Page 1

Operator's Manual

Snow Thrower

7.75 Horsepower

26-inch Dual Stage

Model 536.887750

CAUTION: Before using this

product, read this manual and

follow all of its Safety Rules and

Operating Instructions.

Manual del usario

Quitanieves

de 26 pulgadas

7.75 caballos de fuerza (hp)

Bietapico

Modelo 536.887750

PRECAUCION: Antes de usar este producto,

lea este manual y siga todas las reglas de

seguridad e instrucciones de operaci6n.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F-011068L www.sears.com/craftsman

Page 2

NnIL,'q:] ! =l[o]d[_o__Innl=1_In_

WARRANTY STATEMENT ......

SAFETY RULES ...............

INTERNATIONAL SYMBOLS . ..

ASSEMBLY ...................

OPERATION ..................

MAINTENANCE ...............

SERVICE AND ADJUSTMENT ..

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow thrower is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Craftsman will repair, free of charge, any defect in material or workman-

ship.

If this Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap-

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

Items which become worn during normal use, such as spark plugs, drive belts and shear

pins.

Repair necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWERTO THE NEAREST CRAFTSMAN SERVICE CENTER/DEPARTMENT IN

THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS

IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates. IL 60179

2 STORAGE .................... 33

2 TROUBLE SHOOTING CHART.. 34

4 REPAIR PARTS ............... 38

6 ENGINE REPAIR PARTS ....... 54

12 SPANISH (ESPAI_IOL) .......... 63

19 PARTS ORDERING/SERVICE ..

23 BACK COVER

_k OOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

F-O11068L 2

IT MEANS-- ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

_k ARNING: Always discon-

IMPORTANT: Safety standards re-

quire operator presence controls to

minimize the risk of injury. Your snow

thrower is equipped with such controls.

Do not attempt to defeat the function of

the operator presence control under any

circumstances.

nect the spark plug wire

and place it where it cannot

make contact with spark plug to

prevent accidental starting during:

Preparation, Maintenance, or Stor-

age of your snow thrower.

Page 3

TRAINING

1. Read the operating and service instruction

manual carefully. Be thoroughly familiar

with the controls and the proper use of the

equipment. Know how to stop the unit and

disengage the controls quickly.

2. Never allow children to operate the equip-

ment. Never allow adults to operate the

equipment without proper instruction.

3. Keep the area of operation clear of all per-

sons, particularly small children and pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor).

3. Do not operate the equipment without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces.

4. Handle fuel with care; it is highiy flam-

mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en-

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with

fuel in the tank inside of a building

where fumes may reach an open flame

or spark.

f. Check fuel supply before each use, al-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5. For all units with electric starting motors

use electric starting extension cords certi-

fied CSA/UL Use only with a receptacle

that has been installed in accordance with

iocal inspection authorities.

6. Adjust the snow thrower height to clear

gravel or crushed rock surface.

7. Never attempt to make any adjustments

while the engine (motor) is running (except

when specifically recommended by manu-

facturer).

8. Let engine (motor) and snow thrower ad-

just to outdoor temperatures before starting

to dear snow.

F-011068L

Always wear safety glasses or eye shields

during operation or while performing an ad-

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

OPERATION

1. Do not operate this machine if you are tak-

ing drugs or other medication which can

cause drowsiness or affect your ability to

operate this machine.

2. Do not use this machine if you are mentally

or physically unable to operate this ma-

chine safely.

3. Do not put hands or feet near or under ro-

tating parts. Keep clear of the discharge

opening at all times.

4. Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

5. After striking a foreign object, stop the en-

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

6. If the unit should start to vibrate abnormal-

ly, stop the engine (motor) and check im-

mediately for the cause. Vibration is

generally a warning of trouble.

7. Stop the engine (motor) whenever you

leave the operating position, before un-

clogging the auger/impeller housing or dis-

charge chute and when making any

repairs, adjustments, or inspections.

8. When cleaning, repairing, or inspecting,

make certain the auger/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

9. Take all possible precautions when leaving

the snow thrower unattended. Disengage

the auger/ impeller, stop engine (motor),

and remove key.

10. Do not run the engine (motor) indoors, ex-

cept when starting the engine (motor) and

for transporting the snow thrower in or out

of the building. Open the outside doors; ex-

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS).

11. Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do not at-

tempt to clear steep slopes.

12. Never operate the snow thrower without

proper guards, plates or other safety pro-

tective devices in place.

Page 4

13.Neveroperatethesnowthrowernearen-

2. Never store the snow thrower with fuel in

closures,automobiles,windowwells,

drop-offs,andthelikewithoutproperad-

justmentofthesnowdischargeangle.

Keepchildrenandpetsaway,

14.Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

15.Neveroperatethemachineathightrans-

3. Always refer to operator's guide instruc-

portspeedsonslipperysurfaces.Lookbe-

hindandusecarewhenbackingup.

16.Neverdirectdischargeatbystandersor

allowanyoneinfrontoftheunit.

17.Disengagepowertothecollector/impeller

whensnowthroweristransportedornotin

use.

18. Use only attachments and accessories ap-

proved by the manufacturer of the snow

thrower (such as tire chains, electric start

kits, ect.),

19. Never operate the snow thrower without

good visibility or light, Always be sure of

your footing and keep a firm hold on the

handles. Walk;never run,

20. Do not over-reach, Keep proper footing

and balance at all times.

21, Do not attempt to use snow thrower on a

roof.

MAINTENANCE AND

STORAGE

1, Check shear bolts and other bolts at fre-

quent intervals for proper tightness to be

sure the equipment is in safe working

condition,

4. Maintain or replace safety and instruction

5. Run the snow thrower a few minutes after

_lb WARNING: This snow thrower is

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi-

dences, garages, porches or other such

structures or buildings.

the tank inside a building where ignition

sources are present such as hot water and

space heaters, clothes dryers, and the like.

Allow the engine (motor) to cool before

storing in any enclosure.

tions for important details if the snow

thrower is to be stored for an extended

period.

labels, as necessary.

throwing snow to prevent freeze-up of the

auger/impeller.

for use on sidewalks, driveways

and other ground level surfaces.

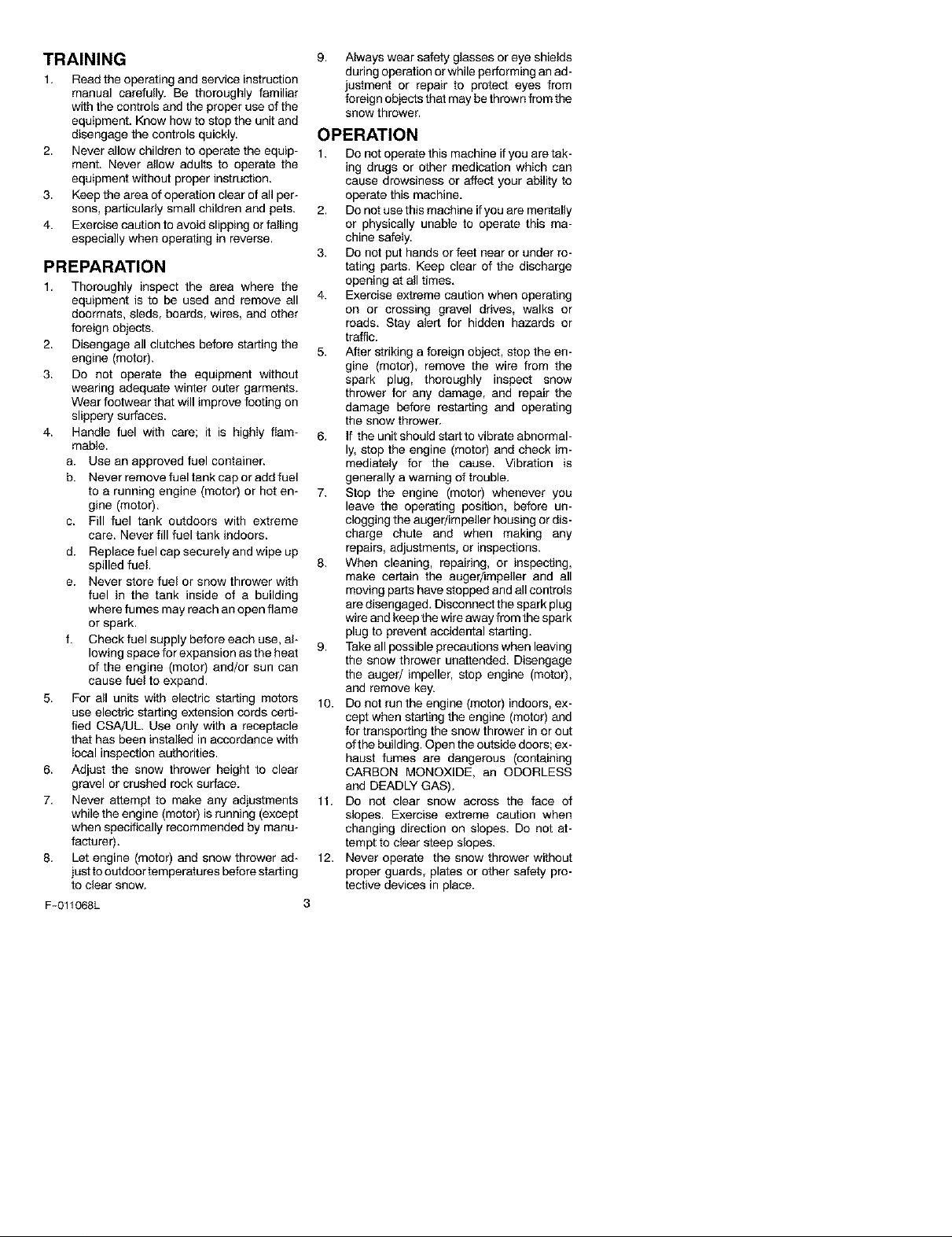

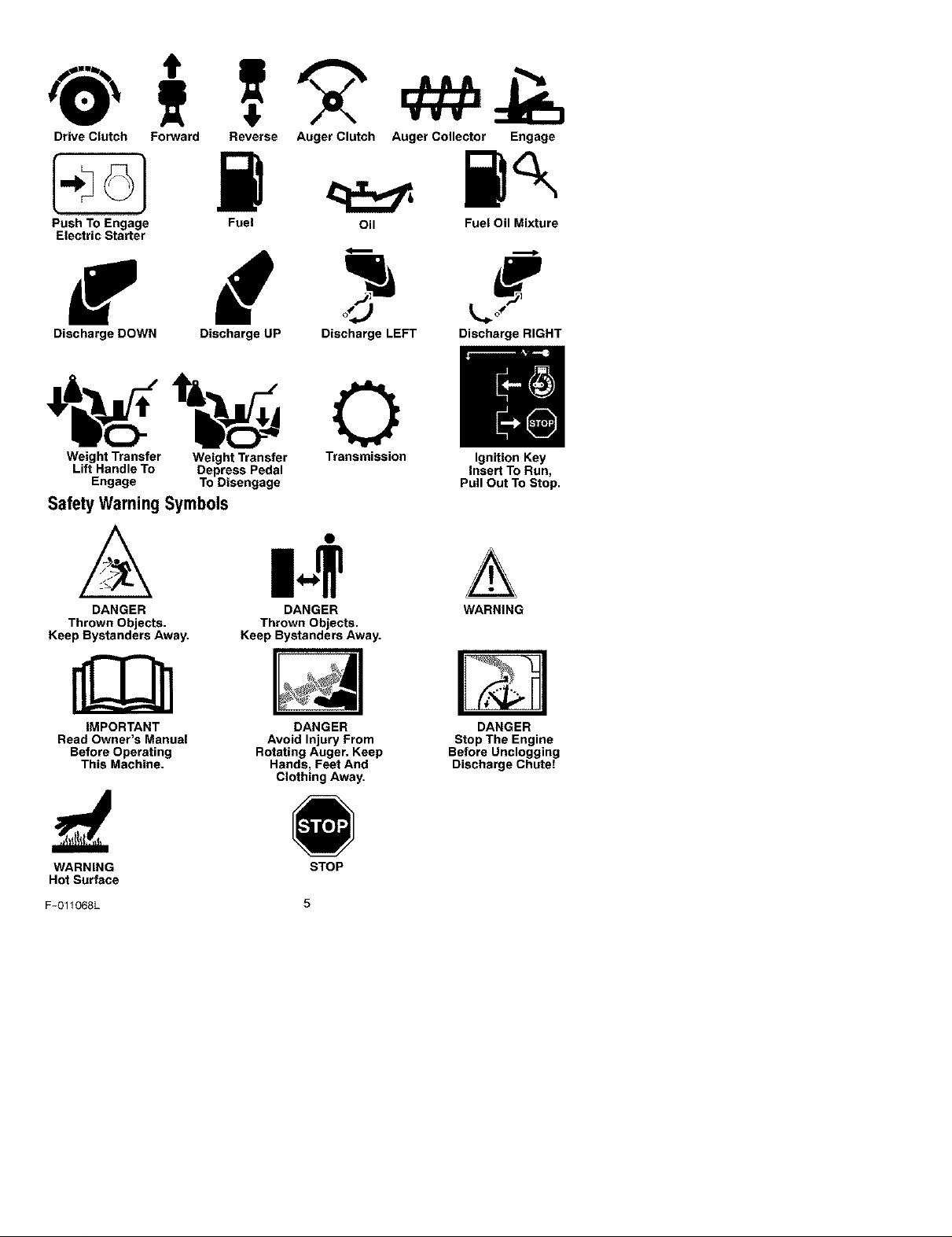

iMPORTANT: Many of the following symbols are located on your unit or on literature sup-

plied with the product. Before you operate the unit, learn and understand the purpose for

each symbol.

CONTROL AND OPERATING SYMBOLS

Slow Fast Electric Start Engine Start Engine Run

I-I N

Engine Off Engine Stop On Choke Off Choke On

U

Throttle Primer Button

F-011068L

Ignition Key

4

®Q

Ignition Off Ignition On

Neutral

Page 5

Drive Clutch Forward Reverse Auger Clutch Auger Collector Engage

Push To Engage

Electric Starter

Discharge DOWN Discharge UP Discharge LEFT Discharge RIGHT

Weight Transfer Weight Transfer Transmission Ignition Key

Lift Handle To Depress Pedal Insert To Run,

Engage To Disengage Pull Out To Stop.

Fuel Oil FueI OilMixture

Safety WarningSymbols

DANGER

Thrown Objects.

Keep Bystanders Away.

DANGER

Thrown Objects.

Keep Bystanders Away.

WARNING

IMPORTANT

Read Owner's Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-O11068L 5

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

STOP

DANGER

Stop The Engine

Before Unclogging

Discharge Chute!

Page 6

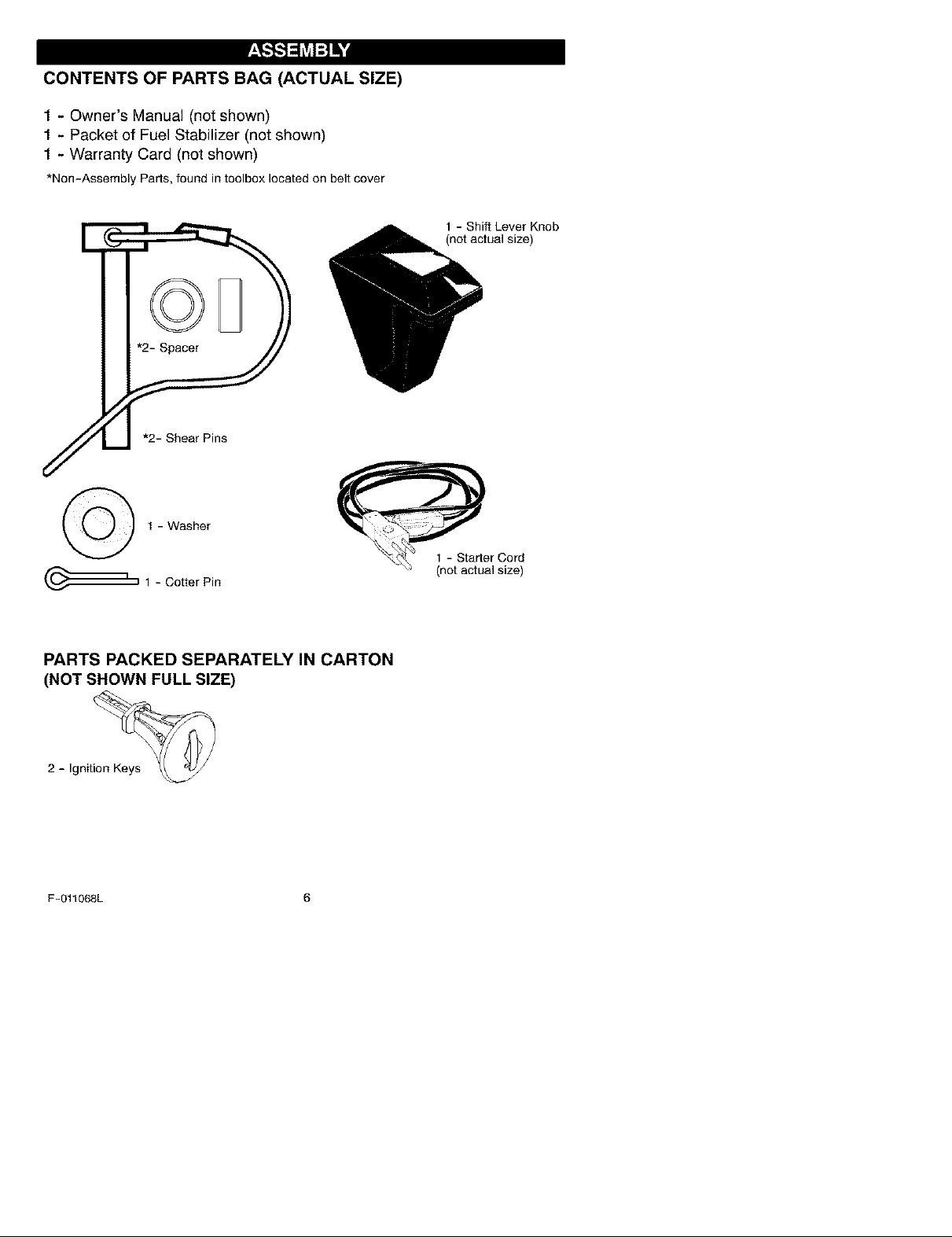

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assembly Parts,foundintoolboxlocatedon beltcover

1 - Shift Lever Knob

(not actual size)

(_ 1 - Washer

_1 - Cotter Pin

PARTS PACKED SEPARATELY IN CARTON

(NOT SHOWN FULL SIZE)

