Page 1

3.5 Horsepower

9 Inch

EDGER

MODEL NO.

536.772101

Caution:

Read and follow all Safety Rules

and Operating Instructions before

first use of this product.

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

F^01101M

Page 2

TABLE OF CONTENTS

WARRANTY STATEMENT 2 SERVICE AND ADJUSTMENT 17

SAFETY RULES 3 TROUBLE SHOOTING CHART 20

INTERNATIONAL SYMBOLS 5 EDGER REPAIR PARTS 21

ASSEMBLY 6 ENGINE REPAIR PARTS 25

OPERATION 10 SPANISH (ESPAÑOL) 31

MAINTENANCE 14 PARTS AND SERVICE BACK COVER

WARRANTY STATEMENT

LIMITED ONE-YEAR WARRANTY ON CRAFTSMAN EDGER

For one year from the date of purchase, when this Craftsman Edger is maintained, lubri

cated, and tuned up according to the operating and maintenance instructions in the owner's

manual. Sears will repair, free of charge, any defect in material or workmanship.

If this Craftsman Edger is used for commercial or rental purposes, this warranty applies for

only 90 days from the date of purchase.

This warranty does not cover the following:

• Expendable items which become worn during normal use, such as spark plugs, etc.

• Repairs necessary because of operator abuse or negligence, including bent crank shafts

and the failure to maintain the equipment according to the instructions contained in the

owner’s manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN EDGER TO

THE NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates, IL 60179

A WARNING:

A

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

IMPORTANT: This unit is equipped with an internal combustion engine and must not be

used on or near any unimproved forest-covered, brush-covered or grass-covered land

unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it must be maintained in

effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws. Federal laws apply on fed

eral lands. A spark arrester/muffler is available through your nearest Sears Service Cen

ter (see the REPAIR PARTS section in this manual).

F-001101M 2

Page 3

A

SAFETY RULES

Safe Operation Practices for Edger.

WARNING; Look for this symbol to point out important safety precautions.

It means; “Attention! Become Aiert! Your Safety is Involved.”

WARNiNG: To prevent acciden

tai starting when setting-up,

A

piug wire and put wire where it cannot

contact the spark plug .

transporting, adjusting or mak

ing repairs, aiways disconnect spark

Before Use

• Read the owner’s manual carefully. Be

thoroughly familiar with the controls and

the proper use of the Edger. Know how to

stop the Edger and disengage the controls

quickly.

• Do not operate the Edger without wearing

adequate outer garments. Wear footwear

that will improve footing on slippery sur

faces.

• Keep the area of operation clear of all per

sons, particularly small children and pets.

• Thoroughly inspect the area where the

Edger is to be used and remove all foreign

objects.

Fuel Safety

• Handle fuel with care; it is highly flam

mable.

• Use an approved container.

• Check fuel supply before each use, allow

ing space for expansion as the heat of the

engine and/or sun can cause fuel to ex

pand.

• Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Replace fuel

tank cap securely and wipe up spilled fuel.

• Never remove the fuel tank cap or add fuel

to a running or hot engine.

• Never store fuel or Edger with fuel in the

tank inside a building where fumes may

reach an open flame.

F-001101M

Operating Safety

• Never allow children or young teenagers to

operate the Edger. Keep them away while

it is operating. Never allow adults to oper

ate the Edger without proper instruction.

• Do not operate this machine if you are tak

ing drugs or other medication which can

cause drowsiness or affect your ability to

operate this machine.

• Do not use this machine if you are mentally

or physically unable to operate this ma

chine safely.

• Always wear safety glasses or eye shields

during operation or while performing an

adjustment or repair to protect your eyes

from foreign objects that may be thrown

from the Edger.

• Do not put hands or feet near or under ro

tating parts.

• Exercise extreme caution when operating

on or crossing gravel drives, walks, or

roads. Stay alert for hidden hazards or

traffic.

• Exercise caution to avoid slipping or falling.

• Never operate the Edger without proper

guards, plates, or other safely protective

devices in place.

• Never operate the Edger at high transport

speeds on slippery surfaces. Look behind

and use care when backing.

• Never allow bystanders near the Edger.

• Keep children and pets away while

operating.

• Never operate the Edger without good visi

bility or light.

• Do not run the engine indoors. The ex

haust fumes are dangerous, containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS.

• Take all possible precautions when leaving

the Edger unattended. Stop the engine.

• Do not overload the Edger capacity by at

tempting to till too deep at too fast a rate.

Page 4

SAFETY RULES

Safe Storage

Always refer to the owner's manual instruc

tions for Important dotails If the Edger is to

be stored for an extended period.

Never store the Edger with fuel in the fuel

tank inside a building where ignition

sources are present such as water and

space heaters, clothes dryers, and the like.

Allow the engine to coo! before storing in

any enclosure.

Keep the Edger in safe working condition.

Check all fasteners at frequent intervals for

proper tightness.

Repair / Adjustments Safety

• After striking a foreign object, stop the en

gine. Remove the wire from the spark plug,

and keep the wire away from the plug to

prevent accidental starting. Thoroughly in-

spect the Edger for any damage, and re

pair the damage before restarting and

operating it.

If Edger should start to vibrate abnormally,

stop engine and check immediately for the

cause. Vibration is generally a warning of

trouble.

Stop the engine whenever you leave the

operating position. Also, disconnect the

spark plug wire before unciogging the

blade and when making any repairs, ad

justments, or inspections.

When cleaning, repairing, or inspecting,

shut off the engine and make certain all

moving parts have stopped.

Never attempt to make any adjustments

while the engine is running except when

specifically recommended by the manufac

turer.

