Craftsman 57211629 Owner’s Manual

Owner's Manual

ERRFTSMRN,

CONTOUR SANDER

Model No. 572.11629

Caution:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Safety

Operation

Maintenance

Parts

Espa5ol

Table of Contents Page

Warranty ..................................................... 2

Power Tool Safety Rules ...................................... 3-4

Symbols ..................................................... 5

Functional Description and Specifications .......................... 6

Operating Instructions ........................................ 7-8

Accessory Tips ................................................ 8

Tool Tips ................................................... 8-9

Maintenance ............................................... 9-10

Service Parts .............................................. 11-12

Sears Warranty

Full One Year Warranty on Craftsman Contour Sander

If this Craftsman Contour Sander fails to give complete satisfaction within one

year from the date of purchase, Sears will replace it free of charge.

If this Contour Sander is used for commercial or rental purposes, this warranty

applies for only one year from the date of purchase.

Warranty Service

Warranty service is available by returning this Craftsman Contour Sander to

your nearest Sears Store in the United States.

This warranty applies only while this Contour Sander is used in the United

States.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

2

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not change the plug in any way. Double

Insulation [] eliminates the need for the

three wire grounded power cord and

grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage

marked on the nameplate. Do not use "AC

only" rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased

risk of electric shock if your body is

grounded. If operating the power tool in

damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to

supply the power to your tool. Electrician's

rubber gloves and footwear will further

enhance your persona] safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

When operating a power tool outside,

use an outdoor extension cord marked

"W-A" or "W." These cords are rated for

outaoor use and reduce the risk of electric

shock. Refer to "Recommended sizes of

Extension Cords" in the Accessory section

of this manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

jewelry, or long hair can be caught in

moving parts. Keep handles dry, clean and

free from oil and grease.

Avoid accidental starting. Be sure switch

is "OFF" before plugging in. Carrying

tools with your finger on the switch or

plugging in tools that have the switch "ON"

invites accidents.

Remove adjusting keys or wrenches

before turning the tool "ON". A wrench or

a key that is left attached to a rotating part

of the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

1end to toss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do

the job better and safer at the rate for which

it is designed.

Do not use tool if switch does not turn it

"ON" or "OFF". Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the

tool. Such preventive safety measures

reduce the risk of starting the tool

accidentally. Store idle tools out of reach

of children and other untrained persons,

Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly

maintained tools, with sharp cutting edges

are less likely to bind and are easier to

control. Any alteration or modification is a

misuse and may result in a dangerous

condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another toot.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. F_

example: internal wires may be misplaced

or pinched, safety guard return springs ma

be improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions il

the Maintenance section of this manual.

Use of unauthorized parts or failure to

follow Maintenance Instructions may creab

a risk of electric shock or injury. Certain

cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

Unplug the sander before changing

accessories. Accidental start-ups may

occur if sander is plugged in while changing

an accessory.

Always wear eye protection and a dust

mask for dusty applications and when

sanding overhead. Sanding particles can

be absorbed by your eyes and inhaled

easily and may cause health complications.

Use special precautions when sanding

chemically pressure treated lumber,

paint that may be lead based, or any

other materials that may contain

carcinogens. A suitable breathing

respirator and protective clothing must be

worn by all persons entering the work area.

Work area should be sealed by plastic

sheeting and persons not protected should

be kept out until work area is thoroughly

cleaned.

Do not wet sand with this sander. Liquid:

entering the motor housing are an electric_

shock hazard.

Clamp or secure workpiece when

sanding. Clamping the workpiece prevent

it from being ejected from under the sancle

and leaves both hands free to control the

tool,

Keep the cord away from the accessory

The cord can become entangled with the

pad or contour.

