Craftsman 580.752550 Owner's Manual

HIGH PRESSURE WASHER

6.5 HORSEPOWER

2550 PSI

2.5 GPM

PRESSURE WASHER

CUSTOMER HELPLINE

1-800-222-3136

Model No. 580.752550

CAUTION:

Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CT)

Part No. 192059 Draft 3 (05/27/2003)

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

Owner ’s Manual

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Español

Read this manual carefully and become

familiar with your pressure washer. Know its

applications, its limitations, and any hazards

involved.

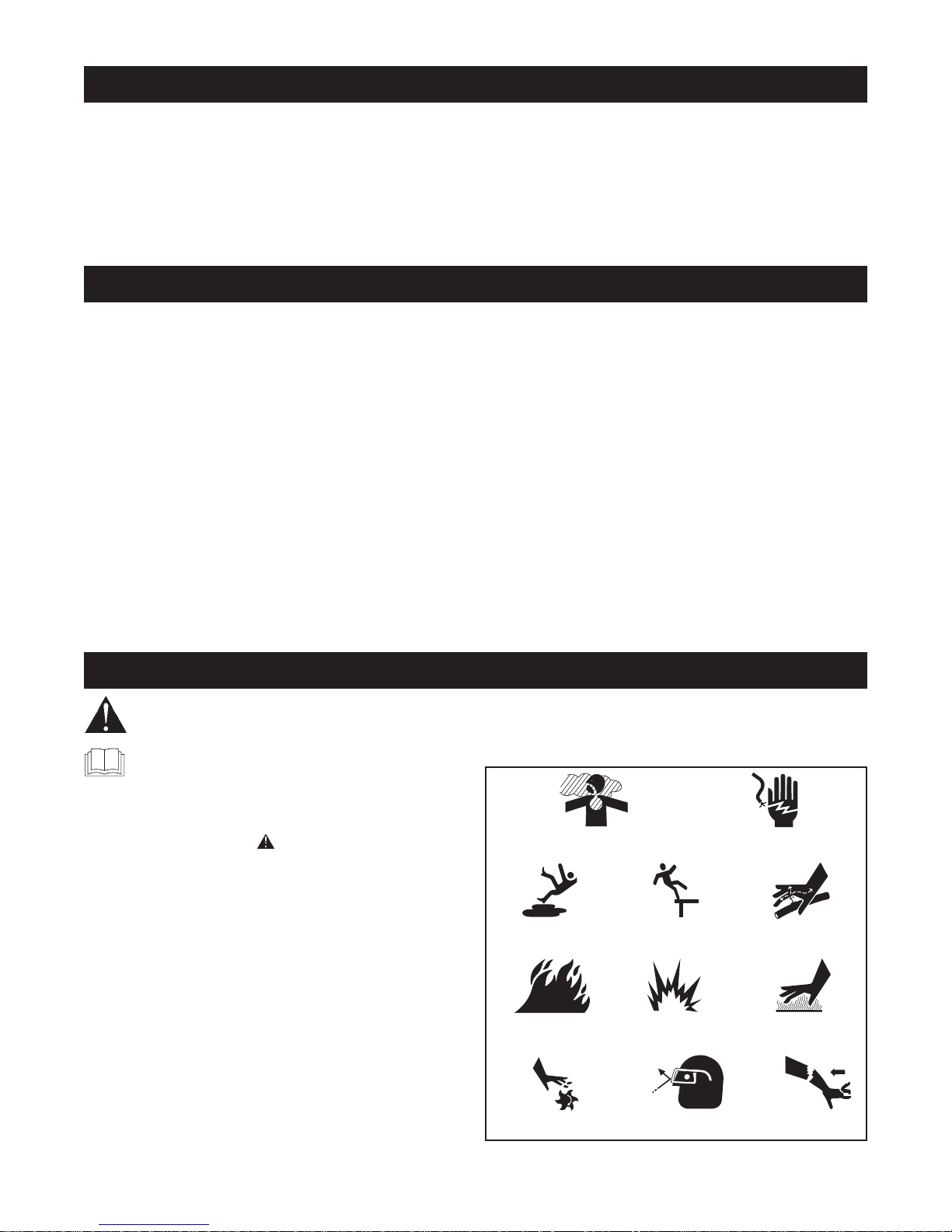

The safety alert symbol ( ) is used with a signal

word (DANGER, CAUTION, WARNING), a pictorial

and/or a safety message to alert you to hazards.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury. WARNING indicates a

hazard which, if not avoided, could result in death or

serious injury. CAUTION indicates a hazard which, if

not avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol,

indicates a situation that could result in equipment

damage. Follow safety messages to avoid or reduce

the risk of injury or death.

Hazard Symbols and Meanings

2

TABLE OF CONTENTS

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

KNOW YOUR PRESSURE WASHER. . . . . . . . . . . . . . . . 5

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 & 27

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . 19

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . 20-25

EMISSION CONTROL WARRANTY. . . . . . . . . . . . . . . . 26

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-47

HOW TO ORDER PARTS . . . . . . . . . . . . . . . BACK PAGE

WARRANTY

LIMITED WARRANTY ON CRAFTSMAN PRESSURE WASHER

For one year from the date of purchase, when this Craftsman pressure washer is maintained and operated

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase. If this pressure washer is used for rental purposes, this warranty applies for only 30 days after date

of purchase.

This warranty does not cover:

• Expendable items such as spark plugs or air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the pressure washer to the nearest Sears service center or dealer in

the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

SAFETY RULES

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Fire

Explosion

Toxic Fumes

Hot Surface

Moving Parts

Electrical Shock

Slippery Surface

Fall

Kickback

Flying Objects

Fluid Injection

3

In the State of California a spark arrester is required

by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws.

Federal laws apply on federal lands. If you equip the

muffler with a spark arrester, it must be maintained in

effective working order.You can order a spark arrester

through your authorized Sears service dealer.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

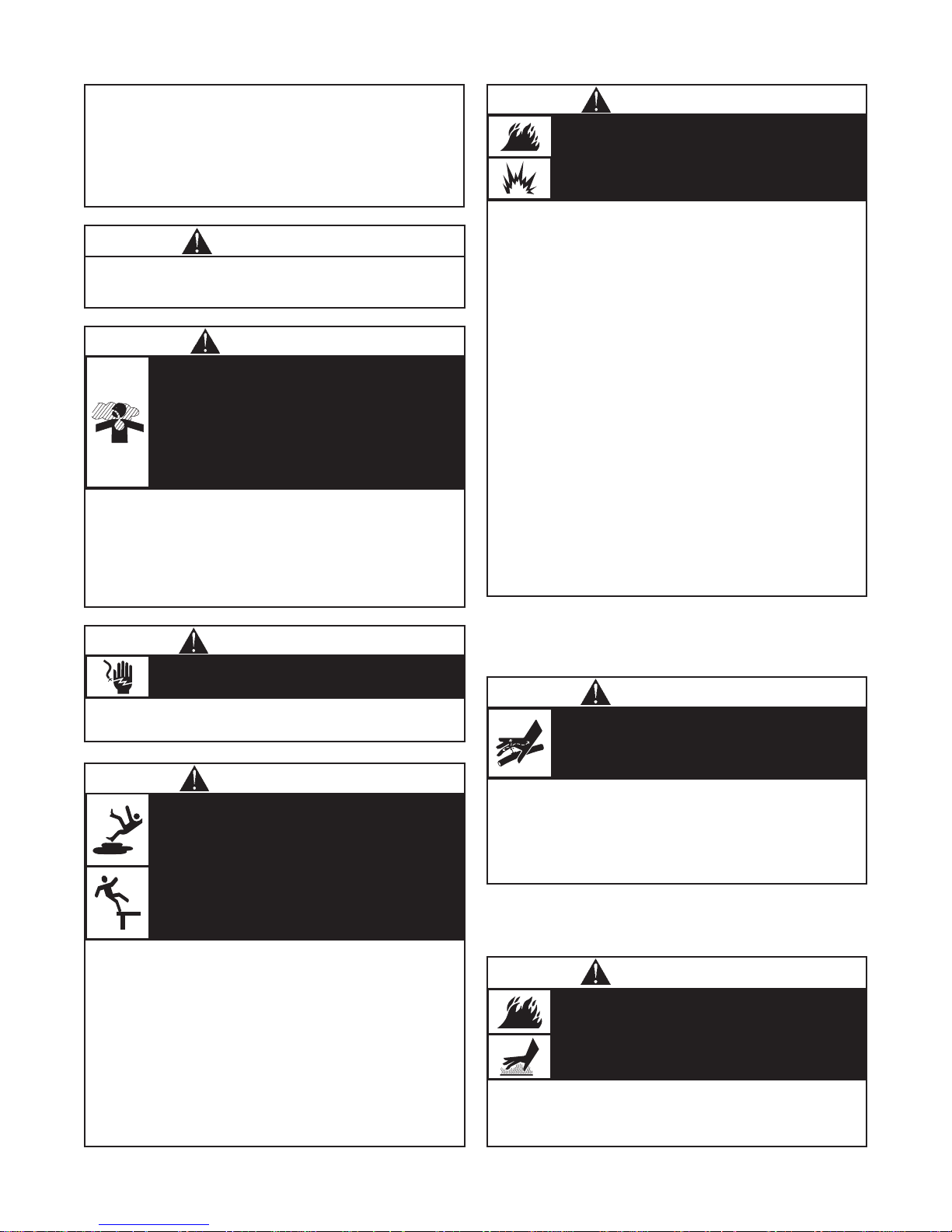

WARNING

• NEVER aim spray gun at people, animals or plants.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury

and possible amputation.

