Craftsman 580.752880 User Manual

Operator'sIVlanual

2700 MAX PSi*

2.3 MAXGPIVi

iViodelNo. 580.752880

®

,, Safety

HOURS: IVlon.- Fri. 8 a.m. to 5 p.m. (CT)

,, Assembly

,, Operation

WARNING

Beforeusing this product, readthis

manualand follow all Safety Rules

and Operatinginstructions.

* This pressure washer is rated in accordanceto the PressureWasher Manufacturers Association

(PWMA) standard PWI01 (Testing and Rating Performance of Pressure Washers).

* Esta limpiadora a presiOnest_ clasificada conforme a la norma PWl01 (comprobaciOn y clasificaciOn de rendimiento de limpiadoras

a presiOn)de laAsociaciOn defabricantes de bombas a presiOn(Pressure WasherManufacturers Association, PWMA).

SearsBrands ManagementCorporation,HoffmanEstates,IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

Part No. 316055GS Draft A (12/21/2011)

Antes de utilizar el producto, leaeste

manualy siga todas las Reglasde

Seguridad e Instrucciones de Uso.

ADVERTENCIA

,,Maintenance

,, Parts

,, Espafiol, p. 34

WARRANTY .......................................... 2

REPAIRPROTECTIONAGREEMENT........................ 2

SAFETYRULES...................................... 3-5

FEATURESAND CONTROLS.............................. 6

ASSEMBLY........................................ 7-11

OPERATION....................................... 12-15

SPECIFICATIONS..................................... 16

MAINTENANCE.................................... 17-21

STORAGE........................................... 22

TROUBLESHOOTING.................................. 23

REPLACEMENTPARTS.............................. 24-31

EMISSIONCONTROLWARRANTY..................... 32-33

ESPANOL......................................... 34-59

HOWTO ORDERPARTS ........................ BACKPAGE

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfrom the dateof purchase,this product is warrantedagainst any defects in material or workmanship. A

defective product will receivefree repair or replacementif repair is unavailable.

Forwarranty coveragedetails to obtain free repair or replacement,visit the web site:www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warranty coveragedoes NOTinclude:

* Expendableitems that canwear out from normal usewithin the warranty period, such as spray guns, hoses, nozzle

extensions, nozzles,spray tips, filters or sparkplugs.

* Product damageresulting from user attempts at product modification or repair or caused by product accessories.

* Repairs necessarybecauseof accident or failure to operateor maintain the product according to all supplied

instructions.

* Preventivemaintenance,or repairsnecessarydue to improper fuel mixture, contaminatedor stale fuel.

This warranty is void if this product is ever usedwhile providing commercial servicesor if rentedto another person.

This warranty givesyou specific legal rights, and you may also haveother rights which vary from state to state.

SearsBrandsManagement Corporation,HoffrnanEstates,IL 60179

Congratulations on making a smart purchase.

Your new Craftsman® product is designed and manufactured

for years of dependableoperation. But like all products, it

may requirerepair from time to time. That's when having a

Repair Protection Agreement can saveyou money and

aggravation.

Here's whatthe Repair Protection Agreement* includes:

* Expert service by our 10,000 professional repair

specialists

, Unlimited serviceand no chargefor parts and labor on

all coveredrepairs

* Product replacementupto $1500 if your covered

product can't be fixed

* Discountof 25% from regular priceof serviceand related

installed parts not covered by the agreement;also, 25%

off regular price of preventivemaintenancecheck

* Fasthelp byphone-we caii it Rapid Resolution- phone

support from a Sears representative.Think of us as a

"talking owner's manual".

Onceyou purchasethe Repair Protection Agreement,a

simple phonecarlis all it takes for you to schedule service.

You cancall anytimeday or night, or schedulea service

appointment online.

The Repair ProtectionAgreement is a risk-free purchase, if

you cancelfor any reasonduring the product warranty

period,we will provide a full refund.Or, a prorated refund

anytime after the product warranty period expires. Purchase

your RepairProtectionAgreement today!

Some limitations and exclusions apply. Forpricesand

additional informationin the U.S.A. call 1-800-827-6655.

* Coverage in Canada varies on someitems. Forfuji

details, caii Sears Canadaat 1-800-361-6665.

Sears Installation Service

ForSears professional installation of home appliances,

garagedoor openers,water heaters,and other major home

items, inthe U.S.A.or Canadacall 1-800-4-1VlY-HOIVlE®.

© 2012

Readthis manualcarefully and becomefamiliar

with yourpressurewasher. Knowitsapplications,

itslimitations, and any hazardsinvolved.

importantSafetyinformation

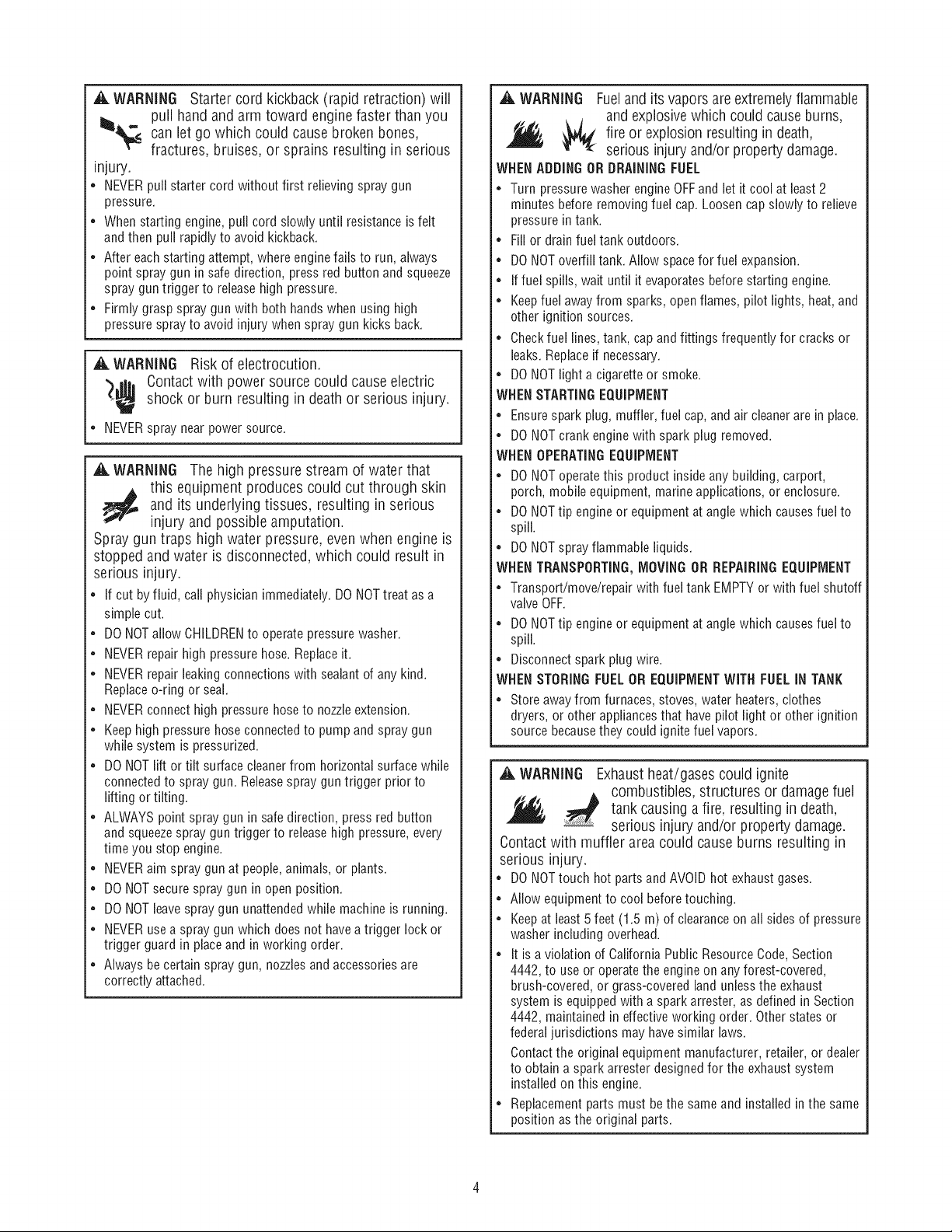

Safety Symbols and Meanings

WARNING The engine exhaustfrom this product

contains chemicals known to the Stateof California to

cause cancer,birth defects,or other reproductive harm.

A WARNING This product contains lead and lead

compounds, known to the Stateof Californiato cause

birth defects or other reproductive harm. Washyour

handsafter handling this product.

Operator'sManual ToxicFumes

SlipperySurface Fail

Fire

MovingParts Flying Objects Hot Surface

Explosion Kickback Projectile

ChemicalBurn

ElectricalShock

FluidInjection

,&. Thesafetyalertsymbol indicatesa potential personal

injury hazard.A signalword (DANGER,WARNING,or

CAUTION)is usedwith the alertsymbol to designatea

degreeor levelof hazardseriousness. A safety symbol may

be usedto representthe typeof hazard.The signalword

NOTICEis usedto address practices not relatedto personal

injury.

_. BANGERindicates a hazardwhich, if not avoided, will

result in deathor serious injury.

_. WARNINGindicatesa hazardwhich, if not avoided, could

result in deathor serious injury.

,&. CAUTIONindicates a hazardwhich, if not avoided, could

result in minor or moderate injury.

NOTICEaddress practicesnot relatedto personal injury.

_, WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

_ reathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

Some chemicals or detergents could be harmful if inhaled

or ingested, resulting in death, serious injury, nausea,

fainting or poisoning.

• Operatethis product ONLYoutdoors.

• Keep exhaustgas from entering a confinedareathrough

windows, doors, ventilationintakes,or other openings.

• DO NOToperatethis product inside any building, carport,

porch, mobile equipment, marineapplications, or enclosure,

evenif windows and doors areopen.

• Usea respirator or maskwhenever there is a chancethat

vapors may be inhaledwhen using chemicals.

• Readall instructions with mask so you arecertain the maskwill

provide the necessaryprotection against inhaling harmful

vapors when using chemicals.

_, WARNING ChemicalBurn Hazard.

Chemicalscould causeburns resulting in death,

serious injury, and/or property damage.

• DONOTusecausticliquidwith pressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

,A,WARNINGStartercordkickback(rapidretraction)will

puiihandandarmtowardenginefasterthanyou

,_can letgowhichcouldcausebrokenbones,

fractures,bruises,orsprainsresultinginserious

injury.

• NEVERpullstartercordwithoutfirstrelievingspraygun

pressure.

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlytoavoidkickback.

• Aftereachstartingattempt,whereenginefailstorun,always

pointsprayguninsafedirection,pressredbuttonandsqueeze

sprayguntriggertoreleasehighpressure.

• Firmly graspspray gunwith both hands when using high

pressure sprayto avoid injury when spraygun kicks back.

A WARNING Risk of electrocution.

'_.dh Contactwith power sourcecould causeelectric

shock or burn resulting in death or serious injury.

