Craftsman 580326010 Owner’s Manual

Sears

owners

manual

MODEL NO.

580.326010

CAUTION: READ

INSTRUCTIONS AND

RULES FOR SAFE

OPERATIONS CAR EFULLY

TO PREVENT ACCIDENTS,

GENERAL INFORMATION

INSTALLATION

OPERATING INSTRUCTIONS

MAINTENANCE

REPAIR PARTS

Sears, Roebuck and Co., Ct-deago, 1]1.60684 U.S.A.

4500 WATT

HEAVY DUTY

PORTABLE ALTERNATOR

ALTERNATOR

Record in space provided below the Model No. and Serial No.

of the alternator, Model No, and Serial No. are both located

on the Nameplate, just below Alternator Control Panel.

Model Noo Serial No,

Retain these numbers for future reference,,

FULL ONE YEAR WARRANTY

For one year from the date of purchase, Sears will repair any defect in

material or workmanship in this alternator at no charge°

If the alternator is used for commercial or rental purposes, this warranty

applies for only thirty days from the date of purchase.

Warranty service is available by contacting the nearest Sears Store or Service

Center throughout the United States.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co.

Sears Tower

BSC 41-3

Chicago, I L 60684

INTRODUCTION

Your Owner's Manual is meant to provide you with instructions for safe and proper operation of

the 4500 watt portable alternator, Read its contents carefully and comply with all instructions

and rules for' safe operation. With proper care, your alternator will give years of dependable elec-

tric power.

_IL CAUTION

Engines are shipped without oil. Any attempt to start your alternator before the recom =

mended oil has been properly added will result in an engine failure.

RULES FOR SAFE OPERATION

_ Your portable alternator' produces

dangerously high voltages,, Never permit un-

qualified people especially children to

operate the unit.

_Never handle electrical equipment

while standing in water, while barefoot, or

while hands are wet, This carl result in

dangerous electrical shock_

Maintain electrical power' cords in

good condition. Worn, bare or frayed elec-

trical cords are dangerous.

Make sure the wire gauge sizes of

electrical power cords are large enough to

handle the largest anticipated amperage of

electrical equipment. Using wires that are too

small to handle the amperage load is

dangerous.

enclosure or compartment that might

obstruct the free flow of cooling air. Severe

heat damage to the unit will occur.

_ Gasoline is highly flammable and ex-

plosive. Comply with local laws governing the

storage and handling of gasoline,

_1_ Use care when using your' alternator.

Keep clear of moving parts. Never work on the

unit while it is running. Keep equipment clean

and check frequently for loose, missing,

rusted or damaged nuts, bolts, and other

fasteners,.

_ Never try to adjust governed eng]ne

speed. High engine speed is dangerous, The

alternator will produce the required voltage

and frequency only at 3600 rpm.

Never install the alternator in any

Never run the alternator in any enclos-

ed area. Gasoline engines consume oxygen

and give off DEADLY carbon monoxide gas.

