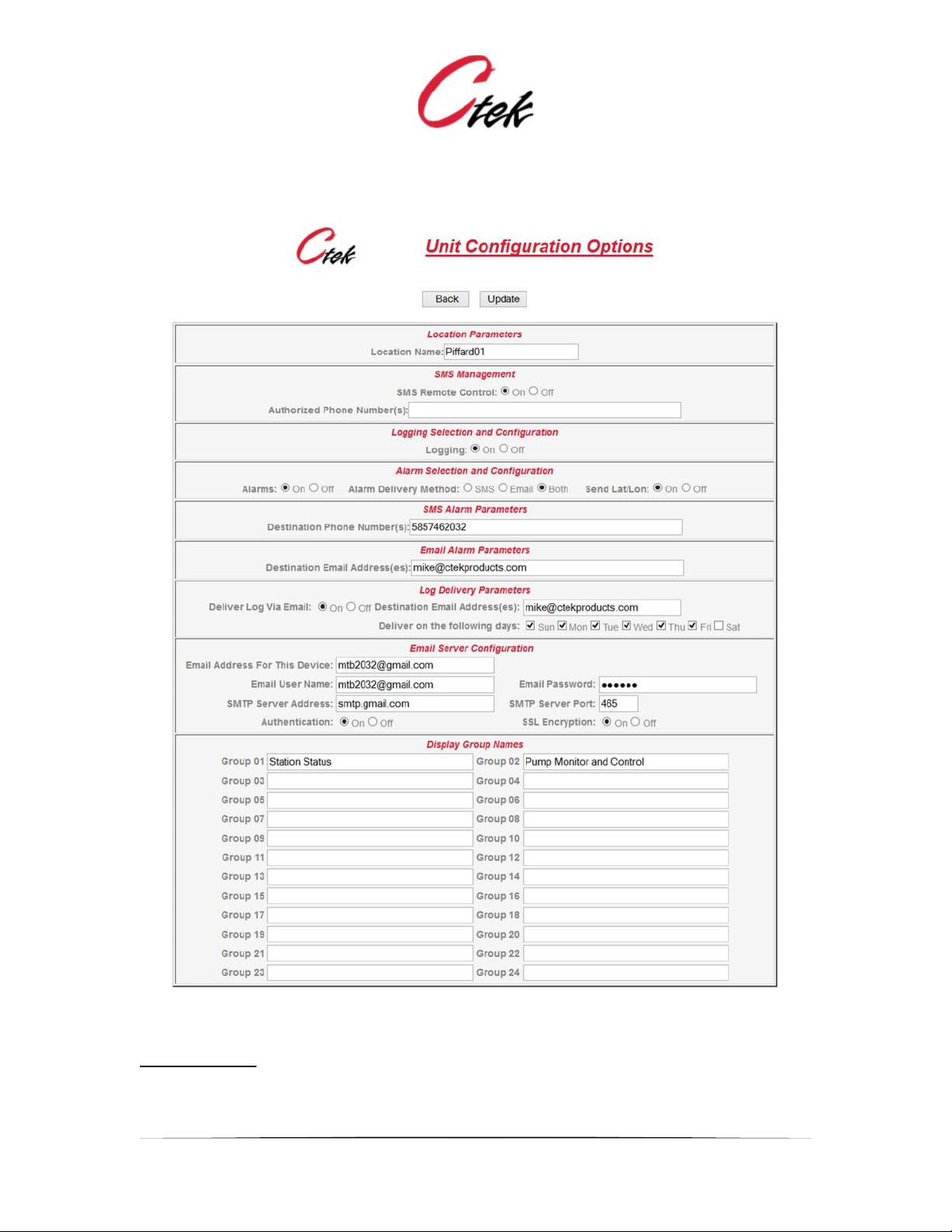

Selecting the Unit Configuration menu item causes the screen shown in Figure 4 to be displayed.

A description of each field follows the screen image.

Application Note – Automation Control Application

APN007 25 July, 2014

5

Figure 4 - Unit Configuration

Location Name:

A descriptive name assigned to this controller and its associated I/O modules

Application Note – Automation Control Application

APN007 25 July, 2014

6

SMS Remote Control:

Enable or disable SMS read/write control/monitoring of automation control I/O pins. (Introduced in

release 4.2 – see TechNote TN009 for details)

Authorized Phone Numbers:

A list of between 0 and 5, 10-digit, space separated phone numbers that are permitted to use the

SMS Remote Control feature. A blank field blocks all phone numbers. The * (star) character

allows any number. Although its use is not recommended the * character will also permit SMS

control via the carrier’s email to SMS gateway.

Logging On/Off:

Enable or disable logging. Log files are formatted in the comma separated value (CSV) format

and can be read and manipulated with a spread sheet program such as Excel. Inputs are logged

at a rate defined on each input pin. Output logging is set to either on or off on each individual

output pin. See Logging rules section.

Alarms On/Off:

Enable or disable alarms for the entire controller. Alarms can also be enabled or disabled for

each individual input.

Alarm Delivery Method:

Select whether alarms will be delivered by SMS (text messaging), email, or both.

Send Lat/Lon:

Send the current position (latitude and longitude) of the unit with all alarm entries, both SMS and

email.

Destination Phone Number for Alarms:

The phone number of the handset or device that will receive SMS alarms.

Destination email address for Alarms:

The email address that will receive alarms

Log Delivery Parameters:

Logs are files containing comma separated values that can be directly read into a spread sheet or

database application. Logging options are available for each input and output. Logs can be

delivered by email on a schedule established in this panel.

Email address for this device:

If the controller is going to send email alarms and logs it will require an email address to use as

the sender. This is typically an email address from the customers email domain. All boxes in a

network can use the same email address.

Email User Name and Password

Login information for the SkyRouter email client to use when connecting to the customer's email

server to send alarms and reports.

SMTP Server Address and Port:

Information required about the customer's email server so the SkyRouter can connect to it to

send reports and alarms.

Application Note – Automation Control Application

APN007 25 July, 2014

7

Authentication and SSL Encryption:

Settings specific to each email SMTP server.

Display Group Names:

User assigned names of logical groupings of inputs and outputs that will be used to organize the

display of the Control Panel. Both inputs and outputs can be organized under a single group

name. For example a Power Control group could have a button to turn on/off power and a current

measurement to display the amount of current being drawn.

