Crown WAVE 50 Series Maintenance Manual

MAINTENANCE MANUAL

WAVE 50 SERIES

Order Number: 812562-006

Revision: A • Printed in Germany

This master maintenance manual is subject to continual updates.

It is meant exclusively for businesses authorized by CROWN.

It is not permitted to pass on the contents or copies thereof to third parties.

CROWN Gabelstapler GmbH & Co. KG

– European Headquarter –

Moosacher Str. 52

80809 München

Germany

Phone +49 (0)89 93 00 2 – 0

Fax +49 (0)89 93 00 2 – 133

All rights reserved under international and Pan-American Copyright Agreement.

Copyright 2005

CROWN Equipment Corporation

TABLE OF CONTENTS

MA- SAFETY INSTRUCTIONS PAGE

General maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control of Hazardous Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 INTRODUCTION PAGE

®

WAVE

Lockout/Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operator instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Vehicle Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

®

WAVE

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hydraulic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lifting and blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Model number example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Vehicle data number example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Work Assist Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

M1- LUBRICATION & ADJUSTMENT PAGE

Maintenance program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubricants and maintenance products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Component Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Load Deck (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contactor Panel (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rear Chassis Cover (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Service Panel (5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MRC Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Platform/Mast third Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Steering Control Pod (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Traction Control Pod (9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mast Cap (10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Floorboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Standard Screws/Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Torque Chart – Standard Screws/Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Self Locking Screw/Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Torque Chart – Self Locking Screws/Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

WAVE 50 10/2005 • Printed in Germany

I

M2- HYDRAULIC SYSTEM PAGE

Hydraulic schematic symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Hydraulic Oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Manual Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Accumulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Hydraulic Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Lift Relief Valve Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Precharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Hydraulic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

M3- DRIVE UNIT PAGE

Drive Unit Gearbox Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Gearbox Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Drive Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Caster Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

M4- ELECTRICAL MAINTENANCE PAGE

Component Accessability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chassis (under load deck) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chassis (under platform) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Steering Control Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Traction Control Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Platform Floor Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

POT1 Steering Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

POT1 Steering Potentiometer Linkage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

POT2 Traction Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2135 mm (84 in) Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Control Cable Re-tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2995 mm (118 in) Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Control Cable Re-tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Keypad Programming Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Keypad Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Keypad Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Keypad Replacing Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Part of Platform Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Wiring Color Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

WAVE 50 10/2005 • Printed in Germany

II

System controller, CURTIS 1703 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Mini Fit Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Curtis Handset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Handset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Handset Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Program Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Faults Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Functions Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Programmer Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Controller Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Features and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Handheld Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Cloning Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Feature Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Controller Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Display Troubleshooting Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Handset Troubleshooting Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Service Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Hydraulic Interaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Static Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Platform Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Platform Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Tilt Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Contactor ED (Emergency Disconnect) 24 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Contact Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Coil Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Battery Discharge Indicator,

Lift Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Maintenance Free Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Charging Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Battery Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Traction Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Lift Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Current Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

WAVE 50 10/2005 • Printed in Germany

III

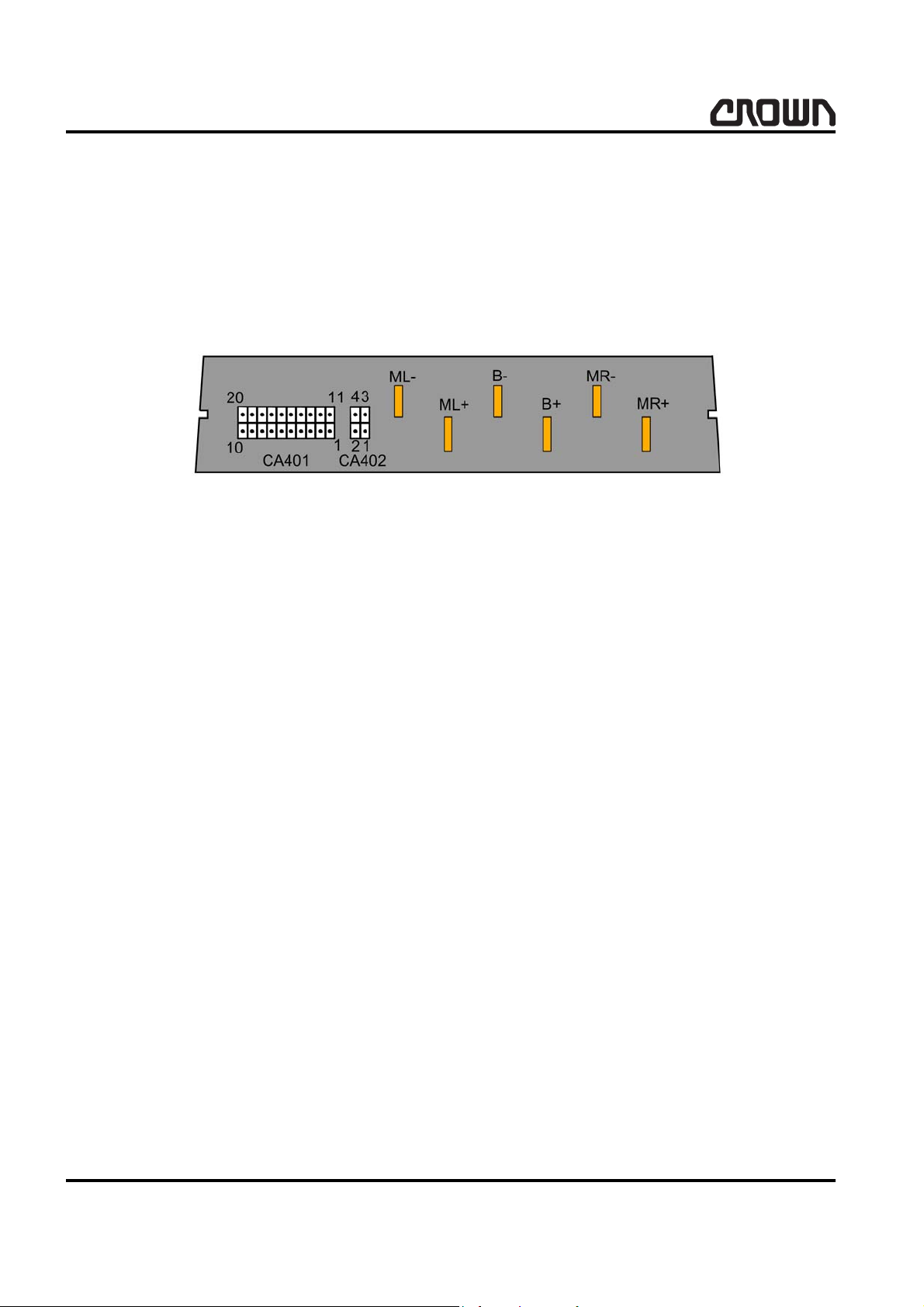

Service Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

M5- BRAKE MAINTENANCE PAGE

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Regenerative Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Parking Brake Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

M7- MAST MAINTENANCE PAGE

2135 mm (84 in) Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Mast Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Mast Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Mast Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Mast Reshimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Top Shims and Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Bottom Shims and Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2995 mm (118 in) Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Mast Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Mast Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Mast Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Mast Reshimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Top Shims and Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Bottom Shims and Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Lift Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Rust and Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Cracked Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Tight Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Protruding or Turned Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chain Side Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Lift Chain Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Lift Chain Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Lift Chain Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Secondary Chain Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Leaf Chain Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

M8- CYLINDER MAINTENANCE PAGE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Hydraulic Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Hydraulic Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Cylinder Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Velocity Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Cylinder Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Cylinder Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

WAVE 50 10/2005 • Printed in Germany

IV

M9- PLATFORM MAINTENANCE PAGE

Load Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Load Tray Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Load Tray Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

M10-GLOSSARY PAGE

Audible Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Contactors/Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Diode Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Suppressor Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

System/Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

DIA- ELECTRICAL DIAGRAMS PAGE

Diagrams (2135 mm, 84 in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Contactor Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Wire Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Diagrams (2995 mm, 118 in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Contactor Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Wire Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

WAVE 50 10/2005 • Printed in Germany

V

VI

WAVE 50 10/2005 • Printed in Germany

Printed in Germany

SAFETY INSTRUCTIONS

1

SAFETY INSTRUCTIONS

Notice:

Printed in Germany

2

SAFETY INSTRUCTIONS

General maintenance

General maintenance

Warning!

