Craftsman 580752212 Owner’s Manual

Operator'sManual

3000 PSI MAX

2.7 GPIViMAX

PRESSUREWASHER

ModelNo. 580.752212

®

• Safety

HOURS: IVlon.- Fri. 8 a.m. to 5 p.m. (CT)

• Assembly

• Operation

WARNING

Beforeusing this product, readthis

manualand follow all Safety Rules

and OperatingInstructions.

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association

(PWMA) standard PW101 (Testing and Rating Performance of Pressure Washers).

Esta iimpiadora a presi6n est_ ciasificada conforme a la norma PW101 (comprobaci6n y ciasificaci6n de rendimiento de limpiadoras

a presi6n) de la Asociaci6n de fabricantes de bombas a presi6n (Pressure Washer Manufacturers Association, PWMA).

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsmanwebsite: www.craftsman.com

Part No. 208817GS Draft A (03/04/2009)

Antes de utilizar el producto, lea este

manualy siga todas las Reglasde

Seguridad e Instrucciones de Uso.

ADVERTENCIA

• Maintenance

• Parts

• Espafiol,p. 36

WARRANTY.......................................... 2

REPAIRPROTECTIONAGREEMENT........................ 2

SAFETYRULES...................................... 3-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-15

SPECIFICATIONS..................................... 16

MAINTENANCE.................................... 17-20

STORAGE........................................... 21

TROUBLESHOOTING.................................. 22

NOTES............................................. 23

REPLACEMENTPARTS.............................. 24-33

EMISSIONCONTROLWARRANTY..................... 34-35

ESPAKIOL......................................... 36-59

HOWTOORDERPARTS........................ BACKPAGE

CRAFTSMANFULLWARRANTY

If this Craftsmanproduct fails due to adefect in material or workmanship within two years from the date of purchase, return it

to anySearsstore, Sears Parts & RepairServiceCenter,or other Craftsmanoutlet in the United Statesfor free repair (or

replacementif repair proves impossible).

This warranty appliesfor only 90 days from the dateof purchase if this product is ever usedfor commercial or rental

purposes.

Thiswarranty coversONLYdefectsin material andworkmanship.Searswill NOTpayfor:

• Expendableitems that canwear out from normal usewithin the warranty period, such as sprayguns, hoses, nozzle

extensions, nozzles,filters and spark plugs.

• Repairsnecessarybecauseof accident, or failure to operateor maintainthe product according to allsupplied instructions.

• Preventivemaintenance,or repairs necessarydue to improper fuel mixture, contaminated or stalefuel.

This warranty givesyou specific legalrights, andyou may also haveother rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Congratulations on making a smart purchase.

Your new Craftsman® product is designed and manufactured

for years of dependableoperation. But like all products, it

may requirerepair from time to time. That'swhen having a

Repair ProtectionAgreement can saveyou money and

aggravation.

Here'swhat the RepairProtectionAgreement*includes:

• Expertservice by our 10,000 professional repair

specialists

• Unlimited serviceand no chargefor parts and labor on

all coveredrepairs

• Product replacement up to $1500 if your covered

product can't be fixed

• Discountof 10% from regular priceof serviceand related

installed parts not covered by the agreement;also, 10%

off regular price of preventivemaintenancecheck

• Fasthelp by phone-we call it Rapid Resolution- phone

support from aSears representative.Think of us as a

"talking owner's manual".

Onceyou purchasethe RepairProtection Agreement,a

simple phonecall is all it takes for you to scheduleservice.

You cancall anytimeday or night, or schedule a service

appointment online.

The Repair Protection Agreement is a risk-free purchase. If

you cancelfor any reasonduring the product warranty

period,we will provide a full refund. Or, a prorated refund

anytime after the product warranty periodexpires. Purchase

your Repair Protection Agreement today!

Somelimitations and exclusionsapply. Forpricesand

additionalinformationin the U.S.A. call 1-800-827-6655.

* Coveragein Canadavariesonsome items. Forfull

details, call SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessional installation of home appliances,

garagedoor openers, water heaters,and other major home

items, inthe U.S.A.or Canadacall 1-800-4-MY-HOME®.

@2009

Readthis manualcarefully and becomefamiliar

with your pressurewasher. Knowits applications,

itslimitations, and anyhazardsinvolved.

Important Safety Information

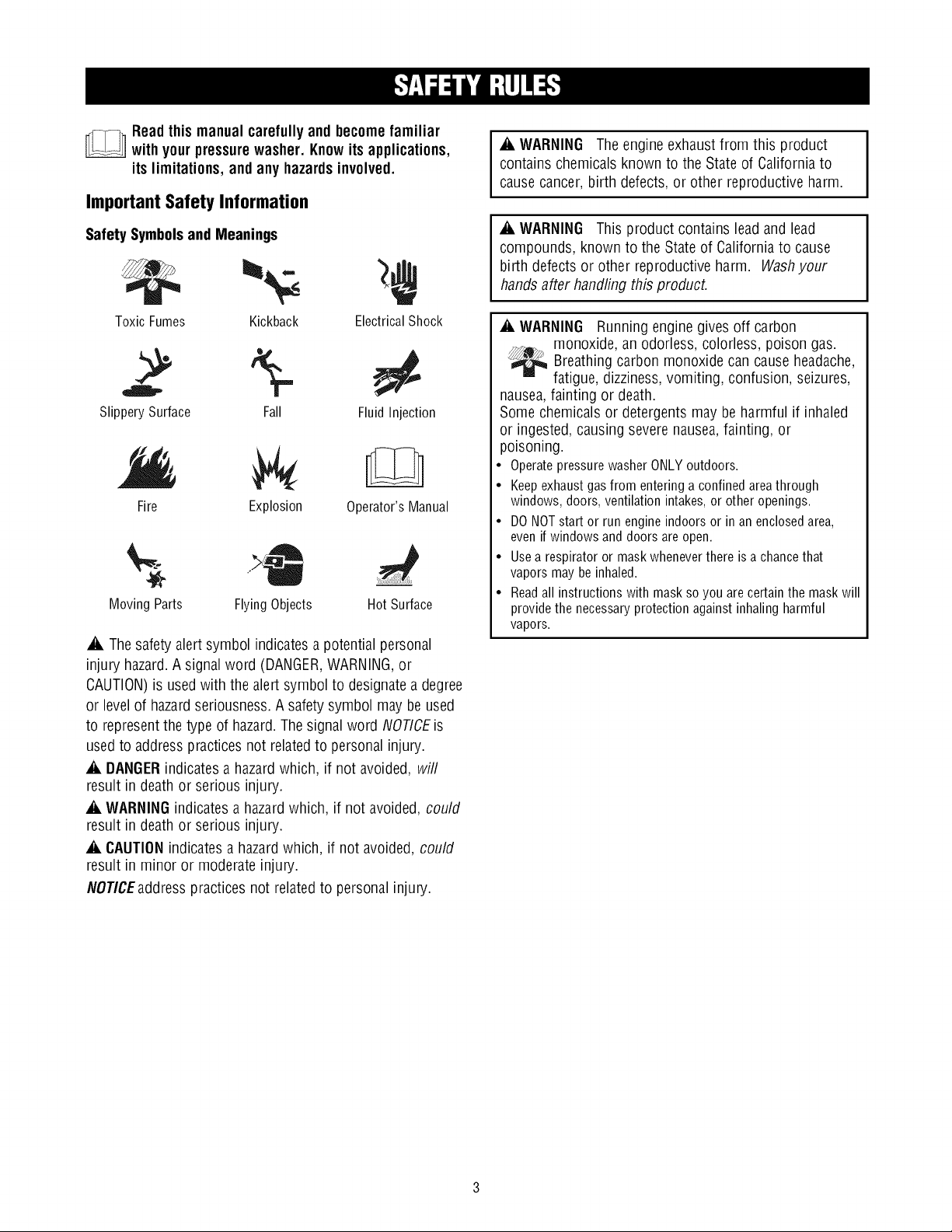

Safety Symbolsand Meanings

A, WARNING The engine exhaustfrom this product

contains chemicals known to the Stateof California to

cause cancer, birth defects,or other reproductive harm.

A, WARNING This product contains lead and lead

compounds, known to the State of Californiato cause

birth defects or other reproductive harm. Washyour

handsafter handlingthis product.

ToxicFumes Kickback

ElectricalShock

2 %

SlipperySurface Fall

Fire

MovingParts

,A The safety alertsymbol indicatesa potential personal

injury hazard.A signalword (DANGER,WARNING,or

CAUTION)is usedwith thealert symbol to designatea degree

or levelof hazardseriousness.A safety symbol may beused

to representthe type of hazard.The signal word NOTICEis

usedto addresspracticesnot relatedto personalinjury.

A, DANGERindicatesa hazardwhich, if not avoided, will

result in deathor serious injury.

A, WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury.

A, CAUTIONindicates a hazardwhich, if not avoided, could

result in minor or moderateinjury.

NOTICEaddress practices not relatedto personal injury.

Explosion Operator'sManual

FlyingObjects Hot Surface

FluidInjection

A, WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

_ Breathingcarbon monoxide headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

Some chemicals or detergentsmay be harmful if inhaled

or ingested, causing severenausea,fainting, or

poisoning.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringa confinedareathrough

windows,doors,ventilationintakes,or otheropenings.

• DONOTstartor run engineindoorsorin anenclosedarea,

evenifwindowsanddoorsareopen.

• Usea respiratorormaskwheneverthereisa chancethat

vaporsmaybeinhaled.

• Readall instructionswith masksoyou arecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

can cause

_k WARNING Starter cord kickback (rapid retraction) can

result in bodily injury. Kickbackwill pull hand and

,_arm toward enginefaster than you can let go.

Broken bones,fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spraygun

pressure.

• When starting engine,pull cord slowly until resistance isfelt

andthen pull rapidly to avoid kickback.

• After each starting attempt, where enginefails to run, always

point spray gun in safe direction, pressred button and squeeze

spray gun trigger to releasehigh pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spraygun kicks back.

