Page 1

CRAFTSMAN

4 Horsepower

9 Inch

EDGER

MODEL NO.

536.797400

Caution:

Read and follow all Safety

Rules and Operating

Instructions before first use

of this product.

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

711044 04/11/97

Page 2

TABLE OF CONTENTS

Table of Contents 2

Warranty 2

Safety Rules 2-3

Contents of Shipping Carton 4

Assembly 4-6

Operation 7-10

Maintenance 11-12

Service and Adjustments

Storage

Troubleshooting

Edger Repair Parts

Engine Repair Parts

Spanish(Espahol)

Parts Ordering/Service

Back Cover

WARRANTY STATEMENT

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN EDGER

For two years from the date of purchase, when this Craftsman Edger is maintained, lu

bricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Craftsman will repair, free of charge, any defect in material or work

manship.

If this Craftsman Edger is used for commercial or rental purposes, this warranty ap

plies for only 90 days from the date of purchase.

This warranty does not cover the following;

• Expendable items which become worn during normal use, such as spark plugs, etc.

• Repairs necessary because of operator abuse or negligence, including bent crank

shafts and the failure to maintain the equipment according to the instructions con

tained in the owner's manual. '*

WARRANPr' SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN EDGER

TO THE NEAREST CRAFTSMAN SERVICE CENTEFIDEPARTMENT IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN

USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which

may vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates, IL 60179

13-14

15

16

17-20

21-24

25-41

SAFETY RULES

Look for this symbol to point, out lirportant safety precautions. It means-

A

ATTENTION!!! Become alert!!! Your safety is involved.

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug to prevent accidental

starting when setting-up, transporting,

adjusting or making repairs.

IMPORTANT: Safety standards require

operator presence controls to minimize the

risk of injury. Your Edger is equipped with

such controls. Do not attempt to defeat the

function of the operator presence control

under any circumstances..

BEFORE USE

• Read the owner's manual carefully. Be

thoroughly familiar with the controls and

the proper use of the Edger. Know how to

stop the edger and disengage the

controls quickly.

• Do not oneretfl the Fdner without

footwear that will improve footing on

slippery surfaces.

• Keep the area of operation clear of all

persons, particularly small children and

pets.

• Thoroughly inspect the area where the

Edger is to be used and remove all

foreign objects.

FUEL SAFETY

• Handle fuel with care; it is highly flam

mable.

• Use an approved container.

• Check fuel su|:^ly before each use,

allowing space for expansion as the heat

of the engine and/or sun can cause fuel to

expand.

• Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Replace fuel

tank can <;eciirelv end wioe uo soitled

Page 3

• Never remove the fuel tank cap or add

fuel to a running or hot engine.

• Never store fuel or Edger with fuel in the

tank inside a building where fumes may

reach an open flame.

OPERATING SAFETY

• Never aliow children or young teenagers

to operate the Edger. Keep them away

while it is operating. Never allow adults to

operate the Edger without proper

instruction.

• Do not operate this machine if you are

taking drugs or other medication which

can cause drowsiness or affect your

ability to operate this machine.

• Do not use this machine if you are

menially or physically unable to operate

this machine safely.

• Always wear safety glasses or eye

shields during operation or while perform

ing an adjustment or repair to protect

your eyes from foreign objects that may

be thrown from the Edger.

• Do not put hands or feet near or under

rotating parts.

• Exercise extreme caution when operating

on or crossing gravel drives, walks, or

roads. Stay alert for hidden hazards or

traffic.

• Exercise caution to avoid slipping or

falling.

• Never operate the Edger without proper

guards, plates, or other safety protective

devices in place.

• Never operate the Edger at high transport

speeds on slippery surfaces. Look behind

and use care when backing.

• Never allow bystanders near the Edger.

• Keep children and pets away while

operating.

• Never operate the Edger without good

visibility or light.

• Do not run the engine indoors. The

exhaust fumes are dangerous, containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS.

• Take all possible precautions when

leaving the Edger unattended. Stop the

engine.

• Do not overbad the Edger capacity by

attempting to edge too deep at too fast a

rate.

SAFE STORAGE

• Always refer to the owner's manual

instructions for important details if the

Edger is to be stored for an extended

period.

• Never store the edger with fuel in the fuel

tank inside a building where ignKion

sources are present such as water and

space heaters, clothes dryers, and the

like. Allow the engine to cool before

storing in any enctosure,

• Keep the Edger in safe wrarking condition. |

Ched< all fasteners at frequent intervals

for proper tightness.

REPAIR/ADJUSTMENTS SAFETY

• After striking a foreign object, stop the

engine (motor). Remove the wire from the

spark plug, and keep the wire away from

the plug to prevent accidental starting.

Thoroughly inspect the Edger for any

damage, and repair the damage before

restarting and operating it.

• if edger should start to vibrate abnormally,

stop engine (motor) and check immedi

ately for the cause. Vibration is generally

a warning of trouble.

• Stop the blade whenever you leave the

operating position. Also, disconnect the

spark plug wire before unclogging the

blade and when making any repairs,

adjustments, or inspections.

• When cleaning, repairing, or inspecting,

shut off the engine and make certain all

moving parts have stopped.

• Never attempt to make any adjustments

while the engine is running except when

specifically recommended by the manu

facturer.

A

WARNING: The engine exhaust

from this product contains chemicals

known to the State of California to cause

cancer, birth defects or other reproductive

harm.

A WARNING : This unit is equipped with

an internal combustion engine arid should

not be used on or near any unimproved for

est-covered, brush-cove red or grass-cov

ered land unless the engine's exhaust sys

tern is equipped with a spark arrester meet

ing applicable local or state laws (if any). If a

spark arrester is used, it should be main

tained in effective working order by the op

erator.

in the state of California the spark arrester is

required by law (Section 4442 of the Califor

nia Public Resources Code). Other states

may have similar laws. Federal laws apply

on federal lands. A spark arrester/muffler is

available through your nearest Craftsman

Authorized Sen/ice Center (See ENGINE

REPAIR PARTS section in this manual).