• NEVERspraynearpowersource.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

• If cut by fluid, call physicianimmediately. DONOTtreat as a

simple cut.

• DONOTallow CHILDRENto operate pressure washer.

• NEVERrepairhigh pressure hose. Replaceit.

• NEVERrepairleaking connections with sealant of any kind.

Replaceo-ring or seal.

• NEVERconnect highpressure hoseto nozzleextension.

• Keep high pressurehose connectedto pump and spraygun

while system is pressurized.

• DO NOTlift or tilt surface cleanerfrom horizontalsurfacewhile

connectedto spray gun. Releasespray gun trigger prior to

lifting or tilting.

• ALWAYS pointspray gun in safedirection, pressred button

andsqueezespray guntrigger to releasehigh pressure, every

time you stop engine.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spraygun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuseaspray gun which does not havea trigger lock or

trigger guard in placeand in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

,A, WARNING Fueland its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death,

serious injury and/or property damage.

WHENADDING OR DRAININGFUEL

• Turn pressurewasher engineOFFandlet it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

• Fill or drain fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills, wait until it evaporates beforestarting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat,and

other ignition sources.

• Checkfuel lines,tank, cap andfittings frequently for cracks or

leaks. Replaceif necessary.

• DONOTlight a cigarette or smoke.

WHENSTARTINGEQUIPMENT

• Ensurespark plug, muffler,fuel cap,and aircleanerare in place.

• DO NOTcrank enginewith spark plugremoved.

WHENOPERATINGEQUIPMENT

• DO NOToperatethis product insideany building, carport,

porch, mobile equipment, marineapplications, or enclosure.

• DONOTtip engine or equipment at angle which causesfuel to

spill.

• DONOTspray flammable liquids.

WHENTRANSPORTING,MOVINGOR REPAiRiNG EQUIPMENT

• Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

• DONOTtip engine or equipment at angle which causesfuel to

spill.

• Disconnect spark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUELiN TANK

• Store away from furnaces, stoves, water heaters,clothes

dryers, or other appliancesthat have pilot light or other ignition

source becausethey could ignitefuel vapors.

A WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank in

causing a fire, resulting death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipment to cool beforetouching.

• Keep at least5 feet (1.5 m) of clearanceon all sidesof pressure

washer including overhead.

• It is a violation of California Public ResourceCode, Section

4442, to use oroperate the engine on anyforest-covered,

brush-covered, orgrass-covered landunlessthe exhaust

system is equippedwith a spark arrester,as definedin Section

4442, maintained in effective working order. Otherstates or

federaljurisdictionsmay havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaust system

installed onthis engine.

• Replacement parts must bethe sameand installed inthe same

position as the original parts.

_, WARNING Use of pressure washer could create

Ll=

Kickback from spray gun could cause you to fall resulting

in death or serious injury.

• Operatepressurewasher from a stable surface.

• Thecleaning areashould haveadequateslopes anddrainageto

reducethe possibility of a fall due to slippery surfaces.

• Beextremely careful if you must usethe pressurewasher from

a ladder,scaffolding, orany other similar location.

• Firmly graspspray gunwith both hands when using high

pressure sprayto avoid injury when spraygun kicks back.

puddles and slippery surfaces causing

_ you to fall resulting in death or serious

F injury.

,&. WARNING Riskof eyeor bodily injury.

Spraycould splash back or propel

objects resulting in serious injury.

• Always wear indirect vented (chemical splash) safetygoggles

markedto comply with ANSIZ87.1 when usingor in vicinity of

this equipment.

• NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

• Always wear protectiveclothing such asa long-sleevedshirt,

long pantsand close-toed shoes.

• NEVERoperate pressure washerwhen barefootor wearing

sandalsor shorts.

_, WARNING Unintentional sparking could causefire or

'_,dh electric shock resulting indeath or

serious injury.

WHENADJUSTINGORMAKINGREPAIRSTOYOURPRESSURE

WASHER

* Disconnectthesparkplugwirefromthe sparkplugandplace

thewirewhereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

* DONOTcheckfor sparkwithsparkplugremoved.

_, WARNING Starter and other rotating parts could

resulting in serious injury.

entangle hands, hair, clothing, or accessories

* NEVERoperatepressure washer without protective housing or

covers.

. DO NOTwear looseclothing, jewelry or anything that could be

caught in the starter or other rotating parts.

. Tie up long hair and removejewelry.

,A CAUTION Excessively high operating speeds could

result in minor injury and/or pressure washer damage.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Pressurewasher supplies correct rated

pressure and flow when running at governed speed.

• DO NOTmodify pressure washer in any way.

NOTICE High pressurespray could damagefragile items

including glass.

• DONOTpointspraygunatglasswhenusingMAXspraypattern

in selectornozzle.

= NEVERaim spray gun at plants.

NOTICE improper treatment of pressure washer could

damage it and shorten its life.

• If you havequestions about intended use,ask dealeror contact

qualified service center.

• NEVERoperate units with broken or missing parts, orwithout

protective housing or covers.

• DO NOTby-pass any safety device on this machine.

• DONOTtamper with governed speed.

• DONOToperate pressurewasher above rated pressure.

• DONOTmodify pressurewasher in any way.

• Before starting pressurewasher in cold weather,check all parts of

the equipment to be sure icehas notformed there.

• NEVERmove machine by pulling on hoses.Use handleprovided

on unit.

• This equipment is designedto be used with Searsauthorized parts

ONLY.If equipmentis used with parts that DONOTcomply with

minimum specifications, user assumesall risksand liabilities.

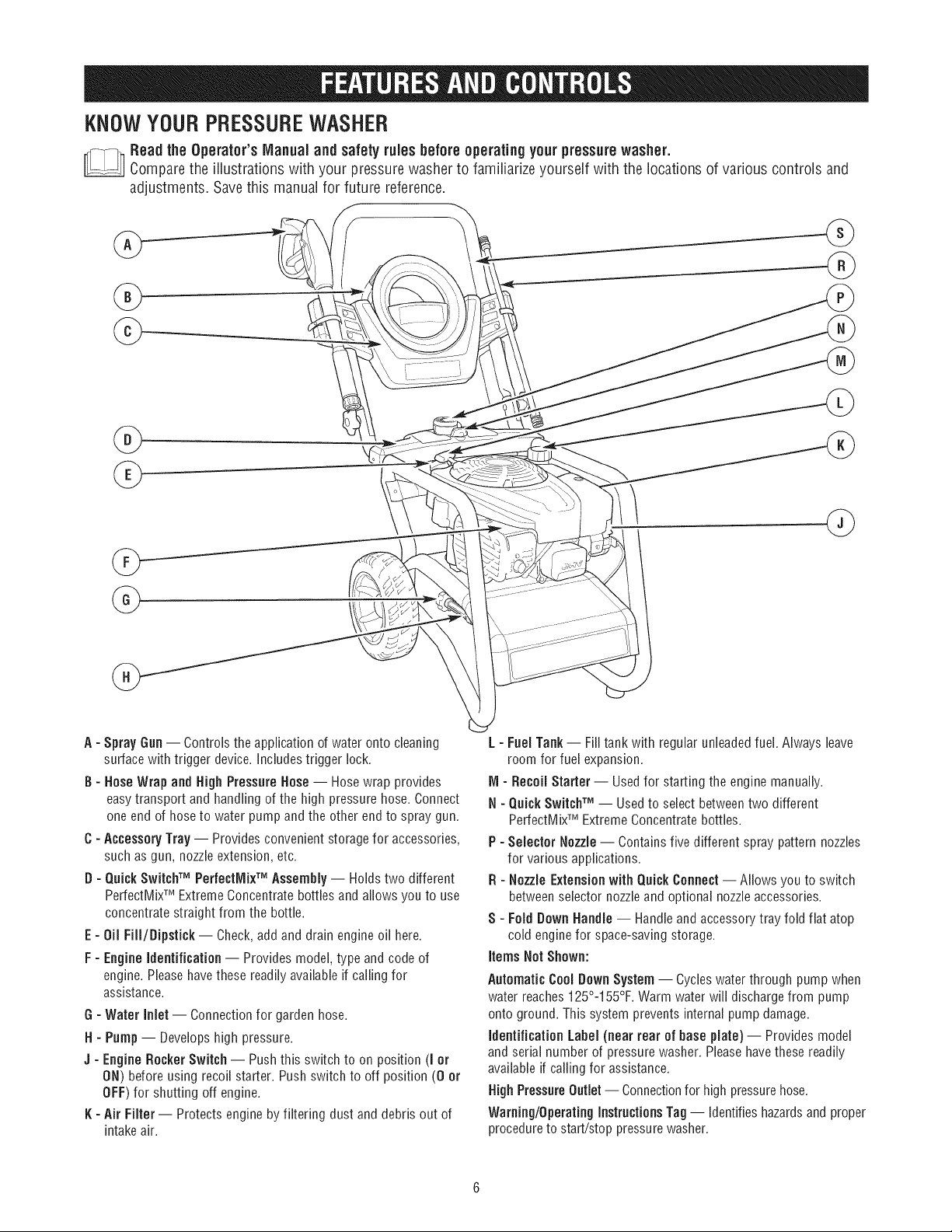

KNOWYOURPRESSUREWASHER

[_ Readthe Operator'sManual andsafetyrules before operating yourpressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

@

___@

A- Spray Gun-- Controls theapplication of water onto cleaning

surface with trigger device.Includes trigger lock.

B- HoseWrap and High PressureHose-- Hosewrap provides

easytransport and handling of the high pressure hose.Connect

one endof hose to water pump and the other end to spray gun.

C- Accessory Tray-- Provides convenient storagefor accessories,

such as gun, nozzleextension, etc.

D - QuickSwitchTM PerfectMixTM Assembly-- Holds two different

PerfectMixTM ExtremeConcentrate bottles and allows you to use

concentrate straight from the bottle.

E- Oil Fill/Dipstick -- Check,add and drain engine oil here.

F - Engine identification-- Provides model, type andcode of

engine. Pleasehavethese readilyavailable if calling for

assistance.

G- WaterInlet-- Connectionfor gardenhose.

H- Pump-- Developshighpressure.

J- EngineRockerSwitch-- Pushthisswitchto onposition(I or

ON)beforeusingrecoilstarter.Pushswitchto off position(0 or

OFF)for shuttingoff engine.

K- AirFilter-- Protectsenginebyfilteringdustanddebrisoutof

intakeair.

L - Fuel Tank -- Fill tank with regular unleadedfuel. Always leave

room for fuel expansion.

IVi- Recoil Starter-- Usedfor starting the engine manually.

N - QuickSwitchTM -- Used to select betweentwo different

PerfectMixTM Extreme Concentratebottles.

P- Selector Nozzle-- Containsfive different spray pattern nozzles

for various applications.

R - Nozzle Extensionwith QuickConnect -- Allows you to switch

between selector nozzleandoptional nozzleaccessories.

