Page 1

Owner’s Manual

CRAFTSMAN

4.5 HORSEPOWER

1800 PSi 2GPM

HIGH PRESSURE WASHER

Model No.

580.761800

CAUTION: Before using this

product, read this manual and

follow all Safety Rules and

Operating Instructions.

HOURS: Mon. - Fri. 8 a.tn. to 5 p.m. (CST)

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Part No. B1818 Draft 0 (11/I2/97)

Page 2

TABLE OF CONTENTS

SAFETY RULES

ASSEMBLY.................................................................... 4-5

OPERATION

MAINTENANCE

................................................................

..................................................................

.........................................................

6-9

10-13

3

STORAGE

TROUBLESHOOTING

REPLACEMENT PARTS

HOW TO ORDER PARTS

......................................................................

......................................................

.............................................

................................

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained and operat

ed according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material

and workmanship.

If this high pressure washer is used for commercial purposes, this warranty applies for only 90 days from the

date of purchase. If this high pressure washer is used for rental purposes, this warranty applies for only 30

days after date of purchase.

This warranty does not cover:

• Expendable items such as spark plugs and air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water being

supplied to pump or failure to maintain the equipment according to the instructions contained in the owner’s

manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE

NEAREST SEARS SERVICE CENTER OR DEALER IN THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to

state.

14

15

16-27

BACK PAGE

SEARS, ROEBUCK AND CO., D/817 WA, Hoffman Estates, IL 60179

Page 3

SAFETY RULES

CAUTION; ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CAN

NOT CONTACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,

TRANSPORTING, ADJUSTING OR MAKING REPAIRS TO YOUR HIGH PRESSURE WASHER.

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

WARNING:

The engine exhaust from this product

contains chemicals known to the State

of Cal'ifomia to cause cancer, birth

defects, or other reproductive harm.

Engine exhaust gases contain DEADLY carbon monoxide

gas. This dangerous gas, if breathed in sufficient concen

trations, can cause unconsciousness or even death.

Operate this equipment only in the open air where ade

quate ventilation is availabie.

Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames, sparks

or heat in the vicinity while handling gasoline. Avoid

spiiiing gasoline on a hot engine. Ailow unit to cooi for 2

minutes before refueiing. Comply with all laws regulating

storage and handling of gasoline.

Locate this pressure washer in areas away from com

bustible materials, combustible fumes or dust.

The high pressure equipment is designed to be used with

Sears authorized parts only. If you use this equipment with

parts that do not comply with minimum specifications, the

user assumes all risks and liabilities.

Some chemicals or detergents may be harmful if inhaled

or ingested, causing severe nausea, fainting or poisoning.

The harmful elements may cause property damage or

severe injury.

Do not allow CHILDREN to operate the Pressure Washer

at any time.

Operate engine only at governed speed. Running the

engine at excessive speeds increases the hazard of per

sonal injury. Do not tamper with parts which may increase

or decrease the governed speed.

Do not wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

Before starting the Pressure Washer in cold weather,

check all parts of the equipment and be sure ice has not

formed there.

Units with broken or missing parts, or without protective

housing or covers should NEVER be operated.

The muffler and air cleaner must be installed and in good

condition before operating the Pressure Washer. These

components act as spark arrestors if the engine backfires.

Check the fuel system for leaks or signs of deterioration

such as chafed or spongy hose, loose or missing clamps

or damaged tank or cap. Correct all defects before operat

ing the Pressure Washer.

Do not spray flammable liquids.

• Never allow any part of the txxiy to come in contact with

the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the high pressure hose.

High pressure streams of fluid this equipment produces

can pierce skin and its underlying tissues, leading to seri

ous injury and possible amputation.

Never aim the gun at people, animals or plants.

High pressure spray can cause paint chips or other parti

cles to become airborne and fly at high speeds.

Always wear eye protection when you use this equipment or

when you are in the vicinity where the equipment is in use.

Operate the pressure at no more than the PSI fluid pres

sure rated for your pressure washer.

Never move the machine by pulling on the high pressure

hose. Use the hancfle provided on the top of the unit.

Always be certain the spray gun, nozzles and accessories

are correctly attached.

Never use a spray gun which does not have a trigger lock

or trigger guard in place and in working order.

Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the mask

so you are certain the mask will provide the necessary

protection against inhaling harmful vapors.

High pressure spray may damage fragile items including

glass. Do not point spray gun at glass when in the jet

spray mode.

Keep the hose connected to machine or the spray gun

while the system is pressurized. Disconnecting the hose

while the unit is pressurized is dangerous.

Hold the spray gun firmly in your hand before you start the

unit. Failure to do so could result in an injury from a whip

ping spray gun. Do not leave the spray gun unattended

while the machine is running.

The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

Keep water spray away from electric wiring or fatal electric

shock may result.

Do not adjust unloader valve to a pressure in excess of

machine rating.

Do not secure trigger gun in the pull-back (open) position.

Do not by-pass any safety device on this machine.

The muffler and engine heat up during operation and

remain hot immediately after shutting it down. Avoid con

tact with a hot muffler or engine or you could be severely

burned.

MAINTENANCE AND STORAGE:

• Operate and store this unit on a stable surface.

• High pressure hose can develop leaks from wear, kinking,

abuse, etc. Water spraying from a leak is capable of inject

ing material into skin. Inspect hose each time before using

it. Check all hoses for cuts, leaks, abrasions or bulging of

cover, or damage or movement of couplings. If any of

these conditions exist, replace hose immediately. Never

repair high pressure hose. Replace it with another hose

that meets minimum pressure rating of your pressure

washer.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS “ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.”

Page 4

ASSEMBLY

CARTON CONTENTS

The following parts are shipped loose with your pressure

washer

• Main Unit — pressure washer with wheels,

guide handle.

• High Pressure Hose

• Manual Bag (which includes the items listed below)

• Ofliper’s Manual

• Nozzle Cleaner Kit

• Parts Box (which includes items listed below)

• Spray Gun

• Wand Extension with Hi/Lo Adjustable Nozzle.

• Wire Form

• Motor Oil

• “0"-RingKit

Become familiar with each piece before assembling the

pressure washer. Check all contents against the illustra

tion on Page 6. If any parts are missing or damaged, call

the Pressure Washer Helpline at 1-800-222-3136.

TO REMOVE PRESSURE WASHER FROM CARTON

• Remove loose parts and parts box included with pres

sure washer. The high pressure hose is packed in the

bottom of the carton on the guide handle end.

Remove the hose.

• Slice two comers at guide handle end of carton from

top to bottom so the panel can be folded down flat,

then remove all packing material.

• Raise guide handle, secure in place and roll the pres

sure washer out the open end of the carton.

