Page 1

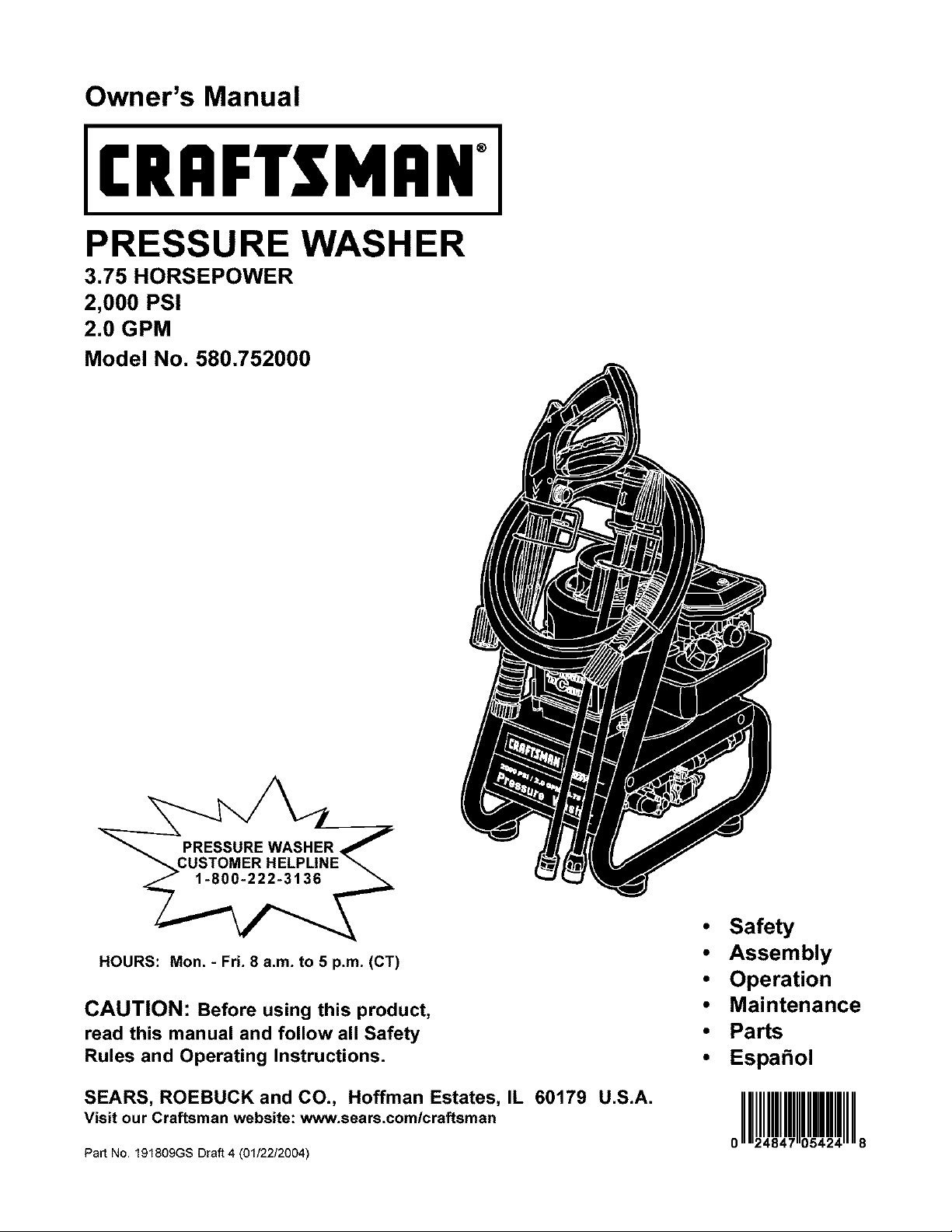

Owner's Manual

ICRRFTSMRN+I

PRESSURE WASHER

3.75 HORSEPOWER

2,000 PSI

2.0 GPM

Model No. 580.752000

HOURS: Mon. - FrL 8 a.m. to 5 p.m. (CT)

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

visit our Craftsman website: www.sears.com/craftsman

Part No. 191809GS Draft 4 (01/2212004)

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espa_ol

01!!1!1!!!1!8

Page 2

WARRANTY .................................... 2

SAFETY RULES ............................... 2-4

ASSEMBLY ................................... 6-7

OPERATION ................................. 8-10

MAINTENANCE .............................. 11-14

SPECIFICATIONS ............................... 11

STORAGE ..................................... 15

TROUBLESHOOTING ............................ 16

REPLACEMENT PARTS ....................... 18-22

EMISSION CONTROL WARRANTY ................. 23

ESPANOL ................................... 24-39

HOW TO ORDER PARTS ................ BACK PAGE

LIMITED WARRANTY ON CRAFTSMAN PRESSURE WASHER

For one year from the date of purchase, when this Craftsman pressure washer is maintained and operated

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

if this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase, if this pressure washer is used for rental purposes, this warranty applies for only 30 days after date

of purchase.

This warranty does not cover:

Expendable items such as spark plugs or air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the pressure washer to the nearest Sears service center or dealer in

the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

,_ This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

_Read this manual carefully and become

familiar with your pressure washer. Know its

applications, its limitations, and any hazards

involved.

The safety alert symbol (,_k) is used with a signal

word (DANGER, CAUTION, WARNING), a pictorial

and/or a safety message to alert you to hazards.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury. WARNING indicates a

hazard which, if not avoided, could result in death or

serious injury. CAUTION indicates a hazard which, if

not avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol,

indicates a situation that could result in equipment

damage. Follow safety messages to avoid or reduce

the risk of injury or death.

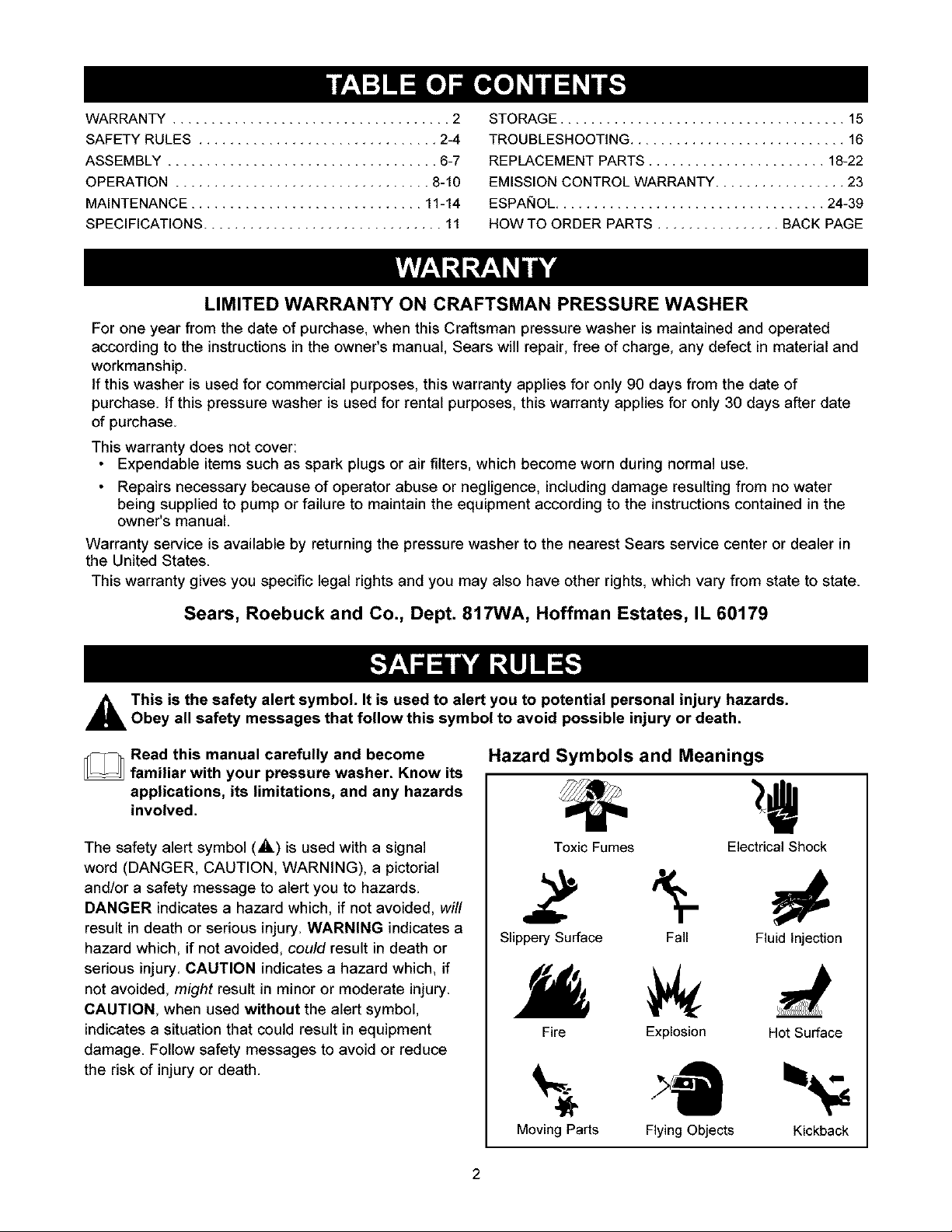

Hazard Symbols and Meanings

Toxic Fumes

Slippery Surface Fall Fluid Injection

Fire Explosion Hot Surface

Electrical Shock

Moving Parts Flying Objects

2

Kickback

Page 3

n the State of California a spark a_rester is required

_y law (section 4442 of the california Public

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, b rth defects, or other reproduct ve harm,

DANGER

• Operate pressure washer ONLY outdoor&

• Use a respirator or mesk whenever there is a _hance

that vapors may be inhaled;

• Read all instructions pocked with mask so you are certain

mask wil! provide necessary protection against inhaling

harmful vapors;

WARNING

WHEN ADDING FUEL

,Turn pressure washer OFF and !et it ceo! at least

2 minutes before removing gas oap.

, Fill fuel tank eutdoersi

,DO NOT overfill tank. A!!ow space for fuel expansion.

Keep fuel away ftorn spark&open flamesi pilot lightsi

heat; and ether ignitien seur_;

DO NOT light a cigarette or' smoke.

WHEN OPERATING EQUIPMENT

, DO NOT tip engine or equipment at ang!e which _auses

fuel to spill

,DO NO]- Spray flammable liquids

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

, Transpert#epeir with fuel tank EMPTY

Valve OFF.

WHEN STORING FUEL OR EQUIPMENT wrrH FUEL IN

TANK

,Store away frem furnase% stoves; water heaters, clothes

dryers Orother appliances that have pilot light Orother

ignition source because they can ignite fuel Vapors.........

WARNING

WARNING

• Keep spray nozzle between 8 to 24 inches away from

cleaning

• Operate this unit on a stable surfacei

• Cleaning area should have adequate slopes and

drainage to reduce possibility of fails due to slippery

surfacesi

, Be extremely carefu! if you must use pressure washer

from a ladderi S_!ding on any other relatiyely unstable

Iocetiom

, F!rmly grasp spray gun with both hands when using high

Pressure spray to avoid injury if gun kicks b_ck.

WARNING

, DO NOT touch hot surfaces:

• Slay clear of exhaust gases,

NEVER move equipment while operating

• Allow equipment to cool before touching

3

Page 4

WARNING CAUTION

WARNING

WARNING

• Always wear eye protection_n using equipment or when

in vicinity of equipment in use,

_ CAUTION

CAUTION

CAUTION

contact Searsi

NEVER operate units with br0ken or missing parts; 0r

without protective housing or covers;

• DO NOT by--pass any sefety device on this machine

,Before starUng pressure washer in cold weatheri check

a!l parts of the equ!pment to be sure ice has not formed

there

NEVER move machine by pu!l!ngon high pressure hose,

Use handle provided on unit,

• Che0k fuel system for leaks or signs o_deterioration,

pongy hceei loose or missing

• DO NOT operate pressure washer above rated pressurei

4

Page 5

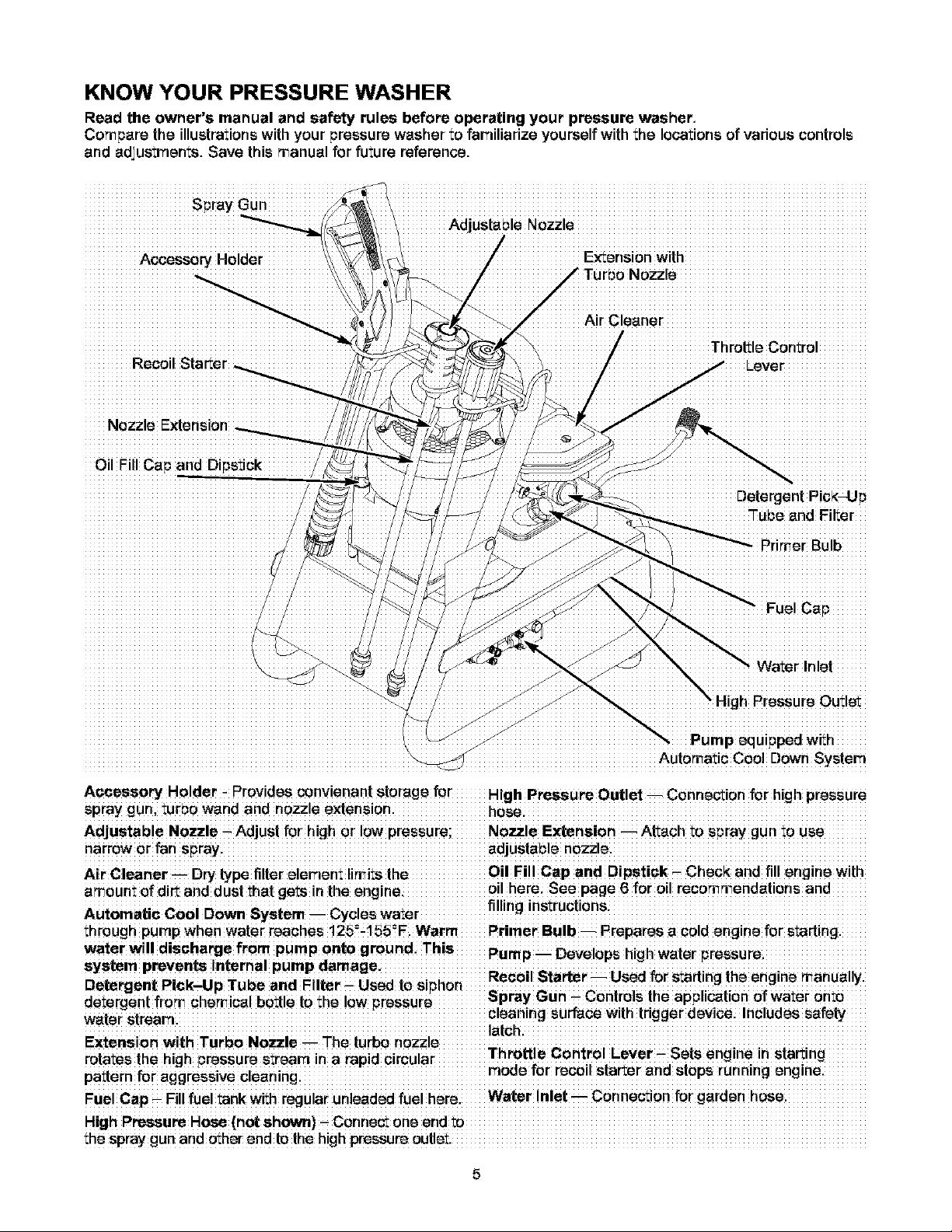

KNOW YOUR PRESSURE WASHER

Read the owner's manual and safety rules before operating your pressure washer,

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

$ ray Gun.............

Adjustable Nozzle

Accessory

el! Fill Cap and Dipstick..........

Ex_enSion With

Cleaner

l"hrottle control

Detergent Pic_:-Up

I'ube and Filter

Primer Bulb

Fue!Cap

Wa_e r Inlet

High Pressure Outl_

_mp equipped with

Automatic Cool Down system

Accessory Holder, provides convienant storage for High Pmesure Outlet _ c0nn_i0n for high preSsUre

spray gun, _urbo wand and nozzle extension ...................... hosei............................................................................

Adjustable Nozzle _ Adjust for high or low pressure; N0zzle ]ExtensiOn_ Attach t_ spray gun to use

narrow or faR s_ray, adjustable nOzzlei

Air Clesner _ Dry type filter element iimits the OilFi!! Cap and Dipstick- Check and f!!l engine with

amount of dir_and_dLIstthat gets in the engine: el! herei See page 6 foroi I recommendations and

Automatic Cool D0wn System _ cycies water ....... ......

through pump when water reaches !2.5=,!55=F. Warm Primer Bulb_ Prepares a co!d engine for starting. ......

water will discharge from pump onto ground This, Pump _ Dove ops hgh ware p essure....... I i r r ...... ........................

system preven_ internal pump damage_ .....................................................................................

....... r........ P.................................................... _............. Recoil Starter _ Used f°r' starting the engine manually

Dete gent iek-Up Tube and Filter- Used to slphon......................

detergent.... from.... chem ca berte to the ow pressure..... Spray Gun - C0ntrols the applicati0n 0f water Oht0.... .....

Waterstream. €!eanmg SUrface w!th tr!gger dev=ca !ncludes Safety

Extension with Turbo Nozzle _ The turbo nozzle......................... _ ........................ ......................... ...................

rotates the high pressure strea_ in a rapid circular Thr°tt! e _0ntr01 Lever-_ets engine in smrting

pa_ern for aggr0ssive Cleaning m0do for re_il star_e_and StoPSrunning engine •

Fuei Cap -Fill fuel tank Wi_ roguiai uni0ad0d fuel her0. war er !nlet _ c0nnect-i0n for garden hose •

High Pressure Hose (not shown)- connect one end_

the spray gun and Otherendte the high preSSure Outlet.

filling instructions

latch.

