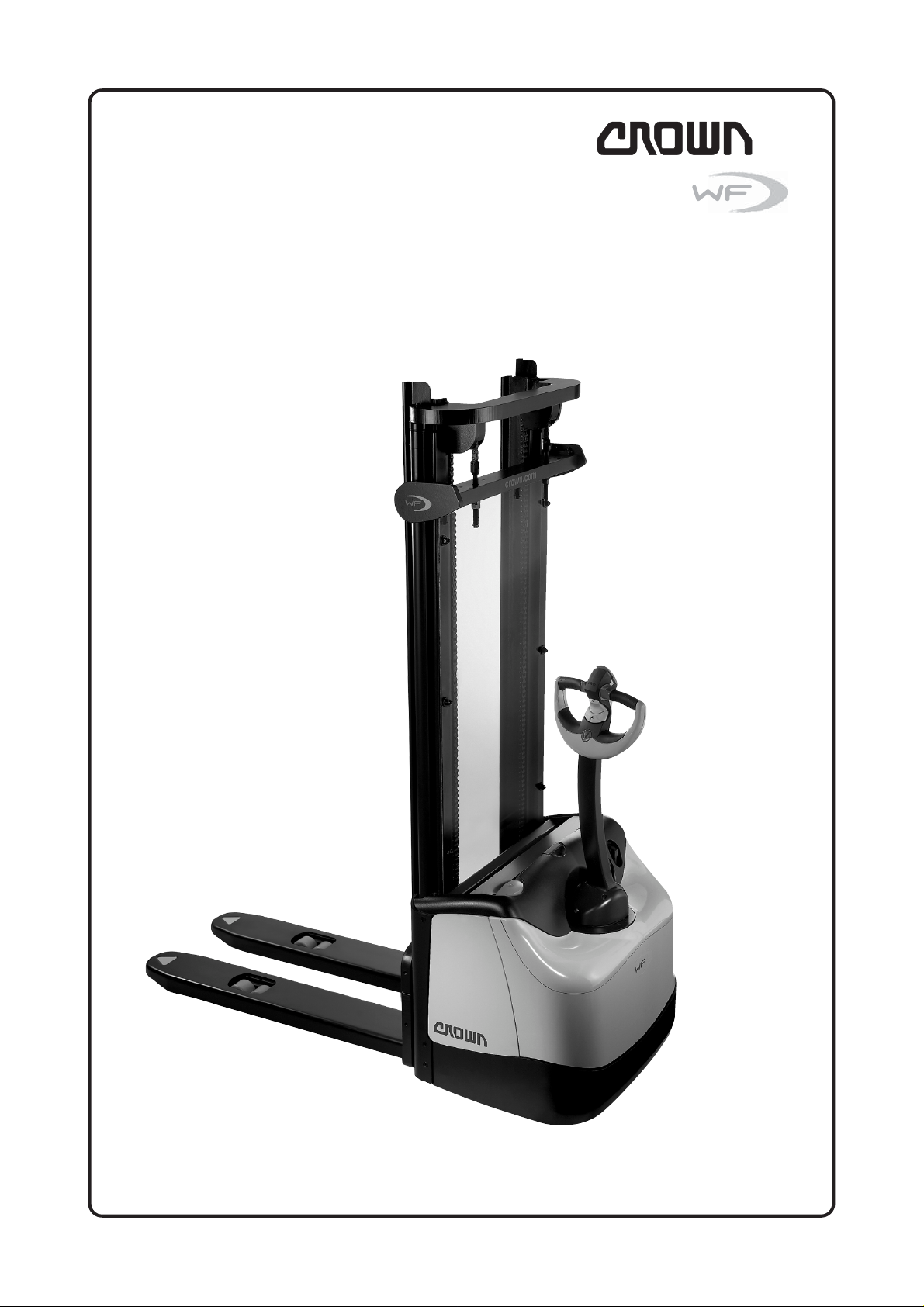

Page 1

Service Manual

WF3000 Series

Printed in

Germany ● Revision Level A

Order Number: 812556-006

Page 2

This master manual is subject to continual updates.

It is meant exclusively for businesses authorized by CROWN.

It is not permitted to pass on the contents or copies thereof to third parties.

CRO WN Gabelstapler GmbH & Co. KG

- European Headquarter -

Moosacher Str. 52

80809 Munich

Germany

Phone +49 (0)89 93 00 2 - 0

Fax +49 (0)89 93 00 2 - 133

All rights reserved under international and Pan-American Copyright Agreement.

CROWN Equipment Corporation

Copyright 2005

Page 3

Overview of Revisions:

REVISION

WF3000 09/2005 • Printed in Germany MS-REV-3300

A

Page 4

Blank page

Printed in Germany

B

Page 5

Printed in Germany

TABLE OF CONTENTS

3

Page 6

Blank page

Printed in Germany

4

Page 7

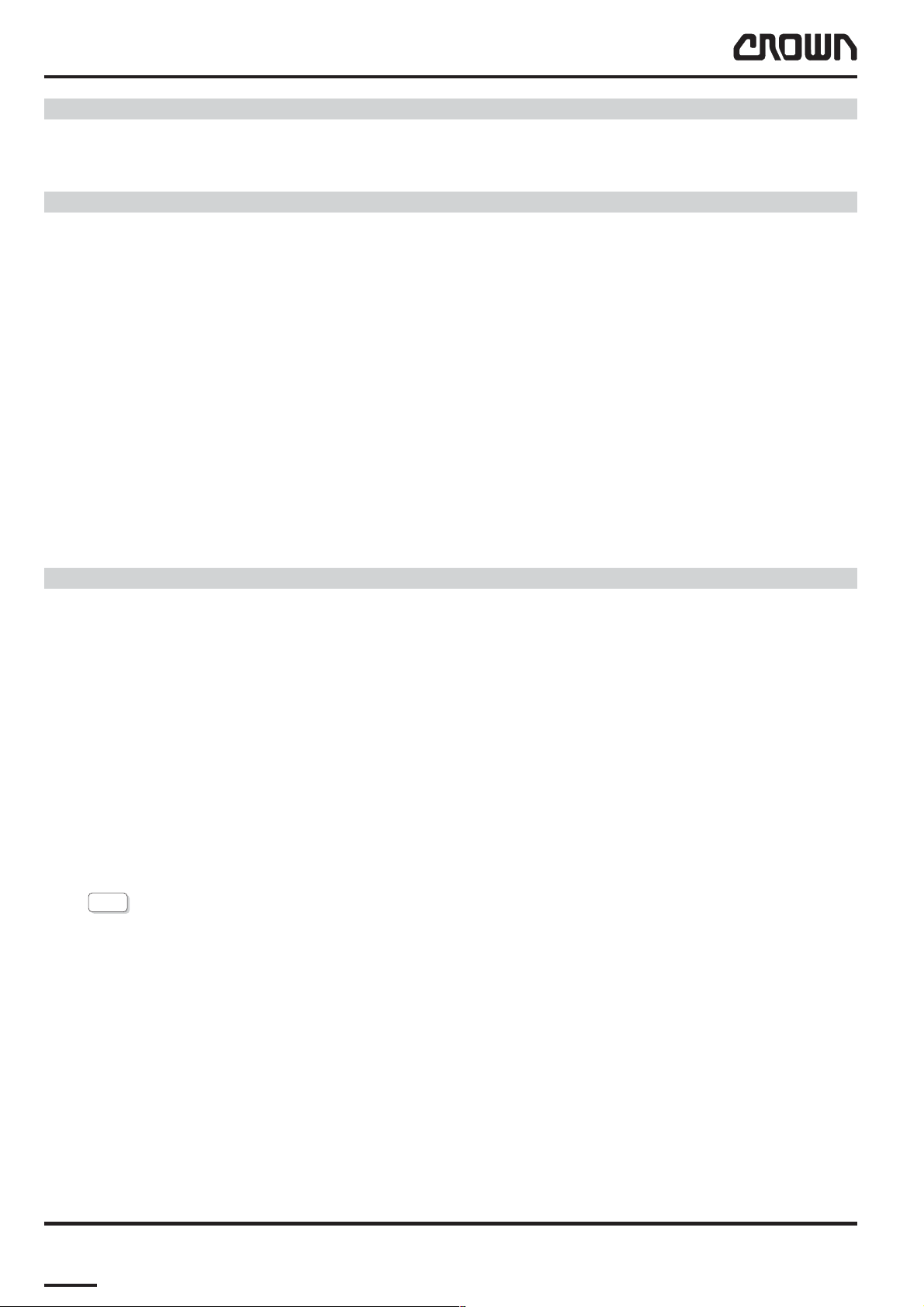

TABLE OF CONTENTS

Table of Contents

MA – SAFETY PAGE SER-NO. CUT.................. REV.

Safety Symbols used in the Manual...................................... 3

ITD – INTRODUCTION PA GE SER-N0. CUT REV.

General Maintenance and Repair Safety Notes ................... 3

Maintenance and Repair ................................................ 3

Before Leaving the Truck ................................................ 4

Before Carrying out Work on the Truck.......................... 4

Before Operating the Tr uck ............................................. 4

Warnings and Labels on the Truck........................................ 4

General..................................................................................... 7

Operating Instructions .................................................... 7

Service Training .............................................................. 7

Ordering Spare Parts...................................................... 7

Using the Manual............................................................ 7

Model-Number ......................................................................... 8

M1 – LUBRICATION AND ADJUSTMENT PAGE SER-N0. CUT .................. REV.

Raising And T owing The Truck ............................................... 11

Raising With Another Forklift Truck................................ 11

Lifting by Crane............................................................... 12

Towing the Truck ............................................................. 13

Component Access ................................................................ 14

Maintenance ............................................................................ 16

Recommended Lubricants and Oils .............................. 16

Lubricants ................................................................... 1 6

Cold Store Trucks........................................................ 16

Taking the tr uck out of service ....................................... 16

Bringing the truck back into service .............................. 16

Lubricant T able ........................................................................ 17

Adjuvants T able ....................................................................... 18

T ruck Tilt Settings ................................................................... 22

Testing and Adjusting the Lateral Inclination ................ 22

Lowering Plumb Test ....................................................... 22

M2 – HYDRAULICS PAGE SER-N0. CUT .................. REV.

