Page 1

OWNER’S

MANUAL

MODEL NO.

580.751781

CRRFTSMii'

7.8 HORSEPOWER

2500 PS! 3 GPM

HOURS:

Mon. - FrI. 8 a.m. to 5 p.m

(CSl)

CAUTION:

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

Part No, 97019 Revision 1 (8/16/95)

HIGH PRESSURE WASHER

Assembly

Operation

Customer Responsibilities

Service and Adjustment

Repair Parts

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Page 2

A

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PUVCE WIRE WHERE IT CANNOT CON*

TACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS TO YOUR HIGH PRESSURE WASHER.

A

TRAINING:

® Engine exhaust gases contain DEADLY carbon monox

ide gas. This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even

death. Operate this equipment only in the open airwhere

adequate ventilation Is available.

o WARNING: Engine exhaust from this product contains

chemicals, known, in certain quantifies, to cause cancer,

birth defects, or other reproductive harm.

® Gasoline is highly FLAMMABLE and its vapors are EX

PLOSIVE. Do not permit smoWng, open flames, sparks

or heat in the vicinity while handling gasoline. Avoid

spilling gasoline on a hot engine. Allow unit to cool for 2

minutes before rekteling. Comply with all laws regulating

storage and handling of gasoline

® Locate this pressure washer in areas away from combus

tible materials, combustible fumes or dust.

® The high pressure equipment is designed to be used with

Sears authorized parts only, if you use this equipment

with parts that do not comply with minimum specifications,

the user assumes ail risks and liabilities

B Some chemicals or detergents may be harmful if inhaled

or Ingested, causing severe nausea, fainting or poisoning

The harmful elements may cause property damage or

severe Injury.

® Do not allow CHILDREN to operate the Pressure Washer

at any time.

PREPARATION:

® Operate engine only at governed speed Running the

engine at excessive speeds increases the hazard of

personal injury. Do not tamper with parts which may

increase or decrease the governed speed.

® Do not wear loose clothing, jewelry or anything that may

be caught In the starter or ottier rotating parts.

® Before starting the Pressure Washer in cold weather,

check all parte of the equipment and be sure ice has not

formed there.

® Units with broken or missing parts, or without protective

housing or covers should NEVER be operated.

B The muffler and air cleaner must be installed and in good

condition before operating the Pressure Washer, These

components act as spark arrestors if the engine backfires.

® Check the fuel system for leaks or signs of deterioration

such as chafed or spongy hose, loose or missing clamps

or damaged tank or cap. Correct ail defects before oper

ating the Pressure Washer.

OPERATION:

B Do not spray flammable liquids.

® Never aim the gun at people, animals or plants,

B Never allow any part of the body to come in contact with

the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the high pressure hose

® High pressure stream of fluid that this equipment can

produce can pierce skin and its underlying tissues, lead

ing to serious injury and possible amputation.

® High pressure spray can cause paint chips or other par

ticles to become airborne and fly at high speeds,

e Always wear eye protection when you use this equipment

or when you are in the vicinity where the equipment is in

use,

a Operate the pressure at no more tfian the PSI fluid

pressure rated for your pressure washer.

® Never move the machine by puiling on the high pressure

hose. Use the handle provided on the top of the unit.

B Always be certain the spray gun, nozzles and accessories

are correctly attached.

B Never use a spray gun whicfi does not have a trigger lock

or trigger guard in place and in working order.

a Use a respirator ormask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask so you are certain the mask will provide the neces

sary protection against inhaling harmful vapors

® High pressure spray may damage fragile items including

glass. Do not point spray gun at glass when in the jet

spray mode.

B Keep the hose connected to machine or the spray gun

white the system is pressurized. Disconnecting the hose

while the unit is pressurized is dangerous.

® Hold the spray gun firmly in your hand before you start

the unit. Failure to do so could result in an injury from a

whipping spray gun. Do not leave the spray gun unat

tended while the machine is running,

® The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

® Keep water spray away from electric wiring or fatal electric

shock may result.

® Do not adjust unloader valve to a pressure in excess of

machine rating.

® Do not secure trigger gun in the pull-back (open) position.

® Do not by-pass any safety device on this machine.

B Do not leave trigger closed for more than 5 minutes with

engine running This could damage the pump.

® The muffler and engine heat up during operation and

remain hot immediately after shutting it down. Avoid

contact with a hot muffler or engine or you could be

severely burned,

MAINTENANCE AND STORAGE:

® Operate and store this unit on a stable surface.

® High pressure hose can develop leaks from wear, kinking,

abuse, etc. Water spraying from a leak is capable of

injecting materia! into skin, Inspect hose each time before

using it. Check all hoses for cuts, leaks, abrasions or

bulging of cover, or damage or movement of couplings. If

any of these conditions exist, replace tiose Immediately,

Never repair high pressure hose. Replace it with another

hose that meets minimum pressure rating of your pres

sure washer.

A

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS “ATTENTION!!! BE

COME ALERT!!! YOUR SAFETY IS INVOLVED.”

Page 3

CONGRATULATIONS on your purchase of a Sears Crafts

man high pressure washer. It has been designed, engi

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department or call the 1-800 number listed on the front

of this manual. We have competent, well-trained techni

cians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your high pressure

washer properly. Always obsen/e the “SAFETY RULES.”

MODEL

NUMBER

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE PRES

SURE WASHER.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

580.751781

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod

uct. Contact your nearest Sears store for details.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

PUMP PRESSURE

FLOW RATE

DETERGENT MIX

DETERGENT RATIO

WATER SUPPLY

TEMPERATURE

SUCTION HEIGHT

Engine Specifications

RATED HORSEPOWER

DISPLACEMENT

SPARKPLUG: Type:

Set Gap To.

GASOLINE CAPACITY

OIL (20 oz. capacity)

SOLID STATE IGNITION

AIR GAP

In the State of California a spark arrestor is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands.

NOTE: If you equip the engine of your pressure washer with

a spark arrestor muffler, the spark arrestor must be main

tained in effective working order by the owner operator.

Adjustable to 2500 psi

3gpm

Use undiluted detergent

Adjustable to 73.1

Not to exceed 140°F

3 FT. maximum

7.8

220cc

Champion RC12yc

or equivalent

0.030 inch (0.76mm)

4 U.S. gallons

SAE 30 weight

0.0125 inch

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

® Follow regular schedule in maintaining, caring for and

using your high pressure washer.

You can order a spark arrestor through your Sears Service

Center. See Repair Parts section of engine for part num

bers.

Page 4

TABLE OF CONTENTS

SAFETY FiULES................................................................... 2

PRODUCT SPECIFICATIONS................................................3

ACCESSORIES AND ATTACHEMENTS

CONTENTS OF HARDWARE PACK

ASSEMBLY..........................................................................7-8

OPERATION......................................................................9-13

...............................

.....................................

_ A-

Air Cleaner

Assembly

Remowng from Carton

Tools Required..............

Setup

..............................

...........

............................7-8

9,16

..............

............

Gun and Wand Assembly .8,9,10

7

,7

Hardware Pack............................6

High Pressure Hose

-B-

Before Starting.....................11-12

Low OH Pressure System ... 13

_C-

Customer Responsibilities ,., 3

Statement

Schedule....

Changing OH

Checking Oil Level...........

General Recommendations... 14

Pressure Washer..................... 14

Pump....................................... 15

Replace Spark Plug

Service Air Cleaner,

Spark Arrestor..........................16

......

.. ....................... 3

......................

...........

.................15

........

.................

14-16

............... 15

......

_E-

Engine Speed

...........................

16

16

17

Maintenance

Engine

........

Pump

...

..............

Nozzle , ,. .........................

Oii, Engine

Operation

Detergent Application

Stopping,...

To Start Engine

To Turn On Washer

To Use...................................... 10

............................

.............................

CUSTOMER RESPONSIBILITIES...................................14-16

SERVICE AND ADJUSTT/IENTS

5

STORAGE.............................................................................18

6

TROUBLESHOOTING

REPLACEMENT PARTS.................................................20-26

WARRANTY..........................................................................27

..........................................................

-G-

Pressure Regulator

.........................................

_p„

.................

-H-

................

6-8

Repair Parts..........................20-26

-R-

-S-

-M-

............................. 15

..................

-o-

.......................

.................

17-18

3-11

............

16

11

10

12

12

Safety Latch

Safety Rules

Service and Adjustments . 17-18

Storage...................................... 18

Engine..................................... 18

Pressure Washer Pump

Troubleshooting....................... 19

Valve, thermal relief

War ranty...

................

...............................

-T-

_V—

.................

W-

...............................

_ ,. 12

.........