Loosen knobs

to leise handle

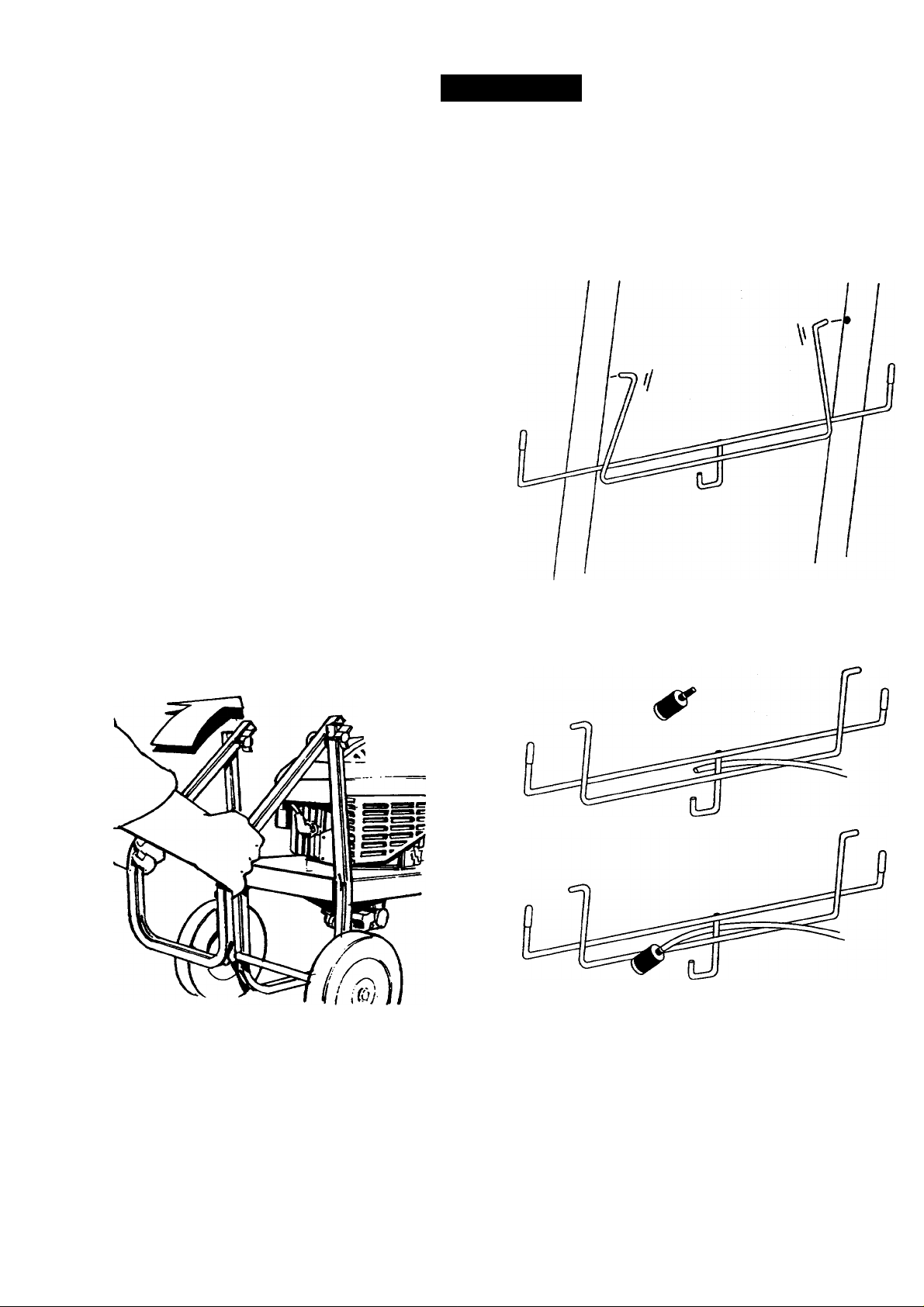

HOW TO SET UP YOUR PRESSURE WASHER

For the most part, your Craftsman High Pressure Washer

has been assembled at the factory. You must, however,

attach the wire form, assemble the spray gun, and attach

the high pressure hose to the pump and spray gua

• While facing the rear of the Pressure Washer, insert

the wire sup^rt with the longer arm positioned on the

left. From this view the hook should resemble a “J".

Cut tie wrap on chemical Ejection tube. Rernove chemi

cal irqectkxi filter, thread chemical rr^ecfion titoe through

the wire form and reinsert fitter mto tube.

Tighten knobs

when handle is

straight.

Check carton for additional loose parts.

\\\^

Page 5

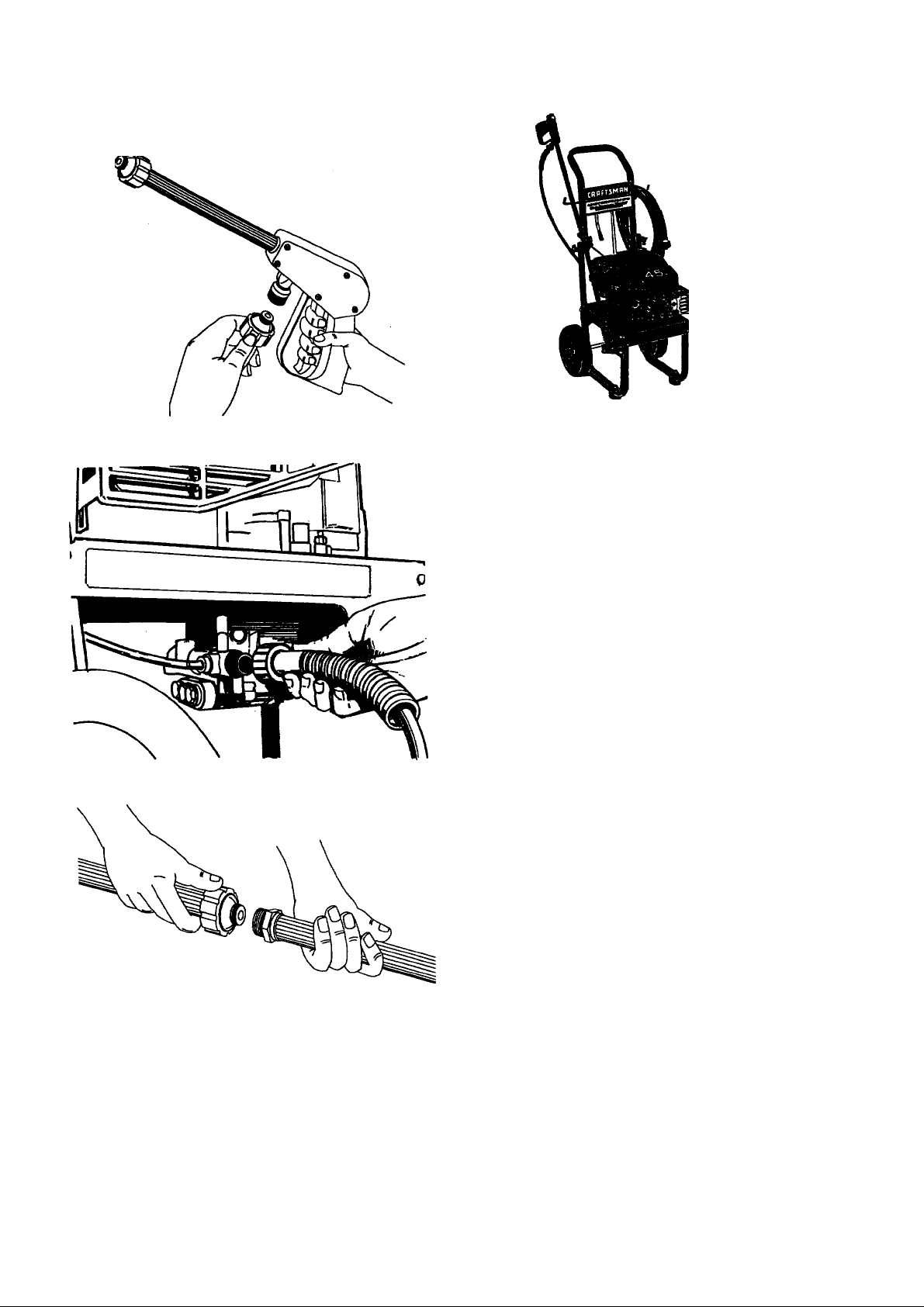

• Cut the tie wraps on the high pressure hose and

connect high pressure hose to gun. Tighten by

hand.

Remove plastic cap and connect high pressure

hose to pump. Tighten by hand.

Attach nozzle extension to spray gun.

Place assembled spray gun on holder.

CHECKLIST

Before you operate your new high pressure washer

please review the following checklist:

• All assembly instructions have been completed.

• The high pressure hose connections to the spray

gun and to the pump are tight and secure.

While learning how to use your high pressure

washer, pay extra attention to the following important

items:

• Engine oil is at proper level

Important: Any attempt to crank or start the engine

before it has been properly serviced with the recom

mended oil may result in an engine failure. See Page

8 for instructions on adding oil and proper oil specifi

cations.

Important: The water supply to your pressure wash

er must be connected and turned on prior to starting

your engine.

• Be sure gas tank is filled properly with clean,

fresh, unleaded gasoline.

• Become familiar with all controls - their location

and function. Operate those controls before start

ing the engine.

