Page 1

I CRRFTSMRN1

Operator's Manual

Snow Thrower

7.75 Horsepower

Electric Start

26-inch Dual Stage

Model 536.887751

CAUTION: Before us=ngthis product,

read this manual and follow all of =ts

Safety Rules and Operat=ng Instruct=ons

Manual del usario

Quitan ieves

de 26 pulgadas

7.75 caballos de fuerza (hp)

Bietapico

Arranque electrico

Modelo 536.887751

PRECAUCION: Antes de usar este producto,

lea este manual y slga todas las reglas de

segundad e _nstrucc_ones de operac_6n

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F_)21027L www.sears.com/craftsman

Page 2

nf'._-] U:l[o]d[H_o]_i I _ _i1,,2

WARRANTY STATEMENT ....... 2

SAFETY RULES ............... 2

INTERNATIONAL SYMBOLS .... 4

ASSEMBLY ................... 6

OPERATION ................... 12

MAINTENANCE ................ 19

SERVICE AND ADJUSTMENT ... 22

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow thrower is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Sears will repair, free of charge, any defect in material or workmanship.

If this Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap-

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

Items which become worn dudng normal use, such as spark plugs, drive belts and shear

pins.

Repair necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWER TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates. IL 60179

STORAGE .................... 33

TROUBLESHOOTINGTABLE ... 34

REPAIR PARTS ................ 38

ENGINE REPAIR PARTS ........ 56

SPANISH (ESPANOL) .......... 63

PARTS ORDERING/SERVICE .

BACK COVER

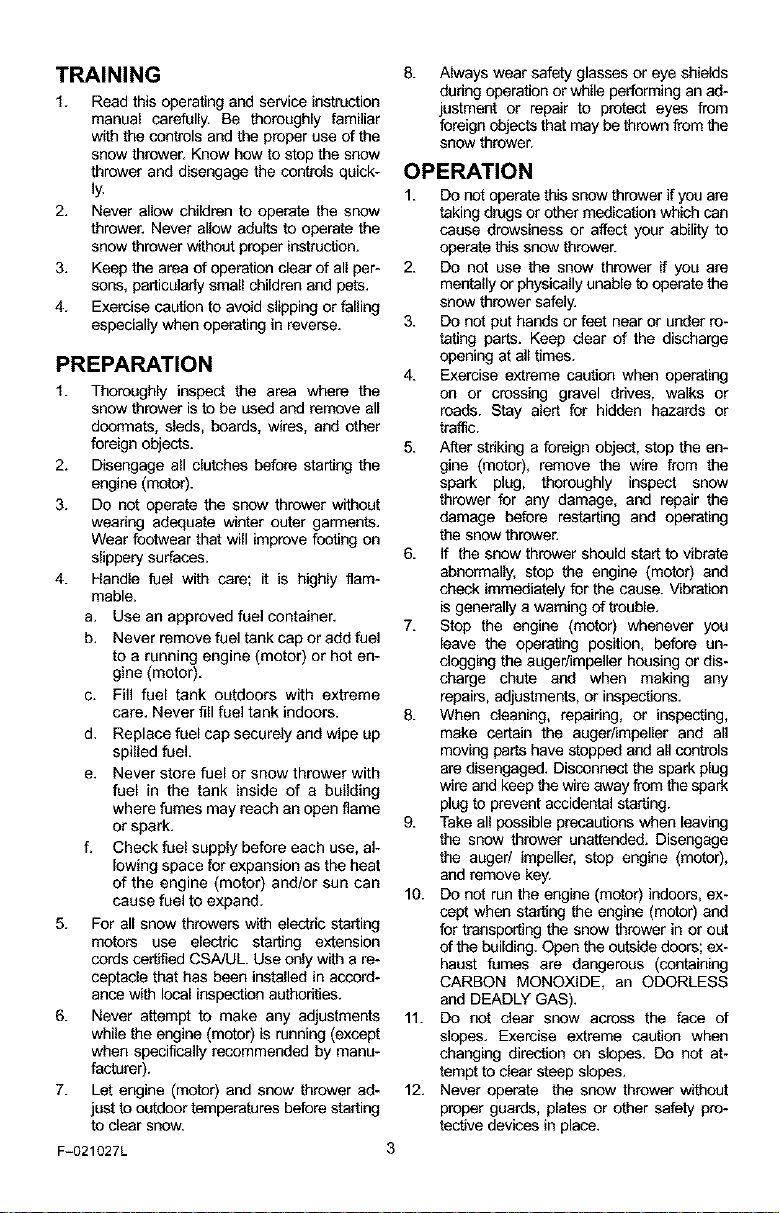

_k OOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

Engine Exhaust, some of its constituents, end

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm.

Battery posts, terminals and related accessories

contain lead end lead compounds, chemicals

known to the State of California to cause cancer

end birth defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

F-021027L 2

IT MEANS-- ATTENTION!!! BECOME ALERT!H YOUR SAFETY IS INVOLVED.

d_ WARNING: Always discon-

IMPORTANT: Safety standards re-

quire operator presence controls to

minimize the risk of injury. Your snow

thrower is equipped with such controls.

Do not attempt to defeat the function of

the operator presence control under any

circumstances.

nect the spark plug wire

and place it where it cannot

make contact with spark plug to

prevent accidental starting during:

Preparation, Maintenance, or Stor-

age of your snow thrower.

Page 3

TRAINING

1. Read this oberaiing and service instruction

manual carefully. Be thoroughly familiar

with the controls and the proper use of the

snow thrower. Know how to stop the snow

thrower and disengage the controls quick-

]y.

2. Never allow children to operate the snow

thrower. Never allow adults to operate the

snow thrower without proper instruction.

3. Keep the area of operation clear of all per-

sons, perticulady small children and pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

snow thrower is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor).

3. Do not operate the snow thrower without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces.

4. Handle fuel with care; it is highly flam-

mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en-

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with

fuel in the tank inside of a building

where fumes may reach an open flame

or spark.

f. Check fuel supply before each use, al-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5. For all snow throwers wflh electric starting

motors use electric starting extension

cords certified CSA/UL. Use only with a re-

ceptacle that has been installed in accord-

ance with local ieepection authorities.

6. Never attempt to make any adjustments

while the engine (motor) is running (except

when specifically recommended by manu-

tacturer).

7. Let engine (motor) and snow thrower ad-

just to o_door temperatures before starting

to clear snow.

F-021027L

Always wear safety glasses or eye shields

during operation or while performing an ad-

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

OPERATION

1. Do not operate this snow thrower ifyou are

taking drugs or other reedication which can

cause drewsiness or affect your ability to

operate this snow thrower.

2. Do not use the snow thrower if you are

mentally or physicallyunable to operate the

snow thrower safely.

3. Do not put hands or feet near or under ro-

tating parts. Keep clear of the discharge

opening at all times.

4. Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

5. After striking a foreign object, stop the en-

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

6. If the snow thrower should start to vibrate

abnormally, stop the engine (motor) and

check immediately for the cause. Vibration

is generally a warning of trouble.

7. Stop the engine (motor) whenever you

leave the operating position, before un-

clogging the augedimpeller housing or dis-

charge chute and when making any

repairs, adjustments, or inspections.

8. When cleaning, repairing, or inspecting,

make certain the auger/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

9. Take all possible precautions when leaving

the snow thrower unattended. Disengage

the auger/ impeller, stop engine (motor),

and remove key.

10. Do not run the engine (motor) indoors, ex-

cept when starting the engine (motor) and

for transporting the snow thrower in or out

of the building. Open the outside doors; ex-

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS).

11. Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do not at-

tempt to clear steep slopes.

12. Never operate the snow thrower wflhout

proper guards, plates or other safety pro-

tective devices in place.

Page 4

13.Neveroperatethe snow thrower near en-

closures, automobiles, window wells, drop-

offs, and the like without proper adjustment

of the snow discharge angle. Keep children

and pets away.

14. Do not overload the snow thrower capacity

by attempting to clear snow at too fast a

rate.

15. Never operate the snow thrower at high

transport speeds on slippery surfaces.

Look behind and use care when backing

up.

16. Never direct discharge at bystanders or

allow anyone in front of the snow thrower.

17. Disengage power to the collectodimpeller

when snow thrower is transported or not in

use.

18. Use only attachments and accaesedes ap-

proved by the manufacturer of the snow

thrower (such as tire chains, electdc start

kits, ect.).

19. Never operate the snow thrower without

good visibility or light. Always be sure of

your footing and keep a firm hold on the

handles. Walk;never run.

20. Do not over-reach. Keep proper footing

and balance at all times.

21. Do not attempt to use snow thrower on a

roof.

MAINTENANCE AND STORAGE

1. Check shear bolts and other bolts at fre-

queet intervals for proper tightness to be

sure the snow thrower is in safe working

condition.

2. Never store the snow thrower with fuel in

the tank inside a building where ignition

sources are present such as hot water and

space heaters, clothes dryers, and the like.

Allow the engine (motor) to cool before

stodng in any enclosure.

3. Always refer to operator's guide instruc-

tions for important details if the snow

thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction

labels, as necessary.

5. Run the snow thrower a few min_es after

throwing snow to prevent freeze-up of the

anger/impellec

_1= WARNING: This snow thrower isfor use on sidewalks, driveways

and other ground level surfaces.

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi-

dences, garages, porches or other such

structures or buildings.

]

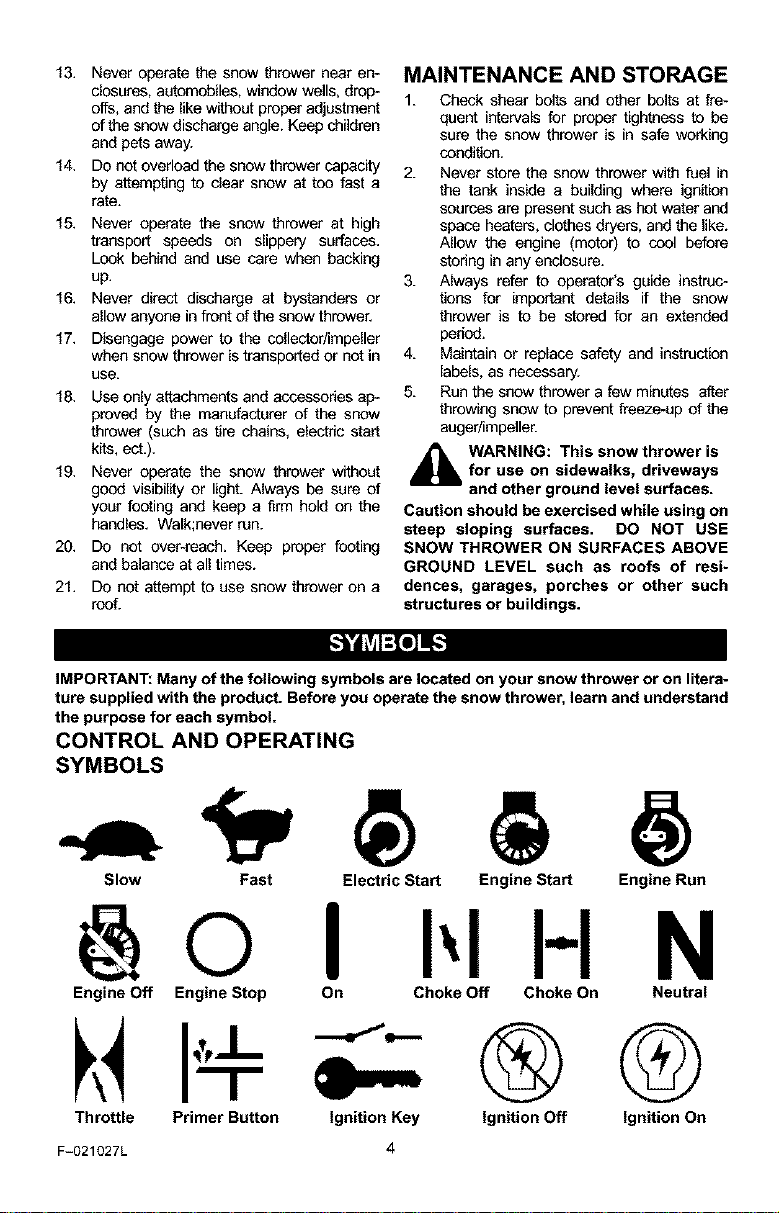

IMPORTANT: Many of the following symbols are located on your snow thrower or on litera-

ture supplied with the product. Before you operate the snow thrower, learn and understand

the purpose for each symbol.

CONTROL AND OPERATING

SYMBOLS

Slow Fast Electric Start Engine Start Engine Run

H N

Engine Off Engine Stop On Choke Off Choke On Neutral

®G

Throttle Primer Button Ignition Key

F-021027L 4

Ignition Off Ignition On

Page 5

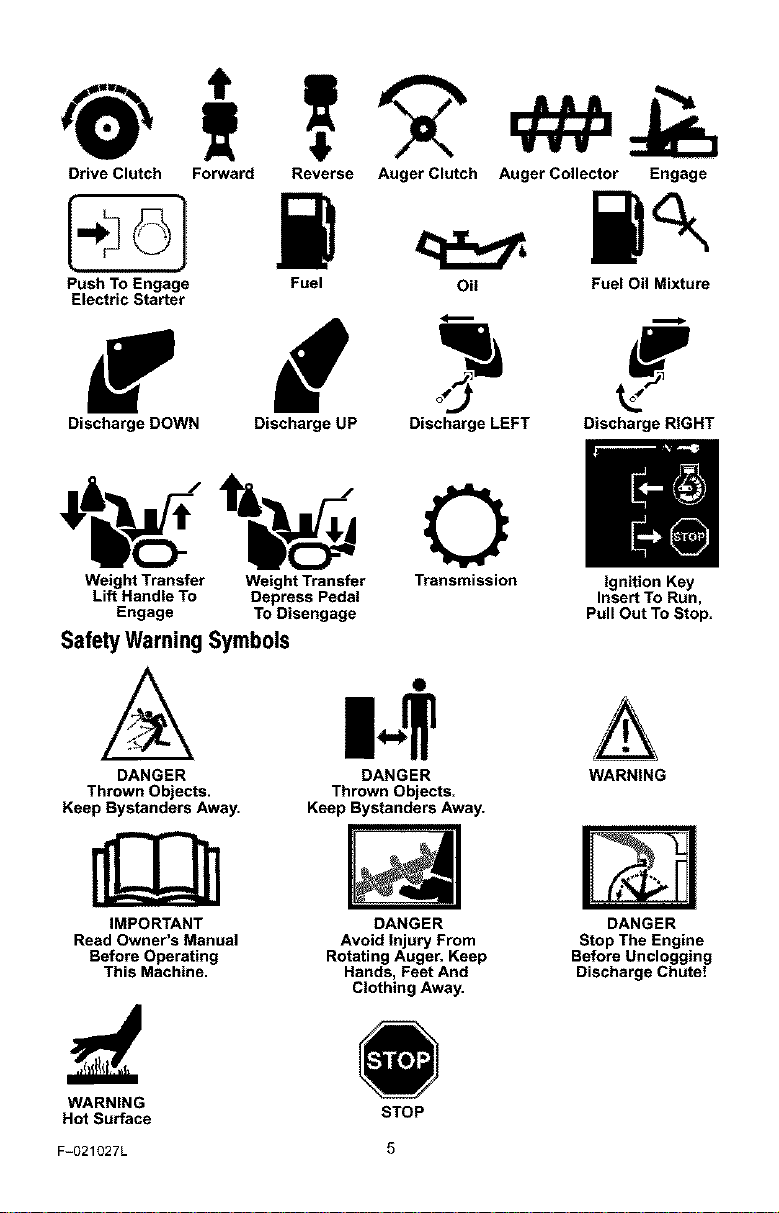

DriveClutch Forward

ReverseAugerClutchAugerCollector Engage

PushToEngage

ElectricStarter

Fuel Oil FuelOilMixture

f

Discharge DOWN Discharge UP Discharge LEFT Discharge RIGHT

Weight Transfer Weight Transfer Transmission Ignition Key

Lift Handle To Depress Pedal Insert To Run,

Engage To Disengage Pull Out To Stop.

Safety Warning Symbols

O

A

DANGER

Thrown Objects.

Keep Bystanders Away.

DANGER

Thrown Objects.

Keep Bystanders Away.

WARNING

IMPORTANT

Read Owner's Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-O21027L 5

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

STOP

DANGER

Stop The Engine

Before Unclogging

Discharge Chute!

