Page 1

Page 2

Page 3

K SERIESK SERIES

BALANCED CURRENT AMPLIFIER

Enable

Clip

Thermal

Signal

IOC

2

1

0 dB

3

1

5

7

9

11

13

15

17

19

21

25

45

30

100

1

0 dB

3

1

5

7

9

11

13

15

17

19

21

25

45

30

100

?

K SERIES

K SERIESK SERIES

Service Manual

BALANCED CURRENT AMPLIFIER

BALANCED CURRENT AMPLIFIER

BALANCED CURRENT AMPLIFIER

PROFESSIONAL AUDIO AMPLIFIERSPROFESSIONAL AUDIO AMPLIFIERS

PROFESSIONAL AUDIO AMPLIFIERS

PROFESSIONAL AUDIO AMPLIFIERSPROFESSIONAL AUDIO AMPLIFIERS

Models:

K1, K2

15

13

11

17

19

21

25

30

45

100

Thermal

9

7

Clip

5

IOC

3

1

Signal

0 dB

1

1

15

13

11

17

19

9

21

7

25

30

5

Enable

3

1

45

0 dB

100

2

© 1999 by Crown International, Inc., P.O. Box 1000, Elkhart, Indiana 46515-1000 U.S.A. Telephone: 219294-8000.

Current Amplifier

K Series

amplifiers are produced by Crown International, Inc. Trademark Notice:

™ is a trademark, and

Crown®

and

®

BCA

are registered trademarks of Crown

Balanced

International, Inc. Other trademarks are the property of their respective owners.

KSVCK1K2

03/98

Rev. A

Page 4

K Series Service Manual

The information furnished in this manual does not include all of the details of design, production, or variations

of the equipment. Nor does it cover every possible situation which may arise during installation, operation or

maintenance. If you need special assistance beyond the scope of this manual, please contact the Crown

Technical Support Group.

Mail:

P.O. Box 1000 Elkhart IN 46515-1000

Shipping:

Plant 2 S.W., 1718 W. Mishawaka Rd., Elkhart IN 46517

Phone:

(800) 342-6939/(219) 294-8200

FAX:

(219) 294-8301

Web

: www.crownaudio.com

Rev. A

CAUTION

TO PREVENT ELECTRIC SHOCK DO

NOT REMOVE TOP OR BOTTOM

COVERS. NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE

PERSONNEL. DISCONNECT

POWER CORD BEFORE REMOVING

REAR INPUT MODULE TO ACCESS

GAIN SWITCH.

WARNING

AVIS

À PRÉVENIR LE CHOC

ÉLECTRIQUE N’ENLEVEZ

PAS LES COUVERTURES.

RIEN DES PARTIES

UTILES À L’INTÉRIEUR.

DÉBRANCHER LA BORNE

AVANT D’OUVRIR LA

MODULE EN ARRIÈRE.

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE!

The lightning bolt

triangle is used to

alert the user to the

risk of electric shock.

I

The exclamation point

triangle is used to alert the

user to important operating

or maintenance instructions.

©1999 Crown International, Inc.

Page 5

Rev. A

K Series Service Manual

Revision History

Revision Number

None

Rev. A

Date

3-98

6-99

Changes

Initial Printing

Added Revision History, Module and Schematic

Information, and Module Parts Sections.

Upgraded Manual to Facilitate Component-Level

Troubleshooting of PWA’s.

Updated Cover Page and Table of Contents.

©1999 Crown International, Inc.

II

Page 6

K Series Service Manual

Rev. A

This page intentionally left blank

III

©1999 Crown International, Inc.

Page 7

Rev. A

K Series Service Manual

Table of Contents

1 Introduction ............................................................................ 1-1

1.1 Introduction...................................................................... 1-1

1.1.1 The K Series Amplifiers ........................................... 1-1

1.2 Warranty........................................................................... 1-1

1.3 Repair Strategy ................................................................ 1-2

1.4 Service Procedure ........................................................... 1-2

2 Specifications ......................................................................... 2-1

2.1 Performance .................................................................... 2-1

2.2 Controls............................................................................ 2-1

2.3 Indicators ......................................................................... 2-1

2.4 Input/Output..................................................................... 2-2

2.5 Output Signal ................................................................... 2-2

2.6 Protection......................................................................... 2-2

2.7 Construction..................................................................... 2-2

3 Theory...................................................................................... 3-1

3.0 Overview.......................................................................... 3-1

3.1 Power Supplies ................................................................ 3-1

3.1.1 Main Power Supply.................................................. 3-1

3.1.2 Low Voltage Supplies .............................................. 3-1

3.2 Input Stage ...................................................................... 3-2

3.3 DC Servo.......................................................................... 3-2

3.4 Sleep Circuit .................................................................... 3-2

3.5 Error Amp......................................................................... 3-2

3.6 Modulator......................................................................... 3-2

3.7 Triangle Generator ........................................................... 3-3

3.8 Proportional Vcc Generator ............................................. 3-3

3.9 Output.............................................................................. 3-3

3.10 Output Filter ................................................................... 3-3

3.11 Current Limiter ............................................................... 3-3

3.13 Overlap Correction and Adjustment .............................. 3-4

3.14 Display Circuitry............................................................. 3-4

3.15 Control Circuitry ............................................................. 3-4

3.16 Crowbar Circuitry........................................................... 3-5

4 Line Voltage Conversion ........................................................ 4-1

4.1 Line Voltage Conversion .................................................. 4-1

5 Maintenance............................................................................ 5-1

5.1 Where to Begin ................................................................ 5-1

5.2 Disassembly for Inspection & Service ............................. 5-1

©1999 Crown International, Inc.

IV

Page 8

K Series Service Manual

Rev. A

Table of Contents

5.2.1 Cover Removal ........................................................ 5-1

5.2.2 Power Supply Discharge ......................................... 5-2

5.2.3 Back Panel Assembly Removal............................... 5-2

5.2.4 Front Panel Assembly Removal............................... 5-3

5.2.5 Input PWA Removal................................................. 5-3

5.2.6 Main PWA Removal ................................................. 5-3

5.2.7 Output PWA Removal.............................................. 5-4

5.2.8 Control PWA Removal ............................................. 5-4

5.2.9 Line Filter PWA Removal ......................................... 5-4

5.2.10 Power Transformer Removal.................................. 5-4

5.2.11 Display PWA Removal........................................... 5-5

5.2.12 Bridge PWA Removal ............................................ 5-5

5.3 Troubleshooting ............................................................... 5-6

5.3.1 Identifying Symptoms.............................................. 5-6

5.3.2 Identifying and Repairing the Cause....................... 5-6

5.4 Required Test Equipment................................................. 5-8

5.5 Electrical Checkout Procedures....................................... 5-8

5.5.1 Quiescent AC Power Draw ...................................... 5-9

5.5.2 Gain Switches.......................................................... 5-9

5.5.3 “Y” Input Switch Operation...................................... 5-9

5.5.4 Bridge Mono Operation........................................... 5-9

5.5.5 Frequency Response ............................................ 5-10

5.5.6 Short Circuit Test ................................................... 5-10

5.5.7 Output Power......................................................... 5-10

5.5.8 Intermodulation Distortion ..................................... 5-10

5.5.9 Signal to Noise Ratio ............................................. 5-10

5.5.10 Crosstalk at 1 kHz................................................ 5-10

5.5.11 Post Test Settings ................................................ 5-11

5.6 Calibrations.................................................................... 5-11

5.6.1 Gaussian Filter Calibration .................................... 5-11

5.6.2 Overlap Correction and Adjustment...................... 5-11

6 Parts ....................................................................................... 6-1

6.1 General Information ......................................................... 6-1

6.2 Ordering and Receiving Parts ......................................... 6-1

6.2.1 Terms ....................................................................... 6-1

6.2.2 Shipment ................................................................. 6-1

7 Exploded View Parts .............................................................. 7-1

7.1 General Information ......................................................... 7-1

7.2 Main Chassis Assembly................................................... 7-3

7.3 Front Panel Assembly ...................................................... 7-5

7.4 Back Panel Assembly ...................................................... 7-7

V

©1999 Crown International, Inc.