17

19

10

2

18

13

27

Page 5

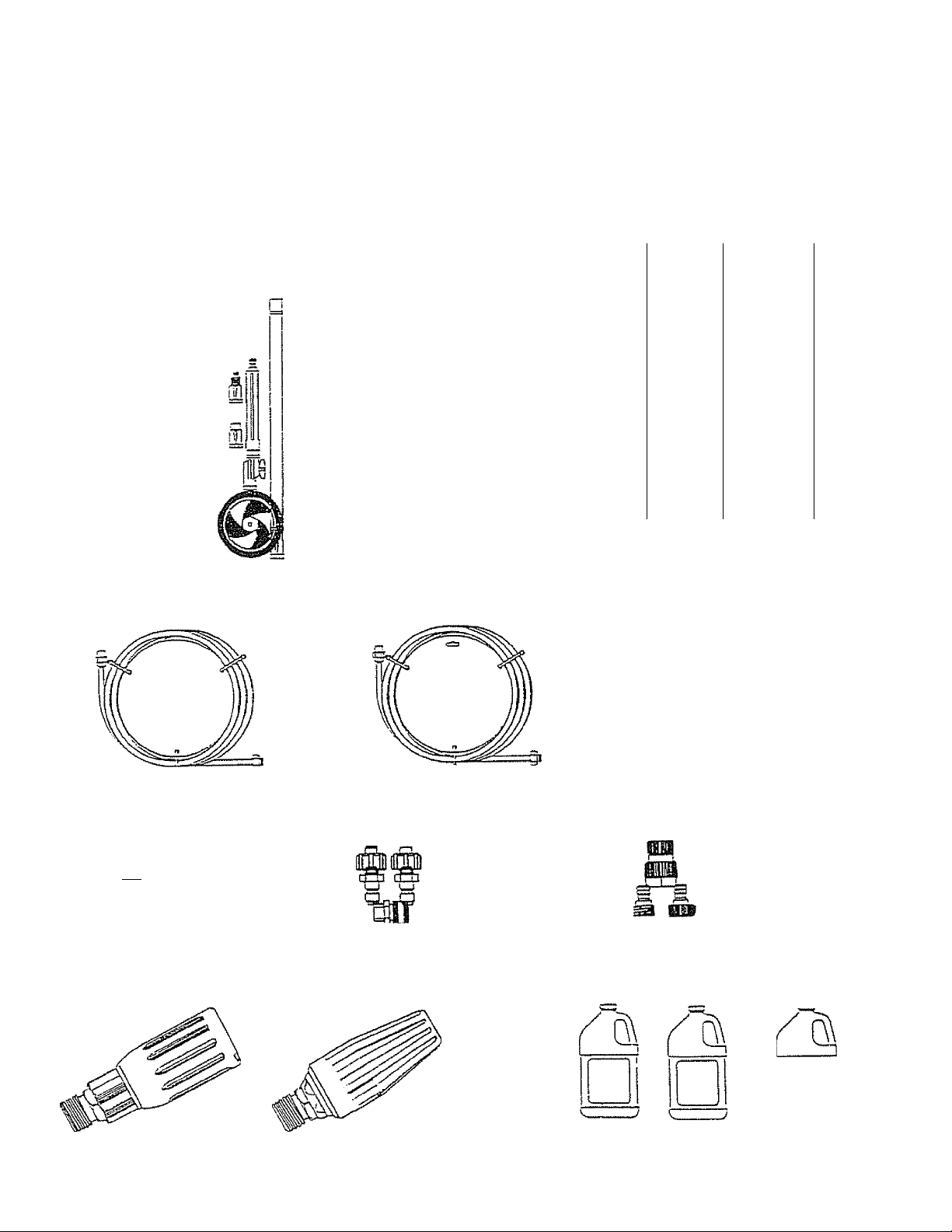

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available when the high pressure washer was purchased. They are also

available at most Sears retail outlets and service centers. Most Sears stores can order these items for you when you

provide the model number of your high pressure washer. Some of these accessories may not apply to your pressure

washer.

|i

n

Sta

1

iTil

FLOOR/SIDING

BRUSH KIT (75190)

1/4” I.D. 25 ft. EXTENSION

HOSE (75192)

rftt

HIGH PRESSURE

HOSE QUICK CON

NECT KIT (75198)

ROTATING BRUSH

KIT (75199)

g

ACCESSORY

QUICK CONNECT

(76188)

y

UTILITY BRUSH Krr

(75189)

3/8* i.D. 50 ft. EXTENSION

HOSE (75913)

ACCESSORY

QUICK CONNECT

STARTER KIT

(75197)

ap

18* STAINLESS

STEEL EXTENSION

(75194)

HIGH PRESSURE

HOSE TO HOSE

COUPUNG

(75191)

ELECTRIC TURBO

NOZZLE

GCZBjaBD

n

CHEMICAL INJECTION

FOAMER (74180)

GARDEN HOSE

QUICK CONNECT

WITH 2 ADAPTORS

(75187) •

ANGLE EXTENSION'

KIT (75196)

PRESSURE

GAUGE (75181)

TURBO HEAD

1800 PS! (max.)

TURBO NOZZLE

2200 and 2500 PSi (75186)

MULTI-PUR-

POSE/HOUSE

WASH (75100)

DECK WASH

(75101)

VEHICLE/BOAT

WASH (75102)

DEGREASER

(75103)

Page 6

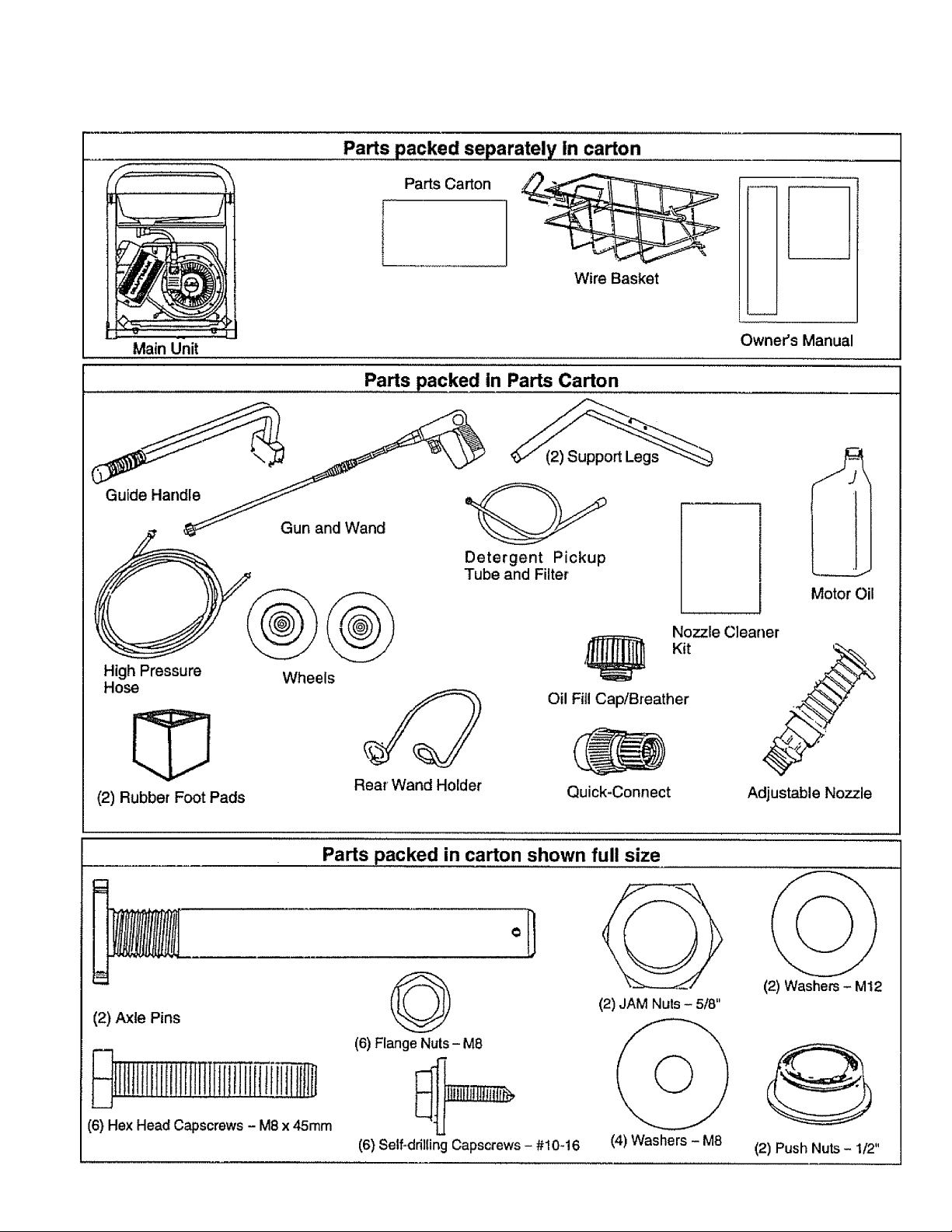

CONTENTS OF HARDWARE PACK

Page 7

ASSEMBLY

Read these instructions and Operator's Manual in its en

tirety before you attempt to assemble or operate your new

high pressure washer. Your high pressure washer has, for

the most part, been assembied at the factory, except those

parts left unassembled. Before you can operate your new

high pressure washer, you must assemble the wheel kit and

properly connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR PRESSURE WASHER, PLEASE CALL THE

PRESSURE WASHER HELPLINE AT 1-800-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

Mallet

2 adjustable wrenches OR the following wrenches:

5/16“ {8mm) combination wrench

1/2" (13mm) combination wrench

11/16“ (18mm) combination wrench

7/8“ (22mm) combination wrench

15/16“ (24mm) combination wrench

TO REMOVE PRESSURE WASHER FROM CARTON

» Remove box for spray gun assembly and support legs

o Remove accessories box from carton.

8 Remove wire basket (wrapped in plastic)

8 Remove your high pressure washer.

Refer to Page 6, “Contents of Hardware Pack" for an

illustrated listing of all Items included with your pressure

washer. Become familiar with each piece before assem

bling pressure washer. Check all contents against iliustrations on Page 6, If any parts are missing or damaged, call

Pressure Washer Helpline, at 1-800-222-3136.