WARNING

WHEN ADDING FUEL

• Turn pressure washer OFF and let it cool at least

2 minutes before removing gas cap.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• Operate pressure washer ONLY outdoors.

• Use a respirator or mask whenever there is a chance

that vapors may be inhaled.

• Read all instructions packed with mask so you are certain

mask will provide necessary protection against inhaling

harmful vapors.

Running engine gives off carbon monoxide,

an odorless, colorless, poison gas.

Some chemicals or detergents may be

harmful if inhaled or ingested, causing

severe nausea, fainting or poisoning.

Breathing carbon monoxide will cause

nausea, fainting or death.

DANGER

• Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

• Operate this unit on a stable surface.

• Cleaning area should have adequate slopes and

drainage to reduce possibility of falls due to slippery

surfaces.

• Be extremely careful if you must use pressure washer

from a ladder, scaffolding or any other relatively unstable

location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

Use of pressure washer can create puddles

and slippery surfaces.

High pressure spray could cause you to fall

if you are too close to the cleaning surface.

WARNING

• Keep water spray away from electric wiring or fatal

electric shock may result.

Spray contact with electrical wiring can

result in electrocution.

WARNING

• DO NOT touch hot surfaces.

• Stay clear of exhaust gases.

• Allow equipment to cool before touching.

Running engines produce heat and hot

exhaust gases. Temperature of muffler and

nearby areas can reach or exceed 150°F

(65°C).

Fire or severe burns can occur.

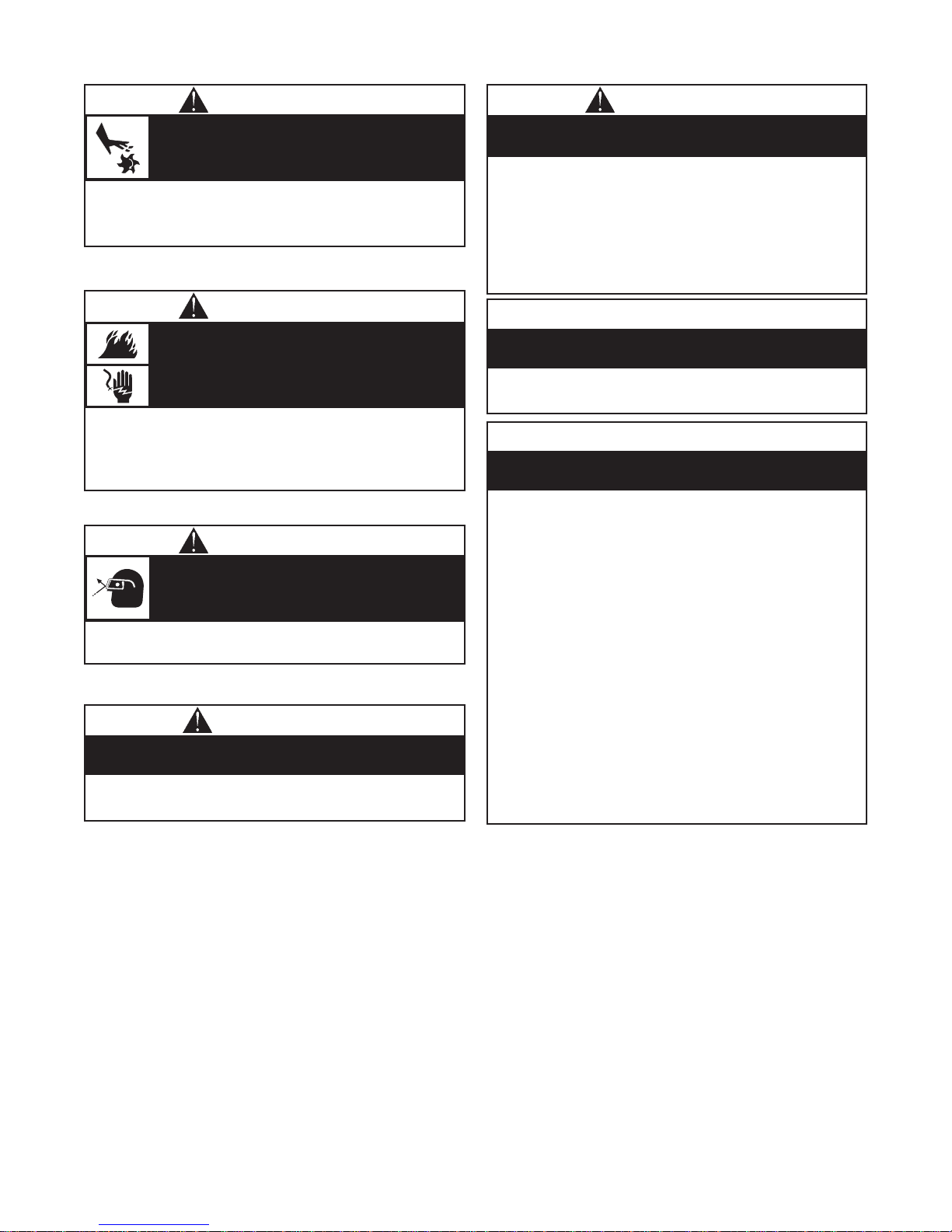

WARNING

4

• If you have questions about intended use, ask dealer or

contact Sears.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by–pass any safety device on this machine.

• Before starting pressure washer in cold weather, check

all parts of the equipment to be sure ice has not formed

there.

• NEVER move machine by pulling on high pressure hose.

Use handle provided on unit.

• Check fuel system for leaks or signs of deterioration,

such as chafed or spongy hose, loose or missing

clamps, or damaged tank or cap. Correct all defects

before operating pressure washer.

• This equipment is designed to be used with Sears

authorized parts ONLY. If equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes all risks and liabilities.

Improper treatment of pressure washer can

damage it and shorten its life.

CAUTION

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

• DO NOT point spray gun at glass when in jet spray mode.

• NEVER aim spray gun at plants.

High pressure spray may damage fragile items

including glass.

CAUTION

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

Excessively high or low operating speeds increase

risk of injury and damage to pressure washer.

CAUTION

• DO NOT wear loose clothing, jewelry or anything that

may be caught in starter or other rotating parts.

• Tie up long hair and remove jewelry.

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

WARNING

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect spark plug wire from spark plug and place

wire where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

• Always wear eye protection when using equipment or when

in vicinity of equipment in use.

High pressure spray can cause paint chips

or other particles to become airborne.

