Page 1

xiViPORTANT MANUAL

Operator’s

Manual

“Tftrow Away

MODEL NO.

3Sa798260-32cc

CUSTOMER

ASSISTANCE

'1-800-235-5878'

ADAmER:

Read the Operator's Mamuii

and Follow All Warnings

and Safety Instructions.

Failure To Do So CanResult

in Serious Ityury.

Always Wear Eye Protection

m/CRAFTSMflN

32ce GAS BRUSHWACKER

2 Cycle Engine

• Assembly

• Operation

Fuel Mix 40:1

• Maintenance

• Repair Parts

TM

Sean, Roebuck and Co., Hoffman Estates, IL 6017P U.S.A.

Page 2

!ONE YEAR LIMITED WASRAMY ON CRAFTSMAN GAS - POWERED BRUSHWACKER® BEADED TRIMMBRt:

For one year from the date ofpurchase, when this Craftsman Gas-Powered Brushwackeris maintained, lubricated, and tuned

up accordingto the operating and maintenance instructions in the operator’s manual, Sears will repair, free of charge, any defect

in materials or workmanship.

This warranty excludes the blade, nylon line, spark plug, and air filter, which are expendable parts and become worn during

normal use.

If this Brushwacker is used for commercial purposes, this warranty applies for only 90 days from the date ofpurchase. If this Bnishwacker

is used for rental purposes, this warranty applies for only 30 days from date of purchase. This warranty applies only while this product is in

use in the United States. ,

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE BRUSHWACKER TO THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. .

Thiswarrantygivesyouspecificlegalrights, and you may also have other rights which vary from state to state,

SEARS, ROEBUCK AND CO. DEPT.817WA HOFFMAN ESTATES, IL 60179

lABLE OF CONTENTS

WARNINGS iVND SAFETY INSTRUCTIONS

KNOW YOUR TOOL................................................................ 5

ASSEMBLY................................................................................. 6

FUELING YOUR ENGINE

STARTING YOUR ENGINE....................................................12

USING YOUR TOOL AS A BRUSIICUTTER

......................................................

......................

......................

11

14

USING YOUR TOOL AS A LINE TRIMMER

3

ACCESSORIES..............................;...................................................20

CUSTOMER RESPONSIBILITIES.....................................................21

REPiVIR PARTS LIST

INDEX

......................................................................................................31

...........................................................................

..............................

...16

2^

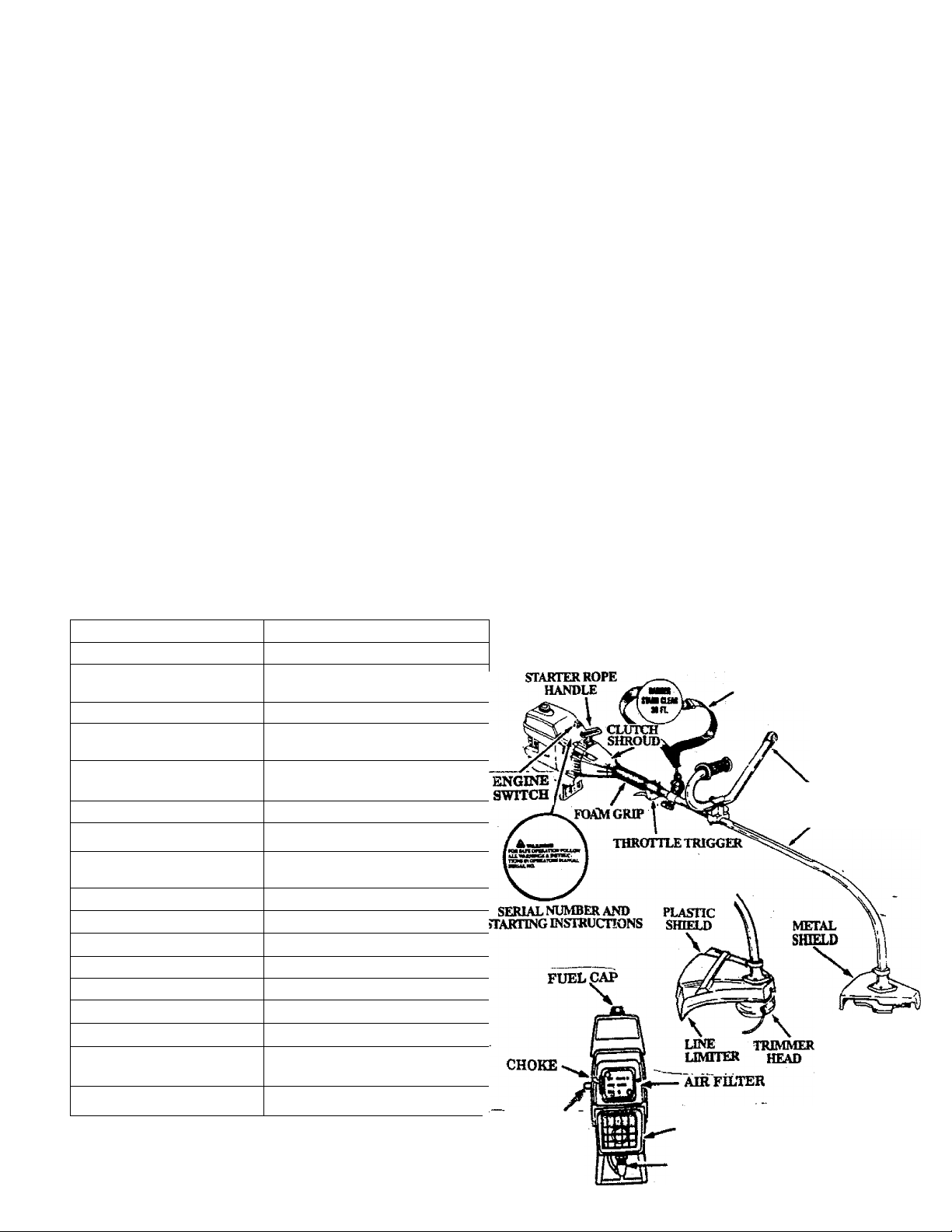

SPECIFICATIONS

ENGINE TYPE:

DISPLACEMENT:

ENGINE RPM:

IGNITION:

IGNITION TIMING:

CARBURETOR:

ENGINE ■OFF":

STARTER:

MUFFLER:

CLUTCH:

FUEL TANK: 17 fl, oz.

SHAFT LENGTH ; 31"

SPARK PLUG

SPARK PLUG GAP:

MODULE AIR GAP:

LUBRICATION:

CUTTING LINE:

BLADE

WHITE CONSOUDATED INDUSTRIES. INC.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U,8. PATENTS;

4 D3S.813! 4,0S2,1g9i 4,112,«53; 4.181,820; 4,1«2,812: 4, 183,138; 4,188,833; 44ll.p®^

4!28S,«?fit 4.382,0«; 4,451,883; 4,788,185; 4,833,465; 4,841,928; 4,840,028) 5,020.225; A

D324,051. OTHER US. AND FOREIGN PATENTS PENDING.

2-Cyde, Air-C<xiled

32cc -

Operating — 7500

Idle -2800 -3200

Solid State

Spark Advance —

Non-adjustabtc

Diaphragm All Pasitions with

adjustable fuel mixture jets .

Push Button

Auto Rewind

Temperature Limiting (not spark

arresting; see Notice, p.6)

Centrifugal

71-83854 (CJ-14)

.025"

.010'7.014"

Gasotine/Oi! Mixture-40:1

,080" Diameter Sears Laser

Line*

4 point 8" Blade

PRIMER BULB

SHOULDER STRAP.

HANDLEBAR

SAFETY LABELS

4TtKrrH

WEKDBLADK

MUFFLEB&

•MUFFLER

GUARD

SPARKPLUG

Page 3

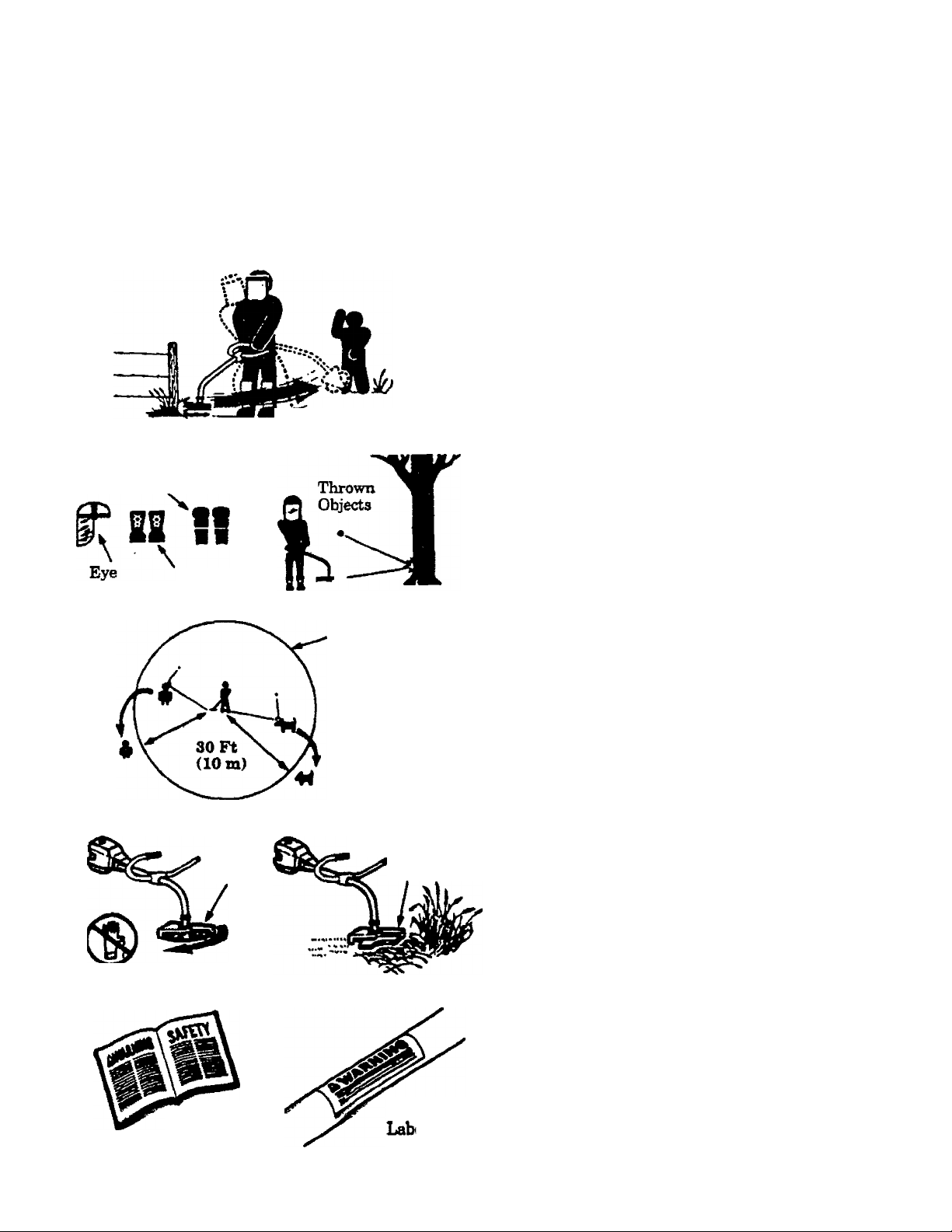

A WARNINGS AND SAFETY INSTRUCTIONS

(See Additional Safety Instructions throughout this Manual) .

A DANGER - THIS POWER TOOL CAN BE DANGEROUS! Thlaimit cancauseserioua

ii^ury including amputation or blindnesa to the operator and others. The warnings and safety instruc

tions in this manual must be followed to provide reasonable safety and efficiency in iising the unit. The

operator is responsible for following the warnings and instructions in this manual and on the unit. Read

the entire Operator’s Manual before assembling and using the uniti Restrict the use of this unit to persons who read,

understand, and foÜow the warnings and instructions in this manual and on the unit.

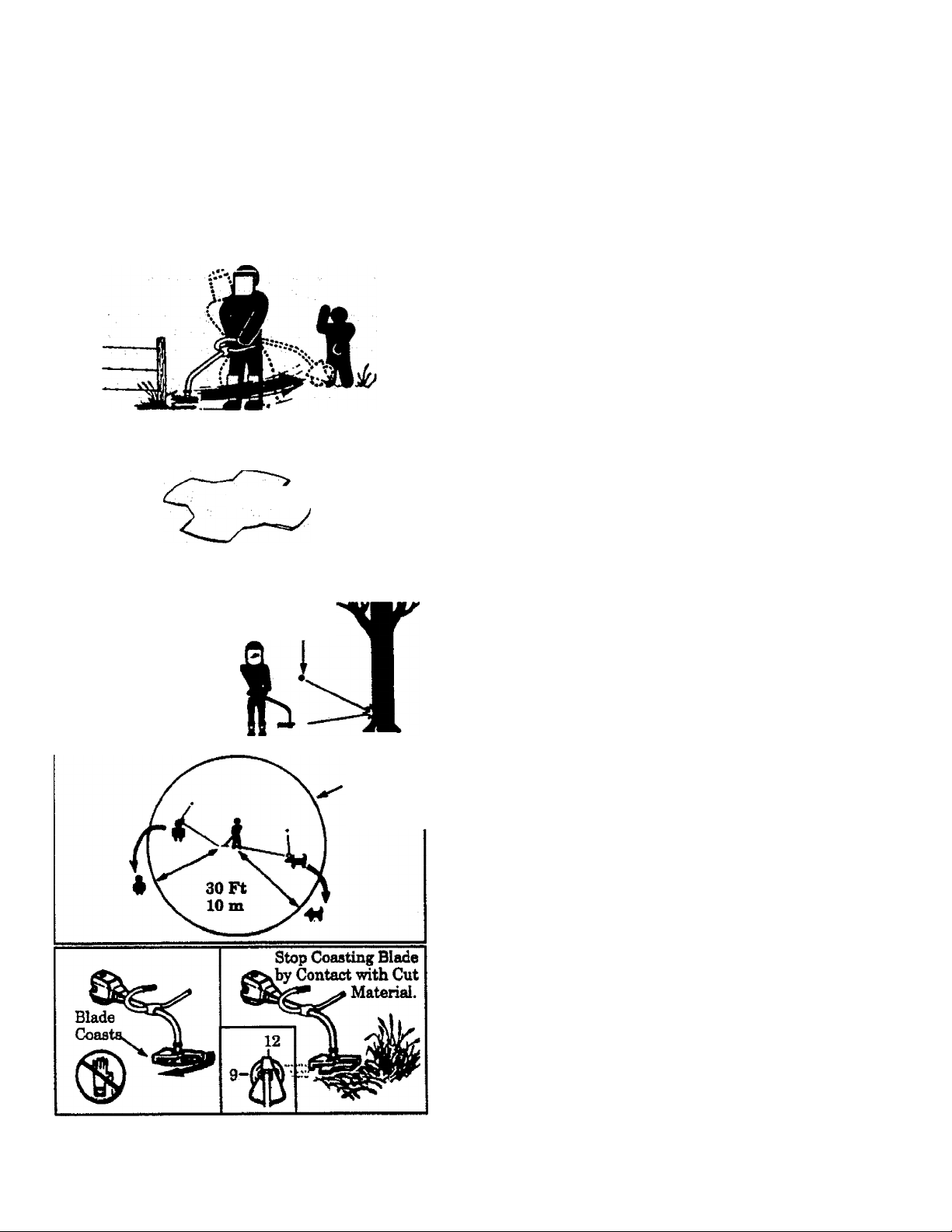

Adanger

BLADE CAN THRUST VIOLENTLY

AWAY FROM MATERIAL IT DOES

■ NOT CUT.