Hydraulic Symbols.................................................................. 27

Hydraulics................................................................................ 31

Hydraulic Reservoir Capacity ......................................... 31

Changing the Hydraulic oil and

Hydraulic Filter................................................................ 31

Hydraulic system ............................................................ 33

Function........................................................................... 33

Lifting (see diagram) ................................................... 33

Lowering (see diagram) .............................................. 34

MOTOR AND PUMP ASSEMBLY................................... 35

Hydraulic Lines and Fittings ....................................... 35

General Rules for Hydraulic Lines and Connections.. 35

Bleeding the Hydraulic System................................... 35

Drift T est...................................................................... 35

Proportional function:................................................ 35

REMOVAL ....................................................................... 35

MOTOR............................................................................ 3 6

PUMP .............................................................................. 36

After replacing the pump: ......................................... 36

WF3000 09/2005 • Printed in Germany MS-IDX-3300

V

Page 8

TABLE OF CONTENTS

M2 – HYDRAULICS PAGE SER-N0. CUT .................. REV.

Replacing the relief valve....................................................... 37

Relief valve test and setting................................................... 37

Hydraulic System Troubleshooting ................................. 38

M3 – DRIVE UNIT PAGE SER-N0. CUT .................. REV .

Gear Unit.................................................................................. 41

Drive unit, general................................................................... 42

Drive unit removal........................................................... 42

Drive motor removal ....................................................... 42

Motor disassembly.......................................................... 43

Motor assembly ............................................................... 43

Drive motor assembly..................................................... 45

Gear unit disassembly.................................................... 46

General ....................................................................... 46

Preparation ................................................................. 46

Draining the oil............................................................ 46

Drive unit removal....................................................... 46

Gear unit cover removal.............................................. 46

Gear unit disassembly ................................................ 47

Gear unit assembly..................................................... 47

Gear unit cover installation ......................................... 49

Adding Oil ................................................................... 49

Drive unit installation ...................................................... 49

M4 – ELEKTRICS PAGE SER-N0. CUT .................. REV.

Electrics - General .................................................................. 53

Wire Colour Codes ......................................................... 53

Abbreviations .................................................................. 54

Electrical Symbols .......................................................... 57

Electrical Components ........................................................... 58

Traction Pod (POT, FS, RS)............................................ 58

Fast / Slow Travel Switch (HSS)..................................... 58

Safety Reverse Switch (SAS)......................................... 58

Brake Switch (BRS) ........................................................ 58

Override Switch (ORS)................................................... 58

Raise / Lower Switches (RAS, LOS) ............................. 59

Limit Switch (LMS).......................................................... 59

Horn Switch (HNS) ......................................................... 59

Key Switch (KYS)............................................................ 59

Emergency Disconnect (BD).......................................... 59

Fuses (FU) ...................................................................... 59

OPTION

Thermal Switch (THS) ......................................... 59

Thermal switch (THS2)................................................... 5 9

Hydraulic Control Module (HCM)................................... 59

Unigage (BDI) ................................................................. 59

Integrated Charger .......................................................... 59

Plug Holder (PC)............................................................. 5 9

Drive motor (M1)............................................................. 59

Hydraulic Motor (M2) ...................................................... 60

Main Contactor (Line/LC) ............................................... 60

Lift Contactor (P/P1+P2) ................................................ 60

Electromagnetic Brake (BRK) ........................................ 60

Ter minal Board (TB) ....................................................... 60

Travel Alarm Driver (DR) ................................................ 60

Aux. Hydraulic Switch (SLS/SRS).................................. 60

VI

WF3000 09/2005 • Printed in GermanyMS-IDX-3300

Page 9

TABLE OF CONTENTS

M4 – ELEKTRICS PAGE SER-N0. CUT .................. REV.

Remote Control Toggle Switch (ECS)............................ 60

Aux. Hydraulic Valves (SVA1/SVA2) .............................. 60

Horn (HN) ........................................................................ 60

Main Circuit Board (MAIN PCB)..................................... 60

Hydraulic Circuit Board (HYD PCB) ............................... 60

Travel Alarm (ALM) ......................................................... 60

Receiver .......................................................................... 60

Transmitter....................................................................... 6 0

SEM0 T raction Controller........................................................ 64

General............................................................................ 64

Precautionary Measures............................................. 64

Functional Characteristics.............................................. 64

Speed control.............................................................. 64

Reduced speed ranges .............................................. 64

Downhill speed control................................................ 64

Regenerative braking.................................................. 64

Anti Roll Down Function ............................................. 65

Hourmeter................................................................... 65

Self-Diagnostic System ............................................... 65

Monitored Circuits....................................................... 65

Safety Mechanisms......................................................... 65

Incorrect polarity ......................................................... 65

Wiring Errors............................................................... 65

Temperature protection............................................... 65

Start sequence ........................................................... 65

Protection rating.......................................................... 65

Maintenance.................................................................... 66

Replacing the SEM0 Traction Controller............................... 67

Parameter Setting after Replacing

the Traction Controller .................................................... 6 7

Preparatory Measures ................................................ 67

Adjustment.................................................................. 67

Status LED ...................................................................... 69

Programmer............................................................................. 70

General............................................................................ 70

Crown Handset P/N 793548 (Includes Cord) ........... 70

Operating SEM0 Controller Menu.......................................... 71

General............................................................................ 71

Menu structure............................................................ 71

Menu Functions .............................................................. 72

PARAMETER CHANGE.............................................. 72

TEST........................................................................... 72

ALARMS ..................................................................... 7 2

PROGRAM VACC ....................................................... 72

CONFIG ...................................................................... 72

Functions Menu, general................................................ 73

Parameter Change Menus ............................................. 74

Settings and Error Messages......................................... 75

Tester Menu..................................................................... 80

TESTER Menu ................................................................ 81

Alar m s M en u ................................................................... 8 2

ALARMS Menu ................................................................ 83

Calibrating the Traction Pod Potentiometer,

PROGRAM VACC menu................................................. 86

Preparatory Measures ................................................ 86

Calibration................................................................... 86

Conf ig . Menu ................................................................... 8 7

CONFIG Menu ................................................................ 88

WF3000 09/2005 • Printed in Germany MS-IDX-3300

VII

Page 10

TABLE OF CONTENTS

M4 – ELEKTRICS PAGE SER-N0. CUT .................. REV.

SET MODEL ............................................................... 88

SET OPTIONS............................................................ 88

ADJUSTMENTS ......................................................... 88

On Board Charger ................................................................... 89

General............................................................................ 89

Battery Charging Phases ............................................... 89

First Phase (I1) ........................................................... 89

Second Phase (P)....................................................... 89

Third Phase (U) .......................................................... 8 9

Fourth Phase (I2)........................................................ 89

End of Normal Charging ............................................. 90

Special Charging Phases............................................... 90

Compensating Charge................................................ 90

Float Charge ............................................................... 90

Partial Charging .......................................................... 90

Charging Errors ............................................................... 91

Green LED is not lit..................................................... 91

Possible Causes: ...................................................... 91

Green LED flashing .................................................... 91

Important Technical Data................................................ 92

Replacing the Charger ................................................... 92

Removal / Installation.................................................. 92

Electric Motors ........................................................................ 93

General Maintenance Instructions ........................................ 93

Preparation...................................................................... 93

Important Maintenance Instructions ........................... 93

Traction Motor Maintenance (WF 1.0 t) ................................. 94

Access to brushes .......................................................... 94

Maintenance.................................................................... 94

Armature ..................................................................... 94

Bearings...................................................................... 94

Traction Motor Maintenance (WF 1.2 t) ................................. 95

Access to brushes .......................................................... 95

Maintenance.................................................................... 95

Armature ..................................................................... 95

Bearings...................................................................... 95

Pump Motor Maintenance ...................................................... 96

Access to brushes .......................................................... 96

Maintenance.................................................................... 96

Armature.......................................................................... 96

Contactors ............................................................................... 97

Inspection........................................................................ 97

Contacts...................................................................... 97

Coils ............................................................................ 97

Springs........................................................................ 97

Servicing ......................................................................... 98

Dismantling ................................................................. 98

Assembly .................................................................... 98

Hydraulic Control Module (HCM)........................................... 99

Battery Discharge Indicator (BDI) ......................................... 100

OPERATION.................................................................... 100

General............................................................................ 101

Battery Discharge Indicator Setting (BDI) ..................... 101

Calibration for wet batteries ........................................... 1 02

TROUBLESHOOTING.................................................... 103

Traction Controller Safety Test ....................................... 104

VIII

WF3000 09/2005 • Printed in GermanyMS-IDX-3300

Page 11

TABLE OF CONTENTS

M5 – BRAKE PAGE SER-N0. CUT .................. REV .

Brake ........................................................................................ 107

Function........................................................................... 107

Disassembly.................................................................... 107

Assembly......................................................................... 109

Air gap setting ................................................................. 109

Brake moment setting ..................................................... 110

Brake test ........................................................................ 110

Definition of run-in/new rotor ...................................... 110

General Notes............................................................. 110

M6 – STEERING PAGE SER-N0. CUT .................. REV.

Steering.................................................................................... 11 5

Live ring bearing ............................................................. 115

Disassembly ............................................................... 115

Installation................................................................... 115

Control handle return springs ............................................... 116

Adjustment ...................................................................... 116

Disassembly.................................................................... 116

Installation ....................................................................... 116

Steering Chain......................................................................... 117

Permissible Elongation................................................... 11 7

Chain Tension Adjustment.............................................. 117

Tiller Handle ............................................................................ 119

Main Components........................................................... 119

Tiller Handle Component Removal / Installation ................. 120

Tiller Handle Shells......................................................... 120

Removing the Upper and Lower Shells ...................... 120

Fitting the Upper and Lower Shells ............................. 121

Switch Unit ...................................................................... 122

Removal...................................................................... 122

Switch Unit Installation................................................ 122

"Fast/Slo w" Toggle Switch .............................................. 123

Removal...................................................................... 123

Installation................................................................... 123

Hydraulic Board .............................................................. 123

Removal...................................................................... 123

Installation................................................................... 123

Potentiometer.................................................................. 124

Removal...................................................................... 124

Installation................................................................... 124

Safety Reverse Switch.................................................... 125

Removal...................................................................... 125

Installation................................................................... 125

Horn Switch..................................................................... 126

Removal...................................................................... 126

Installation................................................................... 126

Handle ............................................................................. 127

Removal...................................................................... 127

Installation................................................................... 127

WF3000 09/2005 • Printed in Germany MS-IDX-3300

IX

Page 12

TABLE OF CONTENTS

M7 – MAST PAGE SER-N0. CUT .................. REV .

