Crown VRack12000HD User Manual

Operation Manual

Obtaining Other Language Versions: To obtain information in another language about the use of this product, please contact your local Crown Distributor. If you need

assistance locating your local distributor, please contact Crown at 574-294-8000.

This manual does not include all of the details of design, production, or variations of the equipment; nor does it cover every possible situation which may arise during

installation, operation or maintenance.

The information provided in this manual was deemed accurate as of the publication date; however, updates to this information may have occurred. To obtain the latest

version of this manual, please visit the Crown website at www.crownaudio.com.

Trademark Notice: Crown, Crown Audio, IQ, BCA, and Amcron are registered trademarks of Crown International. HiQnet is a trademark of

Harman International Industries, Inc. Other trademarks are the property of their respective owners.

Some models may be exported under the name Amcron®.

©2011 by Harman International. 1718 W. Mishawaka Rd., Elkhart, Indiana 46517-9439 U.S.A. Telephone: 574-294-8000.

142483-1 - 5/11

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance with the

manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat registers,

stoves, or other apparatus (including amplifiers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type

plug. A polarized plug has two blades with one wider than the other.

A grounding-type plug has two blades and a third grounding prong.

The wide blade or the third prong is provided for your safety. If the

provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched, particularly

at plugs, convenience receptacles, and the point where they exit from

the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Use only with a cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid injury

from tip-over.

13. Unplug this apparatus during lightning storms or when unused for

long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required

when the apparatus has been damaged in any way, such as powersupply cord or plug is damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus has been exposed to rain

or moisture, does not operate normally, or has been dropped.

15. Use the mains plug to disconnect the apparatus from the mains.

16. WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO

NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

17. DO NOT EXPOSE THIS EQUIPMENT TO DRIPPING OR SPLASHING

AND ENSURE THAT NO OBJECTS FILLED WITH LIQUIDS, SUCH AS

VASES, ARE PLACED ON THE EQUIPMENT.

18. THE MAINS PLUG OF THE POWER SUPPLY CORD SHALL REMAIN

READILY OPERABLE.

TO PREVENT ELECTRIC SHOCK, DO NOT REMOVE TOP OR BOTTOM

COVERS. NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

TO COMPLETELY DISCONNECT THIS EQUIPMENT FROM THE

AC MAINS, DISCONNECT THE POWER SUPPLY CORD PLUG FROM THE

AC RECEPTACLE. THE MAINS PLUG OF THE POWER SUPPLY CORD

SHALL REMAIN READILY OPERABLE.

WATCH FOR THESE SYMBOLS:

The lightning bolt triangle is used to alert the user to the risk of electric

shock.

The exclamation point triangle is used to alert the user to important

operating or maintenance instructions.

IMPORTANT

VRacks require Class 2 output wiring.

MAGNETIC FIELD

CAUTION! Do not locate sensitive high-gain equipment such as

preamplifiers or tape decks directly above or below the unit. Because this

amplifier has a high power density, it has a strong magnetic field which can

induce hum into unshielded devices that are located nearby. The field is

strongest just above and below the unit.

If an equipment rack is used, we recommend locating the amplifier(s) in

the bottom of the rack and the preamplifier or other sensitive equipment at

the top.

FCC COMPLIANCE NOTICE

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

CAUTION: Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

page 2

Operation Manual

DECLARATION OF CONFORMITY

Issued By: Harman International.

1718 W. Mishawaka Rd.

Elkhart, IN 46517 U.S.A.

European Representative’s Name and Address:

David J. Budge

10 Harvest Close

Yateley, GU46 6YS

United Kingdom

Equipment Type: Commercial Audio Power Amplifiers

Family Name: ITECH-HD

Model Names: VRack

EMC Standards:

EN 55103-1:1997 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audiovisual and Entertainment Lighting Control Apparatus for

Professional Use, Part 1: Emissions

EN 55103-1:1997 Magnetic Field Emissions-Annex A @ 10 cm and 20 cm

EN 61000-3-2:2005 & Amd 1: 2008 Limits for Harmonic Current Emissions (equipment input current ≤16A per phase)

EN 61000-3-3:1998 Limitation of Voltage Fluctuations and Flicker in Low-Voltage Supply Systems Rated Current ≤16A

EN 55022:2006 Limits and Methods of Measurement of Radio Disturbance Characteristics of ITE: Radiated, Class B Limits; Conducted, Class A

EN 55103-2:1997 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audiovisual and Entertainment Lighting Control Apparatus for

Professional Use, Part 2: Immunity

EN 61000-4-2:2001 Electrostatic Discharge Immunity (Environment E2-Criteria B, 4k V Contact, 8k V Air Discharge)

EN 61000-4-3:2006 Radiated, Radio-Frequency, Electromagnetic Immunity (Environment E2, Criteria A)

EN 61000-4-4:2007 Electrical Fast Transient/Burst Immunity (Criteria B)

EN 61000-4-5:2006 Surge Immunity (Criteria B)

EN 61000-4-6:2006 Immunity to Conducted Disturbances Induced by Radio-Frequency Fields (Criteria A)

EN 61000-4-11:2004 Voltage Dips, Short Interruptions and Voltage Variation

FOR FIELD SERVICE

QUESTIONS CALL: 1 800 342 6939

Safety Standard:

IEC 60065: 2001: 7Ed & Amd 1: 2005 Safety Requirements - Audio Video and Similar Electronic Apparatus

I certify that the product identified above conforms to the requirements of the EMC Council Directive 89/336/EEC as amended by 92/31/EEC,

and the Low Voltage Directive 73/23/EES as amended by 93/68/EEC.

Signed ______________________

Scott Potosky

Title: Director of Engineering ______________________________________________________________________Date of Issue: February 1, 2010

Operation Manual

page 3

Table of Contents

Features .........................................................................................................................................................................5

Setup .........................................................................................................................................................................6

VRack Power Distribution Overview .........................................................................................................................................9

I-Tech HD Amplifier Specifications .........................................................................................................................................12

Input Panel .......................................................................................................................................................................15

Input Wiring Modes..............................................................................................................................................................16

Analog .......................................................................................................................................................................16

Digital .......................................................................................................................................................................21

Hybrid .......................................................................................................................................................................24

Network Wiring Schematic .................................................................................................................................................26

VDrive .......................................................................................................................................................................27

Output Panel .......................................................................................................................................................................28

Output Wiring Modes ...........................................................................................................................................................29

HiQnet™ Software ................................................................................................................................................................38

System Diagrams .................................................................................................................................................................43

Product Registration ............................................................................................................................................................51

Crown Audio Factory Service Information ......................................................................................................................53

page 4

Operation Manual

Welcome

The VRack is comprised of a rugged touring rack fitted with three Crown IT12000HD amplifiers, a power input panel, and

custom engineered input and output panels. The input panel is mounted at the top rear and supplies CobraNet(TM) network

connections as well as AES/EBU and analog XLR connections. The output panel on the bottom rear of the rack offers 12

Speakon outputs: 3 x 2-way NL4 outputs, 6 x 1-way NL4 outputs, and 3 x 3-way NL8 outputs. The front-mounted power panel

includes a 5-pin Hubbell Twist-Lock connector and a 5-pin CEE-Form connector.

Because the VRack is supplied with all components installed and internally connected, there is no need for laborious rack

building; no chance that a component might be impropery connected; and a dramatically lower chance of connection failure.

