Page 1

IMPORTANT MAI'_AL

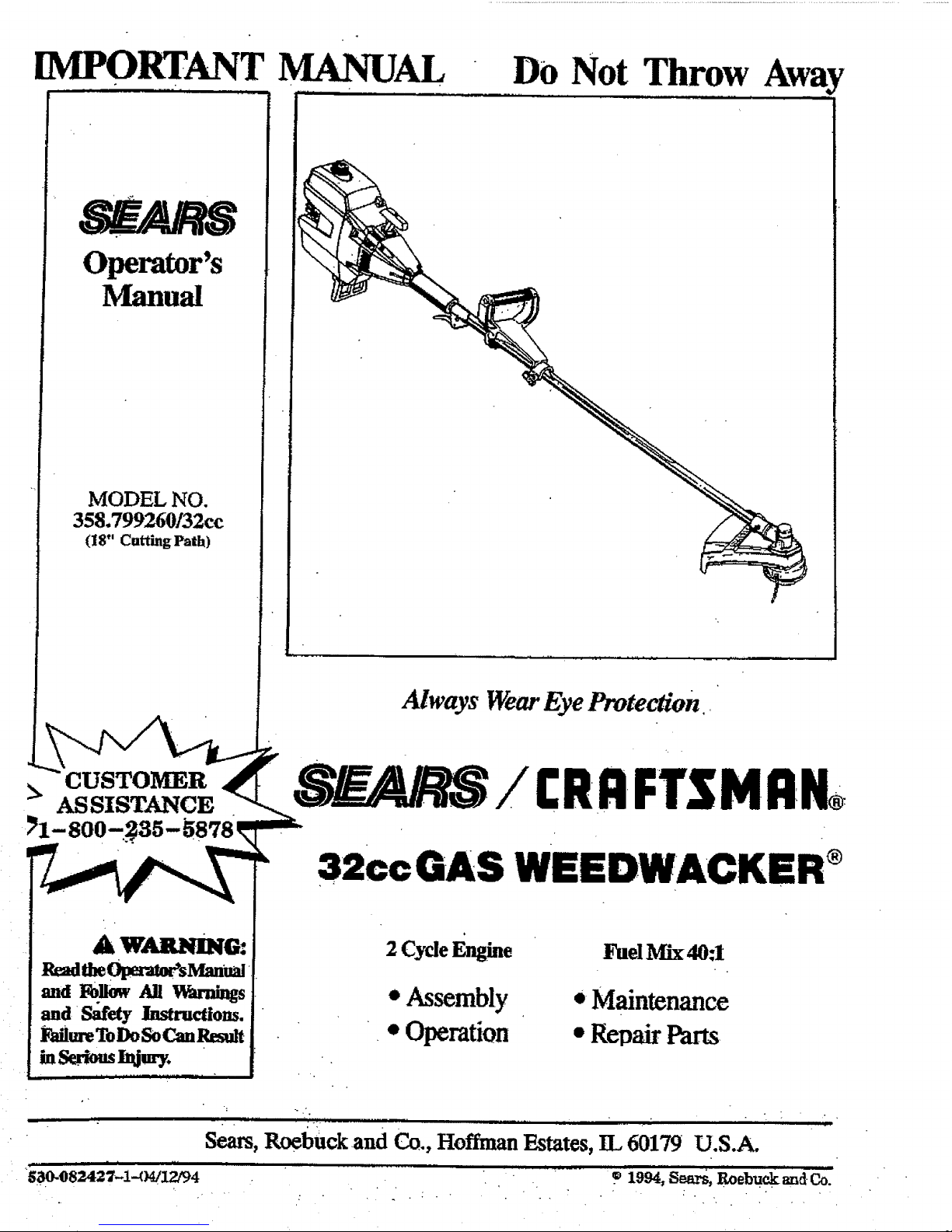

Operator's

Manual

MODEL NO.

358.799260132cc

(I8" Cntting Path)

Do Not Throw Away

Always Wear Eye Protection

/CRR.FTSMRN _z-soo-_35-SsTS .

& W_G:

and Follow All Warnings

and S_ety Instructions.

FaiiareToDoSoCaaRm_

inStr!_ hC,a_

32ccGAS WEEDWACKER ®

2 Cyde Engine

* Assembly

*Operation

lhld Mix 40:1

*Maintenance

• ReD,_. Parts,

•: .. o

......... . . • i ill I - ILl[Jt!t_t-r . ' Jllut

Sears,Roebuck.andC.o.,HoffmanEstates,IL 60179 U.S.A.

_30-08242_-i4_./12/94 " ® 1994, Sears, Roebuck and Co.

Page 2

= ....... -_ ......... . i i _ iii:ii_- ::::7 7 " :=;;;;;;;;;,L -. _ ...... -: :

Lmn D ON C -POWZR V E WAC Za®

whe_t_ _.c-_-_w_ w._.a_er_ mm_ed, lubber, _.dt_ up_g_ theo_" g_d

n_m_ance mm-uc_s m me operator's manure, _ars wm repair, free of c]_rge, any defect in m_ or wor_

a_ follows:

1 YEAR - Partsand Labor,w.henused forhousehold purlms_.

90 DAYS - Parts and Labor, if used for commercial, insti_ational, or professional purposes.

30 DAYS - Parts and Labor, if used for rental purposes.

Thiswarrantyexeahi.desnylonline,sparkplug,and air_ whicham expendablepartsand becomeworn duringnormaluse.

This w at'_n_appl_ onlywhile tl_ pz_tuct i_in use in the United Stat_. WARRANTY S_WIG-_IISAVAILABLEBYRETURNING THE

WEEDWACKERTO _ _ SEA_ SEleCtS _R_DEPARTMENT IN THE UNI_D _ATES.

Thiswerrantygivesyou Slmdfieieilalriglxta,andyoumay alsohaveotherri_tswhichvaryfromstatetostate.

SEAR_I_OF_2BUG'_ANDOOL D_P'JRSI_VA . HO_E_TES, IL 601ff9

TAB_ OF CONTENTS

WARNINGS AND _.FETY INSTRUCTIONS ...............3

KNOW YOUR UNIT .....................................................

ASSEMBLY .................................................................. 6

ACCEb'SORIES ............................................................ 9

FUELING YOUR ENGINE .................. :...................... 10

STARTING YOUR ENGINE ....................................... 11

L_ING YOUR UNIT................................................... 12

CUSTOMER RF_PONSIBILITIES ............................. 16

STORAGE ................................................................. 21

ILLUSTRATBD PARTS LIST ..................................... 23

INDEX .......................................................................26

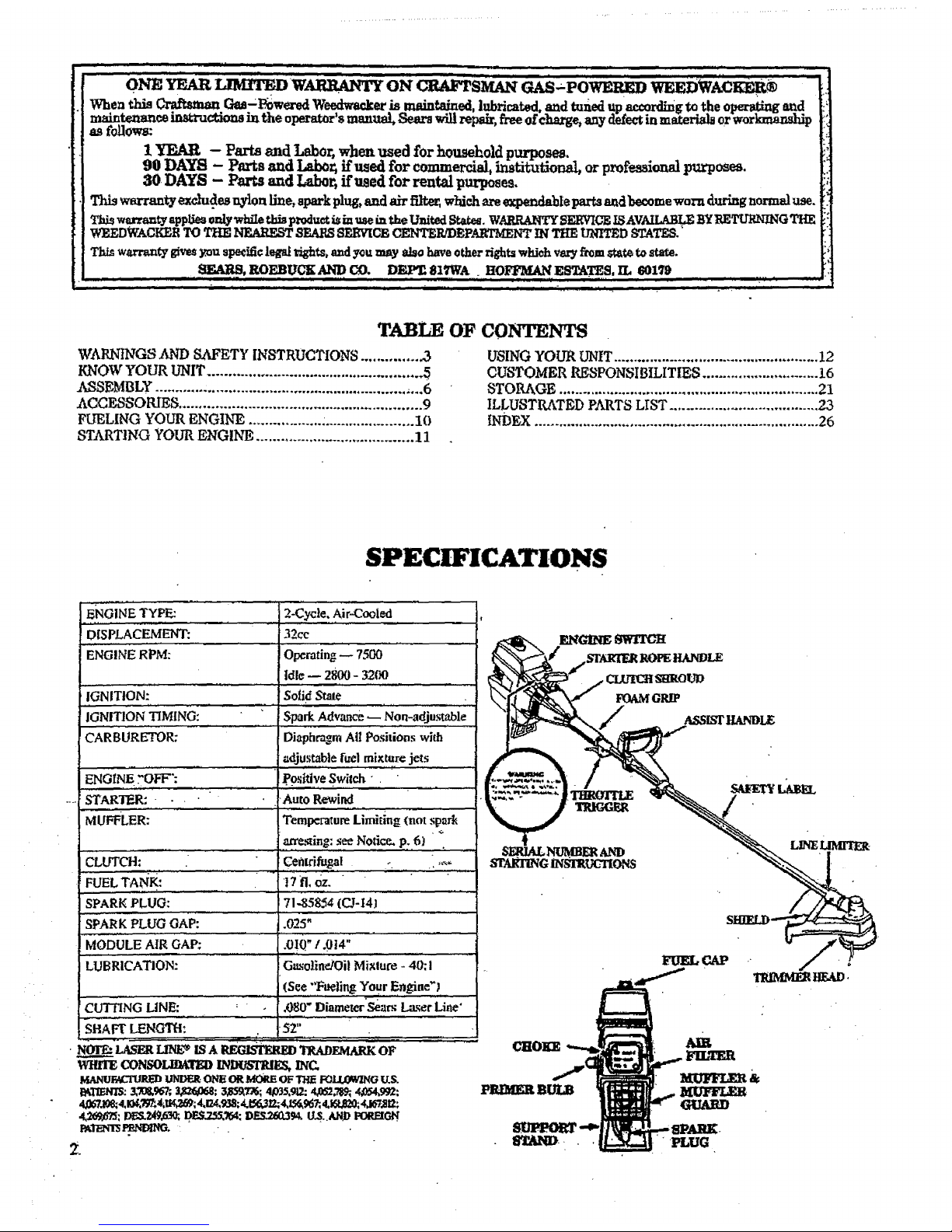

SPECIFICATIONS

._NGINE TYPE: ._ 2._ycle, Air--Cool_'d

!D[SPLACEMKNT: 32cc

-ENGINE RPM: Operating" 7500

Idle -- 2800-3200

IGNITION: Solid Stale

IGNITION TIMINGi iSpark Advance _ Non-adjustable

• .. =.............. _

CARBURETOR: !Diaphragm Ai! Positions with

adjustable _! mixture jets

v.rqO_NEi,_O_F':.... !pgsmyeSwath

STARTF-.R: - !Auto Rewind

MUFFLER: Temperature Limiting (not spa&

an_ing: see Notice. p. 6)

.......... .... . l 7 fl, oz. ....

SPARK PLUG: 171-_5854(CJ-t4}

sP^_:PLUGGAP- .o2s"

'MODULE: A(R GAP: .010" /.014'; ' "

LUBRICATION: ...... '_G_'_o!ineiOff Mixture- 40: |

[(See "FuelingYour Engine"]

CUTTING ILANEi : ' - ",080" Diamctcr'Sears Laser Line"

..... ......... .....................: --- ,

SHAFT LENGTH- 52"

• NO_ _UN_ [SA _ _¢DEMARKOF ....

WHrfE CONSOLI_T_D IN--KS, IN_

M,MqUFACIX/_ _ ONE OR _ OF I"F_ FO_O U.S.

I_.T_9_SPf_NgII_.

2.

PLUG

Page 3

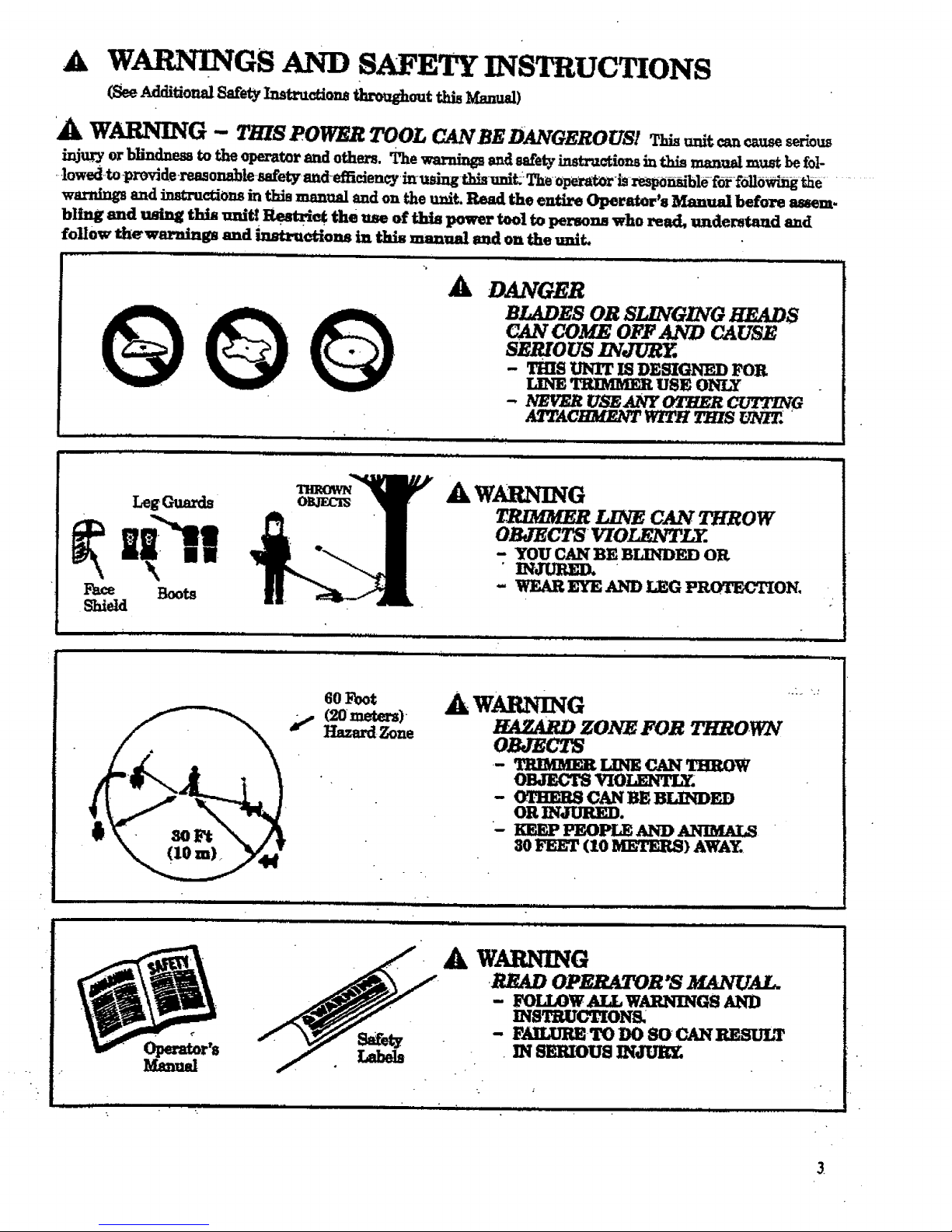

A WARNINGSAND SAFETYINSTRUCTIONS

(SeeAdditio_ SsfetyInst_ions t_=oughoutthisManual)

'_ WARNING - TH!S PO_ TOOL CANB£ DANGEROUS! _ uuitca__u_e_erio_

in_,y or blindness to the operator and others. The warnings andsafety instructions in this manual must be lot-

..towedto pre_ide_reasone_iesafety aud_efficiencyiu us.mg,.__uni_The_o__.__lef__f_o_ _e ............

warnings and instructions in this manual and on the unit. Read the entire Opeestor's Manual before usem-

bltng and using this untt_ .Restri'_ the use of this power tool to persons who read, understaud and

follow the_warnings and instructions in this manual and on the umt.