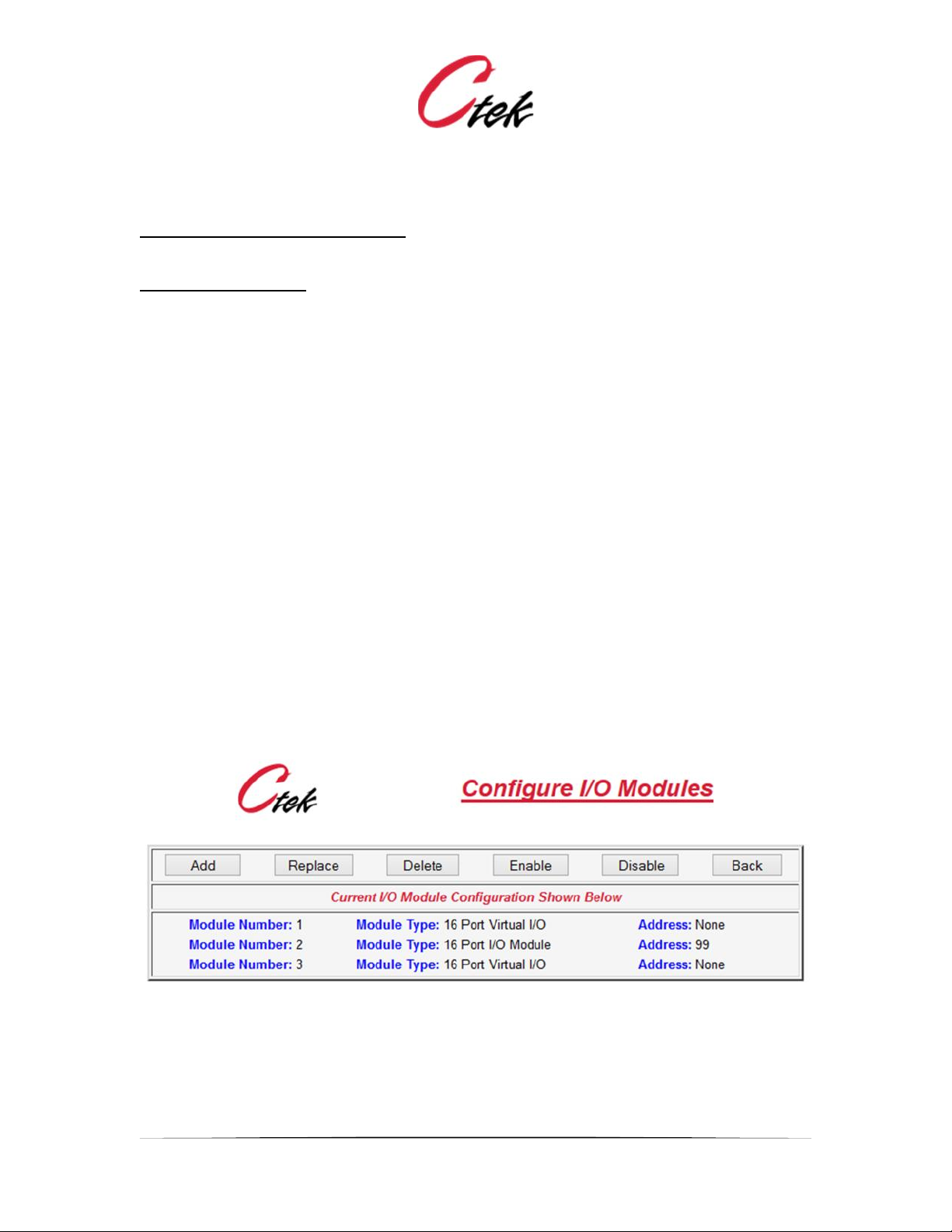

I/O Modules

The I/O modules screens allow the user to Add, Delete, Replace, Enable, or Disable an I/O

module. When an I/O module is added its inputs and/or outputs are automatically assigned. For

relay modules four outputs are automatically assigned. When adding a 16-port I/O module eight

unassigned (not initialized) inputs and eight digital outputs are automatically created. Inputs and

outputs are assigned sequential numbers as modules are installed. To convert an unassigned

input or output to a specific type (analog, digital, pulse, or numeric) the Configure Inputs and

Configure Outputs screens are used to select a specific edit function for the selected pin type.

Replace is a special case designed for maintenance. When using the replace function only the

boards address may be changed and the pre-existing configuration will be assigned to the new

address. The Replace function is useful for both replacing a defective module and to re-address

an existing working module. The Enable and Disable functions apply only to physical modules.

When a physical module is disabled it is taken out of the communications processing meaning

that it is not polled. All settings remain intact and when the module is re-enabled communications

will resume. This feature can be useful in troubleshooting communications problems when

multiple modules are on one string.

Figure 5 - Manage I/O Modules

Application Note – Automation Control Application

APN007 25 July, 2014

8

ABOUT I/O MODULE ADDRESSING

I/O module part numbers B1204S (4-port relay), B1216S (16-port) and Z1216S use RS485

communications. A default address of 99 is assigned to these modules when they leave the

factory. Their addresses may be reassigned under program control from the replace function

under the Configure I/O Modules screen. To readdress these modules first add them (Add

function) as module address 99. Once added the module may be selected by its module number

(not address) and readdressed by doing a replace on that module number with a similar type

module assigned a different address.

NOTE – If a module assigned address 99 is already installed it will either have to be temporarily

disconnected from the RS485 string (use Disable) or readdressed using the process below before

an additional module can be installed using this process. When a module is readdressed all of its

input and output settings are retained so there is no penalty for readdressing a module currently

addressed at 99.

