Page 1

OWNER'S

MANUAL

MODEL NO.

536.797571

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

CRAFTSMRN

3.5 HORSEPOWER

9 INCH

EDGER/TRIMMER

Assembly

Operation

Customer Responsibilities

Service and Adjustments

• Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

Part No. 336765

Page 2

SAFETY RULES

-- CAUTION: ALWAYS DISCONNECT SPARK PLUGWIRE AND PLACE WIRE WHERE IT/_.

C NOTCO.TACTSPARKP'UGTOPREVENTAOC.DENTALSTA.T,NGWHENSET

T,NGuP,TRANSPORT,NG.ADJUST,NGORMAK,.GREPA,RS

BEFORE USE

Read the owner'smanual carefully.Be thoroughly

familiarwiththe controlsand the properuse of the

edger/trimmer.Knowhowto stopthe edger/trimmer

anddisengagethecontrols quickly.

• Do not operate the edger/trimmer without wearing

adequate outergarments. Wear footwear that will

improvefootingonslipperysurfaces.

• Keep the area of operation clear of all persons,

particularlysmallchildrenandpets.

• Thoroughly inspectthe areawheretheedger/trimmer

isto be used and remove allforeignobjects.

FUEL SAFETY

• Handlefuel withcare;it ishighlyflammable.

• Usean approved container.

• Chackfuelsupplybeforeeachuse,allowingspacefor

expansionasthe heat of the engineand/or suncan

causefueltoexpand.

• Fillfueltank outdoorswithextreme care.Neverfill fuel

tankindoors.Replacefuel tankcapsecurelyandwipe

up spilledfuel.

• Never remove the fuel tank cap or add fuel to a

runningorhot engine.

• Neverstorefueloredger/trimmerwithfuelinthetank

insidea buildingwherefumes may reach an open

flame.

OPERATING SAFETY REPAIR/ADJUSTMENTS SAFETY

• Never allowchildrenor young teenagersto operate

the edger/trimmer.Keep them away while it isoper-

ating.Neveraliowadultstooperatetheedger/trimmer

withoutproperinslruction.

• Always wear safety glasses or eye shields during

operationorwhileperforming an adjustmentorrepair

toprotectyoureyesfromforeignobjectsthatmaybe

thrownfrom the edger/trimmer.

• DOnotputhandsorfeet nearor underrotatingparts.

• Exemiseextremecautionwhenoperatingonorcross-

inggraveldrives,walks,orroads.Stayalertforhidden

hazardsortraffic.

Exercise cautiontoavoid slippingor falling.

Never operate the edger/trimmer wilhout proper

guards,plates,or other safety protectivedevices in

place.

• Never operate the edger/trimmer at high transport

speeds on slipperysurfaces. Look behind and use

care when backing.

• Never allow bystandersnearthe edger/trimmer.

• Keep childrenand pets awaywhile operating.

• Never operatetheedger/trimmerwithoutgoodvisibil-

ity or light.

• Donot runtheengineindoors. The exhaustfumesare

dangerous (containingCARBON MONOXIDE, an

ODORLESS and DEADLY GAS).

• Take allpossibleprecautionswhen ioavingtbeedger/

trimmer unattended,Stop the engine.

• Do not overloadthe edger/trimmer capacity by at-

temptingto edge too deep at too fast a rate.

SAFE STORAGE

• Always referto the owner's manual storagesection

for imporfantdetails if the edger/trimmer is to be

stored for an extended period.

• Neverleavethe edger/trimmerwithfuelinthefueltank

insidea building where ignitionsourcesare present

suchas waterandapaceheaters,clothesdryers,and

the like.Allowtheenginetocool before placinginany

enclosure.

• Keep the edger/tdmmer in safe working condition.

Check all fasteners at frequent inte_,als for proper

tightness.

After striking aforeignobject,stopthe engine(motor).

Removethe wire from the spark plug,and keep the

wire away from theplug toprevent accidental starting.

Thoroughly inspectthe edger/trimmer for any dam-

age, and repair the damage before restarting and

operating the edger/trimmer.

If the edger/trimmershould start to vibrate abnor-

mally,stopthe engine (motor)and checkimmediately

for the cause. Vibration is generally a warning of

trouble.

• Stop the blade whenever you leave the operating

position.Also, stopthe engine and disconnect the

spark plugwirebefore uncloggingthe bladeandwhen

makingany repairs,adjustments,or inspections.

• When cleaning, repairing,or inspecting,shutoffthe

engineandmakecertainallmovingpartshavestopped.

• Never attempt to make any adjustmentswhile the

engine is running (exceptwhen specificallyrecom-

mended bythe manufacturer).

A

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT MEANS-,

ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

2

I

Page 3

CONGRATULATIONS on your purchase of a Sears

CraftsmanEdger/trimmer. It hasbeen designed, engi-

neeredand manufacturedto give youthe best possible

dependabilityandperformance.

Shouldyou experienceany problemyou cannot easily

remedy, please contact your nearest Sears Service

Center/Department. We have competent, well-trained

techniciansandthe proper toolsto serviceor repairthis

unit.

Pleasereadandretainthismanual. The instructionswill

enable you to assemble and maintainyour edger/trim-

merproperly. Alwaysobservethe "SAFETY RULES."

MODEL

NUMBER 536.797571

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ON THE FRAME OF THE

EDGER/TRIMMER BEHIND THE ENGINE.

YOU SHOULD RECORD BOTHSERIAL NUMBER

ANDDATE OF PURCHASE AND KEEP IN ASAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product, Contact yournearest Sears Store for details.

