Craftsman 536.881550 User Manual

Operator's Manual

Snow Thrower

6 Horsepower

Electric Start

24-inch Dual Stags

Model 536.881550

CAUTION: Before using this product,

read this manual and foflow all of its

Safety Rules and Operating Instructions.

Manual del usario

Quitanieves

de 24 pulgadas

6 caballos de fuerza (hp)

de dos Uempos

Arranque el6ctdco

Modelo 536.881550

PRECAUCI6N: Antes de usar este producto,

lea este manual y siga todas las reglas de

seguddad e instruccionesde operaci6n.

Sears, Roebuck and Co., Hoffrnan Estates, IL 60179 U.S.A.

F-04101 11L www.sean;.com/craftsman

WARRANTY STATEMENT ......

SAFETY RULES . ..

*.....lw**l •

INTERNATIONAL SYMBOLS ....

ASSEMBLY ...................

OPERATION ..................

MAINTENANCE ...............

SERVICE AND ADJUSTMENT ..

2 STORAGE .................... 33

2 TROUBLESHOOTING TABLE . .. 34

4 REPAIR PARTS ............... 38

6 ENGINE REPAIR PARTS ....... 56

11 SPANISH (ESPA_IOL) .......... 63

18 PARTS ORDERING/SERVICE ..

21 BACK COVER

UMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For twoyesrsfrom the date of purchaes, when this Craftsman Seow thrower is malnlalned,

lubricated, and tuned up according to the operating and maintenance Instructions in the

owner's manual, Sears will repair, free of charge, any defect in material orworkmanship.

ff this _an Snow thrower is used for commercialor rental purposes, this wan'anty ap-

plies for only90 days flora the date of purchase.

This warranty does notcover _ following:

Items whichbecome worn dudngnormaluse, suchas spark plugs,drive baitsand sheer

pins,

Repair necessary because of operator abuseor negligence, includingbent crankshafts

and the failure to maintain the equipment according to the instructions containedin the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWER TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

THIS WARRANTY' APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty givesyou spectticlegal rights, and you may also have other dghtswhich may

vary fl'om state to stafa.

Sears, Roebuck and Co., D817WA, Hoffman Estates. IL 60179

LooK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS- ATTENTIONIII BECOME ALERTI!I YOUR SAFETY IS INVOLVED.

Engine F.x_aust,some of Its constltuent_ and

certain vehlclo components contain or emlt

chemicals known to the State of Califomia to

cause cancer and birth defects or other repro-

ductiveharm.

Battery posts,terminalsand relatedacesssodes

€ontain lead and load compounds, chemicals

known tothe StateofCalifornia tocause cancer

and birth defects or other mproductNe harm.

WASHHANDS AFTER HANDLING.

F-0410111L 2

A WARNING:Alwaysdis€on-

nect the spark plug wire

and placeitwhereitcannot

mako contact with spark plug to

preventaccidental starling during:

Preparation,Maintenance,or Stor-

age of your snow thrower.

IMPORTANT;. Safety standardsre-

quire operator presence controlsto

minimizethe risk of injury.Yoursnow

throwerisequippedwithsuchcontrols.

Do notattempttodefeatthefunc'donof

the operatorpresencecontrolunderany

circumstances.

TRAINING

1. Readthisoperatingandserviceinstruction

manualcarefully.Be _omu_ly familiar

w_ thecontrolsandtheproperuseofthe

snowthrower.Knowhowtostopthesnow

throweranddL_engagethecontrolsquick-

ly.

2. Neverallowchildrento operatethesnow

thrower.Neverallowadultsto operatethe

snowthrowerwi_out properinslnJction.

3. Ksepthe ereaof operationdeerof allper-

sons,parUauiedysmallchildrenandpets.

4. Exercisecautionto avoidslippingorfalling

especiallywhenoperatinginreverse.

PREPARATION

1. Thoroughlyinspectthe areawhere

snowthroweristobeusedandremoveell

doorrnt_, sleds, boards, wires, and other

faragnobje s.

2. Disengagealldutcheebeforestartingthe

engine(motor).

3. Donotoperatethe snowthrowerwithout

wearingadequatewinteroutergarments.

Wearfootwearthatwillimprovefootingon

stipperysurtaces.

4. Handlefuel withcare; it is highlyflam-

mable.

a. Usean approvedfuelcontainer.

b. Neverrercovefueltankc,_poraddfual

toa runningengine(motor)orhoten-

gine(motor).

c. Fillfuel tank outdoorswith extreme

care. Neverfillfueltank indoors.

d. Replacefuel capsecurelyandwipeup

spilledfuel.

e. Neverstorefuelorsnowthrower with

fuel in the tank inside of a building

wherefumesmayreachanopen11ame

orspark.

f. Checkfuelsupplybeforeeachuse,al-

lowingspaceforexpansionasthe hoat

ofthe engine(motor)and/orsuncan

causefuelto expand.

5. Forallsnowthrowerswithelectricstating

motors use al_a'ic sta_ng extension

cordscert_edCSA/UL Useonlywitha re-

ceptesiethathasbeeninstalledinaccord-

ancewithlocalinspec_onauthorities.

6. let engine(motor)andsnowthrowerad-

justtooutdoortsmperafuresbeforestarting

to cieeranow.

7. Alwayswearsefatyglassesoreyeshields

duringopera_n orwhileperforminganad-

justmentor repairto protecteyesfrom

foreigndojeststhattraybethrownfromthe

snowthrower.

F-0410111L 3

OPERATION

1. DOnotoperatethissnowthrowerifyouere

takingd"ugsoro_ermedica_onwhichcan

causedrowsinessoraffectyourabilityto

operatethissnow_wer.

2. Do not use the snowthrower if youare

meotellyorphysicallyt_abietooperate

snowthrowersa_ely.

3. Donotputhandsorfaat neeror underro-

toting parts.Keepdeer of the discharge

openingatall times.

4. Exerciseextremecautionwhenoperating

on or crossinggravel drives,walks or

roads.Stayalert for hiddenhazardsor

traffic.

5. Afterstrndnga foreign object,stopthe en-

gine (motor), removethe wire from the

spark plug, thoroughly inspect snow

throwerfor any damage, and repairthe

damage beforerestarl_and opera_g

thesnowthrower.

6. If thesnowthrowershouldstarttovbrate

abnormally,stopthe engine(motor)and

checki'nmadietelyforthecause.VibralJon

isgenerallya wamingoftrouble.

7. Stopthe engine(motor)whenever you

leave the operatingposition,beforeun-

clogging_ augerJimpellerhousingordis-

charge chute and when maldng any

repairs,ad}ustmants,or inspections.

8. When cleaning,repairing,or inspecting,

make certainthe auger/a_pellerand

movingpartshavestoppedandallcontrols

aredL_angaged.DisconnectthesparkpSug

wireandImapthe wireaway'B'omthesperk

plugto preventaccidentalstarting.

9. Takeallpossibleprece_onswhenleaving

thesnowthrowerunattended.Disengage

auger/impeller,stopengine (motor),

andremovekey.

10. Donotstertorrunangineh sncinsedarea,

evenif doorsor windows are open. Ex-

haustfumes are dangerous(containing

CARBON MONOXIDE, an ODORLESS

andDEADLYGAS).

11. Do not deer snow acrossthe face of

slopes.Exerciseex:l:mmecautionwhen

changhngdirectionon slopes.Do not at-

temptto clearsteepelopes.

12. Neveroperate the snowthrowerwlt_ut

properguards,platesor othersafetypro-

tectlvedevicesin place.

13. Neveroperatethosnowthrowerneeren-

closures,automobiles,windowwells,drop-

offs,andthelikewithoutproperad)ustmant

oflhe snowotschergeangle.Keepchildren

andpetsaway.

14.Donotoverloadthesnowthrowercapaclty

by attem_ngtoclearsnowattsofesta

rate.

15. Neveroperatethe snowthrower at high

_ansport speeds on slippery surfaces.

Lookbehindandusecarewhen becking

up.

16. Never directdischargeat bystandersor

allowanyoneinfrontofthe snowthrower.

17. Disengagepowertothecollastor/impeller

whensnowthroweris_'ansportedornotin

USe.

18. Useonlyattachrsentsandaccessoriesap-

provedby the manufectumrof thesnow

thrower (suchas _re chains,electric start

ecL).

19. Never operate the snowthrowgrwithout

goodvisibilityor light.Alwaysbe sure of

yourfoo_ng andkeepa firm holdon the

handles. Wak;neverrun.

20. Do notover-roach.Keepproperfoot_

andbalanceat alltimes.

21. Do notattemptto usesr=:_thrower on a

roof.

MAINTENANCE AND STORAGE

1. Checkshearbottsandotherboltsat fre-

quent intervalsfor propertightnessto be

surethesnowt_roweris in safeworking

condition.

2. Storethesnowthroworawayfromignition

sourcesor appliancesthat have a pilot

light,suchashotwatorsndspasehestors,

clothesdryers,etc.... Allowtt_ engine

(motor)tocoolbeforestoringinanyenclos-

urB.

3. Always referto operator'sguideins'_uc-

tions for importantdetailsif the snow

thrower is to be storedforan extended

period.

4. Maintainor replace.safetyand instm_on

labels,asnecessary.

5. Runthesnowthrowerafewminutasafter

throwing snowto preventfreeze-upofthe

auger/impeller.

_ ARNING: This snowthrowerIs

Cautionshould bee_erofsedwhlle usingon

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACESABOVE

GROUND LEVEL such as roofs of reel-

dances, garages, porches or other such

structuresor buildings.

for usa on sidewalks, drlvewaye

and otherground levelsurfaces.

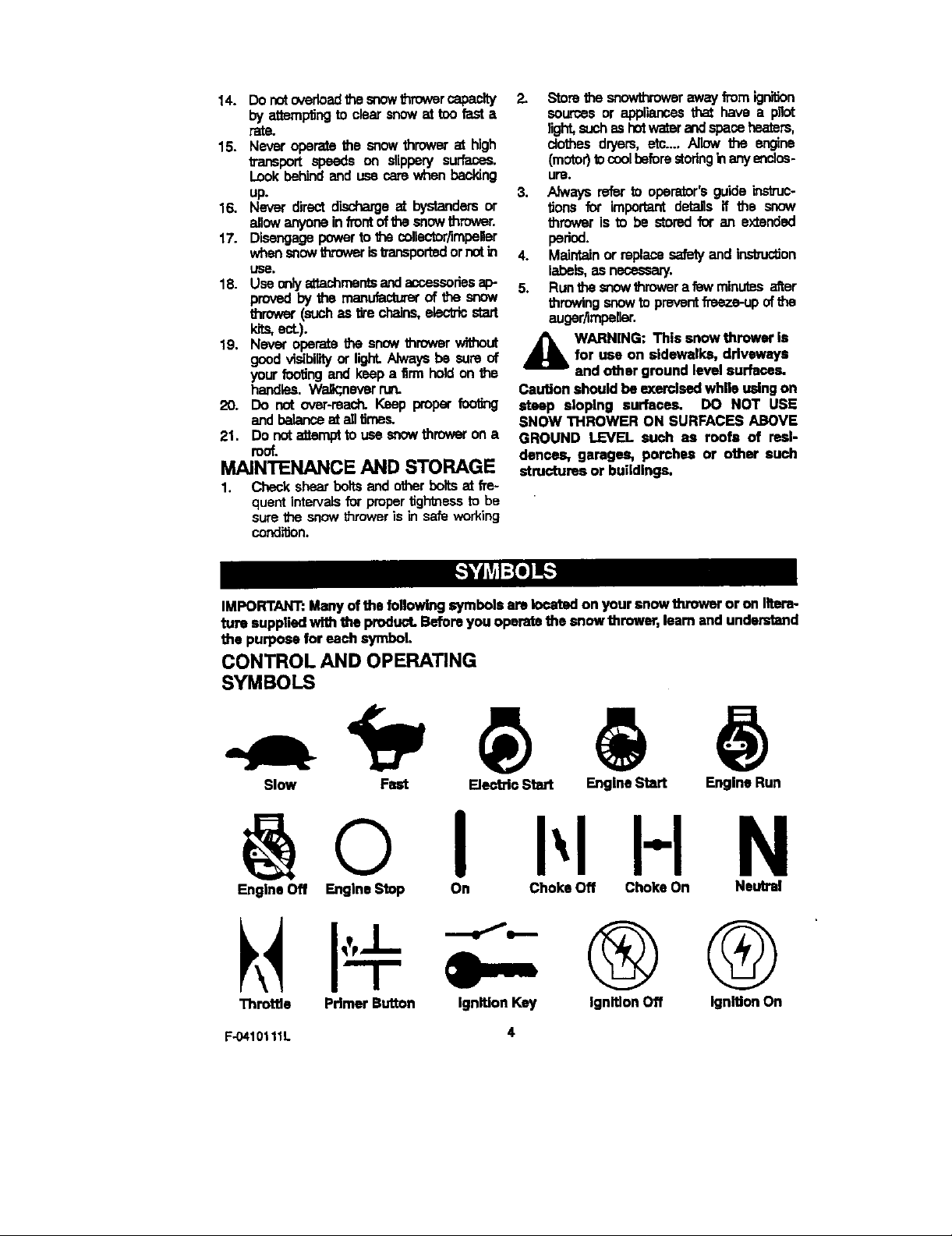

IMPORTANT:Manyof the followltKJsymbolsam Iocstedon your snowthroweror on litera-

ture suppliedwiththe product.Bstomyouoperatethe snowthrower, learnandunderstand

the purposefor eachsymbol.

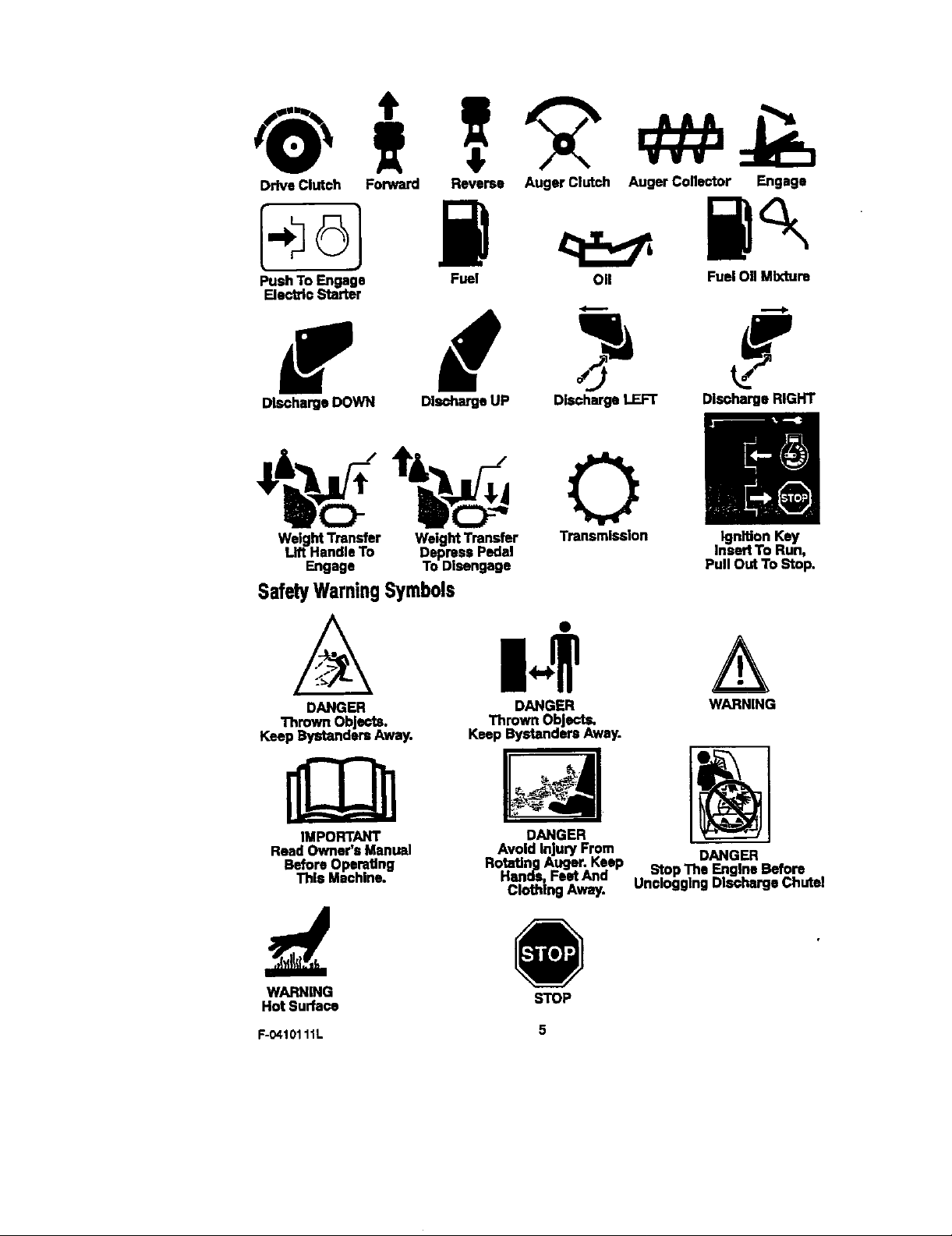

CONTROL AND OPERATING

SYMBOLS

Slow Fast ElectricStart EngineStart Engine Run

@0 1 I-IN

Engine Off Engine Stop On Choke Off ChokeOn Neutral

®Q

Thrcttlo Primer Button Ignltlon Key

F-O410111L 4

Ignition Off IgnitionOn

DriveClutch Forward Reverse Auger Clutch Auger Collector Engage

Push To Engage Fuel 011 Fuel 011Mixture

ElectricStarter

DischargeDOWN DischargeUP DischargeLEFT DischargeRIGHT

|JH

WeigM Transfer WeightTransfer Transmission IgnitionKey

Lift HandleTo DepressPedal InsertTo Run,

Engage To Disengage PullOutTo Stop.