WARNING

5

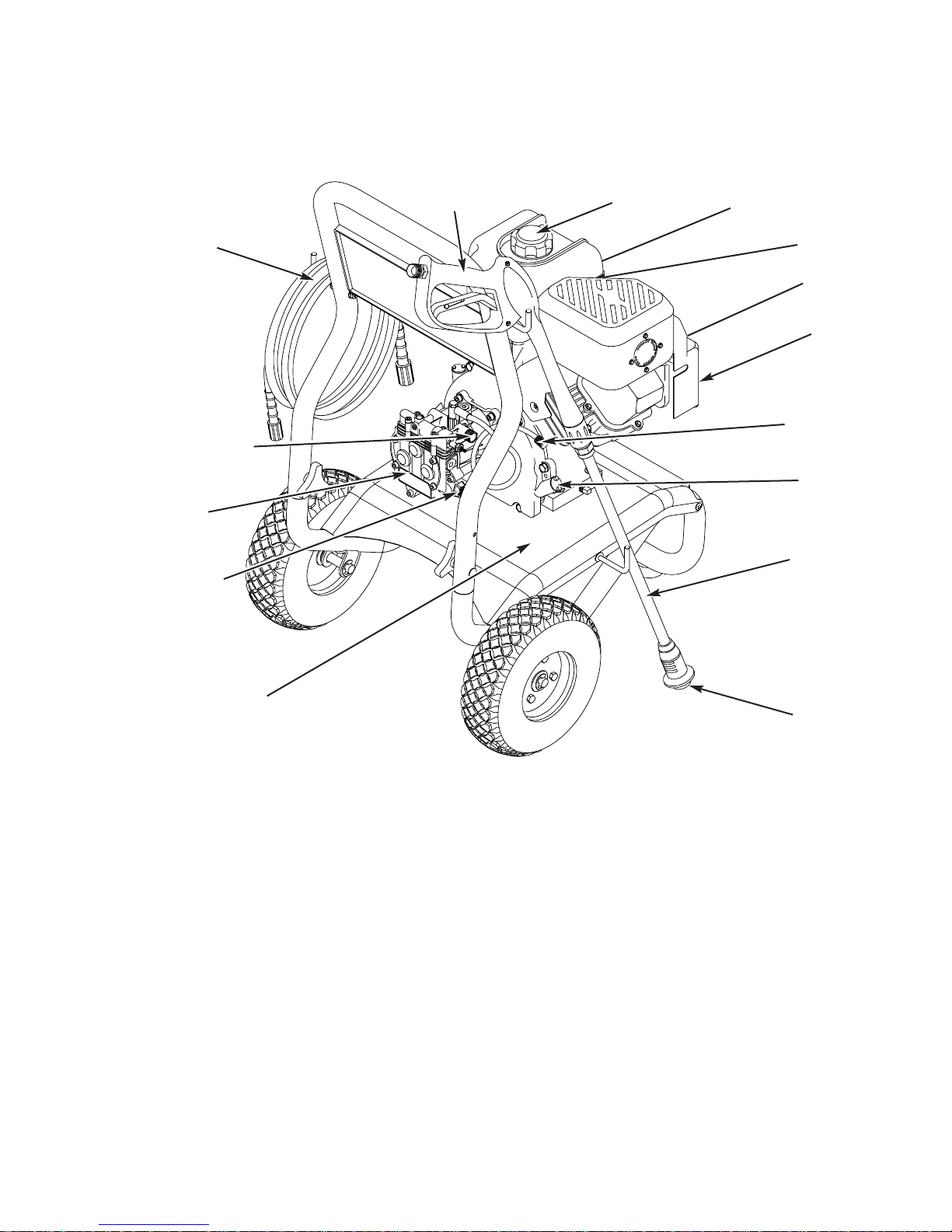

KNOW YOUR PRESSURE WASHER

Read the owner’s manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Adjustable Nozzle – Always attached to nozzle

extension. Pull back for high pressure or push forward

for low pressure; turn clockwise for narrow spray or

turn counterclockwise for fan spray.

Air Filter – Dry type filter element limits the amount of

dirt and dust that gets in the engine.

Choke Knob - Used to help start a cold engine.

Detergent Pick–Up Tube and Filter – Use to draw

detergent from chemical bottle to the low pressure

water stream.

Fuel Cap – Fill engine with regular unleaded fuel here.

High Pressure Hose – Connect one end to the spray

gun and other end to the high pressure outlet.

High Pressure Outlet – Connection for high pressure

hose.

Model Data Decal – Provides model and serial number

of pressure washer. Please have these readily available

when calling for assistance.

Nozzle Extension - Attach to spray gun to use

adjustable nozzle.

Oil Fill Cap – Fill engine with oil here. See page 7 for

oil recommendations.

Pump – Develops high pressure water .

Recoil Starter – Used for starting the engine

manually.

Spray Gun – Controls the application of water onto

cleaning surface with trigger device. Includes safety

latch.

Throttle Control Lever – Sets engine in starting

mode for recoil starter and stops running engine.

Water Inlet – Connection for garden hose.

Spray Gun

High Pressure Hose

Detergent Pick–Up

Tube and Filter

Recoil Starter

Oil Fill Cap

Air Filter

Fuel Cap

High Pressure Outlet

Throttle Control Lever

Water Inlet

Pump

Nozzle Extension

Choke Lever

Adjustable Nozzle

Model Data Decal

6

Your pressure washer requires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your pressure washer, please call the pressure

washer helpline at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

REMOVE PRESSURE WASHER

FROM CARTON

1. Slice two corners opposite guide handle end of

carton from top to bottom so panel can be folded

down flat.

2. Remove fillers, accesories and parts bag shipped

with your pressure washer.

3. Roll pressure washer out open end of carton.

4. Check carton for additional loose parts.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

• The main unit

• Handle

• Spray gun

• High pressure hose

• Nozzle extension with Hi/Lo adjustable nozzle

• Engine oil

• Parts bag (which includes items listed below)

Owner’s manual

Registration card

Handle attachment hardware

Become familiar with each piece before assembling

the pressure washer. Check all contents against the

illustration on page 5. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman high pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

1. Attach handle.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connect pressure hose to spray gun and pump.

5. Connect water supply to the pump.

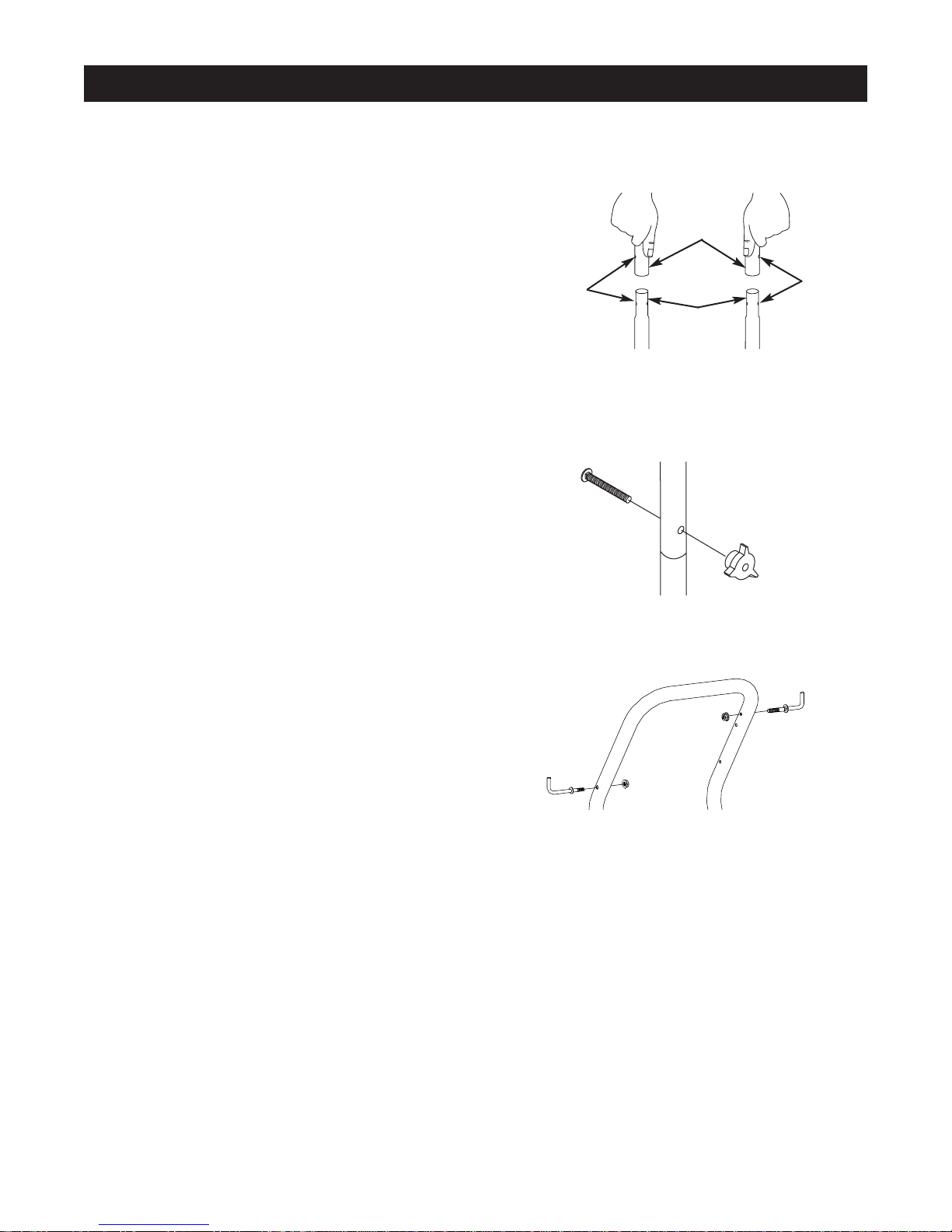

Attach Handle

1. Place handle assembly onto handle supports

connected to main unit. Make sure holes in handle

align with holes on handle supports.

NOTE: It may be necessary to move the handle

supports from side to side in order to align the handle

so it will slide over the handle supports.

2. Insert carriage bolts through holes from outside of

unit and attach a plastic knob from inside of unit.

Tighten by hand.

3. Insert one “L” hook through hole just under billboard

on left side of handle (viewing from rear of unit). Hold

hook in place with pliers and attach locknut with a

7/16” wrench.

4. Insert other “L” hook through hole just above

billboard on right side of handle (viewing from rear

of unit). Hold hook in place with pliers and attach

locknut with a 7/16” wrench.

ASSEMBLY

Align Holes

Handle

Handle

Supports

Hose Hook

Spray Gun

Hook

7

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher rated SAE 30

weight. DO NOT use special additives.

