Crown XTI-1000, XTI-2000, XTI-4000 Service manual

Service Manual

XTi Series

Table of Contents

Section 1…………………….Digital systems Overview

1.1…………………..Amplifier Operation

1.2…………………..Power Supply Operation

1.3…………………..Tracker Supply Operation

Section 2…………………….Assembly Drawings

2.1…………………..XTi1000 PWA BOM 139087-14

2.2………………......XTi1000 Schematic 139087-14

2.3…………………..XTi2000 PWA BOM 139086-14

2.4………………......XTi2000 Schematic 139086-14

2.5…………………..XTi4000 PWA BOM 138349-14

2.6…..……………....XTi4000 Schematic 138349-14

Section 3…………………….Firmware Notes

Section 4…………………….Tech Notes

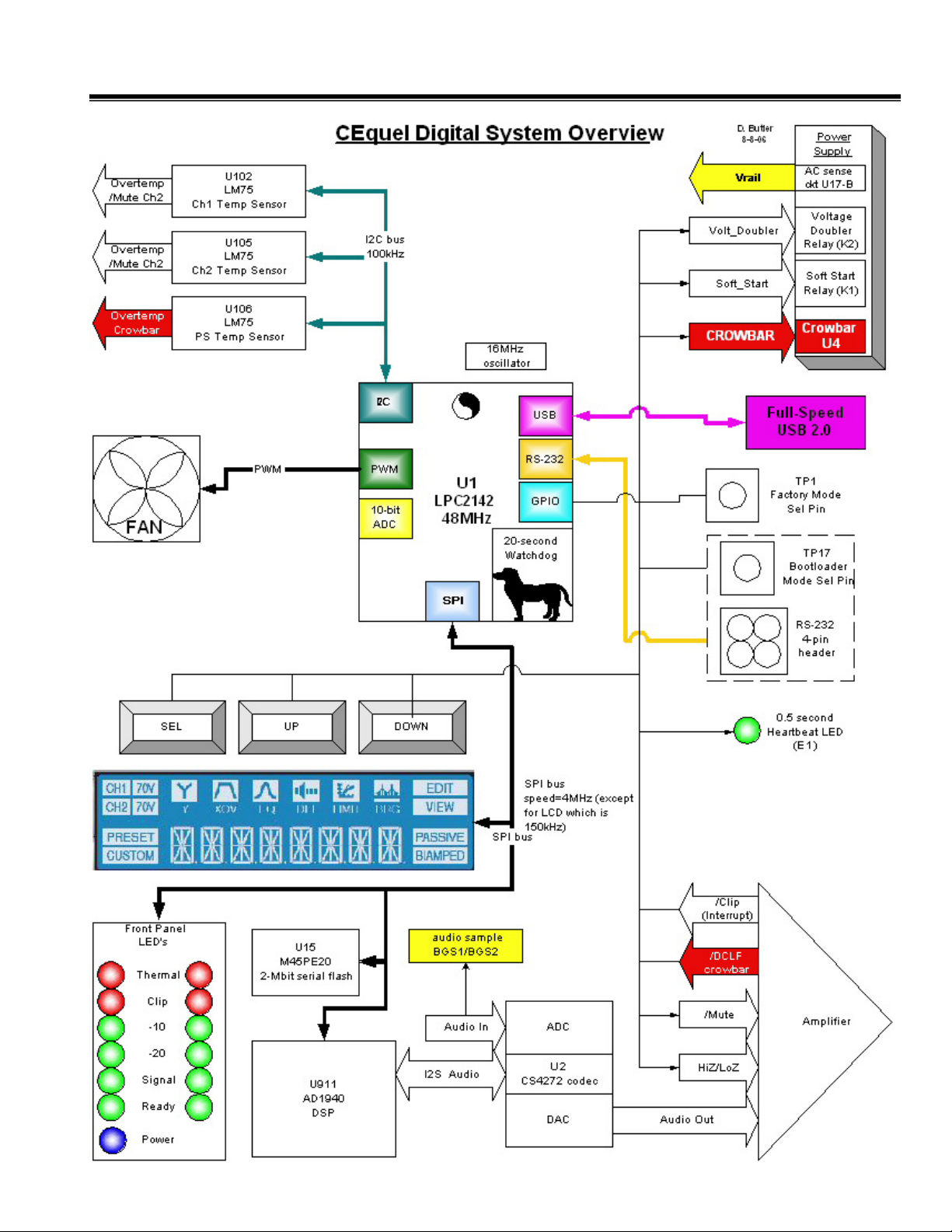

CEquel

Digital Systems Overview

CEquel Digital Systems Overview

Page 2 of 16

CEquel Digital Systems Overview

Modes of Operation

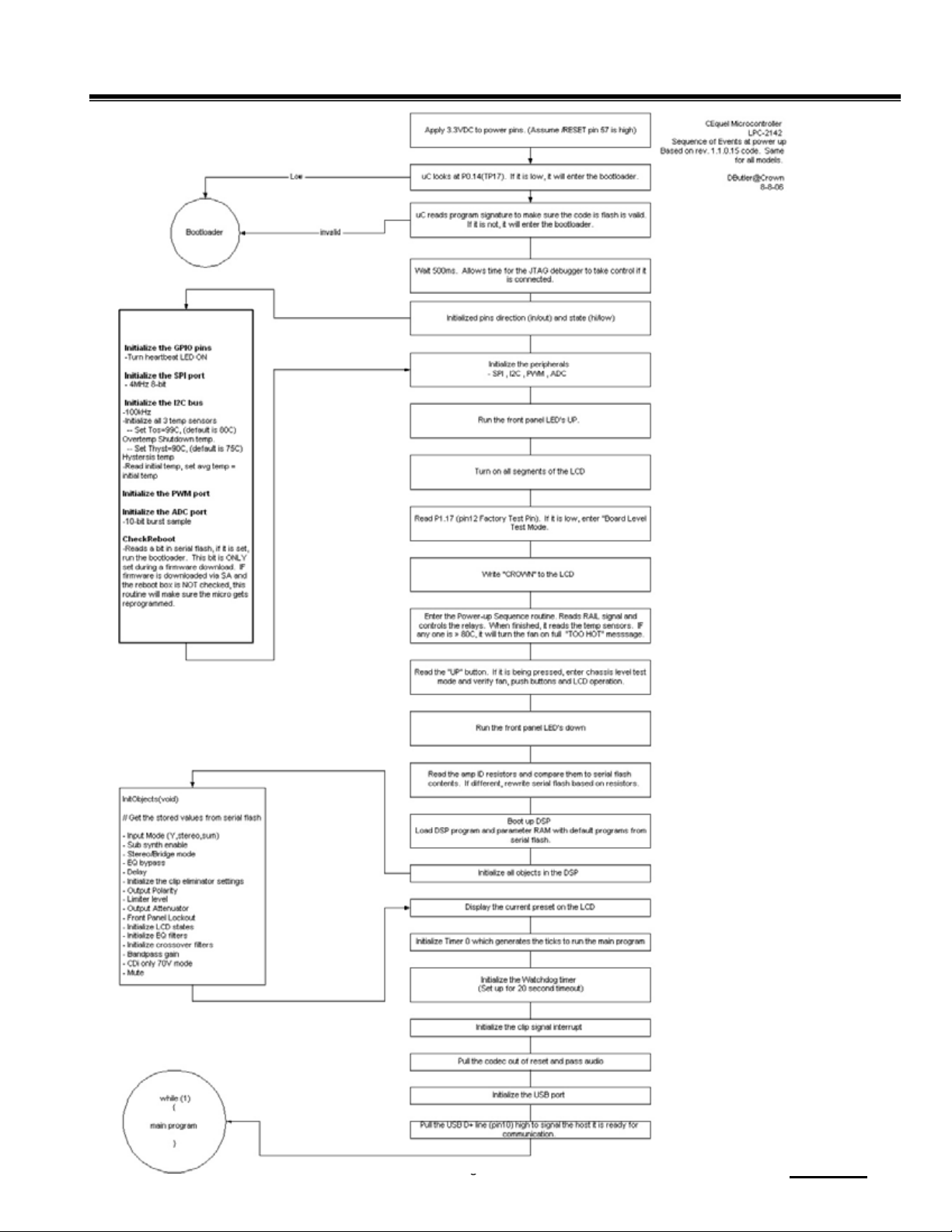

The CEquel microprocessor, LPC2142 can function in several different modes of operation. This

document will describe what those modes are, how to get to them and how to use them. The

Modes are listed below along with a brief description.

Mode Name Description

Normal

Board Level Test

Chassis Level Test (Self Test)

Chassis Diagnostic Test (Amp

Indo –Diagnostics)

Bootloader Mode

Front Panel Lockout

Normal Mode:

This is the default mode of operation. The heartbeat LED (E1) should be beating at about

1Hz (500ms on, 500ms off).

Board Level Test Mode:

Entered by pulling TP1 low at power up.

Exit by pulling TP1 high.

Operation

Turn all front panel LED’s ON

Turn all LCD segments ON

Set the fan PWM to maximum

Set the Soft_start relay OFF (assumes no line voltage is present).

Only used by MFT

Chassis Level Test Mode (Self Test):

Entered by powering up the unit with the PREV button pressed.

Exit by successfully pressing all three buttons

Operation

Turn all front panel LED’s ON

Turn all LCD icons ON and display “PRESS ME”

Set the fan PWM to maximum

Button Check Display which menu button is pressed.

After exiting this mode, the main program should go get valid LM75 temperature readings

and update the fan speed. If the amp is cool, it should turn the fan off

Normal Operating Mode, default

Factory Only, part of functional test, (No line voltage present)

Quick factory test (part of light zap)

More detailed information about the current amp operation

Used to reprogram the microcontroller flash memory

Disables the front panel push buttons for security. Can be

entered from front panel buttons or software.

Page 3 of 16

CEquel Digital Systems Overview

Chassis Diagnostic Test Mode (Amp Info – Diagnostics):

NOTE: This mode is available to all users.

Entered by pressing all three front panel buttons for > 3 seconds.

Exit by successfully pressing SEL at any time.

IMPORTANT!!!!: When you are in the “AMP INFO” screens, the firmware is NOT running

thru all of the normal routines. Clip check is called, but not as fast as normally, you will

see more clipping. The thermal limiter and fan should work just fine. The heartbeat LED

and front panel LEDs will not update. The clip limiter and governor are also not running.

Operation

Display the present Power Supply measured temperature in degrees C

Display the present Ch1 measured temperature in degrees C

Display the present Ch2 measured temperature in degrees C

Display the present Firmware rev level (read from serial flash)

Bootloader Mode:

Entered by pulling TP17 low during power up.

Exit by cycling the power.

Operation

Used to download new firmware to the LPC2142. It copies an internal boot-loader

from flash to RAM, where it executes. It erases the on-chip flash, and reprograms

