Page 1

Operator's Manual

3000 PSi MAX* @ 2.4 GPlVl

2600 PSI @ 2.7 GPlVl MAX*

PRESSURE WASHER

Model No. 580.754880

®

- Safety

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CT)

- Assembly

- Operation

WARNING

Before using this product, read this

manual and follow all Safety Rules

and Operating Instructions.

* This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association

(PWMA) standard PW101-2010 (Testing and Rating Performance of Pressure Washers).

* Esta limpiadora a presi6n esta clasificada conforme a la norma PW101-2010 (comprobaci6n y clasificaci6n de rendimiento de limpiadoras

a presi6n) de la Asociaci6n de fabricantes de bombas a presi6n (Pressure Washer Manufacturers Association, PWMA).

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

Part No. 80008032 Rev A (12/13/2013)

Antes de utilizar el producto, lea este

manual y siga todas las Reglas de

Seguridad e Instrucciones de Uso.

ADVERTENCIA

- Maintenance

" Parts

- Espa_ol, p. 36

Page 2

CRAFTSMAN TWO YEAR FULL WARRANTY

FOR TWO YEARS from the date of purchase, this product is warranted against any defects in material or

workmanship. Defective product will receive free repair or replacement if repair is unavailable.

For warranty coverage details to obtain free repair or replacement, visit the web site: www.craftsman.com

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

• Expendable itemsthat can wear out from normal use within the warranty period, such as spray guns, hoses,

nozzle extensions, nozzles, spray tips. filters or spark plugs.

Product damage resulting from user attempts at product modification or repair or caused by product

accessories.

Repairs necessary because of accident or failure to operate or maintain the product according to aH supplied

instructions.

Preventive maintenance, or repairs necessary due to improper fue_mixture, contaminated or stale fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, _L 60179

Congratulations on making a smart purchase.

Your new Craftsman® product is designed and

manufactured for years of dependab!e operation. But

like aHproducts, it may require repair from time to time.

That's when having a Repair Protection Agreement can

save you money and aggravation.

Here's what the Repair Protection Agreement*

includes:

Expert service by our 10,000 professional repair

specialists

Unlimited service and no charge for parts and

labor on aHcovered repairs

Product replacement up to $1500 if your covered

product can't be fixed

Discount of 25% from regular price of service

and related installed parts not covered by the

agreement; also, 25% off regular price of preventive

maintenance check

Fast hempby phone = we call it Rapid Resolution =

phone support from a Sears representative. Think of

us as a "talking owner's manuaF.

© 2013

Once you purchase the Repair Protection Agreement,

a simple phone call is aHit takes for you to schedule

service. You can call anytime day or night, or schedule

a service appointment online.

The Repair Protection Agreement is a risk-free

purchase. If you cancel for any reason during the

product warranty period, we will provide a full refund.

Or, a prorated refund anytime after the product

warranty period expires. Purchase your Repair

Protection Agreement today!

Some _imitations and exclusions apply. For prices

and additional information in the U.SoA. call 1-800-

827-6655.

* Coverage in Canada varies on some items. For

full details, call Sears Canada at 1o800o361o6665o

Sears Installation Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other

major home items, in the U.S.A. or Canada call

1-800-4°MY-HOME®.

Page 3

Readthismanualcarefully and become

familiar with your pressure washer. Know

its applications, its limitations, and any

hazards involved.

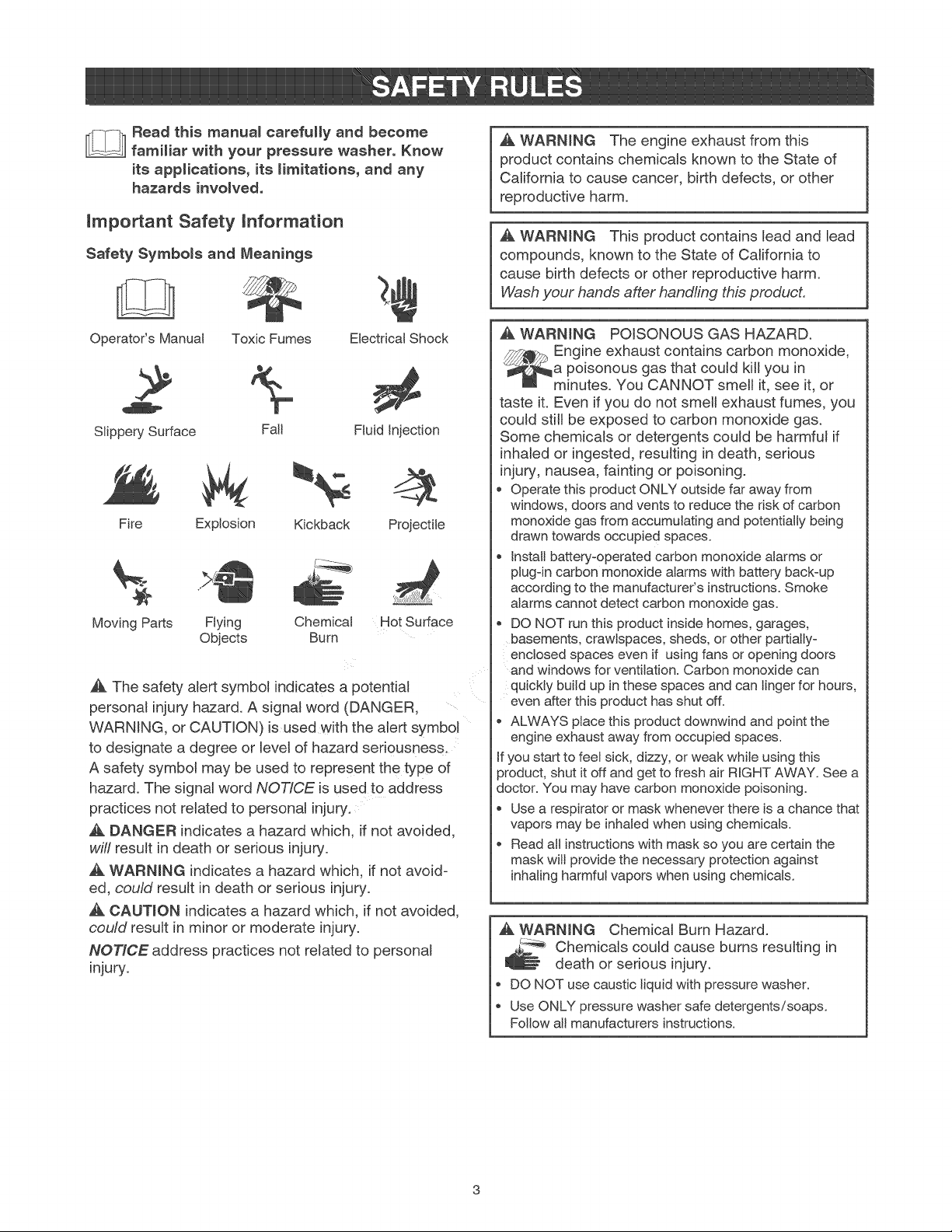

_mportant Safety _nformation

Safety Symbols and Meanings

_, WARNING The engine exhaust from this

product contains chemicals known to the State of

California to cause cancer, birth defects, or other

reproductive harm.

WARNmNG This product contains lead and lead

compounds, known to the State of California to

cause birth defects or other reproductive harm.

Wash your hands after handling this product.

Operator's Manual Toxic Fumes

Slippery Surface Fail Ftuid injection

Fire Explosion Kickback Projectile

Moving Parts Ftying Chemicat Rot Surface

Objects Burn

ElectricalShock

_k The safety alert symbol indicates a potential

personal injury hazard. A signal word (DANGER,

WARNING, or CAUTION) is used with the alert symbo_

to designate a degree or level of hazard senousness.

A safety symbol may be used to represent the type of

hazard. The signal word NOTICE is used to address

practices not related to personal injury.

_, DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoid =

ed, could result in death or serious injury.

CAUTION indicates a hazard which, ifnot avoided,

could result in minor or moderate injury.

NOTICE address practices not related to personal

injury.

_k WARNING POISONOUS GAS HAZARD.

Engine exhaust contains carbon monoxide,

a poisonous gas that could kill you in

minutes. You CANNOT smell it, see it, or

taste it. Even if you do not smell exhaust fumes, you

couJd stir be exposed to carbon monoxide gas.

Some chemicals or detergents could be harmful if

inhaled or ingested, resulting in death, serious

injury, nausea, fainting or poisoning.

o Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

Install battery-operated carbon monoxide atarms or

plug-in carbon monoxide atarms with battery back-up

according to the manufacturer's instructions. Smoke

alarms cannot detect carbon monoxide gas.

, DO NOT run this product inside homes, garages,

basements, crawtspaces, sheds, or other partially=

enclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut off.

, ALWAYS ptace this product downwind and point the

engine exhaust away from occupied spaces.

If you start to feel sick, dizzy, or weak while using this

sroduct, shut it off and get to fresh air RIGHT AWAY. See a

doctor. You may have carbon monoxide poisoning.

, Use a respirator or mask whenever there is a chance that

vapors may be inhated when using chemicals.

, Read atl instructions with mask so you are certain the

mask will provide the necessary protection against

inhaling harmful vapors when using chemicals.

WARNING Chemical Burn Hazard.

_> Chemicals could cause burns resulting in

death or serious injury.

DONOT usecaustic liquid with pressurewasher.

Use ONLYpressure washer safe detergents/soaps.

Followall manufacturersinstructions.

Page 4

WARNING Starter cord kickback (rapid

_, _,. retraction) will pull hand and arm toward

engine faster than you can let go which

could cause broken bones, fractures,

bruises, or sprains resulting in serious injury.

, NEVER pull starter cord without first relieving spray gun

pressure.

When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

After each starting attempt, where engine fails to run,

always point spray gun in safe direction, press red button

and squeeze spray gun trigger to release high pressure.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

A WARNING Risk of electrocution.

Contact with power source could cause

electric shock or burn resulting in death or

serious injury.

, NEVER spraynear powersource.

_, WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

If cut by fluid, call physician immediately. DO NOT treat

as a simple cut.

DO NOT allow CHILDREN to operate pressure washer.

NEVER repair high pressure hose. Replace it.

NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

NEVER connect high pressure hose to nozzle extension.

Keep high pressure hose connected to pump and Spray

gun while system is pressurized.

DO NOT lift or tilt surface cleaner from horizontal surface

while connected to spray gun. Release spray gun trigger

prior to lifting or tilting.

ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

, NEVER aim spray gun at people, animals, or plants.

DO NOT secure spray gun in open position.

DO NOT leave spray gun unattended while machine is

running.

NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

Always be certain spray gun, nozzles and accessories

are correctly attached.

_k WARNING Fuel and its vapors are extremely

explosive

_ flammable and which could

WHEN ADDING OR DRAINING FUEL

, Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

, Fill or drain fuel tank outdoors.

DO NOT overfill tank. Allow space for fuel expansion.

If fuel spills, wait until it evaporates before starting engine.

Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

Check fuel lines, tank, cap and fittings frequently for

cracks or leaks. Replace if necessary.

DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

, Ensuresparkplug, muffler,fuelcap, andair cleaner are in place.

DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

, DO NOT operate this product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

, DO NOT tip engine or equipment at angle which causes

fuel to spill.

, DO NOT spray flammable liquids.

WHEN TRANSPORTING,

MOVING OR REPAIRING EQUIPMENT

, Transport/move/repair with fuel tank EMPTY or with fuel

shutoff valve OFF.

, DO NOT tip engine or equipment at angle which causes

fuel to spill.

- Disconnect spark plug wire.

WHEN STORING FUEL OR EUIPMENT WITH FUEL IN TANK

Store away from furnaces, stoves, water heaters, clothes

dryers, or other appliances that have pilot light or other

ignition source because they could ignite fuel vapors.

WARNING Exhaust heat/gases could ignite

Contact with muffler area could cause burns

resulting in serious injury.

DO NOT touch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

Keep at least 5 feet (1.5 m) of clearance on all sides of

pressure washer including overhead.

It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forest-

covered, brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark arrester, as

defined in Section 4442, maintained in effective working

order. Other states or federal jurisdictions may have

similar taws.

Contact the original equipment manufacturer, retailer,

or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

Replacement parts must be the same and installed in the

same position as the original parts.

cause burns, fire or explosion

resulting in death or serious injury.

combustibles, structures or damage

fuel tank causing a fire, resulting in

death or serious injury.

Page 5

A.WARNINGUseofpressurewashercould

,_ createpuddlesandslippery

surfacescausingyoutofall

resultingindeathorseriousinjury.

Kickbackfromsprayguncouldcauseyoutofall

resultingindeathorseriousinjury.

, Operate pressure washer from a stable surface.

The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

Be extremely careful if you must use the pressure washer

from a ladder, scaffolding, or any other similar location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

_, WARNING Unintentional sparking could cause

fire or electric shock resulting in

death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

, Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

, Use approved spark plug tester.

DO NOT check for spark with spark plug removed.

A. WARNmNG Starter and other rotating parts

could entangle hands, hair, clothing, or

accessories resulting in serious injury.

, NEVER operate pressure washer without protective

housing or covers.

, DO NOT wear loose clothing, jewelry or anything that

could be caught in the starter or other rotating parts.

, Tie up tong hair and remove iewelry.

WARNmNG Risk of eye or bodily injury.

Spray could splash back or propel

objects resulting in serious injury.

, Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

, NEVER substitute safety gtasses or dry-condition

goggles for indirect vented safety goggles.

, Always wear protective clothing such as a tong-sleeved

shirt, tong pants and close4oed shoes.

, NEVER operate pressure washer when barefoot or

wearing sandals or shorts.

CAUTION Excessively high operating speeds

could result in minor injury.

Excessively low speeds impose a heavy load.

, DO NOT tamper with governor spring, links or other parts

to increase engine speed. Pressure washer supplies

correct rated pressure and flow when running at

governed speed.

, DO NOT modify pressure washer in any way.

NOTICE High pressure spray could damage fragile

items including glass.

, DO NOT point spray gun at glass when using MAX spray

pattern in selector nozzle.

, NEVER aim spray gun at plants.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

If you have questions about intended use, ask dealer or

contact qualified service center.

NEVER operate units with broken or missing parts, or with-

out protective housing or covers.

, DO NOT by-pass any safety device on this machine.

, DO NOT tamper with governed speed.

, DO NOT operate pressure washer above rated pressure.

, DO NOT modify pressure washer in any way.

, Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

, NEVER move machine by pulling on hoses. Use handle

provided on unit.

, This equipment is designed to be used with Sears

authorized parts ONLY. If equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes all risks and liabilities.

Page 6

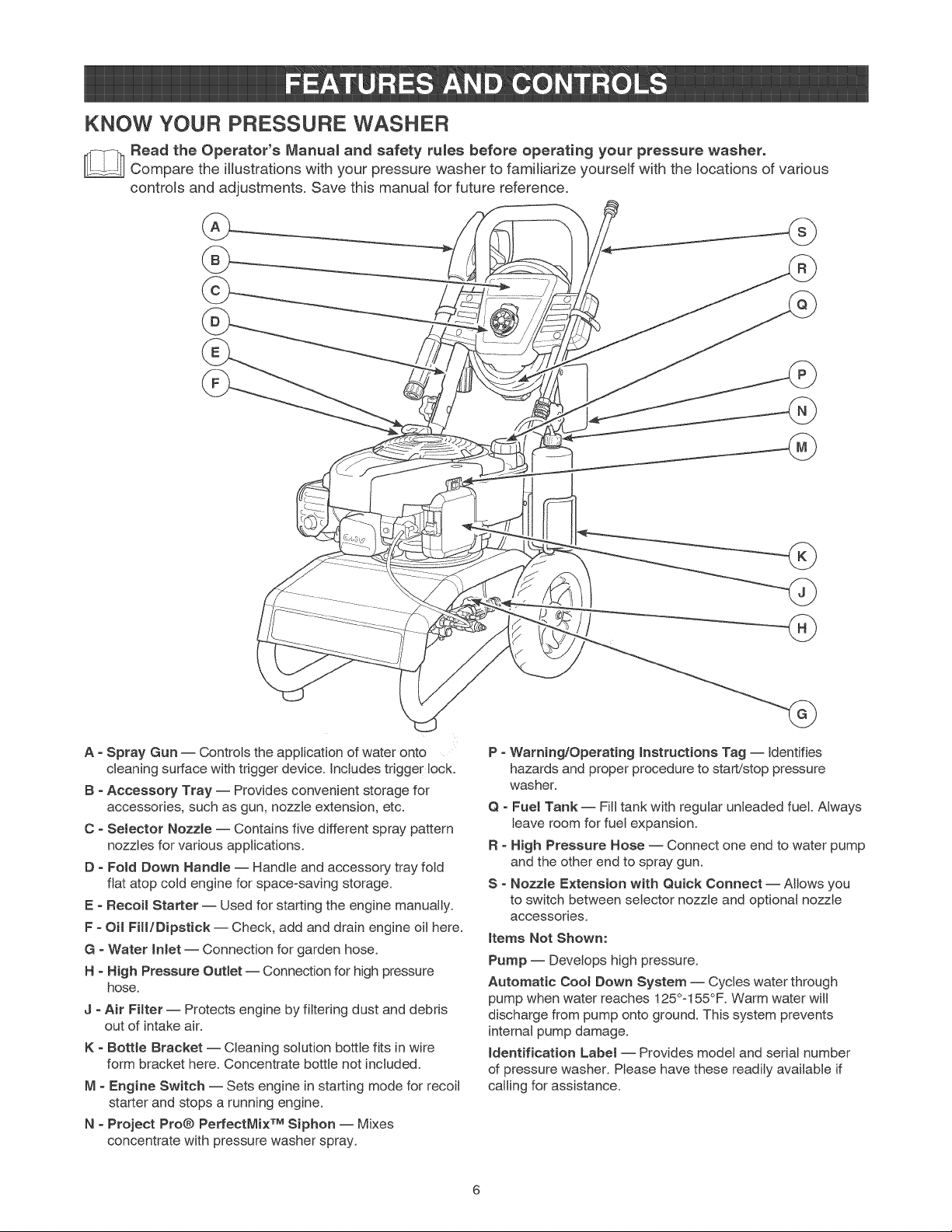

KNOW YOUR PRESSURE WASHER

Read the Operator's ManuaR and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various

controls and adjustments. Save this manual for future reference.