TABI.E OF CONTENTS

WARRANTY ....................... inside Front Cover

RULES FOR SAFE OPERATION

inside Front Cover

SPECIFICATIONS ............................... 1

NOMENCLATURE ........................................... 2

WIRING DIAGRAM ............................................... 3

INSTALLATION OF STAND-BY

POWER SYSTEMS ............................... 4

REPAIR PARTS ........................................ 25-28

Section 1 -- Preparation For Use

Alternator Unpacking and Removal

From Shipping Skid .............................. 5

Parts Shipped With Alternator ......................... 5

Wheel Kit Installation ..................................... 7

Lubrication ........................................... 8

Battery Installation ................................ 9

Battery Connections .................................. 9

Fill Fuel Tank ..................................... 10

Install Fuel Tank ................................ 10

Cord Sets for 120 Volt, 15 Amp Outlets ......... 10

Optional Wiring Connections - 240 Volt

Connector Plug .......................... 11

Optional Wiring Connections - 120 Volt,

30 Amp Connector Plug ....................... 11

Grounding The Alternator .......................... 12

Section 2 -- Operating Instructions

Do and Don't Chart ...................................... 13

Before Starting the Engine ................................ 14

Starting the Engine .................................. 15

Stopping the Engine ................................ 16

Wattage and Power .................................... 16

Using the 120 Volt, 15 Amp Outlets ................. 16

Using the 120 Volt, 30 Amp Outlet ............... 16

Using the 240 Volt, 20 Amp Outlet ................. 17

Don't Overload the Alternator ....................... 17

Motor Starting Requirements ........................ 17

Charging a Battery ......................................... 18

Section 3 -- Preventive Maintenance

Maintenance Chart ....................................... 19

General Inspection ................................... 19

Change Oil ............................................. 20

Service Air Cleaner ............................... 21

Inspect 30 Amp Fuse ............................... 21

Spark Plugs ......................................... 22

Clean Fuel Tank ....................................... 22

Inspect Cooling Fins ........................... 22

De-Carbonize Muffler .................................. 23

Replace Fuel Filter .................................. 23

De-Carbonize Engine Cylinder Heads ............ 23

Storage ............................................... 23

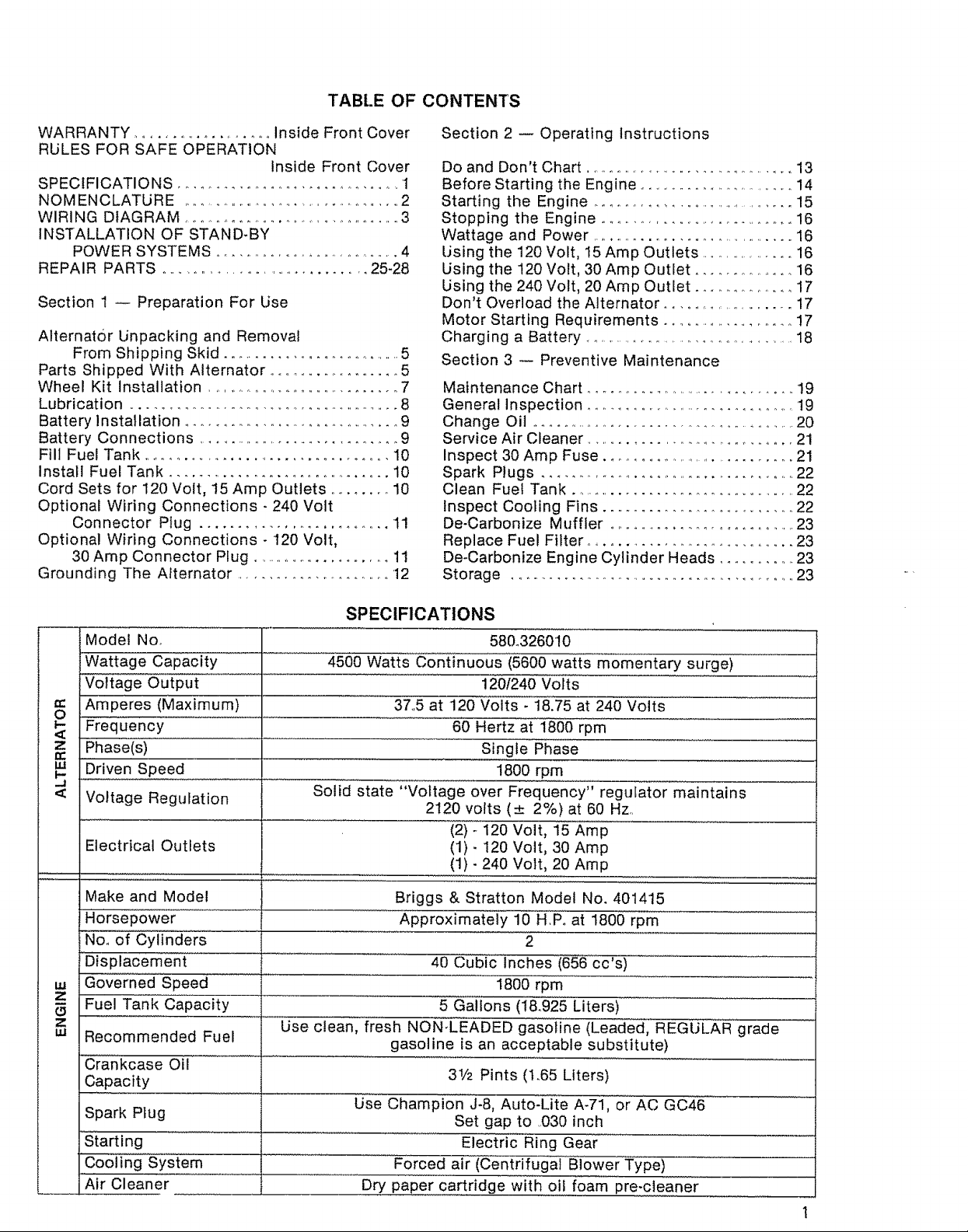

SPECIFICATIONS

Model Noo 58&326010

IWattage Capacity 4500 Watts Continuous (5600 watts m'omentary surgei .............

Voltage Output 120f240 Volts

Amperes (Maximum) ....................................37.,5 at 120 Voi"ts _18175at 240"Volts .......

Frequency ...... i ......................60 Hertz a{ 1800 rpm ...................

==

.....Phase(s) Single Phase

Driven Speed

Voltage Regulation

Electrical Outlets

Make and Model

Horsepower

No. of Cylinders

....Displacemen{ ........

Governed Speed

z

Fuel Tank Capacity

c3

Z

w

Recommended Fuel

Crankcase Oil

Capacity

Solid state "Voltage over Frequency" regulator maintains

2120 volts (_+ 2%) at 60 Hz.

...................... (2io' 120 Volt, 15 Amp

..... ,,, "",::',','L,,,, ......... ,,,

Briggs & Stratton Model No. 401415

Approximatei'y iO HIP. at 1800 rpm

40 Cubic Inches (656 cc's)

5 Gallons (1&925 Liters)

........Use clean, fresh NON:LEADED gasot'ine (Leaded, REGULAR grade

gasoline is an acceptable substitute)

31/2 Pints (I.65 Liters)

1800 rpm

(1) - 120 Volt, 30 Amp

(1) - 240 Volt, 20 Amp

2

1800 rpm

Spark Plug use' Champion J-8, Auto-Lite A-71i"or AC G046 ......

Starting Electric Ring Gear

Cooling System .................... Forced airiCentrifugal' Blower Type) ............................

...... Air Cleaner ......................... ...............Dry paper cartridge w"it'lqoil f0ampre-cieaner '

Set gap to .030 inch

1

CENTRIFUGAL

BLOWER SHROUD

NOMENCLATURE

ENGINE AIR

CLEANER

OIL FILLER & DIPSTICK

120 VOLT, 15 AMP OUTLETS

HANDLES

(SHIPPED WITH

WHEEL KIT)

CRADLE

MUFFLER

WHEELS

(SHIPPED WITH

WHEEL KIT)

STARTER MOTOR

STARTER SOLENOID

INDICATOR

LIGHT

FUSE - 15 AMP

5 GALLON

FUEL TANK

NAMEPLATE

12 VOLT BATTERY

_IIUSTOME R SUPPLI ED

RESTING SUPPORT

(SHIPPED WITH WHEEL KIT)

2

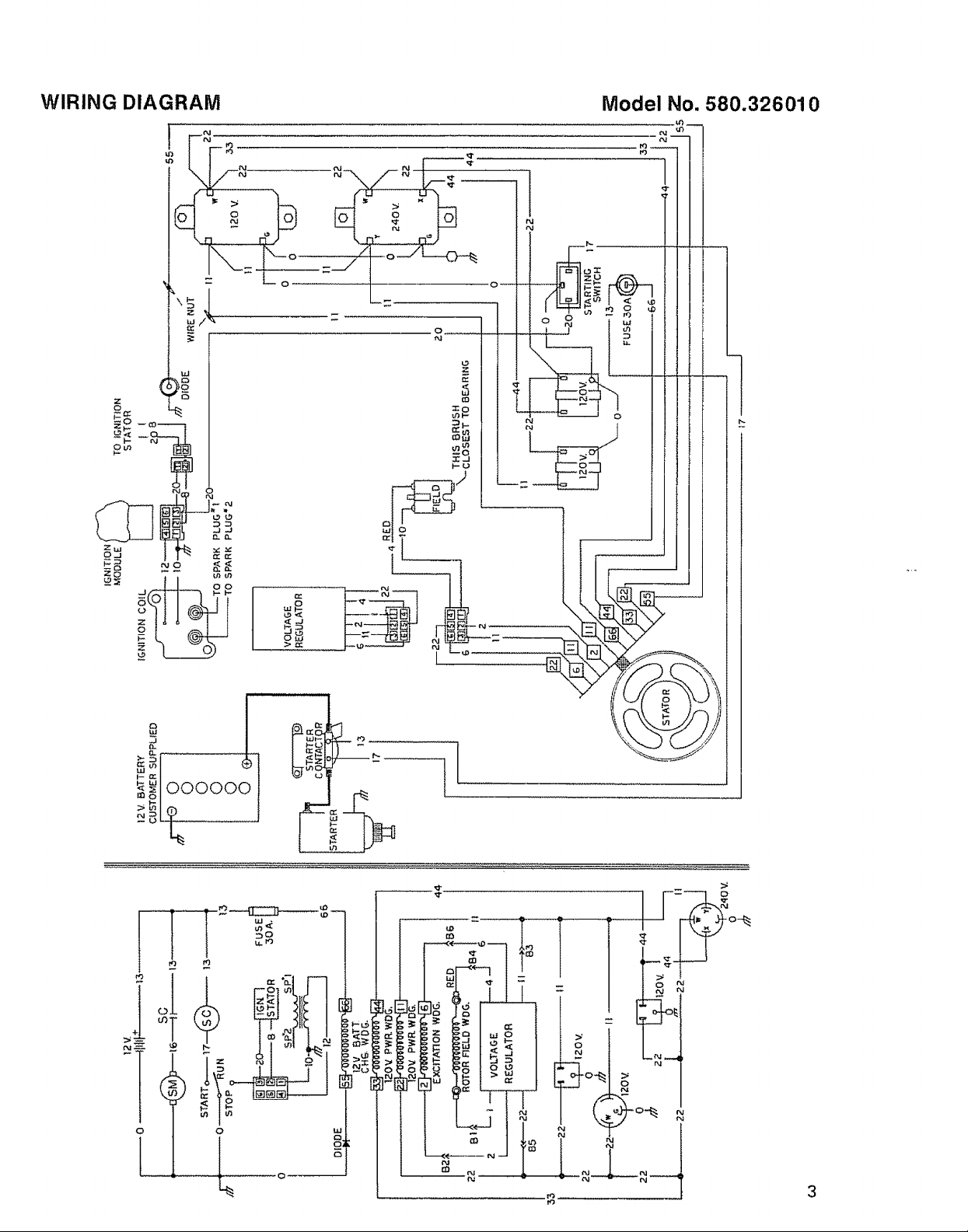

WIRING DIAGRAM

Model No. 580.326010

o !ci

_ oooooo

V)