5

Page 6

Yourpressure washer requires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your pressure washer, please call the pressure

washer helpline at 1-800-222-3t36.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

REMOVE PRESSURE WASHER

FROM CARTON

Open carton and slice two corners opposite guide

handle from top to bottom so the panel can be

folded down flat.

Remove fillers, accessories and parts bag shipped

with your pressure washer.

Remove the pressure washer out the open end of

the carton.

Check carton for additional loose parts.

CARTON CONTENTS

Check all contents, If any parts are missing or damaged,

cell the pressure washer helpline at t-800-222-3136,

The main unit

High pressure hose

Spray gun

Nozzle extension with adjustable nozzle

Turbo wand

Accessory holder

Engine oil

Parts bag (which includes items listed below)

Owner's manual

Registration card

Become familiar with each piece before assembling

the pressure washer. Compare contents against the

view on page 5. If any parts are missing or damaged,

call the pressure washer helpline at 1-800-222_3136.

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman pressure washer was mostly

assembled at the factory, However, you will need to

perform these tasks before you can operate your

pressure washer:

1. Add oil to engine crankcase.

2. Add fuel to fuel tank.

3. Connect high pressure hose to spray gun and

pump.

4. Connect water supply to pump.

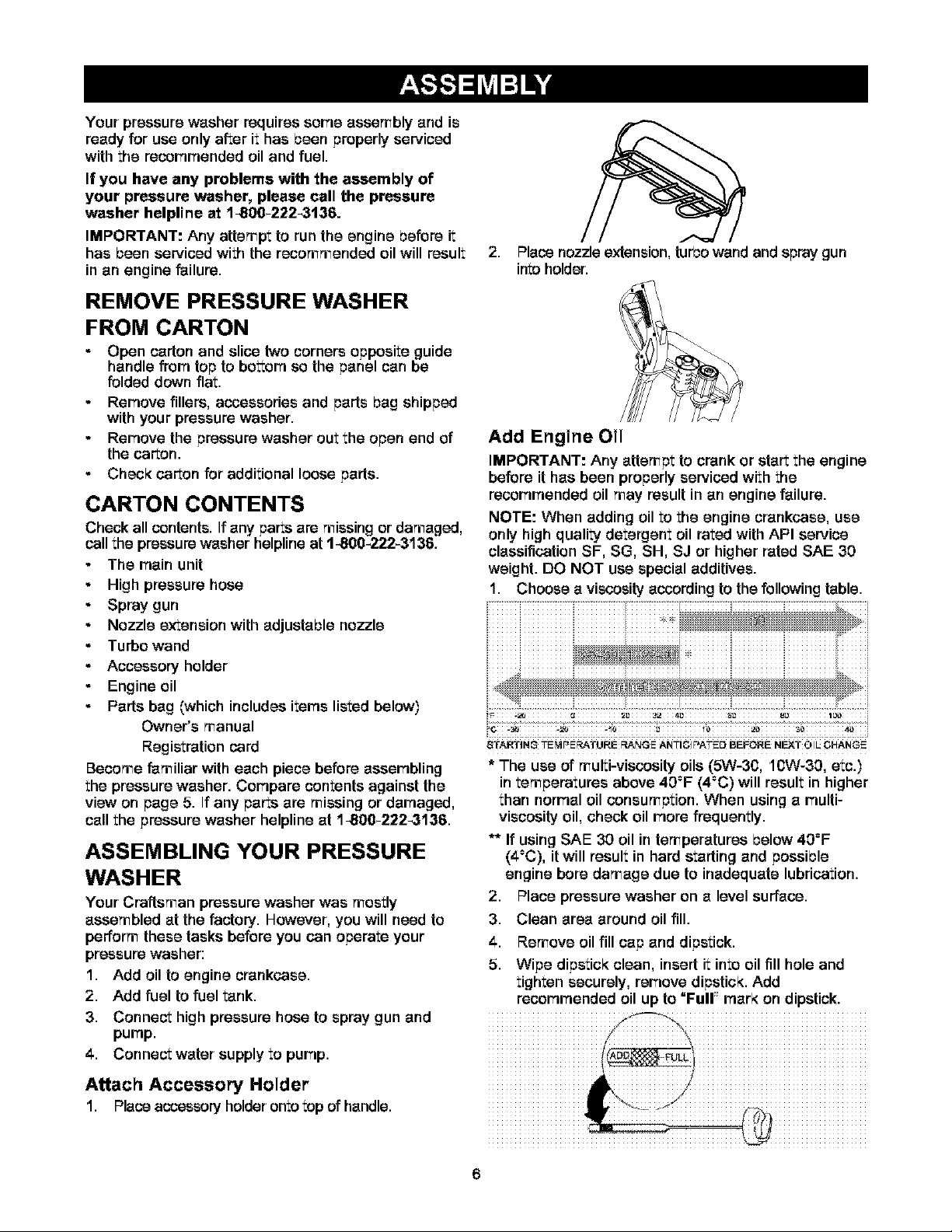

2. Place nozzle extension, turbowand and spray gun

into holder.

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure,

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher rated SAE 30

weight, DO NOT use special additives,

1. Choose a viscosity according to the following table.

STARTING TE_ FERATURE RANGE AINTICI PATE E) BEFORE NEXT OIL CHANGE

* The use of multi-viscesiN oils (5W-30, 10W-30, etc.)

in temperatures above 40=F (4=C) will result in higher

than normal oil consumption. When using a multi-

viscosity oil, check oil more frequently.

** If using SAE 30 oil in temperatures below 40=F

(_=C), it will result in hard starting and possible

engine bore damage due to inadequate lubrication.

2. Place pressure washer on a level surface.

3. Clean area around oil fill.

4. Remove oil fill cap and dipstick.

5. Wipe dipstick clean, insert it intooil fill hole and

tighten securely, remove dipsticK. Add

recommended oil up to "Fall" mark on dipstick.

Attach Accessory Holder

1, Place accessory holderonto top of handle,

6

Page 7

6. Pour slowly. Wipe dipstick clean each time oil

level is checKed. DO NOT overfill.

7. Install oil fill plug and dipstick, tighten securely.

NOTE: ChecK oil often during engine breaK-in.

Add Fuel

,_ WARNINGt NEVER fill fuel tank indoors.

NEVER fill fuel tanK when engine is running or

hot. DO NOT smoKe when filling fuel tank.

,_ WARNINGt NEVER fill fuel tank completely

full. Provide space for fuel expansion. Wipe

away any fuel spillage from engine and

equipment before starting.

1. Use clean unleaded automotive fuel and store in

approved, clean, covered containers. Use clean fill

funnels. NEVER use ::stale"fuel left over from last

season or fuel stored for long periods.

2. Clean area around fuel fill cap, remove cap.

3. Slowly add fuel to fuel tank. Use a funnel to

prevent spillage. Fill tank to about 1.5" below the

top of the filler necK.

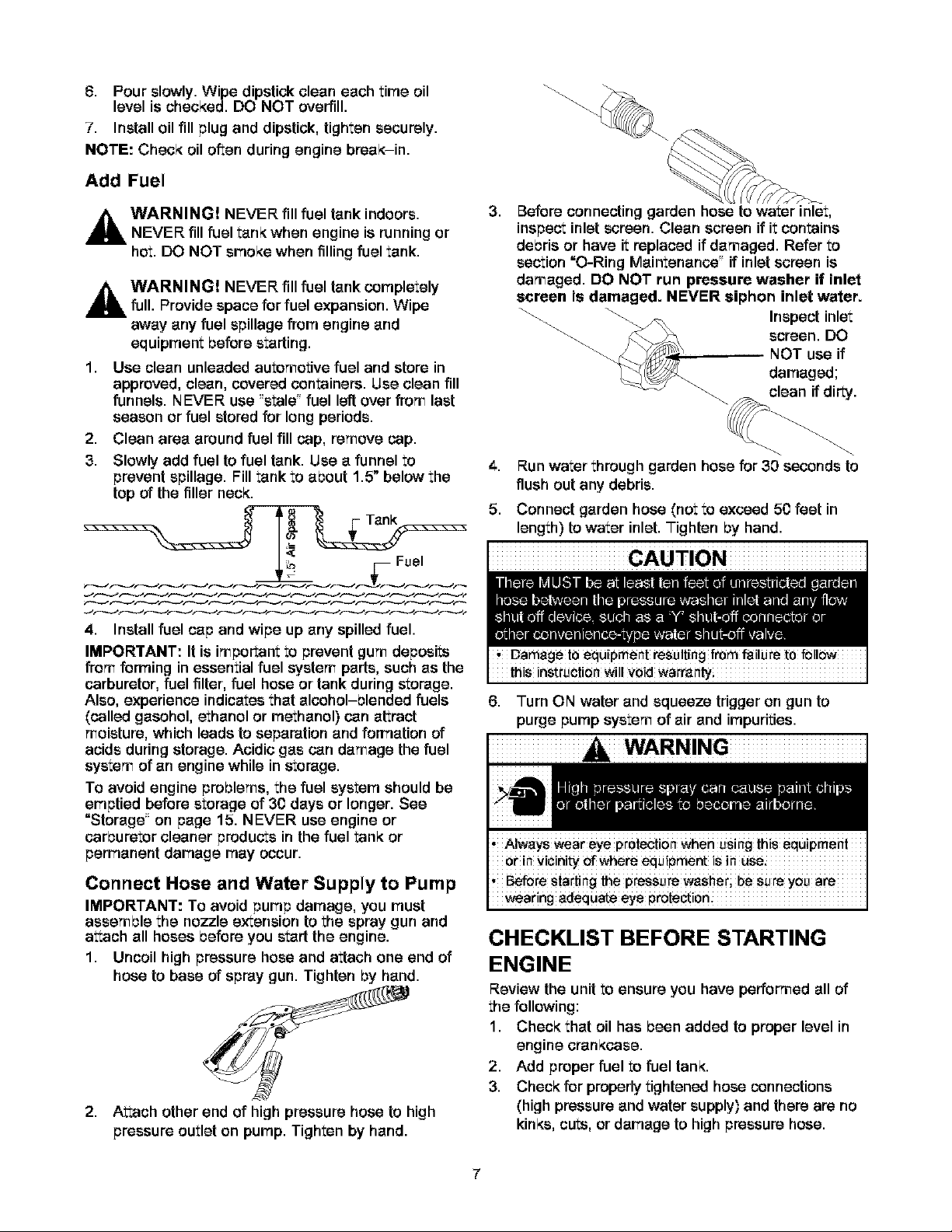

,

Before connecting garden hose to wa1:erinlet,

inspect inlet screen. Clean screen if it con1:ains

debris or have it replaced if damaged. Refer to

section =O-Ring Maintenance" if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen is damaged. NEVER siphon inlet water.

Inspect inlet

screen. DO

NOT use if

damaged;

clean if dirty.

4. Run wa1:erthrough garden hose for 30 seconds to

flush out any debris.

5. Connect garden hose (net 1:oexceed 50 feet in

length) to water inlet. Tighten by hand.

_,_ Fuel

4. Install fuel cap and wipe up any spilled fuel.

IMPORTANT: It is imporl:ant 1:oprevent gum deposits

from forming in essential fuel system parts, such as the

carburetor, fuel filter, fuel hose or tank during s1:orage.

Also, experience indica1:esthat alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract

moisture, which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

sys1:emof an engine while in storage.

To avoid engine problems, the fuel sys1:emshould be

emptied before storage of 30 days or longer. See

=Storage" on page 15. NEVER use engine or

carbure1:or cleaner products in the fuel 1:anKor

permanent damage may occur.

Connect Hose and Water Supply to Pump

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach all hoses before you start the engine.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

2. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

CAUTION

6. Turn ON water and squeeze trigger on gun to

purge pump system of air and impurities.

WARNING

_aringadequate eye protection.

CHECKLIST BEFORE STARTING

ENGINE

Review the unit1:oensure you have performed all of

the following:

1. Check that oil has been added to proper level in

engine crankcase.

2. Add proper fuel 1:ofuel tanK.

3. Check for properly tightened hose connections

(high pressure and water supply) and there are no

kinks, cuts, or damage to high pressure hose.

7

Page 8

Provide proper water supply (not 1:oexceed 100°F).

5.

Be sure 1:oread =Safety Rules" and ::Opera1:ion"

sections before using pressure washer.

,

If s1:artingunit after s1:orage,see ::S1:orage"section

on page 15.

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

To Start Your Pressure Washer

To el:art your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

s1:artinginformation also applies whenever you start

the engine after you have let the pressure washer sit

idle for at leas: a day.

1. Place pressure washer near an outside water

source capable of supplying water at a flow rate

greater than 3.0 gallons per minute and no less than

20 PSI at pressure washer end ofgarden hose.

2,

Check that high pressure hose istightlyconnected

1:ospray gun and pump. See "Assembling Your

Pressure Washer" for illus1:ra1:ions.

,

Make sure unit is in a level position.

4.

Connect garden hose to wa1:erinlet on pressure

washer pump. Turn ON water.

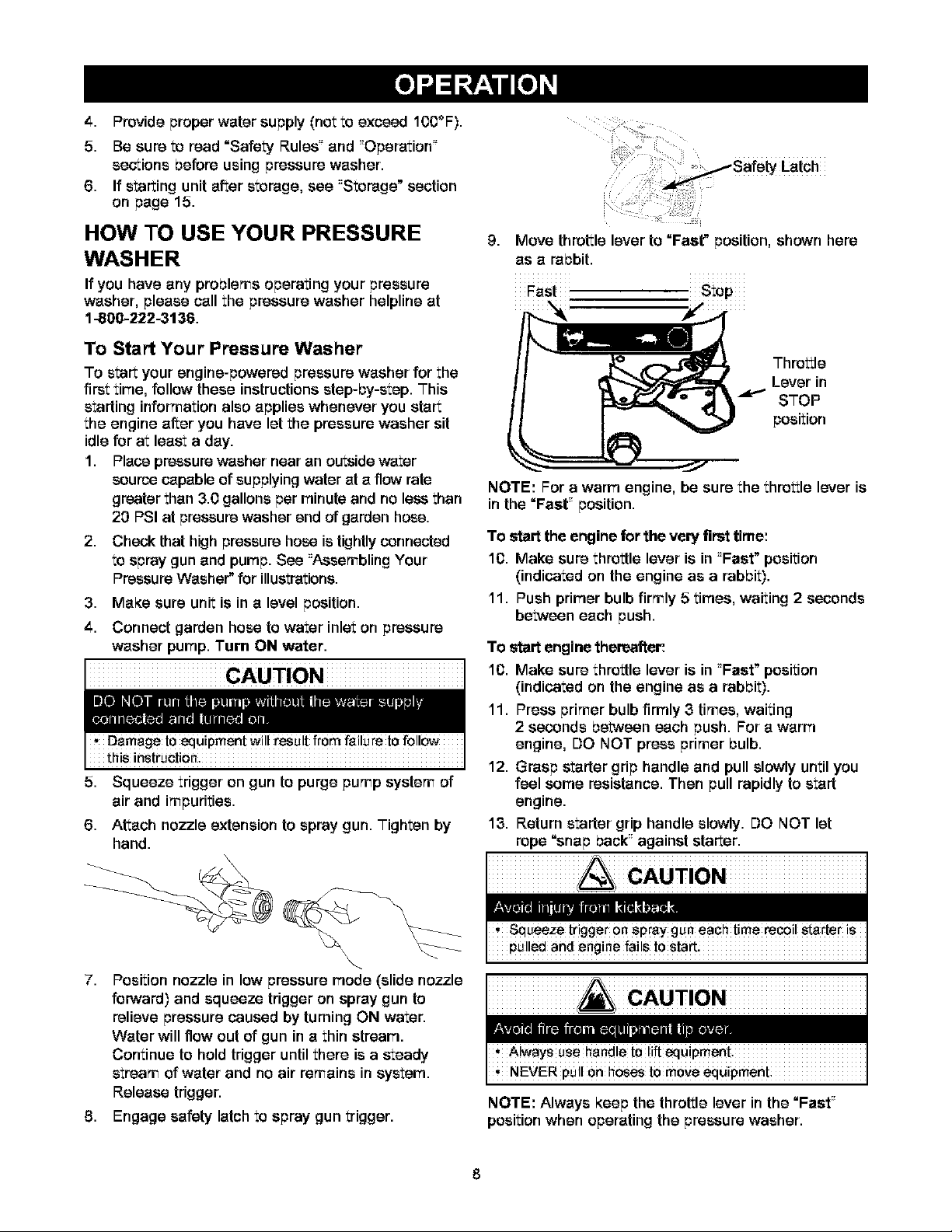

CAUTION

5. Squeeze trigger on gun to purge pump system of

air and impurities.

6. Attach nozzle extension to spray gun. Tighten by

hand.

\\

,

Move throttle lever to =Fast" position, shown here

as a rabbit.

Fast Stop

Threttle

Leverin

STOP

position

NOTE: For a warm engine, be sure the throttle lever is

in the =Fast" position.

To start the engine for the very first time:

10. Make sure throttle lever is in ::Fast" position

(indice1:edon the engine as a rabbit).

11. Push primer bulb firmly 5 times, waiting 2 seconds

between each push.

To start engine thereafter:

10. Make sure throttle lever is in ::Fast" position

(indice1:ed on the engine as a rabbit).

11. Press primer bulb firmly 3 times, waiting

2 seconds between each push. For a warm

engine, DO NOT press primer bulb.

12. Grasp s1:artergrip handle and pull slowly until you

feel some resistance. Then pull rapidly to start

engine.

13. Return s1:arter grip handle slowly. DO NOT let

rope =snap back" against starter.

CAUTION

7,

Position nozzle in low pressure mode (slide nozzle

forward) and squeeze trigger on spray gun to

relieve pressure caused by turning ON wa1:er.

Water will flow out of gun in a thin stream.

Continue to hold trigger until there is a s1:eady

stream of water and no air remains in system.

Release trigger.

8. Engage safety latch 1:ospray gun trigger.

\

CAUTION

NOTE: Always _:eepthe throttle lever in the =Fast"

position when operating the pressure washer.