SafetyWarningSymbols

DANGER DANGER WARNING

ThrownObjects. Thrown Objects.

Keep BystandersAway. Keep BystandersAway.

IMPORTANT

Read Owner's Manual

BeforeOperedng

ThisMachine.

WARNING STOP

Hot Surface

F-0410111L 5

DANGER

Avoid InjuryFrom

RotatingAuger. Keep DANGER

Hands, FeetAnd StopThe Engine Before

ClothingAway. UncloggingDlschergeChutal

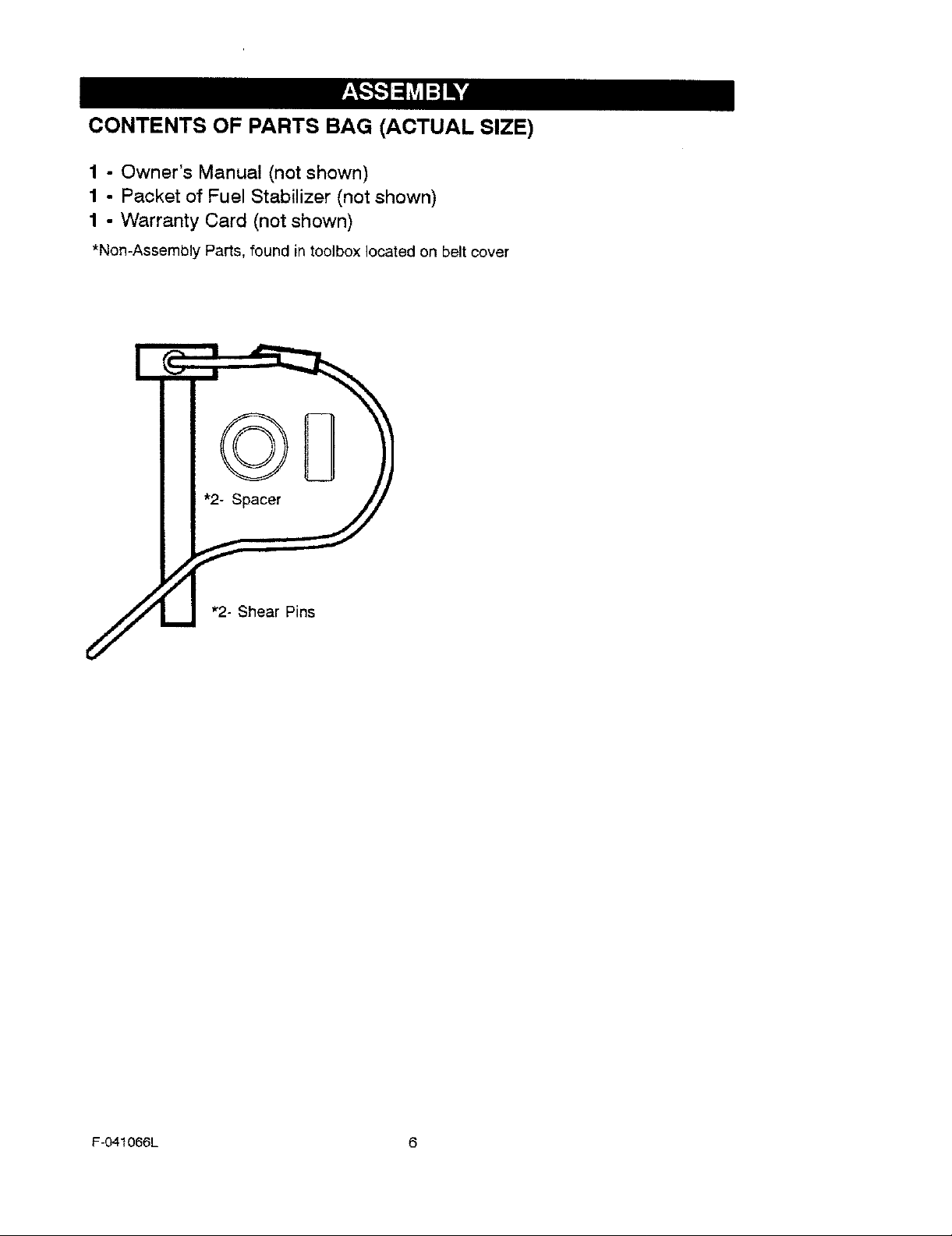

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assembly Parts, found in toolbox located on belt cover

F-O41066L 6

,_ WARNING: Always wearsafety glasses or eye shields

while assembling snow

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knifeto outcarton

2 - 1/2 inch wrenches

(or adjustable wrenches)

2 - 9/16 inchwrenches

(or adjustable wrenches)

2 - 3/4 inch wrenches

(or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1 - Screwdriver

1 - Measuring tape or ruler

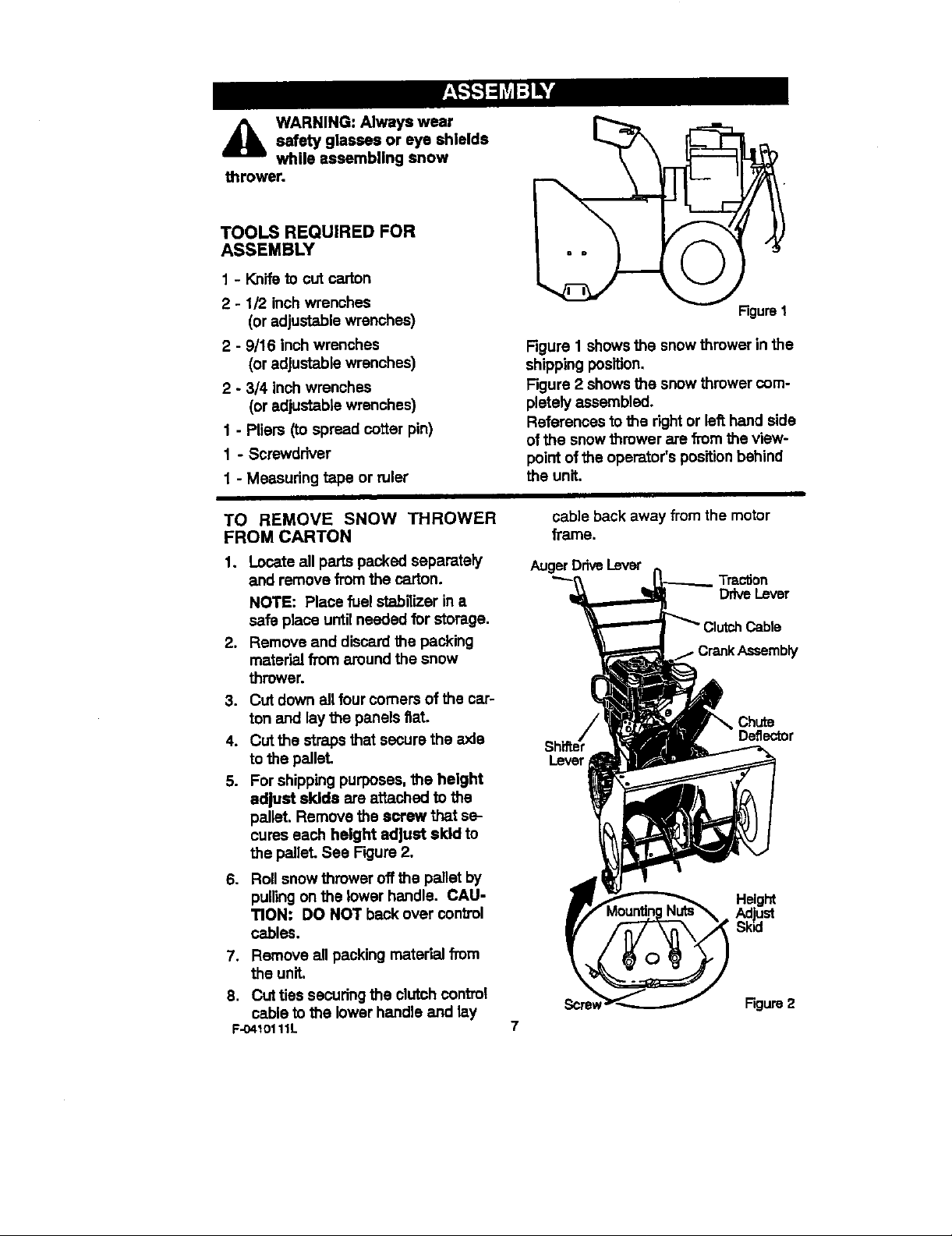

Figure1

Figure 1 shows the snow thrower in the

shipping position.

Figure 2 shows the snow thrower com-

pletely assembled.

References to the right or left hand side

of the snow thrower are from the view-

point ofthe operator's positionbehind

the unit.

TO REMOVE SNOW THROWER

FROM CARTON

1. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a

safe place untilneeded for storage.

2. Remove and discard the packing

material from around the snow

thrower.

3. Cut down all four comers of the car-

ton and laythe panels fiat

4. Cut the straps that secure the axle

to the pallet,

5. For shipping purposes, the height

adjust skids are attached to the

pallet. Remove the screw that se-

cures each height adjust skid to

the pallet. See F'_jure2.

. Roll snow thrower off the pallet by

pullingon the lower handle. CAU-

TION: DO NOT back over contTol

cables.

7. Remove all packing material from

the unit.

8. Cut ties secudng the clutch control

cable to the lower handle and lay

F-0410111L

cable back away from the motor

frame.

AugerDdveLever

Lever

Screw Figure 2

7

Traction

DriveLever

Cable

kAssembly

Chute

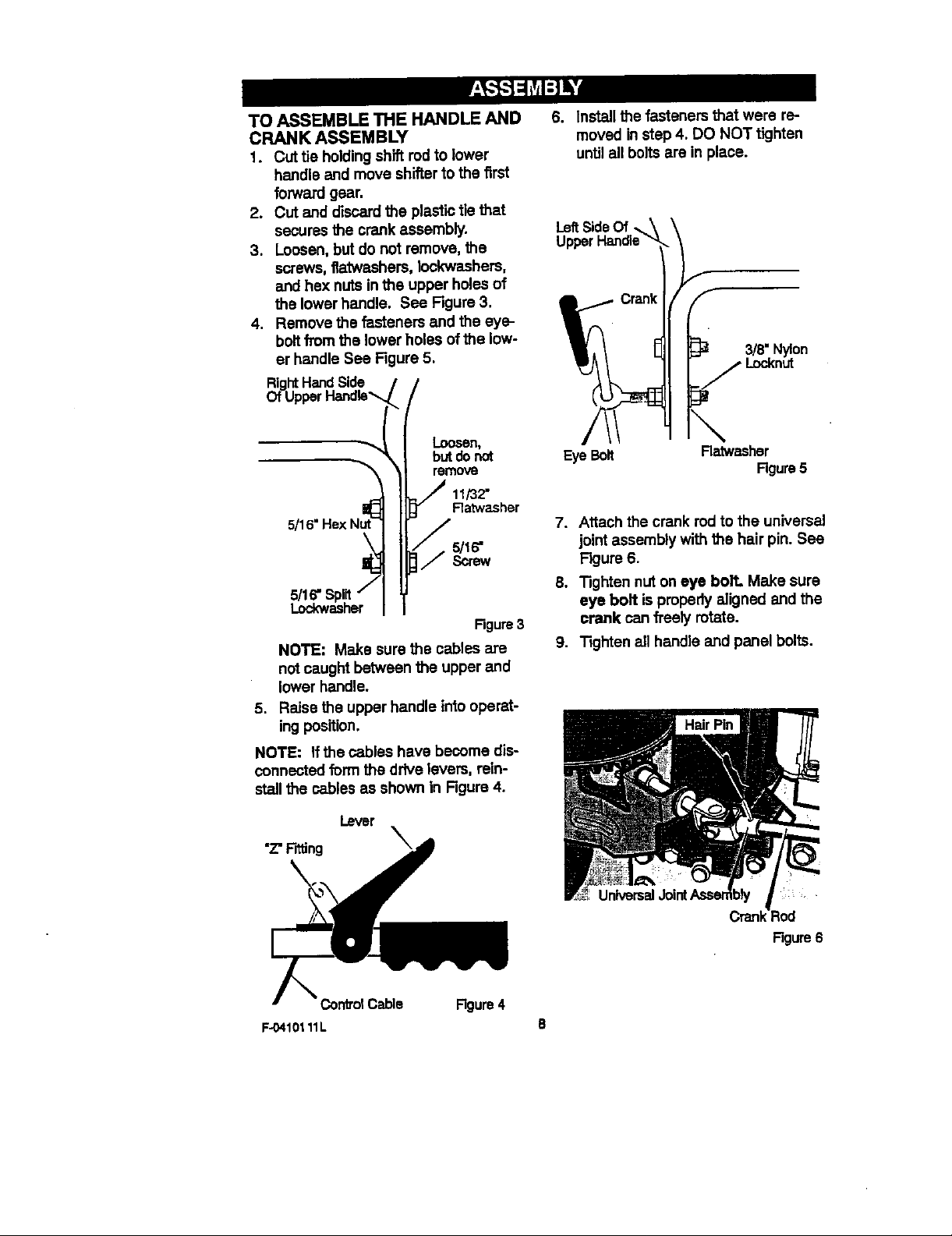

TO ASSEMBLE THE HANDLE AND

CRANK ASSEMBLY

1. Cut tie holdingshift rodto lower

handle and move shifterto the first

forward gear.

2. Cut and discardthe plastic tie that

secures the crank assembly.

3. Loosen, but do not remove, the

screws, f_twashers, Iockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

4. Remove the fasteners and the eye-

boltfrom the lowerholes of the low-

er handle See Figure 5.

RightHand Side j

/

LooseN_

OfUpperHandle_

5/16" Hex Nut_:_

NOTE: Make sure the cables are

not caught between the upper and

lower handle,

5. Raise the upper handle into operat-

ingposition,

NOTE: If the cables have become dis-

connected form the drive levers, rein-

stall the cables as shown in Figure 4.

but do not

remove

11/32"

Ratwasher

Rgum 3

6. Installthe fasteners that were re-

moved instep 4. DO NOT tighten

until all bolts are in place.

LeftSideOf

Upper

3/8= Nylon

Locknut

Eye Bolt Ratwasher

Rgure5

7. Attach the crank rodto the universal

joint assembly with the hair pin. See

Figure 6.

8. "lighten nut on eye bolt. Make sure

eye bolt is properlyaligned and the

crank can fl'eely route.

9. Tighten all handle and panel bolts.

Coht_4 Cable Rgure 4

F-0410111L 8

Cren_Aod

Figure6

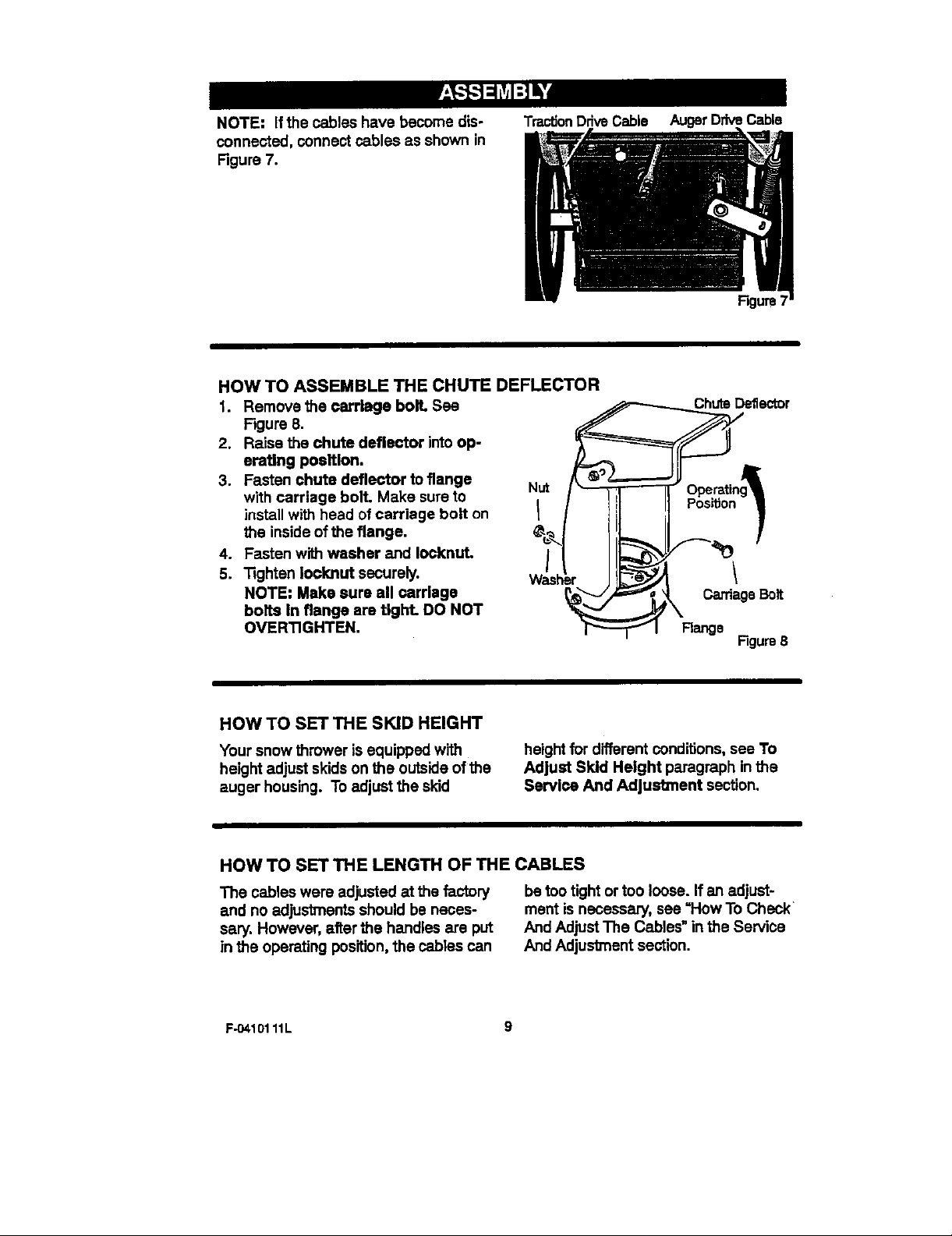

NOTE: Ifthe cables have become dis-

connected, connect cables as shown in

Figure 7.

