Page 1

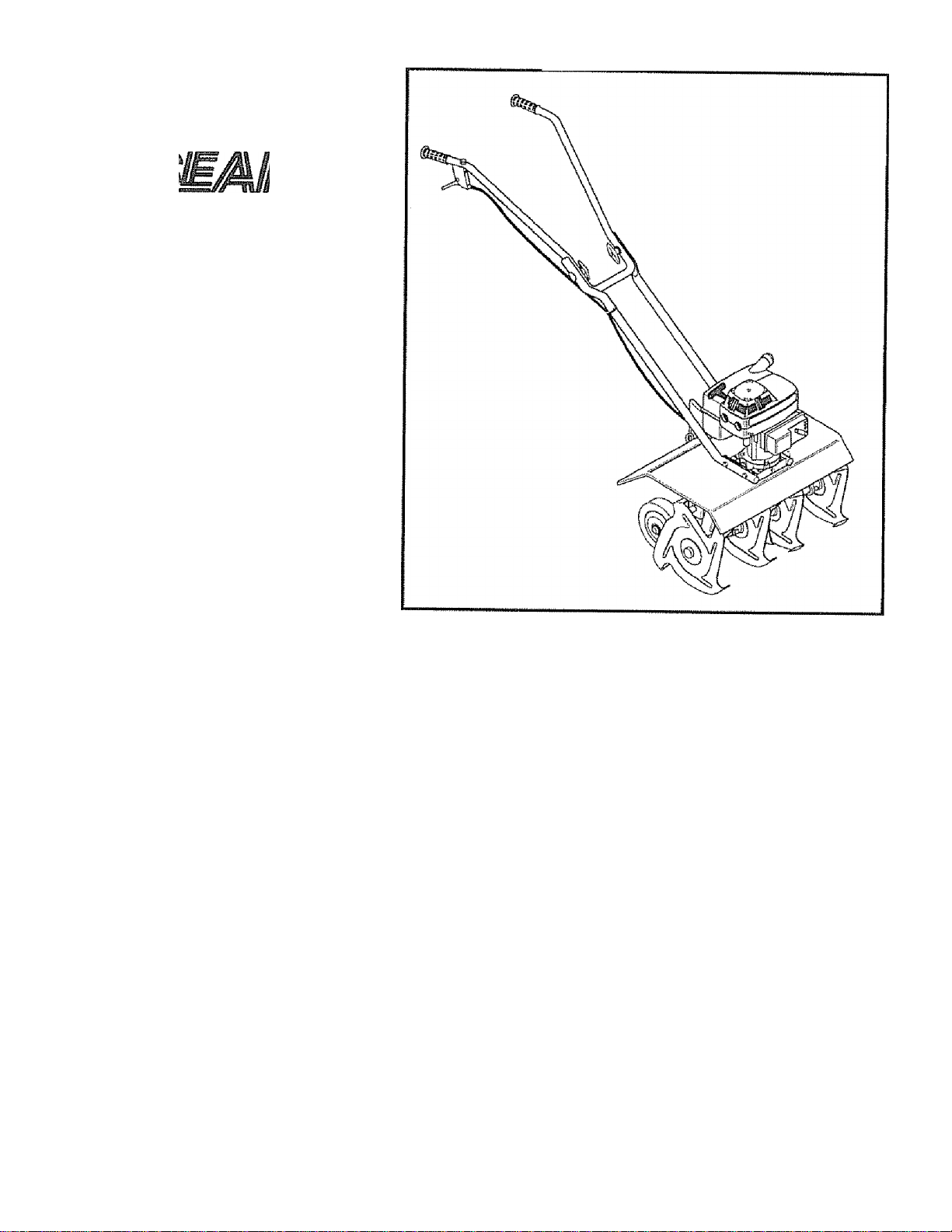

OWNER'S

MANUAL

MODEL NO.

536.797500

Caution:

Read and Follow

Al! Safety Rules

and Instructions

Before Operating

This Equipment

■\"/M ■

№ if :: n.

32.8 cc 2-CYCLE

10 INCH DIAMETER TINES

MINI TILLER/CULTIVATOR

® Assembly

® Operation

® Customer Responsibilities

® Service and Adjustments

® Repair Parts

Ri

SEARS, ROEBUCK AND CO., Hoffman Estates 60179 U.S.A.

Page 2

SAFETY RULES

CAUTION; ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE

IT CANNOT CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING

4

WHEN SETTING-UP, TRANSPORTING, ADJUSTING OR MAKING REPAIRS

IMPORTANT

CACcpy qjaIsidaRDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE RISK OF INJURY YOUR

MINITILLER/CULTIVATOR IS EQUIPPED WITH SUCH CONTROLS DO NOT ATTEMPTTO DEFEATTHE FUNCTION

QP THE OPERATOR PRESENCE CONTROL UNDER ANY CIRCUMSTANCES.

BEFORE USE

® Read the owner’s manual carefully. Be thoroughly farnil*

iar with the controls and the proper use of the mini tiller/

cullivalot. Know how to stop the mini liller/cuitivator and

disengage the confrois quickly.

® Do not operate the mini iiller/cultivator without wearing

adequate outer garments. Wear footwear that will im

prove footing on slippery surfaces

® Keep the area of operation clear of all persons, parlicu-

larly small children and pets.

# Thoroughly inspect the area where the mini tiller/cultiva-

tot is to be used and remove all foreign objects

FUEL SAFETY

® Handle fuel with care; it is highly flammable

# Use an approved container

® Check fuel supply before each use, allowing space for

expansion as the heat of the engine and/or sun can

cause fuel to expand

# Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors Replace fuel tank cap securely and wipe up

spilled fuel

® Never remove the fuel tank cap or add fuel to a running

or hot engine

@ Never store fuei or mini tiller/cultlvator with fuel in the

tank inside a building where fumes may reach an open

flame,.

OPERATING SAFETY

® Never allow children or young teenagers to operate the

mini tiller/cuitivator Keep them away while it is operat

ing. Never allow adults to operate the mini tliler/cultivator

without proper instruction,

# Always wear safety glasses or eye shields during opera

tion or while performing an adjustment or repair to

protect your eyes from foreign objects that may be

thrown from the mini iillef/cultivator

® Do not put hands or feet near or under rotating parts,

® Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads Stay alert for hidden

hazards or traffic.

® Exercise caution to avoid slipping or falling

® Never operate the mini iiller/cultivator without proper

guards, plates, or other safety protective devices in

place.