S - Fold DownHandle -- Handle and accessory tray fold fiat atop

cold enginefor space-saving storage.

items Not Shown:

AutomaticCoolDownSystem-- Cycleswaterthrough pumpwhen

water reaches125°-155°F. Warm water will dischargefrom pump

onto ground. This system preventsinternal pump damage.

identificationLabel (near rear of base plate) -- Provides model

and serial number of pressurewasher. Pleasehavethese readily

available if callingfor assistance.

NighPressure Outlet-- Connectionfor highpressurehose.

Warning/Operating instructionsTag-- identifieshazardsand proper

procedureto start/stop pressurewasher.

Your pressurewasher requires someassembly and is ready

for useonly after it has been properly servicedwith the

recommendedoil andfuel.

If you haveany problemswith theassemblyof your

pressurewasher, pleasecall the pressurewasher helpline

at 1=800-222-3136.

UNPACKTHEPRESSUREWASHER

1. Removeeverything from carton except pressurewasher.

2. Opencarton completely by cutting eachcorner from top

to bottom.

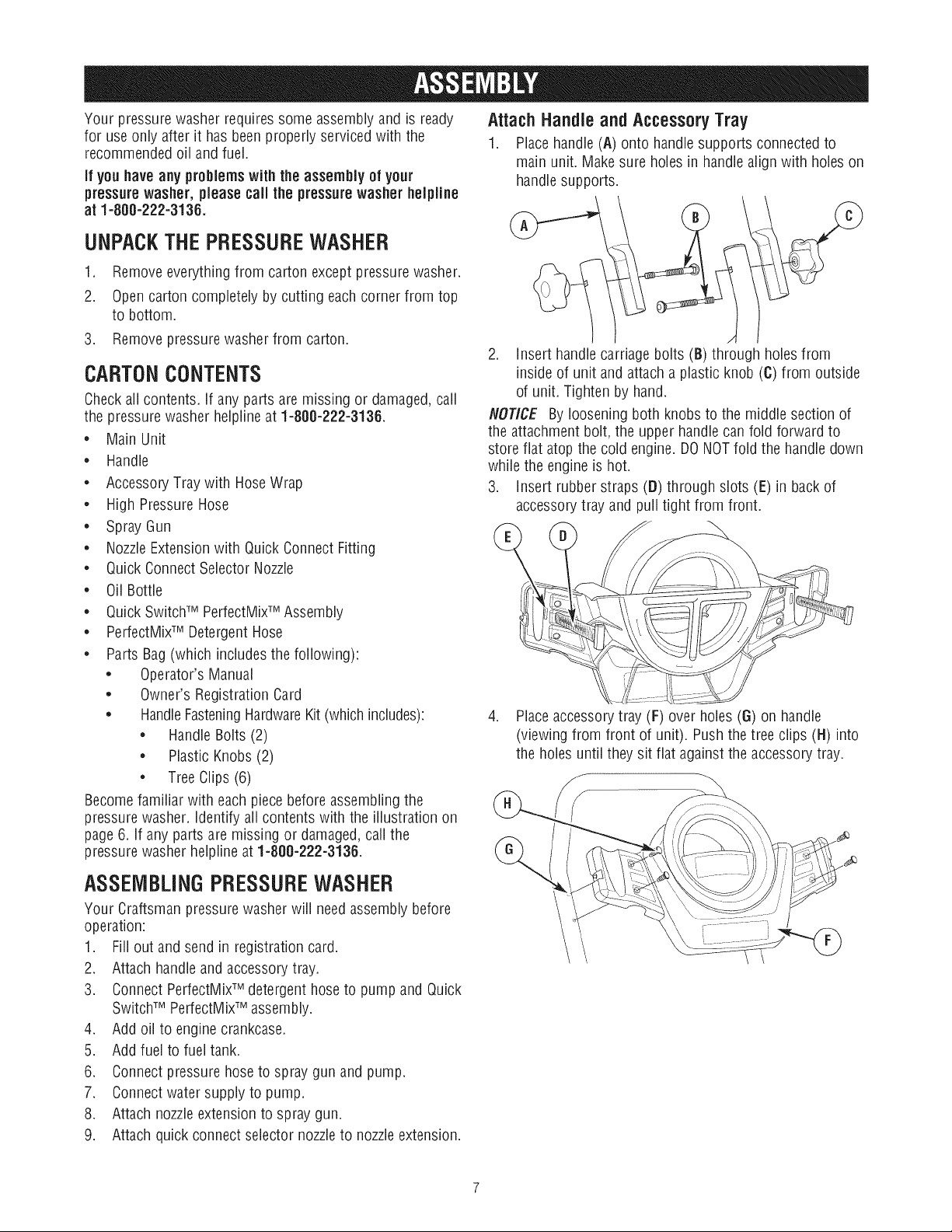

Attach HandleandAccessoryTray

1. Placehandle(A) onto handle supports connectedto

main unit. Make sure holes in handlealign with holes on

handlesupports.

3. Removepressure washer from carton.

CARTONCONTENTS

Checkall contents. If anyparts are missing or damaged,call

the pressure washer helplineat 1-800-222-3136.

* Main Unit

* Handle

* AccessoryTray with HoseWrap

* High PressureHose

* Spray Gun

* NozzleExtensionwith Quick ConnectFitting

* Quick ConnectSelector Nozzle

* Oil Bottle

* Quick SwitchTMPerfectMixTMAssembly

* PerfectMixTMDetergentHose

* Parts Bag(which includes the following):

* Operator's Manual

* Owner's Registration Card

* HandleFasteningHardwareKit (whichincludes):

* HandleBolts (2)

* Plastic Knobs (2)

* TreeClips (6)

Becomefamiliar with eachpiece beforeassembling the

pressure washer, identify aii contents with the illustration on

page 6. if any parts are missing or damaged, call the

pressure washer helpline at1-800-222-3136.

2. insert handlecarriagebolts (8) through holesfrom

inside of unit and attach a plastic knob (C)from outside

of unit. Tighten by hand.

NOTICE Byloosening both knobs to the middle section of

the attachmentbolt, the upper handle can fold forward to

store fiat atop the cold engine. DONOTfold the handledown

while the engineis hot.

3. insert rubber straps (D) through slots (E) in backof

accessorytray and pull tight from front.

4. Placeaccessory tray (F) over holes (6) on handle

(viewing from front of unit). Push thetree clips (H) into

the holes until they sit fiat against the accessorytray.

ASSEMBLINGPRESSUREWASHER

Your Craftsmanpressure washer will needassembly before

operation:

1. Fill outand sendin registration card.

2. Attach handle andaccessory tray.

3. Connect PerfectMixTMdetergent hoseto pump and Quick

SwitchTMPerfectMixTMassembly.

4. Add oil to engine crankcase.

5. Add fuel to fuel tank.

6. Connectpressure hose to spray gun and pump.

7. Connectwater supply to pump.

8. Attach nozzleextension to spray gun.

9. Attach quick connect selector nozzleto nozzleextension.

.

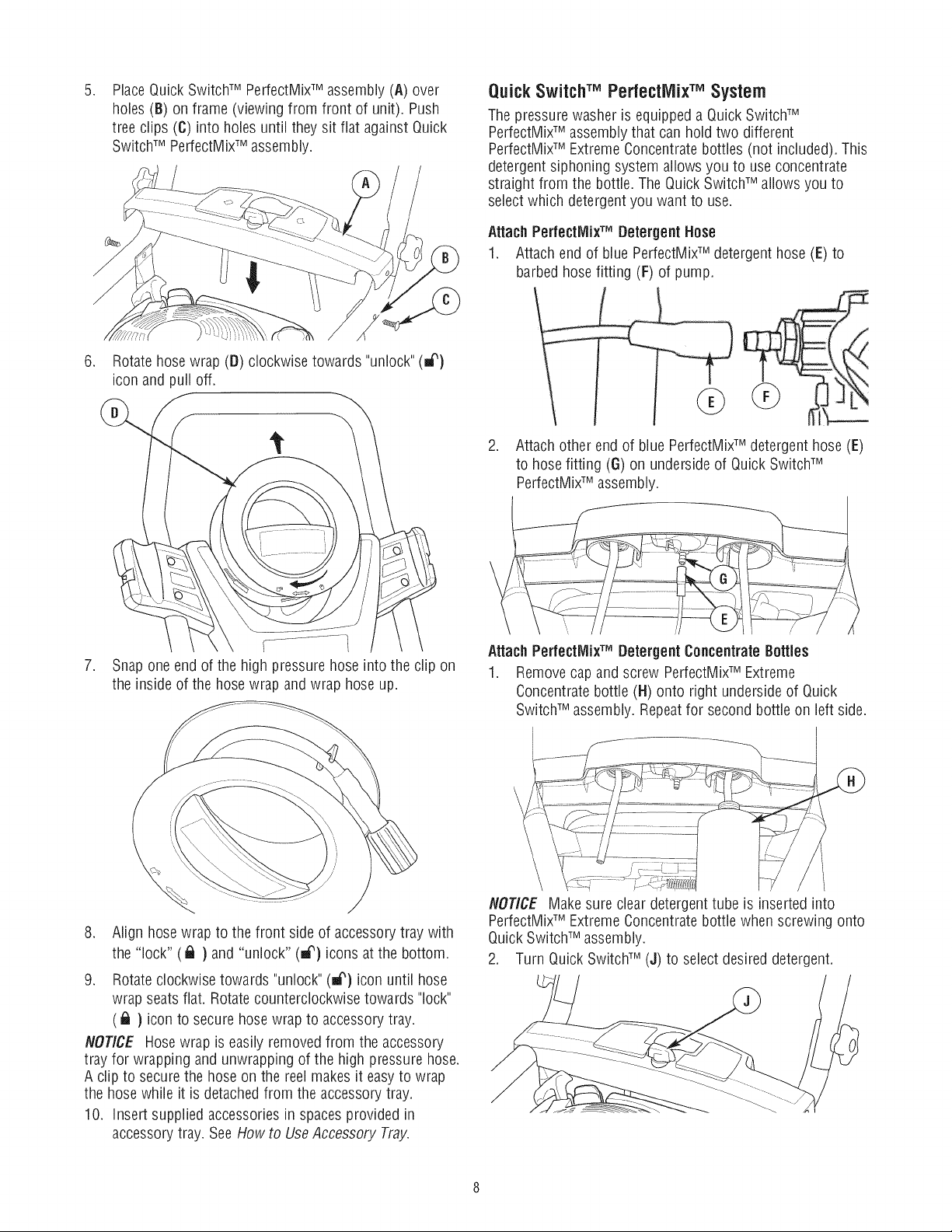

PlaceQuick SwitchTM PerfectMixTM assembly (A) over

holes (B) on frame (viewing from front of unit). Push

tree clips (C) into holes until they sit flat against Quick

SwitchTM PerfectMixTM assembly.

.

Rotate hose wrap (D) clockwisetowards "unlock" (_')

icon and pull off.

QuickSwitchTM PerfectlVlixTM System

The pressure washeris equipped a QuickSwitchTM

PerfectMixTM assembly that can holdtwo different

PerfectMixTM Extreme Concentratebottles (not included). This

detergent siphoning system allows you to use concentrate

straight from the bottle. The QuickSwitchTM allows you to

selectwhich detergent you want to use.

