Craftsman 580327140-1987 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

580.327140

RAFTSMAN°

PORTABLIE GENERATOR,

CUSTOMER

HELPLINIE

120-240 VOLT/4200 WATT

12-VOLT D-C BATTERY CHARGER

DELUXE PORTABLE GENERATOR

HOURS:

Mon.- Frl. 8 a.m. to 5 p.m

(CST)

CAUTION:

Read and Follow

ell Safety Rules

end Instructions

Before Operating

This Equipment

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustment

• Repair Parts

PanNo. B2552 Rev-I (3/27/98)

CRAFTSMAN°

OWNER'S

MANUAL

MODEL No.

580.32714O

IF YOU NEED

REPAIR SERVICE

OR PARTS

120/240 VOLTS / 4200 WATT A-C

12 VOLTS D-C BATTERY CHARGER

DELUXE PORTABLE GENERATOR

Each Portable Generator has its own model number. Each engine has its

own part number.

The model number for your Portable Generator will be found on a decal

attached to the unit.

The part number for your engine will be found on the Blower Housing of

the engine adjacent to the spark plug.

All parts listed herein may be ordered through Seam, Roebuck and Co.

Service Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL-

LOWING INFORMATION:

FOR REPAIR SERVICE CALL

THIS TOLL FREE NUMBER

1"800"4" REPAIR

(1-800-473-7247)

FOR REPLACEMENT PARTS IN-

FORMATION AND ORDERING,

CALL THIS TOLL FREE NUMBER:

1-800-FON-PART

(1-800-366-7278)

• PRODUCT-- PORTABLE GENERATOR

• MODEL NUMBER--580.327140

• PART NUMBER

• PART DESCRIPTION

Your Sears merchandise has added value when you consider that Sears

has service units nationwide staffed with Sears trained technicians....pro-

fessional technicians specifically trained on Sears products, having the

)arts, tools and the equipment to ensure that we meet our pledge to you,

we service what we sell.

SEARS ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CON-

TACT SPARK PLUG, TO PREVENT ACCIDENTAL STARTING WHEN SET'rING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR.

IMPORTANT

THIS GENERATOR IS DESIGNED FOR OUTDOOR USE ONLY. USING THIS GENERATOR INSIDE ANY BUILDING OR

ENCLOSURE INCLUDING THE GENERATOR COMPARTMENT OF A RECREATIONAL VEHICLE (RV), IS DANGEROUS.

FIRE OR AN EXPLOSION MAY RESULT. NO USER PERFORMED MOD F CAT ONS, NCLUD NG VENTING OF EXHAUST

AND/OR COOLING VENTILATION, WILL ELIMINATE THE DANGER.

• If this unit is used for backup power in the event of

a utility power failura, take the followingsteps: BE-

FORECONNECTING THE GENERATOR TO AN

ELECTRICAL SYSTEM OPEN THE MAIN CIR-

CUIT BREAKER OR MAIN SWITCH SERVING

THE SYSTEM TO ISOLATE THE GENERATOR

SYSTEM FROM THE ELECTRIC UTILITY. FAIL-

URE TO ISOLATE THE GENERATOR AND UTIL-

ITY SYSTEMS MAY RESULT IN DAMAGE TO

THE GENERATOR AND MAY ALSO RESULT IN

INJURY OR DEATH TO ELECTRIC UTILITY

WORKERS DUE TO BACKFEED OF ELECTRI-

CAL ENERGY.

• This generator supplies dangerously high electrical

voltages. Use care to prevent extremely hazardous

and possibly lethal electrical shock. Never permit

any unqualified person(s) to operate or service the

unit.

• DO NOT operate this equipment in the rain, while

standing in water, while barefoot, or while hands or

feet are wet. Dangerous electrical shock will result.

• The spark arrestor muffler can become extremely

hot. DO NOT operate this equipment in areas where

combustible material such as grass, leaves or paper

products can come in contact with the muffler.

• Maintain all wiring, extension cords, etc., in good

condition. Worn, bare, frayed, or otherwise dam-

aged wiring and cord sets may cause dangerous

electrical shock and may also result in damage to

equipment and/or property.

• The National Electrical Code requires that the gen-

erator be properly connected to an approved earth

ground. Local electrical codes may also require

proper grounding of the unit. See ASSEMBLY sec-

tion for mere grounding information.

• Wire gauge sizes of wiring and cord sets must be

large enough to handle the maximum electrical load

to which they will be subjected. Most devices re-

quire cord sets rated 125 AC volts at 20 to 30

amperes or 250 AC volts at 20 amps (or greater).

Some devices may require a higher or lower rating.

Refer to the Owner's manual of the electrical device

for the manufacturer's recommendations. Cord

sets that are too small in diameter or too long will

overheat, become damaged and may cause prop-

erty damage and/or electrical shock.

• The generator engine consumes oxygen and gives

off DEADLY carbon monoxide gas through its ex-

haust system. This dangerous gas if breathed in

surf c ent concentrations, can cause unconscious-

ness or even death. Operate this equipment out-

doors only, in well ventilated areas where exhaust

gases cannot accumulate and endanger people or

animals.

• Gasoline is extremely FLAMMABLE and its vapors

are EXPLOSIVE. Comply with all laws regulating

the storage and handling of gasoline. DO NOT

permit smoking, open flames, sparks or heat in the

vicinity while handling gasoline. Avoid spilling

gasoline on a hot engine. DO NOT fill fuel tank:

while engine is running or hot. Clean off any spilled

gasoline before starting engine.

• DO NOT fill fuel tank completely full. Allow room at

top of tank for fuel expansion or fuel may expand

and overflow onto a hot engine.

• Drain all gasoline from tank before transporting your

generator inside your car or other vehicle.

• DO NOT store the generator with fuel in tank where

gasoline vapors might reach an open flame, spark,

or pilot light, as on a fumace, water.heater, dryer,

etc. FIRE or an EXPLOSION might result.

• DO NOT insert any object or tool through cooling air

slots or openings of the engine or generator, even

if the eng=ne is not running. Damage to the unit or

personal injury may result.

• DO NOT attempt to change the engine govemed

speed.. Factory settings are correct when you ra-

calve the unit. Excessively high engine speeds may

result in injury or damage to equipment.

• DO NOT use the unitifit has been damaged. Repair

or replace all damaged or defective components

before you run the unit.

• DO NOT permit children to operate or service the

generator.

• Read your Owner's Manual carefully. Only persons

who are familiar with these safety rules and have

been properly instructed in the use of this product

should be permitted to use the product.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT I

MEANS "ATTENTIONII! BECOME ALERTI!! YOUR SAFETY IS INVOLVED."

I

CONGRATULATIONS on your pumheae of a Sears Crafts-

man Generator. It has been designed, engineered and

manufactured to give you the best possible dependability

and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department or call the 1-800 number listed on the front

of this manual. We have competent, well-trained techni-

cians and the proper tools to service or repair this unit.

Please read and retain this manual The instructions will

enable you to assemble and maintain your generator prop-

erly, Always observe the 'SAFETY RULES."

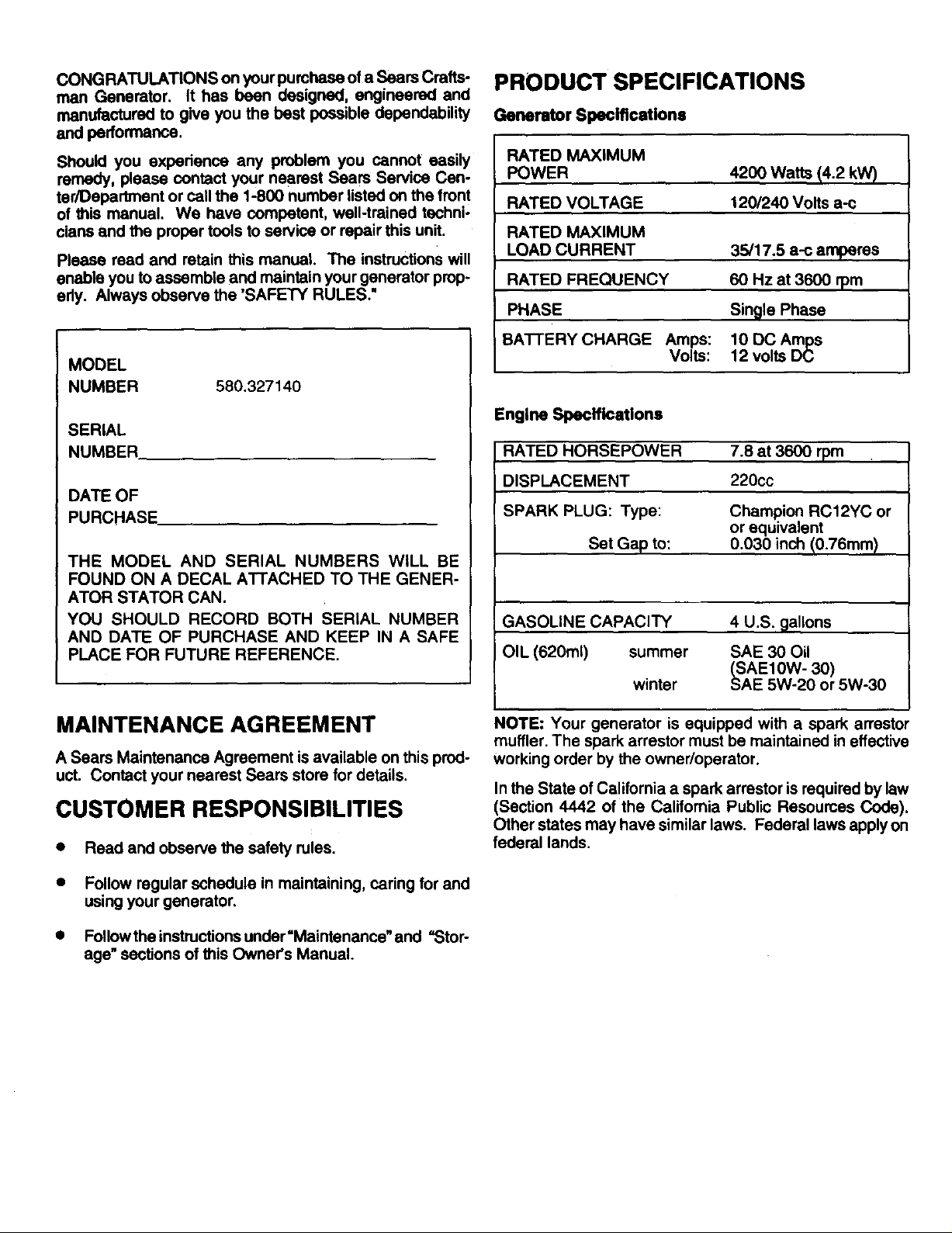

PRODUCT SPECIFICATIONS

Generator Specifications

RATED MAXIMUM

POWER

RATED VOLTAGE

RATED MAXIMUM

LOAD CURRENT

RATED FREQUENCY

PHASE

4200 Watts (4.2 kW)

120/240 Volts a-c

35/17.5 a-c amperes

60 Hz at 3600 rpm

Single Phase

MODEL

NUMBER 580.327140

SERIAL

NUMBER

DATE OF

PURCHASE.

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL A'I-T'ACHED TO THE GENER-

ATOR STATOR CAN.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct, Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

BA'I-FERY CHARGE Amps:

Volts:

Engine Specifications

RATED HORSEPOWER 7.8 at 3600 rpm

DISPLACEMENT 220cc

SPARK PLUG: Type:

Set Gap to:

GASOLINE CAPACITY

OIL (620ml) summer

winter

NOTE: Your generator is equipped with a spark arrestor

muffler. The spark arrestor must be maintained ineffective

working order by the owner/operator.

In the State of California a spark arrestor isrequired by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands.

10 DC Amps

12 volts DC

Champion RC12YC or

or equivalent

0.030 inch !0.76ram)

4 U.S. gallons

SAE 30 Oil

SAAE10W- 30)

E 5W-20 or 5W-30

• Follow regular schedule inmaintaining, caring for and

using your generator,

• Followtheinstructionsunder'Maintenance"and "Stor-

age" sections of this Owner's Manual.