Page 4

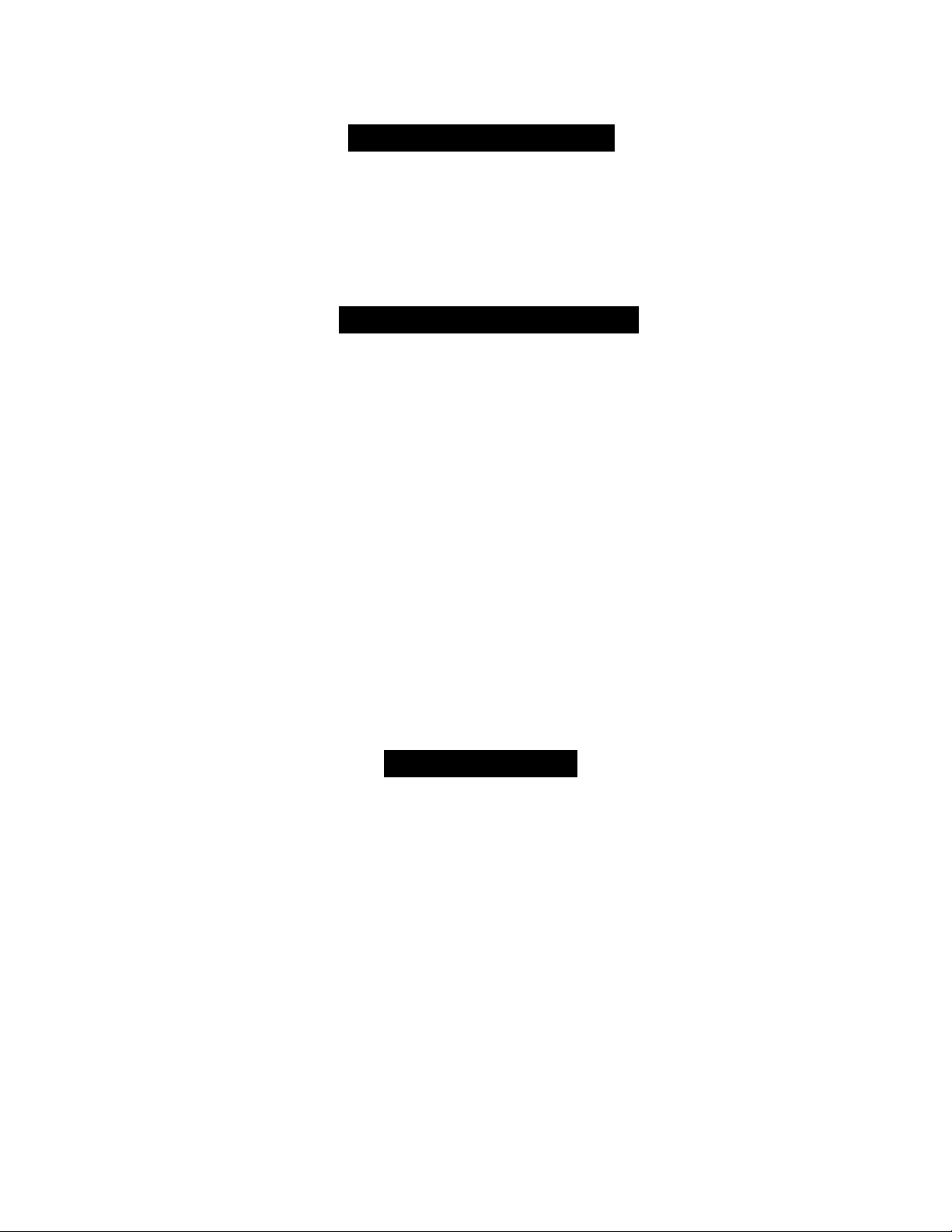

Contents of Parts Bag (shown full size)

X

I—

(2) • Hex Head Nuts

S/16-18

r

(2)-Hex Head Screws

5/16-18X 1-1/4 inch

ii:

;

Parts packed separately in carton (not shown full size)

1 • Container SAE30 Oil(20 ounces)

1 - Owner's Manual (not shown)

1 - Parts Bag (not shown)

(1) -Control Rod

(2) • Hair Pins

ASSEMBLY

AcaUTION: Always wear safety

glasses or eye shields while assembling

Edger.

TOOLS REQUIRED FOR ASSEMBLY

1 - 7/16 inch Wrench

(or adjustable wrench)

2 - 1/2 inch Wrenches .

(or adjustable wrenches)