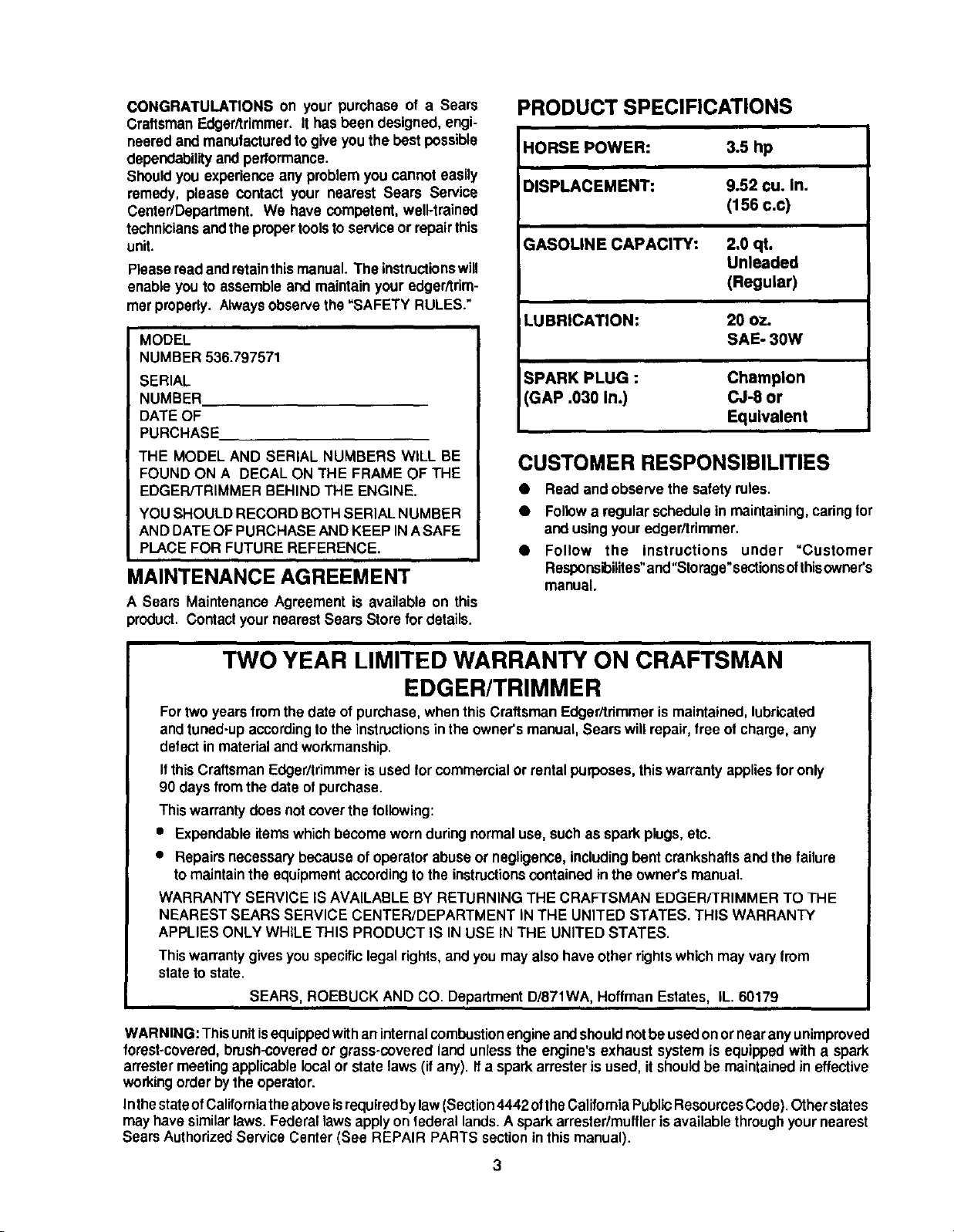

PRODUCT SPECIFICATIONS

HORSE POWER:

DISPLACEMENT: 9.52 cu. In.

GASOLINE CAPACITY:

LUBRICATION: 20 oz.

SPARK PLUG :

GAP .030 In.)

3.5 hp

(156 c.c)

2.0 qt.

Unleaded

(Regular)

SAE- 30W

Champion

CJ-8 or

Equivalent

CUSTOMER RESPONSIBILITIES

• Read and observethe safety rotes.

• Followa regular schedulein maintaining, caringfor

and using youredger/trimmer.

• Follow the Instructions under uCustomer

Responsibilites"and"Storage"sectionsofthisowner's

manual.

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

EDGER/TRIMMER

Fortwo years fromthe date of purchase, whenthis CraftsmanEdger/trimmer is maintained, lubricated

and tuned-up accordingtothe instructionsinthe owner's manual, Sears will repair, free of charge, any

defectin materialand workmanship.

Ifthis CraftsmanEdger/trimmerisused for commercialor rentalpurposes, thiswarranty appliesfor only

90 days fromthe date of purchase.

Thiswarranty does not coverthe following:

• Expendableitems whichbecome wornduringnormal use, such as spark plugs,etc.

• Repairs necessarybecause ofoperator abuseor negligence, includingbent crankshafts andthe failure

to maintain the equipmentaccordingto the instructionscontained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN EDGER/TRIMMER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT iN THE UNITED STATES. THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

Thiswarranty givesyou specificlegal rights,and you may also have other rightswhich may vary from

state to state.

SEARS, ROEBUCK AND CO. Department D/871W,A,Hoffman Estates, IL. 60179

WARNING: This unitisequippedwithan internalcombustion engineandshouldnotbe usedonor nearanyunimproved

forest-covered,brush-coveredor grass-covered land unlessthe engine's exhaust system is equipped with a spark

arrestermeeting applicablelocalor state laws(if any). Ifa sparkarrester is used, it shouldbe maintained in effective

workingorder bythe operator.

Inthestateof Calitorniatheaboveisrequiredbylaw(Section4442 oflhe CallfomiaPublicResourcesCede).Otherslates

may have similarlaws. Federal lawsapplyon federal lands.A sparkarrester/mufflerisavailablethroughyournearest

SearsAuthorizedService Center (See REPAIR PARTS sectionin this manual).

3

Page 4

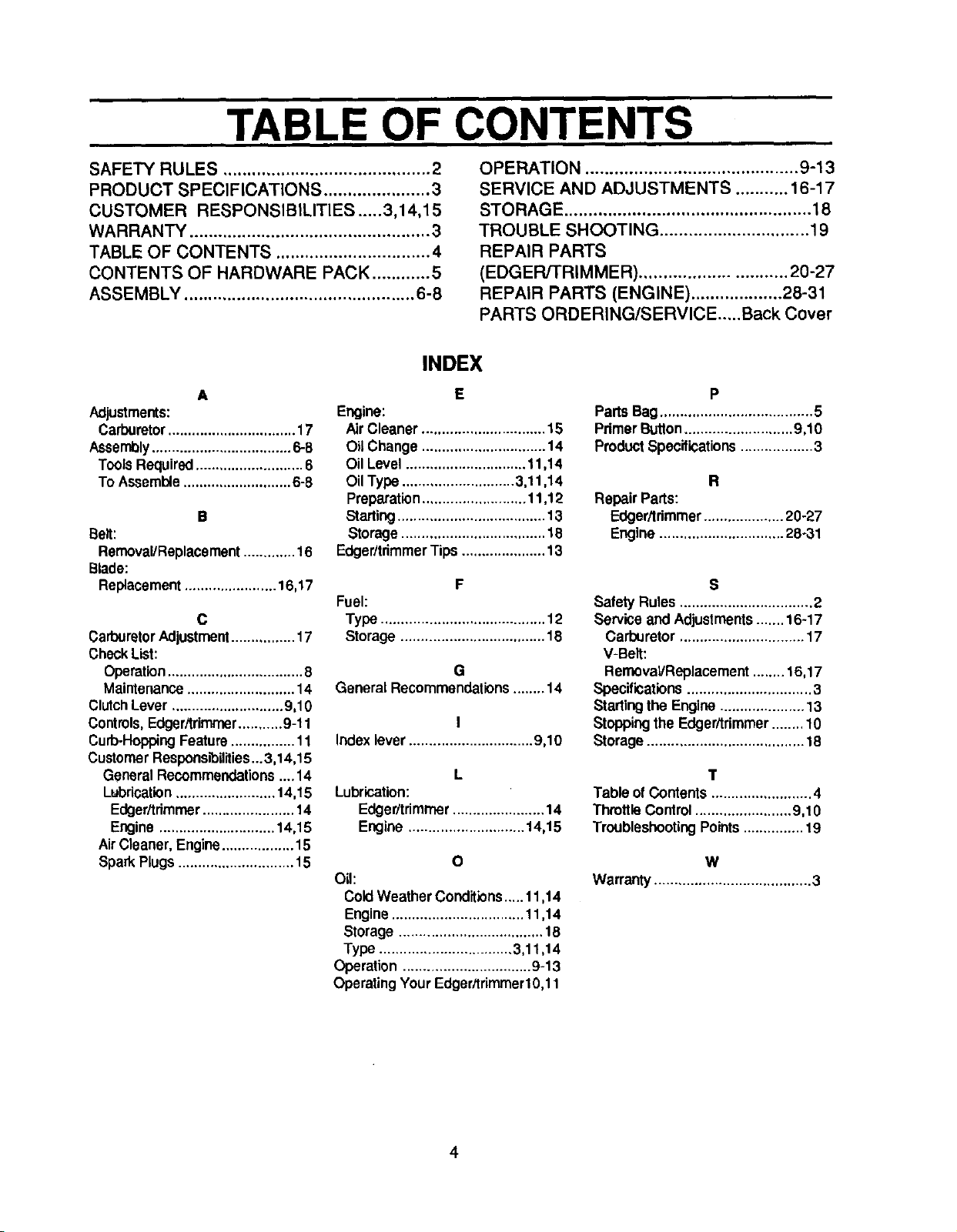

TABLE OF CONTENTS

SAFETY RULES ........................................... 2

PRODUCT SPECIFICATIONS ...................... 3

CUSTOMER RESPONSIBILITIES .....3,14,15

WARRANTY .................................................. 3

TABLE OF CONTENTS ................................ 4

CONTENTS OF HARDWARE PACK ............ 5

ASSEMBLY ................................................ 6-8

INDEX

A

Adjustments:

Carburetor ................................ 17

Assembly ................................... 6-8

Tools Required ........................... 6

To Assemble ........................... 6-8

B

Belt:

Removal/Replacement.............16

Blade:

Replacement....................... 16,17

C

Carburetor Adjustment ................ 17

CheckList:

Operation .................................. 8

Maintenance ........................... 14

Clutch Lever ............................ 9,10

Controls, Edger/trimmer........... 9-11

Curb.Hopping Feature ................ 11

Customer Respensibilities ...3,14,15

General Recommendations....14

Lubrication......................... 14,15

Edger/trimmer....................... 14

Engine............................. 14,15

AirCleaner, Engine.................. 15

Spark Plugs............................. 15

Engine:

Air Cleaner ............................... 15

Oil Change ............................... 14

Oil Level .............................. 11,14

Oil Type ............................ 3,11,14

Preparation.......................... 11,12

Starting..................................... 13

Storage .................................... 18

Edger/tdrnmerTips..................... 13

Fuel:

Type ......................................... 12

Storage .................................... 18

General Recommendations ........14

Indexlever ............................... 9,10

Lubrication:

Edger/trimmer ....................... 14

Engine ............................. 14,15

Oil:

Cold Weather Conditions.....11,14

Engine ................................. 11,14

Storage .................................... 1B

Type ................................. 3,11,14

Operation ................................ 9-13

Operating Your Edger/trimmer10,11

OPERATION ............................................ 9-13

SERVICE AND ADJUSTMENTS ........... 16-17

STORAGE ................................................... 18

TROUBLE SHOOTING ............................... 19

REPAIR PARTS

(EDGER/TRIMMER) .............................. 20-27

REPAIR PARTS (ENGINE) ................... 28-31

PARTS ORDERING/SERVICE.....Back Cover

E

Parts Bag ...................................... 5

PalmerButton........................... 9,10

Product Specifications.................. 3

Repair Parts:

Edger/trimmer.................... 20-27

Engine ............................... 28o31

F

Safety Rules ................................. 2

Service and Adjustments.......16-17

Carburetor............................... 17

V-Belt:

G

I

L

O

Removal/Replacement........ 16,17

Specifications............................... 3

Startingthe Engine ..................... 13

Stoppingthe Edger/trimmer........10

Storage....................................... 18

Table of Contents......................... 4

ThrottleControl ........................ 9,10

TroubleshootingPoints............... 19

Warranty....................................... 3

P

R

S

T

W

4

Page 5

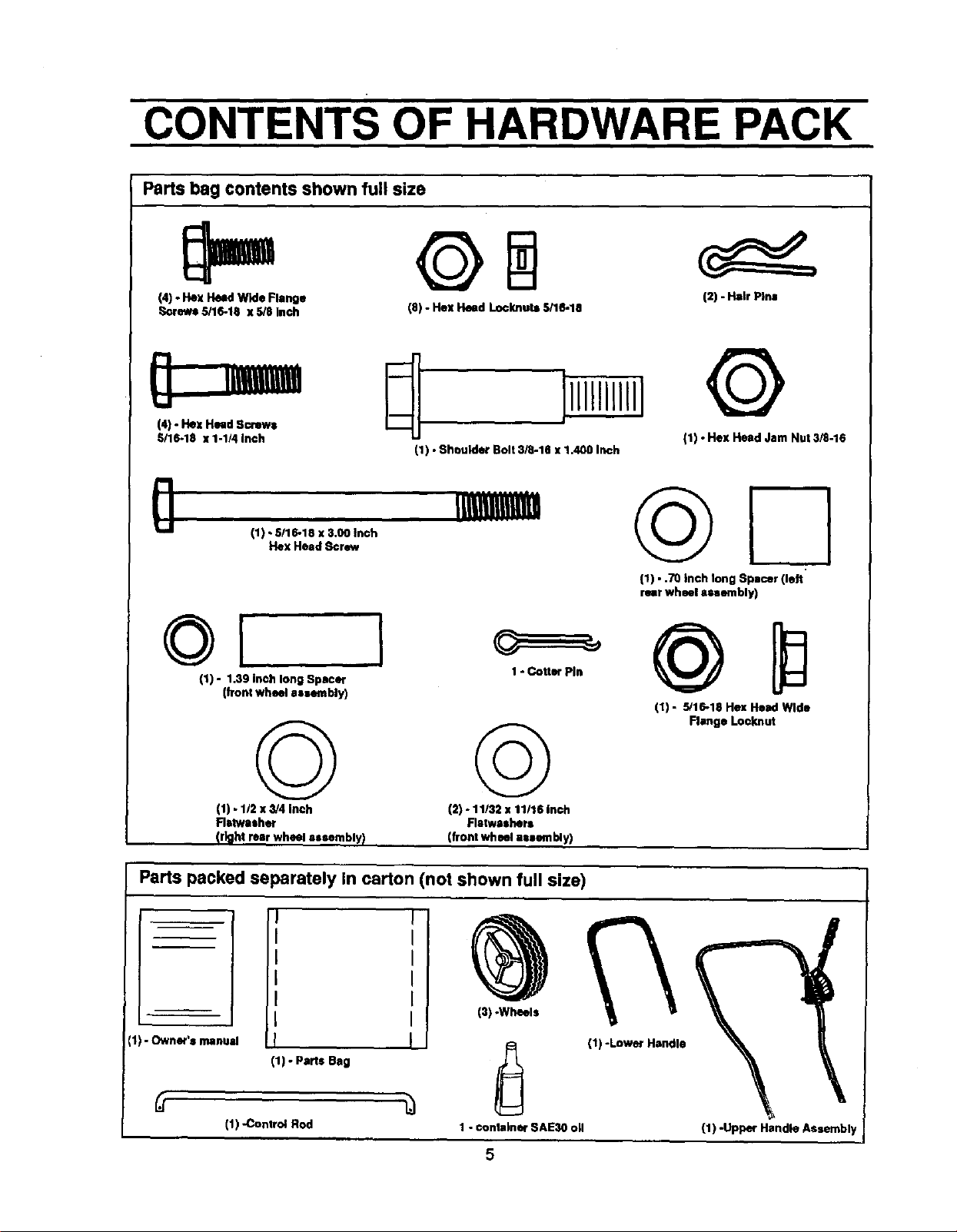

CONTENTS OF HARDWARE PACK

Parts bag contents shown full size

(4) - He= Head Wide Flange

_rews 5/16-18 x 5/8 Inch

(4) - Hax Head Screws

5/16-18 x 1-1/4 inch

(1) "3H/1_18_ 3'?lewrich

(1) - 1.39 Inch long Spacer

(front wheel 8ssembly)

(8) - Flex Head Loclmule 5/16-18

(1) • Shoulder Bolt 3/8-16 x 1.400 Inch

1 - Cotter Pin

(2) - Hair Pins

©

(1) - Hex Head Jam Nut 3/8-16

(1) • .70 Inch long Spacer (left

rear wheel assembly)

(1) - 5/16-18 Hex Head Wide

Flange Locknut

©

(1) - 112x 3/4 inch

Ratwltsher

(right rear wheel assembly)

Parts packed separately In carton (not shown full size)

©

(2) - 11/32 x 11/16 inch

Flatweshers

(front wheel aeaembly)

J

i

I

i

I

I

€1)- Owner's manual

(1) - Parts Bag

(1) -Control Rod

!

