Page 1

Owner’s Manual

HIGH PRESSURE WASHER

7.0 HORSEPOWER

2800 PSI

2.5 GPM

Model No. 580.752400

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CT)

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website;

Part No. 194052 Draft 2 (09/20/2004)

www.sears.com/craftsman

Safety

Assembly

Operation

Maintenance

Parts

Español

0 24847'07614 *' 1

Page 2

TABLE OF CONTENTS

WARRANTY.......................................................................2

SAFETY RULES

ASSEMBLY

OPERATION

SPECIFICATIONS............................................................12

MAINTENANCE..........................................................13-17

............................................................

.....................................................................

................................................................

2-4

6-8

9-12

STORAGE...................................................................18-19

TROUBLESHOOTING

REPLACEMENT PARTS ............................................22-27

EMISSION CONTROL WARRANTY

ESPAÑOL...................................................................30-51

HOW TO ORDER PARTS

.....................................................

..........................

...............................

28-29

BACK PAGE

WARRANT

LIMITED WARRANTY ON CRAFTSMAN PRESSURE WASHER

For one year from the date of purchase, when this Craftsman pressure washer is maintained and operated

according to the instructions in the owner's manual. Sears will repair, free of charge, any defect in material and

workmanship.

if this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase. If this pressure washer is used for rental purposes, this warranty applies for only 30 days after date

of purchase.

This warranty does not cover:

• Expendable items such as spark plugs or air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the high pressure washer to the nearest Sears service center or

dealer in the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

20

Sears, Roebuck and Co., Dept 817WA, Hoffman Estates, IL 60179

SAFETY RULE

This is the safety alert symbol. It Is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

A

Read this manual carefully and become

0

The safety alert symbol (A) is used with a signal

word (DANGER. CAUTION. WARNING), a pictorial

and/or a safety message to alert you to hazards.

hazard which, if not avoided, could result in death or

serious injury. CAUTION indicates a hazard which, if

not avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol,

indicates a situation that could result in equipment

damage. Follow safety messages to avoid or reduce

the risk of injury or death.

familiar with your pressure washer. Know its

applications, its limitations, and any hazards

involved.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury. WARNING indicates a

Hazard Symbols and Meanings

Toxic Fumes

2 % ^

Slippery Surface Fall

Fire Explosion

Electrical Shock

'iñ

Fluid Injection

Hot Surface

H "S N

Moving Parts Flying Objects Kickback

Page 3

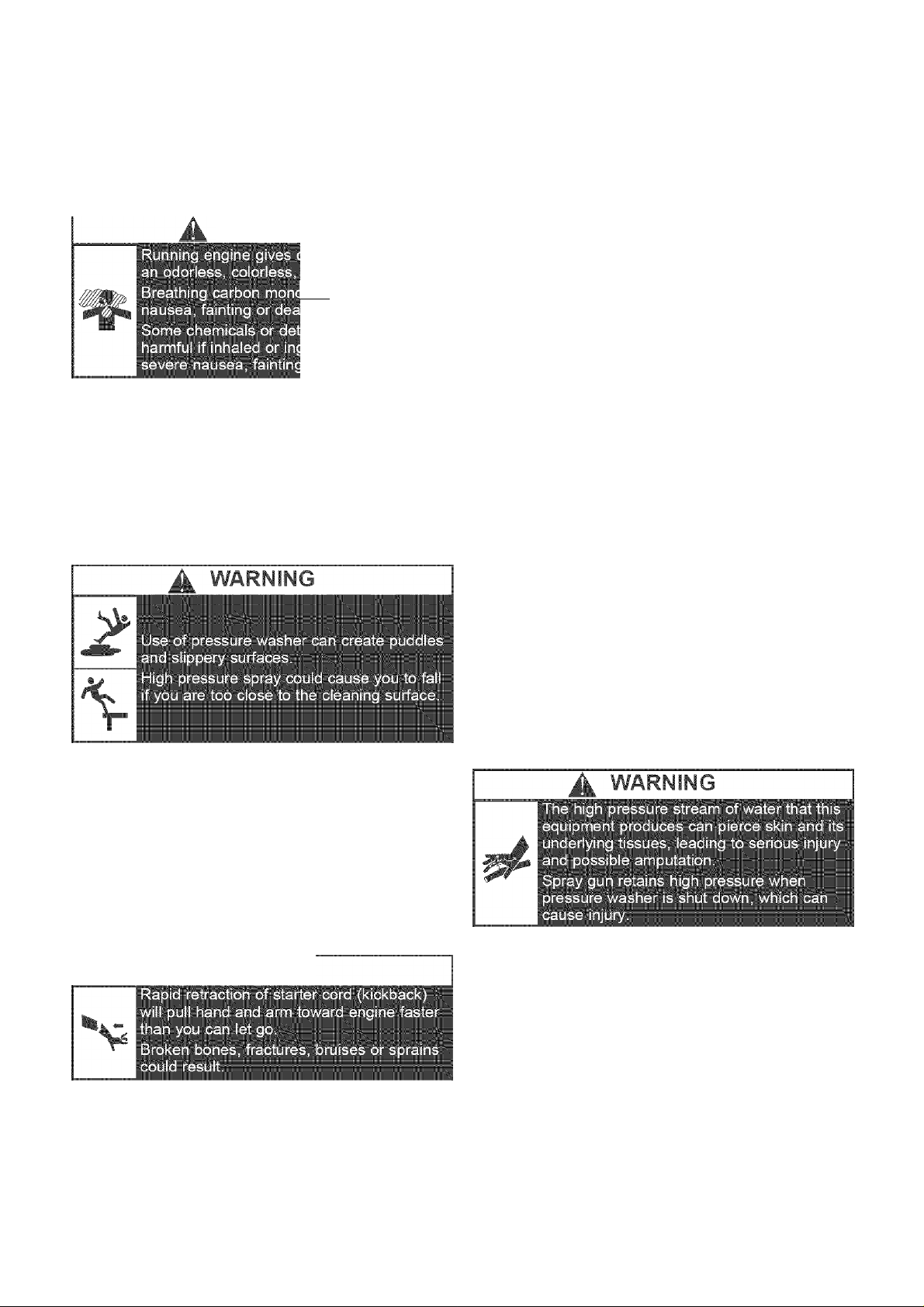

^ WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

DANGER

——

Operate pressure washer ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enclosure.

Use a respirator or mask whenever there is a chance

that vapors may be inhaled.

Read all Instructions packed with mask so you are certain

mask will provide necessary protection against inhaling

harmful vapors.

Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

Operate this unit on a stable surface.

Cleaning area should have adequate slopes and

drainage to reduce possibility of falls due to slippery

surfaces.

Be extremely careful if you must use pressure washer

from a ladder, scaffolding or any other relatively unstable

location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

^WARNING

When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze

trigger on spray gun.

^ WARNING

WHEN ADDING OR DRAINING FUEL

• Turn pressure washer OFF and let it cool at least 2

minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources,

• DO NOT light a cigarette or smoke,

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap and air cleaner are

in place.

• DO NOT crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before starting

engine.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at angle which causes

fuel to spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

NEVER aim spray gun at people, animals or plants.

DO NOT allow CHILDREN to operate pressure washer.

NEVER repair high pressure hose. Replace it.

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

Squeeze trigger on spray gun to relieve trapped

pressure, every time you stop engine. Engage trigger

lock on spray gun.

Page 4

^ WARNING

Spray contact with elec

result in electrocution.

Keep water spray away from electric wiring or fatal

electric shock may result.

a: WARNING

Running engines produce hea

Temoerature of muffler an

Severe

JÉ

DO NOT touch hot surfaces.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from

structures having combustible walls and/or other

combustible materials.

Keep at least 3 feet of clearance on ail sides of pressure

washer for adequate cooling, maintenance and servicing.

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained in effective working order.

Combustible

brush, ect. can catch fi

^ WARNING

lggl|

Always wear eye protection when using equipment or when

in vicinity of equipment in use.

^ CAUTION

xcessively high or low opérât

sk of injury and damage to p

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT secure spray gun in open position,

• DO NOT leave spray gun unattended while machine is

running,

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

CAUTION

DO NOT wear loose clothing, jewelry or anything that

may be caught in starter or other rotating parts.

Tie up long hair and remove jewelry.

^ WARNING

Unintentional soar

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

* •

n result in fire or

• DO NOT point spray gun at glass when in jet spray mode.

• NEVER aim spray gun at plants.

CAUTION

improper treatment of pressure washer ca

damage it and shorten its life.

If you have questions about intended use, ask dealer or

contact Sears.

NEVER operate units with broken or missing parts, or

without protective housing or covers.

DO NOT by-pass any safety device on this machine.

Before starting pressure washer in cold weather, check

all parts of the equipment to be sure ice has not formed

there.

NEVER move machine by pulling on high pressure hose.

Use handle provided on unit.

Check fuel system for leaks or signs of deterioration,

such as chafed or spongy hose, loose or missing

clamps, or damaged tank or cap. Correct all defects

before operating pressure washer.

This equipment is designed to be used with Sears

authorized parts ONLY, if equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes all risks and liabilities.

