Craftsman 536.886621 Owner's Manual

IMPORTANT MANUAL DO NOT THROW AWAY

OWNER'S

MANUAL

MODEL NO.

536.886621

caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This,Equipment

CRRFTSMRN®

8 HORSEPOWER

26" DUAL STAGE

120V. ELECTRIC START

SNOW THROWER

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND

A A

,L PLACE WIRE WHERE IT CANNOTt CONTACT SPARK PLUG AL

TOPREVENTAOO,DENTALSTART.NGW.ENSETT,.GUP

TRANSPORT,N ADJUST,N ORMAK,N REPA,RS

IMPORTANT

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT

AI-FEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCES.

TRAINING

1.

Read the operator's manual carefully. Be

thoroughly familiar with the controls and the

proper use of the snow thrower. Know how to

stop the snow thrower and disengage the

controls quickly.

2. Never allow children to operate the snow thrower

and keep them away while It Is operating. Never

allow adults to operate the snow thrower without

proper Instruction. DO not carry passengers.

3. Keep the area of operetlon clear of all persons,

particularly small children, and pets.

4. Exercise caution to avoid slipping or falling,

especially when operating In reverse.

PREPARATION

1. Thoroughly Inspect the area where the snow

thrower Is to be usedand removeall doormats,

sleds, boards,wires, and otherforeignobjects.

2. Disengage all clutches and shift Into neutral

before startingtheengine (motor).

3. Donotoperetethe snowthrowerwithoutweadng

adequate winterouter garments.Wearfootwear

that will Improvefootingon slipperysurfacse.

4. Handlefuel wIthcare; it Is highlyflammable.

(a) Use an approvedfuel container.

(b) Never removefuel tank cap or add fuel to a

runningengineor hotengine.

(c) Fill fuel tank outdoors with extreme care,

Never fillfueltank Indoors.

(d) Replace fuel tank cap securely and wipe up

spilled fuel.

(e) Never store fuel or snow thrower with fuel In

the tank Inside ofa building where fumes may

reach an open flame or spark.

(f) Check fuelsupplybefore each use,anowlng

spaceforexpenslonastheheatofthe engine

(motor)and/or suncan causefuel toexpend.

5. Useextsnsloncordssnd racaptaclesasspecified

by the manufacturerfor all snowthrowerswith

eiactrlc drivemotors orelectricstartingmotors.

6. Adjust the snow thrower height to clear gravel or

crushed rock surfaces,

7. Never aftempt to make any edjustmsnts while the

engine (motor) Is running (except when

specifically recommended by the manufacturer).

8. Let engine (motor) and snow thrower adjust to

outdoor temperatures before starting to clear

SNOW.

9. Always weer safety glasees or eye shields during

operetlon or while performing an adjustment or

repair to protect eyes from foreign objects that

may be thrown from the snow thrower.

OPERATION

1. Do not put hands or feet near or underrotating

parts. Keepclear of thedischarge openingatall

times.

2. Exercise extreme cautio n when operating on or

crossing gravel drives, walks, or roads. Stay alert

for hidden hazards or traffic.

3. After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors,

thoroughly Inspect the snow thrower for any

damage, and repair the damage before restarting

and operating the snow thrower.

4. If the snow thrower should start to vibrate

abnormally, stop the (motor) and check

Immediately forthe cause. Vlbretlon Is gsnerelly

a warning of trouble.

5. Stop the snglne (motor) wheheveryou leavethe

operating position, before unclogging the auger/

Impeller housing or dlsnherge guide, and when

making a nyrepairs, adjustments, or Inspections.

6. When cleaning, repairing, or Inspecting, make

cartaln the auger/impeller and all moving parts

have stopped. Disconnect the spark plug wire

and keep the wire away from the plug to prevent

accidental starting.

7. Take all possible precautions when leaving the

snow thrower unattended. Disengage the auger/

Impeller, shift to neutral, stop engine, and

remove key.

2

SAFETY RULES

8. DOnot runthe engine indoors, except when starting

the engine and fortransporting thesnow throwerIn

or out of the building. Open the outside doors;

exhaust fumes aredangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY GAS).

9. Do not clear snow across the face of slopes.

Exercise caution when changing direction on

slopes. Do not attempt to clear steep slopes.

10. Never operate the snow thrower without proper

guards, plates or other safety protective devices

In place.

11. Never operate the snow thrower near glass

enclosures, automobiles, window wells,

drop-offs, and the like wit hour proper adjustment

of the snow discharge angle. Keep children and

pets away.

12. Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

13. Neveroperatethesnowthrowerat hlghtransport

speeds on slippery surfaces. Look behind and

use care when becking.

14. Never direct dlscherge at bystanders or allow

anyone In front of the snow thrower.

15. Disengage power to the augerllmpeller when

snow thrower Is transported or not In use.

16. Use only sttachments and accessories approved

by the manufacturer of the snow thrower (such

as tire chains, electric start kits, etc.).

17. Never operate the snow thrower without good

vlslblnty or light. Always be sure of your footing,

and keep a firm hold on the handles. Walk; never

run.

MAI'NTENANCE AND STORAGE

1. Check shear bolts and other bolts at frequent

improper tightness to be sure the snow thrower

is In safe working condition.

2. Never store the snow thrower with fuel in the fuel

tank inside a building whers Ignition sourcee are

present such as hot water and space heaters,

clothes dryers, and the llke. Allow the engine to

cool before storing In any enclosure.