Attach PerfectMW MDetergent Hose

1. Attach end of blue PerfectMixTM detergent hose (E)to

barbed hosefitting (F) of pump.

2. Attach other end of blue PerfectMixTM detergenthose (E)

to hosefitting (G) on undersideof Quick SwitchTM

PerfectMixTM assembly.

.

Snap one end of the high pressure hose into the clip on

the inside of the hosewrap andwrap hose up.

8. Align hosewrap to the front side of accessory tray with

the "lock" ( t_ ) and "unlock" (m") icons at the bottom.

9. Rotateclockwise towards "unlock"(raP)icon until hose

wrap seatsfiat. Rotatecounterclockwise towards "lock"

( t_ ) icon to securehosewrap to accessorytray.

NOTICE Hosewrap is easily removedfrom the accessory

tray for wrapping and unwrapping of the high pressure hose.

A clip to securethe hose on the reelmakesit easyto wrap

the hose while it is detachedfrom the accessorytray.

10. insert supplied accessoriesinspacesprovided in

accessorytray. SeeHow to UseAccessory Tray.

Attach PerfectiVIWMDetergentConcentrate Bottles

1. Removecap andscrew PerfectMixTM Extreme

Concentratebottle (H) onto right undersideof Quick

SwitchTM assembly. Repeatfor second bottle on left side.

NOTICE Makesure clear detergenttube is inserted into

PerfectMixTM ExtremeConcentratebottle when screwing onto

QuickSwitchTM assembly.

2. Turn Quick SwitchTM (J) to selectdesired detergent.

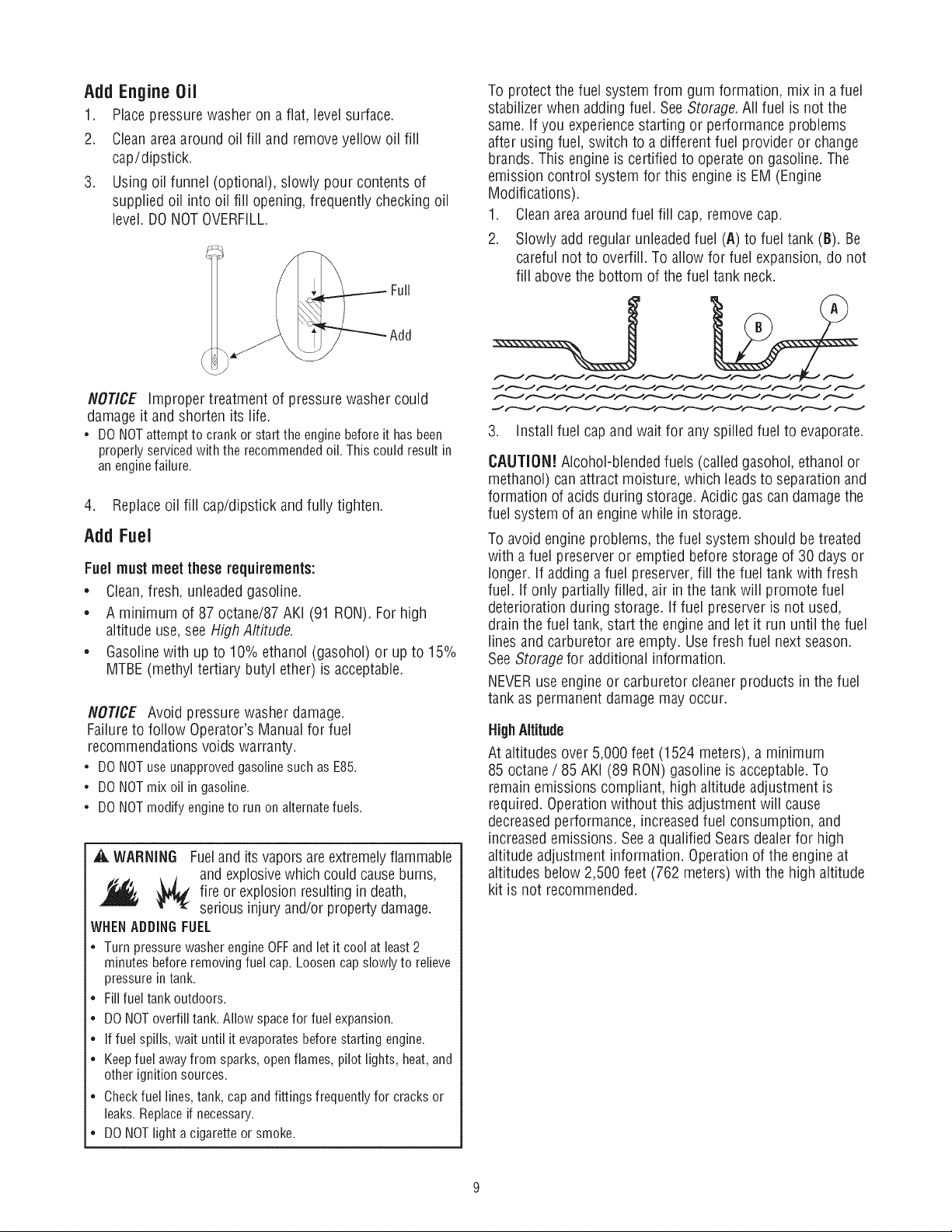

Add EngineOil

1. Placepressure washer on aflat, levelsurface.

2. Cleanarea around oil fill and remove yellow oil fill

cap/dipstick.

3. Using oil funnel (optional), slowly pour contents of

supplied oil into oil fill opening, frequently checking oil

level. DONOTOVERFILL.

Full

NOTICE Improper treatment of pressure washer could

damage it and shorten its life.

• DO NOTattempt to crank or start the engine before it has been

properly servicedwith the recommendedoil. This could result in

an enginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

AddFuel

Fuel must meet theserequirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87 AKi (91 RON).Forhigh

altitude use,seeHigh Altitude.

• Gasolinewith up to 10% ethanol (gasohol) or up to 15%

MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE Avoid pressurewasher damage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoil in gasoline.

• DONOTmodifyengineto runonalternatefuels.

• , WARNING Fuelandits vapors areextremelyflammable

and explosivewhich could causeburns,

,_ ire or explosionresulting in death,

serious injury and/orproperty damage.

WHENADDINGFUEL

• Turn pressure washerengine OFFand let it cool at least2

minutes beforeremoving fuel cap. Loosen cap slowly to relieve

pressure in tank.

• Fill fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat,and

other ignition sources.

• Checkfuel lines,tank, cap andfittings frequently for cracks or

leaks. Replaceif necessary.

• DONOTlight a cigarette orsmoke.

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen addingfuel. See Storage.All fuel is not the

same.If you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline.The

emission control system for this engine is EM(Engine

Modifications).

1. Cleanareaaround fuel fill cap, removecap.

2. Slowly add regularunleadedfuel (A) to fuel tank (B). Be

careful not to overfill. To allow for fuel expansion,do not

fill abovethe bottom of the fuel tank neck.

NNNNNNNNN,,_.-._N N

N NNNNNNNNNN N

J N NNNNNNNNNN N

3. Install fuel cap andwait for any spilledfuel to evaporate.

CAUTION! Alcohol-blended fuels (called gasohol, ethanol or

methanol) canattract moisture, which leadsto separation and

formation of acids during storage.Acidic gascandamagethe

fuel system of an enginewhile in storage.

To avoidengine problems, the fuel system shouldbe treated

with a fuel preserveror emptied beforestorage of 30 daysor

longer. If adding a fuel preserver,fill the fuel tank with fresh

fuel. If only partially filled, air in the tank will promote fuel

deterioration during storage. Iffuel preserver is not used,

drain the fuel tank, start the engineand let it run until the fuel

lines andcarburetor are empty. Usefresh fuel next season.

SeeStoragefor additional information.

NEVERuse engine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

HighAltitude

At altitudes over 5,000 feet(1524 meters), a minimum

85 octane / 85 AKi (89 RON)gasolineis acceptable.To

remainemissions compliant, high altitude adjustment is

required. Operationwithout this adjustmentwiii cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea qualified Searsdealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet(762 meters) with the high altitude

kit is not recommended.

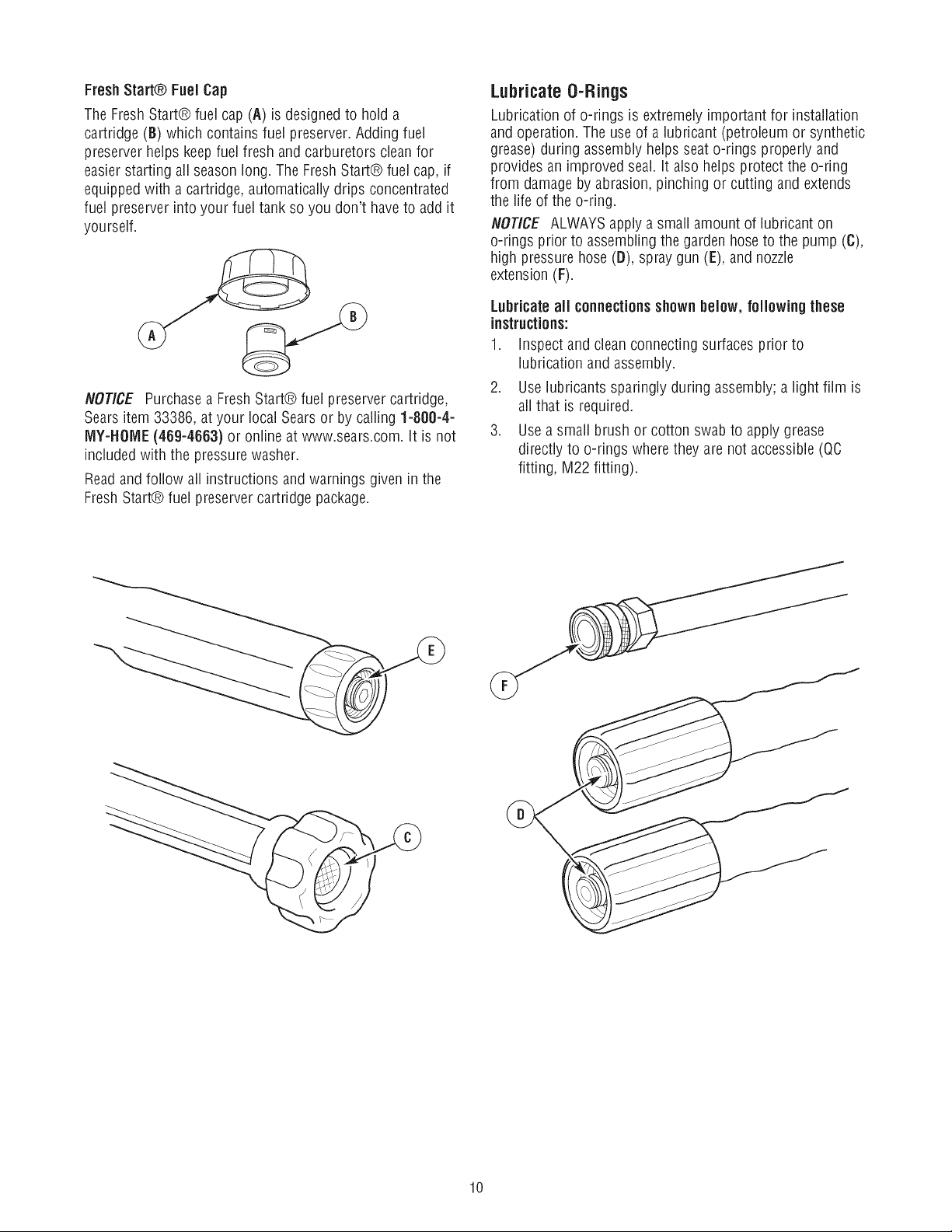

FreshStart® Fuel Cap

The FreshStart® fuel cap (A) is designed to hold a

cartridge (B) which containsfuel preserver. Adding fuel

preserver helps keepfuel fresh and carburetors cleanfor

easierstarting all season long. The FreshStart® fuel cap, if

equipped with a cartridge, automatically drips concentrated

fuel preserverinto your fuel tank so you don't haveto add it

yourself.