2 - Ignit_

F-O11068L 6

Page 7

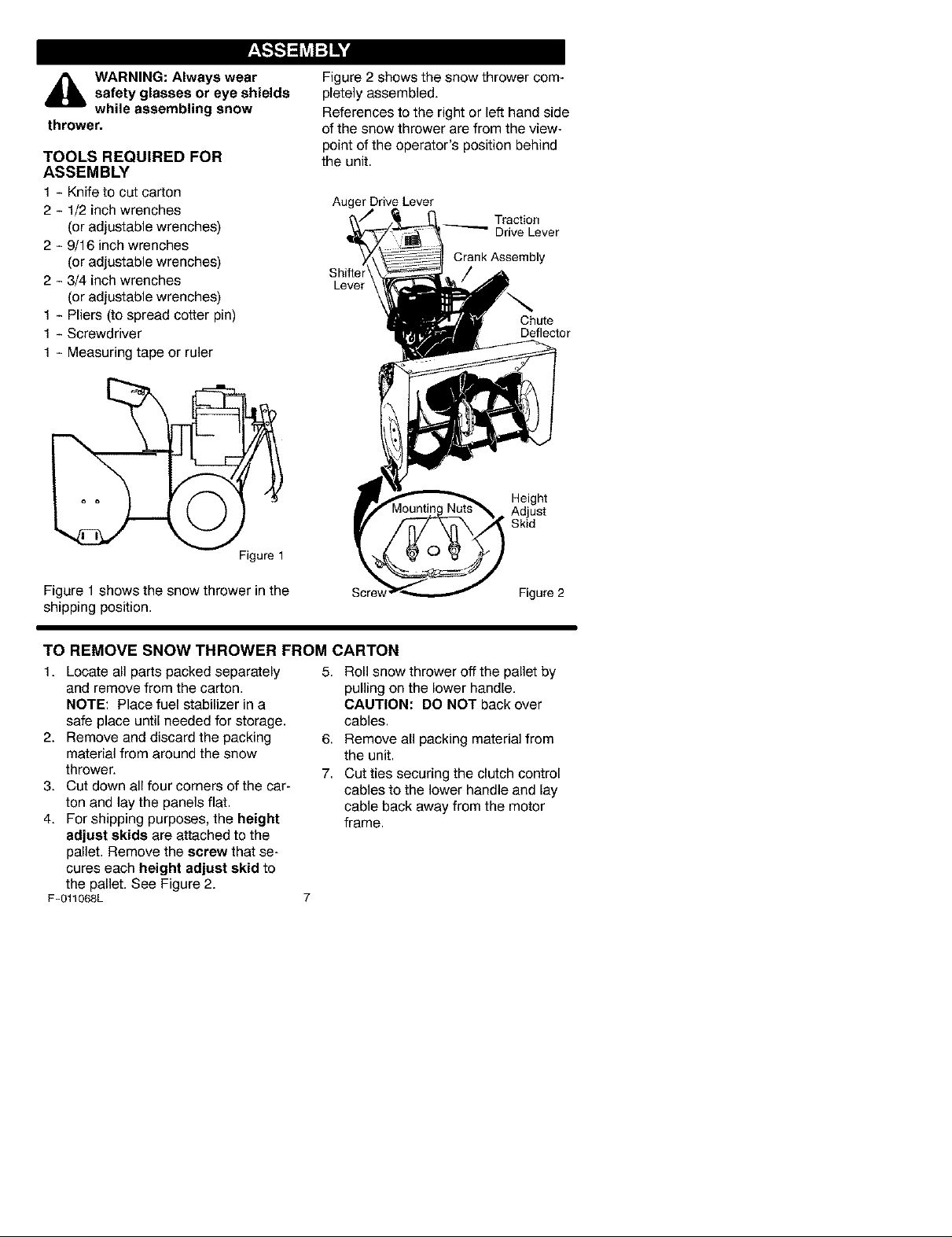

_,"_ _hVJl:11_•&

4_lb WARNING: Always wearsafety glasses or eye shields

while assembling snow

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

2 - 1/2 inch wrenches

(or adjustable wrenches)

2 - 9/16 inch wrenches

(or adjustable wrenches)

2 - 3/4 inch wrenches

(or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1 - Screwdriver

1 - Measuring tape or ruler

o

Figure 1

Figure 2 shows the snow thrower com-

pletely assembled.

References to the right or left hand side

of the snow thrower are from the view-

point of the operator's position behind

the unit.

Auger Drive Lever

Traction

Drive Lever

Shiffe

Lever

Crank Assembly

Chute

Deflector

Height

. Adjust

Skid

Figure 1 shows the snow thrower in the

shipping position.

Scre_ Figure 2

TO REMOVE SNOW THROWER FROM CARTON

1. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a

safe place until needed for storage.

2. Remove and discard the packing

material from around the snow

thrower.

3. Cut down all four corners of the car-

ton and lay the panels flat.

4. For shipping purposes, the height

adjust skids are attached to the

pallet. Remove the screw that se-

cures each height adjust skid to

the pallet. See Figure 2.

F-011068L

5. Roll snow thrower off the pallet by

pulling on the lower handle.

CAUTION: DO NOT back over

cables.

6. Remove all packing material from

the unit.

7. Cut ties securing the clutch control

cables to the lower handle and lay

cable back away from the motor

frame.

Page 8

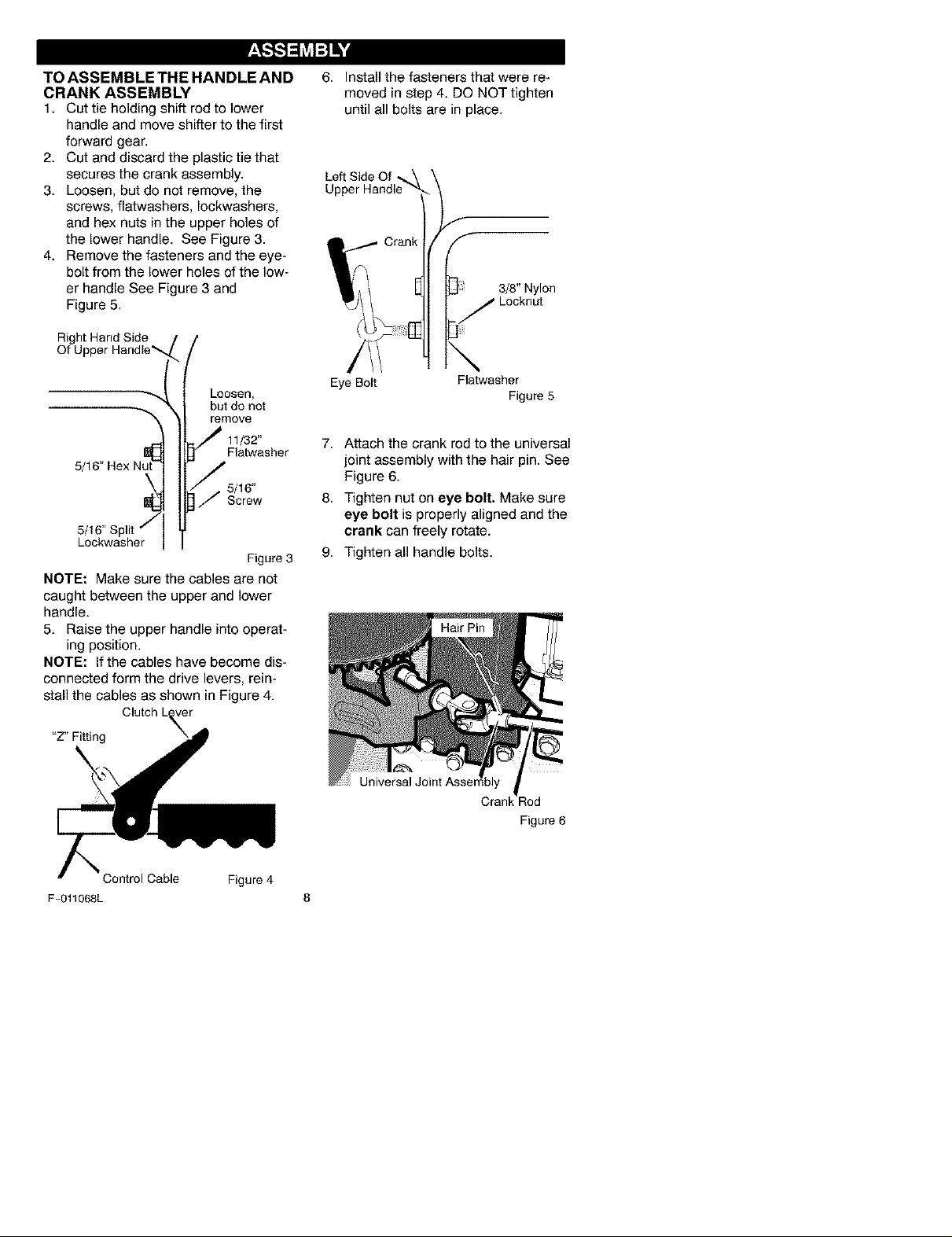

TO ASSEMBLE THE HANDLE AND

CRANK ASSEMBLY

1. Cut tie holding shift rod to lower

handle and move shifter to the first

forward gear.

2. Cut and discard the plastic tie that

secures the crank assembly.

3. Loosen, but do not remove, the

screws, flatwashers, Iockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

4. Remove the fasteners and the eye-

bolt from the lower holes of the low-

er handle See Figure 3 and

Figure 5.

Right Hand Side

Of U

6. Install the fasteners that were re-

moved in step 4. DO NOT tighten

until all bolts are in place.

Left Side Of _\

Upper Handle _k,

3/8" Nylon

Loosen,

but do not

remove

11/32"

Flatwasher

5/

5/16"

Screw

Lookwasher

Figure3

NOTE: Make sure the cables are not

caught between the upper and lower

handle.

5. Raise the upper handle into operat-

ing position.

NOTE: If the cables have become dis-

connected form the drive levers, rein-

stall the cables as shown in Figure 4.

"Z" Fitting

Eye Bolt Flatwasher

Figure 5

7. Attach the crank rod to the universal

joint assembly with the hair pin. See

Figure 6.

8. Tighten nut on eye bolt. Make sure

eye bolt is properly aligned and the

crank can freely rotate.

9. Tighten all handle bolts.

Crank :od

Figure 6

Control Cable Figure4

F-011068L 8

Page 9

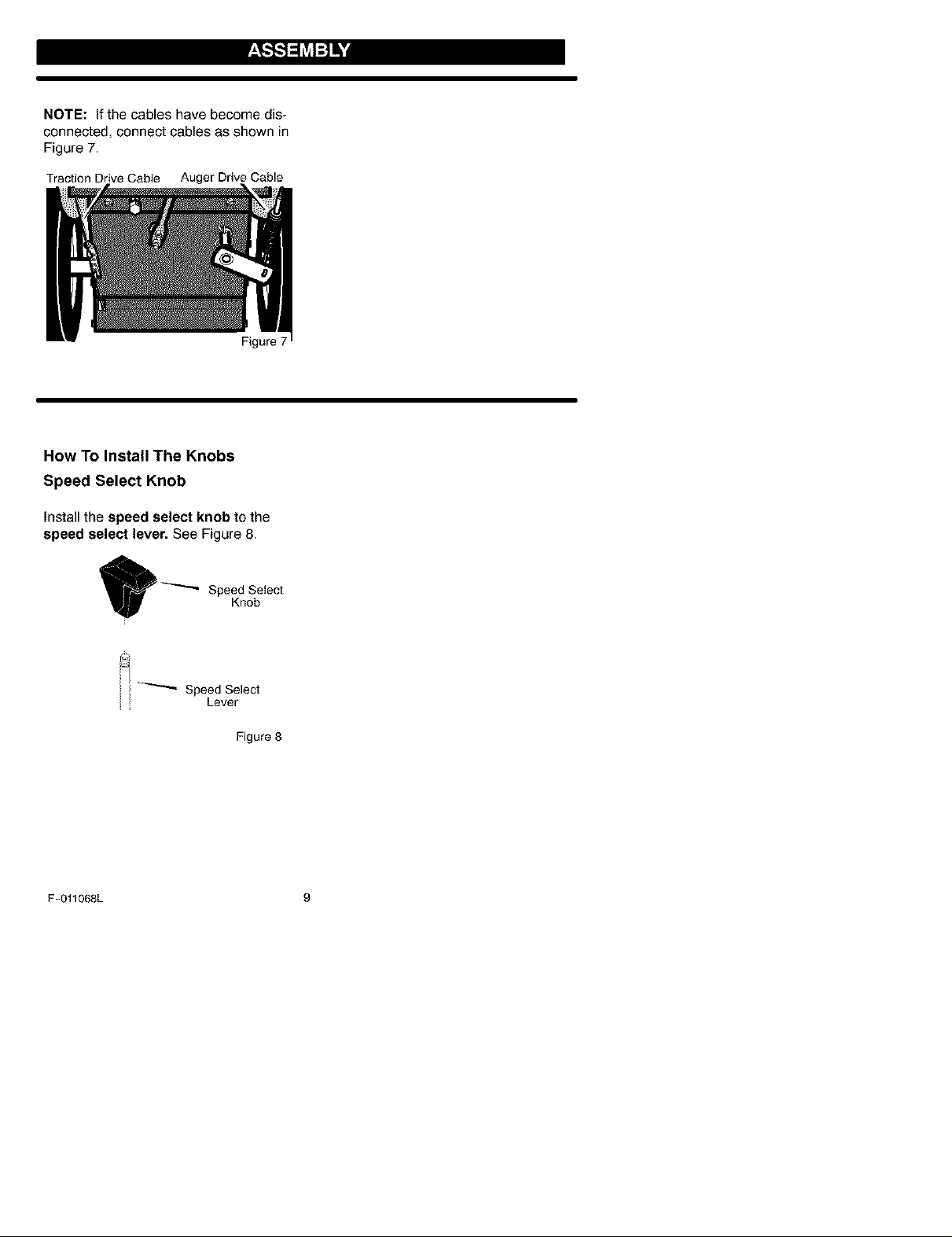

NOTE: If the cables have become dis-

connected, connect cables as shown in

Figure 7.

Traction Drive Cable Auger Drive Cable

Figure 7

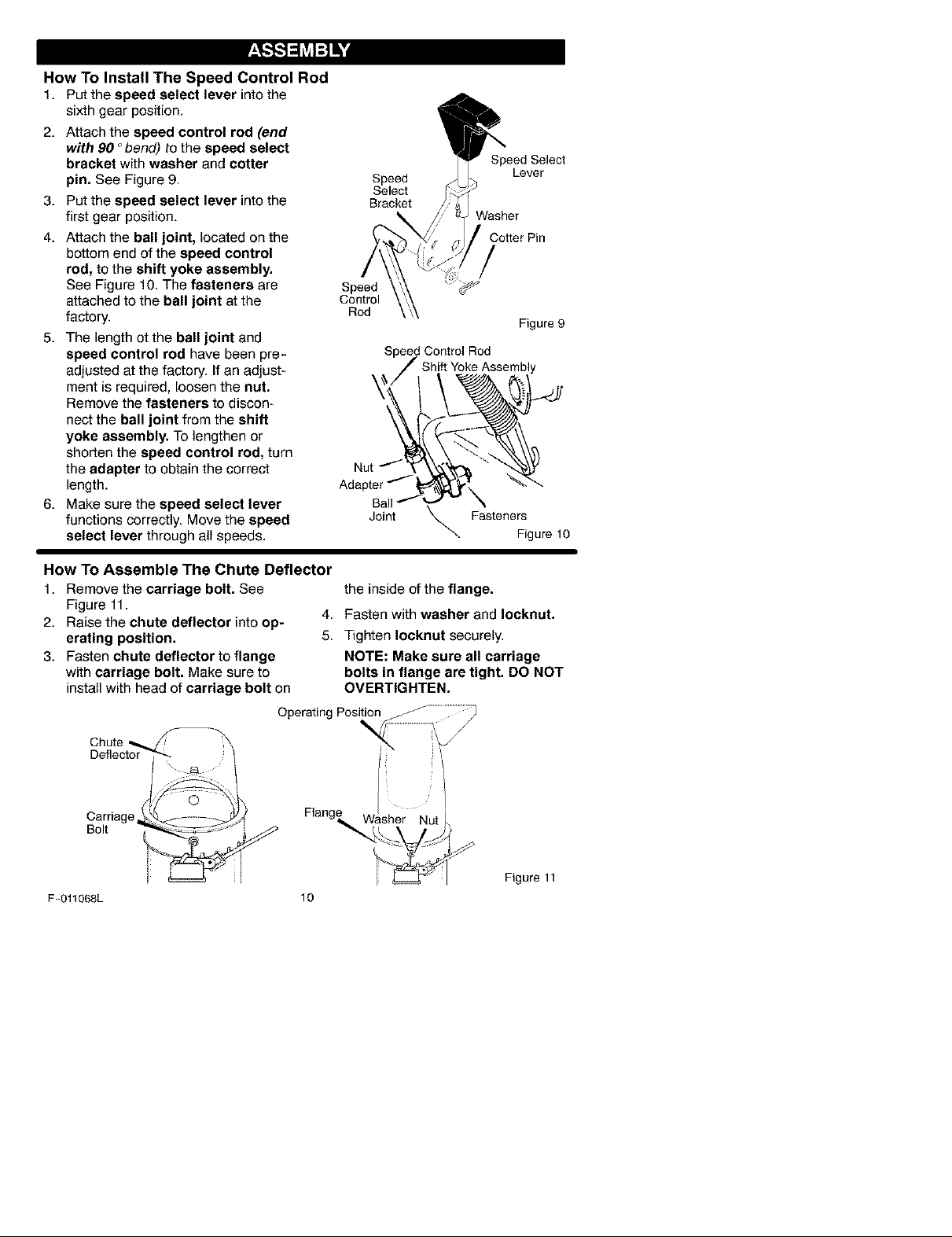

How To Install The Knobs

Speed Select Knob

Install the speed select knob to the

speed select lever. See Figure 8.

Speed Select

Lever

Figure 8

F-011068L 9

Page 10

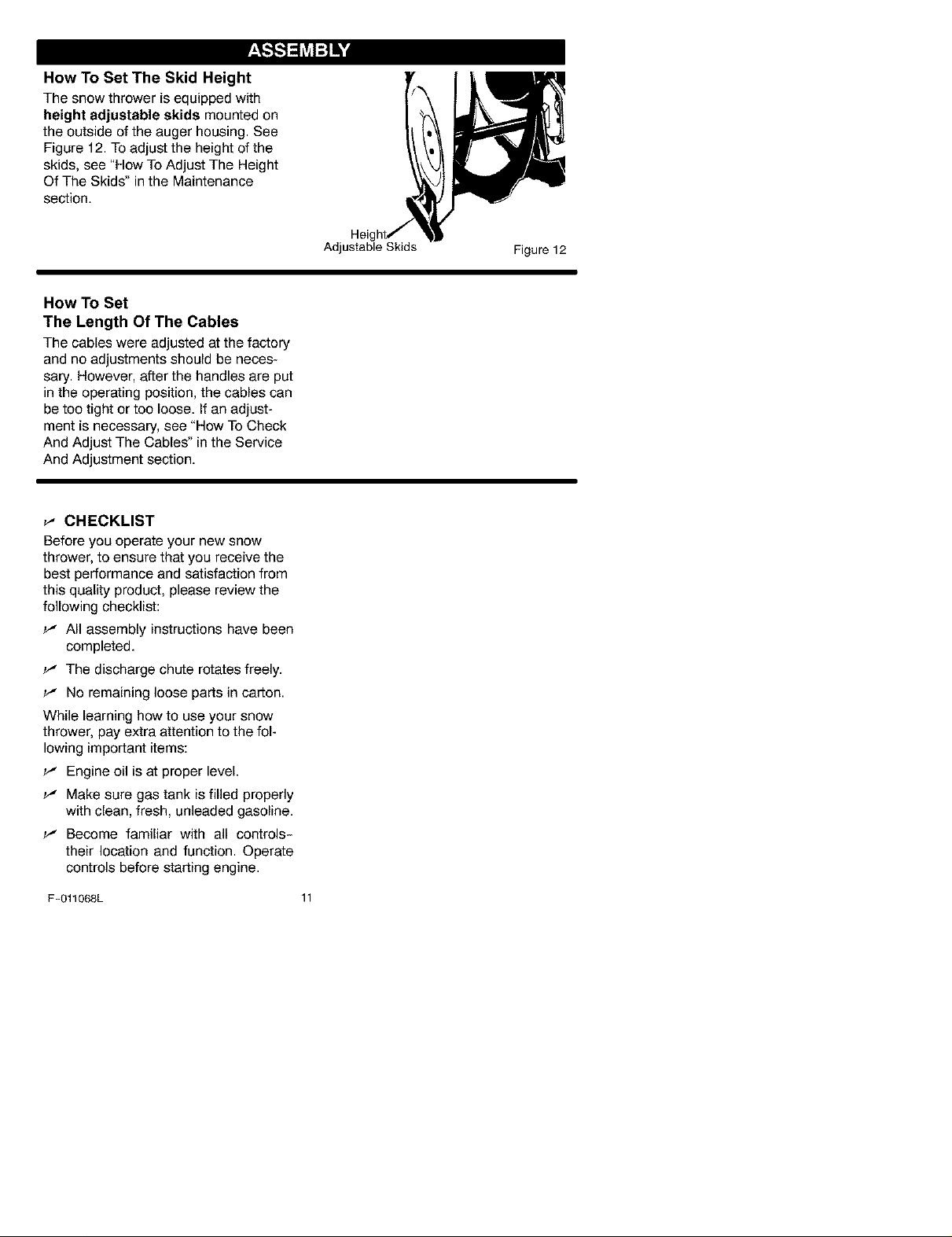

How To Install The Speed Control Rod

1. Put the speed select lever into the

sixth gear position.