O00

DANGER

_E8 OR SLINGING KEAD8

CAN COME OFF AND CAUSE

SERr OU$ INJURY.

- THIS UNIT IS DESIGNED FOR

LINE TRIMMER USE ONLY

- NEVER US_ ANY OTHER _G

ATFAC_ WiTH TH/S "_ "

il i i ,,

LegG_

Face Boots

Shield

A WkRNING

TRIMMER LINE CAN TKROW

OBJEC'I_ VIOLENTLY..

- YOU CAN BE BLINDED OR

- WEAE EYE AND LEG P-_ON,

III 1 II I IIIIIIIIIIIIIH II [_L__ ..... ._

60 Foot

(20mete_)-

Hazard Zone

A

.HAFA__ZONE FOR TIIROWN

OBJECTS

- _LINECANTHROW

OBJECTS VIOLENTLY.

- OTHERS CAN BE BLINDED

OR ]N_.

- EEEP PEOPLE _ ANIMA_

30 FEET (10 METERS) AWAY.

,,,111111 ,,., ; ............. ill! ill i

II II ..... IIlIl ill jill .,IIIWLILt___

READ OPERATOR N MANUAL

- FOLLOWALLWARNINGSAND

• _ F_TO DO SO CAN RESULT

• IN SERIOUS IN_

3

Page 4

WARNINGS AND SAFETY INSTRUCTIONS....(Cont ued)

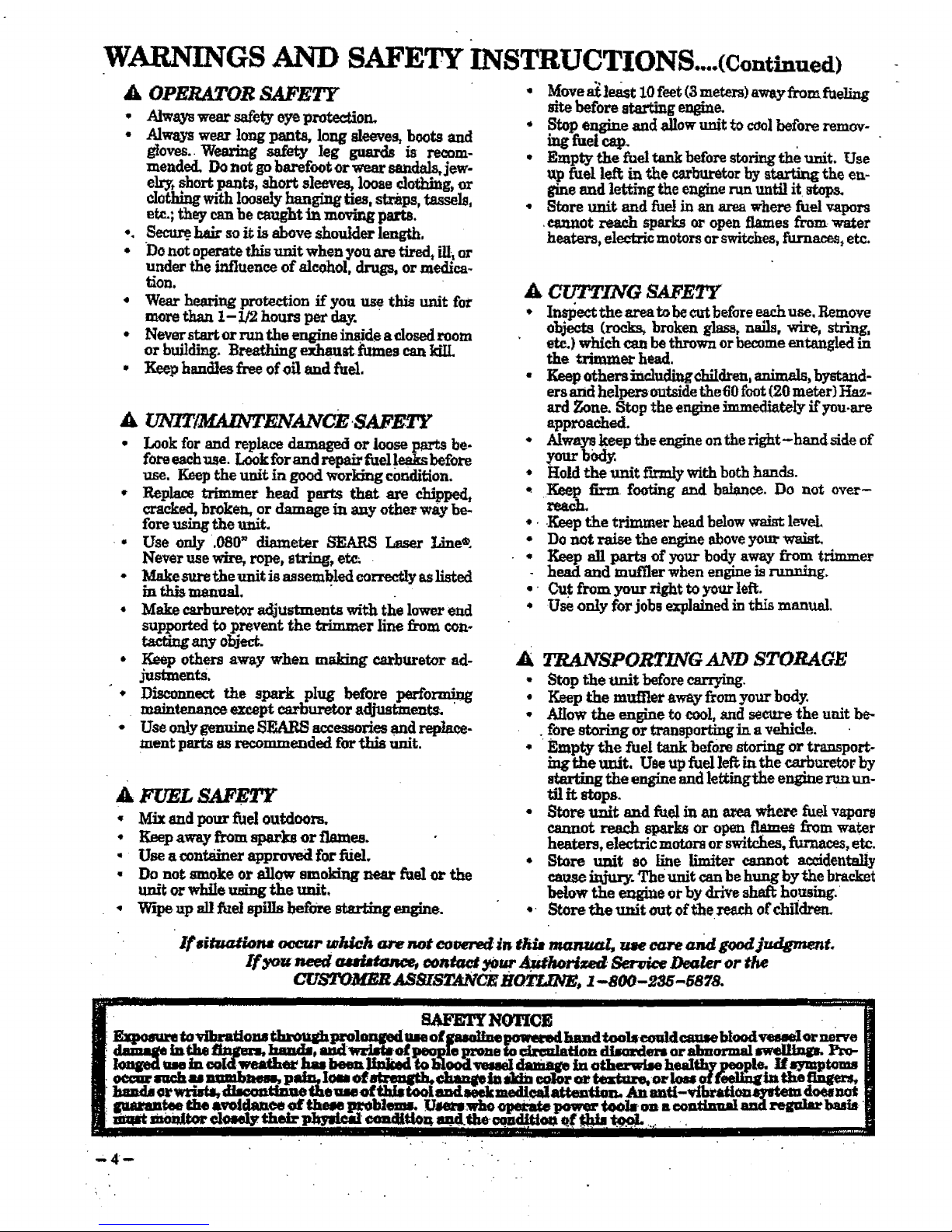

A OPERATOR SAFETY

• Always wear safety eye protection.

• Always wear tong pants, long sleeves, boots and

gloves. Wearing safety leg guards is recom-

mended. Do not gq barefoot or wear sandah, jew-

e_try,short pants, short sleeves, loose clothing, or

cIothing with looselyhangingties, straps,tassels,

etc.;they can be caughtinmoving parts.

•. Secu_. hair soitisabove shoulder length.

• Do not operate this unit when you are tired, ilI)or

under the influence of alcohol, drugs, or medica.

tion.

• Wear hearing protection ff you use this unit for

more than I- 1/2 hours per da_

• Never start or nm t_e e_ne insiide ad_ room

or build_. Breathing _st Runes can

• Keep han_lesfreeof oil and fu_.

• Move atleast10feet(3meters)awayfrom fueling

_te before startingengine,

• Stopengineand allowunittocoolbeforeremov-

• Empty the fuel tank before storing the unit. Use

• Store unit and fue! in an area where fuel vapors

,cannot reach sparks or open flames from water

heaters, electric motors or switches, Rtrnaces, et_

A CUTT/NG SAFETY

* In_ theareatohe cutbeforeeachuse,Remow

objects (rocks, brokenglass, nails,wire,stag,

etc.) which can be thrown or become entangled in

the trimmer head.

_xUArlTI__AAVCE ._AFETY

• Look for and replace damaged or loose parts be.

fore each use. Look for and repair fuel leaks before

use. Keep the unit in good working condition.

, Replace trimmer head psrts that are chipped,

cracked, broken, or damage in any other way be-

* Use only _._0 _ diameter SEARS Laser Line e,

Never use wire, _pe, s_ng, e_

* Make sure the unit is assembled coreectly as listed

in this nmnual,

. Make carburetoradjustmentswiththelowerend

supported to prevent the trimmer line from con-

tactingany objec_

, Keep o_e_ away when making _e_ ad-

justments.

. Discm_nectt_e spark _plug be.fo_re_fforn_.

n_n_nan_ except carburetor adjustments.

* Use only _nume SEARS accesso_ and _p_ce-

ment parts ss recommended for _ umt.

A FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flsmes.

• Use a contsiner approved for fuel.

• Do not smoke or _]]ow smoking near fuel or the

unitorwhileusingtheunit,

° Wipe _ aH fuel spills before starting engine.

approachod_

* Always keep the engine on the right - hand side of

your bo_.

* Hold the unit firmly with both hands.

. .]_eep_flrm,_ footingand bslance.Do not over-

*..Keepthe trimmer headbelowwaistlevel

• Do not raise the engiue above your

, _Keep _l] parts of your body away from trimmer

head and muffler when engine is running.

, Cut from your right to your left.

* -Use only for jobs ex_]alned in this manttal,

TRANSPORTING AND STORAGE

• Stop the unit before carrying.

* Keep the muffler away from your body.

° AIIow the engine to cool, and secure the unit be-

. forestoringorU-amporting in a vehicle.

, Empty the fuel tank before storing or transport-

ing the unit. Use up fuel let_ in the carburetor by

starting the engine and lettingthe engine run un-

til it stops.

• Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames f_vm water

heaters, electricmotorsor switches,furnace,etc.

° Store unit so line_ cannot accidentally

cause injury. The unit can be hung by the bracket

below the engine orby drive shaft housing.

- Store the unit out of the ree_ of children.

F situa_ns oeeur whleh are not eom_d in tSis nmnu_ use care and goodj_t.

lf you need asslstanee, eon_t _ur "An#hor_zed.Service Dealer or the

CUb"TOMER AS_STAN6'E HO_, 1-800-236-6878.

L • .

EM_su_ tovibration_ _p_o_ !e_ged uH ot p_oline_ handtooh•eeuldeause bloodstone []

i dama_ _flmflngm_ham_,_dw_m_-_p_p[e_ne_e_flaflondh_dmor_mo_mfl_ Pro- []

i _ uP. t. eo_d_ _ _effi _-to _ vessel _ in oth_ h__e_._. _ _toffi_

• wris_ eal -

r- IIIIIII II i - .. i_11 ..._- ] i/11 11"['lilil'[I 1 I L ,,._........

_4 _ - o

Page 5

bmo your

jl ....... I Illlll I I Ill l I I i i , ,,,,,,,,, ,,,,,,,,,,,,,,,, ........... ".

A, INTRODUCTION _ CAKTON CONTENTS

Your Trimmer is a versatile product designed to help KEYNO.

you give your lawn a finished appeamnc_

Special_ Include:

* Centrifugal Clutch

* AIl-lmsitio_ Carbgretor

. Adjustable, anti.be, cushioned Assist Handle

• _-Automatlc Trimmer Head

• 18 _.Cut/lagPath

B. UNPEG iNdUCTIONS

1. Remove contents from the carton if y_u have not

done so.

2. Check parts against Lhelist below.

3. Examine pare fordamage, Donor usedarnaged parts.

4. Noc*_ your $¢ars Store immediately ifa part is miss-

NOTE: Yourunit has been shipped with aplastic

shipping guard over the primer bulb (see

_dpecifications" for location). Remove and

discard the plastic shipping guard.

!t is n_to hear the.fuel rater rathe in

aa empty fuel tank.

CAKION CO_:

o Engine

. DriveSha_Oear BoxAssembb'w/SafetyI._i

mxdDustCup ,!

" Shield 1

" Trimmer Head 1

" 2-cycle F.agineOil !