1 - conlelner SAE30 oil

5

(1) -Lower Handle

(1) -Upper Handle Assembl)

Page 6

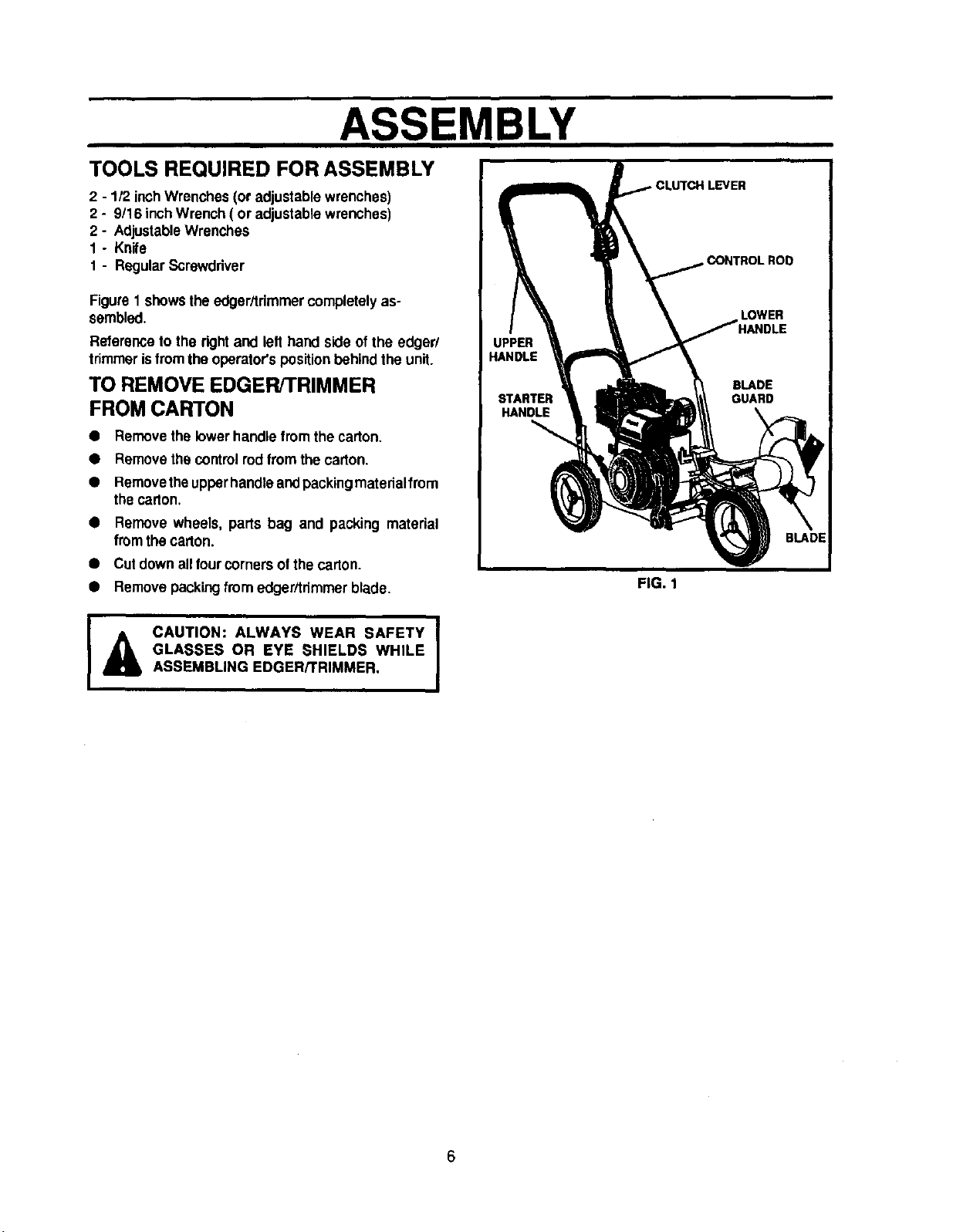

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

2 - 1/2 inchWrenches (Oradjustablewrenches)

2 - 9/16 inchWrench ( or adjustablewrenches)

2 - AdjustableWrenches

1 - Knife

1 - Regular Screwdriver

Figure1showsthe edger/trimmercompletelyas-

sembled.

Referenceto the rightand lelt hand side of the edger/

trimmeris fromthe operator'spositionbehindthe unit.

TO REMOVE EDGER/TRIMMER

FROM CARTON

• Removethe lowerhandlefrom the carton.

• Removethe controlrodfromthe carton,

• Removetheupperhandleandpacking materialfrom

the carton.

• Remove wheels, parts bag and packing material

fromthe carton.

• Cul downalltourcorners of the carton.

• Removepackingfrom edger/trimmerblade.

FIG. 1

I

GLASSES OR EYE SHIELDS WHILE

CAUTION: ALWAYS WEAR SAFETY

ASSEMBLING EDGER/TRIMMER.

6

Page 7

ASSEMBLY

TOASSEMBLE "IHE EDGER/TRIMMER

NOTE: Lower handle should be attached first as it is

difficultto attach lower handlewiththe wheels on.

Place the lower handle inside the edger/trimmer

frame (See Fig. 2) and secure inplace withfour(4)

5/1618 x 5/8 inchhex headwide flange screwsand

four (4) 5/16-18 hex head Iocknuts(found in parts

bag). NOTE: Locknutsshould be onthe insideof

frameas shownin Fig. 2.

I LOWER HANDLE

,

_le-la x_aINCX 1 %V

HEXHEADWIDE / I I

FLANGE SCREWS .5/16-18_ J I

HEX HEAD

I .'% _" I 5118-18XS/81NCH

I / _, _/ HEX HEAD WIDE

I FRAME FLANGE SCREWS

FIG. 2

• Attachthe leftrearwheel to the edger/trimmer (See

Fig. 2B) with a 3/8-16 x 1.39 inch shoulder bolt,

spacer (.70 inchlong) and3/8-16 hexhead jam nut

(foundin parts bag).

_) (VIEW FROM INSIDE LEFT REAR WHEEL)

SPACER SHOULDER BOLT

FRAME

_'_IjAI_IE_u_.HEAD WHEEL

FIG. 2B

• Attachthefrontwheel tothe edger/trimmer(See Fig.

2C) witha 5/1 6-18 x 3.00 inch hex head screw,two

11/32x 11/16inch flatwashers,onespacer(1.39 inch

long) and a 5/16-18 hex head wide flange locknut

(foundin partsbag).

I (VIEW FROM FRONT}

• Attachthedght rearwheel to the wheel suppodrod

of theedger/trimmer (See Fig. 2A) with a 1/2 x 3/4

inchllatwasherand cotterpin (foundin parts bag).

FIG. 2A

FIG. 2C

7

Page 8

ASSEMBLY

• Placetheupperhandleonthe lowerhandle(See Fig.