A - Spray Gun -- Controls the application of water onto

cleaning surface with trigger device, includes trigger lock.

B - Accessory "Fray -- Provides convenient storage for

accessories, such as gun, nozzle extension, etc.

C - SeJector Nozzle -- Contains five different spray pattern

nozztes for various applications.

D - FoJd Down Handle -- Handle and accessory tray fold

flat atop cold engine for space=saving storage.

E - Recoil Starter -- Used for starting the engine manually.

F - OH Fill/Dipstick -- Check, add and drain engine eil here.

G - Water Inlet -- Connection for garden hose.

H - High Pressure Outlet -- Connection for high pressure

hose.

J - Air Filter-- Protects engine by filtering dust and debris

out of intake air.

K - Bottle Bracket -- Cleaning solution bottle fits in wire

form bracket here. Concentrate bottle not included.

M - Engine Switch -- Sets engine in starting mode for recoil

starter and stops a running engine.

N - Project Pro@ PetfectMix TM Siphon -- Mixes

concentrate with pressure washer spray.

P - Warning!Operating instructions Tag -- Identifies

hazards and proper procedure to start!stop pressure

washer.

Q - Fuet Tank -- Fitl tank with regular unleaded fuel. Always

leave room for fuel expansion.

R - High Pressure Hose -- Connect one end to water pump

and the other end to spray gun.

S - NozzJe Extension with Quick Connect -- Allows you

to switch between selector nozzte and optional nozzle

accessories,

items Not Shown:

Pump -- Develops high pressure.

Automatic CooJ Down System -- Cycles water through

pump when water reaches 125°=155°F. Warm water will

discharge from pump onto ground. This system prevents

internal pump damage.

identification LabeJ -- Provides model and seriat number

of pressure washer. Please have these readily available if

calling for assistance.

Page 7

Your pressure washer requires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

if you have any problems with the assembly of

your pressure washer, please caNIthe pressure

washer he_p_ine at 1o800o222o3136.

UNPACK THE PRESSURE WASHER

1. Remove everything from carton except pressure

washer.

2. Open carton completely by cutting each corner

from top to bottom.

3. Remove pressure washer from carton.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the pressure washer helpline at

1o800o222o3136.

• Main Unit

• Handle

• Accessory Tray with Hose Wrap

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Oil Pouch

Bottle Bracket Wireform (2)

PerfectMix Siphoning Unit/Hose

Quick Connect Selector Nozzle

Parts Bag (which includes the following):

Operator's Manual

Owner's Registration Card

Handle Fastening Hardware Kit (which includes):

Handle Bolts (2)

Carriage Bolt (2)

Plastic Knobs for Handle (2)

Plastic Knob (2)

Tree Clips (4)

Become familiar with each piece before assembling

the pressure washer, tdentify all contents with the

illustration on page 6. If any parts are missing or

damaged, call the pressure washer helpline at

1o800o222o3136.

ASSEMBUNG PRESSURE WASHER

Your Craftsman pressure washer will need assembly

before operation:

1. Fill out and send in registration card.

2. Attach handle and accessory tray.

3. Connect detergent siphon hose to pump.

4. Add oil to engine crankcase.

5. Add fuel to fuel tank.

6. Connect pressure hose to spray gun and pump.

7. Connect water supply to pump.

8. Attach nozzle extension to spray gun.

9. Select/attach quick connect selector nozzle to

nozzle extension.

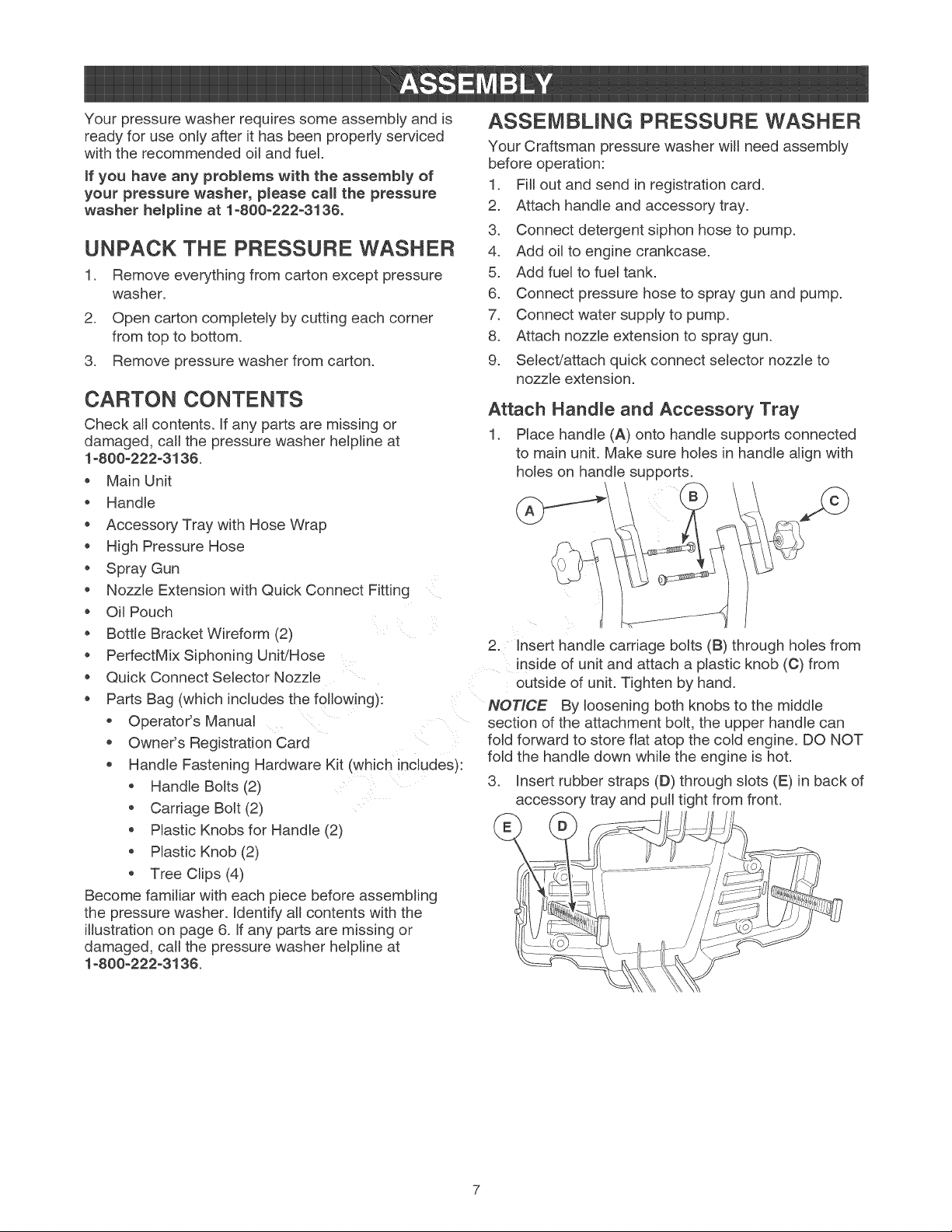

Attach Handle and Accessory Tray

1. Place handle (A) onto handle supports connected

to main unit. Make sure holes in handle align with

holes on handle supports.

2. Insert handle carriage bolts (B) through holes from

inside of unit and attach a plastic knob (C) from

outside of unit. Tighten by hand.

NOTICE By loosening both knobs to the middle

section of the attachment bolt, the upper handle can

fold forward to store flat atop the cold engine. DO NOT

fold the handle down while the engine is hot.

3 Insert rubber straps (D) through slots (E) in back of

accessory tray and pull tight from front.

Page 8

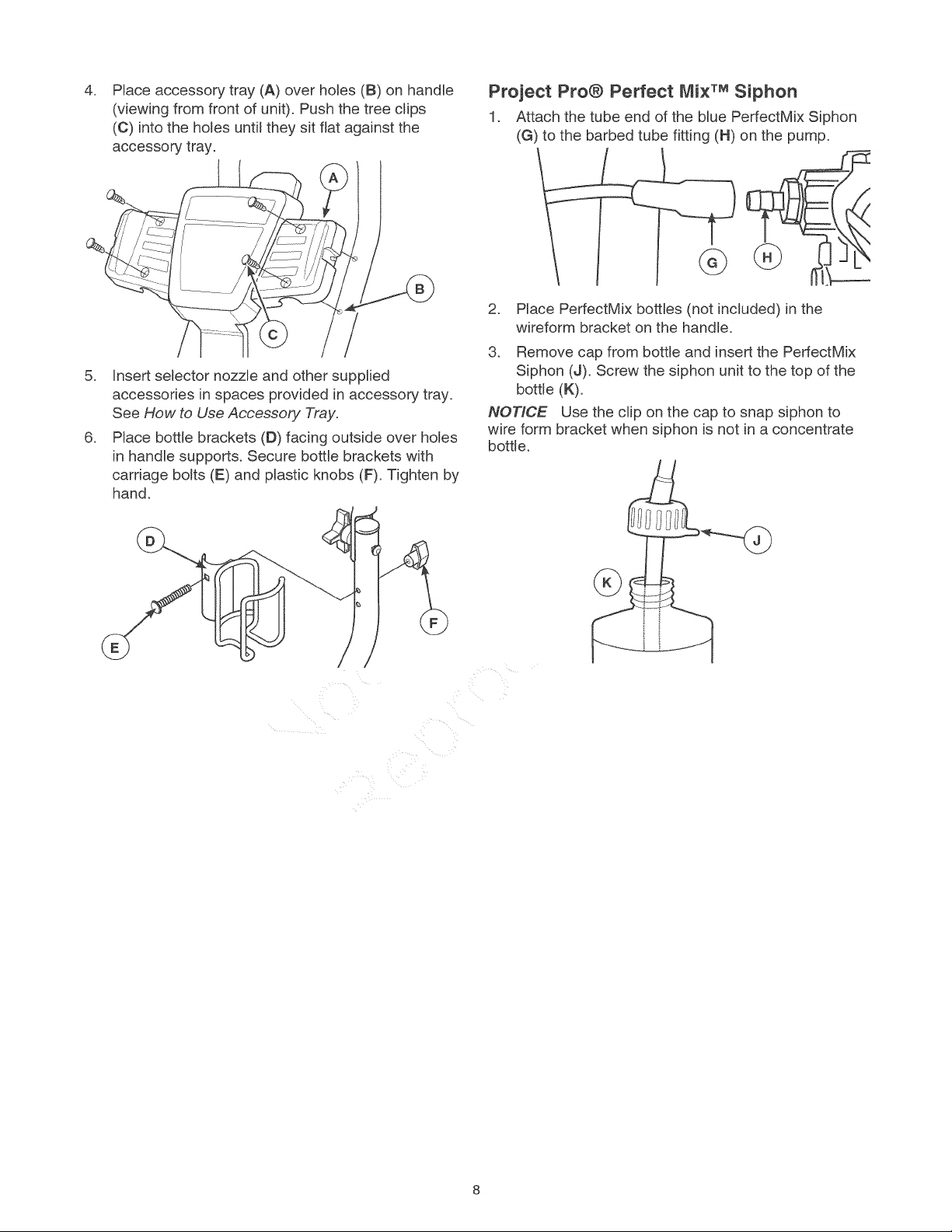

.

Place accessory tray (A) over holes (B) on handle

(viewing from front of unit). Push the tree clips

(C) into the holes until they sit flat against the

accessory tray.

5. Insert selector nozzle and other supplied

accessories in spaces provided in accessory tray.

See How to Use Accessory Tray.

6. Place bottle brackets (D) facing outside over holes

in handle supports. Secure bottle brackets with

carriage bolts (E) and plastic knobs (F). Tighten by

hand.

Project Pro@ Perfect Mix TMSiphon

1. Attach the tube end of the blue PerfectMix Siphon

(G) to the barbed tube fitting (H) on the pump.

.

Place PerfectMix bottles (not included) in the

wireform bracket on the handle.

3.

Remove cap from bottle and insert the PerfectMix

Siphon (J). Screw the siphon unit to the top of the

bottle (K).

NOTICE Use the clip on the cap to snap siphon to

wire form bracket when siphon is not in a concentrate

bottle.

Page 9

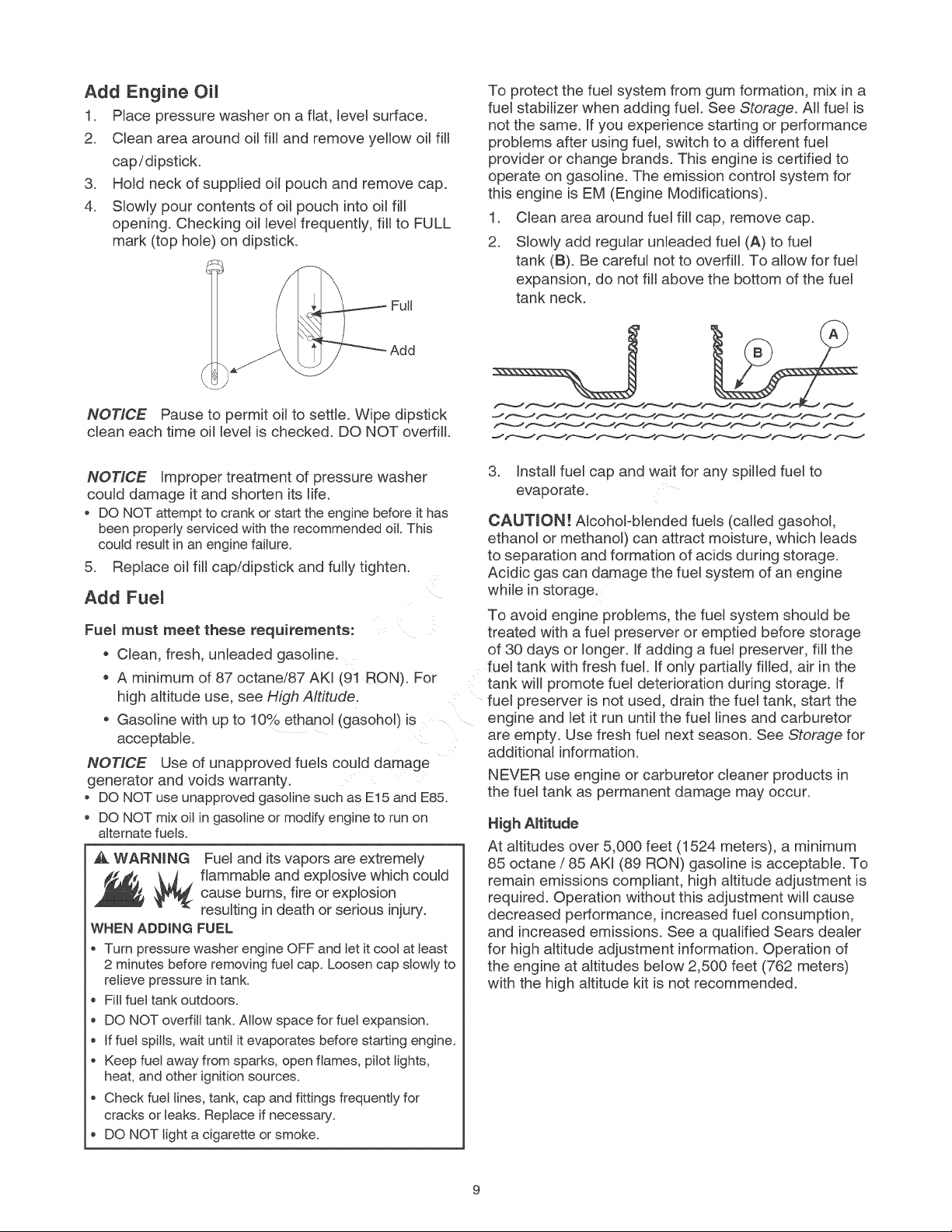

Add Engine Oil

1. Place pressure washer on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill

cap/dipstick.