•. Opcra_'s Mam_ (NotShown) 1

• I.oo_ Putts!_ag(NotSho_n) l

*LOOSEPARTSBAGCO_

" Flex ShaftLube I

" T-_- AssistHandle I

; HcxWnmch-.tmall.. 1

. Her Wrench-Large 1

A. H_Socka HcadScr_v,ClutchShroud 2

B, Slot_d Hex 'He.,adScrew - Shield 4

C. Hex Sock_ HeadSccew. Thrc_qi¢Trigger Housing 1

D. SquareHeadScow - AssistHandle 1

E. HexLock..Na_-C_utchShroudtTdg,_rH_siag 3

Kb_Nm. AssistHa_le • 1

c. Largecup Washer 1

l

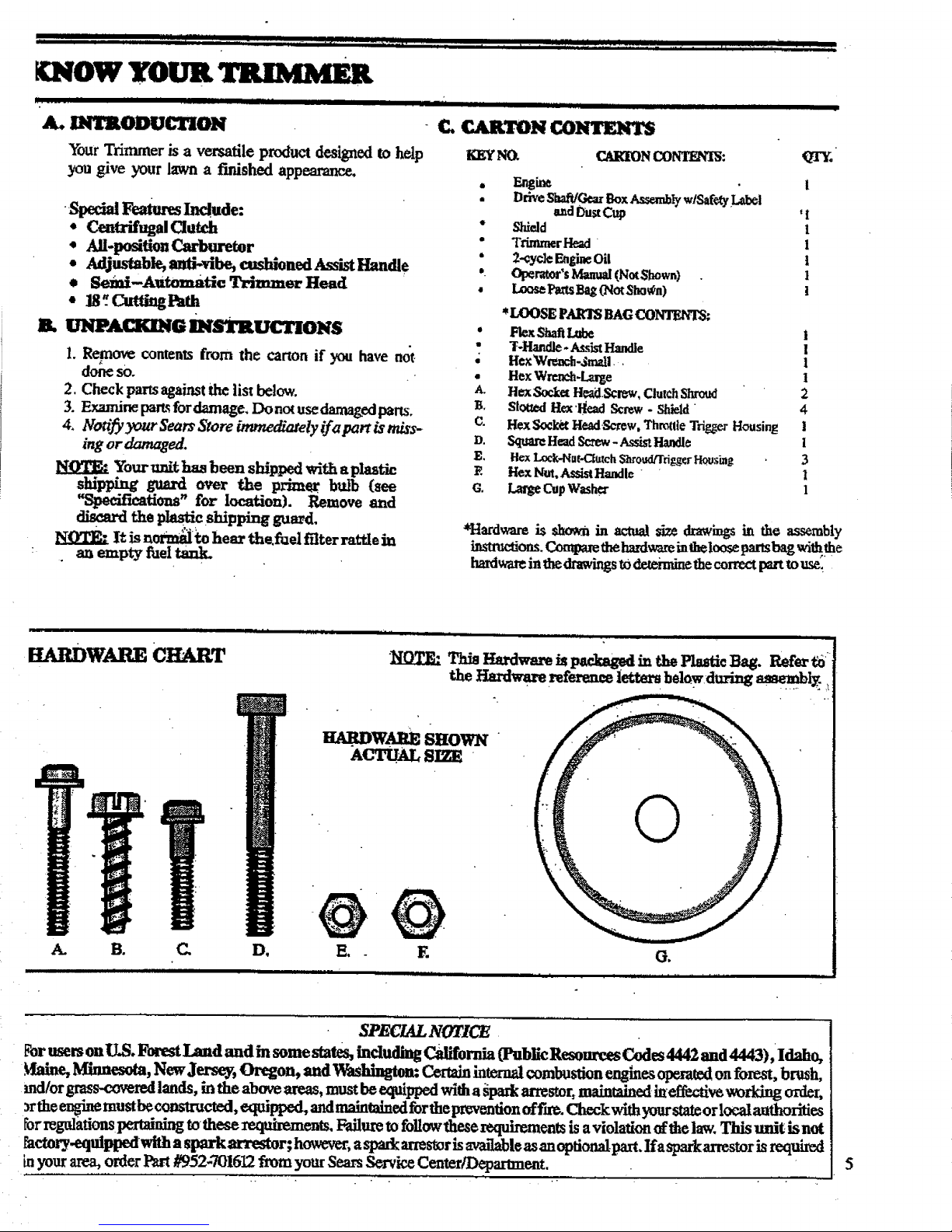

*Hardveza-eis_ in actualsi_ drawingsinthe assembly

_ons. Ccanpa_ tile haxd_e iath_lcose pans bag with the

haS,rarein_ drawingstode_imir_th¢con-ectrafttouse_'

aDWAaE CHART

@0

A. B. C. D. E.- E O.

SPEGIAL NOTICE L

For users on US. Forest land and in some s_tes, including California (Public Resonrees Codes 4442 and 4443) ,Idaho,

I_mesota, New Jersey, Oregon, and Washlastem Certain internal combustion engines operated on forest, brush,

rod/orgrass-coveredlands, in the above areas, must be equipped with a _park arrestor, n_intained ine£Sectiwworking ord_,

_rthe engine mustbeconstructed, equipped, and maintained forthe prevention offire. Checkwlth yourstat_or local authorities

_r regulations pertaining to*these zequimments. Fai!uze to follow the.s¢requirements is a violation of 1helaw. This unit. is not

hctory-equllgmdwttha sparker; howev_,asparkarrestoris_le asanoptionalpart,irasparker _ _

inyour area, order Pat't#952-'/01612 from your Sears Service CenleriDcpartmem.

Page 6

ASSEMBLY

(If tool is reeeivM, assembled, repeat all steps in this section to be.sure assembly is correct and ii ad-

justed for the operator.)

A. PREPARATION

' This Manual is designed to help you _semble the tool

and to provide its safe operation. It is important that

you read the entire manual to become familiar with

the tool before you begin a_sembly. If you have ar_v

questions or need fixrther assistance, car our

CUSTOMER ASSISTANCE HOTLINE at

!-800-235-5878.

_1] ]1 I II IIIIIII I I I/ __ , HI I Illllllllllllll Jill

z. ltead yotw Operator's _

2. Toeh you willaee&

- Hex Wrench ¢avvided with the tool.

_j__ • Wx_.n_orta_ plien

Flat Blade Screwdriver

B.ASSEMBLY ST_PS

Hardware referredtoin.thefollowings_."oneisshown actualsizeintheHardware Chart,page 5.

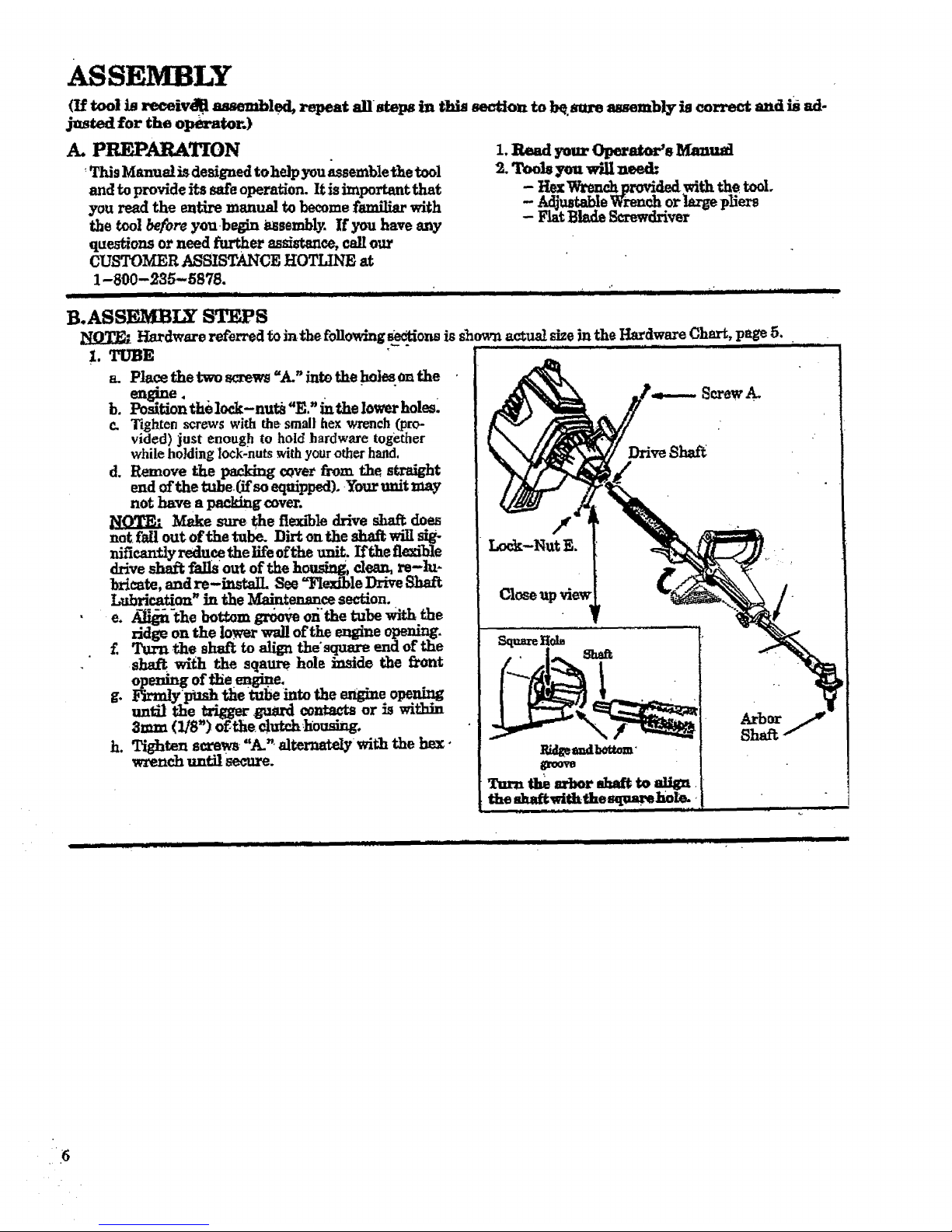

i.Tt_E

v. Place the two screws _L" into the holes on t_e

b. Posltionthe]ock-nutb"E." in the lower holes.

c. Tighten ,scr_-,vswith the-small hex wrench (.pro-

vided) just enoug h to hold hardware together

while homing lock-nuts .with your other hand.

d. Remove the packingcoverfrom the.straight

end of the tube(ifsoequipped). Your unit may

not have a packing cover.

not fall out of the tube_ Dirt on the shaft will sig-

nificantly reduce the life of the unit. If the flex_e

ddve shaft falls out of the housing, clea_ re-]u_

hricate, andi,_-re install See _Flexible Drive Shaft

Lubrication" in the Maintenance section.

e. _the bot_m 8r6o_ ozi"the tube With the

ridge on the lower wall ofthe engine opening.

£ Turn the shafttoalignthe'squvxeend of the

shaft wifllthe sqaure hole insidethe front

opening of the engine,

g.ra_...y_ thence_to theen_ o_..a_.

untll t_e _ ff_d conta_ or _ wRhm

3mm (!/8") ofthe, dutch:_using.

h. Tighten screws "A.". alternately with the hex

wrench until secure.

Shaft

• L....... ' ........ ' "!'2"2

.......... .-- .:_ _

6

Page 7

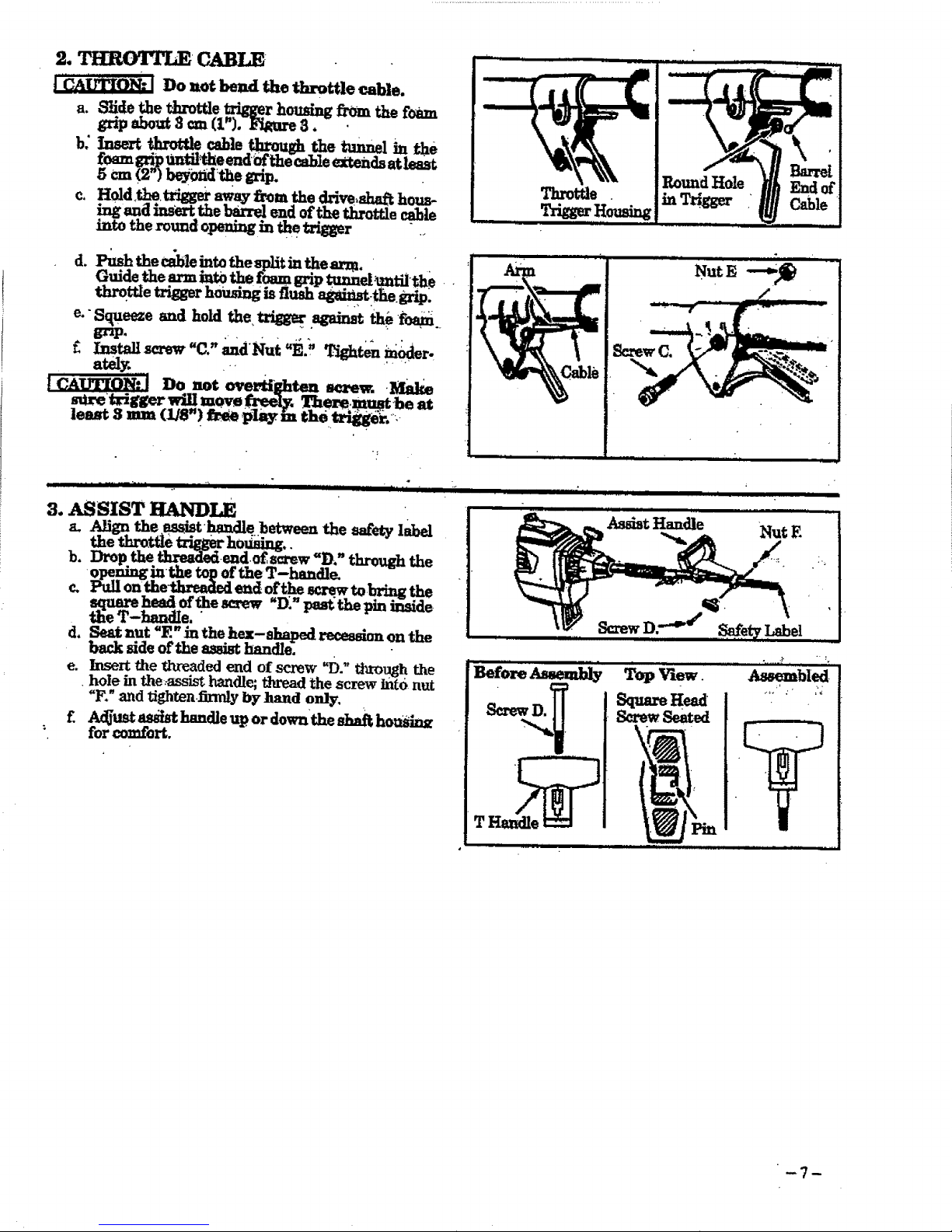

2. TtEP.OTII_ CABLE

Do not bend the throttle cable.

a _de the throttle _r housing from the foam

grip about 8 cm (1%-_eure 8.

b: _ _ csk]ethroughthe _unnet_ _e

fosm grip Until_._e endbfthe cable e_ds at lesst

5 =m(2")bey_l_t]_e_p.

c. Hold.the trigS_ away from the drive,shaft hous-

ing and _ the bsn_ end of the throttle cable

into the roundopeningin _e trig_r ..

d. _ the c_le iuto the _q31itin the arm, _ •

Guide the arm into the foam _i'p tunnel:tmtilthe. •

tt_ro_ tr_,erho._ _ au_h_t_'_.

grip,

£ Inste_ screw "C." andNut _._ Tighten =_'oder.

at_y; ....... ...