® Never operate the mini tiller/cuitivator at high transport

speeds on slippery surfaces Look behind and use care

when backing

® Never aliow bystanders near the mini tiller/cuitivator

® Keep children and pets away white operating

® Never operate the mini tiiler/cuitivalor without good

visibility or light

® Do not run the engine indoors. The exhaust fumes are

dangerous (containing CARBON MONOXIDE, an

ODORLESS and DEADLY GAS)

9 Take al I poss ib!e precau tlo ns when lea ving th e m in i til le r/

cultivator unattended - Stop the engine

® Do not overload the mini tiller/cuitivator capacity by

attempting to till too deep at too fast a rate

SAFE STORAGE

® Always refer to the owner's manual instructions for

important details if the minitiiler/cultivator is to be stored

for an extended period

® Never store the mirii tiiier/cultivalor with fuel in the fuel

tank inside a building where ignition sources ate present

such as water and space heaters, clothes dryers, and

the like Aliow the engine to cool before storing in any

enclosure

# Keep the mini tiller/cuitivator in safe working condition

Check ali fasteners at frequent intervals for proper

tightness

REFAiR/AOJUSTMENTS SAFETY

# After striking a foreign object, stop the engine (motor)

Remove the wire from the spark plug, and keep the wire

away from the plug to prevent accidental starting Thor

oughly inspect the mini iiller/cultivator for any damage,

and repair the damage before restarting and operating

the mini tiller/cuitivaior

@ If the mini tiller/cuitivator should start to vibrate abnor

mally, stop thesngirie (motor) and check immediately for

the cause Vibration is generally a warrting of trouble,

® Stop the engine (motor) whenever you leave the operat

ing position. Also, disconnect the spark plug wire before

uriclogglng the tines and when making any repairs,

adjustments, or inspections,

@ When cleaning, repairing, or inspecting, shutoff the

engine and make certain ail moving parts have slopped,

® Never attempt to make any adjustments while the en

gine is running (except when specifically recommended

by the manufacturer)

/4.1

LOOK FOR THIS SY!

ATTENTION!l! BECO]

mOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. iT MEANS№ ALERT!!! YOUR SAFETY IS INVOLVED.

Page 3

CONGRATULATIONS on your purchase of a Sears

Craftsman Mini tiller/culfivalor It has been designed,

engineered and manufactured to give you the best pos

sible dependability and performance

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. We have competent, welt-trained

technicians and the proper tools to service or repair this

unit

Please read and retain this manual. The instructions wHi

enable you to assemble and maintain your mini tiller/

cultivator properly. Always observe the "SAFETY

RULES."

MODEL

NUMBER 536 797500

DATE

CODE

DATE OF

PURCHASE

THE MODEL AND DATE CODE WILL BE FOUND

ON A DECAL ON THESIDEOFTHE MINITILLER/

CULTIVATOR TINE SHIELD

YOU SHOULDRECORD BOTH DATE CODE AND

DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears Store for details

CUSTOMER RESPONSIBILITIES

® Read and observe the safety rules

• Follow a regular schedule in maintaining, caring for

and using your mini tilier/cultfvator

® Foiiow the instructions under "Customer Responsi-

bi!ities"and "Storage” sections ot this owner’s manual

PRODUCT SPECIFICATIONS

HORSE POWER;

DISPLACEMENT:

GASOLINE CAPACITY:

FUEL/OIL MIX RATIO:

SPARK PLUG :

(GAP .035 in.)

WARNING: This unit is equipped with an internal com

bustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine’s exhaust system is equipped

with a spark arrester meeting applicable local or state

laws (if any) if a spark arrester is used, it should be

maintained in effective working order by the operator

in the state of California the above is required by law

(Section 4442 of the Caiifornia Public Resources Code)

Other stales may have similar laws Federal laws apply

on federal lands A spark arrester/muffler is available

through your nearest Sears Authorized Service Center

(See REPAIR p/s,Rj3 section in this manual)

1.6 hp

2.0 cu. in.

(32.8 C.C)

16 oz.

Unleaded

(Regular)

24:1 Gas To Oil

(5 Oz. Oil/1 Gal.

Gas)

Champion

CJ'8Y

LIMITED ONE-YEAR WARRANTY ON CRAFTSMAN

MINI TILLER/CULTIVATOR

For one year from the date of purchase, when this Craftsman Mini tiller/cuilivator is maintained, lubricated, and

tuned up according to the operating and maintenance instructions in the owner's manual, Sears will repair, free

of charge, any defect in materia! or workmanship '

This warranty excludes tine(s), spark piug, and air cleaner which are expendable parts and become worn

during normal use

If this Mini tilier/cuitivator is used for commercial or rental purposes, this warranty applies lor only 30 days from

the date of purchase This warranty applies only while this product is in use the United States WARRANTY

SERVICE IS AVAILABLE BY RETURNING THE MINI TILLER/CULTIVATOR TO THE NEAREST SEARS

SERVICE CENTER IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state

SEARS, ROEBUCK AND CO.,D817WA, Hoffman Estates, IL 60179 USA

Page 4

TABLE OF

rONTFNTS

1 a— a ^ 1

SAFETY RULES

PRODUCT SPECIFICATIONS...,,,.

...

................................

.............

CUSTOMER RESPONSIBILITIES....3,

WARRANTY.....................

TABLE OF CONTENTS

...........................

.................. ...

CONTENTS OF SHIPPING CARTON

OPERATION......

Adjustments:

Carburetor

Assembly..

Tools Requited..............

To Assemble

Carburetor Adjustment

Choke Corttrol ...............

Check List:

Operation

Maintenance

Cleaning

Controls, Mini tiller/cullivator ,9,10

Guttivafing Hints.,

Customer Responsibilities .3,13-15

General Recommendations

Lubrication.....................

Mini tiiler/cultivator

Air Cleaner, Engine

Cylinder Exhaust Potts ..

Spark Plugs

.........................

........................

...................................

A

.

.....

......

.

.

..,6-8

,13

13,14

.

....

„,.17

.6-8

.....

..,,17

,9,11

.....

,.,.15

,, .12

,,.,13

.,..13

,14

14

,14

6

8

...........................

.......................

G

..........

...........................

....

....................................................

....... .........

.........

.........

..........

........

Fuel:

General Recommendations

Hand Grip

Lubrication:

Operation

Operating

Your Mini tiller/cuitivator

Options

.

.......

.......

2

3

.

13-15

........3

........

.

¿j,

....

6-8

,.,9-12

INDEX

Type

.... ..........................

Storage

Assembly

Spark Arrestof

.........

.......

Mini tiiler/cultivator

Engine

..........................

...........................

SERVICE AND ADJUSTMENTS.

STORAGE...........

............................

TROUBLE SHOOTING.....................

REPAIR PARTS

{MIN! TILLER/CULTIVATOR)

REPAIR PARTS (ENGINE)

PARTS ORDERING/SERVICE

F

Safety Ruies

, 11 Service and Adjustments

.............

...................

,,

G

H

L

.......

0

......

................

. ,17

13

.... 8

,13 Tilling Hints...................

.

.. 11

9-12

.....

10

.......

3

.

Carburetor

Specifications

Starting the Engine

Stopping the Mini tiller/cuitivator 10

Storage

Table of Contents

Throttle Control

Tines

Troubleshooting Points .

Warranty

............................

Assembly

Operation

Replacement

..........

..............

........

......... ......

.................

....................

T

............

......................

..............

W

..........

...........16-17

................