it. See the Programming document for more details. It is impossible to corrupt this

boot-loader. It resides at a special location in internal Flash that is not accessible to

anything. This should ALWAYS work!

Front Panel Lockout:

Entered by holding UP and DOWN buttons down simultaneously.

Exit by holding UP and DOWN buttons down simultaneously.

Operation

After holding down the up and down

buttons for about 3 seconds, the LCD

will display “LOCKED”, this indicates the

amp is now in lockout mode. If any

button is pressed, no action will be

taken, except to display the “LOCKED”

message. IF you continue to hold the

Special Note: The front panel lockout

buttons down they will simply toggle the

mode can also be entered from the

lockout mode on and off.

software. In this case, the software will

supersede the front panel. So, holding

down the up and down buttons will NOT

Page 4 of 16

disable front panel lockout mode. When

enabled from software, it can ONLY be

disabled from software. This operation

is consistent with the ITech.

CEquel Digital Systems Overview

Page 5 of 16

rmware

CEquel Digital Systems Overview

Page 6 of 16

CEquel Digital Systems Overview

Updating Firmware

RS-232 Method

Part 1. If the microcontroller (U1, LPC2142) has NEVER been programmed before

Connect the Serial 4-pin header to J2.

IMPORTANT!! The header MUST be connected with the correct polarity or fatal damage

can result. Pin 1 on the header should be connected to pin 1 of the connector. See figure

below:

Xti Amp (back)

(front) J2 ::

Serial

Interface

board

FRONT

To program a new device connect the header to J2 and apply power. TP17 does NOT have to be

pulled low because the micro does not have a valid program to run and will therefore

automatically enter bootloader mode.

Open up the Philips Flash Utility Program (version 2.2.2)

Under Flash Programming, make sure the correct file is selected to download.

Select the Device (LPC2142),

Select the XTAL Freq. (kHz): 16000

Select the Erase Entire Device button

Select the correct file to load: (currently XTI_LPC_01_00_08b.hex)

Press the Read Device ID button. The Part ID and Bootloader ID will show up. If they do

not and this operation times out, then most likely, the device is not in bootloader mode, there is

something wrong in the configuration or setup or the cable is not correctly connected. If the

device is not in bootloader mode proceed to Part 2.

Select Upload to Flash and the programming will start.

After it is finished you may select Compare Flash. This will read back the flash memory

and compare it to what was just programmed (Pass/Fail)

Cycle the Power to the amp and close the Flash Utility Program.

PC

RS-232

Page 7 of 16

CEquel Digital Systems Overview

Part 2. If the microcontroller (U1, LPC2142) has been previously programmed.

To reprogram a device, it is first necessary to put it in bootloader mode. This is done by

shorting TP17 to ground during a power up. After the unit powers up, the ground can be removed

or left connected, doesn’t matter. (Hint: Use a test lead connected to TP5(GND) on one end and

TP17 on the other). The LCD should be blank.

Again follow the steps in Part 1 to connect the Serial interface board to J2 and open the Philips

Flash Utility.

Press the Read Device ID button. The Part ID and Boot Loader ID should be displayed. Again

follow the steps in Part 1 to send new firmware. If this does not work, there is most likely a

hardware problem, check for shorts, correct power, bridges, other hardware problem.

