Craftsman 580.751651 User Manual

OWNER’S

MANUAL

MODEL NO.

580.751651

PRESSURE WASHERy*»^

CUSTOMER \

HELPLINE X

CRAFTSMAN

6.5 HORSEPOWER

2200 PSI 3 GPM

HOURS:

Mon. - FrI, 8 a.m. to 5 p.m

(CST)

CAUTIONi

Read and Follow

ail Safety Rules

and Instructions

Before Operating

This Equipment

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Part No. 97016 Revision 4 (1V14/95)

HIGH PRESSURE WASHER

Assembiy

Operation

Customer Responsibilities

Service and Adjustment

Repair Parts

A

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CON

TACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS TO YOUR HIGH PRESSURE WASHER.

A

TRAINING:

• Engine exhaust gases contain DEADLY carbon monox

ide gas. This dangerous gas, if breathed in sufficient

concentrafions, can cause unconsciousness or even

deafii. Operate tfiis equipment only in the open air where

adequate ventilation is available.

• WARNING: Engine exhaust from this product contains

chemicals, known, In certain quantities, to cause cancer,

birth defects, or ottier reproductive harm.

• Gasoline is highly FLAMMABLE and its vapors are EX

PLOSIVE, Do not permit smoking, open flames, sparks

or heat in the \^cinity while handling gasoline. Avoid

spilling gasoilne on a hot engine. Allow uriitto cool for 2

minutes before rekieling. Comply with all laws regulating

storage and handling of gasoline.

• Locate this pressure washer in areas away from combus

tible materials, combustible fumes or dust.

• The high pressure equipment is designed to be used with

Sears authorized parts only. If you use this equipment

with iMits that do notcompiy with minimum specifications,

the user assumes ail risks and liabilities.

• Some chemicals or detergents may be harmful if inbaied

or ingested, causing severe nausea, fainting or poisoning.

The harmfui elements may cause property damage or

severe injury.

• .Do not allow CHILDREN to operate the Pressure Washer

at any time.

PREPARATION:

• Operate engine only at governed speed. Running the

engine at excessive speeds Increases the hazard of

personal injury. Do not tamper with parts which may

IllvItsfaoU Ui Uciwlcfcloc? U№ yuVciiTrciU opticu.

• Do not wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

• Before starting the Pressure Washer in cold weather,

check all parts of the equipment and be sure ice has not

formed there.

• Units with broken or missing parts, or without protective

housing or covers should NEVER be operated.

• The muffler and air cleaner must be installed and in good

condition before operating the Pressure Washer, These

components act as spark arrestors if the engine bac Wi res.

• Check the fuel system for leaks or signs of deterioration

such as chafed or spongy hose, loose or missing clamps

or damaged tank or cap. Correct all defecte before oper

ating the Pressure Washer.

OPERATION:

• Do not spray flammable liquids.

• Never aim the gun at people, animals or plants.

• Never allow any part of the body to come in contact with

the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the high pressure hose.

• High pressure stream of fluid that this equipment can

produce can pierce skin and its underlying tissues, lead

ing to serious injury and possible amputation.

High pressure spray can cause paint chips or otiier par

ticles to become airborne and fly at high speeds.

Always wear eye protection when you use tills equipment

or when you are In the vicinity where the equipment is In

use.

Operate the pressure at no more tiian the PSI fluid

pressure rated for your pressure washer.

Never move the machine by pulling on the high pressure

hose. Use the handle provided on the top of the unit.

Always be certain the spray gun, nozzles and accessories

are corredly attached.

Never use a spray gun which does not have a trigger lode

or trigger guard in place and in working order.

Use a respirator or mask whenever there Is a chance that

vapors may be inhaled. Read all instructions with the

mask so you are certain the mask will provide the neces

sary protection against inhaling harmful v^ors.

High pressure spray may damage fragile items including

glass. Do not point spray gun at glass when in the jet

spray mode.

Keep the hose connected to machine or the spray gun

white the system is pressurized. Disconnecting the hose

while the unit is pressurized is dangerous.

Hold the spray gun firmly in your hand before you start

the unit. Failure to do so could result in an injury from a

whipping spray gun. Do not leave the spray gun unat

tended while the machine is running.

The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fail due to slippery

surfaces.

Keep water spray away from electric wiring o r fatal electric

shock may result

Do not adjust unloader valve to a pressure in excess of

machine rating.

Do not secure trigger gun in the pull-back (open) position.