2. Attach the speed control rod (end

with 90 °bend) to the speed select

bracket with washer and cotter

pin. See Figure 9.

3. Put the speed select lever into the

first gear position.

4. Attach the ball joint, located on the

bottom end of the speed control

rod, to the shift yoke assembly.

See Figure 10. The fasteners are

attached to the ball joint at the

factory.

5. The length ot the ball joint and

speed control rod have been pre-

adjusted at the factory. If an adjust-

ment is required, loosen the nut.

Remove the fasteners to discon-

nect the ball joint from the shift

yoke assembly. To lengthen or

shorten the speed control rod, turn

the adapter to obtain the correct

length.

6. Make sure the speed select lever

functions correctly. Move the speed

select lever through all speeds.

Speed Lever

Select

Bracket

Speed

Control

Rod

Speed Control Rod

Shift YokeAssembly

Ball" "2 \

Joint _x Fasteners

Speed Select

Cotter Pin

Figure 9

Figure tO

How To Assemble The Chute Deflector

1. Remove the carriage bolt. See

Figure 11.

2. Raise the chute deflector into op-

erating position,

3. Fasten chute deflector to flange

with carriage bolt. Make sure to

install with head of carriage bolt on

Chute

Deflector

Carriage

Bolt Flang_,_Washer Nut

F-011068L 10

4. Fasten with washer and Iocknut.

5. Tighten Iocknut securely.

the inside of the flange.

NOTE: Make sure all carriage

bolts in flange are tight. DO NOT

OVERTIGHTEN.

Figure 11

Page 11

_,,-,I,,',]=I_vjI--I_-I

How To Set The Skid Height

The snow thrower is equipped with

height adjustable skids mounted on

the outside of the auger housing. See

Figure 12. To adjust the height of the

skids, see "How To Adjust The Height

Of The Skids" in the Maintenance

section.

How To Set

The Length Of The Cables

The cables were adjusted at the factory

and no adjustments should be neces-

sary. However, after the handles are put

in the operating position, the cables can

be too tight or too loose. If an adjust-

ment is necessary, see "How To Check

And Adjust The Cables" in the Service

And Adjustment section.

_" CHECKLIST

Before you operate your new snow

thrower, to ensure that you receive the

best performance and satisfaction from

this quality product, please review the

following checklist:

_' All assembly instructions have been

completed.

v' The discharge chute rotates freely.

v" No remaining loose parts in carton.

While learning how to use your snow

thrower, pay extra attention to the fol-

lowingimportant items:

_' Engine oil is at proper level.

v' Make sure gas tank is filled properly

with clean, fresh, unleaded gasoline.

v' Become familiar with all controls-

their location and function. Operate

controls before starting engine.

Adjustable Skids

Figure 12

F-011068L 11

Page 12

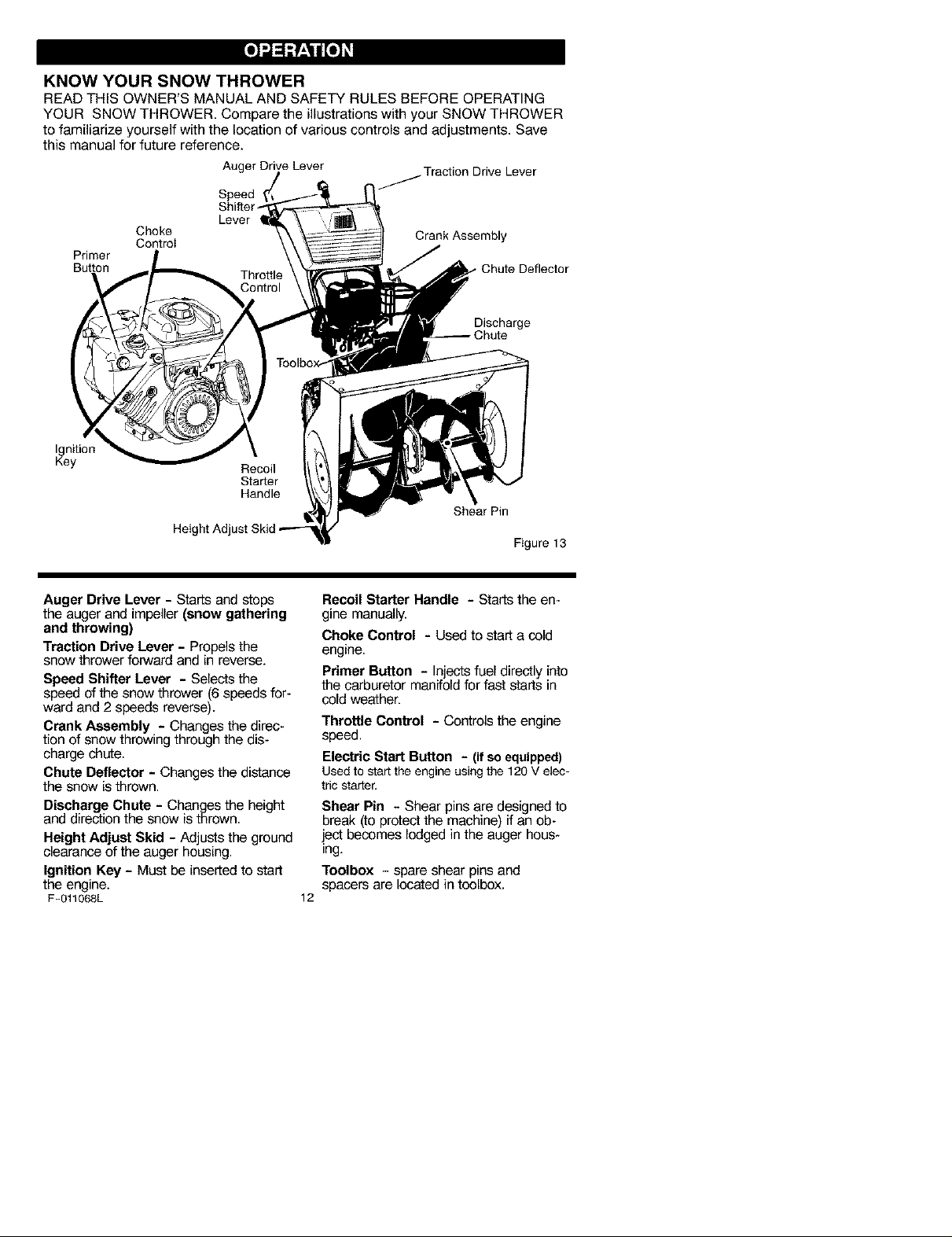

[o]-.l_1:_±'1/ [o]_

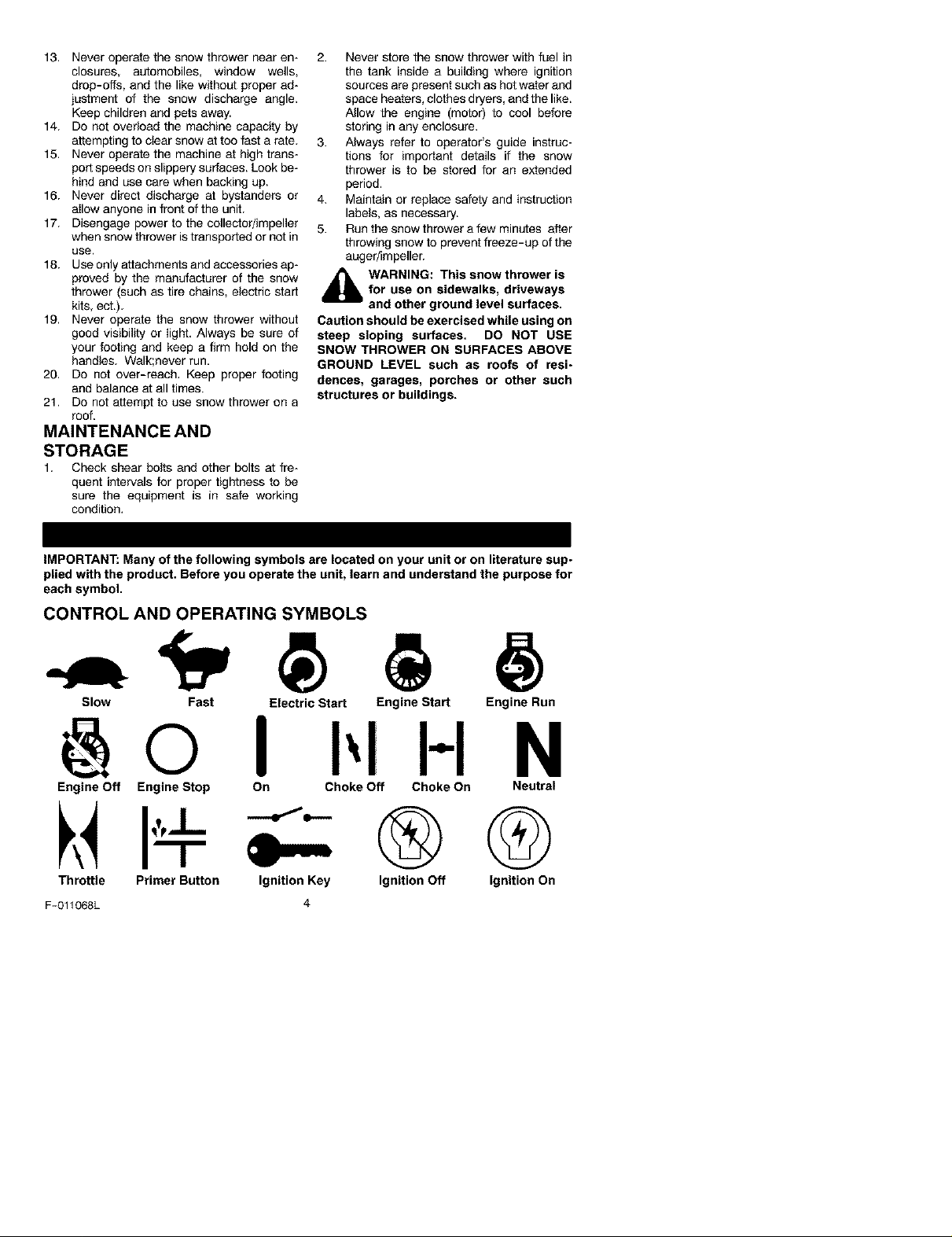

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER. Compare the illustrations with your SNOW THROWER

to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

Auger Drive Lever Traction Drive Lever

Speed

Lever

Choke Crank Assembly

Primer

Button Chute Deflector

Ignition

Key

Control

Discharge

Starter

Handle

Shear Pin

Height Adj

Figure 13

Auger Drive Lever - Starts and stops

the auger and impeller (snow gathering

and throwing)

Traction Drive Lever - Propels the

snow thrower forward and in reverse.

Speed Shifter Lever - Selects the

speed of the snow thrower (6 speeds for-

ward and 2 speeds reverse).

Crank Assembly - Changes the direc-

tion of snow throwing through the dis-

charge chate.

Chute Deflector - Changes the distance

the snow is thrown.

Discharge Chute - Changes the height

and direction the snow is thrown.

Height Adjust Skid - Adjusts the ground

clearance of the auger housing.

Ignition Key - Must be inserted to start

the engine.

F-011068L

Recoil Starter Handle - Starts the en-

gine manually.

Choke Control - Used to start a cold

engine.

Primer Button - Injects fuel directly into

the carburetor manifold for fast starts in

cold weather.

Throttle Control - Controls the engine

speed.

Electric Start Button - (if so equipped)

Usedto startthe engine usingthe120 V elec-

tnc starter.

Shear Pin - Shear pins are designed to

break (to protect the machine) ff an ob-

iect becomes lodged in the auger hous-

ing.

Toolbox - spare shear pins and

spacers are located in toolbox.

12

Page 13

[e]-.l_1:_±'1/ [e]_

The operation of any snow thrower can

result in foreign objects being thrown

into the eyes, which can result in se-

vere eye damage. Always wear safety

glasses or eye shields while operating

the snow thrower.

We recommend standard safety

glasses or a wide vision safety mask for

over your glasses.

_IL ARNING: Read Owner's

charge toward bystanders. Stop the

engine before unclogging discharge

chute or auger housing and before

leaving the machine.

Manual before operating

machine. Never direct dis-

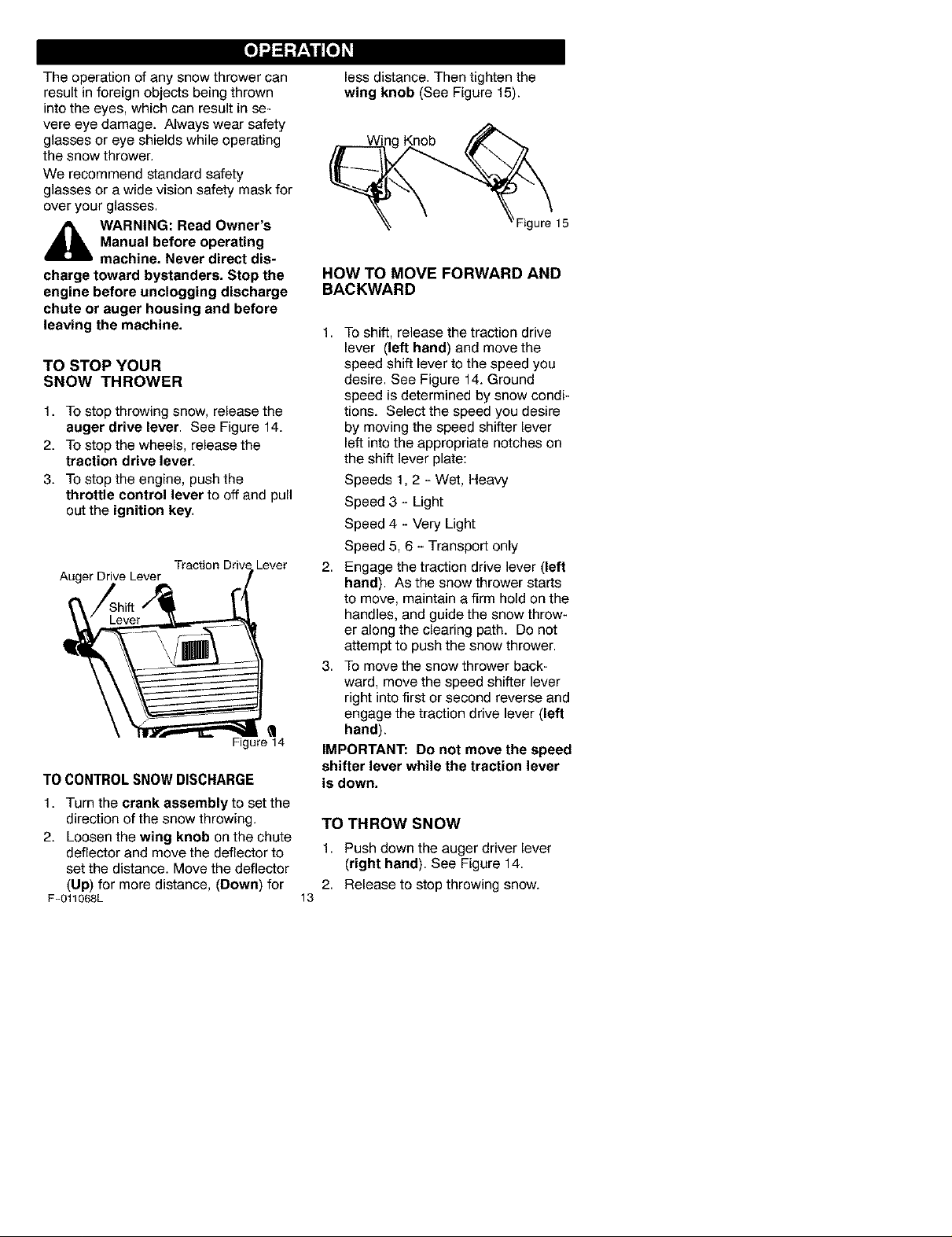

TO STOP YOUR

SNOW THROWER

1. To stop throwing snow, release the

auger drive lever. See Figure 14.

2. To stop the wheels, release the

traction drive lever.

3. To stop the engine, push the

throttle control lever to off and pull

out the ignition key.

Auger Drive Lever

TO CONTROL SNOW DISCHARGE

1. Turn the crank assembly to set the

direction of the snow throwing.

2. Loosen the wing knob on the chute

deflector and move the deflector to

set the distance. Move the deflector

(Up) for more distance, (Down) for

F-011068L

Lever

Figure 14

less distance. Then tighten the

wing knob (See Figure 15).

Knob

HOW TO MOVEFORWARD AND

BACKWARD

1. TO shift, release the traction drive

lever (left hand) and move the

speed shift lever to the speed you

desire. See Figure 14. Ground

speed is determined by snow condi-

tions. Select the speed you desire

by moving the speed shifter lever

left into the appropriate notches on

the shift lever plate:

Speeds 1,2 - Wet, Heaw

Speed 3 - Light

Speed 4 - Very Light

Speed 5, 6 - Transport only

2. Engage the traction drive lever (left

hand). As the snow thrower starts

to move, maintain a firm hold on the

handles, and guide the snow throw-

er along the clearing path. Do not

attempt to push the snow thrower.

3. To move the snow thrower back-

ward, move the speed shifter lever

right into first or second reverse and

engage the traction drive lever (left

hand).

IMPORTANT: Do not move the speed

shifter lever while the traction lever

is down.

TO THROW SNOW

1. Push down the auger driver lever

(right hand). See Figure 14.