................

...........

...........

.Back Cover

s

.........

, 16-17

...........

............

. 11

......

,, . 19

18

19

20-25

26-29

2

, 3

17

4

8

.9

12

, , 16

2

Engine:

Air Cleaner

Gas and Oil Mixture

Preparation

Starting

Storage

.........................

........................

...............................

............................

E

............

....

14

11

10,11

....

11

...

17

P

Parts Bag

Product Specifications

............................

R

Repair Parts:

Mini tiller/cuitivator

Engine.........................

.....

....

5

,.3

20-25

26-29

.

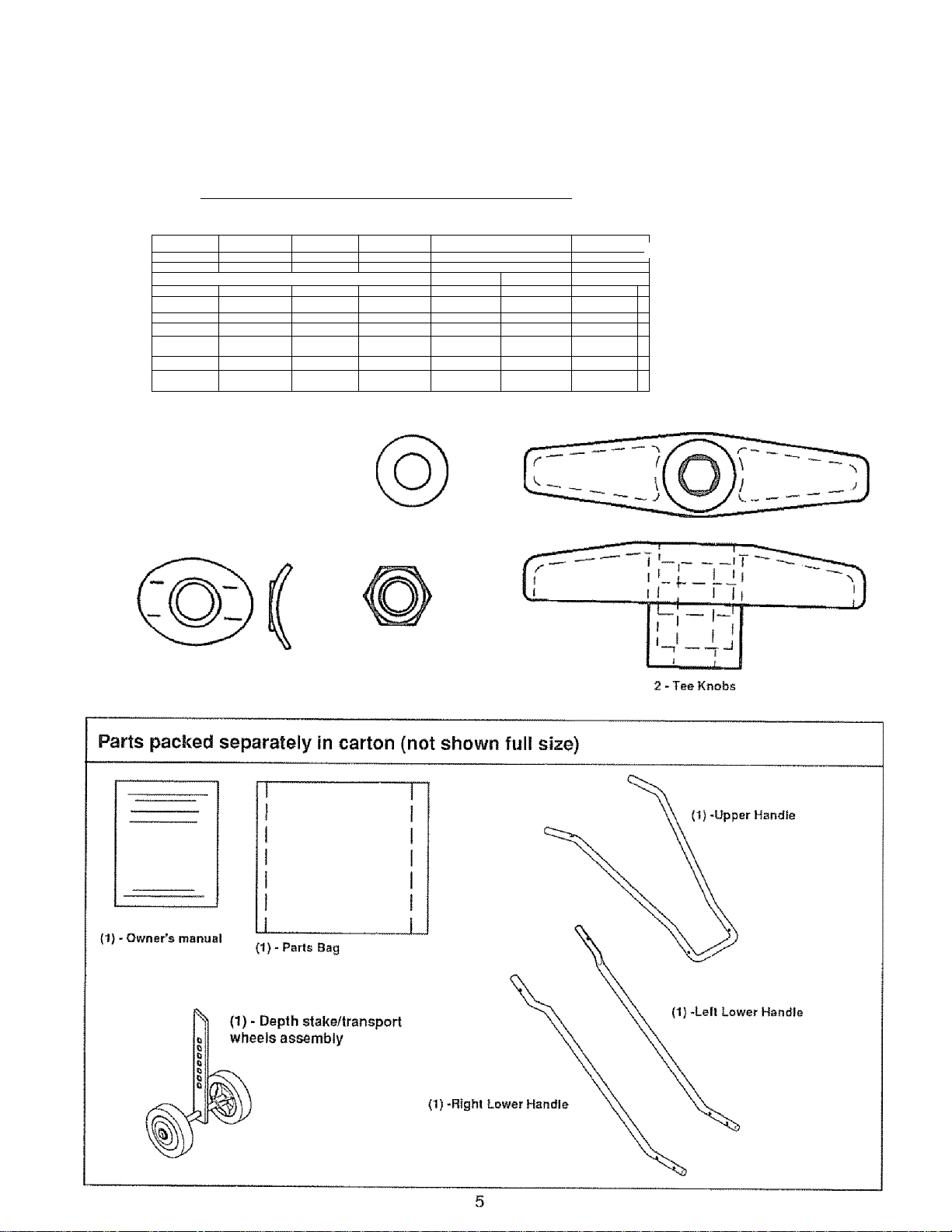

Page 5

CONTENTS OF HABDWARE PACK

CONTENTS OF PARTS BAG (shown actual size)

iiiMiiiii HiiMiHiiuiMmiimuniUiinuuimiui

===@

;

........

f

' ■

. -

big~'~

_____

............

:../

n -

_

b=d

..........

f

VlllliJ

^ 2 - Curved Head Screws

2 - Formed {Curved) Washers

1 - Tie Strap

^

---------

J

T:

-1

_

____

-

----------

..

_

*

2»Hand Grips

2 -11/32 inch Ffatwashers

2-S/16'1BHexNwis

....

1

}

J

.

..............I_

gjiiSSiSI

^

................

SKsSiSSlb

z>

..

'i

[ImOTiTO»

^ 1-10-iex 1-1/2 inch

Washer Head Tap Screw

Page 6

AQQPiiRI Y

CAUTION; ALWAYS WEAR SAFETY

GLASSES OR EYE SHIELDS WHILE

A

TOOLS REQUIRED FOR ASSEMBLY

1-5/16 inch Wrench {or adjustable wrench)

2 - 7/16 inch Wrenches (or adjustable wrenches)