Page 5

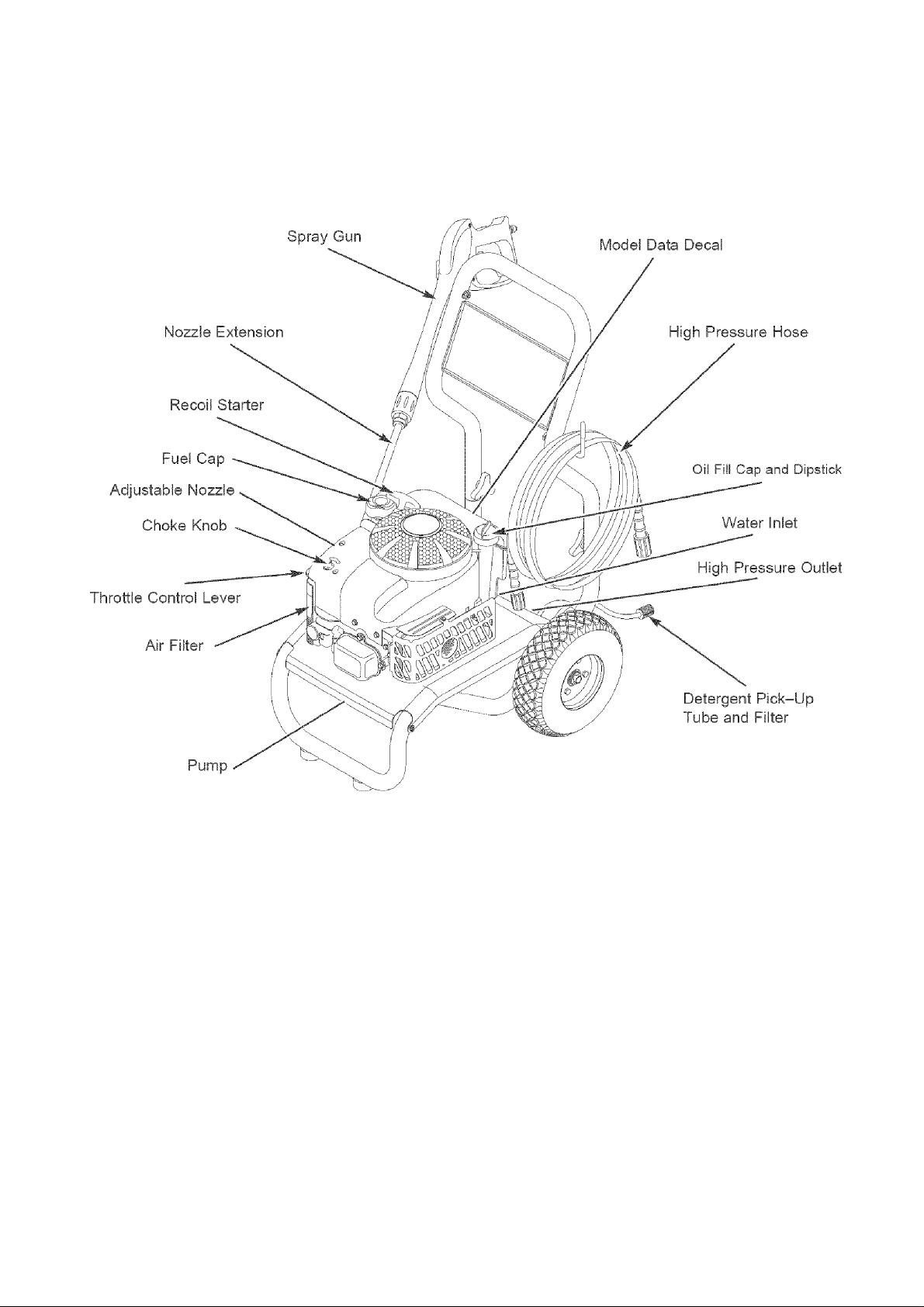

KNOW YOUR PRESSURE WASHER

Read the owner’s manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Adjustable Nozzle - Always attached to nozzle

extension. Pull back for high pressure or push forward

for low pressure; turn clockwise for narrow spray or

turn counterclockwise for fan spray.

Air Filter ”■ Dry type filter element limits the amount of

dirt and dust that gets in the engine.

Choke Knob - Used to help start a cold engine.

Detergent Pick-Up Tube and Filter - Use to draw

detergent from chemical bottle to the low pressure

water stream.

Fuel Cap - Fill engine with regular unleaded fuel here.

High Pressure Hose ^ Connect one end to the spray

gun and other end to the high pressure outlet.

High Pressure Outlet - Connection for high pressure

hose.

Model Data Decal ^ Provides model and serial number

of pressure washer. Please have these readily available

when calling for assistance.

Nozzle Extension - Attach to spray gun to use

adjustable nozzle.

Oil Fill Cap and Dipstick - Check and fill engine with

oil here. See page 6 for oil recommendations and

filling instructions.

Pump - Develops high pressure water.

Recoil Starter - Used for starting the engine

manually.

Spray Gun - Controls the application of water onto

cleaning surface with trigger device. Includes trigger

lock.

Throttle Control Lever - Sets engine in starting

mode for recoil starter and stops running engine.

Water Inlet - Connection for garden hose.

Page 6

ASSEMBLY

Your pressure washer requires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your pressure washer, please call the pressure

washer helpline at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

REMOVE PRESSURE WASHER

FROM CARTON

• Slice two corners opposite guide handle end of

carton from top to bottom so the panel can be

folded down flat.

• Remove fillers, accesories and parts bag shipped

with your pressure washer.

• Roll the pressure washer out the open end of the

carton.

• Check carton for additional loose parts.

CARTON CONTENTS

Check ail contents. If any parts are missing or damaged,

call the pressure washer helpline at 1^00-222-3136.

The main unit

Handle

Spray gun

High pressure hose

Nozzle extension with Hi/Lo adjustable nozzle

Engine oil

Parts bag (which includes items listed below)

Owner’s manual

Registration card

Handle attachment hardware

Become familiar with each piece before assembling

the pressure washer. Check ail contents against the

illustration on page 5. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

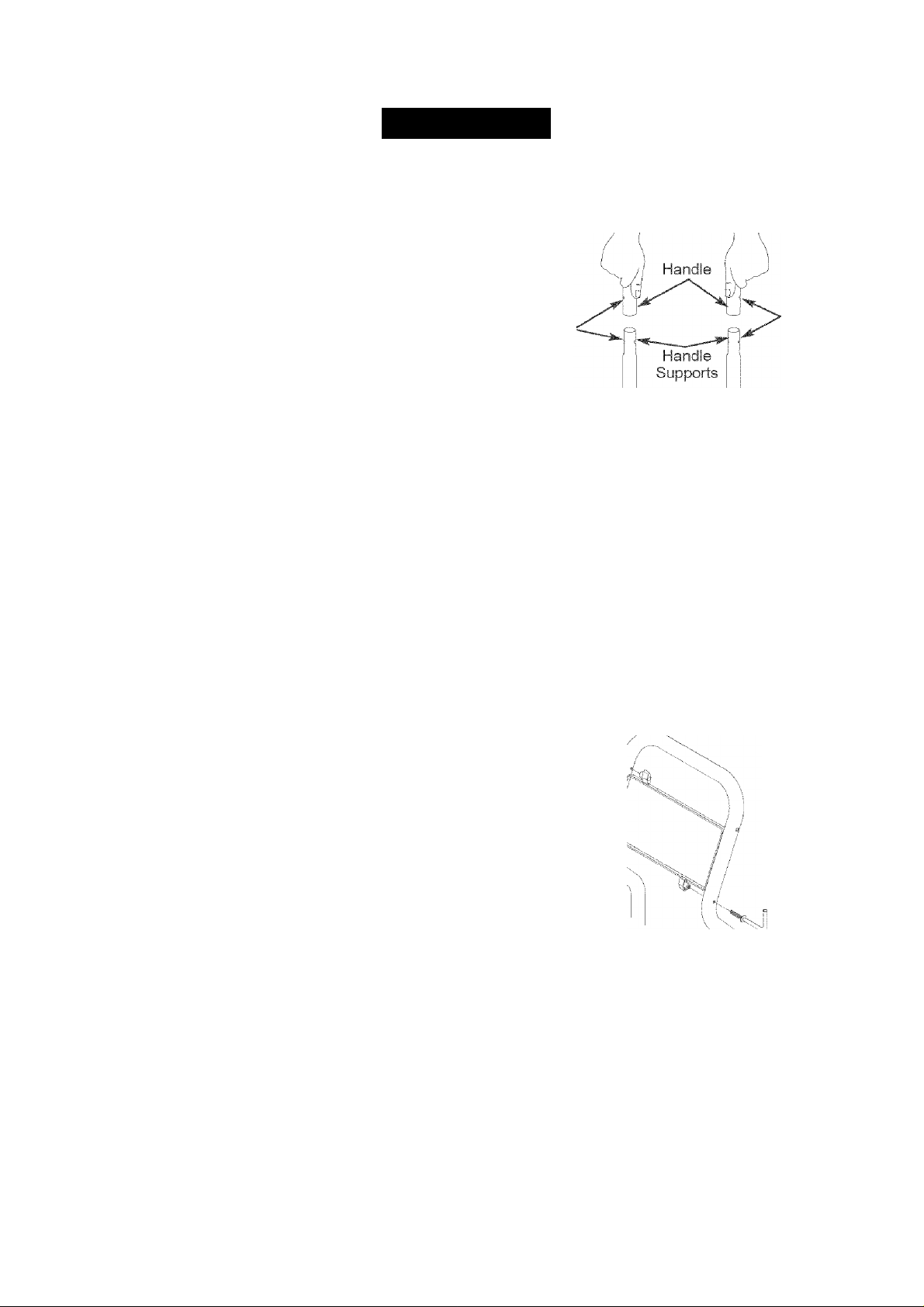

Attach Handle

1. Place handle assembly onto handle supports

connected to main unit. Make sure holes in handle

align with holes on handle supports.

Align Holes*

NOTE: It may be necessary to move the handle

supports from side to side in order to align the handle

so it will slide over the handle supports.

2. Insert carriage bolts through holes from outside of

unit and attach a plastic knob from inside of unit.

Tighten by hand.

V,

a.

3. Insert one “L” hooks through hole just under

billboard on left side of handle (viewing from rear

of unit). Hold hook in place and attach plastic knob

from inside of unit. Tighten by hand.

k

Spray Gun

Hook

Hose Hook

ASSEMBLING YOUR PRESSURE WASHER

Your Craftsman high pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

1. Attach handle.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connect pressure hose to spray gun and pump.

5. Connect water supply to pump.

4. Insert other “L” hook through hole just above

billboard on right side of handle (viewing from rear

of unit). Hold hook in place and attach plastic knob

from inside of unit. Tighten by hand.

Page 7

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher rated SAE 30

weight. DO NOT use special additives.

1. Choose a viscosity according to table below.

B

Synl

F -20 C

‘C -30 -20

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

) 20 32 40 00 80 100

-10 0 10 20 30 40

* The use of multi-viscosity oils {5W-30, 10W-30, etc.)

in temperatures above 40°F (4°C) will result in higher

than normal oil consumption. When using a multi

viscosity oil, check oil more frequently.

** If using SAE 30 oil in temperatures below 40°F

(4°C), it will result in hard starting and possible

engine bore damage due to inadequate lubrication.

2. Place pressure washer on a level surface and

clean area around oil fill.

3. Remove oil dipstick and wipe dipstick with clean

cloth. Replace and tighten dipstick. Remove and

and check oil level.

4. Slowly pour oil into oil fill opening. Pause to permit

oil to settle. Fill to TuH” mark on dipstick. DO

NOT OVERFILL. Remove dipstick and check oil

level.