Page 9

Rev. A

K Series Service Manual

Table of Contents

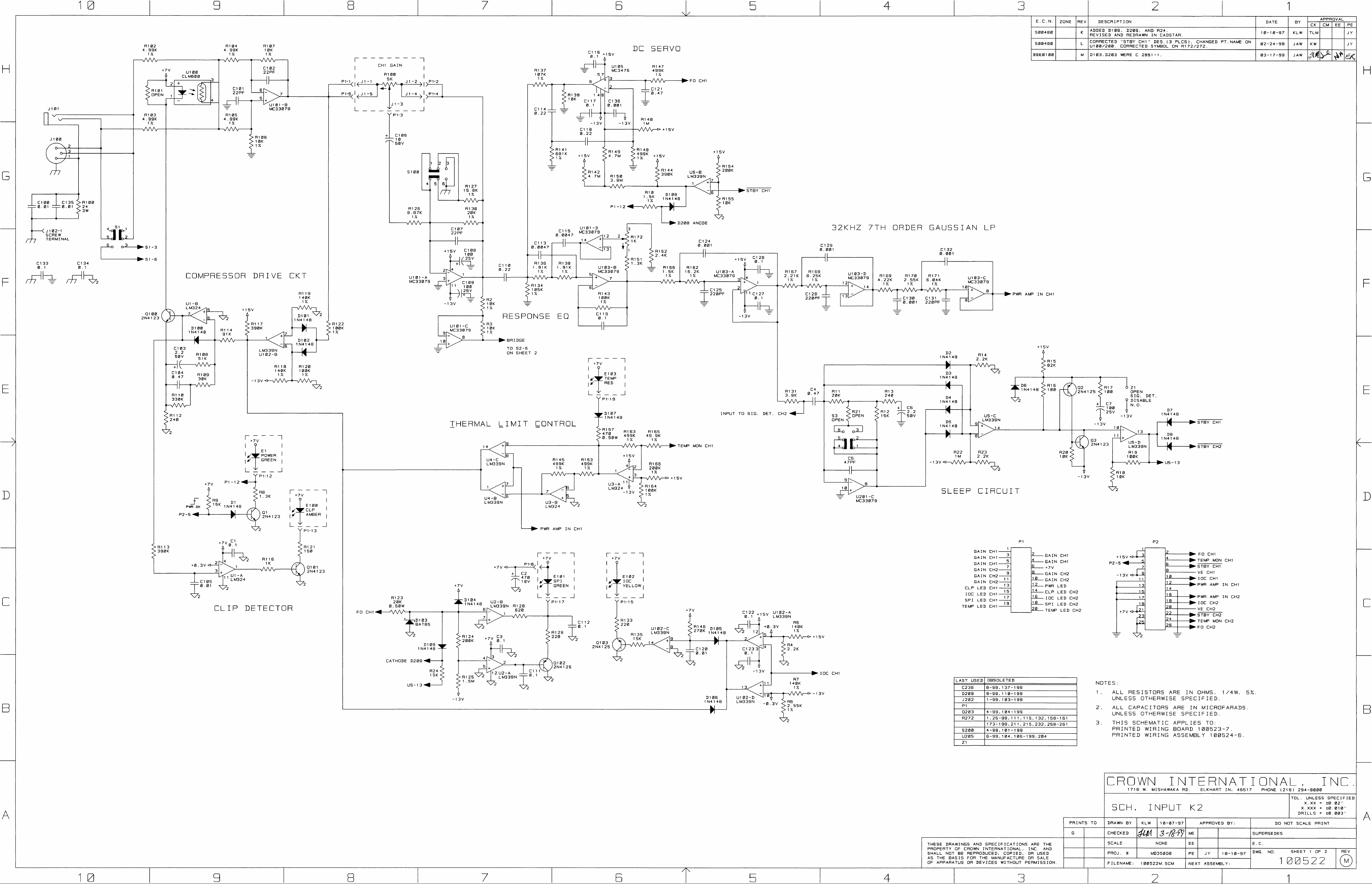

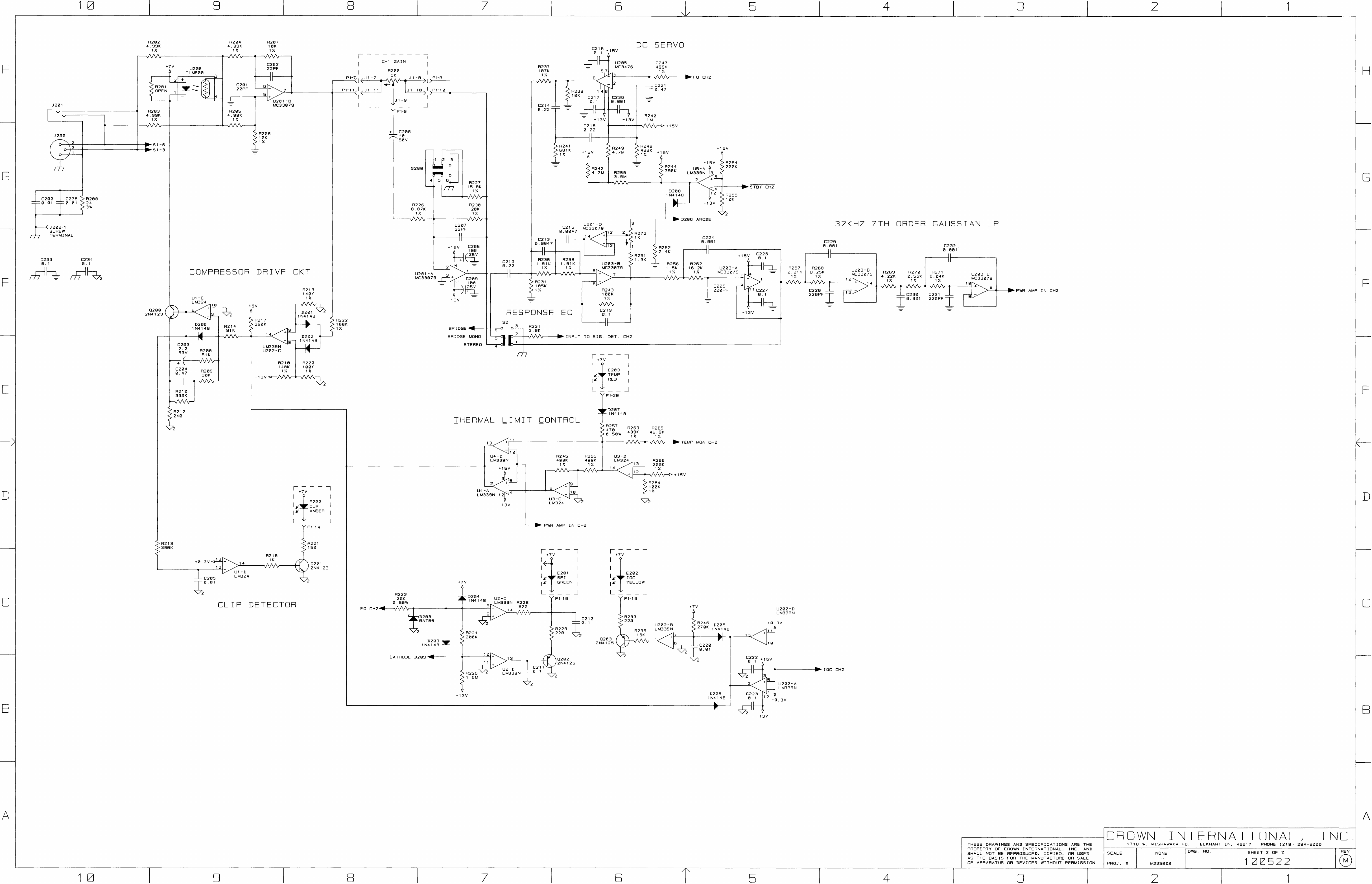

8 Module and Schematic Information...................................... 8-1

8.1 General Information ......................................................... 8-1

8.2 PWAs ............................................................................... 8-1

8.3 Schematics ...................................................................... 8-2

9 Module Parts........................................................................... 9-1

9.1 General Information ......................................................... 9-1

100438 PWA .......................................................................... 9-2

Component Map............................................................... 9-6

101554 Assembly .................................................................. 9-7

100469 PWA .......................................................................... 9-9

Component Map............................................................. 9-11

100497 PWA ........................................................................ 9-12

Component Map............................................................. 9-29

100524 PWA ........................................................................ 9-31

Component Map............................................................. 9-39

101014 PWA ........................................................................ 9-40

Component Map............................................................. 9-42

101809................................................................................. 9-43

Component Map............................................................. 9-51

101850 PWA ........................................................................ 9-52

Component Map............................................................. 9-54

101865 PWA ........................................................................ 9-55

Component Map............................................................. 9-57

102176 PWA ........................................................................ 9-58

Component Map............................................................. 9-62

102175 Assembly ................................................................ 9-63

102552 PWA ........................................................................ 9-65

Component Map............................................................. 9-67

10 Schematics ......................................................................... 10-1

©1999 Crown International, Inc.

VI

Page 10

K Series Service Manual

Rev. A

This page intentionally left blank

VII

©1999 Crown International, Inc.

Page 11

K Series Service ManualRev A.

Enable

Clip

Thermal

Signal

IOC

2

1

0 dB

3

1

5

7

9

11

13

15

17

19

21

25

45

30

100

1

0 dB

3

1

5

7

9

11

13

15

17

19

21

25

45

30

100

BALANCED CURRENT AMPLIFIERBALANCED CURRENT AMPLIFIER

BALANCED CURRENT AMPLIFIER

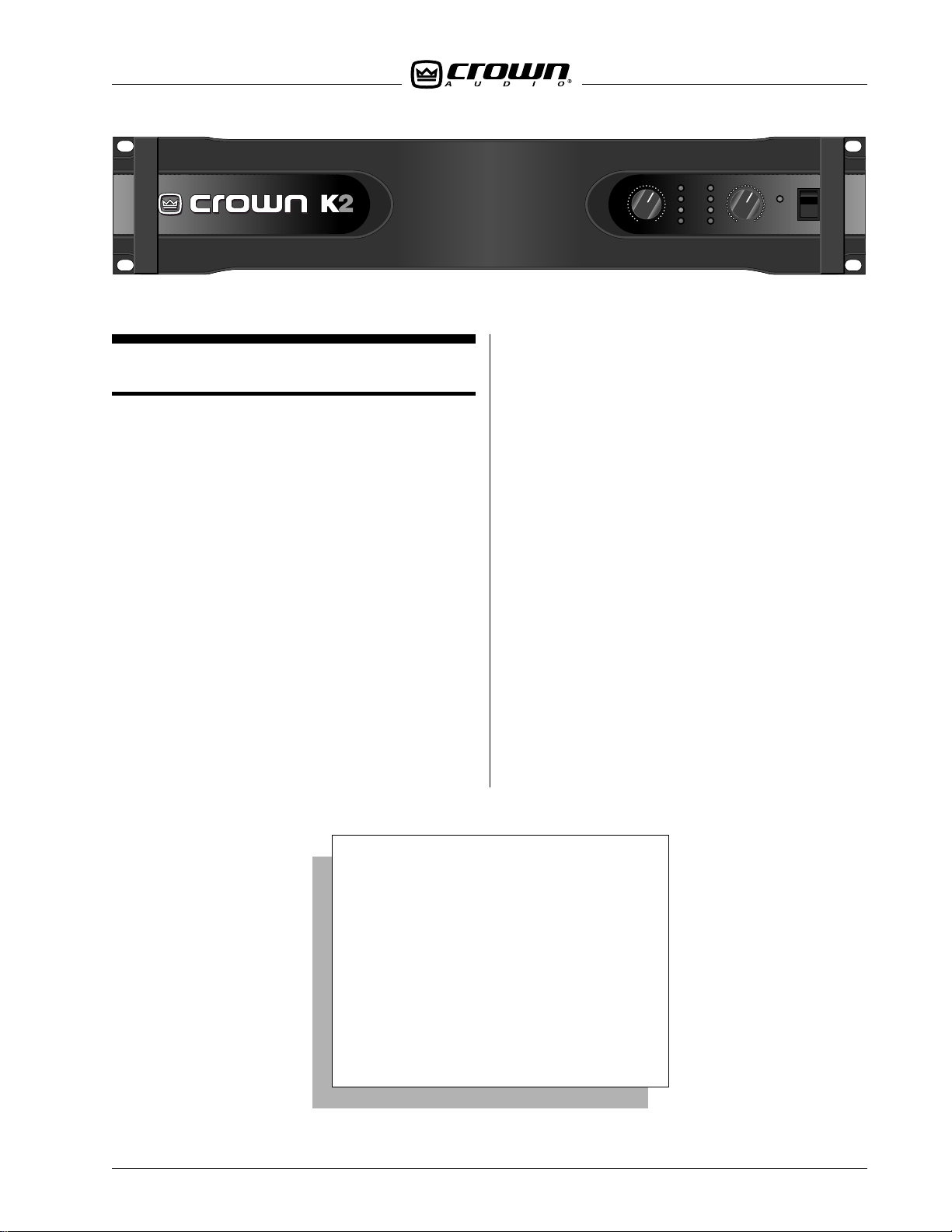

Figure 1.1 The Crown K2 Amplifier

1 Introduction

1.1 Introduction

This manual contains complete service information

on the Crown K1 and K2 power amplifiers. It contains

service information for both non-CE and CE (European) units. It is designed to be used in conjunction

with the Reference Manual; however, some important

information is duplicated in this Service Manual in case

the Reference Manual is not readily available.

NOTE: THE INFORMATION IN THIS MANUAL IS INTENDED FOR USE BY AN EXPERIENCED TECHNICIAN ONLY!

1.1.1 The K Series Amplifiers

The K Series of power amplifiers are efficient, compact, high-power audio amplifiers designed for professional use. They provide full audio bandwidth, highpower amplification with minimum distortion. Crown’ s

patented

for maintenance-free operation with maximum perfor-

Balanced Current Amplifier™

design allows

15

13

11

17

19

21

25

30

45

100

Thermal

9

7

Clip

5

IOC

3

1

Signal

0 dB

1

1

15

13

11

17

19

9

21

7

5

25

30

45

Enable

3

1

0 dB

100

2

mance. Other features include convection cooling,

balanced inputs, Bridge-Mono operation, “Y” Input for

routing one signal to both channels, and input compression for maximum loudspeaker protection.

1.2 Warranty

Each Reference Manual contains basic policies as

related to the customer . In addition, it should be stated

that this service documentation is meant to be used

only by properly trained personnel. Because most

Crown products carry a 3-Year Full Warranty (including round trip shipping within the United States), all

warranty service should be referred to the Crown Factory or Authorized Warranty Service Center. See the

applicable Reference Manual for warranty details. To

find the location of the nearest Authorized Warranty

Service Center or to obtain instructions for receiving

Crown Factory Service, please contact the Crown

Technical Suppor t Group (within North America), or

your Crown/Amcron Importer (outside North America).

If you are an Authorized Warranty Ser vice Center and

have questions regarding the warranty of a product,

please contact the Field Service Manager or the T echnical Support Group.

©1999 Crown International, Inc.

Crown Customer Service

Technical Support Group

Factory Service

Parts Department

Mailing Address:

Shipping Address:

1718 W. Mishawaka Rd., Elkhart IN 46517

http://www.crownaudio.com

P.O. Box 1000, Elkhart IN 46515

Plant 2 S. W.

Phone: (219) 294-8200

Toll Free: (800) 342-6939

Fax: (219) 294-8301

Introduction 1-1

Page 12

K Series Service Manual Rev A.

1.3 Repair Strategy

The

Balanced Current Amplifier

new era in Crown history. Taking full advantage of the

modular design approach used in the design of

ries

amplifiers, we are able to offer a module exchange

program for this product. The concept is that the PW A

(Printed Wire Assembly) as a whole is one component, and when a part of the assembly is defective,

the whole assembly is defective. Exceptions are the

Control, Bridge, Display, and Line Filter PWAs. Those

PWAs may be repair ed at the component level unless

there is sufficient damage or malfunction to warrant

PWA replacement. Non-PW A components are also excluded from this program.

Under the module exchange program, defective

PWAs are returned to Crown for evaluation and rework. The reworked assemblies will then be stocked

in the Crown Parts Department to be sold as refurbished parts.