3), alignupperhandleholesinthe lowerhandle, and

secureinplacewithfour(4) 5/16-1B x 1-1/4 inchhex

headscrewsandfour(4) 5/16-18 hexhead Iocknuts

(foundinpadsbag).Locknutsshouldbetotheinside

ofthe two handlesas shownin Fig. 3.

NOTE: Clutchleverislocated onthe lefthand sideofthe

upper handlewhen properlyinstalled.

• Insertone end of the control rod from left to right

throughthe hole In the clutchlever (See Fig.3) and

attachwitha hair pin(foundinthe parts bag).

• Placethe clutchlever inthefirst depthselection

(Fig. 3) and insertthe other end of the controlrod

throughtheholeinthe quillsupportarm (See Fig.3).

Attachwithhairpin(found in partsbag).

• Movetheclutchlevertorearmost (NEUTRAL) posi-

tionand latchin. See note below.

NOTE: If itis difficultto get the clutch lever intoNEU-

TRAL.It maybenecessarytoloosenthefour screwsand

nutsholdingthe lowerhandlestothe frame (See Fig.4).

Pryup(forward)onthehandlesonlyenoughtoallowthe

clutchleverto lreely enter the NEUTRAL position. Re-

tighten nuts and screws, When the clutch lever is in

NEUTRAL the quill supportarm shouldbe againstthe

spacerand screwbehindit (See Fig.3 inset).

/ CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

EDGER/TRiMMER,WE WISH TOASSURETHATYOURE-

CEIVE THE BESTPERFORMANCEAND SATISFACTION

FROMTHIS QUAL/TYPRODUCT.

PLEASEREVIEWTHEFOLLOWINGCHECKLIST:

/ A_Iassemblyinstructionshavebeencompleted.

,f Noremainingloosepartsincarton.

,,I Allfastenershavebeenproperlyinstalledandtightened.

WHILELEARNINGHOW TO USE YOUR EDGER/TRIM-

MER, PAY EXTRA ATTENTION TO THE FOLLOWING

IMPORTANTiTEMS:

4'.s" Engine oil is at properlevel.

// Fuel tank is filled with fresh, clean, regular Unleaded

gasoline.

/#" Become familiar with all controls-their location and

function.Operate controlsbeforestartingengine.

FIG. 3

FIG. 4

8

Page 9

OPERATION

KNOW YOUR EDGER/TRIMMER

READTHIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR EDGER/

TRIMMER. Comparethe illustrationswith youredger/trimmerto familiarize yoursolfwith the locationof various

controlsand adjustments. Save this manualforfuturereference.

:H LEVER

CONTROLROD

INDEX LEVER

THROTTLE

CONTROL

LEVER_

STARTER

HANDLE

FUEL FILL

CAP

MUFFLE

BLADE

PRIMER BUTTON

VIEW FROM LEFT OF ENGINE

BLADE

ADJUSTABLE

OIL FILL CAP

REAR WHEEL

THROTTLE CONTROL - Used to control the engine

speed.

PRIMER BU'I-I'ON- Injectsfueldirectlyintothe carbure-

tor manifoldfor fasterstarts.

STARTER HANDLE - The engineon thisedger/trimmer

isequippedwithan easy pull recoilstarter.

CLUTCH LEVER - Used to start and stopthe blade and

controlthe depth ofcut.

INDEX LEVER - Permits adjustmentfrom the edging

(vertical) positionto trimming(horizontal) position. To

ADJUSTABLE

FRONT WHEEL

FIG. 5

change position, pullthe index lever and rotatethe quill

assemblyto the desired angle or position.

BLADE GUARD - Used to prevent stones or other

materialfrom beingthrown at the operator.

ADJUSTABLE REAR WHEEL . Right rear wheel is

adjustableIorcurb-hopping(to leveledgedtrimmerwhen

edging alonga curb).

ADJUSTABLE FRONT WHEEL- Front wheel isadjust-

ablefromside-to-sideforbalance. Also, can be adjusted

down for curb-hopplng (to level edger/trimmer when

edgingalong a curb).

9

Page 10

OPERATION

The operationofthisedger/trimrnercanresultinforeignobjectsbeingthrownintothe

eyes,which can result in severe eye damage. Alwayswear safety glassesor eye

shieldswhileoperatingthe edger/tdmmer.

I

HOW TO USE YOUR EDGER/TRIMMER

We recommendstandardsafetyglassesor Wide VisionSafety Maskforover your

glasses.

TO STOP EDGER/TRIMMER

• To stopthe engine, make surethe clutchlever isall

the way beck (or up) and move the throttlecontrol

levertothe STOP position.

CAUTION: NEVER LEAVE THE EDGER/ |

A

TO USE THROTTLE CONTROL

• Runat full enginespeed duringnormal use,

• Push throttle control lever up to increase speed;

TO USE PRIMER BU'I'I'ON

• Pushprimerbuttonfive(5) times(see Fig.5). Wait

NOTE: Do notusepdmerto restartawarm engineafter

a shortshutdown.

TO USE THE CLUTCH LEVER

• Startthe engine and move the clutch leverforward

• Select the edging depth you need. There are 5

iMPORTANT: IFVERY DEEP EDGINGIS REQUIRED,

TRIMMER UNATFENDED WHILE THE EN-

GINE IS RUNNING. ALWAYS DISEN-

GAGE THE CUTTING BLADE AND STOP

THE ENGINE.

downto decrease speed.

abouttwo (2) secondsbetween eachpush.

(or down) to engage the cuttingblade.

selectionsupto 2-3/4 inchesdeep.

WE RECOMM END THAT ASHALLOW

CUTBE MADE FIRST, THEN C UTSAT

GREATER DEPTHS UNTIL THE

DESIRED DEPTH IS OBTAINED.

BE IN THE EXTREME RIGHT POSITION

CAUTION: THE FRONT WHEEL MUST

TO PREVENT THE BLADE FROM STRIK-

ING WHEEL WHILE IN TRIMMING POSI-

TION.

I

FIG. 6

• Pullthe index lever outof its notch(See Fig 7) and

position it inthe notchmarked 90°.

• Reconnectthe sparkplugwiro and startthe engine.

Movethe clutchleverto the desiredtrimmingheight.

_ll AUTION: NEVER LEAVE THE EDGER/

TRIMMER UNATTENDED WHILE THE EN-

GINE IS RUNNING. ALWAYS DISEN-

GAGE THE CUTTING BLADE AND STOP

THE ENGINE.

TO USE THE INDEX LEVER

(TRIMMING OPERATION)

• Stopthe engineanddisconnectthespark plugwire

fromthespark plug.

• Loosentheknob(See Fig.6) onthefrontwheel arm

and slidethe wheel all the way tothe rightside.

• Tightenthe knob securely.

INDEX LEVER

INDEX LEVER IN THE NOTCH MARKED "90"

FIG. 7

10

Page 11

OPERATION

TO USE CURB-HOPPING FEATURE

The adjustablefront and right rear wheelfeature permit

theedger/trimmer tobeusedonanunevensurfaco(such

as a curb]as shownIn Fig. 8.

• Stopthe engineand disconnectthe sparkplugwire

fromthe sparkplug.

• Loosentheknobonthe frontwheel arm bracketand

slidethe wheel to the best positiontoclearthe curb

and balancethe unit.

• Tightenthe knob securely.

Usingthe curb height adjust lever, lower the front

wheel to a positionthat places the edger/trimmer

levelwith the left rear wheel on the uneven (curb)

sudace.

