Page 1

Operation Manual

CTs Multi-Channel USP/CN Series

CTs 4200USP/CN

CTs 8200USP/CN

Obtaining Other Language Versions: To obtain information in another language about the use of this product, please contact your

local Crown Distributor. If you need assistance locating your local distributor, please contact Crown at 574-294-8000.

This manual does not include all of the details of design, production, or variations of the equipment. Nor does it cover every possible

situation which may arise during installation, operation or maintenance.

The information provided in this manual was deemed accurate as of the publication date. However, updates to this information may have

occurred. To obtain the latest version of this manual, please visit the Crown website at www.crownaudio.com.

Trademark Notice: Crown, Crown Audio, Amcron, Com-Tech, IQ System, and Multi-Mode are registered trademarks of Crown

Inter national. HiQnet and System Architect are trademarks of Harman Pro Group. Other trademarks are the property of their respective

own ers.

Some models may be exported under the name Amcron.

©2008 by Crown Audio® Inc., 1718 W. Mishawaka Rd., Elkhart, Indiana 46517-9439 U.S.A. Telephone: 574-294-8000

®

139309-4

10/10

Page 2

CTs Multi-Channel Power Amplifiers

CTs Multi-Channel Power Amplifiers

Important Safety Instructions

Importantes Instructions de Sécurité

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance

with the manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat

reg isters, stoves, or other apparatus (including amplifiers)

that produce heat.

9. Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades with

one wider than the other. A grounding-type plug has two

blades and a third grounding prong. The wide blade or

the third prong is provided for your safety. If the provided

plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched,

par ticularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

11. Only use attachments/accessories specified by the manufac-

turer.

12. Use only with a cart, stand, tripod, bracket, or table specified

by the manufacturer, or sold with the apparatus. When a

cart is used, use caution when moving the cart/apparatus

combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when

unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing

is required when the apparatus has been damaged in any

way, such as power-supply cord or plug is damaged, liquid

has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does

not operate nor mally, or has been dropped.

15. Use the mains plug to disconnect the apparatus from the

mains.

16. WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS APPARATUS TO RAIN OR

MOISTURE.

17. DO NOT EXPOSE THIS EQUIPMENT TO DRIPPING OR

SPASHING AND ENSURE THAT NO OBJECTS FILLED

WITH LIQUIDS, SUCH AS VASES, ARE PLACED ON THE

EQUIPMENT.

18. THE MAINS PLUG OF THE POWER SUPPLY CORD SHALL

REMAIN READILY OPERABLE.

Wichtige Sicherheitsinstruktionen

Instrucciones de Seguridad Importantes

TO PREVENT ELECTRIC SHOCK DO NOT REMOVE TOP OR

BOTTOM COVERS. NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

À PRÉVENIR LE CHOC ÉLECTRIQUE N’ENLEVEZ PAS LES

COUVERCLES. IL N’Y A PAS DES PARTIES SERVICEABLE

À L’INTÉRIEUR. TOUS REPARATIONS DOIT ETRE FAIRE PAR

PERSONNEL QUALIFIÉ SEULMENT.

PARA PREVENIR UN CHOQUE ELÉCTRICO, NO RETIRE LAS

CUBIERTAS SUPERIOR O INFERIOR. NO EXISTEN PARTES QUE

PUEDAN SER REPARADAS POR EL USUARIO AL INTE RIOR.

REMITA EL SERVICICO AL PERSONAL TÉCHNICAL CALIFICADO.

TO COMPLETELY DISCONNECT THIS EQUIPMENT FROM THE

AC MAINS, DISCONNECT THE POWER SUPPLY CORD PLUG

FROM THE AC RECEPTACLE. THE MAINS PLUG OF THE POWER

SUPPLY CORD SHALL REMAIN READILY OPERABLE.

POUR DÉMONTER COMPLÈTEMENT L’ÉQUIPEMENT DE

L’ALIMENTATION GÉNÉRALE, DÉMONTER LE CÂBLE D’ALIMENTATION DE SON RÉCEPTACLE. LA PRISE D’ALIMEN TATION

RESTERA AISÉMENT FONCTIONNELLE.

PARA DESCONECTAR COMPLETAMENTE EL EQUIPO DEL

SUMINSTRO ELECTRICO, DESCONECTE EL CABLE DE ALIMENTACION DE LA TOMA DE CA. LAS PATAS DEL CONEC TOR

DEL CABLE DE ALIMENTACIÓN DEBERAN MANTENERSE EN

BUEN ESTADO.

WATCH FOR THESE SYMBOLS:

The lightning bolt triangle is used to alert the user to the risk of

electric shock.

The exclamation point triangle is used to alert the user to

important operating or maintenance instructions.

REGARDEZ CES SYMBOLES:

La triangle avec le sigle ‘’foudre’’ est employée pour alerter

l’utilisateur au risque de décharge électrique. Le triangle avec

un point d’exclamation est employée pour alerter l’utilisateur

d’instruction importantes pour lors opérations de mainte nance.

ATENCION CON ESTOS SÍMBOLOS:

El triángulo con el símbolo de rayo eléctrico es usado para

alertar al usuario de el riesgo de un choque eléctrico.

El triángulo con el signo de admiración es usado para alertar

al usuario de instrucciones importantes de operación o mantenimiento.

IMPORTANT

CTs Series amplifiers require Class 2 output wiring.

Les amplificateurs de série de CTs exigent des câbles de sortie de

classe 2.

CTs-Reihe-Verstärker verlangen Klasse die 2 Produktionsverdrah tung.

Los amplificadores de la Serie CTs requieren de un cableado de sal ida

Clase 2.

MAGNETIC FIELD

CAUTION! Do not locate sensitive high-gain equipment such as preamplifiers directly above or below the unit. Because this amplifier has a

high power density, it has a strong magnetic field which can induce hum

into unshielded devices that are located nearby. The field is strongest

just above and below the unit.

If an equipment rack is used, we recommend locating the amplifier(s)

in the bottom of the rack and the preamplifier or other sensitive equipment at the top.

FCC COMPLIANCE NOTICE

This device complies with part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

CAUTION: Changes or modifications not expressly approved by the party responsible for

complicance could void the user’s authority to operate the euqipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Crown International, Inc.

Issued By: Crown International, Inc.

European Representative’s Name and Address:

David J. Budge

10 Harvest Close

Yateley GU46 6YS

United Kingdom

Equipment Type: Commercial Audio Power Amplifiers

Family Name: CTs Family

Model Names: CTs 4200USP/CN, CTs 8200USP/CN

EMC Standards:

EN 55103-1:1997 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audio-Visual and Entertainment Lighting Control Apparatus for Professional Use, Part 1: Emissions

EN 55103-1:1997 Magnetic Field Emissions-Annex A @ 10 cm and 20 cm

EN 61000-3-2:2001 Limits for Harmonic Current Emissions (equipment input current less than or equal to 16 A per phase)

EN 61000-3-3:2002 Limitation of Voltage Fluctuations and Flicker in Low-Voltage Supply Systems Rated Current less than or equal to16A

EN 55022:2003 Limits and Methods of Measurement of Radio Disturbance Characteristics of ITE: Radiated, Class B Limits; Conducted, Class A

EN 55103-2:1997 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audio-Visual and Entertainment Lighting Control Apparatus for Professional Use, Part 2: Immunity

EN 61000-4-2:2001 Electrostatic Discharge Immunity (Environment E2-Criteria B, 4k V Contact, 8k V Air Discharge)

EN 61000-4-3:2001 Radiated, Radio-Frequency, Electromagnetic Immunity (Environment E2, criteria A)

EN 61000-4-4:2001 Electrical Fast Transient/Burst Immunity (Criteria B)

EN 61000-4-5:2001 Surge Immunity (Criteria B)

EN 61000-4-6:2003 Immunity to Conducted Disturbances Induced by Radio-Frequency Fields (Criteria A)

EN 61000-4-11:2001 Voltage Dips, Short Interruptions and Voltage Variation

Safety Standard:

IEC 60065: 2001 7th Ed. Safety Requirements - Audio Video and Similar Electronic Apparatus

I certify that the product identified above conforms to the requirements of the EMC Council Directive 89/336/EEC as amended by 92/31/EEC, and the Low Voltage Directive 73/23/EES as amended by 93/68/EEC.

Signed

1718 W. Mishawaka Road

Elkhart, Indiana 46517 U.S.A.

Andrew Stump

Title: Director of Manufacturing

DECLARATION of CONFORMITY

COMPLIANCE QUESTIONS ONLY:

Sue Whitfield

574-294-8289

swhitfield@crownintl.com

Date of Issue: Jan 1, 2006

page 2 page 3

Operation Manual

Operation Manual

DUE TO LINE CURRENT HARMONICS, WE RECOMMEND THAT YOU CONTACT YOUR SUPPLY AUTHORITY BEFORE CONNECTION.

Page 3

Table of Contents

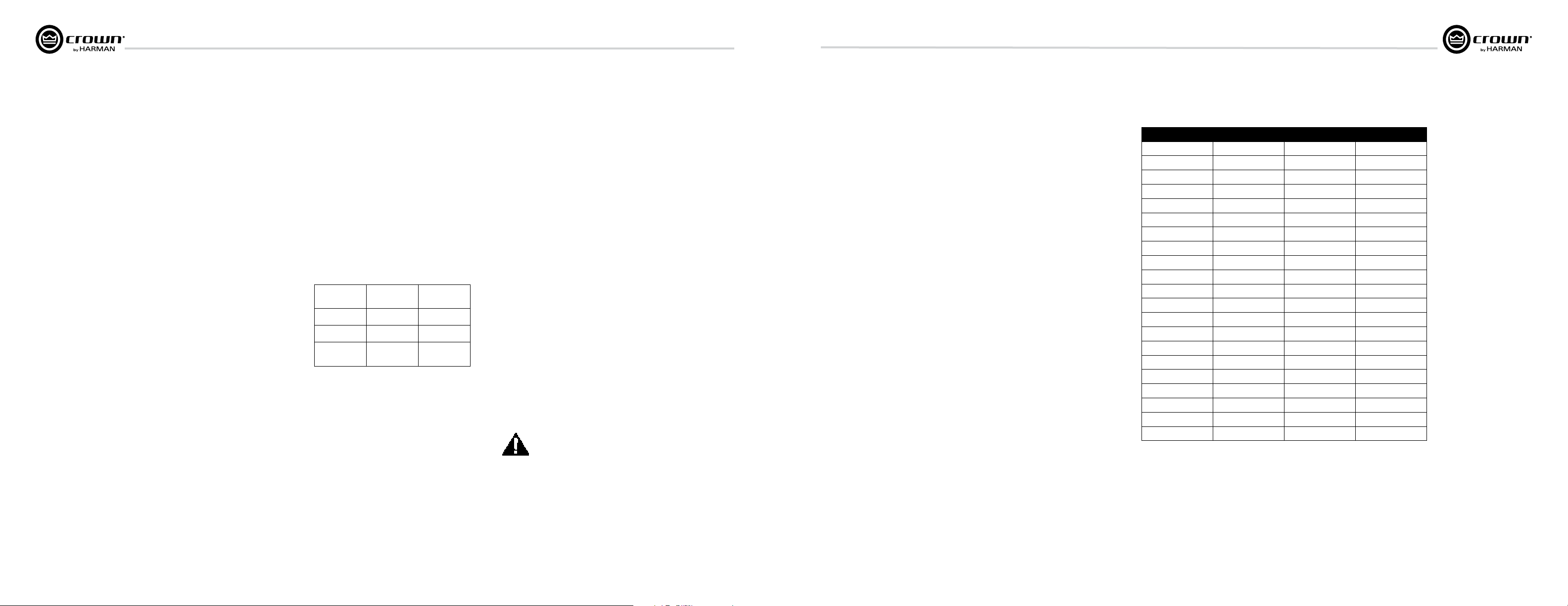

4-ohm (per ch.)