The VRack is best thought of not as just an amp rack, but as a building block for your system. Every time you add 1 VRack

into a system, you are adding 1 block that powers a proper 3:2 ratio of tops and subs for optimal performance, and seamlessly

integrates into your system via analog or digital connections.

Each IT12000HD has 2 channels, each one capable of 2100 watts into 8 ohms and 4500 watts into 4 ohms. The input and

output panels are both engineered by Crown to give the VRack user optimum flexibility when deploying a VRack system

for powering VerTec fullsize (VT4889), midsize (VT4888), compact (VT4887A), or subcompact (VT4886) models and their

companion subwoofers (VT4880, VT4880A, VT4881A, VT4882, VT4883).

The input panel automatically buffers AES signals, reducing or eliminating the need for digital distribution amplifiers. Through

VDrive (pg.27), the user is able to run Ethernet control and AES digital audio over a single Cat5 which jumps from rack to rack.

The output panel is designed to offer easy configuration for a variety of PA systems. It gives the ability to run tops off NL8

and subs off NL4s, monitors or fills off 2-way NL4 outputs, or for VT4887A/VT4881A and VT4886/VT4883 systems, an entire

circuit of tops+subs off a single NL8. See pg.28 for output panel and a summary of wiring configurations.

VRack is manufactured and tested to a single meticulous standard, and then shipped around the world. This means that any

time you supply or cross-rent a VRack it is the same as every other VRack in the world.

Features

• 3 IT12000HD ampliers

• Fully assembled package from one source

• Worldwide power distribution with both L21-30 and 32A CEE-Form connections

• Flexible input panel with Analog, AES, and VDrive

• Versatile output panel

• Fail-over AES and network connection

• Rear rack lighting

• VDrive AES digital distribution over CAT5

• Built-in network control

• Built-in captive suspension

• Shock-mounted rack

• Removable dolly board

• Side-storing rack doors

• Entire package is UL/CSA/ETL

• HiQnet™ control

Operation Manual

page 5

Setup

Rack Specific

Weight: 184 lbs (84.5 kg)

Dimensions:

L x W x H with caster plate – 22 ½” X 23 ½” X 31 ¼” ( 57.2 cm X 59.7 cm X 79.4 cm )

L x W x H without caster plate – 22 ½” X 23 ½” X 25 7/8” (57.2 cm X 59.7 cm X 65.7 cm)

Front View (23-1/2" x 31-1/4")

Top View (23-1/2" x 22-1/2")

Side View (22-1/2" x 31-1/4")

Bottom View (22-1/2" x 23-1/2")

page 6

Rack-Specific Info:

• Colson 3 ½” polyurethane casters rated at 250 lbs (113 kg) per caster

• Polycarbonate, UV stabilized, “virtually unbreakable” front see-through door with 30x the impact resistance of acrylic

• Shock mounting using 8 neoprene rubber isolators rated at 90 lbs (41 kg) vertical and 30 lbs (13.6 kg) horizontal

with steel insert

• Captive pocket door system with a single-slam latch

• Removable caster plate with interlocking stacking system

Operation Manual

Setup

Suspension

Safety Precautions: Before attempting to suspend your speakers or power amplifier rack, read and understand the

following safety information.

Important Suspension Safety Warning!

The information is this section has been assembled from recognized engineering data and is intended for informational

purposes only. None of the information in this section should be used without first obtaining competent advice with respect to

applicability to a given circumstance. None of the information presented herein is intended as a representation or warranty on

the part of Crown. Anyone making use of this information assumes all liability arising from such use.

All information presented herein is based upon materials and practices common to North America and may not directly apply

to other countries because of differing material dimensions, specifications, and/or local regulations. Users in other countries

should consult with appropriate engineering and regulatory authorities for specific guidelines.

Correct use of all hardware is required for secure system suspension. Careful calculations should always be performed

to ensure that all components are used within their rated workload before the array is suspended. Never exceed maximum

recommended load ratings.

Before suspending any speaker system or power amplifier rack, always inspect all components (enclosure, suspension frames,

pins, etc.) for cracks; deformation; corrosion; missing, loose or damaged parts that could reduce strength and safety of the

array. Do not suspend the speaker or power amplifier rack until the proper corrective action has been taken. Use only loadrated hardware when suspending the VRack.

Are You New to Suspension?

If you are new to suspension, you should do the following:

• Read and study.

• Know the Rules for Safe Suspension.

• Attend a safe suspension seminar, such as that presented by professionals like Suspension Seminars™ or by Chain Motor

Hoist manufacturers like Columbus McKinnon Corp. (manufacturers of the C/M Lodestar).

• Meet and establish a relationship with a licensed mechanical or structural engineer. Get in the habit of asking them

questions instead of guessing about their answers. Learn from what they tell you.

• Meet and discuss this aspect of your business with your Insurance Agent.

• Research and understand the codes, practices, and requirements in the venues where you intend to operate your system.

Operation Manual

General Hardware Information

Any hardware used in an overhead suspension application must be load rated for the intended use. Generally, this type of

hardware is available from suspension supply houses, industrial supply catalogs and specialized suspension distributors.

Local hardware stores do not usually stock these products.

Attachment to Structures

A licensed Professional Engineer must approve placement and method of attachment to structures prior to installation of any

overhead object. The following performance standards should be provided to the Professional Engineer for design purposes:

Uniform Building Code as applicable, Municipal Building Code as applicable, Seismic Code as applicable. Installation of

hardware and method of attachment must be carried out in the manner specified by the Professional Engineer. Improper

installation may result in damage, injury or death.

page 7

Setup

Suspension Hardware Inspection & Maintenance

Suspension systems are comprised of mechanical devices and, as such, they require regular inspection and routine

maintenance to ensure proper function ability. The Crown VRack must be inspected for fatigue at least annually. The inspection

shall include a visual survey of all corners and load-bearing surfaces for signs of cracking, water damage, de-lamination, or

any other condition that may decrease the strength of the power amplifier rack enclosure. Accessory suspension hardware

provided with or for the Crown VRack must be inspected for fatigue at least annually. The inspection shall include a visual

material survey for signs of corrosion, bending or any other condition that may decrease strength of the fastener. For other

fittings used, refer to the manufacturer’s inspection and maintenance guidelines for process.

Crown is not responsible for the application of its products for any purpose or the misuse of this information for any purpose.

Furthermore, Crown is not responsible for the abuse of its products caused by avoiding compliance with inspection and

maintenance procedures or any other abuse. Prior to suspending the system, an expert trained and experienced in flying

loudspeaker and power amplifier systems should inspect all suspension parts and components.

Industry Resources

Allen Products

562-424-1100

1635 E. Burnett Street

Signal Hill, CA 90755

www.adapttechgroup.com

M.A.N. Flying Systems

20 Sidar Road Brook Road

Industrial Estate

Rayleight, Essex SS6 7XF U.K.

www.manfly.co.uk

McMaster Carr

Various locations throughout the U.S.A.

For a location near you, visit them online:

www.mcmastercarr.com

Safe Suspension

The Crown VRack is equipped with integral suspension hardware and should only be suspended using the supplied

equipment. The system is designed to facilitate the suspension of the VRacks by a qualified person familiar with suspension

hardware and industry practices. Improper installation may result in damage, injury or death.

Working Load Limit

The working load limit (WLL) for any group of VRack products is noted on the appropriate VRack Array Frame. If interested in

suspending your VRacks, contact your local Crown representative for information on ordering VRack Suspension Frame.