3. Always •refer to operator's manual instructions

for Important details If the snow thrower is to be

stored for an extended period.

4. Maintain or replace safety and Instruction labels,

as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the auger/

impeller.

WARNING

This snow thrower Is for use on sidewalks,

driveways, and other ground level surfaces.

CAUTION should be exercised while using on

steep sloping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE GROUND

LEVEL such as roofs of residences, garages,

porches or other such structures or buildings.

II_ LOOK I_OR THIS SYMBOL TO POINT ouT

I

A

IMPORTANT SAFETY PRECAUTIONS. IT I

MEANS--ATTENTIONll! BECOME ALERTt!!

YOUR SAFETY IS INVOLVED.

3

TABLE OF CONTENTS.

SAFETY RU LES ........................................ 2,3

PRODUCT SPECIFICATIONS ...................... 4

CUSTOMER RESPONSIBILITIES ..... 4,16-18

WARRANTY ................................................. 4

TABLE OF CONTENTS .............................. 5

INDEX ........................................................... 5

ASSEMBLY ................................................ 6-9

OPERATION .......................................... 10-15

SERVICE AND ADJUSTMENTS ........... 19-25

S'_ORAGE ................................................... 26

TROUBLE SHOOTING ............................... 27

REPAIR PARTS CSNOW THROWER)...28-38

REPAIR PARTS (ENGINEI .................... 39-42

PARTS ORDERING/SERVICE ................... 44

A

Adjustment:

Auger ............................................. 24

Belts............................................... 20

Belt Guide...................................... 22

Cable ............................................. 20

Carburetor ..................................... 24

FrictionWheel ................................ 22

Spark Plug...;................................. 25

Traction and Auger........................ 20

Assembly:

Check List ........................................ g

Crank Assembly .............................. 8

Headlight......................................... 9

Skid HeightAdjustment .............7, 19

Unpacking........................................ 7

B

Belts:

AdjustBelts.................................... 20

Belt Guide Adjustment................... 22

Belt Maintenance..................... 20, 21

Replace Belts ..;................ :............ 20

C

Cables. Clutch.......................... 7. 9, 20

Carburetor:................................. 24, 26

Choke ........._.................... t0, 1t, 13,14

Clutch, Auger................... 1O, 11, 13,14

Clutch, Traction............... 10, 11, 13,14

Controls:

Engine .......................... 10, 11, 13,14

Snow Thrower ........................ 10. 11

Crank:

AdjustingRod ............................ 8, 19

Assembly......................................... 8

Operation........................................ 10

Customer Responsibilities........4.16-18

Agreement....................................... 4

Auger Gear Box ............................ 18

Auger Shaft................................... 17

Engine ........................................... 18

General Recommendations.......... 16

Hex Shaft and Gears................ 17-18

Spark Plug..................................... 18

O

Deflector, SnowChute ......... I0. t 1.15

E

ElectricStarter................................. 13

Engine:

Control .................... 10. 11, 13, 14,15

Oil CaD.............. "...................... 12. 18

OilChange ..................................... 18

INDEX

Oil Level ............................. L.... 12, 18

• OilType ............................... _. 12. 18

Speed Governor ............................ 24

Starting the Engine ................... 13,14

Storage ........................... :.............. 26

F

Fuel, Type .................................... 4, 12

Fuel. Storage .............................. 13, 26

Friction Wheel:

Adjustment ..................................... 22

Replacement ................................. 23

G

Gears:

Auger Gear Box ............................. 18

Hex Shaft ....................................... 18

H

Handle, Upperand Lower .................. 7

Headlight............................................. 9

Height AdjustSkids ...................... 7. 19

Hex Shaft ......................................... 18

I

Ignition,Key..................... 10. 11, 13,14

Index .........:........................................ 5

L

Levers:

Auger DriveClutch ........7, 10, 11, 17

Choke ........................... 10, 11, 13,14

Shifter ...................................... 10, 11

Throttle Control ............ 10, 11.13, 14

TractionDrive Clutch..... 7, 10, 11, 14

Lubrication:

Auger Gear Box........................ 17-18

Auger Shaft.................................... 17

DiscDrive Plate............................. 18

Engine ........................................... 18

• Hex Shaft and Gears ............... :..... 17

O

Oil:

Engine ................................. 4, 12, 18

Extreme Cold Weather ............. 12,18

Storage ..................................... ;.._26

Type..................................... 4.12, 18

Operation:

Engine Controls ............ 10. 11.13,14

LockoutPin. Wheel........................ 12

Operating Snow Thrower...................

....................................... 10, 11.13,14

Snow ThrowingTips ...................... 15

Starting theEngine ................... 13.14

Snow Throwar Controls........... 10.11

P

Parts............................................ 28-41

Primer Button.................. 10,11, 13,14

R

Repair/Replacement Parts .......... 28-42

Recoil Starter ................................... 14

Replacements:

Auger Shear Bolt...................... .....24

Belts............................................... 20

FrictionWheel ............................... 22

S

Safety Rules ................................... 2. 3

Service and Adjustments:

Auger HousingHeight ............... 7, 19

Auger Shear Bolt........................... 24

Belts......................................... 20. 21

Belt Guide ....................... ...............22

Belt Replacement .......................... 21

Cable ..................................... 7. g, 20

Carburetor ............................... 24, 26

Chute Crank .................................. 19

FrictionWheel .......................... 22, 23

Scraper Bar ................................... 19

Spark Plug ..................................... 25

Service Recommendations .............. 27

Spark Plug .................................. 18, 25

Specifications ..................................... 4

Speed Governor ............................... 24

Startingthe Engine ...................... 13,14

Stopping the Engine ................... 11, 13

Stopping the Snow Thrower ............. t 1

Shipping Carton .............. ................ 6, 7

Skid Height ................................... 7, 19

Shifter Lever ................................ 10.11

Shear Bolts....................................... 24

Storage ............................................. 26

T

Table of Contents............................... 5

Tire Pressure.................................... 19

Trouble Shooting Chart .................... 27

Tools for Assembly ............................. 6

Traction Drive Belt.................. ..... 20,21

W

Warranty ............................................. 4

Wheel. Lockout Pin .......................... 12

5

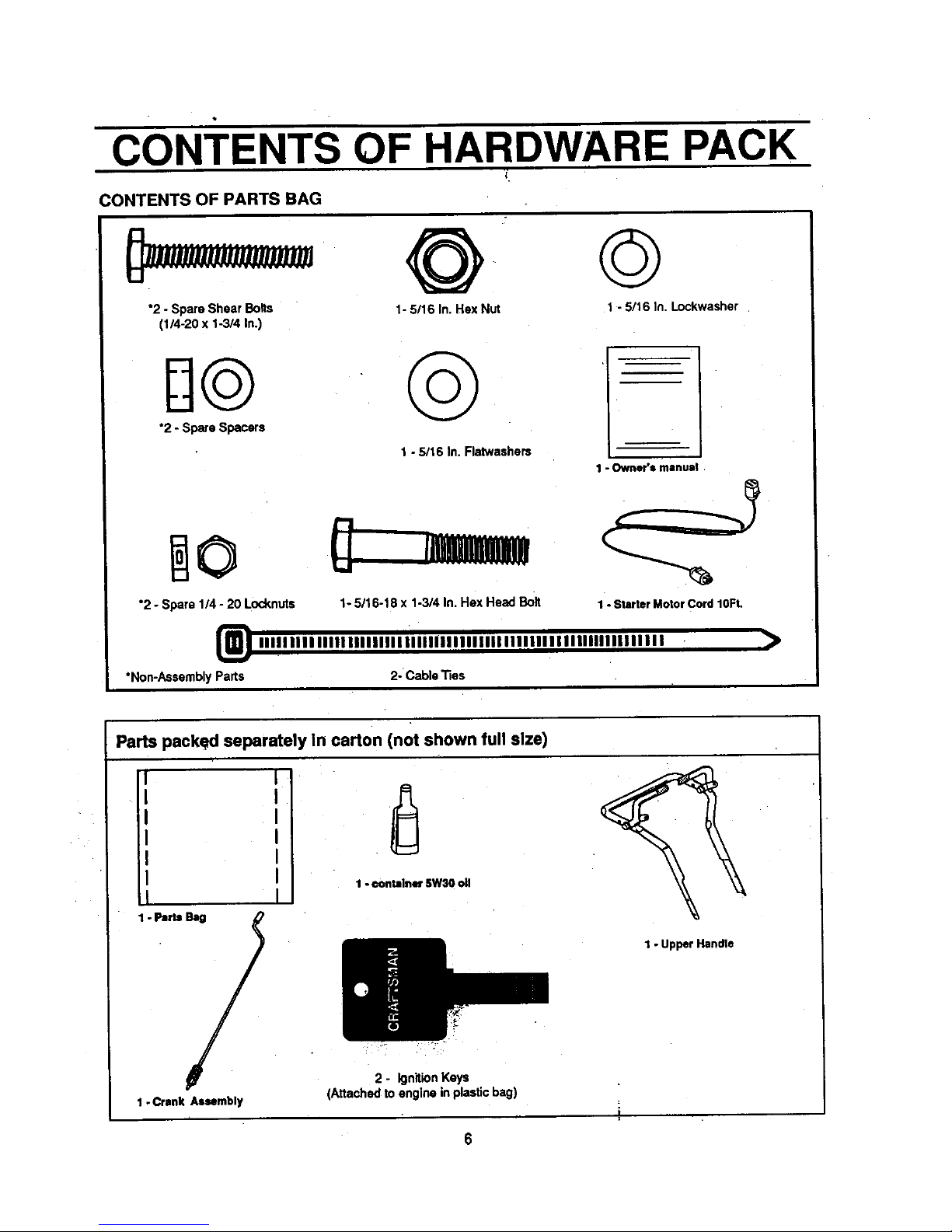

CONTENTS OF HARDWARE PACK

:ONTENTS OF PARTS BAG

"2 - Spare Shear Bolts

(1/4-20 x 1-3/4 in.)

@ ©

1- 5/16 In. Hex Nut

1 - 5/16 In. Lockwasher

H@ @

*2 - Spare Spacers

1 -5/16 In. Flatwashers

*2 - Spare 114- 20 Locknuts

*Non-Assembly Parts

1 "Owner's manual

1- 5/16-18 x 1-3/4 In. Hex Head Bolt

iiIIIIIn iiinlllllllllllllllllllllllll II IIIIIIIInlllllllllllll

2- Cable _es

1 -Starter Moto! Cord 10Ft.

>

Parts packed separately In carton (not shown full size)

I I

I

I

I

I

I

I

1-Parts _

1-Crank Assembly

1- €ontainer5W30 oli

2 - IgnitionKeys

(Attached to engine inplastic bag)

1 - UpperHandle

6

SERVICE AND ADJUSTMENTS

CAUTION: ALWAYS DISCONNECTTHE

SPARK PLUG WIRE AND TIE BACK

AWAY FROMTHE PLUG BEFORE MAK-

ING ANY ADJUSTMENTS OR REPAIRS.