This strategy offers several advantages. One advantage is less time spent in troubleshooting and repairing the amplifier, thus resulting in greater customer

satisfaction. This strategy also allows Crown to collect the necessary information from amplifier failures,

so improvements can be made for even greater product reliability.

technology rings in a

K Se-

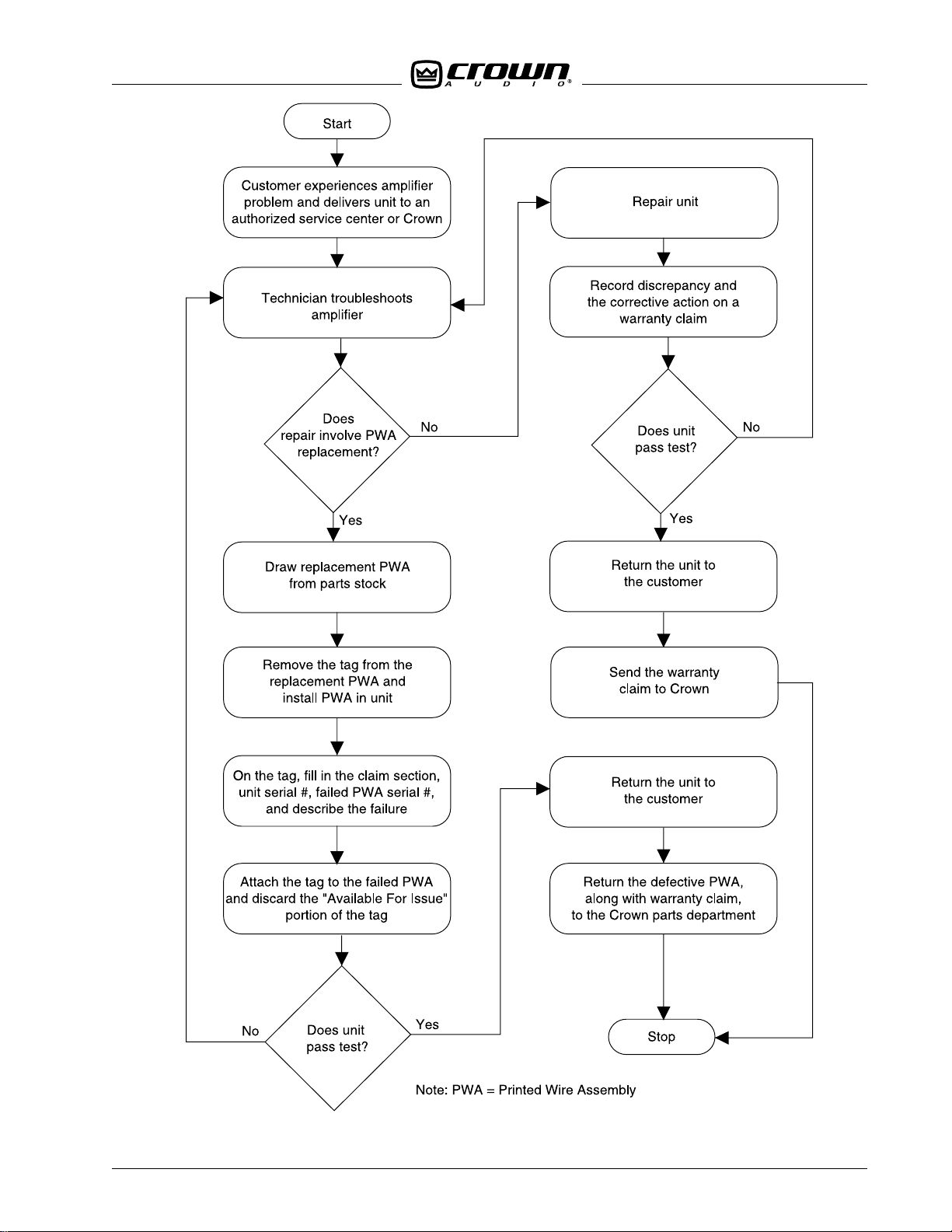

1.4 Service Procedure

Servicing a

tain steps to be followed. See Figure 1.2 for a flow

chart of these steps. It is important that the defective

Printed Wire Assemblies (PWAs) be r eturned to Crown

for evaluation and repair . Under the module exchange

program, warranty claims for PWA replacement will

not be honored unless the defective PWA accompanies the warranty claim. In the event of a non-warranty repair, rebuilt PWAs will be available at a lower

price than new PWAs, and a discount will be given if

the defective PWA is returned to Crown.

Each PWA purchased from the Crown parts department will have a tag indicating that it is “Available for

Issue.” This tag will have two parts. The first part simply states that the PWA is ready for use. It also has

instructions for the PWA and the serial number of the

module. Once the new PWA is installed, this part is to

be discarded. The second part will be filled out by

the service technician. After it is filled out with data

such as the amplifier serial number and a description

of the failure, it will be attached to the failed PWA.

This part has three copies. The first is for the service

center to keep. Copies 2 and 3 will remain together

for use at Crown.

Balanced Current Amplifier

requires cer-

1-2 Introduction

WARNING

Component-level troubleshooting and repair of

PWAs included in the module exchange program

should not be attempted without expressed authorization from the Crown Audio Service Manager.

Such an attempt, without specialized training and

specialized test equipment, will likely result in substantial damage to the amplifier. Crown will not

authorize payment of warranty claims in such an

instance.

©1999 Crown International, Inc.

Page 13

K Series Service ManualRev A.

©1999 Crown International, Inc.

Figure 1.2 Service Procedure Flow Chart

Introduction 1-3

Page 14

K Series Service Manual Rev A.

This page intentionally left blank

1-4 Introduction

©1999 Crown International, Inc.

Page 15

2 Specifications

All specifications relate to both Export and Domestic

units, regardless of voltage and frequency.

2.1 Performance

Frequency Response

±0.25 dB from 20 Hz to 20 kHz. The frequency re-

sponse is band limited with an 8-Hz double-integrated

3rd-order Butterworth high-pass filter and a 30-kHz 7th-

order Gaussian low-pass filter .

K Series Service ManualRev A.

Power

An on/off rocker switch located on the front panel.

Input Sensitivity

A two–position switch for each channel, located on the

back panel near each channel’ s input connectors. Can

be set to 1.4 V for full output power into an 8-ohm load

or a fixed voltage gain of 26 dB.

Bridge Output

An on/off switch located on the back panel between

the input connectors. This switch, when turned on,

bridges the two outputs with the channel one input signal.

Output Power

Measured at 1 kHz with both channels driven to 0.1%

or less true THD.

K1

2 ohm Stereo: 750 watts per channel.

4 ohm Stereo: 550 watts per channel.

8 ohm Stereo: 350 watts per channel.

4 ohm Bridge Mono: 1,500 watts.

8 ohm Bridge Mono: 1,100 watts.

K2

2 ohm Stereo: 1,250 watts per channel.

4 ohm Stereo: 800 watts per channel.

8 ohm Stereo: 500 watts per channel.

4 ohm Bridge Mono: 2,500 watts.

8 ohm Bridge Mono: 1,600 watts.

Signal-to-Noise Ratio

Greater than 100 dB below rated power , A-weighted.

Voltage Gain

1.4 VRMS input sensitivity or a fixed gain of 26 dB

(back panel switchable).

Damping Factor

Greater than 3,000 from 10 Hz to 400 Hz.

Line Voltage Requirements

Universal power supply can be configured to operate

with 100, 120, 200, 230, 240 or 250 V AC at 50 or 60 Hz.

2.2 Controls

Level

A calibrated rotary level control for each channel lo-

cated on the front panel. Each control is labeled from 0

to 100 dB of voltage attenuation.

“Y” Input

An on/off switch located on the back panel between

the input connectors. This switch, when turned on, parallels the two input channels.

2.3 Indicators

Thermal

A red LED for each channel which turns on with a dim

glow shortly before the amplifier needs help dissipating heat. The LED will turn brighter as the Thermal Level

Control (TLC) protection is activated.

Clip

An orange LED for each channel which turns on when

distortion of any type becomes audible in the amplifier

output.

IOC

A yellow LED for each channel which serves as a distortion indicator . This indicator will light long before the

distortion is audible. The IOC indicators include a pulse–

stretching feature that helps make them more noticeable, even with rapid transient signals.

Signal

A green LED for each channel which flashes dimly when

a very low–level signal (as low as 10 mW) is present in

the output. They flash brightly when a louder signal (at

least 1 watt) is present at the output.

Enable

A green LED that turns on when the amplifier has been

turned on and has power. When first turned on, there

will be a brief two–second delay while the amplifier

performs a quick turn–on diagnostic. Then the Enable

indicator will turn on to its full brightness. If no signal is

present, the Enable indicator will switch to a dim level.

©1999 Crown International, Inc.

Specifications 2-1

Page 16

K Series Service Manual Rev A.

2.4 Input/Output

Input Connectors

One balanced ¼–inch phone jack and one 3–pin female XLR connector for each channel.

Input Stage

Input is electronically balanced and employs precision

1% resistors.

Input Impedance

Nominally 20 K ohms, balanced. Nominally 10 K ohms,

unbalanced.

Input Sensitivity

1.4 volts for standard 1 kHz power (33 dB of gain), or

26 dB gain.

Output Connectors

T wo sets of color–coded binding posts for banana plugs,

spade lugs or bare wire. European models do not accept banana plugs.

DC Output Offset

±10 millivolts maximum.

2.5 Output Signal

Stereo

Unbalanced, two channel.

Bridge–Mono

Balanced, single–channel. Channel 1 controls are active; channel 2 should be turned down. For polarity the

same as the input signal, use channel 1 output post as

the speaker positive and the channel 2 output post as

the speaker negative.

Out–of–band low–pass and high–pass filters protect

the amplifier and loads from infrasonic frequencies below 8 Hz and ultrasonic frequencies above 30 kHz.

Tu rn On

State–of–the–art “soft start” feature prevents the amplifier from drawing a large inrush current when it is

first turned on. This feature also assures that no dangerous artifacts are produced by the amplifier.

2.7 Construction

Chassis

Beautiful cast–aluminum front panel coated with a durable powder coat finish. Front panel labels are printed

in color on Lexan for durability and fingerprinting resistance. Aluminum chassis with durable black finish.

Cooling

High performance passive convection cooling system

allows the amplifier to drive 2-ohm loads to high music

sound levels (8 dB into clip) in a 40° C environment

without overthermalling.

Dimensions

Standard 19–inch (48.3-cm) rack mount width (EIA RS–

310–B), 3.5–inch (8.9-cm) height and 16–inch (40.6cm) depth behind front mounting surface.

Weight

K1

32 pounds (14.6 kg).

K2

38 pounds (17.3 kg).

2.6 Protection

General Protection

K-Series

or mismatched loads; overloaded power supplies; excessive temperature, chain destruction phenomena,

input overload damage and high–frequency blowups.

They also protect loudspeakers from input/output DC,

DC offset and turn–on/turn–off transients.

TLC protection circuitry protects the amplifier from excessive heat by subtly and dynamically reducing the

gain only when necessary to reduce heat levels. T ransformer overheating (an extremely unlikely event) will

result in a temporary shutdown; when it has cooled to

a safe temperature, the transformer will automatically

reset itself.

2-2 Specifications

amplifiers are protected against shorted, open

Center of gravity approximately 6 inches (15.2-cm) behind front mounting surface and left-right centered.

©1999 Crown International, Inc.