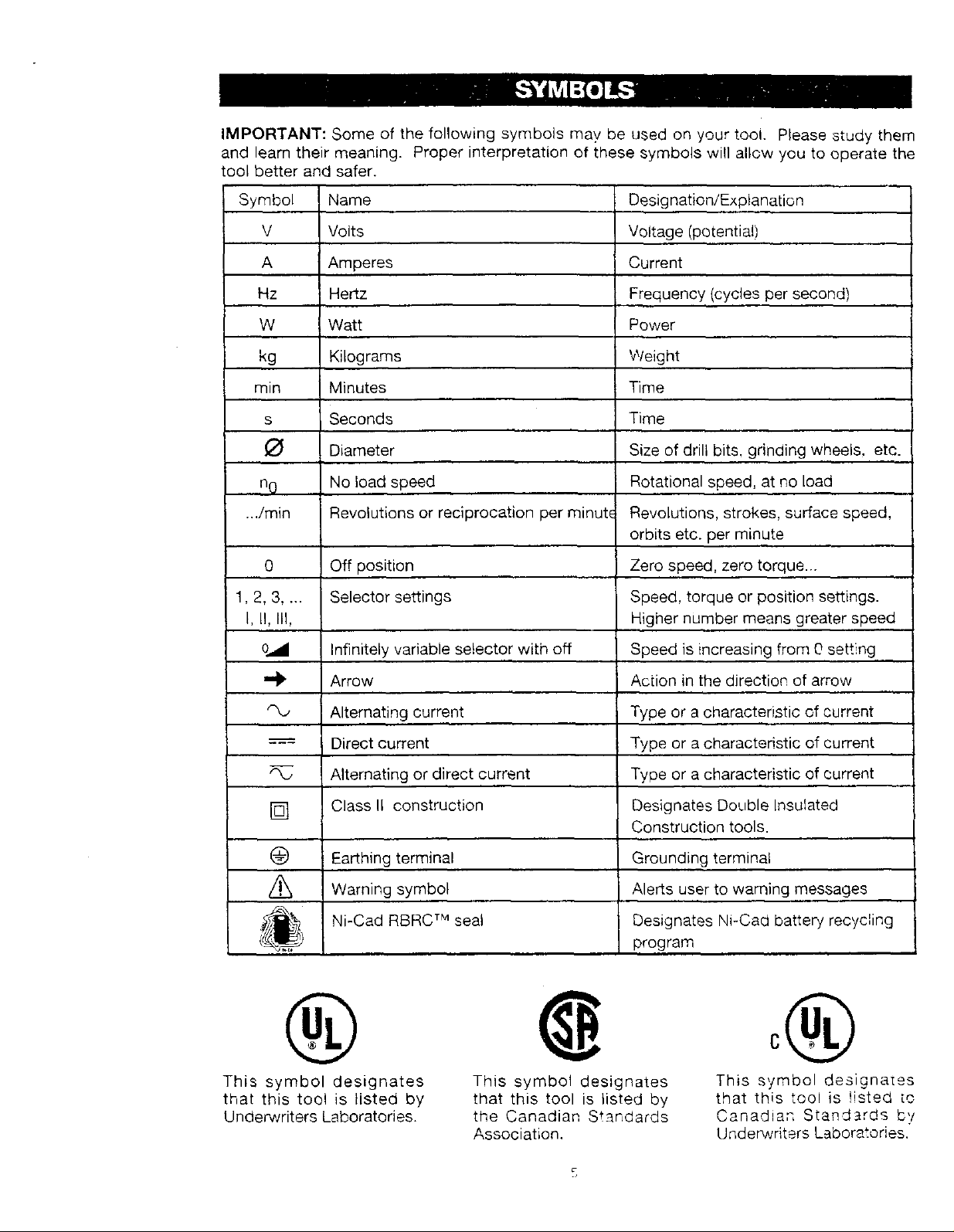

IMPORTANT:Someof thefollowingsymbolsmaybeusedon yourtooi. Pleasestudythem

andlearntheirmeaning.Properinterpretationof thesesymbolswillallowyouto operatethe

tool betterandsafer.

Symbol Name

V Volts

A Amperes

Hz Hertz

W Watt

kg Kilograms

min Minutes

S

O

no

..Jmin

0

1,2,3 ....

I, II, III,

Seconds

Diameter

No load speed

Revolutions or reciprocation per minute

Off position

Selector settings

Designation/Explanation

Voltage (potential)

Current

Frequency (cycles per second)

Power

Weight

Time

Time

Size of drill bits, grinding wheels, etc.

Rotational speed, at no load

Revolutions, strokes, surface speed,

orbits etc. per minute

Zero speed, zero torque...

Speed, torque or position settings.

Higher number means greater speed

Infinitely variable selector with off

Arrow

Alternating current

Direct current

Alternating or direct current

[]

@

Class II construction

Earthing terminal

Warning symbol

Ni-Cad RBRC TM seal

®

This symbol designates

that this tool is listed by

Underwriters Laboratories.

Speed is increasing from 0 setting

Action in the direction of arrow

Type or a characteristic of current

Type or a characteristic of current

Type or a characteristic of current

Designates Double Insulated

Construction tools.