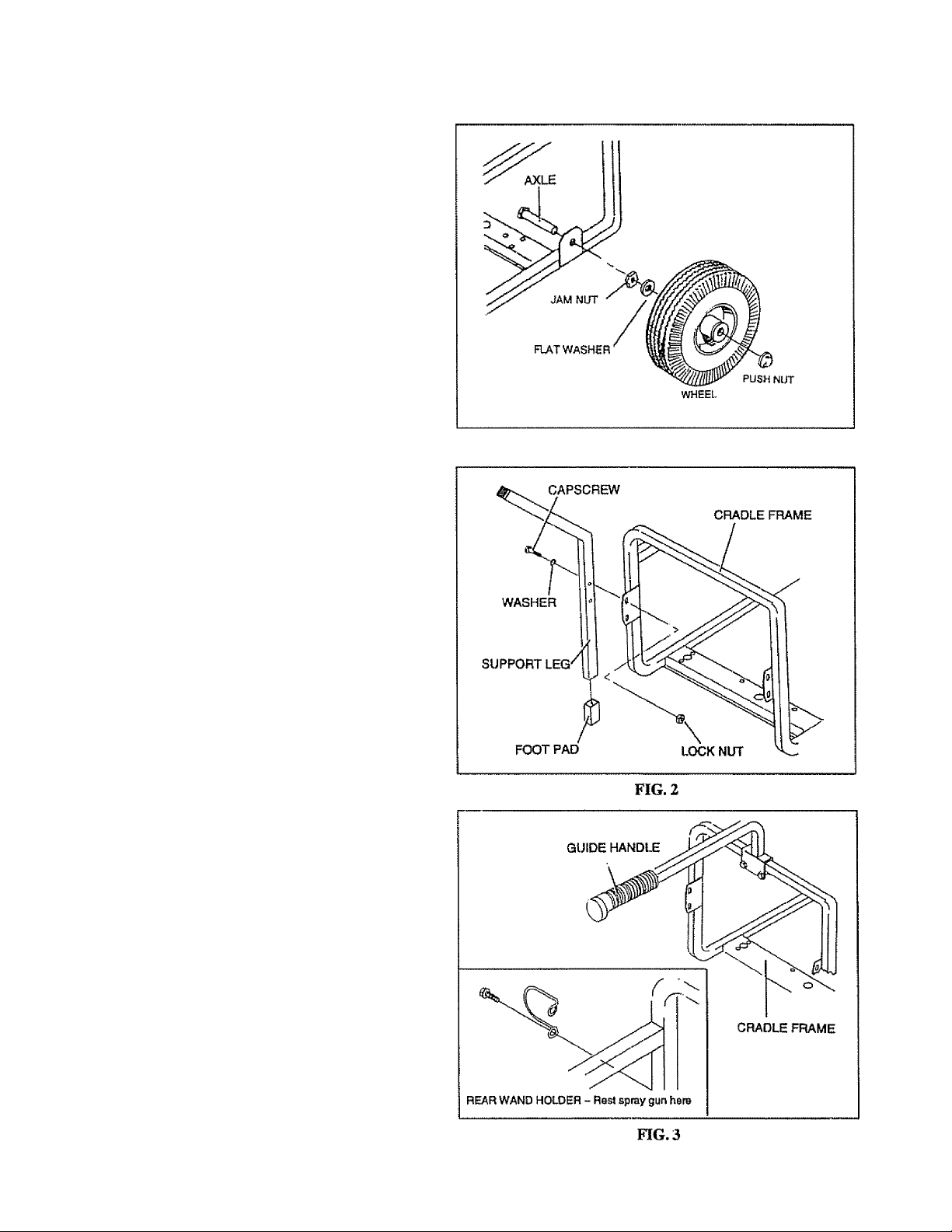

FIG. 1

HOW TO SET UP YOUR PRESSURE WASHER

TO INSTALL THE WHEEL KIT

Installing the wheel kit requires the tools listed above, the

guide handle and items included in the parts carton.

8 Prop up the engine end of the main unit. This will allow

you to slip each axle pin into the holes provided on the

side of the base (Fig. 1)

8 Fasten each axle to base with 5/8"-18 JAM nut then place

M12 fiat washer over axle. Tighten with 15/16" wrench,

8 Place wheels with valve side of wheel facing outboard

side onto the axles and retain each wheel to its axle by

tapping a push nut onto end of axle with a mallet.

8 Insert foot pad into bottom of each support leg (Fig. 2).

8 Using 13mm or 1/2-inch wrench, attach each support

leg to base as shown in Fig. 2 with two MB x 45mm hex

head capscrews, MB washers and M8 flange lock nuts.

8 Attach guide handle to cradle (Fig, 3) with two M8-1.25

X 45mm hex head capscrews and two flange nuts.

Attach rear wand holder using 5/16" (8mm) wrench with

#10-16 self-drilling screws to cradle as shown in Fig. 3.

Page 8

ASSEMBLY

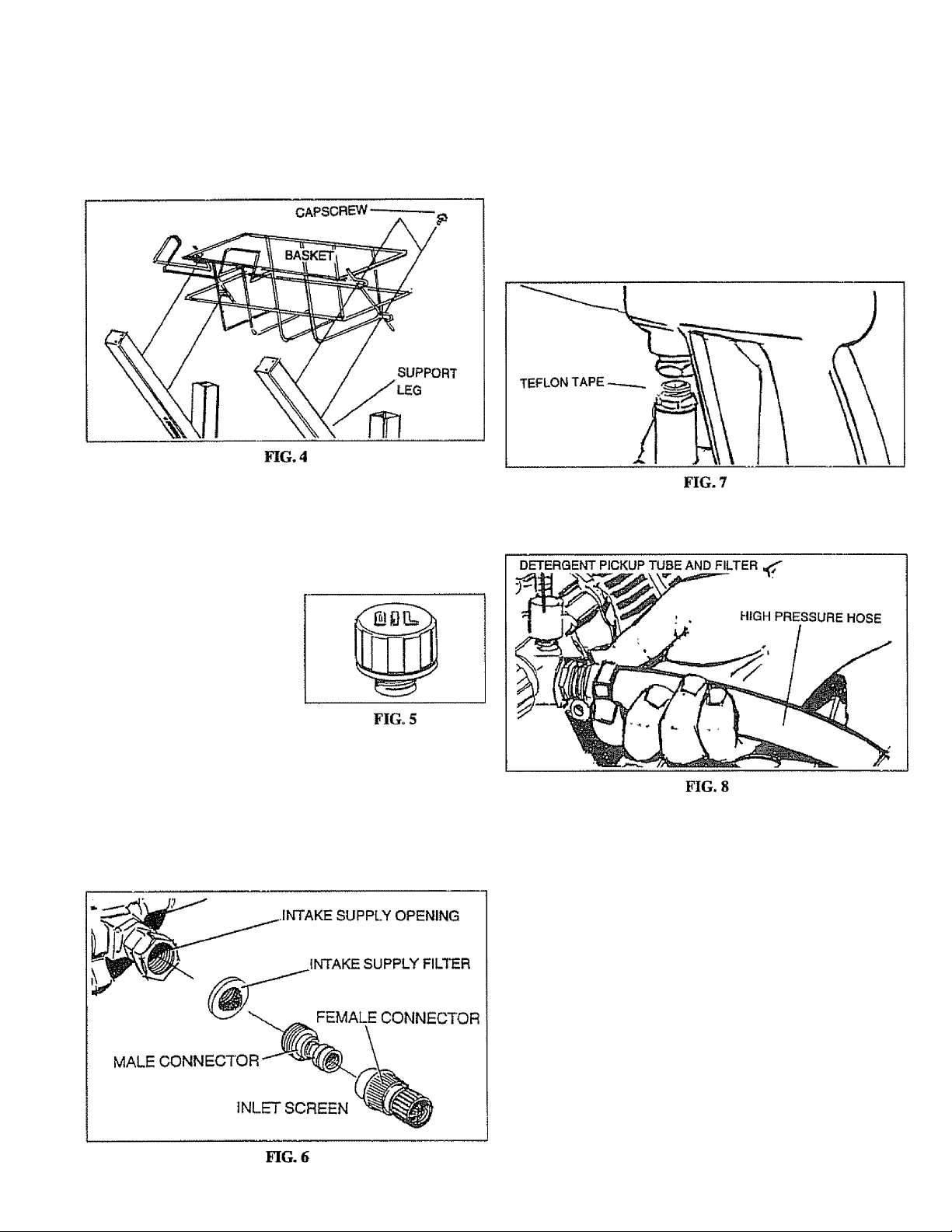

Attach wire basket to bent arms of support legs with

#10 self-drilling screws (Fig. 4) using 5/16“ (8mm)

wrench. The gun holder should be positioned to the

left. Be sure loop of support is pointing upward.

TO ASSEMBLE REMAINING COMPONENTS

IMPORTANT: YOU MUST ASSEMBLE WAND AND AT

TACH ALL HOSES BEFORE YOU START ENGINE.

STARTING ENGINE WITHOUT ALL HOSES CON

NECTED AND WATER SUPPLIED WILL DAMAGE

PUMP.

Unravel high pressure hose, remove protective cap

from end of hose and cfieck other end of hose to see

ttiat threads are properly covered with teflon tape, if

tape is not properly applied, reapply it so frireads are

fully covered. The tape seals the connection from hose

to gun and wand assembly.

Attach fitting with teflon tape to gun and wand assembly

(Fig. 7). You may want to spin gun. Tighten with 7/8“

wrenches or adjustable wrenches.

o Attach the other end of the high pressure hose to high

pressure fitting on pump (Fig. 8). Tighten with adjust

able wrench.

Remove cap from top of

pump and insert oil fill

cap included in parts bag

(Fig. 5).

included with ttiis unit is a Quick-Connect fitting you

attach to Water Inlet on pump. The quick-connect

includes two parts — a Male Connector factory-in

stalled on water inlet and a Female Connector (Fig. 6).

Remove male connector to inspect Intake Supply

Screen in water inlet for cleanliness and inspect Inlet

Screen on female connector, install male connector to

water inlet and attach female connector to garden

hose.

o Unravel Detergent Pickup Tube and place filter in

basket.

IMPORTANT: KEEP DETERGENT PICKUP TUBE AWAY

FROM HOT MUFFLER,

<* Attach Detergent Pickup Tube as shown in Fig. 8.

o To attach the adjustable nozzle, refer to Operation

section, Fig. 11.

CHECKLIST

o Check that fasteners you used to install wheels and

handle are tight. Vibration during operation may

loosen fasteners that are not tight enough.

o Check for proper hose connections (high pressure and

water supply) and for tight connections and that tiiere

are no kinks, cuts, or damage to the high pressure

hose.

o Provide proper water supply (not to exceed 140°F).

o Be sure to read "Safety Rules” and "Operation” sec

tions before using the pressure washer.