Page 6

OPERATION

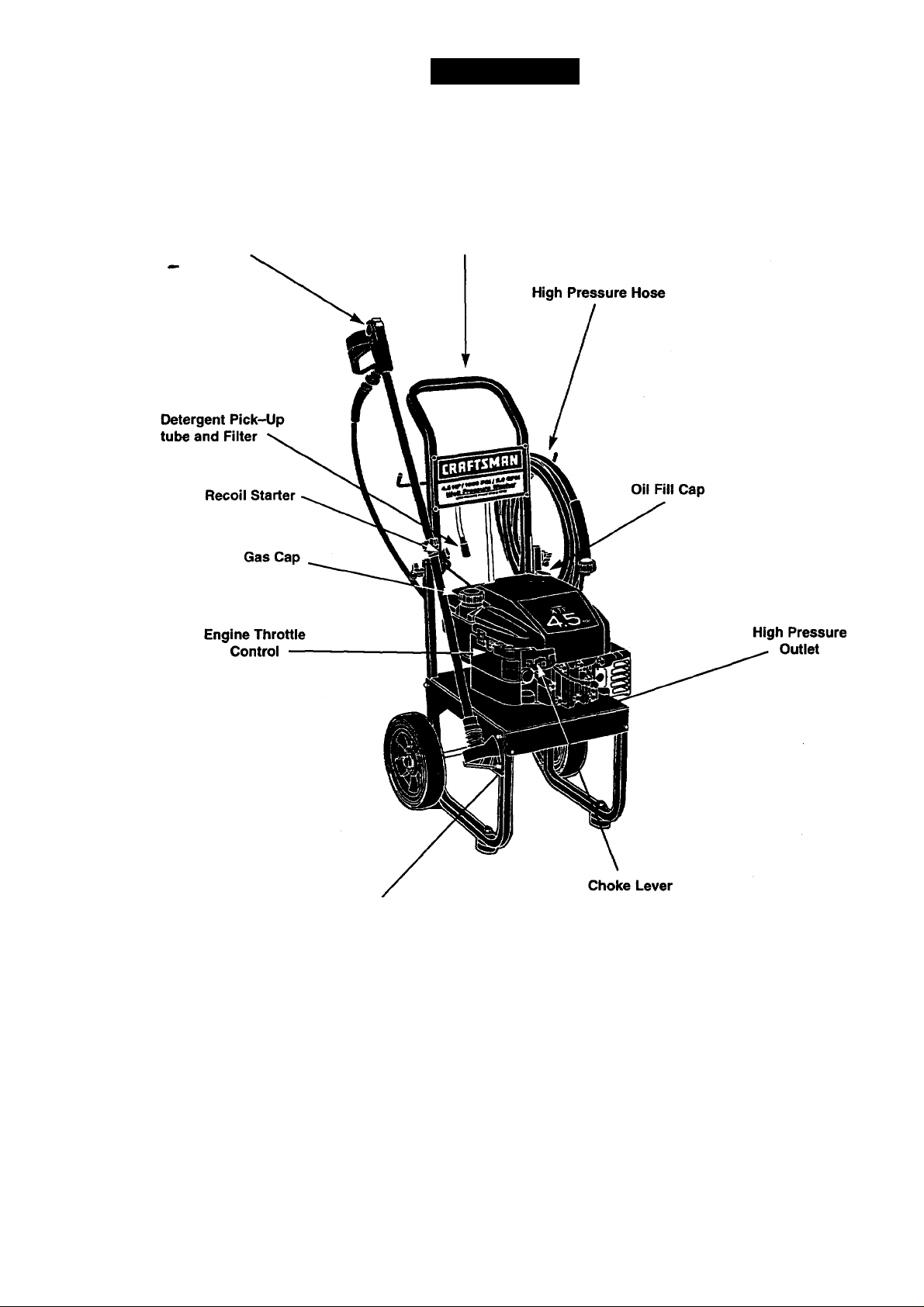

KNOW YOUR HIGH PRESSURE WASHER

Read this owner’s manual and safety rules before operating your high pressure washer. Compare the illustra

tions with your high pressure washer to familiarize yourself with the locations of various controls and adjustments.

Save this manual for future reference.

Spray Gun Assembly

Guide Handle

Water Inlet

Pump - Develops high water pressure.

Engine Throttle Control Lever - Sets engine in starting

mode for recoil starter; STOPS running engine.

Recoil Starter - Used for starting the engine manually.

Choke Lever — Puts a cold engine in starting mode.

Air Cleaner - Dry type filter element limits the amount of

dirt and dust that gets in the engine.

Spray Gun Assernbly - Controls the application of water

onto cleaning surface with trigger device. Includes safety

latch.

Detergent Pick-up Tube and Filter - Mixes water and

detergent in outlet water flow.

High Pressure Outlet - Connection for high pressure

hose.

Water Inlet - Connection for garden hose.

Page 7

HOW TO USE YOUR PRESSURE WASHER

IF YOU HAVE ANY PROBLEMS operating your pres

sure washer, please call the pressure washer helpline

at 1-800-222-3136.

WARNING NEVER adjust ^ray iMttem

when spraying. NEVER put hands in front

of spray nozzle to ac^ust spray pattern.

You could be injured.

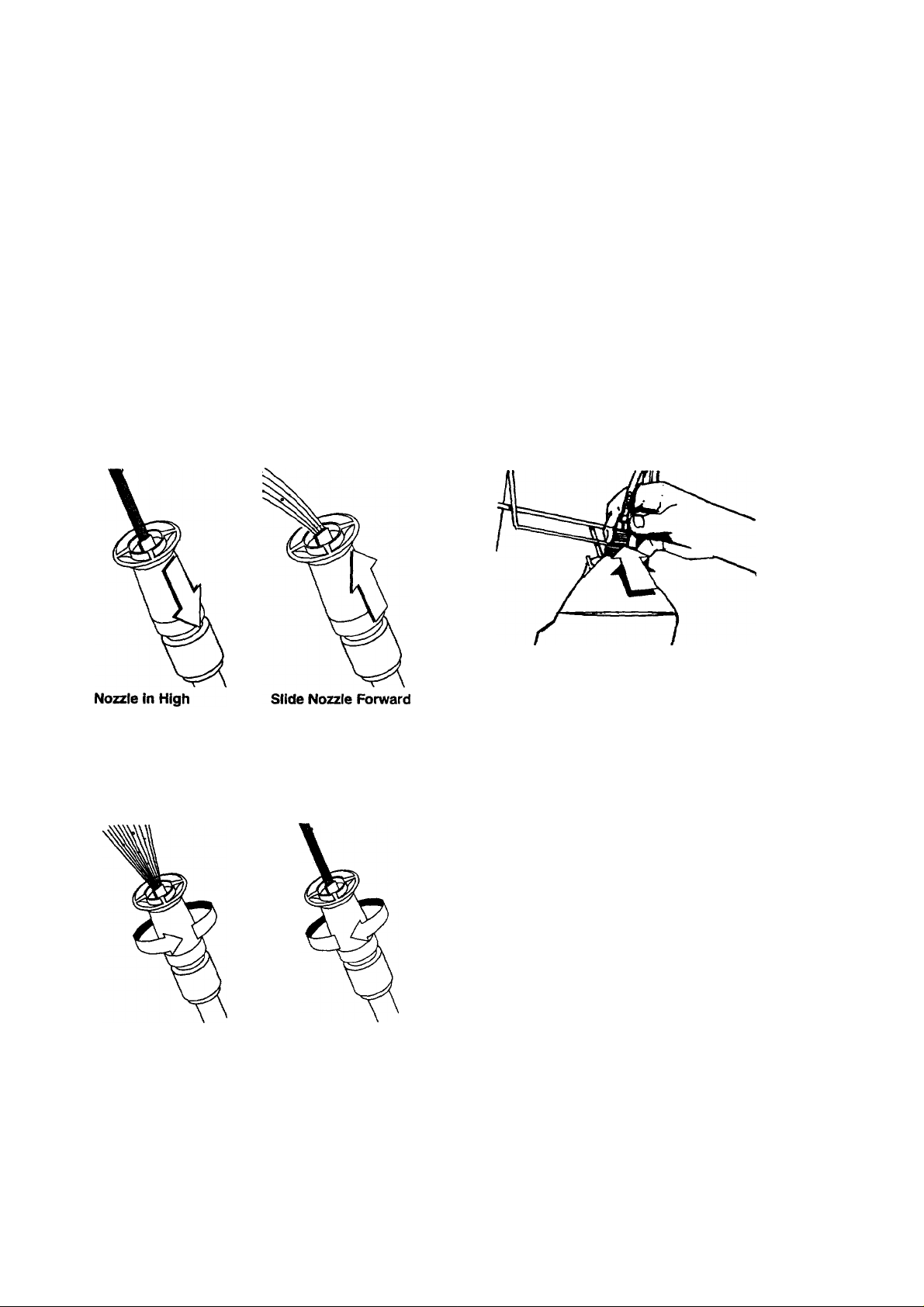

HOW TO USE THB-ADJUSTABLE NOZZLE

On the end of your spray gun is a nozzle that you

can slide forward and backward and that you can

also twist from side to side. With the adjustable noz

zle you can adjust the spray pattern to be either high

pressure or low pressure. You can also adjust the

spray so it is concentrated in a stream pattern or

expanded into a fan pattern.

• Slide the nozzle forward when you wish to adjust

the spray to low pressure mode. Slide the nozzle

backward to achieve high pressure.

• If you get spray nozzle too dose, especially using

high pressure mode, you may damage the clean

ing surface.

