Page 1

OIL-FIRED CENTRAL FURNACE

Installation, Operation, and Service Manual

With Users Information Section

Models:

CSHB60-90XE CSHB60-90XP

c WARNING:

• Do NOT store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

• Improper installation, adjustment, alteration, service, or

maintenance can cause a fire or explosion resulting in property

damage, personal injury, or loss of life. For assistance or additional

information consult a qualified installer or service agency.

These instructions should be:

• read prior to installing the furnace

• retained for reference by qualified service personnel

• reviewed before performing any service or maintenance

Crown Boiler Company

3633 “I” Street

Philadelphia, Pennsylvania 19134

MO-452

ECN 5079-MA MADE IN USA

Page 2

I. SAFETY SECTION

This page contains various warnings and cautions found throughout the Oil Furnace

Manual. Please read and comply with the statements below.

cWARNING AND CAUTIONS:

cWARNING: This furnace is not to be used as a construction heater. See Page 1.

c CAUTION MUST BE TAKEN NOT TO EXCEED 90° ROTATION (OF THE FLUE

ELBOW) COUNTERCLOCKWISE OR RIGHT FROM THE VERTICAL POSITION.

See Page 2.

cWARNING: The predetermined limit location on this Crown oil fired furnace has been

tested and approved by Thermo Products, LLC. Any attempt to relocate this safety control

or replace this safety control with a control that is not approved, or is incompatible, may

result in personal injury, substantial property damage or death. See Page 5.

cWARNING: THE HEAT EXCHANGER MUST BE CLEANED BY A QUALIFIED

SERVICE PERSON. See Page 8.

cCAUTION: DO NOT ATTEMPT TO MAKE REPAIRS YOURSELF! See Page 9.

cWARNING: The area around the furnace should be kept free and clear of combustible

liquids and material, especially papers and rags. See Page 9.

cWARNING: NEVER burn garbage or refuse in your furnace. Never try to ignite oil by

tossing burning papers or other material into your furnace. See Page 9.

cWARNING: Crown oil furnaces are designed to burn No. 1 or No. 2 distillate fuel oil.

NEVER USE GASOLINE OR A MIXTURE OF OIL AND GASOLINE. See Page 9.

cCAUTION: DO NOT ATTEMPT TO START THE BURNER WHEN:

1. Excess oil has accumulated.

2. The furnace is full of vapors.

3. The combustion chamber is very hot.

IF ONE OR MORE OF THESE CONDITIONS EXIST, CONTACT A QUALIFIED

SERVICE PERSON. See Page 9.

i

Page 3

All installations and services must be performed by qualified service personnel.

TABLE OF CONTENTS

SECTION BEGINNING PAGE

I. SAFETY SECTION i

II. GENERAL INSTRUCTIONS 1

A. VENTING 2

B. DRAFT REGULATORS 4

C. DUCT WORK/AIR CONDITIONING 4

D. FILTERS MOUNTED EXTERNAL TO FURNACE 4

E. LIMIT POSITION AND LOCATION 5

F. BURNER INSTALLATION 6

G. BURNER SPECIFICATIONS AND APPLICATIONS 7

H. HEAT EXCHANGER CLEANING INSTRUCTIONS 8

III. USERS INFORMATION SECTION 9

A. OIL SUPPLY 9

B. COMBUSTION AIR SUPPLY 9

C. INSPECTION AREAS 9

D. STARTING THE BURNER 9

E. FILTER CLEANING AND LOCATIONS 10

APPENDIX – A REPLACEMENT PARTS LIST 11

APPENDIX – B WIRING DIAGRAMS 12

ii

Page 4

All installations and services must be performed by qualified service personnel.

II. GENERAL INSTRUCTIONS - READ BEFORE START OF INSTALLATION

1. The heating output capacity of the furnace proposed for installation should be based on a heat loss calculation

made according to the manuals provided by the Air Conditioning Contractors of America (ACCA) or the American

Society of Heating, Refrigeration and Air Conditioning Engineers, Inc. (ASHRAE).