TractionDriveCable AugerDriveCable

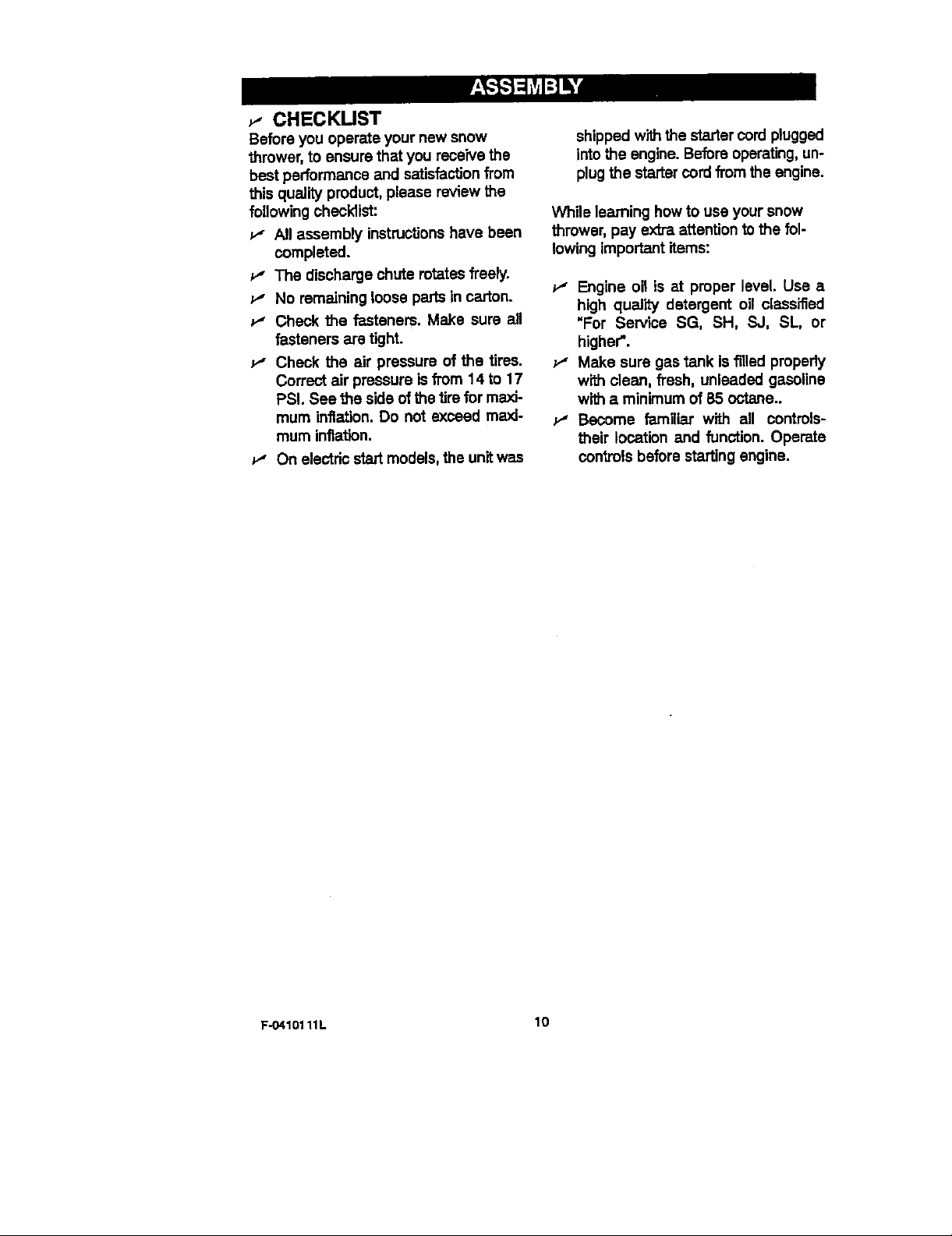

HOW TO ASSEMBLE THE CHUTE DEFLECTOR

1. Remove the carriage boll See

Figure 8.

2. Raise the chute deflector into op-

erating position.

3. Fasten chute deflector toflange

with carriage bolt. Make sure to

install with head of carriage bolt on

the inside of the flange.

4. Fasten with washer and Iocknut.

5. "RghtenIooknut securely.

NOTE: Make sure all cerriage

bolts in flange are tight. DO NOT

OVERTIGHTEN.

jT=z=._._Jj...... __

Nut / -- _, Operatng_l

I I Iii I_o_.oo-I

Figure7

De_ector

/k. ,--.or

Figure8

HOW TO SET THE SKID HEIGHT

Your snow thrower is equipped with

height adjust skids on the outside of the

auger housing. To adjust the skid

height for different conditions, see To

Adjust Skid Height paragraph In the

Service And AdJust_nent section.

HOW TO SET THE LENGTH OF THE CABLES

The cables were adjusted at the factory

and no adjustments should be neces-

sary. However, al_erthe handles are put

in the operating position,the cables can

F-O410111L 9

be too tightor too loose. If an adjust-

ment is necessary, see =How To Check

And Adjust The Cables" in the Service

And Adjustment section.

_- CHECKUST

Before you operate your new snow

threwer, to ensure that you receive the

best performance and satisfac_on from

this quality product,please review the

followingohecldist:

All assembly instructionshave been

completed.

e" The discharge chute rotates freely.

e" No remaining loose parts in carton.

Check the fasteners. Make sure all

fasteners are tight.

v" Check the air pressure of the tires.

Correut air pressure isfrom 14 to 17

PSI. See the side of the _refor maxi-

mum inflation. Do not exceed maxi-

mum inflation.

1t" On e/ectric start medals, the unit was

shipped with the starter cordplugged

intothe engine. Before operating,un-

plug the starter cord from the engine.

While learning howto use your snow

thrower, pay extra attention to the fol-

lowing important items:

v_ Engine oil is at proper level Use a

high quality detergent oil classified

"For Service SG, SH, SJ, SL, or

higher".

Make sure gas tank is filled propedy

with clean, fresh, unleaded gasoline

w_ a minimum of 85 octane..

Become familiar with all controls-

their location and function. Operate

controls before starting engine.

F-O410111L 10

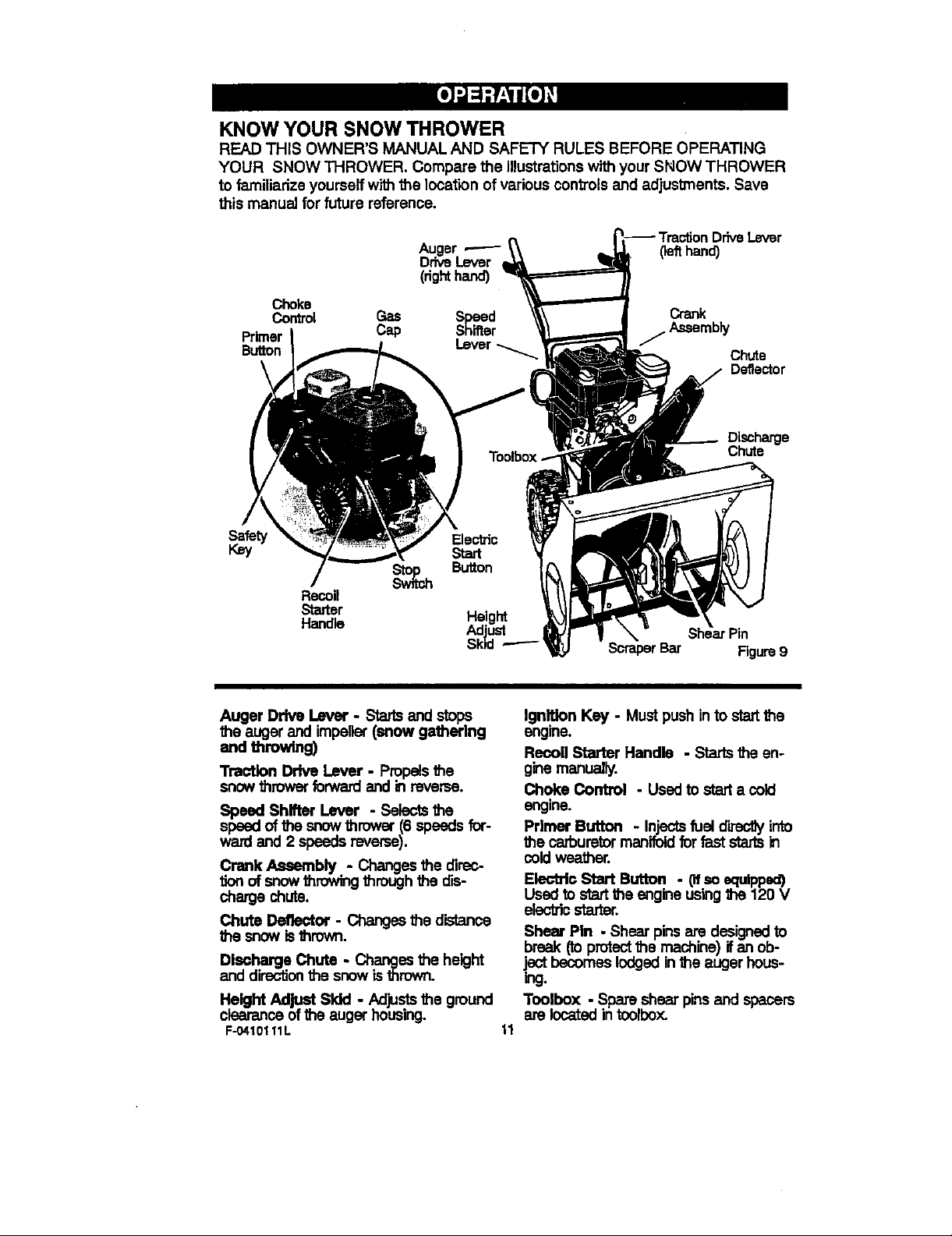

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER. Compare the illustrationswith your SNOW THROWER

to familiarize yourself with the location of various controlsand adjustments. Save

this manual for future reference.

(lefthand)

(righthand)

Choke

Control Gas Crank

Primer Cap / Assembly

Button Chute

Safety

Deflector

Discharge

Chute

Key

Recoil

Starter

Handle

Auger Drive Lever. Starts and stops

the auger and impeller(snow gathering

and throwing)

Traction Drive Lever - Propelsthe

snowthrower forwardand h reverse.

Speed Shifter Lever - Selects the

spsed of the snow thrower (6 speads for-

wa,,dand 2 speeds reverse).

Crank Assembly - Changes the direc-

tion of snow throwingthrough the dis-

charge chute.

Chute Deflector - Changes the distance

the snow is thrown.

Discharge Chute. Changes the height

and directionthe snow isthrown.

Height Adjust Sldd - Adjuststhe ground

clearanceof the auger housing.

F-0410111L

ScraperBar Figure9

Ignition Key - Must push into startthe

engine.

Recoil Starter Handle - Starts the en-

ginemanually.

Choke Control - Usedto startacold

engine.

Primer Button . Injectsfuel directJyinto

the carburetormanifold for fast stads in

coldweather.

Electric Start Button - Ofso equipped)

Used to start the engine using the 120 V

electric starter.

Shear Pin - Shear pinsare designed to

break (toprotectthe machine) if an ob-

j._ becomes lodged inthe auger hous-

_J.

Toolbox - Spare shear pinsand spacers

are located in toolbox.

11

The operation of any snowthrower can

resultin foreign objects being thrown

intothe eyes, which can resultin se-

vere eye damage. Always wear safety

glasses or eye shields while operating

the snow thrower.

We recommend standard safety

glasses or a wide vision safety mask for

over your glasses.

A ARNING: Read Owner's

Manual before operaUng

machlne. Never direct dls-

charge toward bystanders. Stop the

engine before unclogging discharge

chute or auger housing and before

leaving the machine.

TO STOP YOUR

SNOW THROWER

1. To stop throwing snow, release the

auger drive lever.

2. To stop the wheels, release the

traction drive lever.

3. To stop the engine, pull out the

safety key.

CAUTION: To stop the engine, do not

move the choke conb'ol to CHOKE

position. Backfire or engine damage

can occur.

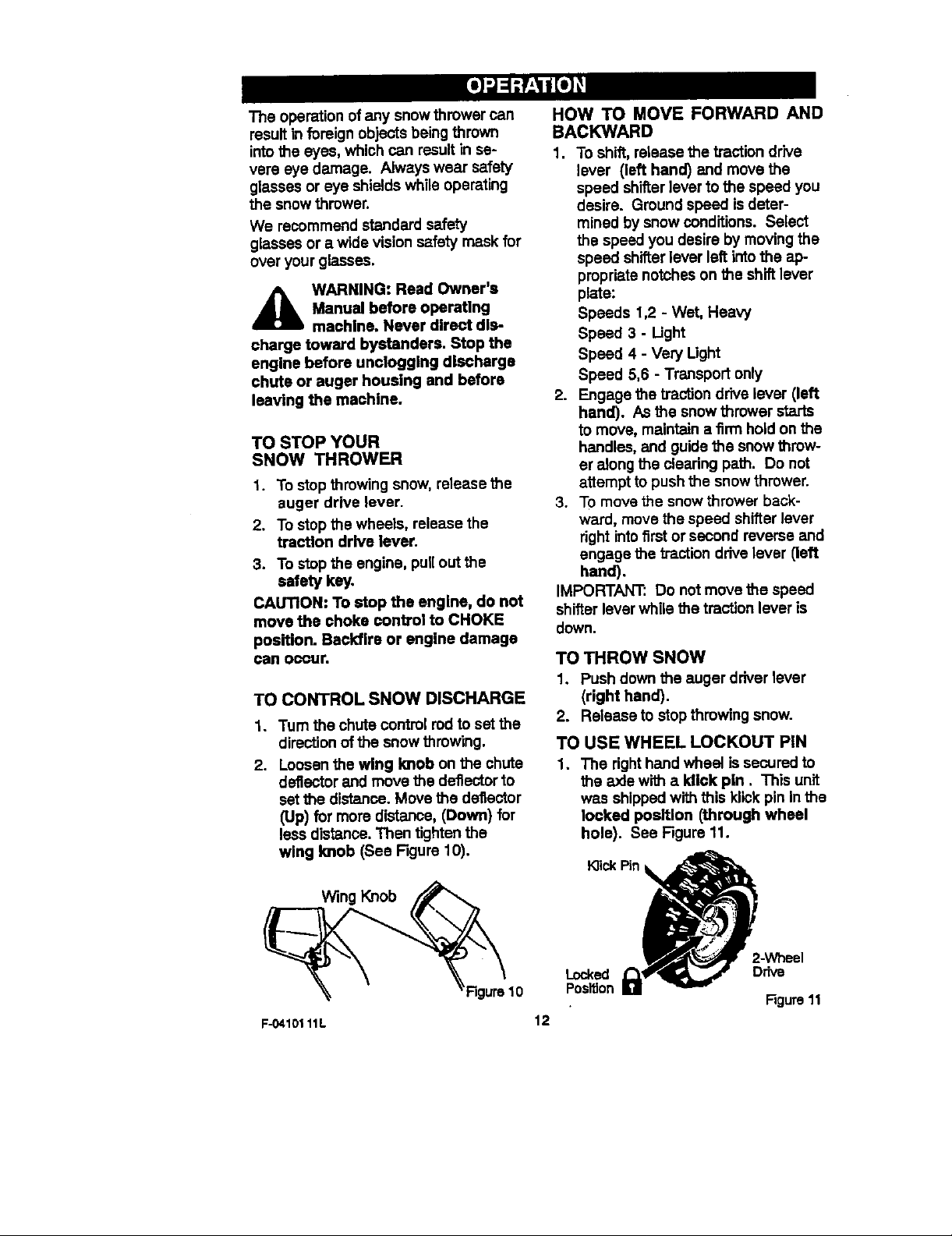

TO CONTROL SNOW DISCHARGE

1. Turn the chute controlrod to set the

direction ofthe snow throwing.

2. Loosenthe wing knob on the chute

deflector and move the deflector to

set the distance. Move the de_ector

(Up) for more distance, (Down) for

less distance. Then tighten the

wing Imob (See Figure 10).

HOW TO MOVE FORWARD AND

BACKWARD

1. To shift,release the traction drive

lever (left hand) and move the

speed shifter lever to the speed you

desire. Ground speed is deter-

mined by snow conditions. Select

the speed you desire by moving the

speed shifterleverleftintotheap-

propriatenotcheson theshiftlever

plate:

Speeds 1,2 - Wet, Heavy

Speed 3 - Light

Speed 4 - Very Ught

Speed 5,6 - Transport only

2. Engage the traction drive lever (left

hand). As the snowthrower starts

to move, maintain a firm hold on the

handles, end guide the snowthrow-

er along the clearing path. Do not

attempt to push the snow thrower.

3. To move the snow thrower back-

ward, move the speed shi_er lever

right intofirst or second reverse and

engage the tractiondrive lever (left

hand).

IMPORTANT: Do not move the speed

shifter lever while the traction lever is

down.

TO THROW SNOW

1, Push down the auger driver lever

(right hand),

2. Release to stop throwing snow.

TO USE WHEEL LOCKOUT PIN

1. The right hand wheel is secured to

the axle witha Idick pin, This unit

was shippedwith this Idickpin inthe

locked position (through wheel

hole). See Figure 11.