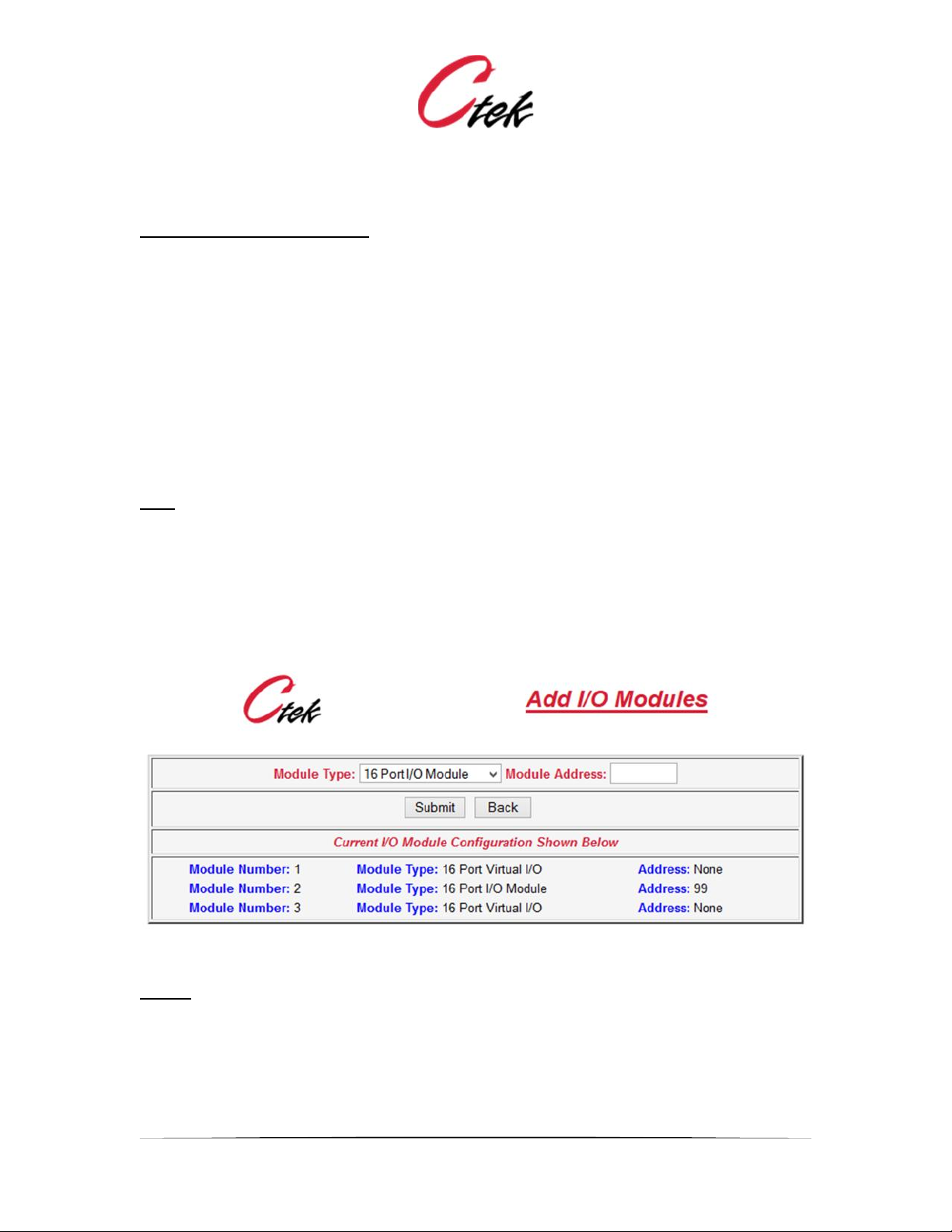

Add:

Add is used to create a new module. When Add is selected the screen shown in Figure 6 will be

displayed. A module type and module address are assigned by the user and submit is pressed.

The newly created module will then be displayed in the module inventory and its associated

inputs and/or outputs will be displayed on those screens. As previously discussed all newly

created modules having inputs will be created with all inputs defined as unassigned. An RS485

module should be assigned a two character hexadecimal address between 01 and FF. RS485

address 00 is reserved for Ctek's PowerMinder module. USB modules are assigned an eight

character address which is supplied with the module.

Figure 6 - Module Add Screen

Delete:

Delete is used to remove a module from the overall configuration. When selected the Delete

screen will be displayed as shown in Figure 7. To delete a module enter the modules number and

press submit. When a module is deleted all of its input and output settings are permanently

erased.

Application Note – Automation Control Application

APN007 25 July, 2014

9

Figure 7 - Module Delete Screen

Replace:

The replace function has three purposes. First it is used to replace an existing module with a

spare. Secondly it can be used to readdress an existing module. In either case all settings

associated with that module will be preserved.

When selected the Replace Module screen will be displayed as shown in Figure 8. To replace a

module in the inventory enter the module number and the address to be assigned to the new

module, and press submit. The input/output configuration of the old module is assigned to the

new address.

Figure 8 – I/O Module Replacement

Restore a Modules Default Address

The replace function can also be used to restore the default (address 99) setting of a module. To

accomplish this connect the module with the unknown address to an SkyRouter Automation

controller. Using the Add function add the module with any address. At this point the module will

not function properly but will appear in the module line up with the address assigned. Next, using

the replace function replace the module having the made up address with the text default in the

address field. The module will be assigned an address of 99 and after a program reload will begin

functioning at that address. Once this is accomplished the module can then be readdressed

(again using the replace function) to any address desired.

Application Note – Automation Control Application

APN007 25 July, 2014

10

Note:

The default commend described above uses a broadcast that will set the address of all physical

modules to 99. You may want to disconnect modules from the line up that do not require their

address to be resored to default.

Disable

Disabling a module removes it from the communications routine. All set up information for the

disabled module remains intact. Disable can be a useful troubleshooting tool when diagnosing

communications problems or configuration issues.To disable a module enter its module number

and press submit.

Figure 9 - Disable I/O Module

Enable

Enabling a module returns a disabled module to service. Setting previously stored on the module

will be used. To enable a module enter its module number and press submit.

Figure 10 - Enable Module

Application Note – Automation Control Application

APN007 25 July, 2014

11

Configure Outputs

A representative portion of the Configure Outputs navigation screen is shown below. This is a

selection screen. Use the Type pull-down and Edit button to select a specific Output for edit. To

completely disable an output select Disabled in the pull-down and then press the associated edit

button.

The default display shows the current status of outputs across all modules. Output pins are

assigned numbers and displayed sequentially starting with the first module installed

Note: Output values are managed in one of four ways:

1. From the individual output's edit screen (output state field or current value + Submit)

2. By an On/Off button on the Control Panel

3. By the Shutoff Timer value on an output

4. Under program control by functions that are triggered by the threshold values of inputs

NOTE:

Each of these methods of changing an output state operates independent of the other, meaning

that one method might change the state of an output pin and another method could immediately

change it back. In other words an output manually turned on could be switched off by a threshold

when it is reached.

Figure 11 - Output Configuration Screen

Application Note – Automation Control Application

APN007 25 July, 2014

12

Output Configuration Screens

Figures 8 – 11 below show the configuration screens for the supported output types,

physical/digital, virtual/digital, and virtual/numeric. Following the screen images is a complete list

of attributes found on these screens and a description of their application on a specific type of pin.

Figure 12 Output - Physical/Digital

Figure 13 - Output Virtual/Digital

Application Note – Automation Control Application

APN007 25 July, 2014

13

Figure 14 - Output Virtual/Numeric

Application Note – Automation Control Application

APN007 25 July, 2014

14

Pin Name

Pin Type

Description

Output Name

All

Assigns a name to the output pin that will be

used in display, logging, and alarms

Local Display

All

Assigns the pin to a specific panel within the

control panel display. Set to Off for pins that

will not be displayed on control panel.

Note – Output pins assigned to the control

panel can be set to a value by a user. To

create a read-only display assign the output pin

to a virtual input pin and display the input pin.

Cloud Display

All

Defines which of 8 possible attributes this pins

value will appear on a SkyCloud pin

Log

All

When set to On changes in the state or value

of the output pin will be entered in the log file.

Note – See Logging Rules for more

information on logging

Program

All Virtual

The program name, selected from a pull down

of defined programs that will be executed when

a numeric or digital pin changes state or value.

Initial Value

All Digital

Specifies how the digital pin will be initialized

upon power up or restart. Choices are On, Off,

or Last. The Last setting will provide a

persistent pin value.

Label for On[Off]

All Digital

Provides labels for the state of a digital pin that

will be used on the control panel.

Output State

All Digital

Displays the current state of a digital output

pin. This value can be changed by the user,

causing the output to change state once the

Submit button is pressed.

Shutoff Timer

All Digital

Once a digital output has been set to On this

timer will return the pin to the Off state after a

specified number of seconds.

Polarity

Physical Digital

Inverts the physical state (open vs. conducting)

of a physical output pin relative to the logical

states of On or Off. In many cases UI

considerations will require that the labels for

On and Off be reversed to compensate for this

setting.

