CRRFTSMRN"

Operator’s Manual

Snow Thrower

8 Horsepower Electric Start Dual Stage

Model 536.881800

CAUTION: Before using this product,

read this manual and follow all of its

Safety Rules and Operating Instructions.

W

»

Manual del usarlo

Quitanieves

8 caballos de fuerza (hp) Bietápico

Arranque eléctrico

Modelo 536.881800

PRECAUCIÓN; Antes de usar este producto,

lea este manual y siga todas las reglas de

segundad e instrucciones de operación.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F-0410108L www.sears.com/craftsman

TABLE OF CONTENTS

WARRANTY STATEMENT

SAFETY RULES

............

INTERNATIONAL SYMBOLS.... 4

ASSEMBLY

OPERATION

...................................

.............................

MAINTENANCE ...........................

SERVICE AND ADJUSTMENT .. 21

...........

.............

2

11

18

2

STORAGE .................................. 33

TROUBLESHOOTING TABLE ... 34

REPAIR PARTS

6

ENGINE REPAIR PARTS

..........................

SPANISH (ESPAÑOL)

PARTS ORDERING/SERVICE ..

BACK COVER

...........

...

.............. 63

WARRANTY STATEMENT

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow thrower is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner’s manuai, Sears will repair, free of charge, any defect in material or workmanship.

If this Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

• Items which become worn during normal use, such as spark plugs, drive belts and shear

pins.

• Repair necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner’s manuai.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWER TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates. IL60179

38

56

SAFETY RULES

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS— ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

A

A A

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro

ductive harm.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

F-0410108L

WARNING: Always discon

A

nect the spark plug wire

and place it where it cannot

make contact with spark plug to

prevent accidental starting during:

Preparation, Maintenance, or Stor

age of your snow thrower.

IMPORTANT: Safety standards re

quire operator presence controls to

minimize the risk of injury. Your snow

thrower is equipped with such controls.

Do not attempt to defeat the function of

the operator presence control under any

circumstances.

TRAINING OPERATION

1. Read this operating and service instruction 1,

manual carefully. Be thoroughly familiar

rwith the controls and the proper use of the

snow thrower. Know how to stop the snow

thrower and disengage the controls quick- ^

ly- '

2. Never allow children to operate the snow

thrower. Never allow adults to operate the ^

snow thrower without proper instruction. '

3. Keep the area of operation clear of all per

sons, particularly small children and pets. ^

4. Exercise caution to avoid slipping or falling '

especially when operating in reverse.

PREPARATION 5

1. Thoroughly inspect the area where the

snow thrower is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor). 6.

3. Do not operate the snow thrower without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces. 7

4. Handle fuel with care; it is highly flam

mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en- 8.

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with 9.

fuel in the tank inside of a building

where fumes may reach an open flame

or spark.

f. Check fuel supply before each use, al- 10-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5. For all snow throwers with electric starting

motors use electric starting extension 11.

cords certified CS/VUL. Use only with a re

ceptacle that has been installed in accord

ance with local inspection authorities.

6. Let engine (motor) and snow thrower ad- 12.

just to outdoor temperatures before starting

to clear snow.

7. Always wear safety glasses or eye shields

during operation or while performing an ad

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

F-0410108L :

Do not operate this snow thrower if you are

taking drugs or other medication which can

cause drowsiness or affect your ability to

operate this snow thrower.

Do not use the snow thrower if you are

mentally or physically unable to operate the

snow thrower safely.

Do not put hands or feet near or under ro

tating parts. Keep clear of the discharge

opening at all times.

Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

After striking a foreign object, stop the en

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

If the snow thrower should start to vibrate

abnormally, stop the engine (motor) and

check immediately for the cause. Vibration

is generally a warning of trouble.

Stop the engine (motor) whenever you

leave the operating position, before un

dogging the auger/impeller housing or dis

charge chute and when making any

repairs, adjustments, or inspections.

When cleaning, repairing, or inspecting,

make certain the auger/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

Take all possible precautions when leaving

the snow thrower unattended. Disengage

the auger/ impeller, stop engine (motor),

and remove key.

Do not start or run engine in enclosed area,

even if doors or windows are open. Ex

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS),

Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do not at

tempt to clear steep slopes.

Never operate the snow thrower without

proper guards, plates or other safety pro

tective devices in place.

13.

Never operate the snow thrower near en

closures, automobiles, window wells, dropoffs, and the like without proper adjustment

of the snow discharge angle. Keep children

and pets away.

14. Do not overload the snow thrower capacity

by attempting to clear snow at too fast a

rate.

15. Never operate the snow thrower at high

transport speeds on slippery surfaces.

Look behind and use care when backing

up.

16. Never direct discharge at bystanders or

ailow anyone in front of the snow thrower.

17. Disengage power to the coliector/impelier

when snow thrower is transported or not in

use.

18. Use only attachments and accessories ap

proved by the manufacturer of the snow

thrower {such as tire chains, electric start

kits, ect.).

19. Never operate the snow thrower without

good visibility or light. Aiways be sure of

your footing and keep a firm hoid on the

handies. Walk;never run.

20. Do not over-reach. Keep proper footing

and balance at aii times.

21. Do not attempt to use snow thrower on a

roof.

MAINTENANCE AND STORAGE

1. Check shear bolts and other bolts at fre

quent intervals for proper tightness to be

sure the snow thrower is in safe working

condition.

SYMBOLS

2. Store the snowthrower away from ignition

sources or appliances that have a pilot

light, such as hot water and space heaters,

clothes dryers, etc.... Allow the engine

(motor) to cool before storing in any enclos

ure.

3. Always refer to operator's guide instruc

tions for important details if the snow

thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction

labels, as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the

auger/impeller.

WARNING: This snow thrower is

for use on sidewalks, driveways

A

and other ground level surfaces.

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi

dences, garages, porches or other such

structures or buildings.

IMPORTANT: Many of the following symbols are located on your snow thrower or on litera

ture supplied with the product. Before you operate the snow thrower, learn and understand

the purpose for each symbol.

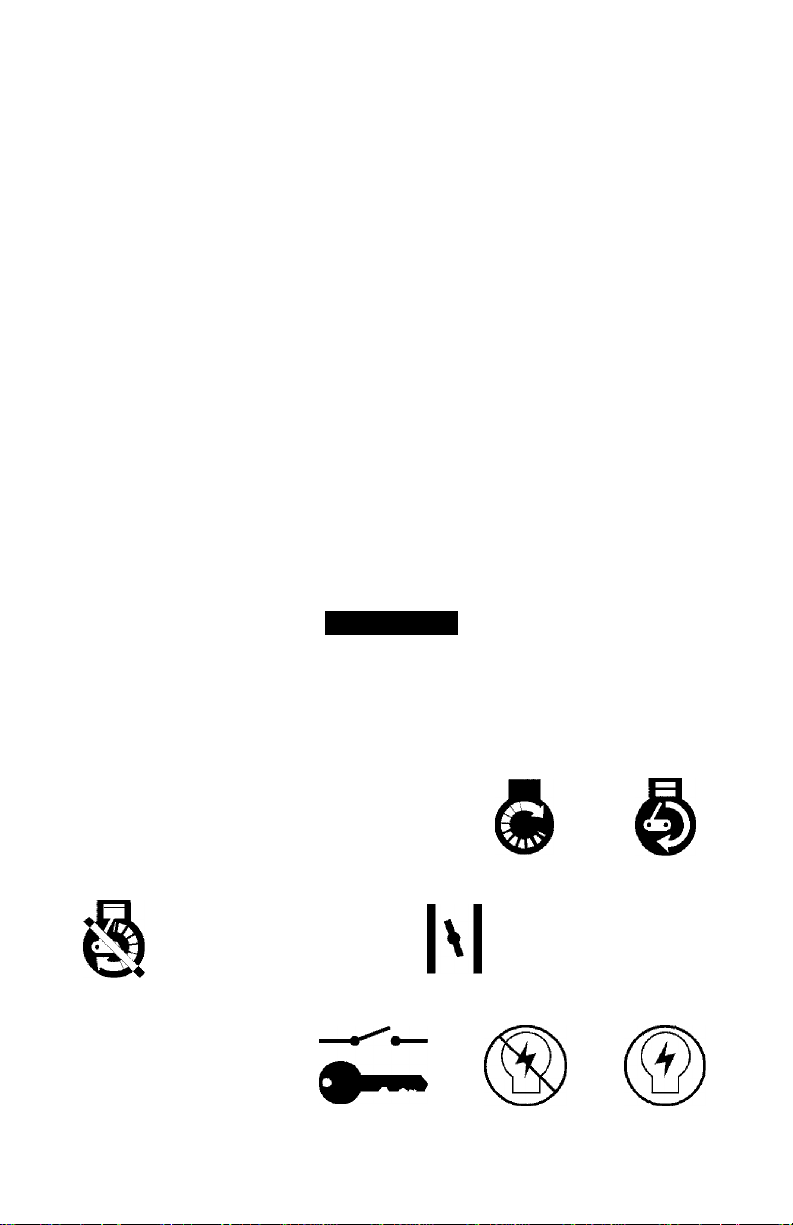

CONTROL AND OPERATING SYMBOLS

if ®

Slow Fast

O I

Engine Off Engine Stop On Choke Off Choke On Neutral

Electric Start Engine Start Engine Run

N

M

Throttle Primer Button ignition Key Ignition Off Ignition On

F-0410108L 4

! 5^ ■##■=&.

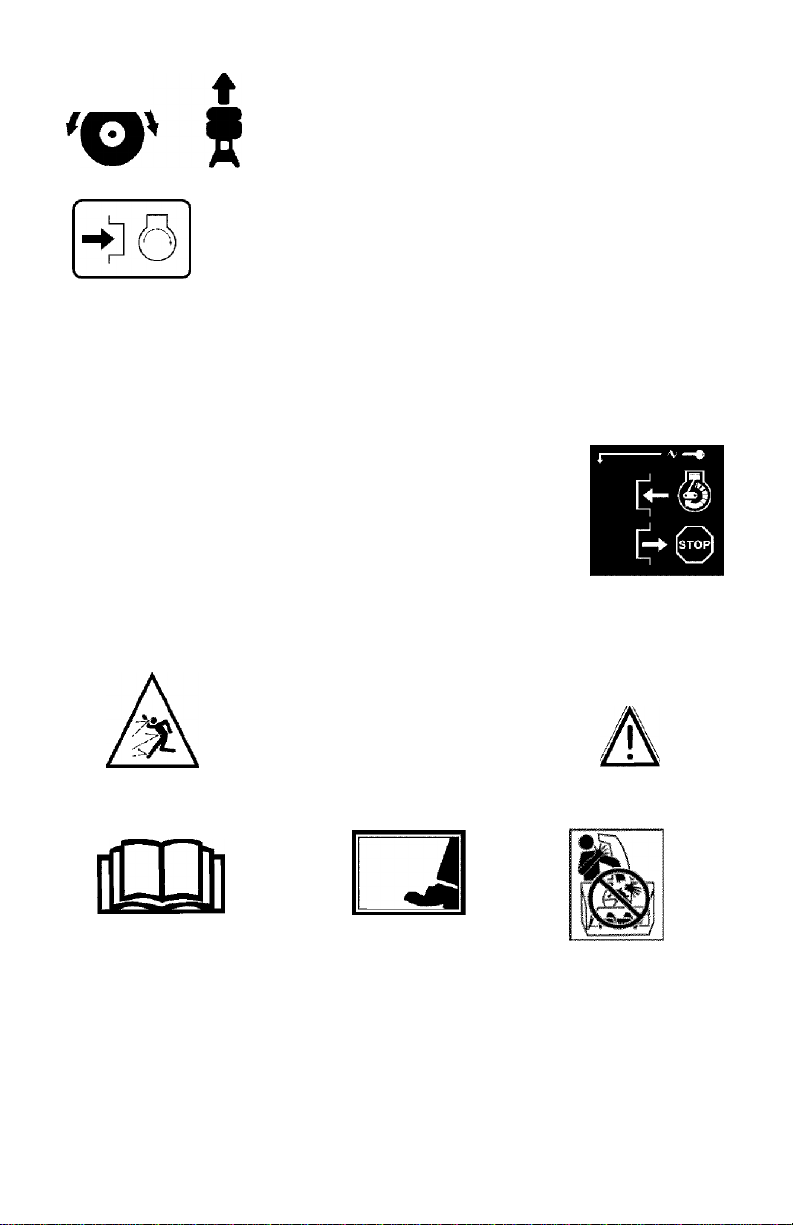

Drive Clutch Forward Reverse Auger Clutch Auger Collector Engage

Push To Engage

Electric Starter

1

Fuel

Oil

a-

é

Discharge DOWN Discharge UP Discharge LEFT Discharge RIGHT

O

Weight Transfer Weight Transfer

Lift Handle To Depress Pedal

Engage To Disengage

Safety Warning Symbols

DANGER

Thrown Objects.

Keep Bystanders Away.

I

Thrown Objects.

Keep Bystanders Away.

Transmission

DANGER

Fuel Oil Mixture

Ignition Key

Insert To Run,

Pull Out To Stop.

WARNING

IMPORTANT

Read Owner’s Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-0410108L

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

cii‘thit^g“Avi^yT Unclogging Discharge Chute!

DANGER

Stop The Engine Before

s

STOP

ASSEMBLY

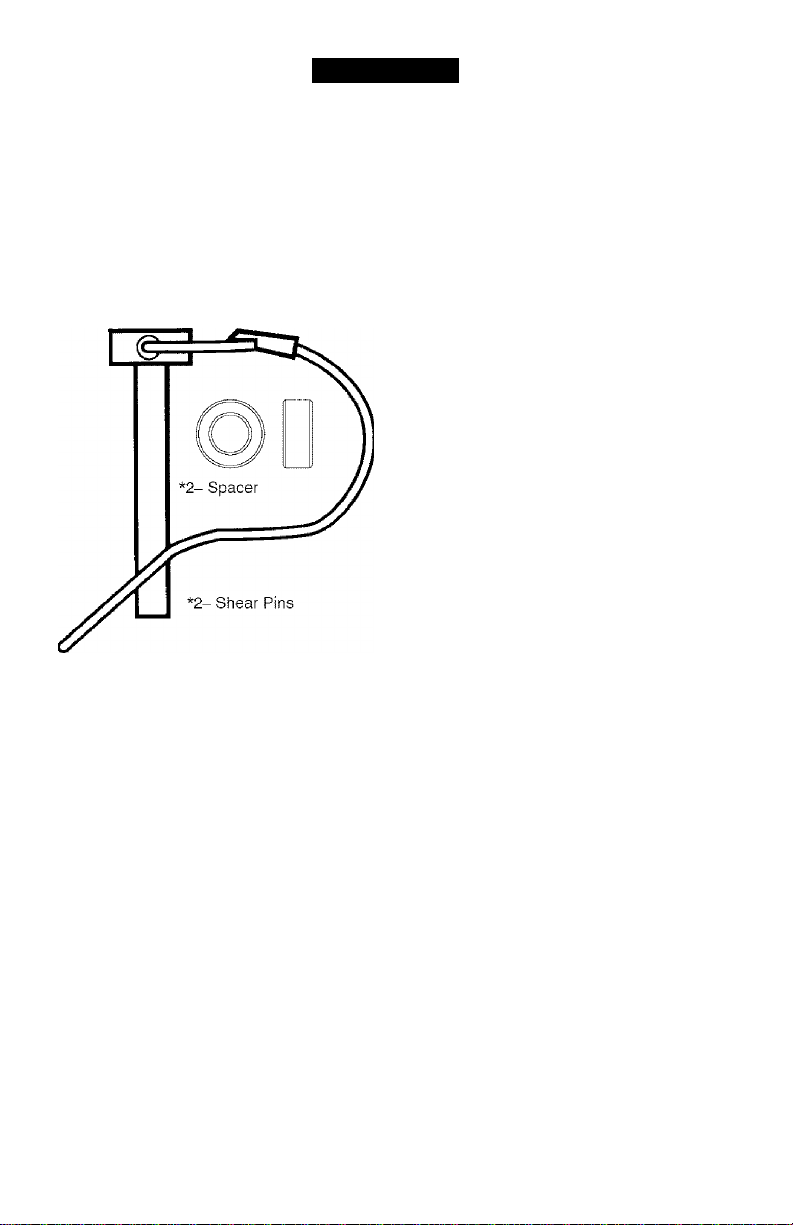

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Ownor’s Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assemb!y Parts, found in toolbox located on belt cover