F-001101M

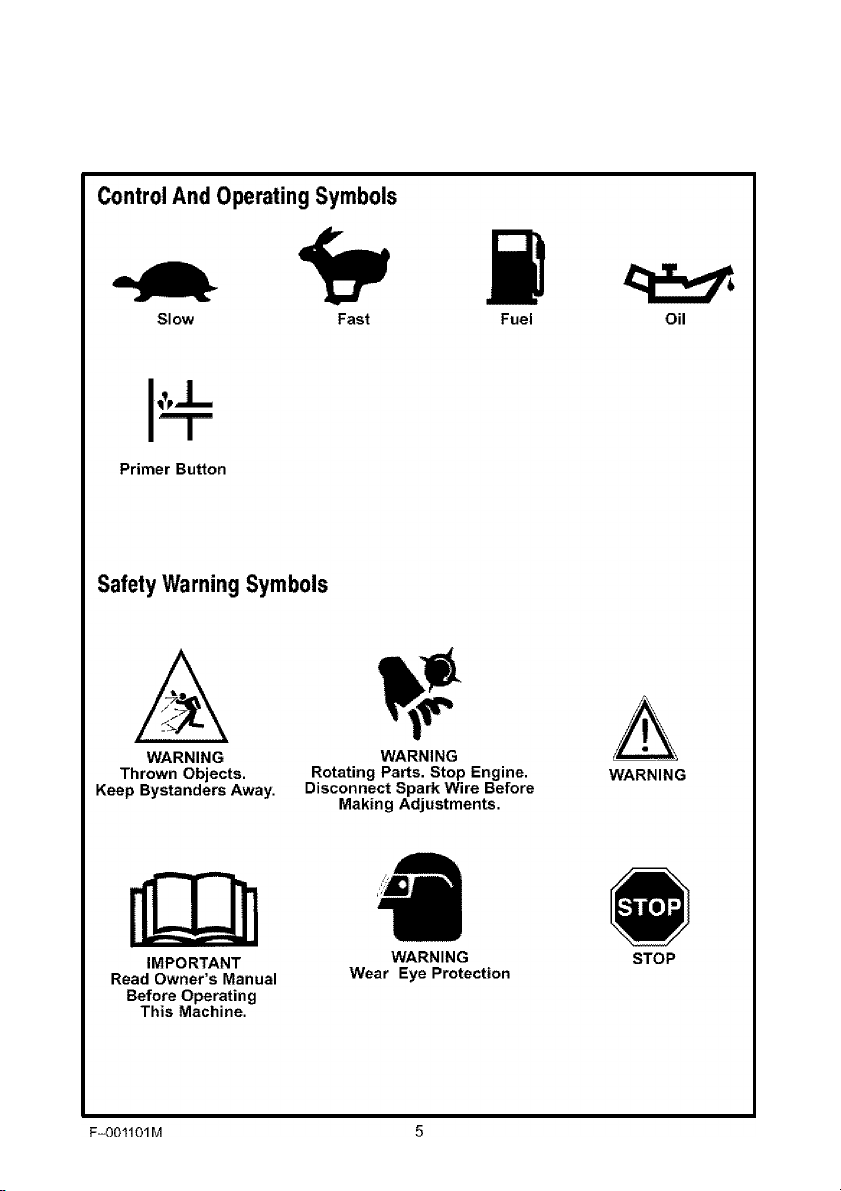

Page 5

SAFETY RULES

INTERNATIONAL SYMBOLS

IMPORTANT; Many of the following symbols are located on your unit or on literature sup

plied with the product. Before you operate the unit, learn and understand the purpose for

each symbol.

Page 6

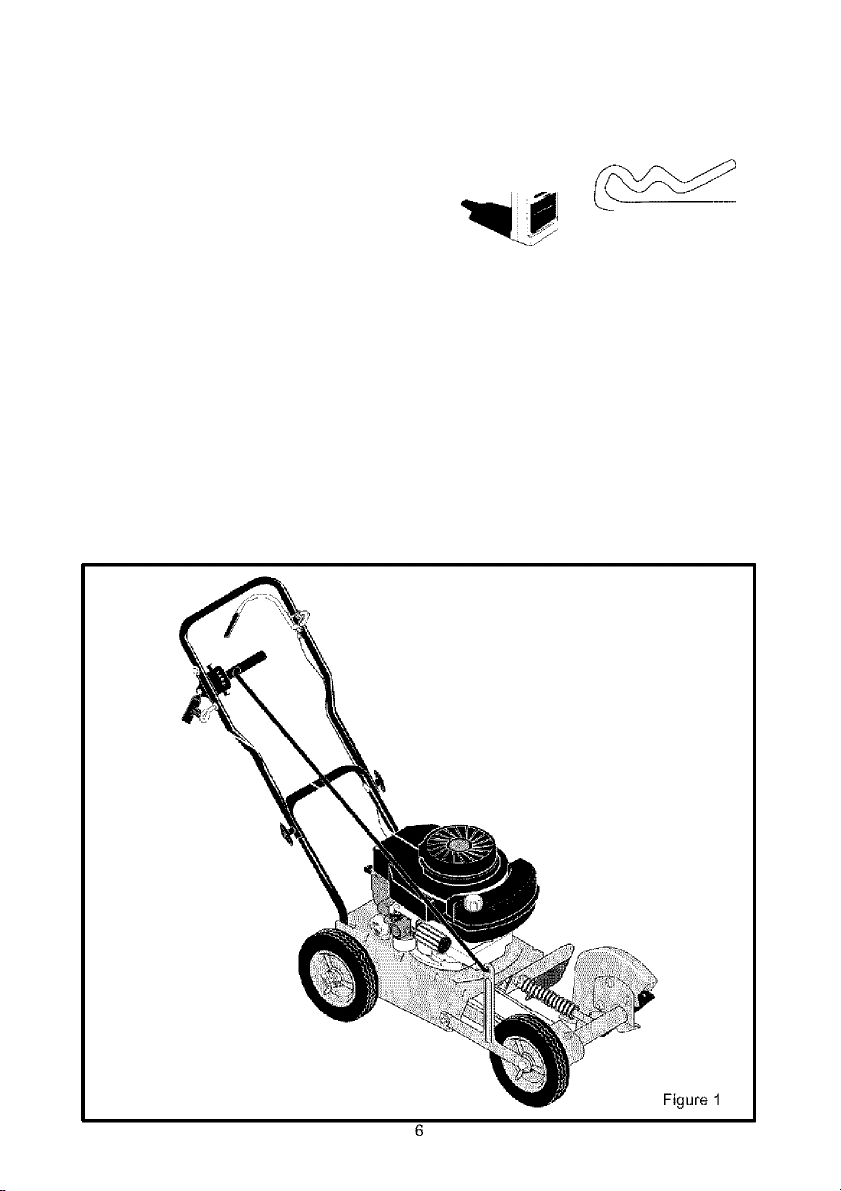

ASSEMBLY

ASSEMBLY

Parts Packed Separately in Carton

1 - Owner's Manual (not shown)

1 - Container Of Oil

2 - Hair Pin

1 - Control Rod

1 - Control Rod

1 - Hair Pin

1 - Container of Oil

WARNING: Always wear safety

A

Figure 1 shows the Edger completely as

sembled.

References to the right or left side of the

Edger are from the viewpoint of the opera

tor’s position behind the unit.

REMOVE THE EDGER FROM THE

CARTON

1. Remove the bottle of oil and parts bag

glasses or eye shields while as

sembling the Edger.

from the carton.

2. Cut down all four corners of the carton.

3. Remove the packing material positioned

around the front and rear of the unit.

Leave the packing material on the bot

tom of the unit until the control rod is as

sembled. This will keep the front wheel

in a stable position.

4. Lift the Edger out of the carton and place

on a hard level surface.