8-ohm (per ch.)

70V (per ch.)

1 kHz

CTs 4200USP/CN

20 Hz–20 kHz

Dual

4 Channels Driven

260W

180W

220W

215W

190W

220W

*

*

4-ohm (per ch.)

8-ohm (per ch.)

70V (per ch.)

1 kHz 20 Hz–20 kHz1 Channel Driven

270W

220W

250W

225W

210W

245W

8-ohm (per ch. pair)

16-ohm (per ch. pair)

100V (per ch. pair)

1 kHz 20 Hz–20 kHz

Bridge-Mono

2 Channel-Pairs Driven

520W

400W

220W

430W

380W

220W

*

*

8-ohm (per ch. pair)

16-ohm (per ch. pair)

100V (per ch. pair)

1 kHz 20 Hz–20 kHz1 Channel-Pair Driven

560W

440W

250W

450W

420W

245W

Maximum Average Power

in watts with 0.1% THD.

*

Constant Voltage full bandwidth power ratings support

100Hz - 20kHz due to automatic High-Pass Filters.

4-ohm (per ch.)

8-ohm (per ch.)

70V (per ch.)

1 kHz

CTs 8200USP/CN

20 Hz–20 kHz

Dual

8 Channels Driven

200W

160W

200W

175W

155W

185W

*

*

4-ohm (per ch.)

8-ohm (per ch.)

70V (per ch.)

1 kHz 20 Hz–20 kHz1 Channel Driven

270W

220W

250W

230W

220W

230W

8-ohm (per ch. pair)

16-ohm (per ch. pair)

100V (per ch. pair)

1 kHz 20 Hz–20 kHz

Bridge-Mono

4 Channel-Pairs Driven

400W

320W

200W

350W

310W

185W

*

*

8-ohm (per ch. pair)

16-ohm (per ch. pair)

100V (per ch. pair)

1 kHz 20 Hz–20 kHz1 Channel-Pair Driven

540W

440W

250W

460W

440W

230W

Maximum Average Power

in watts with 0.1% THD.

*

Constant Voltage full bandwidth power ratings support

100Hz - 20kHz due to automatic High-Pass Filters.

CTs Multi-Channel Power Amplifiers

CTs Multi-Channel Power Amplifiers

Important Safety Instructions ........................................................ 2

Declaration of Conformity ............................................................. 3

1 Welcome ...................................................... 5

1.1 Features ............................................................................. 5

1.2 How to Use This Manual ..................................................... 5

2 Setup .......................................................... 6

2.1 Unpack Your Amplifier ....................................................... 6

2.2 Install Your Amplifier ..........................................................6

2.3 Ensure Proper Cooling ....................................................... 6

2.4 Front Panel Controls and Indicators .................................... 7

2.5 Back Panel Controls and Connectors ................................. 8

2.6 CobraNet and Control Module:

Connectors, Indicators and Controls .................................... 9

2.7 Choose Input Wire and Connectors .................................... 10

2.8 Choose Output Wire and Connectors ................................. 10

2.9 Audio Wiring ...................................................................... 11

2.9.1 Dual 8/4 Mode ........................................................... 11

2.9.2 Dual 70V Mode .......................................................... 11

2.9.3 Bridge-Mono 16/8 Mode ........................................... 12

2.9.4 Bridge-Mono 100V Mode .......................................... 12

2.10 Network Wiring Rules ....................................................... 13

2.11 Network Wiring ................................................................. 13

2.12 Audio and Aux Wiring ....................................................... 13

2.13 Connect to AC Mains ........................................................ 13

2.14 Startup Procedure ............................................................. 13

page 4 page 5

3 Operation .....................................................14

3.1 Precautions ........................................................................14

3.2 CobraNet and Control Module Features ..............................15

4 Advanced Features .........................................21

4.1 Using the Aux Connector ...................................................21

4.1.1 Aux Output .................................................................21

4.1.2 Aux Input ....................................................................21

4.1.3 Listen Bus Wiring .......................................................21

4.2 Protection Systems ........................................................... 22

4.2.1 Thermal Level Control ............................................... 22

4.2.2 Fault .......................................................................... 22

4.2.3 Fault Isolation Topology (FIT) ....................................22

4.2.4 35-Hz High-Pass Filter .............................................. 22

4.2.5 AC Under-Voltage/Over-Voltage Protection ............... 22

4.2.6 Power Fuse ............................................................... 22

4.2.7 Inrush Limiting .......................................................... 22

4.2.8 Variable-speed Fans ..................................................22

4.2.9 Switching Power Supply ........................................... 22

4.2.10 Mode Switch ........................................................... 22

4.2.11 Bridge Mode Indicator.............................................. 22

4.2.12 Channel Level Control ............................................. 23

5 Troubleshooting ............................................ 24

6 Specifications .............................................. 27

7 AC Power Draw and Thermal Dissipation ............... 31

8 Network and CobraNet Basics ............................ 33

8.1. Network Basics ................................................................ 33

8.2 A Closer Look at CobraNet ................................................ 34

8.2.1 Fast Ethernet .............................................................. 34

8.2.2 Audio Specs .............................................................. 35

8.2.3 Bundles and Audio Channels ..................................... 35

8.2.4 The Conductor ........................................................... 35

8.2.5 Repeater Networks ..................................................... 35

8.2.6 Switched Networks ..................................................... 35

9 Service ....................................................... 36

9.1. International and Canada Service ..................................... 36

9.2 US Service ........................................................................ 36

9.2.1 Service at a US Service Center ................................... 36

9.2.2 Factory Service ......................................................... 36

9.2.3 Factory Service Shipping Instructions ........................ 36

9.2.4 Packing Instructions .................................................. 36

9.2.5 Estimate Approval ...................................................... 36

9.2.6 Payment of Non-Warranty Repairs..............................36

10 Warranty ................................................... 37

Product Registration ..................................................................... 41

Crown Factory Service Information Form ..................................... 43

Operation Manual

Operation Manual

1 Welcome

Building on the foundation of the Com-Tech® Series,

Crown’s CTs Series offers new flexibility and value for

installed sound applications. The Com-Tech Series were

the first to offer independent selection of high- and lowimpedance operation for a specific channel, and CTs

Series amplifiers continue that tradition, with power

levels and features carefully chosen to perfectly inte grate

into fixed install design requirements.

Thanks to the factory-installed CobraNet and Control

Module, each amplifier is a network component. It

con nects to the audio control/monitor network using

stan dard 100Mb Ethernet hardware. With this protocol,

an audio system can be interconnected using standard

off-the shelf 100 Mb Ethernet components (switches,

Net work Interface Cards, and cables).

The Crown CTs 4200USP/CN and CTs 8200USP/CN

include SmartAmp features and 3rd-generation DSPbased components. Their SHARC DSP processor gives

the user an enormous amount of digital signal

process ing. Audio routing, faders, meters, polarity &

mute, input compressors, filters, multimode output

limiters, error reporting, and load monitoring are all

available. A built-in noise generator and sine-wave

generator pro vide noise masking and test capabilities.

In addition, the amplifier allows the transport of realtime digital audio via CobraNet™ over the same 100Mb

Ethernet network that is used for amplifier control and

monitoring. This provides a simple to install, singleplug solution for control, monitoring, and fullband width audio distribution. The amplifier can function

independently from the network control. Once the

pro cessing is configured, the unit’s non-volatile

memory allows the amplifier to continue to function with

no external control.

Please take the time to study this manual so that you can

obtain the best possible service from your amplifier.

1.1 Features

®

• Crown

Switching Power Supply for reduced weight

• High power-density, with eight channels in a 3U chassis

and four channels in a 2U chassis

• Selectable constant-voltage (70V/100V) or lowimped ance (8/4 ohm) operation for each channel pair

• In the unlikely event of a channel failure, FIT (Fault

Isola tion Topology) circuitry isolates faults within

affected channels

• 35 Hz High-Pass Filter (70 Hz in CTs 4200) is

automati cally inserted when the channel pair is set for

constant-voltage operation. (corner frequency may be

changed as a service option)

• Comprehensive array of indicators including Power and

Data, along with Bridge, Ready, Signal, Clip, Thermal and

Fault for each channel, provide accurate diagnostics

• Blue Power Indicator flashes if the amplifier shuts off due

to an under-voltage or over-voltage condition on the AC

mains

• Advanced protection circuitry guards against: shorted

outputs, open circuits, DC, mismatched loads, general

overheating, under-voltage or over-voltage, highfre quency overloads and internal faults

• Proven Crown AB+B Multi-Mode® output topology

• Continuously-variable-speed fans optimize cooling

effi ciency

• Built-in CobraNet and Control Module connects to a

CobraNet network. This allows a 100 Mbps Ethernet

sin gle-plug solution for CobraNet audio, and HiQnet

con trol and monitoring

• Analog audio inputs allow CobraNet network audio input,

CobraNet audio backup, or a hardwire emergency

override of CobraNet audio

• 24 bit digital to analog conversion with 32 bit, floating

point DSP processing

• Up to 18 assignable filters per channel

• Over 2 seconds of delay available per channel

• Input compressors and output limiters for each

channel

• Noise generator for noise masking

• Sine generator

• Load supervision

• Full error reporting

• Firmware upgrades via the network

• 10 user selectable presets

• Reliable FLASH memory backup of all parameters

• Three Year, No-Fault, Fully Transferable Warranty

completely protects your investment and

guaran tees its specifications

1.2 How to Use This

Manual

This manual provides you with the necessary

informa tion to safely and correctly setup and operate

your amplifier. It does not cover every aspect of

installation, setup or operation that might occur under

every condi tion. For additional information, please

consult Crown’s Amplifier Application Guide (available

online at www.crownaudio.com), Crown Tech Support,

your system installer or retailer.