3. Hold neck of supplied oil pouch and remove cap.

4. Slowly pour contents of oil pouch into oil fill

opening. Checking oil level frequently, fill to FULL

mark (top hole) on dipstick.

Full

NOTICE Pause to permit oil to settle. Wipe dipstick

clean each time oil level is checked. DO NOT overfill.

To protect the fuel system from gum formation, mix in a

fuel stabilizer when adding fuel. See Storage. All fuel is

not the same. If you experience starting or performance

problems after using fuel, switch to a different fuel

provider or change brands. This engine is certified to

operate on gasoline. The emission control system for

this engine is EM (Engine Modifications).

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel (A) to fuel

tank (B). Be careful not to overfill. To allow for fuel

expansion, do not fill above the bottom of the fuel

tank neck.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

o DO NOT attemptto crank or startthe engine before it has

been properly servicedwith the recommended oil. This

could result in anengine failure.

5. Replace oil fill cap/dipstick and fully tighten.

Add Fuel

Fue_ must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKJ (91 RON). For

high altitude use, see High Altitude.

• Gasoline with up to 10% ethanol (gasoho 0 is

acceptaMe.

NOTICE Use of unapproved fuels could damage

generator and voids warranty.

o DO NOT use unapprovedgasoline such as E15and E85.

, DO NOT mix oil in gasolineor modify engine to run on

alternatefuels.

WARNING Fuel and its vapors are extremely

_i flammable and explosive which could

WHEN ADDING FUEL

, Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap stowty to

relieve pressure in tank.

Fill fuel tank outdoors.

DO NOT overfill tank. Allow space for fuel expansion.

If fuel spills, wait until it evaporates before starting engine.

Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

Check fuel lines, tank, cap and fittings frequently for

cracks or leaks. Replace if necessary.

DO NOT light a cigarette or smoke.

cause burns, fire or explosion

resulting in death or serious injury.

3. Install fuel cap and wait for any spilled fuel to

evaporate.

CAUTION! Alcohol-Mended fuels (called gasohol,

ethanol or methanol) can attract moisture, which leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel system should be

treated with a fuel preserver or emptied before storage

of 30 days or longer, ff adding a fuel preserver, fill the

fuel tank with fresh fuel. If only partially filled, air in the

tank will promote fuel deterioration during storage, if

fuel preserver is not used, drain the fuel tank, start the

engine and let it run until the fuel lines and carburetor

are empty. Use fresh fuel next season. See Storage for

additional information.

NEVER use engine or carburetor cleaner products in

the fuel tank as permanent damage may occur.

High A_titude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane / 85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause

decreased performance, increased fuel consumption,

and increased emissions. See a qualified Sears dealer

for high a_titude adjustment information. Operation of

the engine at altitudes below 2,500 feet (762 meters)

with the high altitude kit is not recommended.

Page 10

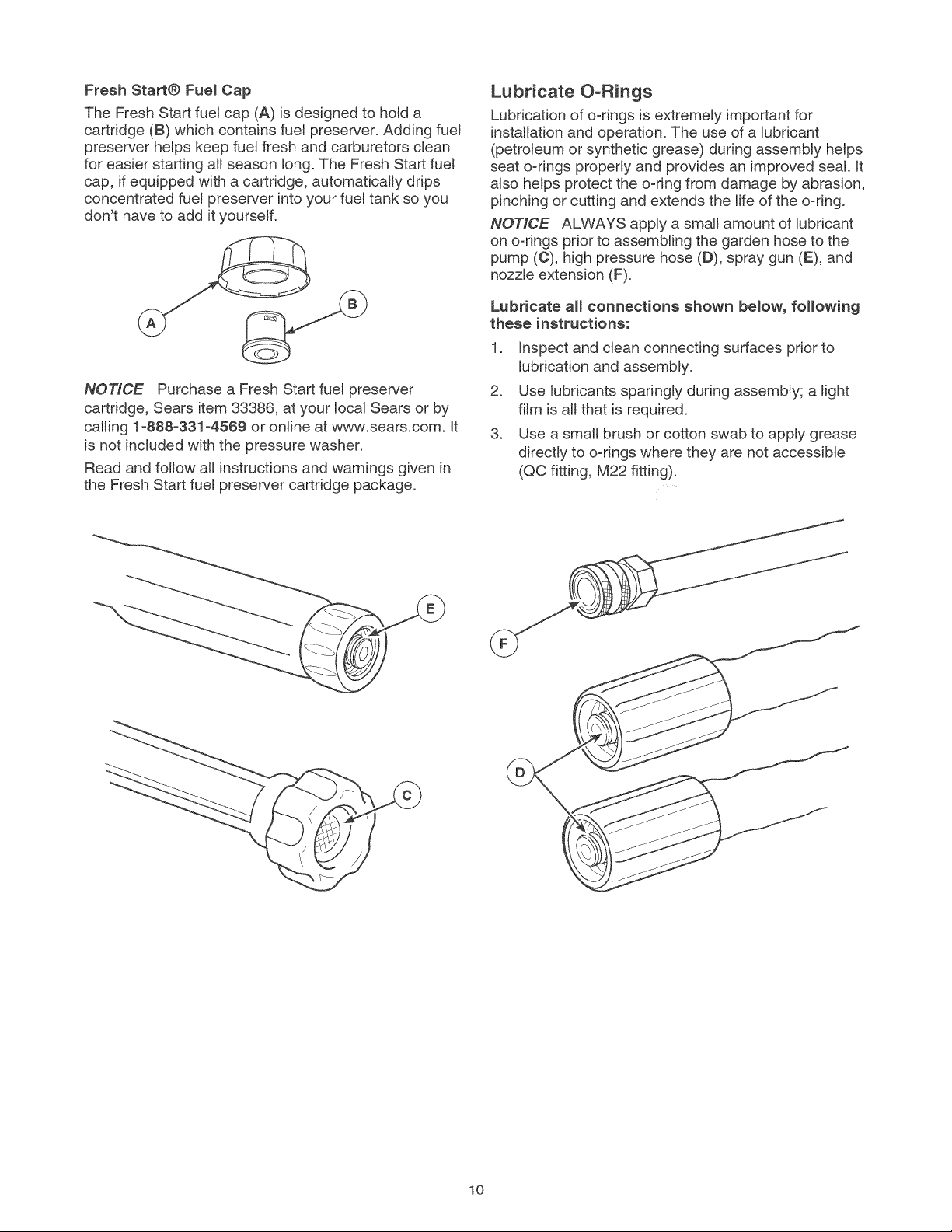

FreshStart@FuelCap

TheFreshStartfuelcap(A)isdesignedtoholda

cartridge(B)whichcontainsfuelpreserver.Addingfuel

preserverhelpskeepfuelfreshandcarburetorsclean

foreasierstartingallseasonlong.TheFreshStartfuel

cap,ifequippedwithacartridge,automaticallydrips

concentratedfuelpreserverintoyourfueltanksoyou

don'thavetoaddityourself.

NOTICE Purchase a Fresh Start fuel preserver

cartridge, Sears item 33386, at your local Sears or by

calling 1o888o331-4589 or online at www.sears.com. Mt

is not included with the pressure washer.

Read and follow all instructions and warnings given in

the Fresh Start fuel preserver cartridge package.

Lubricate O-Rings

Lubrication of o-rings is extremely important for

installation and operation. The use of a lubricant

(petroleum or synthetic grease) during assembly helps

seat o-rings properly and provides an improved seal. It

also helps protect the o-ring from damage by abrasion,

pinching or cutting and extends the life of the o-ring.

NOTICE ALWAYS apply a small amount of lubricant

on o-rings prior to assembling the garden hose to the

pump (C), high pressure hose (D), spray gun (E), and

nozzle extension (F).

Lubricate aH connections shown below, following

these instructions:

1. Inspect and clean connecting surfaces prior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light

film is aHthat is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings where they are not accessible

(QC fitting, M22 fitting).

10

Page 11

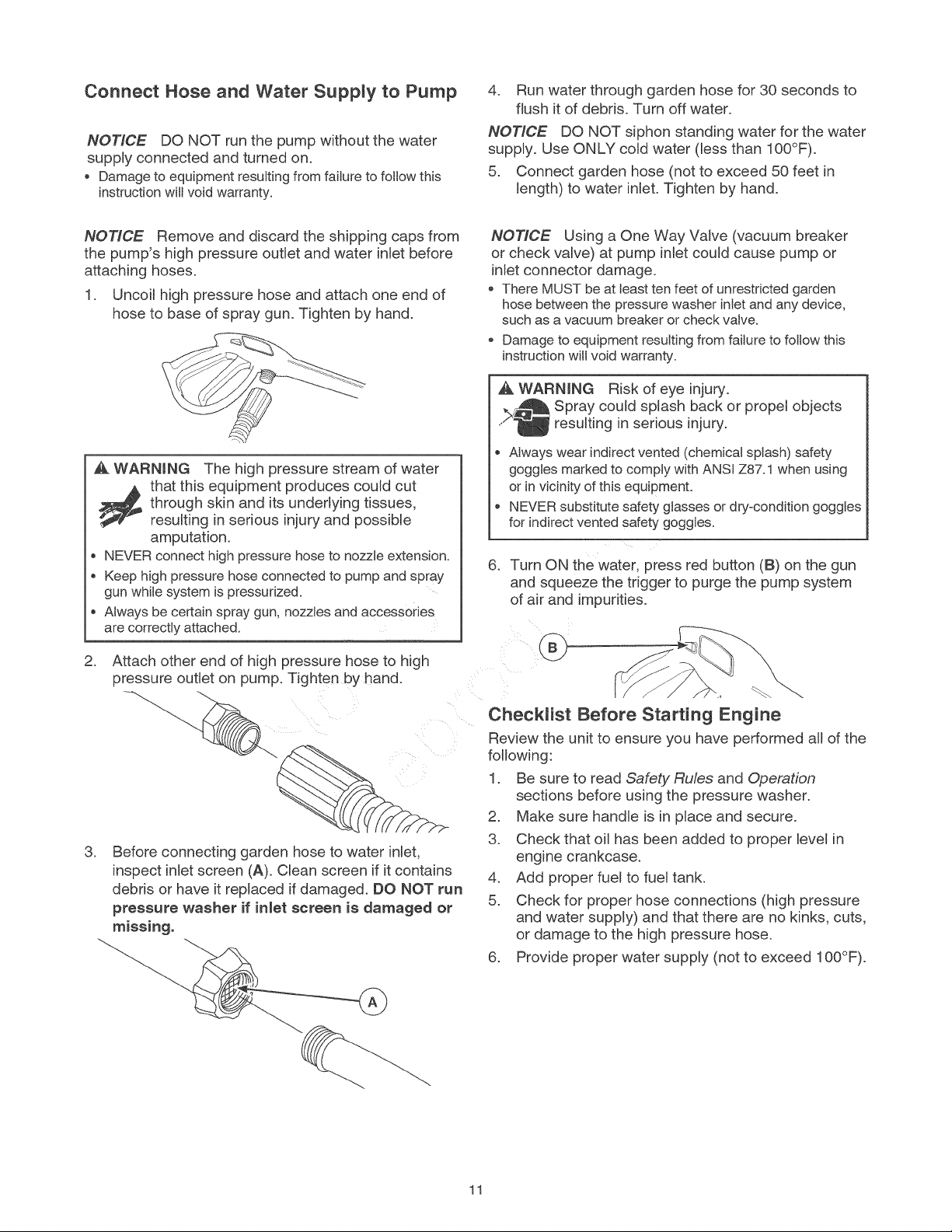

Connect Hose and Water Supply to Pump

NOTICE DO NOT run the pump without the water

supply connected and turned on.

o Damageto equipment resultingfrom failure to follow this

instruction willvoid warranty.

4. Run water through garden hose for 30 seconds to

flush it of debris. Turn off water.

NOTICE DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F).

5. Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

NOTICE Remove and discard the shipping caps from

the pump's high pressure outlet and water inlet before

attaching hoses.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

WARNING The high pressure stream of water

1_ that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

NEVER connecthigh pressurehoseto nozzleextension.

Keep high pressurehose connectedto pumpand spray

gun while systemis pressurized.

Alwaysbe certainspray gun. nozzlesand accessofles

are correctly attached.

2. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

NOTICE Using a One Way Valve (vacuum breaker

or check valve) at pump inlet could cause pump or

inlet connector damage.

There MUST be at least ten feet of unrestricted garden

hose between the pressure washer inlet and any device,

such as a vacuum breaker or check vatve.

Damage to equipment resulting from failure to follow this

instruction will void warranty.

_, WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

NEVER substitute safety gtasses or dry-condition goggles

for indirect vented safety goggtes.

6 Turn ON the water, press red button (B) on the gun

and squeeze the trigger to purge the pump system

of air and impurities,

3. Before connecting garden hose to water inlet,

inspect inlet screen (A). Clean screen if it contains

debris or have it replaced if damaged. DO NOT run

pressure washer if inlet screen is damaged or

missing.

Checklist Before Starting Engine

Review the unit to ensure you have performed all of the

following:

1 Be sure to read Safety Rules and Operation

sections before using the pressure washer.

2. Make sure handle is in place and secure.

3. Check that oil has been added to proper level in

engine crankcase.

4. Add proper fuel to fuel tank.

5. Check for proper hose connections (high pressure

and water supply) and that there are no kinks, cuts,

or damage to the high pressure hose.

6. Provide proper water supply (not to exceed 100°F).

11

Page 12

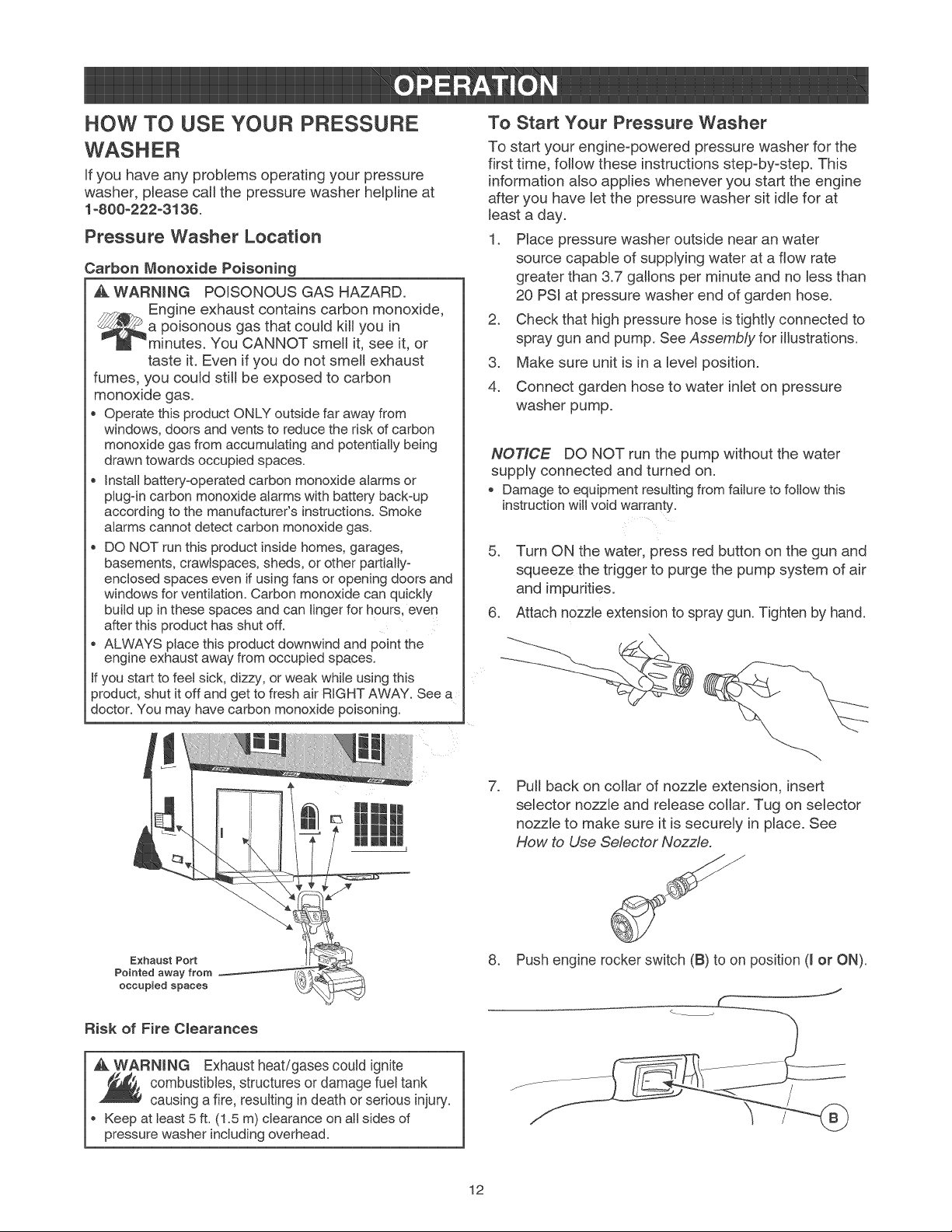

HOW TO USE YOUR PRESSURE

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

Pressure Washer Location

Carbon Monoxide Poisoning

WARNING POISONOUS GAS HAZARD.