8

Page 9

How to Stop Your Pressure Washer

1. Move throttle lover to "Stop" position.

2. Squeeze trigger on spray gun to relieve

pressure in hose,

NOTE: A small amount of water will squirt out when

you release the pressure.

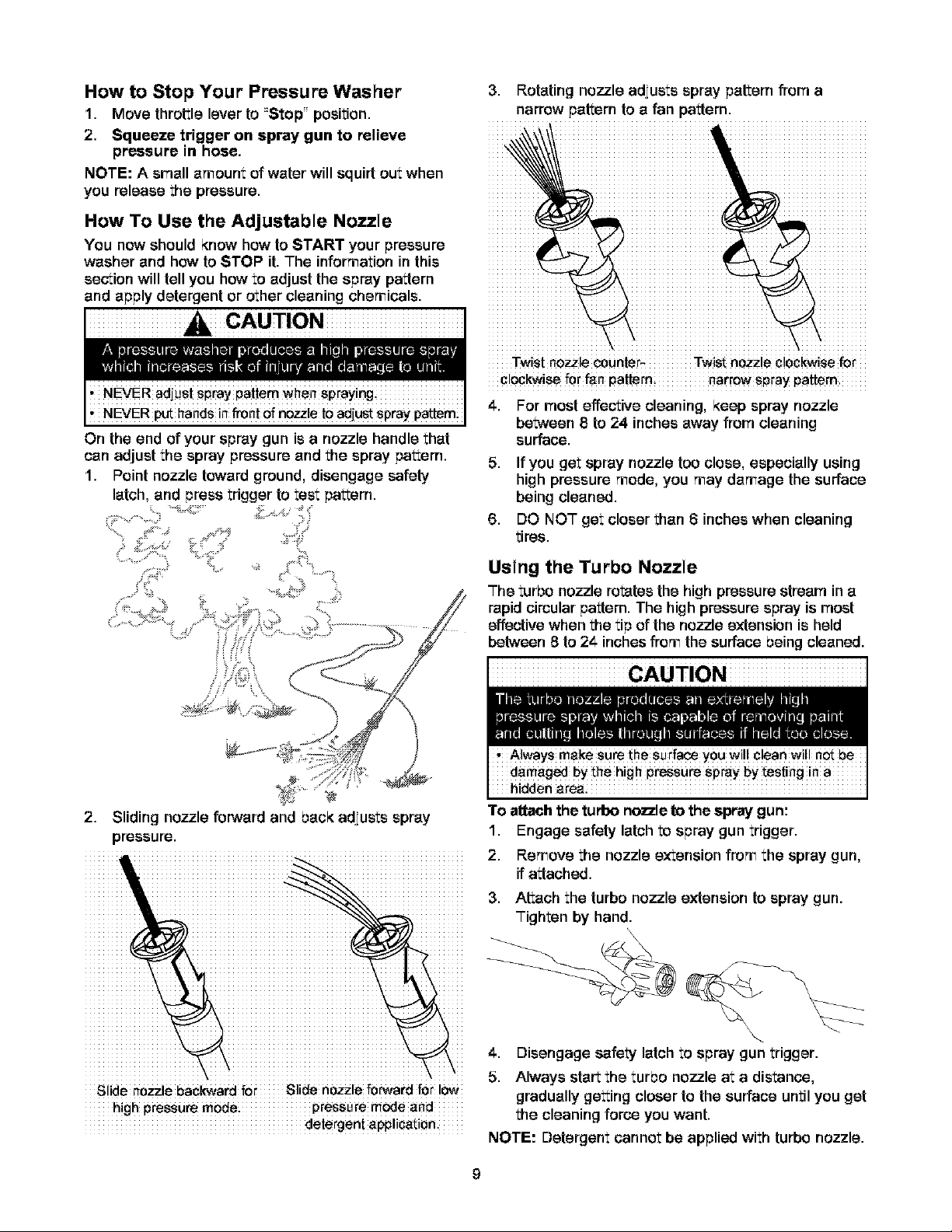

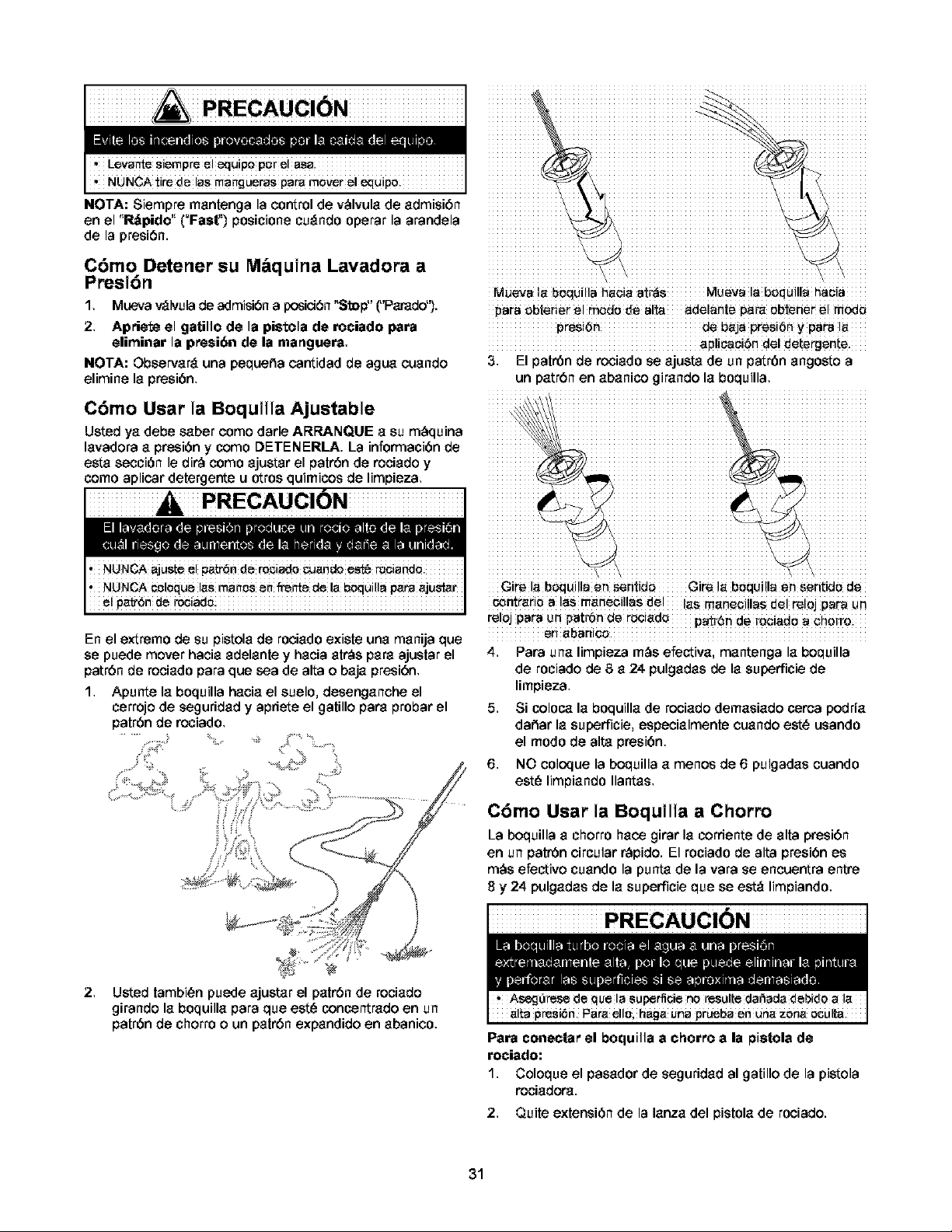

How To Use the Adjustable Nozzle

You now should Know how to START your pressure

washer and how to STOP it. The information in this

section will tell you how to adjust the spray pattern

and apply detergent or other cleaning chemicals.

CAUTION

• NEVER adjustspraypatternwhen spraying.

• NEVERput handsinfront ofnozzle toadjustsprayp_tern

On the end of your spray gun is a nozzle handle that

can adjust the spray pressure and the spray pa_ern.

1. Point nozzle toward ground, disengage safety

latch, and press trigger to l:est pa_ern.

3. Rotating nozzle adjusts spray pattern from a

narrow pattern to a fan pattern.

Twist no>71ecounter- Twist nozzle ¢!o¢_ise for

clockwise for fan Pattern narrow spray pattern,

4. For most effective cleaning, Keep spray nozzle

between 8 to 24 inches away from cleaning

surface.

5. If you get spray nozzle too close, especially using

high pressure mode, you may damage the surface

being cleaned.

6. DO NOT get closer than 6 inches when cleaning

tires.

2. Sliding nozzle forward and bacK adjusts spray

pressure.

Using the Turbo Nozzle

The turbo nozzle rotates the high pressure stream in a

rapid circular pattern. The high pressure spray is most

effective when the tip of the nozzle extension is held

between 8 to 24 inches from the surface being cleaned.

CAUTION

hiddenarea.

To attach the turbo nozzle to the spray gun:

1, Engage safety latch to spray gun trigger,

2. Remove the nozzle extension from the spray gun,

ifattached.

3. Attach the turbo nozzle extension to spray gun.

_. Disengage safety latch to spray gun trigger.

5. Always start the turbo nozzle at a disl:anca,

Siide nozziebackward Slide nozzle f0P,_vatdfor I_ gradually getting closer to the surface until you get

high pressurem0dei p_essuremode and the cleaning force you want.

detergent app!i_tion.

NOTE: Detergent cannot be applied with turbo nozzle.

9

Page 10

Applying Detergent with Adjustable Nozzle

IMPORTANT: Use chemicals designed specifically for

pressure washers. Household detergents could

damage the pump.

CAUTION

To apply detergent, follow these steps:

1. Review use of adjustable nozzle.

2. Prepare detergent solution as required by job.

3. Place filter end of detergent siphoning tube into

detergent container.

Pressure Washer Rinsing

For Rinsing:

1. Slide nozzle backward to high pressure, press

trigger and wait for detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

2. Keep spray gun a safe distance from area you

plan to spray.

WARNING

,Keep Sp!ayn_le b_een 8 t024 inches away from

CAUTION €leaningtrace

Imlm_mM_llgJm _'{'dil"_[ttlim m _r_ Ira

/ lIE IIEaiI/

', When inserting the fi!ter into a detergent solution bottle, ....Unstableiocatien........................................................

route the tube s0 as t0 keep it fr0m inadvertently ............ ......

c0nta_ing _e hot raUffler. Firrn!ygraS#SpraygunWithb°th hands when us!nghigh

4. Slide adjustable nozzle forward to low pressure 3. Apply a high pressure spray to a small area, then

mode. Detergent cannot be applied with nozzle in

high pressure position.

5. MaKe sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Start engine.

6. Apply detergent to a dry surface, starting from

bottom and working up.

7. Allow detergent to =soak in" for 3-5 minutes before

rinsing. Reapply as needed to prevent surface

from drying.

8. For washing, start at lower portion of area to be

washed and work upward, using long, even,

overlapping strokes.

IMPORTANT: You must flush the chemical injection

system after each use by placing the filter into a clean

bucket of water and running the pressure washer in

low pressure for 1-2 minutes.

, Operate this unit on a stablesurface:

, Be extremely carefulisyoumust use thepressure

washer from a !adderiscaffo!djng or any other relatively

pressure spray to ayoid injury ifgun kicks back.

check surface for damage. If no damage is found,

it is okay to continue cleaning.

Start at top of area to be rinsed, working down

with same overlapping strokes as you used for

washing and applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures above 125=F. The system engages to

cool the pump by discharging the warm water onto

the ground.

10

Page 11

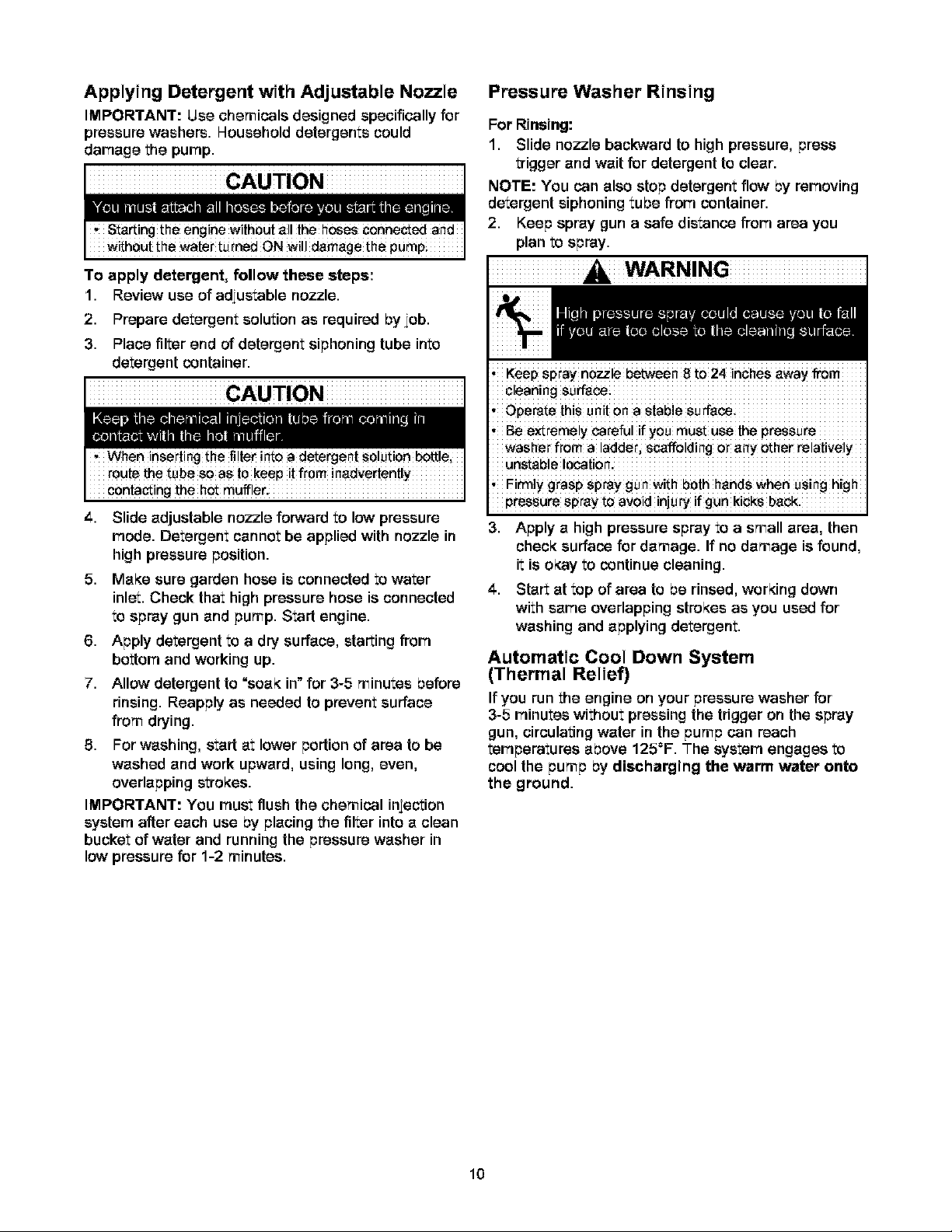

OWNER'S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCE SCHEDULE I

FILLIN DATESASYOUCOMPLETE HOURI-YOPERATING i sERvicE DATES

REGULAR SERVICE INTERVAL

Before EV_ 25 EVe_50 Every 100

PRESSURE WASHER

Pur_epumpofairandContaminants

Change purepQii mmmm_mmmmmm x _ i ]

ENGINE I X I I

ChgPk 0il !e_e!

Charge engine _il

Servi_ sparkplug

If unit !St0 remain id!e for

I ongerthan30days. (

Cleonifclogged. Replace if perforatedortorn.

= Changeoilafterthefirst(5) operating hoursandevery50 hoursor yearly thereafter.

Change sooner when operating under dirtyor dusty conditions.

Replacemoreoftenunderdirty or dusty conditions.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure....................... 2,000 PSI

FlowRate ...................... 2.0 GPM

Chemical Mix.................... Use as directed

Water SupplyTemperature ......... Not to exceed 100°F

Shipping Weight ................. 48 Ibs,

Engine Specifications

RatedHorsepower................. 3.75 HP

Spark PlugType:

Resistor .................... ChampionRJ-19LM

SetGap To: ................... 0,030inches(0.76turn)

FuelCapacity.................... 1.0Quarts

Oil

Above40+:F .................. SAE30

0+F- 40+F .................... SAE5W-30or 10W-30

GENERAL RECOMMENDATIONS

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual including proper storage as

detailed in =Storage" on page 15.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

=Maintenance Schedule" chart above.

NOTE: Once a year you should clean or replace the

spark: plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

If equipped with inflatable tires, _eep the air pressure

at the value marked on the tire or within 15 and 40 psi.

BEFORE EACH USE

1. Check engine oil level.

2. Check water inlet screen for damage.

3. Cheek in-line filter for debris.

4. Cheek high pressure hose for leaks.

5. Cheek chemical filters for damage.

8. Cheek gun and nozzle extension assembly for

leaks.

7. Purge pump of air and contaminants.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

I I

Usel ¥_y I YearlyI Yearly

11

Page 12

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. Ifany of these

conditionsexist, replace hose immediately.

WARNING

pressure rating 0f Unit,

Check Gun and Nozzle Extension

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back inl:o place when you release it. Engage

safety lal:ch and test trigger. You should not be able to

press trigger. Replace gun immediately if it fails any of

these tests.