F-001101M

Page 7

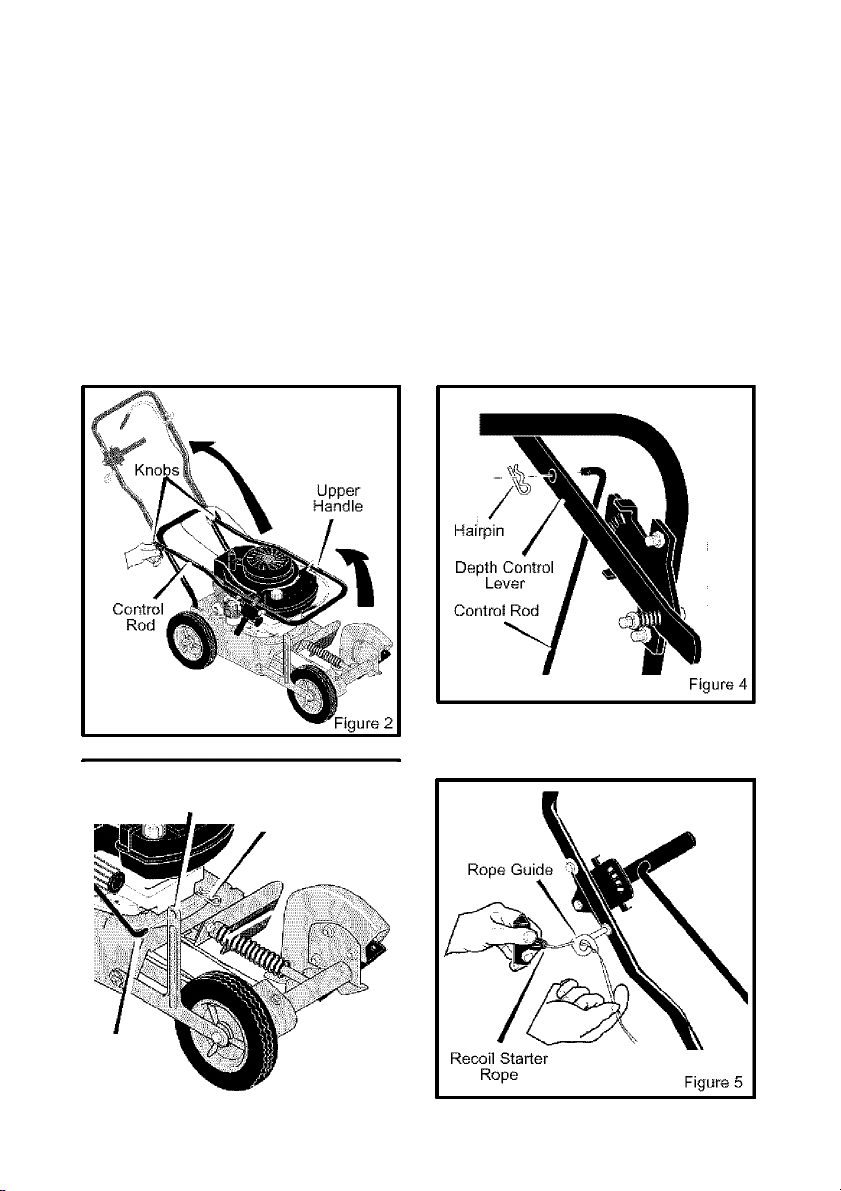

HOW TO RAISE THE HANDLE

ASSEMBLY

Loosen the knobs and raise the upper

handle to the upright position. See

Figure 2.

2.

Tighten the knobs. Make sure the

knobs are to the outside of the handles

as shown in Figure 2.

3.

Insert the end of the control rod, from

RIGHT to LEFT, through the hole in the

front wheel arm. Attach with hair pin

found in parts bag. See Figure 3.

Push down on the handle to tilt the unit

back.

5. Insert the other end of the control rod,

from RIGHT to LEFT, through the hole in

depth control lever and fasten with

the

hair pin. See Figure 4.

6. Move the depth control lever forward to

the STARTING and TRANSPORT posi

tion.

7. Remove any packing material from the

bottom of the unit.

8. To attach the recoil starter rope to the

rope guide, twist the recoil starter rope

through the rope guide. See Figure 5.