These vehicles may become hazardous if adequate

maintenance is neglected. Therefore, adequate maintenance facilities, trained personnel and procedures

should be provided.

Maintenance and inspection shall be performed in conformance with the following practices:

z A scheduled planned maintenance, lubrication and

inspection system should be followed.

z Only qualified and authorized personnel shall be

permitted to maintain, repair, adjust and inspect

vehicle.

z Before leaving the vehicle:

– Stop the vehicle.

– Fully lower the platform.

Risk of accident!

To prevent serious risk of injury

to yourself and others observe

the following safety instructions.

– Use chocks or other positive positioning de-

vices.

– Block load engaging means, inter masts or

chassis before working under them.

– Operation to check performance of vehicle or

attachments shall be conducted in an authorized safe clearance area.

z Before starting to operate the vehicle:

– Be in operating position.

– Place directional control in neutral.

– Before operating the vehicle, check the func-

tions of lift systems, directional control, speed

control, steering, warning devices and brakes.

Warning!

Fire hazard!

Fire or flame can cause severe

personal injury or property

damage.

Do not use an open flame to

check level or for leakage of

electrolyte and fluids or oil.

Do not use open pans of fuel or

flammable cleaning fluids for

cleaning parts.

– Place directional controls in neutral.

– Turn off power (Battery disconnect).

– Remove key.

– Block the wheels if vehicle is on an incline.

z Before working on the vehicle

– Raise drive wheels free of floor or disconnect

power sources.

z Avoid fire hazards and have fire protection equip-

ment present.

z Keep shop well ventilated, clean and dry.

z Brakes, steering mechanisms, control mecha-

nisms, guards and safety devices shall be inspected regularly and maintained in a safe operating condition.

WAVE 50 10/2005 • Printed in Germany

MA-2450

02 Rev. 12/01

3

SAFETY INSTRUCTIONS

General maintenance

z Capacity, operation and maintenance instruction

plates or decals shall be maintained in legible condition.

z All parts of lift mechanisms shall be inspected to

maintain them in safe operating condition.

z All hydraulic systems shall be regularly inspected

and maintained in conformance with good practice.

Cylinders, valves and other similar parts shall be

checked to assure that “drift” has not developed to

the extent that it would create a hazard.

z Batteries, motors, controllers, limit switches, pro-

tective devices, electrical conductors and connections shall be maintained in conformance with

good practice. Special attention shall be paid to the

condition of electrical insulation.

z Vehicles shall be kept in a clean condition to mini-

mize fire hazards and facilitate detection of loose

or defective parts.

z Modifications and additions which affect capacity

and safe vehicle operation shall not be performed

by the customer or user without manufacturers

prior written approval. Capacity, operation and

maintenance plates or decals shall be changed accordingly.

z Care shall be taken to assure that all replacement

parts are interchangeable with the original parts

and of equal quality to that provided in the original

equipment.

z Be sure that any equipment added to the truck (ter-

minal, fan, clipboard, etc.) is positioned so that it

does not block your vision or interfere with safe and

efficient operation of the truck.

MA-2450

4

WAVE 50 10/2005 • Printed in Germany

02 Rev. 12/01

SAFETY INSTRUCTIONS

Equipment Cleaning

Equipment Cleaning

WAVE® Vehicle Procedures

z Prefer dry pressured air for cleaning built up dirt

and dust from electric material handling equipment.

z For localized degreasing use of an appropriate sol-

vent such as "TOUGH ON GREASE" (Crown P/N

063009-005) is recommended.

If these methods are not effective and power washing

is the only alternative, extreme care must be exercised.

Caution!

Risk of damage!

Power washing or cleaning solvents can damage electrical

components including connectors, terminal boards and wiring.

Mineral and chemical residue

left on or in components (i.e. circuit boards, contactors, encoders, switches, potentiometers,

etc.) after washing is a proponent of oxidation and corrosion.

All electronic components including motors must be protected or even removed to eliminate the risk of damage.

Functional integrity of contaminated components may

be questionable. Nuisance fault logging, intermittent

operation or immediate failure could be the resultant of

power washing.

Power washing will also remove and/or destroy lubricants in or on the surface of shafts, unsealed bearings,

hinges, exposed gears, bushings, chains, linkages,

etc.

z These items must also be protected before clean-

ing or properly lubricated after cleaning.

Consideration must also be given to metal surfaces.

The cleaning process can strip away paint and protective coatings applied to components (i.e. hydraulic

lines, terminal strips, linkages) for freezer/corrosion environment.

z Paint and/or protective coating must be reapplied

to these areas to reduce the chance of oxidation

and corrosion.

z Remove solvent residue and dry the component

thoroughly before installing removed components,

lubricating or returning the equipment to service.

WAVE 50 10/2005 • Printed in Germany

MA-2450

5

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Control of Hazardous Energy

Lockout/Tagout

WAVE® Work Assist Vehicle

In the interest of safety and to ensure compliance with

the OSHA Regulations, (Standards - 29 CFR), The

control of hazardous energy (lockout/tagout) -

1910.147, Crown has developed guidelines for proper

energy control when performing service and maintenance on the WAVE.

z Review the appropriate sections in this service

manual for additional procedures to be followed,

before performing any service or maintenance on

the WAVE.

In addition, Crown recommends that all mechanics

wear appropriate protective items, such as safety

glasses, work gloves, and steel toed shoes, whenever

performing service or maintenance work on Crown

equipment.

Battery

z If electrolyte comes in contact with eyes, flush im-

mediately and thoroughly with clean water. Obtain

medical attention immediately.

z Should electrolyte be spilled on skin, rinse

promptly with clean water and wash with soap.

z A baking soda solution (one pound to one gallon of

water) will neutralize acid spilled on clothing, floor

or any other surface. Apply solution until bubbling

stops and rinse with clean water.

z Keep vent plugs firmly in place at all times except

when adding water or taking hydrometer readings.

Danger!

This gas remains in the battery cells long after charging

has stopped.

Risk of explosion!

Gas formed during charging is

highly explosive and can cause

serious personal injury. There

also may be a danger of release

of harmful substances.

Never smoke or bring flame

near the battery.

Safety rules

Warning!

Risk of injury!