A, WARNING Riskof electrocution.

"_,dh Contactwith power sourcecan causeelectric

shock or burn.

• NEVERspraynearpowersource.

_k WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• DONOTallow CHILDRENto operate pressure washer.

• NEVERrepair high pressure hose.Replaceit.

• NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hose to nozzleextension.

• Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

• ALWAYS pointspray gun in safedirection, pressred button

andsqueezespray gun trigger to releasehigh pressure, every

time you stop engine.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spraygun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuse a spray gun which does not have atrigger lock or

trigger guard in placeand in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

_k WARNING Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns

or death.

WHENADDING OR DRAININGFUEL

• Turn pressurewasher OFFand let it cool at least 2 minutes

before removing fuel cap. Loosencapslowly to relievepressure

in tank.

• Fill or drain fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DONOTlight a cigaretteor smoke.

WHENSTARTINGEQUIPMENT

• Ensurespark plug, muffler,fuel cap,and air cleanerare in place.

• DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

• DONOTtip engine or equipment at anglewhich causes fuel to

spill.

• DONOTsprayflammable liquids.

WHENTRANSPORTINGOR REPAIRINGEQUIPMENT

• Transport/repair with fuel tank EMPTYor with fuel shutoff valve

OFF.

• Disconnectspark plug wire.

WHENSTORINGFUEL OR EQUIPMENTWITH FUELIN TANK

• Store away from furnaces, stoves, water heaters,clothes

dryers, or other appliancesthat have pilot light orother ignition

source becausethey can ignitefuel vapors.

_k WARNING Contact with muffler area can result in

serious burns.

_ _ Exhaust heat/gases can ignite

fuel tank causing a fire.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipmentto cool before touching.

• Keepat least5 feet (152 cm) of clearanceon all sides of

pressure washer including overhead.

• It is a violation of California Public Resource Code,Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federaljurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designedfor the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed in the same

position as the original parts.

combustibles, structures or damage

_i, WARNING Use of pressure washer can create

,_ Kickback from spray gun can cause you

• Operatepressurewasher from a stable surface.

• Thecleaning areashould have adequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

• Beextremely careful if you must usethe pressurewasher from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spraygun kicks back.

_i, WARNING Unintentional sparking can result in fire or

WHENADJUSTINGOR MAKINGREPAIRSTO YOURPRESSURE

WASHER

• Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approved spark plug tester.

• DONOTcheckfor sparkwith spark plug removed.

_i, WARNING Starter and other rotating parts can

entangle hands, hair, clothing, or accessories.

• NEVERoperatepressure washerwithout protective housing or

covers.

• DO NOTwear looseclothing, jewelry or anythingthat maybe

caught in the starter or other rotating parts.

• Tie up long hair and removejewelry.

puddles and slippery surfaces.

to fall.

_¢ electric shock.

A WARNING Risk of eyeinjury.

Spray cansplash back or propel objects.

• Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSIZ87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

NOTICE High pressure spray may damage fragile items

including glass.

• DONOTpointspraygunatglasswhenusingMAX(0°) nozzle.

• NEVERaimspraygunat plants.

NOTICE Improper treatment of pressure washer can

damage it and shorten its life.

• If you have questions about intended use,ask dealer or contact

Sears.

• NEVERoperate units with broken or missing parts, or without

protective housing or covers.

• DO NOTby-pass any safety device on this machine.

• DONOTtamper with governed speed.

• DONOToperate pressure washer above rated pressure.

• DONOTmodify pressure washer in any way.

• Beforestarting pressure washer in cold weather,check all parts

of the equipmentto besure ice has not formed there.

• NEVERmove machine by pulling on hoses. Usehandle provided

on unit.

• Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank orcap. Correct all defects before operating pressure washer.

• This equipment is designedto be used with Searsauthorized parts

ONLY.If equipmentis used with parts that DONOTcomply with

minimum specifications, userassumesall risks and liabilities.

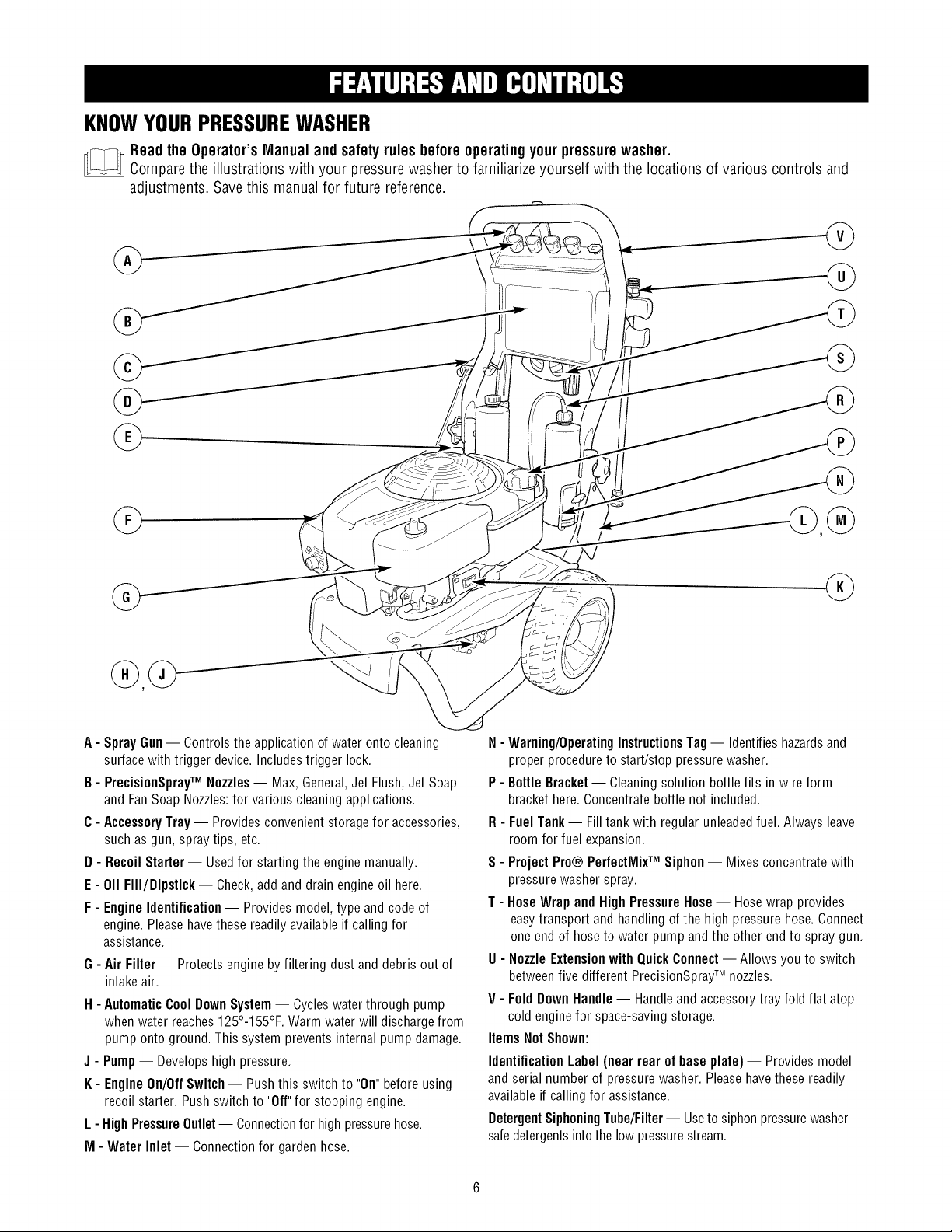

KNOWYOURPRESSUREWASHER

Readthe Operator'sManual andsafetyrules before operatingyour pressure washer.

Comparethe illustrations with your pressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

(_ .....

A- SprayGun-- Controls the application of water onto cleaning

surface with trigger device. Includestrigger lock.

B- PrecisionSprayTM Nozzles-- Max,General, Jet Flush, Jet Soap

and FanSoap Nozzles:for various cleaning applications.

C- Accessory Tray -- Providesconvenient storagefor accessories,

such as gun, spray tips, etc.

D - RecoilStarter-- Usedfor starting the engine manually.

E - Oil Fill/Dipstick -- Check,add and drain engine oil here.

F - EngineIdentification -- Provides model, type and code of

engine. Pleasehavethese readilyavailable if calling for

assistance.

G - Air Filter-- Protects engine by filtering dust and debris out of

intakeair.

H - AutomaticCoolDown System-- Cycleswater through pump

when water reaches 125°-155°F. Warm water will dischargefrom

pump onto ground. This system prevents internal pump damage.

J - Pump-- Develops high pressure.

K- EngineOn/Off Switch-- Push this switch to "On"before using

recoil starter. Pushswitch to "Off"for stopping engine.

L - HighPressureOutlet-- Connectionfor high pressurehose.

M - Water Inlet -- Connection for garden hose.

N- Warning/OperatingInstructionsTag-- Identifies hazardsand

proper procedureto start/stop pressure washer.

P - Bottle Bracket-- Cleaning solution bottle fits inwire form

bracket here. Concentrate bottle not included.

R - Fuel Tank -- Filltank with regular unleadedfuel. Always leave

room for fuel expansion.

S - Project Pro@ PerfectMW MSiphon-- Mixes concentrate with

pressure washer spray.

T - Hose Wrap and High Pressure Hose-- Hose wrap provides

easytransport and handling of the high pressure hose. Connect

oneend of hoseto water pump and the other end to spray gun.

U - Nozzle ExtensionwithQuickConnect -- Allows you to switch

betweenfive different PrecisionSprayTM nozzles.

V - Fold Down Handle -- Handleand accessory tray fold flat atop

cold enginefor space-saving storage.

Items Not Shown:

IdentificationLabel (nearrear of base plate) -- Provides model

and serial number of pressure washer. Pleasehave these readily

available if callingfor assistance.

DetergentSiphoningTube/Filter-- Useto siphon pressurewasher

safedetergentsintothe low pressurestream.