1 ' Regular Screwdriver

1 - Pair Scissors

1 ' Hammer

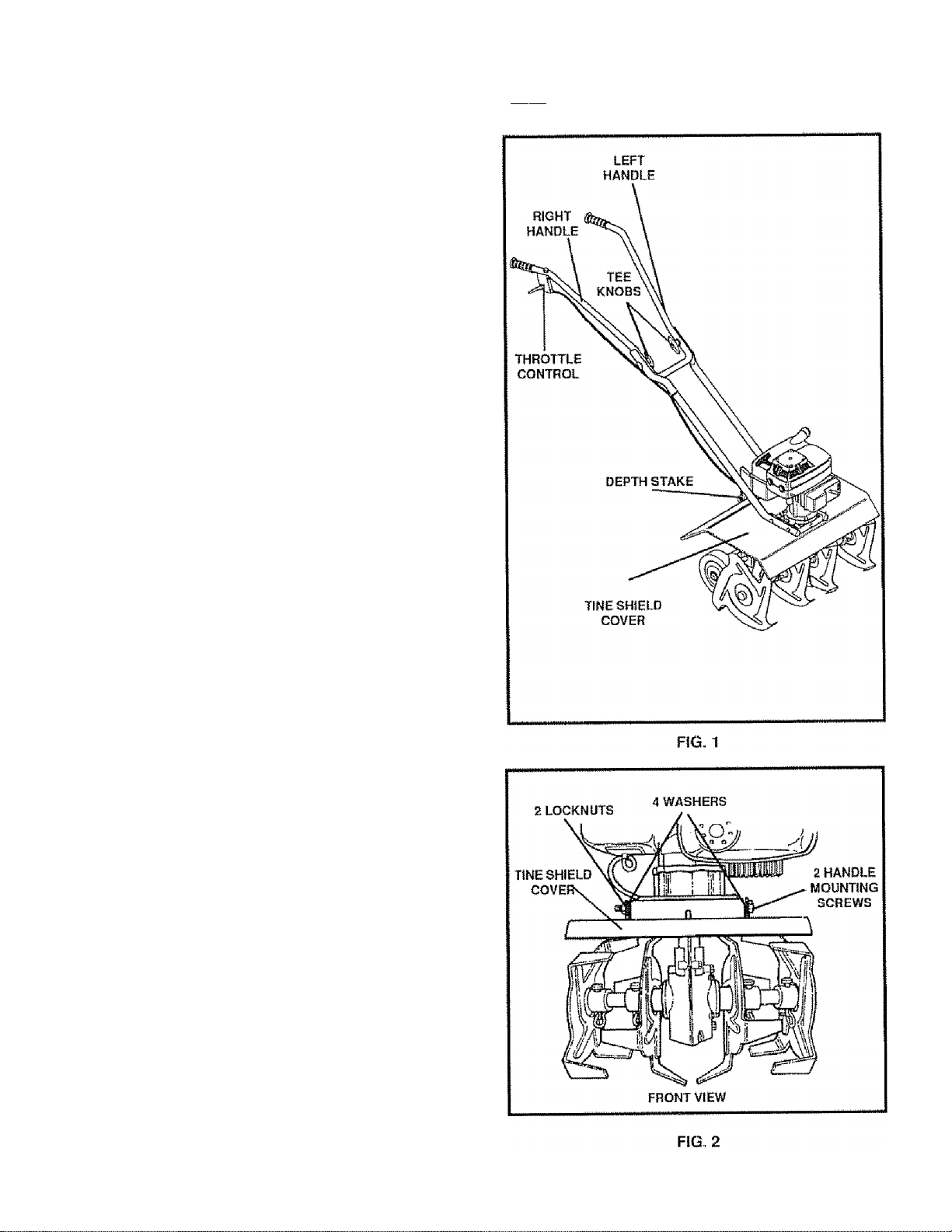

Figure 1 shows the mini tiller/cultivator completely

assembled

Reference to the right and let! hand side of the mini tiller/

cultivator is from the operator’s position behind the unit

TO REMOVE MINI TILLER/CULTIVA

TOR FROM CARTON

# Remove the piastic parts bag from the carton

® Remove the handles 1rom the carton

® Remove packing insert trom carton that contains

depth stake/transport wheels assembly

® Lift the tiller/mini tiller/cultivator out of the carton and

place on a hard level surface

® Remove packing material from around tines

ASSEMBLING TILLER/ MINI TILLER/

CULTIVATOR.

|L-, pMi d i— I

TO INSTALL THE HANDLE ASSEMBLY

The lower handles have a short bend at the bottom end

arid are flattened at the top to allow the upper handle to

be placed between the lower handles To assemble the

handles, do the following:

® Unwind the throttle control from around the engine

and straighten the cable Be careful you do not kink

the cable.

® Remove two iocknuts, four washers and two handle

mounting screws from the tine shield (see Fig 2)

Page 7

ASSEMBLY

® Insert the right side lower handle section info the

mouniirig channel between the tine shield and the

engine casting {see Fig 3) Push the mounting

screws through the tine shield. handle and approxi

mately haft way into the engine casting Be sure a

washer is on each mounting screw (see Fig 4) It

may be necessary to rotate the lower handle to align

the mounting holes. To allow proper mounting of the

upper handle section be sure the flat portion of the

lower handle is facing inward

@ Position the left side lower handle section info the

mounting channel between the tine shield and the

engine casting Align the holes in the handle with the

engine casting and the tine shield, then push the

mounting screws completely through the engine

casting, handle and tine shield install a washer onto

the mounting screws and secure the lower handle

sections using two locknuts previously removed (see

Fig 4). Finger tighten the locknuts at this lime

® Place the upper handle between the lower handies

(see Fig. 5) and secure with two curved head car

riage bolts, two formed washers, two 11/32 inch

fiatwashers and two tee knobs on the inside of the

handle You must insert a hex nut Into each tee

knob. Finger tighten only Pul! back on the tee knob

to engage the hex opening with the hex nut Tighten

the tee knob. The nut will be pulled into the cavity and

locked. The lower handles have two holes at the top

end to allow the upper handle to be positioned at two

different heights,

# Using two 7/16 inch wrenches, tighten the locknuts

on the screws in the lower ends of the lower handles

just enough to hold the lower handles firmly in place

IMPORTANT: OVERTIGHTENING THE SCREWS

ENOUGH TO CHANGE THE SHAPE

OF THE HANDLES CAN RESULT IN

DAMAGE TO THE ENGINE CASTING

@ Hold the curved head carriage boll against the out

side of the lower handle while tightening the tee

knobs securely (see Fig 5)

Page 8

ASSEMBLY

TO INSTALL THE THROTTLE CONTROL ASSEMBLY

@ Place a No 10 x 1-1/2 inch hex head screw down

through the hole in the upper handle right side and

attach the throttle control to the underside of the handle

(see Fig, S),

m Attach the throttle cable to the right lower handle by

threading a tie strap through the hole in the lower

handle and around the throttle cable on the outside o1

the handle.

# Thread the pointed end of the strap through the other

(square) end of the strap and pull tight around the

throttle cable and lower handle.

NOTE: One side of the tie strap is rough, while the other

side is smooth The rough side must be on the inside of the

loop formed when the ends of the tie strap are put together,

® Try to loosen the tie strap, if it will loosen, it is put

together with the smooth side to the inside of the loop

Remove the tie strap and reverse the direction

® Cut off excess strap

HANDGRIP ASSEMBLY

# Install the hand grips onto the upper handies (see Fig

5). It may be necessary to lubricate the handles with

soap and water to aid assembly

Cui* fy. imi' W

BEFORE YOU OPERATE AND ENJOY YOUR NEW

MINI TILLER/CULTIVATOR, WE WISH TO ASSURE THAT

YOU RECEIVE THE BEST PERFORMANCE AND SATISFAC^

riON FROM THIS QUALITY PRODUCT

PLEASE REVIEW THE FOLLOWING CHECKLIST.

/ All assembly instrudions have been completed

/ Ha remaining loose parts in carton.