To verify serial flash and check the current firmware version number

At any time hold down all three front panel buttons for at least 3 seconds. This puts the amplifier

into a diagnostic mode. NOTE: While in this mode the front panel LED’s will NOT be updated.

Also, the governor is disabled. Use the Next and Prev buttons to scroll thru the displays. They

are outlined below:

Screen 1: Power Supply Temperature Sensor Read out in degrees C

Screen 2: Ch1 Temperature Sensor Read out in degrees C

Screen 3: Ch2 Temperature Sensor Read out in degrees C

Screen 4: Firmware version number read back from Serial Flash (eg. 1. 1. 0.15)

NOTE: The temperatures displayed are the raw unprocessed readings. They are updated

approximately every 600ms and should be accurate.

LCD display looks to be corrupted.

If the text on the LCD looks to be bogus, it most likely is because the serial flash is blank

or corrupt or is out of sync with the microcontroller program.

This problem can be resolved by updating the firmware via USB. This method ensures

that both the serial flash and microcontroller are reprogrammed.

Page 8 of 16

CEquel Digital Systems Overview

Programming the microcontroller (U1) and serial flash (U15) via USB

Connect the amplifier to a PC via USB.

Open up the CLoader Utility 2.10 or newer

If fw is older than 1.0.22.0 send .hex file. Otherwise, send .s file

How to Use the CLoader Utility

Instructions:

Simply run this utility with an amplifier connected to USB, it should show up in the dialog window.

If it does not, unplug the USB cable, cycle power on the amp, plug in the USB cable again and try

again.

If amplifier still does not show up, verify that the D+ USB data line is pulled high thru R19. With

the USB cable unplugged, use a meter to measure R19, it should be pulled up to +3.3V thru Q23.

Pulling this line high tells the USB host that the device is ready for communications.

After the amp shows up in the window, select "Load File" and select the firmware file to be

downloaded. Wait for amp to reboot and download successful display.

****** To run from a command line ******************************************

Simply type the name of the utility space and the name of the file to be loaded.

When run from a command line, it creates a file named "LdrError.txt". There is a number inside

this file as follows:

0 - Success

1 - Amplifier not found

2 - File invalid or not found

3 - USB communications error

4 - Abort Button pressed

The loader terminates upon encountering an error, or when successfully programming the

amplifier. The error file is blown away if found when the loader starts, and is written just before it

terminates.

It helps to have the utility and firmware file in the same directory and with no spaces in the folder

names. If there are spaces, use " " around the path name.

Page 9 of 16

CEquel Digital Systems Overview

****************** Revision History *****************************************

Version 1.03

Supports command line calls. Writes error log. displays message when finished

Version 1.04

Added the word "Delay" in the title bar, so there is no confusion about the version to use.

The text also indicates that it's finalizing before it puts up that programming has completed

successfully after the 5 second delay. The Amplifier is almost through its rebooting process at

this point, but it's probably safe to shut down.

Version 1.06

When it is done uploading firmware, if the amplifier does not already have a serial number it

generates one using the Windows API function and sends it to the amplifier. If the Amplifier

already has a serial number, it reports that back as well.

Version 1.07

Fixes bug with USB version number if > 1.000. Supports both .bin and .hex file downloads.

NOTE: This loader only works with .hex files. DO NOT try to load .bnd or bin files with this utility.

Version 2.10

Supports both .hex and binary .s file downloads. The hex file is required for updating amps with

older firmware 1.0.22.0 and older. The serial number check and programming is done much

quicker in this version as well. This version will not allow you to download a hex file to an amp

with program version number 1.0.22 or later.

Where do I find all this stuff??

-The place to look for production released firmware is the ProductionProgrammingFiles folder.

This is where we store the released version of firmware for all products. It can also usually be

found in the forums section of the Crown web site (www.crownaudio.com)

-The next place to look would be my share drive. I usually keep beta firmware and different

versions of the CLoader Utility there.

//butler/ShareNew/CEquel_Files

- If you wish to run the System Architect Software application to monitor/control the devices, that

can be found either on my share drive or the HiQnet web site. The web site will only provide

“Released” versions of the software while my share most likely will have a beta version (read as

“buggy, use Beta at your own risk!!, operation NOT guaranteed”).

