Craftsman 536.88113 User Manual

11.0 Horsepower

30 Inch Dual Stage

120V, Electric Start

SNOW THROWER

MODEL NO.

536.881130

a

a

0

Caution:

Read and follow all Safety Rules

and Operating Instructions before

first use of this product.

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

F-001060J 08/25/99

ll

a

g

I

i_'_Jnl= L'_J_Ko]LrI_;I_ii_"]

WARRANTY STATEMENT ......

SAFETY RULES ...............

INTERNATIONAL SYMBOLS ....

ASSEMBLY ...................

OPERATION ..................

MAINTENANCE ...............

SERVICE AND ADJUSTMENT ...

2 STORAGE .................... 28

2 TROUBLE SHOOTING CHART .. 29

4 REPAIR PARTS ................ 30

6 ENGINE REPAIR PARTS ........ 46

11 SPANISH (ESPAI;IOL) .......... 55

17 PARTS ORDERING/SERVICE ..

20 BACK COVER

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow thrower is madntained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Craftsman will repair, free of charge, any defect in material or workman-

ship.

Ifthis Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap-

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

Items which become worn dudng normal use, such as spark plugs, drive belts and shear

pins.

Repair necessaP/because of operator abuse ornegligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained inthe

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWERTO THE NEAREST CRAFTSMAN SERVICE CENTER/DEPARTMENT IN

THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS

IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D617WA, Hoffman Estates. IL 60179

,_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

F÷OO1060J 2

IT MEANS-- ATTENTION!!! BECOME ALERTI!! YOUR SAFETY IS INVOLVED.

the spark plug wire and place it

WARNING: Always disconnect

where It cannot make contact

with spark plug to prevent accidental

starting during: Preparation, Mainte-

nance, or Storage of you snow thrower.

IMPORTANT: Safety standards require oper-

ator presence controls to minimize the risk of in-

jury. Your snow thrower is equipped with such

controls. Do not attempt to defeat the function

oftheoperatorpresencecontrolunderany cir-

cumstances.

TRAINING

1. Read the operating and service instruction

manual carefully. Be thoroughly familiar

withthe controls and the proper use of the

equipment. Know how to stop the unit and

disengage the controls quickly.

2. Never allow children to operate the equip-

merit. Never allow adults to operate the

equipment without proper instruction.

3. Keep the area of operation clear of all per-

sons, padiculady small children and pets.

4. Exercise caution to avoid slippingor falling

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor).

3. Do not operate the equipment without

wearing adequate winter outer garments.

Wear footwear that will improve footing an

alippery surfaces.

4. Handle fuel with care; it is highly flam-

mable.

a, Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en-

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

Never store fuel or snow thrower with

fuel in the tank inside of a building

where fumes may reach an open flame

or spark,

Check fuel supply before each use, al-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5.

For all units with electric starting motors

use electric starting extension cords certi-

fied CSfVUL. Use only with a receptecle

that has been installed in accordance with

local inspection authorities.

6.

Adjust the snow thrower height to clear

gravel or crushed rock surface,

F-OOIO60J

7. Never attempt to make any adjustments

while the engine (motor) is running (except

when specifically recommended by manu-

facturer).

8. Let engine (motor) and snow thrower ad-

just to outdoortemperatures before starting

to clear snow.

9. Always wear safety glasses or eye shields

during operation orwhile performing an ad -

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

OPERATION

1. Do not operate this machine if you are tak-

ing drugs or other medication which can

cause drowsiness or affect your ability to

operate this machine.

2. Do nat use this mechine ifyou are mentally

or physically unable to operate this ma-

chine sefaly.

3. Do not put hands or feet near or under ro-

tating parts. Keep clear of the discharge

opening at all times.

4. Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

5. After striking a foreign object, stop the en-

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

6. If the unit should start to vibrate abnormal-

ly, stop the engine (motor) end check im-

mediately for the cause. Vibration is

generally e warning of trouble.

7. Stop the engine (motor) whenever you

leave the operating position, before un-

clogging the auger/_mpallar housing ordis-

charge chute and when making any

repairs, adjustments, or inspections.

8. When cleaning, repairing, or inspecting,

make certain the augar/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

9. Take all possible precautions when leaving

the snow thrower unattended. Disengage

the auger/ impener, stop engine (motor),

and remove key.

10. Do notrun the engine (motor) indoors, ex-

cept when starting the engine (motor) and

for transporting the snow thrower in or out

of the building.Open the outside doors; ex-

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS).

11. Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do net at-

tempt to clear steep slopes,

12 Never operate the snow thrower without

proper guards, plates or other safety pro-

tective devices in place.

t3. Never operate the snow thrower near en-

closures, automobiles, window wells,

droppers, and the like without proper ad-

justment of the snow discharge angle.

Keep children and pets away,

14. Do not overload the machine capacity by

attempting to clear snow at too fast a rate,

15. Never operate the machine at high trans-

port speeds on slippery surfaces, Look be-

hind and use care when backing up.

16. Never direct discharge at bystanders or

allow anyone in front of the unit.

17, Diseegage power to the colleetor/impeller

when snow thrower is transported or not in

use.

18. Use only attachments and accessorias ap-

proved by the manufacturer of the snow

thrower (such as tire chains, electric start

kits, ect).

19. Never operate the snow thrower without

good visibility or light. Always be sure of

your footing and keep a firm hold on the

handles, Walk;never run.

20. Do not over-reach. Keep proper footing

and balance at all times.

21. Do not attempt to use snow thrower on a

roof.

MAINTENANCE AND STORAGE

1. Cheek shear bolts and other bolts at fre-

quent intervals for proper tightness to be

sure the equipment is in safe working

condition,

2, Never store the snow thrower with fuel in

the tank inside a building where ignition

sources are present such as hot water and

space heaters, clothes dryers, and the like.

Allow the engine (motor) to cool before

storing in any enclosure,

3. Always refer to operator's guide instruc-

tions far important details if the snow

thrower is to be stored for an extended

peded.

4. Maintain or replace safety and instruction

labels, as necessary.

5. Run the snow thrower e few minutes after

throwing snow to prevent freeze-op of the

anger/impeller.

,_ WARNING: This snow thrower isfor use on sidewalks, driveways

and other ground level surfaces.

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi-

dences, garages, porches or other such

structures or buildings.

