Page 1

Caution:

Read and Follow

All Safety Rules

and Instructmns

,,,,,,,,,, ,,, , .........

3 HORSEPOWER .

9 iNCH

Before Operating

EDGER

This Equipment

o Assembly

" Operation

o Customer Responsibilities

° Serviceand Adjustments

• Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, iL 60179 U.S.A.

=

PartNo,33_58SC

Page 2

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT A

CANNOT CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SET-

TING-UP, TRANSPORTING, ADJUSTING OR MAKING REPAIRS

4t

BEFORE USE

• Read the owner's manual carefully+ Be thoroughly

familiar with the controls and the proper use of the

edger. Know howtostop the edger anddisengage the

controls quickl'y.

@ Do not operatethe edger withoul wearing adequate

outer garments. Wear footwear thatwillimprove foot-

ing on sUpperysurfaces.

@ Keep the area of operation clear of all persons,

particularly small children_lndpets+:

@ Thoroughly inspect the area wheretheedger istobe

used and remove all foreign objects,

FUEL SAFETY

• Handte fuel with care; it is highly flammable°

• Use an approved container.

• Checkfuelsupplybeforeeachuse, allowingspacefor

expansion as the heat of the engine and/or sun can

cause fuel to expand..

• FiUfuettankoutdoorswith extreme care=Neverfilliuel

tank indoors+Replace |uel tankcap securely and wipe

up spilled fuel+

• Never remove the fuel tank cap or add fuel to a

runningor hot engine,.

• Neverstorefuel oredgerwith fuelinthetank inside a

buitdingwhere fumes may reach an openflame+

OPERATING SAFETY

@ Never allow childrenor youngteenagers to operate

the edger+ Keep them away while it is operating.

Never allow aduttsto operate the edgedtdmmer with+

out proper instruction+

Ill Nways wear safety glasses or eye shields during

operationor while performing an adjustment orrepair

toprotect your eyes from foreign objects that may be

thrownfrom the edger+

@

Donot put hands orfeet near or under rotating parts+

@

Exercise extreme caution when operating onorcross-

{nggravel drives, walks, or roads.Stayalert forhidden

hazards or traflic.

@ Exercise caution to avoid slipping or falling.

@ Neveroperate the edgerwithout properguards,plates,

or other safety protective devices in place.

@ Never operate the edger at high transportspeeds or+

slipperysurfaces. Look behind and use care when

backing.

@ Never allow bystanders near the edger.

@ Keep childrenand petsaway whileoperating+

• Neveroperatetheedgerwithoutgood v!sibilityorlight.

• Donot runtheengineindoors.Theexhaustfumes are

dangerous (containingCARBON MONOXIDE, an

ODORLESS and DEADLY GAS).

@ Take a!l possibteprecautionswhenleavingthe edger

unattended+ Stopthe engine+

@ Do not overload the edger capacityby attemptingto

edge toodeet_at too fast a rate.

SAFE STORAGE

@

Always reter to the owner'smanual storage section

for importantdetails if the edgeris to be stored for an

extended period+

@

Neverleave the edger with fuel in the fuel tank inside

abuilding where ignition sources are present such as

water andspaceheaters, clothesdryers, and thelike.

Allow the engine to cool before placing in any enclo-

sure.

@ Keep the edger in safe working condition. Check all

fasteners at frequent intervalsfor proper tightness

REPAiR!ADJUSTMENTS SAFETY'

@ Afterstdking aforeign object, stopthe engine (motor).

Remove the wire from the spark plug, and keep the

wire away fro mthe plug to prevent accidental starting..

Thoroughly inspectthe edger for any damage, and

repair the damage before restarting andoperating the

edger.

@ litheedger shouldstartto vibrate abnormally, stopthe

engine (motor) andcheck immediately {orthe cause

Vibration is generaUy a warning of troubte.

@ Stop the blade whenever you leave the operating

position. Also, stop the engine and disconnect the

spark plug wire before unclogging theblade andwhen

making any repairs, adjustments, or inspections

@ When cteaning, repairing,or inspecting, shuto{{ the

engine andmakecertain allmovingpartshave stopped

@ Never attempt to make any adjustments while the

engine is running (except when specitically recom-

mended by themanufacturer).

+

! oo, o+0L+0++0u++o.+++

ATTENTIONIt! BECOME ALERTLI! YOUR SAFETY IS INVOLVED, 1

Page 3

CONGRATULATIONS on your purchase of a Sears

Craftsman Edger. tt has been designed, engineered and

manufactured togive youthe best possible dependability

and per/ormanceo

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Deparlment. We have competent, well-trained

technicians and the proper tools to service or repair this

unit,.

Please read and retain this manual.. The inslruc!ions will

enable you to assemble and maintain your edgei: prop-

erlyo Always observe the "SAFETY RULES."

MODEL

NUMBER 536,797540

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ON THE FRAME OF THE

EDGER BEHIND THE ENGINE.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN ASAFE

PLACE FOR FUTURE REFERENCE..

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears Store for details.

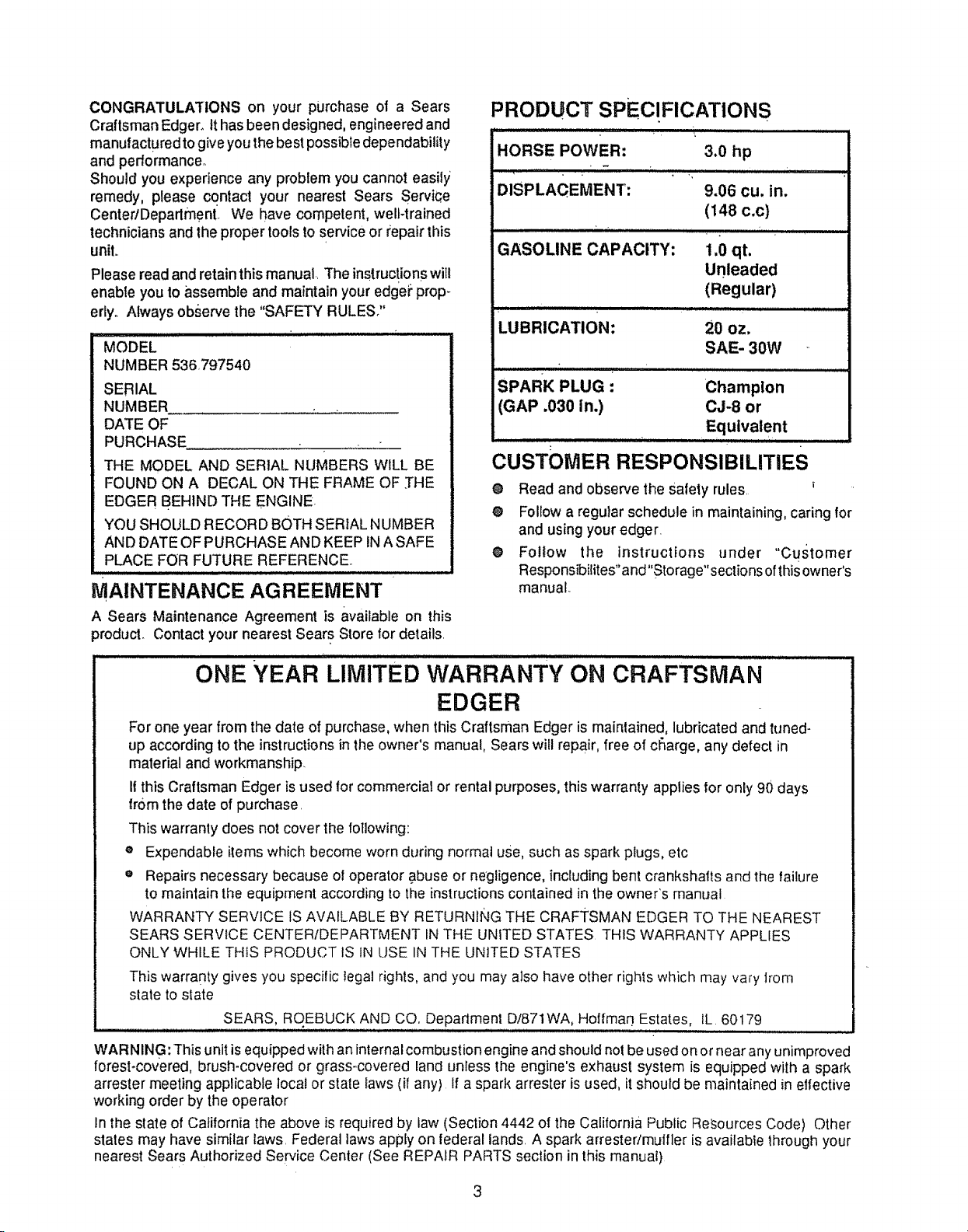

PRODUCT sPEC!FICATIONS

" " i i i i lll l i

_HORSE POWER; 3.0 hp

DISPLACEMENT: 9.06 cu. in.

(148 c.c)

GASOLINE CAPACITY: 1,0 qt.

Unleaded

(Regular)

20 oz.

SAE- 3OW

SPARK PLUG : Champion

(GAP .030 in.) CJ-8 or

Equivalent

CUSTOMER RESPONSIBILITIES

e Read and observe the Safety rules.

@ Follow a regular schedule in maintaining, caring for

and using your edger.

@ Follow the instructions under "Customer

Responsibilites"and"Storage" sections of thisowner's

manual

ONE YEAR LIMITED WARRANTY ON CRAFTSMAN

EDGER

For one year from the date of purchase,when this Craftsman Edger is maintained, lubricated and tuned-

up according to the instructions in the owner's manual, Sears will rePair, free of cl_arge, any detect in

material and workmanship

I! this Craftsman Edger is used for commercial or rental purposes, this warranty applies for only 90 days

{rbmthe date of purchase.

This warranty does not cover the following:

e Expendable items which become worn during normat use, such as spark plugs, etc

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure

to maintain the equipment according to the instructionscontained in the owner's manual

WARRANTY SERVICE ISAVAILABLE BY RETURNING THE CRAFTSMAN EDGER TO THE NEAREST

SEARS SERVICE CENTERIDEPARTMENT IN THE UNITED STATES THIS WARRANTY APPLIES

ONLY WHILE THiS PRODUCT tS IN USE IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have other righls which may vary trom

state to state

SEARS, ROEBUCK AND CO. Depadment D/871WA, Hoffmar] Estates, {L 60179

WARNING: This unit is equipped with aninternal combustion engine and should not beused on or near anyunimproved

foresFcovered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark

arrester meeting applicable local or state taws (if any) If a spark arrester is used, it should be maintained in effective

working order by the operator

In the state of California the above is required by law (Section 4442 of the California Public Resources Code) Other

states may have similar laws. Federal laws apply on federal lands A spark attester/muffler [savailable lhrough your

nearest Sears Authorized Service Center (See REPAIR PARTS section in this manuaI)

3

Page 4

TABLE OF CONTEN rs

SAFETY RULES ,_......................................... 2

PRODUCT SPECIFICATIONS ...................... 3

CUSTOMER RESPONSIBILITIES ..... 3,12,13

WARRANTY .................................................. 2

TABLE OF CONTENTS .............. ................... 4

CONTENTS OF HARDWARE PACK ............ 5

ASSEMBLY ................................................ 6-7

INDEX

A

Adjustments:

Carburetor................................ 15

Assembly ..........................................6-7

Tools Required ............................ 6

To Assemble ........................... 6-7

B

Belt:

Removal/Replacement ................14

Blade:

Replacement ..........................14,15

CarburetorAdjustment...................15

Check List:

Operation ...........................................7

Maintenance ............................ 12

Clutch ......................._......................8,9

Controls,Edger ..............................8,9

Customer Respons_ilities.°.3,12,13

General Recommendations ....12

Lubrication.......................... 12,13

Edger ...............................................12

Er_jlne ...............................12,13

/kit Cleaner, Engine...................13

Spark Plugs ....................................13

Engine:

Air Cleaner .................................13

Oil Change ....:........................... 12

Oil Level ...................................9,12

Oil Type ................................3,9,12

Preparation ..................................9

Starting................................................11

Storage...........................................16

Edger Tips .......................................11

Fuel:

Type ........................................................9

Storage ..........................................16

General Recommendations .........12

Lubrication:

Edger ......................................12

Engine .......................................12,13

Oil:

Cold Weather Conditions ......9,12

Engine ..............................................9,12

Storage............................................16

Type ......................................3,9,12

Operation ..........................................8-11

Operating Your Edger ......................9

OPERATION..., ........................................ 8-11

SERVICE AND ADJUSTMENTS .., ........ 14-15

STORAGE .............................................. ,....16

TROUBLE SHOOTING ............................... 17

REPAIR PARTS (EDGER)..; ................ 18-24

REPAIR PARTS (ENGINE) ................... 25-28

PARTS ORDERING/SERVICE .....Back Cover

E

PartsBag..............................................5

PrimerButton.......,........................8,9

ProductSpech'ications.................. 3

Repair Pads:

Edger ................................................18-24

Engine ..................................25-28

F

Safety Rules ....................................2

Service and Adjustments ..........t4-15

Carburetor.................................15

V-Belt:

G

L

O

Removal/Replacemer_t ....................14

Specifications......................................3

Starting the Engine ...........................11

Stoppingthe Edger ..._..............................9

Storage.............................................16

Table of Contents .............................4

ThrottleControl...............................9

TroubleshootingPo{nts ..................... 1 7

Warranty...............................................2

P

R

S

T

W

Page 5

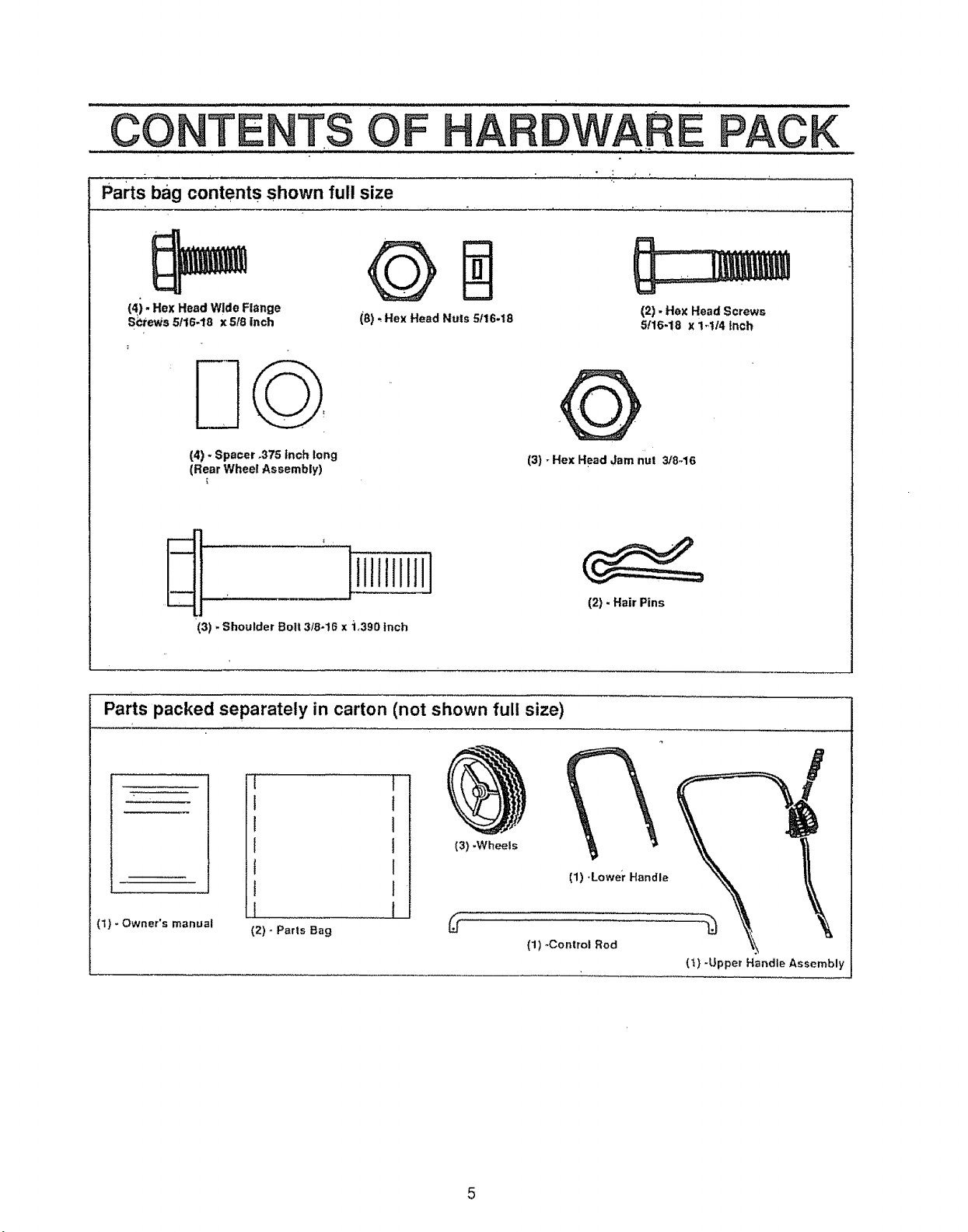

CONTENTS OF

Parts bag contents shown full size

ARDW'ARE

PACK

(4i" Hex Head Wide Range

S_tews 5/16-18 x 518 inch

(4) -Spacer .375 inch Gong

(Rear Wheel Assembly)

(3) -Shoulder Bolt 3/8-!6 x 1,390 inch

Parts packed separately in carton (not shown full size)

(8) * Hex Head Nuts 5t16-18

(3) - Hex Head Jam n'ut 3/8-16

1

(2) - Hex Head Screws

5116-18 x 1,1/4 inch

(2) - Hair PEns

.....t,

l

1

f

f

J

(1} - Owner's manual ._

(2)- Parts Bag

(3) -Wheels

(1) -Lowe;r Handle

(1) -Control Rod

(t) -Upper Handle Assembly

Page 6

EMBLY

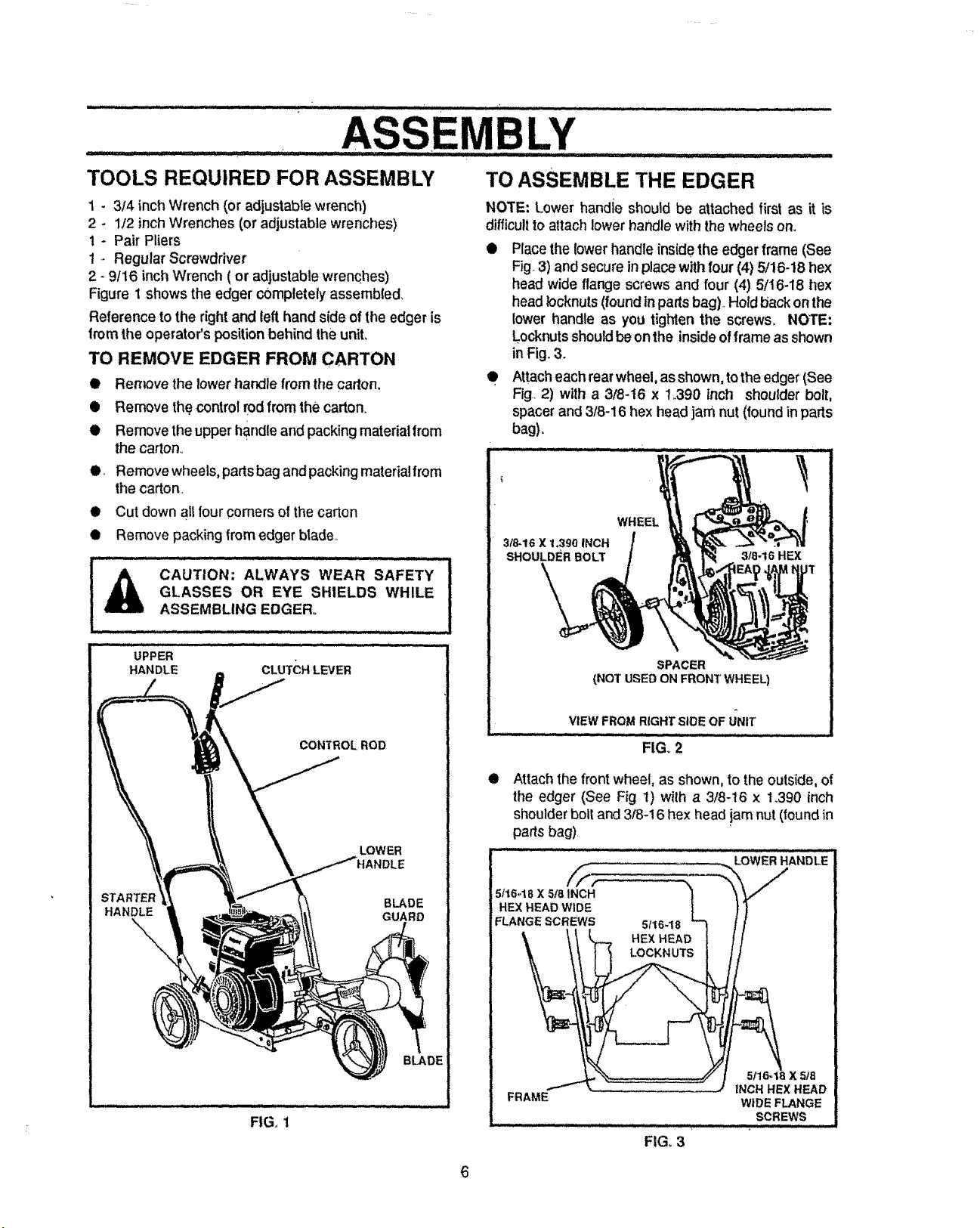

TOOLS REQUIRED FOR ASSEMBLY TO ASSEMBLE THE EDGER

1 - 314inch Wrench (or adjustable wrench)

2 - 1/2 inch Wrenches (or adjustable wrenches)

1 - Pair Pliers Ill

1 - Regular Screwdriver

2- 9/!6 inch Wrench ( or adjustable wrenches)

Figure 1 shows the edger completely assemb(ed_

Reference to the rightand left hand side of the edger is

from the operator's position behind the unit.

TO REMOVE EDGER FROM CARTON

tt

Remove the lower handle from the carton.

e

Remove the control rodfrom the carton.

e

Remove theupper handleandpackingmaterialfrom

the carton_

e.. Remove wheels,partsbagand packingmaterialfrom

the carton.

• Cut downall four comersof the carton

• Remove packingfrom edgerblade_

....,_ CAUTION: ALWAYS WEAR 'SAFETY !

GLASSES OR EYE SHIELDS WHILE |

ASSEMBLING EDGER.

NOTE: Lower handle should be attached first as it is

difficult to attach lower handle with the wheels on.

Place the lower handle inside the edgerlrame (See

Fig.3) and secure inplace withfour (4) 5/16-18 hex

head wide flange screws and four (4) 5;/16-18 hex

head Iocknuts (found inparts bag), Hold back on the

lower handle as you tighten the screws,. NOTE:

Locknuts should be on the inside of frame as shown

in Fig. 3.

• Attach each rear wheel,as shown, to the edger (See

Fig 2) with a 3/8-t6 x i_390 inch shoulder bolt,

spacer and 3/8-16 hex head jam nut (found in parts

bag).

........... ............ _ L ....

WHEEL

3/8-16 X 1,390 INCH

SHOULDER BOLT 318-16 HEX

1

FIG. 1

SPACER

(NOT USED ON FRONT WHEEL)

VIEW FROM RIGHT SIDE OF UNIT

FIG. 2

ill Attach the front wheel, as shown, to theoutside, of

the edger (See Fig 1) with a 3/8-t6 x 1.390 inch

shoulder boll and 3/8-16 hex head jam nut (found in

parts bag)

_: ii ,i i, LowER HANDLE ....

HEX.EADW_OE | t/

FLANGE SCREWS 5t16-18 _'3 { /

\ \\ % HE .E O1 //

I_" 7"7: .. -': ..j INCH HEXHEAD

FRAME WIDE FLANGE

....................1# °,,°,,ox,,=

...... : , ,iuLJ

FIG, 3

SCREWS

6

Page 7

ASS L¥

" • ' _ u,1,,i,iii, t ....'

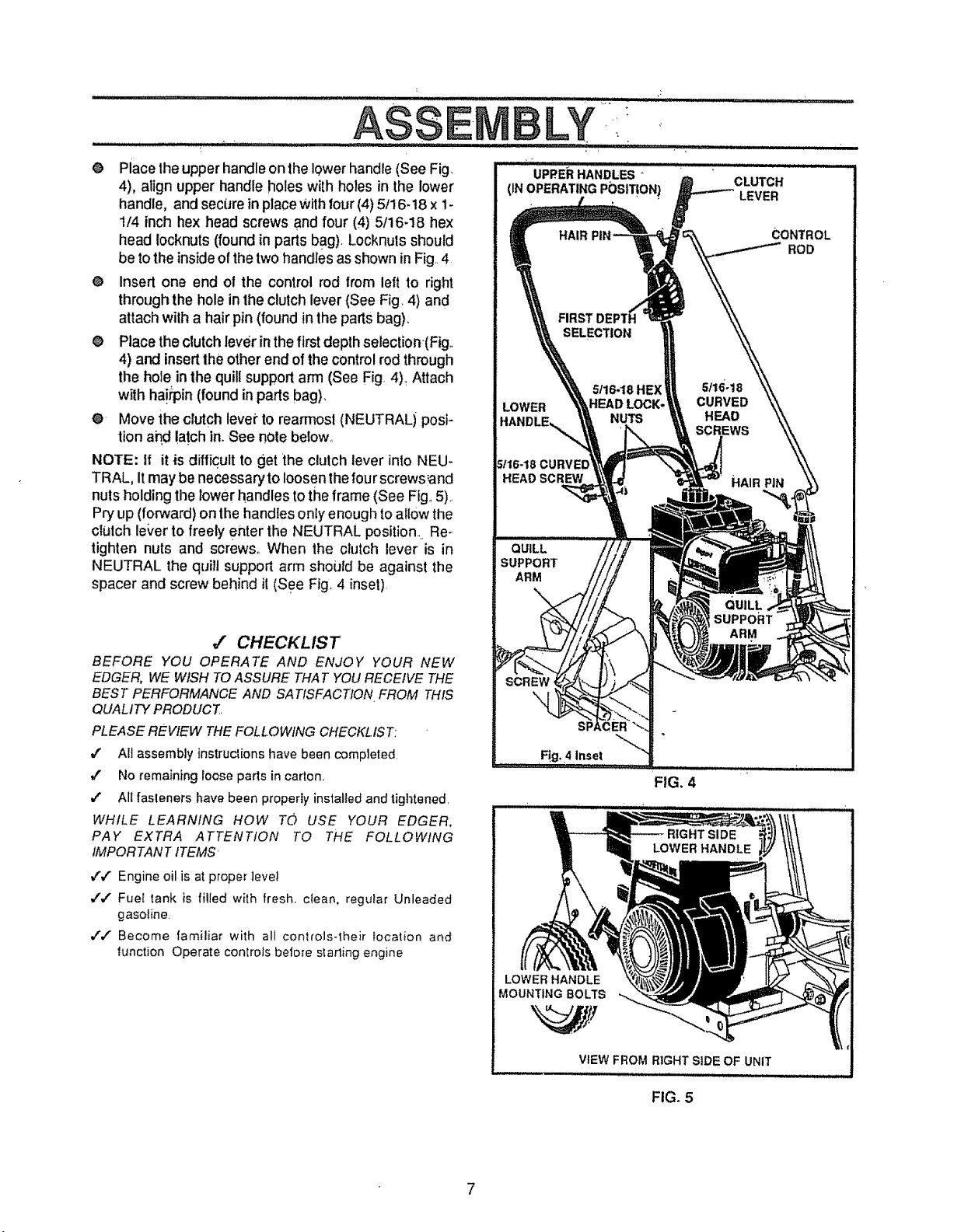

• Place theupper handle on the lower handle (See Fig.