Control

Rod

F-001101M

Front

Wheel Arm

Hair Pin

Figure 3

Page 8

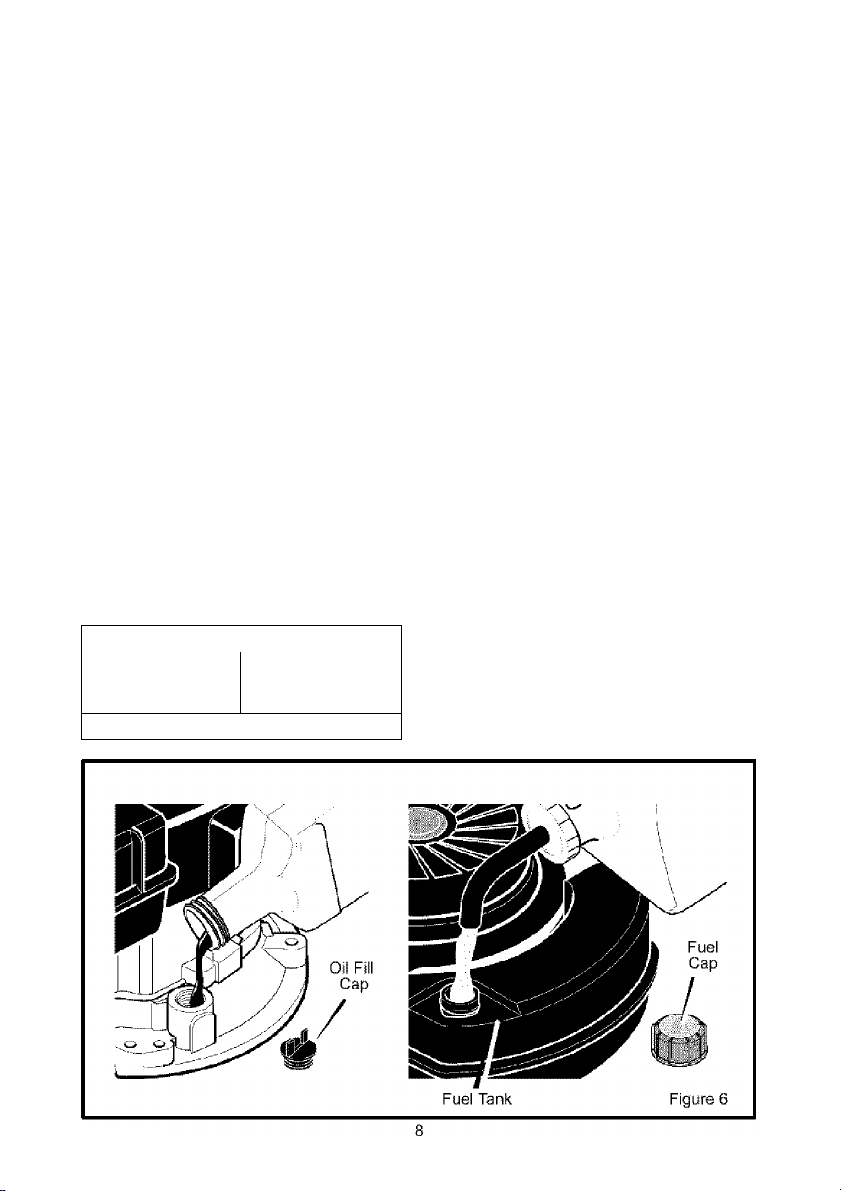

ASSEMBLY

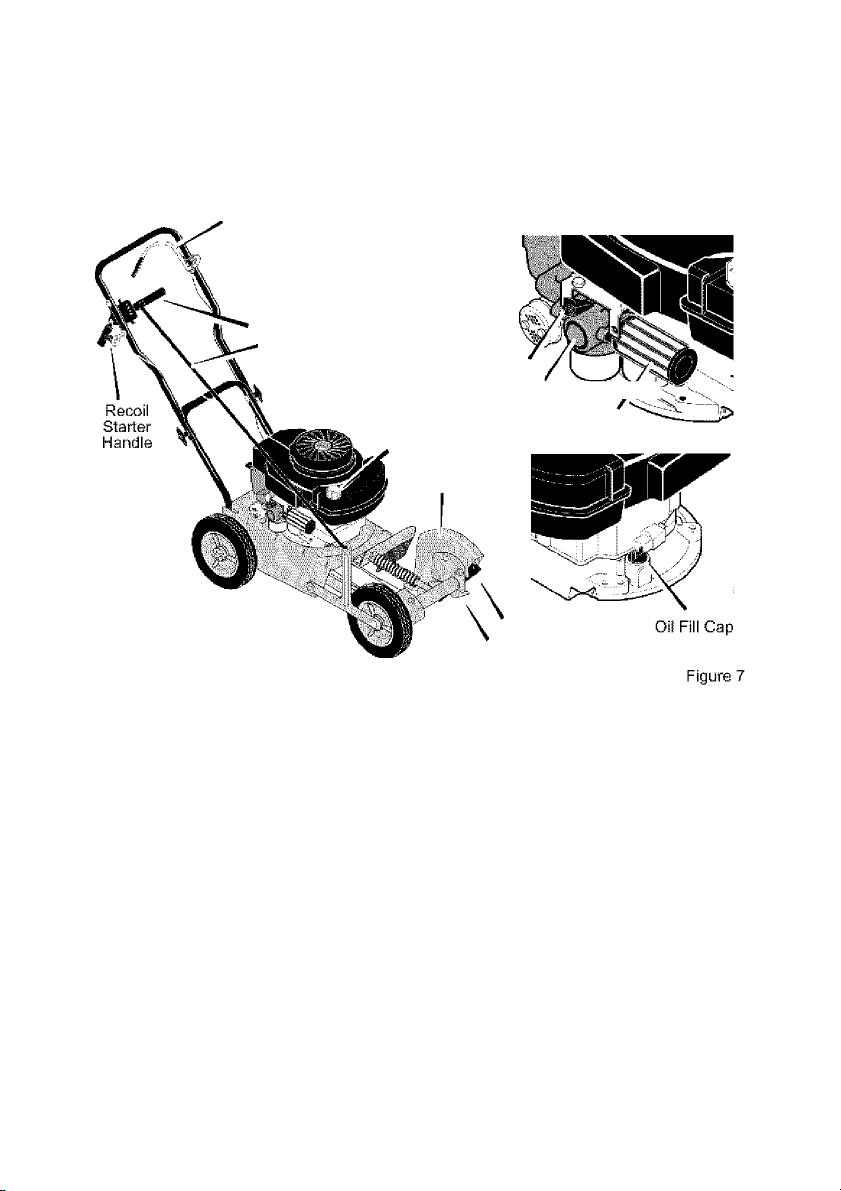

HOW TO PREPARE THE ENGINE

Fill With Oil

This Edger was shipped with a 20 ounce

container of SAE30 motor oil. Add this oi! to

the engine before operating. To fill the crank

case, remove the oil fill cap/dipstick and add

the SAE30 motor oil. DO NOT OVERFILL.

NOTE: The engine may contain a small

amount of oil. When adding oil, frequently

insert the oil fill cap/dipstick and check

the amount of oil in the engine. DO NOT

OVERFILl.

Oi! Recommendations

Only use high quality detergent oil rated with

API service classification SG. Select the oil's

SAE viscosity grade according to your ex

pected operating temperature. Although mul

ti-viscosity oils (5W30, 10W30, etc.) improve

starting in cold weather, these multi-viscosity

oils will result in increased oil consumption

when used above 32 degrees. Check the

engine oil level more frequently to avoid pos

sible engine damage from running the en

gine low on oil.

32“

Colder ------- — — --------Warmer

<■----------------------- ---------------------->

5W30

SAE30

How To Add The Engine Oii

1. Put the Edger on a level surface.

2. Remove the oil fill cap (Figure 6).

3. Slowly fill the engine crankcase. DO NOT

OVERFILL.

How To Fill With Gasoline

Make sure that the gasoline container is

clean and free from dust or other foreign ma

terial. Never use gasoline that could be stale

from long periods of storage.

1. Remove the fuel cap.

2. Fill the fuel tank with clean, fresh, un

leaded grade automotive gasoline.

WARNING: Always use a safety

fuel container. Do not smoke

A

NOTE; ENGINES WHICH ARE CERTIFIED

TO COMPLY WITH CALIFORNIA AND US

EPA EMISSION REGULATIONS FOR

ULGE ENGINES, are certified to operate

on regular unleaded gasoline. Include the

following emission control system(s):

EM, TWC (if so equipped). Include any

user adjustable features - therefore no

other adjustments are needed.

when adding the fuel mixture to

the engine. When inside an enclosure,

do not fill the fuel tank. Before you add

the fuel mixture, stop the engine. Let the

engine cool for several minutes.

F-001101M

Page 9

ASSEMBLY

CHECKLIST

For the best performance and satisfaction

from this quality product, please review the

following checklist before you operate the

Edger;

y All assembly instructions have been

completed.

y Check carton. Make sure no loose

parts remain in the carton.

y

All fasteners have been properly tights

ened.

As you learn how to use the Edger, pay extra

attention to the following Important items:

yy

Engine oil is at proper level.

yy

Fuel tank is filled with a fresh, clean,

regular Unleaded gasoline.

yy

Become familiar and understand the

function of all controls. Before your

start the engine, operate all controls.

F-001101M

Page 10

OPERATION

KNOW YOUR EDGER

READ THE OWNER’S MANUAL AND ALL SAFETY RULES BEFORE YOU OPERATE the

Edger. To familiarize yourself with the location of the controls, compare the illustrations with

your Edger. Save this manual for future reference.

Engine Stop Lever

Depth Control Lever

Control Rod

Throttle Control ^ _

Primer Button

Fuel Tank

Cap

Blade Guard

Blade

Blade Guide

Air Filter

Throttle Control - Controls the engine

speed.

