Craftsman 536270340 Owner’s Manual

Operator's Manual

ICRFIFTSMRN°I " a,ety

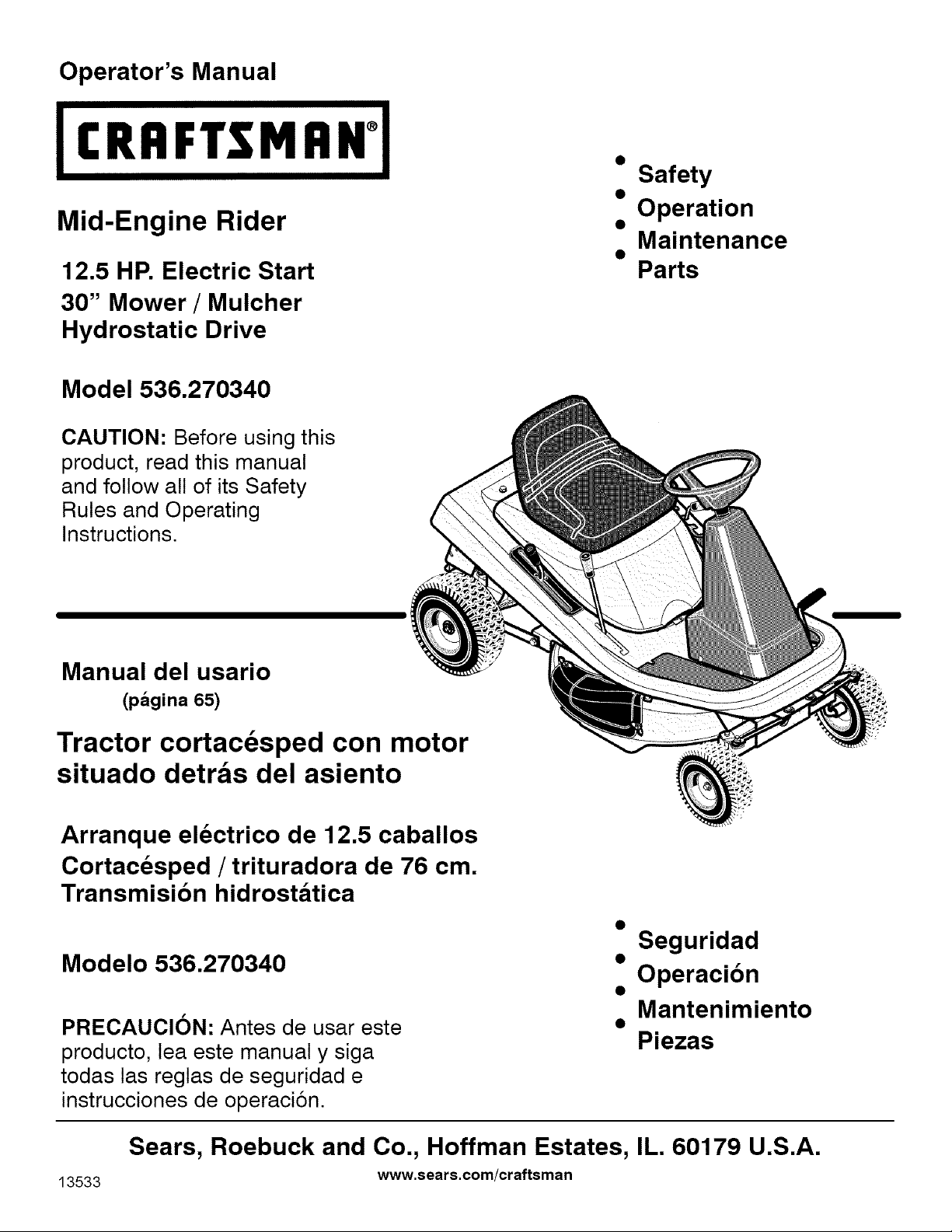

Mid-Engine Rider

12.5 HP. Electric Start

30" Mower / Mulcher

Hydrostatic Drive

Model536.270340

CAUTION: Before using this

product, read this manual

and follow all of its Safety

Rules and Operating

Instructions.

Operation

Maintenance

Parts

Manual del usario

(pagina 65)

Tractor cortacesped con motor

situado detras del asiento

Arranque electrico de 12.5 caballos

Cortacesped /trituradora de 76 cm.

Transmision hidrostatica

Modelo 536.270340

PRECAUCION: Antes de usar este

producto, lea este manual y siga

todas las reglas de seguridad e

instrucciones de operaci6n.

Seguridad

Operacion

Mantenimiento

Piezas

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

13533 www.sears.com/craftsman

TABLE OF CONTENTS

WARRANTY .................................... 2 MAINTENANCE ................................. 22

PRODUCT SPECIFICATIONS ..................... 3 SERVICE AND ADJUSTMENT .................... 28

SAFETY RULES ................................. 4 TROUBLESHOOTING CHART .................... 36

PREPARATION .................................. 7 SLOPE GUIDE .................................. 39

OPERATION .................................... 10 REPAIR PARTS ................................. 40

LIMITED WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years from the date of purchase, if this Craftsman Riding Equipment is maintained, lubricated and tuned up

according to the instructions in the owner's manual, Sears will repair or replace free of charge any parts that are found to be

defective in material or workmanship according to the guidelines of coverage listed below.

Sears will also provide free labor for these applicable warranted parts for the two full years. During the first 30 days of purchase,

there will be no charges to service the product at your home for issues covered by this warranty. (See exclusions below).

For your convenience, IN HOME warranty service will still be available after the first 30 days of purchase, but a trip charge will

apply. This charge will be waived if the Craftsman product is dropped off at an authorized Sears location. For the nearest

authorized Sears location, please call 1-800-4-MY-HOME_ _,. This warranty applies only while this product is within the United

States.

This Warranty does not cover:

• Expendable items which become worn during normal use, including but not limited to blades, spark plugs, air cleaners,

belts, and oil filters.

• Standard Maintenance Servicing, oil changes, or tune-ups

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage caused by towing objects beyond the

capability of the riding equipment, impacting objects that bend the frame or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused

by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear of flammable

debris, or failure to maintain the equipment according to the instructions contained in the owner's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In general, fuel

should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

• Riding equipment used for commercial or rental purposes.

LIMITED WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery included with this riding equipment proves defective in material or

workmanship and our testing determines the battery will not hold a charge, Sears will replace the battery at no charge. During

the first 30 days of purchase, there will be no charges to replace the battery at your home. After the first 30 days, for your conve-

nience, IN-HOME warranty service will still be available but a trip charge will apply. This charge will be waived if the Craftsman

product is dropped off at an authorized Sears location. For the nearest authorized Sears location, please call 1-800-4-MY-

HOME_ _,. This Warranty applies only while this product is within the United States. This warranty gives you specific legal rights,

and you may also have other rights, which vary, from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

13533 2

CongratulationsonyourpurchaseofaCraftsmanMid-Engine

Rider.Ithasbeendesigned,engineeredandmanufacturedto

giveyouthebestpossibledependabilityandperformance.

Ifyouexperienceanyproblemsyoucannoteasilyremedy,please

seeyournearestSearsServiceCenter.Wehavecompetent,well

trainedtechniciansandthepropertoolstoserviceorrepairthis

unit.

Pleasereadandkeepthismanual.Theinstructionswillenable

youtoassembleandmaintainyourunitproperly.Alwaysobserve

the"SafetyRules".

Craftsman Mid-Engine Rider

Record in the space below the serial number and the date

of purchase of this unit.

The model number and serial number are found on a decal

attached to the unit.

Model Number: 536.270340

Serial Number:

PRODUCT SPECIFICATIONS

Engine .................. 12.5 HP.

Bore .................. 3.44 in. (87.31 mm)

Stroke ................ 3.06 in. (77.78 ram)

Displacement ......... 28.42 cu. in. (466 cc)

Armature air gap ...... 0.010-0.014 in. (0.25-0.36 mm)

Valve Clearance with valve springs installed and piston

0.25 in. (6 mm) past top dead center (check when engine

is cold)

Intake ................. 0.003-0.005 in. (0.08-0.13 mm)

Exhaust ............... 0.005-0.007 in. (0.13-0.18 mm)

Charging System ......... 3 amperes at 3600 rpm

Fuel Tank Size ........... 1.1 gallon

Type of Fuel ............. Unleaded Regular

Oil Capacity .............. 48 ounces (3 pints)

Oil Type ................. Above 32 degrees SAE 30

.......................... Below 32 degrees SAE 5W30

Spark Plug (Gap 0.030") .. Champion RJ4C

Tire Air Pressure ......... Front 22 psi (See tire sidewall)

Tire Air Pressure ......... Rear 14 psi (See tire sidewall)

Drive System ............ Hydrostatic

Ground Speed Range ..... Forward 5.0 mph

.......................... Reverse 2.5 mph

Tilt Seat ................. Access to engine and battery.

Mower Housing .......... Floating suspension, one blade.

Cutting Height ........... 6 positions from 11/2to 4 inches.

Blade Nut Torque ......... 30 foot-pounds (ft-lbs)

Power Ratings: The power ratings for an individual engine mod-

el are initially developed by starting with SAE (Society of Automo-

tive Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure) (Revision 2002-05). Given both the wide array

of products on which our engines are placed, and the variety of

environmental issues applicable to operating the equipment, it

may be that the engine you have purchased wil! not develop the

rated horsepower when used in a piece of power equipment (ac-

tual "on-site" power). This difference is due to a variety of factors

including, but not limited to, the fol!owing: differences in altitude,

temperature, barometric pressure, humidity, fuel, engine lubrica-

tion, maximum governed engine speed, individual engine to en-

gine variability, design of the particular piece of power equipment,

the manner in which the engine is operated, engine run-in to re-

duce friction and clean out of combustion chambers, adjustments

to the valves and carburetor, and other factors. The power ratings

may also be adjusted based on comparisons to other similar en-

gines utilized in similar applications, and will therefore not neces-

sarily match the values derived using the foregoing codes.

NOTE: Actual sustained horsepower will likely be lower due

to operating limitations and environmental factors.

13533

Date of Purchase:

Keep these numbers for future reference.

REPAIR PROTECTION AGREEMENT

A Repair Protection Agreement is available on this unit. See the

nearest Sears Store for information.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm,

Battery posts, terminals and related accesso-

ries contain lead and lead compounds, chemi-

cals known to the State of California to cause

cancer and birth defects or other reproductive

harm. WASH HANDS AFTER HANDLING.

NOTE: This unit is equipped with an internal combustion engine

and must not be used on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting applicable local

or state laws (if any). If a spark arrester is used, it must be

maintained in effective working order by the operator.

In the State of California, the above is required by law (Section

4442 of the California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands. See a

Sears Service Center for a spark arrester for the muffler.

in some areas, local law requires the use of a resistor spark plug

to control the ignition signals. See a Sears Service Center for a

resistor spark plug for the engine.

In the state of California, Model Series 280000 engines are certi-

fied by the California Air Resources Board to meet emissions

standards for 125 hours. Such certification does not grant the

purchaser, owner or operator of this engine any additional war-

ranties with respect to the performance or operational life of this

engine. This engine is warranted solely according to the product

and emissions warranties stated elsewhere in this manual.

SAFETY RULES

Safe Operation Practices for Ride-on Mowers

The safety symbol _i, is used to identify safety information about hazards that can result in personal injury. A signal word (DAN-

GER, WARNING, or CAUTION) is used with the alert symbol to indicate the likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in death or serious injury,

WARNING indicates a hazard which, if not avoided, could result in death or serious injury,

CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury,

CAUTION when used without the alert symbol, indicates a situation that could result in damage to the engine,

WARNING: This cutting machine is capable of amputating hands and feet and throwing objects, Failure to observe the

following safety instructions could result in serious injury or death.

I. General operation

1. Read, understand and follow all instructions in the Instruction

Book, on the machine, the engine and with any attachments be-

fore starting.

2. Only allow responsible adults, who are familiar with the instruc-

tions, to operate the machine.

3. Clear the area of objects such as rocks, toys, wire, etc., which

could be picked up and thrown by the blade.

4. Be sure the area is clear of other people before mowing. Stop

the machine if anyone enters the area.

5. Never carry passengers.

6. Turn off power to the blades or any attachments before backing

up. Do not mow in reverse unless absolutely necessary. Always

look down and behind before and while backing.

7. Be aware of the mower discharge direction and do not point it

at anyone. Do not operate the mower without either the entire

grass bagger or the mower guard in place.

8. Slow down before turning.

9. Never leave a machine unattended with the engine running. Al-

ways turn off the blade(s), set the parking brake, stop the en-

gine and remove the key before dismounting.

10. Turn off power to attachment(s) when transporting or not in use.

Turn off the blade(s) when not mowing.

11. Stop the engine before removing the grass bagger or unclog-

ging the chute.

12. Mow only in daylight or good artificial light.

13. Do not operate the machine while under the influence of alcohol

or drugs or when very tired.

14. Watch for traffic when operating near or crossing roadways.

15. Use extra caution when loading or unloading the machine into

a trailer or truck.

16. Disengage all attachment clutches and shift into Neutral before

attempting to start the engine.

17. Always wear goggles, safety glasses, or an eye shield when

you operate the unit to protect your eyes from foreign objects

that can be thrown from the unit. Always wear eye protection

when you make an adjustment or repair to the machine.

18. Use care when pulling loads or using heavy equipment.

a. Use only approved drawbar hitch points.

b. Limit loads to those you can safely control.

c. Do not turn sharply. Use care when backing.

d. Use counterweights or wheel weights when suggested in the

Instruction Book.

13533

19. Do not operate this machine if you are taking drugs or other me-

dication which can cause drowsiness or affect your ability to op-

erate this machine.

20. Do not use this machine if you are mentally or physically unable

to operate this machine safely.

21. Data indicates that operators, age 60 years and above, are in-

volved in a large percentage of riding mower related injuries.

These operators should evaluate their ability to operate a riding

mower safely enough to protect themselves and others from

serious injury.

II. Slope operation

Slopes and rough terrain are major factors related to loss-of-con-

trol and tip over accidents, which can result in severe injury or

death. ALL slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on the slope, do not mow it. See the

"Slope Guide" in the back of this book to check for safe operation.

DO

1. Mow up and down slopes, not across.

2. Remove obstacles such as rocks, limbs, etc...

3. Watch for holes, ruts or bumps. Uneven terrain could overturn

the machine. Taft grass can hide obstacles.

4. Follow the manufacturer's recommendations for wheel weights

or counterweights to improve stability.

5. Use extra care with grass baggers or other attachments, they

can change the stability of the machine.

6. Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

7. Avoid starting or stopping on a slope. If tires lose traction, turn

off the blades and proceed slowly straight down the slope.

DO NOT

1. Do not turn on slopes unless absolutely necessary, then only

turn slowly and gradually downhill, if possible.

2. Do not mow drop-offs, ditches or embankments. A wheel over

the edge or an edge caving in could cause a sudden overturn

and an injury or death.

3. Do not mow on wet grass. Reduced traction could cause slid-

ing.

4. Do not try to stabilize the machine by putting your foot on the

ground.

5. Do not use a grass bagger or other rear mounted accessories

on steep slopes (greater than 10 degrees).

SAFETY RULES

III. Children

Tragic accidents can occur if the operator is not alert to the presence

of children. Children are often attracted to the machine and the

mowing activity. NEVER assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and in the watchful care

of another responsible adult.

2. Be alert and turn the engine off if children enter the area.

3. Before and when backing, look behind and down for small

children.

4. Never carry children or any passengers, even with the blades

off. They may fall off and be seriously injured or interfere with

the safe operation of the machine.

5. Never allow children to operate the machine, instruct children

in the potential dangers of the machine.

6. Use extra care when approaching blind corners, shrubs, trees

or other objects that may obscure vision.

IV. Towing

1. Tow only with a machine that has a hitch designed for towing.

Do not attach towed equipment except at the hitch point.

2. Follow the manufacture's recommendation for weight limits for

towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may cause loss

of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

V. Safe Handling Of Gasoline

To avoid personal injury or property damage, use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors

are explosive.

1. Extinguish all cigarettes, cigars, pipes, and other sources of

ignition.

2. Use only an approved gasoline container.

3. Never remove gas cap or add fuel with the engine running. Al-

low engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there is an

open flame, spark, or pilot light such as on a water heater or oth-

er appliances.

6. Never fill containers inside a vehicle or on a truck or trailer bed

with a plastic liner. Always place containers on the ground away

from your vehicle before filling.

7. Remove gas-powered equipment from the truck or trailer and

refuel it on the ground. If this is not possible, then refuel such

equipment with a portable container, rather than from a gaso-

line dispenser nozzle.

8. Keep the nozzle in contact with the rim of the fuel tank or con-

tainer opening at all times until the fueling is complete. Do not

use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing immediately.

10. Never overfill fuel tank. Replace gas cap and tighten securely.

Vl. Service

1. Use extra care when handling gasoline and other fuels. Fuels

are flammable and the vapors are explosive.

13533

a. Use only an approved container.

b. Never remove the gas cap or add fuel with the engine run-

ning. Allow the engine to coo! for several minutes before

refueling. Do not smoke.

c. Never refuel the machine indoors or near appliances with

pilot lights, heaters, or other ignition sources.

d. Never store the machine with fuel in the tank or fuel con-

tainer inside where there is an open flame, such as a water

heater.

2. Never start or run the engine inside a closed area.

a. Make sure that spark plug, muffler, fuel cap and air cleaner

are in place.

b. Do not crank engine with spark plug removed.

c. If fuel spills, wait until it evaporates before starting engine.

d. Do not start if there is LP or natural gas leakage in the area.

3. Keep all nuts and bolts, especially the blade attachment nuts

tight. Frequently check the blade(s) for wear or damage such

as cracks and nicks. A blade that is bent or damaged must be

immediately replaced with an original equipment blade from an

authorized service dealer. For safety, replace the blade every

two years. Keep the equipment in good condition.

4. Never tamper with the safety devices. Check their proper oper-

ation regularly.

5. To reduce fire hazards, keep the machine free of grass, leaves

or other debris build-up. Clean up oil or fue! spills. Allow the ma-

chine to cool before storing.

a. Allow muffler and engine areas to cool before touching.

6. Stop and inspect the equipment if you strike an object. Repair,

if necessary, before restarting.