2. Release to stop throwing snow.

13

ure 15

Page 14

[o]-.l_1:_±'1/ [o]_

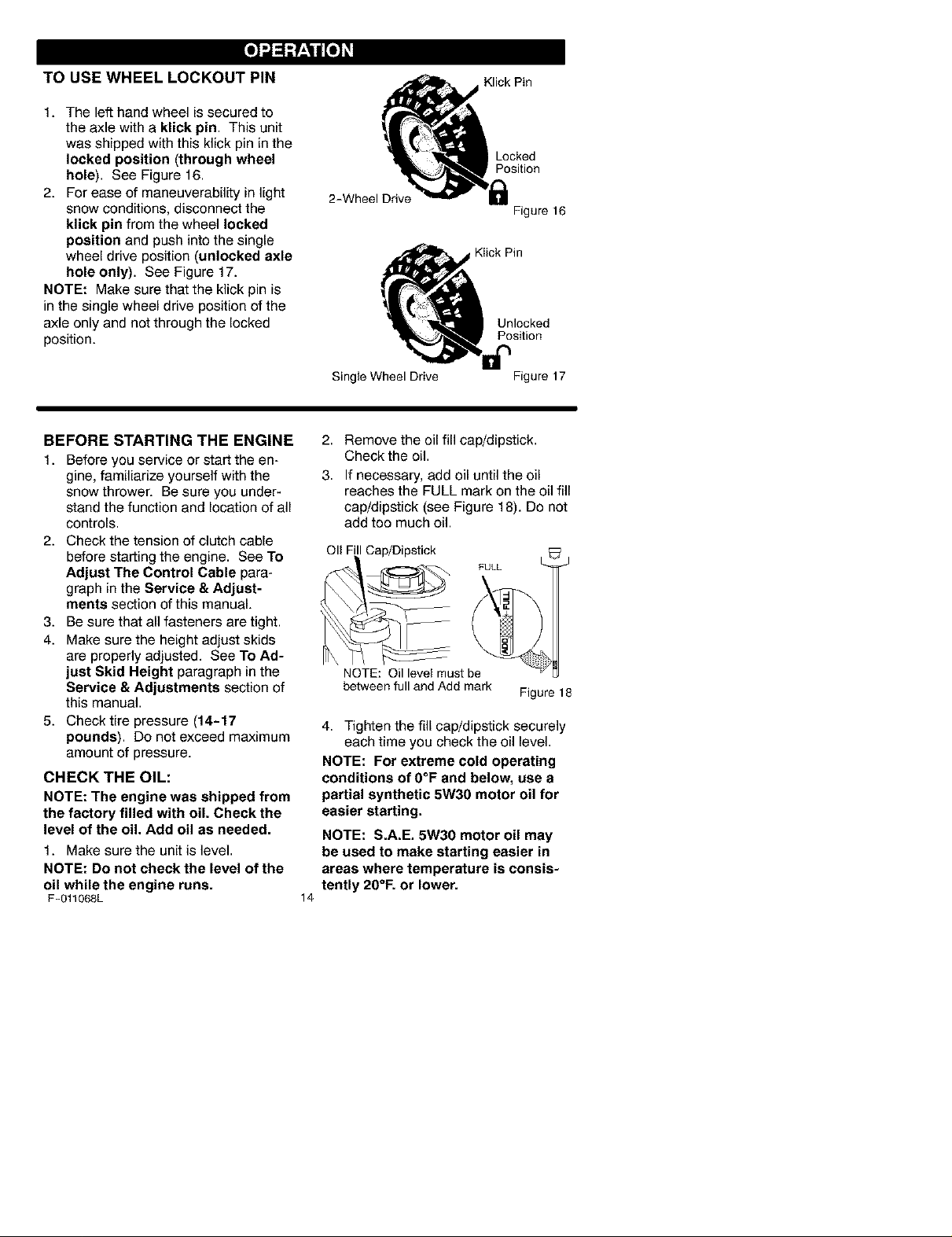

TO USE WHEEL LOCKOUT PIN

1. The left hand wheel is secured to

the axle with a klick pin. This unit

was shipped with this klick pin in the

locked position (through wheel

hole). See Figure 16.

2. For ease of maneuverability in light

snow conditions, disconnect the

klick pin from the wheel locked

position and push into the single

wheel drive position (unlocked axle

hole only). See Figure 17.

NOTE: Make sure that the klick pin is

in the single wheel drive position of the

axle only and not through the locked

position.

Klick Pin

Locked

Position

2-Wheel Drive

Single Wheel Drive Figure 17

Kiick Pin

Unlocked

Position

Figure 16

BEFORE STARTING THE ENGINE

1. Before you service or start the en-

gine, familiarize yourself with the

snow thrower. Be sure you under-

stand the function and location of all

controls.

2. Check the tension of clutch cable

before starting the engine. See To

Adjust The Control Cable para_

graph in the Service & Adjust-

ments section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are properly adjusted. See To Ad-

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Check tire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

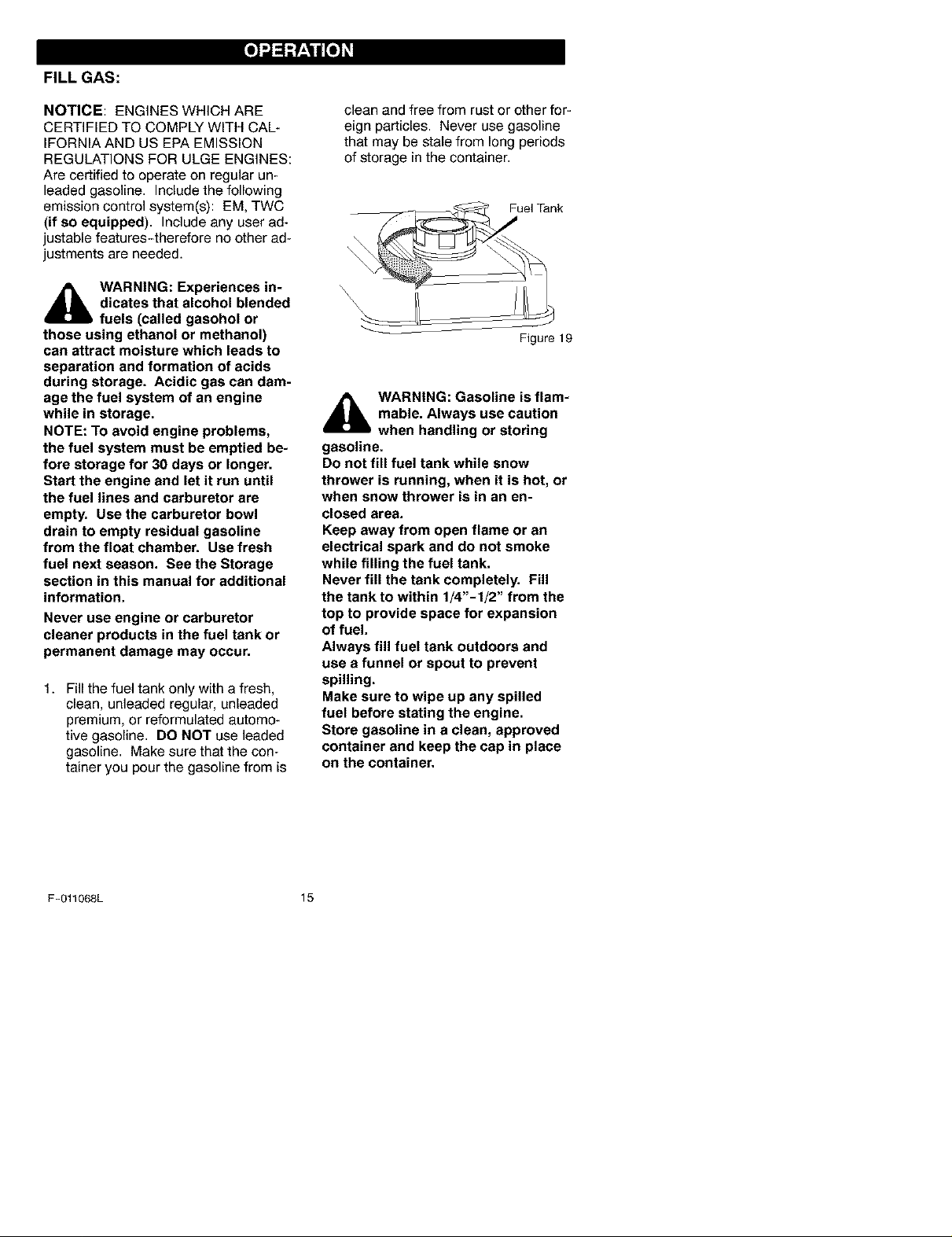

CHECK THE OIL:

NOTE: The engine was shipped from

the factory filled with oil. Check the

level of the oil. Add oil as needed.

1. Make sure the unit is level.

NOTE: Do not check the level of the

oil while the engine runs.

F-011068L

2. Remove the oil fill cap/dipstick.

Check the oil.

3. If necessary, add oil until the oil

reaches the FULL mark on the oil fill

cap/dipstick (see Figure 18). Do not

add too much oil.

OII Fill Cap/Dipstick

NOTE: Oil level must be

between full and Add mark Figure 18

FULL

4. Tighten the fill cap/dipstick securely

each time you check the oil level.

NOTE: For extreme cold operating

conditions of O°F and below, use a

partial synthetic 5W30 motor oil for

easier starting.

NOTE: S.A.E. 5W30 motor oil may

be used to make starting easier in

areas where temperature is consis-

tently 20°F. or lower.

14

Page 15

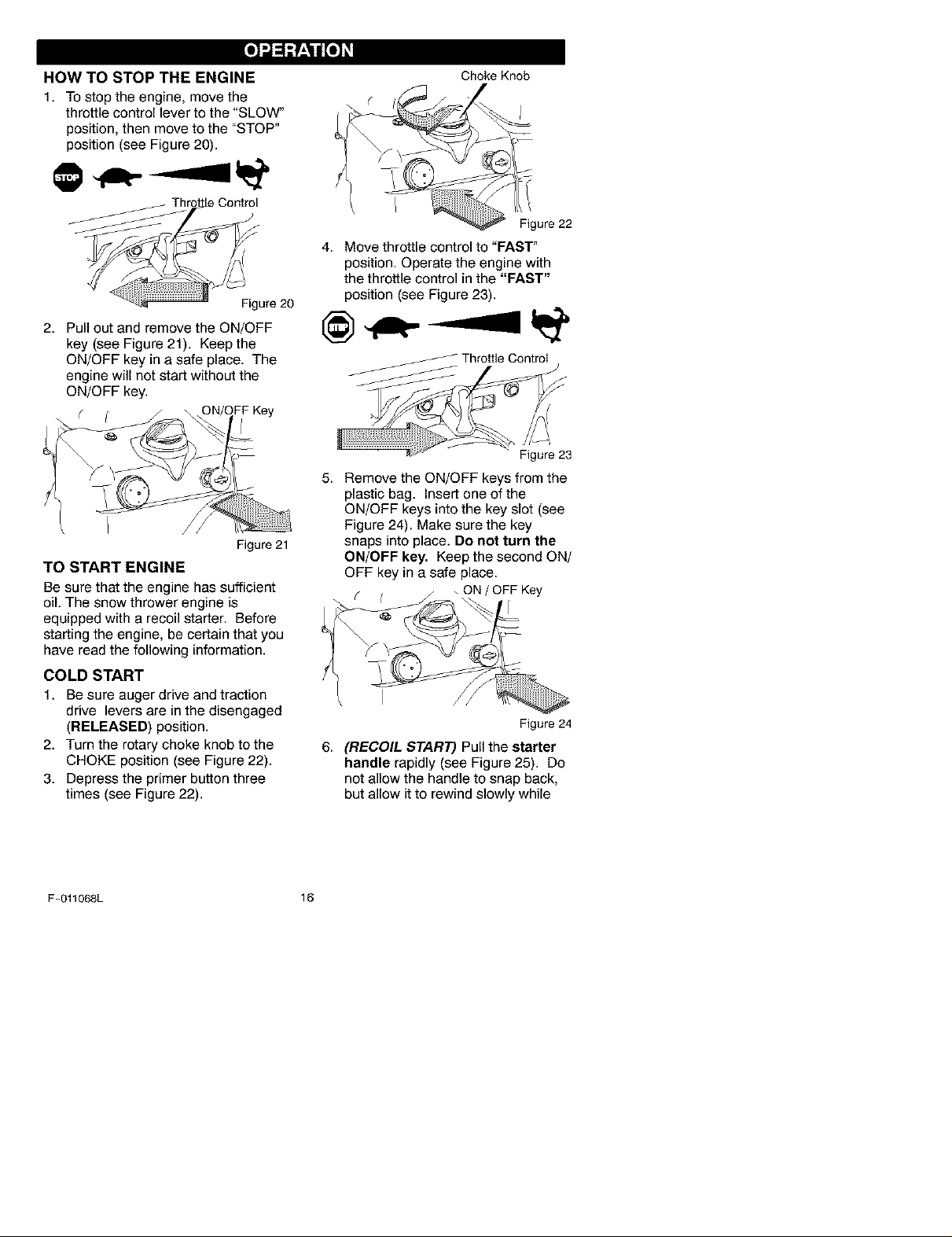

FILL GAS:

[o]-.l_1:_±'1/ [o]_

NOTICE: ENGINES WHICH ARE

CERTIFIED TO COMPLY WITH CAL-

IFORNIA AND US EPA EMISSION

REGULATIONS FOR ULGE ENGINES:

Are certified to operate on regular un-

leaded gasoline. Includethe following

emission control system(s): EM, TWC

(if so equipped). Include any user ad-

justable features-therefore no other ad-

justments are needed.

_[b WARNING: Experiences in-

dicates that alcohol blended

fuels (called gasohol or

those using ethanol or methanol)

can attract moisture which leads to

separation and formation of acids

during storage. Acidic gas can dam-

age the fuel system of an engine

while in storage.

NOTE: To avoid engine problems,

the fuel system must be emptied be-

fore storage for 30 days or longer.

Start the engine and let it run until

the fuel lines and carburetor are

empty. Use the carburetor bowl

drain to empty residual gasoline

from the float chamber. Use fresh

fuel next season. See the Storage

section in this manual for additional

information.

Never use engine or carburetor

cleaner products in the fuel tank or

permanent damage may occur.

1. Fill the fuel tank only with a fresh,

clean, unleaded regular, unleaded

premium, or reformulated automo-

tive gasoline. DO NOT use leaded

gasoline. Make sure that the con-

tainer you pour the gasoline from is

clean and free from rust or other for-

eign particles. Never use gasoline

that may be stale from long periods

of storage in the container.

Fuel Tank

Figure 19

_ ARNING: Gasoline is flam-

mable. Always use caution

when handling or storing

gasoline.

Do not fill fuel tank while snow

thrower is running, when it is hot, or

when snow thrower is in an en-

closed area.

Keep away from open flame or an

electrical spark and do not smoke

while filling the fuel tank.

Never fill the tank completely. Fill

the tank to within 1/4"-1/2" from the

top to provide space for expansion

of fuel.

Always fill fuel tank outdoors and

use a funnel or spout to prevent

spilling.

Make sure to wipe up any spilled

fuel before stating the engine.

Store gasoline in a clean, approved

container and keep the cap in place

on the container.

F-011068L 15

Page 16

[i] ".l_1:7±'1/ [e]_

HOW TO STOP THE ENGINE

1. To stop the engine, move the

throttle control lever to the "SLOW"

position, then move to the "STOP"

position (see Figure 20).

Figure 20

2. Pull out and remove the ON/OFF

key (see Figure 21). Keepthe

ON/OFF key in a safe place. The

engine will not start without the

ON/OFF key.

f ( =FKey

Figure 21

TO START ENGINE

Be sure that the engine has sufficient

oil. The snow thrower engine is

equipped with a recoil starter. Before

starting the engine, be certain that you

have read the following information.

COLD START

1. Be sure auger drive and traction

drive levers are in the disengaged

(RELEASED) position.

2. Turn the rotary choke knob to the

CHOKE position (see Figure 22).

3. Depress the primer button three

times (see Figure 22).

Choke Knob

!

4. Move throttle control to "FAST"

position. Operate the engine with

the throttle control in the "FAST"

position (see Figure 23).

Throttle Control

Figure 23

5. Remove the ON/OFF keys from the

plastic bag. Insert one of the

ON/OFF keys into the key slot (see

Figure 24). Make sure the key

snaps into place. Do not turn the

ON/OFF key. Keep the second ON/

OFF key in a safe place.

# f _ON / OFF Key

Figure 24

6. (RECOIL START) Pull the starter

handle rapidly (see Figure 25). Do

not allow the handle to snap back,

but allow it to rewind slowly while

F-011068L 16

Page 17

[o]-.l_1:_±'1/ [o]_

keeping a firm hold on the starter /_ I _ -_

handle.

i

Recoil Starter Handle

Starter Button

Figure 25

_ ARNING: The starter is

equipped with a three-wire

power cord and plug and is

designed to operate on 120 volt AC

household current. It must be prop-

erly grounded at all times to avoid

the possibility of electrical shock

which may be injurious to operator.

Follow all instructions carefully as

set forth in the "To Start Engine"

section. Determine that your house

wiring is a three-wire grounded sys-

tem. Ask a licensed electrician if you

are not sure. If your house wire sys-

tem is not a three-wire system, do

not use this electric starter under any

conditions. If your system is

grounded and a three-hole recep-

tacle is not available at the point

your starter will normally be used,

one should be installed by a licensed

electrician. When connecting 120

volt AC "Power Cord", always con-

nect the cord to the Switch Box" on

the engine first, then plug the other

end into the three-hole grounded re-

ceptacle. When disconnecting "Pow-

er cord", always unplug the power

cord from the three-hole grounded

receptacle first.

7. (ELECTRIC START) Connect the

power cord to the engine and de-

press the starter button.

F-011068L

8.

As the engine warms up, move

choke lever to "1/2 choke" position.

When engine runs smoothly, move

choke lever to "No Choke" Posi-

tion.

NOTE: Allow the engine to warm

up for several minutes before

blowing snow in temperatures

below 0°F.

9. Run engine at full throttle "FAST"

when throwing snow.

WARM START

If restarting a warm engine after a short

shutdown, leave choke at "OFF" and do

not push the primer button. If the en-

gine fails to start, follow the Cold Start

instructions.

FROZEN STARTER

Ifthe starter is frozen and will not turn

engine:

1. Pull as much rope out of the starter

as possible.

2. Release the starter handle and let it

snap back against the starter.

Ifthe engine still fails to start, repeat the

two previous steps until the engine

starts. Then continue with the direc-

tions for cold start.

To help prevent possible freeze-up of

recoil starter and engine controls, pro-

ceed as follows after each snow remov-

al job.

1. With the engine running, pull the

starter rope hard with a continuous

full arm stroke three or four times.

Pulling of starter rope will produce a

17

Figure 26

Page 18

[e]-J_1:_±,1/ [e]_

loud clattering sound. This is not

harmful to the engine or starter.

2. With the engine not running, wipe all

snow and moisture from the carbu-

retor cover in area of control levers.

Also move throttle control, choke

control, and starter handle several

times.

_IL ARNING: Never run en-

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

The temperature of muffler and

nearby areas may exceed 150°F.

Avoid these areas.

DO NOT allow children or young

teenagers to operate or be near

snow thrower while it is operating.

gine indoors or in enclosed,

poorly ventilated areas. En-

_lb ARNING: Do not attempt

without taking the following precau-

tions:

• Release auger drive lever.

• Move throttle lever to stop posi-

• Remove (do not turn) ignition

• Disconnect spark plug wire.

• Do not place your hands in the

to remove any item that may

become lodged in auger

tion.

key.

auger or discharge chute. Use a

pry bar.

SNOW THROWING TIPS

1. For maximum snow thrower efficien-

cy in removing snow, adjust ground

speed, NEVER the throttle. Go

slower in deep, freezing or wet

snow. If the wheels slips, reduce

forward speed. The engine is de-

signed to deliver maximum perfor-

mance at full throttle and should be

run at this power setting at all times.

2. Most efficient snow throwing is ac-

complished when the snow is re-

moved immediately after if falls.

3. For complete snow removal, slightly

overlap each path previously taken.

4. The snow should be discharged

down wind whenever possible.

5. For normal usage, set the skids so

that the scraper bar is 1/8" above

the skids. For extremely hard-

packed snow surfaces, adjust the

F-011068L

skids upward so that the scraper

bar touches the ground.