Page 9

OPERÄTfOlSl

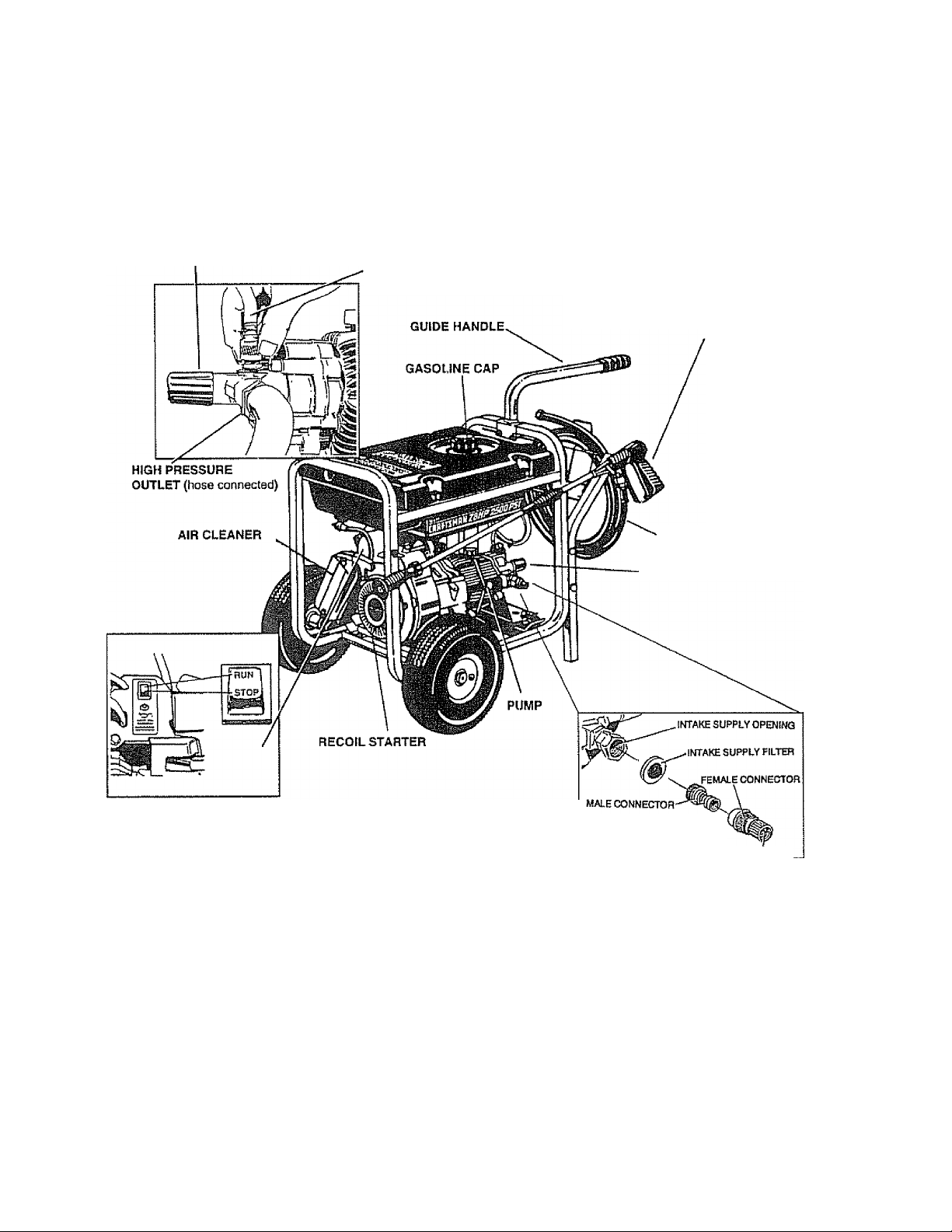

KNOW YOUR HIGH PRESSURE WASHER

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HIGH PRESSURE WASHER.

Compare the illustrations with your high pressure washer to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

PRESSURE

REGULATOR

DETERGENT PICK TUBE

AND FILTER

GUN AND WAND

ASSEMBLY

■ HIGH PRESSURE HOSE

ENGINE RUN/STOP SWITCH

FIG. 9

PUMP —Develops high pressure.

PRESSURE REGULATOR — Allows you to adjust the

pressure of the outlet stream.

ENGINE ON-OFF CONTROL — Sets engine in starting

mode for recoil starter; turns OFF mnning engine.

RECOIL STARTER — Used for starting the engine manu

ally.

AIR CLEANER - Dry type filter element limits the amount

of dirt and dust that gets in the engine.

GUN AND WAND ASSEMBLY—Controls the application

of water onto cleaning surface with trigger device. Includes

safety latch.

-PRESSURE REGULATOR

INLET SCREEN

QUICK-CONNECT

HIGH PRESSURE HOSE — Connect one end to water

pump and other to spray wand.

INTAKE SUPPLY FILTER — Filters inlet water supply.

DETERGENT PICKUP TUBE AND FILTER—Mixes water

and detergent in outlet water flow.

HIGH PRESSURE OUTLET — Connection for high pres

sure hose.

QUICK-CONNECT — Easy connection for intake water

supply.

Page 10

OPERATiON

HOW TO USE YOUR WASHER

IF YOU HAVE ANY PROBLEMS OPERATING YOUR

PRESSURE WASHER, PLEASE CALL THE PRESSURE

WASHER HELPLINE AT 1-800-222-3136.

STOPPING YOUR PRESSURE WASHER

» First, move engine RUN/STOP switch to "OFF" position

(Fig. 10).

FIG. 10

e Simply shutting OFF engine will not release pres

sure In the system. Pull the trigger on the spray wand

assembly to relieve the pressure in the hose,

NOTE: A small amount of water will squirt out when you

release the pressure.

SPRAY NOZZLES

Your high pressure washer comes equipped with an adjust

able nozzle (Fig. 11). You can order a turbo nozzle (Fig,

12). Attach either nozzle as shown in Fig. 11 and HAND

TIGHTEN the plastic knob.

HOWTO USE ADJUSTABLE NOZZLE

WARNING; NEVER ADJUST SPRAY PATTERN

A

WHEN SPRAYING. NEVER PUT HANDS IN FRONT

OF SPRAY NOZZLE TO ADJUST SPRAY PAT

TERN.

With the adjustable nozzle you can adjust the spray pattern

to be either high pressure or low pressure. You can also

adjust the spray so it is concentrated in a stream pattern or

expanded into a fan pattern. Use this nozzle to apply

detergent.

« Push the nozzle attachment forward when you wish to

adjust the spray to low pressure mode (Fig. 13). Push

the nozzle backwatxi to achieve high pressure.

o Twisting the nozzle adjusts the spray pattern from a

narrow stream to an expanded stream.

You can also adjust the pressure by turning the pressure

control knob (Fig. 14) to the desired pressure setting.

Turning this knob ail the way clockwise produces the high

est pressure. Do not unscrew the pressure control valve

more than 3 turns. It will come off.

FIG. 14

NOZZLE IN HIGH

PRESSURE MODE

PUSH NOZZLE FORWARD FOR

LOW PRESSURE MODE AND DE

TERGENT APPLICATION

TWIST NOZZLE TO

EXPAND SPRAY

FIG. 13

10

TWIST NOZZLE TO NARROW

SPRAY STEAM

Page 11

OPERATION

APPLYING DETERGENT WITH ADJUSTABLE

NOZZLE

IMPORTANT: USE SOAPS DESIGNED SPECIFICALLY

FOR PRESSURE WASHERS. HOUSEHOLD DETER

GENTS COULD DAMAGE THE PUMP.

IMPORTANT: YOU MUST ATTACH ALL HOSES BE

FORE YOU START THE ENGINE. STARTING THE EN

GINE WITHOUT ALL THE HOSES CONNECTED WILL

DAMAGE THE PUMP.

Pressure washers are useful cleaning tools designed to

clean almost any surface in two easy steps.

o The first step involves applying an appropriate deter-

gent/solvent solution to penetrate and loosen grime.

The detergent is applied at low pressure to avoid

splashing, overspraying and waste. Leave the solution

on surface for 3 to 5 minutes to allow solution to work,

o The second step involves cleaning the surface you

have prepared with the pressure washer and then

rinsing it clean.

To apply detergent follow these steps:

o Prepare your detergent solution as required by your

job.

o Place small filter of the clear, detergent siphoning tube

into the detergent container (Fig. 15),

o To stop flow of detergent, turn knob clockwise or re

move filter from detergent or set nozzle to high pres

sure position,

NOTE: Detergents are most effective when applied to a dry

surface.

PRESSURE WASHING/RINSING

WARNING: BE EXTREMELY CAREFUL IF YOU

A

MUST USE PRESSURE WASHER FROM LADDER,

SCAFFOLDING OR ANY OTHER RELATIVELY UN

STABLE LOCATION. PRESSURE IN A RUNNING

WASHER BUILDS IN THE WAND AS YOU CLIMB.

WHEN YOU PRESS THE TTHGGER, THE RECOIL

FROM THE INITIAL SPRAY COULD FORCE YOU

TO FALL, OR IF YOU ARE TOO CLOSE TO THE

CLEANING SURFACE, HIGH PRESSURE COULD

FORCE YOU OFF CLIMBING APPARATUS.

Set nozzle to low pressure mode. Detergent is not

siphoned in the high pressure mode (Fig. 13).

Start washer and apply detergent to a dry surface,

starting from the bottom and working up. You can

adjust the concentration of detergent by turning the

knob on the detergent injector (Fig. 16).

o Hook up water supply (Fig, 17).

o Adjust nozzle to select high pressure mode.

NOTE: Detergent will not flow when in the high pressure

mode.

o Start washer and work from the top of the surface to

the bottom,

NOTE: The high pressure mode is most effective when the

tip of the wand is held between 6 inches to two feet from

the surface being cleaned.

HOW TO USE OPTIONAL TURBO NOZZLE

8 The optional rotating turbo nozzle, in essence, expands

the area of the high pressure stream,

8 You cannot adjust the spray pattern with this nozzle.

8 You cannot apply detergent with this nozzle.

BEFORE STARTING THE ENGINE

To operate the engine you will need the following:

ENGINE OIL

IMPORTANT: ANY ATTEMPT TO CRANK OR START

THE ENGINE BEFORE IT HAS BEEN PROPERLY SERV

ICED WITH THE RECOMMENDED OIL RESULTS IN AN

ENGINE FAILURE,

A 20 oz. bottle of SAE 30 weight oil is included in the parts

carton,

11

Page 12

OPERATION

NOTE; When adding oii to the engine crankcase in the

future, use only higti quality detergent oil rated with API

service classification SC, SD, SE, SF, SG rated SAE 30

weight. Use no special additives. Select the oil’s viscosity

grade according to your expected operating temperature.

colder

5W30

Although multi-viscosity oils (5W30,10W30, etc.) improve

starting in cold weather, these multi-viscosity oils will result

in increased oil consumption when used above 32°F.

Check your engine oil level more frequently to avoid possi

ble damage from running low on oil. Oil sump capacity is

21 ounces,

ADD ENGINE OIL;

CAUTION: ANY ATTEMPT TO CRANK OR START

THE ENGINE BEFORE IT HAS BEEN PROPERLY

SERVICED WITH THE RECOMMENDED OIL RE

SULTS IN AN ENGINE FAILURE.

Place pressure washer on a level surface and remove

one of yellow Oil Fill Caps (Fig. 18), insert clean funnel

in opening, and add engine oil from the enclosed bottle

until level is at point of overflowing. Check engine oii

level before starting each time thereafter. If oil level is

below point of overflowing, fill to proper level. Crank

case oil capacity is about 620ml or 21 fluid ounces.