7. Never make adjustments or repairs with the engine running.

The carburetor can be adjusted with the engine running. Do not

change the engine governor settings or over-speed the en-

gine.

8. Grass bagger components are subject to wear, damage and

deterioration, which could expose moving parts or allow objects

to be thrown. For storage, always make sure the grass bag is

empty. Frequently check components and replace with man-

ufacturer's recommended parts when necessary.

9. Mower blade(s) are sharp and can cut. Wrap the blade(s) or

wear gloves and use extra caution when servicing them or the

blade housing area.

10. Check the brake operation frequently. Adjust and service as re-

quired.

11. Wait for all movement to stop before servicing any part of the

unit.

RESPONSIBILITY OF THE OWNER

Environmental Awareness

Do not fill the engine's fuel tank completely full.

Drain fuel for off-season storage.

Use only unleaded gasoline.

Service the air cleaner regularly.

Change oil regularly. Use oil rated 30 in the summer.

Tune-up the engine regularly.

Keep equipment in efficient operating condition.

Dispose of used engine oi! properly.

5

INTERNATIONAL PICTORIALS

IMPORTANT: Some of the following pic-

torials are located on your unit or on

literature supplied with the product. Be-

fore you operate the unit, learn and un-

derstand the purpose for each pictorial.

Safety Warning Pictorials

1 Warning

2 Shield Eyes. Explosive Gases Can

Cause Blindness Or Injury.

3 No Sparks, Flames or Smoking.

4 Sulphuric Acid Can Cause Blindness

Or Severe Burns

5 Flush Eyes Immediately With Water.

6 IMPORTANT: Read Owner's Manual

7 WARNING: Thrown Objects. Keep

8 WARNING: Do Not Use This Machine

9 DANGER: Keep People, Especially

A @

SAFETY RULES

Get Medical Help Fast.

Before Operating This Machine.

Bystanders Away. Read User

instructions Before Operating This

Machine.

On Slopes Greater Than 15 Degrees.

Children, Away From Unit.

10 DANGER: No Step.

11 DANGER: Keep Feet And Hands

Away From Rotating Blade.

12 DANGER: Keep Hands Away From

Rotating Blade.

13 DANGER: Disconnect Spark Plug

Wire Before Servicing Unit.

14 WARNING: Hot Surface.

15 WARNING: Use Caution When

Connecting Or Disconnecting

Accessories.

16 WARNING: Crushed Fingers.

_/

1 2 3

7 8 9

12 13 14 15 16

Control And Operating Pictorials

1 Engine Start

2 Engine Stop

3 Select Reverse T`'

4 Engine Run

5 Brake

6 Parking Brake

7 Clutch

8 Slow

9 Fast

6

10 11

MAX± 90N MAX± 150N

10 Choke

11 Oil

12 Blade Rotation Control

13 Raise

14 Fue!

13533

I

9 10 11

6

2_

5 6

/

12 13 14

PREPARATION

PREPARATION 1.

Read and follow the preparation instructions for your mower. All

fasteners are in the parts bag. Do not discard any parts or material

until the unit is assembled.

NOTE: In this instruction book, left and right describe the loca-

tion of a part from the viewpoint of someone sitting in the oper-

ator's seat.

_ WARNING: Before doing any preparation or mainte-

nance to the mower, remove the wire from the spark

plug.

HOW TO REMOVE FROM THE CARTON

To remove the unit from the carton, follow the instructions below.

2.

3.

4.

5. Repeat the process on the tear tabs at the bottom of the carton.

6. Set the panels aside.

7. Move the shift lever to the neutral (N) position.

8. If the parking brake is engaged, completely depress the

9. Move the lift lever to the highest position.

10. Remove the mower from the shipping skid.

Locate the two tear tabs at the top of the carton.

Pull the tear tape no more than twelve inches at a time.

Re-grasp the tear tape next to the carton and pull again.

One the tear tape has been completely removed from both

ends, remove the top wood and set aside.

NOTE: See the Operation section, page 10, for the location

of the controls.

clutch/brake pedal to release the brake.

CAUTION: Check the bottom of the carton for staples.

Remove any staples that are in the path of the tires.

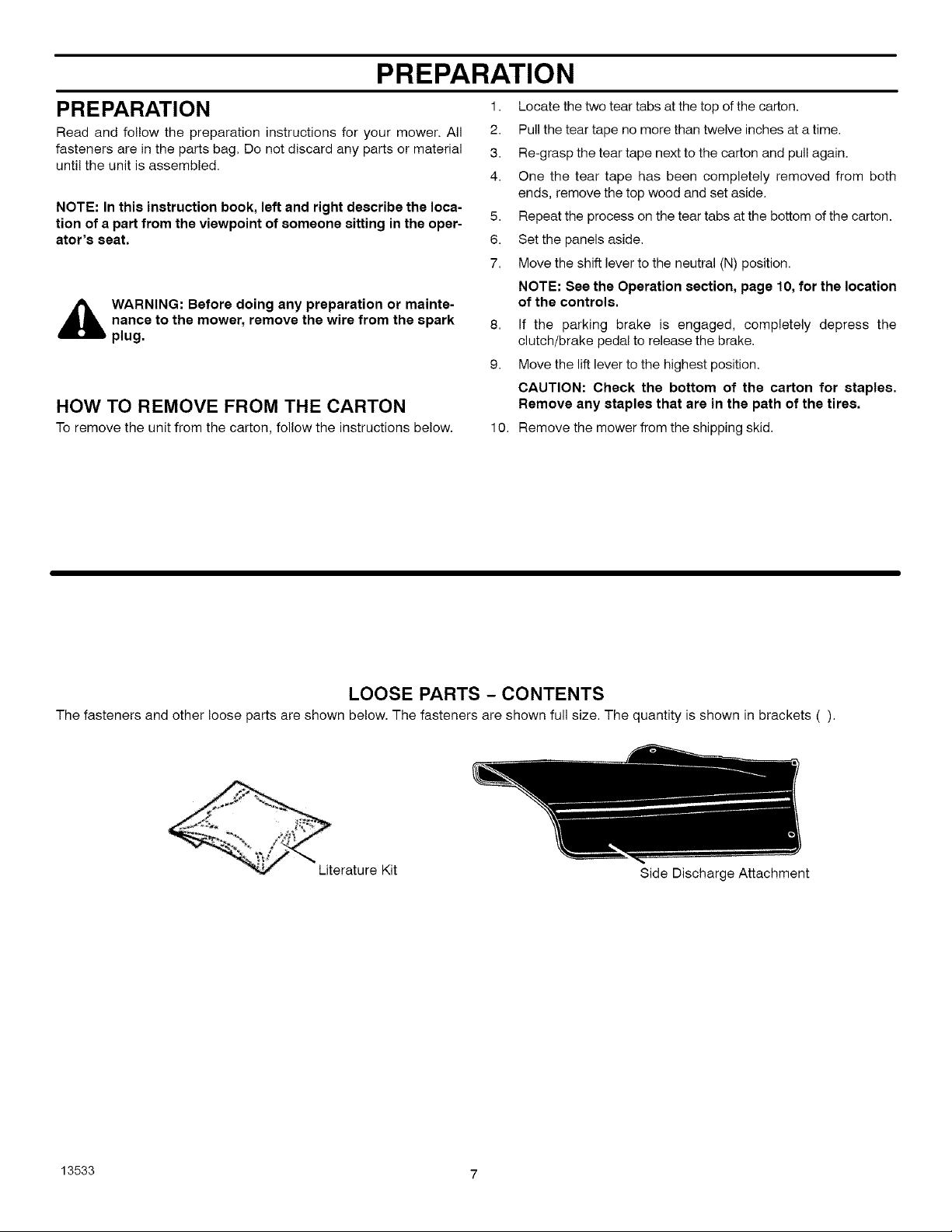

LOOSE PARTS - CONTENTS

The fasteners and other loose parts are shown below. The fasteners are shown full size. The quantity is shown in brackets ().

Literature Kit

Side Discharge Attachment

13533 7

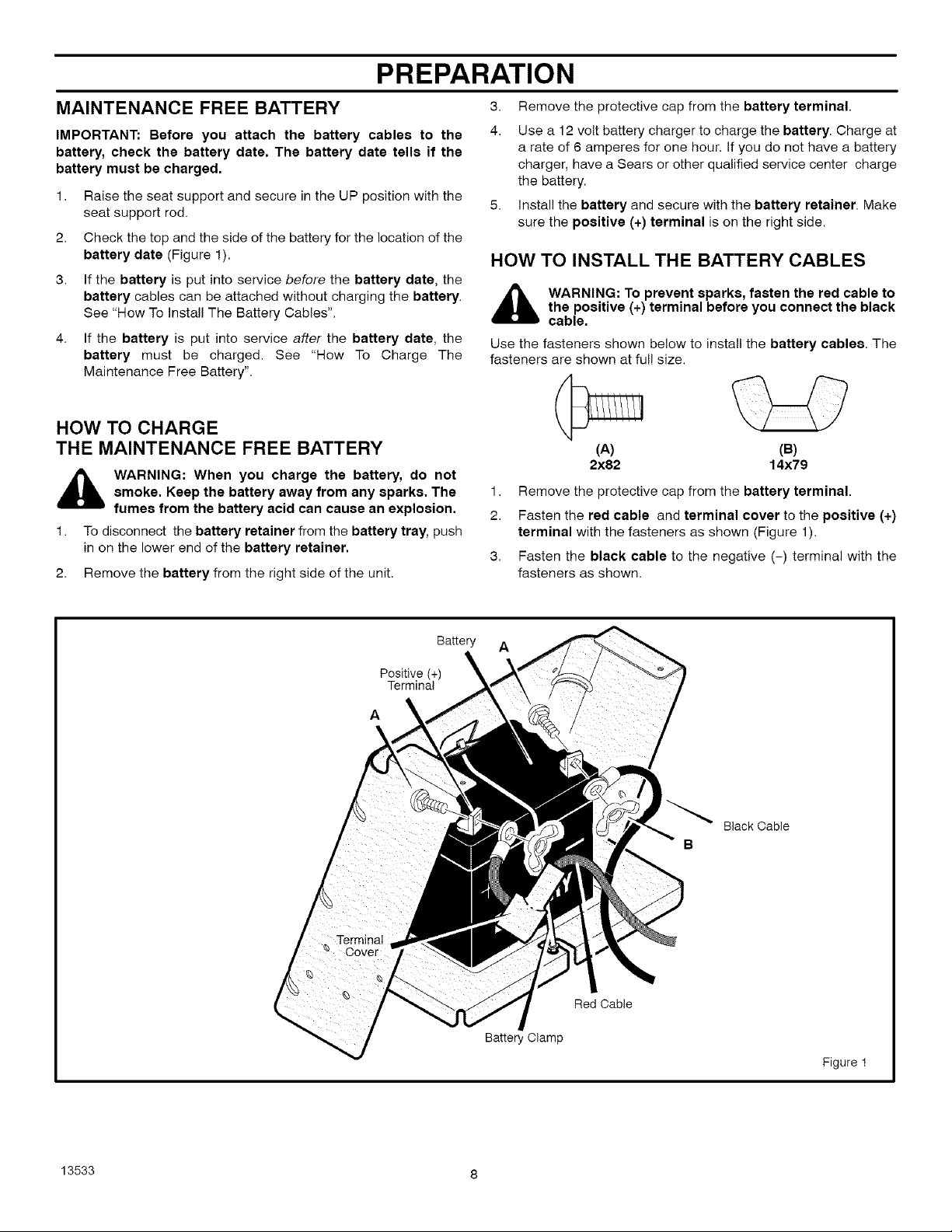

PREPARATION

MAINTENANCE FREE BATTERY 3

IMPORTANT: Before you attach the battery cables to the

battery, check the battery date. The battery date tells if the

battery must be charged.

1. Raise the seat support and secure in the UP position with the

seat support rod.

2. Check the top and the side of the battery for the location of the

battery date (Figure 1).

3. If the battery is put into service before the battery date, the

battery cables can be attached without charging the battery.

See "How To Install The Battery Cables",

4. If the battery is put into service after the battery date, the

battery must be charged. See "How To Charge The

Maintenance Free Battery".

HOW TO CHARGE

THE MAINTENANCE FREE BATTERY

_ WARNING: When you charge the battery, do not

1. To disconnect the battery retainer from the battery tray, push

2. Remove the battery from the right side of the unit.

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

in on the lower end of the battery retainer.

Remove the protective cap from the battery terminal.

4.

Use a 12 volt battery charger to charge the battery. Charge at

a rate of 6 amperes for one hour. If you do not have a battery

charger, have a Sears or other qualified service center charge

the battery.

5.

Install the battery and secure with the battery retainer. Make

sure the positive (+) terminal is on the right side.

HOW TO INSTALL THE BATTERY CABLES

_ WARNING: To prevent sparks, fasten the red cable to

Use the fasteners shown below to install the battery cables. The

fasteners are shown at full size.

1. Remove the protective cap from the battery terminal.

2. Fasten the red cable and terminal cover to the positive (+)

3. Fasten the black cable to the negative (-) terminal with the

the positive (+) terminal before you connect the black

cable.

(A) (B)

2x82 14x79

terminal with the fasteners as shown (Figure 1 ).

fasteners as shown.

Positive (+)

Terminal

A

Battery A

Black Cable

B

Red Cable

Battery Clamp

Figure 1

13533 8

PREPARATION

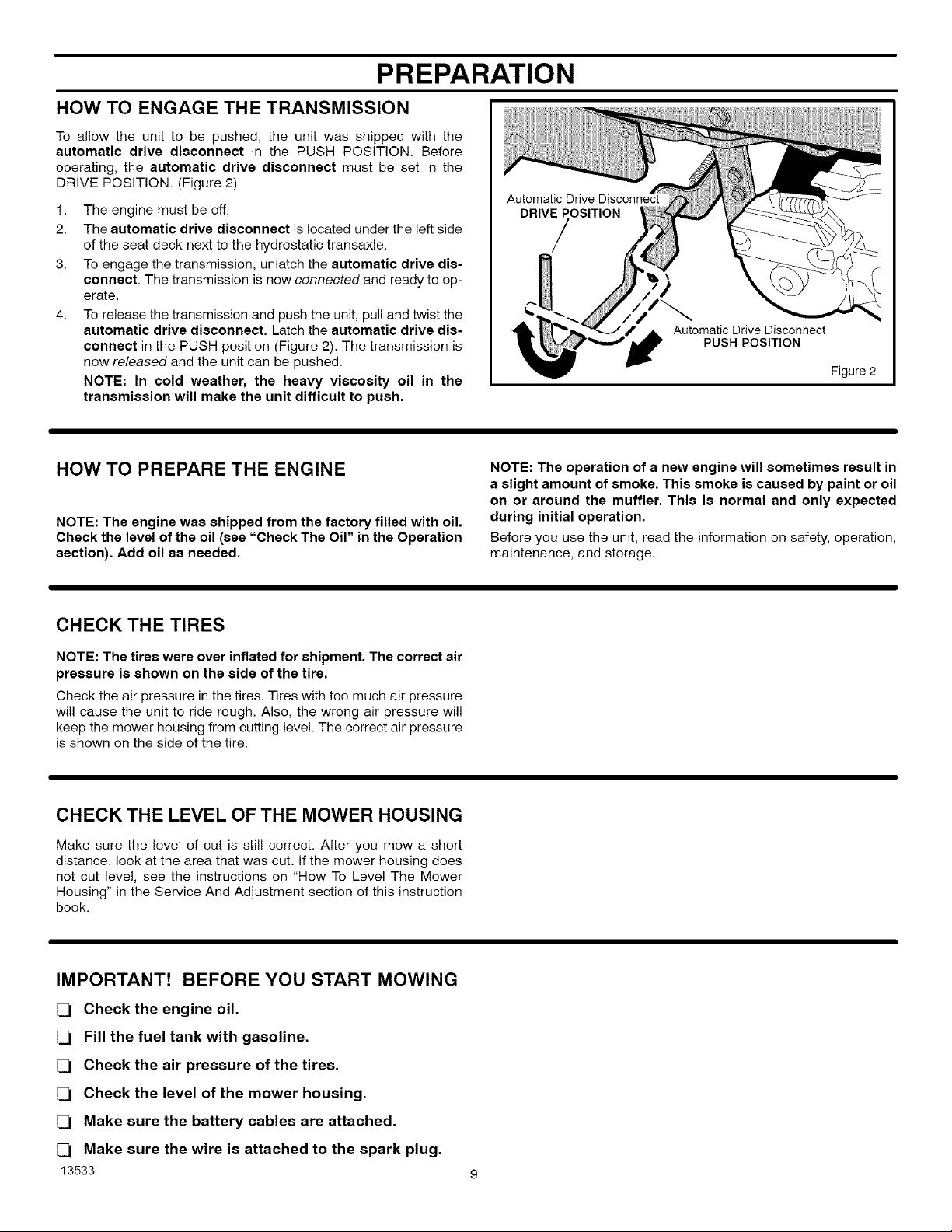

HOW TO ENGAGE THE TRANSMISSION

To allow the unit to be pushed, the unit was shipped with the

automatic drive disconnect in the PUSH POSITION. Before

operating, the automatic drive disconnect must be set in the

DRIVE POSITION. (Figure 2)

1. The engine must be off.

2. The automatic drive dicconnect is located under the left side

of the seat deck next to the hydrostatic transaxle.

3. To engage the transmission, unlatch the automatic drive dis-

connect. The transmission is now connected and ready to op-

erate.

4. To release the transmission and push the unit, pull and twist the

automatic drive disconnect, Latch the automatic drive dis-

connect in the PUSH position (Figure 2). The transmission is

now released and the unit can be pushed.

NOTE: In cold weather, the heavy viscosity oil in the

transmission will make the unit difficult to push.

Automatic Drive Disconnect

DRIVE POSITION

/

Automatic Drive Disconnect

PUSH POSITION

Figure 2

HOW TO PREPARE THE ENGINE

NOTE: The engine wac chipped from the factory filled with oil.

Check the level of the oil (cee "Check The Oil" in the Operation

section). Add oil ac needed.

CHECK THE TIRES

NOTE: The tires were over inflated for shipment. The correct air

pressure ic shown on the side of the tire.

Check the air pressure in the tires. Tires with too much air pressure

will cause the unit to ride rough. Also, the wrong air pressure will

keep the mower housing from cutting level. The correct air pressure

is shown on the side of the tire.