I

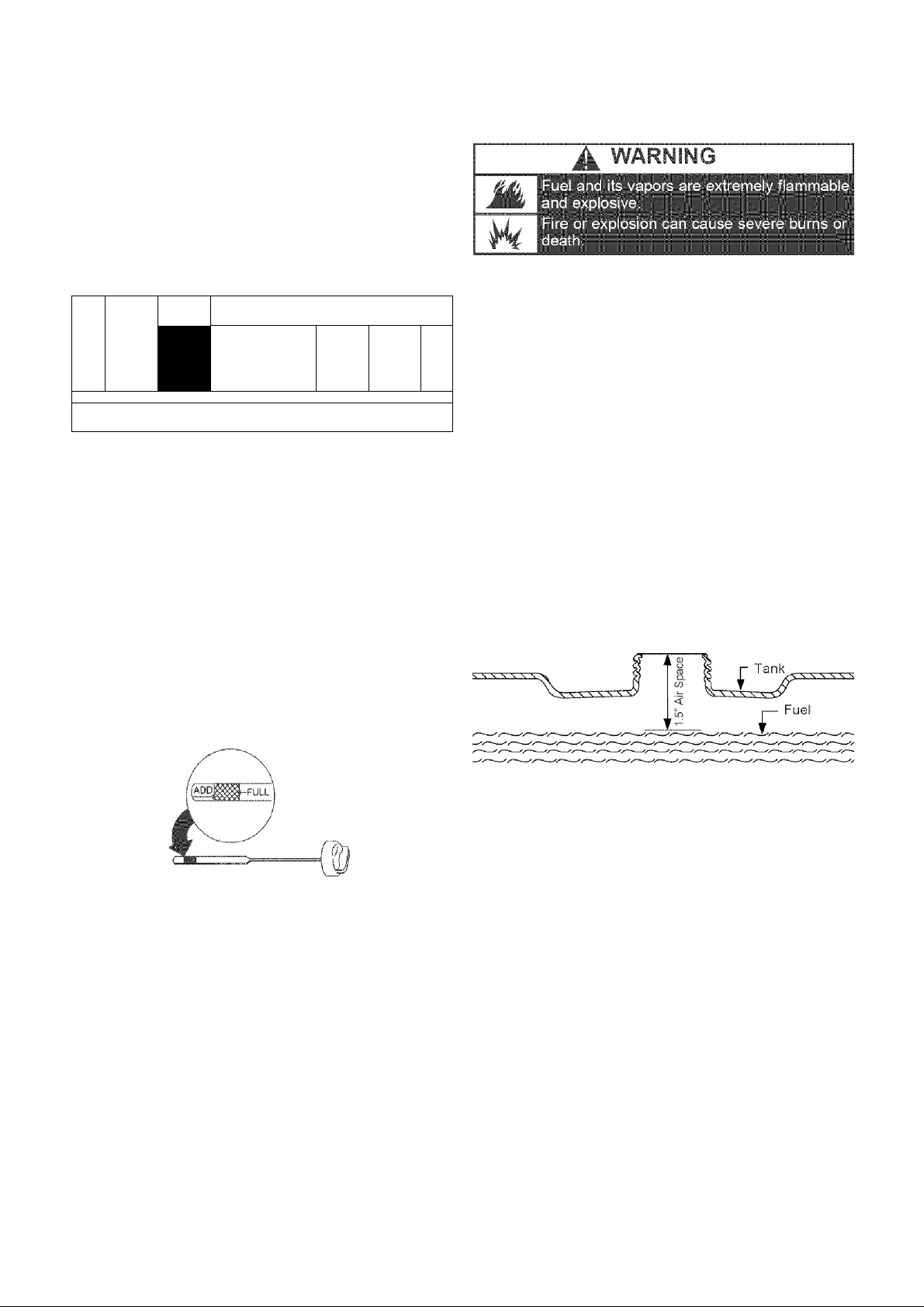

Add Fyel

WHEN ADDING FUEL

• Turn pressure washer OFF and let it cool at least 2

minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

■ Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

• DO NOT light a cigarette or smoke.

NOTE: This gasoline engine is certified to operate on

gasoline. Exhaust Emission Control System: EM

{Engine Modifications).

1. Use clean, fresh, regular UNLEADED fuel with a

minimum of 77 octane with equipment. DO NOT

use fuel which contains Methanol. DO NOT mix oil

with fuel.

2. Clean area around fuel fill cap, remove cap.

3. Slowly add regular unleaded fuel to fuel tank. Be

careful not to overfill. Allow about 1.5" of tank

space for fuel expansion, as shown here.

NOTE: You may not need to use all the supplied oil.

5. Replace and tighten dipstick.

NOTE: Check oil often during engine break-in.

4. Install fuel cap and wipe up any spilled fuel.

CAUTION! Alcohol-blended fuels (called gasohoi,

ethanol or methanol) can attract moisture, which leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Drain the

fuel tank, start the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next season.

See “Storage” on pages 18-19 for additional information.

NEVER use engine or carburetor cleaner products in

the fuel tank as permanent damage may occur.

Page 8

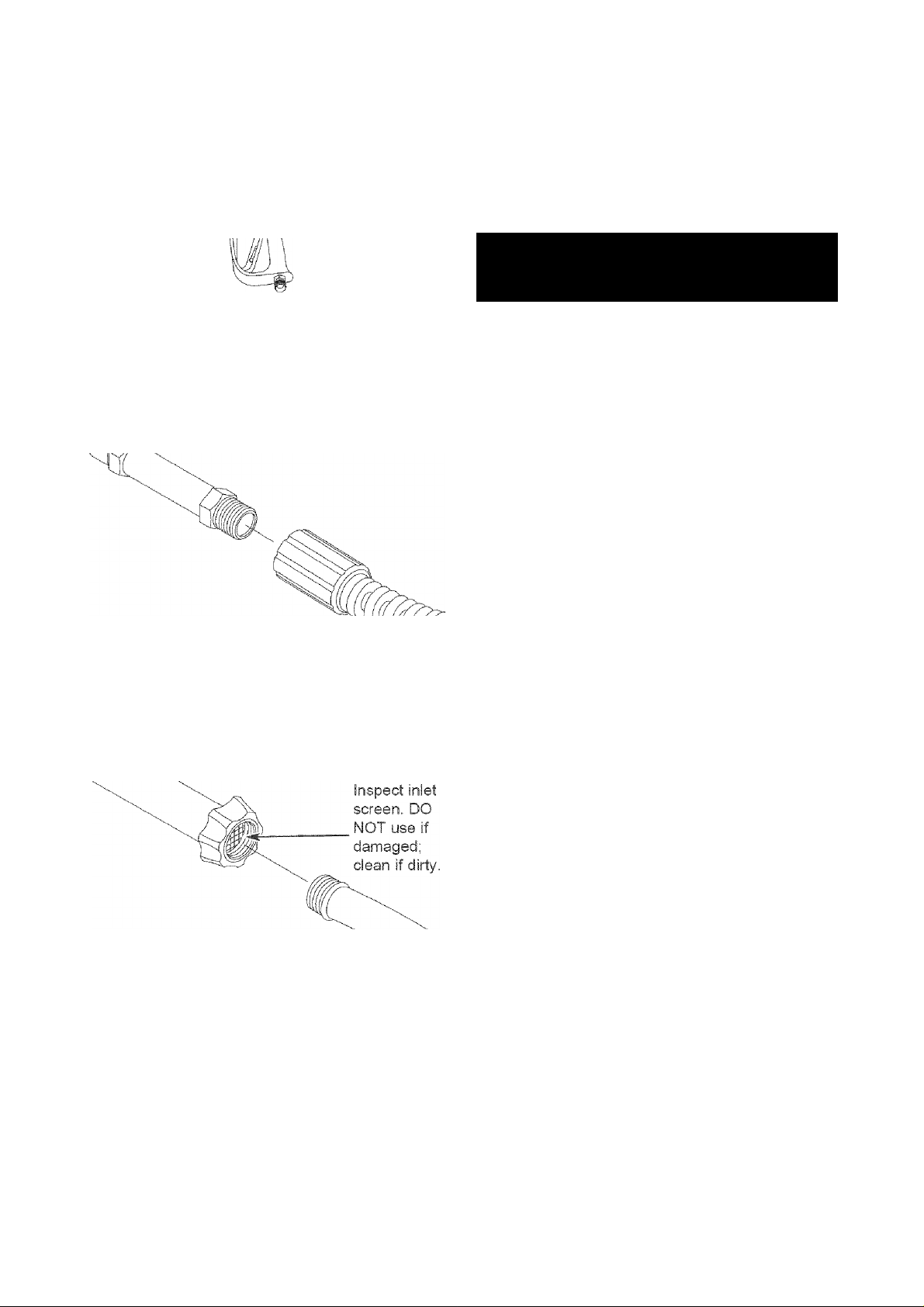

Coririect Hose and Water Supply to Pomp

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach ail hoses before you start the engine.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

2.

Remove and discard shipping caps from pump

inlet and outlet.

3.

Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

IMPORTANT: DO NOT siphon standing water for the

water supply. Use ONLY cold water (less than 100°F).

6. Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

CAUTION

re MUST be at least ten feet of unrestricted g

e between the pressure washer inlet and any

t off device, such as a ‘Y’ shut-off

other convenience-type water shut-o1

Damage to equipment resulting from failure to follow

this instruction will void warranty.

7. Turn ON water and squeeze trigger on spray gun

to purge pump system of air and impurities.

■

Always wear eye protection when using this equipment

or in vicinity of where equipment is in use.

Before starting the pressure washer, be sure you are

wearing adequate eye protection.

4.5.Before connecting garden hose to water inlet,

inspect inlet screen. Clean screen if it contains

debris or have it replaced if damaged. Refer to

section “O-Ring Maintenance” if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen is damaged.

Run water through garden hose for 30 seconds to

flush it of debris. Turn off water.

CHECKLIST BEFORE STARTING

ENGINE

Review the assembly to ensure you have performed

all of the following:

1. Check that oil has been added to proper level in

engine crankcase.

Add proper fuel to fuel tank.

2.

Check for properly tightened hose connections

3.

(high pressure and water supply) and for tight

connections and that there are no kinks, cuts, or

damage to the high pressure hose.

Provide proper water supply (not to exceed

4.

100°F).

Be sure to read “Safety Rules” and “Operation”

5.

sections before using the pressure washer.

If starting unit after storage, see “Storage” section

6.

on pages 18-19.

Page 9

OPERATIC

I

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1^800^222^3136.

Pressure Washer Location

Pressure Washer Clearance

^ DANGER

Operate pressure washer ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enclosure.

The pressure washer must be at least 5 ft. (152 cm)

from structures having combustible walls and/or other

combustible materials. Leave at least 3 ft. (92 cm) all

around pressure washer including overhead, for

adequate cooling, maintenance and servicing.

Place pressure washer in a well ventilated area, which

will allow for removal of deadly exhaust gas. DO NOT

place pressure washer where exhaust gas could

accumulate and enter inside or be drawn into a

potentially occupied building. Ensure exhaust gas is

kept away from any windows, doors, ventilation

intakes or other openings that can allow exhaust gas

to collect in a confined area. Prevailing winds and air

currents should be taken into consideration when

positioning pressure washer.

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

1. Place pressure washer near an outside water

source capable of supplying water at a flow rate

greater than 3.5 gallons per minute and no less than

20 PSI at pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected

to spray gun and pump. See “Assembling Your

Pressure Washer” for illustrations.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON water.

• Damage to equipment will result from failure to follow

this Instruction.

5. Squeeze trigger on gun to purge pump system of

air and impurities.

6. Attach nozzle extension to spray gun. Tighten by

hand.

Position nozzle in low pressure mode (slide nozzle

forward) and squeeze trigger on spray gun to

relieve pressure caused by turning ON water.

