Page 1

Owner's Manual

CRRFTSMRN°

6.25 HORSEPOWER

2,100 PSI

2.0 GPM

HIGH PRESSUR

Model No. 580.768310

WASHER

HOURS: Mon.- Fri. 8 a.m. to 5 p.m. (CT)

CAUTION" Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

Part No. B5656 Draft 0 (5/8/2000)

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espahol

Page 2

WARRANTY ................................... 2

SAFETY RULES .............................. 2-3

ASSEMBLY .................................. 4-5

OPERATION ................................. 6-9

MAINTENANCE ............................ 10-13

SPECIFICATIONS ............................. 10

STORAGE ................................... 14

TROUBLESHOOTING .......................... 15

REPLACEMENT PARTS ...................... 16-23

EMISSION CONTROL WARRANTY ................ 24

ESPANOL ................................. 25-39

HOW TO ORDER PARTS ............... BACK PAGE

LIMITED WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman pressure washer is maintained and operated

according to the instructionsin the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase. If this high pressure washer is used for rental purposes, this warranty applies for only 30 days after

date of purchase.

This warranty does not cover:

• Expendable items such as spark plugs or air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the high pressure washer to the nearest Sears service center or

dealer in the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects, or

other reproductive harm.

,_ CAUTION! When setting up, transporting,

adjusting or making repairs to your high

pressure washer, always disconnect the spark

plug wire from the spark plug and place the wire

where it cannot contact spark plug.

,_ DANGER! Engine exhaust gases contain

DEADLY carbon monoxide gas. This dangerous

gas, if breathed in sufficient concentrations, can

cause unconsciousness or even death. Operate

this equipment only in the open air where

adequate ventilation is available.

,_ DANGER! Gasoline is highly FLAMMABLE and

its vapors are EXPLOSIVE. Do Not permit

smoking, open flames, sparks or heat in the

vicinity while handling gasoline. Avoid spilling

gasoline on a hot engine. Allow unit to cool

before refueling. Comply with all laws regulating

storage and handling of gasoline.

Read this manual carefully and become familiar

with your pressure washer. Know its applications,

its limitations, and any hazards involved.

• Locate this pressure washer in areas away from

combustible materials, combustible fumes or dust.

• The high pressure equipment is designed to be

used with Sears authorized parts only. If you use

this equipment with parts that do not comply with

minimum specifications, the user assumes all risks

and liabilities.

• Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting or poisoning. The harmful elements may

cause property damage or severe injury.

Page 3

• DoNotallowCHILDRENtooperatethepressure

washeratanytime.

• Operateengineonlyatgovernedspeed.Running

theengineatexcessivespeedsincreasesthe

hazardofpersonalinjury.DoNottamperwithparts

whichmayincreaseordecreasethegoverned

speed.

• DoNotwearlooseclothing,jewelryoranything

thatmaybecaughtinthestarterorotherrotating

parts.

• Beforestartingthepressurewasherincold

weather,checkallpartsoftheequipmentandbe

sureicehasnotformedthere.

• Neveruseaspraygunwhichdoesnothavea

triggerlockortriggerguardin placeandinworking

order.

• Keepthehoseconnectedtomachineorthespray

gunwhilethesystemispressurized.Disconnecting

thehosewhiletheunitispressurizedisdangerous.

• Unitswithbrokenor missingparts,orwithout

protectivehousingorcovers,shouldNEVERbe

operated.

• Checkthefuelsystemforleaksorsignsof

deterioration,suchaschafedorspongyhose,

looseormissingclamps,ordamagedtankorcap.

Correctalldefectsbeforeoperatingthepressure

washer.

• DoNotsprayflammableliquids.

• Usearespiratorormaskwheneverthereisa

chancethatvaporsmaybeinhaled.Readall

instructionswithmasksoyouarecertainthemask

willprovidethenecessaryprotectionagainst

inhalingharmfulvapors.

• Neveraimthegunatpeople,animalsor plants.

Thehighpressurestreamofwaterthatthis

equipmentproducescanpierceskinandits

underlyingtissues,leadingtoseriousinjuryand

possibleamputation.

• Neverallowanypartofthebodyto comeincontact

withthefluidstream.DoNotcomeincontactwith

afluidstreamcreatedbya leakinthehigh

pressurehose.

• Alwaysweareyeprotectionwhenyouusethis

equipmentorwhenyouareinthevicinitywhere

theequipmentisinuse.

• Highpressurespraycancausepaintchipsorother

particlestobecomeairborne.

• DoNotoperatethepressurewasherabovethe

ratedpressure.

• Nevermovethemachinebypullingonthehigh

pressurehose.Usethehandleprovidedonthe

unit.

• Alwaysbecertainthespraygun,nozzlesand

accessoriesarecorrectlyattached.

• DoNotsecurethesprayguninthe(open)

position.

• Highpressurespraymaydamagefragileitems

includingglass.DoNotpointspraygunatglass

wheninthejetspraymode.

• Holdthespraygunfirmlyinyourhandbeforeyou

starttheunit.Failuretodosocouldresultinan

injuryfromawhippingspraygun.DoNotleavethe

spraygununattendedwhilethemachineis

running.

• Thecleaningareashouldhaveadequateslopes

anddrainagetoreducethepossibilityofafalldue

toslipperysurfaces.

• Keepwatersprayawayfromelectricwiringorfatal

electricshockmayresult.

• DoNotby-passanysafetydeviceonthis

machine.

• Themufflerandengineheatupduringoperation

andremainhotimmediatelyaftershuttingitdown.

Avoidcontactwithahotmufflerorengineasyou

couldbeseverelyburned.

• Operateandstorethisunitona stablesurface.

• Highpressurehosecandevelopleaksfromwear,

kinking,abuse,etc.Watersprayingfromaleakis

capableofinjectingmaterialintoskin.Inspecthose

eachtimebeforeusingit.Checkallhosesforcuts,

leaks,abrasionsorbulgingofcover,ordamageor

movementofcouplings.Ifanyoftheseconditions

exist,replacehoseimmediately.Neverrepairhigh

pressurehose.Replaceitwithanotherhosethat

meetsmaximumpressureratingofyourunit.

• Themufflerandaircleanermustbeinstalledandin

goodconditionbeforeoperatingthepressure

washer.Thesecomponentsactassparkarresters

iftheenginebackfires.

IntheStateofCaliforniaasparkarresterisrequiredby

law(Section4442oftheCaliforniaPublicResources

Code).Otherstatesmayhavesimilarlaws.Federal

lawsapplyonfederallands.

NOTE:Ifyouequipthemufflerwithasparkarrester,it

mustbemaintainedineffectiveworkingorder.Youcan

orderasparkarresterthroughyourauthorizedSears

servicedealer.

_ Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.

Obeyallsafetymessagesthatfollowthissymboltoavoidpossibleinjuryordeath.

Page 4

Yourpressurewasherrequiressomeassemblyandis

readyforuseonlyafterit hasbeenproperlyserviced

withtherecommendedoilandfuel.

Ifyouhaveanyproblemswiththeassemblyof

yourpressurewasher,pleasecallthepressure

washerhelplineat 1-800-222-3136.

IMPORTANT:Anyattempttoruntheenginebeforeit

hasbeenservicedwiththerecommendedoilwillresult

inanenginefailure.

REMOVE PRESSURE WASHER

FROM CARTON

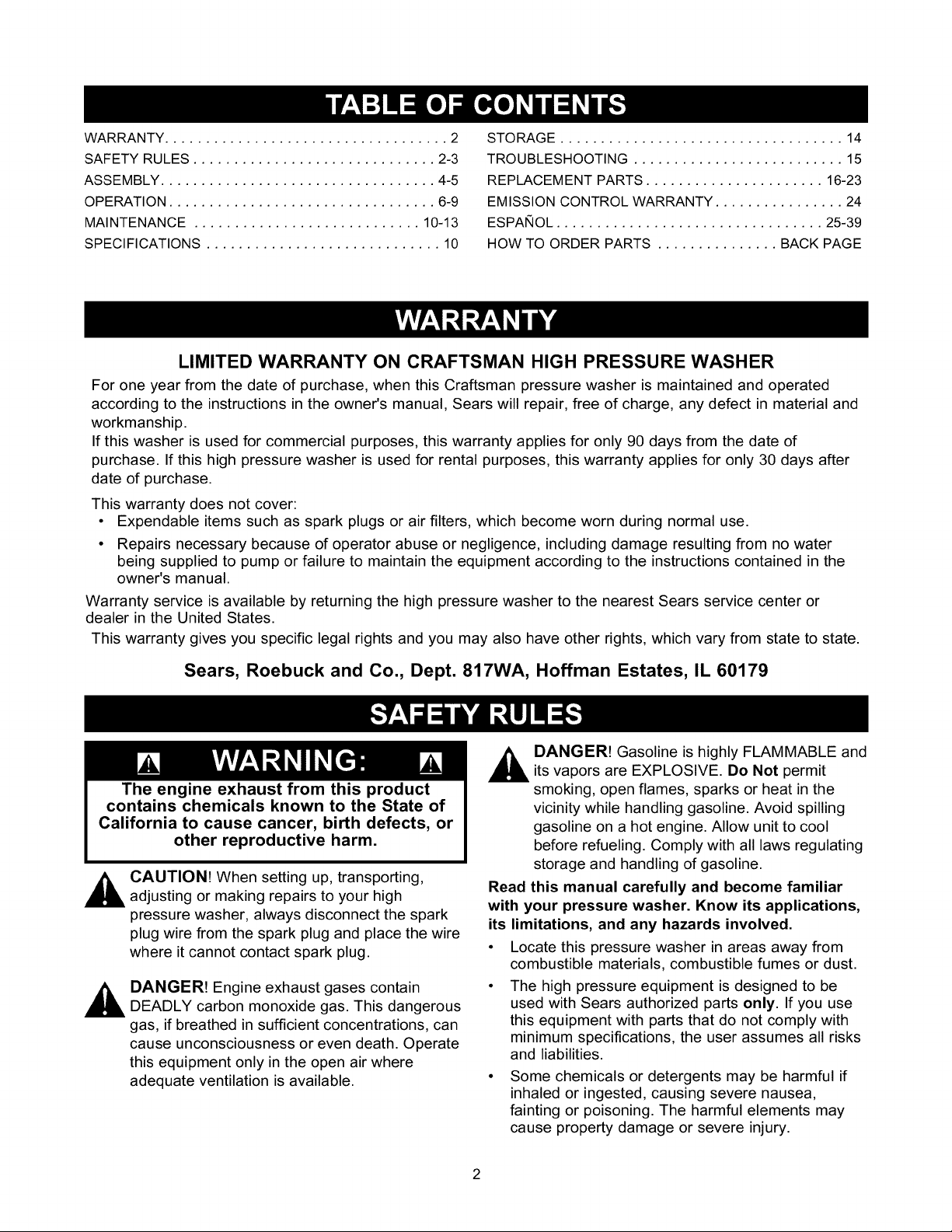

• Open carton and slice two corners opposite guide

handle from top to bottom so the panel can be

folded down flat.

• Remove fillers and parts box shipped with your

pressure washer.

• Roll the pressure washer out the open end of the

carton.

• Raise guide handle, secure in place.

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman high pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

• Add oil to engine crankcase.

• Add fuel to fuel tank.

• Connect high pressure hose to the spray gun and

the pump.

• Connect water supply to the pump.