• Loosenthetee knobon the inside rightrear of the

mainframe that securesthe wheel supportrod(See

Fig. 8).

• Slidethe rearwheel downuntilthe edgeritrimmeris

levelwhen the leftwheel ison the curb.

• "13ghtenthetee knob securely.

• Reconnectthespark plugwire and startthe engine.

Thedepthofcutedjustment isthesameasdescribed

inEdging Operation paragraph.

I& CAUTION: KEEP AWAY FROM THE RO- |

TATING BLADE. THE BLADE CAN

CAUSE INJURY.

BEFORE STARTING ENGINE

PRE-USE CHECK OF CONTROLS

Allcontrolsshouldbecheckedforproperfunctionbefore

servicingor startingthe engine.

• Move the clutch lever into all six(6) positions inthe

selectorplate. Make surethe clutchleversnaps into

all six (6) holes. (Fig. 5)

• Returnthe clutch lever to the rearmost hole in the

selector plate.

FILL/ADD OIL:

This edger/trimmer was shipped with a container of

SAE30 motoroil. This oil must be added to the engine

beforeoperating. Remove the oilfUicap/dipstickandflit

the crankcaseto FULL line on dipstick(20 ounces).

NOTE: Engine may already contain some residual

oil Check frequently when filling the crankcase. Do

not overfill.

Tightenthefillcap/dipsticksecurelyeachtimeyoucheck

the oillevel.

I

I

FIG. 8

I 32OF

COLDER(€

_== -- -- == -- ----------- I

--5W _'_'_u-- -- --I

OIL RECOMMENDATIONS

OnlyusehighqualitydetergentoilratedwithAPI service

classificationSG. Select the oirs SAE viscositygrade

accordingto yourexpectedoperatingtemperature:

NOTE: Althoughmulti-viscosityoils(5W30, 10W30,etc.)

improvestartingincoldweather,thesemulti-viscosityoils

willresultinincreasedoilconsumptionwhenused above

32°F. Checkyourengineoillevelmorefrequentlytoavoid

possible enginedamage from runninglowon oil,

TO ADD ENGINE OIL

• Placethe edger/trimmeron a level surface.

• Remove the oilfillcap (Fig. 9),

• Fill the engine crankcase, pouring slowly. Do not

overfill. For approximate capacity see PRODUCT

SPECIFICATIONS on page 3 ofthis manual.

- --)>WARMER

SAE30

11

Page 12

OPERATION

AND CAUTION MUST BE USED WHEN

CAUTION: GASOLINE IS FLAMMABLE

HANDLING OR STORING IT. DO NOT

FILL FUEL TANK WHILE EDGER/TRIMMER IS

RUNNING, HOT, ORWHEN EDGER/TRIMMER IS

IN AN ENCLOSED AREA. KEEP AWAY FROM

OPEN FLAME, ELECTRICAL SPARK, AND DO

NOT SMOKE WHILE FILLING THE FUEL TANK.

NEVER FILL FUEL TANK COMPLETELY; BUT

FILL THE TANK TO WITHIN 1/4 - 1/2 INCH FROM

THE TOP TO PROVIDE SPACE FOR EXPANSION

OFFUEL.ALWAYSFILL FUEL TANK OUTDOORS

AND USE A FUNNEL OR SPOUT TO PREVENT

SPILLING. MAKE SURE TO WIPE UP ANY

SPILLED FUEL BEFORE STARTING THE EN-

GINE.

STORE GASOLINE IN A CLEAN, APPROVED

CONTAINER, AND KEEP THE CAP IN PLACE ON

THE CONTAINER. KEEP GASOLINE IN A COOL,

WELL VENTILATED PLACE; NEVER IN THE

HOUSE. NEVER BUY MORE THAN A 30 DAY

SUPPLY OF GASOLINE TO ASSURE VOLATIL-

ITY. GASOLINE IS INTENDED TO BEUSED AS A

FUEL FOR INTERNAL COMBUSTION ENGINES;

THEREFORE, OONOT USEGASOLINE FOR ANY

OTHERPURPOSE. SINCE MANYCHILDREN LIKE

THE SMELL OF GASOLINE, KEEP IT OUT OF

THEIR REACH BECAUSE THE FUMES ARE

DANGEROUS TO INHALE, AS WELL AS BEING

EXPLOSIVE.

FIG. 9

• Reinstallthe oil fillcap andtighten securely.

• Check oil before each use. Add if needed.

• Change oilafterthe first 2 operatinghoursand every

25 operatinghoursthereafter.

FILL GAS:

Fillthe fuel tank (See Fig. 9) with clean,trosh,unleaded

grads automotivegasoSne. Be surethat the container

youpourthegasoitnefromisclean andfree fromdustor

otherforeign particles. Never use gasoline that may be

stale from longperiods of storage in the container.

WARNING: Experience indicatesthat alcoholblended

fuels(calledgasoholorusingmethanol)can attractmois-

ture which leads to separation and formation of acids

duringstorage.Acidicgascandamagethe fuelsystemof

an enginewhileinstorage.Toavoidengineproblems,the

fuel systemshouldbe emptiedbeforestorageof 30 days

orlonger,Drainfueltank,startengineand letitrununtilfuel

linesand carburetorare empty. Usefresh fuel next sea-

son. See Storage Instructionsfor additionalinformation.

Never use engineor carburetor cleaner productsin the

fuel tank or permanentdamage may occur.

12

Page 13

OPERATION

TO START THE ENGINE

Beforestartingthe engine, be sureyou have read and

understoodallthe instructionson the precedingpages.

The edger/trimmer isequippedwith a recoilstarter.The

operationofthe engineiscontrolledbythethrottlecontrol

lever,

• Pullthe clutchlever all the way back (or up) to the

rearmosthole to raise and disengagethe blade.

• Movethethrotttecontrol lever(See Fig.5)totheRUN

position.

• Pushpdmerbuttonfive (5) times (see Fig.5). Wait

abouttwo (2) secondsbetween each push.

NOTE: Do notuse pdmerlo restarta warmengine alter

a shortshutdown.

To start engine, grasp the engine starter handle

firmlyyour righthand.

Hold the edger/trimmer handle firmly withyour left

hand.

Pullup sharplyonthe recoilstarterhandle.DO NOT

allowthestartsr ropetosnapback,letit rewindslowly

whileholdingthe stader handle.

NOTE: If enginefailsto start after three (3) pulls,push

primerbuttontwo (2) timesand pull starterrope again.

• Whenthe enginestarts.Pushthrottlecontrolleverup

toincreasespeed;down todecrease speed. Run at

full engine speed duringnormaluse.

NOTE: The cutting blade speed is controlled by the

enginespeed.TOreduce the cuttingblade speed, push

downonthe throttlecontrol lever.To increase the blade

speed,push the throttlecontrol lever up.

• To stoptheengine, make surethe clutchlever isall

theway back (or up) and movethe throttlecontrol

leverto theSTOP position.

iiiii

CAUTION: NEVER RUN THE ENGINE IN-

A

DOORS OR IN A POORLY VENTILATED

AREA. ENGINE EXHAUST CONTAINS

CARBON MONOXIDE, AN ODORLESS

GAS AND DEAOLY GAS.

KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING

PARTS ON THE ENGINE OR EDGER/

TRIMMER.

WARNING - AVOID THE MUFFLER AND

SURROUNDING AREAS (SEE FIG. 6).

TEMPERATURES MAY EXCEED 150° F.

EDGING TIPS

Edgingisbestperformedwhenconditions aredry. If

thesoilistoowet, dirtbecomespackedinandaround

the blade causing premature belt wear and de-

creased perlormanoe.