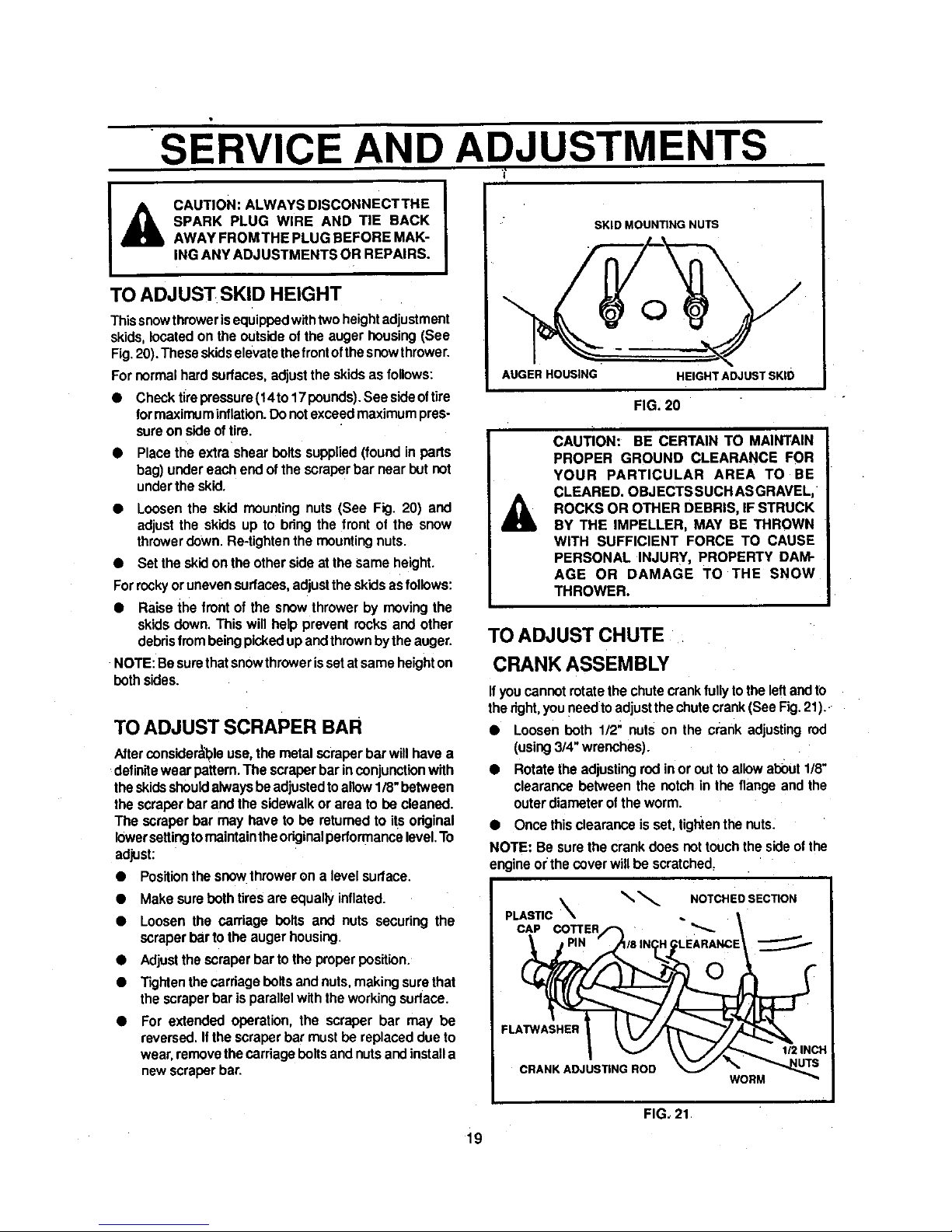

TO ADJUST SKID HEIGHT

Thissnowthroweris equippedwithtwoheightadjustment

skids,located onthe outsideof the auger housing(See

Fig.20).These skidselevatethefront ofthesnowthrower.

For normalhardsudaces, adjustthe skids as follows:

• Check tirepressure(14to17 pounds).See sideoftire

formaximuminflation.Donotexceedmaximumpres-

sureon sideof tire.

• Place the extra shear boltssupplied(found in parts

bag) undereach end of thescraperbar near but not

underthe skid.

• Loosen the skid mountingnuts (See Fig. 20) and

adjustthe skids up to bring the front of the snow

throwerdown. Re-tightenthe mounting nuts.

• Set the skid on the othersideat the same height.

Forrockyoruneven surfaces,adjustthe skidsasfollows:

• Raise the frontof the snowthrower by movingthe

skids down.This will help prevent rocks and other

debrisfrombeingpickedup andthrownbythe auger.

NOTE: Besurethatsnowthrowerissetat sameheighton

both sides.

TOADJUSTSCRAPER BAR

Afterconsiderableuse,the metal scraper bar willhave a

definitewear pattern. The scraperbar inconjunctionwith

theskids shouldalwaysbe adjustedtoallow1/8"between

the scraperbar and the sidewalkor area to be cleaned.

The scraper bar may have to be returned to itsoriginal

lowersettingtomaintaintheoriginalperformancelevel.To

adjust:

• Positionthe snowthroweron a level sudace.