Grounding terminal

Alerts user to warning messages

Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

the Canadian Standards

Association,

This symbol designates

that this tool is !isted [c

Canadian Standards b'!

UndenNriters Laboratories.

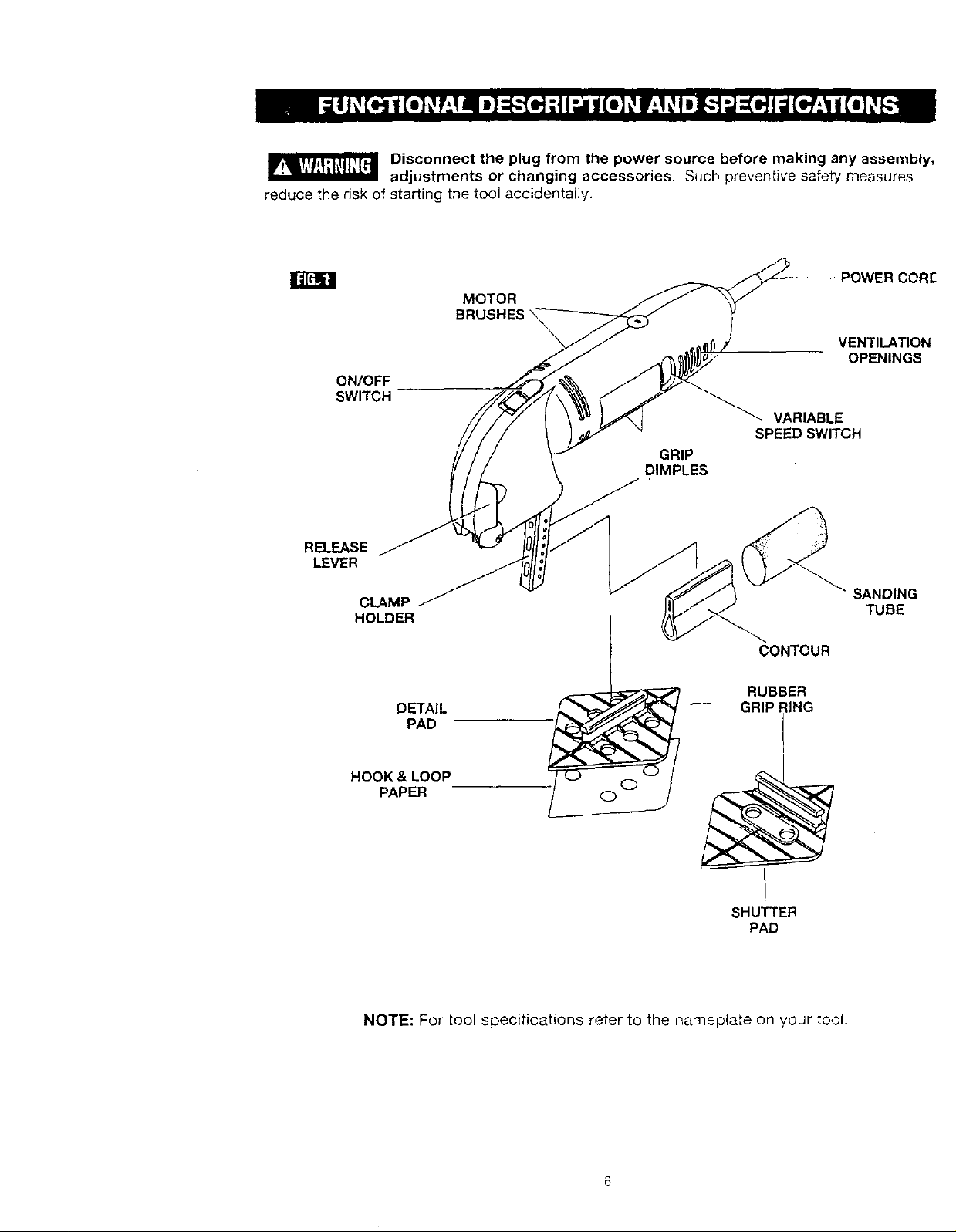

Disconnect the plug from the power source before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

I;AtM!

SWITCH

RELEASE

LEVER

ON/OFF

CLAMP

HOLDER

DETAIL

PAD

MOTOR

BRUSHES

--POWER CORE

\

VARIABLE

SPEED SWITCH

GRIP

DIMPLES

CONTOUR

RUBBER

GRIP lING

I

VENTILATION

OPENINGS

SANDING

TUBE

HOOK & LOOP

PAPER

y

SHUTTER

PAD

NOTE: For tool specifications refer to the nameplate on your tool.