Page 6

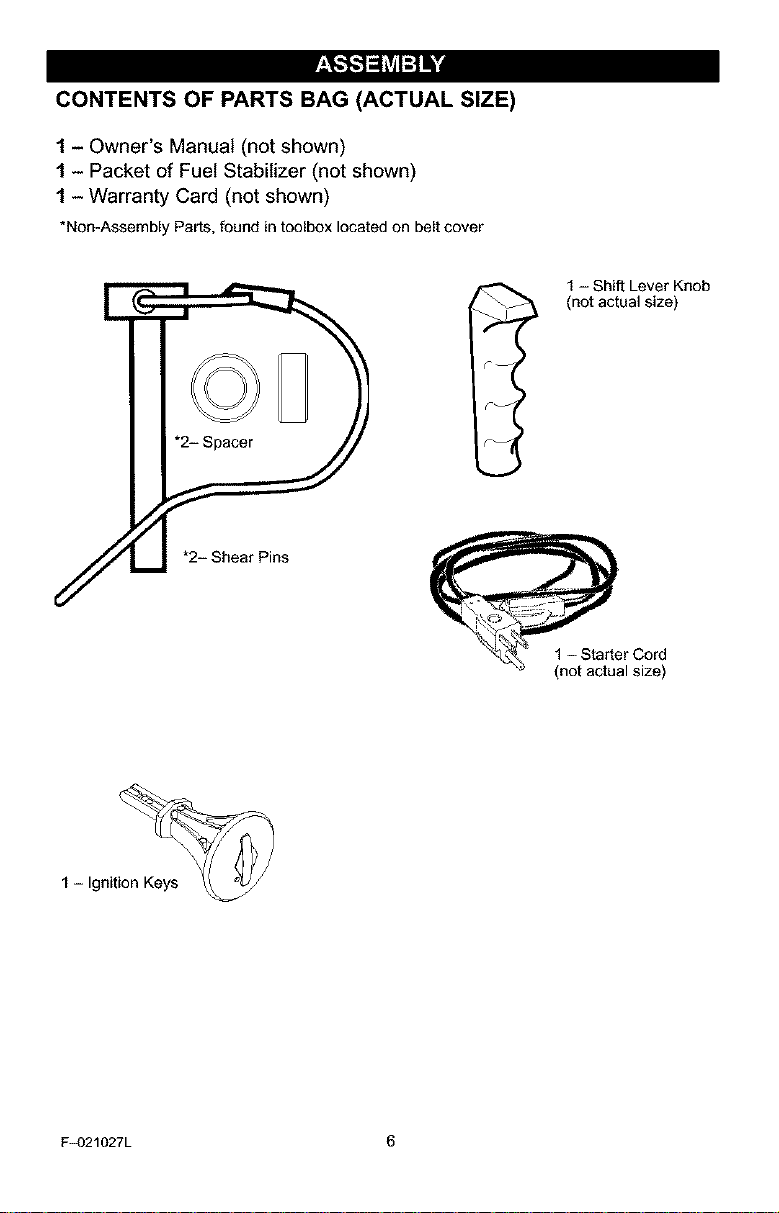

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assembly Parts,foundintoolboxlocatedon beltcover

(not actual size)

r I

1 - Shift Lever Knob

F_)21027L 6

Page 7

,_ WARNING: Always wearsafety glasses or eye shields

while assembling snow

thrower.

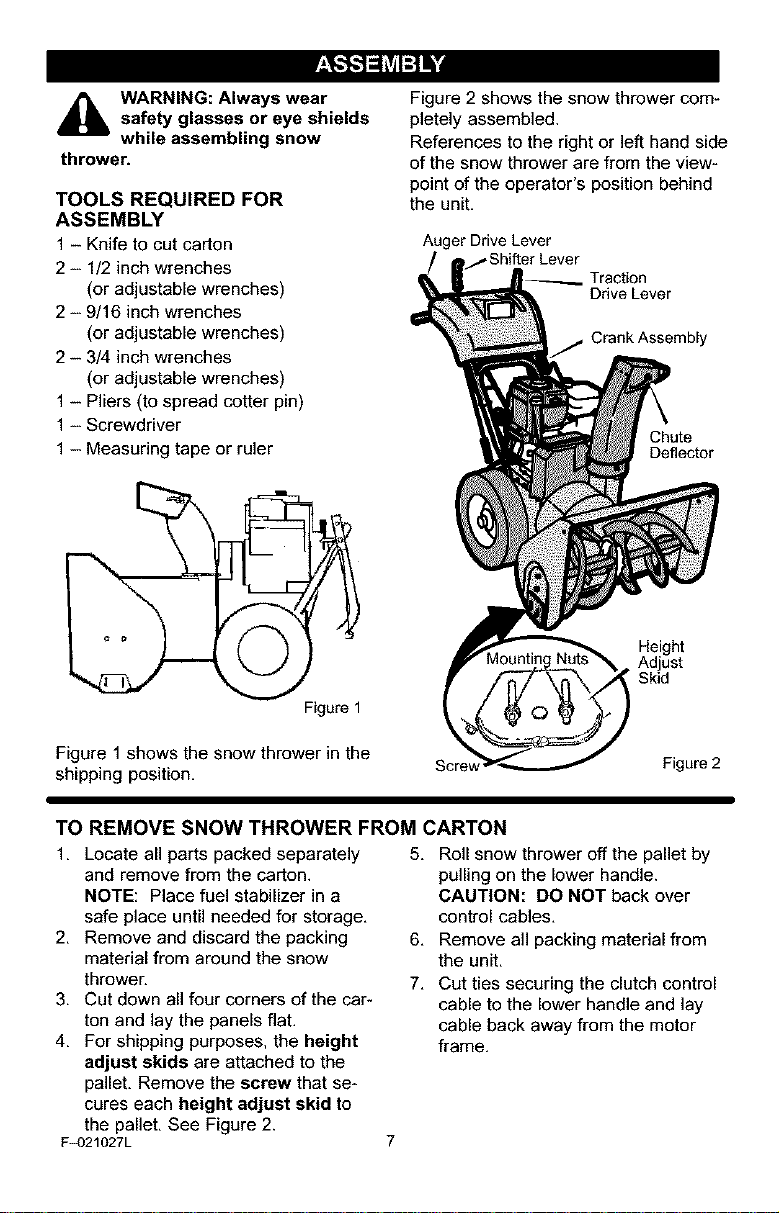

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

2 - 1/2 inch wrenches

(or adjustable wrenches)

2 - 9/16 inch wrenches

(or adjustable wrenches)

2 - 3/4 inch wrenches

(or adjustable wrenches)

1- Pliers (to spread cotter pin)

1- Screwdriver

1- Measuring tape or ruler

Figure 1

Figure 2 shows the snow thrower com-

pletely assembled.

References to the right or left hand side

of the snow thrower are from the view-

point of the operator's position behind

the unit.

Auger Drive Lever

Traction

Drive Lever

Crank Assembly

Chute

Deflector

Height

Adjust

Skid

Figure1 shows the snow thrower in the

shipping position,

Scre_ Figure 2

TO REMOVE SNOW THROWER FROM CARTON

1. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a

safe place until needed for storage.

2. Remove and discard the packing

material from around the snow

thrower.

3. Cut down all four corners of the car-

ton and lay the panels flat.

4. For shipping purposes, the height

adjust skids are attached to the

pallet. Remove the screw that se-

cures each height adjust skid to

the pallet. See Figure 2.

F_)21027L

5. Roll snow thrower off the pallet by

pulling on the lower handle.

CAUTION: DO NOT back over

control cables.

6. Remove all packing material from

the unit.

7. Cut ties securing the clutch control

cable to the lower handle and lay

cable back away from the motor

frame.

Page 8

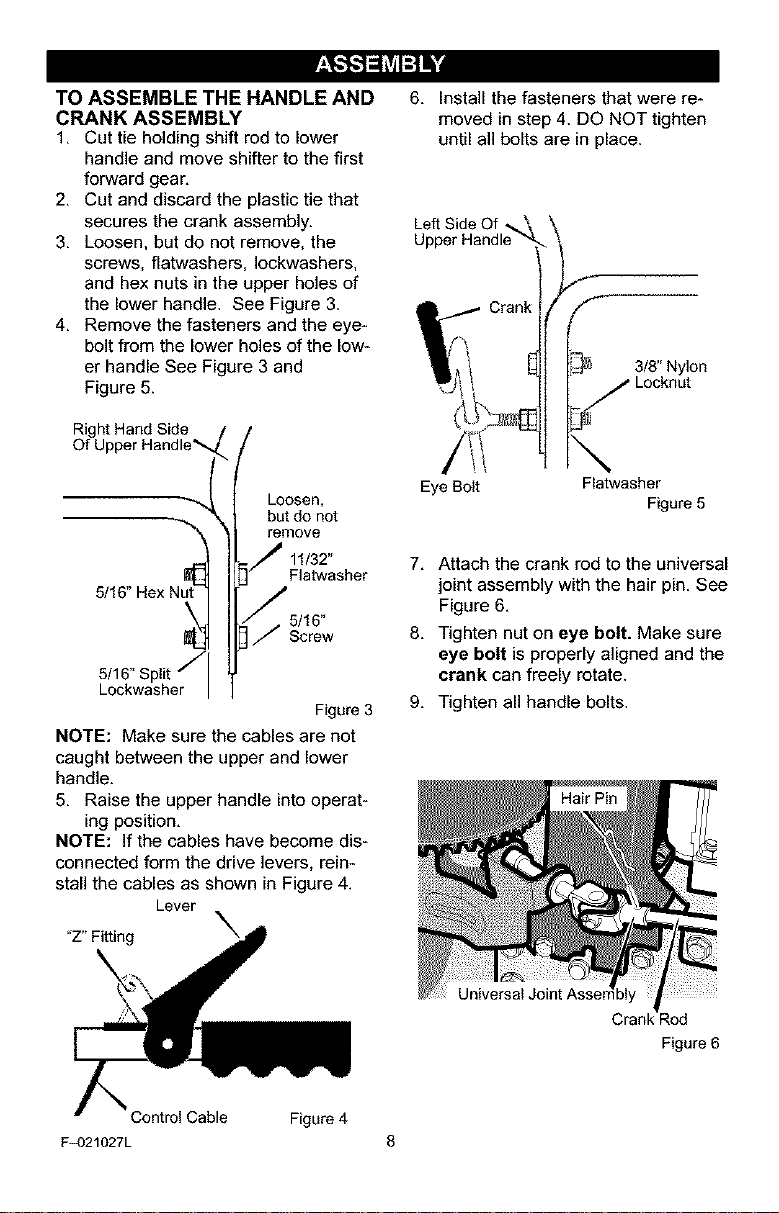

TO ASSEMBLE THE HANDLE AND

CRANK ASSEMBLY

1. Cut tie holding shift rod to lower

handle and move shifter to the first

forward gear.

2. Cut and discard the plastic tie that

secures the crank assembly.

3. Loosen, but do not remove, the

screws, flatwashers, Iockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

4. Remove the fasteners and the eye-

bolt from the lower holes of the low-

er handle See Figure 3 and

Figure 5.

Right HandSide

Of U

Loosen,

but do not

remove

11/32"

5/16" Hex Nu

NOTE: Make sure the cables are not

caught between the upper and lower

handle.

5. Raise the upper handle into operat-

ing position.

NOTE: If the cables have become dis-

connected form the drive levers, rein-

stall the cables as shown in Figure 4.

Lever

"Z" Fitting

Flatwasher

5/16"

Screw

Figure 3

6. Install the fasteners that were re-

moved in step 4. DO NOT tighten

until all bolts are in place.

Left Side Of -_\

Upper Handle

3/8" Nylon

j Locknut

\

Eye Bolt

7. Attach the crank rod to the universal

joint assembly with the hair pin. See

Figure 6.

8. Tighten nut on eye bolt. Make sure

eye bolt is properly aligned and the

erank can freely rotate.

9. Tighten all handle bolts.

Flatwasher

Figure 5

Control Cable Figure 4

F_)21027L 8

Cran_ _od

Figure 6

Page 9

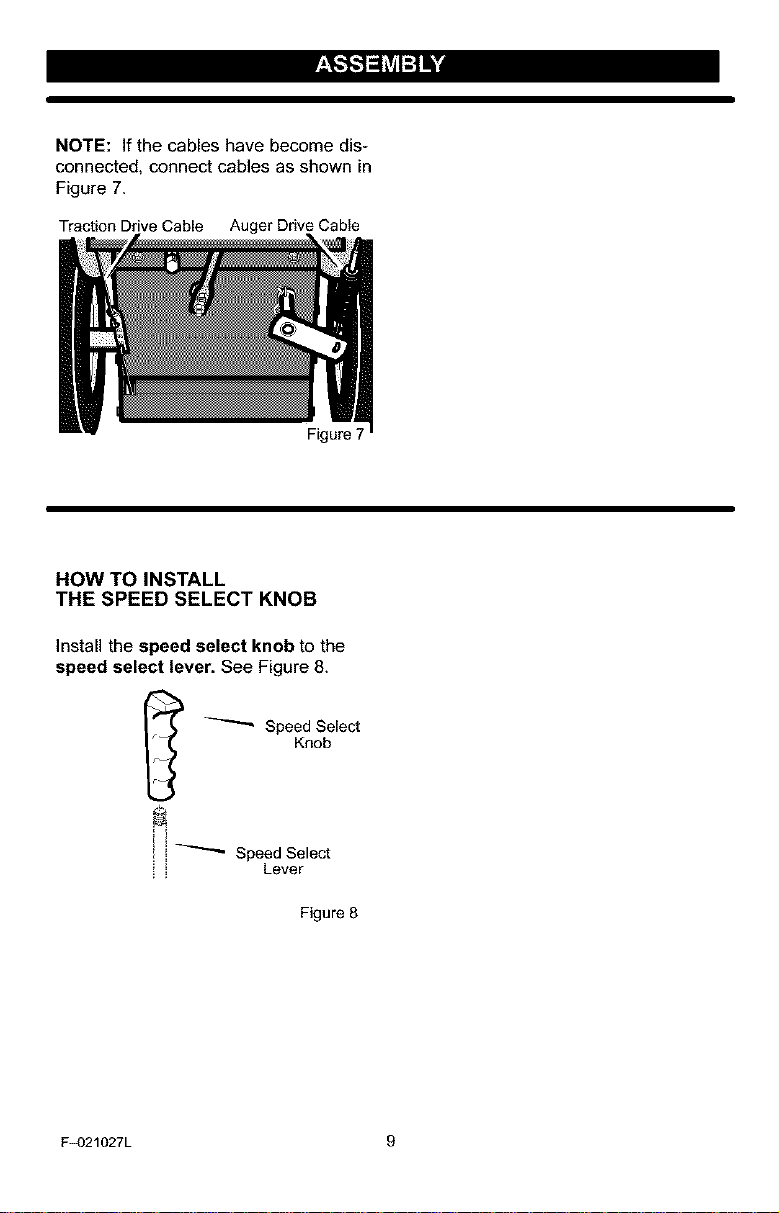

NOTE: If the cables have become dis-

connected, connect cables as shown in

Figure 7.

Traction Drive Cable Auger Drive Cable

Figure 7

HOW TO INSTALL

THE SPEED SELECT KNOB

Install the speed select knob to the

speed select lever. See Figure 8.

Knob

_ Speed Select

,!i!_ Speed Select

Lever

Figure 8

F_)21027L g

Page 10

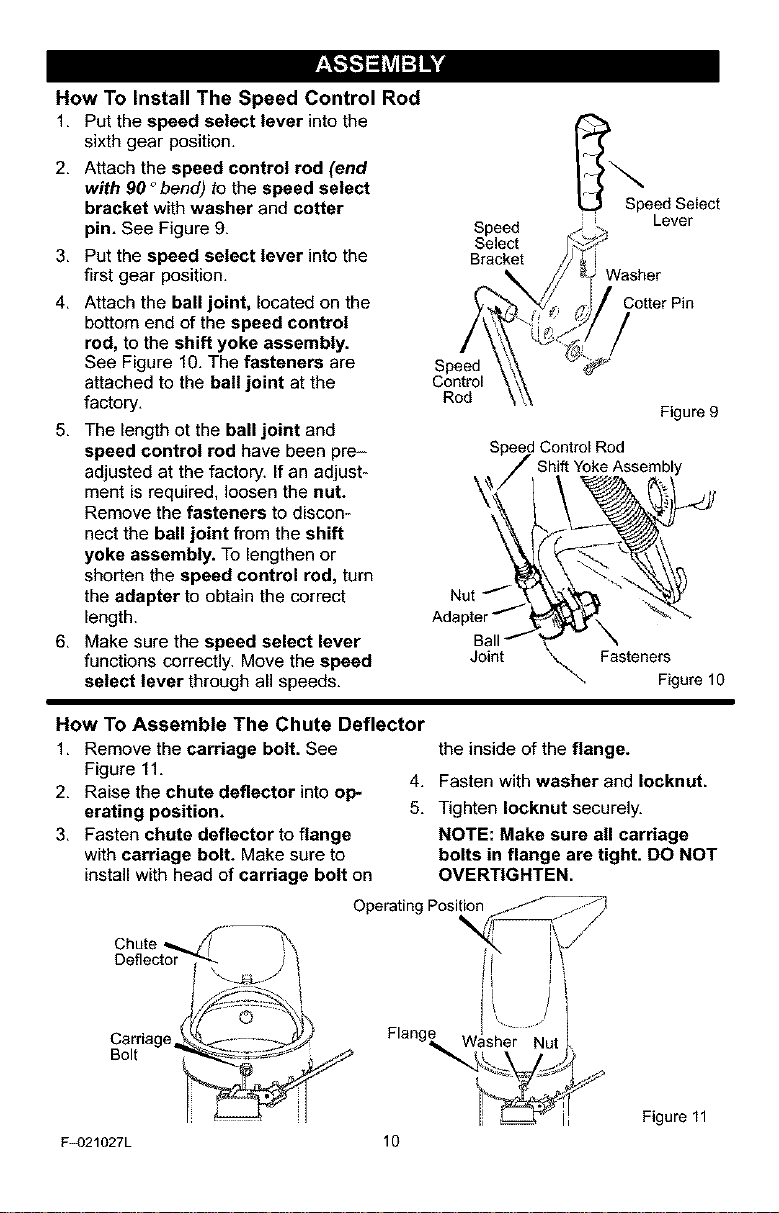

How To Install The Speed Control Rod

1. Put the speed select lever into the

sixth gear position.

2. Attach the speed control rod (end _.

with 90 °bend) to the speed select

bracket with washer and cotter Speed Select

pin. See Figure 9. Speed

3. Put the speed select lever into the Bracket

first gear position.

4. Attach the ball joint, located on the Cotter Pin

bottom end of the speed control

rod, to the shift yoke assembly.

See Figure 10. The fasteners are Speed

attached to the ball joint at the Control

factory. Rod

5. The length ot the ball joint and

speed control rod have been pre-

adjusted at the factory, if an adjust-

ment is required, loosen the nut.