• Make sureboth tiresare equallyinflated.

• Loosen the carriage bolts and nuts securing the

scraperbar tothe augerhousing.

• Adjustthe scraper bar tothe properposition.

• Tightenthecarriagebolts and nuts,makingsurethat

the scraperbar is parallelwiththe workingsurface.

For extended operation, the scraper bar may be

reversed. Ifthe scraper barmust be replaceddue to

wear,removethecarriage bolts andnutsandinstalla

newscraperbar.

SKID MOUNTING NUTS

AUGER HOUSING

HEIGHTADJUSTSKID

FIG. 20

A

CAUTION: BE CERTAIN TO MAINTAIN

PROPER GROUND CLEARANCE FOR

YOUR PARTICULAR AREA TO BE

CLEARED. OBJECTSSUCH ASGRAVEL,

ROCKS OR OTHER DEBRIS, IF STRUCK

BY THE IMPELLER, MAY BE THROWN

WITH SUFFICIENT FORCE TO CAUSE

PERSONAL INJURY, PROPERTY DAM-

AGE OR DAMAGE TO THE SNOW

THROWER.

TO ADJUST CHUTE

CRANK ASSEMBLY

Ifyou cannot rotatethe chutecrankfully tothe leftandto

thedght,youneedto adjustthechutecrank(See Fig.21).

• Loosen both 1/2" nuts on the crank adjustingrod

(using3/4" wrenches).

• Rotatethe adjustingrod inor outto allowabout1/8"

clearancebetween the notch in the flange and the

outerdiameter ofthe worm.

• Once thisclearance isset, tigtltenthe nuts.

NOTE: Be surethe crankdoes not touchthe sideofthe

engineor the coverwillbe scratched.

_ NOTCHED SECTION

PLASTIC

CAP COTTER "_-

FLATWASHER

CRANK ADJUSTING ROD

WORM

1/2 INCH

FIG, 21

i9

SERVICE AND ADJUSTMENTS

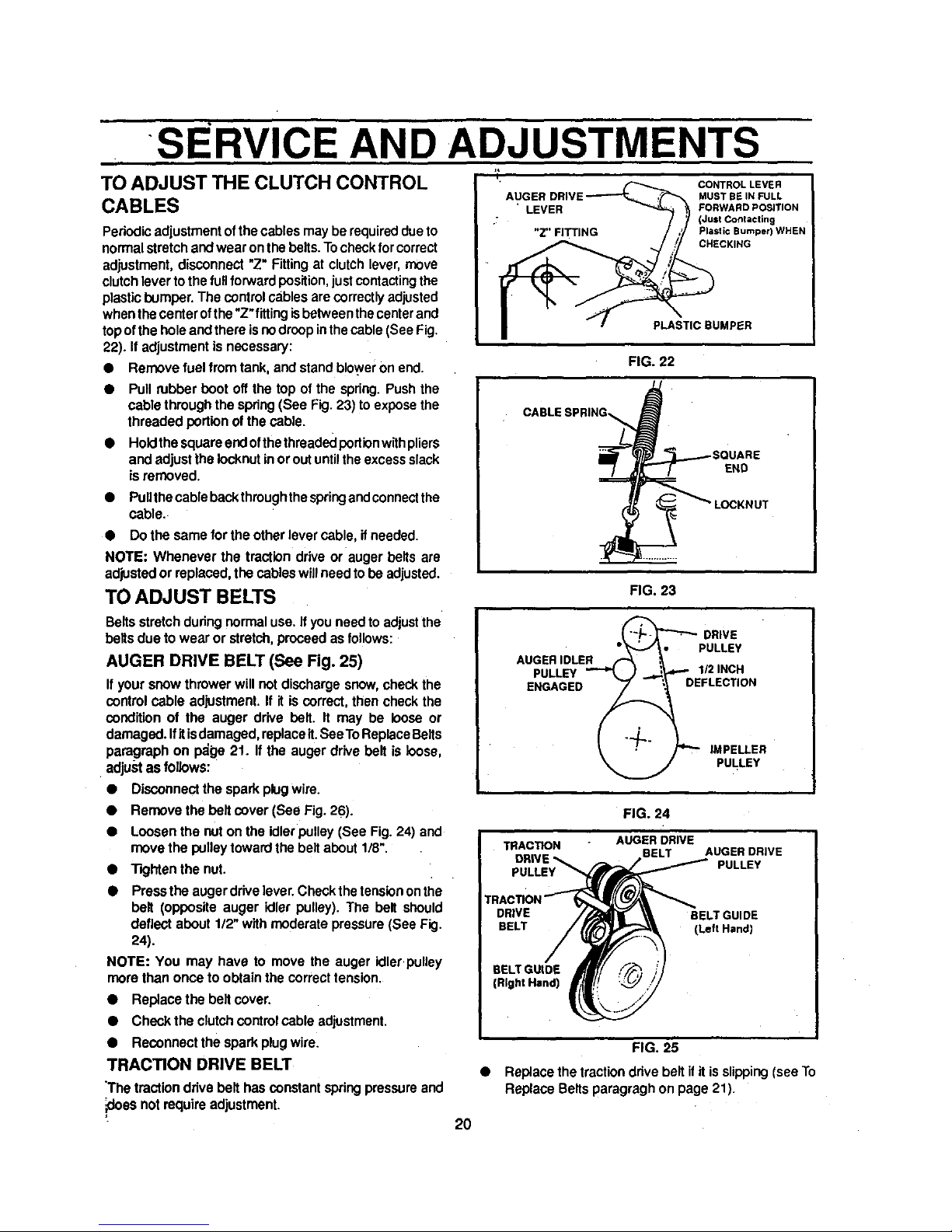

TO ADJUST THE CLUTCH CONTROL

CABLES

Periodic adjustmentofthe cables may be required dueto

normalstretch andwear onthe belts. Tocheckfor correct

adjustment, disconnect "Z" Fittingat clutch lever, move

clutch lever to the fullforward position, just contactingthe

plastic bumper. The control cablesarecorrectly adjusted

when the centerofthe "Z"fittingisbetween the centerand

top ofthe hole and there is no droop in thecable (See Fig.

