Page 1

,,m,.i,

owner's

manual

Model No.

536.270211

CAUTION:

Read And Follow

All Safety Rules

And Instructions

Before Operating

This Equipment.

£RRFTSMRN

13.5 HP. ELECTRIC START

30" MOWER / MULCHER

5 SPEED

REAR ENGINE RIDER

• Assembly

• Operation

• Customer Responsibilities

° ServiceAnd Adjustment

F-99636 Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A. PrintedinUSA

Page 2

TABLE OF CONTENTS

WARRANTY ......................................... 2

CUSTOMER RESPONSIBILITIES ...................... 3

RESPONSIBILITY OF THE OWNER ....... ::: ........ :;:: 5

ACCESSORIES AND ATTACHMENTS ;..: ;_:: !. i:i...:.. :. 6

: ASSEMBLY ........ :;'i: ........ ,i:i'ii ;i 7

MAINTENANCE FREE BATTERY ,_., ..i;i; ._ _;,__,:;_, ._ • •, i 8 HOW TO REMOVE THE SIDE PANEL ......................

HOW TO ASSEMBLE THE STEERING WHEEL i, _. _., _....,.. 9 i BATTERY SERVICE

CUSTOMER RESPONSIBILITIES ......................

MAINTENANCE CHART ; ............

CHECK THE TIRES..., •;'i..., ......... , ;. ; • .......... ,:,, ..

3

HOW TO REMOVE AND INSTALL THE BLADE ........... ...

4

HOW TO SHARPEN THE BLADE ..........................

HOW TO ADJUST THE ATTACHMENT CLUTCH .............

HOW TO CHECK AND ADJUST THE DRIVE BRAKE .........

HOW TO CHECK AND ADJUST THE CLUTCH ..............

HOWTOASSEMBLETHEHUBCAPS : "oWToCHARGETH; 'B' , 'F;;'IIIIIIIIIIIIIIIIIII'.IIIII

CHECK THE TIRES;_.;.,.:,.,:_..:.,I:..I.I:.;:.,..I:.,..... 19 : : :WHERE TO LUBRICATE :.:..:...:.,.; ............... ; .....

CHECKTHEDR!VEBRAKE;,:._;,I::;_,..,I_;.,.. ,...... 9: ::: : HOW TO CHECK THE OIL i ..... .... _._ ....... .;:..,,i:,,

CHECK THE;:BELTS:I:;:, ;:i:.:.:;..._:_ _ .._... !;..i;,, .. :.,..., : 9 :: HOW TO CHANGE THE OIL ...................... .........

: HOW TO INSTALL THE SEAT:;::. :::;.::_ ::.: ::. _.. _.. _... :. _t0 : HOW T0 CLEAN THE COOLING SYSTEM... ............

CHECK THE LEVEL OF THE MOWER HOUSING .... ; ....... 10 HOW TO CHECK THE MUFFLER ..... . :.., : ...... _........

OPERATION;_I;_;;._!::_.:_:.IiI!!:;_I_....:_..;....:...;.. 11, _ : HOW TO CLEAN THE AIR FILTERS . I:........... i,i ........

:::LocATION oFcoNTROLs __i :.i..; ._,,, !, ,:,,..:ii_ i !.._ ...... HOW TOCHECK THE SPARK PLUG .......................

HOW TOUSE THE ;THROTTLE CONTROL:. i. _!, .. !2 :::: SERVICE AND ADJUSTMENT .........................

HOW ToUsE THE ATTACHMENT CLUTCH ..............

:: HOWTO USE THE SHiFTLEVER i::::_ .i::: '.:::iii!: i_ : 12 ........ HOW TO REMOVE THE MOWER HOUSING ................

HOW TO SET THE PARKING BRAKE :i"; _' ................ 13 HOW TO INSTALL THE MOWER HOUSING .................

HOW TO CHANGE THECUTTING HEIGHT ................. 13

HOW TO STOP THE UNIT. :i .............................. 13

HOW TO TRANSPORT THE UNIT .......................... 13

HOW TO OPERATE WITH THE MOWER HOUSING .......... 14

HOW TO OPERATE THE UNIT ON HILLS ................... 14

BEFORE STARTING THE ENGINE ......................... 15

HOW TO START THE ENGINE ............................. 15

HOW TO START WITH A WEAK BATTERY ................. 15

HOW TO CHANGE THE MULCHER PLATE ................. 16

OPERATING TIPS ........................................ 17

MOWING AND BAGGING TIPS ............................ 17

MULCHING TIPS

...... . ....... ;:.,,;; ;:,: ._, ::::17 :REPAIR:PARTS

HOW TO LEVEL THE MOWER HOUSING ...................

HOW TO REPLACE THE MOTION DRIVE BELT .............

HOW TO REPLACE THE MOWER DRIVE BELT .............

HOW TO REPLACE THE FUSE .:. .... ::il. :----. *...........

HOW TO SET THE CUTTING HEIGHT ......................

HOW TO CLEAN THE MOWER HOUSING ......... , ........

FRONT WHEEL ALIGNMENT ..............................

STORAGE (OVER 30 DAYS) ...............................

TROUBLE SHOOTING CHART ........................

SLOPE GUIDE .......................................

INDEX ..............................................

18

t8

18

19

19

20

21

21

22

22

22

23

24

24

24

24

25

25

26

26

27

27

28

29

3O

31

31

31

31

32

33

34

35

36

....... LIMITED TWO YEAR wARRANTY _

ON ELECTRIC START RIDING EQUIPMENT H

.... ii..... ....: .... .... : ........ .... H !

Fortwo(2)yearsfremthedateotpurchase,ifthi_ri_ingequipmentis_a=_tained,_ub_ioatedandtunedupaccordingtothe I_:iil]

instructions in the owner's manuaI, Sears will repair or replace, free of charge any parts found to be defective in material or H

workmanshiP-i i .... : : : : : : : : :: : :: ti:it

This warranty does not cover i : : : li:!t

• Expendable items which become worn during normal use, such as blades, spark plugs, air cleaners and belts. [:]

: Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps or giass H

Repairs necessary because of operator abuse, negligence, improper :storage or acc dent orthe failure:to maintain the I:::I

• equipment according to the instructions contained inthe owner's manual, : : ti]

Riding equipment used for commercial or rental purposes. ' :: : .... t:!:!I

LIMITED 90 DAY WARRANTY ON BATTERY : liil]

For 90 days from the date of purchase, if any battery :included with this riding equipment proves defective in material or _1

workmanship and our testing determines the battery will not hold a charge, Sears will replace the battery at no charge Ii t

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE RIDING EQUIPMENT TO THE NEAREST SEARS SERVICE/_l!:il

CENTER/DEPARTMENT IN THE UNITED STATES. :: i ::: :.... : H

This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state l_:ili!_t

Sears, Roebuck and Coo, DI871WA, Hoffman Estates, illinois 60179 i

..... F-99636 .............................................. ...... 2 ..........................................................................

I!

I]

H

Page 3

Congratulations on your purchase of a Sears Rider it has been

designed, engineered and manufactured to give you the best

possible dependability and performance

If you experience any problems you cannot easily remedy, please

see your nearest Sears Service Department. We have competent,

well trained technicians and the proper tools to service or repair this

unit.

Please read and keep this manual. The instructions will enable you

to assemble and maintain your unit propedy Always observe the

"Safety Rules".

NOTE: This unit isequipped with an internal combustion engine and

must not be used on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting applicable local

or state laws (if any). If a spark arrester is used, it must be

maintained in effective working order by the operator.

fnthe State of California, the above is required by law (Section 4442

of the California Public Resources Code) Other states may have

similar laws. Federal laws apply on federal lands. See anAuthorized

Service Center for aspark arrester for the muffler.

CUSTOMER RESPONSIBILITIES

• Carefully read and follow the rules for safe operation Inspect

the unit.

• Follow all the assembly instructions. Carefully adjust the unit.

- Know how tooperate all standard and accessary equipment on

the unit, Make sure the operator can correctly operate the unit.

• operate the unit only with guards, shields and other safety .... .........

items inplace and working correctly.

• Complete all maintenance onthe unit. Service the unit only with

authorized or approved replacement parts MAINTENANCE AGREEMENT

• See the Maintenance Chart.

A Sears Maintenance Agreement is available on this unit See the

nearest Sears Store for information.

PRODUCT SPECIFICATIONS

Engine ...................... 13.5 HP

Charging System ......... 3 amperes at 3600 rpm

Fuel Tank Size ........... 1 gallon

Type of Fuel ............. Unleaded Regular

Oil Capacity ......... 32 ounces (1 quart)

Oil Type .................

Spark Plug (Gap 0.030") o,

Tire Air Pressure .........

Tire Air Pressure ......... Rear 14 psi (See tire sidewall)

All Gear Transaxle ........ 5 forward speeds and 1 reverse

Ground Speed Range ..... Forward 4 3 mph

.......... Reverse 2 1 mph

Tilt Seat. _............... T_ltsforward to access the battery.

Mower Housing .......... Full-floatingsuspension,oneblade

Cutting Height ...... 8 positions from 14/2to 4 inches.

Blade Nut Torque ......... 30 foot-pounds (ft-lbs)

F-99636 3

Above 32 degrees SAE 30

Below 32 degrees SAE 5W30

Champion RJ4C

Front 22 psi (See tire sidewall)

Rear Engine Rider

Record in the space below theserial number and the date

of purchase of this unit.

The model number and serial number are found on a decal

attached to the rear of the frame.

Model Number: 536,270211

Serial Number:

Date of Purchase:

Keep these numbers for future reference

Page 4

OWNER'S INFORMATION

SAFETY RULES

Safe Operation Practices for Ride-on Mowers

WARNING: This cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result inserious injury :or death.

i.

•., =L"-eneral oper-'*ion ......

1. Read, understand andfollow allinstructionsintheinstructionBook,onthe machine, the engineandwith any attachmentsbeforestarting

2. Only a!ow responsibleadults, who are familiarwith the instructions,to operate the machine

3. Clear the area:of objectssuchas r0cksl toysi:wire_etc which could be picked up and thrownby the blade

4. Be sure the area is clear of other people before mowing Stopthe machine ifanyone entersthe area.

5. Nevercarry passengers. : :: ....

6. Turn offpower tothe blades or any attachments before backing up. Do not mow in reverse unlessabsolutely necessary Always look

down and behind before and while backing.

7. Be aware ofthe mowerdischarge directionand donotpointitat anyone. Do notoperatethe mowerwithouteithertheentiregrassbagger

or the mower guard inplace_ : :

8. Slow down before turning :

9. Never leave a machine unattended withthe engine running.Always turnoff the blade(s), set the parkingbrake, stop the engine and

remove the key before dismounting

10 Turn offpowerto attachment(s) when transportingor not in use. Turn off the blade(s) when not mowing

11. Stop the engine before removing the grass bagger or uncloggingthe chute.

12 Mow only indaylightor goodartificial light

t3. Do not operatethe machinewhile underthe influenceof alcoholor drugs or when very tired

14. Watch for trafficwhen operating near or crossingroadways.

' 15. Use extra caution when loadingor unloadingthe machine into a trailer ortruck.

16. Always wear goggles,safety glasses, or an eye shieldwhen you operate the unit to protectyoureyes from foreignobjectsthat can be

thrownfrom the unit. Always wear eye protectionwhen you make an adjustment or repair to the machine

17. Use care when pullingloadsor using heavy equipment

a. Use only approved drawbar hitchpoints

b. Limitloads to those you can safely control

c. Do not turn sharply. Use care when backing.

d. Use counterweightsor wheel weights when suggested in the Instruction Book

18. Do not operatethis machineif you are takingdrugs or other medication which can cause drowsinessor affect yourability to operate

this machine.

19 Do notuse thismachine if you are mentally or physically unableto operate this machine safely

!1. Slope operation

Slopes and rough terrain are major factors related to loss-of-control and tip-over accidents, which can result in severe injury

or death. ALL slopes require extra caution. If you cannot back up the slope or if you feel uneasy on the slope, do not mow it. See

the "Slope Guide" in the back of this book to check for safe operation.

DO

1. Mow up and down slopes, not across.

2. Remove obstacles such as rocks, limbs, etc...

3. Watch for hoIes, rutsor bumps. Uneven terrain could overturn the machine. Tallgrass can hide obstacles.

4. Follow the manufacturer's recommendations for wheel weights or counterweights to improve stability.

5. Use extra care with grass baggers or other attachments they can change the stability of the machine.

6 Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction.

7. Avoid starting or stopping on a slope. If tires lose traction, turn off the blades and proceed slowly straight down the slope

DO NOT

1. Do not turn on slopes unless absolutely necessary, then only turn slowly and gradually downhill, if possible

2. Do not mow drop-offs, ditches or embankments A wheel over the edge or an edge caving in could cause a sudden overturn and an

injury or death

3 Do not mow on wet grass Reduced traction could cause sliding

4. Do not try to stabilize the machine by putting your foot on the ground

5. Do not use a grass bagger or other rear mounted accessories on steep slopes (greater than 10 degrees)

I!i. Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted tothe machine and

the mowing activity. NEVER assume that children will remain where you last saw them.

1. Keep children out of the mowing area and in the watchful care of another responsible adult

2 Be alert and turn the engine off if chi|dren enter the area

3. Before and when backing, took behind and down for small children.

F-99636

Page 5

OWNER'S INFORMATION

4 Never carry children or any passengers, even with the blades off. They may fall off and be seriously injured or interfere with the safe

operation of the machine

5. Never alfow children tooperate the machine. Instruct children in the potential dangers of the machine

6. Use extra care when approaching blind comers, shrubs, trees or other objects that may obscure vision.

IV.

Service

1.

Use extra care when handlinggasotineand otherfuels Fuets are flammable and the vapors are explosive

a Use only an approved container.

b Never remove the gas cap or add fuel with the engine running Atlow the engine to cool for several minutes before refueling Do

not smoke. .... _ : , : :

c. Never refuelthe machine indoors,

i 2,

! 3.

: 4

d Never store the machine withfuel in the tank or fuel container inside where there is an open flame, such as a water heater.