32°F warmer

SAE30

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS

TEM OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM SHOULD BE

EMPTIED BEFORE STORAGE OF 30 DAYS OR

LONGER. SEE “STORAGE” ON PAGE 17. NEVER USE

ENGINE OR CARBURETOR CLEANER PRODUCTS IN

THE FUEL TANK OR PERMANENT DAMAGE MAY OC

CUR.

o Clean area around fuel fill cap, remove cap,

o Add “UNLEADED" regular gasoline, slowly, to fuel

tank,

«• Install fuel cap and wipe up any spilled gasoline.

TO TURN ON WASHER

0 Attach one end of a garden hose to a cold water source.

Water supply should not exceed 140°F (55°C).

o Check that high pressure hose is attached to pump

outlet and that water supply is attached to pump inlet.

o Turn ON water,

a Press trigger on gun and wand assembly to force air

from high pressure hose,

a Start engine according to ‘TO START THE ENGINE."

TO START THE ENGINE

IMPORTANT; DO NOT RUN PUMP WITHOUT THE

WATER SUPPLY CONNECTED AND TURNED ON

a Start, store and fuel the unit in a level position,

a Open fuel shut-off valve,

a Press trigger on pressure washer wand to relieve high

pressure and/or purge the inlet hose of air.

a Adjust safety latch on spray gun to the ON position.

This disables the trigger so you cannot inadvertently

actuate a high pressure spray (Fig, 19).

ADD GASOLINE:

CAUTION: DO NOT OVERFILL THE FUEL TANK.

ALWAYS ALLOW ROOM FOR FUEL EXPANSION.

WARNING: NEVER FILL FUEL TANK INDOORS.

NEVER FILL RJEL TANK WHEN ENGINE IS RUN

NING OR HOT. DO NOT LIGHT A CIGARETTE OR

SMOKE WHEN FILLING FUEL TANK.

a Use regular UNLEADED gasoline with the pressure

washer engine. Regular leaded gasoline may also be

used if UNLEADED is not available. Fuel tank capacity

is 4 U.S. gallons.

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL SYS

TEM PARTS SUCH AS THE CARBURETOR, FUEL FIL

TER, FUEL HOSE OR TANK DURING STORAGE. ALSO,

EXPERIENCE INDICATES THAT ALCOHOL-BLENDED

FUELS (CALLED GASOHOL OR USING ETHANOL OR

METHANOL) CAN ATTRACTMOISTURE WHICH LEADS

Locate the Run/Stop switch (Fig, 20 on Page 13) next

to the engine cylinder head and set it to RUN,

Close the choke to FULL position (Fig. 21 on Page 13)

by sliding it to far position in direction indicated by arrow

on air cleaner housing.

Turn pressure control knob counterclockwise, two

turns from maximum pressure.

12

Page 13

OPERATION

FIG. 20

o Grasp the starter grip and pull slowly until you fee!

resistance. Then pull rapidly one time.

® When engine starts, move choke lever to "RUN" posi

tion. If engine fails to start, move choke lever to "RUN"

position and puli starter rope (maximum 2 pulls).

® If engine fails to start, repeat the previous two steps.

o Once engine has started, place the Safety Latch on

spray gun to the OFF position.

o Press trigger on gun and wand assembly. Water should

spray out the nozzle.

o Adjust nozzle for correct pressure, spray angle. You

can also turn the pressure control knob to the desired

pressure setting.

o Your pressure washer is ready to use.

IMPORTANT: AN INTERNAL THERMAL RELIEF VALVE

HAS A MAXIMUM TEMPERATURE SETTING OF 140°F

(60°C). IF YOU RUN THE PUMP FOR 5 MINUTES WITH

OUT PRESSING THE TRIGGER ON THE SPRAY GUN,

1/2 TO 1 OUNCE OF WATER IS RELEASED THROUGH

THE VALVE TO COOL THE UNIT. THE SMALL AMOUNT

OF WATER WILL DRIP OUT THE BOTTOM OF PUMP.

LOW OIL PRESSURE SHUTDOWN SYSTEM

The engine is equipped with a low oil pressure sensor that

shuts down the engine automatically when the oil pressure

drops below 6 psi. If the engine shuts down by itself and

the fuel tank has enough gasoline, check engine oil level.

INITIAL STARTUP

A delay built in the shutdown system allows oil pressure to

build during starting. The delay allows the engine to run for

about 10 seconds before sensing oil pressure.

SENSING LOW OIL PRESSURE

If the system senses low oil pressure during operation, the

engine shuts down. As the system shuts down, Oie low oil

light comes ON. However, once the engine has stopped

rotating, this light will go OFF, See Fig. 22 for schematic.

RESTARTING

If you try to restart the engine within 5 seconds after it shuts

down, the engine may NOT start, The system needs 5 to

10 seconds to reset.

If you do restart the engine after such a shutdown and

have not corrected the low oil pressure, the engine

runs for about 10 seconds as described above and then

stops.

SIPHONING

We recommend that you DO NOT siphon your water supply

from sources other than from connecting to household

water supply.

TIPS

Initially clean an area and then check the surface for

damage. If no damage is found, you can assume it is

okay to continue cleaning. Detergents work best when

applied to dry surface.

For most effective cleaning, keep spray nozzle be

tween 8 to 24 inches of cleaning surface.

Allow the detergent to soak in between 3-5 minutes

before washing and rinsing.

For cleaning, start at lower portion of area to be washed

and work upward, using long, even overlapping

strokes.

For rinsing, push nozzle sleeve to high pressure and

wait for detergent to clear. Start at top of area to be

rinsed, working down with same action as for cleaning.

Never use garden hose inlet to siphon detergent or

wax.

If you get the spray nozzle too close, especially using

high pressure mode, you may damage the cleaning

surface.

If you have the spray nozzle too far away, the cleaning

will not be as effective.

Do not get closer than 6 inches when cleaning automo

bile tires.

13

Page 14

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK

PRESSURE WASHER

Check/clean inlet filter and screen

Check high pressure hose.

Check detergent hose.

Check gun and wand for leaks.

Check pump oil ❖ X

Purge pump of air and contaniments

ENGINE

Check oil level

Change engine oil. « X*

Rétorqué head bolts.

Service air cleaner.

Clean/replace spark plug.

Clean spar k arrestor screen.

Prepare for storage,.

HOURLY OPERATING INTERVAL

Every 25

Before

Each Use

XV

X

X

X

X

X

Prepare unit for storage if it is to remain idle

longer than 30 days

Hours or

Yearly

X**

Every 50

Hours or

Yearly

SERVICE DATES

Every 100

Hours or

Yearly

X

X

X

V Clean if clogged. Replace if perforated or torn ♦ ChangeoHafterfirstShours, then after every 50 hours.

* Chnnge sooiicr when qpemliiig under heavy load or high ambicnl temperature ** Clean more often under dusty conditions or wt)cn jarbome debris is present

GENERAL RECOMMENDATIONS

The warranty of the high pressure washer does not cover

items that have been subjected to operator abuse or negiigence. To receive full value from the warranty, operator

must maintain high pressure washer as instructed in this

manual

Some adjustments will need to be made periodicaliy to

properly maintain your high pressure washer.

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season,

o Once a year you should replace the spark plug and

clean or replace the air filter and check the gun and

wand assembly for wear. A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

BEFORE EACH USE

o Check engine oil level.

o Check water inlet filter and quick-connect screen for

damage.

e Check high pressure hose for leaks,

o Check detergent inlet hose and filter for damage.

o Check gun and wand assembly for leaks,

o Purge pump of air and contaniments.

PRESSURE WASHER MAINTENANCE

Check and Clean Inlet Supply Filter and inlet Screen:

Remove quick-connect and examine inlet screen on the

female connector and filter on pump inlet fitting. Clean if

either is clogged or replace if either is torn.

Check High Pressure Hose: High pressure hose can

develop leaks from wear, kinking, abuse. Inspect hose

each time before using it. Check for cuts, leaks, abrasions

or bulging of cover, or damage or movement of couplings.

If any of these conditions exist, replace hose immediately.

DANGER: WATER SPRAYING FROM A LEAK £ CA

PABLE OF INJECTING MATERIAL INTO SKIN. NEVER

REPAIR HIGH PRESSURE HOSE. REPLACE WITH

HOSETHATMEETS MINIMUM PRESSURE RATING OF

YOUR PRESSURE WASHER.

Check Detergent Hose: Examine the filter on the deter

gent hose and clean if clogged. Hose should fit tightly on

barbed fitting. Examine hose for leaks or tears. Replace

the filter or hose if either is damaged.

Check Gun and Wand: Examine hose connection to gun

and make sure it is secure. Test trigger by pressing it and

making sure it springs back into piace when you release it.

Put safety latch in ON position and test trigger. You should

not be able to press trigger.

Check Pump Oil: Refer to PUMP MAINTENANCE for

information.

14

Page 15

CUSTOMER RESPONSIBILITIES

Purge Pump of Air and Contanlments;

To remove the air from the pump, follow these steps:

o Set up the pressure washer as described in the AS

SEMBLY section and connect the water supply.

<9 Remove the nozzle attachment from the gun.

o Pull the trigger on the gun and hold.

To remove the contanlments from the pump, foliow these

steps:

» Set up the pressure washer as described in the AS

SEMBLY section, connect the water supply and start

the engine according to instructions in the OPERA

TION section.

e Remove the nozzle attachment from the gun.

o Pull the trigger on the gun and hold.

o When thewatersupplyissteadyandconstant.you may

refasten the nozzle attachment and start the pump.

PUMP MAINTENANCE

WARNING: DO NOT ATTEMPT TO DISASSEMBLE

A

THE PUMP. WITHOUT THE PROPER TECHNIQUE,

ATTEMPTING TO DISASSEMBLE PUMP MAY

CAUSE PERSONAL INJURY. FOR SERVICE, CON

SULT A SEARS AUTHORIZED SERVICE CENTER

OR CONTACT YOUR PLACE OF PURCHASE.

CHANGING ENGINE OIL

o Change oil after first 8 hours of operation. Change oil

every 50 hours thereafter, if you are using your pres

sure washer under extremely dirty or dusty conditions,

or in extremely hot weather, change oil more often.

6 Change oil white engine is still warm from running, as

follows:

CAUTION: DISCONNECT SPARK PLUG WIRE

A

FROM SPARK PLUG AND KEEP IT AWAY FROM

SPARK PLUG.

Clean area around oil drain plug, remove plug and drain

oil completely into a suitable container (Fig. 23).