Mast.......................................................................................... 131

General............................................................................ 131

Torque Requirements ................................................. 131

Lifting Gear Minimum Capacity................................... 131

Mast Removal ................................................................. 131

Installation ....................................................................... 132

Fork Carriage Removal .................................................. 132

Fork Carriage Installation............................................... 132

Fork Carriage Adjustment .............................................. 133

Mast Maintenance .......................................................... 134

Lubricating Roller Tracks............................................. 134

Lowering Plumb Test .............................................................. 135

Preparatory measures.................................................... 135

Carrying out the vertical plumb test............................... 135

Lift chains ................................................................................ 136

General............................................................................ 136

Inspection........................................................................ 136

Cleaning...................................................................... 136

Wear ........................................................................... 136

Freedom of Movement of Chain Links ........................ 137

Chain Tension ............................................................. 137

Chain Anchor and Pulleys .......................................... 138

Worn Connection Plates ............................................. 138

Protruding or Turned Chain Pins................................. 138

Corrosion .................................................................... 138

Chain Lateral Wear ..................................................... 13 9

Uneven Chain Tension .............................................. 139

Misaligned Lift Components ..................................... 139

Lift Chain Lubrication...................................................... 140

Separating Lift Chains .................................................... 14 1

Tools and Equipment Required ...................................... 141

Detachment..................................................................... 141

Fork Tines ................................................................................ 142

General............................................................................ 142

Terms .......................................................................... 142

Fork Identification ....................................................... 142

Repairs ............................................................................ 142

Fork Inspection ............................................................... 142

Crack Inspection ......................................................... 142

V erticality Test ............................................................. 143

Fork Blade Warping .................................................... 143

Measuring the Fork Tip Width........................................ 143

Fork Tine Height Difference ........................................... 143

Fork Stop......................................................................... 143

Fork Blade Wear ............................................................. 144

WF3000 09/2005 • Printed in GermanyMS-IDX-3300

X

Page 13

TABLE OF CONTENTS

M8 – CYLINDERS PAGE SER-N0. CUT .................. REV .

Cylinders.................................................................................. 147

General............................................................................ 147

Safety when working on hydraulic systems ................ 147

General Instructions for Repairing Hydraulic

Components ............................................................... 147

Rod Seal Assembly................................................................. 148

General............................................................................ 148

Large Rod Seal Assembly.............................................. 148

Small Seal Rod Assembly .............................................. 149

Rod Seal Assembly, Sealing Lip First............................ 150

Cylinders.................................................................................. 151

TL Mast Lift Cylinder....................................................... 151

Seal Replacement ...................................................... 151

Installing TL Mast Lift Cylinders.................................. 152

TF Mast Lift Cylinders .................................................... 154

Removing the TF Mast Lift Cylinders.......................... 154

Seal Replacement ...................................................... 154

Installing TF Mast Lift Cylinders.................................. 155

Free Lift Cylinder TF and Mono Mast ............................ 156

Seal Replacement ...................................................... 156

Installing Free Lift Cylinder............................................. 157

Cylinder Bleeding and Flushing ..................................... 157

Bleeding — Mast Lift Cylinders................................... 157

Bleeding — Free Lift Cylinder (if applicable) .............. 1 57

Flushing – Mast Lift Cylinders

and Free Lift Cylinders (if applicable) ......................... 158

Drift T est...................................................................... 15 8

Cylinder Shimming .......................................................... 158

Lift Cylinder Shims...................................................... 158

Free Lift Cylinder Shims .............................................. 15 8

DIA – ELECTRICAL DIAGRAMS PAGE SER-N0. CUT .................. REV.

WF 3000-10 Standard.............................................................. 163

Overview.......................................................................... 163

WF3000-10 Standard,

Traction Controller - SEM0 Logic ................................... 164

WF3000-10 Standard,

Traction Controller - SEM0 Power Circuit...................... 165

WF3000-10 Standard,

Power Unit Control Circuit .............................................. 166

WF3000-10 Standard,

Control Handle - Control Circuit..................................... 167

WF3000-10 Standard,

Hydraulic Control Module (HCM)................................... 168

WF3000-10 with Options ........................................................ 169

Overview.......................................................................... 169

WF3000-10 with Options,

Traction Controller - SEM0 Logic ................................... 170

WF3000-10 with Options,

Traction Controller - SEM0 Power Circuit...................... 171

WF3000-10 with Options,

Power Unit - Control Circuit............................................ 172

WF3000-10 with Options,

Control Handle - Control Circuit..................................... 1 73

WF3000-10 with Options,Hydraulic Control Module (HCM)

- Travel Alarm and Flashing Beacon.............................. 174

WF3000 09/2005 • Printed in Germany MS-IDX-3300

XI

Page 14

TABLE OF CONTENTS

DIA – ELECTRICAL DIAGRAMS PAGE SER-N0. CUT .................. REV.

WF 3000-12 Standard.............................................................. 175

Overview.......................................................................... 175

WF3000-12 Standard,

Traction Controller - SEM0 Logic ................................... 176

WF3000-12 Standard,

Traction Controller - SEM0 Power Circuit...................... 177

WF3000-12 Standard,

Power Unit Control Circuit .............................................. 178

WF3000-12 Standard,

Control Handle - Control Circuit..................................... 179

WF3000-12 Standard,

Hydraulic Control Module (HCM)................................... 180

WF3000-12 with Options ........................................................ 181

Overview.......................................................................... 181

WF3000-12 Swith Options,

Traction Controller - SEM0 Logic ................................... 182

WF3000-12 with Options,

Traction Controller - SEM0 Power Circuit...................... 183

WF3000-12 with Options,

Power Unit - Control Circuit............................................ 184

WF3000-12 with Options,

Control Handle - Control Circuit..................................... 1 85

WF3000-12 with Options, Hydraulic Control Module (HCM)

- Travel Alarm and Flashing Beacon.............................. 186

Wire Harness ........................................................................... 187

Control Handle Wiring .................................................... 188

Power Cab les .................................................................. 18 9

HYD – HYDRAULIC SCHEMATICS PAGE SER-N0. CUT .................. REV .

Hydraulik Schematic Standard Lift ....................................... 193

Hydraulik Schematic Soft Lift ................................................ 194

XII

WF3000 09/2005 • Printed in GermanyMS-IDX-3300

Page 15

Printed in Germany

SAFETY

1

Page 16

Blank page

Printed in Germany

2

Page 17

SAFETY

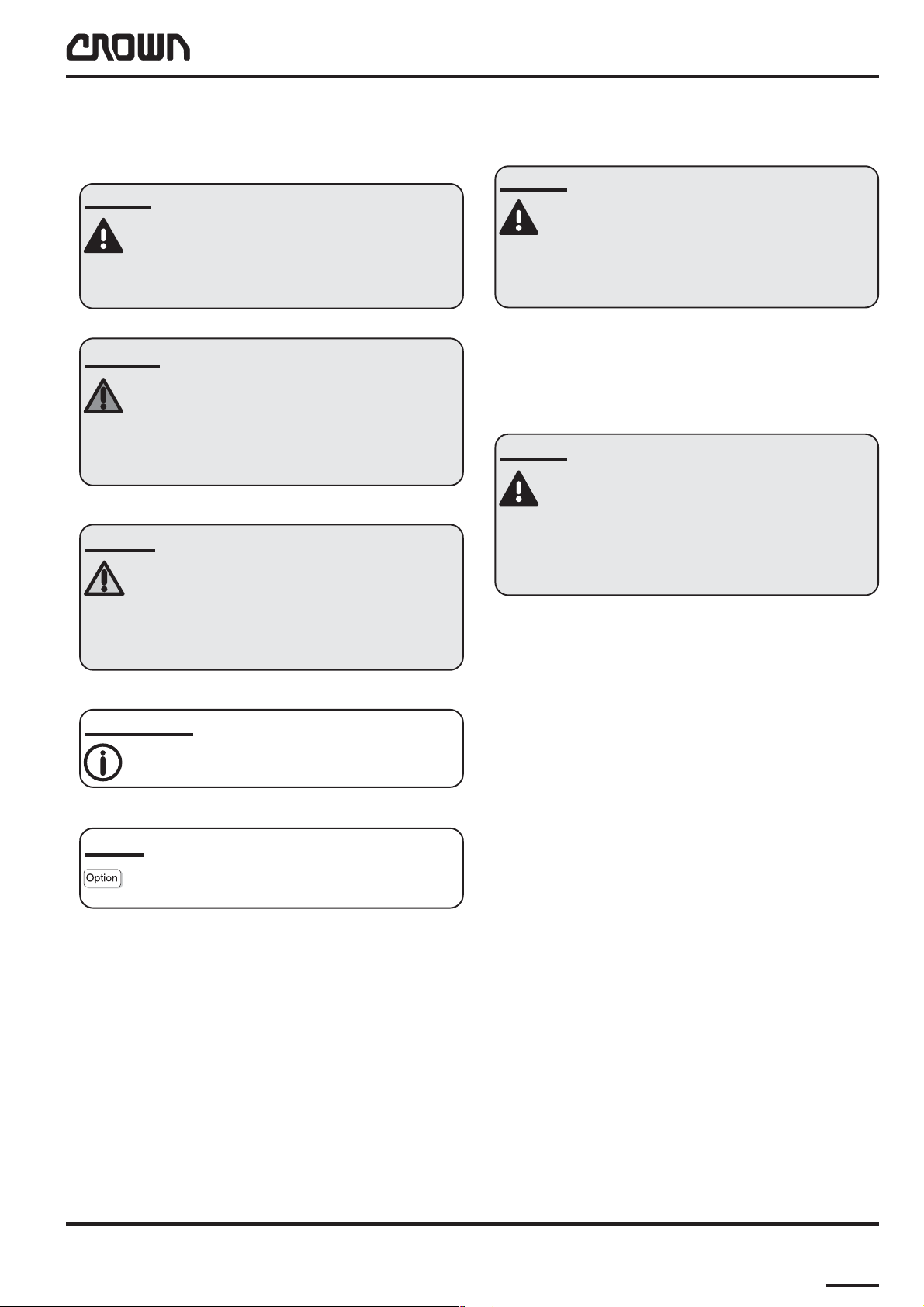

Safety Symbols used in the Manual

T o help guide you through the man ual and to highlight particular danger areas, we have used graphic illustrations:

DANGER

This symbol indicates life-threatening

risks

● Failure to comply with this notice may result in

fatal injuries to yourself or other people.