Water will flow out of gun in a thin stream.

Continue to hold trigger until there is a steady

stream of water and no air remains in system.

Release trigger.

Engage trigger lock to spray gun trigger.

Trigger Lock

9. Move throttle lever to “Fast” position, shown here

as a rabbit.

Page 10

10. Move choke knob to “Choke” position.

NOTE: For a warm engine, be sure the choke knob is

in the “Run” position.

11. Grasp handle and pull recoil starter lightly until you

feel some resistance, then pull briskly.

^ WARNING

When starting engine, puli cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze

trigger on spray gun.

12. Return recoil starter slowly. DO NOT let rope

“snap back” against starter.

13. When engine starts, slowly move choke knob to

“Run” position as engine warms. If engine falters,

move choke knob to “Choke” position, then to

“Run” position.

14. If engine fires, but does not continue to run,

squeeze trigger on spray gun to relieve internal

pump pressure. Move choke knob to “Run”

position, and repeat steps 11 through 13.

15. If engine fails to start after six pulls, move choke

knob to “Run” position, and repeat steps

11 through 13.

IMPORTANT: If engine floods, place choke lever in

“Run” position and crank until engine starts.

NOTE: Always keep the throttle lever in the “Fast”

position when operating the pressure washer.

WARNING

m

How to stop Yoyr Pressure Washer

1. Let engine idle for two minutes.

2. Move throttle lever on engine to “Stop” position.

A CAUTION

Backfire, fire or engine damage could occur.

DO NOT stop engine by moving choke lever to “Choke”

position.

3. Squeeze trigger on spray gun to relieve

trapped pressure in hose to avoid injury.

NOTE: A small amount of water will squirt out when

pressure is released.

A WARNING

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

Squeeze trigger on spray gun to relieve trapped

pressure, every time you stop engine. Engage trigger

lock on spray gun.

4. Engage trigger lock on spray gun when not in use.

How To Use the Adjustable Nozzle

You now should know how to START your pressure

washer and how to STOP it. The information in this

section will tel! you how to adjust the spray pattern

and apply detergent or other cleaning chemicals.

^ CAUTION

er produces a high pressi

risk of injury and damage

NEVER adjust spray pattern when spraying.

NEVER put hands in front of nozzle to adjust spray pattern.

On the end of your spray gun is an adjustable nozzle

that you can use to adjust the spray pattern and the

spray pressure.

1. Slide nozzle forward for low pressure spray; slide

backward for high pressure spray.

DO NOT touch hot surfaces.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from

structures having combustible walls and/or other

combustible materials.

Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained in effective working order.

Slide nozzle backward for

high pressure mode.

10

Slide nozzie forward for low

pressure mode and

detergent application.

Page 11

2. Point nozzle towards a hard surface, disengage

trigger lock, and press trigger to test pattern.

3. Twisting nozzle adjusts spray pattern from a

narrow pattern to a fan pattern.

Twist nozzle counter

clockwise for fan pattern.

Twist nozzle clockwise for

narrow spray pattern.

4. For most effective cleaning, keep spray nozzle

from 8 to 24 inches away from cleaning surface.

5. If you get spray nozzle too dose, especially using

high pressure mode, you may damage the surface

being cleaned.

6. DO NOT get closer than 6 inches when cleaning

tires.

Applying Detergent with the Adjustable

Nozzle

IMPORTANT: Use chemicals designed specifically

for pressure washers. Household detergents could

damage the pump.

CAUTION

u must attach all hoses before you start the engine.

Starting the engine without all the hoses connected and

without the wafer turned ON will damage the pump.

To apply detergent, follow these steps:

1. Review use of adjustable nozzle.

2. Prepare detergent solution as required by job.

3. Place filter end of detergent siphoning tube into

detergent container.

CAUTION

Keep the chemical injection

contact with the hot muffler.

When inserting the filter into a detergent solution bottle,

route the tube so as to keep it from inadvertently

contacting the hot muffler.

4. Slide adjustable nozzle forward to low pressure

mode. Detergent cannot be applied with nozzle in

high pressure position.

5. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Start engine.

6. Apply detergent to a dry surface, starting from

bottom and working up.

7. Allow detergent to "soak in” for 3-5 minutes before

rinsing. Reapply as needed to keep surface wet.

8. For washing, start at lower portion of area to be

washed and work upward, using long, even,

overlapping strokes.

Pressure Washer Rinsing

For Rinsing:

1. Slide nozzle backward to high pressure, press

trigger and wait for detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

2. Keep spray gun a safe distance from area you

plan to spray.

A WARNING

Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

Operate this unit on a stable surface.

Be extremely careful if you must use the pressure

washer from a ladder, scaffolding or any other relatively

unstable location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

Apply a high pressure spray to a small area, then

check surface for damage. If no damage is found,

it is okay to continue cleaning.

4.

Start at top of area to be rinsed, working down

with same overlapping strokes as you used for

washing and applying detergent.

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures above 125°F. The system engages to

cool the pump by discharging the warm water onto

the ground.

11

Page 12

ENGINE TECHNICAL INFORMATION

This is a single cylinder, overhead valve (OHV), air

cooled engine. It is a low emissions engine.

In the State of California, Model Series 120000

engines are certified by the California Air Resources

Board to meet emissions standards for 125 hours.

Such certification does not grant the purchaser, owner

or operator of this engine any additional warranties

with respect to the performance or operational life of

this engine. The engine is warranted solely according

to the product and emissions warranties stated

elsewhere in this manual.

Power Ratings

The power ratings for an individual engine model are

initially developed by starting with SAE (Society of

Automotive Engineers) code J1940 (Small Engine

Power & Torque Rating Procedure) (Revision 2002

05). Given both the wide array of products on which

our engines are placed, and the variety of

environmental issues applicable to operating the

equipment, it may be that the engine you have

purchased will not develop the rated horsepower when

used in a piece of power equipment (actual “on-site”

power). This difference is due to a variety of factors

including, but not limited to, the following; differences

in altitude, temperature, barometric pressure, humidity,

fuel, engine lubrication, maximum governed engine

speed, individual engine to engine variability, design of

the particular piece of power equipment, the manner in

which the engine is operated, engine run-in to reduce

friction and clean out of combustion chambers,

adjustments to the valves and carburetor, and other

factors. The power ratings may also be adjusted

based on comparisons to other similar engines utilized

in similar applications, and will therefore not

necessarily match the values derived using the

foregoing codes.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure

Flow Rate

Chemical Mix.............................Use as directed

Water Supply Temperature. . . . Not to exceed 100°F

Shipping Weight

Engine Specifications

Rated Horsepower

Bore............................................2.69 in. (68mm)

Stroke

Displacement ................ 11.58 in. (190 cc)

Spark Plug

Set Gap To: ............... 0.020inch (0.50mm)

Armature Air Gap:

Valve clearance with valve springs installed and piston 1/4 in.

(6 mm) past top dead center (check when engine is cold).

intake.......................................... 0.004-0.006 in.

Exhaust

Fuel Capacity

Oil Type:

Above 40° F

Below 40° F

....................................

..................................

........................

.....................

.........................................

Long Life Platinum ......... Champion RC12PYP

Resistor ................. Champion RC12YC

.....................

.....................................

.............................

............................

...........................

2,800 PSI

2.5 GPM

74 lbs.

7 at 3600 rpm

2.04 in. (52mm)

0.010-0.014 in.

(0.25-0.36mm)

(0.10-0.15 mm)

0.004-0.008 in.

(0.10-0.20 mm)

1.6 Quarts

SAE 30

SAE 5W-30 or 10W-30

12

Page 13

MAINTENANCE

OWNER’S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

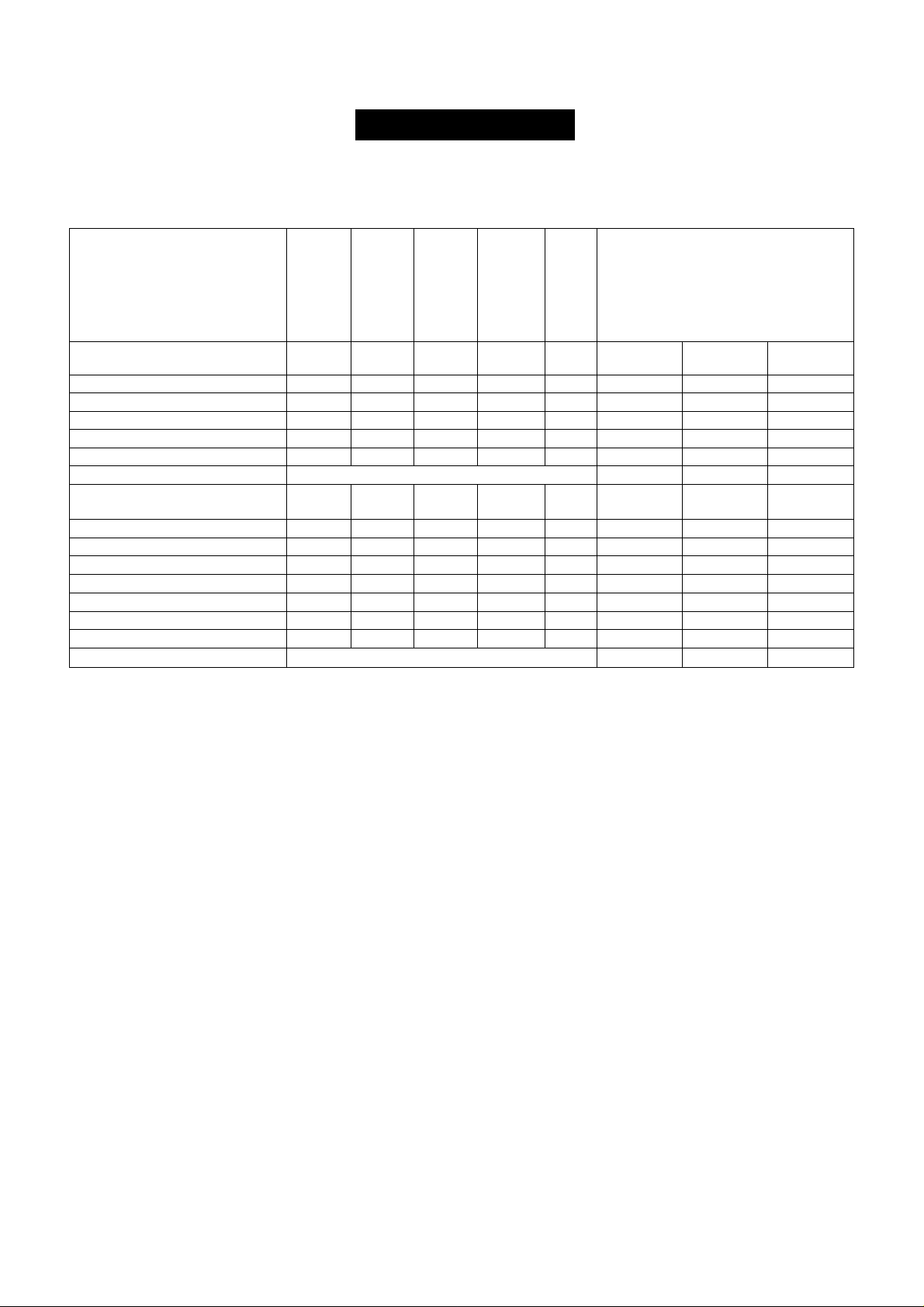

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU

COMPLETE REGULAR SERVICE

MAINTENANCE TASK

PRESSURE WASHER

Check/dean water inlet screen

Check high pressure hose X

Check detergent hose X

Check spray gun and assembly for leaks X

Purge pump of air and contaminants X

Change pump oil X

Prepare pump for storage below 32'’F See Storage on pages 18-19.