Remove the fasteners to discon-

nect the ball joint from the shift

yoke assembly. To lengthen or

shorten the speed control rod, turn

the adapter to obtain the correct

length.

6. Make sure the speed select lever

functions correctly. Move the speed

select lever through al speeds.

Select

Speed Control Rod

Jo _ se eF_gurelo

I

Lever

Figure 9

Shift Yoke Assembly

How To Assemble The Chute Deflector

1. Remove the carriage bolt. See

Figure 11.

2. Raise the chute deflector into oP-

erating position.

3. Fasten chute deflector to flange

with carriage bolt. Make sure to

install with head of carriage bolt on

Operating Pos

Chute

Deflector

/l

F_)21027L

Carriage

Bolt

Flang_,Washer Nut

10

the inside of the flange.

4. Fasten with washer and Iocknut.

5. Tighten Iocknut securely.

NOTE: Make sure all carriage

bolts in flange are tight. DO NOT

OVERTIGHTEN.

Figure 11

Page 11

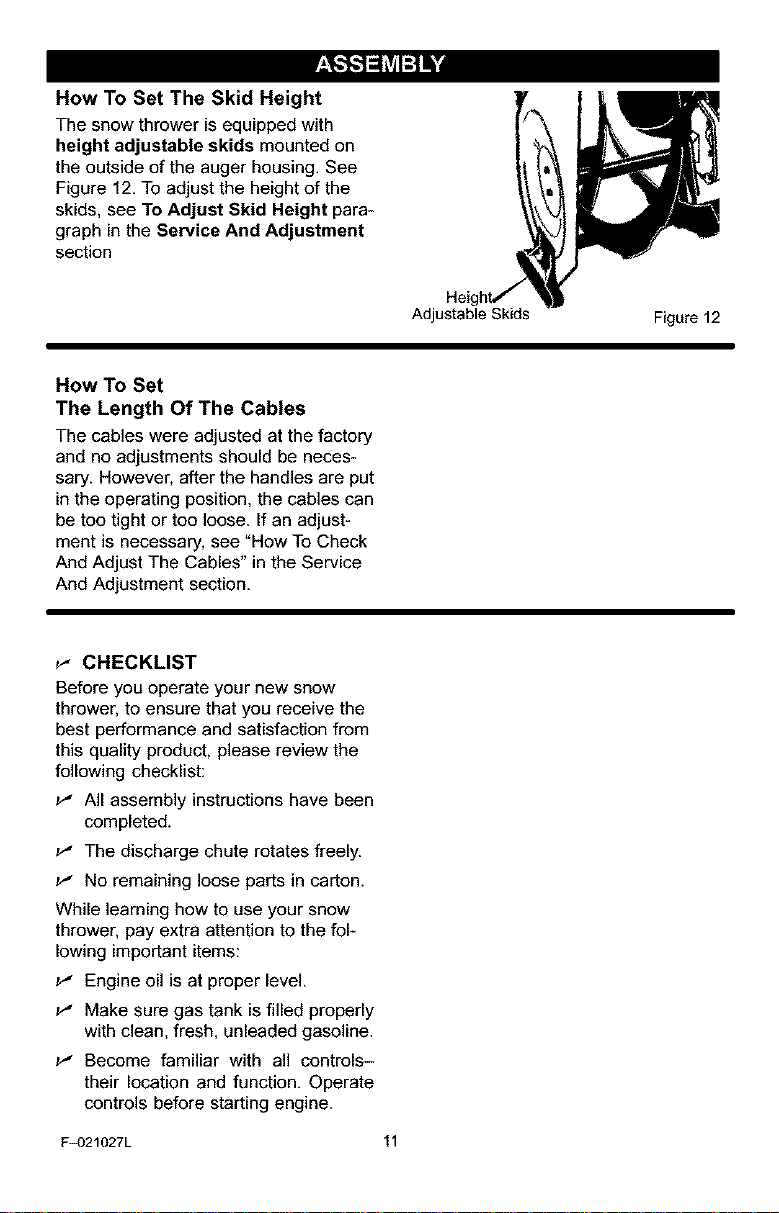

How To Set The Skid Height

The snow thrower is equipped with

height adjustable skids mounted on

the outside of the auger housing. See

Figure 12. To adjust the height of the

skids, see To Adjust Skid Height para-

graph in the Service And Adjustment

section

How To Set

The Length Of The Cables

The cables were adjusted at the factory

and no adjustments should be neces-

sary. However, after the handles are put

in the operating position, the cables can

be too tight or too loose. If an adjust-

ment is necessary, see "How To Check

And Adjust The Cables" in the Service

And Adjustment section.

_" CHECKLIST

Before you operate your new snow

thrower, to ensure that you receive the

best performance and satisfaction from

this quality product, please review the

following checklist:

_" All assembly instructions have been

completed,

_" The discharge chute rotates freely,

_" No remaining loose parts in carton,

While learning how to use your snow

thrower, pay extra attention to the fol-

lowing important items:

_" Engine oil is at proper level,

_" Make sure gas tank is filled properly

with clean, fresh, unleaded gasoline,

_" Become familiar with all controls-

their location and function, Operate

controls before starting engine,

Adjustable Skids

Figure 12

F_)21027L 11

Page 12

[i]-.]_l;ralil[i]_]

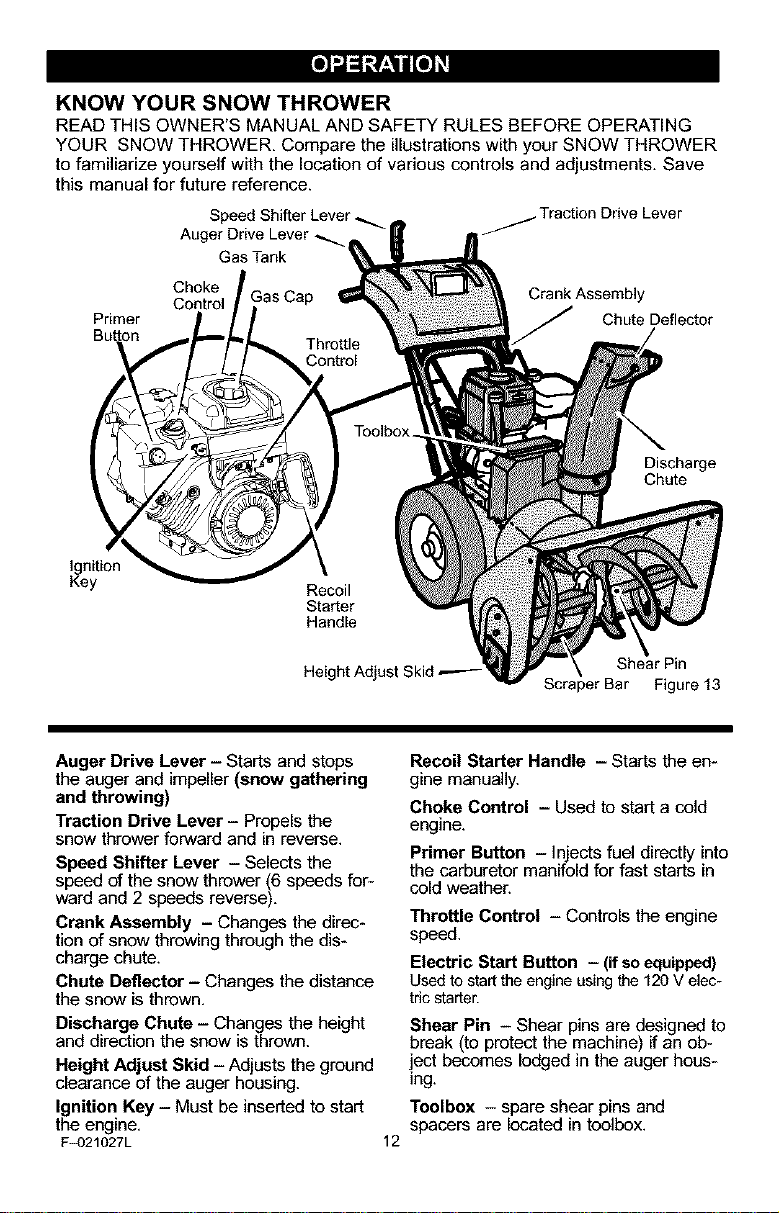

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER, Compare the illustrations with your SNOW THROWER

to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

Traction Drive Lever

Crank Assembly

Chute Deflector

Discharge

Chute

Primer

Ignition

Key

Speed Shifter Lever,

Auger Drive Lever _.

Gas Tank

Choke

Control

Recoil

Starter

Handle

Height Adjust Skid

Auger Drive Lever - Starts and stops

the anger and impeller (snow gathering

and throwing)

Traction Drive Lever - Propels the

snow thrower forward and in reverse.

Speed Shitter Lever - Selects the

speed of the snow thrower (6 speeds for-

ward and 2 speeds reverse),

Crank Assembly - Changes the direc-

tion of snow throwing through the dis-

charge chute.

Chute Deflector - Changes the distance

the snow is thrown,

Discharge Chute - Changes the height

and direction the snow is thrown.

Height Adjust Skid - Adjusts the ground

clearance of the auger housing.

Ignition Key - Must be inserted to start

the engine,

F_)21027L

Shear Pin

Scraper Bar Figure 13

Recoil Starter Handle - Starts the en-

gine manually.

Choke Control - Used to start a cold

engine.

Primer Button - Injects fuel directly into

the carburetor manifold for fast starts in

cold weather.

Throttle Control - Controls the engine

speed.

Electric Start Button - (if so equipped)

Used to start the engine using the 120 V elec-

tric starter.

Shear Pin - Shear pins are designed to

break (to protect the machine) if an ob-

ject becomes lodged in the auger hees-

ing.

Toolbox - spare shear pins and

spacers are located in toolbox.

12

Page 13

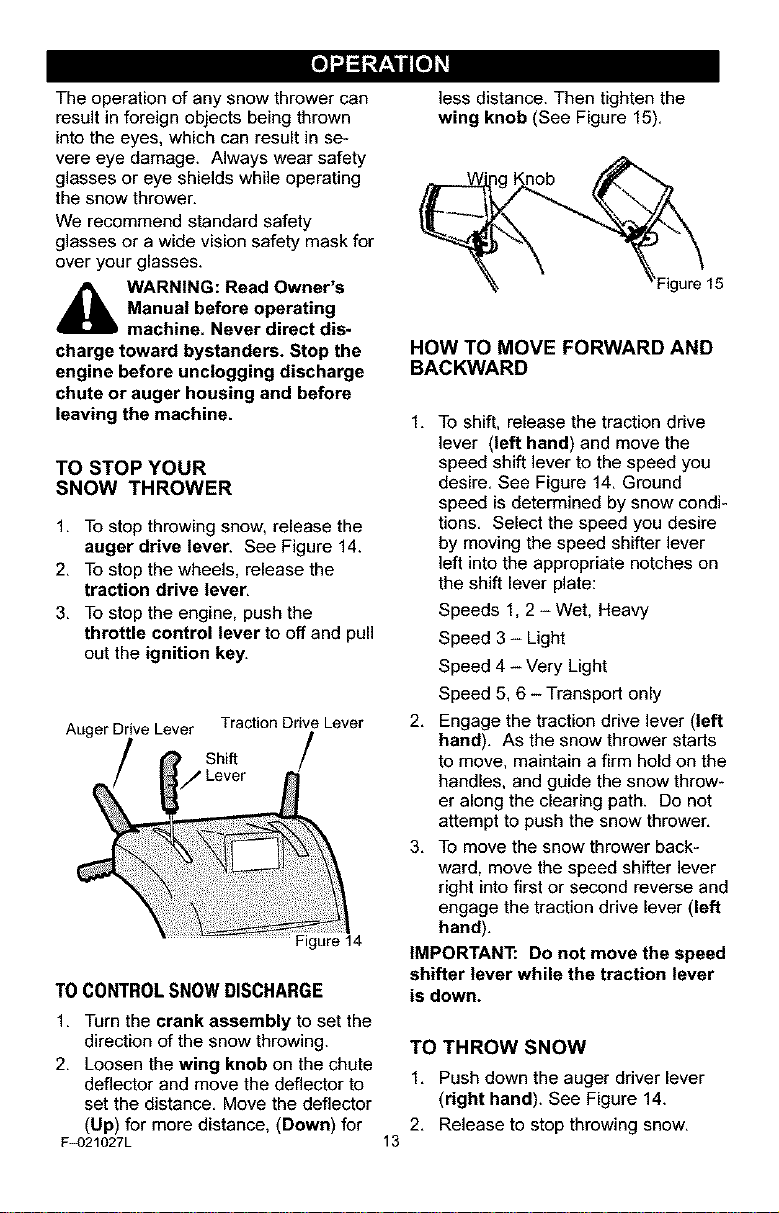

[e]-.]_=;rz_lil[e]_3

The operation of any snow thrower can

result in foreign objects being thrown

less distance. Then tighten the

wing knob (See Figure 15).

into the eyes, which can result in se-

vere eye damage. Always wear safety

glasses or eye shields while operating

the snow thrower.

We recommend standard safety

glasses or a wide vision safety mask for

over your glasses.

_IL ARNING: Read Owner's

charge toward bystanders. Stop the

engine before unclogging discharge

Manual before operating

machine. Never direct dis-

HOW TO MOVE FORWARD AND

BACKWARD

chute or auger housing and before

leaving the machine.

1,

To shift, release the traction drive

lever (left hand) and move the

TO STOP YOUR

SNOW THROWER

speed shift lever to the speed you

desire. See Figure 14. Ground

speed is determined by snow condi-

1. To stop throwing snow, release the

auger drive lever. See Figure 14.

2. To stop the wheels, release the

traction drive lever,

3. To stop the engine, push the

throttle control lever to off and pull

out the ignition key.

tions. Select the speed you desire

by moving the speed shifter lever

left into the appropriate notches on

the shift lever plate:

Speeds 1, 2 - Wet. Heavy

Speed 3 - Light

Speed 4 - Very Light

Speed 5. 6 - Transport only

Auger Drive Lever Traction Drive Lever

2. Engage the traction drive lever (left

hand), As the snow thrower starts

to move, maintain a firm hold on the

handles, and guide the snow throw-

er along the clearing path. Do not

attempt to push the snow thrower.

3. To move the snow thrower back-

ward, move the speed shifter lever

right into first or second reverse and

engage the traction drive lever (left

hand),

IMPORTANT: Do not move the speed

shifter lever while the traction lever

TO CONTROL SNOW DISCHARGE is down.

1. Turn the crank assembly to set the

direction of the snow throwing.

2. Loosen the wing knob on the chute

deflector and move the deflector to

set the distance. Move the deflector

(Up) for more distance, (Down) for

F_)21027L 13

TO THROW SNOW

1. Push down the auger driver lever

(right hand). See Figure 14.

2. Release to stop throwing snow.

Page 14

[i]-.]_l;ralil[i]_3

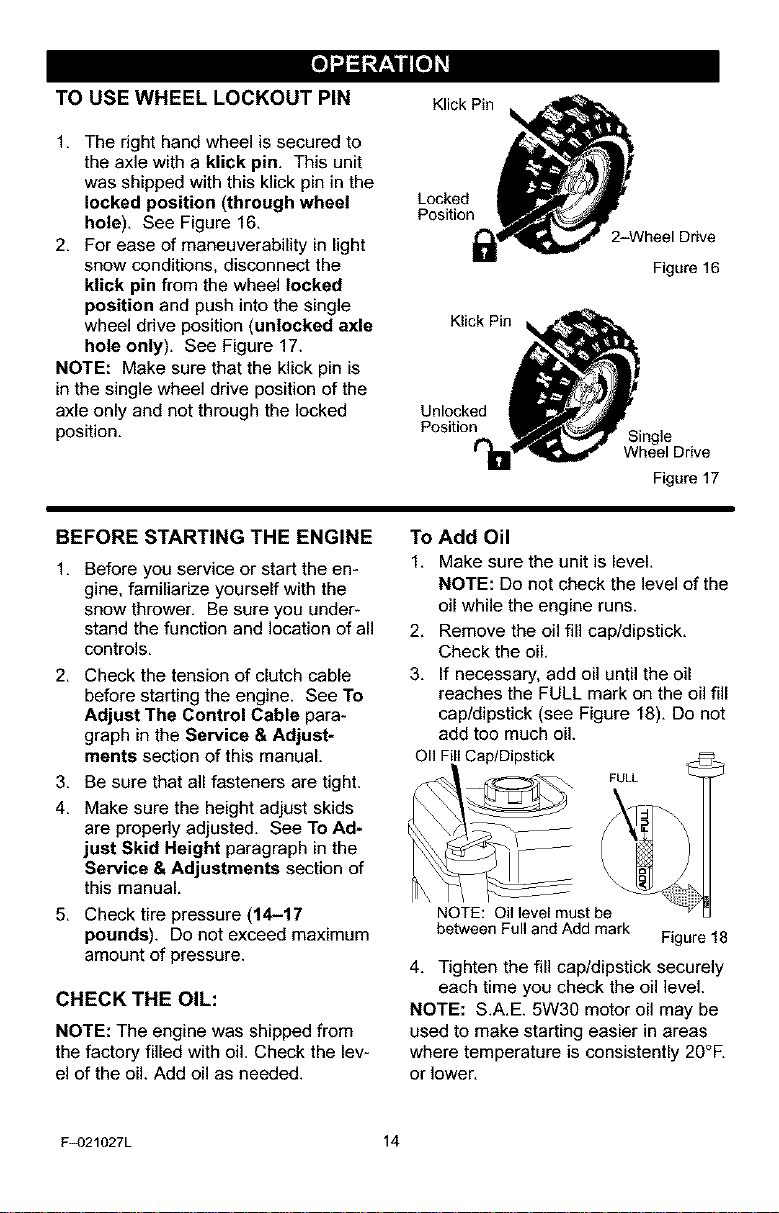

TO USE WHEEL LOCKOUT PIN

1. The right hand wheel is secured to

the axle with a klick pin. This unit

was shipped with this klick pin in the

locked position (through wheel

hole). See Figure 16.