2. All local codes and/or regulations take precedence over the instructions in this manual and should be followed

accordingly. In the absence of local codes, installation must conform with these instructions and regulations of the

National Fire Protection Association, and to the provisions of the

National Electrical Code (ANSI/NFPA 70-1999 or

latest edition).

3. The installed furnace must be level and positioned in a central location with respect to outlet registers. It should

be located near the chimney to minimize any horizontal run of flue pipe, which may be required.

4. A furnace installed in a residential garage must be installed so the burner and ignition source are located higher

than 18 inches above the floor, unless the required combustion air is taken from the exterior of the garage. Also, the

furnace must be located or protected to avoid physical damage by vehicles.

cWARNING: This furnace is not to be used as a construction heater.

5. Listed below are definitions of "COMBUSTIBLE MATERIAL" and "NON-COMBUSTIBLE MATERIAL."

COMBUSTIBLE MATERIAL:

Material made of or surfaced with wood, compressed paper, plant fibers, plastics, or other material that will ignite

and burn, whether flame resistant or not.

NON-COMBUSTIBLE MATERIAL:

Material that is not capable of being ignited and burned. Such materials consist entirely of, or a combination of,

steel, iron, brick, tile, concrete, slate, or glass.

TYPE OF UNIT MODEL NO.

HIGHBOY

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

1

FROM

SIDES OF

FRONT

FURNACE

CSHB60-90 0” Note

1

TOP &

SIDES OF

PLENUM

FROM THE

FLUE/VENT

1” 7” 0”

REAR

Notes:

1

CSHB60-90 front clearance 6” for Closet, 24” for Alcove.

The minimum clearances listed in the preceding table are for fire protection. Clearance for servicing the front of the

furnace should be at least 24 inches. A clearance of 24 inches is recommended for passage to all points on the

furnace requiring service access.

NOTE: The CSHB60-90 furnaces may be installed on combustible flooring.

NOTE: The CSHB60-90 furnace is approved for closet installation. If the CSHB60-90 is installed in a closet, it

requires two openings in the closet door for combustion air, each having a minimum area of 162 sq. inches. This

free area for the CSHB60-90 intentionally exceeds the recommended minimum free area of 2 square inches per

1000 BTUH of input rate.

1

Page 5

All installations and services must be performed by qualified service personnel.

Power (Side-Wall) Venting-Important Note Regarding

cCAUTION: Crown Boiler Company will NOT assume responsibility for damage to, and

deterioration of, exterior building materials, e.g. brick, siding, clapboards, and etc., in close

proximity to the vent terminal due to operation of a power vented, oil furnace. This policy

is applicable regardless of the cause of sooting.

Two (2) problems typically arise when power venting any oil-fired appliance.

1) Soot buildup may occur at an accelerated rate on critical components of the

furnace oil burner, e.g. the primary control flame sensor (“cad cell”), the burner

head, oil nozzle, and etc.

2) Severe damage may occur to external surfaces of the structure in the event the

furnace continually produces a high level of smoke in the flue gases. Excess

smoke and soot can be produced for many reasons, some of which cannot be

successfully controlled by the installer and the appliance manufacturer.

NOTICE: Crown Boiler recommends the use of a chimney to vent our residential oil

furnaces. If a power venter must be used, it is the responsibility of the installer and power

venter manufacturer to design and assemble a satisfactory power vent system.

A. VENTING:

NOTE: On the CSHB60-90 it is possible to rotate the flue elbow (which is factory installed for vertical discharge)

90° counterclockwise from the vertical position to adapt to various venting systems.

c CAUTION MUST BE TAKEN NOT TO EXCEED 90° ROTATION (OF THE FLUE

ELBOW) COUNTERCLOCKWISE OR RIGHT FROM THE VERTICAL POSITION.