We strongly recommend you read all instructions,

warnings and cautions contained in this manual. Also,

for your protection, please send in your warranty

reg istration card today, or register online at www.

crownaudio.com. And save your bill of sale—it’s your

official proof of purchase.

Page 4

CTs Multi-Channel Power Amplifiers

Power

Data

12

Bridge34Bridge

Fault

Thermal

Clip

Signal

Ready

CTs Multi-Channel Power Amplifiers

2 Setup

2.1 Unpack Your Amplifier

Please unpack and inspect your amplifier for

any damage that may have occurred during

transit. If damage is found, notify the

transpor tation company immediately. Only you

can ini tiate a claim for shipping damage. Crown

will be happy to help as needed. Save the

shipping carton as evidence of damage for the

shipper’s inspection.

We also recommend that you save all packing

materials so you will have them if you ever need

to transport the unit. Never ship the unit

without the factory pack.

YOU WILL NEED (not supplied):

• Input wiring cables

• Output wiring cables

Rack for mounting amplifier (or a stable surface

for stacking)

WARNING: Before you start to set up

your amplifier, make sure you read and

observe the Important Safety Instructions found at the beginning of this

manual.

2.2 Install Your Amplifier

CAUTION: Before you begin, make sure

your amplifier is disconnected from the

power source, with the power switch in

the “off” position and all level controls

turned completely down (counterclockwise).

Use a standard 19-inch (48.3-cm) equipment

rack (EIA RS-310B). See Figure 2.1 for ampli fier

dimensions.

You may also stack amps without using a

cabinet.

NOTE: When transporting, amplifiers should be

supported at both front and back.

2.3 Ensure Proper Cooling

When using an equipment rack, mount units

directly on top of each other. Close any open

spaces in rack with blank panels. DO NOT block

front, rear or side air vents. The side walls of the

rack should be a minimum of two inches (5.1

cm) away from the amplifier sides, and the back

of the rack should be open.

Figure 2.2 illustrates standard amplifier airflow.

2 Setup (continued)

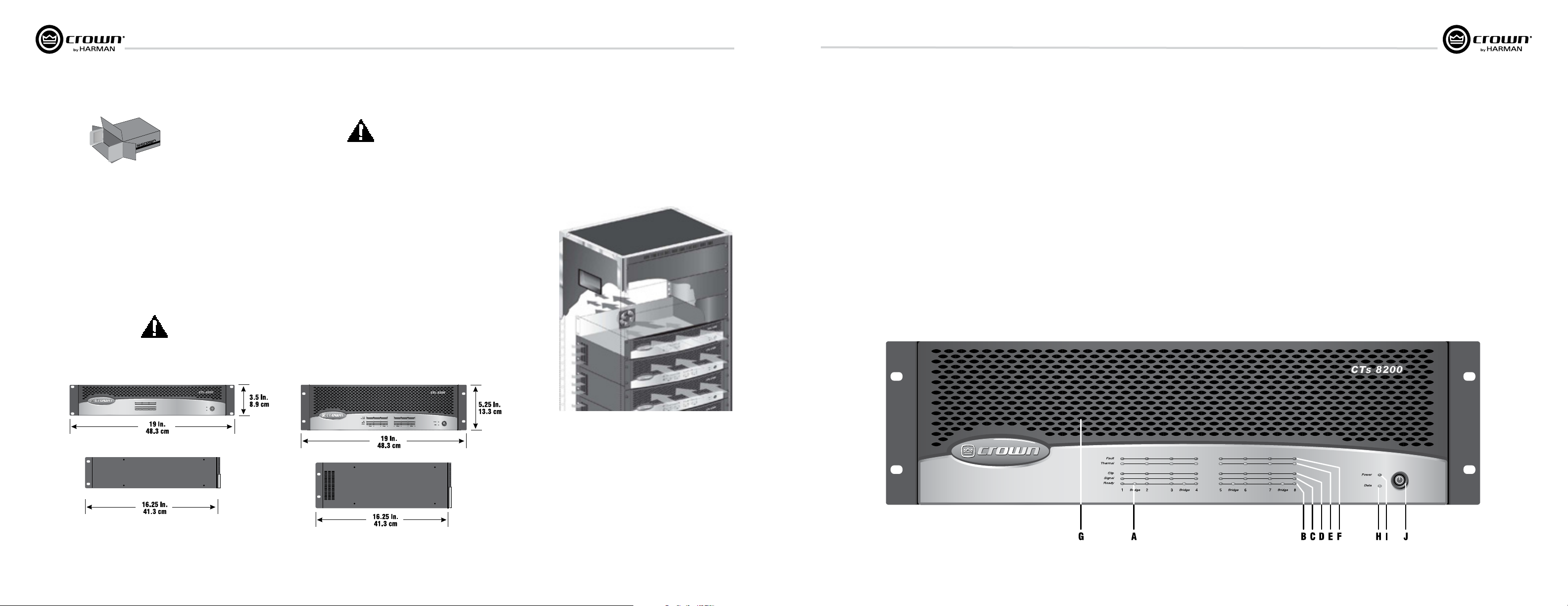

2.4 Front Panel Controls

and Indicators

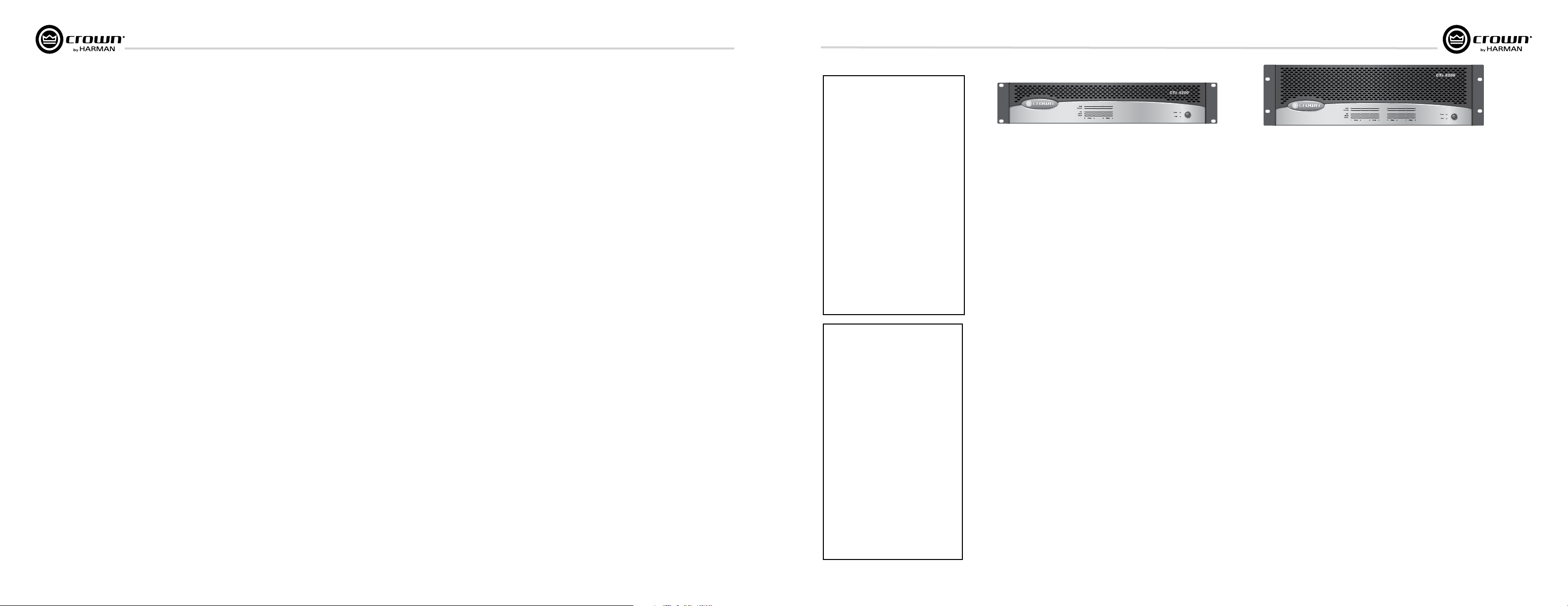

Note: CTs 8200USP/CN is shown. Some CTs 4200

USP/CN features are in different locations.

A. Bridge Mode Indicator

Yellow LED, one per channel pair, illuminates when

the channel pair’s Mode Switch is set to the “Bridge”

position. If Mode switch is changed while amplifier is

powered up, Bridge LED will flash, indicating that the

amplifier must be powered off and on to reset the

Mode.

B. Ready Indicator

Green LED, one per channel, illuminates when the

channel is initialized and ready to produce audio

out put.

C. Signal Indicator

Green LED, one per channel, illuminates to indicate

the presence of analog input signals above –40 dBu.

D. Clip Indicator

Red LED, one per channel, illuminates when the THD

of the channel’s output signal rises to a level typically

considered as the onset of audible clipping. The Clip

Indicator also will illuminate during Thermal Level

Control (TLC) or input overload.

E. Thermal Indicator

Red LED, one per channel, flashes when the channel

has shut down due to thermal stress or overload. If the

power supply goes into thermal overload, all channel

LEDs will flash.

F. Fault Indicator

Red LED, one per channel, illuminates when the

amplifier output channel has stopped operating.

G. Ventilation Grille

Front-to-rear forced airflow.

H. Data Indicator

Yellow LED flashes whenever a command addressed to

the module is received. A similar LED is on the back panel,

and the two LEDs flash simultaneously.

I. Power Indicator

Blue LED indicates amplifier has been turned on and AC

power is available. Indicator also flashes if the amplifier

shuts off due to an under/over-voltage condition on the

AC mains.

J. Power Switch

Amplifier is on when the switch is in the IN position.