2. For ease of maneuverability in light

snow conditions, disconnect the

klick pin from the wheel locked

position and push into the single

wheel drive position (unlocked axle

hole only). See Figure 17.

NOTE: Make sure that the klick pin is

in the single wheel drive position of the

axle only and not through the locked

position.

Klick Pin

Locked

Position

2-Wheel Drive

Figure 16

Figure 17

BEFORE STARTING THE ENGINE

1. Before you service or start the en-

gine, familiarize yourself with the

snow thrower. Be sure you under-

stand the function and location of all

controls.

2. Check the tension of clutch cable

before starting the engine. See To

Adjust The Control Cable para-

graph in the Service & Adjust*

ments section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are properly adjusted. See To Ad-

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Check tire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

CHECK THE OIL:

NOTE: The engine was shipped from

the factory filled with oil. Check the lev-

el of the oil. Add oil as needed.

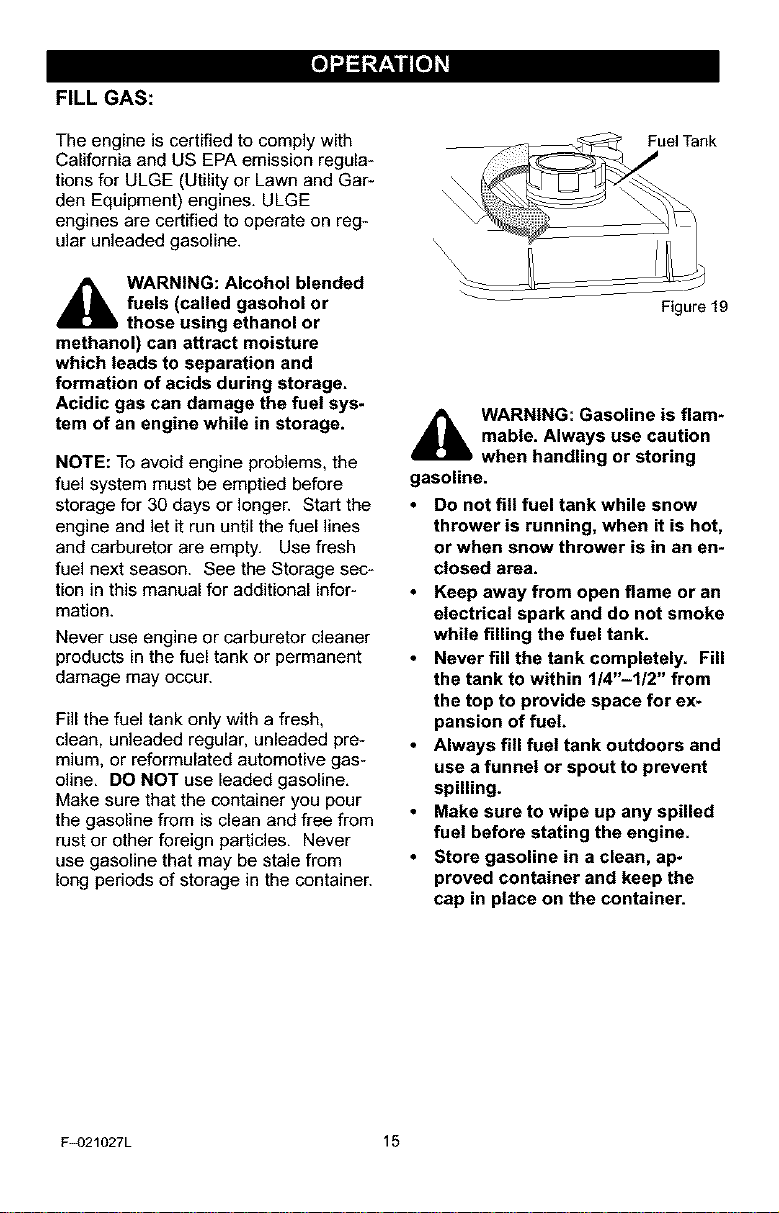

To Add Oil

1. Make sure the unit is level.

NOTE: Do not check the level of the

oil while the engine runs.

2. Remove the oil fill cap/dipstick.

Check the oil.

3. If necessary, add oil until the oil

reaches the FULL mark on the oil fill

cap/dipstick (see Figure 18). Do not

add too much oil.

OI1 Fill Cap/Dipstick

FULL

NOTE: Oil level must be

between Full and Add mark Figure 18

4, Tighten the fill cap/dipstick securely

each time you check the oil level.

NOTE: S.A,E. 5W30 motor oil may be

used to make starting easier in areas

where temperature is consistently 20°R

or lower.

F_)21027L 14

Page 15

FILL GAS:

[e]-.]_=;ralil[e]_j

The engine is certified to comply with

California and US EPA emission regula-

tions for ULGE (Utility or Lawn and Gar-

den Equipment) engines. ULGE

engines are certified to operate on reg-

ular unleaded gasoline.

_L ARNING: Alcohol blended

fuels (called gasohol or

those using ethanol or

methanol) can attract moisture

which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

NOTE: To avoid engine problems, the

fuel system must be emptied before

storage for 30 days or longer. Start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. See the Storage sec-

tion in this manual for additional infor-

mation.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

Fill the fuel tank only with a fresh,

clean, unleaded regular, unleaded pre-

mium, or reformulated automotive gas-

oline. DO NOT use leaded gasoline.

Make sure that the container you pour

the gasoline from is clean and free from

rust or other foreign particles. Never

use gasoline that may be stale from

long periods of storage in the container.

Fuel Tank

Figure 19

_IL ARNING: Gasoline is flam*

mable. Always use caution

when handling or storing

gasoline.

• Do not fill fuel tank while snow

thrower is running, when it is hot,

or when snow thrower is in an en*

closed area.

• Keep away from open flame or an

electrical spark and do not smoke

while filling the fuel tank.

• Never fill the tank completely. Fill

the tank to within 1/4"-1/2" from

the top to provide space for ex-

pansion of fuel.

• Always fill fuel tank outdoors and

use a funnel or spout to prevent

spilling.

• Make sure to wipe up any spilled

fuel before stating the engine.

• Store gasoline in a clean, ap-

proved container and keep the

cap in place on the container.

F_)21027L 15

Page 16

[e]-.]_=;rz_lil[e]_3

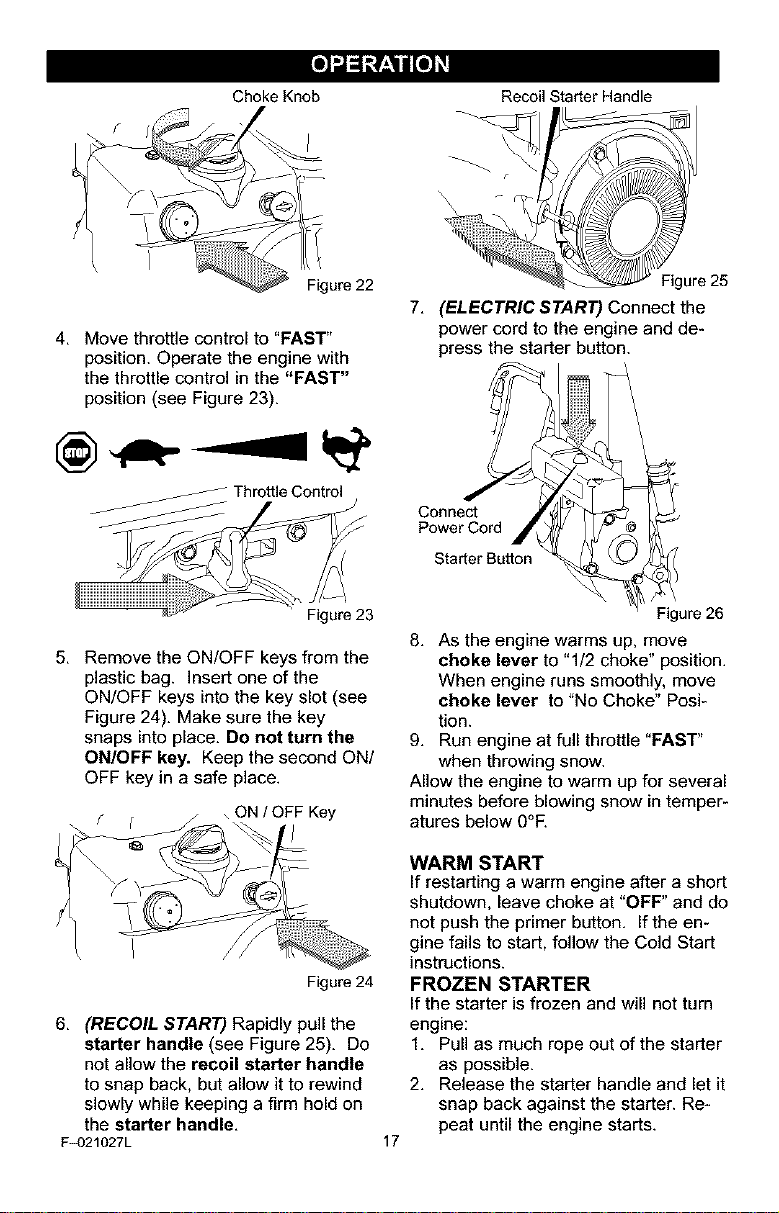

HOW TO STOP THE ENGINE

1. To stop the engine, move the

throttle control lever to the "SLOW"

position, then move to the "STOP"

position (see Figure 20).

ontml

Figure20

2. Pull out and remove the ON/OFF

key (see Figure 21). Keep the

ON/OFF key in a safe place. The

engine will not start without the

ON/OFF key.

_IL ARNING: The starter is

designed to operate on 120 volt AC

household current. It must be prop-

edy grounded at all times to avoid

the possibility of electrical shock

which may be injurious to operator.

• Follow all instructions carefully

• Determine that your house wiring

• If your system is grounded and a

• When connecting 120 volt AC

equipped with a three-wire

power cord and plug and is

as set forth in the "To Start En-

gine" section.

is a three-wire grounded system.

Ask a licensed electrician if you

are not sure. If your house wire

system is not a three-wire system,

do not use this electric starter un-

der any conditions.

three*hole receptacle is not avail*

able at the point your starter will

normally be used, one should be

installed by a licensed electrician.

"Power Cord", always connect the

cord to the Switch Box on the en=

gine first, then plug the other end

into the three*hole grounded re=

ceptacle. When disconnecting

"Power Cord", always unplug the

end in the three*hole grounded re=

ceptacle first.

Figure21

TO START ENGINE

Be sure that the engine has sufficient

oil. The snow thrower engine is

equipped with a recoil starter. Before

starting the engine, be certain that you

have read the following information.

F_]21027L 16

How To Start A Cold Engine

1. Be sure auger drive and traction

drive levers are in the disengaged

(RELEASED) position.

2. Turn the rotary choke knob to the

CHOKE position (see Figure 22).

3. Depress the primer button three

times (see Figure 22).

Page 17

Choke Knob Recoil Starter Handle

4. Move throttle control to "FAST"

position. Operate the engine with

the throttle control in the "FAST"

position (see Figure 23).

gure 25

7. (ELECTRIC START) Connect the

power cord to the engine and de-

press the starter button.

_ Throttle Control

Figure 23

5. Remove the ON/OFF keys from the

plastic bag. Insert one of the

ON/OFF keys into the key slot (see

Figure 24). Make sure the key

snaps into place. Do not turn the

ON/OFF key. Keep the second ON/

OFF key in a safe place.

Figure24

6. (RECOIL START) Rapidly pull the

starter handle (see Figure 25). Do

not allow the recoil starter handle

to snap back, but allow it to rewind

slowly while keeping a firm hold on

the starter handle,

F_)21027L

Connect

Power Cord

Starter Button

8. As the engine warms up, move

choke lever to "1/2 choke" position.

When engine runs smoothly, move

choke lever to "No Choke" Posi-

tion.

9. Run engine at full throttle "FAST"

when throwing snow.

Allow the engine to warm up for several

minutes before blowing snow in temper-

atures below 0°E

WARM START

If restarting a warm engine after a short

shutdown, leave choke at "OFF" and do

not push the primer button. If the en-

gine fails to start, follow the Cold Start

instructions.

FROZEN STARTER

If the starter is frozen and will not turn

engine:

1. Pull as much rope out of the starter

as possible.

2. Release the starter handle and let it

snap back against the starter. Re-

peat until the engine starts.

17

Figure26

Page 18

Tohelppreventpossiblefreeze-upof

recoilstarterandenginecontrols,pro-

ceedasfollowsaftereachsnowremov-

aljob.

1. Withtheenginerunning,pullthe

starterropehardwithacontinuous

fullarmstrokethreeorfourtimes.

Pullingofstarterropewillproducea

loudclatteringsound.Thisisnot

harmfultotheengineorstarten

2. Withtheenginenotrunning,wipeall

snowandmoisturefromthecarbu-

retorcoverinareaofcontrollevers.

Alsomovethrottlecontrol,choke

control,andstarterhandleseveral

times.

_lb ARNING: Never run en*

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

• The temperature of muffler and

• DO NOT allow children oryoung

gine indoors or in enclosed,

poorly ventilated areas. En*

nearby areas may exceed 150°F.

Avoid these areas.

teenagers to operate or be near

snow thrower while it is operat*

ing.

HOW TO REMOVE OBJECTS

FROM AUGER

_lb ARNING: Do not attempt

without taking the following precau-

tions:

to remove any item that may

become lodged in auger

SNOW THROWING TIPS

1. For maximum snow thrower efficien-

cy in removing snow, adjust ground

speed, NEVER the throttle. Go

slower in deep, freezing or wet

snow. If the wheels slips, reduce

forward speed. The engine is de-

signed to deliver maximum perfor-

mance at full throttle and should be

run at this power setting at all times.

2. Most efficient snow throwing is ac-

complished when the snow is re-

moved immediately after if falls.

3. For complete snow removal, slightly

overlap each path previously taken.

4. The snow should be discharged

down wind whenever possible.

5. For normal usage, set the skids so

that the scraper bar is 1/8" above

the skids. For extremely hard-

packed snow surfaces, adjust the

F_)21027L 18

Release auger drive lever.

Move throttle lever to stop position.

Remove (do not turn) ignition key.

Disconnect spark plug wire.

Do not place your hands in the au-

ger or discharge chute. Use a pry

bar.

skids upward so that the scraper

bar touches the ground.

6. On gravel or crushed rock surfaces,

set the skids at 1-1/4" below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu-

al. Rocks and gravel must not be

picked up and thrown by the ma-

chine.

7. After the snow throwing job has

been completed, allow the engine to

idle for a few minutes, which will

melt snow and accumulated ice off

the engine.

8. Clean the snow thrower thoroughly

after each use.

9. Remove ice and snow accumulation

and all debris from the entire snow

thrower, and flush with water (if pos-

sible) to remove all salt or other

chemicals. Wipe snow thrower dry.

Page 19

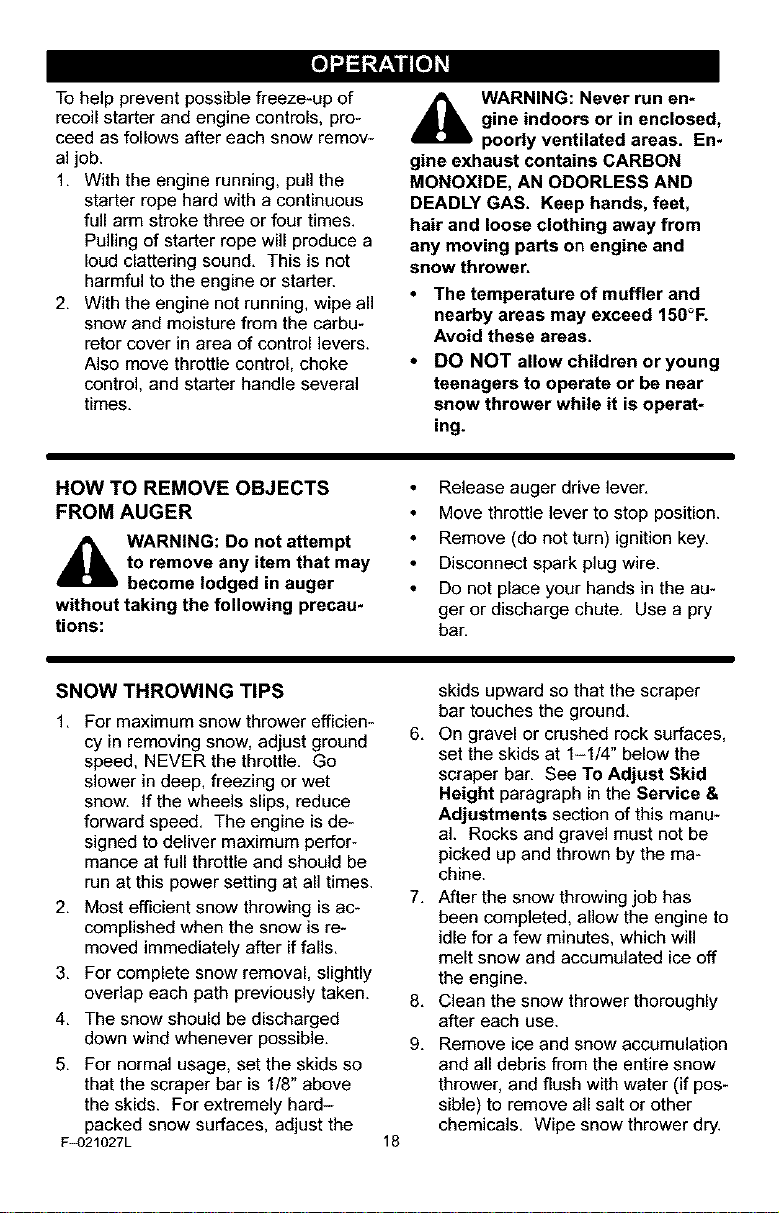

SERVICERECORDS

Fill indatesasyou Before Every Every Every

completeregular Each 5 10 25 E_h Before SERVICE

service. Use Often Hours Hours Hours Seas_l Storage DATES

LubricateAuger Shaft _ _/

Check Engine Oil Level _/ _/ _/

Check Spark Plug _/ ,,/

Adjust Drive Belt _/ ["_

* Adjust after 2 to 4 hours of use.