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

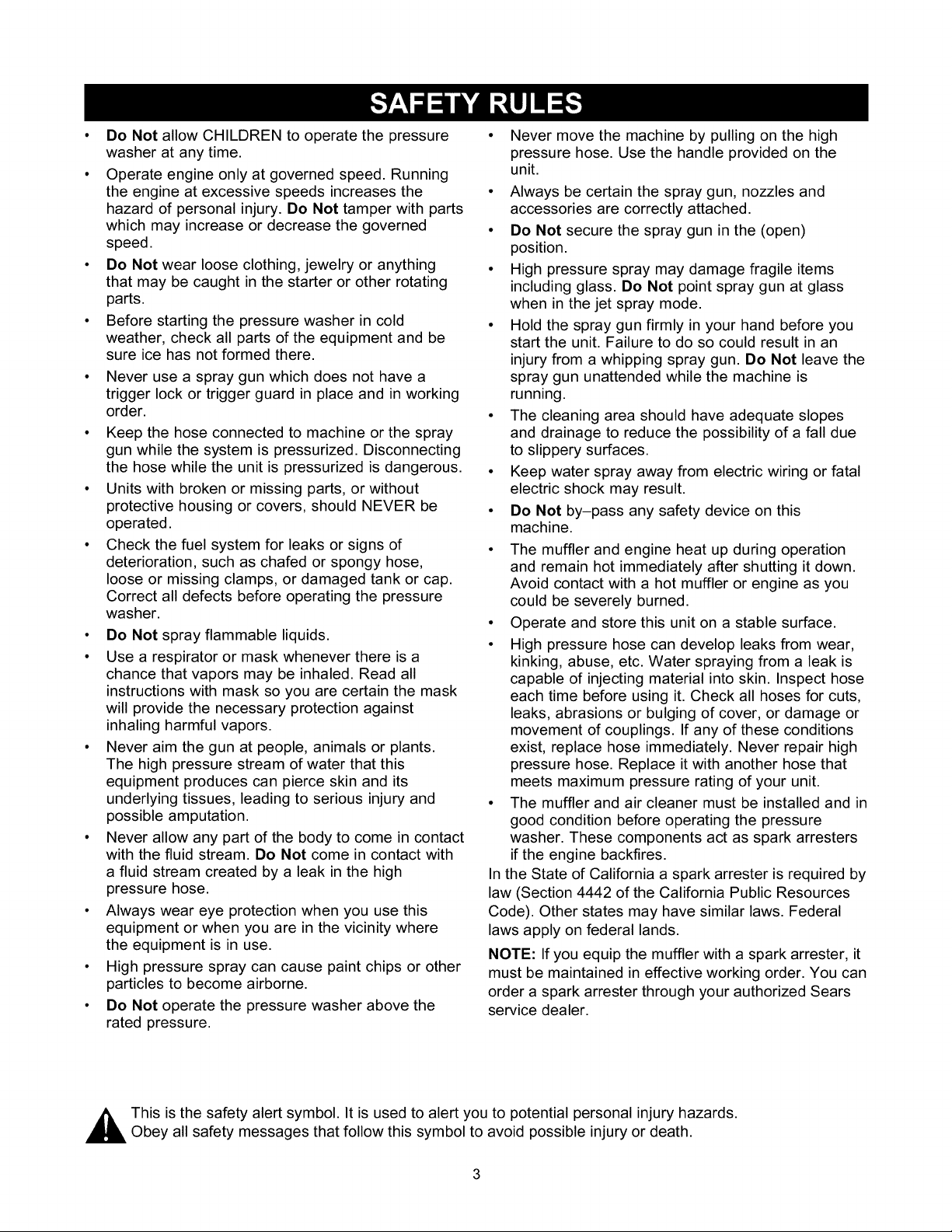

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SH, SG, or SH/CD rated SAE 30

weight.

• Place pressure washer on a level surface.

• Clean area around oil fill.

• Remove oil fill cap and dipstick.

• Wipe dipstick clean, insert it into oil fill hole and

tighten securely, remove dipstick. Add

recommended oil up to "Full" mark on dipstick.

Pour slowly. Wipe dipstick clean each time oil level

is checked. Do Not overfill.

Lift the handle to upright

position and slide the

locking caps into place.

• Check carton for additional loose parts.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

• The main unit

• Parts box (which includes items listed below)

High pressure hose

Spray gun

Nozzle extension with adjustable nozzle

Engine oil

Owner's manual

Nozzle cleaning kit

O-Ring maintenance kit

Become familiar with each piece before assembling

the pressure washer. Compare contents against the

view on page 6. If any parts are missing or damaged,

call the pressure washer helpline at 1-800-222-3136.

• Install oil fill plug and dipstick, tighten securely.

NOTE: Check oil often during engine break-in.

Page 5

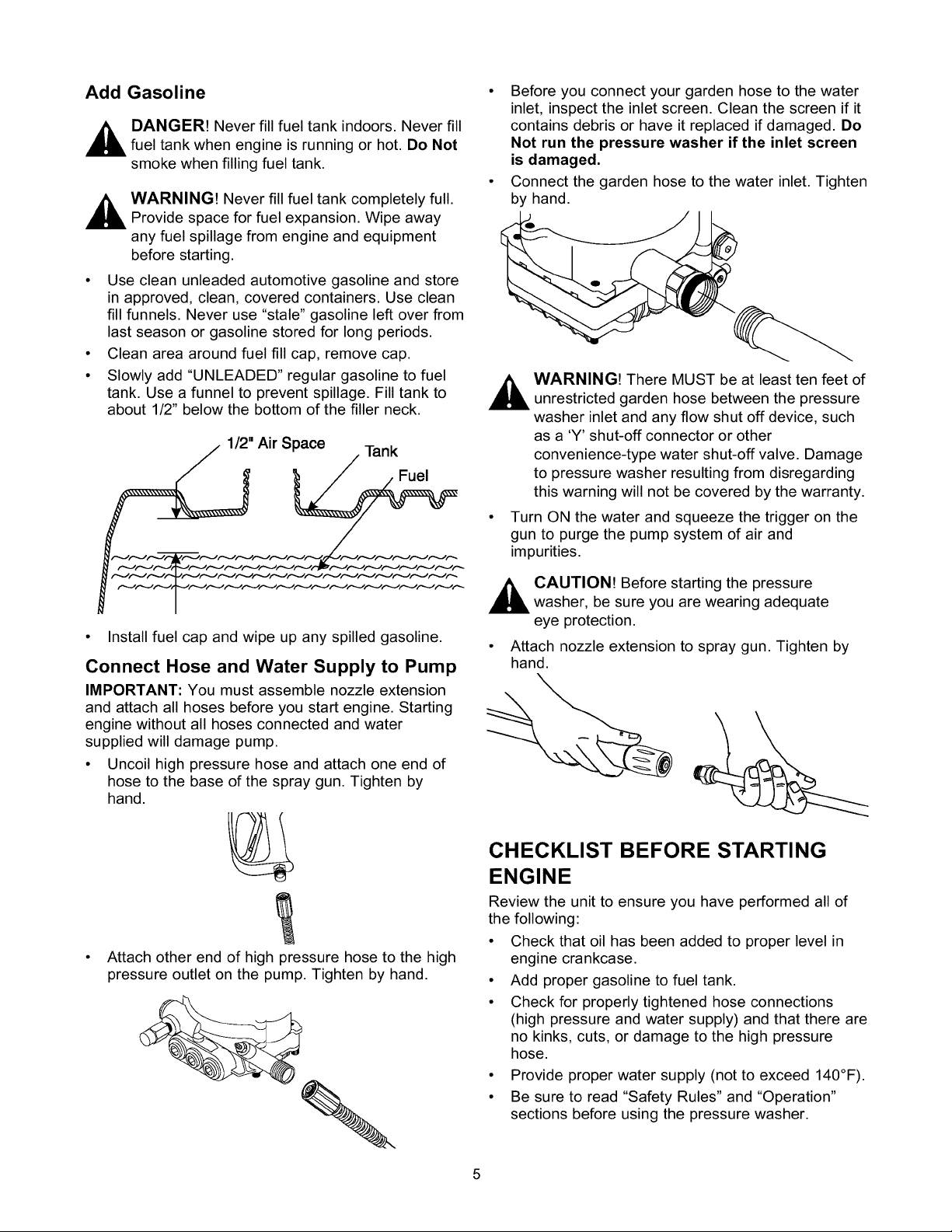

Add Gasoline

_ DANGER! Never fill fuel tank indoors. Never fill

fuel tank when engine is running or hot. Do Not

smoke when filling fuel tank.

_ ARNING! Never fill fuel tank completely full.

Provide space for fuel expansion. Wipe away

any fuel spillage from engine and equipment

before starting.

• Use clean unleaded automotive gasoline and store

in approved, clean, covered containers. Use clean

fill funnels. Never use "stale" gasoline left over from

last season or gasoline stored for long periods.

• Clean area around fuel fill cap, remove cap.

• Slowly add "UNLEADED" regular gasoline to fuel

tank. Use a funnel to prevent spillage. Fill tank to

about 1/2" below the bottom of the filler neck.

1/2" Air Space Tank

Fuel

• Before you connect your garden hose to the water

inlet, inspect the inlet screen. Clean the screen if it

contains debris or have it replaced if damaged. Do

Not run the pressure washer if the inlet screen

is damaged.

• Connect the garden hose to the water inlet. Tighten

by hand.

_ ARNING! There MUST be at least ten feet of

unrestricted garden hose between the pressure

washer inlet and any flow shut off device, such

as a 'Y' shut-off connector or other

convenience-type water shut-off valve. Damage

to pressure washer resulting from disregarding

this warning will not be covered by the warranty.

• Turn ON the water and squeeze the trigger on the

gun to purge the pump system of air and

impurities.

• Install fuel cap and wipe up any spilled gasoline.

Connect Hose and Water Supply to Pump

IMPORTANT: You must assemble nozzle extension

and attach all hoses before you start engine. Starting

engine without all hoses connected and water

supplied will damage pump.

• Uncoil high pressure hose and attach one end of

hose to the base of the spray gun. Tighten by

hand.

• Attach other end of high pressure hose to the high

pressure outlet on the pump. Tighten by hand.

_ CAUTION! Before starting the pressure

washer, be sure you are wearing adequate

eye protection.

• Attach nozzle extension to spray gun. Tighten by

hand.

CHECKLIST BEFORE STARTING

ENGINE

Review the unitto ensure you have performed all of

the following:

• Check that oil has been added to proper level in

engine crankcase.

• Add proper gasoline to fuel tank.

• Check for properly tightened hose connections

(high pressure and water supply) and that there are

no kinks, cuts, or damage to the high pressure

hose.

• Provide proper water supply (not to exceed 140°F).

• Be sure to read "Safety Rules" and "Operation"

sections before using the pressure washer.

Page 6

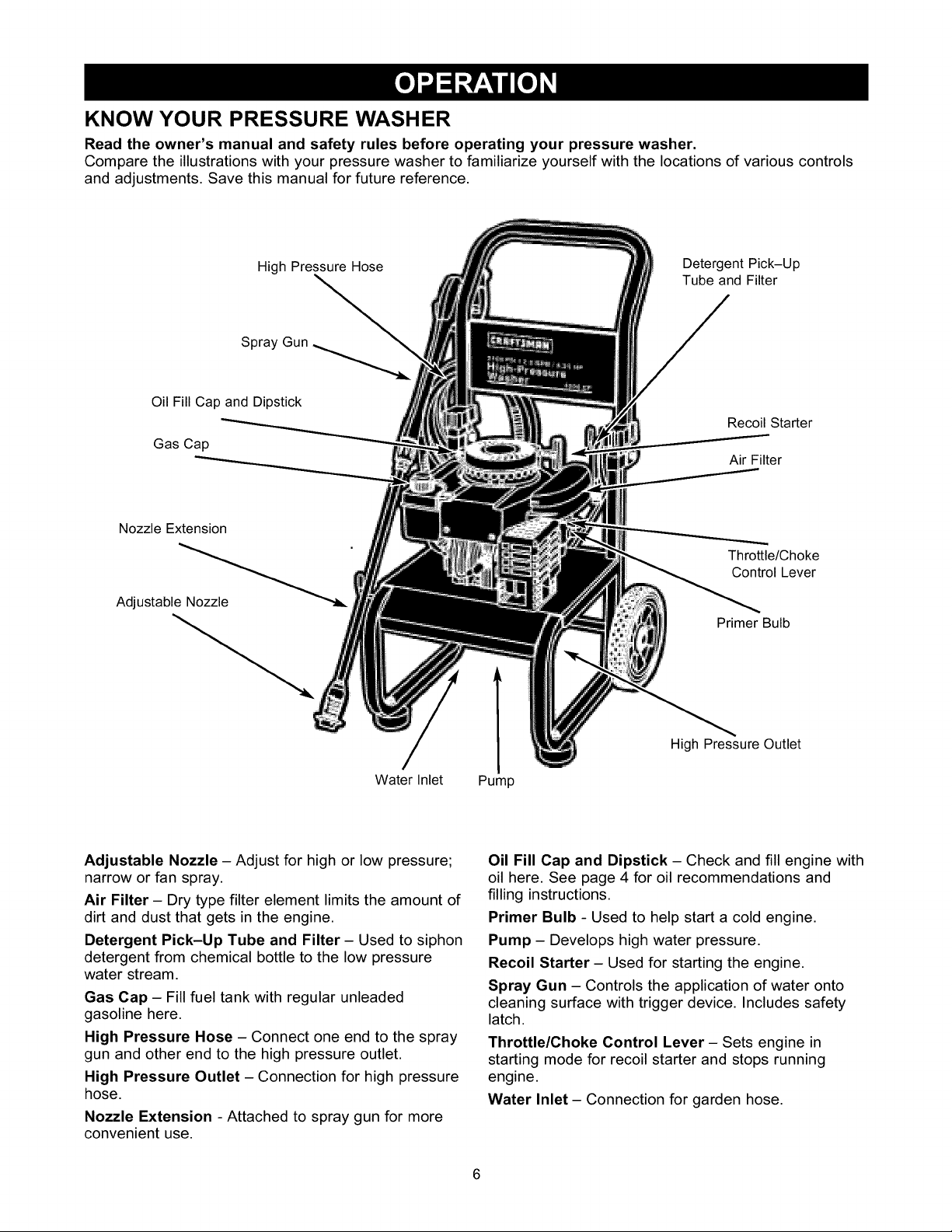

KNOW YOUR PRESSURE WASHER

Read the owner's manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Oil Fill Cap and Dipstick

Gas Cap

Nozzle Extension

Adjustable_

High Pressure Hose

Spray Gun

Detergent Pick-Up

Tube and Filter

Recoil Starter

Air Filter

Throttle/Choke

Control Lever

Primer Bulb

Water Inlet

Adjustable Nozzle - Adjust for high or low pressure;

narrow or fan spray.