F-0410108L

WARNING: Always wear

A

safety glasses or eye shields

while assembling snow

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

2-1/2 inch wrenches

(or adjustable wrenches)

2-9/16 inch wrenches

(or adjustable wrenches)

2 - 3/4 inch wrenches

(or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1 - Screwdriver

1 - Measuring tape or ruler

ASSEMBLY

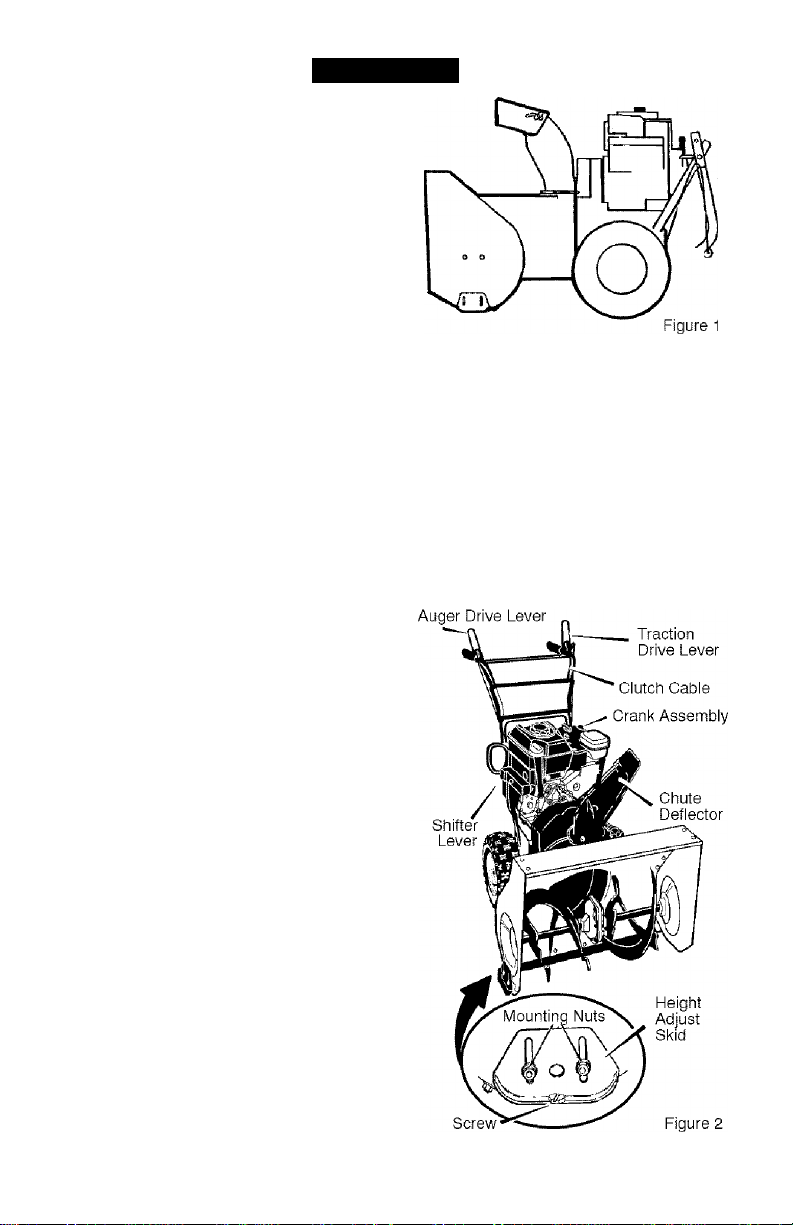

Figure 1 shows the snow thrower in the

shipping position.

Figure 2 shows the snow thrower com

pletely assembled.

References to the right or left hand side

of the snow thrower are from the view

point of the operator’s position behind

the unit.

TO REMOVE SNOW THROWER

FROM CARTON

1. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a

safe place until needed for storage.

2. Remove and discard the packing

material from around the snow

thrower.

3. Cut down all four corners of the car

ton and lay the panels flat.

4. Cut the straps that secure the axie

to the pallet.

5. For shipping purposes, the height

adjust skids are attached to the

pallet. Remove the screw that se

cures each height adjust skid to

the pallet. See Figure 2.

6. Roll snow thrower off the pallet by

pulling on the lower handle. CAU

TION; DO NOT back over control

cables.

7. Remove all packing material from

the unit.

8. Cut ties securing the clutch control

cable to the lower handle and lay

F-0410108L

cable back away from the motor

frame.

ASSEMBLY

TO ASSEMBLE THE HANDLE AND

CRANK ASSEMBLY

1. Cut tie holding shift rod to lower

handle and move shifter to the first

forward gear.

2. Cut and discard the plastic tie that

secures the crank assembly.

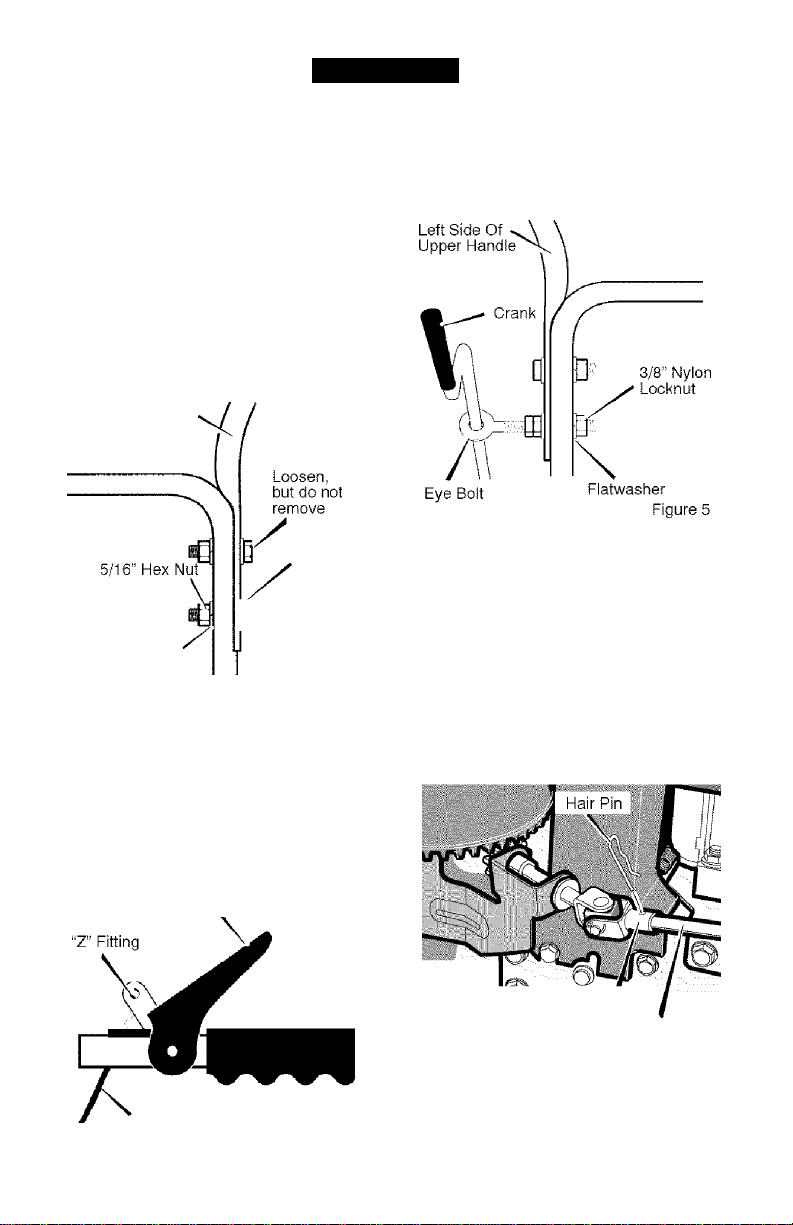

3. Loosen, but do not remove, the

screws, flatwashers, lockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

4. Remove the fasteners and the eye

bolt from the lower holes of the low

er handle See Figure 5.

Right Hand Side

Of Upper Handle

11/32"

Flatwasher

te / 6”

y / Screw

5/16” Split

Lockwasher

Figure 3

NOTE: Make sure the cables are

not caught between the upper and

lower handle.

5. Raise the upper handle into operat

ing position.

NOTE: If the cables have become dis

connected form the drive levers, rein

stall the cables as shown in Figure 4.

6. Install the fasteners that were re

moved in step 4. DO NOT tighten

until all bolts are in place.

Attach the crank rod to the universa!

joint assembly with the hair pin. See

Figure 6.

Tighten nut on eye bolt. Make sure

eye bolt is properly aligned and the

crank can freely rotate.

Tighten all handle and panel bolts.

F-0410108L

Lever

Universal Joint Assernbly

Crank'Rod

Figure 6

Control Cable Figure 4

ASSEMBLY

NOTE: If the cables have become dis

connected, connect cables as shown in

Figure 7.

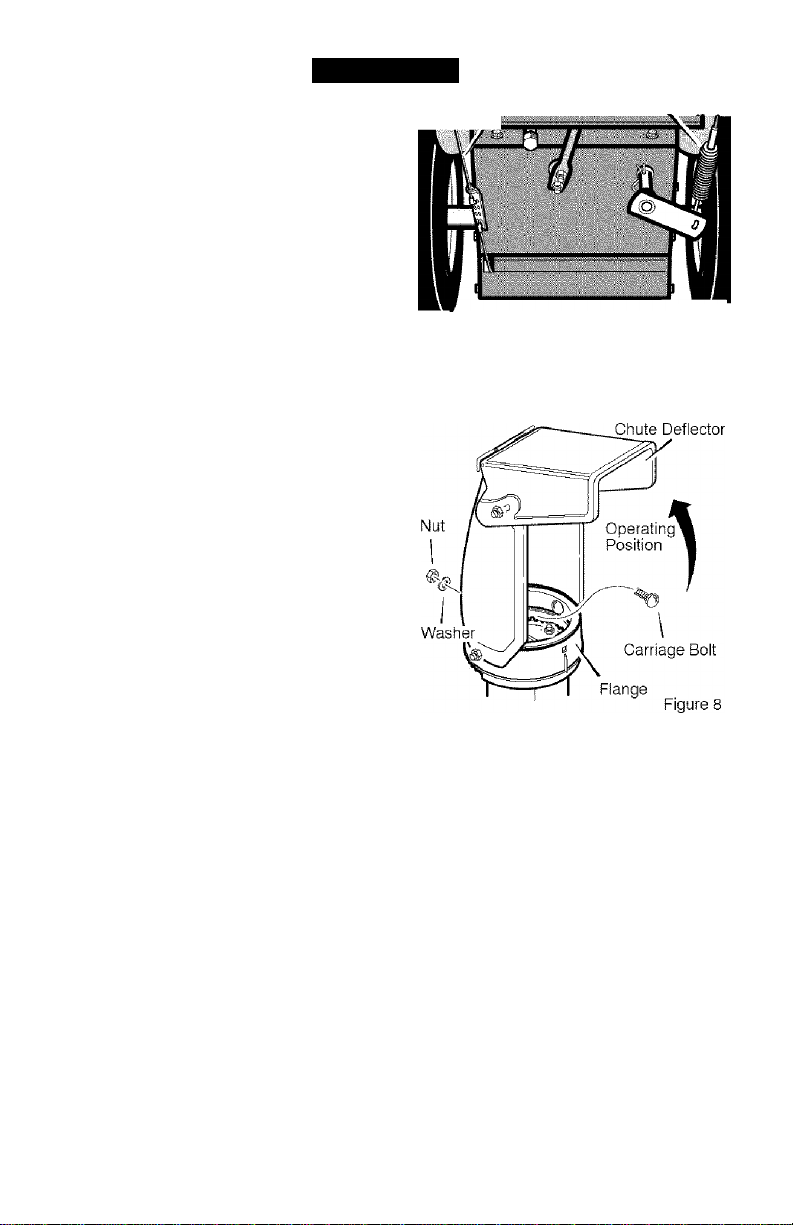

HOW TO ASSEMBLE THE CHUTE DEFLECTOR

1. Remove the carriage bolt. See

Figure 8.

2. Raise the chute deflector into op

erating position,

3. Fasten chute deflector to flange

with carriage bolt. Make sure to

install with head of carriage bolt on

the inside of the flange.

4. Fasten with washer and locknut.

5. Tighten locknut securely.

NOTE: Make sure all carriage

bolts In flange are tight. DO NOT

OVERTIGHTEN.

Traction Drive Cable

Auger Drive Cable

Figure 7

HOW TO SET THE SKID HEIGHT

Your snow thrower is equipped with

height adjust skids on the outside of the

auger housing. To adjust the skid

HOW TO SET THE LENGTH OF THE CABLES

The cables were adjusted at the factory

and no adjustments should be neces

sary. However, after the handles are put

in the operating position, the cables can

F-0410108L

height for different conditions, see To

Adjust Skid Height paragraph in the

Service And Adjustment section.

be too tight or too loose, if an adjust

ment is necessary, see “How To Check

And Adjust The Cables” in the Service

And Adjustment section.

ASSEMBLY

CHECKLIST

Before you operate your new snow

thrower, to ensure that you receive the

best performance and satisfaction from

this quality product, please review the

following checklist:

y" All assembly instructions have been

completed.

y The discharge chute rotates freely.

y No remaining loose parts in carton.

y Check the fasteners. Make sure all

fasteners are tight.

y Check the air pressure of the tires.

Correct air pressure is from 14 to 17

PSI. See the side of the tire for maxi

mum inflation. Do not exceed maxi

mum inflation.

y On electric start models, the unit was

shipped with the starter cord plugged

into the engine. Before operating, un

plug the starter cord from the engine.

While learning how to use your snow

thrower, pay extra attention to the fol

lowing important items:

y Engine oil is at proper level. Use a

high quality detergent oil classified

“For Service SG, SH, SJ, SL, or

higher”.

y Make sure gas tank is filled properly

with clean, fresh, unleaded gasoline

with a minimum of 85 octane.

y Become familiar with all controls-

their location and function. Operate

controls before starting engine.