/ All fasteners have been properly installed and tightened

WHILE LEARNING HOW TO USE YOUR MINI TILLER/CUL TiVATOR. PAY EXTRA ATTENTION TO THE FOLLOWING

IMPORTANT ITEMS:

// Fuel tank is filled with correct gasoiine and oil mixture

// Become familiar with all controis-their location and

function, operate controls before starting engine,

Page 9

OPERMIOW

KNOW YOUR MINI TILLER/CULTIVATOR

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR MINI

TILLER/CULTIVATOR Compare the illustrations with your mini tiller/cultivalor to familiarize yourself with the

location of various controls and adjustmenfs Save this manual for future reference

SEARS MINI TiLLER/CULTiVATOR conforms to the safety standards of the

American National Standards Institute B71 8

THROTTLE CONTROL - Controls the engine speed and

the tine rotafion. This mini tiiler/cuitivatoris equipped with

a centrifugai dutch that engages the tine drive system

when the engine speed is increased

CHOKE CONTROL LEVER - Used to assist in sfarting a

co!d engine,

SHUT-OFF SWITCH ^ Used to stop the engine

RECOIL STARTER HANDLE - The engine on this mini

tiller/cultivatoris equipped with an easy pull recoil starter

DEPTH STAKE/TRANSPORT WHEELS ASSEMBLYUsed (with wheels up) when tilling or cultivating to adjust

the depth of the cut it also acts as a brake to help the

operator control the direction and speed of the unit

The depth stake/transport wheel assembly (with wheels

down) can be used for transporting the unit

Page 10

©PERÄTiOM

The operation of this mini liller/cullivator can result in foreign objects being thrown

into the eyes, which can result in severe eye damage Always wear safety glasses

or eye shields while operating the mini tiller/cuitivator,

We recommend standard safety glasses or Wide Vision Safety Mask for over your

glasses.

TO STOP MINI TILLER/CULTIVATOR

® Release the throttle control to stop the tines

® Move the shuboff switch on the engine to the "OFF"

position

TO OPERATE

MINI TILLER/CULTIVATOR

® Set the depth stake/transporl wheels assembly to the

desired tilling position as follows:

# Remove the hairpin cotter t ro m the cievi spin securing

'the depth slake (see Figure 8} Remove the clevis pin

and adjust the depth stake upward to dig shallower or

downward to dig deeper Reinstall the clevis pin and

hairpin cotter

# Start the engine, tilt the unit back on the depth stake

untli the tines are off the ground and squeeze ihe

throttle control all the way up against the hand grip

The engine is governor controlled and should be run

at full throttle

® Gras p the h a ndtes fir ml y and slowly till 1 he u nit to rward

to begin the lilting action

@ As the tines begin to make contact with the ground,

hold back on the handles so that the tines will dig and

not ride forward over the ground Hold back until the

tines dig into the soil

© If the tilled depth is too deep ortoo shallow, turn off the

engine and reset the depth stake

# If depthstake is not controiling forward action, lower

the depth stake If the unit is not going forward, raise

the depth stake

CAUTION: GASOLINE IS FLAMMABLE

AND CAUTION MUST BE USED WHEN

ä

FILL FUEL TANK WHILE MINI TILLER/CULTIV ATOR IS RUNNING, HOT, OR WHEN MINI TILLER/

CULTIVATOR IS IN AN ENCLOSED AREA. KEEP

AWAY FROM OPEN FLAME, ELECTRICAL

SPARK, AND DO NOT SMOKE WHILE MIXING

FUEL OR FILLING THE FUEL TANK. NEVER

FILL FUEL TANK COMPLETELY; BUT FILL THE

TANK TO WITHIN 1 /4 -1/2 INCH FROM THE TOP

TO PROVIDE SPACE FOR EXPANSION OF FUEL.

ALWAYS FILL FUEL TANK OUTDOORS AND

USE A FUNNEL OR SPOUTTO PREVENT SPILL

ING. MAKE SURE TO WIPE UP ANY SPILLED

FUEL BEFORE STARTING THE ENGINE.

STORE GASOLINE IN A CLEAN, APPROVED

CONTAINER, AND KEEP THE CAP IN PLACE ON

THE CONTAINER. KEEP GASOLINE IN A COOL,

WELL VENTILATED PLACE; NEVER IN THE

HOUSE. NEVER BUY MORE THAN A 30 DAY

SUPPLY OF GASOLINE TO ASSURE VOLATIL

ITY. GASOLINE IS INTENDED TO BE USED AS A

FUEL FOR INTERNAL COMBUSTION ENGINES;

THEREFORE, DO NOT USE GASOLINE FOR

ANY OTHER PURPOSE. SINCE MANY CHIL

DREN LIKE THE SMELL OF GASOLINE, KEEP IT

OUT OF THEIR REACH BECAUSE THE FUMES

ARE DANGEROUS TO INHALE, AS WELL AS

BEING EXPLOSIVE.

HANDLING OR STORING IT. DO NOT

BEFORE STARTING ENGINE

A

CAUTION: KEEP AWAY FROM THE RO

TATING TINES. ROTATING TINES CAN

CAUSE INJURY.

FILL GAS

The two cycle errgine used on this mini tiller/cuitivator

requires a mixture of gasoline and oil for lubrication of the

bearings and other moving parts The correct fuel mixture

ratio is 24:1 (see Fuel Mixture Chart) Gasoline and oil

must be premixed in a clean gasoline container Always

use fresh, clean unleaded gasoline

WARNING: Experience indicates that alcohol blended

fuels (called gasahol or using ethanol or methanol) can

attract moisture which leads to separation and formation

of acids during storage Acidic gas can damage the fuel

system of an engine white in storage To avoid engine

problems, the fuel system should be emptied before

storage for 30 days or longer. Drain the gas tank, start

10

Page 11

OPERATION

the engine and iet it run until the fuel lines and carburetor

are empty Use fresh fuel next season See Storage

Instructions for additional information. Never use en

gine or carburetor cleaner products In the fuel tank or

permanent damage may occur

GASOLINE AND OIL MIXTURE

Mix gasoline and oil (See Fig 7) as follows;

® Pour 1 U S quart of fresh, clean, unleaded automo

tive gasoline into a gallon gasoline container.

® Add (5 oz,) of clean, high quality SAE 30 or SAE 40

two-cycle oil into the gasoline container

ÍMPORTANT: DO NOT USE OUTBOARD MOTOR

OIL OR MULTI-VISCOSITY OILS,

SUCH AS 10W-30 OR 10W-40.

® Reinstall the cap on the gasoline container and shake

container vigorously so the oil mixes with the gasoline

® Add an additional 3 Li S quarts of gasoline to the

gallon container and shake the container again

FUEL MIXTURE CHART (Mixture 24:1)

u. s.

GAS

1 Gal.

2 Gal. 11 oz.

5 Gal. 27 01.

otu

EÜPOní 031}

..

"•*.*"

j'fryflTTIWtlii

1 E1.S, CJUXOK

® This completes the special gasoline mixing (24:1)

procedure. It can now be poured into the mini tiller/

cultivator fuel tank

IMPORTANT: DO NOT FILL FUEL TANK WITH

OIL

5 oz.