ENGINE

Check oil level

Clean debris X

Change engine oil X=

Service air cleaner X"

Service spark plug X

Service spark arrester X

Clean cooling system X'

Check valve clearance X

Prepare for storage If unit is to remain idle for longer than 30 days.

Before

Each Use

X

SEF

Every 25

Hours or

Yearly

¡VICE DAT

Every 50

Hours or

Yearly

ES

Every 100

Hours or

Yearly

Yearly

SERVICE DATES

Clean if clogged. Replace if perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter.

Change sooner when operating under dirty or dusty conditions.

Replace more often under dirty or dusty conditions.

GENERAL RECOMMENDATIONS

Regular maintenance will improve the performance

and extend the life of the pressure washer. See any

authorized Sears dealer for service.

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual including proper storage as

detailed in “Storage” on pages 18-19.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

“Maintenance Schedule” chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

EMISSION CONTROL

Maintenance, replacement or repair of the emission

control devices and systems may be performed by any

non-road engine repair establishment or individual.

BEFORE EACH USE

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screen for damage.

4. Check in-line filter for debris.

5. Check high pressure hose for leaks.

6. Check chemical filters for damage.

7. Check gun and nozzle extension assembly for

leaks.

8. Purge pump of air and contaminants.

help your engine run better and last longer.

If equipped with inflatable tires, keep the air pressure

at the value marked on the tire or within 15 and 40 psi.

13

Page 14

PRESSURE WASHER MAINTENANCE

Clean Debris

Daily or before use, dean accumulated debris from

pressure washer. Keep linkage, spring and controls

clean. Keep area around and behind muffler free from

any combustible debris.

Pressure washer parts should be kept clean to reduce

the risk of overheating and ignition of accumulated

debris.

CAUTION

Improper treatment of pressure washer c;

damage it and shorten its life.

DO NOT insert any objects through cooling slots.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil,

etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on

the pressure washer. These openings must be kept

dean and unobstructed.

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

^ WARNING

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury

and possible amputation.

NEVER repair high pressure hose. Replace it.

Replacement hose rating MUST exceed maximum

pressure rating of unit.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making

sure it springs back into place when you release it. Put

trigger lock in UP position and test trigger. You should

not be able to press trigger. Replace spray gun

immediately if it fails any of these tests.

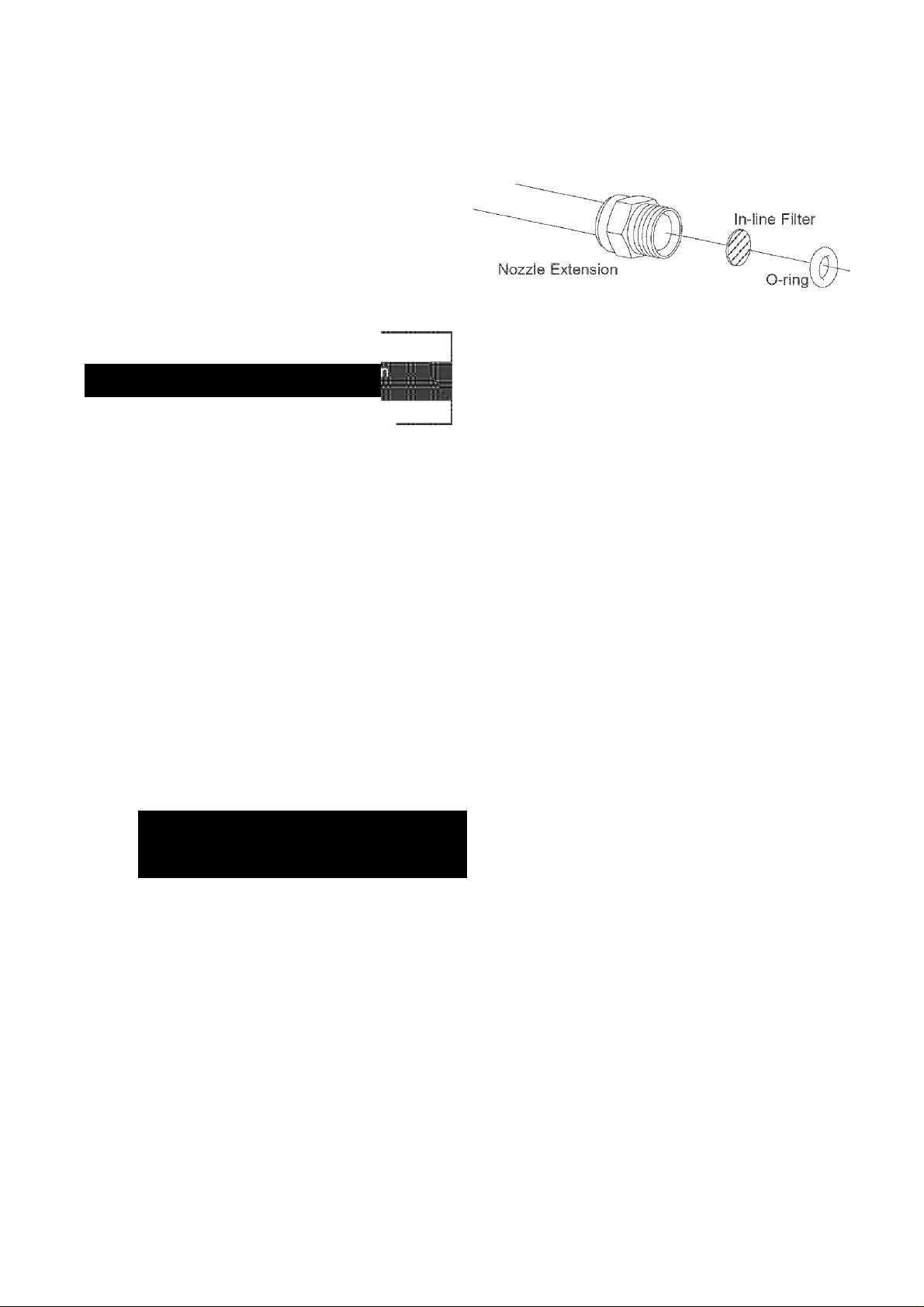

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

1. Detach spray gun from high pressure hose.

Detach nozzle extension from spray gun and

remove o-ring and screen from nozzle extension.

Flush screen, spray gun, and nozzle extension

with clean water to clear debris.

2. Place in-line filter screen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care to not bend

screen.

3. Place o-ring into recess. Push o-ring snugly

against in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps;

1. Set up pressure washer as described in

"Assembling Your Pressure Washer” section and

connect water supply.

2. Pull trigger on gun and hold until a steady stream

of water appears.

To remove contaminants from the pump, follow these

steps;

1. Set up pressure washer as described in

"Assembling Your Pressure Washer” section, and

connect water supply.

Remove nozzle extension from gun.2.

3.

Start engine according to instructions in "How To

Use Your Pressure Washer” section.

4.

Pull trigger on gun and hold.

5.

When water supply is steady and constant,

engage trigger lock and refasten nozzle extension.

14

Page 15

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the orifice following these instructions:

1. Shut off engine and turn off water supply.

2. Remove orifice from end of nozzle extension.

Separate nozzle extension from spray gun. Twist

nozzle clockwise to stream position. Using a 2mm

(5/64) alien wrench, remove orifice from end of

nozzle extension.

I

3,4,Remove in-line filter from other end of nozzle

extension.

Use a small paper clip to free any foreign material

clogging or restricting orifice.

■

...........

.......

.........

%

0- Ring Maintenance

Purchase an O-Ring Repair Kit, item number

71-75116, at your local Sears or by calling

1- 800-366-PART or online at www.sears.com. It is not

included with the pressure washer. This kit includes

replacement o-rings, rubber washer and water inlet

filter. Refer to the instruction sheet provided in the kit

to service your unit’s o-rings.

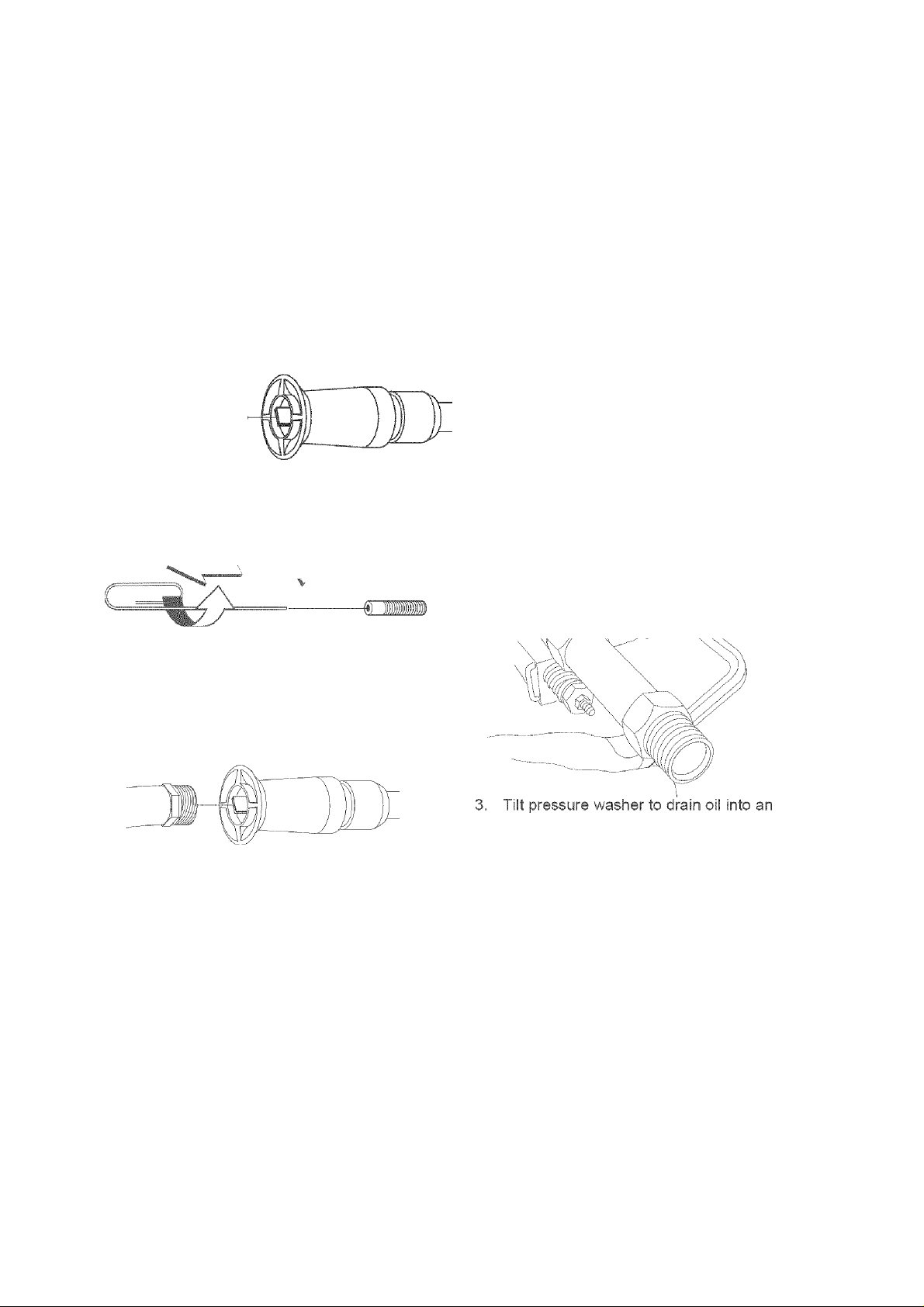

Pymp Maintenance

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE: You must purchase a premeasured bottle of