F-O410111L

Wing Knob

K]ickPin

j,

Locked Drive

Position

12

-Wheel

Figure11

,

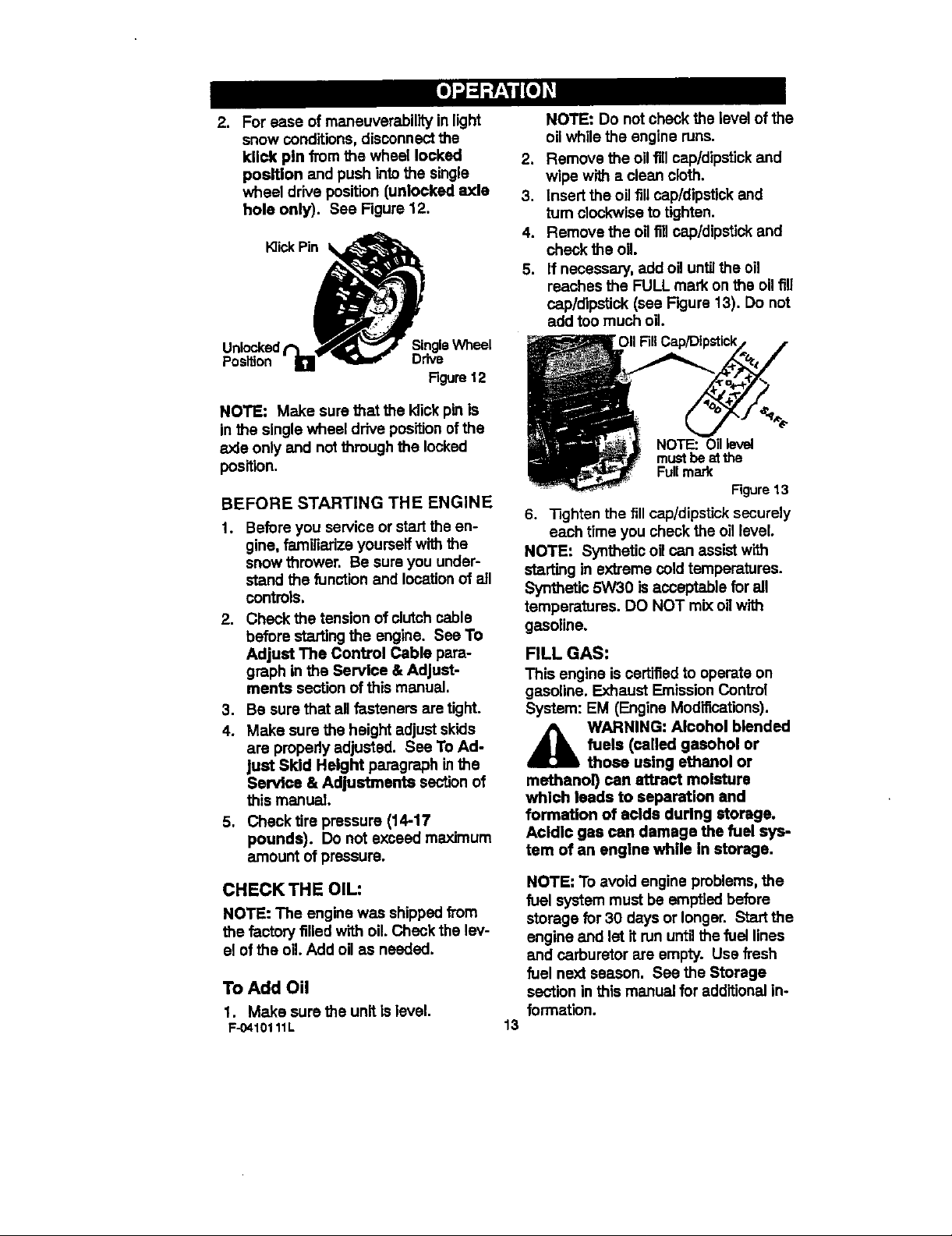

Foreaseofmaneuverabilityinlight

snow conditions,disconnect the

kllck pin from the wheel locked

position and push intothe single

wheel drive position (unlocked axle

hole only). See Figure 12.

K]ickPin

Position D_ive

Unlocked Single Wheel

Figure 12

NOTE: Do not check the level of the

oilwhile the engine runs.

2. Remove the oilfill cab/dipstickand

wipe with a clean cloth.

3. Insert the oil fill cab/dipstick and

turn clockwise to tighten.

4. Remove the oNfillcab/dipstick and

check the oil

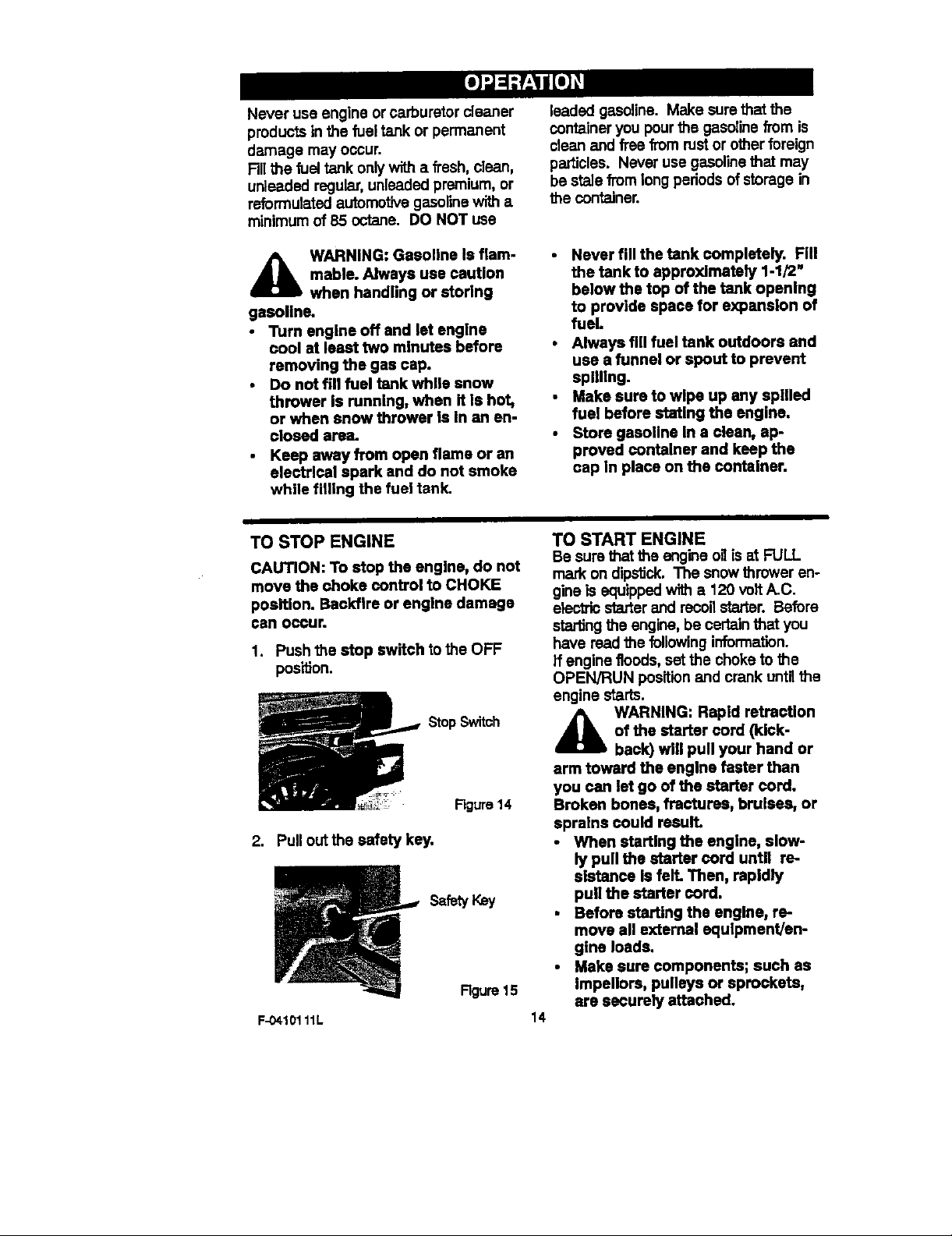

5. If necessary, add oil untilthe oil

reaches the FULL mark on the oil fill

cap/dipstick (see F_ure 13). Do not

add too much oil.

NOTE: Make sure that the Idiokpinis

in the single wheel drive position of the

axle only and not through the locked

position.

BEFORE STARTING THE ENGINE

1. Before you service or startthe en-

gine, familiarize yourseff with the

snow thrower. Be sure you under-

stand the function and location of all

controls.

2. Check the tension of clutch cable

before startingthe engine. See To

Adjust The Control Cable para-

graph inthe Service & Adjust-

merits section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are pmpedy adjusted. See To Ad-

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Checktire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

CHECK THE OIL:

NOTE: The engine was shipped from

the fectoPJfilled with oil. Check the lev-

el of the oil. Add oil as needed.

To Add Oil

1. Make sure the unit is level.

F-0410111L

%

NOTE: OII level

must be at the

Full mad(

Figure 13

6. Tighten the fill cap/dipstick securely

each time you check the oillevel.

NOTE; Synthetic oilcan assist with

starting inextreme cold temperatures.

Synthetic 5W30 is acceptable for all

temperatures. DO NOT mixo=1with

gasoline.

FILL GAS:

This engine is certifiedto operate on

gasoline. Exhaust EmissionControl

System: EM (Engine Modifications).

4_b WARNING: Alcohol blended

fuels (eelied gasohol or

those using ethanol or

methanol) can attract moisture

which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

NOTE; To avoid engine problems, the

fuel system must be emptied before

storage for 30 days or longer. Start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. See the Storage

section in this manual for additionalino

formation.

13

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

RII the fuel tank only _ a fresh,dean,

unleaded regular, unleaded premium, or

reformulated automotive gasoline with a

minimumof 85 octane. DO NOT use

4_b WARNING: Gasoline Is flam-

gasolins.

• Turn engine off and let engine

mable. Always use caution

when handling or storing

cool at least two minutes before

removing the gas cap.

Do not fill fuel tank while snow

thrower is running, when it is hot,

or when snow thrower is in an en-

closed area.

Keep away from open flame or an

electrlcal spark and do not smoke

while filling the fuel tank.

leaded gasoline. Make sure that the

containeryou pourthe gasolinefrom is

clean and free from rustor otherforeign

particles. Never use gasolinethat may

be staJefrom long periods of storage in

the container.

Never fill the tank completely. Fill

the tank to approxlmataly 1-1/2"

below the top of the tank openlng

to provide space for expansion of

fuel.

Always fill fuel tank outdoors and

use a funnel or spout to prevent

spilling.

Make sure to wipe up any spilled

fuel before stating the engine.

Store gasoline In a clean, ap-

proved container and keep the

cap in place on the container.

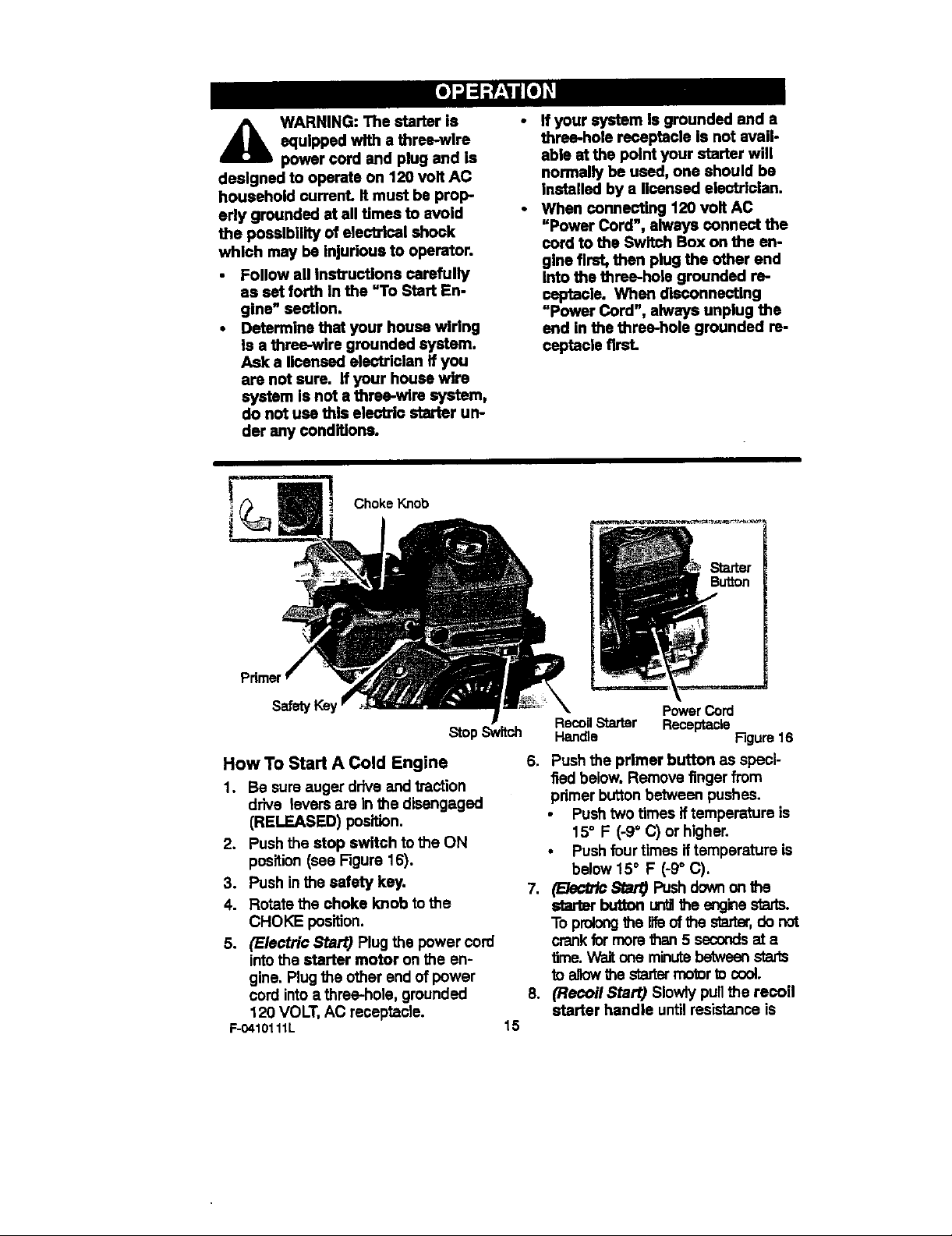

TO STOP ENGINE

CAUTION: To stop the engine, do not

move the choke control to CHOKE

position. Backfire or engine damage

can occur.

1. Pushthe stop switch to the OFF

posi_on.

StopSwitch

Figure14

2, Pull out the safety key,

safe,/

Figure15

F-0410111L

TO START ENGINE

Be sure that the engine oHis at FULL

mark on dip_ck. The snow thrower en-

gine is equippedwith a 120 volt/_C.

electricstarterand recoilstarter.Before

startingtheengine,be certainthatyou

have readthefollowinginformation.

Ifenginefloods,setthechoketothe

OPEN/RUN positionand crankuntilthe

enginestarts.

_k ARNING: Rapid retraction

arm toward the engine faster than

you can let go of the starter cord.

Broken bones, fractures, bruises, or

sprains could result.

• When starting the engine, slow-

• Make sure components; such as

14

of the starter cord (kick-

back) will pull your hand or

ly pull the starter cord until re-

slstanco is fell Then, rapidly

pull the starter cord.

Before starting the engine, re-

move all external equipment/en-

gine loads.

impellors, pulleys or sprockets,

are securely attached.

A ARNING:Thestarteris

equippedwithathree-wire

powercordandplugandis

designedtooperateon120voltAC

householdcurrent.Itmustbeprop-

erlygroundedatalltimestoavoid

theposslbifityofelectricalshock

whichmay be injurious to operator.

Follow all inst_'uctions carefully

as set forth In the "To Start En-

gine" section.

• Determine that your house wiring

Is a three-wire grounded system.

Ask a licensed electrician If you

are not sure. If your house wire

system is not a throe-wire system,

do not use this electric starter un-

der any conditions.

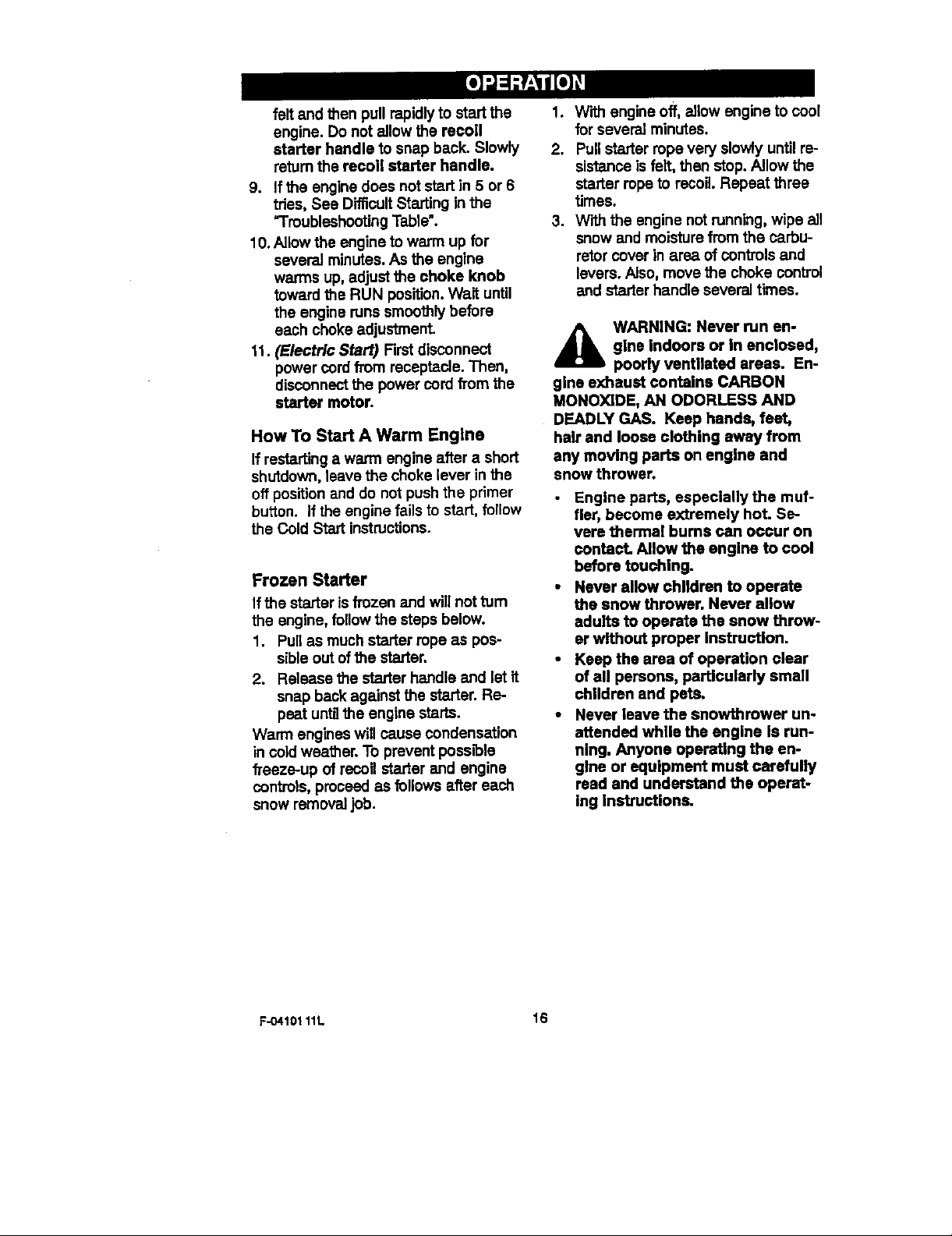

Choke Knob

If your system Is grounded and a

three-hole receptacle is not avail-

able at the point your starter will

normally be used, one should be

Installed by a licensed electrician.

