Page 1

]CRRFTSMRN 1

Operator's Manual

Snow Thrower

11 Horsepower

Electric Start

30-inch Dual Stage

Model 536.881114

CAUTION: Before using this product,

read this manual and follow all of its

Safety Rules and Operating Instruction

Manual del usario

Quitanieves

de 30 pulgadas

11 caballos de fuerza (hp)

Biet&pico

Arranque el_ctrico

Modelo 536.881114

PRECAUCI6N: Antes de usar este producto,

lea este manual y siga todas las reglas de

seguridad e instrucciones de operaci6n.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F-031001L www.sears.com/craftsman

Page 2

WARRANTY STATEMENT ...... 2

SAFETY RULES ............... 2

INTERNATIONAL SYMBOLS .... 4

ASSEMBLY ................... 6

OPERATION .................. 12

MAINTENANCE ............... 18

SERVICE AND ADJUSTMENT .. 21

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when thisCraftsman Snow thrower is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Sears will repair, free of charge, any defect in material or workmanship.

If this Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap-

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

Items which become wom during normal use, such as spark plugs, drive belts and shear

pins.

Repair necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWER TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffmen Estates. IL 60179

STORAGE .................... 31

TROUBLESHOOTING TABLE . .. 32

REPAIR PARTS ............... 36

ENGINE REPAIR PARTS ....... 57

SPANISH (ESPA_IOL) .......... 65

PARTS ORDERING/SERVICE ..

BACK COVER

_lb OOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

F-031001L 2

IT MEANS-- ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

nect the spark plug wire

WARNING: Always discon-

and place it where it cannot

make contact with spark plug to

prevent accidental starting during:

Preparation, Maintenance, or Stor-

age of your snow thrower.

IMPORTANT: Safety standards re-

quire operator presence controls to

minimize the risk of injury. Your snow

thrower is equipped with such controls.

Do not attempt to defeat the function of

the operator presence control under any

circumstances.

Page 3

TRAINING

1. Read this operating and service instruction

manual carefully. Be thoroughly familiar

with the controls and the proper use of the

snow thrower. Know how to stop the snow

thrower and disengage the controls quick-

ly.

2. Never allow children to operate the snow

thrower. Never allow adults to operate the

snow thrower without proper instruction.

3. Keep the area of operation clear of all per-

sons, particularly small children end pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

snow thrower is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor).

3. Do not operate the snow thrower without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces.

4. Handle fuel with care; it is highly flam-

mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en-

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with

fuel in the tank inside of a building

where fumes may reach an open flame

or spark.

f. Check fuel supply before each use, al-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5. For all snow throwers with electric starting

motors use electric starting extension

cords certified CSA/UL. Use only with a re-

ceptecle that has been installed in accord-

ance with local inspection authorities.

6. Never attempt to make any adjustments

while the engine (motor) is running (except

when specifically recommended by manu-

facturer).

7. Let engine (motor) and snow thrower ad-

just tooutdoor temperatures before starting

to clear snow.

F-031001L

8_

Always wear safety glasses or eye shields

during operation or while performing an ad-

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

OPERATION

1. Do not operate this snow thrower ifyou are

taking drugs or other medication which can

cause drowsiness or affect your ability to

operate this snow thrower.

2. Do not use the snow thrower # you are

mentally or physicallyunable to operate the

snow thrower safely.

3. Do not put hands or feet near or under ro-

tating parts. Keep clear of the discharge

opening at all times.

4. Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

5. After striking a foreign object, stop the en-

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

6. If the snow thrower should start to vibrate

abnormally, stop the engine (motor) and

check immediately for the cause. Vibration

is generally a warning of trouble.

7. Stop the engine (motor) whenever you

leave the operating position, before un-

clogging the auger/impaller housing or dis-

charge chute and when making any

repairs, adjustments, or inspections.

8. When cleaning, repairing, or inspecting,

make certain the auger/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

9. Take all possible precautionswhen leaving

the snow thrower unattended. Disengage

the auger/ impeller, stop engine (motor),

and remove key.

10. Do not run the engine (motor) indoors, ex-

cept when starting the engine (motor) and

for transporting the snow thrower in or out

of the building. Open the outside doors; ex-

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS).

11. Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do not at-

tempt to clear steep slopes.

12. Never operate the snow thrower without

proper guards, plates or other safety pro-

tective devices in place.

Page 4

13.Neveroperatethesnowthrowernearen-

closures,automobiles,windowwells,drop-

offs,andthelike without proper adjustment

of Me snow discharge angle. Keep children

and pets away.

14. Do not overload the snow thrower capacity

by attempting to clear snow at too fast a

rate.

15. Never operate the snow thrower at high

transport speeds on slippery surfaces.

Look behind and use care when backing

up.

16. Never direct discharge at bystanders or

allow anyone in front of the snow thrower.

17. Disengage powar to the collector/impeller

when snow thrower is transported or not in

use.

18. Use anly attachments and ascassorias ap-

proved by the manufacturer of the snow

thrower (such as tire chains, electric start

kits, ect.).

19. Never operate the snow thrower without

good visibility or light. Always be sure of

your footing and keep a firm hold on the

handles. Walk;never run.

20. Do not over-reach. Keep proper footing

and balance at all times.

21. Do not attempt to use snow thrower on a

roof.

MAINTENANCE AND STORAGE

1. Check shear bolts and other bolts at fre-

quent intervals for proper tightness to be

sure the snow thrower is in safe working

condition.

2. Never store the snow thrower with fuel in

the tank inside a building where ignition

sources are present such as hot water end

space heaters, clothas dryers, and the like.

Allow the engine (motor) to cool before

storing in any enclosure.

3. Always refer to operator's guide instruc-

tions for important details if the snow

thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction

labels, as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the

augedimpeller.

_IL WARNING: This snow thrower isfor use on sidewalks, driveways

and other ground level surfaces.

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi-

dences, garages, porches or other such

structures or buildings.

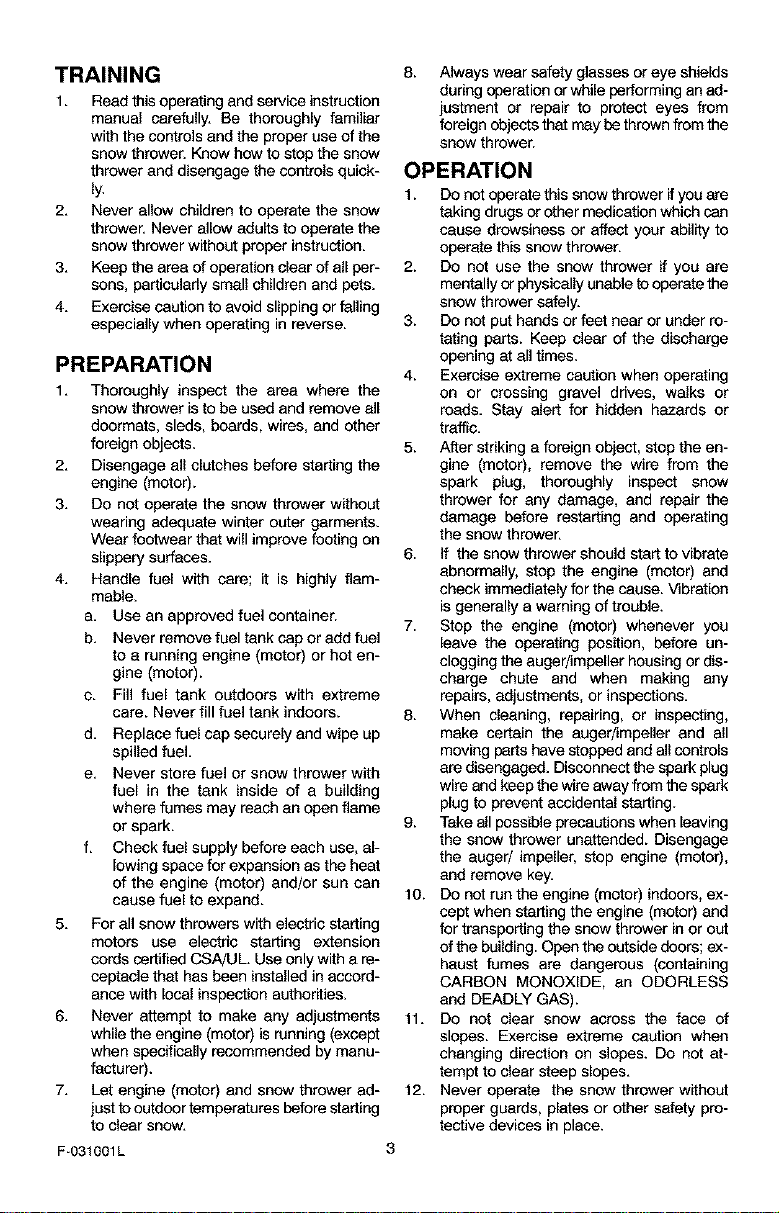

IMPORTANT: Many of the following symbols are located on your snow thrower or on litera-

ture supplied with the product. Before you operate the snow thrower, learn and understand

the purpose for each symbol.

CONTROL AND OPERATING

SYMBOLS

Slow Fast Electric Start Engine Start Engine Run

H N

Engine Off Engine Stop On Choke Off Choke On Neutral

®G

Throttle Primer Button Ignition Key

F-031001L

Ignition Off Ignition On

Page 5

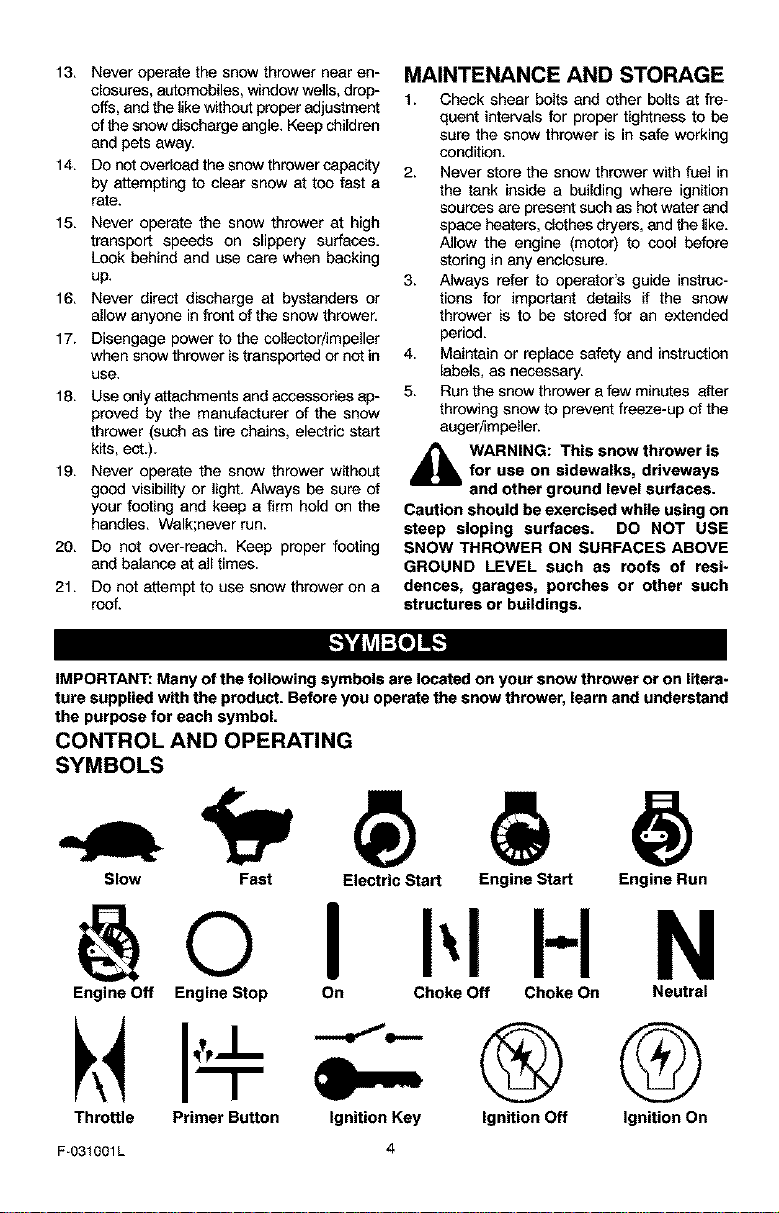

Drive Clutch Forward

Reverse Auger Clutch Auger Collector Engage

Push To Engage

Electric Starter

Discharge DOWN Discharge UP Discharge LEFT Discharge RIGHT

Weight Transfer Weight Transfer Transmission Ignition Key

Lift Handle To Depress Pedal Insert To Run,

Engage To Disengage Pull Out To Stop.

Fuel Oil Fuel Oil Mixture

Safety Warning Symbols

O

A

DANGER

Thrown Objects.

Keep Bystanders Away.

DANGER

Thrown Objects.

Keep Bystanders Away.

WARNING

IMPORTANT

Read Owner's Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-O31001L 5

DANGER

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

DANGER

Stop The Engine

Before Unclogging

Discharge Chute!

STOP

Page 6

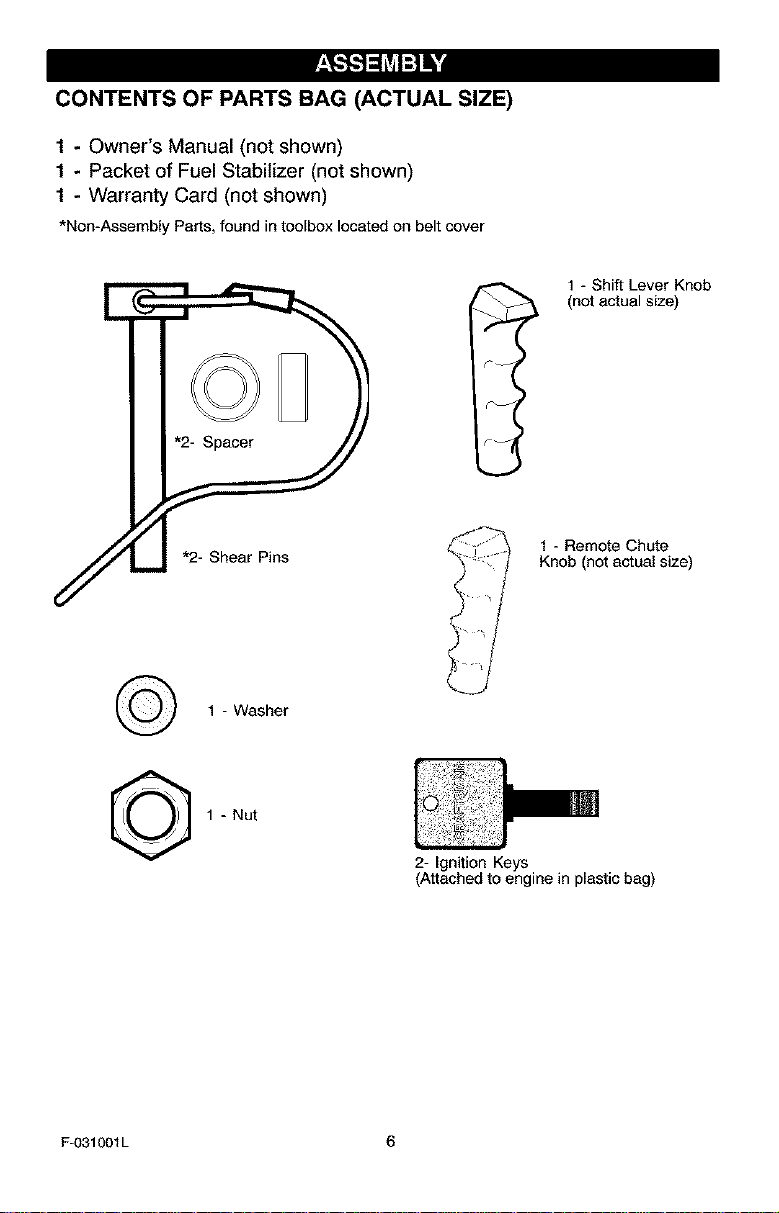

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assembly Parts,foundintoolboxlocatedonbeltcover

(not actual size)

©

1 - Washer

1 - Nut

¢- I

2- Ignition Keys

(Attached to engine in plastic bag)

1 - Shift Lever Knob

F-O31001L 6

Page 7

_b ARNING: Always wear

safety glasses or eye shields

while assembling snow

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

2 - 1/2 inch wrenches

(or adjustable wrenches)

2 - 9/16 inch wrenches

(or adjustable wrenches)