Figure 2.2 Airflow

Figure 2.1 Dimensions

Left: CTs 4200USP/CN Right: CTs 8200USP/CN

Figure 2.3 CTs 8200USP/CN Front Panel

page 6 page 7

Operation Manual

Operation Manual

Page 5

CTs Multi-Channel Power Amplifiers

A

B

C

D

E

CTs Multi-Channel Power Amplifiers

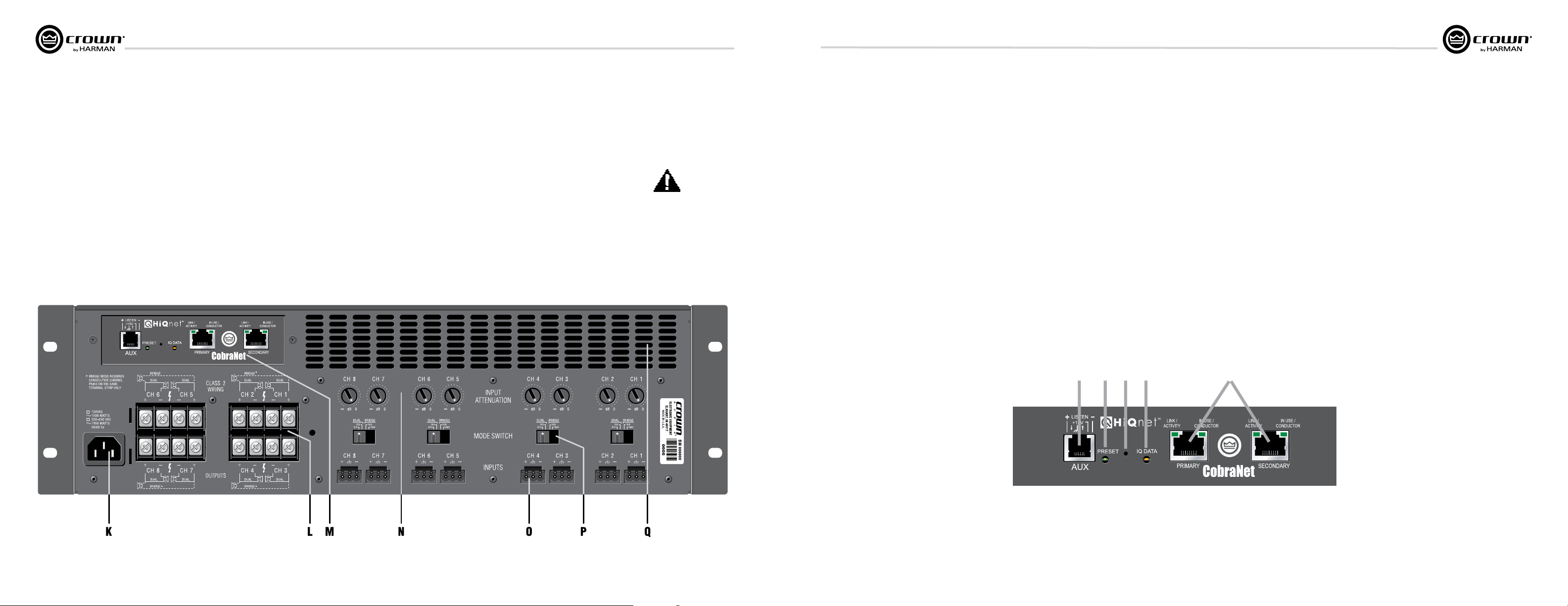

2 Setup (continued)

2.5 Back Panel Controls

and Connectors

Note: CTs 8200USP/CN is shown. Some CTs

4200USP/CN features are in different

loca tions.

K. AC Power Cord Connector

Standard IEC type 320 inlet.

120V models: 15-amp.

220-240V models: 10-amp.

Voltage is indicated above IEC inlet.

L. Output Connectors

One four-pole terminal strip for every two

chan nels with touch-proof cover. Accepts up to

10 AWG terminal forks. To connect outputs, first

remove the touch-proof cover plate covering

the terminal strip by removing the screw which

holds it in place.

M. USP/CN Module

Built into the amplifier, this module allows

con nection to a CobraNet network. Please see

Sec tion 2.6 for details.

N. Channel Level Controls

One 21-position detented rotary potentiometer

per channel, ranging from infinity (-70 dB) to

0 dB attenuation. Refer to Section 4.2.12 for

precise dB attenuation increments for each

detent.

O. Input Connectors

Removable Phoenix-style barrier connectors for

balanced input. Also can be used as a CobraNet

input or a backup for Cobranet (see Section

3.2.6).

P. Mode Switch

Used on each consecutive pair of channels, this

four-position switch is used to select the

amplifier’s mode of operation: Dual 8/4 ohms,

Dual 70V, Bridge-Mono 16/8 ohms, and

Bridge-Mono 100V.

IMPORTANT: Be sure to power off the

amplifier before change the Modeswitch setting. If this is not done, the Bridge

light will flash to indicate that the power must

be cycled off and back on to reset the mode.

Q. Cooling Vents

Front-to-rear forced airflow.

2 Setup (continued)

2.6 CobraNet and Control Module:

Connectors, Indicators and

Con trols

A. AUX Connector

AUX input, AUX output, and Foldback. See

Sections 3.2.7, 3.2.8, and 4.1.

B. Preset Indicator

Signals the number of the current preset, if

active, by flashing a series of flashes equal

to the current preset number. See Section

3.2.2.

C. Reset/Preset Switch

Activated by inserting a small item, such as

a paper clip, this switch is used to change

presets, restore settings to factory default or

restore all the presets to the factory defaults.

During operations of the switch, the Data

indicator flashes as an aid to the user. See

Section 3.2.9.

D. Data Indicator

Flashes when the amplifier receives a valid

command that is addressed to the amplifier.

See Section 3.2.1.

E. CobraNet Network Connectors

The dual RJ45 CobraNet connectors allow a

Primary & Secondary connection to the 100

Mbps Ethernet network. Should the Primary

connection lose link activity with the

net work, the module will automatically

switch to the Secondary connection to

ensure uninterrupted audio and control. The

indicators on the RJ45 connectors display

network information concerning the Ethernet

and CobraNet connections. See Sections

3.2.3, 3.2.4, and 3.2.5.

page 8 page 9

Figure 2.4 CTs 8200 USP/CN Back Panel

(Shown with Touch-proof Cover Removed)

Operation Manual

Operation Manual

Figure 2.5 USP/CN Controls, Indicators and Connectors

(Note: Actual Product Artwork May Vary Slightly)

Page 6

CTs Multi-Channel Power Amplifiers

CH 4

DUAL DUAL

BRIDGE

CH 3

CH 2

DUAL DUAL

BRIDGE

CH 1

CH 4

DUAL DUAL

BRIDGE

CH 3

CH 2

DUAL DUAL

BRIDGE

CH 1

70V

70V

CTs Multi-Channel Power Amplifiers

2 Setup (continued)

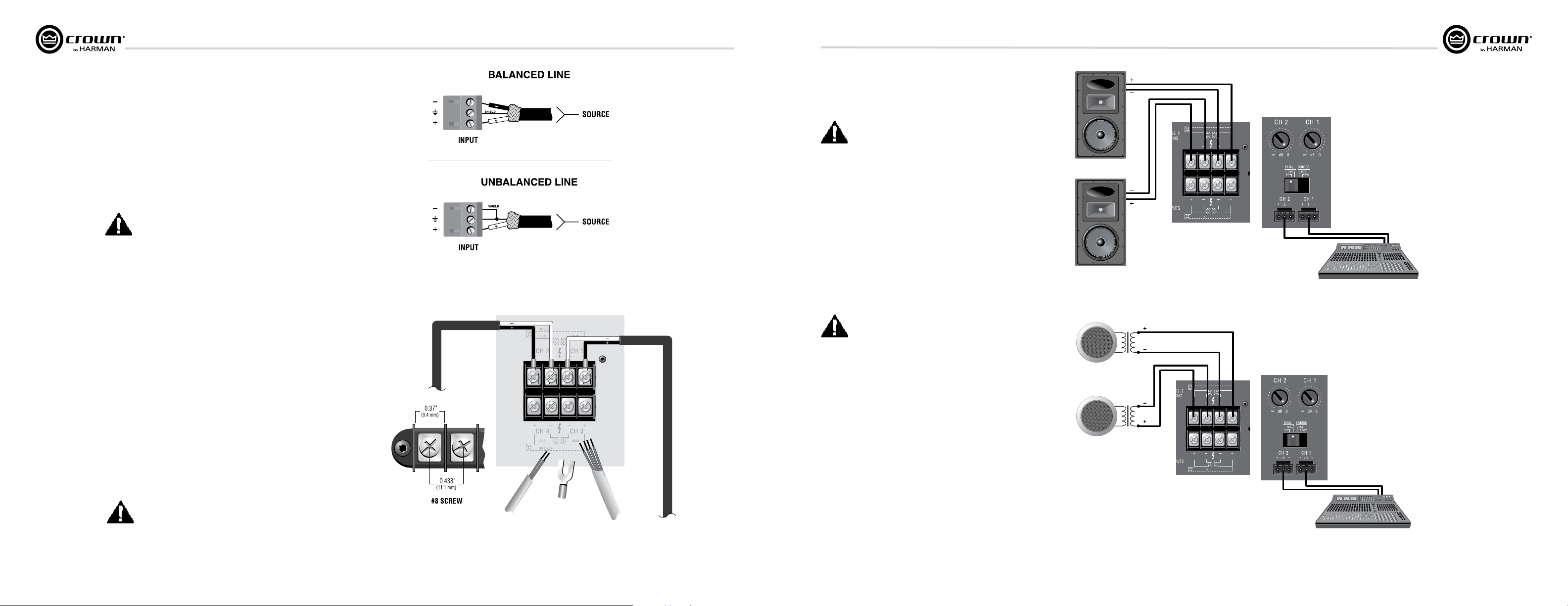

2.7 Choose Input Wire and Connectors

If you will be connecting an analog audio signal to the CTs amplifier, please

read this section. Figure 2.6 shows connector pin assignments for balanced

wiring, and Figure 2.7 shows connector pin assignments for unbalanced

wir ing.

When possible, use balanced wiring for signal input, which provides better

rejection of unwanted noise and hum. For more information, refer to the Crown

Amplifier Application Guide, available online at www.crownaudio.com

NOTE: Custom wiring should only be performed by qualified

per sonnel.

2.8 Choose Output Wire and Connectors

Crown recommends using professionally constructed, high-quality, two- or

four-conductor, heavy gauge speaker wire and connectors. You may use

ter minal spade lugs or bare wire for your output connectors (see Figure 2.8).