APPLYING DETERGENT AND CLEANING WITH

ADJUSTABLE NOZZLE

IMPORTANT: Use soaps designed specifically for

pressure washers. Household detergents could dam

age the pump.

IMPORTANT: You must attach all hoses before you

start the engine. Starting the engine without all the

hoses connected and without the water turned ON

will damage the pump.

To apply detergent follow these steps;

• Prepare the detergent solution as required by the

job.

• Hang the detergent solution on the "J” hook on

the wire forni on the guide handle.

• Place small filter on the clear, chemical injection

tube into the detergent container.

Pressure Mode

Twisting the nozzle adjusts the spray pattern from

a narrow pattern to a fan pattern.

Twist nozzle counter

clockwise for fan

spray pattern

For most effective cleaning, keep spray nozzle

between 8 to 24 inches away from cleaning sur

face.

for low pressure

mode and detergent

application

Twist nozzle clock

wise for narrow

spray pattern

• Slide the adjustable nozzle forward to low pres

sure mode. Detergent cannot be applied with

nozzie in high pressure position.

Note: The first step involves applying an appropriate

detergent/solvent solution to penetrate and loosen

grime. The detergent is applied at low pressure to

avoid splashing, overspraying and waste. Leave the

solution on surface for 3 to 5 minutes to allow solu

tion to work.

Note: The second step involves cleaning the surface

you have prepared with the pressure washer and

then rinsing it clean.

• Review the use of the adjustable nozzle.

• Connect garden hose to water inlet (see “TO

START PRESSURE WASHER”), check that high

pressure hose is connected to spray gun and

pump (see ASSEMBLY), and start engine.

• For cleaning, start at lower portion of area to be

washed and work upward, using long, even over

lapping strokes.

• Allow the detergent to soak in between 3-5 min

utes before washing and rinsing.

Page 8

RINSING WITH THE PRESSURE WASHER

WARNING Be extremely careful if you must

use the pressure washer from ladder, scaf

folding or any other relatively unstable loca

tion. Pressure in a running washer builds in

the wand as you climb. When you press the

trigger, the recoil from the initial spray could

force you to fall, or if you are too close to the

cleaning surface, high pressure could force

you off a climbing apparatus.

Note: When adding oil to the engine crankcase in the

future, use only high quality detergent oil rated with API

service classification SF or SG rated SAE 30 weight. Use

no special additives.

Select the oil’s viscosity grade according to your expect

ed operating temperature.

colder

5W30

— 32°F -

■

------1--------

—► warmer

SAE 30

• Hook up the water supply and start your pressure

washer (see TO START THE PRESSURE WASHER).

• Slide adjustable nozzle back to high pressure position

and wait for detergent to clear. Detergent will not flow

when in the high pressure mode.

• When detergent has cleared you may want to expand

the spray pattern for a more gentle rinsing action.

Start at top of area to be rinsed, working down with

same action as for cleaning.

You can also stop detergent from flowing by simply

removing siphon from bottle.

HOW TO STOP YOUR PRESSURE WASHER

• Move the Throttle Control Lever to the ‘Slow’ position

Fast

Slow

• Wait for the engine to idle down.

• Move the Throttle Control Lever to the ‘Stop’ position.

• Simply shutting off the engine wiil not release

pressure In the system. Squeeze trigger on the

spray gun to relieve pressure in the hose.

Note: A small amount of water will squirt out when

you release the pressure.

Stop

BEFORE STARTING THE PRESSURE WASHER

To operate the engine you will need to do the following:

ENGINE OIL

• A 20 oz. bottle of SAE 30 weight oil is included in the

parts carton. Fill engine crankcase with recommended

oil until oil level is at FULL point on dipstick. Do not

overfill above that mark. POUR SLOWLY.

Although multi-viscosity oils (5W30, 10W30, etc.) improve

starting in cold weather, these multi-viscosity oils will

result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to

avoid possible damage from running low on oil.

• Place pressure washer on a level surface

• Clean area around oil fill and remove oil dipstick.

• Wipe dipstick clean.

• Pour oil from enclosed bottle into the oil fill opening

until oil reaches FULL mark on the dipstick. Stop and

check the oil level periodically. DO NOT OVERFILL.

• Install oil dipstick, hand tighten securely.

ADD GASOLINE

WARNING NEVER fill fuel tank indoors.

NEVER fill fuel tank when engine is running

or hot. DO NOT light a cigarette or smoke

when filling the fuel tank.

CAUTION: Do not overfill the fuel tank.

Always leave room for expansion.

• Use regular UNLEADED gasoline with the pressure

washer engine. Regular leaded gasoline may also be

used if UNLEADED is not available. Fuel tank capaci

ty is 1.6 U.S. quart.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel filter, fuel hose or tank during storage.

Also, experience indicates that alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract moisture

which leads to separation and formation of acids during

storage. Acidic gas can damage the fuel system of an

engine while in storage. To avoid engine problems, the

fuel system should be emptied before storage of 30 days

or longer. See “Storage" on page 13. Never use engine

or carburetor cleaner products in the fuel tank or perma

nent damage may occur.

• Clean area around fuel fill cap, remove cap.

• Add “UNLEADED” regular gasoline, slowly, to fuel

tank.

• Install fuel cap and wipe up any spilled gasoline.

Page 9

TO START YOUR PRESSURE WASHER

You have assembled your high pressure washer and

have prepared the engine for starting. You are now ready

to clean your car, boat or whatever you plan to clean.

• Place the pressure washer in an area close enough to

an outside water source that can flow at a rate of at

least 2 gallons per minute. Connect a garden hose to

the water spout.

• Check that thejiigh pressure hose is tightly connected

to the spray gun and to the pump. See ASSEMBLY

section for illustrations.

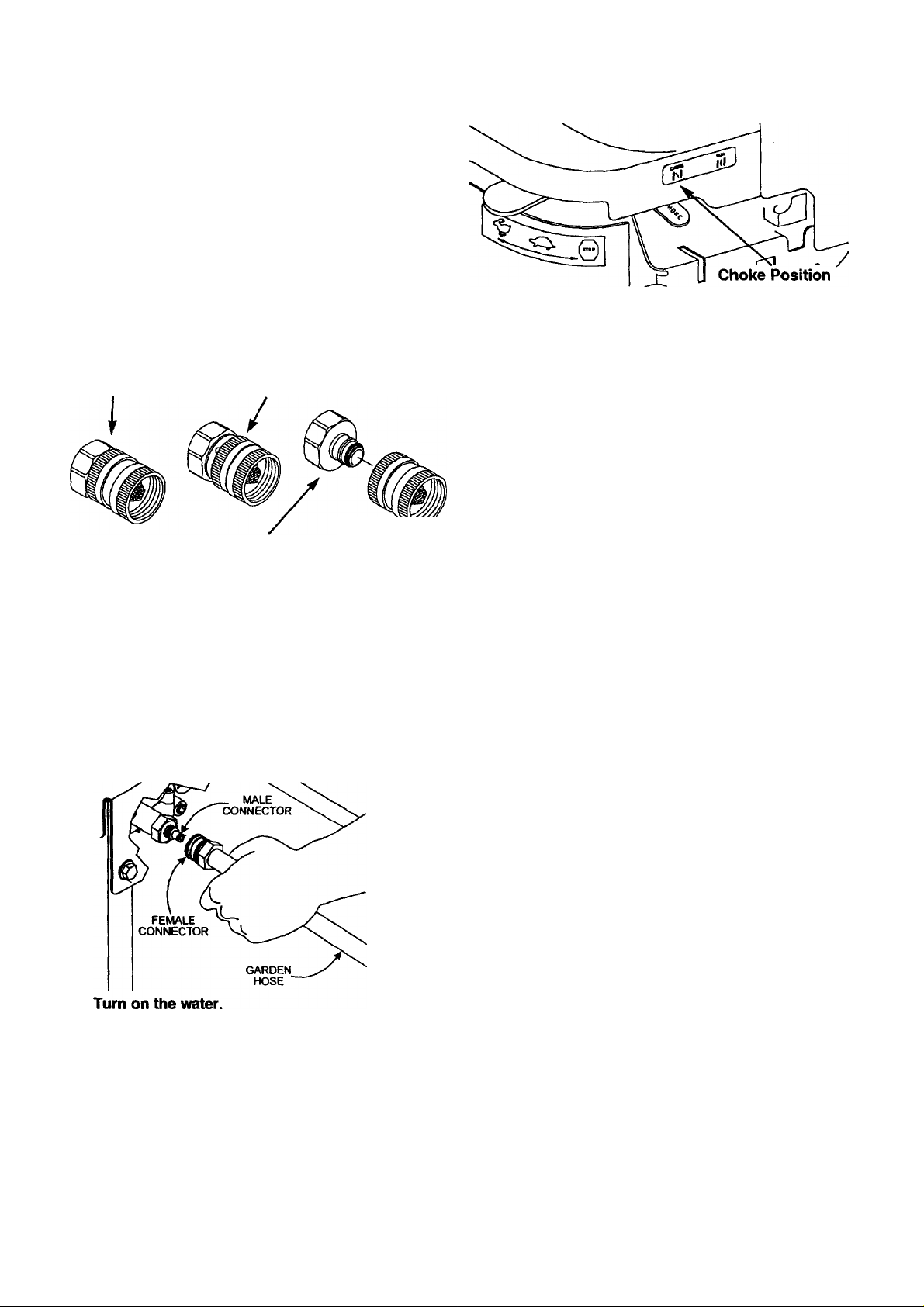

• Pull back on the locking collar to remove the female

quick-connect from pump.