DO

0 0

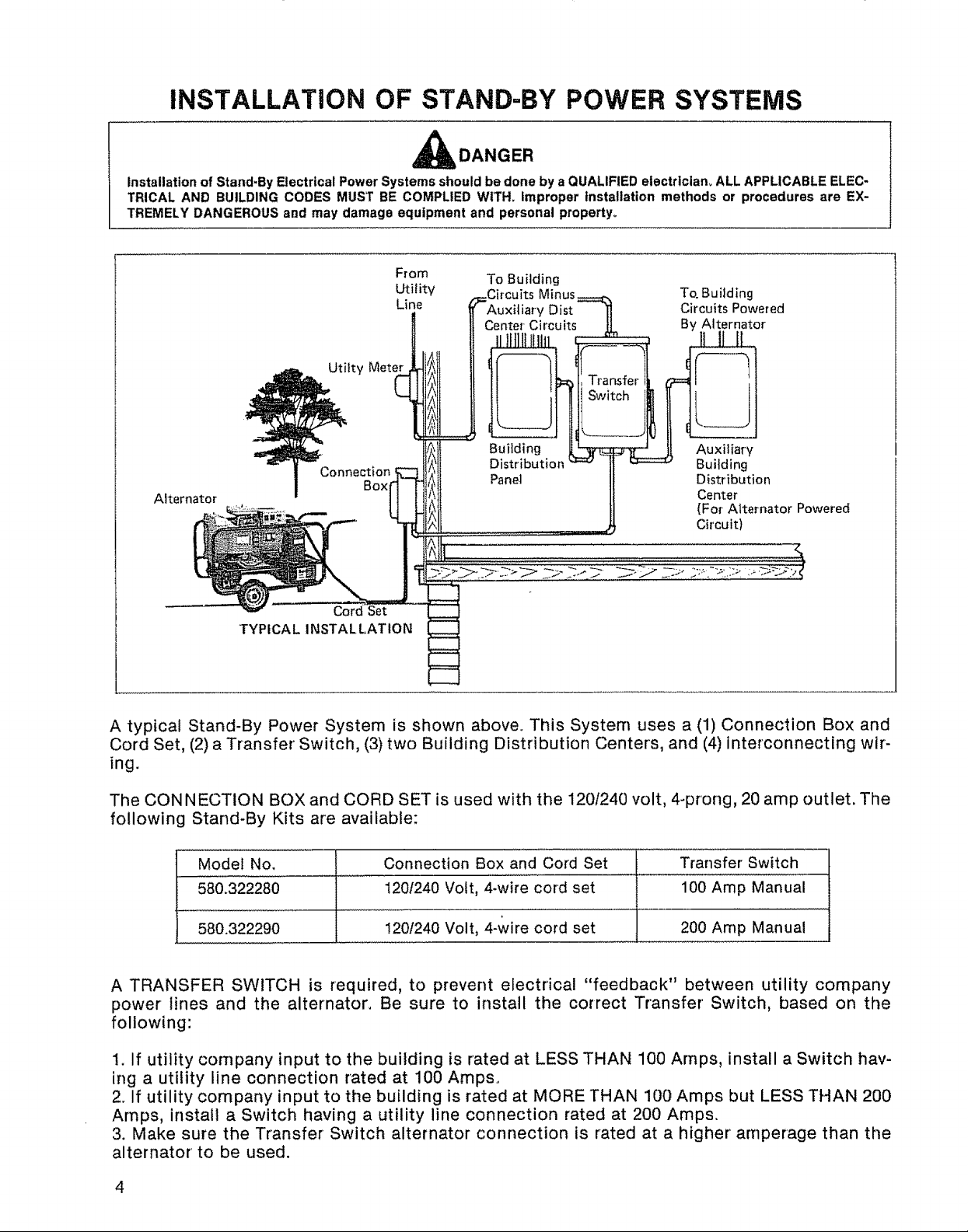

INSTALLATION OF STAND-BY POWER SYSTEMS

_I_DANGER

installation of Stand-By Electrical Power Systems should be done by a QUALIFIED electrtctam ALL APPLICABLE ELEC-

TRICAL AND BUILDING CODES MUST BE COMPLIED WITH. improper installation methods or procedures are EX-

TREMELY DANGEROUS add may damage equipment and personal property°

Alternator

Meter _

Box _

Cord Set

TYPICAL INSTALLATION

F! om

Utility

Line

To Building

Circuits To.Bu liding

Auxiliary Dist Circuits Powered

enter Circuits By Alternator

Building

Distribution I AuxiliaryBuilding

1\

Panel _ DistributionCenter

.... Circuit)

(For-Alternator Powered

A typical Stand-By Power System is shown above° This System uses a (1) Connection Box and

Cord Set, (2) a Transfer Switch, (3) two Building Distribution Centers, and (4) interconnecting wir-

ing.

The CONNECTION BOX and CORD SET is used with the 120/240 volt, 4-prong, 20 amp outlet. The

following Stand-By Kits are available:

Model No. Connection Box and Cord Set Transfer Switch

580.322280 120/240 Volt, 4-wire cord set 100 Amp Manual

580.322290 !201240 Volt, 4-wire cord set 200 Amp Manual

A TRANSFER SWITCH is required, to prevent electrical "feedback" between utility company

power lines and the alternator. Be sure to install the correct Transfer Switch, based on the

following:

1. if utility company input to the building is rated at LESS THAN 100 Amps, install a Switch hav-

ing a utility line connection rated at 100 Amps.

2. If utility company input to the building is rated at MORE THAN 100 Amps but LESS THAN 200

Amps, install a Switch having a utility line connection rated at 200 Amps.

3. Make sure the Transfer Switch alternator connection is rated at a higher amperage than the

alternator to be used.