VRack Connectors

IEC 309

Pin + Sleeve style

Loop out

Walther 430

IEC 309

Pin + Sleeve style

Input

Walther 635

NEMA L21-30

Panel mount

Hbl2815

page 8

Operation Manual

Setup

Type of Connectors to Use with VRack

L21-30

Mcaster-Carr

Female: 7184K35

Male: 7184K34

Hubbel Catalog

Female: HBL2813

Male: HBL2811

IEC 309 Pin + Sleeve

Walther-Electric

Female: 330

Male: 230

Cooper Crouse-Hinds

Female: CH532C6W

Male: CH532P6W

VRack Power Distribution Overview

The VRack Power Distribution panel offers worldwide use capabilities as well as multiple AC operations when used with

120VAC input. This power distribution system allows 120VAC input to 120VAC output, 120VAC input to 208VAC output when

used with 3 phase power, 220VAC – 240VAC input to 220VAC – 240VAC output. It also features a 32A per circuit, 3-pole,

single-throw breaker as well as an LCD readout that indicates AC Voltage. Built-in +5V and +12V outputs power the VRack’s

built-in network switch and rear rack lighting features. Combine this worldwide capable power distro with the I-Tech HD’s

Universal, Power-Factor-Corrected Power Supply and the VRack can be used anywhere in the world.