WARNING

This symbol indicates the risk of serious

injury and/or serious material damage.

● Failure to comply with this notice may result in

severe injuries to yourself or other people and/or

serious material damage.

CAUTION

This symbol indicates the risk of minor

injury and/or minor material damage.

General Maintenance and Repair

Safety Notes

DANGER

Read the safety notices in the truck

Maintenance and Operator's Manuals.

● Failure to do so could result in severe or fatal

injuries to maintenance personnel and/or other

persons.

Motorised vehicles can be dangerous if maintenance and

service are neglected. For this reason maintenance and

inspections must be carried out at regular short intervals

by trained personnel working to approved company guidelines.

DANGER

Follow all national/local safety regulations applicable for maintenance work,

e.g. for work on higher levels.

● Failure to do so could result in severe or fatal

injuries to maintenance personnel and/or other

persons.

● Failure to comply with this notice may result in

minor injuries to yourself or other people and/or

minor material damage.

INFORMATION

Contains additional information with

supplementary notes and hints.

OPTION

These items relate to optional features

not supplied with the standard version.

Maintenance and Repair

1. Maintenance work must only be carried out in

accordance with the test and maintenance

program contained in the present Maintenance

Manual and any applicable service notices.

2. Only qualified and authorised personnel may

carry out work on the truck.

3. Always keep fire extinguishers in good working

condition. Do not approach fluid levels or leaks

with a naked flame.

4. To clean, use a non flammable, non combustible

cleaning solution which is groundwater-neutral.

Only carry out cleaning with an oil separator.

Protect the electrical system from dampness.

5. Keep the service area clean, dry and wellventilated.

6. Do not allow oil to penetrate the ground or enter

the draining system. Used oil must be recycled.

Oil filters and desiccants must be treated as

special waste products. Relevant applicable

regulations must be followed.

7. Neutralise and thoroughly rinse any spilled

battery fluid immediately.

8. Keep the truck clean. This will facilitate the

location of loose or faulty components.

WF3000 09/2005 • Printed in Germany MS-MA-0000

3

Page 18

SAFETY

9. Make sure that capacity and data plates, warnings

and labels are legible at all times.

10. Alterations or modifications by the owner or

operator are not permitted without the express

written authorisation from Crown.

11. Only use original Crown spare parts to ensure

the reliability, safety and suitability of the Crown

truck.

Before Leaving the Truck

● Stop the truck.

● Lower the fork carriage fully.

● Apply the parking brake.

● Turn off the truck and remove the key.

● Block all wheels when parking on an uneven

surface.

Before Carrying out Work on the Truck

● Raise the truck to free the drive wheel. Press the

emergency Stop button and disconnect the

battery.

Warnings and Labels on the Truck

During regular maintenance check that the warnings and

labels on the truck are complete and legible.

● Clean any illegible labels.

● Replace any faulty or missing labels.

The order and meaning of the warnings and labels on

the truck are described in section 10.9 of the parts

manual.

● Prevent the truck from rolling away.

● Before carrying out work on the hoist frame, the

lift mast or on the fork carriage: Block these parts

according to maintenance instructions in order to

prevent them from dropping.

● Only carry out operational testing when there is

sufficient room to manoeuvre, to avoid the risk of

injury to yourself and others.

Before Operating the Truck

● Check the safety devices.

● Get into the driver's seat.

● Check the operation of the lifting device, travel

direction switch, speed control, steering, warning

devices and brakes.

WF3000 09/2005 • Printed in GermanyMS-MA-0000

4

Page 19

Printed in Germany

INTRODUCTION

5

Page 20

Blank page

Printed in Germany

6

Page 21

INTRODUCTION

General

The present manual is designed for Customer Service

engineers who wish to familiarise themselves with the

maintenance work required for the various truck components.

It also contains troubleshooting sections which can be

used to identify and remedy truck faults.

INFORMATION

This book is not an operating manual. It is

designed solely for specialist personnel

who have been trained and authorised to

carry out the work described in the

manual.

This manual therefore contains fewer and less detailed

warnings than the Operator's Manual, as the latter is

aimed at persons who have very little or no prior

experience at all.

This information can be found on the truck's data plate.

Only if this information is provided can the order be

processed quickly, correctly and reliably.

Please refer to the Technical Specifications Sheet for the

utilisable loads, technical data and dimensions for

thisseries. Brochures can be obtained from y our CROWN

dealer or from the following address:

CROWN Gabelstapler GmbH & Co.KG

Moosacher Str. 52

80809 Munich

GERMANY

Tel.: +49 (0)89 / 93 002 -0

Fax: +49 (0)89 / 93 002 -175 or133

Using the Manual

The manual is divided into sections. The following table

shows how the manual is structured.

ecnanetniaMsnoitceS

Operating Instructions

This manual contains no operating instructions. An

operating instructions manual is supplied with the vehicle.

Additional copies can be ordered as required.

With the help of this manual you and your personnel will

be able to ensure the long service life, operational saf ety

and error free functioning of your CROWN vehicle.

Service T raining

CROWN offers the appropriate vehicle related training

for service personnel. Details on this training can be

obtained from CROWN on request.

Ordering Spare Parts

The maintenance manual does not cover spare parts.

These are listed in a separate manual.

Spare parts can be ordered by quoting:

● The truck specification number

noitceS noitpircseD

XDItnetnoCfoelbaT

AMytefaS

DTInoitcudortnI

1MtnemtsujdAdnanoitacirbuL

2MsciluardyH

3MtinUevirD

4MlacirtcelE

5MekarB

6MgnireetS

● The truck model number

● The truck serial number

WF3000 09/2005 • Printed in Germany MS-ITD 3300

7MmsinahceMgnitfiL/tsaM

8MrednilyC

AIDsmargaiDlacirtcelE

DYHcitamehcSciluardyH

A01M-gb

7M1.0-0000-00077

Page 22

INTRODUCTION

Model-Number

This manual describes the maintenance and repairs for the following truck versions:

WF 3000-1.0

WF 3000-1.2

WF3000 09/2005 • Printed in GermanyMS-ITD-3300

8M1.0-0000-00088

Page 23

Printed in Germany

LUBRICATION AND ADJUSTMENT

9

Page 24

Blank page

10

Printed in Germany

Page 25

LUBRICATION AND ADJUSTMENT

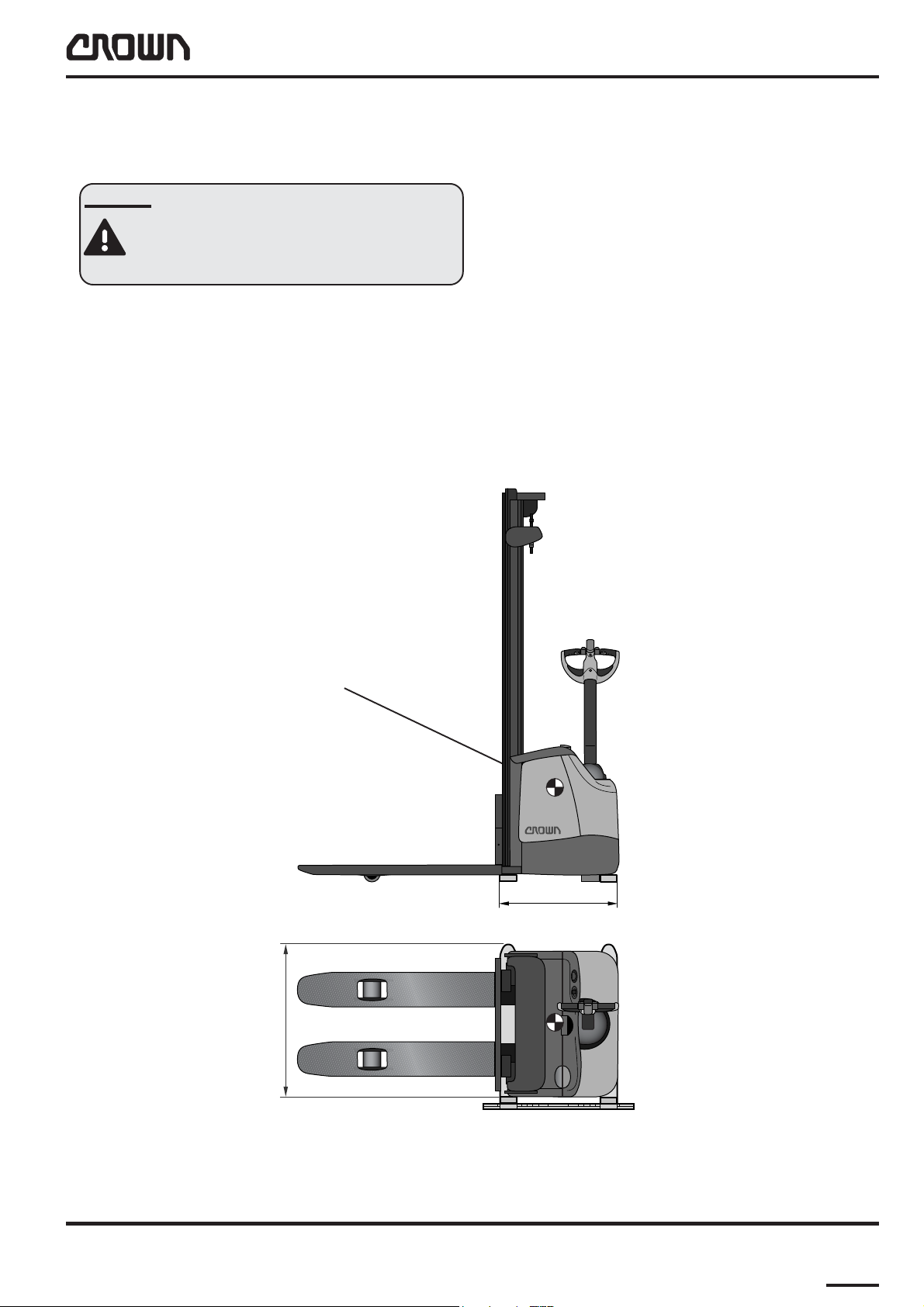

Raising And T owing The T ruck

Raising With Another Forklift Truck

DANGER

Failure to read the instructions can

cause the truck to tip over or fall from the

forks. Fatal accidents could result.