pump oil, item number 190585GS, by calling

1-800-366-PART or online at vww.sears.com.

Change pump oil as follows;

1. Drain engine oil and fuel from pressure washer.

2. Use a 8mm alien wrench to remove black pump

oil cap between high pressure outlet and garden

hose inlet.

Insert wire into orifice and turn back

and forth to clear obstruction.

5,

Using a garden hose, remove additional debris by

back flushing water through nozzle extension.

Back flush between 30 to 60 seconds. Turn

adjustable nozzle extension to stream spray and

move nozzle from low to high while flushing.

6.

Reinstall orifice and in-line filter into nozzle

extension. DO NOT overtighten orifice with alien

wrench.

7.

Reconnect nozzle extension to spray gun.

8.

Reconnect water supply, turn on water, and start

engine.

9.

Test pressure washer by operating with nozzle in

high and low positions.

'f

container until it drips slowly from pump.

4.

Tilt pressure washer in opposite direction and

empty premeasured pump oil bottle into same

opening (a small funnel may be helpful).

5.

Install black pump oil cap and tighten firmly.

6.

Set pressure washer in upright position. Add fuel

and engine oil.

Oil Cap

15

Page 16

ENGINE MAINTENANCE

^ WARNING

Ml ilH

1

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Checking Oil Level

Oil level should be checked prior to each use or at

least every 5 hours of operation. Keep oil level

maintained.

Changing Oil

Change engine oil after the first 5 hours and every

50 hours thereafter. If you are using your pressure

washer under extremely dirty or dusty conditions, or in

extremely hot weather, change oil more often.

lIBWi

5. Wipe dipstick clean, insert it into oil fill hole and

tighten securely, remove dipstick. Add

recommended oil up to “Full” mark on dipstick.

Pour slowly. Wipe dipstick clean each time oil

level is checked. DO NOT overfill.

6. Install oil fill plug and dipstick, tighten securely.

7. Wipe up any remaining oil.

8. Reconnect spark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run it with a dirty air cleaner.

Service the air cleaner once every 25 hours of

operation or once each year, whichever comes first.

Service more often if operating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

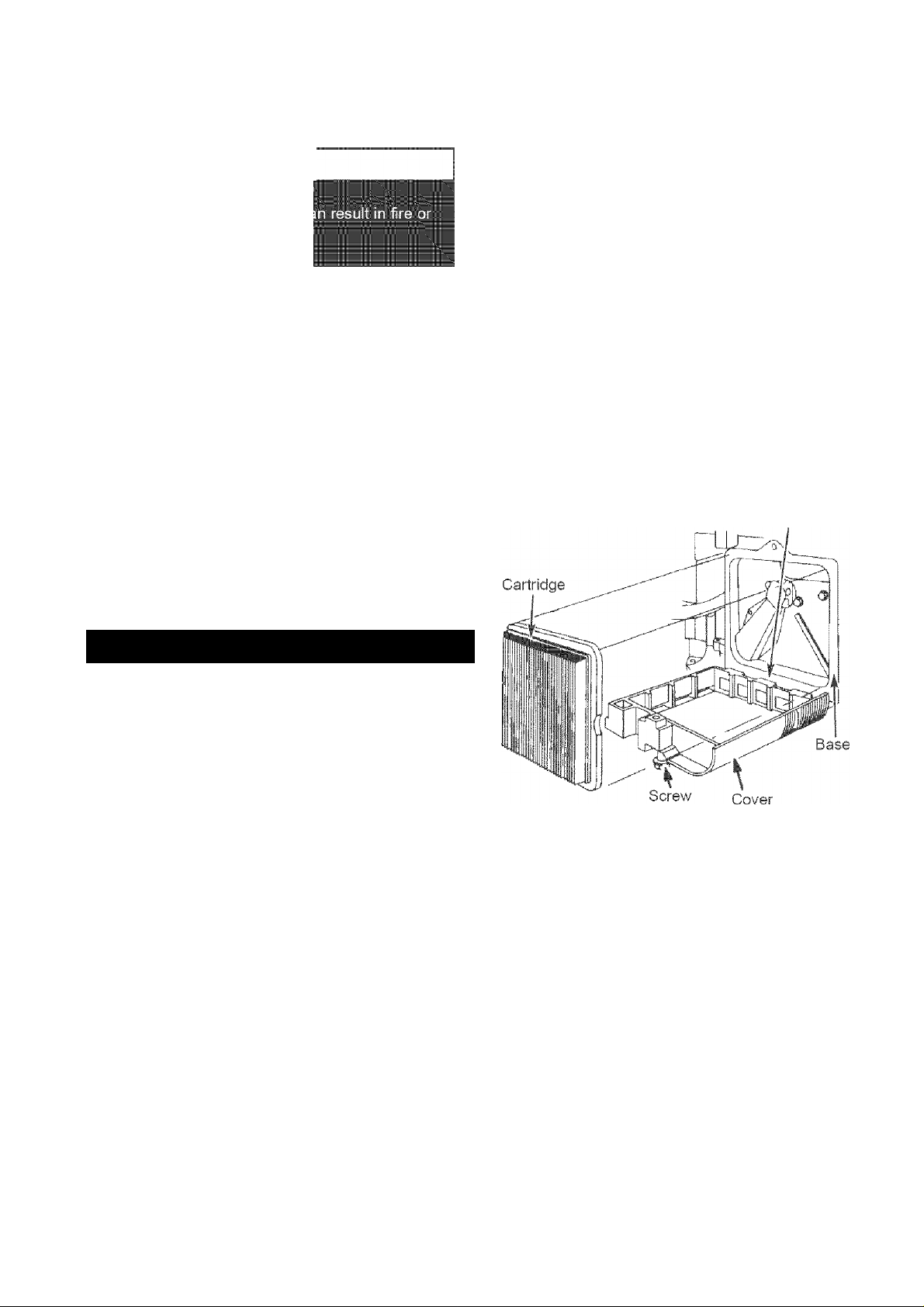

To service the air cleaner, follow these steps;

1. Loosen screw and tilt cover down.

Tabs and Slots

^ CAUTION

Avoid prolonged or repeated skin contact with used

motor oil.

Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN.

DON'T POLLUTE. CONSERVE

RESOURCES, RETURN USED OIL TO

COLLECTION CENTERS.

Change oil while engine is stil! warm from running, as

follows:

1. Drain fuel tank by running pressure washer until

fuel tank is empty.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Clean area around oil fill, remove oil fill

cap/dipstick. Wipe dipstick dean.

4. Tip your pressure washer to drain oil from oil fill

into a suitable container making sure you tip your

unit away from spark plug. When crankcase is

empty, return pressure washer to upright position.

Carefully remove cartridge assembly.

To clean cartridge, gently tap pleated paper side

on a flat surface.

Reinstall dean or new cartridge assembly inside

cover.

Insert cover’s tabs into slots in bottom of base.

Tilt cover up and tighten screw securely to base.

NOTE: You can purchase new air filter elements by

calling 1^800^366^PART.

16

Page 17

Service Spark Plug

Service the spark plug every 100 hours of operation or

yearly, whichever occurs first.

1. Clean area around spark plug.

Remove and inspect spark plug.

Replace spark plug if electrodes are worn, or if

insulator is cracked or chipped.

For replacement use either the standard resistor

spark plug, Champion RC12YC or the long life

platinum spark plug. Champion RC12PYP.

Check electrode gap with wire feeler gauge and

set gap at 0.020 inches (0.50mm), if necessary.

6. Install spark plug, tighten securely.

NOTE: You can purchase a new spark plug by calling

1^800^366^PART.

Carburetor

If you think your carburetor needs adjusting, see your

nearest Sears service center. Engine performance

may be affected at altitudes above 3000 feet. For

operation at higher elevations, contact your nearest

Sears service center.

Spark Arrester Service

Your engine is not factory-equipped with a spark

arrester. In some areas, it is illegal to operate an

engine without a spark arrester. Check local laws and

regulations. A spark arrester is available from your

nearest Sears service center. If you need to order a

spark arrester, please call 1-800-366-PART.

The spark arrester must be serviced every 50 hours to

keep it functioning as designed.

If the engine has been running, the muffler will be very

hot. Allow the muffler to cool before servicing the

spark arrester.

• Remove spark arrester screen for cleaning and

inspection.

• Replace if screen is damaged.

WARNING

Running engines produce

Temperature of muffler and nearby

can reach or exceed ISO'^F (65''C).

Severe burns can occur on co

M

DO NOT touch hot surfaces.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from

structures having combustible walls and/or other

combustible materials.

Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained In effective working order.

Combustible debris, such as le

brush, ect. can catch fi

Air Cooling System

Over time debris may accumulate in cylinder cooling

fins and cannot be observed without partial engine

disassembly. For this reason, we recommend you

have an authorized Sears service dealer clean the

cooling system per recommended intervals (see

“Maintenance Schedule” on page 13). Equally

important is to keep top of engine free from debris.

See “Clean Debris”.

........

I

17

Page 18

STORAGE

after each use

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump

parts and “freeze” pump action. Follow these

procedures after every use:

1. Flush detergent siphoning tube by placing filter

into a pail of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minutes.

Shut off engine, let it cool, then remove all hoses.

Disconnect spark plug wire from spark plug.

Empty pump of all liquids by pulling recoil handle

about 6 times. This should remove most liquid in

pump.