,,,,,, , ii a|r ...... -............ i I / "

s. ASSZST

a, Align the,essist _e. between the sa_'ety lebel

the _ triggerhouaipg_ .. ,, ,,

b. Drop the _ede@d._screw D. through the

opening inthe top of the T.handle.

C, t_U on thethreaded end_ o_t_h_,ecrU. to_-ng the

_headofthescrew D. past the pin inside

ti_e T-handIe. "

d, Seatnut _E_iuthehex-shapedrecessi_onthe

back side of the assist ltsndle. . -

e. Insert the threaded end of screw =D._ ttu-ough the

•hote in the._assisthandle; thread the screw into nut

_F._and tighten.firmlyby hand only.

£ Ac_ust as_st handle up or downthe sha_ ho_

forcomfort.

lllllllllllllllll . l ....... II . IIIVRIOII[I IIIII

I I

.........Assist;Handle

....._'_'.

,.. Screw D. ..Safety.Label ....

T Handle

-7-

Page 8

III IIIII J Jl.__ _ ................................. Tit

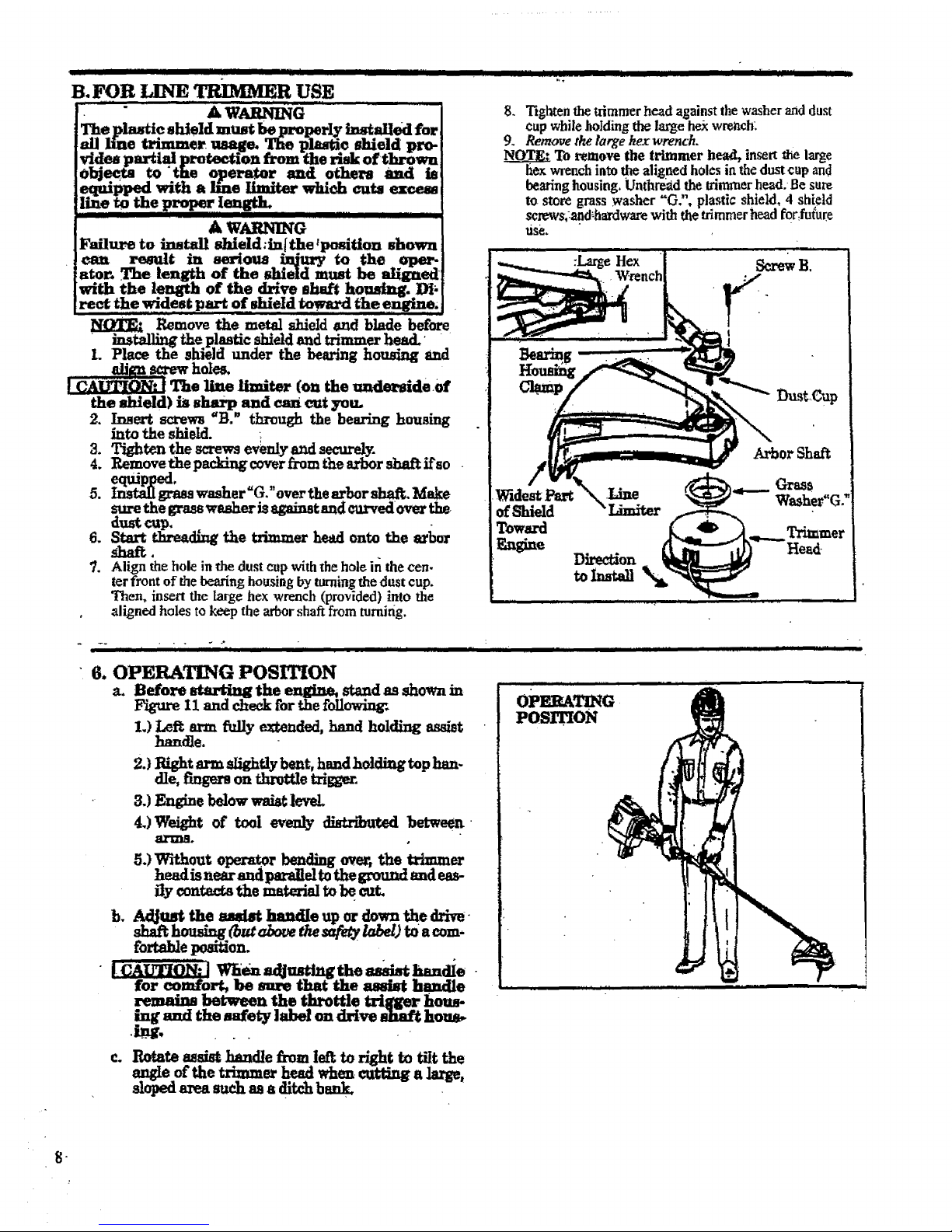

B. FOR LI]qE _ USE

....... |Moo. ,m i

- ' A WARNING ..............

&WARNING

Failure to install shteld:tnlthe Iposition shown i

can remdt in serious injury to the ope_

!ator. The length of the s_e|d must be _eti _',

with the length of the drive shaft _. Dll

rect the widest part of shield toward the engine.i

Remove the metal shield _md blade before

• _talli_. the plastic shield and trimmer hea_L--

L Place the shield under the bearing housing and

..........alien_ hole_

The line ltmlter (on the unde_ide.of

the shield) is sha_ and can cut you.

2. Insert sc_,ew_ _B." through the bearing h_u_

into the shield.

3. Tighten the screws evenly and securely. - ,.

4. Remove thepackingcover from the arbor snar_ if so •

5. _s_gr_ washer"G." over the arbor sh_, Make

sure the gra_ washor is agent and curved over the.

6. Start the trimmer head onto the _rbor

shaf_.

7. Align the hole in the dust cup with thehole in the ccn-

zerfront of thebearing housing by turningthe dust cup.

Then, insc_ the Largehex wrench (provided) into the

aligned holes to keep the arborshaft from turning.

8. Tightenthe trimmer head against thewasher and dust

cup white holding the large hei wre_¢h:

9. Remove the large hex wrench.

To remove the trimmer head, inert _e la_e

hex wrenchinto the aligned holes in thedust cup and

bearinghousing, Unthr¢_tdthe Irimmexhead. Be su_

to store grass ,washer"GD, plastic shield, 4 shield

scwws_:and_hardwarewith the trimmerhead lot',future

USe.

/

Arbor Shaft

6. OPERATING POSITION

a. Before starting the engine, stand _ showain

Figure II and check for thefoLl_

L) Lef_ arm fully extended, hand holding assist

handle.

23 Right arm slightly bent, hand holding top ban.

dle,fingerson throttle trigger.

33 Engine below wais_ level

4.) Weight of tool evenly dlstrflmt_l between

5.)Without operatorbendingover,the t_mmer

headis near and parallelto the ground end eas-

ily contec_the materialto_ cut.

b. Ad_u_ the mudst handleup or downt_edrive-

sha_ housing (but aboce the sa/_/abe2) tOacom-

fortable posi_on.

_rW_ez a__ theas_t bzndie -

be sure that the assist handle

remains between the throttle trigger hous-

ing and the safe_y label on drive ehTofg houa_

POSITION

e. Rotate ezsist handle fromleft to right to tilt the

m_le of the trmmer headwhen.cutt_ a lar_,

_oped arcusuch as a _t_ b_k,

.

Page 9

" . • .........." _ i . Ii iiiiii iiiiiiii i mmlllm|lr......... _ "

I I i ununulrlrn _. I II Ill .. L_

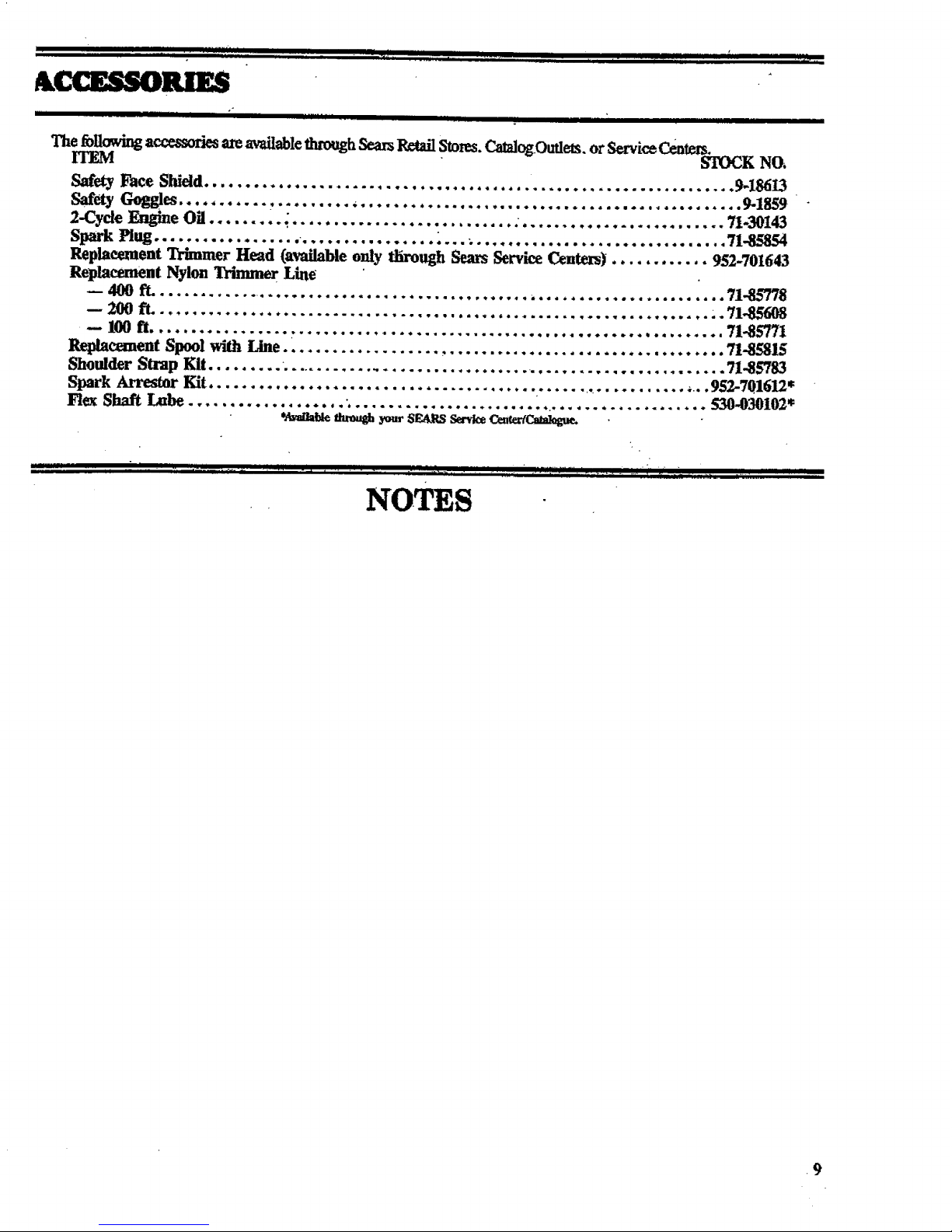

Th_llowing a_ areav_labletJm_h _ RetailSto_e_.CatdogO_e_s.orServi_ C_t_OCK NO,

Safety Face Shield ................................................................. 9-18613

Safety_ ..................... ,............................................... 9-1SS9

2-Cyde Engine Oil " - 71.30143

Spark Plug • 71-8$8$4

Replacement Trimmer Head (available only tliroug_ Sears Service C_te_) ............ 95_701643

Replacement Nylon Trinnner Line

-- 400 ft. .............................................. . ....................... 71-8._78

-- 200 ft. ................................................................... :. 71._,';608

-- 100 fl ...................................................................... 71-85771

lltl_e_m_t Spool with Line. _,..................................................., 71-K_15

Sho_r Strap Kit ......... ............................... ........................ 71-8_/83

Spark _ Kit ........................................................... ,. ,952-70,1612"

• 530-030102"

FI_ Shaft Lube

*_b_e tJ_eu_hyourS_ Ser_ Om_r/(_tz_e.

i, nnnilllmmnmm i E IIII I I ill " I- _ .......... " "[" _i_i ._ • _ . - _ "'" _ . , , . _ . " _" .ll_llll[.ini aft i . IIIIIII "Jl "" " ..... I T

NOTES

9

Page 10

FUELING YOUR ENGI

BEFORE FUFJANG ENGINE:

A WARNING

Be sure to read _e file[ safety information in the Warn-

ings and SmOkyInstructions section on page 4 of this

manual before you begin.

IfYou do not understand _ fuel safety section DO NOT

iattempt to fueI your unit; seek help from someone that

doe_ understand the fuel safety section or call the Cus-

tomer Assistance Hofline at 1-800-235-5878.

2-CYCLE OIL:

CRAFTS1KAN 40:! 2 cycle oil is strongly recommende&

This off is specially blended with fuel stabiiizers for

increased fuel .stability (extends fuel life up to 5 times

longer) and reduced smoke.

CRAFTSMAN 2 cycle oil is not a_le, use e good

quality 2 cycle AIR-COOLED en_me oil tha_ has a

recommended fuel mix 40:1.

IMt_RTANT! no not use_

The two-cycleengineon thisproductrequiresa_el mix-

tareof regularunleadedgasolineand a high qualityew

gineoilforlubricationofthe beariugsand othermoving

parts.The correct fuel/oilmixture is40:1 (see Fuel Mix-

ture Chart).Too littleoil or the iueormct off type will

cause poor performanceand may cause the engine to over-

heat and seize,

Gasolinean_ oilmustbe premixedin acleanapprovedfuel

containe_Always usefreshregularunleadedgasoline.