Engine exhaust contains carbon monoxide,

a poisonous gas that could kill you in

minutes. You CANNOT smell it, see it, or

taste it. Even if you do not smell exhaust

fumes, you could still be exposed to carbon

monoxide gas.

, Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

, Install battery-operated carbon monoxide alarms or

plug-in carbon monoxide alarms with battery back-up

according to the manufacturer's instructions. Smoke

alarms cannot detect carbon monoxide gas.

, DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other partially-

enclosed spaces even if using fans or opening doors and

windows for ventilation. Carbon monoxide can quickly

build up in these spaces and can linger for hours, even

after this product has shut off.

, ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

If you start to feel sick, dizzy, or weak while using this

9roduct, shut it off and get to fresh air RIGHT AWAY. See a

doctor. You may have carbon monoxide poisoning.

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

information also applies whenever you start the engine

after you have let the pressure washer sit idle for at

least a day.

1. Place pressure washer outside near an water

source capable of supplying water at a flow rate

greater than 3.7 ga/ons per minute and no less than

20 PSI at pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected to

spray gun and pump. See Assemb(y for illustrations.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump.

NOTICE DO NOT run the pump without the water

supply connected and turned on.

Damageto equipment resulting from failure to follow this

instructionwillvoid warranty.

5. Turn ON the water, press red button on the gun and

squeeze the trigger to purge the pump system of air

and impurities.

6. Attach nozzle extension to spray gun. Tighten by hand.

Exhaust Port

Pointed away from

occupied spaces

Risk of Fire Clearances

_, WARNING Exhaust heat/gases could ignite

combustibles, structures or damagefuel tank

causing a fire, resulting indeath or serious injury.

o Keep at least5 ft. (1.5 m) clearance on all sides of

pressure washer includingoverhead.

7. Pul back on collar of nozzle extension, insert

selector nozzle and release collar. Tug on selector

nozzle to make sure it is securely in place. See

How to Use Selector Nozzle.

8. Push engine rocker switch (B) to on position (I or ON).

J

12

Page 13

NOTICE Before starting the pressure washer, be sure

,ou are wearing safety goggles as described below.

_, WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

o Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using or

in vicinity of this equipment.

NEVER substitute safety glasses or dry-condition goggles

for indirect vented safety goggles.

NOTICE This unit is equipped with a ReadyStart®

engine. A ReadyStart engine means there is no priming

or choking required.

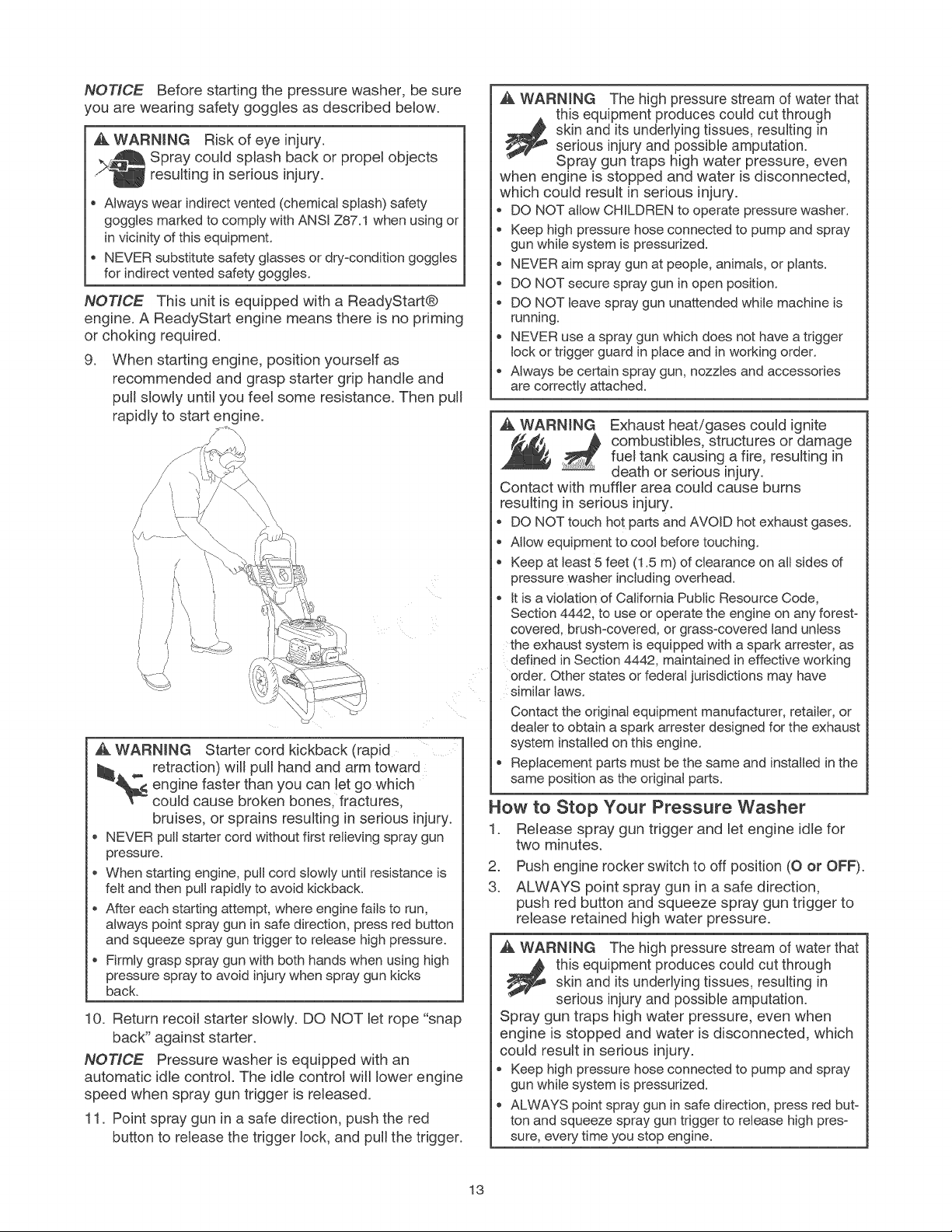

9. When starting engine, position yourself as

recommended and grasp starter grip handle and

pull slowly until you feel some resistance. Then pull

rapidly to start engine.

WARNING Starter cord kickback (rapid

retraction) will pull hand and arm toward

engine faster than you can let go which

could cause broken bones, fractures,

bruises, or sprains resulting in serious injury.

NEVER pull starter cord without first relieving spray gun

pressure.

When starting engine, pult cord slowly until resistance is

felt and then pull rapidty to avoid kickback.

After each starting attempt, where engine fails to run,

always point spray gun in safe direction, press red button

and squeeze spray gun trigger to release high pressure.

, Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

10. Return recoil starter slowly. DO NOT let rope "snap

back" against starter.

NOTICE Pressure washer is equipped with an

automatic idle control. The idle control will lower engine

speed when spray gun trigger is released.

11. Point spray gun in a safe direction, push the red

button to release the trigger lock, and pull the trigger.

WARNING The high pressure stream of water that

this equipment produces could cut through

:_ skin and its underlying tissues, resulting in

when engine is stopped and water is disconnected,

which could resuJt in serious injury.

_, WARNING Exhaust heat/gases could ignite

Contact with muffler area could cause burns

resulting in serious injury.

, Replacement parts must be the same and installed in the

serious injury and possible amputation.

Spray gun traps high water pressure, even

DO NOT allow CHILDREN to operate pressure washer.

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

NEVER aim spray gun at people, animals, or plants.

DO NOT secure spray gun in open position.

DO NOT leave spray gun unattended while machine is

running.

NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

Always be certain spray gun, nozzles and accessories

are correctly attached.

combustibles, structures or damage

fuel tank causing a fire, resulting in

death or serious injury.

DO NOT touch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

Keep at least 5 feet (1.5 m) of clearance on all sides of

pressure washer including overhead.

It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forest-

covered, brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark arrester, as

defined in Section 4442, maintained in effective working

order. Other states or federal jurisdictions may have

similar taws.

Contact the original equipment manufacturer, retailer, or

dealer to obtain a spark arrester designed for the exhaust

system installed on this engine.

same position as the original parts.

How to Stop Your Pressure Washer

1. Release spray gun trigger and let engine idle for

two minutes.

.

Push engine rocker switch to off position (0 or OFF).

3.

ALWAYS point spray gun in a safe direction,

push red button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water that

this equipment produces could cut through

skin and its underlying tissues, resulting in

serious injury and possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

Keep high pressurehose connectedto pumpand spray

gun whitesystem is pressurized.

ALWAYSpoint spraygun in safe direction, press redbut-

tonand squeeze spraygun trigger to release high pres-

sure, everytime youstop engine.

13

Page 14

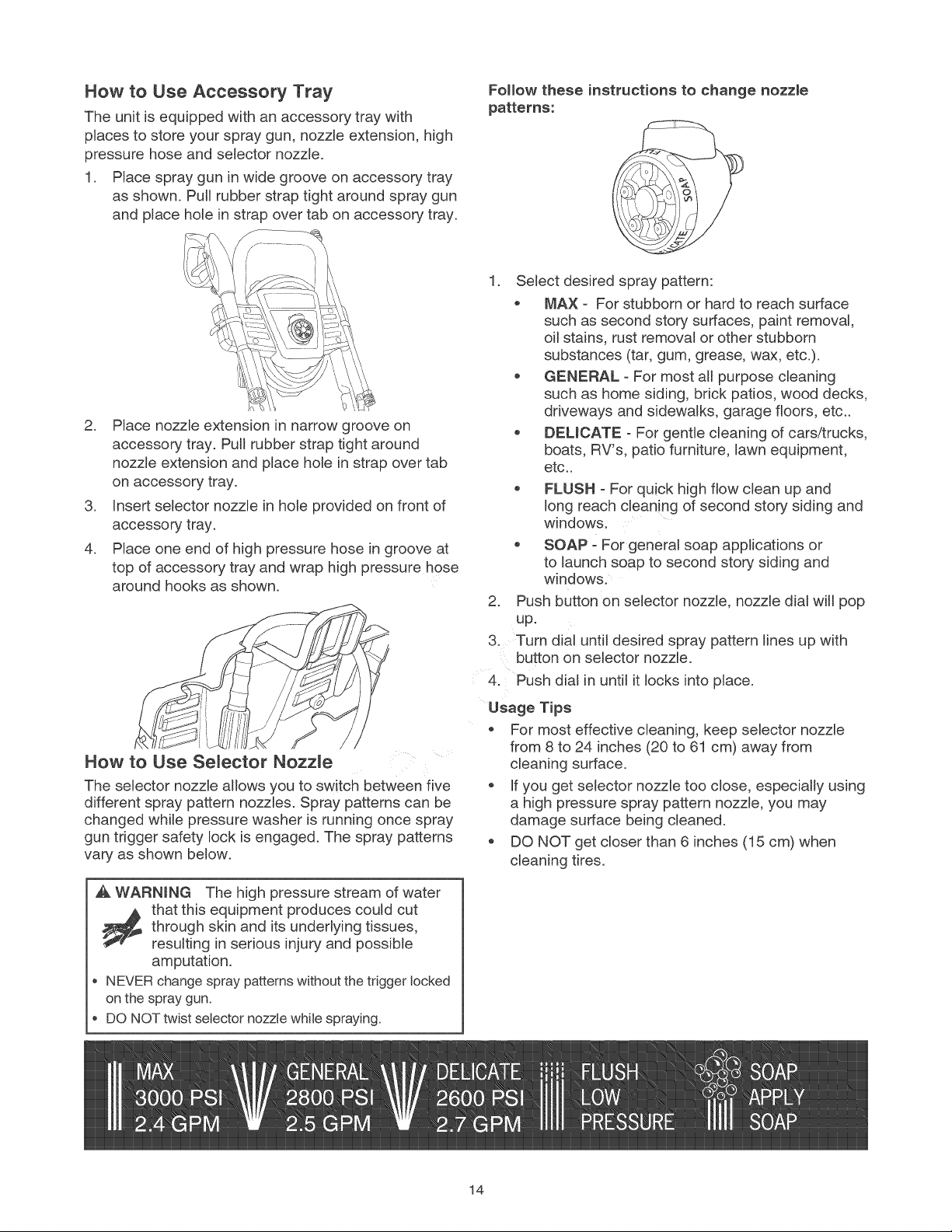

How to Use Accessory Tray

The unit is equipped with an accessory tray with

places to store your spray gun, nozzle extension, high

pressure hose and selector nozzle.

1. Place spray gun in wide groove on accessory tray

as shown. Pull rubber strap tight around spray gun

and place hole in strap over tab on accessory tray.

2. Place nozzle extension in narrow groove on

accessory tray. Pull rubber strap tight around

nozzle extension and place hole in strap over tab

on accessory tray.

3. insert selector nozzle in hole provided on front of

accessory tray.

4. Place one end of high pressure hose in groove at

top of accessory tray and wrap high pressure hose

around hooks as shown.

Follow these instructions to change nozzle

patterns:

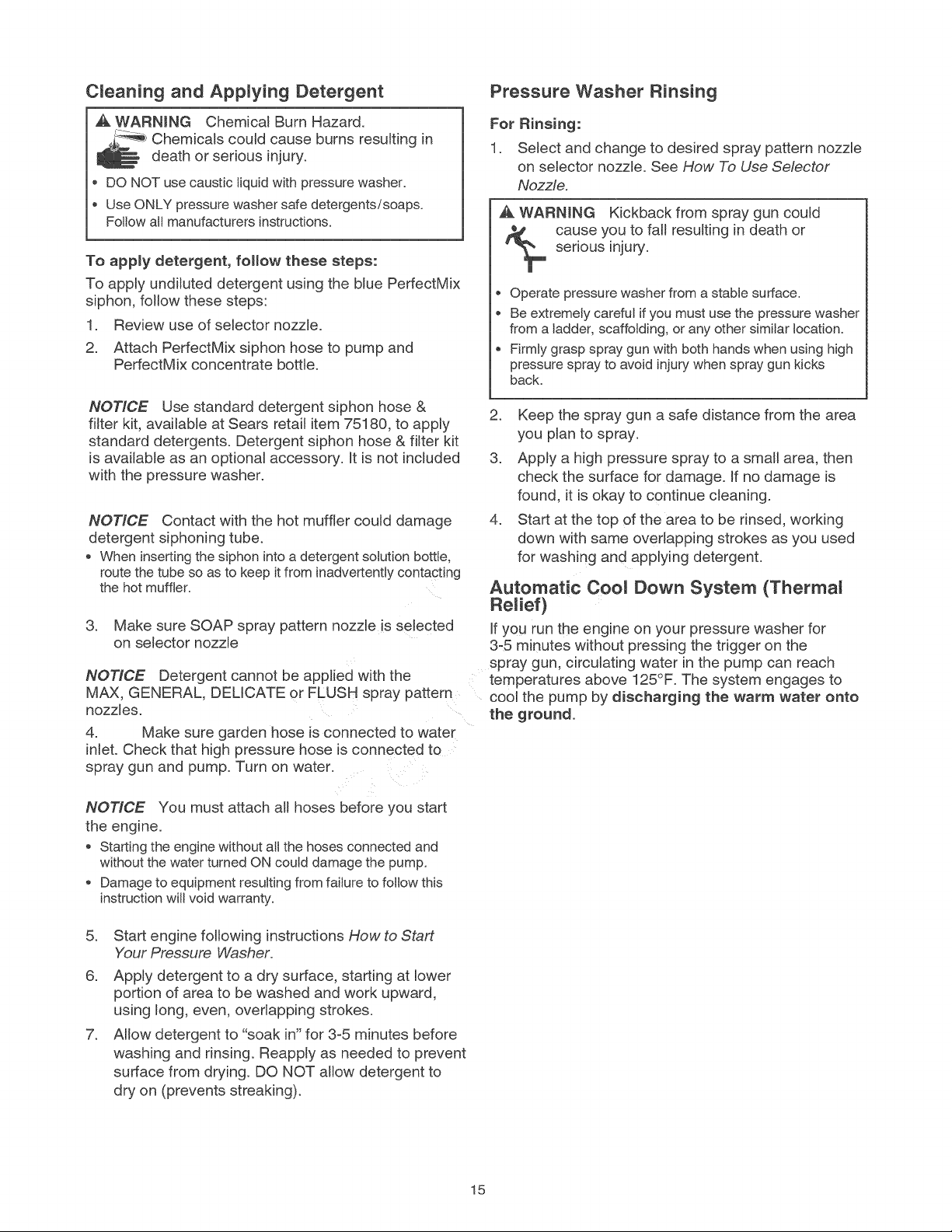

1. Select desired spray pattern:

• MAX - For stubborn or hard to reach surface

such as second story surfaces, paint removal,

oil stains, rust removal or other stubborn

substances (tar, gum, grease, wax, etc.).