Pump Oil: Change pump oil after first 50 hours of opera

tion. Change pump oil every time you change the engine

oil. To change pump oil, follows these steps:

<* Place a proper container beneath the pump (Fig. 22).

OIL, LEVEL GAUGE

OIL DRAIN PLUG

BTG. 22

» Remove the Oil Drain Plug of pump and drain oil into

the container.

» When oil has drained completely, reinstall oil drain

plug.

o Remove pump's oil fill plug, insert funnel and add

recommended SAE 80W-90 oil until level reaches full

mark on gauge located on side of the pump. Capacity

is 5 ounces (150 grams).

» Reinstall the pump’s oii fill plug.

plug.

a Remove yellow oil fill plug and insert a clean fill funnel

into plug opening. Fill engine crankcase with recom

mended oii until oil level is at point of overflowing. Do

not overfili above the point or overflowing. About 21

ounces {620ml) is required. POUR SLOWLY.

o When engine crankcase is filled to proper level. Install

and tighten oil fili plug.

RETORQUE HEAD BOLTS

After 50 hours of operation, retorque the head bolts for this

GN-Series engine to 4.0 kg/m (29 foot-pounds).

ENGINE MAINTENANCE

CHECKING OIL LEVEL

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

Fig 24.

15

Page 16

CUSTOMER RESPONSÎBILITES

SERVICE AIR CLEANER

CAUTION: NEVER RUN THIS UNIT WITHOUT THE

A

COMPLETE AIR CLEANER SYSTEM INSTALLED

ON THE ENGINE. THIS COULD RESULT IN PRE*

MATURE WEAR TO THE ENGINE.

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

Clean or replace the air cleaner paper filter (Fig. 25) once

every 25 hours of operation or once a year, whichever

comes first. Clean or replace more often if operating under

dusty or dirty conditions. Clean foam pre-filter every 25

hours of operation or sooner under dusty conditions.

FOAM

PRE-FiLTER

COVER

CLEAN/REPLACE SPARK PLUG

Change tfie spark plug every 100 hours of operation or

once each year, whichever comes first. This will help your

engine to start easier and run better. Replace with Cham

pion RC12YC or equivalent type spark plug. Set spark plug

gap 0-030 inch (0,76mm).

CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor screen,

inspect and clean the screen every 100 hours of operation

or once each year, whichever comes first.

WARNING: LET THE MUFFLER COOL BEFORE

A

WORKING ON IT. CONTACT WITH A HOT MUF

FLER OR ENGINE CAN CAUSE SEVERE BURNS.

FIG. 25

To clean or replace foam pre-filler:

« Remove air cleaner cover, tfien foam pre-filter.

0 Wash pre-filter in soap water. Squeeze pre-cleaner dry

in clean cloth (DO NOT TWIST).

« Clean air cleaner cover before installing it.

To clean or replace paper air filter;

» Remove air cleaner cover; then remove foam pre-filter

(service if necessary) and remove paper filter.

0 Clean air filter by tapping it gently on a solid surface. If

the filter is too dirty, replace it witfi a new one. Dispose

of the old filter properly.

0 Clean air cleaner coverthen Insert pre-filter into cover.

Next insert new paper filter into cover to hold pre-filter

in place and assemble ail of them to the base of the air

cleaner.

FIG. 26

NOTE: If you use your pressure washer on any forest-cov

ered, brush-covered or grass-covered unimproved land, it

must have a spark arrestor. The spark arrestor must be

maintained in good condition by the owner/operator.

Clean and inspect the spark arrestor as follows:

a To remove the muffler guard from the muffler, remove

the three screws that connect tfie guard to the muffler

bracket (Fig. 26)

a Remove four screws that attach the spark arrestor

screen.

0 Inspect screen and replace if torn, perforated or other

wise damaged. DO NOT USE a defective screen. If

screen is not damaged, clean it with commercial sol

vent.

o Reattach the screen and the muffler guard.

16

Page 17

SERVICE AND ADJUSTMENTS

ENGINE SPEED

CAUTION: ENGINE SPEED WAS PROPERLY AD

A

JUSTED AT THE FACTORY AND SHOULD RE

QUIRE NO ADDITIONAL ADJUSTMENT. DO NOT

ATTEMPT TO CHANGE ENGINE SPEED. IF YOU

BELIEVE THE ENGINE IS RUNNING TOO FAST OR

TOO SLOW, TAKE YOUR PRESSURE WASHER TO

SEARS AUTHORIZED SERVICE CENTER FOR RE

PAIR AND ADJUSTMENT. CHANGING ENGINE

GOVERNED SPEED WILL VOID ENGINE WAR

RANTY.

Your pressure washer runs at a constant speed. This

constant operating speed is maintained by a mechanical,

flyweight type, fixed speed governor. DO NOT try to adjust

the governed speed setting for the following reasons:

o High engine speeds are dangerous and increase the

risk of personal Injury or damage to equipment.

Low engine speeds impose a heavy load on the engine

when sufficient engine power is not available and may

shorten engine life.

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust the

valve clearance in the engine.

When adjusting valve clearance, engine should be at room

temperature and piston should be at Top Dead Center

(TDC) of compression stroke (both valves closed). Correct

clearance is 0.05-0.1 mm. Adjust valve clearance as fol

lows:

o Loosen the rocker arm jam nut. Use an alien wrench

to turn the pivot ball stud while checking clearance

between the rockerarm and the vaive stem with a feeler

gauge (Fig. 27).

o When valve clearance is correct, hold pivot ball stud

with alien wrench and tighten rocker arm jam nut with

crows foot. Tighten jam nut to 65-85 inch-pounds

torque. After tightening jam nut, recheck valve clear

ance to make sure it did not change (Fig. 28).

NOZZLE MAINTENANCE

If the nozzle becomes restricted or clogged with foreign

materials, such as dirt, excessive pump pressure may

develop. A partially clogged nozzle can cause a pulsing

sensation during use. This generally is not a pump related

problem, but rather a clogged or partially restricted nozzle.

If the nozzle becomes clogged or partially restricted, imme

diately clean the nozzle with the kit included with your

pressure washer by following tiiese instructions:

o Shut off the engine and turn off the water supply.

0 Separate the wand from the gun.

o Remove nozzle from the end of the wand using a 2mm

or 5/64 alien wrench (like the one included in the kit).

o Use the wire included in the kit (Fig. 29) or a small paper

clip to free the foreign materials clogging or restricting

the nozzle.

17

Page 18

SERVICE AND ADJUSTMENTS

Remove additional debris by back flushing water sup

ply through wand (Fig. 30). Back flush between 30 to

60 seconds. Turn wand to stream spray and move

nozzle from low to high while flushing.

Reinstall nozzle into the wand. DO NOT overtighten.

Reconnect the wand to the gun

Reconnect the water supply, turn on the water, and

start the engine.

STORAGE

AFTER EACH USE

Water should not remain in the unit for long periods of time.

Sediments of minerals can deposit on pump parts and

“freeze” pump action. Follow these procedures after every

use:

o Flush detergent hose by placing the injector filter into

a pail of clear water while running Pressure Washer

with nozzle in low pressure mode. Flush until you can

see clear water running ttirough the tube.

o Shut off the engine and let it cool, then remove all

hoses.

CAUTION: BE SURE THE THROTTLE LEVER IS IN

A

“STOP” POSITION BEFORE YOU CONTINUE. IF

YOU START THE ENGINE WfTHOUTTHE PROPER

WATER SUPPLY CONNECTED, YOU CAN DAM

AGE THE PUMP.

® Empty the pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most of the

liquid in the pump.

o Coil the high pressure hose and inspect it for damage.

Cuts in ttie hose or fraying of it could result in leaks and

loss of pressure. Should any damage be found, replace

the hose. DO NOT attempt to repair a damaged hose

and use it. Replace the hose with the genuine Crafts

man part.

® Drain water from hose and properly hang it on the wire

support provided on the guide handle.

NOTE: To protect the unit from freezing temperatures, you

can draw windshield washer fluid into the pump by pouring

the washer fluid into a 3-foot section of garden hose con

nected to the inlet adaptor and pulling the recoil handle

twice,

® Store in a clean, dry area.

LONG TERM STORAGE

WARNING: NEVER STORE ENGINE WITH FUEL IN

A

TANK INDOORS OR IN ENCLOSED, POORLY VEN

TILATED AREAS WHERE FUMES MAY REACH AN

OPEN FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES DRYER

OR OTHER GAS APPLIANCE.

If you do not plan to use the Pressure Washer for more than

30 days, you must prepare the engine for long term storage.

Test the pressure washer by operating with nozzle in

the high and in the low position.

NOTE: As always, prepare the pressure washer pump as

you would after each use.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also, experience

indicates that alcohol-blended fuels (called “gasohol" or

using ethanol or methanol) can attract moisture which leads

to separation and formation of acids during storage. Acidic

gas can damage the fuel system of an engine while in

storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow these

instructions:

Protect Fuel System; Engines stored over 30 days need

to be protected or drained of fuel to prevent gum deposits

from forming in fuel system or on essential carburetor parts.

® For engine protection use a fuel stabilizer. Mix stabilizer

with fuel in fuel tank and run engine for short time to

circulate stabilizer through carburetor.

• If you did use “gasohol", run engine until engine stops

from lack of fuel. Make sure you have water supply to

pump inlet connected and turned ON.

Change Oil: While engine is still warm, drain oil from

crankcase. Refill with recommended grade.

Oil Cylinder Bore: Remove spark plug and pour about 1/2

ounce (15ml) of engine oil into the cylinder. Cover spark

plug hole with rag. Crank slowly to distribute oil.

CAUTIONI AVOID SPRAY FROM SPARK PLUG

A

HOLE WHEN CRANKING ENGINE SLOWLY.

o Install spark plug. Do not connect spark plug wire.

OTHER

® Do not store gasoline from one season to another.

® Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

e If possible, store your unit indoors and cover it to give

protection from dust and dirt. BE SURE TO EMPTY

THE FUEL TANK.

a Cover your unit with a suitable protective cover that

does not retain moisture.

IMPORTANT: NEVER COVER YOUR PRESSURE

WASHER WHILE ENGINE AND EXHAUST AREAS ARE

WARM.

18

Page 19

TROUBLESHOOTING

PROBLEM

Pump has foliowing problems:

failure to produce pressure, erratic

pressure, chattering, loss of pressure,

low water volume.

Detergent fails to mix with spray.