4), aiign upper handle holes with holes in the lower

handle, and secLJreinplace Withfour (4) 5/16-18 x 1-

1/4 inch hex head screws and four (4) 5/16-18 hex

head locknuts (found in parts bag). Locknuts should

be to the insideof the two handles asshown in Fig..4

O Insert one end ol the control rod from left to right

through the hole in the clutch lever (See Fig, 4) and

attach with a hair pin (found in the parts bag),

O Place the clutch lever inthe first depth selection-(Figo

4) and insert the other end of the control rod through

the hole in the quill support arm (See Fig. 4)_Attach

with ha!qoin(found in parts bag),

@ Move the clutch levei"to rearmost (NEUTRALi posi-

tion ahd !a!ch in. See note below_

NOTE: tf it is difficult to get the clutch lever into NEU-

TRAL, It may be necessary to loosen the four screws'and

nuts holding the lowerhandles to the frame (See Fig•.5).

Pry up (forward) on the handles onty enough to allow the

clutch le_,erto freely enter the NEUTRAL position.. Re-

tighten nuts and screws° When the clutch lever is in

NEUTRAL the quitl support arm shoiJid be against the

spacer and screw behind it (See Fig. 4 inset),

J CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

EDGER,WE WISHTOASSURE THATYOURECEIVETHE

BEST PERFORMANCEAND SATISFACTION.FROM THIS

QUALITYPRODUCT

PLEASEREVIEWTHEFOLLOWINGCHECKLIST:

4' Aft assemblyinstrucl[onshave beencompleted.

J Noremainingioosepartsin carton..

,/ All {asleners have been properly installed and tightened,

WHILE LEARNING HOW TO USE YOUR EDGER,

PAY EXTRA ATTENTION TO THE FOLLOWING

1MPORTANTtTEMS'

JJ' Engine oil is at proper level

,/'v" Fuel tank is filled with fresh• ctean, regutar Unleaded

gasoline.

,/,f Become familiar wilh all controls-their Iocafion and

function Operate conlrolsbefores_,arling engine

UPPER HANDLES °

(IN OPERATING POSIT!ON!

HAIR CONTROL

SELECTION

LOWER HEAD LOCK. CURVED

HANDLE_ NUTS HEAD

ED

HEAD SCREW

QUILL

SUPPORT

ARM

F!g. 4 Inset

LOWER HANDLE

MOUNTING BOLTS

ii,,, ,, ,,,

CLUTCH

LEVER

ROD

5f16-18 HE]< 5116-18

SCREWS

HAIR PiN

QUILL

SUPPORT

ARM

FIG. 4

FIGo 5

Page 8

OPERATION

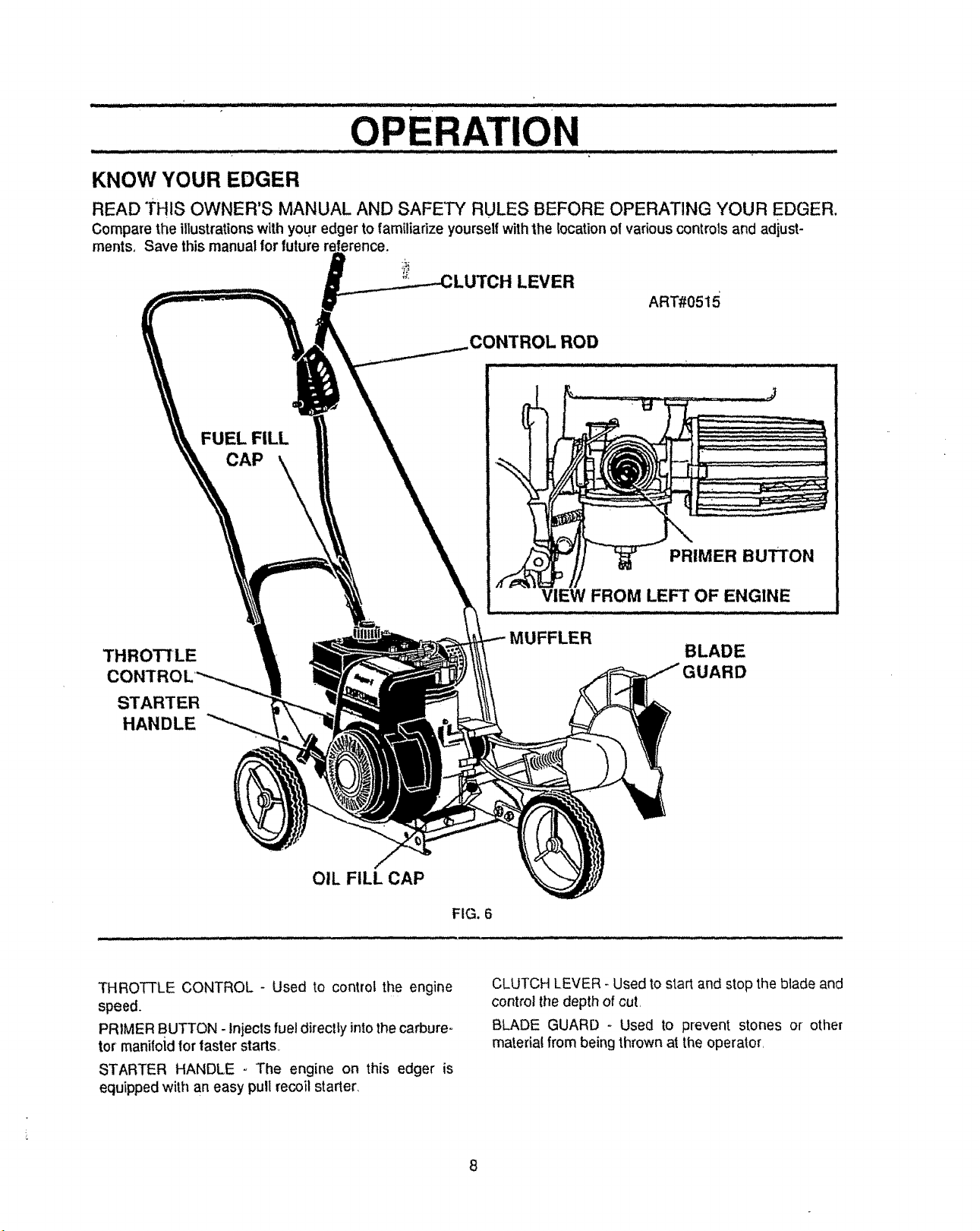

KNOW YOUR EDGER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR EDGER.

Compare the illustrationswith you? edger to familiarize yourselfwith the location of various controls and adiust-

merits, Save this manual forfuture

LEVER

ART#0515

CONTROL ROD

FUEL FILL

CAP \,_

PRIMER BUTTON

THROTTLE

CONTROL

STARTER

HANDLE

OIL FILL CAP

THROTTLE CONTROL - Used to control the engine

speed.

PRIMER BUTTON - Injects fuel directly into the carbure o

tot manifoid for faster starts,

STARTER HANDLE - The engine on this edger is

equippedwith an easy pull recoil starter_

VIEW FROM LEFT OF ENGINE

BLADE

ARD

FIG. 6

CLUTCH LEVER - Used to start and stop the blade and

control the depth of cut

BLADE GUARD - Used to prevent stones or other

material from being thrown at the operator

Page 9

............................................ERA'rUo............•.....

The operationof this edgercan resultinforeign objectsbeing'thmwn int0the eyes,

which can result in severe eye damage. Always Wearsafety glasses oreye shields

whileoperatingthe edger.

We recommend Standard safety glasses or Wide Vision Safety Mask for over your

: :: ::! !: i ii,ul,,ll,u,ull, i i i,,i _ .......... ,

HOW TO USE YOUR EDGER

glasses,,

TO STOP EDGER

O

To stop the engine, make sure the clutchlever is all

the way back (or up) and move the throttlecontrol

lever to the STOP position

. ,i IIIIIIlU'IHIIn"Ii,ilnl _ -

CAUTION: NEVER LEAVE THE EDGER IUNATTENDED WHILE THE ENGINE IS i

RUNNING. ALWAYS DISENGAGE THE ! J

CUTTING BLADE AND STOP THE I

ENGINE. , " I

TO USE THROTTLE CONTROL

O Run at fullengine speed during normal user

O. Push throttle control lever up to increase speed;

down to decrease speed,

TO USE PRIMER BUTTON

e Push pdmer button five (5) times (see Fig. 6)o Wait

about two (2) seconds between each push.

NOTE: Do not use primer to restart a warm engine after

a short shutdown,

TO USE THE CLUTCH LEVER

e Start the engine and move the clutch lever forward

(or down) to engage the cutting blade.

e Select the edging depth you need There are 5

selections up to 2-3/4 inches deep,,

IMPORTANT: IFVERY DEEP EDGING ISREQUIRED,

WE RECOMM EN DTHAT A SHALLOW

C[,ITBE MADE FIRST, THEN CUTS AT

GREATER DEPTHS UNTIL THE

DESIRED DEPTH IS OBTAINED

TATING BLADE. THE BLADE CAN

CAUTION; KEEP AWAY FROM THE RO- I

CAUSEiNJURY. " I

:7 _ ]_III11]111 H ,llrllll , "r' I 11111]11111_I,t I

BEFORE STARTING ENGINE

PRE-USE CHECK OF CONTROLS

Al!controls should becheckedfor proper func!ionbefore

servicingor starting the engine.

O Move the clutch leverintoall six (6) positionsirl the

selectorplate° Make sure theclutch lever snaps into

all six(6) holes, (Fig. 6)

O Return the clutch lever to the rearmost hole in the

selectorplate

FILL/ADD OIL:

The engine on thisedger was shipped with littleor nooi!,

Add oilbefore you start the engine,

OIL RECOMMENDATIONS

Only use highquality detergent oi1rated withAPI service

classification SG Select the"oil's SAE viscositygrade

according to your expected operating temperature:

32OF ' ]

COLDER<< ! - _>WARMER

5W30 SAE30

NOTE: Although•multi-Viscosity oits(5W30, 10W30, etc.)

improvestarting incoldweather,thesemultFviscosity oils

willresuti inincreasedoilconsumptionwhenused above

32°F Check yourengineoillevel morefrequently toavoid

possible engine damage from running low on oil

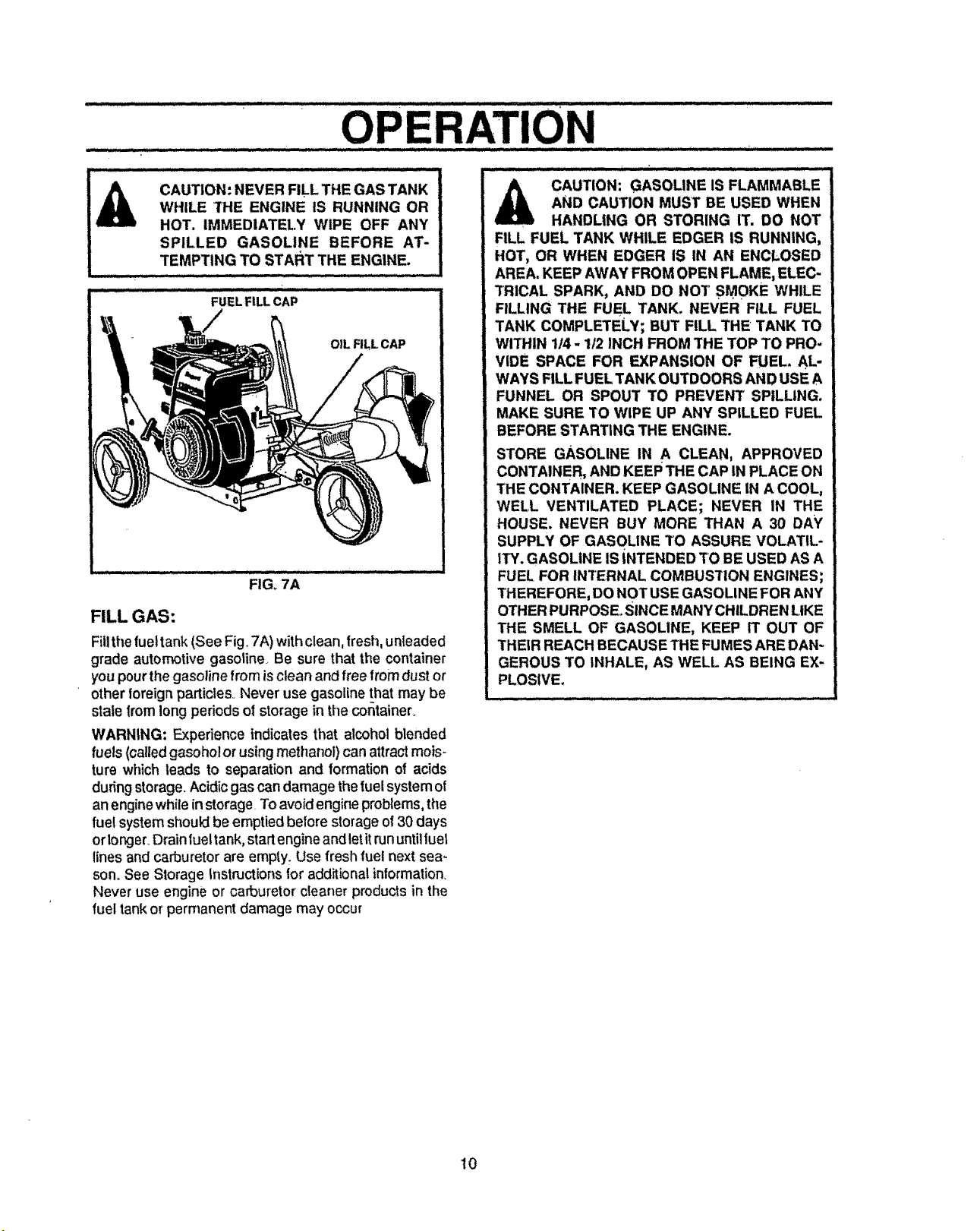

TO ADD ENGINE OIL

@ Place the edger on a level surface

@

Remove the oil fitl cap (Fig 7A)

e

Fill the engine crankcase, pouring slowly Do not

overfill. For approximate capacity see PRODUCT

SPECIFICATIONS on page 3 of this manual

®

Reinstall the oil fi!l cap and tighten securely.

®

Check oil before each use. Add if needed

®

Change oil afterthe first2 operating hours and every

25 operating hours thereafter.