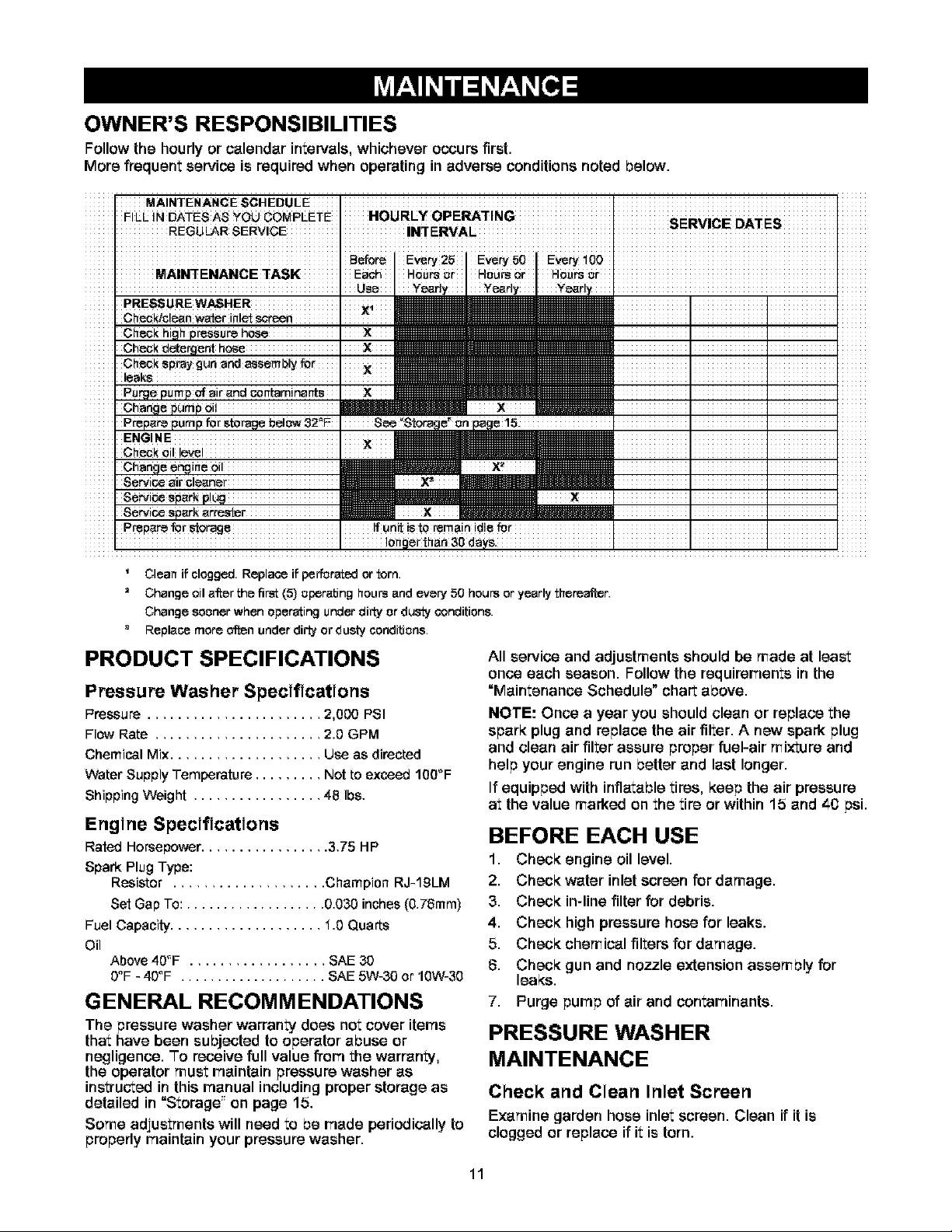

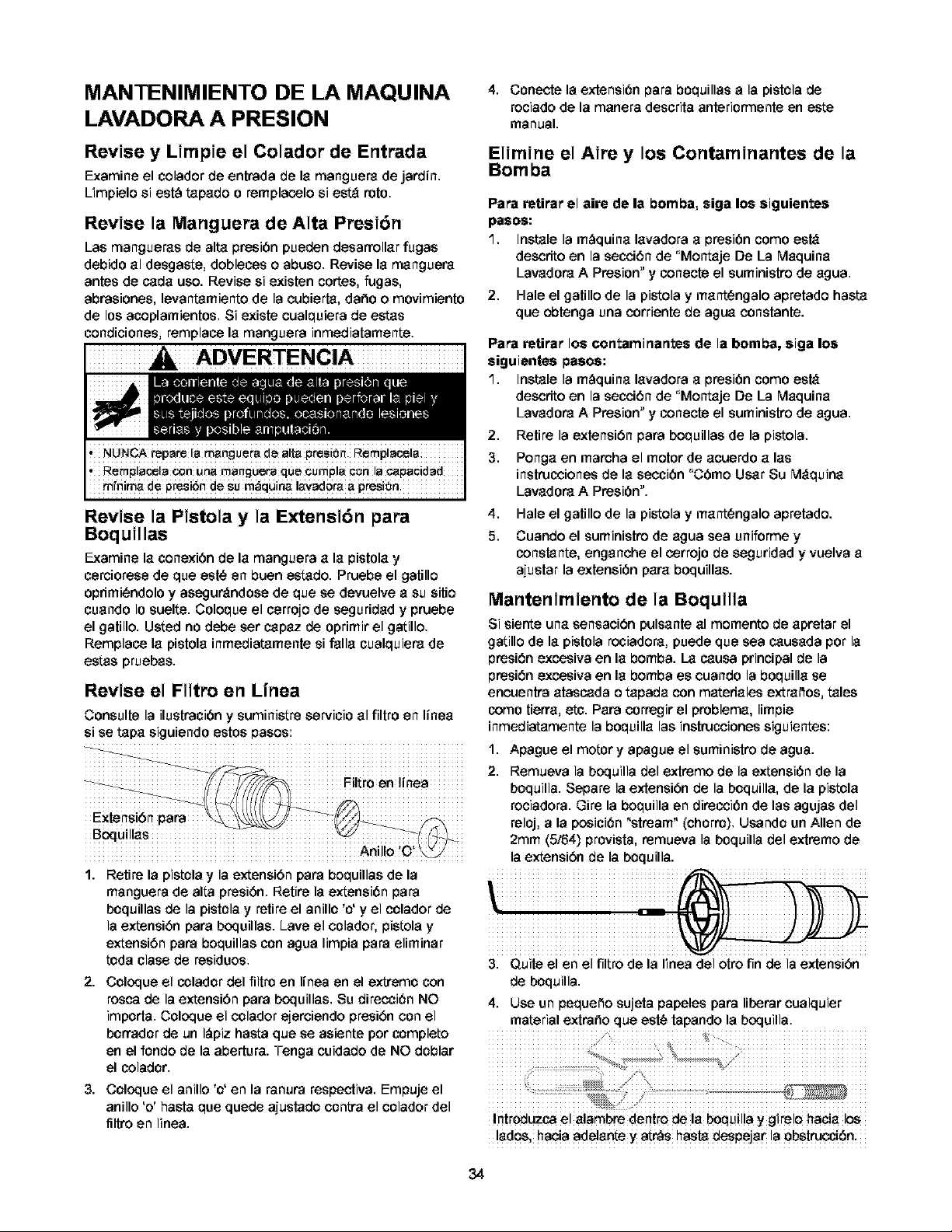

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

To remove contaminants from the pump, follow these

steps:

1. Set up pressure washer as described in

::Assembling Your Pressure Washer" section, and

connect water supply.

2. Remove nozzle extension from gun.

3. Start engine according 1:oinstructions in =How To

Use Your Pressure Washer" section.

4. Pull trigger on gun and hold.

5. When water supply is s1:eadyand cons1:ant, engage

safety la1:chand refes1:ennozzle extension.

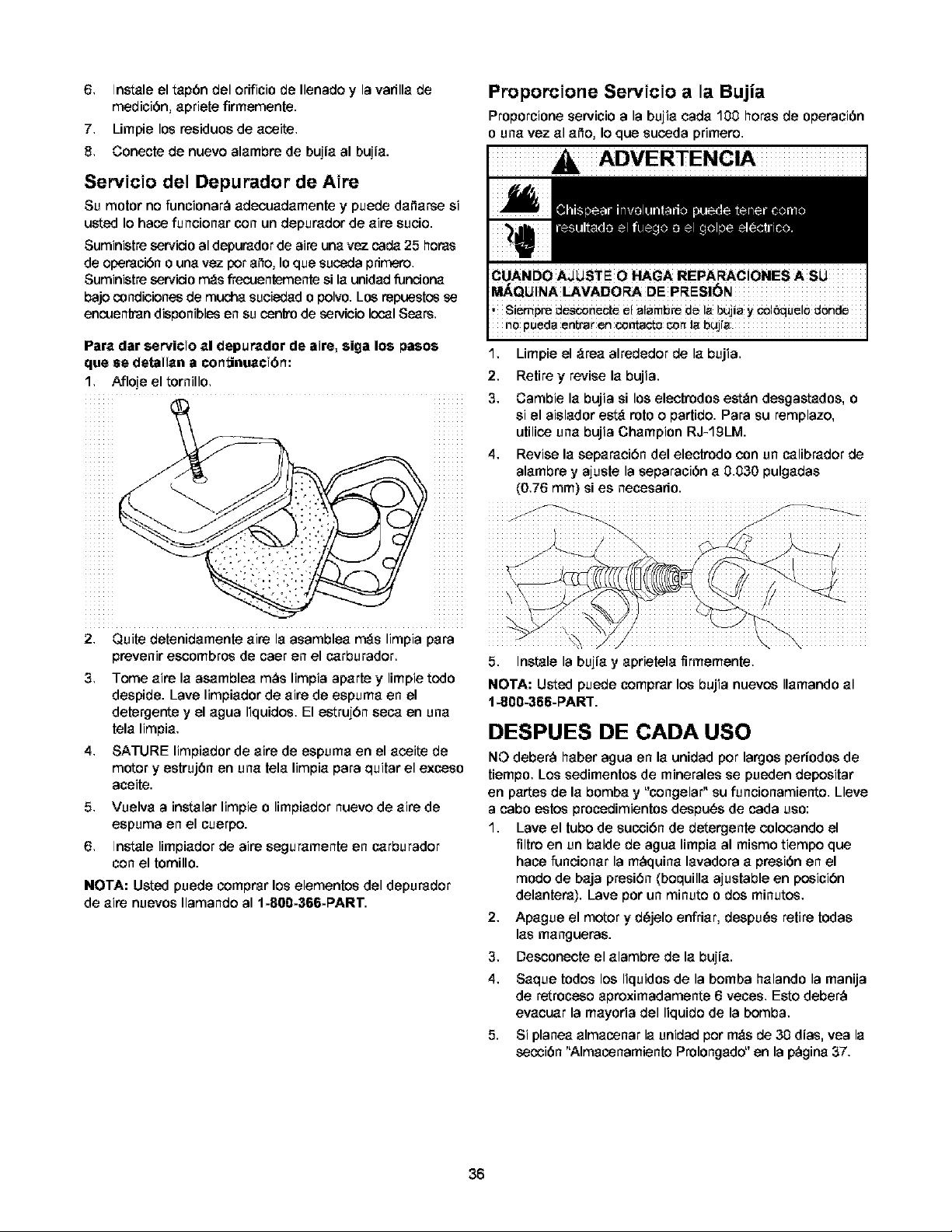

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, e1:c.To correct the problem, immedia1:ely

clean the nozzle following these ins1:ructions:

1. Shut off engine and turn off water supply.

2. Remove nozzle from end of nozzle extension.

Separa1:e nozzle extension from spray gun. Twist

nozzle clockwise to stream position. Using a 2ram

(5/64) allen wrench, remove orifice from end of

nozzle extension.

N0zzle extension = 3. Remove in-line filter from other end of nozzle

1. De1:achnozzle extension from gun and remove 4. Use a small paper clip to free any foreign material

o-ring and screen from nozzle extension. Flush clogging or restricting orifice.

screen, gun, and nozzle extension with clean water

to clear debris.

2. Place in-line fil1:erscreen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests fiat

at bottom of opening. Take care not to bend

screen.

3. Place o-ring into recess. Push o-ring snugly against and forth t0 Clear 0bstructi0ni

in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps:

1. Set up pressure washer as described in

::Assembling Your Pressure Washer" section and

connect water supply.

2. Pull trigger on gun and hold until a steady stream

ofwater appears.

O-ring

extension.

Insertwireint00rificoandtumback

5. Using a garden hose, remove additional debris by

back flushing wa1:erthrough nozzle extension. Back

flush belween 30 to 60 seconds. Turn adjustable

nozzle extension to stream spray and move nozzle

from low to high while flushing.

12

Page 13

6. Reinstall orifice and in-line filter inl:o nozzle

extension. DO NOT overtighl:enorifice with allen

wrench.

7. Reconnect nozzle extension 1:ospray gun.

8. Reconnect wa1:ersupply, turn on wa1:er,and s1:art

engine.

9. Test pressure washer by operating nozzle in high

and low positions.

O-Ring Maintenance

Purchase an O-Ring Repair Kit, i1:emnumber 7175116,

a1:your local Sears or by calling 1-800-366-PART or

onlineat www.ssers.com. It is not included with the

pressure washer. This kit includes replacement o-rings,

rubber washer and water inlet filter. Refer to the

ins1:ructionshee1:provided in the kit to service your units

o-rings.

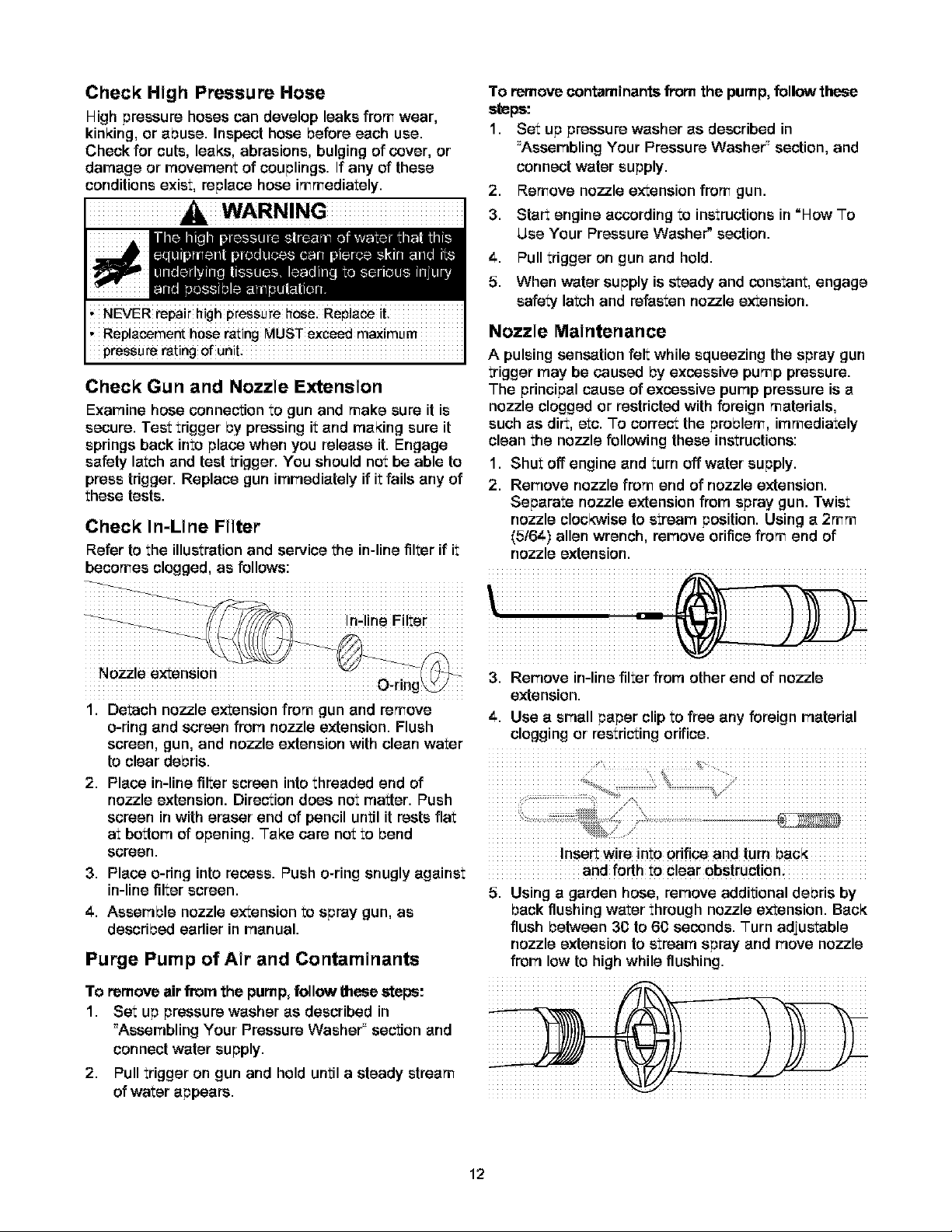

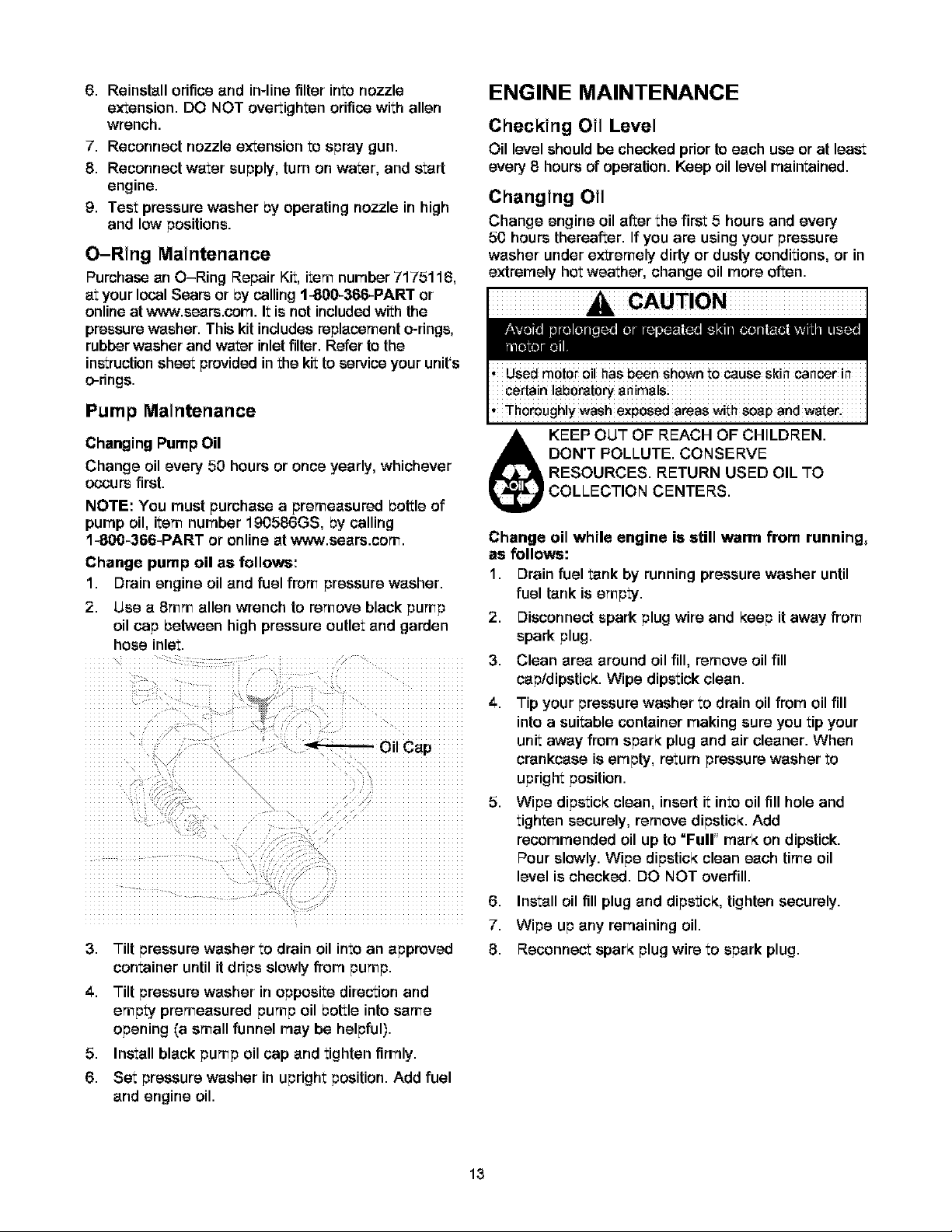

Pump Maintenance

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE: You must purchase a premeasurad bottle of

pump oil, i1:emnumber 19C586GS, by calling

1-800-366-PART or online at www.sears.cem.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use a 8ram allen wrench to remove black pump

oil cap between high pressure outle1:and garden

hose inle1:.