TABLE OF CONTENTS

SAFETY RULES .................................. INSIDE COVER

MAINTENANCE AGREEMENT ................................... 1

PRODUCT SPECIFICATIONS ....................................... 1

CONTENTS OF HARDWARE ..................... 3

ASSEMBLY .......................................... 3

OPERATION ...................................... 4-8

MAINTENANCE ....................................... 9-10

-A- -H-

Air Cleaner... ......... 4, 10

Assembly ................ 3

-B-

Before Starting ............ 5

Battery Charging ........... 7

Battery Safety ............. 6

Head boils .............. 11

Idle Control ............... 6

Low Oil Shutdown .......... 8

Lubrication .............. 5,9

-C-

--M--

Carburetor. .............. 11

Circuit Breakers .......... 3,5

Cord Sets ................ 3

Customer Responsibilites .... 1

-E-

Engine

Carburetoradjustment ........ 11

Ot/level .................... 11

Speed..................... 11

Electrical Loads ........... 8

Maintenance

Agreement .................. 1

Cleaning generator............ 9

Engine maintenance........... 9

General Recommendations..... 9

Generator Maintenance ........ 9

OilLevel ................. 9

Operation ............... 4-8

Overloading .............. 8

-G-

Gasoline ................. 5

Grounding Lug ............ 3

Parts, repair ........... 16-21

SERVICE AND ADJUSTMENTS ............................. 11

SERVICE RECOMMENDATIONS. .................. 12

STORAGE .................................................................... 12

TROUBLESHOOTING POINTS ...................... 13

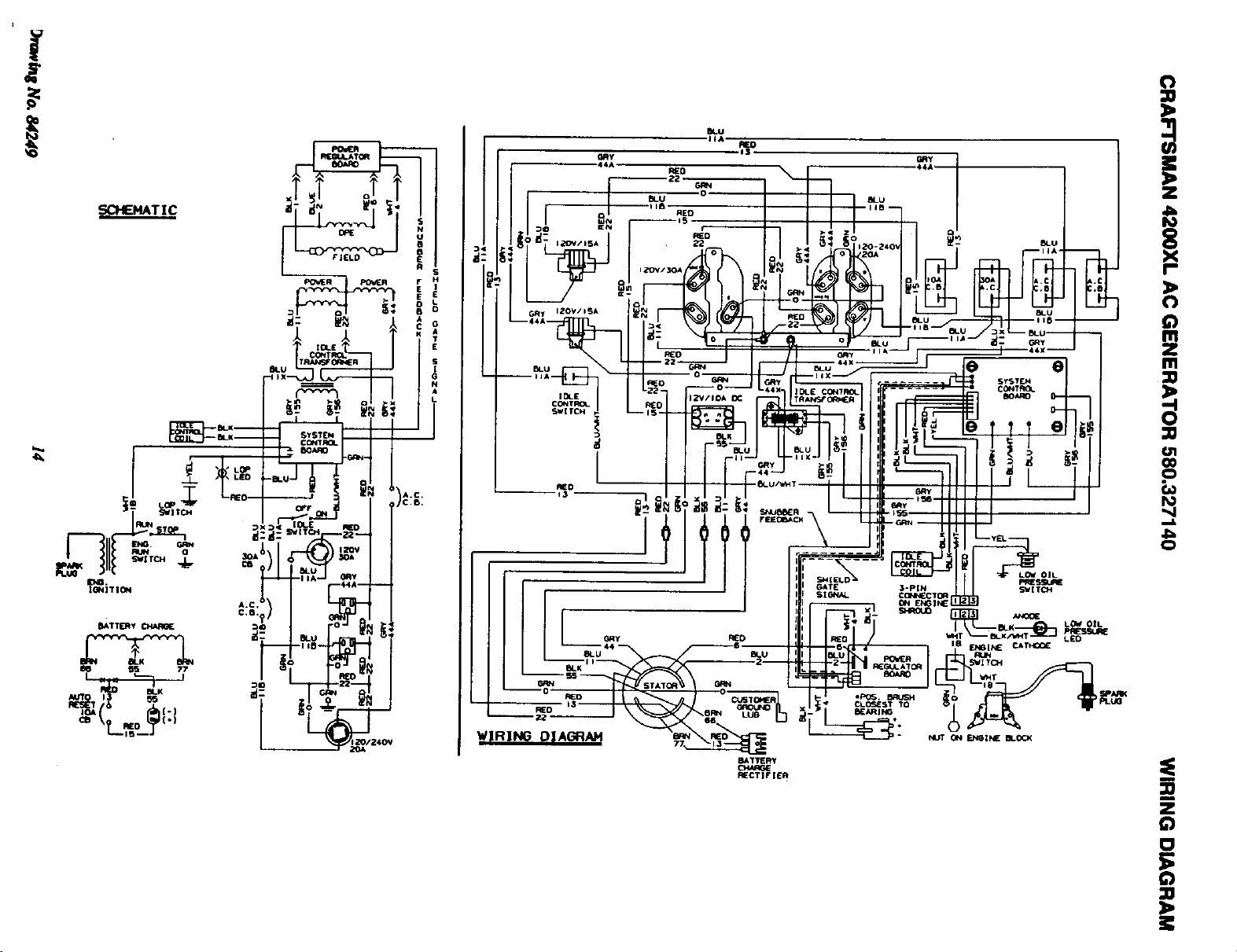

WIRING DIAGRAM ......................................... 14

REPAIR PARTS ....................................................... 16-21

WARRANTY ............................................................ 22-24

PARTS ORDERING. .................... BACK COVER

Index

-R-

Receptacles .............. 3

Retorque head bolts ....... 11

-I-

-S-

-L-

Safety Rules ...... inside cover

Service and Adjustments... 11

Service Recommendations . 12

Specifications ............. 1

Starting Engine ............ 5

Stopping Engine ........... 6

Storage ................. 12

-T-

Troubleshooting .......... 13

-O-

Warranty .............. 22-24

Wattage Reference Guide... 8

Widng Diagram ........... 14

-W-

-p-

2

ASSEMBLY

Your AC generator was completely assembled at the fac-

tory. It is ready for use after it has been propedy serviced

with the recommended lubricatingoil and fuel.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR GENERATOR, PLEASE CALL THE GENERA-

TOR HELPLINE AT 1-800-222-3136.

IMPORTANT: ANY ATTEMPT TO RUN THE ENGINE

BEFORE IT HAS BEEN SERVICED WITH THE RECOM-

MENDED OIL WILL RESULT IN AN ENGINE FAILURE.

TO REMOVE GENERATOR FROM CARTON

• Set the carton on a flat rigid surface with 'qHIS SIDE

UP" arrows pointing upward.

• Carefully open the top flaps of shipping carton.

• Cut down corners at one end of shipping carton and

lay that side of carton down flat.

• Remove packing material, carton fillers, etc.

• Remove generator from shipping carton.

PARTS SHIPPED LOOSE WITH UNIT

• Battery Charge Cables

• Spark Plug Wrench and Screw Driver

• EngineOil

• Wheel Kit

CORD SETS AND CONNECTOR PLUGS

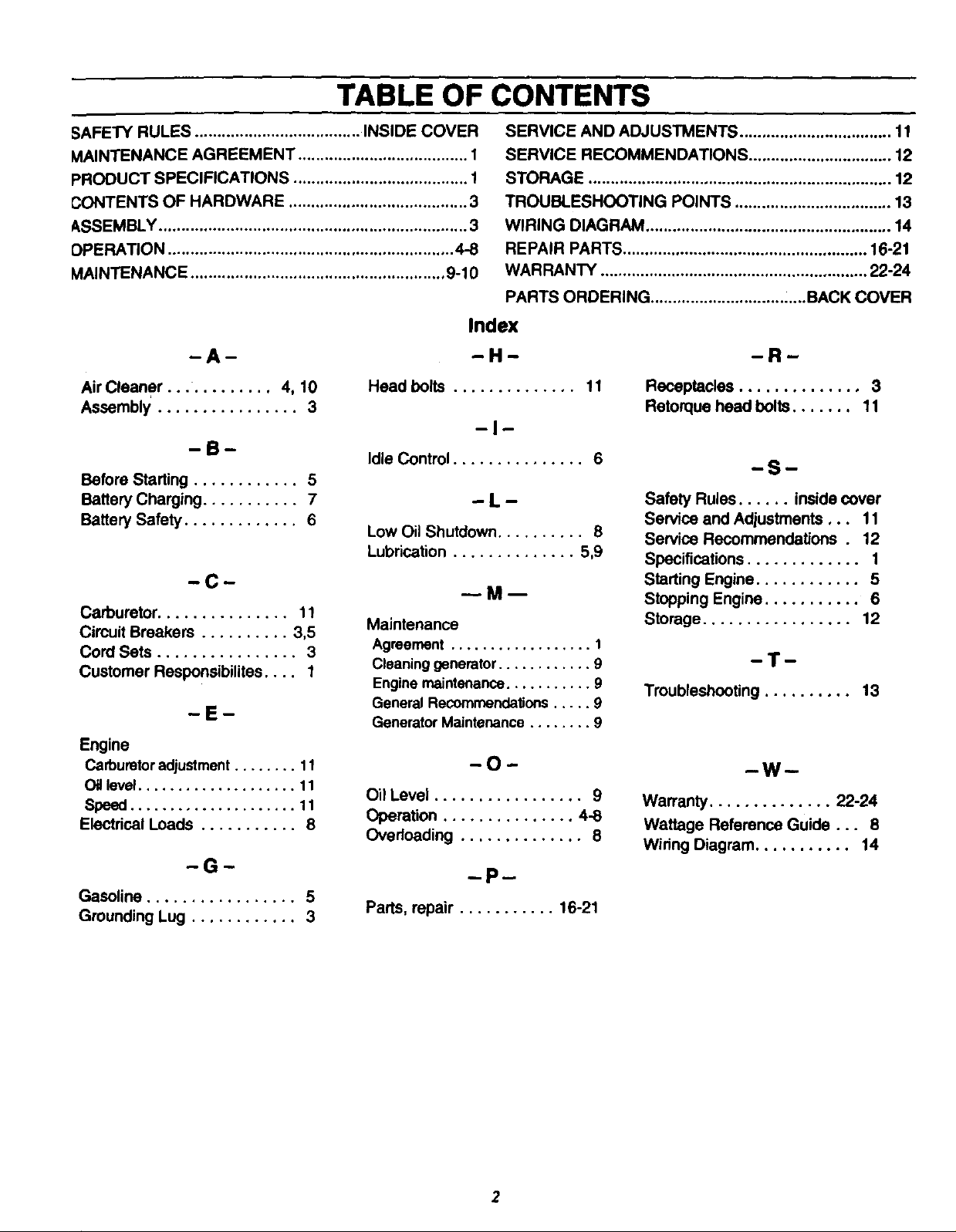

120 VOLTS DUPLEX RECEPTACLE

Use only high quality, !

well-insulated, extension i

cords with the 120-volt

"duplex"type electrical

receptacles (Fig. 1). All

cord sets used should be

rated 125 volts at 15 a-c

amps or greater for most

electrical devices.

FIG. 1

Keep extension cords as short as possible, preferably

less than 15 feet long to prevent voltage drop and wires

from overheating.

120 VOLTS, 30 AMP RECEPTACLE

R.,RCI--I/_ED

3NtlRE COI_

120 V_3

; ; i:i , N_JIWAL(N)

GROUND(G)

FIG. 2

_vd Set

F)Tc-_d

(c-re_)

FIG. 3

GROUNDING THE GENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUNDING WING NUT is pro-

vided on the base of the cradle (Fig. 4). Generally, con-

necting a No. 12 AWG (American Wire Gauge) stranded

copper wire to the grounding lug and to an earth-driven

copper or brass grounding rod (electrode) provides ade-

quate protection against electrical shock. Be sure to keep

ground wire attached when you connect electrode.