Jl

GASO- LINE THAT DOES NOT HAVE

OIL MIXED IN IT DO NOT USE GASO

LINE ADDITIVES BECAUSE THE EN

GINE MAY BE DAMAGED SHAKETHE

GASOLINE CONTAINER BEFORE

EACH FILLING OF THE FUEL TANK

S. 1. (METRIC)

GAS OIL

4 Liters .167 L

8 Liters .333 L

20 Liters .833 L

■

FIG. 7

TO START THE ENGINE

Before starting the engine, be sure you have read and

understood all the instructions on the preceding pages

® Fill the fuel tank (to 1/2 inch below the bottom of the fill

neck) with fresh fuel mix and reinstall the fuel lank cap

securely Never use fuel that may be stale from long

periods of storage

@ Move the shut-oft switch to the ON position

® Move the choke controi (see Fig 6) to the FULL choke

position (ail the way down)

NOTE: A warm engine should not require choking

CAUTION: DO NOT TOUCH THE

THROTTLE CONTROL WHILE START

ING THE ENGINE. THE MINI TILLER/

CULTIVATOR WILL PROPEL ITSELF IF

THE ENGINE SPEED IS ADVANCED

FROM IDLE.

@ Tilt the mini tiller/cuilivator back on the depth stake or

transport wheels to raise the tines off the ground

@ Grasp the upper handle firmly lo stabilize the mini

tiiler/cultivator and pull the starter handle with short

quick puiis Do not allow the starter handle to snap

back, let it rewind slowly while holding the starter rope

It will take a few pulls on the starter handle to leed gas

from the fuel tank to the carburetor

@ When engine starts, move the choke control to 1/2

choke position until the engine runs smoothly Then

move choke control to OFF position

® If engine taiters, move choke control to 1/2 choke

position until engine runs smoothly Then move

choke control to OFF position

® If engine fires, but does not continue to run, move

choke control to no choke position and repeat starting

instructions

NOTE: If the tines do not stop when the throttle control is

released, adjust the carburetor Idle speed as instructed in

Step 5 ot Carburetor Adjustment paragraph in the

ServIce/Adjustments section ot this manual

® To stop the engine, release the throttle control and

move the shut-off switch to the OFF position

® If the engine becomes flooded, see the Spark Plug

Maintenance paragraph in the Maintenance section

of this manual Then pull the starter rope with the

choke "OFF"

CAUTION: THE MUFFLER AND SUR

ROUNDING AREAS BECOME HOT AF

A

TER RUNNING THE ENGINE, AVOID

THESE AREAS,

11

Page 12

OPERATION

TILLING HINTS

® Tilling is digging in, turning over and breaking up

packed soil before planting. Loose unpacked soil

helps root growth Best tilling depth is 4 to 6 inches, A

tiller will also clear the soil of unwanted vegetation.

The decomposition of this vegetation matter enriches

the soil. Depending on the climate (rainfall and wind),

it may be advisable to til! the soil at the end of the

growing season to turfher condition the soil,

® Avoid 1iHing t he soil f hat is too dry as the soil puIverizes

and produces a dust that will not hold water Also,

tilling soil that is too wet will produce unsatisfactory

clods besides being hard on the machine.

® Better growth will be obtained in tilled ground if a

relatively small area is tilled properly and the tilled

ground used soon aftertillingto preserve the moisture

content,

® The depth stake (on the back of the mini tiller/

cultivator)serves actual purpose (see Fig 8) It helps

regulate the depth of the cut to a uniform level and also

acts as a brake to help the operator control the speed

oiihe mini tiller/cultivator.

9 Lowering the depth stake will slow the mini tiller/

cultivator and make it till deeper Raising the depth bar

will allow the mini tiiler/cultivator to move faster and till

more shallow.

® if the tiller mini tiiler/cultivator stops forward motion

and fries to dig deeper than necessary, move the

handles from side to side to start forward motion

CULTIVATING HINTS

9 When cultivating (weed killing) il is best to till no

deeper than 1 -1 /2 inches Tilling deeper will oniy pull

to the surface ungerminated weed seeds You may

want to raise the depth bar to lessen the braking

action

® When cultivating around plants or dose areas you

may want to remove the outside tines (see Tine

Reptacemetit parag r aph in the Service/Adjustments

section of this manual)

12

Page 13

CUSTOMIE3 RESPONSIBILITIES

SERVICE RECORDS

SCHEDULE

Fill in dates as you compiGte reguiar service

Tighten All Screws and Nuts

Lubricate Transmission

Lubricate Tine Shaft

Clean and Re-Oil Air Cleaner Fitter

Check Spark Plug

Cylinder Exhaust Ports

Drain Fuel

Before After

Each

Use Hours

first 2

Every

25

Hours

GENERAL RECOMMENDATIONS

The warranty on this mini liller/cultivator does not cover

items that have been subjected to operator abuse or

negiigence To receive full value from the warranty, the

operator must maintain the mini tiiler/cuitivator as in

structed in this manual. The following Service Recom

mendations Chart is provided to assist the operator in

properly maintaining the mini tiiler/cuitivator

SERVICE DATES

Every

Before

75

Storage

Hours Season

# Check the condition of the felt washer in the side of Ihe

AIR VENT SCREW

Before

Each

transmissionatihelineshaU(seeF(g 9) Replace Ihe

felt washer if it is damaged (see Repair Parts section

in this manuail

TRANSMISSION

FELT WASHER

LUBRICATION

Every 25 hours and/or at the beginning of each season,

thegearboxshouldbefifiedwithfubhcani- Tubesofgear

lubricant are available from most automotive supply

stores Use portable tool grease such as Lubriplate

630AA (Product No 06787-1-3/4oz tube) orLubriplaie

GR-132 (Product No 15892-10 oz tube). The tine shaft

should have oil applied before storage and after clean

ing, if the mini tiiler/cuitivator is flushed with water The

fofiowing illustration is provided to assist the operator in

properly maintaining the mini tilier/cultivator

CAUTION: ALLOW THE TRANSMISSION

TO COOL BEFORE FILLING WITH

GREASE,

® Remove both left side tines (see Adjustments/ Re

pairs section) in this manual.

@ Remove the airvent screw (see Fig 9)fromthetopleft

side of the fransmission

® Using a grease gun, fill the transmission through the

grease filling until the new grease begins to come out

of the air vent screw hole

® Reinstall the air vent screw.

TINE SHAFT

Oil the tine

shaft before

storage and

after

cleaning, If

the mini tiller/

cultlsialor is

GREASE

FITTING

(Lubricate the

gear box with

lubriplate

03OAA or

Lubriplate

GR-132

VIEW OF LEFT SIDE WITH TINES REMOVED

flushed with

aterj

FIG. 9

Clean tine shaft, spread a few drops of oil on shaft in

line replacement areas Reinslall the tines

Remove the right side tines Check the felt washer for

damage, clean and oil the tine shaft Reinstall the

tines.