Your pressurewasher requires some assembly and is ready

for useonly after it has been properly serviced with the

recommendedoil and fuel.

If you haveanyproblems with the assemblyofyour

pressurewasher, please call the pressurewasher helpline

at 1-800-222-3136.

UNPACKTHE PRESSUREWASHER

1. Removeeverything from carton except pressurewasher.

2. Opencarton completely by cutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

CARTONCONTENTS

Checkall contents. If anyparts aremissing or damaged,call

the pressure washer helplineat 1-800-222-3136.

• Main Unit

• Handle

• AccessoryTray

• High PressureHose

• Spray Gun

• NozzleExtensionwith Quick ConnectFitting

• Oil Bottle

• HoseWrap

• DetergentSiphoning Hose/Filter

• Bottle Bracket Wireform (2)

• PerfectMixTM Siphoning Unit/Hose

• Parts Bag(which includes the following):

• Operator's Manual

• Owner's Registration Card

• Bag containing 5 PrecisionSprai MNozzles

• HandleFasteningHardwareKit (whichincludes):

• HandleBolts (2)

• CarriageBolt (2)

• RopeGuide(1)

• PlasticKnobsfor Handle(2)

• PlasticKnob (3)

• TreeClips (4)

Becomefamiliar with eachpiece before assembling the

pressure washer Identify all contents with the illustration on

page 6 If any partsare missing or damaged, call the

pressure washer helpline at1-800-222-3136.

6 Connectpressure hose to spray gun and pump

7 Connectwater supply to pump

8 Attach nozzleextension to spray gun

9 Select/attach quick connect PrecisionSprayTM nozzleto

nozzleextension

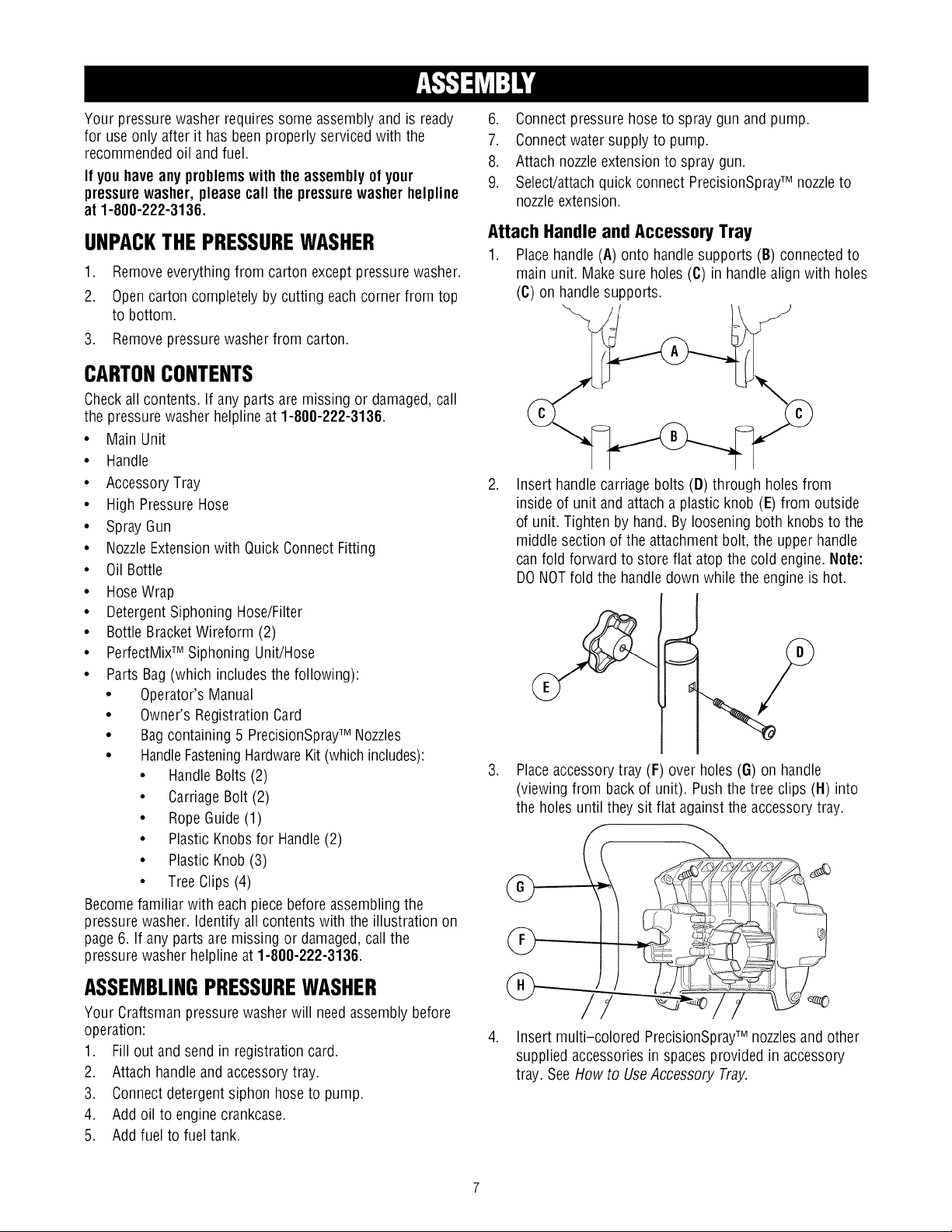

Attach Handle and Accessory Tray

1 Placehandle(A) onto handle supports (B) connected to

main unit Makesure holes (6) in handlealign with holes

(6) on handlesupports

,

Insert handle carriagebolts (D) through holes from

inside of unit and attach a plastic knob (E) from outside

of unit Tighten by hand Byloosening both knobsto the

middle section of the attachment bolt, the upperhandle

canfold forward to storeflat atop the cold engine Note:

DONOTfold the handledown while the engine is hot

,

Placeaccessory tray (F) over holes (6) on handle

(viewing from backof unit) Pushthe tree clips (H) into

the holes until they sit flat againstthe accessory tray

ASSEMBLINGPRESSUREWASHER

Your Craftsmanpressurewasher will needassembly before

operation:

1 Fill out and send in registration card

2 Attach handle and accessory tray

3 Connectdetergent siphon hoseto pump

4 Add oil to enginecrankcase

5 Add fuel to fuel tank

/

,

Insert multi-colored PrecisionSprai Mnozzlesand other

supplied accessoriesin spacesprovided in accessory

tray SeeHow to UseAccessory Tray

.

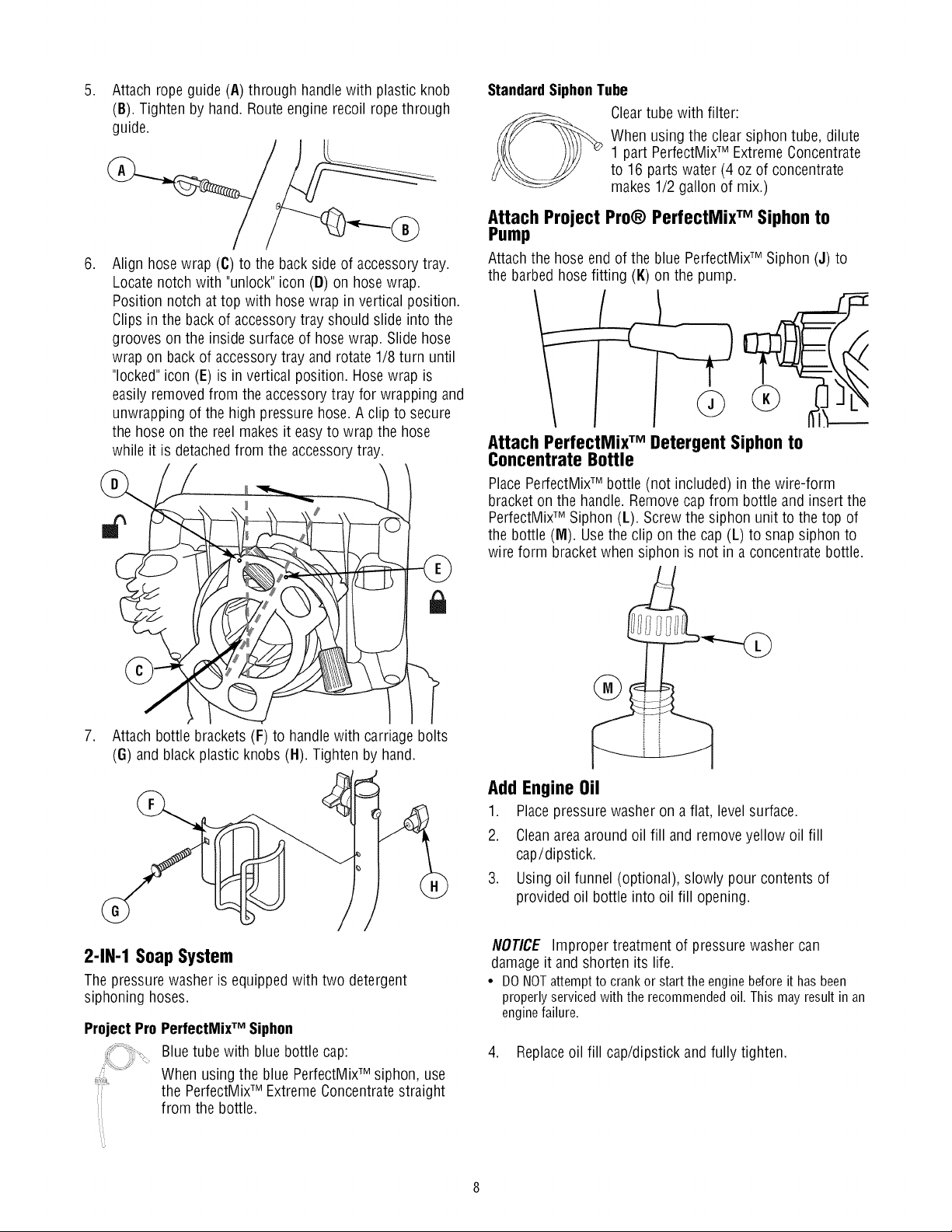

Attach rope guide (A) through handlewith plastic knob

(B). Tighten by hand. Route engine recoil rope through

guide.