- BLADE THRUST CAN CAUSE

AMPUTATION OF ARMS OR LEGS.

~ KEEP PEOPLE AND ANIMALS

30 FEET (10 METERS) AWAY.

TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

- YOU CAN BE BLINDED

OR INJURED.

- WEAREYEANDLEG

PROTECTION.

Protection

BLADE'T^'^^

A WARNING

Leg Guards

Boots

Blade

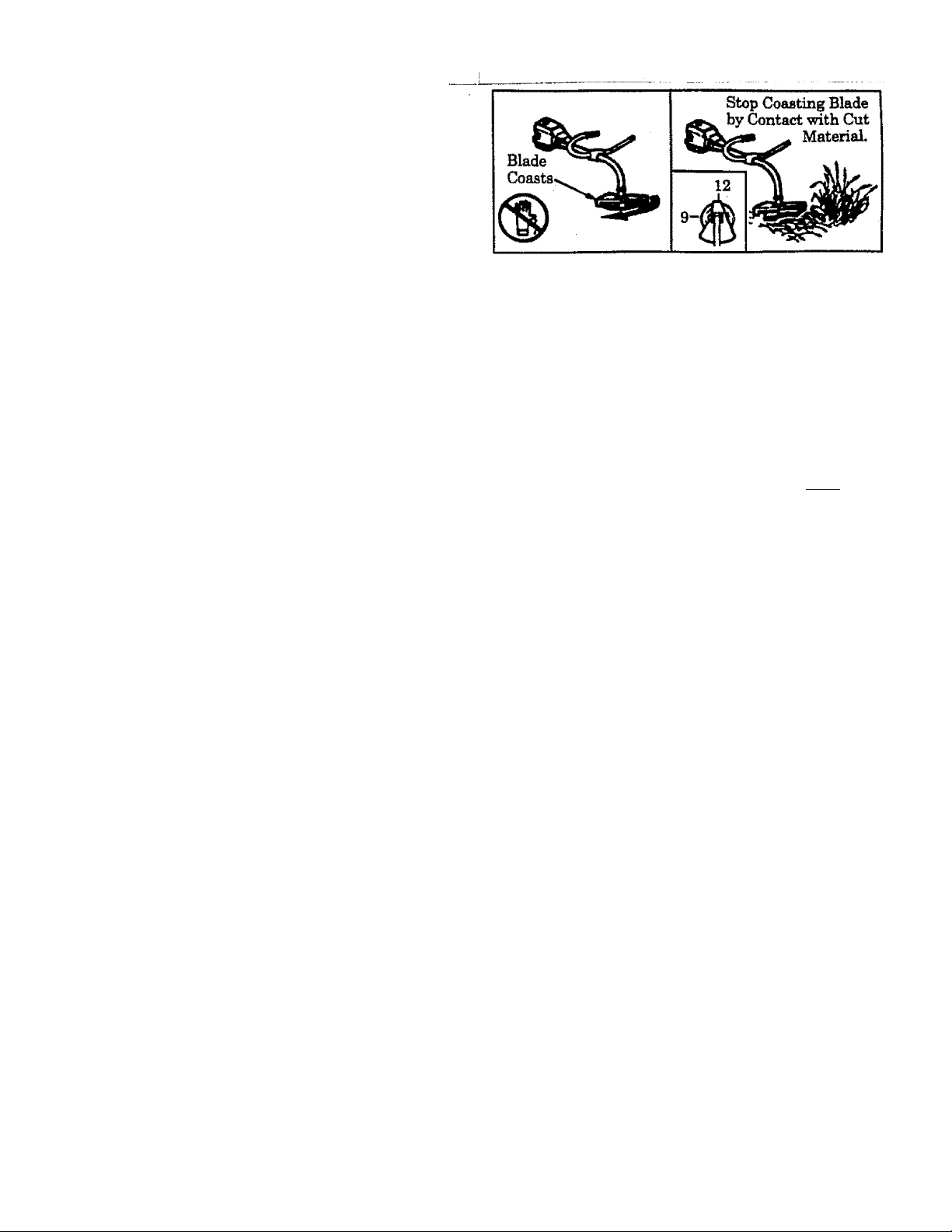

Coasts

60 Foot (20 meter)

Hazard Zone

Stop Coasting

Blade by Contact

I with Cut

Material.

AWARNING

HAZARD ZONE FOR THROWN

OBJECTS.

- BLADE/TRIMMER LINE CAN

THROW OBJECTS VIOLENTIY.

- OTHERS CAN BE BLINDED

OR INJURED.

- KEEP PEOPLE AND ANIMALS

30 FEET (10 METERS) AWAY.

--------------------------------------------------------------

AWARNING

BLADE COASTS AFTER THE

THROTTLE IS RELEASED.

- THE BLADE CAN SERIOUSLY

CUT YOU OR OTHERS.

STOP THE BLADE WITH CUT

MATERIAL.

AWARNING

READ OPERATOR'S MANUAL

- FOLLOW ALL WARNINGS

AND INSTRUCTIONS.

Optfitof'i

Manual

sis

« FAILURUTODOeOCAN

RESULT IN SERIOUS INJURY.

Page 4

WARNINGS AND SAFETY INSTRUCTIONS... .(Continued)

> mi/J,9LnikJL JEli* Mi/ JL Je

Always wear safely eye protection.

Always wear heavy, long pants, long sleeves,

boots, and gloves, waring safety leg guards is rec

ommended. Do not go barefoot or wear sandals,

jewelry, short pants, short sleeves, loose clothing,

or clothing with loosely han^g ties, straps, tas

sels, etc.; they can be caught in moving parts. Be

ing fully covered will help protect you from pieces

of toxk plants such as poison ivy thrown by blade

or trimmer head which could be more of a hazard

than touching the plant itseE

Secure hair so it is above shoulder length.

Do not operate unit when you are tired, ill, or un

der the influence of alcohol, drop, or medication.

Wear hearing protection if you use the unit for

more than I-1/2 hours per day. .

Never start or run the engine inside a closed room

or building. Breathing eadiauat fumes can loll.

Keep handles free of oil and fuel.

Always use the handlebar and a properly adjusted

shoulder strap with a blade. See “Assembly.”

. UNITIMAINTENANCE SAFETY

Look for and replace damaged or loose parts be

fore each use. Look for and repair fuel leaks before

use. Keep the unit in good working condition.

Throw away blades that are bent, warped,

cracked, broken, or damaged in any other way.

Beplace trimmer head parts that are cracked,

chipped, broken, or damaged in any other way be

fore using the unit.

Maintain the unit according to recommended pro

cedures. Keep the blade sharp. Keep the cutting

line at the proper length.__________________

Use only .080” diameter SEARS Laser Line®.

Never use wire, rope, string, etc.

Install the reqxured shield properly before using

the unit. Use the metal shield for all weed blade

use. Use the plastic shield for all line trimmer use.

Use only specified blade or trimmer head; make

sure it is properly installed and securely fastened.

Never start engine with clutch shroud removed.

The clutch can fly off and cause serious ^ury

Be sure blade or trimmer head stops turning when

engine idles.

Disconnect the spark plug before performing

maintenance (except carburetor adjustments).

Make carburetor a^ustmenta with the lower end

supported to pre^nt the blade or trimmer line

from contacting any object. Hold the unit by hand;

do not use the shoulder stnqp for support.

‘ Keep others away when malting carburetor ad

justments.

Use only genuine SEARS accessories as rerom

mended for this unit.

.................................

Ifaituationê occur which are not covered in thie manual u*e care and good judgment.

CUSTOMER ASSISTANCE HOTUNE» 1 -800-23^878j,

---------------------------------

If you need euaistanee, contact your Autiuoriz&i Service Dealer or the

_ _

_________

• Have all maintenance and service not explained

in this manual performed by aij Authorized Ser

vice Dealer.

A FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the

unit or while using the unit.

• Wipe up aU fuel mills before starting engine.

• Move at least 10 feet (3 meters) away from fueling

site before starting engine.

• Stop engine and allow unit to cool before remov

ing fuel cap.

• Empty the fuel tank before storing the unit. Use

up fuel left in the carburetor by starting the en

gine and letting it run until it stops.

• Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, furnaces, etc.

A rtTfrriirTKri^ QA VV'TfV

• Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string,

etc.) which can be thrown or become entangled in

the blade or trimmer head.

• Keep others including duldren, animals, bystand

ers, and helpers outside the 60 foot (20 meter)

Haz^ Zone. Stop the engine immediately E you

are approached.

• Always keep engine" on the right-hand side of

our body

fold the unit firmly with both hands.

?

• Keep firm footing and balance. Do not over-

reacm.

• Keep blade or trimmer head below waist level.

• Do not raise the engine above your waist.

• Keep all parts of your bodv away from blade, trim

mer head, and mtifiler when engine is runnning.

• Cut from your right to your left.

• Use only for jobs explamed in this mamlal.

A TRANSPORTING AND STORAGE

• Stop the unit before carrying.

• Keep the muffler away from your body.

• Allow en^e to cool and secure unit before i

ing or trmisltirting it in a vehicle.

• Emply the rael tank before storing or transportingthe unit. Use up fuel left in the carburetor by

staitmg^eengineandlettingitrununtiHtstops.

• Store unit and fuel in an area where fUel vapors

cannot reach ^arks or open flames from water

heaters, electric motors or switches, furnaces, etc.

• Store unit so the blade or line limiter cannot acci

dentally cause injury The unit can be hung by the

bracket below engine or by tube.

• Store the tmit out of reach of children.

............................................

.................

I stor-

Exposure to vibratioiia throng prolonged use of gasoline powered hand tools could canae blood vessel or n^e

SAFETYNOnCB

damage in the fingers, hands, and wrists of people prone to circulation disorders or abnormal sweUings. Pro-

occur such as numbness, pain, loss of strength, change in sldn color or texture, or loss of feeling in the fingers,

hands orwrists, disconthiue theuse of this tool andsoekmediealattentten. An anti-vibration »lem does not

goarastM the ayoldaBoo of these probleiaa. Uiere who opcmte tools on « oonthtoal aBd regular basis

must memiter closely their physical condition and the condition of this tooL

Page 5

KMOW YOUR TOOL

A. IMTROmiCTlON

____________________

Your Weedwacker” is a high quality product designed for

tough jobs. Its versatility will help you make short work

of a variety of jobs.

Special Features Include:

. • Reversible4>point\¥eedBladeforgras$, weeds and

brush up to'/4 inch in diameter. -

• Semi—automatic line feed trimmer head for trim

ming, mowing, sweeping, and scalping.

UNPAGICING INSTRUCTIONS

1. Remove contents from the carton if you have not

done so.

2. Check parts against the list below.

3. Examine parts for damage. Do not use damaged parts.

4. Notify your Sears Store immediately if a part is miss

ing or damaged.

NOTE; Your unit has been shipped with a plastic

shipping guard over the primer bulb (see

“Specifications” for location). Remove and

discard the plastic shipping guard.

NOTE: It is normal to hear the fuel filter rattle in an empty

fuel tank.

___________

<

,

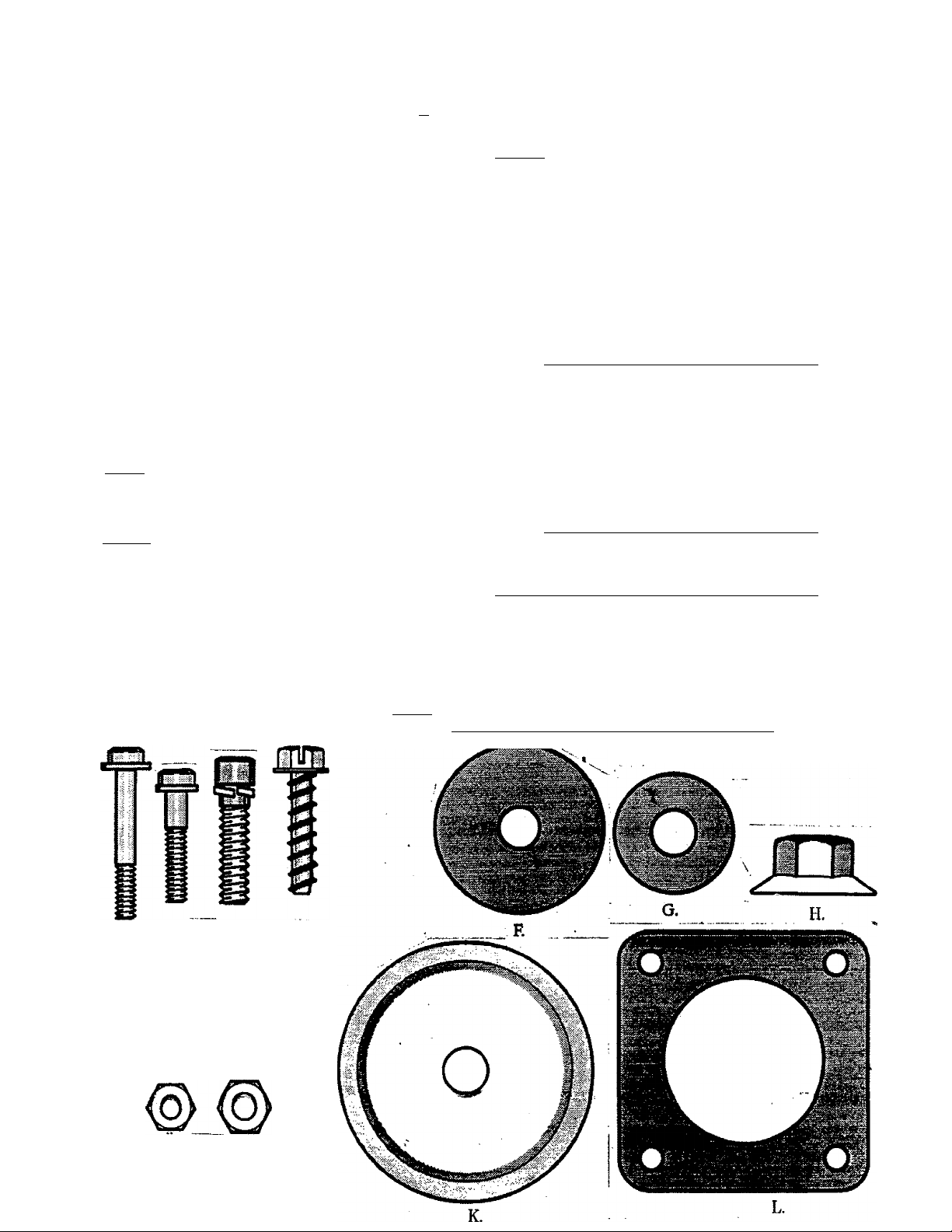

CARTON CONTENTS

KEY

Na

• '

•

■ :

-•-“1

"*• i

«,

* • j

■ •

•

•

^ •

'"V "'

■ A. B.

D.

E.

• ■■E .

*

1.

■J. , Hex Nut 1

K.

* L

Engine .

Drive Shaft/Bearing Housing Assembly

w/Safcty Labels

Handlebar

Plastic Shield - Trimmer Head

Trimmer Head

Metal Shield * Blade

Weed Blade - 8 inch, 4-point

Shoulder Strap w/Waming '

• 1

2-cycle Engine Oil

Operator’s Manual (not shown)

■ Lwse Parts Bag {not shown)

. (

LOOSE PARTS BAG CONTENTS:

Mounting Block • Handlebar 1

Cover-Handlebar 2

Shoulder Strap Clamp

T-Handle

Hex Wrench - Small I

Hex Wrench - Large 1

Flex Shaft Lube

Hex Screw - Engine

Screw-Handlebar

"Hex ScrcwT- Throttle Trigger Housing "

Screw - Plastic Shield

Square-Head Screw

Fiat Washer - Blade

Beveled Washer - Blade

Flange Hex Nut - Blade

Hex Nut - Engine 2

Large Cup Washer - Trimmer Head

Retention Plate - Metal Shield

QTY.