\

Oil Cap

3. Tilt pressure washer to drain oil in1:oan approved

con1:ainer until it drips slowly from pump.

4. Tilt pressure washer in opposite direction and

empty premeasured pump oil bottle into same

opening (a small funnel may be helpful).

5. Ins1:allblack pump oil cap and tighten firmly.

6. Set pressure washer in upright position. Add fuel

and engine oil.

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked priorto each use orat leas1:

every 8 hours of operation. Keep oil level main1:ained.

Changing Oil

Change engine oil after the firs1:5 hours and every

50 hours thereafter. If you are using your pressure

washer under extremely dirty or dusty conditions, or in

extremely hot weather, change oil more often.

CAUTION

KEEP OUT OF REACH OF CHILDREN.

DON'T POLLUTE. CONSERVE

_ RESOURCES. RETURN USED OIL TO)COLLECTION CENTERS.

Change oil while engine is still warm from running,

as follows:

1. Drain fuel tank by running pressure washer until

fuel tank is empty.

2. Disconnect spark plug wire and Keep itaway from

spark plug.

3. Clean area around oil fill, remove oil fill

cap/dipsticK. Wipe dipstick clean.

4. Tip your pressure washer to drain oil from oil fill

into a sui1:ablecontainer making sure you tip your

unit away from sparK plug and air cleaner. When

crankcase isempty, re1:urnpressure washer to

upright position.

5. Wipe dipstick clean, insert it in1:ooil fill hole and

tigh1:en securely, remove dipsticK. Add

recommended oil up to "Full" mark on dipstick.

Pour slowly. Wipe dipstick clean each time oil

level is checked. DO NOT overfill.

6. Install oil fill plug and dipsticK, tighten securely.

7. Wipe up any remaining oil.

8. Reconnect spark plug wire to spark plug.

13

Page 14

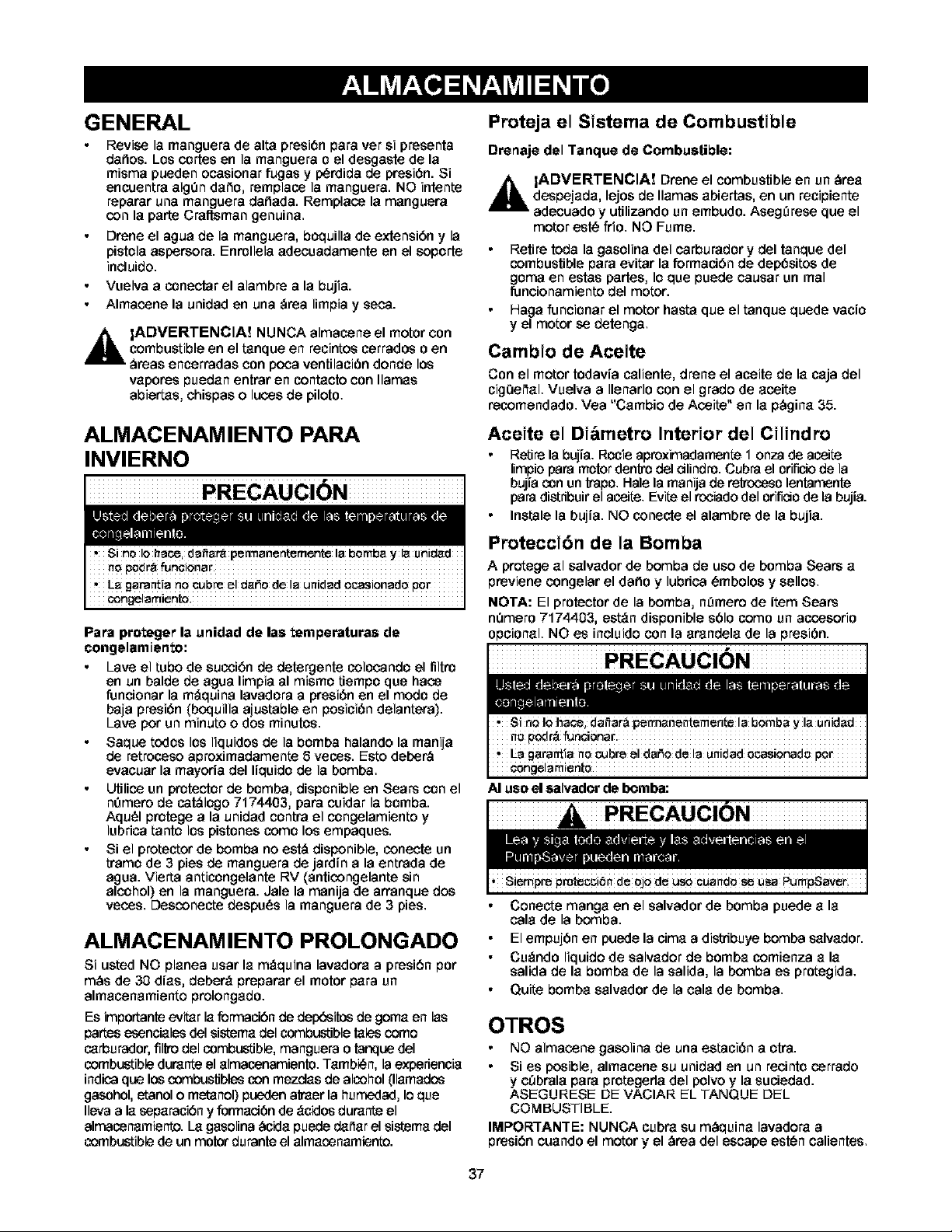

Service Air Cleaner

Your engine will not run properly and may be

damaged ifyou run it with a dirty air cleaner.

Service the air cleaner once every 25 hours of

operation or once each year, whichever comes first.

Service more often if operating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

To service the air cleaner, follow these steps:

1. Remove screw.

2. Carefully remove air cleaner assembly to prevent

debris from falling intocarburetor. AFTER EACH USE

3. "]'a_e air cleaner assembly apart and clean all

parts. Wash foam air cleaner in liquid de;ergent

and water. Squeeze dry in a clean cloth.

4. SATURATE foam air cleaner in engine oil and

squeeze in a clean cloth to remove excess oil.

5. Reins;all clean or new foam air cleaner in body.

6. Install air cleaner securely on carburetor with

screw.

NOTE: You can purchase now air cleaner elements by

calling 1-800_366-PART.

Service Spark Plug

Service the spark plug every 100 hours of operation or

yearly, whichever occurs first.

WARNING

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug with recommended plug if

electrodes are worn or if insulator is cracked or

chipped.

4. Check electrode gap with wire feeler gauge and

set gap at 0.030 inches (0.76ram), if necessary.

5. Install spark plug, tighten securely.

NOTE: You can purchase a new spark plug by calling

1-800-366-PART.

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump

parts and _freeze" pump action. Follow these

procedures after every use:

1. Flush detergent siphoning tube by placing filter

into a pail of clean wa;er while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minu;es.

2. Shut off engine and let it cool, then remove all

hoses.

3. Disconnect spark plug wire from spark plug.

Empty pump of all liquids by pulling recoil handle

about 6 times. This should remove most of the

liquid in pump.

If storing for more than 30 days see "Long Term

Storage" on page 15.

14

Page 15

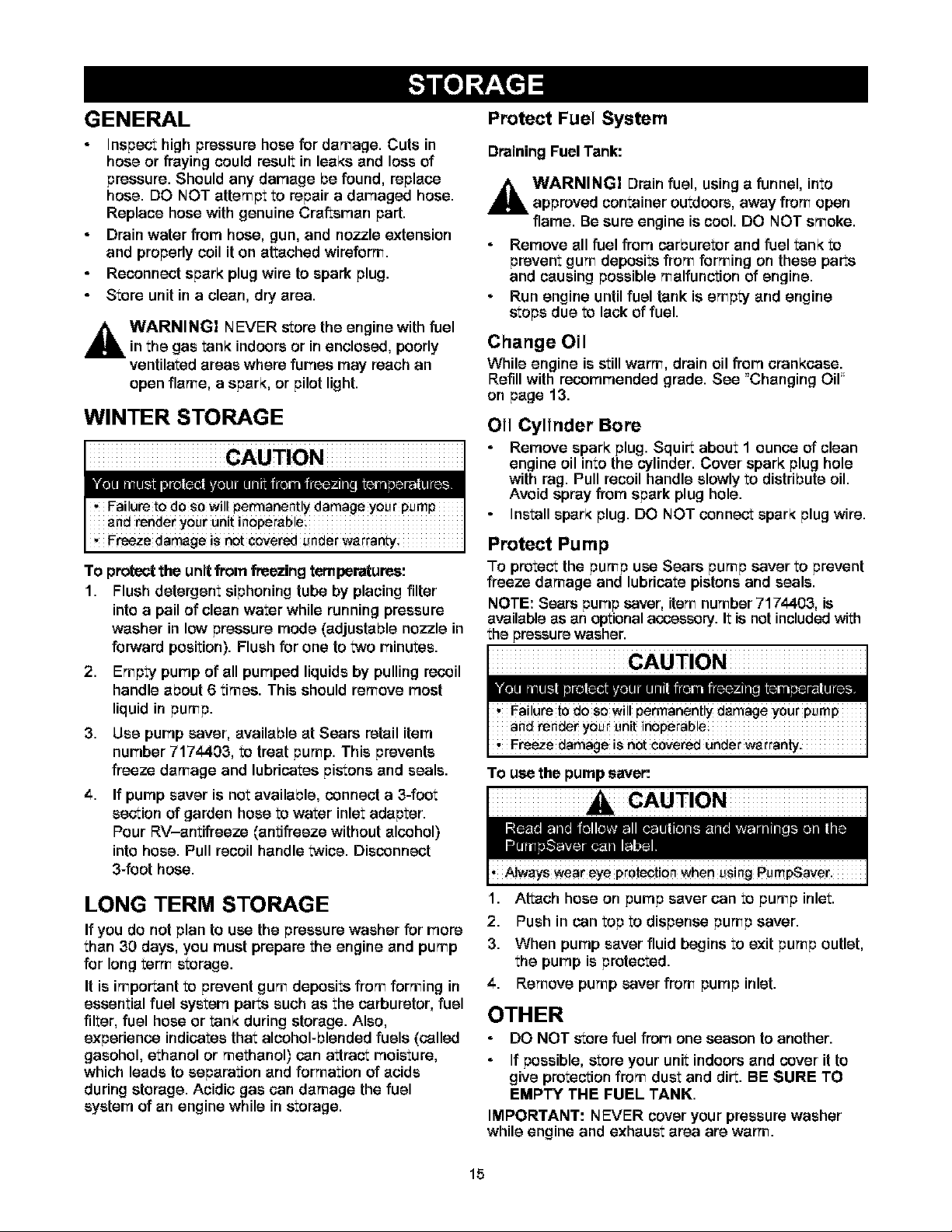

GENERAL

Inspect high pressure hose for damage. Cuts in

hose or fraying could result in leaks and loss of

pressure. Should any damage be found, replace

hose. DO NOT attempt to repair a damaged hose.

Replace hose with genuine Craftsman part.

Drain water from hose, gun, and nozzle extension

and properly coil it on attached wiraform.

Reconnect spark plug wire to spark plug.

Sl:oraunit in a clean, dry area.

Protect Fuel System

Draining Fuel Tank:

,_ WARNINGI Drain fuel, using a funnel, into

approved con1:ainer outdoors, away from open

flame. Be sure engine is cool. DO NOT smoke.

Remove all fuel from cerbure1:or and fuel 1:anK1:o

prevent gum deposits from forming on these parts

and causing possible malfunction of engine.

Run engine until fuel tank is empty and engine

s1:opsdue 1:olack of fuel.

,_ WARNINGI NEVER store the engine with fuel

in the gas l:anKindoors or in enclosed, poorly

ventilated areas where fumes may reach an

open flame, a sparK, or pilot light.

WINTER STORAGE

CAUTION

, Freeze damage is not covered under warranty

To protect the unit from freezing temperatures:

1. Flush detergent siphoning tube by placing filter

into a pail of clean wal:er while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minul:es.

2. Empty pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most

liquid in pump.

3. Use pump saver, available at Sears retail item

number 7174403, 1:otreat pump. This prevents

freeze damage and lubricates pis1:onsand seals.

4. If pump saver is not available, connect a 3-foot

section of garden hose 1:owa1:erinlet adapter.

Pour RV-antifreeze (antifreeze without alcohol)

into hose. Pull recoil handle twice. Disconnect

3-foot hose.

Change Oil

While engine iss1:illwarm, drain oil from crankcase.

Refill with recommended grade. See "Changing Oil"

on page 13.

Oil Cylinder Bore

Remove spark plug. Squirt about 1 ounce of clean

engine oil into the cylinder. Cover spark plug hole

with rag. Pull recoil handle slowly to distribute oil.

Avoid spray from spark plug hole.

Ins1:allspark plug. DO NOT connect spark plug wire.

Protect Pump

To protect the pump use Sears pump saver to prevent

freeze damage and lubricate pistons and seals.

NOTE: Sears pump saver, item number 717,_03, is

available as an optionalaccessory. It is not included with

the pressure washer.

CAUTION

,Failure to de so wi!l permanentlydamageyour pump

and render you_unit ineperablei

_ Freezedamage !Sn_ c0veredunderwarran_ •

To use the pump saver:

CAUTION

LONG TERM STORAGE

If you do not plan to use the pressure washer for more

than 30 days, you must prepare the engine and pump

for long 1:erms1:orage.

It is imporl:ant 1:oprevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or 1:anKduring storage. Also,

experience indice1:es that alcohol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture,

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in s1:orage.

1. Attach hose on pump saver can 1:opump inlet.

2. Push in can top to dispense pump saver.

3. When pump saver fluid begins to exit pump outlet,

the pump is protected.

4. Remove pump saver from pump inlet.

OTHER

DO NOT store fuel from one season to another.

If possible, s1:oreyour unit indoors and cover it to

give pro1:ectionfrom dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

IMPORTANT: NEVER cover your pressure washer

while engine and exhaust area are warm.

15

Page 16

CaLISQ Co--Jot1

!i NOzzle in !ow pressure mode. !. Pu!! nezz!e backward for high

2. Water inlet is block:ed: ................ 2. cleariniet.

3i Inadequate wal:er sUpp!y. 3. Provide adequate water flowi

_-. Inlet h0se is _:inked or leaking. 4. Straighten inlet hose; patch

Pump has following problems:

leak,

failure to produce pressumi 5i C Ogged n et hOSestra neri CheCk:and€ ean ne_hOSe

erratic pressUrei chatteringi ioss strainer.

of pressure;!ow water v0!ume; 6. water Supply is over i00_F. 16. ProVidecooler water Supply

High pressure hose is blocked Clear blOck:sin Outlethosei

orleahcsi i

8. Gunieaks.

9i Nozzle is obs_uctedi g. Clean nozzlei

!0; PUmp is fau!ty. ! O. ContaPt Sears se_ico facility

li Detergent Siphoning tube is not 1. Insert detergent siphoning l:ube

.submerged into del:ergent.

