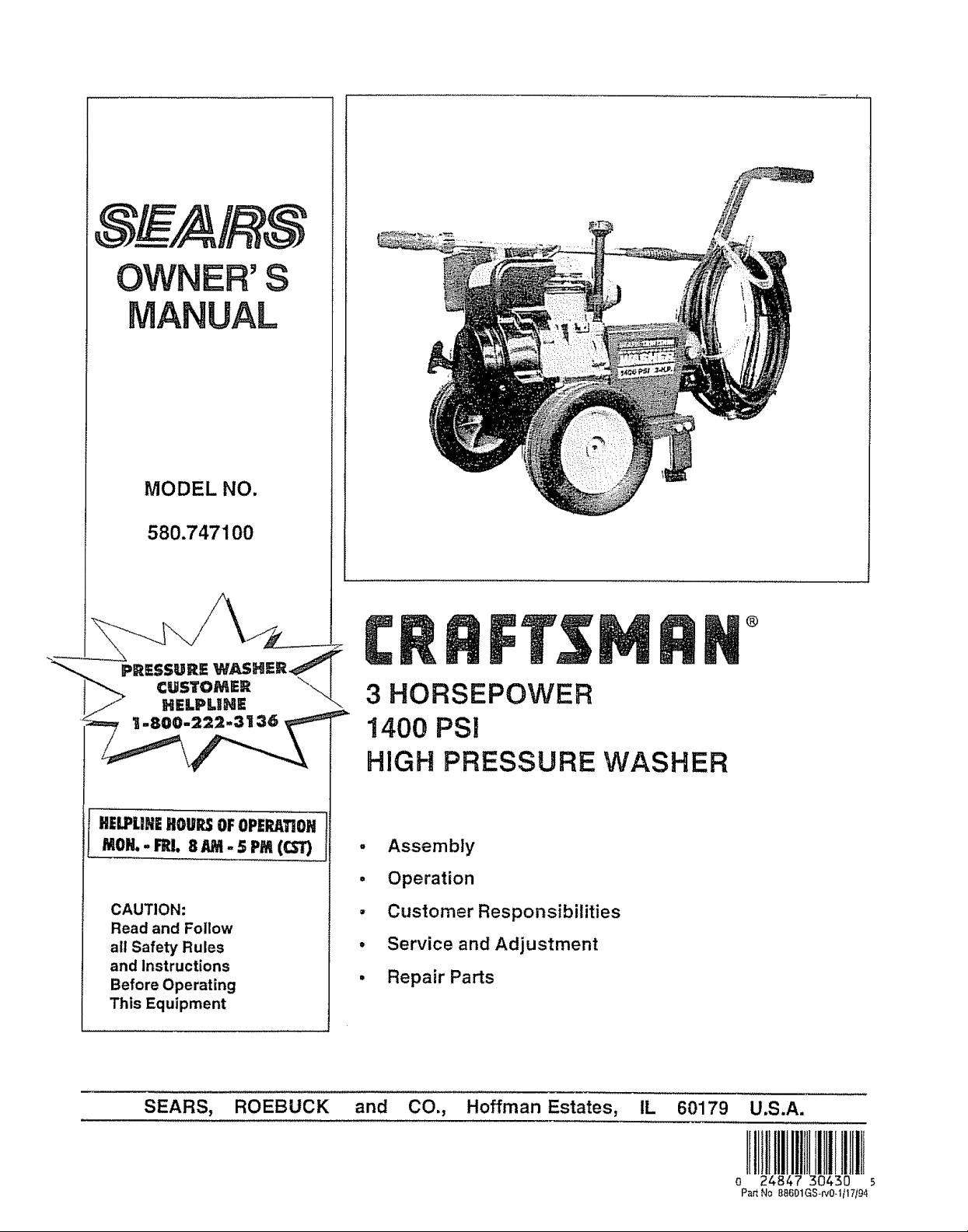

Page 1

OWNER'S

MANUAL

MODEL NO.

580.747100

®

3 HORSEPOWER

1400 PSi

HIGH PRESSURE WASHER

HELPUHEHOURSOFOPERATIOH

_oH.. F_L8 AM-SPM(CS_

CAUTION:

Read and Follow

all Safety Rules

and instructions

Before Operating

This Equipment

SEARS, and CO., Hoffman Estates, IL 60179 U.S.A.

. Assembly

• Operation

• Customer Responsibilities

° Service and Adjustment

• Repair Parts

!lllll

o 24847 30430 5

Par_No 88601GS_rv0.1/17/94

Page 2

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT

CONTACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANS-

PORTING, ADJUSTING OR MAKING REPAIRS TO YOUR HIGH PRESSURE WASHER.

TRAINING:

= Engine exhaust gases contain DEADLY carbon mon-

oxide gas., This dangerous gas, if breathed in suffi-

cient concentrations, can cause unconsciousness or

. even death., Operate this equipment only in the open

air where adequate ventilation is avaitable_

• Gasoline is higl_ly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the vicinity while handling gasoline.

Avoid spilling gasoline on a hot engine° Allow unit to

cool for 2 minutes before refueling. Comply with all

taws regulating storage and handling of gasoline.

" Locate this pressure washer in areas away from corn-

bustible materials, combustible fumes or dust..

o The high pressure equipment is designed to be used

with Sears authorized parts only. If you use this

equipment withparts that do not comply with minimum

specifications, the user assumes all risks and liabili-

ties.,

• Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea, fainting

or poisoning. The harmful elements may cause prop-

erty damage or severe injury..

o Do not allow CHILDREN to operate the Pressure

Washer at any time.

PREPARATION:

o Operate engine only at governed speed.. Running the

engine at excessive speeds increases the hazard of

personal injury. Do not tamper with parts which may

increase or decrease the governed speed.,

o Do not wear loose clothing, jewelry or anything that

may be caught in the starter or other rotating parts,.

= Before starting the Pressure Washer in cold weather,

check all parts of the equipment and be sure ice has

not formed there,.

" Units with broken or missing parts, or without protec-

tive housing or covers should NEVER be operated.,

o The muffler and air cleaner must be installed and in

good condition before operating the PressureWasher.

These components act as spark arrestors ifthe engine

backfires_

• Check the fuet system for leaks or signs of deteriora-

tion such as chafed or spongy hose, loose or missing

clamps or damaged tank or cap. Correct all defects

before operating the Pressure Washer.

OPERATION;

" Do not spray flammable liquids,

o Never aim the gun at people, animals or plants..

= Never allow any part of the body to come in contact

with the fluid stream. DO NOT come incontact with a

fluid stream created by a leak in the high pressure

hose.

• High pressure stream of fluid that this equipment can

produce can pierce skin and its underlying tissues,

leading to serious injury and possible amputationv

• High pressure spray can cause paint chips or'other

particles to become airborne and fly at high speeds.

• Always wear eye protection when you use this equip-

ment or when you are inthe vicinity where the equip-

ment is in use.

• Operate the pressure at no more than the PS1 fluid

pressure rated for'your pressure washer,.

'_ Never move the machine by pulling on the high pres-

sure hose,. Use the handle provided on the top of the

unit,,

o Always be certain the spray gun, nozzles and acces-

sories are correctly attached.

• Never use a spray gun which does not have a trigger

lock or trigger' guard in place and in working order.

• Use a respirator or mask whenever there is a chance

that vapors may be inhaled,. Read all instructions with

the mask so you are certain the mask will provide the

necessary protection against inhaling harmful vapors.

• High pressure spray may damage fragile items includ-

ing glass, Donot point spray gun at glass when in the

jet spray mode,

• Keep the hose connected to machine or the spray gun

while the system is pressurized.. Disconnecting the

hose while the unit is pressurized is dangerous,

• Hold the spray gun firmly in your' hand before you start

the unit., Failure to do so could result in an injury from

a whipping spray gun_ Do not leave the spray gun

unattended while the machine is running.

• The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to

slippery surfaces_

• Keep water spray away from electric wiring or fatal

electric shock may resulL

o Do not adjust unloader valve to a pressure in excess

of machine rating.

o Do not secure trigger gun in the pull-back (open)

position.

• Do not by-pass any safety device on this machine,

• Do not leave trigger closed for more than 5 minutes

with engine running. This could damage the pump.

• The muffler and engine heat up during operation and

remain hot immediately after shutting it down. Avoid

contact with a hot muffler or engine or you could be

severely burned.

MAINTENANCE AND STORAGE;

• Operate and store this unit on a stable surface.

• High pressure hose can develop leaks from wear,

kinking, abuse, etc. Water spraying from a leak is

capable of injecting material into skin, Inspect hose

each time before using iL Check all hoses for cuts,

leaks, abrasions or bulging of cover, or damage or

movement of couplings. If any of these conditions

exist, replace hose immediately_ Never repair high

pressure hose. Replace it with another hose that

meets minimum pressure rating of your' pressure

washer.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS° IT MEANS "ATTENTION!!! BE-

COME ALERT!!! YOUR.SAFETY IS INVOLVED."

Page 3

CONG RATULATtONS on your purchase ofa Sears Crafts-

man high pressure washer° it has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department We have competent, well-trained techni-

cians and the proper tools to service or repair this unit.

Please read and retain this manual, The instructions will

enable you to assemble and maintain your high pressure

washer properly, Always observe the "SAFETY RULES."

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

OUTLET PRESSURE

FLOW RATE

DETERGENT MIX

WATER SUPPLY

TEMPERATURE

SUCTION HEIGHT

1400 psi

2 gpm

Use undiluted detergent

Not to exceed 140°F

3 FT'.maximum

MODEL

NUMBER 580_741700

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE PRES-

SURE WASHER.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP 1N A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

" Read and observe the safety rules.

o Follow regular schedule in maintaining, caring for and

using your high pressure washer.

o Follow the instructions under "Customer Responsibili-

ties" and "Storage" sections of this Owner's Manual,.

Engine Specifications

RATED HORSEPOWER

DISPLACEMENT

SPARK PLUG: Type:

Set Gap To.

GASOLINE CAPACITY

OIL (20 oz. capacity)

SOLID STATE IGNITION

AIR GAP

In the State of California a spark arrestor is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar taws. Federal laws apply on

federal lands

NOTE: If you equip the engine of your pressure washer with

a spark arrestor muffler, the spark arrestor must be main-

tained in effective working order by the owner/operator

You can order a spark arrestor through your Sears Service

Center. See Pages 16 and 17 for details.

3HP

9.06 CU.inches (_

Champion J-8C

or equivalent

0.030 inch (0,76m.m) ....

1 U.S. quart

SAE 30 weight

0.0125 inch

ONE YEAR LIMITED WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained and operated

according to the instructions in the owner's manual, Sears wilt repair, free of charge, any defect in material and

workmanship.

If the Craftsman High Pressure Washer is used for commercial purposes, this warranty applies for only 90 days

from the date of purchase,. If the high pressure washer is used for rental purposes, this warranty applies for only

30 days after date of purchase.

This warranty does not cover:

Expendable items

o Repairs necessary because of operator abuse or negligence, including both crankshaft and the failiure to

maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state,

SEARS, ROEBUCK AND CO,, D/817 WA, Hoffman Estates, IL 60179

Page 4

TABLE OF CONTENTS

SAFETY RULES ................................................................2

PRODUCT SPECIFICATIONS .................................3

ACCESSORIES AND ATTACHEMENTS ............. 4

CONTENTS OF HARDWARE PACK ...................... 5

ASSEMBLY .............................................................................6

OPERATION ............................................................7-10

-A-

Air Cleaner , .............. 7,12

Assembly

Removingfrom Carton ........... 6

Tools Required ..................... 6

Set Up ................................... 6

ma_

Before Starting ........... :.. 9

--C--

Carburetor _............... 12

Customer Responsibilities . 1,11

Changing Oil ...................... 11

Checking Oil Level .................... 1 t

General Recommendations ....... 11

Pump ................................. 12

Replace Spark Plug ................ 12

Service Air Cleaner .................. 12

-E-

Engine Speed ............... 12

Gun and Wand Assembly .. 6, 7

Hardware Pack ............. 5

High Pressure Hose ......... 7

Maintenance

Engine .......................... 12

Pump ............................ 11, 13

Oil, Engine .................. 9

Operation

Detergent Application .............. 8

Stopping ............................. 8

To Start Engine .................. 10

To Turn On Washer ............. 9

To Use .......................... 8

CUSTOMER RESPONSIBILITIES ................. 11-12

SERVICE AND ADJUSTMENTS .......................... 12

STORAGE ............................................................ 13

TROUBLESHOOTING ............................................. 14

REPLACEMENT PARTS ................................ 15-19

INDEX

-G-

-H-

Parts Shipped Loose ....... 6

Preparing Washer ........... 6

Pressure Regulator ........... 7

-p-

-R-

Repair Parts ............ 15-19

-M-

-S-

Safety Latch ............... 9

Service and Adjustments °.. 12

Storage ................... 13

-O-

Engine ....................... 13

PressureWasher Pump ....... 13

-T-

Troubleshooting .......... 14

-W-

Warranty .................. 3

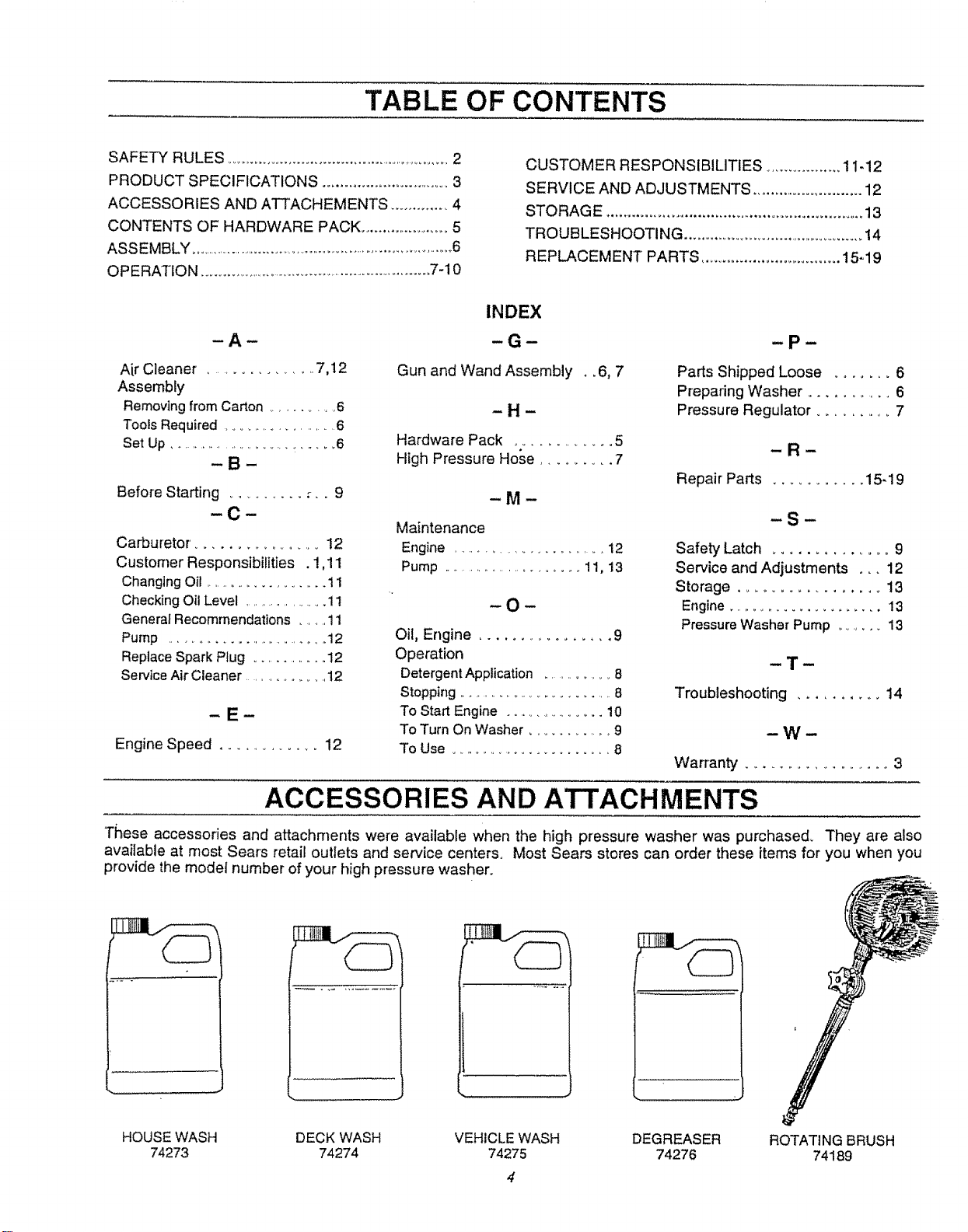

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available when the high pressure washer was purchased° They are also

available at most Sears retail outlets and service centers. Most Sears stores can order these items for you when you

provide the model number of your high pressure washer.

HOUSE WASH DECK WASH VEHICLE WASH DEGREASER ROTATING BRUSH

74273 74274 74275 74276 74189

4

Page 5

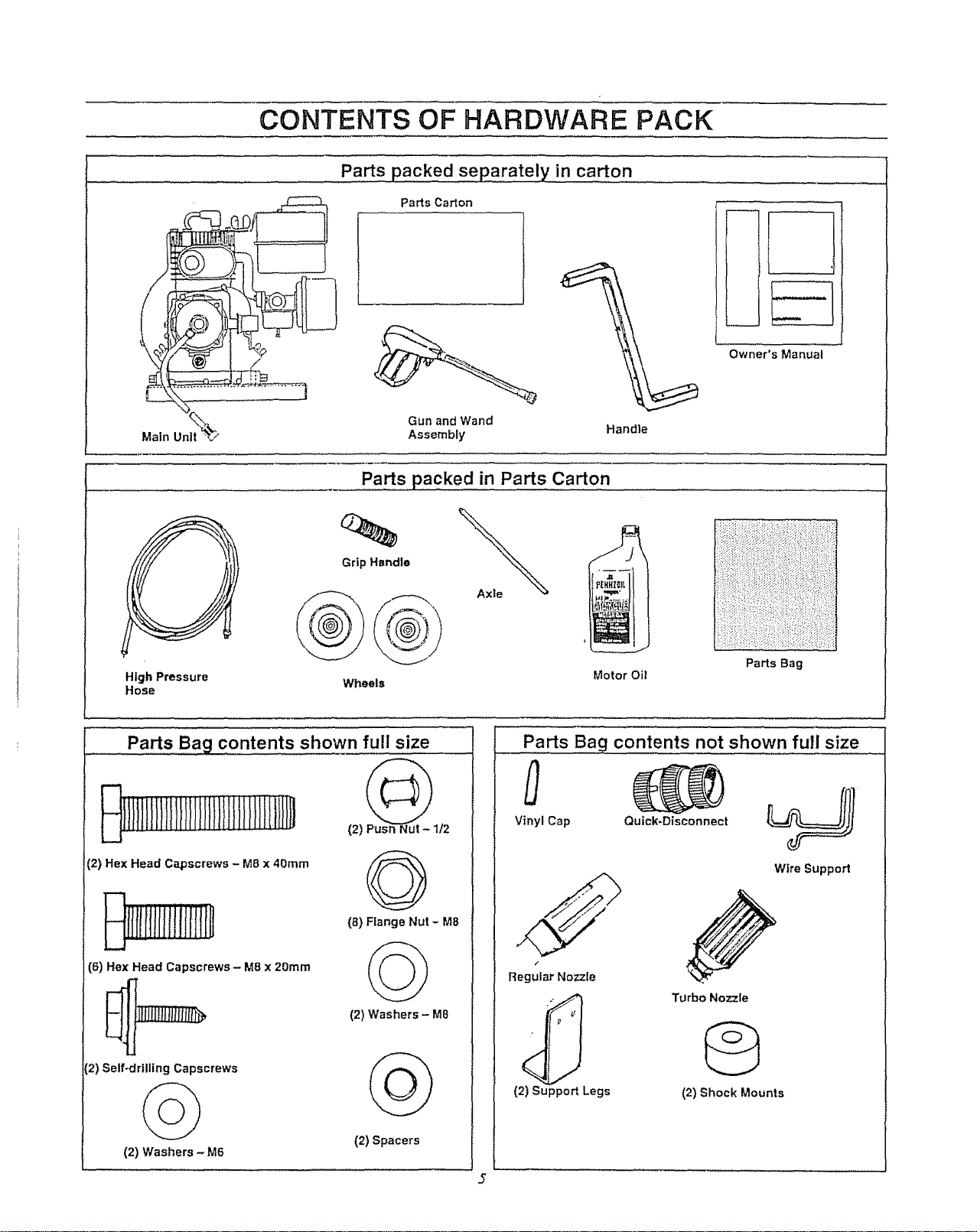

Main

CONTENTS OF HARDWARE PACK

Parts packed separately in carton

Parts Ca_on

Owner's Manual

Gun and Wand

Assembly Handle

Parts packed in Parts €,,a,_o,n........

Grip Hsndle

High Pressure

Hose

Parts Bag contents shown full size

(2) Hex Head Capscrews - M8 x 40ram

irliilriitffrJir

(6) Hex Head Capscrews - M8 x 20mm

2) Self-drilling Capscrews

Wheels

O

(8) Flange Nut - M8

(2) Washers - M8

Motor Oi!

Parts Bag contents not shown full size

Vinyl Cap Quick*Disconnect __.JJ II

/

Regular Nozzle

Turbo Nozzle

Parts Bag

Wire Support

G

(2) Support Legs

(2) Shock Mounts

(2) Washers _ M6

(2) Spacers

5

Page 6

Read these instructions and Operator's Manual in its en-

tirety before you attempt to assemble or operate your new

high pressure washer. Your high pressure washer has, for

the most part, been assembled at the factory, except those

parts left unassembted. Before you can operate your' new

high pressure washer, you must assemble the wheel kit and

properly connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEM-

BLY OF YOUR PRESSURE WASHER, PLEASE

CALL THE PRESSURE WASHER CUSTOMER

HELPLINE AT 1-800-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

• Mallet

• Socket wrench with 1/2-inch or 13ram Sockets

• Crescent Wrenches or Combination Wrenches

• 8ram nut driver

TO REMOVE

PRESSURE WASHER FROM

CARTON

Remove guide handle (wrapped in plastic)o

Remove accessories box from carton_

Q

Remove gun/wand assembly from cardboard holder.

Remove all other packing material from box before

removing your high pressure washer.

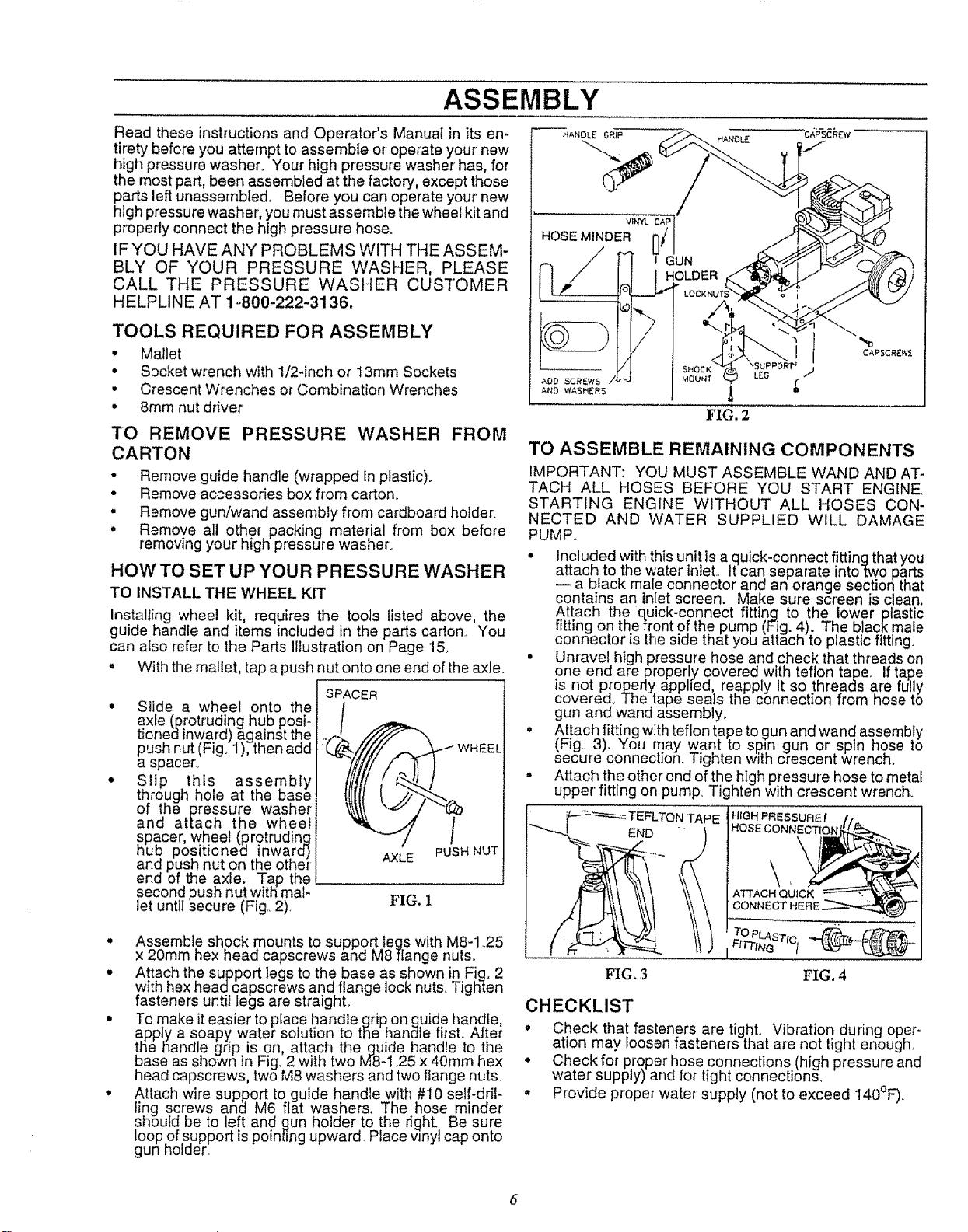

HOWTO SET UP YOUR PRESSURE WASHER

TO INSTALL THE WHEEL KIT

Installing wheel kit, requires the tools listed above, the

guide handle and items included in the parts carton. You

can also refer to the Parts Illustration on Page 15.

• With the mallet, tap a push nut onto one end of the axle.

Slide a wheel onto the

axle (protruding hub posi-

tionedinward) against the

push nut (Fig. 1),then add

a spacer',

Slip this assembly

through hote at the base

of the pressure washer

and attach the wheel

_pacer, wheel (protruding

ub positioned inwara)

and push nut on the other

end of the axle. Tap the

second push nut with mal-

let until secure (Fig. 2)

SPACER

AXLE PUSH NUT

FIG. 1

TO ASSEMBLE REMAINING COMPONENTS

IMPORTANT: YOU MUST ASSEMBLE WAND AND AT-

TACH ALL HOSES BEFORE YOU START ENGINE.

STARTING ENGINE WITHOUT ALL HOSES CON-

NECTED AND WATER SUPPLIED WILL DAMAGE

PUMP.

• Included withthis unit is a quick-connect fitting that you

attach to the water inlet, Itcan separate into two parts

a black male connector and an orange section that

contains an inlet screen. Make sure screen is clean.

Attach the quick-connect fitting to the lower plastic

fitting on the front of the pump (Fig. 4). The black male

connector is the side that you attach to plastic fitting

• Unravel high pressure hose and check that threads on

one end are properly covered with teflon tape. If tape

is not proper],/apphed, reapply it so threads are fully

covered, The tape seals the connection from hose to

gun and wand assembly_

• Attach fitting with teflon tape to gun and wand assembly

(Fig. 3). You may want to sp)n gun or spin hose to

secure connection. Tighten with crescent wrench.

• Attach the other end of the high pressure hose to metal

upper' fitting on pump. Tighten with crescent wrench.

rAPE

END

• Assemble shock mounts to support legs with M8-1 25

x 20mm hex head capscrews and M8 flange nuts.

• Attach the support legs to the base as shown in Fig, 2

with hex head capscrews and flange lock nuts. Tighten

fasteners until legs are straight.