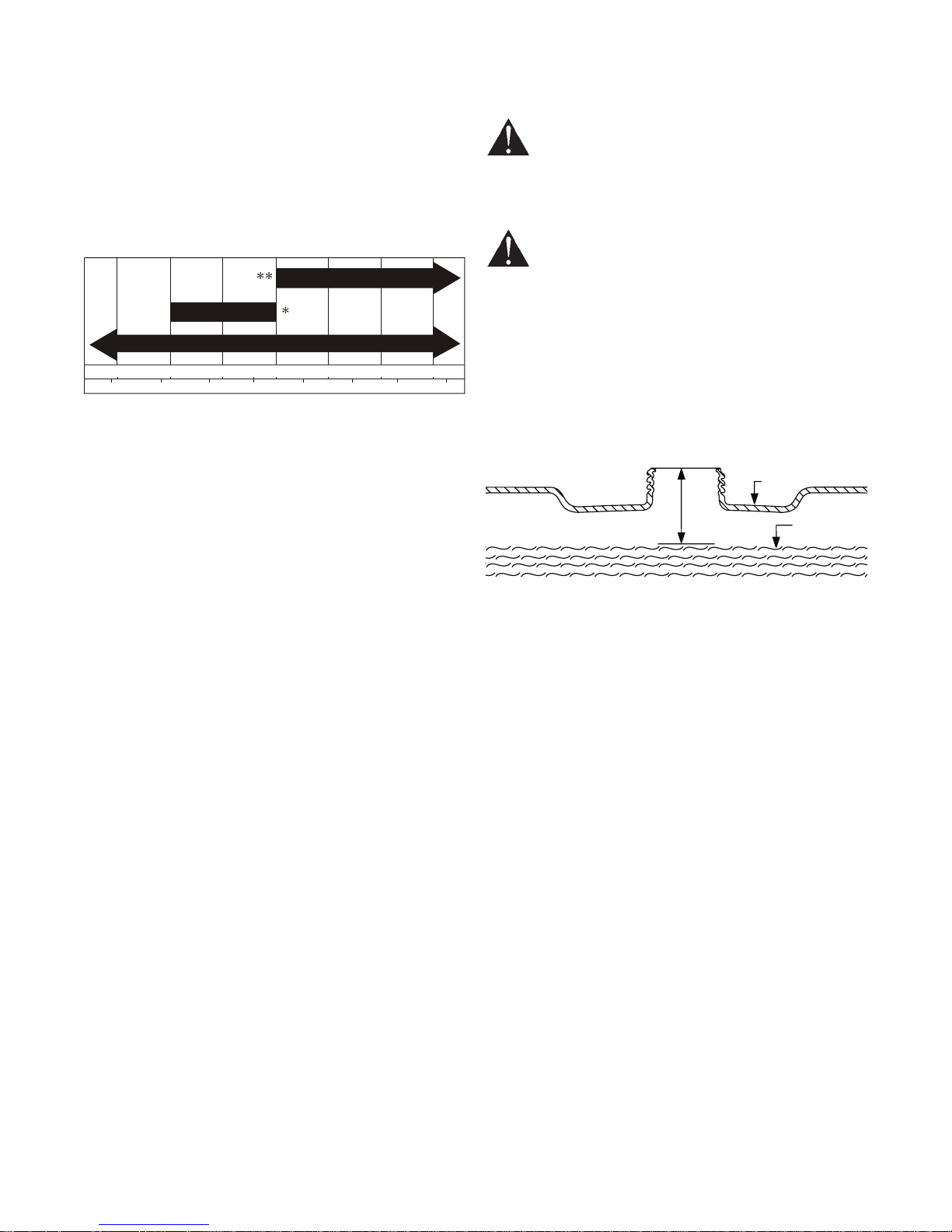

1. Choose a viscosity according to table below.

* The use of multi-viscosity oils (5W-30, 10W-30, etc.)

in temperatures above 40°F (4°C) will result in higher

than normal oil consumption. When using a multiviscosity oil, check oil more frequently.

** If using SAE 30 oil in temperatures below 40°F

(4°C), it will result in hard starting and possible

engine bore damage due to inadequate lubrication.

2. Place pressure washer on a level surface.

3. Clean area around oil fill.

4. Remove oil fill cap.

5. Pour oil slowly. Fill to the point of overflowing.

6. Replace oil fill cap, tighten securely.

NOTE: Check oil often during engine break–in.

Add Fuel

WARNING! NEVER fill fuel tank indoors.

NEVER fill fuel tank when engine is running or

hot. Allow unit to cool for two minutes before

refueling. DO NOT light a cigarette or smoke

when filling the fuel tank.

WARNING! NEVER fill fuel tank completely

full. Provide space for fuel expansion. Wipe

away any fuel spillage from engine and

equipment before starting.

• Use fresh, clean unleaded automotive fuel and

store in approved, clean, covered containers. Use

clean fill funnels. NEVER use “stale” fuel left over

from last season or fuel stored for long periods.

• Clean area around fuel fill cap, remove cap.

• Slowly add fuel to fuel tank. Use a funnel to

prevent spillage. Fill tank to about 1.5” below top

of the filler neck.

• Install fuel cap and wipe up any spilled fuel.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts, such as

the carburetor, fuel filter, fuel hose or tank during

storage. Also, experience indicates that

alcohol–blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leads to

separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. See

“Storage” on pages 16-17. NEVER use engine or

carburetor cleaner products in the fuel tank or

permanent damage may occur.

Fuel

Tank

1.5” Air Space

Synthetic 5W-30, 10W-30

5W-30, 10W-30

30

°F -20 0 20 32 40 60 80 100

°C -30 -20 -10 0 10 20 30 40

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

8

Connect Hose and Water Supply to Pump

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach all hoses before you start the engine.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

2. Remove and discard shipping caps from pump

inlet and outlet.

3. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

4. Before connecting garden hose to water inlet,

inspect inlet screen. Clean screen if it contains

debris or have it replaced if damaged. Refer to

section “O-Ring Maintenance” if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen is damaged.

5. Run water through garden hose for 30 seconds to

flush it of debris. Turn off water.

IMPORTANT: DO NOT siphon standing water for the

water supply. Use ONLY cold water (less than 100°F).

6. Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

7. Turn ON water and squeeze trigger on spray gun

to purge pump system of air and impurities.

CHECKLIST BEFORE STARTING

ENGINE

Review the assembly to ensure you have performed

all of the following:

1. Check that oil has been added to proper level in

engine crankcase.

2. Add proper fuel to fuel tank.

3. Check for properly tightened hose connections

(high pressure and water supply) and for tight

connections and that there are no kinks, cuts, or

damage to the high pressure hose.

4. Provide proper water supply (not to exceed

100°F).

5. Be sure to read “Safety Rules” and “Operation”

sections before using the pressure washer.

6. If starting unit after storage, see “Storage” section

on pages 16-17.

Inspect inlet

screen. DO

NOT use if

damaged;

clean if dirty.

CAUTION

• Damage to equipment resulting from failure to follow

this instruction will void warranty.

There MUST be at least ten feet of unrestricted garden

hose between the pressure washer inlet and any flow

shut off device, such as a ‘Y’ shut-off connector or

other convenience-type water shut-off valve.

• Always wear eye protection when using this equipment

or in vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are

wearing adequate eye protection.

High pressure spray can cause paint chips

or other particles to become airborne.

WARNING

9

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

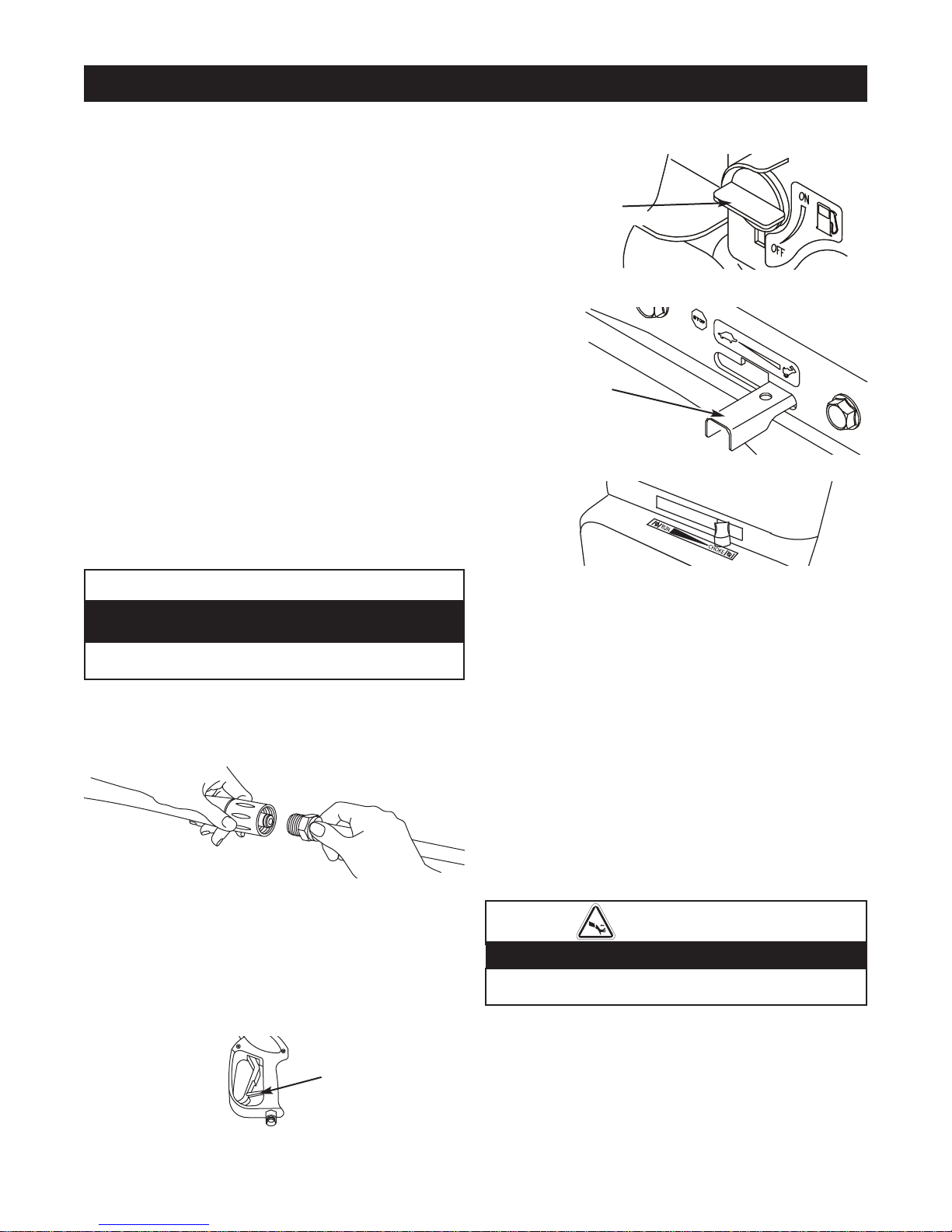

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

1. Place pressure washer near an outside water

source capable of supplying water at a flow rate

greater than 3.5 gallons per minute and no less

than 20 PSI at pressure washer end of garden

hose.