● Position the forks of the truck which is doing the

lifting as shown by the diagram below.

● The centre of gravity of the WF 3000 with and

without the battery is near the battery compartment. It should always be between the forks of

the truck doing the lifting.

● Secure the WF 3000 firmly to the forks of the

truck which is doing the lifting (e.g. with appropriate straps).

Schwerpunkt

> 850

> 650

MO-3300-014

WF3000 09/2005 • Printed in Germany MS-1.0-3300

11

Page 26

LUBRICATION AND ADJUSTMENT

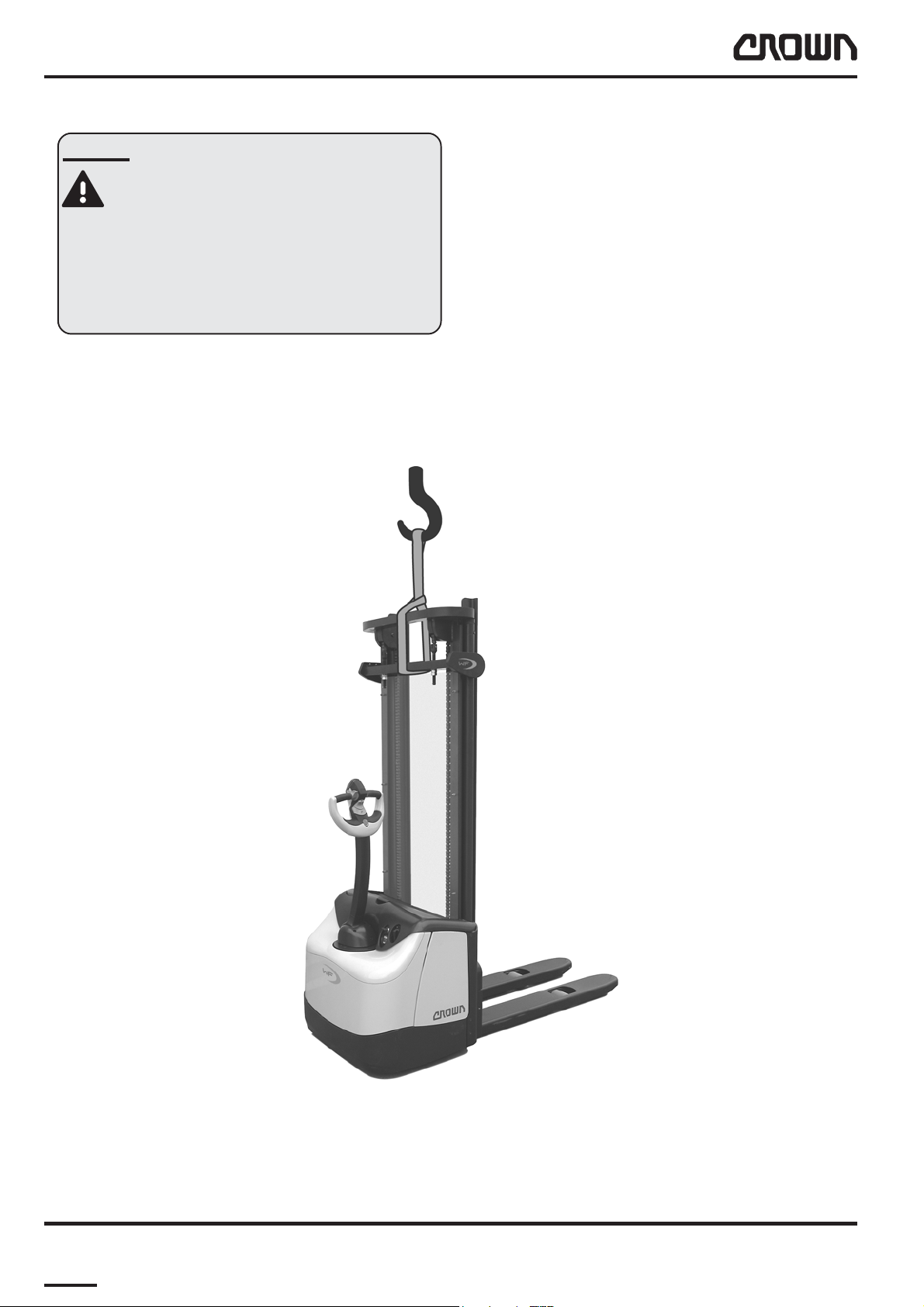

Lifting by Crane

DANGER

Make sure the crane / fork lift and the

lifting equipment have sufficient capacity.

If the crane / lift truck crash or a load

falls, fatal injuries can result.

Capacity required: 900 kg

Attach lifting gear as shown in the following diagram and

prevent the truck from slipping.

12

MO-3300-013

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

Page 27

LUBRICATION AND ADJUSTMENT

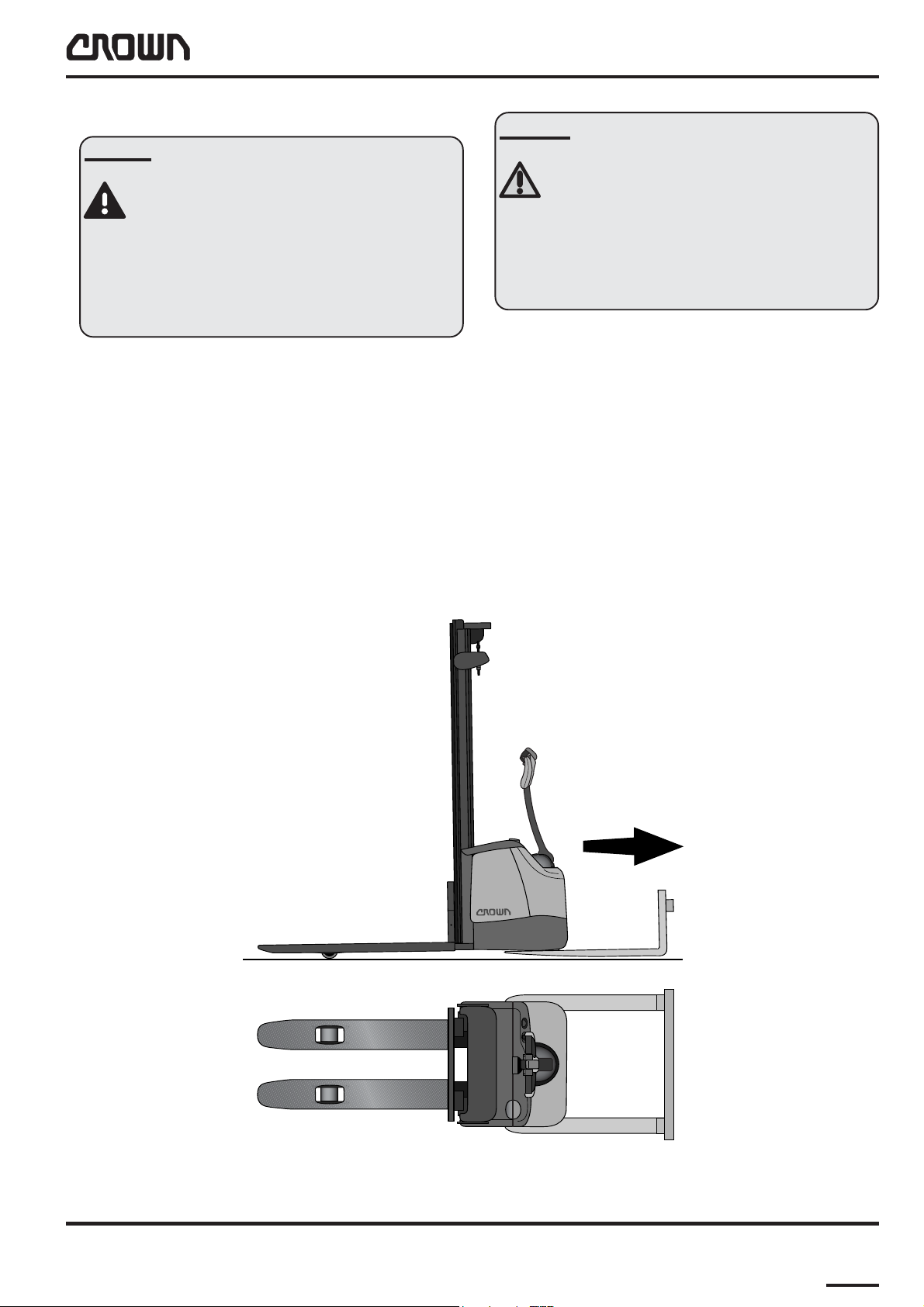

Towing the Truck

DANGER

Tipovers can result in fatal accidents.

If the towing truck negotiates a bend, a

fork will slip under the truck that is being

towed. This can cause the towed truck to

tip over and result in fatal injuries.

Only travel straight ahead when towing.

When the truck is de-energised, the brake (acting on the

drive wheel) is applied. To remove the truck from an aisle,

for example , it can be raised and pulled by a f orklift truck.

The required capacity (WF unladen, with battery , 800 kg):

1100 kg. The load wheels remain on the ground when

the truck is towed.

CAUTION

Risk of damage to the drive system.

If the drive wheel is still touching the

ground, the drive system will be damaged when the truck is towed.

Only raise the truck so far that the drive

wheel is not touching the ground.

● Position the forks as shown in the diagram.

● Raise the truck (at its front) approx. 20 mm, but

no higher than necessary as otherwise the

bottom of the WF’s fork tips will scratch the

ground.