Air Filter - Dry type filter element limits the amount of

dirt and dust that gets in the engine.

Detergent Pick-Up Tube and Filter- Used to siphon

detergent from chemical bottle to the low pressure

water stream.

Gas Cap - Fill fuel tank with regular unleaded

gasoline here.

High Pressure Hose - Connect one end to the spray

gun and other end to the high pressure outlet.

High Pressure Outlet - Connection for high pressure

hose.

Nozzle Extension - Attached to spray gun for more

convenient use.

High Pressure Outlet

Pump

Oil Fill Cap and Dipstick - Check and fill engine with

oil here. See page 4 for oil recommendations and

filling instructions.

Primer Bulb - Used to help start a cold engine.

Pump - Develops high water pressure.

Recoil Starter- Used for starting the engine.

Spray Gun - Controls the application of water onto

cleaning surface with trigger device. Includes safety

latch.

Throttle/Choke Control Lever - Sets engine in

starting mode for recoil starter and stops running

engine.

Water Inlet - Connection for garden hose.

Page 7

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

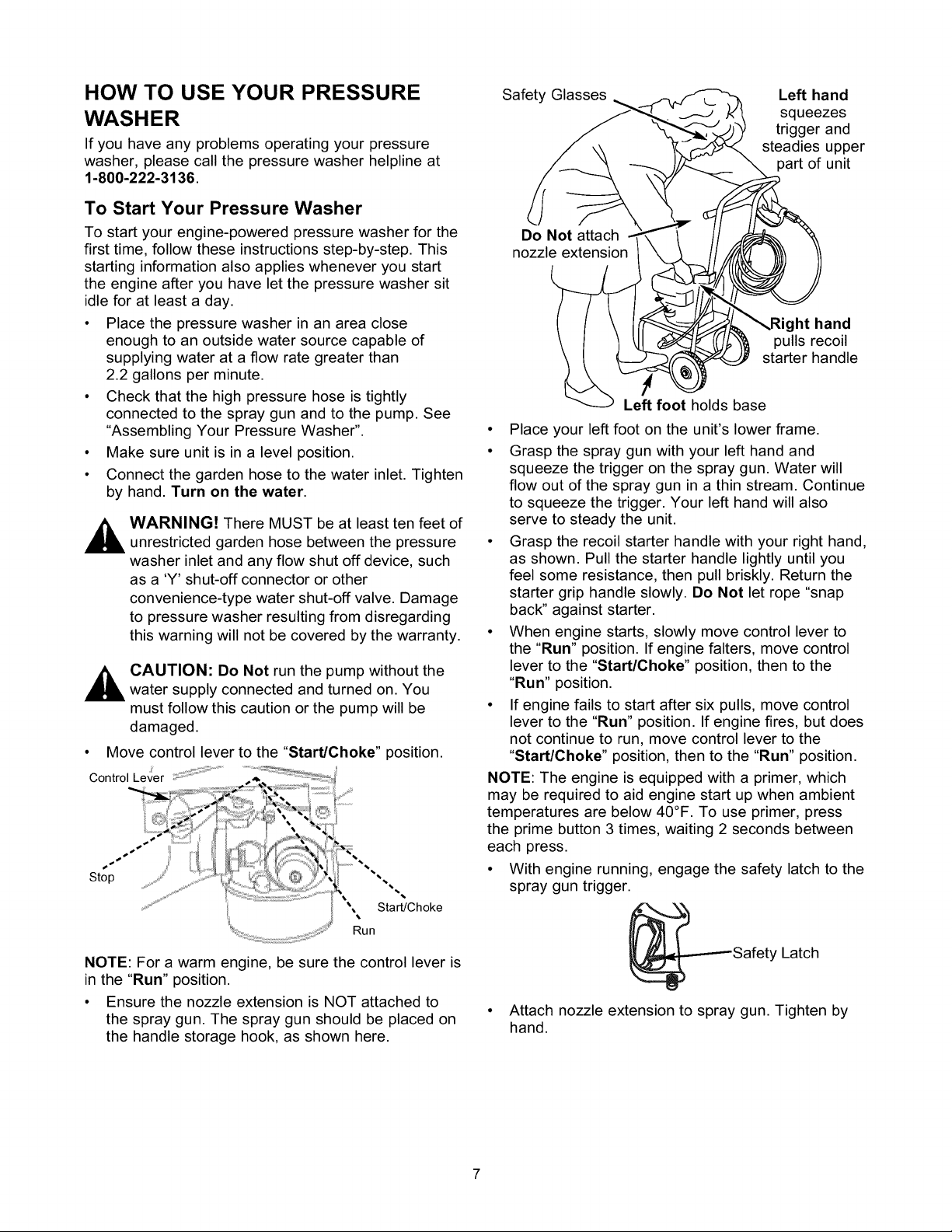

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

• Place the pressure washer in an area close

enough to an outside water source capable of

supplying water at a flow rate greater than

2.2 gallons per minute.

• Check that the high pressure hose is tightly

connected to the spray gun and to the pump. See

"Assembling Your Pressure Washer".

• Make sure unit is in a level position.

• Connect the garden hose to the water inlet. Tighten

by hand. Turn on the water.

WARNING! There MUST be at least ten feet of

unrestricted garden hose between the pressure

washer inlet and any flow shut off device, such

as a 'Y' shut-off connector or other

convenience-type water shut-off valve. Damage

to pressure washer resulting from disregarding

this warning will not be covered by the warranty.

CAUTION: Do Not run the pump without the

water supply connected and turned on. You

must follow this caution or the pump will be

damaged.

• Move control lever to the "Start/Choke" position.

Control Lever

Stop

Safety Glasses

Do Not attach

nozzle extension

Left foot holds base

• Place your left foot on the unit's lower frame.

• Grasp the spray gun with your left hand and

squeeze the trigger on the spray gun. Water will

flow out of the spray gun in a thin stream. Continue

to squeeze the trigger. Your left hand will also

serve to steady the unit.

• Grasp the recoil starter handle with your right hand,

as shown. Pull the starter handle lightly until you

feel some resistance, then pull briskly. Return the

starter grip handle slowly. Do Not let rope "snap

back" against starter.

• When engine starts, slowly move control lever to

the "Run" position. If engine falters, move control

lever to the "Start/Choke" position, then to the

"Run" position.

• If engine fails to start after six pulls, move control

lever to the "Run" position. If engine fires, but does

not continue to run, move control lever to the

"Start/Choke" position, then to the "Run" position.

NOTE: The engine is equipped with a primer, which

may be required to aid engine start up when ambient

temperatures are below 40°F. To use primer, press

the prime button 3 times, waiting 2 seconds between

each press.

• With engine running, engage the safety latch to the

spray gun trigger.

Left hand

squeezes

trigger and

steadies upper

of unit

ht hand

pulls recoil

starter handle

NOTE: For a warm engine, be sure the control lever is

in the "Run" position.

• Ensure the nozzle extension is NOT attached to

the spray gun. The spray gun should be placed on

the handle storage hook, as shown here.

Latch

• Attach nozzle extension to spray gun. Tighten by

hand.

Page 8

How to Stop Your Pressure Washer

• Move control lever to "Stop" position.

• Squeeze trigger on the spray gun to relieve

pressure in the hose.

NOTE: A small amount of water will squirt out when

you release the pressure.

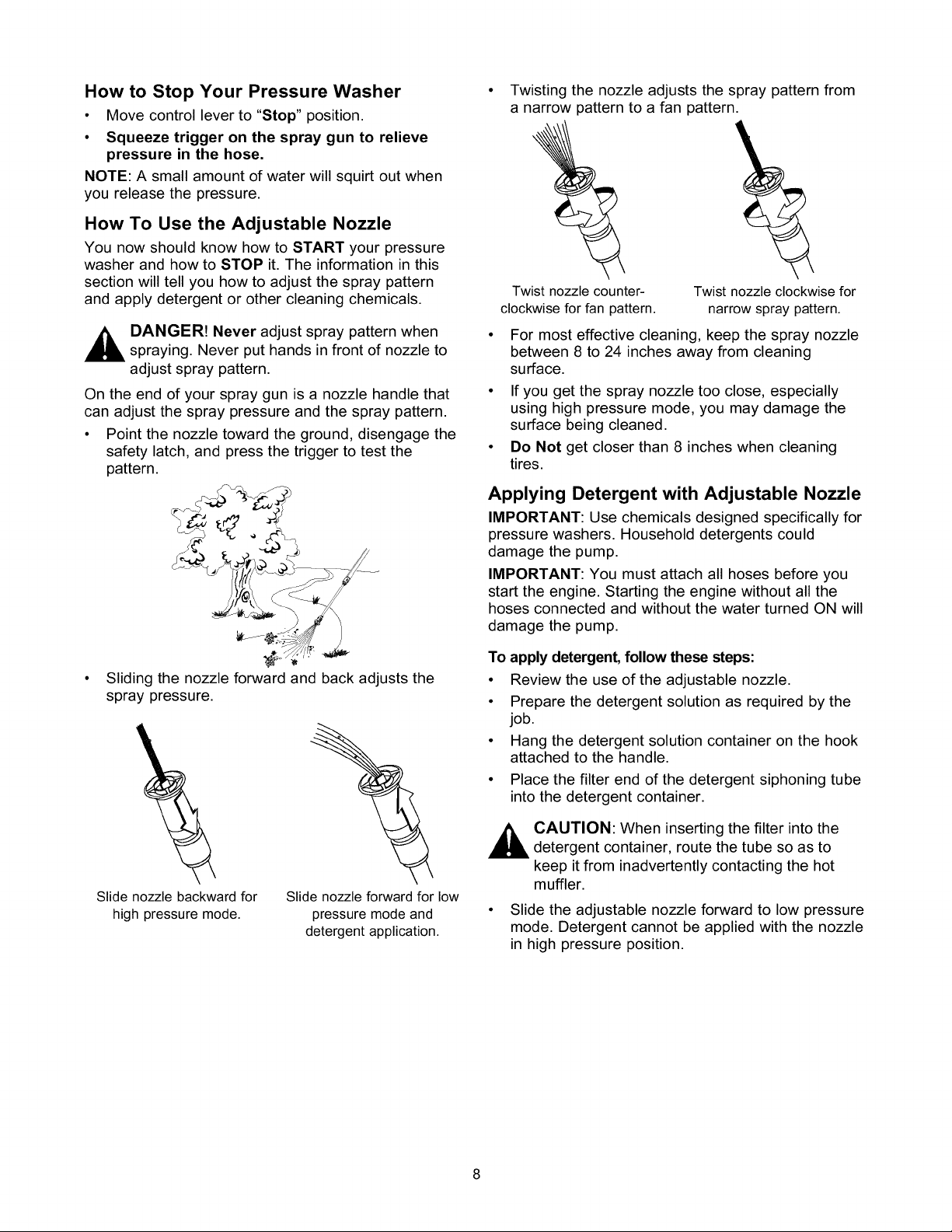

How To Use the Adjustable Nozzle

You now should know how to START your pressure

washer and how to STOP it. The information in this

section will tell you how to adjust the spray pattern

and apply detergent or other cleaning chemicals.

_ DANGER! Never adjust spray pattern when

spraying. Never put hands in front of nozzle to

adjust spray pattern.

On the end of your spray gun is a nozzle handle that

can adjust the spray pressure and the spray pattern.

• Point the nozzle toward the ground, disengage the

safety latch, and press the trigger to test the

pattern.

Twisting the nozzle adjusts the spray pattern from

a narrow pattern to a fan pattern.

Twist nozzle counter-

clockwise for fan pattern.

Twist nozzle clockwise for

narrow spray pattern.

• For most effective cleaning, keep the spray nozzle

between 8 to 24 inches away from cleaning

surface.

• If you get the spray nozzle too close, especially

using high pressure mode, you may damage the

surface being cleaned.

• Do Not get closer than 8 inches when cleaning

tires.

Applying Detergent with Adjustable Nozzle

IMPORTANT: Use chemicals designed specifically for

pressure washers. Household detergents could

damage the pump.

IMPORTANT: You must attach all hoses before you

start the engine. Starting the engine without all the

hoses connected and without the water turned ON will

damage the pump.

Sliding the nozzle forward and back adjusts the

spray pressure.

Slide nozzle backward for Slide nozzle forward for low

high pressure mode. pressure mode and

detergent application.

To apply detergent, follow these steps:

• Review the use of the adjustable nozzle.