2 - 3/4 inch wrenches

(or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1 - Screwdriver

1 - Measuring tape or ruler

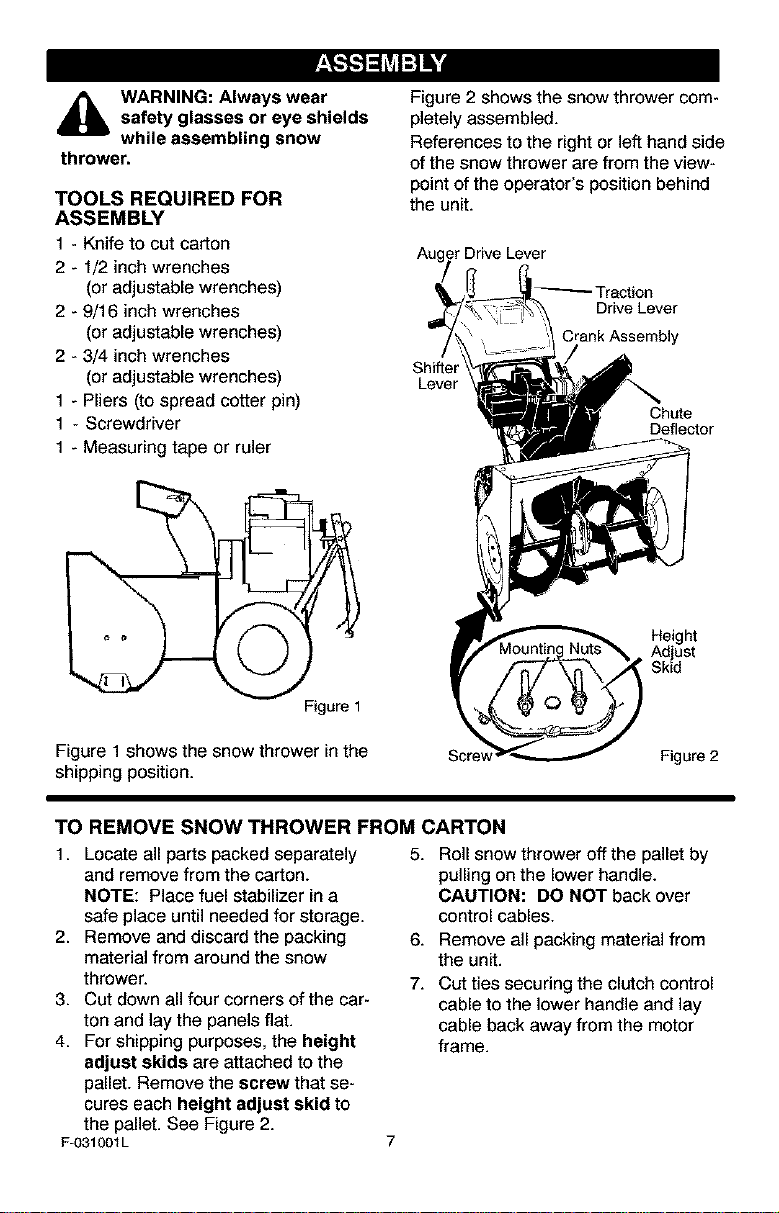

Figure 2 shows the snow thrower com-

pletely assembled.

References to the right or left hand side

of the snow thrower are from the view-

point of the operator's position behind

the unit.

Auger Drive Lever

!_ Traction

Shifter

Lever

Drive Lever

Crank Assembly

Chute

Deflector

Height

Adjust

' Skid

Figure 1

Figure 1 shows the snow thrower in the

Scre\ Figure 2

shipping position.

TO REMOVE SNOW THROWER FROM CARTON

1. Locate all parts packed separately

and remove from the carton.

NOTE: Place fuel stabilizer in a

safe place until needed for storage.

2. Remove and discard the packing

material from around the snow

thrower.

3. Cut down all four corners of the car-

ton and lay the panels flat.

4. For shipping purposes, the height

adjust skids are attached to the

pallet. Remove the screw that se-

cures each height adjust skid to

the pallet. See Figure 2.

F-031001L

5. Roll snow thrower off the pallet by

pulling on the lower handle.

CAUTION: DO NOT back over

control cables.

6. Remove all packing material from

the unit.

7. Cut ties securing the clutch control

cable to the lower handle and lay

cable back away from the motor

frame.

Page 8

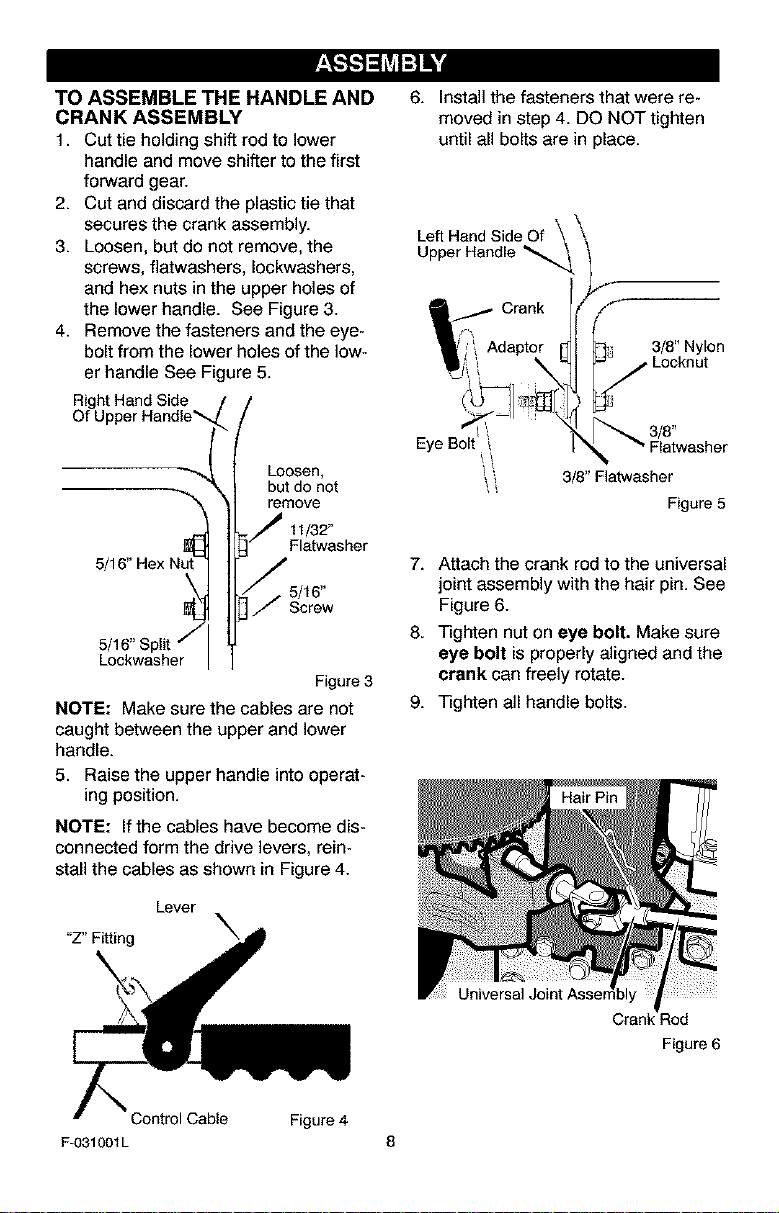

TO ASSEMBLE THE HANDLE AND

CRANK ASSEMBLY

1. Cut tie holding shift rod to lower

handle and move shifter to the first

forward gear.

2. Cut and discard the plastic tie that

secures the crank assembly.

3. Loosen, but do not remove, the

screws, flatwashers, Iockwashers,

and hex nuts in the upper holes of

the lower handle. See Figure 3.

4. Remove the fasteners and the eye-

bolt from the lower holes of the low-

er handle See Figure 5.

Right Hand Side

Of U

Loosen,

but do not

remove

11/32"

Flatwasher

5/

5/16"

Screw

5/16"Split j

Lockwasher

Figure3

NOTE: Make sure the cables are not

caught between the upper and lower

handle.

5. Raise the upper handle into operat-

ing position.

NOTE: If the cables have become dis-

connected form the drive levers, rein-

stall the cables as shown in Figure 4.

6. Install the fasteners that were re-

moved in step 4. DO NOT tighten

until all bolts are in place.

Left Hand Side Of

Upper Handle

3/8" Nylon

_ Locknut

Eye Bolt

_"Flatwasher

3/8" Flatwasher

Figure 5

7. Attach the crank rod to the universal

joint assembly with the hair pin. See

Figure 6.

8. Tighten nut on eye bolt. Make sure

eye bolt is properly aligned and the

crank can freely rotate.

9. Tighten all handle bolts.

Lever

"Z" Fitting

Control Cable Figure 4

F-031001L 8

Figure 6

Page 9

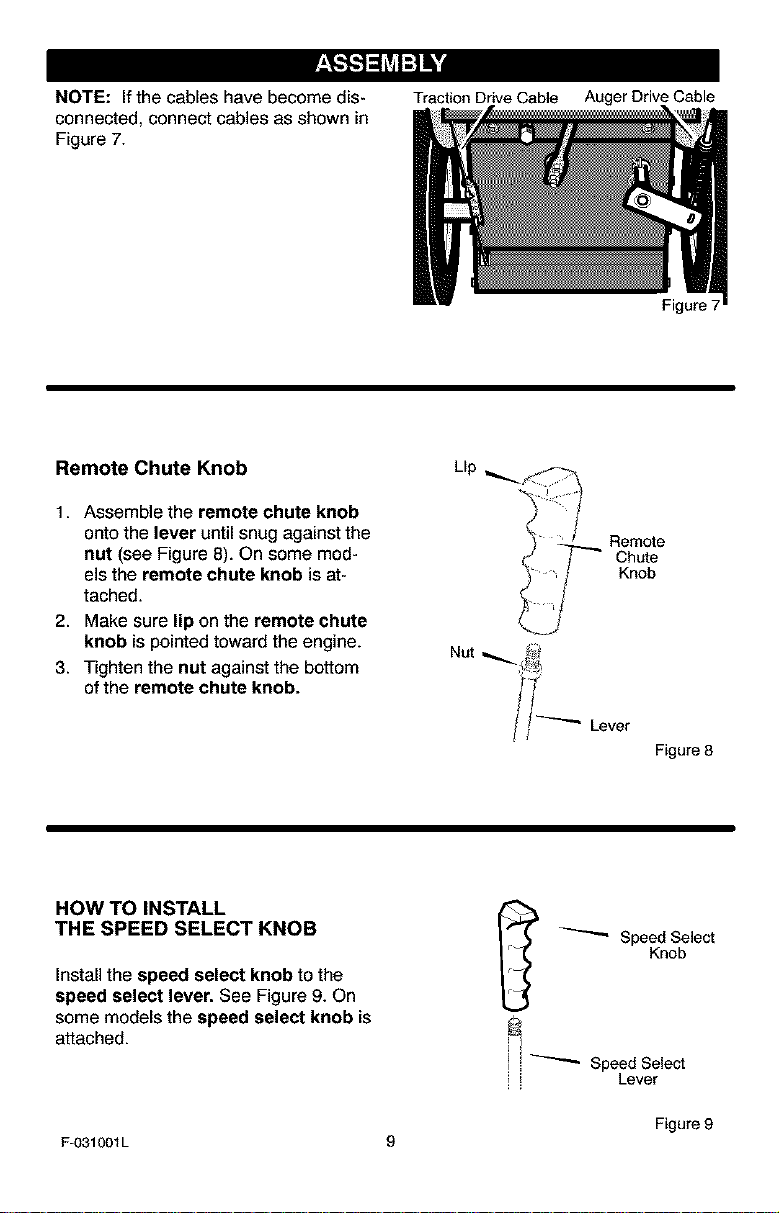

NOTE: If the cables have become dis-

connected, connect cables as shown in

Figure 7.

Remote Chute Knob

1. Assemble the remote chute knob

onto the lever until snug against the

nut (see Figure 8). On some mod-

els the remote chute knob is at-

tached.

2. Make sure lip on the remote chute

knob is pointed toward the engine.

3. Tighten the nut against the bottom

of the remote chute knob.

Traction Drive Cable Auger Drive Cable

Figure 7

Rem_e

Chute

Knob

HOW TO INSTALL

THE SPEED SELECT KNOB

Install the speed select knob to the

speed select lever. See Figure 9. On

some models the speed select knob is

attached.

F-031001L 9

Lever

Figure 8

Knob

_ Speed Select

_ _-""_ Speed Select

I Lever

Figure 9

Page 10

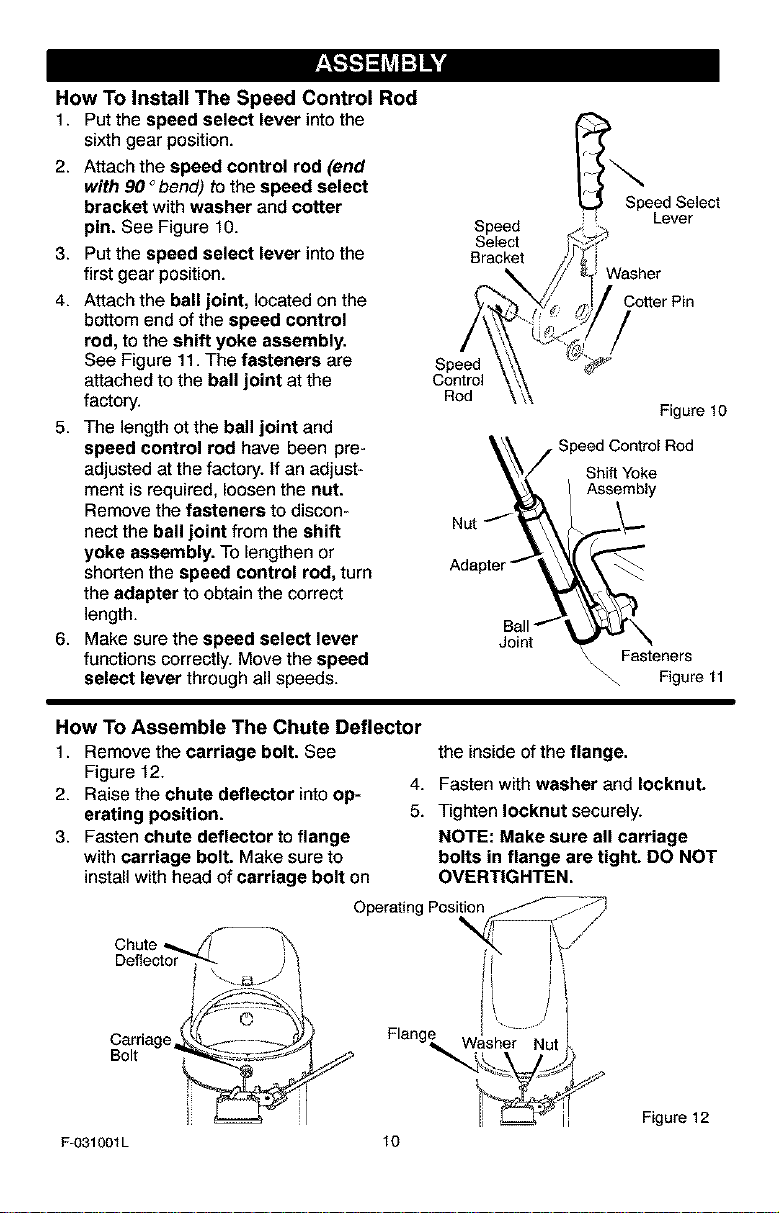

How To Install The Speed Control Rod

1. Put the speed select lever intothe

sixth gear position.

2. Attach the speed control rod (end

with 90 °bend) to the speed select

bracket with washer and cotter

pin. See Figure t0.

3. Put the speed select lever into the Bracket

first gear position.

4. Attach the ball joint, located on the

bottom end of the speed control

rod, to the shift yoke assembly.

See Figure 11. The fasteners are Speed

attached to the ball joint at the Control

factory. Rod

5. The length ot the ball joint and

speed control rod have been pre-

adjusted at the factory, if an adjust-

ment is required, loosen the nut.

Remove the fasteners to discon-

nect the ball joint from the shift Nut _'_'

yoke assembly. To lengthen or

shorten the speed control rod, turn Adapter

the adapter to obtain the correct

length.

6. Make sure the speed select lever

Joint

functions correctly. Move the speed

select lever through all speeds.