Page 10 of 16

CEquel Digital Systems Overview

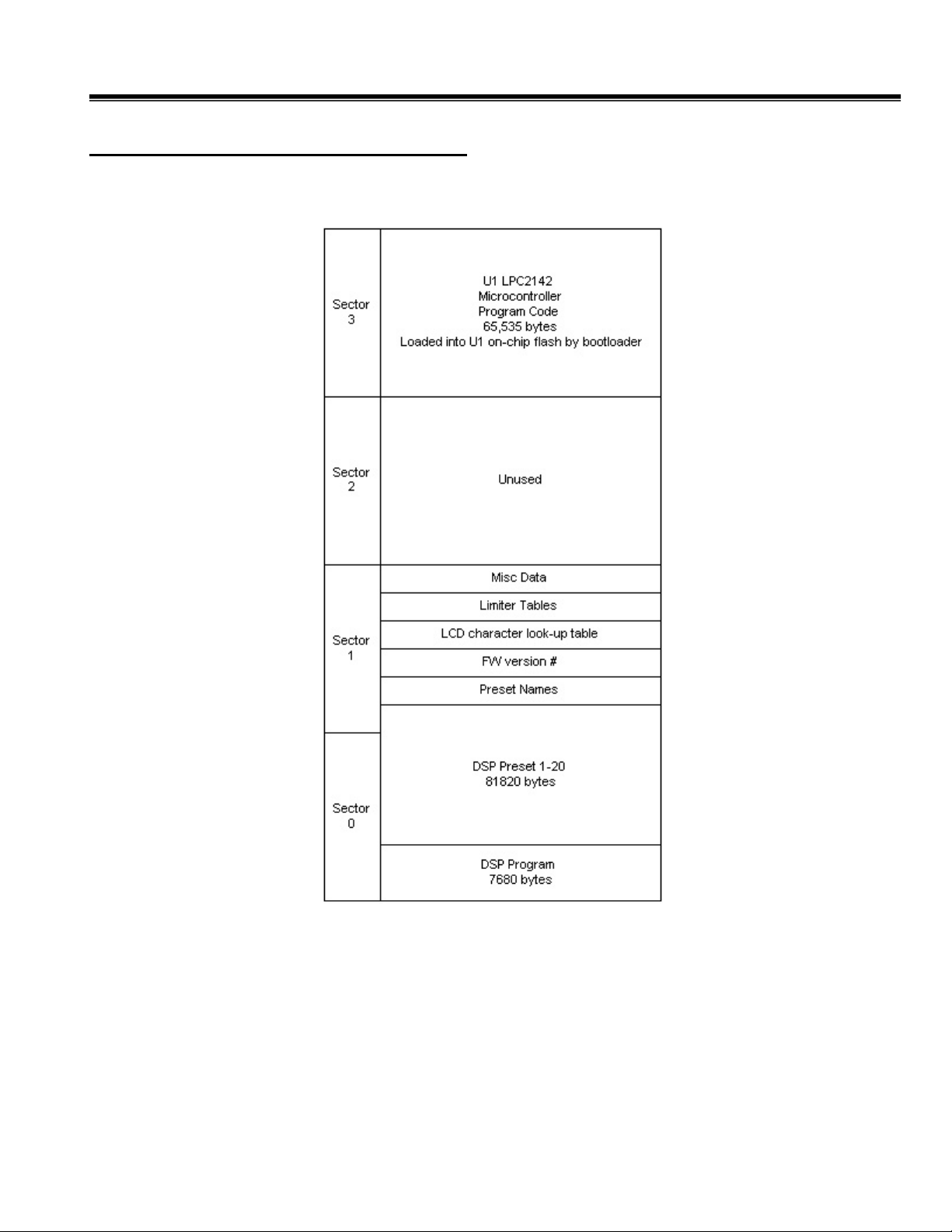

Quick explanation of firmware update operation (Bootloaders)

There are two sources of non-volatile flash on the CEquel amps.

1. 64kBytes of on-chip flash on U1 the microcontroller. (Program)

2. 2M-bits (256 kBytes) of serial flash U15. (Program and Data Memory)

When firmware is loaded via RS-232, it uses a very low level bootloader on the microcontroller and only

the on-chip flash is reprogrammed. The serial flash is not changed.

When firmware is loaded via USB, it uses a high level bootloader written by me and it runs in RAM. It

follows this sequence of events.

1. Start receiving the firmware download packets via USB

2. After 256-bytes (1-page) have been received, program that page in serial flash.

3. After the serial flash has been completely reprogrammed, the download is finished

4. Set the reboot flag in serial flash.

5. Load the bootloader from on-chip flash to RAM and jump to it.

6. Erase the entire on-chip flash

7. Program the on-chip flash with the data stored in Sector 3 of serial flash

8. When finished clear the reboot flag and go to an infinite loop and wait for the watchdog to time out

and reboot.

You can see the the most critical steps are 5 and 6. This is the only place you can really screw things up.

If something goes wrong in steps 5 or 6 and they can not complete, you will have to reprogram the micro

using the RS-232 method.

Notice in step 4 a reboot flag is set, this was implemented because the current firmware update utility in

System Architect can NOT guarantee a reboot command will be sent and thus a complete firmware

update. The reboot flag is only cleared after the micro on-chip flash has been successfully reprogrammed.

This flag is checked at every power up. If it is set, the bootloader will be called.

If a USB download is interrupted, it should not cause any fatal problems. I will simply leave the serial flash

in some undefined state. The micro should boot-up normally. However, the DSP program and parameter

can be corrupted causing serious problems (although most likely it will not pass audio). Also the LCD will

most likely appear to look corrupted, because any LCD segment can be on or off given bogus data in

serial flash. Most importantly, the micro should run and another USB firmware download can be

attempted.

Page 11 of 16

CEquel Digital Systems Overview

Serial Flash Memory Map (M45PE20)

Page 12 of 16

Protection Features

Thermal Limiter

The thermal limiter should have the following profile. The limiter threshold should be

ramped down very smooth and slow to -24dB (0.25 dB/sec). The release from -24dB to 0

should also be very smooth and slow (0.125 dB/sec). The jump to -36dB and -42dB will be

quick and fast, however, the output should be squashed down so much at this point, I

don’t think it will be a problem.

Heat Up

= 80C Turn the front panel red thermal LED ON

= 81C Slowly ramp down -3dB

= 82C Slowly ramp down -6dB

= 83C Slowly ramp down -9dB

= 84C Slowly ramp down -12dB

= 85C Slowly ramp down -15dB

= 86C Slowly ramp down -18dB

= 87C Slowly ramp down -21dB

= 88C Slowly ramp down -24dB

> 90C Flash the LCD message “OVR TMP”

= 92C Set limiter to -36dB

= 98C Set limiter to -42dB

= 99C Flash the LCD message “TMP MUTE” and mute that amp ch

= 110C Fire the Crowbar and shut the amp down (last chance protect)

Cool Down

= 96C Unmute amp channel, Limiter set to -42dB – Flash “OVR TMP”

= 92C Set limiter back to -36dB

= 90C Set limiter back to -24dB

< 90C Stop Flashing “OVR TMP”

= 86C Very Slowly ramp up to -21dB

= 85C Very Slowly ramp up to -18dB

= 84C Very Slowly ramp up to -151dB

= 83C Very Slowly ramp up to -12dB

= 82C Very Slowly ramp up to -9dB

= 81C Very Slowly ramp up to -6dB

= 80C Very Slowly ramp up to -3dB

= 79C Very Slowly ramp up to 0dB Turn the front panel red Thermal LED OFF

CEquel Digital Systems Overview

Page 13 of 16

CEquel Digital Systems Overview

Clip Eliminator

The clip eliminator is based completely on the clip signal from the amplifier. The DSP/uP has

no other information about output signal of the amplifier. Given the latency of the amplifier

and conversion stages, the fastest the output signals can be limited is about 15ms. So if a

heavily clipped signal comes out of the amplifier, gain reduction will not start until about 15ms

later. So….. the clip limiter is not perfect, in fact it is quite crude. Here is how the clip limiter

algorithm will adjust the limiter threshold based on clip events. The clip signal is detected by

an ISR(Interrupt Service Routine), which simply counts clip events (VERY FAST), almost

never misses. The clip limiter routine is called every 100us and adjusts the limiter threshold;

so the limiter threshold can be adjusted quite quickly. Also, the amplifier generates the clip

signal at every zero crossing. For example, a clipped 20k sine waveform(Period=50us), will

generate 4 clip events every 100us, one for each zero crossing. The clip eliminator routine

will adjust the limiter based on this number of clip events.

1st clip event Set limiter threshold to 0.0dB

2nd clip event Set limiter threshold to -0.2dB

3rd clip event Set limiter threshold to -0.3dB

4th clip event Set limiter threshold to -0.4dB

5th clip event Set limiter threshold to -0.2dB

6th clip event Set limiter threshold to -0.3dB

7th clip event Set limiter threshold to -0.4dB

8th clip event Set limiter threshold to -0.5dB

9th clip event Set limiter threshold to -0.6dB

10th clip event Set limiter threshold to -0.7dB

13th clip event Set limiter threshold to -1.0dB

:

:

23rd clip event Set limiter threshold to -2.0dB

rd

clip event Set limiter threshold to -3.0dB

43

rd

83

clip event Set limiter threshold to -4.0dB

:

:

rd

243

clip event Set limiter threshold to -24.0dB

Actually, the maximum gain reduction provide by the clip limiter is based on the amp model

The 1000 amplifiers will only provide -9.0dB, while the 2000 and 4000 will go all the way down

to -24dB.

The clip LED has also been somewhat desensitized. A single clip event will not fire the LED.

To turn the clip LED on, there must be more than 2 clip events occur in a 100us period.