Do not by-pass any safety device on this machine.

Do not leave trigger closed for more than 5 minutes with

engine running. This could damage the pump.

The muffler and engine heat up during operation and

remain hot Immediateiy after shutting it down. Avoid

contact with a hot muffler or engine or you could be

severely burned,

MAINTENANCE AND STORAGE:

Operate and store this unit on a stable surface.

High pressure hose can develop leaks from wear, kJnking,

abuse, etc. Water spraying from a leak is capable of

injecting material into skin. Inspect hose each time before

using it. Check all hoses for cuts, leaks, abrasions or

bulging of cover, or damage or movement of couplings. If

any of these conditions exist, replace hose immediately.

Never repair high pressure hose. Replace it with another

hose that meets minimum pressure rating of your pres

sure washer.

A

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS “ATTENTION!!! BE

COME ALERT!!! YOUR SAFETY IS INVOLVED.”

CONGRATULATiONS on your purchase of a Sears Crafts

man high pressure washer. It has been designed, engi

neered and manufactured to give you the best possible

dependability and performance.

ihould you experience any problem you cannot easily

•jmedy, please contact your nearest Sears Service Cen-

•ir/Department or call the 1-800 number listed on the front

J this manual. We have competent, well-trained techni

cians and the proper tools to service or repair this unit.

PRODUCT SPECIFICATIONS

PUMP PRESSURE

FLOW RATE

DETERGENT MiX

DETERGENT RATIO

Adjustable to 2200 psl

3gpm

_________________

Use undiluted detergent

Adjustable to 73:1

Please read and retain this manual. The instructions will

enable you to assemble and maintain your high pressure

washer properly. Always observe the ‘‘SAFETY RULES."

MODEL

NUMBER

SERIAL

NUMBER,

DATE OF

PURCHASE,

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE PRES

SURE WASHER.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

580.751651

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement Is available on this prod

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

« Read and observe the safety rules.

6 Follow regular schedule in maintaining, caring for and

using your high pressure washer.

• Follow the instructions under “Customer Responsibili

ties“ and “Storage” sections of this Owner’s Manual.

WATER SUPPLY

TEMPERATURE

SUCTION HEIGHT

Engine Specifications

ENGINE MODEL

RATED HORSEPOWER

DISPLACEMENT

SPARKPLUG: Type:

Set Gap To.

GASOLINE CAPACITY

OIL (20 oz. capacity}

SOLID STATE IGNITION

AIR GAP

NOTE: The engine of the pressure washer is ©quipped with

a spark arrestor muffler. The spark arrestor must be main

tained in effective working order by the owner/operator.

in the State of California a spark arrestor is required by taw

(Section 4442 of the Cailfomia Public Resources Code}.

Other states may have similar laws. Federal laws apply on

federal lands.

Not to exceed 140°F

3 FT. maximum

GN-Series

6.5

190CC

Champion RC12YC

or equivalent

0.030 inch (0.76mm)

1 U.S. gallon

SAE 30 weight

0.0125 inch

TABLE OF CONTENTS

SAFETY RULES

PRODUCT SPECIFiCATIONS

ACCESSORIES AND ATTACHEMENTS

CONTENTS OF HARDWARE PACK............................................ 6

ASSEMBLY.......................................................................... 7-8

OPERATION

Assembly

Removing from Carton.

Before Starting

Customer Responsibilities

Schedule,

General Recommendations,

Pump

Engine Speed.

........................................................................

...................................................

......................................

...................................................................

, 9,16 Hardware Pack ......... . 6 Repair Parts...........................

7

....7

.. 7-8

B

11-12

....3

14-16

...15

...15

...14

...14

... IS

...16

...16

...16

IE

. 17

High Pressure Hose.

Low Oil Pressure System .

Maintenance Pressure Washer Pump ...

Engine

Pump......................................

Oil, Engine

Operation

Detergent Application ...... .. 11

Stopping.

To Start Engine ........... .. 12

To Turn On Washer

To Use

3

9-13

....................................

.....

..........................

...

.........................

....................................

2

CUSTOMER RESPONSIBILITIES..........................................14-16

SERVICE AND ADJUSTMENTS.................................................17

5

STORAGE................................................................................ 18

TROUBLESHOOTING................................................................ 19

REPLACEMENT PARTS.......................................................20-26

WARRANTY

-H-

..................

-L-

- M-

- 0 -

............ ....

_p_

.....

.................................................................... 27

. 6.8

_s-

,. 13

.. 15

.. 15

3,11

.