Speed Select

Lever

Cotter Pin

Figure 10

Shift Yoke

Assembly

\\ Fasteners

\\. Figure 11

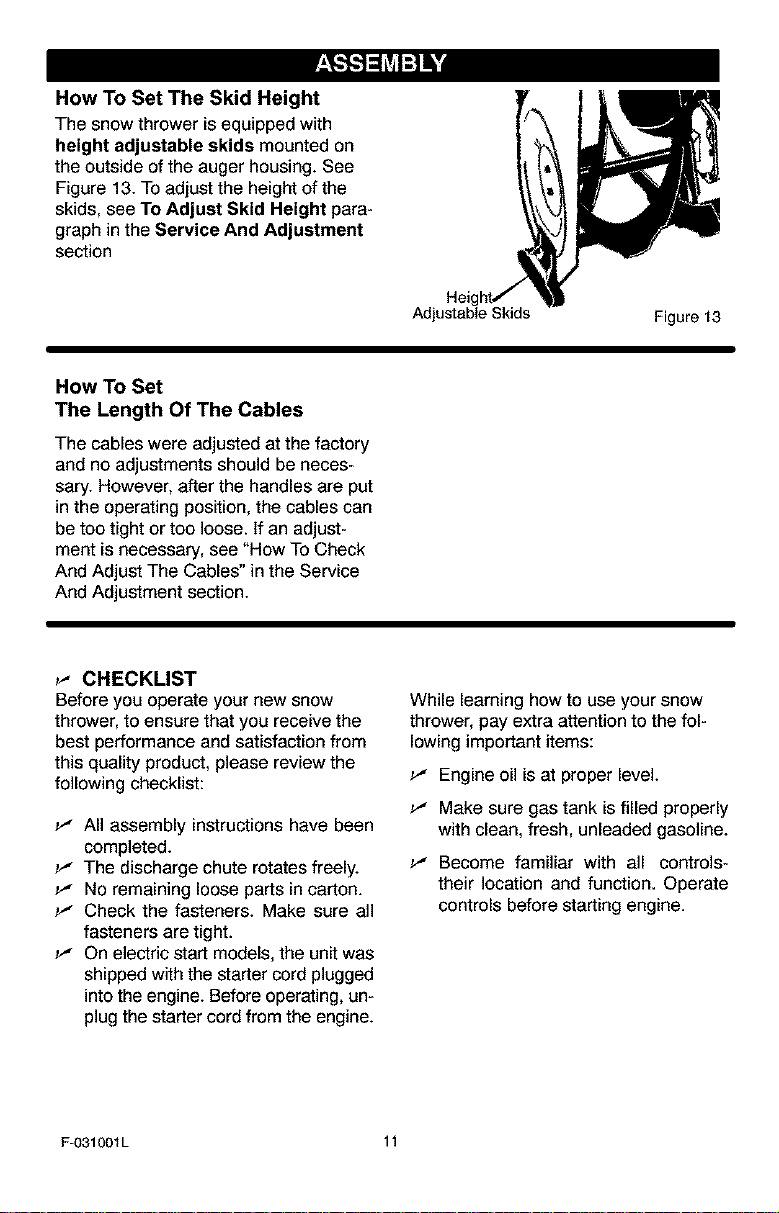

How To Assemble The Chute Deflector

1. Remove the carriage bolt. See

Figure 12.

2. Raise the chute deflector into op-

erating position.

3. Fasten chute deflector to flange

with carriage bolt. Make sure to

install with head of carriage bolt on

Chute

Deflector

Carriage,_

Bolt

F-031001L

10

the inside of the flange.

4. Fasten with washer and Iocknut.

5. Tighten Iocknut securely.

NOTE: Make sure all carriage

bolts in flange are tight. DO NOT

OVERT|GHTEN.

Washer Nut

Figure 12

Page 11

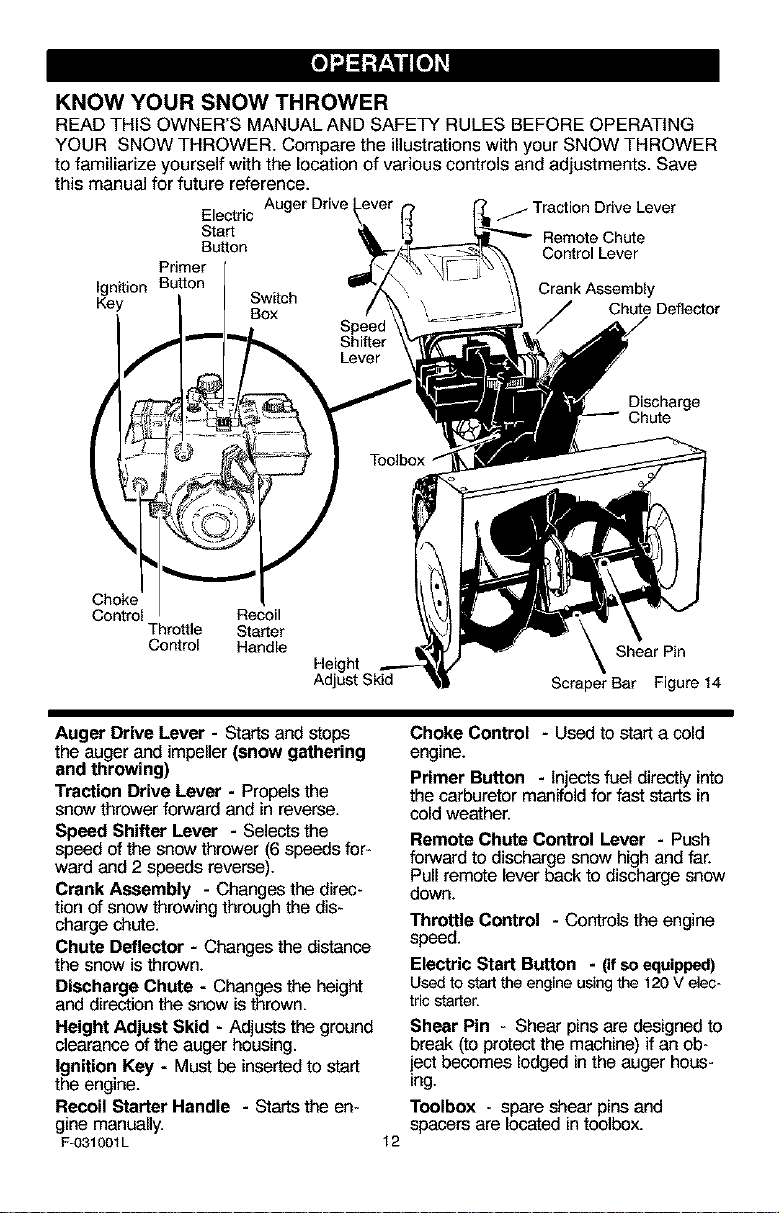

How To Set The Skid Height

The snow thrower is equipped with

height adjustable skids mounted on

the outside of the auger housing. See

Figure 13. To adjust the height of the

skids, see To Adjust Skid Height para-

graph in the Service And Adjustment

section

How To Set

The Length Of The Cables

The cables were adjusted at the factory

and no adjustments should be neces-

sary. However, after the handles are put

in the operating position, the cables can

be too tight or too loose. If an adjust-

ment is necessary, see "How To Check

And Adjust The Cables" in the Service

And Adjustment section.

_" CHECKLIST

Before you operate your new snow

thrower, to ensure that you receive the

best performance and satisfaction from

this quality product, please review the

following checklist:

_" All assembly instructions have been

completed.

_" The discharge chute rotates freely.

_" No remaining loose parts in carton.

_" Check the fasteners. Make sure all

fasteners are tight.

_" On electric start models, the unit was

shipped with the starter cord plugged

into the engine. Before operating, un-

plug the starter cord from the engine.

Adjustable Skids Figure 13

While learning how to use your snow

thrower, pay extra attention to the fol-

lowing important items:

_" Engine oil is at proper level.

_" Make sure gas tank is filled properly

with clean, fresh, unleaded gasoline.

_" Become familiar with all controls-

their location and function. Operate

controls before starting engine.

F-O31001L 11

Page 12

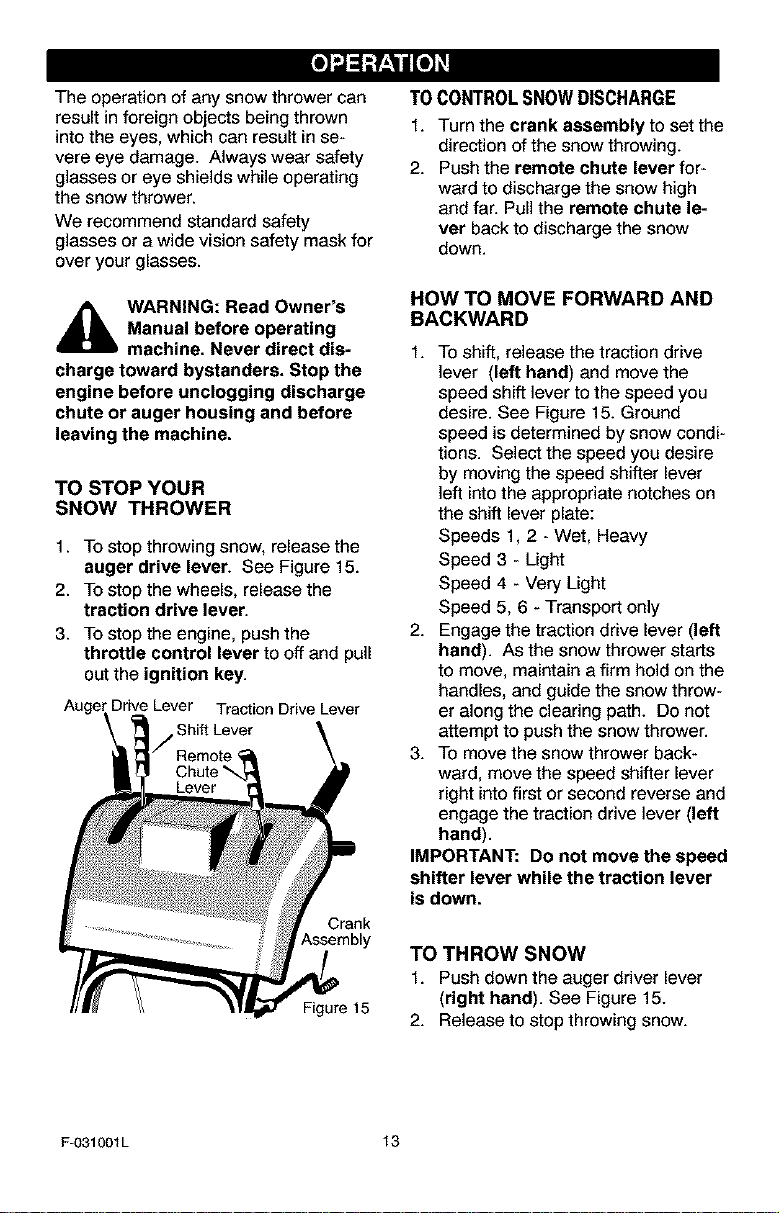

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER. Compare the illustrations with your SNOW THROWER

to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

Electric Auger Drive

Start

Button

Primer

Ignition Button Crank Assembly

Key Switch

Choke

Control Recoil

Throttle Starter

Control Handle

Box ChuteDeflector

Height

Adjust Skid Scraper Bar Figure 14

Traction Ddve Lever

Remote Chute

Control Lever

Discharge

Chute

Shear Pin

Auger Drive Lever - Starts and stops

the auger and impeller (snow gathering

and throwing)

Traction Drive Lever - Propels the

snow thrower forward and in reverse.

Speed Shifter Lever - Selects t_e

speed of t_e snow thrower (6 speeds for-

ward and 2 speeds reverse).

Crank Assembly - Changes the direc-

tionof snow throwingthrough the dis-

charge chute.

Chute Deflector - Changes the distance

the snow is thrown.

Discharge Chute - Changes the height

and direction t_e snow is thrown.

Height Adjust Skid - Adjusts the ground

clearance ofthe auger housing.

Ignition Key - Must be inserted to start

the engine.

Recoil Starter Handle - Starts the en-

gine manually.

F-031001L

Choke Control - Used to _ a cold

engine.

Primer Button - Injects fuel directly into

the carburetor manifold for fast starts in

cold weather.

Remote Chute Control Lever - Push

forward to discharge snow high and far.

Pull remote lever back to discharge snow

down.

Throttle Control - Controls the engine

speed.

Electric Start Button - (if so equipped)

Usedtostarttheengineusingthe120V elec-

tricstarter.

Shear Pin - Shear pins are designed to

break (to protectthe machine) if an ob-

iect becomes lodged in the auger hous-

ing.

Toolbox - spare shear pins and

spacers are located in toolbox.

12

Page 13

Theoperationofanysnowthrowercan

resultinforeignobjectsbeingthrown

intotheeyes,whichcanresultinse-

vereeyedamage.Alwayswearsafety

glassesoreyeshieldswhileoperating

thesnowthrower.

Werecommendstandardsafety

glassesorawidevisionsafetymaskfor

overyourglasses.

_lb ARNING: Read Owner's

charge toward bystanders. Stop the

engine before unclogging discharge

chute or auger housing and before

leaving the machine,

TO STOP YOUR

SNOW THROWER

1. To stop throwing snow, release the

2. To stop the wheels, release the

3. To stop the engine, push the

Auger Drive Lever Traction Drive Lever

Manual before operating

machine. Never direct dis-

auger drive lever. See Figure 15.

traction drive lever.

throttle control lever to off and pull

outthe ignition key.

Shift Lever

Crank

Assembly

Figure 15

TOCONTROLSNOWDISCHARGE

1. Turn the crank assembly to set the

direction of the snow throwing.

2. Push the remote chute lever for-

ward to discharge the snow high

and far. Pull the remote chute le-

ver back to discharge the snow

down.

HOW TO MOVE FORWARD AND

BACKWARD

1. TO shift, release the traction drive

lever (left hand) and move the

speed shift lever to the speed you

desire. See Figure 15. Ground

speed is determined by snow condi-

tions. Select the speed you desire

by moving the speed shifter lever

left into the appropriate notches on

the shift lever plate:

Speeds 1, 2 - Wet, Heavy

Speed 3 - Light

Speed 4 - Very Light

Speed 5, 6 - Transport only

2. Engage the traction drive lever (left

hand). As the snow thrower starts

to move, maintain a firm hold on the

handles, and guide the snow throw-

er along the clearing path. Do not

attempt to push the snow thrower.

3. To move the snow thrower back-

ward, move the speed shifter lever

right into first or second reverse and

engage the traction drive lever (left

hand).

IMPORTANT: Do not move the speed

shifter lever while the traction lever

is down.

TO THROW SNOW

1. Push down the auger driver lever

(right hand). See Figure 15.

2. Release to stop throwing snow.

F-O31001L 13

Page 14

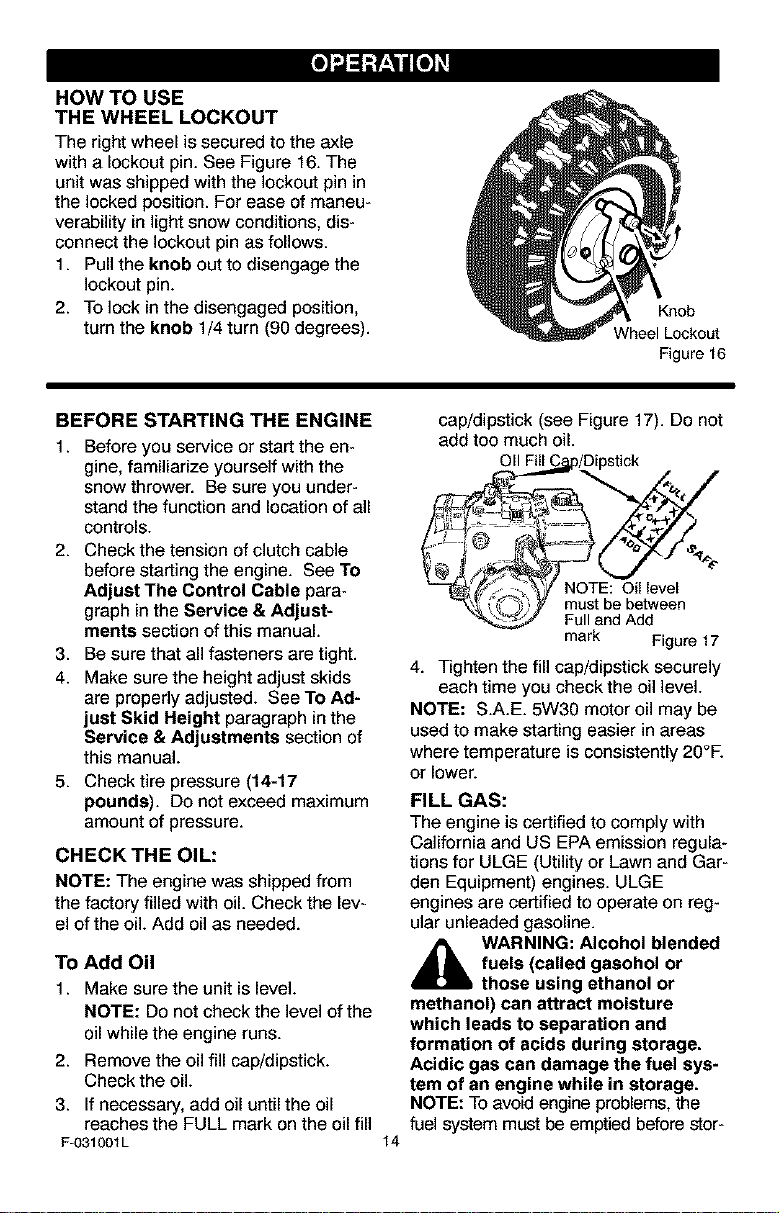

HOW TO USE

THE WHEEL LOCKOUT

The right wheel is secured to the axle

with a lockout pin. See Figure 16. The

unit was shipped with the lockout pin in

the locked position. For ease of maneu-

verability in light snow conditions, dis-

connect the lockout pin as follows.