2. Check that high pressure hose is tightly connected

to spray gun and pump. See “Assembling Your

Pressure Washer” for illustrations.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON water.

5. Squeeze trigger on gun to purge pump system of

air and impurities.

6. Attach nozzle extension to spray gun. Tighten by

hand.

7. Position nozzle in low pressure mode (slide nozzle

forward) and squeeze trigger on spray gun to

relieve pressure caused by turning ON water.

Water will flow out of gun in a thin stream.

Continue to hold trigger until there is a steady

stream of water and no air remains in system.

Release trigger.

8. Engage safety latch to spray gun trigger.

9. Rotate fuel shut-off valve to “On” position (fully

counter-clockwise).

10. Move throttle lever to “Fast” position, shown as a

rabbit.

11. Move choke lever to “Choke” position.

NOTE: For a warm engine, be sure the choke lever is

in the “Run” position.

12. Grasp handle and pull the recoil starter lightly until

you feel some resistance, then pull briskly.

13. Return recoil starter slowly. DO NOT let rope

“snap back” against starter.

14. When engine starts, slowly move choke lever to

“Run” position as engine warms. If engine falters,

move choke lever to “Choke” position, then to

“Run” position.

15. If engine fires, but does not continue to run,

squeeze trigger on spray gun to relieve internal

pump pressure. Move choke lever to “Run”

position, and repeat steps 12 through 14.

16. If engine fails to start after six pulls, move choke

lever to “Run” position, and repeat steps

12 through 14.

How to Stop Your Pressure Washer

• Move throttle lever on engine to “Stop” position.

• Squeeze trigger on the spray gun to relieve

pressure in the hose.

NOTE: A small amount of water will squirt out when

you release the pressure.

Safety Latch

OPERATION

Fuel Valve shown in

“On” position

Throttle Lever in

“Fast” Position

CAUTION

• Damage to equipment will result from failure to follow

this instruction.

DO NOT run the pump without the water supply

connected and turned on.

CAUTION

• Squeeze trigger on spray gun each time recoil starter is

pulled and engine fails to start.

Avoid injury from kickback.

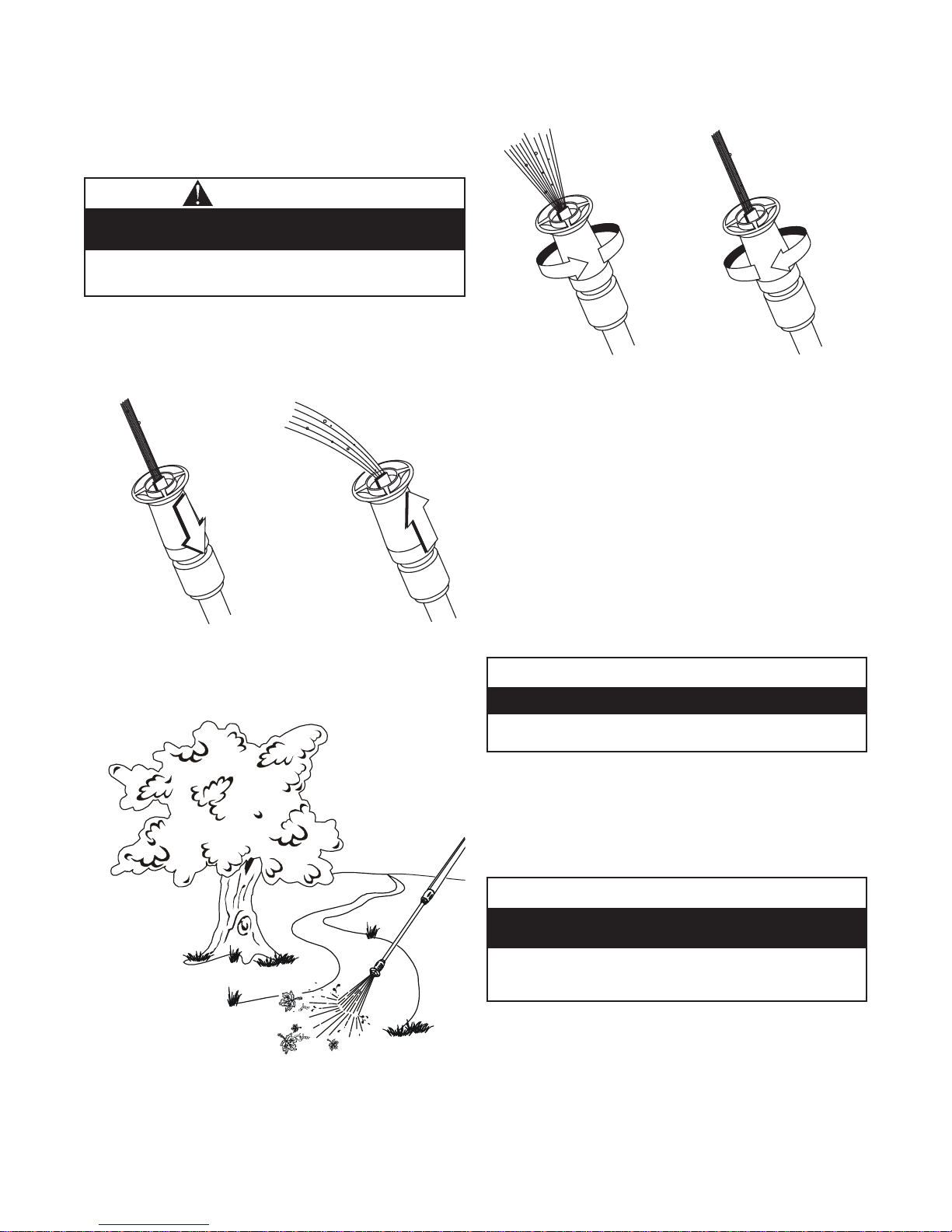

How To Use the Adjustable Nozzle

You now should know how to START your pressure

washer and how to STOP it. The information in this

section will tell you how to adjust the spray pattern

and apply detergent or other cleaning chemicals.

On the end of your spray gun is an adjustable nozzle

that you can use to adjust the spray pattern and the

spray pressure.

1. Slide nozzle forward for low pressure spray; slide

it backward for high pressure spray.

2. Point nozzle towards a hard surface, disengage

safety latch, and press trigger to test pattern.

3. Twisting nozzle adjusts spray pattern from a

narrow pattern to a fan pattern.

4. For most effective cleaning, keep spray nozzle

from 8 to 24 inches away from cleaning surface.

5. If you get the spray nozzle too close, especially

using high pressure mode, you may damage the

surface being cleaned.

6. DO NOT get closer than 6 inches when cleaning

tires.

Applying Detergent with the Adjustable

Nozzle

IMPORTANT: Use chemicals designed specifically

for pressure washers. Household detergents could

damage the pump.

To apply detergent, follow these steps:

1. Review use of adjustable nozzle.

2. Prepare detergent solution as required by job.

3. Place filter end of detergent siphoning tube into

detergent container.

4. Slide adjustable nozzle forward to low pressure

mode. Detergent cannot be applied with nozzle in

high pressure position.

5. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Start engine.

10

• NEVER adjust spray pattern when spraying.

• NEVER put hands in front of nozzle to adjust spray pattern.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

CAUTION

• Starting the engine without all the hoses connected and

without the water turned ON will damage the pump.

You must attach all hoses before you start the engine.

CAUTION

• When inserting the filter into a detergent solution bottle,

route the tube so as to keep it from inadvertently

contacting the hot muffler.

Keep the chemical injection tube from coming in

contact with the hot muffler.

Slide nozzle backward for

high pressure mode.

Slide nozzle forward for low

pressure mode and

detergent application.

Twist nozzle counter-

clockwise for fan pattern.

Twist nozzle clockwise for

narrow spray pattern.

11

6. Apply detergent to a dry surface, starting from

bottom and working up.

7. Allow detergent to “soak in” for 3-5 minutes before

rinsing. Reapply as needed to keep surface wet.

8. For washing, start at lower portion of area to be

washed and work upward, using long, even,

overlapping strokes.