F-0410108L

10

OPERATION

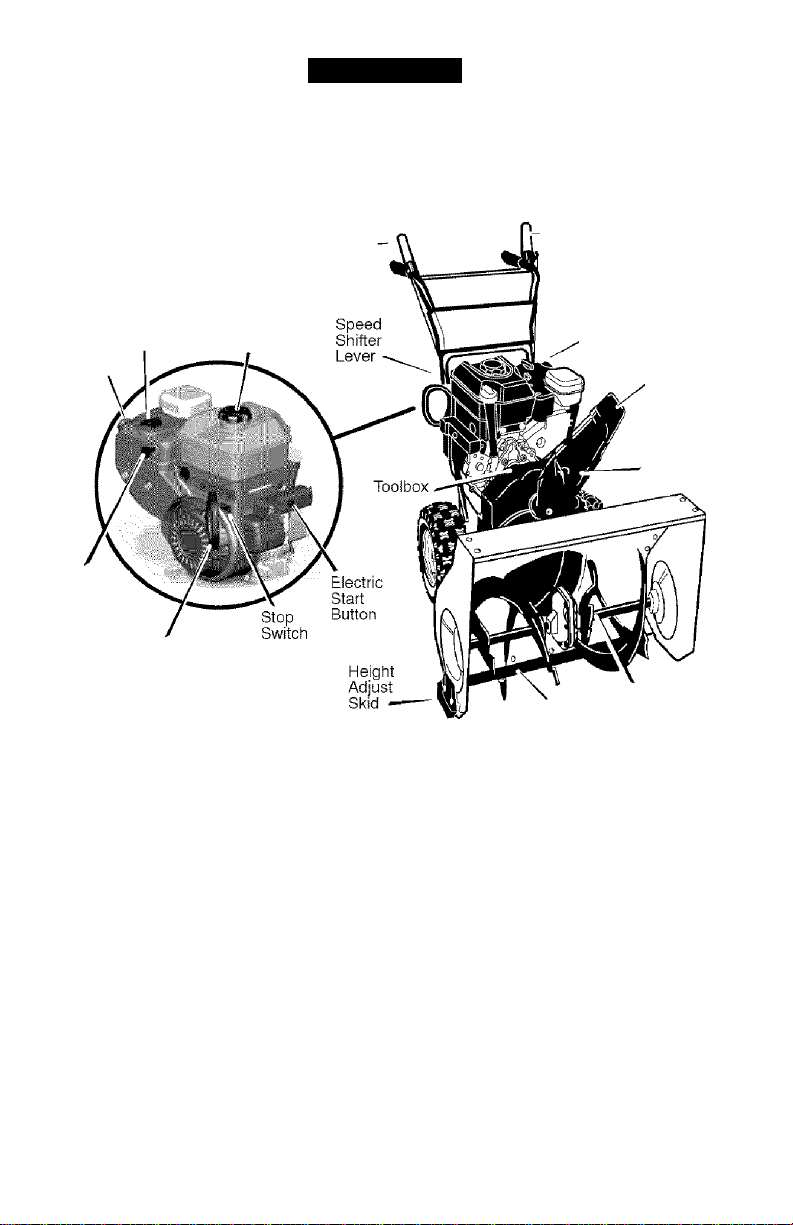

KNOW YOUR SNOW THROWER

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER. Oompare the illustrations with your SNOW THROWER

to familiarize yourseif with the location of various controls and adjustments. Save

this manual for future reference.

Auger ——

Drive Lever

(right hand)

Choke

Control Gas

Primer I

Button

Safety

Key

Recoil

Starter

Handle

Auger Drive Lever - Starts and stops

the auger and impeller (snow gathering

and throwing)

Traction Drive Lever - Propels the

snow thrower forward and in reverse.

Speed Shifter Lever - Selects the

speed of the snow thrower {6 speeds for

ward and 2 speeds reverse).

Crank Assembly - Changes the direc

tion of snow throwing through the dis

charge chute.

Chute Deflector - Changes the distance

the snow is thrown.

Discharge Chute - Changes the height

and direction the snow is thrown.

Height Adjust Skid - Adjusts the ground

clearance of the auger housing.

F-0410108L 11

Traction Drive Lever

(left hand)

Crank

Assembly

Chute

Deflector

Discharge

Chute

Scraper Bar

Shear Pin

Figure 9

Safety Key - Must push in to start the

engine.

Recoil Starter Handle - Starts the en

gine manually.

Choke Control - Used to start a cold

engine.

Primer Button - Injects fuel directly into

the carburetor manifoid for fast starts in

cold weather.

Electric Start Button - (If so equipped)

Used to start the engine using the 120 V

electric starter.

Shear Pin - Shear pins are designed to

break (to protect the machine) if an ob

ject becomes lodged in the auger hous

ing.

Toolbox - Spare shear pins and spacers

are located in toolbox.

OPERATION

The operation of any snow thrower can

result in foreign objects being thrown

into the eyes, which can result in se

vere eye damage. Always wear safety

glasses or eye shields while operating

the snow thrower.

We recommend standard safety

glasses or a wide vision safety mask for

over your glasses.

WARNING; Read Owner’s

A

charge toward bystanders. Stop the

engine before unclogging discharge

chute or auger housing and before

leaving the machine.

TO STOP YOUR

SNOW THROWER

1. To stop throwing snow, release the

2. To stop the wheels, release the

3. To stop the engine, pul! out the

CAUTION; To stop the engine, do not

move the choke control to CHOKE

position. Backfire or engine damage

can occur.

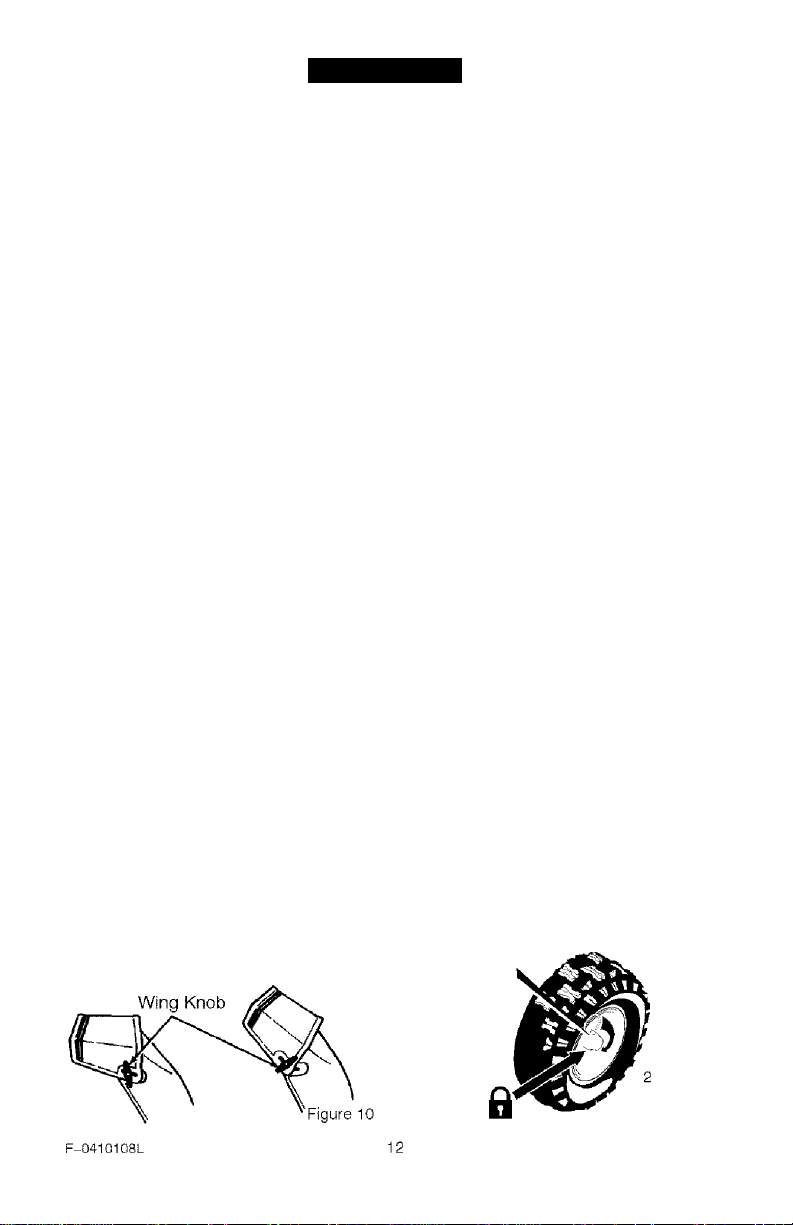

TO CONTROL SNOW DISCHARGE

1. Turn the chute control rod to set the

2. Loosen the wing knob on the chute

Manual before operating

machine. Never direct dis

auger drive lever.

traction drive lever.

safety key

direction of the snow throwing.

deflector and move the deflector to

set the distance. Move the deflector

(Up) for more distance, (Down) for

less distance. Then tighten the

wing knob (See Figure 10).

HOW TO MOVE FORWARD AND

BACKWARD

1. To shift, release the traction drive

lever (left hand) and move the

speed shifter lever to the speed you

desire. Ground speed is deter

mined by snow conditions. Select

the speed you desire by moving the

speed shifter lever left into the ap

propriate notches on the shift lever

plate:

Speeds 1,2 - Wet, Heavy

Speed 3 - Light

Speed 4 - Very Light

Speed 5,6 - Transport only

2. Engage the traction drive lever (left

hand). As the snow thrower starts

to move, maintain a firm hold on the

handles, and guide the snow throw

er along the clearing path. Do not

attempt to push the snow thrower.

3. To move the snow thrower back

ward, move the speed shifter lever

right into first or second reverse and

engage the traction drive lever (left

hand)

IMPORTANT: Do not move the speed

shifter lever while the traction lever is

down,

TO THROW SNOW

1. Push down the auger driver lever

(right hand).

2. Release to stop throwing snow.

TO USE WHEEL LOCKOUT PIN

1. The right hand wheel is secured to

the axle with a klick pin . This unit

was shipped with this klick pin in the

locked position (through wheel

hole). See Figure 11.

Klick Pin

Locked

Position

-Wheel

Drive

Figure 11

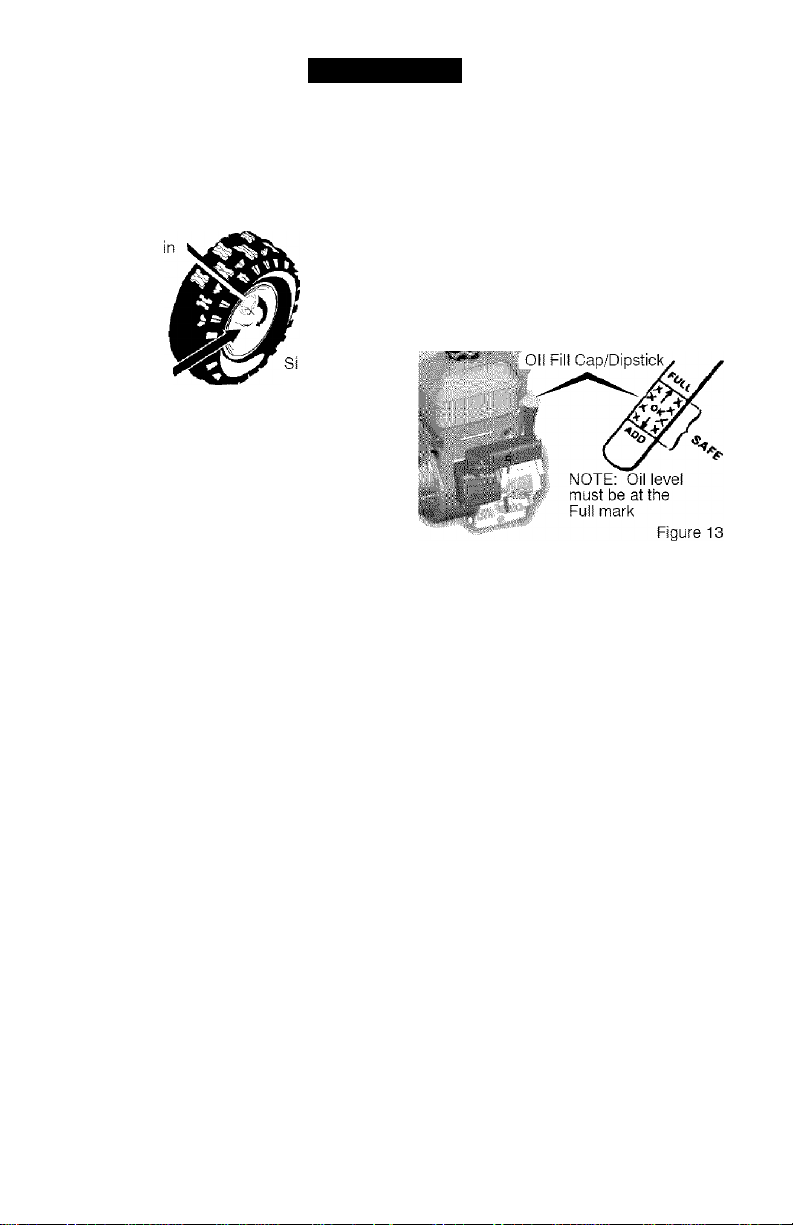

2. For ease of maneuverability in light

snow conditions, disconnect the

klick pin from the wheel locked

position and push into the single

wheel drive position (unlocked axle

hole only). See Figure 12.

Klick P

Unlocked^ ,

Position n

ngle Wheel

Drive

Figure 12

NOTE; Make sure that the klick pin is

in the single wheel drive position of the

axle only and not through the locked

position.

OPERATION

NOTE; Do not check the level of the

oil while the engine runs.

2. Remove the oil fill cap/dipstick and

wipe with a clean cloth.

3. Insert the oil fill cap/dipstick and

turn clockwise to tighten.

4. Remove the oil fill cap/dipstick and

check the oil.

5. If necessary, add oil until the oil

reaches the FULL mark on the oil fill

cap/dipstick (see Figure 13). Do not

add too much oil.

BEFORE STARTING THE ENGINE

1. Before you service or start the en

gine, familiarize yourself with the

snow thrower. Be sure you under

stand the function and location of all

controls.

2. Check the tension of clutch cable

before starting the engine. See To

Adjust The Control Cable para

graph in the Service & Adjust

ments section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are properly adjusted. See To Ad

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Check tire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

CHECK THE OIL;

NOTE; The engine was shipped from

the factory filled with oil. Check the lev

el of the oil. Add oil as needed.

To Add Oil

1. Make sure the unit is level.

F-0410108L 13

6. Tighten the fill cap/dipstick securely

each time you check the oil level.

NOTE; Synthetic oil can assist with

starting in extreme cold temperatures.

Synthetic 5W30 is acceptable for all

temperatures. DO NOT mix oil with

gasoline.

FILL GAS:

This engine is certified to operate on

gasoline. Exhaust Emission Control

System: EM (Engine Modifications).

WARNING; Alcohol blended

fuels (called gasohol or

A

those using ethanol or

methanol) can attract moisture

which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys

tem of an engine while in storage.

NOTE; To avoid engine problems, the

fuel system must be emptied before

storage for 30 days or longer. Start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. See the Storage

section in this manual for additional in

formation.

OPERATION

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

Fill the fuel tank only with a fresh, clean,

unleaded regular, unleaded premium, or

reformulated automotive gasoline with a

minimum of 85 octane.

DO NOT use

leaded gasoline. Make sure that the

container you pour the gasoline from is

clean and free from rust or other foreign

particles. Never use gasoline that may

be stale from long periods of storage in

the container.

WARNING: Gasoline is flam

A

mable. Always use caution

when handling or storing

gasoline.

• Turn engine off and iet engine

cool at least two minutes before

removing the gas cap.

• Do not fill fuel tank while snow

thrower is running, when it is hot,

or when snow thrower is in an en

closed area.

• Keep away from open flame or an

electrical spark and do not smoke

while filling the fuel tank.

TO STOP ENGINE

CAUTION: To stop the engine, do not

move the choke control to CHOKE

position. Backfire or engine damage

can occur.

1. Push the stop switch to the OFF

position.

^ Stop Switch

Figure 14

2. Pull out the safety key.

^ Safety Key

Figure 15

F-0410108L

Never fill the tank completely. Fill

the tank to approximately 1-1/2”

below the top of the tank opening

to provide space for expansion of

fuel.