If storing for more than 30 days see “Long Term

Storage” on next page.

Coil high pressure hose and inspect it for damage.

Cuts in hose or fraying could result in leaks and

loss of pressure. Should any damage be found,

replace hose. DO NOT attempt to repair a

damaged hose. Replace hose with genuine Sears

part.

Disconnect hose from spray gun and high

7.

pressure outlet on pump. Drain water from hose,

gun, and nozzle extension. Use a rag to wipe off

the hose.

8.

Coil hose and properly hang it on wire support

provided.

9.

Reconnect spark plug wire to spark plug.

10. Store unit in a clean, dry area.

WINTER STORAGE

CAUTION

You must protect your ur reeztng temperatures.

Failure to do so will permanently damage your pump

and render your unit inoperable.

Freeze damage is not covered under warranty.

To protect the unit from freezing temperatures;

1.

Flush detergent siphoning tube by placing filter

into a pai! of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minutes.

2.

Empty pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most

liquid in pump.

Use pump saver, available at Sears retail item

71-74403, to treat pump. This minimizes freeze

damage and lubricates pistons and seals.

4.

If pump saver is not available, connect a 3-foot

section of garden hose to water inlet adapter. Pour

RV-antifreeze (antifreeze without alcohol) into

hose. Pull recoil handle twice. Disconnect 3-foot

hose.

WARNING! NEVER store the engine with fuel

in the gas tank indoors or in enclosed, poorly

A

ventilated areas where fumes may reach an

open flame, a spark, or pilot light.

18

Page 19

LONG TERM STORAGE

If you do not plan to use the pressure washer for more

than 30 days, you must prepare the engine and pump

for long term storage.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also,

experience indicates that alcohol-blended fuels {called

gasohoi, ethanol or methanol) can attract moisture,

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

Protect Fuel System

Fuel Additive:

If adding a fuel additive, fill the fuel tank with fresh

fuel. If only partially filled, air in the tank will promote

fuel deterioration during storage. Engine and fuel can

be stored up to 24 months with additive.

• Add fuel additive following manufacturer’s

instructions.

• Make sure you have water supply to pump inlet

connected and turned ON.

• Run the engine outdoors for 10 minutes to be sure

that treated fuel has replaced the untreated fuel in

the carburetor.

If fuel additive is not used, remove all fuel from tank

and run engine until it stops from lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade. See "Changing Oil” on

page 16.

Oil Cylinder Bore

• Remove spark plug. Squirt about 1 tablespoon of

clean engine oil into the cylinder. Cover spark plug

hole with rag. Pull recoil handle slowly to distribute

oil. Avoid spray from spark plug hole.

• Install spark plug. DO NOT connect spark plug

wire.

Protect Pump

To protect the pump use Sears pump saver to prevent

freeze damage and lubricate pistons and seals.

NOTE: Sears pump saver, item number 71-74403, is

available as an optional accessory. It is not included

with the pressure washer.

CAUTION

You must protect your unit from freezing temperatures.

Failure to do so will permanently damage your pump

and render your unit Inoperable.

Freeze damage is not covered under warranty.

To use the pump saver;

^ CAUTION

Read and follow al

PumpSaver can la

Always wear eye protection when using PumpSaver.

1. Attach hose on pump saver can to pump inlet.

2. Push in can top to dispense pump saver.

3. When pump saver fluid begins to exit pump outlet,

the pump is protected.

4. Remove pump saver from pump inlet.

OTHER

• DO NOT store fuel from one season to another.

• If possible, store your unit indoors and cover it to

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

IMPORTANT: NEVER cover your pressure washer

while engine and exhaust area are warm.

19

Page 20

TROUBLESHOOTIN

Problem Cause Correction

Pump has following problems:

failure to produce pressure, erratic

pressure, chattering, loss of

pressure, low water volume.

Detergent fails to mix with spray.

Engine runs good at no-load but

"bogs" when load is added.

Engine will not start; or starts and

runs rough.

1. Nozzle in low pressure mode.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose strainer.

6. Water supply is over 100°F.

7. High pressure hose is blocked

or leaks.

8. Gun leaks.

9. Nozzle is obstructed.

10. Pump is faulty.

1. Detergent siphoning tube is not

submerged.

2. Chemical filter is clogged or

cracked.

3. Dirty in-line filter.

4. Nozzle is in high pressure

mode.

Engine speed is too slow. Move throttle control to FAST

1. Low oil level. 1. Fill crankcase to proper level.

2. Dirty air cleaner. 2. Clean or replace air cleaner.

3. Out of gasoline. 3. Fill fuel tank.

4. Stale gasoline. 4. Drain gas tank; fill with fresh

5. Spark plug wire not connected

to spark plug.

6. Bad spark plug. 6. Replace spark plug.

7. Water in gasoline. 7. Drain gas tank; fill with fresh

8. Overchoking. 8. Open choke fully and crank

9. Excessively rich fuel mixture. 9. Contact Sears service facility.

10. Intake valve stuck open or

closed.

11. Engine has lost compression. 11. Contact Sears service facility.

1. Pull nozzle backward for high

pressure mode.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch

leak.

5. Check and clean inlet hose

strainer.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace gun.

9. Clean nozzle.

10. Contact Sears service facility.

1. Insert detergent siphoning tube

into detergent.

Clean or replace filter/detergent

siphoning tube.

See "Check In-Line Filter".

Push nozzle forward for low

pressure mode.

position. If engine still "bogs down",

contact Sears service facility.

fuel.

5. Connect wire to spark plug.

fuel.

engine.

10. Contact Sears service facility.

Engine shuts down during

Out of gasoline. Fill fuel tank.

operation.

Engine lacks power. Dirty air filter. Replace air filter.

Engine "hunts" or falters. Choke is opened too soon.

20

Move choke to halfway position until

engine runs smoothly.

Page 21

NOTES

21

Page 22

PARTS

CRAFTSMAN 2800 PSI Pressure Washer 580.752400 Main Unit — Exploded View and Parts List

KT

. 11

V

Item Part #

1

192393GS

2

E194719GS

3

194048GS

4

194548GS

5

192133GS

6

192131GS

7

B3263GS

8

B2203GS

9

192310GS

Items Not Illustrated

Part # Description

194052GS MANUAL. Owner’s

194263GS KIT, Decals

AB3061BGS OIL, Bottle

Optlonai Accessories

7175187GS

7175197GS

7175199GS

190249GS

7175116GS

7174400GS

B3635GS

7174402GS

7174403GS

7174300GS

7174301GS

7174302GS

7174303GS

7174307GS

Description

BASE

HANDLE

ASSY, Billboard

HOSE

KIT, Engine Mounting Hardware

KIT, Pump Mounting Hardware

GUN

KIT, Handle Connector

KIT, Vibration Mount

item

Part#

10

192309GS

11

194264GS

12

191265GS

13

195303EGS

14

B1236EGS

15

192317GS

16

23139DGS

17

194059GS

900

NSP

Not Illustrated

Garden Hose Quick Connect

Accessory Quick Connect

Rotating Brush Kit

25' Replacement Hose

O Ring Repair Kit

Turbo Nozzle

25' Extension Hose

Hose Reel

Pump Saver

House Wash Concentrate (makes 4 gallons)

Deck Wash Concentrate (makes 2 gallons)

Vehicle/Boat Wash Concentrate (makes 4 gallons)

Degreaser Concentrate (makes 4 gallons)

Mold/Mildew Concentrate (makes 2 gallons)

-12

Description

KIT, Hook, Base

KIT, Hook, Handle

KIT, E-Ring

ASSY, Wand

ORIFICE

KIT, Wheel

KEY

ASSY, Pump (see page 23)

ENGINE

22

Page 23

CRAFTSMAN 2800 PSI Pressure Washer 580.752400 Pump — Exploded View and Parts List

Item Part# Description ItemEPart# Description

19 190571GS CAP, Oil E 193806GS KIT, CHECK VALVES

28 190574GS MANIFOLD F 190592GS KIT, INLET CHECK

45 190578GS PIN G 190593GS KIT, CHEMICAL INJECTION

62 190581GS CAP H 193807GS KIT, SEAL SET

76 194298GS THERMAL RELIEF J 189971GS KIT, CHEMICAL HOSE

77 190585GS OIL BOTTLE (not shown) K 193971GS KIT, PIPE FITTING

A 190594GS KIT, UNLOADER L 193972GS KIT, UNLOADER SEAT

B 190588GS KIT, WATER INLET, ANODIZED

C 190589GS KIT, OUTLET. ANODIZED NOTE: Items A - _ are service kits and include all

D 193808GS KIT, HEAD BRASS parts shown within the box.

23

Page 24

ENGINE, 7 HP, Briggs and Stratton, 12G612 - Exploded View

Page 25

ENGINE, 7 HP, Briggs and Stratton, 12G612 - Exploded View

843

365

443

966

425®^

842

^63^

^ OP

529

977 CARBURETOR GASKET SET

137

276©

5240

25

51

51 (O

633©

633A©

163

Page 26

ENGINE, 7 HP, Briggs and Stratton, 12G612 - Exploded View

472

356

305

930 (

1005

Page 27

ENGINE, 7 HP, Briggs and Stratton, 12G612 - Parts List

Item Part#

1 697893

2 399269

3 299819

4 498983

5 695276

7 695166

8 495786

9 272481

10 691125

11 691260

12 692232

13 691137

15 691680

16 691457

20 399781

22 691092

23 697586

24 222698

25 690021

694167

694168

694169

26 499631

692785

692786

692787

27 691866

28 499423

29 499424

32 691664

32A 695759

33 499642

34 499641

35 691304

36 691304

37 694086

40 692194

43 691997

45 690977

46 694039

51 692668

51A 692799

55 691421

58 692259

60 281434

65 690837

78 691108

95 691636

97 499682

104 691242

108 691182

109 693866

117 692677

118 497315

121 692703

125 698953

127 694468

130 691203

133 398187

134 398188

137 693981

146 690979

163 692667

187 691050

188 691147

190 690940

192 694543

202 691303

209 691290

222 693378

227 690783

238 691300

276 271716

287 690940

300 697590

304 499676

305 691108

306 691232

307 690345

324 695161

Description

Cylinder Assembly

Bushing/Seal Kit (Magneto Side)

Oil Seal

Engine Sump

Cylinder Head

Cylinder Head Gasket

Breather Assembly

Breather Gasket

Screw (Breather Assembly)

Breather Tube

Crankcase Gasket

Screw (Cylinder Head)

Oil Drain Plug

Crankshaft

Oil Seal (PTO Side)

Screw (Engine Sump)

Flywheel

Flywheel Key

Piston Assembly i

Piston Assembly i

Piston Assembly i

Piston Assembly y..