Page 17

3 Theory

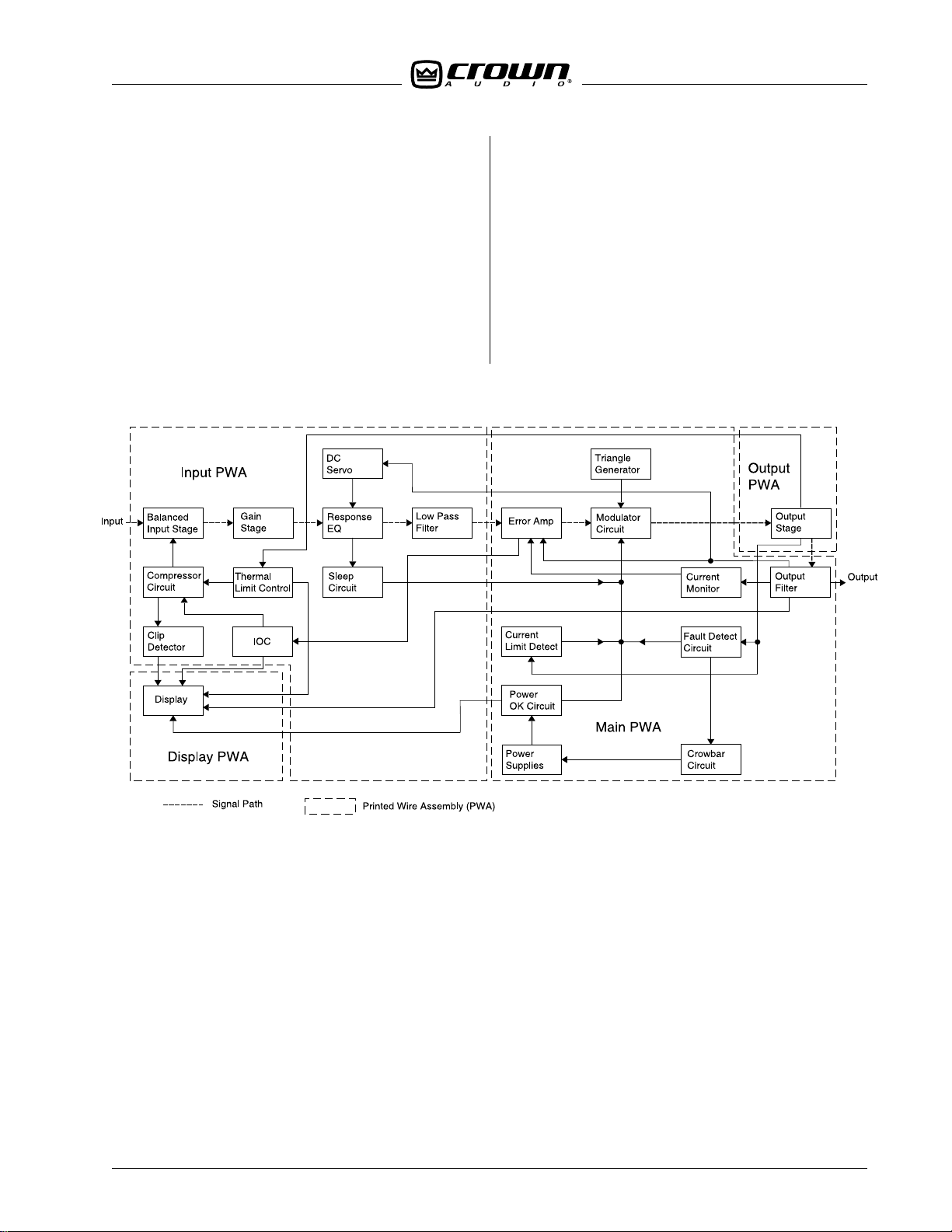

3.0 Overview

This section of the manual explains the general op-

eration of the K Series power amplifier. Topics cov-

ered include Power Supplies, Input Stage, DC Servo,

Sleep Circuit, Error Amp, and Modulator. For Simplic-

ity, the circuit theory will only refer to channel one. It

may be assumed that channel two is identical to chan-

nel one.

3.1 Power Supplies

There are numer ous power supplies and voltage regu-

lators found within the K Series amplifiers. The main

high energy power supply and the low energy power

supplies are located on the main module.

3.1.1 Main Power Supply

The AC line cord is terminated through the fuse to the

AC line filter circuit. C1 is a .22uF capacitor and is

located across the line and neutral leads. C2 and C3

are .0047uF capacitors. C2 is connected from line to

ground and C3 is connected from neutral to ground.

This filter prevents unwanted emissions from contami-

nating the AC power line. The AC power then is routed

to the control board where the power-on relay, soft

start circuit and the AC line voltage configuration cir-

cuits take place.

When S1 is closed and power is first applied the relay

K1 is open and current passes through PTC (R1) to

the power transformer primary. The PTC restricts the

amount of inrush current while the transformer is en-

ergizing. When the power supply voltage reaches op-

erating voltage level the relay (K1) closes and by-

passes the PTC resistor. D1 is a diode bridge that is

configured to filter out any DC component on the AC

line. This is included to eliminate the possibility of

“T ransformer Buzz” which can occur when a torroidial

transformer is subjected to “dirty” or “noisy” AC power .

The primary wiring configuration for the multi-tap

torroidial power transformer (T1) is accomplished with

a connector plug that contains 9 connections. The

jumpers on the plug determine the amplifiers line volt-

age operating level. Line voltage reconfiguration can

be achieved by inserting the appropriately wired pug

(See Section 4) or by rewiring the existing plug.

K Series Service ManualRev A.

Full wave rectification is achieved by the bridge rectifying units D1 and D2 for the high energy supplies

(±Vcc). C5 and C7 filter unwanted AC ripple from the

±Vcc power supplies.

D3, D4 and R1 detect low energy by sampling the

transformer secondary voltage levels and passing this

on to the Power OK circuit located on the Main module (to be covered later).

3.1.2 Low Voltage Power Supplies

On power up the ±Vcc power supplies first initiate.

Once the +Vcc supplies are up to an operational level

they power up the 125KHz oscillator: U9 and the gate

driver: U10. The +Vcc is fed through F1 (3 amp fuse),

L1 and R6. This sends+15V to both U9 and U10. The

output of U10 is amplified by Q2, rectified by D3 and

filtered by C15. The result is a regulated +15VDC. This

+15V feeds U4 (+5V) which starts a 4MHz generator

Y1/U6D (main schematic). The 4MHz output of U6D

is sent to a divide-by chip, U5. U5 generates two outputs:

1. 500KHz–routed to the triangle generator (see Triangle generator circuit description).

2. 125KHz–routed back to the low voltage power supply. This 125KHz signal is fed back in order to drive a

high frequency switch mode power supply . This SMPS

consists of D4, D5, U11A, U11B, Q3 and Q4. U11A

and B drive the 2 FET devices Q3 and Q4. The resulting output is a +7V 125KHz signal. The output of this

switch mode power supply is routed in three directions:

1. Through C23 this supply is rectified and filtered by

D10, D11, C24, and L5. The output is –13V.

2. Through C22 a 7VAC (15Vp-p) source is routed to

the output stage. In the output stage T1 relays the

power source to the full wave bridge (D01 and D02).

Power Supply filtering is provided by C1, C2, C3 and

C4. This +15V now feeds U03A and U03B (output

stage FET drivers) and a +5V regulator (U01).

3. T1 Transformation:

a. Using the primary coil of T1 the signal is filtered by

C26 and L6 to supply +7V. This +7V is used to

feed a number of 5V regulators found on the main

module.

b. T1 secondary #1: this power supply uses -Vcc as a

reference point. The output is labeled -Vcc+12.

Since the K2 Vcc is ±103V the output of this power

supply is –103V +12V = –98V. D12 and D13 provide rectification and C27 and C28 provide filtering.

©1999 Crown International, Inc.

Theory 3-1

Page 18

K Series Service Manual Rev A.

c. T1 secondary#2: After rectification (D14 and D15)

and filtering (C29 and C30) B2+7 and B2-7

d. T1 secondary#3: After rectification (D16 and D17)

and filtering (C31 and C32) B1+7 and B1-7

4. Oscillator Sync: the final destination of the 125KHz

signal is to synchronize the original 125KHz oscillator

U9.

3.2 Input Stage

Both XLR and phone jack input connectors are in par allel with each other. While in most audio products

the incoming shield is tied to the amplifiers ground

network,

(R100) paralleled with two .01uf capacitors(C100 and

C135) for the purpose of inhibiting ground loop circulating currents and RFI protection.

The signal is fed to the balanced to unbalanced gain

stage. Input impedance is 20K ohm balanced and

10K ohm unbalanced.

K Series

lections: 26dB and 1.4V. With the gain switch (S100)

out the inverting gain stage is unity (gain of 1). With

the gain switch (S100) in the inverting gain stage adds

(depending on the amplifier model) the necessary

gain to achieve 1.4V input sensitivity.

K Series

amplifiers come with two input sensitivity se-

amplifiers insert a 24 ohm resistor

mount. There are three filters that eliminate any AC

component:

1. R147 and C121 for a 1 pole filter (-3 point is 8Hz).

2. The RC networks C114/R141 and C118/R148 each

form a single pole filter.

The combination of all three filters form a three-pole

filter leaving only the DC voltage.

3.4 Sleep Circuit

The sleep circuit monitors each channel for a signal.

When no signal is present for approximately six seconds the sleep circuit sends a Standby signal to the

main module turning off the carrier frequency within

the modulator circuit. It takes approximately 0.5mV of

input signal to bring the amplifier out of Sleep mode.

Signal is sampled from the second stage (U103A pin

1) of the Gaussian low pass filter. U5D generates the

Standby control signal to place the amplifier in sleep

mode. R17, R15 and C7 form the RC timing network

that determines the time of switching states of U5D

from +0.9V (awake) and –13V (asleep). The Standby

control signal is routed to the base of Q102 through

the diode D111.

Inherent within all PWM amplifiers is a rise in gain at

higher frequencies. Because of this a 7th order

Gaussian low pass filter has been included in the input stage of the

filter is found immediately after the gain stage. U103A,

U103B, U103C, U103D comprise this filter . U101D and

R172 form the gain calibration stage for this 7th order

Gaussian filter.

K Series

amplifiers. This Gaussian

3.3 DC Servo

Because the K series of amplifiers are DC coupled

from the Gaussian Filter through to the amplifier output DC offset voltages can appear. This DC voltage

can be amplified and the audio signal ride on top shifting its reference point r esulting in nonsymmetrical clipping. For this reason a DC correction circuit has been

added. The non-inverting input of U105 is tied to the

speaker output.

Since the purpose of U105 is to compensate for DC

offset voltages elimination of any AC signal is para-

3.5 Error Amp

The audio signal enters the main module from the input module. the audio and negative feedback signals

are both processed by the error amplifier U100D. From

the error amplifier the signal is divided and is fed to

the modulator . Since the modulator circuit is balanced

the drive signal for the positive modulator is inverted

by U100C.

3.6 Modulator

U101 and U103 are high speed differential comparators. The comparator section has two outputs: inverting and non-inverting. Therefore the output is balanced. The audio signal is applied to the inverting

input of both differential comparators. The 250KHz

triangle wave is applied to the non-inverting input of

both differential comparators. With no audio signal the

250KHz is passed on to the NAND gate section of the

differential comparator unchanged. Each NAND gate

has two inputs: the modulated signal from the high

speed comparater section and current limiter

signal(U6A). In the event of over current the current

limiter (U6A) signal is shut off disabling the NAND

3-2 Theory

©1999 Crown International, Inc.

Page 19

K Series Service ManualRev A.

gates. This results in disrupting of the signal path.

The output of U101 is balanced and forms the posi-

tive portion of the output waveform (Vp). The output

of U103 is balanced and forms the negative portion

of the output waveform (Vn). These two balanced sig-

nal lines are routed to the output stage drivers, U02

and U52.

3.7 Triangle Generator

The 250KHz triangle wave has its origins from the

4MHz generator . After entering the divide-by chip (U5),

a 500KHz output signal (pin 9) is routed to U12B. The

output of U12B is a 250KHz square wave.

The 250KHz signal is then sent through U2C. U2C is

a linear IC with R186, R187, C153 and C154 in its

feedback loop. This stage converts the 250KHz

square wave into a triangle wave. From Pin 8 of U2C

and through C152 the 250Kz triangle wave is sent to

U105 which has two functions: gain and high fre-

quency filtering. C150, C151 and R162 serve to filter

the triangle wave signal.

The output of U105 is the 250KHz signal that is routed

to the positive and negative modulators, U101 and

U103.

cuitry . The output of U02 and U52 are then sent to the

output MOSTFET drivers.

U03A, U03B, U53A and U53B are dual inverting high

speed drivers designed to interface low current digital circuitry (U02 and U52) with power MOSFETs.

U03A, U03B, U53A and U53B are used to drive the

gates of the output FETs (Q1-Q4, Q51-Q54).

The output stage is divided into two sections, positive

and negative. The signal is then routed to the BCA

filter inductors (Ln and Lp) and the current sense resistors (R13/R14 and R63/R64). The combining point

is then sent to the Output Filter.

With no audio modulation both negative and positive

FET stages conduct. The frequency, phase and amplitude of output FET conduction is identical. Since

the FET conduction signals are the same but opposite in polarity complete cancellation takes where the

BCA filter inductors and current sense resistors connect. As the fundamental center frequency (250KHz)

is modulated with audio differences in frequency,

phase and amplitude appear and audio output develops from the BCA filter. This signal is then routed

back to the Output Filters located on the main module.

3.8 Proportional Vcc Generator

The Proportional Vcc generator outputs a DC voltage

that varies as the ±Vcc levels vary. This varying DC

voltage influences the 250KHz output level. Because

output signal gain in a PWM amplifier can deviate as

VCC varies a DC voltage proportional to the Vcc sup-

plies is applied to the Triangle generator circuit.

U3C functions as the Proportional Vcc generator.