CHECK THE LEVEL OF THE MOWER HOUSING

Make sure the level of cut is still correct. After you mow a short

distance, look at the area that was cut. If the mower housing does

not cut level, see the instructions on "How To Level The Mower

Housing" in the Service And Adjustment section of this instruction

book.

NOTE: The operation of a new engine will sometimes result in

a slight amount of smoke. This smoke ic caused by paint or oil

on or around the muffler. This ic normal and only expected

during initial operation.

Before you use the unit, read the information on safety, operation,

maintenance, and storage.

IMPORTANT! BEFORE YOU START MOWING

Check the engine oil,

Fill the fuel tank with gasoline,

Check the air pressure of the tires.

Check the level of the mower housing,

Make sure the battery cables are attached.

Make sure the wire is attached to the spark plug,

13533

OPERATION

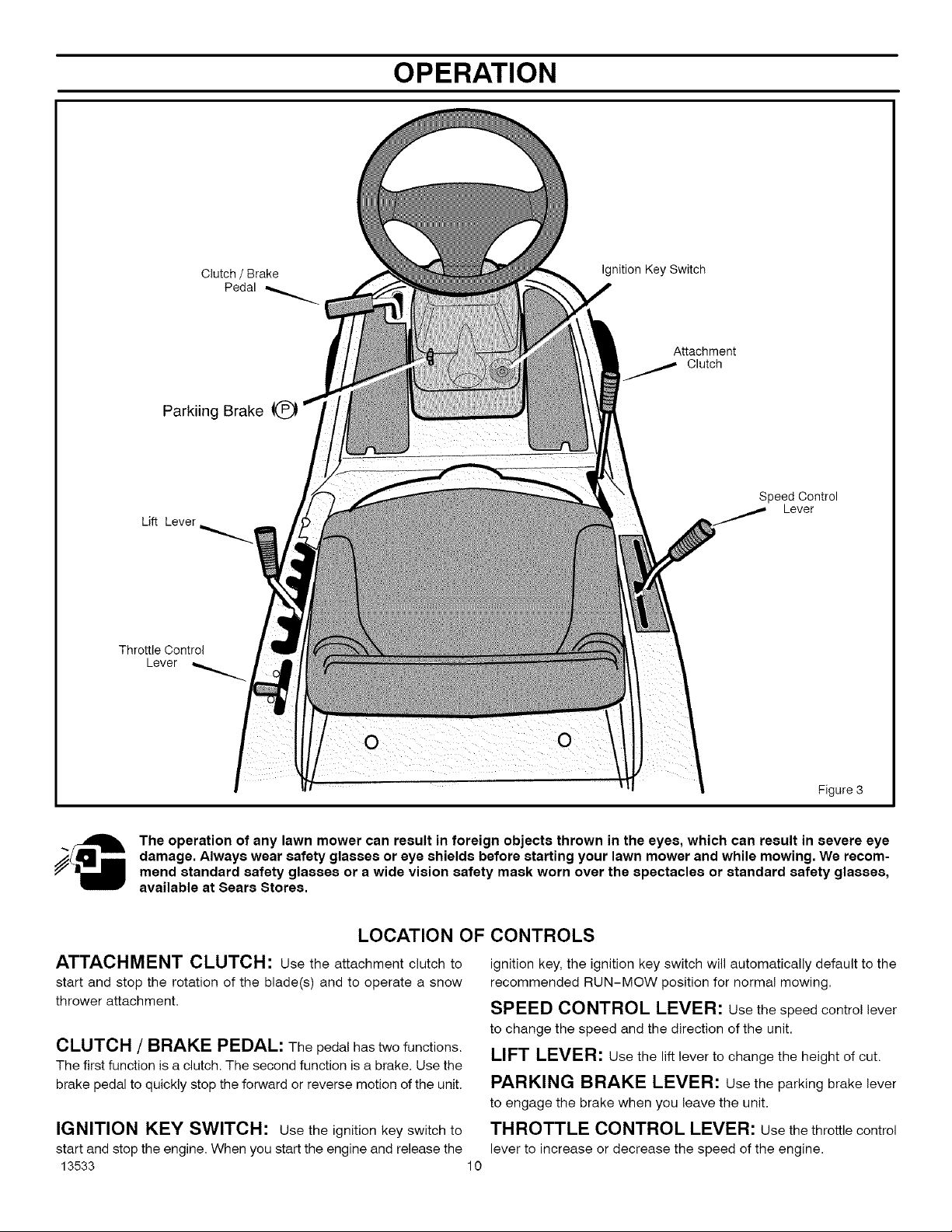

Parkiing Brake

Lift Lever

Throttle Control

Lever

Clutch / Brake

Pedal

Ignition Key Switch

Attachment

Clutch

Speed Control

Lever

The operation of any lawn mower can result in foreign objects thrown in the eyes, which can result in severe eye

damage. Always wear safety glasses or eye shields before starting your lawn mower and while mowing. We recom-

mend standard safety glasses or a wide vision safety mask worn over the spectacles or standard safety glasses,

available at Sears Stores.

LOCATION OF CONTROLS

ATTACHMENT CLUTCH: Use the attachment clutch to

start and stop the rotation of the blade(s) and to operate a snow

thrower attachment.

CLUTCH / BRAKE PEDAL: The pedal has two functions.

The first function isa clutch. The second function is a brake, Use the

brake pedal to quickly stop the forward or reverse motion of the unit,

IGNITION KEY SWITCH: Use the ignition key switch to

start and stop the engine. When you start the engine and release the

13533 10

Figure 3

ignition key, the ignition key switch will automatically default to the

recommended RUN-MOW position for normal mowing.

SPEED CONTROL LEVER: Usethe speed control lever

to change the speed and the direction of the unit.

LIFT LEVER: Use the lift lever to change the height of cut.

PARKING BRAKE LEVER: Usethe parking brake lever

to engage the brake when you leave the unit.

THROTTLE CONTROL LEVER: Use the throttle control

lever to increase or decrease the speed of the engine.

ATTACHMENTS

OPERATION

This unit can use many different attachments. See the attachment

page in this book. This unit can pull attachments like a lawn

sweeper, a lawn aerator, a hopper spreader, or a small trailer. This

unit cannot use attachments that engage the ground like a plow, a

disk harrow, or a cultivator.

For all pull behind attachments or trailers, the maximum gross

ELECTRICAL SAFETY SYSTEM

The electrical system has three primary components, an Operator

Presence System and a Select Reverse T_System, and a Run-Mow

System.

Operator Presence System (Seat)

The seat has an Operator Presence System to shut off the engine

when the operator leaves the seat. This system is not intended for

regular use in stopping the engine or the blade(s). Before leaving the

seat, move the blade rotation control to the DISENGAGE position,

shift to neutral, set the parking brake and stop the engine.

Select Reverse'" System

The Select Reverse T" system will allow the mower blade(s) to

continue to rotate when traveling in reverse. See "How To Operate

The Ignition Key Switch" and "How To Start The Engine" for further

details.

How To Check The Safety Interlock Switches

To check the function of the safety interlock switches, follow the

steps below.

weight is 200 pounds. Gross weight is the weight of the attachment

or trailer and any load that might be on or in it.

Do not operate on a slope that is greater than 10 degrees when

using a pull behind attachment or trailer. We have included a slope

guide in this book to help you determine the slope on which you will

be operating your unit. Never allow someone to stand or ride on or

in an attachment or trailer.

1. Check the attachment clutch switch, Sit inthe seat. Depress

the clutch/brake pedal. Move the attachment clutch to the EN-

GAGE position. Turn the ignition switch to the START position.

The engine should not start, if the engine starts, the switch is

defective and must be replaced.

2. Check the clutch/brake switch, Sit in the seat. Move the at-

tachment clutch to the DISENGAGE position. DO NOT de-

press the clutch/brake pedal. Turn the ignition switch to the

START position. The engine should not start. If the engine

starts, the switch is defective and must be replaced.

3. Check the Operator Presence System switch, DO NOT sit

in the seat. Depress the clutch/brake pedal. Move the attach-

ment clutch to the DISENGAGE position. Turn the ignition

switch to the START position. The engine should not start, if

the engine starts, the switch is defective and must be replaced.

4. Check the Select ReverseT_ switch. Sit in the seat. Depress

the clutch/brake pedal. Move the attachment clutch to the DIS-

ENGAGE position. Start the engine and move the drive control

to the reverse (R) position. With the engine running, move the

attachment clutch to the ENGAGE position. The engine should

stop running, if the engine continues to run, the Select Re-

verse T`_switch is defective and must be replaced.

HOW TO OPERATE THE IGNITION KEY SWITCH

Use the ignition key switch to start and stop the engine. When you

start the engine and release the ignition key, the ignition key switch

will automatically default to the recommended RUN-MOW position

for normal mowing.

START - Use this position to start the engine.

RUN-MOW - When you start the engine and release the ignition

key, the ignition key switch will automatically default to the

recommended RUN-MOW position for normal mowing. In the

RUN-MOW position, the system will stop the engine and the

blade(s) when the speed control pedal/shift lever is put in the

reverse position.

SELECT REVERSE T_ - The optional Select Reverse T'_

position will allow the mower blade(s) to continue to rotate when

traveling in reverse. Always go back to the recommended

RUN-MOW position for normal mowing when operation in Select

Reverse T_ is not absolutely necessary. NEVER use the Select

ReverseT_ option if children are on or near the property.

_ WARNING: Operators are strongly discouraged

cautions are taken. Never use this Select Reverse T_option if

children are on or near the property. Always look down and

behind before and while backing. After using the Select Re-

verse T_position, move the ignition key back to the RUN-MOW

position.

STOP - Use this position to stop the engine.

from using this option unless the operator de-

cides it is absolutely necessary and that safe pre-

11 13533

OPERATION

HOW TO STOP THE UNIT

1. Completely push the clutch/brake pedal forward to stop the

unit. Keep your foot on the pedal.

2. Move the attachment clutch to the DISENGAGE position.

3. Move the speed control lever to the NEUTRAL position.

4. Set the parking brake.

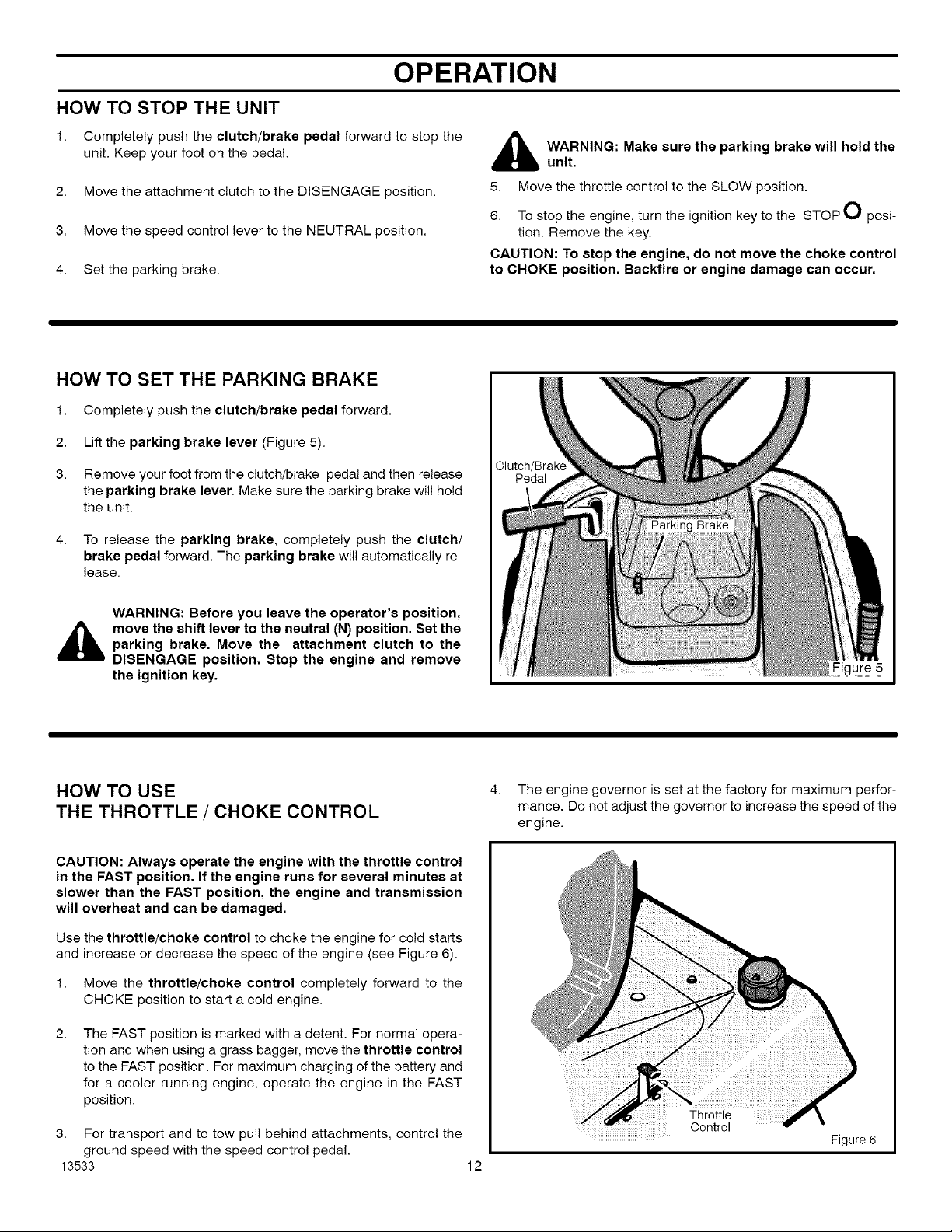

HOW TO SET THE PARKING BRAKE

1. Completely push the clutch/brake pedal forward.

2. Lift the parking brake lever (Figure 5).

_ ARNING: Make sure the parking brake will hold the

unit.

5. Move the throttle control to the SLOW position.

6. To stop the engine, turn the ignition key to the STOP 0 posi-

tion. Remove the key.

CAUTION: To stop the engine, do not move the choke control

to CHOKE position. Backfire or engine damage can occur.

3. Remove your foot from the clutch/brake pedal and then release

the parking brake lever. Make sure the parking brake will hold

the unit.

4. To release the parking brake, completely push the clutch/

brake pedal forward. The parking brake will automatically re-

lease.

WARNING: Before you leave the operator's position,

_b move the shift lever to the neutral (N) position. Set the

parking brake. Move the attachment clutch to the

DISENGAGE position. Stop the engine and remove

the ignition key.

HOW TO USE

THE THROTTLE / CHOKE CONTROL

CAUTION: Always operate the engine with the throttle control

in the FAST position. If the engine runs for several minutes at

slower than the FAST position, the engine and transmission

will overheat and can be damaged.

Pedal

4.

The engine governor is set at the factory for maximum perfor-

mance. Do not adjust the governor to increase the speed of the

engine.

Figu_re5_

Use the throttle/choke control to choke the engine for cold starts

and increase or decrease the speed of the engine (see Figure 6).

1. Move the throttle/choke control completely forward to the

CHOKE position to start a cold engine.

2.

The FAST position is marked with a detent. For normal opera-

tion and when using a grass bagger, move the throttle control

to the FAST position. For maximum charging of the battery and

for a cooler running engine, operate the engine in the FAST

position.

3. For transport and to tow pull behind attachments, control the

ground speed with the speed control pedal.

13533

Throttle

Contro

Figure 6

12

OPERATION

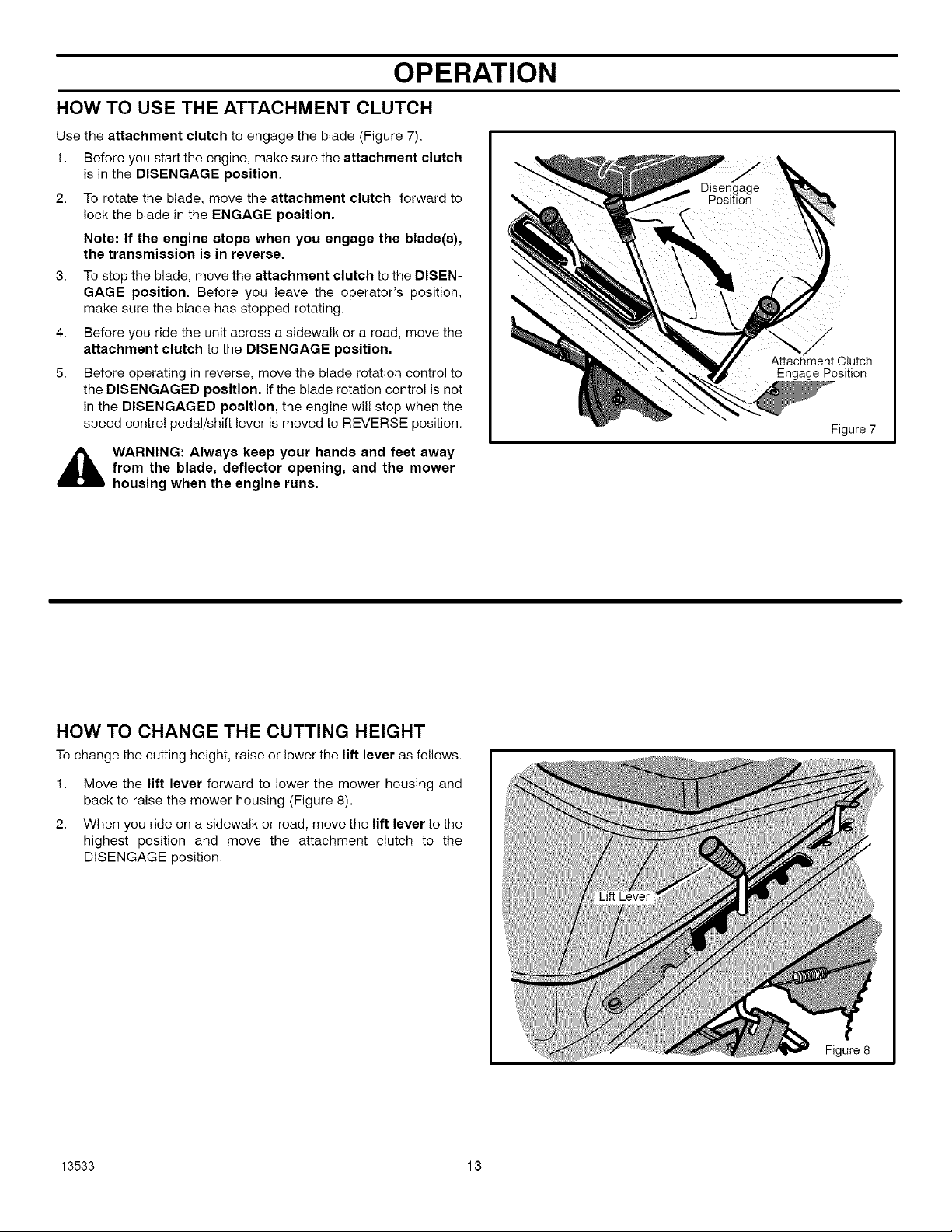

HOW TO USE THE ATTACHMENT CLUTCH

Use the attachment clutch to engage the blade (Figure 7).