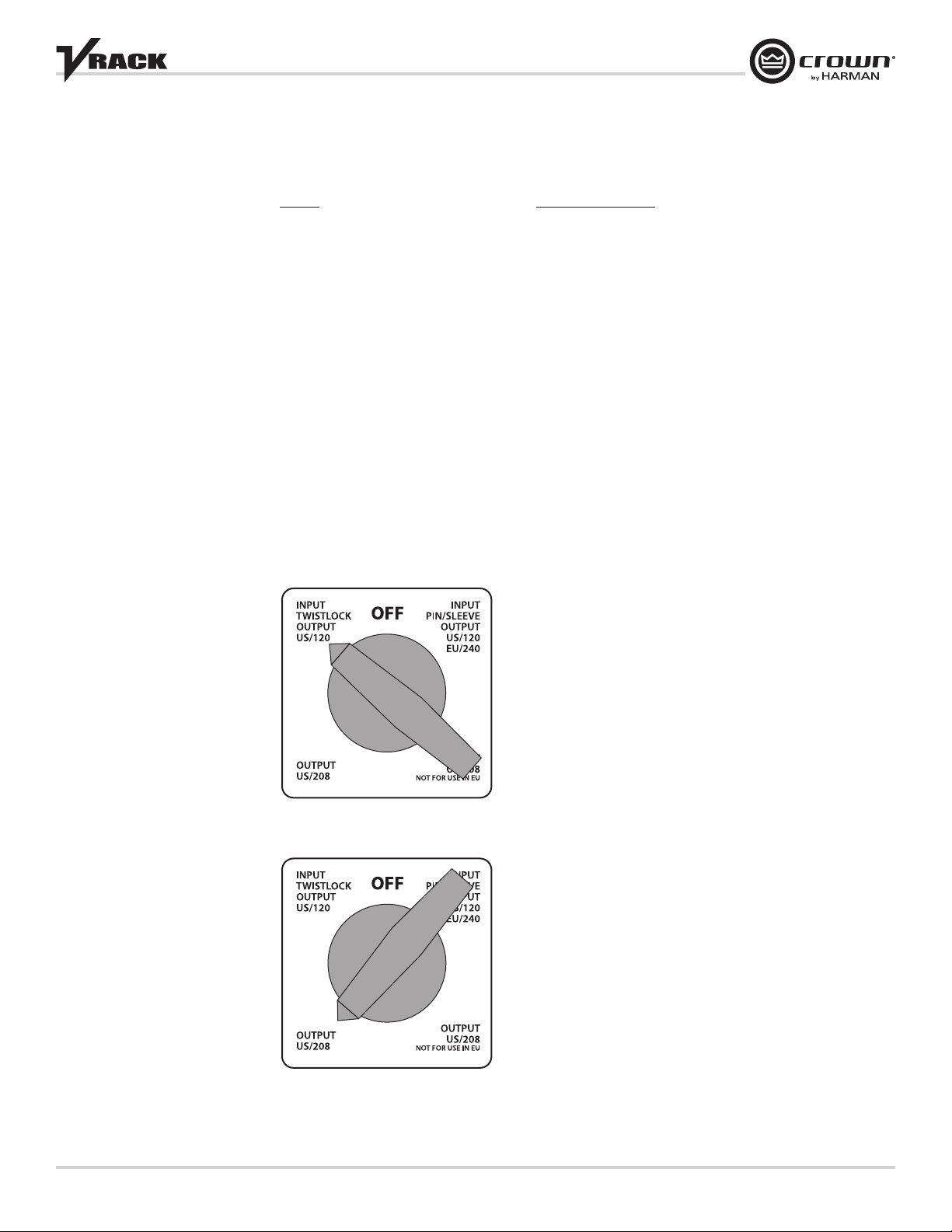

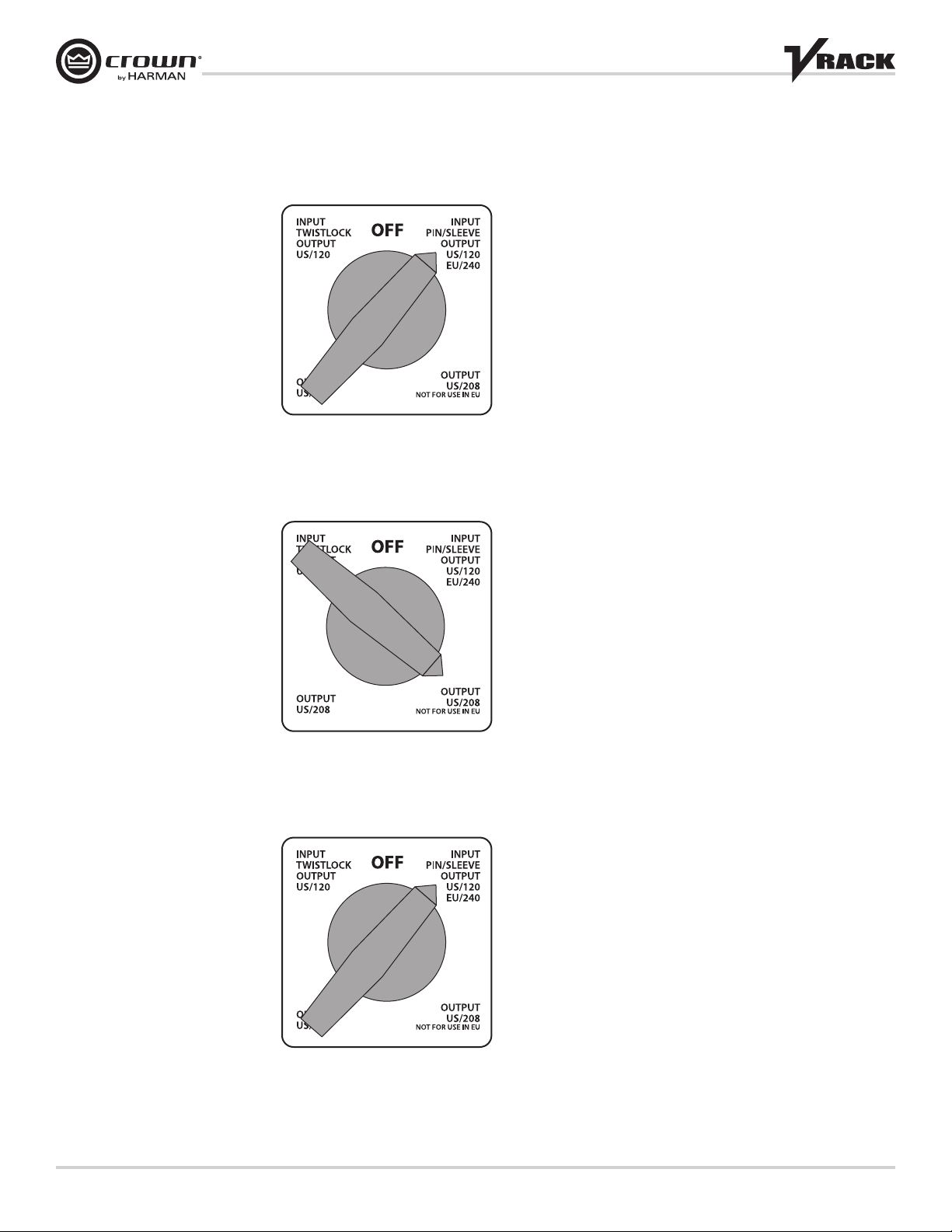

Hubbell L21-30 U.S. Operation

Hubbell L21-30 12 120VAC Operation

Switch position “Input Twistlock, Output US/120” provides the user with 120V

operation to the I-Tech HD amplifiers in the rack. From an external power

distribution system, send 3 phase 120VAC power to the X, Y, and Z pin of the

Hubbell connector and the VRack will operate in 120V mode. Each I-Tech HD

amplifier will see a dedicated X, Y, or Z phase to the line input, neutral, and

Ground connection.

Amp 1 = X, Neutral, and GND

Amp 2 = Y, Neutral, and GND

Amp 3 = Z, Neutral, and GND

Hubbell L21-30 208VAC Operation

Switch Position “Input Twistlock, Output US/208” provides the user with

208VAC operation to the I-Tech HD amplifiers in the rack. From an external

power distribution system, send 3 phase 120VAC power to the X, Y, and Z

pin of the Hubbell connector and the VRack will operate in 208V mode. Each

I-Tech HD amplifier will see a dedicated line-to-line and ground connection

resulting in the VRack operating in 208VAC mode.

Amp 1 = X, Y, and GND

Amp 2 = Y, Z, and GND

Amp 3 = X, Z, and GND

Operation Manual

page 9

Setup

Cee-Form U.S. Operation

Cee-Form 120VAC Operation

Switch Position “Input Pin/Sleeve, Output US/120 EU/240” provides 120VAC

operation from the Cee-Form pin and sleeve connector. From an external

power distribution system, send 3 phase 120VAC power to the X, Y, and Z pin

of the Cee-Form connector and the VRack will operate in 120VAC operation

mode. Each I-Tech HD amplifier will see a dedicated line-to-neutral connection

as well as a ground. Once the Cee-Form connector is landed to the VRack,

one can link to the next VRack using a Cee-Form jumper cable. (***To link

VRacks using this method at 110VAC-120VAC, the end user must ensure they

have proper AC current available. Also, please refer to the I-Tech HD Thermal

and Current Draw specifications to ensure you are not overloading the AC lines,

resulting in breakers opening. It is recommended if you wish to link VRacks,

they be operated at 220VAC-240VAC.)

Amp 1 = X, Neutral, and GND

Amp 2 = Y, Neutral, and GND

Amp 3 = Z, Neutral, and GND

Cee-Form 208VAC Operation

Switch Position “Input Pin/Sleeve, Output US/208” provides 208VAC Operation

from the Cee-Form pin and sleeve connector. From an external power

distribution system, send 3 phase 120VAC power to the X, Y, and Z pin of the

Cee-Form connector and the VRack will operate in 208VAC operation mode.

Each I-Tech HD amplifier will see a dedicated line-to-line connection as well

as ground. In “Input Pin/Sleeve, Output US/208” mode, the end user is able

to link 2 VRacks together. Amp 1 = X, Y, and GND

Amp 2 = Y, Z, and GND

Amp 3 = X, Z, and GND

Cee-Form Non-U.S. Operation

Cee-Form 220VAC-240VAC Operation

Switch Position “Input Pin/Sleeve, Output US/120 EU/240” provides 220VAC-

240VAC operation from the Cee-Form pin and sleeve connector. From an

external power distribution system, send 3 phase 220VAC-240VAC power

to the X, Y, and Z pin of the Cee-Form connector and the VRack will operate

in 220VAC-240VAC operation mode. Each I-Tech HD amplifier will see a

dedicated line-to-neutral connection as well as a ground. Once the Cee-Form

connector is landed to the VRack, one can link to the next VRack using a CeeForm jumper cable. (***To link VRacks using this method at 220VAC-240VAC,

the end user must ensure they have proper AC current available. Also, please

refer to the I-Tech HD Thermal and Current Draw specifications to ensure you are

not overloading the AC lines, resulting in breakers opening. It is recommended

if you wish to link VRacks, they be operated at 220VAC-240VAC.)