IMPORTAN_ Experience indicates that alcohol

blended lusts €_dled gasohol (or using ethanol or metha-

nol) can attract mo'mture, which leads to oiFgas separa-

tion and forma_denofacidsduring storage. Acidic gas

can dams_e the fue! system of an en_ne while in storage_

To avoid engine problems, the fuel system should be

emptied before storage for S0 days or longer. Drain the

gas tank, then rrm the fuel out ofthe carburetor and fuel

linesby startingtheengine and lettingitrun untilit

stops. Use fresh fuel next season. See STORAGE

instm_ons foradditionalinformation.Never useen-

gine or carburetorcleanerproductsinthe fuelt_r or

permanent damage may occu_

• AUTOMOTIVE OIL

• BOAT OILS _ BIA. etc.)

These oils do not have proper additives iror 2-cycle,

AIR-COOLED enginesand cancause engine damage.

GASOLINEAND OIL TURE

Mix gaso-Iineand oilas follows:

* Consultchartforcorrectquantities.

. Do notmix gasdlineand oildirectlyinthefueltan_

FOR ONE GALLON:

* Pour 3.2 ounces of high quali_ 2-cycle engine off

into an empW, approved one gallon: gasoline con-

tainer,

. Add one gallon ofregular unleaded gasoline to the

gallon eon_dner, then Securely replace the cap.

Shake the container momentarily. •

• The mixture is now ready for use. Fuel stabilizer

can be added at this time if desired; follow mixing

instructionson the label.

FUEL STABILIZER

Fuel st,sb_]_er is an acceptable alternative in ___;,_g

the form_ion of fuel gum deposits during storage. Add

stabilizer ,to gasoline in fuel tank or storage eontainer.

Always follow the fuel mix ratio found on the _tabi]izer

container. Run engine at least 10 minutes after adding

stetdlizer to allow the stabi_.er to reach, the carburetor.

You do not have to drain the _el _ for storage ifyou are

using fuel stabilize_

CRAFTSMAN 40:I 2 cyele engine oil is specially blended

with fuel stabilizers. If you do not use this Sears oil, you

can adda fuel stabilizer (_uch as Craftzman N o. 33,500) to

your fuel tan!_

FUEL MIXTURE CHART

40:1 Fu_l:Ofl Mix l_tlo

t fia_zline Off (ft. oz,)

1 gallon 3.2

L25 gal!ons 4.0

2.5 gallons 8.0

-i r 11 r __

I0

Page 11

STARTING YOUR ENGINE

(For location of eentmk, refer to _S_")

BEFORE STARTING THE F24GIN_

• Fuel e_ne. Move 10 feet (3 metres) awe_yfi'omfuel-

ling site.

A WARNING

The trimmer head u/t/turn w/te_ the engine

starts.

• Rest engine _ shield on ground, supporting lower

end off ground.

Removeand discard the Izle__icshi_

on the primer bulb (ifso equil_ed).

STARTING A COLD ]_GM OB WARM ENGINE

AFrER RUNNING OUT OF

• _ Move the swlt_ to the "On" l_z3ition.

• Move the choke lever to the "F_II Choke" position{

• Slowly press the primer bulb 6 times,

• S.queez. e and hold the throttle trigger, Ke_ the

throa_ _g_er f_y _ un_ th_ _.

smooth/y.

• Pu!! starter rope sharply 5 times+

The engine rosy sound _ .if it is tryin_ to

start before the 5_pull. _Ifso, go to the next step Im-

mediately.

• Move the choke lever to the "Half Choke" position+

• Pull the starter rope sharl:_ until tke engine runs,

but no more than 6 pulis.

.,hu not start_ after 6 pulls (at

to make sure the switch and the

choke lever are in the proper posi_ons. Then, move

the choke lever to t_e "Ftdl Choke" position and

press the primer b_b 6 times; s_jueeze and h_oldthe

_.t_ot_etrigger_mdp_._the_ _ z more

times. Mo_ the ehoke lever to HalfChoke _mdpttU

the starter rope until the engine runs, but no more

than 6 more pulis.

flooded+Proc_to Starti_aFioo_. _ _

• Allow the _e to run 15 seconds,then move the

choke lever to OffChoke. AIIow the unit to rtm for

30 mo_ seconds at "Off Choke _ beferereleasing the

throttle tr_er,

If engine dies with the ehoke lever at the "Off

Choke" _pogiti_, move the __pke lever to "Ha_

Choke" _ pull the rope unt9 the engine runs.

• To stopthe enl_ue, move _ to the'_O/_ position.

I.... --- iaW G. L+ I

IAvoid any bodily contact _th the muffler when |

• t._gawm, menffine+ Ahotm_ercanee_ase|

tserto_ _ !

STARTING A FLOODED ENGINE:

Flooded e.___ can be start_"l_, mo_'the mm"i.+t+t_

tothe"On _itienandplacingthe&+ke k_v+ m

the "_ Choke"po_i_tiom_en, pu_+the ro_ to _ear

the enl_ ofexcess fit+ This <_d requ+3re+p.umng

the starter _repemany times depending on how oacuy

• the trait is flee&d.

OPERATING INSTRUCTIONS

• Do.o,

neeeNa_.

the _ is run at less than fun tl_rottle. At l__wer

cu_ linew_ last!ongerand willbe lese_eleselikelyto

.

to_ ,oIdle_ Whe_-o*_.

Ifthe trlmmer heed do_ not tur_ when the en

_ ts _ceelerated, make rare the &ire _tit hous.

_Assembly-Drive Shaft Houmn+g,. • +

• To 8to_ the • +_

• Releeseth-e_e _

• Move the switch to the Off" position+

- +o,%,

Switch

Choke Lever

" !1

Page 12

4.i_a warm_ilae(_n_ehunliout

enllull):

Refuelen_ne,Mow10feetawayfromfuetingsite.

b. Move On/Off Sw_tch to "on."

c. Move Choke to"'full" position.

d.C,nupFromC,_anesqu_z_"nu,o_'rdg__y.

Keep Throttle Trisger fully $_wcZed _ engine

r!1_.

PuttSurerRopesharplyun$engineauemp_to

run, but no more than 5 pulls.

f. Move Choleto"off" position..

g. Full_ Rq_ u_e_in_ nm, lx_nomc_han

NOTE: Heaginchas not staned,lmll _r P,ag¢

5 more Falls. Ifeng_ still does hot run, it is pro-

bably flooded. Waita f_w minutes and_ pro-

cedure with L"ho_ at "off". _.

D.oemaTmGmsnu..on..ore

1: Before entering the material to be eul, bring the

engine to cutting speed by squeezing the _e

trigger.

a. Do not run theengineat a hlgher,speedthan

necessary. The cul_ag line wi_ cut effieie_y

when the engine is run at less than full thn_..e.

At lower sleds there is less _no'_ and

vibration.The-trimmerlinewilllastloagei,,and

will be less likely to "'weld" .ont_.the spooL:

b. If the Trinket Head does not luru whenthe

engineisaccelerated,make,suretheD/ireShaft

Housingisproperlyseatedinthe¢lu_ Shn_.

. Refer to "Assembly-Driv_ SlmftHousing:' •

_-. :.,',',',','D,,-_-,,,

2. Always releasethe Throttle THgger and allow the

engine to retain te idle speed whm not cutting.

3. Mal_ sate the_rimmer Heads_ps awning'what

thelhmllkTriggerisreleasedandtheenglne

rims al idle speed, For om'ecfion refer i_ "Ca_u-

r_torAdjusunenls:'

4.to stoptheeagiae:

L Release the Throttle Trigger.

b. Move On/Off Switch to the "Off' position.

,m i ,,,,m , i Ill l II HI __ IHI_HHNJ

, "ll i I tiif_ " _' r, f a ' .""'I"!'""!!.!!!::.--..... ; :i ' ,:I"'I'_"!" ....... :__ : =,

USING YOUR UNIT

_._1............. IIIII II Illlllll II I , ,r_ I IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIj ......... ] "'111 IIII I II ...... i/ I IIIIIIIIIIII .... .......

AW G - T OWSO JWrs

The rapicHymoving line causes objects toI_ thrownviolently.

The shied will not providecomplete protectiontotheopera-

tot or o_rs. The operator must wear a safety fa_s_g!d

orgogg_ Alwayswear heavy, longpantsandboots. Keep .

oUhersat leb_ 30 feet away.

12

i

i1 IIIUl 11 I I llllllllllll i

._.. Trimm_Head

UseOn_y__p_mnents_

:+

_- ,it

tool will throw objects and cut.Keep others including

children, animals, bystanders, and helpers at least 30 feet

away from the opem_or and tool. Stop the engineifyouare

approached.

AW_G -- SbtMA_ l_l_m4m

iw.

Trimmer head. parts that are chipped, cracked, bmkeI1, or

dan_d _any_ caneymar_an_causes_ous i_ury,

Donotuse.Throwdamagedpartsaway.Replacedantaged

+ • ,

parts be_m'eusing the tool

Page 13

IIIII III I IIIIIII I_I.II III 7 7 I

..... U IIIIIIIIIIIII I I ...... i I llllllllllllllllll

xJ W SAt'E

1, OPERATOR SAFETY

a. Always wear eye .p_te_. ion when Ol_X"at-

your uni_

b. _ wear heav_ lo_ng trousez_ boots,

and glov.es. Do not go bad'efoot or wear san.

_ewe_.@ort_., Jo_e_othtng,or

-fray _ w_ help pt'oteet you _ piec_

of toxic plan_ inch as pox_m ivy thrown by the

trimmer _ which could be more of a hgzard

than touching the plant itee_.

c. Do not Operate_ this unit when you are

tired, ill or under the influenee Of aleo-

hoI, _ or meal/cation.

d. Do not swing the tool with sueh fot_e

that you are in dang_ of lining yo_ bat_h_l.

anee.

e. Never start or ,run.the _ inside a

dosed room or building. B__haust

Lfumes czn kilL

f, Keep handles free of _ andfueL

2. TOOL 8AFEq_

L _t the _ t_Jol before each uee,

Check for fuel lealm

andmekeN pkceand_e-

cur_ _tened.

b. Useonly.OSO_dhmetn-Se_s LaserLine, Never

use wire, st_g, ro_, etc.

e...Make sure the tlrtmmer head is property

:L_ed and seeurely fastened:: P_er/_3

:_Assembly."

d. Be sure trimmer head _stops

when enstne idles, See"¢_d_ur_r A_._.

me_ts."

e. Make earbm_ttor a_tjus_ents witi_ the

lower end supported to px'evmxt the trim-

Hold the unit by ha_xd; do no_ use me opuonm

shoulder strap for support.

f. Keep ot]:ter_ away when making earbu.

rettor adjustments.

g. Use only aeeessories or attachments as

recommended by the manufacture_.

& L_FrING SAFETY

a. Impect the area to be cut before eaeh

Alw_ _the engine on the right side

c. Hold the tool _h-mly with both hands.

d. _,.,_/_ footing and balance. Do not

e. Keep the trimmer head belowwaist level.

f. Do not rzdze the en#ne above your waist.

_..Keep aUp_u.tsofy_ourb_'_ oaway_m me

trimmer line mKd muffle_ when. the en.

It, Use only for jobs explained in this man.

uaL

........... & WAS_ " -

" " L ",r . I H !I!!Hy

l[I[]l I I " 'I* _ " II • II_II1111 |_ II __

B. TRIMMER LINE ADVANCE "'

• The _ une_wm._ a_e_- ..... 'AwAC_ "

z Inene_ each t/lae,the bottmn _d_the Use only .OgO"diameter SEARS Laser Line. Other sizes of"

_er head is tap_., on the g_und With line will not advance properly andcan cause _rious injury.,

the engine ruanmg at x_ throt_e.

• _e mo_ el_Sete_ ltae length is the max/. De not u_e other materials such as wire. sung. rope. etc.

[en_ t_Owed by the]hie ][tlatte_ Wire can breakoff during cutting and become a dangerous

•

.... _ , it t '=' . ..7 g ]l _ I._ I II I i I I ri r

i ......::: . w,umm .

• __ _e: IUse ndnimum ,qpeed. and do not erowd the nnel:

1. O!_atetheengtneatfi,dlthro_e. " i_ei.eute__ha, do_ee_(me_grav_!

2, .Hold the trinnner hea_ parallel to and above lfeaee t_te. ere), wh!eh ean dmnage_ the tt;tmmer i

me grassy are& . . " |head,-bee0me entsnSl, ed in th_ line, or be[

It_ emudn_ a ,_46us _; . - |

.._ theb_tm ofthe_ _. t_ oa ..........

I_ _ _ ' _e _ter _t_ Line

t ,

aaph_em_uN_ee_arto_etrim. .-

If the line i_ worn down to two A "

taehm or less, moz_ than eue trap will be re-

quiredto obtainthe most efficim_]_ne lent_

Now_

13

Page 14

.............. iiiiiiiii_ iiiiiiiii i ...... , ...................,, ,|,, i iiiiiiiii i +

+_ _ ii _._ .y _++ ,,,,,,,,,,,,,,,,,,,,+!, ,.,, _,,r,I .... m!! _,,,,,,,_,,, "=' _ , ........ _._,., .--. ,,_,,,+,+,"''_'" ,...... ""+ "--_l_T'_ -_ + .......... I

.C. CIHTING METHODS

• The tip of the line does the cutting. You wi_

achieve, the best perform_ce and mhfimum line

wear by not crowdb_ line into eutt_g area+ The

right end wrong ways are shown in

• The line will easily remove grass and weeds

from _d wtd_ feuo_b gvoes and flower

beds, but _ o2_o eun cut the tender bark of

tre_ or #h4_ and gear fenee_ To help avoid

_ to delicatevegetationortrees

• with _nderbark, shorten line to 4-5 inches and

use at less than full throttle.

e For trimming or sealpir, g. use less than full

throttle to increase line life and decrease heed

wear, especial:

- duringlightduty +u+mng.

near objects around "w_ch the line can wrap

suchas smsllposts,treesorfencewire.

e For mowi_ or sweeping, use full throttle for a

good_eanjob.