1. Before you start the engine, make sure the attachment clutch

is in the DISENGAGE position.

2. To rotate the blade, move the attachment clutch forward to

lock the blade inthe ENGAGE position.

Note: If the engine stops when you engage the blade(s),

the transmission is in reverse.

3. To stop the blade, move the attachment clutch to the DISEN-

GAGE position. Before you leave the operator's position,

make sure the blade has stopped rotating.

4. Before you ride the unit across a sidewalk or a road, move the

attachment clutch to the DISENGAGE position.

5. Before operating in reverse, move the blade rotation control to

the DISENGAGED position. If the blade rotation control is not

in the DISENGAGED position, the engine will stop when the

speed control pedal/shift lever ismoved to REVERSE position.

Attachment Clutch

Engage Position

Figure 7

_b WARNING: Always keep your hands and feet away

from the blade, deflector opening, and the mower

housing when the engine runs.

HOW TO CHANGE THE CUTTING HEIGHT

To change the cutting height, raise or lower the lift lever as follows.

1. Move the lift lever forward to lower the mower housing and

back to raise the mower housing (Figure 8).

2. When you ride on a sidewalk or road, move the lift lever to the

highest position and move the attachment clutch to the

DISENGAGE position.

13533 13

Figure 8

OPERATION

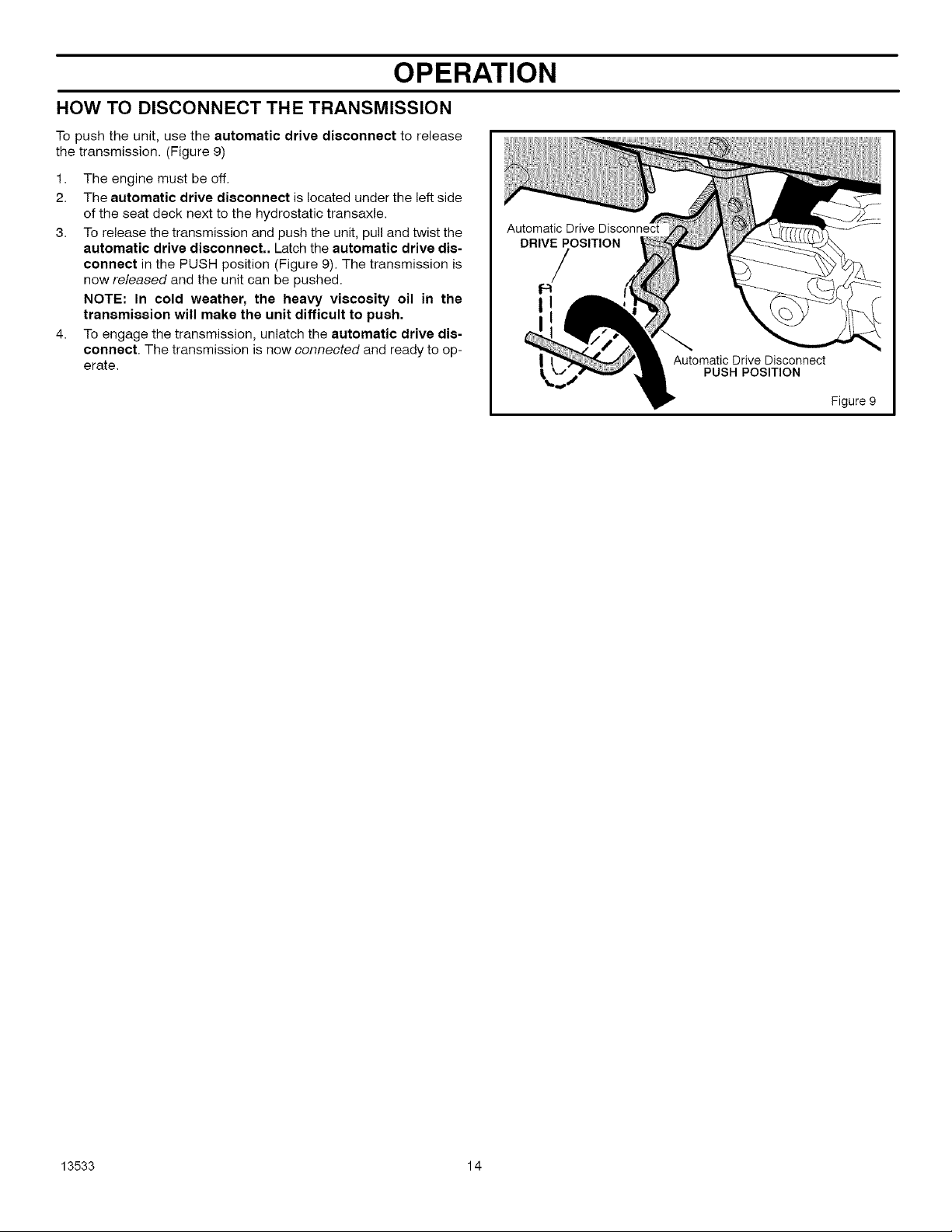

HOW TO DISCONNECT THE TRANSMISSION

To push the unit, use the automatic drive disconnect to release

the transmission. (Figure 9)

1. The engine must be off.

2. The automatic drive disconnect is located under the left side

of the seat deck next to the hydrostatic transaxle.

3. To release the transmission and push the unit, pull and twist the

automatic drive disconnect.. Latch the automatic drive dis-

connect in the PUSH position (Figure 9). The transmission is

now released and the unit can be pushed.

NOTE: In cold weather, the heavy viscosity oil in the

transmission will make the unit difficult to push.

4. To engage the transmission, unlatch the automatic drive dis-

connect. The transmission is now connected and ready to op-

erate.

Automatic Drive Disconnect

DRIVE POSITION

/

Automatic Drive Disconnect

PUSH POSITION

Figure 9

13533 14

OPERATION

HOW TO USE THE SPEED CONTROL LEVER

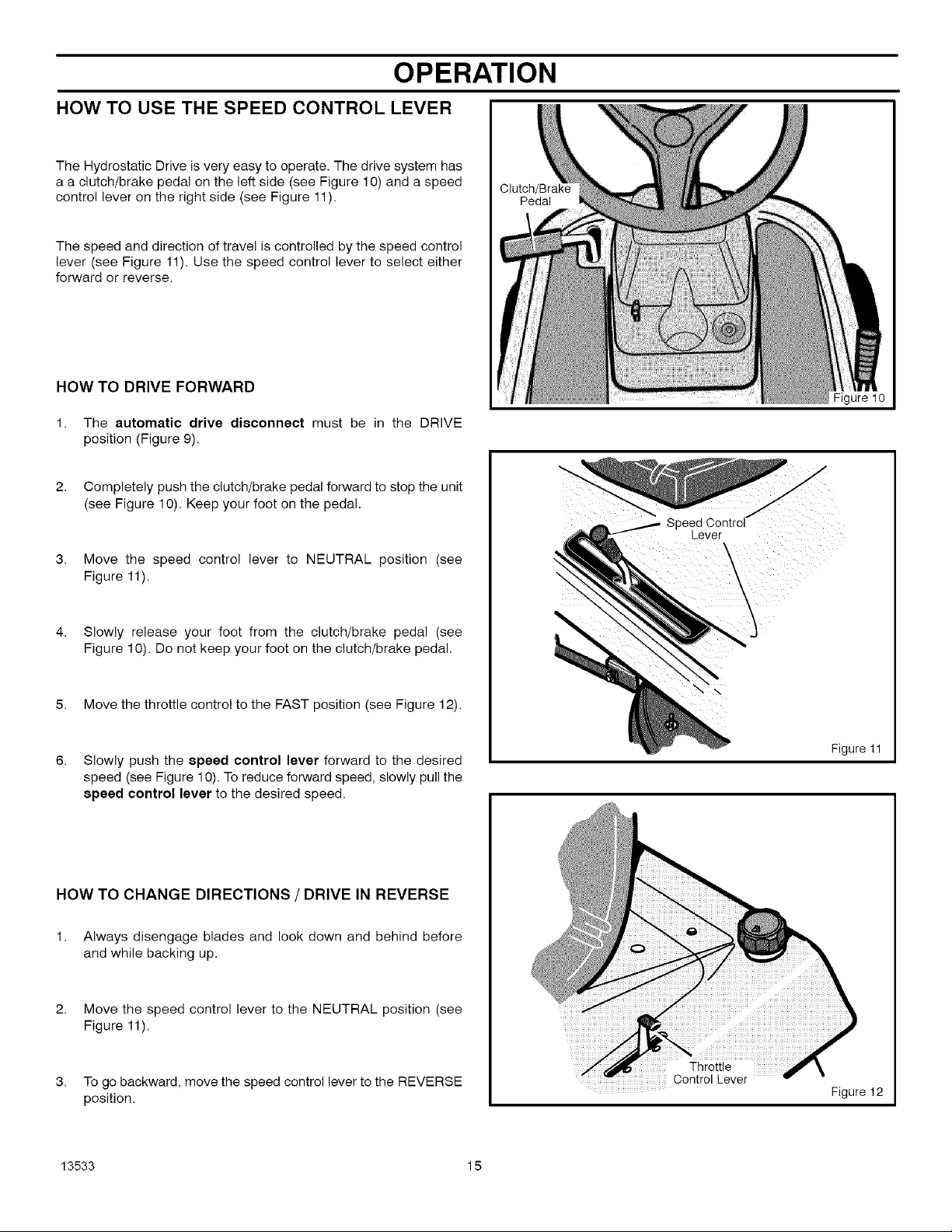

The Hydrostatic Drive is very easy to operate. The drive system has

a a clutch/brake pedal on the left side (see Figure 10) and a speed

control lever on the right side (see Figure 11).

The speed and direction of travel is controlled by the speed control

lever (see Figure 11). Use the speed control lever to select either

forward or reverse.

HOW TO DRIVE FORWARD

1. The automatic drive disconnect must be in the DRIVE

position (Figure 9).

2.

Completely push the clutch/brake pedal forward to stop the unit

(see Figure 10). Keep your foot on the pedal.

3.

Move the speed control lever to NEUTRAL position (see

Figure 11).

4.

Slowly release your foot from the clutch/brake pedal (see

Figure 10). Do not keep your foot on the clutch/brake pedal.

5. Move the throttle control to the FAST position (see Figure 12).

6. Slowly push the speed control lever forward to the desired

speed (see Figure 10). To reduce forward speed, slowly pull the

speed control lever to the desired speed.

Figure 10

Speed Control

Lever

Figure 11

HOW TO CHANGE DIRECTIONS / DRIVE IN REVERSE

1. Always disengage blades and look down and behind before

and while backing up.

2. Move the speed control lever to the NEUTRAL position (see

Figure 11).

3. To go backward, move the speed control lever to the REVERSE

position.

13533 15

............. Control Lever ...........

Throttle

Figure 12

OPERATION

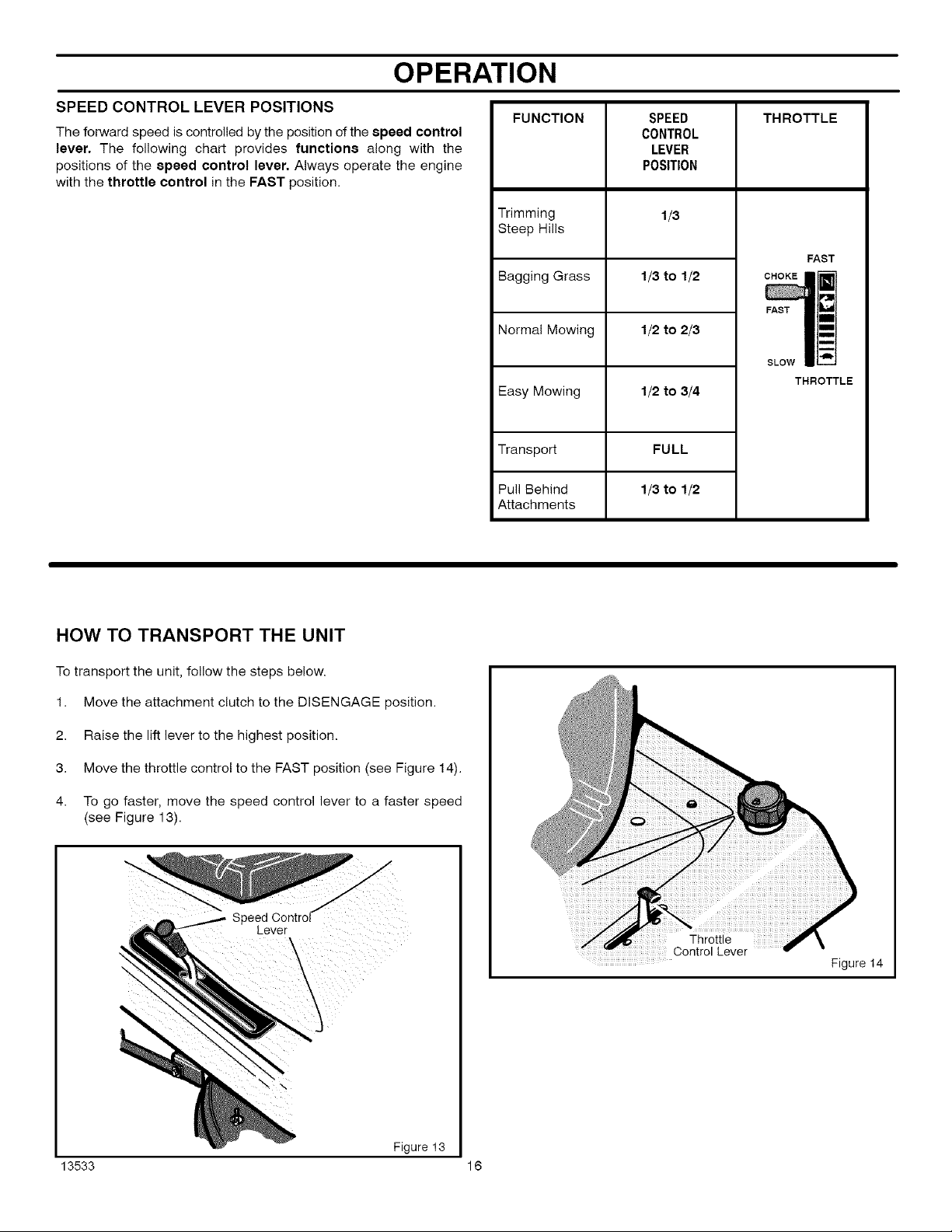

SPEED CONTROL LEVER POSITIONS

The forward speed is controlled by the position of the speed control

lever. The following chart provides functions along with the

positions of the speed control lever. Always operate the engine

with the throttle control in the FAST position

FUNCTION

Trimming

Steep Hills

Bagging Grass 1/3 to 1/2

Normal Mowing 1/2 to 2/3

Easy Mowing 1/2 to 3/4

Transport

Pull Behind

Attachments

SPEED

CONTROL

LEVER

POSITION

1/3

FULL

1/3 to 1/2

THROTTLE

FAST

CHOKE

FAST L-_

SLOW

THROTTLE

HOW TO TRANSPORT THE UNIT

To transport the unit, follow the steps below.

1. Move the attachment clutch to the DISENGAGE position.

2. Raise the lift lever to the highest position.

3. Move the throttle control to the FAST position (see Figure 14).

4. To go faster, move the speed control lever to a faster speed

(see Figure 13_.

/

Speed Control

_ever

\

\ \

................................Control Lever

Throttle

Figure 14

Figure 13

13533 16

OPERATION

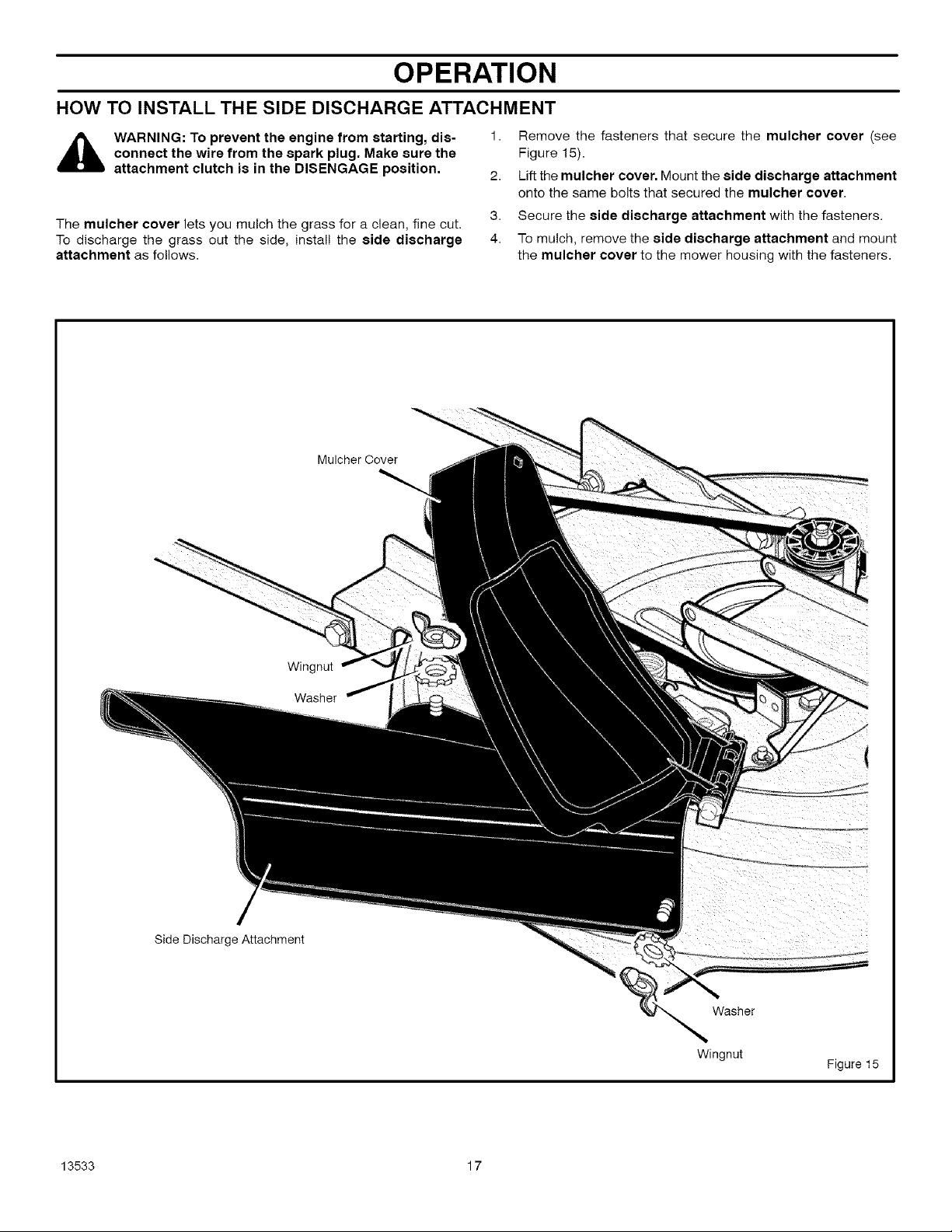

HOW TO INSTALL THE SIDE DISCHARGE ATTACHMENT

1. Remove the fasteners that secure the mulcher cover (see

,_ WARNING: To prevent the engine from starting, dis-

The mulcher cover lets you mulch the grass for a clean, fine cut.