Primer Button - Injects fuel directly into

the carburetor for faster starts.

Recoil Starter Handle - The engine is

equipped with an easy pull recoil starter.

Depth Control Lever - Use to control the

EYE PROTECTION

Always wear safety glasses. If you wear eye

glasses, put a Wide Vision Safety Mask over

your eye glasses.

F-001101M 10

depth of cut.

Blade Guard - Use to prevent stones or

other material from being thrown at the oper

ator.

Engine Stop Lever — Must be engaged

to allow the engine to start and run. Re

lease to stop the engine.

WARNING: Debris thrown from

the Edger can result in foreign

A

eyes, which can cause severe eye dam

age. Always wear safety glasses or eye

shields when operating the Edger.

objects being thrown into the

Page 11

OPERATION

WARNING

runs, the blade will rotate. To

A

feet away from blade.

HOW TO STOP THE EDGER

1. Move the depth control lever forward to

A

the cutting blade and stop the engine.

HOW TO USE

THE ENGINE STOP LEVER

1. Release the engine stop lever and the

2. If the engine continues to run, move the

IMPORTANT: Before you start the engine,

operate the engine stop lever several

times. Make sure the engine stop cable

moves freely, if the engine stop cable is

bent or damaged, replace the cable. If the

problem continues, take the Edger to a

Sears Service Center to correct the prob

lem.

prevent injury, keep hands and

raise the blade. Then, release the engine

stop lever. See Figure 8.

WARNING: Never leave the

Edger unattended while the en

gine is running. Always raise

engine and the blade will automatically

stop. To run the engine, hold the

stop lever in the operating position. See

Figure 8.

throttle control to the STOP position.

When the engine HOW TO USE

engine

THE DEPTH CONTROL LEVER

1. start the engine.

control lever back.

3. Select the edging depth that you need.

There are three selections with an

approximately depth of two inches.

NOTE; For deep edging, first cut at shal

low depths. Then, cut at greater depths

until the desired depth is obtained.

Engine Stop Lever

(Operating Position)

pull the depth2. To lower the cutting blade,

Figure 8

HOW TO USE

THE PRIMER BUTTON

When starting a cold engine, push the prim

er button five times (see Figure 9). Wait

approximately two seconds between each

push.

IMPORTANT: When starting a warm en

gine, do not use the primer button.

HOW TO USE

THE THROTTLE CONTROL

1. Push the throttle control forward to in

crease engine speed, or pull back to de

crease engine speed (see Figure 9).

F-001101M

2. During normal use, run the engine at full

speed.

Page 12

OPERATION

HOW TO STOP THE ENGINE

To stop the engine, release the engine stop

lever. If the engine continues to run, move

the throttle control to the STOP position.

If the engine will not stop, hold a screwdriver

against the spark plug and against the en

gine cooling fins. The spark will go to ground

and the engine will stop.

HOW TO START THE ENGINE

WARNING; When the engine

runs, the blade will rotate. To

A

IMPORTANT: Before you start the engine,

move the edger to the desired location. Op

erate the controls several timer. Make sure

all controls move freely.

1. Check the oil.

2. Fill the fuel tank with regular unleaded

NOTE: Do not use gasohol or methanol. Do

not use premium unleaded gasoline.

A

the engine cool for several minutes.

3. Make sure the spark plug wire Is con

4. Pull the engine stop lever back to the EN

5. Move the throttle control lever to the

6. When starting a cold engine, push the

prevent injury, keep hands and

feet away from blade.

gasoline. Make sure the gasoline is

clean. Leaded gasoline will increase de

posits and shorten the life of the valves.

WARNING; Always use a safety

gasoline container. Do not

smoke when adding gasoline to

the fuel tank. When inside an enclo

sure, do not add gasoline. Before you

add gasoline, stop the engine and let

nected to the spark plug.

GAGED position. Hold the engine stop

lever against the handle.

FAST position.

primer button five times. Wait approxi

mately two seconds between each push.

See Figure 10,

Throttle

Control

Primer

Button

NOTE: Do not use the primer button to start

a warm engine.

7. To start engine, hold the recoil starter

handle firmly with your right hand.

8.

Quickly pull the recoil starter handle. DO

NOT allow the starter rope to snap back.

Let the starter rope slowly rewind. If en

gine fails to start after three pulls, push

primer button two times and again pull

the recoil starter handle.

When the engine starts, move the throttle

control lever to the FAST position. During

normal use keep the throttle in the FAST

position.

10. If the engine does not start in 5 or 6 tries,

see the instructions in the “Trouble

Shooting Chart”.

NOTE: The cutting blade speed is con

trolled by the engine speed. To reduce the

cutting blade speed, decrease the engine

speed. To increase the cutting blade speed,

increase the engine speed.

WARNING; Never run the en

gine indoors or in a poorly ven

A

tilated area. Engine exhaust

contains carbon monoxide, an odorless

and deadly gas. Keep hands, feet, hair

and loose clothing away from any mov

ing parts. Avoid the muffler and sur

rounding areas. Temperatures can ex

ceed 150 degrees.

n/b

Figure 10

F-001101M

12

Page 13

OPERATION

EDGING TIPS

• Edging is best performed when conditions

are dry. If the soil is to wet, dirt becomes

packed around the biade causing prema

ture belt wear and decreased perfor

mance.

• if dirt does become packed around the

blade, stop the engine and remove the

wire from the spark piug. Remove the

packed dirt and debris from the biade.

• For deep edging, first cut at shaiiow

depths. Then, cut at greater depths untii

the desired depth is obtained.

• For uniform edging, make sure the blade

guide rides on the surface.

• Edging can be customized by varying the

number of passes and by the distance the

blade is from the surface.

WARNING: Read the Owner’s

Manual. Know location and

A

Never allow children or uninstructed

adults to operate the Edger. Shut off en

gine before unclogging blade or making

repairs. Keep bystanders away from ma

chine. Keep away from the blade all ro

tating parts, which cause injury.

functions of all controls. Keep

all safety devices and shields in place.

F-001101M

13

Page 14

MAINTENANCE

CUSTOMER RESPONSIBILITIES

SERVICE

RECORDS

Fill in dates as you

complete regular

service.

Lubricate All Pivot v .

Points

....................

Lubricate Wheel

Axles

Check Engine Oil

Level

.....................

Change Engine Oil

Replace Air Cleaner

Filter

......................

Check Spark Plug

Before

Each

Use Ollen

V

■

Every

10

Hours

Every

Before

Each

25

Hours

Season

V V

V V

V ■

V

V

Before

Storage

' \¡ "

SERVICE

DATES

Check Drive Belt

Tighten All Fasteners

Check Blade For ..

Wear Or Damage

Lubricate Quill Rod/

tube

.....

....