GENERAL RECOMMENDATIONS

The warranty on this snow thrower

does not cover items that have been

subjected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the snow thrower as instructed in this

manual.

Some adjustments will need to be

made periodically to properly maintain

your snow thrower.

F_)21027L 19

AFTER EACH USE

Run the machine to clear the auger

of snow.

To prevent freezing of the auger or

controls, remove all snow and slush

from the snow thrower.

Check for any loose or damaged

parts.

Tighten any loose fasteners.

Check and maintain the auger.

Check controls to make sure they

are functioning properly.

If any parts are worn or damaged,

replace immediately.

Page 20

PRODUCT SPECIFICATIONS

HORSEPOWER 7.75 HP

DISPLACEMENT 206cc

GASOLINE 4 quarts

CAPACITY (unleaded)

OIL CAPACITY 5W30

(20oz capacity)

SPARK PLUG: Longlife platium

P/N5066

VALVE Intake: 0.004-0.006 in.

CLEARANCE: Exhaust: 0.009-0.011 in.

SNOW THROWER

AUGER DRIVE BELT

Adjust the auger drive belt after the first

2 to 4 hours of use, again about mid-

season and twice each season thereaf-

ter (See "Belt Adjustment" in the

Service and Adjustment section).

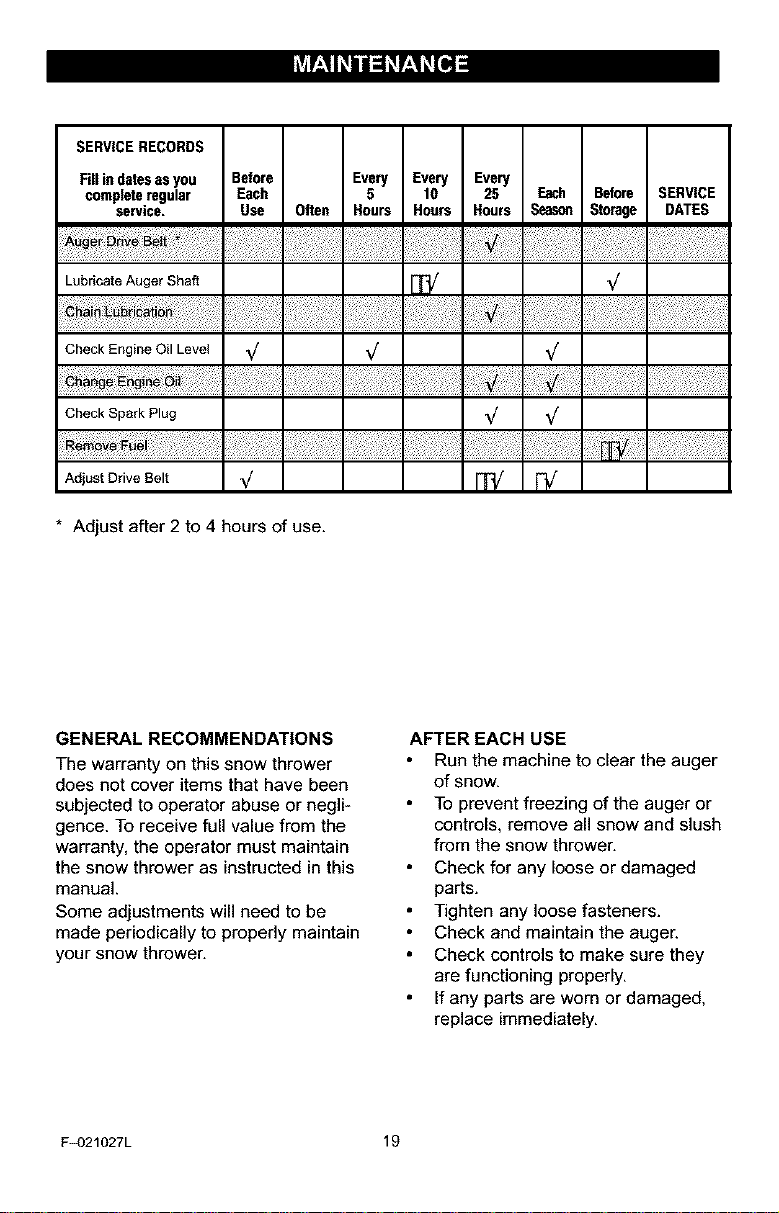

AUGER SHAFT LUBRICATION

EVERY 10 HOURS

1. Lubricatethe Zerk fittings (A) every ten

hours with a grease gun,

2. Each time a shear bolt is replaced,

the auger shaft MUST be greased.

See Figure 27. See To Replace Au-

ger Shear Bolt in the Service and

Adjustment section.

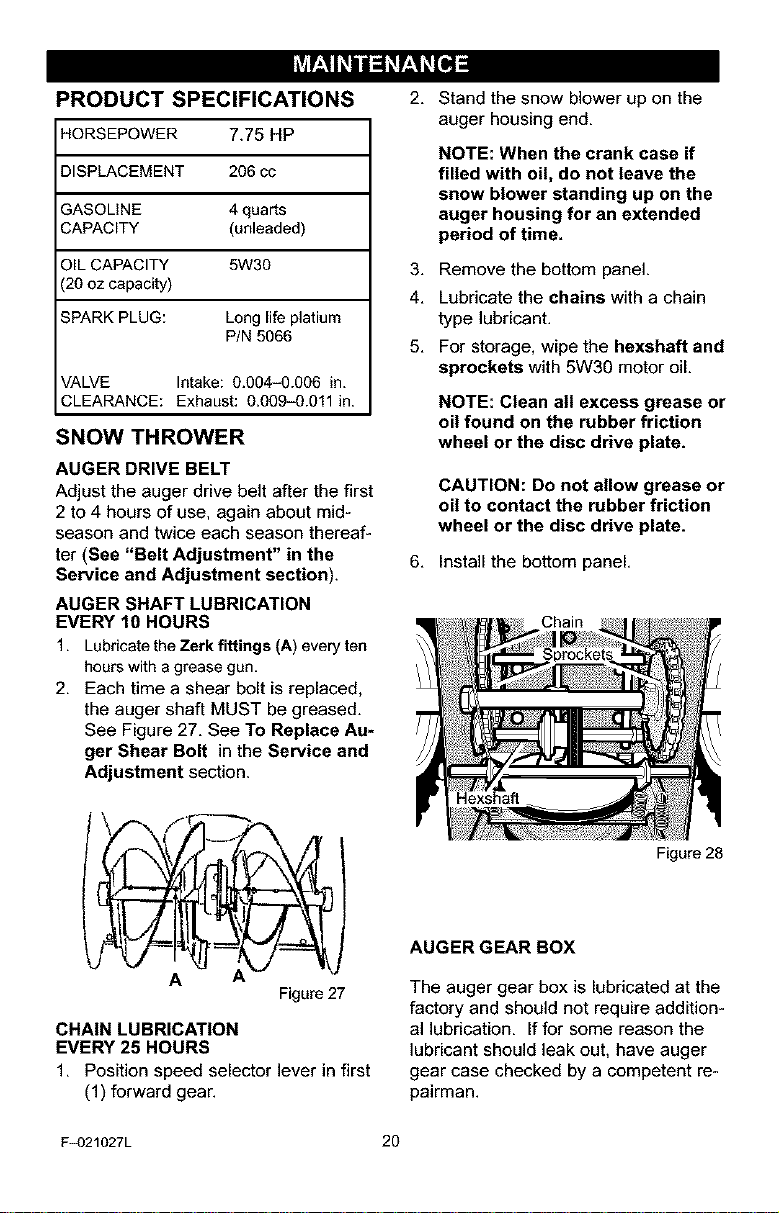

2,

Stand the snow blower up on the

auger housing end.

NOTE: When the crank case if

filled with oil, do not leave the

snow blower standing up on the

auger housing for an extended

period of time.

3. Remove the bottom panel.

4. Lubricate the chains with a chain

type lubricant.

5. For storage, wipe the hexshaft and

sprockets with 5W30 motor oil.

NOTE: Clean all excess grease or

oil found on the rubber friction

wheel or the disc drive plate.

CAUTION: Do not allow grease or

oil to contact the rubber friction

wheel or the disc drive plate.

6. Install the bottom panel.

Hexshaff

A

Figure27

CHAIN LUBRICATION

EVERY 25 HOURS

1. Position speed selector lever in first

(1) forward gear.

F_)21027L 20

Figure 28

AUGER GEAR BOX

The auger gear box is lubricated at the

factory and should not require addition-

al lubrication. If for some reason the

lubricant should leak out, have auger

gear case checked by a competent re-

pairman.

Page 21

ENGINE

LUBRICATION

Check the crankcase oil level before

starting the engine and after each five

(5) hours of continuous use. Add S.A.E.

5W30 motor oil as needed. Tighten fill

cap/dipstick securely each time you

check the oil level.

Oil Fill Cap/Dipstick _ <:_

FULL

Figure 29

Figure 30

Change the oil every twenty-five (25)

hours or at least once a year if the

snow thrower is not used for twenty-five

(25) hours.

TO CHANGE ENGINE OIL

1, Position the snow thrower so that

the oil drain plug is at the lowest

point on the engine,

2, Remove the oil drain plug and the

oil fill cap/dipstick. Drain the oil

into a suitable container.

NOTE: The oil will drain more freely

when the engine is warm.

3. After draining all the oil, reinstall the

oil drain plug securely.

4. Fill the engine crankcase with

S.A.E. 5W30 motor oil, pouring

slowly. DO NOT OVERFILL, See

"To Add Oil" in the Operation Sec-

tion.

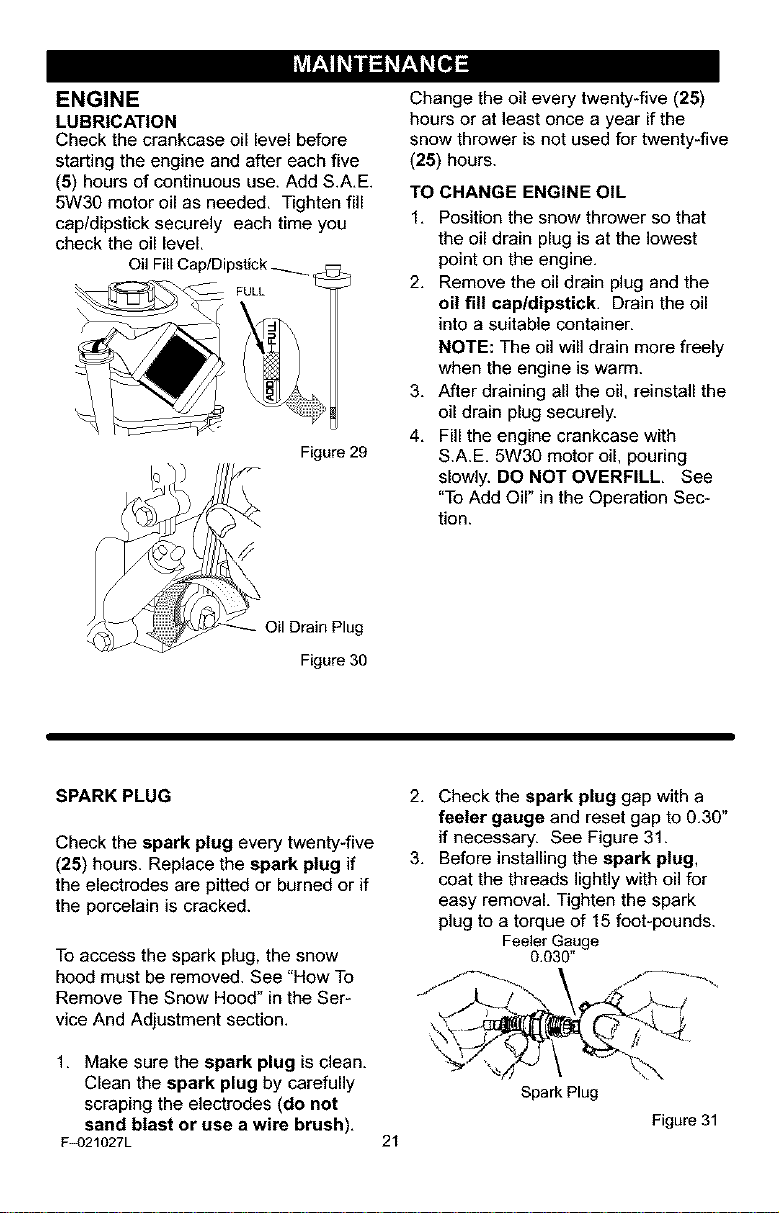

SPARK PLUG

Check the spark plug every twenty-five

(25) hours. Replace the spark plug if

the electrodes are pitted or burned or if

the porcelain is cracked.

To access the spark plug, the snow

hood must be removed. See "How To

Remove The Snow Hood" in the Ser-

vice And Adjustment section.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

F_)21027L

2. Check the spark plug gap with a

feeler gauge and reset gap to 0.30"

if necessary. See Figure 31.

3. Before installing the spark plug,

coat the threads lightly with oil for

easy removal. Tighten the spark

plug to a torque of 15 foot-pounds.

FeelerGauge

0.030"

Spark Plug

21

2_.../

Figure 31

Page 22

[."_ej= r;1_l"] f,.1,,]tLl_"]ad_VAl_bi

_ ARNING: Always discon*

make contact with spark plug to pre-

vent accidental starting when mak-

ing any adjustments or repairs.

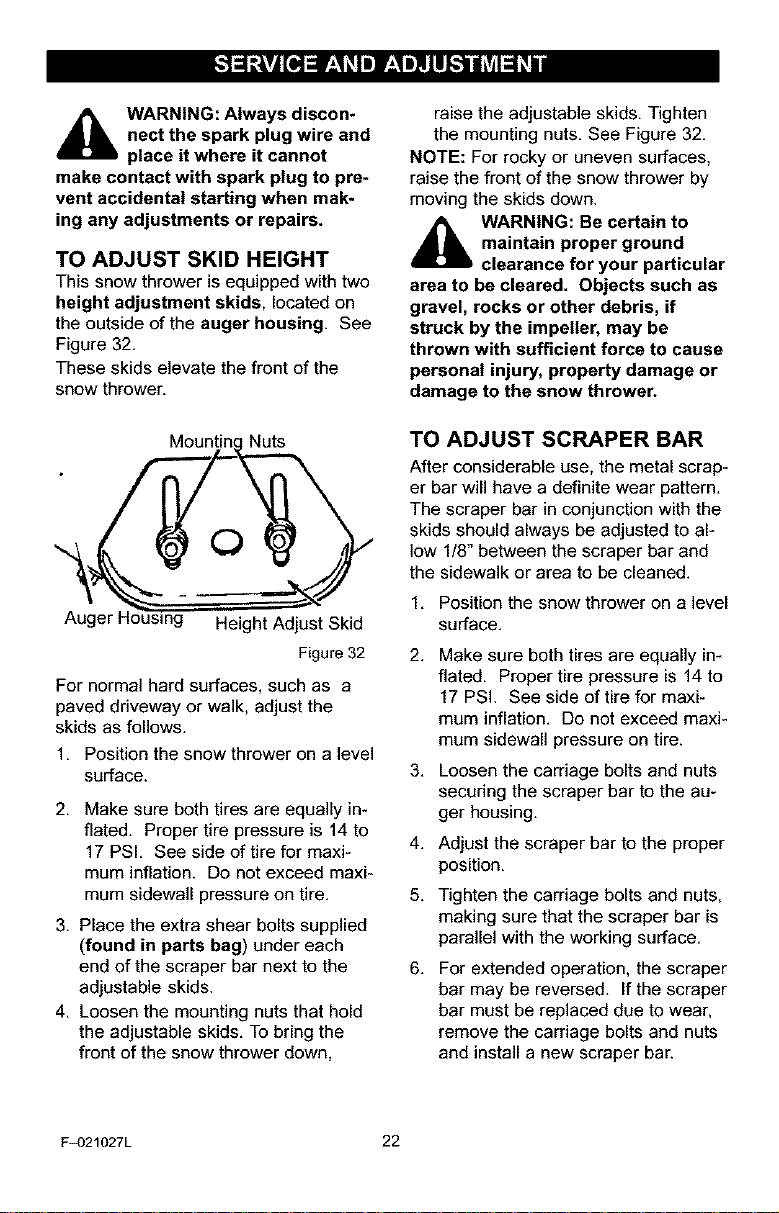

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 32,

These skids elevate the front of the

snow thrower,

nect the spark plug wire and

place it where it cannot

raise the adjustable skids. Tighten

the mounting nuts. See Figure 32.

NOTE: For rocky or uneven surfaces,

raise the front of the snow thrower by

moving the skids down.