MO-3300-015

WF3000 09/2005 • Printed in Germany MS-1.0-3300

13

Page 28

LUBRICATION AND ADJUSTMENT

Component Access

Undo the 3 screws securing the dashboard. Lift off the

dashboard and panel to gain access to the components

beneath the panel.

Note: The illustration shows the model with the TT mast.

Mast

Fork

Load wheel

Safety Screen

Control handle

Free lift cylinder

Dashboard

Control handle knuckle

Controller and contactors

Traction and pump motors

Caster wheel

14

Battery and battery connector

Drive wheel

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

Page 29

LUBRICATION AND ADJUSTMENT

After disassembling the top panel you will be able to

access the:

● Diagnostic LED on the TCM

● Fuse FU1 (travel power fuse)

● Fuse FUS (raise power fuse)

● Combination instrument

● Fuse FU3 (signal)

● Fuse FU4 (cold store versions only)

After lifting off the bottom panel you will be able to

access the:

● Traction motor

● Power unit

● Brake

● Pump motor

The control handle knuckle contains the:

● BRS (brake switch)

● ORS (brake override zone switch)

The mast contains the:

● FLS (flashing light)

● LMS (lift limit switch)

● Hydraulic unit

● Horn

● Alarm transmitter

● Diode block

● Main contactor

● Relay K2

● Alarm filter block

● TCM (traction control module)

● HCM (hydraulic control module)

The hand grip contains:

● HNS1 & HNS2 (horn switches)

● LOS1 & LOS2 (fork lower switches)

● RAS (raise switch)

● HSS (fast / slow travel switch)

● SAS (safety reverse switch)

● FS, RS, POT (travel switch unit and

potentiometer)

WF3000 09/2005 • Printed in Germany MS-1.0-3300

15

Page 30

LUBRICATION AND ADJUSTMENT

Maintenance

Recommended Lubricants and Oils

Lubricants

The next page shows typical lubricants used by Crown

itself in its factories. Howe ver , you can use any lubricants

provided they meet the same technical criteria.

Cold Store Trucks

Special hydraulic oil, lubrication oil and grease must be

used for cold store trucks operating in low temperature

conditions (see table on following page). An anticorrosion

fluid (Crown no. 805236-004) must be applied to all

screws, washers, nuts, pins, retaining rings etc. Carefully protect all electrical connections and components

against corrosion. F or detailed information, refer to chapter 4.

Service intervals must be adapted to the conditions of

use. This means they must be reduced as far as possible to prevent excessive wear.

Taking the truck out of service

● Every 3 months connect the battery, carry out a

daily inspection and activate all the truck functions. Now disconnect the battery again.

Bringing the truck back into service

● If you wish to bring the truck back into service,

proceed as follows:

● Remove any anti-corrosion agents which have

been additionally applied (apart from the cold

store agents)*.

● Jack up the truck, remove the wooden blocks and

lower the truck.

● Charge the battery or fit a charged battery.

● Connect the battery.

● Carry out the daily inspection.

* Do not apply high pressure cleaning agents and/or

solvents to the truck. Do not use metallic brushes. Do not

wet clean the electrical system and do not use flammable solvents.

If you wish to take the truck out of service for more than

3 months, proceed as follows:

● Disconnect the battery from the truck.

● Decommission the battery in accordance with the

manufacturer’s instructions.

● Clean the truck*). Lubricate in accordance with

the maintenance manual.

● If the truck is to be stored in harsh conditions

(e.g. saline atmosphere) treat the surface of the

truck with a suitable preservative to prevent

corrosion.

● Do not park the truck in the open air or in a

humid environment. The ideal place is a dry room

where the temperature and air humidity are as

constant as possible. If the truck has to be

covered, use an air-permeable material. Do not

use plastic sheets. Otherwise, condensation may

form.

● Jack up the truck. Lower the chassis onto suit-

able wooden blocks so that the wheels clear the

ground (prevents the wheels from flattening from

constant pressure).