PRODUCT SPECIFICATIONS

Model No.: 536.772101

Date Of Purchase;

Horse Power: 3.5

Displacement:

Oil Capacity:

Spark Plug:

Spark Plug Gap:

10 cu. in.

(163 cc.)

20 oz. SAE-30W

Champion

RJ19LM

0.030 inch

■V

V

..

V

V

GENERAL RECOMMENDATIONS

The warranty on this Edger does not cover

items that have been subjected to operator

abuse or negligence. To receive full value

from the warranty, the operator must main

tain the Edger as instructed in this manual.

Some adjustments must be made periodical

ly to properly maintain your Edger.

All adjustments in the Service and Adjust

ments section of this manual must be

checked at least once each season.

F-001101M

14

Page 15

MAINTENANCE

LUBRICATION

After each 25 hours, appiy a small amount of

engine oil to all moving parts, particularly the

wiheels.

How To Change The Engine Oil

Change the oil in the engine crankcase after

each 25 hours of use.

NOTE: The oil will drain more freely when

the engine is warm.

1. Disconnect the spark plug wire from the

spark plug.

2. Remove the oil drain plug (see

Figure 11). Drain the oil into a flat pan.

3. After draining all the oil, install and tight

en the oil drain plug.

4. Remove the oil fill cap (see Figure 12).

Fill the engine crankcase. Pour slowly.

Do not overfill. See “Product Specifica

tions” for amount and type of oil. Install

oil fill cap.

the

5. Connect the spark plug wire to the spark

plug.

HOW TO CHANGE THE AIR FILTER

Replace the air filter once a year: more often

in dusty or dirty conditions.

NOTE: DO NOT clean or oil the air filter.

The air filter is not serviceable and must

be replaced.

1. Disconnect the spark plug wire from the

spark plug.

2. Turn the cover to the left (counterclock

wise). Remove the cover and the air fil

ter from the flange, (see Figure 13).

3. Discard the air filter.

4. Clean the cover and the flange.

5. Install a new air filter into the cover.

6. Push the cover firmly against the

flange. Turn the cover to the right

(clockwise) until tight. Make sure the re

tainers are locked around the flange.

7. Connect the spark plug wire to the spark

F-001101M 15

CAUTION: Never run the engine without

the air filter. A defective air filter will

cause a loss of engine power. If dirt or

dust enters the engine through the carbu

retor, the result will be excessive wear or

damage to the engine. Replace a dam

aged or clogged air cleaner immediately.

To Remove,

Turn Counterclockwise

Air Filter

Retainer

To Install,

Turn Clockwise

Figure 13

Page 16

MAINTENANCE

SPARK PLUG

Check the spark plug every 25 hours. Re

place the spark plug if the electrodes are

pitted, burned, or if the porcelain is cracked.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully scrap

ing the electrodes (do not sand blast or

use a wire brush).

2. Check the spark plug gap with a feeler

gauge.

3. Before Installing the spark plug, coat

the threads lightly with oil for easy re

CARBURETOR ADJUSTMENT

Never make unnecessary adjustments to the

carburetor. The carburetor was set at the

factory to operate efficiently under most ap

plications. However, if adjustments are re

quired, we recommend you contact your

nearest Sears Service Center.

WARNING: The engine gover

nor is set at the factory. Do not

A

tory setting can be dangerous. If you

think the engine governor needs an ad

justment, contact your nearest Sears

Service Center.

change the governor setting.

Over speeding the engine above the fac

moval. Tighten the spark plug to a torque

of 15 foot-pounds.

F-001101M

16

Page 17

SERVICE AND ADJUSTMENT

HOW TO REMOVE THE BELT

The belt made of a special compound. !f the

belt becomes worn or breaks, replace the

belt with an original equipment belt.

1. Disconnect the spark plug wire from the

spark plug.

2. Drain the gasoline and oil from the en

gine.

3. Tip the Edger backwards on the handle.

Block the top of the handle against a wall

or under a bench.

4. Remove the screws from the belt guard

(see Figure 15).

5. To compress the spring and release ten

sion on the belt, push the blade bearing

housing back toward the engine (see

Figure 16).

6. Carefully note the twist of the belt around

the engine pulley. Remove the old belt.

Replace with an original equipment belt.

7. To install a new belt, reverse the above

steps. Make sure to twist the new belt as

shown in Figure 16.

NOTE: If the belt is not installed properly,

the blade will not turn in the proper direc

tion and can damage the blade or belt.

Engine Pulley Blade Housing Bearing

F-001101M

17

Note

Of

Figure 16

Page 18

SERVICE AND ADJUSTMENT

HOW TO REPLACE THE BLADE

The blade is subject to wear and damage,

such as nicks and dents. This will not gener

ally affect its function.

The blade is designed to not require sharp

ening. Do not attempt to sharpen the blade.

The blade is also reversible. If nicks or

dents are excessive, remove the blade and

turn it around. This will provide a fresh cut

ting edge. Replace the blade if both sides

are worn or damaged.

WARNING: Do not sharpen the

blade. Sharpening can damage

A

others.

To replace the blade, follow the steps below.

the blade and cause it to break,

which can cause injury to yourself or to

1. Disconnect the spark plug wire from the

spark plug.

2. Remove the blade locknut that holds

the blade to the drive shaft.

WARNING: To remove or tigh

ten the blade locknut, always

A

wrench on the nut behind the blade.

3. Remove the blade.

4. Install a new blade and blade locknut.

5. Connect the spark plug wire to the spark

use the method shown in

Figure 17. Always position the holding

Tighten the blade locknut to a torque of

40-45 foot pounds.

plug.

Turn Wrench

F-001101M

Hold Nut,

Do Not Turn

Figure 17

18

Page 19

SERVICE AND ADJUSTMENT

STORAGE

WARNING: Never store the

Edger indoors with fuel in the

A

ciosed, pooriy ventilated area where

fumes could reach an open flame, a

spark or a pilot light as on a furnace, wa

ter heater or clothes dryer.

A

or a fire.

When the Edger is put in storage for thirty

days or more, follow the steps below to

make sure the Edger is in good condition the

following season.

Edger

• Completely clean the Edger.

• Check the Edger for worn or damaged

• Apply a small amount of engine oil to all

• Put the Edger in a building that has good

• Cover the Edger with a suitable protec

IMPORTANT: Never cover the Edger while

the engine and exhaust areas are still

warm.

NOTE; A yearly checkup or tune-up by a

Sears Service Center is a good way to

make sure that your Edger will provide

maximum performance for the next sea

son.

Engine

IMPORTANT: It is important to prevent

gum deposits from forming in fuel system

fuel tank. Never store in an en-

WARNING: Do not remove gas

oline while inside a building,

near a fire, or while you smoke.

Gasoline fumes can cause an explosion

parts. Tighten all loose hardware.

moving parts, particularly the wheels.

ventilation.

tive cover that does not retain moisture.