Through a resistor dropping network (R23/R24) +Vcc

is applied to the non-inverting input. Through another

resistor dropping network (R22/R21) –Vcc is applied

to the inverting input. On the output of U3A is a DC

voltage of 6.2VDC.Through diode D21 and resistor

R20 5.1VDC is applied to U12B.

3.9 Output

The modulated 250KHz signal exits the main module

and enters output assembly by means of U02 (Vp)

and U52 (Vn). U02 and U52 are optically coupled

gates giving electrical isolation from main module cir -

3.10 Output Filter

The output filter is made up of three individual filters:

a 250KHz filter (L101/C127), a 500KHz filter (L102/

C131) and a final 250KHz filter. The signal passes

through these three filters to eliminate both any residual 500KHz and 250KHz signals. The audio signal

is the connected to the output speaker connectors.

3.11 Current Monitor

Audio output current levels are monitored by the use

of transformer T100. A small primary winding is in

series with the output line and the secondary develops a voltage related to the output current of the amplifier. This output current information is used for two

purposes:

1. Negative feed back.

2. Current feedback information for the Triangle wave

generator.

3.12 Current Limiter

To prevent excessive output current the K series am-

©1999 Crown International, Inc.

Theory 3-3

Page 20

K Series Service Manual Rev A.

plifiers are incorporated with a current limiting protection circuit. The output current is sense by the cur rent sense resistors found in series with the BCA filter

inductors. The voltage dropped across these two resistors is sent back to U106A and U106B. The voltage windows for U106A and U106B are set by the

dropping resistors R303/R310 and the zener diodes

D113/D114. The window voltage is ±0.7V. The outputs of the window comparator are normally +0.6V.

This positive voltage is sent to U107A, an optically

coupled gate. Pin 2 of U107A is tied to B1-7 and as

long as pin 1 is positive the device conducts. The

output is an inverting stage so when its input is positive its output will be negative. If the current limit detector switches states (becomes negative) pin 1 is

negative and pin 7 becomes positive.

The output of U107A is routed to U6A (exclusive NOR)

and as long its inputs are negative the output of U6A

will be positive allowing the modulating network (U101

and U103) to output signal. If the output of U107A

goes positive the output of U6A goes negative thus

disabling the modulating circuit.

3.13 Overlap Correction and Adjustment

The Overlap adjustment corrects for DC shift in the

T riangle waveform. In order to track thermal variations

the Overlap adjustment potentiometer (R25) is located

on each of the Output assemblies. A positive DC voltage is routed from the wiper arm of R26 to the Triangle wave gain stage. This DC voltage varies the

DC component of the 250KHz waveform.

3.14 Display Circuitry

The

IOC

(Input Output Comparator) circuit uses the

error signal from the error amplifier (U100D). With a

window of ±0.3V U102A and U102D have a positive

output. This in turn biases off D105 leaving a positive

voltage on the base of Q103. If an error signal appears the ±0.3V window is overcome and the combined outputs become negative. This results in the

output of U102C to go negative and in turn biasing on

Q103. As Q103 biases on, E102 illuminates.

nal. When initialized U1B output (pin 7) becomes positive. After routed through the non-inverting input of

U1A this positive signal turns on E100.

The signal used to switch on the Power LED comes

from the Power OK control circuit. As this lime goes

positive Q1 conducts lighting E1.

3.15 Control Circuitry

After initial power supply power up the outputs of U7C

and U7D become positive (+1.2V). The output of U7

C and U7D is routed to two places: 1.) the first is the

Power OK LED and 2.) then the Modulator able/disable comparator, U108A.. This positive logic signal

causes the output of U108A to become positive

(+1.3V) which next biases on Q102. With Q102 biased on the collector/emitter voltage is low (0.6V).

Since U6A is a NOR gate and both inputs are low the

output is a logic high allowing the modulator circuits

(U101 and U103) to pass signal.

There are four functions that can disable the modulator circuit and disable the amplifier. These four inputs

all effect the control line connected to pin 5 of U108A.

The normal logic levels for this control line are: ON/

0.6 and OFF/–14). The four control functions are:

1. Initial Turn On Delay (U8A). On initial turn on the

control line to U108A is logic low causing the modulator to be disabled. Once the capacitor found within

the RC timing network (C161/R302) charges this comparator stage switches states allowing the Modulator

to conduct. (Normal logic levels are ON/0.6 and OFF/

-14).

2. Over Temperature (U108B). In the event the amplifier overheats the output of U108B switches states

disabling the Modulator.

3. Proportional Vcc (U8C). The Proportional Vcc circuit monitors the ±Vcc power supplies. In the event

that the line voltage drops to far below the rated line

voltage (causing erratic operation) U8C switches

states disabling the Modulator circuit.

4. Current Limit (U108D).

A sample of the amplifier output (Fo CH1) is sent to

U2A and U2B. This audio waveform sample then

drives Q102 varying the current to the SPI (Signal Presence Indicator) LED E101.

The compressor circuit is initiated by either the

initialization signal or The Thermal Limit Control sig-

IOC

3-4 Theory

If the amplifiers current limit is exceeded because of

low impedances or a short circuit loading, U108D

switches states and disables the modulator circuit.

©1999 Crown International, Inc.

Page 21

K Series Service ManualRev A.

3.16 Crowbar Circuit

U13B and U13C form the DC protection comparator

circuitry. R191, R192 and C156 form a combination

resistive dividing and low pass filter networks. Signals below 8Hz (including DC voltages) cause the

combined outputs to become a logic low (–14V). This

logic level is inverted by the next comparator stage,

U7B. a logic high (0.6V) causes Q10 to conduct. Once

U7B switches states (logic high) U7A inverts this logic

level and latches the Fault circuit in the Crowbar disabled condition. In order to clear this latched state

the amplifier must be first turned off.

When the amplifier is turned on the line current conducts through the R1 (power supply circuit diagram)

until the relay energizes. The relay primary is energized when Q8 is biased on. Q8 is biased on when

Q7 is biased off (high collector/emitter voltage). When

the relay closes R1 is bypassed allowing full power

supply energy available to the output stage. If Q10

conducts Q7 is biased on and Q8 is biased off. This

disables the power input relay.

©1999 Crown International, Inc.

Figure 3.1 Amplifier Block Diagram

Theory 3-5

Page 22

K Series Service Manual Rev A.

This Page Intentionally Left Blank

3-6 Theory

©1999 Crown International, Inc.

Page 23

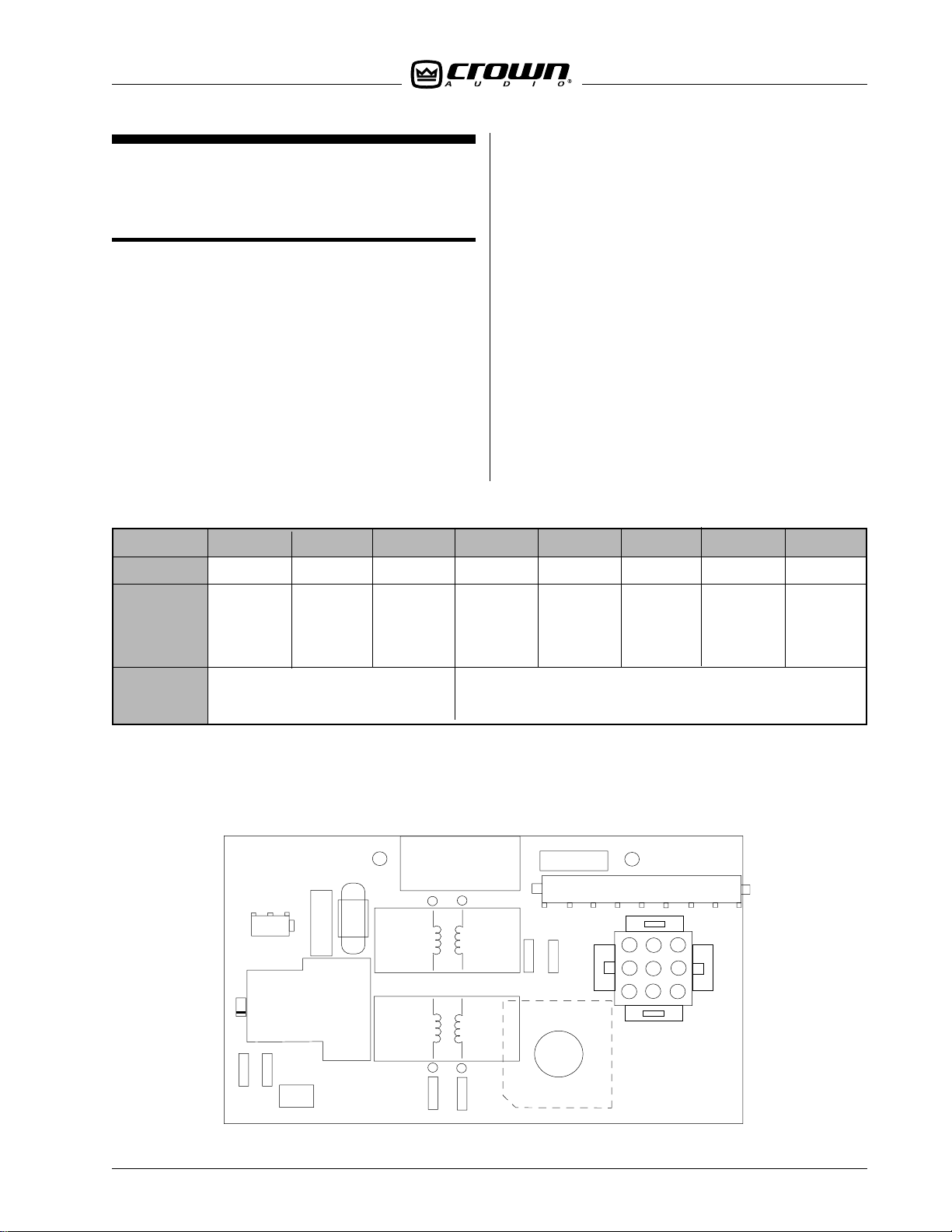

4 Line Voltage

Conversion

K Series Service ManualRev A.

appropriate operating voltage. Figure 4.1 has information on jumper location for each voltage.

When wiring the molex connector the proper insertion

and removal too should be used (example, Amp

#458994-2).

4.1 Line Voltage Conversion

The

K Series

any line voltage in the world. It is also made to operate

at 50- or 60-hertz frequency with no modification. To

amplifier can be configured to operate at

When converting from the 100V range to the 200V range,

or vice versa, be sure and change the back panel line

fuse. The fuse values and Crown Part Numbers are

listed in Figure 4.1.

convert from one line voltage to another, change the

V oltage Plug (P7), a 9 pin connector plug on the Control PWA. Refer to Figure 4.1 for the Crown Part Number of the plug you need. These plugs are available

from the Crown Parts Department.

For your reference, Figure 4.2 shows the Control PWA,

P7, and the pin configuration of P7. T o access the Con-

trol PWA, remove the bottom cover of the amplifier.

The Control PWA is located in the center of the chas-

sis. For additional information on disassembly and asThe Voltage Plugs have jumpers installed which con-

sembly of the amplifier refer to Chapter 5.

figure the primary power transformer windings for the

Voltage 100V 120V 130V 200V 220V 230V 240V 250V

Plug Part # 101230-1 101231-1 NA* NA* 101232-1 101233-1 101234-1 NA*

Voltage 5–7 5–8 1-8 2–4 2–4 2–4 1–4 1–4

Plug 6–2 6–1 3-4 5–7 5–8 5–9 5–8 5–9

Jumpers 3–4 3–4 5-9

Fuse K1: A10285-27, 15A K1: A10285-40, 8A

K2: A10285-28, 20A K2: A10285-26, 10A

* Voltage Plug not available. Voltage may be obtained by positioning the jumpers as indicated.

The Crown Part Number for the Voltage Jumper Wire is A11555-P025P.

The Crown Part Number for the 9-Pin Molex Connector is C10303-3.

D2

P12

©1999 Crown International, Inc.

Figure 4.1 Line V oltage Selection T able

C3

C1

R1

C2

1

1

P6

L2

P10

P11

1

2

3

P5

P7

4

7

8

5

6

9

Voltage Plug

L1

P8

P9

D1

Line Voltage Conversion 4-1

P13

K1

1

P4

Figure 4.2 Control PW A with Voltage Plug

Page 24

K Series Service Manual Rev A.

This page intentionally left blank

4-2 Line V oltage Conversion

©1999 Crown International, Inc.