Never start or run the engine inside a closed area

Keep all nuts and bolts, especially the blade attachment nuts tight Frequently Check the blade(s) for wear or damage such as cracks

and nicks A blade that isbent or damaged must be immediately replaced with an original equipment blade from an authorized service

dealer. For safety, replace the blade every two years. Keep the equipment in good condition

Never tamper with the safety devices, Check their proper operation regularly.

5

To reduce fire hazards, keep the machine free of grass, leaves or other debris build-up Clean up oil or fuel spills Allow the machine

to cool before stodng.

6

Stop and inspect the equipment ff you strike an object Repair, if necessary, before restarting.

7

Never make adjustments or repairs with the engine running The carburetor can be adjusted with the engine running. Do not change

the engine governor settings or over-speed the engine.

8.

Grass bagger components are subject to wear, damage and deterioration, which could expose moving parts or allow objects to be

thrown Forstorage, always make sure the grass bag is empty. Frequently check components and replace with manufacturer's recom-

mended partswhen necessary

9.

Mower b ade(s) are sharp and can cut. Wrap the b ade(s) or wear g oves and useextra caution when servicing them or the blade housing

area.

10.

Check the brake operation frequently. Adjust and service as required ........

11.

Wa_ for all movement to stop before servicing any part of the unit.

RESPONSIBILITY OF THE OWNER

Environmental Awareness

• Do not fill the engine's fuel tankcompletely full.

• Drain fuel for off-season storage .....

• Use only unleaded gasoline. :

• Service the air cleaner regularly.

• Change oil regularly Use 30W oil in summer.

• Tune-up the engine regularly

• Keep equipment in efficient operating condition.

Dispose of used engine oil properly

precautions. This symbol indicates: "Attention!

Look for this symbol to indicate important safety

Become Alert! Your Safety Is At Risk,"

H

F-99636 5

Page 6

ACCESSORIES AND ATTACHMENTS

i

ACCESSORIES AND ATTACHMENTS

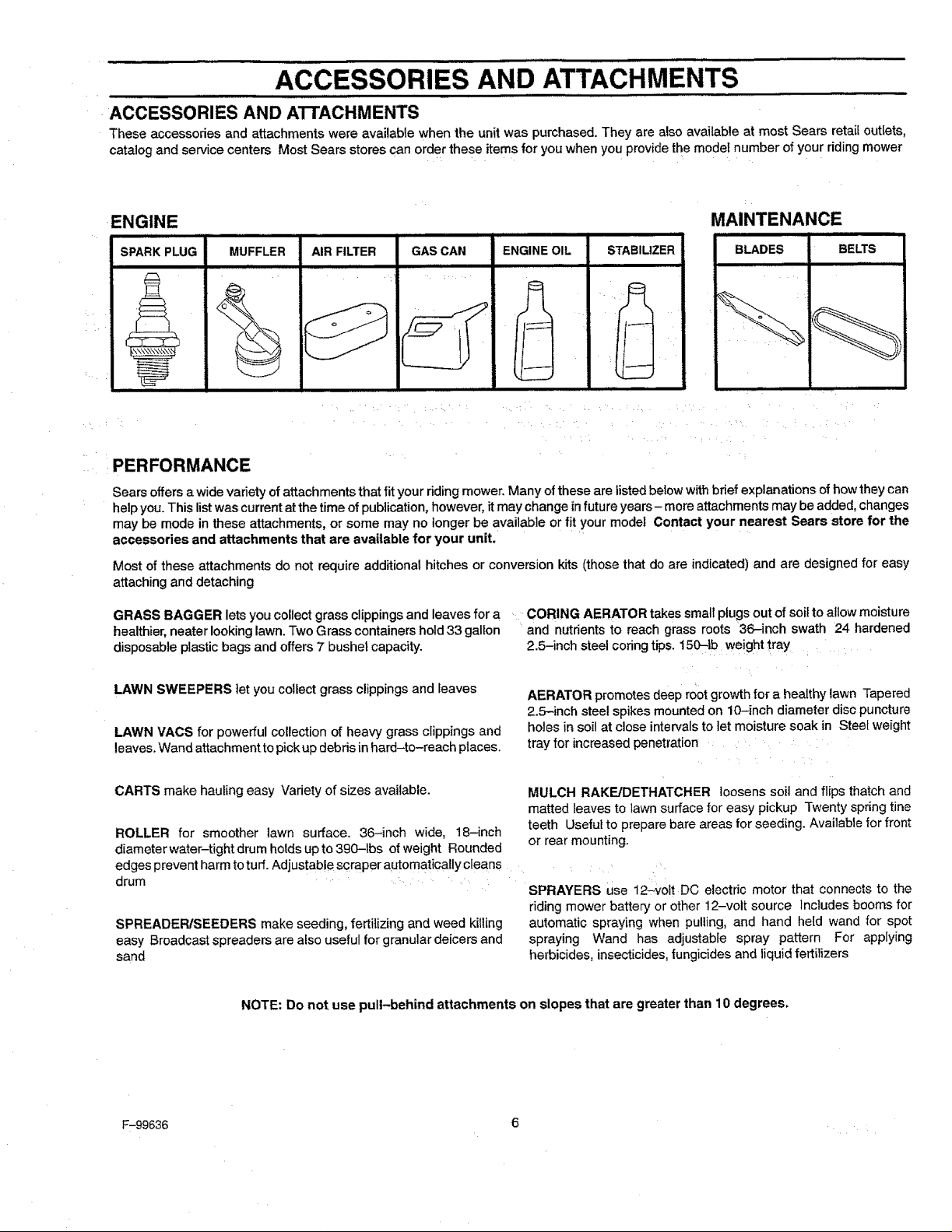

These accessories and attachments were available when the unit was purchased.They are also available at most Sears retailoutlets,

catalog and service centers Most Sears stores can order these itemsfor you when you provide the mode_ number of your riding mower

ENGINE

SPARKPLUG

MUFFLER AIR FILTER ENGINEOIL

PERFORMANCE

Sears offersa wide variety of attachmentsthat fityour ridingmower. Many of these are listed below withbrief explanations of howthey can

help you. This listwas current at the time of publication, however, itmay change in future years- more attachments may be added, changes

may be mode in these attachments, or some may no longer be available or fit your modei Contact your nearest Sears store for the

accessories and attachments that are available for your unit.

Most of these attachments do not require additional hitches or conversion kits (those that do are indicated) and are designed for easy

attaching and detaching

STABILIZER

GRASS BAGGER lets you collect grass clippingsand leaves for a CORING AERATOR takes small plugs out of soil to allow moisture

healthier,neater lookinglawn.Two Grass containers hold33 galfon and nutrientsto reach grass roots 36-inch swath 24 hardened

disposable plasticbags and offers7 bushel capacity. 2.5-inch steel coringtips.150-|b weght tray ......

LAWN SWEEPERS ]et you collect grass clippings and leaves

LAWN VACS for powerful collection of heavy grass clippings and

leaves. Wand attachment to pickup debris in hard-to-reach places.

CARTS make hauling easy Variety of sizes available.

ROLLER for smoother lawn surface. 36-inch wide, 18-inch

diameter water-tight drum holds up to 390-|bs of weight Rounded

edges prevent harm toturf. Adjustab e scraperautomatically cleans

drum

SPREADER/SEEDERS make seeding, fertilizing and weed killing

easy Broadcast spreaders are also useful for granular deicers and

sand

NOTE: Do not use pull-behind attachments on slopes that are greater than 10 degrees,

AERATOR promotesdeep root growth for a healthylawn Tapered

2.5-inch steel spikes mounted on 10-_nch diameter disc puncture

holes in soil at close intervals to let moisture soak in Steel weight

tray for increased penetration

MULCH RAKFJDETHATCHER loosens soil and flips thatchand

matted leaves to lawn surface for easy pickup Twenty spring tine

teeth Useful to prepare bare areas for seeding. Available for front

or rear mounting.

SPRAYERS use 12.Vott DC electric motor that connects to the

riding mower battery or other 12-volt source Includes booms for

automatic sprayLng when pulling, and hand held wand for spot

spraying Wand has adjustable spray pattern For applying

herbicides,insecticides,fungicidesand tiquid fertilizers

F-99636 6

Page 7

ASSEMBLY

PREPARATION

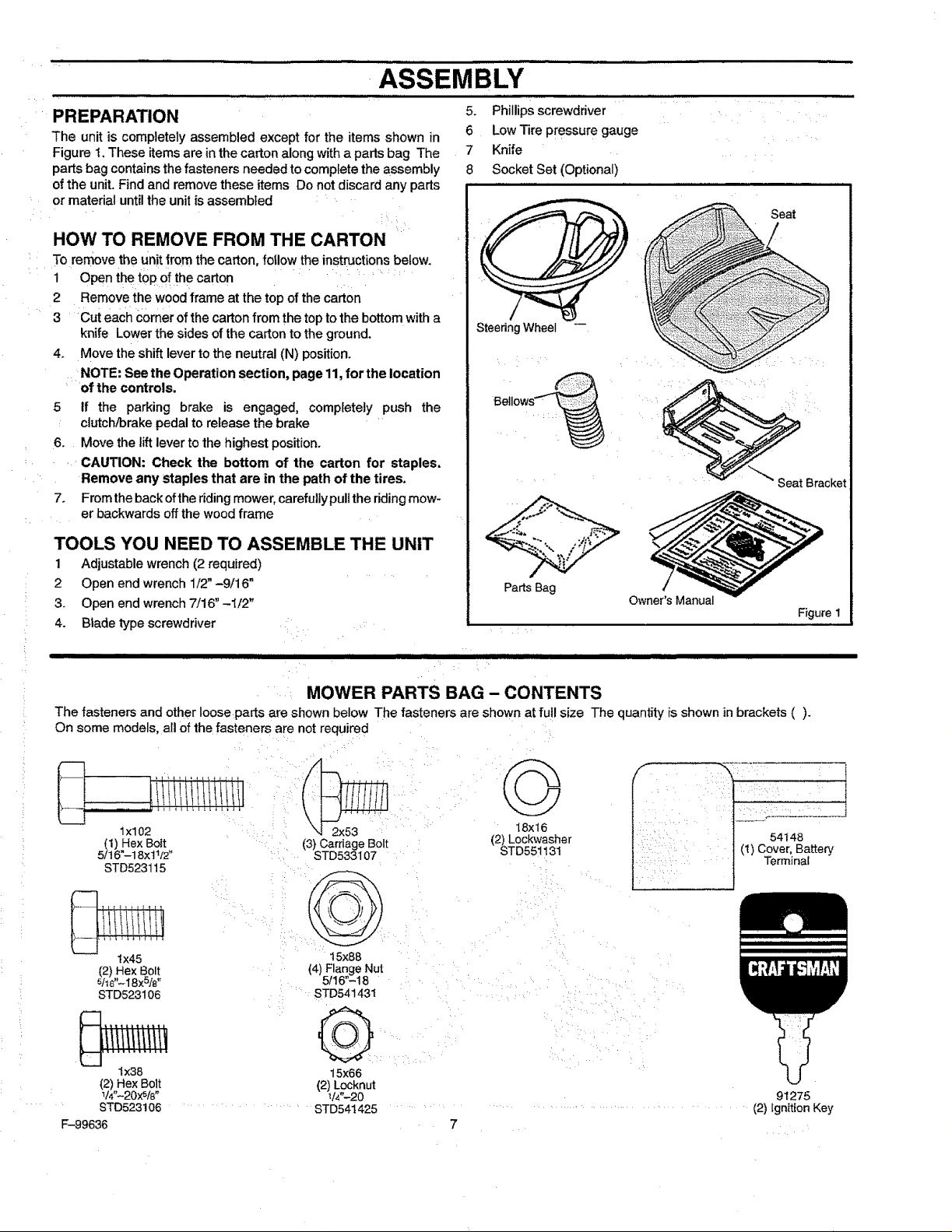

The unit is completely assembled except for the items shown in

Figure 1,These items are in the carton along with a parts bag The

parts bag contains the fasteners needed to complete the assembly

of the unit. Find and remove these items Do not discard any parts

or material until the unit is assembled

HOW TO REMOVE FROM THE CARTON

To remove the un!t from the carton, follow the instructions below.

1 Open the top 0{ the carton : ' :

2 Remove the wood frame at the top of the carton

3 Cut each corner of the carton from the top to the bottom with a

knife Lower the sides of the carton to the ground.

4. Move the shift lever to the neutral (N) position.

NOTE: See the Operation section, page 11,for the location

of the controls.

5

If the parking brake is engaged, completely push the

clutch/brake pedal to release the brake

6,

Move the lift lever to the highest position.

CAUTION: Check the bottom of the carton for staples,

Remove any staples that are in the path of the tires,

7.

From the back of theriding mower, carefully pull the riding mow-

er backwards off the wood frame

TOOLS YOU NEED TO ASSEMBLE THE UNIT

1 Adjustable wrench (2 required)

2 Open end wrench 1/2" -9/16"

3. Open end wrench 7/16"-'{/2"

4. Blade type screwdriver

5. Phillips screwdriver

6 Low Tire pressure gauge

7 Knife

8 Socket Set (Optional)

SteeringWheel --

Parts Bag

SeatBracket

Owner's Manual

Figure 1

MOWER PARTS BAG - CONTENTS

The fasteners and other loose parts are shown below The fasteners are shown at full size The quantity is shown in brackets ().