If the amp is in bridge mode, only the ch1 clip eliminator routine is used. A clip event on either

ch1 or ch2 is used.

.

Page 14 of 16

CEquel Digital Systems Overview

Shorted Output Protection (2000/4000 models only)

This is really an extension of the clip limiter. It is based on the number of clip events. If the clip

eliminator routine has counted 243 clip events and run the limiter all the way down to -24dB, it

continues to count clip events. If the clip count gets up to 5243 (approximately 500ms after full

attenuation), then a “SHORT” routine is entered. The channel is muted, the ready LED turned off

and a message is displayed on the LCD “SHORT 1”; 1 for ch1 or a 2 for ch2. If the amp is in

bridge mode, both channels should mute and the display message will be for ch1.

The amp channels are held in mute for one second. After that, they are unmuted, if the short

condition persists, they are muted again. The amp should be capable of enduring this condition

indefinitely. Because during a short condition, there is no output voltage, the tracker will keep the

rails at the minimum 30V, so amplifier is not in a highly stressful state.

Crowbar

The microcontroller has 3 different conditions that can cause it to fire the crowbar and shut down

the amplifier. Firing the crowbar is considered a fatal event and the amp must be power cycled to

recover from it.

1. Overtemp: If any temp sensor reads ≥ 110˚C.

2. DCLF: If the DCLF signal goes low for ≥ 90ms.

3. If the AC sense line (RAIL signal) is ≥ 3.0V (approx. 300VAC on AC line)

Page 15 of 16

CEquel Digital Systems Overview

Page 16 of 16

Section 1.1

Amplifier Operation

Cequal Amplifier Operation Details Rev A 8-28-2006 AA

1.0 OVERVIEW

Note: Sketches and waveform tifs have been added to this section to clarify the various concepts

related to the amplifier and its system level behavior.

For XTI 1000 and DSI 1000 amplifier schematics with voltage and currents references, use

channel 1 of 139087-6ref.tif which is sheet 4.

Amplifier heat sinks are tied to +/- Vbulk.

For XTI2000, DSI2000, CDI1000, CDI2000 amplifier schematics with voltage and currents

references, use channel 1 of 139086-6ref.tif which is sheet 4.

Amplifier heat sinks are tied to moving tracker voltages.Below is using 138086-6ref.tif channel 1

of XTI2000 (Also, see REPAIRnotes.txt) and (Notes below) for root cause and repair.

Functional Blocks Description

1) Amplifier stages

a) Biasing and Mute_1not

Bias is developed with the general components D117, D118, Q100, R104, D134, R182, C102,

R107, and Q102. Bias is on when D117 and D118 are allow to conduct, so the base of Q100 will

sit at about +2.4Vdc (4 diode drops.). This is a 3 state node, it gets control from the DSP via

Mute1_not, normally +3V (ON) , 0V (OFF) , the LM75 sensor under HS1 (+Vbulk) sink at +3V

(ON) when not over temp, about 100 deg C, and the DCLF / Low Vbulk comparator U103A,B

also in a high output (pulled up thru R325 to +15V) state. All four controls must be good in

order for bias to come up. If all four controls are good, than Q100 base will be about +2.4Vdc.

If the Mute1_not is good from the DSP, and the comparator Q103 goes low due to either low

Vbulk ( < 60% of nominal rail +/- voltage) or too much DC for too long a time on the amplifier

output terminals then Q100 base (10Hz@vmax) will go to about +1.0Vdc from the +2.4V. At

that moment when Q100 base went down to the 2

is now discharging. If the DC on the output of the amplifier is there long enough and/or high

enough level then C102 will discharge enough to cut the bias to off and mute the amplifier and

let its output return back to zero volts. Thus C102 lets some DC for a level and time before a

protect via mute is activiated. If the DSP or the LM75 sensor tells the amplifier to mute ,3

state, but not the local comparator DCLF path then when they go low the base of Q100 will be

about 0-0.6Vdc negative, being clamped there by D126 . Time estimates for C102 from a mute

command to actual mute is about 30ms. If a large LF output is there but not long enough you

might see a DCLF at U103 but C102 will still hold up the bias. Mute1_not could be a write or a

read state line.

b) Input differential stage

The differential input stage consists of Q103, Q104, and Q116 and Q134, getting its b ias from

Q102. Q102s current source is divided evenly to Q103 and Q104 . The bases of Q116 and Q134

are set to about -13.5v with R78 and R79. This locks the collectors of both Q103 an d Q104 to

about -13V no matter what. This removes high and unequal voltages from them. So Q116 and

Q134 just pass current and take the heat. See note 1 below for Q116 and Q134.

c) Error gain amplifier and bias servo

The error gain amplifier and bias servo are set up with Q105, Q107, with the measurable

amplified error signal of the total amplifier at the opposite end of R133 from Q105 (see note 3).

Qperating currents of this stage is scaled for higher voltage product over the XTI1000. It is gated

and controlled the bases of Q107 and Q108 (A and B on the schematic, with approximate

voltages with respect to C the –Vbulk.). Q141 (in high voltage units) is for distributing the

nd

state, Q100 is off but C102, the hold-up cap

rd

voltage stresses on Q105 and Q107. The temperature compensated servo transistor Q109 is

located under the same heat sink ( + ) and near the LM75. The bias set string with D174, R180,

R144 and R179 run about 400ua and are not under that heat sink. With the pot R144 centered an

bias on the collector to emitter voltage of Q109 measured across C109 should land about 1.9 to 2

volts. C109 provides filtering and holdup charge. Q108, Q106, R135 and R142 set the servo and

pre-driver (Q112 and Q113) currents (see note 2) . C108 is slew rate limiting. Bias can be

measured across the two TO-220 heat sinks and may be set ( at room temp) to about 0.8v +/.05V. See note 4.

d) Pre-driver, driver Stage and TO-3 outputs.

Pre-dirvers Q112 and Q113 , when bias is on are biased on with R147 and R148 (see note 5) to

about 1.8ma via drivers Q114 and Q115 whose currents are about 6 to 7ma. Their collectors are

tied to the TO-220 sinks (see note 6). In any product these sinks at idle should not produce much

heat to the touch. About 0.5 watts each at idle. The TO-3 devices are normally off, class B mode.

Diodes D180, D181, D182 and D191 across R150 reduce common mode currents of the output

devices (see note 6).

e) Output filter and feedback paths and Output loading information

The Output de-coupling inductor L100 and Rs and Cs around it form the filter. The amplifer

feedback lines are in pcb foil and with 1 ohm connecting resistors for remote sense location

depending on the product and output connector location. On a product with both speakons and

binding posts , the feedback connections are referenced off the binding posts (SPECS). High side

low frequency feedback is R84. High side high frequency feedback is C65. Low side low passed

remote sense feedback is thru R87 (note 7).

On the larger Tracker based units (note 8) the use of a load of at least 24 ohm (suggested for

THD1 test) , maybe 32 ohm (not higher) is needed due to a tracker based gate drive charge pump

in order to get proper tracker voltage drive to the amplifier rails otherwise positive rail clipping

might occur causing DSP compression off of the clip_not function.