ROTATION OF FRONT FLUE ELBOW

When an installation requires that the flue exit out the left hand side casing on a front flue unit, remove screw

securing the 90 deg. elbow and rotate it 90°

vent through the opening.

NOTE: ROTATION OF FLUE PIPE IS ONLY ALLOWED FOR LEFT HAND SIDE VENTING

APPLICATIONS.

The CSHB60-90 may be vented through a standard correctly sized chimney.

The CSHB60-90 may also be horizontally vented through a side wall. Crown has available the Field model FDVS45/FVOP-415 side wall vent kit for such applications. When installing the FDVS-45/FVOP-415 side wall vent kit,

outside combustion air must also be applied to the burner. The following table identifies application order

information.

counterclockwise. Then, remove knock-out in side casing and extend

2

Page 6

All installations and services must be performed by qualified service personnel.

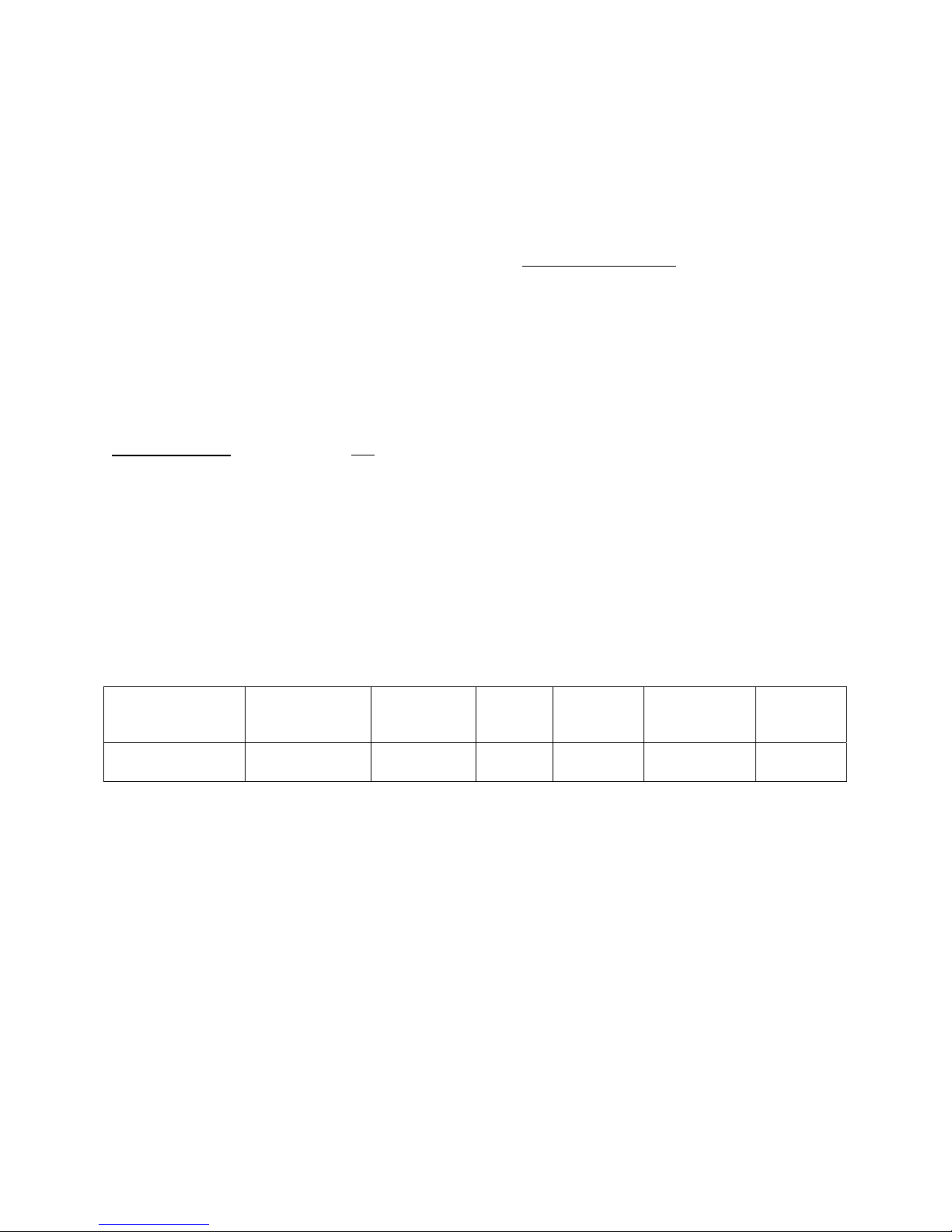

SIDE WALL VENTING APPLICATION ORDER INFORMATION

FIELD VENT

TERMINATION KIT

(15’ application MAX)

BURNER

Beckett AFG 160930 160945

Beckett NX 160932 160948

Riello BF3 160935 160946

The Field vent kit is set up with 4 inch diameter vent pipe with concentric through-the-wall vent termination/inlet

air vent hood. The combustion air inlet pipe diameter is also 4 inch diameter. For Riello, the combustion air inlet

pipe will be reduced to 3 inch diameter with the included Riello side wall vent kit. For Beckett, the combustion air

inlet pipe will be reduced to 3” diameter with the included Beckett side wall vent k it.

The side wall vent may be installed either through the upper knock-out on the left side casing of the unit or

vertically out the top opening of the vestibule. The 4” flexible vent pipe included w/ Field vent kit is able to be

installed at 2” clearance to combustibles.

The combustion air inlet can be installed through either the lower left side casing knock-out or the lower right side

casing knock-out.

PART NUMBER

COMBUSTION AIR

INTAKE KIT

(FOR COMBUSTION AIR

APPLICATIONS ONLY)

PART NUMBER

3

Page 7