On some models, all of the fasteners are not required

%

2x_53 " 18x1_6

lx102

(I) Hex Bolt

5/16"-18x1_/2 "

STD523115

lx45

(2) Hex Bolt

_/le"-18x5i¢'

STD523106

(3) Carriage Bolt (2) Lockwasher

STD533107 STD551131

15x88

(4)FlangeNut

51t6_-18

STD541431

54"148

(1)Cover,Battery

Terminal

Q

F-99636

I x38

(2)HexBolt

114"20x518°

STD523106

15x66

(2)Locknut

V4%-20

STD541425

91275

(2) Ignition Key

Page 8

ASSEMBLY

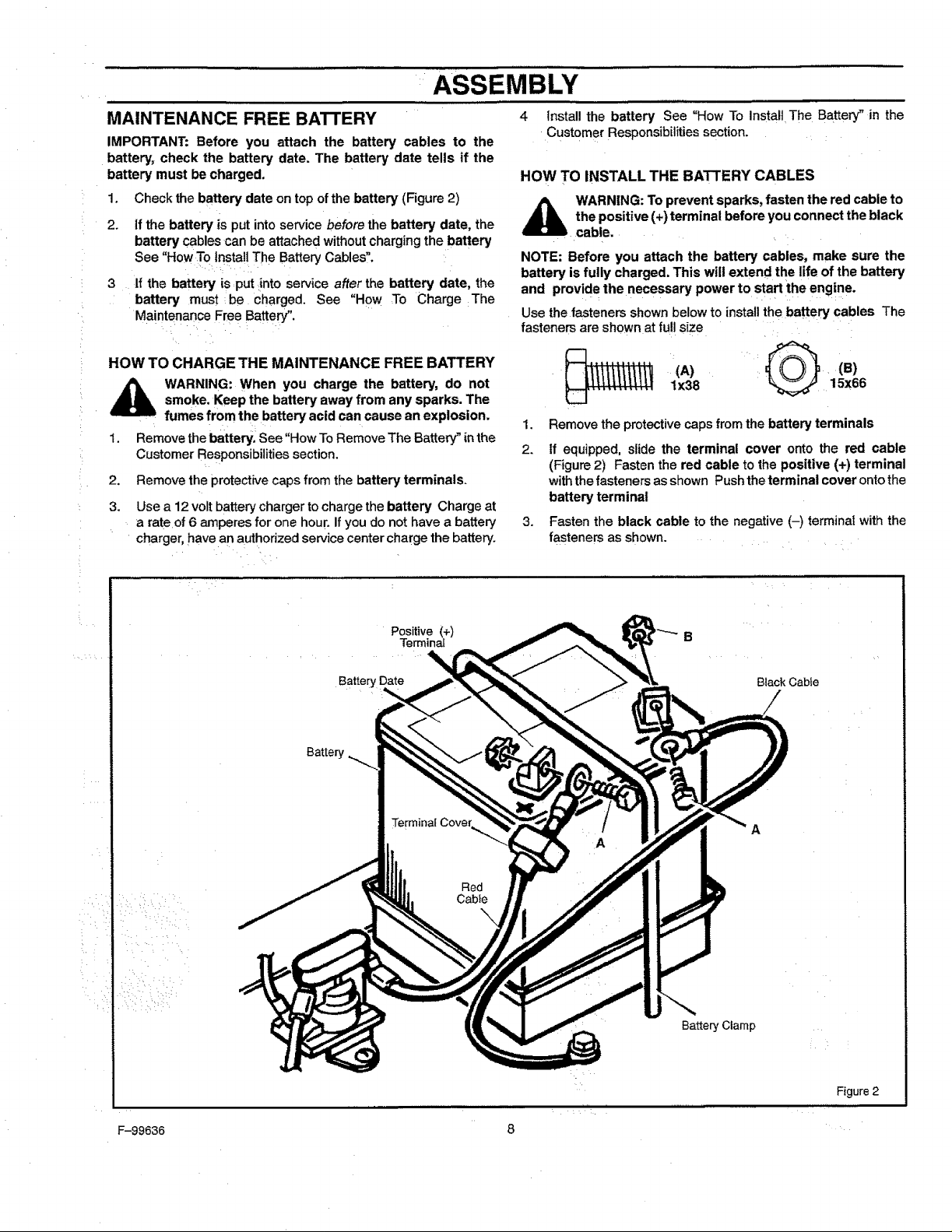

MAINTENANCE FREE BA'I-rERY

IMPORTANT: Before you attach the battery cables to the

battery, check the battery date. The battery date tells if the

battery must be charged.

1. Check the battery date on top of the battery (Figure 2)

2. If the battery is put into service before the battery date, the

battery cables can be attached without charging the battery

See "How To Install The Battery Cables".

3 If the battery is put into service after the battery date, the

battery must be charged. See "How To Charge The

Maintenance Free Battery",

HOW TO CHARGE THE MAINTENANCE FREE BATTERY

,_ WARNING: When you charge the battery, do not

1. Remove the battery. See "How To Remove The Battery" in the

2. Remove the protective caps from the battery terminals.

3. Use a 12 volt battery charger to charge the battery Charge at

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

Customer Responsibilities section.

a rate of 6 amperes for one hour. If you do not have a battery

charger, have an authonzed service center charge the battery.

4 Install the battery See "How To Install The Battery* in the

Customer Responsibilities section....

HOW TO INSTALL THE BATTERY CABLES

_ WARNING: To prevent sparks, fasten the red cable to

NOTE: Before you attach the battery cables, make sure the

battery is fully charged. This will extend the life of the battery

and provide the necessary power to start the engine.

Use the fasteners shown below to install the battery cables The

fasteners are shown atful! size

the positive (+) terminal before you connect the black

cable.

IA!!!!!!!!!! , x°o

1,

Remove the protective caps from the battery terminals

2.

If equipped, slide the terminal cover onto the red cable

(Figure 2) Fasten the red cable to the positive (+) terminal

with the fasteners as shown Push the terminal cover onto the

battery terminal

3.

Fasten the black cable to the negative (-) terminal with the

fasteners as shown.

Z i

Battery

Battery [

Positive (+)

Terminal

Terminal

Red

CaNe

B

Black Cable

A

A

Battery Clamp

F-99636 8

Figure 2

Page 9

ASSEMBLY

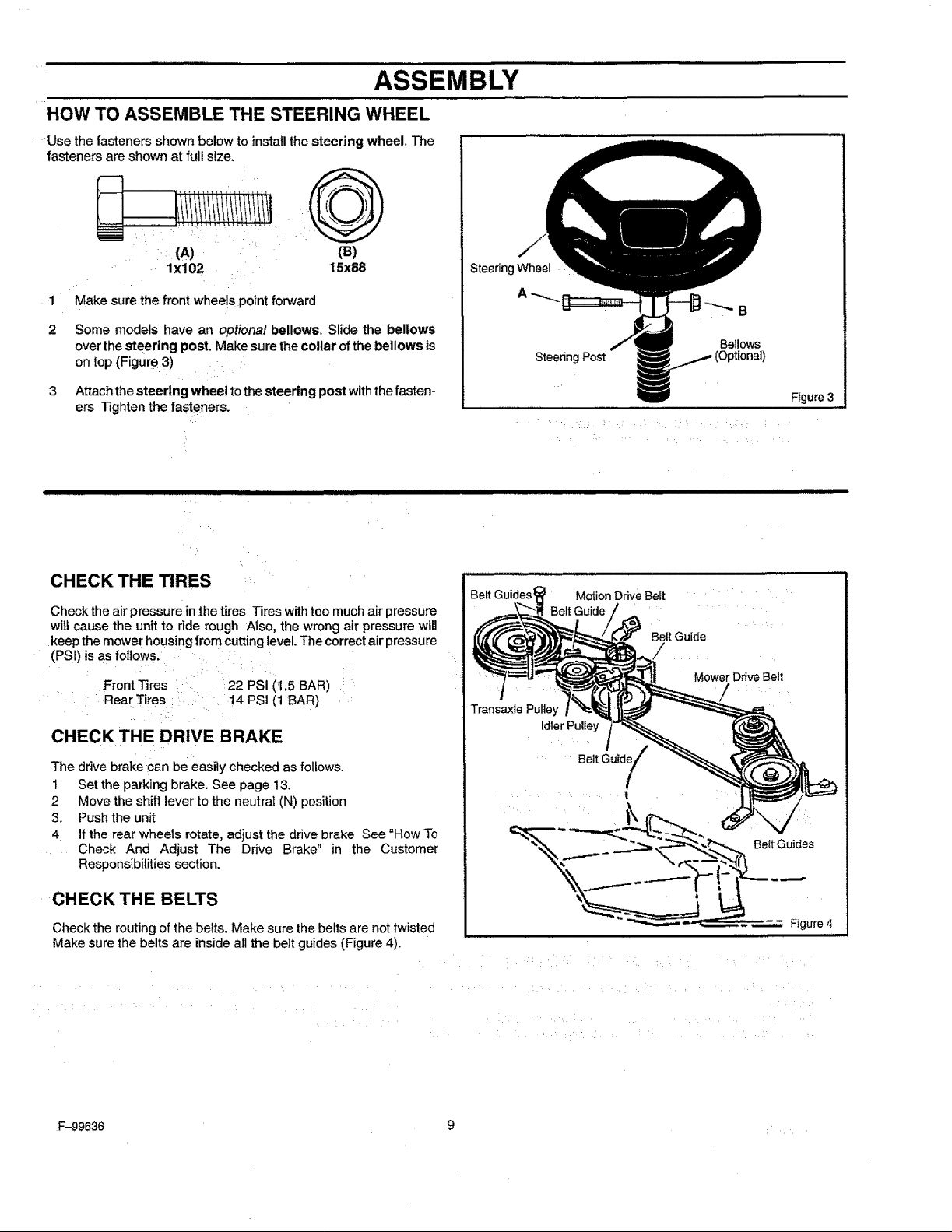

HOW TO ASSEMBLE THE STEERING WHEEL

Use the fasteners shown below to instatlthe steering wheel, The

fasteners are shown at full size.

illll ii,i i

(A)

lx102

(B)

15x88

1 Make sure the front wheels point forward

2 Some models have an optional bellows, Slide the bellows

overthe steering post. Make sure the collar of the bellows is

on top (Figure 3)

3 Attach the steering wheel to thesteering post withthefasten-

ers Tighten the fasteners.

CHECK THE TIRES

Check the air pressure inthe tires Tires withtoo much air pressure

will cause the unit to ride rough Also, the wrong air pressure will

keep the mower housing from cutting level. The correct air pressure

(PSD is as follows, i ....

Front Tires : :22 PS1(1.5 BAR)

Rear Tires 14 PSI (1 BAR)

CHECK THE DRIVE BRAKE

SteeringWheel

Steering Post

Belt Guides_

Transaxte Pulley

Idler Pulley

B

Bellows

(Optional)

Figure 3

MotionDriveBelt

BeltGuide

MowerDriveBelt

The drive brake Can be easily checked as follows.

1 Set the parking brake. See page 13.

2 Move the shift lever to the neutral (N) position

3. Push the unit

4 If the rear wheels rotate, adjust the drive brake See "How To

Check And Adjust The Drive Brake" in the Customer

Responsibilities section.

CHECK THE BELTS

Check the routing of the belts. Make sure the belts are not twisted

Make sure the belts are inside all the belt guides (Figure 4).

F-99636 9

: i :¸ i • •

Page 10

ASSEMBLY

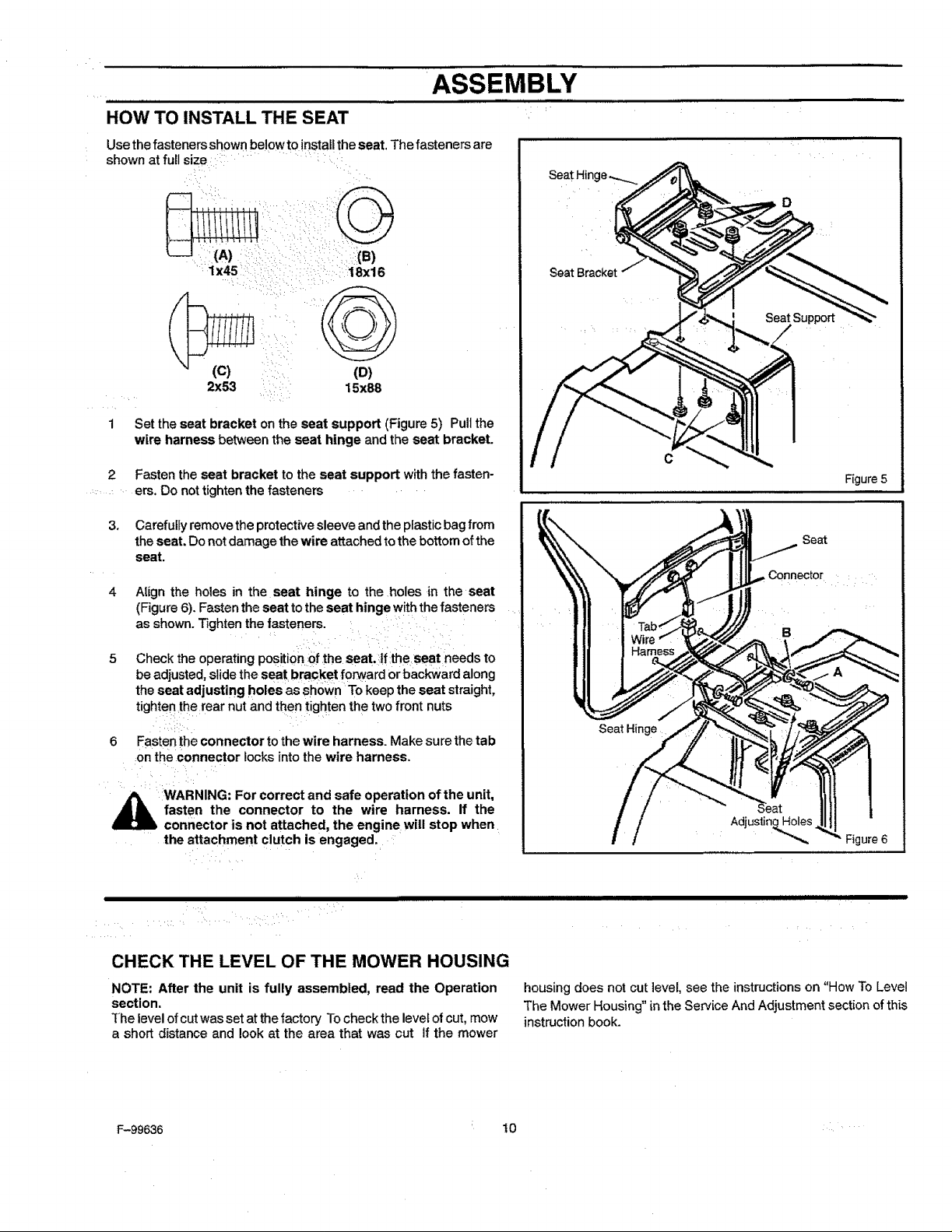

HOW TO INSTALL THE SEAT

Use the fasteners shown belowto install theseat. The fasteners are

shown at full size: :_ .... :

i :

i i i ,i

Seat Hinge

D

'_lx45 :::: ;: i::18x16

:i{B)

..... (D)

2x53 .... 15x88

1 Set the seat bracket on the seat support (Figure 5) Pull the

wire harness between the seat hinge and the seat bracket.