1. Pull the knob out to disengage the

lockout pin.

2. To lock in the disengaged position,

turn the knob 1/4 turn (90 degrees).

Knob

Wheel Lockout

Figure 16

BEFORE STARTING THE ENGINE

1. Before you service or start the en-

gine, familiarize yourself with the

snow thrower. Be sure you under-

stand the function and location of all

controls.

2. Check the tension of clutch cable

before starting the engine. See To

Adjust The Control Cable para-

graph in the Service & Adjust-

ments section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are properly adjusted. See To Ad-

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Check tire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

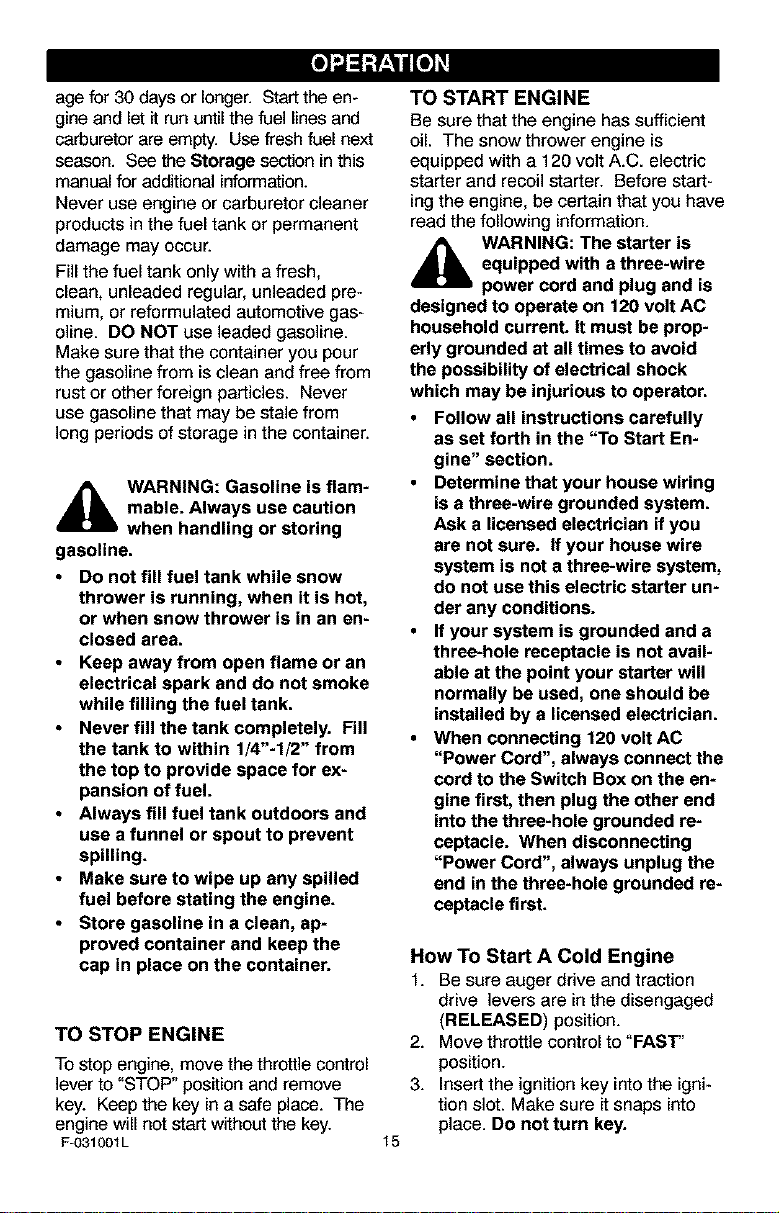

CHECK THE OIL:

NOTE: The engine was shipped from

the factory filled with oil. Check the lev-

el of the oil. Add oil as needed.

TO Add Oil

1. Make sure the unit is level.

NOTE: Do not check the level of the

oil while the engine runs.

2. Remove the oil fillcap/dipstick.

Check the oil.

3. If necessary, add oiluntil the oil

reaches the FULL mark on the oil fill

F-031001L

cap/dipstick (see Figure 17). Do not

add too much oil.

011FillC_p/Dipstick

-_%'_,,'NOTE: Oil level

_y must.be between

FullandAdd

mark Figure 17

4. Tighten the fill cap/dipstick securely

each time you check the oil level.

NOTE: S.A.E. 5W30 motor oil may be

used to make starting easier in areas

where temperature is consistently 20°E

or lower.

FILL GAS:

The engine is certified to comply with

California and US EPA emission regula-

tions for ULGE (Utility or Lawn and Gar-

den Equipment) engines. ULGE

engines are certified to operate on reg-

ular unleaded gasoline.

,_ WARNING: Alcohol blended

fuels (called gasohol or

those using ethanol or

methanol) can attract moisture

which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

NOTE: To avoid engine problems, the

fuel system must be emptied before stor-

14

Page 15

agefor30daysorlonger.Starttheen-

gineandlet it run until the fuel lines and

carburetor are empty. Use fresh fuel next

season. See _e Storage section in this

manual for additional information.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

Fill the fuel tank only with a fresh,

clean, unleaded regular, unleaded pre-

mium, or reformulated automotive gas-

oline. DO NOT use leaded gasoline.

Make sure that the container you pour

the gasoline from is clean and free from

rust or other foreign particles. Never

use gasoline that may be stale from

long periods of storage in the container.

4_b WARNING: Gasoline is flam-

gasoline.

• Do not fill fuel tank while snow

• Keep away from open flame or an

• Never fill the tank completely. Fill

• Always fill fuel tank outdoors and

• Make sure to wipe up any spilled

• Store gasoline in a clean, ap-

TO STOP ENGINE

To stop engine, move the throttle control

lever to "STOP" position and remove

key. Keep the key in a safe place. The

engine will not start without the key.

F-031001L

mable. Always use caution

when handling or storing

thrower is running, when it is hot,

or when snow thrower is in an en-

closed area.

electrical spark and do not smoke

while filling the fuel tank.

the tank to within 1/4"-1/2" from

the top to provide space for ex-

pansion of fuel.

use a funnel or spout to prevent

spilling.

fuel before stating the engine.

proved container and keep the

cap in place on the container.

TO START ENGINE

Be sure that the engine has sufficient

oil. The snow thrower engine is

equipped with a 120 volt A.C. electric

starter and recoil starter. Before start-

ing the engine, be certain that you have

read the following information.

4_lb WARNING: The starter is

designed to operate on 120 volt AC

household current. It must be prop-

erly grounded at all times to avoid

the possibility of electrical shock

which may be injurious to operator.

• Follow all instructions carefully

• Determine that your house wiring

• If your system is grounded and a

• When connecting 120 volt AC

How To Start A Cold Engine

1. Be sure auger drive and traction

2. Move throttle control to "FAST'

3. Insert the ignition key into the igni-

15

equipped with a three-wire

power cord and plug and is

as set forth in the "To Start En-

gine" section.

is a three-wire grounded system.

Ask a licensed electrician if you

are not sure. If your house wire

system is not a three-wire system,

do not use this electric starter un-

der any conditions.

three-hole receptacle is not avail-

able at the point your starter will

normally be used, one should be

installed by a licensed electrician.

"Power Cord", always connect the

cord to the Switch Box on the en-

gine first, then plug the other end

into the three-hole grounded re-

ceptacle. When disconnecting

"Power Cord", always unplug the

end in the three-hole grounded re-

ceptacle first.

drive levers are in the disengaged

(RELEASED) position.

position.

tion slot. Make sure it snaps into

place. Do not turn key.

Page 16

4. Rotatechokeknobclockwisetothe

chokeONposition.

5. (Electric Start) Plug the power cord

into the switch box on the engine.

Plug the other end of power cord

into a three-hole, grounded 120

VOLT, AC receptacle.

6. Push the primer button as speci-

fied below. Remove finger from

primer button between pushes.

Do not push if temperature

above 50° F (10° C).

Push two times if temperature is

50° F (10° C) to 15°F (-10° C).

Push four times if temperature is

below 15° F (-10° C).

Push five times if temperature is

below 0° F (-18 ° C).

7. (Electric Start) Push down on the

starter button until the engine

starts. Do not crank for more than

10 seconds at a time. This electric

starter is thermally protected. If

overheated it will stop automatically

and can be restarted only when it

has cooled to a safe temperature (a

wait of about 5 to 10 minutes is re-

quired).

8. (Recoil Start) Rapidly pull the re-

coil starter handle. Do not allow

the recoil starter handle to snap

back. Slowly return the recoil start-

er handle.

9. Ifthe engine does not start in 5 or 6

tries, See Difficult Starting in the

"Troubleshooting Table".

10. When the engine starts, move the

choke control to "1/2 choke" posi-

tion. When engine runs smoothly,

move choke control to the off

Position.

11. (Electric Start) First disconnect

power cord from receptacle. Then,

disconnect the power cord from the

switch box.

12. Run engine at full throttle "FAST"

when throwing snow.

Allow the engine to warm up for several

minutes before blowing snow in temper-

F-031001L

atures below 0°F.

How To Start A Warm Engine

If restarting a warm engine after a short

shutdown, leave the choke lever in the

off position and do not push the primer

button. If the engine fails to start, follow

the Cold Start instructions.

FROZEN STARTER

If the starter is frozen and will not turn

engine:

1. Pull as much rope out of the starter

as possible.

2. Release the starter handle and let it

snap back against the starter. Re-

peat until the engine starts.

To help prevent possible freeze-up of

recoil starter and engine controls, pro-

ceed as follows after each snow remov-

al job.

1. With the engine running, pull the

starter rope hard with a continuous

full arm stroke three or four times.

Pulling of starter rope will produce a

loud clattering sound. This is not

harmful to the engine or starter.

2. With the engine not running, wipe all

snow and moisture from the carbu-

retor cover in area of control levers.

Also move throttle control, choke

control, and starter handle several

times.

,_ WARNING: Never run en-

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

• The temperature of muffler and

• DO NOT allow children or young

16

gine indoors or in enclosed,

poorly ventilated areas. En-

nearby areas may exceed 150°R

Avoid these areas.

teenagers to operate or be near

snow thrower while it is operat-

ing.

Page 17

HOWTOREMOVESNOWFROM

AUGER

_[b WARNING: Do not attempt

auger without taking the following

precautions:

A cleaning stick is attached to the top of

the auger housing. Use the cleaning

stick to remove snow from the auger

housing.

to remove snow or debris

that may become lodged in

Release auger drive lever.

Move throttle lever to stop position.

Remove (do not turn) ignition key.

Disconnect spark plug wire.

Do not place your hands in the au-

ger or discharge chute. Use the

cleaning stick to remove snow.

SNOW THROWING TIPS

1. For maximum snow thrower efficien-

cy in removing snow, adjust ground

speed, NEVER the throttle. Go

slower in deep, freezing or wet

snow. Ifthe wheels slips, reduce

forward speed. The engine is de-

signed to deliver maximum perfor-

mance at full throttle and should be

run at this power setting at all times.

2. Most efficient snow throwing is ac-

complished when the snow is re-

moved immediately after if fails.

3. For complete snow removal, slightly

overlap each path previously taken.

4. The snow should be discharged

down wind whenever possible.

5. For normal usage, set the skids so

that the scraper bar is 1/8" above

the skids. For extremely hard-

packed snow surfaces, adjust the

skids upward so that the scraper

bar touches the ground.

6. On gravel or crushed rock surfaces,

set the skids at 1-1/4" below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu-

al. Rocks and gravel must not be

picked up and thrown by the ma-

chine.

7. After the snow throwing job has

been completed, allow the engine to

idle for a few minutes, which will

melt snow and accumulated ice off

the engine.

8. Clean the snow thrower thoroughly

after each use.

9. Remove ice and snow accumulation

and all debris from the entire snow

thrower, and flush with water (if pos-

sible) to remove all salt or other

chemicals. Wipe snow thrower dry.

F-031001L 17

Page 18

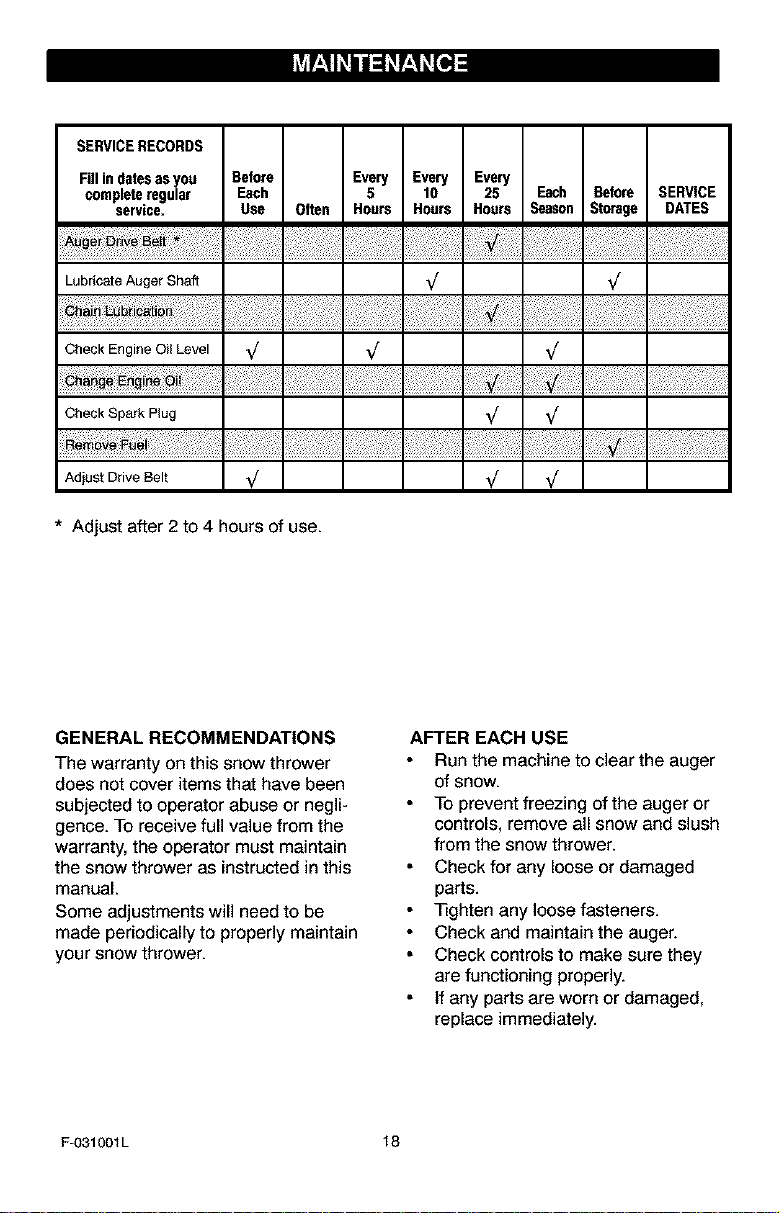

SERVICERECORDS

Fillindatesasyou Before Every Every Every

completeregular Each 5 10 25 Each Before SERVICE

service. Use Often Hours Hours Hours Season Stcrage DATES

Lubricate Auger Shaft _

Check Engine 0il Level _/ V V

Check Spark Plug _

vo

AdjustDrive Belt V V V

* Adjust after 2 to 4 hours of use.

GENERAL RECOMMENDATIONS

The warranty on this snow thrower

does not cover items that have been

subjected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the snow thrower as instructed in this

manual.

Some adjustments will need to be

made periodically to properly maintain

your snow thrower.

F-O31OOIL 18

AFTER EACH USE

Run the machine to clear the auger

of snow.

To prevent freezing of the auger or

controls, remove all snow and slush

from the snow thrower.

Check for any loose or damaged

parts.

_ghten any loose fasteners.

Check and maintain the auger.

Check controls to make sure they

are functioning properly.

If any parts are worn or damaged,

replace immediately.

Page 19

PRODUCT SPECIFICATIONS

CHAIN LUBRICATION

EVERY 25 HOURS

HORSEPOWER 11 HP

DISPLACEMENT 21.82 cu, in.

GASOLINE 4quads

CAPACITY (unleaded)

OIL CAPACITY 5W30

(20 oz capacity)

SPARK PLUG: Champion RJt9LM

(Gap .030 in,) er

equivalent

VALVE CLEARANCE: Inteke: ,010 In,

Exhaust: .010 In,

SNOW THROWER

AUGER DRIVE BELT

Adjust the auger drive belt after the first

2 to 4 hours of use, again about mid-

season and twice each season thereaf-

ter (See "Belt Adjustment" in the

Service and Adjustment section).