• To make it easier' to place handle grip.on guide handle,

appJy a soapy water solution to the handle first. Af!er

!he handle grip is on attach the guide handle to the

Dose as shown in Fig, 2 with two M8-1,25 x 40mm hex

head capscrews, two M8 washers and two flange nuts.

• Attach wire support to guide handle with #I0 self-dril-

ling screws and M6 flat washers. The hose minder

should be to left and gun holder to the right. Be sure

loop of support is pointing upward Place wnyt cap onto

gun holder,.

TO PLASTrc,

FITTING t

FIG. ,3

FIG. 4

CHECKLIST

o Check that fasteners are tight. Vibration during oper-

ation may loosen fasteners that are not tight enough_

• Checkfor proper hose connections (high pressure and

water supply) and for tight connections,

• Provide proper' water supply (not to exceed 140°F).

6

Page 7

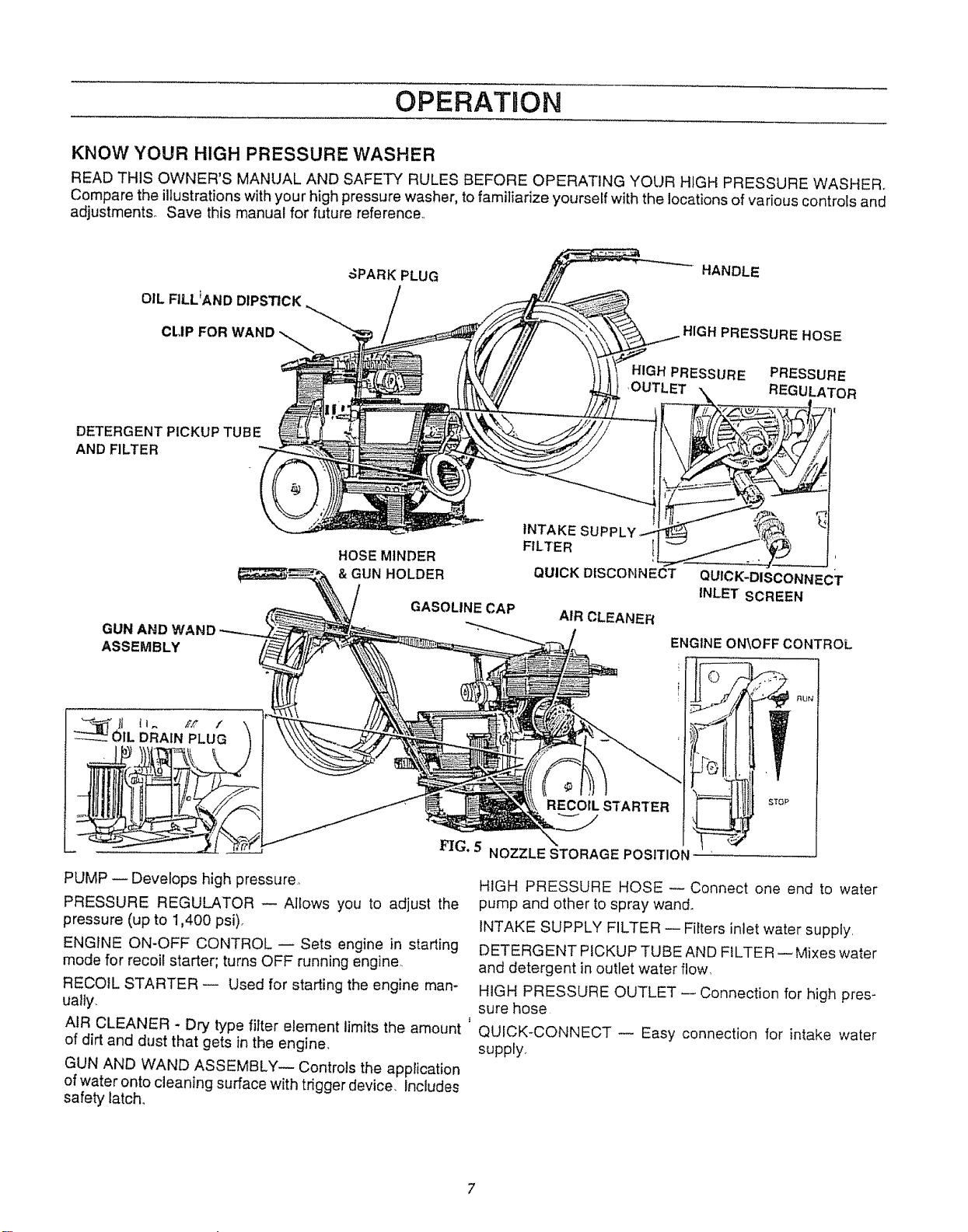

OPERATION

KNOW YOUR HIGH PRESSURE WASHER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HIGH PRESSURE WASHER.

Compare the illustrations with your high pressure washer, to familiarize yourself with the locations of various controls and

adjustments° Save this manual for future reference.,

OIL FILL_AND DIPSTICK

CLIP FOR

DETERGENT PICKUP TUBE

AND FILTER

GUN AIi

ASSEMBLY

SPARK PLUG

HOSE M1NDER

& GUN HOLDER

GASOLINE CAP

HIGH PRESSURE PRESSURE

INTAKE SUPP

FILTER I

QUICK DISCONNECT

AIR CLEANER

HANDLE

HIGH PRESSURE HOSE

REGULATOR

QUICK-DISCONNECT

INLET SCREEN

ENGINE ON\OFF CONTROL

_UN

DRAIN PLUG

F,[G+ 5 NOZZLE STORAGE POSITION

PUMP -- Develops high pressure

PRESSURE REGULATOR -- Allows you to adjust the

pressure (up to 1,400 psi).

ENGINE ON-OFF CONTROL -- Sets engine in starting

mode for recoil starter; turns OFF running engine,,

RECOIL STARTER -- Used for starting the engine man-

ually.

AIR CLEANER. Dry type filter element limitsthe amount

of dirt and dust that gets in the engine.

GUN AND WAND ASSEMBLY-- Controls the application

of water onto cleaning surface with trigger device. Includes

safety latch.

RECOIL STARTER

HIGH PRESSURE HOSE --Connect one end to water

pump and other to spray wand.

INTAKE SUPPLY FILTER i Filters inlet water supply,

DETERGENT PICKUP TUBE AND FILTER --Mixes water

and detergent in outlet water flow,

HIGH PRESSURE OUTLET -- Connection for high pres-

sure hose

QUICK-CONNECT -- Easy connection for intake water

supply,

Page 8

OPERATION

HOW TO USE YOUR WASHER

tF YOU HAVE ANY PROBLEMS OPERATING YOUR

PRESSURE WASHER, PLEASE CALL THE PRESSURE

WASHER CUSTOMER HELPLINE AT 1-800-222-3136.

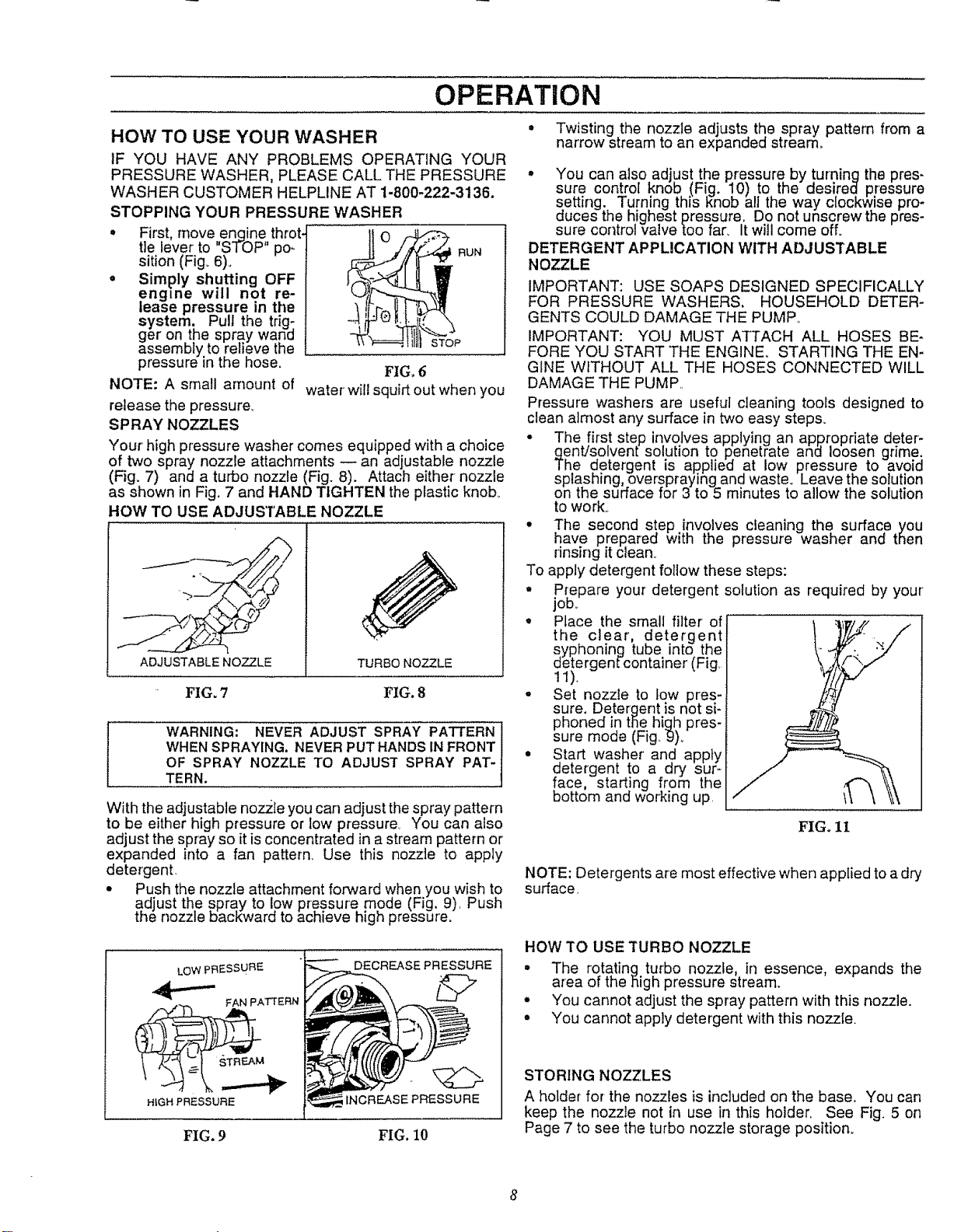

STOPPING YOUR PRESSURE WASHER

• First, move engine throt-

tle lever to "STOP" po_ nun

sition (Fig. 6)°

° Simply shutting OFF

engine will not re-

lease pressure in the

system. Pull the trig;

ger on the spray wan(]

assembly to relieve the

pressure in the hose.

NOTE: A small amount of

water will squirt out when you

release the pressure.

SP RAY NOZZLES

Your' high pressure washer comes equipped with a choice

of two spray nozzle attachments -- an adjustable nozzle

(Fig. 7) and a turbo nozzle (Fig. 8). Attach either nozzle

as shown in Fig. 7 and HAND TIGHTEN the plastic knob_

HOW TO USE ADJUSTABLE NOZZLE

ADJUSTABLENOZZLE TURBO NOZZLE

FIG. 7 FIG. 8

WARNING: NEVER ADJUST SPRAY PATTERN

WHEN SPRAYING. NEVER PUT HANDS IN FRONT

OF SPRAY NOZZLE TO ADJUST SPRAY PAT-

TERN.

With the adjustable nozile you can adjust the spray pattern

to be either high pressure or tow pressure. You can also

adjust the spray so it is concentrated in a stream pattern or

expanded into a fan pattern. Use this nozzle to apply

detergent

* Push the nozzle attachment forward when you wish to

adjust the spray to low pressure mode (Fig. 9) Push

the nozzle bacl_ward to achieve high pressure.

STOP

FIG. 6

• Twisting the nozzle adjusts the .spray pattern from a

narrow stream to an expanded stream.

• You can also adjust the pressure by turninq the pres-

sure control knob (Fig. 10) to the desired pressure

setting. /urning this _nob all the way clockwise pro-

duces the highest pressure, Do not unscrew the pres-

sure comrot vazve too rat, It will come off.

DETERGENT APPUCATION WiTH ADJUSTABLE

NOZZLE

IMPORTANT: USE SOAPS DESIGNED SPECIFICALLY

FOR PRESSURE WASHERS, HOUSEHOLD DETER-

GENTS COULD DAMAGE THE PUMP.

IMPORTANT: YOU MUST ATTACH ALL HOSES BE-

FORE YOU START THE ENGINE. STARTING THE EN-

GINE WITHOUT ALL THE HOSES CONNECTED WILL

DAMAGE THE PUMR

Pressure washers are useful cleaning tools designed to

clean almost any surface in two easy steps.

• The !irs.t step involves applying an appropriate deter-

gem/solyent solution to penetrate anu loosen grime:

The oetergent is applied at low pressure to avoia

splashing, overspraying and waste° Leave the solution

on the surface for 3 to 5 minutes to allow the solution

to work°

• The second step involves cleaning the surface you

have prepared with the pressure washer and then

rinsing it clean.

To apply detergent follow these steps:

° P!epare your detergent solution as required by your'

IOD,,

° Place the small filter of

the clear', detergent

syphoning tube into the

detergenfcontainer (Fig

11),

• Set nozzle to low pres-:i

sure. Deter.qent is not si-i

phoned in tile high pres-

sure mode (Fig. 9)_

• Start washer' and apply

detergent to a dry sur-

face, starting from the

bottom and working up \\ \

FIGo11

NOTE:Detergentsare mosteffectivewhenappliedtoad_

surface

LOW PRESSURE

FAN pATTERN

HiGH PRESSURE INCREASE PR'ESSURE

DECREASE PRESSURE

£IG.9 FIG. 10

HOW TO USE TURBO NOZZLE

• The rotatinq turbo nozzle, in essence, expands the

area of the }Sighpressure stream.

° You cannot adjust the spray pattern with this nozzle.

• You cannot apply detergent with this nozzle.

STORING NOZZLES

A holder for the nozzles is included on the base. You can

keep the nozzle not in use in this holder. See Fig. 5 on

Page 7 to see the turbo nozzle storage position.