• Prepare the detergent solution as required by the

job.

• Hang the detergent solution container on the hook

attached to the handle.

• Place the filter end of the detergent siphoning tube

into the detergent container.

_ AUTION: When inserting the filter into the

detergent container, route the tube so as to

keep it from inadvertently contacting the hot

muffler.

• Slide the adjustable nozzle forward to low pressure

mode. Detergent cannot be applied with the nozzle

in high pressure position.

Page 9

• Makesurethegardenhoseisconnectedtothe

waterinlet.Checkthatthehighpressurehoseis

connectedtothespraygunandthepump.Start

theengine.

• Applydetergenttoadrysurface,startingfromthe

bottomandworkingup.

• Allowthedetergentto"soakin"for3-5minutes

beforerinsing.Reapplyasneededtoprevent

surfacefromdrying.

• Forwashing,startatlowerportionofareatobe

washedandworkupward,usinglong,even,

overlappingstrokes.

IMPORTANT:Youmustflushthechemicalinjection

systemaftereachusebyplacingthefilterintoaclean

bucketofwaterandrunningthepressurewasherin

lowpressurefor1-2minutes.

Pressure Washer Rinsing

_ ARNING: Be extremely careful if you use the

pressure washer from a ladder, scaffolding or

any other relatively unstable location. Pressure

in a running washer builds as you climb. When

you press the trigger, the recoil from the initial

spray could cause you to fall. The high pressure

spray could also cause you to fall if you are too

close to the cleaning surface.

For Rinsing:

• Slide the nozzle backward to high pressure, press

the trigger and wait for the detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

• Keep the spray gun a safe distance from the area

you plan to spray.

• Apply a high pressure spray to a small area, then

check the surface for damage. If no damage is

found, it is okay to continue cleaning.

• Start at the top of the area to be rinsed, working

down with same overlapping strokes as you used

for washing and applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures between 140-145°F. The automatic cool

down system engages at this temperature and cools

the pump by discharging the warm water onto the

ground, preventing internal pump damage.

Page 10

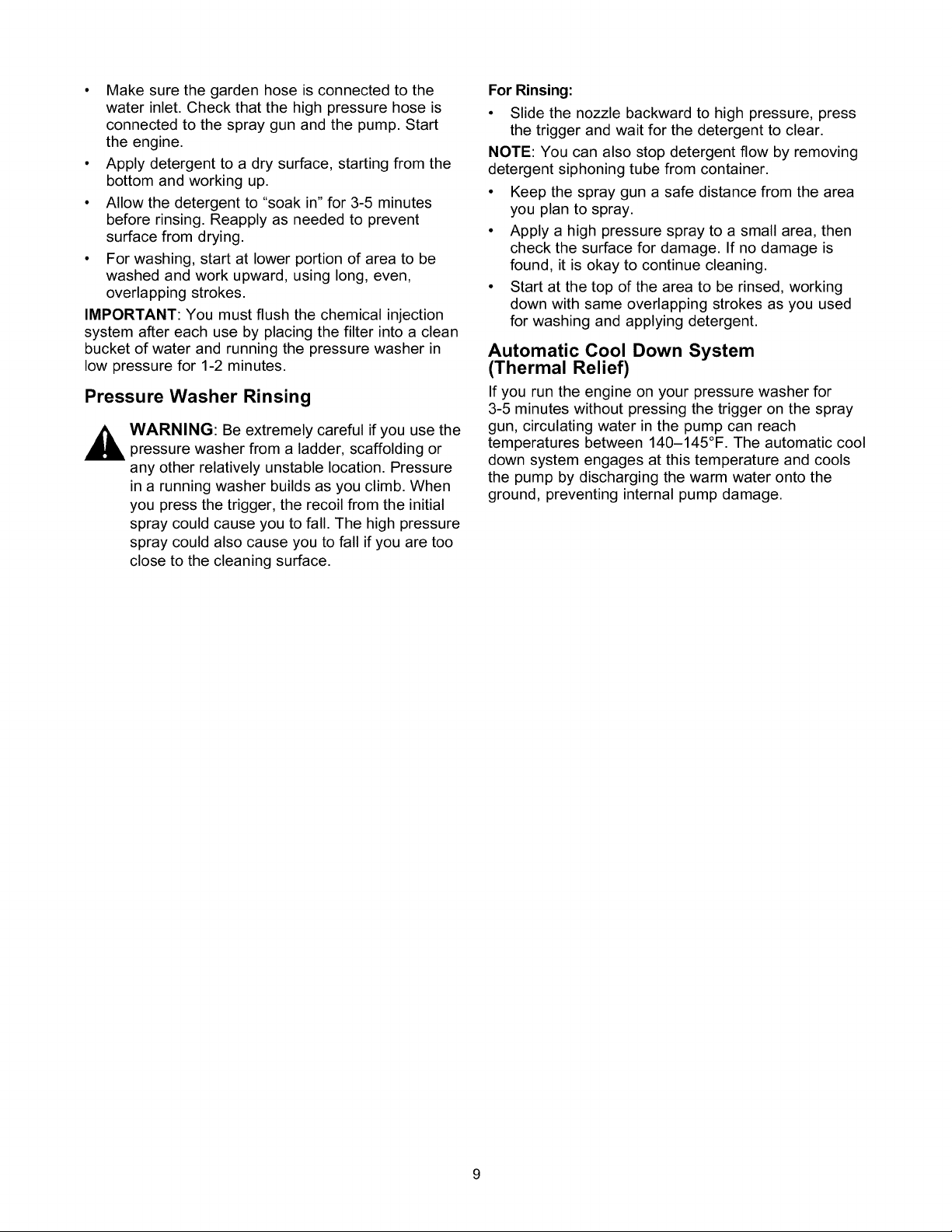

OWNER'S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

HOURLY OPERATING

INTERVAL

Before Each

Use

Every 25

Hours or

Yearly

Every 100

Hours or

Yearly

SERVICE DATES

MAINTENANCE TASK

PRESSURE WASHER

Check/clean water inlet screen

on quick-connect. XI"

Check high pressure hose. X

Check detergent hose. X

Check spray gun and assembly for leaks. X

Purge pump of air and contaminants. X

ENGINE

Check oil level. X

Change engine oil. X*

Service air cleaner. X**

Service spark plug. X

Prepare for storage. Prepare unit for storage if it is to

remain idle for longer than 30 days.

1 Clean if clogged. Replace if perforated or torn.

* Change oil after the first (2) operating hours and every 25 hours or yearly thereafter. Change sooner when operating under

dirty or dusty conditions.

** Replace more often under dirty or dusty conditions.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure...................... 2,100 PSI

FlowRate..................... 2.0 GPM

Chemical Mix .................. Useas directed

Water Supply Temperature ........ Not to Exceed 140°F

Engine Specifications

Rated Horsepower .............. 6.25 liP

Spark Plug

Type: ....................... Champion RJ-19LM

Set Gap To: .................. 0.030inch (0.76mm)

Gasoline Capacity............... 1.5 Quarts

Oi .......................... SHe30

GENERAL RECOMMENDATIONS

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

"Maintenance Schedule" chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

10

Page 11

BEFORE EACH USE

• Check engine oil level.

• Check water inlet screen for damage.

• Check in-line filter for damage.

• Check high pressure hose for leaks.

• Check chemical filters for damage.

• Check gun and nozzle extension assembly for

leaks.

• Purge pump of air and contaminants.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

_ ANGER: Never repair a high pressure hose.

Replace with hose that exceeds the maximum

pressure rating of your pressure washer.

Check Gun and Nozzle Extension

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Engage

safety latch and test trigger. You should not be able to

press trigger. Replace gun immediately if it fails any of

these tests.

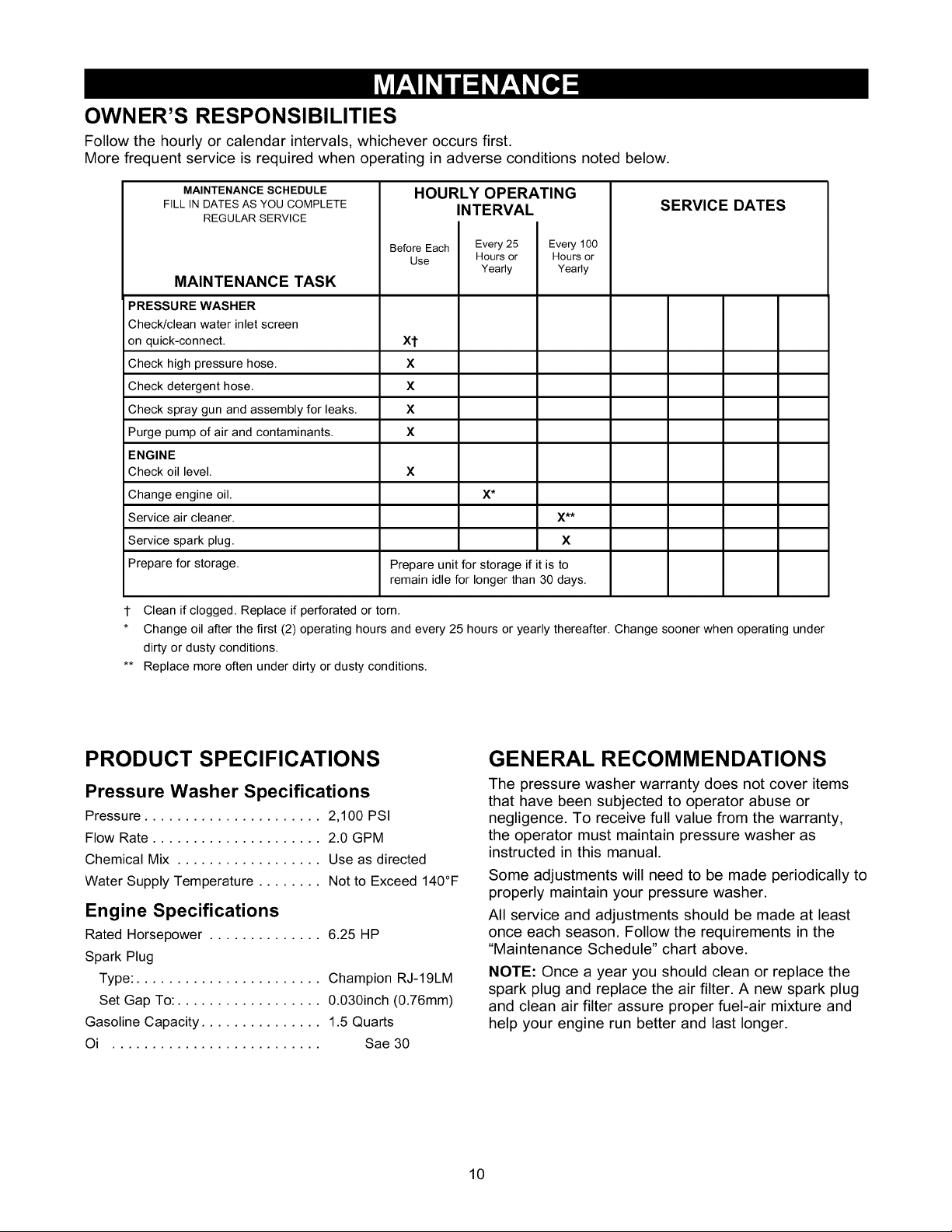

Check In-Line Filter

Refer to the illustrationand service the in-line filter if it

becomes clogged, as follows:

In-line Filter

Nozzle extension

O-ring

.

Detach nozzle extension from gun and remove o-

ring and screen from nozzle extension. Flush the

screen, gun, and nozzle extension with clean

water to clear debris.

.

If the screen is damaged, the o-ring kit contains a

replacement in-line filter screen and an o-ring. If

undamaged, reuse screen.

.

Place the in-line filter screen into the threaded end

of the nozzle extension. Direction does not matter.

Push the screen in with the eraser end of a pencil

until it rests flat at the bottom of the opening. Take

care to not bend the screen.

4. Place the o-ring into the recess. Push the o-ring

snugly against the in-line filter screen.

5. Assemble the nozzle extension to the spray gun,

as described earlier in this manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps:

• Set up the pressure washer as described in the

ASSEMBLY section and connect the water supply.

• Pull the trigger on the gun and hold until a steady

stream of water appears.

To remove contaminants from the pump, follow these

steps:

• Set up the pressure washer as described in the

ASSEMBLY section, and connect the water supply.

• Remove the nozzle extension from the gun.

• Start the engine according to instructions in

OPERATION section.

• Pull the trigger on the gun and hold.

• When the water supply is steady and constant,

engage the safety latch and refasten the nozzle

extension.

Nozzle Maintenance

If the nozzle becomes restricted or clogged with

foreign materials such as dirt, excessive pump

pressure may develop. A partially clogged nozzle can

cause a pulsing condition during use. This generally is

not a pump related problem, but rather a clogged or

partially restricted nozzle.