.. 10

.. 12

,, 10

Safety Latch

Safety Rules....................

Service and Adjustments . 17-18

Storage

Engine..................................

Troubleshooting

Valve, friermal relief....

Warranty

....................

.................................

— T —

......................

_ V —

-W-

............... — ...

..

..

. 20-26

...12

__ _

2

...18

... 18

... 18

.. . 19

,. . 13

...27

Gun and Wand Assembly... 8,9

Pressure Regulator

....................

. . 10

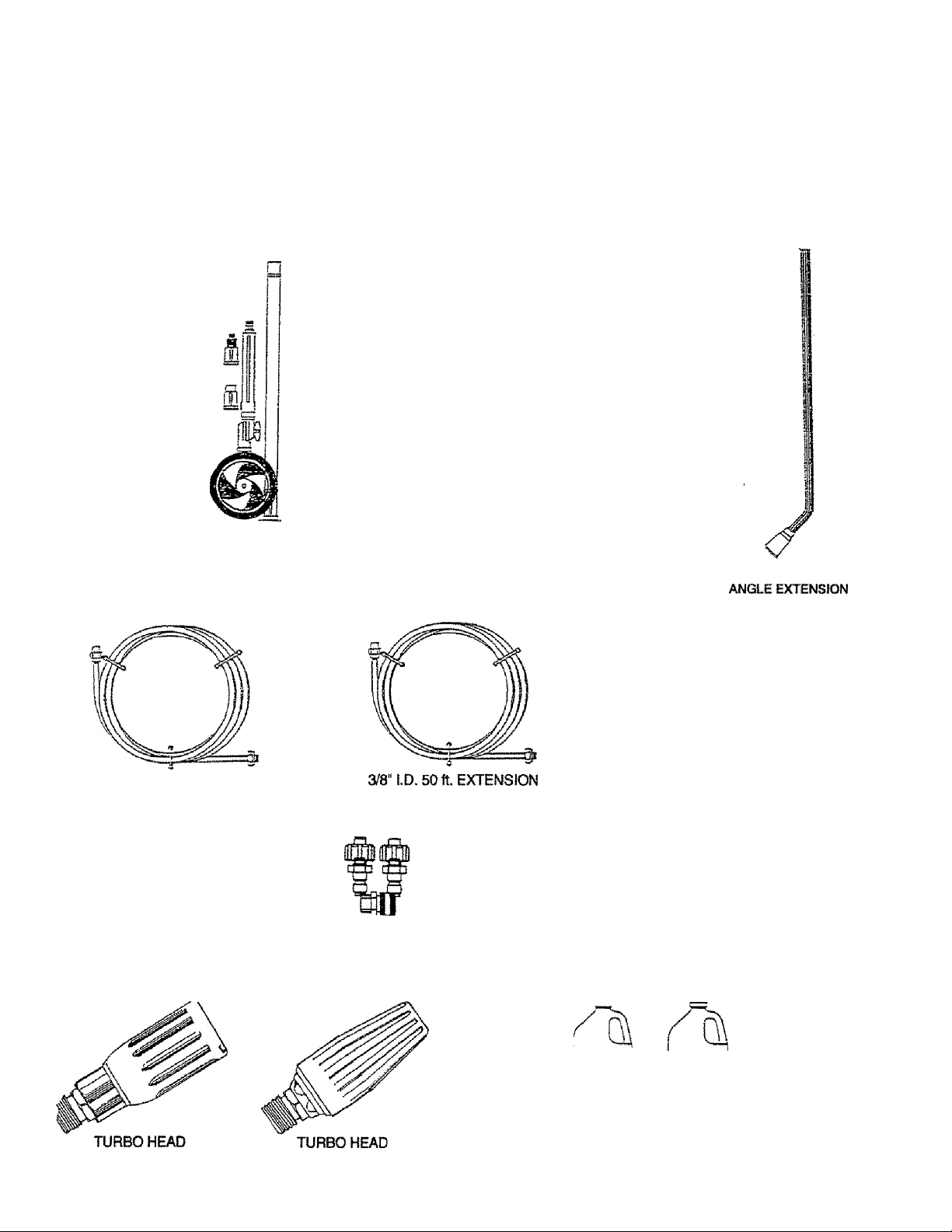

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available when the high pressure washer was purchased. They are also

vallable at most Sears retail outlets and service centers. Most Sears stores can order №ese items for you when you

irovide the model number of your high pressure washer. Some of these accessories may not apply to your pressure

asher.