Page 25

5 Maintenance

K Series Service ManualRev A.

5.2 Disassembly for Inspection & Service

The extent of disassembly required will depend upon

the extent of inspection and service required.

5.1 Where to Begin

Effective repair involves three basic steps: 1) Determine the symptom(s) of the problem; 2) Identify the

cause(s) of the symptom(s); 3) Repair the unit to eliminate the cause(s). To deter mine the symptoms, you

will want to get as much information from the user as

possible. Get as much information as you can about

the system and how the amplifier is used. There is

always the possibility that the problem will show up

only if used in a specific way.

Once you have all the information about the symptom(s),

it is time to inspect the amplifier. A careful visual inspection is valuable for most problems which you may

encounter . T o inspect the inside of the amplifier r emove

the cover as described in Section 5.2.1.

Begin the inspection by looking for anything which

appears abnormal, like loose connectors, broken wires

and burnt or visibly damaged components. Inspect

the printed circuit assemblies for broken traces and

loose connections. Be thorough. The time you spend

visually inspecting the amp is time well spent.

NOTE: TO A V OID THE RISK OF ELECTRIC SHOCK,

TURN OFF AND UNPLUG THE AMPLIFIER FROM

THE AC PO WER OUTLET BEFORE DISASSEMBLY

OR REASSEMBLY IS ATTEMPTED .

5.2.1 Bottom Cover Removal

To remove the cover of the amplifier you will need a

#15 torx bit (TX15). After the cover is removed, and

before any internal cables are disconnected, discharge

the supplies. See Section 5.2.2.

1. Turn the amplifier on its side on your workbench.

The only access to the inside of the amplifier is the

bottom cover .

2. Using the TX15 bit, remove the 14 screws around

the perimeter of the cover .

3. The cover lifts straight up after the screws are removed.

4. Vacuum out any metal particles in the unit that are a

result of the lock washers digging into the chassis.

The cover on early units may appear to be symetrical

but it’s not. When installing it onto the unit, make sure

there is no gap between the front edge of the cover

and the lip of the front panel extrusion. If installed backwards, there will be an

1

/8-inch overhang out the back of the unit.

1

/8-inch gap at the front, and an

WARNING

Amplifier components are ESD sensitive.

When servicing the amplifier , the technician

must have approved ESD protection. Proper

grounding straps and test equipment are

required. Failure to use proper protection

will result in component failure.

©1999 Crown International, Inc.

WARNING

Before unplugging or plugging in any connectors or wires in the amplifier , discharge

the power supplies. See section 5.2.2 for

instructions. Failure to do so will result in

circuit failure.

Maintenance 5-1

Page 26

K Series Service Manual Rev A.

5.2.2 Power Supply Discharge

Before any connectors and PWAs are removed, the

Power Supplies need to be discharged. Follow these

simple steps.

1. Make sure the amplifier is unplugged from the AC

power source.

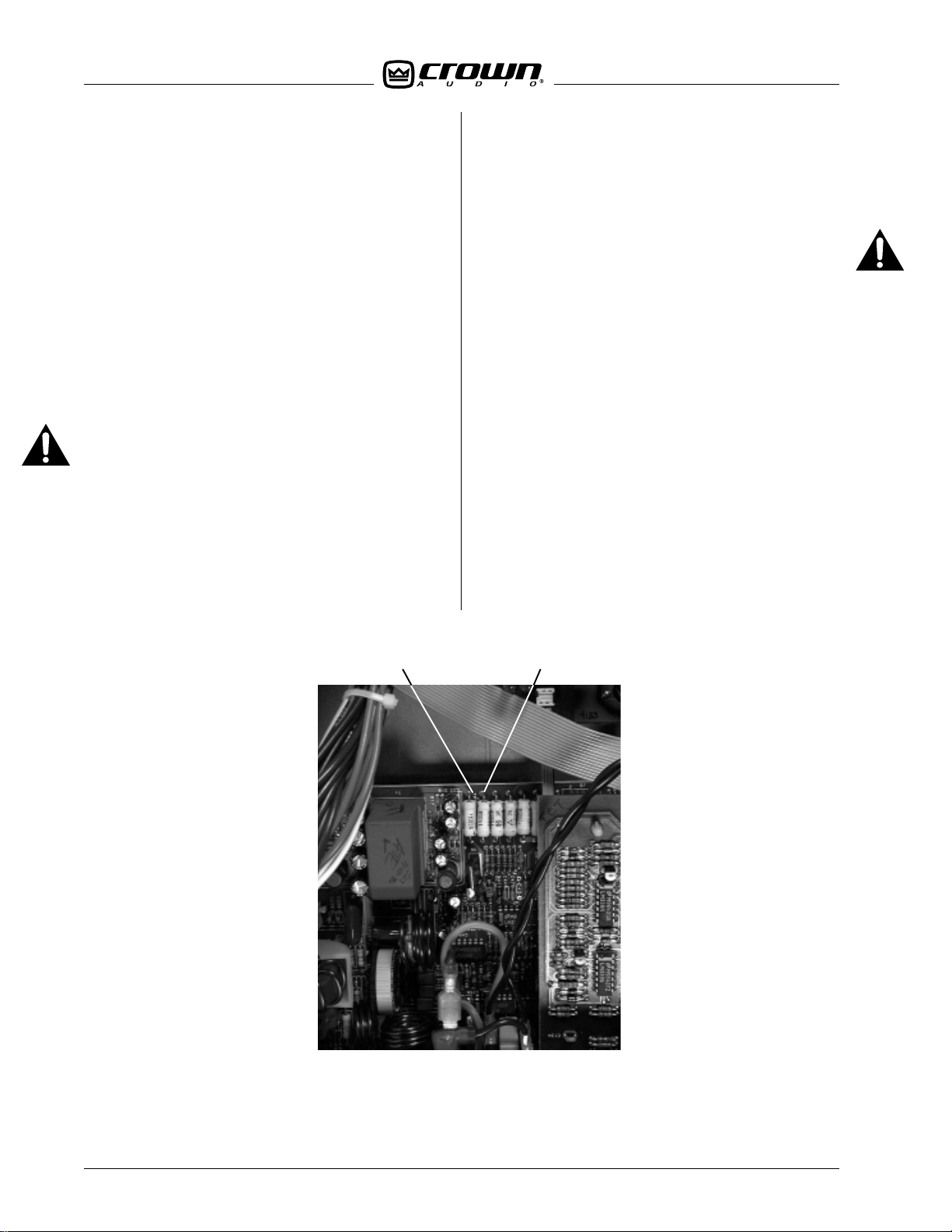

2. Locate Test Point 1 (TP1) on the Main PWA. See

Figure 5.1.

3. With a flat blade screwdriver or another metal object, short TP1 to the nearest resistor pad. This resistor

is the second one from the end of a row of seven 3W

resistors. Once the short is made you do not have to

hold the screwdriver in place. The initial short triggers

a latching triac circuit which discharges the supplies.

4. Wait a few seconds before attempting to disassemble the amplifier.

Caution: the three-watt resistors will become hot as

the power supplies discharge.

5.2.3 Back Panel Assembly Removal

The back panel assembly is removed to access the

Input and Main PWAs.

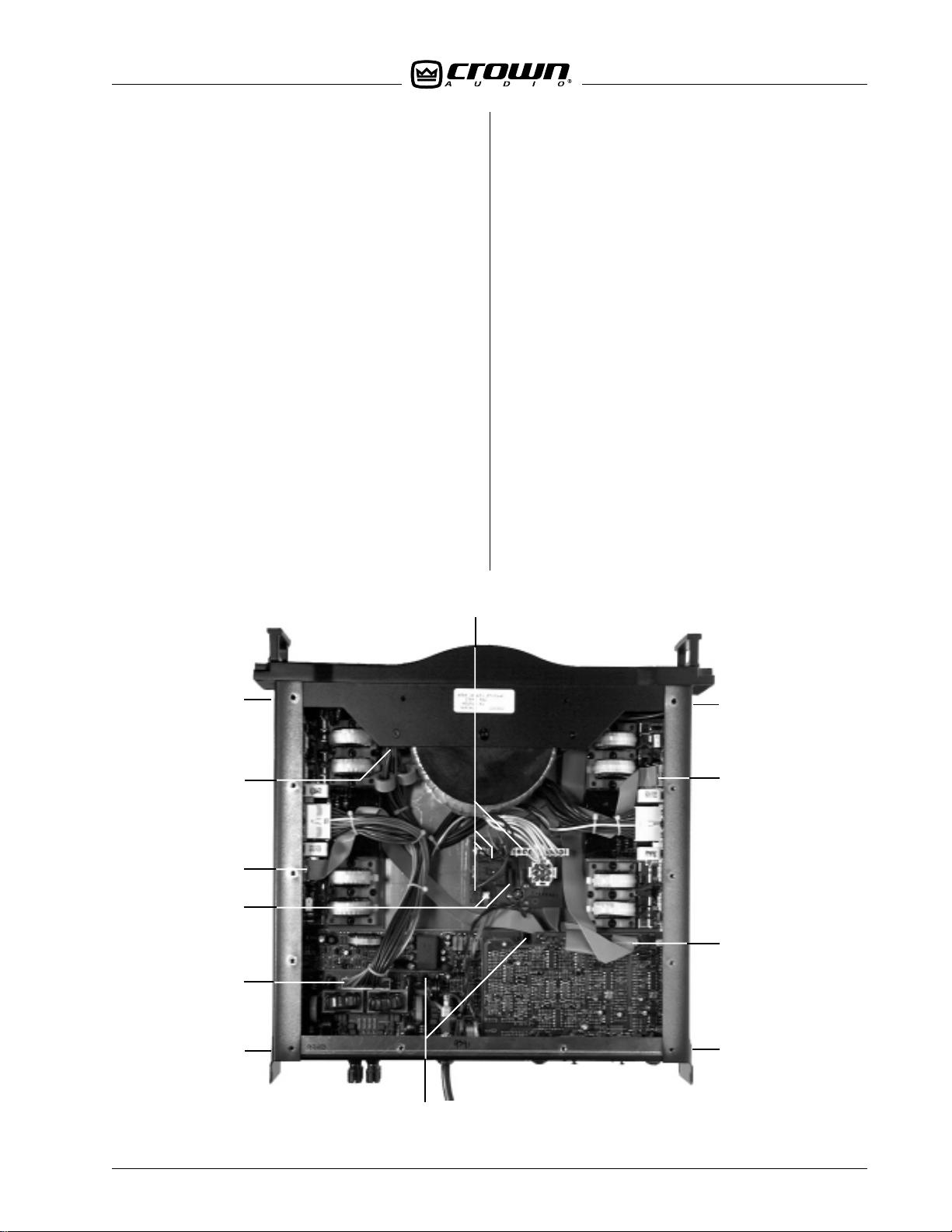

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Remove the aluminum shield by removing the two

screws on the rear and the one on the control board.

Note: This shield is not used on early non-CE units.

3. Using a TX15 bit, remove the two screws on each

side of the amp that hold the rear supports. See Figure 5.2.

Item A

4. Remove the five TX15 screws along the top rear of

the amplifier.

Caution: These screws are shorter than the other

cover screws and must be reinstalled in the same

location or Main PW A will be shorted to chassis.

5. Remove the two TX15 screws on the Main PWA.

See Figure 5.2.

Item B

6. Unplug the black and white wires (P8 & P9) and the

ribbon cable (P4) from the Control PWA. See Figure

5.2.

Item C

7. Unplug the P1 ribbon cable from the Input PWA.

See Figure 5.2.

Item D

8. Unplug the main wiring harness from the Main PWA.

See Figure 5.2.

Item E

9. Remove the necessary tie wraps and unplug the

ribbon cables from the Output PWAs. See Figure 5.2.

Item F

10. Gently slide the back panel assembly straight out

the back of the amplifier. Note that the PC cards slide

in the rails formed in the aluminium heatsink. Be careful of the wires and cables that will come with the assembly.

TP1 Resistor Pad

Figure 5.1 Discharge Test Point

5-2 Maintenance

©1999 Crown International, Inc.

Page 27

K Series Service ManualRev A.

5.2.4 Front Panel Assembly Removal

The front panel assembly is removed to access the

Power Switch, Display PWA, Bridge PWA and the Power

Transformer.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Using a TX 15 bit, remove two screws on each side

of the amp located directly behind the rack ears. See

Figure 5.2.

Item G

3. Remove the four TX 15 screws along the top front of

the amplifier.

4. Unplug the main wiring harness from the Bridge

PWA. See Figure 5.2.