4

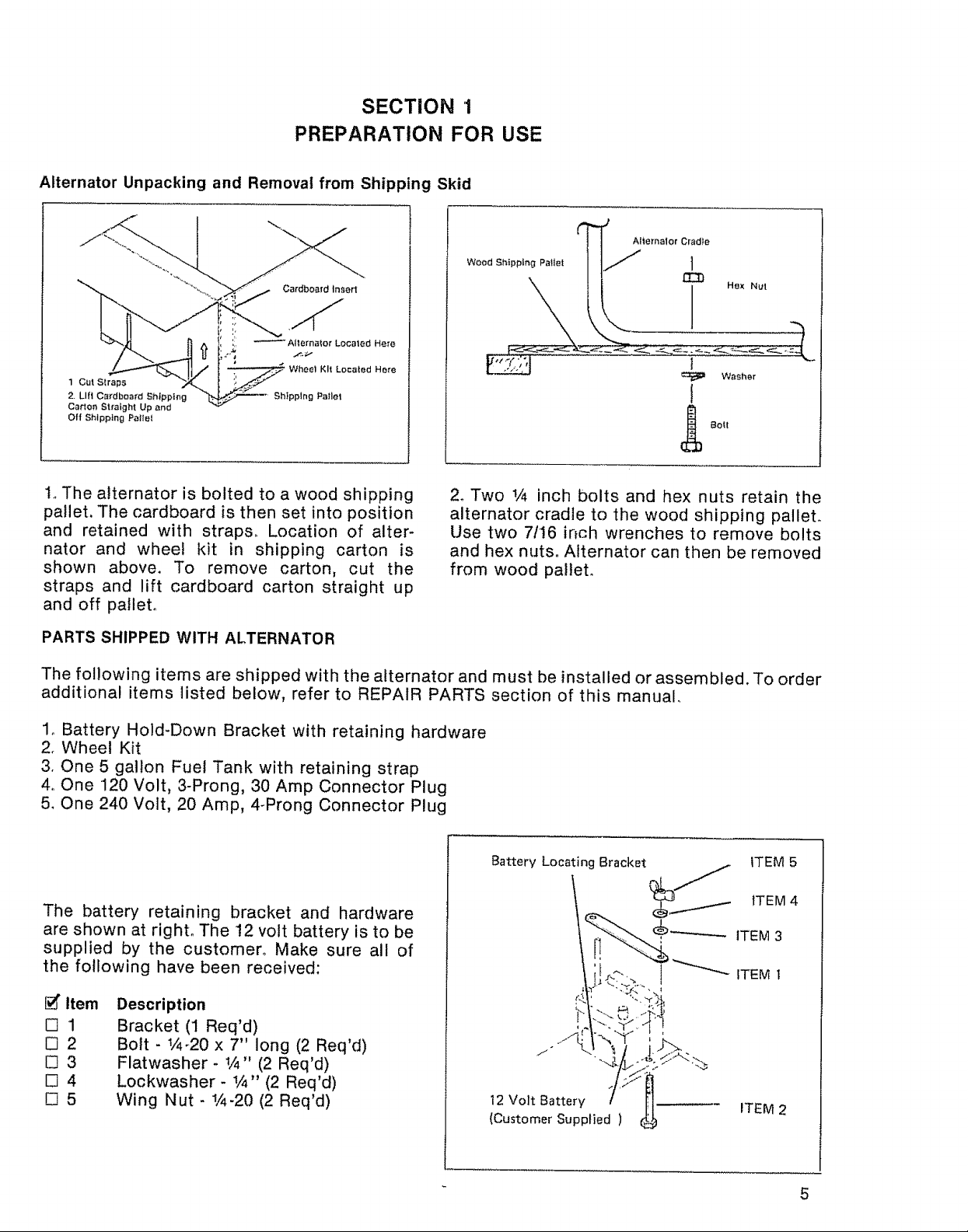

SECTION 1

PREPARATION FOR USE

Alternator Unpacking and Removal from Shipping Skid

Cardboard Insert

Alternator Localed Here

1 Cut Straps

2. Lift Cardboard Shtpplng

Carton Straight Up and

Off Shipping Pallet

Kit Located Here

Shipping Pallet

¢ "4

| Alternator Cradle

Wood Sh,pping PatIet " !.j ]

?

Washer

!

_b Bolt

1oThe alternator is bolted to a wood shipping

pallet, The cardboard is then set into position

and retained with straps., Location of alter-

nator and wheel kit in shipping carton is

shown above. To remove carton, cut the

2. Two 1/4 inch bolts and hex nuts retain the

alternator cradle to the wood shipping palleL

Use two 7/16 inch wrenches to remove bolts

and hex nuts° Alternator can then be removed

from wood pallet°

straps and lift cardboard carton straight up

and off pallet°

PARTS SHIPPED WITH ALTERNATOR

The following items are shipped with the alternator and must be installed or assembled. To order

additional items listed below, refer to REPAIR PARTS section of this manual.

1_ Battery Hold-Down Bracket with retaining hardware

2. Wheel Kit

3. One 5 gallon Fuel Tank with retaining strap

4o One 120 Volt, 3-Prong, 30 Amp Connector Plug

5. One 240 Volt, 20 Amp, 4-Prong Connector Plug

Battery Locating Bracket ITEM 5

__ ITEM 4

The battery retaining bracket and hardware

are shown at right° The 12 volt battery is to be

@_.--.f

ITEM 3

supplied by the customer° Make sure all of

the following have been received:

_ ITEM I

[_ Item

D1

N2

_3

E34

D5

Description

Bracket (1 Req'd)

Bolt - V4-20 x 7" long (2 Req'd)

Flatwasher- %" (2 Req'd)

Lockwasher - 1/4" (2 Req'd)

Wing Nut - _/4-20 (2 Req'd)

t2 Volt Battery ITEM 2

(Customer Supplied )

5

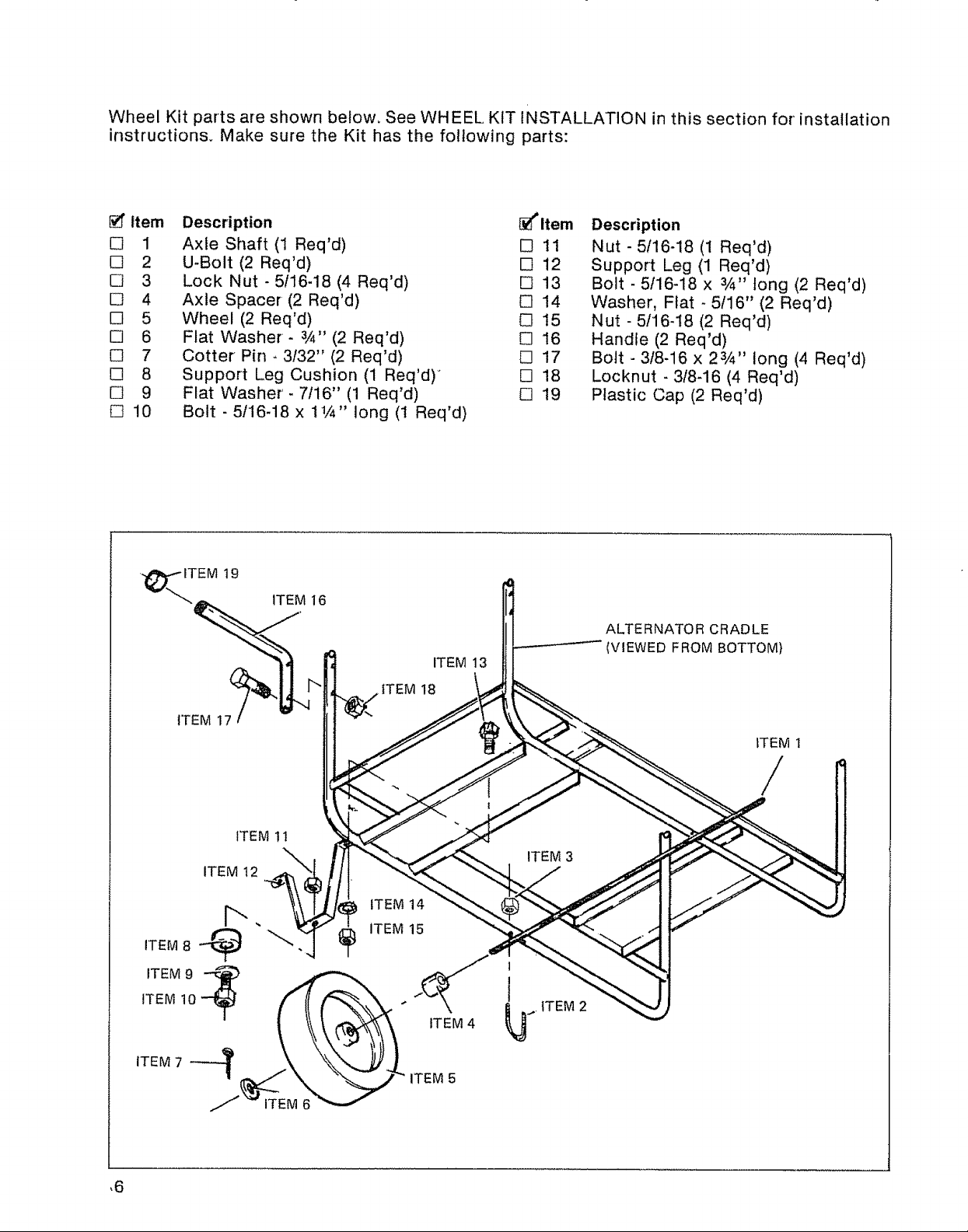

Wheel Kit parts areshownbelow,SeeWHEELKITINSTALLATIONinthis section for installation

instructions. Make sure the Kit hasthe following parts:

_" Item

[] 1

[] 2

[] 3

[] 4

[] 5

[] 6

[] 7

[] 8

[] 9

[]10

Description [_ltem

Axle Shaft (1 Req'd) [] 11

U-Bolt (2 Req'd) [] 12

Lock Nut - 5/16-18(4Req'd) [] 13

Axle Spacer (2Req'd) [] 14

Wheel (2 Req'd) C] 15

Flat Washer- a/4"(2 Req'd) [] 16

Cotter Pin - 3/32" (2 Req'd) [] 17

Support Leg Cushion (1 Req'd)" [] 18

Flat Washer'- 7116" (1 Req'd) [] 19

Bolt - 5/16-18 x 11/4" long (1 Req'd)

19

ITEM 16

ITEM 13

ITEM 18

Description

Nut - 5/16-18 (1 Req'd)

Support Leg (1 Req'd)

Bolt - 5/16-18 x 3/4" tong (2 Req'd)

Washer, Flat - 5/16" (2 Req'd)

Nut - 5116-t8 (2 Req'd)

Handle (2 Req'd)

Bolt - 318-16 x 2s,4" long (4 Req'd)

Locknut -3/8-16 (4 Req'd)

Plastic Cap (2 Req'd)

ALTERNATOR CRADLE

(VIEWED FROM BOTTOM)

ITEM 17

ITEM 12

ITEM 8 __._!

T-

ITEM 11

" ITEM 15

ITEM t

/

ITEM 3

ITEM 14

1

1

ITEM 2

ITEM 4

ITEM 5

,6

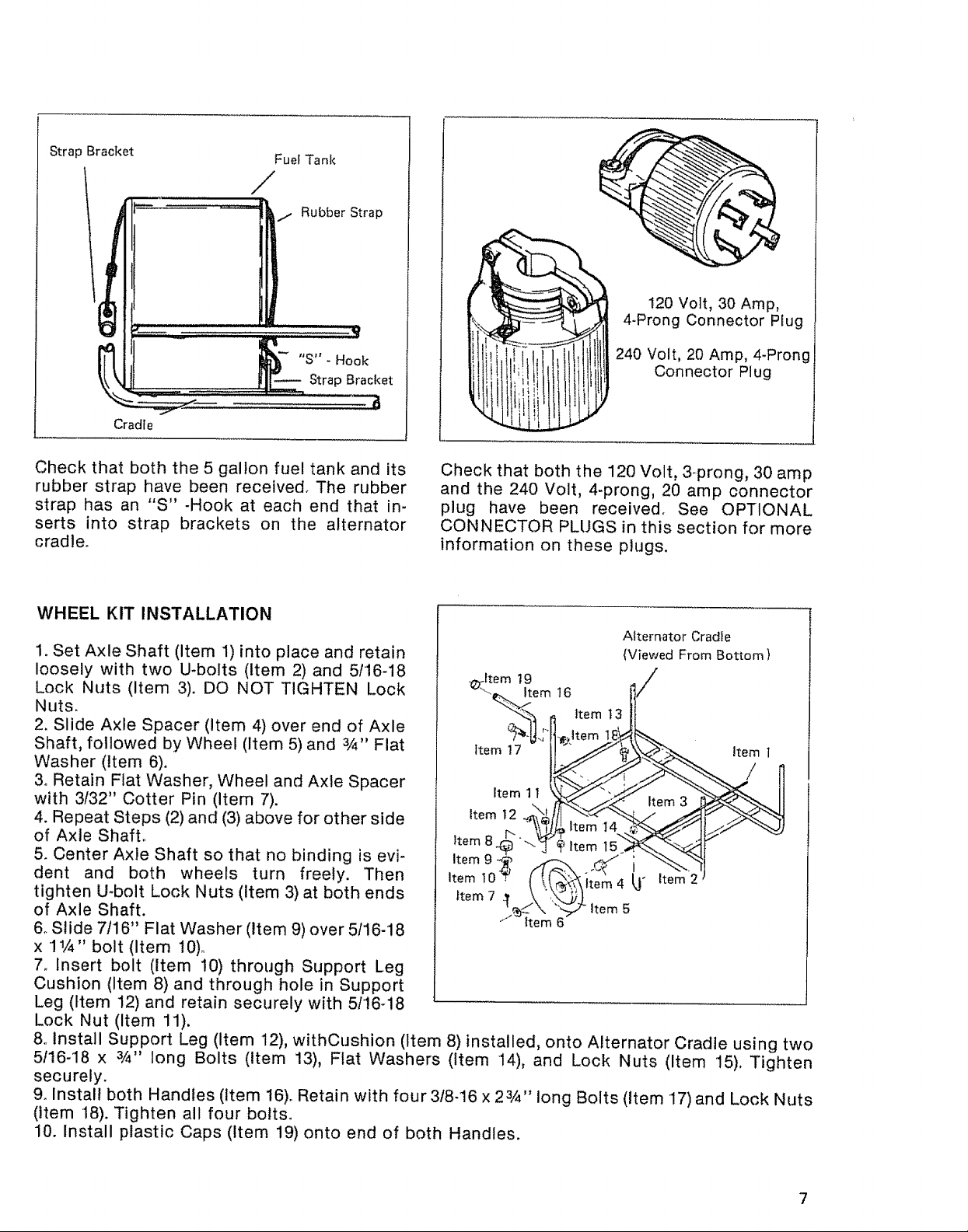

Strap Bracket

Fuel Tanl<

/

,i, Rubber Strap

120 Volt, 30 Amp,

4-Prong Connector Plug

240 Volt, 20 Amp, 4-Prong

Connector Plug

!

Check that both the 5 gallon fuel tank and its

rubber strap have been received. The rubber

strap has an "S" -Hook at each end that in-

serts into strap brackets on the alternator

cradle°

Check that both the 120 Volt, 3-prong, 30 amp

and the 240 Volt, 4-prong, 20 amp connector

plug have been received. See OPTIONAL

CONNECTOR PLUGS in this section for more

information on these plugs.