1

1

I

1

1

1

I

1

i

1

1

1

1

1

^ 2

8

1

4

1

1

1

1

1

1

D. HARDWARE USAGE

A. B. "C :D.

E.

NOTE; This Hardware is packaged in the Plastic Bag. Refer to

the Hardware reference letters below during assembly.

HARDWARE SHOWN ACTUAL SIZE

nMn

J.

Page 6

ASSEMBIiY

(If tool is received assembled, repeat all steps in this section to be sure assembly is correct pnd is ad

justed for the operator.)

PREPARATION

This Manual is designed to help you assemble the tool

and to provide its safe operation. It is important that

you read the entire manual to become familiar with

the tool before you begin assembly. If you have any

questions or need further assistance, call our

CUSTOMER ASSISTANCE HOTLINE at

1-800-235-5878.

1. Read your Operator’s Manual

2. Tools you will need;

— Hex Wrench provided with the tool.

— Adjustable Wrench

— Standard Screwdriver

ASSEMBLY STEPS (Refer to illustrations)

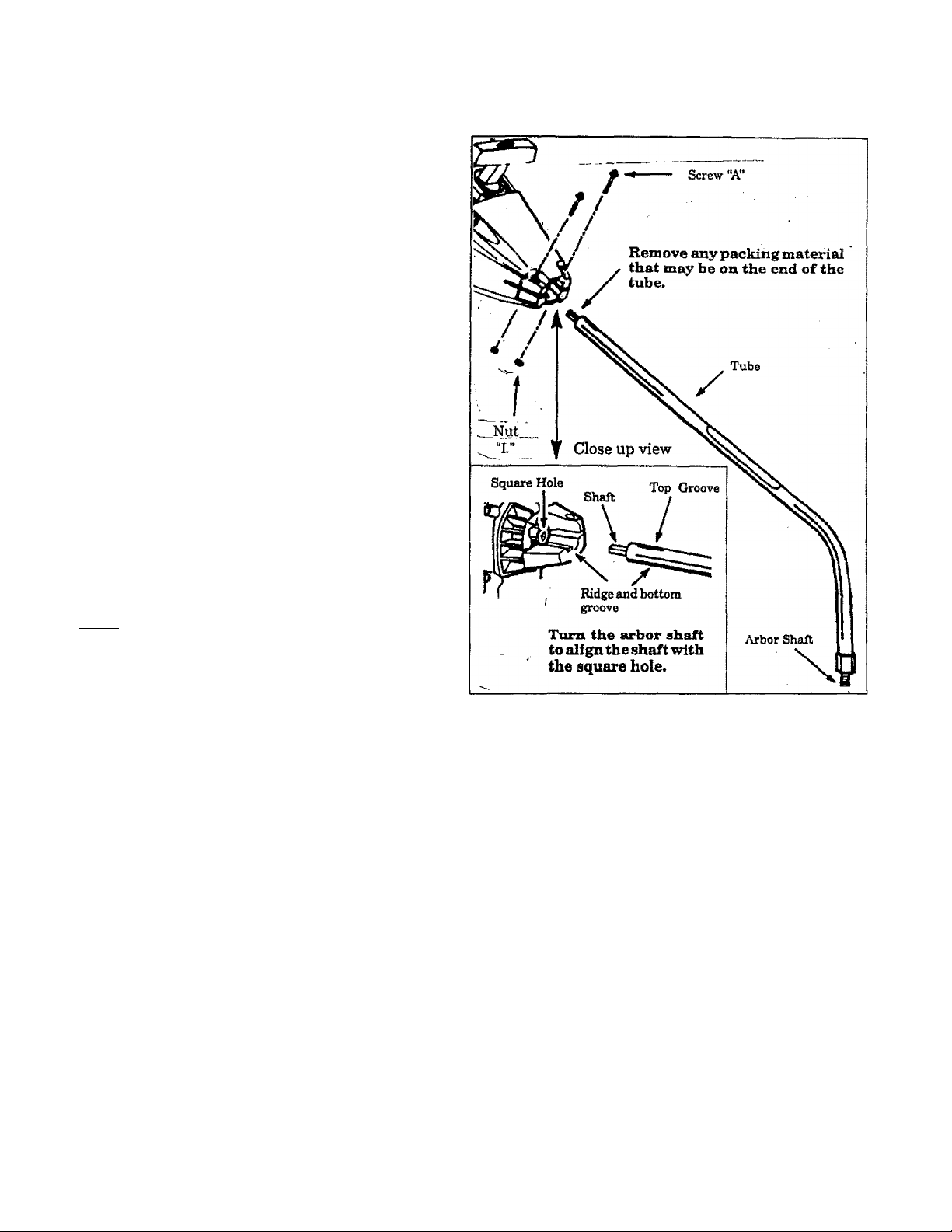

TUBE

• Place the two screws “A.” into the holes on the

engine as shown in the illustration. Make sure

screws are fully seated in the holes.

• Position the. nuts . “ I. ” in the lower holes.

• Tighten the screws with the hex wrench (pro

vided) just enough to hold the hardware to

gether while holding the locknuts with your

other hand.

• Remove the packing cover from the straight

end of the shaft housing if so equipped. Your

unit may not have a packing cover.

NOTE; Make sure the shaft inside the tube does

not fall out of the tube. Dirt on the shaft will sig

nificantly reduce the life of the unit. If the drive

shaft falls out of the housing, clean, re-lubricate,

and re-install. See “Drive Shaft Lubrication” in

the Customer Responsibilities section.

• Align the bottom groove on the tube with the

ridge on the lower wall of the engine opening.

• Turn the shaft to align the sguare end of the

shaft with the square hole inside the front

opening of the engine.

• Firmly push the tube into the en^ne opening

until the top groove is no longer visible.

• Tighten screws “A.” alternately with the hex .

wrench until secure.

__

-6

Page 7

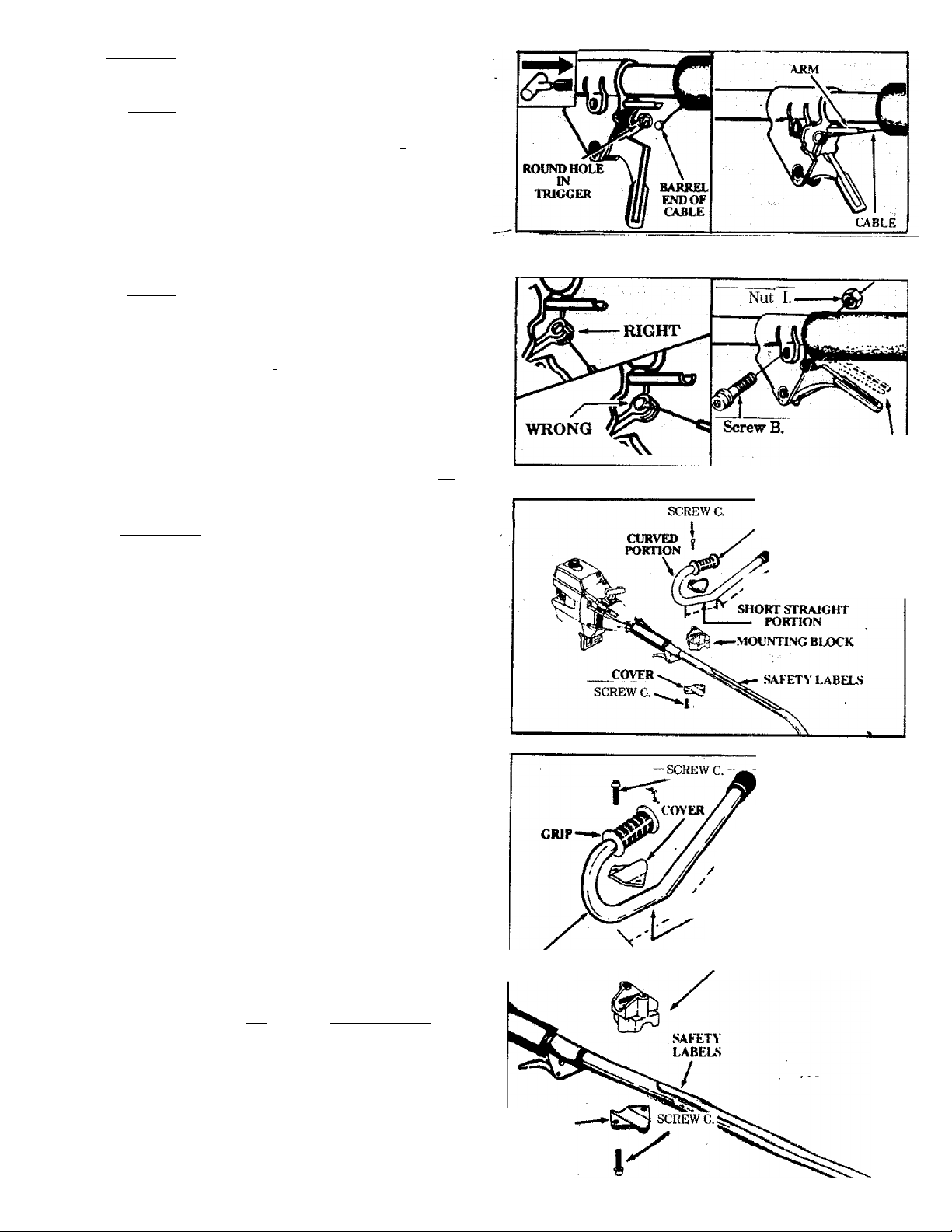

2.THmcrrrLE CABLE

fCAimowil Do not kink the throttle cable.

a. Slide the Throttle Trigger Housing away from the

Foam Grip.

NOTE: Before performing step “b”, push the barrel

end of thè throttle cable into the sheath until the

barrel contacts the sheath.____________ f

b. Insert the Throttle Cable through the tunnel in the

Foam Grip until the end of the Cable extends at

least 2 inches be^nd the Grip.

c. Hold the Trigger away from the Drive Shaft Hous

ing and insert the barrel end of the Throttle Cable

into the round opening in the Trigger. _________

NOTE: When inserting the barrel end of the

Throttle Cable into the round opening in the

Trigger, make sure that the barrel is completely

inserted and the Throttle Cable is located in the split

in the Arm. _______

, ’

d. Push the Trigger back into the Housing while guid

ing the Cable through the split in the aim. Guide^

the arm into the Foam Grip tunnel while replacing,

the Throttle Trigger Housing flush against the Grip?

e. Hold Trigger against the Foam Grip while insert- '

ing the screw “B.” and Nut “I.” See Caution below.

___________

_

_

1/8 "PLAY

ICAUTIOM; I Do not overtighten the screw. Make

sure the trigger will move freely. There must be at

least 1/8 "free play in the trigger. Make sure the

trigger will move freely so the engine can fully

return to idle when the trigger is released. The

trimmer head must not turn at Idle speed to avoid

serious injury to the operator and others.

__________

3.HANDLEBAR

i^WARNlNG

The handlebar mounting block must be placed above the

point of the arrow on the safety labels. The handlebar

is a barrier to keep the blade away from the operator’s

feet.

a. Position either side of the mounting block on the^

drive shaft Hou'sing above the arrow on the Safety

Labels.

b. Place one of the covers below the drive shaft Hous

ing and secure it to the mounting block with 2

screws finger^ti^ten only.

c.

Align the Handlebar with the straight barrier por

tion to the left and the curved portion to the right.

d. Position the Mounting Block between the arrows

on the short, straight section of the.Handlebar.

e. Place the remaining Cover over the Handlebar and

secure it with two screws “C.”; finger tighten onlyT

f. Be sure the Handlebar is installed correctly, then

- tighten each screw securely with a wrench.

________________

CURVED

PORTION

GRIP

\ BARRIER

PORTION

>

/ BARRIER

portion

Cs«' SHORT

X ^STRAIGHT

PORTION

MOUNTINt:

BLOCK

AW4RN1II0

The long, straight portion of the Handlebar must be

installed to provide a barrier between the operator

and the spinning blade.

COVER

Page 8

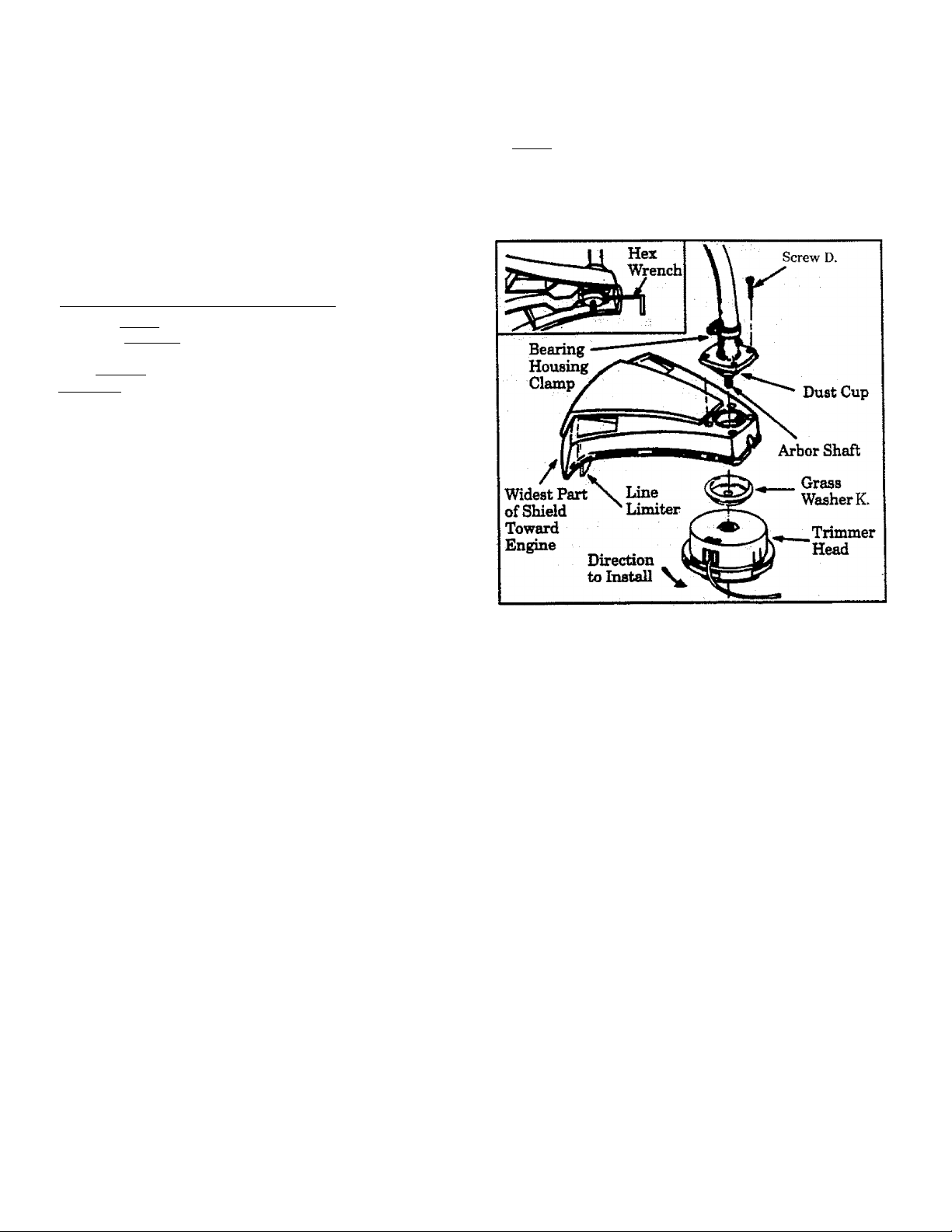

B.FOE LINE TMMMEB USE

A WARNING

The plastic shieM must be properly installed for

all Ime trimmer usage. The plastic shield pro

vides partial protection &om the risk of thrown

objects to the operator and others and is

equipped with a line limiter which cuts excess

line to the proper length. ____________________________

A WARNING

Failure to install shield in the position shown

can result in serious iipjury to the oper

ator. The length of the shield must be aligned

with the len^h of the drive shaft housing. Di

rect the widest part of shield toward the engine

NOTE; Remove the metal shield md blade before

inatAlling the plastic shield and tnmmer head.