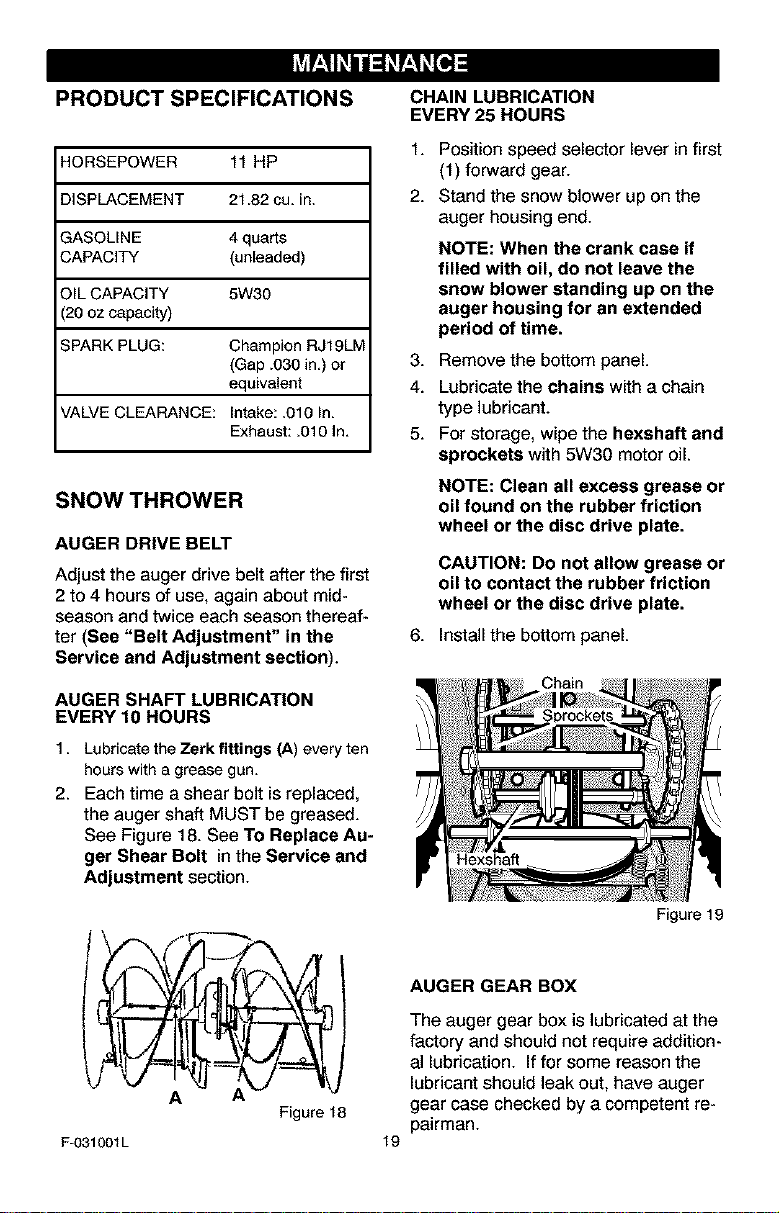

AUGER SHAFT LUBRICATION

EVERY 10 HOURS

1. Lubricetethe Zerk fittings (A) everyten

hourswith a grease gun.

2. Each time a shear bolt is replaced,

the auger shaft MUST be greased.

See Figure 18. See To Replace Au-

ger Shear Bolt in the Service and

Adjustment section.

1. Position speed selector lever in first

(1) forward gear.

2. Stand the snow blower up on the

auger housing end.

NOTE: When the crank case if

filled with oil, do not leave the

snow blower standing up on the

auger housing for an extended

period of time.

3. Remove the bottom panel.

4. Lubricate the chains with a chain

type lubricant.

5. For storage, wipe the hexsheft and

sprockets with 5W30 motor oil.

NOTE: Clean all excess grease or

oil found on the rubber friction

wheel or the disc drive plate.

CAUTION: Do not allow grease or

oil to contact the rubber friction

wheel or the disc drive plate.

6. Installthe bottom panel.

F-031001L

Figure 19

AUGER GEAR BOX

The auger gear box is lubricated at the

factory and should not require addition-

al lubrication. If for some reason the

A

Figure 18

lubricant should leak out, have auger

gear case checked by a competent re-

pairman.

19

Page 20

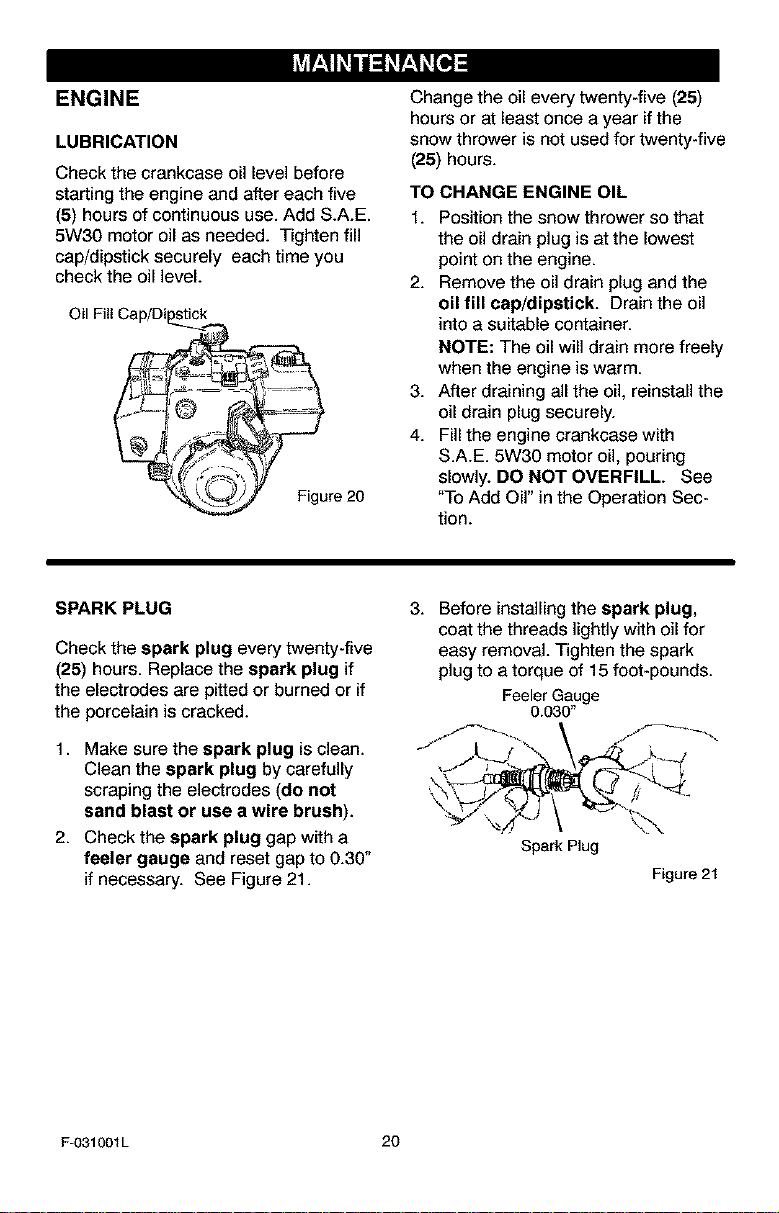

ENGINE

LUBRICATION

Check the crankcase oil level before

starting the engine and after each five

(5) hours of continuous use. Add S.A.E.

5W30 motor oil as needed. Tighten fill

cap/dipstick securely each time you

check the oil level.

Oil Fill Cap/Di_

Figure 20

Change the oil every twenty-five (25)

hours or at least once a year if the

snow thrower is not used for twenty-five

(25) hours.

TO CHANGE ENGINE OIL

1. Position the snow thrower so that

the oil drain plug is at the lowest

point on the engine.

2. Remove the oil drain plug and the

oil fill cap/dipstick. Drain the oil

into a suitable container.

NOTE: The oil will drain more freely

when the engine is warm.

3. After draining all the oil, reinstall the

oil drain plug securely.

4. Fill the engine crankcase with

S.A.E. 5W30 motor oil, pouring

slowly. DO NOT OVERFILL. See

"To Add Oil" in the Operation Sec-

tion.

SPARK PLUG

Check the spark plug every twenty-five

(25) hours. Replace the spark plug if

the electrodes are pitted or burned or if

the porcelain is cracked.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

2. Check the spark plug gap with a

feeler gauge and reset gap to 0.30"

if necessary. See Figure 21.

F-031001L 20

3. Before installing the spark plug,

coat the threads lightly with oil for

easy removal. Tighten the spark

plug to a torque of 15 foot-pounds.

FeelerGauge

O.03O"

Spark Plug

Figure 21

Page 21

_lb ARNING: Always discon-

make contact with spark plug to pre-

vent accidental starting when mak-

ing any adjustments or repairs.

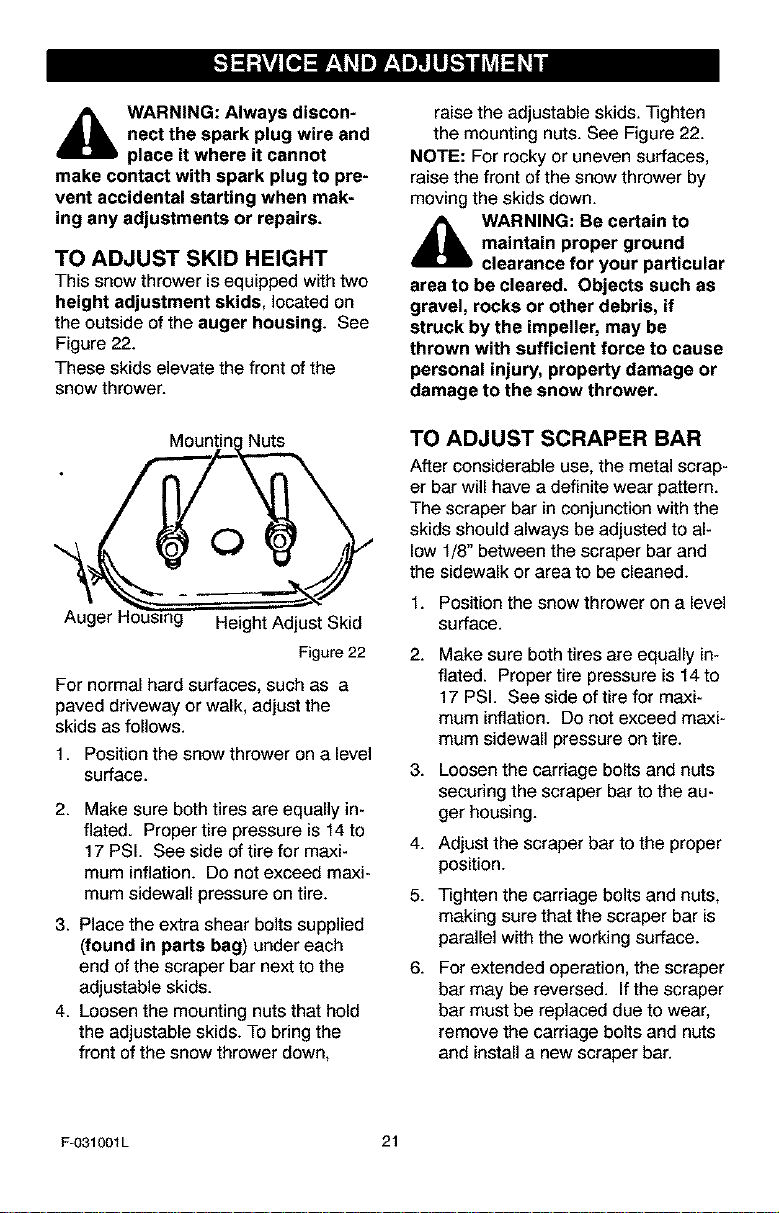

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 22.

These skids elevate the front of the

snow thrower.

nect the spark plug wire and

place it where it cannot

raise the adjustable skids. Tighten

the mounting nuts. See Figure 22.

NOTE: For rocky or uneven surfaces,

raise the front of the snow thrower by

moving the skids down.

_lb ARNING: Be certain to

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

maintain proper ground

clearance for your particular

Nuts

0

Auger t- Height Adjust Skid

Figure22

For normal hard surfaces, such as a

paved driveway or walk, adjust the

skids as follows.

1. Position the snow thrower on a level

surface.

2. Make sure both tires are equally in-

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3. Place the extra shear bolts supplied

(found in parts bag) under each

end of the scraper bar next to the

adjustable skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bring the

front of the snow thrower down,

TO ADJUST SCRAPER BAR

After considerable use, the metal scrap-

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al-

low 1/8" between the scraper bar and

the sidewalk or area to be cleaned.

1. Position the snow thrower on a level

surface.

2.

Make sure both tires are equally in-

flated. Proper tire pressure is 14to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3.

Loosen the carriage bolts and nuts

securing the scraper bar to the au-

ger housing.

4.

Adjust the scraper bar to the proper

position.

5.

Tighten the carriage bolts and nuts,

making sure that the scraper bar is

parallel with the working surface.

6.

For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage bolts and nuts

and install a new scraper bar.

F-O31001L 21

Page 22

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant

spring pressure and does not require

an adjustment. If the traction drive belt

is slipping, replace the belt. See "How

To Replace The Belts" in the Service

And Adjustment section.

Auger Drive Belt

Ifyour snow blower will not discharge

snow, check the control cable adjust-

ment. If it is correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see "How

To Replace The Belts" in this section of

the manual).

1. Disconnect spark plug wire.

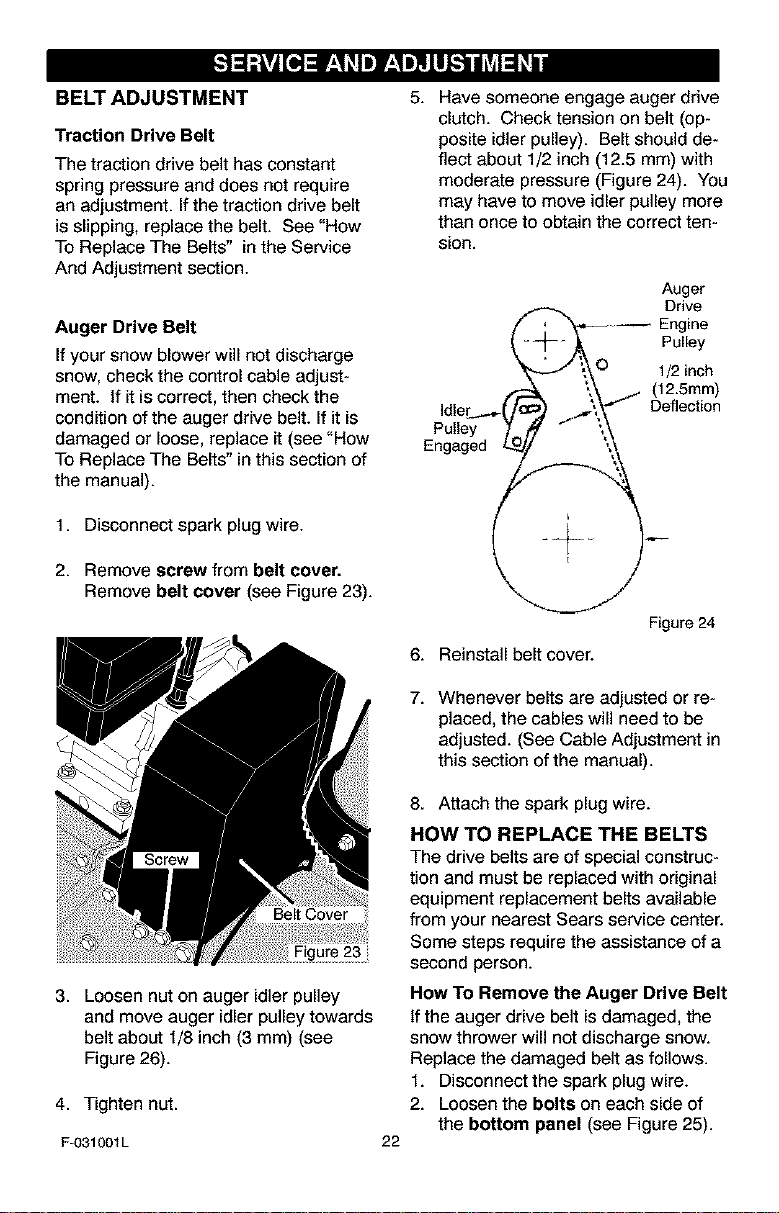

2. Remove screw from belt cover.

Remove belt cover (see Figure 23).