Always fill fuel tank outdoors and

use a funnel or spout to prevent

spilling.

Make sure to wipe up any spilled

fuel before stating the engine.

Store gasoline in a clean, ap

proved container and keep the

cap in place on the container.

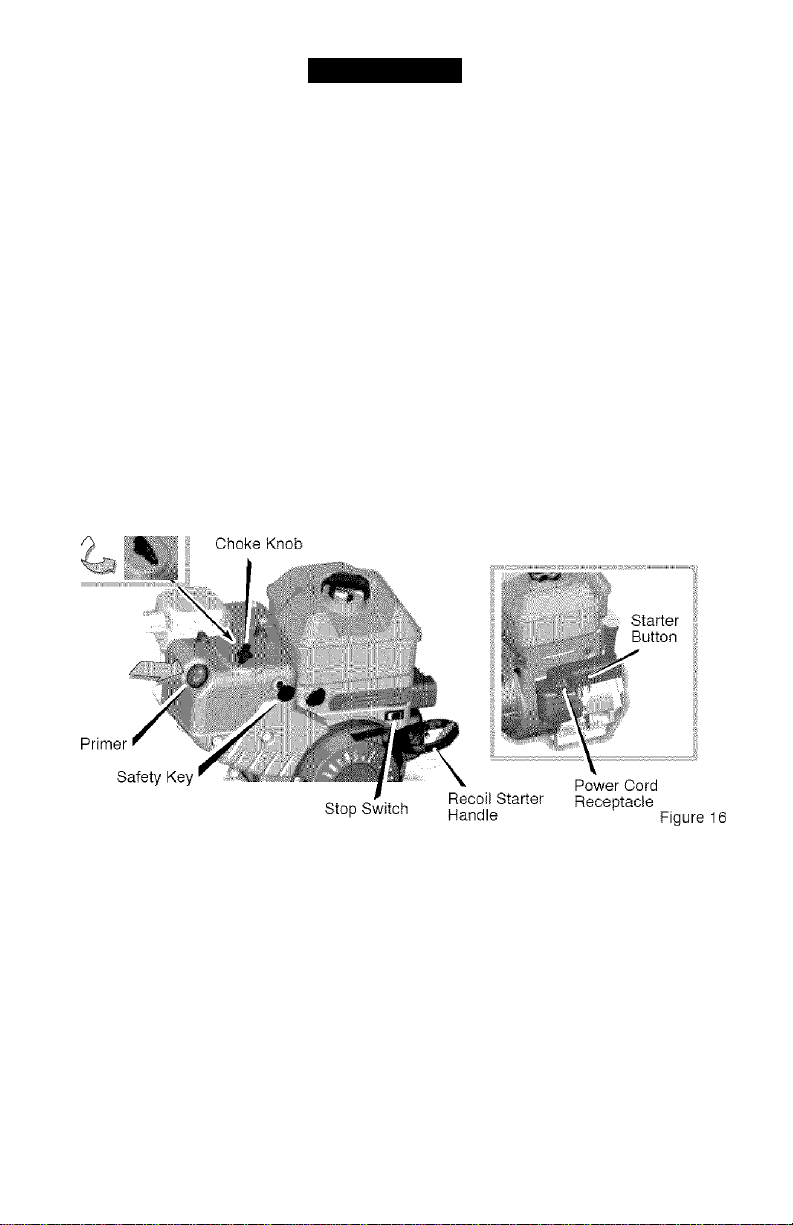

TO START ENGINE

Be sure that the engine oil is at FULL

mark on dipstick. The snow thrower en

gine is equipped with a 120 volt A.C.

electric starter and recoil starter. Before

starting the engine, be certain that you

have read the following information.

If engine floods, set the choke to the

OPEN/RUN position and crank until the

engine starts.

WARNING: Rapid retraction

A

of the starter cord (kick

back) will pull your hand or

arm toward the engine faster than

you can let go of the starter cord.

Broken bones, fractures, bruises, or

sprains could result.

• When starting the engine, slow

ly pull the starter cord until re

sistance Is felt. Then, rapidly

puli the starter cord.

• Before starting the engine, re

move all external equipment/engine loads.

• Make sure components; such as

impellers, pulleys or sprockets,

are securely attached.

14

OPERATION

WARNING: The starter is

A

designed to operate on 120 volt AC

household current. It must be prop

erly grounded at all times to avoid

the possibility of electrical shock

which may be injurious to operator.

• Follow all instructions carefully

• Determine that your house wiring

equipped with a three-wire

power cord and plug and is

as set forth in the “To Start En

gine" section.

is a three-wire grounded system.

Ask a licensed electrician if you

are not sure. If your house wire

system is not a three-wire system,

do not use this electric starter un

der any conditions.

If your system is grounded and a

three-hole receptacle is not avail

able at the point your starter will

normally be used, one should be

installed by a licensed electrician.

When connecting 120 volt AC

“Power Cord”, always connect the

cord to the Switch Box on the en

gine first, then plug the other end

into the three-hole grounded re

ceptacle. When disconnecting

“Power Cord”, always unplug the

end in the three-hole grounded re

ceptacle first.

How To Start A Cold Engine

1. Be sure auger drive and traction

drive levers are in the disengaged

(RELEASED) position.

2. Push the stop switch to the ON

position {see Figure 16).

3. Push in the safety key.

4. Rotate the choke knob to the

CHOKE position.

5. (Electric Start) Plug the power cord

into the starter motor on the en

gine. Plug the other end of power

cord into a three-hole, grounded

120 VOLT, AC receptacle.

F-0410108L 15

Push the primer button as speci

fied below. Remove finger from

primer button between pushes.

• Push two times if temperature is

15° F (-9° 0) or higher.

• Push four times if temperature is

below 15° F (-9° 0).

(Electric Start) Push down on the

starter button until the engine starts.

To prolong the life of the starter, do not

crank for more than 5 seconds at a

time. Wait one minute between starts

to allow the starter motor to cool.

(Recoil Start) Slowly pull the recoi!

starter handle until resistance is

felt and then pull rapidly to start the

engine. Do not allow the recoil

starter handle to snap back. Slowly

return the recoil starter handle.

9. If the engine does not start in 5 or 6

tries, See Difficult Starting in the

“Troubleshooting Table”.

10. Allow the engine to warm up for

several minutes. As the engine

warms up, adjust the choke knob

toward the RUN position. Wait until

the engine runs smoothly before

each choke adjustment.

11. (Electric S tart) First disconnect

power cord from receptacle. Then,

disconnect the power cord from the

starter motor.

How To Start A Warm Engine

If restarting a warm engine after a short

shutdown, leave the choke lever in the

oft position and do not push the primer

button. If the engine fails to start, follow

the Cold Start instructions.

Frozen Starter

If the starter is frozen and will not turn

the engine, follow the steps below.

1. Puli as much starter rope as pos

sible out of the starter.

2. Release the starter handle and let it

snap back against the starter. Re

peat until the engine starts.

Warm engines will cause condensation

in cold weather. To prevent possible

freeze-up of recoil starter and engine

controls, proceed as follows after each

snow removal job.

OPERATION

1. With engine off, allow engine to cool

2. Puli starter rope very slowly until re

3. With the engine not running, wipe all

A

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

• Engine parts, especially the muf

* Never allow children to operate

• Keep the area of operation clear

• Never leave the snowthrower un

for several minutes.

sistance is felt, then stop. Allow the

starter rope to recoil. Repeat three

times.

snow and moisture from the carbu

retor cover in area of controls and

levers. Also, move the choke control

and starter handle several times.

WARNING; Never run en

gine indoors or in enclosed,

poorly ventilated areas. En

fler, become extremely hot. Se

vere thermal burns can occur on

contact. Allow the engine to cool

before touching.

the snow thrower. Never allow

adults to operate the snow throw

er without proper instruction.

of all persons, particularly small

children and pets.

attended while the engine is run

ning. Anyone operating the en

gine or equipment must carefully

read and understand the operat

ing instructions.

F-0410108L

16

OPERATION

TO REMOVE SNOW FROM AUGER

WARNING; Do not attempt

A

auger with your hands. Use the

cleaning stick to remove snow or

debris.

A cleaning stick is attached to the top of

the auger housing. Use the cleaning

SNOW THROWING TIPS

1. For maximum snow thrower efficien

2. Most efficient snow throwing is ac

3. For complete snow removal, slightly

4. The snow should be discharged

5. For normal usage, set the skids so

6. On gravel or crushed rock surtaces,

to remove snow or debris

that may become lodged In

cy in removing snow, adjust ground

speed. Go slower in deep, freezing

or wet snow. If the wheels slips, re

duce forward speed.

complished when the snow is re

moved immediately after if falls.

overlap each path previously taken.

down wind whenever possible.

that the scraper bar is 1/8” above

the skids. For extremely hard-

packed snow surfaces, adjust the

skids upward so that the scraper

bar touches the ground.

stick to remove snow from the auger

housing.

• Release auger drive lever.

• Remove (do not turn) safety key.

• Disconnect spark plug wire.

• Do not place your hands in the au

ger or discharge chute. Use the

cleaning stick to remove snow.

set the skids at 1-1 /4” below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu

al. Rocks and gravel must not be

picked up and thrown by the ma

chine.

7. After the snow throwing job has

been completed, allow the engine to

idle for a few minutes, which will

melt snow and accumulated ice off

the engine.

8. Clean the snow thrower thoroughly

after each use.

9. Remove ice and snow accumulation

and al! debris from the entire snow

thrower, and flush with water (if pos

sible) to remove ail salt or other

chemicals. Wipe snow thrower dry.

F-0410108L

17

MAINTENANCE

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

Check Engine Oil Level

Change Engine Oil

Ti ghten M Screws and

Nuts

...............................

Check and Clean Spark

Plug

Replace Spark Plug

Clean and Inspect

Spark Arrestor

Lubricate Chute Control

Flange

...........................

Check Fuel

Check Adjustment of

Auger Control Cable

Auger Drive Beit

Check Tire Pressure

* Adjust after 2 to 4 hours of use,

Before

Each

Use

V

Often

Every

8

Hours

V

GENERAL RECOMMENDATIONS

The warranty on this snow thrower does

not cover items that have been subjected

to operator abuse or negligence. To re

ceive full value from the warranty, the op

erator must maintain the snow thrower as

instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your

snow thrower.

Maintenance, replacement, or repair of the

emission control devices and systems can

be performed by any non-road engine re

pair establishment or individual. Regular

maintenance will improve the performance

and extend the life of the engine.

WARNING; Do not strike the

A

flywheel with a hammer or a

hard opject. If done, the fly

wheel can shatter during operation.

Do not tamper with the governor

spring, links or other parts to in

crease engine speed.

F-0410108L IE

Every

Hours

Every

25

Hours

50

Every

100

Hours

Each

Season

....

AFTER EACH USE

• Run the machine to clear the auger

of snow.

• To prevent freezing of the auger or

controls, remove all snow and slush

from the snow thrower.

• Check for any loose or damaged

parts.

• Tighten any loose fasteners.

• Check and maintain the auger.

• Check controls to make sure they

are functioning properly,

• If any parts are worn or damaged,

replace immediately.

Before

Storage

■V '

MAINTENANCE

ENGINE SPECIFICATIONS

HORSEPOWER

DISPLACEMENT 206 CC

BORE 68mm (2.677 in.)

STROKE 56mm (2.205 in.)

GASOLINE 3 quarts

CAPACITY (unleaded)

OIL CAPACITY

(18 oz capacity)

SPARK PLUG: Champion RJ19LM

VALVE Intake 0.004-0.006 in.

CLEARANCE: Exhaust: 0.009-0.011 in.

ARMATURE

AIR GAP:

S HP

5W30

(Gap .030 in.) or

equivalent

0.010-0.014 in.

POWER RATINGS

The power ratings for an individual

engine model are initially developed by

starting with SAE (Society of Automo

tive Engineers} code J1940 {Small

Engine Power & Torque Rating Proce

dure) (Revision 2002-05). Given both

the wide array of products on which our

engines are placed, and the variety of

environmental issues applicable to

operating the equipment, it may be that

the engine you have purchased will not

develop the rated horsepower when

used in a piece of power equipment

(actual “on-site” power). This difference

is due to a variety of factors including,

but not limited to, the following: differ

ences in altitude, temperature, baro

metric pressure, humidity, fuel, engine

lubrication, maximum governed engine

speed, individual engine to engine

variability, design of the particular piece

of power equipment, the manner in

which the engine is operated, engine

run-in to reduce friction and clean out of

combustion chambers, adjustments to

the valves and carburetor, and other

factors. The power ratings may also be

adjusted based on comparisons to

other similar engines utilized in similar

applications, and will therefore not

necessarily match the values derived

using the foregoing codes.

F-0410108L

SNOW THROWER

AUGER DRIVE BELT

Adjust the auger drive belt after the first

2 to 4 hours of use, again about mid

season and twice each season thereaf

ter (See to “Belt Adjustment” in the

Service and Adjustment section).

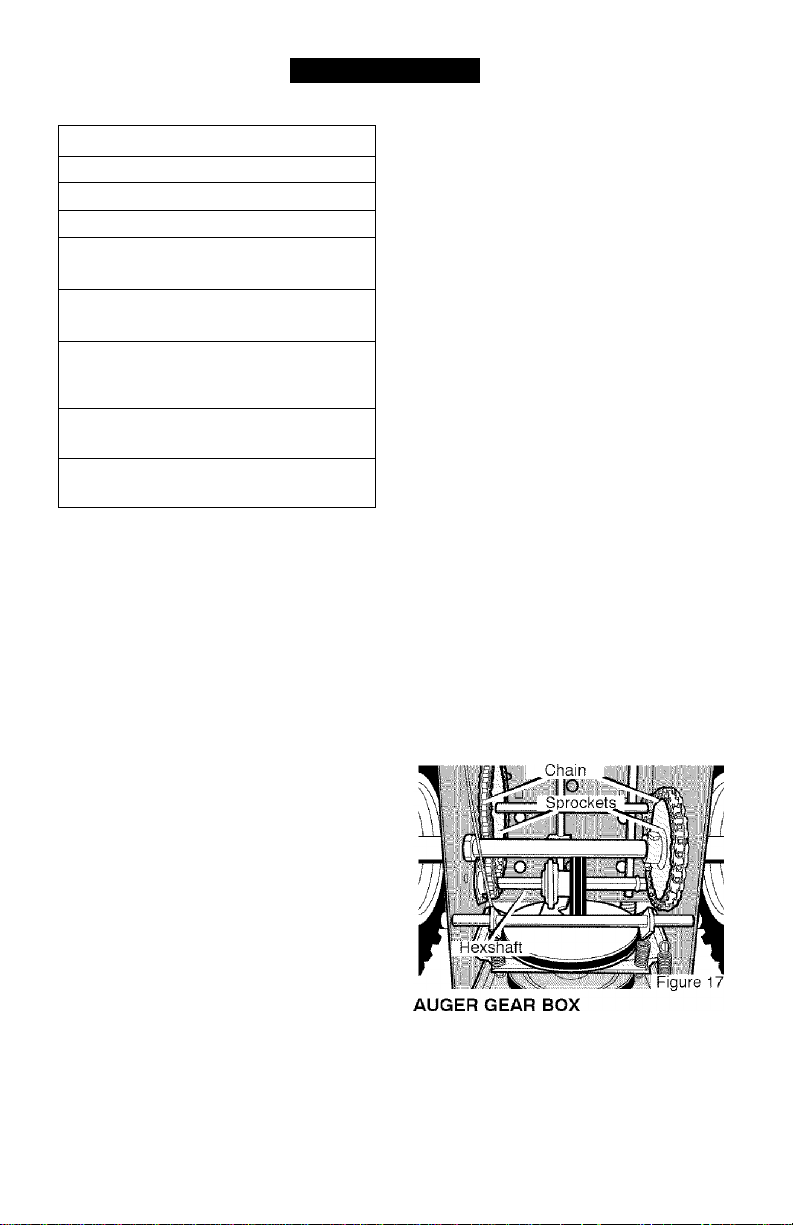

CHAIN LUBRICATION

EVERY 25 HOURS

1. Position speed selector lever in first

(1) forward gear.