Electrolyte contained in batteries can cause severe personal

injury or property damage if

coming in contact with eyes,

skin, clothing or floor

Avoid any contact of electrolyte

with eyes or skin

Wear protective clothing, such

as, rubber apron, gloves, boots

and full face shield when performing any maintenance on

batteries

Warning!

z Do not allow dirt, cleaning solution or other foreign

material to enter cells. Impurities in electrolyte has

a neutralizing effect reducing available charge.

z If battery repair is planned, follow the battery man-

ufacturer's instructions concerning repair practices

and procedures.

Risk of arcing!

Do not lay metallic or conductive objects on battery. Otherwise arcing will result and

cause property damage.

MA-2450

6

WAVE 50 10/2005 • Printed in Germany

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Charging

Warning!

z Make certain the charger being used matches the

voltage and amperage of the truck battery. This

voltage is listed on the truck serial plate.

Caution!

Danger!

Risk of property damage!

NEVER operate truck with an

undersized battery, otherwise

the truck can be seriously damaged.

Make certain battery used

meets weight, size and voltage

requirements of truck (refer to

serial plate).

Risk of injury!

Unauthorised component removal or improper maintenance

can result in significant danger

to the user.

Only qualified and experienced

personnel should perform

maintenance and repair on batteries.

Risk of accident!

Current flowing between battery

and charger can cause shock

hazard and result in serious injury to you, the battery and

charger.

NEVER connect or disconnect

batteries to a charger while the

charger is “ON”.

Make sure the charger is “OFF”

before disconnecting or connecting batteries.

Caution!

Warning!

Never use a match or lighter. Battery fumes are explosive.

z Consult the charger manufacturer’s manual cover-

ing your charger for hints on operation and maintenance.

Risk of injury!

Unauthorised component removal or improper maintenance

can result in significant danger

to the user.

Only qualified and experienced

personnel should perform

maintenance and repair on batteries.

Risk of explosion!

Gas formed during charging is

highly explosive and can cause

serious personal injury. There

also may be a danger of release

of harmful substances.

Never smoke or bring flame

near the battery.

z Make certain battery used meets weight, size and

voltage requirements of truck (refer to serial plate).

NEVER operate truck with an undersized battery.

WAVE 50 10/2005 • Printed in Germany

MA-2450

7

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Battery removal

Caution!

When removing a battery, move truck to area intended

for battery care. Floor must be level.

Turn keyswitch or toggle switch to "off" position and remove key. Disconnect battery and lockout or tagout

truck as described in Battery - Lockout/Tagout in this

section. Lower load engaging means completely.

Risk of short-circuit!

Do not allow any metallic object

to come in contact with the top

of the battery cells. This may

cause a short circuit when removing, transporting a battery.

Use an insulator (such as plywood, plastic caps) to cover the

top of battery posts before and

during removal.

Battery installation

Warning!

Caution!

Risk of injury!

A non-stable or rolling truck

may cause injury to you or others.

When installing a battery, move

truck to area intended for battery care.

Floor must be level.

Turn keyswitch or toggle switch

to "off" position and remove

key.

Risk of short-circuit!

Do not allow any metallic object

to come in contact with the top

of the battery cells. This may

cause a short circuit when removing, transporting a battery.

Use an insulator (such as plywood, plastic caps) to cover the

top of battery posts before and

during removal.

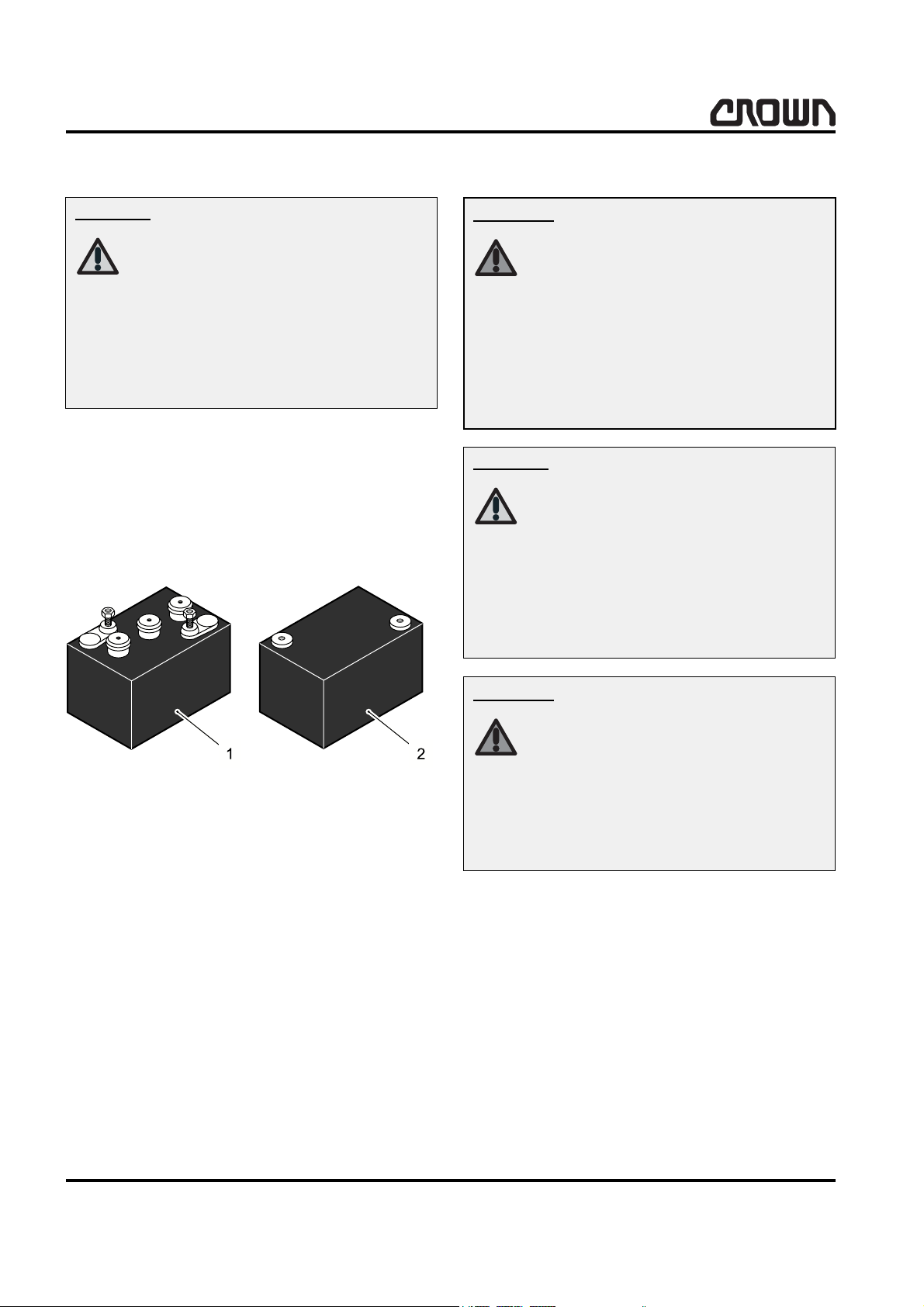

1 Wet cell battery

2 Maintenance free battery

12024

Warning!

z Lockout or tagout truck as described in Battery -

Lockout/Tagout in this section.

Risk of property damage!

NEVER operate truck with an

undersized battery, otherwise

the truck can be seriously damaged.

Make certain battery used

meets weight, size and voltage

requirements of truck (refer to

serial plate).