NOTICE Purchasea FreshStart® fuel preserver cartridge,

Searsitem 33386, at your local Searsor by calling 1-800-4-

MY-HOME(469-4663) or online at www.sears.com, it is not

included with the pressurewasher.

Readand follow all instructions andwarnings given inthe

FreshStart@fuel preservercartridge package.

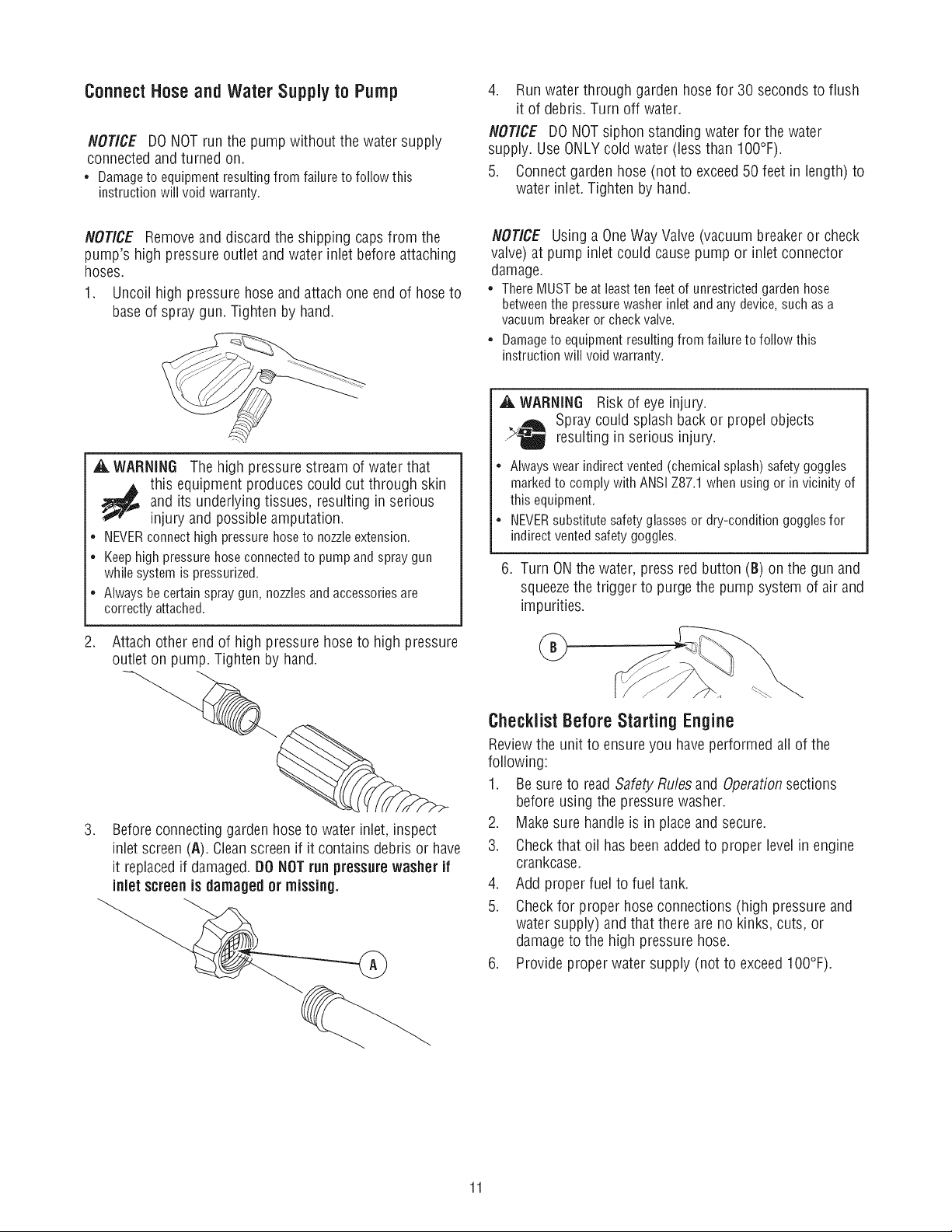

Lubricate O-Rings

Lubrication of o-rings is extremely important for installation

and operation. The useof a lubricant (petroleum or synthetic

grease)during assembly helpsseat o-rings properly and

provides animproved seal. It also helps protect the o-ring

from damageby abrasion, pinching or cutting and extends

the life of the o-ring.

NOTICE ALWAYSapply a small amount of lubricant on

o-rings prior to assemblingthe gardenhose to the pump (C),

high pressurehose(D), spray gun (E), and nozzle

extension(F).

Lubricateall connectionsshownbelow,following these

instructions:

1. inspect and clean connecting surfacesprior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light film is

all that is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings wherethey are not accessible(QC

fitting, M22 fitting).

10

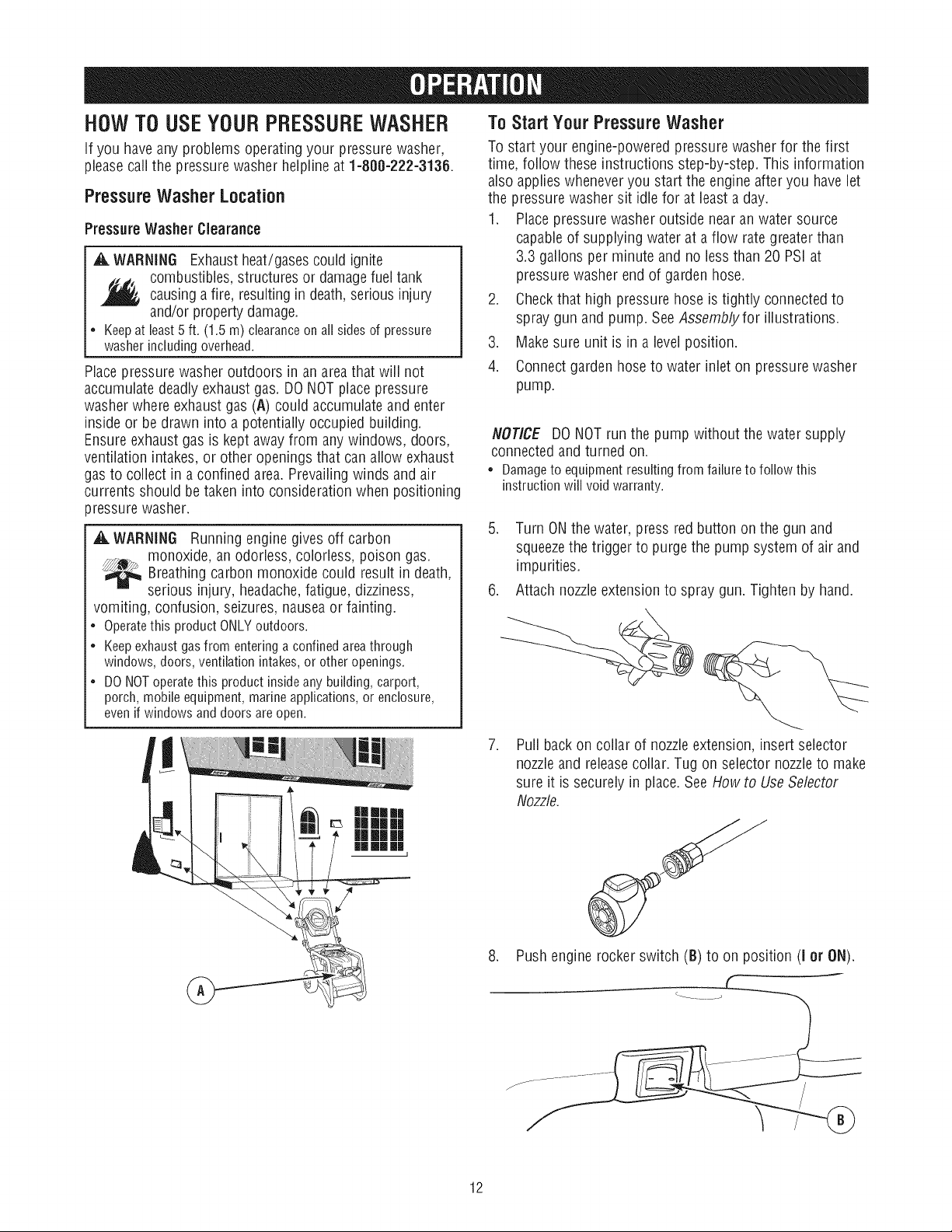

ConnectHoseandWater Supplyto Pump

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

= Damagetoequipmentresultingfrom failuretofollowthis

instructionwill voidwarranty.

4. Runwater through garden hosefor 30 secondsto flush

it of debris.Turn off water.

NOTICE DONOTsiphon standing water for the water

supply. Use ONLYcold water (less than 100°F).

5. Connectgarden hose(not to exceed50 feet in length) to

water inlet. Tightenby hand.

NOTICE Removeand discardthe shipping capsfrom the

pump's high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressurehose and attachone end of hoseto

baseof spray gun. Tighten by hand.

_, WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

• NEVERconnect highpressure hoseto nozzleextension.

• Keep high pressurehose connectedto pump and spraygun

while system is pressurized.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

2. Attach other end of high pressure hoseto high pressure

outlet on pump. Tightenby hand.

NOTICE Using a OneWay Valve (vacuumbreaker or check

valve) at pump inlet could cause pump or inlet connector

damage.

= ThereMUSTbeatleasttenfeetofunrestrictedgardenhose

betweenthepressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

• Damageto equipment resultingfrom failure to follow this

instruction will void warranty.

_, WARNING Risk of eyeinjury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirectvented (chemicalsplash) safetygoggles

markedto comply with ANSIZ87.1 when usingor in vicinity of

this equipment.

• NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

6. Turn ONthe water, press redbutton (B) on the gun and

squeezethe trigger to purgethe pump system of air and

impurities.