Suggested amplifier loading for initial system verification is 24 ohms and starting with the

THD1 test specified at MFT. Units that start and crowbar immediately for an unknown reason

should be without a load and then re-started.

Non tracker based units (1000s) have a full VI limiter and can drive inductive loads at low

levels. Loads down to 1 ohm can be driven as well but due to the VI term the allowed output

voltage peak collapses to less than 25v and thus for the non-tr acker based units use of a 1 ohm

load will not give the a peak current limit you might expect off a data sheet 2 ohm power

number.

Tracker based units have no V term in the limiter so a 1 or a 2 ohm (better) load may be used to

witness the true peak current limit. Tracker based can drive 45 degree inductive loads but a pure

inductor or torture load is not really recommended at this time.

On any products , driving into less than 8 ohms at high voltage levels and at and above 15khz

long enough ( longer than a music based signal) is very likely to invoke the clip based

compression off the DSP.

Driving into a short of thru a cable to a short with a non-tracker unit will result in a full collapse

of its current limit and the display may say “SHORT” until either the drive or output shor t is

removed.

Forcing a tracker based unit into a short with a continous sinewave is not recommended at this

time. Driving a tracker based unit thru a long cable into a short may result in a display of

“SHORT” until it is removed or invoke the DSP compression.

2) Filter Stage

a) Input cheb differential filter from codec to amplifier.

U10 forms a differential to single ended chebychev 22khz low pass filter for the CODEC

to the amplifier differential front end thru R138 and C124. Under normal signal

conditions the absolute expected peak output of U10 pin 1 should be less than +/-5v.

b) Amplifier high pass filters

C124 is a dc block and thus provides some high pass. R130, R132 (main feedback) and

C104 form the voltage feedback and high pass function for the power stage. D3 is a

clamp function. Using standard long stepped bursts of waveforms will result a normal

high pass step recovery of the at the amplifier output, which may initially look abnormal

to other high passed amplifiers. It is not , only these units are high passed around 10hz,

not the typical 2hz or 5hz like others.

3) Protection blocks

a) DCLF detect Clip_not and Low Vbulk detect

Comparator U103 is used for DCLF and a low +/-Vcc detection. A DCLF = low for a

constant 100ms or more is interpreted as a amplifier fault and the DSP invokes the

crowbar to the power supply. A “not” DCLF with a clip_not = low for 100ms or more

may invoke the “SHORT” command from the DSP and compress the output until the

offending short is removed. Lessor than 100ms clip_not = low may invoke the DSP

compression.

b) Time dependant current limit.with and without Tracker

Current limiting is set up with Q110, C115, R151, R798 (2ks,4Ks) R194 and more for

the V term in the 1000s. Q111, R152, C116, R799 (2ks,4ks) R194 and more for the

Vterm in the 1000s.

c) Temperature compression and shut down

Temperature compression is driven by any one of the 3 LM75s . Simultaneously

pressing all 3 front panel buttons ques the product into an info mode. The temperatures

of the 3 LM75s and other important information may be obtained by scrolling thru the

menu, including the effective loaded “RAIL” voltage from U17 pin 7.

d) VI limiter without Tracker..XTI000,DSI1000

e) Power Governor

4) Signal I/O blocks

a) Bias

b) Clip_not

c) Mon1

d) DCLF

e) CH1PDRV, CH1NDRV

Miscellaneous notes for root cause and diagnosis ideas for repairs

1) DCLF, crowbar related; (fully discharge supply before ohmic measurements)

A crowbar event can fall generally into three catagories.

Nondestructive_Normal means nothing wrong, just an unwanted signal or load.

Nondestructive means something is open like a solder connection or resistor but not

In a place where transistors will likely blow up when parts of the protection are defeated.

Destructive means either a device has blown or will if standard root cause methods are

used to defeat a protection (like DCLF reporting) to force the unit on to be able to root cause.

For the latter two, the unit is likely to briefly power up, flash the display on then. Shut down

with no clues, other than the power supply is trying to start and something on its secondary is

loading it down. First, for this case, make sure your loads are removed to see if any unresolved

DC on the output does not flow thru the load and thus pull power supply current uncontrolled thru

a device and load. Remove any loading externally.

a) Nondestructive_normal.One generated by a DCLF > 100ms and then clears if there is no

abnormal load to the power supply, hence the unit will be able to restart normally.

b) Nondestructive. Here, bias is not likely to come on. Remove any load. The following tags

may accompany this; XTI_LED_CHECK_NORM, XTI_Meas_pV1_VBP. Try an ohm reading,

even at neighboring pads the parts are supposed to connect to, at the following that had stopped

bias to enable but did not destroy any other items;

REF CH1; R137, R136, R142, R133, R135, R134.

Other suspects; Q116,Q134 leakey? Try REPAIRnotes.txt 1st page with “power off”.

c) Destructive. Discharge power caps. TP26 to TP27. Remove any load. Measure the

following;

1) TO-220 to TO-220 sink…should be >90 ohms. If not,

D180, D181, D182, D191 are shorted.

2) Q114 (TO-220 sink) to HS1 amp + sink…should be >>1K….suspect Q114 device

3) Q115 (TO-220 sink) to HS2 amp – sink…should be >>1K…..suspect Q115 device

( refer to REPAIRnotes.txt for heat sink replacement)

4) For a pulled Q114, or Q115 measure R147 and R148 if open.

5) Measure Q112, Q113 collector to emitter while TO-220 part is out…>1K

6) Measure HS1 to CH1 red post….>>1K…suspect HS1

7) Measure HS2 to CH1 red post….>>1K…suspect HS2

8) Turn over PWA and check the soldered base pins of each TO-3 device. Check for

missing pin or not soldered well.

2) Voltage gain related, CH1 REF

Check R132 value.

Check disc caps C228 and C240 (15pf) vs C290 and C299 (220pf) for not swapped.

Check for soldered end of C124, C13, C38, C20 well or not.

3) Power supply / amplifier related.

THD1 is the heat sink to foil connection

4) Tracker / amplifier related

THD1 is the heat sink to foil connection

5) MFT tags

One tag XTI_nVcc_cur_Draw was a bent openTO-3 PNP base pin, lightly hitting the

Amplifier heat sink.

NOTES;

1) Q116 or Q134, if leaky the bases may read -17v or so.

2) Q108, Q106, R135, R142, R137. a possible open 0603, no bias.

3) R133. One end is the error amp output. Check for non-intermittent solder at pad.

4) Bias is not sensitive, set wiper to center should be 0.8 about.

5) R147,R148. If a TO-220 driver was shorted chances are that one of these resistors were also

opened on the process and an opposite polarity device like a TO-92 pre-driver or TO-3 went too.

A shorted To-220 can mask the 340 resistor or TO-92 transistor measurement as good or not.

6) If the TO220 sink to sink is not about <<100ohms then the diodes are shorted across R150.

7) the amplifier will still work if the low side low passed feedback resistor R87 wasn’t there, only

damping factor, crosstalk and an indicator of > +/-100mv of DC offset will result.

