Page 1

Operator's Manual

CRRFTSMRN

1.4 cu.in./24cc 2-Cycle

205 MPH/410 CFM

GASOLINE POWERED

BLOWERNAC

Model No.

358.797290

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use ofthis product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.---Sat., or 10 am-7 pm, Sun.

• 1-800-235-5878 (.o==_._=._..=,_m)

Sears J_oebuck and Co., Hoffman Estates, IL 60179 USA

530-087632 07/10/98

Page 2

I

Warranty Statement 2 Storage 10

Safety Rules 2 TroubleshootingChart 11

Assembly 4 Pads Ust 13

Operation 6

Maintenance 8 Spanish 16

Service & Adj_,stments - 9 Parts and Ordering Back

FULL TWO YEAR WARRANTY ON CRAFTSMAN ® GAS BLOWER

Fo_o (2) years from date of purchasa,when this Gas Blower is maintained,

lubncatad, and tuned up accordingto the instructionsinthe operator'smanual,

Sears will repair,free of charge, any defects in material orworkmanship.

Thb warran_j excludes blowertubes, spark plug,and aircleaner, which are ex-

pe_dabl9 parts and become worn dudng normaluse.

IftM_-:bl0wer__ forcommemial purposes,thiswarrantyappliesfor 90 daysfrom

the date.ofpumhase. Ifthis Bloweris usedfor rentalpurposes,this warrantyapplies

for 30 days from the date of pumhase. Thiswarranty appliesonly whilethisproduct

is inuse inthe United States.

WARRANTY SERVICE IS AVAJ_LE BY RETURNING THE BLOWER TO THE NF.JkREST

SEJ_RSSERVICE CENTFR IN THE UNITED STATES,

This warrdntygives you specificlegal rights,and you may also have otherrights

whichvary from state tostate.

Sears, Roebuck and Co. D/S17WA Hoffman Estates, IL 60179

Failure tofollow all Safety Rules and Pre-

cautionscan result inseriousinjury.

KNOW YOUR UNIT

• Read your Operator's Manual care-

fullyuntilyoucompletely understand

and can followall warningsand

safety rulesbefore operatingthe unit.

• Restrict unitto userswho understand

and will follow all warningsand safety

rules inthis manual.

PLAN AHEAD

• Alwayswear eye pmteclionwhen op-

-era_ng,servicing,or performingmain-

tenance on unit.Woaringeye protec-

tion v_llhelpto praOentrocksor debris

from'being blownor ricochetingInto

eyes and face which can resultin

blindnessand/or seriousinjury.

• Always wear respirator or face mask

iwhen workingwith unit in dusty envi-

ronments.

• Secure hair above shoulder length.

Secure or remove jewelry, loose

clothing, or Clothing_th loosely

hanging straps, ties, tassels, etc.

They can be caught in moving pads.

• Do notoperate unitwhen youare tired,

ili,upset,or ifyou are underthe influ-

ence of alcohol,drugs,or medication.

• Keep children,bystanders, and ani-

mals away from work area a mini-

mum of 50 feet (15 m) when starting

or operatingunit.

• Inspectarea beforestarlingunit.Re-

move all debrisand hard objectssuch

as rocks,glass,wire,etc.thst canrico-

chet,he thrown, or otherwisecause

injuryordamage duringoperal_n,

HANDLE FUEL WITH CAUTION

• Eliminateall sources ofsparks or

flame (includingsmoking,open

flames, or workthat can cause

sparks) inthe areas where fuel is

mixed,poured, or stored.

• Mixand pourfuel in an outdoorarea;

store fuel in a cool,dry,well ventilated

place;use an approvecl,marked con-

taber for all fuelpurposes.

• Do notsmoke while handlingfuel or

while operating the unit.

• Do notfillfuel tank while engine is

running.

-2-

Page 3

• Wipe up fuel spills before starting en-

gine.

• Move at'least 10 feet (3 meters)

away from fuel and fueling site before

starting engine.

OPERATE YOUR UNIT SAFELY

• Stopthe engine before Openingthe

vacuum inlet door.The engine must

be stopped and the impellerblades

nolongerturning to avoidsedous in-

juryfrom the rotatingblades.

• Inspect unit bafom each use for

worn, loose, missing,, or damaged

parts.Do not use until unitis in

properworkingorder.

• Keep outside surfacesfree from oil

and fuel.

• Never start or run engine inside a

dosed room or building. Breathing

exhaust fumes can Idll.

• To avoid static electricityshock, do

notwear rubbergloves or any other

insulatedgloves while operating unit.

• Do notset uniton any surface except

a clean, hard area while engine is

running. Debds such as gravel, sand,

dust, grass, etc. could be picked up

by the airintake and thrown out

throughdischarge opening, damag-

ing unit,property,or causing serious

injuryto bystanders or operator.

• Avoid dangerous environments. Do

not use in unventilated areas or

where explosivevapors or carbon

monoxidebuild up could be prssenL

• Do notoverreach or use fromunsta-

ble surfaces suchas ladders, trees,

steep slopes, rooftops,etc. Keep firm

footing and balance at all times.

• Never place objects inside the blower

tubes; always direct the blowing de-

bds away from people, animals,

glass__d solid objectssuch as

trees, automobiles, walls_etc. The

force of air can cause rocks,dirt, or

sticksto be thrown or to dcochet

whichcan hurtpeople or animals,

break glass, or cause otherdamage.

• Never run unitwithout the proper

equipment attached. When using

your unit as a blower, always install

blowertubes. When using the option-

al vacuum kit, always installvacuum

tubes and vacuum bag assembly.

Make sure vacuum bag assembly is

coml_lately zipped.

• Check air intake opening, blower

tubes, and vacuum tubas frequently,

always with engine stopped and

spark plug disconnected. Keep vents

and discharge tubes free of debris

which can accumulate and restrict

proper air flow.

• Never place any object in air intake

opening as this could restrict proper air

flow and causedamage to the unit.