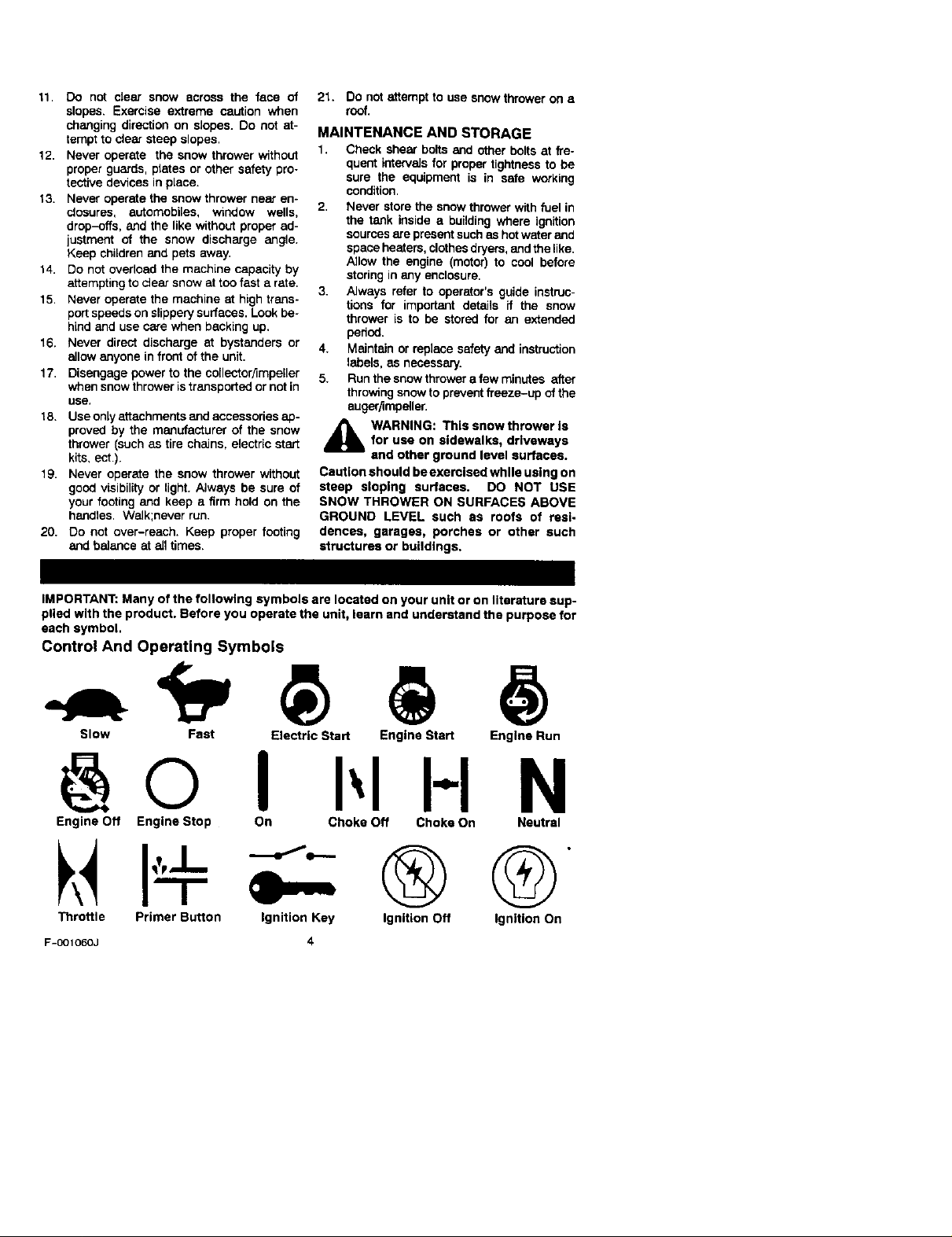

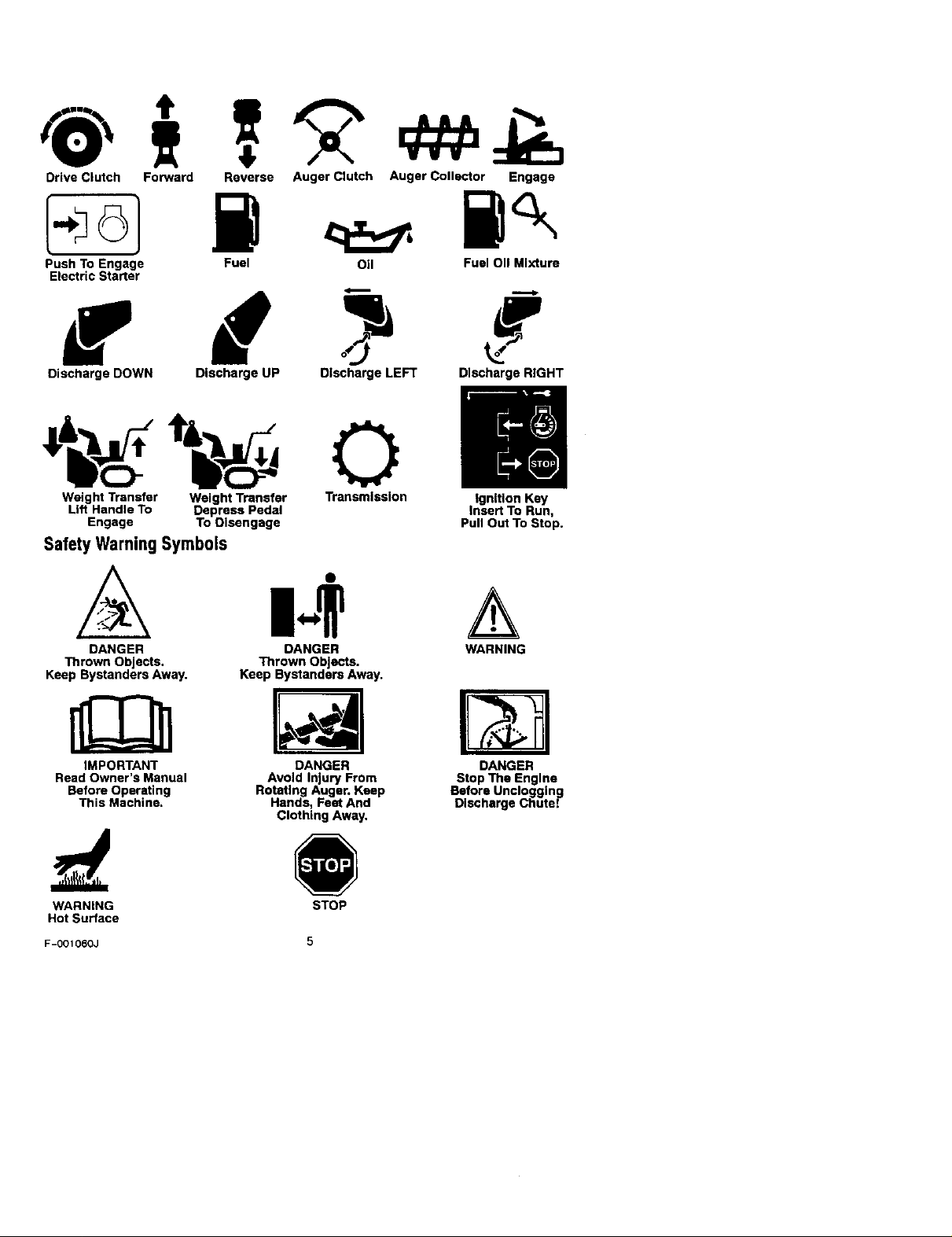

IMPORTANT: Many of the following symbols are located on your unit or on literature sup-