MA-2450

8

WAVE 50 10/2005 • Printed in Germany

SAFETY INSTRUCTIONS

Control of Hazardous Energy

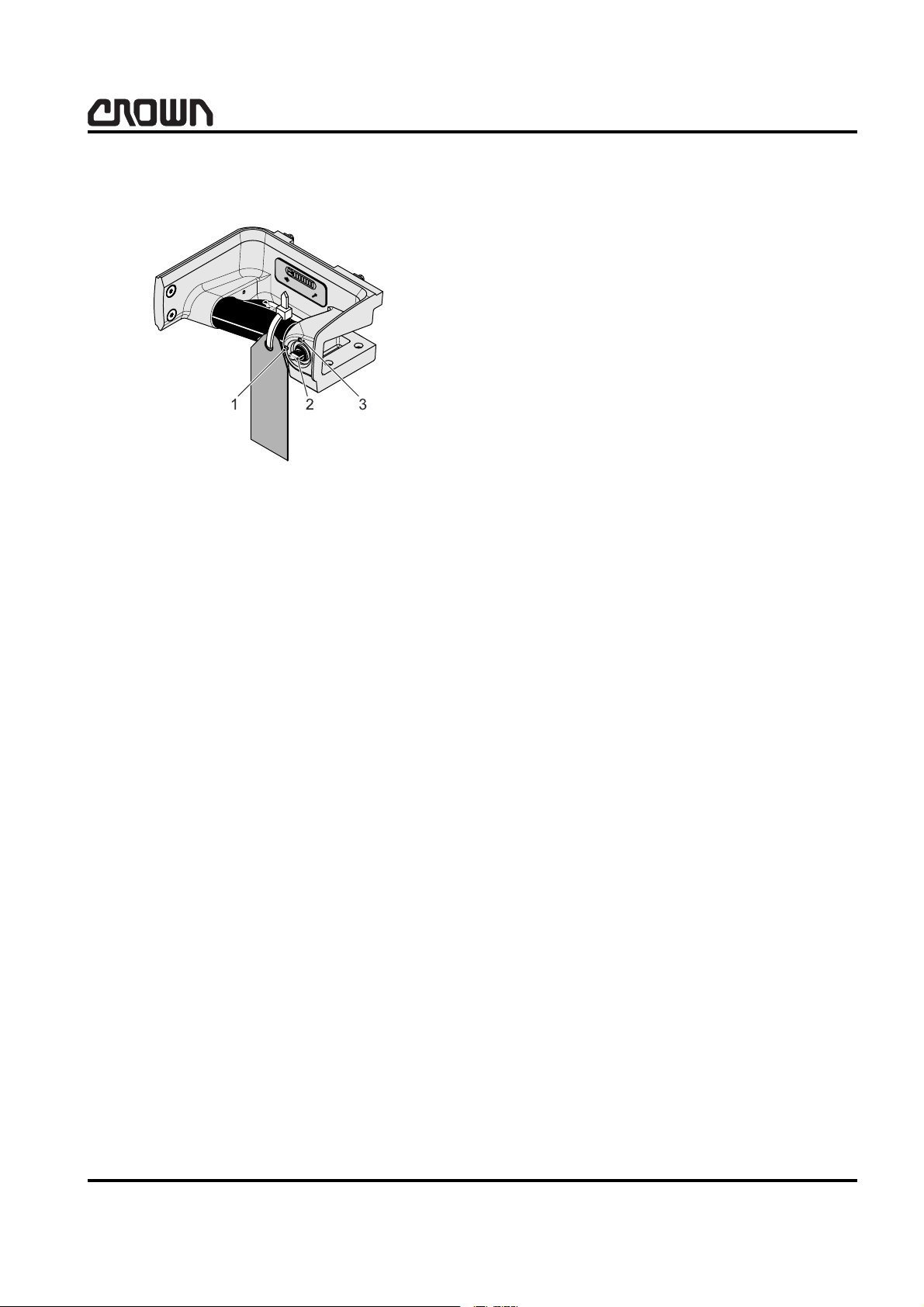

Battery Lockout/Tagout

1 Key switch, OFF

2Key

3 Key switch, ON

When maintenance is performed and the batteries are

removed from the truck:

z remove the main power fuses,

z install a lockout device on the trucks battery con-

nector if possible,

z or if possible install a tag with a cable tie on the

trucks battery connector so it cannot be removed

!

53

easily warning that the truck is not available for operation.

MS-2450-002

z Always turn key (2) switch to "off" (1), remove key

(2) and apply tag to steering pod with cable tie

warning others truck is being serviced.

When maintenance is performed and the batteries are

left in the truck:

z disconnect batteries,

z remove the main power fuses and

z install a commercially available lockout device on

battery connector.

WAVE 50 10/2005 • Printed in Germany

MA-2450

9

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Hydraulic

Danger!

Any fluid injected into the skin under high pressure

should be considered as a serious medical emergency

despite an initial normal appearance of the skin. There

is a delayed onset of pain, and serious tissue damage

may occur. Medical attention should be sought immediately by a specialist who has had experience with this

type of injury.

Risk of accident: high pressure

fluid!

Escaping fluid under pressure

can penetrate the skin causing

serious injury.

Relieve pressure before disconnecting hydraulic lines.

Tighten all connections before

applying pressure.

Keep hands and body away

from pin holes which eject fluids under high pressure.

Use a piece of cardboard or paper to search for leaks.

Do not use your hand.

When maintenance is to be performed on the hydraulic

system, make sure the hydraulic system is not under

pressure:

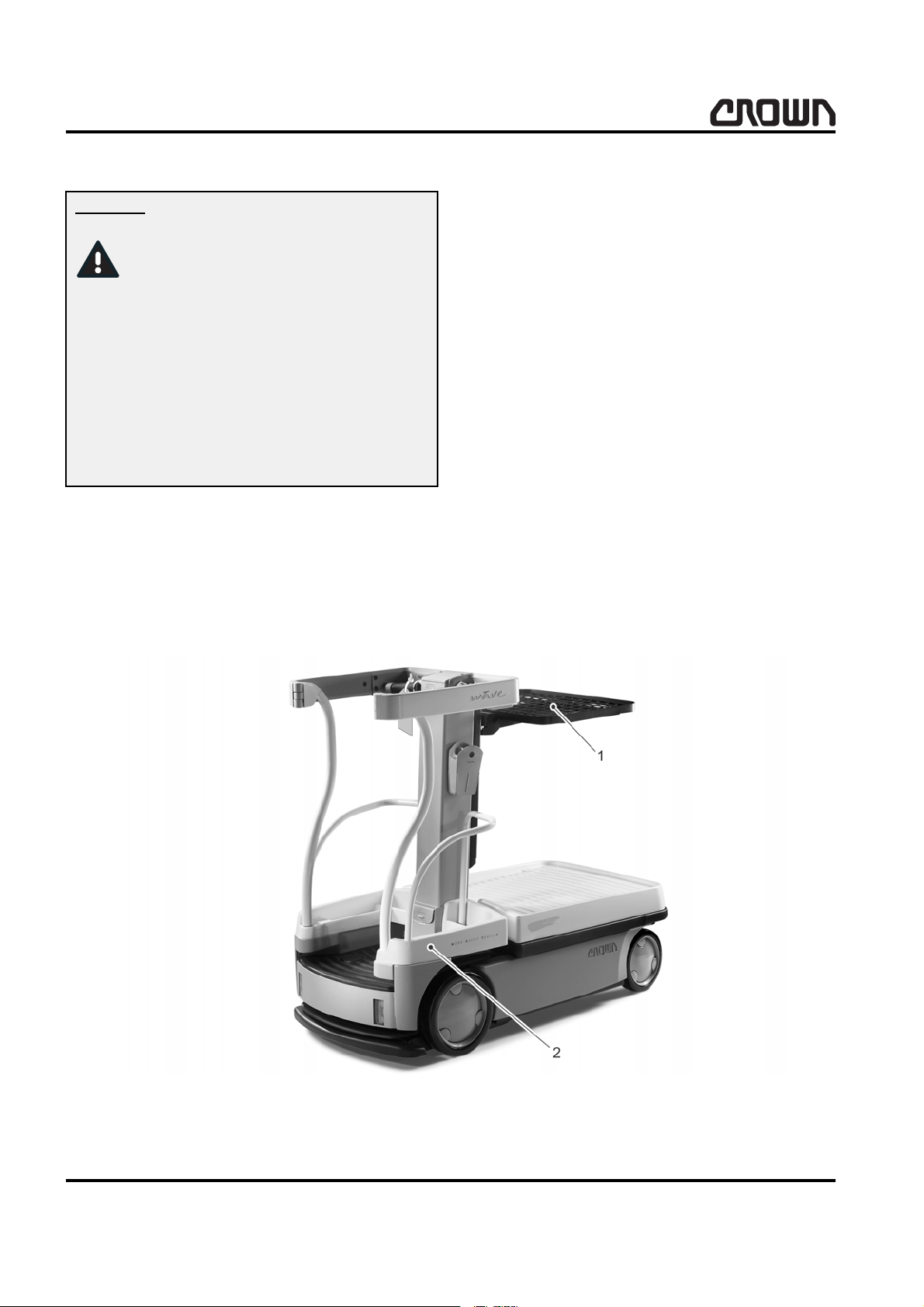

z Move truck to a secure non traffic maintenance

area with a level floor.

z No load on load tray (1).

z Completely lower load engaging means or, if re-

quired for maintenance, block truck at appropriate

height as described in Lifting and blocking,

page 11.

z Actuate the hydraulic switch to remove any hy-

draulic pressure that may be present.

z Lockout or tagout truck as described in Battery

Lockout/Tagout in this section.

1 Load tray 2 Platform

MA-2450

10

MS-2450-003

WAVE 50 10/2005 • Printed in Germany

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Lifting and blocking

z Move vehicle to a secure non traffic maintenance

area with a level floor.

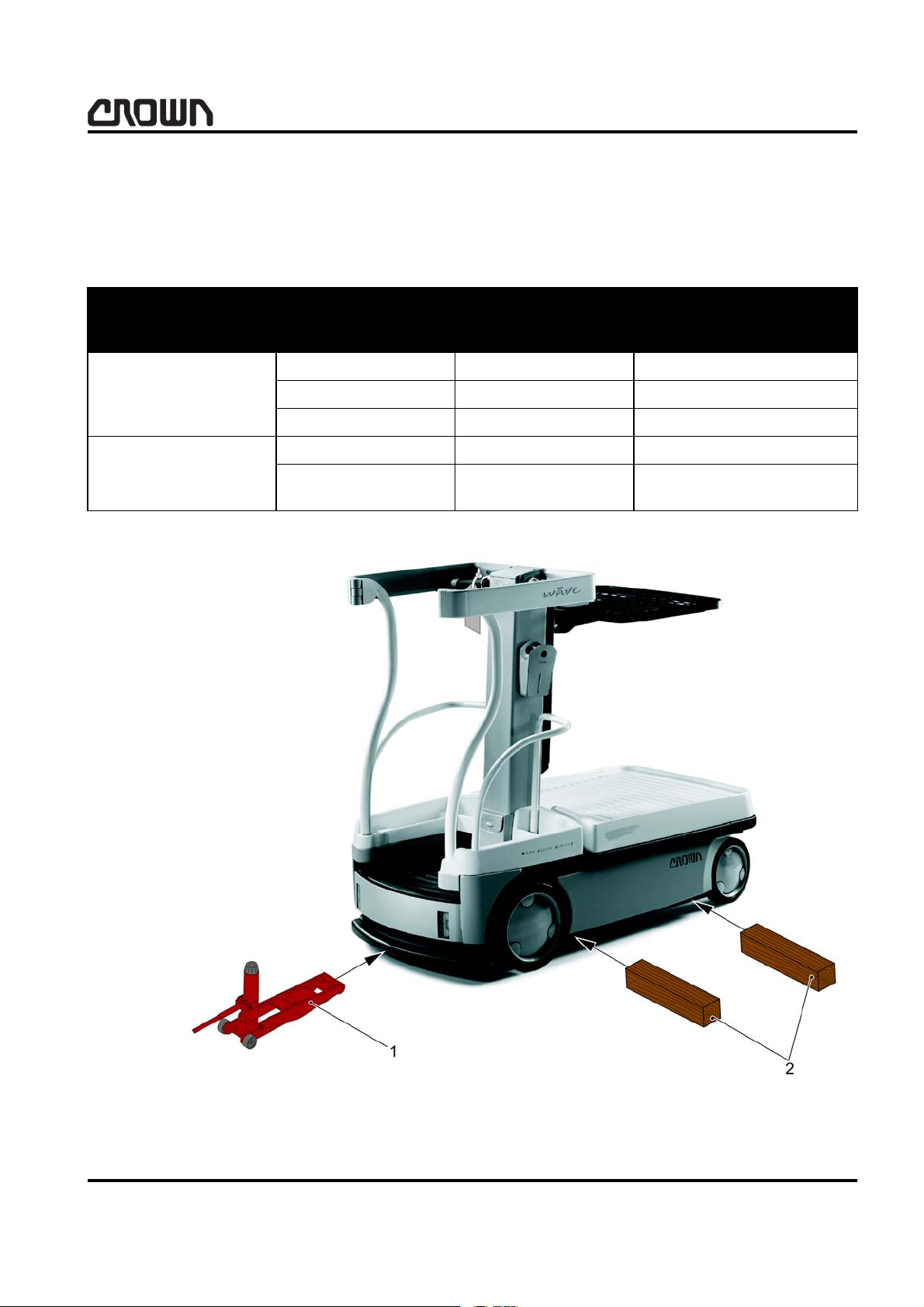

Tool Properties Value Crown Part

Capacity: 3620 kg (8000 lb) 122599

Hydraulik Jack

Hardwood blocks

Collapsed height (min.): 60 mm (2.25 in)

Raised height maximum: 400 mm (16 in)

Quantity 2

Dimensions: 100 x 100 x 762 mm

z No load on load tray.

z Lower platform completely.

z Lockout or tagout vehicle as described in Battery -

Lockout/Tagout in this section.

number

(4 x 4 x 30 in)

1 Hydraulic jack 2 Hardwood block

WAVE 50 10/2005 • Printed in Germany

12027

MA-2450

11

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Mast

&

)

)