8

Page 9

OPERATION

PRESSURE WASHING/RINSING

WARNING: BE EXTREMELY CAREFUL IF YOU

MUST USE PRESSURE WASHER FROM A LAD-

DER OR SCAFFOLDING OR FROM ANY OTHER

RELATIVELY UNSTABLE LOCATION° PRESSURE

IN A RUNNING WASHER BUILDS IN THE WAND AS

YOU CLIMB. WHEN YOU PRESS THE TRIGGER,

THE RECOIL FROM THE INITIAL SPRAY COULD

FORCE YOU TO FALL, OR IF YOU ARE TOO

CLOSE TO THE CLEANING SURFACE, HIGH

PRESSURE COULD FORCE YOU OFF CLIMBING

APPARATUS.

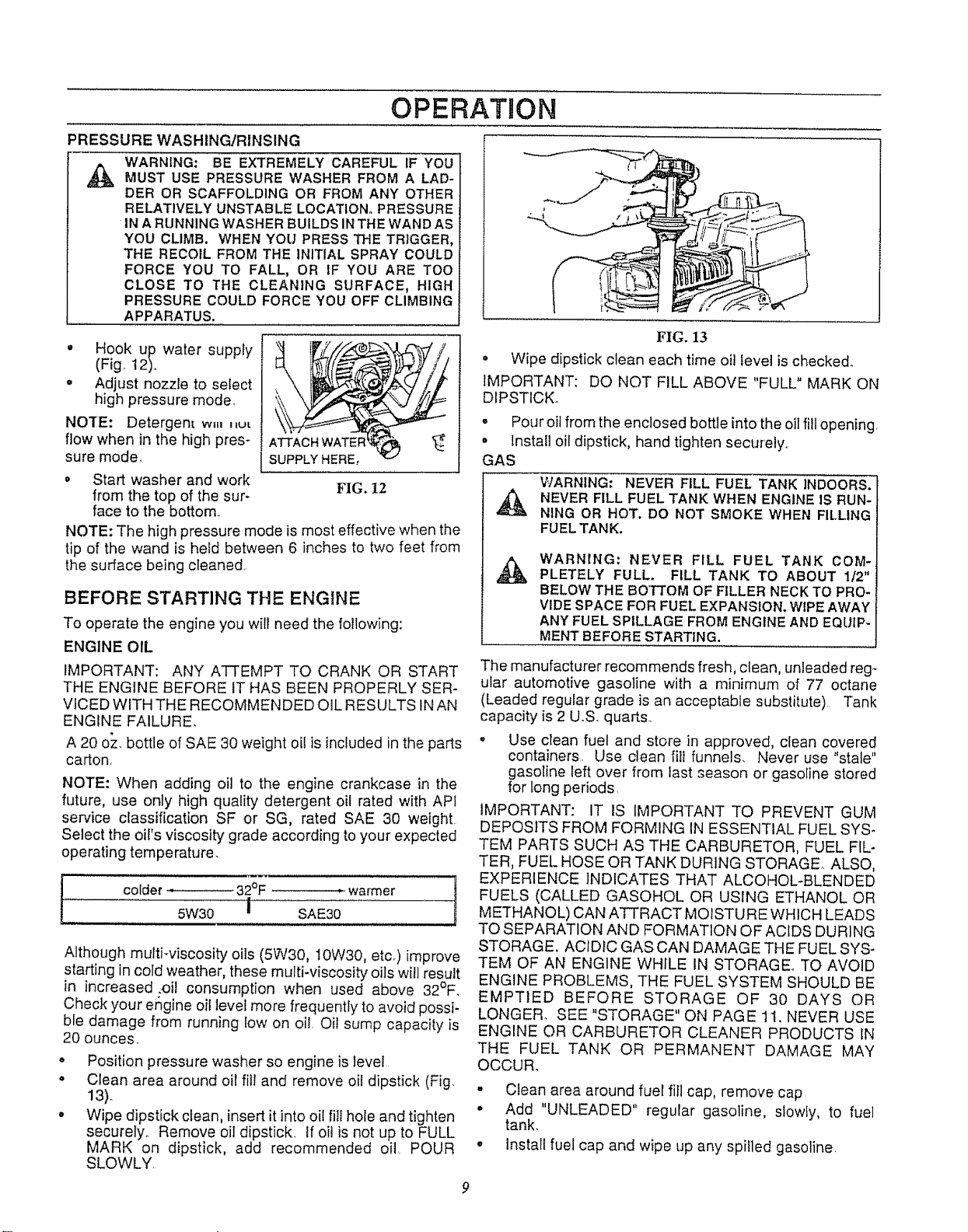

• Hook up water supply

(Fig 12).

, Adjust nozzle to select

high pressure mode.

NOTE: Detergent wu, ,_u_

flow when in the high pres-

sure mode.

• Start washer and work

from the top of the sur-

face to the bottom..

NOTE: The high pressure mode is most effective when the

tip of the wand is held between 6 inches to two feet from

the sudace being cleaned..

BEFORE STARTING THE ENGINE

To operate the engine you will need the following:

ENGINE OIL

IMPORTANT: ANY ATTEMPT TO CRANK OR START

THE ENGINE BEFORE IT HAS BEEN PROPERLY SER-

VICED WITH THE RECOMMENDED OIL RESULTS tNAN

ENGINE FAILURE,

A 20 oz. bottle of SAE 30 weight oil is included in the parts

carton.

NOTE: When adding oil to the engine crankcase in the

future, use only high quality detergent oil rated with APt

service classification SF or SG, rated SAE 30 weight.

Select the oil's viscosity grade according to your expected

operating temperature.

colder = 32°F - warmer

5W30 i SAE30

Although multi-viscosity oils (5W30, 10W30, etcr)improve

starting in cold weather, these multi-viscosity oils will result

in increased .oil consumption when used above 32°F.

Check your e6gine oil level more frequently to avoid possi-

ble damage from running low on oil. Oil sump capacity is

20 ounces.

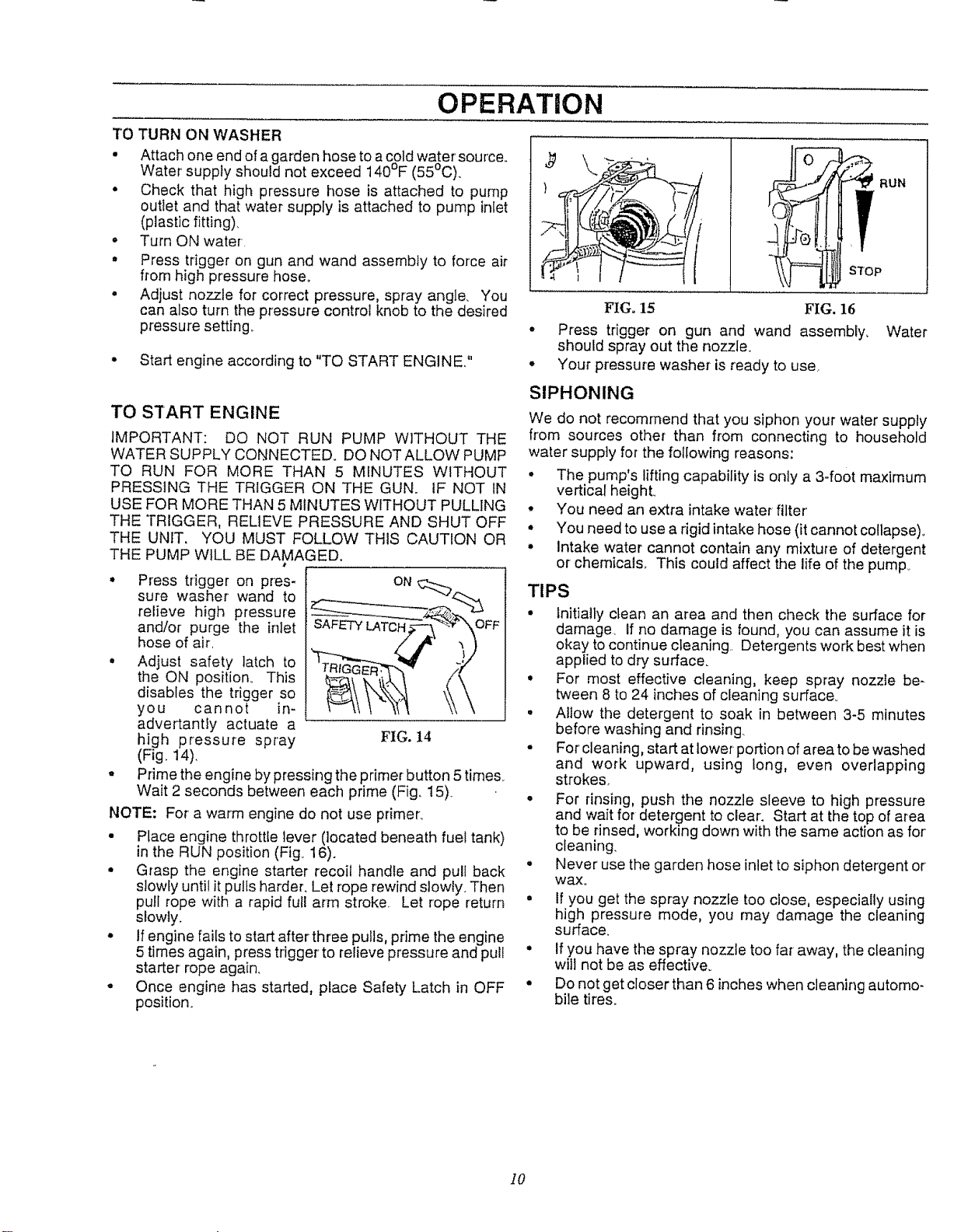

• Position pressure washer so engine is level

• Clean area around oil fill and remove oi! dipstick (Fig.

13).

, Wipe dipstick clean, insert it into oil fill hole and tighten

securely.. Remove oil dipstick. If oil is not up to FULL

MARK on dipstick, add recommended oil. POUR

SLOWLY.

FIG. 13

° Wipe dipstick clean each time oil level is checked°

IMPORTANT: DO NOT FILL ABOVE "FULL" MARK ON

DIPSTICK°

- Pour oil from the enclosed bottle into the oil fill opening,

, Install oil dipstick, hand tighten securely..

GAS

WARNING: NEVER FILL FUEL TANK INDOORS.

NEVER FILL FUEL TANK WHEN ENGINE IS RUN-

,&

NING OR HOT. DO NOT SMOKE WHEN FILLING

FUEL TANK.

WARNING: NEVER FILL FUEL TANK COM-

,A,

PLETELY FULL. FILL TANK TO ABOUT 112"

BELOW THE BOTTOM OF FILLER NECK TO PRO-

VIDE SPACE FOR FUEL EXPANSION. WIPE AWAY

ANY FUEL SPILLAGE FROM ENGINE AND EQUIP-

MENT BEFORE STARTING. i

The manufacturer recommends fresh, clean, unleaded reg_

ular automotive gasoline with a minimum of 77 octane

(Leaded regular grade is an acceptable substitute) Tank

capacity is 2 U.S. quarts..

- Use clean fuel and store in approved, clean covered

containers. Use clean fill funnels, Never use "stale"

gasoline left over from last season or gasoline stored

for long periods

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL SYS-

TEM PARTS SUCH AS THE CARBURETOR, FUEL FIL-

TER, FUEL HOSE OR TANK DURING STORAGE ALSO,

EXPERIENCE INDICATES THAT ALCOHOL-BLENDED

FUELS (CALLED GASOHOL OR USING ETHANOL OR

J

METHANOL) CAN ATTRACT MOISTURE WHICH LEADS

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS-

TEM OF AN ENGINE WHILE IN STORAGE_ TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM SHOULD BE

EMPTIED BEFORE STORAGE OF 30 DAYS OR

LONGER. SEE "STORAGE" ON PAGE 11, NEVER USE

ENGINE OR CARBURETOR CLEANER PRODUCTS IN

THE FUEL TANK OR PERMANENT DAMAGE MAY

OCCUR_

• Clean area around fuel fill cap, remove cap

• Add "UNLEADED" regular gasoline, slowly, to fuel

tank.

• Install fuel cap and wipe up any spilled gasoline,

Page 10

OPERATION

TO TURN ON WASHER

• Attach one end of agarden hose to acold water' sou rce_

Water' supply should not exceed 140°F (55°C)_

• Check that high pressure hose is attached to pump

outlet and that water supply is attached to pump inlet

(plastic fitting),

• Turn ON water.

• Press trigger on gun and wand assembly to force air

from high pressure hose..

• Adjust nozzle for correct pressure, spray angle. You

can also turn the pressure control knob to the desired

pressure setting.

• Start engine according to "TO START ENGINE."

TO START ENGINE

IMPORTANT: DO NOT RUN PUMP WITHOUT THE

WATER SUPPLY CONNECTED. DO NOT ALLOW PUMP

TO RUN FOR MORE THAN 5 MINUTES WITHOUT

PRESSING THE TRIGGER ON THE GUN. IF NOT tN

USE FOR MORE THAN 5 MINUTES WITHOUT PULLING

THE TRIGGER, RELIEVE PRESSURE AND SHUT OFF

THE UNIT, YOU MUST FOLLOW THIS CAUTION OR

THE PUMP WILL BE DAMAGED.