However, local codes may vary widely. Consult with a

local electrician for grounding requirements in your area.

Proper grounding of generator will help prevent electricel

shock inthe event of a ground fault condition inthe gener-

ator or in connected electrical devices. Proper grounding

also helps dissipate static electricity, which often builds up

in ungrounded devices.

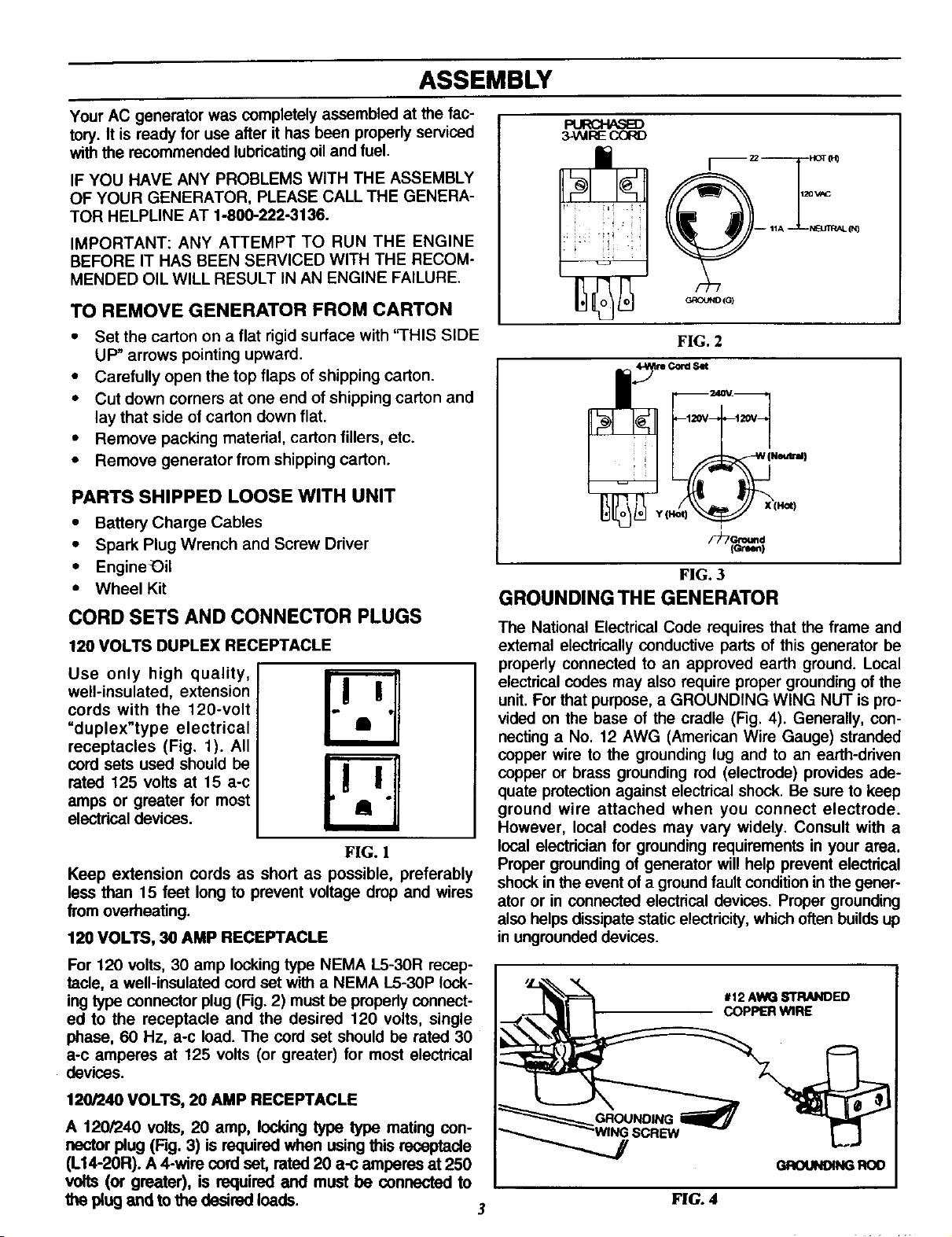

For 120 volts, 30 amp locking type NEMA L5-30R recep-

tacle, a well-insulated cord set with a NEMA L5-30P lock-

ing type connector plug (Fig. 2) must be properly connect-

ed to the receptacle and the desired 120 volts, single

phase, 60 Hz, a-c load. The cord set should be rated 30

a-c amperes at 125 volts (or greater) for most electrical

devices.

120/240 VOLTS, 20 AMP RECEPTACLE

A 120/240 volts, 20 amp, locking type type mating con-

nector plug (Rg. 3) is required when using this receptacle

(L14-2OR). A 4-wire cord set, rated 20 a-c amperes at 250

volts (or greater), is required and must be connected to

the plug and to the desired loads.

#12 AWG STRANDED

COPPER WIRE

GROUNO4NGROD

3

FIG. 4

OPERATION

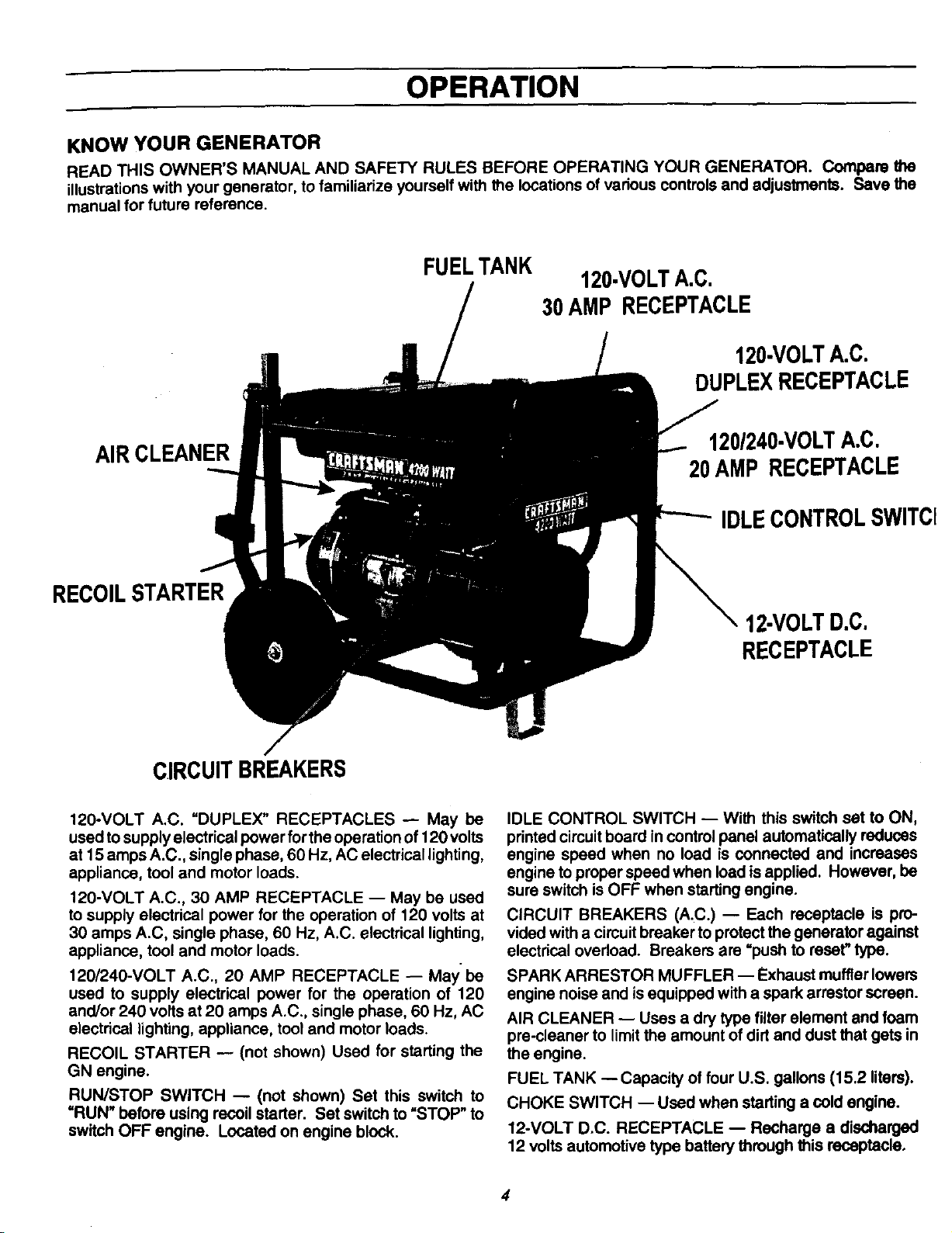

KNOW YOUR GENERATOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR GENERATOR. Compare the

illustrationswith your generator,tofamiliarizeyourselfwiththe locationsof variouscontrolsand adjustments. Save the

manualfor future reference.

AIR CLEANER

RECOILSTARTER

FUELTANK

120-VOLTA.C.

30AMP RECEPTACLE

120-VOLTA.C.

DUPLEXRECEPTACLE

120/240-VOLTA.C.

20AMP RECEPTACLE

IDLECONTROLSWlTCl

12-VOLTD.C.

RECEPTACLE

CIRCUITBREAKERS

120-VOLT A.C. "DUPLEX" RECEPTACLES -- May be

used to supply electrical Ix}wer for the operation of 120 volts

at 15 amps A.C., single phase, 60 Hz, AC electrical lighting,

appliance, tool and motor loads.

120-VOLT A.C., 30 AMP RECEPTACLE -- May be used

to supply electrical power for the operation of 120 volts at

30 amps A.C, single phase, 60 Hz, A.C. electrical lighting,

appliance, tool and motor loads.

120/240-VOLT A.C., 20 AMP RECEPTACLE -- May be

used to supply electrical power for the operation of 120

and/or 240 volts at 20 amps A.C., single phase, 60 Hz, AC

electrical lighting, appliance, tool and motor loads.

RECOIL STARTER -- (not shown) Used for starting the

GN engine.

RUN/STOP SWITCH -- (not shown) Set this switch to

=RUN" before using recoil starter. Set switch to "STOP" to

switch OFF engine. Located on engine block.

IDLE CONTROL SWITCH -- With this switch set to ON,

printed circuit board in control panel automatically reduces

engine speed when no load is connected and increases

engine to proper speed when load is applied. However, be

sure switch is OFF when starting engine.

CIRCUIT BREAKERS (A.C.) -- Each receptacle is pro-

vided with a circuit breaker to protect the generator against

electrical overload. Breakers are =push to reset" type.

SPARK ARRESTOR MUFFLER -- Exhaust muffler lowers

engine noise and is equipped with a spark arrestor screen.

AIR CLEANER -- Uses a dry type filter element and foam

pre-cleaner to limit the amount of dirt and dust that gets in

the engine.

FUEL TANK --Capacity of four U.S. gallons (15.2 liters).

CHOKE SWITCH -- Used when starting a cold engine.

12-VOLT D.C. RECEPTACLE -- Recharge a discharged

12 voltsautomotivetypebatterythroughthisreceptacle.

4

OPERATION

IF YOU HAVE ANY PROBLEMS OPERATING YOUR

GENERATOR, PLEASE CALL THE GENERATOR

HELPLINE AT 1-800-222-3136.