13

Page 14

CUSTOR/IER RESPONSIBILITIES

ENGINE

AIR CLEANER MAINTENANCE

The air cteaner filter should be cleaned and reoiled atter

every 25 hours of use Clean more often under dusty

conditions

IMPORTANT: THE ENGINE CAN BE WORN OUT IN

A VERY SHORT PERIOD OF TIME IF

DIRT OR GRIT IS ALLOWED TO EN

TER THE ENGINE,,

To clean the air filter, do the following:

# Loosen screws on air cleaner cover (see Fig 10) and

remove the cover.

® Remove foam element from air cleaner

® Wipe inside of the air cteaner housing clean

® Glean the foam element by washing in a strong

solution of water and household detergent. Then

rinse thoroughly in clean water.

® Wrap foam element in clean cloth and squeeze out

(do not twist) all the liquid until dry.

# Cover the ends and side of the foam element with

same oil used in fuel mixture Knead the foam

element between fingers to distribute oil and remove

excess oil

® Reinstall foam element in air cleaner housing.

® Service the foam element carefully, inspection for

deterioration or damage A defective, improperly

sen/iced, or misassembled air filter will allow dirt

particies to enter the engine.

® Reassemble the filter (see Fig 10) Place the cover

on the air cleaner housing and tighten screws to

secure cover to the housing.

SPARK PLUG MAINTENANCE

if the engine is flooded, clean the area around the spark

plug base to prevent foreign material from entering the

cylinders when the plug is removed Remove and dry the

spark plug Regap the electrodes to 035 if necessary If

a new spark plug is needed, refer to the Engine Opera

tion and Maintenance manual lor the proper replace

ment sparkplug Tighten the spark plug firmly if a torque

wrench is available, torque the spark plug to 15 foot

pounds

CYLINDER EXHAUST PORTS

The cylinder exhaust ports should be cleaned after each

seventy-five (75) to one hundred (100) hours of opera

tion For this procedure we recommend that you take

your unit to a technician trained to work on two cycle

engines, such as a SEARS Service Center

A

CAUTION: NEVER RUN THE ENGINE

WITHOUTTHE AIR CLEANER ELEMENT

INSTALLED. A DEFECTIVE AIR

CLEANER CAN RESULT IN LOSS OF

ENGINE POWER AND CAN CAUSE EX

CESSiVE WEAR OR DAMAGE TO THE

ENGINE COMPONENTS IF DIRT OR

DUST IS PERMITTED TO ENTER THE

ENGINETHROUGH THE CARBURETOR.

AN AIR CLEANER THAT IS CLOGGED

WITH DUST OR DIRT SHOULD BE

CLEANED AND RE-OILED.

14

Page 15

eiJg l?£FONSIBiUTIES

CLEANING

Always remove the dirt and debris from the mini tiller/

cultivator after each use (see Fig, 11) Remove atiy

string, wire or vegetation that may become lodged in the

mechanism and stop the tine rotation Proceed as fol

lows;

® Release the throttle control and move the shut-off

switch to the OFF position, then disconnect the spark

plug wire

® Remove the hairpin and clevis pin securing the tine(s)

assemb ly to I he shaft and re move the tine (s) (see Fig

11).

# Remove the lodged material. Reassemble the tine(s)

on the shaft and secure with a clevis pin and hairpin

@ Reconnect the sparkplug wire and restart the engine

FRONT VIEW

TINE SHIELD

LOOGED ITEM

CLEVIS PINS

RIGHT SIDE ‘

TINES

HAIRPINS

TRANSMISSION

FIG. 11

LEFT SIDE

TINES

HAIRPINS

15

Page 16

SE™CE AMD ADJUSTIIEMTS

TINE REPLACEMENT

The mini tilier/cultivator is ieft hand or right hand as

viewed from the operator's position behind the unit

All four tines on this unit are different and cannot be

interchanged The tines must be properly installed as

shown in figures 12 and 13 or the mint tilier/cultivator will

not function property

The outside tines may be removed to reduce the tilling

width to about 7 inches, for working close around plants

orinsmall areas, if desired. When reinstaiiing the outside

tines see below.

CAUTION: THE TINES ARE SELFSHARPENING AND WILL BECOME

A

The lines will all wear fairly eveniy. If the tines are being

replaced because of wear, we recommend that ai! four

tines be replaced at the same time To replace the tines,

do the following:

# Place the shut-off switch to the OFF position and

@ Removethehairpinsandthedevispinslromthetines

9 Clean the tine shaft and oil the shaft at the tine

® Piace the inside tine on the tine shaft and reinstall the

® Whenthe tines are properly installed, the letter "R" will

• Place the outside tine on the tine shaft and reinstall f tie

® The outside tine cutting tips wiil all bend in toward the

® Repeat steps on the opposite side of the unit

® Check to make sure the tines are installed on correct

QUITE SHARP FROM USE. HANDLE

CAREFULLY.

disconnect the spark plug wire

on one side of the unit and remove the fines.

locations.

clevis pin and hairpin,

be visible on the outside of the right-hand tine (the

letter "L" on the left-hand tine). The letter should

appear opposite the small hole in the side of the tine

clevis pin and hairpin cotter,

inside line The letter"R‘'onthe right sideorT“on the

left side should be visible from the outside of the unit,

side of the unit

RIGHT SIDE

TINES

FRONT VIEW

• 1 i'!

Í i iLi

CLEVtg PINS

HAIRPINS

FIG. 12

ilillffHf

I LEFT SIDE

TINES

16

Page 17

SERVICE AMD ADJUSTMEWTS

CARBURETOR ADJUSTMENT

A dirty air cleaner will cause the engine to run

improperiy and/or smoke excessively. Be sure the

air cleaner is clean before adjusting the carburetor.

Never make unnecessary adjustments to the carburetor

The carburetor was set at the factory to operate efficiently

under most applications However, if adjustments are

required, we recommend you contact your nearest SEARS

Service Center If you feel that you are competent to

make carburetor adjustment proceed as foiiows:

CAUTIDNiUSEEXTREIViECAREWHEN

MAKING ADJUSTMENTS THAT RE

A

® Turn the mixture adjustment screw {see Fig 14)

clockwise to close

IMPORTANT: TIGHTEN THE ADJUSTING SCREW

# Turn the mixture screw counterclockwise (open) one

(1) turn,

® Start the engine and let it warm up approximately 3 to

5 minutes Do not adjust the carburetor when the

engine is cold

® if the engine falters or stops after the choke lever is

moved to the OFF position, open the mixture adjusting

screw an additional 1/8 turn counterclockwise

# With the engine running, release the throttle control

(idle position) to make the mixture adjustments

a. Turn the mixture adjusting screw (see Fig, 14)

b. Turn the mixture adjusting screw slowly counter

c. Turn the mixture adjusting screw clockwise until

QUIRE THE ENGINE TO BE RUNNING,

KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING

PART.