_J

t

Page 10

WHILE THE ENGINE IS RUNNING OR

CAUTION: NEVER FILL THE GAS TANK

HOT, IMMEDIATELY WIPE OFF ANY

SPILLED GASOLINE BEFORE AT-

TEMPTING TO START THE ENGINE,

FIGo7A

FILL GAS:

Fillthefueltank(See Fig. 7A) withclean, fresh,unleaded

grade automotive gasoline_ Be sure that the container

you pour the gasoline from isclean and free from dust or

otherforeign particles.. Never use gasoline that may be

stale fromlong periods of storage in the container.

WARNING: Experience indicates that alcohol blended

fuels (called gasoho! or using methanol) can attract mois-

ture which leads to separation and formation of acids

dudng storage. Acidic gas can damage thefue!system of

anengine while in storage. Toavoid engine problems, the

fuel system should be emptied before storage of 30 days

or lor_jer_Drain fuel tank, start engine andletitrununtil fuel

lines and carburetor are empty_ Use fresh fuel next sea-

son. See Storage Instructions for additional information_

Never use engine or carburetor cleaner products in the

fuel tankor permanent damage may occur

AND CAUTION MUST BE USED WHEN

CAUTION: GASOLINE IS FLAMMABLE

HANDLING OR STORING IT. DO NOT

FILL FUEL TANK WHILE EDGER IS RUNNING,

HOT, OR WHEN EDGER IS IN AN ENCLOSED

AREA. KEEP AWAY FROM OPEN FLAME, ELEC-

TRICAL SPARK, AND DO NOT SMOKE WHILE

FILLING THE FUEL TANK. NEVER FILL FUEL

TANK COMPLETELY; BUT FILL THE TANK TO

WITHIN 1/4 - 1/2 INCH FROM THE TOP TO PRO-

VIDE SPACE FOR EXPANSION OF FUEL. AL-

WAYS FILL FUEL TANK OUTDOORS AND USE A

FUNNEL OR SPOUT TO PREVENT SPILLING.

MAKE SURE 1'O WIPE UP ANY SPILLED FUEL

BEFORE STARTING THE ENGINE.

STORE GASOLINE IN A CLEAN, APPROVED

CONTAINER,. AND KEEP THE CAP IN PLACE ON

THE CONTAINER. KEEP GASOLINE IN A COOL,

WELL VENTILATED PLACE; NEVER IN THE

HOUSE, NEVER BUY MORE THAN A 30 DAY

SUPPLY OF GASOLINE "tO ASSURE VOLATIL-

ITY. GASOLINE IS INTENDED TO BE USED AS A

FUEL FOR INTERNAL COMBUSTION ENGINES;

THEREFORE, DO NOT USE GASOLINE FOR ANY

OTHER PURPOSE. SINCE MANY CHILDREN LIKE

THE SMELL OF GASOLINE, KEEP IT OUT OF

THEIR REACH BECAUSE THE FUMES ARE DAN-

GEROUS TO INHALE, AS WELL AS BEING EX-

PLOSIVE.

Jj...,.ll_ Ii i. _....,_

10

Page 11

TO START THE ENGINE

Before starting the engine, be sure you have read and

understoodall the instructionson the precedingpages.

The edgerisequippedwithe recoilsta_er.The operation

ofthe engine ts controlledby tile throttlecontroliever.

O Pul!the clutch lever allthe way back (or up) to the

rearmosthole to raise and disengage the btade,,

o

Movethethrottlecontrollever(See Fig,6) totheRUN

position.

O

Pushprimer button five (5) times (see Fig. 6)_ Wait

about two (2) seconds between each push_

NOTE: Do not use primer to restart a warm engine alter

a short shutdown.

0 To start engine, grasp the engine starter handle

firmlyWithyour righthand

O Holdthe edger handle firmly with your lefthand:

O Pullup sharplyon the recoil starterhandle..DO NOT

allowthe starterrope tosnapback,letitrewind slowly

while holding the starter handle.

NOTE: tf enginefails to start after three (3) pulls,push

primerbutton two (2) times and pullstarter rope again.

O Whenthe enginestarts..Pushthrottlecontrolleverup

to increasespeed; down todecrease speed..Runat

full engine speed during normaluse

NOTE: The cutting blade speed is controlled by the

engine speed. To reduce the cuttingblade speed, push

downon the throttlecontrollever_To increasethe blade

speed, pushthe throttlecontrol lever up.

O To stopthe engine, make sure the clutchlever is all

the way back (or up) and move the throttle control

leverto the STOP position..

CAUTION: NEVER RUN THE ENGINE IN-

DOORS OR IN A POORLY VENTILATED

AREA. ENGINE EXHAUST CONTAINS

CARBON MONOXIDE_ AN ODORLESS

GAS AND DEADLY GAS.

KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING

PARTS ON THE ENGINE OR EDGER,

WARNING - AVOID THE MUFFLER AND

SURROUNDING AREAS (SEE FIG. 6).

TEMPERATURES, MAY EXCEED 150oF.

EDGING TIPS

O

Edging is best performed when conditions are dry. If

the soil is to wet,did becbmes packed inand around

the blade causing premature belt wear and de-

creased performance

0 If dirt does become packed around the blade, stop

the engine, remove the spark plug wire, and remove

the packed debris before continuing to edge.

0 If very deep edging is required, we recommendthat

a shallow cutbemade first,then cuts atgreater depth

until the desired depth is obtained_

0 Uniform edging can be performed when the blade

guide rides on and against the surface which you are

edging

@ Edging can be Customized by varying the numberof

passes and by the distance your blade is from the

surface you are edging

1t

Page 12

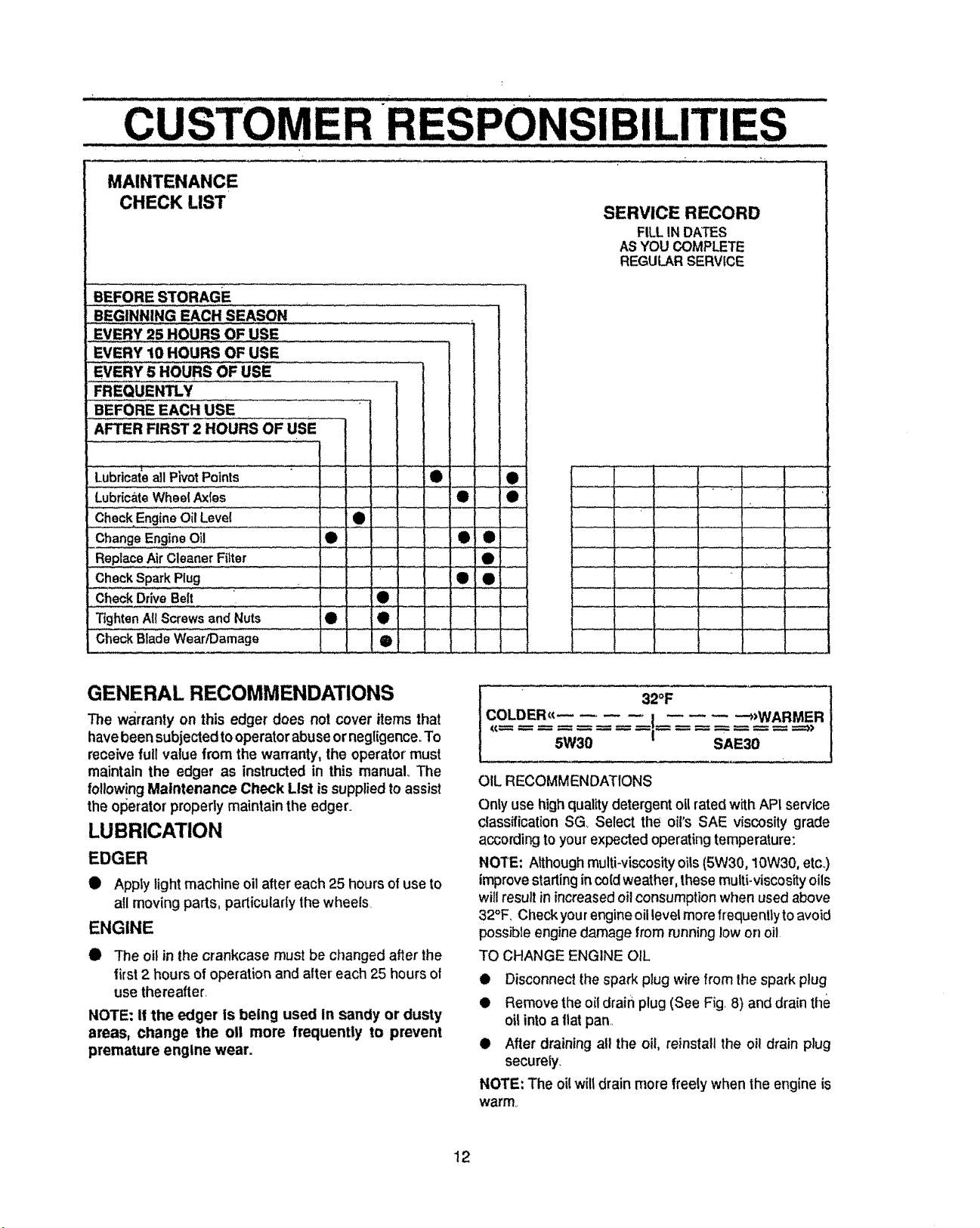

CUSTOMER RESPONSIBILITIES

MAINTENANCE

CHECK LIST

BEFORE STORAGE

BEGINNING EACH SEASON

....EVERY 25 HOURS OFUSE

EVERY 10 HOURS OF USE

EVERY 5 HOURS OF USE

FREQUENTLY

BEFORE EACH USE

AFTER FIRST 2 HOURS OF USE

SERVICE RECORD

FILLIN DATES

ASYOU COMPLETE

REGULARSERVICE

LubricateallP_votPoints

LubricateWheelAxles

CheckEngine OilLevel

ChangeEngineOi!

ReplaceAir CleanerFitter

Check Drive Belt

Tighten All Screws and Nuts

Check Blade Wear/Damage

P_

..... e

GENERAL RECOMMENDATIONS

The warranty on this edger' does not cover items that

havebeen subjected tooperatorabuse ornegligence. To

receive full value from the warranty, the operator must

maintain the edger as instructed in this manual.. The

followingMaintenance Check List is supplied to assist

the operator properly maintain the edger.

LUBRICATION

EDGER

• Apply light machine oil after each 25 hours of use to

all moving parts, particularly thewheels.

ENGINE

The oil in the crankcase must be changed after the

first2 hours of operation and alter each 25 hours of

use thereafter.

NOTE: If the edger is being used In sandy or dusty

areas, change the oll more frequently to prevent

premature engine wear.

e

e

e

e

e

e

COLDER<_ ,,I *>WARMERs>

OIL RECOMMENDATIONS

Only use highquality detergentoil rated with APt service

classification SG Select the oil's SAE viscosity grade

according to your expected operating temperature:

NOTE: Although multiwiscosity oils (5W30, 10W30, etc.)

improve starting in cold weather, thesemulti-viscosity oils

will result inincreasedoil consumption when used above

32°F. Check your engine oil levelmore frequently to avoid

possible engine damage from runninglow on oil

TO CHANGE ENGINE OIL

• Disconnect the spark plug wire from the spark plug

! Remove the oil drain plug (See Fig 8) and drain the

oil into a fiatpan..

i After draining all the oil, reinstall the oil drain plug

securely.

NOTE: The oilwilt drain more freely when the engine is

warm

f

32OF

5W30 SAE30

12

Page 13

- CUSTO ...................."....................................ESPONSm.. 'lLmTl

O Remove the oilfillcap (see Fig,,7A),

e Fill the engine crankcase, pouring slowly. Do not

overfill. Foi" approximate capacily see PRODUCT

SPECIFICATIONS on page 3 of this manual,

e Reinstall the 0il fill cap and tighten securely,

NOTE: The quillassembly bearings are factory sealed

and willrequire no lubrication.

e Reconnect the spark plug wire on the spark plug.

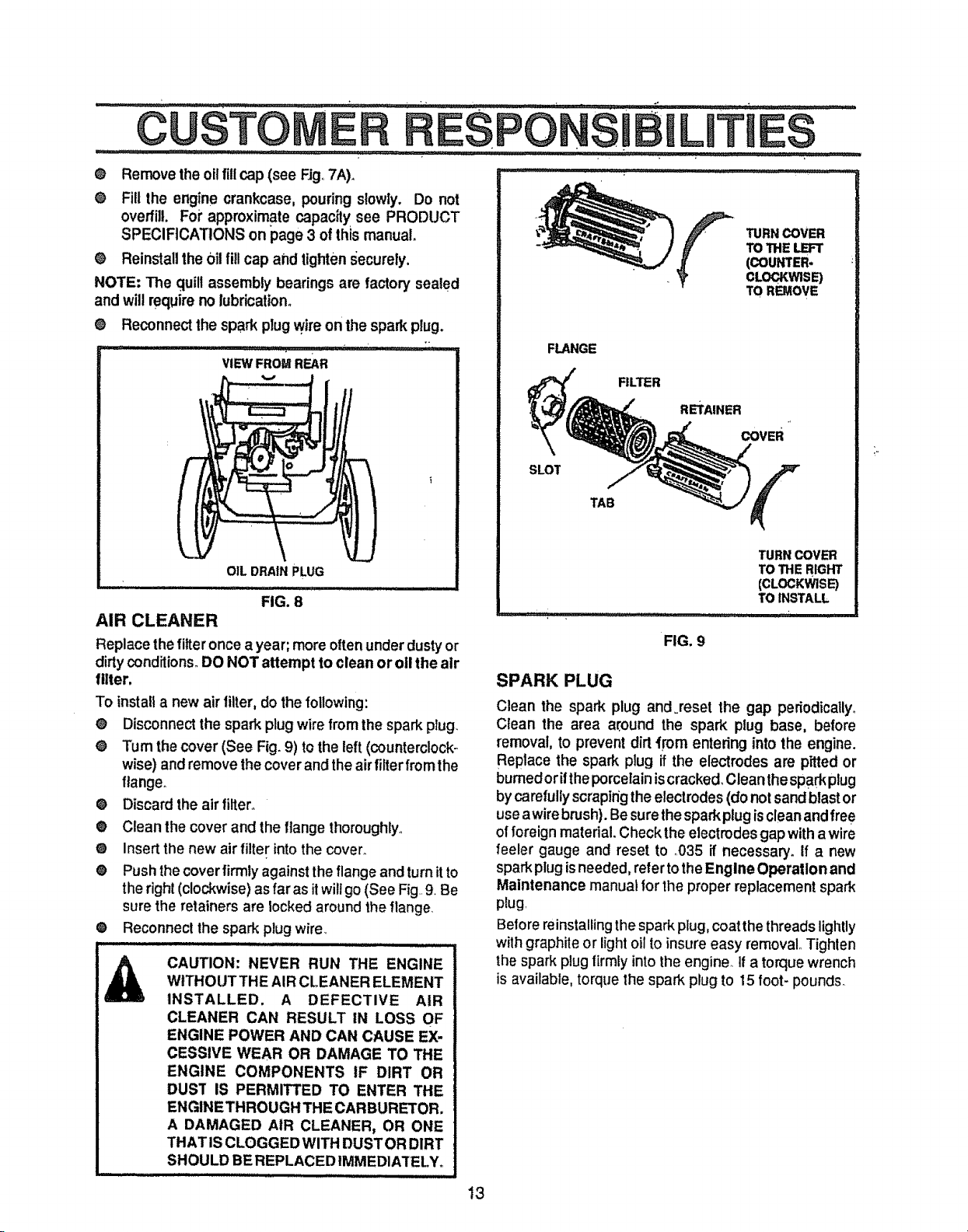

i=,l '_1= r_l _Vl,Ii r I ,=,,=l,,ul_ H"