1 - Pair Pliers

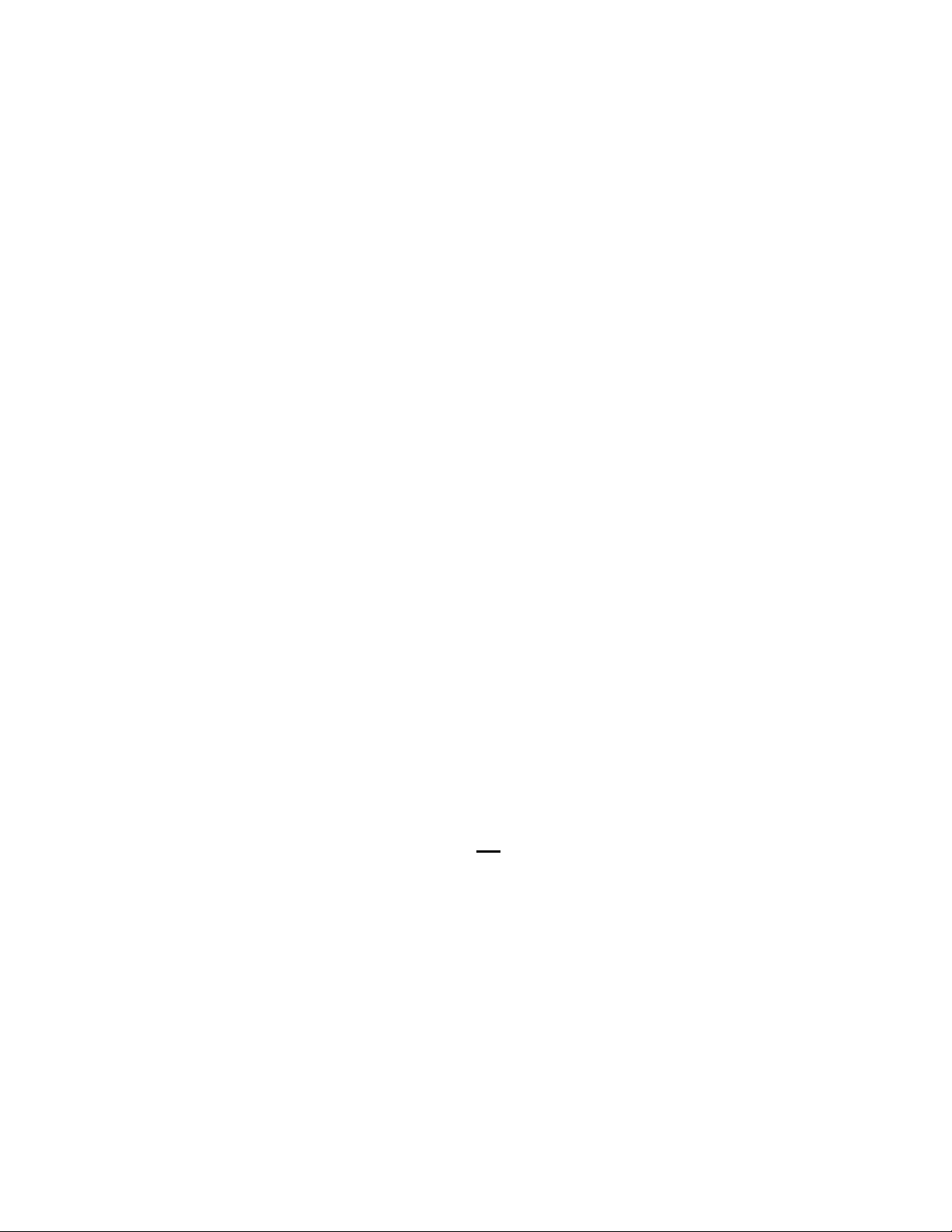

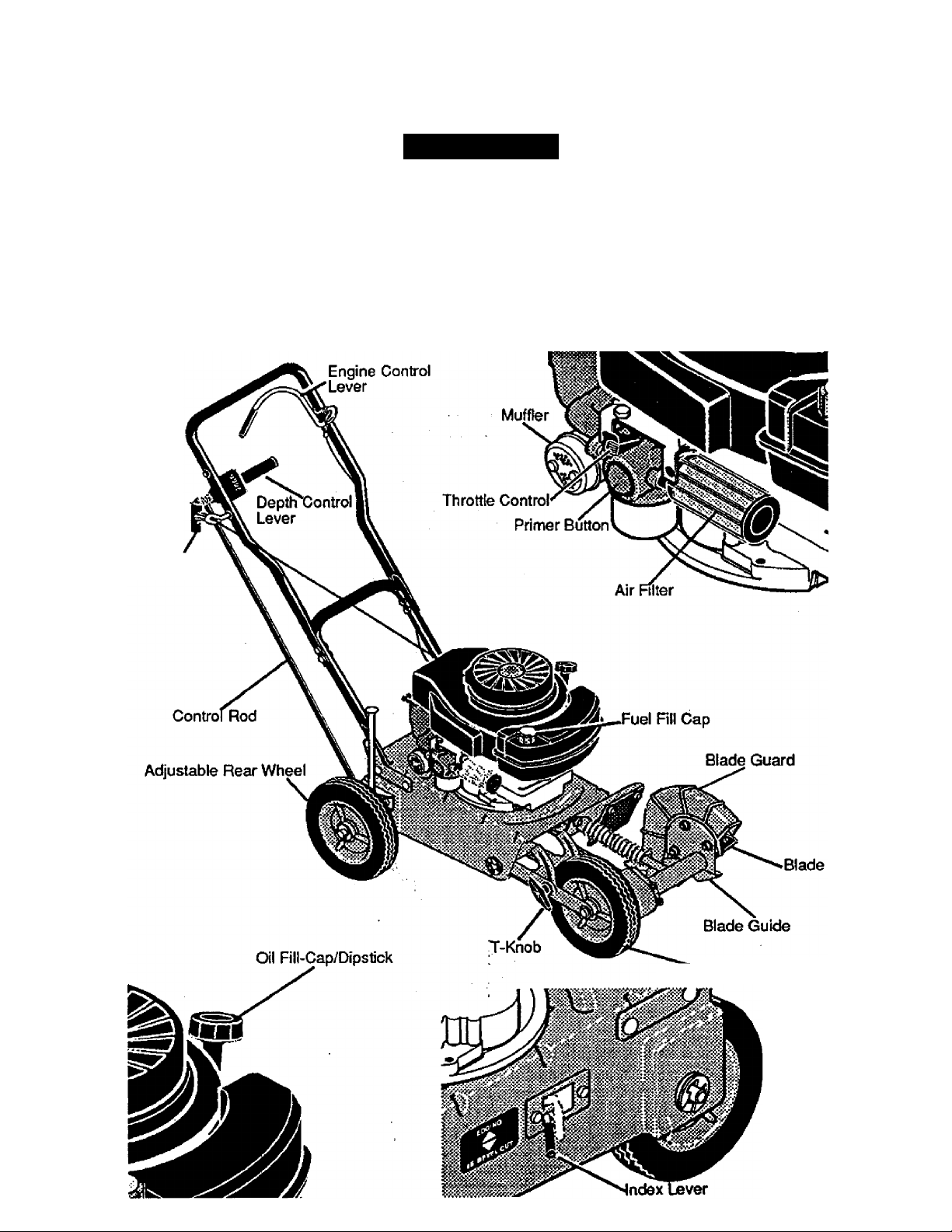

The figure to the right shows the Edger

completely assembled. -

References to the right or left hand side

of the Edger are from the viewpoint of the

operator's position behind the unit.

TO REMOVE EDGER FROM CARTON

• Remove the control rod and packing

material from carton

• Cut down all four corners of the carton.