• Never use for spreading chemicals

fertilizers,or other substanceswhich

may contain toxicmaterials.

• To avoid spreading fire, do not use

near leaf or brushfires, fireplaces,

barbecue pits, ashtrays, etc.

• Use onlyfor jobe explainedin this

manual.

MAINTAIN YOUR UNIT PROPERLY

• Have all maintenance other than the

recommendedprocedures described

in the Operator's Manual performed

by Sears Service.

• Disconnectspark plug before per-

forming maintenanceexcept for car-

buretor adjustments.

• Use only recommendedCRAFTS-

MAN• replacement parts;use ofany

other partsmay voidyour warranty

and cause damage to your unit.

• Emptyfueltank beforestoring the unit.

Use up fuelleftin carburetorby starting

engineand letiJngit mn untilitstops.

• Do notuse any accessoryor attach-

ment otherthanthoserecommended

bymanufacturerfor use withyourunit.

• Do not store the unit or fuel in a

closed area where fuel vapors can

reach sparks or an open flame from

hotwater heaters, electdc motorsor

switches,fomaces, etc.

• Store in a dry area out of reach of

children.

SPECIAL NOTICE: For users on U.S.

Forest Land and in some states, in-

cludingCalifornia(PublicResources

Codes 4442 and 4443), Idaho, Maine,

Minnesota, New Jersey, Oregon, and

Washington: Certain internal combus-

tion enginesoperated onforest, brush,

and/or grasscovered land in the above

areas are requiredto be equipped with

a spark arrestor,maintained in effective

worldngorder,or the engine must be

constmoted, equipped, and maintained

for the preventionof fire. Check with

your state or local authoritiesfor regu-

lationspertaining to these require-

ment_ Failure to followthese require-

ments is a violationof the law. This unit

Page 4

is not factory equipped with a spark ar-

restor;, however, a spark arrestor is

available as an optional pad. If a spark

arrestor is required in your area, con-

tact Sears Service for the correct kit.

The spark arrestor, blower tubes, and

nozzles must be assembled to unit to

be in full compliance with regulations.

SPECIAL NOTICE: Exposure to w'ora-

tJonsthrough p_longed useof gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to cir-

culation disorders or abnormal swelling.

Prclongeduse incold we_ has been

linkedto bloodvesseldamage in other-

wisehealthypeopla.If _ occur

suchas n4mbnees,pa_, lossof

strength,change in skincoloror texture,

or lossof feelingin the fingers,hands, or

joints,discontinuethe use of this tool

and seek medicalattention.An

antivibrstionsystemdoes not9uarantse

the avoidanceofthese problems.Users

who operatepowertooison a continual

and rsgular basis must monitor clssely

theirph_'w,al conditionand the condition

ofthistool.

CARTON CONTENTS

Check carton contents against the fol-

lowinglist.

Model 358.797290

• Blower

• Blower tube

• Vacuum bag

• Upper vacuum tube

• Lower vacuum tube

• 2-Cycle Engine Oil

NOTE: Itis normal for the fuel filterto

rattle inthe empty fuel tank.

ASSEMBLY

WARNING: If received assembled,

repeat all steps to ensure your unit is

properlyassembled and all fasteners

are secure.