.

Beforeconnecting garden hoseto water inlet, inspect

inlet screen (A). Cleanscreenif it contains debris or have

it replacedif damaged.DO NOTrunpressurewasher if

inlet screenis damaged or missing.

Checklist BeforeStarting Engine

Reviewthe unit to ensureyou haveperformedall of the

following:

1. Besure to readSafetyRules and Operationsections

before using the pressurewasher.

2. Makesure handleis in placeand secure.

3. Checkthat oil has beenaddedto proper levelin engine

crankcase.

4. Add properfuel to fuel tank.

5. Checkfor proper hoseconnections (high pressureand

water supply) andthat there are no kinks, cuts, or

damageto the high pressurehose.

6. Provide proper water supply (not to exceed100%).

11

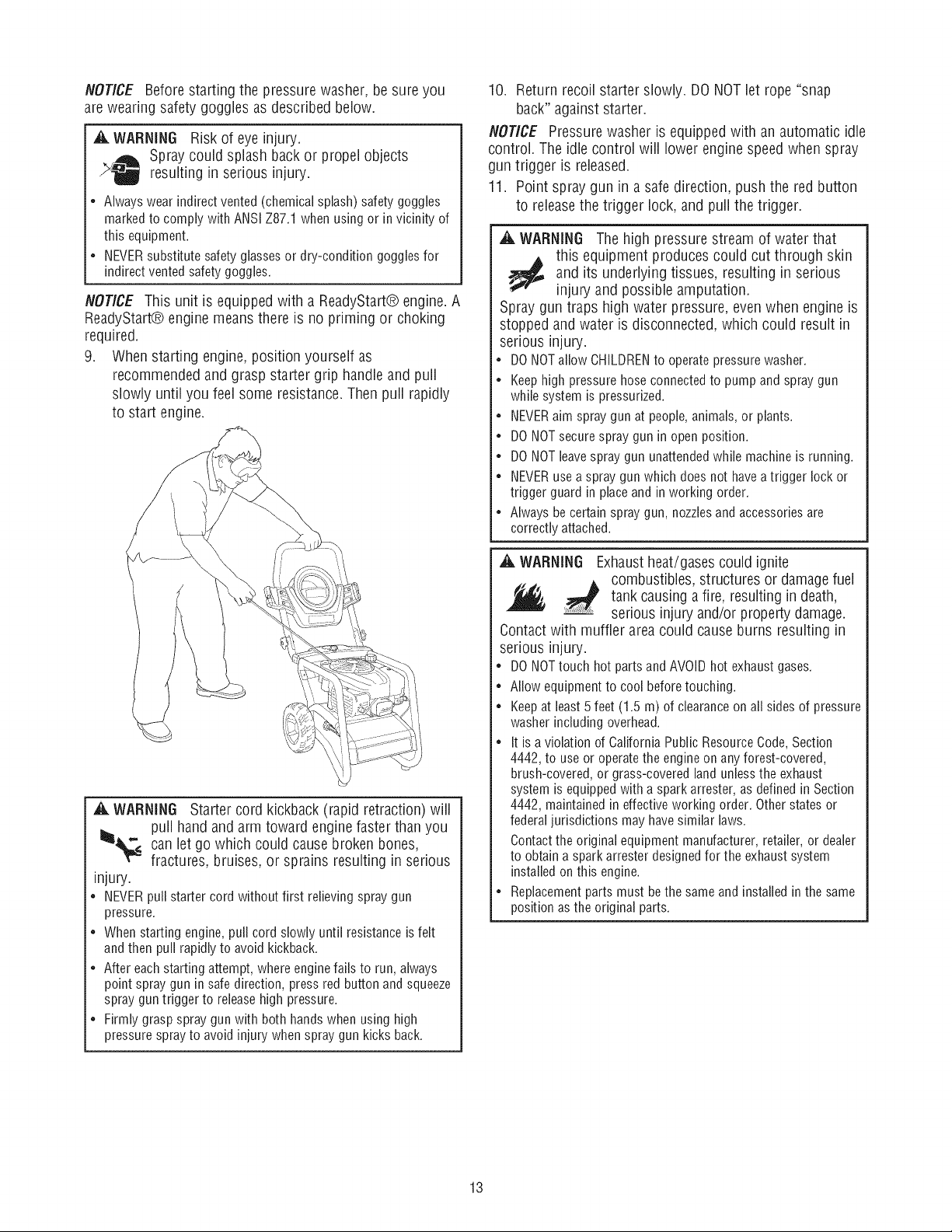

HOWTO USEYOURPRESSUREWASHER

If you haveanyproblems operating your pressure washer,

pleasecall the pressure washerhelpline at 1-800-222-3136.

PressureWasherLocation

PressureWasher Clearance

A. WARNING Exhaustheat/gasescould ignite

combustibles, structuresor damagefuel tank

causing afire, resultingin death,serious injury

and/or property damage.

. Keepat least5 ft. (1.5m) clearanceonall sidesof pressure

washerincludingoverhead.

Placepressure washer outdoors in an areathat will not

accumulate deadlyexhaust gas. DONOTplacepressure

washer where exhaustgas (A) could accumulate and enter

inside or be drawn into a potentially occupiedbuilding.

Ensureexhaust gas is kept awayfrom anywindows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect in aconfined area. Prevailingwinds and air

currents should betaken into consideration when positioning

_ressurewasher.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

_ reathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

• Operatethis product ONLYoutdoors.

= Keep exhaustgas from entering a confined areathrough

windows, doors, ventilation intakes,or other openings.

• DO NOToperatethis product inside any building, carport,

porch, mobile equipment, marineapplications, or enclosure,

evenif windows and doors areopen.

To StartYour Pressure Washer

To startyour engine-powered pressurewasherfor the first

time, follow these instructions step-by-step. This information

alsoapplies wheneveryou start the engineafteryou havelet

the pressure washer sit idle for at leasta day.

1. Placepressurewasher outside nearan water source

capableof supplying water at aflow rate greaterthan

3.3 gallons per minute and no less than 20 PSi at

pressurewasher endof garden hose.

2. Checkthat high pressure hose is tightly connectedto

spray gun and pump. SeeAssembly for illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hoseto water inlet on pressurewasher

pump.

NOTICE DONOTrun the pump without the watersupply

connectedand turned on.

= Damageto equipmentresultingfromfailureto followthis

instructionwill voidwarranty.

5. Turn ONthe water, pressred button on the gun and

squeezethe trigger to purgethe pump system of airand

impurities.

6. Attach nozzleextension to spray gun. Tighten by hand.

.

Pull backon collar of nozzleextension, insert selector

nozzleand releasecollar. Tug on selector nozzleto make

sure it is securelyin place. See How to UseSelector

Nozzle.

8. Pushengine rocker switch (B) to on position (I or ON).

12

NOTICE Beforestarting the pressurewasher, be sureyou

are wearing safetygoggles asdescribed below.

• , WARNING Risk of eye injury.

Spraycould splash back or propelobjects

resulting in serious injury.

• Always wear indirectvented (chemicalsplash) safetygoggles

markedto comply with ANSIZ87.1 when usingor in vicinity of

this equipment.

• NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

NOTICE This unit is equipped with a ReadyStart® engine.A

ReadyStart® engine meansthere is no priming or choking

required.

9. Whenstarting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feel someresistance. Then pull rapidly

to start engine.

10. Return recoil starter slowly. DO NOTlet rope "snap

back"against starter.

NOTICE Pressurewasher is equippedwith anautomatic idle

control. The idle control will lower enginespeed when spray

gun trigger is released.

11. Point spray gun in a safe direction, push the red button

to releasethe trigger lock, andpull the trigger.

,&. WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

• DONOTallow CHILDRENto operatepressure washer.

• Keep high pressurehose connectedto pump and spraygun

while system is pressurized.

• NEVERaim spraygun at people,animals, or plants.

• DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuse a spray gun which doesnot haveatrigger lock or

trigger guard inplace and in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

• , WARNING Starter cord kickback (rapid retraction) will

puii hand and arm toward engine faster than you

_,_.< can let go which could cause broken bones,

fractures, bruises, or sprains resulting in serious

injury.

• NEVERpullstarter cord without first relieving spraygun

pressure.

• When starting engine, pull cord slowly until resistanceisfelt

andthen pull rapidly to avoid kickback.

• After each starting attempt, where enginefails to run, always

point spray gun insafe direction, press red button and squeeze

spray gun trigger to releasehigh pressure.

• Firmly graspspray gunwith both hands when using high

pressure sprayto avoid injury when spraygun kicks back.

,&. WARNING Exhaust heat/gases could ignite

tank causing a fire, resulting in death,

combustibles, structures or damage fuel

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipment to cool beforetouching.

• Keep at least5 feet (1.5 m) of clearanceon all sidesof pressure

washer including overhead.

• It is a violation of California PuNic ResourceCode, Section

4442, to use oroperate the engine on anyforest-covered,

brush-covered, orgrass-covered landunlessthe exhaust

system is equippedwith a spark arrester,as definedin Section

4442, maintained in effective working order. Otherstates or

federaljurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaustsystem

installed onthis engine.

• Replacementparts must bethe same andinstalled inthe same

position as the original parts.

13

Nowto StopYourPressureWasher

1. Releasespray guntrigger and let engineidle for two

minutes.

.

Push engine rockerswitch to off position (0 or OFF),

3.

ALWAYSpoint spraygun in asafe direction, push red

button and squeezespraygun trigger to releaseretained

high water pressure.