Engine Control Lever

clipper Handle

—Depth Control Lever

Blade Guard

Control Rod

Blade

Page 5

TO ASSEMBLE THE EDGER

• Pivot the upper handle upward being

careful not to pinch or pull the engine

control wire, until the mounting holes in

the upper handle align with the mounting

hoies in the lower handle. Install (2) 5/1618x1-1/4 inch hex head screws and (2)

5/16-18 hex lock nuts (found in parts ,

bag) in the empty handle holes and

tighten ail four clamping bolts. Locknuts

should be to the inside of the handles as

shown in figure below.

• All four bolts must be tightened to the

point that the head of the bolt cuts into

the paint on the handles. This will allow a

good connection allowing the engine

control lever to stop the engine when

released.

5/16-18

Hex Head

Locknut

Lower

Handle

Rear

Selection

Contro!

Rod

Loosen the adjustable front wheel T-knob,

and push down on the T-knob until the

front of the unit comes to a resting point.

The engine mounting surface should be

parallel to the surface the unit is resting

on for best edging results.

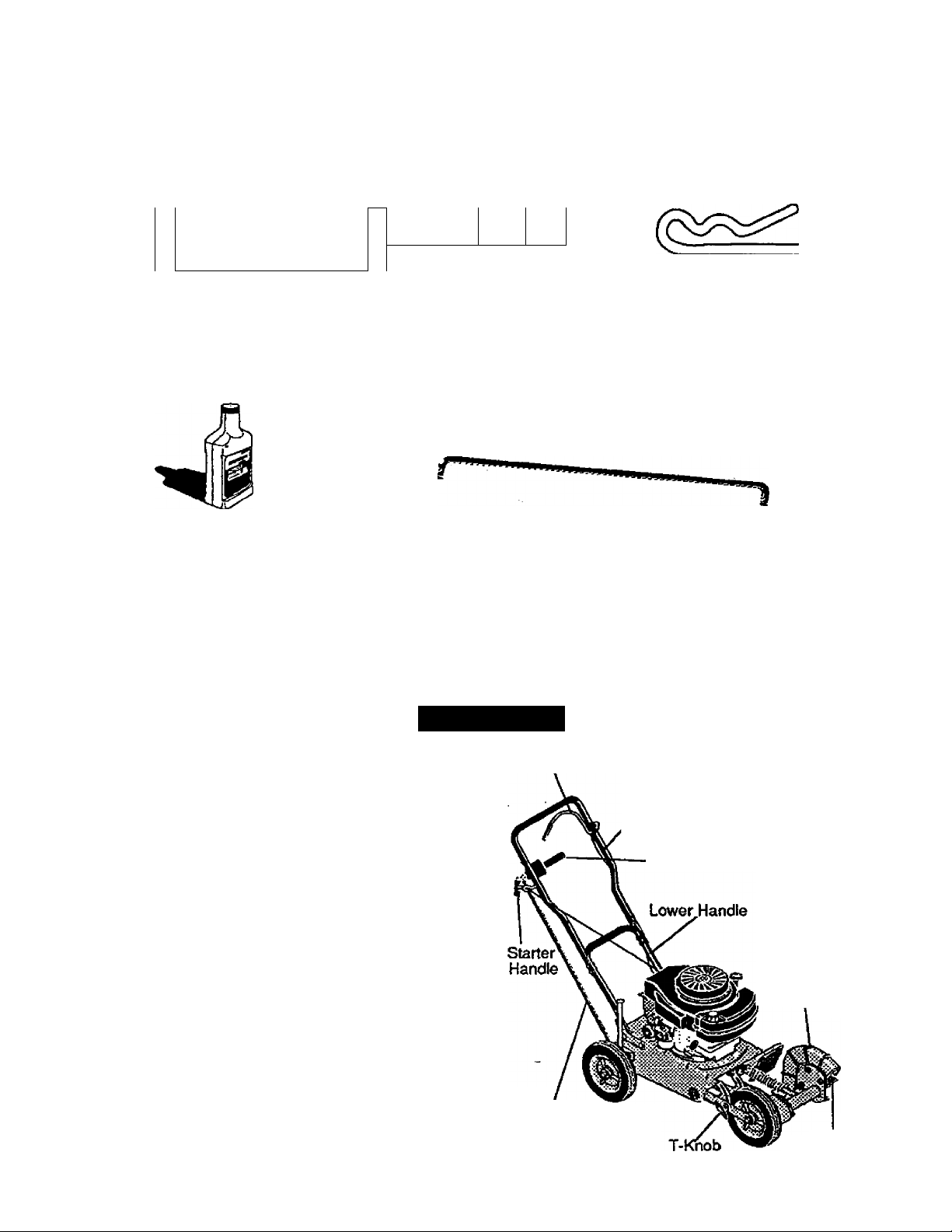

Loosen the rope guide nut (1/4-20 hex

head cenlerlock) located on the inside of

the right handle enough to let starter rof

through as shown below.

Thread starter rope through the guide.

Tighten rope guide nut.

Rope Guide Nut

(1/4-20 Reghexctrik)

5/16-18X1-1/4inch

Hex Head Screw

Insert one end of the control rod from right

to left through the hole in the linkage

bracket located inside the frame on the

rear axle. Attach with hairpin found in

parts bag. See figure below.

Place the depth control lever in the rear

selection slot. While pushing down on the

upper handle to the point that the front

wheel is raised off the ground, pul! up on

the other end of the control rod until you

can insert the end of the control rod from

right to left through the hole in the depth

control lever. Attach with hairpin. See next

figure.

Return depth control lever to the forward

most selection slot for transport and

starting.

Hair Pin

Linkage Bracket

Confrol

✓ CHECKLIST

Before you operate your new Edger, to

ensure that you receive the best perfor

mance and satisfaction from this quality

product, please review the following

checklist:

✓ All assembly instructions have been

completed.

✓ No remaining loose parts in carton.

Keep in safe place.

✓ All fasteners have been properly in

stalled and tightened.

While learning how to use your Edger,

pay extra attention to the following impor

tant Hems:

✓ ✓ Engine oil is at proper level.

✓ ✓ Fuel tank is filled with fresh, clean,

regular Unleaded gasoline.

✓ ✓ Become familiar with all controls, their

location and funclton. Operate controls

before starting engine.