If the nozzle becomes clogged or partially restricted,

immediately clean the nozzle with the kit included with

your pressure washer by following these instructions:

• Shut off the engine and turn off the water supply.

• Separate the nozzle extension from the gun.

• Rotate to stream setting.

• Remove nozzle from the end of the nozzle

extension using a 2 mm or 5/64 allen wrench.

11

Page 12

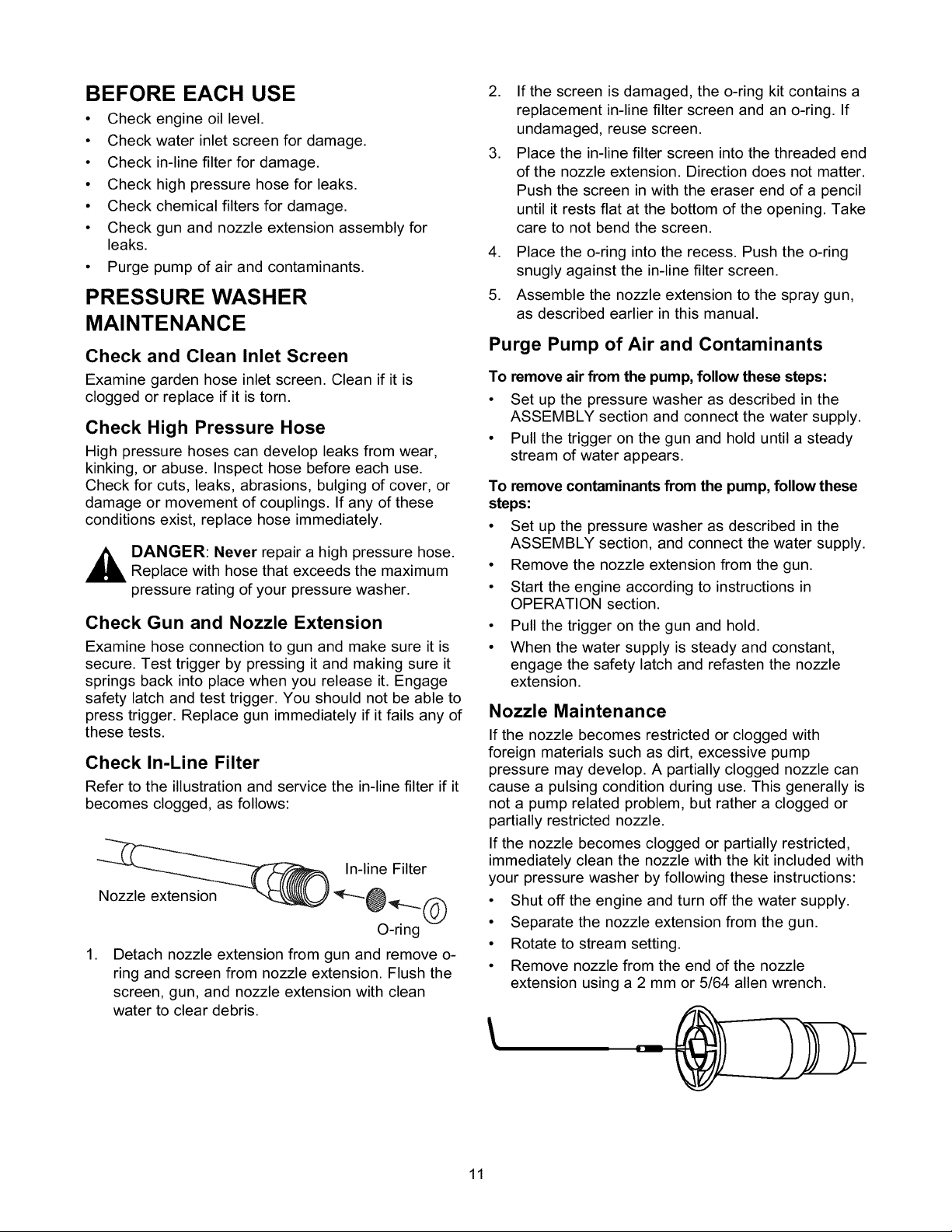

• Use the wire included in the kit or a small paper

clip to free the foreign materials clogging or

restricting the nozzle.

Insert wire into nozzle and turn back

and forth to clear obstruction.

Remove additional debris by back flushing water

supply through nozzle extension. Back flush

between 30 to 60 seconds. Turn nozzle extension

to stream spray and move nozzle from low to high

pressure while flushing.

• Reinstall nozzle into nozzle extension. Do Not

overtighten.

• Reconnect nozzle extension to spray gun.

• Reconnect the water supply, turn ON the water,

and start the engine.

• Test the pressure washer by operating with nozzle

in the high and the low pressure positions.

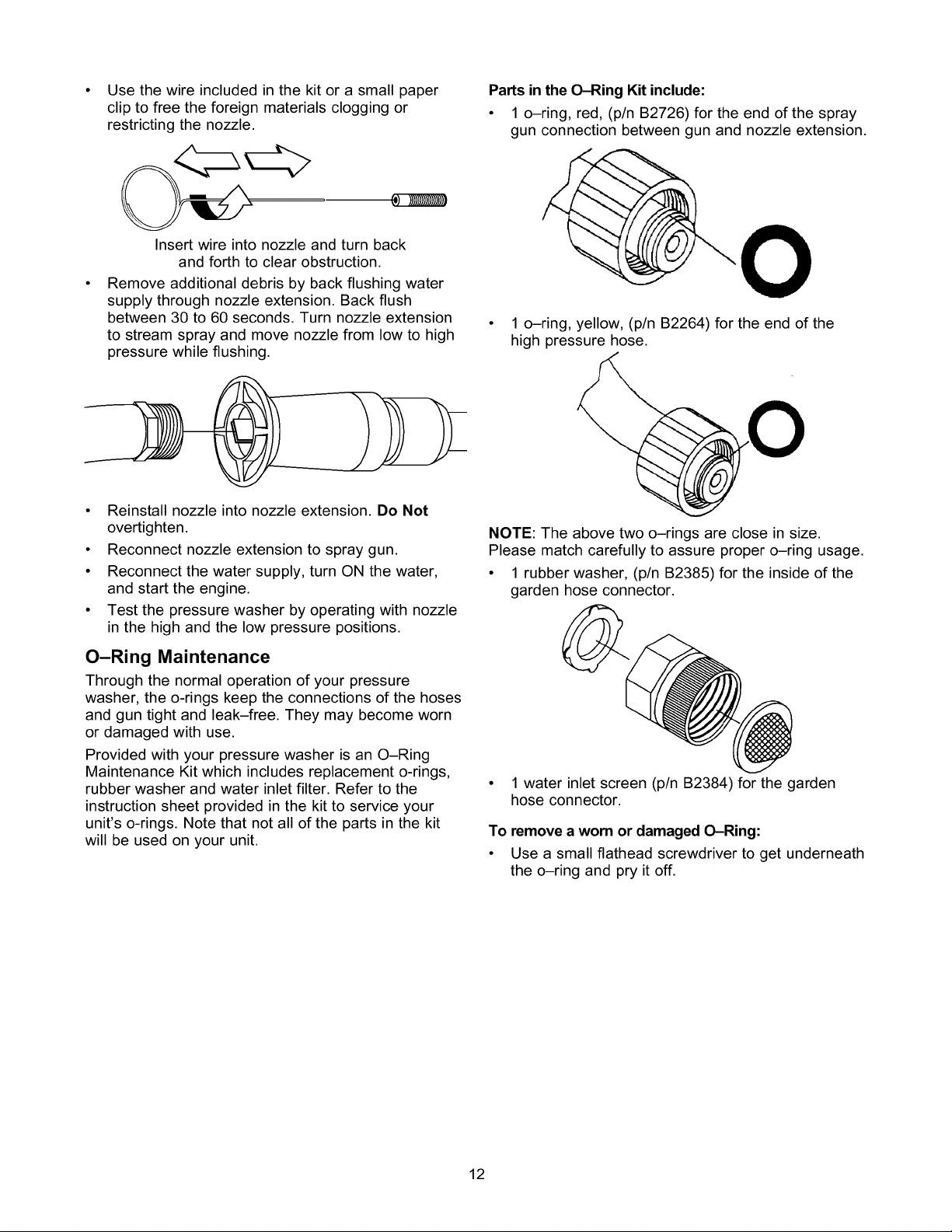

Parts inthe O-Ring Kit include:

• 1 o-ring, red, (p/n B2726) for the end of the spray

gun connection between gun and nozzle extension.

O

1 o-ring, yellow, (p/n B2264) for the end of the

high pressure hose.

NOTE: The above two o-rings are close in size.

Please match carefully to assure proper o-ring usage.

• 1 rubber washer, (p/n B2385) for the inside of the

garden hose connector.

O-Ring Maintenance

Through the normal operation of your pressure

washer, the o-rings keep the connections of the hoses

and gun tight and leak-free. They may become worn

or damaged with use.

Provided with your pressure washer is an O-Ring

Maintenance Kit which includes replacement o-rings,

rubber washer and water inlet filter. Refer to the

instruction sheet provided in the kit to service your

unit's o-rings. Note that not all of the parts in the kit

will be used on your unit.

• 1 water inlet screen (p/n B2384) for the garden

hose connector.

To remove a worn or damaged O-Ring:

• Use a small flathead screwdriver to get underneath

the o-ring and pry it off.

12

Page 13

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked prior to each use or at

least every 5 hours of operation. Keep oil level

maintained.

Changing Oil

Change engine oil after the first 2 hours and every 25

hours thereafter. If you are using your pressure

washer under extremely dirty or dusty conditions, or in

extremely hot weather, change oil more often.

Change oil while engine is still warm from running, as

follows:

• Drain fuel tank by running pressure washer until

fuel tank is empty.

• Clean area around oil fill, remove oil fill

cap/dipstick. Wipe dipstick clean.

• Tip your pressure washer to drain oil from the oil fill

into a suitable container making sure you tip your

unit away from the spark plug. When crankcase is

empty, return the pressure washer to upright

position.

• Wipe dipstick clean, insert it into oil fill hole and

tighten securely, remove dipstick. Add

recommended oil up to "Full" mark on dipstick.

Pour slowly. Wipe dipstick clean each time oil level

is checked. Do Not overfill.

• Install oil fill plug and dipstick, tighten securely.

• Wipe up any remaining oil.

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run itwith a dirty air cleaner.

Replace the air cleaner once every 100 hours of

operation or once each year, whichever comes first.

Replace more often if operating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

To replace the air cleaner, follow these steps:

• Remove cover by pulling tab away from body while

lifting cover upward.

• Remove dirty air filter element carefully to prevent

debris from falling into carburetor. Discard.

• Clean inside of cover and body thoroughly.

• Install new air filter elements in body. You can

purchase new air filter elements by calling

1-800-366-PART.

• Install cover by hooking slot of cover over tab on

body. Push cover down, snapping cover onto body.

Service Spark Plug

Service the spark plug every 100 hours of operation or

yearly, whichever occurs first.

_ CAUTION: Disconnect spark plug wire from

spark plug and keep wire away from spark plug

while servicing engine.

• Clean area around spark plug.

• Remove and inspect spark plug.

• Replace spark plug if the electrodes are worn, or if

the insulator is cracked or chipped. For

replacement use Champion RJ-19LM.

• Check electrode gap with wire feeler gauge and set

gap at 0.030 inches (0.76mm), if necessary.

• Install spark plug, tighten securely.

Carburetor

If you think your carburetor needs adjusting, see your

nearest Sears service center. Engine performance

may be affected at altitudes above 7000 feet. For

operation at higher elevations, contact your nearest

Sears service center.

AFTER EACH USE

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump

parts and "freeze" pump action. Follow these

procedures after every use:

• Flush detergent siphoning tube by placing the filter

into a pail of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

the forward position). Flush for one to two minutes.

• Shut off the engine and let it cool, then remove all

hoses.

• Disconnect spark plug wire from spark plug.

• Empty the pump of all liquids by pulling recoil

handle about 6 times. This should remove most of

the liquid in the pump.

13

Page 14

GENERAL

• Inspect the high pressure hose for damage. Cuts in

the hose or fraying could result in leaks and loss of

pressure. Should any damage be found, replace

the hose. Do Not attempt to repair a damaged

hose. Replace the hose with the genuine

Craftsman part.

• Drain water from hose and properly coil it on the

attached wireform.

• Reconnect spark plug wire to spark plug.

• Store unit in a clean, dry area.

LONG TERM STORAGE

If you do not plan to use the pressure washer for more

than 30 days, you must prepare the engine for long

term storage.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture,

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

_ ANGER: Never store the engine with fuel in

the gas tank indoors or in enclosed, poorly

ventilated areas where fumes may reach an

open flame, a spark, or pilot light.