GENERAL - For most all purpose cleaning

such as home siding, brick patios, wood decks,

driveways and sidewalks, garage floors, etc..

DEUOATE - For gentle cleaning of cars/trucks,

boats, RV's, patio furniture, lawn equipment,

etc..

FLUSH - For quick high flow clean up and

long reach cleaning of second story siding and

windows.

SOAP For general soap applications or

to launch soap to second story siding and

windows.

2. Push button on selector nozzle, nozzle dial will pop

up.

3. Turn dial until desired spray pattern lines up with

button on selector nozzle.

4. Push dial in until it locks into place.

How to Use SeJector NozzJe

The selector nozzle allows you to switch between five

different spray pattern nozzles. Spray patterns can be

changed while pressure washer is running once spray

gun trigger safety lock is engaged. The spray patterns

vary as shown below.

WARNING The high pressure stream of water

through skin and its underlying tissues,

that this equipment produces could cut

resulting in serious injury and possible

amputation.

o NEVER changespray patterns withoutthetrigger locked

on the spray gun.

DO NOT twist selector nozzlewhile spraying.

Usage Tips

• For most effective cleaning, keep selector nozzle

from 8 to 24 inches (20 to 61 cm) away from

cleaning surface.

• If you get selector nozzle too close, especially using

a high pressure spray pattern nozzle, you may

damage surface being cleaned.

• DO NOT get closer than 6 inches (15 cm) when

cleaning tires.

14

Page 15

C_eaning and Applying Detergent

_k WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in

death or serious injury.

, DO NOT usecaustic liquid with pressurewasher.

, Use ONLY pressurewashersafe detergents/soaps.

Follow all manufacturersinstructions.

To apply detergent, follow these steps:

To apply undiluted detergent using the blue PerfectMix

siphon, follow these steps:

1. Review use of selector nozzle.

2. Attach PerfectMix siphon hose to pump and

PerfectMix concentrate bottle.

Pressure Washer Rinsing

For Rinsing:

1. Semectand change to desired spray pattern nozzle

on selector nozzle. See How To Use Selector

Nozzle.

WARNmNG Kickback from spray gun could

cause you to fall resulting in death or

serious injury.

, Operate pressure washer from a stable surface.

, Be extremely careful if you must use the pressure washer

from a ladder, scaffolding, or any other similar location.

, Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

NOTICE Use standard detergent siphon hose &

filter kit, available at Sears retail item 75180, to apply

standard detergents. Detergent siphon hose & filter kit

is available as an optional accessory. It is not included

with the pressure washer.

NOTICE Contact with the hot muffler could damage

detergent siphoning tube.

, When inserting the siphon into a detergent solution bottte,

route the tube so as to keep it from inadvertently contacting

the hot muffler.

3. Make sure SOAP spray pattern nozzle is selected

on selector nozzle

NOTICE Detergent cannot be applied with the

MAX, GENERAL, DELICATE or FLUSH spray pattern

nozzles.

4. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected to

spray gun and pump. Turn on water.

NOTICE You must attach all hoses before you start

the engine.

, Starting the engine without all the hoses connected and

without the water turned ON could damage the pump.

, Damage to equipment resulting from failure to follow this

instruction will void warranty.

2. Keep the spray gun a safe distance from the area

you plan to spray.

3. Apply a high pressure spray to a small area, then

check the surface for damage. If no damage is

found, it is okay to continue cleaning.

4. Start at the top of the area to be rinsed, working

down with same overlapping strokes as you used

for washing and applying detergent.

Automatic Cool Down System (Therma_

Relief}

if you run the engine on your pressure washer for

3°5 minutes without pressing the trigger on the

spray gun, circulating water in the pump can reach

temperatures above 125°F. The system engages to

cool the pump by discharging the warm water onto

the ground.

.

Start engine following instructions How to Start

Your Pressure W/asher.

6.

Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward,

using long, even, overlapping strokes.

.

Allow detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. DO NOT allow detergent to

dry on (prevents streaking).

15

Page 16

ENGINE TECHNICAL iNFORMATiON

This is a single cylinder, overhead valve (OHV), air

cooled engine. In the State of California, Model 120000

engines are certified by the California Air Resources

Board to meet emissions standards for 125 hours.

Such certification does not grant the purchaser, owner

or operator of this engine any additional warranties with

respect to the performance or operational life of this

engine. The engine is warranted solely according to the

product and emissions warranties stated elsewhere in

this manual.

Power Ratings

The gross power rating for individual gasoline engine

models is labeled in accordance with SAE (Society

of Automotive Engineers) code J1940 Small Engine

Power & Torque Rating Procedure, and is rated in

accordance with SAE J1995. Torque values are

derived at 2600 RPM for those engines with "rpm"

called out on the label and 3060 RPM for all others;

horsepower values are derived at 3600 RPM.

The gross power curves can be viewed at www.

BRIGGSandSTRATTON.COM. Net power values are

taken with exhaust and air cleaner installed whereas

gross power values are collected without these

attachments. Actual gross engine power will be higher

than net engine power and is affected by, among other

things, ambient operating conditions and engine-to-

engine variability. Given the wide array of products on

which engines are placed, the gasoline engine may not

develop the rated gross power when used in a given

piece of power equipment. This difference is due to a

variety of factors including, but not limited to, the variety

of engine components (air cleaner, exhaust, charging,

cooling, carburetor, fuel pump, etc.), application

limitations, ambient operating conditions (temperature,

humidity, a_titude), and engine-to engine variability.

Due to manufacturing and capacity limitations, Briggs &

Stratton may substitute an engine of higher rated power

for this engine.

PRODUCT SPECtNCATIONS

Pressure Washer Specifications

Max Outlet Pressure .................... 3000 PSI*

Max Flow Rate ......................... 2.7 GPM

Detergent Mix .................... Use as directed

Water Supply Temperature ..... Not to exceed 100°F

Engine Specifications

Bore ......................... 2.688 in. (68.28 mm)

Stroke ........................ 2.040 in. (51.82 mm)

Displacement ..................... 11.58 in. (190 cc)

Spark Plug

Type: .................. Briggs & Stratton 692051

Set Gap To: ................ 0.020 inch (0.051 mm)

Armature Air Gap: ...... 0.010-0.014 in.(0.25-0.36mm)

Valve clearance with valve springs installed and piston

1/4 in. (6 ram) past top dead center (check when engine

is cold).

Intake ................ 0.004-0.008 in.(0.10-0.20 mm)

Exhaust............... 0.004-0.008 in.(O.10-0o20mm)

Fuel Capacity ...... .... : ................ 1.6Quarts

Oil Capacity .... :. :.. :. : ........ 20 Ounces (0.6 liter)

NOTICE For practical operation, the engine load

should not exceed 85% of rated power. Engine power

will decrease 3-1/2% for each 1,000 feet (300 meters)

above sea level and 1% for each 10° F (5.6° C) above

77° F (25° C). It should operate satisfactorily at an

angle up to 15°.

* This pressure washer is rated in accordance to

the Pressure Washer Manufacturers Association

(PWMA) standard PW101-2010 (Testing and Rating

Performance of Pressure Washers).

16

Page 17

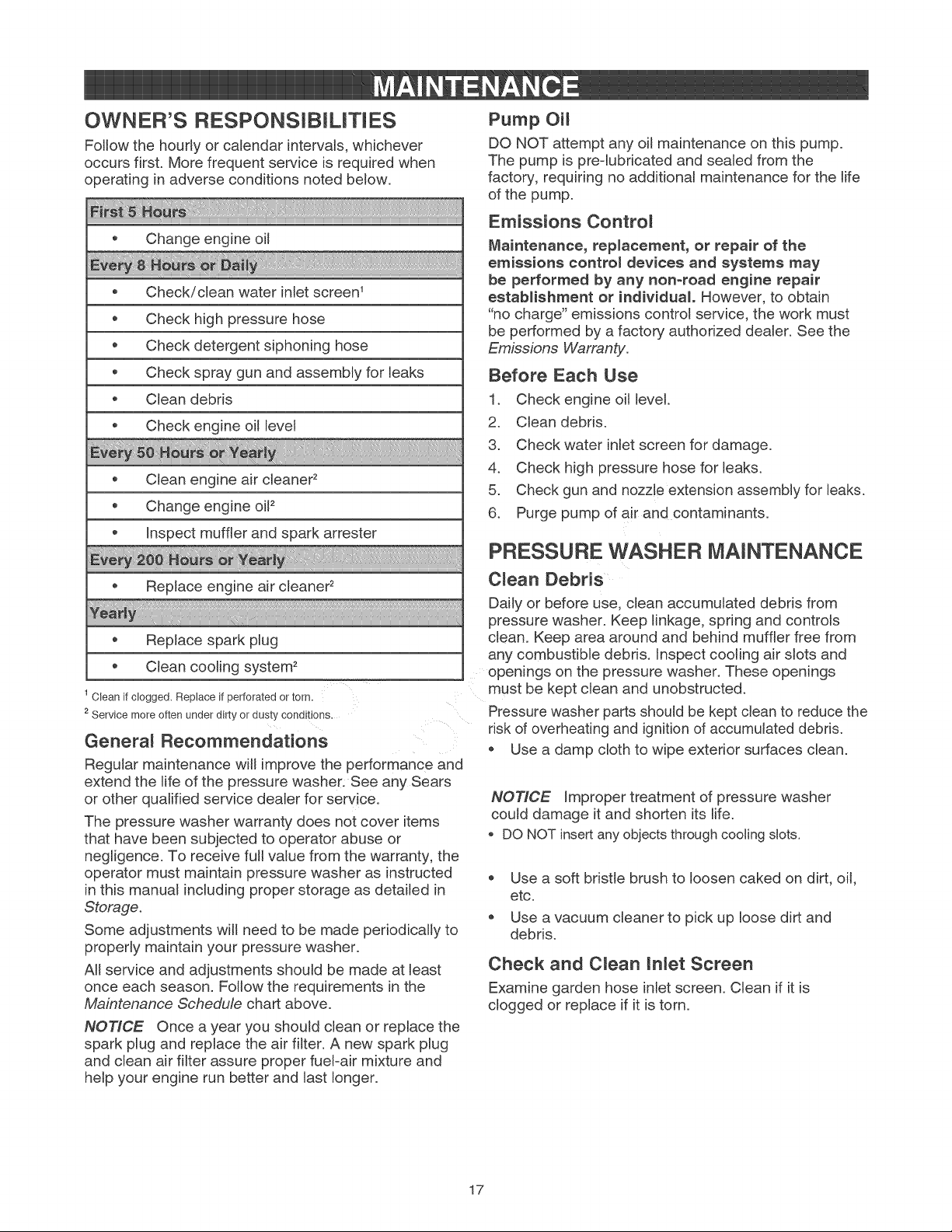

OWNER'S RESPONSIBILiTiES

Follow the hourly or calendar intervals, whichever

occurs first. More frequent service is required when

operating in adverse conditions noted below.

* Change engine oil

®

Check/clean water inlet screen _

®

Check high pressure hose

®

Check detergent siphoning hose

®

Check spray gun and assembly for leaks

®

Clean debris

®

Check engineoillevel

®

Clean engine air cleaner

®

Change engine oiF

®

Inspect muffler and spark attester

Pump Oil

DO NOT attempt any oil maintenance on this pump.

The pump is prequbricated and sealed from the

factory, requiring no additional maintenance for the life

of the pump.

Emissions Control

Maintenance, repJacement, or repair of the

emissions contro_ devices and systems may

be performed by any non-road engine repair

establishment or individual. However, to obtain

"no charge" emissions control service, the work must

be performed by a factory authorized dealer. See the

Emissions Warranty.

Before Each Use

1. Check engine oHlevel

2. Clean debris.

3. Check water inlet screen for damage.

4. Check high pressure hose for leaks.

5. Check gun and nozzJeextension assembly for leaks.

6. Purge pump of air and contaminants.

PRESSURE WASHER MAINTENANCE

® Replace engine air cleaner

® Replace spark plug

® Clean cooling system _

1 Clean if clogged. Replace if perforated or torn,

2 Service more often under dirty or aus_y cona_tions

General Recommendations

Regular maintenance will improve the performance and

extend the life of the pressure washer. See any Sears

or other qualified service dealer for service.

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty, the

operator must maintain pressure washer as instructed

in this manual including proper storage as detailed in

Storage.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

AHservice and adjustments should be made at least

once each season. Follow the requirements in the

Maintenance Schedule chart above.

NOTICE Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fueFair mixture and

help your engine run better and last longer.

Clean Debris

Daily or before use, clean accumulated debris from

pressure washer. Keep linkage, spring and controls

clean. Keep area around and behind muffler free from

any combustible debris. Inspect cooling air slots and

openings on the pressure washer. These openings

must be kept clean and unobstructed.

Pressure washer parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

® Use a damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

, DO NOT insert anyobjects throughcooling stots.

® Use a soft bristle brush to loosen caked on dirt, oil,

etc.

® Use a vacuum cleaner to pick up loose dirt and

debris.

Check and C_ean tnlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

17

Page 18

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

_, WARNING The high pressure stream of water

_ hat this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

o NEVER repairhigh pressure hose. Replace it.

Replacement hose ratingMUSTequal or exceed

maximum pressure ratingof unit.

Check Detergent Siphoning Tube

Examine the filter on detergent tube (if equipped) and

clean if clogged. The tube should fit tightly on the

barbed fitting. Examine the tube for leaks or tears.

Replace the filter or tube if either is damaged.

Detergent Siphoning Check Ball

Occasionally check bah in detergent siphoning

system may become stuck from storage, dried soap,

or minerals in water. The check ball can be freed by

performing the following:

NOTICE Before performing this procedure, be sure

,ou are wearing safety goggles as described below.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

.

Remove detergent siphoning hose from barbed

fitting on pump.

4.

Using a firm, Munt object 7/64" in diameter or

smaller, by at least 1" long, such as an Allen

wrench, slowly insert the object into the barbed

fitting until you meet resistance. This resistance is

the check balL

5. Slowly push down until you feel the ball move

slightly, push no more than 1/8". Slight pressure

may be required to free the ball.

6. Repeat steps 4 and 5 if necessary.

7. Reinstall detergent siphoning hose onto barb

fitting.

8. Treat with PumpSaver as described in Protecting

the Pump during storage to prevent reoccurrence.

Check Spray Gun

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making sure

it springs back into place when you release it. Do not

depress red button and test trigger. You should not be

able to press trigger. Replace spray gun immediately if it

faWsany of these tests.

Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

NEVER substitute safety glasses or dry-condition

goggtes for indirect vented safety goggtes.

Shut off engine and turn off water suppJy.

.

ALWAYS point spray gun in a safe direction,

press red button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water

:_ that this equipment produces could cutthrough skin and its underlying tissues,

resuffing in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

Keep high pressurehose connectedto pumpand spray

gun while systemis pressurized.

ALWAYS pointspraygun in safe direction, press red

button and squeezespray gun trigger to releasehigh

pressure,everytime you stop engine.

18

Page 19

Selector Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is

a nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the nozzles followin 9 these instructions:

1. Shut off engine and turn off water supply.

2. ALWAYS point spray gun in a safe direction, press

red button and and squeeze spray gun trigger to

release retained high water pressure.

_, WARNING The high pressure stream of water

through skin and its underlying tissues,

that this equipment produces could cut

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

o Keep high pressure hoseconnected to pump and spray

gun while system ispressurized.

ALWAYS pointspraygun insafe direction, press redbut-

ton and squeeze spraygun trigger to release high pres-

sure, every timeyou stop engine.

.

Remove selector nozzle from end of nozzle

extension.

4.

Use a small paper clip to free any foreign material

clogging or restricting each nozzle (A) in the

selector nozzle.

.

Remove nozzle extension from spray gun.

6.

Using a garden hose, remove additional debris by

back flushing water through nozzle extension. Back

flush between 30 to 60 seconds.

O-Ring Maintenance

Purchase an O=Ring Repair Kit, Sears item 75116, at

your local Sears or by calling 1-888-331-4569 or online

at www.sears.com. It is not included with the pressure

washer. This kit includes replacement o=rings and a

water inlet filter. Refer to the instruction sheet provided

in the kit to service your unit's o=rings.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

NEVERrepair leaking connections with sealantof any

kind. Replaceo-ringor seal.