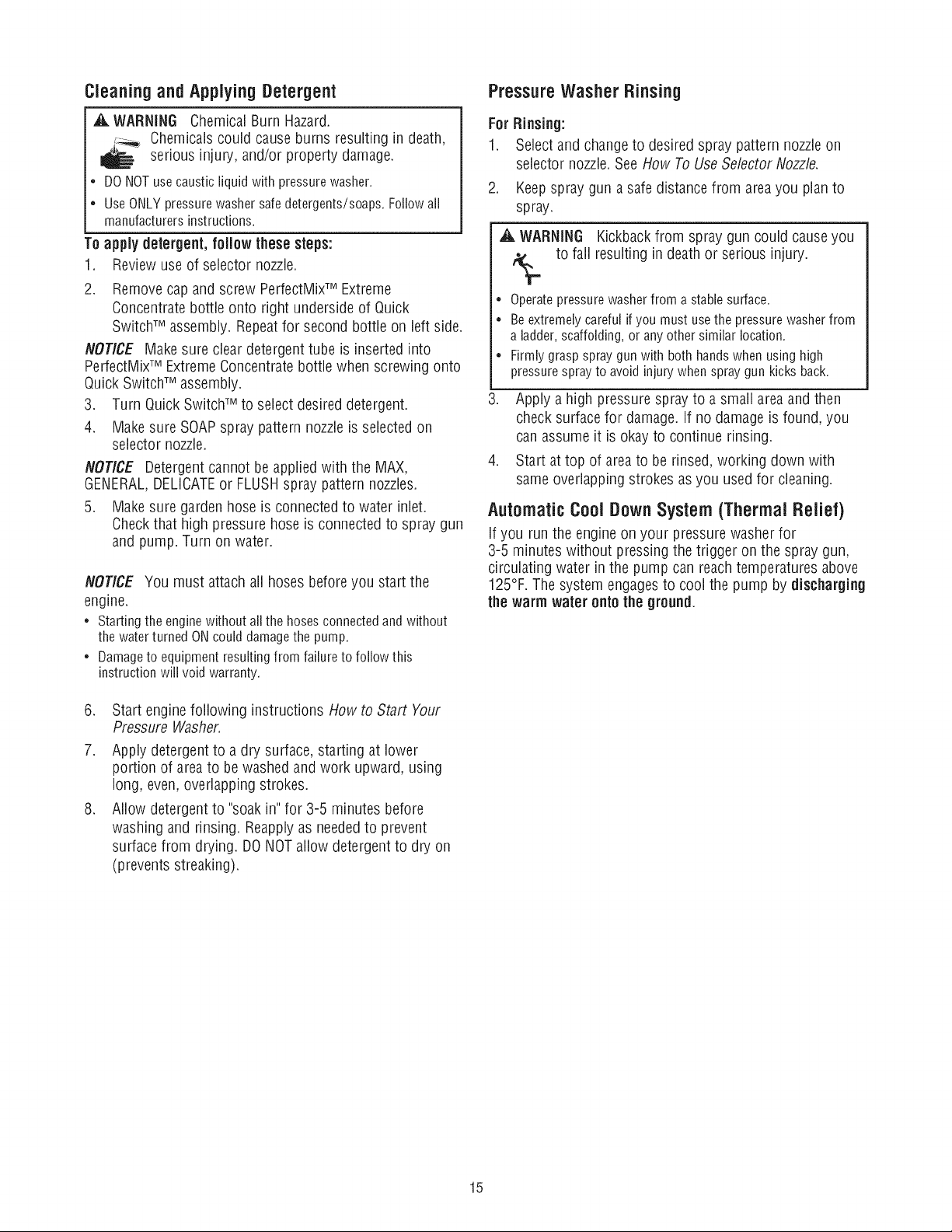

Nowto Use Selector Nozzle

Theselector nozzleallows you to switch betweenfive

different spray pattern nozzles.Spray patterns can be

changedwhile pressurewasher is running once spray gun

trigger safety lock is engaged.The spray patternsvary as

shown below.

_, WARNING The highpressurestream of waterthat

,A WARNING The high pressurestream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spraygun traps high water pressure,even when engineis

stopped and water is disconnected, which could result in

serious injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

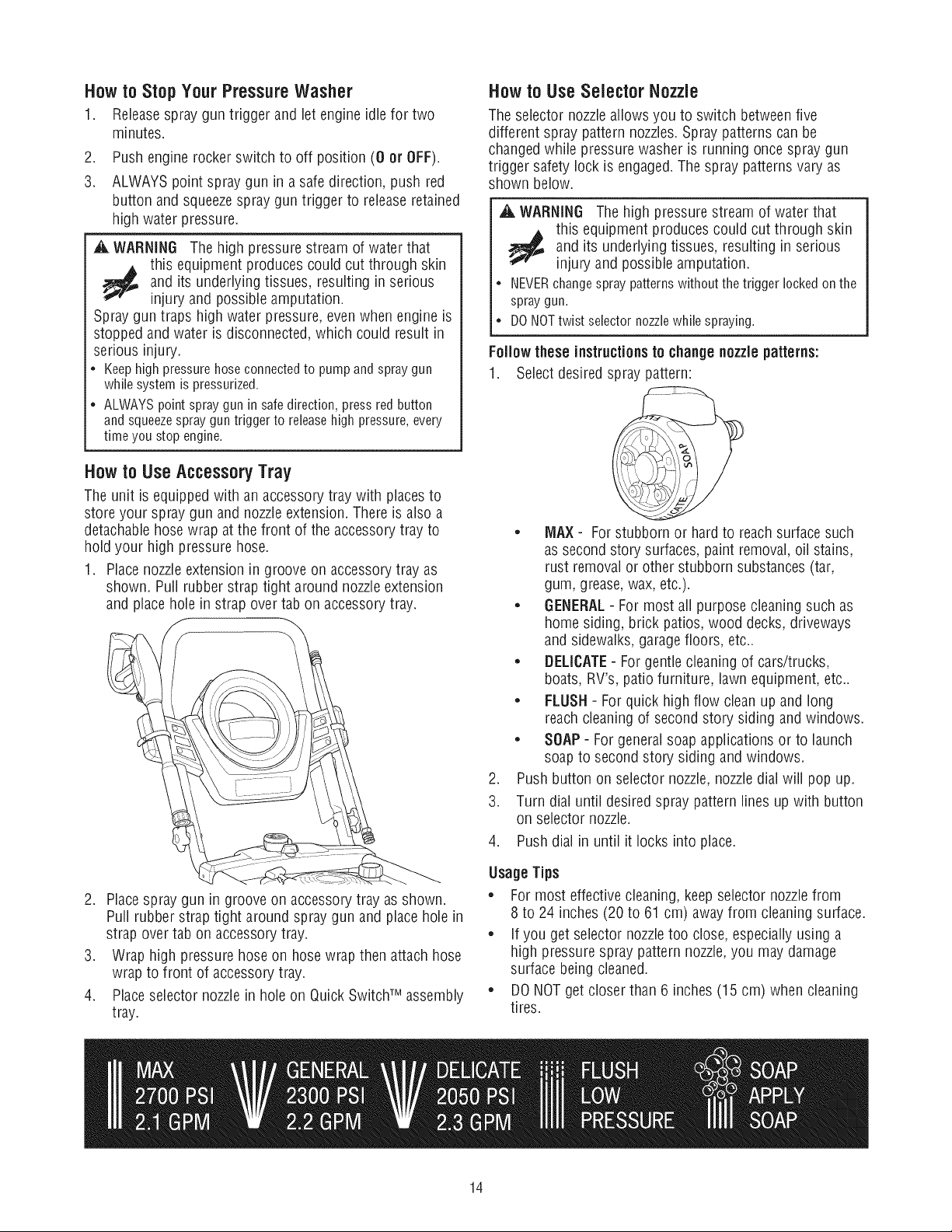

Nowto Use Accessory Tray

The unit is equippedwith an accessorytray with places to

store your spray gun and nozzleextension. Thereis also a

detachablehosewrap atthe front of the accessorytray to

hold your high pressurehose.

1. Placenozzleextension in groove on accessorytray as

shown. Pull rubber strap tight around nozzleextension

and placehole in strap overtab on accessory tray.

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

• NEVERchangespraypatternswithoutthetriggerlockedonthe

spraygun.

• DONOTtwist selectornozzlewhilespraying.

Follow theseinstructionsto change nozzlepatterns:

1. Select desiredspray pattern:

• NAX- Forstubborn or hard to reach surfacesuch

as second storysurfaces, paint removal,oilstains,

rust removalor other stubborn substances (tar,

gum, grease,wax, etc.).

• GENERAL- For most all purpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garagefloors, etc..

• DELICATE- For gentle cleaningof cars/trucks,

boats, RV's, patiofurniture, lawn equipment, etc..

• FLUSH- Forquick high flow clean up and long

reachcleaning of second story siding and windows.

• SOAP- Forgeneral soapapplications or to launch

soapto second story siding and windows.

2. Push button on selector nozzle,nozzledial will pop up.

3. Turn dial until desiredspray patternlines up with button

on selector nozzle.

4. Push dial in until it locks into place.

2. Placespray gun in groove on accessorytray asshown.

Pull rubber strap tight around spray gun and place hole in

strap over tab on accessorytray.

3. Wrap high pressure hoseon hosewrap then attach hose

wrap tofront of accessorytray.

4. Placeselector nozzlein holeon QuickSwitchTM assembly

tray.

UsageTips

* For most effective cleaning,keep selector nozzlefrom

8 to 24 inches (20 to 61 cm) away from cleaning surface.

, If you get selector nozzletoo close, especiallyusing a

high pressurespray pattern nozzle,you may damage

surface being cleaned.

, DONOTget closer than 6 inches (15 cm) when cleaning

tires.

14

Cleaning andApplying Detergent

AWARNIN6 Chemical BurnHazard.

j_, Chemicalscould cause burns resultingin death,

serious injury,and/or property damage.

• DONOTusecausticliquidwithpressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

To apply detergent,follow these steps:

1. Reviewuse of selector nozzle.

2. Removecap andscrew PerfectMixTM Extreme

Concentratebottle onto right undersideof Quick

SwitchTM assembly. Repeatfor second bottle on left side.

NOTICE Make sure cleardetergent tube is inserted into

PerfectMixTM ExtremeConcentratebottle when screwing onto

Quick SwitchTM assembly.

3. Turn Quick SwitchTM to select desireddetergent.

4. Make sure SOAPspray pattern nozzleis selectedon

selector nozzle.

NOTICE Detergentcannot beapplied with the MAX,

GENERAL,DELICATEor FLUSHspray pattern nozzles.

5. Make sure gardenhose is connected to water inlet.

Checkthat high pressurehose is connected to spray gun

and pump.Turn on water.

NOTICE You must attach all hoses before you start the

engine.

• Starting the engine without allthe hoses connected and without

the waterturned ON could damagethe pump.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

PressureWasher Rinsing

ForRinsing:

1. Selectand changeto desired spraypattern nozzleon

selector nozzle.See How ToUseSelector Nozzle.

2. Keepspray gun a safe distancefrom areayou plan to

spray.

,& WARNIN6 Kickback from spray gun could cause you

to fall resulting in death or serious injury.

• Operatepressurewasher from a stable surface.

• Beextremely careful if you must use the pressurewasher from

a ladder,scaffolding, or anyother similar location.

• Firmly graspspray gun with both handswhen using high

pressure sprayto avoid injury when spraygun kicks back.

3. Apply a high pressure spray to a small areaand then

checksurface for damage. If no damage is found, you

canassume it is okayto continue rinsing.

4. Start at top of areato be rinsed, working down with

sameoverlapping strokes as you used for cleaning.

Automatic CoolDownSystem(ThermalRelief)

If you runthe engine onyour pressure washer for

3-5 minutes without pressing the trigger on the spraygun,

circulating water in the pump can reachtemperatures above

125°F.The systemengagesto cool the pump by discharging

the warm water onto the ground.

6. Start enginefollowing instructions How to Start Your

Pressure Washer.

7. Apply detergent to a dry surface,starting at lower

portion of areato be washedand work upward, using

long, even,overlapping strokes.

8. Allow detergent to "soakin"for 3-5 minutes before

washing andrinsing. Reapplyas neededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

15

ENGINETECHNICALiNFORMATiON

This is a single cylinder, overheadvalve (OHV), air cooled

engine, it is alow emissions engine.