Page 6

OPERATION

KNOW YOUR EDGER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

EDGER. Compare the illustrations with your EDGER to familiarize yourself with the location

of various controls and adjustments. Save this manual for future reference.

Starter Handle

Fast Slow

Stop

Primer Button

Adjustable Front Wheel

Page 7

Throttte Control - Used to control the en

gine speed.

Primer Button - injects fuel directly into the

carburetor manifold for faster starts.

Starter Handle - The engine on this edger

is equipped with an easy pud recoil starter.

Depth Control Lever - Controls the depth

of the blade.

Blade Guard - Used to prevent stones or

other material from being thrown at the op

erator.

Engine Control Lever - Must be held back

to allow engine to start and run.

Index Lever - Permits adjustment from the

edging (vertical) position to beveling (45“)

position. To change position, pull the index

lever and rotate the quill assembly to the

desired angle or position.

Adjustable Rear Wheel- Right rear wheel

is adjustable to level Edger when edging

along a curb(curb-hopping). ■ '

AJustable Front Wheel-Front wheel can

be adjusted down for curb-hopping. - '

TO USE THE ENGINE CONTROL

LEVER

• Pull the engine control lever back with

your left hand and hold it in contact with

the upper handle cross tube to allow en

gine to start and run. See next figuro.

• Release the engine control lever to stop

the engine.

NOTE: If engine continues to i^after

lever is released.Use the stop ® position

on the throttle control to stop the engine

and then see your Craftsman Service Cen

ter to correct the engine control lever prob

lem.

CAUTION: Always stop the engine

and make sure all parts have stopped

whenever leaving the operator's position or

when cleaning, replacing or inspecting the

Edger.

Engine Control

Lever

WARNING: Blade is rotating when

engine is running or being started. Keep.

hands and feet away from blade to prevent

injury.

HOW TO USE YOUR EDGER

WARNING: The operation of this

Edger can result in foreign objects being

thrown into the eyes, whidn can cause se

vere eye damage. Always wear safety

glasses or eye shields while operating the

Edger.

We recommend standard safety glasses or

Wide Vision Safety Mask for over your

glasses.

TO STOP EDGER

• Make sure the depth control lever Is all

the way forward and release engine

control lever. There is a ^ STOP

position on the throttle control lever in

case of a failure with the engine control

lever. Wait for all moving parts to stop

before leaving the operator position.

A CAUTION: Never leave the Edger

unattended while the engine is running.

Always raise the cutting blade and Stop the

engine.

TO USE THROTTLE CONTROL

• Run at full engine speed during

normal use.

• Push throttle control lever forward to

increase speed; back to decrease rrfilspeed.

• Pulling the throttle control lever all tfte

way back will stop ^ the engine.

TO USE PRIMER BUTTON

• Push primer button In^five times. See

page 6 figure for tocation. Wait about two

seconds between each push.

NOTE: Do not use primer button to re

start a warm engine after a short shut

down.

Page 8

TO USE THE DEPTH CONTROL

LEVER

• Position your Edger in desired edging lo

cation, before operating.

• Start the engine and move the depth

control lever back to lower the cutting

blade.

• Select the edging depth you need.

There are 4 selections up to approxi

mately 2-1/2 inches deep.

IMPORTANT: If very deep edging is

required, we recommend that a shallow

cut be made first, then cut at greater

depths until the desired depth is, ob

tained.

A WARNING; Keep away from the rotat

ing blade. The blade can cause injury.

TO USE THE INDEX LEVER

(BEVELING OPERATION) *

• Stop engine and disconnect the spark

plug wire from the spark plug. . ,

INDEX LEVER IN THE NOTCH MARKED

BEVEL CUT

■ Pull the index lever out of the edging

notch as shown above and position it in

the notch marked bevel cut.

• Reconnect the spark plug wire and

start the engine. Move the dutch lever

to the desired beveling depth.

• Stop the engine and disconnect the

spark plug wire from the spark plug.

• With the front wheel and the left rear

wheel on the top of the curb and support

ing the Edger with your right hand, reach

into the inside right rear of the main

frame and loosen the fluted knob that se

cures the wheel support rod as shown

below.

• As the fluted knob is loosened the rear

wheel wilt slide dovwi.

• Hold the Edger so that the top of the

main frame is level with the top of the

curb and retighten the fluted knob.

• Turn the Edger so that the front wheel

will be on the same surface as the right

rear wheel. The left rear wheel is on

top of the curb and the right rear wheel

is supporting the Edger on the lower

surface.

• While standing on the right side of the

Edger, loosen the T-knob on the front

wheel bracket.

• With your left hand, lift the front of the

Edger using the T-knob until the main

frame is again level with the top of the

curb.

• With your right hand, push the front

wheel down until the wheel makes con

tact with the surface below.

• Hold the front of the main frame level

with your right hand and retighten the Tknob with your left hand. Check level of

main frame to top of curb and make any

adjustments.

• Reconnect the spark plug wire and start

the engine. The depth of cut adjustment

is the same as described in Edging Op

eration paragraph.

WARNING: Keep away from the rotating

blade. The blade can cause injury.

A CAUTION: Never leave the Edger

unattended while the engine is running.

Prior to adjusting the indexing blade posi

tion, always raise the cutting blade and

stop the engine.

TO USE CURB HOPPING FEATURE

The adjustable front and right rear wheel

feature permits the Edger to be used on

Page 9

TO USE THE BEVEL CUT FEATURE

Bevel edging reduces the need to edge as

often creating a type of trench along your

sidewalk, driveway and etc. Move the in

dex lever to the bevel cut position and se

cure index lever in the slot. Prior to starting

the engine, line the Edger up as if you were

going to bevel cut and move the depth con

trol lever down to test the blade location.

Return the depth control lever to the for

ward slot of the adjustment bracket to raise

the blade. Start the engine and move the

depth control lever to the desired depth of

cut.

BEFORE STARTING ENGINE

TO ADD ENGINE OIL

• Place the Edger on a level surface.

• Remove the oil fill cap/dipstick as shown

in next figure.

• Fill the engine crankcase, pouring slowly.

DO NOT OVERFILL. For approximate

capacity see PRODUCT SPECIFICA

TIONS on page 11 of this manual.