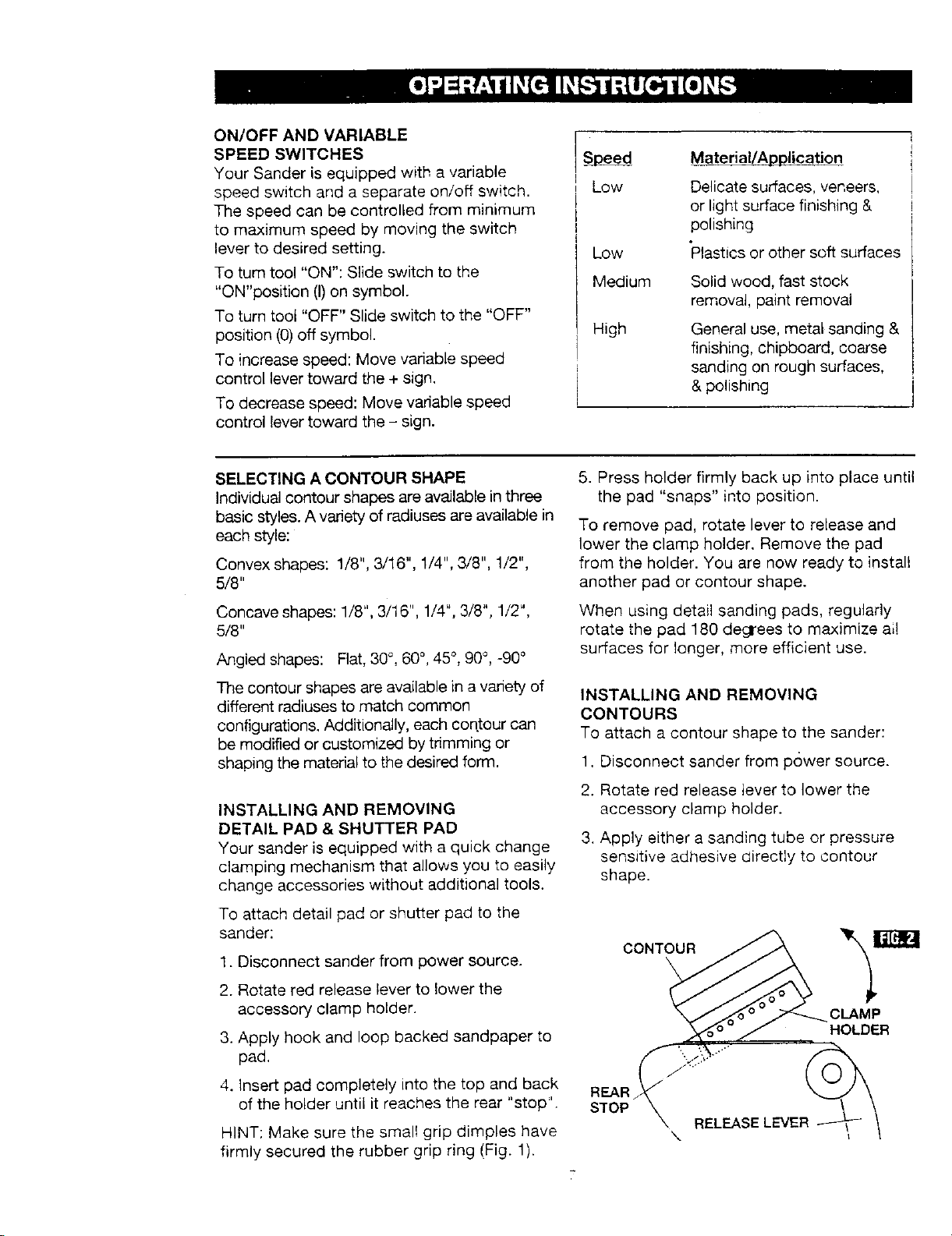

ON/OFF AND VARIABLE

SPEED SWITCHES

Your Sander is equipped with a variable

speed switch and a separate on/off switch.

The speed can be controlled from minimum

to maximum speed by moving the switch

lever to desired setting.

To turn tool "ON": Slide switch to the

"ON'position (I)on symbol.

To turn tool "OFF" Slide switch to the "OFF"

position (0) off symbol.

To increase speed: Move variable speed

control lever toward the + sign.

To decrease speed: Move variable speed

control Fevertoward the - sign.