2 Fastenthe seat bracket to the seat support with the fasten-

.... ers. Do nottightenthe fasteners .....

3. Carefully remove the protective sleeve and the plastic bag from

the seat, Do not damage the wire attached to the bottom of the

seat.

Atign the holes in the seat hinge to the holes in the seat

(Figure 6). Fasten the seat to the seat hinge withthefasteners

as shown. Tighten the fasteners.

Check the operatingposition ofthe seat. :If:the seat needs to

be adjusted, slide the seat bracket forward orbackward along

the seat adjusting holes as shown Tokeep the seat straight,

tightenthe rear nut and thentighten the two front nuts

Seat Bracket

Figure 5

Seat

Fastenthe connector to the wire harness. Make sure the tab

on the connector locksintothe wire harness.

fasten the connector to the wire harness. If the

WARNING: For correct and safe operation ofthe unit,

connector is not attached, the engine will stop when

the attachment clutch is engaged.

CHECK THE LEVEL OF THE MOWER HOUSING

NOTE: After the unit is fully assembled, read the Operation

section.

The level ofcut wasset at thefactory To check the levelof cut, mow

a short distance and look at the area that was cut If the mower

F-99636 t 0

Adjustin_°_les "_ gure 6

housing does not cut level, see the instructionson "How To Level

The Mower Housing" inthe Service And Adjustment section of this

instruction book.

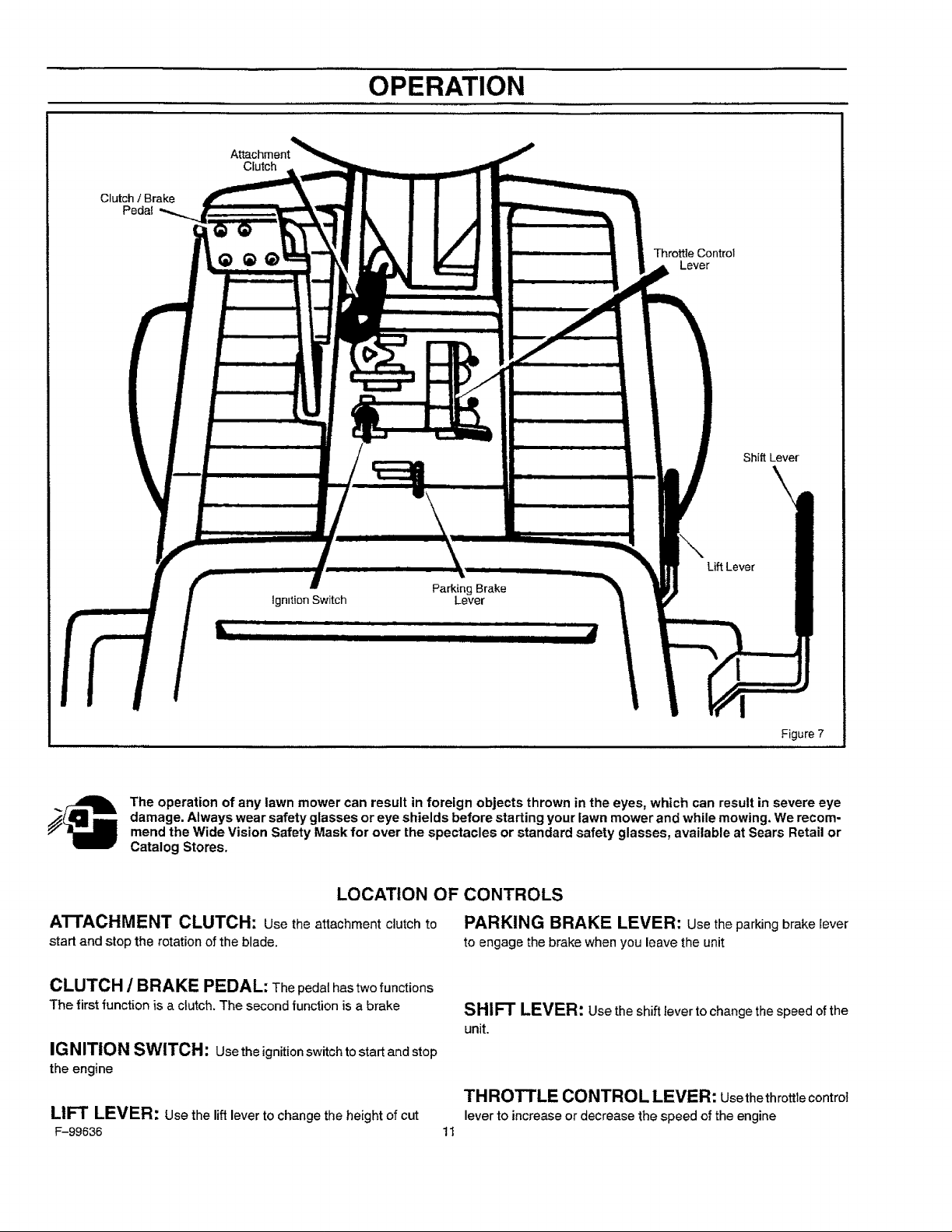

Page 11

Clutch / Brake

Pedaf

OPERATION

Clutch

Throttle Control

Lever

Shift Lever

Lift Lever

Ignition Switch Lever

Ik _ . ' ..... ,m

The operation of any lawn mower can result in foreign objects thrown in the eyes, which can result in severe eye

damage. Always wear safety glasses or eye shields before starting your lawn mower and while mowing. We recom-

mend the Wide Vision Safety Mask for over the spectacles or standard safety glasses, available at Sears Retail or

Catalog Stores.

ParkingBrake

[111 I

Figure 7

LOCATION OF CONTROLS

ATFACHMENT CLUTCH: Use the attachment clutch to PARKING BRAKE LEVER: Use the parking brake lever

start and stop the rotation of the blade, to engage the brake when you leave the unit

CLUTCH / BRAKE PEDAL: The pedal has two functions

The firstfunctionis a clutch. The second function is a brake

SHIFT LEVER: Use the shift lever to change the speed of the

unit.

IG NITION SWITCH: Usethe ignitionswitch to start and stop

the engine

THROTTLE CONTROL LEVER: Usethe throttle controt

LIFT LEVER: Use the lift lever to change the height of cut

F-99636

lever to increase or decrease the speed of the engine

11

Page 12

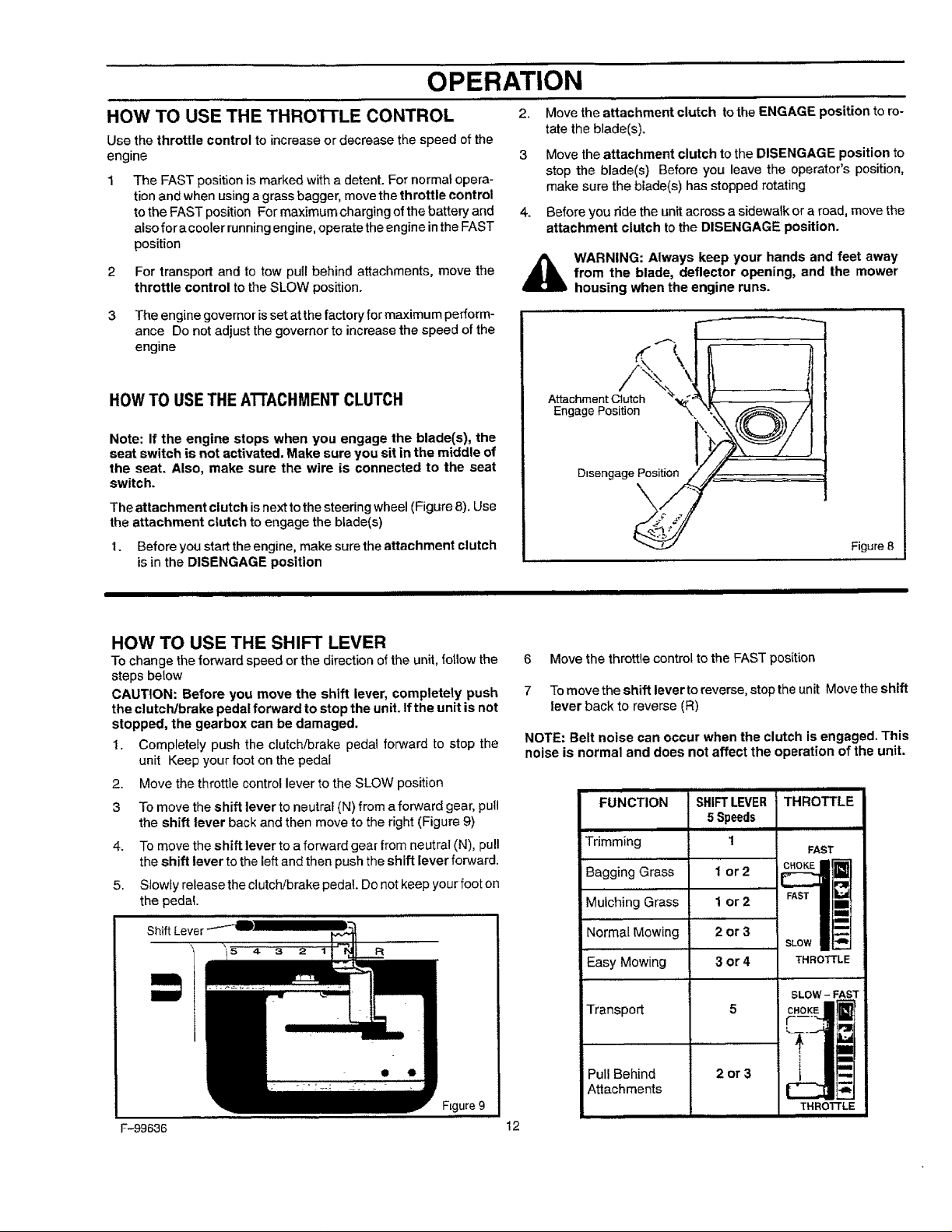

OPERATION

HOW TO USE THE THRO'I-rLE CONTROL 2

Use the throttle control to increase or decrease the speed of the

engine

The FAST position is marked witha detent. For normal opera-

tion and when using a grass bagger, move the throttle control

to the FAST position For maximum charging of the battery and

also for acooler running engine, operate the engine inthe FAST

position

2 For transport and to tow pull behind attachments, move the

throttle control to the SLOW position.

3 The engine governor isset at the factory for maximum perform-

ance Do not adjust the governor to increase the speed of the

engine

HOW TO USE THE A'I'rACHMENT CLUTCH

Note: If the engine stops when you engage the blade(s), the

seat switch is not activated. Make sure you sit in the middle of

the seat. Also, make sure the wire is connected to the seat

switch.

The attachment clutch isnext to the steering wheel (Figure 8). Use

the attachment clutch to engage the blade(s)

!. Before you start the engine, make sure the attachment clutch

is in the DISENGAGE position

Move the attachment clutch to the ENGAGE position to ro-

tate the blade(s),

3

Move the attachment clutch tothe DISENGAGE position to

stop the blade(s) Before you leave the operator's position,

makesure the blade(s) has stopped rotating

4,.

Before you ride the unit across a sidewalk or a road, move the

attachment clutch to the DISENGAGE position.

_ WARNING: Always keep your hands and feet away

from the blade, deflector opening, and the mower

housing when the engine runs.

>f

AttachmentClutch _._

Disengage_Position /_

Figure 8

HOW TO USE THE SHIFT LEVER

To change the forward speed orthe direction of the unit,fotlowthe

steps below

CAUTION: Before you move the shift lever, completely push

the clutchlbrake pedal forward to stop the unit. If the u nit is not

stopped, the gearbox can be damaged,

1. Completely push the clutch/brake pedal forward to stop the

unit Keep your foot on the pedal

2.

Move the throttle control lever to the SLOW position

3

Tomove the shift lever to neutral (N) from a forward gear, pull

the shift lever back and then move to the right (Figure 9)

4.

To move the shift lever to a forward gear from neutral (N), pul!

the shift lever to the left and then push the shift lever forward.

5.

Slowly release the clutch/brake pedal. Do not keep your foot on

the pedal.

ShiftLever

Figure 9

F-99636 12

6 Move the throttlecontrol to the FAST position

7 To move the shift lever to reverse,stop the unit Move the shift

lever back to reverse (R)

NOTE: Belt noise can occur when the clutch is engaged. This

noise is normal and does not affect the operation of the unit.