• No tools are required for assembly,

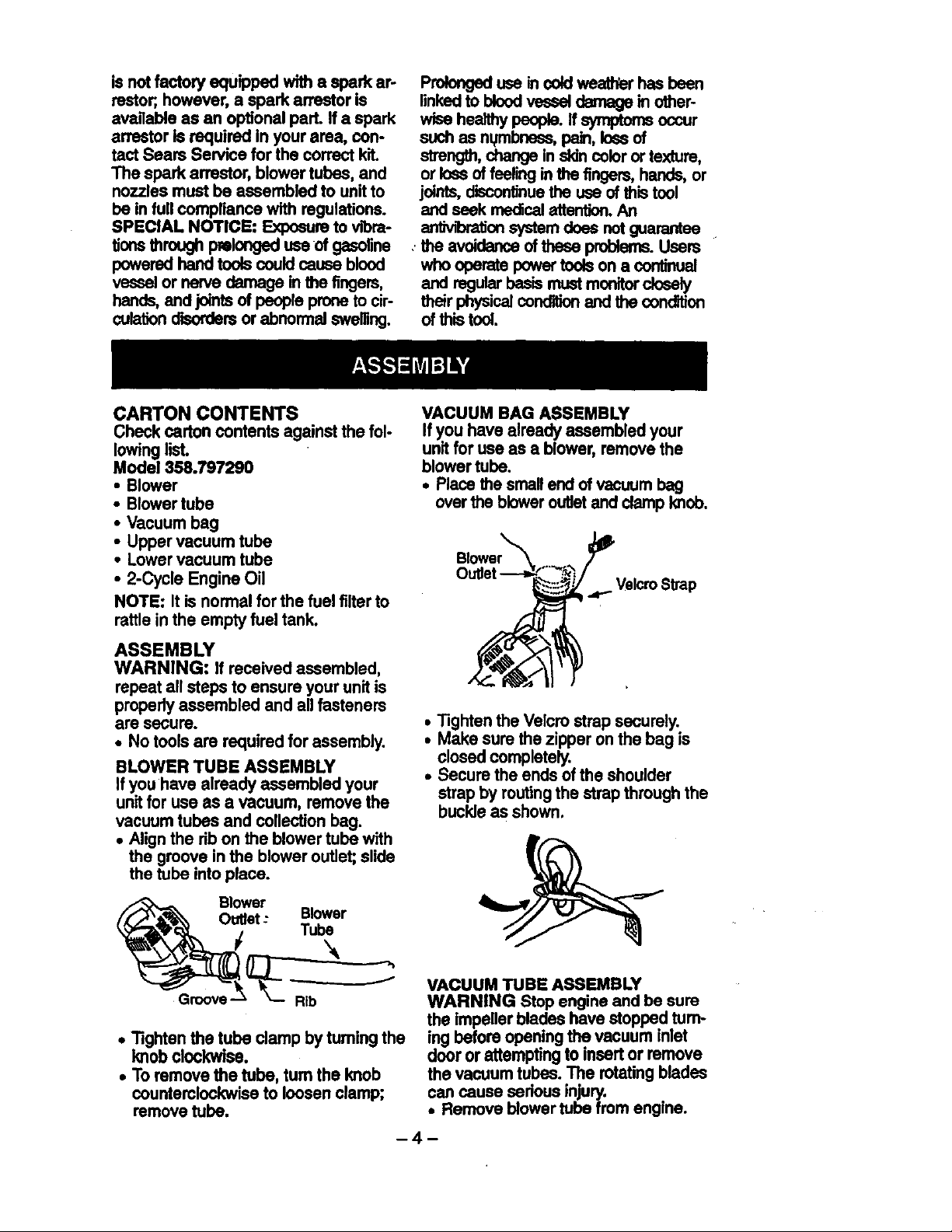

BLOWER TUBE ASSEMBLY

Ifyouhave already assembled your

unitfor use as a vacuum, remove the

vacuum tubes and collectionbag.

• Align the rib on the blowertube with

the groovein the bloweroutlet; slide

the tube into place.

BIt_w_r: Blower

• Tighten the tube clamp by tuming the

knob clockwise.

• To remove the tube, turn the knob

counterclockwise to loosen clamp;

remove tube.

VACUUM BAG ASSEMBLY

If you have already assembled your

unitfor use as a blower,removethe

blowertube.

• Place the smallend of vacuum bag

overthe blower outletandclamp knob.

Blower

VelcroStrap

• "lightenthe Velcrc strap securely.

• Make sure the zipper on the bag is

closed completely.

• Secure the ends of the shoulder

strap by routingthe strap throughthe

buckle as shown.

VACUUM TUBE ASSEMBLY

WARNING Stop engine and be sure

the impellerblades have stoppedturn-

ing beforeopening the vacuum inlet

door or attemptingto insertor remove

the vacuum tubes. The rotatingblades

cancause serious injury.

• Remove blowertubefrom engine.

-4-

Page 5

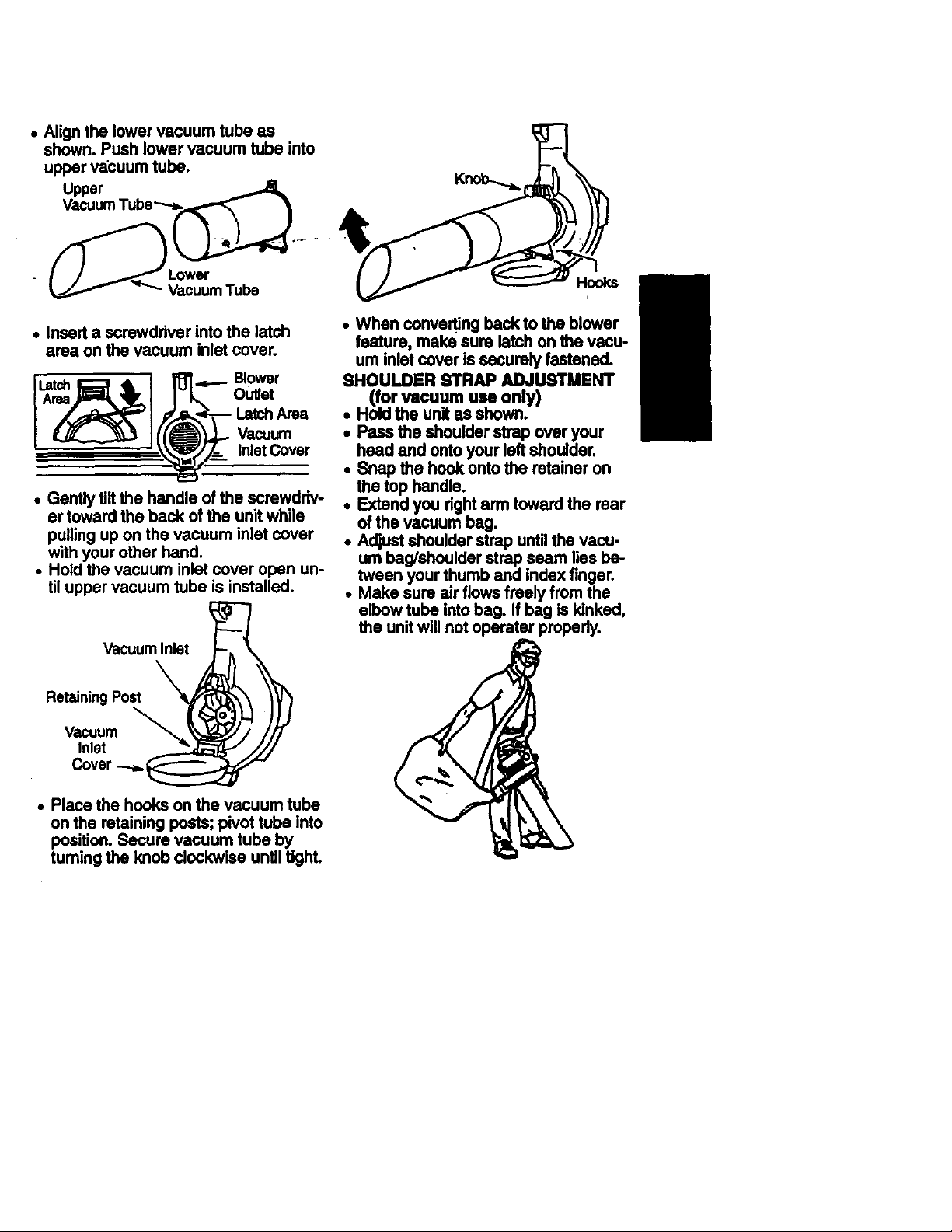

• Align the lower vacuum tube as

shown. Push lower vacuum tube into

upper vacuum tube.