Item H

5. Remove the P1 ribbon connector from the Input

PWA. See Figure 5.2.

Item D

6. Remove the P5 and P6 transformer wire connectors, and P10, P11, P12 and P13 switch wires from the

Control PWA. See Figure 5.2.

Item I

7. The Front Panel Assembly will now come off of the

amplifier. Pull on the front panel handles while securing the chassis of the amplifier . Be careful of the wir es

and cables that will come with the assembly. When

reinstalling the Front Panel, make sure the capacitors

on the Bridge PWA clear the aluminum heat sink and

the Output PWA.

5.2.5 Input PWA Removal

The Back Panel Assembly must be removed to gain

access to the Input PWA.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Remove the P2 ribbon cable from the Input PWA.

3. Using a #1 Phillips bit, remove the four screws that

hold the two female XLR jacks on the back panel.

4. Using a 5/8-inch nut driver, remove the two plastic

nuts that hold the 1/4-inch input jacks in place.

5. Using a TX15 bit, remove the two screws on the

back panel that hold the Input PWA in place.

6. Locate the plastic board stand–off between the Main

and Input PWAs. Using your fingernail or pliers, press

the release tab on the stand–off while gently lifting the

Input PWA off the stand–off.

7. While guiding the input jacks out of the holes in the

back panel, slowly lift the PWA out of the assembly.

5.2.6 Main PWA Removal

The Back Panel Assembly must be removed to gain

access to the Main PWA.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

I

G

H

G

F

F

C

D

E

A

A

©1999 Crown International, Inc.

B

Figure 5.2 Bottom View

Maintenance 5-3

Page 28

K Series Service Manual Rev A.

2. Remove the P2 ribbon cable from the Input PWA.

3. Using a needle nose pliers, unplug the six red wires

that go to the positive output binding posts. Note where

they go.

4. Using a TX15 bit, remove the three screws that secure the Main PWA to the back panel.

Caution: Do not power up the amplifier without replacing these screws, or circuit damage to the Output PWAs will occur.

5. Locate the plastic board stand–off between the Main

and Input PWAs. Using your fingernail or pliers, press

the release tab on the stand–off while gently separating the two PWAs.

6. Lift the Main PWA away from the back panel.

When installing the Main PWA onto the Back Panel

Assembly be careful not to bend the capacitor located

under the Line Filter PWA. If the unit is an early non-CE

unit, the clearance between a capacitor on the Line

Filter and a capacitor on the Main PWA is very small.

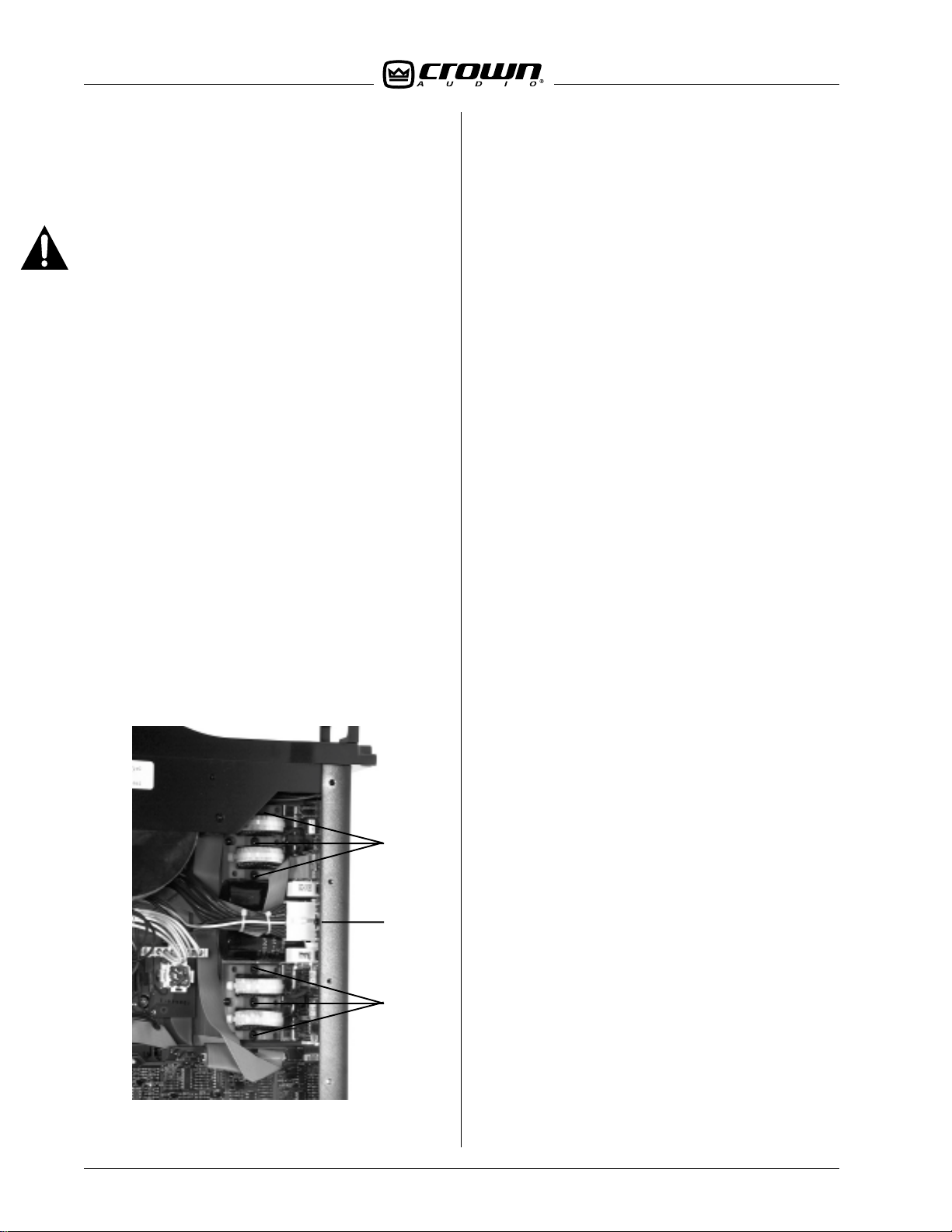

5.2.7 Output PWA Removal

The left and right Output PWAs are identical.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Unplug the P01 ribbon connector and the P3 wiring

harness connector from the Output PWA.

3. Using a TX15 bit, remove the screw located at the

center–top of the assembly. See Figure 5.3.

Item A.

4. Using a TX20 bit, remove the six screws located by

the four large coils on the assembly. See Figure 5.3.

Item B

Be very careful not to damage the coils with your screwdriver . Note that the screws have belleville washers on

them. When replacing the screws be sure the cupped

side of the washer is down toward the assembly.

5. Carefully lift the assembly out of the chassis. When

reinstalling the Output Assembly use a new insulator

pad and make sure there are no metal shavings on the

pad or the heatsinks. Any metal shavings will result in

a “blow–up” when the unit is first turned on. T o be sure

that the insulator is free of shavings, and is installed

correctly, use an Ohm Meter to check for continuity

between the assembly heatsink and the chassis. There

should be no continuity.

5.2.8 Control PWA Removal

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Remove EMC shield on all but early non-CE units.

3. While noting where each wire goes, disconnect each

connector on the Control PWA. The white wire goes on

P9, and the black wire on P8. The two orange wires go

on P10 and P11. The two purple wires go on P12 and

P13.

4. To remove the Bridge Rectifier (D1) along with the

PWA, use an

11

/32 -inch (.86 cm) nut driver to remove

the nut. If you wish to leave the Bridge installed to the

chassis then desolder the four rectifier pads.

5. Using a TX15 bit, remove the three screws that hold

the Control PWA in place.

6. Lift the Control PWA out of the chassis.

Figure 5.3 Output PWA Screws

If replacing the PWA with a new one, be sure and remove the Voltage Plug (P7) and install it on the new

PWA.

If replacing the Bridge Rectifier , be sur e and use ther mal heatsink compound between the rectifier and the

chassis.

B

5.2.9 Line Filter PWA Removal (Early non-CE Units Only)

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

A

2. While noting where each wire goes, disconnect each

wire from the PWA. The blue power cord wire goes on

P4. The long black wire goes on P1, the white on P2.

The short black wire from the fuse goes on P3.

B

3. Using a TX15 bit, remove the two screws that attach

the assembly to the back panel.

4. Lift the Line Filter PWA out of the chassis.

5.2.10 Power Transformer Removal

The Front Panel Assembly must be removed in order

to remove the Power T ransformer .

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

5-4 Maintenance

©1999 Crown International, Inc.

Page 29

K Series Service ManualRev A.

2. Clip the tie wrap which holds the orange and purple

wires to the T ransformer Bracket.

3. Unplug the white wires from the Bridge PWA (P11,

P12 and P13). Note that the white wire with the black

ring attaches to P12.

4. Using a TX15 bit, remove the two screws which

hold the T ransformer Bracket to the Front Panel.

5. Using a TX25 bit, remove the bolt which goes through

the center of the transformer . The plastic bracket can

now be removed.

6. While carefully lifting the transformer out of the

front panel, route the white wires underneath the Bridge

PWA. The transformer will now lift free of the front panel.

5.2.11 Display PWA Removal

The Front Panel Assembly must be removed in order

to remove the Display PWA.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. The two level control knobs on the front panel are

press fit onto the shafts. Remove these knobs.

3. Using a

7

/

-inch nut driver, remove the nuts on the

16

level control shafts. Also remove the flat washers.

4. Lift the Display PWA out of the Front Panel Assembly.

5.2.12 Bridge PWA Removal

The Front Panel Assembly must be removed in order

to remove the Bridge PWA.

1. Follow the instructions in Section 5.2.2. Supply

discharge is necessary to avoid circuit damage.

2. Unplug the white transformer wires from the PWA.

Note that the white wire with the black ring goes to

P12.

3. Using a T20 bit, remove the two screws that hold

the bridge rectifiers to the front panel. The screws have

bellville washers. When installing the screws with the

washers, make sure the cupped side of the washer is

toward the bridge.

4. Using a T20 bit, remove the screw in the center of

the PWA.

5. The bridge assembly will now lift out of the front

panel. When installing it back into the front panel,

make sure there is thermal heatsink compound between

the bridges and the front panel.

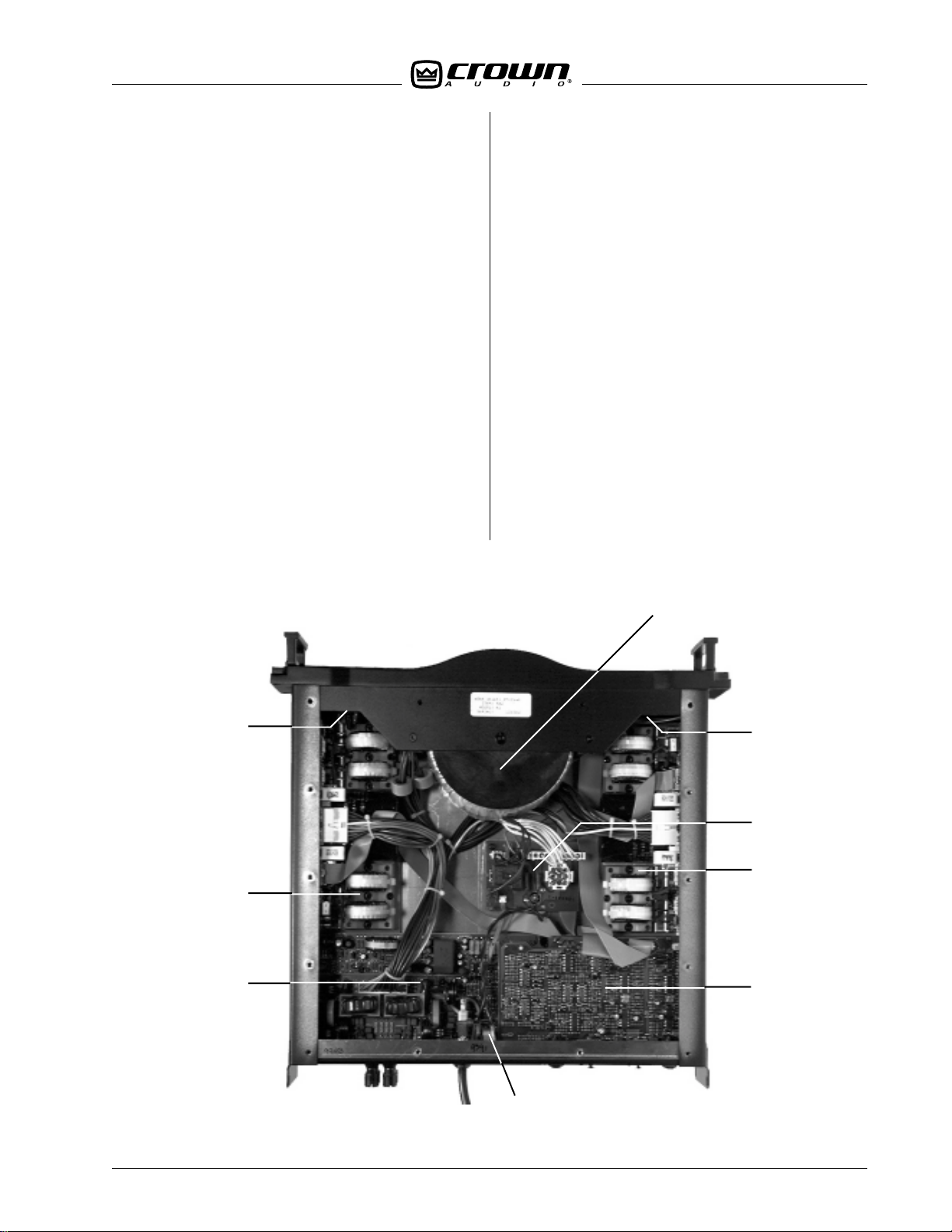

Bridge PWA

Output PWA

Main PWA

Power Transformer

Display PWA

Control PWA

Output PWA

Input PWA

Figure 5.4 Discharge Test Point

©1999 Crown International, Inc.