Amp 1 = X, Neutral, and GND

Amp 2 = Y, Neutral, and GND

Amp 3 = Z, Neutral, and GND

page 10

Operation Manual

Setup

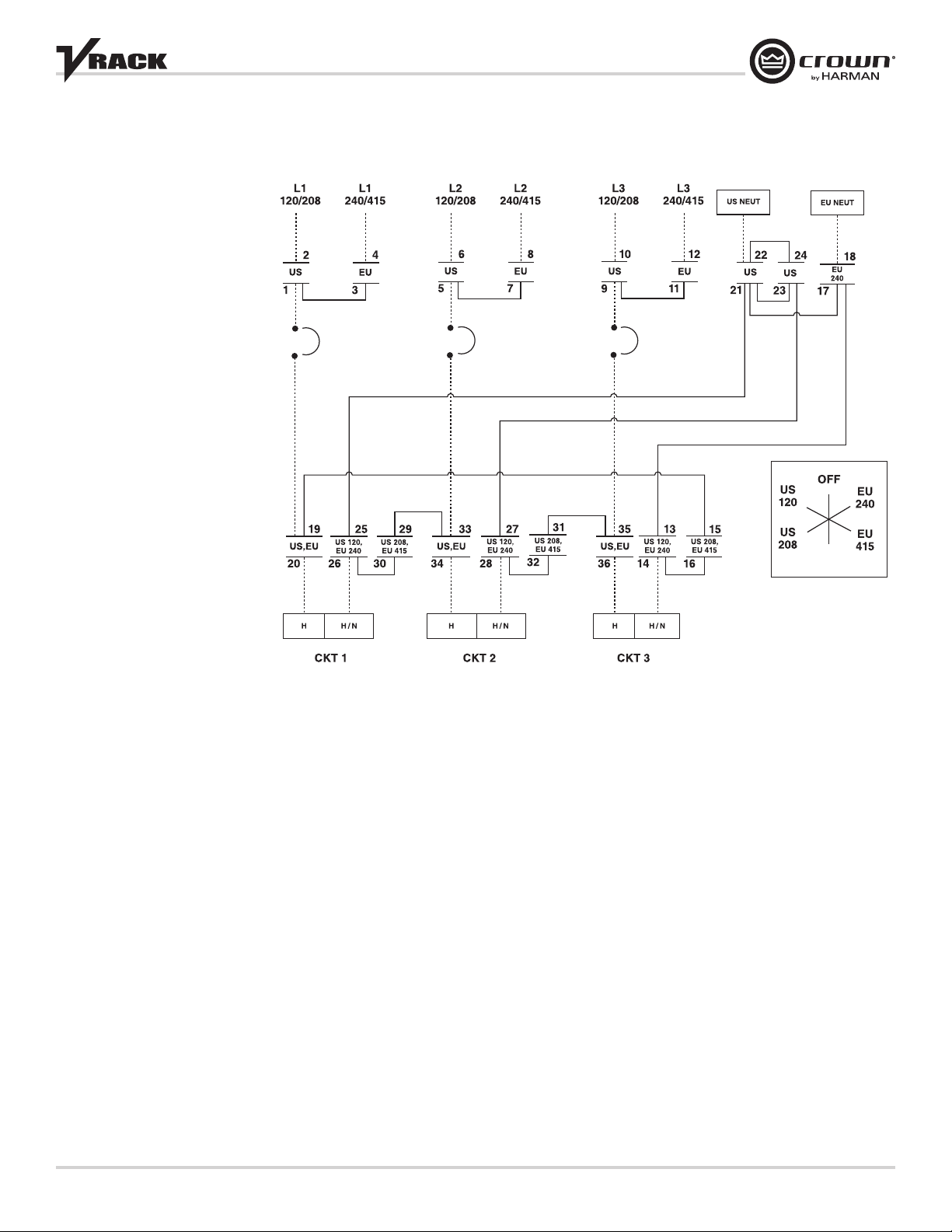

Power Supply Schematic

Operation Manual

page 11

I-Tech HD Amplier Specications

The Crown® I-Tech HD Series offers amazing power, light weight and ease of use for tour sound applications. Unlike other

amplifiers, it includes onboard high-definition DSP, an LCD control screen, and a built-in network connection.

Modern power amplifiers are sophisticated pieces of engineering capable of producing extremely high power levels. They

must be treated with respect and correctly installed if they are to provide the many years of reliable service for which they

were designed.

In addition, I-TechHD Series amplifiers include a number of features which require some explanation before they can be used

to their maximum advantage. Please take the time to study this manual so that you can obtain the best possible service from

your amplifier.

For more information please refer to I-Tech HD manual.

Features

• Global Power Supply with PFC (Power Factor Correction) works anywhere in the world

• High power density, up to 8000 watts in a 2U chassis

• Highest output voltage in the industry (200V peak) provides clean transient peaks

• Third-generation patented Class I (BCA®) circuitry couples power efficiently to the load and provides low AC current draw

• Onboard high-denition DSP with 24-bit, 192 kHz Cirrus Logic SHARC A/D and D/A converters; advanced IIR lters and

linear phase FIR filters

• Pushbutton presets simplify setup; custom presets for various loudspeakers can be downloaded or created

• AES/EBU digital audio input

• EtherCon® Ethernet connector for HiQnet™ control or CobraNet™ digital audio transport – this “Single Plug” connection

allows HiQnet™ protocol and CobraNet™ digital audio through the same CAT 5 cable

• Analog and digital thru connectors

• LCD Control Screen is used to adjust the amplier’s attenuation and muting, congure the amp, set up and view error

monitoring, and recall DSP presets to reconfigure the amp for various applications

• Comprehensive array of indicators provide accurate diagnostics: Power, Data, along with Ready, Signal, Clip, Thermal and

Fault for each channel

• AC mains indicator in power switch glows green when AC power is present

• Front-panel USB connector accepts a USB drive to transfer presets from the drive to the amplier DSP, and vice versa

• Lightweight due to aluminum chassis, special internal construction and switching power supply

• Thermal management controller and two discrete thermal zones with variable-speed fans, forced-air cooling

• Advanced protection circuitry guards against: shorted outputs, DC, mismatched loads, general overheating, under/over

voltage, high-frequency overloads and internal faults

• Five-Year, No-Fault, Fully Transferable Warranty completely protects your investment and guarantees its specications