When connecting 120 volt AC

"Power Cord", always connect the

cord to the Switch Box on the en-

gine first, than plug the other end

Into the three-hole grounded re-

ceptacle. When disconnecting

"Power Cord", always unplug the

end in the three-hole grounded re-

ceptacle first.

Pdmer

safetyKey

Stop Switch

How To Start A Cold Engine 6.

1. Be sure auger drive and traction

drive levers are in the disengaged

(RELEASED) position.

2. Push the stop switch tothe ON

position (see Figure 16).

3. Push inthe safety key. 7.

4. Rotate the choke knob to the

CHOKE position.

5. (Electric Start) Plug the power cord

intothe starter motor on the en-

gine. Plugthe other end of power

cord intoa three-hole, grounded 8.

120 VOLT, AC receptacle.

F-0410111L 15

PowerCord

RecoilStarter Receptacle

Handle F]gum 16

Push the primer button as speci-

fied below. Remove finger from

pdmer button between pushes.

• Push two times if temperature is

15° F (-9° C) or higher.

• Push four times if temperature is

below 15° F (-9° C).

(Bec_ Star0 Pushdownon f_

starer button LaYdlthe enginestads.

To prolongthe life ofthe sta,'tar,do not

crank formornthen 5 secondsata

time. Wait one minutebetweenstarts

to allowthe startermotorto cool.

(Recoil Start) Slowly pullthe recoil

starter handle untilresistance is

feltandthen pull rapidlyto start the

engine. Do not allow the recoil

starter handle to snap back. Slowly

return the recoil starter handle.

9. If the engine does not start Jn5 or 6

tries, See DifficultStarting in the

=Troubleshooting Table'.

10.Allow the engine to warm up for

several minutes. As the engine

warms up, adjust the choke knob

toward the RUN position.Wait until

the engine runs smoothlybefore

each choke adjustment.

11. (Electric Start) First disconnect

power cord from receptacle. Then,

disconnectthe power cordfrom the

starter motor.

How To Start A Warm Engine

If restaK_nga warm engine after a short

shutdown, leave the choke Feverin the

off positionand do not push the primer

button, if the engine fails to start, follow

the Cold Start instructions.

Frozen Starter

Ifthe starter is frozen and will not turn

the engine, follow the steps below.

1. Pullas much starter rope as pos-

sible out of the starter.

2. Release the starter handle and let it

snap back against the starter. Re-

peat untilthe engine starts.

Warm engines will cause condensation

in coldweather. To prevent possible

fTeeze-up of recoil starter and engine

controls, proceed as follows after each

snow removaljob.

1. With engine off, alisw engine to cool

for several minutes.

2. Pullstarter rope very slowly until re-

sistance is felt, then stop. Allow the

starter rope to reooi_.Repeat three

times.

3. W'_ the engine not running, wipe all

snow and moisture from the carbu-

retor cover in area of controls and

levers. Also, move the choke control

and starter handle several times.

A WARNING: Never run en-

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

gine indoors or in enclosed,

poorly ventilated areas. En-

Engine parts, especially the muf-

fler, become extremely hot. Se-

vere thermal burns can occur on

contact. Allow the engine to cool

before touching.

Never allow chlldran to operate

the snow thrower. Never allow

adults to operate the snow throw-

er without proper instruction.

Keep the area of operation clear

of all persons, particularly small

children and pets.

Never leave the snowthmwer un.

attended while the engine Is run-

ning. Anyone operating the en-

gine or equipment must carefully

read and understand the operat-

Ing instructions.

F.O410"_11L 16

TO REMOVE SNOW FROM AUGER

stickto remove snow from the auger

housing.

_IL ARNING: Do not attempt

to remove snow or debris

that may become lodged in

auger with your hands. Use the

cleaning stick to remove snow or

debris.

A cleaning stick isattached to the top of

the auger housing. Use the cleaning

SNOW THROWING TIPS

1. For maximum snow thrower efficien-

cy inremoving snow,adjust ground

speed. Go slower in deep, freezing

or wet snow. If the wheels slips, re-

duce forward speed.

2. Mostefficient snow throwing is ac-

complished when the snow is re-

moved immediately after iffalls.

3. For complete snow removal, sligh'dy

overlap each path previously taken.

4. The snow should be discharged

down wind whenever possible.

5. For normal usage, set the skids so

that the scraper bar is 1/8" above

the skids. For extremely hard-

packed snow surfaces, adjust the

skids upward so that the scraper

bar touches the ground.

6, On gravel or crushed rock surfaces,

Release auger drive lever.

Remove (do not turn) safety key.

Disconnect spark plug wire.

Do not place your hands in the au-

ger ordischarge chute. Use the

cleaning stick to remove snow.

set the skids at 1-1/4" below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu-

al. Rocks and gravel must not be

picked up and thrown bythe ma-

chine.

.

After the snow throwing job has

been completed, allow the engine to

idlefor a few minutes, which will

melt snow and accumulated ice off

the engine.

,

Clean the snowthrower thoroughly

after each use.

9.

Remove ice and snow accumulation

and all debris from the entire snow

thrower, and flush with water (if pos-

sible) to remove all salt or other

chemicals. Wipe snow thrower dry.

F-0410111L 17

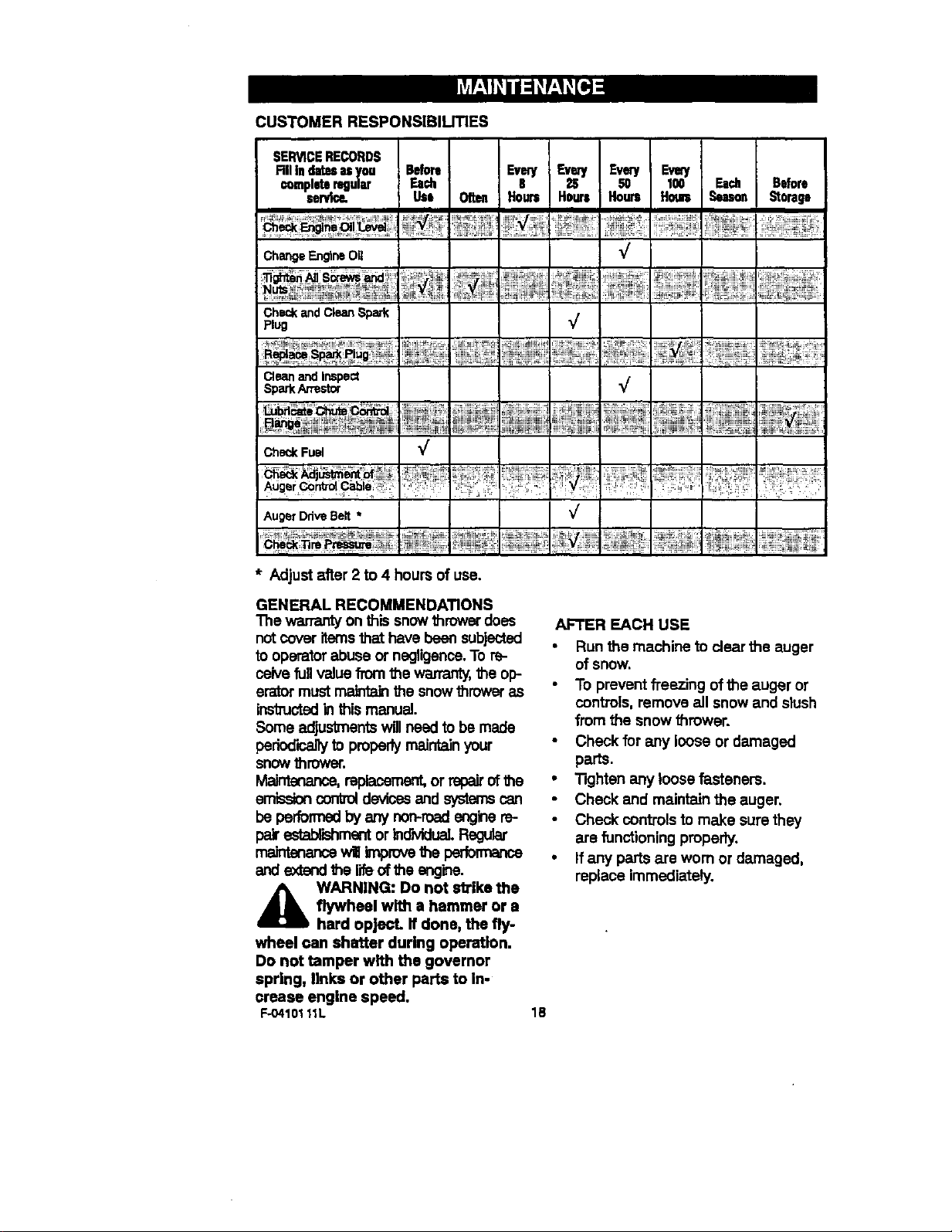

CUSTOMER RESPONSIBILITIES

SERVICERECORDS

RII indatesas you Before Even/ Every Eve_ Even/

Completeregular Each B 2S 50 100 Ea_ Before

servl_ Use O[t_ Hours Hours Hours Houm Seas_ Storage

ChangeEn_neO_

CheckandCleanSpark

Plug

Cleanand InspeCt

SparkArrestor

_b_ _: ............ :,i '.' _.iil:

¢

;!iJ!i :l..........................................

Check Fuel 3/" I

,u,e,on,,Se,.

* Adjust after 2 to 4 hours of use.

GENERAL RECOMMENDATIONS

The warrantyon this snowthrower does

not cover itemsthat have been subjected

to operator abuse or negligence.To re-

ceive fullvalue from the warranty,the op-

erator must malrda_ the snowthrower as

instructedinthis manual.

Some adjustmentswillneed to be made

periodicallyto properlymaintainyour

snow thrower.

MalrTtenance,radlacement,or repairof the

emissioncontrol devicesand systemscan

be performedby any _o_ engine_-

pa_ establishmentor indviduaL Regular

ma_-r_e_er_e win improve the pedo_Ta,_e

and ex|andther_.oftheangine.

I

AFTER EACH USE

• Run the machine to clear the auger

of snow.

To prevent freezing of the auger or

controls, remove all snow and slush

from the snow thrower.

Check for amy loose or damaged

parts.

• TIghtan any loose fasteners.

Check and maintain the auger,

Check controls to make sure they

are functioning properly.

• If any parts ate worn or damaged,

replace immediately.

iiiiliiiii!! iiiiiii!i'

_b ARNING: Do not strike the

wheel can shatter during operation.

Do not tamper with the governor

spring, links or other parts to in-

crease engine speed.

F-O4101 11L

flywheel with a hammer or a

hard opject. If done, the fly-

18

ENGINE SPECIFICATIONS

HORSEPOWER 6 HP

DISPLACEMENT 206 cc

BORE 68mm (2.677 in.)

STROKE 56ram (2.205 in.)

GASOLINE 3 quarts

CAPACITY {unleaded)

OIL CAPACITY

(18 oz capacity) 5W30

SPARK PLUG: Champion RJ19LM

(Gap .030 in.) or

equivalent

VALVE Intake: 0.004-0.006 in.

;LEARANCE: Exhaust: 0.009..0.011 in.

ARMATURE

AIR GAP: 0.010-0.014 in.

POWER RATINGS

The power ratings for an individual

engine model are initiallydeveloped by

starting with SAE (Society ofAutomo-

tive Engineers) code J1940 (Small

Engine Power & Torque Rating Proce-

dure) (Revision 2002-05). Given both

the wide array ofproducts onwhich our

engines are placed, and the variety of

environmental issues applicable to

operating the equipment, itmay be that

the engine you have purchased will not

develop the rated horsepower when

used in a piece of power equipment

(actual "on-site" power). This difference

is due to a variety of factors including,

but not limitedto, the following: differ-

ences in altitude,temperature, baro-

metric pressure, humidity,fuel, engine

lubrication, maximum governed engine

speed, individualengine to engine

variability, design ofthe particular piece

of power equipment, the manner in

which the engine is operated, engine

run-in to reduce frictionand clean out of

combustion chambers, adjustmentsto

the valves and carburetor,and other

factors. The power ratingsmay also be

adjusted based on comparisons to

other similar engines utilized in similar

applications, and willtherefore not

necessarily match the values derived

using the foregoing codes.

F-04101 11L

SNOW THROWER

AUGER DRIVE BELT

Adjust the auger drive belt after the first

2 to 4 hours of use, again about mid-

season and twice each season theraaf-

tar (See to "Belt Adjustment" in the

Service and Adjustment section).

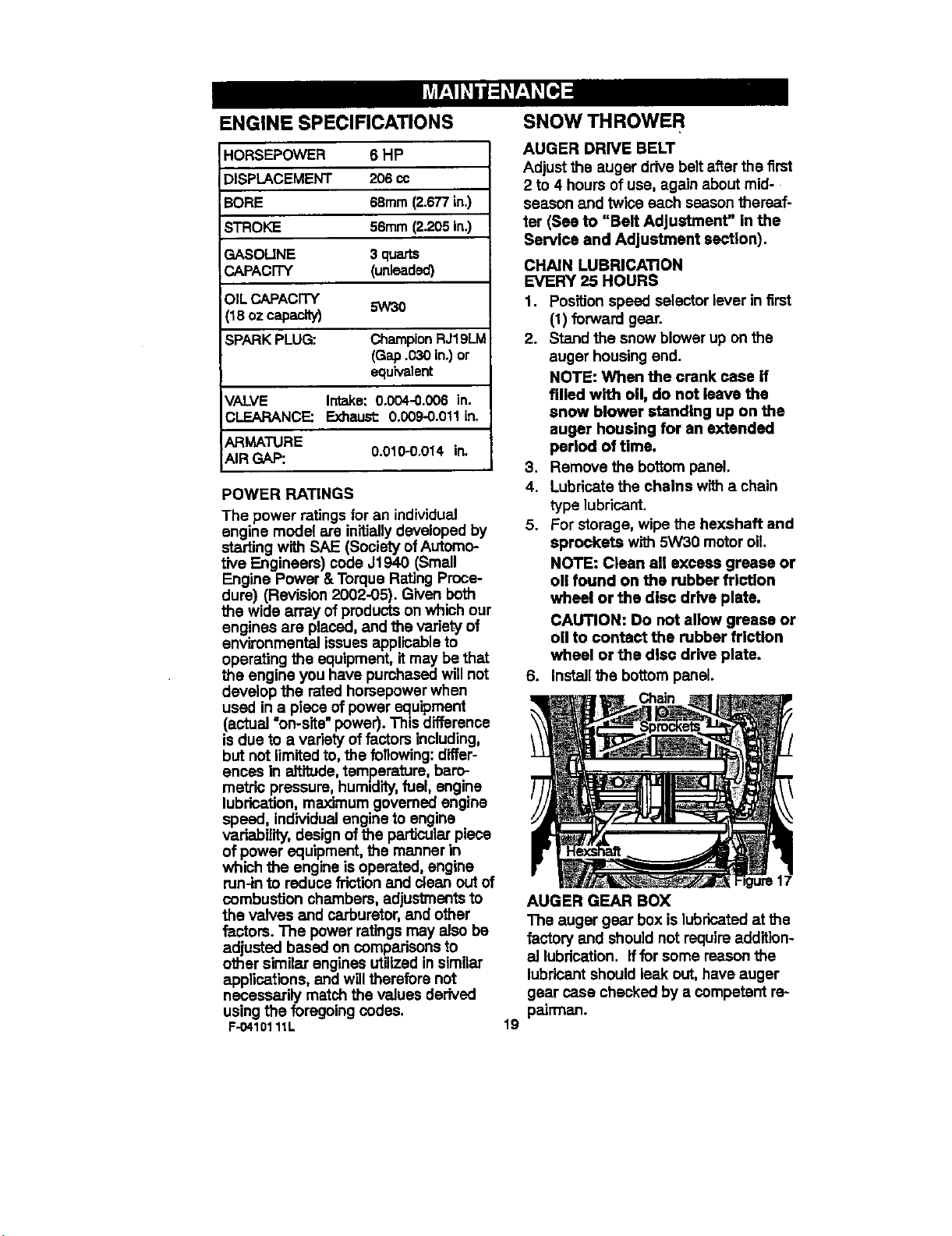

CHAIN LUBRICATION

EVERY 25 HOURS

1. Position speed selector lever in first

(1) forward gear.