6. On gravel or crushed rock surfaces,

set the skids at 1-1/4" below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu-

al. Rocks and gravel must not be

picked up and thrown by the ma-

chine.

7. After the snow throwing job has

been completed, allow the engine to

idle for a few minutes, which will

melt snow and accumulated ice off

the engine.

8. Clean the snow thrower thoroughly

after each use.

9. Remove ice and snow accumulation

and all debris from the entire snow

thrower, and flush with water (if pos-

sible) to remove all salt or other

chemicals. Wipe snow thrower dry.

18

Page 19

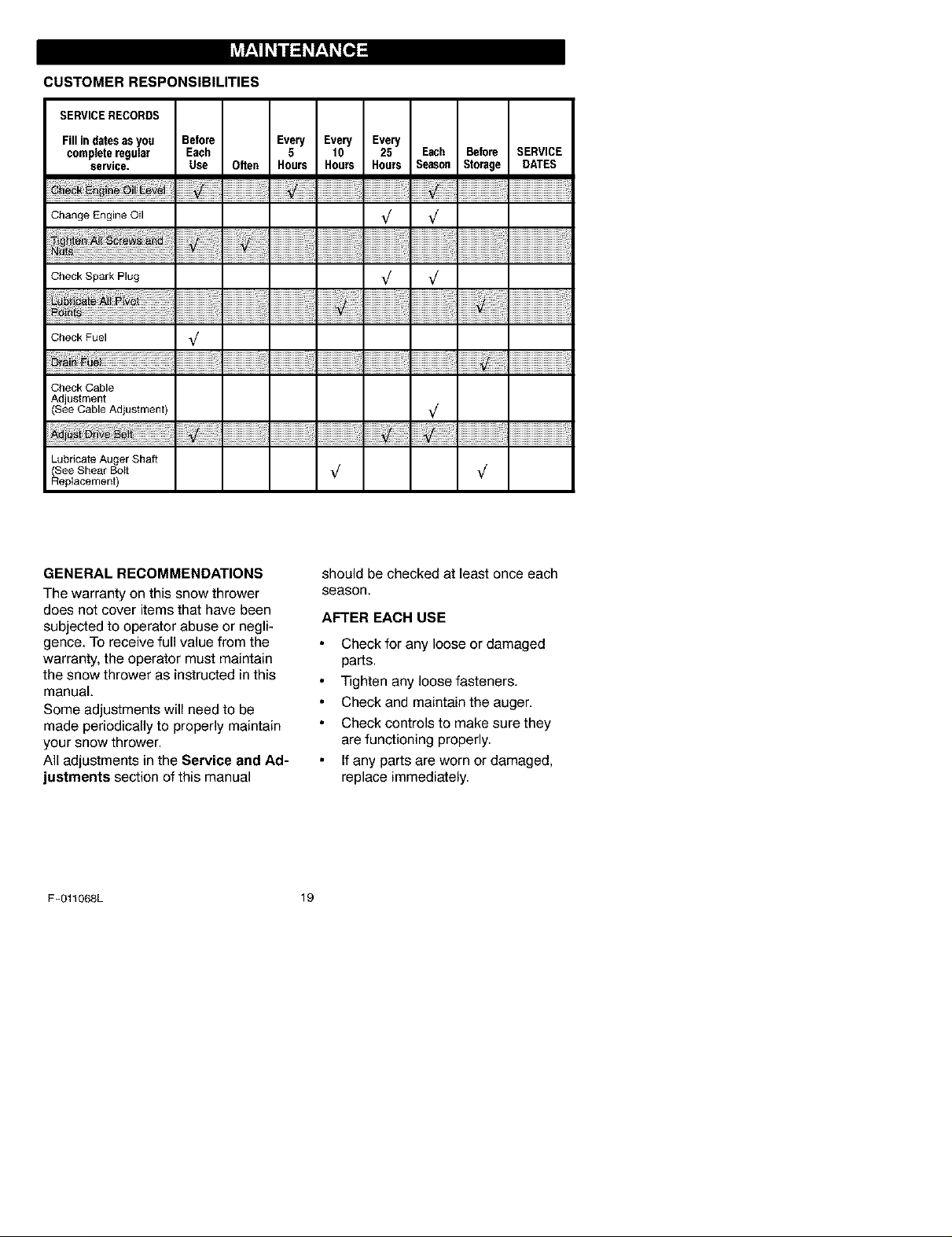

CUSTOMER RESPONSIBILITIES

SERVICERECORDS

Fillindatesasyou Before

completeregular Each

service. Usa Often

Change Engine Oil

Every Every Every

5 10 25 Each Before SERVICE

Hours Hours Hours Season Storage DATES

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii ili!i!;!

,/ ,/

_ ...........................::::::::::::::::::::::

Check Spark Plug

Check Fuel _/

Check Cable

Adjustment

See Cable Adjustment)

Lubricate Auger Shaft

See Shear Bolt

Replacement)

GENERAL RECOMMENDATIONS

The warranty on this snow thrower

does not cover items that have been

subjected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the snow thrower as instructed in this

manual.

Some adjustments will need to be

made periodically to properly maintain

your snow thrower.

All adjustments in the Service and Ad-

justments section of this manual

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii'ii'ii i ii!!i!

,/ ,/

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii'ii'ii i ii !i!

,/

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiij i i!i!;!

,/

should be checked atleast once each

season.

AFTER EACH USE

Check for any loose or damaged

parts.

Tighten any loose fasteners.

Check and maintain the auger.

Check controls to make sure they

are functioning properly.

If any parts are worn or damaged,

replace immediately.

,/

F-011068L 19

Page 20

PRODUCT SPECIFICATIONS

HORSEPOWER 7.75 HP

DISPLACEMENT 206cc

GASOLINE 4 quarts

CAPACITY (unleaded)

OIL CAPACITY 5W30

(20oz capacity)

SPARK PLUG: Longlife ptatium

P/N5066

VALVE Intake: 0.004-0.006 in,

CLEARANCE: Exhaust: 0.009-0.011 in,

SNOW THROWER

AS REQUIRED

The following adjustment should be

preformed more than once each sea-

son.

1. Auger drive belt should be adjusted

after the first 2 to 4 hours of use,

again about mid-season and twice

each season thereafter (See to Ad-

just Belts paragraph in the Ser-

vice and Adjustment section).

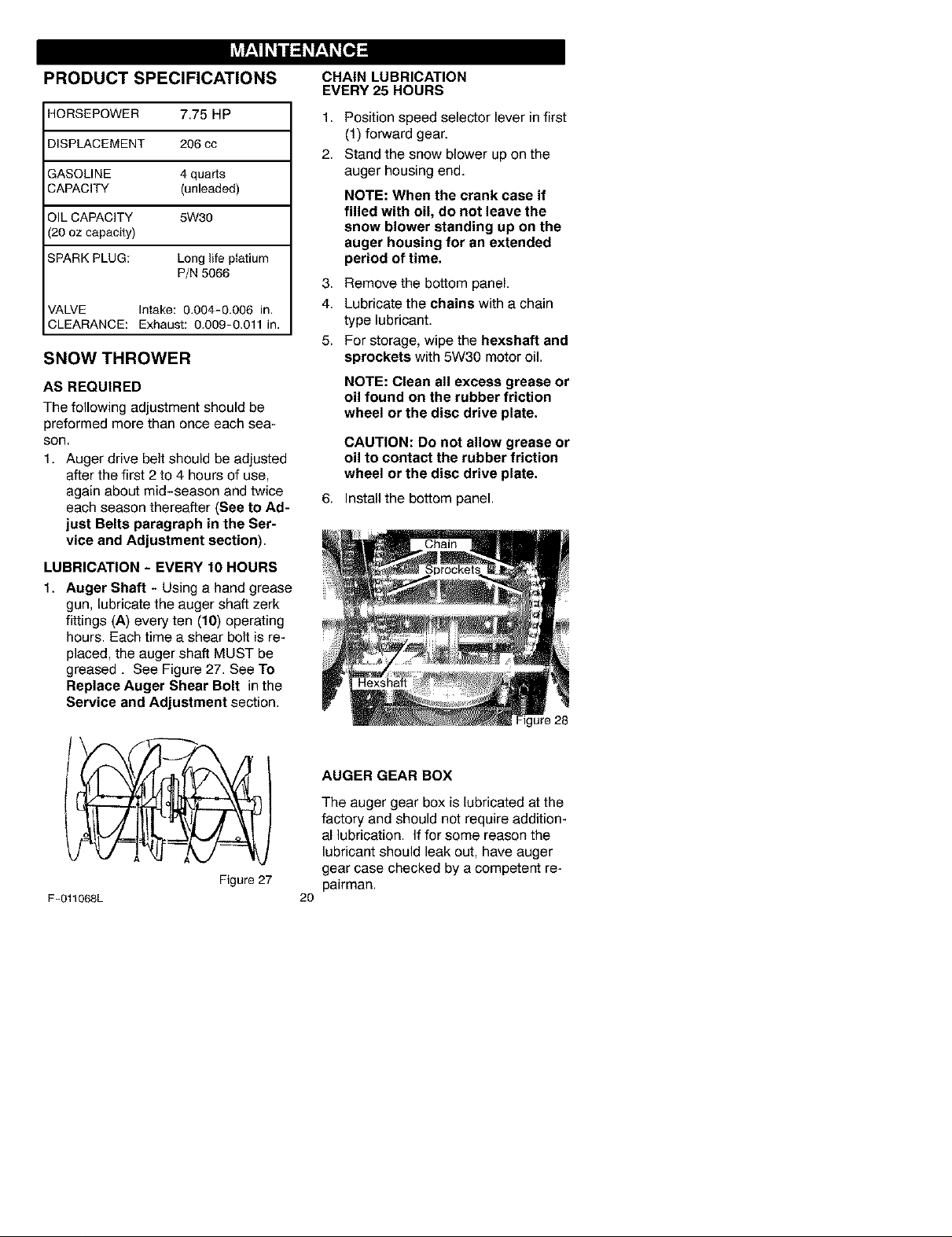

LUBRICATION - EVERY 10 HOURS

1. Auger Shaft - Using a hand grease

gun, lubricate the auger shaft zerk

fittings (A) every ten (10) operating

hours. Each time a shear bolt is re-

placed, the auger shaft MUST be

greased. See Figure 27. See To

Replace Auger Shear Bolt in the

Service and Adjustment section.

CHAIN LUBRICATION

EVERY 25 HOURS

1. Position speed selector lever in first

(1) forward gear.

2. Stand the snow blower up on the

auger housing end.

NOTE: When the crank case if

filled with oil, do not leave the

snow blower standing up on the

auger housing for an extended

period of time.

3. Remove the bottom panel.

4. Lubricate the chains with a chain

type lubricant.

5. For storage, wipe the hexsheft and

sprockets with 5W30 motor oil.

NOTE: Clean all excess grease or

oil found on the rubber friction

wheel or the disc drive plate.

CAUTION: Do not allow grease or

oil to contact the rubber friction

wheel or the disc drive plate.

6. Install the bottom panel.

Figure 28

F-011068L

Figure 27

AUGER GEAR BOX

The auger gear box is lubricated at the

factory and should not require addition-

al lubrication. If for some reason the

lubricant should leak out, have auger

gear case checked by a competent re-

pairman.

2O

Page 21

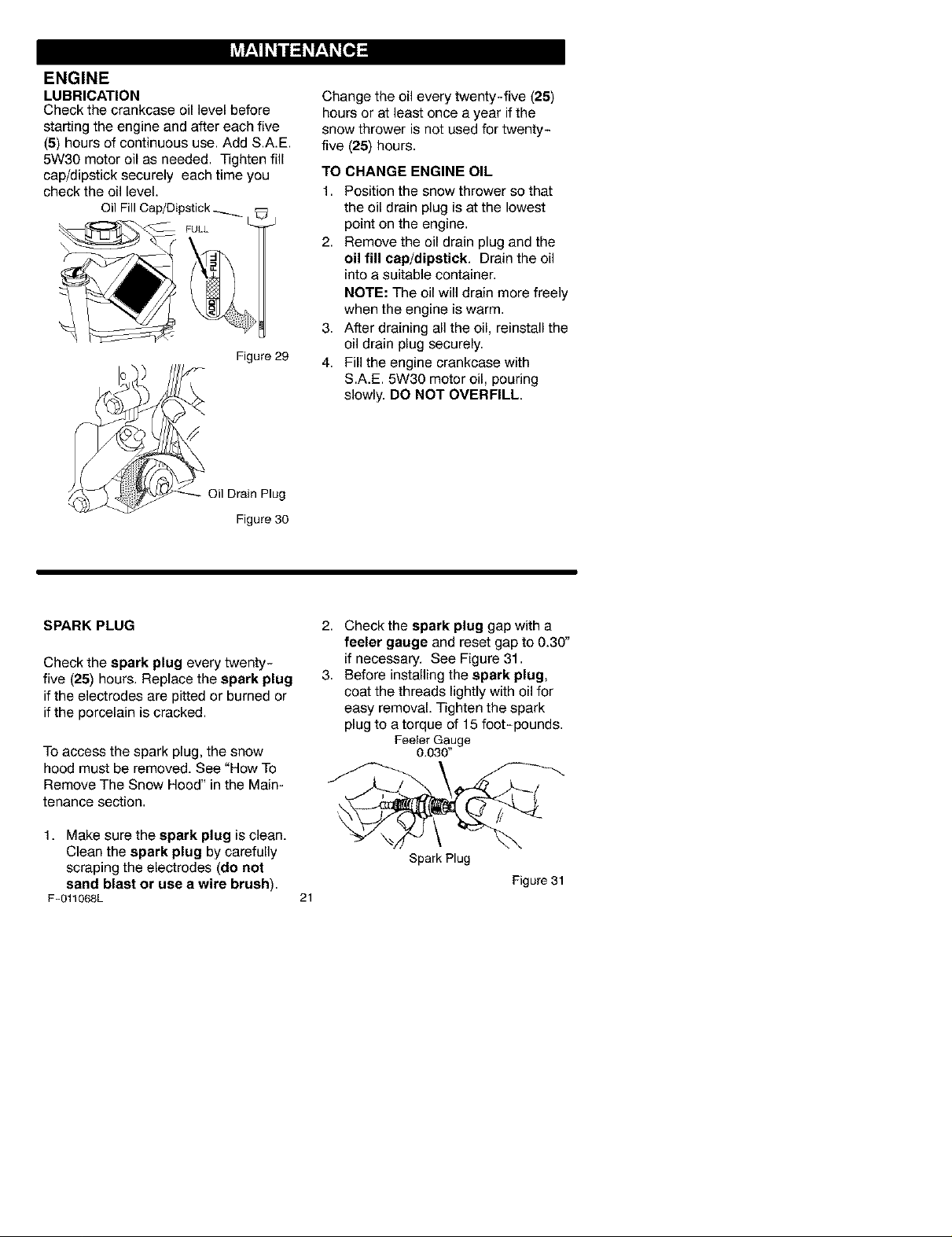

ENGINE

LUBRICATION

Check the crankcase oil level before

starting the engine and after each five

(5) hours of continuous use. Add S.A.E.

5W30 motor oil as needed. Tighten fill

cap/dipstick securely each time you

check the oil level.

Oil FillCap/Dipstick __.__

FULL L_

Figure 29

Figure 30

Change the oil every twenty-five (25)

hours or at least once a year if the

snow thrower is not used for twenty-

five (25) hours.

TO CHANGE ENGINE OIL

1. Position the snow thrower so that

the oil drain plug is at the lowest

point on the engine.

2. Remove the oil drain plug and the

oil fill cap/dipstick. Drain the oil

into a suitable container.

NOTE: The oil will drain more freely

when the engine is warm.

3. After draining all the oil, reinstall the

oil drain plug securely.

4. Fill the engine crankcase with

S.A.E. 5W30 motor oil, pouring

slowly. DO NOT OVERFILL.

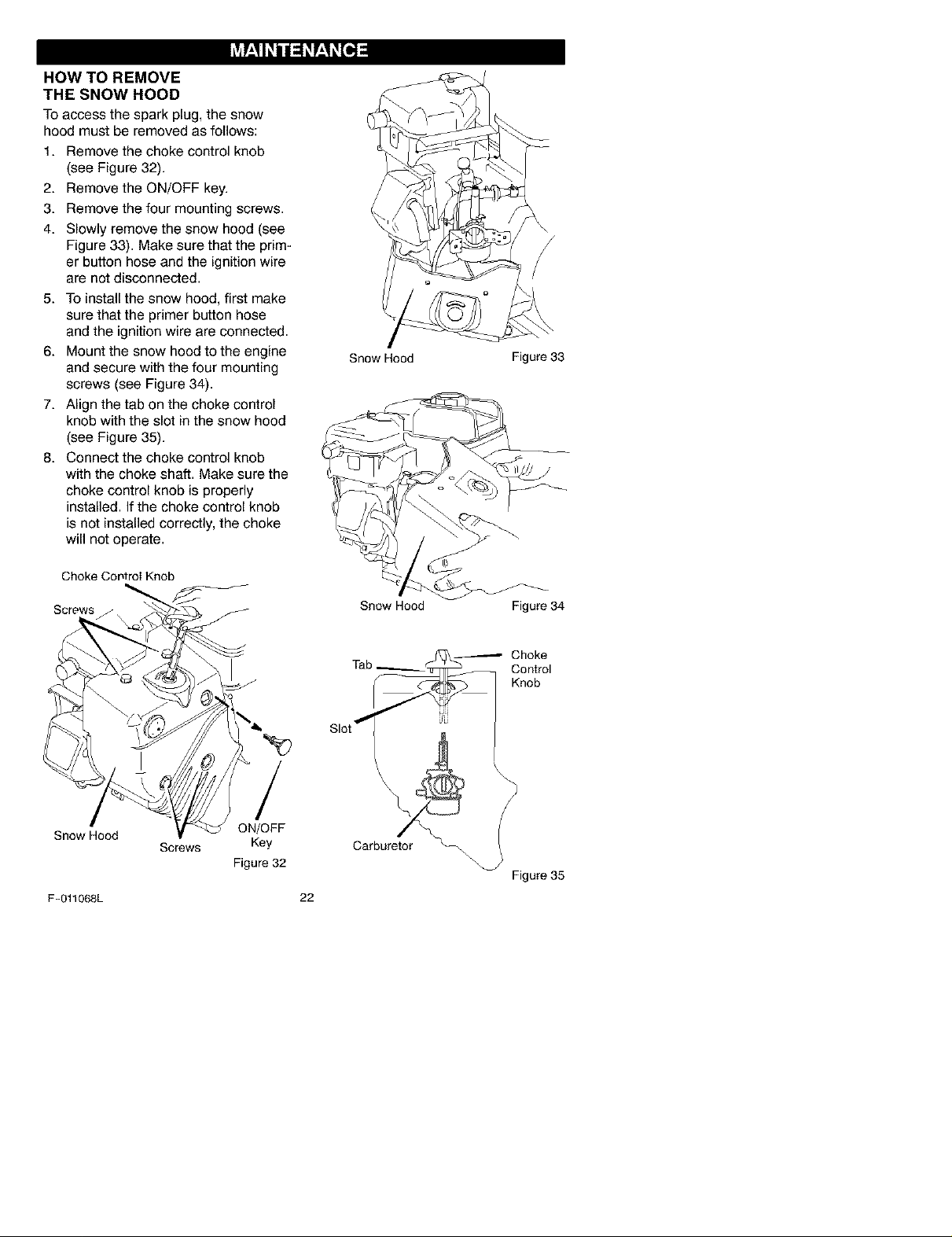

SPARK PLUG

Check the spark plug every twenty-

five (25) hours. Replace the spark plug

if the electrodes are pitted or burned or

if the porcelain is cracked.