SE

u

w

FLOOFVSIDING

BRUSH KIT

1/4“

,D. 25 ft. EXTENSION

HOSE

Cai!fw23

HIGH PRESSURE

HOSE QUICK CON

NECT KIT

ROTATING BRUSH

KIT

ACCESSORY

QUICK CONNECT

UTILITY BRUSH KIT

ACCESSORY

QUICK CONNECT

STARTER KIT

18* STAINLESS

STEEL E>tTENSION

HOSE

HIGH PRESSURE

HOSE TO HOSE

COUPLING

ELECTRIC TURBO

NOZZLE

a @

............

CHEMICAL INJECTION

FOAMER

A

GARDEN HOSE

QUICK CONNECT

WITH 2 ADAPTORS

KIT

'am

PRESSURE

GAUGE

1800 PSI (max.)

2200 and 2500 PSI (max.)

MULTI-PUR-

POSE/HOUSE

WASH

DECK WASH

VEHICLBBOAT

WASH

DEGREASER

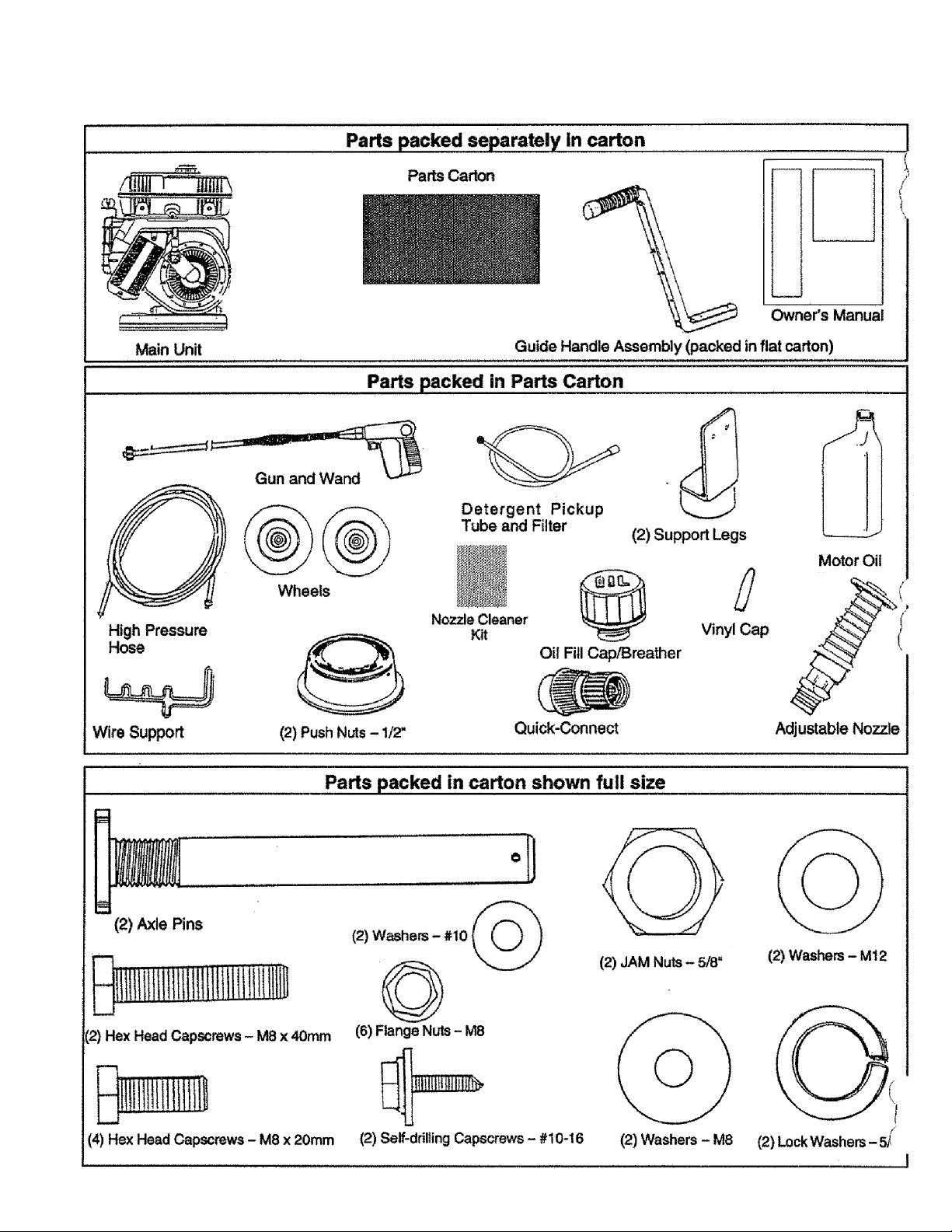

CONTENTS OF HARDWARE PACK

ASSEMBLY

Read these instructions and Operator's Manual in its en

tirety before you attempt to assemble or operate your new

high pressure washer. Your high pressure washer has, for

he most part, been assembled at the factory, except those

>a Its i eft unassembled. Before you can operate your new

high pressure washer, you must assemble the wheel kit and

properly connect the hi^ pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR PRESSURE WASHER, PLEASE CALL THE

PRESSURE WASHER HELPLINE AT 1-800-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

Maliet

2 adjustable wrenches OR the following wrenches:

5/16" (8mm) combination wrench

1/2" (13mm) combination wrench

5/8“ (16mm) combination wrench

11/16" (18mm) combination wrench

7/8" (22mm) combination wrench

15/16" (24mm) combination wrench

TO REMOVE PRESSURE WASHER FROM CARTON

' Remove two boxes marked "PARTS INSIDE” and re

move the parts contained in both boxes.

Remove unit with one hand under pump and one hand

under recoil starter.

Refer to Page 6, "Contents of Hardware Pack” for an

illustrated listing of all the items included with your pressure

washer. Become familiar with each piece before assen>

bling the pressure washer. Check all contents against the

illustrations on Page 6. If any parts are missing or dam

aged, call the Pressure Washer Helpline at 1-800-222

3136.