2. Stand the snow blower up on the

auger housing end.

NOTE: When the crank case if

filled with oil, do not leave the

snow blower standing up on the

auger housing for an extended

period of time.

3, Remove the bottom panel.

4. Lubricate the chains with a chain

type lubricant.

5. For storage, wipe the hexshaft and

sprockets with 5W30 motor oil.

NOTE: Clean all excess grease or

oll found on the rubber friction

wheel or the disc drive plate.

CAUTION: Do not allow grease or

oil to contact the rubber friction

wheel or the disc drive plate.

6. Installthe bottom panel.

Chain

AUGER GEAR BOX

The auger gear box is lubricated at the

factory and should not require addition-

al lubrication. If for some reason the

lubdcant should leak out, have auger

gear case checked by a competent re-

pairmen.

19

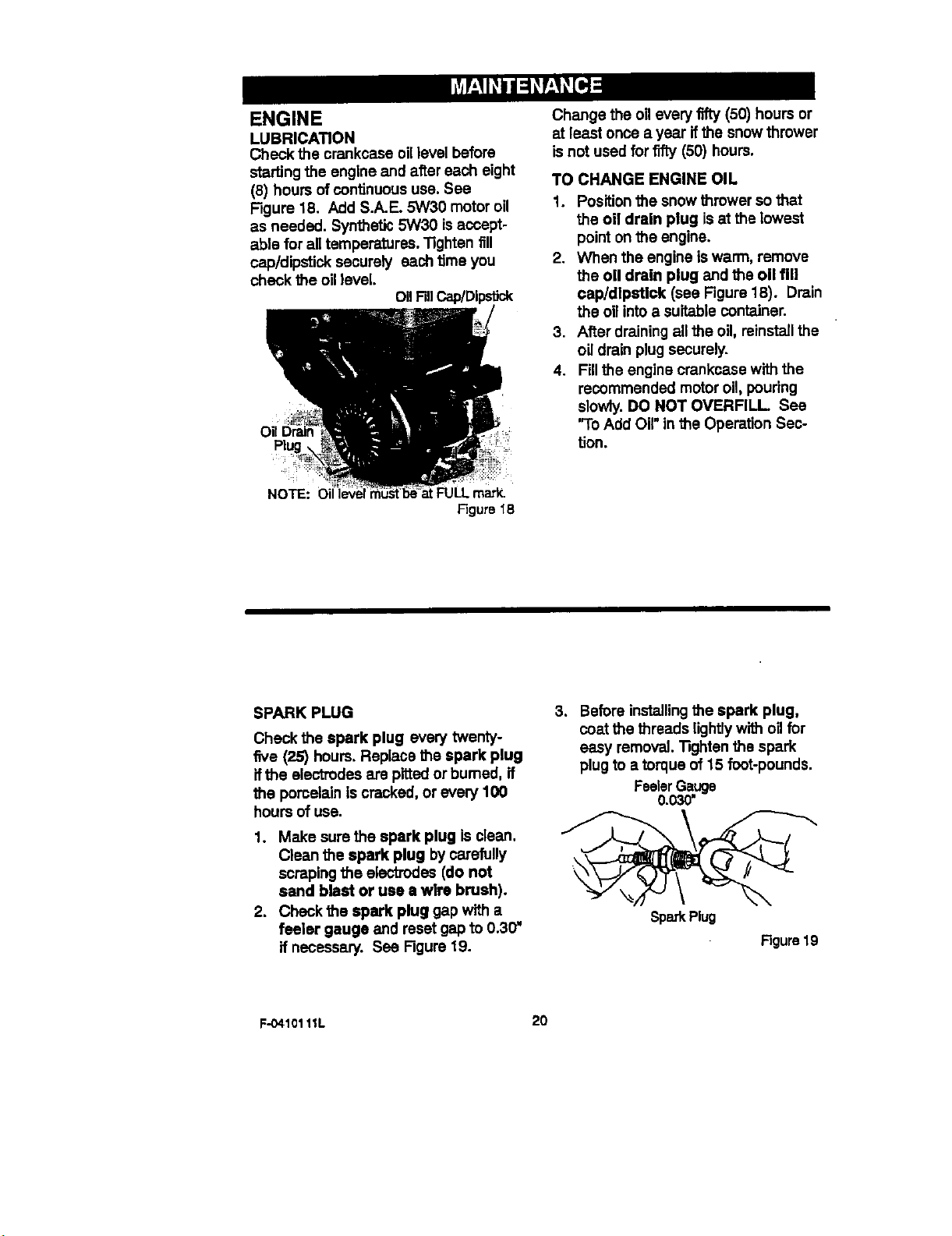

ENGINE

LUBRICATION

Check the crankcase oillevel before

starting the engine and after each eight

(8) hours ofcontinuoususe. See

Figure 18. Add S.A.E. 5W30 motorog

as needed. Synthetic 5W30 is accept-

able for alltempemturas. "_ghtenfill

cap/dipstick securely each time you

check the oil level.

OIIFillCap/Dipstick

Change the all every fifty (50) hoursor

at least once a year if the snow thrower

isnot used for fiity (50) hours.

TO CHANGE ENGINE OIL

1. Positionthe snow thrower so that

the oil drain plug is at the lowest

point on the engine.

2. When the engine is warm, remove

the oil drain plug and the oil fill

cap/dipstick (see Figure 18). Drain

the oil intoa suitable container.

3. After drainingall the oil, reinstall the

oil drain plug securely.

4. Fillthe engine crankcase withthe

recommended motoroil, pouring

slowly. DO NOT OVERFILL See

'To Add Oil"in the Operation Sec-

tion.

NOTE: O

FULL mark.

Figure 18

SPARK PLUG

Check the spark plug every twenty-

five (25) hours. Replace the spark plug

ifthe electrodes are pitted or bumed, if

the pomalaln iscracked, or every 100

hours of use.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

2. Check the spark plug gap with a

feeler gauge end reset gap to 0.30"

if necessary. See Figure 19.

3. Before installingthe spark plug,

coat the threads lightly with oil for

easy removal. TIghten the spark

plug to a torque of 15 foot-pounds.

FeelerGauge

0.030"

Spark Plug

Figure19

F-0410111L 20

,_ WARNING: Always discon-

nect the spark plug wire and

place it where It cannot

make contact with spark plug to pre-

vent accidental starting when mak-

ing any adjustments or repairs.

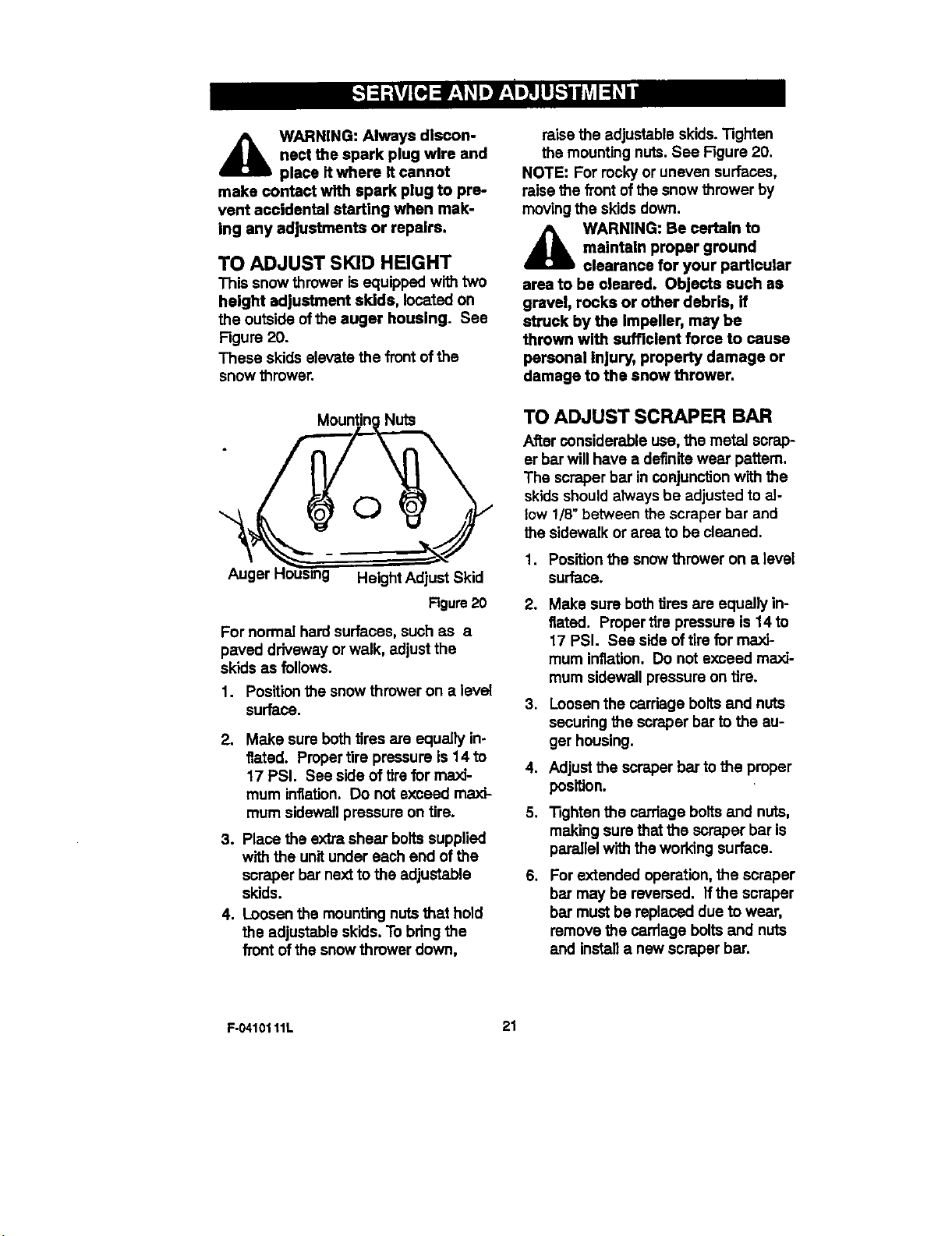

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 20.

These skids elevate the front of the

snow thrower.

raise the adjustable skids. Tighten

the mounting nuts.See Figure 20.

NOTE: For rockyor uneven surfaces,

raise the front of the snow thrower by

movingthe skids down.

_lb ARNING: Be certain to

maintain proper ground

clearance for your particular

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

Nuts

©

Auger Height Adjust Skid

Figure20

For normal hard surfaces, such as a

paved driveway orwalk, adjust the

skids as follows.

1. Positionthe snow thrower on a level

surface.

2. Make sure bothtires are equally in-

flated. Propertire pressure is 14to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure ontire.

3. Place the extra shear boltssupplied

with the unit under each end of the

scraper bar nextto the adjustable

skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bdng the

front of the snow thrower down,

TO ADJUST SCRAPER BAR

Alter considerable use, the metal scrap-

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al-

low 1/8" between the scraper bar and

the sidewalk or area to be cleaned.

1. Positionthe snowthrower on a level

surface.

.

Make sure bothtires are equally in-

flated. Proper tirepressure is 14 to

17 PSI. See side of tirefor maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3.

Loosen the cardage bolts and nuts

secudng the scraper bar to the au-

ger housing.

.

Adjust the scraper bar to the proper

position.

5.

Tighten the carriage bottsand nuts,

making sure that the scraper bar is

parallel with the working surface.

.

For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage boltsand nuts

and installa new scraper bar.

F.0410111L 21

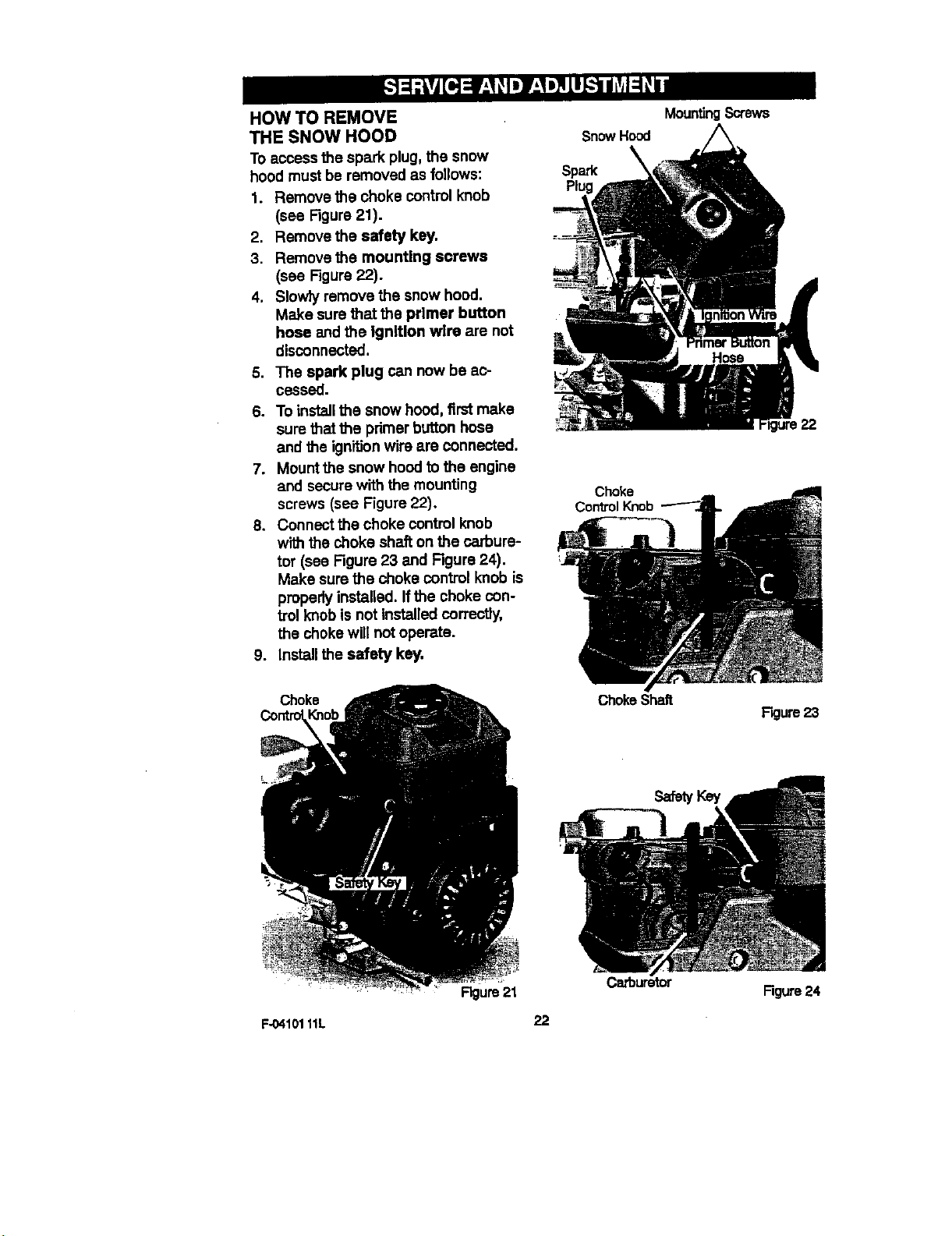

HOW TO REMOVE

THE SNOW HOOD

To accessthe spark plug,the snow

hood must be removed as follows:

1. Remove the choke control knob

(see Figure21).

2. Remove the safety key.

3. Remove the mounting screws

(see Figure22).

4. Slowly remove the snow hood.

Make sure that the primer button

hose and the Ignition wire are not

disconnected.

5. The spark plug can now be ac-

cessed.

6. To installthe snow hood, firstmake

sure that the primer button hose

and the ignitionwire are connected.

7. Mount the snow hoodto the engine

and secure with the mounting

screws (see Figure 22).

8. Connectthe choke control knob

with the choke shafton the carbure-

tor (see Figure 23 and Figure 24).

Make sure the choke control knob is

properly installed. If the choke con-

trol knob is not installedcorrectJy,

the choke will not operate.