All installations and services must be performed by qualified service personnel.

B. DRAFT REGULATORS:

A draft regulator is supplied with the furnace and should be installed according to the regulator manufacturers

recommendations. With the burner operating, use a draft gauge to adjust the regulator to the proper setting. (refer to

the instructions enclosed with draft regulator to adjust to the proper setting). When the burner air supply and draft

are properly adjusted, the overfire draft should be a negative (-).01" to (-).02" WC

1

, as measured at the 5/16"

overfire air tap (See Fig. 4). This tap is provided in the upper burner mounting plate. To measure the flue draft,

punch a small hole in the vent connector pipe as close to the furnace as possible and always before the draft

regulator.

Note: 1. Draft overfire may be positive for high fire applications but not to exceed (+).02" WC.

C. DUCT WORK/AIR CONDITIONING:

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed parallel

with or on the upstream side of the evaporator coil to avoid condensation in the furnace heat exchanger. If the

cooling unit is installed with a parallel flow arrangement, dampers or other means used to control flow of air should

be provided to prevent chilled air from entering the furnace. If such a damper is manually operated, it must be

equipped with a means to prevent operation of either unit, unless the damper is in the full heat or cool position.

The duct system should again follow the current design standard of Air Conditioning Contractors of America

(ACCA) or ASHRAE

Fundamentals volume.The most common location for the A-shaped coil (A style) is shown in

Fig. 1.

Fig 1: Acceptable locations for the air conditioner evaporator coil.

NOTICE: The minimum coil pan clearance for a drum type heat exchanger is three inches unless specified

otherwise by the individual coil manufacturer.

D. FILTERS MOUNTED EXTERNAL TO FURNACE

highboy furnaces, it is necessary to cut the return air opening in the side or rear casing, depending upon the

On

needs of the specific installation.