.

Align hosewrap (6) to the back side of accessorytray.

Locate notch with "unlock"icon (D) on hosewrap.

Position notch at top with hosewrap invertical position.

Clips in the backof accessorytray should slide into the

grooves on the inside surface of hosewrap. Slidehose

wrap on back of accessorytray and rotate 1/8 turn until

"locked"icon (E) is invertical position. Hosewrap is

easily removed from the accessory tray for wrapping and

unwrapping of the high pressure hose. A clip to secure

the hoseon the reel makes it easyto wrap the hose

while it is detachedfrom the accessory tray.

StandardSiphonTube

Cleartube with filter:

When using the clear siphon tube, dilute

1 part PerfectMixTM ExtremeConcentrate

to 16 parts water (4 oz of concentrate

makes1/2 gallon of mix.)

Attach Project Pro® PerfectMix TM Siphon to

Pump

Attach the hose end of the blue PerfectMixTM Siphon (J) to

the barbed hosefitting (K) on the pump.

Attach PerfectMix TM Detergent Siphon to

Concentrate Bottle

PlacePerfectMixTM bottle (not included) in the wire-form

bracketon the handle. Removecap from bottle and insert the

PerfectMixTM Siphon (L). Screwthe siphon unit to the top of

the bottle (M). Usethe clip on the cap (L) to snapsiphon to

wire form bracketwhen siphon is not in a concentrate bottle.

.

Attach bottle brackets (F) to handlewith carriage bolts

(6) and black plastic knobs (H). Tighten by hand.

G

2-1N-1 Soap System

The pressurewasher is equippedwith two detergent

siphoning hoses.

Project ProPerfectMixTM Siphon

Blue tube with blue bottle cap:

When usingthe blue PerfectMixTM siphon, use

the PerfectMixTM ExtremeConcentratestraight

from the bottle.

®

Add Engine Oil

1. Placepressurewasher ona flat, level surface.

2. Cleanareaaround oil fill and removeyellow oil fill

cap/dipstick.

3. Usingoil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE Improper treatment of pressure washer can

damage it and shorten its life.

• DONOTattemptto crank or startthe engine before it has been

properly serviced with the recommended oil. This may result in an

enginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

Add Fuel

Fuel mustmeet these requirements:

• Clean,fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON).High altitude

use, see HighAltitude.

• Gasolinewith up to 10% ethanol (gasohol) or up to 15%

MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE Avoid pressure washer damage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoil in gasoline.

• DONOTmodifyengineto runonalternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. SeeStorage.All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engine is EM (Engine

Modifications).

_i, WARNING Fueland its vapors are extremely

flammable and explosive.

Fireor explosion can causesevere burns

or death.

WHENADDINGFUEL

• Turn pressure washerOFFand let it cool at least2 minutes

before removing fuel cap. Loosencapslowly to relievepressure

in tank.

• Fill fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DONOTlight a cigarette or smoke.

CAUTION!Alcohol-blendedfuels (calledgasohol, ethanol or

methanol) can attract moisture, which leadsto separation and

formation of acidsduring storage.Acidic gascandamagethe

fuel system of an enginewhile in storage.

To avoid engine problems, the fuel system should be treated

with a fuel preserveror emptied beforestorage of 30 days or

longer. If adding a fuel preserver,fill the fuel tank with fresh

fuel. If only partially filled, air inthe tank will promote fuel

deterioration during storage. If fuel preserver is not used,

drain the fuel tank, start the engineand let it run until the fuel

lines and carburetor are empty. Usefresh fuel next season.

See Storage for additional information.

NEVERuse engine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

HighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85AKI (89 RON)gasolineis acceptable.To

remainemissions compliant, highaltitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea qualified Searsdealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

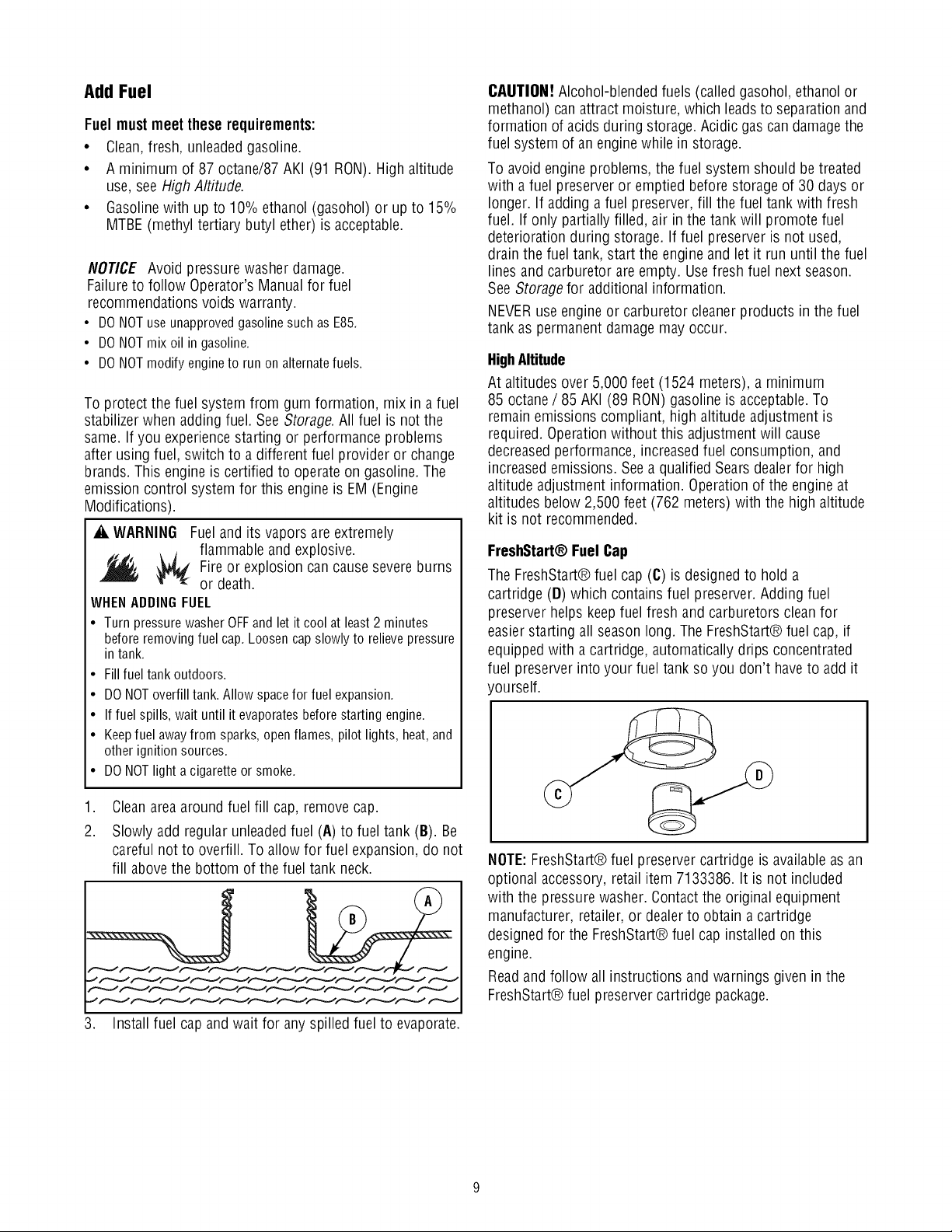

FreshStart® Fuel Cap

The FreshStart® fuel cap (C) is designedto hold a

cartridge (O)which contains fuel preserver.Adding fuel

preserver helps keepfuel fresh and carburetors cleanfor

easier starting all season long. TheFreshStart® fuel cap, if

equipped with a cartridge, automatically drips concentrated

fuel preserver into your fuel tank so you don't haveto add it

'ourself.

.

Cleanarea around fuel fill cap, remove cap.

2.

Slowly add regularunleadedfuel (A) to fuel tank (B). Be

careful not to overfill. To allow for fuel expansion, do not

fill abovethe bottom of the fuel tank neck.

3. Install fuel capand wait for any spilled fuel to evaporate.

NOTE:FreshStart®fuel preservercartridge is available as an

optional accessory, retail item 7133386. It is not included

with the pressure washer. Contactthe original equipment

manufacturer, retailer, or dealerto obtain acartridge

designed for the FreshStart® fuel cap installed on this

engine.

Readand follow all instructions and warnings given in the

FreshStart® fuel preserver cartridge package.

Connect Hose and Water Supply to Pump

NOTICE DO NOTrun the pump without the water supply

connectedand turned on.

• Damageto equipmentresultingfrom failuretofollowthis

instructionwillvoidwarranty.

4. Run water through garden hose for 30 secondsto flush

it of debris.Turn off water.

IMPORTANT:DONOTsiphon standing water for the water

supply. Use ONLYcold water (less than 100°F).

5. Connectgarden hose(not to exceed50 feet in length) to

water inlet. Tightenby hand.

NOTE:Removeand discard the shipping caps from the

pump's high pressure outlet and water inlet before attaching

hoses.