Upper

Lower

VacuumTube

• Insert a screwdriver intothe latch

area on the vacuum inletcover.

.,p_.. Blower

Outlet

Latch Area

Vacuum

InletCover

• Gently tilt the handle of the screwdriv-

er toward the back of the unit while

pulling up on the vacuum inlet cover

with your other hand.

• Hold the vacuum inlet cover open un-

til upper vacuum tube is installed.

Vacuum Inlet

Retaining Post

Vacuum

Inlet

Cover ....._q

• Place the hooks on the vacuum tube

on the retaining posts; pivot tube into

position. Secure vacuum tube by

tuming the knob clockwise until tight.

Hooks

• When conva_ng back to the blower

feature, make sure latch on the vacu-

um inletcover is securelyfastened.

SHOULDER STRAP ADJUSTMENT

(for vacuum use only)

• Hold the unitas shown.

• Pass the shoulder strap over your

head and onto your left shoulder.

• Snap the hook onto the retainer on

the top handle.

• Extend you right arm toward the rear

of the vacuum bag.

• Adjust shoulder strap until the vacu-

um bag/shoulder strap seam lies be-

tween your thumb and index finger.

• Make sure air flows freely from the

elbow tube into bag. If bag is kinked,

the unit will not operatar properly.

Page 6

MULCHING BLADES

t

Your blower is equipped with mulching blades as a standard feature. When using the

optionalvacuum attachment, the mulching blades automaticallyreduce debris at a

ratioof up to 16:1.

KNOW YOUR BLOWER

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE

OPERATING Y4DURUNIT. Compare the illustrationswithyour unitto familiarize

yourselfwiththe locationof the vadous controlsand adjustments.Save this

manual forfuture reference.

ON/STOP SWITCH

The ON/STOP switch is used to stop

the engine. The switch stays in the ON

position. To stop engine, push and hold

the switch in the STOP position until

the engine comes to a complete stop.

RoTrLELEVER(9

:The Throttle Lever 1 controlsengine

speed. Move it all the way forwardfor

full speed operation. Move itall the way

_reerward for idlespeed.

PRIMER BUTTON ._)

The Primer Button(_) removes air from

the fuelfines and fillsthem with fuel.

OPERATING TIPS

• To reduce the risk of headng loss

associated with sound level(s), hear-

ingprotectionis required.

• To rsduca the dskof bjury assodsted

wi_ contaoting rota_ngparts,stopthe

enginebeforeinstallingor removing

This allows you to start the engine with

fewer pulls on the starter rolbe. Activate

Pdmer Button _) by pressing it and al-

lowing it to return to its original position,

C.OKEU W ®

The choke helps to supply fuel to the

carburetordudng starting. This allows

you to start a cold engine. Activate the

choke by moving the choke lever to

the FULL position. After the engine has

started, move the choke to the RUN

postition.

i

attachment_ Do notoperatewithout

gt_(s) in place.

• Operatepowerequipmentonlyat rea-

sonablehours-cot earlyin the moming

or lateat nightwhenpeoplemightbe

disturbed.Complywithtimes Estedin

localord'mnces. Usual recommenda-

-6-

Page 7

tionsare_.00 a.m. to 5:00 p.m.,

MondaythoughSaturday.

• To reduce noise levels, limitthe num-

ber ofpieces of equipment used at

any one time.

• To reduce noise levels, operate pow-

er blowersat the lowest_esib|e "-

throttlespeed todo the job.

•"Use rakes and brooms to loosen

debrisbefore blowing.

• In dustyconditions,slightlydampen

surfacesor use a misterattachment

when water isavailable.

• Conservewaterbyusingpowerblow-

ersinsteadofhosesformanylawn

and gardenapplications,including

areassuch as gutters,screens,pe_los,

gdlls,porches, and gardens.

• Use the full blower nozzle extension

so the air stream can work close to

the ground.

• After usingblowers and other equip

ment, CLEANUP!Dispose of debris in

trash receptacles.

OPERATING

POSITION

read and follow the safety rules relating

to fuel before fuelingyour unit.

IMPORTANT

Expedence indicatesthat alcohol

blended fuels (called gasoholor using

ethanol or methanol) can attract mois-

ture whichleads to separation and

formationof acids duringstorage. Acid-

icgas can damage the fuel system of

an engine while in storage.

To avoid engine problems, emptythe

fuel system before storage for 30 days

or longer.Drainthe gas tank, start the

engine and let it run untilthe fuel lines

and carburetorare empty.Use fresh

fuel next season.

Never use engine or carburetorcleaner

products inthe fuel tank or permanent

damage may occur.

Fuel stabilizer is an acceptable alterna-

tive in minimizing the formationof fuel

gum deposits duringstorage. Crafts-

man brand oilis already blended with

fuel stabilizer.See the STORAGEsec-

tion for additionalinformation.

STOPPING YOUR ENGINE

• To stop the engine, press and hold

the stop (:_ switchuntileng,ne stops.

STARTING YOUR ENGINE

BEFORE STARTING THE ENGINE

You MUSTmake sure the tubes are se-

curebefore using the unit.

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

informationin the safety rules before

you begin. If you do not understand the

safety rules, do not attempt to fuel your

unit.Call f_800-235-5878.

FUELING ENGINE

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality2-cycle air-oooled engine oil.

We recommend Craftsman brand oil.

Mix gasoline and oil at a ratio of 40:1

(A 40:1 ratiois obtained by mixing 3.2

ounces of oil with1 gallon of unleaded

gasoline). DONOT USE automotive oil

or boat oil.These oilswillcause engine

damage. When mixing fuel, follow

inetru.qtlo_n_sgdnted on container.

Once oIT_;dded to gasoline, shake

container momentarilyto assure that

the fuel isthoroughly mixed. Always

• Fuel engine. Move at least 10 feet (3

meters) away from the fueling site.

• Hold the unit inthe startingposition

as shown. Make surethe blower end

isdirected away from people, ani-

mals, glass, and solid objects.