page 12

Operation Manual

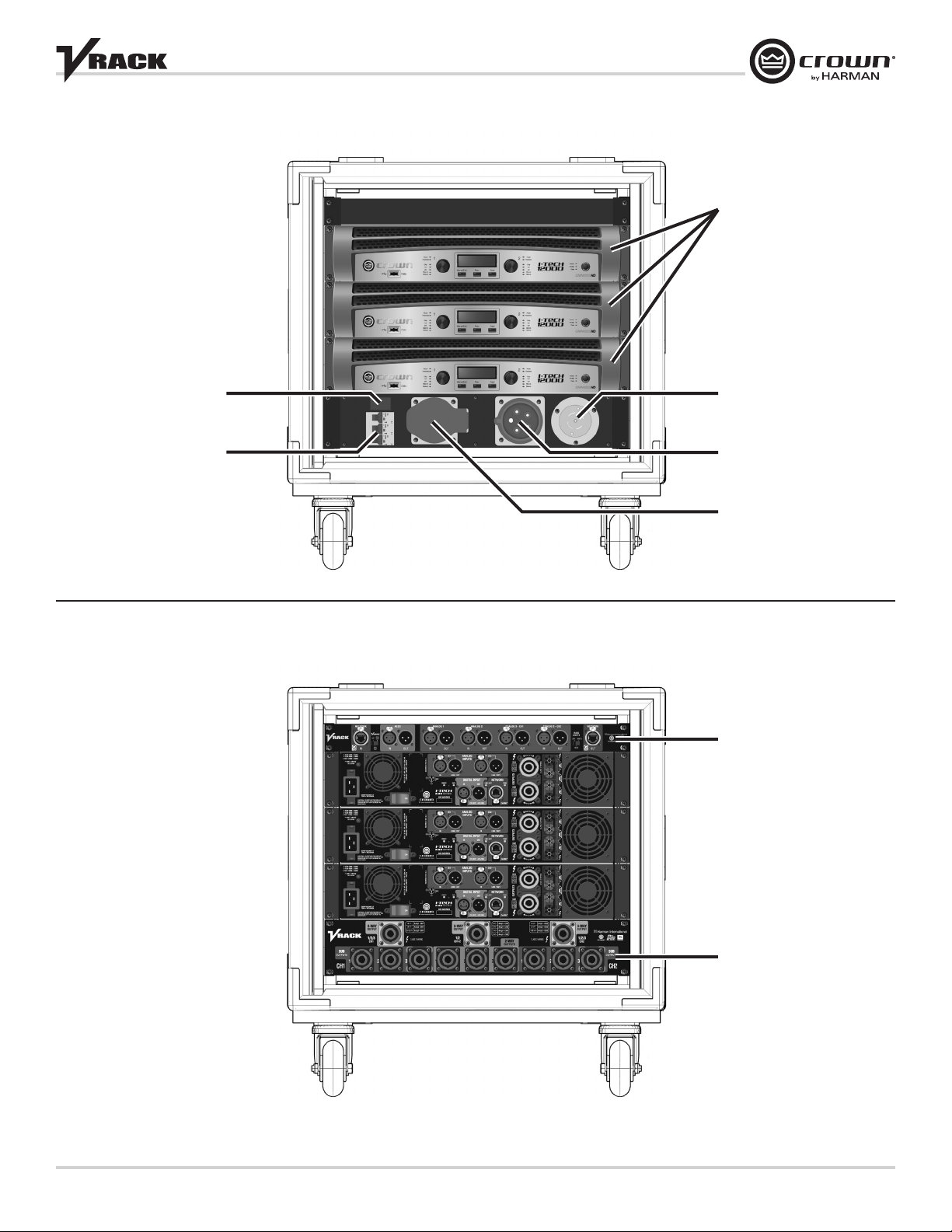

Front Panel Features

Three IT12000HD Amplifiers

LCD Voltage Readout

Back Panel Features

L21-30 Hubbell Connector

5-Pin Cee-Form Input32A Breakers

5-Pin Cee-Form Loop Out

Input Panel

Operation Manual

Output Panel

page 13

Setup

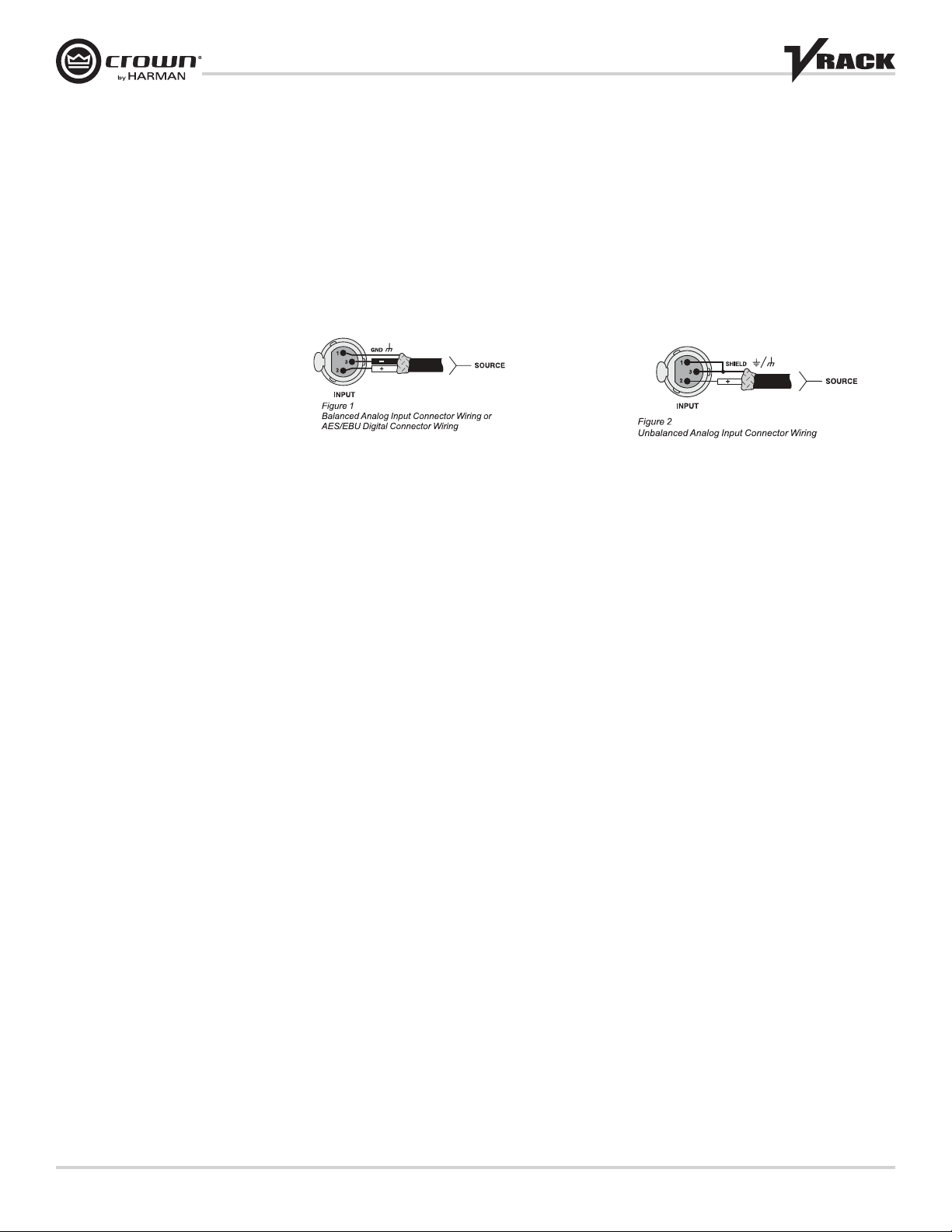

Choose Input Wire and Connectors

Crown recommends using pre-built or professionally wired, balanced line (two-conductor plus shield), 22-24 gauge cables

with 3-pin XLR connectors. Unbalanced line may also be used but may result in noise over long cable runs.

Figure 1 shows connector pin assignments for balanced analog wiring or AES/EBU digital wiring. (The use of standard

analog cable with AES/EBU will result in diminished performance) For best results, 110 ohm shielded twisted-pair

cable for AES/EBU signals is highly recommended. Figure 2 shows connector pin assignments for unbalanced analog wiring.

NOTE: Custom wiring should only be performed by qualified personnel.

Choose Output Wire and Connectors

Crown recommends using pre-built or professionally wired, high-quality, two-, four- or eight-conductor, heavy gauge speaker

wire and connectors. Use Class 2 output wiring. You may use a 4- or 8-pole Speakon® connector. To prevent the possibility of

short circuits, wrap or otherwise insulate exposed loudspeaker cable connectors.

CAUTION – SHOCK HAZARD: Potentially lethal voltages exist at the output connectors when the amplifier is

turned on and is passing a signal.

Using the guidelines below, select the appropriate size of wire based on the distance from amplifier to speaker.

Distance Wire Size

up to 25 ft. (up to 7.62 m) 16 AWG

26-40 ft. (7.62-12.2 m) 14 AWG

41-60 ft. (12.2-18.3 m) 12 AWG

61-100 ft. (18.3-30.5 m) 10 AWG

101-150 ft. (30.5-45.7 m) 8 AWG

151-250 ft. (45.7-76.2 m) 6 AWG

CAUTION: Never use shielded cable for output wiring.