Ring Set (Standard)

Ring Set (.010” Oversize)

Ring Set (.020" Oversize)

Ring Set (.030" Oversize)

Piston Pin Lock

Piston Pin

Connecting Rod

Screw (Connecting Rod)

Screw (Connecting Rod)

Exhaust Valve

intake Valve

Valve Spring (Intake)

Valve Spring (Exhaust)

Flywheel Guard

Valve Retainer

Governor/Oil Slinger

Valve Tappet

Camshaft

intake Gasket

intake Gasket

Rewind Starter Housing

Starter Rope (Cut to Required Length)

Starter Rope Grip

Screw (Rewind Starter)

Screw (Flywheel Guard)

Screw (Throttle Valve)

Throttle Shaft

Float Hinge Pin

Choke Valve

Choke Shaft

Main Jet (Standard)

Main Jet (High Altitude)

Carburetor Overhaul Krt

Carburetor

Welch Plug

Throttle Valve

Carburetor Float

Needle/Seat Kit

Gasket-Float Bowl

Timing Key

Air Cleaner Gasket

Fuel Line (Cut to Required Length)

Screw (Control Bracket)

Screw (Fuel Tank)

Rocker Arm Ball

Mechanical Governor Link

Governor Spring

Control Bracket

Governor Control Lever

Valve Cap

Sealing Washer

Screw (Dipstick Tube)

Muffler

Housing-Blower

Screw (Blower Housing)

Shield-Cylinder

Screw (Cylinder Shield)

Cup-Flywheel

(Standard)

(.010" Oversize)

(.020" Oversize)

(.030" Oversize)

Item

Part# Description

690662 Nut (Flywheel)

332

333

802574 Armature-Magneto

334

691061 Screw (Magneto Armature)

337

692051 Sparkplug

—Note'

For Platinum equiva!ent-696073-use 5066, 4173, or 4174

sold in multi-packs only. Reset gap to .020")

356 692390 Wire-Stop

358 694090 Engine Gasket Set

365 691136 Screw (Carburetor)

404 690272 Washer (Governor Crank)

25 690670 Screw (Air Cleaner Cover)

443 691637 Screw (Air Cleaner Primer Base)

443A 692523 Screw (Air Cleaner Primer Base)

445 491588 Filter- Air Cleaner Cartridge

456 692299 Retainer-Spring

459 281505 Plate-Pawl Friction

472 693809 Choke Shaft Knob

505 231082 Nut (Governor Control Lever)

523 499621 Dipstick

524 92296 Dipstick Tube Seal

525 495265 Dipstick Tube

529 691923 Grommet

562 92613 Bolt (Governor Control Lever)

564 693808 Screw (Control Cover)

584 692342 Breather Passage Cover

585 691879 Breather Passage Gasket

592 690800 Nut (Rewind Starter)

597 691696 Screw (Pawl Friction Plate)

601 95162 Clamp-Hose

604 693807 Cover-Control

608 497680 Starter-Rewind

613 691108 Screw (Muffler)

613A 691140 Screw (Muffler)

615 690340 Retainer-Governor Shaft

616 691308 Crank-Governor

619 691108 Screw (Cylinder Head Plate)

621 692310 Switch-Stop

633 693867 Seal-Choke/Throttle Shaft

633A 691321 Seal-Choke/Throtfle Shaft

635 66538 Boot-Sparkplug

670 692294 Spacer-Fuel Tank

684 690345 Screw (Breather Passage Cover)

689 691855 Spring-Friction

692 690572 Spring-Detent

718 690959 Pin-Locating

741 691830 Gear-Timing

830 694544 Stud (Rocker Arm)

832 691466 Guard-Muffler

836 691147 Screw (Muffler Guard)

836A 697551 Screw (Muffler Guard)

842 691031 Dipstick/Tube Seal

843 691884 Lever Sleeve

847 692047 Dipstick/Tube Assembly

851 493880 Terminal-Sparkplug

868 692044 Seal-Valve

883 691893 Gasket-Exhaust

886 696268 Gasket Kit-Cyiinder/Plate

914 691108 Screw (Rocker Covert

914A 691127 Screw (Rocker Cover)

930 692675 Guard-Rewind

957 692046 Cap-Fuel Tank

966 693863 Base- Air Cleaner Primer

968 692298 Cover-Air Cleaner

972 693372 Fuel Tank

975 493640 Bowl-Float

977 692704 Gasket Set-Carburetor

993 694088 Cylinder Head Plate Gasket

1005 691346 Fan-Flywheel

1022 691890 Gasket-Rocker Cover

1023 499624 Cover-Rocker

1026 692045 Rod-Push

1029 691230 Rocker Arm

1034 691343 Guide-Push Rod

1059 692311 Screw/Washer Kit

1095 694091 Valve Gasket Set

1102 691255 Guide-Pilot

1210 498144 Pulley/Spring Assembly (Pulley)

1211 498144 Pulley/Spring Assembly (Spring)

27

Page 28

MISSION CONTROL WARRANTY STATEMENT

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB) and

the United States Environmental Protection Agency (U.S.EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS

APPLICABLE TO CERTIFIED ENGINES PURCHASED IN

CALIFORNIA IN 1995 AND THEREAFTER WHICH ARE

USED IN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997 AND LATER ENGINES WHICH ARE

PURCHASED AND USED ELSEWHERE IN THE UNITED

STATES {AND AFTER JANUARY 1, 2001 IN CANADA).

California and U.S, ERA Emission Control Warranty

Statement Your Warranty Rights and Obligations

The California Air Resources Board (CARB), U.S.EPA and

Sears are pleased to explain the Emission Control System

Warranty on your model year 2000 and later small off-road

engine (SORE). In California, new small off-road engines

must be designed, built and equipped to meet the State's

stringent anti-smog standards. Elsewhere in the United

States, new non-road, spark-ignition engines certified for

model year 1997 and later, must meet similar standards set

forth by the U.S.EPA. Sears must warrant the emission

control system on your engine for the periods of time listed

below, provided there has been no abuse, neglect, or

improper maintenance of your small off-road engine.

Your emission control system may include parts such as the

carburetor or fuel-injection system, the ignition system, and

catalytic converter. Also included may be hoses, belts,

connectors and other emission related assemblies.

Where a warrantable condition exists, Sears will repair your

small off-road engine at no cost to you including diagnosis,

parts and labor.

Sears Emission Control Defects Warranty Coverage

The 1995 and later small off-road engines are warranted for

two years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Sears.

Owner's Warranty Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in this

owner's manual. Sears recommends that you retain all your

receipts covering maintenance on your small off-road

engine, but Sears cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the small off-road engine owner, you should however be

aware that Sears may deny you warranty coverage if your

small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road

engine to an approved Sears Service Center as soon as a

problem exists. The warranty repairs should be completed in

a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a Sears Service

Representative at 1-800-469-4663.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your

Emission Control Defects Warranty Coverage.

1. Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emission control systems parts) to the

extent these parts were present on the engine purchased.

In the USA and Canada, a 24-hour hotline,

maintenance information.

1-800-469-4663, has a menu of pre-recorded messages offering you product

a.b.Fuel Metering System

Cold start enrichment system

Carburetor and infernal parts

Fuel Pump

Air Induction System

Air cleaner

Intake manifold

c. Ignition System

Spark plug(s)

Magneto ignition system

d. Catalyst System

Catalytic converter

Exhaust manifold

Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

Vacuum, temperature, position, time sensitive valves

and switches

Connectors and assemblies

2. Length of Coverage

Sears warrants to the initial owner and each subsequent

owner that the Warranted Parts shall be free from

defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years

from the date the engine is delivered to a retail

purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be

performed at no charge to the owner, including

diagnostic labor which leads to the determination that a

Warranted Part is defective, if the diagnostic work is

performed at an approved Sears Service Center.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the

provisions of the Sears Warranty Policy. Warranty

coverage shall be excluded for failures of Warranted

Parts which are not original Sears parts or because of

abuse, neglect or Improper maintenance as set forth in

the Sears Engine Warranty Policy. Sears is not liable to

cover failures of Warranted Parts caused by the use of

add-on. non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for

replacement as required maintenance or which is

scheduled only for regular inspection to the effect of

"repair or replace as necessary" shall be warranted as to

defects for the warranty period. Any Warranted Part

which is scheduled for replacement as required

maintenance shall be warranted as to defects only for

the period of time up to the first scheduled replacement

for that part. Any replacement part that is equivalent in

performance and durability may be used in the

performance of any maintenance or repairs. The owner

is responsible for the performance of all required

maintenance, as defined in this owner's manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any

engine components caused by the failure of any

Warranty Part still under warranty.

28

Page 29

Emissions Dyrability Period and Air Index

Information On Your Engine Emissions Label

Engines that are certified to meet the California Air

Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period

and Air Index. The engine manufacturer makes this

information available to the consumer on emission labels.

The Emissions Durability Period describes the number of

hours of actual running time for which the engine is certified

to be emissions compliant, assuming proper maintenance in

accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate: Engine is certified to be emission compliant for

125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant

for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for

500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used

20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating

would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative

level of emissions for a specific engine family. The lower the

Air Index, the cleaner the engine. This Information is

displayed in graphical form on the emissions label.

Emissions Compliance Period On Engine

Emissions Compliance Label

After July 1,2000 certain Sears engines will be certified to

meet the United States Environmental Protection Agency

(USEPA) Phase 2 emission standards. For phase 2 certified

engines, the Emissions Compliance Period referred fo on

the Emissions Compliance label indicates the number of

operating hours for which the engine has been shown to

meet Federal emission requirements. For engines less than

225 cc displacement. Category C = 125 hours, В = 250

hours and A = 500 hours. For engines of 225 cc or more.

Category C = 250 hours, В = 500 hours and A = 1000 hours.

This engine has a moderate rating with and Air Index of 3.

The EPA Emissions compliance period is Category C. The

displacement of this engine is 190 cc.

Below is a generic representation of the emission label

typically found on a certified engine.

['! Г..1 i . ;кг." 'ir'A'il', Л'-Л'Ь •■■■ .!••!

.....

Г'> ' ,!‘F

MU.' {¡"LPiriJiA : '

-ppj, I Read and follow Operating

'--I Instructions before running

Sasoline is flammable. Alio* engine to

:ool ai feast 2 minutes before refueling.

Engines emit

'Wbi

DO NOT run in

engine.

carbon monojtide,

enclosed

area.

29

Page 30

TABLA DE CONTENIDO

GARANTIA..............................................................30

INSTRUCCIONES DE SEGURIDAD

MONTAJE..........................................................34-36

OPERACION .......................... .37-41

ESPECIFICACIONES

...........................................

...............

30-32

41

MANTENIMIENTO ............................................42-46

ALMACENAMIENTO .........................................47-48

REPARACION DE DAÑOS REPUESTOS

GARANTIA DEL CONTROL DE EMISIONES . .50-51

COMO ORDENAR PARTES . PAGINA POSTERIOR

i.

.

............

49

GARANTIA

GARANTIA LIMITADA DE LA MAQUINA LAVADORA DE ALTA PRESION CRAFTSMAN