WARNING: When startingengine,hold

the unites illostmted.Do notset uniton

anysurfacees_pt a dem, hardarea

whenstarUngeegineorwhilsanginels

running.Debrissuchasgravel,sand,

dust,gnus,etc_couldbepid<edupby

theairintakeandthrownoutthroughthe

dischargeopenir_,,dsmeflir_thetxCto,

Page 8

property,or causingsedous Injuryto by-

standersor the operator.

STARTING A COLD ENGINE OR A

WARM ENGINE AFTER RUNNING

OUT OF FUEL

• Move the throttlelever (_ to the fast

,r_ position.

• Press the primer button (_) slowly 12

times. -_ ..... ..

• Move the choke lever (_ tothe Pull

Choke position.

Throttle

Lever _ Switch

®

Choke

Lever_

• Pull starterhandle sharply untilthe

engine attemptsto run, but no more

that 5 pulls(below 30°F, 8 pulls).

NOTE: If the engine attempts to start

before the 5th pull, go to the next

step Immediately.

• Move choke lever (_) to Half Choke.

• Pull the starter handle sharply until

the engine runs, but no more than 5

pulls(below 30°F, 10 pulls).

• After a 5 second warm-up, movethe

choke lever (_) to the Run position.

• Allowthe unitto runfor 30 more se-

conds at Run before movingthe

throttlelever (_) tothe _ position.

Ifthe engine has not startsdafter 5

pulls(at Half Choke), repeat the Start-

ing a ColdEngine Procedure. If the en-

gine stilldoes not =dart,proceed to

Starting a Rooded Engine.

• Tostop the englne, press and hold

the stop (_ switch untilengine stops.

FOR A WARM ENGINE

•• Move the throttle lever (_) to the fast

_IP position.

• Pull the starter handle sharply until

the engine starts, but nomore than 5

pulls.

NOTE: If the engine has notstarted,

pullstarter handle sharply for 5 more

pulls.If engine still does not run, it is

probablyflooded. Proceed to Starting

a Flooded Engine.

• To stopthe engine, pressand hold

the stop O switch untilengine stops.

DIFFICULT STARTING OR STARTING

A FLOODED ENGINE

Rooded enginescanbe startedby plac-

ing thechokelever in the Off Choke

position.Movethrottle lever tofast _ ;

then, pullrope untilenginestarts.After

enginestarts,movethe throttle lever to

to allow engineto Idle.

Startingcouldrequirepuffingthe starter

ropemanytimesdepencfingon how

badlythe unit isflooded.Ifthe unit_II

doesn'tstart,referto the Troubleshooting

Chartor call 1-800-235-5878.

CUSTOMERRESPONSIBILITIES

CARE & MAINTENANCE TASK

Check for Loosefasteners and parts

Check for damaged or wom parts

.-; Clean unit and labels

Clean air filter

Replace spark-plug

Replace fuel filter

GENERALRECOMMENDATIONS

The warranty on this unit does not cov-

er items that have been sub|acted to

operator abuse or negligence. To re-

ceive full value from the warranty,the

operator must maintain unitas Instruct-

ed in this manual. Various adjustments

willneed to be made periodicallyto

_p_r.opedymalntaln your uniL

WHEN TO PERFORM

Before each use

Beforeeach use

Aftereach use

Every5 hours of operation

Yasdy

Yearly

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Rlter

• HousingScrews

CHECK FOR DAMAGED OR

WORN PARTS

Refer replacement of damaged/worn

partsto your Sears Service Center.

-8-

Page 9

•On/StspSwitch-EnsureOn/Stsp

switch prope,ly.Tostopen-

gice, pushand holdswitchinthe STOP

posen toacom-

pleta stop.Make sure enginestops;

thenrestartengineand continus.

• • FuslTank- Do not ueeualt iffueltank

showssignsofdemageorleaks.

° Optional Vacuum Bag - Do notuse

vacuum bag if it istom or damaged.

CLEAN UNIT & LABELS

• Clean the uKItusinga damp cloth

with a mild detergent.

• Wipe offunit with a clean dry cloth.

CLEAN AIR FILTER

Do not clean filterin gasoline or other

flammable solvent. Doing so can

create a fire hazard or produce harmful

evaporative emissions.

Cleaning the air filter:

A dirtyair filterdecreases engine per-

formance and increases fuel consump-

tionand harmful emissions. Always

clean after every 5 hoursof operation.

/_ Alr Rlter ,_veFir Iter

• Clean the cover and the area around

itto keep debrisfromfailing intothe

carburetor chamber when the cover

is removed.

Remove parts as illustrated.

Wash the filterin soap and water.

• Allowfilterto dry.

• Apply a few drops of oUtotheflfter;

squeeze filtertodistributeoil..

• Repleceparts.

REPLACE SPARK PLUG

Replace spark plugeach year to en-

surethe engine starts easier and runs

better. Set spark plug gap at .025in.

Ignitiontimingis f_ed,nonadjustable.

• Twist, then pull offspark plug boot.

• Remove spark plugfrom cylinderand

discard.

• Replace with Champion CJ-SYspark

plugand tightenwith a 3/4in. socket

wrench (10-12 ft.-Ibs).

• Reinstallthe spark plugboot.

REPLACE FUEL RLTER

To replace fuel filter, drain unitby run-

ningitdry of fuel, then remove fuel cap/

retainerassembly from tank. Pull filter

from tank and removeit from the fuel

line• Installnew fuel filteron fuel line;

reinstallpads.

We recommend all service and adjust-

ments not listed in this manual be per-

formed b -v,:yourSears Service Center.

CARBURETOR ADJUS3"MENT

Carburetor adjustment is criticaland if

done improperlycan permanently dam-

age the engine as well as the carbure-

tor. If you requirefurther assistance or

are unsure about performing this pro-

cedure, call our customer assistance

help line at 1-800-235-5878.

Old fuel, a dirtyair filter,a dirtyfuel fil-

ter, or flooding may givethe impression

of an improperlyadjusted carburetor.

Check these conditions before adjust-

ingthe e,ai_ouretor.