To discharge the grass out the side, install the side discharge

attachment as follows.

connect the wire from the spark plug. Make sure the

attachment clutch is in the DISENGAGE position.

Mulcher Cover

Figure 15).

2. Lift the mulcher cover. Mount the side discharge attachment

onto the same bolts that secured the mulcher cover.

3. Secure the side discharge attachment with the fasteners.

4. To mulch, remove the side discharge attachment and mount

the mulcher cover to the mower housing with the fasteners.

Side Discharge Attachment

Wingnut

Washer

Washer

Wingnut

Figure 15

13533 17

OPERATION

BEFORE STARTING THE ENGINE 2.

NOTE: The engine was chipped from the factory filled with oil

rated 30. Check the level of the oil, Add oil as needed.

1. Make sure the unit is level.

NOTE: Do not check the level of the oil while the engine

runs.

GASOLINE REQUIREMENTS

All gasoline is not the same. If a starting or performance problem is

encountered after new gasoline has been used, try another service

station or change brands.

Type of gasoline to use

Always use gasoline that meets these requirements:

• Clean, fresh, unleaded gasoline.

• A minimun of 87 octane/87 AKI (91 RON). At altitudes over

5,000 feet, see "High-altitude use".

• Gasoline with up to 10% ethanol (gasohol) or up to 15%

MTBE (methyl tertiary butyl ether), is acceptable.

Clean the area around the dipstick. Remove the dipstick. Wipe

the oil from the dipstick.

3.CHECK THE OIL

Insert the dipstick into the oil fill tube. Turn the dipstick clock-

wise until it is tight. Remove the dipstick. Check the oil level on

the dipstick. The oil level must reach the FULL mark on the

dipstick.

4.

If necessary, add oil until the oil reaches the FULL mark on the

dipstick. The quantity of oil needed from ADD to FULL is shown

on the dipstick. Do not add too much oi!.

Use of any gasoline other than those approved above will

void the engine warranty. Some areas require that fuel

pumps be marked if the gasoline contains alcohols or ethers.

If you are not sure if your gasoline contains alcohol or ethers

that are different than those approved above, then check with

the service station operator.

Do not modify the engine fuel system or carburetor to run on

alternative fuels.

Never mix oil with gasoline.

This engine is designed to operate on gasoline. The emission

control system for this engine is EM (Engine Modifications).

ADD GASOLINE

WARNING: Always use a safety gasoline container.

,_ Do not smoke when adding gasoline to the fuel tank.Do not add gasoline when you are inside an enclo-

sure. Before you add gasoline, stop the engine and

let the engine cool for several minutes.

1.

Stop the engine. Before you remove gas cap, let the engine

cool at least 2 minutes.

2.

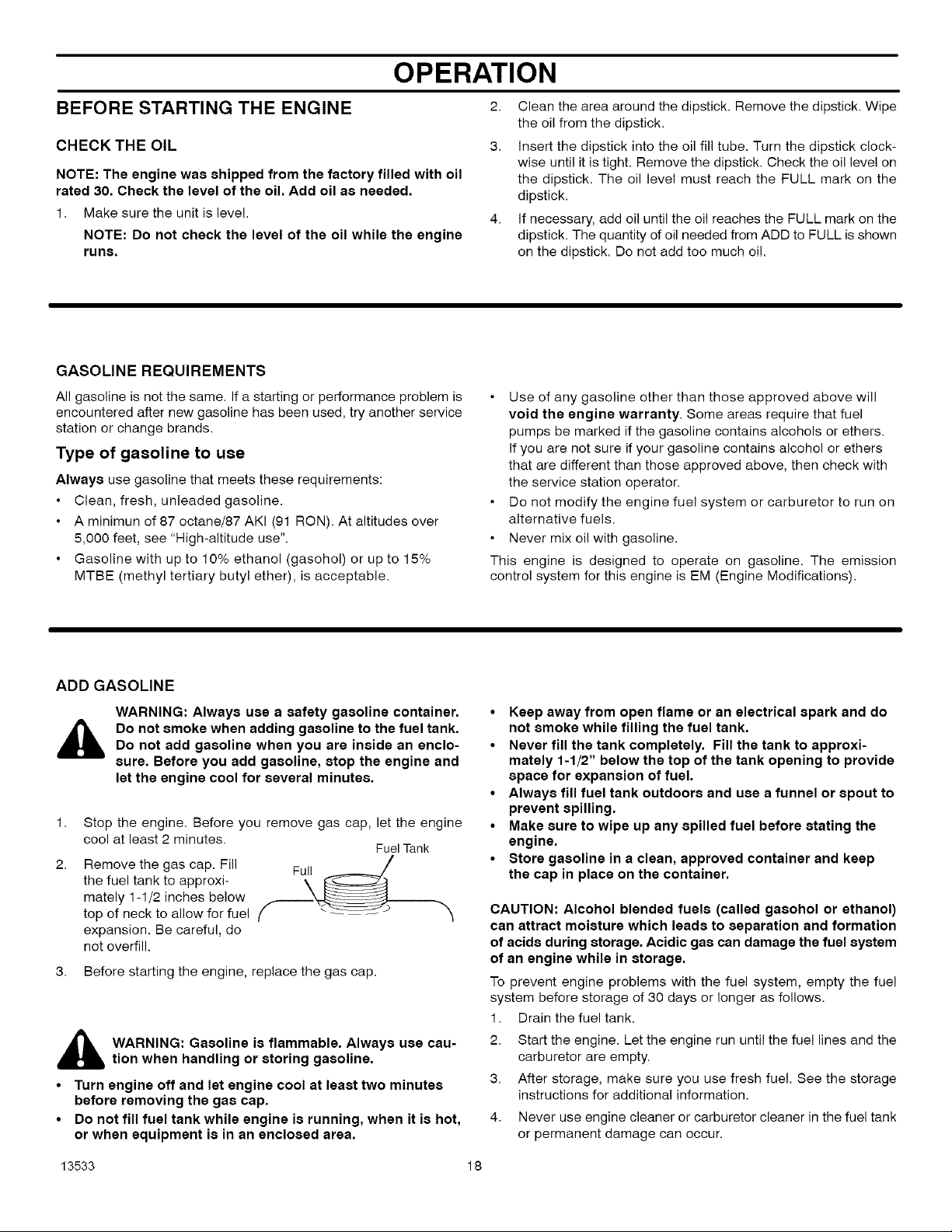

Remove the gas cap. Fill _ /z

the fuel tank to approxi-

mately 1-1/2 inches below

top of neck to allow for fuel

expansion. Be careful, do

not overfill.

3. Before starting the engine, replace the gas cap.

,_ WARNING: Gasoline is flammable. Always use cau-

tion when handling or storing gasoline.

• Turn engine off and let engine cool at least two minutes

before removing the gas cap.

• Do not fill fuel tank while engine is running, when it is hot,

or when equipment is in an enclosed area.

Fuel Tank

• Keep away from open flame or an electrical spark and do

not smoke while filling the fuel tank.

• Never fill the tank completely. Fill the tank to approxi-

mately 1-1/2" below the top of the tank opening to provide

space for expansion of fuel.

• Always fill fuel tank outdoors and use a funnel or spout to

prevent spilling.

• Make sure to wipe up any spilled fuel before stating the

engine.

• Store gasoline in a clean, approved container and keep

the cap in place on the container.

CAUTION: Alcohol blended fuels (called gasohol or ethanol)

can attract moisture which leads to separation and formation

of acids during storage. Acidic gas can damage the fuel system

of an engine while in storage.

To prevent engine problems with the fuel system, empty the fue!

system before storage of 30 days or longer as follows.

1. Drain the fuel tank.

2. Start the engine. Let the engine run until the fue! lines and the

carburetor are empty.

3. After storage, make sure you use fresh fuel. See the storage

instructions for additional information.

4. Never use engine cleaner or carburetor cleaner in the fuel tank

or permanent damage can occur.

13533 18

CARBURETOR

OPERATION

The factory settings for the carburetor are for most conditions. If the

engine is operated under the following conditions, the carburetor

may require an adjustment. For service, contact a Sears or other

qualified service center.

1. The engine has a loss of power or does not run smooth.

HOW TO START THE ENGINE

WARNING: The electrical system has two primary

components, an operator presence system and a

Select Reverse T' system. The operator presence

system determines if the operator is sitting on the

seat. This system will stop the engine when the

operator leaves the seat. The Select Reverse T`'

system gives the operator the ability to temporarily

mow in reverse if he decides such operation is

absolutely necessary and safe operating precautions

are taken. For your protection, always make sure

these systems operate correctly.

NOTE: The engine will not start unless you depress the

clutch/brake pedal or engage the parking brake and move the

attachment clutch to the DISENGAGE position.

1. Make sure the spark plug wire is connected to the spark plug.

2. A change from summer to winter operation.

3. A 40 degree change in the operation temperature. The carbure-

tor was adjusted at 80 degrees at the factory.

4. The engine is operated above 4,000 feet above sea level.

4.

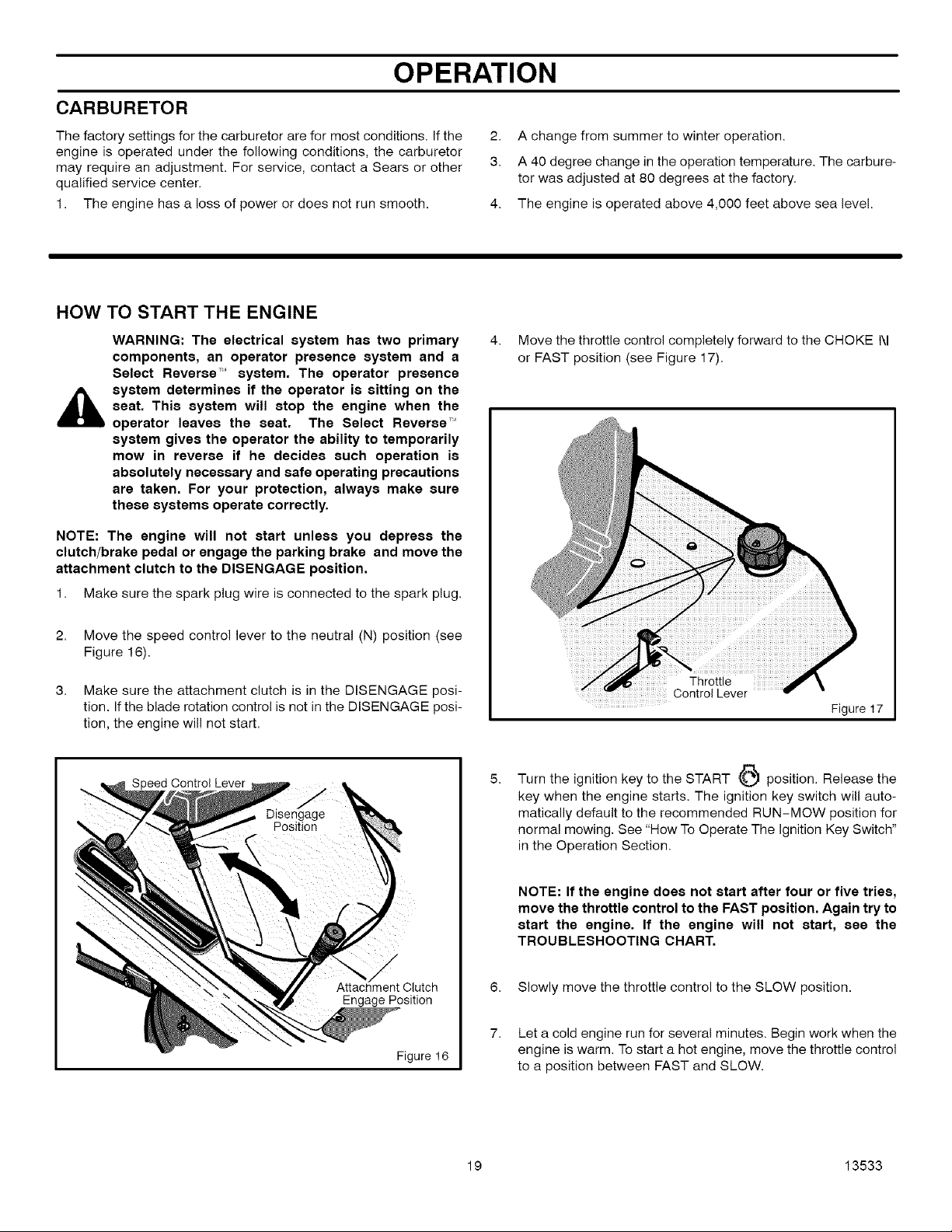

Move the throttle control completely forward to the CHOKE i\l

or FAST position (see Figure 17).

2. Move the speed control lever to the neutral (N) position (see

Figure 16).

3. Make sure the attachment clutch is in the DISENGAGE posi-

tion. If the blade rotation control is not in the DISENGAGE posi-

tion, the engine will not start.

Speed Control Lever

Attachment Clutch

Engage Position

Figure 16

Throttle

Contro Lever

5.

Turn the ignition key to the START _._) position. Release the

key when the engine starts. The ignition key switch will auto-

matically default to the recommended RUN-MOW position for

normal mowing. See "How To Operate The Ignition Key Switch"

in the Operation Section.

NOTE: If the engine does not start after four or five tries,

move the throttle control to the FAST position. Again try to

start the engine. If the engine will not start, see the

TROUBLESHOOTING CHART.

6.

Slowly move the throttle control to the SLOW position.

7.

Let a cold engine run for several minutes. Begin work when the

engine is warm. To start a hot engine, move the throttle control

to a position between FAST and SLOW.

Figure 17

19 13533

OPERATION

HOWTO OPERATEWITH THE MOWERHOUSING

WARNING: The mulch cover is a safety device. Do not

remove the mulch cover. The side discharge attach-

_IL ment forces the discharged material toward the

ground. Always keep the side discharge attachment

in the down position. If the side discharge attachment

is damaged, replace the with an original equipment

part from a Sears Service Center.

IMPORTANT: When you operate with the mower housing,

always operate with the throttle control in the FAST position.

1. Push the clutch/brake pedal completely forward.

2. Start the engine.

3. Put the speed control lever in the NEUTRAL position.

4. Slowly release the clutch/brake pedal.

5. Move the lift lever to a height of cut position. In high or thick

grass, cut the grass in the highest position first and then lower

the mower housing to a lower position.

CAUTION: Do not operate with the mower housing in the

LEVEL ADJUSTMENT position. If you operate in the

LEVEL ADJUSTMENT position, the mower housing and

blades can be damaged.

6.

Move the throttle control to the SLOW position.

7.

Move the attachment clutch to the ENGAGE position.

8.

Move the speed control lever forward.

NOTE: When you mow in heavy grass or mow with a

bagger, operate at a slow forward speed.

9.

Move the throttle control to the FAST position. If you need to go

faster or slower, move the speed control lever forward or back-

ward.

10.

Make sure the level of cut is still correct. After you mow a short

distance, look at the area that was cut. If the mower housing

does not cut level, see the instructions on "How To Level The

Mower Housing" in the Service And Adjustment section.

_ ARNING: For better control of the unit, always

select a safe speed.

HOW TO OPERATE THE UNIT ON HILLS

,_ WARNING: Do not ride up or down slopes that are too

1. Before you ride up or down a hill, move the speed control lever

2. Do not stop or change speed settings on a hill. If you must stop,

steep to back straight up. Never ride the unit across

a slope. See the "Slope Guide" in the back of this

book for information on how to check slopes.

to a slow speed.

quickly push the clutch/brake pedal forward and set the parking

brake.

3. To start again, make sure the speed controUever is in a slow

speed. Move the throttle control to the SLOW position. Slowly

release the pedal.

4. If you must stop or start on a hill, always have enough space

for the unit to roll when you release the brake and engage the

clutch.

5. Be very careful when you change directions on a hill. When on

a slope or in a turn on a hill, move the throttle control to the

SLOW position to help prevent an accident.

13533 20

OPERATING TIPS

1.

Check the attachment clutch for correct adjustment. For the

blade(s) to disengage correctly, the adjustment must be cor-

rect.

2.

Before you use the unit, check the oil in the engine and add oil

if necessary.

3.

If the engine will not start, first make sure the wire is attached

to the spark plug.

4.

Make sure all the belts are inside all the belt guides. See the in-

structions on how to remove and install the motion drive and

mower drive belts.

MOWING AND BAGGING TIPS

OPERATION

5. Before you make an inspection, adjustment (except for the car-

buretor) or repair, make sure the wire from the spark plug is dis-

connected.