Assembled

Quick-Connect

Note: You will also need to pull back on the locking collar

to attach the female quick-connect.

• Check inlet screen. If the screen is dirty, clean

before attaching to garden hose. If the screen is

damaged, Do not connect to the garden hose. Call

the pressure washer customer helpline to order a

replacement.

• Attach the female quick-connect to garden hose and

then attach the garden hose to the water inlet. Make

sure the quick-connect is locked together.

Pull back on locking

collar to separate

Disassembled

male end

Disassembled

female end

/

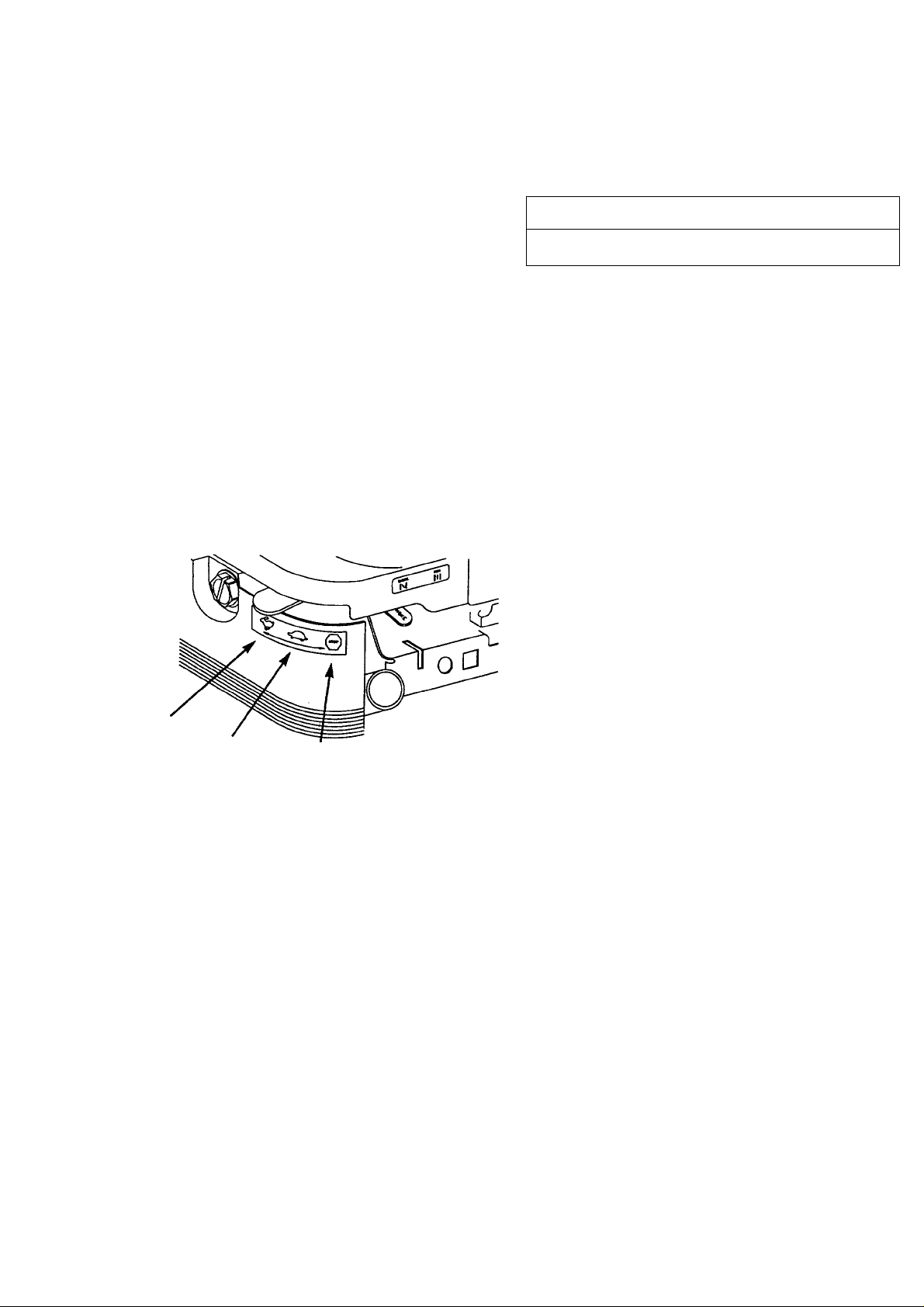

Set Choke Lever to “Choke” position. Note: This is a

multi-position choke.

Note: For a warm engine, be sure the Throttle Control

Lever is in the ‘Fast’ position and the Choke Lever is in

the “Run” position.

• Position the nozzle in the low pressure mode (nozzle

slid forward) and squeeze the trigger on the spray gun

to relieve the air pressure caused by turning ON the

water. Water will spew out the gun in a thin stream.

Continue to hold trigger until you have a steady

stream of water and no air remains in the system. This

will make it easier to pull start the engine. Release the

trigger.

• Engage the safety latch on the gun.

• Grasp rope handle and pull slowly until you feel some

resistance. Then pull cord rapidly to overcome com

pression, prevent kickback and start the engine. Let

rope return to starter

Note: Always keep the Throttle Control Lever in the ‘Fast’

position when operating the pressure washer.

• When the engine starts, gradually move the Choke

Lever from one position to the next until it is in the

“Run” position.

Note: If after 3 pulls the engine fails to start, move the

Choke Lever to the ‘Run’ position and pull the recoil

starter handle rapidly (Max. 3 pulls).

slowly.

SIPHONING

We recommend that you DO NOT siphon standing water

for your water supply. Contaminated, brackish or dirty

water can damage the pump. Connect only to household

water supply.

IMPORTANT: Do not run pump without the water supply

connected and turned on. You must follow this caution or

the pump will be damaged.

• Move the Throttle Control Lever to the ‘Fast’

position

TIPS

• Never use the garden hose inlet to siphon detergent or

wax.

• If you have the spray nozzle too far away, the cleaning

will not be as effective.

Page 10

MAINTENANCE

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

RLL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK

PRESSURE WASHER

Check/clean water inlet screen

on quick-connect.

Check high pressure hose.

Check detergent hose.

Check spray gun and assembly for leaks.

Purge pump of air and contaminants.

ENGINE

Check oil level.

Change engine oil.

Service air cleaner.

Clean/replace spark plug.

Prepare for storage.

t Clean if clogged. Replace if perforated or tom.

* Change sooner when operating under heavy load or high ambient temperature.

" Clean more often under dirty or dusty conditions.

HOURLY OPERATING INTERVAL

Before Each

Use

xt

X

X

X

X

X

Prepare unit for storage if it is to

remain idle for longer than 30 days.

Every 25

Hours or

Yearly

X*

X"

SERVICE DATES

Every too

Hours or

Yearly

X

GENERAL RECOMMENDATIONS

The warranty of the high pressure washer does not cover

items that have been subjected to operator abuse or neg

ligence. To receive full value from the warranty, operator

must maintain high pressure washer as instructed in this

manual.

Some adjustments will need to be made periodically to

properly maintain your high pressure washer.

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season.

• Once a year you should clean or replace the spark

plug and clean or replace the air filter and check the

gun and wand assembly for wear. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

PRESSURE

FLOW RATE 2GPM

DETERGENT MIX Use undiluted deteraent

WATER SUPPLY

TEMPERATURE Not to Exceed 140°F

1800 DSi

Engine Specifications

ENGINE MODEL Briaas & Stratton

RATED HORSEPOWER 4.5

DISPLACEMENT

SPARK PLUG: Type:

190CC

Champion J-19LM

or equivalent

Set Gap to:

GASOLINE CAPACITY

0.030 inch (0.76mm)

1.6 U.S. Quart

OIL SAE 30 weight

SOLID STATE IGNITION

0.0125 inch

AIR GAP

In the State of California a spark arrestor is required by

law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws

apply on federal lands.