plied with the product. Before you operate the unit, learn and understand the purpose for

each symbol.

Control And Operating Symbols

Slow Fast

No

Engine Off Engine Stop

Electric Start Engine Start Engine Run

I H N

On Choke Off Choke On Neutral

®@

Throttle Primer Button Ignition Key

F-0OIOSOJ 4

Ignition Off Ignition On

DriveClutch Forward ReverseAugerClutchAugerCollectorEngage

PushToEngage Fuel O]1 FuelOIIMixture

ElectricStarter

f

Discharge DOWN Discharge UP Discharge LEFT Discharge RIGHT

Edl-

mo]

Weight Transfer Weight Transfer Transmission Ignition Key

Lift Handle To Depress Pedal Insert To Run,

Engage To Disengage Pull Out To Stop.

Safety Warning Symbols

DANGER DANGER WARNING

Thrown Objects. Thrown Objects.

Keep Bystanders Away. Keep Bystanders Away.

IMPORTANT

Read Owner's Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-001060J 5

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

STOP

DANGER

Stop The Engine

Before Unclogging

Discharge Chutel

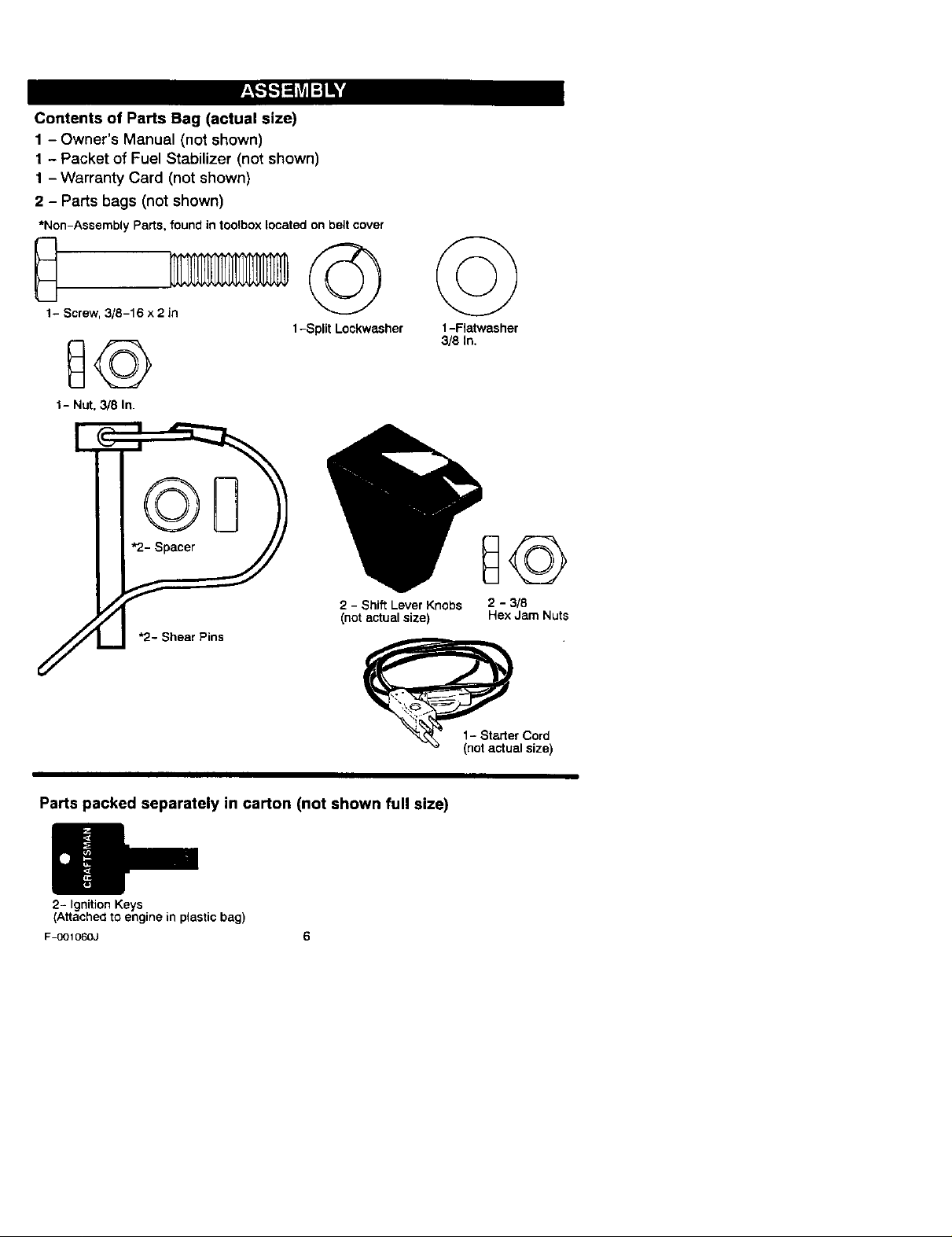

Contents of Parts Bag (actual size)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

2 - Parts bags (not shown)

*Non-Assembly Parts, found in toolbox located on belt cover

1- Screw, 3/8-16 x 2 in

1-Split Lockwasher

1- Nut, 3/8 In.

©

1-Flatwasher

3/8 In.

2 - Shift Lever Knobs 2 - 3/8

(not actual size) Hex Jam Nuts

Parts packed separately in carton (not shown full size)

2- Ignition Keys

(Attached to engine in plastic bag)