WINTER STORAGE

_ AUTION: You must protect your unit from

freezing temperatures. Failure to do so will

permanently damage your pump and render

your unit inoperable.

To protect the unit from freezing temperatures:

• Flush detergent siphoning tube by placing the filter

into a pail of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

the forward position). Flush for one to two minutes.

• Disconnect hose connected to chemical inject

fitting on the pump.

• Empty the pump of all pumped liquids by pulling

recoil handle about 6 times. This should remove

most of the liquid in the pump.

• Connect a 3-foot section of garden hose to the

water inlet adapter. Pour RV-antifreeze (antifreeze

without alcohol) into the hose. Pull the recoil

handle twice. Disconnect 3-foot hose.

Protect Fuel System

Draining Fuel Tank:

_ ANGER: Drain fuel, using a funnel, into

approved container outdoors, away from open

flame. Be sure engine is cool. Do Not smoke.

• Remove all gasoline from carburetor and fuel tank

to prevent gum deposits from forming on these

parts and causing possible malfunction of engine.

• Run engine until fuel tank is empty and engine

stops due to lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade. See "Changing Oil".

Oil Cylinder Bore

• Remove spark plug. Squirt about 1 ounce of clean

engine oil into the cylinder. Cover spark plug hole

with rag. Pull recoil handle slowly to distribute oil.

Avoid spray from spark plug hole.

• Install spark plug. Do Not connect spark plug wire.

OTHER

• Do Not store gasoline from one season to another.

• If possible, store your unit indoorsand cover itto

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

IMPORTANT: NEVER cover your pressure washer

while engine and exhaust area are warm.

14

Page 15

Problem Cause Correction

1. Nozzle in low pressure mode. 1. Pull nozzle backward for high

pressure mode.

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose strainer.

6. Water supply is over 140°F.

7. High pressure hose is blocked or

leaks.

8. Gun leaks.

9. Nozzle is obstructed.

10. Pump is faulty.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose

strainer.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace gun.

9. Clean nozzle.

10. Contact Sears service facility.

Detergent fails to mix with

spray.

Engine runs good at no-load

but "bogs" when load is

added.

Engine will not start; or

starts and runs rough.

1. Detergent siphoning tube is not

submerged.

2. Chemical filter is clogged.

3. Nozzle is in high pressure mode.

Engine speed is too slow.

1. Low oil level.

2. Dirty air cleaner.

3. Out of gasoline.

4. Stale gasoline.

5. Spark plug wire not connected to

spark plug.

6. Bad spark plug.

7. Water in gasoline.

8. Overchoking.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or

closed.

11. Engine has lost compression.

1. Insert detergent siphoning tube

into detergent.

2. Clean or replace filter/detergent

siphoning tube.

3. Push nozzle forward for low

pressure mode.

Move throttle control to FAST

position. If engine still "bogs down",

contact Sears service facility.

1. Fill crankcase to proper level.

2. Clean or replace air cleaner.

3. Fill fuel tank.

4. Drain gas tank; fill with fresh

fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain gas tank; fill with fresh

fuel.

8. Open choke fully and crank

engine.

9. Contact Sears service facility.

10. Contact Sears service facility.

11. Contact Sears service facility.

Engine shuts down during 1. Out of gasoline. 1. Fill fuel tank.

operation. 2. Low oil level. 2. Fill crankcase to proper level.

Engine lacks power. Dirty air filter.

Engine "hunts" or falters. Choke is opened too soon.

15

Replace air filter.

Move choke to halfway position until

engine runs smoothly.

Page 16

CRAFTSMAN 2,100PSI Pressure Washer 580.768310

Main Unit m Exploded View

/

/

6_

/--24

/ _9

_1o

\\\\\\

31

43

_28

900_

\

\

\

\

\

\

_16

/

/

35

34_

_45

44_

>

4O

16

Page 17

CRAFTSMAN 2,100 PSI Pressure Washer 580.768310

Main Unit m Parts List

Item PaN #

2 B5833

3 96307

4 EB5647

5 NSP

6 B5668

7 30809

8 B1631B

9 B2142

10 75402

11 52858

12 27007

13 39288

14 B1735

15 B1880

16 A1040B

17 A1041

18 98300

19 31669

20 48031G

21 B3468A

23 94804

24 49808

25 EB5653

26 B1779

27 B2347

28 B2759

29 B2071

30 46476

31 B2516

32 21424

34 B5693

35 97566

36 B3335A

37 B3263

38 B5830

39 B3708

40 B5656

41 AB3061B

42 50190

43 B1460

44 B4224

45 97837

900 NSP

Qty. Description

1 DECAL, Instructions

1 DECAL, 1-800 Number

1 BASE, Powder Green

1 DECAL, Data

1 DECAL, Unit

1 GROMMET, Chemical Hose

1 BILLBOARD

2 TIRE, 2"x 9" Plastic

2 PUSHNUT, 1/2"

2 NUT, M8 Locking Flange

2 MOUNT, Vibration

2 HHCS, M8- 1.25 x 55

3 STUD, Double Ended

3 NUT, with Washer

1 HOSE, Chemical

1 FILTER, Chemical Hose

1 SEAL, Engine Donut

1 CARRIAGE BOLT, 1/4"- 20 x 1 3/4"

1 CLAMP, Hose

1 ASSY., Pump (See pages 18-19)

1 NOZZLE, Replacement

2 WASHER, M12 Flat

1 HANDLE, Powder Green

2 COVER, Hinge

2 CAP, End

1 HOOK, Chemical Bottle

2 NUT, 1/4"-20 Locking Flange

2 CAP, Plug

3 CAP, Vinyl

1 CONNECTOR, Garden Hose

1 HOSE, 1/4" x 25'

1 TAG, Nozzle Instructions

1 WAND, Adjustable Nozzle

1 GUN, High Pressure

1 KIT, Maintenance

1 KIT, Nozzle, Cleaning

1 MANUAL

1 OIL, Engine

2 WASHER, Flat, .34" x 1"

1 CAP, Vinyl

1 SCREEN, Gun Inlet

1 O-RING, Hi- Pressure

1 ENGINE (See pages 20-23)

17

Page 18

CRAFTSMAN 2,100 PSI Pressure Washer 580.768310

Pump m Exploded View

--16 1 I 11

3

12

10

25

/

27

26

24

37

O--' 141

43 42

%j6

_--------8

3°_/33_

38-_ 3__7 30

/

39 40

4-t

37

32

18

Page 19

CRAFTSMAN 2,100PSI Pressure Washer 580.768310

Pump m Parts List

Item PaN #

1 98300

2 97962

3 96795

4 21429

5 97835

6 21783

7 93680

8 97831

9 B2702

10 98227

11 B2310

......

......

......

12 ......

13 ......

14 ......

15 ......

16 ......

17 185287

18 ......

19 ......

20 ......

21 ......

22 ......

28 ......

23 185711

21 ......

24 ......

25 ......

26 ......

27 ......

29 ......

30 B3513

31 ......

32 ......

37 ......

Qty. Description Item Part #

1 SEAL, Engine Donut 33 B3286

3 SHCS, M6 - 1 x 25 34 97837

3 SLEEVE, Grommet Spacer

6 BUSHING, Rubber Mount 35 97841

1 O-RING, Housing Seal 36 97840

1 THERMAL RELIEF 37 40946

3 SEAL, Oil Piston 15 TC4 38 B4186

3 SPACER, Pilot 37 ......

1 HOUSING, Piston 39 ......

1 ADAPTER, Engine 40 ......

0 KIT, AXIAL CAM SERV 41 B2312

1 SEAL, Engine Donut 1 ......

3 SHCS, M6- 1x 25 2 ......

1 O-RING, Housing Seal 5 ......

1 WASHER, Brg. 36 x 65 x 6Thk 42 ......

1 ASSY., Brg. Cage 45 x 65 43 ......

1 WASHER, Brg. 45 x 65 x 1 44 ......

1 CAM, Axial 5.6 VS 45 B1933

1 BALL BEARING, 35 x 72 x 17 1 ......

0 KIT, CHEM INJECT 2 ......

1 FITTING, Chem Inject 5 ......

1 BALL, Chem Inject 7 ......

1 SPRING, Chem Inject 21 ......

1 O-RING, Venturi & Seat, Black 25 ......

1 VENTURI, Chem Inject 28 ......

1 O-RING, Venturi, Yellow 31 ......

0 KIT, UNLOADER 33 ......

1 O-RING, Venturi & Seat, Black 34 ......

1 CAP, Unloader

1 O-RING, Unloader Cap 36 ......

1 SPRING, 2000 Unloader 37 ......

1 PISTON, Unloader

1 SEAT, 2000 Unloader

0 KIT, CHECK VALVES

6 O-RING, Check Valve

6 ASSY., Check Valve

4 SHCS, M6-1.0 x 35

Item numbers 11, 17, 23, 30, 38, 41, and 45 are

service kits and include all parts shown within the box.

Items previously described are not listed under the

service kit number. Certain items are available only as

a part of a kit.

Qty. Description

3 SEAL, Double-Lip

1 O-RING, Hi-Pressure

Transfer

3 CAP, Outlet Check Valve

3 O-RING, Outlet CV Cap

4 SHCS, M6-1.0 x 35

0 KIT, HEAD CASTING SFG

4 SHCS, M6-1.0 x 35

1 HEAD, Pump

1 PLUG, 1/8-28 W/VIBR

0 KIT, PISTON & SPRING

1 SEAL, Engine Donut

3 SHCS, M6- 1 x 25

1 O-RING, Housing Seal

3 RETAINER, Piston Spring

3 PISTON, Dia. 15 x 65

3 SPRING, Piston Return

0 KIT, O-RING/SEAL SERV

1 SEAL, Engine Donut

3 SHCS, M6- 1 x 25

1 O-RING, Housing Seal

3 SEAL, Oil Piston 15 TC4

2 O-RING, Venturi & Seat, Black

1 O-RING, Unloader Cap

1 O-RING, Venturi, Yellow

6 O-RING, Check Valve

3 SEAL, Double-Lip

1 O-RING, High Pressure

Transfer

3 O-RING, Outlet CV Cap

4 SHCS, M6-1.0 x 35

19

Page 20

ENGINE, 6.25 HP, Tecumseh, 143.006204 - Exploded View - Engine

4_

i:2

4i

2g?

20

Page 21

ENGINE, 6.25 HP, Tecumseh, 143.006204 - Parts List - Engine

Item Part # Qty. Description Item Part #

1 37465 1 Cylinder 174 30200

2 26727 2 Dowel Pin 178 29752

6 33734 1 Breather Element 179 30593

7 36557 1 Breather Ass'y. 182 6201

12A 36558 1 Breather Cover & Tube 184 26756

14 28277 1 Washer

15 30589 1 Governor Rod 185 37466

16 34839A 1 Governor Lever 186 32653

17 31335 1 Governor Lever Clamp 200 37267

18 651018 1 T-15, 8-32 x 19/64" Screw, 206 610973

Torx 207 34336

19 33578 1 Extension Spring 209 30200

20 32600 1 Oil Seal 215 32410

30 37479 1 Crankshaft 216 33086

40 40027 1 Piston, Pin & Ring Set (Std.) 223 650451

40 40028 1 Piston, Pin & Ring Set (.010" 223A 651074

OS) 224 36786

41 40025 1 Piston & Pin Ass'y. (Std.) 238 650806

41 40026 1 Piston & Pin Ass'y. (.010" OS) 239 34338

42 40006 1 Ring Set (Std.) 240 37115

42 40007 1 Ring Set (.010" OS) 245 37116

43 20381 2 Piston Pin Retaining Ring 245A 37117

45 36777 1 Connecting Rod Ass'y. 250 37118

46 32610A 2 Connecting Rod Bolt 260 37497

48 27241 2 Valve Lifter 261 30200

50 37460 1 Camshaft 261A 650737

52 29914 1 Oil Pump Ass'y.