9. Install the safety key.

MountingScrews

Snow Hood

Spark k

P_

22

Choke

Control Knob

Choke

Rgure21

F-0410111L 22

ChokeShah

F_ure 23

Cafouretor

Figure24

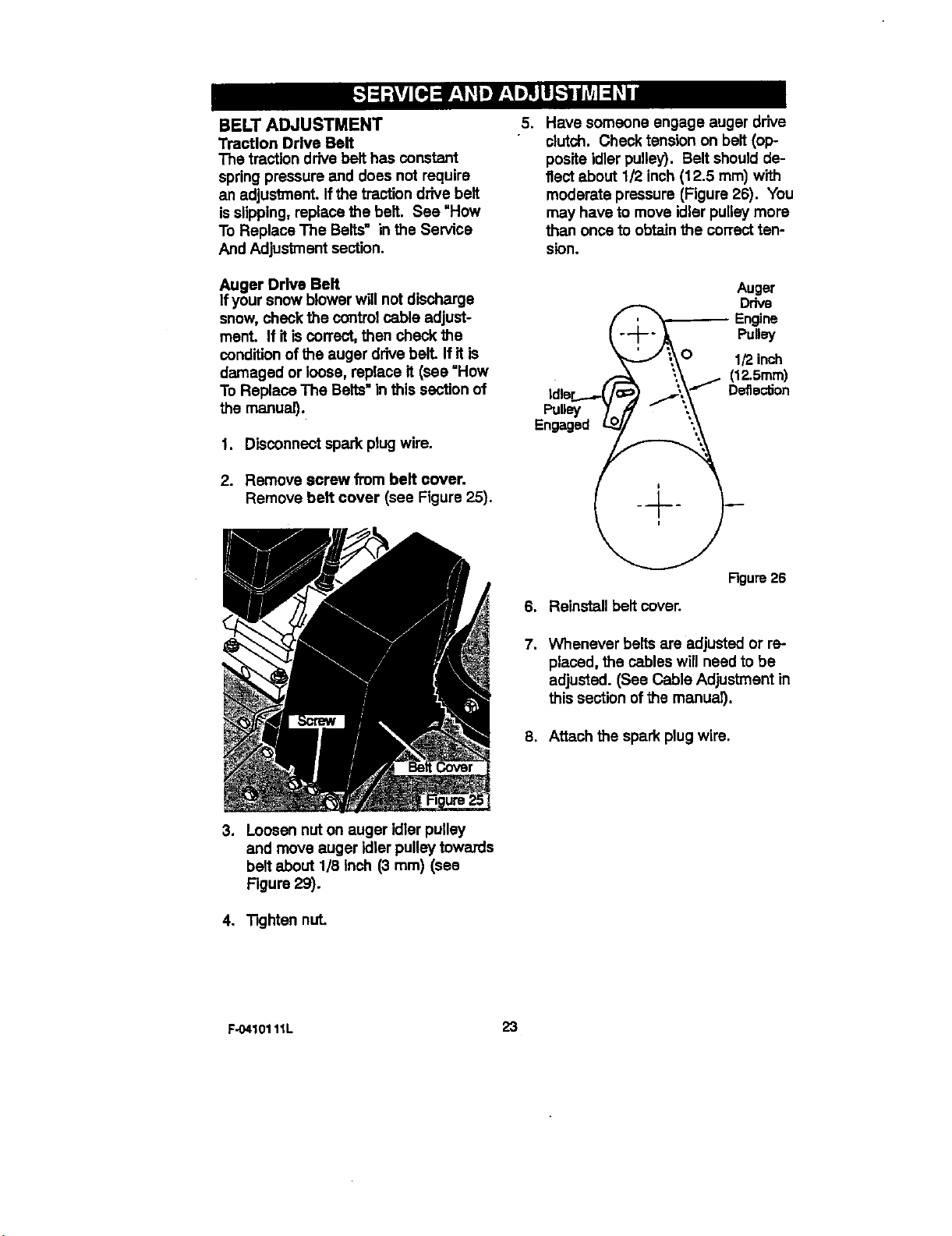

BELT ADJUSTMENT

Traction Drive Belt

The tractiondrive belt has constant

springpressure and does not require

an adjustment. Ifthe traction drive belt

is slipping, replace the belt. See "How

To Replace The Belts" inthe Service

And Adjustment section.

5. Have someOne engage auger drive

clutch. Check tension on belt (op-

posite idler pulley). Belt should de-

flect about 1/2 inch(12.5 ram) with

moderate pressure (Figure 26). You

may have to move idler pulleymore

than once to obtainthe correct ten-

sion.

Auger Drive Belt

If your snow blower will not discharge

snow,check the controlcable adjust-

ment. If itis correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see "How

To Replace The Belts" in this section of

the manual).

1. Disconnect spark plug wire.

2. Remove screw from belt cover.

Remove belt cover (see Figure 25).

Auger

Drive

Pulley

_ Engine

O 1/2 inch

(12.5mm)

Pul_=y

Engaged

Idler'E'*_"_. Defle_°n

Figure 26

6. Reinstall belt cover.

7. Whenever belts are adjusted or re-

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the mariuS.

8. Attach the spark plug wire.

.

Loosen nuton auger idler pulley

and move auger idler pulley towards

belt about 1/8 Inch (3 ram) (see

Figure 29).

4. "Rghtennut.

F-0410111L 23

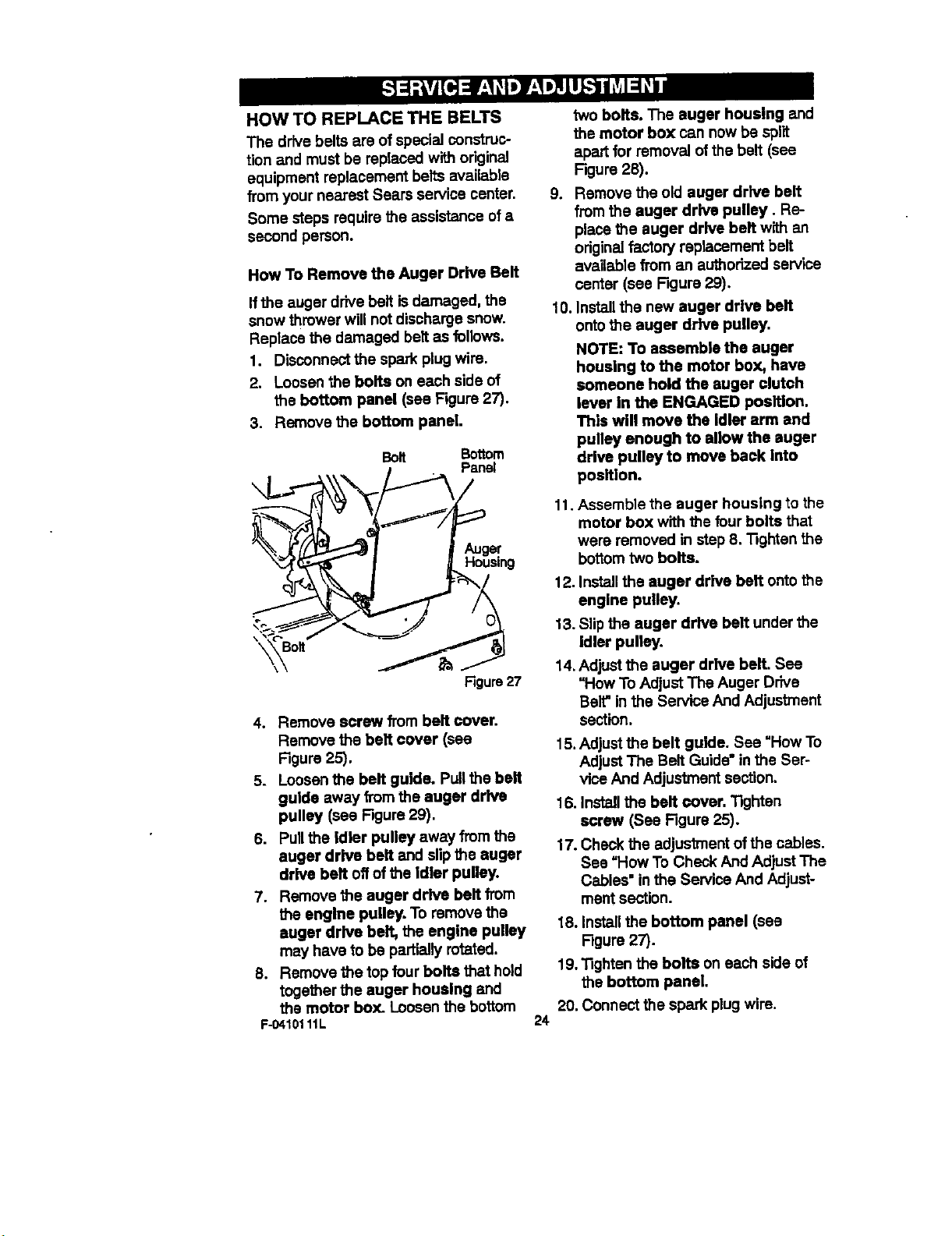

HOW TO REPLACE THE BELTS

The drive belts are of special construc-

tion and must be replaced with odginal

equipment replacement belts available

from your nearest Sears service center.

Some steps require the assistance of a

second person.

How To Remove the Auger Drive Belt

Ifthe auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

1. Disconnect the spark plugwire.

2. Loosenthe bolts on each side of

the bottom panel (see Figure 27).

3. Remove the bottom panel.

BOlt Bottom

Panel

\

Auger

Housing

\ Bolt "_

Rgure27

4. Remove screw from belt cover.

Remove the belt cover (see

Figure 25).

5. Loosenthe belt guide. Pull the belt

guide away from the auger drive

pulley (see Figure 29).

6. Pull the idler pulley away from the

auger drive belt and slip the auger

drive belt off ofthe idler pulley.

7. Remove the auger drive belt from

the engine pulley. To remove the

auger drive belt, the engine pulley

may have to be partially rotated.

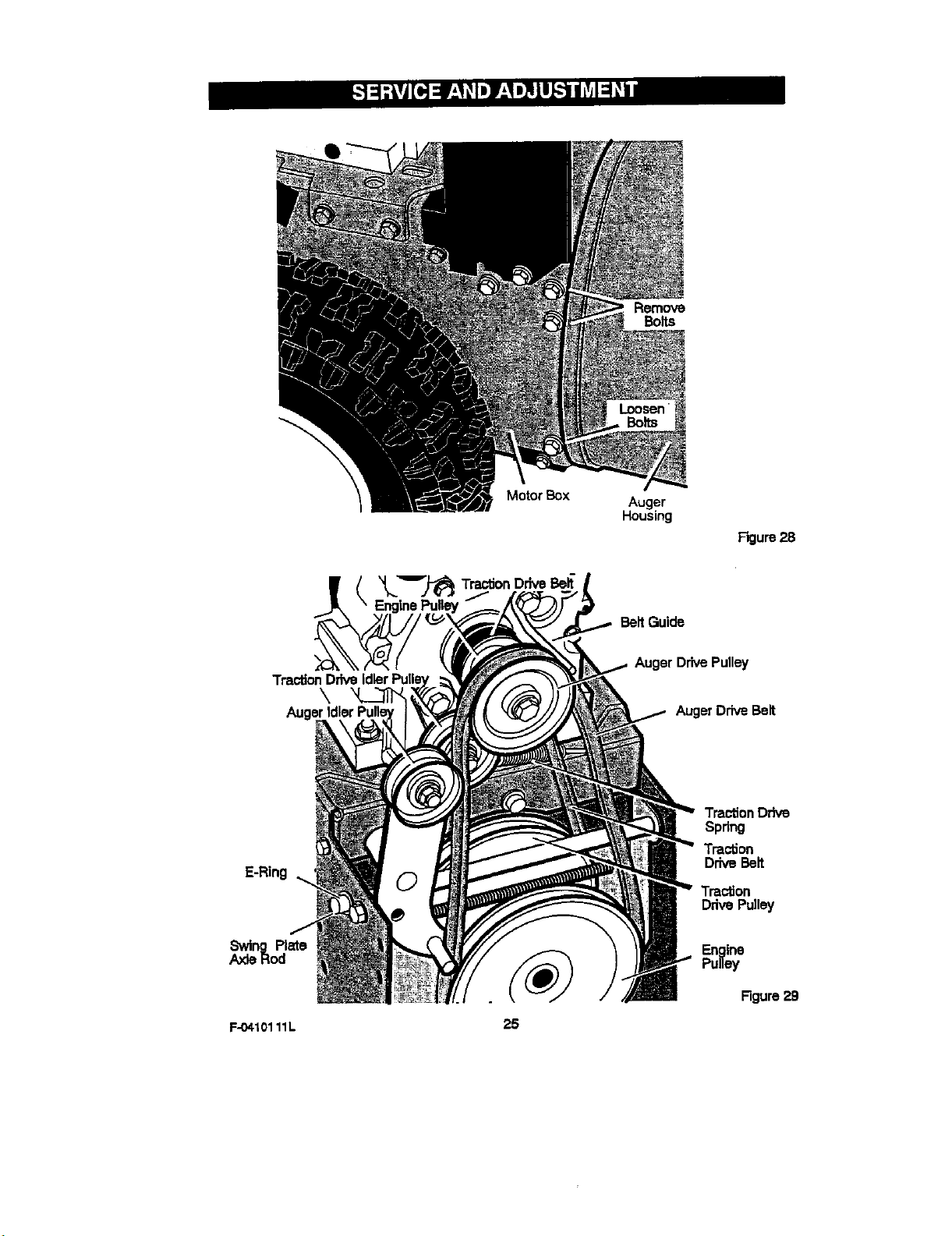

B. Remove the top four bolts that hold

together the auger housing and

the motor box. Loosen the bottom

F-0410111L

two bolts. The auger housing and

the motor box can now be spilt

apart for removal of the belt (see

F.:jure28).

9. Remove the old auger drive belt

from the auger drive pulley. Re-

place the auger drive belt wfth an

originalfactory replacement belt

available fi'oman authodzed service

center (see Figure 29).

10. Installthe new auger drive belt

ontothe auger drive pulley.

NOTE: To assemble the auger

housing to the motor box, have

someone hold the auger clutch

lever In the ENGAGED position.

This will move the idler arm and

pulley enough to allow the auger

drive pulley to move back into

position.

11. Assemble the auger housing to the

motor box with the four bolts that

were removed in step B. "i3ghtanthe

bottomtwo bolts.

12. Installthe auger drive belt onto the

engine pulley.

13. Slip the auger drive belt under the

idler pulley.

14. Adjust the auger drive belt. See

"How To Adjust The Auger Drive

Belt"inthe Service And Adjustment

section.

15.Adjust the belt guide. See "How To

Adjust The Belt Guide" in the Ser-

vice And Adjustment section.

16. Install the belt cover, 13ghten

screw (See Figure 25).

17. Check the adjustment of the cables.

See =HowTo Check And Adjust The

Cables" in the Service And Adjust-

ment section.

18. Installthe bottom panel (see

Figure 27).

19. "13ghtenthe bolts on each side of

the bottom panel.

20. Connect the spark plugwire.

24

Bolts

Traction

Auger

E-Ring

Swing Plate

.aodeRod

Motor Box

Auger

Housing

Figure 28

Belt Guide

Auger Drive Pulley

\

Auger Drive Belt

Traction Drive

Spdng

Traction

DriveBelt

Traction

DrivePulley

Engine

Pulley

F-04101 11L

Figure29

25

How To Remove

The Traction Drive Belt

If the snow thrower will not move for-

ward, check the traction drive belt for

wear or damage. If the traction drive

belt isworn or damaged, replace the

belt as follows.

1. Disconnectthe spark plug wire.

2. Remove the auger drive belt. See

"HowTo Remove The Auger Drive

Belt"in the Service And Adjustment

section.

plate ispropertysecured (see

Figure 30).

!

3. Remove the e-ring from one end of

the swing plate axle rod. Remove

the swing plate axle rod to allow

the swing plateto pivot forward (see

Figure 29).

4. Remove the traction drive spring.

5, Remove the old traction drive belt

from the traction drive pulley and

from the engine pulley. Replace

the traction drive belt with an origi-

nal equipment replacement belt

available from a Sears service cen-

ter.

6. Install the new traction drive belt

ontothe traction drive pulley and

onto engine pulley.

7. Make sure the traction drive Idler

pulley is pmparly aligned withthe

traction drive belt.

8. Attach the traction drive spring.

9. Install the swing plate axle rod and

secure with the e-ring removed

earlier.

10.The bottomofthe swing plate must

be positioned between the align-

ment tabs. Make sure the swing

F-04101 11L

Alignment Tabs Figure 30

NOTE: If the drive will not engage

after the traction drive belt has

been replaced, then check to

make sure that the swing plata is

positioned between the align-

ment tabs.

11. Install and adjust the auger drive

belt. See "How To Remove The Au-

ger Drive Belt"inthe Service And

Adjustment section.

12. Adjust the bell guide. See "How To

Adjust The Belt Guide" inthe Ser-

vice And Adjustment section.

13. Install the bottom panel (see

Figure 27).

14."13ghtenthe bolts on each side of

the bottom panel.

15.Installthe belt cover.Tighten

screw (seeFigure25).

16. Check the adjustmentof the cables.

See "HowTo Check And Adjust The

Cables" in the Service And Adjust-

ment section.

17. Connect the spark plugwire.

26

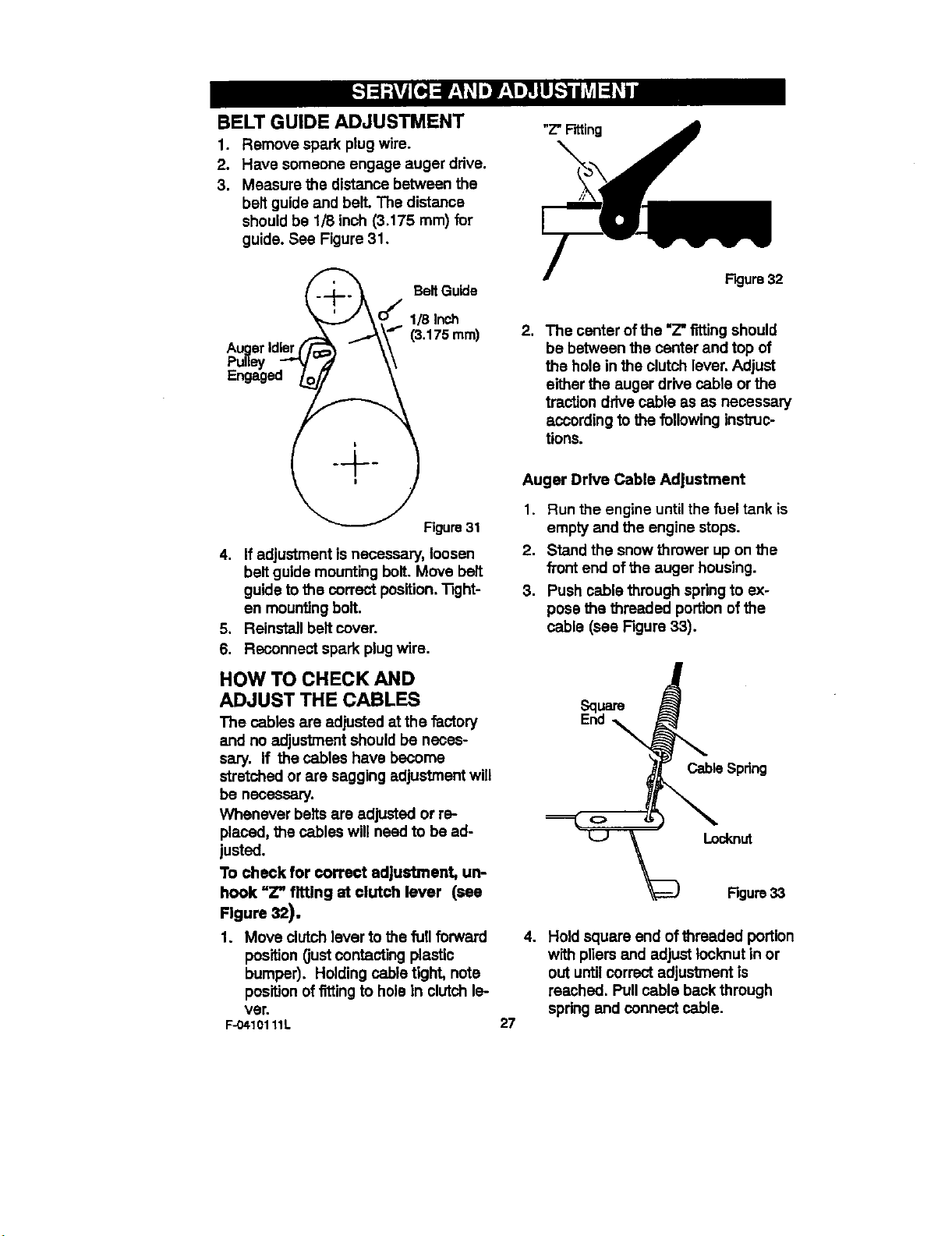

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage auger drive.