Note: If you equip the engine of your pressure washer

with a spark arrestor muffler, the spark arrestor must be

maintained in effective working order by the owner/operator.

You can order a spark arrestor through your Sears

Service Center.

10

Page 11

BEFORE EACH USE

Check water inlet screen for damage.

Check high pressure hose for leaks.

Check detergent inlet hose and filter for damage.

Check gun and wand assembly for leaks.

Purge pump of air and contaminants.

Check engine oil level.

PRESSURE WASHER MAINTENANCE

Check and Clean Inlet Screen: Remove quick-con

nect and examine inlet screen on the female connec

tor. Clean if it is clogged or replace if it is torn.

Check High Pressure Hose: High pressure hose

can develop leaks from wear, kinking, abuse. Inspect

hose each time before using it. Check for cuts, leaks,

abrasions or bulging of cover, or damage or move

ment of couplings. If any of these conditions exist,

replace hose immediately.

DANGER: Water spraying from a leak is

▲

capable of injecting material into skin.

NEVER repair high pressure hose.

Replace with hose №at meets minimum

^ pressure rating of your pressure washer.

Check Detergent Hose: Examine the filter on the

detergent hose and clean if clogged. Hose should fit

tightly on barbed fitting. Examine hose for leaks or

tears. Replace the filter or hose if either is damaged.

Check Gun and Wand: Examine hose connection to

gun and make sure it is secure. Test trigger by press

ing it and making sure it springs back into place when

you release it. Put safety latch in UP position and test

trigger. You should not be able to press trigger.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps:

• Set up the pressure washer as described in the

ASSEMBLY section and connect the water sup

ply.

• Remove the wand extension from the gun.

• Pull the trigger on the gun and hold.

To remove the contaminants from the pump, follow

these steps:

• Set up the pressure washer as described in the

ASSEMBLY section, and connect the water sup

ply.

• Remove the nozzle attachment from the gun.

• Start the engine according to instructions in

OPERATION section.

• Pull the trigger on the gun and hold.

• When the water supply is steady and constant,

engage the safety latch and refasten the nozzle

attachment.

ENGINE MAINTENANCE

CHECKING OIL LEVEL

Oil level should be checked prior to each use or at

least every 5 hours of operation. Keep oil level main

tained.

CHANGING ENGINE OIL

Change engine oil every 25 hours. If you are using

your pressure washer under extremely dirty or dusty

conditions, or in extremely hot weather, change oil

more often.

• Change oil while engine is still warm from run

ning, as follows:

• Before you tip the pressure washer to drain oil,

drain fuel tank by running pressure washer until

fuel tank is empty.

• Clean area around oil fill, remove oil fill cap/dipstick. Wipe dipstick clean.

• Tip your pressure washer to drain oil completely

from the oil fill tube into a suitable container.

When crankcase is empty, return the pressure

washer to upright position.

• Fill engine crankcase with recommended oil until

oil level is at FULL point on dipstick. Do not over

fill above that mark. POUR SLOWLY.

• When engine crankcase is filled to proper level,

install and tighten oil cap/dipstick.

SERVICE AIR CLEANER

Your engine will not run properly and may be dam

aged if you run it with a dirty air cleaner.

Clean or replace the air cleaner once every 25 hours

of operation or once each year, whichever comes

first. Clean or replace more often if operating under

dirty or dusty conditions. Replacements are available

at your local Sears Authorized Service Center.

To clean or replace the air cleaner, follow these

steps:

• Remove screw on the air cleaner cover.

• Remove air cleaner carefully to prevent debris

from falling into carburetor.

• Take air cleaner apart and clean all parts and ser

vice the foam element.

• Wash foam element in liquid detergent and water.

If the element is damaged or very dirty, replace

the element.

• Squeeze the element dry in a clean cloth.

• Saturate the foam element in engine oil. Squeeze

the saturated element in a clean cloth to remove

excess oil.

• Reassemble all parts and fasten securely to the

carburetor with the screw.

II

Page 12

CLEAN/REPLACE SPARK PLUG

CAUTION: Disconnect spark plug wire

from spark plug and keep wire away from

spark plug.

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

your engine to start easier and run better. Replace with

champion J-19LM or equivalent type spark plug. Set the

spark plug gap to 0.030 inch (0.76mm).

If you think your carburetor needs adjusting, see your

nearest Sears Service dealer. Engine performance may

be affected above 4,000 feet in altitude. To improve

engine performance, see your nearest Sears Service

dealer.

Remove nozzle from the end of the wand using the

alien wrench included with the kit or a 2mm or 5/64

alien wrench.

V.

Use the wire included in the kit or a small paper clip

to free the foreign materials clogging or restricting the

nozzle.

clear obstruction.

Remove additional debris by back flushing water sup

ply through wand. Back flush between 30 to 60 sec

onds. Turn wand to stream spray and move nozzle

from low to high pressure v\4iile flushing.

NOZZLE MAINTENANCE

If the nozzle becomes restricted or clogged with foreign

materials, such as dirt, excessive pump pressure may

develop. A partially clogged nozzle can cause a pulsing

sensation during use. This generally is not a pump relat

ed problem, but rather a clogged or partially restricted

nozzle.

If the nozzle becomes clogged or partially restricted,

immediately clean the nozzle with the kit included with

your pressure washer by following these instructions:

• Shut off the engine and turn off the water supply.

• Separate the wand from the gun.

• Rotate to stream setting.

Reinstall nozzle into wand. DO NOT overtighten.

Reconnect wand extension to spray gun.

Reconnect the water supply, turn ON the water, and

start the engine.

Test the pressure washer by operating with nozzle in

the high and the low pressure positions.

12

Page 13

0-RING MAINTENANCE

Through the normal operation of your pressure washer,

0-Rings, which keep the connections of the hoses and

gun tight and leak-free may become worn or damaged.

Provided with your pressure washer is an 0-Ring

Maintenance Kit which provides replacement 0-Rings,

Rubber Washer and Quick Connect filter.

Parts in the 0-Ring Kit Include:

• 1 0-Ring (p/£97837) for the end of the spray gun

connection between gun and high/low spray wand.

2 0-Rings (p/n B2264) for the ends of the high pres

sure hose.

1 O-Ring (p/n B2386) for the outside of the Male

Quick-Connect.

1 Water Inlet Screen (p/n B2384) for the Female

Quick-Connect.

To remove a worn or damaged O-Ring:

• Use a small flathead screwdriver to get underneath

the O-Ring and pry it off.

Note: The above two 0-Rings are close in size. Please

match carefully to assure proper O-Ring usage.

• 1 Rubber Washer (p/n B2385) for the inside of the

Male Quick-Connect.

13

Page 14

STORAGE

AFTER EACH USE

Water should not remain in the unit for long periods of time.

Sediments of minerals can deposit on pump parts and

“freeze” pump action. Follow these procedures after every

use:

• Flush detergent hose by placing the injector filter into

a pail «f clear water while running Pressure Washer

with nozzle in low pressure mode. Flush until you can

see clear water running through the tube.

• Shut off the engine and let it cool, then remove all

hoses.

CAUTION: Be sure throttle lever is in

“STOP” position before you continue. If

you start engine without the proper water

supply connected, you can damage the

pump.

________________________________

Empty the pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most of the

liquid in the pump.

Coil the high pressure hose and inspect it for damage.

Cuts in the hose or fraying of it could result in leaks

and loss of pressure. Should any damage be found,

replace the hose. DO NOT attempt to repair a dam

aged hose. Replace the hose with the genuine

Craftsman part.

Drain water from hose and properly hang it on the

wire support provided on the guide handie.

DANGER: NEVER store engine with fuel in

tank indoors or in enclosed, poorly ventilat

ed areas where fumes may reach an open

flame, spark or pilot light as on a furnace,

water heater, clothes dryer or other gas

appliance.

• Store in a clean, dry area.

________________________

WINTER STORAGE

CAUTION: You must protect your unit

from freezing temperatures. Failure to do so

will permanently damage your pump and

render your unit inoperable.

To protect the unit from freezing temperatures:

• Draw windshield washer fluid into the pump by pour

ing the washer fluid into a 3-foot section of garden

hose connected to the inlet adapter and pulling the

recoil handle twice.