6. Make sure the seat switch wire is connected. If the wire is not

connected, the engine will not start.

7. For longer life of the battery, charge the battery every three

months.

8. Use the shift lever to change the ground speed, not the throttle

control.

9. Belt noise can occur when the blade or clutch is engaged. This

noise is normal and does not affect the operation of the unit.

10. To move forward, always release the clutch/brake pedal slowly.

1. For a lawn to look better, check the cutting level of the mower

housing. See "How To Level The Mower Housing" in the Ser-

vice And Adjustment section.

2. For the mower housing to cut level, make sure the tires have

the correct amount of air pressure (PSI) and use slow ground

speeds when turning.

3. Every time you use the unit, check the blade. If the blade is bent

or damaged, immediately replace the blade. Also, make sure

the nut for the blade is tight.

4. Keep the blade(s) sharpened. A worn blade(s) wil! cause the

ends of the grass to turn brown.

5. Do not cut or bag grass that is wet. Wet grass will not discharge

correctly. Let the grass dry before cutting.

6. Use the left side of the mower housing to trim near an object.

7. Discharge the cut grass onto the mowed area. The result is a

more even discharge of cut grass.

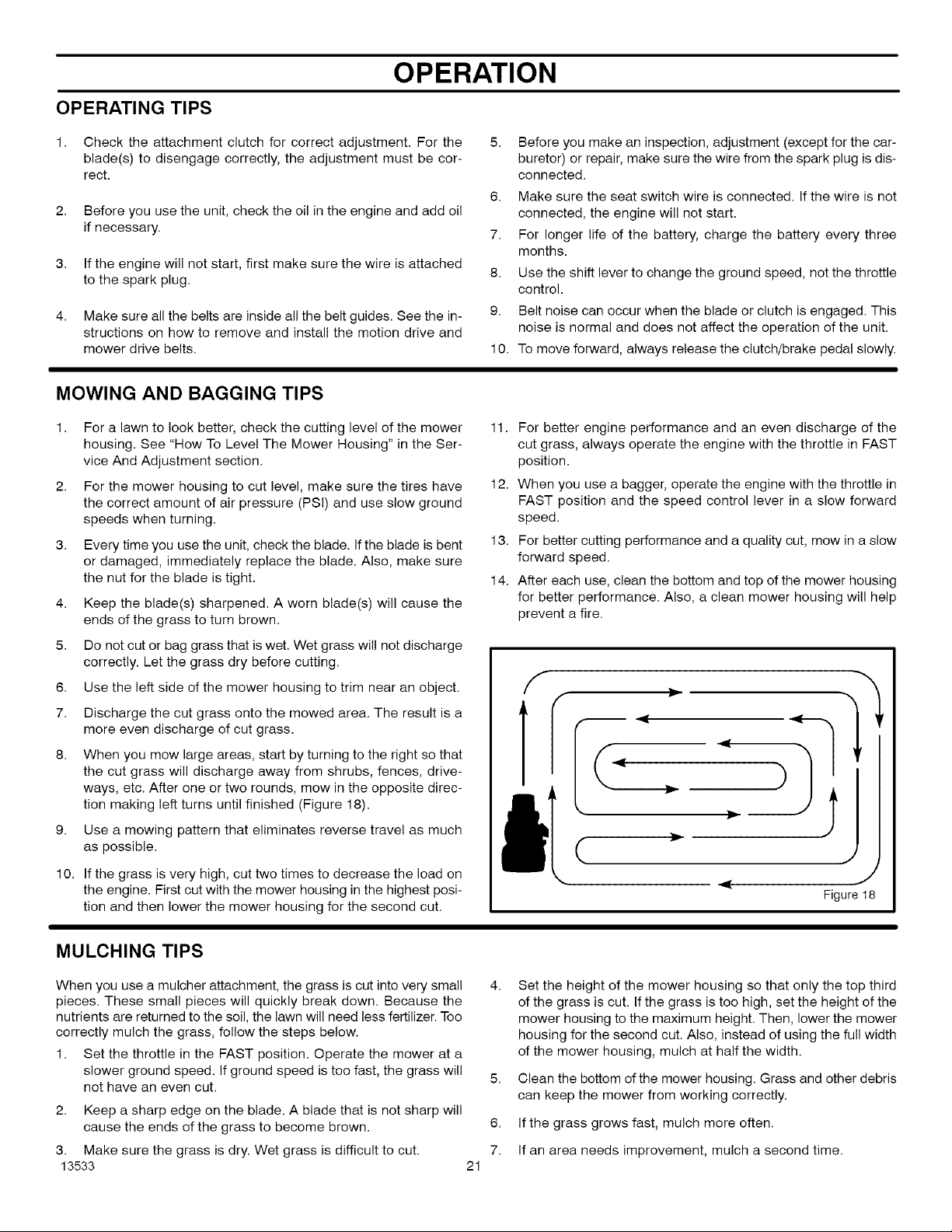

8. When you mow large areas, start by turning to the right so that

the cut grass will discharge away from shrubs, fences, drive-

ways, etc. After one or two rounds, mow in the opposite direc-

tion making left turns until finished (Figure 18).

9. Use a mowing pattern that eliminates reverse travel as much

as possible.

10. If the grass is very high, cut two times to decrease the load on

the engine. First cut with the mower housing in the highest posi-

tion and then lower the mower housing for the second cut.

11. For better engine performance and an even discharge of the

cut grass, always operate the engine with the throttle in FAST

position.

12. When you use a bagger, operate the engine with the throttle in

FAST position and the speed control lever in a slow forward

speed.

13. For better cutting performance and a quality cut, mow in a slow

forward speed.

14. After each use, clean the bottom and top of the mower housing

for better performance. Also, a clean mower housing will help

prevent a fire.

• J

= J

Figure 18

MULCHING TIPS

When you use a mulcher attachment, the grass is cut into very small 4.

pieces. These small pieces will quickly break down. Because the

nutrients are returned to the soil, the lawn will need less fertilizer. Too

correctly mulch the grass, follow the steps below.

1. Set the throttle in the FAST position. Operate the mower at a

slower ground speed. If ground speed is too fast, the grass will 5.

not have an even cut.

2. Keep a sharp edge on the blade. A blade that is not sharp will

cause the ends of the grass to become brown. 6.

3. Make sure the grass is dry. Wet grass is difficult to cut. 7.

13533 21

Set the height of the mower housing so that only the top third

of the grass is cut. If the grass is too high, set the height of the

mower housing to the maximum height. Then, lower the mower

housing for the second cut. Also, instead of using the full width

of the mower housing, mulch at half the width.

Clean the bottom of the mower housing. Grass and other debris

can keep the mower from working correctly.

If the grass grows fast, mulch more often.

If an area needs improvement, mulch a second time.

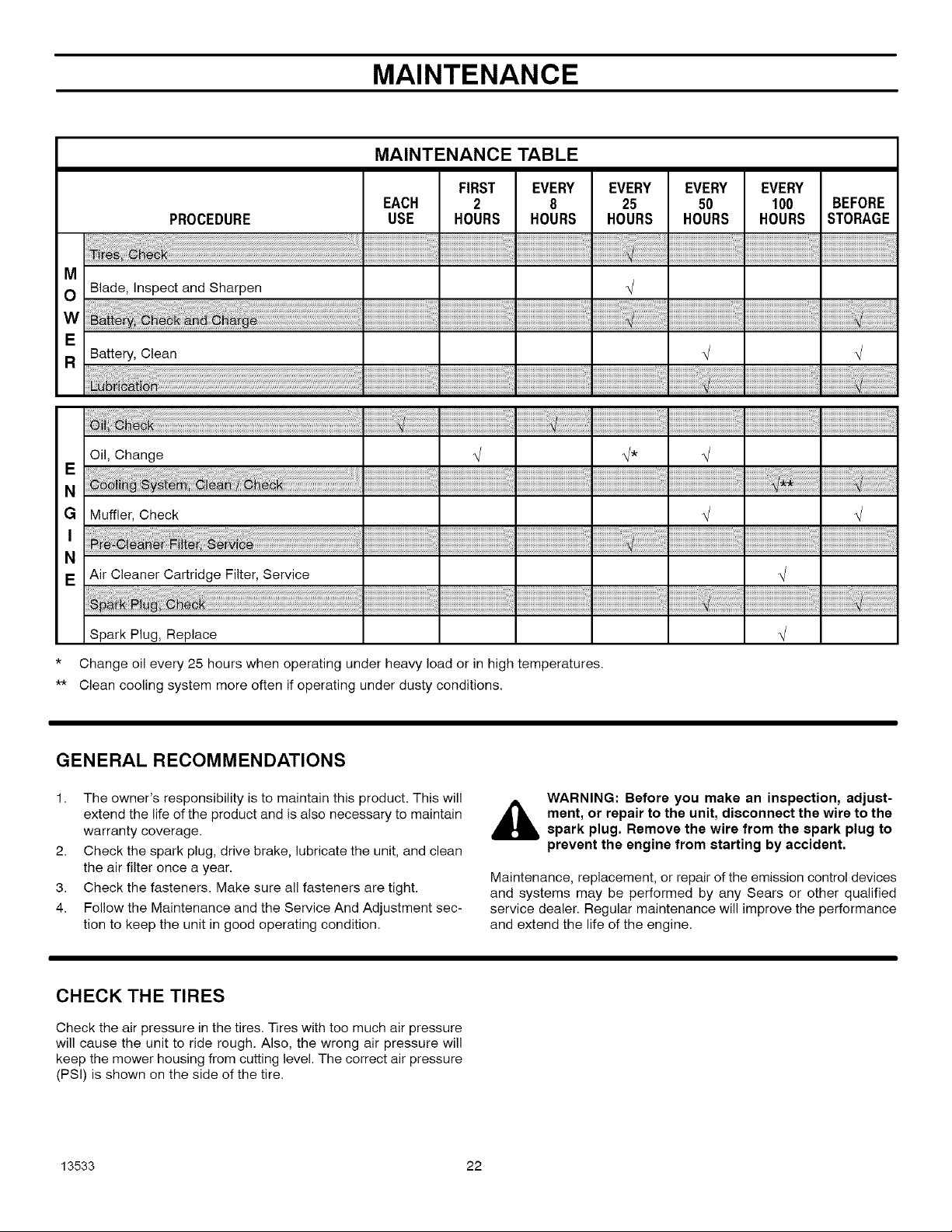

PROCEDURE USE HOURS HOURS HOURS HOURS HOURS STORAGE

M

0 Blade, Inspect and Sharpen

W gatte

E

R Battery, Clean

E

N

G

Muffler, Check

I

N

Air Cleaner Cartridge Filter, Service

E

MAINTENANCE

MAINTENANCE TABLE

FIRST EVERY EVERY EVERY EVERY

EACH 2 8 25 50 100 BEFORE

Spark Plug, Replace

* Change oil every 25 hours when operating under heavy load or in high temperatures.

** Clean cooling system more often if operating under dusty conditions.

GENERAL RECOMMENDATIONS

1. The owner's responsibility is to maintain this product. This will

extend the life of the product and is also necessary to maintain

warranty coverage.

2. Check the spark plug, drive brake, lubricate the unit, and clean

the air filter once a year.

3. Check the fasteners. Make sure all fasteners are tight.

4. Follow the Maintenance and the Service And Adjustment sec-

tion to keep the unit in good operating condition.

,_ ment, or repair to the unit, disconnect the wire to the

Maintenance, replacement, or repair of the emission control devices

and systems may be performed by any Sears or other qualified

service dealer. Regular maintenance will improve the performance

and extend the life of the engine.

WARNING: Before you make an inspection, adjust-

spark plug. Remove the wire from the spark plug to

prevent the engine from starting by accident.

CHECK THE TIRES

Check the air pressure in the tires. Tires with too much air pressure

will cause the unit to ride rough. Also, the wrong air pressure will

keep the mower housing from cutting level. The correct air pressure

(PSI) is shown on the side of the tire.

13533 22

MAINTENANCE

INSPECT BLADE

WARNING: Before you inspect or remove the blade,

disconnect the wire to the spark plug. If the blade

,_'_lLi hits an object, stop the engine. Check the unit for

If you keep the blade sharp and inspect the blade for damage,

the blade will cut better and be more safe to operate. Frequently

check the blade for excessive wear, cracks, or other damage.

Frequently check the nut that holds the blade. Keep the nut tight.

If the blade hits an object, stop the engine. Disconnect the wire to

the spark plug. See if the blade is bent or damaged. Check the

blade adapter for damage. Before you operate the unit, replace

damaged parts with original equipment parts. See a Sears

Service Center in your area. Every three years, have a qualified

service person inspect the blade or replace the old blade with an

original equipment part.

damage. The blade has sharp edges. When you

hold the blade, use gloves or cloth material to pro-

tect your hands.

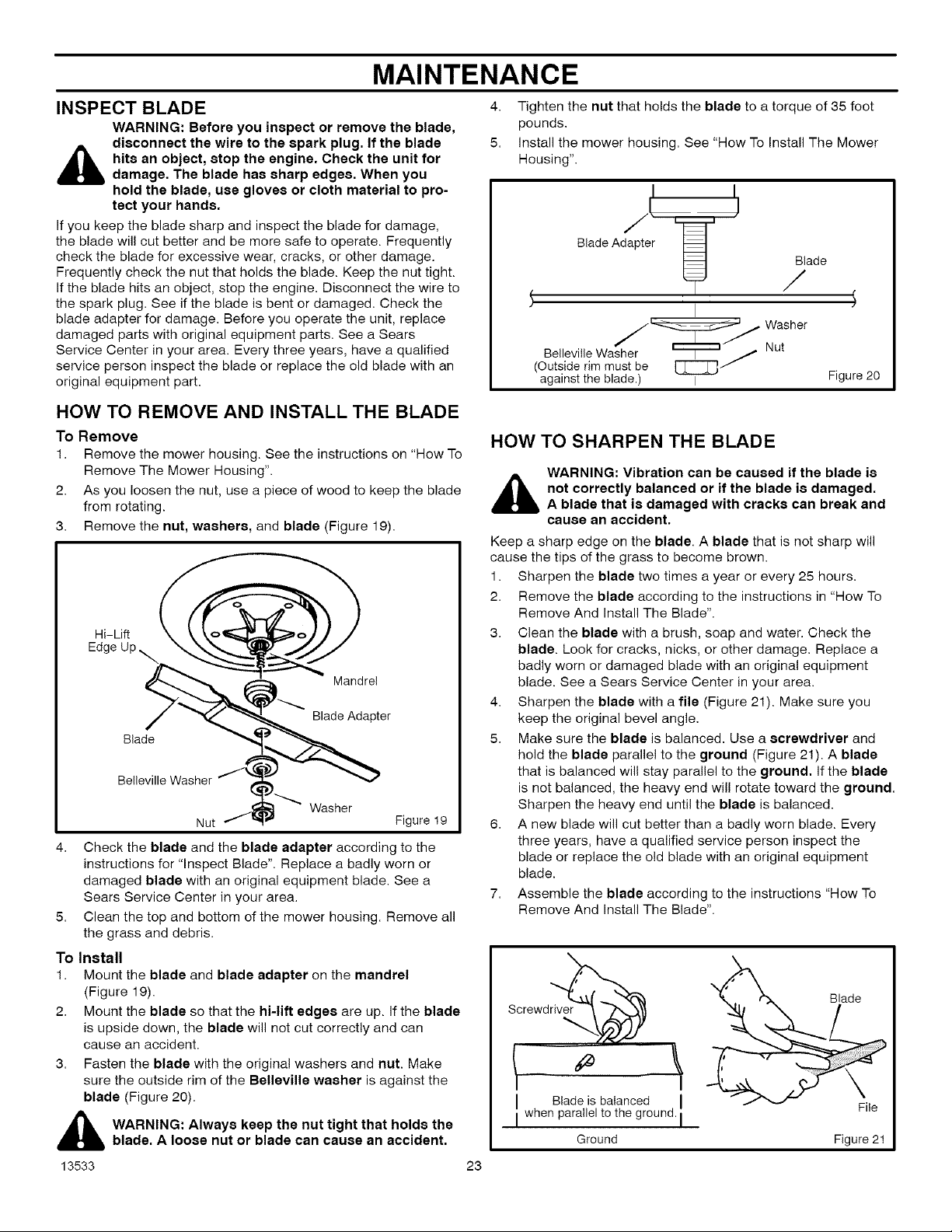

HOW TO REMOVE AND INSTALL THE BLADE

To Remove

1. Remove the mower housing. See the instructions on "How To

Remove The Mower Housing".

2. As you loosen the nut, use a piece of wood to keep the blade

from rotating.

3. Remove the nut, washers, and blade (Figure 19).

BeevieNut Washewashe ' r

Figure 19

4. Check the blade and the blade adapter according to the

instructions for "Inspect Blade". Replace a badly worn or

damaged blade with an original equipment blade. See a

Sears Service Center in your area.

5. Clean the top and bottom of the mower housing. Remove all

the grass and debris.

To Install

1. Mount the blade and blade adapter en the mandrel

(Figure 19).

2. Mount the blade so that the hi-lift edges are up. If the blade

is upside down, the blade will not cut correctly and can

cause an accident.

3. Fasten the blade with the original washers and nut. Make

sure the outside rim of the Belleville washer is against the

blade (Figure 20).

_i ARNING: Always keep the nut tight that holds the

13533

blade. A loose nut or blade can cause an accident.

4. Tighten the nut that holds the blade to a torque of 35 foot

pounds.

5. Install the mower housing. See "How To Install The Mower

Housing".

Blade Ada_pter_ _ Blade

7' J Washer

BelleviIle Washer _j Nut

(Outside rim must be

against the blade.) I

HOW TO SHARPEN THE BLADE

WARNING: Vibration can be caused if the blade is

_i ot correctly balanced or if the blade is damaged.

Keep a sharp edge on the blade. A blade that is not sharp will

cause the tips of the grass to become brown.

1. Sharpen the blade two times a year or every 25 hours.

2. Remove the blade according to the instructions in "How To

3. Clean the blade with a brush, soap and water. Check the

4. Sharpen the blade with a file (Figure 21). Make sure you

5. Make sure the blade is balanced. Use a screwdriver and

6. A new blade will cut better than a badly worn blade. Every

7. Assemble the blade according to the instructions "How To

23

A blade that is damaged with cracks can break and

cause an accident.