WITH YOUR FINGERS TO PREVENT

DAMAGE TO THE CARBURETOR OR

ADJUSTING SCREW.

slowly clockwise until the engine falters Note this

location.

clockwise until the engine starts to sputter Note

this location

it is halfway between the first position where the

engine faltered and the second position where

the engine started to sputter

-fl il ^ '

IDLE SPEED

ADJUSTING

SCREW

ENGINE SHOWN WITH AIR CLEANER REMOVED

CAUTION: NEVER TAMPER WITH THE

ENGINE GOVERNOR WHICH IS FAC

TORY SET FOR PROPER ENGINE

SPEED. OVER-SPEEDING THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BE DANGEROUS. IF YOU

THINK THE ENGINE GOVERNED HIGH

SPEEDS NEEDS ADJUSTING, CONTACT

YOUR NEAREST SEARS SERVICE CEN

TER WHICH HAS THE PROPER EQUIP

MENT AND EXPERIENCETO MAKE ANY

NECESSARY ADJUSTMENTS.

The idle speed may need to be adjusted after making

the mixture adjustment If the tines do not turn when

the engine is running and the throttle control is re

leased, the idle speed will not need adjusting If the

tines turn when the throttle control is released, do the

fo! lowing;

a Have someone hold the mini tiller/cultlvalor back

on thedepthbarwiththeti nes off t he g round

b Start the engine.

C- Wilh the throttle in the released (idle) position,

turn the idle speed adjusting screw counterclock

wise until the tines stop rotaiing

MIXTURE CARBURETOR

ADJUSTING

SCREW

FIG. 14

17

Page 18

STORAGE

CAUTION: NEVER STORE ENGINE

WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED

AREA WHERE FUEL FUMES MAY

REACH AN OPEN FLAME, SPARK OR

PILOT LIGHT AS ON A FURNACE, WA'

TER HEATER CLOTHES DRYER ETC

NOTE: The tlier/mint tiiler/cullivator should be immedi

ately prepared tor storage at the end of the season ot if

the unit

will not be used for 30 days or more

I I Inn i| V V H I lUn I H Whrh * %iP Mm %m I Vr Iwt Inn \tf f WI «

f MMV * V winnv» I MW I l| 1— nnr ¥ c I %w Inn Inr I I I MM-I 1^ Inn I Mann

MINI TiLLER/CULTIVATOR

® Thoroughly clean the mini tiller/cuitivator Remove ail

dirt and debris from the engine and unit

@ Remove the tines and oil the tine shaft and reinstall the

tines (see Service/Adjustments section in this

manual)

® Loosen the tee knobs that secure the upper handle to

the tower handle

® Carefully fold the upper handle down making sure the

throttle is not kinked Tigtiten the tee knobs.

@ The cross piece of the upper handle (between the

lower handles) cart now be used as a carry handle or

can be hooked over a wail hook to stor e the mini tiller/

cultivator up off the floor out of the way

NOTE; A yearly checkup or tuneup by a SEARS Service

Center is a good way to insure that your mini tiller/

cultivator wit! provide maximum performance for the next

season

ENGINE

IMPORTANT: IT IS IMPORTANT TO PREVENTGUM

DEPOSITS FROM FORMING IN ES

SENTIAL FUEL SYSTEM PARTS

SUCH AS THE CARBURETOR, FUEL

FILTER, FUEL HOSE OR TANK DUR

ING STORAGE. ALSO. EXPERIENCE

INDICATES THAT ALCOHOL

BLENDED FUELS (CALLED GASO-

HOLOR USING ETHANOL OR METHA

NOL) CAN ATTRACT MOISTURE

WHICH LEADS TO SEPARATION

AND FORMATION OF ACIDS DUR

ING STORAGE ACIDIC GAS CAN

DAMAGE THE FUEL SYSTEM OF AN

ENGINE WHILE IN STORAGE

® Drain the fuel from the fuel tank into an approved

container outdoors, away from open flame

# Startandajntheengineuntilitstopsduetolackoffuel

® Pull the starter handle slowly until you feel resistance

due to compression pressure, then stop

# Release the starter tension slowly to prevent the

engine from reversing due to compression pressure

This position wilt close both the intake and exhaust

ports to prevent corrosion of the piston and cylinder

bore

OTHER

® If possible, store your mini tiller/cultlvalor indoors and

cover it to give protection from dust and dirt

# Cover the mini tiiler/cultivator with a suitable protec

tive cover that does not retain moisture Do not use

plastic

IMPORTANT: NEVER COVER THE MINI TILLER/

CULTIVATOR WHILE THE ENGINE

AND EXHAUST AREAS ARE STILL

WARM

18

Page 19

TROUBLE SHOOT!WG

TROUBLE

Difficult starting

Engine runs erraticaily

Engine will not run at

full speed

Engine speed does not

increase properly

Engine smokes

excessively

Tines continue to

rotate when throttle the

control is released

Tines will not turn

CAUSE

Staie fuel mixture

Too much oil in mixture

Dirt in fuel tank or out of fuel

Carburetor out of adjustment

Fouled spark plug

Plugged air cleaner

Debris interferring with throttle linkage

Plugged air cleaner

Too much oil in fuel mixture

Carburetor out of adjustment

Foreign object lodged in tine

CORRECTION

Drain fuel tank Fll! with fresh mixture

Check fuel mix chart and mix fresh fuel

Clean fuei tank. Fuel tank should be half full

when starting engine

See carburetor adjustment section

Clean and re-gap plug

Clean and re-oil air cleaner

Biow dirt and debris off top of carburetor

Clean and re-oil air deaner

Check fuel mix chart and mix fresh fuel

Adjust carburetor idle speed. See

Carburetor Adjustment paragraph in

Service/Adjustments section of this manual

Remove lodged item See Keep

Tiller/Cutlivator Clean paragraph in the

Operation section of this manual

Unit does not ttii

properiy

incorrect tine instaiiatlon

Check the tines for proper installation See the

Tine Replacement paragraph in the

Service/Adjustment section of this manual

19

Page 20

mMm

OWNER’S

MANUAL

MODEL NO.

536.797500

32.8CC 2-CYCLE

10 INCH DIAMETER TINERS

MINI TILLER/CULTIVATOR

Each CULTIVATOR has its own MODEL NUMBER found on the tine shield.

Each ENGINE has its own MODEL NUMBER

found on the BLOWER HOUSING.

Always mention these MODEL NUMBERS when

requesting service or Repair Parts for your

CULTIVATOR.

All parts may be ordered through any Sears,

Roebuck and Company Service Centers and

most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS

GIVE THE FOLLOWING INFORMATION:

HOW TO ORDER

REPAIR PARTS

* PRODUCT - MINI TILLER/CULTIVATOR

* MODEL NUMBER - S36.797S00

* ENGINE MODEL NUMBER - 143.941600

* PART NUMBER

* OAQT ni^Qr^DIOTIAM

“Your Sears merchandise has added value when you

consider that Sears has service units nationwide stalled

with Sears trained teGhnicians, Prolessional technicians

specifically trained on Sears Products, having the parts,

tools and equipment to insure that we meet our pledge

to you we service what we sell"

SEARS, ROEBUCK ÄND CO., Hoffman Estates, IL60179 USA

331S18 12/01/93 Printed in U.S.A.

Loading...

Loading...