LONG TERM STORAGE

If you do not plan to use the Pressure Washer for more than

30 days, you must prepare the engine for long term storage.

Note: As always, prepare the pressure washer pump as

you would after each use.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel fil

ter, fuel hose or tank during storage. Also, experience

indicates that alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture which leads to .

separation and formation of acids during storage. Acidic

gas can damage the fuel system of an engine while in

storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow these

instructions;

PROTECT FUEL SYSTEM

DANGER: Drain fuel into approved con

tainer outdoors, away from o^n flame. Be

sure engine is cool. Do not smoke.

• Remove all gasoline from the fuel tank to prevent gum

deposits from forming on these parts and causing pos

sible malfunction of engine.

• Run engine until engine stops from lack of fuel. Make

sure you have water supply to pump inlet connected

and turned ON.

CHANGE OIL

While engine is still warm, drain oil from crankcase. Refill

with recommended grade. (See Changing Oil Level on

Page 11.)

OIL CYLINDER BORE

• Remove spark plug and pour about 1/2 ounce (15ml)

of engine oil into the cylinder. Cover spark plug hole

CAUTION: Avoid spray from spark plug

hole when cranking engine slowly.

with rag. Crank slowly to distribute oil.

• Install spark plug. Do not connect spark plug wire.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your unit indoors and cover it to give

protection from dust and dirt. BE SURE TO EMPTY

THE FUEL TANK.

• Cover your unit with a suitable protective cover that

does not retain moisture.

IMPORTANT: NEVER cover your pressure washer while

engine and exhaust area are warm.

14

Page 15

TROUBLESHOOTING

PROBLEM

Pump has following problems;

failure to produce pressure, or

erratic pressure, chattering, loss of

pressure, low water volume.

Detergent fails to mix with,

spray.

CAUSE

1. Nozzle in low pressure mode.

2. Water inlet is blocked. 2. Clear inlet

3. Inadequate water supply

4. Inlet hose is kinked or leaking 4. Straighten inlet hose, patch leak.

5. Clogged water inlet screen.

6. Water supply is over 140°F.

7. Outlet hose is blocked.

8. Outlet hose leaks. 8. Replace outlet hose if leaking.

9. Gun leaks.

10. Nozzle is obstructed.

11. Pump is faulty.

1. Detergent line is not submerged,

in detergent spray

2. Chemical filter is clogged.

3. Nozzle is in high pressure mode.

CORRECTION

1. Pull nozzle backward for high

pressure mode.

3. Provide adequate water flow at

least 2 gpm.

5. Replace / clean water inlet screen.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

9. Replace o-ring or gun if necessary.

10. Clear nozzle.

11. Contact Sears Service Department.

1. Insert chemical line into detergent.

2. Clean or replace filter/detergent

line.

3. Push nozzle fonivard for

low pressure mode.

Engine runs good when not spraying

but dies when you begin to spray.

Engine will not start; or starts

and runs rough 2. Out of gasoline.

Engine shuts down during

operation

Engine lacks power. Dirty air filter. Replace air filter.

Engine speed is too slow.

1. Dirty air cleaner

3. Stale gasoline.

4. Spark plug wire not connected

to spark plug.

5. Bad spark plug. 5. Replace spark plug.

6. Water in gasoline.

7. Overchoking or flooded

8. Excessively rich fuel mixture.

9. Intake valve stuck open or closed.

10. Engine has lost compression.

1. Out of gasoline. 1. Fill fuel tank.

2. Air filter dirty 2. Replace Air filter.

Contact Sears Service Department.

1. Clean or replace air cleaner.

2. Fill fuel tank.

3. Drain gas tank; fill with fresh fuel.

4. Connect wire to spark plug.

6. Drain gas tank; fill with fresh fuel.

7. Set engine throttle control lever to

fast position, choke in run position.

8. Contact Sears Service Department.

9. Contact Sears Service Department.

10. Contact Sears Service Department.

15

Page 16

PARTS

CRAFTSMAN 1800 PSi HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

615 o 230 Cs5

2271

562%

N

592 ®

3

9

y

REF. PART

NO. NO.

1 493260 Cylinder Assembly

2

293708

3 *299819

5 214626 Head-Cylinder

7*0272916 Gasket-Cylinder Head 307

8 495786 Breather Assembly

9*0272481

10 94650 Screw-Hex.

11

231685

13 94547 Screw-Hex.

51 *272199 Gasket-Intake

54 94526 Screw-Hex.

116 *280393 Seal-O-Ring

116A *280966

Included in Gasket Set-Part Number 497316.

Included in Carburetor Kit-Pait Number 498260.

DESCRIPTION

Bushing

Seal-Oil 284

Gasket-Breather 383

Tube-Breather

Seal-O-Ring

______________________________★ REQUIRES SPECIAL TOOLS

11058 OWNER’S MANUAL I ffsTfSIcnomWAI^^^^^^

REF PART

NO. NO. DESCRIPTION

227

492349 Lever-Governor

230

67072 Washer

94511 Screw-Shoulder

306

224324 Shield-Cylinder

94515 Screw-Hex.

337

802592 Plug-Spark

89838 Wrench-Spark Plug

523 495264 Dipstick

525

495265 Tube-ai Fill

562

92613 Bolt-Carriage

584

224328 Baffle-Cylinder

585

*272238

592 231082

615 94474

Assemblies include all parts siwwn in frames.

Gasket-Breather

Nut-Hex.

Retainer

* Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Vblve Overhaul Gasket SetrPart No. 498528.

REF PART

NO. NO.

616 263175

625

497465

635 66538

847 495263

869

213512

870 213513

871 262001

273693

1058

DESCRIPTION

Crank-Govomor

ManifokNntake

Boot-Spark Plug

Dipstld^ube

Assembly

Seat-Valve

(Intake)

Seat-Valve

(Exhaust)

Bushing-^uide

(Exhaust Valve)

-----

Note —

63709 Bushing-Guide

(Intake Valve)

Owner's Manual

16

Page 17

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

REF.

NO.

PART

NO. DESCRIPTION

16 498571 Crankshaft 28

222698 Key-Flywheel (Standard)

24

499429 Piston Assembly

25

26 499425 Ring Set 32 94699 Screw-Hex. 146 94388 Key-Timing

27

(Standard) (Standard) 45

(Standard)

263190 Lock-Piston Pin

REF.

PART

NO.

29 499424 Rod-Connecting 40 93312

33 262651 Valve-Exhaust 741 262598 Gear-Timing

NO. DESCRIPTION

499423 Pin-Piston

REF.

NO.

34 262652

35

PART

NO. DESCRIPTION

262224 Spring-Valve

262204

Valve-Intake

Retainer-Valve

Tappet-VSIve

ir Induded in Gasket Set-Part Number 497316.

• Included in Carburetor Kit-Part Number 498260.

♦ Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overhaul Gasket Set-Part No. 498526.

Assemblies Include all narts shown In frames.

77

Page 18

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

REF.

NO.

* Included in Gasket Set-Part Nunn>er 497316.

• Included in Carburetor Kit-Pait Number 498260.

PART

NO.

4 493279 Sump-Engine

12 *272198 Gasket-Crankcase

15 94720 Plug-on Drain

DESCRIPTION

REF.

NO.

PART

NO.

20 *399781 Seal-Oil

22 94220 Screw-Hex.

DESCRIPTION

4 Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overhaul Gasket Set-Part No. 498528.

REF.

NO.

PART

NO.

43 493737 Govemor/Oil Slinger

46 498275 Gear-Cam

DESCRIPTION

Assemblies include all parts shown in frames.

18

Page 19

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

124

REF.

NO.

104 *231371 Pin-Float Hinge

108 223471 Valve-Choke

110 *♦ Seal-O-Ring

117 498978 Jet-Main

w Included in Gasket Set-Part Number 497316.

• IrKhided in Carburetor Kit-Part Number 498260.

PART

NO.

94 *493765 Valve-Idle At^ustment

95 94098 Screw-Slotted

98 398185 Screw-Idle Speed

DESCRIPTION

(Sold in Kit Only)

(Standard)

497315 JetT-Main

(High Altitude)

REF.

NO.

PART

NO.

124 94525

125 499059

127 *

130 223470

131 493267

133 398187

134 *398188

137 *♦

DESCRIPTION

Screw-Hex.

Carburetor

Plug-Welch

(Sold in KH Only)

Valve-Throttle

Shatt-Throttle

Float-Carburetor

Valve-Needle

(Includes Seat)

Gasket-Float Bowl

(Sold in Kit Only)

♦ Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overhaul Gasket Set-Part No. 498528.

REF.