ENGINE MAHNTENANCE

WARNING Unintentional sparking could cause

fire or electric shock resulting in

death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

, Disconnect the spark p!ug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

, Use approved spark plug tester.

DO NOT check for spark with spark plug removed.

Oil

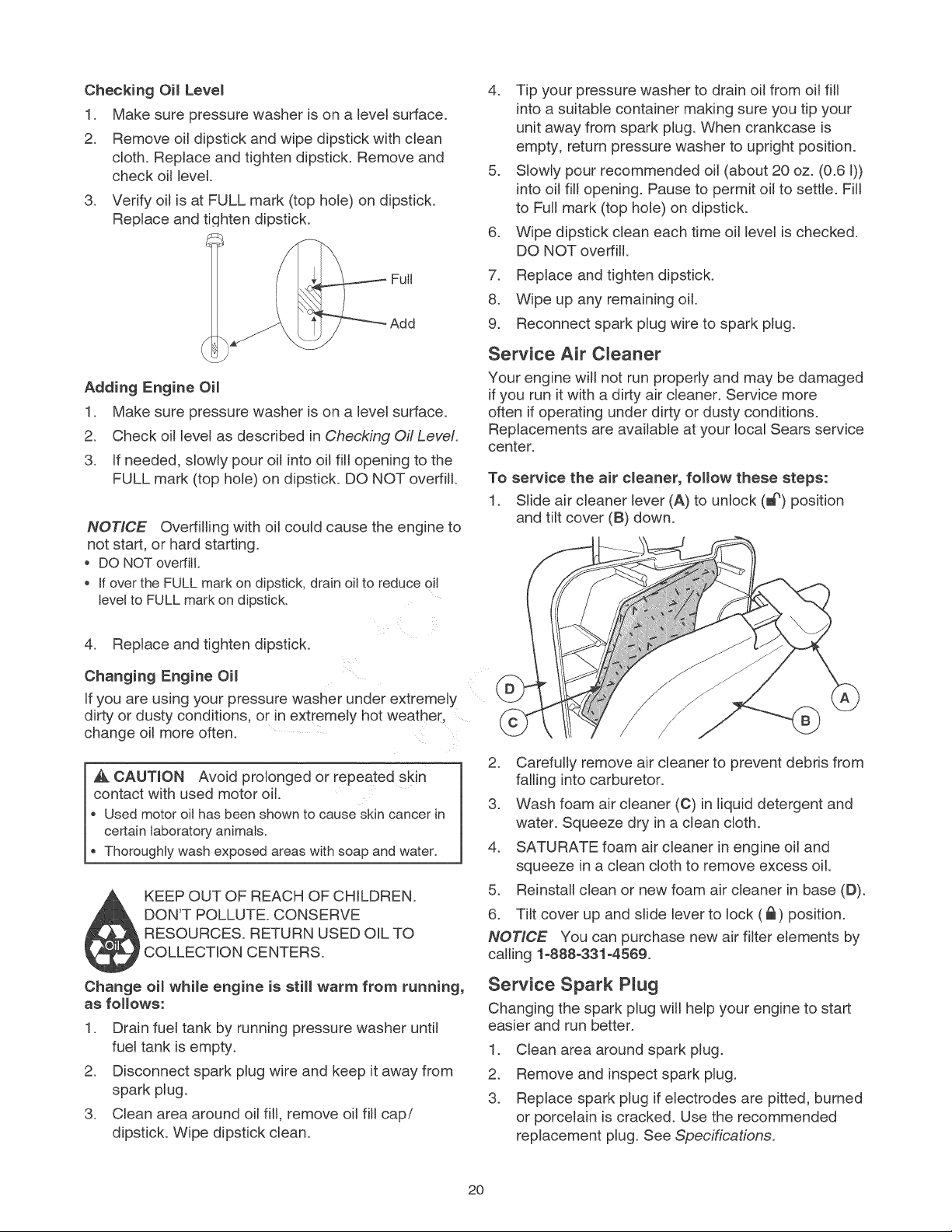

OiJ Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified otis for best performance. Other high-quality

detergent oils are acceptable if classified for service

SF. SG, SH, SJ or higher. DO NOT use special

additives.

Outdoor temperatures determine the proper oil

viscosity for the engine. Use the chart to select the best

viscosity for the outdoor temperature range expected.

oF

% 40

°C

.

Reinstall selector nozzle into nozzle extension.

8.

Reconnect nozzle extension to spray gun.

9.

Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to

spray gun and pump. Turn on water.

10. Start engine following instructionsHow to Start

Your Pressure Washer.

11. Test pressure washer by operating in each spray

pattern.

86 i_

68 i_

104 ___. ,

50 i_

32 _

14

_4

-22 _

* Below 40°F (4°C) the use of SAE 30 will result in hard

starting.

** Above 80°F (27°C) the use of 10W30 may cause increased

oil consumption. Check oil level more frequently.

19

._20

; 3o

10

-20

-30

Page 20

Checking Oi_ Leve_

1. Make sure pressure washer is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean

cloth. Replace and tighten dipstick. Remove and

check oil level.

3. Verify oil is at FULL mark (top hole) on dipstick.

Replace and tiqhten dipstick.

Full

Adding Engine Oi_

1. Make sure pressure washer is on a level surface.

2. Check oil level as described in Checking Oil Level

3. If needed, slowly pour oil into oil fill opening to the

FULL mark (top hole) on dipstick. DO NOT overfill.

NOTICE Overfilling with oil could cause the engine to

not start, or hard starting.

DO NOT overfill.

o If over the FULL mark on dipstick, drain oil to reduce oit

level to FULL mark on dipstick.

4. Tip your pressure washer to drain oil from oil fill

into a suitable container making sure you tip your

unit away from spark plug. When crankcase is

empty, return pressure washer to upright position.

5. Slowly pour recommended oil (about 20 oz. (0.6 I))

into oil fill opening. Pause to permit oil to settle. Fill

to Full mark (top hole) on dipstick.

6. Wipe dipstick clean each time oil level is checked.

DO NOT overfill.

7. Replace and tighten dipstick.

8. Wipe up any remaining oil.

9. Reconnect spark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be damaged

if you run it with a dirty air cleaner. Service more

often if operating under dirty or dusty conditions.

Replacements are available at your local Sears service

center.

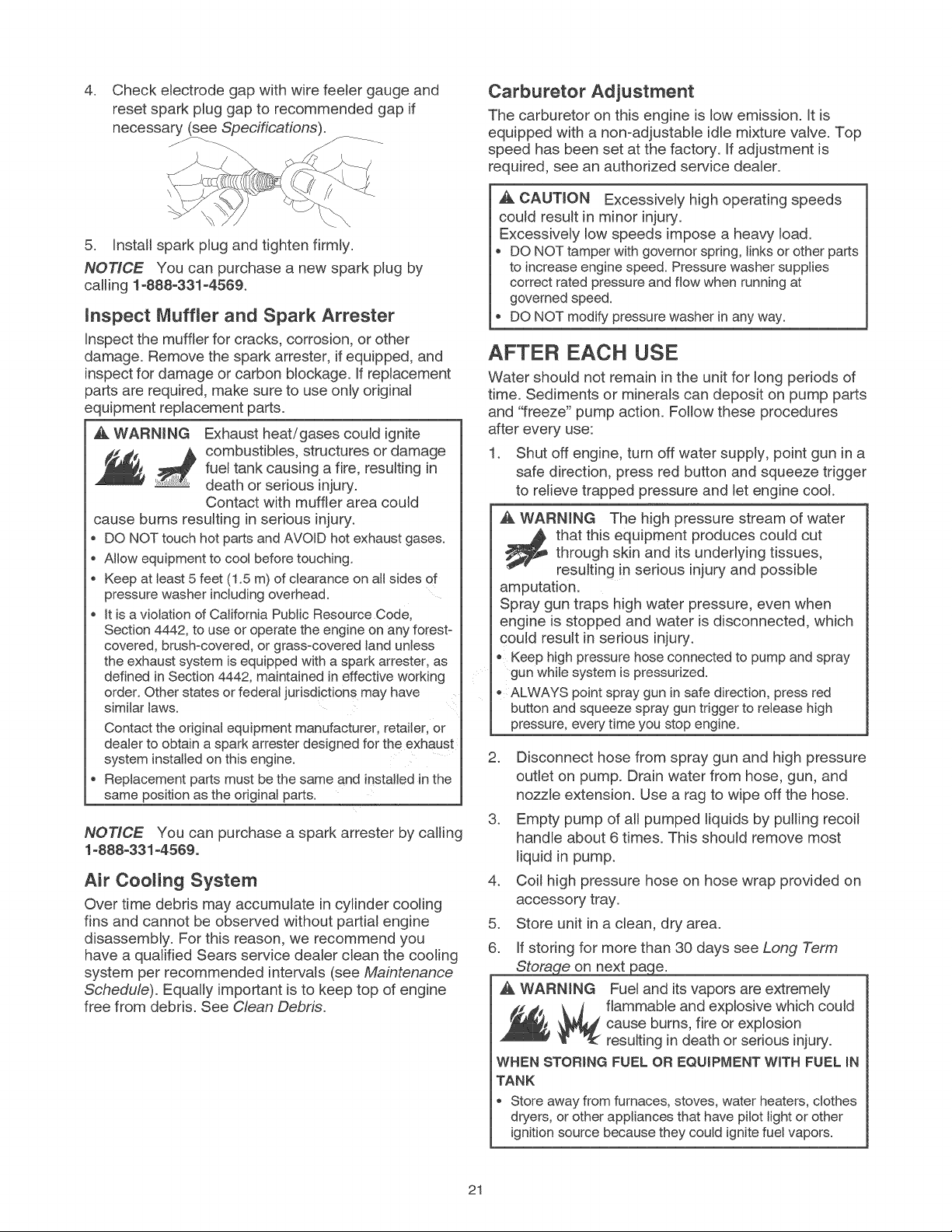

To service the air cleaner, follow these steps:

1. Slide air cleaner lever (A) to unlock (_') position

and tilt cover (B) down.

4. Replace and tighten dipstick.

Changing Engine Oil

If you are using your pressure washer under extremely

dirty or dusty conditions, or in extremely hot weather,

change oil more often.

_, CAUTION Avoid prolonged or repeated skin

contact with used motor oil.

Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN.

DON'T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

Change oil while engine is still warm from running,

as follows:

1. Drain fuel tank by running pressure washer until

fuel tank is empty.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Clean area around oil fill, remove oil fill cap/

dipstick. Wipe dipstick clean.

2 Carefully remove air cleaner to prevent debris from

falling into carburetor.

3 Wash foam air cleaner (C) in liquid detergent and

water. Squeeze dry in a clean cloth.

4. SATURATE foam air cleaner in engine oil and

squeeze in a clean cloth to remove excess oil.

5. Reinstall clean or new foam air cleaner in base (D).

6. Tilt cover up and slide lever to lock (_) position.

NOTICE You can purchase new air filter elements by

calling 1o888-331o4569.

Service Spark Plug

Changing the spark plug will help your engine to start

easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if electrodes are pitted, burned

or porcelain is cracked. Use the recommended

replacement plug. See Specifications.

2O

Page 21

.

Check electrode gap with wire feeler gauge and

reset spark plug gap to recommended gap if

necessary (see Specifications).

5. Install spark plug and tighten firmly.

NOTICE You can purchase a new spark plug by

calling 1-888-331-4569.

_nspect Muffler and Spark Attester

Inspect the muffler for cracks, corrosion, or other

damage. Remove the spark arrester, if equipped, and

inspect for damage or carbon blockage, tf replacement

parts are required, make sure to use only original

equipment replacement parts.

_, WARNmNG Exhaust heat/gases could ignite

combustibles, structures or damage

fuel tank causing a fire, resulting in

death or serious injury.

Contact with muffler area could

cause burns resulting in serious injury.

, DO NOT touchhot parts and AVOID hot exhaust gases.

, Allow equipment to cool before touching.

, Keep at least5 feet (1.5 m) of clearance on all sides of

pressure washer includingoverhead.

It is a violationofCalifornia Public Resource Code,

Section 4442,to use or operate the engine on any forest-

covered, brush-covered,or grass-covered land unless

the exhaust system isequippedwith a spark attester, as

defined in Section 4442, maintainedin effective working

order.Other statesor federal ]udsd!ctions may have

similar taws.

Contact theoriginal equipment manufacturer,retailer, or

dealer to obtaina sparkarresterdesigned for theexhaust

systeminstalledon this engine.

, Replacement partsmust bethe same and installed inthe

same position asthe original parts.

NOTICE You can purchase a spark arrester by calling

1-888-331 °4569°

Air Cooling System

Over time debris may accumulate in cylinder cooling

fins and cannot be observed without partial engine

disassembly. For this reason, we recommend you

have a qualified Sears service dealer clean the cooling

system per recommended intervals (see Maintenance

Schedule). Equally important is to keep top of engine

free from debris. See Clean Debris.

Carburetor Adjustment

The carburetor on this engine is low emission. It is

equipped with a non-adjustable idle mixture valve. Top

speed has been set at the factory. If adjustment is

required, see an authorized service dealer.

_, CAUTION Excessively high operating speeds

could result in minor injury.

Excessively low speeds impose a heavy load.

o DO NOT tamper with governor spring, links or other parts

to increase engine speed. Pressure washer supplies

correct rated pressure and flow when running at

governed speed.

DO NOT modify pressure washer in any way.

AFTER EACH USE

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump parts

and "freeze" pump action. Follow these procedures

after every use:

1. Shut off engine, turn off water supply, point gun in a

safe direction, press red button and squeeze trigger

to relieve trapped pressure and let engine cool.

WARNmNG The high pressure stream of water

through skin and its underlying tissues,

that this equipment produces could cut

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

Keep high pressurehose connectedto pumpand spray

gun whilesystem is pressurized.

ALWAYSpoint spraygun in safe direction, press red

button and squeezespray gun trigger to releasehigh

pressure,everytime you stop engine.

.

Disconnect hose from spray gun and high pressure

outlet on pump. Drain water from hose, gun, and

nozzle extension. Use a rag to wipe off the hose.

.

Empty pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most

liquid in pump.

.

Coil high pressure hose on hose wrap provided on

accessory tray.

5.

Store unit in a clean, dry area.

6.

If storing for more than 30 days see Long Term

Storac_ on next page.

_, WARNmNG Fuel and its vapors are extremely

_1 lammable and explosive which couJd

WHEN STORING FUEL OR EQUIPMENT WiTH FUEL iN

TANK

, Storeaway fromfurnaces, stoves, water heaters,clothes

dryers,orother appliances that have pilot lightor other

ignitionsource becausethey could ignitefuel vapors.

cause burns, fire or explosion

resulting in death or serious injury.

21

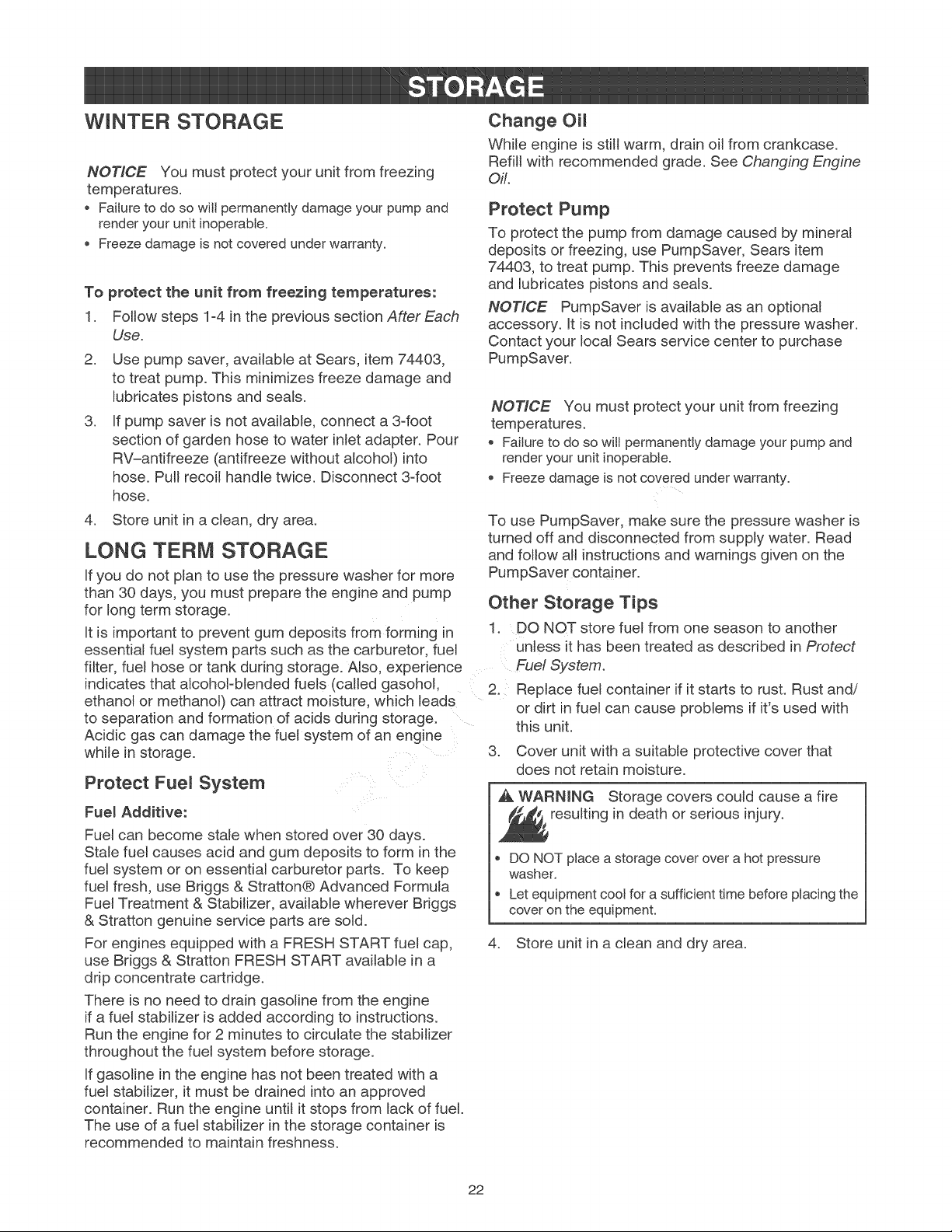

Page 22

WHNTER STORAGE

NOTICE You must protect your unit from freezing

temperatures.

o Failure to do so will permanently damage your pump and

render your unk inoperable.