1. Place the shield under the bearing housing and

align screw holes.

r.AtmONTl The line limiter (on the underside of

the shield) is sharp and can cut you. .

2. Insert screws “D.” through the bearing housing

into the shield. ^

Tighten the screws evenly and securely.

3.

Remove the packing cover from the arbor shaft if so

4.

equipped.

Install grass washer “K.” over the arbor shaft. Make

sure the grass washer is against and curved over the

dust cup. _ . ,

Start threading the trimmer head onto the arbor

6.

shaft. ^ . .

Align the hole in the dust cup with the hole in the

7,

center front of the bearing housing by turning the

dust cup. Then, insert the small hex wrench (pro

vided) into the migned holes to keep the arbor shaft

from turning. .

__________

'' ■

8. Tighten the trimmer head agEunst the washer and

dust cup while holding the hex wrench.

9. Remàve the Hex wrench.

NOTE; To remove the trimmer head, insert the

hex wrench into thè aligned holes in the dust cup

and hearing housing. Unthread the trimmer hean.

Be sure to store ^ass washer “K.”, plastic shield, 4

shield screws, and hardware with the trimmer head

for future use.

Page 9

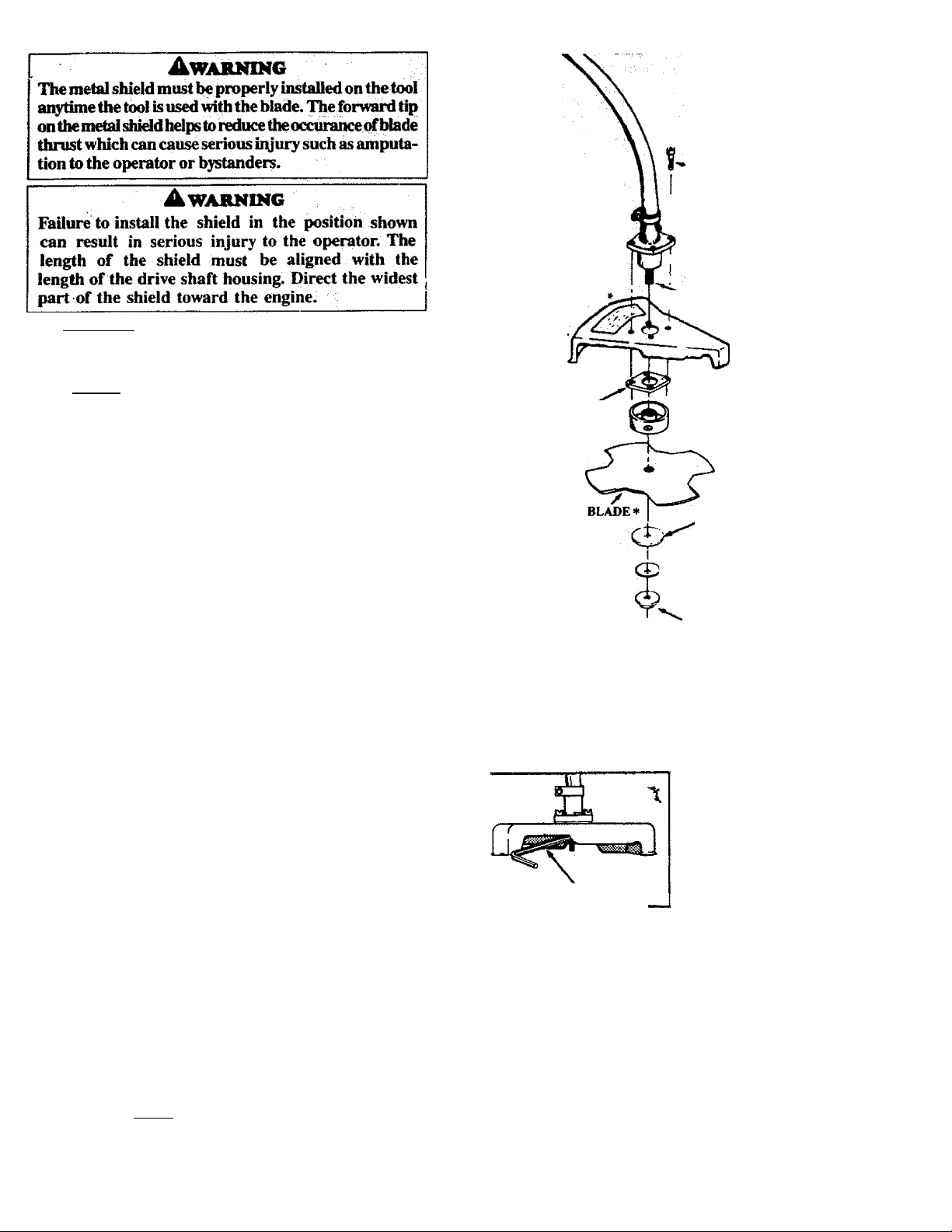

S. fUR WEED BLADE USE

■EAJUNti

HOUSINC^

CLAMf-^

•Screw“C.

CAUTION; I Wear protective gloves when

handling or perform ing maintenance on the blade to

help avoid injury.

NOTE; Remove the Plastic Shield, Trimmer Head,

and Grass Washer before installing the Metal Shield

and Blade.

a. Place the Metal Shield under the Bearing Housing,

aligning screw holes. Be sure wide end of metal shield

is toward the engine.

b. Position the retention plate “ L.” on the underside

of the Metal Shield and align screw holes. Make sure the

flat side of the Plate is against the Shield.

c. Insert screws “C.” (one at a time) through the Bearing

Housing, Shield, and Retention Plate.

d. Tighten the Screws evenly and securely with a hex

wrench.

e. Install the Dust Cup over the Arbor Shaft.

f. Install the Blade over Arbor Shaft, making sure the

hole in the center of the Blade is fitted around the raised

center .step on the Dust Cup.

g. Install flat washer “F.”, cupped washer “G.”, and

nut “H.”„ Be sure cupped washer “G.” is installed

as shown in (lower inset).

METAL

SHIELD

\

Retention

Plate“ L.”*'

1^ARBOR

SHAFT

DUST CUP

Washer “F.” •

Washer “G." •

(see inset)

Nut “H."*

V -

h. Line up the hole in the Dust Cup with the hole irt the

side of the Bearing Housing by turning the Dust Cup.

i. Insert the smal I hex wrench provided into the al igned

holestokeeptheArborShaftfromtuming.

j. Tighten nut *“II." firmly with a wrench while hold

ing hex wrench in position.

k. Remove the hex wrench.

l. Turn Blade by hand. If the Blade binds against the

Shield, the Blade is not centered. Reinstall the Blade.

m. Proceed to “Should Strap” instructions, this section.

NOTE; To remove the Blade, insert rod Into

aligned holes. Unthread the Hex Flange Nut and

• remove pans. Be sure to store the Retention Plate,

Hex Flange Nut, Beveled ’Vfeher, Flat ^^(hsher and

Metal StUeld with the Blade for safe keeping.

Cupped Side

Toward

Blade

HEX WRENCH

* Awarndig

Barts iMted with * are critical and must be

supplied by Sears. fUlure to use proper p<uts

can cause the blade to fly off and seriouBly hull

Washer “G.’

Page 10

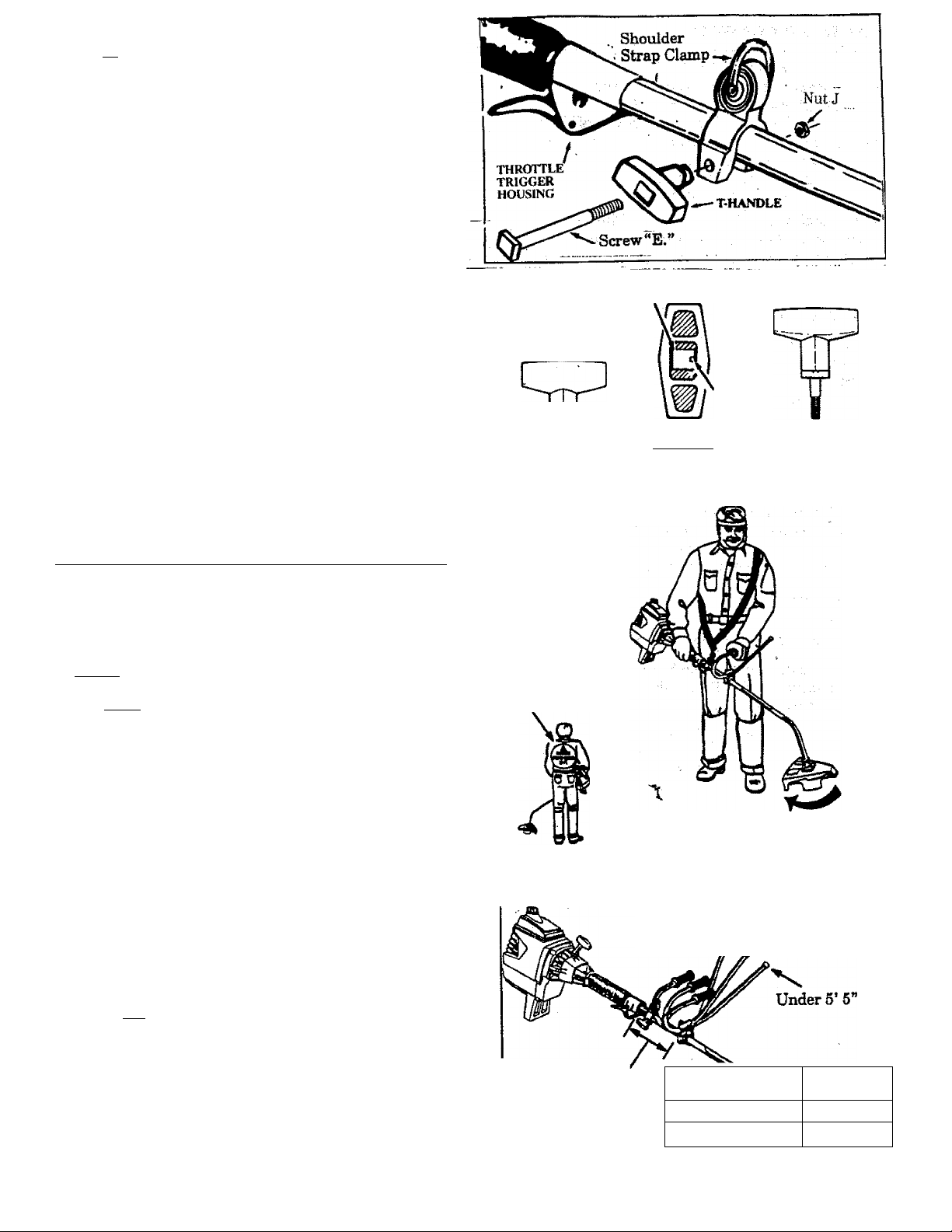

ft.SHOuuimsmAJ’CLAMi* „

a. Align the shoulder strap damp between the assist

hantUe and the throttle trigger housing.

b. Firmly push the shoulder strap damp onto the

drive shaft housing. Be sure that the shoulder

strap damp is installed with the „hex

shaped recession (on the damp) facing the same

side of the drive shaft housing as the barrier por

tion of the handlebar.

c. Drop the threaded end of screw “E.” through the

opening in the top of the T—handle.

d. Pull on the threaded end of the screw to bring the

square head of the screw past the pin inside the

T-handle.

e. Seat nut “ 1 in the hex-shaped recession on the

back side of the shoulder strap damp.

f. Insert the threaded end of screw “ E." through the

hole in the shoulder strap damp; thread the screw

into nut “ J. ” and tighten firmly by hand only.

...............................

_______________

__________ _____

Screw E.

SQUAREHEAD

SCREWSEATED

PIN

I. SHOULDER STRAP

A WARNING

Proper shoulder strap and handlebar adi«»**

ments before starting the engine are required for

safe and efficient use.

1. Try on shoulder strap and adjust for fit and balance

before starting the engine and beginning a cutting

operation. _

2. Place shoulder strap on vour left shoulder with the

Danger Bign on your back and hook to the ri|ht side

of your waist.

NOTE; A one-half twist is built in the shoulder strap

to allow the strap to rest flat on the shoulder.

To Tnake sure the strap rests flat on your body,

place the double portion across your front and the

single portion across your hack. .

3. Adjust the strap so that the hook will be about 10 in

ches below the waist when the hook is attached to

the shoulder strap.

4. Fasten the shoulder strap hook to the clamp and lift

the tool to the operating position.

5. Check for the following:

a. Left arm fuUy extended, hand holding handlebar

grip,

b. Right hand holding the top handle, fingers on

the throttie tri^r. .

c. Engine below waist level.

d. Shoulder strap pad centered on left shoulder.

e. Danger sign centered on your back.

f. Full weight of tool on left shoulder.

g. Without operator bending over, the blade or

trimmer head is near and parallel to the ground

and easily contacts material to be cut.

6. Modify these mitiai adjustments as necessary for

comfort and control but do not locate the handlebar

mounting block below the point of the arrow on the

safety labels. Do not locate the shoulder strap clamp

dlebar mounting Mock.

Position the handlebar for height. .

Be sure the handlebar is installed correctly, then

________________

tighten each screw secturefy with the larp hex

wrench.

10

.....

T-HANDLE

TOP VIEW OF

T-HANPLE

OPERATING POSITION

Danger Sign

Centered on

Your Back

POSITION HANDLEBAR FOR

Over 6’—*#

Distance A'

T-HANDLE AND

SCREW ASSEMBLED

Rotation

Direction

OPERATING HEIGHT

------

Operator’s Height

Less than 6 feet

6 feet & over

6’to 5’5"

Distance A

4 inches

2 inches

Page 11

FUELING YOUR ENGINE

BEFORE FUELING ENGINE:

AWARNESTG

Be sure to read the fuel safety information in the Warn

ings and Safety Instructions section on page 4 of this

manual before you begin.

If you do not understand the fuel safety section DO NOT

attempt to fuel your unit; seek help from someone that

does understand the fuel safety section or call the Cus

tomer Assistance Hotline at 1-800—235-5878,

GASOLINE

The two—Qfcle engine on this product requires a fuel mix

ture of regular unleaded gasoline and a high quality en

gine oil for lubrication of the bearings and other moving

parts. The correct fuel/oil mixture is 40:1 (see Fuel Mix

ture Chart). Too little oil or the incorrect oil type will

cause poor performance and may cause the engine to over

heat and seize.

Gasoline and oil must be premixed in a clean approved fuel

container. Always use fresh regular unleaded gasoline.