HOW TO SET UP YOUR PRESSURE WASHER

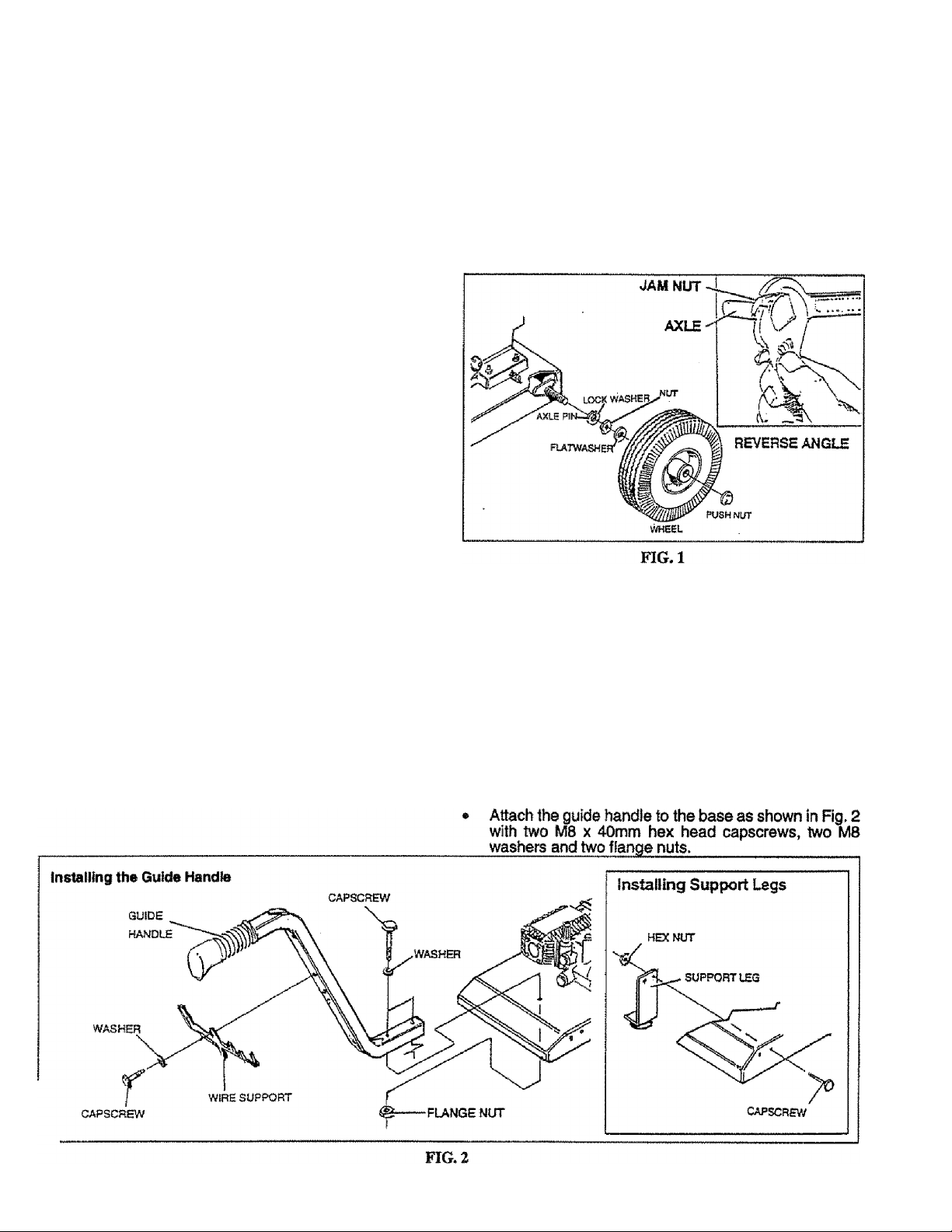

TO INSTALL THE WHEEL KiT

Installing the wheel kit requires the tools listed, the guide

handle and items included in the parts carton.

» Prop up the engine end of the main unit. This will allow

you to slip each axle pin into the holes provided on the

side of the base (Fig, 1).

With the axle pin inserted inside the base, grip the end

of the axle pin as shown with an adjustable or 15/16"

combination wrench. This will keep the axle from spin

ning as you fasten the axle to the base with a 5/8" lock

washer, a 5/8''-l8 JAM nut, and an M12 fiat washer.

Place wheels on the axles so the valve side of hub is

facing outward.

Retain each wheel to its axle pin by tapping a push nut

onto end of axle with a mallet.

Attach support legs to base as shown in Fig. 2 with M8

X 20mm hex head capscrews and flange lock nuts.

Tighten with 13mm or 1/2-tnch wrench on each fas

tener. Be sure legs are straight when you are finished.