Engine ains good at no-load but "bogs

CAUSE

1, Nozzle in low pressure mode.

2. Low regulator pressure

3 Water inlet is blocked

4. Inadequate water supply

5,. Inlet hose is kinked or leaking

6 Clogged inlet hose strainer.

7. Detergent line is not submerged.

0, Water supply is over 140°F.

9. Outiet hose Is blocked or leaks.

10. Gun leaks.

11. Nozzle is obstructed.

12. Pump is faulty.

1. Detergent line is not submerged.

2 Chemical filter is clogged.

3. Nozzle is in high pressure mode.

4. Chemical adjuster is closed.

Engine speed is too slow.

CORRECTION

1. Pull nozzle backward for high

pressure mode.

2, Adjust regulator to desired setting.

3. Clear inlet

4. Provide adequate water flow.

5. Straighten inlet hose, patch leak,

6. Check and clean Inlet hose strainer,

7. Submerge detergent line

8. Provide cooler water supply.

9. Clear blocks in outlet hose.

10, Replace gun.

11. Clear nozzle.

12. Contact Sears Service Department.

1. Insert chemical line into detergent

2. Clean or replace fliter/detergent line.

3. Push nozzle fonvard for

low pressure mode.

4. Open chemical adjuster

Contact Sears Sen/ice Department.

Engine will not start; or starts

and runs rough

Engine shuts down during operation

Engine lacks power,.

1, Low oil level

2. Dirty air cleaner

3. Out of gasoline.

4. Stale gasoline.

5. Spark plug wire not connected

to spark plug

6. Bad spark plug.

7. Water in gasoline.

8. Oveirhoking.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or closed.

11, Engine has lost compression.

1. Out of gasoline.

2 Low oil level.

Dirty air filter.

1 Fill crankcase to proper level.

2. Clean or replace air cleaner.

3. Fill fuel tank.

4. Drain gas tank; fill with fresh fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain gas tank; fill with fresh fuel,

8. Open choke fully and crank engine.

9. Contact Sears Service Department.

10 Contact Sears Service Department

11. Contact Sears Service Department.

1. Fill fuel tank,

2. Fill crankcase to proper level.

Replace air filter.

Engine “hunts” or falters.

Choke is opened too soon.

19

Move choke to halfway position

until engine runs smoothly.

Page 20

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

Drawing No.. 97023 20

Page 21

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

ITEM PART NO. DESCRIPTION ITEM

1

3 84021

4

5 90878 Fuel Cap (1 req.) 46 95194

6

7

8 96404

9

10

11

12

13 87840 Tank Heat Shield

14

15 84687 #21/4“ thick Insulation {1 req.)

16 95203 Cradle (1 req.)

17

18 70644 M8-1.25 X 20mm Screw (3 req.)

19 84346 M8-1.25 X 35mm Capscrew {2 req)

20 52858 M8-1.25 Flange Lock Nut {19 req )

21 95635 Pump Support Bracket (1 req )

22 38750 M6-1.0 X 30mm Capscrew (2 req)

24 87985 Rear Wand Holder (1 req.)

25 86292 #10-16 Capscrew (6 req.)

26 87836 Wire Basket (1 req)

27 93728A Axle Pin (2 req.)

28 94222Q 5/8“ JAM Nut (2 req.)

29 49808 M12 Flat Washer (2 req.)

30 88521 Wheel Assembly (2 req.)

31 75402 1/2“ Push Nut (2 req )

32

33 39287

34

35 46476 1" square Cap Plug {2 req.)

36 94135 Rubber Fool Pad (2 req.)

37

38 89712

39

40 92535 Muffler Support Bracket (1 req.)

41 40976 M8-1.25 X 20mm Capscrew (2 req.)

42

90508

88325 Fuel Tank (1 req ) 45

78298 Tank Valve {1 req.) 47 77584

78299 Plastic Tank Bushing (1 req.) 48 89634

96405

78831B

83465 Tank Grommet {4 req)

77395 M6 Range Lock Nut (4 req.)

85000 Insulation Clip

84508 45-degree Vibration Mount (4 req)

95189

50190

88688 Muffler Assembly (1 req.)

90300 Muffler Support Bracket p req.)

80314

7.8 HP Engine (1 raq.)

Engine Support {1 req) 44 56893

Starting Instructions Decal (1 req ) 49 96168

Danger Decal (1 req.)

M6-1.0 x 60mm Capscrew (4 req.)

Support Leg (2 req)

M8-1.25 X 45mm Capscrew (6 req)

5/16" Flat Washer (4 req.,)

Wire Muflier Guard (1 req.)

Exhaust Gasket (1 req.)

PART NO.

43 90299

83083

50 95567

51 95587-B

52

53 96016

54 95319C

55 93790

56 94944

57 96542

58 96865

59 96430-A

60 96542

62

63 93871

64 23707

65

66 40945

67 95441

68

69 93887

70 93873

71 95454

72 52857

73 92659

74

75 93873

76 96581F

77 93723

78 94197

79 51767

81 82580A

82 48031G

95456

95165

92479

94738 Belleville Washer (1 req.)

40945

97019

DESCRIPTION

M5 X 10mm Screw (9 req.)

#10-24 Ciimptite Screw (2 req.)

Spark Arrester Screen (1 req.)

Guide Handle (1 req.)

Handle Grip (1 req.)

3/8“ I.D. Hose Assembly (1 req.)

Chemical Injector Hose

Assembly (l req.)

Gun Assembly (1 req.)

Adjustable Nozzle (1 req.)

Quick-Connect, male (1 req.)

Quick-connect, female f1 req.)

Pump Head Assembly (1 req.)

0-ring 2.62 X113.97 (1 req.)

Piston Pivot Shoe (3 req.)

Roller Thrust Bearing (1 req.)

3.0 GPM Axial Cam (1 req.)

Engine Adaptor (1 req.)

Roller Thmst Bearing (1 req.)

Engine Shaft Adaptor (1 req.)

Engine Adaptor Gasket (1 req.)

5/16"-24 X 1“ Capscrew (4 req.)

M8 Ribbed Lock Washer (4 req.)

M6-1,0 X 20mm Screw (6 req.)

Engine Adaptor Sleeve (1 req.)

Ml 6-1,5 JAM Nut(1 req.)

M6 Ribbed Lock Washer (6 req.)

Oil Fill Cap/Breather(1 req.)

M6-1.0 Locking Flange Nut (2 req.)

Replacement Nozzle [red] {1 req.)

M6-1.0 X 20 mm Capscrew (3 req.)

M6 Ribbed Lock Washer (3 req.)

Preset Unloader Assembly (1 req.)

Spindle Seat 0-ring (1 req.)

Pressure Gauge [optional] (1 req.)

M6-1.0 X 45mm Capscrew (2 req.)

Hose (1 req.)

3/16" Hose Clamp (2 req.)

Owner's Manual [not shown] (1 req.)

21

Drawing No. 97023

Page 22

CRAFTSMAN 2500 PS! HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

Drawing No. 97020

22

Page 23

CRAFTSMAN 2200 PSI HIGH PRESSURE WASHER 580.751651

REPAIR PARTS

ITEM PART NO. DESCRIPTION ITEM

1 93871 Engine Adaptor Gasket (1 req.)

2 96430-A Engine Adaptor (1 req.) 41 95367

3 93869 Thrust Ball Bearing (1 req.) 42 95372

5 95165 Engine Adaptor (1 req.) 43 95378

6 96865 Axial Cam (1 req) 44 95377

7 96542

8 93790 114x119x2,6 O-ring (1 req.) 46 93787

9 95386 Piston Spring Retainer (3 req) 47

10 95217 Piston, D15S.S. (3req.)

11 96400 Piston Return Spring (3 req.) 49

12

13 93873

14 40945 M6 X 1.0 X 20mm Capscrew (7 req.)

15 94404 Aluminun Crankcase (1 req,)

16 93680 Pistlon Oil Seal (3 req.)

17 93668 Pilot Spacer (3 req.)

18 93667 Seal (3 req.)

19 96015 Bearing Ring Sea! (3 req.)

20

21

22

23 95504 Back-up Ring (1 req.)

24 95503 O-Ring 2.62 X 17.12 mm (6 req.)

25 96005 Valve Check Kit (6 req )

26 95896 Check Valve Seat Support (3 req.)

27 23707 5/16"-24 X 1" Bolt (4 req.)

28 93652 Thetmal By-pass Spring (1 req.)

29

30 94402 Spacer Plate (1 req )

31 93673 O-ring 4,5 X 8 X1.8 (2 req.)

32

33

34 93644

35 95320 Garden Hose Connector (1 req.)

36 95138 Cylinder Head (1 req.)

37 95382 Spindle Seat (1 req.)

38 93722 O-Ring, 0.68 X 0.81 x 0.06 (2 req.)

39

92479 M8 Ribbed Lock Washer (10 req.) 50 95384

95454 Oil Fill/Breather (1 req.)

95895 High Pressure Port Tower (3 req.)

96053 High Pressure Sea! [black] (3 req.)

95416 By-pass Piston (1 req.)

93678 M5-0.8 X 20 Truss Head Bolt (2 req.)

93645

93874

Thrust Roller Bearing (1 req.) 45 93788

M6 Ribbed Lock Washer (9 req.)

Head Gasket (1 req )

Thermal By-pass Actuator (1 req.)

M8-125 X 75mm Capscrew (6 req.)

PART NO.

40 95373

95376

48

51 95364-B

52 95381-B

53 96137

54 93723

55 95216

56 95369

57

58

59 95363

60 96069

61 95506

62 95453

63 57163

64 95371

65 95380

66 94738

67

68 95366

69 95441

71 94944

72 94284

73

74

75 93656

76 93657

77

78

95374

95375

95368

95370

93887

93876

95379

51767

DESCRIPTION

Unloader Assembly Spindle (1 req.)

Unloader Piston Guide (1 req.)

0-ring 1.78 X 14mm (1 req.)

Chemical Injector Fitting (1 req.)

High Pressure Outlet Adaptor {1 req.)

0-ring 1.78 X 12.4mm (1 req.)

O'ling 1.78 X 15.6mm (1 req.)

Spring (1 req.)

High Pressure Outlet Piston (1 req.)

O'ring, #2.4 X 4.3 {1 req.)

Pressure Adjust Spring (1 req.)

Pressure Adjust Adaptor with groove

{1 req.)

Pressure Adjust Handle [red] (1 req.)