CTs amplifier terminal strips accept up to 10 AWG terminal forks which fit over

a #8 screw. For best results, Crown recommends Panduit part #PV10-10LF-L

or equivalent terminal spade lug. Screw spacing is shown in Figure 2.8.

To connect outputs, first remove the touch-proof cover plate covering the

ter minal strip by removing the screw which holds it in place.

To prevent the possibility of short-circuits, wrap or otherwise insulate exposed

loudspeaker cable and connectors. Also, a touch-proof cover plate, which

covers the terminal strips, is provided to help prevent short circuits. The cover

plate should be reinstalled after connecting outputs.

Suggested below are guidelines to select the appropriate size of wire based on

the distance from amplifier to speaker. Check with local code as this may vary.

Distance Wire Size

up to 25 ft. (7.6 m) 16 AWG

26-40 ft. (7.9-12.2 m) 14 AWG

41-60 ft. (12.5-18.3 m) 12 AWG

Over 60 ft. (18.3 m) 10 AWG

CAUTION: Never connect the speaker return to the chassis of the

amplifier, or damage to the amplifier may result.

CAUTION: Never use shielded cable for output wiring.

Figure 2.6 Balanced Input

Connector Wiring

See the Crown Amplifier

Appli cation Guide, available

online at www.crownaudio.com,

for pin assignments for

commonly used connector

types.

Figure 2.7 Unbalanced Input

Connector Wiring

NOTE: CTs 8200 USP/CN is shown. Some CTs 4200 USP/CN features are in different locations.

Output panel

shown with

touch-proof

cover plate

removed.

Figure 2.8 Output Connector Wiring

(Typical of Two C hannels)

2 Setup (continued)

2.9 Audio Wiring

CAUTION: Never change the position of

the Mode Switch while the amplifier

power is on.

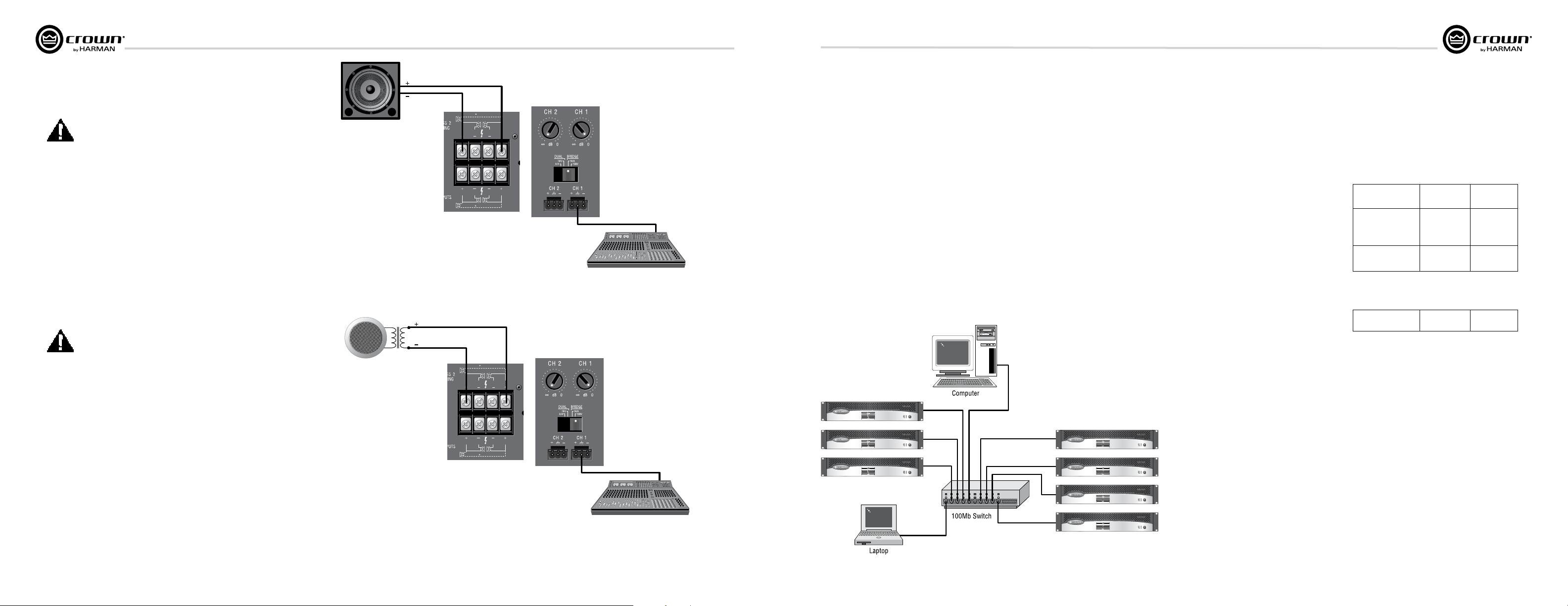

2.9.1 Dual 8/4 Mode

Typical analog input and output wiring, along

with level control and Mode Switch settings are

shown in Figure 2.9. Make sure the Mode switch

is set to the “Dual 8/4” position. Cobranet

input wiring is covered in Section 2.11.

INPUTS: Connect input wiring for each channel.

OUTPUTS: Maintain proper polarity (+/–) on

output connectors.

Connect the Channel 1 speaker’s positive (+) lead

to amplifier Channel 1 positive terminal; repeat

for negative (–). Repeat each channel wir ing as

for Channel 1.

2.9.2 Dual 70V Mode

CAUTION: Never change the position of

the Mode Switch while the amplifier

power is on.

Typical input and output wiring, along with level

control and Mode Switch settings are shown in

Figure 2.10. Make sure the Mode switch is set to

the “Dual 70V” position.

INPUTS: Connect input wiring for each channel.

OUTPUTS: Maintain proper polarity (+/–) on

output connectors.

Connect Channel 1 positive (+) speaker load to

Channel 1 positive terminal of amp; repeat for

negative (–). Repeat each channel wiring as for

Channel 1.

See the Crown Amplifier

Appli cation Guide, available

online at www.crownaudio.com,

for pin assignments for

commonly used connector

types.

Output panel

shown with

touch-proof

cover plate

removed.

Figure 2.9 System Wiring and Control Settings, Dual Mode, 8/4 Ohm

Output panel

shown with

touch-proof

cover plate

removed.

Figure 2.10 System Wiring and Control Settings, Dual Mode, 70V

page 10 page 11

Operation Manual

Operation Manual

Page 7

CTs Multi-Channel Power Amplifiers

CH 4

DUAL DUAL

BRIDGE

CH 3

CH 2

DUAL DUAL

BRIDGE

CH 1

CH 4

DUAL DUAL

BRIDGE

CH 3

CH 2

DUAL DUAL

BRIDGE

CH 1

100V

CTs Multi-Channel Power Amplifiers

2 Setup (continued)

2.9.3 Bridge-Mono 16/8 Mode

CAUTION: Never change the position of

the Mode Switch while the amplifier

power is on.

Typical analog input and output wiring, along

with level control and Mode Switch settings are

shown in Figure 2.11. Make sure the Mode

switch is set to the “Bridge 16/8” position.

INPUTS: Connect input wiring only to the lower(odd-) numbered channel pair.

OUTPUTS: Connect the speaker across the

posi tive terminals of each channel pair. Do not

use the negative terminals of the channel pair

when the pair is being operated in Bridge-Mono

mode.

NOTE: When operating the channel pair in

Bridge-Mono mode, turn down (full CCW) the

level control for the higher (even)-numbered

channel of the channel pair. The lower (odd)numbered level control works both channels.

2.9.4 Bridge-Mono 100V Mode

CAUTION: Never change the position of

the Mode Switch while the amplifier

power is on.

Typical analog input and output wiring, along

with level control and Mode Switch settings are

shown in Figure 2.12. Make sure the Mode

switch is set to the “Bridge 100V” position.

INPUTS: Connect input wiring only to the lower(odd-) numbered channel pair.

OUTPUTS: Connect the speaker across the

posi tive terminals of each channel pair. Do not

use the negative terminals of the channel pair

when the pair is being operated in Bridge-Mono

mode.

NOTE: When operating the channel pair in

Bridge-Mono mode, turn down (full CCW) the

level control for the higher (even)-numbered

channel of the channel pair. The lower (odd)numbered level control works both channels.

Figure 2.11 System Wiring and Control Settings, Bridge-Mono Mode, 16/8 Ohm.

Figure 2.12 System Wiring and Control Settings, Bridge-Mono Mode, 100V

See the Crown

Amplifier

Appli cation

Guide, available

online at www.

crownaudio.

com, for pin

assignments for

commonly used

connector types.

2 Setup (continued)

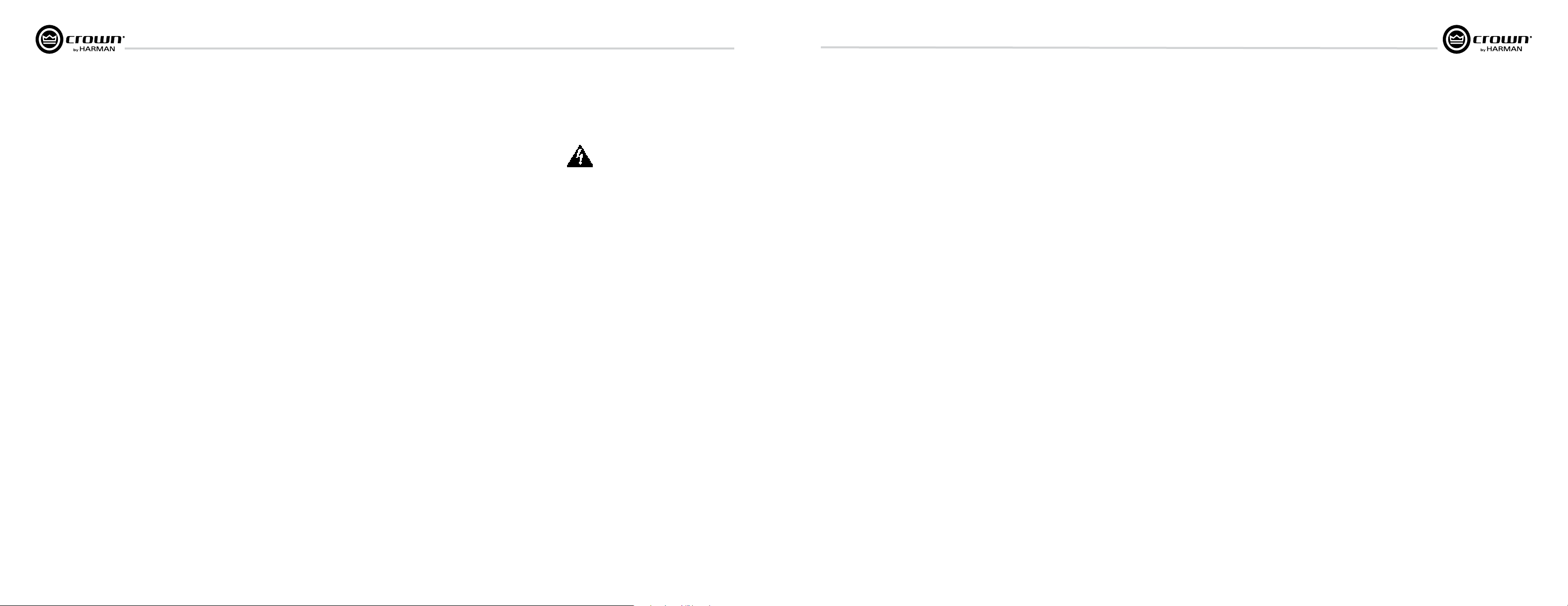

2.10 Network Wiring Rules

IMPORTANT: Please read the wiring rules below before

installing the wiring.