The filter rack provided with the furnace, refer to Fig. 2, will serve as a template to scribe a mark for the return air

opening on the casing. Place the filter rack on a side casing approximately one inch up from the bottom of the

furnace and centered from side to side. Place the securing flange against the casing when locating the return air

opening. For your convenience, (4) locator knock-outs have been placed at the proper locations on both the left and

right side casings.

4

Page 8

All installations and services must be performed by qualified service personnel.

PLEASE NOTE: While scribing the return air opening, the filter rack can be held in position by tape or similar

temporary means.

Fig. 2: A typical filter rack and dimensions for the CSHB60-90 furnace.

Position the open end of the filter rack so as to provide access for filter replacement. Once the filter rack is

positioned correctly, scribe a line along the inside of the securing flange on three of the sides. To scribe a line on the

fourth side (the open end), use the open end support as a guide.

Remove the filter rack and cut the return air opening in the casing. Now the filter rack can be anchored to the

furnace with screws or pop-rivets through the securing flange of the filter rack.

Connect the return air plenum to the filter rack and slide the filter into place. Dimensions for adapting the return air

plenum to the filter rack are provided (See Fig. 2).

E. LIMIT POSITION AND LOCATION

cWARNING: The predetermined limit location on this Crown oil fired furnace has been

tested and approved by Thermo Products, LLC. Any attempt to relocate this safety control or

replace this safety control with a control that is not approved, or is incompatible, may result in

personal injury, substantial property damage or death.

The unit listed in the table below must have the fan and limit control installed at the time of u nit installation.

TABLE 2: Installation location of

the fan and limit control for each

furnace

Fig. 3: Limit location for CSHB60-90

5

Page 9

All installations and services must be performed by qualified service personnel.

F. BURNER INSTALLATION:

NOTICE: Remove all cardboard packing from around chamber before installing burner.

The oil burner will mount on three stud mounting bolts on the lower mounting plate covering the opening in the

front of the heat exchanger. The end of the burner tube should be inserted no further than 1/4 inch back from the

inside surface of the combustion chamber. A distance further than 1/4 inch back from the inside chamber wall may

cause impingement and sooting. This unit is equipped with a chamber retainer (refer to Fig.4). This retainer secures

the chamber during shipping and helps to maintain insertion depth. DO NOT remove this retainer when installing

burner.

Fig. 4: Typical location of the overfire air tap and components in burner mounting plate area

Fig. 5: Burner insertion illustration (Top view)

When mounting the burner, the mounting plate (Fig. 4) must be removed to provide access to the area in front of the

combustion chamber. A fiber insulating sleeve or amulet is provided on the burner tube of specific burners.(see Fig.

5). See burner application chart for type of insulator. Do not allow the burner tube or end cone to physically touch

or protrude into the chamber, as excess heat transfer could result in destruction of the tube, end cone or both. The

burner tube/end cone is properly positioned, when the end is ¼ inch back from the inside surface of the combustion

chamber wall.

6

Page 10

All installations and services must be performed by qualified service personnel.

G. BURNER SPECIFICATIONS AND APPLICATIONS

*

FURNACE MODEL

CSHB60-90

BURNER

BECKETT (AFG) 130200S N AFG-4.5” F4 3-3/8

BURNER

SPEC

NO.

BURNER

MODEL & TUBE

INS

LENGTH

HEAD STATIC

PLATE

MAXIMUM

NOZZLE

SIZE**

0.75X80° A 0.60X80° A

SHIPPED

NOZZLE

SIZE

OIL

PUMP

PRESSURE

(PSIG)

120

BECKETT (NX) 130201S S NX-4.5” N/A N/A

CARLIN 130210S N

RIELLO 130220S S BF3-4.5” N/A N/A

EZ-1 HP/ 4.5”

77958 N/A

0.60X70° A 0.50X70° A

0.75X70° A 0.60X70° A

0.70X80° A 0.60X80° A

150

150

145

* INSULATOR S = SLEEVE OR N = NONE

THE NOZZLE SIZE GIVES THE NOMINAL FLOWRATE, IN GPH, FOLLOWED BY THE SPRAY

ANGLE, IN DEGREE’S, AND THE SPRAY PATTERN, EITHER “A” FOR HOLLOW CONE OR “B”

FOR SOLID CONE. FOR EXAMPLE, A NOZZLE RATED AT 0.65 GPH @ 100 PSIG THAT PROVIDES

AN 80° SPRAY ANGLE AND A HOLLOW SPRAY PATTERN WOULD BE ABBREVIATED IN THE

TABLE AS “0.65 X 80

°A”.