Ii ......................4 w_G ......- ........................................I

Alwa_ wear eye. prqtecflou_ N.evor lean over the !

henri: _ or debr_ can rlooohet orl

be gbrown int_ eyes and+ face and c_aJe bKud-|.

nessor.,_er +se_+ous in+my. ............ • !

L TRIMMING - Mid the bottom ofthe trimme_

heed about 3 inches above the ground and at an

at_e- Allow only the tip of the Line to

make contact. Do not force the trimmer line into

the work are_

2. SCALPING -The sca]ph_ technique removes

unwonted vegetation. Hold the bottom of the

trimmer head about 3 inches- above the ground

and at an a___ AUow tip of "line+to strike

ground around trees, posts, monuments, eW-

T_ _ it.creases _

8. MOWING- Your trimmer is ideal for mowing

in pieces conventional lawn mowers cv_xot

reach. In the mowing•position,, ke_ the

line parallel to the ground. Avoid+pressing the

head into the ground as this can scalp the ground

and ckn._ the untt+ •

4. _PIN(g -The fanni__ action oftherotating

' ]hm can be used for a qui_ .and easy clean up.

being sweptand movetheunitfromside to side,

MOWING

16

NOTES

Page 15

_'Z."_r'- _+ i_mm " _ Ii + II _ I 1 lilt I

.... il II iiiiii

D.LINE REPLACEMENT

• For proper line fee_

:+

le

- Use only genuine Sea_ pre-wound spools and

.!180" diameter Sears Laser Line brand line.

Use of o_cr types of spools or lines can result

in excessive bw_ge, i_ weldi.g and improper

line feed.

- Pre-wound spools offer the most convert.

lent method for replacing line as well as

optimum performance.

--dd .pooland

perfm_m_ _ type m_.

Installing Spool with Line

a+ HoId the trimmer head M shownin

Press the lock tab and turn the loc_ ri_ as

shown in

b. Remove the lock ring, tap button_ and spool

c. Clean dirt and debris from all parts,

_.. ............A w.ct,_o ......... !

head part+that are ,_lipped,emmked+t

or damge+._- .anyoth_erway eaffi__!

iadam. _ cause _*lOUl _ uo not use+ _!

Ipl_ __ befo_ using.the tooL+ .................!

NOTE." The aluminum line saver canbecome

during use. b_er a groove is worn

into the line saver, remove it _rom the

_er _ t,J_n-it upside down, and .rein-

stall it (with the spool removed) to-pro_de a

new wear surface.

I+L ...... ,,_w,mm.mmG I

liue_vermu.m;belustaRedoulyfeomthe _.1

e of the trimmer head+ Ill]retailed on the out- I

of the trimmer head, the line saver can flyl

._ _e. I.,+

e. Insertthe end oft_ liue_ the tine saver.

Place the spool_in trimmer head. Pr_ess the

spool do_ then mrn it enough tolo_

the lu_ .on tile spool under the lugs on the

drive gear.

t_e _ et SlX_l and the wall of trinnn_ hes,_

over _e tames onthe hub; push the lock _

downon the hub and turnit clockwise un_ the

_n_hes lock_to pb_e,

I • I

.I.--_U_ mmrt be ful_med and the lock tab,[

llatehedL tu the Ixmk Ring. It'+_talled tueor.[

Ireet_ the .L_.Ring eant_ off aud become al

...... +....... !

•_ ___ sun) the 1_ ___.-

on_ If' tt comes ot_ renlnst_ _

h. Pull onthe .linetoy.haremthe spool from the

lockedpositionto me _ !m,ai_on:.

:: : " llllllmlllllllml..... [i WI i lllTT iiiii

Catch

Lock Tab

L Obtain t_ecorrect line length (4-6 inches) by

pressing the tap button (Figure.22) and pulZ-

ing ontheline _.

_. Es_. time the tap buttonis p_ssed,

2. Spool Replacement

k_ o_ are_ o!_reducedinmze,orbro-

b. T_o_ __fo_t_ _m

o

Page 16

,,,,i IllI I ........................

3. installing Line on Spool

To replace the Line on existing Spook

Fellow "Installing Spool w/Line,"Ste_

"a.-d." and remove any line remaining on

the spot.

b, Usea4Ofoot_ o_J{)gOmdialtle_r_.._t_La_F

Line.

Inert 1/16 _ to 1/8" of"the end of the line

tb_ugb the hole in the q_l.

Allow no more then 1/8" line to extend in.

side the spool.

d. Wrap the line onto the spool firmly and

evenly in the direction ehown by the arrow

on the _I.

NgZ[_ The line must be wrapped firmly end_

eveuly for proper li_e fee_

e, Follow "InstaEingSpool with Lin_" steps

_If the line b_ offor bae3ks up inthe trim.

met head, follow "Installing Spool w/Li-e, _

steps _s.-dZ Pulls]a_in line untilthe line.is

tightly wound on the spool, le_.ng 4-6 in_es

of ext_ded line. Continue with steps "e,-L"

Lug

WORN

.............. SPOOL

.... .. " iiiiiii llll_ : . .i / ii .

For best results, use only ,_80"

m i ....... - iiiiiiiiiiiiiiiiiiiiiiii . I'i iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

4. Trouble Shooting the Trimmer Head and Line

• Does not adwm_e or b_ while cut- • WeI_ onto spo_

e

ttu_

- Improperly wound onto spool.

- Line size incorrect.

- Too little line otttside head.

Pulls back into bee&

- Too little line outside of head.

......................... . " . UIIU

. USTOMER RESPONSIBH,ITIES

Make sure the air filter is fitted

of the eover to keep dust

from entering the engine and eav_ing en-

gine damage.

NOTE-. If repla_ng the air filter, _ the

Accessory List for proper part number,

Air Filter Corners

Cover

1. Mai_ain unit according to recommended

proeedu__.s. Keep cutting Rue at proper length.

•2. Disconnect spark plug beforeperforming

maintenance except carburetor adjustments.

3, Mak_ c_rburetor adjustments with drive

,shaft ho_using SUpl_rted to prevent the

trimmer-fine From contacting any object.

4, Keep others away when making carburetor

v_dstments,

chipped or damaged before using

the uni_

II .......... I [ MII _ I IIIII. - II

A dirty air filter decreases the life. and

performance of the engine and may increase fuel

c0nsumption and harmful emissions. ,

I. Clean the Air Filter:

• Always after 6 tanks of fuel or 6 hours of

operation, whichever is less.

" e, More frequently; in dusty conditions.

a, .Loosenthe two screwson the airfilter cover

enou_ to remove the cover- from engine.

b. Remove the air filter from the cover.

c. W_h flIter in soap and water.

d, Squeeze Filter dry .v_d replace in cover.

DO not _ the air falter In ffaso-

other ammable solvent; doing

so may create a fire hazard or produce

• harmful evaporative emissions,

16 Reinstall the air filter cover, making sure

•the choke exit dot is placed over the choke

MAINTENANCE SAFETY

6. Useo.ly_S0"diameterSearsLaserLke .N_,,

usewir___1_,_xin_,._c.

7. Use only ffenume .SEI_P_S"replaoemen_

parts. Use ot"other brands ofreplac_ment pexts

can ease _d_mageto y0_ Unit_ _L_y tot_e oI_

erator or others, Ydur warrauty does not cover

danmge orliab_H_causedby tl_euse ofaccesso.

ries end/or attachments not sp_eificalIy recom-

mended by SEARS.

8, _ct the entire unit. Replace damaged

par_.Check forfuel leaks and make sure all fas-

_ners areinplace and securelyfastened.

Ill II IIIIIII,. . ° • II I I llJll ,

I II I I IIIIIll I W[1[ mill I I I III

- Line size incorrect.

- Incorrect spool

- _ line egainst materiat being cut.

- Cuttingat higher speedsthannecessa_.

Page 17

• iiiiiilii i Ili I iii1"_ - __ i iiii1_11_"11 1" • i ..... H. i - _1

A_

.; ........ . r ._

_W_

Do aot remo,_e tl)erelaini_ tab mK! _ to x'emov_

puUey.'huespringbeneath_ pu_eyisundertemion

audcaunyoutcaustugserlousiu,lur_.UauyparteRhe

_mUeytmus_assm_damageaotheram-_rope,

donotusethetool_ittoyour SearsServ_ Ceater.

I. Di_.,onaect Slm-'I¢Plug Wke.

2. Remov_ tl_ __:and Nut int!m _ Tdgged

from Drive Shaft Housing and _ ThrOttle

c_Ie from_. _-c_.,gl_leoutof Biamo_

t).tmael.

3. RemovethefourClutchShroudScrews_ the.small

hexwrenchp_",,iced.

4. _the O_ _x_ from_Engir,e.

5. Hold tl_ "Flats" of the Clutch with an adju_te

wrench and remove the Nut cotmtetelockwise with

a 9_6" socketwrench.

........ nnviii |1 nnl • inn IIIIII .....................

JJ,,,iiiii i . ii J t

_ sc:g,l_l¢_t

I)rt_) .,.€Im,e_

e,_-d_U,:.

.

7.

8.

9_

" 10.

H.

12.

au_ wiU_deoff_ c=aksh_in_t.

r_ di,m_erable clutch.

Removethe.l_led Washer,Clutch,andLargeFlat

%hsher as shomain

Remowthe Pulle_ Housing fromti_.

RemcweRope l_ten_i_n Screw. Remow any remain-

ing rope.

HoldPall_y Homing andhand mm thePulley dock-

wis_ as far as it wi!lgo. Them,mm thcPulleycounter-

clockwise tm_ th_Pulley Notch is aligned with the

Housing Nol_ next_ the Retaining'_b andScrew.

Next, mm thel_alleyoaeaanpletemm counter-

dm.kwise untiltl_ notch_s are aligaed again.

Insert the small he,xw_nch intothe holeformedby

theNotches to hold the Pulley in position.

Usea42 #length of rep_eatt Rope.

Mov_av_ 00f_) fmmtim fud tin& wi_htt_ replace

meatRol_ Usea mamhandmeltboth ends of_eRope

17

Page 18

13. Pullthemeltedendstli_jgh athick,dean ragwhile ""

the I_pe isstiff hottoobtain smooth, pointedends.

14., insert one end of the Rope _ the Handle and

so.re witha kn_

15. Insert the other end of the P,_pe throu_ the Pope Exit

,Hole, intothcinsideoftl_Hottsing_ int_thePtdl_y,

and up through the I_._ey Hole. See Inset,

t_ WrapR,_ cotm_eloek-wise ar_tmdthe Pdt_ Rat_t

and tuck loose end under Rope wl-_re it c_mes out of

the Pu_ey Hole, Leavea I-inch udllayingflat 0ntop_

thePt_ey between__P, ib and_ Rope_

tion ScrewfPost.

17. Reinstall _e Rope Retention Screw into the r_tew

tion post. Tighten until snug.

NOTE: Do not overagh_n the Screw.O_rt_tea-

ing the screw can cause flaethreads in thescrewpost

to strip out.

18. Hold Pope taut at Pope Exit Hole so it will not move

•and remove hex wrench.

t9 Slowly feed rope into the Pulley Housing.

2(1. Make saw Spacer is in place then reverse steps to

Whenreinaan_ thedutda,tighten

the nut just until the beveled washer is flattened

against the dutch. Over or tmdertighteni_ the nut

can came engine damage.

II i ii i_1 _ I I ..... .11_ ,

I.... "" * ....................' . I ,r .... [11111;1111" ii iiiiiiiiiiiiiiiiiiiiii1_1111 _ 11 "" iiili_'ll " i ii _" iiiii " . IIIIIIIIIJhJ[..J......... I ] i

D. _LE DRIVE SHAFT LUBRIr_rlON

• Lubrieate the lqe:n'ble Drive Shaft:

- After each ten (10) hours of operation.

- Before operating ff the toot has been

stored fo_ 90 days or longer.

. When ord_ flex shaft lube, see the

Accessory List for proper part number.

enginehas_us_t b_en o]_erated , avmd toue.l_mg ]

r_ue murtJe_ _x .oz mul_er can emme Sertousl

burn& _ .............. • , ,..... _]

.......8...Remo_e-the, flexJble:dadvec_aft frem-thetube,

4. Cl_eckflexibledriveshs_ forbroken wires,

twistsorkinks, and replaceff demege is found.

5. Using a denn cloth, wipe surface o_ flex_le ....

drive shaft thoroughly to remove any grease.

6. Apply a uniform coat of lube to the entire sur-

face of the fle_'ble drive sha_.

7, I_ectthere'_maigingcontentsoft_etube into

the top ofthe tube.

8. Replace flexlq_le drive shaft in the tube.

,_ Lay the fle_ble drive.shaft on a

dean surface. Avoid laving the shaft on the

floo_ ground or on. any other _ pat 9. Reassemble the gear box to the robe. Tighten

may ha_ dirtor debt'_-.Evena_y wiping ......screwsS_zely.....................:.... .....

Ute st_'r, _gresse residue ean pick Up dirt [ __ ,_.

par_ot.es that can cause _lamage or prema. _ Gear Box

T_ke eare.l_ avoid tnj _u_ to ygur i ...

hsnds and fingers wit_ broken wireswhen

checki__ for damage or wapmg the flexible

drive shaft. A cloth will not prevent broken

wir romp,meturingortear yourskin, t ,

Re o othe the [ ,,| .... -- t

eatingscrewfrom the gear-bo_- .........

2, Remove the gear box from the tube.

18 ."

Page 19

L oumm_tt Anjl__

• Tht_is a co_ task.It is im_t to follow

instructions in sequence as indicated.

AWARNING

Make carburetor adjt_s'_anents wi_ the drive shaft

housing supported to prevent the trimmer _ from

contacting any object, Hold the tool with your hand;

do not use the _ shoulder strap for support.

Keep others

_idjustments.