Freeze damage is not covered under warranty.

To protect the unit from freezing temperatures:

1. Follow steps 1-4 in the previous section After Each

Use.

.

Use pump saver, available at Sears, item 74403,

to treat pump. This minimizes freeze damage and

lubricates pistons and seals.

.

Lfpump saver is not availaMe, connect a 3-foot

section of garden hose to water inlet adapter. Pour

RV-antifreeze (antifreeze without alcohol) into

hose. Pull recoil handle twice. Disconnect 3-foot

hose.

4. Store unit in a clean, dry area.

LONG TERM STORAGE

Lfyou do not plan to use the pressure washer for more

than 30 days, you must prepare the engine and pump

for long term storage.

Ltis important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also, experience

indicates that alcohol-blended fuels (called gasohol.

ethanol or methanol) can attract moisture, which Leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

Protect Fuel System

Fue_ Additive:

Fuel can become stale when stored over 30 days.

Stale fuel causes acid and gum deposits to form in the

fuel system or on essentia} carburetor parts. To keep

fuel fresh, use Bdggs & Stratton® Advanced Formula

Fuel Treatment & Stabilizer, available wherever Briggs

& Stratton genuine service parts are sold.

For engines equipped with a FRESH START fuel cap,

use Briggs & Stratton FRESH START available in a

drip concentrate cartridge.

There is no need to drain gasoline from the engine

if a fuel stabilizer is added according to instructions.

Run the engine for 2 minutes to circulate the stabilizer

throughout the fuel system before storage.

If gasoline in the engine has not been treated with a

fuel stabilizer, itmust be drained into an approved

container. Run the engine until it stops from lack of fuel.

The use of a fuel stabilizer in the storage container is

recommended to maintain freshness.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade. See Changing Engine

Oil.

Protect Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver, Sears item

74403, to treat pump. This prevents freeze damage

and lubricates pistons and seals.

NOTICE PumpSaver is available as an optiona_

accessory. It is not included with the pressure washer.

Contact your local Sears service center to purchase

PumpSaver.

NOTICE You must protect your unit from freezing

temperatures.

Failure to do so will permanently damage your pump and

render your unit inoperable.

Freeze damage is not covered under warranty.

To use PumpSaver, make sure the pressure washer is

turned off and disconnected from supply water. Read

and follow aHinstructions and warnings given on the

PumpSaver container.

Other Storage Tips

1 DO NOT store fuel from one season to another

unless it has been treated as described in Protect

Fuel System.

2. Replace fue_container if it starts to rust. Rust and/

or dirt in fuel can cause problems if it's used with

this unit.

3 Cover unit with a suitable protective cover that

does not retain moisture.

_, WARNING Storage covers could cause a fire

resulting in death or serious injury.

DO NOT place a storage cover over a hot pressure

washer.

Let equipment cool for a sufficient time before placing the

cover on the equipment.

4. Store unit in a clean and dry area.

22

Page 23

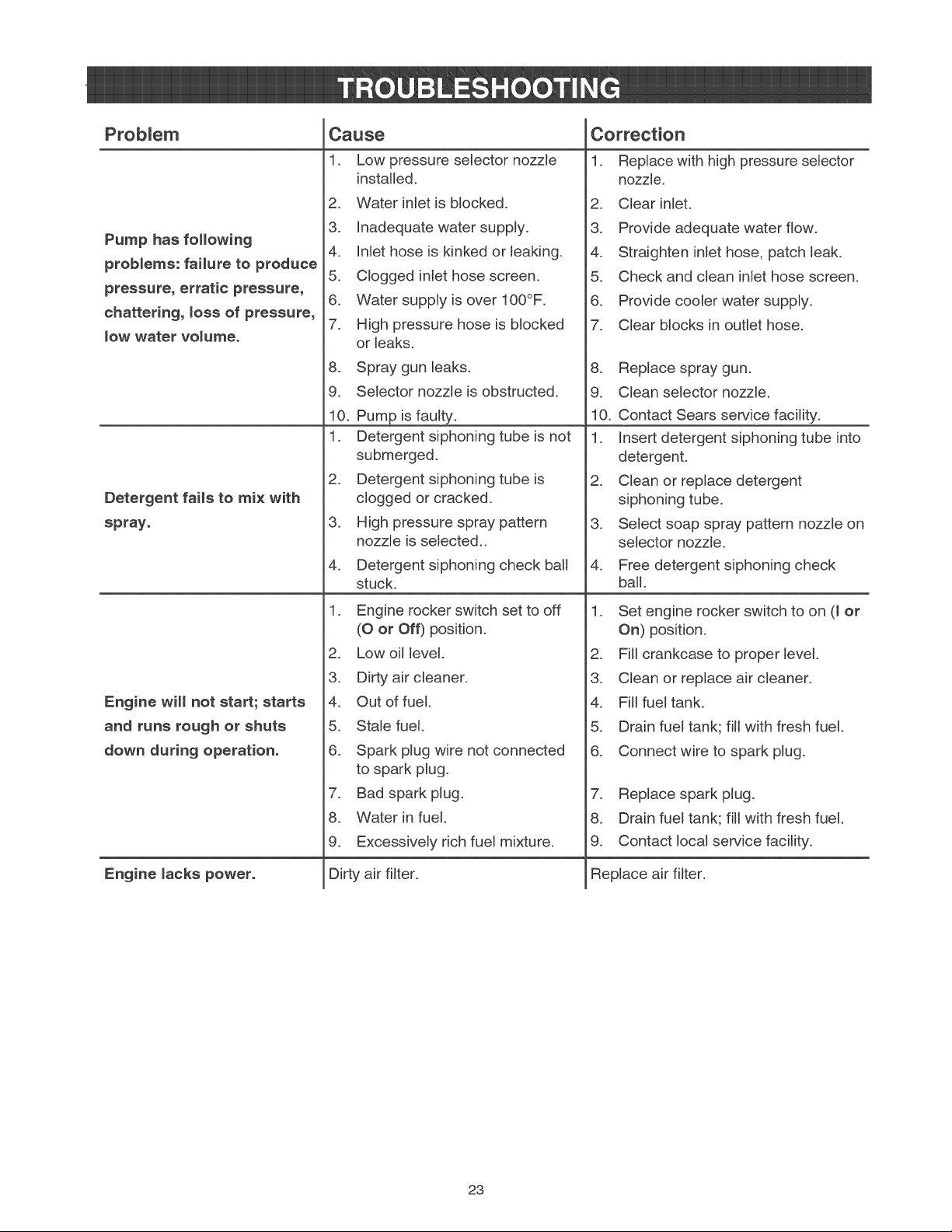

Problem

Cause

Correction

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

Detergent fails to mix with

spray.

Engine will not start; starts

and runs rough or shuts

down during operation.

1. Low pressure selector nozzle

installed.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose screen.

6. Water supply is over 100°F.

7. High pressure hose is blocked

or leaks.

8. Spray gun leaks.

9. Selector nozzle is obstructed.

10. Pump is faulty.

1. Detergent siphoning tube is not

submerged.

2. Detergent siphoning tube is

clogged or cracked.

3. High pressure spray pattern

nozzle is selected..

4. Detergent siphoning check ball

stuck.

1. Engine rocker switch set to off

(O or Off) position.

2. Low oil level.

3. Dirty air cleaner.

4. Out of fuel.

5. Stale fuel.

6. Spark plug wire not connected

to spark plug.

7. Bad spark plug.

8. Water in fuel.

9. Excessively rich fuel mixture.

1. Replace with high pressure selector

nozzle.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose screen.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

.

Replace spray gun.

9.

Clean selector nozzle.

10.

Contact Sears service facility.

1.

Insert detergent siphoning tube into

detergent.

.

Clean or replace detergent

siphoning tube.

.

Select soap spray pattern nozzle on

selector nozzle.

4. Free detergent siphoning check

ball.

1. Set engine rocker switch to on (Jor

On) position.

2. Fill crankcase to proper level.

3. Clean or replace air cleaner.

4. Fill fueltank.

5. Drain fuel tank; fill with fresh fuel.

6. Connect wire to spark plug.

7. Replace spark plug.

8. Drain fuel tank; fill with fresh fuel.

9. Contact local service facility.

Engine lacks power.

Dirty air fi_ter.

Replace air rifler.