Remove And Install The Blade".

blade. Look for cracks, nicks, or other damage. Replace a

badly worn or damaged blade with an original equipment

blade. See a Sears Service Center in your area.

keep the original bevel angle.

hold the blade parallel to the ground (Figure 21). A blade

that is balanced will stay parallel to the ground. If the blade

is not balanced, the heavy end will rotate toward the ground.

Sharpen the heavy end until the blade is balanced.

three years, have a qualified service person inspect the

blade or replace the old blade with an original equipment

blade.

Remove And Install The Blade".

Screwdriv__

I Blade is balanced

I when parallel to the ground, i

Ground

Figure 20

File

Figure 21

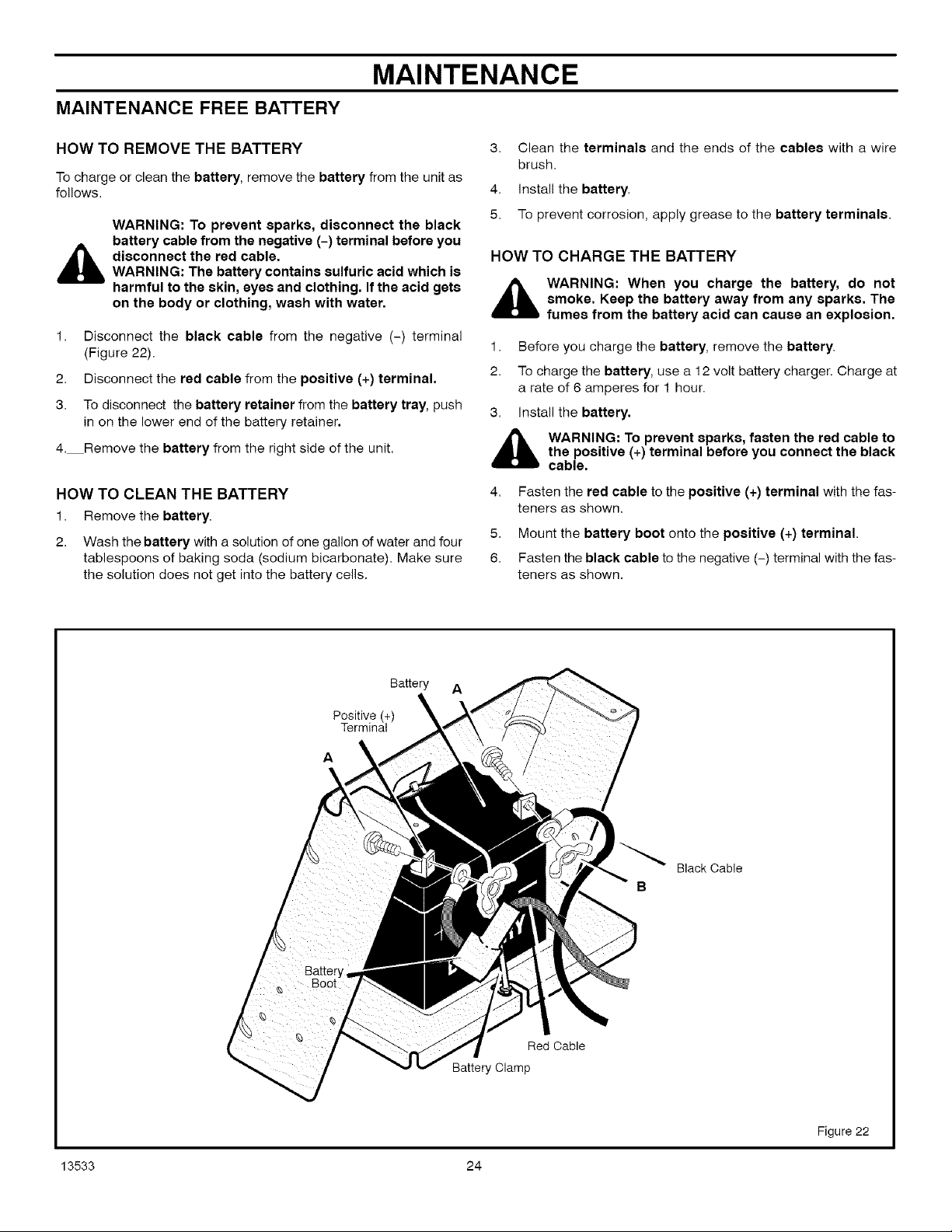

MAINTENANCE FREE BATTERY

MAINTENANCE

HOW TO REMOVE THE BATTERY

To charge or clean the battery, remove the battery from the unit as

follows.

WARNING: To prevent sparks, disconnect the black

battery cable from the negative (-) terminal before you

_IL disconnect the red cable.

1. Disconnect the black cable from the negative (-) terminal

2. Disconnect the red cable from the positive (+) terminal.

3. To disconnect the battery retainer from the battery tray, push

4. Remove the battery from the right side of the unit.

HOW TO CLEAN THE BATTERY

1. Remove the battery.

2. Wash the battery with a solution of one gallon of water and four

WARNING: The battery contains sulfuric acid which is

harmful to the skin, eyes and clothing. If the acid gets

on the body or clothing, wash with water.

(Figure 22).

in on the lower end of the battery retainer,

tablespoons of baking soda (sodium bicarbonate). Make sure

the solution does not get into the battery cells.

3. Clean the terminals and the ends of the cables with a wire

brush.

4. Install the battery.

5. To prevent corrosion, apply grease to the battery terminals.

HOW TO CHARGE THE BATTERY

_ WARNING: When you charge the battery, do not

1. Before you charge the battery, remove the battery.

2. To charge the battery, use a 12 volt battery charger. Charge at

3. Install the battery.

_IL WARNING: To prevent sparks, fasten the red cable to

4. Fasten the red cable to the positive (+) terminal with the fas-

5. Mount the battery boot onto the positive (+) terminal.

6. Fasten the black cable to the negative (-) terminal with the fas-

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

a rate of 6 amperes for 1 hour.

the positive (+) terminal before you connect the black

cable.

teners as shown.

teners as shown.

Positive (+)

Terminal

A

Battery A

Black Cable

B

Red Cable

Battery Clamp

Figure 22

13533 24

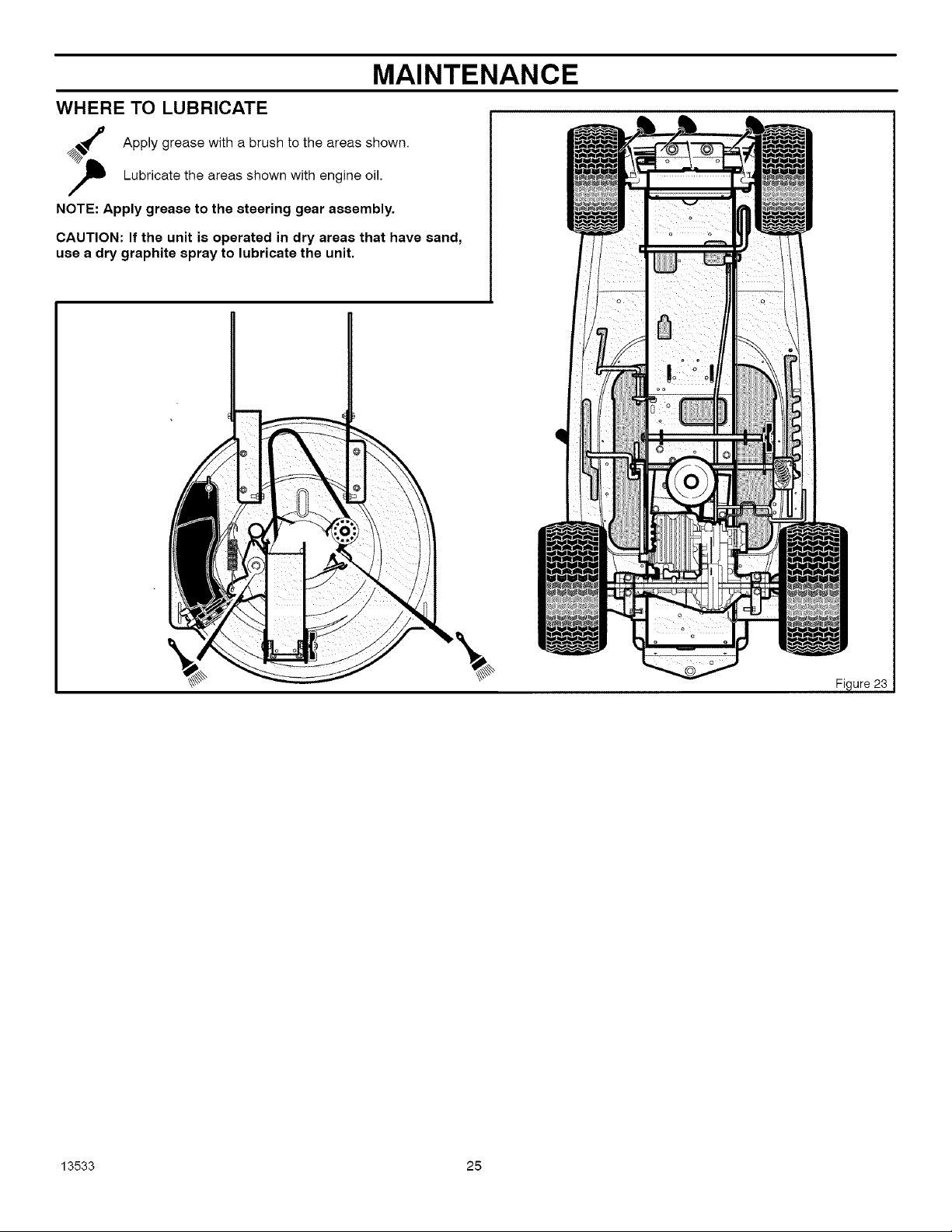

MAINTENANCE

WHERE TO LUBRICATE

_,,%_ Apply grease with a brush to the areas shown.

Lubricate the areas shown with engine oil.

NOTE: Apply grease to the steering gear assembly.

CAUTION: If the unit is operated in dry areas that have sand,

use a dry graphite spray to lubricate the unit.

Fi ure 23

13533 25

MAINTENANCE

ENGINE 2.

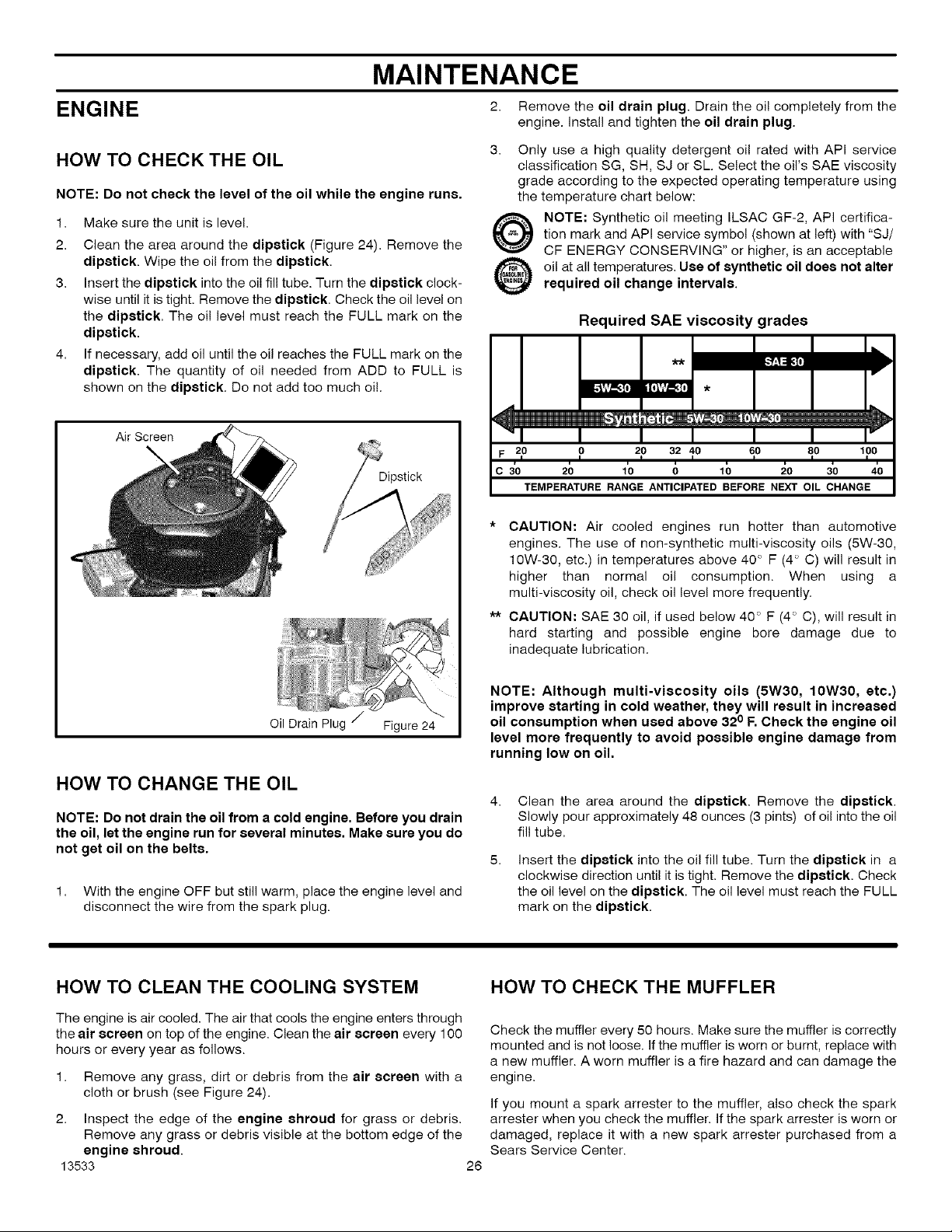

HOW TO CHECK THE OIL

NOTE: Do not check the level of the oil while the engine runs.

1. Make sure the unit is level.

2. Clean the area around the dipstick (Figure 24). Remove the

dipstick. Wipe the oil from the dipstick.

3. Insert the dipstick into the oil fill tube. Turn the dipstick clock-

wise until it is tight. Remove the dipstick. Check the oil level on

the dipstick, The oi! level must reach the FULL mark on the

dipstick.

4. If necessary, add oil until the oil reaches the FULL mark on the

dipstick. The quantity of oil needed from ADD to FULL is

shown on the dipstick. Do not add too much oi!.

Air Screen

Dipstick

3.

F 20 0 20 32 40 60 80 100

c 30 20 1_ _ 1_ _0 3'0 40

* CAUTION: Air cooled engines run hotter than automotive

** CAUTION: SAE 30 oil, if used below 40 ° F (4 ° C), will result in

Remove the oil drain plug. Drain the oil completely from the

engine, install and tighten the oil drain plug.

Only use a high quality detergent oil rated with API service

classification SG, SH, SJ or SL. Select the oil's SAE viscosity

grade according to the expected operating temperature using

the temperature chart below:

tion mark and API service symbol (shown at left) with "S J/

NOTE: Synthetic oil meeting ILSAC GF-2, API certifica-

CF ENERGY CONSERVING" or higher, is an acceptable

oil at all temperatures. Use of synthetic oil does not alter

required oil change intervals.

Required SAE viscosity grades

- 0,

,I I 1 I I I I ,

TEMPERATURERANGEANTICIPATEDBEFORE NEXT OIL CHANGE

engines. The use of non-synthetic multi-viscosity oils (5W-30,

10W-30, etc.) in temperatures above 40 ° F (4 ° C) will result in

higher than normal oil consumption. When using a

multi-viscosity oil, check oil level more frequently.

hard starting and possible engine bore damage due to

inadequate lubrication.

I [-%_II_I,]I

Oil Drain Plug Figure 24

HOW TO CHANGE THE OIL

NOTE: Do not drain the oil from a cold engine. Before you drain

the oil, let the engine run for several minutes. Make sure you do

not get oil on the belts.

1. With the engine OFF but still warm, place the engine level and

disconnect the wire from the spark plug.

HOW TO CLEAN THE COOLING SYSTEM

The engine is air cooled. The air that cools the engine enters through

the air screen on top of the engine. Clean the air screen every 100

hours or every year as follows.

1. Remove any grass, dirt or debris from the air screen with a

cloth or brush (see Figure 24).

2. Inspect the edge of the engine shroud for grass or debris.

Remove any grass or debris visible at the bottom edge of the

engine shroud.

13533

NOTE: Although multi-viscosity oils (5W30, 10W30, etc.)

improve starting in cold weather, they will result in increased

oil consumption when used above 320 F.Check the engine oil

level more frequently to avoid possible engine damage from

running low on oil.

4.

Clean the area around the dipstick. Remove the dipstick.

Slowly pour approximately 48 ounces (3 pints) of oil into the oil

fill tube.

5.

Insert the dipstick into the oil fill tube. Turn the dipstick in a

clockwise direction until it is tight. Remove the dipstick. Check

the oil level on the dipstick. The oil level must reach the FULL

mark on the dipstick.

HOW TO CHECK THE MUFFLER

Check the muffler every 50 hours. Make sure the muffler is correctly

mounted and is not loose. If the muffler is worn or burnt, replace with

a new muffler. A worn muffler is a fire hazard and can damage the

engine.

If you mount a spark arrester to the muffler, also check the spark

arrester when you check the muffler. If the spark arrester is worn or

damaged, replace it with a new spark arrester purchased from a

Sears Service Center.