&wAumo

away when making carburetor "

• l_r engine performance can be a result of other

causes such as dirty air"f'dter, carbon build-up

on muffler outlets, etc. See "Trouble Shooting

Chart" before proceeding with carburetor

• The carburetor has been carefully _ at fl_e

factory. However, the operator must be _ that

adjustnients are made when any of the conditions

eccur as mentioned in "Troulde Sheeting Sugges-

tions" below.

• Y_ry small adjustments can affect engine perf6r-

mauce. It is important to turn the screw a verysmall

amount per.adjustmefit and test performan.c_e before

makingguttheradjustments. Each adjustmentshould

be no more than the width of the slot in the adjusting

SCOWS.

L TROUBLE SHOOTING SUGGESTIONS °

-- Engine will not continue to run at idle posltiolt.

See "bY Idle Speed Adjustment" and "e. Low

Speed Mixture Adjustment"

-- TrimmerHead centinuestospin whentheengine

idles, See "ix Idle Speed Adjustment" and "d.

Deceleration Check:

-- EnginediesorhesiUttes whenitshouldaccele-a_

See "c. Acceleration Cheek."

-- Lossofcuttingpowerwhichcannotbeco_

_ d,mi_the_r, lt_.See"f.m__mix-

ture AdjmtmentY

• -- Engine does not return to idle from full throttle

within 2 semmds. See "d. Decelexalion Check:

--Engine wal not run. See"TroubleShoot_

Onwt."_, iftbecarburetorrequlresadjt_t-

me_ _with'2. _k Carburetorsenin_ "

' . dLWARNIMG

The trimmer hne will be spinning during most of'this

procedur_ Wear your pmtectiveequipment and observe

2. BASIC CARBImETOR SEtTInGS

NOTE: In most cases, your _gine can be made to

mn Wot_ly with minor carb_r adj_ent_.

Refer to "_muble Shooting Suggestions" in the left

column for the condition you axe expe_ienci_ and

follow the L_tmcti0ns. The basic carburetor settings

areprovidedincase_y a_ required.

a. Tam theLow Speed Mixture Screwand the High

Speed Mixture Screm clockwise until theystop.

Do nottarn thescrews umil they are aght as danutge

to theneedle seats can occur.

b. Tarathe Low Speed _ and High SpeedMix-

ture Screws one full mrn countoreloel_se.

c. Fol!ow instructions "a. Preparation" through "f.

High Speed,Mixture Adj_nt:'

3.PR0CEDURE

a. PREPARATION

• Lt * " v'_

l.)Useafreshfuelnux.See FuelingYourE_.

2.)Make sum the tine extends tothe length atlowed

by the line limiter to provide correct load on

engine.

3.)Stm the engir,e. Cut gross for3 minutes to warm

engine. Theengine must be at operaang temper-

ature before carburetor adjustraems w.n be per-

formedcorrectly

4,)Stop engine and rerno_ air filter by pulling itout/

wifl_your fingers. Refer to "Specifieatiom" for, ....

location, .::

_ mLZSn_.DJU_

L)Allow engine to idle:

2.)Adjust Idle Speed Screw until the engine

continues to run without stalling and Without

the trimmer head moving.

-- Turnscrewclockwiservincrenseenginespeed

if the engine stalls or dies.

-- Turns¢.mwcountemloctm_ise to slow engine

down and/or to keep trimmer head from

turm'ng.

3.)Follow instructions in "c. Acceleration Check"

and "d. Deceleration Check:'

4.)No further adjustments are n¢cessa_ if the

trimmer head does not turn at idlespeed and

If perfo_ is satisfa_ry.

_kWARNING

•Recheckidle speed after eachadjustment. "l'netrimmer

headmnst not turn atidlespeed toavoid _riousinjury

to the operator and other.

Page 20

€.ACCELERATIONCHECK

l.)Allow e_.gine to idle.

2.)Squ_ T_iggexfully

a. If_is_,pmce_ to'_.

Denigration Check;'

b. If the engine does not accelerate smoothly,

turn tl_ Low Speed Mixttlte Set_W counter

clockwise a small amount (no more

than the width of the slot in the adjust-

ing screw.

3.)Relxat step "2.)"until smooth acceleration is

obtained.

NOTE: It may be necessary to repeat "b. Idle

Speed Adj_tment'" through '_c.Accet_'ation

Cheek:' to obtain correct adjustments.

4.)FoIlowinstructions in "d, Deceleration Check:'

d.DECELERA_ION CHECK

1.)Allow engine to idle, then squeezeThrottleTrig-

get fully,

2,)Allow engine to run at full speed for about 1

second,

3.)Release the Throttle Trigger to the idle position

and listen to thedeeelexation ofthe engine, It must

,return to idle _y'and within I to2 seeonds.

a. If performance is satisfactory,proceed to

step "4.)"

b. lfthe enginesiowly or erratically retuD__ to

idle or idleserrafieaay, repeat"b, Idle Speed,

Adjustment" orcontinuethrough Low Speed

•Mixtureandl4aghSpeedMixtureAdjtmments

to obtain proper deceleration_

4.)Recheek idle speed.

-- --_ i """'- : .... " -"' I • Ii1111 II " [" I'1 I '

E GEAR BOX LUBRICATION

€.LOWSP£EDMIXTLrKEADJUSlaV/J_T

l.)Allow engine to idle.

2-)_dmtl_ Low Speed Mixture Screw skr,vly

clockwise tmtil the speed starts to drop.

Note this position.

3,yTum the Low Speed MixtureScrewcounter-

,_ untiithespeedinmcasesand_a starts

-todrop again. Notethis position.

4.)Set the Low Speed Mixture Screwat the mid-

point between the two positions.

5.)Follow instructions in "c, Acceleration Check"

and "d. DecelerationCheek.*'

f. mGH SPEED MIX_ ADJUSTMENT

IcAtrnoN:l Do not operate engine at full

tlu-ottle forprolonged periods while makinghigh

speed adjuslmentsas damage to the engine

¢altl Ot'_'llr.

1,)Support the drive shaft housing so the trimmer

fine is offthe ground and will not make contact

with awy object.

2. )Allow engine toidle, Lhensqueeze Throttle Trig-

get fully.

NOTF_ Pedorm steps "3.y' through "5.);"

at full throttle.

3,)'IhmHighSpeed _ Screw very slowly

clockwise uatil engine speedis fenced,

4.)Turn High Speed Mixture Screw veryslowly

counterclockwise, Stop when the engine begins

torunroughly.

5.)Turn the screw slowly the miaimum amount ,

dockwi_seuntiltheengine runs smoothly.

6.)Follow instrucfiomin "c. Aoeeleration Cheek"

and "d. Deceleration Check:'

["_OZ¢:i If the engine does.not operate :_

aomrding totheselmtructiom after _ting

theadjusting steps,do_mtusethetool._E[ke

it to _ur Sears _rviee _mer,

t.mm_rAtz, _ rma_

Be sure filter is clean, See 'Air Filter" for

instructions.

ICAUI_ON: ] Fit air filter intothe corners o!'the

_to keepdkt_ma enterlngtlmengin"eand

7 = Iii i _111111=11 I I llJ

....... _ .---- , ".', .........

i i

2O

• Lubricate the gear _lx after eveR 50 hours of

operation.

• Use Lithium based gear grease asailablefr1_mmost

automotive stores.

I. Remove the Screw and Washer on the Gear Box

using.a,wrench.

2. F_:Gear Box with gear lube.

3, l_tace WasherkndScrew.TtghteaSctewsecurely.

Page 21

......................................................STORAGE "; .........................................................

I ..... : :. II II II I .=_,1 ................... i i I IIIII]111111111 II IIIIIIII I -- . . : ,1...............

Immediately prepare yourunitfor storage at the end of the

season or if itwill not be usedfor 30 days or more,

wARNING- ..... ' ....

ALLOWTHE ENGINE TO COOL, AND SE-

CURE THE UNIT BEFORE STORING OR

TRANSPORTING IT IN A VEHICLE.

STORE UNIT AND FUEL IN AN AREA

WHERE FUEL VAPORS CANNOT REACH

SPARKS OR OPEN FLAMES FROM WA-

TiER HEATERS, ELECTRIC •MOTORS OR

SWITCHES, FURNACES, ETC.

STORE UNff WII_H ALL GUARDS IN

PLACE. POSITION SO THAT ANY SHARP

OBJECT SUCH AS BLADES CANNOT

ACCIDENTLY CAUSE INJURY TO PASS-

ERS BY.

STORE THE UNIT OUT OF THE REACH

OF CHILDREN.

GAS TRIMMER/BRUSHCUTTER STORAGE

INSTRUCTIONS

f your trimmer/brushoutter is to be stored for a period of

time, clean it thoroughlypriorto storage. Remove any

• dirt, sawdust, leaves,oil,grease, etc. Store ina clean dry

area.

e

Clean the entire unit.

Clean air filter. Refer to =Customer Responsibilities".

Open the line head assembly and c4eanany dirt,grassor

debris that has collected. Inspect the cutting line, if old

(chalky-look and stickyto the touch), remove and dLs-

card. Install fresh new line the next time productIsto be

used.

. Lightly oil extem;d metal surfaces to prevent rust from

forming;

ii , • _ , " , _, ........ ,,

-_ CAUTION: Wear protective gloves when t =

handling blade; The blade is sharp and

....... _ can out you even when it...l....s..n.o.tmovinq.

If your un'rtis equipped with a blade, remove ithorn the

unit. Refer to "Assemb|y". Appiy a coating of oil to the

entire surface of the blade and-wi'ap it in heavy paper,

cloth, or plastic. Also applya light-coatof ofltogear hous-

!ng threads, then tighten blade nut securely for storage,

Reassemble all loose parts, being, surethat al!:hanoqes

• and guards are in placeand are securely fastened. Re-

.lace any damaged parts.

ENGINE

Never use engine or carburetorcleaner productsin the fuel

tank or permanent damage may occur to fuel systemcom-

ponents.

Followthese instructions:

a. Drain the fuel from the unit into an approved

fuel container.

b. Drainthe fuel lines _ carburetor t)y starting

the engine and letting it run unti'titstops.

c. Allow the engine to coo] before storage.

IMPORTANT: It is important to prevent gum depositsfrom

formingin essential fuel system parts such as the carbure-

tor,fuel filter,fuel line or tank during storage. Also,experi-

en_. indicates that alcohol blended fuels, those that use

ethanol or methanol (called gasohol or oxygenated fuel),

can attractmoisture and form acidic gas whichwilldamage

your engine. To avoid engine problems, the fuel system

shouldbe emptied before storage of 30 daysor longer.

Fuel stabgizer isan acceptable artemative in mini-

mizing the formation of fuel gum deposits during storage.

Addstabilizer to the gasoline inthe fuel tankor fuelstorage

container. Akvays followthe mixinstructionsfoundonstabi-

lizer container. Run engine at least 5 minutes after adding

stabir_.erto allow the stabilizer to reach the carburetor.

Craftsman 40:1 2-cycle engine oil is:specially

blended withfuel stabilizers. If you do not use this SEARS

oil,you can add a fuel stabilizer (suchas Craftsman #33500)

to yourfuel tank.

o Remove spark p_ugand pour I teaspoon of 40:1 oilmix

throughthe spark plug opening. Slowly pull the starter

rope 8 to 10 times to distn'bute oil to inner enginesu_'-

faces.

°. Replace spark plugwith a new one of the recommended

type and heat range. Refer to =Product Specificatior_s".

o Clean air filter. Refer to "Customer Responsibilities'.

• Reinstall all covers and hardware removed for access;

tighten all screws and fasteners.

• Check entire unitfor loose screws, nuts,and bolts. Re-

place any damaged, broken.,or worn parts.

• Usefreshfueihavingthepropergasolinetooilratioatthe

beginningofthe next season.

OTHER

° Do notstore gasoline from one season to another.

- Replsceyourgasoline can ifyour can sta_sto rust.Rust

and/or dirtin your fuel system will cause problems.

• Store your unit in a well.ventilated area and covered, if

possible, to prevent dust and dirtaccurnuta_on. Do not

coverwith plastic. Plastic cannot breathe and wilt induce

condensation and eventual rust or conosion:

IMPQ.RTANT_ Never cover unit while engine and exhaust

areas are still warm.

.2[

Page 22

22

II I Jill I

...... : J,T,,I,IT

G. TROUBLE SHOOTING CHAKT

SYMPTOM CAUSE

,,,,,,,,,,,,,,,,,,,,,,............

_._ _ts_ ]. Fueltar_empty

• or will ranoaly for 2. Engi_flooded.

"afew seconds atter 3. Spark plug not faing.

starting 4. Fadnotreachinge.a_t_tor.

Eagiaewillnotidle

properly

2,

2.

power,or dies 3.

.undera load 4.

F.agia¢will not

accelerate, lacks

Enginesmokes

excessively

Engine rims hot

IIIIIIIIIIIIIIIIIIIII II III III /IWIIII .

.................. _ 1 lli_ _ _ ................

5. Cartmrgtor _adjusm_nt.

None ofthe above,

' :-. : ,,,,,,,,,,,,,,,,,,, ,. i i i

1. Idle speed set too fast or too slow.

2. Low speedmixturere,quires adjusm,.ent. 2.

3. Throttletriggersct=wtoofight. 3.

4. N'o_ oftheahoy. 4.

I _1111 loll IIIII I IIII HIIIIH III II I

Air m_r_y.

Sparkplugfouled.

Carburetorrequiresadjustmeta.

Muffler outletsplugged.

5. None oftheabove.

1, Air filter dirty. I.

2. Fuel mL_reincorrect. 2.

L Fuel mixturein_rrect_ I.

2. Highs_ mixtu_settoolow(lean), 2,

3.Sparkplugincorre_, 3.

I I II I I II1 IlJll II 11 _ _ ...............

4.

Trimmer head mms I.

atidlespeed 2.

3.

Trimmer5¢ad 1.

stops_a Ioador 2.