69 37130 1 Mounting Flange Gasket 262 650831

70 34311E 1 Mounting Flange 275 37498A

72 36083 1 Oil Drain Plug 277 650988

72A 28534 1 Oil DrainPlug 279 30200

75 27897 1 Oil Seal 279A 650902

80 30574A 1 Governor Shaft 280 37499

81 30590A 1 Washer 285 35287A

82 30591 1 Governor Gear Ass'y. 287 650926

83 30588A 1 Governor Spool 290 34357

86 650488 6 Screw, 1/4-20 x 1-1/4" 292 26460

89 610961 1 Flywheel Key 298 28763

90 611213 1 Flywheel 300 34476a

92 650815 1 Belleville Washer 301 33032

93 650816 1 Flywheel Nut 305 35577

100 34443B 1 Solid State Ignition 306 36996

101 610118 1 Spark Plug Cover 307 35499

103 651007 2 Screw, Torx T-15, 10-24 x 309 650562

15/16" 310 35578

104 37480 1 Cam Bushing 313 34080

110 36230 1 Ground Wire 361 651075

119 36787 1 Cylinder Head Gasket 370A 36261

120 36825 1 Cylinder Head 370C 37318

125 37288 1 Exhaust Valve (Std.) 370G 37500

126 37289 1 Intake Valve (Std.) 370K 36695

130 6021A 8 Screw, 5/16-18 x 1-1/2" 380 640276

135 35395 1 Resistor Spark Plug (RJ 19LM) 390 590763

150 31672 2 Valve Spring 400 36792B

151 31673 2 Valve Spring Cap 416 36085

151A 40017 1 Intake Valve Seal 417 650821

169 36783 1 Valve Cover Gasket 900 0

172 36784 1 Valve Cover

Qty. Description

2 Screw, 10-24 x 9/16"

2 Nut & Lock Washer, 1/4-28

1 Retainer Clip

2 Screw, 1/4-28 x 7/8"

1 Carburetor To Intake Pipe

Gasket

1 Intake Pipe

1 Governor Link

1 Control Bracket

1 Terminal

1 Throttle Link

2 Screw, 10-32 x 9/16"

1 Control Knob

1 R.P.M. Adjusting Lever

2 Screw, 1/4-20 x 1"

1 Intake Pipe Stud

1 Intake Pipe Gasket

2 Screw, 10-32 x 5/8"

1 Air Cleaner Gasket

1 Air Cleaner Body (Black)

1 Air Filter (Poly)

1 Breather Filter (Poly)

1 Air Cleaner Cover (Black)

1 Blower Housing

1 Screw, 10-24 x 9/16"

1 Screw, Torx T-30, 1/4-20 x

3/8"

2 Screw, 1/4-20 x 1/2"

1 Muffler

2 Screw, 1/4-20 x 2-5/16"

1 Screw, 10-24 x 9/16"

1 Screw, 10-32 x 7/16"

1 Heat Shield

1 Starter Cup

2 Screw, 8-32 x 21/64"

1 Fuel Line

2 Fuel Line Clamp

3 Screw, 10-32 x 35/64"

1 Tank Fuel

1 Fuel Cap

1 Oil Fill Tube

1 "O"-Ring

1 "O"-Ring

1 Screw, 10-32 x 1/2"

1 Dipstick

1 Spacer

1 Lock Nut

1 Lubrication Decal

1 Primer Decal (3X)

1 Instruction Decal

1 Starter Decal

1 Carburetor

1 Rewind Starter

1 Gasket Set

1 Spark Arrester Kit (Optional)

1 Screw, 10-32 x 1/2" (Optional)

0 Replacement Engine NONE

21

Page 22

ENGINE, 6.25 HP, Tecumseh, 143.006204 - Exploded View and Parts List - Recoil

--8

Item

0

1

2

3

4

5

Part # Qty. Description

590763 1 Rewind Starter

590599A 1 Spring Pin

590600 1 Washer

590696 1 Retainer

590601 1 Washer

590697 1 Brake Spring

Item

6

7

8

11

12

13

Part#

590698

590699

590700

590764

590535

590701

6

Qty. Description

2 Starter Dog

2 Dog Spring

1 Pulley & Rewind Spring Ass'y

1 Starter Housing Ass'y.

1 Starter Rope

1 Starter Handle

22

Page 23

ENGINE, 6.25 HP, Tecumseh, 143.006204 - Exploded View and Parts List - Carburetor

/14

j7

f

(_\20A

Item

0

1

2

4

5

6

7

10

11

14

16

17

18

Pan # Qty.

640276 1

631615 1

631767 1

631184 2

631183 2

640070 1

650506 2

630973 1

632045 1

632790 1

631807 1

651025 1

630766 1

60

Description

Carburetor

Throttle Shaft & Lever

Assembly

Throttle Return Spring

Dust Seal Washer

Dust Seal

Throttle Shutter

Shutter Screw

Choke Shaft & Lever

Assembly

Choke Return Spring

Choke Shutter

Fuel Fitting

Throttle Crack Screw/Idle

Speed Screw

Tension Spring

23

Item

20

20A

25

27

28

29

30

31

35

36

37

40

44

47

48

60

Pan # Qty.

640027 1

640053 1

631867 1

631024 1

632019 1

631028 1

631021 1

631022 1

36045A 1

632745 1

632547 2

640032 1

27110A 1

630748 1

631027 1

632760 1

Description

Idle Restrictor Screw

Idle Restrictor Screw Cap

Float Bowl

Float Shaft

Float

Float Bowl "O" Ring

Inlet Needle, seat & Clip

Spring Clip

Primer Bulb/Retainer Ring

Main Nozzle Tube

"O" Ring, Main Nozzle Tube

High Speed Bowl Nut

Bowl Nut Washer

Welch Plug, Idle Mixture Well

Welch Plug, Atmospheric Vent

Repair kit

Page 24

Your Warranty Rights and Obligations

The California Air Resources Board ("CARB") and Sears

Roebuck and Co., USA, are pleased to explain the Emission

Control System Warranty on your model year 2000 and later

small off-road engine (engine). In California, new engines

must be designed, built and equipped to meet the State's

stringent anti-smog standards. Sears must warrant the

emission control system on your engine for the periods of

time listed below provided there has been no abuse, neglect,

or improper maintenance of your engine.

Your emission control system includes parts such as the

carburetor and the ignition system.

Where a warrantable condition exists, Sears will repair your

engine at no cost to you. Expenses covered under under

warranty include diagnosis, parts, and labor.

Manufacturer's Warranty Coverage

The model year 2000 and later engines are warranted for

two years. If any emission related part on your engine (as

listed below) is defective, the part will be repaired or

replaced by Sears.

Owner's Warranty Responsibilities

As the engine owner, you are responsible for the

performance of the required maintenance listed in this

owners manual. Sears recommends that you retain all

receipts covering maintenance on your engine, but Sears

cannot deny warranty solely due for the lack of receipts or

for your failure to ensure the performance of all scheduled

maintenance.

As the engine owner, you should be aware that Sears may

deny you warranty coverage if your engine or a part of it has

failed due to abuse, neglect, improper maintenance,

unapproved modifications, or the use of parts not made or

approved by the original equipment manufacturer.

You are responsible for presenting your engine to a Sears

authorized repair center as soon as a problem exists.

Warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized

service center or call Sears at 1-800-473-7247.

If you have any questions regarding your warranty rights

and responsibilities, your should contact your nearest

authorized service center or call Sears at

1-800-473-7247.

Warranty Period

Any warranted part which is not scheduled for replacement

as required maintenance, or which is scheduled only for

regular inspection to the effect of "repair or replace as

necessary" shall be warranted for 2 years. Any warranted

part which is scheduled for replacement as required

maintenance shall be warranted for the period of time up to

the first scheduled replacement point for that part.

Diagnosis

The owner shall not be charged for diagnostic labor which

leads to the determination that the warranted part is

defective if the diagnostic work is performed at an approved

Sears service center.

Consequential Damages

Sears may be liable for damages to other engine

components caused by the failure of a warranted part still

under warranty.

WHAT IS NOT COVERED

All failures caused by abuse, neglect, or improper

maintenance are not covered.

Add-on or Modified Parts

The use of add-on or modified parts can be grounds for

disallowing a warranty claim. Sears is not liable to cover

failures of warranted parts caused by the use of add-on or

modified parts.

How to File a Claim

If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized

service center or call Sears at 1-800-473-7247.

Where to Get Warranty Service

Warranty services or repairs shall be provided at all Sears

authorized service centers.

Warranty Commencement Date

The warranty period begins on the date the engine is

delivered.

Length of Coverage

Sears warrants to the initial owner and each subsequent

purchaser that the engine is free from defects in materials

and workmanship which cause the failure of a warranted

part for a period of two years.

WHAT IS COVERED

Repair or Replacement of Parts

• Repair or replacement of any warranted part will be

performed at no charge to the owner at an approved

Sears service center.

Maintenance, Replacement and Repair of

Emission Related Parts

Any Sears approved replacement part used in the

performance of any warranty maintenance or repair on

emission related parts will be provided without charge to the

owner if the part it under warranty.

Emission Control Warranty Parts List

1. Carburetor Assembly

2. Ignition System

a. Spark Plug, covered up to maintenance schedule.

b. Ignition Module

3. Crankcase Breather Tube

4. Exhaust Manifold

24

Page 25

GARANTIA................................... 25

INSTRUCCIONESDESEGURIDAD............. 25-26

MONTAJE................................. 27-28

OPERACION............................... 29-32

MANTENIMIENTO........................... 33-36

ESPECIFICACIONES........................... 33

ALMACENAMIENTO........................... 37

REPARACIONDEDAI_OS....................... 38

GARANTIADELCONTROLDEEMISIONES......... 39

COMOORDENARPARTES...... PAGINAPOSTERIOR

GARANTIA LIMITADA DE LA MAQUINA LAVADORA DE ALTA PRESION CRAFTSMAN

Durante un a_o a partir de la fecha de compra, Sears reparar& sin cargo alguno, cualquier defecto en material y mano de

obra, siempre y cuando esta maquina lavadora de alta presi6n Craftsman haya sido mantenida y puesta en funcionamiento

de acuerdo alas instrucciones suministradas en el manual del propietario.

Siesta maquina lavadora es usada para fines comerciales, la garantia se aplicara tan solo por 90 dias a partir de la fecha

de compra. Siesta maquina lavadora de alta presi6n es usada para alquiler, la garantia se aplicara tan solo por 30 dias

despu6s de la fecha de compra.

Esta garantia no cubre:

• Elementos perecederos como bujias o filtros de aire, los cuales se desgastan con el uso normal.

• Reparaciones necesarias debido al abuso o negligencia del operador, incluyendo daSos ocasionados por la ausencia de

suministro de agua a la bomba o por no mantener el equipo de acuerdo alas instrucciones contenidas en el manual del

propietario.

El servicio de garantia se hace efectivo devolviendo la maquina lavadora de alta presi6n al centro de servicio o distribuidor

Sears mas cercano en los Estados Unidos.

Esta garantia le proporciona derechos legales especificos; usted tambi6n puede tener otros derechos, los cuales varian de

estado a estado.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

iPELIGRO! La gasolina es altamente INFLAMABLE

y sus vapores son EXPLOSIVOS. No permita que

El escape del motor de este producto contiene

elementos quimicos reconocidos en el Estado

de California por producir cancer, defectos de

nacimiento u otros dahos de tipo reproductivo.

iPRECAUCION! Cuando transporte, instale, ajuste

o haga reparaciones a su maquina lavadora de alta

presi6n, siempre desconecte el alambre de la bujia y

col6quelo donde No pueda entrar en contacto con la

bujia.

iPELIGRO! Los gases del sistema de escape del

motor contienen gas de mon6xido de carbono

MORTAL. Si este gas peligroso se inhala en

concentraciones suficientes, puede causar p6rdida de

la consciencia o incluso la muerte. Opere este equipo

Qnicamente al aire libre, donde exista ventilaci6n

adecuada.

,_ ESTE ES EL SIMBOLO DE ALERTA DE SEGURIDAD. ES USADO PARA INDICARLE SITUACIONES

CON PELIGROS POTENCIALES DE LESION PARA EL PERSONAL. SIGA LAS INSTRUCCIONES DE

fumen, que existan llamas abiertas, chispas o calor a

su alrededor cuando manipule gasolina. Evite regar

gasolina sobre un motor caliente. Permita que la

unidad se enfrie antes de volver a colocarle

combustible. Cumpla con todas las leyes que regulan

el almacenamiento y el manejo de gasolina.

Lea este manual minuciosamente y conozca a fondo las

partes y el funcionamiento de su maquina lavadora a

presion. Conozca sus aplicaciones, sus limitaciones y

los peligros involucrados.

• Coloque esta maquina lavadora a presi6n en Areas

alejadas de materiales combustibles, humos o polvo

combustibles.

• El equipo de alta presi6n esta diseSado para ser

utilizado UNICAMENTE con las partes autorizadas

Sears. Si utiliza este equipo con partes que No cumplan

con las especificaciones minimas, el usuario asume

todos los riesgos y responsabilidades.

TODOS LOS MENSAJES DE SEGURIDAD QUE APARECEN DESPUES DE ESTE SIMBOLO PARA

EVITAR POSIBLES LESIONES O MUERTE.

25

Page 26

• Algunos quimicos o detergentes pueden ser nocivos si

se inhalan o ingieren, causando nausea severa,

desmayos o envenenamiento. Los elementos nocivos

pueden ocasionar daSo a la propiedad o lesiones

severas.

• No permita en ning6n momento que NINOS operen la

maquina lavadora a presi6n.

• Opere el motor 6nicamente a la velocidad de mando.

Hacer funcionar el motor a velocidades excesivas

aumenta el riesgo de lesiones personales. No juegue

con partes que puedan aumentar o disminuir la

velocidad de mando.

• No use ropa suelta, joyas o elementos que puedan

quedar atrapados en el arranque o en otras partes

rotatorias.