Decimal Scale

Virtual Numeric

Assigns levels of decimal precision to the value

represented by the output pin. Choices are 2

digits, 6 digits, or zero digits.

Current Value

Virtual Numeric

Much like the Output State setting for digital

pins this setting allows the user to change the

value stores on the numeric Input pin.

Initial Value (numeric)

Virtual Numeric

Specifies how the numeric pin will be initialized.

upon power up or restart. Choices are “Last

Value” or a user defined value

Figure 15 - Output Pin Definitions

Application Note – Automation Control Application

APN007 25 July, 2014

15

Configure Inputs

This is a selection screen. Use the Type pull-down and Edit button to select a specific Input for

edit. To completely disable an Input select Disabled in the pull-down and then press the

associated edit button.

The default display shows the current status of Inputs across all modules. Input pins are assigned

numbers and displayed sequentially starting with the first module installed

Note that the active individual inputs are color coded"

Purple = Analog Input

Green = Pulse Input

Blue = Digital Input

Figure 16 - Input Configuration Screen

Input Configuration Screens

Figures 8 – 11 below show the configuration screens for the supported Input types,

physical/digital, physical/analog, physical/pulse, virtual/digital, and virtual/numeric. Following the

screen images is a complete list of attributes found on these screens and a description of their

application on a specific type of pin.

Application Note – Automation Control Application

APN007 25 July, 2014

16

Figure 17- Input Physical/Digital

Figure 18 - Input Physical/Analog

Application Note – Automation Control Application

APN007 25 July, 2014

17

Figure 19 - Input Physical/Pulse

Figure 20 - Input Virtual/Digital

Application Note – Automation Control Application

APN007 25 July, 2014

18

Figure 21 - Input Virtual/Numeric

Application Note – Automation Control Application

APN007 25 July, 2014

19

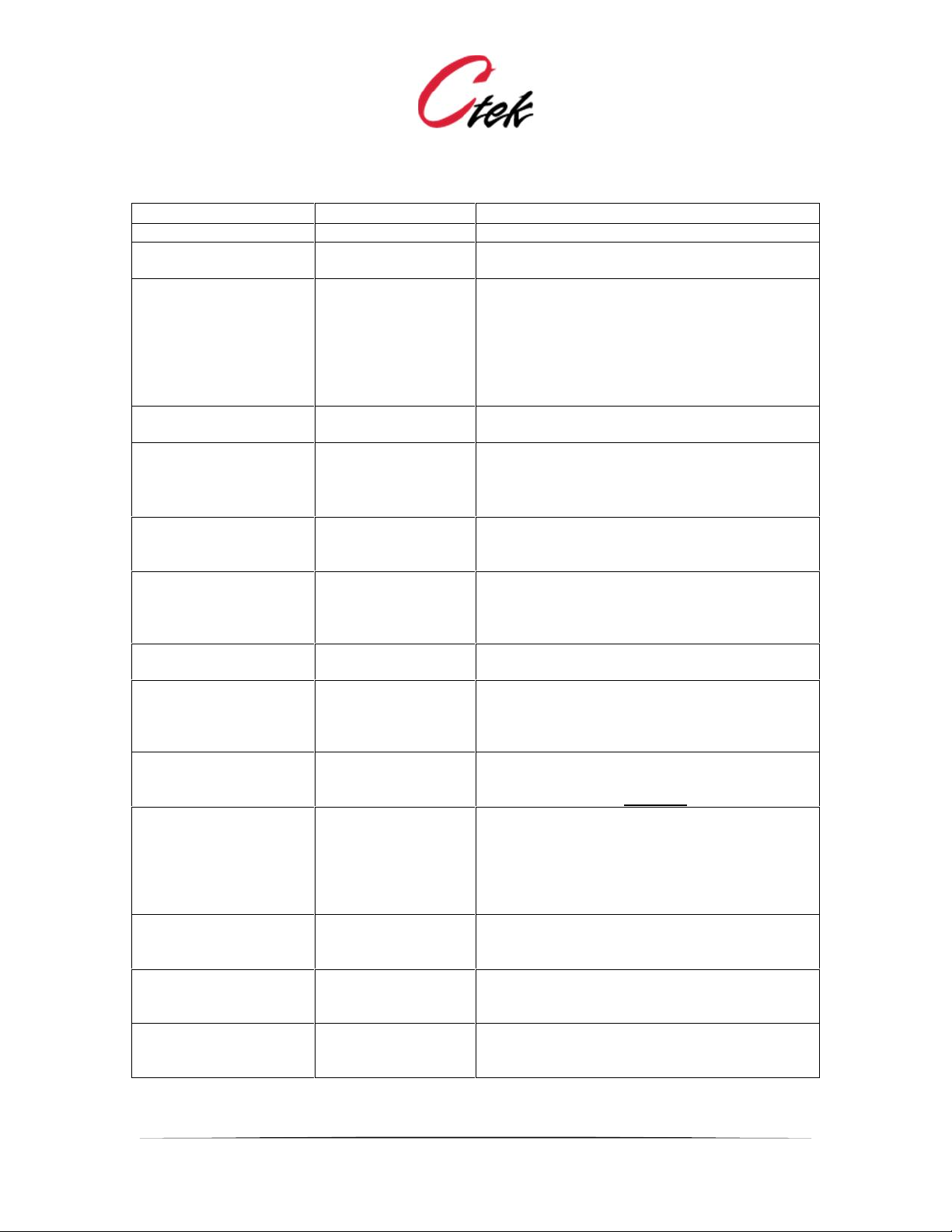

Input Pin Name

Pin Type

Description

Key: PD = Physical Digital, PA = Physical Analog, PP = Physical Pulse VD = Virtual Digital, VN = Virtual Numeric VD = Virtual Digital, VN

= Virtual Numeric

Input Name

All

Assigns a name to the Input pin that will be used in display, logging, and alarms

Display

All

Assigns the pin to a specific panel within the control panel display. Set to Off for pins that

will not be displayed on control panel.

Note – Output pins assigned to the control panel can be set to a value by a user. To

create a read-only display assign the input pin to a virtual input pin and display the input

pin.

Cloud Display

All

Defines which of 8 possible attributes this pins value will appear on a SkyCloud pin

Log

All

Specifies in seconds the frequency at which the pins value will be logged. If set to zero (0)

logging on this pin is turned off.

Note – See Logging Rules for more information on logging

Initial Value

VD, VN

Specifies how the pin will be initialized upon power up or restart. Choices for digital are

On, Off, or Last. The Last setting will provide a persistent pin value. Numeric pins are set

to the value as specified.

Unit of Measure

PA, PP, VN

This field defines the units of measure to be used with the input, PSI or degrees for

instance. The control panel display will use this value in combination with the sensor

reading to create a display such as 27.3 PSI.

Threshold 1 – n

PA, PP, VN

Pull down field to define threshold type, Less Than or Greater Than and Edge Sensitive or

Level Sensitive.