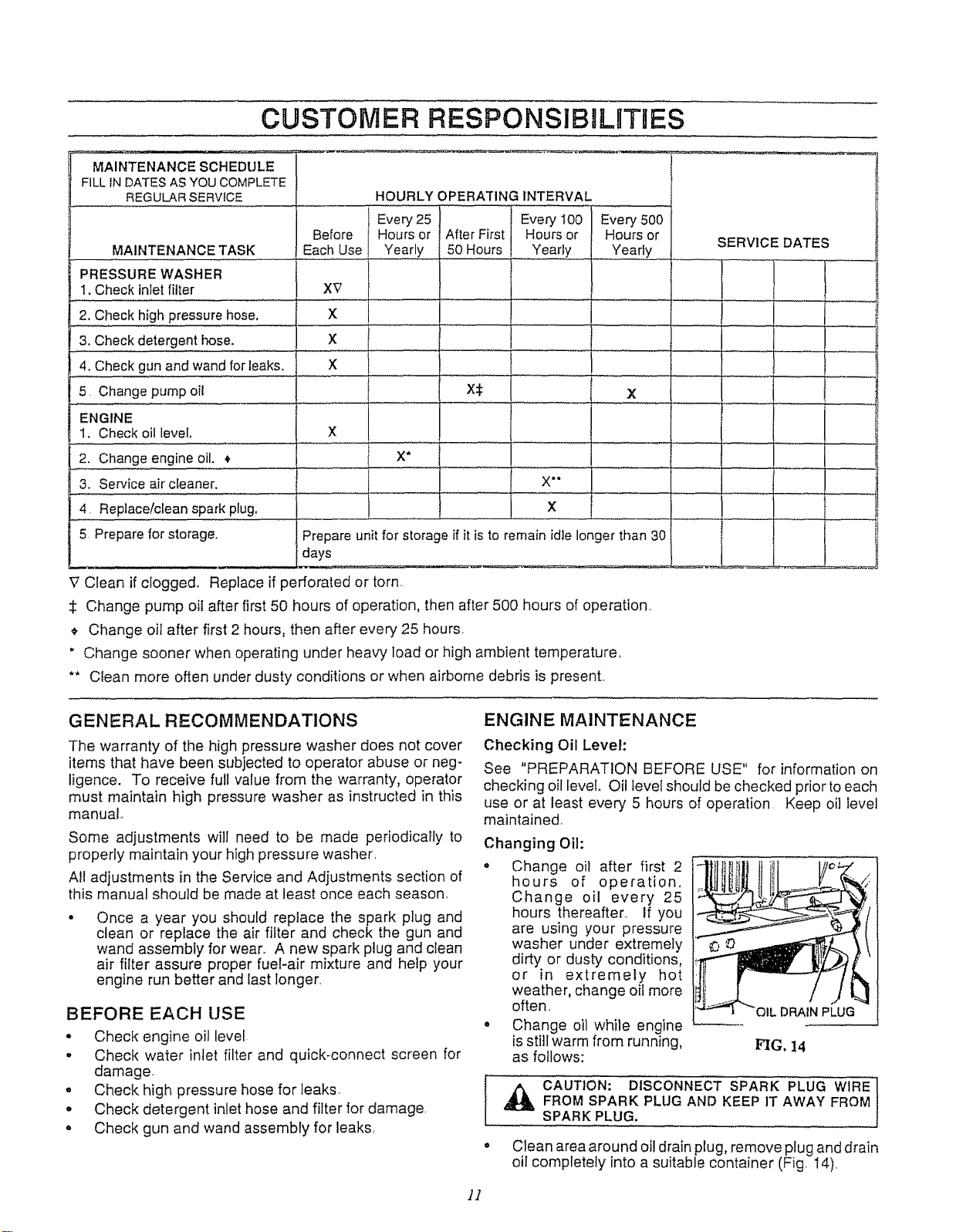

Press tdgger on pres-

sure washer wand to

relieve high pressure

and/or purge the inlet

hose of air.

Adjust safety latch to

the ON position.. This

disables the trigger so

you cannot in-

advertantly actuate a

high pressure spray

(Fig. 14).

• Prime the engine by pressing the primer button 5 time&

Wait 2 seconds between each prime (Fig, 15)

NOTE: For a warm engine do not use primer.

• Place engine throttle lever (located beneath fuel tank)

in the RUN position (Fig_ 16).

° Grasp the engine starter recoil handle and pull back

slowly until it pulls harder. Let rope rewind slowly. Then

pull rope with a rapid full arm stroke. Let rope return

slowly.

• If engine fails to start after three pulls, prime the engine

5 times again, press trigger to relieve pressure and pull

starter rope again.

• Once engine has started, place Safety Latch in OFF

position.

ON

FIG. 15 FIG. 16

° Press trigger on gun and wand assembly,

should spray out the nozzle.

° Your pressure washer is ready to use.

Water

SIPHONING

We do not recommend that you siphon your water supply

from sources other than from connecting to household

water supply for the following reasons:

• The pump's lifting capability is only a 3-foot maximum

vertical heighL

• You need an extra intake water filter'

• You need to use a rigid intake hose (it cannot co!lapse)_

° intake water cannot contain any mixture of detergent

or chemicals_ This could affect the life of the pumF

TIPS

• Initially clean an area and then check the surface for

damage, if no damage is found, you can assume it is

okay to continue cleaning. Detergents work best when

applied to dry surface.

° For most effective cleaning, keep spray nozzle be-

tween 8 to 24 inches of cleaning surface..

• Allow the detergent to soak in between 3-5 minutes

before washing and rinsing.

• For' cleaning, start at lower-portion of area to be washed

and work upward, using long, even overlapping

strokes.

° For rinsing, push the nozzle sleeve to high pressure

and wait for detergent to clear. Start at the top of area

to be rinsed, working down with the same action as for'

cleaning.

° Never use the garden hose inlet to siphon detergent or

wax.

° If you get the spray nozzle too close, especially using

high pressure mode, you may damage the cleaning

surface.

° Ifyou have the spray nozzle too fat away, the cleaning

will not be as effective.

• Do not get closer than 6 inches when cleaning automo-

bile tires.

10

Page 11

CUSTOMER RESPONSIBILHTHES

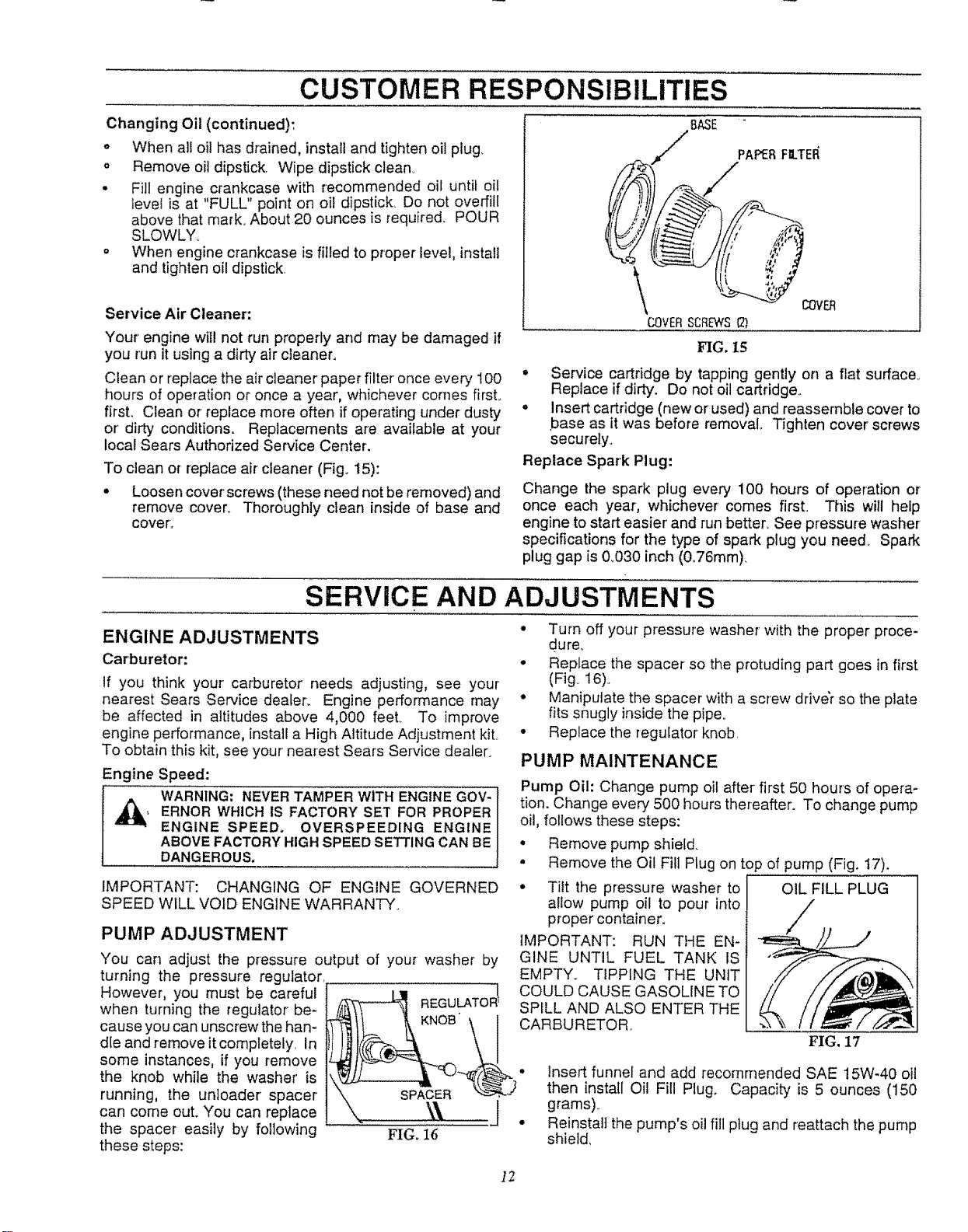

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK

PRESSUREWASHER

1.Check inlet filter

2. Check high pressure hose.

3. Check detergent hose.

4. Check gun and wand for leaks.

5 Change pump oil

ENGINE

1. Check oil level,

2. Change engine oil.

3. Service air cleaner.

4 Replace!clean spark plug,

5. Prepare for storage°

HOURLY OPERATING INTERVAL

Before Hours or Hours or

Each Use Yearly Yearly

Every 25 Every 500

After First Hoursor

50 Hours Yearly

Every I00

XV

X

X

X

X:I:

X

x

X*

X *o

X

Prepare unit for storage if it is to remain idle longer than 30

days

SERVICE DATES

i

i

i

V Clean if clogged° Replace if perforated or torn

Change pump oil after first 50 hours of operation, then after 500 hours of operation.

, Change oil after first 2 hours, then after every 25 hours,

" Change sooner when operating under heavy load or high ambient temperature,

** Clean more often under dusty conditions or when airborne debris is present,

GENERAL RECOMMENDATIONS

The warranty of the high pressure washer does not cover

items that have been subjected to operator abuse or neg-

ligence. To receive full value from the warranty, operator

must maintain high pressure washer as instructed in this

manual°

Some adjustments will need to be made periodically to

properly maintain your high pressure washer

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season.

Once a year you should replace the spark plug and

clean or replace the air filter and check the gun and

wand assembly for wear., A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

BEFORE EACH USE

* Check engine oi! level

o Check water inlet filter and quick-connect screen for

ENGINE MAINTENANCE

Checking Oil Level:

See "PREPARATION BEFORE USE" for information on

checking oil level, Oil level should be checked prior toeach

use or at least every 5 hours of operation Keep oil level

maintained,

Changing Oil:

• Change oil after first 2

hours of operation.

Change oil every 25

hours thereafter, If you

are using your pressure

washer under extremely

dirty or dusty conditions,

or in extremely hot

weather, change oil more

often,

• Change oil while engine

is still warm from running,

as follows:

damage,

o Check high pressure hose for leaks,

* Check detergent inlet hose and filter for damage

I A CAUTION: DISCONNECT SPARK PLUG WIRE

FROM SPARK PLUG AND KEEP IT AWAY FROM

SPARK PLUG.

° Check gun and wand assembly for leaks,

° Clean area around oil drain plug, remove plug and drain

oil completely into a suitable container (Fig. 14),

OIL DRAIN PLUG

FIG. 14

]]

Page 12

CUSTOMER RESPONSIBILITIES

Changing Oil (continued):

', When all oil has drained, install and tighten oil plug.

o Remove oil dipstick. Wipe dipstick clean

• Fill engine crankcase with recommended oil until oil

level is at "FULL" point on oil dipstick. Do not overfill

above that mark° About 20 ounces is required. POUR

SLOWLY°

o When engine crankcase is filled to proper level, install

and tighten oil dipstick.

Service Air Cleaner:

Your engine will not run properly and may be damaged if

you run it using a dirt,/air cleaner.

Clean or replace the aircleaner' paper filter once every 100

hours of operation or once a year, whichever comes firsL

first. Clean or replace more often if operating under dusty

or' dirty conditions. Replacements are available at your

local Sears Authorized Service Center.

To clean or replace air cleaner (Fig. 15):

° Loosen cover screws (these need not be removed) and

remove cover. Thoroughly clean inside of base and

cover.,

BASE "

I.._/ PAPERFILTEI_

VER

COVERSCREWS{2)

FIG,15

,, Service cartridge by tapping gently on a flat surface.

Replace if dirty. Do not oil cartridge.

• Insert cartridge (new or used) and reassemble cover to

base as it was before removal Tighten cover screws

securely.

Replace Spark Plug:

Change the spark plug every 100 hours of operation or'

once each year, whichever comes first. This will help

engine to start easier' and run better, See pressure washer'

specifications for the type of spark plug you need. Spark

plug gap is &030 inch (0o76mm).

SERVICE AND ADJUSTMENTS

ENGINE ADJUSTMENTS

Carburetor:

If you think your carburetor needs adjusting, see your

nearest Sears Service dealer. Engine performance may

be affected in altitudes above 4,000 feet. To improve

engine performance, install a High Altitude Adjustment kiL

To obtain this kit, see your nearest Sears Service dealer.

Engine Speed:

WARNING: NEVER TAMPER WITH ENGINE GOV-

, ERNOR WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING ENGINE

ABOVE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS.

iMPORTANT: CHANGING OF ENGINE GOVERNED

SPEED WILL VOID ENGINE WARRANTY.

PUMP ADJUSTMENT

You can adjust the pressure output of your washer by

turning the pressure regulator,

However, you must be careful

when turning the regulator be-

cause you can unscrew the han-

dle and remove it completely, In

some instances, if you remove

the knob while the washer' is

running, the unloader spacer

can come out. You can replace

the spacer easily by following

these steps:

_II_ _ KNOB \ 1 CARBIJRETOR'

\. _,l 1' grams). . .

\,. _I, J • Reinstall the pump's oil fill plug and reattach the pump

REGULATOR SPILL AND ALSO ENTER THE

.t,lt_. J._ shield,

• Turn off your pressure washer with the proper proce-

dure,

• Replace the spacer so the protuding part goes in first

(Fig. 16)..

• Manipulate the spacer with a screw driver so the plate

fits snugly inside the pipe.

° Replace the regulator knob.

PUMP MAINTENANCE

Pump Oil: Change pump oil after first 50 hours of opera-

tion. Change every 500 hours thereafter. To change pump

oil, follows these steps:

• Remove pump shield.