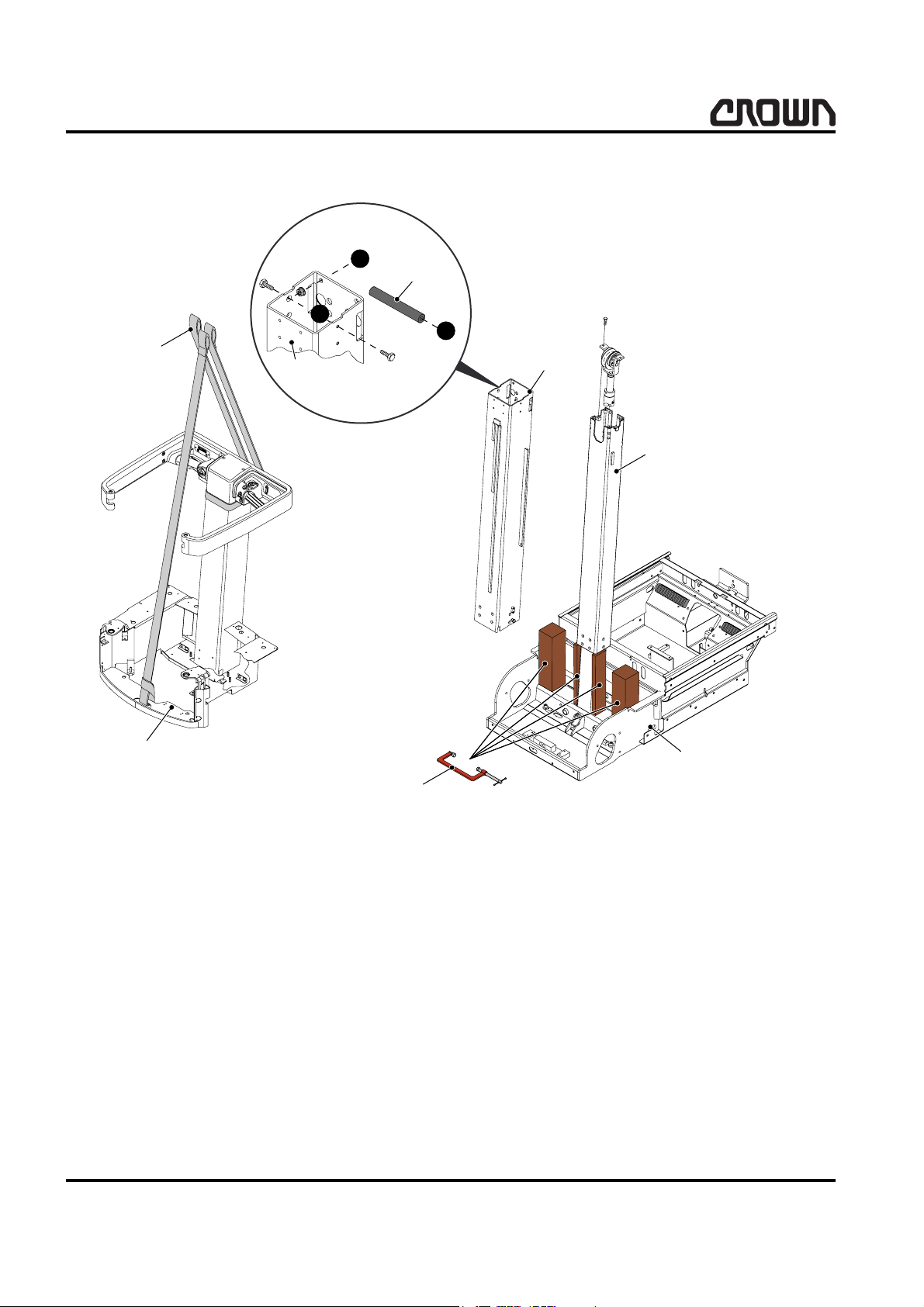

1 Straps 6 Second Stage Mast

2Platform 7Chassis

3 Third Stage Mast 8 Hardwood Block

4 Part of Third Stage Mast 9 Clamping Tool

5 Lifting Tool

2YHUKHDG9LHZ

/HIW

5HDU

)URQW

5LJKW

12028

MA-2450

12

WAVE 50 10/2005 • Printed in Germany

SAFETY INSTRUCTIONS

Control of Hazardous Energy

z Move vehicle to a secure non traffic maintenance

area with a level floor.

z Raise platform (2) to height necessary.

z Block the second stage mast (6) and platform (2)

using the appropriate length and size hardwood

blocks (8).

Tool Dimensions

100 x 100 mm [4 x 4 in]

Hardwood blocks

50 x 100 mm [2 x 4 in])

z Clamp hardwood blocks (8) to chassis (7), lower

platform (2).

z Disconnect electrical and chain connections nec-

essary to remove platform (2), third stage mast (3)

and second stage mast (6).

z Remove guides and shims necessary to remove

platform (2), third stage mast (3) and second stage

mast (6).

z Insert lifting tool (5) into top of third stage mast (3)

to assist in removing third stage mast (3).

z Lockout or tagout vehicle as described in Battery -

Lockout/Tagout in this section.

WAVE 50 10/2005 • Printed in Germany

MA-2450

13

SAFETY INSTRUCTIONS

Control of Hazardous Energy

Capacitance

Capacitance voltage is present in the traction motor

controller. When performing maintenance which may

permit contact with the bus bars and associated power

cables, discharge the capacitors.

z Move truck to a secure non traffic maintenance

area with a level floor.

z Lockout or tagout truck as described in Battery -

Lockout/Tagout in this section.

z Place a minimum 100

B+ and B- terminals of the controller for three or

more seconds.

Ω, 2 W resistor between the

12033

MA-245015Printed in Germany

14

WAVE 50 10/2005 • Printed in Germany

INTRODUCTION

INTRODUCTION

Notice:

16

Printed in Germany

INTRODUCTION

This manual is intended for the service mechanic who

is seeking information about maintenance.

It contains a section on troubleshooting which will enable a qualified mechanic to locate and solve problems

which may occur.

Operator instructions

Information

This manual does not contain

operator instructions. Operator

instructions in booklet form are

sent with each vehicle.

Additional copies can be ordered if required. These

booklets are for you and your personnel to insure years

of safe, trouble free operation.

Service training

Complete Service Training is available to the mechanic

upon request.

Choice of dash number depends on language. When

ordering, refer to chart below and complete the part

number the correct dash number

.

Dash

number

-001 German -004 Dutch

-002 French -005 Italian

-003 Spanish -006 English

This manual is arranged by major sections. The first

part of the Control Number, found in the footer of each

page, denotes the section in which a particular form will

be located. The section descriptions are as follows:

Section Description

M1 Lubrication and Adjustments

M2 Hydraulics

M3 Drive Unit

M4 Electrical

M5 Brake

Language Dash

number

Language

Publications

Copies of publications can be obtained from your

Crown Dealer:

Crown

Kronstadter Straße 11

81677 München,

Deutschland

Phone: (089) 930 02 – 0,

Fax: (089) 930 02 – 133, crown.com

or from

A Division of Crown Equipment Pty Ltd.