F-CO 1060J 6

C z'e'l

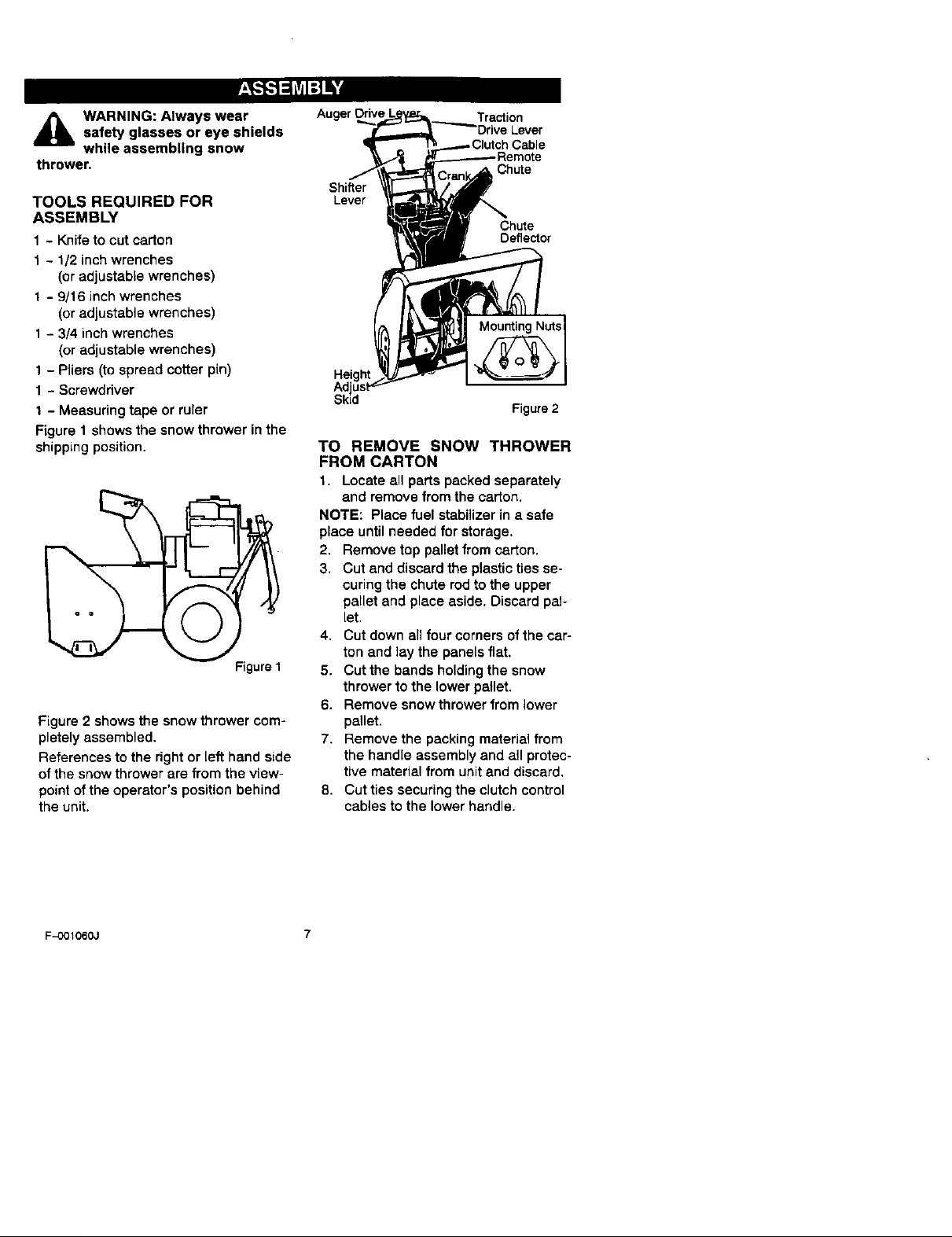

_lh ARNING: Always wearsafety glasses or eye shields

while assembling snow

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

t - 1/2 inch wrenches

(or adjustable wrenches)

1 - 9/16 inch wrenches

(or adjustable wrenches)

1 - 3/4 inch wrenches

(or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1 - Screwdriver

t - Measuring tape or ruler

Figure 1 shows the snow thrower in the

shipping position.

Figure 1

Figure 2 shows the snow thrower com-

pletely assembled,

References to the right or left hand side

of the snow thrower are from the view-

point of the operator's position behind

the unit.

Auger

Shifter

Lever

Traction

Lever

Cable

Chute

Chute

Deflector

Figure 2

TO REMOVE SNOW THROWER

FROM CARTON

t. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a safe

place until needed for storage.

2. Remove top pallet from carton.

3. Cut and discard the plastic ties se-

curing the chute rod to the upper

pallet and place aside. Discard pal-

let.

4, Cut down all four corners of the car-

ton and lay the panels flat.

5. Cutthe bands holding the snow

thrower to the lower pallet.

6. Remove snow thrower from lower

pallet.

7. Remove the packing material from

the handle assembly and all protec-

tive material from unit and discard,

8. Cut ties securing the clutch control

cables to the lower handle.