NO.

PART

NO. DESCRIPTION

141 494218 Shaft-Choke

617 **270344 Seal-Intake Manifold

634 *• Washer

975 493640 Bowl-Roat

(Sold in Kit Only)

Assemblies include ail parts shown In frames.

19

Page 20

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

930

843

356

ctMi-6. 670A'

1871

333

334?

851

267

REF.

NO.

181 397974

187 298049 Line-Fuel

188

1B8A 398540

202 262579

209 692488

* Included in Gasket Set-Part Number 497316.

• Included in Cartxiretor Kit-Part Number 498^.

PART

NO.

65 94696

94644

DESCRIPTION

Screw-Phillips

Cap-Fuel Tank

(Cut To Required

Length)

Screw-^ex.

Screw-Shoulder

Link-Mechanical Gov.

Spring-Governor

Assemblies include all parts shown in frames.

REF

NO.

PART

NO. DESCRIPTION

265

213146 Clamp-Casing

267

94694 Screw-Slotted Hex.

284

94511 Screw-Shoulder

333

802574 Armature-Magneto

334

94731 Screw-Hex

356

497833 Wire-Stop

601

95162 Clamp-Hose

(Green)

20

REF

NO.

670A

^ IrKkJded in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overbaul Gasket Set-Part No. 498528.

PART

NO.

620

499737

621

396847 Switch-Stop

670

A493823 Spacer

280512 Spacer-Fuel Tank

843

272616

930

497233

972

495224 Tank-Fuel

DESCRIPTION

Bracket-Control

Sleeve-Lever

Cover-Blower Housirv

Page 21

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

969^4

968

332

1036 LABEL KIT-EMISSIONI

REF.

NO.

161

300

304

305

* Included in Gasket Set-Part Number 497316.

• Included in Carburetor Kit-Part Nimtber 498260.

PART

NO. DESCRIPTION

492893 Flywheel 332

23

224511 Guard-Flywheel 346

37

223664 Lock-Muiner Screw 455

81

496116 Base-^r Cleaner 529 281299 Grommet 971A

163a««272653 Gasket-Air Cleaner

496106 Muffler-Exhaust

493294 Housing-Blower

94744 Screw-Hex.

Assrsmblies include all parts shown In frames.

REF.

NO.

PART

NO. DESCRIPTION

92284 Nut-Flywheel

94602 Screw-Hex.

225121 Cup-Flywheel

613 94231 Screw-Shoulder 974

632 494224 Guard-Muffler

967

491588 Fitter-Air

^ Itrcluded in Carburetor Gasket Set-Part Number 498261.

0 Irrduded in Valve Overhaul Gasket Set-Part No. 498528.

REF.

21

NO.

968

969

971

976

1036

PART

NO.

281340 Cover-Air Cleaner

94872

94873

94749

224815

496115

499341

DESCRIPTION

Screw-Slotted Hex.

Screw-Hex.

Screw-Hex.

Bracket-Support

Primer-Carburetor

Lable Kit-Emission

Page 22

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

REF.

NO.

★ Included in Gasket Set-Part Number 497316.

• Included in Carburetor Kit-Part Number 498260.

PART

NO.

55

497440 Housing-Rewind

58

280399 Rope-Starter

DESCRIPTION

Starter

(Cut To Required

Length)

REF.

NO.

PART

NO.

60 281434 Grip-Starter Rope

65A 94686 Screw-Hex.

144 498144 Pulley-Hope Start

373 92987 Nut-Hex.

456 281503 Retainer-Spring

DESCRIPTION

♦ Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overhaul Gasket Set-Part No. 498528.

REF.

NO.

PART

NO.

459 281505 Pawl-Ratchet

461 94943 Screw-Shoulder

608 497680 Starter-Rewind

689 263073 Spring-Friction

DESCRIPTION

Assemblies Include all parts shown in frames.

22

Page 23

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

BRIGGS & STRATTON 4-CYCLE ENGINE 12F802-2407-E1

REF.

NO.

104 *2313Л

110*^

* Included in Gasket Set-Part Number 497316.

* Included in Carburetor Kit-Part Number 498260.

PART

NO. DESCRIPTION

3 A299819

7*0272916

9*0272481

12 *272198

20 *399781

51 *272199

94 *493765

116 *280393

116A *280966

Seal-Oil

Gasket-Cylinder Head

Gasket-Breather

Gasket-Crankcase

Seat-Oii

Gasket-Intake

Valve-Idle Adjustment

Pin-Float Hinge

Washer-Bowl

(Sold in Kit Only)

Seat-O-Ring

Seat-O-Ring

REF.

NO.

PART

NO. DESCRIPTION

121 498260 Carburetor Kit

127 • Plug-Welch

134 *398188 Valve-Needle

137 *♦ Gasket-6owl

163**^272653 Gasket-Air Cleaner

358 497316 Gasket Set

585 *272238 Gasket-Breather

(Sold in Kit Only)

(Includes Seal)

(Sold in Kit Only)

♦ Included in Carburetor Gasket Set-Part Number 498261.

0 Included in Valve Overhaul Gasket Set-Part No. 498528.

REF.

NO.

PART

NO.

617*^270344 SeaMntake Manifold

634 *♦ Washer-Shaft

670 *493823 Spacer

977 498261 Gasket Set

1095 498528 Gasket Set-Valve

DESCRIPTION

(Sold in KH Only)

(Includes 2)

Carburetor

Overhaul

Assemblies include all parts shown in frames.

25

Page 24

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

24

Page 25

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14 21206

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47 97009

PART NO.

21416D LEG, VS PW

B2200

96307

B1793D BASE, VSPW

97998

97769

20441

B1819

81895

B1024D GUARD, Hose

30809

B1786

97741

75402

52858

A1408

21782

21781

87841

39414

B1735

B1880

A1040B HOSE, Chemical

A1041

B1820

98300

B1797 FASTENER, Clip

48031G

B1262A

97100

91373

79552

B2157D

97178

99369

97082

97912

B1969

97566

98317B

98541

B1459

21208

B2382

B1818

DESCRIPTION.

DECAL, Instructions

DECAL, 1-800 Number

BOLT, Eye 1

CUP, Gun

SCREW, 1/4” -14 Self Driller

DECAL, Logo 1800 PSI

CAP, Tubing 3/4”square 4

GROMMET, Chem Hose 1

BILLBOARD 1

ASSY, PWAxle 1

TIRE, 2” X 8” Black Mag 2

PUSHNUT, 1/2” 2

NUT, M8 Locking Flange

CAP, Quick Disconnet 1

QUICK DISCONNECT, Female 1

QUICK DISCONNECT, Male 1

MOUNT, Rubber Foot 2

HHCS, M8X 1.25X35 Long 2

STUD, Double Ended 3

NUT, with Washer

FILTER, Chemical Hose 1

ENGINE, B & S 4.5 HP Quantum

SEAL, Engine Donut

CLAMP, Hose 3/16”

ASSY. Pumo EG w/ Thermal 1

CAP, High Pressure

DECAL, Data

OVERLAMINATE, Decal

HANDLE, VS PW

KNOB, PW Handle 2

PLATE, S.S. Wear

CLIP, Holding Handle

BOLT, 1/4”-20 X 2.25" Carriage

HOSE, 1/4” X 25’

HANG TAG, Nozzle

WAND, Adjustable Nozzle

GUN, High Pressure

CAP, Vinyl Black

WIREFORM

KIT, Maintenance 0-Ring *

MANUAL

KIT, Cleaning Nozzle

QTY.

2

1

1

1

1

16

1

1

2

3

1

1

1

4

1

T”

1

1

1

2

2

1

1

1

1

1

2

1

1

1

1

25

Page 26

CRAFTSMAN 1800 PSI HIGH PRESSURE WASHER 580.761800

26

Page 27

CRAFTSMAN 1800 PSI MAQUINA LAVADORA DE ALTA PRESION 580.761800

PARA LISTE DE PARTES

VEA PAGINA 27

VERSION DE INGLES

27

Page 28

Sears se complace en ofrecer a sus clientes ser

vicio de reparación de aparatos electro-domésti

cos y electrónicos de todas las marcas.

En Sears, usted puede contar con operadores en

español, a los que puede llamar sin cargo

alguno.

Para pedir servicio de reparación

^ a domicilio,

Llamme 24 horas al día., 7 días a la semana

1-800-676-5811

I

Para ordernar piezas con entrega

a domicilio.

Llame de 7 am a 7 pm, 7 días a la semana

1-800-659-7084

REPAIR SERVICES

America's Repair Specialists

Loading...

Loading...