2. Stand the snow blower up on the

auger housing end.

NOTE; When the crank case if

filled with oil, do not leave the

snow blower standing up on the

auger housing for an extended

period of time.

3. Remove the bottom panel.

4. Lubricate the chains with a chain

type lubricant.

5. For storage, wipe the hexshaft and

sprockets with 5W30 motor oil.

NOTE: Clean all excess grease or

oil found on the rubber friction

wheel or the disc drive plate.

CAUTION: Do not allow grease or

oil to contact the rubber friction

wheel or the disc drive plate.

6. Install the bottom panel.

The auger gear box is lubricated at the

factory and should not require addition

al lubrication. If for some reason the

lubricant should leak out, have auger

gear case checked by a competent re

pairman.

19

MAINTENANCE

ENGINE

LUBRICATION

Check the crankcase oil level before

starting the engine and after each eight

{8) hours of continuous use. See

Figure 18. Add S.A.E. 5W30 motor oil

as needed. Synthetic 5W30 is accept

able for aii temperatures. Tighten fill

cap/dipstick securely each time you

check the oil level.

Oil Fill Cap/Dipstick

Oil Drain

Plug

■ ,/

Change the oil every fifty (50) hours or

at least once a year if the snow thrower

is not used for fifty (50) hours.

TO CHANGE ENGINE OIL

1. Position the snow thrower so that

the oil drain plug is at the lowest

point on the engine.

2. When the engine is warm, remove

the oil drain piug and the oil fili

cap/dipstick (see Figure IS). Drain

the oil into a suitable container.

3. After draining aii the oil, reinstall the

oil drain plug securely.

4. Fill the engine crankcase with the

recommended motor oil, pouring

slowly. DO NOT OVERFILL. See

“To Add Oil” in the Operation Sec

tion.

NOTE: Oil level niusi be at FULL mark.

Figure 18

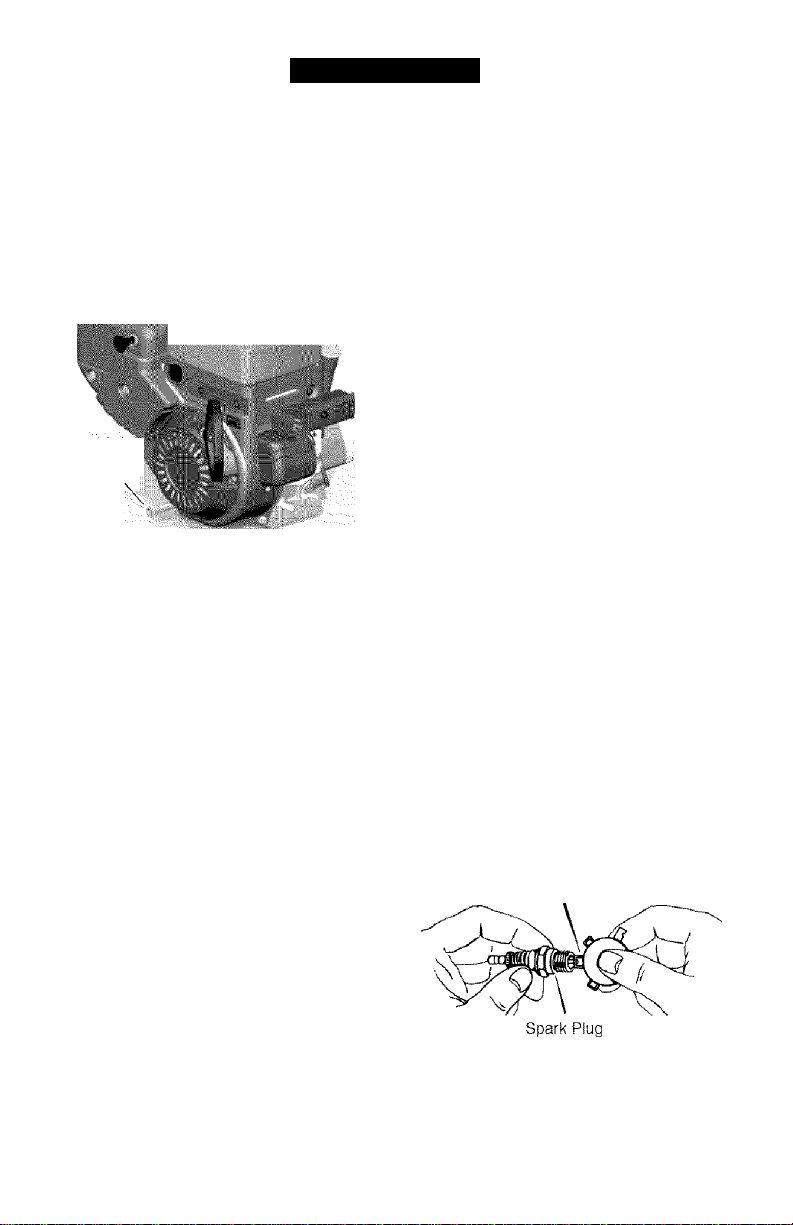

SPARK PLUG

Check the spark plug every twentyfive (25) hours. Replace the spark plug

if the electrodes are pitted or burned, if

the porcelain is cracked, or every 100

hours of use.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

2. Check the spark plug gap with a

feeler gauge and reset gap to 0.30”

if necessary. See Figure 19.

3. Before installing the spark plug,

coat the threads lightly with oil for

easy removal. Tighten the spark

plug to a torque of 15 foot-pounds.

Feeler Gauge

0.030”

Figure 19

F-0410108L

20

SERVICE AND ADJUSTMENT

WARNING: Always discon

A

nect the spark plug wire and

place it where it cannot

make contact with spark plug to pre

vent accidental starting when mak

ing any adjustments or repairs.

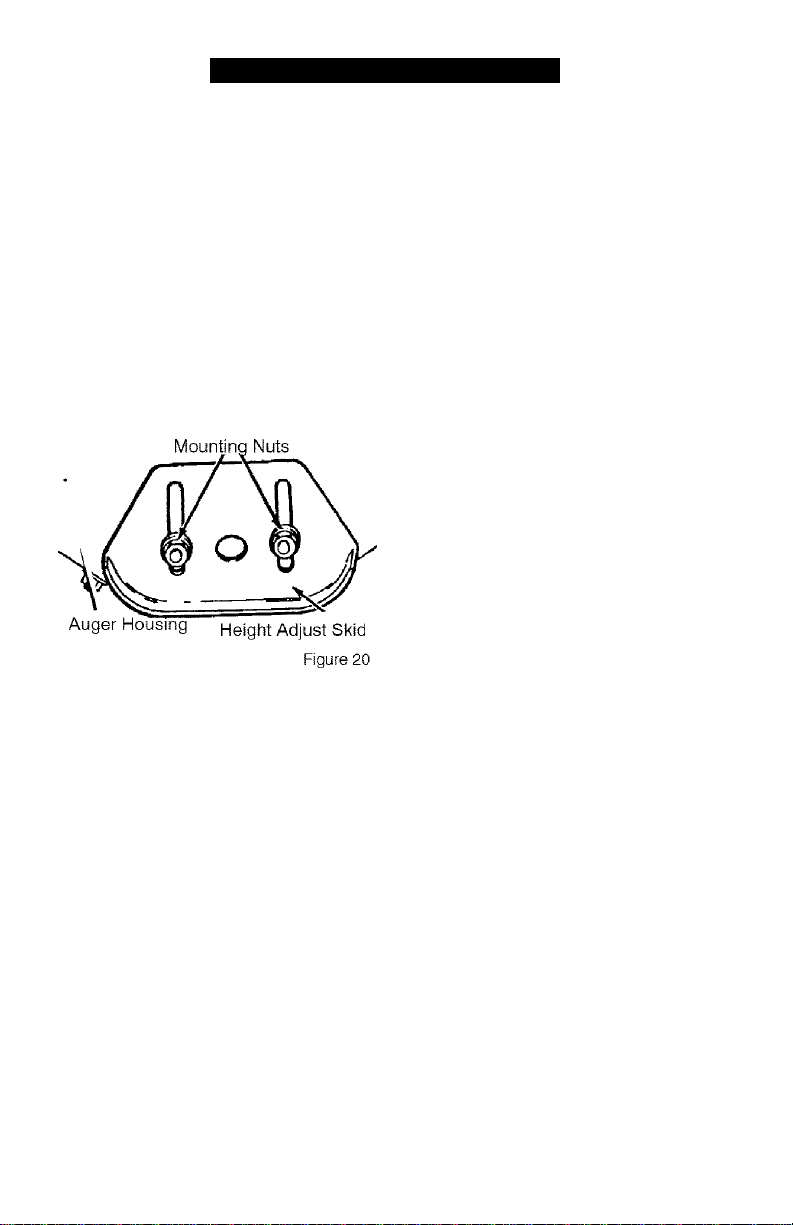

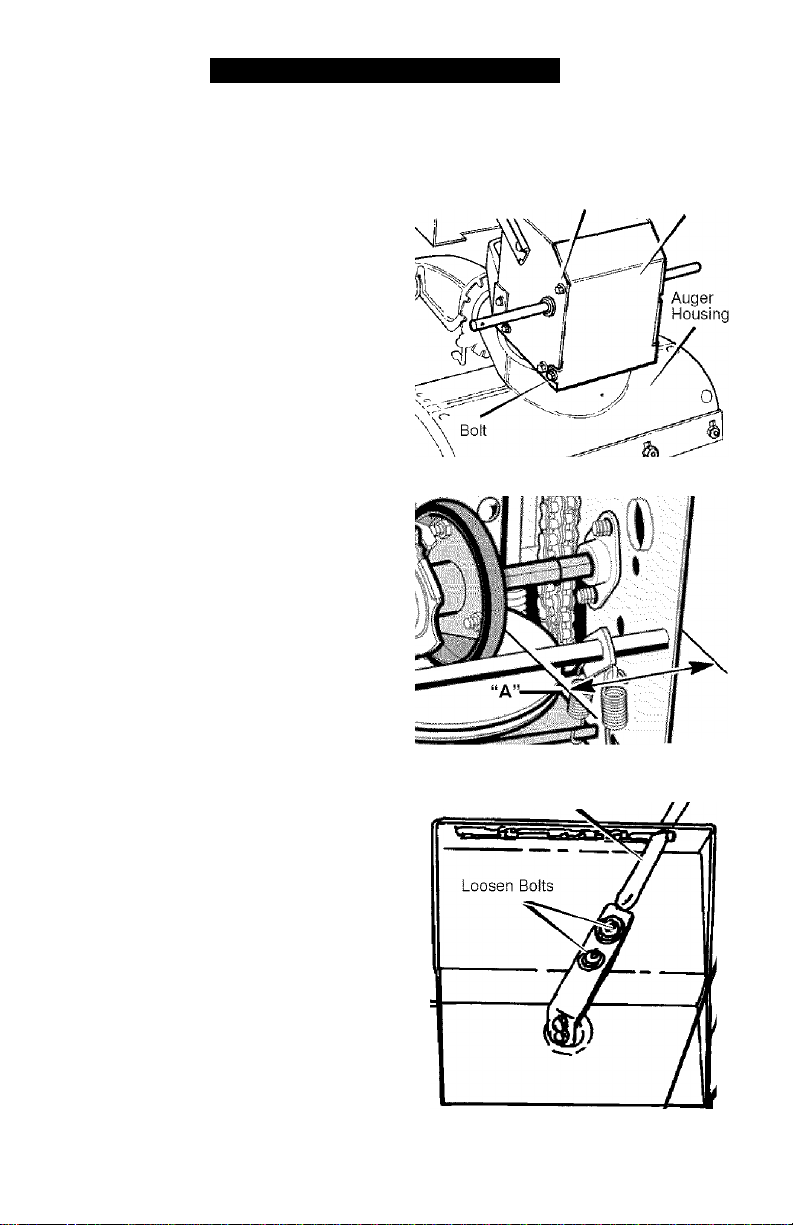

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 20.

These skids elevate the front of the

snow thrower.

For normal hard surfaces, such as a

paved driveway or walk, adjust the

skids as follows.

1. Position the snow thrower on a level

surface.

2. Make sure both tires are equally in

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi

mum inflation. Do not exceed maxi

mum sidewall pressure on tire.

3. Place the extra shear bolts supplied

with the unit under each end of the

scraper bar next to the adjustable

skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bring the

front of the snow thrower down,

raise the adjustable skids. Tighten

the mounting nuts. See Figure 20.

NOTE: For rocky or uneven surfaces,

raise the front of the snow thrower by

moving the skids down.

WARNING: Be certain to

A

maintain proper ground

clearance for your particular

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

TO ADJUST SCRAPER BAR

After considerable use. the metal scrap

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al

low 1 /8” between the scraper bar and

the sidewalk or area to be cleaned.

1.

Position the snow thrower on a level

surface.

2.

Make sure both tires are equally in

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi

mum inflation. Do not exceed maxi

mum sidewall pressure on tire.

3.

Loosen the carriage bolts and nuts

securing the scraper bar to the au

ger housing.

4. Adjust the scraper bar to the proper

position.

5.

Tighten the carriage bolts and nuts,

making sure that the scraper bar is

parallel with the working surface.

For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage bolts and nuts

and install a new scraper bar.

F-0410108L

21

SERVICE AND ADJUSTMENT

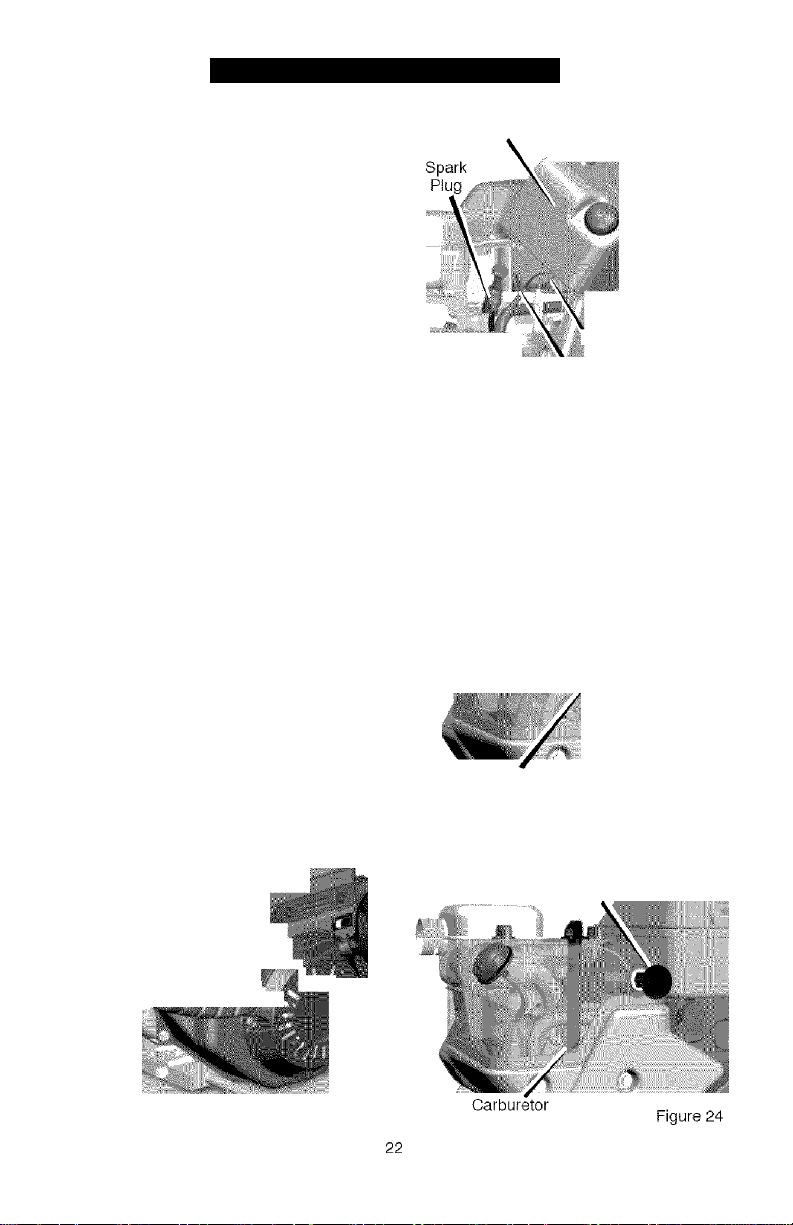

HOW TO REMOVE

THE SNOW HOOD

To access the spark plug, the snow

hood must be removed as follows:

1. Remove the choke control knob

(see Figure 21).