• If dirtdoes become packed around the blade, stop

the engine,removethesparkplugwire,and remove

the packeddebrisbefore continuing toedge.

• Ifverydeep edgingisrequired,we recommendthat

ashallowcutbe madefirst,thencutsatgreaterdepth

untilthedesired depth isobtained.

• Unilorm edgingcan be performed when the blade

guideridesonandagainstthe surfacewhichyouare

edging.

• Edgingcan be customizedbyvaryingthe numberof

passesand bythe distanceyour blade is from lhe

surfaceyou are edging.

13

Page 14

CUSTOMER RESPONSIBILITIES

MAINTENANCE

CHECK LIST

BEFORE STORAGE

BEGINNING EACH SEASON

EVERY 25 HOURS OF USE

EVERY 10 HOURS OF USE

EVERY 5 HOURS OF USE

FREQUENTLY

BEFORE EACH USE

AFTER FIRST 2 HOURS OF USE

LubriCateall Pivot Points

LubricateWheal Axles

Check Engine Oil Level

Change EngineOil

Replace AirCleaner Filter

Check Spark Plug

Check Drive Belt

TbghtanAll So'ews and Nuts

Check BladeWear/Damage

SERVICE RECORD

FILLIN DATES

ASYOU COMPLETE

REGULARSERVICE

GENERAL RECOMMENDATIONS

Thewarrantyonthisedger/trimmerdoesnotcoveritems

that have been subjectedto operator abuse or negli-

gence. To receive full value from the warranty, the

operatormustmaintain the edger/trimmeras instructed

inthismanual. The followingMaintenance Check LIStis

supplied to assist the operator properly maintain the

edger/trimmer.

LUBRICATION

EDGER/TRIMMER

• Applylightmachineoilafter each25 hoursof use to

all movingparts, particularlythe wheels.

ENGINE

• The oil inthe crankcasemustbe changed alter the

first2 hoursof operationanclafter each 25 hoursof

usetherealter.

NOTE: If the edger/trimmer Is being used In sandy or

dusty areas, change the oll more frequently to pre-

vent premature engine wear.

32OF

COLDER_= I: -_>WARMER___.===_

5W30 SAE30

OIL RECOMMENDATIONS

Onlyuse highquality detergentoilratedwith API service

classificationSG. Select the oil's SAE viscositygrade

accordingtoyour expectedoperatingtemperature:

NOTE: Althoughmulti-viscosityoils(5W30, 10W30, etc.)

improvestartingincoldweather, these multi-viscosityoils

willresultin increasedoilconsumption when used above

32°F. Checkyourengineoillevelmorofrequentlyto avoid

pessPoleenginedamage fromrunninglow on oil.

TO CHANGE ENGINE OIL

• Disconnectthe spark plug wire from the spark plug.

• Removetheoildrain plug(See Fig. 10) anddrainthe

oilinto a flat pan.

• After drainingall the oil, reinstall the oil drain plug

securely.

NOTE: Theoilwill drain more freely when the engine is

warm.

14

Page 15

CUSTOMER RESPONSIBILITIES

• Removethe oilfillcap (see Fig.9).

• Fill the engine crankcase, pouring slowly. Do not

overfill. For approximate capacity see PRODUCT

SPECIFICATIONS on page 3 ofthis manual,

• Reinstallthe oil tillcap and tightensecurely.

NOTE: The quillassembly bearingsare factory sealed

andwill requireno lubrication.

• Reconnectthe spark plugwire on the sparkplug.

TO REMOVE

VIEW FROM REAR

OIL DRAIN PLUG

FIG. 10

AIR CLEANER

Replacethe tilteroncea year; moreoftenunderdustyor

dirtyconditions.DO NOT attempt to clean or oil the air

filter.

To installa new air filter,do theto,owing:

• Disconnectthe sparkplugwire fromthe sparkplug.

• Turnthecover (See Fig. 11)to the left(counterclock-

wise)andremovethecoverand the airfilterfromthe

flange,

Discardthe airfilter.

Clean thecover and the flange thoroughly.

Insertthe new air filter intothe cover.

Pushthecoverfirmlyagainsttheflange andturn itto

the right(clockwise)asfar as itwillgo (See Fig, 11.

Be surethe retainersare lucked aroundthe flange.

Reconnectthe spark plugwire.

CAUTION: NEVER RUN THE ENGINE

WITHOUT THE AIRCLEANER ELEMENT

INSTALLED. A DEFECTIVE AIR

CLEANER CAN RESULT IN LOSS OF

ENGINE POWER AND CAN CAUSE EX-

CESSIVE WEAR OR DAMAGE TO THE

ENGINE COMPONENTS IF DIRT OR

DUST IS PERMITTED TO ENTER THE

ENGINETHROUGH THECARBURETOR.

A DAMAGED AIR CLEANER, OR ONE

THAT IS CLOGGED WITH DUSTOR DIRT

SHOULD BE REPLACED IMMEDIATELY.

FLANGE

FILTER

RETAINER

COVER

SLOT

TURNCOVER

TOTHE RIGH1

(CLOCKWISE

TO INSTALL

FiG. 11

SPARK PLUG

Clean the spark plug and reset the gap periodically.

Clean the area around the spark plug base, before

removal, to prevent dirtfrom entering into the engine.

Replace the spark plug if the electrodes are pitted or

burnedorifthepomelainiscracked.Cleanthe sparkplug

bycarefully scrapingthe electrodes(donot sandblast or

useawire brush),Besurethesparkplugiscleanandfree

offoreign material.Checktheelectrodesgapwitha wire

feeler gauge and reset to .035 it necessary. If a new

sparkplugisneeded, refertothe Engine Operation and

Maintenance manualforthe properreplacement spark

plug.

Beforereinstallingthe sparkplug,coatthethreadslightly

with graphiteor lightoilto insureeasy removal,Tighten

the spark plugfirmly intothe engine. If a torquewrench

isavailable, torquethe spark plugto 15 foot- pounds.

15

Page 16

SERVICE AND ADJUSTMENTS

AND DISCONNECT THE SPARK PLUG

WIRE BEFORE MAKING ANY REPAIRS

CAUTION: ALWAYS STOP THE ENGINE I

TO THE EDGER/TRIMMER.

V-BELT REPLACEMENT

Your edger/trimmerisequippedwitha V-belt madeof a

specialcompound.Ifthe belt becomes worn or breaks,

replaceit withan original equipment belt as shownin

theRepair Parts sectionofthismanual.NEVER USE A

SUBSTITUTE,

• Disconnectthe sparkplugwirefrom the sparkplug.

• Pull the clutch lever back (or up) to release the

tensionfrom the belt.

Removethe twotopscrewsfromthe enginepulley

cover (See Fig. 12) and remove the cover.

NOTE: Make sureyoudo notlosethespaceronthe roar

screwor the two longspacerson the inside.

• Remove the front screw secudng the belt guide

(See Fig. 12) to the engine. Then loosen the rear

screwand swingthe belt guideaway fromthe belt.

• Removethetwo (2) screwsfromthe beifguard(See

Fig. 13). Remove the belt guard.

• Carefully,spread open thefrontbelt guideenough

to allowbeltto beremoved fromquill pulley.

• Removethebeltfromtheengineand quillassembly

pulleysand installthe new bell in reverse order of

removal.

• Installand securefrontbeltguard.

• Secure the beltguide loosenedearlier.

• Reinstallthe enginepulleycoverandreconnectthe

sparkplugwire.