° Remove the Oil Fill Plug on top of pump (Fig. 17).

° Tilt the pressure washer to OIL FILL PLUG

allow pump oil to pour into /

proper container.

IMPORTANT: RUN THE EN-

GINE UNTIL FUEL TANK IS

EMPTY. TIPPING THE UNIT

! COULD CAUSE GASOLINETO

/

12

Page 13

STORAGE

PRESSURE WASHER PUMP

Water should not remain in the unit for long periods of time.

Sediments of minerals can deposit on pump parts and

"freeze" pump action.. If you do not plan to use the Pressure

Washer for more than 30 days, follow this procedure:

• Flush detergent hose by placing the injector filter into

a pail of clear water while running Pressure Washer

with nozzle in tow pressure mode.. Flush for five min-

utes,

• Shut off the engine and let it cool, then remove all

hoses,

Place throttle lever in "STOP" position.

CAUTION: BESURE THE THROTTLE LEVER ISIN

"STOP" POSITION BEFORE YOU CONTINUE. IF

YOUSTART THEENGINE WITHOUTTHE PROPER

WATER SUPPLY CONNECTED, YOU CAN DAM-

AGE THE PUMP.

o Empty the pump of all pumped liquids by pulling recoil

handle about 6 times, This should remove most of the

liquid in the pump.

NOTE: To protect the unit from freezing temperatures, you can draw

windshield washer fluid into the pump by pouring the washer fluid

Into a 3-foot section of garden hose connected to the inlet adaptor

and pulling the recoil handle twlce_

° Store in a clean, dry area_

ENGINE

WARNING: NEVER STORE ENGINE WITH FUEL IN

TANK INDOORS OR IN ENCLOSED, POORLY VEN-

TILATED AREAS WHERE FUMES MAY REACH AN

OPEN FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES DRYER

OR OTHER GAS APPLIANCE.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also, experience

indicates that alcohol-blended fuels (called "gasoho]" or

using ethanol or methanol) can attract moistu re which leads

to separation and formation of acids during storage. Acidic

gas can damage the fuel system of an engine while in

storage

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer Follow these

instructions:

Drain Fuel System: Remove all gasoline from carburetor

and fuel tank to prevent gum deposits from forming on

these parts and causing possible malfunction of engine.

TAINER OUTDOORS, AWAY FROM OPEN FLAME.

BE SURE ENGINE IS COOL. DO NOT SMOKE.

• If you did use "gasohol", run engine until engine stops

from lack of fuelo Make sure you have water supply to

pump inlet connected and turned ON.

• Fuel stabilizer (such as STA-BIL ®) is an acceptable

alternative in minimizing fuel gum deposits during stor-

age.

Change Oil: While engine is still warm, drain oil from

crankcase_ Refill with recommended grade,

Oil Cylinder Bore: Remove spark plug and pour about 1/2

ounce (15ml) of engine oil into the cylinder_ Cover spark

plug hole with rag. Crank slowly to distribute oil.

t ,_ CAUTION' AVOID SPRAY FROM SPARK PLUG !

HOLE WHEN CRANKING ENGINE SLOWLY,

* Install spark plug,, Do not connect spark plug wire,

OTHER

o Do not store gasoline from one season to another,

° Replace your gasoline can if your can starts to rust,

Rust and/or dirt in your gasoline will cause problems_

o tf possible, store your unit indoors and cover it to give

protection from dust and dirt,,

• Cover you unit with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

does not breathe, which allows condensation to form

and will cause your unit to rusL

IMPORTANT: NEVER COVER YOUR PRESSURE

WASHER WHILE ENGINE AND EXHAUST AREAS ARE

WARM.

]3

Page 14

TROUBLESHOOTING

PROBLEM

Pump has the following problems: 1_

failure to produce pressure, erratic 2o

pressure, chattering, loss of pressure, 3.

low water volume. 4.

Detergent fails to mix with spray,

Engine runs good at no-load but "bogs

CAUSE CORRECTION

Low regolator pressure

Water inlet is blocked.

Inadequate water supply

inlet hose is kinked or leaking

5.

Clogged inlet hose strainer.

6.

Detergent line is not submerged°

7.

Water supply is over 140°E,

8.

Outlet hose is blocked or leaks,

9.

Gun leaks,

10.

Nozzle is obstructed

11.

Pump is faulty

1,, Detergent line is not submerged.,

2. Chemical filter is clogged,

3,, Nozzle is in high pressure setting.

Engine speed is too slow.

1. Adjust regulater to desired setting_

2. Clear inlet

3. Provide adequate water flowo

4. Straighten inlet hose, patch leak.

5. Check and clean Inlet hose strainer

6. Submerge detergent line,

7, Provide cooler water supply.

8. Clear blocks in outlet hose_

9, Replace gun,

l& Clear nozzle.

11. Contact Sears Service Department

t, Insert chemical line into detergent,.

2, Clean or replace filter/detergent line,

3. Set nozzle to low pressure.

Contact Sears Service Department,,

Engine will not start; or starts t,

and runs rough 2

10. Engine has lost compression_

Engine shuts down during operation

Engine lacks power,.

Engine "hunts" or falters_

1. Out of gasoline,

2, Low oil bevel,

Dirty air filter.

Dirty air cleaner

Out of gasoline.

3 Stale gasoline.

4 Spark plug wire not connected

to spark plug.

5. Bad spark plug,

6o Water in gasoline,

7, Overchoking.

8 Excessively rich fuel mixture.

9, Intake vatve stuck open or closed,,

I, Choke is opened too soon.

2 Carburetor is running too rich

or too lean.

1. Clean or replace air'cleaner°

2. Fill fuel tank,.

3. Drain gas tank; fill with fresh fuel

4,, Connect wire to spark ptug

5, Replace spark plugo

6, Drain gas tank; fill with fresh fuel

7, Open choke fully and crank engine.

8, Contact Sears Service Department.

9 Contact Sears Service Department_

10, Contact Sears Service Department,

1_ Fill fuel tank

2, Fill crankcase to proper level.

Replace air filter.

t. Move choke to halfway position until

engine runs smoothly,

2. Adjust carburetor,,

]4

Page 15

CRAFTSMAN 1400 PSI HIGH PRESSURE WASHER 580.741700 REPAIR PARTS

I

"B"

I

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

PART

91122

87627

22147

39414

91091

22129

52858

70I 16

89314

91104

39253

91094

91629

50190

75402

87841

91129

/

DESCRIPTION ITEM PART NO,

NO.

3 H.Po Tecumseh Engine (1 REQ.,) 18 89800

2 GPM Pump (I REQ) 19 90065

5/16"-24 x 1" Capscrew (4 REQ) 20 91092

M8 x 35ram Capscrew (4 REQ,) 21 91096

Mounting Plate (1 REQ) 22 86292

M8 Lock Washer (4 REQ.) 23 88618

M8-1.25 Flange Nut (12 REQ.) 24 57821

M5-0,8 x 12mm Screw 25 91093

with Iock_asher (4 REQ°) 26 77584

3/16" sq. x I-7/8" Key (1 REQ:) 27 92029

Spray Gun Assembly (1 REQ.) 2B 92235

M8-1.25 x 20mm Capscrew (6 REQ,) 29 91106

Wheel (2 REQ ) 30 91107

Hose Assembly (1 REQ.) 31 92272

M8 Flat Washers (2 REQ ) 32 65852

1/2" Push Nut (2 REQ,) 33 92067

Shock Mount (2 REQ,) 34 22473

Hose Quick Disconnect (1 REQ,) -- 88601

28

DESCRIPTION

Injector Tube and Filter (1 REQ.)

Plastic Garden Hose Neck (1 REQ,)

Support Leg (2 REQ)

Zinc Axle (1 REQ,)

#10 Self-drilling Screw (3 REQ,)

Pump Shroud (1 REQ,)

M8-1,25 x 40m Capscrew (2 RE(D,)

Guide Handle (1 REQ,)

Handle Grip (1 REQ-)

Gun and Hose Holder (t REQ,)

Nozzle Grommet (1 REQ.)

Turbo Head (1 REQ)

HFLo Adjustable Head (1 REQo)

Wheel Spacer (2 REQ)

Spring Clip (1 REQ.)

Vinyl Cap (1 REQ,)

M6 Fiat Washer (2 REQ)

Owner's Manual (1 REQ.)[not shown]

15 Drawing No., 88602

Page 16

CRAFTSMAN 4-CYCLE ENGINE 143.943009 REPAIR PARTS

86

75

\

3tl

/

312

370A

182 18

184

MOOELendSERIAL

NUMBERSHERE

370B

172

\

_'174

186 <209 14

173

179

'_"215

262

15

Page 17

CRAFTSMAN 4-CYCLE ENGINE 143.943009

ITEM. PART NO.

1 34708A

2 26727

14 28277

15 31334

16 31336

17 31335

18 65O548

19 34953

20 32600

25 3.3342

25A 3.5883

26 650802

26A 650928

40 34514

41 325386

42 28986

43 20381

45 309636

46 32610A

48 27241

49 28594

50 33149A

60 29745

62 650760

65 650128

66 650738

69 27677A

70 34683A

72 27642

75 25208

80 30574A

81 30590A

82 30591

83 30588A

86 650488

89 32589

90 611080

92 650815

93 650816

100 34443B

101 510116

102 650872

103 650814

110 35182

119 36437

120 36438

125 29313C

126 293146

130 6021A

131 650694A

132 650708

135 33636

34515

34516

32648B

32549B

28987

28988

29315C-

29315C

DESCRIPTION ITEM PART NO.

Cylinder (Includes 2, 20 & 72) [1 req] 150 31672

Dowel Pin (2 reqo) 151 31673

Washer (1 mq.)

Governor Rod Assyo t70 27666

Governor Lever (1 mq.) 171 31410

Governor Lever Clamp (1 req) 172 34146

No. 8-32 x 5/16" Hex Screw (t req.) 173 35350

Extenston Spring (1 raq.) 174 30200

Oil Seal (1 reqo) 178 29752

Blower Housing Baffler (1 req.) 179 30593

Baffle Extension (1 req_) 182 6201

t/4-20 x 518"Screw (2 mq.) 184 31666A

#8-32 X 21/64" Screw (I REQ,) 185 34597

Piston, Pin & Ring Assyo (STD,) 186 31341

Piston, Pin & Rtng Assy, (0o01 O,S,) 200 33858A

Piston, Pin & Ring Assy. (0.02 O._S.) 206 610973

Piston & Pin Assy. (STD.) 209 650139

Piston & Pin Assy. (0_01 O.S.) 209A 30322

Piston & Pin Assy. (0.02 O,S)o 215 32410

Piston Ring Set (STD.) 223 650451

Piston Ring Set (0_01 ORS.) 224 32649A

Piston Ring Set (0.,02 O,S,) 238 650152

Platen Pin Retaining Ring (1 req) 239 27272A

Connect|ng Rod Assy. (1 req_) 241 33266

Connecting Rod Bolt (t req) 242 31914

Valve Lifter (1 req.) 243 28820

Oii Dipper (I reqo) 245 30727

Camshaft [BCR] (1 req.) 250 31715

Blower Housing Exto (1 req) 260 35585

Screw [optional] (1 req) 262 29212

No. 10-24 x 112" Screw (1 req) 275 36493

1/4-20 x 5/8" Screw (t req) 277 650988

Cylinder Cover Gasket (1 reqo) 284 34422

Cyliner Cover As_yo (1 req) 284A 650760

Oil Drain Plug (2 req..) 285 34694

OilSeat (t req.) 287 650926

Governor Shaft (1 req_) 290 29774

Flat Washer (I req) 292 26460

Governor Gear (1 req., incl.. No., 81) 298 650665

Governor Spool (1 req.) 300 35591

1/4-20 x 1-1J4" Screw (7 req) 301 35355

Flywheel Key (1 req..). 305 35554

Flywheel (1 reqo) 307 35499

Bellevllie Washer (1 req) 308 35539

Flywheel Nut (1 req.) 310 35556

Solid State Assembly (1 req.) 311 27625

Spark Plug Cover (1 req ) 312 26973

Soiid State Mounting Stud (2 req.) 313 34080

Nee t 0-24 x 1" Torx Screw (2 req.,) 327 35392

Ground Wire 339 28212

Cylinder Head Gasket (1 req) 340 35926

Cylinder Head (1 req.) 342 650751

Sid. Exhaust Valve (1 req.) 345 32664

OoS. Exhaust Valve (1 req_) 370 33107

Std. intake Valve (1 req.) 370A 36260

O.S. Intake Valve (1 req.) 370B 34346

5/I6-18 x 1-.t/2" Flange Screw (1 req) 380 632569

5/I6*18 x 2" Screw (7 req_.) 390 590688

Washer (1 reqo) 400 36439

Spark Plug [RJ-17LM] (1 req) 416 36085

169 "27234A

420 730225

REPAIR PARTS

DESCRIPTION

Va|ve Spring (2 req.)

Lower Valve Spring Cap (2 req.)

Breather Gasket (2 req.)

Breather Body (1 req.)

Breather Element (t req,,)

Breather Cover (1 req,)

Breather Tube (1 req.)

No., 10-24 x 9/16" Screw (2 req,)

1/4-28 Lock Nut (2 reqo)

Retainer Clip (1 req,,)

1/4-28 x 7/8" Screw (2 req.)

Carburetor Gasket (1 reqo)

Intake Pipe (1 req.)

Governor Link (1 reqo)

Control Bracket Assembly (1 req.)

Terminal Assembly (1 req3

No. 8"32 x 1/2" Screw (2 req.)

No. 8.32 Lock Nut (2 reqo)

Control Knob (1 req.)

5/15-18 x 1" Screw (2 req.)

Intake Pipe Gasket (1 req.)

No. 10_32 x 3/8" Screw (2 req..)

Atr Cleaner Gasket (1 reqo)

Air Cleaner Bracket (1 req.)

Air Cleaner Bracket (1 req.)

No. 10-32 x 1/2" Screw (2 req.)

Air Cleaner Element (1 req.)

Air Cleaner Cover (1 reqo)

Blower Housing (1 req,)

1/4-28 x 7/16" Screw (2 reqo)

Muffler (1 req.)

114-20 x 2-5/16" Screw (2 req.)

Muffler Deflector (t req.)

No. 8-32 x 3,/8" Screw (1 req_)

Starter Hub (1 req.)