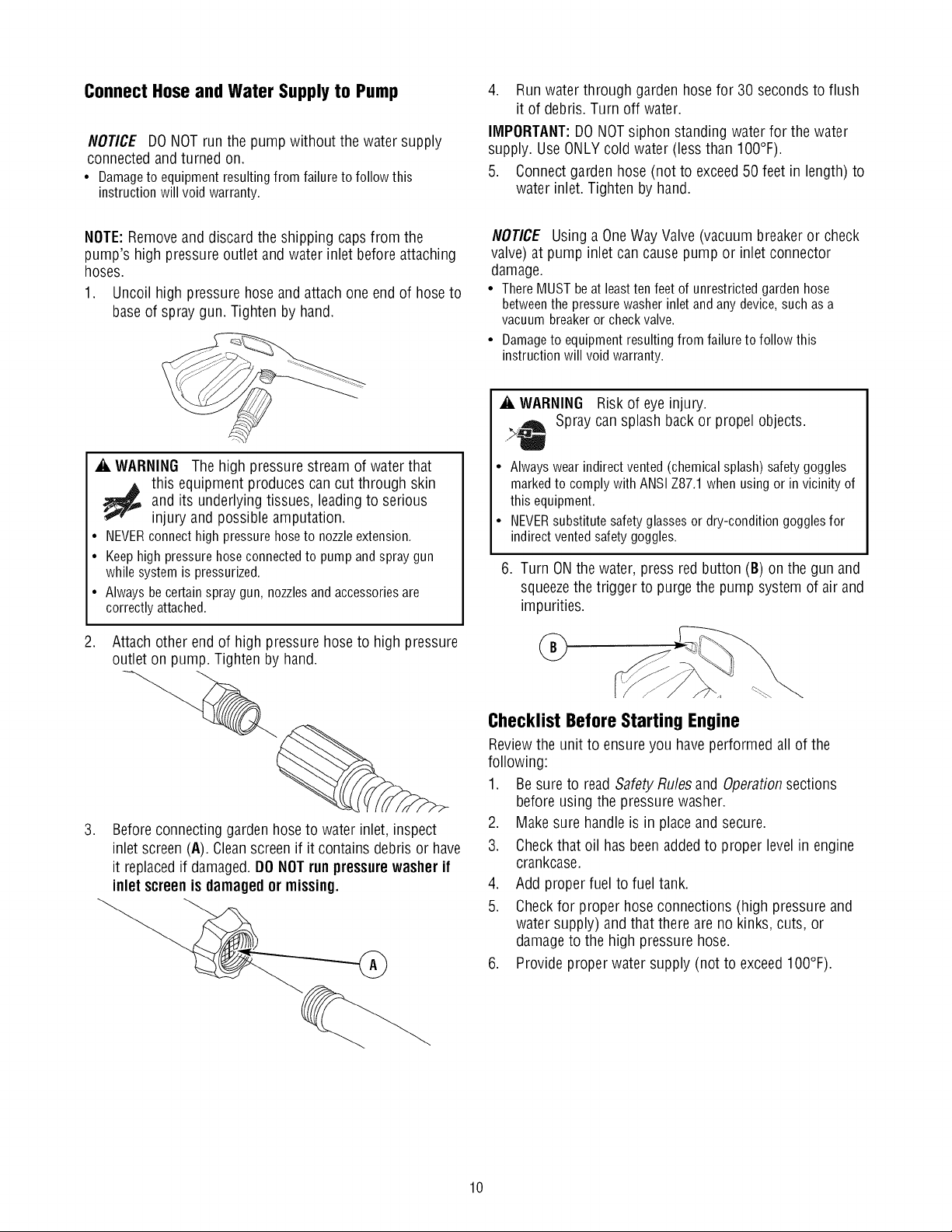

1. Uncoil high pressure hose and attachone end of hoseto

baseof spray gun. Tighten by hand.

_i, WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

• NEVERconnect high pressure hose to nozzleextension.

• Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

• Always becertain spray gun, nozzlesand accessoriesare

correctly attached.

2. Attach other end of high pressurehoseto high pressure

outlet on pump. Tighten by hand.

NOTICE Using a OneWayValve (vacuumbreaker or check

valve) at pump inlet can cause pump or inlet connector

damage.

• ThereMUSTbeatleasttenfeetofunrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

_i, WARNING Risk of eyeinjury.

Spray cansplash back or propel objects.

• Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSIZ87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

6. Turn ONthe water, press red button (B) on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

.

Beforeconnectinggarden hose to water inlet, inspect

inlet screen (A). Cleanscreen if it contains debris or have

it replacedif damaged.DONOTrunpressure washerif

inlet screenis damagedor missing.

Checklist Before Starting Engine

Reviewthe unit to ensureyou haveperformed all of the

following:

1. Besure to read SafetyRules and Operationsections

before using the pressure washer.

2. Makesure handleis in placeand secure.

3. Checkthat oil has beenadded to proper level in engine

crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor proper hose connections (high pressure and

water supply) andthat there are no kinks, cuts, or

damageto the high pressure hose.

6. Provide proper water supply (not to exceed100°F).

10

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operating your pressure washer,

pleasecallthe pressure washer helpline at 1-800-222-3136.

Pressure Washer Location

PressureWasherClearance

_i, WARNING Exhaustheat/gases can ignite

combustibles, structures or damagefuel tank

causing a fire.

• Keepat least5 ft. (152 cm) clearanceon all sides of pressure

washer including overhead.

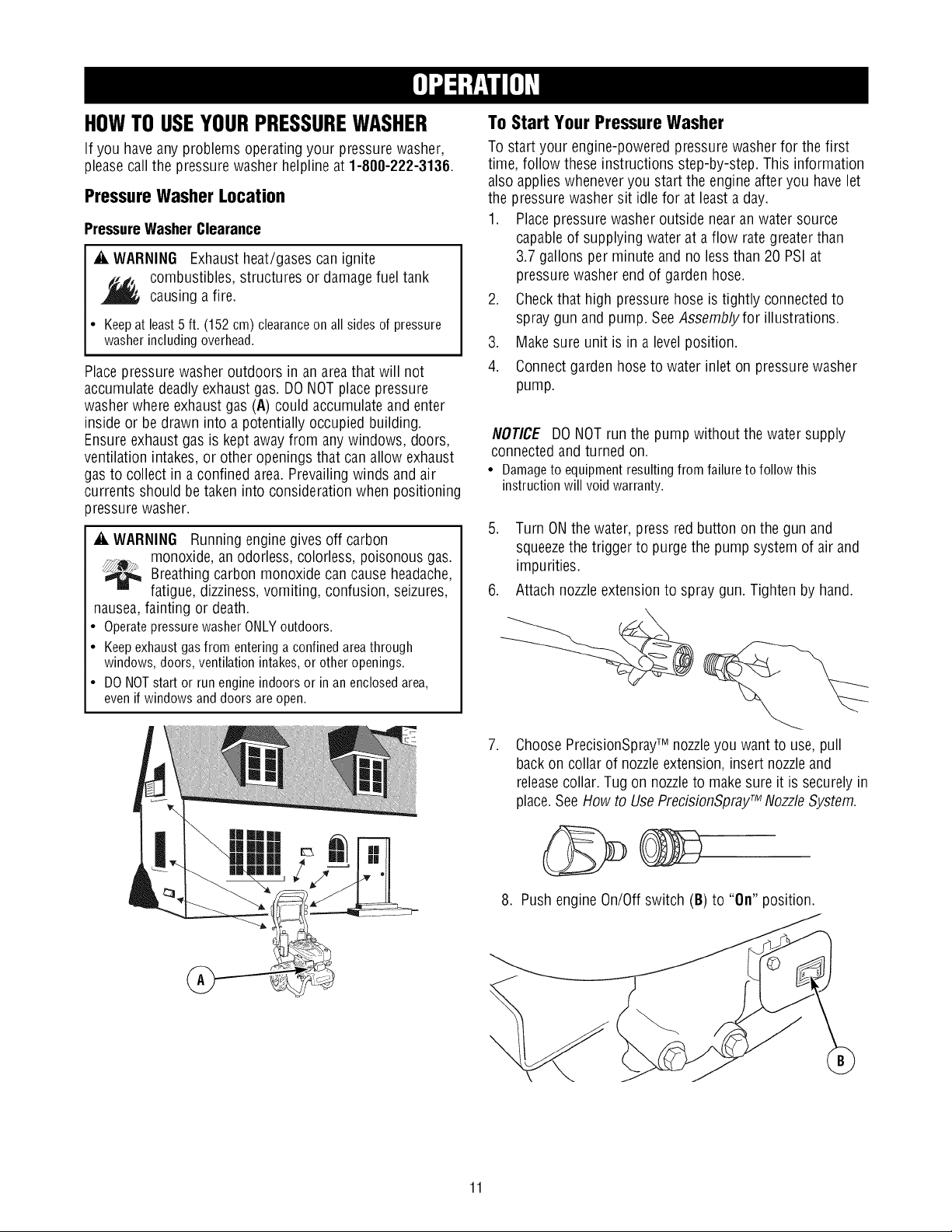

Placepressure washer outdoors in an area that will not

accumulate deadly exhaust gas. DONOTplacepressure

washer where exhaustgas (A) could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensureexhaustgas is keptawayfrom any windows, doors,

ventilation intakes, or other openings that can allow exhaust

gasto collect in aconfined area. Prevailingwinds and air

currents should betaken into consideration when positioning

_ressurewasher.

_i, WARNING Runningenginegives off carbon

monoxide,an odorless, colorless, poisonousgas.

_ Breathing can cause headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringa confinedareathrough

windows,doors,ventilationintakes,orotheropenings.

• DONOTstartor runengineindoorsor in anenclosedarea,

evenifwindowsanddoorsareopen.

carbon monoxide

To Start Your Pressure Washer

To start your engine-powered pressurewasherfor the first

time, follow these instructions step-by-step. This information

alsoapplies wheneveryou start the engineafter you have let

the pressure washer sit idle for at leasta day.

1. Placepressurewasher outside nearan water source

capableof supplying waterat a flow rate greaterthan

3.7 gallons per minute and no less than 20 PSI at

pressurewasher end of garden hose.

2. Checkthat high pressure hose is tightly connected to

spray gun and pump. SeeAssemblyfor illustrations.

3. Makesure unit is in alevelposition.

4. Connectgarden hoseto water inlet on pressurewasher

pump.

NOTICE DONOTrun the pump without the watersupply

connectedand turned on.

• Damageto equipmentresultingfromfailureto followthis

instructionwill voidwarranty.