page 14

Operation Manual

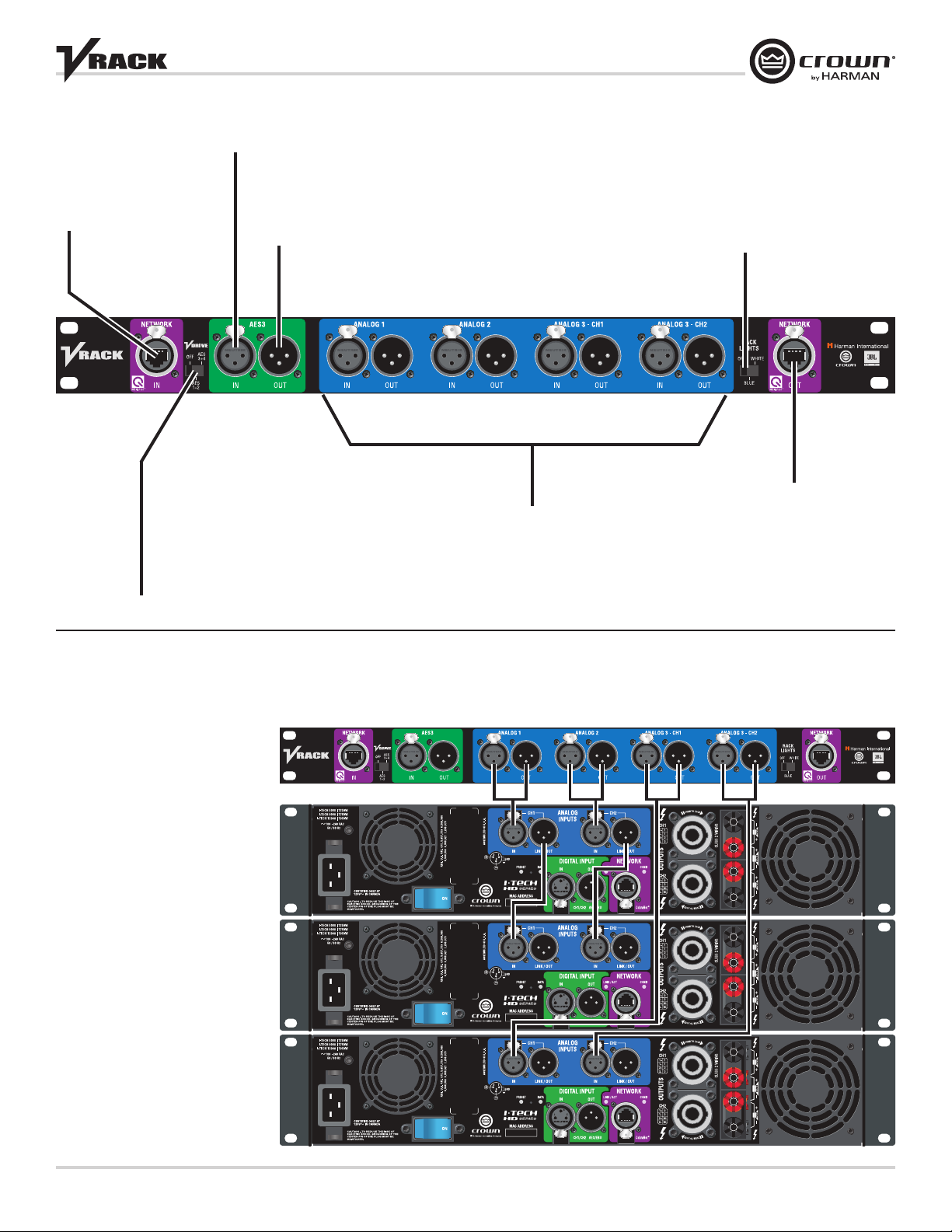

Input Panel

Network Link input.

Also distributes VDrive

digital audio.

VDrive - This selector switch serves two functions.

Function 1 - sends AES3 that is plugged into the AES3

connector to the right of this switch over the Network

Connection. Function 2 - If no AES3 connection is landed

to the rack, this will pull the AES3 signal from a VRack

within the network's ring topology that has AES3 landed

to its connector and the VDrive switch engaged. See

VDrive section for more information (page 27).

AES3 Input - Input AES3 into this connector, the signal

will go directly to the amplifiers. If AES 1+2 or AES 3+4

is selected, the AES3 fed into this connector will send

AES3 to the Network connection via VDrive.

AES Link Output - If power is applied to the rack, the

AES3 signal is buffered. If the rack is not powered on,

the AES3 signal is not buffered.

Analog Input Section. See

Analog Input Mode Section

for more information.

Rear Rack lighting with Blue,

White, and off settings.

Network Link

output. Also

distributes VDrive

digital audio.