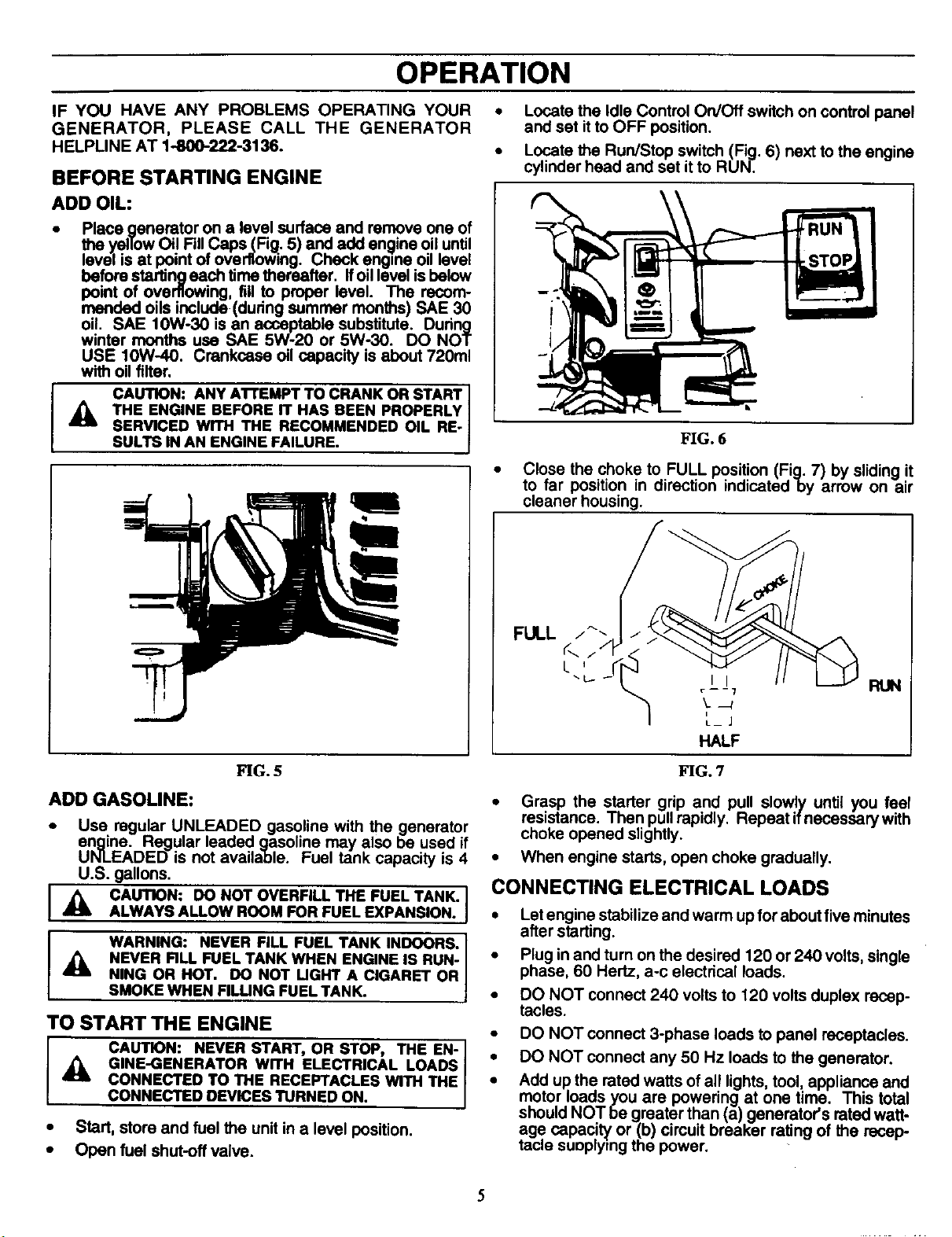

BEFORE STARTING ENGINE

ADD OIL:

Place generator on a level surface and remove one of

.they..ellowOil .FillCaps (Rg. 5) and add engine oil unti!

levm is at point owovernowmg. Check engine oil levee

before starting each time thereafter. If oil level is below

point of overflowing, fill to proper level. The recom-

mended oils include (during summer months) SAE 30

oil. SAE 10W-30 is an acceptable substitute. During

winter months use SAE 5W-20 or 5W-30. DO NOT

USE lOW-40. Crankcase oil capacity is about 720ml

with oil filter.

CAUTION: ANY AI"rEMPT TO CRANK OR START

THE ENGINE BEFORE IT HAS BEEN PROPERLY

SERVICED WITH THE RECOMMENDED OIL RE-

SULTS IN AN ENGINE FAILURE.

• Locate the Idle Control On/Off switch on control panel

and set it to OFF position.

• Locate the Run/Stop switch (Fig. 6) next to the engine

cylinder head and set it to RUN.

\

FIG. 6

• Close the choke to FULL position (Fig. 7) by sliding it

to far position in direction indicated by arrow on air

cleaner housing.

FIG. 5 FIG. 7

ADD GASOLINE:

• Use regular UNLEADED gasoline with the generator

engine. Regular leaded gasoline may also be used if

UNLEADED is not available. Fuel tank capacity is 4

U.S. gallons.

_1= CAUTION: DO NOT OVERFILL THE FUEL TANK.

ALWAYS ALLOW ROOM FOR FUEL EXPANSION.

WARNING: NEVER FILL FUEL TANK INDOORS.

NEVER RLL FUEL TANK WHEN ENGINE IS RUN-

NING OR HOT. DO NOT UGHT A CIGARET OR

SMOKE WHEN FILUNG FUEL TANK.

TO START THE ENGINE

CAUTION: NEVER START, OR STOP, THE EN-

GINE-GENERATOR WITH ELECTRICAL LOADS

CONNECTED TO THE RECEPTACLES WITH THE

CONNECTED DEVICES TURNED ON.

• Start, store and fuel the unit in a level position.

• Open fuel shut-off valve.

FULL

RUN

• Grasp the starter grip and pull slowly until you feel

resistance. Then pull rapidly. Repeatif necessarywith

choke opened slightly.

• When engine starts, open choke gradually.

CONNECTING ELECTRICAL LOADS

• Let engine stabilize and warm up for about five minutes

after starting.

• Plug in and turn on the desired 120 or 240 volts, single

phase, 60 Hertz, a-c electrical loads.

• DO NOT connect 240 volts to 120 volts duplex recep-

tacles.

• DO NOT connect 3-phase loads to panel receptacles.

• DO NOT connect any 50 Hz loads to the generator.

• Add up the rated watts of all lights tool appliance and

motor loads you are powering at one time. This total

should NOT be greater than (a) generator's rated watt-

age. capac!_ or (b) circuit breaker rating of the recep-

tac=esuoplymg the power.

OPERATION

STOPPING THE ENGINE

• Disconnect all electrical loads and let engine run at

no-load for about five minutes to stablize internal tom-

peratures of engine and generator.

• Tum off the engine by moving the Run/Stop switch to

STOP position.

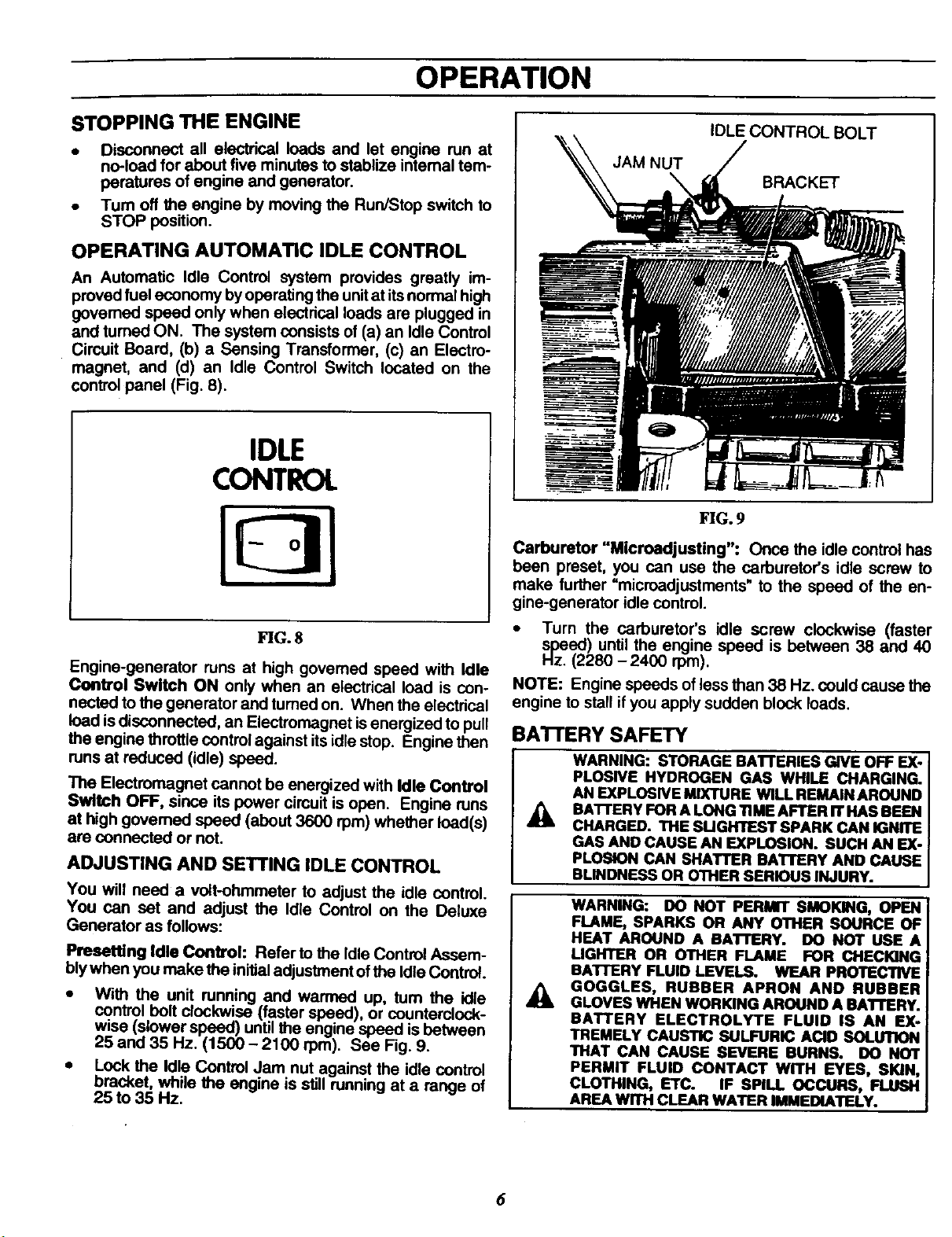

OPERATING AUTOMATIC IDLE CONTROL

An Automatic Idle Control system provides greatly im-

proved fuel economy by operating the unitat itsnormal high

govemed speed only when electrical loads are plugged in

and tumed ON. The system consists of (a) an Idle Control

Circuit Board, (b) a Sensing Transformer, (c) an Electro-

magnet, and (d) an Idle Control Switch located on the

control panel (Fig. 8).

IDLE

CONTROL

FIG. 8

Engine-generator runs at high governed speed with Idle

Control Switch ON only when an electrical load is con-

nected to the generator and turned on. When the electrical

load isdisconnected, an Electromagnet isenergized to pull

the engine throttle control against itsidle stop. Engine then

runs at reduced (idle) speed.

The Electromagnet cannot be energized with Idle Control

Switch OFF, since its power circuit is open. Engine runs

at high govemed speed (about 3600 rpm) whether load(s)

are connected or not.