BLADE REPLACEMENT

A

ENGINE

PULLEY

COVER

SCREWS

CAUTION: DO NOT ATTEMPT TO

SHARPEN THIS BLADE, YOU COULD

CAUSE DAMAGE TOTHE BLADEWHICH

COULD RESULT IN BREAKAGE AND

POSSIBLE USER OR BYSTANDER IN-

JURY.

ENGINE

PULLEY

PULLEY

REAR

FRONT BELT

SCREW GUIDE

FIG. 12

The cuttingbladeis subjecttowear anddamage suchas

nicksanddents.Thiswillnotgenerallyaffectitsfunction.

Thisblade is speciallydesignedtonot requiresharpen-

ing. DO NOT A'I-I'EMPT TO SHARPEN THIS BLADE.

The blade is reversible. It the nicks and dents are

excessive,removetheblade,turn itaroundandreinstall.

This willprovideafreshcutiingedge. Ifwornordamaged

the blade shouldbe replaced.

CAUTION: WHEN REMOVING OR

&

TIGHTENINGTHE BLADE NUT,ALWAYS

USE THE METHOD SHOWN IN FIGURE

14. THE HOLDING WRENCH MUST AL-

WAYS BE POSITIONED ON THE NUT

BEHIND THE CUTTING BLADE.

BELT

BELT

SCREWS

FIG. 13

16

Page 17

SERVICE AND ADJUSTMENTS

TO replace the blade, do the following:

• Disconnect the sparkplug wire.

• Removethe 1/2-20 Iocknut (See Fig. 14) secudng

the bladeto the drive shaft,

• Removethe blade,

• installthe newblade and reinstall nut.Tightenthe

nutsecurely,

• Reconnectthe spark plugwire.

TO ADJUST CARBURETOR

The carburetor(See Fig. 15) has been pre-set at the

factoryand readjustmentshouldnotbe necessary.How-

ever,itthe carburetordoes needto be adjusted,proceed

asfollows:

• Closethehighspeed adjustingscrewbyhand.

• Do notover-tighten.

• Thenopenit 1-1/4 to 1-1/2 turns.

• Startthe engineand letitwarm up,

• SetthethrottlecontroltoRUN. Adjustthehighspeed

adjustingscrew In untilthe enginespeed or sound

alters.Adjustthe screw out until the erKJinespeed

sound alters. Note the differencebetween the two

limitsandsetthe Screwinthe middleofthe range,

• Iftheenginetendstostallunderloadornotaccelerste

fromlowspeedtohighspeedproperly,adjustthehigh

speed screw out in 1/8 turn increments until the

problemisresolved.

• Let the engine run undisturbedfor 30 seconds be-

tweeneachsettingto allow the engineto reacttothe

previousadjustments.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED.

OVERSPEEDING THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BE DANGEROUS. IF

YOU THINK THE ENGINE - GOV-

ERNED HIGH SPEED NEEDS AD-

JUSTING, CONTACT YOUR NEAR-

EST SEARS SERVICE CENTER,

WHICH HAS THE PROPER EQUIP-

MENT AND EXPERIENCE TO MAKE

ANY NECESSARY ADJUSTMENTS.

TIGHTENING

WRENCH

BLADE LOCKNUT

FIG. 14

_ CARBURETOR

I._ HIGH SPEED ADJUSTING

"_(Cloee finger tight only)

FIG. 15

8CREW

17

Page 18

STORAGE

CAUTION: NEVER STORE YOUR

&

EDGER INDOORS OR IN AN EN-

CLOSED, POORLY VENTILATED AREA

IF GASOLINE REMAINS IN THE TANK

FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT FROM A FUR-

NACE, WATER HEATER, CLOTHES

DRYER, ClGARETI'E, ETC.

EDGER

• Clean the edger thoroughly;remove all debris and

wipethe unitdry.

• Inspectthe edger for worn or damaged parts and

tightenall loose hardware.

• OilallpointsdescitbedintheLubrlcaUon paragraph

in the Customer Responsibilities section of this

manual.

• Store the edger ina protected area and cover for

additionalprotection.

IMPORTANT: A YEARLY CHECKUP OR TUNE-UP

BY A SEARS SERVICE CENTER IS A

GOOD WAY OF ENSURING THAT

YOUR EDGER WILL PROVIDE

MAXIMUM PERFORMANCE FORTHE

NEXT SEASON.

ENGINE

IMPORTANT:

To preventenginedamage ( ifedger isnotusedformore

than 30 days) follow the stepsbelow.

To remove gasoline,runthe engineuntilthe tank is

empty and the engine stops.

Ifyoudonotwantto removegasoline,a fuelstabilizer

(suchas Sears Craftsman fuel stabilizerNo.33500)

may be added to any gasoline left in the tank to

minimize gum deposits and acids. If the tank is

almostempty, mixstabilizerwithfreshgasoline in a

separate container and add some to the tank. AL-

WAYS FOLLOWlNSTRUCTIONS ON STABlUZER

CONTAINER. THEN RUN ENGINE AT LEAST 10

MINUTES AFTER STABILIZER IS ADDED TO

ALLOW MIXTURE TO REACH CARBURETOR.

STORE EDGER IN A SAFE PLACE. SEE WARN-

ING ABOVE.

Store theedger inthe wheels-down,operatingposi-

tion. If the edger is stored in any other position, oil

fromthecrankcasecould enterthecylinder,causing

a serviceproblem.

You can keep your engine In good operating condi-

tion during storage by:

• Changing oil.

Lubricating the piston/cylinderarea. This can be

done by first removingthe spark plug and squirting

clean engineoil intothe sparkplughole.Thencover

the spark plug hole with a rag to absorb oil spray.

Next, rotatethe enginebypullingthe startertwo or

three times. Finally, reinstallspark plug and attach

spark plugwire.

IT IS IMPORTANTTO PREVENT GUM

DEPOSITS FROM FORMING IN ES-

SENTIAL FUEL SYSTEM PARTS

SUCH AS THE CARBURETOR, FUEL

FILTER, FUEL HOSE, OR TANK DUR-

ING STORAGE. ALSO, EXPERIENCE

INDICATES THAT ALCOHOL-

BLENDED FUELS (CALLED GASO-

HOLOR USING ETHANOLOR METHA-

NOL) CAN ATTRACT MOISTURE

WHICH LEADSTO SEPARATION AND

FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAM-

AGE THE FUEL SYSTEM OF AN EN-

GINE WHILE IN STORAGE.

18

Page 19

TROUBLE SHOOTING

TROUBLE

Difficult starting

Engine runs erratic

Cuffing blade fails to

turn

Bladefalls to cut

properly

CAUSE

Stalefuel

Defectivespark plug

Cloggedfuelfilter

Blockedfuel line or empty fuel tank

Carburetoroutof adjustment

Fouledsparkplug

Clogged aircleaner

Jammeddue to foreign object

Looseblade

DefectiveV-belt

Defectivequillbearings

Damagedor worn blade

CORRECTION

Drainfuel tank. Fillwithfreshfuel.

Clean and re-gap sparkplug.

ill

Replace fuel filter.

Clean fuel line; checkgas tank.

m

Have carburetoradjusted.

Clean and adjust gap.

Tap clean or replace aircleaner.

Clear obstruction,

Tightenblade retainingnut.

Replacethe V-belt.

Replacethe bearings.

Reverse blade or replace blade.

Excessive vibration

Looseparts

Stop engine immediately;tightenall bolts.If

vibrationcontinues,take the unit intothe

nearest SEARS Service Center.

19

Loading...

Loading...