IMPORTANT! Experience indicates that alcohol

blended fuels called gasohol (or using ethanol or metha

nol) can attract moisture, which leads to oil/gas separa

tion and formation of acids during storage. Acidic gas

can damage the fuel system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage, for 30 days or longer. Drain the

gas tank, then run the fuel out of the carburetor and fuel

Knes by starting the engine and letting it run until it

stops. Use fresh fuel next season. See STORAGE

instructions for additional information. Never use en

gine or carburetor cleaner products in the fuel tank or

permanent damage may occur.

2-CYCLE OIL:

CRAFTSMAN 40:1 2 cycle oil is strongly recommended.

This oil is specially blended with fuel stabilizers for

increased fuel stability (extends fuel life up to 5 times

longer) and reduced smoke. ■

If CRAFTSMAN 2 cycle oil is not available, use a good

quality 2 cycle AIR-COOLED engine oil that has a

recommended fuel mix 40:1.

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA. etc.)

These oils do not have proper additives for 2—cycle,

AIR-COOLED engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

Mix gasoline and oil as follows:

• Consult chart for correct quantities.

• Do not mix gasoline and oil directly in the fuel tank.

FOR ONE GALLON:

• Pour 3.2 ounces of high quality, 2-qycle engine oil

into an empty, approved one gallon gasoline con

tainer.

• Add one gallon of regular unleaded gasoline to the

gallon container, then securely replace the cap.

Shake the container momentarily. ^

• The mixture is now ready for use. Fuel stabilizer

can be added at this time if desired; follow mixing

instructions orn^he label.

FUEL STABILIZER ,

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or storage container.

Always follow the fuel mix ratio found on the stabilizer

container. Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the carburetor.

You do not have to drain the fuel tank for storage if you are

using fuel stabilizer.

CRAFTSMAN 40; 12 cycle engine oil ii specially Wended

with fUel stabilizers. If you do not use this Sears oil, you

can add a fuel stabilizer (such as Craftsman No. 33500) to

your fuel tank.

FUEL MIXTURE CHART

40:1 FuehOil Mix Ratio

Gasoline

1 gallon

1.25 gallons

2.5 gallons

Oil (fl. oz.)

3.2

4.0

8.0

-

Page 12

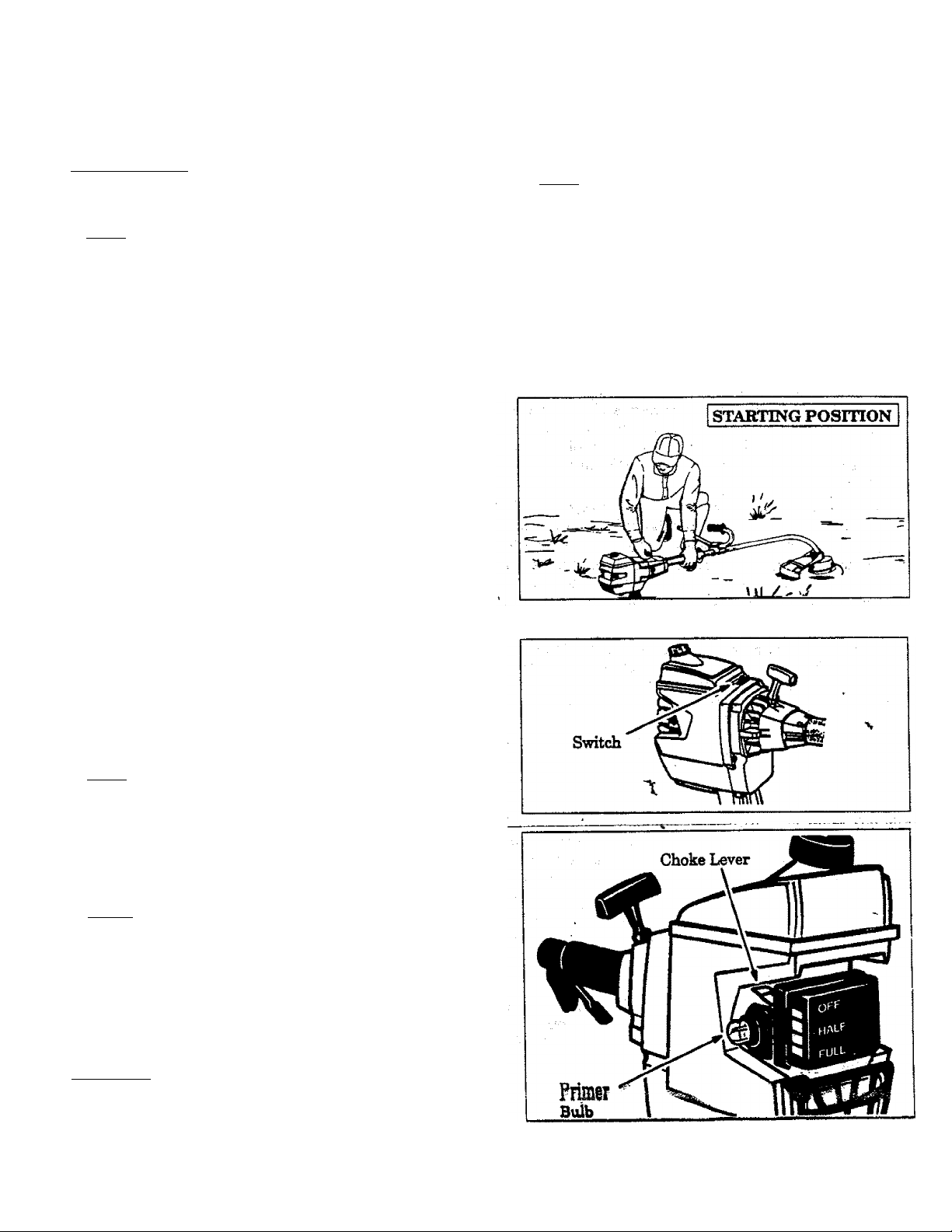

C. STARTING IMSmUCnONS (For location

BEFORE STARTING THE ENGINE:

• Fuel engine. Move 10 feet (3 meters) away from fuel

ing site.

A WARNING ^ ~

The trimmer head will turn when the engine

starts, ■

• Rest engine and shield on ground, supporting trim

. mer head off ground.

NOTE; Remove and discard the plastic shipping

guard on the primer bulb (if so eqtiipped).

STARTING A COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL:

• Make sure the switch is in the "On” position.

• Move the choke lever to the “Full Choke” position.

• Slowly press the primer bulb 6 times.

• Squeeze and hold the throttle trigger. Keep the

throttle trigger fully squeezed until tm engine runs

smoothly.

• PuU starter rope sharply 5 times.

Mom The en^

start before the 5

mediately.

________________________________

of controls, refer to “Specifications,”)

• Squeeze and hold the throttle trigger. iCeep iAe

throttle trigger fully squeezed until the engine runs

smoothly.

» Pull starter rope sharply until engine runs, but no

more than 5 pulls.

• Allow the engine to ran 15 seconds, then move the

choke lever to “Off Choke.”

NOTE; If engine has not started, pull starter rope 5

more pulls. If engine still does not ran, it is probably

flooded. Proceed to “Starting a Flooded Engine.”

• To stop the engine, move switch to the “Off” position.

STARTING A FLOODED ENGINE;

Flooded en^es can be started by placing the switch

in the “On” position and the choke lever in the “Off

Choke” position; then, puH the rope to clear the en

gine of excess fiiel. This could require pulling the

starter rope many times depending on how badly the

unit is flooded.

If the unit still doesn’t start, саП the Customer Assis

tance Hotline at 1—800—235—6878.

• Move the choke lever to the “Half Choke” position.

• PuR the starter rope sharply until the engine runs,

but no more than 6 pulls. .

ишт If the enmne has not started after 6 pulls (at

half choke), check to make зггге the switch and the

choke lever are in the proper positiona. Then, move

the choke lever to the ‘'Full Choke” position and

press the primer bulb 6 times; squeeze and hold the

throttle trigger and ргШ the starter rope 2 more

times. Move the choke lever to “HalfChoke” and pull

the starter rope until the engine runs, but no more

than 6 more pulls.

NOTE; If the engine still has not started, it is prob

ably flooded. Proceed to “Starting a Flooded En

gine”

• Allow the engine to run 15 seconds, then move the

choke lever to “Off Choke." Allow the unit to run for

30 more seconds at “Off Choke” before releasing the

throttle trigger.

NOTE: If engine dies with the choke lever at the “Off

Choke” position, move the choke lever to “Half

Choke” and pull the rope until the engine runs.

• To stop the engine, move the switch to “Off.”

_

____

A WARNING

Avoid any bodily contact with the muffler when

atarting a warm engine. A hot muffler can cauae

seriousbuma._________________

STAKTOIO A WASM ШОШЕ THAT ИА1 NOT

ЯШ OOT OF FUIX.|

a Make sure the switch is in the "On” position.

* Move the choke lever to the “Half Choke” position.

12

Page 13

D. OPERATING INSTRUCTIONS

• When using the blade, bring the engine to full

throttle before entering the material to be cut. The

blade has maximum cutting power at fuU throttle and

is less likely to bind, stall, or cause blade thrust,

which can result in serious iiyury to the operator or

others. Refer to “Guard Against Blade Thrust”.

> When using the trimmerhead, do not run the en

gine at a higher speed than necessary. The cutting

line will cut efficiently when the engine is run at less

than full throttle. At lower speeds, there is less engine

noise and vibration. The cutting line will last longer

and will be less Hkely to “weld” onto the spool.

^ If the blade or trinuner head does not turn

when the engine is accelerated, make sure the

tube is properly seated in the engine shroud.

► Always release throttle trigger and allow en

gine to return to idle speed when not cutting.

• The blade or trimmer head should not turn

when the engine runs at idle speed. If the blade

or trimmer head on your unit turns when the engine

is at idle speed, refer to “Trouble Shooting Chart.”

I To stop engines

• Release the throttle trigger.

• Move ignition switch to the “Off” position.

• Stop the blade by allowing the “9 o’clock” posi

tion to contact cut material. ^

_______________

A WARNING

The blade continues to spin after the engine is

turned off. The coastingblade can throw objects

or seriously cut you if accidentally touched.

Stop blade by contacting the left-hand side of

the coasting blade with material alreac^ cut.

Awarning

The operator or others must not try to clear

away cut material with the engine running or

the made tuimihg to avoid serious injury. Stop

engine and hlacfe before removing materials

wrapped around blade.

MOTES

13

Page 14

USING YOUR TOOL AS A WEEDCUTTER - w/BLADE

(The 4 point, 8 inch blade ie designed to cut grass, weeds and woody brush up to 1/2 inch diameter.)

A DANGER - THIS POWER TOOL CAN BE DANGEROUS!

This tool can came seriom injury including amputaUon or blindness to the operator and others. The warnings and safety

instructions in this manual must be followed to provide reasonable safety and efficiency in ming this tool. The operator is

responsible-for following the warnings and instructions in this manual and on the tool. Read the entire Operator’s

Manual before using this tool! Restrict the use of this power tool to persons who read, understand and

follow the warnings and instructions in this manual and on the tool.

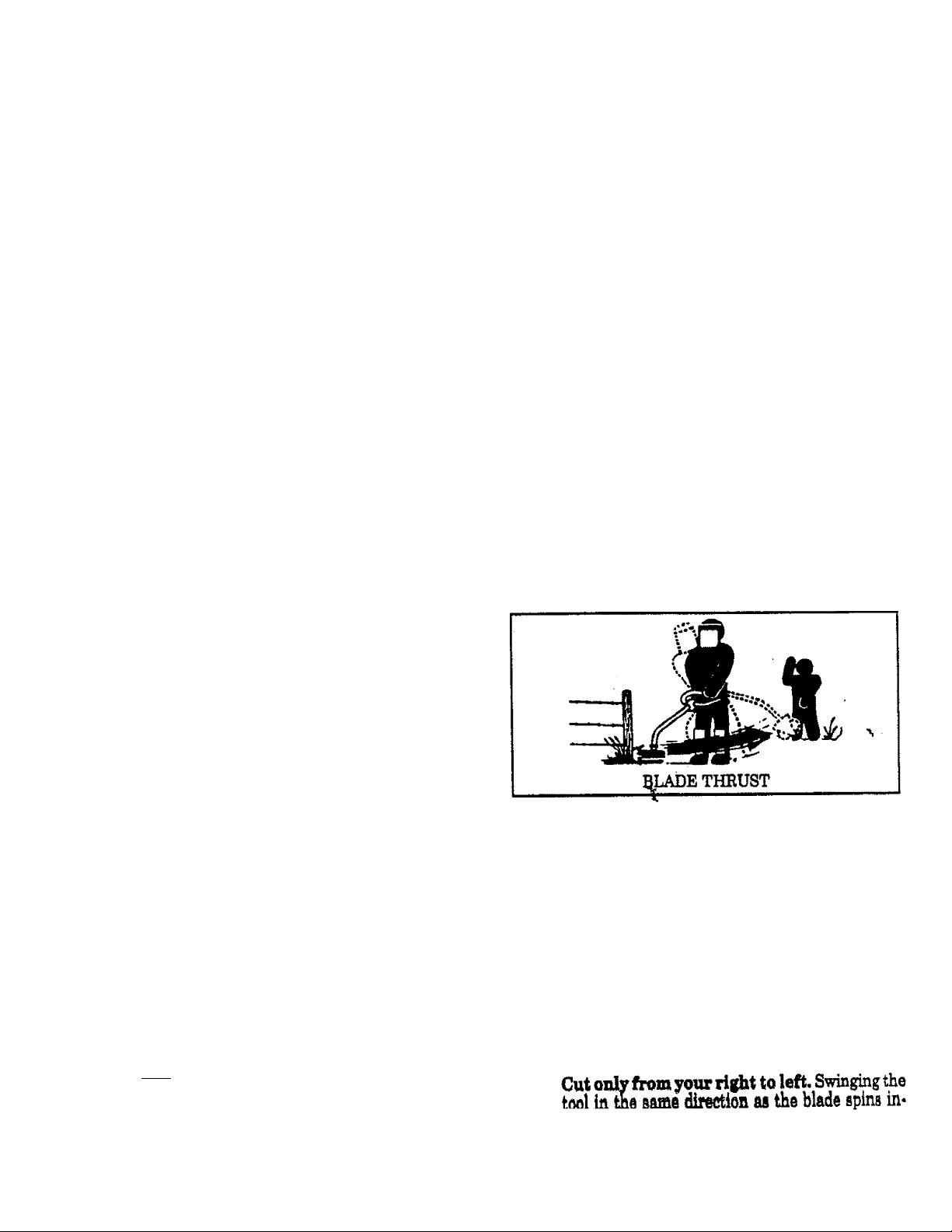

A DANGER - BLADE THRUST When the spin

ning blade contacts anything it does not cut, a dan

gerous reaction can occur earning the entire tool and

operator to be thrust violently in any direction. This

reaction is called Blade Thrust. As a result, the op

BLADE THRUST

erator can lose control of the tool. Use handlebar,

shoulder strap.