2. Chemical filter is clogged. 2. Clean or replace filter/detergent

Detergent fai!s t0 mix with Sprayi Siphoning tU_e•

3i Di_ in-line f!!ter. 3. see i'check in--L!ne Fi!ter"

_. Nozzle is in high pressure 4. Push nozz!e forward for !ow

,,_,_e _r_, gooo a_ =o_oao If engine Still t'b0gs down'i,

Engine speed is t0o s!ow Move thrott!e _ntr01 to FAST

•...,_--.._,.._=_ '_ J jcontactsears se_ico facility

li Dirty air cleaneri

2i outeffueli 2. Fillfuell:an_i

3. Sta!e fuel ................................... 3. Drain gas l:ank:;fi!! with fresh .......

fuel.

spark plug wire not connected 4. Connect wire _ spark plug.

_0 sparkplug. I

and runs rough, ,

5 Bad spark piUg '5. Repiacasparkpiug

6i water infueli 6. Drain gas l:ank:;fill Withfresh

fuel

7i Excassively rich fuel mixture. 7. Contact Sears service facilityi

8i Infa_e valve stuck open or .8. Contact Sears service facilityi

closed. I

gi Engine has los1:compressioni g. Contact Sears service facility:

Engine shuts down during Out 0f fuel. Fill fuei _ank.

operationi J

Engine lacks power. Di_ air fi!teri Rep!a_ air fi!teri

16

Page 17

17

Page 18

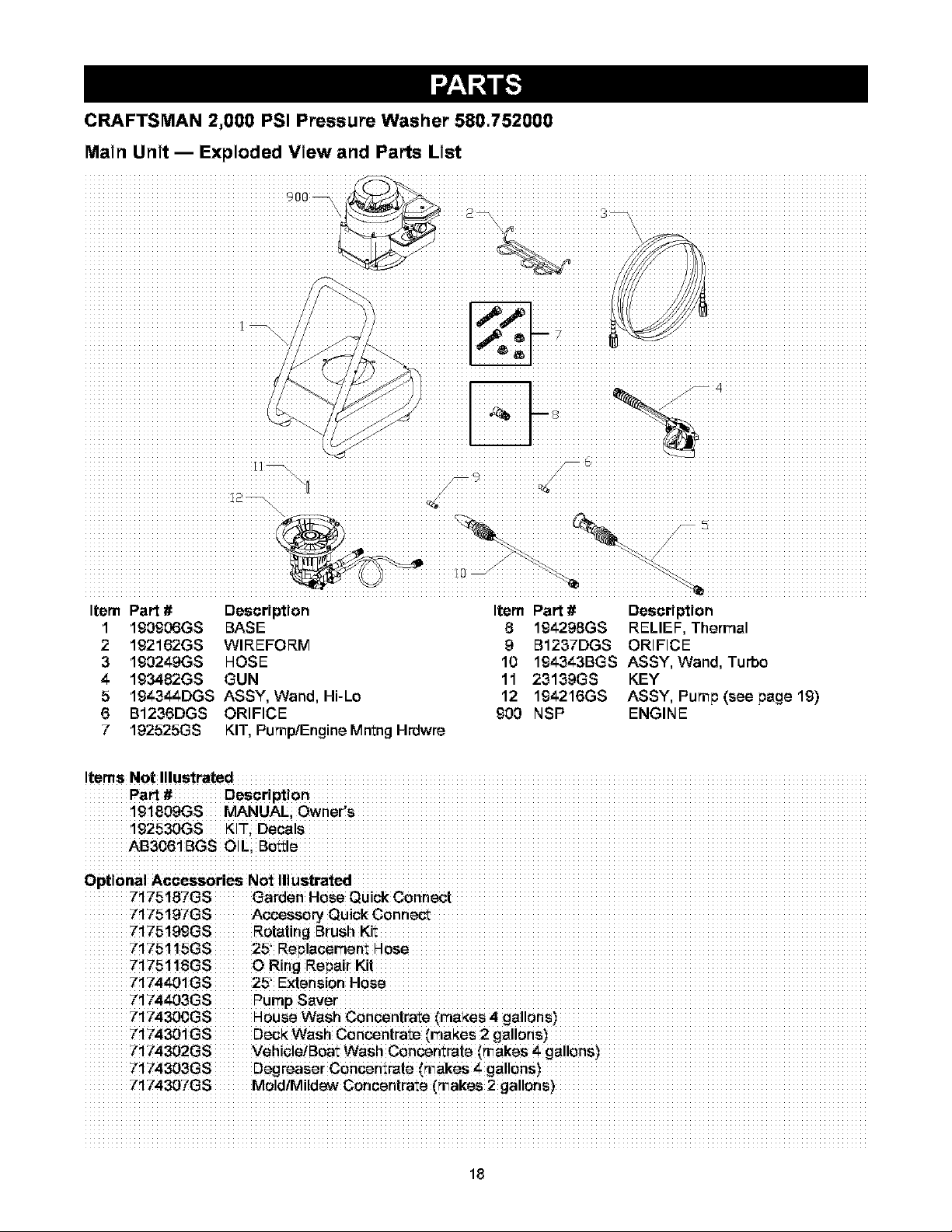

CRAFTSMAN 2,000 PSI Pressure Washer 580.752000

Main Unit -- Exploded View and Parts List

Item Part # Description

1 190906GS BASE

2 192162GS WIREFORM

3 190249GS HOSE

4 193482GS GUN

5 194344DGS ASSY, Wand, Hi-Lo

6 B1236DGS ORIFICE

7 192525GS KIT, Pump/Engine Mntng Hrdwre

Items Not Illustrated ..............................................................................................................................................

Part# Description

191809GS MANUALi Owner!s

192530GS KIT;Decals

AB3061BGS OILi Bottle

Optiona! Access0ries NOt II!ustrated

7"175187GS Garden Hose QUick Connect

!"175!9_G$ Acc_sS0_ QUiCk conne_

Rotating Brush Kit

7175115G$

7175116GS O Ring Repair Kit

7174_01GS 25' ExtenSion HOSe

7"174403G$ PUmPsaver

7t74300GS House Wash Concentral:e (maKes 4 gallons)

7t74301GS Deck Wash Concentral:e (maKes 2 gallons)

7174302GS Vehicle/Boat Wash Concentrate (makes 4 gail0ns)

7174303GS Degreaser concentrate (makes _ gallons)

7174307GS Mold/Mildew concentrate (makes 2 gallons)

Item Part # Description

8 194298GS RELIEF, Thermal

9 B1237DGS ORIFICE

10 194343BGS ASSY, Wand, Turbo

11 23139GS KEY

12 194216GS ASSY, Pump (see page 19)

900 NSP ENGINE

18

Page 19

CRAFTSMAN 2,000 PSI Pressure Washer 580.752000

Pump -- Exploded View and Parts List

_E,L >_, .....................................

Item Part # Description Item Part #

19 190571GS CAP, Oil A NSP

28 190827GS MANIFOLD B 190832GS

29 190575GS O-RING C 19063_-GS

30 190576GS SCREW E 190591GS

34 190577GS CONNECTION, Chemical Inlet F 190592GS

45 190578GS PIN G 190593GS

46 190629GS VALVE, Seat Plate, Plastic H 190628GS

47 190630GS VALVE, Seat, Plastic J 189971GS

62 190581GS CAP K 190636GS

68 190582GS BALL, SS

69 19058,_-GS O-RING

76 194298GS THERMO RELIEF

NOTE: Item letters B - K are service _:itsand include

all parts shown within the box..

19

Description

ASSY, CASE, PISTON

KIT, WATER INLET, ALUM

KIT, OUTLET, ALUM

KIT,CHECK VALVES

KIT, INLET CHECK

KIT, CHEMICAL INJECTION

KIT, UNLOADER STEM

KIT, CHEMICAL HOSE

KIT, SEAL SET

Page 20

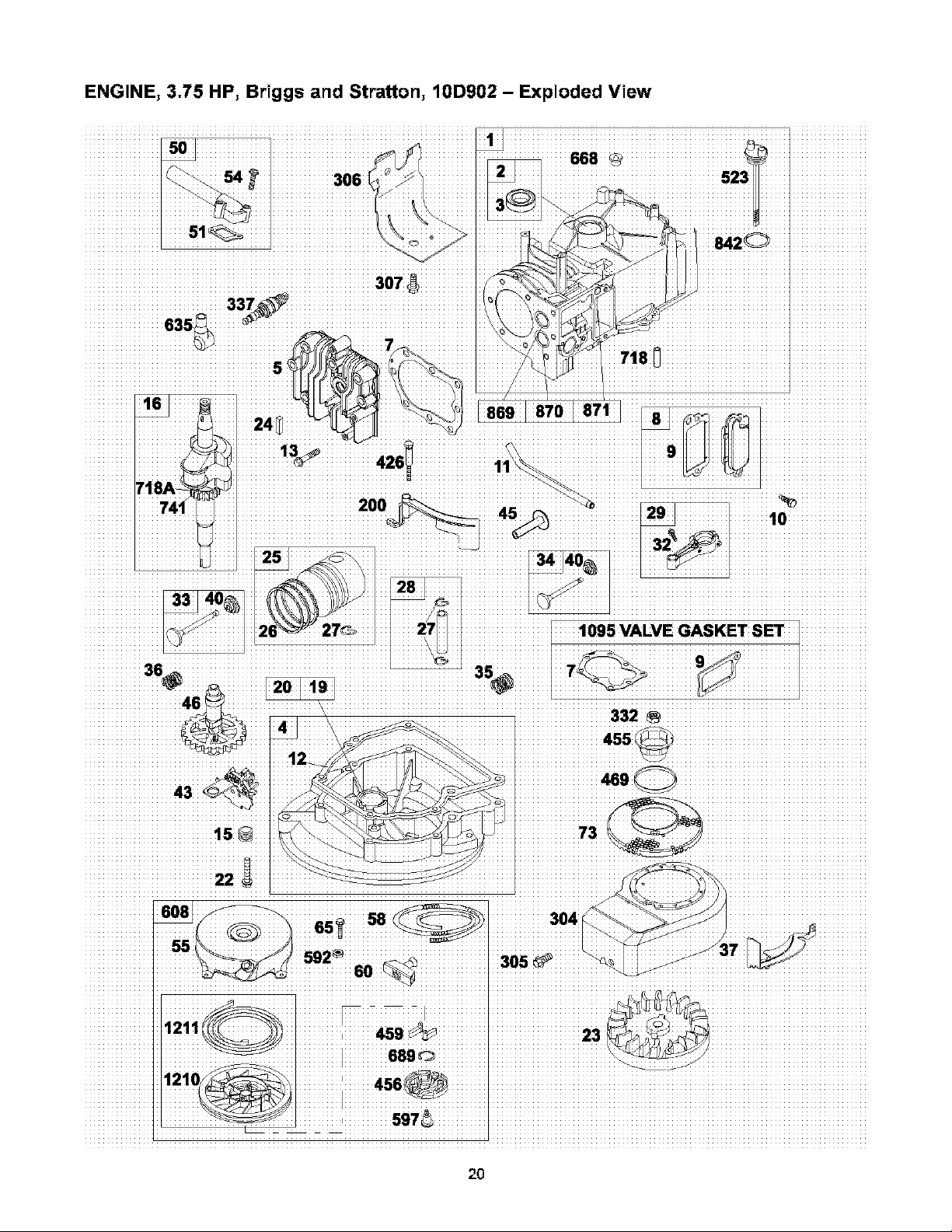

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Exploded View

iiiiiii51i_iiiii

306

523

iiii842_iiii

718_

200

1095 VALVE GASKET SET

22,

iiiiiiiiiiiiiiii iiiiiiiiii_iiiii_iiiii,iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii¸¸......_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

_ ,59__

11210__1 i 456_

2O

Page 21

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Exploded View

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii3"i iiiiiiiiiiiiiiisz9 iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

163

121_

393

356

106

!24_

356A

9

.............i3_iiiiiii

21

Page 22

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Parts List

Item Part# DeecripUon Item Part#

1 399164 CylinderAssembly 200 691912

2 399269 Kit-Bushing/Seal (Magneto Side) 201 690347

3 299819 Seal-Oil (Magneto Side) 209 691862

4 698691 Sump-Engine 211 691859

5 690386 Head-Cylinder 222 691445

7 692288 Gasket-Cylinder Head 300 394569

8 495785 BreatherAssembly 304 692536

9 695890 Gasket-Breather 305 692198

10 691666 Screw(BreatherAssembly) 306 690400

11 691245 Tube-Breather 307 690345

12 692218 Gasket-Crankcase (,015", Standard) 332 690662

270895 Gasket-Crankcase (.005") 333 496914

270896 Gasket-Crankcase (.009") 334 691061

13 691697 Screw (Cylinder Head) 337 802592

15 691680 Plug-Oil Drain 356 692390

16 692989 Crankshaft 356A 398808

19 293709 Kit-Bushing/Side (PTO Side) 358 298989

20 391483 Seal-Oil (PTO Side) 365 692200

22 691662 Screw (Engine Sump) 390 691839

23 690843 Flywheel 393 691837

24 222698 Key-Flywheel 394 495770

25 498668 Piston Assembly (Standard) 426 691107

498669 Piston Assembly (,010" Oversize) 455 691236

498670 Piston Assembly (,020" Oversize) 456 692299

498671 Piston Assembly (,030" Oversize) 469 694420

26 498680 Ring Set (Standard) 523 691913

498681 Ring Set (,010" Oversize) 529 692189

498682 Ring Set (,020" Oversize) 534 691417

498683 Ring Set (,030" Oversize) 535 698369

27 691588 Lack-Piston Pin 536 698472

28 298909 Pin-Piston (Standard) 592 690800

298908 Pin-Piston (,005" Undersize) 597 691696

29 496792 Rod-Connecting 608 499706

32 691664 Screw (Connecting Rod) 612 496046

33 296676 Valve-Exhaust 617 270344

34 296677 Valve-Intake 621 692310

35 690520 Spring-Valve (Intake) 633 691321

36 690520 Spring-Valve (Exhaust) 635 66538

37 691209 Guard-Flywheel 668 692889

40 692194 Retainer-Valve 670 691633

43 698690 Slinger-Governor/Oil 689 691855

45 691762 Tappet-Valve 718 690959

46 691998 Camshaft 718A 499047

50 693446 Manifold-Intake 741 691805

51 270345 Gasket-Intake 832 691443

54 691111 Screw (Intake Manifold) 836 691443

55 692144 Housing-Rewind Starter 842 691876

58 692259 Rope-Starter 851 493880

60 691915 Grip-Starter Rope 869 691701

65 690837 Screw (Rewind Starter) 870 691702

73 691235 Screen-Rotating 871 231348

90 498811 Carburetor 63709

97 691931 Shaft-Throttle 913 494409

106 691901 Seat-Inlet 957 497929

130 691190 Valve-Throttle 976 694394

163 271139 Gasket-AirCleaner 1095 498526

180 494406 Tank-Fuel 1210 499901

190 691697 Screw (Fuel Tank) 1211 499901

190A 692198 Screw(FuelTank) 1218 695866

Description

Blade-Governor

Link-Air Vane

Spring-Governor

Spring-Governed Idle

Bracket-Control

Muffler

Housing-Blower

Screw (Blower Housing)

Shield-Cylinder

Screw (Cylinder Shield)

Nut (Flywheel)

Armatu re-Mag neto

Screw (Magneto Armature)

Plug-Spark

Wire-Stop

Wire-Stop

Gasket Set-Engine

Screw (Carburetor)

Spring-Choke Diaphragm

Screen-Carburetor

Gasket-Carburetor Pump

Screw (Governor Blade)

Cup-Flywheel

Plate-Pawl Friction

Ring-Rotating Trim

Dipstick

Grommet

Screw (Air Cleaner)

Filter-Air Cleaner Foam

Cleaner-Air

Nut (Rewind Starter)

Screw (Pawl Friction Plate)

Starter-Rewind

Tube-Pick Up

SeaI-O Ring (Intake Manifold)

Switch-Stop

SeaI-ChoketThrotUe Shaft

Boot-Spark Plug

Spacer

Spacer-Fuel Tank

Spring-Friction

Pin-Locating

Pin-Locating

Gear-Timing

Guard-Muffler

Screw (Muffler Guard)

SeaI-O Ring (Dipstick)

Terminal-Spark Plug

Seat-Valve (Intake)

Seat-Valve (Exhaust)

Bushing-Guide (Exhaust)

Bushing-Guide (Intake)

Seat-Check Valve

Cap-Fuel Tank

Primer-Carburetor

Gasket Set-Valve

Pulley/Spring Assembly (Pulley)

Pulley/Spring Assembly (Spring)

SeaI-O Ring (Carburetor)

22

Page 23

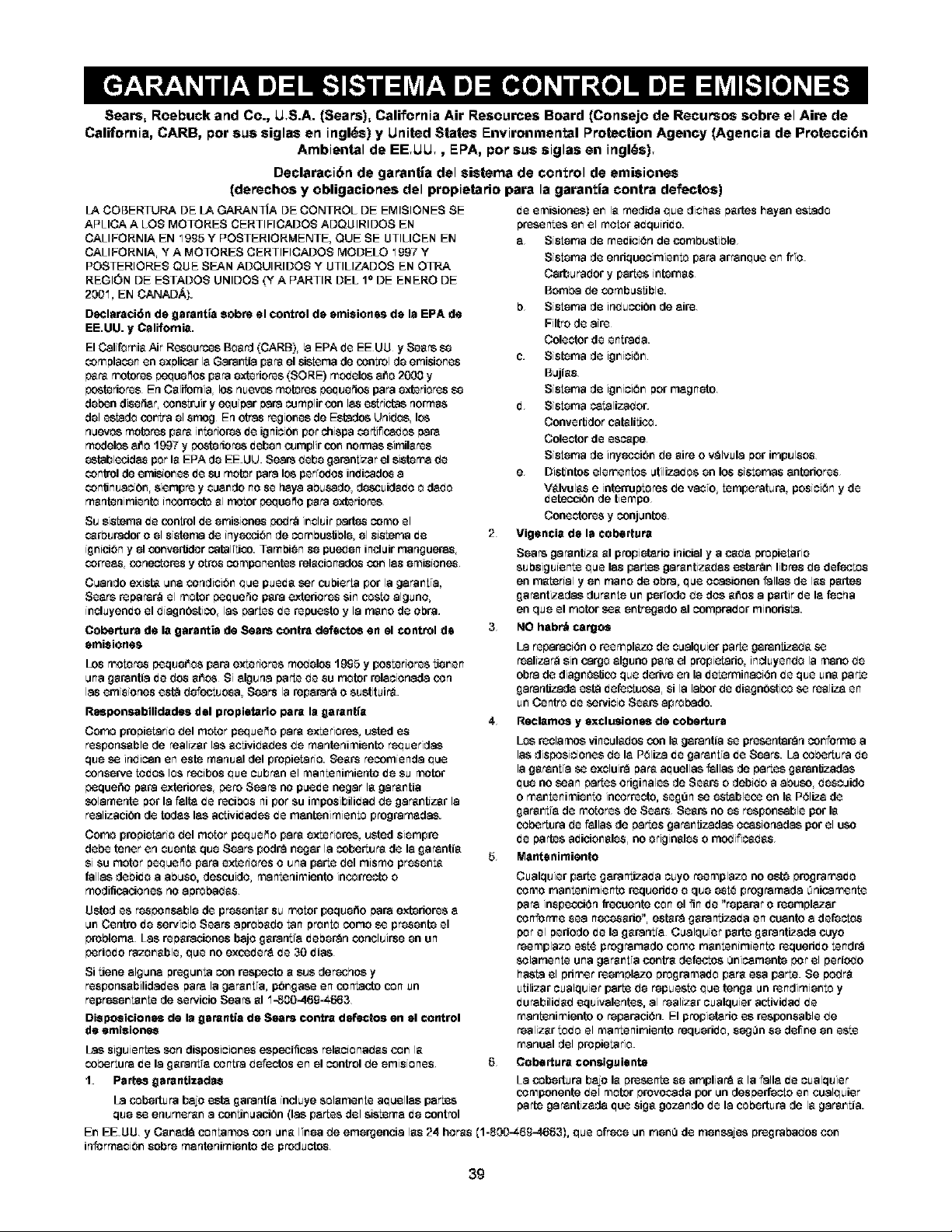

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB) and

the United States Environmental Protection Agency (U.S.EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS a, Fuel Metedng System

APPLICABLE TO CERTIFIED ENGINES PURCHASED IN

CALIFORNIA IN 1995 AND THEREAFTER WHICH ARE

USED IN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997"AND LATER ENGINES WHICH ARE

PURCHASED AND USED ELSEWHERE IN THE UNITED

STATES (AND AFTER JANUARY 1, 2001 IN CANADA).