Do not use plastic.

parts such as the carburetor, fuel filter,

fuel hose, and tank during storage. Also,

using alcohol-blended fuels (called gasohol, ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an en

gine while in storage.

To prevent engine damage when the Edger

is in storage for 30 days or more, follow the

steps below:

• Let the engine run until it is out of gaso

line.

• If you do not want to remove the gaso

line, add a fuel stabilizer to any gasoline

left in the fuel tank. A fuel stabilizer will

minimize gum deposits and acids. If the

fuel tank is almost empty, mix the fuel

stabilizer with fresh gasoline in a sepa

rate container and add the mixture to the

fuel tank. Always follow the instructions

on the stabilizer container. Start the en

gine. Let the engine run for 10 minutes

to allow the mixture to reach the carbu

retor.

• Change the engine oil. See “How To

Change The Engine Oil” in the Mainte

nance section.

• Lubricate the piston/cylinder area. This

can be done by first removing the spark

plug and squirting a small amount of

clean engine oil into the spark plug hole.

Then, cover the spark plug hole with a

rag to absorb oil spray. Next, rotate the

engine by pulling the starter two or three

times. Finally, install the spark plug and

attach the spark plug wire.

• Store the Edger in the operating position

with the wheels down. If the Edger is

stored in any other position, oil from the

crankcase will enter the cylinder and

cause a service problem.

F-001101M

19

Page 20

TROUBLE SHOOTING CHART

TROUBLE CAUSE CORRECTION

Engine difficult to start

stale fuel Drain fuel tank. Fill with fresh

fuel.

or

Clogged fuel filter Replace fuel filter

Dirt in fuel tank or out of fuel Clean fuel tank.

Engine runs eiraticaily

Carburetor out of adjustment Take unit to a Sears Service

Center.

or

Fouled spark plug Clean and set spark plug

gap.

Engine wiil not run at full

speed

Engine smokes

excessively

Dirty air filter Replace air filter.

Plugged air filter Replace air filter.

Debris interfering with blade Clean debris from blade.

Cutting biade will not

rotate

Loose blade Tighten blade nut.

Defective V-belt Replace V-belt.

Defective quill bearings Replace the quill assembly.

Blade will not cut properly

Damage or worn blade Reverse the blade or replaoe

the blade.

Excessive vibration Loose parts Stop engine immediately.

Tighten all fasteners. If

vibration continues, take the

unit to a Sears Service

Center.

Engine does not shut off

when engine control lever

is released

F-001101M

Loose handle Tighten handle knobs.

20

Page 21

CRAFTSMAN 536.772101 REPAIR PARTS

339589C

KEY KEY

DESCRIPTION PART N0.

NO.

DESCRIPTION PART N0.

N0.

10 3.5 HP 143.003502 Engine 311 Bolt, Carriage 57072

(See Engine pages)

12 Screw 47792

20 Pulley, V3L 52052

22 Key, Hi Pro #505 338490

100 Frame, Edger 740121~~.833

300 Quill Assembly 339283

301 Spring 51603

302 Spring Pin 412281

305 Belt, V4L 32668

313 Nut, 5/16-18 710205

314 Flat washer 22265

315 Blade, Edger 740297

316 Nut, 1/2-20 46023

317 Deflector, Rubber 338582

318 Plate, Rubber Flap 337792-833

320 Belt Guard 336631

321 Screw, 10-16X.50 710271

_

Instruction Manual F-001101M

310 Blade Guard 331076-833

F-001101M

21

Page 22

CRAFTSMAN 536.772101 REPAIR PARTS

418

F-001101M

REF.

FRAME ASSY,

343712C

22

Page 23

CRAFTSMAN 536.772101 REPAIR PARTS

KEY

DESCRIPTION PART N0.

NO.

401 Bolt, 5/16-18X.75 711558

402 Nut, 5/16^18 45174

403 Lower Handle 740128-853

405 Handle, Depth 740130-853

406 Screw 180081

407 Spring, Compression 25644

408 Nut, 5/16-18 1498

409 Brkt, Adj. Quadrant 740143-853

410 Rope Guide 672510

411 Screw, 1/4-20x1.25 180024

412 Nut, 1/4-20 782585

415 Upper Handle 740142-853

416 Bail, Operator Control 337744

417 Torsion Spring 337775

418 Nut, Push On 314276

419 Cap, Operator Control 339489

420 Insulator, Oper Control 339229

421 Screw, #6x.50 57796

422 Clip, Grounding 340162

423 Cabie Tie 712267

424 Bolt, 5/16-18X.75 315288

425 Wing Knob 5/16-18 671294

426 Rod, Control 740144-853

427 Hair Pin 36368

428 Washer, Exik. 138485

F-001101M

23

Page 24

CRAFTSMAN 536.772101 REPAIR PARTS

103

113

343716B

KEY

DESCRIPTION PART N0.

N0.

KEY

DESCRIPTION PART N0.

N0.

101 Rod, Axle Front 740091 109 Screw 180091

103 Ring, Ret E. 20864 110 Flat washer 120393

104 Arm, Front Wheel 740126-833 111 Nut, 5/16-18 710205

105 Rod, Axle R. 740095 112 Washer, Nylon 711008

106 Flat washer 417098 113 Spacer, Sleeve 740046

107 Spring Washer 710258 114 Tire & Rim 339079

108 Tire & Rim 339079 121 Flat washer 17x91

F-001101M

24

Page 25

CRAFTSMAN 143.003502

REPAIR PARTS

F-001101M

25

Page 26

CRAFTSMAN 143.003502

REPAIR PARTS

KEY PART KEY PART

NO. DESCRiPTION

NO.

0 RPM High 3050 to 3350 45 36777 Connecting Rod Ass'y.

0 RPM Low 2400 to 2700

27625 Oil Fill Plug

29673 Oil Fill Plug Gasket

1 37230 Cylinder (Incl. 2,20 & 150)

2 26727 Dowel Pin

6 33734 Breather Element

7 36557

12 36775 Breather Tube

12A 36558 Breather Cover & Tube

12B 36694 Breather Tube Elbow 81 30590A Washer

14 28277 Washer 82 30591 Governor Gear Ass'y.

15 30589 Governor Rod (Incl. 14)

16 34839A Governor Lever

17 31335 Governor Lever Clamp

18 651018 Screw, Torx

19 36231 Extension Spring

20 32600 Oil Seal

30 36833 Crankshaft

40 35544A Piston, Pin & Ring Set (Std.)

40 35545A Piston, Pin & Ring Set

40 35546 Piston, Pin & Ring Set 110A 36816 Ground Wire

41 35541 Piston & Pin Ass'y. (Std.)

41 35542 Piston & Pin Ass'y.

41 35543 Piston & Pin Ass'y.

42 35547A Ring Set (Std.)

42 35548A Ring Set (.010” OS)

42 35549 Ring Set (.020 OS)

43 20381 Piston Pin Retaining Ring

Breather Ass'y.