Trigger Value

PA, PP, VN

The measured value at which the threshold will occur

Reset Value

PA, PP, VN

Sometimes referred to as the hysteresis band. The value associated with a trigger value

at which the threshold will be reset so that it can be triggered again. Example: If a level

sensor triggers at greater than 17 feet it might be assigned a reset value of less than 15

feet. Once the level was sensed at 17 feet the tank level would have to return to 15 feet

before another 17 foot event could be triggered. The zone between trigger and reset

eliminates multiple alarms if the value is oscillating at approximately the trigger point.

Application Note – Automation Control Application

APN007 25 July, 2014

20

Alarm

PA, PP, VN

On/Off for SMS and email Alarms associated with a specific threshold

Alarm Repeat

PA, PP, VN

The number of times that an alarm for a single threshold will be repeated. A value of zero

(0) will allow only one alarm to occur.

Repeat Rate

PA, PP, VN

The interval in minutes between alarms when a repeat value is set.

Program

PA, PP, VN

The program name, selected from a pull down of defined programs that will be executed

when a threshold is reached.

Program Repeat

PA, PP, VN

The number of times that an program for a single threshold will be run. A value of zero (0)

will allow only one program execution to occur. A value of 9999 will cause the program to

execute perpetually at the repeat rate.

Repeat Rate (program)

PA, PP, VN

The interval in minutes between program executions when a repeat value is set.

Formula

PA, VN

The numeric ID of a formula assigned to this input. In most cases formula 1 (standard

input formula) will be assigned.

Polarity

PD, VD

Establishes the input level that will indicate On and Off. Choices are 0=Off or 0=On.

Label For On[Off]

PD, VD

Provides labels for the state of a digital pin that will be used on the control panel.

Input Source

(Digital)

PD, VD

Identifies the source(s) that will be used to define the state of a digital input. The state of

multiple pins can be combined using Boolean to arrive at a final state. Also, digital events

occurring on the SkyRouter platform can be assigned as part or all of a pin’s value. See

digital input sources table below.

On[Off] Alarm

PD, VD

On/Off for SMS and email Alarms associated with the On state and the Off state of a

digital input.

On[Off] Alarm Repeat

PD, VD

The number of times that an alarm for a single state will be repeated. A value of zero (0)

will allow only one alarm to occur.

On[Off] Repeat Rate

PD, VD

The interval in minutes between alarms when a repeat value is set.

On[Off] Program

PD, VD

The program name, selected from a pull down of defined programs that will be executed

when the state (On/Off) is reached.

On[Off] Program

Repeat

PD, VD

The number of times that an program for a state will be run. A value of zero (0) will allow

only one program execution to occur. A value of 9999 will cause the program to execute

perpetually at the repeat rate.

On[Off] Repeat Rate

PD, VD

The interval in minutes between program executions when a repeat value is set.

Min[Max] Range

PA

Range refers to the range or precision of the analog to digital (A/D) conversion. Ctek 1216

I/O modules provide 12 bit conversion resulting in a theoretical 4096 discrete values, 0 -

4095. Ctek I/O modules start with a range offset of 7 making the theoretical available

range 7 - 4095. Once the sensor is calibrated the actual available range may be

Application Note – Automation Control Application

APN007 25 July, 2014

21

somewhat smaller than the theoretical due to sensor characteristics and minor variations

in the reference voltage.

Min[Max] Units

PA

This is a quantitative value for the low end of the expected engineering value

measurement of this sensor. For example for a temperature sensor that is designed to

measure between 10° and 300° the minimum Units would be 10, the Max Units would be

300, and the Units of Measure would be degrees.

Correction

PA

A specific correction or offset for this input. This can be used to correct for minor

variations in sensors that cannot be corrected in a common input formula.

Multiplier

PP

The value of an individual pulse. For example, if the multiplier value is for a gallons per

minute calculation is 10 each pulse will be counted as 10 gallons and the value (10 *

number of pulses * 60) would yield a gallons per minute value.

Interval

PP

The time interval in seconds to be used in scaling the pulse input for control panel output.

For instance, an input measured in gallons per minute (GPM) would use an interval of 60

seconds (1 minute) to scale the input.

Input Source

(Numeric)

VN

Identifies the source(s) that will be used to define the state of a virtual numeric input. The

value of other input pins or virtual output pins can be assigned through this setting. Also,

numeric events occurring on the SkyRouter platform can be assigned as a pin’s value.

Examples of the later would be RSSI or Latitude. See table of Numeric Input sources

below.

Initial Reference

(Numeric)

PA, PP, VN

The initial reference is the first value that a numeric or analog pin will be compared to after

a power up or execute new configuration. The initialization comparison will be made

against the Initial Value (see next) which is assigned to a pin during the start up. Alarms

are not issued during the initialization comparison but program actions will occur. This

provides a starting point (usually at one of the extremes) for evaluating the pin against

actual values once the initialization has completed which in turn provides a method of

conditioning the managed machines or devices to a quiescent state before normal

operation begins.

Initial Value

(Numeric)

PA, PP, VN

The initial value that will be assigned to a pin for comparison during the initialization

(power up) phase. See Initial Reference above.

Decimal Scale

VN

Assigns levels of decimal precision to the value represented by the virtual numeric input

pin. Choices are 2 digits, 6 digits, or zero digits.

Figure 22 - Input Pin Definitions

Application Note – Automation Control Application

APN007 25 July, 2014

22

Digital Input Pins – Source of Inputs

Figure 23 - Input Sources (Digital)

Digital input pins can receive inputs from themselves, any other digital input or output pin, or the

following internal sources listed in the table below. Up to four input sources can be combined

using the boolean operator AND or the boolean operator OR. All input processing is completed

before the pin is evaluated.

Input Definitions – Virtual Digital Inputs

Input Pins

Any Input pin (physical or virtual)

*

Output Pins

Any Output pin (physical or virtual)

*

Relay In

Reflects the state of the relay input contact

(discrete input) that is available on the

SkyRouter platform

GPS Status

Reflects the state of the internal GPS receiver

as shown on the Navigation Unit Configuration

Screen. 1 = OK; 0 = GPS unavailable

WWAN Status

Reflects the state of the Wireless WAN as

reflected on the Wireless Configuration Screen.

1 = Enabled; 0 = Disabled

* Caution – Be sure that pins assigned to other pins are of the same type. Example: Analog to

numeric is OK but Analog to Digital will yield unpredictable results.

Figure 24 - Input Sources (Digital Virtual)

Application Note – Automation Control Application

APN007 25 July, 2014

23

Numeric Input Pins – Source of Inputs

Figure 25 - Input Sources Numeric

Analog or numeric input pins can receive inputs from themselves, any other numeric input or

output pin, or the following internal sources listed in the table below. A formula assigned to a pin

will be processed before the pin is evaluated.