Long & Cooper Streets

Smithfield, N.S.W. 2164

Sydney, Australia

Phone: (61) 29 604 6000

Fax: (61) 29 609 2787

crown.com

M6 Not Used

M7 Mast

M8 Cylinder

M9 Platform

M10 Glossary

DIA Wiring Diagrams

WAVE 50 10/2005 • Printed in Germany

22450

02 Rev. 10/04

17

INTRODUCTION

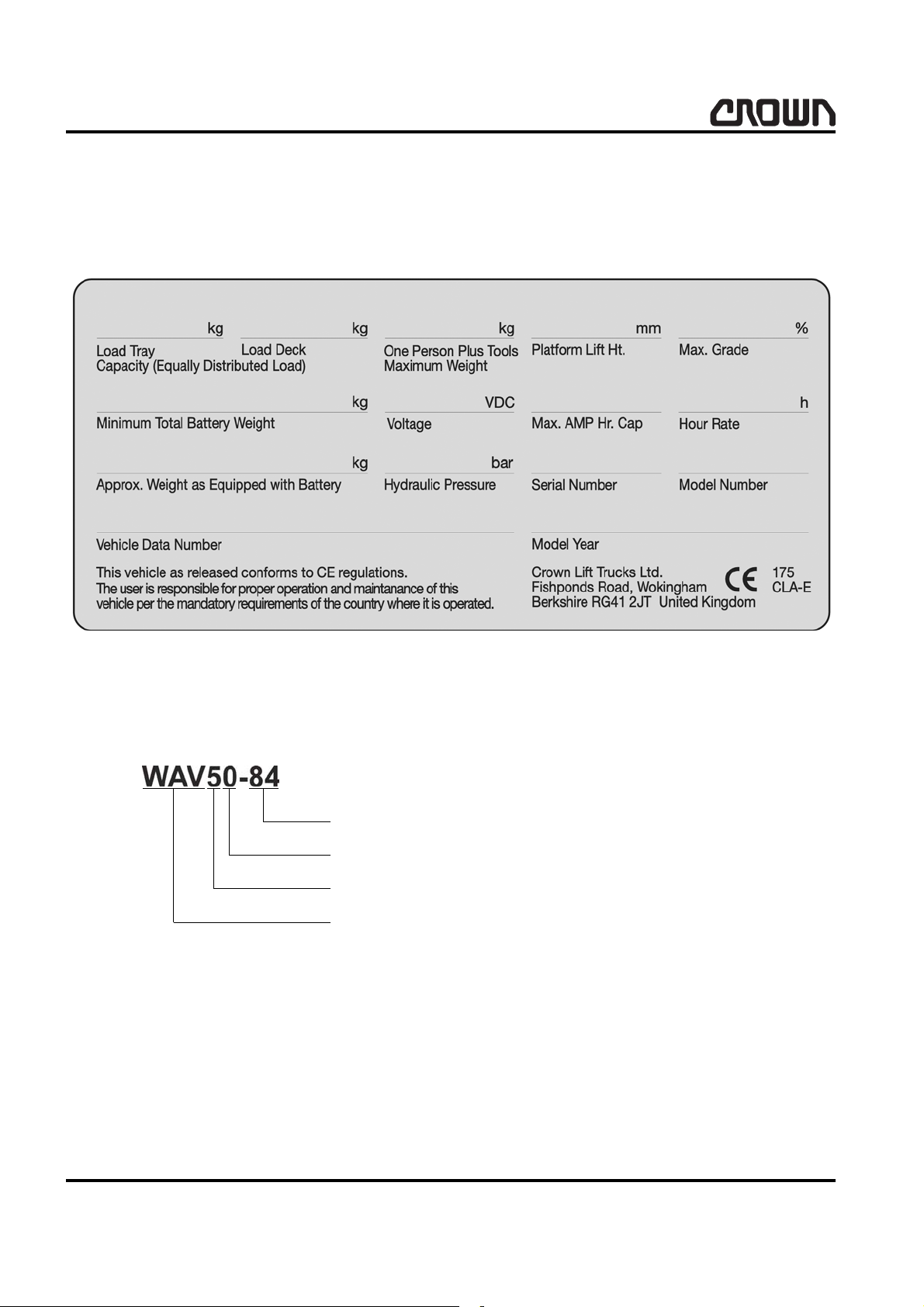

Data plate

The data plate is located on the lower rear section of

the third stage mast in the operator compartment and

includes a model number and a vehicle data number.

From these two numbers the vehicle model, series, series updates, vehicle size and specific vehicle data can

be determined. The following will explain the model

and vehicle data numbering system.

Model number example

MS-2450-006

6982-01

1 Image generator – Work Assist Vehicle

2 Series update: Significant change(s) to the product that

would not merit a new series number (generation)

3 Version: Characteristic that distinguishes vehicle from other

versions

4 Lift height: 2135 mm (84 in) or 2995 mm (118 in)

22450

18

WAVE 50 10/2005 • Printed in Germany

02 Rev. 10/04

INTRODUCTION

Vehicle data number example

The vehicle data number provides you and your dealer

with a wealth of information to ensure the selection of

proper parts for your vehicle.

You may simply provide this number to your dealer, or

use the following breakdown if selecting your own part

numbers or service information from this manual.