ASSEMBLY

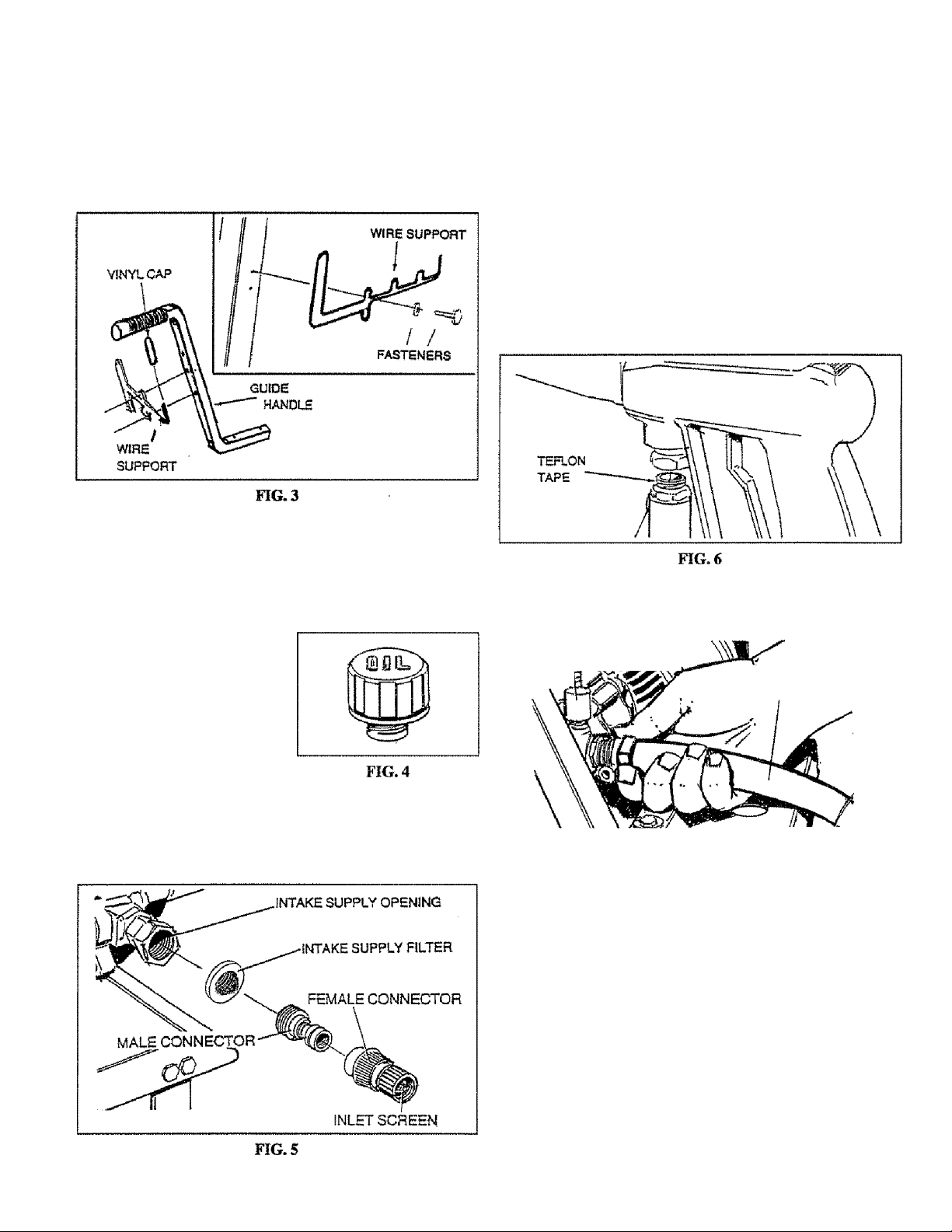

Attach wire support to two lower holes in guide handle

with #10 self-drilling screws and #10 flat washers (Fig.

3). The hose minder should be to the left and gun holder

to the right. Be sure loop of support is pointing upward.

Place vinyl cap onto gun holder.

TO ASSEMBLE REMAINING COMPONENTS

IMPORTANT: YOU MUST ASSEMBLE WAND AND AT

TACH ALL HOSES BEFORE YOU START ENGINE.

STARTING ENGINE WITHOUT ALL HOSES CON

NECTED AND WATER SUPPLIED WILL DAMAGE

PUMP.

Remove cap from top of

pump and insert oil fill

cap attached to other

end of yellow warning

tag. .

Screen In water inlet for cleanliness and inspect Inlet

Screen on female connector. Reattach male connector

to water inlet and attach female connector to garden

hose,

Unravel high pressure hose, remove protective cap

from end of hose and check other end of hose to see

that threads are properly covered with teflon tape. If

tape is not properly applied, reapply it so threads are

fully covered. The tape seals the connection from hose

to gun and wand assembly.

Attach fitting with tefi on tape to gun and wand assembly

(Fig. 6). You may want to spin gun. Tighten with adjust

able wrench to keep hose from twisting.

Attach the other end of the high pressure hose to htgh(

pressure fitting on pump (Fig. 7). Tighten with adjust-'

able wrench. (

DETERGENT PICKUP TUBE

iGH PRESSURE

nwoC

Included with this unit is a Quick-Connect fitting you

attach to Water Inlet on pump. The quick-connect

includes two parts — a Male Connector factory-in

stalled on water inlet and a Female Connector (Fig. 5).

Remove male connector to inspect Intake Supply

FIG. 7

• Attach Detergent Pickup Tube and Filter as shown in

Fig. 7.

• To attach the adjustable nozzle, refer to Operation

section, Fig, 9.

CHECKLIST

• Check that fasteners you used to instali wheels and

handle are tight. Vibration during operation may

loosen fasteners that are not tight enough.

• Check for proper hose connections (high pressure and

water supply) and for tight connections and that there

are no kinks, cuts, or damage to the high pressure

hose.

• Provide proper water supply (not to exceed 140®F).

• Be sure to read “Safety Rules” and “C^eration” Sfci>

tions before using the pressure washer.