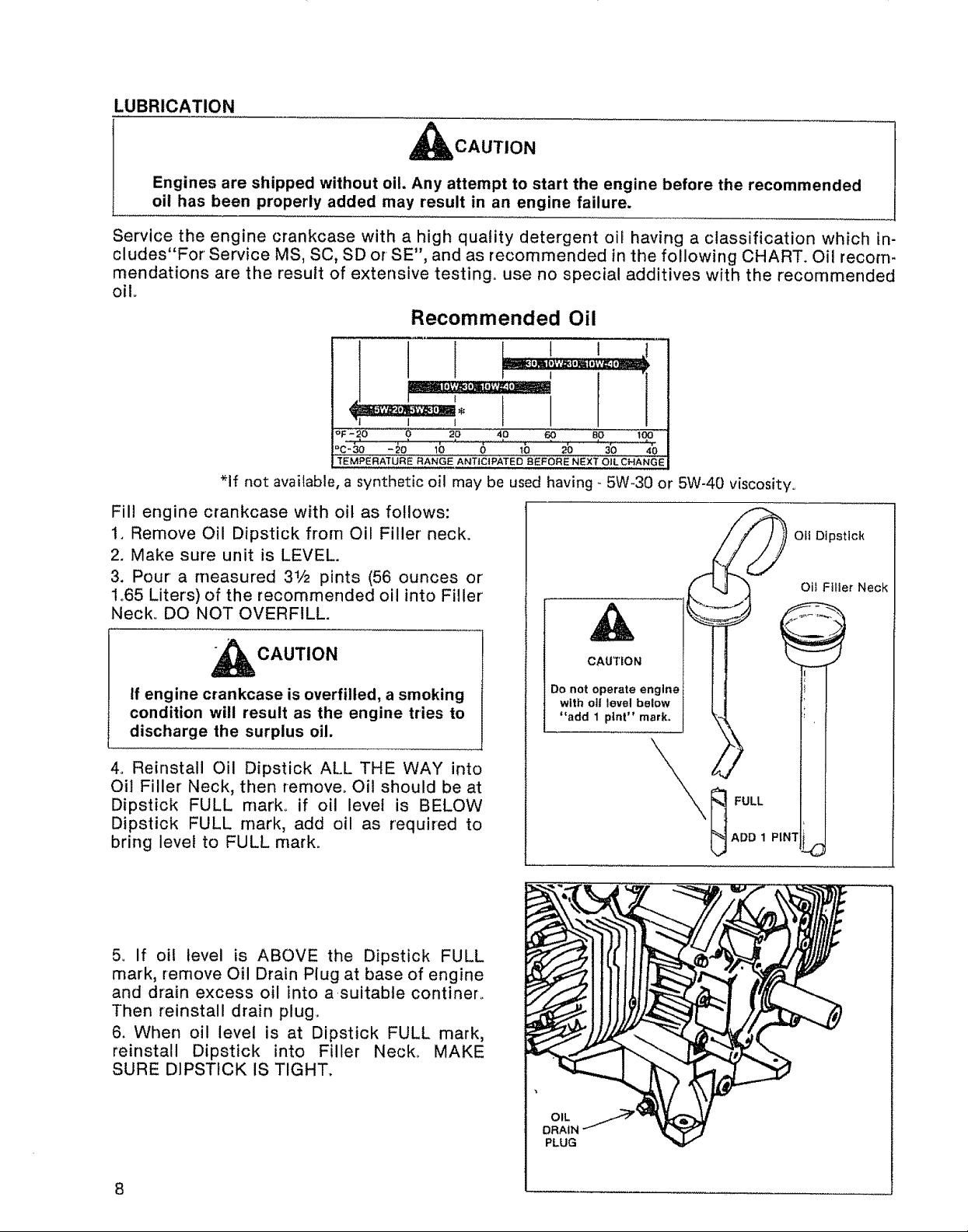

WHEEL KIT INSTALLATION

Alternator Cradle

1. Set Axle Shaft (Item 1) into place and retain

loosely with two U-bolts (Item 2) and 5/16-18

Lock Nuts (item 3). DO NOT TIGHTEN Lock

Nuts.

2. Slide Axle Spacer (Item 4) over end of Axle

._Item 19 /

_'-_em 16

"_'3 f Item t 3

(Viewed From Bottom)

Shaft, followed by Wheel (item 5) and 3/4" Fiat

Washer (Item 6).

3_ Retain Flat Washer, Wheel and Axle Spacer

with 3/32" Cotter Pin (Item 7).

4. Repeat Steps (2) and (3) above for other side

of Axle Shaft.

te 11 __ Item3

Item 12 ._j_ it_--em__

5. Center Axle Shaft so that no binding is evi-

dent and both wheels turn freely. Then

tighten U-bolt Lock Nuts (Item 3) at both ends

of Axle Shaft.

Item 10 'I" ( !t _Xitem 4 [,.1" item 2

Item 7 _m_j item 5

6o Slide 7116" Fiat Washer (Item 9) over 5116-18

x ! 1/4" bolt (Item t0)o

7_ Insert bolt (Item 10) through Support Leg

Cushion (Item 8) and through hole in Support

Leg (Item 12) and retain securely with 5116-i8

Lock Nut (Item 11).

8o Install Support Leg (Item 12), withCushion (Item 8) installed, onto Alternator Cradle using two

5/16-18 x 3/4" long Bolts (Item 13), Flat Washers (Item 14), and Lock Nuts (Item 15). Tighten

securely.

9. install both Handles (Item 16)o Retain with four 3/8-16 x 23/4'' long Bolts (Item 17) and Lock Nuts

(Item 18). Tighten all four bolts.

10. Install plastic Caps (Item 19) onto end of both Handles.

7

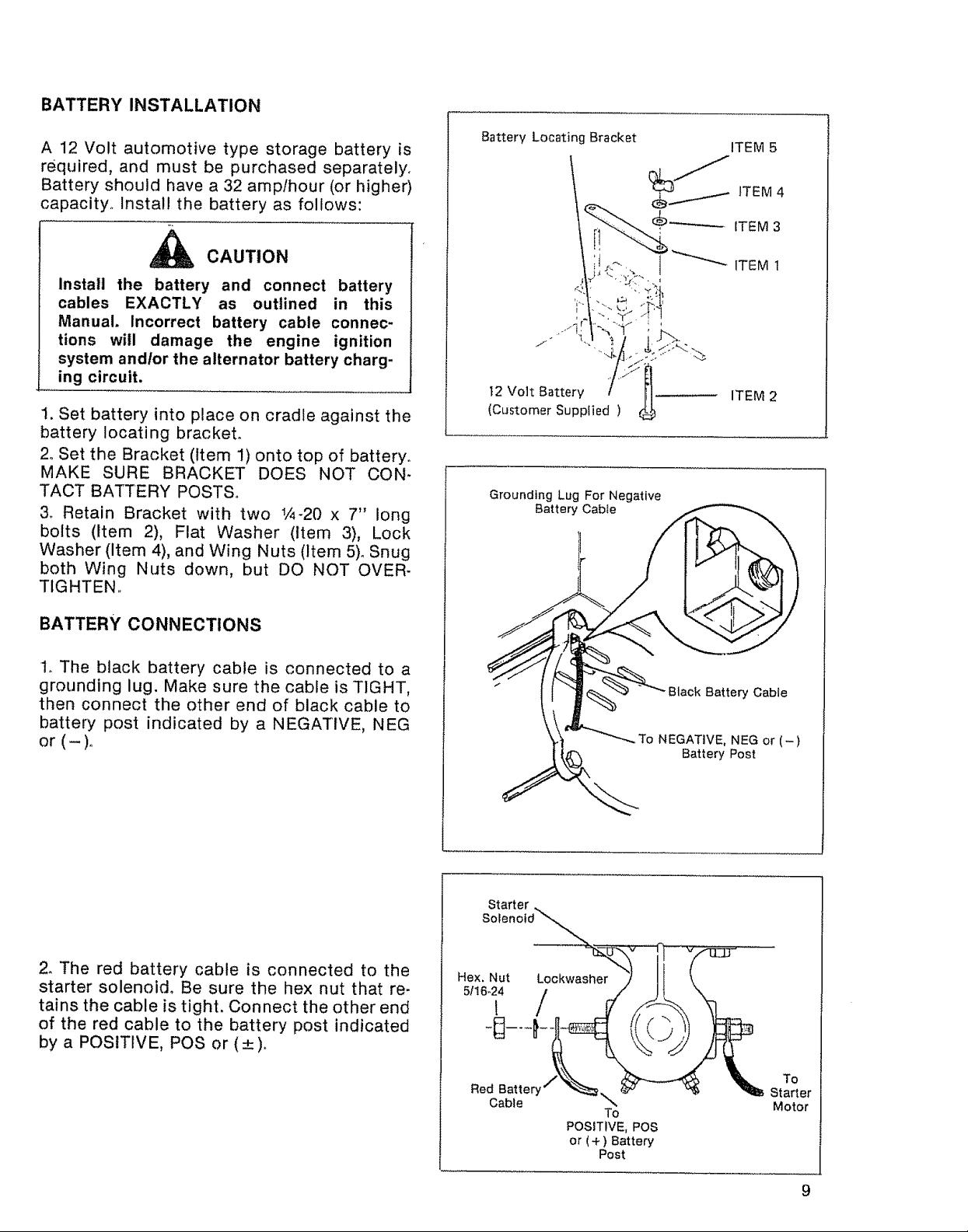

LUBRICATION

CAUTION

Engines are shipped without oil. Any attempt to start the engine before the recommended

oil has been properly added may result in an engine failure.