Pressure Washer Rinsing

For Rinsing:

1. Slide nozzle backward to high pressure, press

trigger and wait for detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

2. Keep spray gun a safe distance from area you

plan to spray.

3. Apply a high pressure spray to a small area, then

check surface for damage. If no damage is found,

it is okay to continue cleaning.

4. Start at top of area to be rinsed, working down

with same overlapping strokes as you used for

washing and applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures above 125°F. The system engages to

cool the pump by discharging the warm water onto

the ground.

• Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

• Operate this unit on a stable surface.

• Be extremely careful if you must use the pressure

washer from a ladder, scaffolding or any other relatively

unstable location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

High pressure spray could cause you to fall

if you are too close to the cleaning surface.

WARNING

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure . . . . . . . . . . . . . . . . . . . 2550 PSI

Flow Rate . . . . . . . . . . . . . . . . . . 2.5 GPM

Chemical Mix . . . . . . . . . . . . . . . Use as directed

Water Supply Temperature . . . . . Not to Exceed 100°F

Shipping Weight . . . . . . . . . . . . . 75 lbs.

Engine Specifications

Rated Horsepower . . . . . . . . . . . 6.5 HP

Spark Plug Type:

Long Life Platinum . . . . . . . Champion RC12PYP

Resistor . . . . . . . . . . . . . . . Champion RC12YC

Set Gap To: . . . . . . . . . . . . . 0.020 inches

(0.50mm)

Fuel Capacity . . . . . . . . . . . . . . . 3.0 Quarts

Oil

Above 40°F . . . . . . . . . . . . . SAE 30

0°F - 40°F . . . . . . . . . . . . . . . SAE 5W-30 or 10W-30

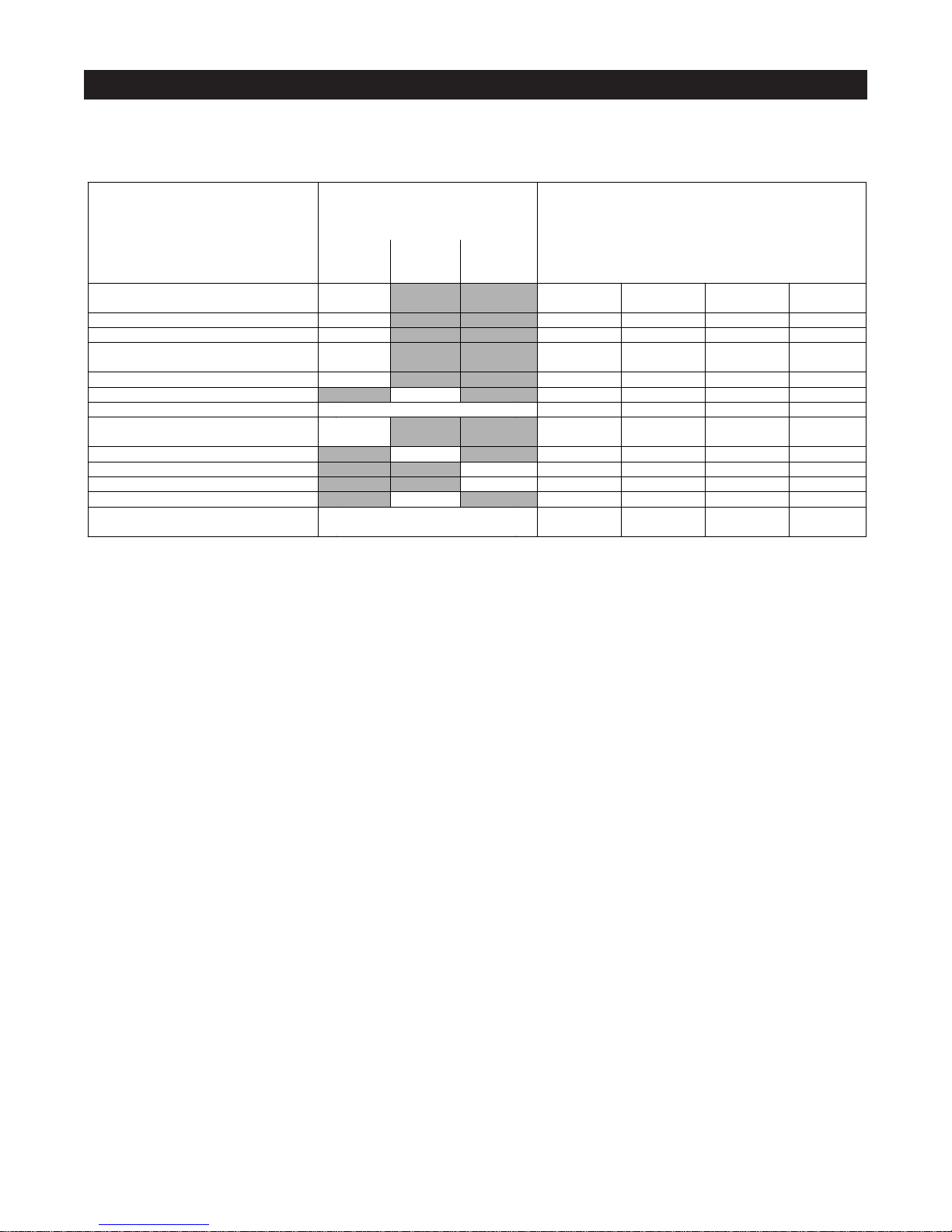

GENERAL RECOMMENDATIONS

The pressure washer’s warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual including proper storage as

detailed in “Storage” on pages 16-17.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

“Maintenance Schedule” chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

If equipped with inflatable tires, keep the air pressure

at the value marked on the tire or within 15 and 40 psi.

BEFORE EACH USE

1. Check engine oil level.

2. Check water inlet screen for damage.

3. Check high pressure hose for leaks.

4. Check chemical filters for damage.

5. Check spray gun and nozzle extension assembly

for leaks.

6. Purge pump of air and contaminants.

12

MAINTENANCE

OWNER’S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

¹ Clean if clogged. Replace if perforated or torn.

² Change oil after the first (5) operating hours and every 50 hours or every year, whichever occurs first, thereafter.

Change sooner when operating under dirty or dusty conditions.

³ Replace more often under dirty or dusty conditions.

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

HOURLY OPERATING

INTERVAL

SERVICE DATES

MAINTENANCE TASK

Before

Each Use

Every 50

Hours or

Yearly

Every 100

Hours or

Yearly

PRESSURE WASHER

Check/clean water inlet screen

X¹

Check high pressure hose

X

Check detergent hose

X

Check spray gun and assembly for

leaks

X

Purge pump of air and contaminants

X

Change pump oil

X

Prepare pump for storage below 32°F

See “Storage” on page 16.

ENGINE

Check oil level

X

Change engine oil

X²

Service air cleaner

X³

Service spark plug

X

Service spark arrester

X

Prepare for storage

If unit is to remain idle for

longer than 30 days.

13

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making

sure it springs back into place when you release it. Put

safety latch in UP position and test trigger. You should

not be able to press trigger. Replace spray gun

immediately if it fails any of these tests.