To access the spark plug, the snow

hood must be removed. See "How To

Remove The Snow Hood" in the Main-

tenance section.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

F-011068L

2. Check the spark plug gap with a

feeler gauge and reset gap to 0.30"

if necessary. See Figure 31.

3. Before installing the spark plug,

coat the threads lightly with oil for

easy removal. Tighten the spark

plug to a torque of 15 foot-pounds.

Feeler Gauge

0.030"

Spark Plug

21

Figure 31

Page 22

HOW TO REMOVE

THE SNOW HOOD

To access the spark plug, the snow

hood must be removed as follows:

1. Remove the choke control knob

(see Figure 32).

2. Remove the ON/OFF key.

3. Remove the four mounting screws.

4. Slowly remove the snow hood (see

Figure 33). Make sure that the prim-

er button hose and the ignition wire

are not disconnected.

5. To install the snow hood, first make

sure that the primer button hose

and the ignition wire are connected.

6. Mount the snow hood to the engine

and secure with the four mounting

screws (see Figure 34).

7. Align the tab on the choke control

knob with the slot in the snow hood

(see Figure 35).

8. Connect the choke control knob

with the choke shaft. Make sure the

choke control knob is properly

installed. If the choke control knob

is not installed correctly, the choke

will not operate.

Snow Hood Figure 33

Choke Control Knob

Screws

Snow Hood

F-011068L

Scows

/

ON/OFF

Key

Figure 32

Snow Hood

Tab

_-_ Control

__ Choke

Slot _

Carbur_

22

Figure 34

Knob

\\

Figure 35

Page 23

_lb ARNING: Always discon-

make contact with spark plug to pre-

vent accidental starting when mak-

ing any adjustments or repairs.

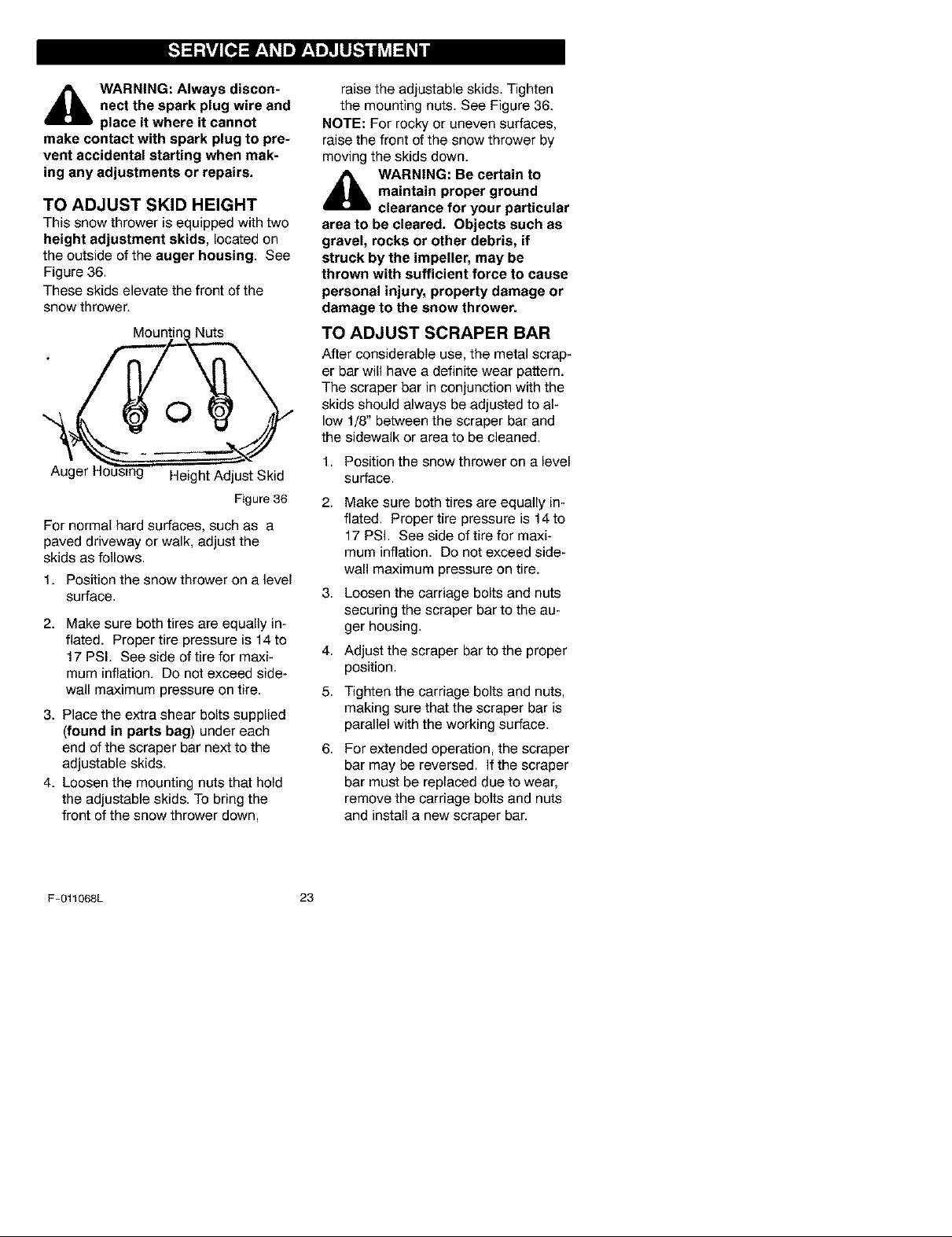

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 36.

These skids elevate the front of the

snow thrower.

nect the spark plug wire and

place it where it cannot

Nuts

O

Auger F

For normal hard surfaces, such as a

paved driveway or walk, adjust the

skids as follows.

1. Position the snow thrower on a level

surface.

2. Make sure both tires are equally in-

flated. Proper tire pressure is 14to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed side-

wall maximum pressure on tire.

3. Place the extra shear bolts supplied

(found in parts bag) under each

end of the scraper bar next to the

adjustable skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bring the

front of the snow thrower down,

Height Adjust Skid

Figure36

raise the adjustable skids. Tighten

the mounting nuts. See Figure 36.

NOTE: For rocky or uneven surfaces,

raise the front of the snow thrower by

moving the skids down.

_ WARNING: Be certain to

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

maintain proper ground

clearance for your particular

TO ADJUST SCRAPER BAR

After considerable use, the metal scrap-

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al-

low 1/8" between the scraper bar and

the sidewalk or area to be cleaned.

1. Position the snow thrower on a level

surface.

2,

Make sure both tires are equally in-

flated. Proper tire pressure is 14to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed side-

wall maximum pressure on tire.

3,

Loosen the carriage bolts and nuts

securing the scraper bar to the au-

ger housing.

4.

Adjust the scraper bar to the proper

position.

5.

Tighten the carriage bolts and nuts,

making sure that the scraper bar is

parallel with the working surface.

6.

For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage bolts and nuts

and install a new scraper bar.

F-011068L 23

Page 24

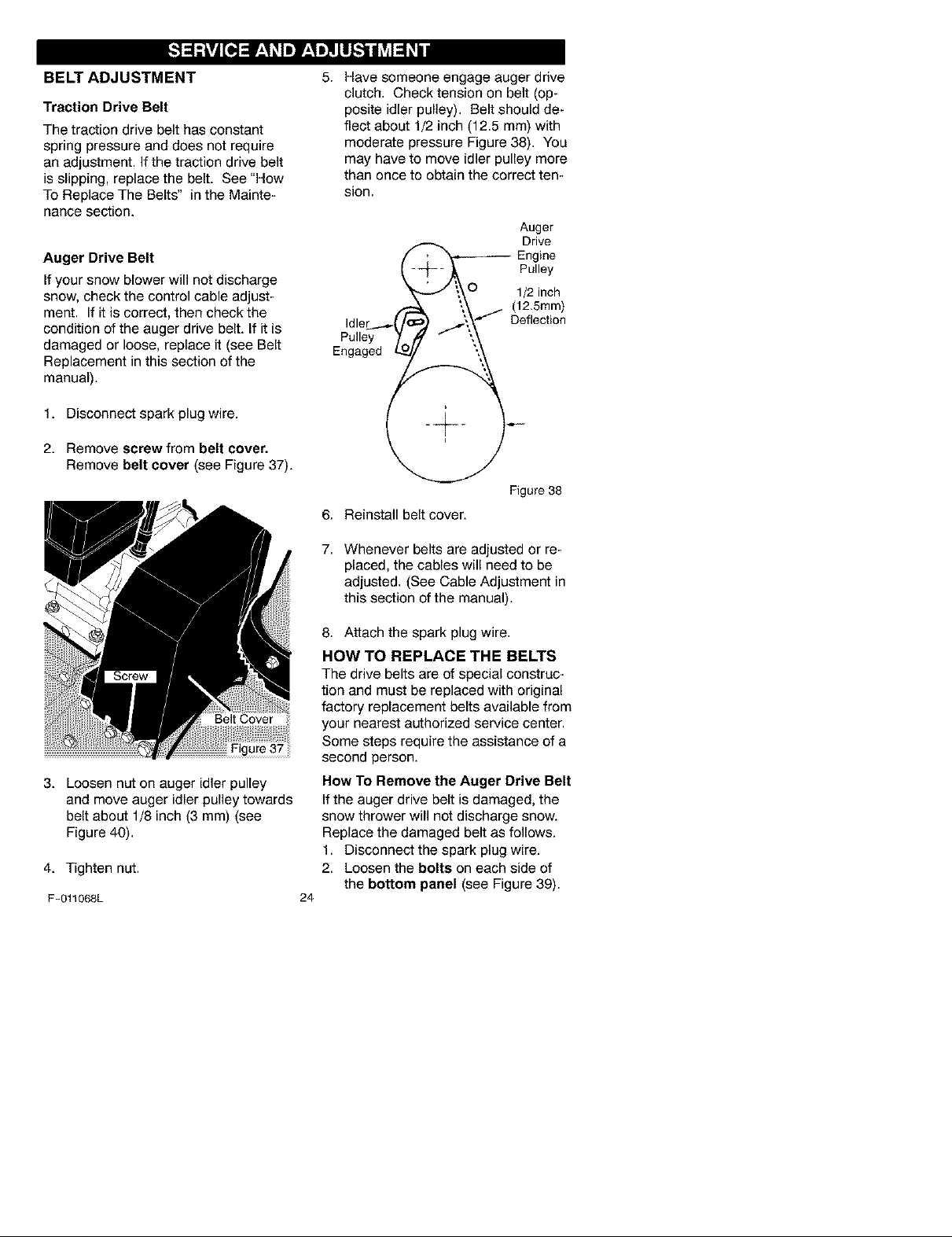

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant

spring pressure and does not require

an adjustment. If the traction drive belt

is slipping, replace the belt. See "How

To Replace The Belts" in the Mainte-

nance section.

Auger Drive Belt

Ifyour snow blower will not discharge

snow, check the control cable adjust-

ment. If it is correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see Belt

Replacement in this section of the

manual).

1. Disconnect spark plug wire.

5. Have someone engage auger drive

clutch. Check tension on belt (op-

posite idler pulley). Belt should de-

flect about 1/2 inch (12.5 mm) with

moderate pressure Figure 38). You

may have to move idler pulley more

than once to obtain the correct ten-

sion.

Auger

Drive

l "_-- Engine

--_ _ Pulley

J i_ O 1/2 inch

Idler_,.._('/_ /', _-"_ Deflection

,._ \_.j (12.5mm)

P°"°Y1o, "

2. Remove screw from belt cover,

Remove belt cover (see Figure 37).

Figure 37

3. Loosen nut on auger idler pulley

and move auger idler pulley towards

belt about 1/8 inch (3 ram) (see

Figure 40).

4. Tighten nut.

F-011068L

Engaged ___

Figure38

6. Reinstall belt cover.

7. Whenever belts are adjusted or re-

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the manual).

8. Attach the spark plug wire.

HOW TO REPLACE THE BELTS

The drive belts are of special construc-

tion and must be replaced with original

factory replacement belts available from

your nearest authorized service center.

Some steps require the assistance of a

second person.

How To Remove the Auger Drive Belt

Ifthe auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

1. Disconnect the spark plug wire.

2. Loosen the bolts on each side of

the bottom panel (see Figure 39).

24

Page 25

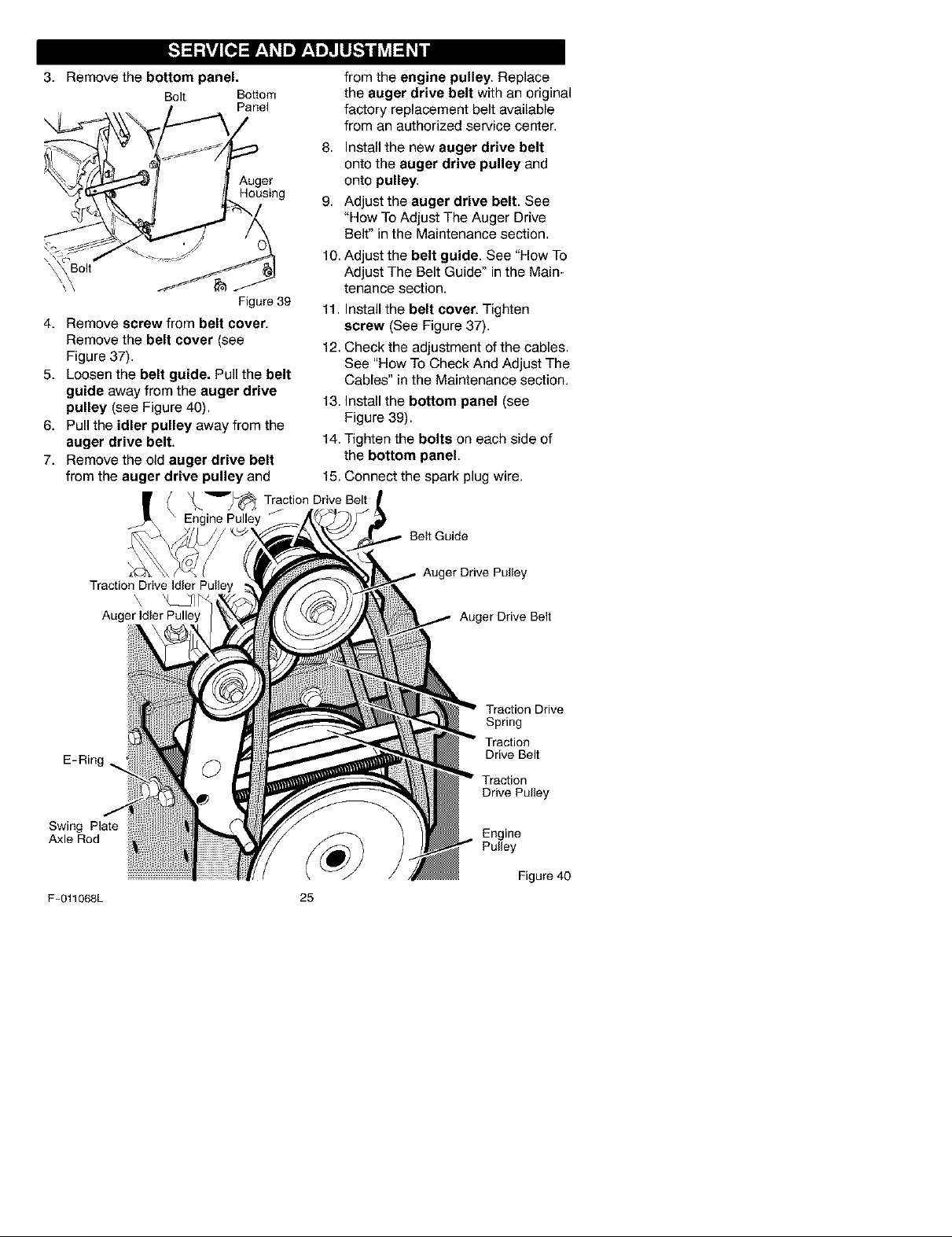

3. Remove the bottom panel.

Bolt Bottom

Panel

from the engine pulley. Replace

the auger drive belt with an original

factory replacement belt available

from an authorized service center.

8. Install the new auger drive belt

onto the auger drive pulley and

Auger

Housing

onto pulley.

9. Adjust the auger drive belt. See

"How To Adjust The Auger Drive

Belt" in the Maintenance section.

10. Adjust the belt guide. See "How To

Adjust The Belt Guide" in the Main-

tenance section.

Figure 39

4. Remove screw from belt cover.

Remove the belt cover (see

Figure 37).

5. Loosen the belt guide. Pull the belt

guide away from the auger drive

pulley (see Figure 40).

6. Pull the idler pulley away from the

auger drive belt.

7. Remove the old auger drive belt

from the auger drive pulley and 15. Connect the spark plug wire.

X__'_'_ Traction Drive Belt

Engine Pulley

11. Install the belt cover. Tighten

screw (See Figure 37).

12. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Maintenance section.

13. Install the bottom panel (see

Figure 39).

14. Tighten the bolts on each side of

the bottom panel.

Beit Guide

'\ _CJl/_

Auger Idler Pulley Auger Drive Belt

E-Ring

Swing Plate

Axle Rod

F-011068L 25

Auger Drive Pulley

Traction Drive

Spring

Traction

Drive Belt

Traction

Drive Pulley

Engine

Pulley

Figure 40

Page 26

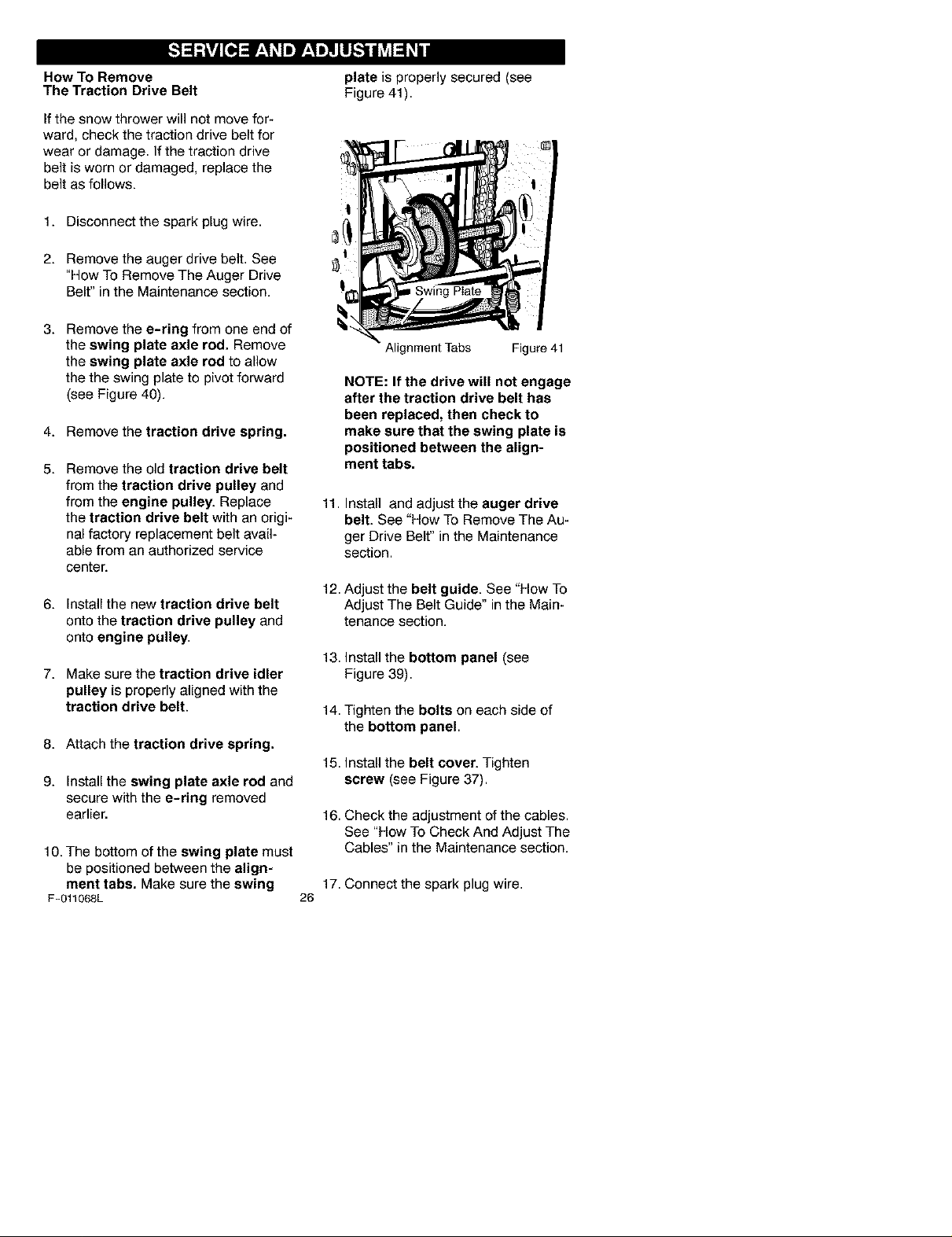

How To Remove

The Traction Drive Belt

Ifthe snow thrower will not move for-

ward, check the traction drive belt for

wear or damage. If the traction drive

belt is worn or damaged, replace the

belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See

"How To Remove The Auger Drive

Belt" in the Maintenance section.