22). If adjustment is necessary:

• Remove fuel from tank, and stand blo_'er on end.

• Pull rubber boot off the top of the spring. Push the

cablethrough the spring(See Fig. 23)toexposethe

threaded portionof thecable.

• Holdthe squareendofthethreadedportionwithpliers

and adjustthe Iocknutinoroutuntiltheexcessslack

isremoved.

• PuUthe cableback thmughthe springandconnectthe

cable.

• Do the same for theother levercable, ifneeded•

NOTE" Whenever the traction drive or auger belts are

adjusted or replaced, the cableswill needto be adjusted.

TO ADJUST BELTS

Beltsstretchduring normal use. If you needto adjustthe

beltsdue to wear or stretch, proceedas follows:

AUGER DRIVE BELT (See Fig. 25)

Ifyour snow thrower will not dischargesnow,check the

control cable adjustment.If it is correct, then checkthe

condition of the auger drive belt. It may be loose or

damaged.Ifit isdamaged,replaceit.SeeToReplaceBelts

paragraph on p_ge 21. If the auger drive belt is loose,

adjust as follows:

• Disconnectthe sparkplugwire.

• Remove the beltcover (See Fig.26).

• Loosenthe nuton the idlerpulley (See Fig. 24) and

movethe pulleytoward the belt about1/8".

• TKjhtenthe nut.

• Pressthe augerdrive lever.Checkthetensiononthe

belt (opposite auger idler pulley). The belt should

deflect about 1/2" withmoderate pressure(See Fig.

24).

NOTE: You may have to move the auger idler.pulley

mere than once to obtain the correcttension.

• Replacethe belt cover.

• Check the clutchcontrolcable adjustment.

• Reconnectthe sparkplugwire.

TRACTION DRIVE BELT

The tractiondrive belt hasconstantspringpressure and

_doesnot requireadjustment.

2O

•.UGEn0.,VE .

' LEVER _'_ _1 FORWARDPOSITION

.T _ (Just Contacting

"Z"FITTING / ,_ PlaslicBumper)WHEN

| "I- P ,,oau.PEn

FIG. 22

i

OAaLESPR,NG\L

.__ LOCKNUT

FIG. 23

ii

_ DRIVE

_'_-,,/_ • PULLEY

AUGER DLER _ ,_

PULLEY "_ )_..._"" 1/2 INCH

ENGAGED _ i EFLECTION

_, : /"-" IMPELLER

_ PULLEY

FIG. 24

FIG. 25

• Replacethe tractiondrive beltif it isslipping(seeTo

Replace Beltsparagraghon page21).