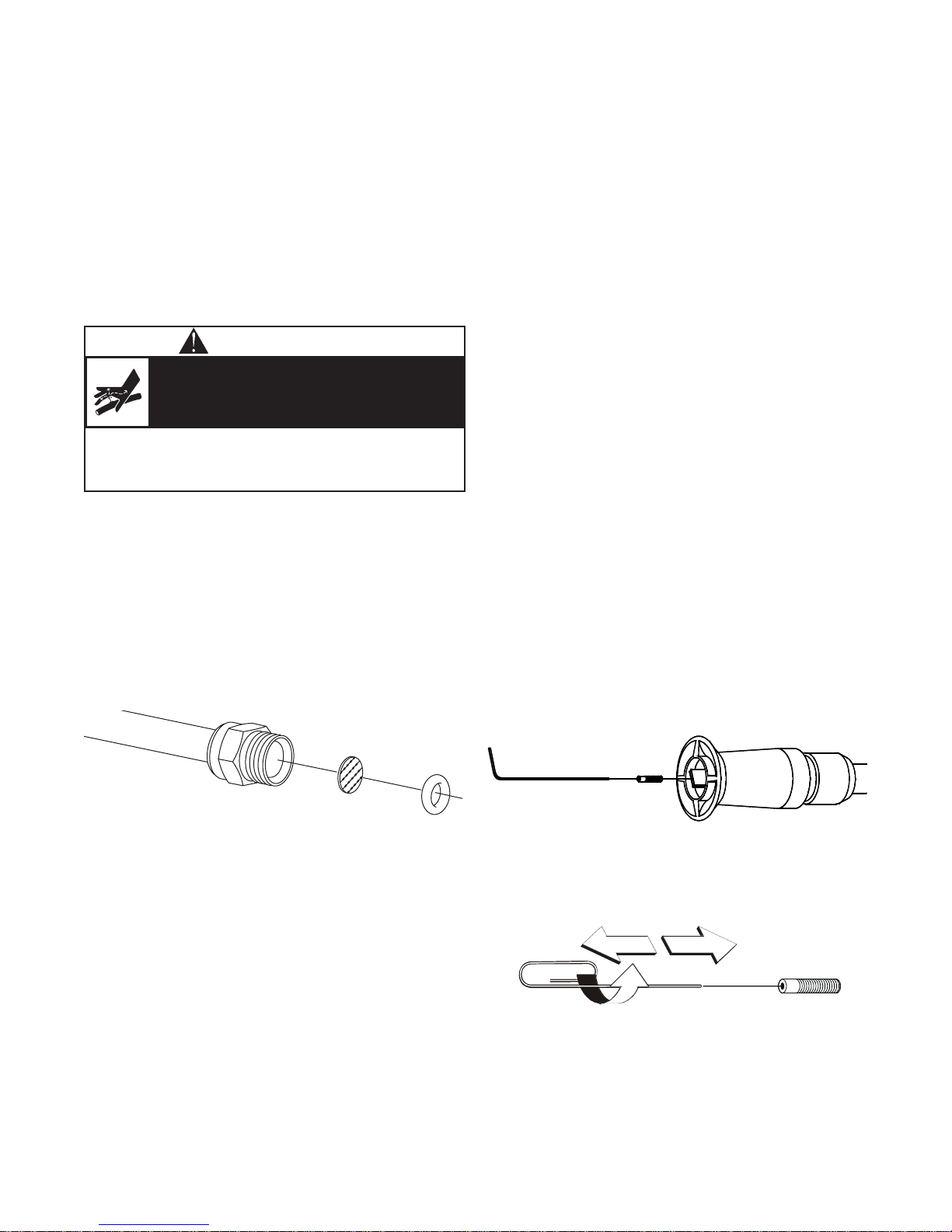

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

1. Detach spray gun from high pressure hose.

Detach nozzle extension from spray gun and

remove o-ring and screen from nozzle extension.

Flush screen, spray gun, and nozzle extension

with clean water to clear debris.

2. Place in-line filter screen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care to not bend

screen.

3. Place o-ring into recess. Push o-ring snugly

against in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps:

1. Set up pressure washer as described in

“Assembling Your Pressure Washer” section and

connect water supply.

2. Pull trigger on gun and hold until a steady stream

of water appears.

To remove contaminants from the pump, follow these

steps:

1. Set up pressure washer as described in

“Assembling Your Pressure Washer” section, and

connect water supply.

2. Remove nozzle extension from gun.

3. Start engine according to instructions in “How To

Use Your Pressure Washer” section.

4. Pull trigger on gun and hold.

5. When water supply is steady and constant,

engage safety latch and refasten nozzle

extension.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the nozzle following these instructions:

1. Shut off engine and turn off water supply.

2. Separate nozzle extension from spray gun. Twist

nozzle clockwise to stream position. Using a 2mm

(5/64) allen wrench, remove orifice from end of

nozzle extension.

3. Remove in-line filter from other end of nozzle

extension.

4. Use a small paper clip to free any foreign material

clogging or restricting orifice.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST exceed maximum

pressure rating of unit.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury

and possible amputation.

WARNING

Nozzle Extension

In-line Filter

O-ring

Insert wire into nozzle and turn back

and forth to clear obstruction.

14

5. Using a garden hose, remove additional debris by

back flushing water through nozzle extension.

Back flush between 30 to 60 seconds. Turn

adjustable nozzle extension to stream spray and

move nozzle from low to high while flushing.

6. Reinstall orifice and in-line filter into nozzle

extension. DO NOT overtighten orifice with allen

wrench.

7. Reconnect nozzle extension to spray gun.

8. Reconnect water supply, turn on water, and start

engine.

9. Test pressure washer by operating with nozzle in

high and low positions.

O–Ring Maintenance

Purchase an O–Ring Repair Kit, item number

7175116, at your local Sears or by calling

1-800-366-PART or online at www.sears.com. It is not

included with the pressure washer. This kit includes

replacement o-rings, rubber washer and water inlet

filter. Refer to the instruction sheet provided in the kit

to service your unit’s o-rings.