Application Note – Automation Control Application

APN007 25 July, 2014

24

Input Definitions – Virtual Numeric Inputs

Input Pins

Any Physical or Virtual Input pin

*

Output Pins

Any Physical or Virtual pin

*

Voltage In

Input voltage to the SkyRouter

Temp Cent

Internal Temperature of SkyRouter - C

Temp Farn

Internal Temperature of SkyRouter - F

WWAN RSSI

Signal Strength of cellular signal

GPS LAT

Latitude measured by internal GPS

GPS LON

Longitude measured by internal GPS

GPS Speed

Speed measured by internal GPS

GPS Course

Course measured by internal GPS

Sys Errors

System error count as senses by Automation

Control

Time Hr

The current hour reflected in the 24 hour

system clock

Time Min

The current minute reflected in the 24 hour

system clock

Time Hr:Min

The current hours and minutes reflected in the

system clock. Provides a complete 24 hour

clock value.

I/O – Rate

The rate in milliseconds at which all connected

I/O module pins are being scanned and set.

This time represents the time required to

completely process inputs and outputs on all

connected I/O modules.

* Caution – Be sure that pins assigned to other pins are of the same type. Example: Analog to

numeric is OK but Analog to Digital will yield unpredictable results.

Figure 26 - Input Definitions (Numeric)

More About Digital Inputs and Outputs

Understanding The Input and Output Polarity Setting

A digital input pin is evaluated as a 1 or 0 (On or Off, True or False) solely on the voltage level

present at the input pin, or in the case of a virtual pin the value (1 or 0) assigned to it from another

input, output, or program. Simply stated a digital input having greater than 4 volts present on it will

be evaluated as a 1 and that same pin will evaluate to 0 if its input voltage is less than 1 volt.

The polarity setting on an input does not affect the way the pin is evaluated. Instead, the polarity

setting inverts the logic (On or Off) that determines which program will run and if an alarm will be

issued.

In the case of a digital output the On state indicates that pin is conducting (sinking current) and

the Off state is when the pin is not conducting. Polarity selection for an output reverses the logic

that will cause a pin to turn on.

Application Note – Automation Control Application

APN007 25 July, 2014

25

Min/Max Range and Sensor Calibration:

Range refers to the range or precision of the analog to digital (A/D) conversion. Ctek 1216 I/O

modules provide 12 bit conversion resulting in a theoretical 4096 discrete values, 0 - 4095. Ctek

I/O modules start with a range offset of 7 making the theoretical available range 7 - 4095. Once

the sensor is calibrated the actual available range may be somewhat smaller than the theoretical

due to sensor characteristics and minor variations in the reference voltage.

Calibrating an Analog sensor - The Min and Max range fields can be used to

automatically calibrate the sensor. To perform calibration the sensor must be powered up

and properly configured within the Automation Control application. Once the sensor is

configured the application automatically records the extremes (high/low) values for the

sensor. Some sensors have a built in calibration feature. In that case select the minimum

(low) level calibration on the sensor and leave it in that position for at least 10 seconds.

Repeat this process for the high or maximum value, again waiting at least 10 seconds.

If the sensor does not have an internal calibration feature there are two possible

approaches to calibration. First, consult the sensor vendor's literature. The vendor will

certainly define the Min and Max units that the sensor is defined for, for instance -30 to

+70 degrees. Also, it is common for the specifications to indicate a minimum and

maximum output of the sensor at a specified reference voltage. Those values can be

used to trim the Min and Max range inputs for the sensor. As an example, if a sensor is

specified to output 0.25 volts on the low end of the scale for a reference voltage of 5 volts

that would equate to 5% (0.25 / 5.00) of the total range which would make the Min Range

equal to 205 (4095 * 0.05) and the Max Range equal to 3890.

An internal calibration feature is also available that analyzes the actual reference values

available on the module. To use this feature the input pin is connected to the I/O modules

ground for 10 seconds followed by connecting the input pin to the sensors reference

voltage for 10 seconds. Once the input pin has been exposed to the extremes for 10

seconds each simply enter an asterisk (*) character in the MIN and Max range fields and

press submit. The asterisk characters will be replaced with the Min and Max range values

sensed during the calibration process.

Application Note – Automation Control Application

APN007 25 July, 2014

26

Analog Input Processing

Figure 27 - Analog Input Processing

Thresholds

There are three key concepts to understand about thresholds. The first is to recognize that

thresholds have a directional component, meaning that each threshold is defined in terms of a

less than or greater than modifier. A Less than threshold only triggers (causes an action) when

the measured value is decreasing, and a greater than thresholds only triggers when the

measured value is increasing. Although thresholds only trigger in their defined (less than/greater

than) direction they are logged in both directions to create a complete record of events.

The second key concept is that thresholds have a temporal (time sensitive) component that is

defined by level sensitive or edge sensitive. A level sensitive threshold is based on the

currently measured value. A level sensitive threshold is state (current status) driven. For example,

less than 10 feet level sensitive is true for an input that is currently at 9.5 feet and had

previously come from a level greater than 10 feet. If a lower threshold, say less than 6 feet level

sensitive is also defined programs (actions) associated with the less than 6 feet level sensitive

threshold will occur once that level is reached.

Edge sensitive thresholds are event driven. They mark events that have occurred in a defined

direction. For instance, the event less than 8 feet edge sensitive will occur as the measured

value decreases from the 10 foot level to the 6 foot level. Because the less than 8 feet edge

sensitive threshold is event driven any action (program) assigned to the event will occur as the

transition through less than 8 feet is achieved without regard to any level sensitive thresholds

that may be in effect. One practical application of edge sensitive thresholds is to mark the

Application Note – Automation Control Application

APN007 25 July, 2014

27

boundaries of an operating range that would otherwise be in conflict with level sensitive

thresholds. The diagram and tutorial following demonstrates this application.

The last key concept is the order in which thresholds are evaluated. This is critical because

thresholds MUST be defined on the input screen in the order that they will be evaluated. In MOST

cases this means that the smallest value to be considered must be on the first threshold line of

the input edit screen and that the largest value to be considered must be on the last line of the

input edit screen. Values between the largest and the smallest should be entered in increasing

value from the top.

Thresholds – An Example

Figure 18 shows a simple example of an application designed to keep a tank level between 2 and

8 feet. As the tank level rises past eight feet pump #1 and the level light come on. If the tank level

continues to rise past fifteen feet pump #2 is started. At the eighteen foot level an alarm is issued.

As the tank is pumped down a below eight feet the level light is turned off and at the two foot level

both pumps are turned off.

The eight foot decreasing level edge triggered threshold demonstrates one application of edge

triggering. The requirement is to both turn the light on and turn it off at the eight foot level. Clearly

these two things would be in conflict if level sensitive thresholds were used. However, because

the light is on at any level above 8 feet and turned off on any transition below eight feet this

requirement can be met.

Figure 28 - Threshold and Direction

Application Note – Automation Control Application

APN007 25 July, 2014

28

Pulse Input - Latching

The setting Greater Than Latch Function is a special case unique to the pulse input. It is

designed to be used to capture and execute upon single pulse type inputs that have the

possibility of recurring. A typical use of this type of input is to capture (latch) the depression of a

momentary switch. When set with a value of 0.00 it will launch its assigned program each time

the switch is pressed to cause a pulse.