• Reinstall the oil fill cap/dipstick and

tighten securely. Wipe away excess oil.

• Check oil before each use. Add if

needed.

PRE-USE CHECK OF CONTROLS

All controls should be checked for proper

function before servicing or starting the

engine.

• Move the depth control lever into all four

positions in the selector plate. Make sure

the depth control lever snaps irrto'airfour

holes as shown in figure on page 6; '

• Return the depth control lever to the

forward hole in the selector plate.

FILUADD OIL:

This Edger was shipped with a 20 ounce

container of SAE30 motor oil. This oil must

be added to the engine before operating.

Remove the oil fill cap/dipstick and fill the

crankcase to FULL line on dipstick. Your

engine may not require the entire 20

ounces of oil. DO NOT OVERFILL. Tighten

the fill cap/dipstick securely each time you

check the oil level. , ,

OIL RECOMMENDATIONS ' v ^

Only use high quality detergent oil rated

with API service classification SG. Select

the oil's SAE viscosity grade according to

your expected operating temperature:

Colder «

---------

^30 ' 5AP3Ó ^

NOTE: Although multi-viscosity oils (5W30,

10W30, etc.) improve starting in cold

weather, these multi-viscosity oils will result

in increased oil consumption when used

above 32®F. Check your engine oil level

more frequently to avoid possible engine

damage from running low on oil.

32'’F

— I — — » Warmer

Oil Fill Tube

Oil Fill Cap/

Dipstick

CAUTION: Never fill the gas tank

while the engine is running or hot.

Immediately wipe off any spilled gasoline

before attempting to start the engine.

Fuel Fill Cap

FILL GAS:

Fill the fuel tank with clean, fresh, unleaded

grade automotive gasoline. Be sure that

the container you pour the gasoline from is

dean and free from dust or other foreign

particles. Never use gasoline that may be

stale from bng periods of storage in the

container. Reinstall fuel cap.

WARNING: Experience indicates that

alcohol blended fuels (called gasohol or

using methanol) can attract moisture which

leads to separation and formation of acids

during storage. Acidic gas can damage the

fuel system of an engine while in storage.

To avoid engine problems, the fuel system

should be emptied before storage of 30

days or tonger. Drain fuel tank, start engine

and let it run until fuel lines and carburetor

are empty. Use fresh fuel next season. See

Storage Instructions for additional informa

tion. Never use engine or carburetor

cleaner products in the fuel tank or perma

nent damage may occur.

Page 10

WARNING: Gasoline is flammable

and caution must be used when handling or

storing It. Do not fill fuel tank while Edger is

running, hot, or when Edger is in an

enclosed area. Keep away from open

flame, electrical spark, and do not smoke

while filling the fuel tank. Never fill fuel tank

completely; but fill the tank to within 1/4-1/2

inch from the top to provide space for

expansion of fuel. Always fill fuel tank

outdoors and use a funnel or spout to

prevent spilling. Make sure to wipe up any

spilled fuel before starting the engine. Store

gasoline in a clean, approved container,

and keep the cap in place on the container.

Keep gasoline in a cool, well ventilated ,

place; never in the house. Never buy more

thari a 30 day supply of gasoline to ensure

volatility. Gasoline is intended to be used as

a fuel for internal combustion engines:

therefore, do not use gasoline for any other

purpose. Since many children like the smell

of gasoline, keep it out of their reach

because the fumes are dangerous to

inhale, as well as being explosive. , ,

TO START THE ENGINE

Before starting the engine, be sure ÿou

have read and understood all the instruc

tions on the preceding pages. The edger is

equipped with a recoil starter. The opera

tion of the engine is controlled by the ’

throttle control lever. See page 6.

• Push the depth control lever forward and

latch in the forward slot of the adjustment

bracket to raise the blade.

• Move the throttle control lever, see figure

on page 6, to the FAST position.

• Push primer button five times, see

figure on page 6. Wait about two

seconds between each push. ;

NOTE: Do not use primer to restart a

warm engine after a short shutdown.

• Pull the engine control lever back to

contact the upper handle tube and hold

the edger handle and control lever firmly

with your left hand.

• To start engine, grasp the engine starter

handle firmly with your right hand.

• Pull back sharply on the recoil starter

handle. DO NOT allow the starter rope to

snap back, let it rewind sbwly while

NOTE: If engine fails to start after three

pulls, push primer button two times and

pull starter rope again.

• When the engine starts, run at full engine

speed during normal use.

NOTE: The cutting blade speed is

controlled by the engine speed. To

reduce the cutting blade speed, push

back on the throttle control lever. To

increase the blade speed, push the

throttle control lever fonward.

• To stop ^ the engine, make sure the

depth control lever is all the way forward

and release the engine control lever to

the stop position or push the throttle

control lever to stop See figure on

page 6.

As. WARNING: Never run the engine

indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide,

an odorless gas and deadly gas. Keep

hands, feet, hair and loose clothing away

from any moving parts on the engine or

edger. Avoid the muffler and surrounding

areas. Temperatures may exceed 150® F.

EDGING TIPS

■ Edging is best performed when conditions

are dry. If the soil is too wet, dirt becomes

packed in and around the blade causing

premature belt wear and decreased

performance.

• If dirt does become packed around the

blade, stop the engine, remove the spark

plug wire, and remove the packed debris

before continuing to edge.

• If very deep edging is required, we

recommend that a shallow cut be made

first, then cuts at greater depth until the

desired depth is obtained.

• Uniform edging can be performed when

the blade guide (see figure on page 6)

rides on and against the surface which

you are edging.

• Edging can be customized by varying the

number of passes and by the distance

your blade is from the surface you are

Page 11

CUSTOMER RESPONSIBILITIES

MAINTENANCE

SERVICE

RECORDS

Fill In dates as

you complete

regular service

Lubricate all Pivot Points

Lubricate Wheel Axles

Check Engine Oil Level

Change Engine Oil

Replace Air Cleaner Filter

Check Spark Plug

Check Drive Belt

Tighten All Screws and Nuts

Check Blade Wear/Damage

Lubricate Quill Rod/Tube

HORSE POWER:

DISPLACEMENT:

After

First

2

Hours

4

9.06 cu. in. (148 cc)

GASOLINE CAPACITY: 1.25 qt. ’■

Before

Each

Use

(unleaded regular)

Fre

quently

SCHEDULE

SERVICE

DATES

Every

5

Hours

Every

Hours

10

I/'

Every

25

Hours

Begin

Each

Season

Before

Storage

NOTE: If the Edger is being used in sandy

or dusty areas, change the oil more fre

quently to prevent premature engine wear.