- FUNCTION

Trimming

Bagging Grass

Mulching Grass

Normal Mowing

Easy Mowing

Transpo_

SHIFTLEVER

5Speeds

1

1 or2

1 or2

2or3

3or4

THROTTLE

FAST

i FAST

SLOW

THROTTLE

SLOW - FAUST

C.OKEI lib

II

Illll

m

m

j

Pull Behind

Attachments

i

2or3

t

THROTTLE

Page 13

OPERATION

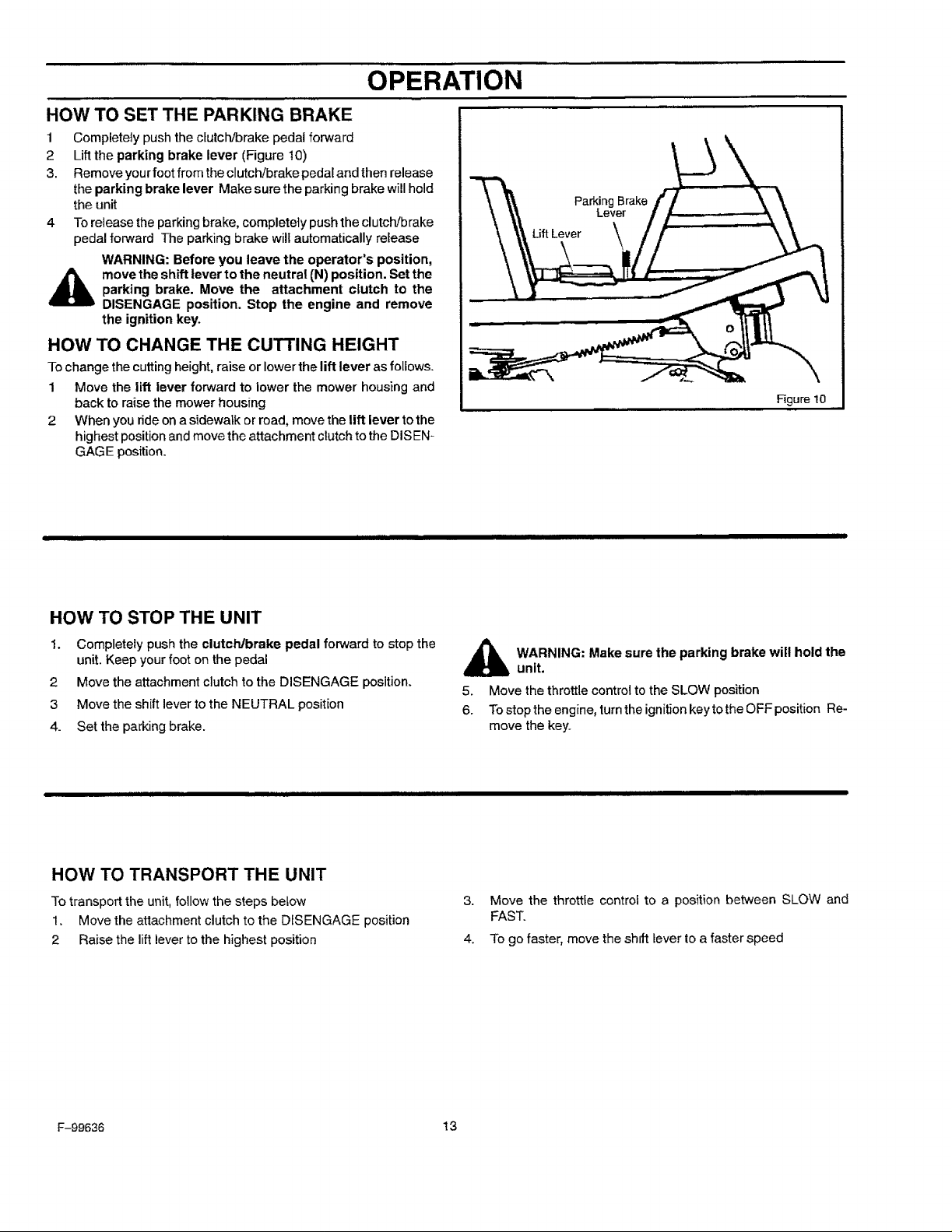

HOW TO SET THE PARKING BRAKE

1 Completely push the clutch/brake pedal forward

2 Lift the parking brake lever (Figure !0)

3. Remove yourfoot from the clutch/brake pedal and then release

the parking brake lever Make sure the parking brake will hold

the unit

4 To release the parking brake, completely push the clutch!brake

pedal forward The parking brake will automaticallyrelease

WARNING: Before you leave the operator's position,

Lift Lever

Parking Brake

Lever

,_ move the shift lever to the neutral (N) position. Set the

parking brake. Move the attachment ctutch to the

DISENGAGE position. Stop the engine and remove

the ignition key.

HOW TO CHANGE THE CUTTING HEIGHT

Tochange the cutting height, raise or lower the lift lever as follows.

1 Move the lift lever forward to lower the mower housing and

back to raise the mower housing

2 When you ride on asidewalk or road, move the lift lever to the

highest position and move the attachment clutch tothe DISEN-

GAGE position.

HOW TO STOP THE UNIT

1. Completely push the clutch/brake pedal forward to stop the

unit. Keep yourfoot on the pedal

2 Move the attachment clutch to the DISENGAGE position.

3 Move the shift lever to the NEUTRAL position

4. Set the parking brake.

Figure 10

,_ WARNING: Make sure the parking brake will hold the

5. Move the throttle control to the SLOW position

6. Tostop the engine, turntheignit]onkeytotheOFFposition Re-

unit.

move the key.

HOW TO TRANSPORT THE UNIT

To transport the unit, follow the steps below

1. Move the attachment clutch to the DISENGAGE position

2 Raise the lift lever to the highest position

F-99636 !3

3.

Move the throttle control to a position between SLOW and

FAST.

4.

To go faster, move the shtft lever to a faster speed

Page 14

OPERATION

HOWTO OPERATEWITHTHE MOWERHOUSING

WARNING: The deflector is a safety device. Do not re-

move the deflector. The deflector forces the dis-

,_ charged material toward the ground. Always keep the

deflector in the down position. If the deflector is dam-

aged, replace thedeflector with an original equipment

part from an authorized service center.

t Start the engine.

2. Move the lift lever to a height of cut position In high or thick

grass, cut the grass in the highest positionfirst and then lower

the mower housing to a lower position.

3 Move the throttle control to the SLOW position.

4. Move the attachment clutch to the ENGAGE position.

5. Push the clutch!brake pedal completely forward.

HOW TO OPERATE THE UNIT ON HILLS

6 Move the shift lever to one of the speed settings

NOTE: When you mow in heavy grass or mow with a

bagger, put the shift lever in the slowest speed.

7,

Slowly release the clutch/brake pedal

8.

Move the throttle control to the FAST position. If you needto go

faster or slower, stop the unit and move the shift lever toanother

speed setting.

9,

Make sure the level of cut is still correct. After you mow a short

distance, look at the area that was cut. If the mower housing

does not cut level, see the instructions on"How To Level The

Mower Housing" in the Service And Adjustment section.

,_ WARNING: For better control of the unit, always

select a safe speed.

,_ WARNING: Do not ride up or down slopes that are too

steep to back straight up. Never ride the unit across

a slope. See the "Slope Guide" in the back of this

book for information on how to check slopes.

1. Before you dde up or down a hill, move the shift lever to the

slowest speed.

2 Do not stop or change speed settings on a hil!. If you must stop,

quickly push the clutch/b rake pedal forward and set the parking

brake

3. To start again, make sure the shift lever is inthe slowest speed.

Move the throttle control to the SLOW position Slowly release

the pedal.

4. If you must stop or start on a hill, always have enough space

for the unit to roll when you release the brake and engage the

clutch.

5.

Be very careful when you change directions on a hill When on

a slope or in a turn on a hill, move the throttle control to the

SLOW position to help prevent an accident.

F-99636 14

Page 15

OPERATION

BEFORE STARTING THE ENGINE

CHECK THE OIL

NOTE: The engine was shipped from the factory filled with SAE

30 weight oil. Check the level of the oil. Add oil as needed.

1 Make sure the unitis level

NOTE: Do not check the level of the oil while the engine

runs.

2 Clean the area around the dipstick Remove the dipstick. Wipe

the oil from the dipstick

3. Insert the dipstick into the oil fill tube. Turn the dipstick clock-

wise until it istight. Remove the dipstick. Check the oil level on

the dipstick. The oil level must reach the FULL mark on the

dipstick,

4. Ifnecessary, add oil until the oil reaches the FULL mark on the

dipstick The quantity of oil needed from ADD to FULL is shown

on the dipstick. Do not add too much oil.

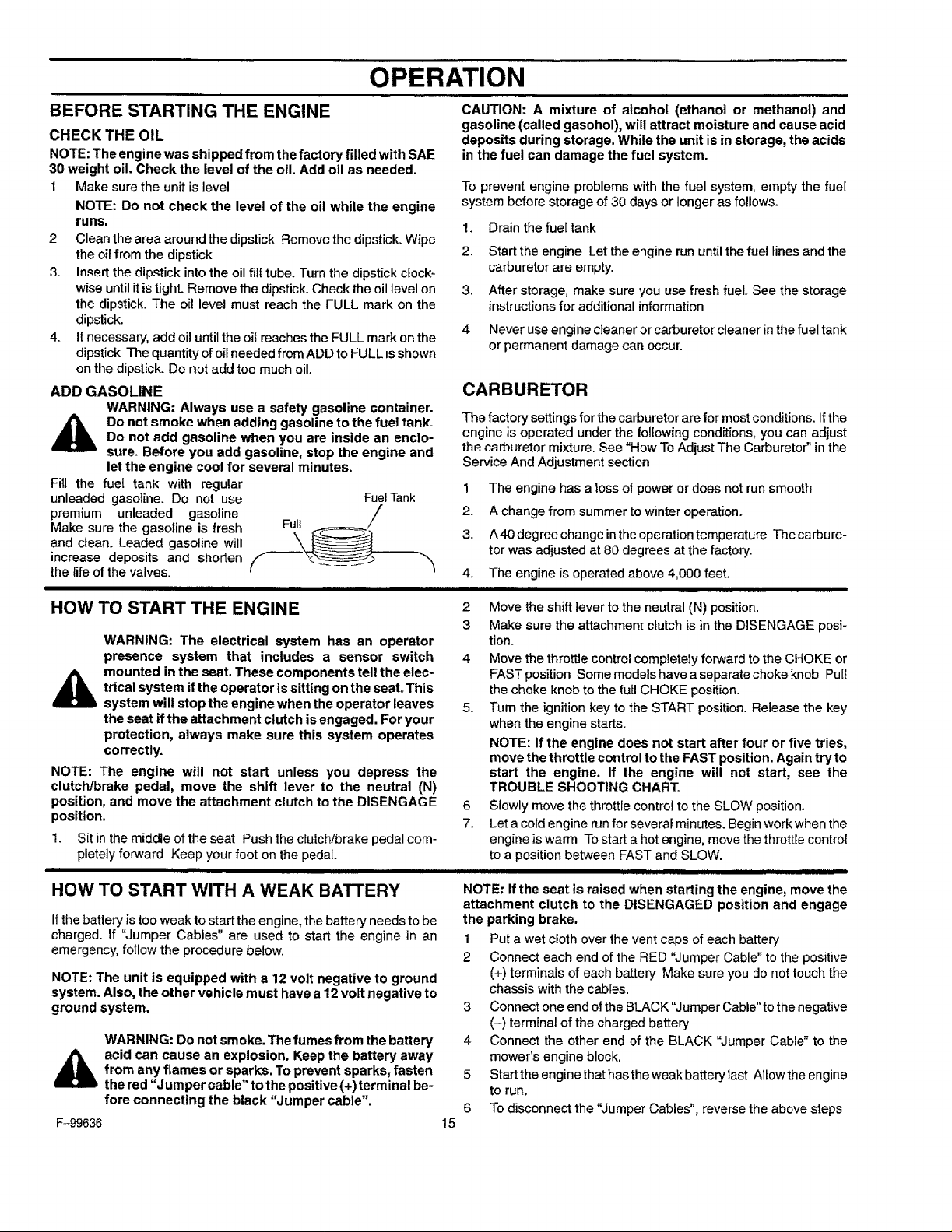

ADD GASOLINE

WARNING: Always use a safety gasoline container.

A Do not smoke when adding gasoline to the fuel tank.

Do not add gasoline when you are inside an enclo-

sure. Before you add gasoline, stop the engine and

let the engine cool for several minutes.

Fill the fuel tank with regular

unleaded gasoline. Do not use

premium unleaded gasoline

Make sure the gasoline is fresh

and clean. Leaded gasoline will

increase deposits and shorten

the tife of the valves.

Fuel Tank

- 3.

HOW TO START THE ENGINE

WARNING: The electrical system has an operator

presence system that includes a sensor switch

trical system if the operator is sitting on the seat. This

mounted in the seat. These components tell the elec-

system will stop the engine when the operator leaves

the seat if the attachment clutch isengaged. For your

protection, always make sure this system operates

correctly.

NOTE: The engine will not start unless you depress the

clutch/brake pedal, move the shift lever to the neutral (N)

position, and move the attachment clutch to the DISENGAGE

position.

1. Sit in the middle of the seat Push the clutch/brake pedal com-

pletely forward Keep your foot on the pedal.

I Jllll 1 I1[111[ [ IIII I

HOW TO START WITH A WEAK BATTERY

Ifthe battery is too weak to start the engine, the battery needs to be

charged. If =Jumper Cables" are used to start the engine in an

emergency, follow the procedure below.

NOTE: The unit is equipped with a 12 volt negative to ground

system. Also, the other vehicle must have a 12volt negative to

ground system.

WARNING: Do not smeke. The fumes from the battery

A acid can cause an explosion, Keep the battery away

F-99636 15

from any flames or sparks. To prevent sparks, fasten

the red "Jumper cable" tothe positive (+) terminal be-

fore connecting the black "Jumper cable".

CAUTION: A mixture of alcohol (ethanol or methanol) and

gasoline (called gasohol), will attract moisture and cause acid

deposits during storage. While the unit is in storage, the acids

in the fuel can damage the fuel system.

To prevent engine problems with the fuel system, empty the fuel

system before storage of 30 days or longer as follows.

1. Drain the fuel tank

2. Start the engine Let the engine run until the fuel lines and the

carburetor are empty.

3. After storage, make sure you use fresh fuel. See the storage

instructionsfor additional information

4 Never use engine cleaner or carburetor cleaner in the fuel tank

or permanent damage can occur.

CARBURETOR

The factory settings for the carburetor are for most conditions. Ifthe

engine is operated under the following conditions, you can adjust

the carburetor mixture. See =HowTo Adjust The Carburetor _ in the

Service And Adjustment section

1

The engine has a loss o| power or does notrun smooth

A change from summer to winter operation.