8) Amp sinks HS1,2,5,6 are tied to the Vbulk for the 1000s, and +/-30v at idle for the tracker

based units. In an amplifier “mute=bias off” mode the + amplifier sinks (CH1P,CH2P) in a tracker

based unit may float up to +90vdc. This is normal. When bias is on they come back down to the

30v.

Section 1.2

Power Supply Operation

XTi Power Supply Operation Rev 1 8/9/06 EMB

Note: Any component references will be to the –8 revision level but should be backward

compatible except where additions have been made.

139087, 2K: 139086, 4K: 138349

1K:

Brief summary of operation

The power supplies within all of the XTi models are very similar. The topology

employed is a half-bridge series resonant converter. The use of this topology allows for

soft switching of the main semiconductors Q28 and Q31 reducing heat both at idle and

throughout a good portion of the operating power range.

Initial start up

Upon closing the switch S7, current is drawn from the AC source through the PTC RT6,

rectified by D24, and stored in the bulk storage capacitors C57-C60. The control

circuitry is powered directly from this stored charge through a series of resistors R370R373. The resistors immediately begin charging capacitor C196 which will provide a

kick-start to the power supply control circuitry.

Comparator U16 plays two rolls in the power up sequence. Firstly the voltage on C196

must be greater then 26-volts or so before the output of U16A is allowed to enter a high

impedance state. Secondly, the AC voltage must be at least 95-100Vrms before the

output of U16B is allowed to enter a high impedance state. Both of these comparator

circuits have hysteresis around the trigger points such that chatter does not result. U16A

allows a high state from about 26V all the way down to 12V. U16B allows a high state

of a few volts from the 95-100V trigger point.

Once in a high stage, the resistors R374 and R378 will pull the voltage across D31 up to

16V allowing the regulator made up of Q39-Q41 to power the controller, U14, and the

gate driver, U18.

Kick start

Once voltage is present on U14, switching begins. The clock frequency is determined by

C69 and R367 and oscillates at approximately 250-260kHz. 180-degree phased clock

signals are provided to U18 for generation of the low and high side gate drive waveforms

on pin 7 and 5, respectively. The transistors Q26-Q30 serve to increase the current drive

to the IGBTs Q28 and Q31.

Switching commences for the time allotted by the discharge of C196, or approximately

100mS. During this time period the IGBTs transfer energy from the primary bulk storage

(C57-C60) and the AC line through the resonant tank (C68 & L3) to the transformer, T1.

The energy is magnetically coupled to the secondary of the transformer and hence C43C48.

Energy is also transferred back to C196 through D26. If the voltage at C196 is

maintained at a point greater then the lower bound for the Vkstart sense comparator,

U16B, then the controller circuitry becomes sustained by the converter itself and the kick

start cycle is terminated. If for any reason the converter does not sustain the voltage on

C196, the kick start cycle will repeat indefinitely approximately every 500-800mS.

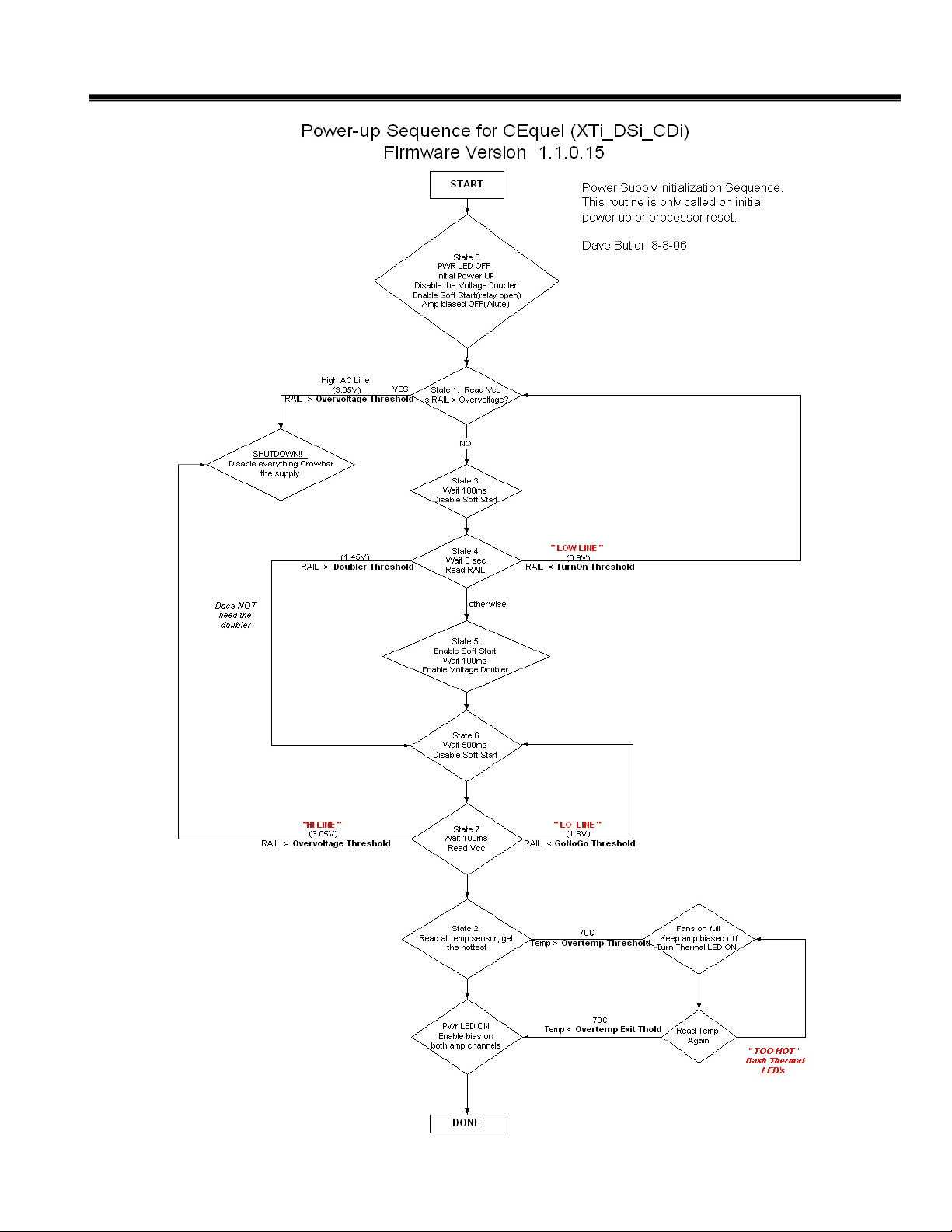

Power up

Now that the converter is sustaining the control circuitry, the amplifier has rails of either

half of the nominal or nearly the full amount depending on the input source. If the input

voltage is 120V, the rails are nearly half of the nominal value. If the input is 240V the

rails are now sitting nearly at the full operating voltage.