Service the engine crankcase with a high quality detergent oil having a classification which in-

cludes"For Service MS, SC, SD or SE", and as recommended in the following CHART. Oil recom-

mendations are the result of extensive testing° use no special additives with the recommended

oilo

Recommended Oil

l t !,

oFT20 o 29 49 _ ................8o mo

°C- 30 - 20..............!0 ........... 0 10 20 30 40

"TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

*if not available, a synthetic oil may be used having- 5W-30 or 5W-40 viscosity.

Fill engine crankcase with oil as follows:

1. Remove Oil Dipstick from Oil Filler neck.

2. Make sure unit is LEVEL.

3. Pour a measured 31/2 pints (56 ounces or'

1o65 Liters) of the recommended oil into Filler'

Neck_ DO NOT OVERFILL.

CAUTION

If engine crankcase is overfilled, a smoking

condition will result as the engine tries to

discharge the surplus oil.

4. Reinstall Oil Dipstick ALL THE WAY into

Oil Filler Neck, then remove° Oil should be at

Dipstick FULL mark° if oil level is BELOW

Dipstick FULL mark, add oil as required to

bring level to FULL mark°

t

A

CAUTION

Do not operate engine

with oll level below

"add 1 pint" mark.

FULL

ADD 1 PINTt_

Oii FIHer Neck

Oft Dipstick

5o if oil level is ABOVE the Dipstick FULL

mark, remove Oil Drain Plug at base of engine

and drain excess oil into asuitable continer_

Then reinstall drain plug.

6. When oil level is at Dipstick FULL mark,

reinstall Dipstick into Filler Neck° MAKE

SURE DIPSTICK IS TIGHT.

8

OIL _'

DRAIN

PLUG

BATTERY INSTALLATION

A 12 Volt automotive type storage battery is

required, and must be purchased separately.

Battery should have a 32 amplhour (or higher)

capacity° Install the battery as follows:

_ CAUTION

install the battery and connect battery

cables EXACTLY as outlined in this

Manual. Incorrect battery cable connec-

tions will damage the engine ignition

system andlor the alternator battery charg-

ing circuit,

1. Set battery into place on cradle against the

battery locating bracket.

2. Set the Bracket (Item 1) onto top of battery.

MAKE SURE BRACKET DOES NOT CON*

TACT BATTERY POSTS.

3o Retain Bracket with two t/4-20 x 7" long

bolts (Item 2), Flat Washer (Item 3), Lock

Washer (item 4), and Wing Nuts (Item 5). Snug

both Wing Nuts down, but DO NOT OVER-

TIGHTEN..

Battery Locating Bracket

t2 Volt Battery fl

(Customer Supplied )

Grounding Lug For Negative

Battery Cable

ITEM 5

h

ITEM 2

BATTERY CONNECTIONS

1o The black battery cable is connected to a

grounding lug. Make sure the cable is TIGHT,

then connect the other end of black cable to

battery post indicated by a NEGATIVE, NEG

or (-)o

2. The red battery cable is connected to the

starter solenoid° Be sure the hex nut that re-

tains the cable is tight. Connect the other end

of the red cable to the battery post indicated

by a POSITIVE, POS or (4-).

Red BatteQ

Cable

..To NEGATIVE, NEG or (-)

To

POSITIVE, POS

or (+ ) Battery

Post

Black Battery Cable

Battery Post

To

Starter

Motor

9

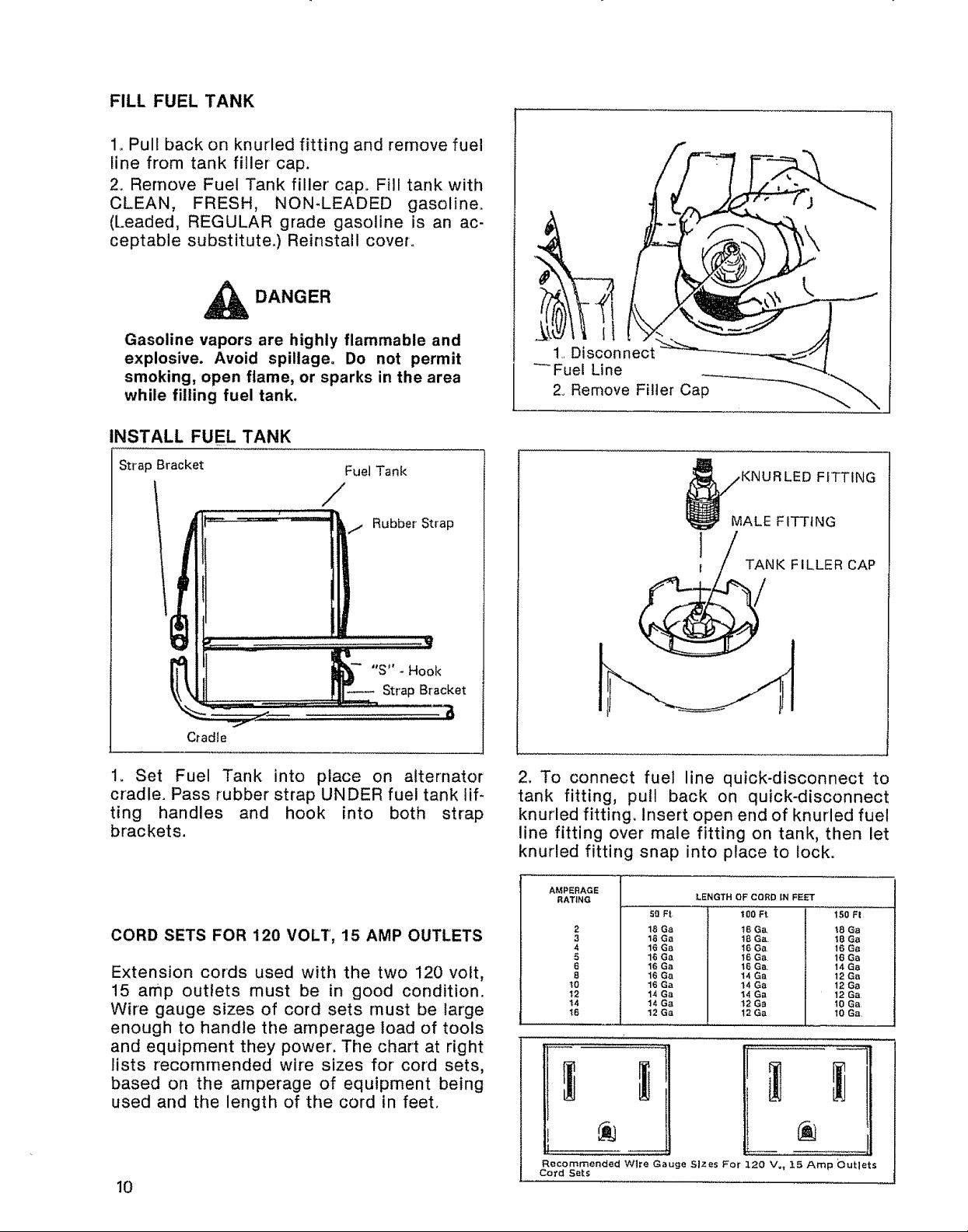

FILL FUEL TANK

1_ Pull back on knurled fitting and remove fuel

line from tank filler cap.