F.o=

V

OILDRAINPLUG

,,,_,_,r::_:::: FIG, 8

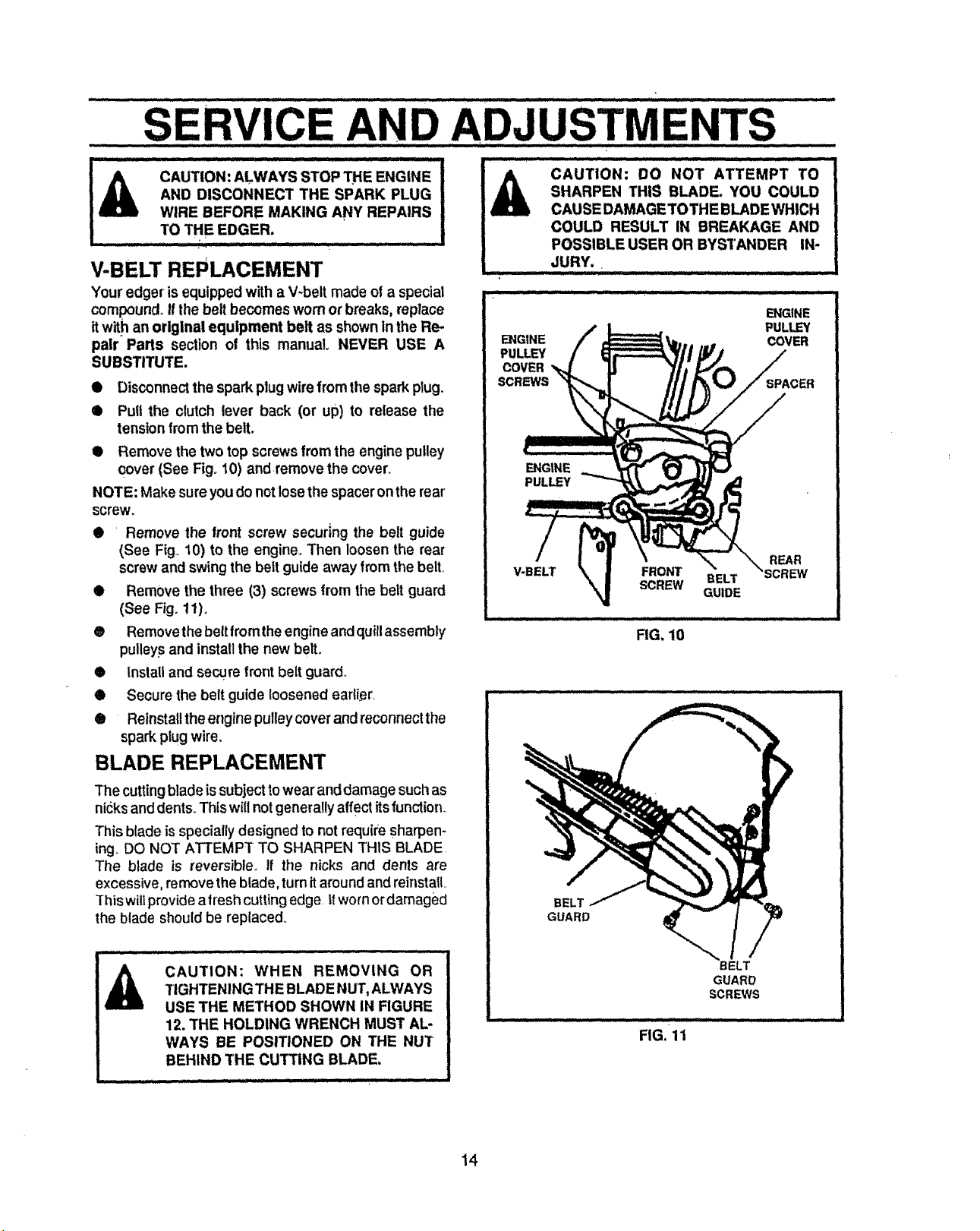

AIR CLEANER

Replace the filteronce a year; moreoftenunder dustyor

dirtyconditions°DO NOT attempt to clean or oll the air

filter,

To instalta new airfilter,dothe following:

e Disconnectthe spark plugwire from the spark plug.

e Turn the cover (See Fig.9) to the left (counterclock-

wise) andremove the cover and theairfilter from the

flanger

@ Discard the air filter.

e Clean the cover and the flange thoroughly_

e Insert the new air filter into the cover.

@ Push the cover firmly against the flange and turn itto

the right (clockwise) as far as itwilt go (See Fig,,9. Be

sure the retainers are locked around the flange,

• Reconnect fhe spark plug wire_

CAUTION: NEVER RUN THE ENGINE

WITHOUT THE AIR CLEANER ELEMENT

INSTALLED. A DEFECTIVE AIR

CLEANER CAN RESULT IN LOSS OF

ENGINE POWER AND CAN CAUSE EX-

CESSIVE WEAR OR DAMAGE TO THE

ENGINE COMPONENTS IF DIRT OR

Dus'r IS PERMITTED TO ENTER THE

ENGINETHROUGH THE CARBURETOR,

A DAMAGED AIR CLEANER, OR ONE

THAT ISCLOGGEDWITH DUSTOR DIRT

SHOULD BEREPLACED IMMEDIATELY°

IIIIIII IIII ii i i

FLANGE

FILTER

RETAINER

SLOT

TAB

FIG. 9

SPARK PLUG

Clean the spark plug and =reset the gap periodically.

Clean the area around the spark plug base, before

removal, to prevent dirt _[om entering into the engine.

Replace the spark plug if the electrodes are pitted or

burned or ifthe porcelain iscracked. Clean thesparkplug

bycarefully scraping the electrodes (do not sand blast or

usea wire brush). Be surethe spark plug iscleanand free

of foreign material. Check the electrodes gapwith awire

feeler gauge and reset to ,,035 if necessary. If a new

spark plug isneeded, refer to the Engine Operation and

Maintenance manual for the proper replacement spark

plug

Before reinstalling the spark plug, coat the threads lightly

with graphite or light oil to insure easy removal° Tighlen

the spark plug lirmly into the engine,, If a torque wrench

is available, torque the spark plug to 15 foot- pounds_

13

TURNCOVER

TOTHE _

(COUNTER.

CLOCKWISE)

TO REMOVE

COVER

TURN COVER

TO THE RIGHT

(CLOCKWISE)

TOINSTALL

"1

Page 14

SERVICE AND ADJUS rMEN rs

AND DISCONNECT THE SPARK PLUG |

CAUTION: ALWAYS STOP THE ENGINE I

WIRE BEFORE MAKING ANY REPAIRS |

............;toT,EEDGER....... i

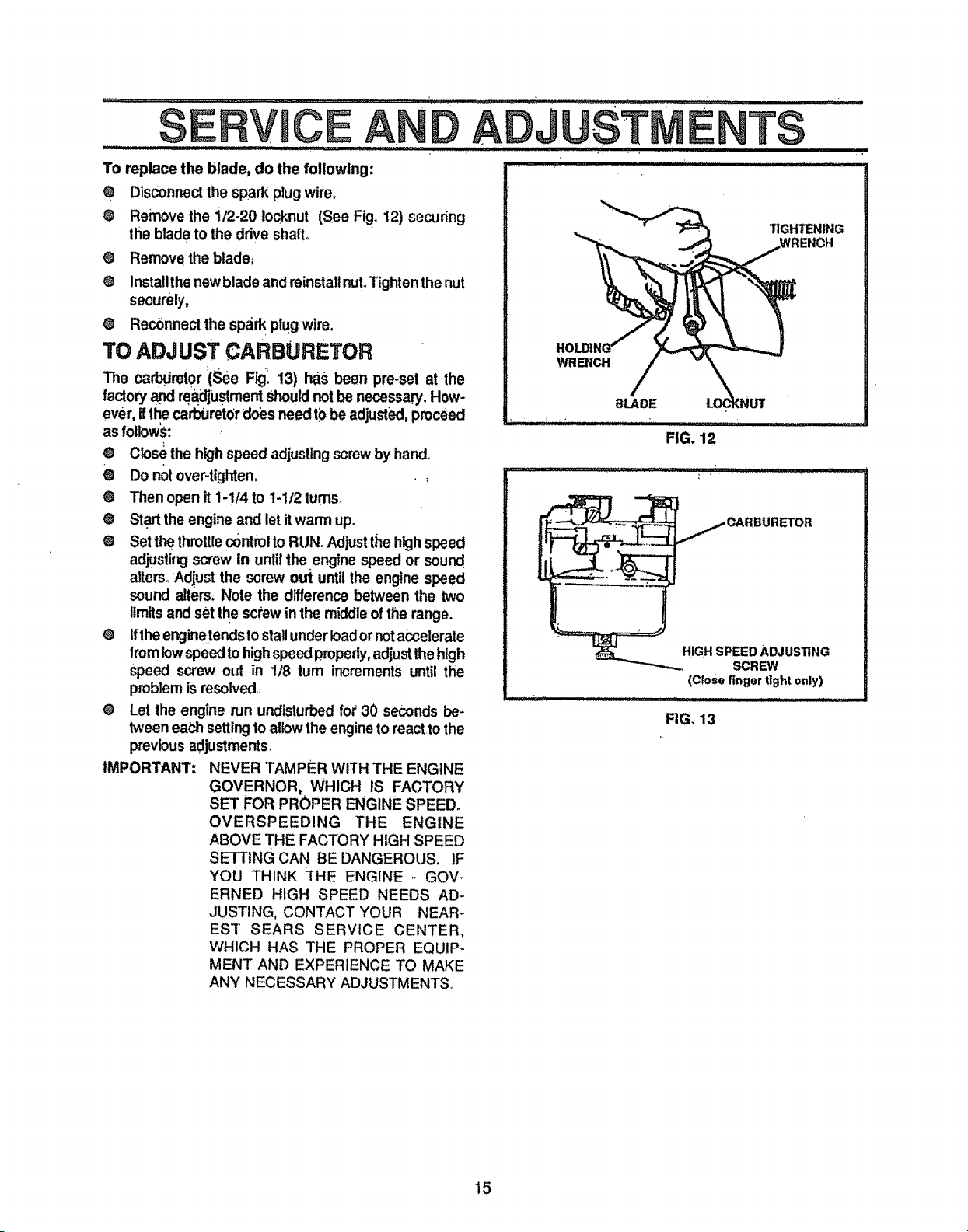

V-BELT REPLACEMENT

Your edger is equippedwith a V_beitmade of a special

compound°If the belt becomes worn or breaks, replace

itwith an original equipment belt as shown in the Re-

pair Parts section o! this manual. NEVER USE A

SUBSTITUTE.

@ Disconnectthe sparkplug wirefrom the sparkplug.

@ Pull the clutch lever back (or up) to release the

tensionfrom the belt.

• Remove the twotop screws from the engine pulley

cover (See Fig° 10) and.remove the cover.

NOTE: Make sure youdonot losethe spacer onthe rear

screw.

@ ' Remove the front screw securing the belt guide

(See Fig..t0) to the engine. Then loosen the rear

screw and swing the belt guide away from the bell

€ Remove the three (3) screws from the belt guard

(See Fig°11)o

@ Remove the belt from the engine andquill assembly

pulleys and install the new belt.

@ Install and secure front belt guard,,

@ Secure the belt guide loosenedeart[er_

® Reinstall the engine pulley cover and reconnect the

spark plug wire.

BLADE REPLACEMENT

SHARPEN THIS BLADE. YOU COULD

CAUTION: DO NOT ATTEMPT TO

CAUSE DAMAGETOTHE BLADE WHICH

COULD RESULT IN BREAKAGE AND

POSSIBLE USER OR BYSTANDER IN-

JURY,

_7 -- = I i iiiiiii iiii iiiiii iii jji !uii i1[ iii iii

ENGINE

ENGINE

PULLEY

COVER

ENGINE

PULLEY

V-BELT FRONT

SCREW BELT

GUIDE

PULLEY

COVER

REAR

RG. 10

The cutting blade is subject to wear and damage such as

nicks and dents_Th_swillnotgenerally affect its function,_

This blade is specially designed to not require sharpen-

ing_DO NOT ATTEMPT TO SHARPEN THIS BLADE

The blade is reversible,, if the nicks and dents are

excessive, remove the blade, turn itaround and reinstall

This willprovide atresh cutting edge, _!worn ordamaged

the blade should be replaced.

CAUTION: WHEN REMOVING OR

TIGHTENING THE BLADE NUT,ALWAYS

USE THE METHOD SHOWN IN FIGURE

12. THE HOLDING WRENCH MUST AL-

WAYS BE POSITIONED ON THE NUT

BEHIND THE CUTTING BLADE.