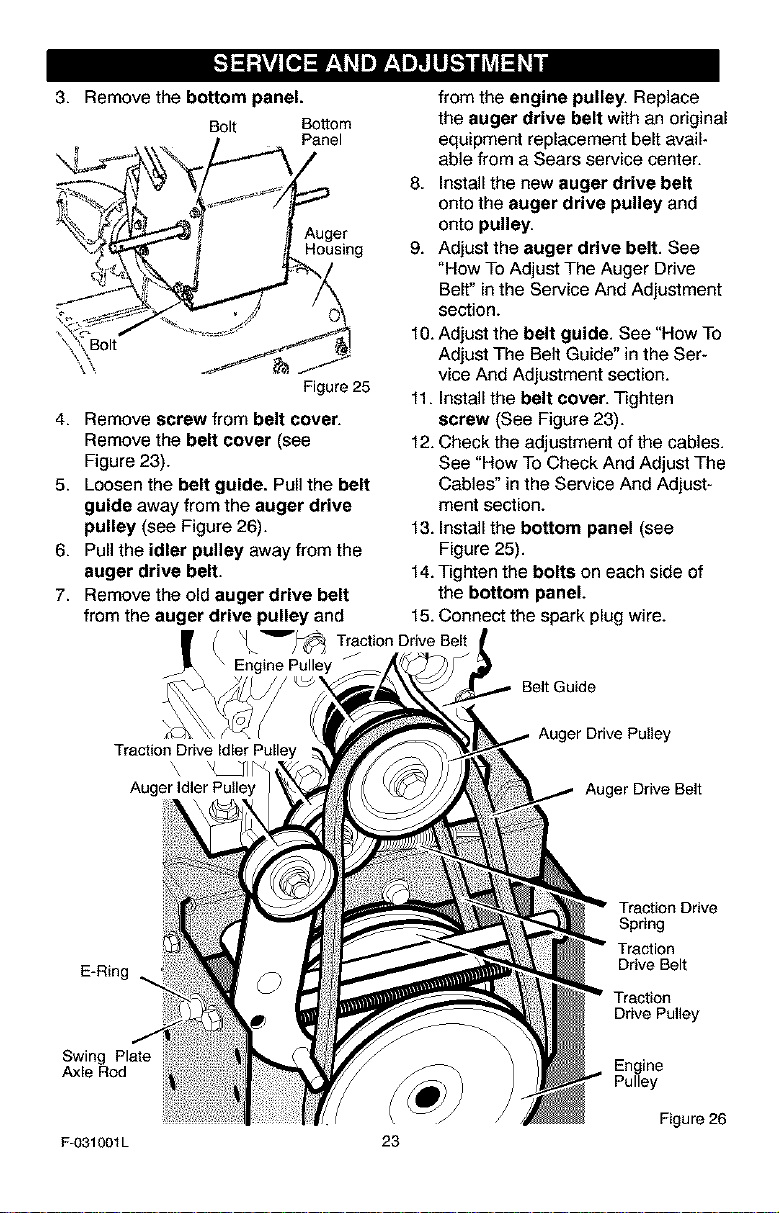

5. Have someone engage auger drive

clutch. Check tension on belt (op-

posite idler pulley). Belt should de-

flect about 1/2 inch (12.5 mm) with

moderate pressure (Figure 24). You

may have to move idler pulley more

than once to obtain the correct ten-

sion.

Auger

( e

--_ ,_ Pulley

j ;,_O 1/2 inch

._- '.,_ (12.5ram)

Idler_s- (_ ._'_\/ Deflection

Pu,,ey " :,\

Engaged L_ ,,

Figure24

6. Reinstall belt cover.

Belt Cover

3. Loosen nut on auger idler pulley

and move auger idler pulley towards

belt about 1/8 inch (3 mm) (see

Figure 26).

4. Tighten nut.

F-031001L

7. Whenever belts are adjusted or re-

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the manual).

8. Attach the spark plug wire.

HOW TO REPLACE THE BELTS

The drive belts are of special construc-

tion and must be replaced with original

equipment replacement belts available

from your nearest Sears service center.

Some steps require the assistance of a

second person.

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

1. Disconnect the spark plug wire.

2. Loosen the bolts on each side of

the bottom panel (see Figure 25).

22

Page 23

3. Remove the bottom panel,

Bolt Bottom

Panel

Auger

Housing

4. Remove screw from belt cover.

Remove the belt cover (see

Figure 23).

5. Loosen the belt guide. Pull the belt

guide away from the auger drive

pulley (see Figure 26).

6. Pull the idler pulley away from the

auger drive belt.

7. Remove the old auger drive belt

from the auger drive pulley and

_ Traction DriveBe,t

Engine Pulley

from the engine pulley. Replace

the auger drive belt with an original

equipment replacement belt avail-

able from a Sears service center.

8. Install the new auger drive belt

onto the auger drive pulley and

onto pulley.

9. Adjust the auger drive belt. See

"How To Adjust The Auger Drive

Belt" in the Service And Adjustment

section.

10. Adjust the belt guide. See "How To

Adjust The Belt Guide" in the Ser-

vice And Adjustment section.

11. Install the belt cover. Tighten

screw (See Figure 23).

12. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section.

13. Install the bottom panel (see

Figure 25).

14. Tighten the bolts on each side of

the bottom panel.

15. Connect the spark plug wire.

Belt Guide

'\ WII _

Auger Idler Pulley

E-Ring

Swing Plate

Axle Rod

F-031001L 23

Auger Drive Pulley

Auger Drive Belt

Traction Drive

Spring

Traction

Drive Belt

Traction

Drive Pulley

Engine

Pulley

Figure 26

Page 24

How To Remove

The Traction Drive Belt

Ifthe snow thrower will not move for-

ward, check the traction drive belt for

wear or damage. If the traction drive

belt is worn or damaged, replace the

belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See

"How To Remove The Auger Drive

Belt" in the Service And Adjustment

section.

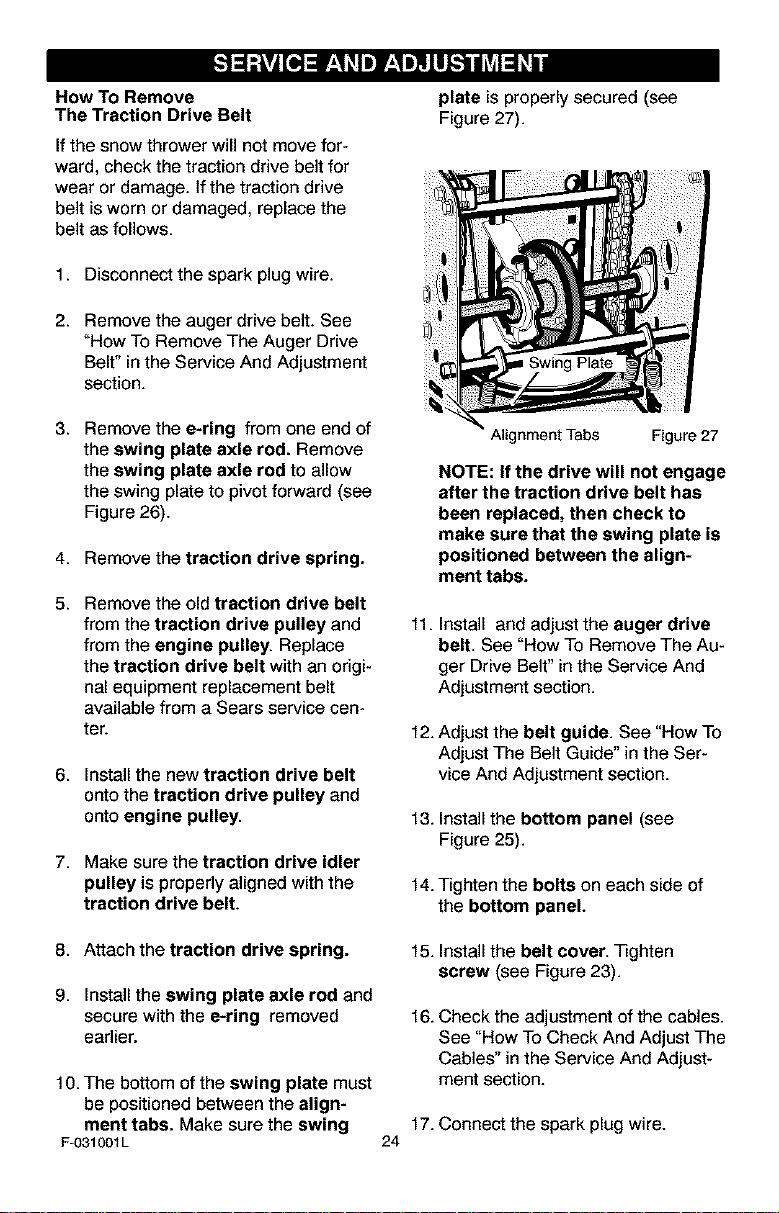

plate is properly secured (see

Figure 27).

3. Remove the e-ring from one end of

the swing plate axle rod. Remove

the swing plate axle rod to allow

the swing plate to pivot forward (see

Figure 26).

4. Remove the traction drive spring.

5. Remove the old traction drive belt

from the traction drive pulley and

from the engine pulley. Replace

the traction drive belt with an origi-

nal equipment replacement belt

available from a Sears service cen-

ter.

6. Installthe new traction drive belt

onto the traction drive pulley and

onto engine pulley.

7. Make sure the traction drive idler

pulley is properly aligned with the

traction drive belt.

8. Attach the traction drive spring.

9. Installthe swing plate axle rod and

secure with the e-ring removed

earlier.

10. The bottom of the swing plate must

be positioned between the align-

ment tabs. Make sure the swing

Fu031001L

Alignment Tubs Figure 27

NOTE: If the drive will not engage

after the traction drive belt has

been replaced, then check to

make sure that the swing plate is

positioned between the align-

ment tabs.

11.

Install and adjust the auger drive

belt. See "How To Remove The Au-

ger Drive Belt" in the Service And

Adjustment section.

12. Adjust the belt guide. See "How To

Adjust The Belt Guide" in the Ser-

vice And Adjustment section.

13.Installthe bottom panel (see

Figure 25).

14. Tighten the bolts on each side of

the bottom panel.

15.Installthe belt cover.Tighten

screw (see Figure 23).

16. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section.

17. Connect the spark plug wire.

24

Page 25

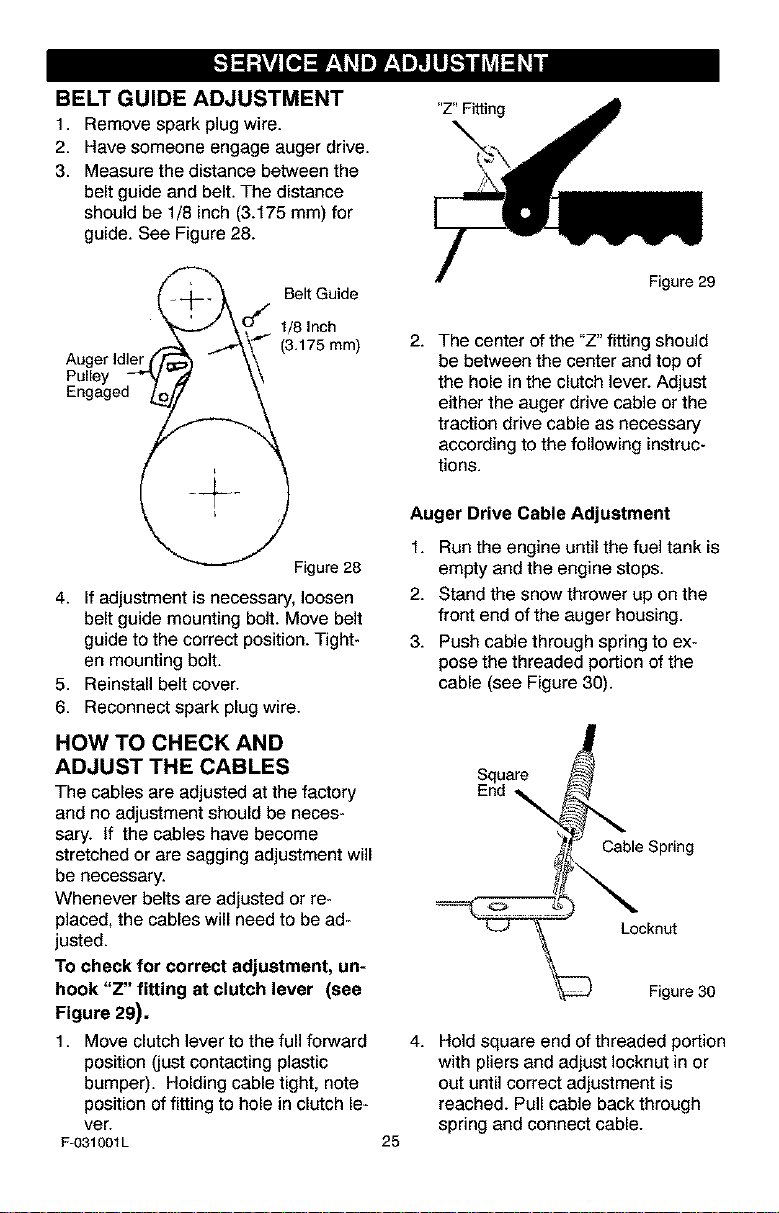

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage auger drive.

3. Measure the distance between the

belt guide and belt. The distance

should be 1/8 inch (3.175 mm) for

guide. See Figure 28.

"Z" Fitting

__. Belt Guide

_'_" O_ 1/8 Inch

Auger Idler (_[ _ _'_" (3,175 ram)

EPnu_eYed_i___

Figure 28

4. If adjustment is necessary, loosen

belt guide mounting bolt. Move belt

guide to the correct position. Tight-

en mounting bolt.

5. Reinstall belt cover.

6. Reconnect spark plug wire.

HOW TO CHECK AND

ADJUST THE CABLES

The cables are adjusted at the factory

and no adjustment should be neces-

sary. If the cables have become

stretched or are sagging adjustment will

be necessary.

Whenever belts are adjusted or re-

placed, the cables will need to be ad-

justed.

To check for correct adjustment, un-

hook "Z" fitting at clutch lever (see

Figure 29).

1. Move clutch lever to thefull forward

position (just contacting plastic

bumper). Holding cable tight, note

position of fitting to hole in clutch le-

ver.

Fu031001L

Figure 29

2. The center of the "Z" fitting should

be between the center and top of

the hole in the clutch lever. Adjust

either the auger drive cable or the

traction drive cable as necessary

according to the following instruc-

tions.

Auger Drive Cable Adjustment

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Push cable through spring to ex-

pose the threaded portion of the

cable (see Figure 30).

Square

End

Cable Spring

Locknut

Figure 30

4. Hold square end of threaded portion

with pliers and adjust Iocknut in or

out until correct adjustment is

reached. Pull cable back through

spring and connect cable.

25

Page 26

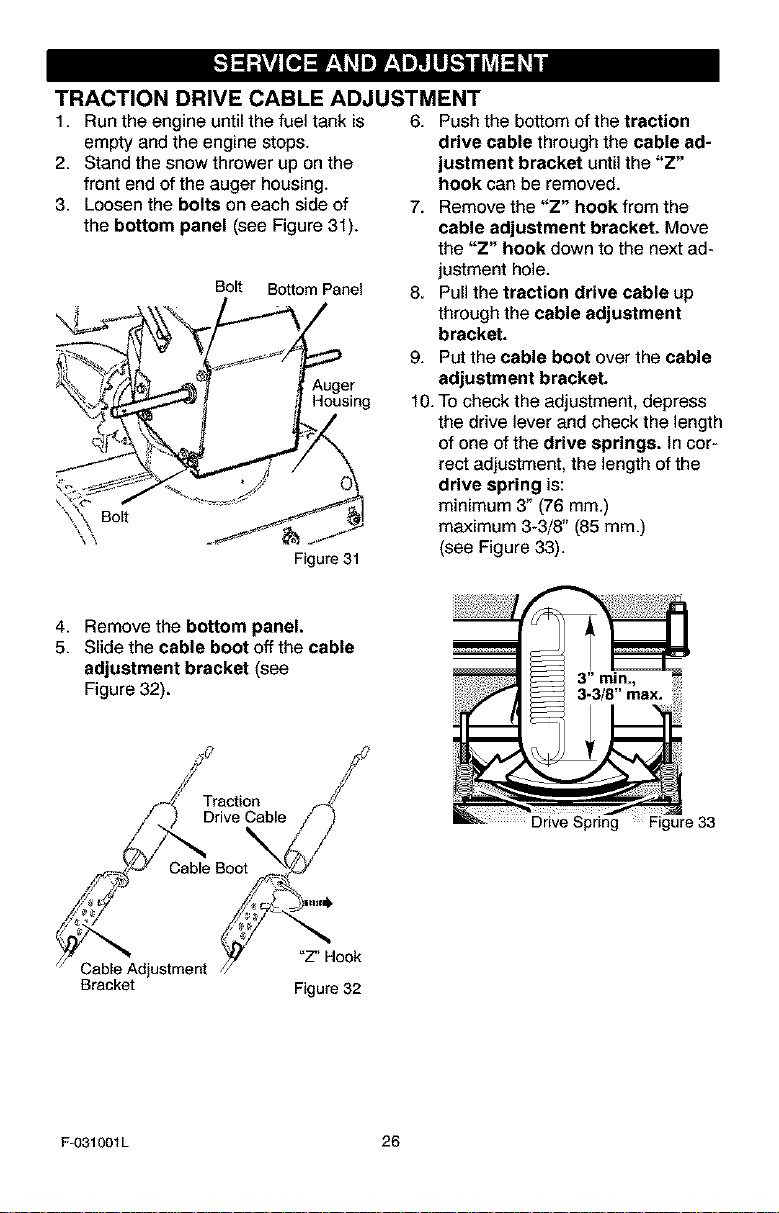

TRACTION DRIVE CABLE ADJUSTMENT

1. Runthe engineuntilthefueltank is 6. Puehthe bottomofthe traction

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

3. Loosen the bolts on each side of

the bottom panel (see Figure 31).