Make sure others are at least 30 feet (lO me

ters) away. Keep blade sharp. Cut at full

throttle and from ^ur right to left. Keep

hands, feet and tool In proper position; refer to

“Guard Against Blade Thrust.”

and r .......................................

shield in place._. ke^ _

8 inch WEED BLADE #7l-8573S‘

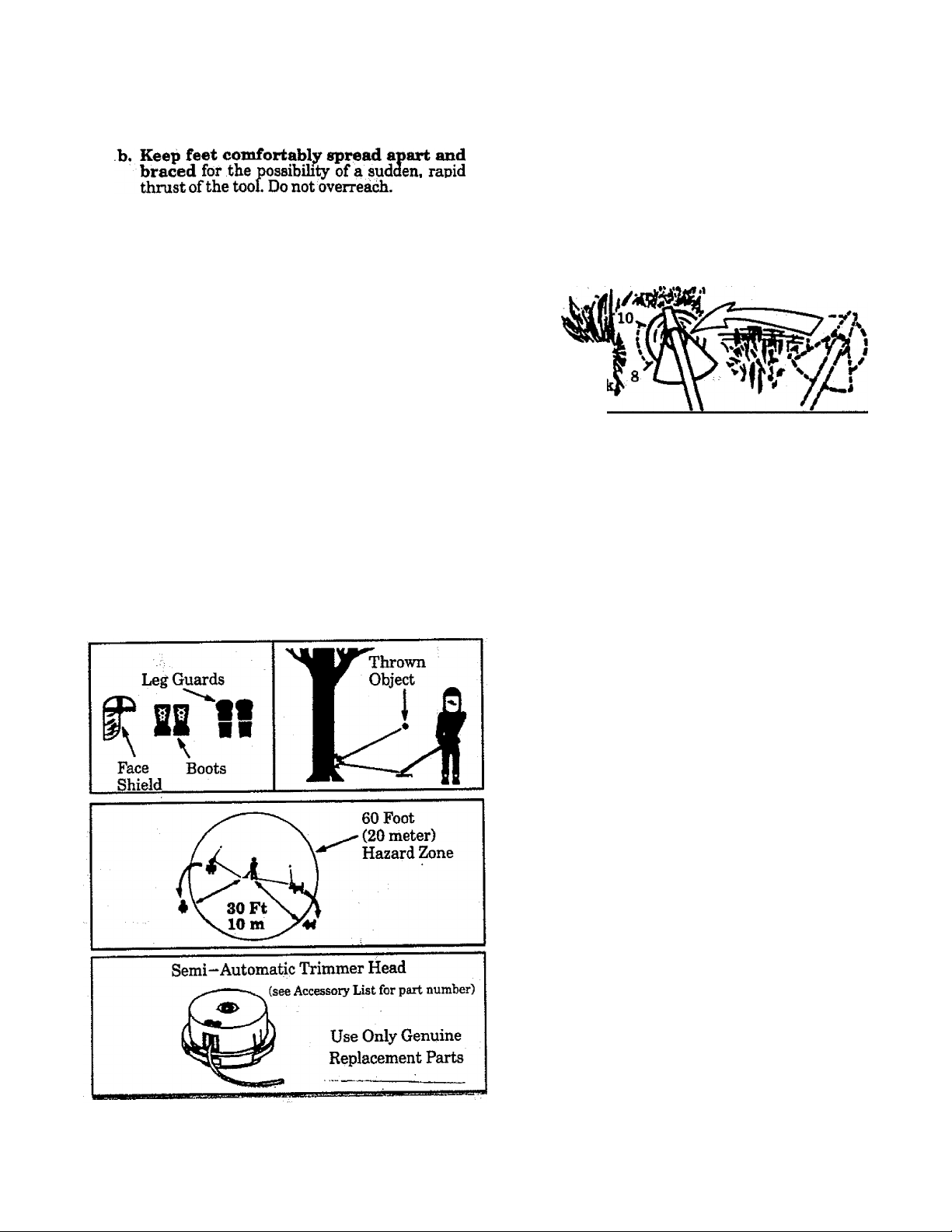

Leg Guards

\ \

Place Shield Boots

l°n II

Thrown

Object

1” ARBOR

OPENING:

60 Foot

(20 meter)

Hazard

Zone

AdANGER - PROPER BLADE

Use only the 4 point, 8 inch blade and proper

' hardware. The me of any other parts can result in

seriom injury. Do not use any accessory or at

tachment other than those recommended by

the manufacturer for use with this tool. Blades

that are bent, warped, cracked, broken, or damaged

can fly apart and came seriom injury. Do not use.

Throw away.

A WARNING - THROWS OBJECTS

The rapidly moving blade causes objects to be

thrown violently. The shield will not provide com

plete protection to the operator or others. The op

erator must wear a safety face shield or gog-

[les. Alwa3?B wear safety leg guards and boots.'

eep others at least 30 feet away.

AwABNING - HAZARD ZONE

This tool will throw obj^s and cut. Keep others

including children, animals, bystanders, and

helpers at least SO feet (10 meters) away from

the operator and tool. Stop the engine and

blade immediately if you are approached.

NOTE: In areas where other people and animals are

present, such as near sidewall^, streets, houses, etc.,

It is strongly recommended that the operator use the

buddy system; that is, have another person serve as

a “look out,” keeping himself and others at least 30

feet (10 meters) away from the operotor,

%d

^WARNING - COASTING BLADE

The blade contmues to spin after the engine is

stopped or the throttle is released. The coasting

blade can thrust, throw objects, or seriously cut you

if accidentally touched. Stop blade by leaving it

in contact with material already cut. Use the

*'9 o’clook” poiition u the point of oontact.

Page 15

A. BLADE SAFETY

OPERATOR SAFETY

1.

a. Always wear a safely face sMeM or gog

gles, See “Accessories.

b. Always wear heavy, long pants, long

sleeves, boots, gloves and safety leg

guards. See “Accessories.” Do not wear loose

clothing, jewelxT, short pants, short sleeves,

sandals, or go barefoot. Secure hair so it is

above shoulder length.

Do not operate this tool when you are

c.

tired, ill or under the influence of alco

hol, drugs or medication-

1. Always use the handlebar and a properly

adjusted shoulder strap. See ‘Assemoly.”

e. Do not swing the tool with such force

that you are in danger of losing your bal

ance.

Never start or run the engine inside a

f.

closed room or building. Breathing exhaust

fumes can kiE.

Keep handles free of oil and fuel.

2. TOOL SAFETY

Inspect the entire tool before each use.

a.

Replace damaged parts. Check for fuel leaks

and make sure all fasteners are in place and se

curely fastened.

Be sure the metal shield is properly at

b.

tached. The metal shield must be installed for

all blade usage.

d. Be sure the blade stops turning when the

engine idles. See “Trouble Shooting Chart.”

e. Make carburetor adjustments with the

lower end supported to prevent the blade

from contacting any object. Hold tool by

hand; do not use shoulder strap for support.

f. Keep others away when making carbure

tor adjustments.

3. CUTTING SAFETY

a. Inspect the area to be cut before each

use. Remove objects (rocks, broken glass,

nails, wire, string, etc.) which can be thrown or

become entangled in the blade.

b. Always keep the engine on the right side

of your body. Hold the tool firmly with both

■ hands.

c. Keep firm footing and balance. Do not

over-reach.

d. Keep blade below waist level.

e. Do not raise the engine above your waist.

The blade can come dmgerously close to your

body.

f. Cut at full throttle .

g. Cut from your right to your left.

h. Use only for jobs explained in this man

ual. Do not use the blade as an edger. The

. shield does not provide adequate protection.

B. GUARD AGAINST BLADE THRUST

* Blade Thrust is a reaction that only occurs when

using a bladed tool. This reaction can cause seri

ous uyury such as amputation. Carefully study

this section. It is important that you understand

what causes blade thrust, how you can reduce the

chance of its occurring, and how you can remain

in control of the tool it blade thrust occurs.

• The forward tip on the shield helps to reduce the

occurrence of blade thrust but cannot prevent the

occurrence. The operator must follow the warn

ings and safety instructions in this section to

lessen the chance of blade thrust occui^g and to

maintain control of the tool if the reaction does oc

cur.

1. WHAT CAUSES BLADE THRUST. Blade

Thrust can occur when the spinning blade con

tacts an object that it does not cut. This contact

causes the blade to stop for an instant and then

suddenly move or “thrust” away from the object

that was hit. The “thrusting” reaction can be vio

lent enough to cause the operator to be propeUed

in any direction and lose control of the tool. The

uncontrolled tool can cause serious iiyury if the

blade contacts the operator or others.

2. WHEN BLADE THRUST OCCURS, Blade

thrust can occur without warning if the blade

Rfiftgs, stalls, or binds. This is more likely to occur

in «resi wher9 it is c^sult to see the material be

ing cut. By using the tool properly, the occurrence

of blodc thrust wUl be reduced and the operator

will be less likely to lose control.

3, REDUCE THE CHANCE OF BLADE THRUST

a. Cut only grass, weeds and woody brush up

to 1/2 incn diameter. Do not let the blade con

tact material it cannot cut such as stumps, rocks,

fences, metal, etc., or clusters of hard, woody

brush having a diameter greater than 1/2 inch.

b. Keep the blade sharp. A dull blade is more

likely to snag.

c. Cut only a fall throttle. The blade has maxi

mum cutting power at full throttle and is less

likely to bina or stall,

<L “Peed" the blade deliberately and not too

rapidly. The blade can thrust away if it is fed too

rapidly.

creases the cutting action.

15

Page 16

4. MAINTAIN CONTROL

a. Use tlie shoulder strap and keep a firm

grip on the tool with both hands. A prop

erly àcyuflted shoulder strap will support the

weight of the tool, freeing your anna and hands

to control and guidé the cutting motion.

Keep firm

footing and balance.

G. CUTTING METHODS

1. Establish a rhythmic cutting procedure.

a. Plantfeet firmly, comfortably apart.

b. Cut while swingingthe upper part of your body

from right to left.

c. Move forward to the next area to be cut after

the return swing and plant feet once more.

2. Use the 8 o’clock to 10 o’clock position for

cutting.

3. Stop the engine and blade, then uncUp the

shoulder strap from the tool before clearing

cut material.

4. To reduce the chance of material wrapping

around thé blade, follow these steps:

a. Cut at fuU throttle.

b. Swing the tool into material to be cut from

your right to left.

c. Avoid the material just cut as you make the re

turn swing.

Keep the blade below waist leTel. It will he

easier to maintain control of the tool. '

Do not raise the engine above your waist

as the blade can come dangerously close to

your body.

Do not swing the tool with such force

that you are in danger of losing your bal

ance. '' '

Direction to Cut

Cut Between

the 8 o’clock

and 10 o’cloc]

Position

Awarning

The operator or others must not try to clear

awav cut material with the engine runnJi^ or

the made turning to avoid serious Injury. Stoi

engine and Made before removing materii

wrapped around blade.

USING YOUR UNIT AS A LINE TRIMMER

The rapidly moving line causes objects to be

thrown violently. The shield will not provide

complete protection to the operator or others.

The operator must wear a safety f^e

shield or goggles. Always wear hea^,

longpants and boots. Keep others at least

30 feet (10 meters) away.

WARNING - HAZARD ZONE

This tool will throw objects and cut. Keep oth

ers including children, animals, bystand

ers and helpers at least 30 feet (10 meters)

away from the operator and tool. Stop

the engine if you are approached, ^ "

A WARNING - DAMAGED

Trimmer head parts that are chipped, cracked

or damaged in any other way can fly apart and

cause serious ityury. Do not use. Replace

damaged parts before using the tool. >

wahning-throws objects

1

TRIMMER HEAD

A. LINE TRIMMER SAFETY

1. OPERATOR SAFETY

a. Always wear eye protection when operating,

16

iervicing, or performing maintenance on your

b. Do not operate this tool when you are tired, ill

or under the influence of alcohol, drugs, or

medication,

Page 17

с.

Always wear heavy, long pants, boots, and

gloves. Do not go barefoot or wear sandals,

short pants, jewelry, loose clothing, or clothing

with loosely hanging straps, ties, tassels, etc.;

they can be caught in moving parts. Secure

hair so it is above shoulder length; Being fully

covered will help protect you from pieces of

toxic plants such as poison ivy thrown by the

blade, which could be more of a hazard than

touching the plant itself.

Do not swing the tool with such force that you

are in danger of losing your b^ance.

e.

Never start or run the engine inside a closed

room or building. Breathing exhaust fumes

can kill. •

Keep handles free of oil and fuel.

f.

TOOL SAFETY

a. Inspect the entire tool before each use. Re

place damaged parts. Check for fuel leaks and

make sure all fasteners are in place and se

curely fastened.

b. Use only .080” diameter SEARS Laser Line. Never

use wire, rope, string, etc. _

__ __

c. Be sure the shield is properly attached." “

d. Make sure trimmer head is properly installed

and securely fastened. Refer to “Assembly.”

e. Be sure trimmer head stops turning when en

gine idles. See “Carburetor Adjustments.”

f. Make carburetor adjustments with the drive

shaft housing supported to prevent the trim

mer line from contacting any object.

g. Keep others away when making carburetor ad

justments.

h. Use only acces^ries or attachments as recom

mended by Sears forthis tool.

CUTTING SAFETY

_______

. .

a. Inspect the area to be cut before each use. Re

move objects {rocks, broken glass, nails, wire,

string, etc.) which can be thrown or become en

tangled in the trimmer head.

b. Always keep the engine on the right side of

your body.

c. Hold the tool firmly with both hands.

d. Keep firm footing and balance. Do not over

reach.

e. Keep the trimmer head below waist level.

f. Do not raise the engine above your waist.

g. Keep all parts of your body away from the trim

mer line and muffler when engine is running.

h. Use only for jobs explained in this manual.

B. TRIMMER LINE ADVANCE

• The trimmer line will advance approxi

mately 2 inches each time the bottom of the

trimmer head is tapped on the ground with

the engine running at full throttle.

• The most efficient line length is the maxi

mum length allowed by the line limiter.

• Always keep the shield in place when the

tool is being operated. Figure 35 .

• To Advance Line:

1. Operate the engine at full throttle.

2. Hold the trimmer head parallel to and above

the grassy area.

3. Tap bottom of trimmer head lightly on ground

onetime. Approximately' 2 inches of line

will be advanced with each tap. , ___ _

NOTE; Always tap trimmer head on a grassy

area. Tapping on surfaces such as concrete or

asphalt can cause excessive wear to the trim

mer head.

NOTE; If the line is worn down to two

inches or less, more than one tap will be re

quired to obtain the most efficient line length.

Use only .080” diameter Scars leaser Line. Other

A WARNING

sizes, of ^line^will not advance properly. Do.

not use_ other 'materials .such..as wirè;._

string, rope, etòrWiré can break off during cut

ting and become a dangerous missile that can

possibly cause serious injury.____________________________

............

...........................

A WARNING

Use mixumum speed and do not crowd the line

when cutting around hard objects (rock, ^avel,

fence posts, etc), which can damage the trimmer

head, become entangled in the line, or be

thrown causing a serious hazard.

To Advance Line

Tap Bottom Of

____________________

Line Limiter Cuts Line

To Proper Length.