5. Turn ONthe water, press red button on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

6. Attach nozzleextension to spray gun. Tighten by hand.

,

ChoosePrecisionSprayTM nozzleyou want to use, pull

backon collar of nozzleextension, insert nozzleand

releasecollar. Tug on nozzleto makesure it is securelyin

place.SeeHow to Use PrecisionSprayTM NozzleSystem.

8. Push engine On/Offswitch (B) to "On" position.

\

11

IMPORTANT:Beforestarting the pressure washer, be sure

'ou are wearing safety goggles as described below.

_k WARNING Riskof eyeinjury.

Spraycan splash backor propel objects.

• Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSIZ87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

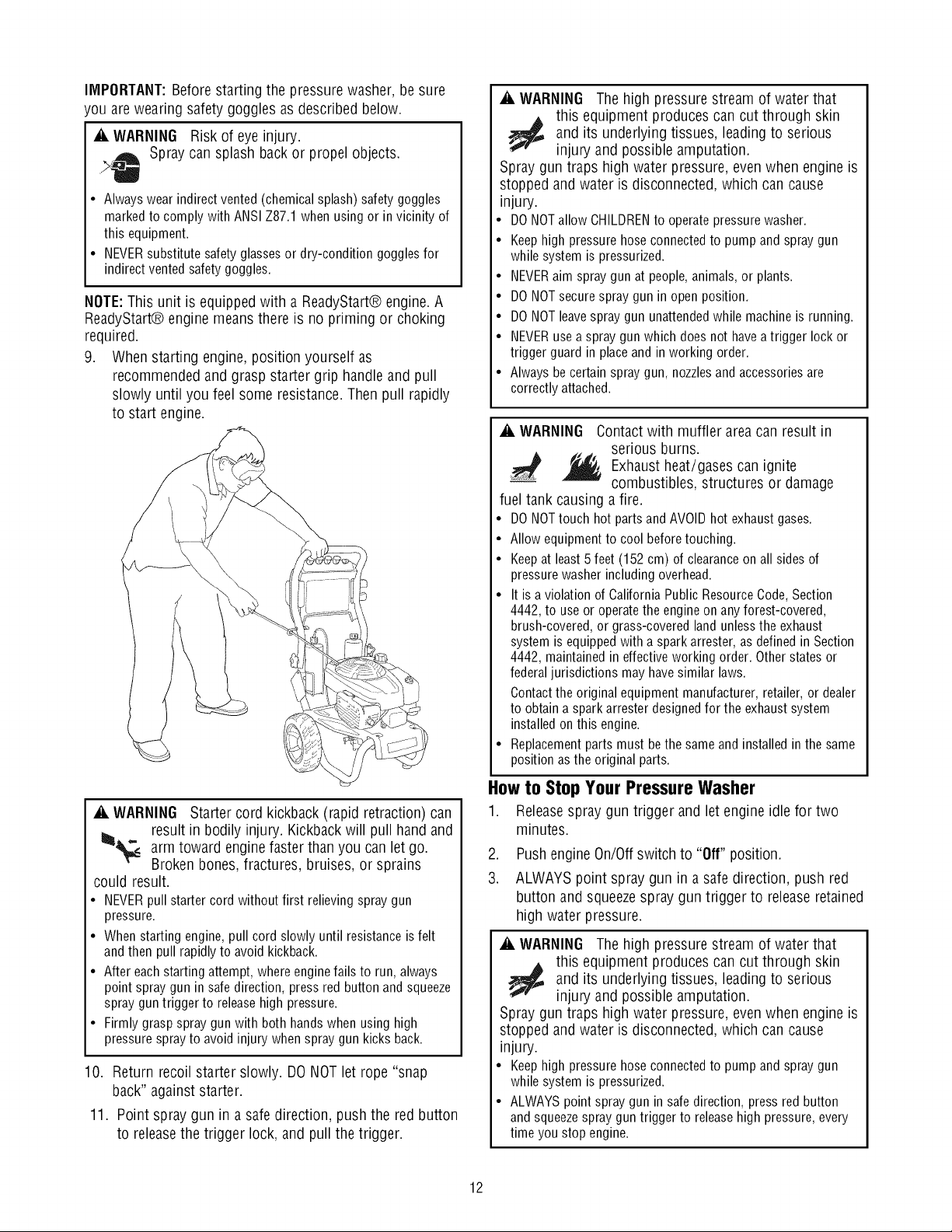

NOTE:This unit is equipped with a ReadyStart® engine.A

ReadyStart® engine means there is no priming or choking

required.

9. Whenstarting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feel some resistance.Then pull rapidly

to start engine.

_i, WARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leading to serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• DONOTallow CHILDRENto operatepressure washer.

• Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuse a spray gun which does not haveatrigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

_i, WARNING Contact with muffler area can result in

serious burns.

Exhaust heat/gases can ignite

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipmentto cool before touching.

• Keepat least5 feet (152 cm) of clearanceon all sides of

pressure washer including overhead.

• It is a violation of California Public ResourceCode, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equippedwith a spark arrester, as defined in Section

4442, maintained in effective working order. Otherstates or

federaljurisdictions may havesimilar laws.

Contactthe original equipment manufacturer,retailer, or dealer

to obtain a spark arrester designedfor the exhaustsystem

installed onthis engine.

• Replacementparts must bethe same and installed in the same

position as the original parts.

_i, WARNING Starter cord kickback (rapid retraction) can

result in bodily injury. Kickback will pull hand and

_. arm toward engine faster than you can let go.

v-

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spraygun

pressure.

• When starting engine,pull cord slowly until resistance isfelt

andthen pull rapidly to avoid kickback.

• After each starting attempt, where enginefails to run, always

point spray gun in safe direction, pressred button and squeeze

spray gun trigger to releasehigh pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spraygun kicks back.

O. Return recoil starter slowly. DONOT let rope "snap

back" against starter.

11. Point spray gun in a safedirection, push the redbutton

to releasethe trigger lock, and pull the trigger.

Howto Stop Your Pressure Washer

1. Release spray gun trigger and let engine idle for two

minutes.

.

PushengineOn/Offswitch to "Off" position.

3.

ALWAYSpoint spray gun in a safe direction, push red

button andsqueezespray gun trigger to releaseretained

high water pressure.

_i, WARNING The highpressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

12

IMPORTANT:Spray gun traps high water pressure,even

when engine is stopped and water is disconnected.

How to Use Accessory Tray

The unit is equipped with an accessorytray with places to

store your spray gun, nozzleextension andquick connect

spray tips. Thereis also a detachable hosewrap at the back

of the accessory tray to hold your high pressure hose.

1. Placenozzleextension in clip on back of accessory tray.

f .............

2. Placespray gun through hole on accessorytray on right

side of unit.

3. Insert multi-colored PrecisionSprayTM nozzlesin spaces

provided in accessorytray.

4. Wrap high pressure hoseon hosewrap then attach hose

wrap to backof accessory tray.

5. Hook provided on back of accessory tray for safely

storing safety goggles.

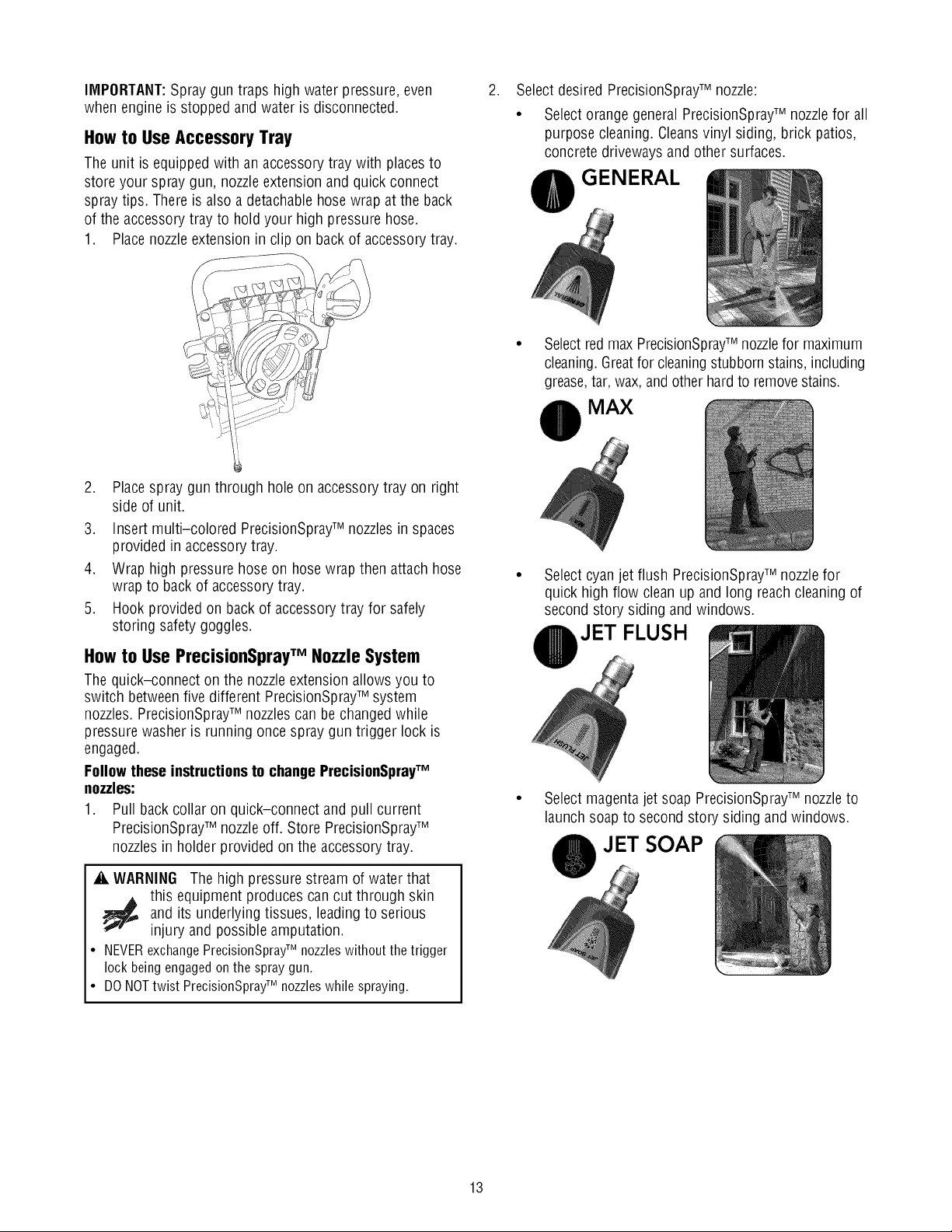

How to Use PrecisionSprayTM Nozzle System

The quick-connect on the nozzleextension allows you to

switch betweenfive different PrecisionSprayTM system

nozzles. PrecisionSprai Mnozzlescan be changedwhile

pressure washer is running once spray gun trigger lock is

engaged.