26

MAINTENANCE

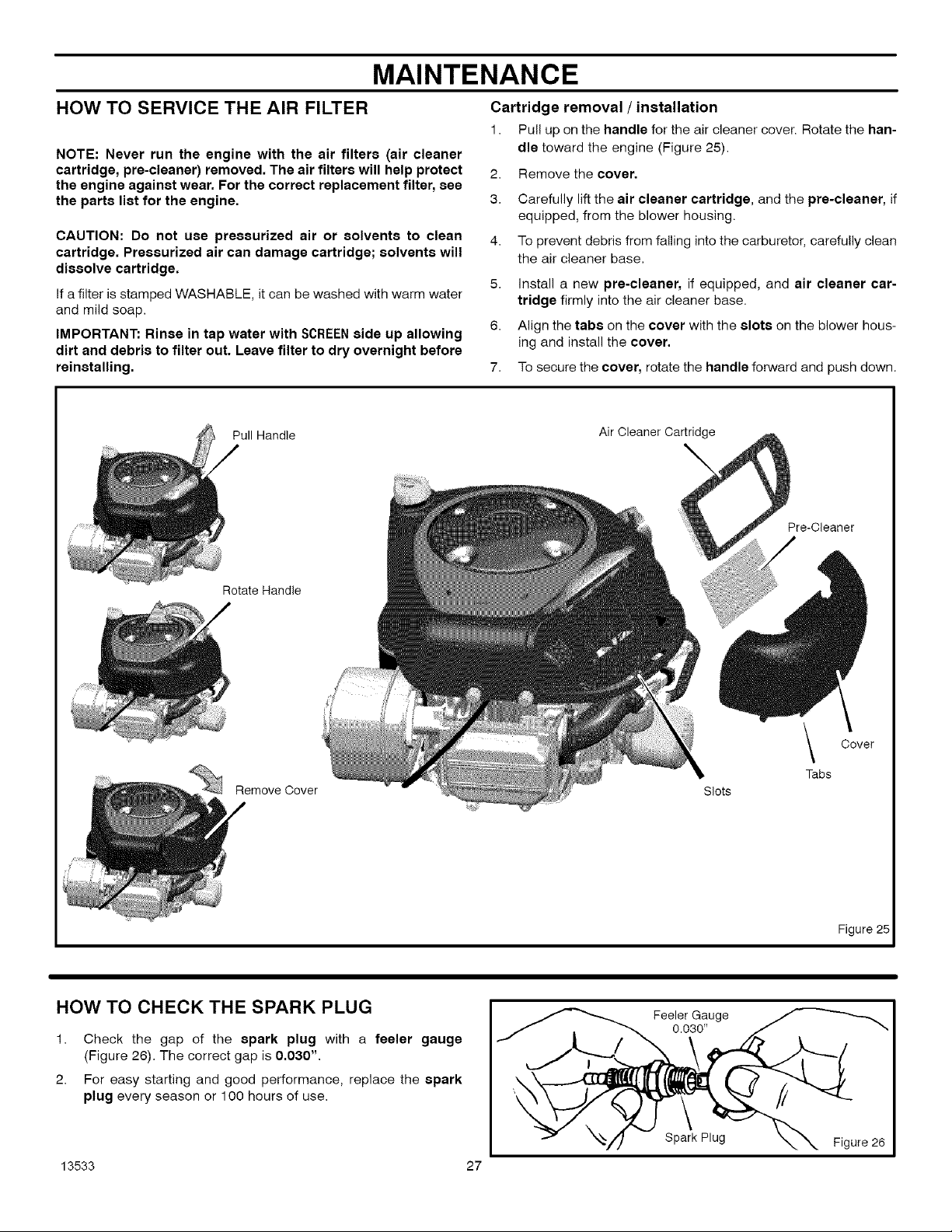

HOW TO SERVICE THE AIR FILTER

NOTE: Never run the engine with the air filters (air cleaner

cartridge, pre-cleaner) removed. The air filters will help protect

the engine against wear. For the correct replacement filter, see

the parts list for the engine.

CAUTION: Do not use pressurized air or solvents to clean

cartridge. Pressurized air can damage cartridge; solvents will

dissolve cartridge.

If a filter is stamped WASHABLE, it can be washed with warm water

and mild soap.

IMPORTANT: Rinse in tap water with SCREENside up allowing

dirt and debris to filter out. Leave filter to dry overnight before

reinstalling.

Pull Handle

Cartridge removal / installation

1. Pull up on the handle for the air cleaner cover. Rotate the han-

dle toward the engine (Figure 25).

2. Remove the cover.

3. Carefully lift the air cleaner cartridge, and the pre-cleaner, if

equipped, from the blower housing.

4. To prevent debris from falling into the carburetor, carefully clean

the air cleaner base.

5. install a new pre-cleaner, if equipped, and air cleaner car-

tridge firmly into the air cleaner base.

6. Align the tabs on the cover with the slots on the blower hous-

ing and install the cover.

7. To secure the cover, rotate the handle forward and push down.

Ige

\

Pre-Cleaner

Rotate Handle

Remove Cover Slots

HOW TO CHECK THE SPARK PLUG

1. Check the gap of the spark plug with a feeler gauge

(Figure 26). The correct gap is 0.030".

2. For easy starting and good performance, replace the spark

plug every season or 100 hours of use.

Feeler Gauge

0.030"

Cover

Tabs

Figure 25

13533 27

Spark Plug

Figure 26

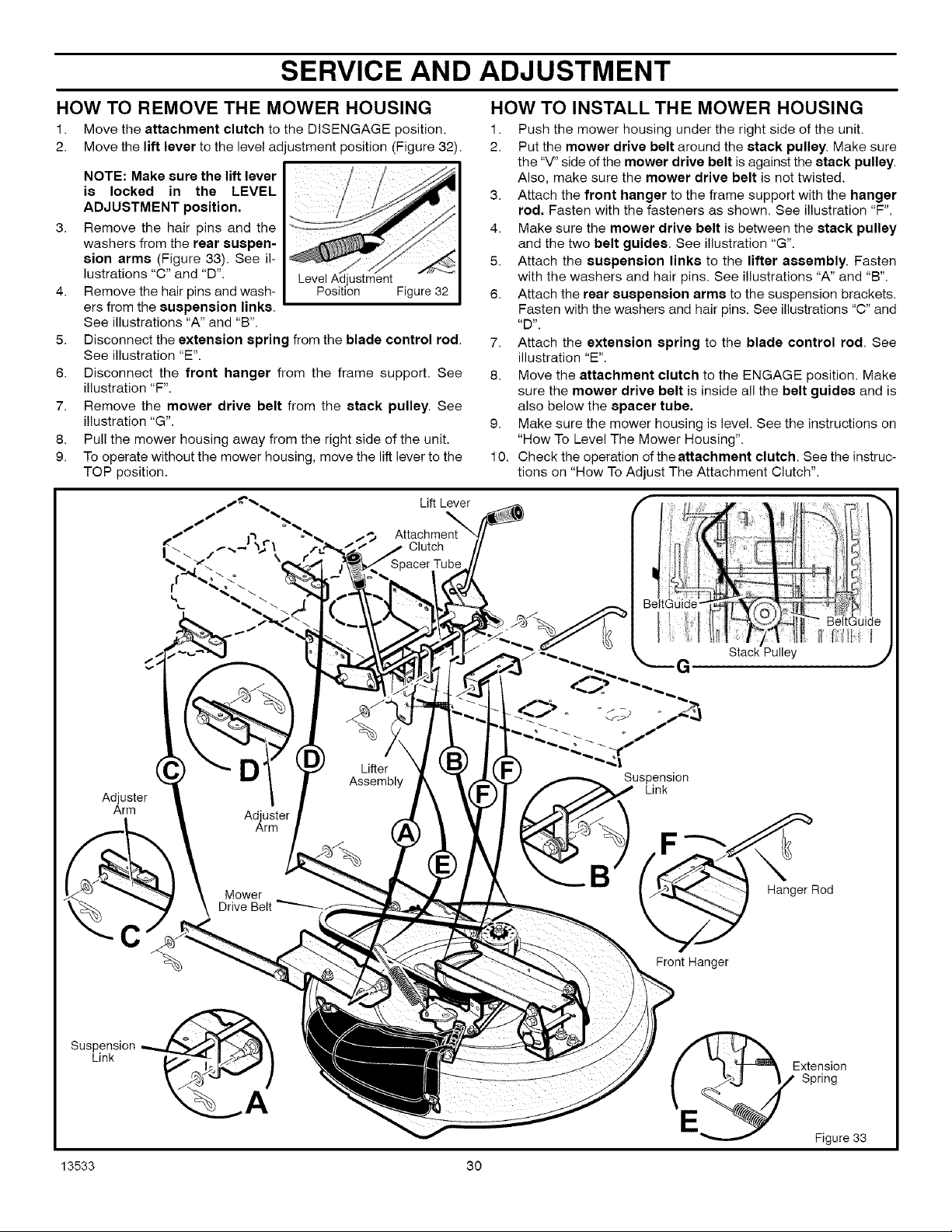

SERVICE AND ADJUSTMENT

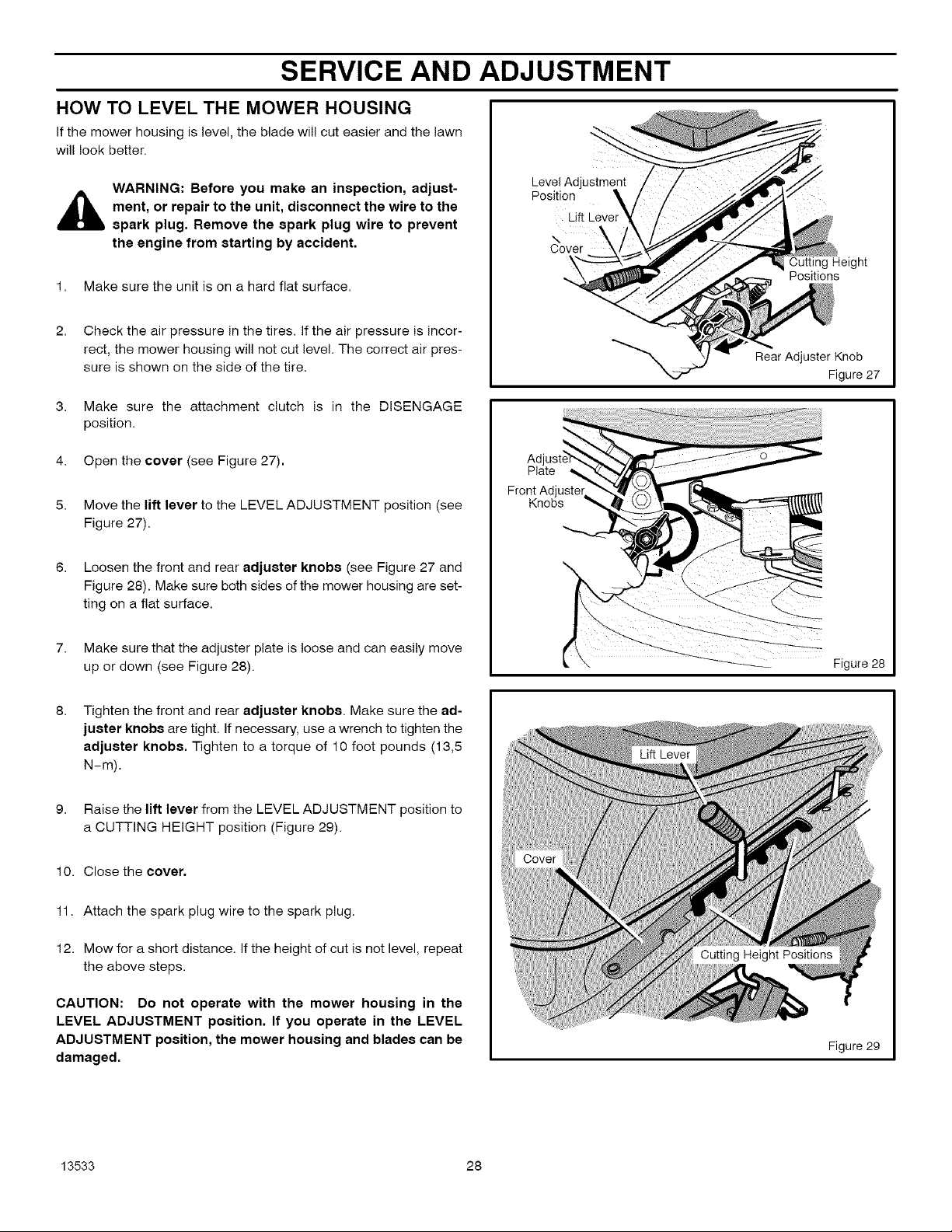

HOW TO LEVEL THE MOWER HOUSING

If the mower housing is level, the blade will cut easier and the lawn

will look better.

WARNING: Before you make an inspection, adjust-

,_ ment, or repair to the unit, disconnect the wire to the

spark plug. Remove the spark plug wire to prevent

the engine from starting by accident.

1. Make sure the unit is on a hard flat surface.

2.

Check the air pressure in the tires. If the air pressure is incor-

rect, the mower housing will not cut level. The correct air pres-

sure is shown on the side of the tire.

8.

Make sure the attachment clutch is in the DISENGAGE

position.

4.

Open the cover (see Figure 27).

5.

Move the lift lever to the LEVEL ADJUSTMENT position (see

Figure 27).

8.

Loosen the front and rear adjuster knobs (see Figure 27 and

Figure 28). Make sure both sides of the mower housing are set-

ting on a flat surface.

Level Adjustmc

Position

\

Cover

Plate

Front Adjuster

Knobs

Lift Lever

Cutting Height

Positions

Rear Adjuster Knob

Figure 27

7.

Make sure that the adjuster plate is loose and can easily move

up or down (see Figure 28).

8.

Tighten the front and rear adjuster knobs. Make sure the ad-

juster knobs are tight. If necessary, use a wrench to tighten the

adjuster knobs. Tighten to a torque of 10 foot pounds (13,5

N-m).

9. Raise the lift lever from the LEVEL ADJUSTMENT position to

a CUTTING HEIGHT position (Figure 29).

10. Close the cover.

11. Attach the spark plug wire to the spark plug.

12. Mow for a short distance. If the height of cut is not level, repeat

the above steps.

CAUTION: Do not operate with the mower housing in the

LEVEL ADJUSTMENT position. If you operate in the LEVEL

ADJUSTMENT position, the mower housing and blades can be

damaged.

Figure 28

Figure 29

13533 28

SERVICE AND ADJUSTMENT

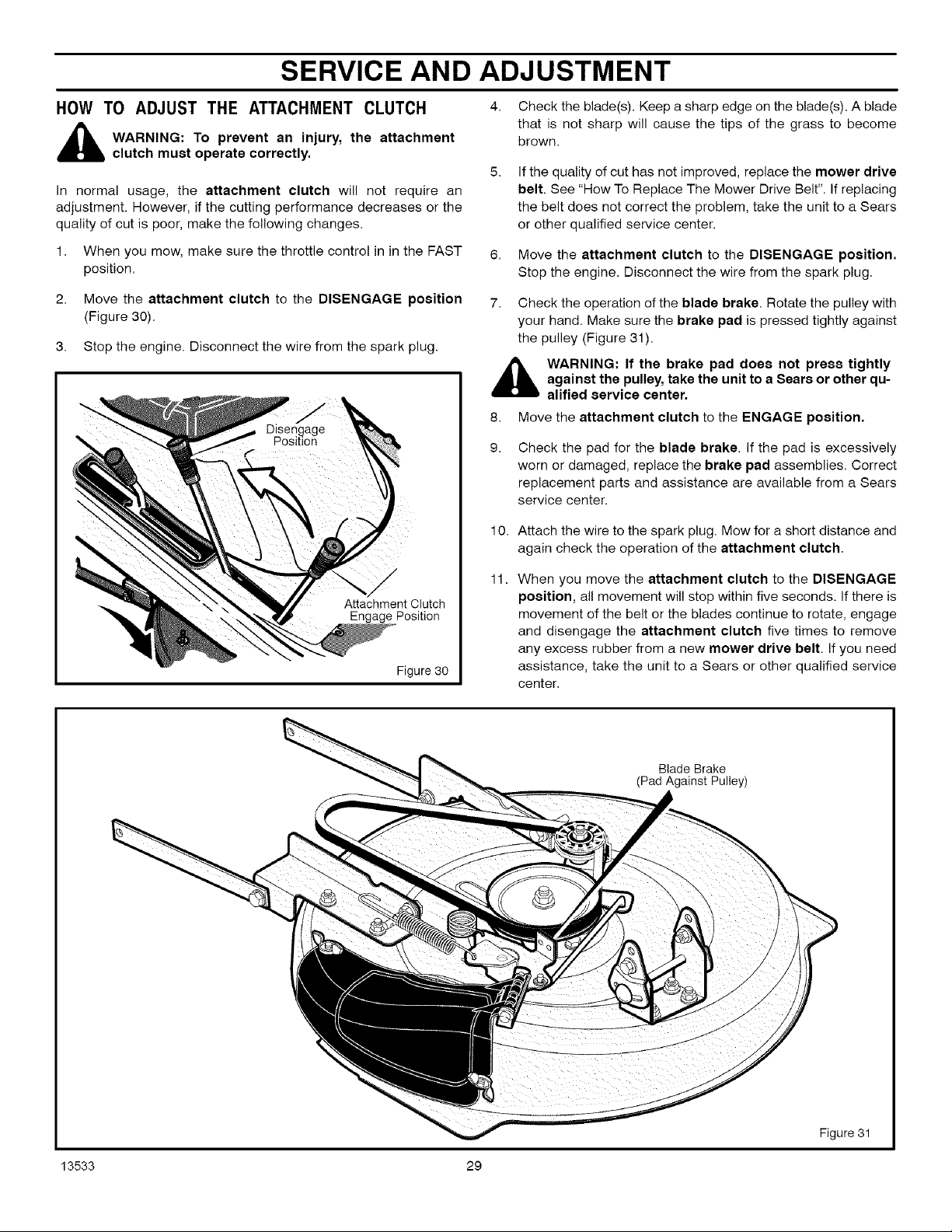

HOW TO ADJUST THE ATTACHMENT CLUTCH

_ ARNING: To prevent an injury, the attachment

In normal usage, the attachment clutch will not require an

adjustment. However, if the cutting performance decreases or the

quality of cut is poor, make the fol!owing changes.

1. When you mow, make sure the throttle control in in the FAST

2. Move the attachment clutch to the DISENGAGE position

3. Stop the engine. Disconnect the wire from the spark plug.

clutch must operate correctly.

position.

(Figure 30).

4.

Check the blade(s). Keep a sharp edge on the blade(s). A blade

that is not sharp will cause the tips of the grass to become

brown.

5.

If the quality of cut has not improved, replace the mower drive

belt. See "How To Replace The Mower Drive Belt". If replacing

the belt does not correct the problem, take the unit to a Sears

or other qualified service center.

6.

Move the attachment clutch to the DISENGAGE position.

Stop the engine. Disconnect the wire from the spark plug.

7. Check the operation of the blade brake. Rotate the pulley with

your hand. Make sure the brake pad is pressed tightly against