Crown CT12018 Original Instructions Manual

Content / Содержание / Зміст / Мазмұны

English

Explanatory drawings ���������������������������������������������������������������������������������������������������������������page

General safety rules, instructions manual ����������������������������������������������������������������������������� pages34 - 8

Русский

Пояснительные рисунки ������������������������������������������������������������������������������������������������� страница

Общие указания по ТБ, инструкция по эксплуатации ������������������������������������������������� страницы39 - 13

Украïнська

Пояснювальні малюнки ���������������������������������������������������������������������������������������������������� сторінкa

Загальні вказівки по ТБ, iнструкція з експлуатації ��������������������������������������������������������� сторінки314 - 18

Қазақ тілі

Түсіндіргіш әлеміштер �������������������������������������������������������������������������������������������������������������� бет

Жалпы қауіпсіздік жөніндегі ұсыныстар, пайдалану нұсқаулығы ���������������������������������������� беттер319 - 23

2

3

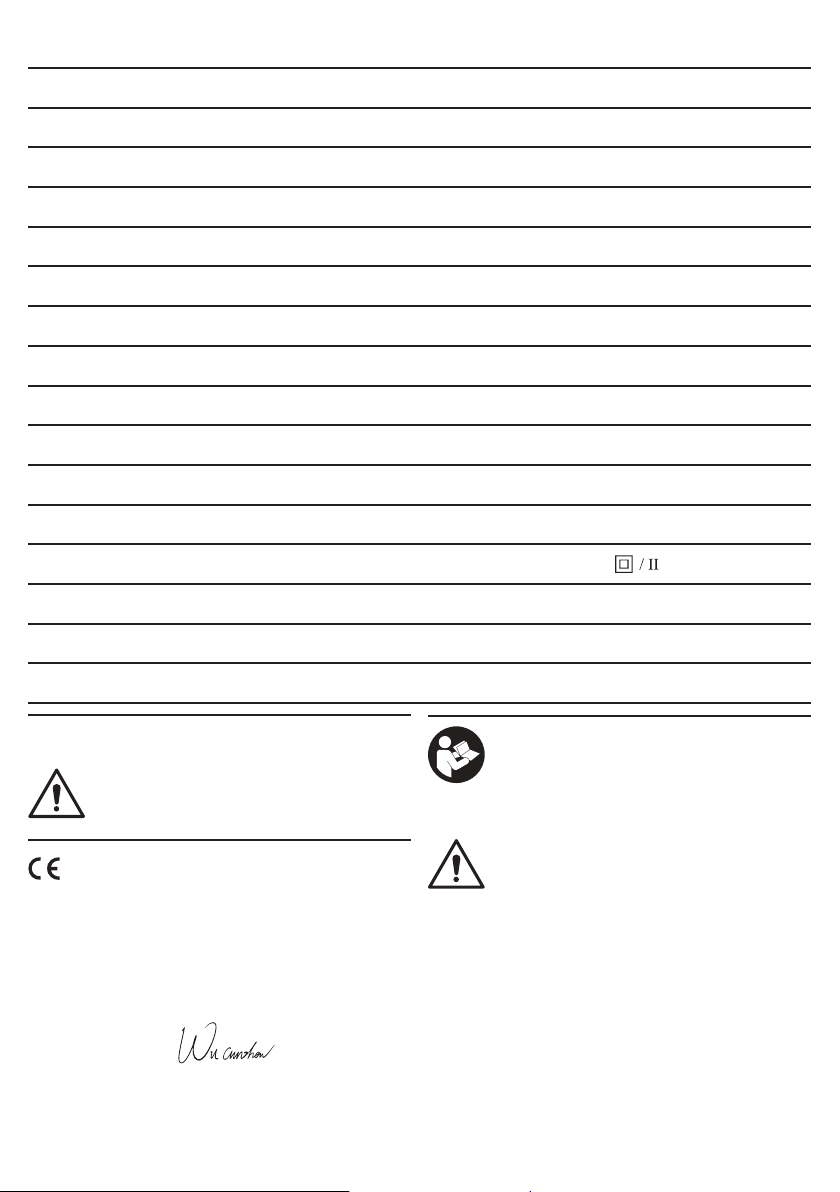

Power tool specications

Impact wrench CT12018

Power tool code [220-230 V ~50/60 Hz] 421630

Rated power [W] 900

Power output [W] 470

Amperage at voltage 220-230 V [A] 4�3

No-load speed [min-1] 2100

Torque [Nm] 320

Percussion (impact) rate [min-1] 2700

Min. diameter of screws

Max. diameter of screws

Tool holder (external square)