For more specific burner information, contact Crown Boiler Co, P.O. Box 14818 3633 I St.. Philadelphia, PA 19134

INPUT CAPACITY SELECTION CHART

EQUIVALENT

HEAT INPUT

RATE*

(BTU/HR)UNITS

CSHB60-90 70,000 60,000 0.50 x 80° A 0.40 x 70° A 0.50 x 70° A 0.50 x 80° A

CSHB60-90 85,000 73,000 0.60 x 80° A 0.50 x 70° A 0.60 x 70° A 0.60 x 80° A

CSHB60-90 106,250 90,000 0.75 x 80° A 0.60 x 70° A 0.75 x 70° A 0.70 x 80° A

All rates shown achieved with 120 PSIG pump pressure for Beckett AFG, 150 PSIG pump pressure for Beckett

NX, 150 PSIG pump pressure for Carlin, and 145 PSIG pump pressure for Riello.

* Based on #2 domestic heating fuel oil having heating value of 140,000 BTU per gallon.

** Based on thermal efficiency of 84%-85%.

EFFECTIVE

HEATING

CAPACITY**

(BTU/HR)

NOZZLE SIZE ( GPH x TYP E)

Beckett AFG Beckett NX Carlin Riello

7

Page 11

All installations and services must be performed by qualified service personnel.

H. HEAT EXCHANGER CLEANING INSTRUCTIONS:

cWARNING: THE HEAT EXCHANGER MUST BE CLEANED BY A QUALIFIED

SERVICE PERSON.

It is important to inspect and clean the heat exchanger once a year, or as necessary, to remove any build-up of soot.

A layer of soot on the inside of the heat exchanger will act as an insulator and reduce heat transfer, resulting in less

efficiency.

To clean the heat exchanger, first turn off all power to the unit. Remove clean-out plugs, the vent connector pipe to

the chimney, the burner, and the burner mounting plates. When removing the clean-out plugs, remove the screw at

the 12 o’clock position. Then, pull clean-out plug straight back.

Fig. 6: Clean-out plug removal

With access to the inside of the heat exchanger through the burner area, clean-out openings, and vent pipe

connection, it is possible to use a long, flexible wire brush and an industrial type vacuum cleaner to remove any soot

build-up. NOTE: A one inch (outside diameter) vacuum cleaner hose will fit into the radiator.

To vacuum and brush the outer radiator of the heat exchanger, go through the clean-out openings in both directions,

as shown in figure 7, below.

Fig. 7: Recommended method and device for cleaning inside of heat exchanger.

Reassemble the furnace to its original construction*. Remount the burner being certain that the air tube is properly

inserted into the chamber opening (see section F). If heavy soot deposits were found in the heat exchanger, this may

indicate the burner is out of adjustment.

*When returning clean-out plugs to their original position, insert plug and replace screw at the 12 o’clock position.

This is sufficient for sealing the access tube.

8

Page 12

All installations and services must be performed by qualified service personnel.

III. USERS INFORMATION SECTION

A. OIL SUPPLY: Do not allow the fuel tank to run completely empty. During the summer, keep the tank full to

prevent condensation of moisture on the inside surface of the tank. If the fuel tank runs completely dry, it may be

necessary to purge the lines of trapped air. Contact a qualified technician to bleed the lines and restart the burner.