BELT

GUARD

ELT

GUARD

SCREWS

FIG, 11

14

Page 15

: :: : ,, _iiii,ii

SERVHCE

To replace the blade, do the following:

O Disconnect the spark plugwire.

Q Remove the 112-20 Iocknut (See Fig° 12) securing

the blade to ttie drive shall

O Remove the blade_

O Insta!lthe newblade and reinstall nutoTighten the nut

securely,

• Re_nnect the spark plug wire.

I':,,ADJUSTME

l'T_ j I I IIII I II III"I I JIII II 11111IIIUU

TO ADJUST CARBURETOR

The carl_Jretor'(See F_. 13) has been pre-set at lhe

factoryand rea_djustmentshouldnotbe necessary_How-

ever, ifthe carburetordoes need to be adjusti_l,proceed

as followS:

O Closethe high speed adjusting screwby hand.

® Do not over-tighten. .

O Then open it 1-!/4 to t-1/2 turns.

O Start the engine and let it warm up.

O Setthe.throttle c0ntiol toRUN. Adjust the high speed

ad_sting screw in untilthe engine speed or sound,

a_ers. Adiust the screw old untilthe engine speed

sound alters, Note the difference between the two

limits and set the screw in the middle of the range.

O Iftheenginetends to stallunder Ioador notaccelerate

fromlow speed toh_ghspeed properly,adjustthe high

speed screw out in 1/8 turn increments until the

problem is resolved.,

O Let the engine run undisturbed for 30 seconds be-

tweeneach setting to allow the engine to react to the

previous adjustments.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED°

OVERSPEEDING THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BE DANGEROUS, 1F

YOU THINK THE ENGINE - GOV-

ERNED HIGH SPEED NEEDS AD-

JUSTING, CONTACT YOUR NEAR-

EST SEARS SERVICE CENTER.

WHICH HAS THE PROPER EQUIP°,

MENT AND EXPERIENCE TO MAKE

ANY NECESSARY ADJUSTMENTS,,

" " T$

i .......................

TIGHTENING

WRENCH

BLADE

FIG. 12

HIGH SPEED ADJUSTING

SCREW

(Close finger tight only)

FIG, 13

15

Page 16

i...... : .......... :: : : ..... _ : ::::: ' ...... .: .... + : + ii_+mlUimL111111¸¸¸

STORAGE

+ ...... ............. ........... : _ + ........ " ............. ENGINE

CAUTION: NEVER STORE YOUR

EDGER INDOORS OR IN AN EN-

CLOSED, POORLYVENTILATED AREA

IF GASOLINE REMAINS IN THE TANK

FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT FROM A FUR-

NACE, WATER HEATER, CLOTHES

DRYER, CIGAREI"r E, ETC.

....... : -: : +++ .

EDGER

0

Clean the edger thoroughly; remove all debris and

wipe the unit dry.

O

inspect the edger for worn or damaged parts and

tighten all loose hardware+

0

Oil allpoints described intheLubrlcatlon paragraph

in+the Customer Responsibilities section of this

manua!:

O

Store the edger in a protected area and cover for

additional protection+

IMPORTANT:

A YEARLY CHECKUP OR TUNE+UP

BY A SEARS SERVICE CENTER IS A

GOOD WAY OF ENSURING THAT

YOUR EDGER WILl. PROVIDE

MAXIMUM PERFORMANCE FORTHE

NEXT SEASON.

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMLNG IN ES-

SENTIAL FUEL SYSTEM PARTS

SUCH AS THE CARBURETOR, FUEL

FILTER, FUEL HOSE, OR TANK DUR-

ING STORAGE, ALSO, EXPERIENCE

INDICATES THAT ALCOHOL-

BLENDED FUELS (CALLED GASO-

HOLOR USING ETHANOL ORMETHA-

NOL) CAN ATTRACT MOISTURE

WHICH LEADS TO SEPARATION AND

FORMAT!ON OF ACIDS DURING

STORAGE+ ACIDIC GAS CAN DAM-

AGE THE FUEL SYSTEM OF AN EN-

GINE WHILE IN STORAGE.

To prevent engine damage (ifedger:is not Usedfor more

than 30 days) followthe steps below,

• To remove gasoline, run the engine until the tank is

empty and the engine stops.,

O

ifyoudo not wantto remove gasbline, a fuelstabilizer

(such as Sears Craftsmanfuel stabilizer No+33500)

may be added to any gasoline left in the tank to

minimize gum deposits and acids, If the tank is

almost empty, mix stabilizer with fresh gasoline in a

separate container and add some to the tank+AL-

WAYS FOLLOW INSTRUCTIONS ON STABILIZER

CONTAINER. THEN RUN ENGINE AT LEAST 10

MINUTES AFTER STABILIZER IS ADDED TO

ALLOW MIXTURE TO REACH CARBURETOR.

STORE EDGER IN A SAFE PLACE. SEE WARN-

ING ABOVE.

O

Storethe edger inthe wheels-down, operatingposi-

tion. If the edger is stored in any other position, oil

from the crankcase could enter the cylinder, causlng

a service problem.

You can keep your engine in good operating condi-

tion during storage by:

• Changing oil+

O

Lubricating the piston!cylinder area, This, can be

done by first removing the spark plug and squirting

clean engine oil intothe spark plug holeoThen cover

the spark plug hole with a rag to absorb oil spray

Next, rotate the engine by pulling the starter'two or

three times. Finally, reinstallspark plug and attach

spark plug wire+

16

Page 17

TROU L SHOOTRNG

TROUBLE

Difficult starting

Englne runs erratic

Cutting blade falls to

turn

Blade fails to cut

properly

::: : :11111111

Excessive vibration

CAUSE

Stale fuel

Defective spark plug

Clogged fuel fil!er

Blocked.fuel line or empty fuel tank

Carburetor outOfadjustment

Fouledspark plug

........... i " ....................................

Clogged air cleaner.•.......... .

Jammed due to foreignobject

Looseblade

Defective V-belt

Defective quill bearings

Damaged or worn blade

= .

CORRECTION

..i..11111............

Drain fuel tank. Fillwilh fresh fuel

Clean and re-gap spark plug-.

r_l_l..i i.....i.ll...lll •. ....i,iiHi

Replace fue!filtero ' '

Clean fuel line;check gas tank.

:--.:-:- ".................. r;,,; " • ......................

Have caP'_Jretoradjusted.

C!ean and adjust gap.

Tap Cleanor replace air cleaner,

Clear obstruction,.

Tighten blade retaining nuL

Replace the V-belL

Replace the bearings.

,iirH LIH..',i.l.....Hii

Reverse blade or replace blade,

Stop engine immediaiely; tighten all bolts. If

vibration continues, take the unit into the

nearest SEARS Service Center_

17

Page 18

CRAFTSMAN 9"- 3 H.R EDGER 536.797540

ENGINE ASSEMBLY 13

12

1

\

I1

10

16

\

NOTE: ALWAYS USE ORIGINAL

EQUIPMENT PARTS Use of service/

replacement parts other than odginal

pads may void your warranty

REF.!

No. !

1

2

3

4 !

5 ,

6

7

8

9

PART NO.

331570

48148

314781

181608

120638

45602

32668

313011

320353

PARTNAME

Engine, Edger Tecumseh 3hp

Screw, 3/8-16 x 1..00

Pulley, Half V3L

Screw, 5/16-24x 1_00HHC

Washer, SPTLK _328x.60x,09

Washer, Flat o333x.87xolt9

Belt, V 4L 32_60LG

Screw and Washer Assembly

Retainer', Bell

REF.

NO.

10

1I

12

13

14

15

16

17

ALL UNNUMBERED

ITEMS ARE INTERCHANGEABLE

WITH OPPOSITE SIDE

PARTNO. PARTNAME

309300

181624

53407

173030

308237

315095

323534-854

308154-854

331585

Cover, Engine Pulley

Screw, 5/16-24x3.00 HHC

Spacer, Sleeve 335x.43x2.37

Screw, 5f16-24x3.75

Spacer, _3221D_562OD 80 TK

Spacer, Sleeve,335xA31x2.50

Frame, Assy Edger

Strap

Owner's Manual

18

!

t8

Page 19

CRAFTSMAN 9" - 3 H.P=EDGER 536.797540

FRONT WHEEL ASSEMBLY

REF°

NO.

1

2

3

4

PARTNO.

51796-854

180077

309902

1498

PART NAME

Arm, Front Wheel Support

Screw, 5/16-!8 x .75

Bolt, o500x°094 HHSH 5116-18

Nut, 5/16-18 REGHEXCTRLK

19

Page 20

CRAFTSMAN 9" - 3 H.P. EDGER 536.797540

N

GUARD ASSEMBLY

REF.

NO.

PARTNO.

1

320222

57072

2

3

120393

4

1498

5

308262

6

411666

7

1501

PARTNAME

Guard, Blade

Bolt, 5116-18x 63 CARR

Washer, Flat .344x 69x 065

Nut, 5116-18 REGHE×CTRLK

Guard, Belt

Screw, 10-16x ,50

Washer, tlat 203x °56 x .040

BLADE ASSEMBLY

9

1E0

11

\

\

8

REF._

NO_

1

2

3

4

5

6

7

8

9

10

11

PARTNO.

120396

308539

308254

1499

308243

411666

336391

315233

412281

20562-853

46023

PART NAME

Washer, Flat .531 x 1.06x .095

Quill Supportt Assembly

Bolt, 500 x 3275 HHSH 318_16

Nut, 3f8-16 REGHXCTRLK

Delfector, Rubber

Screw, 10-16x ,50

Quill Assy, Large Suppoit

Spring, compression

Pin, Spring _250DIAx1.00LG

Blade, Edger 9"

Nut, 12-20 WDFL

20

Page 21

CRAFTSMAN 9"- 3 H.P. EDGER 536.797540

DECALS

\

REFo

NO,

1

2

3

4

5

6

PARTNO.

69711

332077

324860

324475

324476

312548

PARTNAME

Decal, InformationDANGER

Decal; 3°0 HP

Edger/Craltsrr

Decal, Blade F , Edger

Decal, Dangel Blade, Edger

Decal, Warning, Edger Blade

Decal, Quadrant Setector

3

/

!

21

Page 22

CRAFTSMAN 9"- 3 H.R EDGER 536;797540

HANDLE ASSEMBLY

7

3

7

i8

REF.

NO.

1

2

3

4

5

6

PARTNO,

308253-853

580292-853

310146-853

51333

1498

180081

36368

1498

I

'4

PARTNAME

Handle, Lower

Rod, Control 25 65 LG

Handle, Upper

Screw, 5116-18 x ,63

Nut, 5/16-t8 REGHXCTRLK

Screw, 5/16-18xl _25

Pin, Hair ,072 DIAx 1,i3LG

Nut, 5t16-t8 REGHXCTRLK

22

Page 23

CRAFTSMAN 9" - 3 H.P. EDGER 536.797540

DEPTH ADJUST HANDLE ASSEMBLY

12

6

9

12

REF TO

UPPER

REF.

NO.

!

2

3

4

5

6

7

8

9

t0

1t

12

PARTNO.

310052-853

180024

1502

310050-853

180081

25644

1498

56924

310053

1499

311670

1498

PART NAME

Plate, Sector

Screw, t/4-20xl,25 HHC

Nut, 1/4-20 REGHEXCTRLK

Handle, Depth Adiust

Screw, 5/16-18xlo25 HHC

Spdng

Nut, 5/16-18 REGHEXCTRLK

Grip, Hand r75x425

Stud

Nut, 3/8.16 REGHXCTRLK

Strap, Lever

Nut, 5/16-18 REGHEXCTRLK

23

Page 24

CRAFTSMAN 9"- 3 H.P. EDGER 536.797540

WHEEL ASSEMBLY

3

3

Ho. i pARTNO.

331578

,23763

3 41529

4 21882

i

/

1

PARTNAME

Tire & Rim Assembly

Bolt, 500xl .39 HHSH 3/8-16

Nut, 3/8d 6 Jam Nut

Spacer Sleeve .406x _83x.375

24

Page 25

CRAFTSMAN 4-CYCLE ENGINE MODEL NUMBER: 143.953005

131

' \_,_t1_1

f-

312

.224 172

\

238 _.s _"

171

209

ze5 92

93

ze?/

_q

25

Page 26

CRAFTSMAN 4-CYCLE

REF.

NO.

t

2

14

15

!6

17

18

19

20

25

25A

26

26A

3O

40

40

4O

41

41

4t

42

42

42

43

+45

46

48

49

50

60

65

69

70

72

75

80

81

82

83

86

89

90

92

93

100

lo2

103

t10

t19

120

125

125

126

126

130

13t

132

135

PART NO.

0

0

36560

26727

28277

31334

31336

31335

65O548

34593

32600

36552

35883

650802

65O926

359O2

34514

34515

34516

32538B

32548B

32549B

28986

28987

28988

2O381

30963B

32610A

27241

28594

33149A

29745

65O128

27677A"

35863A

27642

26208

30574A

30590A

30591

30588A

650488

610961

611195

65O815

650816

34443A

650872

650814

35182

36437"

36438

36471

36472

29314B

29315C

650694A

6021A

850708

33636

RPM Higl_3300 tO3600

RPM Low t700 to 2000

Cyclinder (tnc+2,20,72;&125)

Dowel Pin

Washer

Governor Rod

Governor Lever

Governor Lever Clamp

Screw 8+32 x 5/16+"

Extension Spring

oi! Seal

Blower Housing Baffla(tnc 262)

Baffle Extension

Screw t/4-20x5/8"

Screw 8-32x21/64"

Crankshaft

Piston, Pin & Ring Set iStd)

Piston, Pin & Ring Set (,.010" OS)

Piston, P+n& Ring Set (°020" OS)

Piston& Pin Assy (Std)(Inc. 43)

Piston & Pin Assy (.010" OS}(Inci 43)

Piston & Pin Assy (.020" OS)(Inc143

Ring Set (Std)

Ring Set (+010" OS)

Ring Set ( 020" OS)

Piston Pin Retaining Ring

Connecting Rod Assy

(IncL 46 & 49)

Connecting Rod Boli

Valve Lifter

Oil Dipper

Camshaft (BCR)

Blower Housing Extension

Screw 10-24xl/2"

Cylinder Cover Gasket

Cyctinder Cover (Incl..75-83 311&31;

Oil Drain Ptug

Oil Seal

Governor Shaft

Washer

Governor Gear Assy (!ncL 8!)