16

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

Rev. 01/03

Page 31

Lubricant T able

LUBRICATION AND ADJUSTMENT

epyTtnacirbuL noitpircseDtcudorP

)esoprupitlum(esaerG

woL esaergerutarepmet 2LKSebularA

liociluardyH

erutarepmetwoL liociluardyh23IVHleOztueDrenkcolK900-100350DD

-unaM

rerutcaf

2PLHebularA

esaerG-ML

2AsulugeR

2PEnocaeB

2PE

2PEexuliboM

XLxaniteR

IMWGL

PEpmetoLxerinU

23FGmatiV

23-SWAnipsyH

23HotuN

42ETD

23sulleT

23ZLnardyH

011B

larA

lortsaC

yrutneC

ossE

loxaM

liboM

llehS

FKS

larA

liboM

larA

lortsaC

ossE

liboM

llehS

loniF

shcuF

ekrewlölareniM

HbmG

100-200350B

500-200350BB

300-100350D

.oNtraPnworC epyT

09W58pyH

lionoissimsnarT

erutarepmetwoL noissimsnart

lio

lionoitacirbuL

erutarepmetwoL lionoitacirbul626CHSliboM800-200350GG

gnisserdlynivdnarebbuR---------H

09W58D-XG

09/58DHebuliboM

09BMxaripS

426CHSliboMliboM900-200350AA

04lawoK

04+XDHebulossE

0421cavleD

larA

ossE

liboM

llehS

larA

ossE

liboM

400-200350A

700-200350G

L01_Lubricants_WF-GB

WF3000 09/2005 • Printed in Germany MS-1.0-3300

17

Page 32

LUBRICATION AND ADJUSTMENT

Adjuvants T ab le

tnavujdA noitpircseDtcudorP noitacilppA .oNtraPnworC

tnegaevisorroc-itnAlytceT

tniaplaesraelCkcalralKK2

dnuopmocgnitnioJokriDgnirlE

roftnegaevisorroc-itnA

.skcurterotsdloc

laesraelctnatsiser-dicA

noitcartroftniap

dlocnidesusrellortnoc

.serots

rofdnuopmocgnitnioJ

diuqil(srevoctinuraeg

.)laes

-----------------

-----------------

:egdirtraclm013

200-632508

:ebutg001

100-632508

L01_Adjuvants_WF_GB

18

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

Page 33

metI noitcA

LUBRICATION AND ADJUSTMENT

)erotSdloC=C,dradnatS=X(eludehcSecnanetniaMdnatseT

stnacirbuL=...,M,A/noitacirbuL=L,noitcepsnI=I sruoHecivreS/shtnoM

3

6

001

21

42

052

005

0001

1-I

2-I

3-I

4-I

1-L

2-L

5-I.gnittesevlavfeilerkcehC C/X

6-I.rotomciluardyhnoreffubrebburkcehC C/X

7-I

8-I.raewdnaegamadrofgnilpuocrotompmupkcehC C/X

9-I.stnemhcattarotomtfildnarotomnoitcartehteuqroT C/X

01-I.levelliotinuraegkcehc,tnemhcattatinuraegehteuqroT C/X

-D/D

D

-D/D

D

.raew

.thgit

raewrofkcehc

retfasruoh05rokcurtwenanostunleehwevirdehteuqroT

.yrassecenfihsinelper,levelliociluardyhkcehC C/X

liociluardyhecalpeR C/X

.)4retpahcees(raew

dnasgniraebleehwretsacdnaleehwdaolehtfoecnaraelcehtkcehC

rofleehwevirddnasleehwretsac,sleehwdaolehtfoserytehtkcehC

.shtnom21yreverosruoh005yreve,retfaerehT.ylbmessa/lavomer

erasnoitcennockcehcdna,egamadrofsesohdnasenilciluardyhkcehC

rofsrotomnoitcartdnapmupforotatummocdnasehsurbnobrackcehC

C/X

C/X

C/X

C/X

C/X

11-I.snoitcennocelbacrewopllaeuqroT C/X

21-I.sgnirpstcatnockcehcdnastcatnocrotcennocyrettabnaelC C/X

31-I

41-I

51-I.egamadrofelbacgnitcennocregrahckcehC C/X

61-I

3-LBB/B.kcollenapyrettabdnasegnihetacirbuL C/X

.selbacdnasgnirps

.noisnet-erpelbackcehC

.noisorrocrofkcehcdnaeruceserasnoitcennocdna

tcatnoc,gnisuohrotcennockcehC.stcatnocrotcennocyrettabnaelC

?tneserpfeilerniartS.thgiterasnoitcennocgulperusnE:selbactsaM

sehctiwserusnedna,noitalusniotegamadrofsenillacirtcelellakcehC

C/X

C/X

C/X

L04_WF-GB

WF3000 09/2005 • Printed in Germany MS-1.0-3300

19

Page 34

LUBRICATION AND ADJUSTMENT

)erotSdloC=C,dradnatS=X(eludehcSecnanetniaMdnatseT

stnacirbuL=...,M,A/noitacirbuL=L,noitcepsnI=I sruoHecivreS/shtnoM

metI noitcA

71-I.raewrofkcehcdnastcatnocrotcatnocpmupnaelC C/X

81-I.raewrofkcehcdnastcatnocrotcatnocniamnaelC C/X

91-I .tnemhcattarellortnocnoitcarteuqroT.golrorrerellortnocnoitcartdaeR C/X

3

001

6

21

42

052

005

0001

02-I

12-I

22-I.sgnirpseldnahlortnocehtfoecrofgnirotserehtkcehC C/X

32-I.noisnetniahcgnireetsehtkcehC C/X

42-I.kcurtehtfotnemngilasixalaretalehtkcehC C/X

52-I .)tsetbmulpgnirewol(kcurtehtottsamehtfotnemngilaehtkcehC C/X

62-I.kcalsrofsrellorkcehcdna,skcarcrofegairrackrofkcehC C/X

72-I.egairrackrofdnaskrofneewtebkcalskcehC C/X

82-I.raewdnaegamadrofskrofkcehC C/X

92-I.raewrofkcehcdnasecafrustcatnoctsamnaelC C/X

40-LBB/B.secafrustcatnoctsametacirbuL C/X

03-I .)noitagnole(raewdnanoisorroc,egamadrofkcehc,sniahctfilllanaelC C/X

50-LGG/G.sniahctfiletacirbuL C/X

13-I.skcarcdnanoisorroc,egamadrofsrohcnaniahckcehC C/X

23-I.kcalsdnaraewrofsrellortsamkcehC C/X

60-LBB/B.srelloregairrackrofdnasrellortsametacirbuL C/X

.pagriakcehC.egamad

.stnenopmocdegamadronrowynaecalpeR.egamad

rofelppinlacinocehtkcehC.ekarbninoisarbaotriadesirusserpylppA

dnaraewrofkcehcdnastnenopmocllanaelC.ekarbehteltnamsiD

C/X

C/X

33-I .dettifylerucessitierusnednaegamadroftserkcabdaolkcehC C/X

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

20

L05_WF-GB

Page 35

metI noitcA

LUBRICATION AND ADJUSTMENT

)erotSdloC=C,dradnatS=X(eludehcSecnanetniaMdnatseT

stnacirbuL=...,M,A/noitacirbuL=L,noitcepsnI=I sruoHecivreS/shtnoM

3

6

001

21

42

052

005

0001

43-I

70-LH .srelloresohetacirbuL C/X

80-LGG/G.syellupniahcetacirbuL C/X

90-LAA/A.yrassecenfihsinelper,levellioraegkcehC C/X

01-LAA/AlioraegecalpeR C/X

53-I

-

-)4retpahcees,tsetytefasrellortnocnoitcart(tsetTMP yllaunnax1

.kcalsdnaegamad

.sesuftnemhcattarednilyckcehC.delaes

.)snoitalugerlanoitan

,raewrofgninoihsuctimiltsamdnasrelloresoh,ekoyyellup,syellupkcehC

sirednilycerusnednaegamadrofsdornotsiprednilycciluardyhkcehC

otrefer,seirtnuocrehtoroF.ylnoynamreG(.noitcepsniVVUehttuoyrraC

C/X

C/X

L06_WF-GB

yllaunnax1

WF3000 09/2005 • Printed in Germany MS-1.0-3300

21

Page 36

LUBRICATION AND ADJUSTMENT

T ruck Tilt Settings

DANGER

Truck tipovers can result in fatal injuries.

The risk of a tipover is greatly increased

by setting the truck tilt angle beyond the

tolerance level.

Adjust the truck tilt angle regularly and

with care.

The stability of the truck requires the tilt

angle to be kept as low as possible.

Maximum stability is achieved by measuring the lateral

inclination and carrying out a lowering plumb test on the

mast with appropriate adjustment.

The inclination of the truck and therefore the mast

changes as the drive wheel and / or the caster wheel

increasingly wear.

● Fix the caster wheel again. Repeat the measurement to check the adjustment.

● If necessary, repeat the adjustment until the

difference in height on the two sides is within the

tolerance lev el.

● Now carry out the lowering plumb test.

Lowering Plumb Test

Test the lateral inclination before carrying out the

lowering plumb test.

The truck must be parked on a flat, level surface. The

max. permissible deviation from the evenness and

levelness of the 4 contact points on the truck (the

two load wheels, caster wheel and drive wheel) must

be less than 1 mm.

● Attach a test load (the maximum weight at maximum lift height and with the correct load centre of

gravity - see capacity plate).

The inclination of the truck must be checked and if necessary adjusted in the following cases:

● Lateral inclination and lowering plumb test at the

intervals given in the maintenance schedule.

● Replacing the drive wheel

● Replacing the caster wheel

● Replacing the mast

Testing and adjustment take place in 2 stages:

Testing and Adjusting the Lateral Inclination

The truck must be parked on a flat, level surface. The

max. permissible deviation from the evenness and

levelness of the 4 contact points on the truck (the

two load wheels, caster wheel and drive wheel) m ust

be less than 1 mm.

● Measure the skir t height off the ground (at the

separating joint) on the left and right hand sides.

The difference between the left and right hand

sides should not exceed +/- 1mm.

● Adjust the height of the caster wheel to correct

the lateral inclination of the chassis. To do this,

undo the locking screw (3, Fig. MP-3300-007) and

adjust the height via the setscrew (1).

● Raise the test load approx. 300 mm.

● Attach a lowering plumb to the back of the fork

carriage.

● Prepare a paper rectangle: 50 mm long and 20

mm wide. Mark out the middle of the rectangle.

● Wait until the plumb has finished oscillating and

stick the previously prepared paper rectangle

onto the ground below the plumb. The centre

should lie underneath the tip of the plumb. The

long side of the rectangle (50 mm) should be

perpendicular to the truck’s longitudinal axis.

● Now extend the mast as far as the stop and then

lower it a few millimetres. It is important that the

mast is not tensioned at the limit positions.

● Check the position of the lowering plumb. The

plumb should not now be pointing outside the

rectangle.

● If the plumb is pointing outside the rectangle in

the lateral direction, the lateral mast inclination

must be compensated using shims 813875-001/-

002. The shims are positioned between the base

of the outer mast and the truck base (RH or LH)

and screwed to the rear panel of the battery.

22

WF3000 09/2005 • Printed in GermanyMS-1.0-3300

Page 37

LUBRICATION AND ADJUSTMENT

● If the plumb is pointing outside the rectangle in

the longitudinal direction, either the drive and

caster wheels or the load rollers are heavily worn.

In this case, check the wheels and rollers for

wear and replace any worn wheels and rollers.

Now repeat the lateral inclination setting and the

vertical plumb test.

1

2

3

4

5

6

14

13

12

9

7

11

10

8

WF3000 09/2005 • Printed in Germany MS-1.0-3300

9

MP-3300-007

10

23

Page 38

Blank page

24

Printed in Germany

Page 39

Printed in Germany

HYDRAULICS

25

Page 40

Blank page

26

Printed in Germany

Page 41

Hydraulic Symbols

Vented reservoir

with lines above the fluid level

Vented reservoir

with lines below the fluid level

Filter or strainer

M

M

HYDRAULICS

Electric motor

with unidirectional turn and speed

Electric motor

with unidirectional turn

and variable speed

Hydraulic line with full flow

(tubing or hose)

Pilot or drain line or drainage

with limited flow

Lines crossing; not connected

Lines crossing and connected

Hydraulic pump

with fixed displacement

and single direction of turn

Hydraulic motor,

bi-directional

Pressure gauge

Thermometer

Plugged port (test por t )

Flow meter

M3559

WF3000 09/2005 • Printed in Germany

Accumulator gas charged

diaphragm type

MS-2.0-0000

M1.0-0000-00027M-1.0-0000-0002727

Page 42

HYDRAULICS

Pressure switch

Double-acting cylinder;

unequal area

Double-acting cylinder;

equal area

Single-acting cylinder

with spring returned

(rod end vented)

Single-acting cylinder

ram type

Manual actuator

Spring, (bias to normal deenergised position)

Solenoid single coil or winding

Hydraulic pilot operated

Single-acting cylinder,

with cushion

Assembly housing,

manifold block

Manual lever actuator

Solenoid valve, pilot operated

Dual solenoid

Proportional solenoid

Pilot check valve (pilot to open)

M3560

MS-2.0-0000

M1.0-0000-00028M-1.0-0000-0002828

WF3000 09/2005 • Printed in Germany

Page 43

HYDRAULICS

Throttle, fixed

Throttle, adjustable

Pressure-compensated

flow control, fixed

Pressure-compensated

flow control with reverse

flow bypass; fixed.

Shuttle valve

Single counterbalance valve

assembly in manifold

Flow divider/combiner

Velocity fuse

Relief valve, fixed setting

Relief valve, adjustable

Check valve

Bypass flow control

with controlled flow,

pressure-regulated

Shut-off valve, manual

P

T

T

P

L

R

Torque generator

Hydraulic steer unit

M3561

WF3000 09/2005 • Printed in Germany

MS-2.0-0000

M1.0-0000-00029M-1.0-0000-0002929

Page 44

HYDRAULICS

2/2 way valve

(two way, two switch positions)

3/2 way valve

(three way, two switch positions)

4/2 way valve

(four way, two switch positions)

Valve block with

3 operating units

4/3 way valve

(four way, two switch positions)

4/3 way valve

(four way, two switch positions);

manual activation and spring centered

3/2 way valve

(three way, two switch positions);

Spring bias solenoid control

M3562

MS-2.0-0000

M1.0-0000-00030M-1.0-0000-0003030

WF3000 09/2005 • Printed in Germany

Page 45

HYDRAULICS

Hydraulics

Hydraulic Reservoir Capacity

The hydraulic reservoir has a capacity of 5.4 litres up to

the max. oil le vel mark. The marking on the hydraulic reservoir serves to indicate the maximum capacity. When

checking the hydr aulic oil lev el, mak e sure that the cylinders are fully retracted and that the entire hydraulic system is fully bled.

Only start the truck once the reservoir has been filled

with the approved hydraulic oil up to the maximum level.

For the correct grade, ref er to the lubricant table in Chapter 1.

The hydraulic oil is filled up to the marking on the hydraulic reservoir. The oil le vel should not de viate by more

than +/-3 mm from this level.

Changing the Hydraulic oil and Hydraulic Filter

WARNING

De-pressurise all components before

carrying out maintenance work on the

hydraulic system.

High pressure hydraulic oil can cause

serious injuries.

Whenever a high pressure fluid enters

the skin it must be treated as an emergency, even if the skin initially shows no

reaction.

Physical effects may take time to set in.

Secure all connections before re-apply-

ing system pressure. Keep hands and

body away from any ports as high pressure hydraulic oil can emerge.

MS-3300-001

Use absorbent paper to trace leaks,

never use your hands!

● Fully lower the forks. Retract the mast fully.

● Turn the key switch OFF. Remove the key. Dis-

connect the battery.

● Attach a warning tag to the control handle to

advise others that the truck is being serviced.

● Chock the drive wheel and load wheels.

● Remove the front cover from the drive unit to

access the hydraulic reservoir.

● Remove the knuckle cover and the two-part

centre cover of the control handle. Rotate the

control handle 90° (towards the hydraulic reservoir). This will give you better access to the

hydraulic system components.

● Undo the retaining strap which secures the motor

to the chassis. Push the strap up to loosen it from

the chassis.

WF3000 09/2005 • Printed in Germany MS-2.1-3300

31

Page 46

HYDRAULICS

● Separate the hydraulic lines from the hydraulic

pump. Seal the hydraulic ports immediately to

minimize oil loss and prevent hydraulic system

contamination.