2. Remove Fuel Tank filler cap° Fill tank with

CLEAN, FRESH, NON-LEADED gasoline.

(Leaded, REGULAR grade gasoline is an ac-

ceptable substitute.) Reinstall cover.

_ DANGER

Gasoline vapors are highly flammable and

explosive. Avoid spillage. Do not permit

smoking, open flame, or sparks in the area

while filling fuel tank.

INSTALL FUEL TANK

2. Remove Filler Cap

Strap Bracket

Fuel Tank

/

/ Rubber Strap

"S" - Hook

Strap Bracket

Cradle

1. Set Fuel Tank into place on alternator

cradle. Pass rubber strap UNDER fuel tank lif-

ting handles and hook into both strap

brackets.

CORD SETS FOR 120 VOLT, 15 AMP OUTLETS

Extension cords used with the two 120 volt,

15 amp outlets must be in good condition.

Wire gauge sizes of cord sets must be large

enough to handle the amperage load of tools

and equipment they power. The chart at right

lists recommended wire sizes for cord sets,

based on the amperage of equipment being

used and the length of the cord in feet.

1 T_NK FILLER CAP

2. To connect fuel line quick-disconnect to

tank fitting, pull back on quick-disconnect

knurled fitting. Insert open end of knurled fuel

line fitting over male fitting on tank, then let

knurled fitting snap into place to locko

AMPERAGE

RATING

2

3

4

5

6

8

!0

t2

14

t6

18 Ga

18 Ga

16 Ga

16 Ga

16 Ga

16 Ga

16 Ga

14 Ga

14 Ga

12 Ga

LENGTH OF CORD IN FEET

50 Ft j

100 Ft 150 F!

18 Ga, t8 Ga

18 Ga, t8 Ga

16 Ga 16 Ga

16 Ga 16 Ga

16 Ga. 14 Ga

14 Ga 12 Ga

14 Ga 12 Ga

14 Ga 12 Ga

12 Ga 10 Ga

12 Ga 10 Ga

10

Outlets

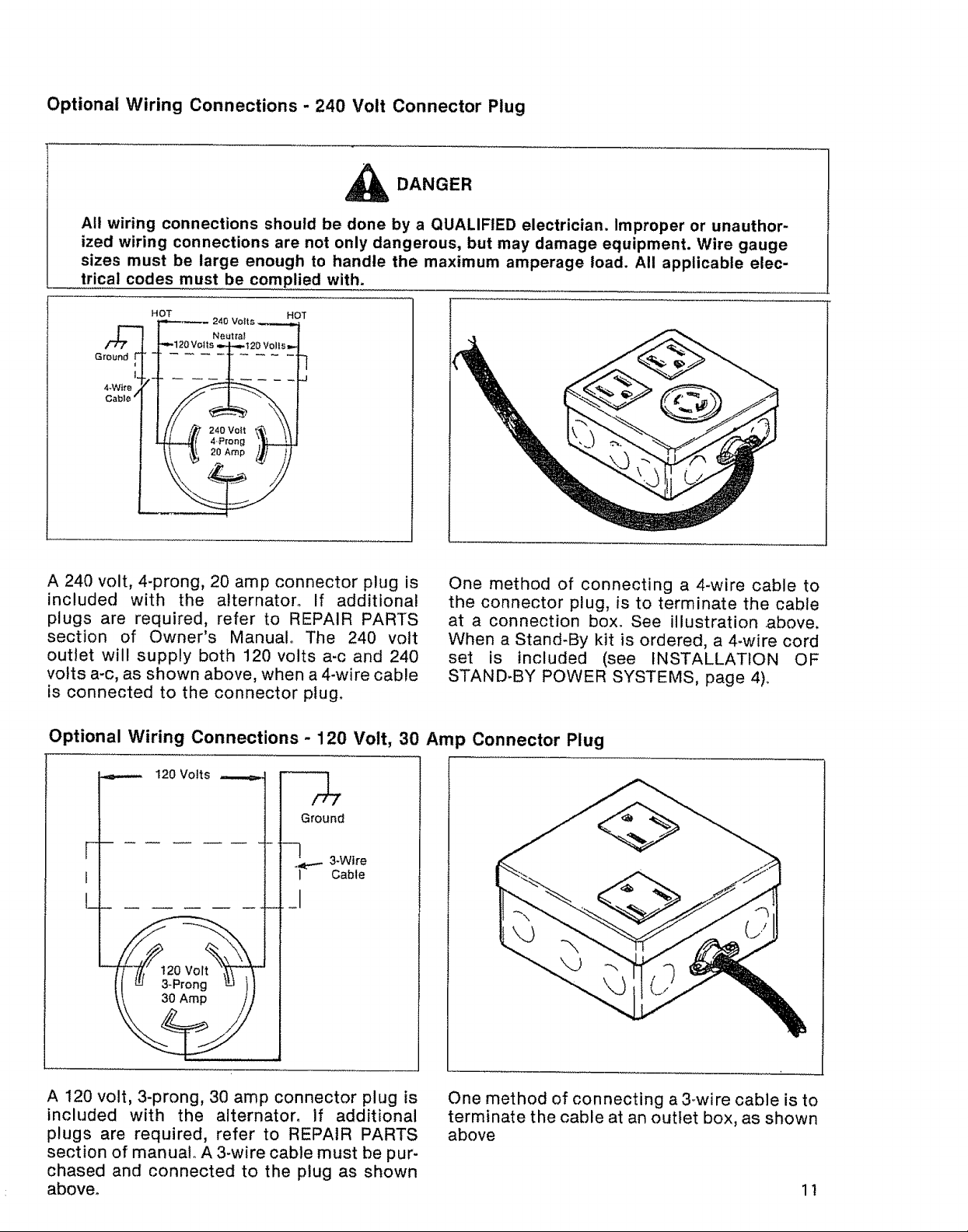

Optional Wiring Connections - 240 Volt Connector Plug

_1_ DANGER

All wiring connections should be done by a QUALIFIED electrician. Improper or unauthor-

ized wiring connections are not only dangerous, but may damage equipment. Wire gauge

sizes must be large enough to handle the maximum amperage load. All applicable elec-

trical codes must be complied with.

HOT HOT

Ground

A 240 volt, 4-prong, 20 amp connector plug is

included with the alternatoro If additional

plugs are required, refer to REPAIR PARTS

section of Owner's Manual. The 240 volt

outlet will supply both 120 volts a-c and 240

volts a-c, as shown above, when a 4-wire cable

is connected to the connector plug.

Optional Wiring Connections - 120 Volt, 30 Amp Connector Plug

240 Volts

One method of connecting a 4-wire cable to

the connector plug, is to terminate the cable

at a connection box. See illustration above.

When a Stand-By kit is ordered, a 4-wire cord

set is included (see INSTALLATION OF

STAND-BY POWER SYSTEMS, page 4)_

,==,.,...- I20 Volts ,,,....,.,,_,

F" 3-Wlre

! Cable

/#i"

Ground

-2--

L __1

A 120 volt, 3-prong, 30 amp connector plug is

included with the alternatoro if additional

plugs are required, refer to REPAIR PARTS

section of manual° A 3-wire cable must be pur-

chased and connected to the plug as shown

above.

One method of connecting a 3-wire cable is to

terminate the cable at an outlet box, as shown

above

11

Loading...

Loading...