Speed

Low

Low

Medium

High

Material/Application

Delicate surfaces, veneers,

or light surface finishing &

polishing

"Plasticsor other soft surfaces

Solid wood, fast stock

removal, paint removal

General use, metal sanding &

finishing, chipboard, coarse

sanding on rough surfaces,

& polishing

SELECTING A CONTOUR SHAPE

Individual contour shapes are available in three

basic styles. A variety of radiuses are available in

each style:

Convex shapes: 1/8", 3/16", 1/4", 3/8", 1/2",

5/8"

Concave shapes: 1/8", 3/16", 1/4", 3/8", 1/2",

5/8"

Angled shapes: Flat, 30°, 60°, 45 °, g0°, -90 °

The contour shapes are available in a variety of

different radiuses to match common

configurations. Additionally, each contour can

be modified or customized by trimming or

shaping the material to the desired form.

INSTALLING AND REMOVING

DETAIL PAD & SHUTTER PAD

Your sander is equipped with a quick change

clamping mechanism that allows you to easily

change accessories without additional tools.

To attach detail pad or shutter pad to the

sander:

1. Disconnect sander from power source.

2. Rotate red release lever to lower the

accessory clamp holder.

3. Apply hook and loop backed sandpaper to

pad.

5. Press holder firmly back up into place until

the pad "snaps" into position.

To remove pad, rotate lever to release and

lower the clamp holder. Remove the pad

from the holder. You are now ready to install

another pad or contour shape.

When using detail sanding pads, regularly

rotate the pad 180 degrees to maximize ai!

surfaces for longer, more efficient use.

INSTALLING AND REMOVING

CONTOURS

To attach a contour shape to the sander:

1. Disconnect sander from power source.

2. Rotate red release lever to lower the

accessory clamp holder.

3. Apply either a sanding tube or pressure

sensitive adhesive directly to contour

shape.

CONTOUR

CLAMP

HOLDER

4. Insert pad completely into the top and back

of the holder until it reaches the rear "stop".

HINT: Make sure the small grip dimples have

firmly secured the rubber grip ring (Fig. 1).