2. Remove the safety key.

3. Remove the mounting screws

(see Figure 22).

4. Slowly remove the snow hood.

Make sure that the primer button

hose and the ignition wire are not

disconnected.

5. The spark plug can now be ac

cessed.

6. To install the snow hood, first make

sure that the primer button hose

and the ignition wire are connected.

7. Mount the snow hood to the engine

and secure with the mounting

screws (see Figure 22).

8. Connect the choke control knob

with the choke shaft on the carbure

tor (see Figure 23 and Figure 24).

Make sure the choke control knob is

properly installed. If the choke con

trol knob is not Installed correctly,

the choke will not operate.

9. Install the safety key.

Mounting Screws

Snow Hood A

JUm

icnitio'h Wire

ittoi

■ M

Choke

Control Knob

PriTer Button -fi

3M Figure 22

'I

Cont'oVkncb

F-0410108L

} ’mg

Figure 21

Choke Shaft

Safety Key

Figure 23

SERVICE AND ADJUSTMENT

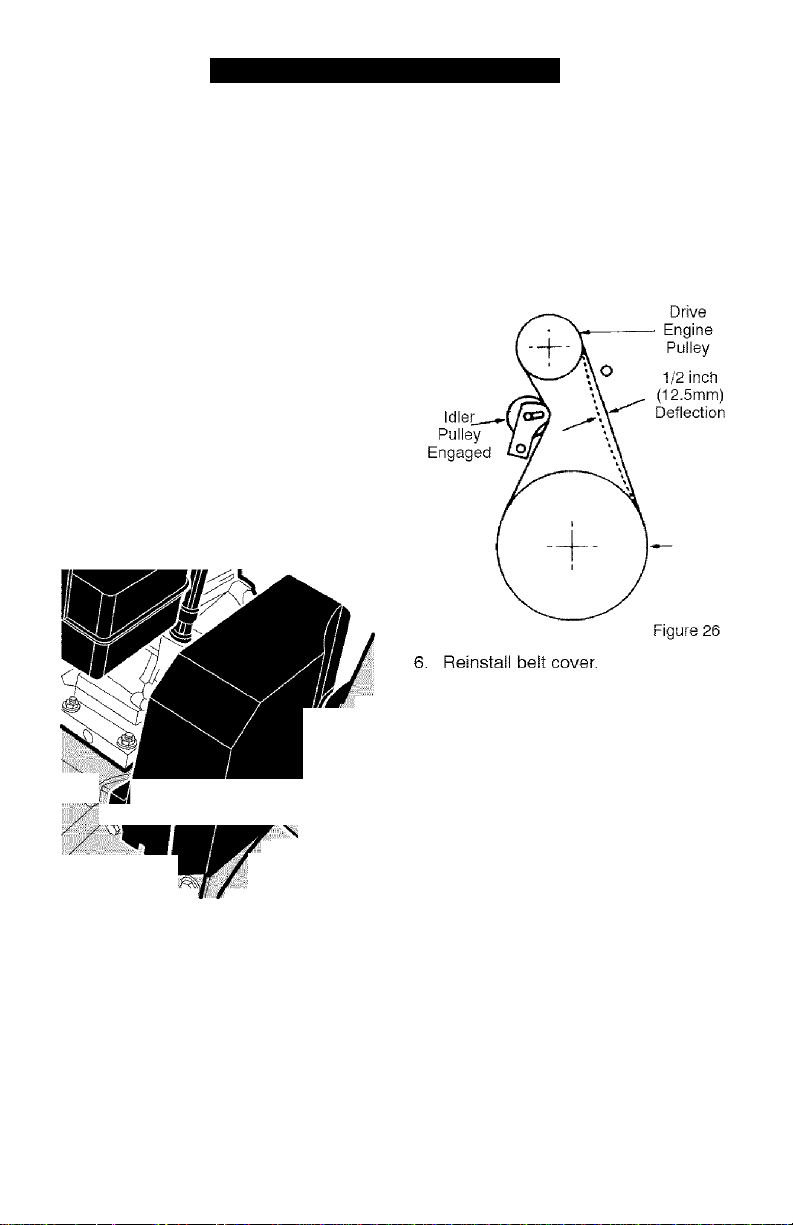

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant

spring pressure and does not require

an adjustment. If the traction drive belt

is slipping, replace the belt. See “How

To Replace The Belts” in the Service

And Adjustment section.

5. Have someone engage auger drive

clutch. Check tension on belt (op

posite idler pulley). Belt should de

flect about 1/2 inch (12.5 mm) with

moderate pressure (Figure 26). You

may have to move idler pulley more

than once to obtain the correct ten-

Auger Drive Belt

If your snow blower will not discharge

snow, check the control cable adjust

ment. If it is correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see “How

To Replace The Belts” in this section of

the manual).

1. Disconnect spark plug wire,

2. Remove screw from belt cover.

Remove belt cover (see Figure 25).

Belt Cover

. ■' ■ ;■

.

..................... ■■ ■■ ■ ■ ■■ Figu-'e 25 i

Auger

7. Whenever belts are adjusted or re

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the manual).

8. Attach the spark plug wire.

3. Loosen nut on auger idler pulley

and move auger idler pulley towards

belt about 1/8 inch (3 mm) (see

Figure 29).

4. Tighten nut.

F-0410108L

23

SERVICE AND ADJUSTMENT

HOW TO REPLACE THE BELTS

The drive belts are of special construc

tion and must be replaced with original

equipment replacement belts available

from your nearest Sears service center.

Some steps require the assistance of a

second person.

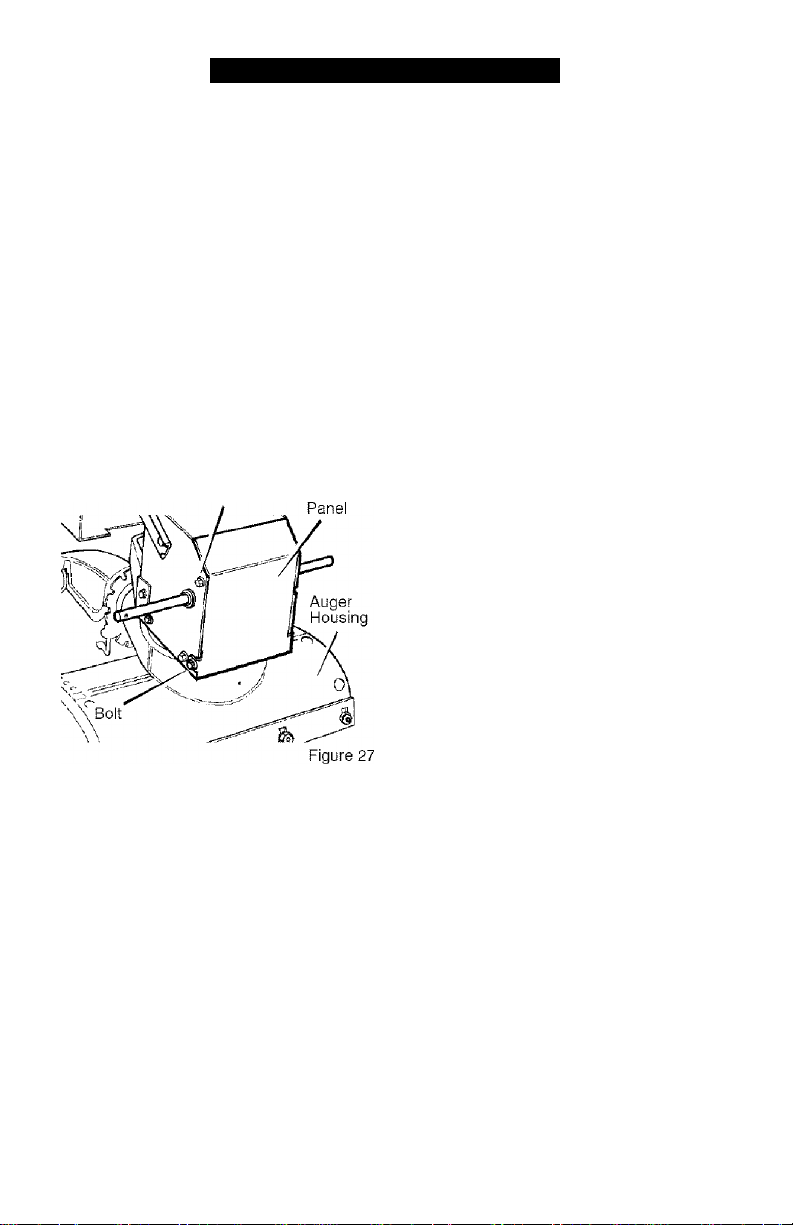

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

1. Disconnect the spark plug wire.

2. Loosen the bolts on each side of

the bottom panel (see Figure 27).

3. Remove the bottom panel.

Bolt

4. Remove screw from belt cover.

Remove the belt cover (see

Figure 25).

5. Loosen the belt guide. Pull the belt

guide away from the auger drive

pulley (see Figure 29).

6. Puli the idler pulley away from the

auger drive belt and slip the auger

drive belt off of the idler pulley.

7. Remove the auger drive belt from

the engine pulley. To remove the

auger drive belt, the engine pulley

may have to be partially rotated.

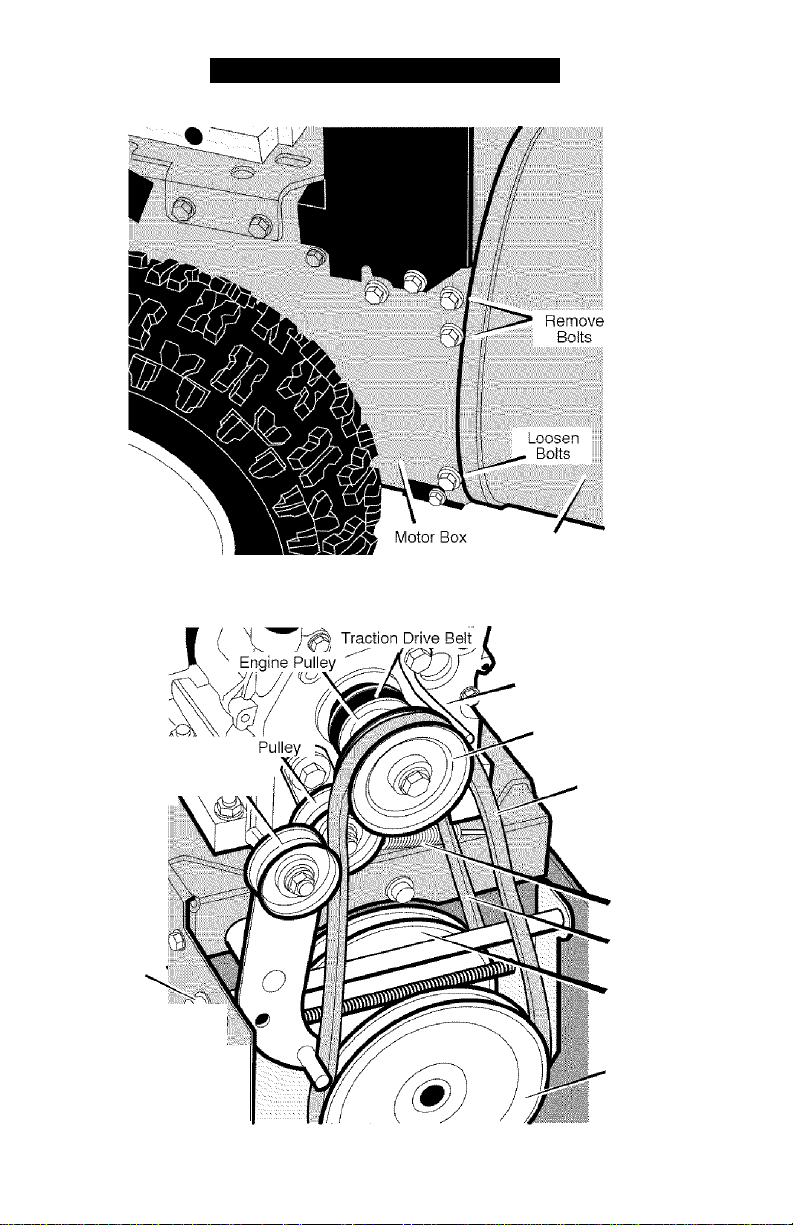

8. Remove the top four bolts that hold

together the auger housing and

the motor box. Loosen the bottom

F-0410108L

Bottom

two bolts. The auger housing and

the motor box can now be split

apart for removal of the belt (see

Figure 28).

9. Remove the old auger drive belt

from the auger drive pulley . Re

place the auger drive belt with an

original factory replacement belt

available from an authorized service

center (see Figure 29).

10. Install the new auger drive belt

onto the auger drive pulley.

NOTE: To assemble the auger

housing to the motor box, have

someone hold the auger clutch

lever in the ENGAGED position.

This will move the idler arm and

pulley enough to allow the auger

drive pulley to move back into

position.

11. Assemble the auger housing to the

motor box with the four bolts that

were removed in step 8. Tighten the

bottom two bolts.

12. Install the auger drive belt onto the

engine pulley.

13. Slip the auger drive belt under the

Idler pulley.

14. Adjust the auger drive belt. See

“How To Adjust The Auger Drive

Belt” in the Service And Adjustment

section.

15. Adjust the belt guide. See “How To

Adjust The Belt Guide” in the Ser

vice And Adjustment section.

16. Install the belt cover. Tighten

screw (See Figure 25).

17. Check the adjustment of the cables.

See “How To Check And Adjust The

Cables” in the Service And Adjust

ment section.

18. Install the bottom panel (see

Figure 27).

19. Tighten the bolts on each side of

the bottom panel.