1 Work Assist Vehicle 9 Wheel Color

2 Issue 10 Alarms

3 Truck Version 11 Meter

4 Lift height 12 Strobe

5 Vehicle 13 Storage

6 Batteries 14 Aisle Guide

7 Battery Charger 15 System Controller

8 Color 16 Language Code

MS-2450-007

WAVE 50 10/2005 • Printed in Germany

22450

02 Rev. 10/04

19

INTRODUCTION

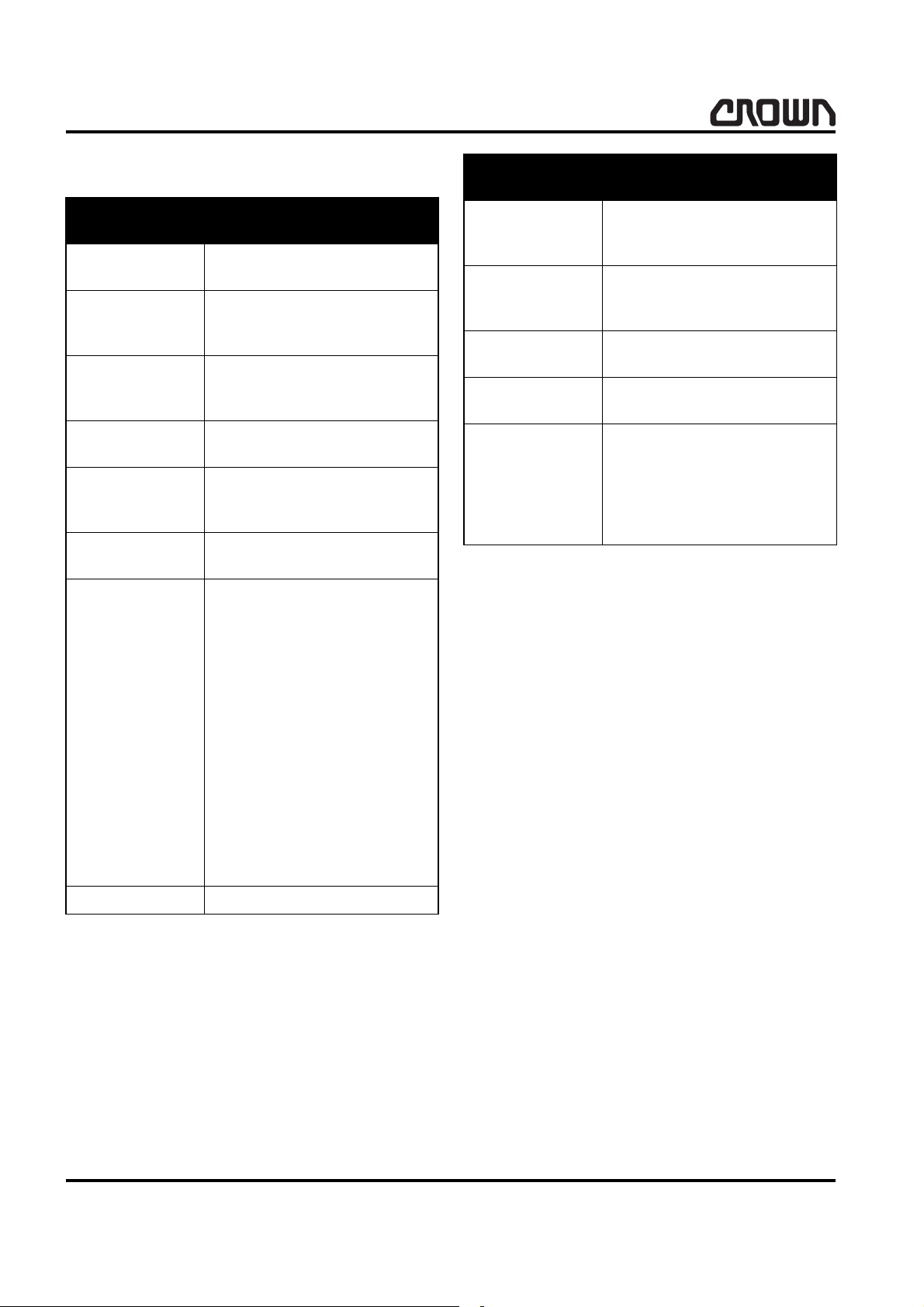

Data number information

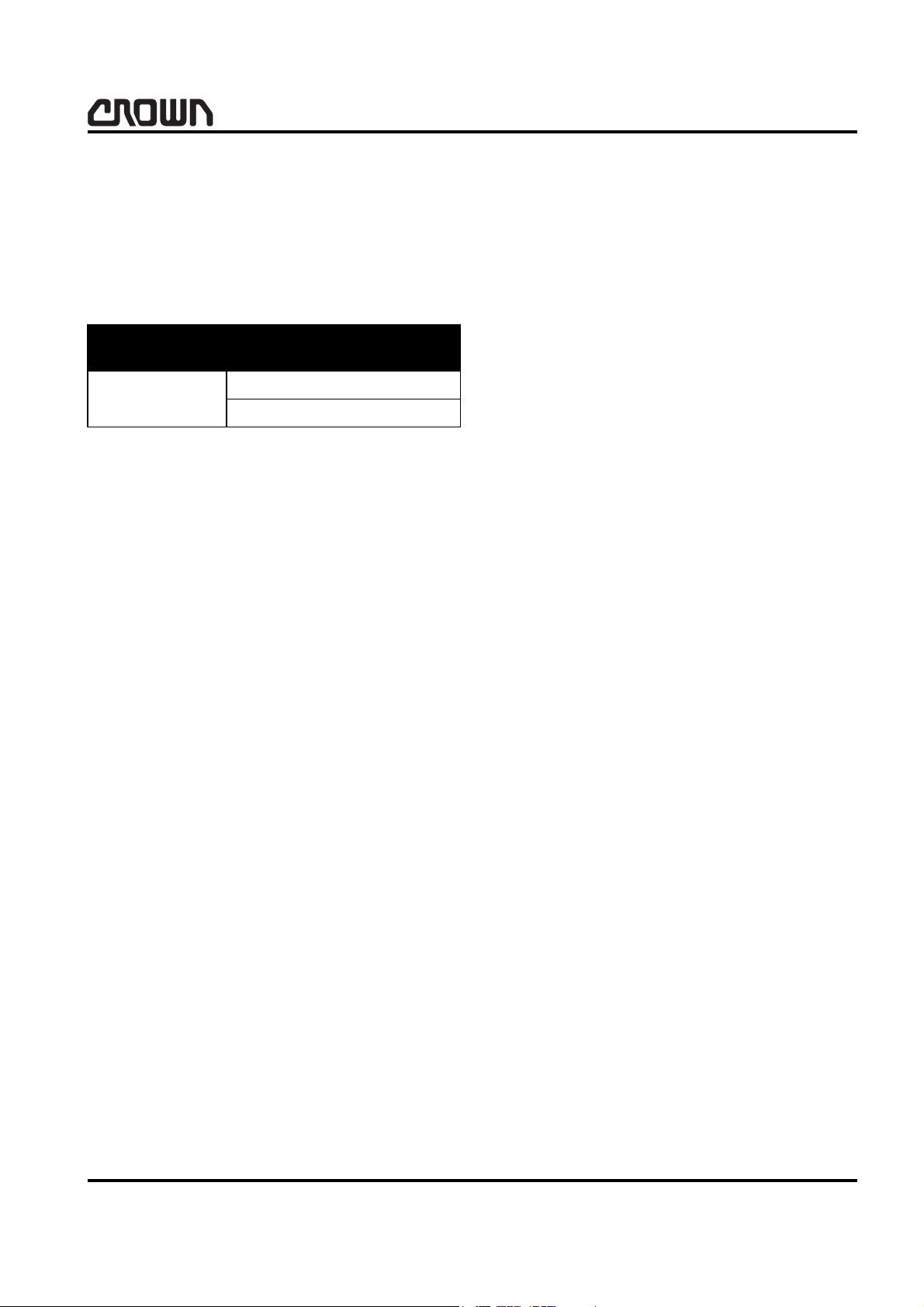

Information Meaning

Information Meaning

Lift height

Vehicle

Batteries

Battery Charger

Color

Wheel Color

Alarm

84 = 2135mm (84 in)

118 = 2995mm (118 in)

– = Standard

C = Custom

S = Special

1 = Wet 160 A

2 = Wet 205

3 = Maintenance Free 195 A

1 = 15 A

2 = 25 A

1 = Maui Yellow

2 = Seafoam Green

3 = Alpine White

1 = Yellow

2 = Black

A = Forward

B = Reverse

C = Lift

D = Lower

E = Forward Reverse

F = Forward Lift

H = Forward Lower

I = Reverse Lift

J = Reverse Lower

K = Lift Lower

L = Forward Reverse Lift

M = Forward Reverse Lower

N = Reverse Lift Lower

O = Forward Lift Lower

P = Forward Reverse Lift, Lower

Q = None

Strobe

Storage

Aisle Guide

System Controller

Language code

– = No Strobe

1 = Strobe

– = No Storage

1 = One Pocket

2 = Two Pockets

-- = No Guidance

35 = Actual Width

– = No Handset

1 = Handset

A = French

B = German

C = British English

D = Spanish

E = Italian

F = Dutch

Meter HM = Hour Meter

22450

20

WAVE 50 10/2005 • Printed in Germany

02 Rev. 10/04

LUBRICATION & ADJUSTMENT

Printed in Germany

21

LUBRICATION & ADJUSTMENT

Notice:

22

Printed in Germany

Loading...

Loading...