Application Note – Automation Control Application

APN007 25 July, 2014

29

Configure Formulas

Ctek's Automation Control application provides support for user defined formulas that can be

applied to analog and numeric inputs. Formulas are applied as a part of the input processing prior

to the pin being evaluated.

A standard conversion formula is released with the firmware. In many cases this standard formula

will suffice for input processing. Users may create additional formulas using postfix notation, an

input format colloquially known as RPN or Reverse Polish Notation.

[NB. Reverse Polish pays homage to the nationality of logician Jan Łukasiewicz, who

invented (prefix) Polish notation in the 1920s. The antithesis of prefix (Polish) notation is

postfix (reverse Polish) notation.]

A simple albeit useful explanation of postfix (RPN) notation is that it is a mathematical notation

wherein every operator follows all of its operands. As an example 2 [Enter] 5 [Multiply] = 10. The

result, 10 is then pushed on the top of the stack where it becomes the next operand in line.

Therefore, 2 [Enter] 5 [Multiply] = 10 and 2 [Enter] 5 [Multiply] 7 [Multiply] = 70.

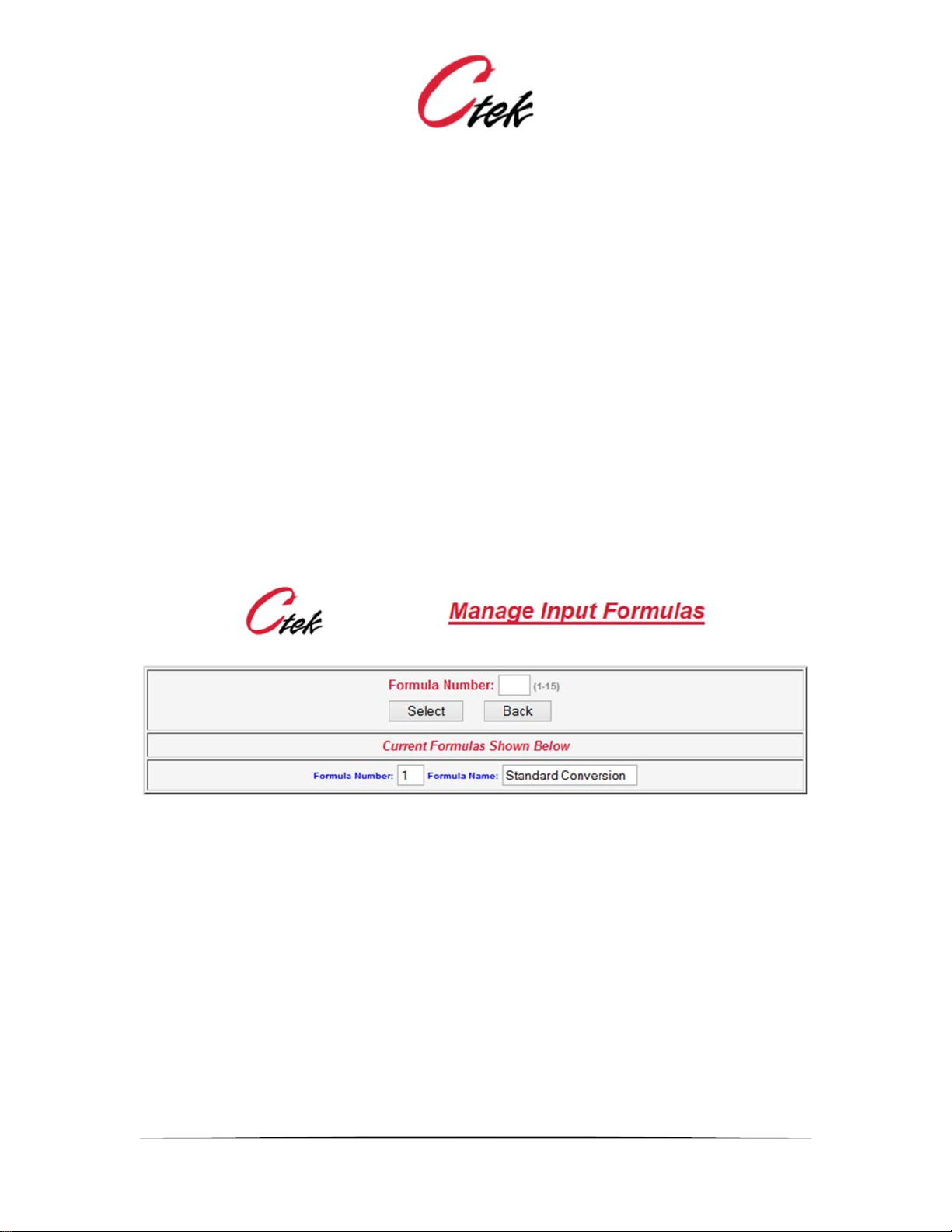

From the top level Automation Control Configuration menu selecting Formulas presents the

following selection screen which allows a user to select an existing formula for modification or

create a new formula by entering an unused formula number.

Figure 29 - Input Formula Selection Screen

Selecting a new or existing formula for edit brings up the following screen. The left hand column

provides a selection of pull-down operands. The right hand column provides a pull down selection

of operators. Constants are entered in the center column. An explanation of field selection

follows.

Application Note – Automation Control Application

APN007 25 July, 2014

30

Figure 30 - Edit Input Formula

Operands

Current Input Pin:

Selects the input value provided by the pin to which the formula is attached as an operand

Other Input Pin:

Selects the value on the input pin referenced in the right hand column

Output Pin =

Selects the value on the output pin referenced in the right hand column

Constant Value =

Use the constant entered in the center column as the next operand

Correction:

The correction value associated with this input becomes the next operand

Min Range:

The minimum range value associated with this input becomes the next operand

Max Range:

The maximum range value associated with this input becomes the next operand

Max – Min Range

The value (Maximum Range - Minimum Range) becomes the next operand

Min Units:

The minimum units value associated with this input becomes the next operand

Max Units:

The maximum units value associated with this input becomes the next operand

Application Note – Automation Control Application

APN007 25 July, 2014

31

Max – Min Units:

The value (Maximum Units - Minimum Units) becomes the next operand

(fn) Average Memory 1 and (fn) Average Memory 2

Both functions do the same thing but each can only be used by one pin so the 2 environments

allow for a total of 2 averaging inputs. These are functions are performed on the value in the X

register with the results being returned to the X register. Just like on a calculator when you have a

value on the screen and you hit a function key like square root. This means that operator field

(Ent, Sub, Add, etc.) is optional if the function is the last step in a formula. However, if it is an

intermediate step you can use an operator on the average value or push it on the stack (Ent) for

further calculations. The variable field of the formula step must contain a value between 1 and

100 indicating how many samples should be averaged. During the first N samples (1 – 100 as

defined in the formula) a value of zero will be returned. Once N samples have been processed, a

new average value, based on the last N samples will be returned with each execution of the

function.

Operators

Ent

Enter the defined operands value

Sub

Subtract

Add

Add

Mul

Multiply

Div

Divide

Xch

Exchange the current operand with the previous one

An explanation of the standard conversion formula

The standard formula is releases with the Automation Control application. In many cases it will

provide all of the input processing required. The standard conversion formula is shown below on

the edit screen. An explanation follows.