F_301060J 7

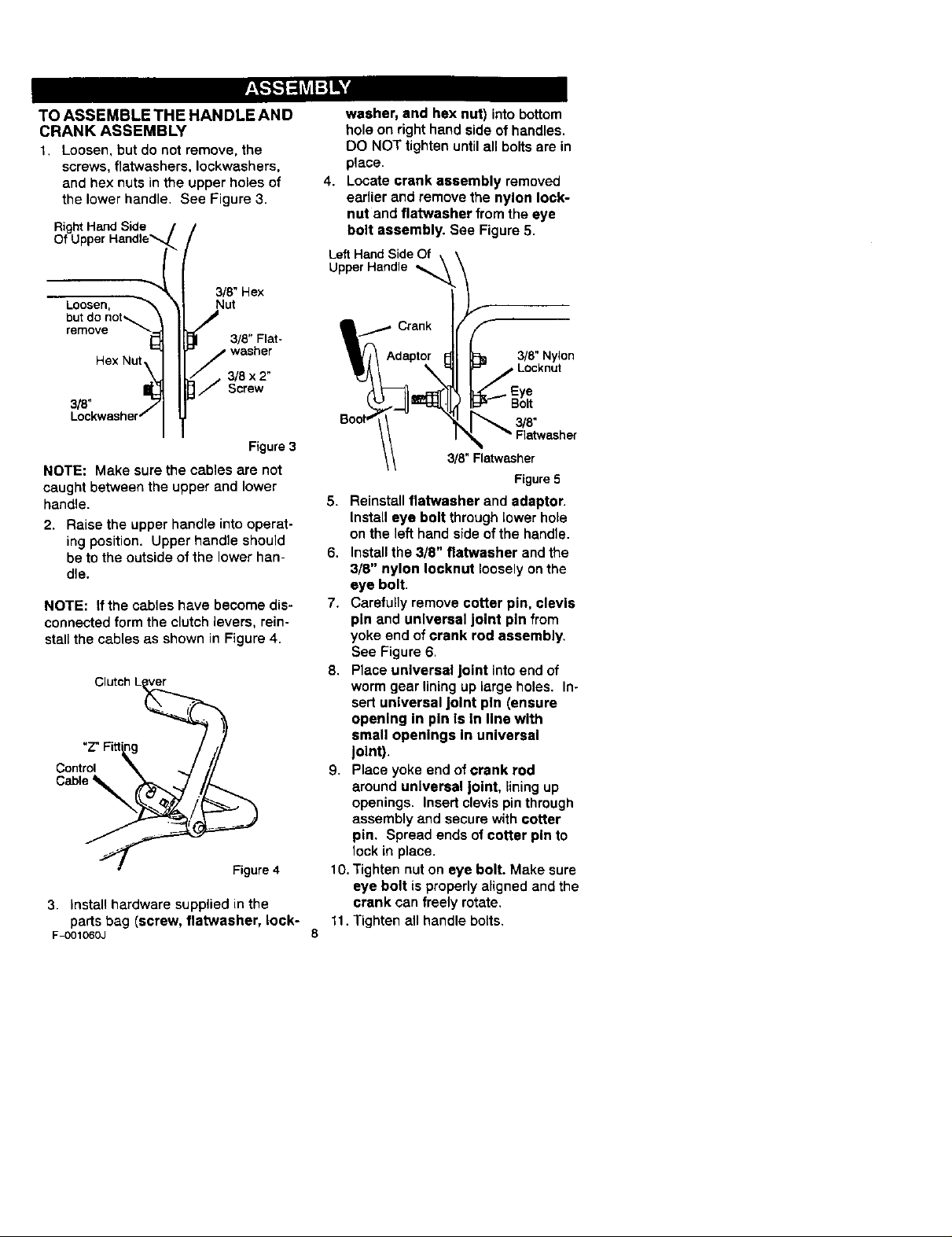

TO ASSEMBLE THE HANDLEAND

CRANK ASSEMBLY

t. Loosen, but do not remove, the

screws, flatwashers, Iockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

Right Hand Side

Of L

Loosen, Nut

but do not*,,

remove

Hex Nut,

3/8" Hex

3/8" Flat-

3/8 x 2"

Screw

3/8"

Figure 3

NOTE: Make sure the cables are not

caught between the upper and lower

handle.

2. Raise the upper handle into operat-

ing position. Upper handle should

be to the outside of the lower han-

die.

NOTE: Ifthe cables have become dis-

connected form the clutch levers, rein-

stall the cables as shown in Figure 4.

Clutch L_

Cont;cZ"IFitly, J

Cable _(_/

Figure4

3. Install hardware supplied in the

parts bag (screw, flatwasher, Iock-

F-O01060J

washer, and hex nut) into bottom

hole on right hand side of handles.

DO NOT tighten until all bolts are in

place.

4. Locate crank assembly removed

earlier and remove the nylon lock-

nut and flatwasher from the eye

bolt assembly. See Figure 5.

Left Hand Side Of

Upper Handle

3/8" Nylon

, Locknut

3/8"

3/8" Flatwasher

Figure 5

5. Reinstall flatwasher and adaptor.

Install eye bolt through lower hole

on the left hand side of the handle.

6. Install the 3/8" flatwasher and the

3/8" nylon Iocknut loosely on the

eye bolt.

7. Carefully remove cotter pin, clevis

pin and universal joint pin from

yoke end of crank rod assembly.

See Figure 6.

8. Place universal joint into end of

worm gear lining up Large holes. In-

sert universal joint pin (ensure

opening in pin Is In line with

small openings In universal

joint).

9. Place yoke end of crank rod

around universal Joint, lining up

openings. Insert clevis pin through

assembly and secure with cotter

pin. Spread ends of cotter pin to

lock in place.

10. Tighten nut on eye bolt. Make sure

eye bolt is properly aligned and the

crank can freely rotate.