20. Connect the spark plug wire.

24

SERVICE AND ADJUSTMENT

Auger

Housing

Figure 28

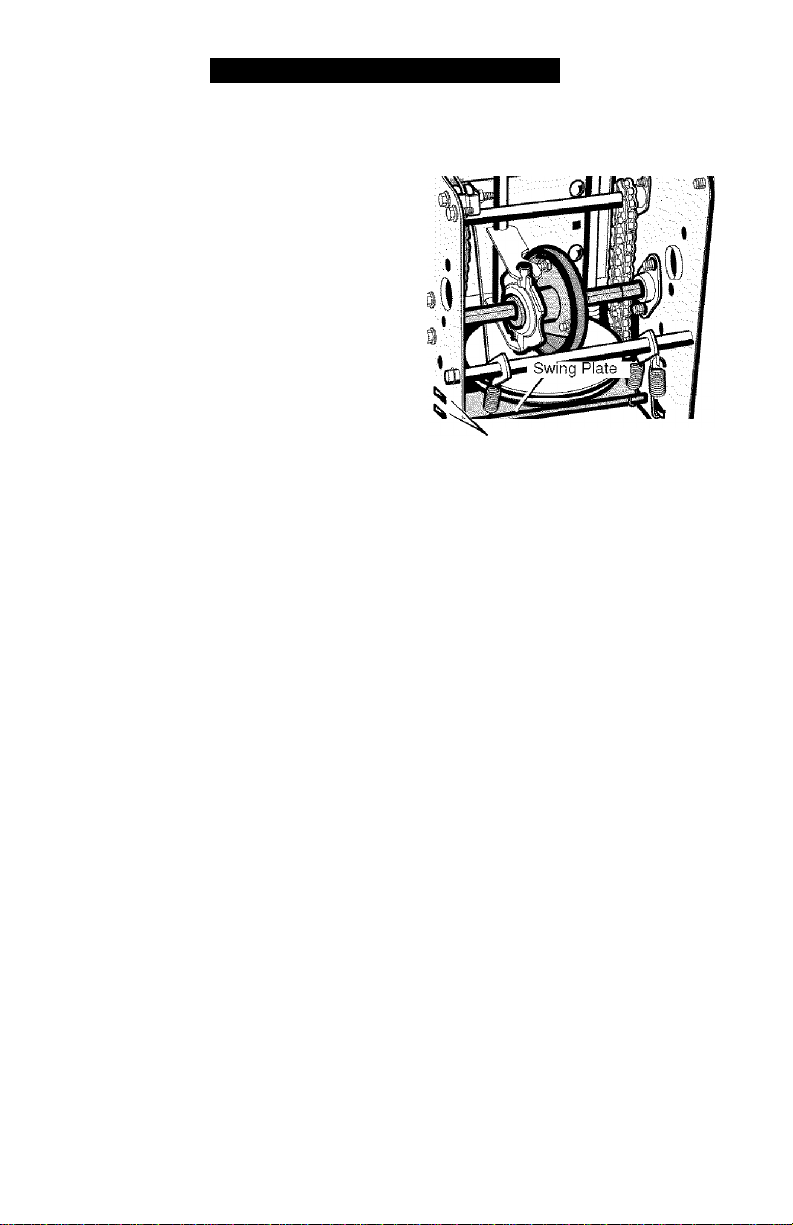

Traction Drive Idler

E-Ring

Swing Plate

Axle Rod ^

F-0410108L

Auger |(j|er Pulley

Beit Guide

Auger Drive Pulley

Auger Drive Belt

Traction Drive

Spring

Traction

Drive Belt

Traction

Drive Pulley

V

25

Engine

Pulley

Figure 29

SERVICE AND ADJUSTMENT

How To Remove

The Traction Drive Belt

If the snow thrower will not move for

ward, check the traction drive belt for

wear or damage. If the traction drive

belt is worn or damaged, replace the

belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See

“How To Remove The Auger Drive

Belt" in the Service And Adjustment

section.

plate is properly secured (see

Figure 30).

3. Remove the e-ring from one end of

the swing plate axle rod. Remove

the swing plate axle rod to allow

the swing plate to pivot forward (see

Figure 29).

4. Remove the traction drive spring.

5. Remove the old traction drive belt

from the traction drive pulley and

from the engine pulley. Replace

the traction drive belt with an origi

nal equipment replacement belt

available from a Sears service cen

ter.

6. Install the new traction drive belt

onto the traction drive pulley and

onto engine pulley.

7. Make sure the traction drive idler

pulley is properly aligned with the

traction drive belt.

8. Attach the traction drive spring.

9. Install the swing plate axle rod and

secure with the e-ring removed

earlier.

10. The bottom of the swing plate must

be positioned between the align

ment tabs. Make sure the swing

F-0410108L

Alignment Tabs

NOTE; If the drive will not engage

after the traction drive belt has

been replaced, then check to

make sure that the swing plate is

positioned between the align

ment tabs.

11. Install and adjust the auger drive

belt. See “How To Remove The Au

ger Drive Belt” in the Service And

Adjustment section.

12. Adjust the belt guide. See “How To

Adjust The Belt Guide” in the Ser

vice And Adjustment section.

13. Install the bottom panel (see

Figure 27).

14. Tighten the bolts on each side of

the bottom panel.

15. Install the belt cover. Tighten

screw (see Figure 25).

16. Check the adjustment of the cables.

See “How To Check And Adjust The

Cables” in the Service And Adjust

ment section.

17. Connect the spark plug wire.

26

Figure 30

SERVICE AND ADJUSTMENT

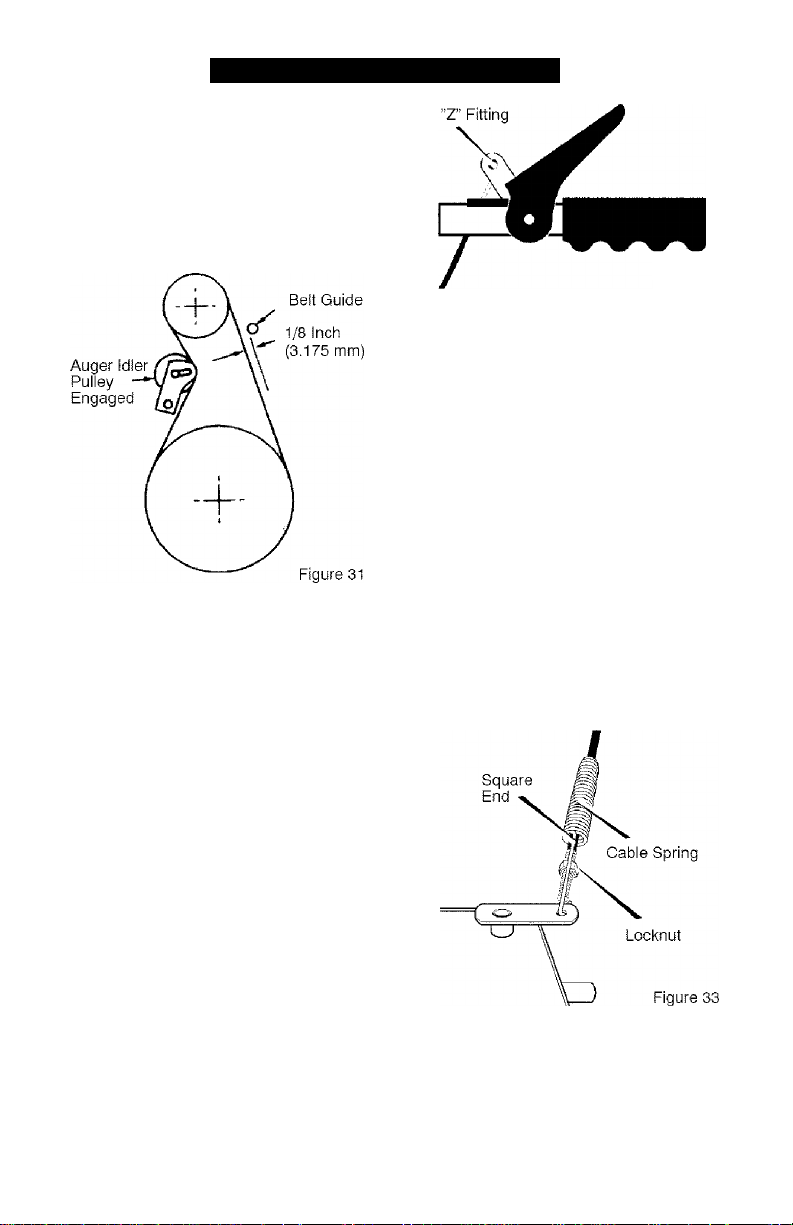

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage auger drive.

3. Measure the distance between the

belt guide and belt. The distance

should be 1/8 inch (3.175 mm) for

guide. See Figure 31.

if adjustment is necessary, loosen

belt guide mounting bolt. Move belt

guide to the correct position. Tight

en mounting bolt.

Reinstall belt cover.

Reconnect spark plug wire.

Figure 32

2. The center of the “Z” fitting should

be between the center and top of

the hole in the ciutch lever. Adjust

either the auger drive cable or the

traction drive cable as as necessary

according to the following instruc

tions.

Auger Drive Cable Adjustment

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Push cable through spring to ex

pose the threaded portion of the

cable (see Figure 33).

HOW TO CHECK AND ADJUST THE CABLES

The cables are adjusted at the factory

and no adjustment should be neces

sary. If the cables have become

stretched or are sagging adjustment will

be necessary.

Whenever belts are adjusted or re

placed, the cables will need to be ad

justed.

To check for correct adjustment, un

hook “Z” fitting at clutch lever (see

Figure 32).

1. Move clutch lever to the full forward

position {just contacting plastic

bumper). Holding cable tight, note

position of fitting to hole in clutch le

ver.

F-0410108L

Hold square end of threaded portion

with pliers and adjust locknut in or

out until correct adjustment is

reached. Puli cable back through

spring and connect cable.

27

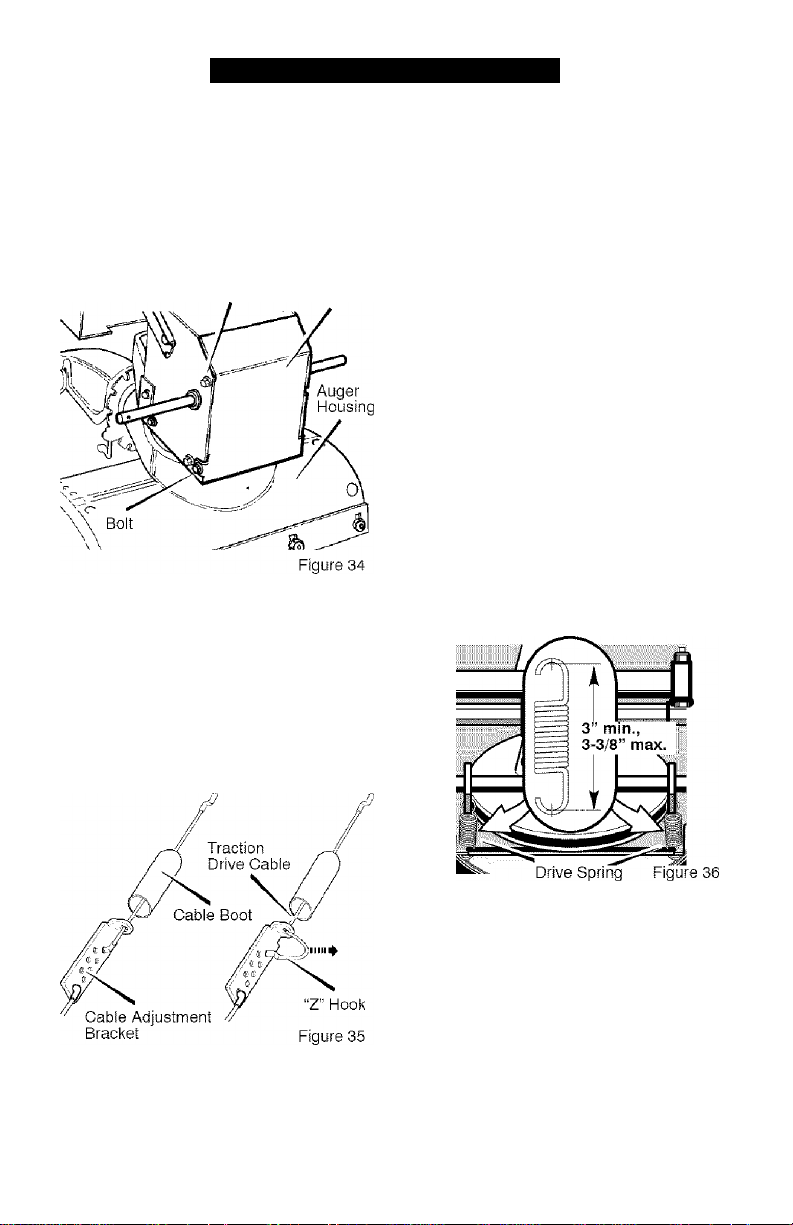

SERVICE AND ADJUSTMENT

TRACTION DRIVE CABLE ADJUSTMENT

Run the engine until the fuel tank is

empty and the engine stops.

Stand the snow thrower up on the

front end of the auger housing.

Loosen the bolts on each side of

the bottom panel (see Figure 34).

Bolt Bottom Panel

4. Remove the bottom panel.

5. Disconnect the “Z” fitting from the

drive lever (see Figure 32).

6. Slide the cable boot off the cable

adjustment bracket (see

Figure 35).

7. Push the bottom of the traction

drive cable through the cable ad

justment bracket until the “Z"

hook can be removed.

8. Remove the “Z” hook from the

cable adjustment bracket. Move

the “Z” hook down to the next ad

justment hole.

9. Pull the traction drive cable up

through the cable adjustment

bracket.

10. Put the cable boot over the cable

adjustment bracket.

11. Install the “Z” hook to the traction

drive lever (see Figure 32).

12. To check the adjustment, depress

the drive lever and check the length

of one of the drive springs. In cor

rect adjustment, the length of the

drive spring Is;

minimum 3” (76 mm.)

maximum 3-3/8” (85 mm.)

(see Figure 36).

F-0410108L

28

SERVICE AND ADJUSTMENT

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL

How To Check The Friction Wheei

If the snow thrower will not move for

ward, check the traction drive belt, the

traction drive cable or the friction wheel.

If the friction wheei is worn or damaged,

it must be replaced. See “How To Re

place the Friction Wheel” in this section.

If the friction wheel is not worn or dam

aged, check as follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing

(see Figure 37).

3. Disconnect the spark plug wire.

4. Loosen the bolts on each side of

the bottom panel (see Figure 37).

5. Remove the bottom panel.

6. Position the shift speed lever in

the lowest forward speed.

7. Note the position of the friction

wheel (see Figure 38). The correct

distance “A” from the right side of

the friction wheel to the outside of

the motorbox is as follows:

Tire Size Distance “A”

12 and 13 inch 4-1/8”

16 inch 4-5/16”

If the friction wheel is not in the

correct position, adjust according to

the following instructions.

5. Install the bottom panel (see

Figure 37).

6. Tighten the bolts on each side of

the bottom panel.

Bolt Bottom Panel

Figure 37

Figure 38

Speed Control Rod

How To Adjust The Friction Wheel

1. Position the shift speed lever in

the lowest forward speed.

2. Loosen the bolts on the speed

control rod (see Figure 39).

3. Move the friction wheel to the cor

rect position (see Figure 38),

4. Tighten the bolts on the speed

control rod (see Figure 39).