(Inc!. 6 & 12A)

(Inc!. 12B)

(.010” OS)

(.020” OS)

(Inc!. 43)

(.010” OS) (Incl. 43)

(.020” OS) (Incl. 43)

N0.

100 34443B Solid State Ignition

103 651007 Screw, Torx T-15

110 36230 Ground Wire

119 37028 Cylinder Head Gasket

120 36825 Cylinder Head

125 37288 Exhaust Valve (Std.)

126 37289 Intake Valve (Std.)

130 6021A Screw, 5/16-18 X 1-1/2”

135 35395 Resistor Spark Plug

150 31672 Valve Spring

NO. DESCRlPTiON

(Incl. 46)

46 3261OA Connecting Rod Bolt

48 27241 Valve Lifter

50 37032 Camshaft (NCR)

52 29914 Oil Pump Ass'y.

69 35261 Mounting Flange Gasket

70

32612C

72 36083 ON Drain Plug

75 27897 Oil Seal

80 30574A Governor Shaft

83 30588A Governor Spool

86 650488 Screw, 1/4™20 x 1-1/4"

89 610961 Flywheel Key

90 611213 Flywheel

92 650815 Belleville Washer

93 650816 Flywheel Nut

Mounting Flange

(Incl. 72 thru 83)

(Incl. 81)

(Incl. 151)

(Incl. 151)

(RJ19LM)

F-001101M

26

Page 27

CRAFTSMAN 143.003502

151 31673 Valve Spring Cap 275 36790A Muffler

151A 40017 Intake Valve Seal 277 650988 Screw, 1/4-20 x 2-5/16”

169 36783 Valve Cover Gasket 285 35000A Starter Cup

172 36784 Valve Cover 287 650926 Screw, 8-32 x 21/64”

174 30200 Screw, 10"“24 x 9/16” 290 34357 Fuel Line

178 29752 Nut & Lock Washer 292 26460 Fuel Line Clamp

179 30593 Retainer Clip 300 35586 Fuel Tank (Incl. 292 & 301)

182 6201 Screw, 1/4-28 x 7/8” 301 35355 Fuel Cap

184 26756 Carburetor To Intake Pipe 311 27625 Oil FIN Plug Ass’y

185 36785 Intake Pipe

186 34337 Governor Link

200 33205A Control Bracket

202 36482 Compression Spring

203 31342 Compression Spring

204 651029 Screw, Torx T-10

205 651019 Screw, Torx T-10

206 610973 Terminal

207 34336 Throttle Link

209 30200 Screw, 10-24 x 9/16”

215 32410 Control Knob

223 650451 Screw, 1/4-20 x 1”

224 36786 Intake Pipe Gasket

238 650932 Screw, 10-32 X 49/64”

239 34338 Air Cleaner Gasket

241 35797 Air Cleaner Collar 417 650821 Screw, 10-32 X 1/2”

245 35066 Air Cleaner Filter

250 35065 Air Cleaner Cover

260 36834 Blower Housing

261 30200 Screw, 10-24 x 9/16”

262 650831 Screw, 1/4-20 x 1/2"

Gasket

(Inc!. 202 thru 206)

313 34080 Spacer

355 590701 Starter Handle (Black)

370A 36261 Lubrication Decal

370B 35169 Control Decal

370C 37318 Primer Decal 3 X)

370R 37317 Warning Decal

380 640262 Carburetor (Incl. 184)

390 590737 Rewind Starter (NOTE;

400 37029A Gasket Set (Incl. Items

416 36085 Spark Arrestor Kit

900 0 Replacement Engine

900 0 Replacement S/B 750831,

REPAIR PARTS

This engine could have

been built with 590694

starter).

Marked PK in Notes)

Incl. Part #’s 26756

(1),28833 (1), 34338(1),

35261 (1), 36783(1),

36786(1), 37028(1),

36832 (1), 36996 (1)

(Incl. 417) (Optional)

(Optional)

NONE, order from 71-999

order from 71-999

F-001101M

27

Page 28

CRAFTSMAN 143.003502

REPAIR PARTS

I ^40 3SA ^

F-001101M

28

Page 29

CRAFTSMAN 143.003502

REPAIR PARTS

KEY PART

NO.

4 631184 Dust Seal Washer

5 631183 Dust Seal (Throttle)

6 640070 Throttle Shutter

7 650506 Shutter Screw

16 631807 Fuel Fitting

17 651025 Throttle Crack Screw/ldle Speed Screw

18 630766 Tension Spring

20 640018 Idle Restrictor Screw

20A 640200 Idle Restrictor Scrwe Cap (Black)

25 631867 Float Bowl

27 631024 Float Shaft

28 632019 Float

29 631028 Float Bowl ”0" Ring

30 631021 Inlet Needle, Seat, & Clip (Incl. 31)

31 631022 Spring Clip

35 640259 Primer Bulb/Retainer Ring

36 640080 Main Nozzle Tube

36A 632766 Carburetor Tube

37 632547 ”0” Ring, Main Nozzle Tube

40 640175 High Speed Bowl Nut

44 27110A Bowl Nut Washer

47 630748 Welch Plug, Idle Mixture Well

48 631027 Welch Plug, Atmospheric Vent2

60 632760B Repair kit (Incl. Items Marked PK in Notes)

NO. DESCRIPTiON

0 640262 Carburetor (Incl. 184 of Engine Parts List)

1 631615 Throttle Shaft & Lever Assembly

2 631767 Throttle Return Spring

F-001101M

29

Page 30

CRAFTSMAN 143.003502

REPAIR PARTS

5

2

F-001101M

KEY PART

NO.

0 590694 Recoil Starter

1 590599A Spring Pin (Incl. 4)

2 590600 Washer

3 590696 Retainer

4 590601 Washer

5 590697 Brake Spring

6 590698 Starter Dog

7 590699 Dog Spring

8 590700 Pulley & Rewind Spring Ass'y.

11 590695 Starter Housing Ass’y.

12 590535 Starter Rope ( 98” X 9/64" dia.)

13 590701 Starter Handle

NO. DESCRIPTION

30

Page 31

For the repair or replacement parts you

need delivered directly to your home

Call 7am-7pm, 7days a week

1-800-366-PART

(1-800-366-7278)

Para ordenar piezas con entrega

a domicilio - 1-800-659-7084

For in-house major brand repair service

Call 24 hours a day, 7days a week

1-800-4-RE PAIR

(1-800-473-7247)

Para pedir servicio de reparación a

domicilio- 1-800-676-5811

For the location of a Sears Parts and

Repair Center in your area

Call 24 hours a day, 7days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance agreement or to inquire

about an existing Agreement

Call 9am-5pm, Monday-Saturday

1-800-827-6655

When requesting service or ordering

parts, always provide the following infor

mation:

• Product Type • Part Number

• Model Number • Part Description

America's Repair ^ciásts

Printed in U.S.A.

Loading...

Loading...