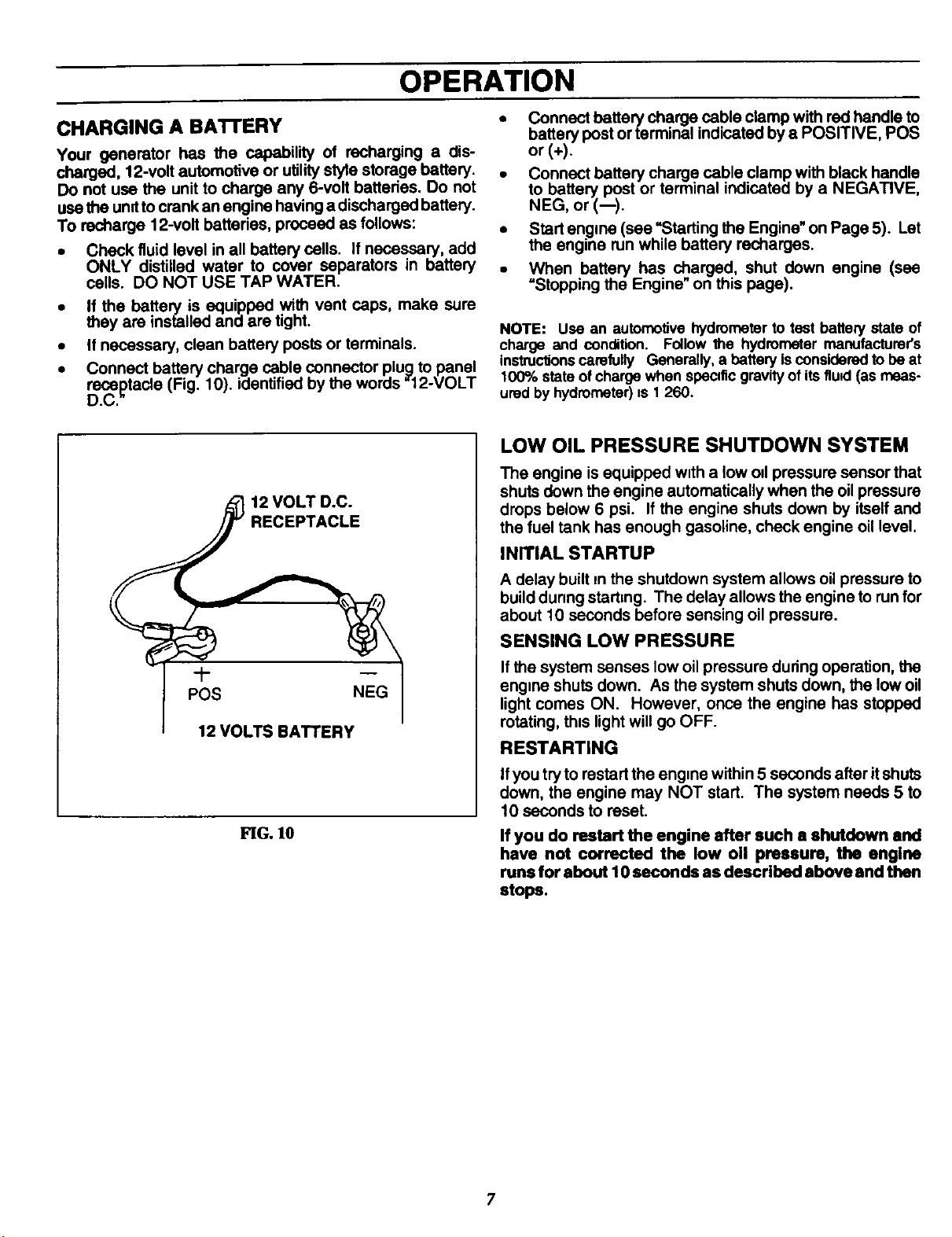

ADJUSTING AND SETTING IDLE CONTROL

You will need a volt-ohmmeter to adjust the idle control.

You can set and adjust the Idle Control on the Deluxe

Generator as follows:

Presetting Idle Control: Refer to the Idle Control Assem-

bly when you make the initial adjustment oi the idle Control.

• With the unit running and warmed up, tum the idle

control bolt clockwise (faster speed), or counterclock-

wise (slower speed) until the engine speed is between

25 and 35 Hz. (1500 - 2100 rpm). See Fig. 9.

• Lock the Idle Control Jam nut against the idle control

bracket, while the engine is still running at a range of

25 to 35 Hz.

IDLE CONTROL BOLT

JAM NUT

BRACKET

FIG.9

Carburetor "Microadjusting": Once the idle control has

been preset, you can use the carburetor's idle screw to

make further =microadjustments" to the speed of the an-

gine-generator idle control.

• Turn the carburetor's idle screw clockwise (faster

_4Oezed ) until the engine speed is between 38 and 40

(2280 - 2400 rpm).

NOTE: Engine speeds of less than 38 Hz. could cause the

engine to stall if you apply sudden block loads.

BA'I-rERY SAFETY

WARNING: STORAGE BAI"rERIES GIVE OFF EX-

PLOSIVE HYDROGEN GAS WHILE CHARGING.

AN EXPLOSWE MIXTURE WILL REMAIN AROUND

BATTERY FOR A LONG 11MEAFTER IT HAS BEEN

A

CHARGED. THE SUGHTESTSPARK CAN IGNITE

GAS AND CAUSE AN EXPLOSION. SUCH AN EX-

PLOSION CAN SHATTER BATTERY AND CAUSE

BLINDNESS OR OTHER SERIOUS INJURY.

WARNING: DO NOT PERMIT SMOKING, OPEN

FLAME, SPARKS OR ANY OTHER SOURCE OF

HEAT AROUND A BAI"rERY. DO NOT USE A

UGHTER OR OTHER FLAME FOR CHECKING

BATfERY FLUID LEVELS. WEAR PROTECTIVE

GOGGLES, RUBBER APRON AND RUBBER

GLOVES WHEN WORKING AROUND A BATrERY.

BATTERY ELECTROLYTE FLUID IS AN EX-

TREMELY CAUSTIC SULFURIC ACID SOLUTION

THAT CAN CAUSE SEVERE BURNS. DO NOT

PERMIT FLUID CONTACT WITH EYES, SKIN,

CLOTHING, ETC. IF SPILL OCCURS, FLUSH

AREA WITH CLEAR WATER IMMEDIATELY.

6

OPERATION

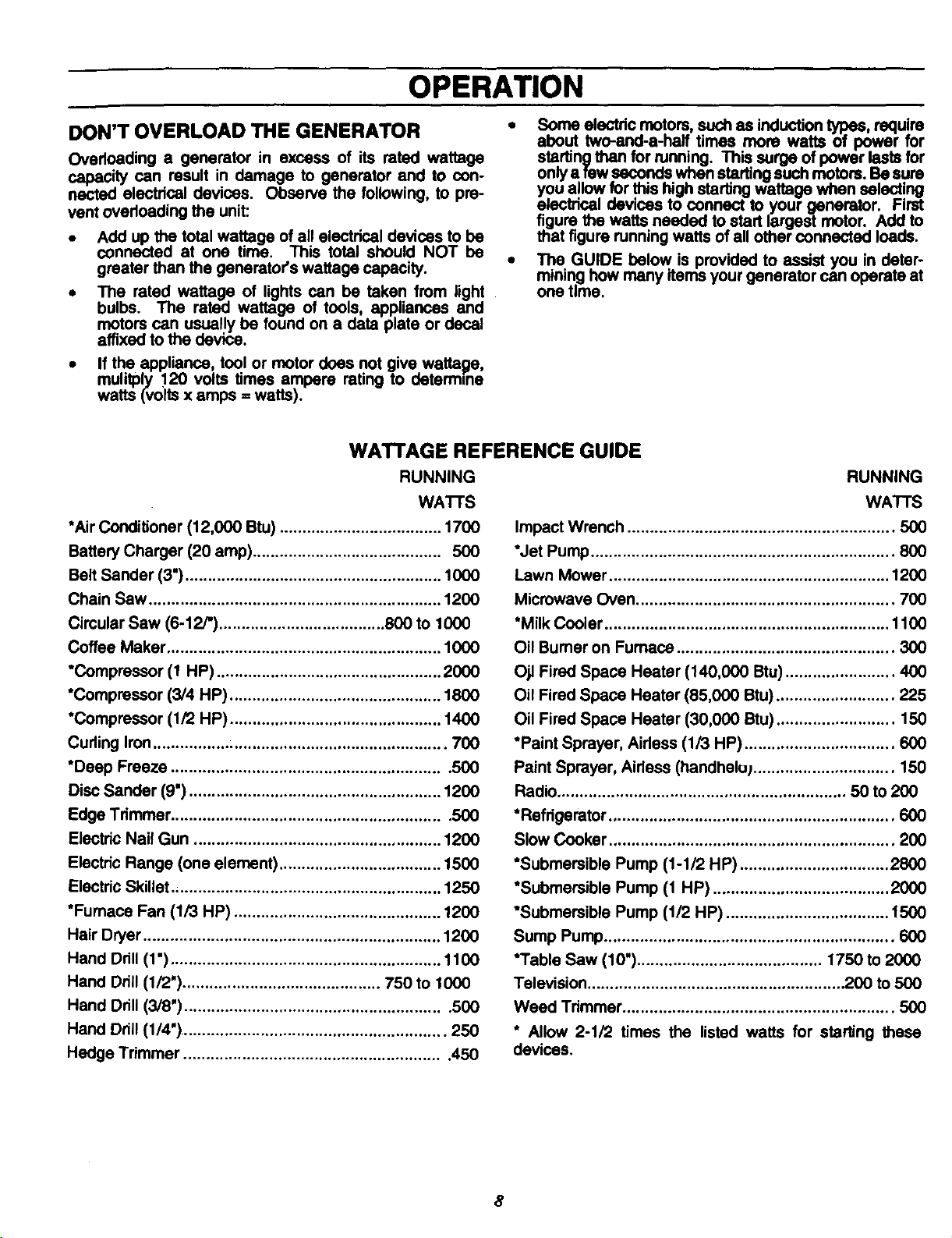

CHARGING A BA1TERY

Your generator has the capability of recharging a dis-

charged, 12-volt automotive or utility style storage battery.

Do not use the unit to charge any 6-volt batteries. Do not

use the unit to crank an engine having a discharged battery.

To recharge 12-volt battedas, proceed as follows:

• Check fluid level in all battery cells. If necessary, add

ONLY distilled water to sever separators in battery

cells. DO NOT USE TAP WATER.

• If the battery is equipped with vent caps, make sure

they are installed and are tight.

• If necessary, clean battery posts or terminals.

• Connect battery charge cable connector plug to panel

recaptacle (Fig. 10). identified by the words =12-VOLT

D.C.

Connectbatterycharge cable clamp with red handle to

battery post or terminal indicated by a POSITIVE, POS

or(*).

• Connect battery charge cable clamp with black handle

to battery post or terminal indicated by a NEGATIVE,

NEG, or (--).

. Start en.g=ne(see =Starting the Engine" on Page 5). Let

the engine run while battery recharges.

• When battery has charged, shut down engine (see

=Stopping the Engine" on this page).

NOTE: Use an automotive hydrometer to test batterystate of

charge and condition. Follow the hydrometer manufacturer's

instruc_onscarefully Generally,a battery isconsidered tobe at

100% stateof charge when speQtic gravityof itsflu_ (as meas-

ured by hydrometer)is 1 260.

LOW OIL PRESSURE SHUTDOWN SYSTEM

The engine is equipped w_tha low od pressure sensor that

shuts down the engine automatically when the oil pressure

drops below 6 psi. If the engine shuts down by itself and

the fuel tank has enough gasoline, check engine oil level.

INITIAL STARTUP

A delay built m the shutdown system allows oil pressure to

build dunng starting. The delay allows the engine to run for

about 10 seconds before sensing oil pressure.

SENSING LOW PRESSURE

If the system senses low oil pressure during operation, the

eng=ne shuts down. As the system shuts down, the low oil

light comes ON. However, once the engine has stopped

rotating, this light will go OFF.

RESTARTING

FIG. 10

Ifyou try to restart the eng=ne within 5 seconds after itshuts

down, the engine may NOT start. The system needs 5 to

10 seconds to reset.

If you do restart the engine after such a shutdown and

have not corrected the low oil pressure, the engine

runs for about 10 seconds as described above and then

stops.

7

OPERATION

DON'T OVERLOAD THE GENERATOR

Overloading a generator in excess of its rated wattage

capacity can result in damage to generator and to con-

nected electrical devices. Observe the following, to pre-

vent overloading the unit:

• Add up the total wattage of all electrical devices to be

connected at one time. This total should NOT be

greater than the generator's wattage capacity.

• The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usual!y be found on a data plate or decal

affixed to the device.

• If the appliance, tool or motor does not give wattage,

mulitply !20 volts Umas ampere rating to detarmnne

watts (volts x amps = watts).