SERVICE AND ADJUSTMENTS

t

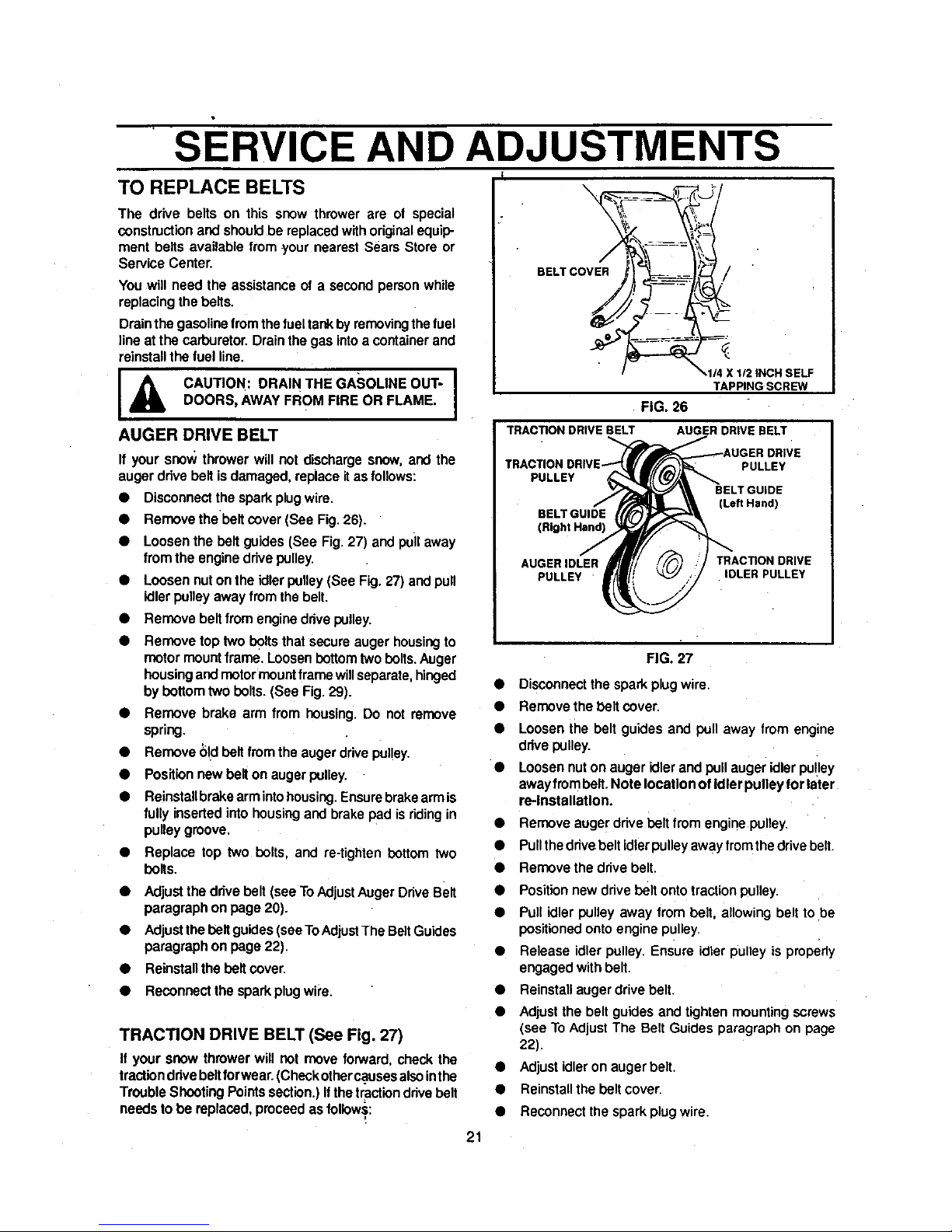

TO REPLACE BELTS \

The drive belts on this snow thrower are ot special

constructionandshould bereplacedwithoriginalequip-

ment belts available from your nearestSears Store or

Service Center.

You will need the assistanceof a secondpersonwhile

replacingthebelts.

Drainthe gasolinefromthe fueltar¢_byremovingthefuel

line atthe carburetor.Drainthegas intoa containerand

reinstallthe fuelline.

BELT COVER /

IA CAUTION: DRAIN THE GASOLINE OUT" I

DOORS, AWAYFROM FIRE OR FLAME.

AUGER DRIVE BELT

If your snow throwerwill not dischargesnow,and the

augerdrive beltis damaged, replaceitas follows:

• Disconnectthe sparkplugwire.

• Removethebelt cover (See Fig. 26).

• Loosen the belt guides (See Fig. 27) and puil away

from the enginedrivepulley.

• Loosen nuton the idlerpulley(See Fig.27) and pull

idlerpulleyaway from thebelt.

Remove beltfrom enginedrivepulley.

Remove toptwo boltsthat secureauger housingto

motormount frame. Loosenbottom two bolts.Auger

housingand motormount framewillseparate,hinged

by bottom two bolts. (See Fig. 29).

• Remove brake arm from housing.Do not remove

spring.

• Remove bid belt fromthe augerdrivepulley.

• Positionnewbelton augerpulley.

• Reinstallbrakearmintohousing.Ensurebrakearmis

fullyinsertedinto housingandbrakepad isriding in

pulleygroove.

• Replace top two bolts, and re-tightenbottom two

bolts.

• Adjustthe drive belt(seeToAdjust Auger DriveBelt

paragraphon page20).

• Adjustthe beltguides(seeToAdjustThe BeltGuides

paragraphon page22).

• Reinstallthe belt cover.

• Reconnectthe sparkplugwipe.

TRACTION DRIVE BELT (See Fig. 27)

If your snow throwerwill not move forward, check the

tractionddvebeltforwear.(Checkotherc.ausesalsointhe

TroubleShootingPointssection.)If thetractiondrivebelt

needsto be replaced,proceedas follows:

TAPPINGSCREW

FIG. 26

AUGERDRIVE BELTTRACTIONDRIVEBELT

PULLEY

PULLEY

BELTGUIDE

(Left Hand)

BELTGUIDE

(Right Hand)

AUGER IDLER TRACTION DRIVE

PULLEY IDLER PULLEY

FIG. 27

Disconnectthe sparkplugwire.

Remove the beltcover,

Loosen the belt guides and pull away from engine

drivepulley.

Loosennuton auger idlerand pullauger idlerpu!ley

awayfrombelt.Note locationof Idler pulley for later

re-Installation.

Remove augerdrivebeltfrom enginepulley,

Pullthedrivebeltidlerpulleyawayfrom thedrivebelt.

Removethe drivebelt,

Positionnew drivebelt onto tractionpulley.

Pullidler pulley away from belt, allowing belt tobe

positioned onto engine pulley.

Release idler pulley. Ensure idler pulley isproperly

engaged with belt.

Reinstall augerdrive belt.

Adjust the belt guidesand tighten mounting screws

(see To Adjust The Belt Guides paragraph on page

22).

Adjust idleron auger belt.

Reinstall the belt cover.

Reconnect the spark plug wire.