REAR

STOP

RELEASE LEVER

\

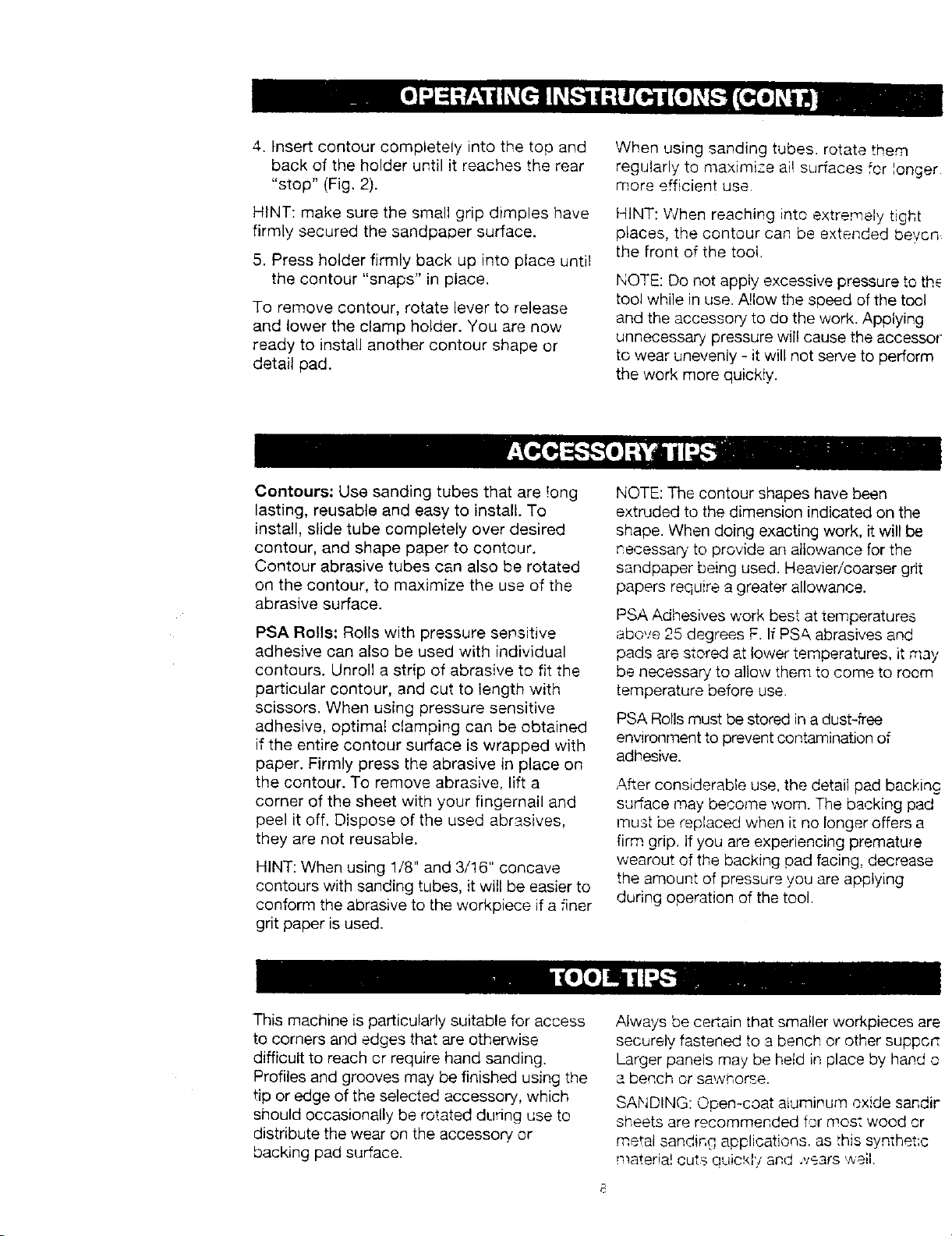

4. Insert contour completely into the top and

back of the holder until it reaches the rear

"stop" (Fig. 2).

When using sanding tubes, rotate them

regularly to maximize all surfaces for longer

more efficient use.

HINT: make sure the small grip dimples have

firmly secured the sandpatuer surface.

5. Press holder firmly back up into place until

the contour "snaps" in place,

To remove contour, rotate lever to release

and lower the clamp holder. You are now

ready to install another contour shape or

detail pad.

Contours: Use sanding tubes that are !ong

lasting, reusable and easy to install. To

install, slide tube completely over desired

contour, and shape paper to contour.

Contour abrasive tubes can also be rotated

on the contour, to maximize the use of the

abrasive surface.

PSA Rolls: Rolls with pressure sensitive

adhesive can also be used with individual

contours. Unroll a strip of abrasive to fit the

particular contour, and cut to length with

scissors, When using pressure sensitive

adhesive, optimal clamping can be obtained

if the entire contour surface is wrapped with

paper. Firmly press the abrasive in place on

the contour. To remove abrasive, lift a

corner of the sheet with your fingernail and

peel it off. Dispose of the used abrasives,

they are not reusable.

HINT: When using 1/8" and 3/16" concave

contours with sanding tubes, it will be easier to

conform the abrasive to the workpiece if a finer

grit paper is used.

HINT: When reaching into extremely tight

places, the contour can be extended beycn

the front of the tool.

NOTE: Do not apply excessive pressure to th_

tool while in use. A!low the speed of the tool

and the accessory to do the work. Applying

unnecessary pressure wil! cause the accessor

to wear unevenly - it will not serve to perform

the work more quickly.

NOTE: The contour shapes have been

extruded to the dimension indicated on the

shape. When doing exacting work, it will be

necessary' to provide an allowance for the

sandpaper being used. Heavier/coarser grit

papers require a greater allowance.

PSA Adhesives work best at temperatures

above 25 degrees F. If PS& abrasives and

pads are stored at lower temperatures, it may

be necessary to allow them to come to room

temperature before use.

PSA Rolls must be stored in a dust-free

envwonment to prevent contamination of

adhesive.

After considerable use. the detail pad backing

sudace may become worn. The backing pad

must be replaced when it no longer offers a

firm grip. If you are experiencing premature

wearout of the backing pad facing, decrease

the amount of pressure you are applying

during operation of the tool.

This machine is particularly suitable for access

to corners and edges that are otherwise

difficult to reach cr require hand sanding.

Profiles and grooves may be finished using the

tip or edge of the selected accessory, which

should occasionally be rotated during use to

distribute the wear on the accessory or

backing pad surface.

Always be ceRain that smaller workpieces are

securely fastened to a bench or other suppcr:

Larger panels may be held in place by hand o

a bench or sawhorse.

SANDING: Open-coat aluminum oxide sandir

sheets are recommended for mos: wood cr

metal sanding applications, as this synthetlc

materia! cuts quic'.d'! and _vears well.

Loading...

Loading...