3. Remove the e-ring from one end of

the swing plate axle rod. Remove

the swing plate axle rod to allow

the the swing plate to pivot forward

(see Figure 40).

4. Remove the traction drive spring.

5. Remove the old traction drive belt

from the traction drive pulley and

from the engine pulley. Replace

the traction drive belt with an origi-

nal factory replacement belt avail-

able from an authorized service

center.

6. Installthe new traction drive belt

onto the traction drive pulley and

onto engine pulley.

7. Make sure the traction drive idler

pulley is properly aligned with the

traction drive belt.

8. Attach the traction drive spring.

9. Install the swing plate axle rod and

secure with the e-ring removed

earlier.

10. The bottom of the swing plate must

be positioned between the align-

ment tabs. Make sure the swing

F-011068L

plate is properly secured (see

Figure 41).

I

Alignment Tabs Figure 41

NOTE: If the drive will not engage

after the traction drive belt has

been replaced, then check to

make sure that the swing plate is

positioned between the align-

ment tabs.

11.

Install and adjust the auger drive

belt. See "How To Remove The Au-

ger Drive Belt" in the Maintenance

section.

12. Adjust the belt guide. See "How To

Adjust The Belt Guide" in the Main-

tenance section.

13.Installthe bottom panel (see

Figure39).

14. Tighten the bolts on each side of

the bottom panel.

15. Install the belt cover. Tighten

screw (see Figure 37).

16. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Maintenance section.

17. Connect the spark plug wire.

26

Page 27

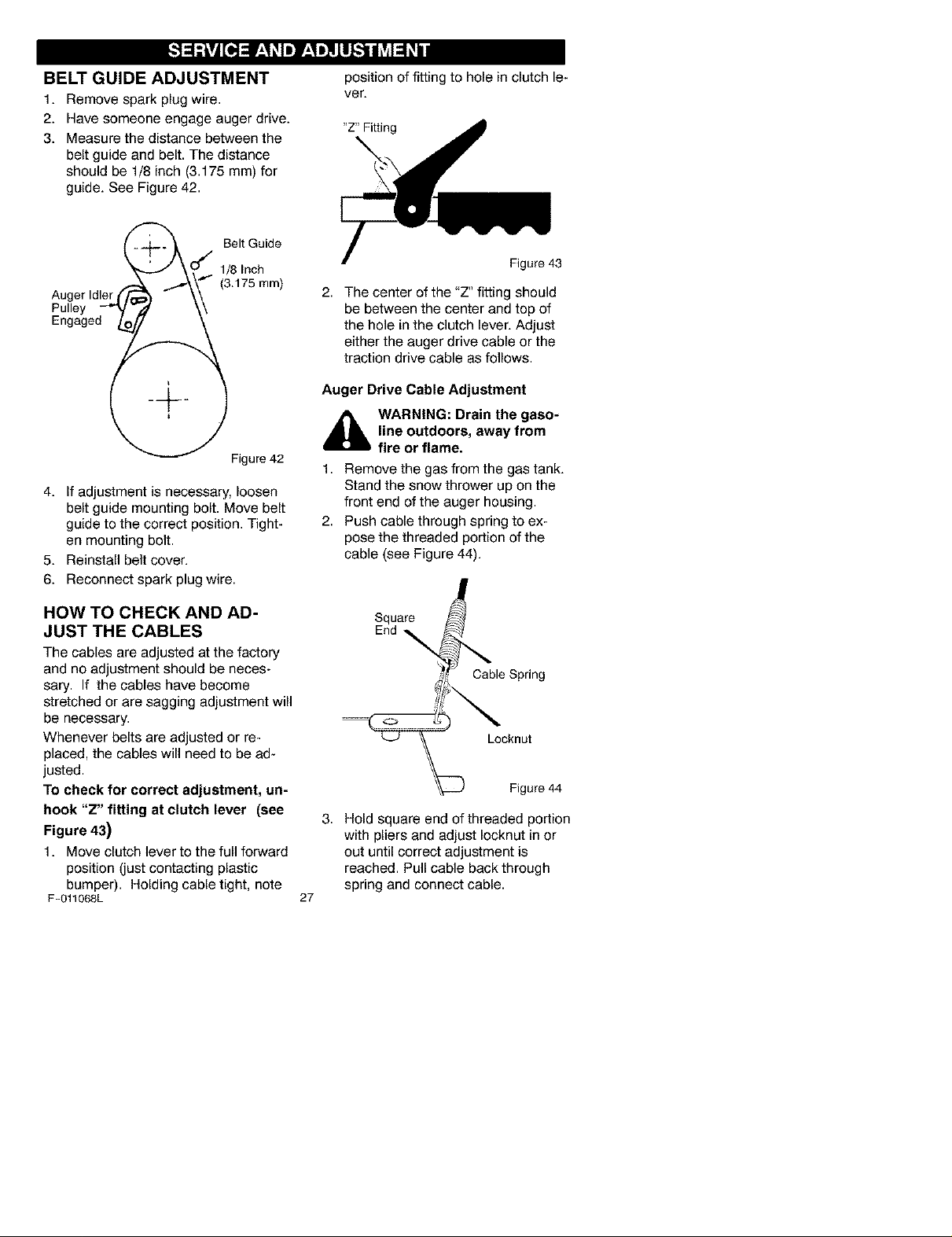

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage auger drive.

3. Measure the distance between the

belt guide and belt. The distance

should be 1/8 inch (3.175 ram) for

guide. See Figure 42.

Belt Guide

1/8 Inch

Auger Idler

Pulley LC;J

Engaged

(3.175 ram)

position of fitting to hole in clutch le-

ver.

"Z" Fitting

Figure 43

2. The center of the "Z" fitting should

be between the center and top of

the hole in the clutch lever. Adjust

either the auger drive cable or the

traction drive cable as follows.

Auger Drive Cable Adjustment

Figure42

4. If adjustment is necessary, loosen

belt guide mounting bolt. Move belt

guide to the correct position. Tight-

en mounting bolt.

5. Reinstall belt cover.

6. Reconnect spark plug wire.

HOW TO CHECK AND AD-

JUST THE CABLES

The cables are adjusted at the factory

and no adjustment should be neces-

sary. If the cables have become

stretched or are sagging adjustment will

be necessary.

Whenever belts are adjusted or re-

placed, the cables will need to be ad-

justed.

To check for correct adjustment, un-

hook "Z" fitting at clutch lever (see

Figure 43)

1. Move clutch lever to the full forward

position (just contacting plastic

bumper). Holding cable tight, note

F-O11068L

_ ARNING: Drain the gaso-

line outdoors, away from

fire or flame.

1. Remove the gas from the gas tank.

Stand the snow thrower up on the

front end of the auger housing.

2. Push cable through spring to ex-

pose the threaded portion of the

cable (see Figure 44).

Square

End

Cable Spring

Locknut

3. Hold square end of threaded portion

with pliers and adjust Iocknut in or

out until correct adjustment is

reached. Pull cable back through

spring and connect cable.

27

Figure 44

Page 28

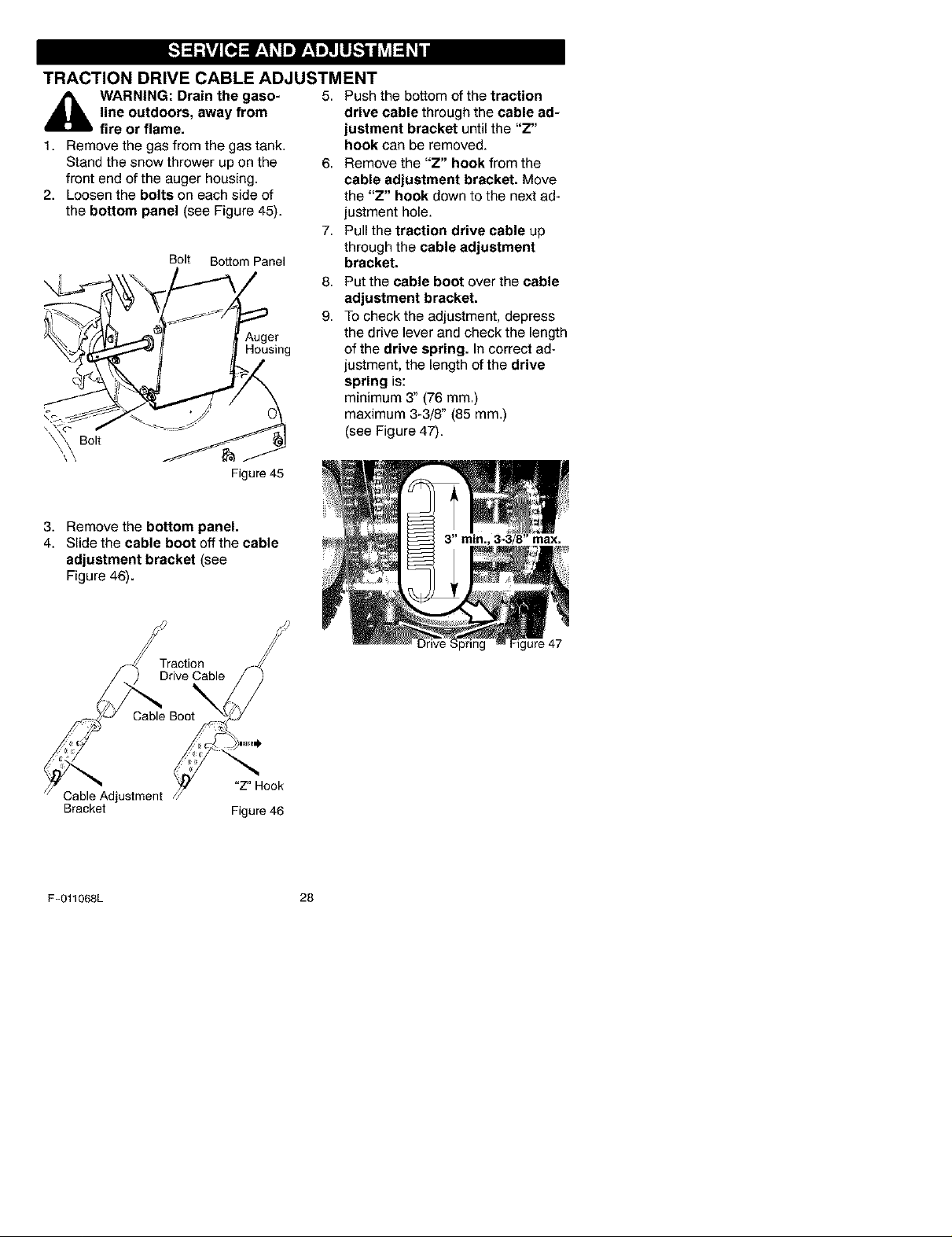

TRACTION DRIVE CABLE ADJUSTMENT

_lb WARNING: Drainthe gaso- 5. Pushthe bottomof thetraction

line outdoors, away from

fire or flame, justment bracket untilthe "Z"

1. Remove the gas from the gas tank.

Stand the snow thrower up on the

front end of the auger housing.

2. Loosen the bolts on each side of

the bottom panel (see Figure 45).

drive cable through the cable ad-

hook can be removed.

6. Remove the "Z" hook from the

cable adjustment bracket. Move

the "Z" hook down to the next ad-

justment hole.

7. Pull the traction drive cable up

Bolt Bottom Panel

through the cable adjustment

bracket.

8. Put the cable boot over the cable

adjustment bracket.

9. To check the adjustment, depress

Auger

Housing

the drive lever and check the length

of the drive spring. In correct ad-

justment, the length of the drive

spring is:

minimum 3" (76 ram.)

maximum 3-3/8" (85 mm.)

(see Figure 47).

\ \ Bolt _/._J

Figure45

3. Remove the bottom panel.

4. Slide the cable boot off the cable

3" min., 3-3/8" max.

adjustment bracket (see

Figure 46).

Cable Boo

i 9'""")

?

Cable Adjustment /_/ "Z" Hook

Bracket Figure46

F-011068L 28

Drive Spring Figure 47

Page 29

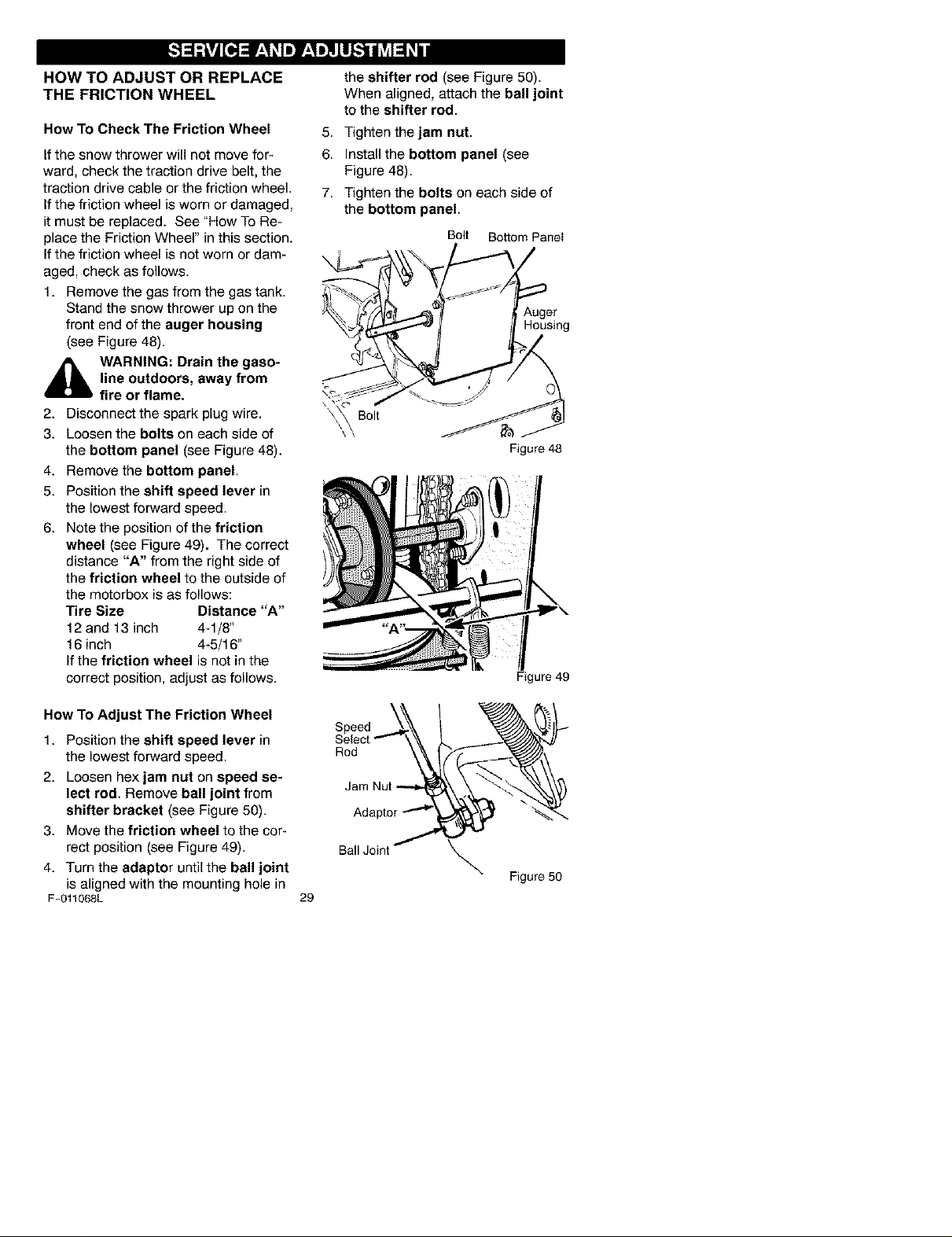

HOW TO ADJUST OR REPLACE the shifter rod (see Figure 50).

THE FRICTION WHEEL When aligned, attach the ball joint

to the shifter rod.

How To Check The Friction Wheel

Ifthe snow thrower will not move for-

ward, check the traction drive belt, the

traction drive cable or the friction wheel.

Ifthe friction wheel is worn or damaged,

it must be replaced. See "How To Re-

place the Friction Wheel" in this section.

Ifthe friction wheel is not worn or dam-

aged, check as follows.

1. Remove the gas from the gas tank.

Stand the snow thrower up on the

front end of the auger housing

(see Figure 48).

5. Tighten the jam nut.

6. Installthe bottom panel (see

Figure48).

7. Tighten the bolts on each side of

the bottom panel.