1/8" NPT Pipe Plug (1 req.)

“0" Ring 2.6 X 20.2 (1 req.)

Pressure Relief Valve Body (1 req.)

Back-up O-ring 11 x 12.4 (1 req.)

Unloader Piston (1 req.)

O-ring 1.78x7.65(1 req.)

Spring Support (1 req.)

Quad-Ring 0.09 x 1.06“ (3 req )

Back-up Ring (3 req.)

Sight Gauge Assembly

3/8" NPT Magnetic Plug (1 req.)

Piston Support O-ring {1 req.)

Chemical Injector Spring (1 req)

Belleville Washer (1 req.)

Ml6-1.6 JAM Nut {1 req.)

M18X1.0 Nut(1 req.)

Engine Adaptor Sleeve (1 req.)

Piston Pivot Shoe (3 req.)

“C” Ring Retainer (3 req.)

O-Ring, 0.12 X 0.25 x 0.6 (1 req.)

Ball (1 req.)

0-Ring 1.78x6.07(1 req.)

Back-up Ring 1.24 x 6.7 (1 req.)

Unloader Assembly (1 req.)

M6-1.0 X 45mm Capscrew (2 req.)

23

Drawing No, 97020

Page 24

CRAFTSMAN 2200 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

Drawing No. 97064

24

\

CO

ro

e

i

c

Page 25

CRAFTSMAN 2200 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

ITEM PART NO. DESCRIPTION

1 90508

2 77182E

3

81675

4 81810

5 83312

6 90695A

7

90876

8

78631

9

10 78608A

11

12 78602

13 83015

14

15 90051

16 91846

17

18 90947

19 82774

20 86962

21

22

24

25

26 86384

27

28 78643

29 83503

30 89739

90948

78601

81671

78609

78604

83502

83782

86037

83781

Engine, Taper Shaft (1 req)

Flywheel Assembly (1 req.)

Ignition Coil Assembly {1 req.)

Ml 6-1,5 Hex Nut (1 req)

Conical Washer (1 req)

Blower Housing (1 req.)

Carburetor Assembly (1 req )

Carb /Manifold Gasket {1 req)

HS Intake Manifold (1 req )

Air Cleaner Cover (1 req.)

Air Filter Element (1 req.)

Air Filter Pre-Cleaner (1 req.)

Recoil Cup (1 req.)

Recoil Assembly (1 req.)

Manifold/Head Gasket (1 req.)

Carburetor/Alr Cleaner Gasket (1 req)

Bolt - Air Cleaner Cover (2 req)

Breather Hose (1 req.)

4x19 Woodruff Key (1 req.)

Governor Lever Ass (1 req.)

Governor Spring (1 req.)

Governor Adjusting Screw (1 req.)

idle Control Coil (1 req)

Anti-Lash Extension Spring (1 req.)

Governor Rod (1 req.)

Gov, Adjust Bracket (1 req)

Carburetor Mtng. Bolt (2 req.)

M5-0.8 Lock Nut (1 req)

Bottom Wrapper (1 req.)

ITEM PART NO. QTY. DESCRIPTION

31 78607

32

33

34

35 72347

36

37

38

39 59635

40 83504

42

43 82981

44

45

46 22097

47

48

49

51

56

57

58 92978

61

62

64

68

69

78651C

92984

80303

45756

66476

80316

81668

78653

49813

83512

86753

77667

84195

85953

91848

87221A

88758

94820

66311

49811

Air Cleaner Base (1 req.)

Blower Housing Back Plate (1 req.)

Top Wrapper (1 req.)

Breather Canal Cover (1 req.)

RC12YC Spark Plug

[Champion] (1 req.)

M6-1.0 X 10mm Bolt (5 req.)

M6-1.0 X 12mm Capscrew (11 req.)

with lock washer {2 req.)

M6‘1.0 X 30mm Capscrew

with lock washer (1 req )

No. 8 X 3/8" Plastite Screw {1 req.)

Choke Lever Knob (1 req)

M6-1.0 X 10mm Capscrew with

lock washer (6 req.)

M6'1.0 X 30mm Taptite Bolt {2 req)

Shut-off Switch (1 req.)

M8-1.0 Hex Nut (2 req )

M6 Lock Washer (1 req.)

M8 X 15 mm Taptite Bolt (1 req.)

Low Oil indicator LED {1 req.)

4 psi Oil Pressure Switch (1 req.)

LOS Engine Decal (1 req.)

Carburetor Wear Washer (1 req)

Oil Fitter Pad Gasket {1 req.)

M6-1.0 X 20mm Screw (2 req)

LOS Module [optional] (1 req.)

By-pass Adaptor [optional] {1 req.)

Expansion Plug (1 req)

JAM-M8-1.25 Hex Nut (1 req)

M6-12.5 O.D, Flat Washer (1 req)

25

Drawing No. 97064

Page 26

CRAFTSlUiAN 2500 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

Drawing No. 88588

26

Page 27

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 580.751781

REPAIR PARTS

ITEM PART NO. DESCRIPTION

1

2 76389 Piston Pin {1 req.)

3 88411 Piston Ring Set [standard Size] (1 req.)

4 81694

5 72683 1/8" Npt Pipe Plug (1 req.)

6 88057 75mm dla. Piston {1 req)

7

8 83337

9 78658 Governor Ami “R” Pin (1 req)

10 76354

11

12 76349 Sleeve Bearing (1 req.)

13 81695

14

15 78645 Governor Retainer [“C” Ring] (1 req)

16 76365 Governor Spool {1 req )

17 78699B 12mm l.d. Dowel Sleeve (3 req)

10

19 89096 Crankcase Flange Gasket (1 req.)

21 88058

22

23

24

25

26 78606 M6-1.0X 12mm Screw

27 76361

28 89230 Flanged Hex Head Capscrew {6 req)

76380 Connector Rod and Cap Assembly {1 req)

1/4' Npl Magnetic Pipe Plug (1 req.)

76390 Piston Pin Retainer (2 req.)

89213A Crankcase Sub-assembly (1 req.)

76359 Governor Gear Assembly (1 req.)

83335 Camshaft Assembly {1 req.)

78691 Oil Pressure Spring Retainer (1 req.)

76367

76362 Oil Pressure Bail {1 req.)

78692

Crankshaft Assembly With Gear (1 req)

Governor Arm (1 req)

Crankshaft Oil Seal (2 req.)

Cylinder Head Gasket (1 req)

on Pressure Spring (1 req )

M5 Thread-forming Bolt (1 req)

and Lock Washer (4 req)

Thrust Washer <1 req )

ITEM PART NO.

29 89665A

30 86293

31 8B401

32

33 83152

34

35 78659

36

37

38

39 8B396A

40

41

42 88397

43 77161

44

45 76307

46 88403

47

48 68412

49 76329

50 72B57

51 83153

52

53 84186

54

57 83773F

88590

76381

88404B

90082

90081

83235 Tappet (2 req .)

80336

77160 Rocker Arm {2 req.)

77168

86254

88156

DESCRIPTION

Gear Cover Sub-assembly (1 req.)

Valve Spring Retainer Valve (2 req.)

Valve Spring (2 req.)

0 10 X 20 Dowel Pin (1 req.)

Inner Gerotor (1 req.)

Connecting Rod Boll {2 req,)

Governor Arm Washer (1 req.)

Cylinder Head Casting Assembly

Exhaust Valve {1 req.)

Intake Vali« (1 req.)

Push Rod {2 req.)

OH Pickup Assembly (1 req.)

Rocker Cover Gasket (1 req.)

Bali Pivot Stud (2 req.)

Jam Nut [rocker Arm] (2 req.)

Push Rod Guide Plate (1 req.)

M8 X 52mm Head Bolt (5 req.)

Rocker Cover Breather Assembly (1 req.)

Ol! Fill Plug {1 req )

1/4" Npt Pipe Plug (1 req )

Outer Gerotor (1 req.)

“0" Ring [17..8- l.d. x 2.4' Thick] (1 req.)

Wear-valve Spring Washer

Intake Valve Seat (2 req.)

Decal - Serial Number (1 req )

FULL ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained and operated according

to the instnjctions in the owner's manual, Sears will repair, free of charge, any defect in material and workmanship.

If this washer is used for commercial purposes, this warranty applies for only 90 days from the dale of purchase. If this high

pressure washer is used for rental purposes, this warranty applies for only 30 days after date of purchase.

FULL TWO YEAR WARRANTY ON CRAFTSMAN ENGINE

For two years from the date of purchase, when this Crafstman engine is maintained and operated according to the instructions

in the owner's manual, Sears will repair, free of charge, any defect in material and workmanship.

if the Craftsman Engine is used for commercial or rental purposes, this warranty applies for only one year from the date of

purchase.

This wamanty does not cover:

* Expendable items such as spark plugs and air filters, which become worn during normal use.

6 Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instmctions contained in the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, Hoffman Estates, !L 60179

27

Drawing No. 88588

Page 28

BEAm CRRFTSMflN’

OWNER’S

MANUAL

MODEL NO.

580.751781

IF YOU NEED

REPAIR SERVICE

OR PARTS

7.8 HORSEPOWER

2500 PSI 3.0 GPM

HIGH PRESSURE WASHER

Each High Pressure Washer has its own model number. Each engine has

its own part number.

The model number for your pressure washer will be found on a decal

attached to tfie unit.

The part number for your engine will be found in the parts list.

All parts listed herein may be ordered through Sears, Roebuck and Co.

Sen/ice Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL

LOWING INFORMATION:

® PRODUCT — HIGH PRESSURE WASHER

FOR REPAIR SERVICE CALL

THiS TOLL FREE NUMBER

® MODEL NUMBER — 580.751781

1-800-4®REPA!R

® PART NUMBER

(1-800-473-7247)

® PART DESCRIPTION

FOR REPLACEMENT PARTS

INFORMATION AND ORDER

ING, CALL THIS TOLL FREE

NUMBER:

1-800-FON-PART

(1-800-366-7278)

SEARS, ROEBUCK and CO,, Hoffman Estates, IL 60179 U.S.A.

Your Seam merchandise has added value when you consider that Sears

has service units nationwide staffed with Sears trained technicians....pro

fessional technicians specifically trained on Sears products, having the

parts, tools and the equipment to ensure that we meet our pledge to you,

we service what we sell.

Part No.. 97019 Revision 0 (4/27/95)

Printed in U.S.A

Loading...

Loading...