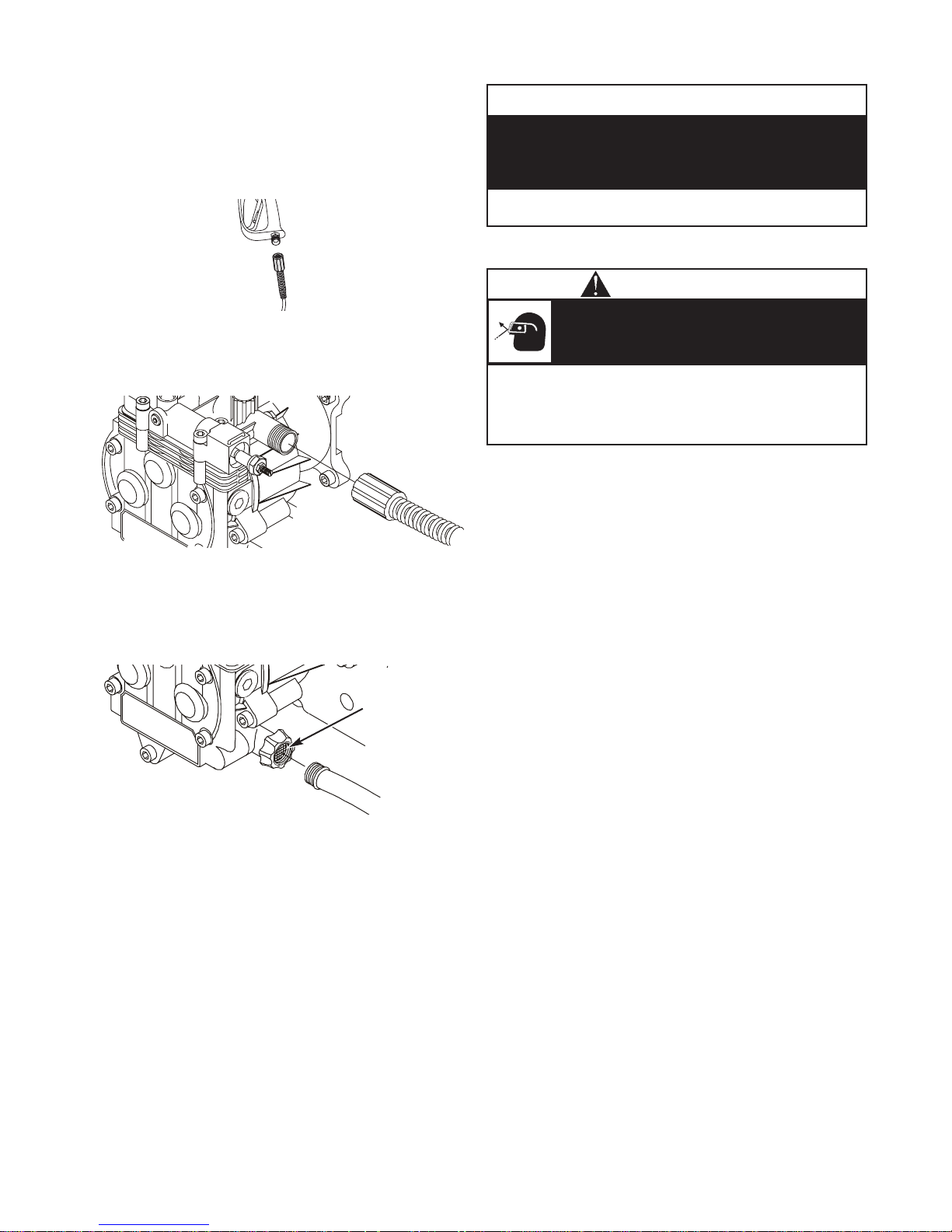

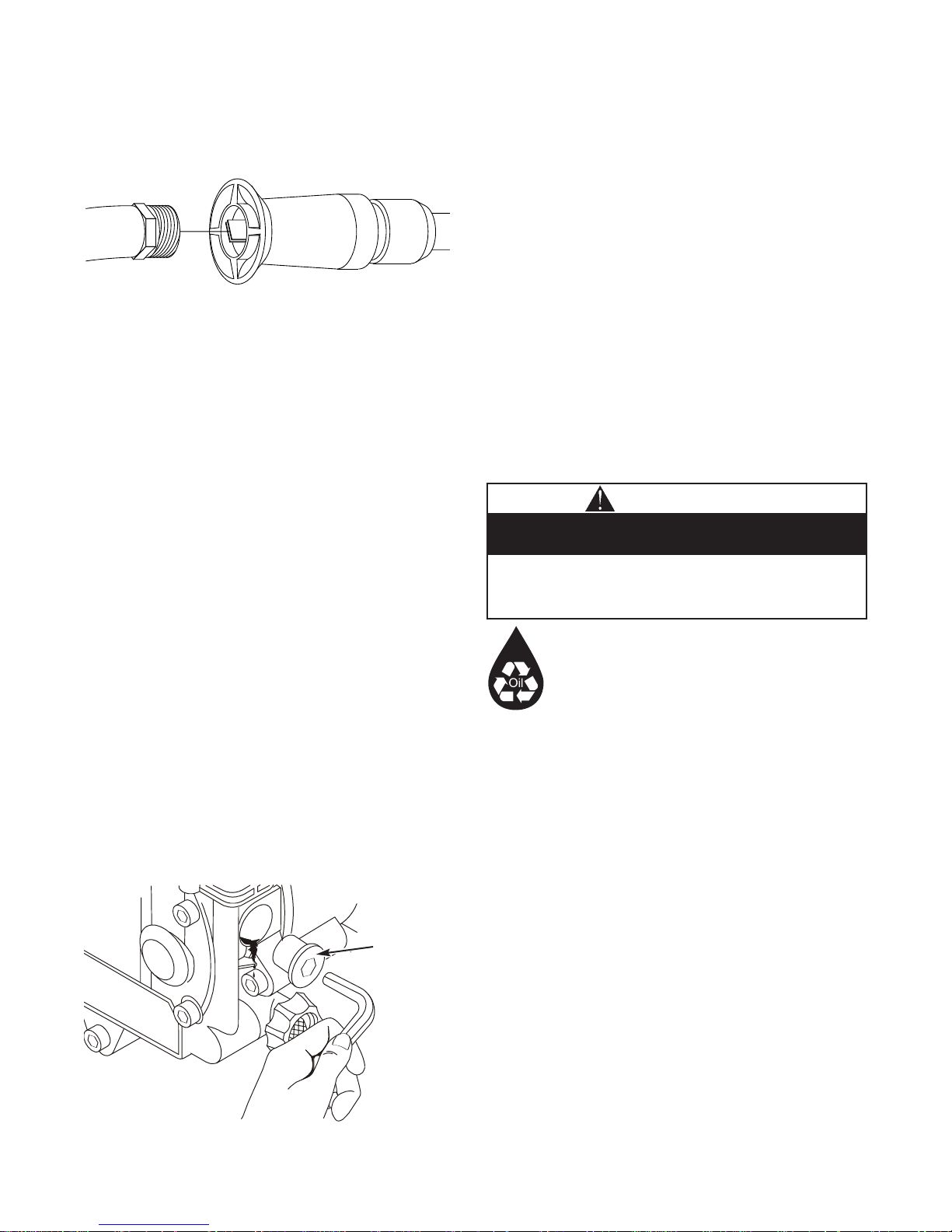

Pump Maintenance

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE: You must purchase a premeasured bottle of

pump oil, item number 190585GS, by calling

1-800-366-PART or online at www.sears.com.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use a 8mm allen wrench to remove black pump

oil cap between high pressure outlet and garden

hose inlet.

3. Tilt pressure washer to drain oil into an approved

container until it drips slowly from pump.

4. Tilt pressure washer in opposite direction and

empty premeasured pump oil bottle into same

opening (a small funnel may be helpful).

5. Install black pump oil cap and tighten firmly.

6. Set pressure washer in upright position. Add fuel

and engine oil.

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked prior to each use or at

least every 5 hours of operation. Keep oil level

maintained.

Changing Oil

Change engine oil after the first 5 hours and every

50 hours thereafter. If you are using your pressure

washer under extremely dirty or dusty conditions, or in

extremely hot weather, change oil more often.

KEEP OUT OF REACH OF CHILDREN.

DON'T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

Change oil while engine is still warm from running, as

follows:

1. Drain fuel tank by running pressure washer until

fuel tank is empty.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Remove oil drain plug and drain oil into

appropriate receptacle.

4. Reinstall drain plug. Remove oil fill cap.

5. Fill to point of overflowing at oil fill cap with

recommended oil.

6. Reinstall oil fill plug and tighten securely.

7. Wipe up any remaining oil.

8. Reconnect spark plug wire to spark plug.

Oil Cap

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

15

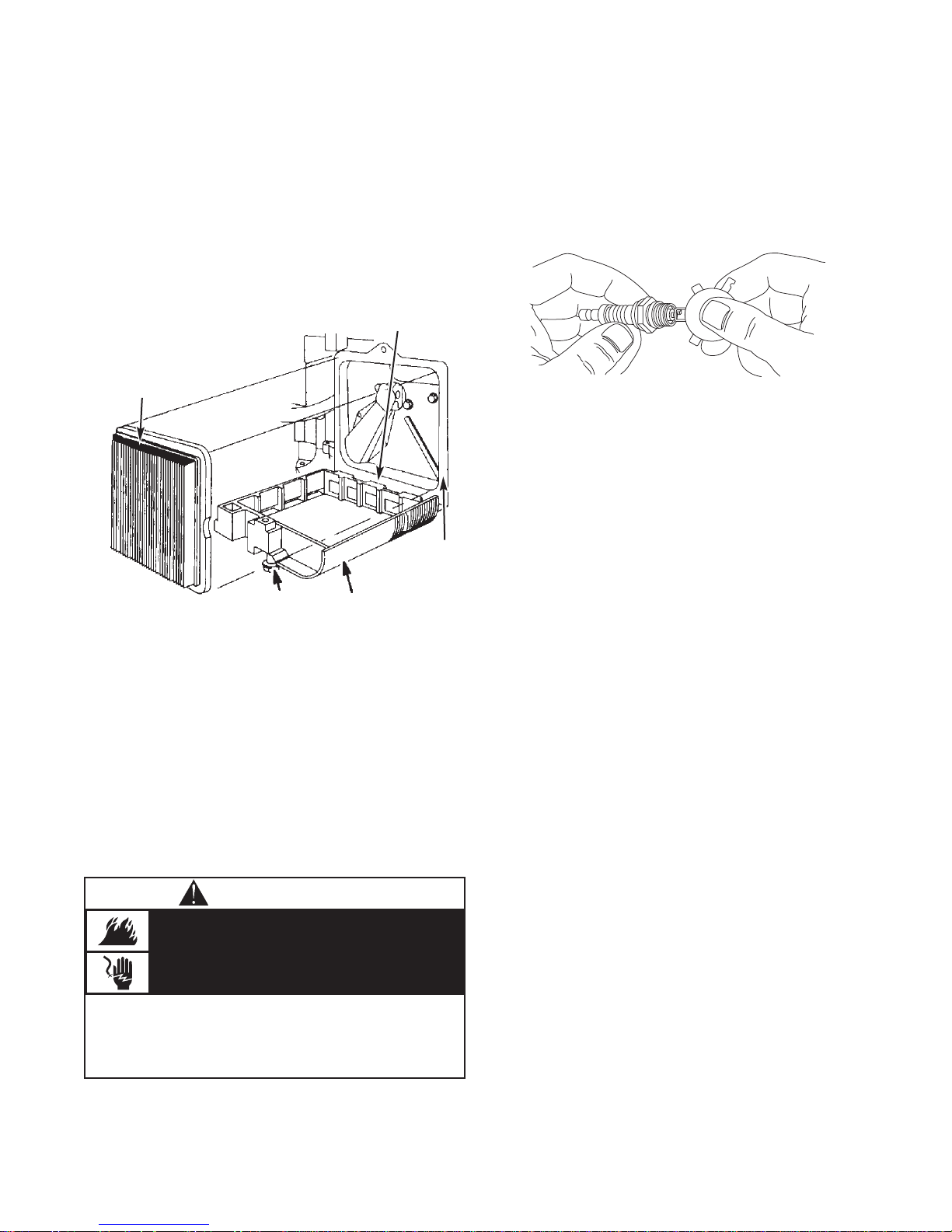

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run it with a dirty air cleaner.

Service the air cleaner once every 100 hours of

operation or once each year, whichever comes first.

Service more often if operating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

To service the air cleaner, follow these steps:

1. Loosen screw and tilt cover down.

2. Carefully remove cartridge assembly.

3. To clean cartridge, gently tap pleated paper side

on a flat surface.

4. Reinstall clean or new cartridge assembly inside

cover.

5. Insert cover’s tabs into slots in bottom of base.

6. Tilt cover up and tighten screw securely to base.

NOTE: You can purchase new air filter elements by

calling 1-800-366-PART.

Service Spark Plug

Service the spark plug every 100 hours of operation or

yearly, whichever occurs first.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if electrodes are worn, or if

insulator is cracked or chipped.

4. For replacement use either the standard resistor

spark plug, Champion RC12YC or the long life

platinum spark plug, Champion RC12PYP.

5. Check electrode gap with wire feeler gauge and

set gap at 0.020 inches (0.50mm), if necessary.

6. Install spark plug, tighten securely.

NOTE: You can purchase a new spark plug by calling

1-800-366-PART.

Carburetor

If you think your carburetor needs adjusting, see your

nearest Sears service center. Engine performance

may be affected at attitudes above 7000 feet. For

operation at higher elevations, contact your nearest

Sears service center.

Spark Arrester Service

Your engine is not factory-equipped with a spark

arrester. In some areas, it is illegal to operate an

engine without a spark arrester. Check local laws and

regulations. A spark arrester is available from your

nearest Sears service center. If you need to order a

spark arrester, please call 1-800-366-PART.

The spark arrester must be serviced every 50 hours to

keep it functioning as designed.

If the engine has been running, the muffler will be very

hot. Allow the muffler to cool before servicing the

spark arrester.

• Remove spark arrester screen for cleaning and

inspection.

• Replace if screen is damaged.

Cartridge

Screw

Cover

Base

Tabs and Slots

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect spark plug wire from spark plug and place

wire where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

Loading...

Loading...