Weight

Safety class

Sound pressure [dB(A)] 102

[mm]

[inches]

[mm]

[inches]

[mm]

[inches]

[kg]

[lb]

M8

5/16"

M24

15/16"

12,7x12,7

1/2"x1/2"

3,5

7�72

Acoustic power [dB(A)] 113

Weighted vibration [m/s2] 16,16

Noise information

Always wear ear protection if the sound

pressure exceed 85 dB(A).

Declaration of conformity

We declare under our sole responsibility that the

product described under "Power tool specications"

is in conformity with all relevant provisions of the directives 2006/42/EC including their amendments and

complies with the following standards: EN 60745-1,

EN 60745-2-2�

Certication Wu Cunzhen

manager

Merit Link International AG

Stabio, Switzerland, 17�10�2017

English

General safety rules

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool�

Work area safety

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents�

• Do not operate power tools in explosive atmos-

pheres, such as in the presence of ammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes�

4

WARNING - To reduce the risk of injury,

user must read instruction manual!

WARNING! Read all safety warnings and

all instructions. Failure to follow the warn-

ings and instructions may result in electric

shock, re and / or serious injury.

• Keep children and bystanders away while oper-

ating a power tool. Distractions can cause you to lose

control�

Electrical safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Un-

modied plugs and matching outlets will reduce risk

of electric shock�

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded�

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electric shock�

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock�

• When operating a power tool outdoors, use an ex-

tension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock�

• If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock� NOTE! The term "residual current

device (RCD)" may be replaced by the term "ground

fault circuit interrupter (GFCI)" or "earth leakage circuit

breaker (ELCB)"�

• Warning! Never touch the exposed metal surfaces

on gearbox, shield, and so on because touching metal

surfaces will be interfered with the electromagnetic

wave, thus causing potential injury or accidents.

Personal safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and / or battery pack, picking up or

carrying the tool. Carrying power tools with your n-

ger on the switch or energising power tools that have

the switch on invites accidents�

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations�

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts�

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

English

these are connected and properly used. Use of dust

collection can reduce dust-related hazards�

• Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles� A careless action can cause

severe injury within a fraction of a second.

• Warning! Power tools can produces an elec-

tromagnetic field during operation� This field may

under some circumstances interfere with active or

passive medical implants� To reduce the risk of se-

rious or fatal injury, we recommend persons with

medical implants to consult their physician and the

medical implant manufacturer before operating this

power tool�

Power tool use and care

• The persons with lowered psychophysical or men-

tal aptitudes as well as children can not operate the

power tool, if they are not supervised or instructed

about use of the power tool by a person responsible

for their safety�

• Do not force the power tool. Use the correct

power tool for your application� The correct power

tool will do the job better and safer at the rate for which

it was designed�

• Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired�

• Disconnect the plug from the power source and /

or the battery pack from the power tool before making any adjustments, changing accessories, or

storing power tools� Such preventive safety measures

reduce the risk of starting the power tool accidentally�

• Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users�

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools�

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control�

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the work

to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation�

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations�

• Note that when you operate a power tool, please

hold the auxiliary handle correctly, which is helpful

when controlling the power tool� Therefore, proper

holding can reduce the risk of accidents or injuries.