TO CHANGE ENGINE OIL

• Disconnect the ^ark plug wire from the

spark plug.

LUBRICATION:

SPARK PLUG:

(Gap .030)

20 oz. SAE-30W

Champion RJ19LM

or Equivalent

GENERAL RECOMMENDATIONS

The warranty on this Edger does not cover

items that have been subjected to operator

abuse or negligence. To receive full value

from the warranty, the operator must main

tain the Edger as instructed in this manual.

The above chart is provided to assist the

operator in properly maintaining the Edger.

LUBRICATION

• After each 25 hours of use of your Edger,

apply light machine oil to all moving

parts, particularly the wheels.

• We recommend that the oil in the engine

crankcase be changed after the first

2 hours of operation and after each 25

hours of use thereafter.

V Remove the oil drain plug as shown in

first figure on page 12 and drain the oil

into a flat pan.

• After draining all the oil, reinstall the oil

drain plug securely.

NOTE: The oil will drain more freely when

the engine is warm.

• Remove the oil fill cap/dipstick. See first

figure on page 9.

• Fill the engine crankcase, pouring slowly.

DO NOT OVERFILL. For approximate ca

pacity see PRODUCT SPECIFICA

TIONS on this page.

NOTE: The quill assembly bearings are

factory sealed and will require no lubrica

tion.

• Reconnect the spark plug wire on the

spark plug.

11

Page 12

Oil Drain Rug

Replace the fitter once a year; more often

under dusty or dirty conditions. DO NOT

attempt to clean or oil the air filter.

To install a new air filter, do the following:

• Disconnect the spark plug wire from the

spark plug.

• Turn the cover as shown below to the left

(counterclockwise) and remove,the cover

and the air filter from the flange.

• Discard the air filter.

• Clean the cover and the flange thor

oughly.

• Insert the new air filter into the cover.

• Push the ojver firmly against the flange

and turn it to the right (clockwise) as far

as it will go as shown in figure below. Be

sure the retainers are bcked around the

flange.

• Reconnect the spark plug wire.

CAUTION: Never run the engine without

the air deaner element installed. A

defective air deaner can result in loss of

engine power and can cause excessive

wear or damage to the engine components

if dirt or dust is permitted to enter the

engine through the carburetor. A damaged

air cleaner, or one that is clogged with dust

or dirt should be replaced immediately.

SPARK PLUG

Clean the spark plug and reset the gap

periodically. Clean the area around the

spark plug base before removal, to prevent

dirt from entering the engine. Replace the

spark plug if the electrodes are pitted or

burned or K the porcelain is cracked. Clean

the spark plug by carefully scraping the

electrodes (do not sand blast or use a wire

brush). Be sure the spark plug is clean and

free of foreign material. Check the elec

trodes gap with a wire feeler gauge and

reset to .030 in. if necessary. If a new spark

plug is needed, refer to the PRODUCT

SPECIRCATtONS on page 11 for the

proper replacement spark plug.

Before reinstalling the spark plug, coal the

threads lightly with graphite or tight oil to

insure easy removal. Tighten the spark jiMug

firmly into the engine. If a torque wrench is

available, torque the spark plug to 15 foot

pounds.

Turn cover to the left

(cou nterclockwi se)

to remove

Turn cover

to the right

(clodtwise)

to install

Page 13

SERVICE AND ADJUSTMENTS

CAUTION: Always stop the engine

and disconnect the spark plug wire before

making any repairs to the Edger.

V-BELT REPLACEMENT

Your edger is equipped with a V-beit made

of a special compound. If the belt becomes

worn or breaks, replace it with an orignal

equipment belt as shown in the Repair

Parts section of this manual. Never use a

substitute.

• Disconnect the spark plug wire.

• Drain gasoline and oil from Edger.

• Tip Edger backwards on handle and

block top of handle against wall or bench.

• Remove three screws and flatwashers

from the belt guard as shown in figure

below.

'Screws

BLADE REPLACEMENT

The cutting blade is subject to wear and

damage such as nicks and dents. This will

not generally affect its function.

This blade is specially designed to not re

quire sharpening. Do not attempt to sharpen

this blade. If worn or damaged the blade

should be replaced.

CAUTION: When removing or tightening

the blade nut, always use the method

shown in figure below. The holding wrench

must always be positioned on the nut be-

ihind the cutting blade.

A CAUTION: Do not attempt to sharpen

this blade. You could cause damage to the

blade which could result in breakage and

possible user or bystander injury.

To replace the blade, do the following;

• Disconnect spark plug wire.

• Remove the 1/2-20 locknut shown in

• Remove the blade.

' ensure proper re-assembly. The blade is

• Position the replacement blade against

• Reconnect the spark plug wire.

i\de

Bearing

Note direction of J Housing

twist

* Push blade bearing housing back towards

engine to compress spring and release

tension on belt.

* Remove old belt {carefully note direction

of twist around engine pulley).

* While spring is compressed, install new

belt on quill and engine pulleys being sure

to twist belt in proper direction as shown

in figure above.

NOTE; If belt is not installed properly the

blade will not turn in the proper direction and

could damage the blade or belt. Refer to

figure above for proper direction of belt

travel.

WARNING; Always wear gloves when

working on blade, it is sharp.

13

figure below securing the blade to the

drive shaft.

IMPORTANT; Note the position of the

washer and the blade cutting edge to

marked THIS SIDE OUT.

the washer on the drive shaft and secure

with flange nut. Be sure to tighten nut

securely to 40-45 ft. lbs,

Tightening

Wrench

Holding

Wrench

Locknut

Blade

Page 14

LEVELING ADJUSTMENT

• When the depth control lever is in the

forward adjustment sbt, the engine

platform should be approximately level

and the edging blade tip should be 1-1/4

to 1-1/2 inches above the surface of the

ground.