11. Tighten all handle bolts.

8

CotterPin

Clevis Pin

Crank Rod

Figure 6

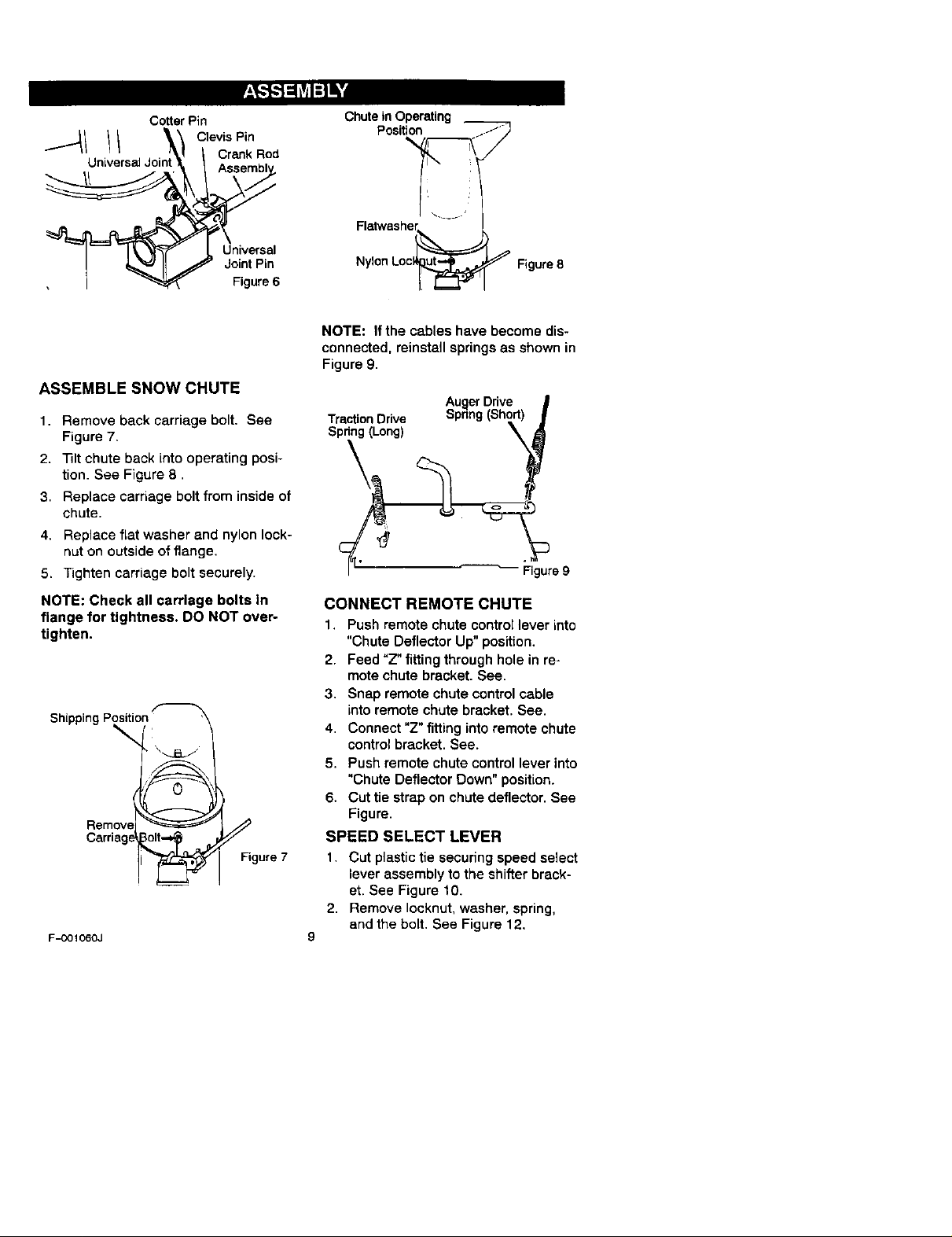

ASSEMBLE SNOW CHUTE

1. Remove back carriage bolt. See

Figure 7.

2. Tilt chute back into operating posi-

tion. See Figure 8.

3. Replace carriage bolt from inside of

chute.

4. Replace fiat washer and nylon lock-

nut on outside of flange.

5. Tighten carriage bolt securely.

NOTE: Check all carriage bolts in

flange for tightness. DO NOT over-

tighten.

Shipping Position

\

Carriage

Remow

F-OOIO60J

Figure 7

Chutein Operating __

Position

Figure 8

NOTE: If the cables have become dis-

connected, reinstall springs as shown in

Figure 9.

AugerDrive I

TractionDrive Spring(Short ,_

Spring(Long) _

I ' ' -- Figure9

CONNECT REMOTE CHUTE

1. Push remote chute control lever into

"Chute Deflector Up" position.

2. Feed "Z" fitting through hole in re-

mote chute bracket. See.

3. Snap remote chute control cable

into remote chute bracket. See.

4. Connect "Z" fitting into remote chute

control bracket. See.

5. Push remote chute control lever into

"Chute Deflector Down" position.

6. Cut tie strap on chute deflector. See

Figure.

SPEED SELECT LEVER

1. Cut plastic tie securing speed select

lever assembly to the shifter brack-

et. See Figure 10.

2. Remove Iocknut, washer, spring,

and the bolt. See Figure 12.

Loading...

Loading...