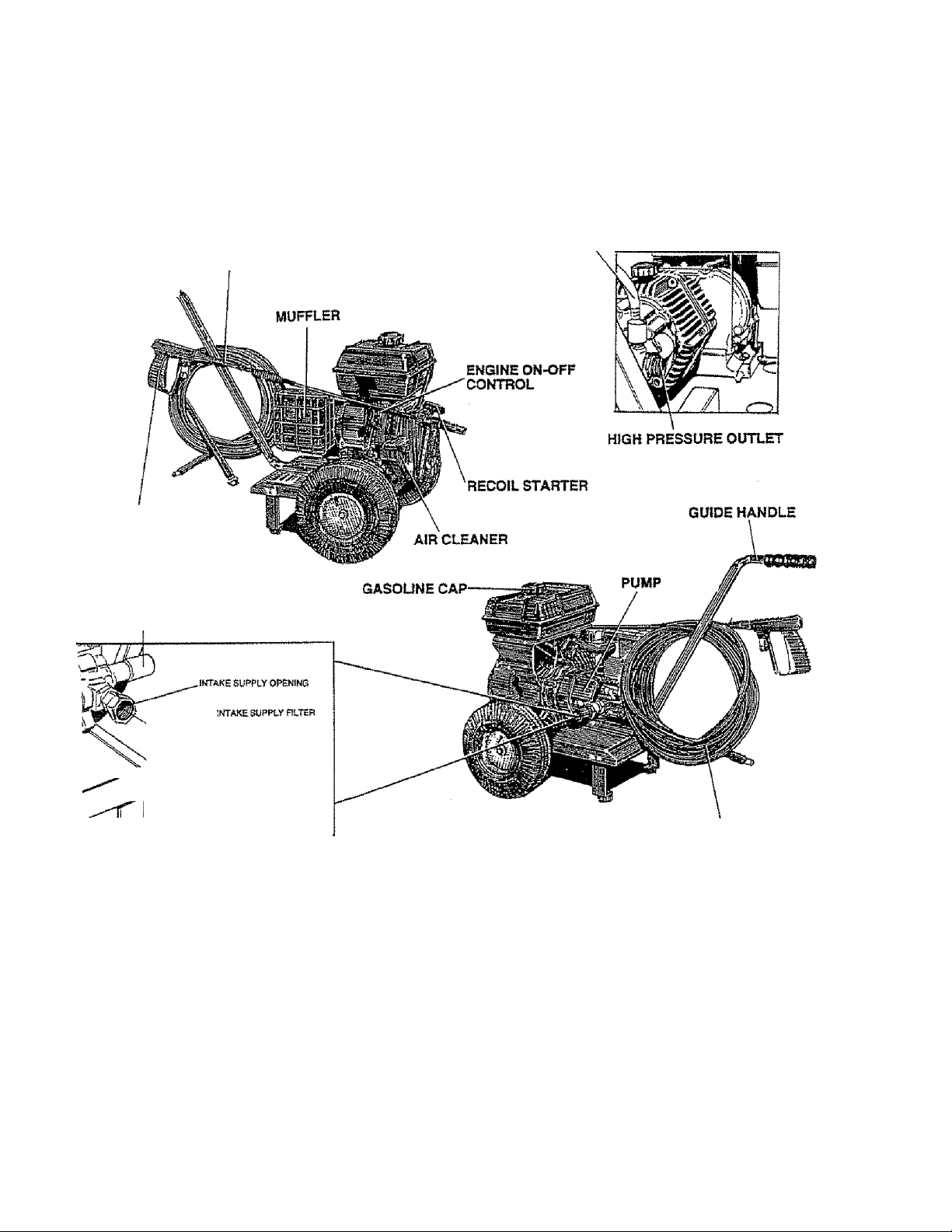

OPERATION

KNOW YOUR HIGH PRESSURE WASHER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HIGH PRESSURE WASHER.

Compare the illustrations with your high pressure washer to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

WIRE SUPPORT FOR

GUN AND HOSE STORAGE

GUN AND WAND

ASSEMBLY

PRESSURE

REGULATOR

DETERGENT PICKUP TUBE

AND FILTER

OIL HLL OPENING

FcMAL£ CONNECTOR

MALE CONNECTOR\

iNLST SCREEN

QUICK-CONNECT

PUMP •— Develops high pressure.

PRESSURE REGULATOR — Allows you to adjust the

pressure of the outlet stream.

ENGINE ON-OFF CONTROL — Sets engine in starting

mode for recoil starter; turns OFF running engine.

RECOIL STARTER Used for starting the engine manu

ally,

AIR CLEANER - Dry type filter element limits the amount

•'f dirt and dust that gets in the engine.

HIGH PRESSURE HOSE

FIG. 8

GUN AND WAND ASSEMBLY—Controls the application

of water onto cleaning surface with trigger device. Includes

safety latch.

INTAKE SUPPLY FILTER — Filters inlet water supply.

DETERGENT PICKUP TUBE AND FILTER — Mixes water

and detergent in outlet water flow.

HIGH PRESSURE OUTLET — Connection for high pres

sure hose.

QUICK-CONNECT ~ Easy connection for intake water

supply.

Loading...

Loading...