Bolt Bottom Panel

Auger

Housing

,_ WARNING: Drain the gaso-

2. Disconnect the spark plug wire.

3. Loosen the bolts on each side of

4. Remove the bottom panel.

5. Position the shift speed lever in

6. Note the position of the friction

How To Adjust The Friction Wheel

t. Position the shift speed lever in

2. Loosen hex jam nut on speed se-

3. Move the friction wheel to the cor-

4. Turn the adaptor until the ball joint

F-011068L

line outdoors, away from

fire or flame.

the bottom panel (see Figure 48).

the lowest forward speed.

wheel (see Figure 49). The correct

distance "A" from the right side of

the friction wheel to the outside of

the motorbox is as follows:

Tire Size Distance "A"

12 and 13 inch 4-1/8"

16 inch 4-5/16"

If the friction wheel is not in the

correct position, adjust as follows.

the lowest forward speed.

lect rod. Remove ball joint from

shifter bracket (see Figure 50).

rect position (see Figure 49).

is aligned with the mounting hole in

Figure48

Figure 49

Speed _

Select "_- _Jam Nut

Adaptor

Ball Joint/'_

\

Figure 50

29

Page 30

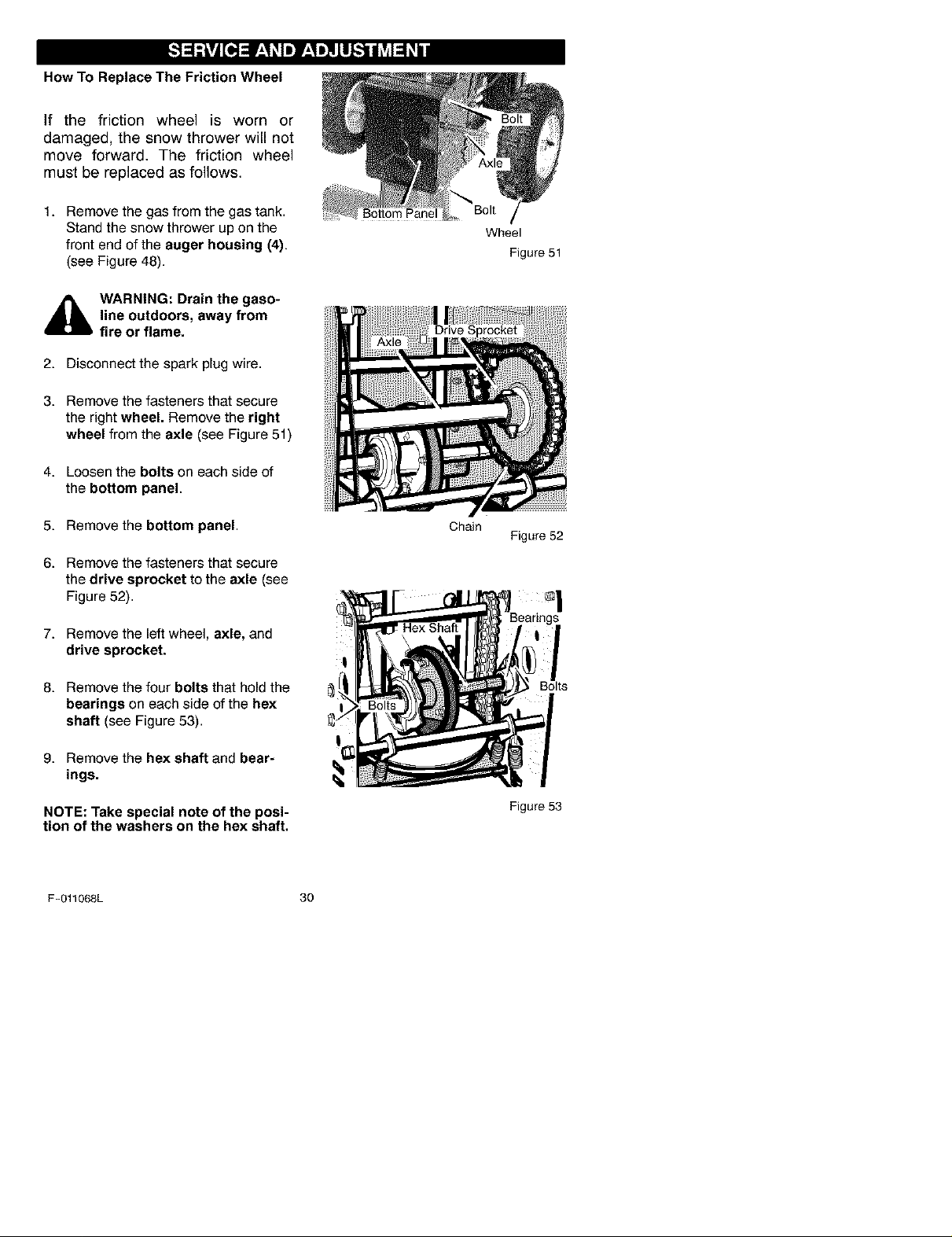

How To Replace The Friction Wheel

If the friction wheel is worn or

damaged, the snow thrower will not

move forward. The friction wheel

must be replaced as follows.

1. Remove the gas from the gas tank.

Stand the snow thrower up on the

front end of the auger housing (4).

(see Figure 48).

_hb ARNING: Drain the gaso-

line outdoors, away from

fire or flame.

2. Disconnect the spark plug wire.

3. Remove the fasteners that secure

the right wheel. Remove the right

wheel from the axle (see Figure 51)

4. Loosen the bolts on each side of

the bottom panel.

5. Remove the bottom panel.

6. Remove the fasteners that secure

the drive sprocket to the axle (see

Figure 52).

7. Remove the left wheel, axle, and

drive sprocket.

Chain

Bolt

Wheel

Figure 51

Figure 52

8. Remove the four bolts that hold the

bearings on each side of the hex

shaft (see Figure 53).

9. Remove the hex shaft and bear-

ings.

NOTE: Take special note of the posi-

tion of the washers on the hex shaft.

F-011068L 30

Bolts

Figure 53

Page 31

10. Remove the three fasteners that

hold the friction wheel to the hub

(see Figure 54).

11. Remove the friction wheel from the

hub. Slip the friction wheel off the

hex shaft.

12. Assemble the new friction wheel

onto hub with the fasteners re-

moved earlier.

13. Install the hex shaft and bearings

with the four bolts removed earlier

(see Figure 55).

Make sure the washers are prop-

erly installed in the original posi-

tion. Also, make sure the two

washers are properly aligned

with the actuator arms.

14. Make sure the hex shaft turns free-

ly.

15. Install the left wheel, axle, and

drive sprocket with the fasteners

removed earlier. Install the chain

onto the drive sprocket (see

Figure 52).

16. Check the adjustment of the friction

wheel. See "How To Adjust The

Friction Wheel" in this section.

17. Make sure the friction wheel and the

disc drive plate are free from grease

or oil.

18. Install the bottom panel (see

Figure 51).

19. Tighten the bolts on each side of

the bottom panel.

20. Install the right wheel to the axle

with the fasteners removed earlier.

21.

Connect the spark plug wire.

Fasteners

Hex Shaft

Friction

Hub Wheel

Fasteners

Figure 54

Actuator Arms

Bearings

\

Washer

F-011068L 31

Bearings

1

Washer

Washer

Figure 55

Page 32

HOW TO REPLACE

THE AUGER SHEAR BOLT

The augers are secured to the auger

shaft with special shear bolts. These

shear bolts are designed to break and

protect the machine if an object be-

comes lodged in the auger housing. Do

not use a harder bolt as the protection

provided by the shear bolt will be lost.

_hb WARNING: For safety andto

To replace a broken shear bolt, proceed

as follows. Extra shear bolts were pro-

vided in the assembly parts bag.

1. Move the throttle control to the stop

2. Disconnect the spark plug wire.

3. Align the hole in the auger with the

4. Connect the spark plug wire.

protect the machine, useonly

original equipment shearbolts.

position. Disengage all controls.

Make sure all moving parts have

stopped.

hole in the auger shaft. Install the

new shear pin and spacer. See

Figure 56.

/ •

_ She_arPin

Figure 56

TO ADJUST

THE CARBURETOR

Ifyou think your carburetor needs ad-

justing, see your nearest Craftsman

Store. Engine performance should not

be affected at altitudes up to 7,000 feet.

For operation at higher elevations, con-

tact your nearest Sears Store.

IMPORTANT: Never tamper with the

engine governor, which is factory set for

proper engine speed. Over-speeding

F-011068L

the engine above the factory high

speed setting can be dangerous. If you

think the engine-governed high speed

needs adjusting, contact your nearest

Sears Store, which has the proper

equipment and experience to make any

necessary adjustments.

TO ADJUST OR REPLACE

THE SPARK PLUG

If you have difficultystarting the snow

thrower, adjust or replacethe spark

plug. Replacethe sparkplug isthe

electrodes are pittedor burnedor ifthe

porcelainis cracked. Followthe instruc-

tions below.

To adjust:

1. Clean spark plug by carefully

scraping the electrodes (Do not

sand blast or use a wire brush).

2. Be sure spark plug is clean and

free of foreign material. Check elec-

trodes gap with a wire feeler gauge

and reset gap to 0.030" if neces-

sary. See Figure 57.

To Replace:

1. If you need a new spark plug, use

only the proper replacement spark

plug.

2. Set the gap to 0.030 inches.

3. Before installing the spark plug,

lightly coat the spark plug threads

with oil or grease to insure easy re-

moval.

4. Firmly tighten the spark plug in the

engine.

5. If a torque wrench is available,

torque the plug to 18 to 23 foot

pounds.

Feeler Gauge

Spark Plug

Figure 57

32

Page 33

_lb ARNING: Never store your

snow thrower indoors or in

an enclosed, poorly venti-

lated area. If gasoline remains in the

tank, fumes may reach an open

flame, spark or pilot light from a fur-

nace, water heater, clothes dryer,

cigarette, etc.

NOTE: To prevent engine damage (if

snow thrower is not used for more than

30 days) follow the steps below.

SNOW THROWER

1. Thoroughly clean the snow thrower.

2. Lubricate all lubrication points. See

the Maintenance section.

3. Be sure that all nuts, bolts and

screws are securely fastened. In-

spect all visible moving parts for

damage, breakage and wear. Re-

place if necessary.

4. Touch up all rusted or chipped paint

surfaces; sand lightly before paint-

ing.

5. Cover the bare metal parts of the

blower housing auger and the im-

peller with rust preventative, such

as a spray lubricant.

NOTE: A yearly checkup or tune-up by

a Sears service center is a good way of

ensuring that your snow thrower will

provide maximum performance for the

next season.

ENGINE

_blL ARNING: Drain the gaso-

Gasoline must be removed or treated to

prevent gum deposits from forming in

the fuel tank, filter, hose, and carburetor

during storage. Also, during storage al-

cohol blended gasoline that uses etha-

nol or methanol (sometimes called

gasohol) attracts water. It acts on the

gasoline to form acids which damage

the engine.

F-011068L

line outdoors, away from

fire or flame.

1,

TO remove gasoline, run the engine

until the fuel tank is empty and the

engine stops.

2.

If you do not remove the gasoline,

use fuel stabilizer supplied with unit

or purchase Craftsman Fuel Stabi-

lizer No. 3550. Add fuel stabilizer to

any gasoline left in the tank to mini-

mize gum deposits and acids. If the

fuel tank is almost empty, mix stabi-

lizer with fresh gasoline in a sepa-

rate container and add some to the

fuel tank.

3,

Always follow the instruction on the

stabilizer container. After the stabi-

lizer is added to the fuel tank, run

the engine at least ten minutes to

allow the mixture to reach the car-

buretor.

4,

Change the engine oil.

5.

Lubricate the piston/cylinder area.

First, remove the spark plug and

squirt a few drops of clean engine

oil into the spark plug hole. Next,

cover the spark plug hole with a rag

to absorb oil spray. Then, pull two or

three times on the recoil starter rope

to rotate the engine. Finally, install

the spark plug and attach the spark

plug wire.

OTHER

1. If possible, store your snow thrower

indoors and cover it to give protec-

tion from dust and dirt.

2. If the machine must be stored out-

doors, block up the snow thrower to

be sure the entire machine is off the

ground.

3. Cover the snow thrower with a suit-

able protective cover that does not

retain moisture. Do not use plastic.

IMPORTANT: Never cover snow

thrower while engine and exhaust areas

are still warm.

33

Page 34

TROUBLE CORRECTION

CAUSE

Difficult starting

Engine runs erratic Blocked fuel line, empty gas Clean fuel line; check fuel

Engine stalls Unit running on CHOKE. Set choke lever to RUN

Engine runs erratic; Water or dirt in fuel system. Use carburetor bowl drain to

Loss of power flush and refill with fresh fuel.

Excessive vibration Loose parts: damaged Stop engine immediately and

Unit fails to propel itself Drive belt ioose or damaged.

Unit fails to discharge

snow

Defectivespark plug.

Wateror dirtin fuel system.

tank, or stale gasoline supply; add fresh gasoline

impeller disconnect spark plug wire.

Incorrect adjustment of

traction drive cable

Worn or damaged friction

wheel,

Auger drive belt loose or

damaged.

Replace spark plug.

Use carburetor bowl drain to

flush and refill with fresh fuel.

position.

Tighten all bolts and make all

necessary repairs. If

vibration continues, have the

unit serviced by a Craftsman

service repairman.

Replace drive belt.

Adjust traction drive cable.

Replace friction wheel.

Adjust auger drive belt;

replace if damaged.

Auger control cable not Adjust auger control cable.

adjusted correctly.

Shear boit broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and

Foreign object lodged in Stop engine immediately and

auger disconnect spark plug wire.

F-011068L 34

disconnect spark plug wire.

Clean discharge chute and

inside of auger housing.

Remove object from auger.

Page 35

SEARS, ROEBUCK AND CO.

Federal and California Emission Control Systems Limited Warranty

Small Off-Road Engines

CALIFORNIA & US EPA EMISSION

CONTROL WARRANTY STATEMENT

The U. S. Environmental Protection Agency

("EPA"), the California Air Resources Board

("CARB") and Sears, Roebuck and Co. are

pleased to explain the Federal and California

Emission Control Systems Warranty on your

new small oft-road engine. In California, new

1995 and later smali oft-road engines must be

designed, built and equipped to meet the

State's stringent anti-smog standards. In oth-

er states, new 1997 and later model year en-

gines must be designed, built and equipped, at

the time of sale, to meet the U.S. EPA regula-

tions for small non-road engines. Sears, Roe-

buck and Co. will warrant the emission control

system on your small oft-road engine for the

periods of time listed below, provided there

has been no abuse, neglect, unapproved mod-

ification, or improper maintenance of your

small oft-road engine.

Your emission control system may include

parts such as the carburetor, ignition system

and exhaust system. Also included may be the

compression release system and other emis-

sion-related assemblies.

Where a warrantable condition exists, Sears,

Roebuck and Co. will repair your small off-

road engine at no cost to you for diagnosis,

parts and labor.

MANUFACTURER'S EMISSION

CONTROL SYSTEM WARRANTY

COVERAGE

Emission control systems on 1995 and later

model year California small oft-road engines

are warranted for two years as hereinafter

noted. In other states, 1997 and later model

year engines are also warranted for two years.

If, during such warranty period, any emission-

related part on your engine is defective in ma-

terials or workmanship, the part will be

repaired or replaced by Sears, Roebuck and

Co.

OWNER'S WARRANTY

RESPONSIBILITIES

As the small oft-road engine owner, you are

responsible for the performance of the re-

F-011068L

quired maintenance listed in your Owner's

Manual, but Sears, Roebuck and Co. will not

deny warranty solely due to the lack of receipts

or for your failure to provide written evidence

of the performance of all scheduled mainte-

nance.

As the small oft-road engine owner, you

should, however, be aware that Sears, Roe-

buck and Co. may deny you warranty cover-

age if your small oft-road engine or a part

thereof has failed due to abuse, neglect, im-

proper maintenance or unapproved modifica-

tions.

You are responsible for presenting your small

oft-road engine to a Sears, Roebuck and Co.

Authorized Service Outlet as soon as a prob-

lem exists. The warranty repairs should be

completed in a reasonable amount of time, not

to exceed 30 days.

Warranty service can be arranged by contact-

ing either a Sears, Roebuck and Co. Autho-

rized Service Outlet, or by contacting Sears,

Roebuck and Co. at 1-800-473-7247.

IMPORTANT NOTE

Esta This warranty statement explains your

rights and obligations under the Emission

Control System Warranty ("ECS Warranty")

which is provided to you by Sears, Roebuck

and Co. pursuant to California law. See also

the Sears, Roebuck and Co. Limited Warran-

ties for Sears, Roebuck and Co. which is en-

closed therewith on a separate sheet and also

is provided to you by Sears, Roebuck and Co.

The ECS Warranty applies only to the emis-

sion control system of your new engine. To the

extent that there is any conflict in terms be-

tween the ECS Warranty and the Sears, Roe-

buck and Co. Warranty, the ECS Warranty

shall apply except in any circumstances in

which the Sears, Roebuck and Co. Warranty

may provide a Iongerwarranty period. Both the

ECS Warranty and the Sears, Roebuck and

Co. Warranty describe important rights and

obligations with respect to your new engine.

Warranty service can only be performed by a

Sears, Roebuck and Co. Authorized Service

Outlet. At the time of requesting warranty ser-

vice, evidence must be presented of the date

of sale to the original purchaser. The purchas-

35

Page 36

ershallpayanychargesformakingservice

callsand/orfortransportingtheproductsto

andfromtheplacewheretheinspectionand/

orwarrantyworkisperformed.Thepurchaser

shallberesponsibleforanydamageorlossin-

curredinconnectionwiththetransportationof

anyengineoranypart(s)thereofsubmittedfor

inspectionand/orwarrantywork.

Ifyouhaveanyquestionsregardingyourwar-

rantyrightsandresponsibilities,youshould

contactSears,Roebuckand Oo. at

1-800-473-7247.

EMISSION CONTROL SYSTEM

WARRANTY

Emission Control System Warranty ("ECS

Warranty") for 1995 and later model year Cali-

fornia small off-road engines (for other states,

1997 and later model year engines):

A. APPLICABILITY: This warranty shall apply

to 1995 and later model year California small

off-road engines (for other states, 1997 and

later model year engines). The ECS Warranty

Period shall begin on the date the new engine

or equipment is delivered to itsoriginal, end-

use purchaser, and shall continue for 24 con-

secutive months thereafter.

B. GENERAL EMISSIONS WARRANTY

COVERAGE: Sears, Roebuck and Co. war-

rants to the original, end-use purchaser of the

new engine or equipment and to each subse-

quent purchaser that each of its small off- road

engines is:

1. Designed, built and equipped so as to con-

form with all applicable regulations adopted by

the Air Resources Board pursuant to its au-

thority in Chapters 1 and 2, Part 5, Division 26

of the Health and Safety Code, and

2. Free from defects in materials and work-

manship which, at any time during the ECS

Warranty Period, will cause awarranted emis-

sions-related part to fail to be identical in all

material respects to the part as described in

the engine manufacturer's application forcer[i-

fication.

C. The ECS Warranty only pertains to emis-

sions-related parts on your engine, as follows:

1. Any warranted, emissions-related parts

which are not scheduled for replacement as

required maintenance in the Owner's Manual

shall be warranted for the ECS Warranty Peri-

od. If any such part fails during the ECS War-

ranty Period, it shall be repaired or replaced by

F-011068L

36

Sears, Roebuck and Co. according to Subsec-

tion 4 below. Any such part repaired or re-

placed under the ECS Warranty shall be

warranted for any remainder of the ECS War-

ranty Period.

2. Any warranted, emissions-related part

which is scheduled only for regular inspection

as specified in the Owner's Manual shall be

warranted for the ECS Warranty Period. A

statement in such written instructions to the ef-

fect of "repair or replace as necessary", shall

not reduce the ECS Warranty Period. Any

such part repaired or replaced under the ECS

Warranty shall be warranted for the remainder

of the ECS Warranty Period.

3. Any warranted, emissions-related part

which is scheduled for replacement as re-

quired maintenance in the Owner's Manual,

shall be warranted for the period of time prior

to the first scheduled replacement point for

that part. Ifthe part fails prior to the first sched-

uled replacement, the part shall be repaired or

replaced by Sears, Roebuck and Co. accord-

ing to Subsection 4 below. Any such emis-

sions-related part repaired or replaced under

the ECS Warranty, shall be warranted for the

remainder of the ECS Warranty Period prior to

the first scheduled replacement point for such

emissions-related part.

4. Repair or replacement of any warranted,

emissions-related part under this ECS War-

ranty shall be performed at no charge to the

owner at a Sears, Roebuck and Co. Autho-

rized Service Outlet.

5. The owner shall not be charged for diagnos-

tic labor which leads to the determination that

a part covered by the ECS Warranty is in fact

defective, provided that such diagnostic work

is performed at a Sears, Roebuck and Co. Au-

thorized Service Outlet.

6. Sears, Roebuck and Co. shall be liable for