Connect each device to the network through its own cable

in a Star Network (Figure 2.13). Do not connect them in a

serial fashion.

Make sure each device has its own Category 5 certified

cable connecting it to a central concentrator, most often a

switch.

2.11 Network Wiring

Use the cable to connect the Primary CobraNet connector

to a 100 Mb port on the Ethernet switch that is used to

form the CobraNet network. For more detail, see Section

3.2.3. We highly recommend that the CobraNet be a

stan dalone or separate-network LAN.

Crown strongly recommends the use of a 100 Mb

Ether net network for control and monitoring.

If network redundancy is required, use a standard CAT5

cable to connect the Secondary CobraNet connector to a

100Mb port on the auxiliary CobraNet network.

HiQnet control is available over the CobraNet network

using Harman Pro System Architect software. The

soft ware can set up CobraNet audio routing and

addressing.

2.12 Audio and Aux Wiring

1. Connect the Audio Input Wiring. The amplifier is

equipped with removable barrier block connectors for

each channel’s input. See Section 2.7 for more detail on

audio wiring.

In System Architect, the analog balanced audio inputs can

be set up to act either as CobraNet backup, an emer gency

override of CobraNet audio, or as an audio input to the

CobraNet network.

2. Connect the AUX wiring if used. See Section 4.1 for

more information.

2.13 Connect to AC Mains

Connect your amplifier to the AC mains power source

(power outlet) with the supplied AC power cordset. First,

connect the IEC end of the cordset to the IEC connector on

the amplifier; then, plug the other end of the cordset to the

AC mains.

WARNING: The third prong of this connector

(ground) is an important safety feature. Do not

attempt to disable this ground connection by

using an adapter or other methods.

Amplifiers don’t create energy. The AC mains voltage and

current must be sufficient to deliver the power you expect.

If the AC line voltage varies out of an acceptable range,

the amplifier’s power supply turns off and the blue Power

LED flashes. The amplifier will turn back on when the AC

line voltage returns to safe operating levels. Fig ure 2.14

provides voltage limits for all amplifier AC volt age

configurations. Also, the amplifier must be run within the

specified mains frequency requirements (indicated on the

amplifier’s back panel label). If you are unsure of the

output voltage of your AC mains, please consult your

electrician.

The various models have the following under-voltage

limits and over-voltage limits:

Models

100VAC

(CTs 8200USP/

CN only)

120 VAC units 108VAC 132VAC

Under-Voltage

Limit

90VAC 110VAC

Over-Voltage

Limit

Figure 2.13 An Example of a Star Network

220V/230V/240V units 198VAC 264VAC

2.14 Startup Procedure

Use the following procedure when first turning on your

amplifier:

1. Turn down the level of your audio source.

2. Turn down the level controls of the amplifier.

3. Turn on the “Power” switch. The Power

indicator should glow.

4. Turn up the level of your audio source to an

opti mum level.

5. Turn up the Level controls on the amplifier

until the desired loudness or power level is achieved.

6. Turn down the level of your audio source to

its nor mal range.

If you ever need to make any wiring or installation changes,

don’t forget to disconnect the power cord.

page 12 page 13

Operation Manual

Operation Manual

Page 8

CTs Multi-Channel Power Amplifiers

CTs Multi-Channel Power Amplifiers

3 Operation

3.1 Precautions

Your amplifier is protected from internal and

external faults, but you should still take the

fol lowing precautions for optimum performance

and safety:

1. Before use, your amplifier first must be

configured for proper operation, including

input and output wiring hookup. Improper

wiring can result in serious operating

diffi culties. For information on wiring and

con figuration, please consult the Setup

section of this manual or, for advanced setup

tech niques, consult Crown’s Amplifier

Applica tion Guide available online at www.

crownaudio.com.

2. Use care when making connections,

selecting signal sources and controlling the

output level. The load you save may be your

own!

3. Do not short the ground lead of an output

cable to the input signal ground. This may

form a ground loop and cause oscillations.

4. WARNING: Never connect the output to a

power supply, battery or power main.

Elec trical shock may result.

5. Tampering with the circuitry, or making

unauthorized circuit changes may be

hazard ous and invalidates all agency

listings, and may also void the product’s

warranty.

6. Do not operate the amplifier with the red

Clip LEDs constantly flashing.

7. Do not overdrive the mixer, which will

cause clipped signal to be sent to the

ampli fier. Such signals will be reproduced

with extreme accuracy, and loudspeaker

damage may result.

8. Use caution when operating the amplifier

with a 2-ohm load impedance on 1 channel.

Do not operate the amplifier with less than a

2-ohm load impedance per channel when

driving more than 1 channel. Due to the

amplifier’s output protection, such a

config uration may result in premature

clipping, speaker damage or a blown power

fuse.

Remember: Crown is not liable for damage that

results from overdriving other system

compo nents.

3 Operation

3.2 CobraNet and Control Module Features

3.2.1 Data Indicator

An amber Data Indicator flashes whenever a command addressed

to the module is received. To assist with troubleshooting, an

option that forces the Data Indicator to remain lit is available

through the software. In addition, the locate feature in System

Architect will cause the Data Indicator to blink rapidly to help you

identify the unit. Another Data Indicator is on the amplifier’s front

panel, and it lights simultaneously with the module’s Data

Indica tor.

3.2.2 Preset Indicator

A green Preset indicator signals the number of the current preset,

if active, by continually flashing a series of flashes equal to the

current preset number, followed by a pause. A preset is

consid ered “active” if the USP/CN settings match those in the

selected preset. If a change is made to any setting then the preset

is con sidered “inactive,” and the indicator stops flashing.

3.2.3 CobraNet Network Connectors

The Primary and Secondary CobraNet RJ-45 connectors can

simultaneously interface to the 100 Mbps HiQnet network. While

the Primary CobraNet connector is the main connection to the

network, the Secondary connector is the “backup” or redundant

connection to the network. If the Primary connection fails due to

cut wire, failed network switch, etc., this port is automatically

enabled and ready to receive the network data within a few

sec onds.

Make connections with a standard CAT5 cable to a network switch

port. Crown strongly recommends the use of switches and not

hubs in the network. Hubs will limit the amount of CobraNet traffic

and create unnecessary limitations in the network.

If the amplifier is not connected to a network, the CobraNet

con nector can connect directly to a computer’s network adapter

port using a crossover cable (TX and RX pairs swapped).

3.2.4 Link/Activity Indicator

The green Link/Activity indicator is provided on the network

con nector to display the status of the Ethernet connection.

Whenever the module is properly connected to another

functioning network port, the indicator lights. When the module

detects the presence of network traffic, the indicator flashes. The

Link/Activity LED flashes for all network traffic, while the Data

LED flashes only for commands addressed to this USP/CN.

(continued)

.3.2.5 CobraNet In-Use/Conductor Indicator

The indicator on the right side of each CobraNet RJ-45 connector

turns ON if the port is in-use (i.e. the link is being used to trans mit

or receive active CobraNet traffic), and will blink if the device is

also the conductor (the timing reference).

3.2.6 Balanced Audio Inputs

Located on the amplifier rear panel, these removable barrier-block

connectors allow line-level audio signals to be input to the USP/

CN. The amplifier accepts line-level analog audio signals in

addition to the digital audio from the CobraNet network. This

analog audio can be used for one of three purposes:

• Backup of the CobraNet network audio: In the unlikely event of

a loss of CobraNet audio to the module, the module automati cally

switches over to the balanced audio inputs.

• Emergency override: If an audio signal appears at the analog

inputs, the module switches to that signal.

• CobraNet network audio inputs: The amplier can act as a

CobraNet audio input source by converting the balanced audio

input signal to CobraNet.

3.2.7 Aux Input/Output Connector

An RJ-11 connector provides three functions: AUX output, AUX

input and Foldback. The AUX output is a multifunctional control

output that delivers 15 VDC limited to 15 mA. It can be config ured

in two modes:

• Manual mode: The output is simply controlled with a

com mand from the software.

• Error reporting mode: The AUX out is active when the

mod ule detects an error. Each error source (Thermal, Clip, Load,

Amp Fault, and Line Voltage) can be individually enabled to

activate the AUX output when the error conditions are met.

An inversion control allows the AUX output functionally to be

inverted for the manual and error reporting modes. The inversion

control is ignored for flash preset mode.

The AUX input is a two-state input with a high state defined as

voltage between 4 and 15 VDC. The low state is defined as

volt ages between 0 and 1.6 VDC. It has a 10K input impedance.

The AUX input can be configured in several modes:

• None: In this mode the module makes no changes to its

operation. However, the AUX input status can be monitored

through the control software and used for functions within the

software.

• Mute All: This mutes the channels when the AUX input is

active. Likewise, the Power Off Both function disables both

channels during an active AUX input.

• AUX Input Inversion: This control allows the low state to

activate the selected function. Normally, the high state activates

the selected AUX input function.

The AUX port provides a power supply for the AUX input. This 15

VDC at 15 mA supply can be connected through a switch to the

AUX input. This allows a simple switch closure to operate the aux

input without the need of an external power supply. See Section

4.1 for details on using the AUX port.

3.2.8 Listen Bus or Foldback

The AUX port is also used for the Foldback connection. Two

pins of the connector provide a balanced line-level audio output

that can be selectively driven by either channel under System

Architect software control.