Service

• Have your power tool serviced by a qualied

repair person using only identical replacement

5

parts. This will ensure that the safety of the power tool

is maintained�

• Follow instruction for lubricating and changing ac-

cessories�

Special safety warnings

• Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and

could give the operator an electric shock�

• Wear ear protectors. Exposure to noise can cause

hearing loss�

Symbol Meaning

Serial number sticker:

CT ��� - model;

XX - date of manufacture;

XXXXXXX - serial number�

Read all safety regulations

and instructions�

Wear safety goggles�

Safety guidelines during power tool

operation

• When operating the power tool, you should pay at-

tention and remain vigilant� You shall not use the pow-

er tool when you feel fatigue or under the inuence of

anesthesia, alcohol or drugs�

• You shall not put your ngers on switch button to

avoid starting up the power tool unconsciously when

the tool is moving�

• When mounting screws, you should ensure other

components matching the screws are fully xed and

reliable before operating the power tool� The switch

shall be started on a safety position and the power

tool shall operate for 30 seconds, which shall be

stopped promptly in case of any serious vibration or

other problem; and arrangement shall be made for

maintenance�

• Before starting, it is necessary to determine the

location of the concealed wiring, water and gas pipelines� In case of damage of electrical wiring or general

utilities (for example, by a bolt screw being screwed)

severe consequences for life and health of the operating personnel are likely to occur�

• Do not use the usual socket wrench sleeve, use the

specially designed sleeve for impact wrench� Impact

wrench sleeve is black, hard and don’t damage the

screw bolt� The sleeve not for the impact wrench is

easy to be damaged, and easy to cause personal in-

jury. Before use, be sure the sleeve without cracks or

other visible damage�

• Change of the construction of socket wrenches as

well as use of detachable attachments or accessories

not suitable for this power tool is prohibited�

• Recoil (a sudden jerk of the power tool) may occur

during operation; in order to avoid dangerous situations (for example loss of balance), keep the power

tool in your hands rmly and maintain a rm posture.

• When processing small blank parts, which own

weight is not sufcient to ensure necessary xation,

use special clamp xtures.

Wear ear protectors�

Wear a dust mask�

Disconnect the power tool

from the mains before instal-

lation or adjustment.

Movement direction�

Rotation direction�

Locked�

Unlocked�

Double insulation / protection class�

Attention� Important�

A sign certifying that the

product complies with essential requirements of the

EU directives and harmonized EU standards�

Symbols used in the manual

Following symbols are used in the operation manual,

please remember their meanings� Correct interpretation of the symbols will allow correct and safe use of