● Disconnect all electrical wiring from the hydraulic

unit. Insulate the wire ends to prevent sparking.

Tag out the wire ends and motor ter minals to

avoid any confusion when you later connect the

wires.

● The reservoir and motor/pump assembly can now

be moved. Carefully raise the reservoir and pull it

forward as far as possible. Remove the reservoir

and the motor/pump assembly from the drive unit

frame.

● Remove the screw from the clamp securing the

motor/pump assembly to the reservoir flange.

Open the clamp until it drops off the flange and

rests on the top of the reservoir.

● Lift the motor/pump assembly from the reservoir.

● Remove the oil from the reservoir and any re-

mains that have built up in the reservoir. Observe

local disposal regulations.

● Fill the reservoir up to the full mark via a filter (at

least 10 micron) using the correct hydraulic oil

grade according to the operating conditions of the

truck (see Chapter 1, Lubricant table).

● Refit the covers of the control handle, and tighten

the mounting screws firmly.

● Refit the front cover of the drive unit, and tighten

the mounting screws firmly.

● Remove the wedge.

● Connect the battery and remove the warning tag

from the control handle.

● Bleed the hydraulic system (see Chapter 8,

Cylinder Bleeding and Flushing).

● Remove the retaining ring of the strainer in the

filter housing of the suction line below the pump.

Replace the filter. Refit the strainer in the filter

housing of the suction line. Attach the strainer

and the retaining ring.

● Fit the motor/pump assembly onto the reservoir.

Centre the pump flange with the flange on the

reservoir.

● Refit the clamp and tighten the mounting screw

firmly.

● Fit the reservoir and the motor/pump assembly in

the drive unit frame.

● Connect the power cables to the pump motor and

tighten the connections securely.

● Reconnect the hydraulic supply lines and the

electrical connections. Tighten the connections

firmly.

● Make sure that the reservoir and motor/pump

assembly are against the frame. Now tighten the

holding strap to secure the motor/pump assembly

to the drive unit frame.

32

WF3000 09/2005 • Printed in GermanyMS-2.1-3300

Page 47

HYDRAULICS

Hydraulic system

Function

Lifting (see diagram)

If the “Raise” switch is pressed down on the control handle, the pump motor is energised and starts to drive the

pump. The pump initially draws oil from the reservoir via

the suction filter, directing it through the internal check

valve and the proportional valve which opens briefly, and

back to the oil reservoir. While the propor tional valve is

fully closed, the operating pressure builds up on the lift

cylinder (soft lift). A relief valve in the circuit keeps the

pressure to the maximum permissible limit.

1 Suction filter

2 Reservoir ventilation

3 Check valve (CV)

4 Overload valve (RV)

5 Cylinder shutoff valve (SVCL)

6 Proportional valve (PV)

7 Pump & motor

8 Line break safety device (LH lift cylinder, opposite

the fork direction)

9 Free lift cylinder line break safety device

10 Reservoir

11 Flow restrictor

12 Line break safety device (RH lift cylinder, opposite

the fork direction)

12

A

Suction line

Pressure line

NT mast

Lift - Hydraulics

TL mast

Lift - Hydraulics

8

A

12

SVCL

M

9

5 3

CV

TF mast

Lift - Hydraulics

8

A

6

PV

11

4

RV

230 bar

A

2

8

WF3000 09/2005 • Printed in Germany MS-2.1-3300

7 1 10

M3435a

33

Page 48

HYDRAULICS

Lowering (see diagram)

If one of the two “Lower” switches (LOS1 or LOS2) is

pressed down on the control handle, the shutoff valve

opens. At the same time the proportional valve opens

according to whether LOS1 or LOS2 has switched fully

or partially. The hydraulic oil can now flow from the

cylinder(s) via the flow restrictor back to the oil reservoir.

If the proportional valve is partially open, lowering is slow.

If the proportional valve is fully open, lowering is fast.

TL mast

Lift - Hydraulics

1 Suction filter

2 Reservoir ventilation

3 Check valve (CV)

4 Overload valve (RV)

5 Cylinder shutoff valve (SVCL)

6 Proportional valve (PV)

7 Pump & motor

8 Line break safety device (LH lift cylinder, opposite

the fork direction)

9 Free lift cylinder line break safety device

10 Reservoir

11 Flow restrictor

12 Line break safety device (RH lift cylinder, opposite

the fork direction)

12

TF mast

Lift - Hydraulics

A

Return

NT mast

Lift - Hydraulics

A

9

12

8

A

8

5 3 6

A

PV

SVCL

CV

RV

M

SX: 205 bar

ST: 175 bar

8

11

4

2

34

7 1 10

M3565a

WF3000 09/2005 • Printed in GermanyMS-2.1-3300

Page 49

HYDRAULICS

MOTOR AND PUMP ASSEMBLY

Hydraulic Lines and Fittings

WARNING

De-pressurise all components before

carrying out maintenance work on the

hydraulic system. High pressure hydraulic oil can cause serious injuries.

Whenever a high pressure fluid enters

the skin it must be treated as an emergency, even if the skin initially shows no

reaction.

Physical effects may take time to set in.

Secure all connections before re-apply-

ing system pressure. Keep hands and

body away from any ports as high pressure hydraulic oil can emerge.

Use absorbent paper to trace leaks,

never use your hands!

General Rules for Hydraulic Lines and Connections

● Apply pressurised air to all hoses and lines

before assembling them, to remove any loose

particles. Bent steel or plastic lines will be permanently damaged. These must be replaced even if

the damage is not externally visible.

● Any hose which bends during operation in its

normal assembly position must also be replaced.

Drift Test

Whenever work has been performed on hydraulic components a drift test must be carried out to ensure that

certain system components are working correctly. The

procedure for doing this can be f ound in Chapter 8 under

“Drift T est”.

Proportional function:

Whenever maintenance work has been perf ormed on the

hydraulic system.

Ensure that the load can start smoothly when the lift motor

is switched on and that the load can also brake smoothly

when lowering is switched off (subjective test).

The HCM (hydraulic control module) ma y have to be calibrated (see Electrics chapter).

REMOVAL

WARNING

De-pressurise all components before

carrying out maintenance work on the

hydraulic system.

High pressure hydraulic oil can cause

serious injuries.

Whenever a high pressure fluid enters

the skin it must be treated as an emergency, even if the skin initially shows no

reaction.

Physical effects may take time to set in.

● All hoses and lines must have sufficient clearance from other surfaces or edges that could

result in wear or cuts or where the hoses or lines

could get caught.

● All connections must be tight and without leaks.

Bleeding the Hydraulic System

Whenever work has been performed on hydraulic components, the hydraulic system must be flushed and b led.

The procedure for doing this can be found in Chapter 8

under “Cylinder Bleeding and Flushing”.

WF3000 09/2005 • Printed in Germany MS-2.1-3300

Secure all connections before re-applying system pressure. Keep hands and

body away from any ports as high pressure hydraulic oil can emerge.

Use absorbent paper to trace leaks,

never use your hands!

● Fully lower the forks. Retract the mast fully.

● Turn the key switch OFF. Remove the key. Dis-

connect the battery.

35

Page 50

HYDRAULICS

● Attach a warning tag to the control handle to

advise others that the truck is being serviced.

● Chock the drive wheel and load wheels.

● Remove the front cover from the drive unit to

access the hydraulic components.

● Disconnect the power cables from the pump

motor. Insulate the wire ends to prevent sparking.

● Disconnect all the hydraulic supply lines and/or

electrical connections that obstruct you when

removing the motor/pump unit.

● Remove the strap (and where applicable the

spacer) which fixes the pump motor to the chassis. Undo the clamp that fixes the motor/pump

assembly to the reservoir.

● Remove the motor/pump assembly from the

reservoir and take it to a suitable work area for

further dismantling.

● Check the connections again for leaks once the

system has reached operating temperature.

MOTOR

Refer to Chapter 4, “Electrics”, for pump motor maintenance and repair instructions.

PUMP

The hydraulic pump cannot be serviced and can only be

replaced as a complete assembly. Before fitting a new

pump, make sure that the pump and all its h ydraulic components are clean. Install a new suction filter (see section on changing the hydraulic oil and filter).

After replacing the pump:

● Use clean, filtered hydraulic oil (at least 10

micron) to replenish the reservoir.

● Never run the pump without oil.

● Star t the installed pump unladen (pressure side

open) and leave it to pump hydraulic fluid for

max. 20 seconds. This will ensure the pump is

bled and that there is sufficient lubrication. Close

the pressure side again as soon as the oil

emerges without bubbles. Bleed the entire system (see Chapter 8, Cylinder Bleeding and

Flushing).

● If the oil is still foaming after approx. 20 seconds,

the system must be checked (see “Hydraulic

System Troubleshooting Table” on following

page).

36

WF3000 09/2005 • Printed in GermanyMS-2.1-3300

Page 51

Replacing the relief valve

● Remove the locking mechanism (4) and unscrew

the relief valve (3),

● Remove the O ring and the strainer from the

valve seat if they are still in there.

● Apply a thin coat of hydraulic oil to the new O ring

and place it in the valve seat with the strainer.

● Apply hydraulic oil to the relief valve, insert it into

the valve seat and tighten. Tap in the new locking

mechanism.

● Refit the hydraulic unit and adjust the relief valve.

Relief valve test and setting

The relief valve protects the hydraulic system and the

lifting mechanism from overloading.

HYDRAULICS

Repeat the test. Repeat the setting until the relief

●

valve opens within the tolerance range.

WARNING

Do not let the pump unit run unless it is

fixed to the chassis.

The amount of torque will twist the unit.

This can result in short circuits and

damage.

ledoM

0.1-0003FWt0,1gk001,1gk002,1

2.1-0003FWt2,1gk023,1gk024,1

● With the truck at operating temperature, raise a

detaR

yticapac

muminiM

daol

daol

H01_GB

test load on the forks that corresponds to 110%

of rated capacity (= minimum load). It should be

easy to raise the load.

● Now raise a test load that corresponds to 110%

of rated capacity + 100 kg (=maximum load). It

should not be possible to raise this load. (relief

valve opens).

3

2

1

MS1723-007

4

mumixaM