• Antes de poner en marcha la maquina lavadora a

presi6n en clima frio, revise todas las partes del equipo y

aseg6rese de que no se haya formado hielo sobre elias.

• Nunca utilice una pistola de rociado que No tenga un

seguro para gatillo o protecci6n para gatillo en su lugar y

en buenas condiciones.

• Mantenga conectada la manguera a la maquina o a la

pistola de rociado cuando el sistema est6 presurizado.

Es peligroso desconectar la manguera cuando la unidad

esta presurizada.

• NUNCA deberan ser operadas las unidades con partes

rotas o ausentes, o sin la caja o cubiertas de protecci6n.

• Revise que el sistema de combustible No presente fugas

o signos de deterioro, como mangueras desgastadas o

porosas, sujetadores flojos o ausentes, tapa o tanque

daSados. Corrija todos los defectos antes de operar la

maquina lavadora a presi6n.

• No rocie liquidos inflamables.

• Utilice un respirador o mascara siempre que exista la

posibilidad de inhalar vapores. Lea todas las

instrucciones de la mascara para asegurarse de que le

brindara la protecci6n necesaria contra la inhalaci6n de

vapores nocivos.

• Nunca apunte la pistola a la gente, animales o plantas.

La corriente de agua de alta presi6n que produce este

equipo pueden perforar la piel y sus tejidos profundos,

ocasionando lesiones serias y posible amputaci6n.

• Nunca permita que partes del cuerpo entren en contacto

con la corriente del fluido. No entre en contacto con la

corriente del fluido creada por una fuga en la manguera

de alta presi6n.

• Siempre use protecci6n para los ojos cuando utilice este

equipo o cuando est6 cerca de donde se est6 usando el

equipo.

• El rociado de alta presi6n puede hacer que particulas

pequeSas de pintura u otras particulas salgan

disparadas y viajen a altas velocidades.

• No opere la maquina lavadora a presi6n con un valor de

presi6n superior a su clasificaci6n de presi6n.

• Nunca mueva la maquina halando la manguera de alta

presi6n. Utilice la manija que viene con la unidad.

• Siempre aseg6rese de que la pistola de rociado,

boquillas y accesorios est6n conectados correctamente.

• No asegure la pistola de rociado en la posici6n (open =

abierto).

• El rociado de alta presi6n puede daSar elementos

fragiles, incluyendo el vidrio. No apunte la pistola de

rociado al vidrio cuando est6 en el modo de rociado a

chorro.

• Sostenga firmemente en su mano la manguera de

rociado antes de poner en marcha la unidad. De No

hacerlo, podrian ocurrir lesiones por el movimiento

brusco de la pistola de rociado. No abandone la pistola

de rociado cuando la maquina est6 en funcionamiento.

• El area de limpieza debera tener inclinaciones y drenajes

adecuados para disminuir la posibilidad de caidas

debido a superficies resbalosas.

• Mantenga el chorro del agua alejado de alambrados

el6ctricos, de Io contrario podrian ocurrir descargas

el6ctricas fatales.

No eluda ning6n dispositivo de seguridad de esta

maquina.

El silenciador y el motor se calientan durante el

funcionamiento y permanecen calientes inmediatamente

despu6s del apagado. Evite el contacto con

silenciadores o motores calientes, o podria quemarse

severamente.

• Opere y almacene esta unidad sobre una superficie

estable.

• La manguera de alta presi6n puede desarrollar fugas

debido al desgaste, dobleces, abuso, etc. El agua que

sale de una fuga es capaz de inyectar materiales en la

piel. Inspeccione la manguera siempre que la vaya a

usar. Revise todas las mangueras para ver si presentan

cortes, fugas, abrasiones o deformaci6n de la cubierta,

daSo o movimiento de acoplamientos. Si existe

cualquiera de estas condiciones, remplace la manguera

inmediata-mente. Nunca repare la manguera de alta

presi6n. Remplacela con una manguera que tenga la

misma capacidad de presi6n maxima de su unidad.

• El silenciador y el depurador de aire deberan estar

instalados yen buenas condiciones antes de operar la

maquina lavadora a presi6n. Estos componentes act6an

como apagachispas si el motor presenta contrafuegos.

En el estado de California es obligatorio, seg6n la ley, el uso

de apagachispas (Secci6n 4442 del C6digo de Recursos

P6blicos de California). Otros estados pueden tener leyes

similares. Las leyes federales se aplican en tierras

federales.

NOTA: Si equipa el silenciador con un apagachispas, este

debera ser mantenido en buenas condiciones de trabajo.

Usted puede ordenar el apagachispas a trav6s de su

distribuidor de servicio autorizado Sears.

26

Page 27

Su maquina lavadora a presi6n requiere de cierto ensamble

y estara lista para ser usada Qnicamente despu6s de haber

depositado el combustible y el aceite recomendado.

Si tiene problemas con el ensamble de su maquina

lavadora a presion, Ilame a la linea de ayuda de la

maquina lavadora a presion al 1-800-222-3136.

IMPORTANTE: Cualquier intento de hacer funcionar el

motor sin haber depositado el aceite recomendado resultara

en falla del mismo.

RETIRE LA MAQUINA LAVADORA A

PRESION DE LA CAJA

• Abra la caja y corte dos esquinas opuestas a la manija

guia de la parte superior a la inferior de tal forma que el

panel pueda ser doblado hacia abajo.

• Retire el material de relleno y la caja de repuestos

enviada con la maquina lavadora a presi6n.

• Saque la maquina lavadora a presi6n de la caja.

• Levante la manija guia, asegQrela en su sitio.

Levante la manija a la posicidn vertical y

mueva la tapas de fijacidn a su sitio.

• Revise la caja para ver si existen partes sueltas

adicionales.

CONTENIDO DE LA CAJA

Revise el contenido de la caja. Si alguna de las pares No

esta presente o esta daSada, Ilame a la linea de ayuda de

la maquina lavadora a presi6n al 1-800-222-3136.

• La unidad principal

• La manguera de alta presi6n

• Caja de pares (incluye los elementos descritos a

continuaci6n)

Pistola de rociado

Extensi6n para boquillas con boquilla ajustable a

Alta/Baja presi6n

Aceite para motor

Manual del operador

Juego para limpiar boquillas

Juego de anillos 'O'

Familiaricese con cada parte antes de ensamblar la

maquina lavadora a presi6n. Compare el contenido con la

ilustraci6n de la pagina 29. Si alguna de la partes No esta

presente o se encuentra daSada, Ilame a la linea de ayuda

de la maquina lavadora a presi6n al 1-800-222-3136.

MONTAJE DE LA MAQUINA

LAVADORA A PRESION

La gran mayoria de su maquina lavadora a presi6n

Craftsman ha sido ensamblada en la fabrica. Sin embargo,

usted debera Ilevar a cabo los siguientes procedimientos

antes de poner en funcionamiento su maquina lavadora a

presi6n:

• Deposite aceite en la caja del cigQeSal del motor.

• Deposite combustible en el tanque.

• Conecte la manguera de alta presi6n a la pistola de

rociado y a la bomba.

• Conecte el suministro de agua a la bomba.

Agregue Aceite de Motor

IMPORTANTE: Cualquier intento de hacer girar o arrancar

el motor antes de que se haya depositado el aceite

recomendado puede resultar en falla del motor.

NOTA: Cuando agregue aceite a la caja del cigQeSal del

motor, use Qnicamente aceite detergente de alta calidad con

clasificaci6n de servicio API SF,SH, SG o SH/CD de peso

30 SAE.

• Coloque la maquina lavadora a presi6n en una superficie

nivelada.

Limpie el Area alrededor del Ilenado de aceite.

Retire el tap6n del orificio de Ilenado y la varilla de

medici6n.

Limpie la varilla de medici6n, ins6rtela en el orificio de

Ilenado y aprietela firmemente; retire la varilla de

medici6n. Deposite el aceite recomendado hasta la

marca "Full" ("Lleno") de la varilla de medici6n.

Deposite el aceite lentamente. Limpie la varilla de

medici6n cada vez que revise el nivel del aceite. No

Ilene excesivamente.

DEPOSITAR LLENO

0.15 LITROS

@

• Instale el tap6n del orificio de Ilenado de aceite y la

varilla de medici6n y aprietela firmemente.

NOTA: Revise el aceite frecuentemente durante el

despegue del motor.

27

Page 28

Agregue Gasolina

,_ iPELIGRO! Nunca Ilene el tanque de combustible

en recintos cerrados. Nunca Ilene el tanque de

combustible cuando el motor est6 funcionando o est6

caliente. No fume cuando est6 Ilenando el tanque de

combustible.

,_ iADVERTENClA! Nunca Ilene por completo el

tanque de combustible. Deje espacio para la

expansi6n del combustible. Limpie cualquier derrame

de combustible del motor y del equipo antes de darle

arranque a la unidad.

• Use combustible limpio y almac6nelo en recipientes

cubiertos, limpios y aprobados. Utilice embudos limpios.

Nunca utilice gasolina "vieja" dejada de la estaci6n

anterior o gasolina almacenada por periodos de tiempo

prolongados.

• Limpie el Area alrededor de la tapa de Ilenado del

combustible, retire la tapa.

• Agregue lentamente gasolina regular"SIN PLOMO" al

tanque de combustible. Use un embudo para evitar que

se derrame. Llene el tanque lentamente hasta

aproximadamente ½" por debajo de la parte inferior del

cuello del tubo de Ilenado.

Espacio de 1/2"

Combustible

• Conecte el otro extremo de la manguera de alta presi6n

a la salida de alta presi6n de la bomba. Apriete con la

mano.

• Antes de que conecte la manguera de jardin a la entrada

de agua, inspeccione el colador de la entrada. Limpie el

colador si tiene residuos o solicite su remplazo siesta

daSado. No haga funcionar la maquina lavadora a

presion si el colador de la entrada esta dahado.

• Conecte la manguera de jardin a la entrada del agua.

Apriete con la mano.

• ABRA el suministro del agua (abra la valvula de

suministro completamente).

• Apriete el gatillo de la pistola para eliminar el aire y las

impurezas del sistema de la bomba.

• Instale la tapa del tanque de combustible y limpie la

gasolina que se haya derramado.

Conecte la Manguera y el Suministro de

Agua a la Bomba

IMPORTANTE: Usted debera armar la extensi6n para

boquillas y conectar todas las mangueras antes de darle

arranque al motor. La bomba resultara daSada si arranca el

motor sin tener todas las mangueras conectadas y el

suministro agua abierto.

• Desenrrolle la manguera de alta presi6n y conecte un

extremo de la manguera a la base de la pistola de

rociado. Apriete con la mano.

,_ iPRECAUCION! Antes de darle arranque a lamaquina lavadora a presi6n, asegQrese de usar

protecci6n adecuada para los ojos.

• Conecte la extensi6n para boquillas a la pistola de

rociado. Apriete con la mano.

LISTA DE REVISION PREVIA AL

ARRANQUE DEL MOTOR

Revise la unidad para asegurarse que ha Ilevado a cabo los

siguientes procedimientos:

• Revise que haya sido depositado aceite y est6 al nivel

correcto en la caja del cigQeSal del motor.

• Deposite la gasolina adecuada en el tanque del

combustible.

• Revise que todas las conexiones de las mangueras (alta

presi6n y suministro de agua) est6n apretadas

correctamente y que no existan dobleces, cortes o daSo

de la manguera de alta presi6n.

• Proporcione el suministro de agua adecuado (que no

exceda los 140°F).

• AsegQrese de leer las secciones "Reglas de Seguridad"

y "Operaci6n" antes de usar la maquina lavadora a

presi6n.

28

Page 29

CONOZCA SU MAQUINA LAVADORA DE ALTA PRESION

Lea el manual del propietario y las reglas de seguridad antes de poner en marcha su maquina lavadora a presion.

Compare las ilustraciones con su maquina lavadora a presiOn para familiarizarse con las ubicaciones de los diferentes

controles y ajustes. Guarde este manual para referencias futuras.

Manguera de Alta

PresiOn

Arrancador de

Pistola de Rociado

Tapa del DepOsito del

Aceite

Tapa de la Gasolina

ExtensiOn

para Boquillas

Retroceso

Filtro y Tubo para

RecolecciOn de Detergente

Filtro de Aire

Palanca de Control de la

Valvula de

RegulaciOn/Cebador

Boquilla Ajustable

Entrada de Agua

Arrancador de Retroceso - Usado para el arranque del

motor.

Bomba - Desarrolla alta presiOn de agua.

Boquilla Ajustable - Ajusta la presiOn a alta o baja presiOn;

rociado a chorro o en abanico.

Entrada de Agua - ConexiOn para la manguera de jardin.

ExtensiOn para Boquillas - Conectada a la pistola de

rociado para un uso mas conveniente.

Filtro de Aire - El elemento de filtro tipo seco limita la