3. Measure the distance between the

belt guide and bell The distance

should be 1/8 inch (3.175 rnrn)for

guide. See Figure 31,

"Z"Fitting

_._ Belt Guide

Jko/

1 - _,.,.,_\'_' (3.175 ram)

AugerIdler(/i - \\

-

Figure 31

4. If adjustment is necessary, loosen

belt guide mounting bolt.Move belt

guide tothe correct position,Tight-

en mounting bolt.

5, Reinstall belt cover.

6, Reconnect spark plug wire,

HOW TO CHECK AND

ADJUST THE CABLES

The cables are adjusted at the factory

and no adjustment should be neces-

sary, If the cables have become

stretched or are sagging adjustment will

be necessary.

Whenever belts are adjusted or re-

placed, the cables will need to be ad-

justed.

To check for correct adjustment, un-

hook "Z" fitting at clutch lever (see

Figure 32).

1. Move clutch lever to the full forward

position (justcontacting plastic

bumper). Holding cable tight, note

positionof fittingto hole in clutch le-

ver.

F-04101 11L

F'_ure 32

2. The center of the "Z"titting should

be between the center and top of

the hole in the clutch lever, Adjust

either the auger drive cable or the

traction drive cable as as necessary

according to the following ins'_uc-

tions.

Auger Drive Cable Adjustment

1. Run the engine until the fuel tank is

empty and the engine steps.

2. Stand the snow thrower up on the

fTontend of the auger housing.

3. Push cable through spring to ex-

pose the threaded portion of the

cable (see Figure 33).

ESqLlar8

nd

Cable Spdng

=__ Locknut

Rgure33

4. Hold square end of threaded portion

with pliers and adjust Iccknut in or

out untilcorrect adjustment is

reached. Pullcable back through

spring and connect cable.

27

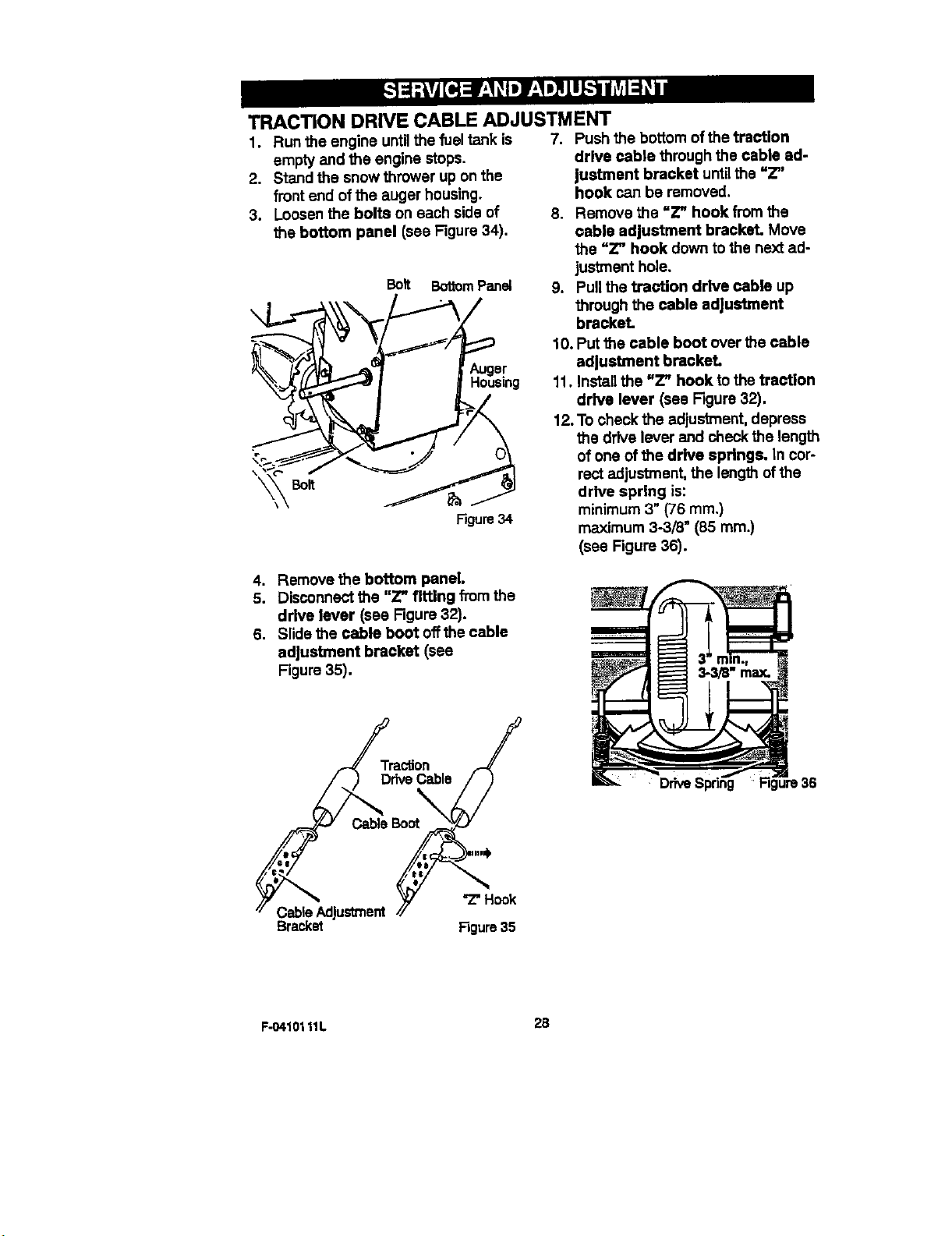

TRACTION DRIVE CABLE ADJUSTMENT

1. Run the engine untilthe fueltank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Loosen the bolts on each side of

the bottom panel (see Figure34).

Bolt BottomPanel

Figure34

7. Pushthe bottom of the traction

drive cable through the cable ad-

justment bracket untilthe =Z"

hook can be removed.

8. Remove the uZ" hook from the

cable adjustment bracket. Move

the "Z" hook down to the next ad-

jus_nent hole.

9. Pull the traction drive cable up

through the cable adjustment

bracket.

10. Put the cable boot over the cable

adjustment bracket.

11. Install the =Z" hook to the traction

drive lever (see Rgure 32).

12.To check the adjustment, depress

the drive lever and check the length

of one of the drive springs. In cor-

rect adjustment, the length of the

drive spring is:

minimum 3" (76 ram.)

maximum 3-3/8m(85 ram.)

(see Figure 36).

4. Remove the bottom panel.

5. Disconnect the "Z" tiffing from the

drive lever (see Figure 32).

6, Slide the cable boot off the cable

adjustment bracket (see

Figure 35),

Traction /

CableBOot/F_

CableAdjustment ./_ "Z"Hook

Bracket Figure35

F-O410111L 2B

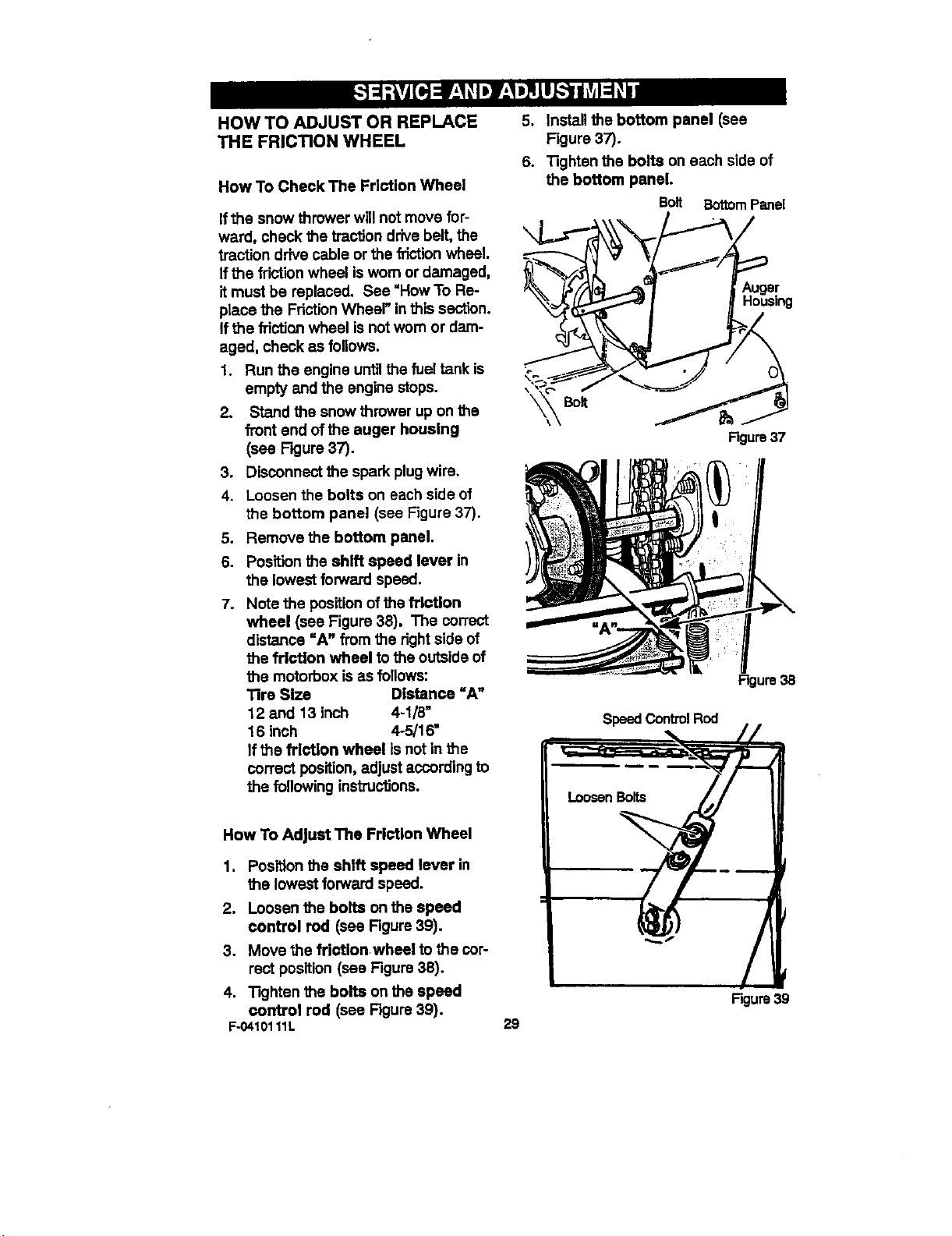

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL

How To Check The Friction Wheel

Ifthe snow thrower will not move for-

ward, check the traction drivebelt, the

traction drive cable or the friction wheel.

If the frictionwheel isworn or damaged,

it must be replaced. See "How To Re-

place the FrictionWheel" in this section.

Ifthe frictionwheel is not worn or dam-

aged, check as follows.

1. Run the engine untilthe fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing

(see F_ure 37).

3. Disconnect the spark plugwire.

4. Loosen the bolts on each side of

the bottom panel (see Figure 37).

5. Remove the bottom panel.

6. Position the shift speed lever in

the lowest forward speed.

7. Note the position ofthe friction

wheel (see Figure 38). The correct

distance =A" from the rightside of

the friction wheel to the outside of

the motorbox is as follows:

Tire Size Distance "A"

12 and 13 inch 4-1/8"

16 inch 4-5/16"

Ifthe friction wheel isnot in the

correct position,adjust accordingto

the following instructions.

5. Install the bottom panel (see

Figure 37).

6. "13ghtanthe bolts on each side of

the bottom panel.

Bolt BottomPanel

\

Auger

Housing

Figure37

Figure3B

SpeedControlRod

How To Adjust The Friction Wheel

1. Position the shift speed lever in

the lowest forward speed.

2. Loosen the bolts on the speed

control rod (see Figure 39).

3. Move the fdcUon wheel to the cor-

rect position (see Figure 38).

4. "13ghtenthe bolts on the speed

control rod (see Rgure 39).

F-04101 11L

Figure 39

29

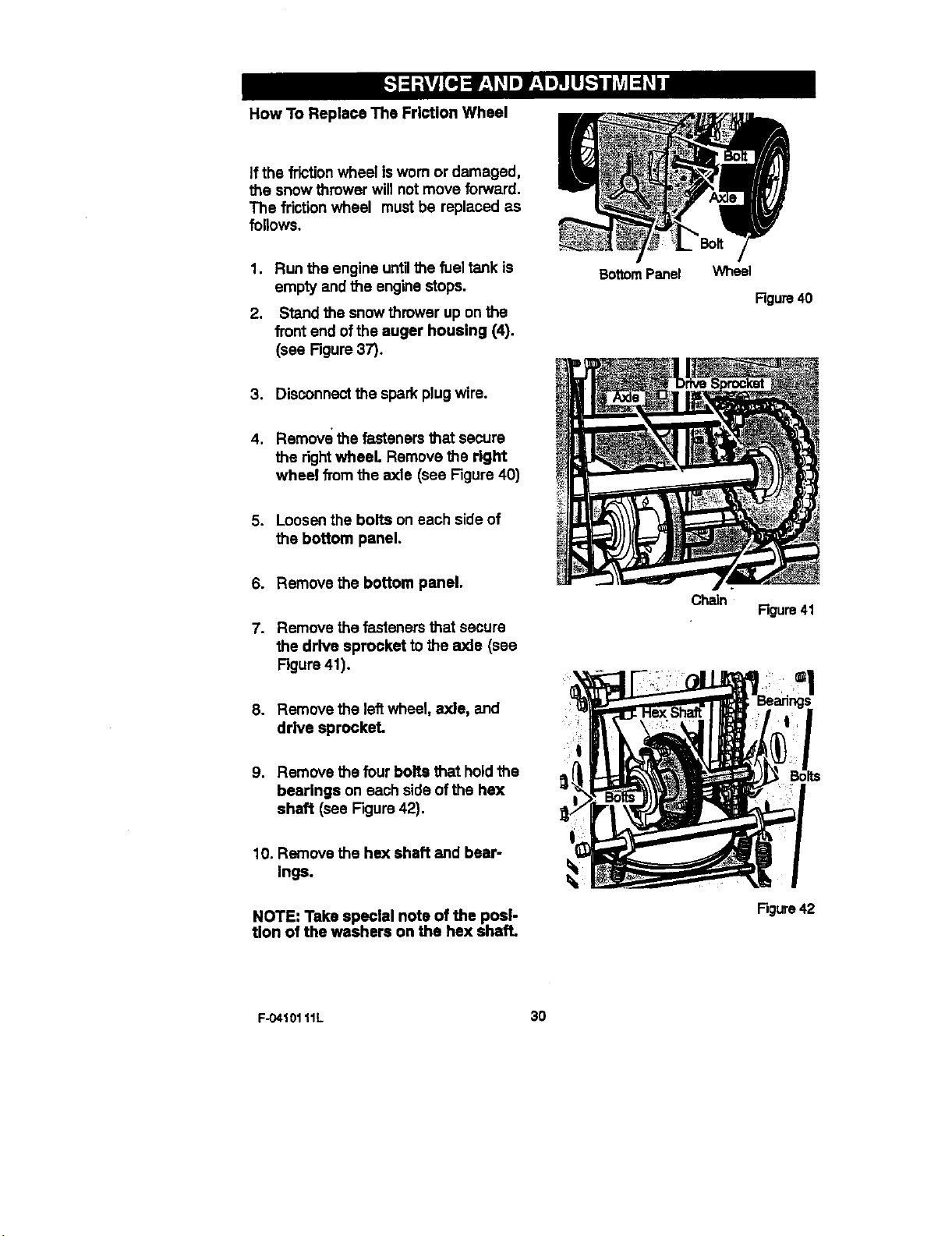

How To Replace The Friction Wheel

If the friction wheel is worn or damaged,

the snow thrower will notmove forward.

The friction wheel must be replaced as

follows.

1, Run the engine untilthe fuel tank is

empty and the engine stops.

2. Stand the snow throwerup on the

front end of the auger housing (4).

(see Figure37).

3. Disconnectthe spark plug wire.

4. Remove the fasteners that secure

the rightwheel Remove the right

wheel from the axle (see Figure 40)

5. Loosen the bolts on each side of

the bottom panel.

6. Remove the bottom panel.

7. Remove the fasteners that secure

the drive sprocket to the axle (see

Figure 41).

8. Remove the leftwheel, axle, and

drive sprocket.

BottomPanel

Wheel

Rgure 40

Chain

Rgure 41

9. Remove the four bolts that holdthe

bearings on each side ofthe hex

shaft (see Figure 42).

10. Remove the he)( shaft and bear-

Ings.

NOTE: Take special note of the posi-

tion of the washers on the hex shaft.

F-04101 11L 30

Figure42

Loading...

Loading...