California and U.S. EPA Emission Control Warranty

Statement Your Warranty Rights and Obligations

The California Air Resources Board (CARB), U.S.EPA and

Sears are pleased to explain the Emission Control System

Warranty on your r'nedel year 2000 and later small off-roed

engine (SORE). In California, new small off-reed engines

must be designed, built and equipped to meet the State's

stringent anti-smog standards. Elsewhere inthe United

States, new non*mad, spark-ignition engines certified for

model year 1997"and later, must meet similar standards set

forth by the U.S.EPA. Sears must warrant the emission

control system on your engine for the pedods of time listed

below, provided there has been no abuse, neglect, or

improper maintenance of your small off-mad engine.

Your emission control system may include parts such as the

carburetor or fuel-injection system, the ignition system, and

catalytic converter. Also included may be hoses, belts,

connectors and other emission related assemblies.

Where a warrantable condition exists, Sears will repair your

small off-road engine at no cost to you including diagnosis,

parts and labor.

Sears Emission Control Defects Warranty Coverage

The 1995 and later small off-road engines are warranted for

two years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Sears.

Owner's Warranty Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in this

owner's manual. Sears recommends that you retain all your

receipts covering maintenance on your small off-mad

engine, but Sears cannot deny warranty solely for the lack of

receipts or for your failure to ensure the perfon'nance of all

scheduled maintenance.

As the small off-road engine owner, you should however be

aware that Sears may deny you warranty coverage if your

small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road

engine to an approved Sears Service Center as soon as a

problem exists. The warranty repairs should be completed in

a reasonable amount of time, not to exceed 30 days.

Ifyou have any questions regarding your warranty rights and

responsibilities, you should contact a Sears Service

Representative at 1-800-459-4553.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your

Emission Control Defects Warranty Coverage.

1, Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emission central systems parts) to the

extent these parts were present on the engine purchased.

Cold start enrichment system

Carburetor and internal parts

Fuel Pump

b. Air Induction System

Air cleaner

Intake manifold

c. Ignition System

Spark plug(s)

Magneto ignition system

d. Catalyst System

Catalytic converter

Exhaust manifold

Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

Vacuum, temperature, position, time sensitive valves

and switches

Connectors and assemblies

2, Length of Coverage

Sears warrants to the initial owner and each subsequent

owner that the Warranted Parts shall be free from

defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years

from the date the engine is delivered to a retail

purchaser.

3, No Charge

Repair or replacement of any Warranted Part will be

performed at no charge to the owner, including

diagnostic labor which leads to the deten'nination that a

Warranted Part is defective, if the diagnostic work is

performed at an approved Sears Service Center.

4, Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the

provisions of the Sears Warranty Policy. Warranty

coverage shall be excluded for failures of Warranted

Parts which are not original Sears parts or because of

abuse, neglect or improper maintenance as set forth in

the Sears Engine Warranty Policy. Sears is not liable to

cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

5, Maintenance

Any Warranted Part which is not scheduled for

replacement as required maintenance or which is

scheduled only for regular inspection to the effect of

"repair or replace as necessary" shall be warranted as to

defects for the warranty period. Any Warranted Part

which is scheduled for replacement as required

maintenance shall be warranted as to defects only for

the period of time up to the first scheduled replacement

for that part. Any replacement part that is equivalent in

performance and durability may be used in the

performance of any maintenance or repairs. The owner

is responsible for the performance of all required

maintenance, as defined in this owner's manual.

6, Consequential Coverage

Coverage hereunder shall extend to the failure of any

engine components caused by the failure of any

Warranty Part still under warranty.

Inthe USA_nd Canadai a 24-hourhotline, "i-800_469_4663ihas amenu of pre_recerdedmessagesOfferingyOUproduct

maintenance information

23

Page 24

GARANTIA .................................... 24

INSTRUCCIONES DE SEGURIDAD .............. 24-26

MONTAJE .................................. 28-29

OPERACION ................................ 30-32

MANTENIMIENTO ............................ 33-36

ESPECIFICACIONES ............................ 33

ALMACENAMIENTO ............................. 37

REPARACION DE DAI_IOS ........................ 38

GARANTIA DEL CONTROL DE EMISIONES ......... 39

COMO ORDENAR PARTES ...... PAGINA POSTERIOR

GARANTIA LIMITADA DE LA MAQUINA LAVADORA DE PRESION CRAFTSMAN

Durante un aria a partir de la fecha de compra, Sears reparar_, sin cargo alguno, cualquier defecto en matedal y mano de

obra, siempre y cuando esta m_quina lavadora de alta presi6n Craftsman haya sido mantenida y puesta en funcionamiento

de acuerdo a lea instrucciones suministradas en el manual del propietado.

Si esta m_quina lavadorg es usada pare fines comereiales, la garantia se aplicar_ tan solo por 90 dies a partir de la fecha

de compra. Siesta mdquina lavadora de alta presi6n es usada pare alquiler, la garantia se aplicard tan solo por 30 dies

despu6s de la fecha de compra.

Esta garantia no cubre:

Elementos perecederos como bujias O filtros de aire, los cuales se desgastan con el usa normal.

Reparaciones necesarias debido al abuso o negligencia del operador, incluyendo danos ocasionados par la ausencia de

suministro de ague ala bomba o par no mantener el equipo de acuerdo a lea instrucciones contenidas en el manual del

propietario.

El servicio de garantia se hace efectivo devolviendo la m_quina lavadora de alta presi6n al centro de servicio o distribuidor

Sears mas cercano en los Estados Unidos.

Esta garantia le proporciona derechos legales especificos; usted tambi6n puede tener otros derechos, los cuales varian de

estado a estado.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

_lk ste es el simbolo de alerta de seguridad, Es usado para indicarle situacione$ con paligros potenciales de

lesion pare el personal. Siga lag instrucciones de todos los mensajes de seguridad que aparscen despues de

este simbolo pars evitar posibles lesiones o muerte.

[_Lea este manual minuciosamente y conozca a

rondo las partes y el funcionamiento de su

m_quina lavadors a presi6n, Conozca sus

aplicaciones, sus limitacione$ y los peligros

involucrados,

El simbolo de alerta de seguddad (_k) es usado con una

palabra (PELIGRO, ADVERTENCIA, PRECAUCI(_N), un

mensaje por escrito o una ilustracibn, pare alertarlo acerca

de cualquier situaci0n de peligro que pueda existir.

PELIGRO indica un riesgo el cual, si no se evita, ceusa_ la

muerte o una herida grave. ADVERTENCIA indica un riesgo

el cual, si no se evita, puede causer la muerte o una hedda

grave. PRECAUCION indica un riesgo, el cual, si no se

evita, puede causer heridas menores o moderadas.

PREOAIJCI6N, cuando se usa sin el simbolo de alerta,

indica una situaci0n que podria resultar en el della del

equipo. Siga los mensajes de seguridad pare evitar o reducir

los desgos de heridas e inclusive la muerte.

Simbolos de Peligro y Significados

Gases T0xicos DescargaElectrica

Superficies Resbalosas Caer Inyecci6nLiquida

Fue£o Explosion Superficie Caliente

Partes en Movimiento Objetos Voladores Contragolpe

24

Page 25

-_-nel estado de California es obligatorio, seg0n la lay, el use

_e apagachispas (Secci6n 4442 del C6digo de Recursos

=0blicos de California), Otros estados pueden tener leyes

_imilares, Las leyes federales se aplican en tierras

'ederales, Si equipa el silensiador con un apagashispas,

_ste debe_ ser mantenido en buenas condiciones de

:rabajo, Usted puede ordenar el apagachispas a tray,s de

_u distribuidor de servicio autorizado Sears,

I ADVERTENClA

El escape del motor de este producto conSene

elementes quimicos reconocido$ en el Estado de

California per producir c_ncer, defecto$ de nacimiento

u arras dafies de t po reproducUvo.

PELIGRO

, Oper'e e] lavadora de presibn SOLAMENTE al sire libr_

, Utilic_ un respirador o mascara siemp_'equa exists la

posib!lidad de inhalar vapores.

' Lea fades las instrucciones de la m_scara paraasegurarse de

qua le brindar,_ la protecoi6n nec_safia contrala inhalacibn de

vapores natives.

ADVERTENCIA

CUAN D0 AI_ADA CoMBUsTI BI-E

, Apague el generador (posici6n OFF) y dejelo enffiar sl menos

pot2 minutGe antes de rem0ver la taps de la gas01ina.

NO iler_ demaslada el tanquei Permits al men0s espaci0 pars

, Mantenga Is gasolina alejada de ahispas, llamas abiertasi

pil_toSi aalor y otraS fU_ de ignition

, NO encienda un cigarfill0 0 fume.

CUANDO OPERE EL. EQUIPO

' NO incli_ el mot0r 0 el equips, de tal manera qua la gasalina

se puede derramar.

NO retie liquides inftamables.

CUANDO TRANSPORTE 0 REPARE EL EQUIPO

, Transp0rte 0 repare el _Uip0 c_n _1 tanqu_ de combustib!e

VaCIOi_ COn la v_Ivula pa_ apagar el COmbustible, apagada

(posici0n OFF)

CUANDO ALMACENE O GUARDE EL EQUIPO CON

COMBUS'I'IBLE EN EL "I'ANQUE

, AIm_e alejado de cald_s, estufaSi calentaderes de agua,

secadaras de raps U 0ires aparatas elactrodom_-s'dcoS qua

pasean pi!ot_s U_ras _en_ d_ igni¢ibn, ponque el!as p_den

engender 10s Vapo_ de la gasolina

de Io contrario podrfan _cw'rir d_argas el6ctrJcas fatales.

'El ar'ea de limpieza deber_ tenet ina!!na_ianes y drenajes

adecoadaa pars disrninui_ la pasibilided de coidas debido

superficies resbalosas.

Oper'e y almacone esta unidad sabr_ una superficie estable

, Sujete !a pistols de la hidrolavadara "firmemerfie- con ambas

manes ,;uanda uti!ice e! t'ociado a a!ta presi_n D_ esl:amanem

evitar_ lesiones praducidas par _1posilale galpe de la pistols

haaia atr_s.

ADVERTENCIA

roaiada cu_ndo el sistema este presurizada:

ADVERTENCIA

' NO toque ias superFiaie.scalierfies.

• Mantengase alejada de !as gases de escape.

, NUNCA mueva el equipo mientras este en "_unrJanamiento.

, Permits qua el_uipo se enfrie antes de rosario.

25

Page 26

PRECAUCION

'NO asegur_ la pistola de rociado en la posicibn (open =

, NUNCA Utilir_ una p_st01ade rociad0 q0e no _:enga un segUro

Para gatill0 0 P_ci0n Para gstill0 en su !ugar Yen buenas

_ondiciones.

PRECAUCION

PRECAUCION

o cuando est6 corca de donde se _t_ usando el equip0

PRECAUCION

, $i 0Sl:ed tiene _lguna preg0n_a _ce_a de ITS5nalidach_s do us0

d_ I gen_rad0 r, Pr'_0nte!_ a SO c0ncos!0nario O ¢_ntac_ a

, NUNCA de_r_n set 0p_mdas las Unidades _n part_ _s o

,NO eluda nirrg0n disp0sitivo de seg0ridad de esta m_q0ina.

Antis de p0ner en ma_cha la mAquina lavadora a p_!_n en

#lima frio. _vise todas !as part_ de! equip0 y aseg0_'P_sed8

qU_ n0 se haya formado hiel0 sobre elias.

, NUNCA mueva la m_q0ina halande la manguera de al_a

presi0n. U_i!!co !a rnanija que viene _n la unidad.

, Revise que el sistema de combustible no present_ fugas o

signos d_ d_i0roi _rno mangue_s de..sgastadas0 po_sasi

26

Page 27

CONOZCA SU MAQUINA LAVADORA DE PRESION

Lea el manual dal propiatario y lae reglae de eaguridad antes de poner an marcha eu m_quina lavadora a preeibn,

Compare las ilustraciones con su mdquina lavadora a presibn para familiarizarse con las ubiceciones de los diferentes

controles y ajustes. Guarde este manual para referencias futuras,

Pislola de Rociado

Boquilla Ajustab!e

ExtensiOn para

Poseedo r Ace..eso ria

Arrancad0r de Retr0ceso

Extension papa B0quillas

Tapa del Depbsito

Filtro deAite Palance de Control dR I_

Vtllvula de Regu!acibn

Filtro y Tubo para

Reco!e¢_iOnde Detergente

Bombilla mc_ls

Principal

pa de la

Gasolina

Entrada de Agua

I'oma deAl_ PresiOn

Elomba equ!pped with

Autom_ice se Enfria Sistema

Arrancador de Retroceso - Usado para el arranque del motor.

Autom_tico ea Enfria Sietema - Los ciclos regan por

bomba cuando agua alcenza 125'_-155'_F. Entibiar agua

deacargar_ de la bomba en el eualo, Eete eietema

previane el daffo intemo de bomba.

Bomba - Desarrolla alta presibn de agua,

Bombilla m_e Principal -- Usada para arranque de

motores frios,

Boquilla Ajuetable -Ajusta la presibn a alta o baja presi6n;

rociado a chorm o en abanice,

Entrada de Agua - ConexiOn para la manguera de jardin.

Exlenei6n para Etoquillea - Conectada a la pistola de

rociado para un uso m_s conveniente.

Exlenei6n para Etoquillea Turbo - La boquilla del turbo

gira la corriente alta de la presiOn en un modelo circular

r_pido para limpiar agresivo.

Filtro de Aire - El elemento de filtro tipo sece limita la

centidad de suciedad y polvo qua se introduce en el motor,

Filtro y Tubo para Recolecci6n de Datergente - Usado

para succionar detergente de la botella de quimices a la

cerriente de agua de baja presi6n,

Manguara de Alta PresiOn (no moetrado) - Conecte un

extremo a la pistola de rociado y el _ro extremo a la toma

de alta presibn.

Palanca de Control de la V_lvula de Regulaci6n - Coloce

el motor en modo de arranque para el arrancedor de

retroceso y detiene el motor en funcionamiento,

Pietola de Rociado - Controla la apliceci6n de agua sobre

la superficie de limpieza con el gatillo, Incluye cerrojo de

seguridad,

Poeeador Acceaoria - Proporeiona cenvienant

almacenamiento para el pistola de rociado, el extension

para boquillas turbo y extensi6n para boquillas.

Tapa de la Geaolina - Liana el tanque del combustible con

gasolina regular sin centenido de plomo en este punto,

Tapa dal Depbeito dal Aceite - Llene el motor con aceite

aqui. Vea la p_gina 28 para las recemendaciones del aceite

y las instrucciones de Ilenado.

Toma de Alta PreaiOn - Conexibn para la manguera de

alta presi6n,

27

Page 28

Su m_quina lavadora a presi6n requiere de oierto ensamble

y estar_ lista para ser usada 0nicamente despu_s de haber

depesitado el combustible y el acoite recomendado.

Si tiene problemas con el ensamble de su m_quina

lavadora a presi6n, Ilame a la linea de ayuda de la

m_quina lavadora a presi6n al 1-800-222-3136.

IMPORTANTE: Cualquier intento de hacor funoionar el

moLor sin haber depesitado el aceite recomendado resultar_

en falla del mismo.

RETIRE LA MAQUINA LAVADORA A

PRESlON DE LA CAJA

Abra la caja y code dos esquinas opuestas a la manija

guia de la parle superior a la inferior de tal forma que el

panel pueda set doblado hacia abajo.

Retire el material de relleno y la caja de repuestos

enviada con la mt=quina lavadora a presi6n.

Retire la m&quina lavadora a presi6n de la caja.