Bolt Bottom Panel

Auger

Housing

Figure31

4. Remove the bottom panel.

5. Slide the cable boot off the cable

adjustment bracket (see

Figure 32).

drive cable through the cable ad-

justment bracket until the "Z"

hook can be removed.

7. Remove the "Z" hook from the

cable adjustment bracket. Move

the "Z" hook down to the next ad-

justment hole.

8. Pull the traction drive cable up

through the cable adjustment

bracket.

9. Put the cable boot over the cable

adjustment bracket.

10. To check the adjustment, depress

the drive lever and check the length

of one of the drive springs. In cor-

rect adjustment, the length of the

drive spring is:

minimum 3" (76 mm.)

maximum 3-3/8" (85 mm.)

(see Figure 33).

3-3/8" max. .....

/ /

' Trection

Cable Boo

j Cable_Adjustment /v_t 'Z" Hook

Bracket Figure32

F-O31001L 26

Page 27

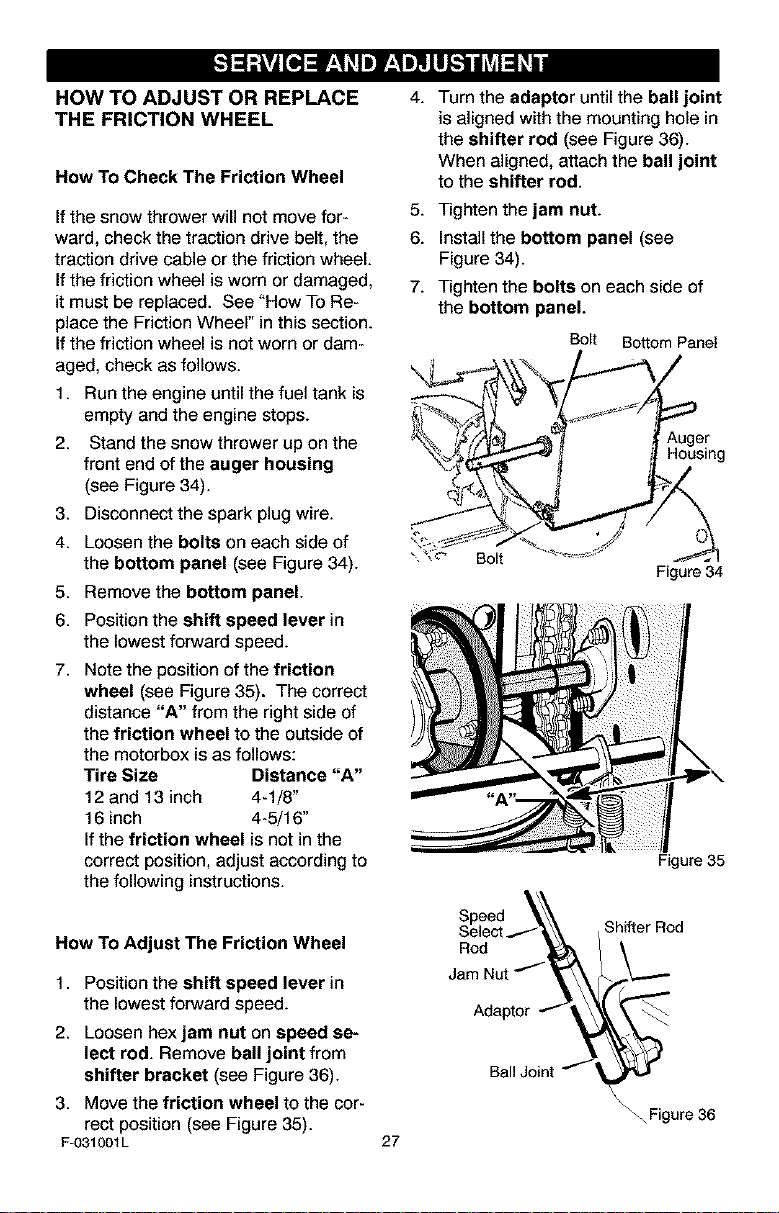

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL

How To Check The Friction Wheel

Ifthe snow thrower will not move for-

ward, check the traction drive belt, the

traction drive cable or the friction wheel.

Ifthe friction wheel is worn or damaged,

it must be replaced. See "How To Re-

place the Friction Wheel" in this section.

Ifthe friction wheel is not worn or dam-

aged, check as follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing

(see Figure 34).

3. Disconnect the spark plug wire.

4. Loosen the bolts on each side of

the bottom panel (see Figure 34).

5. Remove the bottom panel.

6. Position the shift speed lever in

the lowest forward speed.

7. Note the position of the friction

wheel (see Figure 35). The correct

distance "A" from the right side of

the friction wheel to the outside of

the motorbox isas fallows:

Tire Size Distance "A"

12 and 13 inch 4-1/8"

16 inch 4-5/16"

If the friction wheel is not in the

correct position, adjust according to

the following instructions.

4.

Turn the adaptor until the ball joint

is aligned with the mounting hole in

the shifter rod (see Figure 36).

When aligned, attach the ball joint

to the shifter rod.

5.

Tighten the jam nut.

6.

Install the bottom panel (see

Figure 34).

7.

Tighten the bolts on each side of

the bottom panel.

Bolt Bottom Panel

Bolt

Auger

Housing

Figure 34

Figure 35

How To Adjust The Friction Wheel

1. Position the shift speed lever in

the lowest forward speed.

2. Loosen hexjam nut on speed se-

lect rod. Remove ball joint from

shifter bracket (see Figure 36).

3. Move the friction wheel to the cor-

rect position (see Figure 35).

F-031001L

Shifter Rod

Rod

Jam

Adaptor

Ball Joint

\_ Figure 36

27

Page 28

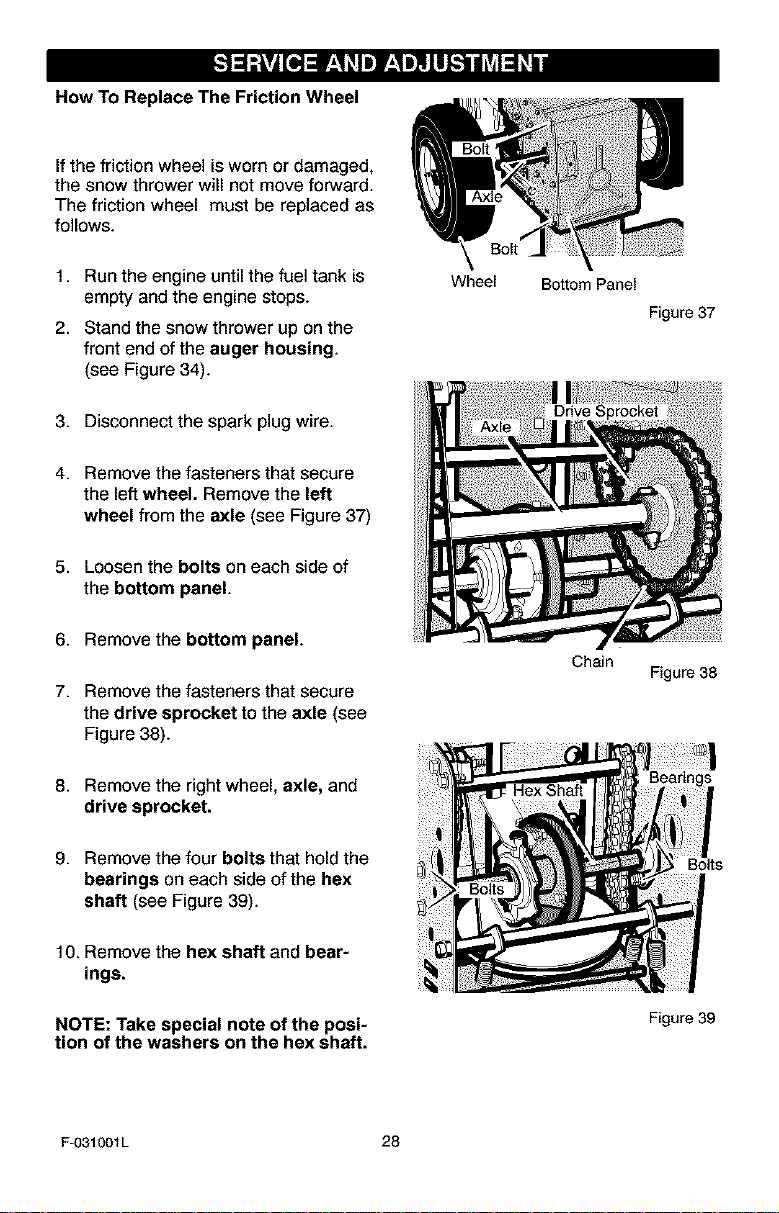

How To Replace The Friction Wheel

Ifthe friction wheel is worn or damaged,

the snow thrower will not move forward.

The friction wheel must be replaced as

follows.

1. Run the engine until the fuel tank is

empty and the engine stops.

2. Stand the snow thrower up on the

front end of the auger housing.

(see Figure 34).

3. Disconnect the spark plug wire.

4. Remove the fasteners that secure

the left wheel. Remove the left

wheel from the axle (see Figure 37)

5. Loosen the bolts on each side of

the bottom panel.

6. Remove the bottom panel.

7. Remove the fasteners that secure

the drive sprocket to the axle (see

Figure 38).

8. Remove the right wheel, axle, and

drive sprocket.

9. Remove the four bolts that hold the

bearings on each side of the hex

shaft (see Figure 39).

Wheel

Bottom Panel

Chain

Figure 37

Figure 38

Bolts

10.Removethe hax shaft and bear-

ings.

NOTE: Take special note of the posi-

tion of the washers on the hex shaft.

F-O31001L 28

Figure 39

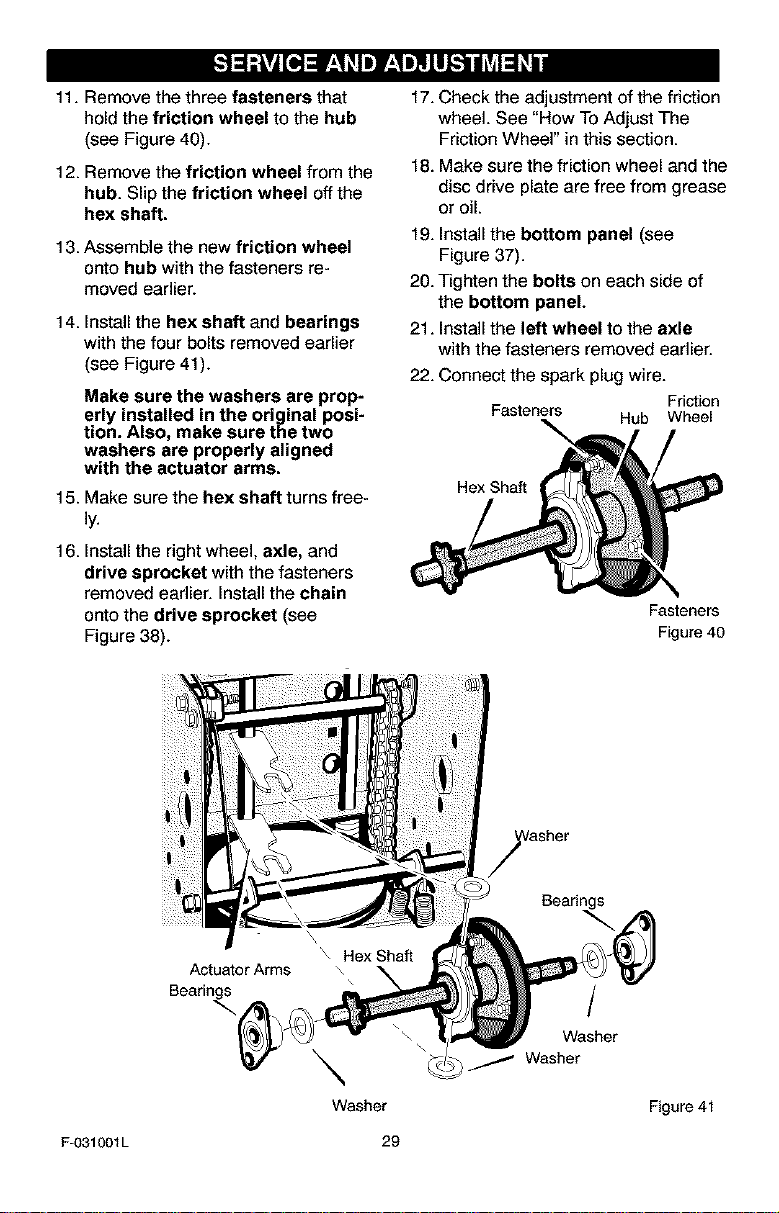

Page 29

11. Remove the three fasteners that

hold the friction wheel to the hub

(see Figure 40).

12. Remove the friction wheel from the

hub. Slip the friction wheel off the

hex shaft.

13. Assemble the new friction wheel

onto hub with the fasteners re-

moved earlier.

14. Install the hex shaft and bearings

with the four bolts removed earlier

(see Figure 41).

Make sure the washers are prop-

erly installed in the original posi-

tion. Also, make sure the two

washers are properly aligned

with the actuator arms.

15.Make sure the hex shaftturns free-

16. Install the right wheel, axle, and

drive sprocket with the fasteners

removed earlier. Install the chain

onto the drive sprocket (see

Figure 38).

17. Check the adjustment of the friction

wheel. See "How To Adjust The

Friction Wheel" in this section.

18. Make sure the friction wheel and the

disc drive plate are free from grease

or oil.

19. Install the bottom panel (see

Figure 37).

20. Tighten the bolts on each side of

the bottom panel.

21. Install the left wheel to the axle

with the fasteners removed earlier.

22. Connect the spark plug wire.

Fasteners Hub Wheel

Hex Shaft

Friction

Fasteners

Figure 40

Actuator Arms

Bearings

\

Washer

F-O31001L 29

Bearings

/

Washer

Washer

Figure 41

Page 30

HOW TO REPLACE

THE AUGER SHEAR BOLT

The augers are secured to the auger

shaff with special shear bolts. These

shear bolts are designed to break and

protect the machine if an object be-

comes lodged in the auger housing. Do

not use a harder bolt as the protection

provided by the shear bolt will be lost.

2. Disconnect the spark plug wire.

Make sure all moving parts have

stopped.