3.2.9 Preset/Reset Switch

The Preset/Reset switch is a recessed pushbutton located

between the Data and Preset indicators. It is activated by a

straightened paper clip or similar object. This switch can be used

to change presets, restore settings to factory default or restore all

the presets to the factory defaults. During operations of the

switch, the Data indicator flashes as an aid to the user.

To select a preset:

1. Remove all audio input signals.

2. With the amplifier powered up, momentarily hold the preset

switch in for one flash of the Data indicator (less than 2 seconds)

and then release.

3. The amplifier will load the next preset in the defined preset

range.

The range of presets is defined by the Maximum Preset and

Min imum Preset controls. Once the Maximum Preset is reached,

the next momentary depression of the switch will cycle the USP/

CN to the Minimum Preset.

4. The Preset indicator will flash the number of the selected pre set

followed by a pause.

5. Restore the audio input signals.

To restore the unit to factory default settings:

1. Remove all audio input signals.

page 14 page 15

Operation Manual

Operation Manual

Page 9

CTs Multi-Channel Power Amplifiers

CTs Multi-Channel Power Amplifiers

3 Operation (continued)

2. Hold the Reset/Preset switch in for two flashes of the Data light

(longer than 2 seconds).

3. The Data indicator will flash rapidly for a moment.

4. Restore the audio input signals.

To restore the unit including presets to factory default

settings:

1. Remove all audio input signals.

2. Hold the Reset/Preset switch while applying power to the unit.

3. The Data and Preset indicator will both light.

4. Release the switch within 5 seconds (before the Data and Pre set

indicators go out).

5. The Data indicator will flash rapidly for a moment.

6. Restore the audio input signals.

3.2.10 User Presets

The control settings for all the functions can be stored as presets.

A total of ten presets can be saved in the USP/CN’s nonvolatile

memory. Each preset can be named with a 30 character name

describing its function, which is also stored in the USP/CN’s

memory.

• The Store Preset Control saves the current setting to the

specified preset.

• The Recall Preset Control recalls the specified preset

set tings.

• The Preset Valid Monitor indicates if a change has been

made to any setting since the last time a preset has be saved or

recalled.

• The Last Stored or Recalled Preset Monitor indicates

what the Last Stored or Recalled preset is.

3.2.11 Clip Event Monitor

A clip detector is provided each channel. These monitors will

indicate any clip condition (> 0.05% distortion) in the amplifier

channel. The clip detectors also can indicate certain errors (See

Section 3.1.25).

3.2.12 Input Signal Level Monitor

The input signal level of each channel can be monitored via

Sys tem Architect software. The measurement range is from +20

dBu to –40 dBu with 0.5 dBu resolution. Each audio channel has

the following monitors:

• Analog audio input: The audio input at the Balanced Audio

Inputs.

• Switched audio input: The audio input after the Input Audio

Router.

• CobraNet audio input: The audio input level from the selected

CobraNet audio channel.

3.2.13 Output Signal Level Monitor

The output signal level of each channel can be monitored via

System Architect software. The measurement range is from 0 dB

to –40 dB with 0.5 dB resolution. The monitors are scaled so that

0 dB is referenced to the full rated output voltage of the amplifier.

3.2.14 Thermal Headroom Level Monitor

The thermal headroom level of each channel can be monitored

with the software. This level represents the percent of available

power/thermal capacity that is currently being used within the

output section of the amplifier. When the thermal headroom level

reaches 100%, the amplifier cannot produce any more power and

it will begin to protect the output devices by limiting their drive

level. The thermal limiter feature of the USP/CN can be set to

engage at a pre-selected thermal level. (See Section 3.2.31).

3.2.15 Power/Standby Control

Each channel can be independently turned on and off.

3.2.16 Signal Mute

The output signal of each channel can be independently muted.

This function produces a minimum 60 dB of attenuation.

3.2.17 Polarity Inverter

The input signal polarity of each channel can be independently

inverted.

3.2.18 Input Signal Fader

Each input signal can be adjusted under software control. The

gain range is +20dB to –100dB in 0.5 dB steps. Each analog

Audio Input has two faders with these functions:

• Trim the Analog Audio Input signal before the Input Router.

• Trim the Analog Audio Input signal after the Input Router.

3.2.19 Amplifier Information

At startup, the module extracts several useful items of informa tion

about the host amplifier. These include manufacturer, model, date

code, and serial number. This information is stored in the software

system inventory and is displayed on the software con trol panels.

3.2.20 User and Channel Labels

In IQwic, the module can store two user labels and channel labels.

In System Architect, the module can store 4 or 8 channel labels

and a unit label.These labels are 30-character strings that can be

set by the user to indicate the function of the amplifier and its

channels. For example, “LOWER RIGHT CLUSTER, FOR DELAY.”

3.2.21 Line Voltage Monitor

The AC line voltage supplied to the amplifier can be monitored with

this function. If the voltage is out of a safe area you can trigger an

error.

3.2.22 Error Reporting

The module can detect three different error conditions per channel

and errors in the AC line voltage. Each error type can be configured

to report the error through the control network and/or the AUX port.

Network reported errors appear in the control software’s Error

Win dow.

The software offer many options to further report errors, including

audible alerts, printout, email, pager, serial port and fax. The options

are set in the software. The following describes each error source.

CLIP: The USP/CN can be configured to report if an excessive

number of clip events occur in either amplifier channel. The clip

events are consider an error if they exceed the defined count per the

defined unit of time. The Count Control sets the maximum number

of events before the error is reported. The range is 1 to 100. The

Time Control defines the amount of time that the events are counted

before starting the counting process over. Its range is 1 to 10

seconds. Note: Clip events are defined as the start of each clip and

every 10 milliseconds the amplifier is in clip thereafter. Using a high

count setting with a short time setting may result in clip error never

being detected.

THERMAL: Errors can be generated for excessive temperature in

the output section of the amplifier channel. The Threshold Control

sets the level that, if exceeded, will generate the error report. This

control has a range of 1 to 100%.

LOAD: If the load monitoring feature is activated, an error report can

be generated if the load impedance moves outside the pre-selected

range. See Section 3.1.33 for instructions on setting up load

monitoring.

LINE VOLTAGE: The AC line voltage can be monitored and an error

generated whenever the voltage is outside of the limits set at the

factory.

3 Operation (continued)

3.2.23 Input Signal Compressor/Limiter

An input signal compressor/limiter is available for each channel.

Five parameters control this feature:

Enable: Enables or disables this function.

Threshold: Sets the level, in dBu, above which the compressor

begins to attenuate the input signal. This level corresponds to the

input level meter reading. The compressor is “feed-forward,”

meaning that the level detection point is located before the gain

control stage. The range is from +20 dBu to – 50 dBu.

Attack Time: Sets the attack time of the compressor. The attack

time is defined as the time it takes the compressor to attenuate the

signal gain by 20 dB. The range is from 1 millisecond to 0.1

second.

Release Time: Sets the release time of the compressor. The

release time is defined as the time it takes the compressor to

increase the signal gain by 20 dB. The range is from 10

millisec onds to 10 seconds.

Compression Ratio: Sets the compression ratio of the

com pressor. The ratio is the relation between the amount of

attenua tion applied by the compressor verses the amount that the

input signal is over the threshold. The available settings are 2:1 to

32:1.

3.2.24 Peak Voltage Limiter

This limits the peak voltage output of the amplifier. Four

parame ters control this limiter for each channel:

Enable: Enables or disables this function.

Threshold: Sets the level, in absolute voltage, which the limiter

will allow from the amplifier. The range is from 12 V

Attack Time: Sets the attack time of the limiter. The attack time is

defined as the time it takes the limiter to attenuate the output

signal by 20 dB. The range is from 1 millisecond to 100

millisec onds.

to 255 V

pk

Release Time: Sets the release time of the compressor. The

release time is defined as the time it takes the limiter to increase

the output signal by 20 dB. The range is from 10 milliseconds to

10 seconds.

3.2.25 RMS Power Limiter

This limits the long-term output power of the amplifier. Four

parameters control this limiter for each channel:

Enable: Enables or disables this limiter.

Threshold: Sets the average power level, in watts, which the

limiter will allow from the amplifier channel. The range is from 10

watts to 600 watts. This level should be set to the connected

loudspeaker’s long-term power rating.

Attack Time: Sets the attack time of the limiter. The attack time is

defined as the time it takes the limiter to attenuate the output

signal by 20 dB. The range is from 1 second to 30 seconds.

Release Time: Sets the release time of the compressor. The

release time is defined as the time it takes the limiter to increase

the output signal by 20 dB. The range is from 1 second to 30

sec onds.

3.2.26 Load Supervision

The load supervision feature allows real-time monitoring of the

load connected to each amplifier channel. When enabled, the

USP/CN continuously monitors the amplifier output voltage and

current, and calculates the long-term average load impedance.

The measured load impedance is compared against the userdefined high and low limits. If either limit is exceeded, the status

indicator and, if enabled, the System Architect Error Reporting

functions alert the user of the problem. There are six controls and

two indicators for each channel:

pk.

Enable: Enables or disables the load-supervision function.

High Limit: Sets the upper bound above which the system will

report a “high” error status.

Low Limit: Sets the lower bound below which the system will

report a “low” error status.

Nominal Load Impedance: Sets the expected average

imped ance for the connected load. This value determines the

output signal level required for the test. This parameter is also

used by the average power limiter to determine the expected

power threshold. (See Section 3.1.29).

Report Error to Network: Enables Error Reporting to send an

error report via the network so that high and low load conditions

are reported to the software.

Report Error to Aux: Enables and high or low load error to be

reported by the AUX output. (See Section 4.1.1).

Test Indicator: This indicator is active when the amplifier out put

signal is sufficient to allow load impedance calculation and test

verification.

Low/Normal/High Indicator: This indicator shows the present

status of the load impedance with respect to the user-defined high

and low limits.

Z Average Monitor: Reports the actual calculated average load

impedance in ohms. Its range is from 0 ohms to 250 ohms.

Load Supervision Applications

The Load Supervision feature can be used to monitor the ampli fier

load in real time with almost any program material. Average load

impedance is calculated as a function of amplifier output voltage

and current. The system requires approximately 20-30 mA of

average amplifier output current for adequate supervision. This

allows typically low average output power levels of less than ½

watt with most loads. The maximum load impedance for reli able

system performance is limited to about 50 ohms. Higher

impedances can be measured but may require higher amplifier

output levels for reliable operation.

page 16 page 17

Operation Manual

Operation Manual

Page 10

CTs Multi-Channel Power Amplifiers

CTs Multi-Channel Power Amplifiers

3 Operation (continued)

Most amplifier/load systems can be configured and supervised

by following these steps:

1. Configure your audio system using a known “good” load,

then enable the Load Supervision feature.