WATTAGE REFERENCE GUIDE

RUNNING

WA'I-rS

*Air Conditioner (12,000 Btu) .................................... 1700

Battery Charger (20 amp) .......................................... 500

Belt Sander (3") ......................................................... 1000

Chain Saw ................................................................. 1200

Cimular Saw (6-12/') ..................................... 800 to 1000

Coffee Maker ............................................................. 1000

"Compressor (1 HP) .................................................. 2000

*Compressor (3/4 HP) ............................................... 1800

*Compressor (1/2 HP) ............................................... 1400

Curling Iron ................. ................................................ 700

"Deep Freeze ............................................................. 500

Disc Sander (9") ........................................................ 1200

Edge Trimmer ............................................................. 500

Electric Nail Gun ....................................................... 1200

Electric Range (one element) .................................... 1500

Electdc Skillet. .......................................................... 1250

*Furnace Fan (1/3 HP) .............................................. 1200

Hair Dryer .................................................................. 1200

Hand Drill (1")............................................................ 1100

Hand Drill (1/2') ............................................ 750 to 1000

Hand Drill (3/8") .......................................................... 500

Hand Ddll (1/4') ........................................................... 250

Hedge Trimmer .......................................................... 450

Some electric motors, such as induction types, require

about two-and-a-half times more watts of power for

s_rtin_ than for running. This surge of power lasts for

omy a few seconds when starting such motors. Be sure

you allow ;or this high starting wattage when selecting

electrical devices to connect to your generator. First

figure the watts needed to start largest motor. Add to

that figure running watts of all other connected loads.

The GUIDE below is provided to assist you in deter-

mining how many items your generator can operate at

one time.

RUNNING

WATTS

Impact Wrench ........................................................... 500

*Jet Pump ................................................................... 800

Lawn Mower .............................................................. 1200

Microwave Oven ......................................................... 700

*Milk Cooler ............................................................... 1100

Oil Burner on Fumaca ................................................ 300

Oil Fired Space Heater (140,000 Btu) ........................ 400

Oil Fired Space Heater (85,000 Btu) .......................... 225

Oil Fired Space Heater (30,000 Btu) .......................... 150

*Paint Sprayer, Airless (1/3 HP) ................................. 600

Paint Sprayer, Aidess (handhelu) ............................... 150

Radio ................................................................ 50 to 200

"Refrigerator ............................................................... 600

Slow Cooker ............................................................... 200

*Submersible Pump (1-1/2 HP) ................................. 2800

*Submersible Pump (1 HP) ....................................... 2000

*Submersible Pump (1/2 HP) .................................... 1500

Sump Pump ................................................................ 600

*Table Saw (10")......................................... 1750 to 2000

Television ........................................................ .200 to 500

Weed Trimmer ............................................................ 500

* Allow 2-1/2 times the listed watts for starting these

devices.

8

MAINTENANCE

GENERAL RECOMMENDATIONS

The Owner/Operator is responsible for making sure that all

periodic maintenance tasks are completed on a timely

basis; that all discrepancies are corrected; and that the unit

is kept ctean and property stored. Never operate a dam-

aged or defective generator.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry envior-

ment where it will not be exposed to exceesive dust, dirt,

moisture or any corrosive vapors. Cooling air slots in the

generator must not become dogged with snow, leaves or

any other foreign material.

Check the cleenliness of the generator fraquentiy and clean

when dust, dirt, oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE: We DO NOT recommend usinga garden hose to clean

thegenerator. Water canenterthe enginefuelsystemand cause

problems. In addition, if water entem the generator through

coolingair slots,some of the water willbe retained in voids and

cracksof the rotorand statorwindinginsulation. Water and dirt

buildupon the generator internal windingswill eventually de-

creasethe insulationresistanceof thesewindings.

TO CLEAN THE GENERATOR:

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft, bristle brush to loosen caked on dirt,oil, etc.

• A vacuum cleaner may be used to pick up loose dirt

and debris.

Low pressure air (not to exceed 25 psi) may be used

to blow away dirt. Inspect cooling air slots and opening

on the generator. These openings must be kept clean

and unobstructed.

CAUTION: NEVER INSERT ANY OBJECT OR

TOOL THROUGH THE AIR COOLING SLOTS, EVEN

IF THE ENGINE IS NOT RUNNING. DAMAGE TO

THE UNIT OR PERSONAL INJURY MAY RESULT.

ENGINE MAINTENANCE

CHECKING OIL LEVEL

See OPERATION sectionon Page 4 forinformationon checking

oillevel. Oil levelshould be checked before each use orat least

every eight hours ofoperation. Keep oillevel maintained.

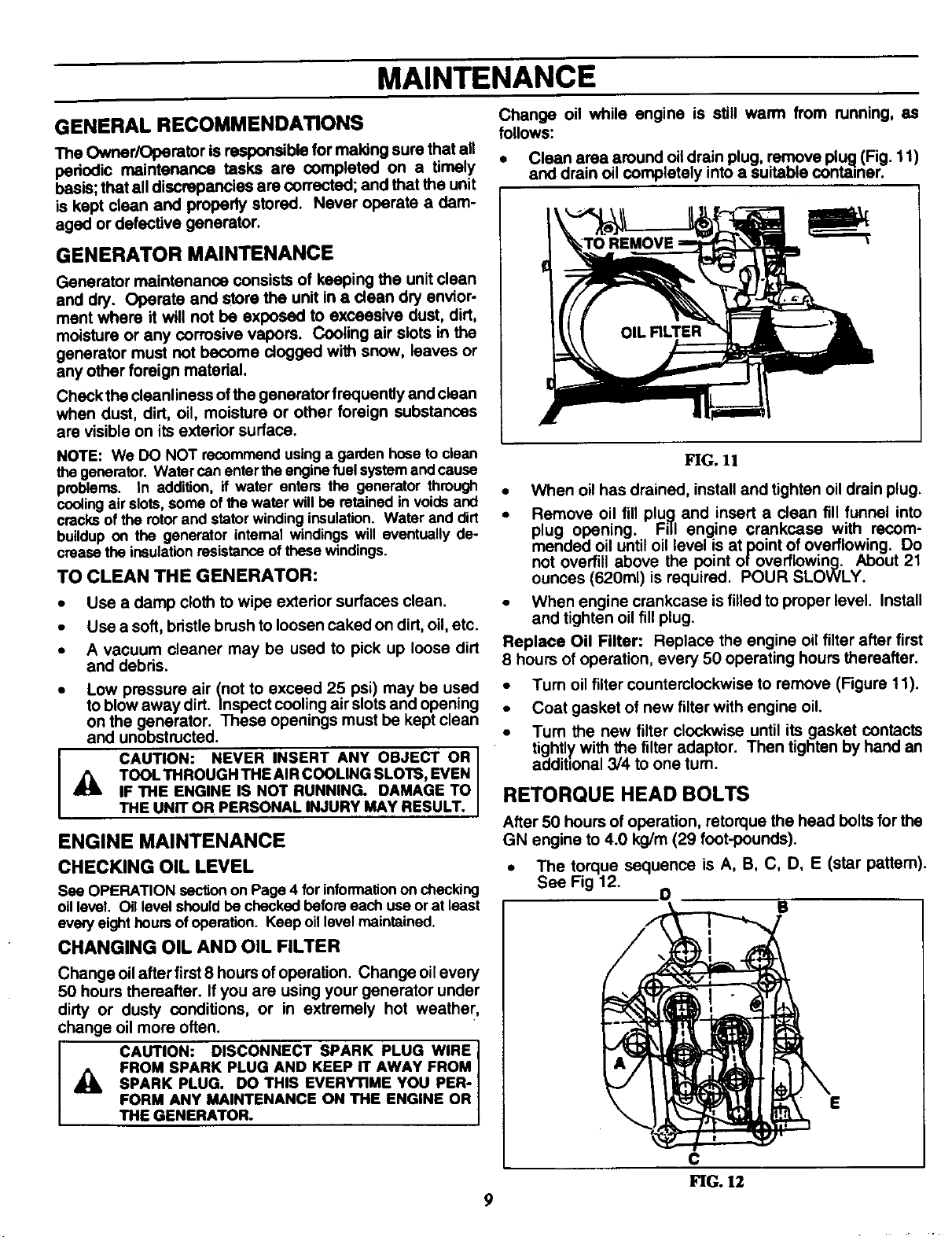

CHANGING OIL AND OIL FILTER

Change oil while engine is still warm from running, as

follows:

• Clean area around oil drain plug, remove plug (Fig. 11)

and drain oil completely into a suitable container.

OIL FILTER

I

A

FIG. 11

• When oil has drained, install and tighten oil drain plug.

• Remove oil fill plug and insert a clean fill funnel into

plug opening. Fill engine crankcase with recom-

mended oil until oil level is at point of overflowing. Do

not overfill above the point of overflowing. About 21

ounces (620ml) is required. POUR SLOWLY.

• When engine crankcase is filled to proper level. Install

and tighten oil fill plug.

Replace Oil Filter: Replace the engine oil filter after first

8 hours of operation, every 50 operating hours thereafter.

• Turn oil filter counterclockwise to remove (Figure 11).

• Coat gasket of new filter with engine oil.

• Turn the new filter clockwise until its gasket contacts

tightly with the filter adaptor. Then tighten by hand an

additional 3/4 to one turn.

RETORQUE HEAD BOLTS

After 50 hours of operation, retorque the head bolts for the

GN engine to 4.0 kg/m (29 foot-pounds).

• The torque sequence is A, B, C, D, E (star pattern).

See Fig 12.

O

B

Change oilafter first 8 hours of operation. Change oil every

50 hours thereafter. If you are using your generator under

dirty or dusty conditions, or in extremely hot weather,

change oil more often.