The microprocessor, U1, samples the across capacitor C182, on the RAIL node. The

voltage on this node is reflective of voltage present on the secondary side of the

transformer, T1. It should be noted that the voltage here not only accounts for converter

sag due to the converter throughput impedance, but also AC line sag due to significant

AC line impedance.

The relay K1 is now commanded to close by U1 at which time the voltage at RAIL is

measured. If it is below 1.4V, the microprocessor commands K1 to open followed by the

closing of K2. The closing of K2 creates a half-wave doubler out of D24 and the bulk

capacitors C57-C60. By doubling the voltage on the primary side, the secondaries are

also doubled and the relay K1 is re-closed finishing the power up sequence.

If the voltage at RAIL is above 1.4V, no more processing is required and the power up

sequence is finished.

Normal Operation

The IGBTs, Q28 and Q31, switch at approximately 42% duty cycle each at a frequency

of 125-130kHz. At idle, circulation current is provided through the magnetization of the

core within T1. This current provides a soft switching action to the IGBTs by

charging/discharging the parasitic capacitance of the devices during dead time, thereby

reducing low power losses. At the HB_OUT node the voltage will have a trapezoidal

appearance.

At higher power levels, another form of soft switching is achieved due to the resonant

tank, C68 and L3. The resonant frequency of the tank circuit is greater than that of the

switching frequency thus the current through the switches is commutated to the opposing

anti-parallel diode thus allowing resonant turn-off of the devices.

The current through the converter is passively limited two main variables. The current

through the converter is directly proportional to the input voltage. The current is also

limited by the tank design itself, C68 and L3.

Section 1.3

Tracker Supply Operation

Tracker Theory of Operations

Ben Carroll

8/4/2006

Rev 1 – initial version

The tracker operation in the XTi products and its derivatives is an extension of the

classic class H supply (used in the XS amplifier) and is also similar to the VZ supply

used in the MA3600 and MA5000. The main power supply provides two distinct rail

voltages that supply power to the tracker’s power stage, which in turn provides the rails

to the amplifier’s output stage. The higher rail voltage is model dependant (approx 120140V), and the lower rail, which is about 30 V independent of model. This lower rail

also supplies the +/-15V, and 3.3V regulators. The trackers are comprised of four power

stages that individually feed: channel #1 positive, channel #1 negative, channel #2

positive, and channel #2 negative. Each of these power stages is a buck regulator

connected in series with a 30V supply. This concept is called partial power processing,

as the buck regulator does not process 100% of the power flowing through the power

stage.

With no or only low-level signals present, the buck regulators are not active and

the lower rails feed the amplifier output stage (thru diodes D35, D36, D42, and D43).

This rail voltage is about the same as a D75. This makes the system very low loss at idle.

The heating due to the bias current in the pre-drivers and drivers is reduced dramatically

compared to what it would be if fed off of the higher voltage rails. Second the switching

MOSFETS (Q47, Q48, Q60, and Q61) are not active, thus dissipate no power.

As the signal level increases the buck power stages become active. When a

positive signal is demanded of channel #1, that respective trackers control loop responds

keeping the instantaneous voltage on the output’s collector terminal approximately 20V

above its base terminal. The control loop works to keep this voltage constant, until the

buck regulator reaches its maximum duty cycle or the amplifiers rail voltage reaches a

preset maximum level. This maximum level limits the voltage across the output stage

during high line conditions. Then as the voltage begins to reduce, the buck regulator

reduces its duty cycle to maintain a constant 20V across the collector to base junction

until the rail voltage drops back down to 30V. Then the channel #1 negative side tracker

becomes active in a similar manor. Channel #2 works similar to channel #1, both

channels are completely independent of each other. Because of this four completely

independent power stages, and control loops are needed.

The following paragraphs will walk through the detailed operation of a trackers

control loop. Each paragraph will explain the operator of an individual block. During the

design process each block was carefully scrutinized to ensure that the maximum

performance was attained from a minimum component count. Therefore some blocks

contain several functions.

Absolute value detector

U23B is an inverting precision absolute value function block that also contains

phase lead compensation (C277 & R392), voltage offset generation (R397), maximum

voltage clamp (D50), and a peak hold function (C174).

Error Amplifier

U23A is an error amplifier is of the inverting type. The demands and feedback

signal both feed a virtual ground at the inverting input. Both local feedback around the

error amplifier and global feedback from the amplifier rail are employed. A single diode

(D73) provides an asymmetric voltage clamp that properly bounds the error amplifier.

Error signal translator

U23D is a matching stage that translates the error amplifier output voltage to the

proper range for the TL494 control IC.

TL494 control IC

U22 is an old and inexpensive switch mode power supply (SMPS) control IC, that

is also used in the main power supply and 3.3V supply. It contains two internal error

amplifier op amps that are to slow to be of use, so they are disabled. The error signal is

driven directly into the feedback pin (#3). An internal sawtooth oscillator runs at

approximately 500 kHz. This frequency is set by C71 and R76. R75 creates a small

positive offset in the sawtooth to extend the maximum duty cycle beyond the published

capability of the IC, while schottky D33 shunts R75 to keep the falling edge of the

sawtooth steep. The internal comparator compares the error signal and the sawtooth

creating the pulse width modulated output (PWM). Note that the signal at pin #3 is

backwards of most of most control ICs. 0V is 100% duty cycle, and 4V is 0% duty cycle.

This makes the modulation method leading edge. Therefore the switching transistors will

always turn off during the falling edge portion of the sawtooth waveform.

PWM level translator

This circuit translates the PWM output of the TL494 control IC at ground level, to the

gate drive IC which is referenced to the negative rail. This circuit is very similar to the

circuit used to translate the BCA modulated output down to the -VCX rail on the CTS

BCA and Itech designs. Q55 is a PNP grounded base stage (cascode), which accepts

current from the emitters of the output stage transistors in the TL494 control IC. The

combination of resistors R77 and R734 sets the translator current. R734 serves a special

purpose to help turn off Q55, by removing stored charge from its emitter to base junction.

Q46 is another grounded base stage (cascode) that is referenced to the negative rails gate

drive supply. It receives the current signal from Q55, and then the current signal is

changed into a voltage signal across R99. Q46 is never turned on. It serves to cancel out

the parasitic capacitance present in Q55.

Gate driver

The purpose of the gate driver is to receive and buffer the logic level signal from

the PWM level translator to a higher level signal that is suitable to drive a power

MOSFET. Each channel has its own gate driver IC (U26). The gate driver has a low and

a high side that operate completely independently. The high side is connected to the

trackers for the positive rail, and the low side for the negative rail. The gatedrive IC and

the negative gate drive buffer (Q43, Q44) are powered from an auxiliary winding off of

the main power transformer that is regulated by linear pass regulator (R1, D1, Q1, Q2).

The high side gate drive supply via a bootstrap supply (D32) and a current source (Q140).

Zener diodes D77 and D79 protect the gate drive IC from over voltage.

Power Stage

Q47, D35, L4, C84/C49 form a buck switching cell. This is area of the circuit

that processes the power. The gate drive signal turns the MOSFET on and off at

Loading...

Loading...