2. Provide typical program material at a level high enough to

light the “test” indicator.

3. Run the system at this level until the average impedance

stabi lizes. This may take seconds to minutes depending on

level, duty-cycle, etc.

4. Set the nominal impedance at the measured value average.

This optimizes the supervision algorithm for voltage and

cur rent levels versus the actual load. Note: a higher nominal

set ting will require higher output levels.

5. Set the high limit at twice average and the low limit at onefourth nominal. (These limits are somewhat arbitrary but

should be a good starting point.)

6. Let the system run for extended periods using any and all

typi cal program material.

7. Adjust the high/low limits, if necessary, to account for any

variance in average measured impedance.

8. Enable error reporting, if desired.

This procedure should work well for most applications. However,

some applications can be a little more difficult. Some very lowlevel and/or low duty-cycle signals may not adequately “test” the

load. Lab and situation testing have shown output levels as small

40 dB below rated amplifier output to be enough for most lowimpedance loads. Higher impedance loads such as those used in

“lightly-loaded” 70V distribution lines may require signal level

near 20 dB below rated output.

The “Nominal Load Impedance” control is used to optimize the

system for the most accurate calculation of load impedance. It

should be set to the expected nominal (or rated) impedance of the

“normal” load. The high limit should be set for at least 2 times the

expected nominal or actual measured load, while the low limit

should be set to ½ the expected nominal or actual mea sured load.

The following example calculates the SPL necessary for

supervi sion of a typical 8-ohm system. While the resulting 80-dB

SPL @ 1 meter is definitely above conversation level, it is not

uncom fortable.

An “8 ohm” example:

30 mA into 8 ohms = 0.007watt.

8-ohm driver sensitivity = 100dB for 1W @ 1 meter.

0.007W/1W = –20dB.

Required SPL for supervision test is 100dB – 20dB = 80dB SPL

@ 1 meter.

3.2.27 Typical Load Characteristics

It is well known that the typical loudspeaker impedance is not the

same for all frequencies. This variance is due to the effect of

elec trical properties such as the expected increase in impedance

at high frequencies due to driver voice-coil inductance, or the

peaks and valleys due to passive crossovers. Testing of various

passive boxes has shown peaks of 100 ohms or more! Lowfrequency impedance variation can come from the interaction of

the driver compliance with that of the box. The low frequency

variations are usually wide bandwidth and may vary from 6 to 30

ohms on an 8-ohm driver.

These anomalies are easily averaged out by the USP/CN

supervi sion algorithm in most systems. However, there may be

some extreme situations for very narrow bandwidth (i.e. singlenote) signals and/or very widely varying loads that the algorithm

sim ply cannot overcome. In these cases, widening the high and

low limits will help decrease the “sensitivity” of supervision and

decrease the chance of “nuisance” error reports.

3.2.28 Filters

Each audio channel has five separate places where filters can be

placed in the system. There are 64 filters total and they can be

placed anywhere within the system. In addition to filtering, each

possesses up to ± 24 dB of gain. The filters will vary based on the

firmware and software being run. The following filters are

available:

• Lowpass: Bessel 2-4, Butterworth1-4, and Linkwitz-Riley 4

(Firmware 2.0 provides up to 8 Linkwitz-Riley filters)

• Highpass: Bessel 2-4, Butterworth1-4, and Linkwitz-Riley 4

(Firmware 2.0 provides up to 8 Linkwitz-Riley filters)

• Lowshelf: Low-frequency shelving EQ

• Highshelf: High-frequency shelving EQ

• Lowpass EQ: Variable Q from 0.1 to 35

• Highpass EQ: Variable Q from 0.1 to 35

• Parametric EQ: Variable Q from 0.1 to 35

• All-Pass: 1st and 2nd order

All-Pass filters provide no gain change to the output, but provide a

phase change at the selected frequency. This corrects the phase

relationship of the output without a gain reduction, such as is

found in other filters.

3.2.29 Delay

Due to the nature of DSP processing, there is some inherent delay

or latency within the system These delays are:

DSP processing: 1 ms or 1000 µs.

Digital-to-analog conversion: 250 µs.

Analog-to-digital conversion: 250 µs.

Amplifier: 100 µs.

In addition to these unavoidable delays, additional delay can be

added to each channel. Each channel is capable of 2.0 seconds of

delay in 20.8 µs increments.

Overall delay = inherent delay + coarse delay + fine delay.

3.2.30 Noise Generator

A noise generator shared between channels allows noise to be

mixed into the audio signal. This is useful for noise masking

applications and testing. Each channel has the following controls:

• Noise On/Off: The channel’s noise generator can be

indepen dently turned on.

• Noise Type: Full spectrum white noise or pink noise.

• Noise Level: A fader to allow the noise level to be controlled.

3.2.31 Sine-wave Generator

A sine-wave signal generator allows the mixing of a single tone

into the audio signal. Typical applications can be for the injection

of a high frequency tone (19 kHz) into the signal in paging type

system to continually drive the speaker, allowing continuous

mon itoring of the speaker load. The following controls exist:

• Sine On/Off: The sine-wave signal generator’s function.

• Sine Frequency: Controllable from 20 Hz to 20 kHz.

• Sine Level: Each channel’s sine-wave signal level can be

independently controlled.

3.2.32 Input Signal Router

Each channel of the module’s signal processing has an Input

Sig nal Router that lets you choose the audio signal that will be

used by the channel. Choose one of the following configurations:

3 Operation (continued)

CobraNet Audio: Assign this in the CobraNet Input section of

the software. See Section 3.3.2 for more details. Choices for the

CobraNet Input are from any of four bundles, and any of the eight

channels available.

CobraNet with Analog Backup: In this mode, if CobraNet

audio is lost, the module automatically switches to the chosen

Balanced Audio Input until CobraNet audio returns.

CobraNet with Analog Override: In this mode, if a signal

appears on the Analog Input, the module’s input signal switches

from CobraNet to the Analog Input. Then the CobraNet audio will

be routed to the channel after 10 seconds.

3.3 CobraNet

CobraNet is a licensed technology developed by Peak Audio, Inc.

consisting of proprietary communications protocol, firmware and

hardware. It allows reliable, deterministic transmission of digital

audio over a 100Base-T Fast Ethernet network. The amplifier

operates as a networked device on a CobraNet network, and

interfaces digital audio from the network to the amplifier. For a

more thorough discussion about CobraNet technology, refer to

Section 8.2 and visit Peak Audio’s CobraNet website at www.

cobranet.info.

This section describes the amplifier’s CobraNet control and

mon itoring features. These features are accessed via the control

soft ware. Please refer to the software documentation if you are

unfamiliar with the software.

3.3.1 CobraNet Module Parameters

The internal CobraNet Network Interface Module contains several

parameters for control and monitor of status of the CobraNet

net work, and do not directly affect the control network. These

vari ables can also be controlled and monitored through the

CobraNet network using CobraCAD™ or other industry-standard

SNMP-enabled network management software. CobraCAD is

software that provides a GUI to design CobraNet networks. It can

be downloaded from www.peakaudio.com.

Conductor

The Conductor is the device in a CobraNet network that acts as

the master clock. Other devices are called “Performers.” Any

CobraNet device can be configured to operate either as Network

Conductor or a Performer.

• Active Indicator: This indicator, viewable in System Archi tect

software, reports the present Conductor status of the device. If the

indicator is ON, the unit is operating as the network Con ductor.

When OFF, the unit is operating as a Performer.

• Priority: This parameter adjusts the priority level for

becom ing the Conductor. When set to zero, the amplifier will

never function as the Conductor, and when set to 255 it will

always function as the Conductor. The higher the priority number,

the more likely unit will act as the Conductor. The Priority object

is stored in presets.

System Name

This parameter can be set to any alpha-numeric string of 30

characters or less. It communicates a unique name for the

partic ular device to a network. The System Name object is stored

in presets.

System Description

This parameter is configured at the factory and is read-only. The

intended use is to communicate a unique device description to a

network.

System Location

This parameter is user-settable to any alpha-numeric string of 30

characters or less. The intended use is to communicate a unique

description of the device location to a network. This object is

stored in presets.

System Contact

This parameter is user-settable to any alpha-numeric string of 30

characters or less. The intended use is to communicate the

des ignated contact person (in case of service or other network

issue) to the network. This object is stored in presets.

Firmware Version

This parameter is configured at the factory and is read-only. The intended

use is to communicate the presently loaded CobraNet module firmware

version to a network.

MAC Address

This parameter is configured at the factory and is read-only. The setting

defines a unique IEEE802-recognized address for use with any Ethernet

based network.

IP Address

This IP address is for the CobraNet control ONLY. It is used by SNMP

agents such as CobraNet Disco to control CobraNet specific functions.

This IP address should not be confused with the control system’s IP

address that is used to control and monitor the CobraNet module.

3.3.2 CobraNet Input Routing

CobraNet input routing includes the following controls:

CobraNet Receive Bundles

The amplifier can receive four unique CobraNet Bundles (RxA, RxB, RxC,

RxD). Each Bundle includes an “Active” indicator to indicate whether the

particular Bundle is being actively transmitted onto the network.

CobraNet Receive Channels

Each CobraNet Bundle contains up to eight digital audio channels. Each

channel is selected at its respective transmitter to contain none, 16-, 20or 24-bit audio sample data. A total of four or eight audio channels can be

processed by the USP/CN at any one time. Any of the eight channels on a

bundle can be can be routed to either of the four or eight processing

channel inputs on the USP/CN.

• Channel Label: Each received digital audio channel can be assigned

a user-specified label to indicate intended use, source or other

informa tion. The label is stored in presets along with the bundle number

and receive channel information.

page 18 page 19

Operation Manual

Operation Manual

Page 11

CTs Multi-Channel Power Amplifiers

6

5

4

321

AUX

CONNECTOR

TO BALANCED

INPUT

+

–

CTs Multi-Channel Power Amplifiers

3 Operation (continued)

3.3.3 CobraNet Output Routing

CobraNet output routing includes the following controls:

CobraNet Transmit Bundles

The amplifier can transmit up to four unique CobraNet Bundles

(TxA, TxB, TxC, TxD). Each Transmit Bundle includes the

follow ing controls and monitor functions:

• Receiver Count: This meter reports the number of CobraNet

nodes actively receiving the Bundle being sourced to the network

by this bundle.