FROM SPARK PLUG AND KEEP IT AWAY FROM

SPARK PLUG. DO THIS EVERYTIME YOU PER-

J ,_ CAUTION: DISCONNECT SPARK PLUG WIRE

FORM ANY MAINTENANCE ON THE ENGINE OR

THE GENERATOR,

E

C

FIG. 12

9

MAINTENANCE

SERVICE AIR CLEANER REPLACE SPARK PLUG

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

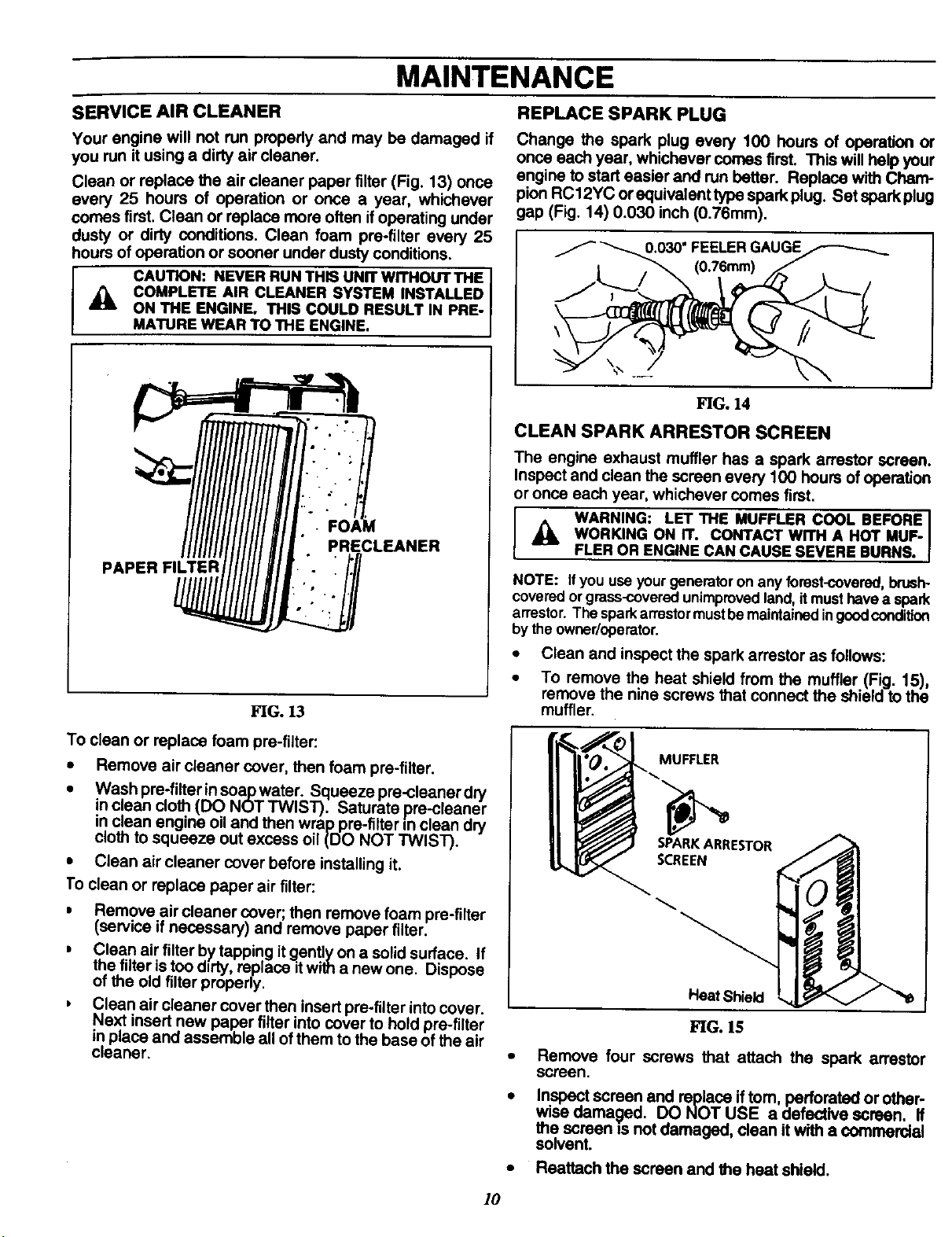

Clean or replace the air cleaner paper filter (Fig. 13) once

every 25 hours of operation or once a year, whichever

comes first. Clean or replace mere often if operating under

dusty or dirty conditions. Clean foam pre-filter every 25

hours of operation or sooner under dusty conditions.

A COMPLETE AIR CLEANER SYSTEM INSTALLED

I CAUTION: NEVER RUN THIS UNIT WITHOUT THE

ON THE ENGINE. THIS COULD RESULT IN PRE-

MATURE WEAR TO THE ENGINE.

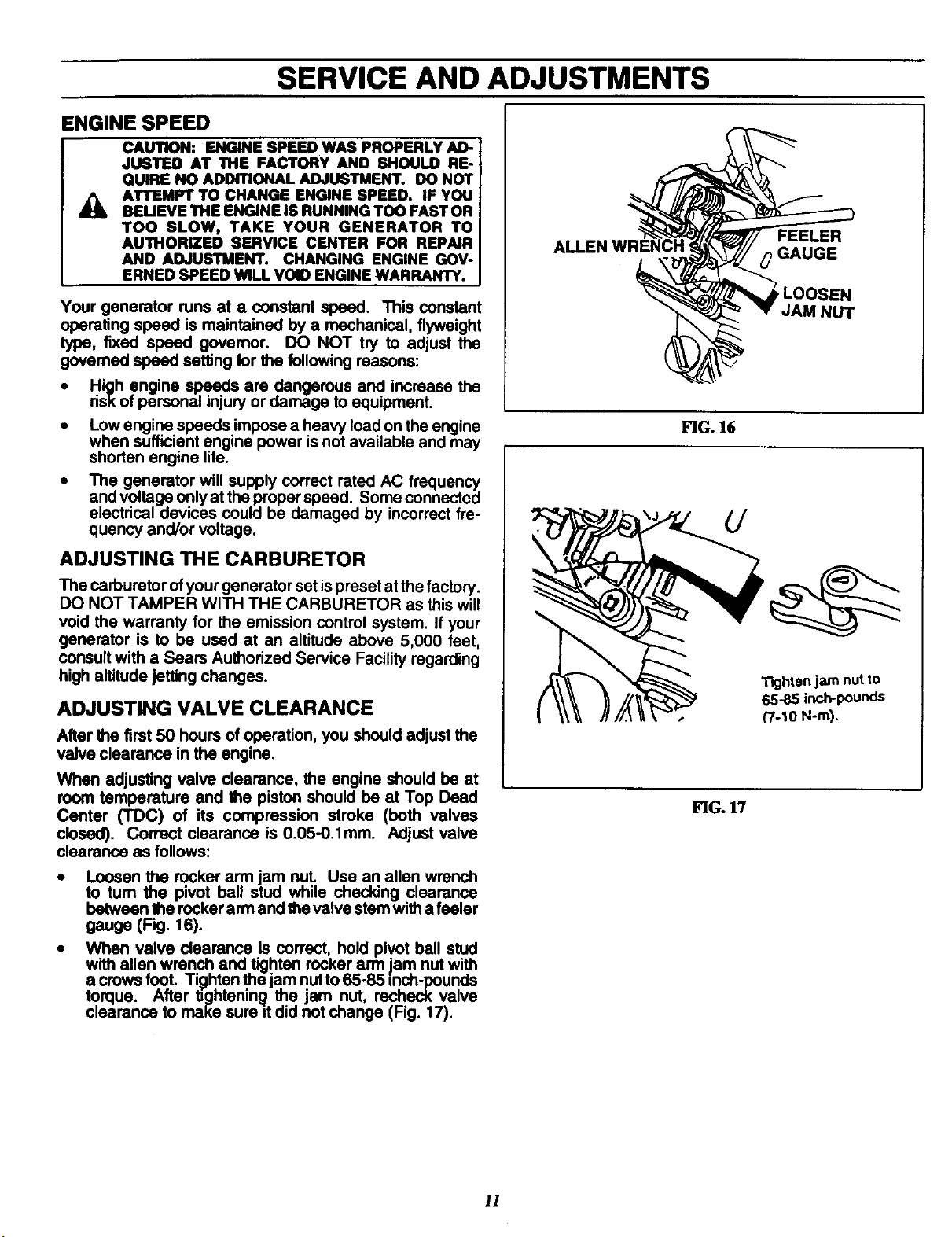

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help your

engine to start easier and run better. Replace with Cham-

pion RC12YC or equivalent type spark plug. Set spark plug

gap (Fig. 14) 0.030 inch (0.76mm).

/ "_.030" FEELERGAUGE

/_ (0.76mm)

FIG. 14

CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor screen.

Inspect and clean the screen every 100 hours of operation

or once each year, whichever comes first.

PRECLEANER

PAPER FILTER

FIG. 13

To clean or replace foam pre-filter:

* Remove air cleaner cover, then foam pre-tilter.

• Wash pre-filter in soap water. Squeeze pre-c eaner dry

in clean cloth (DO NOTTWlST). Saturata pre-c eaner

in clean engine oil and then wrap pre-ti tern clean dry

cloth to squeeze out excess oil (DO NOT TWIST).

• Clean air cleaner cover before installing it.

To clean or replace paper air filter:

• Remove air cleaner cover; then remove foam pre-fi ter

Iservice if necessary) and remove paper tilter.

, Clean air filter bytapping itgently on a solid surface. If

the filter is too durty replace itwith a new one. D spose

of the o d f Iter properly.

b Clean air cleaner cover then insert pre-filter into cover.

Next insert new paper filter into cover to hod pre-filter

in place and assemble all of them to the base of the air

cleaner.

A WORKING ON IT. CONTACT WITH A HOT MUF-

p WARNING: LET THE MUFFLER COOL BEFORE I

NOTE: If you useyourgenerator on any forest-covered,brush°

coveredor grass-coveredunimprovedland, itmust have a spark

arrestor.The sparkarrestormustbe maintainedingoodcondition

by the owner/operator.

• Clean and inspect the spark arrestor as follows:

• To remove the heat shield from the muffler (Fig. 15),

• Reattach the screen and the heat shield.

FLER OR ENGINE CAN CAUSE SEVERE BURNS.

remove the nine screws that connect the shield to the

muffler.

MUFFLER

SPARKARRESTOR

SCREEN

Heat Shield

FIG. 15

Remove four screws that attach the spark arrestor

screen.

Inspect screen and replace if tom, perforated or other-

wise oamaged. DO NOT USE a defective screen. If

the screen is not damaged, clean it with a commercial

solvent.

10

SERVICE AND ADJUSTMENTS

ENGINE SPEED

CAUTION: ENGINE SPEED WAS PROPERLY AD-

JUSTED AT THE FACTORY AND SHOULD RE-

QUIRE NO ADDITIONAL ADJUSTMENT. DO NOT

AI"rEMPT TO CHANGE ENGINE SPEED. IF YOU

BEUEVE THE ENGINE IS RUNNING TOO FAST OR

TOO SLOW, TAKE YOUR GENERATOR TO

AUTHORIZED SERVICE CENTER FOR REPAIR

ANO ADJUSTMENT. CHANGING ENGINE GOV-

ERNED SPEED WILL VOID ENGINE WARRANTY.

Your generator runs at • constant speed. This constant

operating speed is maintained by a mechanical, flyweight

type, fixed speed governor. DO NOT try to adjust the

govemed speed setting for the following reasons:

• High engine speeds are dangerous and increase the

dsk of personal injury or damage to equipment.

• Low engine speeds impose a heavy load on the engine

when sufficient engine power is not available and may

shorten engine life.

• The generator will supply correct rated AC frequency

and voltage only at the proper speed. Some connected

electrical devices could be damaged by incorrect fre-

quency and/or voltage.

ALLEN

FEELER

0 GAUGE

_LOOSEN

JAM NUT

FIG. 16

ADJUSTING THE CARBURETOR

The carburetor of your generator set is preset at the factory.

DO NOT TAMPER WITH THE CARBURETOR as this will

void the warranty for the emission control system. If your

generator is to be used at an altitude above 5,000 feet,

consult with a Sears Authorized Service Facility regarding

high altitude jetting changes.