I does not turnwhen 3.

engineisaccelerat_l

T

does notadvance 1.

or bnml:swhile cutting 2.

3.

4.

-i, i

Line w_lds on spool

2.

3.

4.

Li__releasescontinuousiy L

2.

3.

4.

Lineusage is excessive L

3.

,4.

Line pulls back into head 1.

...._'="lllllllll , l

REMEDY

1. FOltankwith correct furl mixture,

2. See "StartingImmzctions:'

3. Install new plug/check igaidon system.

4. Clean fuel filter; inspectfuelline.

5. See "CarburetorAdjus_ats:'

6. ContactyourSears$erv_ C_nter.

t. ,See "Carburetor Adjustments."

See "Carbur_or Adjustmcats:'

Loosenscrewtofr_tngge¢,

Coatact yourse_ service Ce,ntes- .....

• Illllll'llll..................

I.

2.

3.

4.

5.

Clean orreplace airfilter,

Cleanorreplacesparkplugandr_gap,

See "CarburetorAdjustmeatsY

ContactyourSearsServiceCenter.

ContactyourSearsServiceCcat_r.

Cleanor replaceair filter.

Refud with correctfuelmixture.

See "CarburetorA@hqments:"

See "Fueling Yo_ Unit:'

See "Carburetor AdjmunentsY

Replacewith correct plug.

None of the above.

Carbaretor requitesadjustment.

Thr_e trigs.e:screwtoofight.

au_ _,-_ repair.

r

Drive shaftbrokenornotengaged.

Carburaor require_djustments.

_utch nglui_ repah-.

: i i ml rl

Line improperlyroutedin lIead.

Line improperly woundonto spool.

Line size incorrect.

Too little line outsidehead.

, Illlllllll 'qWIJllm Illlll I

1: Line s'o__incorrect.

4. C0ntactyour SearsServiceCenter. _ ;

I. See "Cadmretor AdjusanentsY

2. Loose.n screw tofreetrigger.

3. Contact yourSearsService Center.

1. P,_ace or see '_tssembly:'

2. See "Carburelvr Adjus_entsY

3. Contact your Sears ServiceCenter.

I. Remove cover.Check linemuting.

2. Rewindlinetightlyandevenly.®

3. Useonly.080"SearsLasetIAne •

4. Remove cover. Pall6" oftine tooutsid_.

1. Useoniy .080" Sears l.aser IAne®. "

Incorrect spool. 2. Use properspool.

Crowdinglineagainst material being cut: 3. Cut withtipofline.

Cuttingat higherspeed than necessary. 4. _Reducecuttingsp_..,.,

Line wound beyondnotches onspool. 1. Rewind line tightlyand evenly,

Line improperlyroul_ hi head, 2. Remo_ cover.Check line muting.

Line size incorrect. 3. Use onlyJ380;"Searslaser Linee.

Shield ill.lied.imProperly. 4. Reinstall shield properly.

Lineimproperly muted inhead. 1.

Linesize incorrect. 2.

Cuttingathighspeedaroundhardobjects. 3.

Crowdinglineagainst _ being cut. 4.

Too little line outsideofhead

Remove cover. Check line muting.

Use only .080" SearsLaserLine®.

Redt_ spe_ aroundhardobjects.

Cutwithtipofline.

R_ov¢ cover. Pall6" of line _ oatsk_.

Page 23

SEARS WEEDWACKER® REPAIR PARTS LIST - MODEL 358.799260-32cc

1

6

16

3738

45

63

7

75

64

Kit i

X

91

\

85

63

l.Kit " ,l

\ \

86 87

_23

Page 24

SEARS WEEDWACKER ®REPAIR PARTS LIST - MODEL 358.799260-32cc

,36 •

8

33

14

2O

27

NO.

1

2

3

4

5

7

lO

11

12

13

14-

15

16

17

18

19

20

21

24

No;

53o-o27549

_3o-094694

STD541025

,530-010958

530,0g?._8

71-85807 •

• 530-069252

53o-069266,

STD611005

530-094570 -_

530-015653

530-094689

680-000139

680-093896

680-09_98 '

_0 -840007

r,OO.-_o4r=85

580-08_27

&30-094568

580-01_5775

Description

Throttle Cable Ass'y.

DriveShaltHousing

Nut

Handle

S=e_

Cuu_.gHe__

DriveShaftGrip

"T"Handle"A_'y.

Shidd Kit_.

(Ind. #_o,ll & 12)

s=_w

Line Limg_

Lockout

Du_ Cup

Slm_ Lubrication

Hub_,°y

Line Saver

GearBox_,_'_

Key

No.

22

23

24

26

26

27

28

29

_0

3!

32

34

35

36

87

38

101

i02 •

103

Part

_.No, Descrlptlon.

_80-015774 ...........

580-010959

53..0-015768

68O'O9464O

530_-_09_t6

530-094612

630--01_28

630-001642-

530-001711

530-031111

530-031098

530-328929

5,.-_0-095121

71-85787

530-401183

520-844102

_30-02_159 '

_0-02S76_

530-O29764

Screw

.T'aro_de ]LeverAr_'y.

(In_ _e22 & 24)

_zw

He_Wxeneh. (_/_2)

He_Wren_(s/_6).

Spring Oap

Me Ge_

Co_r

D_-Sh_Wam_

D_-S_Jd

De_-Anti-V_eHandle

Page 25

SEARS WEEDWACKER® REPAIR PARTS LIST - MODEL 358.799260-32cc '

Key Part

No. No.

1 53O-O15773

2 530-027529

3 530-027530

5_0-015849

5 530-015852

6 530-015254

7 530-027526

8 530-037950

9 530-O69247

10 530-014362

11 530 -035349

12 f 530-019156

13 530--014347

14 530-047096

15 t 550-019154

16 530-027593

17 530-027594

18 530 -014015

19 530-010960

20 530-015789

21 530-010934

22 530-015126

530--015772

530-015780

25 530--027546

26 530-O27547

27 550-015771

28 530-014016

29 530-027545

30 530--027543

31 STD610603

32 530-015162

33 530-025875

34 t 550-019178

35 530-069275'

36 530"032103 "

37 530-015787

38 530--019158

39 530-032102"

40 530--069232

41 530-015777

42 530-027523

43 530-069257

44 530-O364O9

45 530-016080

46 530--039134

47 530-015128

48 530-012235

Description

Key

...............No:..... I%.......

_few

Air Filter Cover

Air Filter

Screw

Spacer

Wave Washer

Choke Shutter

Air Filter Plate

Fue! Line Fit

Fuel Pick-up A_ss'y.

Carburetor

Carburetor Gasket

Fue! CapAss'y. ,

Shroud &_ Ass y.

(Incl.#9,10&13)

Crankcase/ShmudGasket

Reed

Reed Stop

Crankcase/_ Asey.

(Inc__o_ps _ 66)

ConnectingRod Ass?.

(_cL_)

Cranksh_RetainingRing

Crankshaft,AsCy.

FlywheelKey

Screw

Screw

Switch Insulator

Lead Wir_

Screw

Crankcase Ass'y.

_d.#36-39)

Switch Ramp

S_tch SpringAsgy.

Screw

Piston Pin Retainer

Piston Ring

•Cylinder Gasket

Piston Kit

(Incl. #32,33, &pin)

Inner Bear_

Retaining Ring

Cnmkshaft Se_

.Bearing Outer "

Rope Kit

Screw

Retainer

Muffler Kit

Muffler Attachment Spring

Screw

Ignition Module Kit-

Screw

Cylinder

49

50

51

52

53

54

55

56

57

58

59

6O

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

8I

82

83

84

85

86

87

88

89

90

91

92

93

p_ .......... , :

Description

71-85854

530-015768

530-039136

530-347987

530-027517

53O-069291

530-(}29395

530-027569

530-010961

530-094189

530-069254

530-010964

530-015767

530-027511

530-015770

530-015769

530-015496

530-015788

530-015796

STD541137

530-035164

530-035166

530-035178

530-035106

530-.035188

530-035031

530-O35028

530-035014

530-O35151

530-035147

530-035036

530-035142

530-035141

530-035023

530-035208

53O-O352O3

530-035260

530-035185

530-069276

530-015239

530-015717

530-027781

952-701612

530-037972

530-016085

Not Shown

+

+

+

+

*+

*+

*+

530-029734

530 -061348

_;arkPlug

Locknut

PlywheelAss'y.

Washer

Fan Housing

Starter Pulley Kit

(Ind.@45)

StarterSpring

S'mrterHandle

Pulley Housing Ass'y.

CI_ Washer

Clu_h Ass'_.Kit-

Clutc_hHousing

Screw

Spacer

Screw

S_w -

Screw

Spac_

Washer

Nut

*+ Pump Gasket

*+ Pump Diaphragm

+ Inlet Screen

Inlet Needle Valve

Metering Lever Spring

Metering Lever

MetertugPin

Metering Diaphragm

M_ Diaphragm

Gasket

Circuit Plate Gasket

1_ Speed Needle _

Hi Speed Needle

Idle Needle

Idle Needle Spring

IdleSpeed Screw

Garb. Kwik Repair Kit

(+Indicates Oontents)

Carb,GasketJD_phragm

J_t (*Ind]caf, es 0ontents)

Engine Gasket Kit

(tIndicates C_ntents)

Screw

Screw

ldu_ler Guard

Spark Arrestor Kit

BulbAss'y.

Screw

InstructionDecal

Carton

25

Page 26

INDEX

Ill I _ IIII

ADJUSTMENTS

Assist Handle .................................................................. 7

.Carburetor ...................................................................... 19

Line Advance ............................................................... I3

Module Air Gap ................................................................. 2

Spark Pl_ Gap ................................................................... 2

Throttle Cable..................................................................... 7

AIR FILTER,._ .......................................................................... !6

ASSEMBLY

Assi_ Handle ..................................................................... .7

Drive Shaft Housing .......................................................... 6

Preparation ........................................................................ 6

Shield ....................................... 2........................................... 7

Throttle Cable ................................................................ 7

Trimmer Head ................................................................. 8

SEMI-AUTOMATIC LINE FEED ..... ... 13

CARBURETOR ADJUSTMENTS _...................................... 19

CARTON CO'Aq'ENTS ..................................... _................... ..5

COLD ENGINE STARTING ...................... 2.=....................... 11

CONTROLS ...................................................... L.................... .2

CUTTING METHODS ..................................................... 14

DRIVE SHAFT HOUSING ASSEMBLY ............................ .7

ENGINE

Air Filter. .................................................................... 16

Carburetor...................................................................... 20

Contro!s .......................................................................... .2

Fuel Mixture ................................................................. 10

Starter Rope ................................................... .............. 17

Starting Instructions ........................................................ 11

Storage .......................................................................... 5, 9

'lYouble Shooting. ........... ............................................... ,.21

ENGINE OIL

Ratio to Gasoline ............................................................. 10

Types to Use: not to Use .............................. :.................... 10

PILIXP,, AIR .............................................................. :--..16

FLEXIBLE DRIVE SHAFT LUBRICATION..; ................ I8

FtmL

Gasoline/Oil Mixture ..................................................... 1(l

Mixing Fuel ............................. =................................... l0

Pouring Fuel ................................................................... 10

Safety ........................ _........................................ 10

Storage............................ ................................................. 9

GASOLINE

Ratio to Oil................................................................... l0

Type to Use; not to Ose_ ..... _........................... _............... 10

IDLE SPEED ADJUSTMENT ........................ ;........... ;......,. 19

LL!_

Advance............................................................... I3, 21

Breaking .................. _._.. ........................................ 16. 21

Length to Cut as Replacement.__..... ................... :........... 16

• Operation Length ................................. 2....................... I3

Replacement. ......................................... j..................... 15

Rewinding on Spoo/ ...................................................... 16

ROutingin Head ........................................................ 15

Safety ....................................... _...................................... 13

Size to Use ....._................................................. _.............. I6

Welding onto Spool ............................................. 12, 16. 2 !

Trouble Shooting ................ ,.............. d.,......... _......... t6, 21

LUBRICATION

Engine ........................................................................... I0

Flexible Drive Shaft ...................................................... 1g

Gear Box ..................................................................... 20

MAINTENANCE

Air Filter ....................................................................... 16

Carburetor .................................................................... 20

Flexible Drive Shaft ..................................................... 18

Gear Box ...................................................................... 20

Safety ......................................................................... 16

StarterRope ....................... :............................................ 17

Trimmer Head ............................................................. 15

Trouble Shooting Chart. ................... :............................ 21

MODULAR AIR GAP. ................................. ;..................... 2

OIL, ENGINE

Ratio to Gasoline ......................................................... 10

Types to Use; not to Use ............................................... I0

OPERATION

Advancing the Line .......................... ............................. 13

Mowing ................................................... ................... 14

Pre-Operation Checks ............................. ,.................... [1

Position ......................................................................... 8

Safety ..................................................................... 12, t3

Speed ........................................................................ 12

Stopping the Engine ................................................... 12

Sweeping ................................................................... 14

" Trimming ..................................................................... t4

PARTS LIST ................................................................... 22

PRE-OPERATION CHECKS ........... .....2.......................... l I

PREWOUND SPOOLS ................................................... 15

"I_PAI]R PARTS LIST .................................................. .22

SAFETY INSTRIJ_IONS, WARNINGS .................. 3 & 4

SHIELD, ASSEMBLY ....................... ...._.......................... 8

SPARK PLUG GAP ......................................................... 2

SPARKARRESTOR ................................ _.......................... 5

SPECIFICATIONS ................ :.......................................... 2

SPOOL

Installation ................................................................ 15

Maintenance ................................................................. 15

Prewound ......................................................:.............15

Rewinding ................................................................. 16

STARTER ROPE REPLACEMENT ............................... 17

STARTING INSTRUCTIONS .......................... ................ !!

STORAGE..._. .............................................. z....... =...... 4, 9

THROTTLE CABLE ASSEMBLY .............................. 7

TRIMMER HEAD

Assembly .......................................... :........................... 8

Line Routing ............................................................ 15