No. 8"32 x 21/64" Screw (2 req_)

Fuel Line (1 reqo)

Fuel Line Clamp (1 reqo)

114-15 x 718" Screw (2 reqo)

Fuel Tank (tncL 292 & 301)

Fuel Cap (1 req.)_

O|1 Fill Tube

"O" Rtng (1 req,)

Fill Tube Clip (1 req.)

O|l Dipstick (1 req., IncL #306)

Oil Fill Plug (tncl. 312)

Oil Fill Plug Gasket (1 PK)

Spacer (1 req.)

Starter Plug (1 re<l,,)

Spacer (2 req.)

Fuel Tank Bracket (1 req.)

1/4-20 x 7/16" T"30 Torx Screw (4 req)

Heat Baffle (1 reqo)

Instruction Decal (1 req.)

Primer Decal (1 req.)

Lubrication Decal (1 req.)

Carburetor [inci° Nee 184] (1 req_)

Rewind Starter (1 req_)

Gasket Set [items marked "] (1 req.)

Spark Arresting Screen and Cover

[optional] (1 req.)

SAE30 4-cycle Engtne Oil (quart)

17

Page 18

CRAFTSMAN 4-CYCLE ENGINE 143.943009

13

REPAIR PARTS

ITEM

1

2

3

4

5

6

7

8

9

10

1!

12

!3

PART NO.

590599A

590600

590615

590601

590598

590616

590617

590618A

590619

590620

590687

590535

590701

Rewind Starter No. 590688

DESCR!PTION

PIN, SPRING [included No_ 4] (1 REQ.)

WASHER (1 REQ.)

RETAINER (1 REQo)

WASHER (t REQ)

SPRING, BRAKE (1 REQ.)

DOG, STARTER (2 REQ.)

SPRING, DOG (2 REQ.)

PULLEY AND REWIND SPRING ASSEMBLY (1 REQ_)

REWIND SPRING (1 REQ)

SPRING COVER (1 REQ.)

HOUSING ASSEMBLY, STARTER (1 REQ_)

ROPE, STARTER [length 114" & 11/64" dia.] (1 REQ.)

HANDLE ASSEMBLY, STARTER (1 REQ_)

18

Page 19

CRAFTSMAN 4-CYCLE ENGINE 143.943009

,____q

REPAIR PARTS

/ \

f

!

s"

t

2ft

27

)

I

I

/

/

/

ITEM

1

2

4

5

6

7

16

25

27

28

29

30

PART NO,

631615

631767

6.31184

6.31'183

632590

650506

632164

631867

"631024

632019

"631028

"631021

Carburetor No. 632589

DESCRIPTION ITEM

Throttle Shaft and Lever Assembly 31

(1 req,) 35

Throttle Return Spring (1 reqo) 35A

Dust Seal Washer (1 reqo) 40

Dust Seal [throttle] (1 req.) 41

Throttle Shutter (I req,)

Shutter Screw (1 req,) 42

Fuel Fitting (1 req.)

Float Bowl (1 req.) 43

Shaft, Float (1 req.)

Float (1 req.,) 44

"O" Ring, Float Bowl-to-body (1 req ,) 48

inlet Needle, Seat & Spring Clip 60

[incl. Noo 311 (1 req.)

]9

PART NO.

631022

36045

632647

*63259 1

"630740

630739

630738

"27110

"631027

632592

f

DESCRtPTtON

Spring Clip (1 req,)

Primer Bulb/retainer Ring (1 req_)

Primer Bulb Fitter (1 req.)

Main Adjustment Screw (1 req.)

)O" Ring, High Speed Mixture Screw

(1 reqo)

Washer, High Speed Mixture Screw

(1 req,,)

Tension Spring, High Speed

Mixture Screw (1 req)

Bowl Nut Washer (1 req.)

Welch Plug, Atmospheric Vent (1 req)

Repair Kit [incl. Items Marked "]

(1 req.)

Page 20

CRRFTSMRll

OWNER'S

MANUAL

MODEL NO.

580.741700

IF YOU NEED

REPAIR SERVICE

OR PARTS

3 HORSEPOWER

1400 PSI

HIGH PRESSURE WASHER

Each High Pressure Washer has its own model number. Each engine has

itsown model number.

The model number for your pressure washer will be found on a decal

attached to the uniL

The model number for the engine will be found on the Blower Housing of

the engine adjacent to the spark plug_

All parts listed herein may be ordered through Sears, Roebuck and Co.

Service Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL-

LOWING INFORMATION:

• PRODUCT-- HIGH PRESSURE WASHER

FOR REPAIR SERVICE CALL

THIS TOLL FREE NUMBER

1-800-4°REPAIR

(1-800-473-7247)

FOR REPLACEMENT PARTS

INFORMATION AND ORDER-

ING, C_LL THIS TOLL FREE

NUMBER:

1-800-FON-PART

(1-800-366-7278)

e MODEL NUMBER-- 580.747100

e ENGINE PART NO, -- 143.943009

• PART NUMBER

• PART DESCRIPTION

Your Sears merchandise has added value when you consider that Sears

has service units nationwide staffed with Sears trained technicians...pro-

fessiofial technicians specifically trained on Sears products, having the

parts, tools and the equipment to ensure that we meet our pledge to you,

we service what we sell.

o

SEARS, ROEBUCK and CO,, Hoffman Estates, IL 60179 U.S.A.

Part No. 88601 Revision 0 (I11704) Printed in USA,,

Page 21

MANUAL DEL

USARIO

MODELO NO.

580.741700

IIlNE_ DE ASISTEHC_

,,,,._ CLIENTE "... ;

_QUINA _VADOR-_, DE %.\

j .ALTAp._.,o. --_ MAQUINA LAVADORA DE

®

ALTA

___'_ PRES' ON

1400 PSI

3 CABALLOS DE FUERZA

IJNEADE ASISTEKC[AHORAS

DEOPERACIOH

MO#,-FRI. 8 AM - 5 PM (CST)

Lea y Siga todas

las Normas de Seguridad

e instrucciones Antes

de Operar Este Equipo

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

• Montaje

. Operaci6n

° Responsabitidades del Cliente

• Servicio yAjuste

• Repuestos

Page 22

REGLAS DE SEGURIDAD

AM]SO:MANTENGASIEMPREDESCONECTADOEL CABLE DELA BUJIA Y COLOQUELODONDENO PUEDA

TOCAR LA BUJIA, ESTOEVITARAQUE LA UNIDAD SE ENCIENDA'ACCIDENI_ALMENTECUANDOLA ESTE

INSTALANDO,TRANSPORTANDO,AJUSTANDO0 REPARANDO+

PRECAUClONES:

• Losgasesde escapedei motor contienengasde mon6xidede carbono

LETAL Este gas peligroso inhaladoen ciertas concentracionespuede

causerp_rdidadel conocim_entoe inciuso_ muerte Opere esteequipo

sotoatairs libredondeextsiaventilaci6nadecuada

• La gesolinaes aliamenteINFLAMABLEy susvapores son EXPLOSt+

VOS Nopermitaquese fume,l+amasabiertas,chispasocalor en los

s+tioscercanosmientras estemanejandola gasoline. Evitederramar

gasolinasobre el motorcuando esta caliente Permiia queta unidadse

enfrfeper 2 minutes antes de rettenarla+Cumplacon t(xJaslas normas

regulatoriaspareel almacenajey etusede]a gasolina,

'= Sit0e esta m_,quinalavadora de presi6n en _eas lejanas a matedales

combustibles,vaporescombustibleso poivo

• El equipo de alta presi6n esta disenadopare set utJlizado_nicamente

con psrtesautorizadasperSears El usuarioasumeredes los rtesgosy

responsabil+dadessi ut+lizaesteequipocon pa.rtesque no cumplancon

las especificacionesmfn+masy los dispositivosde seguridaddeusedel

equipo

,D Algunosproductosqulmicoso detergentespuedenser petigrosossi son

inhatadoso tngeridos,causandonauseasevera,p_rdidade laconciencia

o envenenamientoEstosefementosde peligropuedencausardaSoa fa

propiedadylesi6nsevere

_' No permitaque NI_.]OSoperenla M_quina Lavadota de Presi6n en

ning0nmemento

PREPARAClON:

• Opereel motor,3nicamentea ia velocidadindicada+El hacerfuncionareli

motora ve]ocidsdesexcesivaslncrementael riesgode lesi6npersonal

No modifiqueotraspiezasdel motorquepudieranincrementaro dismi-

nuirla velocidadindicada

• Nouseropassuelias,joyerla o cuatquierrosa quepuedaquedarseatra-

padaenet arranqueo enotros rotores

.' Antesde encenderta M_quinaLavadorade Presibnen climefr{o, revise

todastas partesdel equipoyasegOresedequeno se haformadohielo

. Lasunidadescon partes roteso perdidas,osin cajade protecci6no cu-

biertasNUNCAdebensetoperadas

• El silenctadory el depuradorde aJredebenser insialsdosyen buenas

condicionesantes de operar la M;_,quinaLavadora de Presi6n Estos

componentesactOancomeatrapa chispassiel motorpeiardea

• Reviseque el sistemade combustibleno tengafugaso signosde deter..

iorocome unamangueradesgastadao esponjosa,abrazaderessuellaso

perdidaso daSoene[ tanque o la iapa CortijaredesIondefectosantes

deoperarla M&quinaLavadorsde Presi6n

OPERAClON"

+ No rocie IIquidosinflamabies.

• Nuncadirija lapistola haciapersonas,animaleso plsntss

+, Nopermita que ningunaparts entre en contactocon la corrientede flu-

ido.NOentreen contactocon la corrlentede fluidocreeds peruna fuga

en tamangueradealia presi6n

., La corriente de alia presi6nde fluido que puede producir este equipo

puede penetrarIs pie] y sus tejidos pro[undes,conllevandoa lesiones

seriesy posibleamputaci6n

• Elrodado de aliapresi6npuedecauserquepa.,llculasdepinturau otras

partfcutasseenaerotra.qsporiadasy viajena aliasvelocidades.

a, Siempreuse protecci6nocularcuandoutiliceesleequipoo cuandoeste

proximoaJsitio deutiIizad6ndel equipo,

• Nuncautitice unapresi6n superiorala presi6nde lluidoPSi clasificada

paresu m&quinslavadoradepresi6n

• Nuncamuevala m&quinatirandodela manguerade aliapresi6n Utitice

elasa quese encuentraenfaparts superiordela unidad

,= Aseg0resesiemprede que Is pistolade rociado,boqui!lasy accesodos

est_ncorrectamenleconectados

• NuncauUliceunapisloiaderociadeque notongaunseguropare elgatit-

Io,oun protectorpars elgatillocolocadoyen buen funcionamiento

. Utiliceun respiradoro unam_soarasiemprequeexistsel riesgodeinha-

ler vapores Lea todas las inslruccbnes de la m,_scarade maneraque

ustedse pueda asegurarde cluela m&scarale dar_,ta proteccbn nece-

sariaen centredela inhalaciSndevaporespeligrosos

,m Efrociadode alia presi6npueded_ar los eiementosfr,_giles,induyende

ei vidrk) No apuntela ptsloladerociadohacia el vidrio cuandoest_

usandoel rociadoachorro,

., Mantengaia mangueraconectadaa la m&quinaota pistolade rociado

mientrase[ sistema esia siendo presurizado.Oesconeciarla manguera

mientrasest,. siendopresurizadaespelkjroso+

=, Sostenga]apistoiade rociadofirmementeen sumaneantes de encend-

+

er launidad Deno hacadoasi ]apistolspodr[aproducirunlatigazopro-

vocando lestonesal ususrio No dejela pistela de rociadodesatendida

mlentrasla m_quinaesl_ funcionando

,D El _ea de iimpiezadebetenorinclinacionesy drenajesaprepiadospars

reducirla posibIlidaddeunacaldaa causade unasuperlicieresbalosa,

,= Mantengael rociadedel ague tejosde lnslatacioneset_ctricasporq+Je

podr(aocasionarunadescargae_ctricafataJ

+, Noajuste ia v,_vulade de"_argaa una presi6nexcesivacon respectoa

la dasilicact6nde tam_quina

= Noasegureel gatillode lapistolaenposici_nttas_ra(_[erta).

• Nopaso peralto ningOndispositivodesegurtdadenesia m_quina.

• Nodejeel gatiliocerradoper m_sde 5minulos coneimotorenfunciona-

miento Estopoddada_iarlabomba+

• E]sitenciadoryel motorse calientanduranle]aoperaot6ny permanecen

calientesinmediaiamentedespu_sdotapagado Evits elcontactocon un

sitenciadoro motorcalienteopoddaresvllarenquemadurasseveras

MANTENIMIENTO Y ALMACENAJE:

Operey a_maceneesla unidadsobreunasuper[icieesiabte,

o

La manguersde alia presi6n puededesarroliarfugasper et desgaste,

enrroscamlento,abuse,etc Elaguerociadade unafugaes capazde in+

troducirmaterial dentro de la pteL Inspeccioneta manguera carlavez

antes de utilize:tie Revise todas las manguerasy observe si existen

codes,luges,abrasioneso protuberanciasdela cubierta,odaSoo movi-

mtentodelos acoplamientosReemplacainmediatarnentela manguerast

exLstecualquierade est_s condiciones Nunca intentsreparar la man-

guerade alia presi6n,Reempl_,celacon ot_amangueraquereenalsscla-

sificacionesdepresi6nmlnimasde sum&qutnatavadoradepresi6n

BUSQUE ESTE SIMBOLO PARA SENALAR IMPORTANTES PRECAUCIONES DE SEGURI-

DAD+ESTO SIGNIFICA "iATENClONt!! iMANTENGASE ALERTA!!! SU SEGURIDAD ESTA

EN PELIGRO."

Page 23

FELIClTAClONESpot su compra de la m_quinatavadorade afta

presi0nSearsCraftsman.,Estaha sidodise_ada,planeaday fabrica-

daparaproporcionarleIa mejorconfiabilidadydesempeSoposibfe

Si tiene cualquierclase de problemaque no puedaresolver f,%il-

mente,potfavorcontactesu CentroiDepartamentodeServicioSears

m&scercanooContamoscon t_cnicoscompetentesy bien entrena-

dos y con las herramientasapropiadaspara servire reparar esta

unidad

Pot favorlea y conserveeste manual. Las instruccionesle capaci-

tar_,n para montar y mantener su generador apropiadamente.,

Siempreobservelas "REGLASDESEGURIDAD"

NUMEROOEL

MODELO

NUMERODE

SERIE

580_741700

FECHADE

COMPRA

LOSNUMERODE[. MODELOYDE SERtESEENCUENTRANENUNA

ETIQUETAADHERIDAA LAMAQUINALAVADORA.