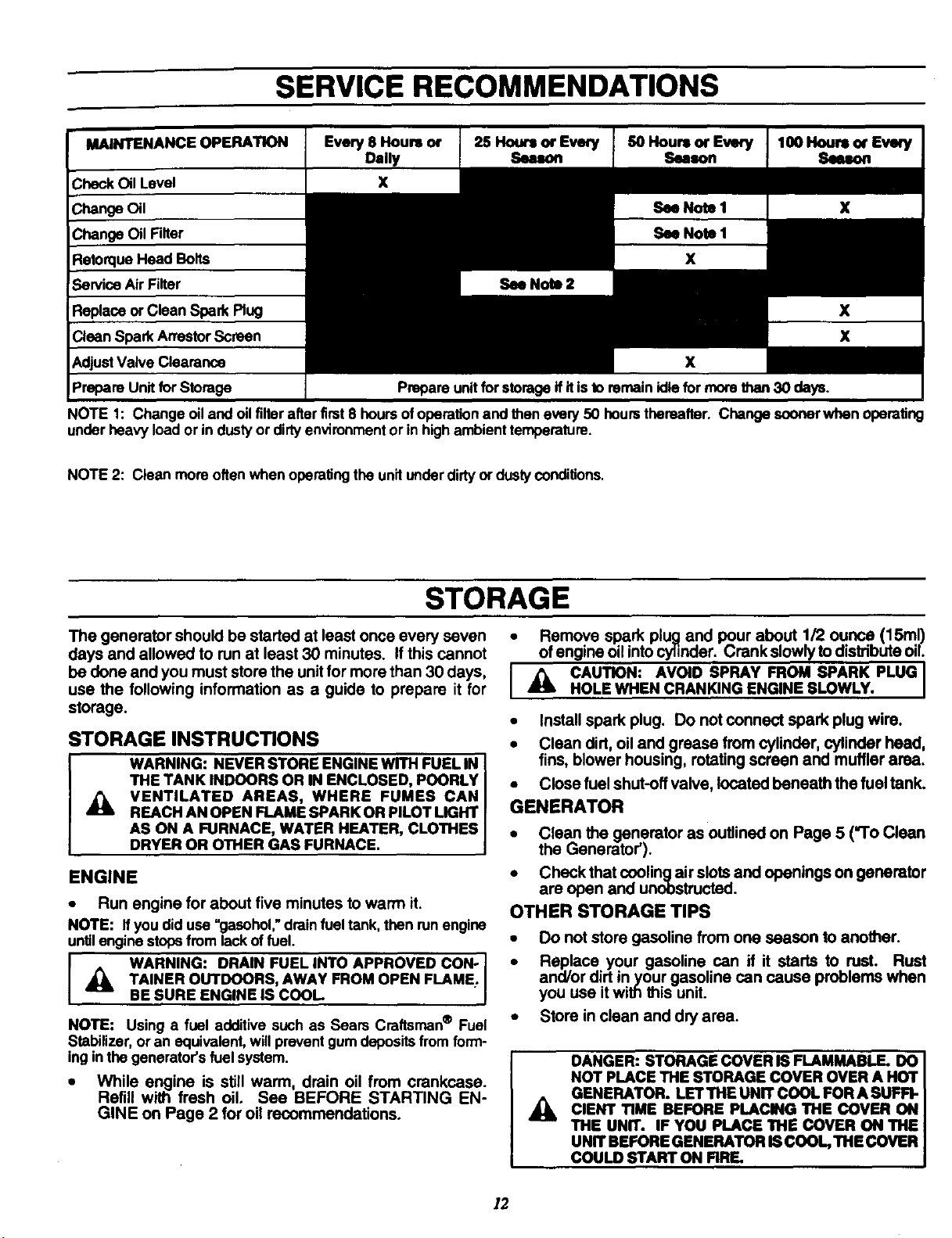

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust the

valve clearance in the engine.

When adjusting valve clearanca, the engine should be at

room temperature and the piston should be at Top Dead

Center ('rDC) of its compression stroke (both valves

closed). Correct clearance is 0.05-0.1mm. Adjust valve

clearance as follows:

• Loosen the rocker arm jam nut. Use an allen wrench

to turn the pivot ball stud while checking clearance

between the rocker arm and the valve stem with a feeler

gauge (Fig. 16).

• When valve clearance is correct, hold pivot bell stud

with allen wrench and tighten rocker arm jam nut with

a crows foot. Tighten the jam nut to65-85 =nch-pounds

torque. After tightenin_,l the jam nut, recheck valve

clearance to make sure itdid not change (Fig. 17).

"F_jhten]am nutto

65-85 inch-pounds

("/-10 N-m).

FIG. 17

1!

SERVICE RECOMMENDATIONS

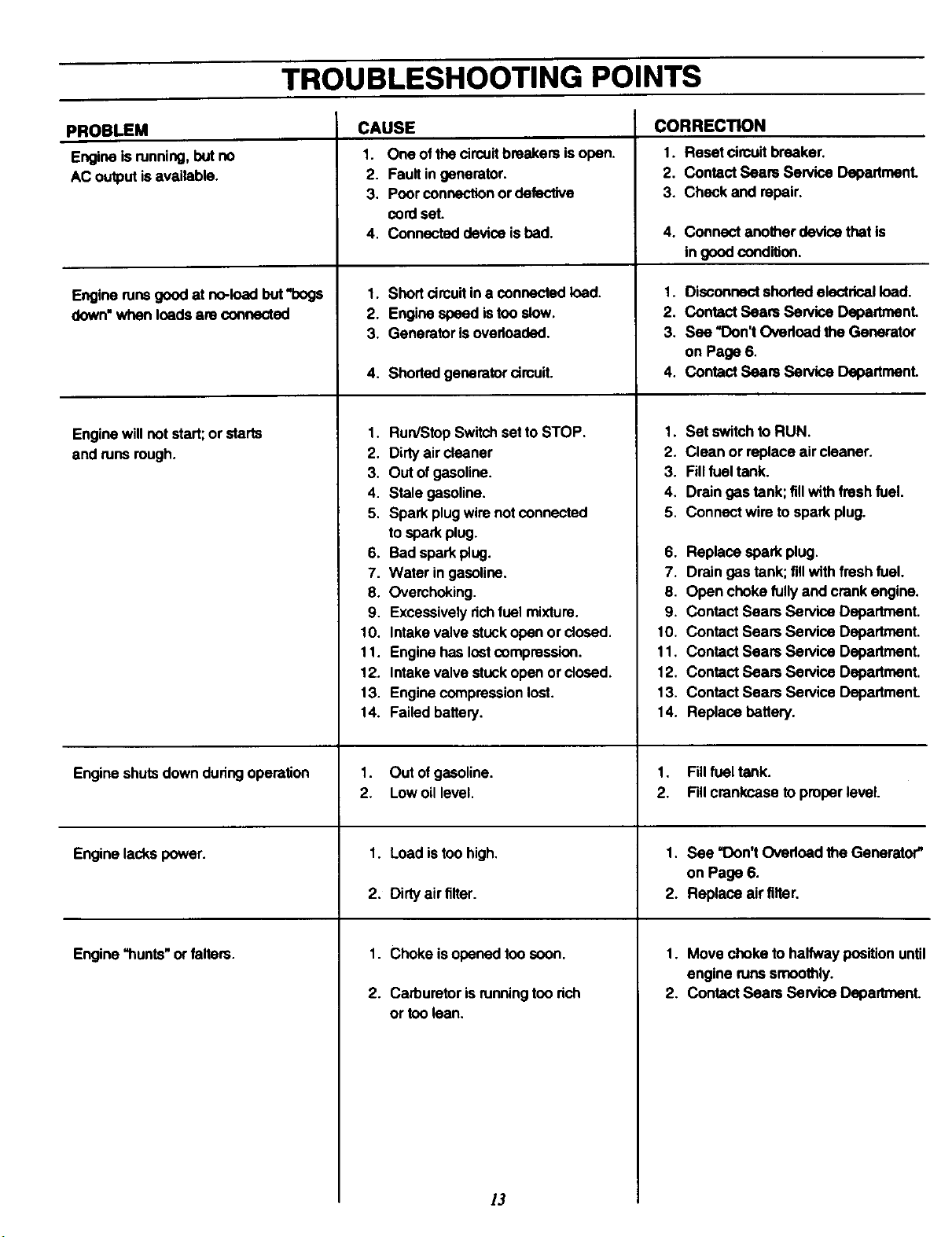

MAINTENANCE OPERATION Every 8 Hours or 25 Hours or Every SOHours or Every 100 Hours or Every

NOTE 1: Change oil and oil filterafterfirst8 hoursofoperationand then every 50 hoursthereafter. Change soonerwhen operating

underheavy load or in dustyor dirtyenvironmentor in highambienttemperature.

NOTE 2: Clean more often when operatingthe unitunderdirtyordustyconditions.

STORAGE

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than 30 days,

use the following information as a guide to prepare it for

storage.

STORAGE INSTRUCTIONS

WARNING: NEVER STORE ENGINE WITH FUEL IN

THE TANK INDOORS OR IN ENCLOSED, POORLY

,_ VENTILATED AREAS, WHERE FUMES CAN

REACH AN OPEN FLAME SPARK OR PILOT LIGHT

AS ON A FURNACE, WATER HEATER, CLOTHES

DRYER OR OTHER GAS FURNACE.

ENGINE

• Run engine for about five minutes to warm it.

NOTE: Ifyou did use =gasohol,"drainfuel tank, then runengine

untilenginestopsfrom lack of fuel.

_ TAINER OUTDOORS, AWAY FROM OPEN

WARNING: DRAIN FUEL INTO APPROVED CON- ] •

BE SURE ENGINE IS COOL J

NOTE: Using a fuel additive such as Sears Craftsman® Fuel •

Stabilizer,or an equivalent,will preventgum depositsfrom form-

ingin the generator's fuel system.

• While engine is still warm, drain oil from crankcase.

Refill with fresh oil. See BEFORE STARTING EN-

GINE on Page 2 for oil recommendations.

FLAME;

I

• Remove spark plug and pour about 1/2 ounce (15ml)

ofengine oil intocylinder. Crank slowly to distribute oil

I _ CAUTION: AVOID SPRAY FROM SPARK PLUG

• Install spark plug. Do not connect spark plug wire.

• Clean dirt, oil and grease from cylinder, cylinder head,

• Close fuel shut-off valve, located beneath the fuel tank.

GENERATOR

• Clean the generator as outlined on Page 5 ("To Clean

• Check that cooling air slots and openings on generator

OTHER STORAGE TIPS

HOLE WHEN CRANKING ENGINE SLOWLY.

fins, blower housing, rotating screen and muffler area.

the Generator').

are open and unobstructed.

Do not store gasoline from one season to another.

Replace your gasoline can if it starts to rust. Rust

and/or dirt in your gasoline can cause problems when

you use it with this unit.

Store in clean and dry area.

DANGER: STORAGE COVER IS FLAMMABLE. DO

NOT PLACE THE STORAGE COVER OVER A HOT

GENERATOR. LETTHE UNIT COOL FOR A SUFFI-

_k CIENT TIME BEFORE PLACING

THE UNIT. IF YOU PLACE THE COVER ON THE

UNIT BEFORE GENERATOR ISCOOL, THE COVER

COULD START ON RRE.

THE

COVER ON

12

TROUBLESHOOTING POINTS

PROBLEM

Engineis running,10utno

AC outputisavailable.

Engine runs good at no-loadbut"bogs

down"when loadsare connected

Enginewillnot start;orstarts

and runsrough.

CAUSE

CORRECTION

1. One ofthe circuitbreakers isopen.

2. Fault ingenerator.

3. Poor connectionor defective

cordset.

4. Connected device is bad.

1.

Shortcircuitin a connectedload. 1.

2.

Enginespeed istoo slow. 2.

3.

Generator isoverloaded. 3.

4.

Shoded generatorcircuit. 4,

1.

Run/Stop Switchset to STOP. 1.

2.

Dirty air cleaner 2.

3.

Outof gasoline. 3.

4.

Stale gasoline. 4.

5.

Spark plugwire notconnected 5.

to spark plug.

.

Bad spark plug. 6.

7.

Water ingasoline. 7.

8.

Overchoking. 8.

9.

Excessivelyrichfuel mixture. 9.

10.

Intakevalve stuckopenor dosed. 10.

11.

Enginehas lostcompression. 11.

12. Intakevalve stuck opan orclosed. 12.

13. Enginecompressionlost. 13.

14. Failed battery. 14.

1. Reset circuitbreaker.

2. Contact Sears Service DepadmenL

3. Check and repair.

4.

Connect anotherdevice that is

in goodcondition.

Disconnectshorted electricalload.

Contact Sears Service Department.

See "Don't Ovedoadthe Generator

on Page 6.

ContactSears Service Department.

Set switchto RUN.

Clean or replaceair cleaner.

Fillfuel tank.

Drain gastank; fillwith freshfuel.

Connect wire to spark plug.

Replace spark plug.

Drain gas tank; till withfreshfuel.

Open choke fully and crankengine.

ContactSears Service Department.

ContactSears Service Department.

ContactSears Service Department.

ContactSears Service Department.

ContactSears Service Department.

Replace battery.

Engine shutsdowndunngoperation

Engine lackspower.

Engine "hunts" orfaltera.

1. Out of gasoline. 1.

2. Lowoil level. 2.

1. Load istoo high. 1.

2. Dirtyair filter. 2.

1. Choke isopened too soon. 1,

2. Carburetorisrunningtoo rich 2.

or toolean.

13

Fillfuel tank.

Fillcrankcase to properlevel.

See "Don'tOverload the Generator"

on Page 6.

Replace air filter.

Move choke to halfway positionuntil

engine runs smoothly.

ContactSears Service Department.

W_[RZNG D| AGRAH

BtTTERy

I_CT]F JER

Loading...

Loading...