the power tool�

English

Do not dispose of the power

tool in a domestic waste

container�

6

Power tool designation

The power tool is intended for tightening and loosing

nuts and bolts�

The area of the tool application can be expanded due

to use of additional accessories�

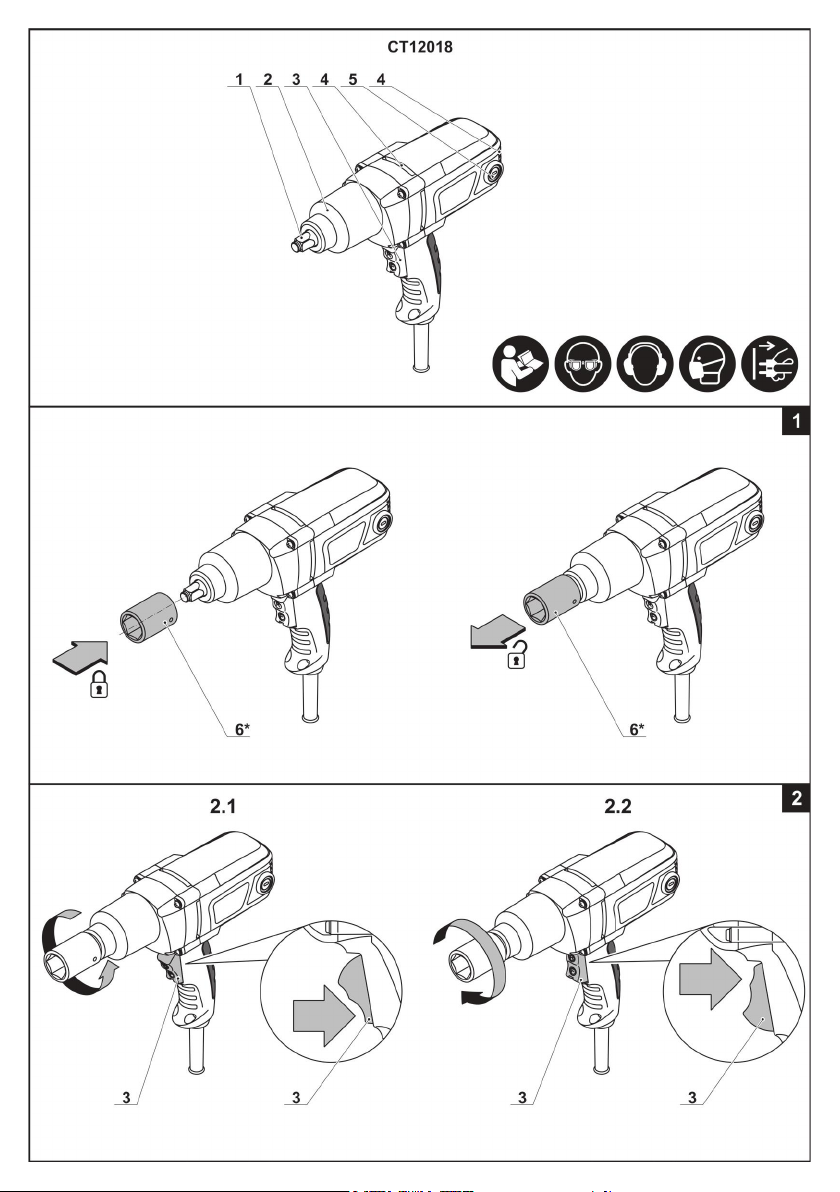

Power tool components

1 Tool holder

2 Body

3 On / off switch (reverse function)

4 Ventilation slots

5 Screw plug

6 Socket wrench *

* Optional extra

Not all of the accessories illustrated or described

are included as standard delivery.

Installation and regulation of power tool

elements

Before carrying out any works on the power tool it

must be disconnected from the mains.

Socket wrench mounting / dismounting (see g. 1)

• Insert the socket wrench 6 onto the tool holder 1 and

press it to x it (see. g. 1).

• Disassembly operations do in reverse sequence�

Initial operating of the power tool

Always use the correct supply voltage: the power supply voltage must match the information quoted on the

power tool identication plate.

Switching the power tool on / off

Rotation to the right

Press and hold the on / off switch 3 on the bottom (see

g. 2.1), to switch off - release it.

Rotation to the left

Press and hold the on / off switch 3 on the top (see

g. 2.2), to switch off - release it.

The torque depends on the impact duration� The

maximum achieved torque results from the sum of

all individual torques achieved through impact� The

maximum torque is achieved after an impact duration of 3-5 seconds� After this duration, the tightening torque is increased only minimally� However, the

transmission housingheats up noticeably�

The consequences of excessive

heating-up are high wear of all hammer

mechanism components and a high

requirement of lubricant.

The impact duration is to be determined for each required tightening torque� The actually achieved tightening torque is always to be checked with a torque

wrench�

Recommendations on the power tool

operation

Apply the socket wrench to the tool holder only when the power tool it is switched

off.

A torque depends on the following factors:

• Strength properties of the screws / nuts�

• Type of backing (washer, disc spring, seal)�

• Strength properties of the material being

screwed / bolted together�

• Lubrication conditions at the screw / bolt connec-

tion�

Hard seat - is given for metal-to-metal screw applications with the use of washers� After a relatively short

impact duration, the maximum torque is reached� Unnecessary long impact duration only causes damage

to the machine�

Spring-loaded seat - is given for metal-to-metal screw

applications, however with the use of spring washers,

disc springs, studs or screws / nuts with conical seat as

well as when using extensions�

Soft seat - is given for screw applications, e� g�, metal

on wood or when using lead washers or bre washers

as backing�

For a spring-loaded seat as well as for a soft seat, the

maximum tightening torque is lower than for a hard

seat� Also, a clearly longer impact duration is required�

The impact duration is to be determined through practical testing�

At temperatures below the freezing point, run the machine for approx� 3 minutes at no-load to improve its

lubricating capacity�

Design features of the power tool

The tool holder 1 with the socket wrench 6 is driven by

an electric motor via a gear and impact mechanism�

The working procedure is divided into two phases:

Screwing in and tightening (impact mechanism in action)� The impact mechanism is activated as soon as

the screwed connection runs tight and thus load is

put on the motor, converting the power of the motor

to steady rotary impacts� When loosening screws or

nuts, the process is reversed�

English

Power tool maintenance / preventive

measures

Before carrying out any works on the power tool

it must be disconnected from the mains.

Cleaning of the power tool

An indispensable condition for a safe long-term exploitation of the power tool is to keep it clean� Regularly

7

ush the power tool with compressed air thought the

ventilation slots 4�

After-sales service and application service

Our after-sales service responds to your questions concerning maintenance and repair of your

product as well as spare parts� Information about

service centers, parts diagrams and information about spare parts can also be found under:

www.crown-tools.com�

Transportation of the power tools

• Categorically not to drop any mechanical impact on

the packaging during transport�

• When unloading / loading is not allowed to use any

kind of technology that works on the principle of clamping packaging�

Environmental protection

Recycle raw materials instead of disposing as waste.

Power tool, accessories and packaging

should be sorted for environment-friendly

recycling�

The plastic components are labelled for categorized

recycling�

These instructions are printed on recycled paper manufactured without chlorine�

The manufacturer reserves the possibility to introduce changes.

English

8

Технические характеристики электроинструмента

Ударный гайковерт CT12018

Код электроинструмента [220-230 В ~50/60 Гц] 421630

Номинальная мощность [Bm] 900

Выходная мощность [Bm] 470

Сила тока при напряжении 220-230 B [A] 4�3

Число оборотов холостого хода [мин-1] 2100

Крутящий момент [Nm] 320

Частота ударов [мин-1] 2700

Мин. диаметр винтов

Макс. диаметр винтов

Держатель принадлежности

(внешний квадрат)

Вес

Класс безопасности

Звуковое давление [dB(A)] 102

[mm]

[дюймы]

[mm]

[дюймы]

[mm]

[дюймы]

[кг]

[фунты]

M8

5/16"

M24

15/16"

12,7x12,7

1/2"x1/2"

3,5

7�72

Акустическая мощность [dB(A)] 113

Вибрация [м/с2] 16,16

Информация о шуме

Носить приспособление для защиты

органов слуха при уровне звукового

давления свыше 85 dB(A).

Соответствия требуемым нормам

Мы заявляем под нашу единоличную ответственность, что описанный в разделе "Технические

характеристики электроинструмента" продукт отвечает всем соответствующим положениям Директив 2006/42/EC, включая их изменения, а также

следующим нормам: EN 60745-1, EN 60745-2-2.

Менеджер по Wu Cunzhen

сертификации

Merit Link International AG

Stabio, Швейцария, 17.10.2017

Русский

Общие правила техники безопасности

привести к поражению электрическим током, возгоранию и / или серьезной травме.

Сохраните все предупреждения и инструкции

для дальнейшего использования.

Термин "электроинструмент", используемый в тексте предупреждений, относится к электроинструменту с питанием от электросети (проводной) или

электроинструменту с питанием от аккумулятора

(беспроводной).

Безопасность рабочего места

• Рабочее место должно быть чистым и хоро-

шо освещенным. В захламленных или темных ме-

стах вероятны несчастные случаи.

9

ПРЕДУПРЕЖДЕНИЕ. Чтобы снизить

риск получения травм, пользователь

должен ознакомиться с руководством

по эксплуатации!

ПРЕДУПРЕЖДЕНИЕ. Прочтите все

предупреждения о технике безопас-

ности и инструкции. Несоблюдение

предупреждений и инструкций может

Loading...

Loading...