OIL SUPPLY VALVE: Turn the oil supply valve off if the burner is shut down for an extended period of time.

B. COMBUSTION AIR SUPPLY: The burner requires a generous amount of clean combustion air to operate

safely. Lack of adequate combustion air can result in erratic operation of the burner, noisy combustion, or fuel odors

in the air.

fan, dryer or return air grill in the furnace room, there should be increased concern and additional efforts may be

required to provide adequate combustion air to the furnace at all times.

C. INSPECTION AREAS

VESTIBULE: The furnace vestibule area or burner compartment should be inspected by removing the front door

of the furnace and looking for signs of excessive heat such as discoloration of components materials damage, from

rust or corrosion, soot or carbon build-up.

EXTERIOR OF FURNACE: The furnace exterior should be inspected for signs of excessive heat such as

discoloration of materials and damage from rust or corrosion.

FLUE PIPE, VENT PIPE OR CONNECTOR: The furnace vent pipe should be inspected for signs of rust,

corrosion pitting or holes in pipe, and leakage around seams in pipe, indicated by soot or condensate streaks.

CHIMNEY OR VENTING SYSTEM: The furnace venting system should be inspected for signs of rust,

corrosion pitting or holes, and signs of condensation or moisture leakage from the venting system.

If any of the above symptoms are evident, call a qualified heating contractor for assistance.

NEVER BLOCK THE FURNACE FROM THE SUPPLY OF COMBUSTION AIR. If there is an exhaust

cCAUTION: DO NOT ATTEMPT TO MAKE REPAIRS YOURSELF!

cWARNING: The area around the furnace should be kept free and clear of combustible

liquids and material, especially papers and rags.

cWARNING: NEVER burn garbage or refuse in your furnace. Never try to ignite oil by

tossing burning papers or other material into your furnace.

cWARNING: Crown oil furnaces are designed to burn No. 1 or No. 2 distillate fuel oil.

NEVER USE GASOLINE OR A MIXTURE OF OIL AND GASOLINE.

cCAUTION: DO NOT ATTEMPT TO START THE BURNER WHEN:

1. Excess oil has accumulated,

2. The furnace is full of vapors

3. The combustion chamber is very hot.

IF ONE OR MORE OF THESE CONDITIONS EXIST, CONTACT A QUALIFIED

SERVICE PERSON

D. STARTING THE BURNER:

1. Turn the main service switch to "OFF" position.

2. Set thermostat substantially above room temperature.

3. Open shut-off valves in oil supply line to burner.

4. Turn service switch to furnace "ON". If burner starts and runs, but stops again on lockout, it may be necessary to

bleed the lines or make burner combustion air adjustments. Contact a qualified service person to adjust and start

burner.

.

9

Page 13

All installations and services must be performed by qualified service personnel.

E. FILTER CLEANING AND LOCATION:

The air filters should be inspected each month and cleaned when dirty. Cleaning the air filters frequently may

reduce airborne contaminants from entering the furnace and depositing in the furnace, duct system and home.

cWARNING: To avoid injury from moving parts, hot surfaces, or electrical shock, shut

off the power to the furnace before removing any furnace access doors to service the air

filters.

The filter rack will be located between the return air plenum and the return air opening on the side of the furnace,

refer to figure 8. Slide the dirty filter out, clean it with a mild soap and water solution. Make sure filter is thoroughly

dry before replacing.

Fig. 8: Location of the air filter on the typical highboy furnace.

10

Page 14

All installations and services must be performed by qualified service personnel.

APPENDIX-A Replacement Parts List

11

Page 15

All installations and services must be performed by qualified service personnel.

APPENDIX-B Wiring Diagrams

COOL = A/C Tap

HEAT = Heating Tap

LOW = Constant air or Dehumifier

BLOWER SPEED TAPS

12

Page 16

All installations and services must be performed by qualified service personnel. All installations and services must be performed by qualified service personnel.

13

13

Loading...

Loading...