A40 degree change intheoperation temperature The carbu re-

ter was adjusted at 80 degrees at the factory.

4.

The engine is operated above 4,000 feet.

III I IIIIII I

2 Move the shift lever to the neutral (N) position.

3 Make sure the attachment clutch is in the DISENGAGE posi-

tion.

4 Move the throttle control completely forward to the CHOKE or

FASTposition Somemodelshaveaseparatechokeknob Pull

the choke knob to the full CHOKE position.

5. Turn the ignitionkey to the START position. Release the key

when the engine starts.

NOTE: If the engine does not start after four or five tries,

move the throttle control to the FAST position. Again try to

start the engine. If the engine will not start, see the

TROUBLE SHOOTING CHART.

6 Slowly move the throttle control to the SLOW position,

7. Let a cold engine runfor several minutes. Begin workwhen the

engine iswarm Tostart a hot engine, move the throttle control

to a position between FAST and SLOW.

NOTE: If the seat is raised when starting the engine, move the

attachment clutch to the DISENGAGED position and engage

the parking brake.

1 Put a wet cloth overthe vent caps of each battery

2 Connect each end of the RED "Jumper Cable" to the positive

(+) terminals of each battery Make sure you do not touch the

chassis with the cables.

3 Connect one end of the BLACK"Jumper Cable" tothe negative

(-) terminal ofthe charged battery

4 Connect the other end of the BLACK "Jumper Cable" to the

mower's engine block,

5 Start the engine that has the weak battery last Allow the engine

to run.

6 To disconnect the"Jumper Cables", reverse the above steps

J I III I II III III

Page 16

OPERATION

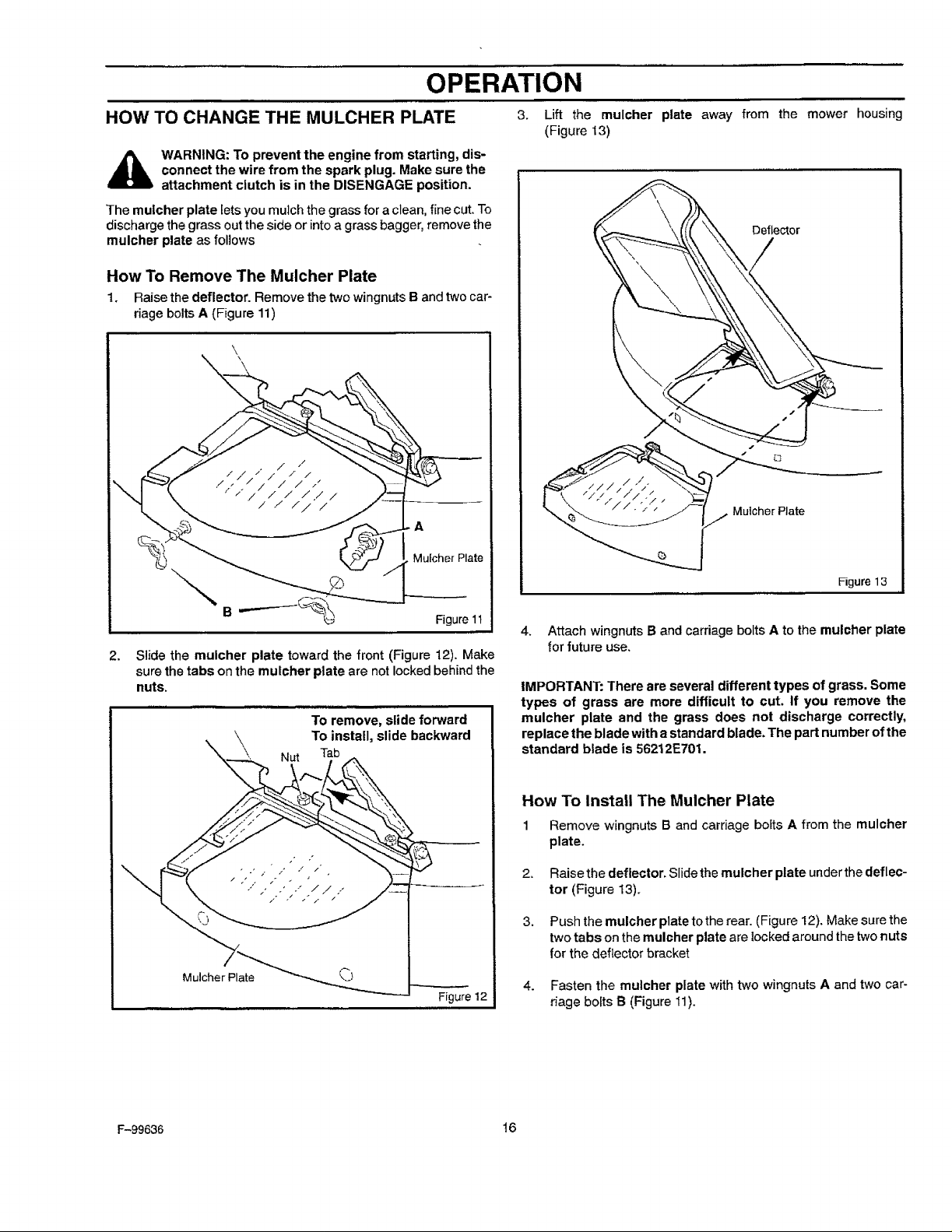

HOW TO CHANGE THE MULCHER PLATE 3.

,_ WARNING: To prevent the engine from starting, dis-

The mulcher plate letsyou mulch the grass for a clean, fine cut. To

discharge the grass out the side or into a grass bagger, remove the

mulcher plate as follows

connect the wire from the spark plug. Make sure the

attachment clutch is in the DISENGAGE position.

How To Remove The Mulcher Plate

1. Raise the deflector. Remove the two wingnutsB and two car-

riage boltsA (Figure 11)

\

\

\

Mufchef Plate

Lift the mulcher plate away from the mower housing

(Figure I3)

Deflector

Mutcher Plate

Figure 13

2.

Slide the mulcher plate toward the front (Figure 12). Make

sure the tabs on the mufcher plate are not locked behind the

nuts.

To remove, slide forward

\ To install, slide backward

Nut

Mulcher Plate

Figure 12

4. Attach wingnuts B and carriage bolts A to the mulcher plate

for future use.

IMPORTANT: There are several different types of grass. Some

types of grass are more difficult to cut. If you remove the

mulcher plate and the grass does not discharge correctly,

replace the blade with a standard blade. The part number of the

standard blade is 56212E701.

How To Install The Mulcher Plate

1 Remove wingnuts B and carriage bolts A from the mulcher

plate.

2. Raise the deflector. Slidethe mulcher plate under thedeflec-

tor (Figure 13).

3. Push the mulcher plate to the rear. (Figure 12). Make sure the

two tabs on the mulcher plate are lockedaround the two nuts

for the deflector bracket

4. Fasten the mulcher plate with two wingnuts A and two car-

dage bolts B (Figure 11).

F-99636 16

Page 17

OPERATING TIPS

OPERATION

1. Check the attachment clutch for correct adjustment. For the 5.

blade(s) to disengage correctly, the adjustment must be cor-

rect

Before you use the unit, check the oil inthe engine and add oil

if necessary

3.

If the engine will not start, first make sure the wire is attached

to the spark plug.

Make sure all the belts are inside all the belt guides See the in-

structions on how to remove and install the motion drive and

mower drive belts.

MOWING AND BAGGING TIPS

For a lawn to look better, check the cutting level ofthe mower

housing. See "How To Level The Mower Housing" in the Ser-

vice And Adjustment section.

2.

For the mower housing to cut level, make sure the tires have

the correct amount of air pressure (PSI)

3,

Every time you use the unit, check the blade. If the blade is bent

or damaged, immediately replace the blade. Also, make sure

the nut for the blade is tight.

4_

Keep the blade(s) sharpened. Wom blades will cause the ends

of the grass to turn brown

Before you make an inspection,adjustment (except for the car-

buretor) or repair, make sure the wire from the spark plug isdis-

connected.

6

Make sure the seat switch wire isconnected. If the wire is not

connected, the engine will not start.

7.

For longer life of the battery, charge the battery every three

months

8

Use the shift lever to change the ground speed, notthe throttle

control.

9

Belt noisecan occur when the blade or clutch isengaged This

noiseis normal and does not affect the operation of the unit.

10. For better engine performance and an even discharge of the

cut grass, always operate the engine with the throttle in FAST

position.

11_ When you use a bagger, operate the engine with the throttle in

FAST position and the shift lever in first or second gear

12. For better cutting performance and a quality cut, mow with the

shift lever in one of the slower speeds.

13. After each use, clean the bottom and top of the mower housing

for better performance. Also, a clean mower housing will help

prevent a fire

5. Do not cut or bag grass that is wet Wet grass wil not discharge

correctly Let the grass dry before cutting.

6. Use the left side of the mower housing to trim near an object

7. Discharge the cut grass onto the mowed area. The result is a

more even discharge of cut grass

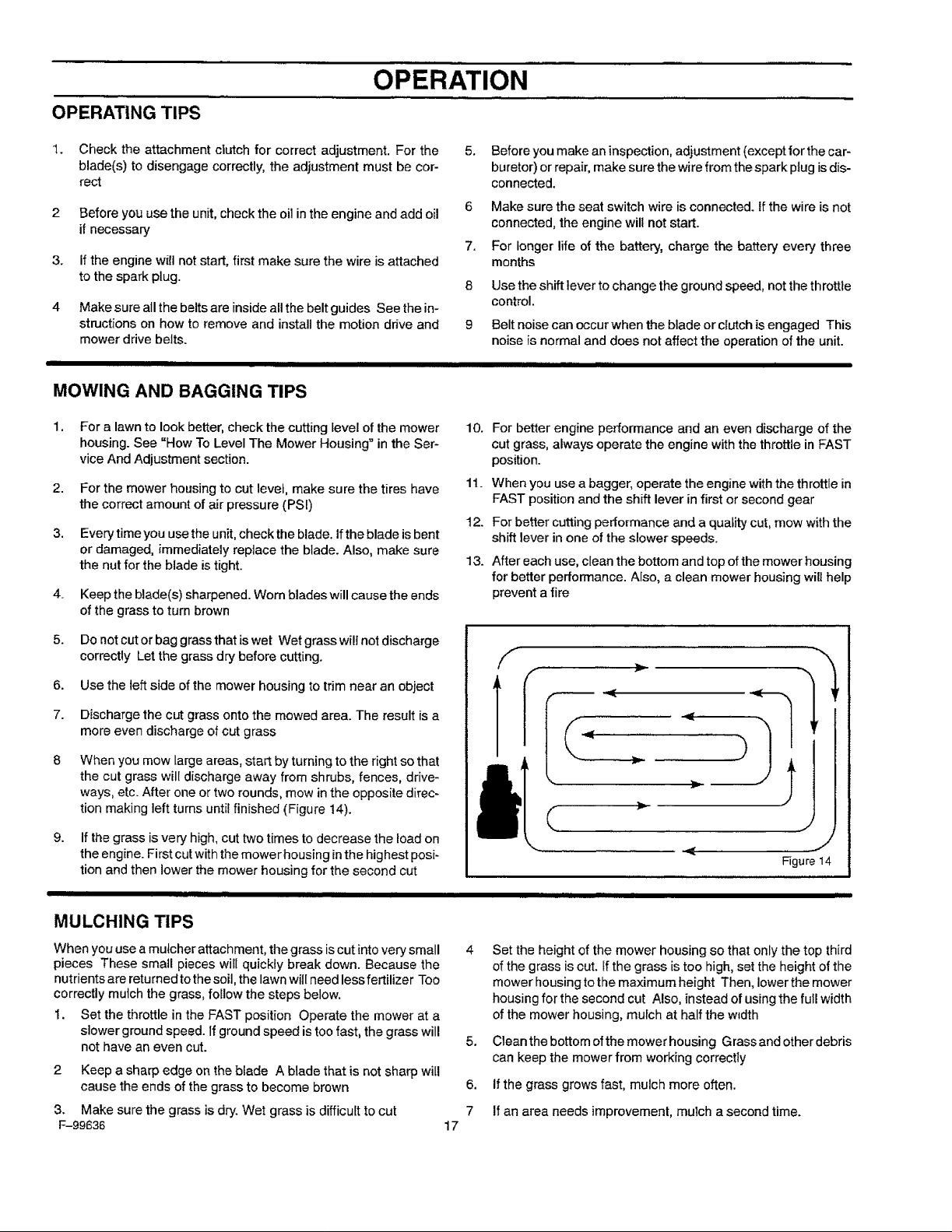

8 When you mow large areas, start by turning to the right so that

the cut grass will discharge away from shrubs, fences, drive-

ways, etc. After one or two rounds, mow in the opposite dkec-

tion making left turns until finished (Figure 14).

9. Ifthe grass is very high, cut two times to decrease the load on

the engine. First cut with the mower housing inthe higbest posi-

tion and then lower the mower housing for the second cut

• IIIml II IIII

MULCHING TIPS

When you use amutcher attachment, the grass iscut into very small 4

pieces These small pieces will quickfy break down. Because the

nutrients arereturned to the soil, the lawn will need less fertilizer Too

correctly mulch the grass, follow the steps below.

1. Set the throttle in the FAST position Operate the mower at a

slower ground speed. If ground speed is too fast, the grass will

not have an even cut. 5.

2 Keep a sharp edge on the blade A blade that is not sharp will

cause the ends of the grass to become brown 6.

3. Make sure the grass is dry. Wet grass is difficult to cut 7

F-99636 17

.J

J

Figure 14

Set the height of the mower housing so that only the top third

of the grass is cut. If the grass istoo high, set the height of the

mower housing to the maximum height Then, lower the mower

housing for the second cut Also, instead of using the full width

of the mower housing, mulch at half the w=dth

Clean the bottom ofthe mower housing Grass and other debris

can keep the mower from working correctly

If the grass grows fast, mulch more often.

If an area needs improvement, mulch a second time.