Application Note – Automation Control Application

APN007 25 July, 2014

32

Figure 31 - Standard Conversion Formula

The standard conversion formula shown above reads the sensors input value and subtracts from

it the minimum range value assigned to the sensor. It then divides the resulting value by the value

of (Max - Min Range). The resulting number is then multiplied by the value of (Max - Min Units)

and also by the correction value assigned. Lastly the value of Minimum Units is added to the

result of all of the preceding operations. This final value will be displayed in the Value field of the

Input screen and on the control panel. As a practical example assume that a 0 - 10 amp current

sensor is installed and when calibrated it has a range of 7 - 4090. The following configuration

would be made on that sensor's Input settings.

Min Range - 7

Max Range - 4090

Min Units 0.00

Max Units - 10.0

Correction Factor 1.0

Unit of Measure - Amps

Sensor value (when read) = 2037

The standard conversion formula would do the following:

Read the sensor (2037) and subtract from it the Min Range (7) resulting in 2030

Divide the result by the value of (Max Range - Min Range) resulting in 0.4972

Multiply by Max Units - Min Units (10 - 0.0) resulting in 4.972

Multiply by correction factor (1.0) resulting in 4.972

Add the value of Min Units (0.00) resulting in 4.972

The Unit of measure (Amps) would then be appended to the calculated value resulting in a

display of 4.97 Amps on the Input screen and the Control Panel.

Application Note – Automation Control Application

APN007 25 July, 2014

33

Programs

Programs are named groups of functions that can be applied to a specific input or output as the

result of a threshold event or level occurring on an input or virtual output. For instance, a program

called Power Indicator OFF (9) could be used to turn on an indicator whenever charging power

is removed from a battery powered system. The same program could also set the application

status to yellow or 1 for display on VDDNS. Programs are assigned names that are made

available in the program pull-down field of the input and virtual output edit screens. To create,

modify, or delete a program select the Program option on the main menu screen. The following

selection screen will be shown.

Figure 32 – Program Select

To view, modify, or delete an existing program select a program number from the display menu.

To create new programs enter a program number that does not currently exist into the selection

field. When a program is displayed, it will appear as in Figure 32 below.

Application Note – Automation Control Application

APN007 25 July, 2014

34

Figure 33 – Program Edit Screen

Program Edit Fields

Program Name

The user defined name assigned to this program

Action

The action field provides a pull-down menu of the different functions that can be executed by this

program.

Parameters

The parameters field contains values that the program will operate upon. Parameters MUST be

space separated.

Function Library

A complete list of functions and associated parameters is found in Appendix A.

Application Note – Automation Control Application

APN007 25 July, 2014

35

Log and Logging

Set Up and Management

The Automation Control application maintains a log file of events and thresholds in near real time

as they occur. Logging is enabled on the unit configuration screen. The unit configuration also

allows the user to specify the frequency at which they wish to receive log files and the frequency

at which events will be logged.

If enabled the log is transmitted to one or more email recipients based on the schedule defined in

the unit configuration screen. The log is also available for online viewing from the Automation

Control menu.

The log file transmitted by email is formatted as a comma separated (CSV) file. It can be read

and manipulated on your desktop using standard spreadsheet applications. Many database

applications can also import CSV files. When the log is emailed to designated recipients the log

information from the previous interval is left on the SkyRouter for online viewing. As an example,

if the log is sent every day one day’s information is left online. If the log is sent every other day

two days information remains on the system.

Logging Rules

Each output has a pull down to enable or disable logging. Input pins have a logging field that

allows the user to specify in seconds the frequency at which the pin will be logged.The rules

governing when events are logged are as follows:

Digital Inputs

Digital Inputs are logged each time they change state and every logging interval as defined on the

individual input’s set-up screen.

Analog, Pulse, and Numeric Inputs

Analog, Pulse, and Numeric inputs are logged whenever a defined threshold is reached and

every logging interval as defined on the individual input’s set-up screen.

Digital Outputs

Digital Outputs are logged each time they change state.

Numeric Outputs

Numeric Outputs are logged each time that the value changes.

Application Note – Automation Control Application

APN007 25 July, 2014

36

The Control Panel

The Control Panel for the Automation Control provides a consolidated view of selected inputs and

outputs that have been selected for display in their specific configuration. The control panel also

provides On/Off buttons for digital outputs and a data entry field for numeric outputs. Inputs are

always displayed as read only..

The Control Panel is accessible from the SkyRouter's top level menu at the same level as the

general administration menu. It can also be accessed from applications category under the

general administration menu.

Figure 34 - Control Panel Selection at Login

Provisioning the Control Panel

After the input and output configurations have been the new settings are deployed by returning to

the top level configuration menu (Figure 3) and pressing the Execute New Configuration button.

There will be a brief delay will all of the input and output settings are deployed and all of the

inputs read. This activity will also create a new Control Panel display. An example of a Control

Panel is shown below.

Application Note – Automation Control Application

APN007 25 July, 2014

37

Figure 35 - Sample Control Panel Display

Application Note – Automation Control Application

APN007 25 July, 2014

38

Appendix A – Function Library

Functions are predefined building blocks used to build user defined programs. Parameters or

arguments to the functions must be separated by a single space.

The following is the current list of functions available for creating user programs: Following the

function list is a detailed description of each individual function.

Function List

Digital I/O – Set

Numeric I/O – Set

Numeric I/O – Add

Numeric I/O – Subtract

Numeric I/O – Multiply

Numeric I/O – Divide

Remote I/O - Set

Timer/Counter – Start

Timer/Watchdog – Start

Timer/Clock – Start

Timer/Counter/Ext/Clk – Start

Timer/Alarm Override - Start

Timer/Any – Stop

Motor Group Control

Application Status – Set

Input Threshold – Set

Execute New Configuration

Function Descriptions

Digital I/O – Set

Digital I/O – Set P1 P2 P3 P4

P1 and P2 define the destination that is being set while P3 and P4 define the source. Use user

defined value 1 to set a pin and user defined 0 to reset a pin.

P1 = i for input or o for output (must be digital)

P2 = pin number (must be digital)

P3 = i for input, o for output or u for user defined value

P4 = pin number or user defined value

Example: Setting digital output pin 6 to On (1)

Action = Digital I/O – Set

Application Note – Automation Control Application

APN007 25 July, 2014

39

Parameters = o 6 u 1

Numeric I/O – Set

Numeric I/O – Set P1 P2 P3 P4

P1 and P2 define the destination that is being set while P3 and P4 define the source

P1 = i for input or o for output (Must be numeric)

P2 = pin number (Must be numeric)

P3 = i for input, o for output or u for user defined value

P4 = pin number or user defined value

Example: Setting numeric input pin 12 to the value of numeric output pin 9

Action: Numeric I/O – Set

Parameters: i 12 o 9

Math functions

Numeric I/O – Add P1 P2 P3 P4

Numeric I/O – Subtract P1 P2 P3 P4