Analog Input Wiring Schematic

Analog Input Rack Wiring Schematic

Operation Manual

page 15

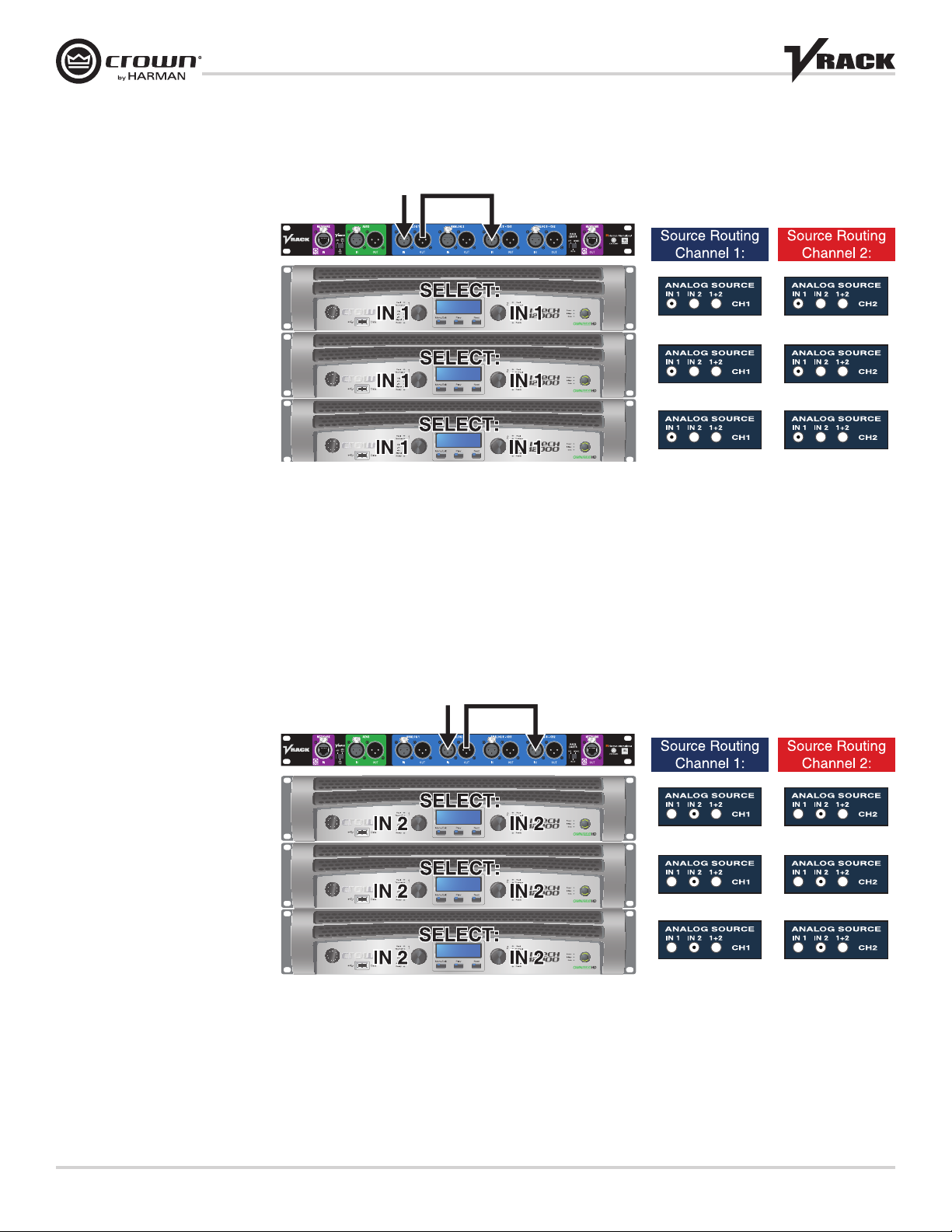

Input Wiring Modes - Analog

Mono 1

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

Mono 2

page 16

Operation Manual

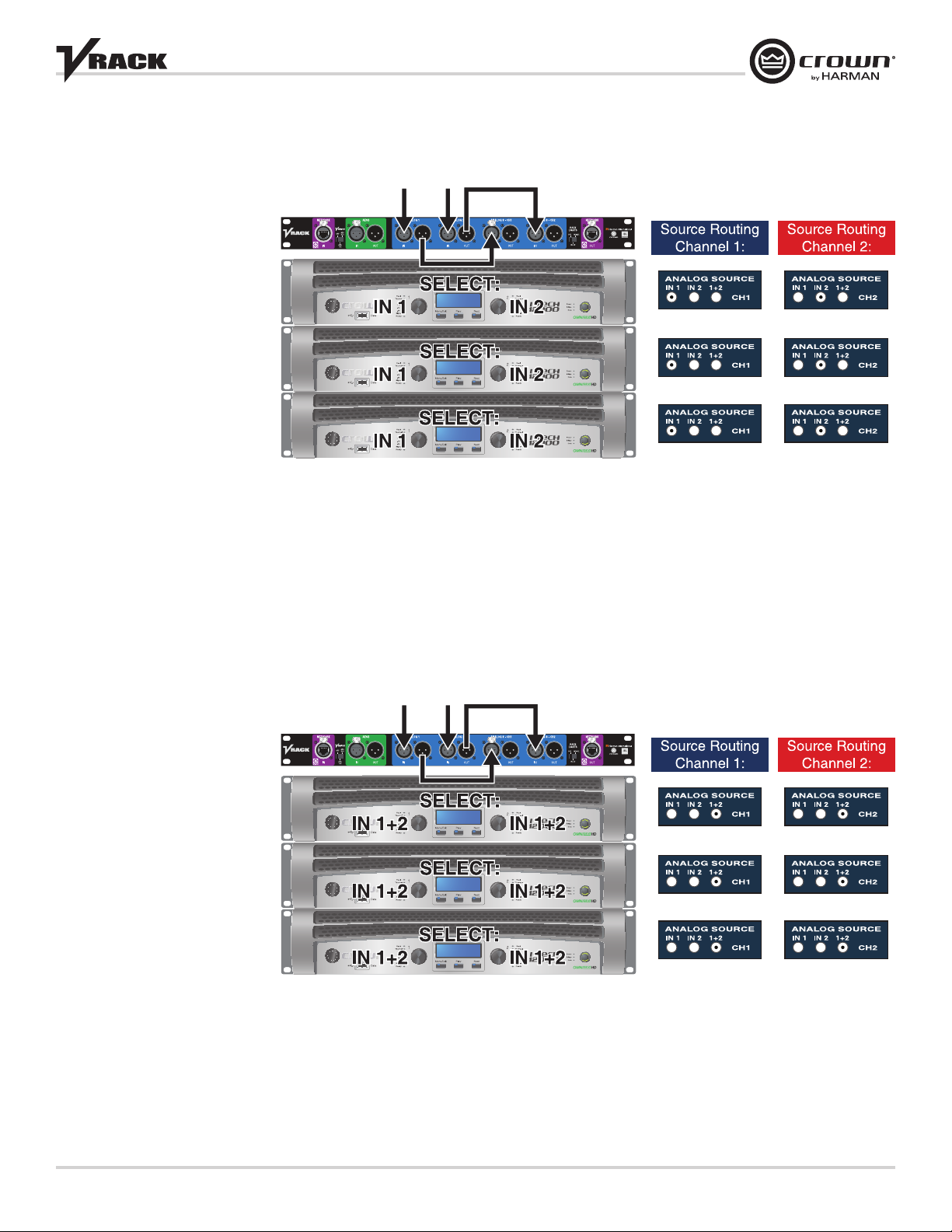

Input Wiring Modes - Analog

Stereo

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

Mono (1+2)

Operation Manual

page 17

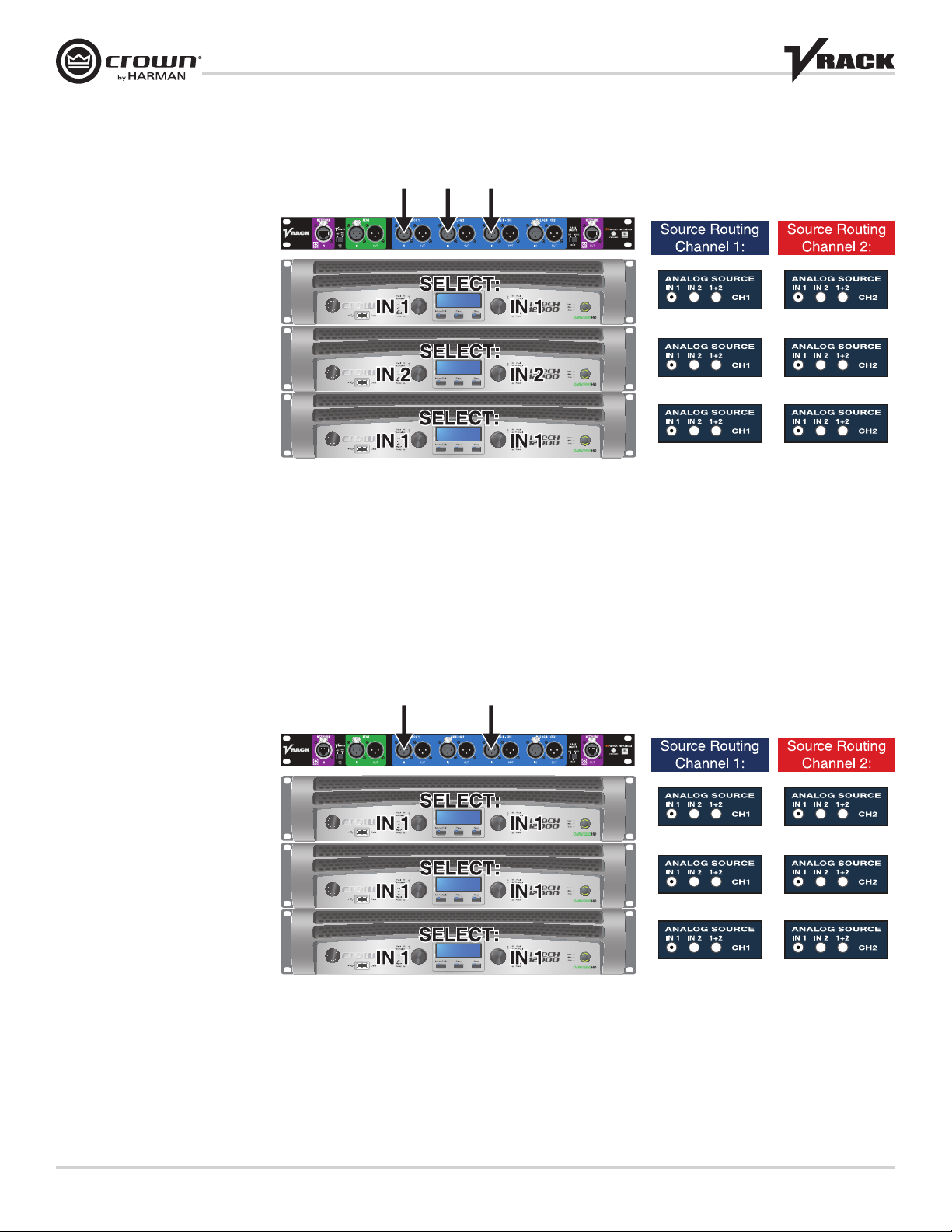

Input Wiring Modes - Analog

3-Mix

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

MONO 1

MONO 2

STEREO

MONO (1+2)

3-MIX

MONO 1 + AUX

MONO 2 + AUX

Mono 1 + Aux

page 18

Operation Manual

Loading...

Loading...