Followtheseinstructionsto changePrecisionSprayTM

nozzles:

1. Pull back collar on quick-connect and pull current

PrecisionSprayTM nozzleoff. Store PrecisionSprayTM

nozzlesin holder provided on the accessorytray.

,

Select desired PrecisionSprayTM nozzle:

• Select orange general PrecisionSprayTM nozzlefor all

purpose cleaning. Cleansvinyl siding, brick patios,

concrete driveways and other surfaces.

GENERAL

Selectred max PrecisionSprayTM nozzlefor maximum

cleaning.Greatfor cleaningstubborn stains,including

grease,tar, wax, and otherhard to removestains.

O MAX

Select cyanjet flush PrecisionSprai Mnozzlefor

quick high flow clean up and long reachcleaningof

second story siding and windows.

JET FLUSH

Select magentajet soap PrecisionSprayTM nozzleto

launch soapto secondstory siding and windows.

JET SOAP

_k WARNING The high pressure stream of water that

and its underlying tissues, leadingto serious

this equipment produces cancut through skin

injury and possible amputation.

• NEVERexchangePrecisionSprayTM nozzleswithoutthetrigger

lockbeingengagedonthespraygun.

• DONOTtwist PrecisionSprayTM nozzleswhilespraying.

13

SelectblackfansoapPrecisionSprayTM nozzlefor

general cleaning. Greatfor applying soap to

vehicles, boats, driveways,decks, andpatios.

FAN SOAP

3. Pullbackon collar,insert new PrecisionSprayTM nozzle

and releasecollar.Tug on nozzleto makesureit issecurely

in place.

UsageTips

• For most effective cleaning, keep PrecisionSprayTM nozzle

from 8 to 24 inches(20 to 61 cm) awayfrom cleaning

surface.

• If you get PrecisionSprayTM nozzletoo close, especially

using a high pressure nozzle,you maydamagesurface

being cleaned.

• DONOTget closer than 6 inches (15 cm) when cleaning

tires.

2-1N-1 Soap System

_i, CAUTION Chemicalscancause bodily injury, and/or

property damage.

• NEVERusecausticliquidwith pressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

CleaningandApplyingDetergentwith the

Project Pro® PerfectMixTM Siphon

To apply undiluted detergent using the blue

PerfectMixTM siphon,follow these steps:

1. Reviewuse of PrecisionSprayTM

nozzles.

2. Attach PerfectMixTM siphon hoseto

pump and PerfectMixTM concentrate

bottle.

NOTICE Contactwith the hot muffler can damage detergent

siphoning tube.

• When inserting the siphon intoa detergent solution bottle, route

thetubesoasto keepit from inadvertently contacting thehot

muffler.

3. Makesure fan soap (black) or jet soap nozzle(magenta)

is installed.

NOTE:Detergent cannot be applied with the high pressure

nozzles(Cyan,Orangeor Red).

4. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connected to spray gun

and pump.Turn on water.

NOTICE You must attachall hoses beforeyou start the

engine.

• Startingtheenginewithoutall the hosesconnectedandwithout

thewaterturnedONwilldamagethe pump.

• Damageto equipmentresultingfrom failureto followthis

instructionwillvoidwarranty.

5. Start engine following instructions How to Start Your

Pressure Washer.

6. Apply detergentto a dry surface,starting at lower

portion of areato be washed and work upward, using

long, even, overlappingstrokes.

7. Allow detergentto "soakin"for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DONOTallow detergent to dry on

(prevents streaking).

Cleaningand ApplyingDetergentwith the StandardClear

Siphon

To apply diluted detergent using the

standard clear siphon tube, follow these

steps:

1. Reviewuse of PrecisionSprayTM

nozzles.

2. Attach clear siphon hoseto barbedfitting on pump.

3. Mix detergent solution as required by job.

4. Placesmall filter end of clear siphoning tube into

container with diluted solution as described above.

NOTE:DONOT insert standard siphon hose in Extreme

Concentrate.Failure to dilute concentratewill causeexcessive

application and consumption of solution.

NOTE:Makesure the filter is fully submerged in fluid while

applying solution.

NOTICE Contactwith the hot muffler can damagedetergent

siphoning tube.

• Wheninsertingthesiphoninto adetergentsolutionbottle,route

thetubeso asto keepitfrom inadvertentlycontactingthehot

muffler.

5. Makesure fan soap (black) or jet soap nozzle(magenta)

is installed.

NOTE:Detergentcannot be applied with the high pressure

nozzles(Cyan, Orangeor Red).

6. Makesure garden hoseis connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn onwater.

NOTICE You must attachall hoses beforeyou start the

engine.

• Startingtheenginewithoutall the hosesconnectedandwithout

thewaterturnedONwilldamagethe pump.

• Damageto equipmentresultingfrom failureto followthis

instructionwillvoidwarranty.

14

.

Start enginefollowing instructions How to Start Your

Pressure Washer.

8.

Apply detergent to a dry surface,starting at lower

portion of areato be washedandwork upward, using

long, even,overlapping strokes.

9. Allow detergent to "soakin" for 3-5 minutes before

washing andrinsing. Reapplyas neededto prevent

surfacefrom drying. DONOTallow detergentto dry on

(prevents streaking).

IMPORTANT:You must flush the detergent siphoning system

after each use by placing the filter into a bucket of clean

water, then run the pressure washer in low pressure for 1-2

minutes.

Pressure Washer Rinsing

ForRinsing:

1. Removesoap PrecisionSprayTM nozzlefrom nozzle

extension.

2. Selectand install desiredhigh pressure nozzlefollowing

instructions How to UsePrecisionSpraSMNozzleSystem.

3. Keepspray gun a safedistance from areayou plan to

spray.

A. WARNING Kickbackfrom spray gun cancauseyou to

fall.

• Operatepressurewasherfromastablesurface.

• Beextremelycarefulif youmustusethepressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

• Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

4. Apply a high pressure spray to a small area and then

checksurface for damage.If no damageis found, you

can assumeit is okay to continue rinsing.

5. Start at top of areato be rinsed, working down with

same overlapping strokesasyou used for cleaning.

Cleaning Detergent Siphoning Tube

If you usedthe cleardetergent siphoning tube, you must

flush it with cleanwater beforestopping the engine.

1. Placedetergent siphoning tube/filter in a bucketfull of

cleanwater.

.

Removehigh pressurenozzlefrom nozzleextension.

3.

Select and install a soap nozzlefollowing instructions

How to Use PrecisionSprayTM NozzleSystem.

.

Flushfor 1-2 minutes.

5.

Shut off engine following instructions How to Stop

Pressure Washerandturn off water supply.

6. ALWAYSpoint spraygun in a safe direction push red

button andsqueezespray gun trigger to releaseretained

high water pressure.

IMPORTANT:Spray gun traps high water pressure,even

when engine is stopped and water is disconnected.

A, WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

Automatic Cool Down System (Thermal Relief)

Ifyou run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125°F.The systemengagesto cool the pump by discharging

the warm water ontothe ground.

15

ENGINETECHNICALINFORMATION

This is a single cylinder, overheadvalve (OHV), air cooled

engine. It is a low emissions engine.

In the State of California, Model 120000 enginesare certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respect to the performanceor

operational life of this engine.Theengine is warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas enginemodels is

labeled in accordancewith SAE(Society of Automotive

Engineers)codeJ1940 (Small EnginePower & Torque

Rating Procedure),and rating performance has been

obtained and corrected in accordancewith SAEJ1995

(Revision 2002-05). Torquevalues are derived at 3060 RPM;

horsepower values are derived at 3600 RPIVI.Actual gross

engine power will be lower and is affectedby, among other

things, ambient operating conditions and engine-to-engine

variability. Givenboth the wide arrayof products onwhich

enginesare placed andthe variety of environmental issues

applicableto operatingthe equipment,the gas engine will not

developthe ratedgross power when used in a given pieceof

power equipment (actual "on-site"or net power). This

difference is due to avariety of factors including, but not

limited to, accessories(air cleaner, exhaust, charging,

cooling, carburetor, fuel pump, etc.), application limitations,

ambient operating conditions (temperature, humidity,

altitude), and engine-to-enginevariability. Dueto

manufacturing andcapacity limitations, Briggs & Stratton

may substitute an engine of higher rated power for this

Seriesengine.

This pressurewasher is rated in accordanceto the Pressure

Washer Manufacturers Association (PWIVIA)standardPW101

(Testing and Rating Performanceof PressureWashers).

PRODUCTSPECIFICATIONS

Pressure Washer Specifications

Max Outlet Pressure ....................... 3,000 PSI

Max Flow Rate............................. 2.7 GPM

DetergentMix ........................ Use as directed

Water SupplyTemperature .......... Not to exceed100°F

Engine Specifications

Bore ................................. 2.69 in. (68mm)

Stroke ............................... 2.04 in. (52mm)

Displacement ........................ 11.58in. (190cc)

SparkPlug

Type:...................... Briggs & Stratton 692051

SetGapTo: ...................... 0.020inch(0.50mm)

ArmatureAir Gap:........... 0.010-0.014in.(0.25-0.36mm)

Valveclearancewithvalvesprings installedand piston 1/4 in.