_1= ARNING: Be certain to

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

maintain proper ground

clearance for your particular

Nuts

O

Auger t- g Height Adjust Skid

Figure32

For normal hard surfaces, such as a

paved driveway or walk, adjust the

skids as follows,

1, Position the snow thrower on a level

surface.

2. Make sure both tires are equally in-

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3. Place the extra shear bolts supplied

(found in parts bag) under each

end of the scraper bar next to the

adjustable skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bring the

front of the snow thrower down,

TO ADJUST SCRAPER BAR

After considerable use, the metal scrap-

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al-

low 1/8" between the scraper bar and

the sidewalk or area to be cleaned.

1. Position the snow thrower on a level

surface.

2,

Make sure both tires are equally in-

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3,

Loosen the carriage bolts and nuts

securing the scraper bar to the au-

ger housing.

4.

Adjust the scraper bar to the proper

position,

5.

Tighten the carriage bolts and nuts,

making sure that the scraper bar is

parallel with the working surface.

6.

For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage bolts and nuts

and install a new scraper bar.

F_)21027L 22

Page 23

[."_ej= r;1_l"] F,.1,,]tLl_"]ad_VAl_bli

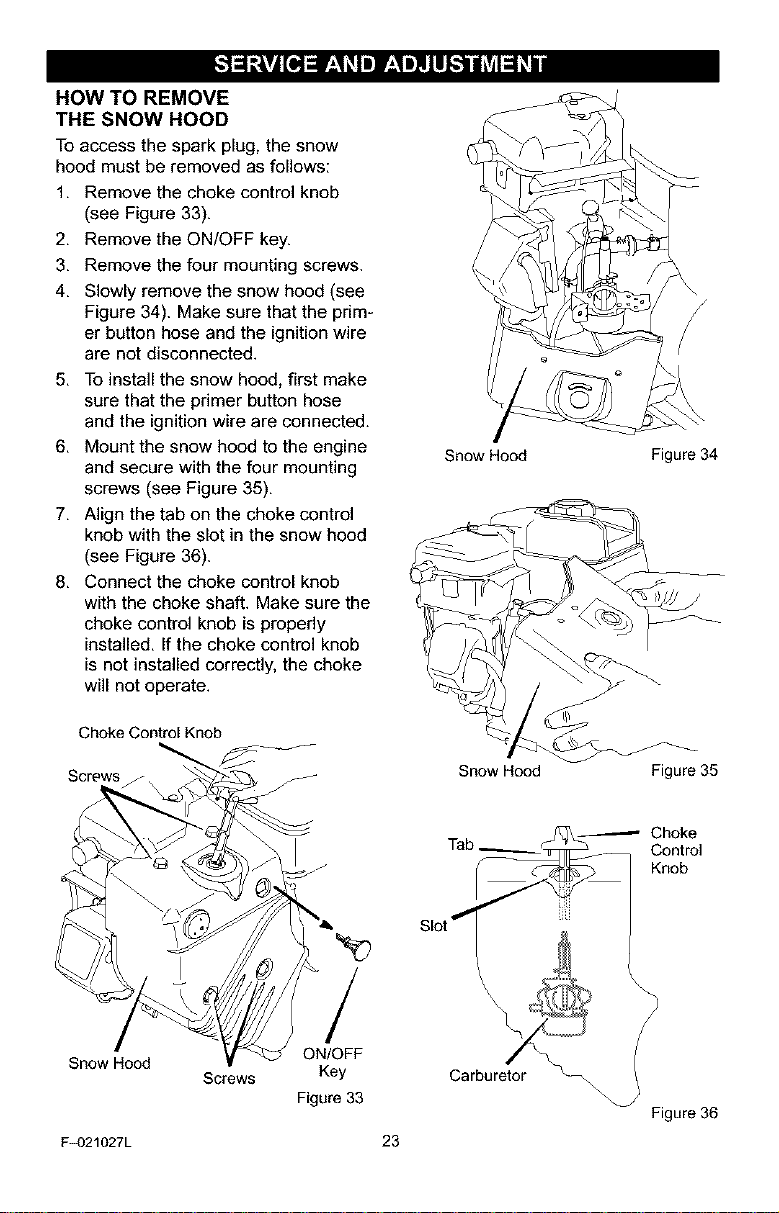

HOW TO REMOVE

THE SNOW HOOD

To access the spark plug, the snow

hood must be removed as follows:

1, Remove the choke control knob

(see Figure 33).

2, Remove the ON/OFF key.

3, Remove the four mounting screws.

4, Slowly remove the snow hood (see

Figure 34). Make sure that the prim-

er button hose and the ignition wire

are not disconnected.

5, To install the snow hood, first make

sure that the primer button hose

and the ignition wire are connected.

6, Mount the snow hood to the engine

and secure with the four mounting

screws (see Figure 35),

7, Align the tab on the choke control

knob with the slot in the snow hood

(see Figure 36).

8, Connect the choke control knob

with the choke shaft. Make sure the

choke control knob is properly

installed, If the choke control knob

is not installed correctly, the choke

will not operate.

Snow Hood Figure 34

Choke Control Knob

Screws

Snow Hood

F_)21027L

Screws

/

ON/OFF

Key

Figure 33

Snow Hood

Tab Control

Slot _ iJii

23

Figure 35

Knob

- Choke

Figure36

Page 24

[."_ej= r:111"]f,.1,,]l.LIl_"]ad_VAl_bli

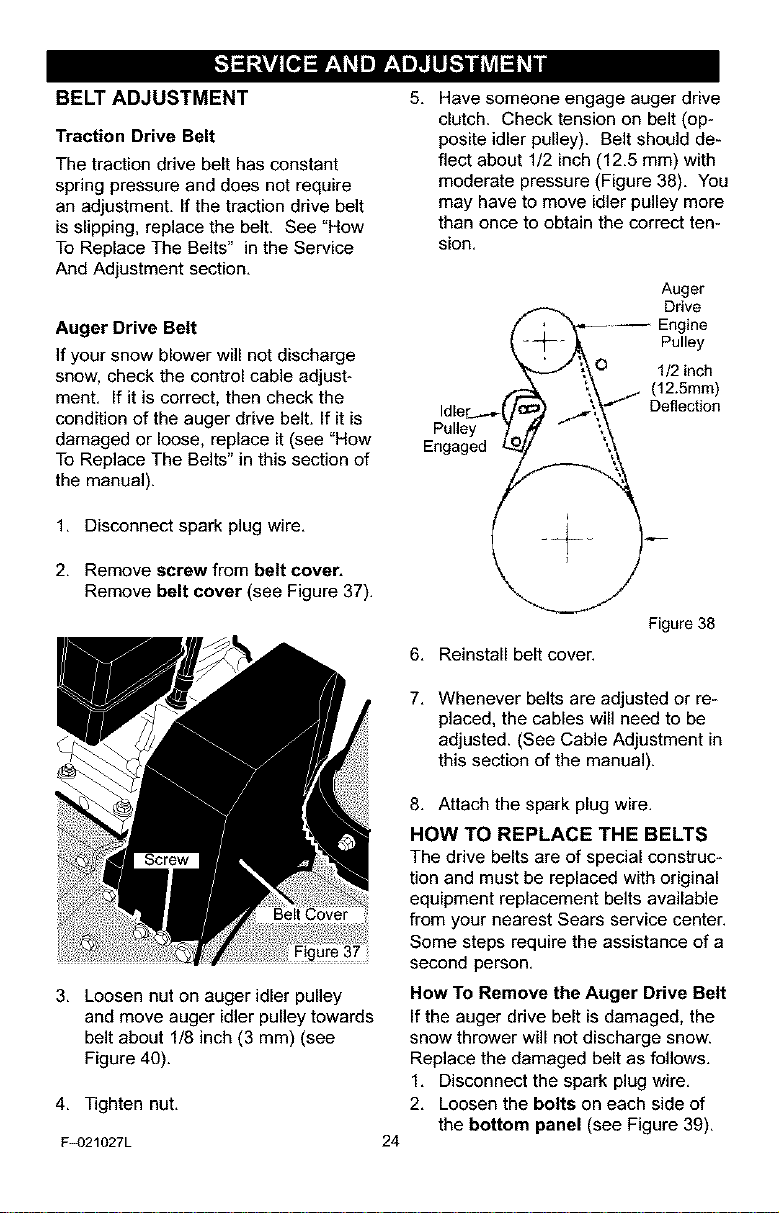

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant

spring pressure and does not require

an adjustment. If the traction drive belt

is slipping, replace the belt. See "How

To Replace The Belts" in the Service

And Adjustment section.

Auger Drive Belt

If your snow blower will not discharge

snow, check the control cable adjust-

ment. If it is correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see "How

To Replace The Belts" in this section of

the manual).

1. Disconnect spark plug wire.

2. Remove screw from belt cover.

Remove belt cover (see Figure 37).

5. Have someone engage auger drive

clutch. Check tension on belt (op-

posite idler pulley). Belt should de-

flect about 1/2 inch (12.5 mm) with

moderate pressure (Figure 38). You

may have to move idler pulley more

than once to obtain the correct ten-

sion.

Auger

--j_ ,_, Pulley

J ;,_0 1/2 inch

._- ".._ (12.5mm)

idler_._._C/tc f'_\_'_" Deflection

Pulley )to, /- ;,\

Engaged _ ',

L "

Figure38

6. Reinstall belt cover.

3. Loosen nut on auger idler pulley

and move auger idler pulley towards

belt about 1/8 inch (3 mm) (see

Figure 40).

4. Tighten nut.

F_)21027L 24

7. Whenever belts are adjusted or re-

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the manual).

8. Attach the spark plug wire.

HOW TO REPLACE THE BELTS

The drive belts are of special construc-

tion and must be replaced with original

equipment replacement belts available

from your nearest Sears service center,

Some steps require the assistance of a

second person,

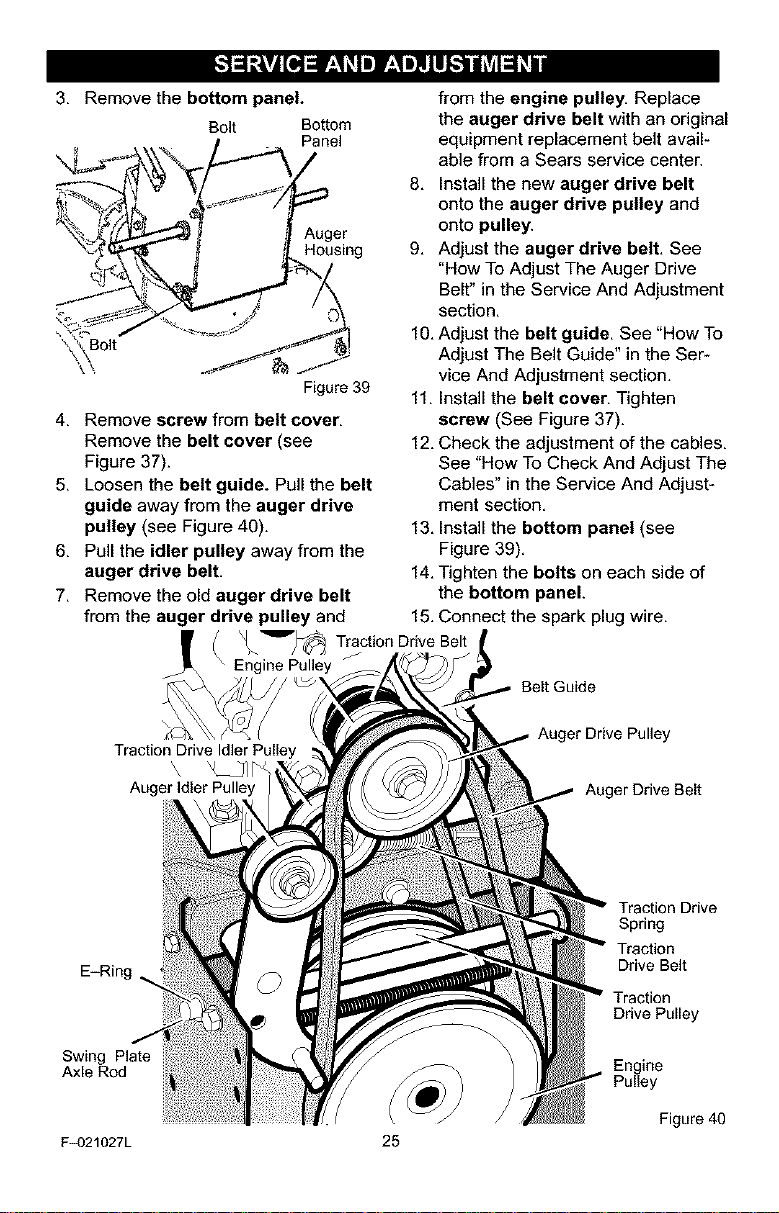

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

1. Disconnect the spark plug wire.

2. Loosen the bolts on each side of

the bottom panel (see Figure 39).

Page 25

[."_ej_ r;lll"] f'.1"]llll_"]ad_VAl_#li

3, Remove the bottom panel.

Bolt Bottom

\\

Pane,

Auger

Housing

Figure 39

4, Remove screw from belt cover,

Remove the belt cover (see

Figure 37).

5, Loosen the belt guide. Pull the belt

guide away from the auger drive

pulley (see Figure 40),

6, Pull the idler pulley away from the

auger drive belt,

7, Remove the old auger drive belt

from the auger drive pulley and

_'_=_/_ Traction Drive Belt

Engine Pulley

from the engine pulley, Replace

the auger drive belt with an original

equipment replacement belt avail-

able from a Sears service center.

8, Install the new auger drive belt

onto the auger drive pulley and

onto pulley.

9, Adjust the auger drive belt, See

"How To Adjust The Auger Drive

Belt" in the Service And Adjustment

section,

10, Adjust the belt guide, See "How To

Adjust The Belt Guide" in the Ser-

vice And Adjustment section,

11, Install the belt cover, Tighten

screw (See Figure 37).

12, Check the adjustment of the cables,

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section,

13, Install the bottom panel (see

Figure 39),

14, Tighten the bolts on each side of

the bottom panel.

15, Connect the spark plug wire,

Belt Guide

Traction Drive Idler Pulley

Auger Idler Pulley

E-Ring

Swing Plate

Axle Rod

F_)21027L 25

Auger Drive Pulley

Auger Drive Belt

Traction Drive

Spring

Traction

Drive Belt

Traction

Drive Pulley

Engine

Pulley

Figure 40

Page 26

[."_ej= r:1_l"]f,.1,,]tLl_"]ad_VAl_bi

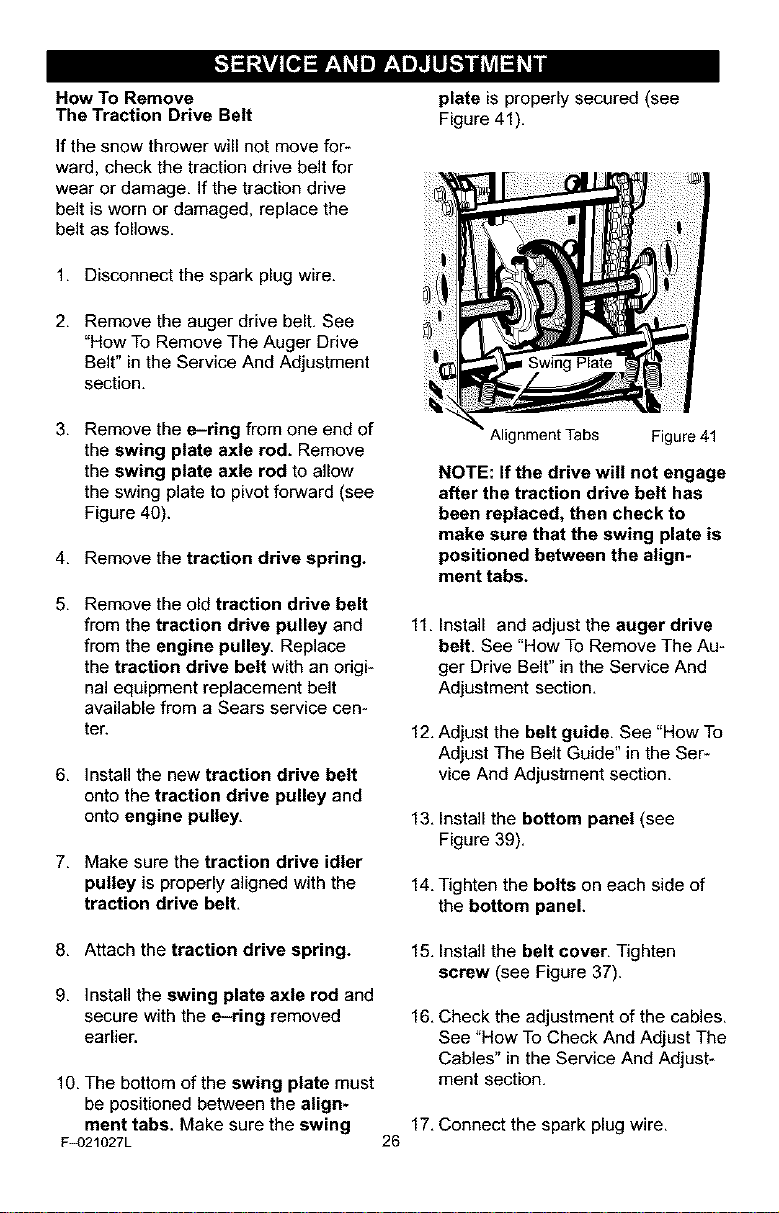

How To Remove

The Traction Drive Belt

If the snow thrower will not move for-

ward, check the traction drive belt for

wear or damage, If the traction drive

belt is worn or damaged, replace the

belt as follows,

1, Disconnect the spark plug wire.