'

Trimmer Head On

Ground One Time

1

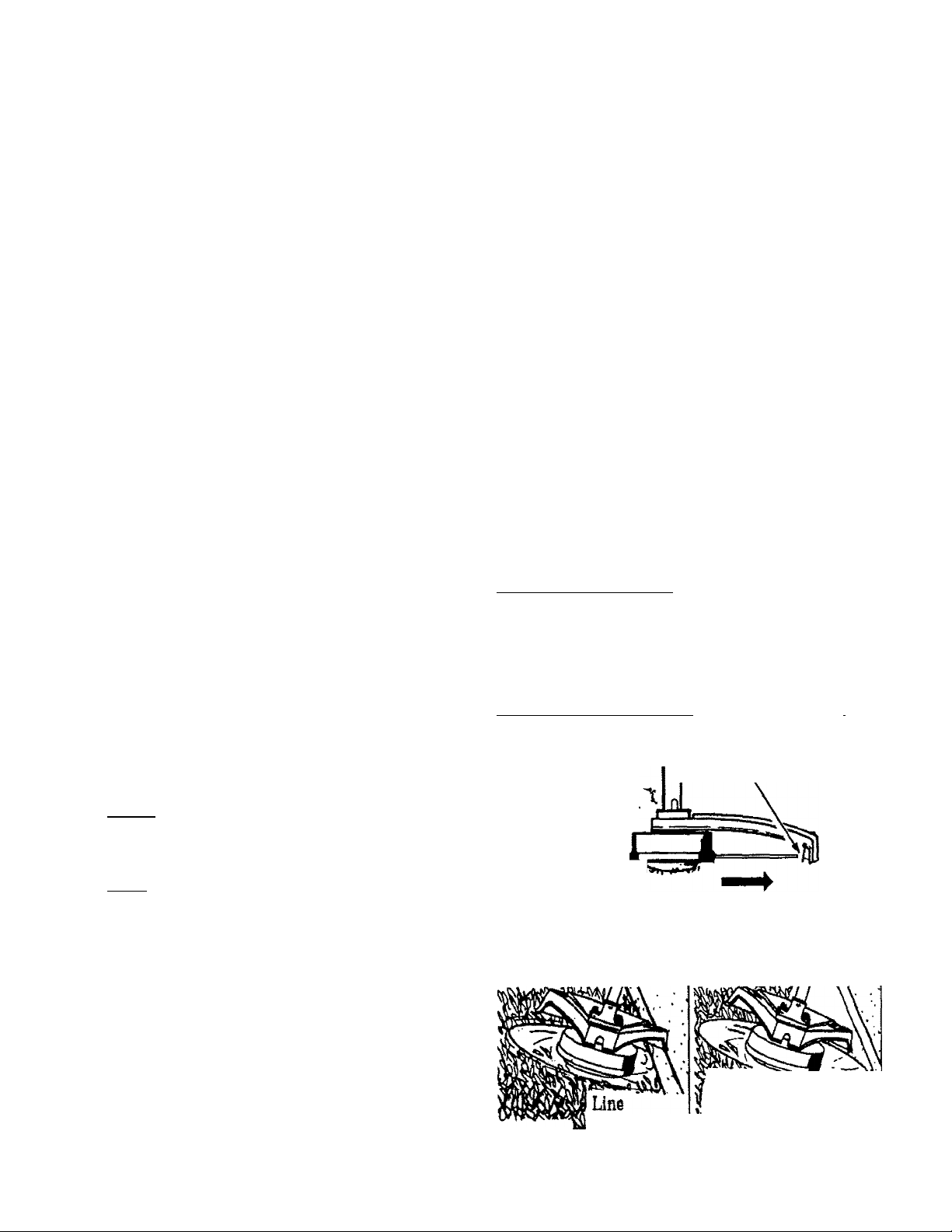

C. CUTTING METHODS

• The tip of the line does the cutting. You vnll

achieve the best performance and minimum line

wear by not crowding line into cutting area. The

right and wrong ways are shown in

t For frimming OF ica|

throttle to increase

ше less than full

espeelallyt

- during light duty cutting.

— near objects around which the line can wrap

such as small posts, trees or fence wire.

Crowded Into

WRONG Work Area

3 Inches I

Above

Ground

RIGHT

Tip of the

Line Does

The Cutting

17

Page 18

• The line will easily remove grass and weeds

firom around walls, fences, trees and flower

beds, but it also can cut the tender bark of

trees or shrubs and scar fences. To help avoid

damage especially to delicate vegetation or trees

with tender bark, shorten line to 4—5 inches and

use at less than full throttle.

• For mowing or sweeping, use full throttle for

a good clean job.

Use minimum speed and do not crowd the line

ik WARNING ^ ■■

when cutting around hard objects (rock, ^avel,

fence posts, etc), which can damage the trimmer

head, become entangled in the line, or be

thrown causing a serious haasard.

.

....

.

3 Inches

Above Tip of the Line

■ Ground ^ Does the Cutting

Always wear eye protection. Never lean over the

trimmer head. Rocks or debris can ricochet or

be thrown into eyes and face and cause blind

ness or other serious injury.

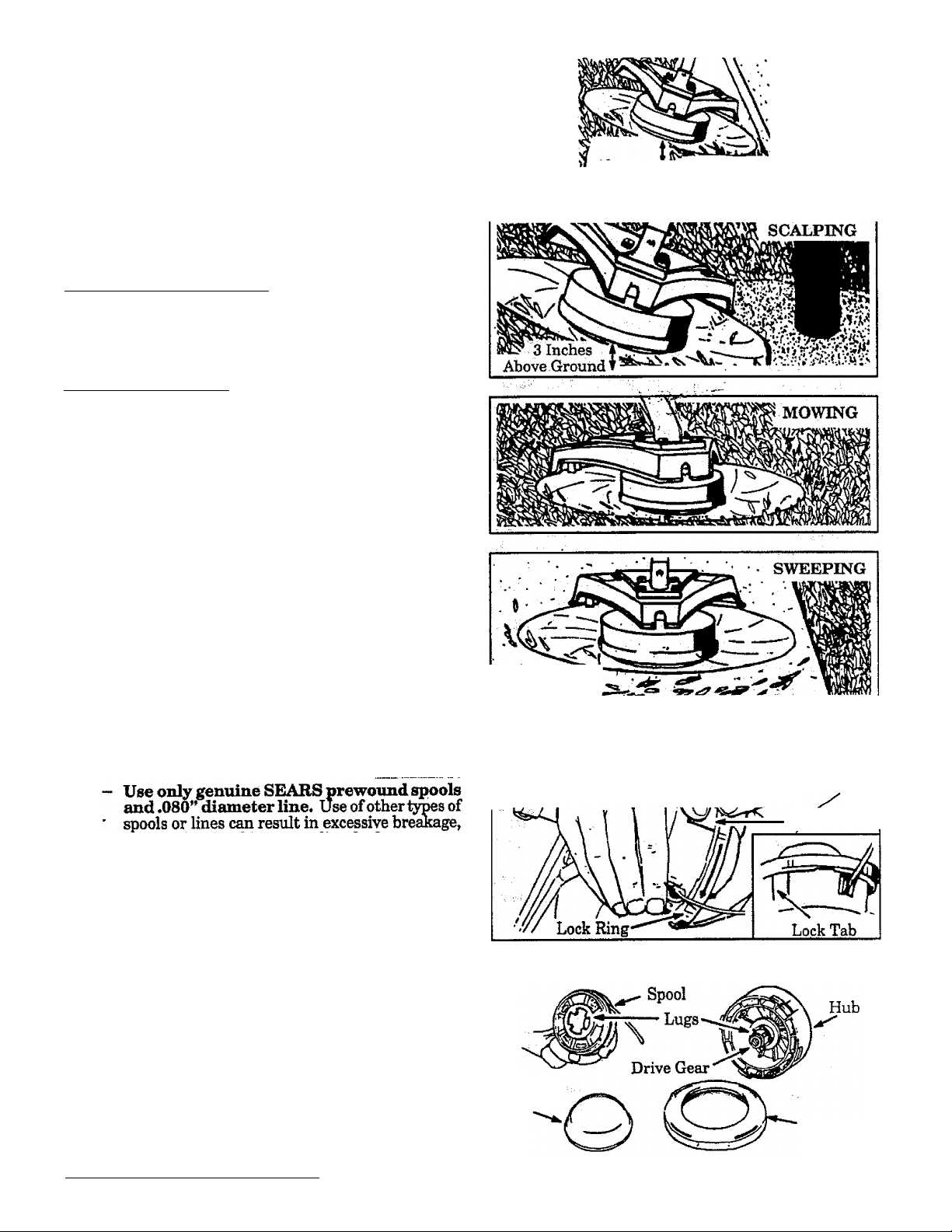

1. TRIMMING- _ Hold bottom of the

trimmer head about 3 inches above ground and at

: an angle. Allow only the tip of the line to make

contact. Do not force trimmer line into work area.

2. SCALPING - The scalping tech

nique removes unwanted vegetation. Hold the

bottom of the trimmer head about 3 inches above

the ground and at an angle. Allow the tip of the

line to strike CTOund around trees, posts, monu

ments, etc. This technique increases line wear.

3. MOWING- Your trimmer is ideal

........

for mowing in places conventional lawn mowers

cannot reach. In the mowing position, keep the

line parallel to the ground. Avoid pressing the

head into the mround as this can scalp the ground

and damage the tool.

4. SWEEPING- Thefanningaction

of the rotating line can be used for a quick and easy

clean up. Keep the line parallel to and above sur

faces being swept and move tool from side to side.

____________________________

D.LINE REPLACEMENT

• For proper line feed;

Une welding, and improper line feed.

A WABNING

To Remove, Turn Lock Ring Counterclockwise

To Replace, Turn Lefck Ring Clockwise

/1 ' ' ^ Y \ /no; \ ^ .'

Lock Tab

18

— Pre-wound spools offer the most conven

ient method for replacing line as well as

optimum performance.

• Always clean dirt and debris from spool and

hub when performing any type maintenance.

1. Installing Spool with Line

a. Hold the trimmer head as shown in ^

Press the lock tab and turn the lock ring

__________

1. ^ ' /

b. Remove the lock ring, tap button, and spool.

c. Clean dirt and debris from all parts.

d. Inspect all trimmer head parts for damage. Re

place damaged parts.

Awaking'................."

Trimmer head parts that are chipped, cracked,

broken, or damaged in any other way can fly

apart and cause serious injury Do not use. Repface damaged parts before using the tool.

.....

" '

Tap

Button

Lock Ring

Page 19

NOTE: The aluminum line saver can become —

worn during use. After a groove is worn

into line saver, remove it from trimmer head, turn

it upside down, and reinstall it {with'spool re

_____

moved) to provide a new wear surface.

Awahning

The line saver must be installed only from the in

side of the trimmer head. If installed on the out

side of the trimmer head, the line saver can fly

off and become a dangerous missile.________________

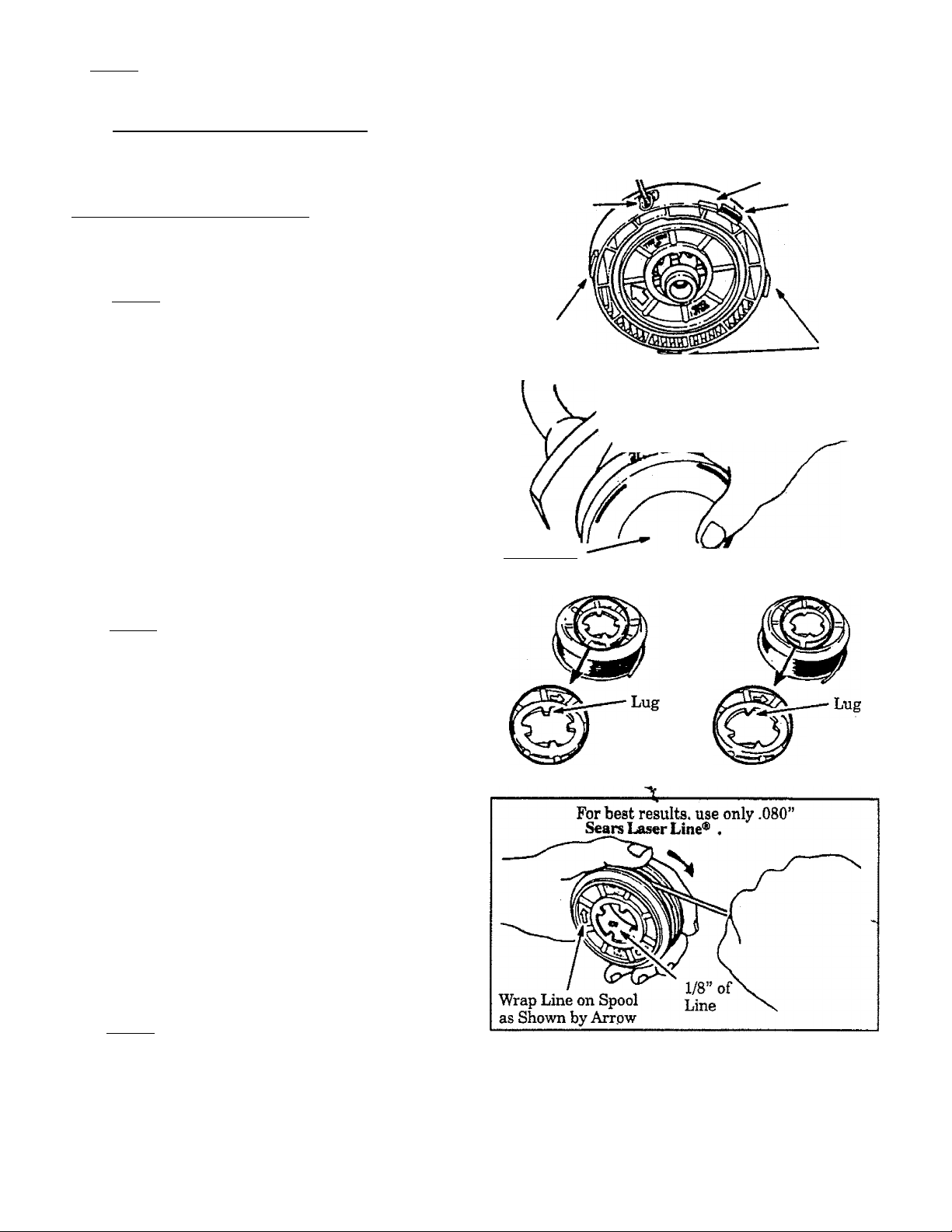

e. Insert the end of the line through the line saver.

Place spool in trimmer head. Press spool

down, then turn it enough to lock lugs on

spool under lugs on drive gear.

NOTE; Make sure the line is not caught between

the rim of spool and the wall of trimmer head.

f. Replace the tap button. Align the lock ring

over the catches on the hub; push the lock ring

down on the hub and turn it clockwise until the

catches lock into place.

_______

A WARNING

All catches must be fastened and the lock tab

latched in the Lock Ring. If installed incor

rectly, the Lock Ring can fly off and become a

dangerous missile.

g. Make sure lock ring is properly fastened by

pulling on it and trying to turn it counterclock

wise. If it comes off, reinstall it properly.

h. Pull on the line to change the spool from the

locked position to the operating position.

i. Obtain the correct line length (4-6 inches) by

pressing the tap button and pulling on the

line again.

NOTE; Each time the tap button is pressed, ap

proximately 2 inches of line can be pulled from

the trimmer head.

2. Spool Replacement

a. Replace the spool when the square comers on

the lugs are rounded off, reduced in size, or bro

ken off.

b. To replace the spool, follow the instructions in

“Installing Spool with Line.”

3. Installing Line on Spool

To replace the Line on existing Spool;

a. Follow “Installing Spool w/Line,” steps

“a.—d." and remove any line remaining on

the spool.

b. Use a 40 foot length of .080” Sears Laser Line.

e. Follow “Installing Spool with Line,” steps

If the line breaks off or backs up in the trim

mer head, follow “Installing Spool' w/Line,”

steps “a.—d.” Pull slack in line until the line is

tightly wound on the spool, leaving 4-~6 inches of

extended line. Continue with steps “e.~i.”

Catch

Line Saver

Catch

Approximately 2 Inches of Line Can

Be Pulled From the Trimmer Head

Each Time the Tap Button is Pressed.

Tap Button

NORMAL

SPOOL,

Lock Tab

Catch

WORN

SPOOL

c. Insert 1/16” to 1/8” of the end of the line

through the hole in the spool.

Allow no more than 1/8” line to extend in

side the spool.

d. Wrap the line onto the sjiool firmly and

evenly in a clockwise direction as shown by

the arrow on the spool.