In the State of California, Model 110000engines are certified

by theCalifornia Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performanceor

operational life of this engine.Theengine is warranted solely

according to the product and emissionswarranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas engine models is

labeled in accordancewith SAE(Society of Automotive

Engineers)code J1940 (Small Engine Power &Torque

Rating Procedure),and rating performance has been

obtained and corrected in accordancewith SAEJ1995

(Revision 2002-05). Torquevalues are derived at 3060 RPM;

horsepower values are derived at 3600 RPM. Thegross

power curves can beviewed at

www.BRiGGSandSTRATTON.COM.Net power values are

taken with exhaust andair cleanerinstalled whereas gross

power values arecollected without these attachments. Actual

gross enginepower will behigher than net engine power and

is affectedby, among other things, ambient operating

conditions and engine-to-engine variability. Giventhe wide

array of products on which enginesare placed, the gas

engine may not developthe ratedgross power when used in

a given pieceof power equipment. This difference is dueto a

variety of factors including, but not limited to, the variety of

engine components (air cleaner, exhaust, charging, cooling,

carburetor, fuel pump, etc.), application limitations, ambient

operating conditions (temperature, humidity, altitude), and

engine-to-enginevariability. Dueto manufacturing and

capacity limitations, Briggs & Stratton may substitute an

engine of higher rated power for this Seriesengine.

PRODUCTSPECIFICATIONS

PressureWasherSpecifications

Max Outlet Pressure ...................... 2,700 PSI*

Max Flow Rate............................. 2.3 GPM

DetergentMix ........................ Use asdirected

Water SupplyTemperature .......... Notto exceed100%

EngineSpecifications

Bore............................. 2.583in. (65.61mm)

Stroke ............................ 2.04in. (51.82mm)

Displacement ........................ 10.69in. (175cc)

SparkPlug

Type:...................... Briggs & Stratton 692051

SetGapTo: ...................... 0.020in. (0.50mm)

ArmatureAir Gap: .......... 0.010-0.014in.(0.25-0.36mm)

Valveclearancewithvalvesprings installedand piston1/4 in.

(6 mm) pasttop deadcenter(checkwhenengineis cold).

Intake.................... 0.004-0.008in.(0.10-0.20mm)

Exhaust .................. 0.004-0.008in.(0.10-0.20mm)

FuelCapacity............................... 1.6Quarts

0il Capacity........................ 20 Ounces(0.6 liter)

NOTICE Forpractical operation, the engineload should not

exceed85% of rated power. Enginepower will decrease

3-1/2% for each1,000 feet (300 meters) above sealevel and

1% for each 10° F(5.6° C) above 77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

* This pressure washer is ratedin accordanceto the

PressureWasher ManufacturersAssociation (PWMA)

standard PW101(Testing and RatingPerformanceof

PressureWashers).

16

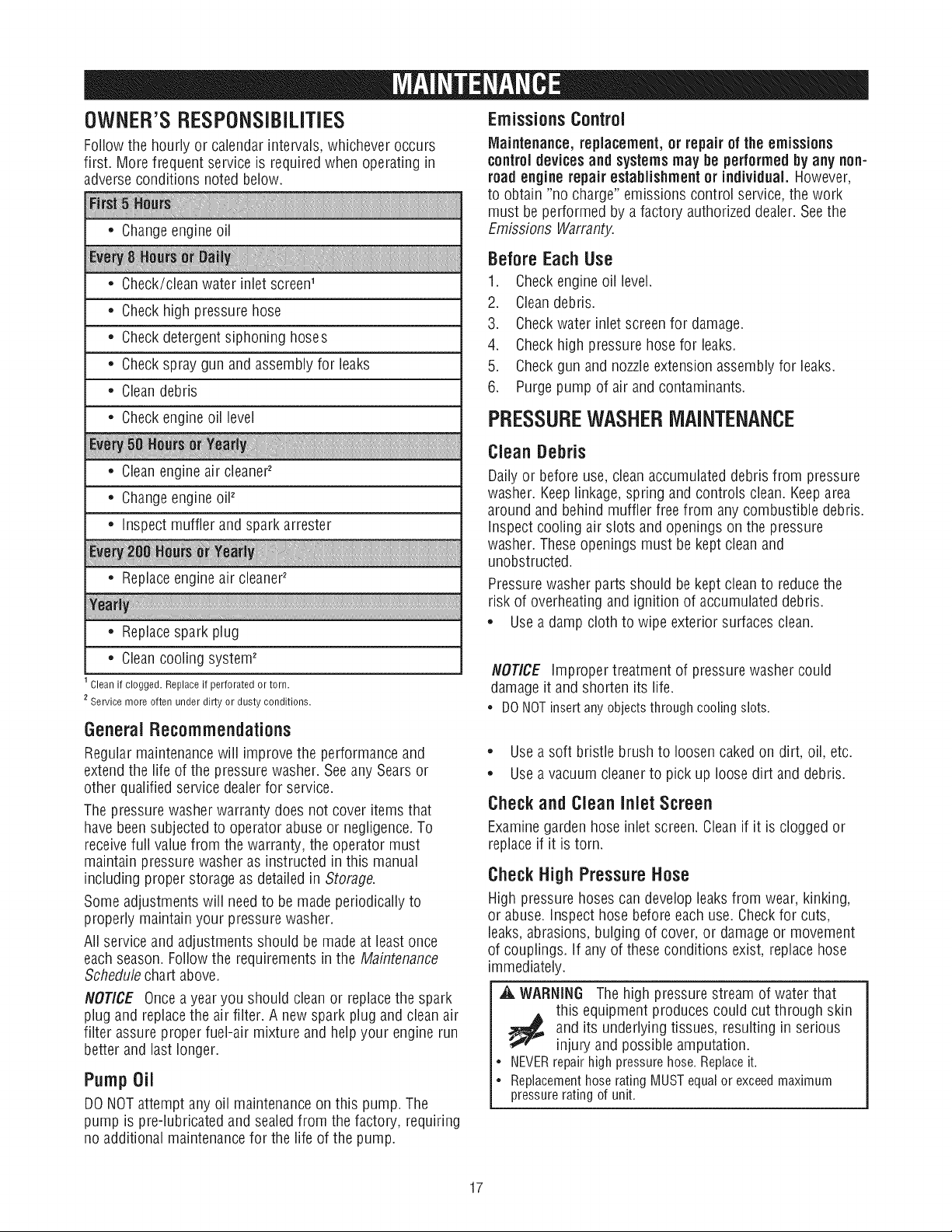

OWNER'SRESPONSiBiLiTiES

Follow the hourly or calendarintervals, whichever occurs

first. More frequentservice is required when operating in

adverseconditions noted below.

• Changeengine oil

• Check/clean water inlet screen'

Checkhigh pressure hose

Checkdetergentsiphoning hoses

Checkspray gun and assemblyfor leaks

Cleandebris

EmissionsControl

Maintenance,replacement,or repairof the emissions

controldevices and systemsmay be performed byany non-

roadengine repair establishment or individual. However,

to obtain "no charge" emissions control service,the work

must beperformed by afactory authorizeddealer. Seethe

Emissions Warranty.

BeforeEachUse

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screenfor damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and nozzleextension assemblyfor leaks.

6. Purge pump of air and contaminants.

Checkengineoil level

f

• Cleanengine air cleaner_

• Changeengine oil_

• inspect muffler and spark arrester

iiiiii

• Replaceengine air cleaner_

• Replacespark plug

• Cleancooling system_

Clean if clogged. Replace if perforated or torn.

2Service more often under dirty or dusty conditions.

GeneralRecommendations

Regularmaintenance will improve the performanceand

extendthe life of the pressurewasher. Seeany Searsor

other qualified service dealerfor service.

Thepressure washerwarranty does not cover items that

havebeensubjected to operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressurewasher as instructed in this manual

including proper storage as detailed in Storage.

Someadjustments will needto be made periodically to

properly maintain your pressurewasher.

All service andadjustments should be made at leastonce

eachseason. Follow the requirementsin the Maintenance

Schedulechart above.

NOTICE Oncea yearyou should cleanor replace the spark

plug andreplacethe air filter. A new spark plugand clean air

filter assureproper fuel-air mixture and helpyour engine run

better and last longer.

PumpOil

DONOTattempt any oil maintenanceon this pump.The

pump is pre-iubricatedand sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

PRESSUREWASHERMAINTENANCE

CleanDebris

Daily or before use,clean accumulateddebris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around andbehind muffler free from any combustible debris.

inspect cooling air slots and openings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept cleanto reduce the

risk of overheating andignition of accumulated debris.

• Usea damp clothto wipe exterior surfacesclean.

NOTICE improper treatment of pressurewasher could

damageit and shorten its life.

• DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosencaked on dirt, oil, etc.

• Usea vacuum cleanerto pick up loosedirt and debris.

CheckandClean Inlet Screen

Examinegarden hoseinlet screen. Cleanif it is clogged or

replaceif it is torn.

CheckHighPressure Hose

High pressurehoses can develop leaksfrom wear,kinking,

or abuse, inspect hose beforeeachuse. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If anyof these conditions exist, replacehose

immediately.

• , WARNING The highpressurestream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

, NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTequalor exceedmaximum

pressureratingofunit.

17

CheckDetergentSiphoningTubes

Examineeachdetergent tubeand clean ifclogged.The tube

should fit tightly on the fittings. Examinetubesfor leaksor

tears. Replacetubes if damaged.

Detergent Siphoning Check Ball

Occasionallycheck ball in detergentsiphoning system may

become stuck from storage, dried soap,or minerals inwater.

Thecheck bailcan befreed by performing the following:

NOTICE Beforeperforming this procedure,be sure you are

wearing safety goggles asdescribed below.

_, WARNING Risk of eyeinjury.

Spraycould splash back or propelobjects

resulting in serious injury.

• Always wear indirectvented (chemicalsplash) safetygoggles

markedto comply with ANSiZ87.1 when using or invicinity of

this equipment.

• NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

Shut off engine andturn off water supply.

.

ALWAYSpoint spraygun in asafe direction, press red

button and squeezespraygun trigger to releaseretained

high water pressure.

.

Removedetergent siphoning hosefrom barbedfitting

on pump.

4.

Using afirm, blunt object 7/64" in diameteror smaller,

by atleast 1" long, such as anAlien wrench, slowly

insert the object into the barbed fitting until you meet

resistance.This resistance is the check ball.

5. Slowly push down until you feel the ball move slightly,

push no more than 1/8". Slight pressure maybe

requiredto freethe ball.

6. Repeatsteps 4 and 5 if necessary.

7. Reinstall detergent siphoning hose onto barb fitting.

8. Treatwith PumpSaveras describedin Protecting the

Pumpduring storage to prevent reoccurrence.

CheckSprayGun

Examinehoseconnection to spraygun and makesure it is

secure.Test trigger by pressingit and makingsure it springs

back into placewhenyou releaseit. Donot depressred button

andtest trigger. You should not beableto press trigger.

Replacespray gun immediatelyif it fails any of thesetests.

_, WARNING The high pressurestream of waterthat

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spraygun traps high water pressure,even when engineis

stopped and water is disconnected, which could result in

serious injury.

= Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

= ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

18

Loading...

Loading...