USTEDDEBEARCHIVARTANTO EL NUMERODE SERIECOMO LA

FECHA DE COMPRA Y MANTENERLOSEN UN LUGAR SEGURO

PARAFUTURASREFERENCIAS.

ACUERDO DE MANTENIMIENTO

Seencuentradisponibleun Acuerdode Mantenimientoen este pro-

ducto..ContactesutiendaSearsm&scercanaparadetalles_.

RESPONSABIL1DADES DEL CLIENTE

,, Leay observetasregtasde seguridad.

• SigaunaprogramaciSnperi0dicaen el mantenimiento,cuidadoy

usodesu m_quinalavadoradealtapresi6n.

• Sigafasinstruccionesqueseencuentranbajotassecciones"Re_

OnSabilidadesdel Cliente"y "Alrnacenaie'de este Manualde!

uario

ESPECIFICACIONES DEL PRODUCTO

Especificacionesdel la M_quinaLavadoradePresi0n

PRESION DE SALIDA

COEFIC1ENTEDE

FLUJO

MEZCLADE

DETERGENTE

TEMPERATURADEL

SUMINISTRO DE AGUA

ALTURADESUCCION

1400psi

"/_,5,Ipm

Utlllce deterq,ente sin dilulr

No e×ceder los 55c

90 cm. m_ximo

Especificaciones delMotor

CABALLOSDEFUERZA

NORMAL 3 HP

DESPLAZAMIENTO _adas_ cua_ (148cc) ......

BUJIA:Ttpo: Champion J-8C

o sfJequivalente

Espacio establecido a

0.030 pulgadas (0.76mm)

CAPACIDADDE

GASOLINA

'1 Iltro aprox.

ACEITE

(600 ml. de capac!dad) _ Peso SAE 30

ESPACIODEAIREDEIGNIClON

TRANSISTORtZADO 32 mm

-

Es requeridopotla ley un contrachispasen el Eslado deCalifornia

(SecciSn4442del C6digodeRecursosP0blicosdeCalitornia).Otros

estadospuedenlenerleyes similares Lasleyesfederalesse aplican

a losterrenosfederales,

GARANTIA LIIVlITADA A UN AI_O DE LA MAQUINA LAVADORA DE ALTA PRESION CRAFSTMAN

Por un a_o a partir de ta fecha de compra, siempre y cuando esta M_quina Lavadora de Alta PresiSn sea mantenida y opera-

da de acuerdo alas instrucciones del manual det propietario, Sears reparar&, sin ning0n cargo, cualquier defecto en los mate-

riates y fa mano de obra..

Esta garant(a se apltcar_ solo por 90 alias si la M_.quina Lavadora de Alta PrestSn es uttlizada para prop6sitos comerciales o

para ser alquifada

Esta garant[a no cubre:

=, Elementos deteriorables

= Reparaciones necesarias debido a abuso o negligencia del operador, incl!._yendo el eje de la manivela y el incorrecto man-

tenimiento del equipo por no seguir las instrucctones contenidas en el manual def usuario,

EL. SERVIClO DE GARANTIA ESTA DISPONIBLE DEVOLVIENDO LA MAQUINA LAVADORA DE ALTA PRESION AL

CENTRO/DEPARTAMENTO DE SERVlCIO SEARS MAS CERCANO EN CUALQUIER PARTE DE LOS ESTADOS UNIDOS.

Esta garantfa le otorga derechos legales y tambi_n podr[a tener derechos adicionales, los cuales pueden varlar de estado a

estado

SEARS, ROEBUCK and CO., D/817 WA, Hoffman Estates, IL 60179

3

Page 24

TABLA DE CONTENIDOS

ACCESORIOSY ADITAMENTOS.................................. 2

REGLASDESEGURIDAD .......................................... 3

ESPECIF1CACIONESDELPRODUCTO ......................... 4

CONTENIDODELACAJADE EMBALAJE ..................... 5

MONTAJE ............................................................ 6

OPERAC1ON..................................................... 7-10

INDICE

-A-

Aceite,Motor. ........................ 9

Almacenaje .............................. !3

Antesde lniciar , ...................... 9

Avisode Seguridad ........................ 9

-B-

Bombadela M_,quinaLavadora

de Presi6n ............................... 13

-C-

Caiade Embalaje .......................... 5

Cambiode Aceite ....................... 11

Cambiode Bujia ..................... 12

Carburador ............................... 12

Conjun_oPistolay Dispositivo

deRiego ................................... 1

-D-

DepuradordeAire ........................ 7

Diagn6sticode Averias .................... 14

Garantia ................................ 4

MangueradeAliaPresi6n ............... 7

Mantenimiento"

Motor ................................. 11

Bomba ................................... 13

Montaje •

Extray6ndolade iaCaja .................... 6

HerramientasNecesadas................. 6

fnstalaci6n ................................... 6

Motor ' 13

........... i........................

Operaci6n•

Aplicaci6nde Detergente ............... 8

Parado ........................................ 8

EncendidodelMotor ........................ 9

ParaEncenderlaM_.quinaLavadora ,. 9

RESPONSABILIDADESDELCUENTE ................... 1!-12

SERV1CIOY AJUSTES ............................................ 12

ALMACENAJE ................................................... !3

DIAGNOSTICODEAVERIAS ................................ 14

PtEZASDE RECAMBIO ....................................... t5-I9

-G-

- !_/1-

Utilizaci6n .................................. 8

.p.

PartesSueLtas ........................ 6

Preparaci6nde la M&quina

Lavadora ................................ 6

-R-

RecomendacionesGenerales ............. 11

Reguladorde Presi6n ........................ 7

Repuestos ......................................15-19

Responsabilidadesde]Cliente ........11,12

Revisi6ndelNivelde Aceite .............. 11

"S"

i'O"

ServiciodelDepuradorde Aire ......... 12

ServicioyAjustes 12

-V-

Velocidaddel Motor .................... 12

ACCESORIOS Y ADITAMENTOS

Estosaccesoriosy aditamentosestuvierondisponiblescuandorue compradala m_quinalavadorade aita presi6n,Tambi_nseencuentran

disponiblesen la mayoriade puntosde ventaal detalde Searsy centrosdeservicio,LamayoriadelastiendasSearspuedenordenarestos

elementosparaustedcuandoproporcioneel numerodelmodelode su m,_quinalavadoradea!Iapresi6n.

PARALAVARLA CASA PARALAVARCUB1ERTAS PARALAVARVEHICULOS PARADESENGRASAR CEPILLOROTATORIO

74273 74274 74275 74276 74t89

4

Page 25

CONTENDIO LA CAJA DE HERRAJE

Parts packed separately in carton

CaJade las Partes

I

Manual de Usarlo

\

Unldad Principal

Partes empaquetas en ia Caja de las Partes

}

Manguera de Alta

Prest6n

Contenido de la Balsa de las Partes

mostrados en tama5 completo

iIIHttllfHI(!

(2) Tom!llo= do ProsL6n do Cabaza Hexagonal

- M8 X40ram

(2) Tuert_ de Empule - 1/2

Conjunto de Plstola y

Dlsposlttvo de Rlego

Asa

Balsa do laa

Aceffa del Motor Partes

Contenido de la Balsa des las Partes no

mostrados en tamafio completo

Tapa de Vlnlo i

Conex_on Raptda

(6) Torn|llos de Proslgn de Cabeza Hexagonal

- MB x 20ram _[_r_

(2) TomffIos do Pres|6n Autorroscantos

(2) Arnndelas - M6

@

(8) Tuarcaa Dentodas- M8

©_)

(2)Arandalos- M8

(2) Espnc(aclorsa

/

Embocadura Regular

Emboc,_dura Turbo

(2) Paras Soporta (2) Manta)as ArtUvtbratorloa

Page 26

MONTAJE

Leaesl_t.sinstruccionesy el Manualdel Opetadoren su tolalidadantes de

intenlar monlat u operar su nuevam_.quinalavadora de alia presi6n. Su

m_quinalavadorade alia presi6nha sidemontadacasl ensu totalicladen la

f_brica,exceplu_do aquellas partesdejades sln monlar, Antes que usted

puedaoperarsu m_quinalavadorade alia presi6ndebe monlar eljuogode

ruedasyconectarapropiadamenlelamangueradealia presi6n,

HERRAM1ENTAS REQUERIDAS PARA EL

MONTAJE

,_ Martillo

* Llavedecubecon Cubesdell2-pulgada o 13 mm

,, LlavesAjustabteso LlavesdeCombinaci6n

PARA EXTRAER LA MAQUINA LAVADORA DE

PRESION DE LA CAJA

, Retirarla agarraderagula (envueltaenpl_stico)

,, RelirarIacajade accesoriosde la caja

o Retirarel grupo de piezas dela pistola y el dispositivede riego det

tableroportatarjetas

, Retirarlode et resto de maleriaJde empaquede la cajaantes de relirar

sum&quinalavadorade altapresi6n

COMe COLOCAR SU MAQUINA LAVADORA DE

ALTA PRESTON PARA INSTALAR EL JUEGO DE

RUEDAS

Parala instalaci6nde! juegode ruedasse tequierentashertamlentaslista-

das anleriormentey los elemenlosincluidosen la cajade accesoriosy el

asagu[a _'

" Conel martitlo,gotpeeunatuercade empujeen unalerminaci6ndeleje

* Comenzandoen la otra terminaci6ndet eie, deslizar una rdeda (cube

salidoposicionadohaciaadenlro) contfala tuercadeernpuje,luegodes-

lizarunespaciador(Fig. 1).

* Deslizat esle conjunto de piezas a trav6s det erificiode la base de la

m_.quinalavadoradepresi6nyadherirelespaciadordela rueda,]a rueda

(cubesalido posicionadohaciaadentro)y la luercadeempuje enla otra

lerminaci6ndefeje

EJE

ESPECtADOR

, Unit lasparasdesoportea la basecomeso mueslra enla Fig 2con los

tomillosdepresi6ndecabezahexagonalylas contraluercasdenladas

• Coloqueel asiderodela manillaenel asa gulay luegouna el asagula a

la basecome semuestraenla Fig 2condos tomillosdepresi6nde ca.

bezahexagonaJdeM8-! .25x 40rnmy doscontraluercasdentadas

• Una el sujetadordal conjuntode la pistola,el disposilivode riego y la

mangueraal asagufacon el torntlloautorroscanle#10

r

ASA DE SUJECCION

TAPA DEVINLO

SOPORTA ,

UNA EL TORN1LLOS MONTAJES

Y AP,.ANDELAS

ANTIVIBRATORIO

PARA MONTAR LOS COMPONENTES

REMANENTES

ADVERTENClA: USTED DEBE MONTAR EL DISPOS[-]

TIVO DE RIEGO Y UNIR TODAS LAS MANGUERAS]

ANTES DE ENCENDER EL MOTOR. EL ENCENDER 1

EL MOTOR SIN TENER CONECTADAS TODAS LASI

MANGUERASDA_ARA LA BOMBA. l

• Reviseelfillroy aseg0msedeque eslD,limpio

t Una et adaptor de conexi6n r_lpida al adaptador pl_stico en

ta parte frontal de la bomba.

,= Desen[olle la manguera de alta presi6n y con6ctela al con-

junto de la pistola y el dispositivo de riego (Fig. 3)° Es posible

que quiera clar vueltas a la pistola o a la manguera para

apretar la conexi6n.

Iit

Una la otra terminaciOn de al manguera de alta presi6n al

adaptador de lat6n en la bomba per debajo de la conexi6n

de la manguera de jardin (Fig. 4)_

,ASA TORNILLOS

DENTADA

[

'-,,./ TORNiLLOS DE

SOPORTE.J CABEZ-A

FIG. 2

TERMAIq_,CION

DE LA MANGUERA

CABEZA

/

TUERCA DE EMPUJE

FIG. 1

Montarlosmonlaiesamorliguadoresa Iaspalas desoportecon lostomil-

los de presi6nde cabezahexagonalde M8-125 x 20mmy las contra-

tuercasdentadasM8-! 25

CONEX1ON

RAPtDA

FIG, 3' FIG. 4

• Unaetpulvei'izadorde aguaa la termtnaci6ndelconjuntodeparlesdela

pistolayeldispositivoderiegoy apri_leloapropiadamenteconla mane

NOTA: Unldo a la base de su m_qutna lavadora de presibn

se encuentra una turbo embocadura que puede utilizar

para ajustar el &ngulo de su patr6n de rlego.

6

Page 27

OPERACION

CONOZCA SU MAQUINA LAVADORA DE ALTA PRESION

LEA ESTE MANUAL DEL OPERADOR Y LAS REGLAS DE SEGURtDAD ANTES DE OPERAR SU MAQUINA LAVADORA DE

PRESION, Compare las ilustraciones con su m&quina lavadora de alta presi6n, para famitiarizarse con las ubicaciones de los dif-

erentes controles y ajustes, Conserve este manual para referenclas futuraso

ASA

BUJIA

LLENADODEACEITEDELMOTOR

MANGUERA DE ALTA PRESION

SALIDA DE ALTA REGULADOR

PRESION DE PRESION

TUBe Y FILTRO

RECOGEDOR DE DETERGENTE

SOSTENEDORDELA PISTOLA

CONJUNTO DE PISTOLA Y

DtSPOSITIVO DE RIEGO

BOMBA - Genera Ia alia presi6n,

REGULADOR DE PRESION - Le permite ajustar fa presi6n

(hasta 1,400 psi),

CONTROL DE ENCENDIDO-APAGADO DEL MOTOR - Pesi-

ciona el motor en la funci6n de encendido para el encendedor

de retroceso; APAGA el motor que est& en funcionamiento

ARRANQUE DE RETROCESO - Utilizado para encender el

motor manualmente.

DEPURADOR DE AtRE - El elemento de filtro de tipo seco

limita la cantidad de suciedad y polvo qua se introduce al

motor,,