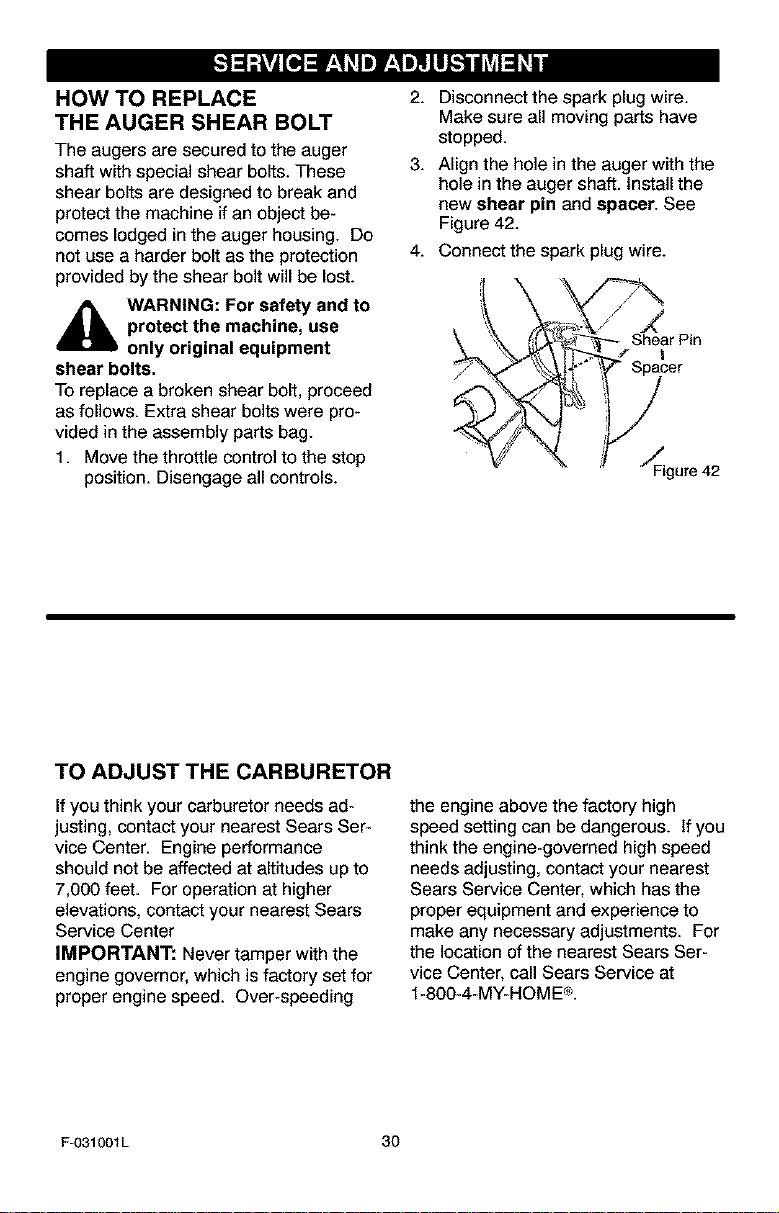

3. Align the hole in the auger with the

hole in the auger shaft. Install the

new shear pin and spacer. See

Figure 42.

4. Connect the spark plug wire.

,_ WARNING: For safety and to

shear bolts.

To replace a broken shear bolt, proceed

as follows. Extra shear bolts were pro-

vided in the assembly parts bag.

1. Move the throttle control to the stop

protect the machine, use

only original equipment

position. Disengage all controls.

TO ADJUST THE CARBURETOR

Ifyou think your carburetor needs ad-

justing, contact your nearest Sears Ser-

vice Center. Engine performance

should not be affected at altitudes up to

7,000 feet. For operation at higher

elevations, contact your nearest Sears

Service Center

IMPORTANT: Never tamper with the

engine governor, which is factory set for

proper engine speed. Over-speeding

_ Sh_etar Piner

4°°,8,2

the engine above the factory high

speed setting can be dangerous. If you

think the engine-governed high speed

needs adjusting, contact your nearest

Sears Service Center, which has the

proper equipment and experience to

make any necessary adjustments. For

the location of the nearest Sears Ser-

vice Center, call Sears Service at

1-800-4-MY-HOME®.

F-031001L 30

Page 31

_lb ARNING: Never store your

snow thrower indoors or in

an enclosed, poorly venti-

lated area. If gasoline remains in the

tank, fumes may reach an open

flame, spark or pilot light from a fur-

nace, water heater, clothes dryer,

cigarette, etc.

To prevent damage (if snow thrower is

not used for more than 30 days) follow

the steps below.

SNOW THROWER

1. Thoroughly clean thesnow thrower.

2. Lubricate all lubrication points. See

the Maintenance section.

3. Be sure that all nuts, bolts and

screws are securely fastened, in-

spect all visible moving parts for

damage, breakage and wear. Re-

place if necessary.

4. Touch up all rusted or chipped paint

surfaces; sand lightly before paint-

ing.

5. Cover the bare metal parts of the

blower housing auger and the im-

peller with rust preventative, such

as a spray lubricant.

NOTE: A yearly checkup or tune-up by

a Sears service center is a good way of

ensuring that your snow thrower will

provide maximum performance for the

next season.

ENGINE

Gasoline must be removed or treated to

prevent gum deposits from forming in

the fuel tank, filter, hose, and carburetor

during storage. Also, during storage al-

cohol blended gasoline that uses etha-

nol or methanol (sometimes called

gasohol) attracts water, it acts on the

gasoline to form acids which damage

the engine.

f,

Run the engine until the fuel tank is

empty and the engine stops.

2.

If you do not remove the gasoline,

use fuel stabilizer supplied with unit

or purchase Craftsman Fuel Stabi-

lizer No. 3550. Add fuel stabilizer to

any gasoline left in the tank to mini-

mize gum deposits and acids. If the

fuel tank is almost empty, mix stabi-

lizer with fresh gasoline in a sepa-

rate container and add some to the

fuel tank.

3,

Always follow the instructions on the

stabilizer container. After the stabi-

lizer is added to the fuel tank, run

the engine at least ten minutes to

allow the mixture to reach the car-

buretor.

4,

Change the engine oil.

5.

Lubricate the piston/cylinder area.

First, remove the spark plug and

squirt a few drops of clean engine

oil into the spark plug hole. Next,

cover the spark plug hole with a rag

to absorb oil spray. Then, pull two or

three times on the recoil starter rope

to rotate the engine. Finally, install

the spark plug and attach the spark

plug wire.

OTHER

1. If possible, store your snow thrower

indoors and cover it to give protec-

tion from dust and dirt.

2. If the snow thrower must be stored

outdoors, put the snow thrower on

blocks to raise it off of the ground.

3. Cover the snow thrower with a suit-

able protective cover that does not

retain moisture. Do not use plastic.

IMPORTANT: Never cover snow

thrower while engine and exhaust areas

are still warm.

F-O31001L 31

Page 32

TROUBLE CORRECTION

CAUSE

Difficult starting

Engine runs erratically Blocked fuel line, empty gas Clean fuel line; check fuel

Engine stalls Unit running on CHOKE. Set choke lever to OFF

Engine runs erratic; Water or dirt in fuel system. Remove fuel from fuel tank.

Loss of power Add fresh fuel,

Excessive vibration Loose parts: damaged immediately stop engine,

Unit fails to propel itself Traction drive belt loose or Replace traction drive belt.

Unit fails to discharge

SnOW

Defectivespark plug,

Wateror dirt in fuel system.

tank, or stale gasoline supply; add fresh gasoline

impeller Remove ignition key, Tighten

damaged.

Incorrect adjustment of Adjust traction drive cable,

traction drive cable

Worn or damaged friction Replace friction wheel,

wheel,

Auger drive belt loose or

damaged.

Replace spark plug.

Remove fuel from fuel tank.

Add fresh fuel.

position.

all fasteners and make all

necessary repairs, if

vibration continues, take the

unit to a Sears service

center.

Adjust auger drive belt;

replace if damaged.

Auger control cable not Adjust auger control cable.

adjusted correctly.

Shear bolt broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and

Foraigno_ectlodgedin

auger

F-O31001L 32

disconnect spark plug wire.

Clean discharge chute and

inside of auger housing.

Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

Page 33

SEARS, ROEBUCK AND CO.

Federal and California Emission Control Systems Limited Warranty

Small Off-Road Engines

CALIFORNIA & US EPA EMISSION

CONTROL WARRANTY STATEMENT

The U. S. Environmental Protection Agency

("EPA"), the California Air Resources Board

("CARB'_ and Sears, Roebuck and Co. are

pleased to explain the Federal and California

Emission Control Systems Warranty on your

new small off-road engine. In California, new

1995 and later small off-road engines must be

designed, built and equipped to meet the

State's stringent anti-smog standards. In oth-

er states, new 1997 and later model year en-

gines must be designed, built and equipped, at

the time of sale, to meet the U.S. EPA regula-

tions for small non-rand engines. Sears, Roe-

buck and Co. will warrant the emission control

system on your small off-road engine for the

periods of time listed below, provided there

has been no abuse, neglect, unapproved mod-

ification, or improper maintenance of your

small off-road engine.

Your emission control system may include

parts such as the carburetor, ignition system

and exhaust system. Also included may be the

compression release system and other emis-

sion-related assemblies.

Where a warrantable condition exists, Sears,

Roebuck and Co. will repair your small off-

road engine at no cost to you for diagnosis,

parts end labor.

MANUFACTURER'S EMISSION

CONTROL SYSTEM WARRANTY

COVERAGE

Emission control systems on 1995 and later

model year California small off-road engines

are warranted for two years as hereinafter

noted. In other states, 1997 and later model

year engines are also warranted for two years.

If, dudng such warranty period, any emission-

related part on your engine is defective in ma-

terials or workmanship, the part will be

repaired or replaced by Sears, Roebuck and

Co.

OWNER'S WARRANTY

RESPONSIBILITIES

As the small off-road engine owner, you are

responsible for the performance of the ra-

F-031001L

quired maintenance listed in your Owner's

Manual, but Sears, Roebuck and Co. will not

deny warranty solely due to the lack of receipts

or for your failure to provide written evidence

of the performance of all scheduled mainte-

nance.

As the small off-road engine owner, you

should, however, be aware that Sears, Roe-

buck and Co. may deny you warranty cover-

age if your small off-road engine or a pert

thereof has failed due to abuse, neglect, im-

proper maintenance or unappraved modifica-

tions.

You are responsible for presenting your small

off-road engine to a Sears, Roebuck and Co.

Authorized Service Outlet as soon as a prob-

lem exists. The warranty repairs should be

completed in a reasonable amount of time, not

to exceed 30 days.

Warranty service can be arranged by contact-

ing either a Sears, Roebuck end Co. Autho-

rized Service Outlet, or by contacting Sears,

Roebuck and Co. at 1-900-473-7247.

IMPORTANT NOTE

This warranty statement explains your rights

and obligations under the Emission Control

System Warranty "(ECS Warranty") which is

provided to you by Sears, Roebuck and Co.

pursuant to California law. See also the Sears,

Roebuck and Co. Limited Warranties for

Sears, Roebuck and Co. which is enclosed

therewith on a separate sheet and also is pro-

vided to you by Sears, Roebuck and Co. The

ECS Warranty applies only to the emission

control system of your new engine. To the ex-

tent that there is any conflict in terms between

the ECS Warranty end the Sears, Roebuck

and Co. Warranty, the ECS Warranty shall ap-

ply except in any circumstances in which the

Sears, Roebuck and Co. Warranty may pro-

vide a longer warranty period. Both the ECS

Warranty and the Sears, Roebuck end Co.

Warranty describe important rights and obliga-

tions with respect to your new engine.

Warranty service can only be performed by a

Sears, Roebuck and Co. Authorized Service

Outlet. At the time of requesting warranty ser-

vice, evidence must be presented of the date

of sale to the original purchaser. The purchas-

33

Page 34

ershallpayanychargesformakingservice

callsand/orfortransportingtheproductsto

andfromtheplacewheretheinspectionand/

orwarrantyworkisperformed.Thepurchaser

shallberasponsibleforanydamageorlossin-

curredinconnectionwiththetransportationof

anyengineoranypart(s)thereofsubmittedfor

inspectionand/orwarrantywork.

Ifyouhaveanyquestionsregardingyourwar-

rantyrightsandresponsibilities,youshould

contactSears,RoebuckandCo. at

1-800-473-7247.

EMISSION CONTROL SYSTEM

WARRANTY

Emisalon Control System Warranty ("ECS

Warranty") for 1995 and later model year Cali-

fornia small off-road engines (for other states,

1997 and later model year engines):

A, APPLICABILITY: This warranty shall apply

to 1995 and later model year California small

off-road engines (for other states, 1997 and

later model year engines). The ECS Warranty

Period shall begin on the date the new engine

or equipment is delivered to its original, end-

use purchaser, and shall continue for 24 con-

secutive months thereafter.

B. GENERAL EMISSIONS WARRANTY

COVERAGE: Sears, Roebuck and Co. war-

rants to the original, end-use purchaser of the

new engine or equipment and to each subse-

quent purchaser that each of its small off-road

engines is:

1. Designed, built and eqalppod so as to con-

form with all applicable regulations adopted by

the Air Resources Board pursuant to its au-

thority in Chapters 1 and 2, Part 5, Division 26

of the Health and Safety Code, and

2. Free from defects in materials and work-

manship which, at any time during the ECS

Warranty Period, will cause a warranted emis-

sions-related part to fail to be identical in all

material respects to the part as described in

the engine manufacturer's application for certi-

fication.

C. The ECS Warranty only pertains to emis-

sions-related parts on your engine, as follows:

1. Any warranted, emissions-related parts

which are net scheduled for replacement as

required maintenance in the Owner's Manual

shall be warranted for the ECS Warranty Peri-

od. If any such part fails during the ECS War-

ranty Period, it shall be rebeired or replaced by

F-031001L

34

Sears, Roebuck and Co. according to Subsec-

tion 4 below. Any such part repaired or re-

placed under the ECS Warranty shall be

warranted for any remainder of the ECS War-

ranty Period.

2. Any warranted, emissions-relatod part

which is scheduled only for regular inspection

as spacified in the Owner's Manual shall be

warranted for the ECS Warranty Period. A

statement in such wdtten instructions to the ef-

fect of "repair or replace as necessary", shall

not reduce the ECS Warranty Period. Any

such part repaired or replaced under the ECS

Warranty shall be warranted for the remainder

of the ECS Warranty Period.

3. Any warranted, emissions-relatod part

which is scheduled for replacement as re-

quired maintenance in the Owner's Manual,

shall be warranted for the period of time prior

to the first scheduled replacement point for

that part. If the part fails prior to the first sched-

uled replacement, the part shall be repaired or

replaced by Sears, Roebuck and Co. accord-

ing to Subsection 4 below. Any such emis-

sions-related part repaired or replaced under

the ECS Warranty, shall be warranted for the

remainder of the ECS Warranty Pedod prior to

the first scheduled replacement point for such

emissions-related part.

4. Repair or replacement of any warranted,

emissions-related part under this ECS War-

ranty shall be performed at no charge to the

owner at a Sears, Roebuck and Co. Autho-

rized Service Outlet.

5. The owner shall not be charged for diagnos-

tic labor which leads to the determinatiee that

a part covered by the ECS Warranty is in fact

defective, provided that such diagnostic work

is performed at a Sears, Roebuck and Co. Au-

thorized Service Outlet.

6. Sears, Roebuck and Co. shall be liable for

damages to other original engine components

or approved modifications proximately caused

by a failure under warranty of an emission-re-

lated part covered by the ECS Warranty.

7. Throughout the ECS Warranty Period,

Sears, Roebuck and Co. shall maintain a sup-

ply of warranted emission-related parts suffi-

cient to meet the expected demand for such

emission-relatod parts.

8. Any Sears, Roebuck and Co. anthorized

and approved emissiee-relatod replacement

part may be used in the performance of any

ECS Warranty maintenance or repair and will

be provided without charge to the owner. Such

Page 35

useshallnotreduceSears.RoebuckendCo.

ECSWarrantyobligations.

9,Unapprovedadd-onormodifiedpartsmay

notbeusedtomodifyorrepairaSears,Roe-

buckandCo.engine,SuchusevoidsthisECS

Warrantyandshallbesufficientgroundsfor

disallowinganECSWarrantyclaim.Sears,

RoebuckendCo.shallnotbeliablehereunder

forfailuresofanywarrantedpartsofaSears,

RoebuckandCo.engine caused by the use of

such an unappraved add-on or modified part.

EMISSION-RELATED PARTS

INCLUDE THE FOLLOWING:

1. Carburetor Assembly and its Internal Com-

ponents

a) Fuel filter

b) Carburetor gaskets

c) Intake pipe

2, Air Cleaner Assembly

a) Air filter element

3, Ignition System, including:

a) Spark plug

b) Ignition module

c) Flywheel assembly

4, Catalytic Muffler (if so equipped)

a) Muffler gasket (if so equipped)

b) Exhaust manifold (if so equipped)

5, Crankcase Breather Assembly end its

Components

a) Breather connection tube

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F-031001L 35

10/22/99 EPA!CARB

Page 36

CRAFTSMAN 30" 11 HP SNOW THROWER 536.881114

ENGINE

2

\

20

22

24

10

/

25-3

15

6

11

\

16

17

/

/

18

/8

3

F-031001L 36

/

9

Ref. Drive Page

Ref. Auger Housing Page

Page 37

CRAFTSMAN 30" 11 HP SNOW THROWER 536.881114

ENGINE

Key

No. Part No. Description

2 143.031101 ENGINE (760644)

3 002x97 BOLT, CARRIAGE

4 028x76 RETAINER, PUSH

5 710026 NUT

6 1501109 PULLEY, ENGINE

7 710247 WASHER

8 71063 WASHER .381D

9 71015 SCREW, 3/8-24Xl.00

10 579932 BELT, V 3L 33.13LG

11 585416 BELT, V 4L 38.1MF16" 5-10

12 1501112 YZ BRACKET ASSEMBLY, IDLER

13 1501065 BUSHING, IDLER BRACKET

14 71060 WASHER, SPLIT

15 910828 SCREW 5/16-24 X 1.00