Revise la caja para vet si existen partes sueltas adicionales.

CONTENIDO DE LA CAJA

Revise el contenido de la caja. Si alguna de las partes NO

est_ presente o est_ dafiada, Ilame a la Iinea de ayuda de

la m_quina lavadora a presiOn al 1-800-222-3136.

La unidad prinoipal

La manguera de alta presibn

l=istola de rociado

Extensidn para boquillas con boquilla ajustable a

Alta/Baja presidn

Boquilla turbo

FIoseedor aocesorJo

Aceite para motor

Caja de parLes (incluye los elementes descdtes a

continuacibn)

Manual del operador

Tarjeta de la matricula

Familiaricose con cada parte antes de ensamblar la

m_quina lavadora a presiOn. Compare el contenido con la

ilustracibn de la p_gina 27. Si alguna de la partes NO est_

presente o se encuentra dafiada, Ilame a la Iinea de ayuda

de la m_quina lavadora a presibn al 1-800-222-3136.

MONTAJE DE LA MAQUINA

LAVADORA A PRESION

La gran mayoda de su m_quina lavadora a presiOn Craftsman

ha sidoensamblada en la fdbrica. Sin embargo, usted deberd

Ilevar a cape los siguientes presedimientes antes de poner en

funcionamiento su m_quina lavadora a presibn:

1. Deposite acoite en la caja del cigiJeffal del motor.

2. Deposite combustible en el tanque.

3. Conecte la manguera de alta presibn a la pistola de

rociado y a la bomba.

4. Conecte el suministro de agua a la bomba.

Fijar el Poseedor Accesorio

1. Coloque al peseedor acoesorio en la cima del manubrio.

2. Coloque al extension para boquillas, boquilla turbo y

pistola de rociado en el peseedor accesorio.

Agregue Aceite de Motor

IMPOR'I'ANTE: Cualquier intento de hacor girar o arrancar

el motor antes de que se haya depesitado el acoite

recomendado puede resultar en falla del motor.

NO'[A: Cuando agregue aceito al compartimiento del motor,

utilise 0nicamento aoeite detergento de alta calidad, designado

con la clesilicaoibn API de servicio SF, SG, SH, SJ o superior,

clesificado con el peso SAE 30. NO use aditives espeoiales.

1. Selecoione una viscosidad de acuerdo a la tabla siguiente.

},

El uso de acoites multigrado (5W-30, 10W-30, etc.) en

temperaLures mayores a los 40'_F (4_C) esesionar_ un

consume de aceite mayor al normal. Cuando utilice un

acoite multigrado, revise con mayor frecuencia el nivel de

acoite del motor.

** Si utiliza aceite SAE 30 en temperaturas inferiores a los

40_F (4'_C), ocasionard que el arranque sea m_s dificil e

incluso que se desbiele el motor debido a su inadecuada

lubricacibn intern&

2. Coloque la mdquina lavadora a presibn en una

superficie nivelada.

3. Limpie area alrededor del Ilenado de aceite.

4. Retire tap6n del of Qdo de Ilenado y la varilla de rTedici6n.

5. Limpie la varilla de medici6n, insertela en el odficio de

Ilenado y aprietela firmemente; retire la varilla de

medici6n. Depesite el acoite recomendado hesta la

marca "Full" ("Lleno") de la varilla de medici6n.

DE_OSITAR {_ LLENO

iiiiiiiiiiiiiiiiiiiiiiiiiiii _iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

........................... .........................

28

Page 29

6, Deposite el aceite lentamente. Limpie la vadlla de

medici6n cada vez que revise el nivel del aceite. NO

Ilene excesivamente,

7, Instale el tap6n del orificio de Ilenado de aceite y la

varilla de medicibn y aprietela firmemente.

NOTA: Revise el aceite frecuentemente durante el

despegue del motor.

Agregue Gasolina

IADVERTENCIA! NUNCA Ilene el tanque de

combustible en recintes cerrades. NUNCA Ilene el

A

tanque de combustible cuando el motor est_

funcionando o est_ caliente. NO fume cuando est_

Ilenando el tanque de combustible.

,_ IADVERTENCIA! NUNCA Ilene pot completo eltanque de combustible, Deje espacio para la

expansibn del combustible, Limpie cualquier derrame

de combustible del motor y del equipo antes de darle

arranque a la unidad,

1, Use combustible limpio y almac_nelo en recipientes

cubiertes, limpies y aprebades. Utilice embudes limpies,

NUNCA utilice gesolina "vieja" dejada de la estaci6n

anterior o gesolina almacenada por periodes de tiempo

prolongades.

2, Limpie el drea alrededor de la tapa de Ilenado del

combustible, retire la tapa.

3, Agregue lentamente gasolina regular"SIN PLOMO" al

tanque de combustible, Use un embudo para evitar que

se derrame, Llene el tanque lentamente hesta

aproximadamente 1.5" pot debajo de la parle la cima

del cuello del tubo de Ilenado.

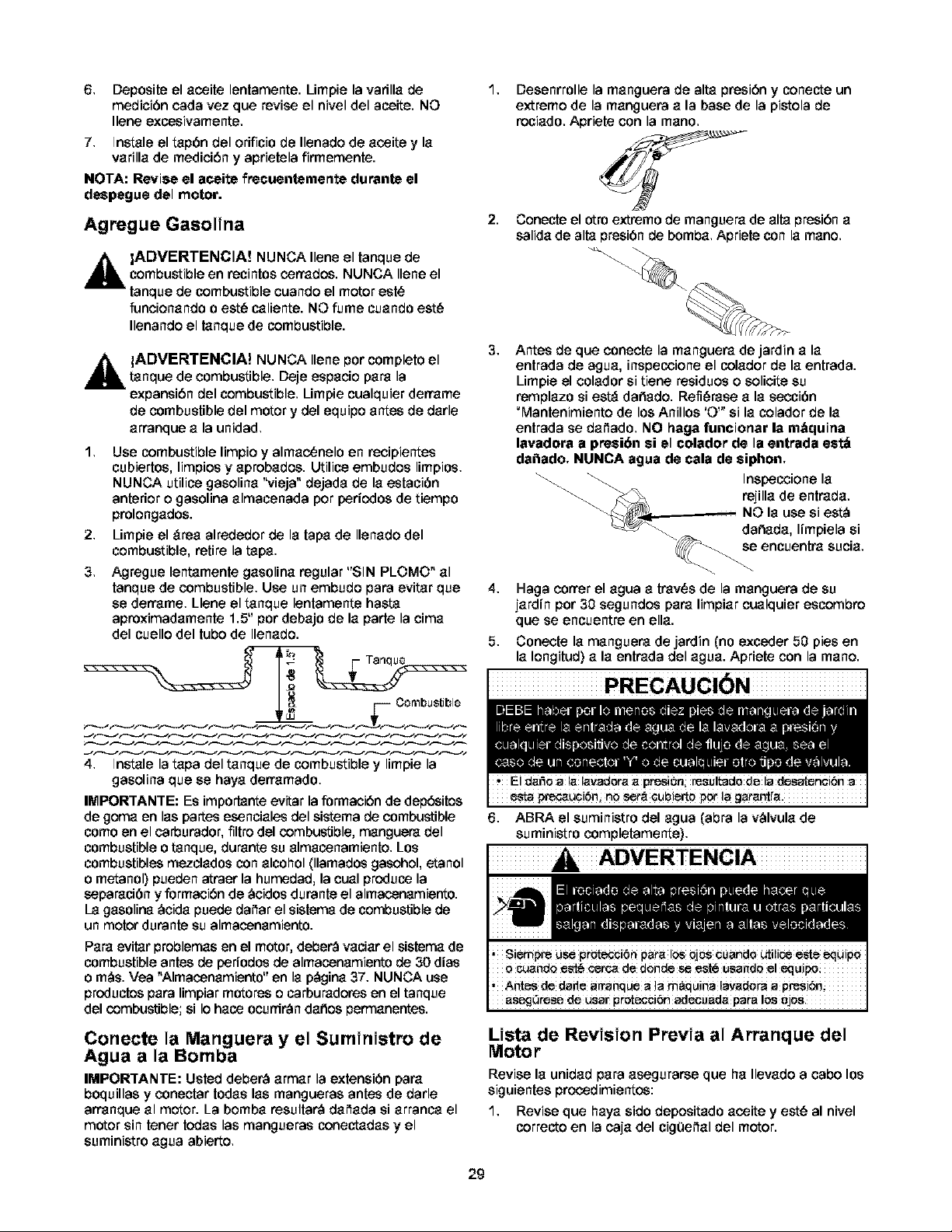

1, Desenrrelle la manguera de alta presibn y conecte un

extremo de la manguera a la base de la pistola de

rociado, Apriete con la mano,

2. Conecte el if(re extremo de manguera de atia presi6n a

salida de alta presi6n de bomba, Apriete con la mano,

3,

Antes de que conecte la manguera de jardin a la

entrada de agua, inspecoione el colador de la entrada.

Limpie el colador si tiene residues o solicite su

remplazo si est_ datiado. Refi(_rase a la secoi6n

=Mantenimiento de los Anilles 'O'" si la colador de la

entrada se dafiado, NO haga funcionar la m_quina

lavadora a preeibn ei el colador de la entrada eet_

dahado, NUNCA agua de cala de siphon,

Inspecoione la

rejilla de entrada,

- NO la use si est_

datiada, limpiela si

_e encuentra sucia,

4, Haga cower el agua a tray,s de la manguera de su

jardin pot 30 segundes para limpiar cualquier escombro

que se encuentre en ella.

5, Conecte la manguera de jardin (no exceder 50 pies en

la Iongitud) a la entrada del agua. Apriete con la mano.

4, Instale la tapa del tanque de combustible y limpie la

gesolina que se haya derramado,

IMPORTANTE: Es importante evitar laformacibn de depbsites

de goma en les partes esenciales del sistema de combustible

como en el carburador, filtre del combustible, manguera del

combustible o tanque, durante su almacenamiento, Los

combustibles mezclades con alcohol (llamades gesohol, etanol

o metanol) pueden atraer la humedad, la cual produce la

separaci6n y formacibn de _cides durante el almacenamiento.

La gesolina _cida puede dafiar el sistema de combustible de

un motor durante su almacenamiento.

Para evitar problemes en el motor, deber_ vaciar el sistema de

combustible antes de periodes de almacenamiento de 30 dies

o m_s. Yes "Almacenamiento" en la p_gina 37, NUNCA use

productes para limpiar motores o cerburadores en el tanque

del combustible; si Iohace esurrir_n daties permanentes.

Conecte la Manguera y el Surninistro de

Agua a la Bornba

IMPORTANTE: Usted deberb armar la extension para

boquilles y conectar todas les mangueres antes de darle

arranque al motor. La bomba resutiar_ dafiada si arranca el

motor sin tenet todes les mangueres conectades y el

suministre agua abierto,

PRECAUCIbN

esta precauc!6ni no ser_Cub!ertopot !a garan_fa.

6, ABRA el suministre del agua (abra la v_lvula de

suministre completamente),

Lista de Revision Previa al Arranque del

Motor

Revise la unidad para aseguraree que ha Ilevado a cabo los

siguientes procedimientes:

1, Revise que haya sido depesitado aceite y est_ al nivel

correcto en la caja del cig0efial del motor.

29

Page 30

2, Deposite la gasolina adecuada en tanque del combustible.

3. Revise que todas las conexiones de las mangueras

(alta presi6n y suministro de agua) est6n apretadas

correctamente y que no existan dobleces, cortes o daf_o

de la manguera de alta presi6n, 8.

4. Proporcione el suministro de agua adecuado (que no

exceda los 100°F),

5. Asegt_rese de leer las secciones "Reglas de Seguridad" y

"Operacidn" antes de usar la m_quina lavadora a presidn.

6. Siva a encender la unidad deepu6s de haber estado

almacenada, consulte la secci6n "Almacenamiento" en

la p_gina 37. 9.

COMO USAR SU MAQUINA

LAVADORA A PRESION

Si tiene problemas operando su m&quina lavadora a

presidn, por favor Ilame a la linea de ayuda para m_quinas

lavadoras a presi6n al 1-800-222-3136

Cbmo Darle Arranque a su M_quina

Lavadora a Presibn

Para darle arranque a su maquina lavadora a presi6n

movida a motor por primera vez, siga estas instrucciones

paso a paso. Esta informaci6n acerca del arranque inicial

tambi6n se aplica cuando vaya a darle arranque al motor

despu6s de haber dejado de la m_quina lavadora a presidn

fuera de uso por al menos un dia.

1. Coloque la m_quina lavadora a presi6n en un _rea cercana

a una suministro de agua exterior capaz de abastecer agua

a un volumen mayor de 3.0 galones por minL_oen no

menos que 20 PSI en el fin de arandela de presi6n de la

manga del jardin.

2. Revise que la manguera de alta presi6n se encuentre

conectada firmemente a la pistola de rociado y a la

bomba. Vea "Armado de Su M_quina Lavadora a Presidn".

3. Asegt_rese que la unidad est6 nivelada.

4. Conecte la manguera de jardin a la entrada del agua.

Aprietela con la mano. Abra el suministro de agua,

PRECAUCION

• El daSo a la lavadora a presi6n, resultado de la desatenci6n a

esta precauci6n, no sera cubierto pot la garantia.

5.

Presione el disparador en la pistola para purgar de aire

e impurezas el sistema de bombeo.

6.

Acople la boquilla de extensi6n a la pistola aspersora.

Apri6tela manualmente.

\

pistola mediante un ligero flujo. Continee sosteniendo el

disparador hasta que haya un flujo estable de agua y

no quede reeiduo alguno de aire en el sistema. Suelte

entonces el disparador.

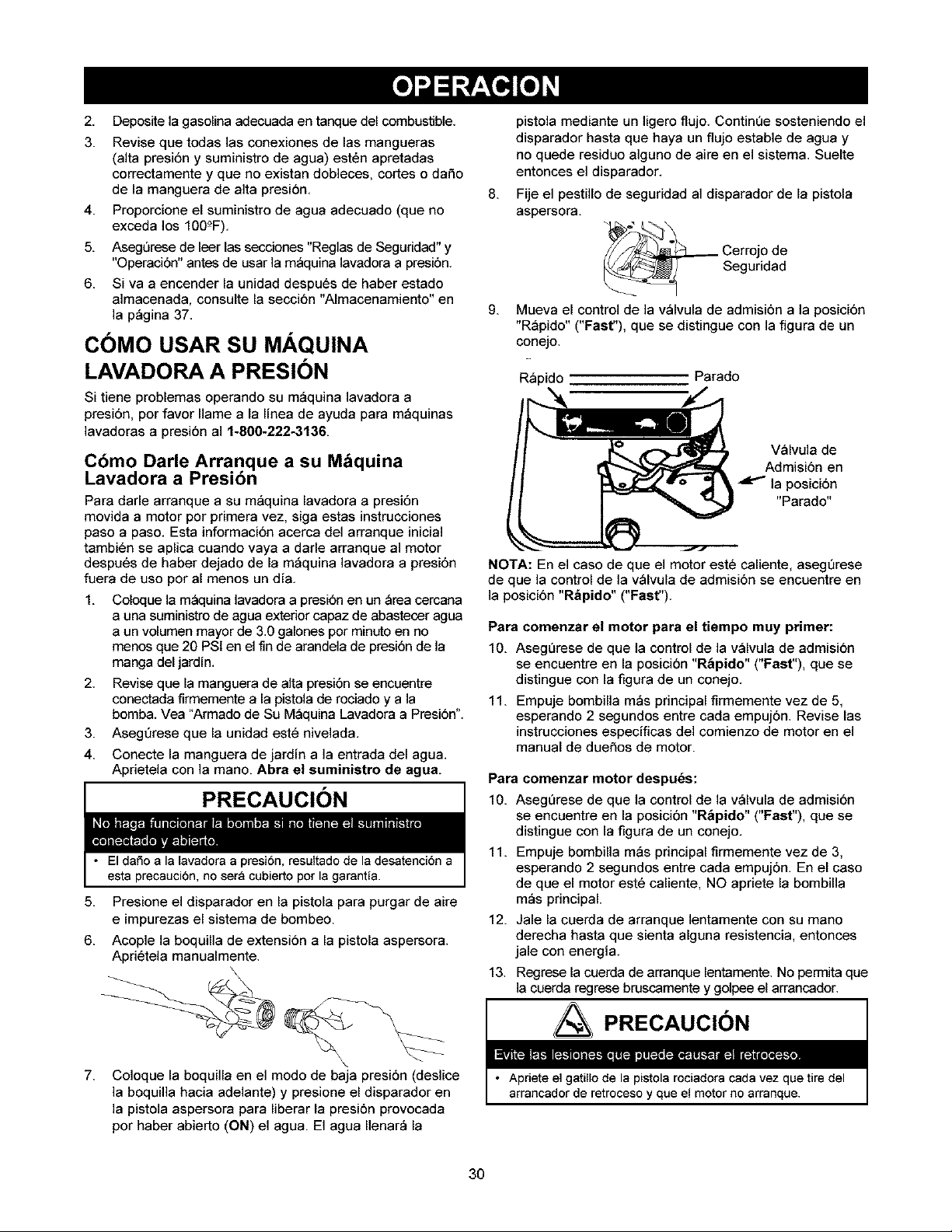

Fije el pestillo de seguridad al disparador de la pistola

aspersora.

Cerrojo de

Seguridad

Mueva el control de la v_lvula de admisidn a la posicidn

"R&pido" ("Fast"), que se distingue con la figura de un

conejo.

R_pido Parado

V_Ivula de

Admisi6n en

la posici6n

"Parado"

NOTA: En el caso de que el motor est6 caliente, asegt_rese

de que la control de la v_lvula de admisi6n se encuentre en

]a posici6n "Rbpido" ("Fast").

Para comenzar el motor para el tiempo muy primer:

10. Asegerese de que la control de la v_lvula de admisi6n

se encuentre en la posici6n "Rbpido" ("Fast"), que se

distingue con la figura de un conejo,