The carburetorhas been carefully set

at the factory.Adjustments may be

necessary ifyou noticeany of the fol-

lowingconditions:

• Engine will notidle. See "Idle Speed"

and "Mixture"underadjusting

procedure.

• Engine dies or hesitates instead of

accelerating.See "Accaiemtion

Check"under adjus6ng procedure.

• Loss of power. See "Mixture" under

adjusting procedure.

CARBURETOR PRESETS

When making carburetorpresetadjust-

ments, de notforce plasticlimitercaps

beyond the stops or damage will occur,

Ifcarburetorpresets are not needed,

proceed to *ADJUSTINGPROCEDURE,

Idle Speed."

Toadjust presets:

Page 10

•Tum the mixture screw counterclock-

wise until it stops.

•Tum the idle speed screw clockwise

until it stops. Now turn counterclock-

wise 4-1/2 turns.

Start motor, let it run for 3 minutes, and

proceed to the adjustment section. If

engine does not start, refer to trouble-

shooting chart or call 1-800-235-5878.

If engine performance is acceptabte at

the preset positions, no further adjust-

ments are necessary.

Idle Speed

Screw

Mixture.Screw

(withUmltsr Cap)

ADJUSTING PROCEDURE

Idle Speed "IDLE"

Allow engine to idle. Adjustspeed until

engine runswithoutstalling.

• Turn clockwiseto incma_e_ngi_e

speed ifengine stallsor dies.

• Turn counterclockwiseto decrease

speed.

No furtheradjustments are necessaryif

performance is satisfactory.

MIxture "MIX"

Allow engineto idle. Then accelerate

the engine and note portormance. If

engine hesitates, bogs down, or

smokes duringacceleration, turn mix-

tun) screw clockwise in 1/16-turnincre-

ments untilperformance is satisfactory.

Repeat thisprocedure as necessary

forproperadjustment. After completing

adjustments,check for acceleration.

Reset if necessary.

Acceleration Check

Ifengine dies or hesitates insteadof

accelerating,turn mixturescrew coun-

temlockwiseuntilyou have smooth ac-

celeration.Recheck and adjustas nec-

essary for acceptable performance.

Prepare unitfor storage at end of sea-

son or if it will notbe used for30 days

or more.

WARNING:

• Allow engine to cool, and secure the

unitbefore stodng ortransporting.

• Store unitand fuel In a well ventilated

area where fuel vapors cannot reach

sparks or open flames fromwater

heaters, electric motors or switches,

furnaces, etc.

• Store unitwith all guards in place.

Positionunitso that any sharp object

cannot accidentallycause injury.

• Store unit and fuel well out of the

reach of children.

EXTERNAL SURFACES

• I! your unit isto be stored for a period

of time, dean it thoroughly .before

storage. Store in a clean dry area.

• Ughtly oil external metal surfaces.

FUEL SYSTEM

Under Fueling Engine in the Operating

Section of this manual, see message

labeled IMPORTANT regarding the use

of gasohol in your engine.

Fuelstabilizeris an acceptable_erne-

rivein minim_'Jngthe _ offuel

gumdelx_'_ during storage.Add _oi-

,zer to gasolineinfuel tankor fuelstor-

age container.Followthe mixinstructions

found on stabiker ccnta_r. Run engine

at least5 minutes afteraddng stabTBer.

CRAFTSMAN40:1, 2-cycle engine oil

(aircooled) isalready blendedwithfuel

stabilizer.If you do not use this Sears

oil,you can add a fuel stab=Tizerto your

fuel tank.

INTERNAL ENGINE

• Remove spark plug and pour I tea-

spoon of 40:1, 2-cycle engine oil (air

cooled) through the spark plug open-

ing. Slowly pull the starter rope 8 to

10 times to_listributs oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam-

aged, broken, or wom parts.

-10-

Page 11

WARRANTY COMMENCEMENT DATE:

The warranty period begins on the date the

lawn and ;iardan equipment engine Is PUr-

chased. LENGTH OF COVERAGE: This

warmntyehailbe forapadod oftwoyears from

the Inl_aidate of purchase. WHAT IS COV-

ERED, REPAIR OR REPLACEMENT OF

PARTS. Repair or replacam.antof a.ny war-

AgencylCailfomta Air Resources Board and rented part Willbe penormeo at no chargeto

SEARS, ROEBUCKANDCO.,aroploasedto the owner at an approved SEARB Service

e:_plainthe emlsslons controlsystem warren- Center. If you have any.questrons..m..garamg

tyonyourJawnand gardenequipment engine, yourwarrantydghts and responslD,lUeS,you

AI nowuti ]tyandlawnano garaonequipment should contact y.ournearest authodze¢_-N.r-

engines muSt be designed, built, and vice center or call SEARS, ROEBUCK AND

equipped to meet the Stringent anfi....--sm_og CO. at 1-000-235-5878 WARRANTY PE-

standams. SEARS, ROEBUCK AND _;0. RIOD: Anywarrantad partwhlchls notached-

mustwarrantthe emission control system on uled for replacement as requlre.d mainta-

yourlawn and garden equlpment engine for nonce, or whichisscheduled onlyTorregular

thepedodsoftime listedbelowproviDeDmere Inspect|ontothe effect of"repairer raplaca as

has been no ai_Jse, neglect, or Improper necessary" shall be warranted for _ y.aare.

maintananca ofyourlawn and gar.danequip- Any warrantedpartwhichIsscneouJeOforre-

mentengme.'_our emlssioncontrolsystemin" placement as required maintenance shall be

dudes parts such as the carburetor and the warranted for the periodoftime up to the first

ignitione_tem. Where a warrantable condl scheduled re.p.lacemantpoint for that part.

lion exits SEARS, ROEBUCK AND CO. will DIAGNOSlS.Theownarshailnotbecharged

repair your lawn and garden equipment an- for dagnostic laborwhlchleess to the deter-

g|no at nocoStto you._xpens..os covered un- ruination that a warrantee part isdetec_ve if

oar warranty includediagnosis, parts and la- the diagnostic work Is.performed at an ap_

bet, MANUFACTURER'S WARRANTY proved SEARS Serwce.uentar. CONSE

GUENTIAL DAMAGES. SEARS, ROE-

YOUR WARRANTY RIGHTS AND OBLIGA-

TIONS: The U. S. Environmental Protection

COVERAGE: If any omissionsrelated parton

yourengine (as listedunder Emissions uon-

trolWarranty Pa_s List) Is Defect.re or a da-

fectlnthe mstedaJsorwo_mansnlp orme en-

gine causes the f!,Uureof such _ emission

related part, the part WillDe repeureoor re-

placed b_, SEARS, ROEBUCK AND CO.