2, Remove the auger drive belt, See

"How To Remove The Auger Drive

Belt" in the Service And Adjustment

section.

plate is properly secured (see

Figure 41),

3, Remove the e-ring from one end of

the swing plate axle rod. Remove

the swing plate axle rod to allow

the swing plate to pivot forward (see

Figure 40).

4, Remove the traction drive spring.

5, Remove the old traction drive belt

from the traction drive pulley and

from the engine pulley. Replace

the traction drive belt with an origi-

nal equipment replacement belt

available from a Sears service cen-

ter.

6, Install the new traction drive belt

onto the traction drive pulley and

onto engine pulley,

7, Make sure the traction drive idler

pulley is properly aligned with the

traction drive belt,

8, Attach the traction drive spring.

9, install the swing plate axle rod and

secure with the e-ring removed

earlier.

10, The bottom of the swing plate must

be positioned between the align-

ment tabs. Make sure the swing

F_)21027L

Alignment Tabs Figure 41

NOTE: If the drive will not engage

after the traction drive belt has

been replaced, then check to

make sure that the swing plate is

positioned between the align*

ment tabs.

11,

Install and adjust the auger drive

belt. See "How To Remove The Au-

ger Drive Belt" in the Service And

Adjustment section,

12, Adjust the belt guide, See "How To

Adjust The Belt Guide" in the Ser-

vice And Adjustment section,

13, Install the bottom panel (see

Figure 39),

14, Tighten the bolts on each side of

the bottom panel.

15, Install the belt cover, Tighten

screw (see Figure 37).

16, Check the adjustment of the cables,

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section,

17, Connect the spark plug wire,

26

Page 27

[,,",]_ej= r;1_l"] f*.1,,]l.LIl_"]ad_VAl_bli

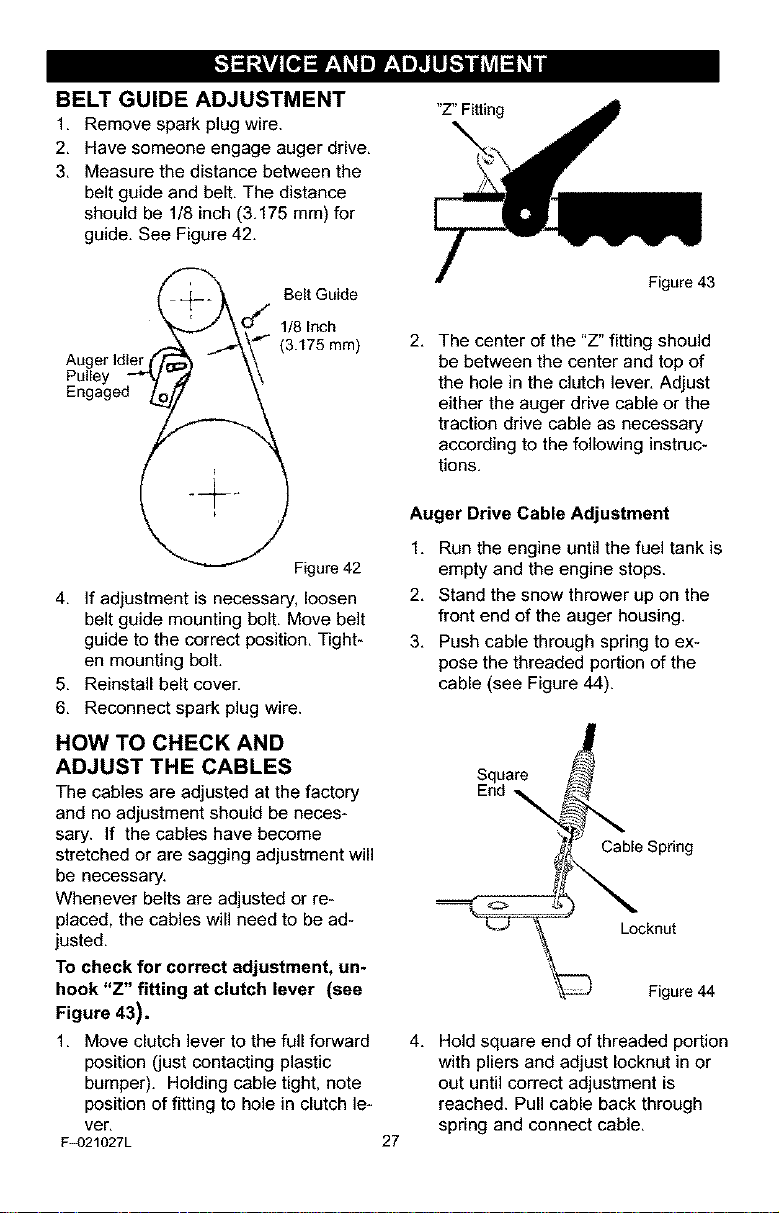

BELT GUIDE ADJUSTMENT

1, Remove spark plug wire,

2, Have someone engage auger drive,

3, Measure the distance between the

belt guide and belt, The distance

should be 1/8 inch (3,175 mm) for

guide. See Figure 42.

_--_ O,_/ Belt Guide

Auger idler, _ _ - \\

Pulley _/'" d \\

"Z" Fitting

Figure 43

2. The center of the "Z" fitting should

be between the center and top of

the hole in the clutch lever. Adjust

either the auger drive cable or the

traction drive cable as necessary

according to the following instruc-

tions.

Engaged 0_._._

Figure42

4. If adjustment is necessary, loosen

belt guide mounting bolt. Move belt

guide to the correct position. Tight-

en mounting bolt.

5. Reinstall belt cover.

6. Reconnect spark plug wire.

HOW TO CHECK AND

ADJUST THE CABLES

The cables are adjusted at the factory

and no adjustment should be neces-

sary. If the cables have become

stretched or are sagging adjustment will

be necessary.

Whenever belts are adjusted or re-

placed, the cables will need to be ad-

justed.

To check for correct adjustment, un-

hook "Z" fitting at clutch lever (see

Figure 43),

1. Move clutch lever to the full forward

position (just contacting plastic

bumper). Holding cable tight, note

position of fitting to hole in clutch le-

ver.

F_)21027L

Auger Drive Cable Adjustment

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Push cable through spring to ex-

pose the threaded portion of the

cable (see Figure 44).

Square

End _

Cable Spring

o

Locknut

Figure 44

4. Hold square end of threaded portion

with pliers and adjust Iocknut in or

out until correct adjustment is

reached. Pull cable back through

spring and connect cable.

27

Page 28

[."_ej= r;1_l"] f,.1,,]l.LIl_"]ad_VAl_bli

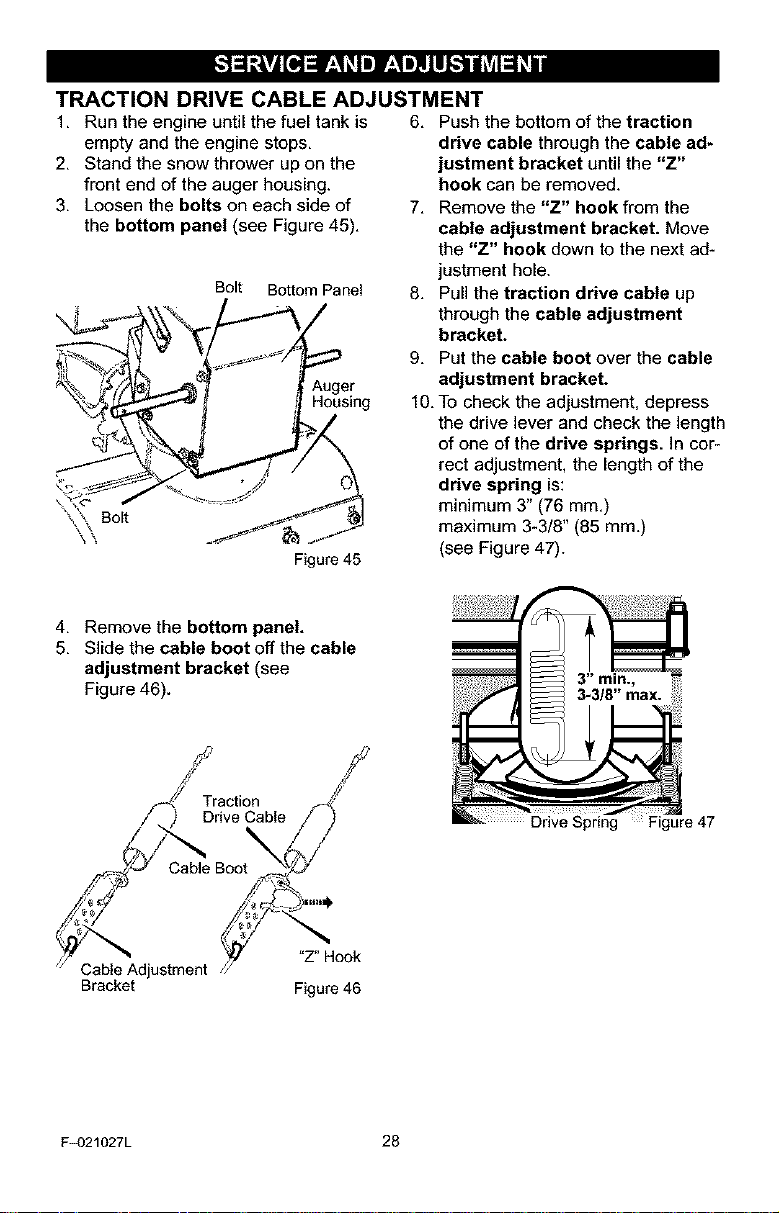

TRACTION DRIVE CABLE ADJUSTMENT

1, Run theengineuntilthe fuel tankis 6, Pushthe bottom ofthetraction

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Loosen the bolts on each side of

the bottom panel (see Figure 45).

Bolt Bottom Panel

Auger

Housing

Bolt

\,,

Figure45

4. Remove the bottom panel.

5. Slide the cable boot off the cable

adjustment bracket (see

Figure 46).

drive cable through the cable ad-

justment bracket until the "Z"

hook can be removed.

7. Remove the "Z" hook from the

cable adjustment bracket. Move

the "Z" hook down to the next ad-

justment hole.

8. Pull the traction drive cable up

through the cable adjustment

bracket.

9. Put the cable boot over the cable

adjustment bracket.

10. To check the adjustment, depress

the drive lever and check the length

of one of the drive springs. In cor-

rect adjustment, the length of the

drive spring is:

minimum 3" (76 mm.)

maximum 3-3/8" (85 mm.)

(see Figure 47).

3-3/8" max.

Traction f4__;pT't

Drive Cable /

Cable Adjustment _/v 7_"Hook

Bracket Figure 46

F_)21027L 28

Drive

Figure 47

Page 29

[."_ej= r;111"]f,.1,,]tLIl_"]ad_VAl_bli

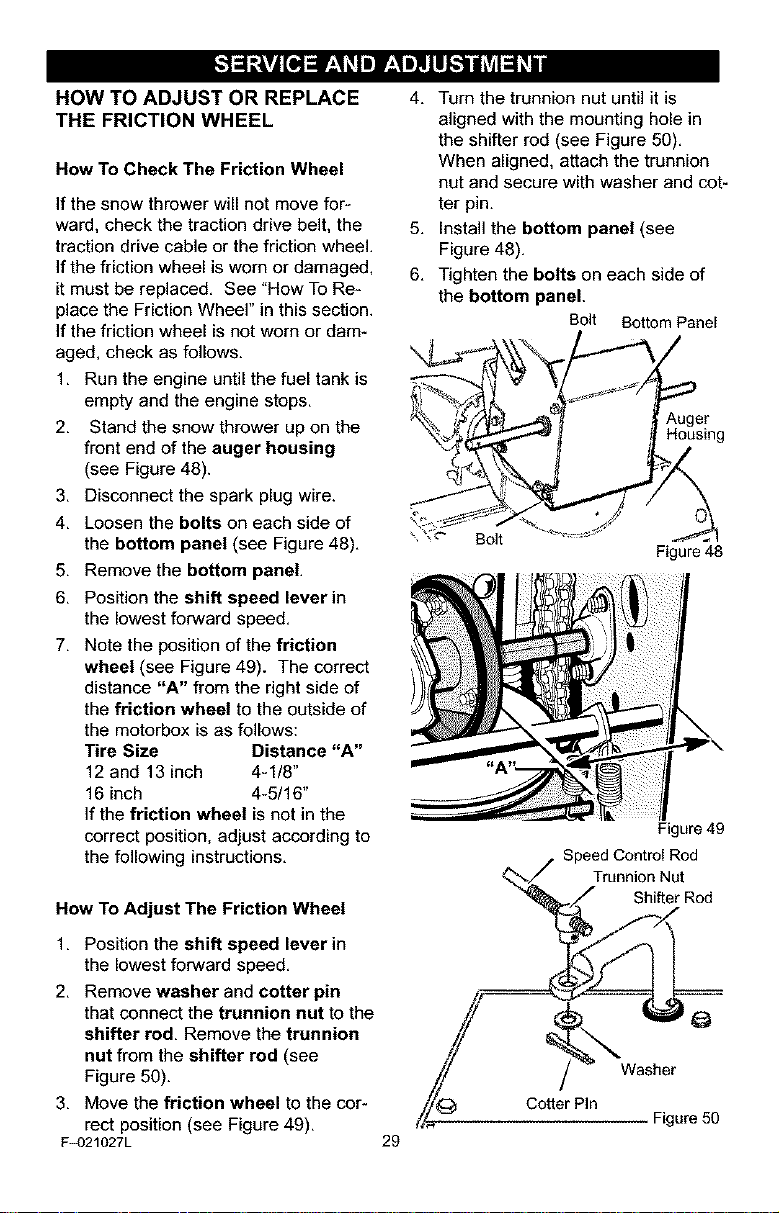

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL

How To Check The Friction Wheel

If the snow thrower will not move for-

ward, check the traction drive belt, the

traction drive cable or the friction wheel.

Ifthe friction wheel is worn or damaged.

it must be replaced. See "How To Re-

place the Friction Wheel" in this section.

If the friction wheel is not worn or dam-

aged, check as follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing

(see Figure 48).

3. Disconnect the spark plug wire.

4. Loosen the bolts on each side of

the bottom panel (see Figure 48).

5. Remove the bottom panel.

6. Position the shift speed lever in

the lowest forward speed.

7. Note the position of the friction

wheel (see Figure 49). The correct

distance "A" from the right side of

the friction wheel to the outside of

the motorbox is as follows:

Tire Size Distance "A"

12 and 13 inch 4-1/8"

16 inch 4-5/16"

If the friction wheel is not in the

correct position, adjust according to

the following instructions,

How To Adjust The Friction Wheel

4. Turn the trunnion nut until it is

aligned with the mounting hole in

the shifter rod (see Figure 50).

When aligned, attach the trunnion

nut and secure with washer and cot-

ter pin.

5. Install the bottom panel (see

Figure 48).

6. Tighten the bolts on each side of

the bottom panel.

Bolt Bottom Panel

Auger

Housing

\ Bolt

Speed Control Rod

Trunnion Nut

Figure 48

Figure 49

1. Position the shift speed lever in

the lowest forward speed.

2. Remove washer and cotter pin

that connect the trunnion nut to the

shifter rod, Remove the trunnion

nut from the shifter rod (see

Figure 50).

3. Move the friction wheel to the cor-

rect position (see Figure 49).

F_)21027L

//_ Cotter Pin - -.

/,/,_-- Figure 50

29

Page 30

[."_ej= r;111"]f,.1,,]l.LIl_"]ad_VAl_bli

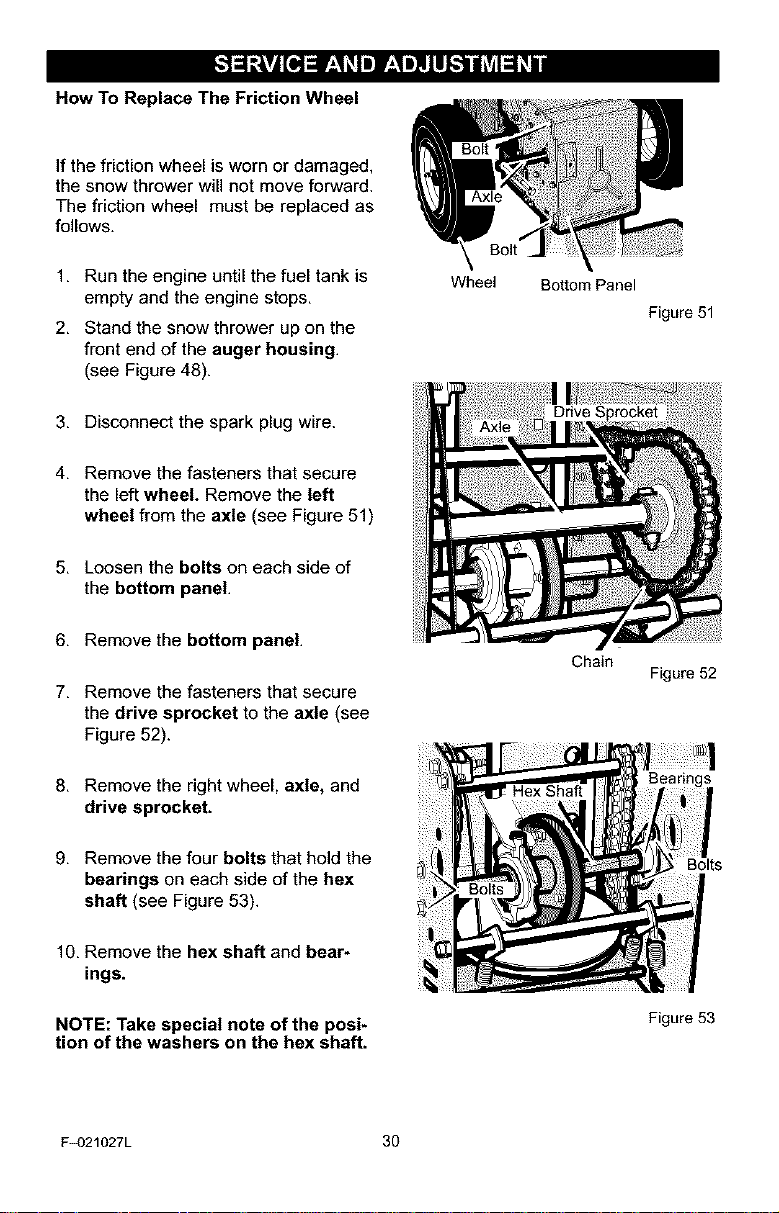

How To Replace The Friction Wheel

If the friction wheel is worn or damaged,

the snow thrower will not move forward.