F-0410108L

Figure 39

29

SERVICE AND ADJUSTMENT

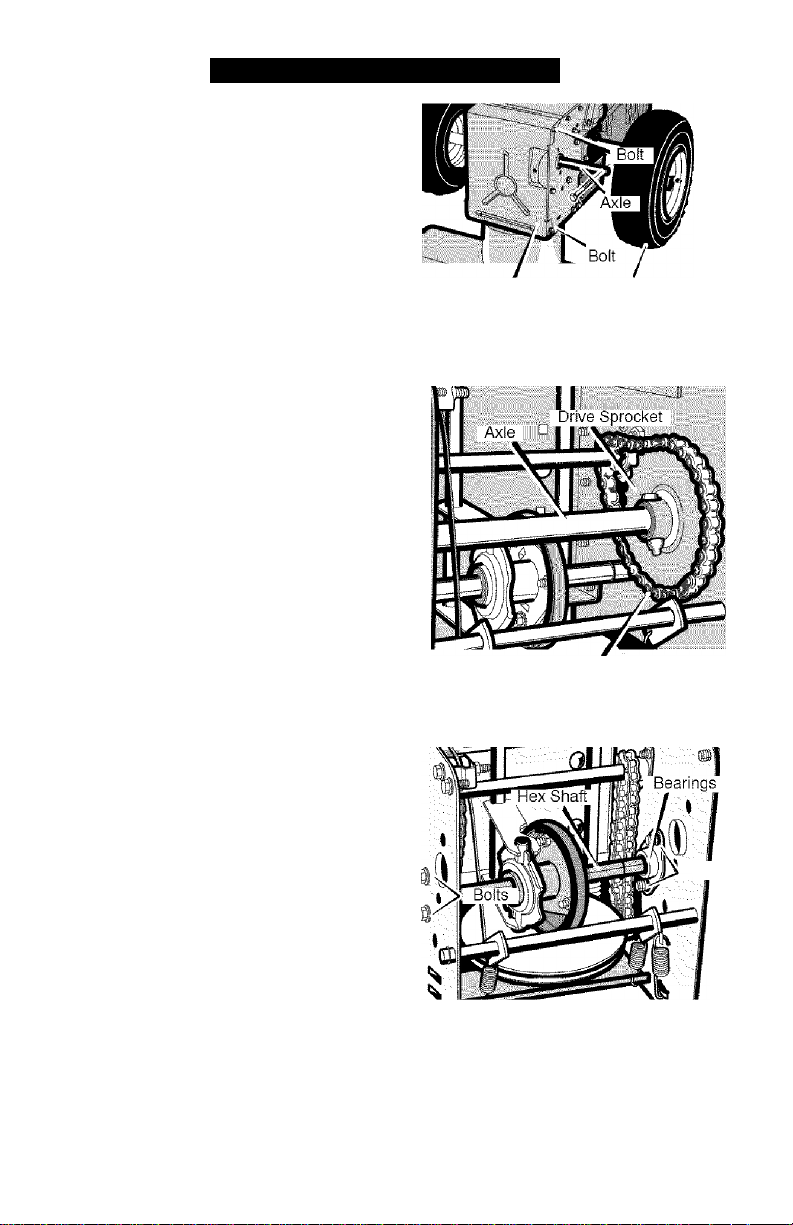

How To Replace The Friction Wheel

If the friction wheei is worn or damaged,

the snow thrower will not move forward.

The friction wheei must be replaced as

follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing (4),

(see Figure 37).

3. Disconnect the spark plug wire.

4. Remove the fasteners that secure

the right wheel. Remove the right

wheel from the axle (see Figure 40)

5. Loosen the bolts on each side of

the bottom panel,

6. Remove the bottom panel.

7. Remove the fasteners that secure

the drive sprocket to the axle (see

Figure 41).

8. Remove the left wheel, axle, and

drive sprocket.

Bottom Pane! Wheel

Chain

Figure 40

Figure 41

9. Remove the four bolts that hold the

bearings on each side of the hex

shaft (see Figure 42).

10. Remove the hex shaft and bear

ings.

NOTE: Take special note of the posi

tion of the washers on the hex shaft.

F-0410108L

Bolts

Figure 42

30

SERVICE AND ADJUSTMENT

11. Remove the three fasteners that

hold the friction wheel to the hub

(see Figure 43).

12. Remove the friction wheel from the

hub. Slip the friction wheel oft the

hex shaft.

13. Assemble the new friction wheel

onto hub with the fasteners re

moved earlier.

14. Install the hex shaft and bearings

with the four bolts removed earlier

(see Figure 44).

Make sure the washers are prop

erly installed in the original posi

tion. Also, make sure the two

washers are properly aligned

with the actuator arms.

15. Make sure the hex shaft turns free

ly-

16. Install the left wheel, axle, and

drive sprocket with the fasteners

removed earlier. Install the chain

onto the drive sprocket (see

Figure 41).

17. Check the adjustment of the friction

wheel. See “How To Adjust The

Friction Wheel” in this section.

18. Make sure the friction wheel and the

disc drive plate are free from grease

or oil.

19. Install the bottom panel (see

Figure 40).

20. Tighten the bolts on each side of

the bottom panel.

21. Install the right wheel to the axle

with the fasteners removed earlier.

22. Connect the spark plug wire.

F-0410108L

Washer

Washer

Figure 44

SERVICE AND ADJUSTMENT

HOW TO REPLACE

THE AUGER SHEAR BOLT

The augers are secured to the auger

shaft with special shear bolts. These

shear bolts are designed to break and

protect the machine if an object be

comes lodged in the auger housing. Do

not use a harder bolt as the protection

provided by the shear bolt will be lost.

WARNING; For safety and to

A

shear boits.

protect the machine, use

only original equipment

To replace a broken shear bolt, proceed

as follows. Extra shear bolts were pro

vided with the unit.

1.

Stop the engine. Disengage all con

trols.

2.

Disconnect the spark plug wire.

Make sure all moving parts have

stopped.

3.

Align the hole in the auger with the

hole in the auger shaft. Install the

new shear pin and spacer. See

Figure 45.

Connect the spark plug wire.

F-0410108L

Figure 45

32

STORAGE

WARNING; Never store your

A

snow thrower with gasoline

in the fuel tank indoors or in

an enclosed, poorly ventilated area.

If gasoline remains in the tank,

fumes may reach an open flame,

spark or pilot light from a furnace,

water heater, clothes dryer, ciga

rette, etc.

To prevent damage (if snow thrower is

not used for more than 30 days) follow

the steps below.

SNOW THROWER

1. Thoroughly clean the snow thrower.

2. Lubricate all lubrication points. See

the Maintenance section.

3. Be sure that all nuts, bolts and

screws are securely fastened. In

spect all visible moving parts for

damage, breakage and wear. Re

place if necessary.

4. Touch up all rusted or chipped paint

surfaces; sand lightly before paint

ing.

5. Cover the bare metal parts of the

blower housing auger and the im

peller with rust preventative, such

as a spray lubricant.

NOTE: A yearly checkup or tune-up by

a Sears service center is a good way ot

ensuring that your snow thrower will

provide maximum performance for the

next season.

ENGINE

Gasoline must be removed or treated to

prevent gum deposits from forming in

the fuel tank, filter, hose, and carburetor

during storage. Also, during storage al

cohol blended gasoline that uses etha

nol or methanol (sometimes called

gasohol) attracts water. It acts on the

gasoline to form acids which damage

the engine.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. If you do not remove the gasoline,

use fuel stabilizer supplied with unit

or purchase Craftsman Fuel Stabi

lizer No. 3550. Add fuel stabilizer to

any gasoline left in the tank to mini

mize gum deposits and acids. If the

fuel tank is almost empty, mix stabi

lizer with fresh gasoline in a sepa

rate container and add some to the

fuel tank.

3. Always foliow the instructions on the

stabilizer container. After the stabi

lizer is added to the fuel tank, run

the engine at least ten minutes to

allow the mixture to reach the car

buretor.

4. Change the engine oil.

5. Remove the spark plug and pour

about 15 ml (1 /2 oz) of engine oil

into the cylinder. Replace the spark

plug and crank slowly to distribute

the oil.

6. Store in a clean and dry area, but

NOT near a stove, furnace or water

heater which uses a pilot light or

any device that can create a spark.

OTHER

1. If possible, store your snow thrower

indoors and cover it to give protec

tion from dust and dirt.

2. If the snow thrower must be stored

outdoors, put the snow thrower on

blocks to raise it off of the ground.

3. Cover the snow thrower with a suit

able protective cover that does not

retain moisture. Do not use plastic.

IMPORTANT: Never cover snow

thrower while engine and exhaust areas

are still warm.

F-0410108L

33

TROUBLESHOOTING

TROUBLE CAUSE CORRECTION

Difficult starting Defective spark plug. Replace spark plug.

Water or dirt in fuel system. Remove fuel from fue! tank.

Add fresh fuel.

Engine runs erratically Blocked fuel line, empty gas

tank, or stale gasoline

Engine stalls Unit running on CHOKE. Set choke lever to OFF

Clean fue! line; check fuel

supply; add fresh gasoline

position.

Engine runs erratic;

Loss of power

Excessive vibration Loose parts: damaged

Water or dirt in fue! system. Remove fuel from fue! tank.

Add fresh fue!.

Immediately stop engine.

impeller

Remove ignition key. Tighten

all fasteners and make all

necessary repairs. If

vibration continues, take the

unit to a Sears service

center.

Unit fails to propel itself Traction drive belt loose or

Replace traction drive belt.

damaged.

Incorrect adjustment of

Adjust traction drive cable.

traction drive cable

Worn or damaged friction

Replace friction wheel.

wheel.

Unit falls to discharge

snow

Auger drive belt loose or

damaged.

Auger control cable not

Adjust auger drive belt;

replace if damaged.

Adjust auger control cable.

adjusted correctly.

F-0410108L

Shear bolt broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and

disconnect spark plug wire.

Clean discharge chute and

inside of auger housing.

Foreign object lodged in

auger

Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

34

(This page applicable in the U.S.A. and Canada only.)

Sears, Roebuck and Co,, U.S.A. (Sears), the California Air Resources Board

(CARB) and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty

Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTIFIED

ENGINES PURCHASED IN CALIFORNIA IN 1995 AND THEREAFTER. WHICH ARE

USED IN CALIFORNIA, AND TO CERTIFIED MODEL YEAR 1997 AND LATER EN

GINES WHICH ARE PURCHASED AND USED ELSEWHERE IN THE UNITED

STATES (AND AFTER JANUARY 1. 2001 IN CANADA).

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board

(CARS), U.S. EPA and Sears are pleased

to explain the Emission Control System

Warranty on your model year 2000 and lat

er small off-road engine (SORE). In Califor

nia, new small off-road engines must be

designed, built and equipped to meet the

State's stringent anti-smog standards.

Elsewhere in the United States, new non

road, spark-ignition engines certified for

model year 1997 and later must meet simi

lar standards set forth by the U.S. EPA.

Sears must warrant the emission control

system on your engine for the periods of

time listed below, provided there has been

no abuse, neglect or improper mainte

nance of your small off-road engine.

Your emission control system Includes

parts such as the carburetor, air cleaner,

ignition system, muffler and catalytic con

verter. Also included may be connectors

and other emission related assemblies.

Where a warrantable condition exists.

Sears will repair your small off-road en

gine at no cost to you including diagnosis,

parts and labor.

Sears Emission Controi Defects Warranty Coverage

Small off-road engines are warranted rel- sions set forth below. If any covered part

ative to emission control parts defects for on your engine is defective, the part will

a period of two years, subject to provi- be repaired or replaced by Sears.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you

are responsible for the performance of

the required maintenance listed in your

Operating and Maintenance Instructions.

Sears recommends that you retain all

your receipts covering maintenance on

your small off-road engine, but Sears

cannot deny warranty solely for the lack

of receipts or for your failure to ensure the

performance of all scheduled mainte

nance.

As the small off-road engine owner, you

should however be aware that Sears may

deny you warranty coverage if your small

off-road engine or a part has failed due to

abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your

small off-road engine to an Authorized

Sears Service Dealer as soon as a prob

lem exists. The undisputed warranty re

pairs should be completed in a

reasonable amount of time, not to exceed

30 days.

If you have any questions regarding your

warranty rights and responsibilities, you

should contact a Sears Service Repre

sentative at 1-800-469-4663.

The emission warranty is a defects war

ranty. Defects are judged on normal en

gine performance. The warranty is not

related to an in-use emission test.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty

Coverage. It is in addition to the Sears engine warranty for non-regulated engines found

in the Operating and Maintenance Instructions.

F-0410108L 35

1. Warranted Parts

Coverage under this warranty ex

tends only to the parts listed below

(the emission control systems

parts) to the extent these parts

were present on the engine pur

chased.

a. Fuel Metering System

• Cold start enrichment sys

tem

• Carburetor and internal

parts

• Fuel Pump

b. Air Induction System

• Air cleaner

Intake manifold

c. Ignition System

• Spark piug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or

pulse valve

e. Miscellaneous Items Used in

Above Systems

• Vacuum, temperature,

position, time sensitive valves

and switches

• Connectors and assem

blies

2. Length of Coverage

Sears warrants to the initial owner

and each subsequent purchaser that

the Warranted Parts shall be free

from defects in materials and work

manship which caused the failure of

the Warranted Parts for a period of

two years from the date the engine

is delivered to a retail purchaser.

3. No Charge

Repair or replacement of any War

ranted Part will be performed at no

charge to the owner, including diag

nostic labor which leads to the de

termination that a Warranted Part is

defective, if the diagnostic work is

performed at an Authorized Sears

Service Dealer. For emissions war

ranty service contact your nearest

Authorized Sears Service Dealer as

listed in the “Yellow Pages” under

“Engines, Gasoline,” “Gasoline En

gines,” “Lawn Mowers,” or similar

category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in ac

cordance with the provisions of the

Sears Engine Warranty Policy. War

ranty coverage shall be excluded

for failures of Warranted Parts

which are not original Sears parts

or because of abuse, neglect or im

proper maintenance as set forth in

the Sears Engine Warranty Policy.

Sears is not liable to cover failures

of Warranted Parts caused by the

use of add-on, non-original, or mo

dified parts.

5. Maintenance

Any Warranted Part which is not

scheduled for replacement as re

quired maintenance or which is

scheduled only for regular inspection

to the effect of “repair or replace as

necessary” shall be warranted as to

defects for the warranty period. Any

Warranted Part which is scheduled

for replacement as required mainte

nance shall be warranted as to de

fects only for the period of time up to

the first scheduled replacement for

that part. Any replacement part that

is equivalent in performance and du

rability may be used in the perfor

mance of any maintenance or

repairs. The owner is responsible for

the performance of all required

maintenance, as defined in the

Sears Operating and Maintenance

Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to

the failure of any engine compo

nents caused by the failure of any

Warranted Part still under warranty.

In the USA and Canada, a 24 hour hot line, 1-800-469-4663, has a menu of pre-re

corded messages offering you engine maintenance information.

F-0410108L

36

Look For Relevant Emissions Durability Period and Air

Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (GARB) Tier 2

Emission Standards must display information regarding the Emissions Durability Pe

riod and the Air Index, Sears, Roebuck and Co,, U.S,A, makes this information avail

able to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running

time for which the engine is certified to be emissions compliant, assuming proper

maintenance in accordance with the Operating & Maintenance Instructions, The fol

lowing categories are used:

Moderate; Engine is certified to be emission compliant for 125 hours of actual

engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual

engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual

engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with an intermediate

rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a

specific engine family. The lower the Air index, the cleaner the engine. This informa

tion is displayed in graphical form on the emissions label.

After July 1, 2000, Look For Emissions Compliance

Period OnEngine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to

meet the United States Environmental Protection Agency (USEPA) Phase 2 emission

standards. For Phase 2 certified engines, the Emissions Compliance Period referred to

on the Emissions Compliance label indicates the number of operating hours for which the

engine has been shown to meet Federal emission requirements. For engines less than

225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours. For

engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

The displacement engines of Model Series 90000 is 148 cc.

The displacement engines of Model Series 120000 is 206 cc.