NOTE; The line must be wrapped firmly and

evenly for proper line feed.

4. Trouble Shooting the Trimmer Head and Line

• Doei not advance/brealu while cutting} • Weldi onto apooli

- Improperly wound onto spool. — Line size incorrect.

Line elzo incorrect. - Incorrect ipool

- Too little line outside head. - Crowding line against material being cut.

• Pulls back into head: - Cutting at higher speeds than necessary.

- Too little line outside of head, • - -

19

Page 20

ACCESSORIES

The following accessories are available through Sears Retail Stores, Catalog, Outlets or Service Centers.

ITEM STOCK NO.

Safety Face Shield ..............................................................

Safety Goggles

2-CycIe Engine Oil

Spark Plug

Replacement Weed Blade

Replacement TVimmer Head (available only through Sears Service Centers) ............. . .952-701643

Replacement .0iS0"Dia. Nylon Trimmer Line

-400ft........................

.— 200 ft.

-100 ft.................

Replacement Spool with Line

Shoulder Strap Kit

Spark Arrestor Kit

Flex Shaft Lube...........................

...

...................

........................................

....................................

...........................................................................................................71-85608

............

................

.......................................................................

......................................................

......

............................

...

................

.............

.....

.....................................................................................

*AvailabIe through your SEARS SERVICE CENTER/CATALOGUE.

.........................

..............................................

.................................................................................

...........................................

...........................................

.............................

............

...........................

............................................................................. 71-85735

...................

...............................

...............................................................530-0301021.

......................

............................................... 71-30143

71-85854

......

........

........................... .71-85778

.............71-85771

.....................................

..................... ...........

.. 952-701612*

..................

..........

9-18613

71-85815

71-85783

NOTES

20

Page 21

CUSTOMER RESPONSIBÌLITIES

A. MAINTENANCE SAFETY

1. Maintain the tool according to recommended pro

cedures. Keep the blade sharp and the cutting line at the pro

per length.

2. Never start the engine with the clutch shroud

removed. The clutch can fly apart and cause serious

injury.

3. Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

4. Make carburetor adjustments with the drive shaft hous

ing supported to prevent the blade or trimmer line from

contacting any object. Hold the tool 1^ hand; do not use the

shoulder strap for support.

5. Keep others away when making carburetor

adjustments.

FLEXIBLE DRIVE SHAFT UIBBICAIION

• Lubricate the Flexible Drive Shaft:

- After each ten (10) hours of operation.

- Before operating If the tool has been

stored for 90 days or longer.

• When ordering flex shaft lube, see the

Accessory List for proper part number.

A WARNING

If engine has just been operated, avoid touching

the muffler. A hot mumer can cause serious

bums.

6. Be sure blade or trimmer head stops turning when

engine idles. See “Carburetor Adjustments.”

7. Wear protective gloves when handling or performing

maintenance on the blade.

8. Throw away blades that are bent, warped, cracked, ;

broken,ordamagedinanyotherway.Replacetrim- i

merheadpartsthatarecracked,chipped, broken,

or damaged In any other way before using the tool.

9. Use only .080" diameter Sears Laser Line. Never

use wire, rope, string, etc.

10. Useonlygenuinereplacement partsasrecommended by Sears.

11. Inspect the entire tool. Replace damaged parts. Check

for fuel leaks and make sure all fa.steners are in place

and securely fastened.

6. Apply a uniform coat of lube to the entire sur

face of the flexible drive shaft.

7. Inject the remaining contents of the tube into

the top of the tube.

8. Replace flexible drive shaft in the tube.

9. Reassemble the gear box to the tube. Tighten

screws securely.

j

CAUTION; I Lay the flexible drive shaft on a

clean surface. Avoid laying the shaft on the

floor, ground or on any other surface that

may have dirt or debris. Even after wiping

the shaft, grease residue can pick up diif

particles that can cause damage or prema

ture failure.

I CAUTION: I Take care to avoid im'ury to your

hands and fingers with broken wires when

checking for damage or wdping the flexible

drive shaft. A cloth will not prevent broken

wires fl'om puncturing or tearing your skin.

1. Remove the gear box clamp screw and the lo

cating screw from the gear box.

2. Remove the gear box from the tube.

3. Remove the flexible drive shaft from the tube.

4. Check flexible drive shaft for broken wires,

twists or kinks, and replace if damage is found.

5. Using a clean cloth, wipe surface of flexible

drive shaft thoroughly to remove any grease.

21

Page 22

C. CjysmiMirroilAPJUSTMiacri

▲warming

Make caiiNiretora4justnieiits with the drive shaft hous*

_____

ing supported to prevent the Blade or trimmer line

from contacting any object.Hold the tool with yourhandi

do not use theoptional shoulder strap for support.

▲warning

Keep others away when making carburetor

adjustments.

- “ follow the instructions. The basic carburetor settings

are provided in the event they are required.

a. Turn the Low Speed Mixture Screw and the High

Speed Mixture Screw clockwise until they stop.

Do not turn the screws until they are tight as

damage to the needle seats can occur

b. Turn the Low Speed Mixture and High Speed Mix

ture Screws one full turn countercloclwise.

c. Follow instructions “a. Preparation,” through “f. !

High Speed Mixture Adjustment.”

▲warning

Serious Injury to the operaUir and others can occur if the

carburetor is not properly adjusted.

• Poor engine performance can be a result of other

causes such as dirty air filter, carbon build-up

on muffler outlets, etc. See “TVouble Shooting

Chart” before proceeding with carburetor

adjustments.

• The carburetor has been carefully adjusted at the

factory. However, the operator must be sure that

adjustments are made when any of the'conditions

occur as mentioned In “Trijuble Shooting Sugges

tions” below.

• Very small adjustments can affect engine perfor

mance. It is important to turn the screw a very small

amount per adjustment and test performance before

making further adjustments. Each adjustment should

be no more than the width of ihe slot in the adjusting

screws.

• This is a complicated task. It Is important to follow

Instructions in sequence as indicated.

1. mOUBLE SHOOTING SUGGOTIONS

— Engine will not continue to run at idle position.

See “b.” Idle Speed Adjustment” and “e. Low

Speed Mixture Adjustment.”

— Blade or Trimmer Head continues to spin when

the engine idles. See “b. Idle Speed Adjustment”

and “d. Deceleration Check.”

— Engine dies or hesitates when it should accelerate.

See “c. Acceleration Check.”

— loss of cutting power which cannot be corrected

by cleaning the air filter. See “f. High Speed Mix

ture Adjustment.”

— Engine does not return to idle from full throttle

within 2 seconds. See ‘‘d. Deceleration Check.”

— Engine will not run. See “TVouble Shooting

Chart.” Then, if the carburetor requires adjust

ment, begin with“2. Basic Carburetor Settuip.”

▲warning

.....

The Blade or trimmer line will be spinning during

most of this procedure. Wearyour protective equipment

and observe all safety instructions. __________________

l.BA81CCAIUItmif01ttETnN0S

NOTE; In most cases, your engine can be made to

ran properly with minor carburetor adjustments.

Refer to “Trouble Shooting Suggestions” in the left

column for the condition you are experiencing and

22

3.PROCEDUR£

a. PREPARATION

1. jUsea fresh fuel mix. See “FuelingTtburEngine."

2. )Mal« sure line extends to the length allowed by line

limiter to provide correct load on engine.

3. jStart the engine. Cut grass for 3 minutes to warm

engine. The engine must be at operating temper

ature before carburetor adjustments can be per~

formed correctly.

4. )Stop engine and remove air filter pulling it out

with your fingers. Refer to “Specifications” for

location.

tx IDLE SPEED ADJUSTMENT

1. jAllow engine to idle.

2. )Adjust Idle Speed Screw until the engine

continues to run without stalling and

without the trimmer head moving.

—^ Turn screw clochme to increase engine speed

if the engine stalls or dies.

— Turn screw counterclockwise to slow engine

dorni and/or to keep blade or trimmer head

from turning.

3. )FoIIowinstructionsin ”c. Acceleration Check”

and “d. Deceleration Check.” .

4. )No further adjustments are necessary if the

trimmer head does not turn at idle speed and

If performance is satisfactory.

¿Warning

Recheck idle speed after each adjustment. The blade or

trimmer head must not turn at idle speed to avoid serious

injury to the operator and others. ___________________

«.ACCELERATION CHECK

1. jAllow engine to idle. ^

2. }Squeeze Trigger fully

a. If performance Issatisfactory, proceed to “d.

Deceleration Check."

b. Ifthe engine does not accelerate smoothly,

turn the Low Speed Mixture Screw counter-

clockwise a small amount (no morei than the

widthofthesiot intheadjustingserew).

_

3. )Repeat step “2.)” until smooth acceleration is

obtained,

NOTE: It may be necessary to repeat “b. Idle

Speed Adjustment” through “c. Acceleration

Check,” to obtain correct adjustments.

4'.)FoIlow instructions in “d. Deceleration Check ."

___________

Page 23

d. DECELERATION CifEGK

1. ) Allow engine to idle, then squeeze Throttle Trig

ger fully.

2. )Allow engine to run at full speed for about 1

second.

3. )Release the Throttle Trigger to the idle position

and listen to the deceleration of the engine. It must

return to idle smoothly and within ! to 2 seconds.

a. If performance is satisfactory,«proceed to

Step "4.)”

b. If the engine slowly or erratically returns to

idle or idles erraticaUy, repeat “b. Idle Speed

Adjustment” or continue through Low Speed

Mixture and High Speed Mixture Adjustments

to obtain proper deceleration.

4. jRecheck idle speed.

luOT SPEE0 MIXTURE ^ ""

ADJUSTMENT SCREW LOW SPEED MIXTURE

IDLE SPEED

ADJUSTMENT

SCREW

ADJUSTMENT SCREW

AIR

FILTER

COVER

c. U»WSPlEDMlXTlIll£AD|USTMfiNT

1. jAIlow engine to idle.

_____

2. Turn the Low Speed MixtureSciew slowly

clockwise until the speed starts to drop.

Note this position.

3. ) Tum the Low Speed Mixture Screw counter

clockwise until the speed increases and then

starts to drop again. Note this position.

4. )Set the Low Speed Mixture Screw at the mid

point between the two positions.

5. )Follow instructions in “c. Acceleration Check"

and “d. Deceleration Check.”

f. HIGH SPEED MIXTURE ADJUSTMENT

I CAUTION; I Do not operate engine at full

throttle for prolonged periods while making high

speed adjustments as damage to the engine

can occur.

1. jSupport the drive shaft housing so the trimmer

line is off the ground and wili not make contact

with any object.

2. )Allow engine to idle, then squeeze Throttle Trig

ger fully.

NOTE: Perform steps ”3.)” through ”5.),”

at full throttle.

............

..................... .............

3. ) Turn High Speed Mixtare Screw \ery slowly

clockwise until engine speed is reduced,

4. )Turn High Speed Mixture Screw very slowly

counterclockwise. Stopwhentheenginebegins

to run roughly.

5. jTlim the screw slowly the minimum amount

clockwise until the engine runs smoothly.

6. ) Follow instructions in “c. Acceleration Check”

and “d. Deceleration Check.”

' [CAunoNTl If the engine does not operate

according to these instructions after repeating

the adjusting steps, do not use the tool. Take

it to your Sears Service Center.

g. REINSTALL AIR FILTER

Be sure filter is clean. See “Air Filter" for

instructions.

I CAUTION; i Fit air filter into the corners of the

housing to keep dirt from entering the engine and

causing engine damage. ' .

D. SmBXCRROPE

Adanger

Never start the engine with the clutch shroud removed.

The clutch wi^ fly apart and cause serious injury.

ikWARmNG

Do not remove the retaining tab and screw to remove

pulley. The spring beneath the pullQ' is under tension

and can fly out causing serious injury. If any part of the

PuUq'hoiKing assemHy is damaged other than the rope,

do not use the tool. Ikke it to your Sears Service Center.

Disconnect Spark Plug Wire.

1.

Remove the Screw and Nut in the Throttle Trigger

2.

Housing. Hold the Throttle Trigger away fiom Drive

Shaft Housing and remove Throttle Cable from

Trigger. Pull Cable out of Foam Grip

tunnel.

RemcA'c the four Clutch Shroud Screws m shown in

3.

with ihe^fiiali hex Wfefleh pfevlded.

4.

Separate the Clutch Shroud tom the Engine.

Adanger

Use only ahandUiol to remove the clutch. Donotuseany

typeofmotormdtoolbrsirikedtedtUchinanyway. Otker-

wise, the clutch will fly apcai and cause serious injury.

.............

REMOVE SCREWS

Shown without Drive Shaft

Housing for clariU'.

CLUTCH “FLATS”

SPARK

PWQ

ШЁ

CLUTCH

SHROUD

23

Page 24

5. Hold the “Flats” of the Clutch with an adjustable

wrench as shown in Figures and remove the Nut

counterclockwise with a 9/16" socket wrench,

NOTE; Clutch will slide off the crankshaft intact. Do

not disassemble dutch.

6. Remove the Beveled Washer, Clutch an^ Large Flat

Washer. _ __

7. Remove the Pulley Housing from the Engine.

_____

8. Remove Rope Retainer Screw. Remove any

remaining rope.

9. Hand turn the Pulley clockwise asfer as it will go. Then,

turn the Pulley counterclockwise until the Pulley

Notch is aligned with the Housing Notch next to the

Retaining Tab and Screw. Next, turn the Pulley one

complete turn counterclockwise until the notches are

aligned again.

________

__

10. Insert the small hex wrench into the hole formed by

the Notches to hold the Pulley in position.

__________

11. Use a42 "length of replacement Rope.

12. Moveaway (10 feet) from the fuel tank with the replace

ment Rope. Use a match and melt both ends of the Rope

to prevent haying.

13. Pull the melted ends through a thick, clean rag while

the Rope is still hot to obtain smooth, pointed ends.

14. Insert one end of the Rope through the Handle and

secure with a knot.

15. Insert the other end of the Rope through the Rope Exit

Hole into the inside ofthe Housing, into the Pulley and

up through the Pulley Hole.

16. Wrap Rope counterclockwise around the Pulley Ratchet

and tuck loose end under Rope where it comes out of

the PuIIq? Hole. Leave a 1-inch tail l^ing flat on top of

ÛiePull^betweentheRetainerRibandtheRopeRetention Screw/Post.

...

............................

17. Reinstall the Rope Retention Screw into the reten

tion post. Tighten until snug.

NOTE; Do not overtighten the Screw. Overtightening

the screw can cause the threads in the screw post

to strip out.

18. Hold Rope taut at Rope Exit Hole so it will not move and

remove hex wrench.

19. Slovvly feed rope into the Pulley Housing.

_____

20. Make sure Spacer is in place as shown then reverse

steps to re-assemble,

_________

Rope

Retainer Screw

Washer

Rope Tail '

24

I CAUTIOmTI WhenreinstalUngtheclutch, tighten

the nut just until the beveled washer is flattened

against the clutch. Over or under tightening the nut

can cause engine damage.

Page 25

_1. AntnilfEE . • ■

......

NOTE: A dirty air filter decreases the life and

performance of the engine and may incre£ise fuel

consumption and harmful emissions.

1. Clean the Air Filter;

• Always after 5 tanka of fuel or 5 hours of

operation, whichever is less.

• More frequently, in dusty conditions.

a. Loosen the two screws on the air filter cover

enough to remove the cover from engine.

b. Remove the air filter from the cover.

c. Wash filter in soap and water.

d. Squeeze filter dry and replace in cover.

I CAUTIÒn7Ì Do not clean the air filter in gaso

line or any other flammable solvent; &ing

so may create a fire hazard or produce

harmful evaporative emissions.