OWNER S WARRANTY RESPONSIBILI-

TIES: As thelawn and garden equipment en-

gineownerryouare responsibletoune penor-

rnance of the required maintenance listed in

your Owner's Manual. SEARS, ROEBUCK

AND CO. recommends thatyoU retainall re-

BUCKAND CO. may beliablefor damages to

other engine components causeS bythe fail-

ure of a warrentodpart aitil under warranty.

WHAT IS NOT COVERED: All failures

caused byabuse, neglect,or impropermain-

tenance are not covered. ADD_ON OR MO-

DIRED PARTS:The useo|sdd-Gnormocked

i_ts canbe roundsford a

able to cover failures of warranted parts

causes by the use of esd-on or modified

parts. HOW TO FILE A CLAIM: If you .have

anyquestionsregardingyourwarrantyrights

and responsibilities,youenouldcontactyou_

nearest authorized service center or ca,

ceipta covering maintenance on your lawn

and garden equipment engine, but SEARS,

ROEBUCK AND CO. cannot deny warranty

solaiyforthetackofreceiptsorforyourla_lure SEARS, ROEBUCK AND CO. at

tO ensure the performance of all scheduled 1-800-235-5878. WHERE TO GET WAR.

maintenance. Asthelawrlandgardanequip- RANTY SERVICE: Warrenty servicesor .re

mentenglne owner,youshouldbe aware that pairsshall beprovided at all SEARS Servl_

SEARS, ROEBUCKAND CO. maydenyyou Centers. Call: 1.800-235-5878 MNNTE

warranty cover.age If your lawn and garden NANCE, REPLACEMENT AND REPAIR OP

equlpmantenglneorapartoflt hasfailoddue EMISSION RELATED PARTS: Any SEARS,

toabuse,neg|ect,|mproper matntenanca,un- ROEBUCK AND CO. approved replacement

appmveam6d ficat ons,ortheuse ofpartsnot part used Inthe perle.rpancaofar!.ywarran_

mess or approves bytheodglnaiequipment maintenance or repair on emission relamo

m_ufacturer. You are responsiblefor pres- parts will be provided without charge to th_

enungyour lawn aria galen equipment an- owner if the part Is under warranty. EMIS.

ginstoa SEARS Service uentaras eden as a SION CONTROLWARRANTY PARTS US1!

problem existS. Warranty repairs should be Carburetor, lgnltlonSystem:SparkPlug(cov

completedinareasonab|eamountoft]me,not area up to maintanen ce___,__h__du_l_e)±.lgr_nltlor

toexceed 30 days. ifyou have anyquastlons Module. MAINTENANCEsTATEME_NI: ln*

regarding your warranty rightsand responsl- ownerls responsibleforthe performanceofal

b_litles,you should contaCt your nearest au- required maintenance as defined inthe own

thonzeOservlca center or call SEARS, ROE- er'Smanual.

BUCK AND CO. at 1-800-235-5878.

Page 12

• At the beginnin_ ofthe next season,

use only.freshf0el having the proper

gasolineto oil ratio.

OTHER

• Do not store gasoline from one sea-

son to another.

• Replace your gasolinecan ifit starts

to rust.

TROUBLESHOOTING CHART

TROUBLE CAUSE

EnginewillnoLt• Engineflooded.

start. ,, • Fueltank empty.

Spark plug notft tng.

Fuel not reachin ] carburetor,

REMEDY

I " See =StartingInstructions."

• Filltank withcorrectfuel mixture.

Installnew Sl:arkplug.

Check for did/ fuel filter;,replace.

Check for kin :ed or splitfuel line;

repair or replace.

• ContactSears Service.

• Compressionlow.

Enginewillnot _ Carburetorrequiresadjustment. • See"CarburetorAdjustmants."

idle properly. Crankshaft seals worn, • Contact Sears Service.

• Compression low. • Contact Sears Service.

Engine willnot : Air filter dirty. _ Clean or replaceair filter. .

accelerate, Spark plug fouled, Clean or replaceel:=rkplug, r_ap,

lacks power,or i CarburetorrequlrssadJustmanL • See =CarburetorA¢iustments."

dies under a Carbon build up. • Contact Sears Sen ice.

load. Compressionlow, • Contact Sears Service.

Engine • Choke partially on. Adjust choke.

smokes • Fuel mixture incorrect. : Emptyfuel tankand refillwith

excessively., correct fuel mixture.

• Air filterdirty. Clean or replaceair filter.

• Carburetor requiresadlustmant :_ See'Carburetor Adjustments."

Engine i Fuel mixtureIncorrect. i See "Fueling Your UnlL"

runshoL Spark plug incorrect. Replace withcorrect sped( plug.

CarburetorrequiresadjustmanL See "CafouretorAdjustments,'_

• Carbonbuildup. Contact Sears Service.

if situations occur which are not covered in this manual, use care and good

judgement. If you need asslstanca contact your Sears Service Center/Depart-

ment or call the Customer Assistance Help ne at 1-800-235-5878.

Page 13

' REPAIR PARTS

AUNqxdn__l_n_nW and

malm_mancenot de_rlbed

•In the O_rlltm_ Manual

mustbeperforatedbyqu4dl-

fled se_lce personnel.