Page 18

CUSTOMER RESPONSIBILITIES

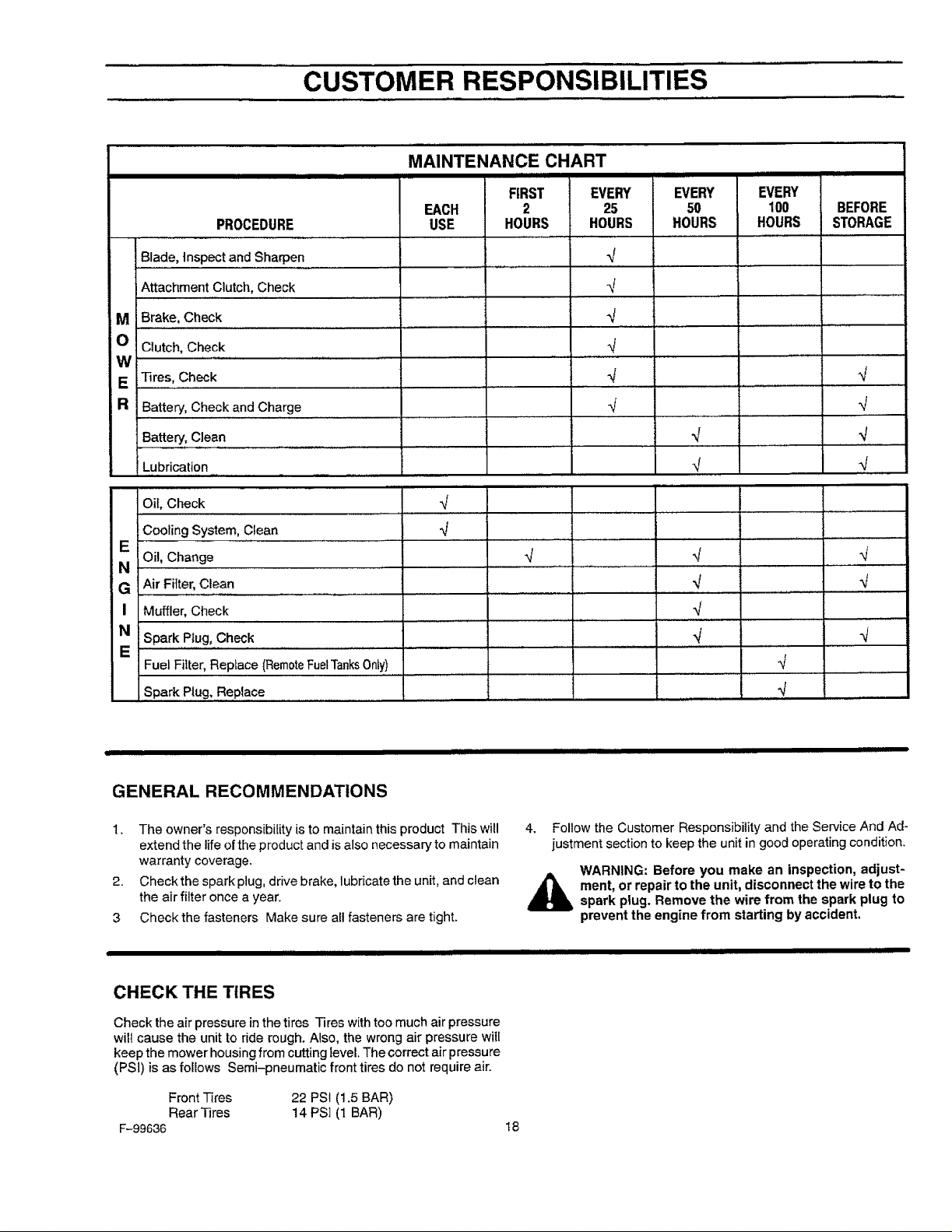

PROCEDURE

Blade, Inspect and Sharpen

Attachment Clutch, Check

M Brake, Check

iO Clutch, Check

W .......

E Tire.s, Check

R

Battery, Check and Charge

Battery, Clean

!Lubrication

Oil, Check

Cooling System, Clean

E Oil, Change

N

G Air Filter,Clean

I Muffler, Check

N Spark Piug, Check

E ...........

Fuel Filter, Replace (RemoteFuelTanksOnly)

Spark Plug, Replace

MAINTENANCE CHART

II IIII

FIRST EVERY

EACH 2 25

USE HOURS HOURS

4

4

4 4

i ii

EVERY

50

HOURS

EVERY

100

HOURS

BEFORE

STORAGE

4

4

4

,, , J

4

4

4

4

4

4

4

4

4

,/

4

4

4

4

4

4

GENERAL RECOMMENDATIONS

1. The owner's responsibility is to maintain this product This will

extend the life of the product and is also necessary to maintain

warranty coverage.

2. Check the spark plug, drive brake, lubricate the unit, and clean

the air filter once a year.

3 Check the fasteners Make sure al! fasteners are tight.

CHECK THE TIRES

Check the air pressure inthe tires Tires withtoo much air pressure

will cause the unit to ride rough. Also, the wrong air pressure will

keep the mower housing from cutting level. The correct air pressure

(PSI) is as follows Semi-pneumatic front tires do not require air.

Front Tires 22 PSt (1.5 BAR)

RearTires 14 PSI (1 BAR)

F-99636

4. Follow the Customer Responsibility and the Service And Ad-

justment section to keep the unit in good operating condition.

WARNING: Before you make an inspection, adjust-

_ ment, or repair to the unit, disconnect the wire to the

18

spark plug. Remove the wire from the spark plug to

prevent the engine from starting by accident.

Page 19

CUSTOMER RESPONSIBILITIES

INSPECT BLADE

WARNING= Before you inspect or remove the blade,

disconnect the wire to the spark plug. If the blade bits

an object, stop the engine. Check the unit for dam-

age. The blade has sharp edges. When you hold the

blade, use gloves or cloth material to protect your

bands.

Ifyou keep the blade sharp and inspectthe blade for damage, the

blade wilf cut better and be more safe to operate Frequently check

the blade for excessive wear, cracks, or other damage. Frequently

check the nut that holds the blade. Keep the nut tight If the blade

hitsan object, stop the engine. Disconnect the wire to the spark plug

See if the blade is bent or damaged Check the blade adapter for

damage. Before you operate the unit, replace damaged parts with

original equipment parts See the authorized service center inyour

area_Every three years, have an authorized service person inspect

the blade or replace the old blade with an original equipment part

HOW TO REMOVE AND INSTALL THE BLADE

! Remove the mower housing See the instructionson "How To

Remove The Mower Housing".

2 Use a piece of wood to keep the blade from rotating

3. Remove the nut that holds the blade (Figure 15).

Hi-Lift

Edge Up

Mandrel

Blade Adapter

Blade

Figure 15

4. Check the blade and the blade adapter according to the in-

structions for "Inspect Blade". Replace a badly worn or dam-

aged blade with an original equipment blade See an

authorized service center in your area

5 Clean thetop and bottom ofthe mower housing Remove atlthe

grass and debris

6 Mount the blade and blade adapter on the mandrel

(Figure t5)

7 Mount the blade so that the hi-lift edges are up. If the blade

is upside down, the blade will not cut correctly and can cause

an accident.

8 Fasten theblade withthe original washers and nut. Make sure

the outside rim of the Belleville washer is against the blade

(Figure 16)

,_ WARNING= Always keep the nut tight that holds the

F-99636 19

blade. A loose nut or blade can cause an accident.

9 Tighten the nut that holds the blade to a torque of 30 foot

pounds (41,5 N-m)

10 Install the mower housing See "How To Install The Mower

Housing".

A&_pt1 1

Blade

er_ Blade

I

BellevilleWasher // Nut

(Outsiderimmust be _/

againstthe blade ) I

Figure 16

HOW TO SHARPEN THE BLADE

WARNING: Vibration can be caused if the blade is

,_not correctly balanced or if the blade is damaged. A

Keep a sharp edge on the blade A blade that isnot sharp will cause

the tips of the grass to become brown.

1. Sharpen the blade two times a year or every 25 hours

2 Remove the blade according to the instructions in "How To Re-

3. Clean the blade with a brush, soap and water Check the

4. Sharpen the blade with a file (Figure 17). Make sure you keep

5 Make sure the blade is balanced Use a screwdriver and hold

6. A new blade will cut better than a badly worn blade. Every three

7. Assemble the blade according to the instructions"How To Re-

blade that is damaged with cracks can break and

cause an accident.

move And Install The Blade".

blade. Look for cracks, nicks, or other damage. Replace a

badly worn or damaged blade with an original equipment blade.

See an authorized service center in your area.

the original bevel angle.

the blade parallel to the ground (Figure 17). A blade that is

balanced will stay parallel to the ground. Ifthe blade is not bal-

anced, the heavy end will rotate toward the ground Sharpen

the heavy end until the blade is balanced.

years, have an authorized service person inspect the blade or

replace the old blade with an original equipment blade

move And Install The Blade"

Blade

Screwddv__ [ "/

I Bladeisbalanced I

whenparalleltothe ground I

Ground Figure17

Page 20

CUSTOMER RESPONSIBILITIES

HOW TO ADJUST THE ATI'ACHMENT CLUTCH

,_ WARNING: To prevent an injury, the attachment

1 Stop the engine. Disconnect the wire from the spark plug

2. Before you adjust the attachment clutch, check and level the

3. Set the height of the mower housing in the lowest position.

4. Move the attachment clutch to the DISENGAGE position

5. Check the attachment clutch. Before the attachment clutch

6

7. Connect the clevis to the pivot rod and bracket assembly

9.

clutch must operate correctly.

mower housing. See "How To Level The Mower Housing"

Make sure the mower housing is level before go to the next

step.

(Figure 18).

engages, there must be 1/8" to 3/8" (3ram to 9mm) of free

movement.

If an adjustment is needed, disconnect the clevis from the

pivot rod and bracket assembly (Figure 19).Turn the clevis

clockwise to decrease the free movement of the attachment

clutch. Turn the clevis counterclockwise to increase the free

movement.

Move the attachment clutch to the DISENGAGE position

Check the free movement of the attachment clutch

Check the operation of the blade brake Rotate the pulley with

your hand Make sure that the blade brake pad presses tightly

against the pulley

Move the attachment clutch to theENGAGE position. Check

the pad for the blade brake If the pad is excessively worn or

damaged, replace the brake pad assembly. Correct

replacement parts and assistance are available from an

authorized service center

AttachmentClutch

EngagePostion

"x,,.._ p'.

%

Free Movement

1/8"-3/8" (3mm- 9ram) Figure 18

10.

Attach the wire to the spark plug. Mow for a short distance and

again check the operation of the attachment clutch

11.

When you move the attachment clutch to the DISENGAGE

position, all movement will stop within five seconds if the ad-

justmentis correct If there is movement of the bettorthe blade

continue to rotate, engage and disengage the attachment

clutch five times to remove any excess rubber from a new

mower drive belt. If there is still blade rotation from the

DISENGAGED position, again adjust the attachment clutch

beginning withthe first step tf you need assistance, take the

unitto an authorized service center.

12.

if you replace the mower drive belt, adjust the attachment

clutch.

Blade Brake

Mower DrLve Belt

F-99636 20

Clevis Pin

PivotRodand

BracketAssembly

Cotter P_n

Figure 19

Page 21

CUSTOMER RESPONSIBILITIES

HOW TO CHECK AND ADJUST THE DRIVE BRAKE

I. Before you adjust the brake, check the clutch adjustment See

the instructions on "How To Check And Adjust The Clutch"

2. Make sure the shift lever is in the neutral (N) position.

3. Disconnect the adjustable nut from the brake arm

(Figure 21),

4 Push the brake arm forward and hold in position.

5. With the brake arm forward, rotate the adjustable nut

counterclockwise on the brake rod until the adjustable nut

is in line with hole in the brake arm.

NOTE: If the adjustable nut will not line up with the hole in

the brake arm, go to step 6. If the adjustable nut does line

up with the hole in the brake arm, go to step 12.

6. Pullthe brake arm tothe rear of the unit.

7. The brake adjustment of the transaxle is located on the

underside ofthe transaxle (Figure 20) Use one wrenchto hold

the brake stud and another wrench to hold the hex nut.

Loosenthe hex nut approximately2 turns.

8 Turn the brake stud clockwise1/2 turn. Try topush the unit. if

the unit roils, again turn the brake stud clockwise 1/2 turn.

Continue this adjustment until you feel resistance from the

brake whenyou pushthe unit.

9. Turn the brake stud countemtockwiseoneturn.Then, holdthe

brake stud with one wrenchwhileyou tightenthe hex nut with

another wrench

10 Push the brake arm forward and hotd in position.

11. With the brake arm forward, rotate the adjustable nut

clockwise until the adjustable nut is in line with the hole inthe

brake arm

t 2. Connect the adjustable nut tothe brake arm with the washer

and cotter pin.

13 Apply the parking brake Try to pushthe unit Ifthe rear wheels

donotturn,the brake iscorrectlyadjusted.Release theparking

brake. Push the unit tosee if the wheels willfreely roll

HOWTO CHECKANDADJUSTTHE CLUTCH

Ifthe motion drive belt is loose,the clutch willslip when, (1) going

upa hill, (2)pulling a heavy load, or (3)the unit wilt not move forward

Check the clearance at the rear of the pedal lever (Figure 21) Ifthe

motion drive belt is loose, the clearance wilt be less than 1/2 inch

and the clutch will slip. Adjust the clutch as follows

I. Disconnect the adjustable nut from the idler bracket

(Figure 21).

2. Turn the adjustable nut clockwise to increase the fength of

the clutch rod. This adjustment will increase the clearance at

the pedal.

3 Connect the adjustable nut to the idler bracket with the

washer and cotter pin Check the clearance at the pedal

There must be 1/2 to 5/8 inch clearance at the back of the

pedal

4. After makingan adjustmenttothe pedal, check the brake rod

asdescribed inthe instructions,"How ToCheck And Adjust The

Drive Brake".