• When the depth control lever is in the rear

adjustment slot the edging guide (see

figure below) should be approximately 1/4

inch above the surface which you

are edging and the blade tip should be

2-5/8 to 2-7/8 inches below the surface of

the ground. The two middle adjustment

slots provide shallower edging depths.

• To adjust the depth control lever to give

proper blade positions, remove the spark

plug wire from the spark plug. Place the

Edger on a work bench or sturdy triple. ^

Position Edger so that the blade can

extend below the top of the table or work

bench, put the depth control lever in the

rear adjustment slot and place a 1/4 inch

thick shim between the edging guide and

the top of the bench or table, see figure

below. Remove the hairpin from the

trunnion nut in the lower control rod and

slide the post out of the hole in the linkage

bracket. Turn the trunnion nut in (clock

wise) to raise the blade and out (counter

Edging Guide-

i

Table or Bench Top

—Blade

/4 inch

1/4

Space

clockwise) to lower the blade. See figure

below. The adjustment is correct when

there is a 1/4 inch space between the

edging guide and the bench or table top.

When the rod is adjusted correctly, insert

the trunnion nut and washers on the rod

into the hole in the linkage bracket and

replace the hairpin in the hole in the post

as shown bebw.

Linkage

Bradtet

• When the adjustment procedure is

complete, put the Edger back on the floor

and install the spark plug wire on the

spark plug. Move depth control lever prior

to starting to ched< assembly.

Ratwasher

Trunnion

Lower Nut

Control Rod

CARBURETOR ADJUSTMENT

The carburetor has been pre-set at the

factory and readjustment should not be

necessary. However, if the carburetor does

need to be adjusted, contact your nearest

Craftsman Service Center.

IMPORTANT: Never tamper with the

engine governor, which is factory set for

proper engine speed. Overspeeding the

engine above the factory high speed

setting can be dangerous. If you think the

engine-governed high speed needs

adjusting, contact your nearest Craftsman

Service Center, which has the proper

equipment and experience to make any

necessary adjustments.

Page 15

STORAGE

A WARNING; Never store your

Edger indoors or in an enclosed, poorly

ventilated area. If gasoline remains in the

tank, fumes may reach an open flame,

spark or pilot light from a furnace, water

heater, clothes dryer, cigarette, etc.

EDGER

• Clean the Edger thoroughly: remove all

debris and wipe the unit dry.

• Inspect the Edger for worn or damaged

parts and tighten all loose hardware.

• Oil all points described in the Lubrication

paragraph in the MAINTENANCE section

of this manual.

• Store the Edger in a protected area and

cover for additional protection.

IMPORTANT:A yearly checkup or tune-

up by a Craftsman Service Cenbr is a

good way of ensuring that your Edger

will provide maximum performance for

the next season.

ENGINE

is added to albw mixture to reach

carburetor. Store Edger in a safe place.

See warning on this page,

• Store the Edger in the wheels-down;

operating position. If the Edger is stored

in any other position, oil from the

crankcase could enter the cylinder,

causing a service problem.

You can keep your engine in good operat

ing condition during storage by:

• Changing oil.

V Lubricating the pislon/cylinder area. This

can be done by first removing the spark

plug and squirting ciean engine oil into

the spark plug hole. Then cover the spark

plug hole with a rag to absorb oil spray.

Next, rotate the engine by pulling the

starter two or three times. Finally,

reinstall spark plug and attach spark plug

wire.

IMPORTANT; it is important to prevent

gum deposits from forming in essential

fuel system parts such as the carburetor,

fuel fitter, fuel hose, or tank during storage.

Also, experience indicates that using

alcohol-blended fuels {called gasohol,

ethanol or methanol) can attract moisture

which leads to separation and formation of

acids during storage. Acidic gas can .

damage the fuel system of an engine while

in storage.

To prevent engine damage (if Edger is not

used for more than 30 days) follow the

steps below.

• To remove gasoline, run the engine

until the tank is empty and the engine

stops.

• If you do not want to remove gasoline,

a fuel stabilizer (such as Craftsman fuel

stabilizer No, 33500) may be added to

any gasoline left in the tank to minimize

gum deposits and acids. If the tank is

almost empty, mix stabilizer with fresh

gasoline in a separate container and add

some to the tank. Always follow instruc

tions on stabilizer container. Then run

engine at least 10 minutes after stabilizer

15

Page 16

TROUBLE SHOOTING

TROUBLE

Difficult Starting

or

Engine runs

erractically

Cutting blade fails

to turn

Blade fails to cut

properly

CAUSE

Stale fuel

Defective spark plug

Clogged fuel line

Blocked fuel line or empty fuel tank

Carburetor out of adjustment

Fouled spark plug

Clogged air cjdaner'_

Jammed due to foreign object

Loose blade

Defective belt Replace V-belt

Defective quill bearings

Damaged or worn blade Replace blade

CORRECTION

Drain fuel tank. Fill with fresh

fuel

Clean and re-gap spark plug

Replace fuel filter

Clean fuel line; check gas tank

Have carburetor adjusted

Clean and adjust gap, replace

Replace air filter

Clear obstruction

Tighten blade retaining nut

Replace the bearings

Excessive vibra

tion

Engine will not

shut off when en

gine control lever

is released

Loose parts

Handle hardware is hot cutting into

tube

Stop engine immediately; tighten

all boHs. If vibration continues,

take the unit into the nearest

Craftsman Senrice Center

Tighten bolts until the head of the

boll cuts into the tubing

Page 17

For the repair or replacement parts you

need delivered directly to your home

Call 7 am-7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

Para ordenar piezas con entrega

a domicilio -1-800-659-7084

For in-house major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247) ...

Para pedir servicio de reparación a

domicilio -1-800-676-5811

For the location of a Sears Parts and

Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Cali 9 am -5pm, Monday-Saturday

1-800-827-6655

When requesting service or ordering

parts, always provide the following

Information:

• Product Type • Part Number

• Model Number • Part Description

REP A IR SE R VI C ES

Am er i ca 's Re p a ir S p ed a Ss t s

Printed In U.S.A.

Loading...

Loading...