Line Filter PWA

Figure 5.4 PWA Layout

Maintenance 5-5

Page 30

K Series Service Manual Rev A.

5.3 Troubleshooting

As mentioned earlier, the three steps to effective repair are: Determine the symptoms; identify the cause

of the symptoms; repair the unit to eliminate the cause.

The purpose of this section is to help you through these

steps in an orderly manner.

5.3.1 Identifying Symptoms

Why was the amplifier brought in for repair? Can you

get it to malfunction again? Some problems can be

intermittent and difficult to find.

Once you have identified and verified the symptoms,

you can look for helpful information in Section 5.3.2 as

to where the cause of the problem is located.

If you don’t observe anything wrong with the amplifier ,

tactfully inquire how the owner used it and try to determine if it was misused or some other component in

their system could have been at fault. Remember that

the protection circuits in this amplifier will protect loudspeakers from problems caused upstream from the

amplifier (DC protect).

If you lack sufficient information about the problem,

and there aren’t any obvious problems with the amplifier , skip to Section 5.4, the Electrical Checkout Procedures.

5.3.2 Identifying and Repairing the Cause

The first step in identifying the cause of the problem is

always a visual inspection. Once the bottom cover is

removed, and the supplies are discharged, look for

loose connectors, broken wires, loose hardware, burnt

components, or bad solder joints on the PC boards.

Any burnt components are a sure sign that the PWA

will need to be replaced.

Once the visual inspection is complete you may proceed in powering up the unit. The best way to positively locate which PWA is at fault is to have a working

PWA of each type on hand and plug them into the

amplifier one at a time to see when the problem goes

away . Output and Input PW As can be plugged into the

amplifier easily without removing the old PWA. When

doing so, use an insulating material to isolate it from

the chassis and other PWAs. The Main PW A, however ,

needs to be installed into the chassis before it can be

properly hooked up.

The following Symptoms and Causes may help you

determine which corrective action to take. We realize

that this list is limited. Please read through the Theory

chapter in this manual to better understand the function of each PWA. This will help you come to your own

conclusion as to the location of the problem.

Amp does not appear to power up. No Enable light.

First, check the power supply fuse. Also, make sure

the AC line voltage is correct for the amplifier you are

working on. Severely low AC line voltage could cause

the amp to not power up. If both check out, then the

amplifier is in a fault mode. The two most likely areas

are the Main PWA or an Output PWA.

First, check the Output PWAs. Discharge the sup-

plies, then disconnect the main wiring harness (P3)

from the PWA in question. Now power up the unit. After the delay , if the enable light comes on, the disconnected Output PWA needs to be repaired or replaced.

To check if the Main PWA is at fault discharge the

supplies, then unplug only one Output PWA from the

main wiring harness (P3), and unplug the Input PWA

(P2) from the Main PWA. Now apply power and check

the +15VDC and the -13VDC. To do this, locate U7 on

the Main PWA (next to where the Input PWA overlaps

5-6 Maintenance

WARNING

Before unplugging or plugging in any connectors

or wires in the amplifier , discharge the power supplies. See section 5.2.2 for instructions. Failure

to do so will result in circuit failure.

©1999 Crown International, Inc.

Page 31

K Series Service ManualRev A.

the Main PWA). Using the chassis as the gr ound refer ence, pin 3 is +15VDC and pin 12 is –13VDC. If the

both voltages are correct, discharge power supplies,

then plug Output PWA back in, and unplug the other

Output PWA. Repeat test. If one or both of the DC

voltages is not correct then repair or replace the Main

PWA.

No Signal; one or both channels. Enable on. IOC on.

A constant IOC condition indicates a problem in the

signal path including the Error Amp circuit. This includes the Main and Output PWA ’s. The problem most

likely exists on the Main PWA.

No Signal; one or both channels. Enable light only.

The problem most likely exists on the Input PWA. If

the Input PWA proves to not be the problem then the

Main PWA is at fault.

To check the Input PWA, inject a signal into the channel at fault and turn the level control up. Locate U103

(Ch1) or U203 (Ch2). With an oscilloscope check to

see if there is signal at pin 8. If there is no signal at this

point discharge the supplies, then repair or replace

the PWA. If there is signal then check U5 pin 13 with a

DC volt meter. If this pin is at –13VDC then the signal

detect circuit is not working. Discharge the supplies,

then repair or replace the Input PWA. If you find signal

at U103/203 pin 8, and U5 pin 13 is high (0 VDC), then

the Input PWA is OK. Discharge the supplies, then

repair or replace the Main PWA.

Distortion; one or both channels. IOC indication.

The problem most likely exists on either the Output

PWA or Main PWA. Check the Output PWA first. If the

Output PWA checks out, repair or replace Main PWA.

Distortion; one or both channels. No IOC.

The problem most likely exists on the Input PWA. First

check levels on affected channels, no load. If levels

check out, discharge the supplies, then repair or re-

place Input PWA.

Amplifier does not meet power specs.

Check your power source. If the AC voltage sags below the specified operating voltage of the amplifier then

the unit will not produce full rated output.

The large power supply filter capacitors located on the

Output PWAs are wired in parallel from one PWA to the

other . If one or mor e of these capacitors has a broken

solder joint it could result in the amplifier not meeting

power specifications. To check the capacitors, dis-

charge the supplies, then remove the Output Assembly. Wiggle the capacitors back and forth. If they appear to be loose then they are bad. Repair or replace

Output PWA.

Check the Main Wiring Harness. Multiple wires are used

in parallel to handle the high supply currents. If one or

more of these wires is broken then it will result in restricted current. This could result in the amplifier not

meeting power specifications.

Frequency Response out of tolerance.

The problem most likely exists on the Input PWA. The

Input PWA has the EQ circuit for a flat response. If this

circuit is faulty the amplifier will have poor frequency

response. Discharge the supplies, then repair or replace Input PWA.

Voltage gain problems.

If you experience voltage gain problems with no distortion, the problem most likely exists on the Input

PWA. The Input Sensitivity/Gain Stage circuitry is located on the Input PWA. Discharge the supplies, then

check the Input PWA. If it is faulty, repair or replace

PWA. If Input PWA checks out, the problem is likely

on the Display PWA, which includes the Level Control

Pots. Discharge the supplies, then check Display

PWA. If Display PWA is faulty, repair or replace PWA.

If you have gain problems with distortion, resulting in

an IOC condition, then the problem most likely exists

on the Main PWA. Discharge the supplies, then check

Main PWA. If faulty, repair or replace PWA.

Amplifier gets extremely warm at idle.

Sleep Mode is indicated on the front panel by the Enable indicator. When it switches to half intensity then

the amplifier is in sleep mode. It takes approximately

6 seconds after the signal is removed before the amplifier goes into Sleep Mode. Note that any signal at

all, even a small one, will keep the amplifier out of

sleep mode and it will get warm to the touch. If, with no

signal at all, the amplifier never goes into Sleep Mode

then the problem most likely exists on the Input PWA.

The Signal Detect circuit for Sleep Mode is located on

the Input PWA. Discharge the supplies, then check

Input PWA. If faulty, repair or replace PWA.

To verify the operation of the Signal Detect Circuit, locate U5 on the Input PWA. Monitor pin 13 with a DC

volt meter referenced to chassis ground. If it switches

to –13VDC 6 seconds after signal is removed then the

circuit is OK. If this circuit is OK, but the amplifier

never goes to Sleep, then the problem exists on the

Main PWA. Discharge the supplies, then repair or replace Main PWA.

Amplifier consistently trips breakers at turn on.

A Soft Start circuit on the Control PWA limits the amount

©1999 Crown International, Inc.

Maintenance 5-7

Page 32

K Series Service Manual Rev A.

of inrush current at turn on. Check the PTC (R1) on the

Control PWA. It should measure approximately 5 ohms.

If it is shorted then replace it. Another possibility is

that the relay (K1) has failed.

If the amplifier trips breakers and you can never get it

powered up, Discharge the supplies, then check the

bridge rectifiers (D1 and D2) at the Bridge PWA located in the Front Panel Assembly.

DC output offset

If there is an IOC indication, the problem most likely

exists on the Main PWA. Discharge the supplies, then

check the Main PWA. if faulty, repair or replace PWA.

If there is no IOC condition then the problem is on the

Input PWA. Discharge the supplies, then repair or

replace Input PWA.

Signal to noise out of spec.

If the ribbon cable between the Display and Input PWA

is not routed properly it can cause high Signal to Noise.

It needs to be lying down and away from the large

coils on the Output PWA. The coils can induce noise

into the ribbon cables.

Turn on/off transient

The problem is most likely on the Input PWA. The only

real way of verifying this is to plug a working Input

PWA into the amplifier and see if the problem goes

away. If it is not the Input PWA, it is pr obably the Main

PWA. The amplifier should be silent at turn-on and turnoff.

5.4 Required Test Equipment

Due to the complex circuitry utilized the the K Series

amplifiers, special calibration procedures and the cor rect test equipment are necessary to insure original

factory specifications are achieved. Following is list of

test equipment needed to successfully service the K

Series amplifier . Recommended models are those used

by Crown:

DeviceDevice

Device

DeviceDevice

Oscilloscope 500 MHz or greater LeCroy 9354A

RequirementsRequirements

Requirements

RequirementsRequirements

*

Recommended ModelRecommended Model

Recommended Model

Recommended ModelRecommended Model

Distortion Analyzer THD and IM measurements Audio Precision A TS-1

DC Power Suppies 103 VDC with I-Limiting and Leader 760-3D (Qty . 2)

*

12-15 VDC with I-Limiting Leader 18-3D

*

Function Generator Hewlett-Packard HP 33120A

AC/DC volt meter dB reading capability Hewlett-Packard HP 34401A

*

Dummy Loads 8 ohm, 550 watt, 4 ohm, 850 watt,

and 2 ohm, 1300 watt

* Requirement for component-level troubleshooting only

5-8 Maintenance

©1999 Crown International, Inc.

Page 33

K Series Service ManualRev A.

5.5 Electrical Checkout Procedures

The test procedures in this section are used to verify

the operation of the amplifier. You may, however, find

these tests helpful in troubleshooting a problem if the

problem is not easily identified.

All tests assume that AC power is from a regulated

source at the voltage the amplifier is set up for. See

Chapter 4 if you need to change the operating voltage.

Test equipment includes an oscilloscope, a DMM, a

signal generator , loads, watt meter , I.M. distortion analyzer, and a true THD meter.

During each test, it is assumed that the following conditions are set on the amplifier unless otherwise noted:

—Level controls fully clockwise.

—Bridge Output switch off.

—“Y” Input switch off.

—Input Sensitivity of both channels set at 26 dB.

5.5.1 Quiescent AC Power Draw

Spec: 100 watts maximum quiescent. 10 watts in sleep

mode.

Procedure: With no load connected to the amplifier,

turn on the amplifier. Inject a small signal into one of