4145 4039

36 35

37

SEARS MODELIS8.797290

24 5 21 78910

31

242526

9 15 78 18 23

48 20 18 17

I I

11

14 12 47

1_46

27

28 16 29 32

U

Re. PatNo. 0w..puon Pot. PanNO.

2. 53004,g_2 Car_reto_"Adaptor 29. 530049617 Gu

3, 530016209 BOI_ 30. 53004_23 Iso_to_,.kmdb

4. 530049526 _ Plate 31. 5300367g2 Isolakx-Cranb:_um

5. 530049324 Thto_tleLinkage 32, 530049311 Hous_-IJtft

6. 530049834 Choke Lever 33. 530015886 Sinew

7. 530016254 Wu_er 34. 530015880 Sinew

8. 530015&S2 Choke Spacer 35. ,53C015_0 Boll

g. 530015775 Screw 3_. 530095,_le Claml>EkMw Tube

10. _ KnobReplacementKit 37. 530049885 I(rK:b--TubeCilrap

11. S300494_S Ludw_e-Swla:_ 38. 530095469 Handle

12. 530Q49494 Wire Clamp 34). 5,._0049879 Muff_r CO_wA_

13. 5300W_4 Garb/_y. Kit0NA.-229) 40. r_OIF.WSO Screw

14. 530048496 I.._KJw_-Grol_d 41. r_06_47 Une Iot-Cad_qge

,_. 5aoo_ea)3 c;_:ke Pl_ 42. s3oo14a_a

17. 530015;157 Screw 44. 530049527 Guket-F_d Tank

18. S3001S849 Screw 45. S,._06_1 e Line IOI.-T_

19. 5300_4_15 AirF_r Cover 46. G,._0,t4kl_ Fue_Cap w/Retaln_-

20. _ Nt Rter 47, 530_9813 GI4_tt Kit

21. 53004_25 Th_tlJe Lever 48. 530049316 Box-_ Rlter

22. 530019246 Se_-Cho._e Plate

530016211 Rotain_-PurQ_ B_flon

24, S300_114 SwitchMozn_ary Not Shown

2G. ._4,g_7 Purge8utSon ,_0_76_ Ot_nmxManual

2_, 530016212 Spr_g--Pur_ Button G,.,_084.4_ Engine_

• 530016207 Nut _ RightDecal

I/

1R

Page 14

REPAIR PARTS

" 36

17 2930

31 36 33

34 3536

47

36

_37

4

i

40 10

/-,

45 5

19 24

18

44

25 49 26 27

16

,J

_. _N_

1. _I0015880

2. 53006_32

3. E

4. 53OO49488

5. N

530O15810

530015815

9. 530019240

10. 530029182

11. 5300_17

12. 530095461

13. ,S,_0015828

14. 53062_

15. _._004_13

10, S304_2043

17. S3004,_9"/

_18, 530019181

19. 530049429

20. S300_12S

21. 6300_124

22. 530019179

23. 530015945

24, 5300_618

25. S3003S20S

26. 5300_3817

27. 530016180

_|cdptlon

So'ew

Rope K_

Starter PulleyKit

StarterHandle

StarterSprl_

Fan Hous_'_wtoeadng

Screw

Impeller ASS"/.

Mulch B;ade/k_'y.

W_t

Nut

Inlet

SlXlng-.RetumCover

Cmnkcl*e Cover

GUI_¢

Crank¢_A.'y.

Inner Beerin0

Outer seerfng

Crankcase Seal

RetainingRing

Crankcase ,A_'y.

(b_ 20-23)

Flywheel S_er

Ref. Parl NO.

28. 530049713

29. 530016203

530049454

530O15941

5_069813

_. _._19247

40. 530016080

41, 530049903

42. 53001516_

43. 5,_00_9945

44. 530069812

4_ 530O16226

47, _

48, &._0191_

49. 530015149

50. 530092322

NotShown

530O644O4

Sea_-F_nHS;...F_..

Muffk."Bolt

MufflerCover Plate

Muf_ K_

Retab_" RIng--C"ch_lt

MufflerSltleld

Serew

Si_uk Plug(CJ-eY)

Gasket Kit

Air Dam

/_itlo_ Module

R_er

P_

(Ir_ 4_&421

RetainerCam

Seadng

romme_n. Module

Wa:¢_r

Loc_her

DeCal

W=mlng

14

Page 15

REPAIR PARTS

Carburetor Aamm_blv Part Number g30069924 - _NA229_

K_ P_

No. No. Descd_ion

1 $300_1403 l.lmiterC_p

2 t_069011 taro. Repair Kit

3 530069944. Gasket/okk Kit

2 3

Va_urrl "rum Aml'v.

5 4

3

KEY +PAR'[ DESCRIPTION

NO. NO.

I _ Va¢ Bag w/Strap

2 5300_470 Elbow-Vat Tube

3 _._095589 LowerTube

4 5,_049686 CI_p-Va¢Tube

S 530049485 Knob-Vat Tube

6 830095468 Upper Tube

Gutter Att_hrMnt Kit IIg_-.TQ6812

/-3 /-s _

mg

-_ nn A_

Kl_lr I PART OF_C_h_rlo N

_o.i .o.

1 53(_N426 Nozzle

2 530402918 Elbow&_OI...._Ring

3 530094425 ExtlmldonTIJ_

4 530004424 PivotTube

5 9,52701645 _Ad_e_r6 530094850

A 530402930 WambtgDecal

15

Page 16

For the repair or replacement parts you need

delivered 'directly to your home

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

I

Para ordenar p|ezas con entrega a

domi¢ilio - 1-800-659-7084

t

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

Para pedir servicio de reparaci6n a

domicilio - 1-800-676-5811

For the location of a Sears Parts and

Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

nmmmmm

muummm

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Call 9 am 5 pro, Monday Saturday

1-800-827-6655

When requesting service or ordering

parts, always provide the following

information:

• Product Type • Part Number

• Model Number • Part Description

SEAR8

America's Repair Specialists

Loading...

Loading...