23

Page 24

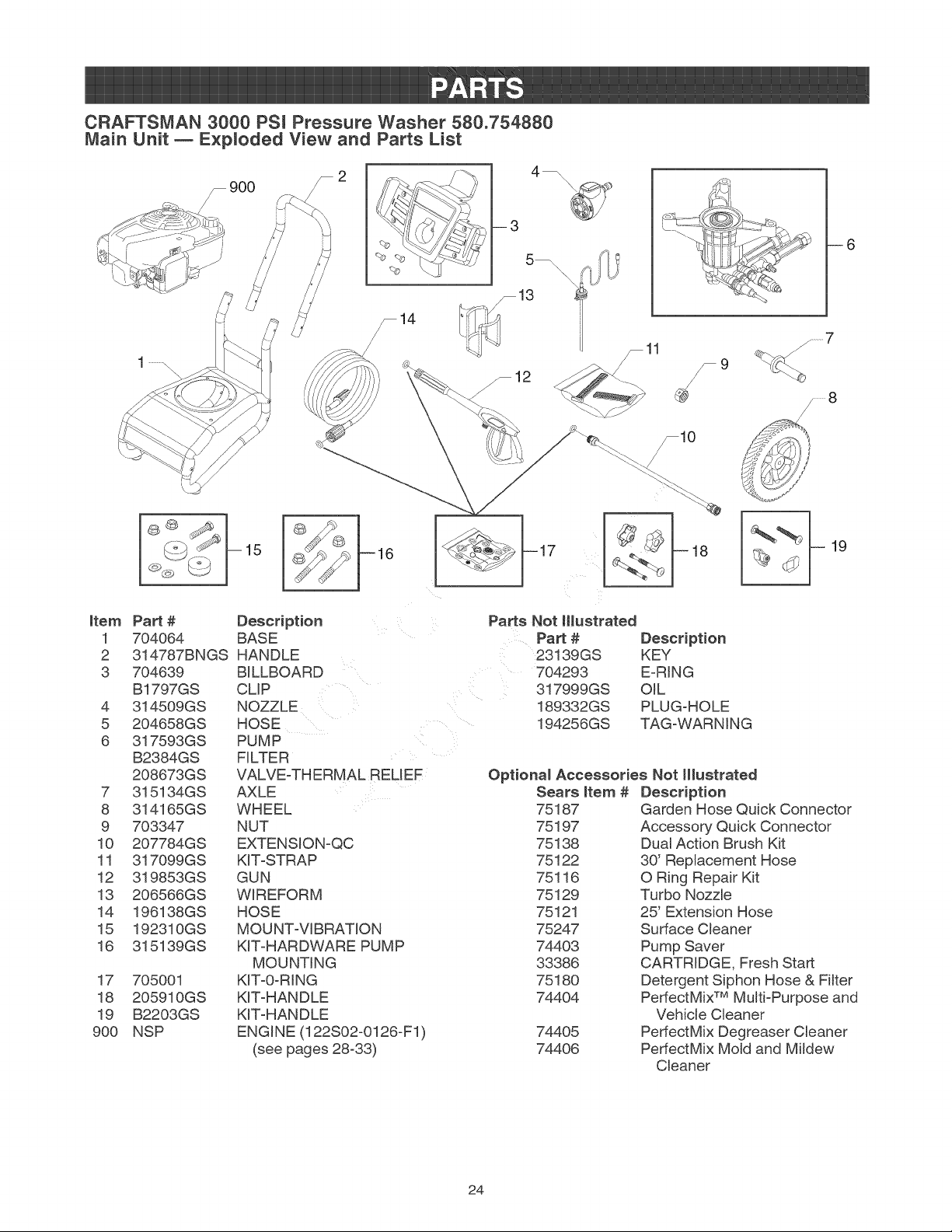

CRAFTSMAN 3000 PSi Pressure Washer 580.754880

Main Unit w E×ploded View and Parts List

900

_14

15

item Part # Description

1 704064 BASE

2 314787BNGS HANDLE

3 704639 BILLBOARD

B1797GS CMP

4 314509GS NOZZLE

5 204658GS HOSE

6 317593GS PUMP

B2384GS FILTER

208673GS VALVE-THERMAL RELEF

7 315134GS AXLE

8 314165GS WHEEL

9 703347 NUT

10 207784GS EXTENSION-QC

11 317099GS KIT-STRAP

12 319853GS GUN

13 206566GS WIREFORM

14 196138GS HOSE

15 192310GS MOUNT-VIBRATION

16 315139GS KIT-HARDWARE PUMP

MOUNTING

17 705001 KIT-0-RING

18 205910GS KIT-HANDLE

19 B2203GS KIT-HANDLE

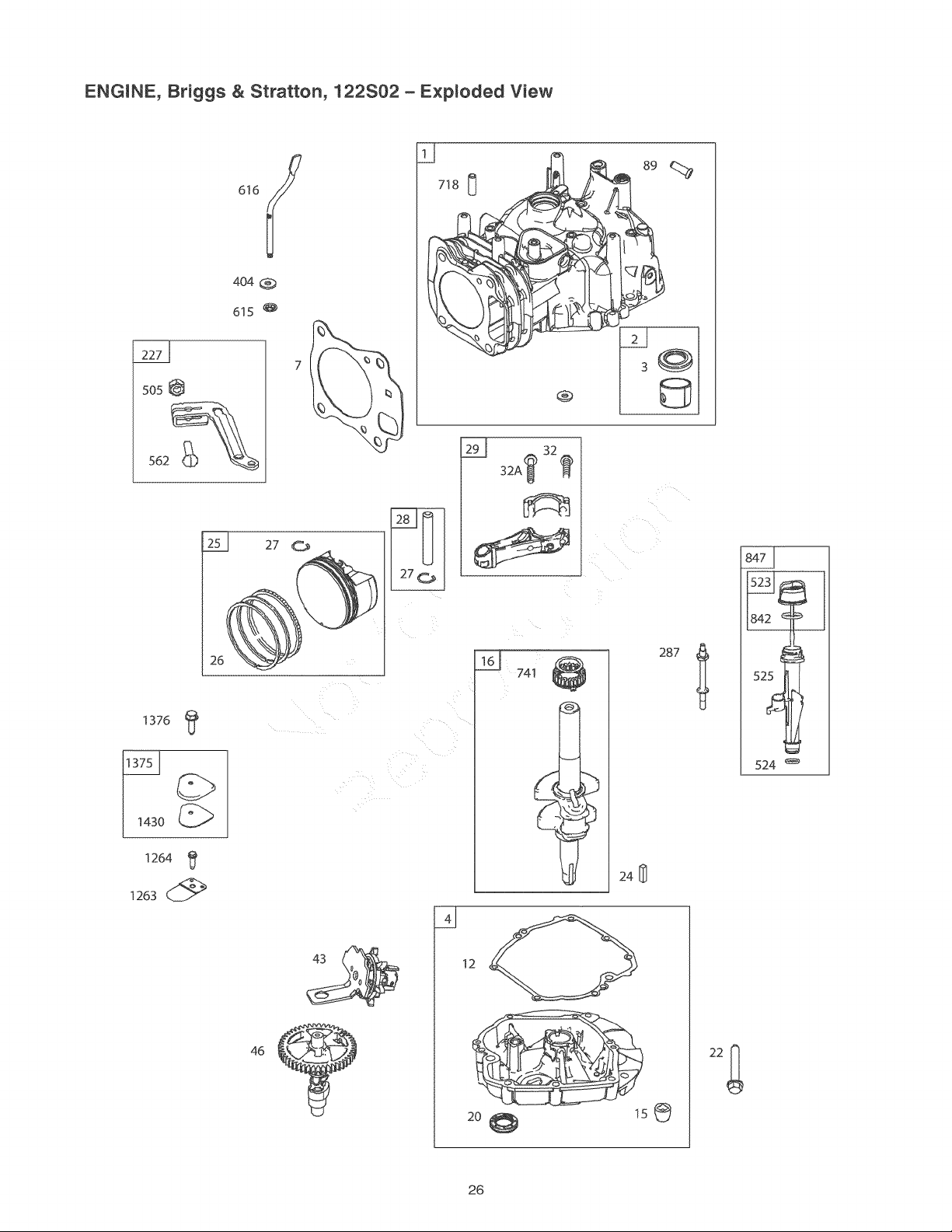

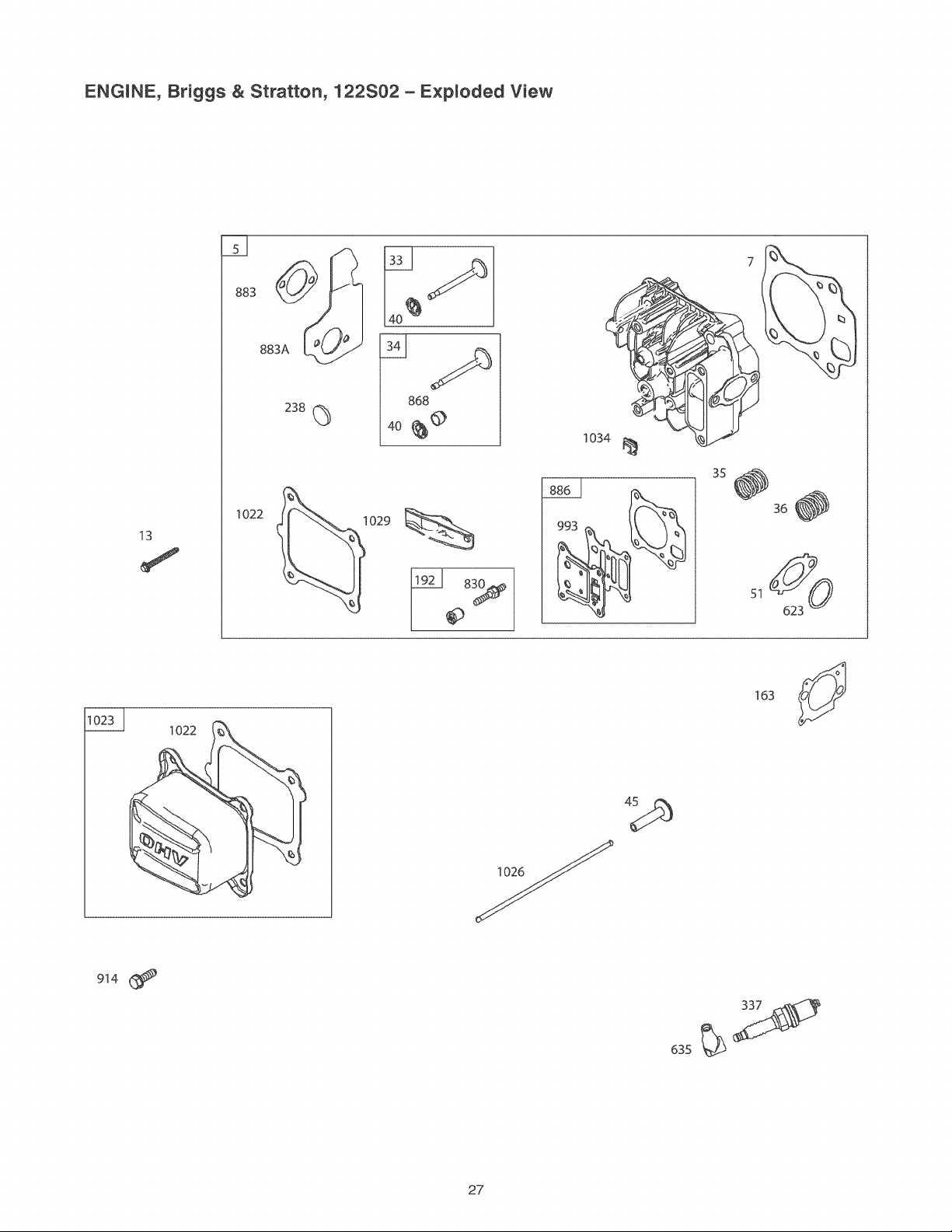

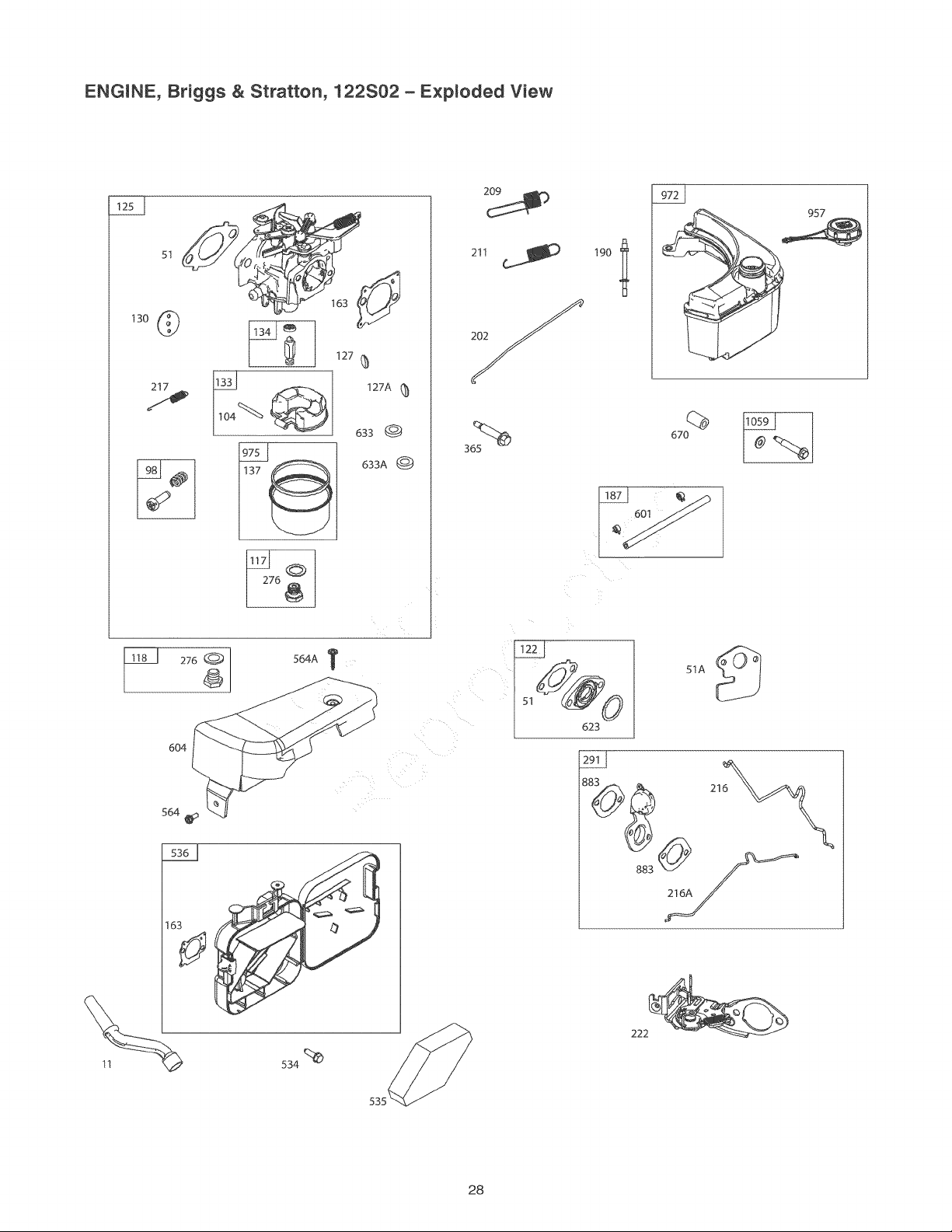

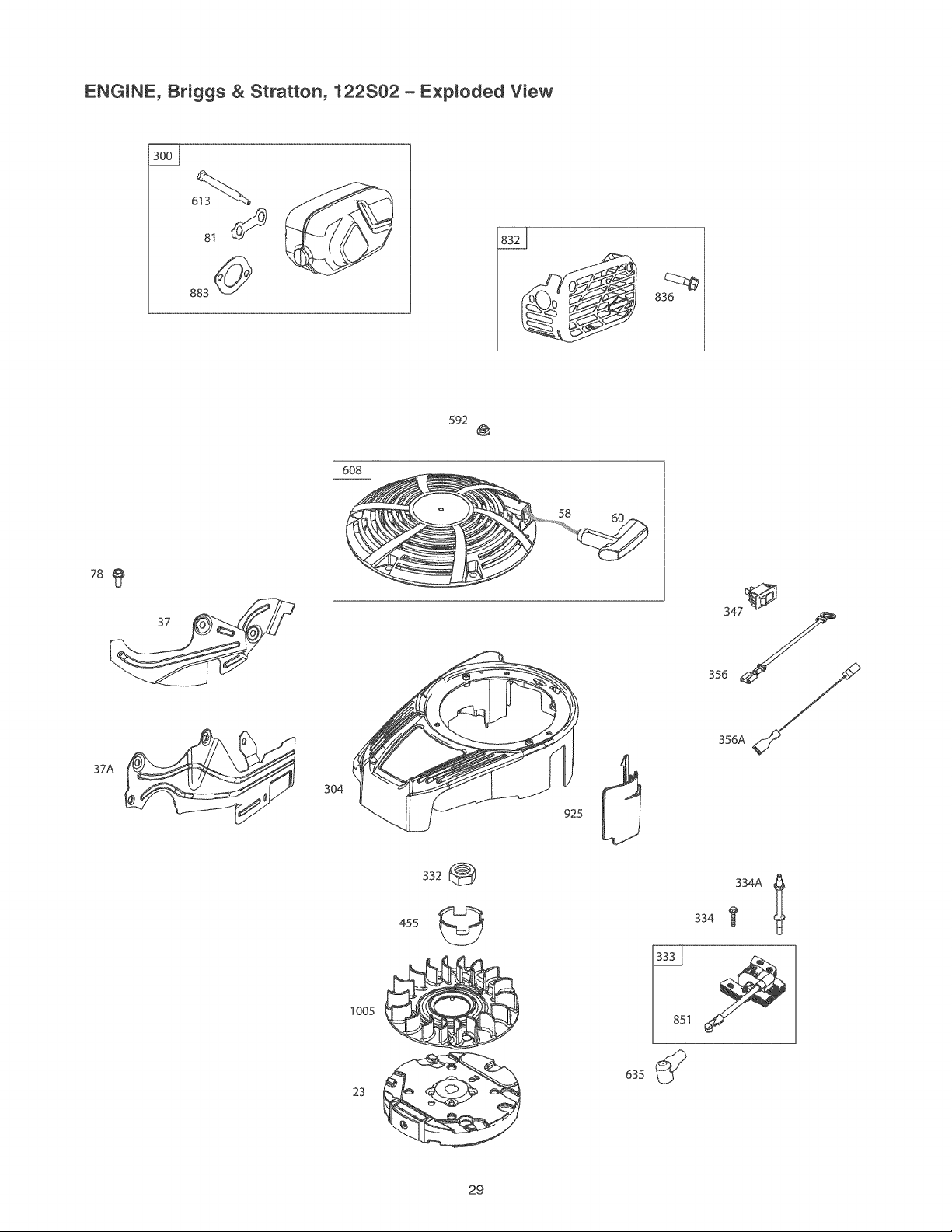

900 NSP ENGINE (122S02-0126-F1)

(see pages 28-33)

4_

m3

\\

\\

\

_13

T9

/

_10

/

Parts Not Illustrated

Part # Description

23139GS KEY

704293 E-RING

317999GS OIL

189332GS PLUG-HOLE

194256GS TAG-WARNING

Optional Accessories Not illustrated

Sears item # Description

75187

75197

75138

75122

75116

75129

75121

75247

74403

33386

75180

74404

Garden Hose Quick Connector

Accessory Quick Connector

Dual Action Brush Kit

30' Replacement Hose

O Ring Repair Kit

Turbo Nozzle

25' Extension Hose

Surface Cleaner

Pump Saver

CARTRIDGE, Fresh Start

Detergent Siphon Hose & Filter

PerfectMix TM Multi-Purpose and

Vehicle Cleaner

74405

74406

PerfectMix Degreaser Cleaner

PerfectMix Mold and Mildew

Cleaner

--6

j----- 7

/ 8

19

24

Page 25

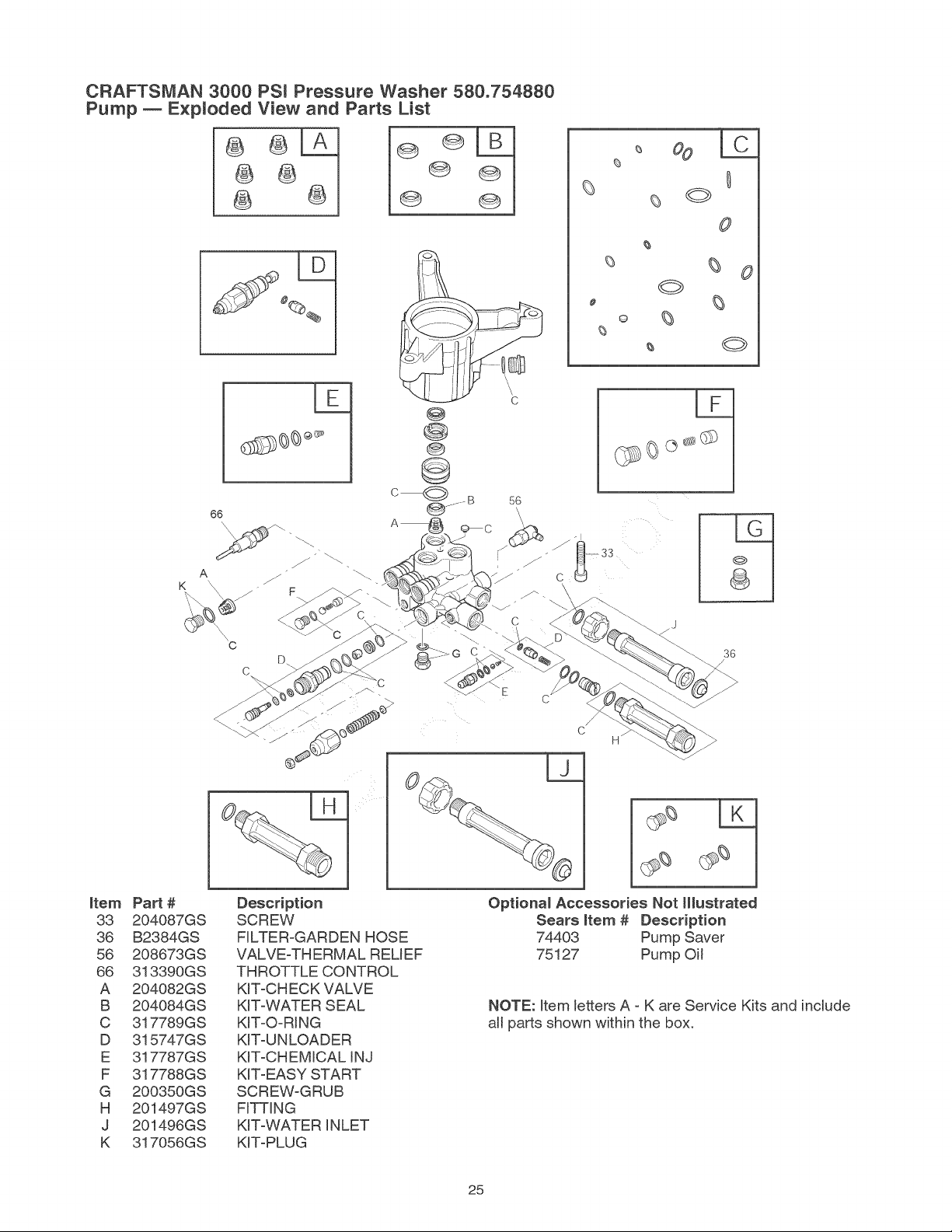

CRAFTSMAN 3000 PSt Pressure Washer 580.754880

Pump w E×ploded View and Parts List

® ®®

56

\

\

%

#

@

Item

33

36

56

66

A

B