The friction wheel must be replaced as

follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

(see Figure 48).

3. Disconnect the spark plug wire.

4. Remove the fasteners that secure

the left wheel. Remove the left

wheel from the axle (see Figure 51)

5. Loosen the bolts on each side of

the bottom panel.

6. Remove the bottom panel.

7. Remove the fasteners that secure

the drive sprocket to the axle (see

Figure 52).

8. Remove the right wheel, axle, and

drive sprocket.

9. Remove the four bolts that hold the

bearings on each side of the hex

shaft (see Figure 53).

Wheel

Bottom Panel

Chain

Figure 51

Figure 52

Bolts

10. Remove the hex shaft and bear-

ings.

NOTE: Take special note of the posi-

tion of the washers on the hex shaft.

F_)21027L 30

Figure 53

Page 31

[."_ej= r:111"]f,.1,,]l.LIl_"]ad_VAl_bli

11. Remove the three fasteners that

hold the friction wheel to the hub

(see Figure 54).

12, Remove the friction wheel from the

hub. Slip the friction wheel off the

hex shaft.

13, Assemble the new friction wheel

onto hub with the fasteners re-

moved earlier,

14, Install the hex shaft and bearings

with the four bolts removed earlier

(see Figure 55).

Make sure the washers are prop*

erly installed in the original posi-

tion. Also, make sure the two

washers are properly aligned

with the actuator arms.

15, Make sure the hex shaft turns free-

ly,

16, Install the right wheel, axle, and

drive sprocket with the fasteners

removed earlier, Install the chain

onto the drive sprocket (see

Figure 52).

17, Check the adjustment of the friction

wheel. See "How To Adjust The

Friction Wheel" in this section,

18, Make sure the friction wheel and the

disc drive plate are free from grease

or oil.

19, Install the bottom panel (see

Figure 51),

20, Tighten the bolts on each side of

the bottom panel.

21, Install the left wheel to the axle

with the fasteners removed earlier.

22, Connect the spark plug wire,

Friction

Fasteners Hub Wheel

Hex Shaft

Fasteners

Figure 54

Actuator Arms

Bearings

\

Washer

F_)21027L 31

Bearings

/

Washer

Washer

Figure 55

Page 32

[."_oj= r;111"] r,.1,,]tLl_"]ad_VAl_bi

HOW TO REPLACE

THE AUGER SHEAR BOLT

The augers are secured to the auger

shaft with special shear bolts. These

shear bolts are designed to break and

protect the machine if an object be-

comes lodged in the auger housing. Do

not use a harder bolt as the protection

provided by the shear bolt will be lost.

2. Disconnect the spark plug wire.

Make sure all moving parts have

stopped.

3. Align the hole in the auger with the

hole in the auger shaft. Install the

new shear pin and spacer. See

Figure 56.

4. Connect the spark plug wire.

_lb ARNING: For safety and to

shear bolts.

To replace a broken shear bolt, proceed

as follows. Extra shear bolts were pro-

vided in the assembly parts bag.

1. Move the throttle control to the stop

protect the machine, use

only original equipment

position. Disengage all controls.

TO ADJUST THE CARBURETOR

If you think your carburetor needs ad-

justing, contact your nearest Sears Ser-

vice Center. Engine performance

should not be affected at altitudes up to

7,000 feet. For operation at higher

elevations, contact your nearest Sears

Service Center

IMPORTANT: Never tamper with the

engine governor, which is factory set for

proper engine speed. Over-speeding

"_ SF_earPinter

0ure 0

the engine above the factory high

speed setting can be dangerous. If you

think the engine-governed high speed

needs adjusting, contact your nearest

Sears Service Center, which has the

proper equipment and experience to

make any necessary adjustments. For

the location of the nearest Sears Ser-

vice Center, call Sears Service at

1-800-4-MY-HOME®.

F_)21027L 32

Page 33

_lb ARNING: Never store your

snow thrower indoors or in

an enclosed, poorly venti*

lated area. If gasoline remains in the

tank, fumes may reach an open

flame, spark or pilot light from a fur*

nace, water heater, clothes dryer,

cigarette, etc.

To prevent damage (if snow thrower is

not used for more than 30 days) follow

the steps below.

SNOW THROWER

1, Thoroughly clean the snow thrower,

2, Lubricate all lubrication points, See

the Maintenance section,

3. Be sure that all nuts, bolts and

screws are securely fastened. In-

spect all visible moving parts for

damage, breakage and wear. Re-

place if necessary.

4. Touch up all rusted or chipped paint

surfaces; sand lightly before paint-

ing.

5. Cover the bare metal parts of the

blower housing auger and the im-

peller with rust preventative, such

as a spray lubricant.

NOTE: A yearly checkup or tune-up by

a Sears service center is a good way of

ensuring that your snow thrower will

provide maximum performance for the

next season.

ENGINE

Gasoline must be removed or treated to

prevent gum deposits from forming in

the fuel tank, filter, hose, and carburetor

during storage. Also, during storage al-

cohol blended gasoline that uses etha-

nol or methanol (sometimes called

gasohol) attracts water. It acts on the

gasoline to form acids which damage

the engine.

1,

Run the engine until the fuel tank is

empty and the engine stops.

2.

If you do not remove the gasoline,

use fuel stabilizer supplied with unit

or purchase Craftsman Fuel Stabi-

lizer No. 3550. Add fuel stabilizer to

any gasoline left in the tank to mini-

mize gum deposits and acids. If the

fuel tank is almost empty, mix stabi-

lizer with fresh gasoline in a sepa-

rate container and add some to the

fuel tank.

3,

Always follow the instructions on the

stabilizer container. After the stabi-

lizer is added to the fuel tank, run

the engine at least ten minutes to

allow the mixture to reach the car-

buretor.

4,

Change the engine oil.

5.

Lubricate the piston/cylinder area.

First, remove the spark plug and

squirt a few drops of clean engine

oil into the spark plug hole. Next,

cover the spark plug hole with a rag

to absorb oil spray. Then, pull two or

three times on the recoil starter rope

to rotate the engine. Finally, install

the spark plug and attach the spark

plug wire.

OTHER

1. If possible, store your snow thrower

indoors and cover it to give protec-

tion from dust and dirt.

2. If the snow thrower must be stored

outdoors, put the snow thrower on

blocks to raise it off of the ground.

3. Cover the snow thrower with a suit-

able protective cover that does not

retain moisture. Do not use plastic.

IMPORTANT: Never cover snow

thrower while engine and exhaust areas

are still warm.

F_)21027L 33

Page 34

i|((ell:J_]M_."]_[eIe_ll_[e']

TROUBLE CORRECTION

Difficult starting

Engine runs erratically Blocked fuel line, empty gas Clean fuel line; check fuel

Engine stalls Unit running on CHOKE. Set choke lever to OFF

Engine runs erratic; Water or dirt in fuel system. Remove fuel from fuel tank.

Loss of power Add fresh fuel.

Excessive vibration Loose parts: damaged Immediately stop engine.

Unit fails to propel itself Traction drive belt loose or Replace traction drive belt.

CAUSE

Defectivespark plug.

Wateror dirt in fuel system.

tank, or stale gasoline supply; add fresh gasoline

impeller Remove ignition key. Tighten

damaged.

Incorrect adjustment of Adjust traction drive cable.

traction drive cable

wheel.

Replace spark plug.

Remove fuel from fuel tank.

Add fresh fuel,

position.

all fasteners and make all

necessary repairs. If

vibration continues, take the

unit to a Sears service

center.

Replace friction wheel.Worn or damaged friction

Unit falls to discharge

slrlow

F_)21027L 34

Auger drive belt loose or

damaged.

Auger control cable not Adjust auger control cable.

adjusted correctly.

Shear bolt broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and

Foreign object lodged in

auger

Adjust auger drive belt;

replace if damaged.

disconnect spark plug wire.

Clean discharge chute and

inside of auger housing.

Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

Page 35

SEARS, ROEBUCK AND CO,

Federal and California Emission Control Systems Limited Warranty

Small Off-Road Engines

CALIFORNIA & US EPA EMISSION

CONTROL WARRANTY STATEMENT

The U. S. Environmental Protection Agency

("EPA"), the California Air Resources Board

("CARB") and Sears, Roebuck and Co. are

pleased to explain the Federal and California

Emission Control Systems Warranty on your

new small off-toed engine. In California, new

1995 and later small off-road engines must be

designed, built and equipped to meet the

State's stringent anti-smog standards. In oth-

er states, new 1997 and later model year en-

gines must be designed, built and equipped, at

the time of sale, to meet the U.S. EPA regula-

tions for small non-road engines. Sears, Roe-

buck and Co. will warrant the emission control

system on your small off-road engine for the

periods of time listed below, provided there

has been no abuse, neglect, unapproved mod-

ification, or improper maintenance of your

small off-road engine.

Your emission control system may include

parts such as the carburetor, ignition system

and exhaust system. Also included may be the

compression release system and other emis-

sion-related assemblies.

Where a warrantable condition exists, Sears,

Roebuck and Co. will repair your small off-

road engine at no cost to you for diagnosis,

parts and labor.

MANUFACTURER'S EMISSION

CONTROL SYSTEM WARRANTY

COVERAGE

Emission control systems on 1995 and later

model year California small off-road engines

are warranted for two years as hereinafter

noted. In other states, 1997 and later model

year engines are also warranted for two years.

If, during such warranty period, any emission-

related part on your engine is defective in ma-

terials or workmanship, the part will be

repaired or replaced by Sears, Roebuck and

Co.

OWNER'S WARRANTY

RESPONSIBILITIES

As the small off-road engine owner, you are

responsible for the performance of the re-

F_)21027L

quired maintenance listed in your Owner's

Manual, but Sears, Roebuck and Co. will not

deny warranty solely due to the lack of receipts

or for your failure to provide written evidence

of the performance of all scheduled mainte-

nance.

As the small off-road engine owner, you

should, however, be aware that Sears, Roe-

buck and Co. may deny you warranty cover-

age if your small off-road engine or a part

thereof has failed due to abuse, neglect, im-

proper maintenance or unapproved modifica-

tions.

You are responsible for presenting your small

off-road engine to a Sears, Roebuck and Co.

Authorized Service Outlet as soon as a prob-

lem exists. The warranty repairs should be

completed in a reasonable amount of time, not

to exceed 30 days.

Warranty service can be arranged by contact-

ing either a Sears, Roebuck and Co. Autho-

rized Service Outlet, or by contacting Sears,

Roebuck and Co. at 1_00-473-7247.

IMPORTANT NOTE

Esta This warranty statement explains your

rights and obligations under the Emission

Control System Warranty "(ECS Warranty")

which is provided to you by Sears, Roebuck

and Co. pursuant to California law. See also

the Sears, Roebuck and Co. Limited Warran-

ties for Sears, Roebuck and Co. which is en-

closed therewith on a separate sheet and also

is provided to you by Sears, Roebuck and Co.

The ECS Warranty applies only to the emis-

sion control system of your new engine. To the

extent that there is any conflict in terms be-

tween the ECS Warranty and the Sears, Roe-

buck and Co. Warranty, the ECS Warranty

shall apply except in any circumstances in

which the Sears, Roebuck and Co. Warranty

may provide a longer warranty period. Both the

ECS Warranty and the Sears, Roebuck and

Co. Warranty describe important rights and

obligations with respect to your new engine.

Warranty service can only be performed by a

Sears, Roebuck and Co. Authorized Service

Outlet. At the time of requesting warranty ser-

vice, evidence must be presented of the date

of sale to the original purchaser. The purchas-

35

Page 36

ershallpayanychargesformakingservice

callsand/orfortransporfingtheproductsto

andfromtheplacewheretheinspectionand/

orwarrantyworkisperformed.Thepurchaser

shallberesponsibleforanydamageorlossin-

curredinconnectionwiththetransportationof

anyengineoranypart(s)thereofsubmittedfor

inspectionned/orwarrantywork.

Ifyouhaveanyquestionsregardingyourwar-

rantyrightsandresponsibilities,youshould

contactSears,RoebuckandCo. at

1-800473-7247.

EMISSION CONTROL SYSTEM

WARRANTY

Emission Control System Warranty ("ECS

Warranty") for 1995 and later model year Cali-

fornia small oft-road engines (for other states,

1997 and later model year engines):

A. APPLICABILITY: This warranty shall apply

to 1995 and later model year California small

oft-road engines (for other states, 1997 and

later model year engines). The ECS Warranty

Period shall begin on the date the new engine

or equipment is delivered to its original, end-

use purchaser, and shall continue for 24 con-

secutive months thereafter.

B. GENERAL EMISSIONS WARRANTY

COVERAGE: Sears, Roebuck and Co. war-

rants to the original, end-use purchaser of the

new engine or equipment and to each subse-

quent purchaser that each of its small oft-road

engines is:

1. Designed, built and equipped so as to con-

form with all applicable regulations adopted by

the Air Resources Board pursuant to its au-

thority in Chapters 1 and 2, Part 5, Division 26

of the Health and Safety Code, and

2. Free from defects in materials and work-

manship which, at any time during the ECS

Warranty Period, will cause a warranted emis-

sions-related part to fail to be identical in all

material respects to the part as described in

the engine manufacturer's application for certi-

fication.

C. The ECS Warranty only pertains to emis-

sions-related parts on your engine, as follows:

1. Any warranted, emissions=related parts

which are not scheduled for replacement as

required maintenance in the Owner's Manual

shall be warranted for the ECS Warranty Peri-

od. If any such part fails during the ECS War-

ranty Period, it shall be repaired or replaced by

F_)21027L 36

Sears, Roebuck and Co. according to Subsec-

tion 4 below. Any such part repaired or re-

placed under the ECS Warranty shall be

warranted for any remainder of the ECS War-

ranty Period.

2. Any warranted, emissions-related part

which is scheduled only for regular inspection

as specified in the Owner's Manual shall be

warranted for the ECS Warranty Period. A

statement in such written instructions to the ef-

fect of "repair or replace as necessary", shall

not reduce the ECS Warranty Period. Any

such part repaired or replaced under the ECS

Warranty shall be warranted for the remainder

of the ECS Warranty Period.

3. Any warranted, emissions-related part

which is scheduled for replacement as re-

quired maintenance in the Owner's Manual,

shall be warranted for the period of time prior

to the first scheduled replacement point for

that part. If the part fails prior to the first sched-

uled replacement, the part shall be repaired or

replaced by Sears, Roebuck and Co. accord-

ing to Subsection 4 below. Any such emis-

sions-related part repaired or replaced under

the ECS Warranty, shall be warranted for the

remainder of the ECS Warranty Period prior to

the first scheduled replacement point for such

emissions-related part.

4. Repair or replacement of any warranted,

emissions-related part under this ECS War-

ranty shall be performed at no charge to the

owner at a Sears, Roebuck and Co. Autho-

rized Service Outlet.

5. The owner shall not be charged for diagnos-

tic labor which leads to the determination that

a part covered by the ECS Warranty is in fact

defective, provided that such diagnostic work

is performed at a Sears, Roebuck and Co. Au-

thorized Service Outlet.

6. Sears, Roebuck and Co. shall be liable for

damages to other original engine components

or approved modifications proximately caused

by a failure under warranty of an emission-re-

lated part covered by the ECS Warranty.

7. Throughout the ECS Warranty Period,

Sears, Roebuck and Co. shall maintain a sup-

ply of warranted emission-related parts suffi-

cient to meet the expected demand for such

emission-related parts.

8. Any Sears, Roebuck and Co. authorized

and approved emission-related replacement

part may be used in the performance of any

ECS Warranty maintenance or repair and will

be provided without charge to the owner. Such

Page 37

useshallnotreduceSears,RoebuckandCo.

ECSWarrantyobligations,

9.Unapprovededd-onormodifiedpartsmay

notbeusedtomodifyorrepairaSears,Roe-

buckandCo.engine.SuchusevoidsthisECS

Warrantyandshallbesufficientgroundsfor

disallowinganECSWarrantyclaim.Sears.

RoebuckandCo.shallnotbeliablehereunder

forfailuresofanywarrantedpartsofaSears,

RoebuckandCo.enginecausedbytheuseof

suchanunapprovedadd-onormodifiedpart.

EMISSION-RELATEDPARTS

INCLUDE THE FOLLOWING:

1. Carburetor Assembly and its Internal Com-

ponents

a) Fuel filter

b) Carburetor gaskets

c) Intake pipe

2. Air Cleaner Assembly

a) Air filter element

3. Ignition System, including:

a) Spark plug

b) Ignition module

c) Flywheel assembly

4. Catalytic Muffler (if so equipped)

a) Muffler gasket (if so equipped)

b) Exhaust manifold (if so equipped)

5. Crankcase Breather Assembly and its

Components

a) Breather connection tube

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F_)21027L 37