_ t,,,-_ Transaxle 1

BrakeStud

(TurnClockwise)

4%1

"% i

,_ WARNING: If you cannot correctly adjust the drive

F-99636 21

brake, take the unit to an Authorized Service Center.

Adjustable Nut (To increase the operation

the brake, turn counterc[ockwise )

Brake Arm

Cotter Pin

Nut

clearance,turnclockwise)

]"_ idler Bracket

Washer \

Cotter Pin

/

CtutchRod

Brake Rod

VIEW FROM UNDERSIDE Figure20J

1/2" to 5/8"

(13ram to 16ram)

Cleat

Pedal

Figure 21

Page 22

CUSTOMER RESPONSIBILITIES

HOW TO REMOVE THE SIDE PANEL 1.

To help service the engine or the battery, each side panel can be

easily removed.

1. Remove the screws that hold the back of the side panel

(Figure 22)

2. Remove the large screws that hold thefront of the side panel

(Figure 23).

3 Slideet;aenSjldepanel back approximately oneinch Remove the

2. Remove the red cable from the positive (+) terminal.

3. Remove the battery clamp from the battery.

4 Remove the battery from the unit.

Remove the black cable from the negative (-) terminal

(Figure 24)

Positive (+) _-...__.

Terminal Nut

DateCode BlackCable

/

Terminal Cover

Bolt

Battery Clamp

Figure 24

Side Panel

Screws

/

Figure 23

BATTERY SERVICE

HOW TO REMOVE THE BATTERY

Tocharge orclean the battery, remove the battery from the unit as

follows.

WARNING: To prevent sparks, disconnect the black

battery cable from the negative (-) terminal before you

,_ disconnect the red cable.

F-99636

WARNING: The battery contains sulfuric acid which is

harmful to the skin, eyes and clothing. If the acid gets

on the body or clothing, wash with water.

HOW TO CHARGE THE BATTERY

,_ WARNING: When you charge the battery, do not

1.

2. Before you charge the battery, remove the battery.

3. Tocharge the battery, use a 12 voltbattery charger Charge at

4 Install the battery. See "How To InstallThe Battery _ in the

HOW TO CLEAN THE BATTERY

1. Remove the battery

2. Wash the battery with a solution of one gallon ofwater and four

3. Clean the terminals and the ends of the cables with a wire

4 install the battery See "How To Insta]t The Battery" in the

5 To prevent corros=on,apply grease to the battery terminals.

22

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

For longer life of the battery, charge the battery every three

months

a rate of 3 amperes for 2 to 3 hours.

Assembly section,

tablespoons of baking soda (sodium bicarbonate). Make sure

the solution does not get into the battery cells.

brush.

Assembly section.

Page 23

CUSTOMER RESPONSIBILITIES

WHERE TO LUBRICATE

Lubricatethe areas shown with engine oil.

-'_ Apply grease with a brush to the areas shown.

NOTE: Apply grease to the steering gear assembly,

CAUTION: If the unit is operated in dry areas that have sand,

use a dry graphite spray to lubricate the unit, Do not lubricate

the nylon bearings for the front wheels. Oil or grease will

damage the bearings.

II

ShiftLever

/

Figure 25

F-99636 23

Page 24

CUSTOMER RESPONSIBILITIES

ENGINE HOW TO CHANGE THE OIL

NOTE: Do not drain the oil from a cold engine. Before you drain

HOW TO CHECK THE OIL

NOTE: Do not check the level of the oil while the engine runs.

1. Make sure the unit is level.

2. Clean the area around the dipstick (Figure 26). Remove the

dipstick. Wipe the oil from the dipstick.

3. Insert the dipstick into the oilfi

CUSTOMER RESPONSIBILITIES

HOW TO CLEAN THE AIR FILTERS

Some engines have two filters, an outer foam filter around an inner

paper filter Clean the air filters every 50 hours tf you operate in

dirty conditions, service more often

NOTE: Never run the engine with the airfilters removed. The air

filters witl help protect the engine against wear. For the correct

replacement filter, see the parts list for the engine.

1. Remove the two wlngnuts from the cover (Figure 27)

2. Remove the cover from the air cleaner

3. Remove the two nuts from the filters.

4. Remove the air filters.

5. Clean the inside of the base and the cover with a cloth.

6. Remove the foam filter from the paper filter.

7. Ifequipped,wash the foam filter in adetergent andwater solu-

tion. To remove the water solution, tightly roll the foam filter in

adry cloth. Remove thefoam filter from the cloth Completely

dry the foam filter

CAUTION: Do not wash the filters in gasoline or other

solvents that will burn.

8. Evenly apply SAE 30W oil to the dry foam filter

9. To clean the paper filter, lightly tap the paper filter against a

hard flat surface

10. Ifthe paper filter is very dirty, replace the paper filter

11. Assemble the air filters with the two nuts

12. Installthe cover Fastenthe cover with the two wingnuts

Wingnut

Cover

Nut

Foam Filter

Base

Figure 27

] I ]]

HOW TO CHECK THE SPARK PLUG

1

Check the gap of the spark plug with a feeler gauge

(Figure 28). The correct gap is 0.030".

2.

For easy starting and good performance, replace the spark

plug every two years.

F-99636 25

Feeler Gauge

0 030"

Spark Ptug

Figure 28

Page 26

SERVICE AND ADJUSTMENT

HOW TO ADJUST THE THROTrLE CONTROL

For the best engine performance, set the throttle control as follows

1 Move thethrottle control to the FAST position (Figure 29).

2.

Loosen the clamp screw so that the throttle control cable

can move in the cable clamp (Figure 30) Do not remove the

cable clamp or disconnect the throttle control cable from the

engine control lever.

3. Move the engine control lever until the stot in the lever is

aligned (lines up) with the hole in the control bracket as

shown.

4. Tighten the clamp screw. Move the throttle control to the

SLOW positionandthen back to the FAST position.Check the

atignment of thethrottle control lever See step 3.

The throttle control is now set at the correct speed When the

throttle control is at the FAST position, the engine speed is

3400 + or - 100 RPM. When the throttle control is in the

SLOW position, the engine speed is 2150 + or- 100 RPM.

IMPORTANT; Do not change the engine governor. If the engine

governor needs an adjustment, go to the nearest Authorized

Service Center. They have the equipment and experience to

make the adjustment.

/

ThrottleControl

Control Bracket

CHOKE

FAST

SLOW

Engine Control Lever - FAST position

(Skitin leveralignedwithholeinbracket)

Throttte Control

Cable

Cable Clamp

Clamp Screw

Figure 29

Figure 30

F-99636 26

Page 27

SERVICE AND ADJUSTMENT

HOW TO REMOVE THE MOWER HOUSING

1. Move the lift lever to the middle position

2

Move the attachment clutch to the DISENGAGE position

(Figure 31 )

3.

Disconnect the blade drive link from the pivot rod and brack-

et assembly See illustration "C".

4.

Remove the hair pins from the adjuster plates See illustra-

tions "A" and "B".

5

Move the mower housing to the left until the right side adjuster

plate separates from the hanger. See illustration "A".

6

Move the mower housing to the rightuntit the left side adjuster

plate separates from the hanger. See illustration "B".

7.

Remove the long pin from the front hanger. See illustration

lIg_ -

Remove the mower drive belt fromthe stack pulley. Slide the

mower drive belt between the stack pulley and the belt

guide

9.

Completely turn the steering wheel to the right. Pull the mower

housing away from the left side of the unit.

StackPulley

t

BeltGuide

HOW TO INSTALL THE MOWER HOUSING

1. Completely turn the steering wheelto the right. Push the mower

housing under the left side of the unit.

2 Slide the mower drive belt between the stack pulley and the

belt guide Put the mower drive belt around the stack pulley

Make sure the "V" side of the mower drive belt is against the

stack pulley. Also, make sure the mower drive belt is not

twisted.

3. Attach the mower housing to the front hanger with the long

pin. Fasten with the washer and hair pin. See illustration "D"

4 Attach the adjuster plates to the hangers with the hair pins

See illustrations"A" and "B"

5 Connect the blade drive link to the pivot rod and bracket

assembly with the fasteners. See illustration "C'.

6. Move the attachment clutch to the ENGAGE position Make

sure the mower drive belt is inside all the belt guides.

7. Make sure the mower housing is level See the instructions on

"How To Level The Mower Housing".

8 Check the operation ofthe attachment clutch. See the instruc-

tions on "How To Adjust The Attachment Clutch".

Attachment Clutch

Blade Drive Link

/

Hanger

B

Adj

Hanger

F-99636 27

HairPin

MowerDnveBelt

\

Lift Lever

LongPin

/"

D

/__1 c B'_lade DnveLink

Front Hanger

Page 28

SERVICE AND ADJUSTMENT

HOW TO LEVEL THE MOWER HOUSING 1.

Ifthe mower housing is level, the blade wiltcut easier and the lawn

will look better.

WARNING: Before you make an inspection, adjust-

_iL ment, or repair to the unit, disconnect the wire to the

1. Make sure the unit is on a hard level surface

2. Check the air pressure in the tires. Ifthe air pressure is mcor-

3. Move the lever for the attachment clutch to the ENGAGE posi-

4. There are two adjustment procedures below that will levet the

THE SIDE TO SIDE ADJUSTMENT

There are measuring points on the mower housing indicated by

small round dimples A, B, C, and D shown in Figure 32. To

determine if an adjustment is needed, use a ruler and measure the

distance from the level surface to the bottom of the mower housing

at points C and D. in correct adjustment, the mower housing at

points C and D must be within 1/4" (6 mm) of the same height If the

difference inthe measurement is more than 1/4" (6 mm), adjust as

follows.

spark plug. Remove the spark plug wire to prevent

the engine from starting by accident.

rect, the mower housing will not cut level Make sure the rear

tires are inflated to 14 psi. (1 BAR) and the front tires to 22 psi.

(1.5 BAR)

tion Move the lift lever to the middle position

mower housing

SIDE VIEW

, _,

bottom

J.m/ ofthe mowerhousing

LEVELSURFACE

Disconnect one or both adjuster plates from the hangers

(Figure 33)

2.

The higher number holes in the adjuster plates will raise the

height of the mower housing The lower number holes will lower

the mower housing

3.

Connect the adjuster plates to the hangers in the holes that

will level the mower housing. Fasten the adjuster plates with

the hair pins

4.

Check the housing for the correct adjustment If necessary, re-

peat the adjustment

\. Hanger

Hair Pin

i///

AdjusterPlate

Figure 33

THE FRONT TO BACK ADJUSTMENT

To determine if an adjustmentis needed, use a rulerand measure

the distance from the level surface to the bottom of the mower

housing at points A and B. In correct adjustment,the front ofthe

mower housingat pointA wiltbe 1/8" to 3/8" (3mm to 9ram) lower

than the back of the mower housingat point B. Adjust asfollows.

1. Loosen the jam nut (Figure 34).

2. Turn the Iocknut clockwise to raise the front of the mower

housing Turn the Iocknut counterclockwiseto lowerthe front

of the mower housing

3 Check the housing for the correct adjustment ifnecessary, re-

peat the adjustment

4. Tighten the jam nut

5. Connect the wire to the spark plug.

C

F-99636 28

D

Figure 32

Suspens=on Bracket

SuspensionRod

Adjusting Clevis Counterclockwise

Jam Nut

Locknut

Figure 34

Page 29

SERVICE AND ADJUSTMENT

HOW TO REPLACE THE MOTION DRIVE BELT

REMOVAL

1. Remove the mower housing See the instructions on "How To

Remove The Mower Housing"

2. Completely push the clutch/brake pedal forward and engage

the parking brake.

3. Try to pull the motion drive belt off the drive pulley If the belt

guides are too close to the drive pulley, loosen the belt

guides (Figure 36)

4. Remove the motion drive belt from the idler pulley

5. Pull the motion drive belt toward the front of the unit.

6. Remove the motion drive belt from the stack pulley. If

necessary, loosen the belt guide at the stack pulley. A correct

replacement part or assistance is available from an authorized

service center in your area

INSTALLATION

1 Slide the motion drive belt between the stack pulley and the

belt guide, install the motion drive belt on the top pulleyofthe

stack pulley. Make sure the "V" side of the belt is against the

pulley (Figure 35).

2 Slide the motion drive belt between the belt retainer and idler

pulley Make sure the ftat side ofthe motion drive belt is against

the idler pulley. Also, make sure the belt is not twisted

3 Install the motion drive belt around the drive pulley

4. Make sure the motion drive belt is inside all the belt guides

5. Make sure all the belt guides are tight

6 Before you usethe unit, check the adjustment of theclutch See

the instructions "How To Check And Adjust The Clutch".

7 install the mower housing See the instructions"How To install

The Mower Housing"

j Pulley

F_gure35

Drive PuIley

BeltRetainel

Belt Guide

O

Stack Pulley

Loosen

BeltGuide

Figure 36

F-99636 29

Page 30

SERVICE AND ADJUSTMENT

HOW TO REPLACE THE MOWER DRIVE BELT

REMOVAL 3

1 Move the lift lever to the lowest position.

2 Slide the mower drive belt between the stack pulley and the

belt guide. Remove the mower drive belt from the stack pulley

3. Pull the belt retainer away from the idler pulley and remove

the mower drive belt (Figure 38).

4. Slide the mower drive belt between the mandrel pulley and 6

the belt guides

originalNOTE: Replace the mower drive belt with an

equipment beltfrom an authorized service center.

INSTALLATION

1. Pullthe belt guides awayfrom the mandrel pulley Slide the

belt between the belt guides andthe mandrel pulley.

2, Make sure the =V"s=deof the mower drive belt is against the

mandrel pulley (Figure 37).

Pull the belt retainer away from the idler pulley. Put the

mower drive belt around the idler pulley

4.

Make sure the mower drive belt is inside all the belt guides

Also make sure the mower drive belt is not twisted.

5

Slide the mower drive belt between the stack pulley and the

belt guide. Install the mower drive belt around the the stack

pulley

Before you mow, check the attachment clutch See the instruc-

tions on =How To Adjust The Attachment Clutch".

_ Pulley

Figure37

Belt Retainer

Idler Pulley

Mower Ddve Belt