Governor Spool

Screw, 114-20x 1+1/4"

Flywheet Key

Flywheel

Belleville Washer

Flywheel Nut

Solid State Ignition

Solid State Mounting Stud

Screw, Torx T+15, 10-24x1

Ground Wire

Cylinder Head Gasket (Kit)

Cylinder Head (Inci t30)

Exhaust Valve (Std) (lncf 151)

Exhaust Vafve (!/32" OS) (Inc] 15t)

Intake Valve (Std)(lnc1151)

Intake Vatve (1t32"OS (inc1151)

Screw, 5116-18x2"

Screw, 5/16+18x1+1/2"

Washer

Resistor Spark Plug (CJ+8)

PART NAME

ENGINE MODEL NUMBER: 143,953005

REF°

p

NOTE: This engine could have been built with 590688 starter

Refer to the design of the air intake louvers for part identifica-

tion. Individual stadet parts do not interchange

PART NO,

150

31672

t511

31673

169

27234A"

170

27666

171 .

3141O

172

34146

173

35350

174

30200

178

29752

179

30593

182

6201

184

31688A*

t85

345.97

186

31341

20O

33858A

203

31342

20;_

650549

206

610973

209

650139

2o9A

30322

215

3241O

223

65O451

224

32649A*

238

650932

239

34338

241

35797

245

35066

250

35065

260

35585

262

65O737

274

3008tA*

275

30996

277

650493

285

36467A

287

650926

290

29774

292

26460

298

650665

3OO

32660A

301

35355

311

27625

3t2

29673 °

31.3

34080

327

35392

339

28212

340

32661

342

650751

345

32664

370A

36261

370B

35703

370C

36501

380

632589-

390

59O732

40O

36439

includes 26754A, 26756, 27234A, 27272A, 27677A,

29673,30081A, 31688A+36437+

Valve Spring

Valve Spring Cap (Kit}

Valve Cover Gasket

Breather Body

Breather Element

Valve Cover

Breather Tube

Screw 10+24x9/16"

Nut & Lock Washer 1/4-28

Retainer Clip

Screw 1/4-28x7t8"

Carburetor To Intake Pipe Gasket

intake Pipe

Governor Link

ControlBracket (tnci 203,204,206

209,209A)

Compression Spring

Screw 5-40x7t16"

Terminal

Screw 8+32x1!2"

Locknut8+32

ControlKnob

Screw 1t4+20x1"

Intake Pipe Gasket (Kit)

Screw 10-32,_49/64"

Air Cleaner Gasket (Kit)

Air Cleaner Collar

Air Cleanre Filter

Air Cleaner Cover

Blower Housing

Screw 1/4+20xt/2"

Exhaust Gasket

Muffler

Screw tt4-20x 1-314"

Starter Cup

Screw 8-32x 21t64"

Fuel Line

Fuel Line Clamp

Screw 1/4.15x7/8"

Fuel Tank (IncL 292 & 301)

Fuel Cap

Oil Fill Plug (lncl+312)

Oit FillP_ugGasket (Kit)

Spacer

Starter Plug

Spacer

Fuel Tank Bracket

Screw, 1/4-20x7116"'

Heat Baftie

Lubrication Decal

Control Decal

Primer Decal

Carburetor (lnci 184)

Rewind Starter

Gasket Set (lncl items marked ")

PART NAME

26

Page 27

CRAFTSMAN 4-CYCLE ENGaNE MODEL NUMBER: 143.953005

CARBURETOR NO. 632589

REF:I

NO. I

6 I

I6 I

25 I

27 I

28 I

29 I

PART NO.

635289

631615

631767

631184

631183

63259O

6505O6

832164

631867

631024"

632019

63t028"

PART NAME

Carburetor

(Inct 184 of Engine Parts List)

Throttle Shaft & Lever Assy

Throttle Return Spring

Dust Seat Washer

Dust Seal (Throttle)

Throttle Shutter

Shutter Screw

Fuel Fitting

Float Bowl

Float Shaft (Kit)

Float

Float Bowl "0" Ring (Kit)

27

REF.

NO ....

30

31

35

35A

40

41

42

43

44

48

6O

PART NO. PART NAME

631021°

631022

36045

632647

632591

63O74O"

630739

63O736

27110"

631027'

632592

inletNeedle, seat, & Clip (lnc131)

Spring Oflp

Primer Bulb/Retainer Ring

Primer Bulb Filter

Main Adj. Screw Assy (lncl 41 thru 44

High Speed Mixture Screw "O" Ring

High Speed Mixture Screw Washer

High Speed Mixtbre Screw Tension

Spring

Bowl Nut Washer (Kit)

Welch Plug, Atmospheric Vent (Kit)

Repair Kit(tnct Items Marked ")

Page 28

CRAFTSMAN 4-CYCLE ENGINE MODEL NUMBER: 143.953005

RECOIL STARTER 590732

11

/

13

_8

7 _ _,_7

REF'

NO.

o

2

3

4

5

6

7

8

1t

12

13

_3

PARTNO_ PARTNAME

590732

590599A

59060O

590696

590601

590697

590698

590699

590700

59O695

590535

59070t

Rewind Starter

Spring Pin (]ncl 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pufley & Rewind Spring Assy

Starter Housing Assy(40 degree

grommet)

Starter Rope (lg 98"x9/64" dia)

Starter Handle

4

28

Page 29

CRAFTSMAN 4=CYCLE ENGINE MODEL NUMBER: 143.953005

RECOIL STARTER 590688 (OPTIONAL)

REF.

PART NO,

NO.

....590688 .........RewindStader

o

t

590599A

2

59O60O

3

590615

4

590601

590598

5

6

590616

7

59O617

8

590618

lO

590620

tl

59O687

59O535

12

13

590701

PART NAME

Spring Pin (tncl 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spi'ing

Pulley Assy (lncl. 9 & 10)

Spring Cover

Starter Housing Assy(40 d

grommet)

Starter Rope (lg 98"x9/64

Starter Handle

29

Page 30

: : ............ -- ,,',, .... ,;,,,,,,,,,,,,,, ........................ .. ,....... _ H

CRAFTSMAN

OWNER'S

MANUAL

MODEL NO.

536.79754O

HOW TO ORDER

REPAIR PARTS

3 HORSEPOWER

9 INCH

EDGER

Each EDGER has itsown MODEL NUMBER on

a model plate on the frame behind the engine.

Each ENGINE has its Own MODEL NUMBER

found on the BLOWER HOUSING.

Always mention these MODEL NUMBERS when

requesting service or Repair Parts for your

EDGER.

All parts listed herein may be ordered through

any Sears Service Ce nter/Departments and most

Sears Stores,

WHEN ORDERING REPAIR PARTs, ALWAYS

GIVE THE FOLLOWING INFORMATION:

* PRODUCT- "EDGER"

* MODEL NUMBER - 536.797540

"ENGINE MODEL NUMBER - 143.953005

* PART NUMBER

* PART DESCRIPTION

'Your Sears merchandise has added value when you

consider that Sears has service units nationwide staffed

with Sears trained technicians, Professional technicians

specifically trained on Sears Products, having the parts.

tools and equipment to ensure that we meet our pledge

toyou,,,,weservice what we sell,,"

.................................................. :........... _ i,,iml : lllll,ll, I II

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179

331585 t2/02/94 Printed in U,S.A.

Page 31

UAL

MODELO NO.

536.797540

Precaucibn:

Leay sigatodas Uas

reglase instrucciones

de seguddadantesde

operareste equipo

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 ESTADOS UNIDOS

3 CABALLOS DE FUERZA

9 PULGADAS

CANTEADORA

°Montaje

oOperacibn

• Responsabilidades del C|iente

°Servicio y Ajustes

° Partes de Repuesto

Part No 3315850

Page 32

REGLAS DE SEGURIDAD

PRECAUCION: SIEMPRE DESCONECTE EL ALAMBRE DE LA BUJtA Y PONGALO EN

DONDE NO PUEDA ENTRAR EN CONTACTO CON ESTA PARA EV1TAR EL ARRANQUE

POR ACCIDENTE DURANTE LA PREPARACION, EL TRANSPORTE, EL ,_JUSTE O

CUANDO SE HAGAN REPARACIONES

ANTESDECADA USO

Q Lea el manual del dueSocuidadosamente. Familiaricese

completamentecon loscontrolesyconetuso adecuado de

la canteadora. Sepa c6mo pararla y desenganchar los

controlesr&pidamente.

• No opere la canteadora sin user ropeexterior adecuada.

Use zapatos que mejoren el equilibrtoen las superficies

resbalosaso

eli Mantenga el &rea de operad6n despejada de toda la

genre, especialmente, los niSospequeSosy losanimales

dom_sticos,.

• Inspeccione cuidadosamente el _Pea en donde se va a

userla canteadora y remueva todoslos objetosextra_os

SEGURIDAD DEL COMBUSTIBLE

Q Maneje el combustibte con cuidado; es altamente

inflamabie_

• Use un envase adecuado,

O

Revise el sumtnistrode combustibleantes de cada uso,

permittendoque exfsta espaciopare la expansionpues el

calor del motory!o sol pueden hacer que se expanda el

combustible.

O

Uene el estanque de combustible afuera con mucho

cuidado_ Nunca Ilane el estanque de combustible en

recintoscerrados_ Vusiva a colocar ta tapa del estanque

de combustible en forma segura y limpie el combustible

derrama.do,

• Nunca remueva la tapa del estanque de combustible o

agregue combustiblea un motorque est_ funcionando o

que est_ ¢altente.

• Nunca almacene combustible o la canteadora con com-

bustible en el estanque dentro de un ed_cio en donde los

gases pueclan aJoanzar una llama exPuesta.

SEGURIDAD DE OPERACION

• Nunca permitaqua los nihoso adolescentes j6venes

operensucanteadora,Mant_ngalosalejadoScuandoest6

en operacl6n,Nunca permitaque losadultosoperenIs

canteadora!recortadorasinlosconocimientosadecuadgs,

• Siempreusaanteojosde seguridado proteccionespare

los oJosdurantela operaci6no cuandohaga ajusteso

reparacionaspareprotegersusojoscontraobjetosextra_os

quelacanteadorapuedalanzar,

e, Nopongafasmanosnilospiescercao debajode partes

rotatorias_

• Tenga sumo cuidado cuando opere o atraviese entradas

de autom6viles deripio, senderosocamlnos. Mant_ngase

alerta de peligros escondidos otr_ficoo

• Tenga cuidado para evitar resbalarse ocaerse..

• Nunca opere la canteadora sin las protecciones y tas

planchas adecuadas, o sin otrosdispositos de protecci6n

de la seguridad en su lugar.

® Nunc.aoperelacanteadora aaltas vsiocidadesde transporte

ensuperficiesresbalosas_ Mirehactaatr_sytenga cuidado

cuandoretrocedao

• Nunca permtta la presencia de espectadores cerca de la

canteadora.

• Mantenga a losnifos y alos anlmalesdom_sticos atejados

mientras se est_ en operaci6n.

• Nunca opere la canteadora sir]buena vtsibilidado luz_

• No haga funcionar el motor en rectntos cerrados. Los

gases de escape son peligrosos(confienen MONOXtDO

DE CARBONO, UN GAS SIN OLOR QUE CAUSA LA

MUERTE).

• Tome todas las precauciones posibles cuando deje fa

canteadoradesatendida. Pare el motor,

• No sobrecarguela capacidadde laeanteadora tratandode

cantear muy profund_mente a mucha velocldad.

ALMACENAMIENTO CON SEGURIDAD

• Siempre refi_rase ala seccl6n de almacenamiento del

manualdelduefiopare verfficar!osdetatles de importancia

silacanteadora/recortadoraseva aalmacenar porunlargo

perfodode tiempo_

• Nunca almacene ta canteadora/recortadoracon combus-

tible en elestanque de combustible dentro de unedificioen

donde se encuentren presentesfuentes de ignici6n, tales

como los catentadoresde aguao del amblente, secadoras

de ropeyotros artefactosparecidos. Permita que seenfr[e

el motorantes de guardarloen alg0n lugar cerrado.

• Mantenga la canteadora/recortadora en condiclones de

trabajoseguras. Revise todoslos sujetadores a inter€aloe

frecuentes para ver_icar si est&n apretados en forma

segura.

SEGURIDAD DE REPARACIONESIAJUSTES

• Despu,_s de pegarle a obJet0s extraSos, pare el motor.

Remueva el alambre de labujia, y mant6ngalo alejado de

6sta para evitar at arranque por accidente, Inspeccione

cuidadosamente la canteadora/recortadora pare veri|icar

si est& daSada y repare los dafios antes de vofver a

arrancar yoperar la canteadora/recortadora.

• Si la canteadoratrecortadora empieza a vibrar

anorma[mente, pare el motor y revise inmedtatamente la

cause. Lavibraci6n,normalmenteesunavisode problemas.

@ P_velacuchillacuando abandonelaposici6nde operaciSn

Tambi_n, pareelmotor ydesconecte el alambre de tabuifa

antesdedestaponar lacuchillay cuandohagareparaciones,

a,_usteso inspecciones_

• Cuando haga fimpiezas, reparaciones o inspecciones,

apague el motor y asegfirese que todas las partes en

movim!ento se hayan detenido

Q Nunca trate de hacer ajustes mientras el motor estd

funcionando (excepto cuando espec|ficamente Io

recomiendeel fabricante).

2

Page 33

FELIClTAClONESperla compradesuCanteadora!

RecortadoraCraftsmanSears..Hasidodisehada,planificada

y fabricada para darte ta mejor confiabilidad y el mejof

rendimiento posibles

En el caso de que se encuentre con cuaiq uierprobtema que no

pueda solucionar f&citmente, haga el favor de ponerse en

contacto con su Centro/DepartamenEo de Servicio Sears m&s

cercano Sears cuenta con tecnicos bien capacitados y

competentes y con {as herramientas adecuadas para darle

servicio opara reparar esta unidad _

Haga el favor de leer y de guardar este manual Estas

instrucciones le permitir&n montar y mantener su canteadora;

recortadora enforma adecuada. Siempre observe Ias"REGLAS

DE SEGURIDAD.."