(6 mm) pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.004-0.008in.(0.10-0.20mm)

Exhaust .................. 0.004-0.008in.(0.10-0.20mm)

FuelCapacity............................... 1.6 Quarts

0il Capacity........................ 20 Ounces(0.6 liter)

NOTE:For practical operation,the engineload should not

exceed85% of ratedpower. Enginepower will decrease

3-1/2% for each1,000 feet (300 meters) above sealeveland

1% for each 10° F (5.6° C) above77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

16

OWNER'SRESPONSIBILITIES

Follow the hourly or calendarintervals, whichever occurs

first. More frequent service is requiredwhen operating in

adverseconditions noted below.

• Changeengine oil

• Check/clean water inletscreen'

• Checkhigh pressurehose

• Checkdetergentsiphoning hose/tanks

• Checkspraygun and assembly for leaks

• Cleandebris

Emissions Control

Maintenance,replacement,or repair ofthe emissions

controldevicesand systemsmay be performedby any non-

roadenginerepair establishmentor individual. However,

to obtain "no charge" emissions control service, the work

must be performed by a factory authorizeddealer. Seethe

Emissions Warranty.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screenfor damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and nozzleextension assemblyfor leaks.

6. Purge pump of air and contaminants.

• Checkengineoil level

• Cleanengine air cleaner2

• Changeengine oil2

• Inspect muffler and spark arrester

• Replaceengine air cleaner_

• Replacespark plug

• Cleancooling systeW

Clean if clogged. Replace if perforated or torn.

2Service more often under dirty or dusty conditions.

General Recommendations

Regularmaintenancewill improve the performance and

extendthe life of the pressurewasher. Seeany Searsor

other qualified service dealerfor service.

Thepressure washer warranty does not cover items that

havebeensubjected to operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressurewasher as instructed in this manual

including proper storage asdetailed in Storage.

Someadjustments will needto be made periodicallyto

properly maintain your pressurewasher.

All service and adjustments should be madeat least once

eachseason.Follow the requirementsin the Maintenance

Schedulechart above.

NOTE:Oncea yearyou should cleanor replacethe spark

plug andreplacethe air filter. A new spark plugand clean air

filter assureproper fuel-air mixture and helpyour engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenanceon this pump. The

pump is pre-lubricatedand sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use,cleanaccumulateddebris from pressure

washer. Keeplinkage, spring and controls clean.Keeparea

around andbehind muffler free from any combustible debris.

Inspect cooling air slots andopenings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept cleanto reduce the

risk of overheating and ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of pressurewasher can

damageit and shorten its life.

• DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosencaked on dirt, oil, etc.

• Usea vacuum cleaner to pick up loose dirt and debris.

Check and Clean Inlet Screen

Examinegarden hoseinlet screen. Cleanif it is clogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses can develop leaksfrom wear, kinking,

or abuse. Inspecthose before each use. Check for cuts,

leaks,abrasions,bulging of cover, or damage or movement

of couplings. If anyof these conditions exist, replacehose

immediately.

_i, WARNING The highpressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

• NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

17

Check Gunand Nozzle Extension

Examinehoseconnectionto spraygun and makesureit is

secure.Testtrigger bypressingit and makingsure it springs

backintoplacewhenyou releaseit.Donotdepressredbutton

andtesttrigger.Youshouldnot beableto presstrigger. Replace

spraygun immediatelyif it failsanyof thesetests.

Nozzle Maintenance

A pulsing sensationfelt while squeezingthe spray gun trigger

may becausedby excessivepump pressure. The principal

causeof excessivepump pressure is a nozzleclogged or

restricted with foreign materials, such asdirt, etc. To correct

the problem, immediately cleanthe nozzlefollowing these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, pressred

button andand squeezespray gun trigger to release

retainedhigh waterpressure.

_i, WARNING The high pressure stream of water that

and its underlying tissues, leadingto serious

this equipment produces cancut through skin

injury and possible amputation.

Spraygun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

.

Removenozzlefrom end of nozzleextension.

4.

Use a small paper clip to free anyforeign material

clogging or restricting nozzle(A).

.

Removenozzleextensionfrom spray gun.

6.

Using a garden hose, remove additional debris by back

flushing water through nozzleextension. Backflush

between 30 to 60 seconds.

7. Reinstallnozzleintonozzleextension.

8. Reconnectnozzleextension to spraygun.

9. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connected to spray gun

and pump.Turn on water.

10. Start enginefollowing instructions How to Start Your

Pressure Washer.

11. Test pressurewasher by operating with each quick

connect nozzle.

O-Ring Maintenance

Purchasean O-Ring RepairKitat your localSearsor by calling

1-800-4-MY-HOME(469-4663) or online at www.sears.com.It

is notincludedwith the pressurewasher.This kit includes

replacemento-rings,rubberwasherandwater inletfilter. Referto

the instructionsheetprovidedin thekit to serviceyour unit's

o-rings.

_i, WARNING The highpressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

• NEVERrepairleakingconnectionswithsealantofanykind.

Replaceo-ringor seal.

ENGINEMAINTENANCE

_i, WARNING Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTINGOR MAKINGREPAIRSTOYOUR PRESSURE

WASHER

• Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Useapproved spark plug tester.

• DONOTcheckfor sparkwith spark plug removed.

Oil

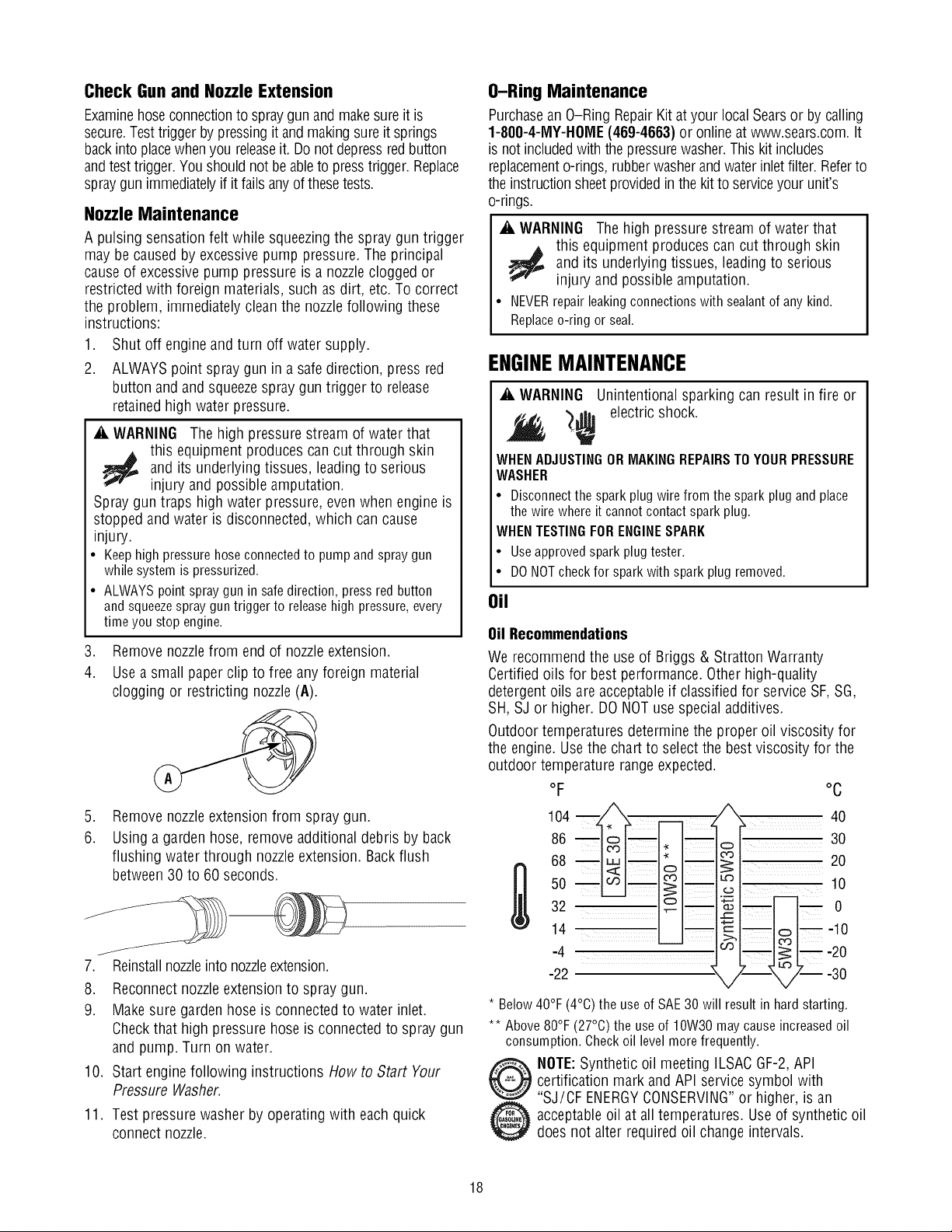

OilRecommendations

We recommendthe use of Briggs & Stratton Warranty

Certifiedoils for bestperformance. Other high-quality

detergent oils areacceptableif classifiedfor serviceSF,SG,

SH,SJ or higher. DONOTusespecial additives.

Outdoortemperatures determine the properoil viscosity for

the engine.Usethe chart to select the best viscosity for the

outdoor temperature range expected.

oF

\ 40

;_30

104___506886 _03o__

32 .o

14

-4

-22

* Below40°F(4°C)the useofSAE30will resultin hardstarting.

** Above80°F(27°C)theuseof 10W30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

certification mark and APIservice symbol with

NOTE:Synthetic oil meeting ILSACGF-2,API

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic oil

does not alter required oil change intervals.

°_20

_m m 0

--_C °

°C

10

-20

-30

18

Loading...

Loading...