21

SERVICE AND ADJUSTMENTS

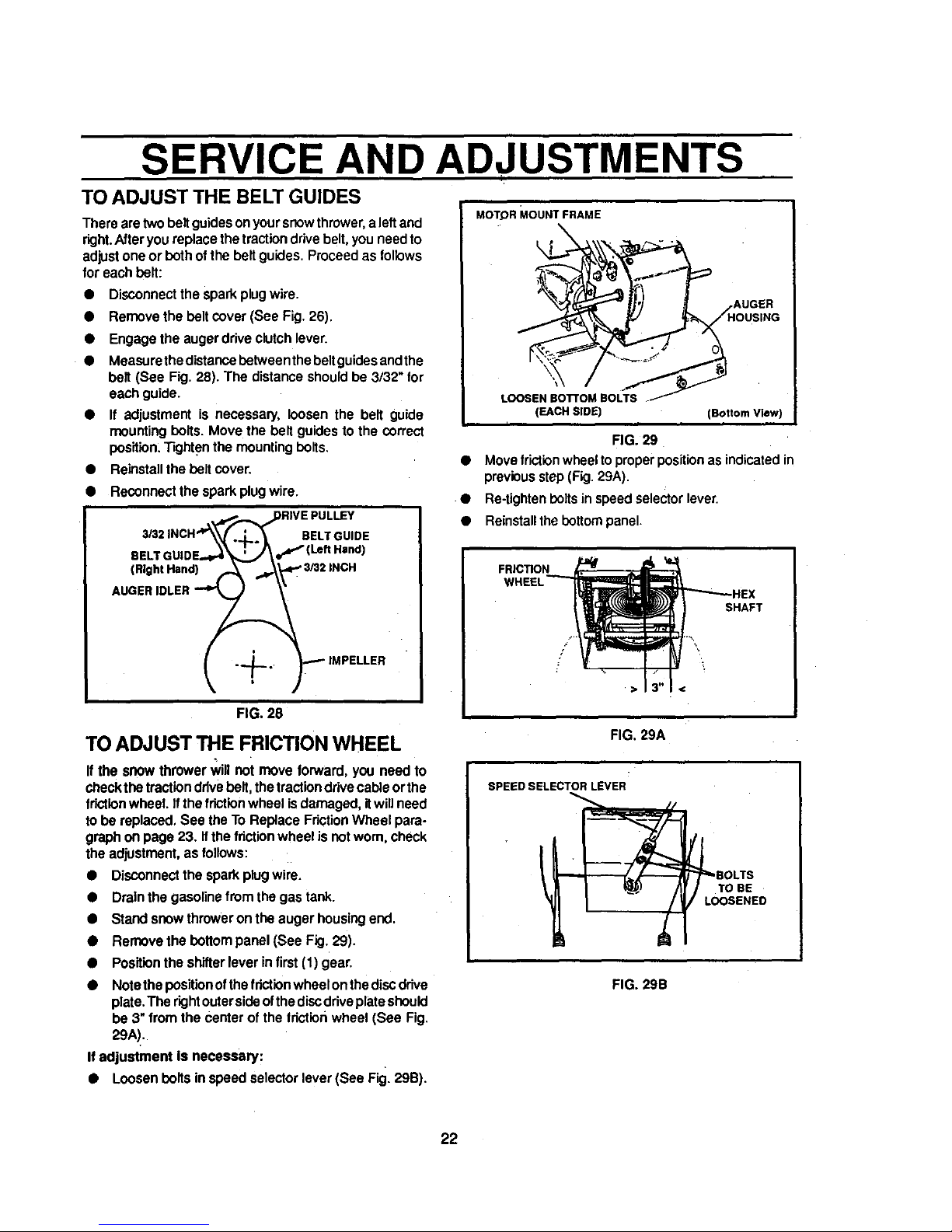

TO ADJUST THE BELT GUIDES

There aretwo beltguidesonyoursnowthrower, a leftand

right.Afteryou replacethe traction drivebelt, youneed to

adjust one or bothof the beltguides. Proceedas follows

for each bolt:

• Disconnectthe spark plugwire.

Removethe bolt cover (See Fig. 26).

Engagethe auger driveclutchlever.

Measurethe distancebotween thebeltguidesendthe

belt (See Fig. 28). The distanceshouldbe 3/32" for

each guide.

• If adjustment is necessary, loosen the belt guide

mountingbolts. Move the belt guidesto the correct

position.Tightenthe mounting bolts.

• Reinstallthe bolt cover.

• Reconnectthe sparkplugwire.

eEL'

(Right Hand)

BELTGUIDE

FIG. 28

TO ADJUST THE FRICTION WHEEL

If the snow thrower_11not move forward,you need to

check the tractionddvebolt, thetractiondrivecable orthe

frictionwheel. Ifthefrictionwheel isdamaged, itwill need

to be replaced, See theTo Replace FdctionWheel para-

graph onpage 23. Ifthe fdctionwheel is notworn, check

the adjustment,as follows:

• Disconnectthe sparkplugwire.

• Drainthe gasolinefrom thegas tank.

• Stand snow throweronthe auger housingend.

• Remove the bottompanel (See Fig. 29).

• Positionthe shitterlever in first(1)gear.

Notethepositionofthefdctionwheelon thediscdrive

plate,The dghtoutersideofthe discdriveplateshould

be 3" from the center of the tdctionwheel (See Fig.

29A).

If adjustment is necessary:

• Loosen bolts in speed selectorlever(See Fig. 29B).

MOTOR MOUNT FRAME

LOOSEN BO'R'OM BOLTS .

(EACH SIDE) (Bottom View)

FIG. 29

• Move frictionwheel toproperpositionasindicatedin

previousstep(Fig.29A).

• Re-tightenboltsinspeedselector lever.

• Reinstallthebottompanel.

FRICTION

SHAFT

/

FIG. 29A

SPEED SELECTOR LEVER

FIG. 29B

22

Loading...

Loading...