NUMERO DE MODELO 536.797540

ESPECIFICACIONES DEL PRODUCTO

C BALLOSDEFUERZA: ,p

DESPLAZAMIENTO "

9,06 pulgadas

cuadradas

(148 c,c )

CAPACIDAD DE

GASOLINA

LuBRIOAOION:

1,0 cuartos

Sin plomo

(regufar)

20 oz

SAE 30W

NUMERO DE SERIE

FECHA DE COMPRA

EL NUMERO DEL MODELO Y EL DE SERIE SE

ENCUENTRAN EN LA CALCOMANIA EN ELBASTIDOR

DE LA CANTEADORNRECORTADORA, DETRAS DEL

MOTOR.

DEBE REGISTRAR TANTO EL NUMERO DE SERIE

COMO LA FECHA DE COMPRA Y MANTENERLOS EN

UN LUGAR SEGURO PARA REFERENCIA EN EL

FUTURO.

ACUERDO DE MANTENIMIENTO

Este producto incluye un Acuerdo de Mantenimiento Sears

Pbngase en contacto con su tiend_ Sears m&s cercana para

informarsesobre losdetalles.

I lU I

BUJIA: Champion

(ABERTURA 0°030 pulg,,) CJ-8 o equivalente

RESPONSABILtDADES DEL CLIENTE

e

Lea y observe las reglas de seguridad

®

Siga unprogramaregular de mantenimienlo, cuidado y uso

de su canteadora/recortadora

O

Siga las instrucciones descritas en las secciones de

"Responsabilidades del Cliente" y "Almacenamiento" de

este Manual det DueSo

GARANTIA LIMEADA DE UN Ai O PARA LA CANTEADORA/

RECORTADORA CRAFTSMAN

Pot uno,_5o a partirdela fecha de compra, cuando esta Canteadora/Recortadora Craftsman se mantenga, iubrique y afinesegun

las instruccionesen el manual del dueSo, Sears i'eparar&, gratis, todo defecto en el material y la mano de obra

Si laCanteadoralRecoriadora Craftsman se usa para fines comerciateso de arriendoo est& garantia se ap_ca solo por 90 dies,

a partir de la fecha de compra

Esta garantia no cubre Io siguiente:

@ Articu!os desgastables que se desgastan durante et us0 normal tales como las buj{as, etc

@ Reparaciones necesarias debido al abuso o a {a negligencia del operador, incluyendosea los cigueSales doblados y a la

lalta de mantenimiento del equipo segun las instrucciones que se encuentran en el manual del dueSo

EL SERVIClO DE GARANTiA ESTA DISPONIBLE AL DEVOLVER LA CANTEADORA/RECORTADORA CRAFTSMAN AL

CENTRO/DEPARTAMENTO DE SERVICIO SEARS MASCERCANO EN LOS ESTADOS UNIDOS ESTA GARANTIA SOLO

SE APLICA CUANDO ESTE PRODUCTO SE USA EN LOS ES'TADOS UNtDOS

Esta Garant{a le otorga derechos legales espec{ticos, y puede que tambi_n tenga olros derechos que varian de estado a estado

SEARS, ROEBUCK AND CO, DepartamentO D1817 WA, Hoffman Estates, LL60179

ADVERTENCiA: Esta unidad viene equipada con un motor de combustion interna y no se debe user sobre, o cerca, deun terreno

no desarrollado cubierto de bosques, de arbustos o de c6sped, a menos que el sistema de escape de!motor venga equipado con un

amortiguador de chispas que cumpla con fas leyes focales o estatales (si existen) Si Seusa un amortiguador de chispas, etoperado;

debe mantenedo en condicionesde trabajo eficientes

Enel estado de Cati|omia, taiey exige 1oanterior (Secci6n 4442 del"California Public Resources Code" (Decrelo de Recursos Publicos

de California)),. Otros estados pqeden contar con otras leyes parecidas. Las {eyesfederales se aplican en Ias tierras {ederales Su

Centro de Servic]o Autorizado Sears m&scercano tiene disponibfe un amortiguador de chispas/silenciador (yea la seccion "PARTES

DE REPUESTO" en este manua!)

3

Page 34

CONTENIDO

REGLAS DE SEGURIDAD .......................... 2

ESPECIFiCAClONES DELPRODUCTO ..... 3

RESPONSABILIDADES DEL CLIENTE ........

.......................................... ................ 3,12,13

GARANTIA ................................................. 2

CONTENIDO .................................................. 4

CONTENIDO DEL PAQUETE CON

ARTICULOS DE FERRETERIA .................. 5

MONTAJE ............................................... 6-7

A

Ajustes:

Carburador .................................... 15

Montaje ................................................6-7

B

Correa:

Rernocl6n/cambio ........................ 14

CuchiUas:

Afilamtento ................................14,15

C

Ajuste del Carburador.................... 15

Listade Revision

Operact0n .................................... 7

Maintenance................................12

Palanca del Embrague ........._.......8,9

Controles, canteadora ..................8,9

Slatar ia Acera ................................. 9

Responsabilidades,dal Cliente..........

.........•...................................... 3,12,13

Recemendaciones Generafes,_ 12

Lubrication ............................12,13

Canteadora........................;..........12

Motor ................................... 12,13

Bujfas ............................................13

Motor:

Cambio de aceite ............... i....... 13

Nivel de aceite ..................................12

Tipo de aceite .............................3,9,t2

Preparacl6n ................................. 9

Armnque ..........................................1t

Almacenamiento...........................16

Consejos para Canteadora ............11

Combustible:

Tipo ................................... ;............9

Almacenamiento....................'.............16

Recomendaciones Generates ...... 12

Lubricaci0n:

Canteadora .................................. 12

Motor .................................... 12,13

Aceite:

Condiciones de clima fr[o ..........9,12

Motor ...................:................... 9,12

Almacenamiento ......................;........16

Tipo .........................................3,9,12

OperactSn................................... 8-11

OperaciSn de la canteadora ..............9

INDICE

E

F

G

L

O

OPERACION ......................................... 8-11

SERViCIO Y AJUSTES ........................ t 4-15

ALMACENAMIENTO .................................... 16

IDENTIFICACION DE PROBLEMAS ........ 17

PARTES DE REPUESTO

(CANTEADORA) (VEA EL INGLES) .... 18-24

PARTES DE REPUESTO

(MOTOR) (VEA EL INGLe:S) ............... 25-28

ORDEN DE PARTEStSERVlCIO. Contratapa

P

Bolsa con laspartes ............................5

Bot0n det cebador..........................8,9

Especificaciones det producto ...........3

R

Partesde repuesto (Yea el manual del

due¢=oen ingt_s) ............................18-28

S

Reglas de seguddad ........................ 2

Servicioy Ajustes ...........................14-15

Ajuste del Carburador .....................14

Correa:

Remoci6n/carnbio..................14,15

Especificaciones................................3

Arranque del motor ...............................11

Parada del tractor ................................9

Almacenamiento ................................16

T

Contenido ..........................................4

Llantas ................_'.................................9

Puntos para la identificacidn de

pmblemas .........................................17

W

Garantfa ..................................................2

4

Page 35

i i L i ............ ,,,,....................................................

CONTENIDO DEL PAQUETE CON ARTICULOS DE FERRETERBA

Contenido de la bolsa con las partes, mostradas del tafio real a menos que se indique

4 - Tom Ilos de brida ancha de

cabeza hexagonal de

5!16-1"8x 5t8 pulg_das

8 * Tuercas de cabeza

hexagonal de 5/16-t8

2 - Torn]llos de cabeza hexagonal

de 5!16-18 x 1-1/4 pulgadas

G

4 - Espactadores (conjunto de la

tueda trasei'a Izqulerda)

Partes empaquetadas en forma separada en la caja de cart6n (no se muestran del tamafio real)

3 - Tuercas de cabeza

hexagonal 3t8-16

2 "Horqulllas

Manual del Duefio

1

f

I

I

I

2 - Bolss con las partes

I

t

1

I

I

(3) ;Rue_a

(1) ,Mango Inferior

I

I - Varilla de control

(1) -Mangos superiores

Page 36

MONrAJE

............ ,....................... _ ,,,,,,,,_,,,,,,,,,,,_,,_ .... ,,..... ,......... ........ .. ..............

HERRAMIENTAS NECESARIAS PARA EL PARA MONTAR LA CANTEADORA

MONTAJE • Ponga etmango inlerior dentro delbastLdordetacanteadora

1 - Ltave de3/4 pulgada (o !lave ajustable) (vea la Fig. 3A) y aseg_relo en su lugar con cuatro (4)

2 - Llaves de !/2 putgada (o llaves ajustabtes) torniItos de brida ancha, de cabeza hexagonal de5!16-18

1- Par de alicates ycuatio (4)tuercasdeseguridad,decabezahexagonatde

1 - Desatotnillador regular 5/16-18 (qua se encuentran en _abolsa con las partes).

2 _ Liave de 9116pulgada (o I_avesajustables) Sujete el mango inferior hacia atr&sa medida que aprieta

lostomitlos.Lastuercasde seguddadse deben encontrar

La Figurai muestra la canteadora completamente montada

Lasreferendasalladoderechoyallado izquierdo delacanteadora

son desde laposidSn deloperador detrAsde la unidad

PARA REMOVER LA CANTEADORA DE LA

CAJA DE CARTON

• Remueva el mango inferior de la caja de cart6no

• Remueva la varifla de control de la caja de cartdno

o Remueva el mango superior y el material de empaque de la

caja de cart6n,

• Remueva las ruedas, la bolsacon faspartesy el material de

empaque de lacaja decart6no

• Corte las cuatro esqutnas de la caja de cartSn_

• Remueva el empaque de la cuchiHade la canteadora

en la parte interior de los dos mangos, segSn se muestra

en la Fig. 3A

O

Adjunte cada rueda trasera, segQn se muestra, ala

canteadora (yea la Fig. 2) con un perno con resalto de 3/

8-16 x t ,390pulgadas, elespaciador y latuerca de cabeza

hexagonalde 31B-16(que se bncuentran en la bolsa con

tas partes).

,, ....... i

L i SEGURIDAD O PROTECCION PARA LOS |

OJOS CUANDO MONTE LA CANTEADORA,

I ..... ............... I

MANGO PALANCA DEL

SUPERIOR

VARILLA DE

PROTECCtONDE

LACUCHILLA

MANGO DEL

ARRANCADOR

FIG, 2

Q

Adjuntela rueda delantera, segOnse muestra, en la parte

exterior de tacanteadora (yea la Fig. 1)con-un perno con

resattode 3t8-.16x 1,.390puigadas y unatuerca decabeza

hexagonal de 3/8-16 (que se eneuentran en la bolsa con

las partes)

........._,,,,,,,,,,,,_, _ --

FIG, 1

_IILL

FIG. 3A

Page 37

TAJE

O Ponga e] mango superior en e] mango inferior (yea ]a Fig

4), alineeelmango superior con losdos agujeros superiores

en el mango inferior y aseg{Jreto en su fugarcon quatre (4)

tornit!os de cabeza hexagonalde 5/16+18x t +t/4pulgadas

yquatre (4) tuercas de seguridad, de cabeza hexagonal de

5/16+18(que se encuentran en [abolsa con laspartes) Las

tuercas de segur]dad se deben encontrar en la parte

interior de los dos mangos, seg_Jnse muestra en +aFig 4

O fnserte un extremo de la varilla de control, desde la

izquierda a la derecha, a tray,s del agujero en ta patanca

del embrague (yea ta Fig,,4) y adjuntelo con una horqui!ta

(que se encuentra en {aboisa con Ins partes)

O Ponga la palanca de{ embrague en la primera profundidad

selecctonabte (yea Ia Fig, 4) e inserte el otto extremo de la

varitla de control a travEs del agujero del brazo de soporte

del cuerpo (vea la Fig, 4)° Adjt_ntela con la horquLtla(que

se encuentra en la bolsa con las partes)

• Mueva la palanca delembrague a la posiciEn m_s trasera

posibte (NEUTRO)y aseg_rela. Vea elaviso acontinuaciEn

AMISO: En el caso de que sea dificil hacer que la palanca del

embrague se meta en NEUTRO, puede set necesario soltar !os

cuatro tornilfos y tuercas que sujetan Ios mangos inferiores al

bastidor (yea la Fig.. 5). Pafanquee (hacia adelante) los man-

gos, sElo lo suficiente parapermitir que Ia patanca del embrague

entre libremente a la posici6n de NEUTRO Vuelva a apretar

Ins tuercas y ios tornillos Cuando la palanca del embrague

est,_ en la postci(_}n de NEUTRO eL Brazo de Soporte de1

Cuerpo tiene que estar en contra del espaciador y del lornillo

delr_s de 6ste (vea la figura insertada dentro de la Fig 4)

MANGOS SUPERIORES

N LA POSICION

E OPERACION)

PBOFUNDIDAD

SELECCIONABLE

TUERCASDE

SEGURIDAD DE

CABEZA

DE5116-18

BRAZO DE

SOPORTE

DELCUERPO

TORNiLLOS

DE CABEZA

HEXAGONAL

DE5t16_18

EMBRAGUE

HORQUILLA

DEL

CUERPO

_J LISTA DE REVISION

ANTES DE OPERAR Y DE DISFRUTAR DE SU

RECORTADORA NUEVO, LE DESEAMOS QUE RECIBA EL

MEJOR RENDIMIENTO Y LAMA YOR SATISFACCIQN DE

ESTE PRODUCTO DE CALIDAD,

HAGA EL FAVOR DE REVISAR LA LISTAA CONTtNUACION;

q Se han completado todas tas instrucciones de montaje

q Noquedan partes suellas en lacaja de cartEn

-V Revise si hay sujetadores sueltos+

AL MISMO TIEMPO QUE APRENDE COMO USAR SU

RECORTADORA, PRESTE ATENCION EX?RA A LOS

PUNTOS DE IMPORTANCIA QUE SE PRESENTAN A

CONTINUACION:

qq El aceite del motor tiene que llegar al nivet adecuado

-,iVElestanque decombustible tieneque eslar lleno congasolina

sin plomo regular, nueva y limpia

-q'qFamiliar[cese con todos los controles + su ubicacion y su

funciSn OpErelos antes de hacer arrancar el motor

PERNOS DE MONTAJE